Page 1

Operator's manual

Scania

Instrumentation

en-GB 2 374 015

Issue 2.0

Page 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Analogue instrument panel . . . . . . . . . . . . . . . 5

Analogue instrument panel for engines without

SCR system . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Analogue instrument panel for engines with SCR

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Display in tachometer . . . . . . . . . . . . . . . . . . . 7

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Starter lock . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Engine speed setting 1 and 2. . . . . . . . . . . . . 11

Idling speed adjustment . . . . . . . . . . . . . . . . 12

Limp home mode . . . . . . . . . . . . . . . . . . . . . 12

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . 13

Digital display . . . . . . . . . . . . . . . . . . . . . . . . . 14

Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

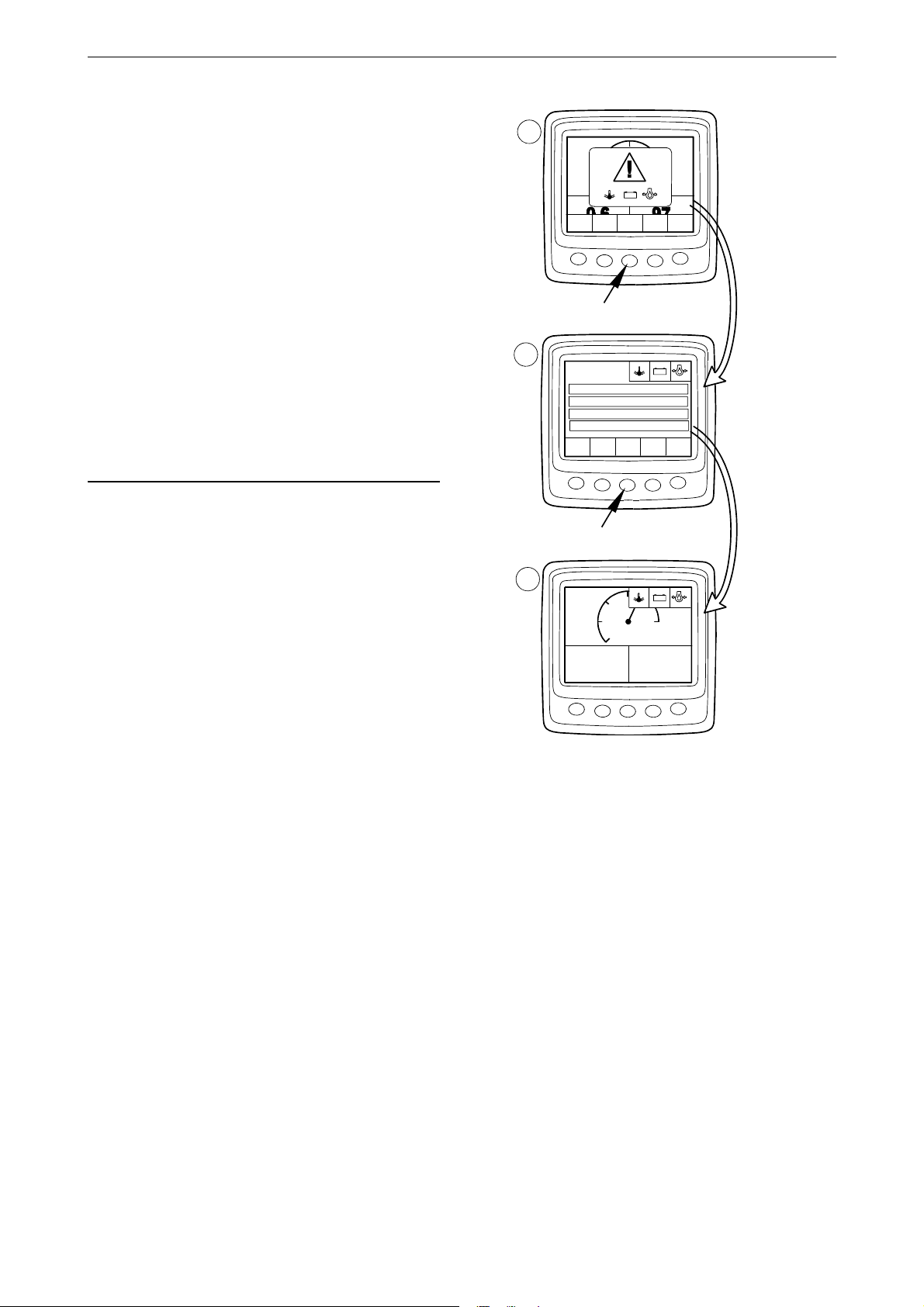

Display structure . . . . . . . . . . . . . . . . . . . . . . 15

Favourite screens. . . . . . . . . . . . . . . . . . . . . . 16

Information (4) . . . . . . . . . . . . . . . . . . . . . . . . . 19

Statistics trip (4.1) . . . . . . . . . . . . . . . . . . . . . 19

Performance (4.2) . . . . . . . . . . . . . . . . . . . . . 19

Fault codes (5). . . . . . . . . . . . . . . . . . . . . . . . . . 21

Information about the highlighted fault code 22

Clear fault codes . . . . . . . . . . . . . . . . . . . . . . 22

Update the fault code list . . . . . . . . . . . . . . . 23

Settings (6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contrast/brightness (6.1). . . . . . . . . . . . . . . . 23

Button beep (6.2). . . . . . . . . . . . . . . . . . . . . . 24

Language (6.3) . . . . . . . . . . . . . . . . . . . . . . . 24

Units (6.4) . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Engine (6.5). . . . . . . . . . . . . . . . . . . . . . . . . . 26

Examples of setting. . . . . . . . . . . . . . . . . . . . 32

Base system (6.6) . . . . . . . . . . . . . . . . . . . . . 33

Alarm and fault code generation . . . . . . . . . . 33

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

External alarm signal . . . . . . . . . . . . . . . . . . 35

Fault code generation . . . . . . . . . . . . . . . . . . 35

OPM 500 en-GB 2

©

Scania CV AB 2014, Sweden

Page 3

Introduction

Note:

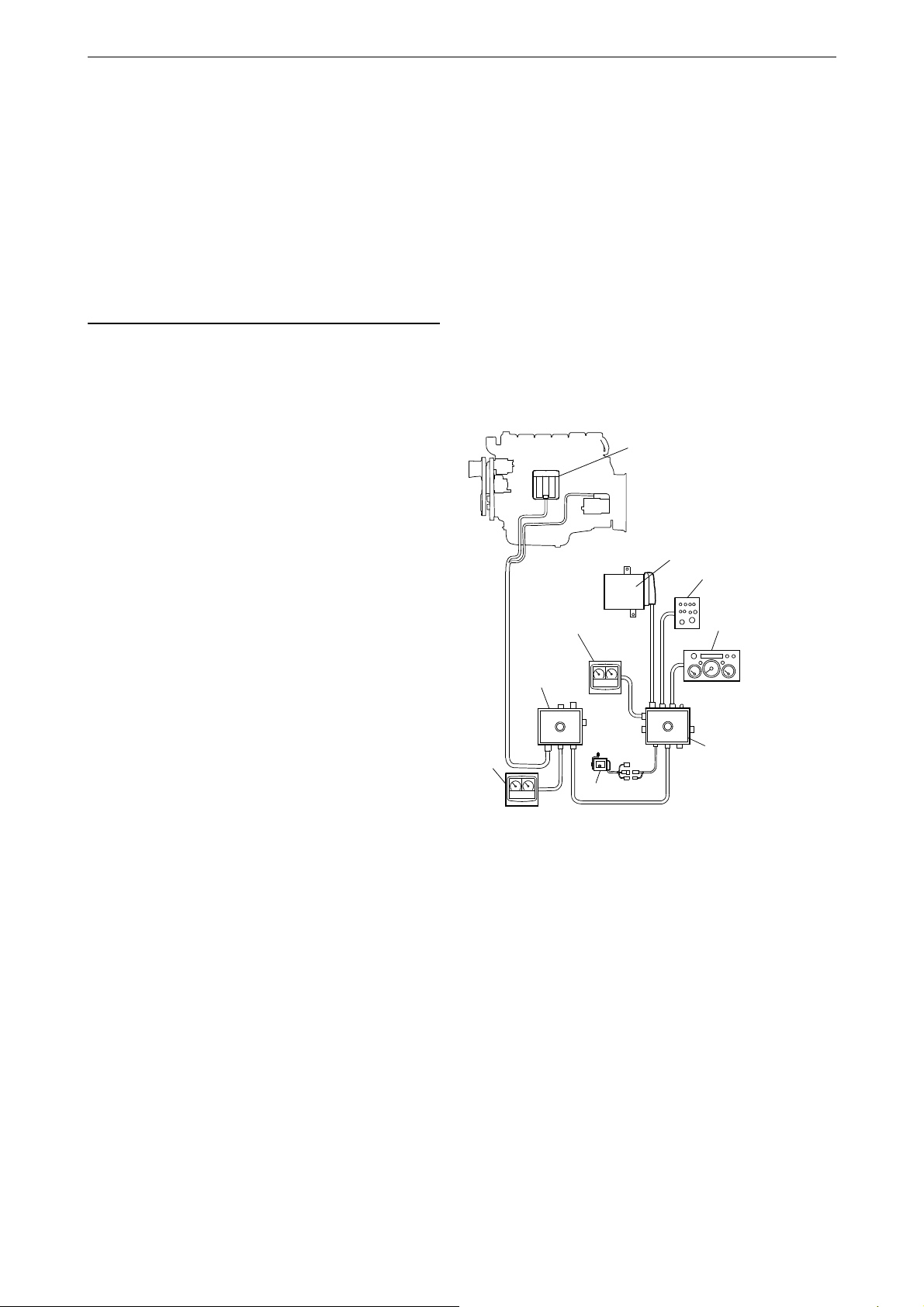

321 034

1

2

3

4

5

6

7

8

4

Base system for industrial engines

1. Engine control unit

2. Main junction box

3. Coordinator

4. Digital display

5. Coordinator junction box

6. Control panel

7. Analogue instrument panel

8. Accelerator pedal sensor

This Operator's manual describes operation of

Scania instrumentation.

The information in this manual was correct at the

time of going to press. Scania reserves the right

to make alterations without prior notice.

Always use Scania spare parts for repair work.

Overview

The base system consists of a coordinator, coordinator junction box and main junction box. The

main junction box is connected directly to the engine control unit. There are a number of different

options for the base system that can be connected

to the system:

Introduction

• A digital display together with a control panel

with starter key.

• An analogue instrument panel that can be

used instead of the digital display or together

with it.

• An accelerator pedal sensor.

• A remote control (for marine engines only).

The entire instrumentation system is Plug and

Play which makes it very easy to install.

This Operator's manual only describes the analogue instrument panel, remote control, digital

display and control panel.

