Page 1

December 2017, en-GB

Dismantling information

P, G, R and S series

Page 2

Page 3

Table of contents

General............................................................................................................................. 1

Dismantling information ..................................................................................................1

Exchange components ...................................................................................................3

Hazardous substances and materials...............................................................................4

Identification of plastics ...................................................................................................9

Lifting and supporting on stands ....................................................................................27

Engine ............................................................................................................................ 38

Engine.........................................................................................................................38

Oil filter .......................................................................................................................41

Rotor ...........................................................................................................................43

Engine oil.....................................................................................................................45

Cooling system ............................................................................................................. 46

Coolant........................................................................................................................46

Fuel and exhaust systems ........................................................................................... 50

Dismantling the silencer ................................................................................................ 50

Reductant tank .............................................................................................................54

Fuel tank......................................................................................................................57

Coupling......................................................................................................................... 60

Connection and operation .............................................................................................60

Gearbox.......................................................................................................................... 63

Gearbox ...................................................................................................................... 63

Brakes - Pneumatic system ......................................................................................... 65

Compressed air tanks ..................................................................................................65

Spring brake chamber...................................................................................................66

Suspension.................................................................................................................... 68

Air suspension .............................................................................................................68

Steering.......................................................................................................................... 71

Removal - Airbag.......................................................................................................... 71

Electrical system........................................................................................................... 75

Chassis central electric unit ..........................................................................................75

Removal - Curtain airbag...............................................................................................77

Batteries ......................................................................................................................81

Page 4

Instrument...................................................................................................................... 83

Removal - Instrument panel...........................................................................................83

Cab - Body - Canopy..................................................................................................... 93

Cab tilt system ............................................................................................................. 93

U4, Refrigerator............................................................................................................95

A/C compressor ...........................................................................................................97

Working with refrigerant ................................................................................................99

Compressor - auxiliary cab cooler (E114) .....................................................................101

Page 5

General - Dismantling information

General

Dismantling information

General

This information is aimed at everybody dealing with reconditioning and scrapping of Scania vehicles. The

information applies to workshops, dismantling and recycling companies.

The information is applicable to new Scania models. However, not all parts are covered by this

information booklet. The information is incomplete.

Draining and removing describes how environmentally hazardous waste should be separated from the

vehicle (pre-treatment).

