Page 1

Procedures and requirements for return units

SCANIA

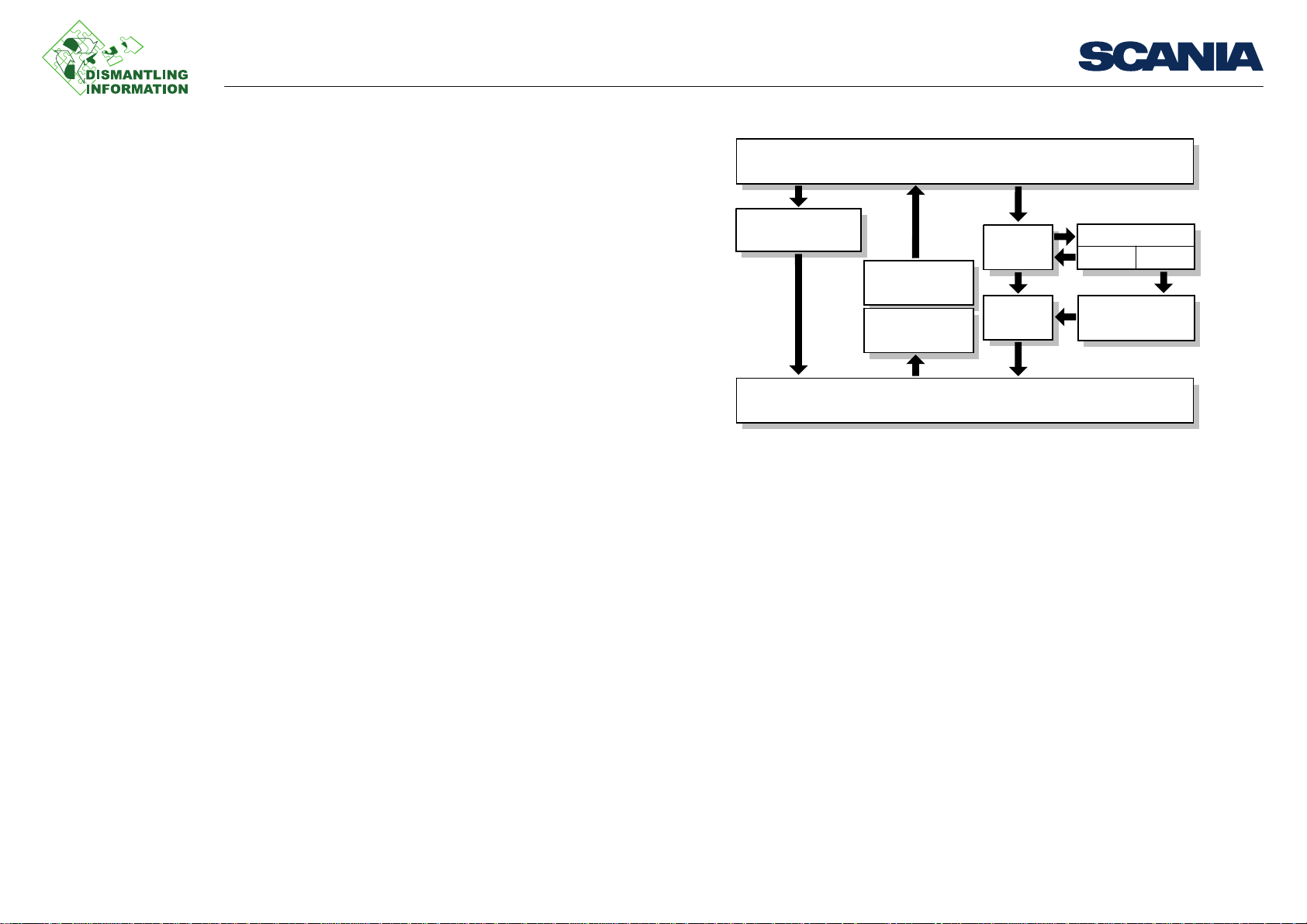

Invoice for exchange

unit and core

Credit

Damage

No

Yes

Credit note

Credit reduced, see

damage codes

Return

packing list

Return of core

DISTRIBUTOR DEALER

General

In addition to new spare parts, Scania offers a broad range of reconditioned components, exchange components for trucks, buses and industrial and marine engines.