OPM 500 en-GB 3

©

Scania CV AB 2014, Sweden

Page 4

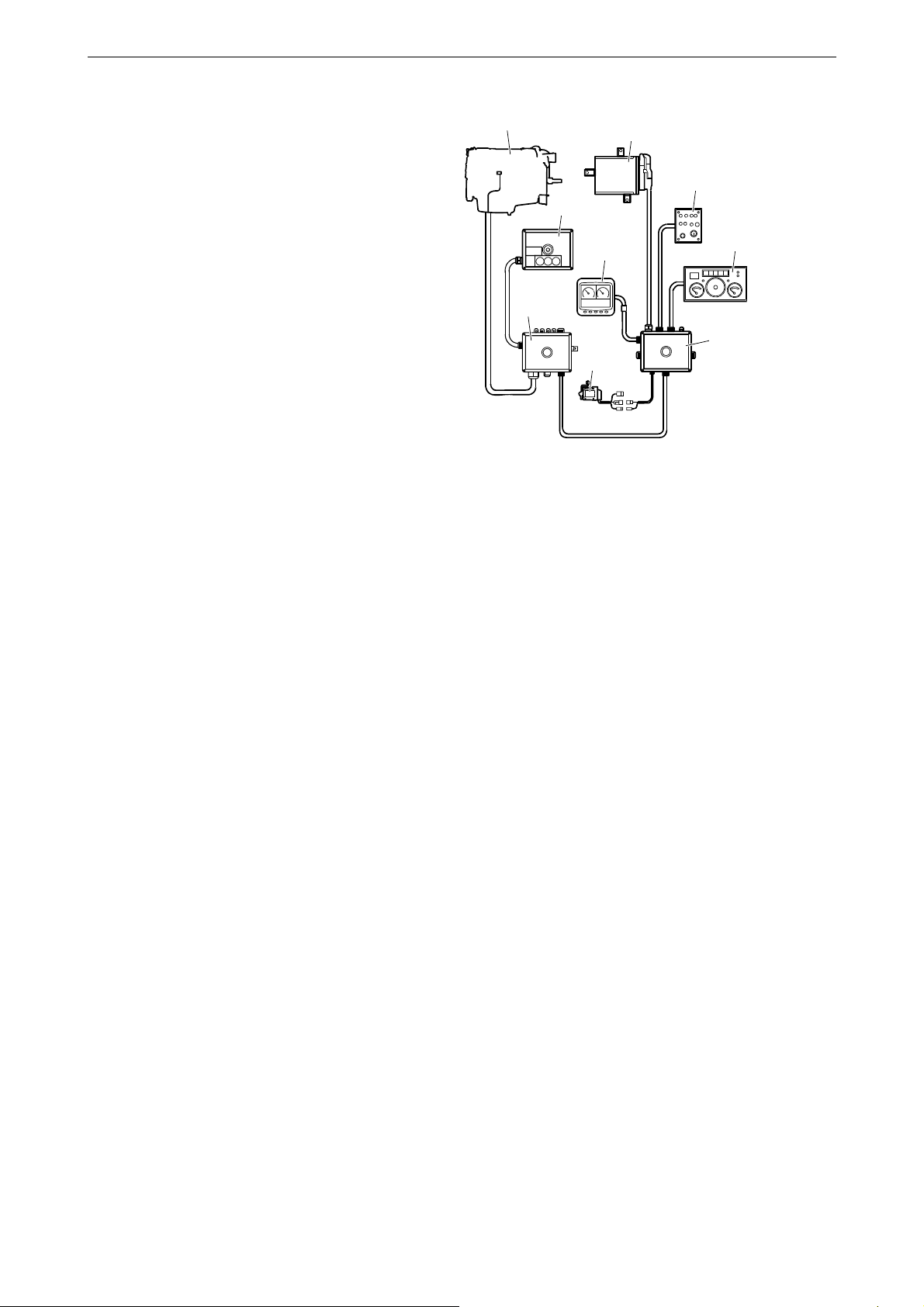

Overview

1

2

3

4

5

6

7

8

9

343 188

Base system for marine engines

1. Engine control unit

2. Remote control

3. Main junction box

4. Accelerator pedal sensor

5. Coordinator junction box

6. Analogue instrument panel

7. Control panel

8. Coordinator

9. Digital display

OPM 500 en-GB 4

©

Scania CV AB 2014, Sweden

Page 5

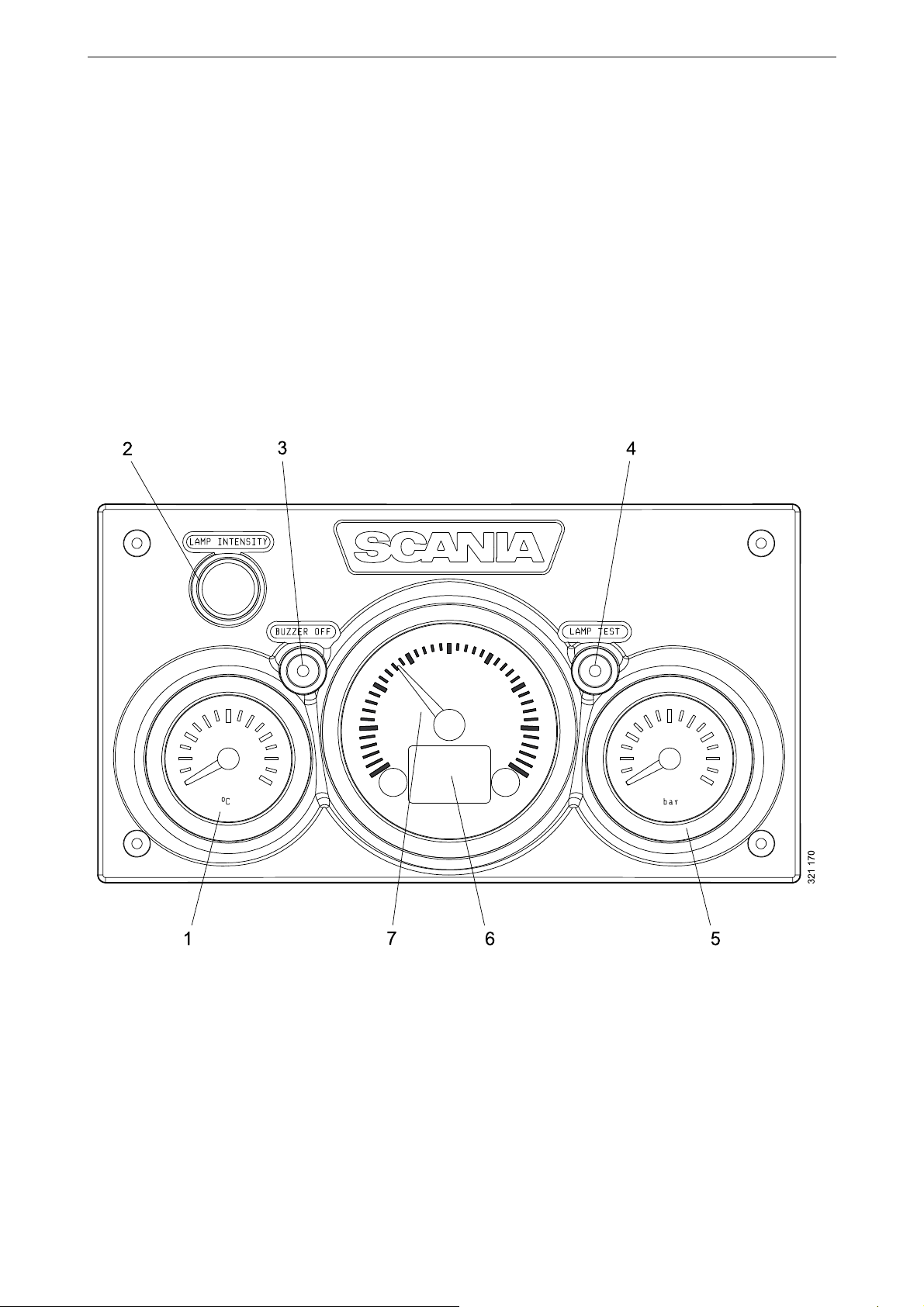

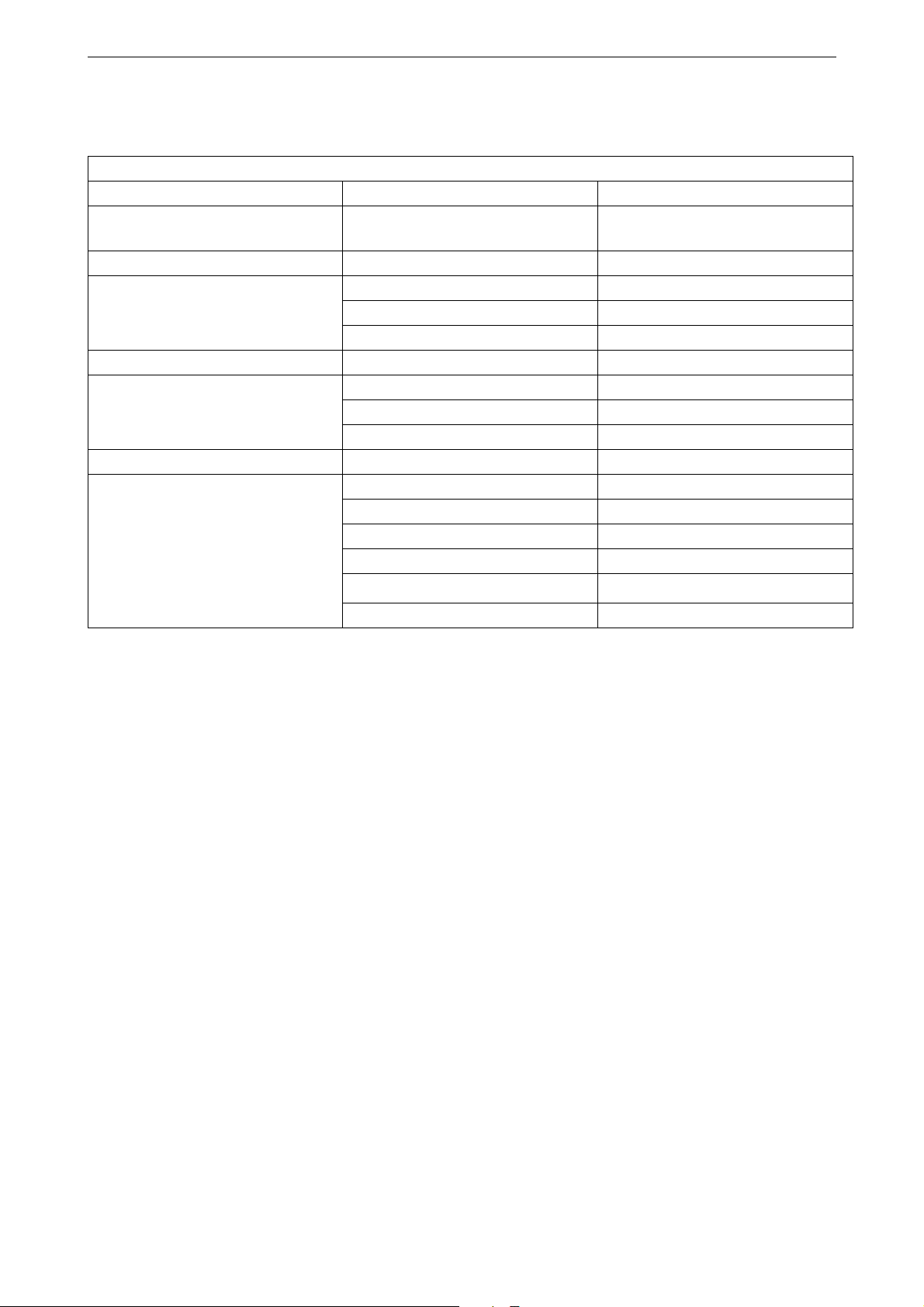

Analogue instrument panel

1. Coolant temperature display

2. Adjusting instrument lighting brightness (Lamp intensity)

3. Buzzer deactivation (Buzzer off)

4. Lamp test (Lamp test)

5. Display for oil pressure

6. Display showing engine data, alarms and fault codes

7. Tachometer

The analogue instrument panel has instruments

for reading engine speed, coolant temperature

and oil pressure. It also has hour counting and diagnostic and alarm switches and lamps.

The analogue instrument panel is available in 2

versions, depending on whether the engine is

equipped with an SCR system or not.