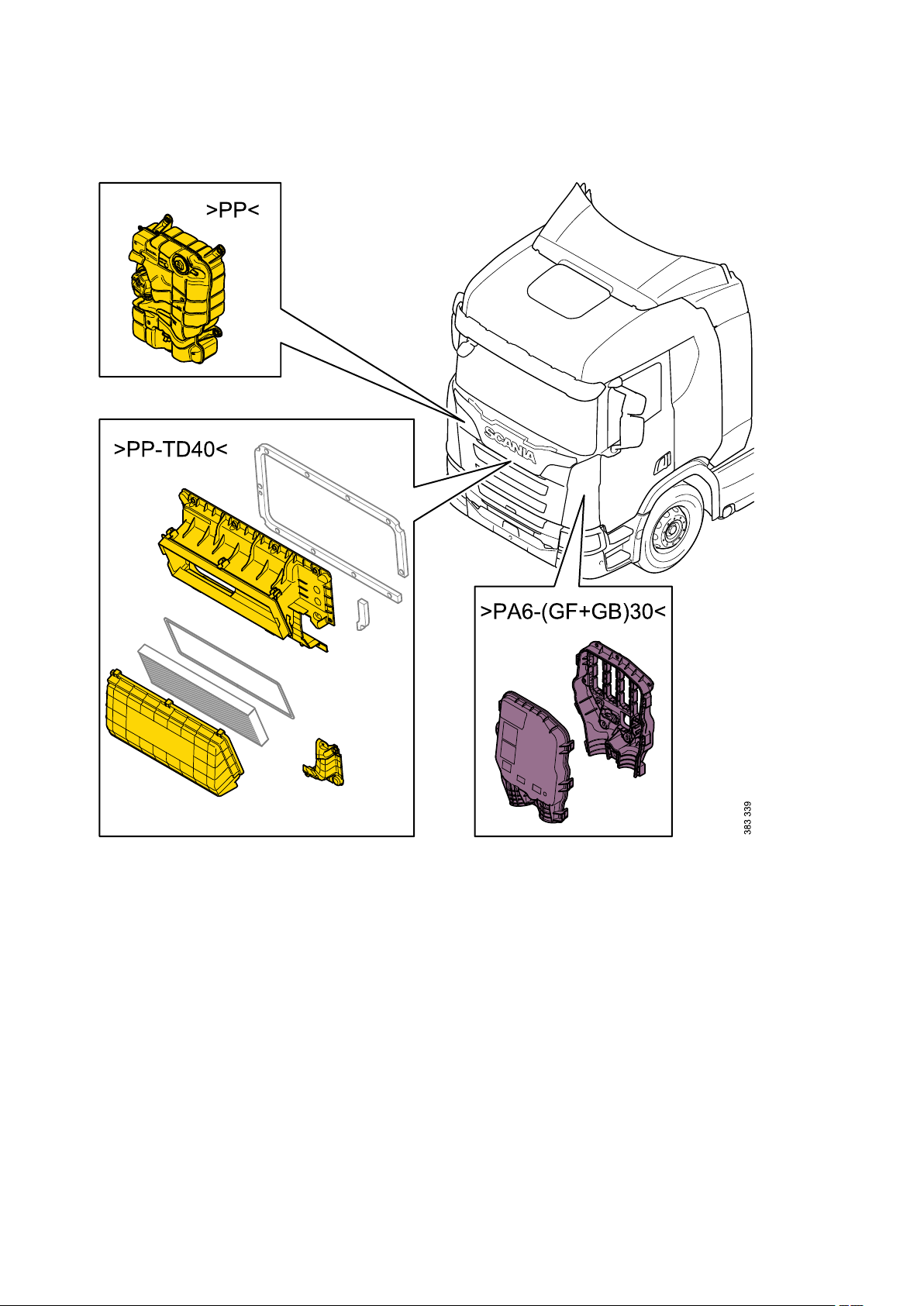

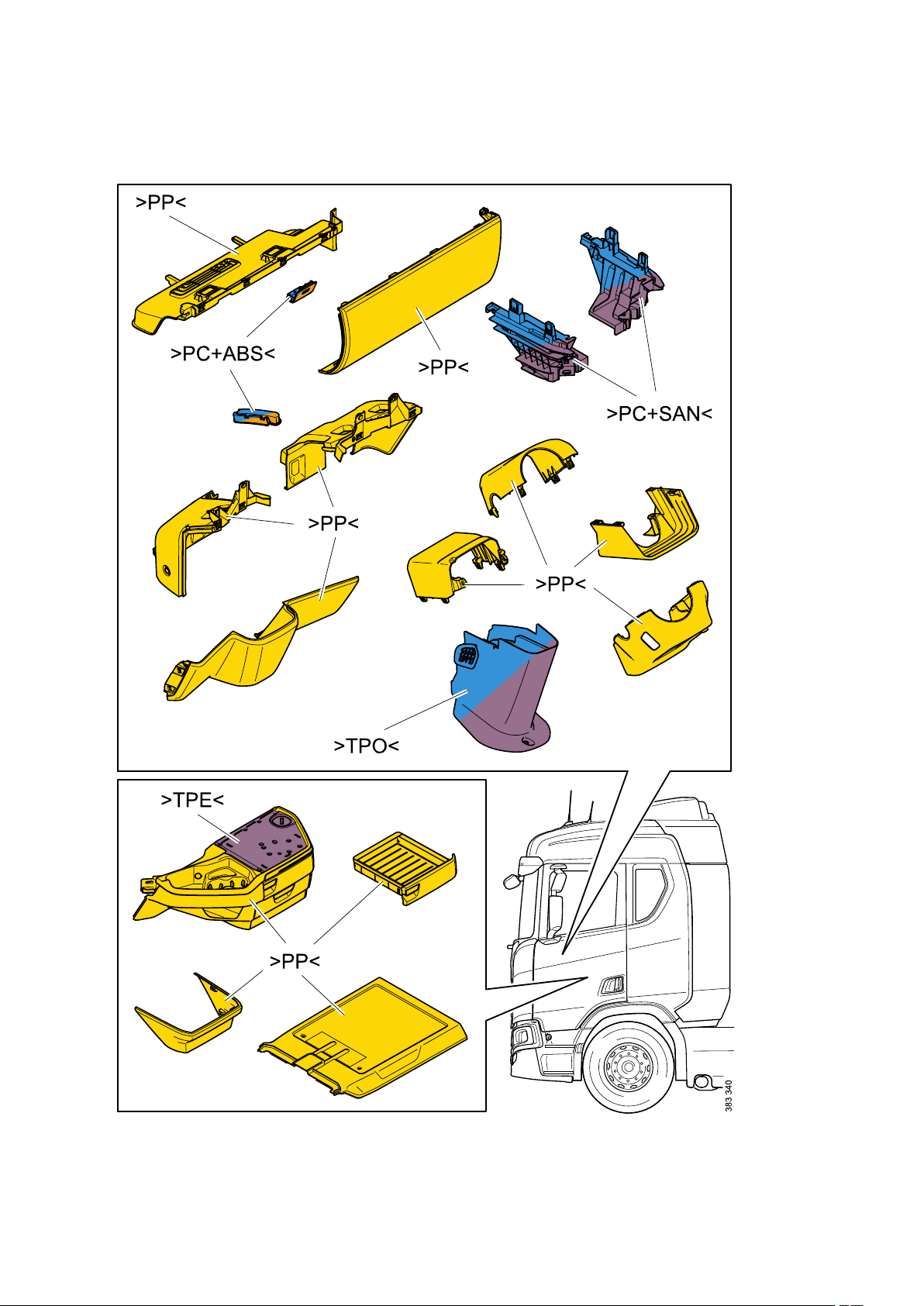

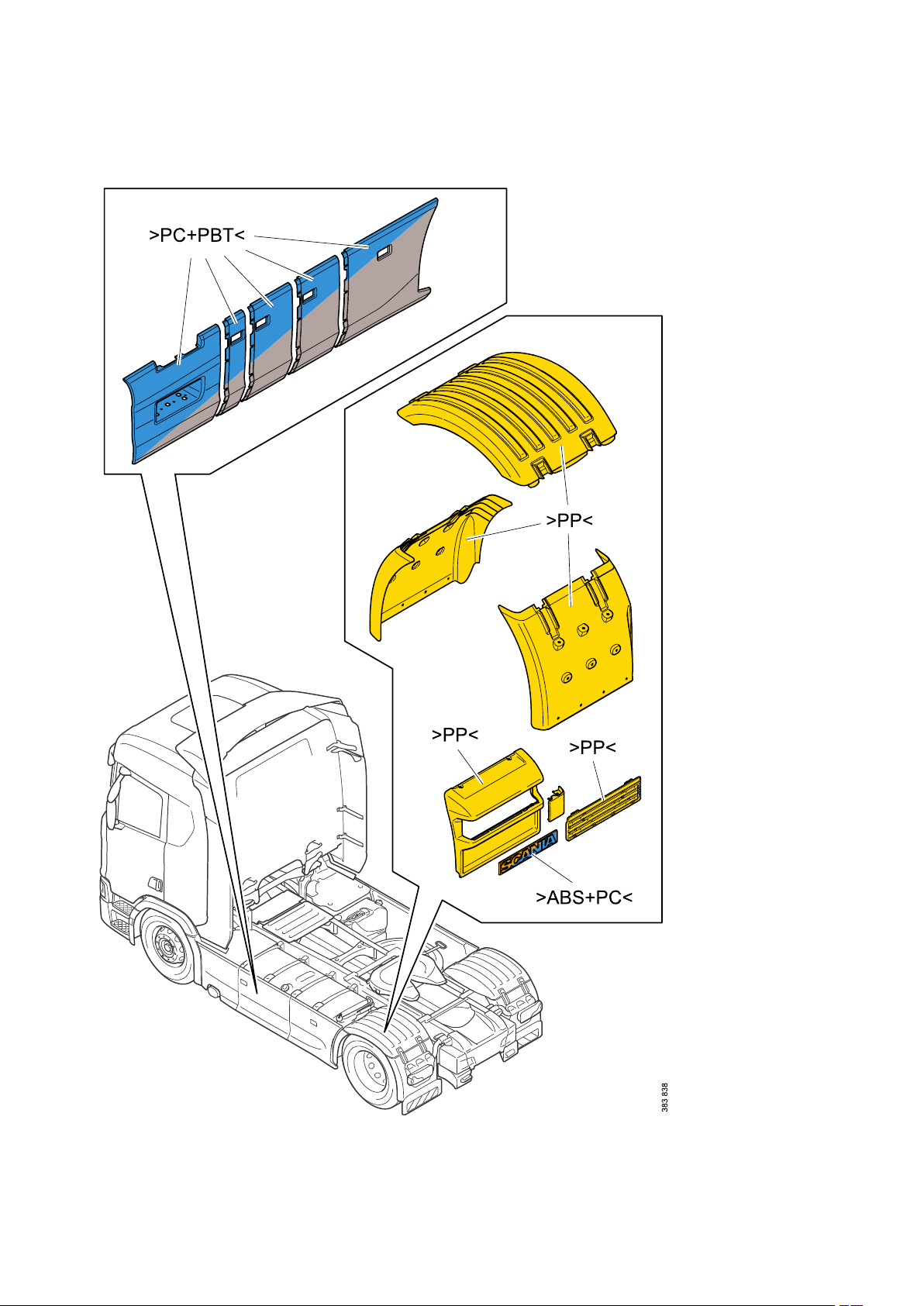

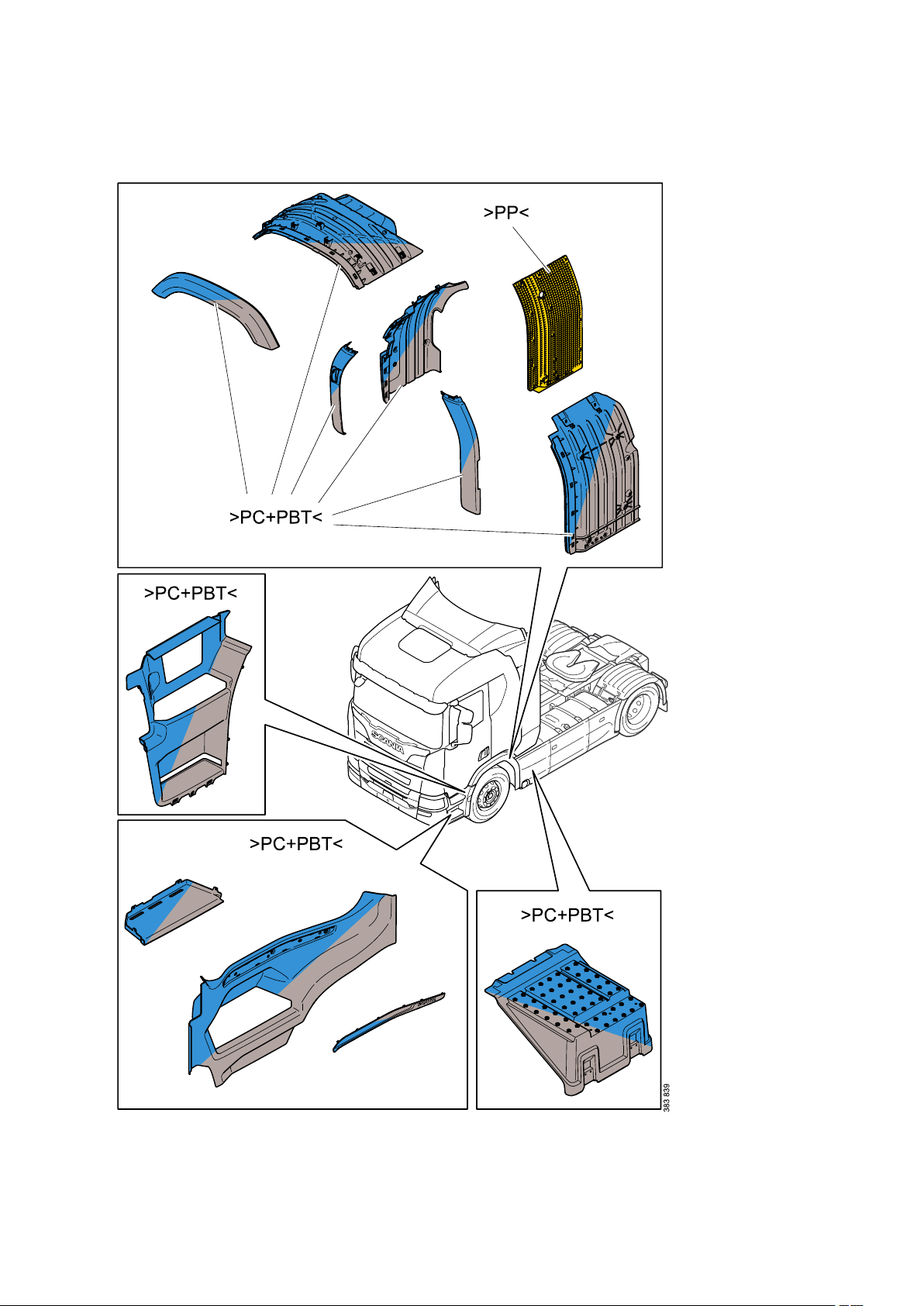

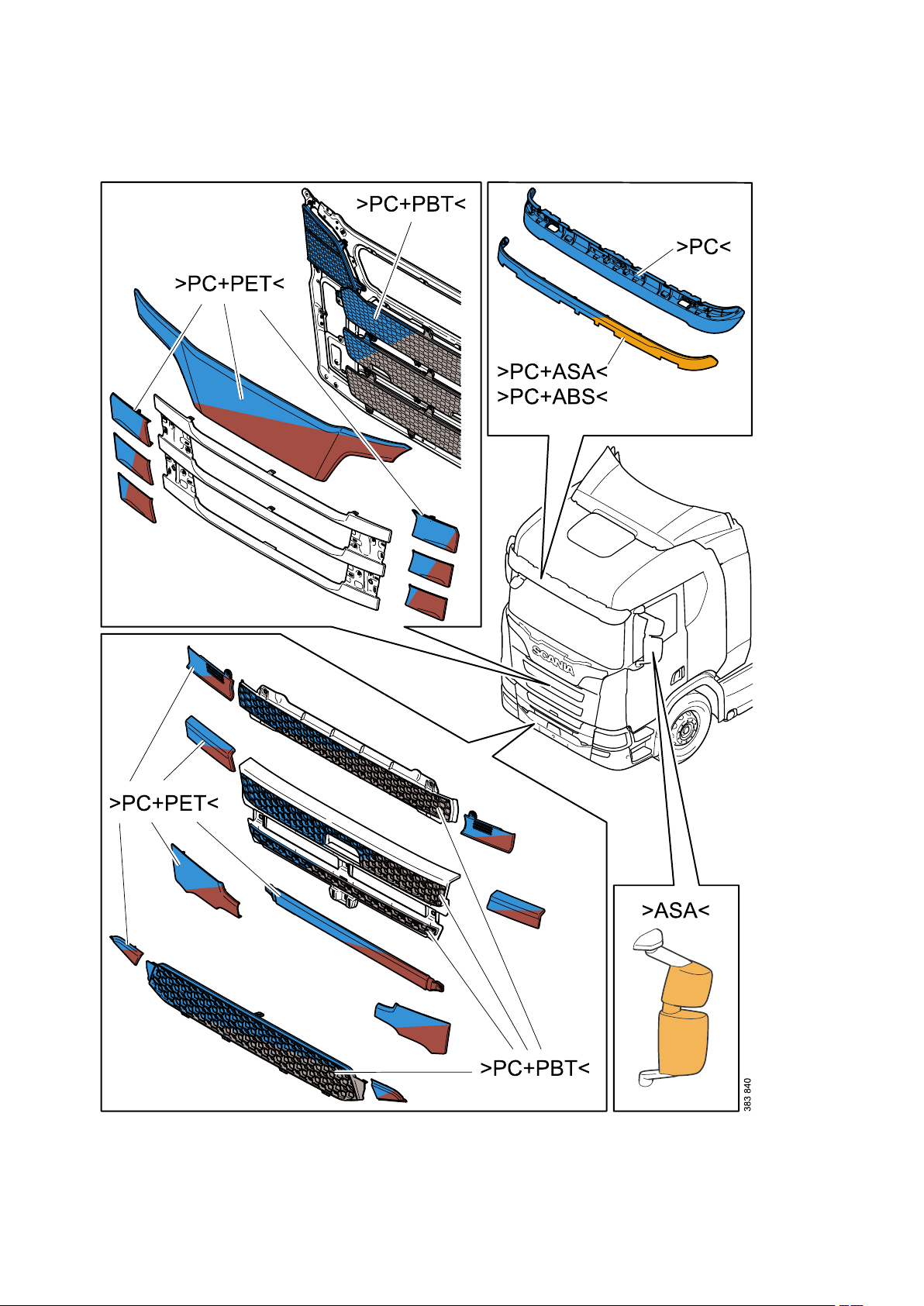

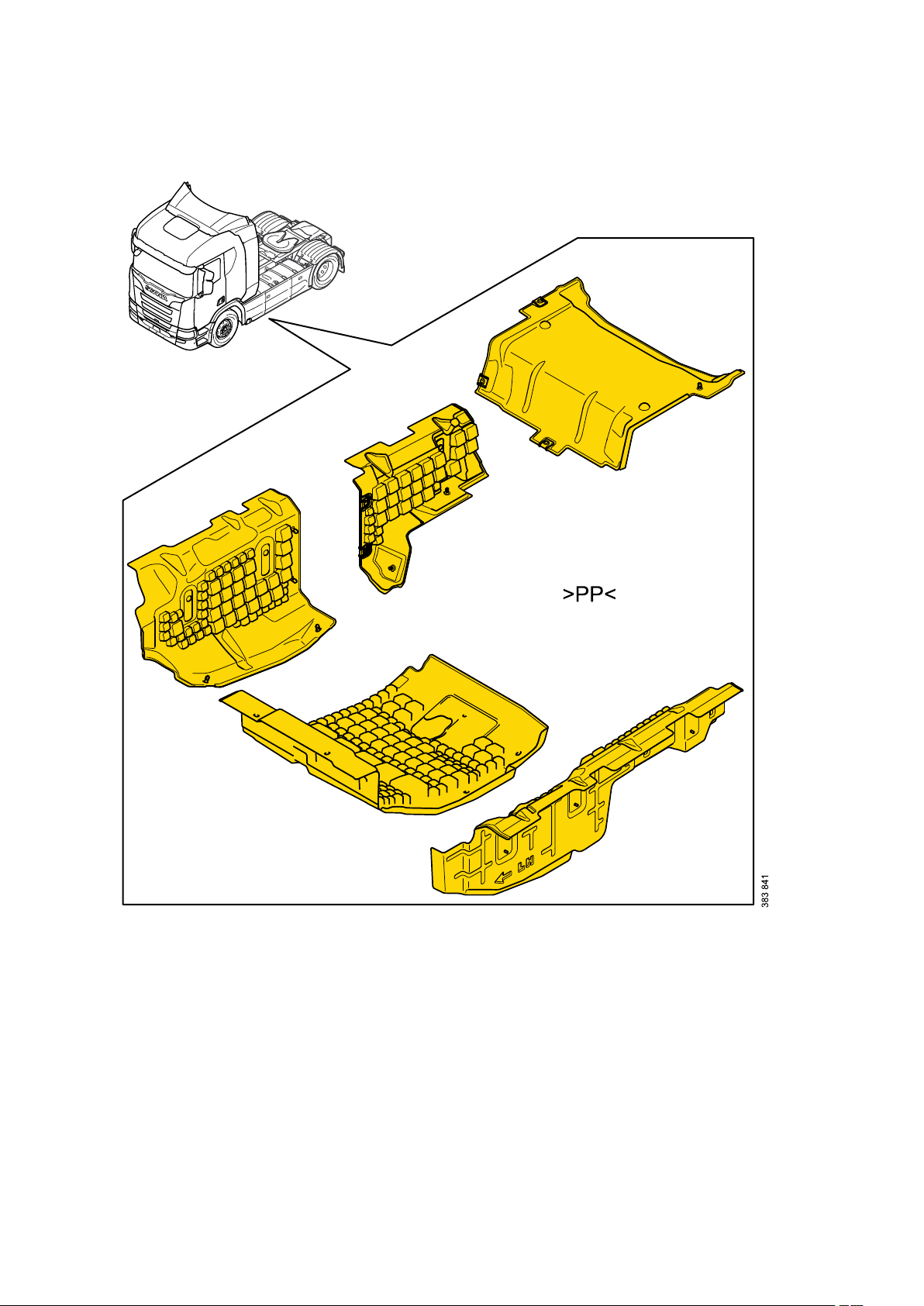

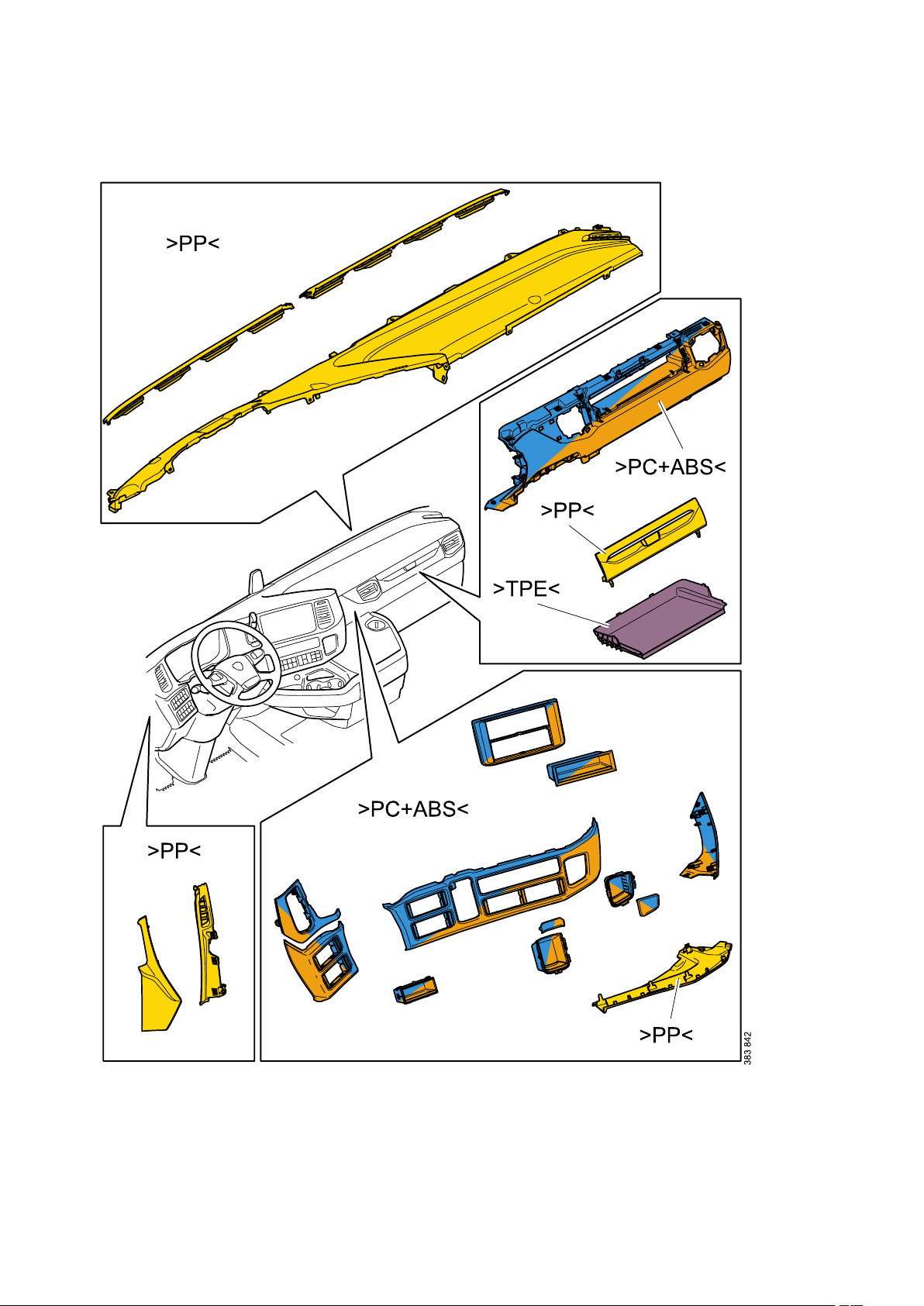

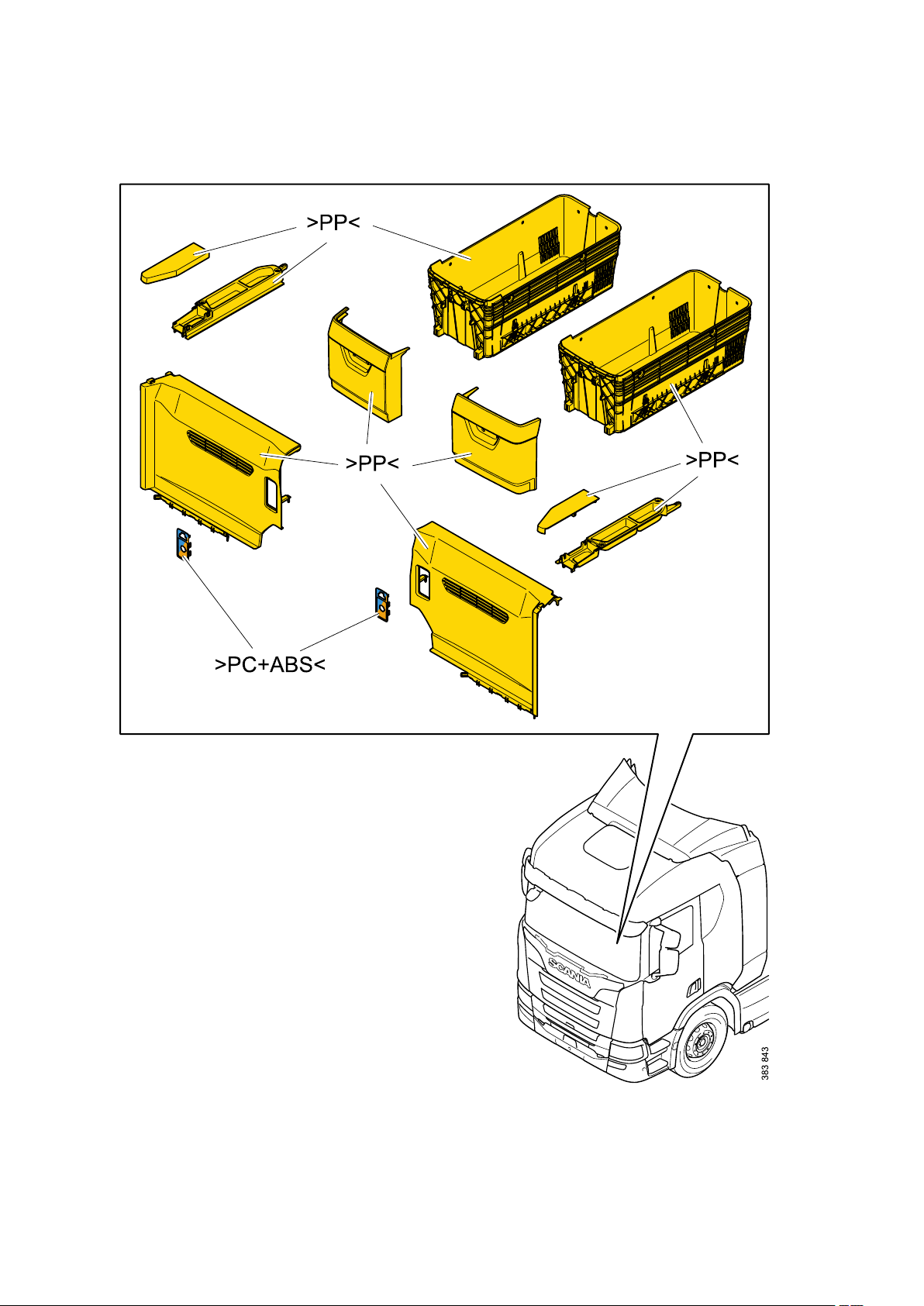

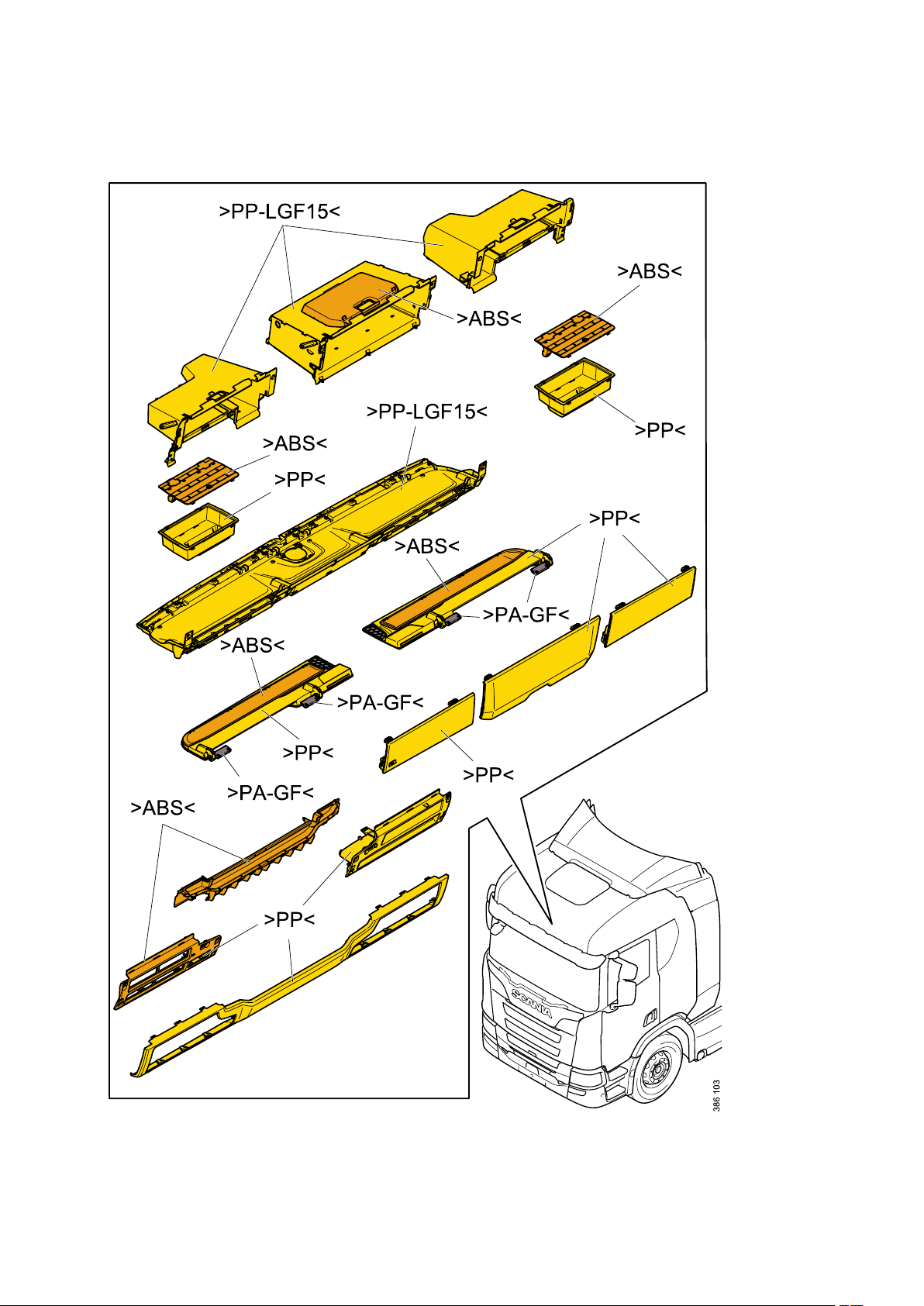

Identification of materials is to facilitate identification and sorting of material for recycling.

Colours and a material code identify polymer materials. Parts consisting of two plastic materials are twocoloured. Where there are more than one variant of a part, the codes of both materials will be stated.

Scania and the environment

Scania works continuously towards products, processes and services with reduced impact on the

environment. The environmental work therefore focuses on doing the right thing from the beginning, and

reducing the consumption of resources such as base materials and energy.

By including environmental aspects in the product development from an early stage, the product's impact

on the environment can be reduced during the whole life cycle - from research and development, via

production and usage, to end-of-life treatment. Lower fuel consumption and reduced exhaust emissions

are always in focus. An environmentally appropriate end-of-life treatment can be made possible by

adapting the design solutions, by choosing materials with little environmental impact, and by avoiding

hazardous materials.

A more environmentally friendly production is obtained by, among other things, reducing the consumption

of water, chemicals, base materials and energy. Residual products such as chips and scrap are utilised.

Scania supports its customers in choosing the right vehicle for a certain transport task. This reduces both

fuel consumption and wear. Scania can also assist with driver training and inspection programmes.

Correct maintenance is important in order to maintain the environmental characteristics of the vehicle.

About 1,500 Scania workshops are found around the world to provide this.

Dismantling information and correct marking of components and materials facilitate end-of-life treatment.

End-of-life treatment of vehicles

With the ever increasing global population and economical development, efficient usage of the resources

is becoming more and more important. Material reuse and recycling are two ways to contribute to efficient

usage of resources.

Scania's involvement in end-of-life treatment issues aims for responsible, environmentally responsible

and resource-efficient after-life management of Scania vehicles.

End-of-life treatment comprises a number of procedures that the vehicle must undergo, for example:

• Pre-treatment: E.g. draining fluids, emptying climate control systems and removing batteries

• Re-use: Parts, reconditioned or non-reconditioned, are being re-used after removal. Scania has its own

service exchange system.

December 2017, en-GB © Scania CV AB

1

Page 6

General - Dismantling information

• Recycling: The material is re-used in the production of new products with the same or a lower quality

rating.

• Energy recovery: Combustion with energy recovery.

Only disposal remains if none of the above alternatives is possible.

2

© Scania CV AB December 2017, en-GB

Page 7

General - Exchange components

Exchange components

General

As part of its efforts to be environmentally-friendly, Scania offers a wide range of Service Exchange

components. Units that have been returned are reconditioned so as to have the same technical status as

a new part. Scania Service Exchange is a sustainable way of reducing harmful carbon dioxide emissions,

energy use and consumption of raw materials.

Exchange components have the same warranty as other spare parts.

Ordering exchange components

Exchange components are ordered from Scania in the same way as other spare parts. Orders for spare

parts and exchange components can be placed on the same order.

Scania service exchange system

For more information about the Scania service exchange system, you can contact a Scania dealer or a

Scania workshop.

December 2017, en-GB © Scania CV AB

3

Page 8

General - Hazardous substances and materials

Hazardous substances and materials

The following list is a guide of lubricants, fluids and parts that are recovered from the truck during pretreatment. Volumes are approximate.