Exchange components have the same warranty as other spare parts.

This document provides information on how the Exchange programme works and

the requirements Scania has for returned cores.

Upon delivery of an exchange component, a charge is levied for the exchange component and the core. Cores are returned to Splitpoint, which inspects each core and

determines whether full reimbursement should be paid or if the amount should be reduced.

Cores are sometimes called return units. A core can be an exchange core or a warranty core.

The Exchange Catalogue in Scania Multi contains most exchange components.

General

Ordering exchange components

Exchange components are ordered from the Scania Order Office the same way as

other spare parts. Orders for spare parts and exchange components can be placed on

the same order.

Invoicing

An exchange component and core are invoiced on the same invoice as other spare

parts. The prices of the exchange component and core are found in the parts list. The

core price is a net price without discounts. The core price is determined by how fit a

core is for reconditioning and may change if the conditions for reconditioning

change.

Price changes for cores are notified 3 months before they are introduced.

03:02-00 Issue 1 en-GB 1 (16)

©

Scania CV AB 2012, Sweden

Page 2

Procedures and requirements for return units

Exchange cores

Each core has its own identity; a core part number that differs from that of the exchange component. The core number is usually created by adding the number 1 in

front of the exchange component part number.

Example:

Exchange component 570 xxx.

Core 1 570 xxx.

Warranty cores

Components returned under warranty that are part of the Exchange programme but

have not been sent to the Warranty department are accepted as cores and can be sent

to Splitpoint like other cores.

Return of exchange cores

Exchange cores

Identification and cleaning

A core that is cleaned but not washed resists corrosion better than a washed core.

To facilitate core handling at Splitpoint and during the reconditioning process, the

core must be cleaned, but normally not washed. The cores must always be drained of

oil or other fluid.

As the type plate, part number or other identification must be easy to read, the area

for identification must be cleaned.

Inspection

Before the core is sent back, it must be inspected to ensure it fulfils Scania's requirements for exchange cores.

03:02-00 Issue 1 en-GB 2 (16)