Analogue instrument panel

for engines without SCR system

Analogue instrument panel

OPM 500 en-GB 5

©

Scania CV AB 2014, Sweden

Page 6

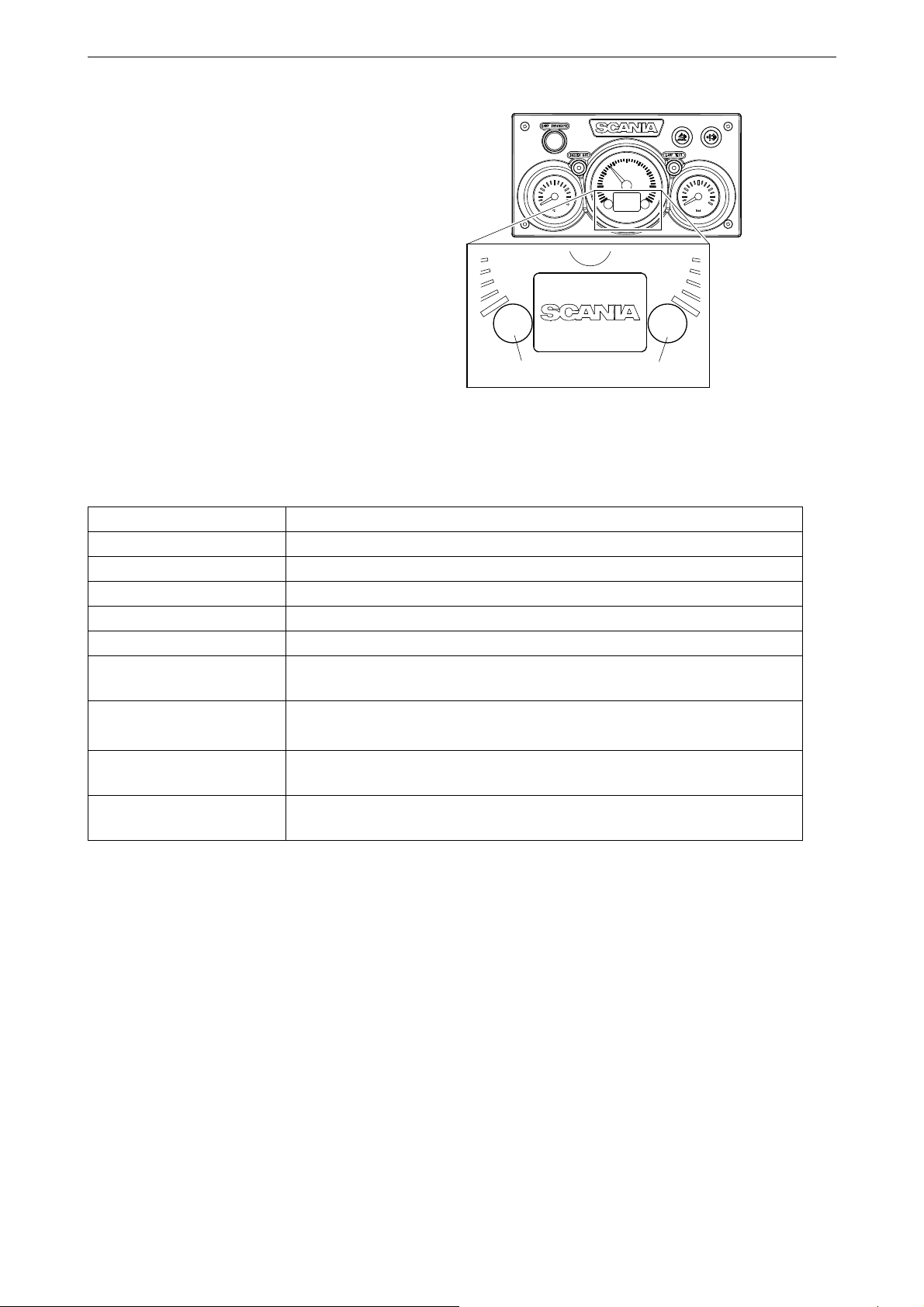

Analogue instrument panel

1. Coolant temperature display

2. Adjusting instrument lighting brightness (Lamp intensity)

3. Buzzer deactivation (Buzzer off)

4. Lamp test (Lamp test)

5. Display for oil pressure

6. Display showing engine data, alarms and fault codes

7. Tachometer

8. Warning lamp for low reductant level

9. Warning lamp for SCR system faults.

for engines with SCR system

Analogue instrument panel

OPM 500 en-GB 6

©

Scania CV AB 2014, Sweden

Page 7

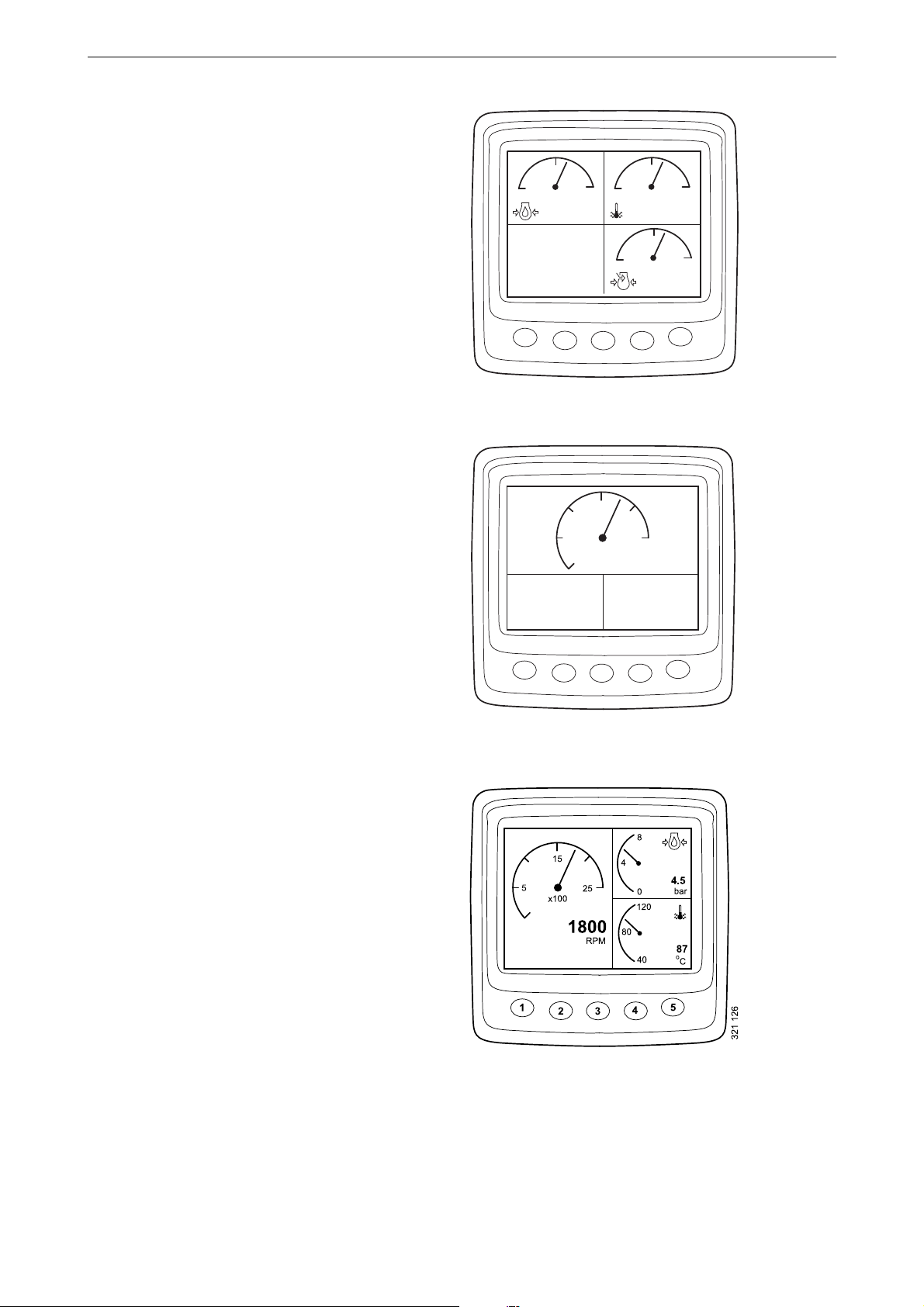

Display in tachometer

322 253

12

Integrated in the tachometer is a digital display

that shows engine data, alarms and fault codes.

Button 1 displays the previous page and button 2

displays the next page. The table below describes

how to go down a level in the structure.

Engine data shown on the display

Analogue instrument panel

Engine data Explanation

Coolant temperature

Oil pressure

Fuel level

Fuel consumption

Charge air pressure

Trip meter

Adjusting instrument lighting brightness

Reset the trip meter by holding buttons 1 and 2 down at the same time for

3 seconds.

Reduce the brightness by holding button 1 down for 3 seconds

Increase the brightness by holding button 2 down for 3 seconds

Settings No settings can be changed. The only available language is English and the

only available unit is metric

Fault codes Display an explanation of active fault codes by holding buttons 1 and 2

down at the same time for 3 seconds.

OPM 500 en-GB 7

©

Scania CV AB 2014, Sweden

Page 8

Alarms

On the display in the tachometer, the following

alarms are shown:

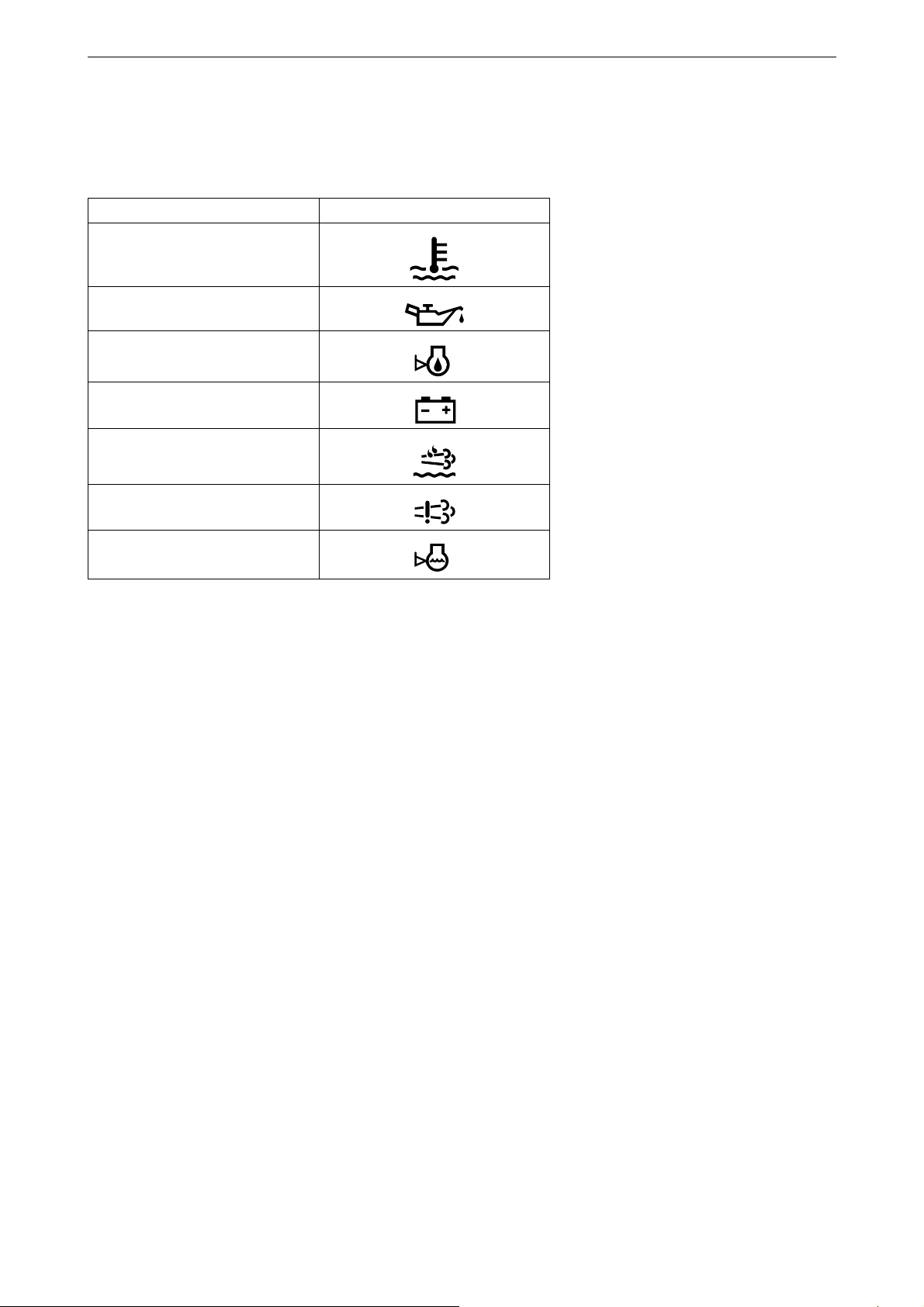

Alarm Symbol

High coolant temperature

Low oil pressure

Analogue instrument panel

Oil level too high or low

1

Alternator not charging

Low reductant level

SCR fault

1

Low coolant level

1. Depending on how the engine is equipped.

1

1

OPM 500 en-GB 8

©

Scania CV AB 2014, Sweden

Page 9

Fault codes

343 928

21

322 255

92.2

Coolant [C˚]

322 256

DTC:

EMS

11

1/16

2100!

1

2

3

4

5

6

When a fault code is generated, a symbol is

shown on the display in the tachometer. Acknowledge the fault code by pressing button 1 or

2.

Once the fault code has been acknowledged, the

fault code symbol remains (refer to illustration)

as long as the fault code is active.

Analogue instrument panel

Fault code description

If you want to see a more detailed description of

the fault code, hold buttons 1 and 2 down at the

same time for 3 seconds.

The fault code contains the following information:

Pos.Information Explanation

1 Shows the con-

trol unit in

which the fault

code was registered

2 Counter Shows how many times

3 Fault code sym-

bol

4 Fault code Shows the fault code in

5 Active fault

code

6 Page Shows which page is ac-

The engine management

system (EMS), coordinator (COO) or SCR control

unit (SCR)

the displayed fault has occurred

hexadecimal form

! is shown if the fault code

is active. If the fault code

is inactive, no ! is displayed

tive and how many pages

there are

OPM 500 en-GB 9

©

Scania CV AB 2014, Sweden

Page 10

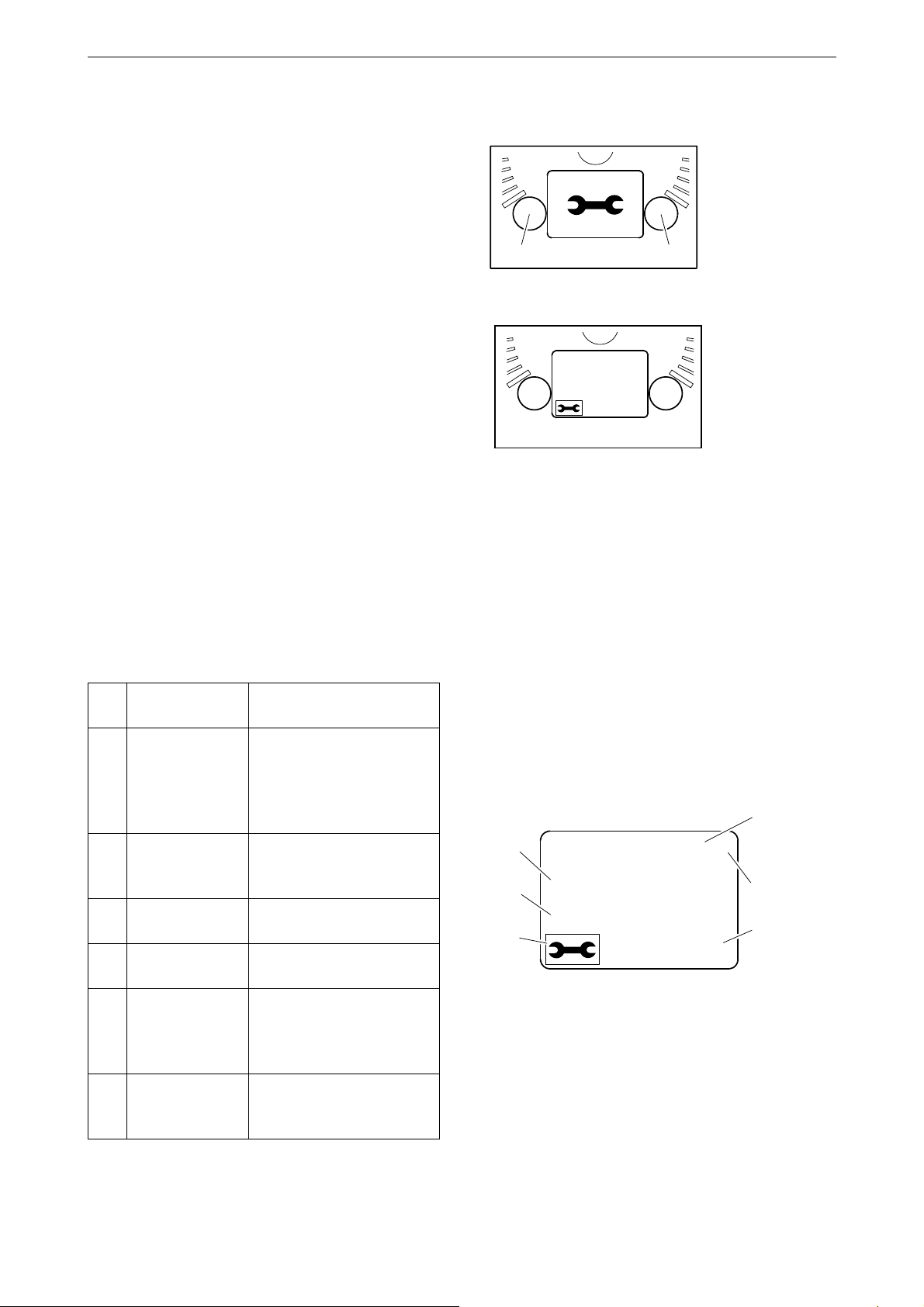

Control panel

23 4 5

19 8

6

7

321 169

The engine is started and shut down from the

control panel, which has a starter lock and functions for engine speed setting and idling setting.

1. Control for adjusting engine speed and idling

speed

2. Control for storing new engine speed and

idling speed

3. Control for activating engine speed setting 1

4. Control for activating engine speed setting 2

5. Control for deactivating engine speed setting

1 (marine engines) or 2 (industrial engines).

6. Indicator lamp for limp home throttle con-

1

trol

7. Limp home throttle control (Limp home)

8. Starter lock

9. Indicator lamp for active panel (Active pan-

el)

1

Control panel

Starter lock

The starter lock (8) is used to start and shut down

the engine.