ENVIRONMENT

Avoid spillage and use a receptacle when handling

hazardous fluids

Engine:

7-9 litre engine

D9/13 XPI Fuel filter housing, diesel

D9/13/16 XPI

13 litre engine

D16 XPI

D13 PDE

16 litre engine

Cooling system: Specification: Quantity:

7-9 litre engine

13 litre engine

16 litre engine

Chassis: Specification: Quantity:

Fuel tank Diesel

Specification: Quantity:

Oil

High pressure fuel pump, oil

Oil

Fuel filter housing, engine,

diesel

Fuel filter housing

Oil

Coolant

Coolant

Coolant

27 - 38 litres

0.4 l

0.3 l

40 - 44 litres

0.2 l

0.3 l

32 - 47 litres

30-52 litres

40-62 litres

45-102 litres

-

Steering: Specification: Quantity:

Steering axle

Gearbox: Specification: Quantity:

Gearbox Oil

Transfer gearbox

Opticruise, longitudinal stroke

damper

Retarder

M33 electric machine

4

Transmission oil, ATF 2.2 litres

13-50 litres

Oil

Oil

Oil

Oil

© Scania CV AB December 2017, en-GB

6.5 litres

0.09 litres

approx. 7.5 litres

5.5 litres

Page 9

General - Hazardous substances and materials

Axle gear:

Axle gear

Axle gear with bogie gear

Portal axle (ZF) Oil

Hub:

Hub reduction gears

ZF hub

Specification: Quantity:

Oil

Oil

9-13 litres

11-12 litres

19.5 litres

Specification: Quantity:

Oil

Oil

2 litres

0.7 litres

Cab: Specification: Quantity:

Refrigerator Refrigerant R134a

Auxiliary cab cooler

A/C

Airbag (H14)

Safety belt with belt pretensioner

Refrigerant R134a

Refrigerant R134a

- -

- -

30-47 g

approx. 1,200 g

(H16, H17)

Side curtain airbags (H30, H31)

- -

Cab tilt system: Specification Quantity

Pump and cylinder Pentosin oil 1.7-2 l

Electrical parts:

Battery, VPS

Starter battery

Battery cable terminals Lead, brass

Wheel

Balancing weights

Specification Quantity

- -

- -

-

Specification Quantity

- -

December 2017, en-GB © Scania CV AB

5

Page 10

General - Hazardous substances and materials

Isocyanates

WARNING!

Isocyanates are found in some paints, putty, adhesive

and plastic foams that are used in motor vehicles.

Inhaling isocyanates in the form of vapour, dust or

aerosols may cause irritation of mucous membranes

causing asthmatic symptoms from the respiratory

passages and an impaired function of the lungs.

Even brief exposure to high concentrations can

cause problems of permanent hypersensitivity

When products containing isocyanates in combined

form are heated to temperatures above 150°C,

isocyanates are released. This results in a high

degree of exposure. This applies for example to

grinding, welding and cutting products to which a top

coat of paint containing isocyanates has been

applied. For this reason, make sure that there is

adequate ventilation in the areas where the work is

carried out. Personnel carrying out such work should

use protection such as respiratory masks with air

supply.

Do not take any risks when carrying out work

involving heating materials that may contain

isocyanates; always presume that the material

contains isocyanates and take the necessary safety

precautions.

6

© Scania CV AB December 2017, en-GB

Page 11

Vehicle fires

WARNING!

Where a vehicle is involved in a fire, a number of

substances that are hazardous to health and the

environment are formed. Smoke and water carry

these substances and to a certain extent they remain

in the vehicle (ashes).

Use protective equipment such as respiratory

protective equipment and gloves when working on

vehicles that have been involved in a fire. Avoid skin

contact with ashes.

When dismantling a vehicle that has been involved in

a fire, the following must be taken into consideration:

General - Hazardous substances and materials

The vehicle may be weakened, which can have a

negative affect on lifting points. This should also be

taken into consideration when tilting cabs.

Gas dampers which have not been punctured

represent an explosion risk, as the material they are

made of may be weakened or damaged.

Wash the vehicle before starting dismantling.

Keep the following in mind:

Do not start dismantling before the cause of the fire

has been fully investigated.

Power should be disconnected on vehicles which

have been involved in a fire as soon as possible, by

disconnecting the battery cables. This is to prevent

short circuits, which can result in a new fire.