©

Scania CV AB 2012, Sweden

Page 3

Procedures and requirements for return units

319 164

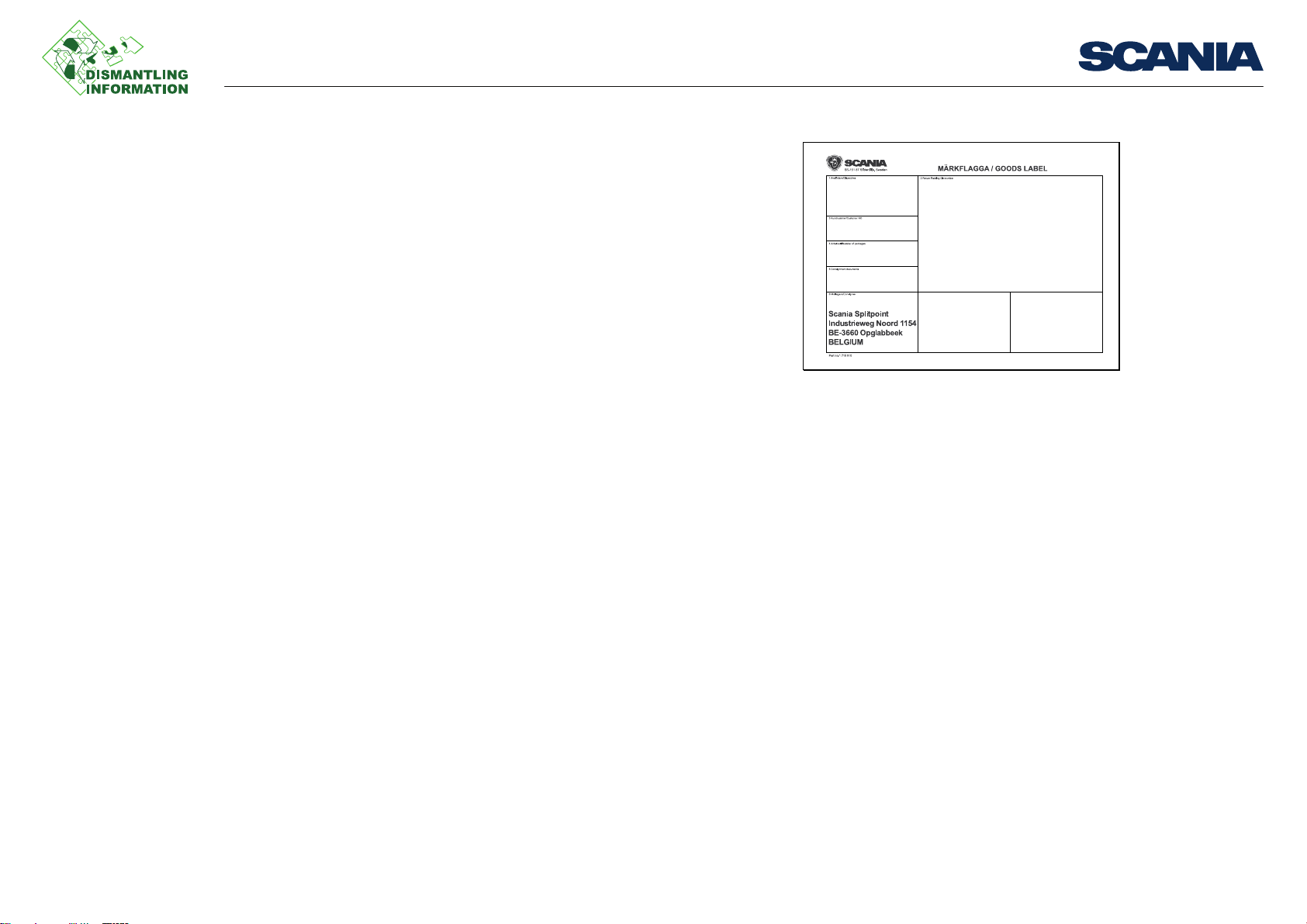

Goods label

Address for returning cores

Scania Splitpoint:

Industrieweg Nord 1154

BE-3660 Opglabbeek

Belgium

Address for returning cores from Sweden, Finland and Estonia:

Kuehne + Nagel AB

Västra Bravikenvägen 10, Box 934

S-60119 - Norrköping

Sweden

Goods marking

Return of exchange cores

Each package (pallet, engine, etc) must have a completely filled-in goods label, part

number 1 715 910, affixed to the outside of the package. The return packing lists

(RPLs) contained in the pallet must be listed on the goods label.

03:02-00 Issue 1 en-GB 3 (16)

©

Scania CV AB 2012, Sweden

Page 4

Procedures and requirements for return units

Note:

Note:

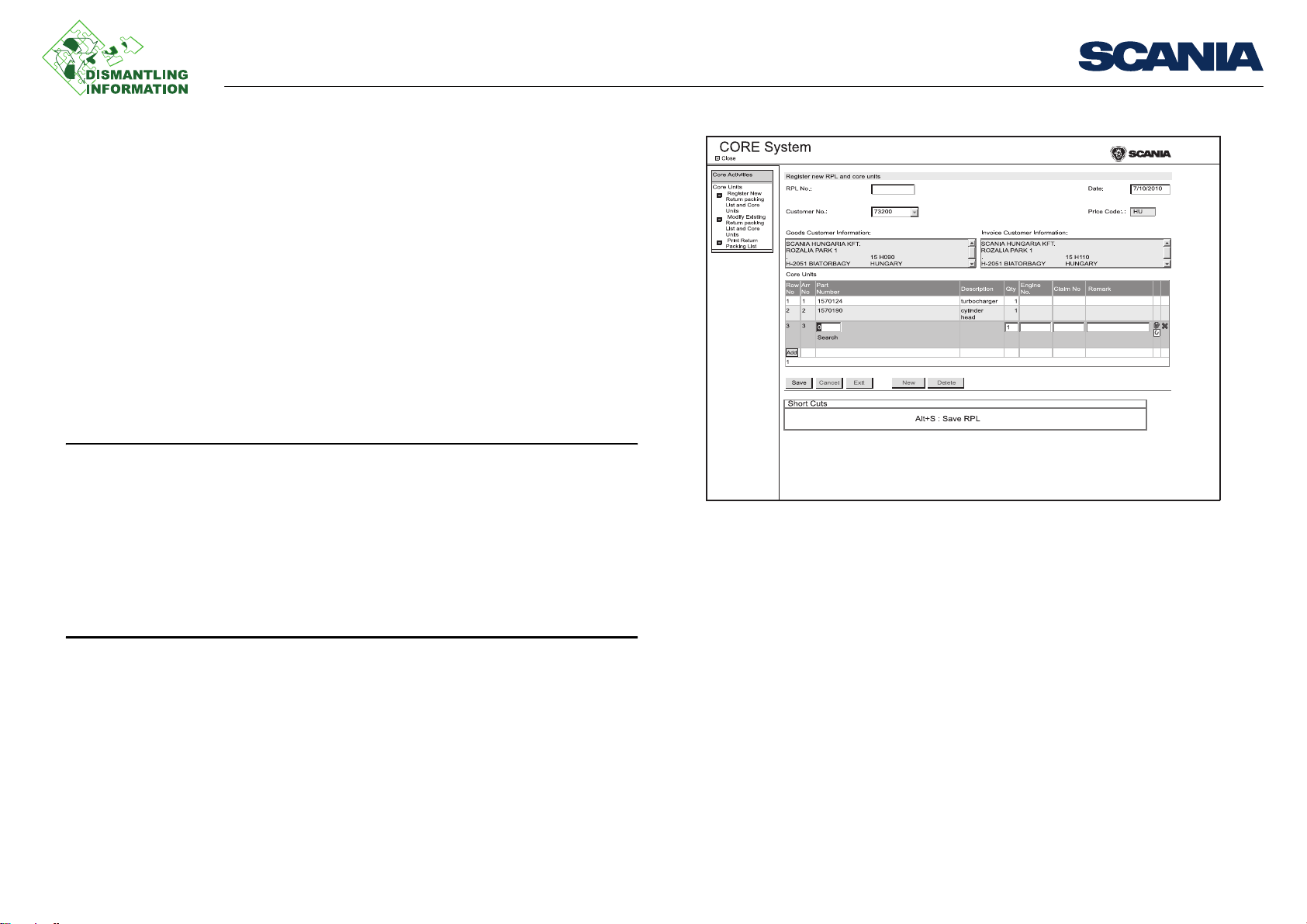

Return packing list in CORE

Return packing list

A return packing list must be included when returning cores. The return packing list

is created in the web application CORE. Alternatively a return packing list, part

number 1 584 567, can be filled in manually and used. The same information on the

printed list can also be used. Several units with the same part number can be written

on one line, but then it is no longer possible to identify an individual unit in the event

of credit reduction. Each engine must be accompanied by a separate return packing

list. The engine serial number must also be listed on the return packing list. If possible, distance driven (km) must also be indicated.

For a warranty core, the claim number must be specified on the return packing list.

Dealers with branch dealerships who send in cores on behalf of these dealerships

must indicate the dealership customer number on the return packing list.

Return of exchange cores

The return packing list must be placed in a plastic cover and secured to the inside of

the package. If the delivery is made up of several packages/pallets, a return packing

333 256

list must be written for each package. In each pallet there must be one (or more) return packing list(s) detailing the contents of the pallet and nothing more.

A copy of the return packing list must be submitted to the carrier as documentation

for clearing customs.

03:02-00 Issue 1 en-GB 4 (16)

©

Scania CV AB 2012, Sweden

Page 5

Procedures and requirements for return units

Note:

301008

Label for exchange core

301009

Label for warranty core

Return number, marking of cores

The following applies to return packing lists filled in manually:

Each core returned to Splitpoint must be marked with a return number for identification. The return number must consist of:

• Return packing list number

• Line number on the return packing list

If CORE is used for reporting, the return number is created automatically.

Each core returned to Splitpoint must be fitted with a hanging label containing:

• Customer number

• Return number

• Part number

The hanging label for an engine must also include the engine serial number and, if

possible, the distance driven (km).

Return of exchange cores

For regular exchange cores, use the hanging label with part number 1 585 563; for

warranty cores, use the label with part number 1 583 843.

The hanging label must be attached to the core and not on any protective packaging.