Position 0: The engine electrical system and the

engine are switched off.

Position 1: The engine electrical system is activated.

Position 2: The starter motor is activated.

1. Only available for marine engines.

OPM 500 en-GB 10

©

Scania CV AB 2014, Sweden

Page 11

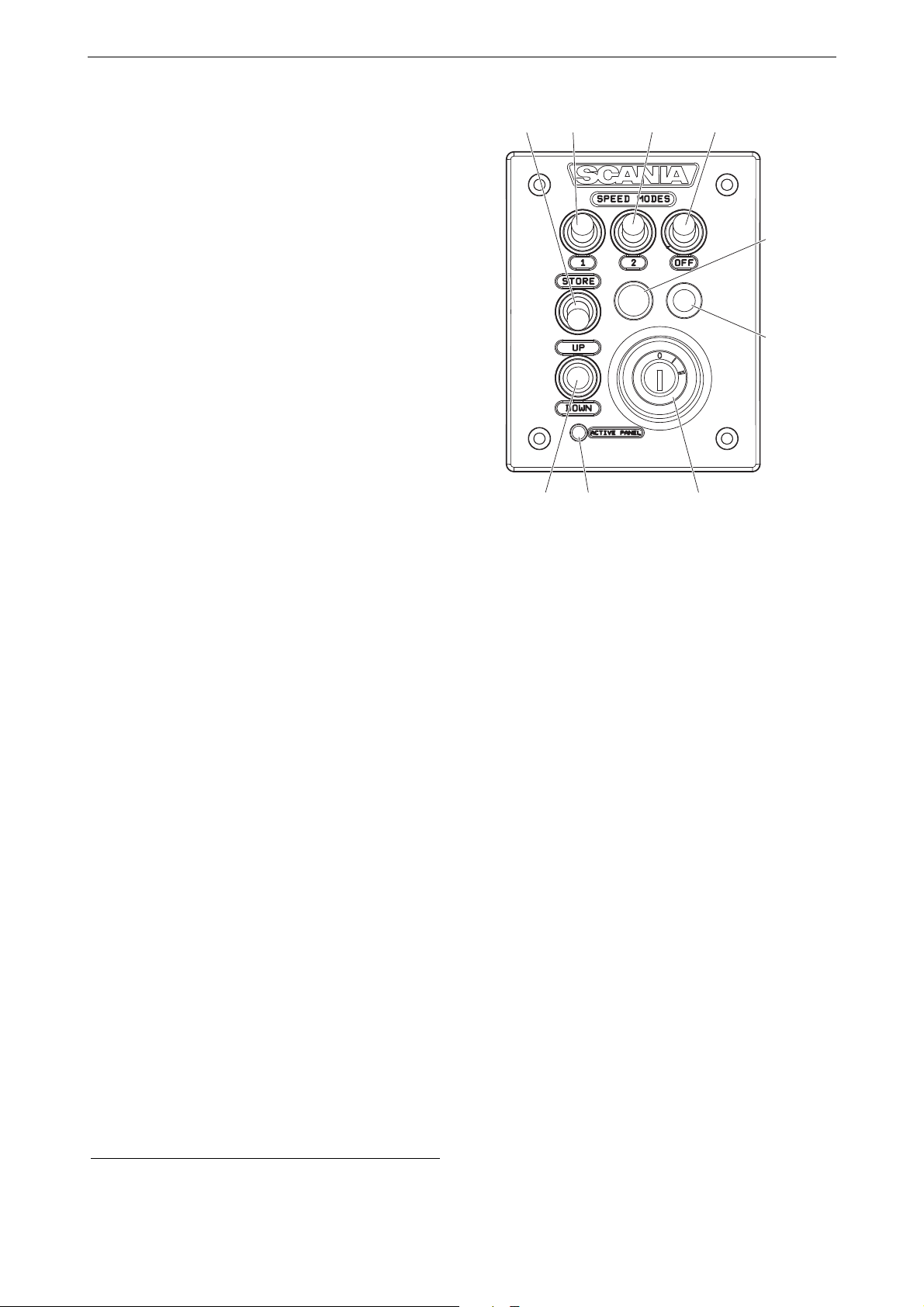

Engine speed setting 1 and 2

Note:

23 4 5

19 8

6

7

321 169

Engine speed setting 1 is an engine speed set between high and low idling. High and low idling

vary depending on the engine. The engine speed

is set with control 3.

Engine speed setting 2 is an engine speed that is

set between 450 and 2,000 rpm. The engine

speed is set with control 4.

For both engine speed settings, torque limitation

can be set via either the digital display or using

SDP3. The engine speed settings are isochronous, i.e. the engine speed is held constant irrespective of load.

When either of the engine speed settings is activated, the engine speed goes up or down to the

last saved engine speed.

Control panel

In order to activate engine speed setting 1 or 2,

the engine must be running, the active panel indicator lamp must be on and the throttle must be

at 0%.

Change the engine speed:

• Activate engine speed setting 1 or 2 with control 3 or 4.

• Adjust engine speed up or down with control

1.

• Save the new setting by holding control 2

down for 3 seconds.

If the setting is not saved, the engine uses the last

saved value next time engine speed setting is activated.

This is how to switch off the engine speed settings:

• Press control 5, touch the accelerator pedal or

switch off the engine.

OPM 500 en-GB 11

©

Scania CV AB 2014, Sweden

Page 12

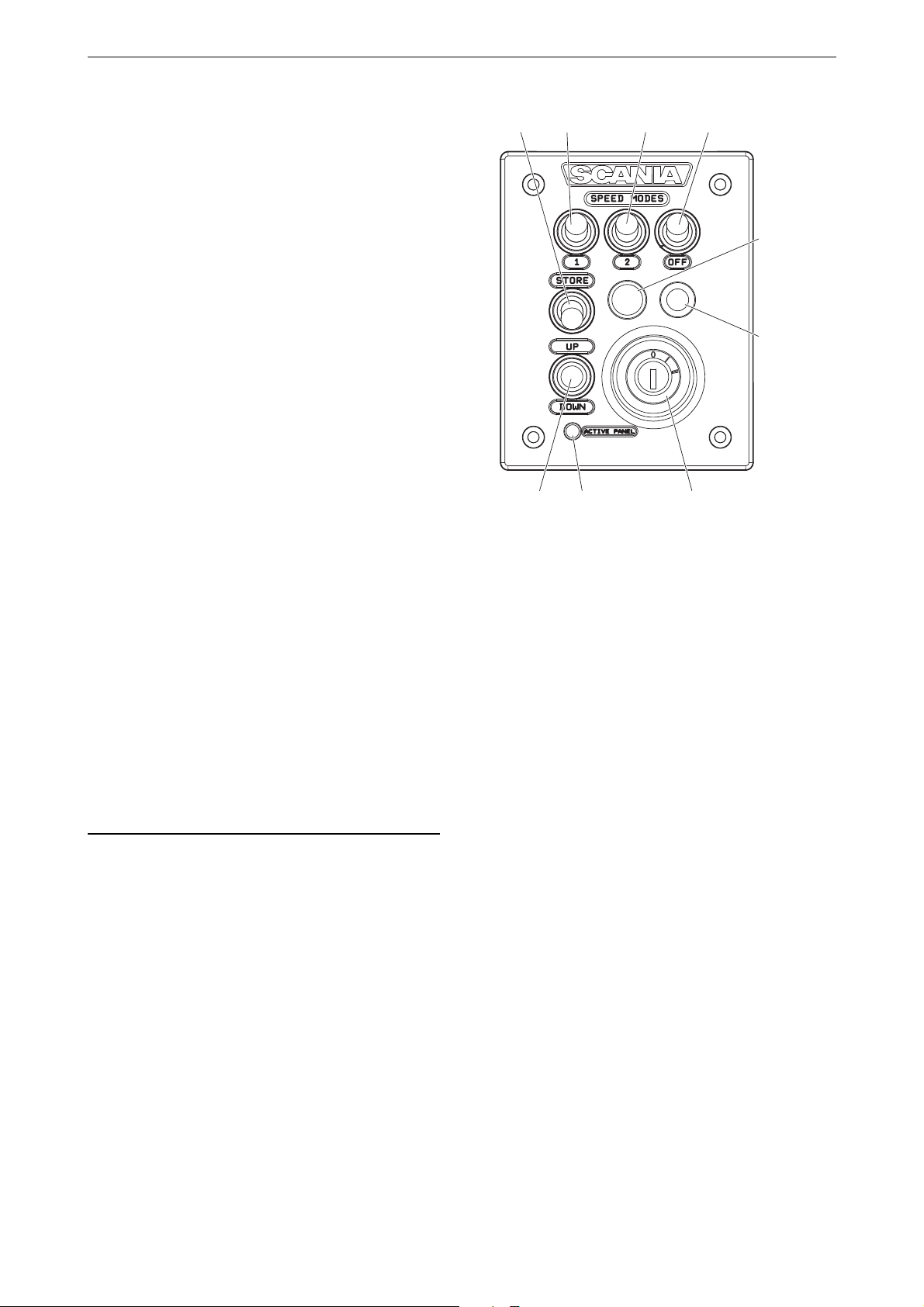

Idling speed adjustment

Note:

23 4 5

19 8

6

7

321 169

Setting range:

Engine type Setting range

XPI engine 600-750 rpm

PDE engine 500-1,300 rpm

Set the engine idling speed:

• Hold control 2 down for 3 seconds. This will

take you to the adjustment mode.

• Adjust idling up or down with control 3.

• Save the new setting by holding control 2

down for 3 seconds.

It is also possible to change engine idling speed

with the digital display or using SDP3.

Control panel

In order to change the idling speed setting, the

coolant temperature must be higher than 50°C

(122°F) with the engine idling.

Limp home mode

Limp home mode is a marine engine function

that is activated if the coordinator or accelerator

pedal fails or if CAN communication is not

working.

If one of these occurs, the indicator lamp for limp

home throttle control 6 and limp home throttle

control 7 is connected.

The limp home throttle consists of a potentiometer on the control panel which can be used to

limp home. The potentiometer value goes directly to connector A2 on the engine control unit.

In order to use the limp home throttle control, the

potentiometer must first be turned to the 0 position and then activated.

OPM 500 en-GB 12

©

Scania CV AB 2014, Sweden

Page 13

Remote control

WARNING!

START

LOCAL

REMOTE

STOP

2

3

1

4

343 187

Remote control

1. Green indicator lamp

2. Starter button

3. Key switch to activate the Local function

4. Stop button

The remote control for marine engines is connected on connector C4044 on the main junction

box. The remote control can be used to lock the

engine so that it cannot be controlled from anywhere other than where the remote control is located.

This can and should only be done when the boat

is moored, i.e. when there is no risk that the boat

will drift out of control. There is a sign on the remote control with this warning text.

There are 2 positions for key switch 3: Local and

Remote.

Remote control

• Local: The engine cannot be controlled from

anywhere other than from the remote control.

• Remote: Normal position, i.e. the engine can

be operated from the other throttle control positions.

When Local mode is activated, the green indicator lamp 1 comes on. At the same time the active

panel indicator lamp on the control panel starts to

flash, which indicates that the control panel cannot be activated.

When the engine is started from the remote control via starter button 2, it only runs at idling

speed whileLocal mode is activated and no other

throttle control can be used.

If the key switch is reset from Local to Remote

when the engine is running, the green indicator

lamp 1 goes out and the engine continues to run

at idling speed. Other control positions can however take command of throttle control, if the control panel is activated. If key switch 3 is reset

from Remote to Local while running, nothing

happens, but this will be regarded as an unintentional action.

If CAN communication fails when the engine

has been started from the remote control, the engine will stop, but the limp home throttle pedal

will not be engaged.

In order to start the engine again, it is necessary

to carry out the following connection:

• Connect pin 50 on the starter relay to the positive pin on the starter motor. The engine

OPM 500 en-GB 13

©

Scania CV AB 2014, Sweden

Page 14

starts but it is only possible to control the

throttle using the limp home throttle control.

In order to switch off the engine you must switch

off the power to the engine control unit by turning the starter key to 0. Alternatively you can

switch off the power via connector C4027 in the

main junction box.