Corrosion is accelerated on vehicles which have

been involved in a fire, for example due to moisture in

combination with ashes and some extinguishing

agents. The vehicle should be processed as soon as

possible, to minimise the risk of undesirable leakage

of environmentally hazardous fluids and substances.

Fire damaged vehicles should be washed in a way

that allows the washing water to be disposed of in an

environmentally responsible way, as it contains

environmentally hazardous contaminants

December 2017, en-GB © Scania CV AB

7

Page 12

General - Hazardous substances and materials

IMPORTANT!

When carrying out any type of work which involves

heating products, the relevant safety regulations for

this type of work should be followed.

Cut the power to the vehicle before starting work.

When working with air bellows, the system must not

be pressurised.

8

© Scania CV AB December 2017, en-GB

Page 13

General - Identification of plastics

Identification of plastics

Plastics are divided into 2 main groups; meltable (thermoplastics) and non-meltable (thermosets).

Thermoplastics are cast or injection moulded and unlike thermosets they lack bonds between the plastic

molecules. Thermoplastics can be recycled with good results.

Thermoplastic recycling is a good way to conserve base materials and save money. There are different

types of thermoplastics and it is important to keep them separate during recycling work so that the

mechanical properties of the recycled material are not impaired. Certain material combinations can be

compensated using additives that make the plastics miscible. Mixing in new base material can also

improve the properties.

Parts made of thermoplastic

Parts made of thermosets

December 2017, en-GB © Scania CV AB

9

Page 14

General - Identification of plastics

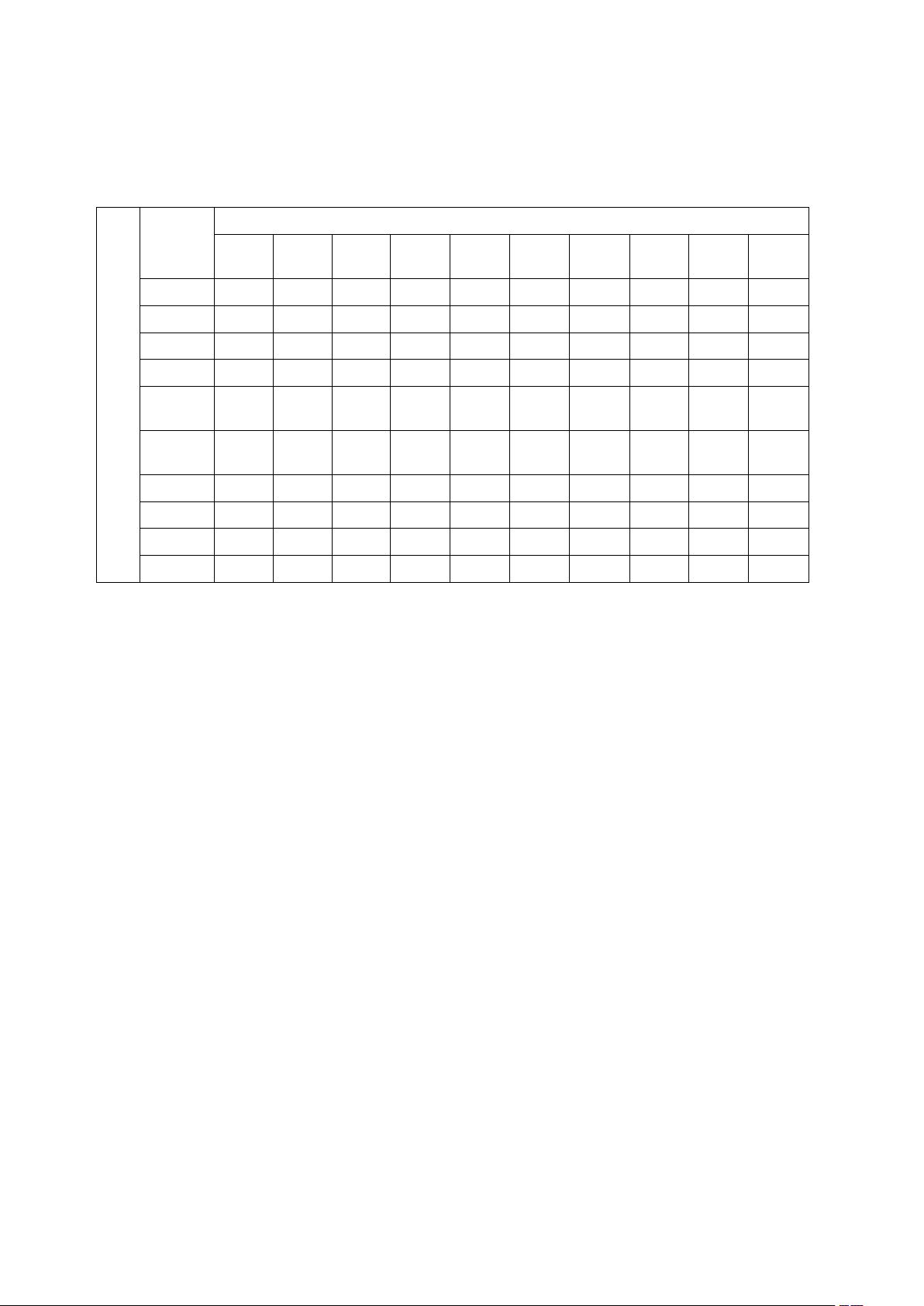

Examples of plastics that are not suitable for mixing are listed in the table below:

Base material

ABS

ABS

PA B A B

PBT A B A A A A B B B

PC

PC

+ABS

PC

Mixing material

+PBT

PE

PMMA A B B A A A B A B B

PP

PVC

=

A

B

C

Compatible

=

Compatible in purer mixtures (<5%)

=

Incompatible

A B A A A A

A

A B A A A A B A B

A

C

C

A

PA PBT

C

C

B

B

C C C C C

A A A A B A B

A A A A B A B

C

C C C C

PC PC

+ABSPC+PBT

C C C

B

C C

PE PMM-APP

C

B B B

A

B A B A

B A B A

A

C

C

A B

PVC

A

C

C

C

C

C

Painting thermoplastics is disadvantageous with respect to recycling even though there are methods of

separating the paint. Plastics age and become brittle. Take a random sample for measuring the melting

index to see how far degradation has advanced. See ISO 1133.

Pure plastic that does not contain a high degree of other material (maximum 5% of another plastic), and

has not degraded due to long periods of damp or heat treatment can be classified as new plastic, though

with reduced properties.

Mixed material or material with molecules degraded to short chains can only be reshaped to very simple

products or used for energy recovery.

Thermosets are plastic prepared with hardeners which bind the plastic molecules to each other.

Thermosets are strong and rigid but brittle. Therefore it is often reinforced with for example glass fibre

mat.

Thermosetting plastics are more difficult to recycle as it is not possible to melt and reshape them. The

methods of recycling available today are energy recovery and, to a certain degree, pulverisation for filling.

Marking of plastics

Scania marks all its plastics (where there is space for a mark) in compliance with Scania Standard STD

387, which in turn is based on ISO 11469 - Generic identification and marking of plastic products.

The marks consists of international designations according to the following standards:

ISO 1043 Plastics - Symbols and abbreviations

ISO 1433 Vulcanised rubber - Choice of required properties

ISO 1629

10

Rubber and latex -Terminology

© Scania CV AB December 2017, en-GB

Page 15

General - Identification of plastics

The marks start and finish with the arrow symbols > and <.

The following is a brief description of the thermoplastics most commonly used by Scania. Plastics are

designated by 2 to 4 capital letters (e.g. >ABS<) and sometimes a mixture of 2 materials (e.g. >ABS

+PC<).

There are often fillers (T for Talcum powder, M for Mineral and G for Glass) and the amount of filler as a

percentage (e.g. >ABS-T20<, which means ABS with 20% talcum powder).

Part numbers are necessary for identification of parts in production as well as for maintenance and spare

parts. Part numbers comprise a five, six or seven digit serial number, e.g. 1234567-LH (part number - lefthand).

The marked date refers to the date of manufacture. The marked date often comprises a date and a time

or just a date field.

Plastics designations

>ABS<

Acrylonitrile butadiene styrene:

ABS is easy to recycle and can be mixed with PC to form PC+ABS after recycling, which is advantageous

since pure ABS can loose impact resistance when remelted.

>ASA<

Acrylonitrile styrene acrylate:

Used for A-pillar panels, windscreen wiper panels, hinge covers, rear view mirror holders and roof hatch

panels. Weather and colour resistant. Easy to recycle.

>EPDM<

Ethylene propylene diene monomer (rubber).

>HDPE<

High density polyethylene.

NR

Nitrile rubber.

>PA<

Polyamide:

The designation is often followed by one of the figures 6, 6.6, 11 or 12. Used primarily for engine

compartment components, compressed air and fuel pipes. Recycling is limited by the availability of

material. Material properties are not impaired to any significant degree as long as the recycling process

takes into account the problems of moisture.

>PBT<

Polybutyleneterephthalate:

Recycling is limited by the relatively small amounts of material available and the lack of material data

collected from recycled material.

December 2017, en-GB © Scania CV AB

11

Page 16

General - Identification of plastics

>PMMA<

Polymethylmethacrylate:

Better known as plexiglas. Used primarily for covers for lighting and instruments. Easy to recycle.

>PC<

Polycarbonate:

At Scania, we use PC in exterior sun visors and as lenses. PC is often used in combination with ABS,

PBT, PETor ASA.

>PC+PBT<

A mixture of PC and PBT, combining the best characteristics from both materials. It is sensitive to

moisture and high temperatures during manufacturing.

Recycling is difficult to assess as the material degrades at high temperatures and after exposure to

moisture for long periods.

>PC+ABS<

A mixture of PC and ABS. Recycling is easier than PC+PBTand works well for material for simpler

products.

>PE<

Polyethylene:

Several designations can occur depending on the density:

• PE - LD where LD means Low Density

• PE - HD where HD means High Density

Used for certain fuel tanks, etc. Polythene is the most recycled material in the world. The material

absorbs fuel which later, and if recycled, emits odour. Material from fuel tanks should therefore undergo

special treatment and be used for energy recovery.

>PP<

Polypropylene:

Normally used for interiors, in low temperature applications around the engine and even externally in

some cases. PP is easy to recycle.

>PUR<

Polyurethane (Thermosets):

Used in squab cushions, armrests and noise reduction mats. This material is difficult to recycle at

present.

>PVC<

Polyvinyl chloride:

Used for cable insulation, for example. This material is difficult to recycle as it is sensitive to impurities. It

also forms hydrochloric acid during incineration.

>TPE<

Thermoplastic elastomer (rubber).

12

© Scania CV AB December 2017, en-GB

Page 17

General - Identification of plastics

>UP<

Unsaturated polyester (Thermosets):

At Scania, UP is used mostly as pressed SMC - Sheet Moulding Compound. SMC is a semi-finished

product comprising fibres (usually glass fibres) and UP mixed with filling, release agent, hardener and

sometimes paint. Used most often for air deflector kits and exterior panels.