03:02-00 Issue 1 en-GB 5 (16)

©

Scania CV AB 2012, Sweden

Page 6

Procedures and requirements for return units

Return packaging

Engines

Engines must be returned on the Exchange programme's transport pallet for engines.

For reasons of safety, the engines must be strapped and firmly secured to the pallet.

All apertures must be covered to prevent the entry of contaminants. Plastic covers

and plastic plugs should be used for this. Strong tape can also be used to cover the

apertures.

Oil and coolant must be drained and the engine must be covered with plastic to minimise corrosion damage.

Crankshafts, gearboxes, planetary gears

Crankshafts, gearboxes, planetary gears as well as other cores with special packaging

must be returned in their Exchange programme packaging.

The core should be secured to prevent the core or the packaging from being damaged.

Do not use any plastic packaging inside wood packaging.

Return packaging

Unit injectors

Unit injectors must be packed in exchange packaging. For PDEs (Bosch), the questions on the packaging must also be answered.

General

Cores must be packed in pallets to prevent damage during transport. In pallets, separator inserts should be used between each layer. Heavy cores must not be placed on

top of lighter cores.

03:02-00 Issue 1 en-GB 6 (16)

©

Scania CV AB 2012, Sweden

Page 7

Procedures and requirements for return units

Exchange component claims

Delivery remarks regarding the exchange component must be registered in RIDE,

which is also used for handling core credit.

Remarks regarding delivery, invoice or order errors must be made to the Order department (Supply Control, SPC).

Warranty claims

Warranty claims are made to the Warranty department the same way as for other

spare parts. All contacts with the customer are handled by the Warranty department.

Cores for approved claims that have not been sent to the Warranty department can be

sent to Splitpoint as warranty cores with a hanging label intended for this purpose.

After an inspection at Splitpoint, credit is paid for the core. Special damage codes apply.

Credit for cores

Exchange component claims

Returned cores are inspected at Splitpoint. Any damage, flaws or incorrect part numbers are registered in the core program, CORE. Credit is paid out after registration is

completed in CORE.

03:02-00 Issue 1 en-GB 7 (16)

©

Scania CV AB 2012, Sweden

Page 8

Procedures and requirements for return units

Cores

Requirements for cores

The general requirements apply to all cores. Certain cores are also subject to supplementary requirements. In order for full credit to be paid out, the core must fulfil the

requirements. If the requirements are not fulfilled, reduced or no credit is paid. There

must be a balance between purchased exchange components and returned cores. If

the number of cores returned is greater than the number of exchange components purchased, return of the overpaid credit will be required.

Cores

03:02-00 Issue 1 en-GB 8 (16)

©

Scania CV AB 2012, Sweden

Page 9

Procedures and requirements for return units

General requirements for cores

• It must be possible to identify the core as a Scania component

• The core must be cleaned (not washed) and drained of oil or other fluid

• The core must not have severe corrosion

• The core must be complete and equipped the same way as the equivalent exchange component

• Where applicable, the core must have a type plate with type designation and serial

number or part number

• The core must not have damage caused by freezing. This type of damage can be

seen as a slight bulge or a crack in the goods

• The core must not have any visible damage caused by fire, corrosion or lack of

lubricant

• There must be no visible cracks

• All connection openings must be fitted with protection against ingress of contaminants

• External threads must be protected with a nut or another means

• The core must be packed as instructed under the heading Return packaging

Cores

If any of the above requirements is not fulfilled, a deduction will be made from the

credit amount.

03:02-00 Issue 1 en-GB 9 (16)

©

Scania CV AB 2012, Sweden

Page 10

Procedures and requirements for return units

A

301011

Allowable cracks in cylinder head

Supplementary requirements and examples of deductions for damage

Engines

The engine serial number and part number must be indicated on the hanging label and

return packing list. The engine core must be delivered on an engine pallet. The engine

core must be cleaned.

Cause Damage

code

Returned without engine pallet 1

Engine core not cleaned 1

Cylinder head

Cause Damage

code

Impact marks or other damage at the parting plane with cylinder block 5

Visible cracks, except cracks between injector nozzle holes and inlet

or exhaust valve seats

5

Supplementary requirements and examples of deductions for damage

Shallow pitting in the combustion chamber caused by the ingress of water may be

acceptable, provided the damage is not to the sealing surface against the cylinder liner.