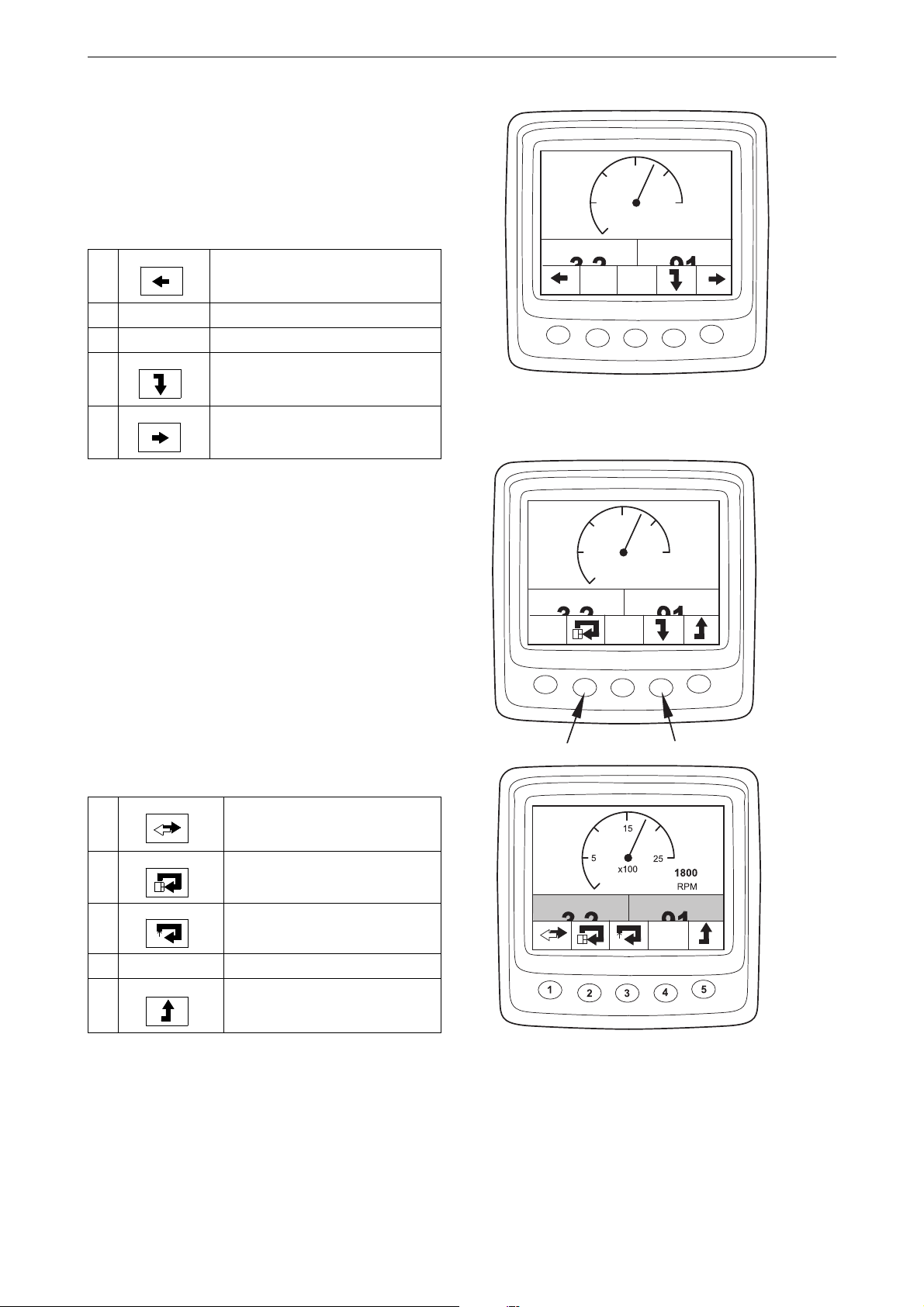

Digital display

The digital display shows engine data and any

alarm systems and fault codes. But the display

can also be used to set certain parameters in the

engine control unit.

Digital display

Function

The information content can be found in different screens according to a tree structure. The are

6 different screens at the top level:

• 3 favourite screens

• Information

• Diagnostics

• Settings

The buttons on the display have different functions depending on which screen is active. Use

buttons 1 and 5 to scroll between the different

screens at the top level, depending on which direction you want to go in the loop.

When one of the favourite screens is active, the

information about each button's function is hidden. The reason for this is to make as big an area

as possible available for presentation. When a

button is pressed, the description of the buttons is

displayed for about 5 seconds. Each window

apart from the favourite screens is numbered at

the top left. The numbering indicates the favourite screen and the level of the structure you are

on.

OPM 500 en-GB 14

©

Scania CV AB 2014, Sweden

Page 15

Display structure

123

Favourite screen (3)

Information

Fault codes

Display modes, levels

Change appearance of Favourite

Change content in window

screen

Statistics trip Display and reset

Performance Display

System data Information

Clear fault codes Acknowledgement

Information on fault code

Update fault code list Acknowledgement

Digital display

Contrast/brightness Adjust

Button beep Change

Language Change

Settings

Units Change

Engine

Base system Change

1. A password is required to change engine settings.

Change engine settings

1

OPM 500 en-GB 15

©

Scania CV AB 2014, Sweden

Page 16

Favourite screens

Favourite screen 1

Favourite screen 2

Favourite screen 3

Digital display

The favourite screens are used to show engine

data during operation. There are 3 different favourite screens which are all at the top level of

the display structure.

4

2

4.5

ENGINE SPEED

1500

RPM

1

2

5

OIL PRESSURE

3.2

bar

84080120

bar

2

0

2.5

4

3

15

25

x100

1800

RPM

COOLANT TEMP

91

o

C

o

87

C

4

bar

5

341 589

1

2

3

5

4

341 590

OPM 500 en-GB 16

©

Scania CV AB 2014, Sweden

Page 17

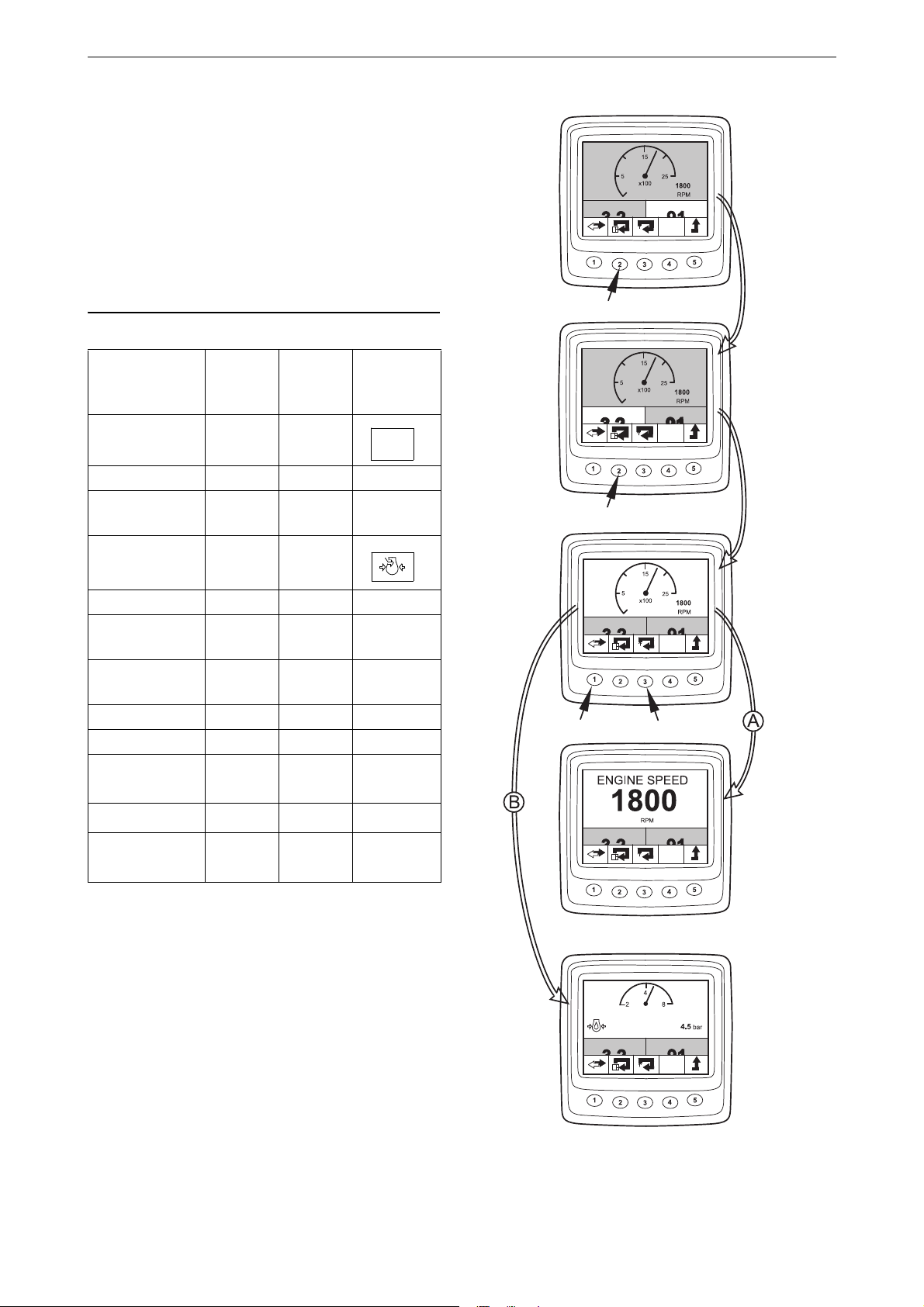

If you want to change from one favourite screen

3

2

1

1

2

7

321 128

3

2

1

1

4

6

321 129

321 130

321 131

321 132

to another favourite screen, press button 1 or 5

depending on which is currently displayed.

In this display mode, the buttons have the following functions:

1 Scroll to the left in the top level

2

3

4 Go down one level in the struc-

ture

5 Scroll to the right in the top level

5

OIL PRESSURE

1

2

15

25

x100

COOLANT TEMP

3

Digital display

1800

RPM

5

4

341 591

Change appearance of Favourite

screen

If you want to change the appearance of a favourite screen, press button 4.

Then press button 2 to change the appearance of

the screen in the sequence on the previous page.

Change content in window

Press button 4 from the change appearance position on the favourite screen to display the button

panel in the table below.

1

2

3

Change between digital and

analogue display

Change active (not greyed)

window

Change content in active (not

greyed) window

5

OIL PRESSURE

1

2

OIL PRESSURE

15

25

x100

COOLANT TEMP

3

COOLANT TEMP

1800

RPM

5

4

341 592

4

5

Go up one level in the structure

OPM 500 en-GB 17

©

Scania CV AB 2014, Sweden

341 593

Page 18

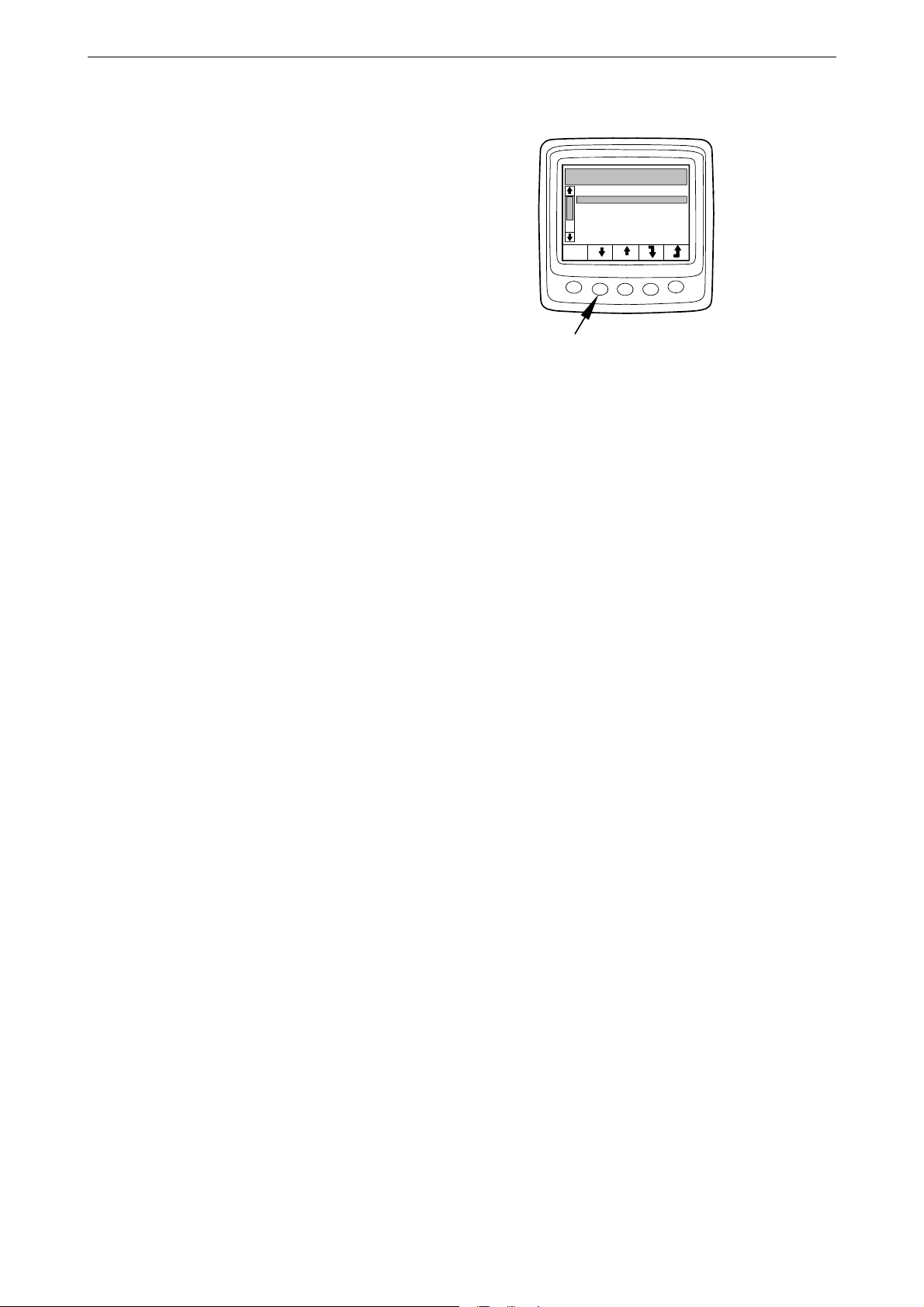

In order to select the contents of a subwindow, it

Note:

OIL PRESSURE

COOLANT TEMP

OIL PRESSURE

COOLANT TEMP

OIL PRESSURE

COOLANT TEMP

OIL PRESSURE

COOLANT TEMP

OIL PRESSURE

COOLANT TEMP

341 594

RPM

321 133

321 134

must be active. Activate a window by pressing

button 2.

The information in the different subwindows can

be displayed in digital or analogue format.

Some information can only be displayed in digital format. Refer to the table.

Digital display

Parameter Digital

display

Analogue

display

Engine speed x x

Oil pressure x x

Coolant tem-

xx

perature

Charge air pres-

xx

sure

System voltage x x

Fuel consump-

x

tion

Load at current

x

engine speed

Operating time x

Throttle x

Oil tempera-

1

ture

Oil level

1

Reductant lev-

1

el

1. Depending on how the engine is ordered.

xx

x

x

Symbol

Switch between analogue and digital display by

pressing button 1 (A).

Change the contents of an activated subwindow

by pressing button 3 (B).

OPM 500 en-GB 18

©

Scania CV AB 2014, Sweden

Page 19

Information (4)

Note:

This is how to go to the Information display

mode from a favourite screen:

Press any button to display the button bar on the

screen.