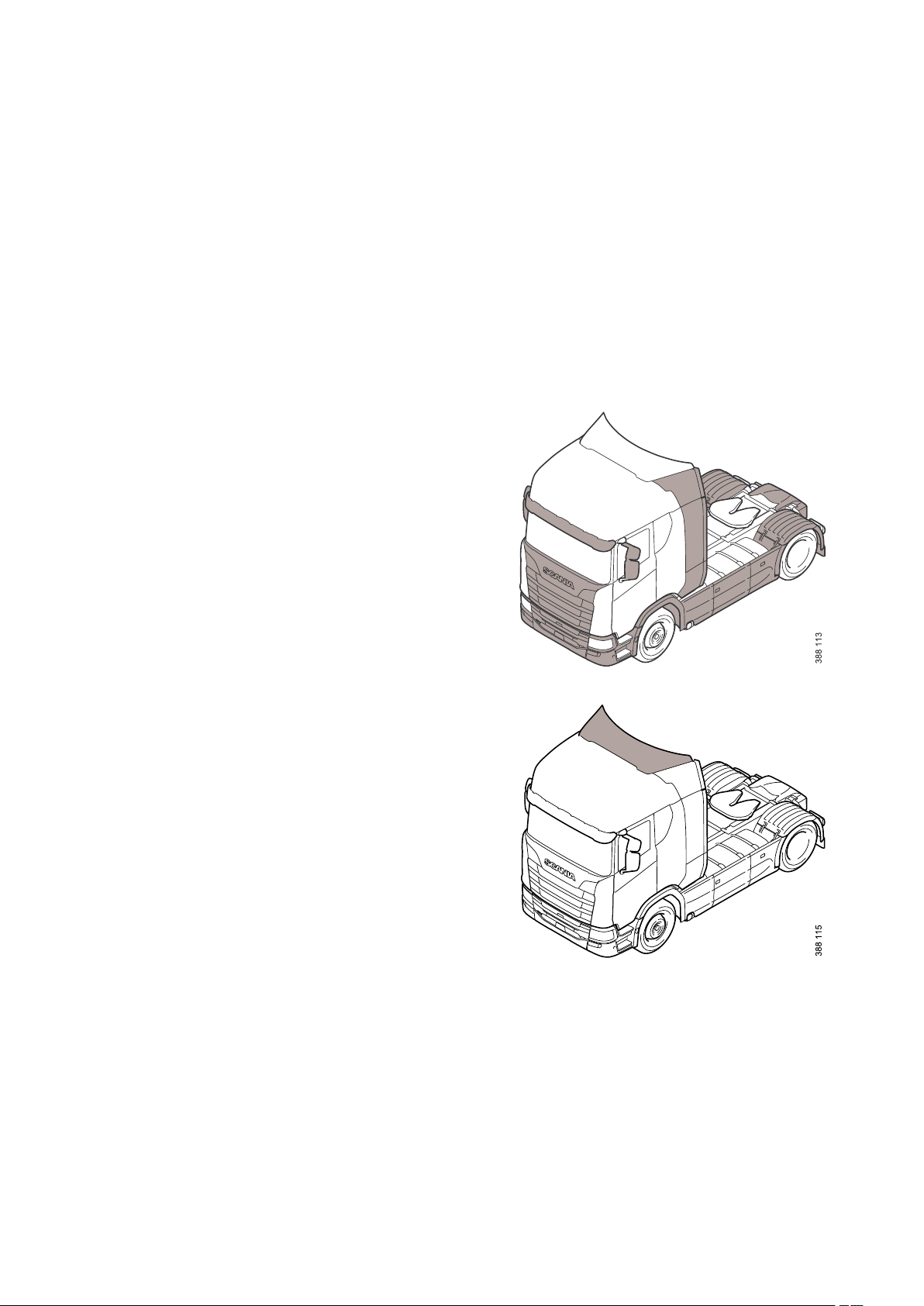

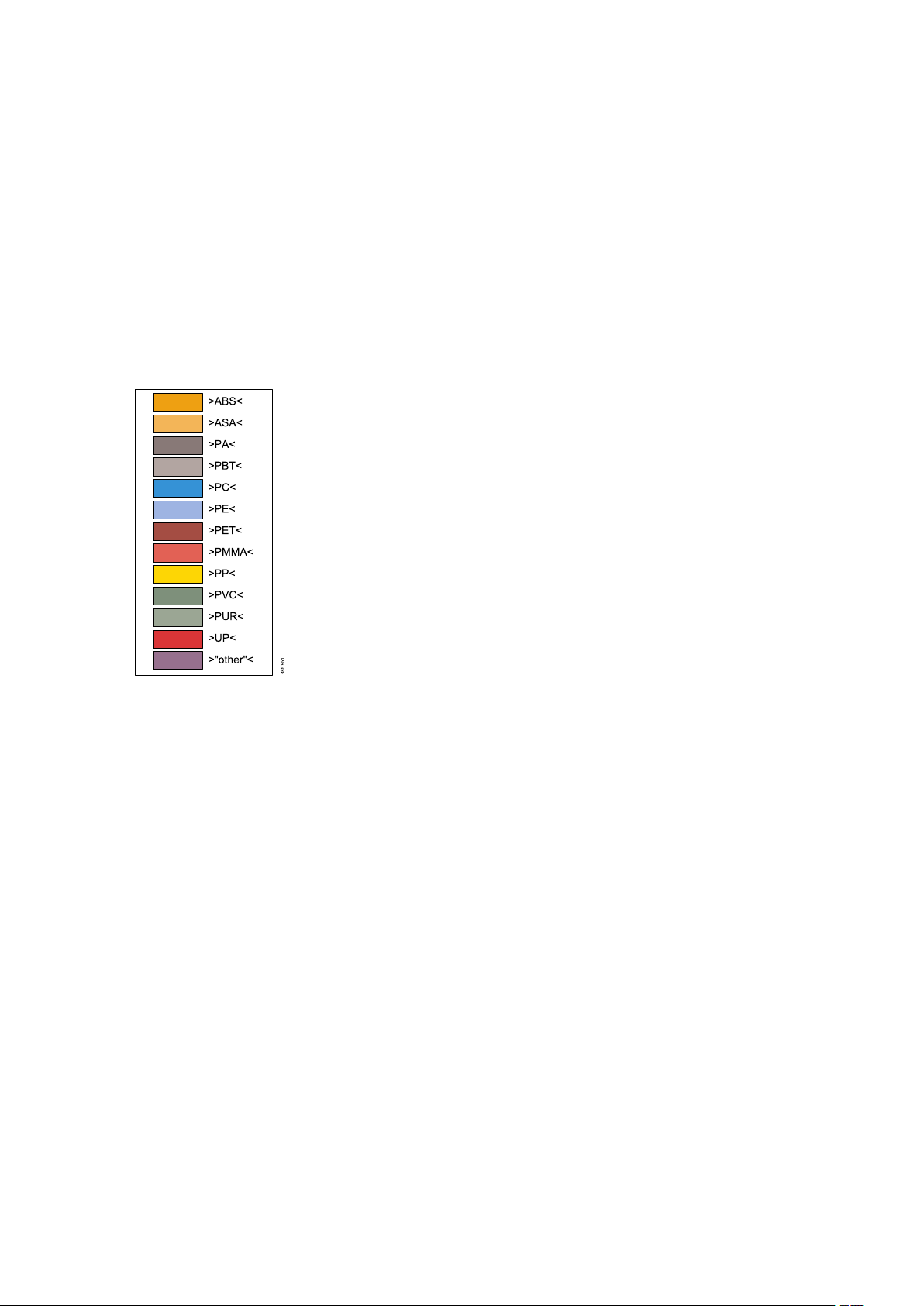

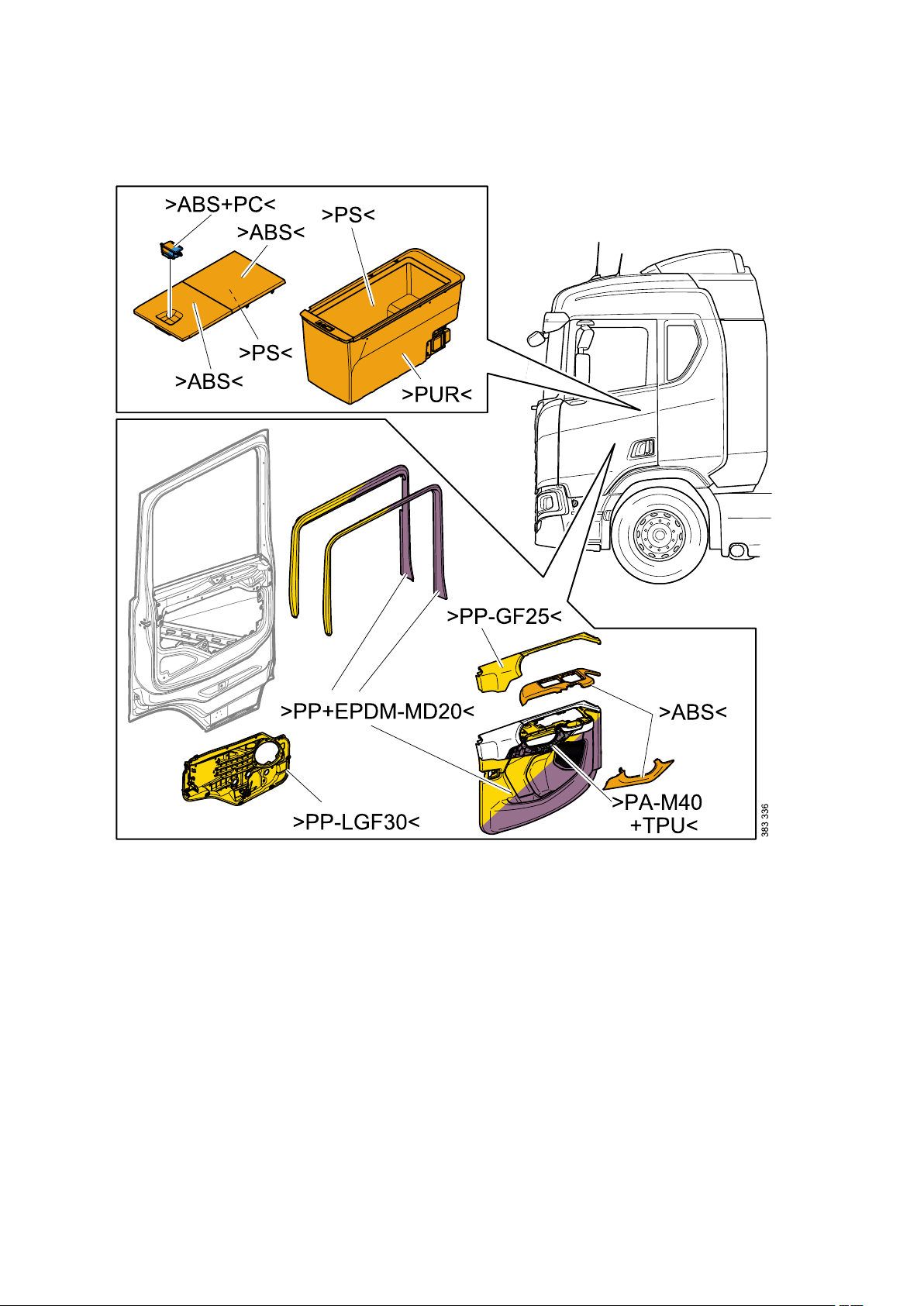

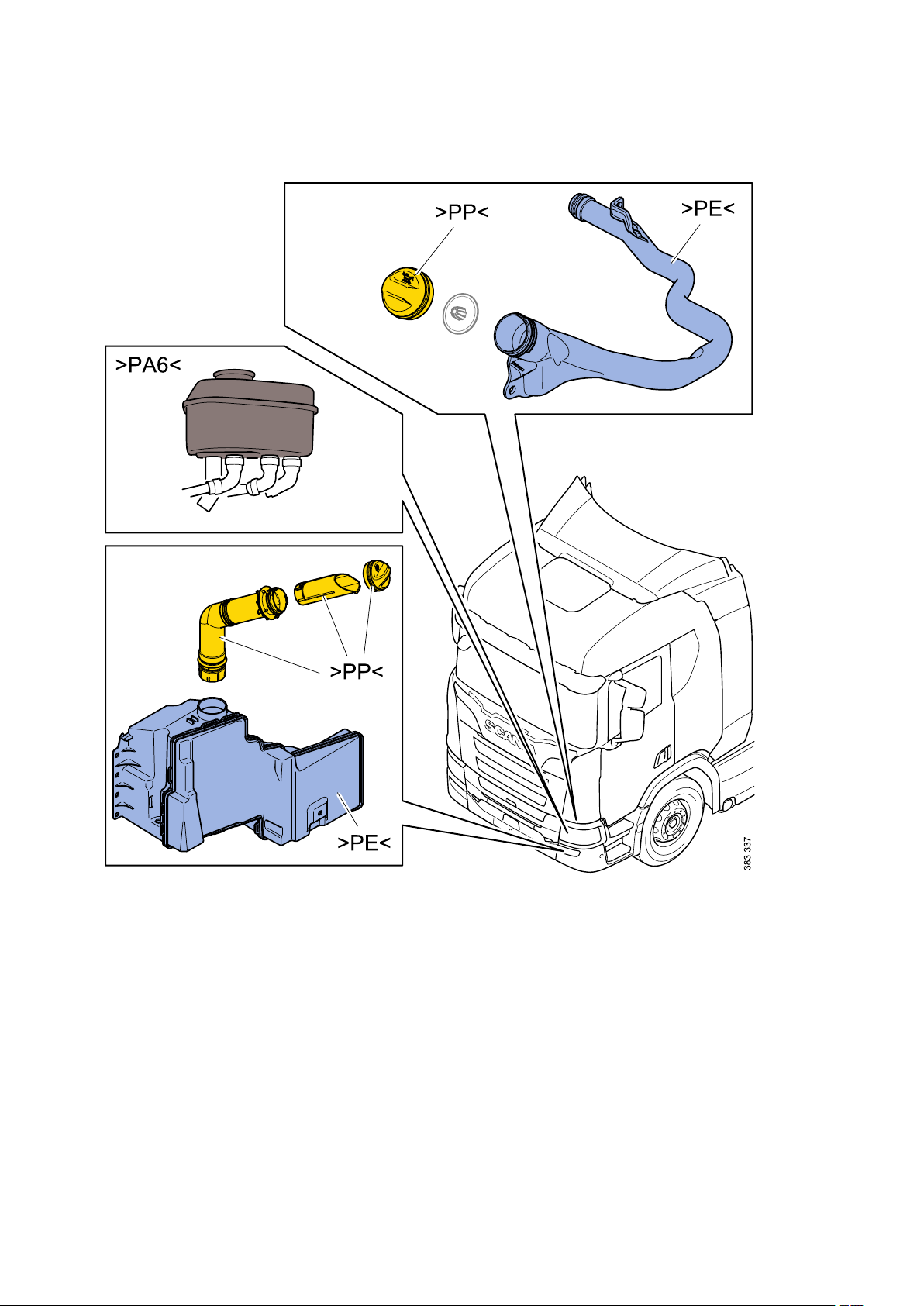

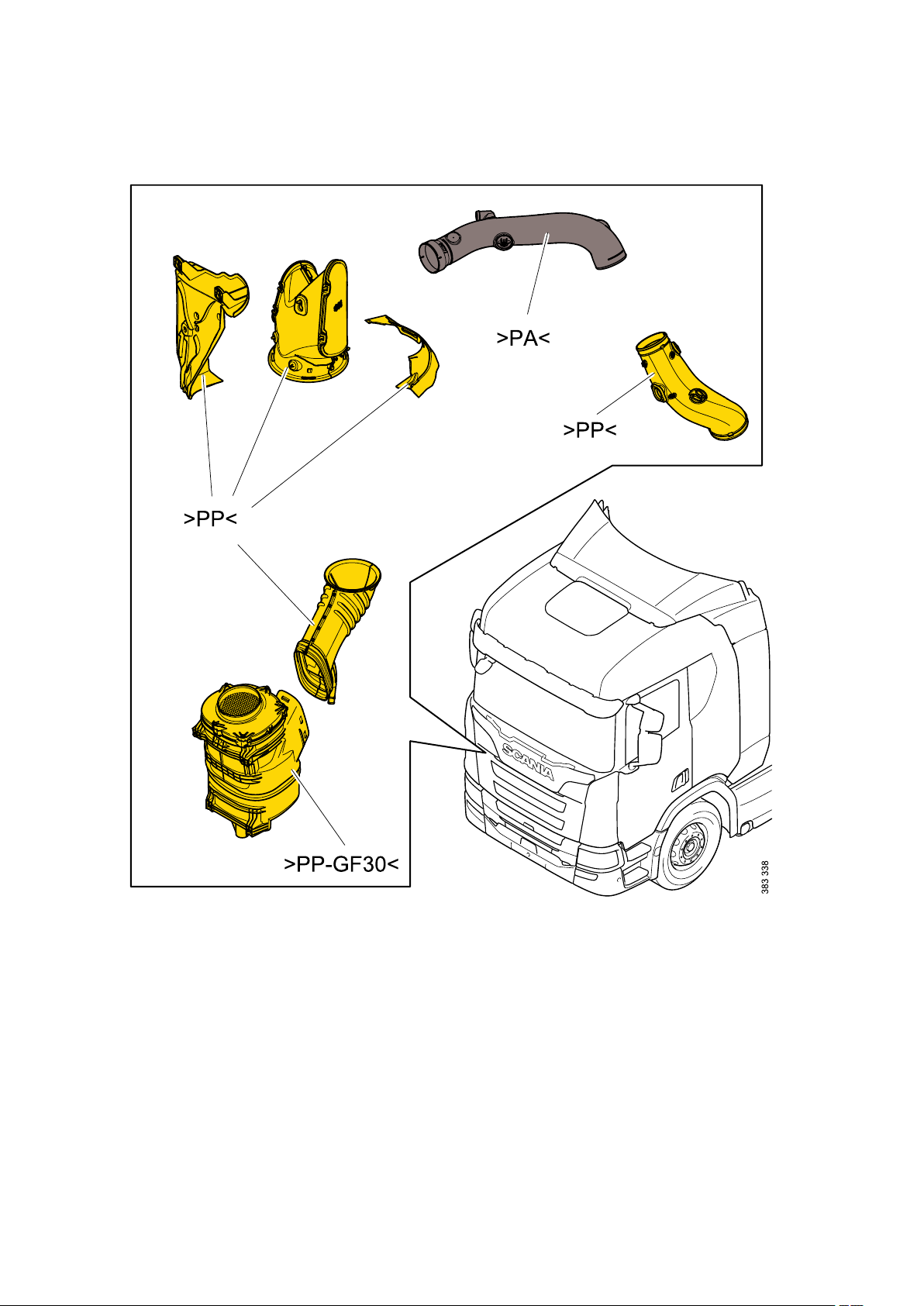

Overview illustrations

Colour codes

"other" = other polymer materials

December 2017, en-GB © Scania CV AB

13

Page 18

General - Identification of plastics

14

© Scania CV AB December 2017, en-GB

Page 19

General - Identification of plastics

December 2017, en-GB © Scania CV AB

15

Page 20

General - Identification of plastics

16

© Scania CV AB December 2017, en-GB

Page 21

General - Identification of plastics

December 2017, en-GB © Scania CV AB

17

Page 22

General - Identification of plastics

18

© Scania CV AB December 2017, en-GB

Page 23

General - Identification of plastics

December 2017, en-GB © Scania CV AB

19

Page 24

General - Identification of plastics

20

© Scania CV AB December 2017, en-GB

Page 25

General - Identification of plastics

December 2017, en-GB © Scania CV AB

21

Page 26

General - Identification of plastics

22

© Scania CV AB December 2017, en-GB

Page 27

General - Identification of plastics

December 2017, en-GB © Scania CV AB

23

Page 28

General - Identification of plastics

24

© Scania CV AB December 2017, en-GB

Page 29

General - Identification of plastics

December 2017, en-GB © Scania CV AB

25

Page 30

General - Identification of plastics

26

© Scania CV AB December 2017, en-GB

Page 31

General - Lifting and supporting on stands

Lifting and supporting on stands

Safety precautions

WARNING!