03:02-00 Issue 1 en-GB 10 (16)

©

Scania CV AB 2012, Sweden

Page 11

Procedures and requirements for return units

301124

1

2

3

4

Crankshaft

Crankshaft

The crankshaft must be oiled with clean oil.

Cause Damage

code

Worn keyways 5

Contact surface (1), bolt hole (2) and guide pin hole (3) damaged 5

Deep scratches in the axial bearing thrust surface (4) or its fillet 5

Visible cracks in the crankshaft 5

Corrosion or blueing (overheating due to lack of lubricant) 5

Turbocharger

The general rules for cleaning do not apply.

Cause Damage

code

Outer damage 2

Too much play in bearing housing 2

Broken shaft 2

Supplementary requirements and examples of deductions for damage

03:02-00 Issue 1 en-GB 11 (16)

©

Scania CV AB 2012, Sweden

Page 12

Procedures and requirements for return units

VG Turbocharger

The general rules for cleaning do not apply.

Cause Damage

code

Not complete 2

Electronic Actuator missing 2

Injector

Cause Damage

code

Not packed in exchange cardboard box 1

Damaged housing 2

Gearbox

The input and output shafts must be greased.

Supplementary requirements and examples of deductions for damage

The hole for gearbox control on the top of the gearbox must be covered with a cover

or strong tape.

Cause Damage

code

Gearbox housing cracked or damaged 4

Coolant pump

Cause Damage

code

Damaged housing 5

03:02-00 Issue 1 en-GB 12 (16)

©

Scania CV AB 2012, Sweden

Page 13

Procedures and requirements for return units

Power steering gear

Cause Damage

code

Thread on output shaft damaged ( must be protected by a nut) 2

Housing cracked or damaged 4

Central gear or planetary gear

Cause Damage

code

Housing cracked or damaged. Inside also to be checked. 4

Starter motor

The general rules for cleaning do not apply.

Alternator

Supplementary requirements and examples of deductions for damage

The general rules for cleaning do not apply.

Cause Damage

code

Broken shaft 5

Thread unprotected 2

Hydraulic pump

Cause Damage

code

Thread unprotected 2

03:02-00 Issue 1 en-GB 13 (16)

©

Scania CV AB 2012, Sweden

Page 14

Procedures and requirements for return units

AC compressor

Cause Damage

code

Fitted pulley missing 2

Cores without a type plate

Cause Damage

code

Type plate missing 2

Core cannot be identified 2

Supplementary requirements and examples of deductions for damage

03:02-00 Issue 1 en-GB 14 (16)

©

Scania CV AB 2012, Sweden

Page 15

Procedures and requirements for return units

Damage codes for credit reduction

Exchange cores

The credit is reduced due to damage or missing parts according to the following damage codes:

Damage codes for credit reduction

Damage

code

0 1.00 Full reimbursement

1 0.97 • Not cleaned

2 0.80 • Minor damage

4 0.30 Major damage, where the cylinder block, gearbox housing,

5 0.00 • Damage so extreme that core cannot be used for recondi-

Factor Example of reason for reduction

• Oil or coolant not drained

• Required packaging missing

Extra work for Splitpoint to handle the core

• Core not complete

central gear housing or steering gear housing is damaged or

cracked

tioning

• Serious corrosion

• Core missing

03:02-00 Issue 1 en-GB 15 (16)

©

Scania CV AB 2012, Sweden

Page 16

Procedures and requirements for return units

Warranty cores

The credit is reduced due to damage or missing parts following the damage codes

listed below.

Damage codes for credit reduction

Damage

code

6 1.0 Full reimbursement for warranty core

7 0.97 • Not cleaned

8 0.80 Core not complete

9 0.00 Warranty core missing or incorrect

Credit is calculated as factor multiplied by core price.

No deduction or credit is given for cores not found on the return packing list.

Factor Example of reason for reduction

• Oil or coolant not drained

• Required packaging missing

Extra work for Splitpoint to handle the core

03:02-00 Issue 1 en-GB 16 (16)

©

Scania CV AB 2012, Sweden

Loading...

Loading...