Press button 5 one to three times, depending on

which favourite screen is active, to open the Information display mode. The button bar now remains on the screen.

OIL PRESSURE

Digital display

COOLANT TEMP

Move up and down the list by pressing buttons 2

and 3.

Statistics trip (4.1)

Go down one level in the Statistics trip structure

by pressing button 4. This displays information

about:

• average fuel consumption,

• total fuel consumption since last reset,

• total operating time since last reset

Reset the measurement by pressing button 1.

Go back to the Information display mode by

pressing button 5.

The maximum measurement time is 999 h. After

this period, the measurement is automatically reset.

STATISTICS TRIP

PERFORMANCE

SYSTEM DATA

STATISTICS TRIP

TRIP FUEL AVG

TRIP FUEL

TRIP HOURS

341 595

Performance (4.2)

Go down one step in the list by pressing button

2. Then press button 4 to go down one step in the

structure to the Performance display mode.

This displays current performance in a well-organised manner.

Go back to the Information display mode by

pressing button 5.

OPM 500 en-GB 19

©

Scania CV AB 2014, Sweden

STATISTICS TRIP

PERFORMANCE

ATA

SYSTEM D

PERFORMANCE

ENGINE SPEED

OIL PRESSURE

COOLANT TEMP

BOOST PRESS

FUEL RATE

LOAD, SPEED

341 596

Page 20

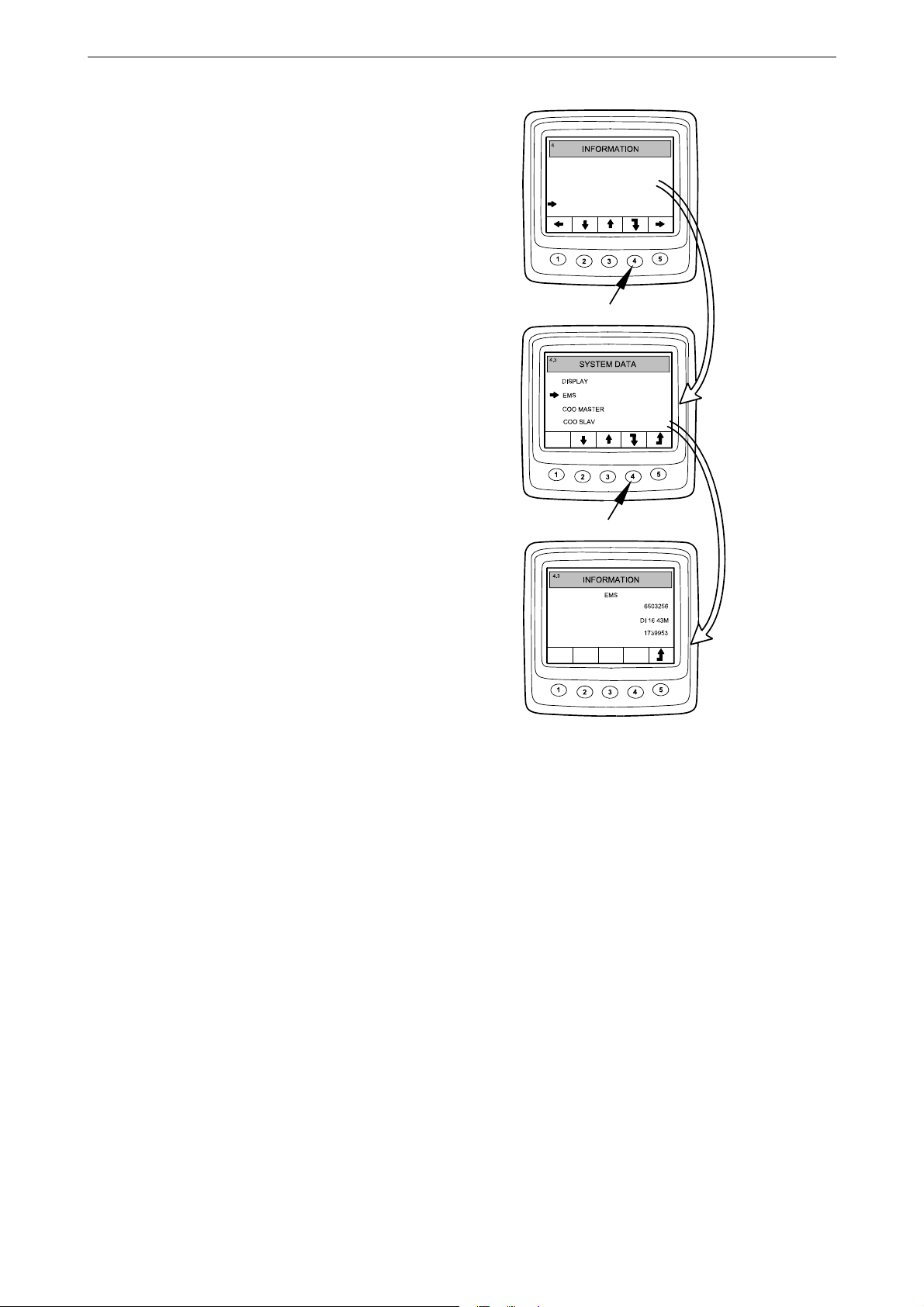

System data (4.3)

STATISTICS TRI

P

PERFORMANCE

SYSTEM D

ENGINE NO

ENGINE

TYPE

PART NO

ATA

341 597

Go down 2 steps in the list by pressing button 2.

Then go down one step in the structure to the

System data display by pressing button 4.

Information about the different system control

units is displayed in this display mode:

• Digital display (Display)

• Engine control unit (EMS)

• Coordinator (COO Master)

• SCR control unit

Move up and down the list by pressing buttons 2

and 3.

Display information about the control unit concerned by pressing button 4.

Digital display (Display)

Information on:

Digital display

• Part number (assembly part number)

• Hardware number

• Software number

• Version number

Engine control unit (EMS)

Information on:

• Engine serial number

• Engine type

• Engine control unit part number

Coordinator

Information on:

• Part number (assembly part number)

• Hardware number

• Software number

• Version number

SCR control unit

Information on:

• Hardware number

• Software number

OPM 500 en-GB 20

©

Scania CV AB 2014, Sweden

Page 21

Fault codes (5)

341 598

3

2

1

1

2

7

321 143

321 144

i

321 145

3

2

1

1

4

6

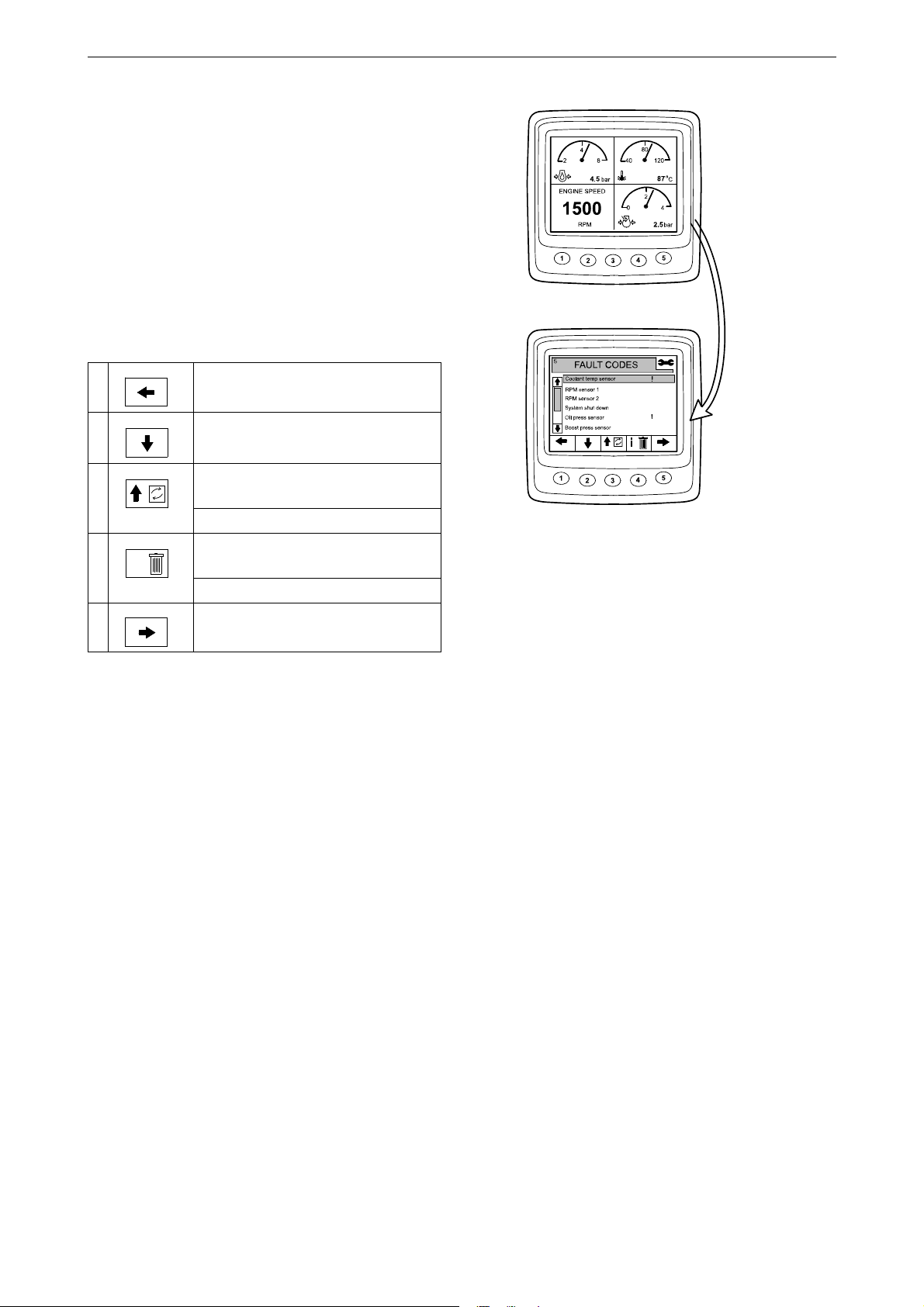

This is how to go to the Fault codes display mode

from a favourite screen:

• Press any button to display the button bar on

the screen.

• Use button 1 or 5 to scroll in a favourite

screen to open the Fault codes display mode.

The button bar changes appearance and remains on the screen.

Digital display

1

Scroll to the left in the top level

2

Go down one step in the list

3 Short press: Go up one step in the

list

Long press (3 s): Update the list

4 Short press: Display information

about the selected fault code

Long press (3 s): Clear fault codes

5

Scroll to the right in the top level

In the example, the Coolant temp sensor and Oil

press sensor are marked with an !, which means

that they are active fault codes.

OPM 500 en-GB 21

©

Scania CV AB 2014, Sweden

Page 22

Information about the high-

341 599

341 600

lighted fault code

In the example on the previous page, Coolant

temp sensor is selected. Give a short press on

button 4 to bring up the information screen for

the fault code.

Digital display

View on dis-

Description In the example

play

EMS Control unit in

which the fault

was registered

Coolant temp

sensor

Name of fault

code

Start problem How the system

reacts when the

fault is active

Code The number of

the selected

fault code

Status Fault status, i.e.

active or passive

Counter How many

times the fault

has occurred

Engine control

unit

Coolant temperature sensor

Starting problems

2001

Active

3 times

Clear fault codes

• Hold control 4 down for 3 seconds.

• Delete all fault codes by pressing button 1.

• Confirm deletion by pressing button 3.

OPM 500 en-GB 22

©

Scania CV AB 2014, Sweden

Page 23

Update the fault code list

341 601

1

2

3

4

5

1

2

3

4

5

6

SETTINGS

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

6

SETTINGS

BRIGHTNESS/LIGH

T

BASE SYSTEM

-

+

-

+

341 602

• Hold control 3 down for 3 seconds.

• Confirm the update by pressing button 3.

Digital display

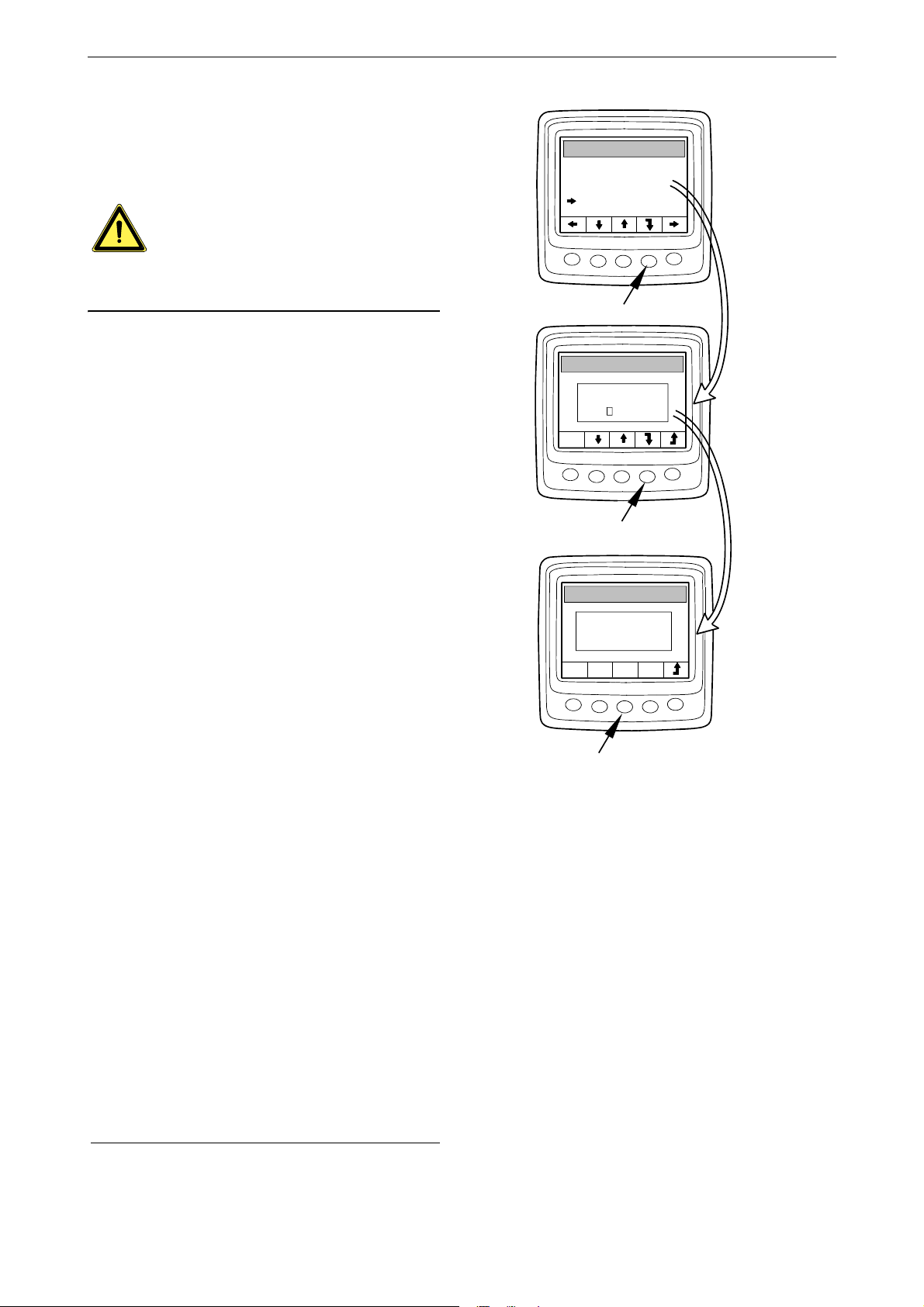

Settings (6)

• Use button 1 or 5 to scroll in a favourite

screen to open the Settings display mode.