Never work under a vehicle only supported by a jack!

IMPORTANT!

Never support on stands or lift a raised vehicle on

parts belonging to the wheel suspension or steering.

Never support on stands or lift underneath the torque

rods or their brackets.

WARNING!

Use reliable and correctly dimensioned axle stands,

struts and locks with standard locking devices.

Ensure that the jack and stands are stable on a level

surface.

WARNING!

Always empty the air bellows or support the frame on

stands before starting work under vehicles with air

suspension. See the Work on vehicles with air

suspension section.

Raising with a jack

NOTE:

Read the safety precautions before starting work!

December 2017, en-GB © Scania CV AB

27

Page 32

General - Lifting and supporting on stands

IMPORTANT!

Lifting under the front axle or rear axle is only

permitted on an unladen vehicle.

Lifting using a jack under driving axles with a high

axle weight can cause the axle housing and gear

housing to become deformed.

No load must be placed on the oil drain plug.

IMPORTANT!

When lifting vehicles with several front axles or rear

axles, the axle weight distribution must be taken into

account.

1.

WARNING!

Chock the wheels and release the parking brake

before jacking up the vehicle, so that the vehicle can

follow the movement of the jack.

Chock the wheels to prevent the vehicle rolling

away and release the parking brake.

2. Lift the vehicle under any of the lifting points

IMPORTANT!

A laden vehicle can only be lifted under the spring

mountings.

3. Secure the vehicle on axle stands.

28

© Scania CV AB December 2017, en-GB

Page 33

General - Lifting and supporting on stands

Raising with wheel lifts

WARNING!

Always empty the bellows before lifting with wheel

lifts.

If there is a loss of air pressure, the axle distance will

change, which can cause the wheel lifts to tip over.

Vehicles with air suspension:

Empty the bellows of air according to Work on vehicles with air suspension.

Supporting on stands under the axle

Front

Always raise all axles with wheel lifts.

Supporting under the axle, front

December 2017, en-GB © Scania CV AB

29

Page 34

General - Lifting and supporting on stands

Rear

Supporting under the axle, rear

Vehicles with leaf spring suspension can also be supported under the springs.

Supporting the vehicle on stands, front

NOTE:

Read the safety precautions before starting work!

1. Remove the air deflector, if fitted, by unscrewing the

screws at the front edge and then unhook the air

deflector from the rear brackets.

2. Raise the vehicle on jacks or wheel lifts.

30

© Scania CV AB December 2017, en-GB

Page 35

3. Place axle stands under the jacking points.

General - Lifting and supporting on stands

4. Lower the vehicle carefully, making sure that it is

secure on the axle stands.

Supporting vehicles with a heavy-duty front on stands

NOTE:

Read the safety precautions before starting work!

Without tools

1. Raise the vehicle on jacks or wheel lifts.

2. Remove the inner rear screws securing the corner

plates.

3. Place axle stands under the jacking points.

4. Lower the vehicle carefully, making sure that it is

secure on the axle stands.

December 2017, en-GB © Scania CV AB

31

Page 36

General - Lifting and supporting on stands

With tools

1. Raise the vehicle on jacks or wheel lifts.

2. Remove the corner plates.

3. Screw tool 99 363 in place.

4. Place axle stands under the jacking tools.

5. Lower the vehicle carefully, making sure that it is

secure on the axle stands.

Supporting vehicles with front underrun protection on stands

NOTE:

Read the safety precautions before starting work!

1. Raise the vehicle on jacks or wheel lifts.

2. Place axle stands under the jacking points.

IMPORTANT!

Only support with stands under the underrun

protection on an unladen vehicle.

32

© Scania CV AB December 2017, en-GB

Page 37

General - Lifting and supporting on stands

3. Lower the vehicle carefully, making sure that it is

secure on the axle stands.

Supporting on stands under rear frame

NOTE:

Read the safety precautions before starting work!

If there is space, supporting the vehicle on stands in front of the axle is permitted. In this case position the

stand as close to the axle as possible.

Position the stands on the frame behind the last rear axle.

On vehicles with the battery at the rear and air suspension, the axle stands can be positioned between

the rear axle and the air bellows.

Supporting vehicles with air suspension, rear

Always use the safety prop when working in a pit under vehicles with air suspension. If the air bellows

fails, this can result in personal injury.

WARNING!

The safety prop must always be fitted parallel on the

left and right sides.

December 2017, en-GB © Scania CV AB

33

Page 38

General - Lifting and supporting on stands

IMPORTANT!

The vehicle must not be driven when the safety prop

is fitted.

Fitting the safety prop to vehicles with air suspension

The safety prop is available in 2 lengths, short: 99 678 and long: 99 677.

Fit the safety prop between the spring shackle and frame. The load on the axles is not to exceed 7.5

tonnes per safety prop.

Clean any dirt from the air spring link before fitting the safety prop.

1. Set the rear air suspension to approximately half of

the air spring height.

2. Fit the safety prop at the top between the screws on

the shock absorber bracket in the frame.

3. Position the foot of the safety prop in front of the air

bellows on the air spring link.

4. Detach the rotary control so that the release button

can be pushed in and then pull the safety prop out to

the correct length.

34

© Scania CV AB December 2017, en-GB

Page 39

5. Finish by tightening the quick extension bar until the

safety prop is stable.

Tighten the rotary control and lock the release

button.

IMPORTANT!

If the air bellows are filled with air during the work, the

safety prop must be adjusted afterwards as

described in steps 4-5.

General - Lifting and supporting on stands

Removing the safety prop

1. Fill the air bellows with air until the safety prop is no

longer under load.

WARNING!

Take care when removing the safety prop, there is a

risk of crush injuries.

Detach the rotary control so that the button on the

safety prop can be pushed in. Push the safety prop

together and remove it.

Maintenance

To ensure that the safety prop can be used safely at all times, the following points must be checked at

regular intervals.

December 2017, en-GB © Scania CV AB

35

Page 40

General - Lifting and supporting on stands

1. Checking screw joints. Check that the screw joints

have not come loose. Max. 7 millimetres of the

thread should be visible (1).

2. Checking the release button. Check that the

release button does not stick and that it goes out to

the locked position. This ensures that it will not

collapse during work.

3. Checking the feet. Check that there is not crack

formation on the safety prop feet.

Also make sure that:

4. The threads are free of dirt.

5. The screws securing the cover are tightened. (See

picture.) This is important, as these bolts also retain

the release button springs.

6. Finally the balls of the joints should be lubricated

with oil if they are stiff.

Renewing the foot on the safety prop

If the feet on the safety prop are damaged or worn, they should be renewed.

1. The threads are locked with adhesive. To unscrew

the feet, heat the thread in a suitable manner.

2. Unscrew the feet.

3. Lock the thread with adhesive.

36

© Scania CV AB December 2017, en-GB

Page 41

4. Fit the new feet. A maximum of 7 millimetres of

thread (1) should be visible.

General - Lifting and supporting on stands

December 2017, en-GB © Scania CV AB

37

Page 42

Engine - Engine

Engine

Engine

Removal - Engine

NOTE:

The gearbox must be removed before removing the

engine.

Tools:

NNuummbbeerr

99 063

98 094

DDeessiiggnnaattiioonn

Lifting yoke

Lifting chain

Picture Tool-board

D4

38

99 611

Lifting eye for V8 engine

© Scania CV AB December 2017, en-GB

Page 43

Engine - Engine

NNuummbbeerr

99 637

587 308 Ratchet lever hoist

99 318

Lifting eye for 9 and 13 litre engines

DDeessiiggnnaattiioonn

Engine support

Picture Tool-board

D5

99 470

2 377 964

1. Tilt the cab in accordance with the applicable safety

precautions. See the section Cab tilt system.

2. Cut the power.

Completing kit for engine support kit

Adapter

99 318

IMPORTANT!

Turn off the power by removing the battery negative

terminals.

3. Detach all pipes and hoses from the engine.

4. Drain the engine of all fluids.

D5

D5

December 2017, en-GB © Scania CV AB

39

Page 44

Engine - Engine

5. Undo the 8 screws. The image shows a V8 engine

but the principle is the same for other engines as

well.

6. Lift off the engine. Use the lifting eyes. The image

shows a V8 engine but the principle is the same for

other engines as well.

IMPORTANT!

V8 engine

The lifting eyes are designed to manage a maximum

inclination angle of 30° when lifting an engine with the

gearbox removed.

1. Lifting eye 99611 for V8 engines

2. Engine-mounted lifting eye

40

© Scania CV AB December 2017, en-GB

Page 45

Oil filter

Removal - Oil filter

WARNING!

Always tilt the cab fully. When working under the cab,

it should be secured in accordance with the safety

precautions. See the section Cab tilt system.

1. Detach the oil filter cover. Let the system drain for 30

seconds.

Engine - Oil filter

December 2017, en-GB © Scania CV AB

Oil filter, 9 and 13 litre engine

41

Page 46

Engine - Oil filter

2. Remove the oil filter.

Oil filter, 16 litre engine

42

© Scania CV AB December 2017, en-GB

Page 47

Rotor

Removal - Rotor

WARNING!

Always tilt the cab fully. When working under the cab,

it should be secured in accordance with the safety

precautions. See the section Cab tilt system.

Removing the rotor, 9 and 13 litre engine

1. Remove the engine noise shields to access the

centrifugal oil cleaner.

Engine - Rotor

2. Unscrew the bottom lid of the centrifugal oil cleaner,

2 rotations. Let the system drain.

NOTE:

Use a waste oil trolley when draining the centrifugal

oil cleaner.

3. Remove the bottom cover together with the rotor.

Remove the rotor from the cover by pulling the rotor

straight up from the cover.

Centrifugal oil cleaner, 9 and 13 litre engine

Bottom cover on centrifugal oil cleaner

December 2017, en-GB © Scania CV AB

43

Page 48

Engine - Rotor

Removing the rotor, 16 litre engine

NNuummbbeerr

588 475 Socket

1. Tilt the cab in accordance with the applicable safety

precautions. See the section Cab tilt system.

2. Remove the engine noise shields to access the

centrifugal oil cleaner.

DDeessiiggnnaattiioonn

Picture Tool-board

MB2

Centrifugal oil cleaner, 16 litre engines

3. Undo the cover with socket 588 475. Remove the

cover and rotor.

1. Cover

2. Rotor

44

© Scania CV AB December 2017, en-GB

Page 49

Engine oil

Draining the engine oil

1. Remove the noise shield underneath the engine.

2. Detach the pipe from the crankcase ventilation and

unscrew the oil plug.

ENVIRONMENT

Drain oil into a suitable container.

Engine - Engine oil

Oil plug, 9 litre engine

December 2017, en-GB © Scania CV AB

45

Page 50

Cooling system - Coolant

Cooling system

Coolant

Draining coolant

WARNING!

If the engine is at operating temperature, the coolant

is very hot and can cause burns.

ENVIRONMENT

Avoid spillage and use a suitable container. Used

coolant must be disposed of as specified in national

and international law.

Tools:

NNuummbbeerr

588 540

99 301

1. Carefully open the expansion tank cap. The cooling

system may be exposed to overpressure.

Coolant trolley (replaces 588 450)

DDeessiiggnnaattiioonn

Adapter (for 588 450)

Picture Tool-board

D5

46

© Scania CV AB December 2017, en-GB

Page 51

2. Remove the rubber plug that protects the drain and

filler nipple of the cooling system.

Cooling system - Coolant

Drain nipple for coolant directly under the cab

front

3. Connect the hose from the coolant trolley (588 540)

to the drain nipple under the cab front. Drain and

collect the coolant.

With the earlier version of the trolley (588 450),

adapter 99 301 is required.

Drain nipple for coolant, V8 engines with EGR

cooler

December 2017, en-GB © Scania CV AB

47

Page 52

Cooling system - Coolant

4. Remove the noise shields to access the lower drain

nipple on the engine cylinder block.

Connect the hose from coolant trolley 588 540 to the

drain nipple.

Drain the coolant as described above.

Drain nipple for coolant on the cylinder block, 16

litre engine

Vehicles with Scania retarder

NNuummbbeerr

588540

Coolant trolley (replaces 588 450)

DDeessiiggnnaattiioonn

Hose to coolant drainage nipple on the cylinder

block, 9 and 13 litre engine

Picture Tool-board

48

© Scania CV AB December 2017, en-GB

Page 53

1. Connect the hose from the coolant trolley (588 540)

to the drain nipple on the engine.

With the earlier version of the trolley (588 450),

adapter 99 301 is required.

Cooling system - Coolant

2. Drain the coolant.

1. Drain nipple for coolant.

December 2017, en-GB © Scania CV AB

49

Page 54

Fuel and exhaust systems - Dismantling the silencer

Fuel and exhaust systems

Dismantling the silencer

Silencer Euro 3, 4, 5

1. Cut away the brackets.

2. Remove the outer protective casing by cutting above

the weld joint which has been highlighted in the

illustration.

50

© Scania CV AB December 2017, en-GB

Page 55

Fuel and exhaust systems - Dismantling the silencer

3. Remove the casing over the catalytic converter by

cutting around the entire weld joint securing the

casing.

4. Remove the outer protective plate by cutting as

illustrated.

December 2017, en-GB © Scania CV AB

51

Page 56

Fuel and exhaust systems - Dismantling the silencer

5. Remove the inner plate by cutting as illustrated.

6. Cut off the pipe according to the marking in the

illustration.

52

© Scania CV AB December 2017, en-GB

Page 57

Fuel and exhaust systems - Dismantling the silencer

7. Remove the plate over the catalytic converter by

cutting under the weld joint as illustrated.

8. Cut off the bracket between the catalytic converters.

9. The catalytic converters are attached to double

plates. Cut through both plates and lift off the

catalytic converters.

December 2017, en-GB © Scania CV AB

53

Page 58

Fuel and exhaust systems - Reductant tank

Reductant tank

Safety precautions and procedures when working on the reductant

circuit

Even though the reductant is not toxic, the following should be taken into account when working on the

reductant circuit.

• In case of eye contact, rinse immediately using an eye bath and then seek medical attention.

• In case of contact with skin, rinse with water.

• Change immediately out of clothes which have spills on.

• If ammonia gas is inhaled, make sure that plenty of fresh air is provided immediately.

WARNING!

Use protective goggles and gloves if there is any risk

of splashing or spraying of reductant or coolant.

WARNING!

When the engine is running, the exhaust system

parts can reach such high temperatures that there is

a risk of personal injury. Make sure that the exhaust

system temperature has decreased to a suitable level

before starting work.

WARNING!

The reductant system is heated by water from the

engine cooling system. The cooling system runs at

overpressure and when the engine is hot the coolant

is hot. Do not open any hoses without first stopping

the coolant flow in the hose.

IMPORTANT!

Cleanliness is very important when working on the

reductant circuit. Clean thoroughly around all parts to

be dismantled to prevent dirt from entering the

system.

IMPORTANT!

Reductant causes certain metals to corrode. Always

rinse away any spillage on e.g. connections and other

parts with lukewarm water to prevent corrosion.

54

© Scania CV AB December 2017, en-GB

Page 59

Fuel and exhaust systems - Reductant tank

IMPORTANT!

When working on the SCR system, e.g. when

renewing hoses for the reductant tank and SCR

pump, connections must only be lubricated with

soapy water or distilled water with a 3% urea mixture.

Any other types of lubricants may block and damage

components in the SCR system.

Draining reductant using tool 588 682

Use the equipment to drain reductant during work that involves removing the reductant tank from the

vehicle.

Clean the filter 588 684 every three uses; refer to the instructions for cleaning filter 588 684 below.

Draining

1. Remove the reductant tank cover.

2.

Side-hung reductant tank: Remove the adapter and

press the draining tool suction hose to the bottom of

the reductant tank.

Hidden reductant tank: Remove the pressurising

hose and the bleed hose from the tank and press the

draining tool suction hose to the bottom of the tank.

3. Connect compressed air to the fuel suction unit.

December 2017, en-GB © Scania CV AB

55

Page 60

Fuel and exhaust systems - Reductant tank

4. Open the compressed air connection tap.

5. Use the filler handle to pump over reductant into the

draining tool drum.

6. Close the compressed air connection tap once the

reductant tank is empty.

7. Side-hung reductant tank: Remove the suction

hose from the reductant tank and refit the adapter.

Hidden reductant tank: Remove the suction hose

from the reductant tank.

56

© Scania CV AB December 2017, en-GB

Page 61

Fuel tank

Draining the fuel tank

Fuel and exhaust systems - Fuel tank

NNuummbbeerr

588 794 Fuel suction unit for fuel tanks

DDeessiiggnnaattiioonn

Picture Tool-board

Fuel suction unit for fuel tanks

The fuel suction unit is intended for ethanol, diesel and petrol. It is fitted with wheels but it can also be

handled with a pallet lifter or a forklift truck. The fuel suction unit is made from stainless steel. Its capacity

is 630 litres and it weighs 145 kg when empty.

The fuel suction unit is equipped with a pneumatic diaphragm pump. An overfill protection device

automatically breaks the air supply to the pump if the fuel level in the fuel suction unit is too high.

Pumping must always be interrupted manually at the marked maximum level on the level pipe.

The fuel suction unit is equipped with a venting hose fitted with a flame guard, which is connected to the

vehicle exhaust extraction system when draining vehicles to achieve odourless fuel handling.

Use of tool 544794.

A - Control lever

B - Off position F - Compressed air

C - Draining position G - Pressure regulator

D - Refilling position H - Flow valve L - Fuel hose with strainer

Always ensure that the pneumatic system is free from water and dirt before the fuel suction unit is

operated. Water and dirt can damage the fuel suction unit.

Never leave the fuel suction unit unattended during operation. Never rely on the automatic overfill

protection device. The operator is responsible for interrupting pumping when it reaches the marked

maximum level on the level pipe.

E - Manometer M - Venting

J - Maximum level

K - Level pipe

December 2017, en-GB © Scania CV AB

57

Page 62

Fuel and exhaust systems - Fuel tank

Position the fuel suction unit on a level surface close to the vehicle that is to be drained. The castor

wheels must be locked during operation. Connect the fuel suction unit to compressed air 4-8 bar.

If the overfill protection is triggered: It is reset by pumping the fuel back, lever in the Refill vehicle position

until the maximum level is no longer exceeded. When pumping is completed, the control lever must be in

the Off position and the fuel hose disconnected from the drain pipe and drain valve so that the coupling is

sealed. In adverse conditions, the fuel may otherwise continue to flow through the pump to the siphon

effect. For complete draining and cleaning of the fuel suction unit: Open the bottom plug with a 10 mm

internal hexagon key.

WARNING!

The fuel suction unit must be fully drained using the

pump before removing the bottom plug.

Q – Bottom plug

ENVIRONMENT

Any fuel spills must be disposed of in compliance

with local regulations.

Fix the ground clamp to an unpainted metal surface with the best possible grounding connection.

WARNING!

Without grounding there is a risk for static electricity

to build up when the fuel is pumped. Static electricity

can cause a spark which in turn can set the fuel

alight.

58

© Scania CV AB December 2017, en-GB

Page 63

Removal - Fuel tank

Fuel and exhaust systems - Fuel tank

NNuummbbeerr

2 378 561

588 794 Fuel suction unit for fuel tanks

588 084

Crowfoot wrench, U-type, 22 mm

DDeessiiggnnaattiioonn

Hydraulic, mobile lifting table

Picture Tool-board

1. Drain the tank using tool 588 794.

2. Detach the electrical connection and hoses from the

fuel pick-up unit.

WARNING!

There may be residual pressure in the pipes. Wear

eye protection during removal.

3. Remove the fuel pick-up unit, separating the plastic

and metal.

4. Drill a hole in the fuel tank to get all the fuel out.

December 2017, en-GB © Scania CV AB

59

Page 64

Coupling - Connection and operation

Coupling

Connection and operation

Draining – clutch fluid

NNuummbbeerr

587 949

588 905

Clutch bleeder/filling equipment

Tool for extracting excess clutch fluid

DDeessiiggnnaattiioonn

WARNING!

Use goggles. Clutch fluid is corrosive and can cause

permanent eye damage.

1. Remove the plastic cover.

Picture Tool-board

2. Unscrew the cap on the clutch fluid reservoir in the

vehicle and remove the strainer.

60

© Scania CV AB December 2017, en-GB

Page 65

3. Connect the cover on clutch bleeder 587 949 to the

clutch fluid reservoir. Tighten the cover so that it is

sealed tightly.

4. Connect compressed air to the clutch bleeder.

Check that the upper manometer shows 2 bar.

Coupling - Connection and operation

5. Connect a bleed hose with a container to the bleed

nipple at the gearbox.

6. Open the tap on clutch bleeder 587 949.

December 2017, en-GB © Scania CV AB

61

Page 66

Coupling - Connection and operation

7. Drain and bleed the system by opening the bleed

nipple.

NOTE:

The clutch pedal must be in its highest position and

must not be actuated during the bleeding phase.

8. Close the tap on the clutch bleeder and disconnect

the tool.

62

© Scania CV AB December 2017, en-GB

Page 67

Gearbox - Gearbox

Gearbox

Gearbox

Gearbox - tools

There are several different models of gearboxes. The following tools are used when removing gearboxes

from Scania vehicles.

NNuummbbeerr

99 644* Base bracket

99 646 Bracket kit

587 313

588 966 Machine lift

DDeessiiggnnaattiioonn

Gearbox jack

Picture Tool-board

F3

F3

-

-

*Tool 99 644 fits most gearbox jacks distributed by Scania. If another type of gearbox jack is used,

another base bracket must be used, see tool sheet for 99 645.

The above combination of lifting accessories is used for lifting components.

For information on how to dismantle a specific gearbox, contact a Scania workshop.

December 2017, en-GB © Scania CV AB

63

Page 68

Gearbox - Gearbox

WARNING!

Always secure the vehicle against collapsing before

starting work. There is a serious danger of crushing.

Both the chassis and moving axle suspension

components must be secured with axle stands to

ensure absolute safety when working under a raised

vehicle.

If the vehicle has air suspension, the air bellows must

be emptied before starting work.

Only move a loaded gearbox jack with the load in the

lowest possible position.

When lowering, make sure that nothing catches and

damages the gearbox jack, component or the lifting

accessory.

Be aware of the risk of crushing when lowering the

gearbox jack and the lifting accessory.

64

© Scania CV AB December 2017, en-GB

Page 69

Brakes - Pneumatic system - Compressed air tanks

Brakes - Pneumatic system

Compressed air tanks

Draining – compressed air tanks

IMPORTANT!

Handle empty compressed air tanks in compliance

with local regulations.

Pull the drain valves to depressurise the tanks.

December 2017, en-GB © Scania CV AB

65

Page 70

Brakes - Pneumatic system - Spring brake chamber

Spring brake chamber

Removal – Spring brake chamber

1. Place wheel chocks in front of and behind at least 2

wheels.

2. Release the parking brake.

3. Unscrew the release bolt until the parking brake is

fully released on the relevant wheel.

WARNING!

When the release bolts are screwed out, the vehicle

has no parking brake on the wheels where the

release bolt has been screwed out. Therefore, use

wheel chocks to prevent the vehicle from rolling.

WARNING!

Always ensure that the parking brake is released

before removing the spring brake chamber. Check

this by rotating the brake disc.

IMPORTANT!

Danger of cross-threading. Clean and oil the bolt. Do

not use a nut runner. If the bolt is damaged, the

parking brake will not release even though the bolt is

unscrewed.

The release bolts (1) are available in different versions. The release bolt is screwed out different lengths

depending on the version. Screw until it stops. On certain versions there is a red pin (2) in the release bolt

centre that indicates that the bolt is screwed out from its normal position.

66

© Scania CV AB December 2017, en-GB

Page 71

Brakes - Pneumatic system - Spring brake chamber

4. Apply the parking brake again on the other wheels

to release the braking pressure.

5. Detach the compressed air connections.

6. Undo the 2 nuts which attach the spring brake

chamber. If there are wear wires, move the wear

sensor cable retainer to the side.

7. Remove the spring brake chamber.

WARNING!

The spring brake unit must not be dismantled.

Dismantling the spring brake unit constitutes a

serious risk of injury due to strong spring tension.

1. Release bolt

2. On some versions, there is a red pin that indicates

that the screw has been turned out of its normal

position.

December 2017, en-GB © Scania CV AB

67

Page 72

Suspension - Air suspension

Suspension

Air suspension

Work on vehicle with air suspension

NOTE:

Always support the vehicle. See the Lifting and

supporting on stands section.

WARNING!

Always support the vehicle on stands when working

on vehicles with air suspension. Empty the air

bellows.

When working on vehicles without stands under the

frame, there is a considerable risk of serious personal

injury. When the bellows lose air pressure, the frame

will drop onto the axles. This will occur when:

– pressurised lines are removed.

– an air bellows is punctured.

– voltage is applied to the valve for the purpose of

emptying the bellows.

– the level sensor lever is moved downwards.

WARNING!

Always empty the bellows before lifting with wheel

lifts.

If there is a loss of air pressure, the axle distance will

change, which can cause the wheel lifts to tip over.

IMPORTANT!

Never support on stands or lift a raised vehicle on

parts belonging to the wheel suspension or steering.

Never support on stands or lift underneath the torque

rods or their brackets.

68

© Scania CV AB December 2017, en-GB

Page 73

IMPORTANT!

Always use new U-bolts and nuts as well as new

washers and screws.

Safety precautions

1. Use reliable and correctly dimensioned axle stands,

struts and locks with standard locking devices.

2. Ensure that the jack and axle stands are stable on a

level surface.

3. Lifting accessories must have been approved for

use.

4. Apply the parking brake.

Suspension - Air suspension

5. Chock the wheels before the vehicle is lifted with a

jack.

Empty the air bellows

Use the level adjustment switch or operation unit to empty the bellows. Hold the button down until the

vehicle rests on the bump stops.

Example of a level adjustment switch

December 2017, en-GB © Scania CV AB

69

Page 74

Suspension - Air suspension

Position of the operation unit.

70

© Scania CV AB December 2017, en-GB

Page 75

Steering - Removal - Airbag

Steering

Removal - Airbag

Action on contact with hazardous substances from the airbag

Hazardous substances in the airbag: An airbag that has not been activated contains hazardous

substances that can cause damage or injury if they leak out. See below and in the product data sheet in

the stores. Before activation an airbag contains sodium azide, potassium nitrate, silicon oxide and iron

oxide.

If inhaled: Go outdoors in the fresh air. Give the person artificial respiration or oxygen, if necessary. The

person should seek medical attention.

Skin contact: Wash with plenty of soap and water.

Eye contact: Rinse with water for at least 15 minutes. Seek medical attention

If ingested: Drink 2-3 decilitres of water and provoke vomiting by inserting one or two fingers down the

throat. Call a doctor. If the person is unconscious or has convulsions, do not try to make him drink water

or provoke vomiting. Call a doctor without delay.

Signal cap with built-in airbag (H14)

WARNING!

Cut the power to the vehicle and wait at least 10

seconds before starting work on the airbag.