• Move up and down the list by pressing buttons 2 and 3.

To get to Settings more quickly, regardless of

where you are in the structure, press buttons 2

and 4 simultaneously.

Contrast/brightness (6.1)

• Select Contrast/brightness and press button 4.

This will take you to the adjustment mode.

• Adjust the brightness and the contrast to current operating conditions.

You can reset the contrast and brightness to the

default settings by holding buttons 2, 3 and 4

down at the same time for 3 seconds.

Go back to the Settings display mode by pressing

button 5.

OPM 500 en-GB 23

©

Scania CV AB 2014, Sweden

Page 24

Button beep (6.2)

Note:

1

2

3

4

5

1

2

3

4

5

6

SETTINGS

6

SETTINGS

BUTTON BLEE

P

OFF

341 603

.2

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

1

23

4

5

1

23

4

5

6

SETTINGS

6

.

3

LANGUAGE

ENGLIS

H

SVENSK

A

FRANCAI

S

DEUTSC

H

IT

ALIAN

O

ESP ANO

L

341 604

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

• Select Button beep and press button 4. This

will take you to the adjustment mode.

• Switch between button beep off and button

beep on by pressing button 3.

Go back to the Settings display mode by pressing

button 5.

The Button beep off setting does not affect the

alarm signal.

Digital display

Language (6.3)

Information on the display can be shown in 7 different languages:

• English

•Swedish

•German

•French

• Spanish

• Italian

• Portuguese

The default setting is English.

• Select Language and press button 4. This will

take you to the adjustment mode.

• Select the required language with buttons 2

and 3.

• Confirm by pressing button 4. The box on the

right will be selected as an acknowledgement

that the change has been saved.

Go back to the Settings display mode by pressing

button 5.

OPM 500 en-GB 24

©

Scania CV AB 2014, Sweden

Page 25

Units (6.4)

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

METRIC

US IMPERIA

L

METRIC

US IMPERIA

L

SETTINGS

UNITS

UNITS

341 605

It is possible to choose between 2 different units

– metric and US Imperial:

Parameter Metric US Imperial

Pressure Bar Psi

Voltage V V

Engine speed rpm rpm

Temperature °C °F

Fuel consumption L/h, L US gallons/h,

US gallons

• Select Units and press button 4. This will take

you to the adjustment mode.

• Select the unit by pressing button 2 or 3.

• Confirm by pressing button 4. The box on the

right will be selected as an acknowledgement

that the change has been saved.

Digital display

Display the information in the above table by

pressing button 1.

Go back to the Settings display mode by pressing

button 5.

OPM 500 en-GB 25

©

Scania CV AB 2014, Sweden

Page 26

Engine (6.5)

WARNING!

1

2

3

4

5

1

2

3

4

5

6

6

1

2

3

4

5

6

ENGINE

.5

P

ASSWORD

0

00

0

SETTINGS

OK

W

ARNING

ENGINE SETTINGS

CAN NOW BE CHANGED

341 606

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

SETTINGS

In this display mode, you can change the default

settings of the engine.

If you change the default settings of the engine,

it can affect safety-critical functions.

• Select Engine and press button 4. This will

take you to the adjustment mode.

1

• Enter the password

• A warning is displayed. Press button 3 to proceed to the list of parameters that can be set.

The engine settings that can be changed are described on this page and on subsequent pages.

and press button 4.

Digital display

Idling (6.5.1)

Low idling for PDE engines can be set between

500 and 1,300 rpm.

Low idling for XPI engines can be set between

600 and 750 rpm.

It is not possible to change the idling setting if

the coolant temperature is below 50°C (122°F)

or if the engine is running at raised low idling

speed for some reason.

1. The default password is 2222, but this can be changed by

OPM 500 en-GB 26

the user. See section 6.5.9.

©

Scania CV AB 2014, Sweden

Page 27

Lower temperature limit (6.5.2)

1

2

3

4

5

6

.5

ENGINE

IDLE SPEED

HIGH TEMP LIMI

T

FIXED SPEED

FIXED SPEED

1

2

SAFETY SWITCH

LOW TEMP LIMI

T

341 607

The lower temperature limit, which has a default

setting of 95°C (203°F), is the level for the alarm

and for torque reduction if torque reduction has

been selected. See section 6.5.8.

The lower temperature limit can be set between

85°C (185°F) and 105°C (221°F). The lower

temperature limit cannot be set to a higher value

than the upper temperature limit.

Upper temperature limit (6.5.3)

The upper temperature limit, which has a default

setting of 105°C (221°F), is the level for the

alarm and also for engine shutdown if engine

shutdown has been selected. See section 6.5.8.

The upper temperature limit can be set between

95°C (203°F) and 105°C (221°F). The upper

temperature limit cannot be set to a lower value

than the lower temperature limit.

Digital display

Engine speed setting 1 (6.5.4)

Engine speed setting 1 is a constant idling speed

set and activated from the control panel. See section Engine speed setting 1 and 2.

An upper torque limitation for engine speed

setting 1 can be set in the digital display. The setting only applies when engine speed setting 1 is

activated.

OPM 500 en-GB 27

©

Scania CV AB 2014, Sweden

Page 28

Engine speed setting 2 (6.5.5)

WARNING!

Engine speed setting 2 is a constant idling speed

set and activated from the control panel. See section Engine speed setting 1 and 2.

An upper torque limitation for engine speed

setting 2 can be set in the digital display. The setting only applies when engine speed setting 2 is

activated.

Idling switch (6.5.6)

The idling switch is a safety function in Scania's

electrical system which checks that the accelerator pedal is functioning correctly.

The idling switch is a closing switch that is activated when the accelerator pedal is activated.

The function can be disengaged.

Digital display

If the idling switch is disengaged, a safety function is disengaged.

Fuel density (6.5.7)

The fuel density affects the calculation of the engine power, and it can be changed in the default

settings for the engine. The default setting is

840 kg/m

tween 700 and 1,000 kg/m

3

, but the fuel density can be set be-

3

.

OPM 500 en-GB 28

©

Scania CV AB 2014, Sweden

Page 29

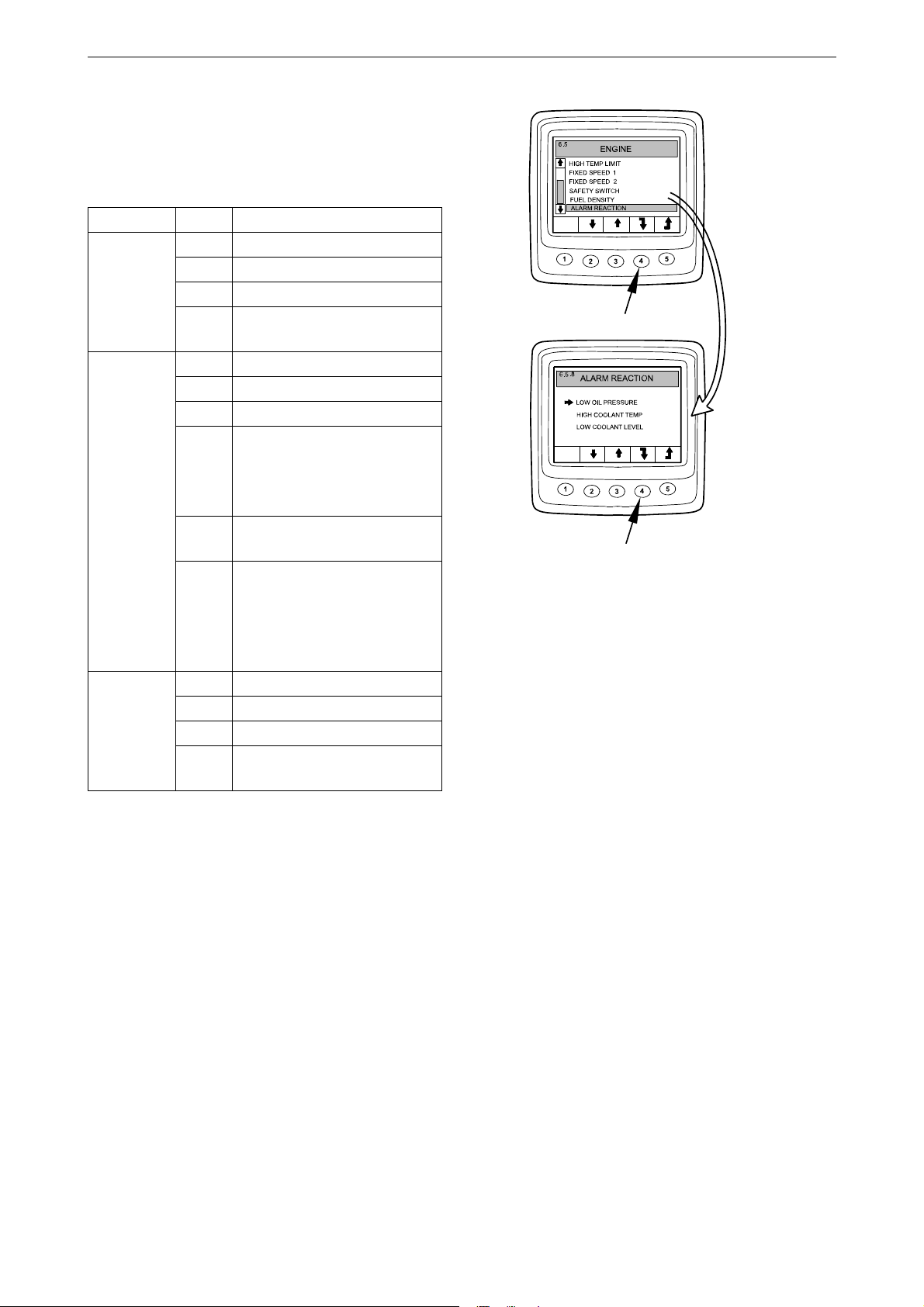

Alarm reaction (6.5.8)

341 608

The engine behaviour may vary depending on

how the engine control unit is programmed.

Signal Line Engine behaviour

1 Alarm only

Low oil

pressure

High coolant temperature

Low coolant level

2 Alarm and torque reduction

3 Alarm and engine shutdown

4 Engine shutdown with over-

ride

1 Alarm only

2 Torque reduction

3 Engine shutdown

Torque reduction at lower

temperature limit

4

Engine shutdown at upper

temperature limit

5 Engine shutdown with over-

ride

Torque reduction at lower

temperature limit

6

Engine shutdown with override at upper temperature limit

1 Alarm only

2 Alarm and torque reduction

3 Alarm and engine shutdown

4 Engine shutdown with over-

ride

Digital display

• Select Alarm reaction and press button 4.

This will take you to the adjustment mode.

• Select signal type by pressing button 2 or 3.

• Press button 4 to go to the next level.