The airbag contains an explosive charge. Do not

perform any other work besides that described here.

Carry the airbag with the Scania badge facing you.

NNuummbbeerr

588390

DDeessiiggnnaattiioonn

Tool kit for panels

Picture Tool-board

1. Turn the wheels to the straight-ahead position.

A latch clamp holds the signal cap in place. To

remove it, you must carry out steps 2-4 below on

both sides of the steering wheel.

December 2017, en-GB © Scania CV AB

71

Page 76

Steering - Removal - Airbag

2. Make a hole in the marked area on the side of the

steering wheel (see illustration) if this has not been

done previously. Use a T30 Torx screwdriver.

3. Press in the screwdriver approx. 3 cm. Then lightly lift

the screwdriver towards the steering wheel and

press it straight in towards the latch clamp.

72

© Scania CV AB December 2017, en-GB

Page 77

4. Keep the pressure against the latch clamp and lift the

edge of the signal cap until there is a gap of approx.

1 cm to the steering wheel.

Use tools from tool kit 588 390 to facilitate removal of

the signal cap.

5. Repeat steps 2-4 on the opposite side of the

steering wheel.

6. Support the signal cap against the steering wheel.

Steering - Removal - Airbag

December 2017, en-GB © Scania CV AB

73

Page 78

Steering - Removal - Airbag

7. Remove the connector for the airbag. For information

on handling of the airbag, see the section Action on

contact with hazardous substances from the airbag.

8. Remove the horn connectors.

74

© Scania CV AB December 2017, en-GB

Page 79

Electrical system - Chassis central electric unit

Electrical system

Chassis central electric unit

Removal - Chassis central electric unit

NOTE:

The instructions below apply to both central electric

unit P8 and central electric unit P11.

1. Tilt the cab, see the Cab tilt system section.

2. Remove the mudguard. The chassis central electric

unit is suspended in the same plate as the

mudguard.

3. Remove the wheel housing.

4. Remove the batteries. See the Batteries section.

WARNING!

The batteries are removed for safety reasons to avoid

short circuits, as there is very little space between the

batteries and the chassis central electrical unit.

5. Remove the battery box for better access to the

chassis central electric unit.

December 2017, en-GB © Scania CV AB

75

Page 80

Electrical system - Chassis central electric unit

6. Unscrew the nuts on the rear of the chassis central

electric unit.

7. Remove the chassis central electric unit.

76

© Scania CV AB December 2017, en-GB

Page 81

Removal - Curtain airbag

H30, Curtain airbag, driver's side

NOTE:

The curtain airbag is regarded as pyrotechnic

equipment and must be handled according to special

rules. Every country has its own legislation regarding

handling, but in general this equipment is considered

explosive goods as soon as it is handled outside the

vehicle.

For the storage, transport or disposal of nondeployed units, check with the relevant country's

Scania importer which rules apply in your country.

Electrical system - Removal - Curtain airbag

For transport between Scania parts warehouses and

workshops, the pyrotechnic equipment is transported

in specially reinforced packaging. The transport is

considered hazardous goods.

WARNING!

Cut the power to the vehicle and wait at least 10

seconds before starting work on the curtain airbag.

The curtain airbag contains an explosive charge. Do

not perform any other work besides that described

here.

Carry the airbag with the metal casing facing away

from you.

Preparatory work

1. Remove the upper bed.

2. Remove the panels:

• Ceiling panel

• The A- and B-pillar cover

• Lower side wall panel

• Upper side wall panel

December 2017, en-GB © Scania CV AB

77

Page 82

Electrical system - Removal - Curtain airbag

Removing the curtain airbag

1. Start by undoing the curtain airbag connectors. Pull

the highlighted part of the connector from the curtain

airbag to detach the connector.

2. Then detach the cable duct in the A-pillar and place it

to one side.

3. Drill out the rivets (2) and remove the screws (1).

Prise the curtain out of its keyhole brackets.

78

© Scania CV AB December 2017, en-GB

Page 83

H31, Curtain airbag, passenger side

NOTE:

The curtain airbag is regarded as pyrotechnic

equipment and must be handled according to special

rules. Every country has its own legislation regarding

handling, but in general this equipment is considered

explosive goods as soon as it is handled outside the

vehicle.

For the storage, transport or disposal of nondeployed units, check with the relevant country's

Scania importer which rules apply in your country.

For transport between Scania parts warehouses and

workshops, the pyrotechnic equipment is transported

in specially reinforced packaging. The transport is

considered hazardous goods.

Electrical system - Removal - Curtain airbag

WARNING!

Cut the power to the vehicle and wait at least 10

seconds before starting work on the curtain airbag.

The curtain airbag contains an explosive charge. Do

not perform any other work besides that described

here.

Carry the airbag with the metal casing facing away

from you.

Preparatory work

1. Remove the upper bed.

2. Remove the panels:

• Ceiling panel

• The A- and B-pillar cover

• Lower side wall panel

• Upper side wall panel

December 2017, en-GB © Scania CV AB

79

Page 84

Electrical system - Removal - Curtain airbag

Removing the curtain airbag

1. Start by undoing the curtain airbag connectors. Pull

the highlighted part of the connector from the curtain

airbag to detach the connector.

2. Then detach the cable duct in the A-pillar and place it

to one side.

3. Drill out the rivets (2) and remove the screws (1).

Prise the curtain out of its keyhole brackets.

80

© Scania CV AB December 2017, en-GB

Page 85

Batteries

Removal - Batteries

The information below applies to starter batteries.

WARNING!

Wear gloves and eye protection, as the vehicle

batteries contain corrosive diluted sulphuric acid and

the toxic metal lead.

If acid splashes into your eyes, rinse immediately with

running water for at least 15 minutes. Always see a

doctor if you get acid in your eyes.

Electrical system - Batteries

If acid splashes on other parts of your body, rinse

immediately with water.

ENVIRONMENT

Handle and store batteries in compliance with local

regulations. Within the EU there are manufacturer

responsibility regulations for batteries. This means

that all Scania workshops are obliged to dispose of

batteries responsibly and ensure that they are

recycled correctly.

The vehicle batteries contain lead. Lead is harmful to

humans and the environment. The batteries must

therefore be handled in accordance with national

regulations on environmentally hazardous

substances.

IMPORTANT!

Be aware of the risks of short-circuiting when working

near the battery terminals. Use a lifting board for

removing and replacing the batteries.

NNuummbbeerr

588 084

December 2017, en-GB © Scania CV AB

DDeessiiggnnaattiioonn

Hydraulic, mobile lifting table

Picture Tool-board

81

Page 86

Electrical system - Batteries

1. Remove the battery from the battery box.

2. Loosen the connections to the central electric unit.

3. Sort the electrical scrap from the cable harness and

recycle.

82

© Scania CV AB December 2017, en-GB

Page 87

Instrument

Removal - Instrument panel

Preparatory work

Tools:

Instrument - Removal - Instrument panel

NNuummbbeerr

587 627

2 397 198

1. Remove the battery negative terminals, see the

Batteries section

2. Open and close the expansion tank cap to release

the overpressure.

3. Drain the A/C circuit of refrigerant; see the section

Working with refrigerant.

Hose pinch-off pliers, 2 off, or 588 603

DDeessiiggnnaattiioonn

Recycling station

Picture Tool-board

-

December 2017, en-GB © Scania CV AB

83

Page 88

Instrument - Removal - Instrument panel

Working from inside the cab

Tools:

NNuummbbeerr

588 390

1. Remove the A-pillar panels.

2. Remove the covers on the driver's side.

3. Remove the covers on the passenger side.

4. Remove the lower storage compartment.

DDeessiiggnnaattiioonn

Tool kit for panels

Picture Tool-board

-

Lower storage, R-cab

Lower storage, S-cab

84

© Scania CV AB December 2017, en-GB

Page 89

5. Remove the bracket to the lower storage.

6. Remove the defroster panel.

Remove the upper attachments of the instrument

panel in the firewall.

Instrument - Removal - Instrument panel

7. Remove the pipe to the exhaust air vent, left-hand

side of floor.

Detach the vertical steering column at the top.

8. Remove the cable harness and air supply on the

driver's side.

1. Remove the door cabling (C14 and C18), floor

cabling (C12, C20, C78) (and C8015, if fitted)

2. Remove the screws (C14 and C18) and floor

cabling (C12, C20, C78) (and C8015, if fitted)

Attach the ground cable to the instrument panel

crossmember with cable ties.

December 2017, en-GB © Scania CV AB

85

Page 90

Instrument - Removal - Instrument panel

9. Remove the cable harness and air supply on the

passenger side.

1. Remove the door cabling (C9, C25 and C218)

2. Remove the cable harness for the roof shelf.

3. Remove the cable harness and the central electric

unit for BWE, between the instrument panel and

floor lead-through

4. Remove the compressed air supply, screw and

electrical ground point (G).

Attach the cable harnesses for the door and roof

shelf with cable ties to the grab handle. Attach the

ground cable to the instrument panel crossmember

with cable ties.

Working from outside the cab

Tools:

NNuummbbeerr

2 397 198

1. Remove the windscreen panels and windscreen

wiper linkage.

Hose pinch-off pliers, 2 off, or 588 603

WARNING!

Use eye protection as washer fluid can splash from

the washer hoses.

2. Remove the coolant hoses. Use tool 2 397 198.

DDeessiiggnnaattiioonn

Picture Tool-board

-

86

Borttagning av kylvätskeslangarna.

© Scania CV AB December 2017, en-GB

Page 91

3. Remove the receiver dryer.

WARNING!

Always use personal protection equipment when

working with refrigerant. Refrigerant could cause

frostbite injury if it comes into contact with the skin.

Immediately contact a doctor if the refrigerant comes

into contact with the eyes. Do not rub! Flush

immediately with plenty of water, preferably running

water.

4. Remove the HVAC housing.

Instrument - Removal - Instrument panel

5. Remove the A/C pipe connection at the expansion

valve.

IMPORTANT!

Vira mjukt torkpapper runt anslutningarna för att

skydda O-ringarna.

Skydda anslutningarna till expansionsventilen.

Röranslutningen för AC vid expansionsventilen.

December 2017, en-GB © Scania CV AB

87

Page 92

Instrument - Removal - Instrument panel

6. Remove the service brake module connections.

7. Remove the connector panel.

A. Sugledning till behållare för kopplingsvätska. B.

Tryckledning från behållare för kopplingsvätska.

88

© Scania CV AB December 2017, en-GB

Page 93

8. Remove the outer frame for the connector panel.

1. Remove the holder for the compressed air lines.

2. Remove the outer frame for the connector panel.

Insert the connector panel through the firewall and

suspend the connector panel with cable ties from

the instrument panel.

9. Remove the pedal panel.

Instrument - Removal - Instrument panel

10. Remove the screws for attachment of the HVAC to

the firewall.

Instrument panel from the cab

WARNING!

Risk of crush injuries when the instrument panel is

lifted out of the cab. Secure the instrument panel in

an overhead hoist and machine lift during the work.

Tools:

Pedalpanelen

Infästningspunkter för HVAC mot torpedplåten.

December 2017, en-GB © Scania CV AB

89

Page 94

Instrument - Removal - Instrument panel

NNuummbbeerr

99 644 Base bracket

99 646 Bracket kit

2 426 173

588 966 Machine lift

DDeessiiggnnaattiioonn

Lifting accessory

Picture Tool-board

-

Spirit level -

Fit the lifting accessory to the instrument panel

1. Push the exhaust air vent to the door aside.

Fit 2 426 173 Lifting accessory for instrument panel

in the instrument panel crossmember.

2. Remove the screw in the crossmember on the

driver's side.

90

© Scania CV AB December 2017, en-GB

Page 95

3. Fit the lifting accessory to the overhead lifting sling.

Tension the lifting sling so that it is stretched.

Instrument - Removal - Instrument panel

4. Fit 2 426 173 Lifting accessory for instrument panel

in the instrument panel crossmember.

Remove the screw to the crossmember on the

passenger side.

Remove the instrument panel from the cab

1. The right-hand side of the instrument panel should

be lifted off by person 1 at the same time as person 2

controls the overhead hoist.

Place the left hand on the lifting accessory and right

hand on the defroster outlet for balance.

Lift the instrument panel out of the cab until only ten

centimetres of the right-hand side of the instrument

panel is in the cab.

December 2017, en-GB © Scania CV AB

91

Page 96

Instrument - Removal - Instrument panel

2. Insert 588 966 Machine lift under the instrument

panel.

Fit the machine lift in the instrument panel

crossmember and in the HVAC, as illustrated.

Use flange screws M8x30.

3. Slightly lift the instrument panel using the machine

lift.

Remove the instrument panel from the cab.

4. Lower the instrument panel using the machine lift,

leave the instrument panel secured to the overhead

lifting sling whilst lowering.

92

© Scania CV AB December 2017, en-GB

Page 97

Cab - Body - Canopy - Cab tilt system

Cab - Body - Canopy

Cab tilt system

Safety - Cab tilt system

Working on the cab tilting mechanism disables the integral safety functions.

Always follow the instructions and use the special tools specified, otherwise there is a risk of personal

injury.

WARNING!

Risk of crushing when the cab is tilted back. The cab

falls freely during the last part of the tilting back

phase.

WARNING!

Do not stand in front of or behind the cab during

tilting.

WARNING!

Do not work under a cab tilted to the intermediate

position.

Always tilt and tilt back the cab fully.

Working under a partially tilted cab can result in

personal injury.

WARNING!

Do not tilt the cab if the anti-roll bar has been

removed.

WARNING!

Do not tilt the cab if the ground slopes more than 10

%.

December 2017, en-GB © Scania CV AB

93

Page 98

Cab - Body - Canopy - Cab tilt system

WARNING!

When driving vehicles equipped with a mechanical

cab tilt pump, the pump valve must be in the tilt-back

position. Otherwise the hydraulics may cause

damage.

WARNING!

Removing and fitting the cab tilt cylinder or cab tilt

pump must only be carried out when the cab is tilted

back with the cab locks in the locked position, unless

otherwise specified in the work description.

94

© Scania CV AB December 2017, en-GB

Page 99

U4, Refrigerator

Refrigerator

1. Fold up the lower bed.

2. Pull out the refrigerator.

Cab - Body - Canopy - U4, Refrigerator

3. Remove the connection.

December 2017, en-GB © Scania CV AB

95

Page 100

Cab - Body - Canopy - U4, Refrigerator

NOTE:

Depending on the refrigerator model, there may be 4

or 6 screws.

Remove the screws.

5. Lift the refrigerator out of the storage compartment.

96

© Scania CV AB December 2017, en-GB

Loading...

Loading...