OPM 500 en-GB 29

©

Scania CV AB 2014, Sweden

Page 30

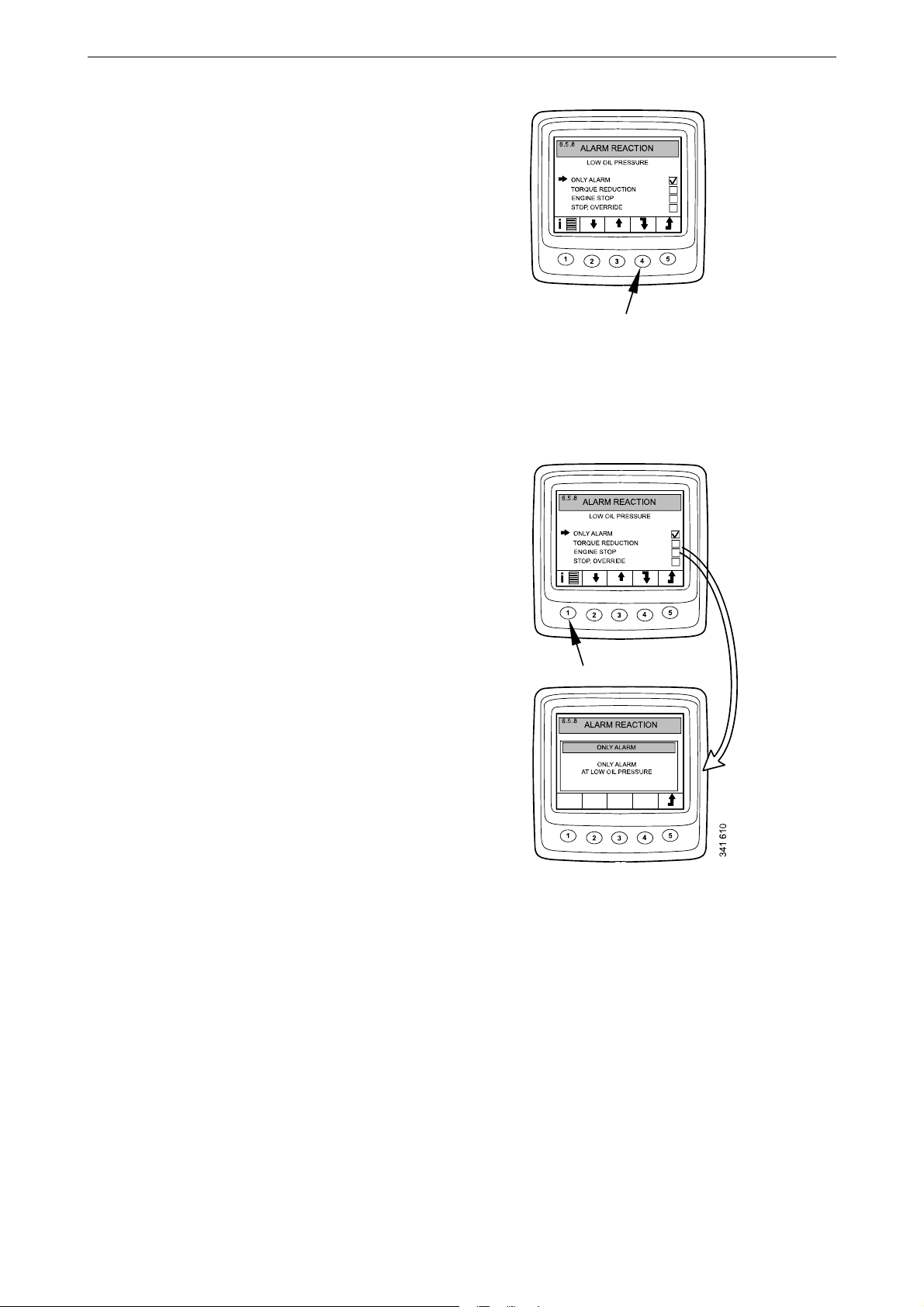

• Select an alarm reaction with buttons 2 and 3.

341 60

9

• Confirm by pressing button 4. The box on the

right will be selected as an acknowledgement

that the change has been saved.

Display a more detailed description of the selected alarm reaction by pressing button 1.

Digital display

Go back to the Settings display mode by pressing

button 5.

OPM 500 en-GB 30

©

Scania CV AB 2014, Sweden

Page 31

Change password (6.5.9)

Note:

1

2

3

4

5

6

.5

ENGINE

FIXED SPEED

FIXED SPEED

1

2

SAFETY SWITCH

FUEL DENSIT

Y

ALARM REACTION

1

23

4

5

6

.5

ENGINE

CHANGE PASSWORD

CHANGE PASSWORD

1

2

3

4

1

2

3

4

5

6

.5

ENGINE

123

4

CONFIRM

1

23

4

5

6

.5

ENGINE

P

ASSWORD

CHANGED

341 6

1

1

OK

You can set a new password. Valid values are

0001–9999.

• Select Change password and press button 4.

This will take you to the adjustment mode.

• Enter the password and press button 4.

• Confirm the password by pressing button 4.

• Go back by pressing button 3.

Contact your nearest Scania distributor if you

have forgotten the password.

Digital display

OPM 500 en-GB 31

©

Scania CV AB 2014, Sweden

Page 32

Examples of setting

Note:

1

2

3

4

5

1

2

3

4

5

6

SETTINGS

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

6

1

2

3

4

5

6

ENGINE

.5

P

ASSWORD

0

00

0

SETTINGS

OK

W

ARNING

ENGINE SETTINGS

CAN NOW BE CHANGED

1

23

4

5

6

.5

ENGINE

IDLE SPEED

HIGH TEMP LIMI

T

FIXED SPEED

FIXED SPEED

1

2

SAFETY SWITCH

LOW TEMP LIMI

T

1

23

4

5

6

ENGINE

.5

.5

-

+

LOW TEMP LIMI

T

(85 C)

95

(105 C)

o

o

341 612

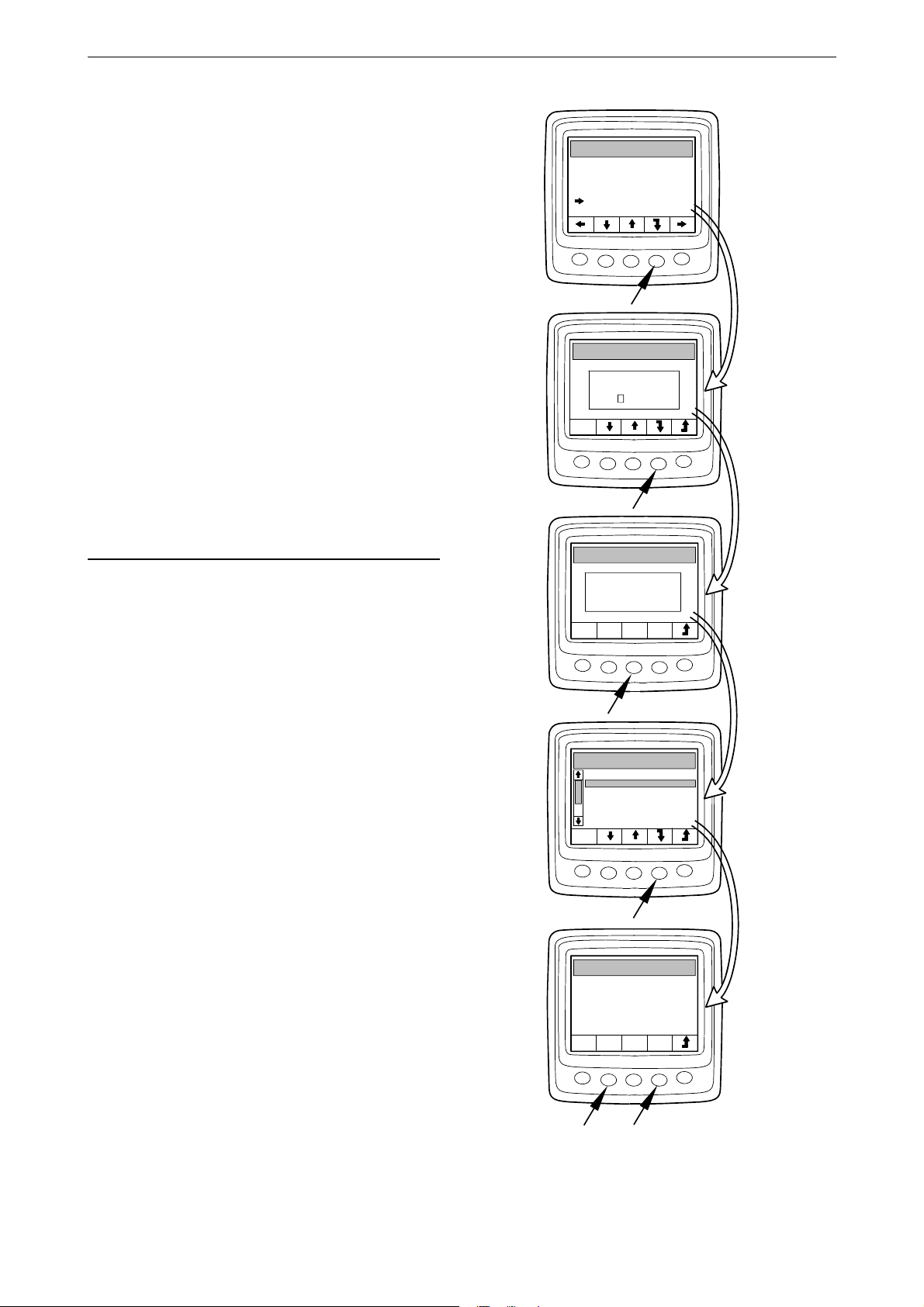

Set lower temperature limit (6.5.2)

• Select Engine and press button 4. This will

take you to the adjustment mode.

• Enter the password and press button 4.

• A warning is displayed. Press button 3 to proceed to the list of parameters that can be set.

• Move up and down the list by pressing buttons 2 and 3.

• Press button 4 when Lower temp limit has

been selected.

• Press button 4 again. This will take you to the

adjustment mode.

• increase or reduce the value by pressing button 2 or 4.

Digital display

When one of the buttons is pressed, the old value

is automatically deleted and the new value saved.

• Go back to the Settings by pressing button 5.

You can set other parameters in the same way.

OPM 500 en-GB 32

©

Scania CV AB 2014, Sweden

Page 33

Base system (6.6)

1

2

3

4

5

6

SETTINGS

BRIGHTNESS/LIGH

T

BUTTON BLEE

P

LANGUAGE

UNITS

ENGINE

BASE SYSTEM

1

23

4

5

6

.6

BASE SYSTEM

NO

SINGLE

DOUBLE

341 613

321 162

321 163

321 164

-

+

321 165

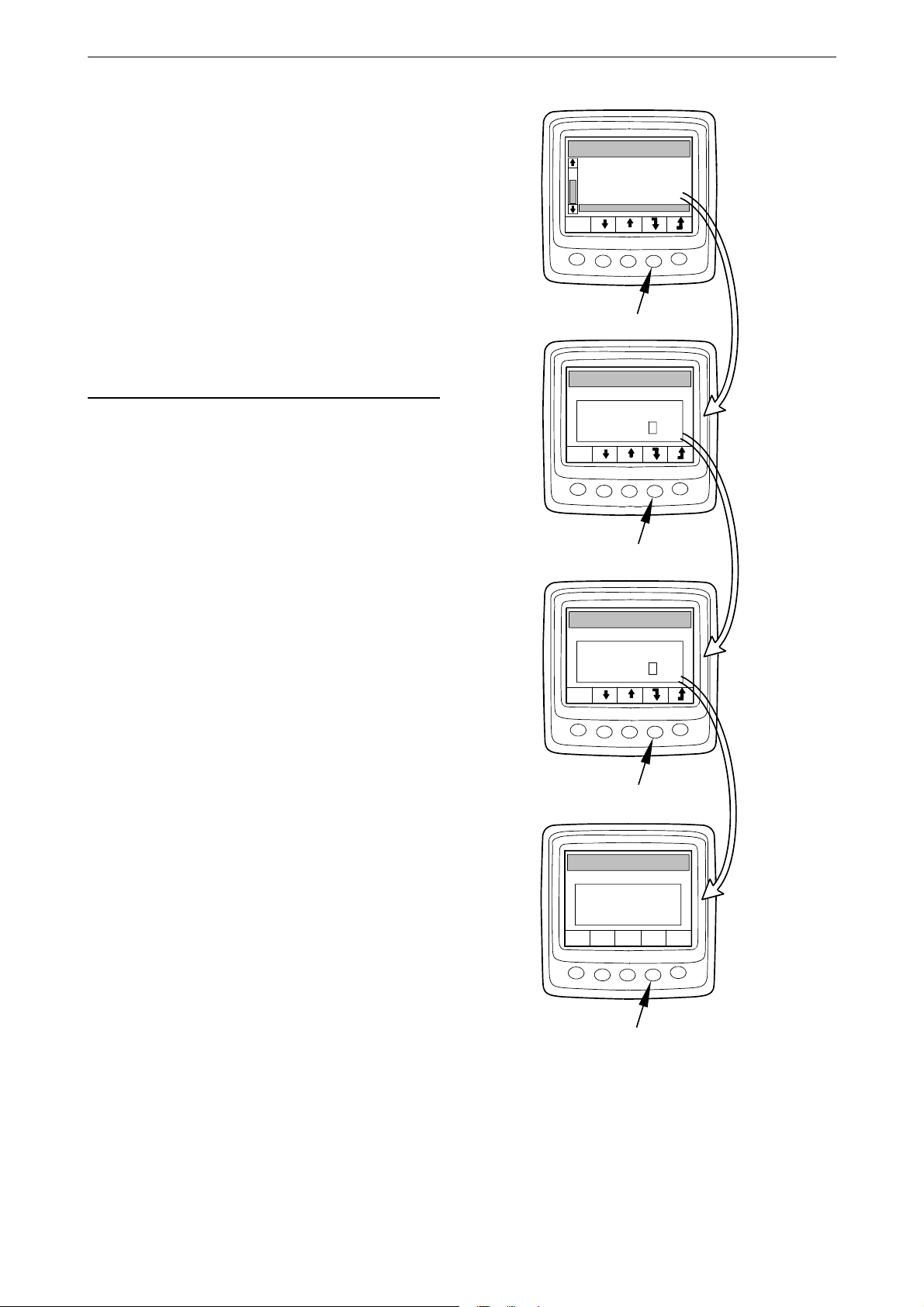

You can configure the digital display for the

electrical system it will be used with in Base system mode. The options are:

•None

•Single

• Double

• Select Base system and press button 4. This

will take you to the adjustment mode.

• Select the type of base system by pressing

button 2 or 3.

• Confirm by pressing button 4. The box on the

right will be selected as an acknowledgement

that the change has been saved.

• Go back to the Settings by pressing button 5.

Alarm and fault code generation

Alarm and fault code generation

Both new alarms and fault codes generate dialogue boxes in the digital display. The dialogue

box for alarm has the highest priority of all functions in the digital display.

Alarms

There are 7 different alarms in the system.

Alarm Icon Comments

Low oil pressure

High coolant temperature

Low coolant level

Alternator not charging System voltage displayed

SCR fault

Low reductant level

Oil level too high or low

OPM 500 en-GB 33

©

Scania CV AB 2014, Sweden

Page 34

Alarm function

Note:

1

23

4

5

1

2

3

4

5

-

+

OK

-

+

-

+

A

B

C

o

C

bar

RPM

1

23

4

5

1800

5

25

x100

OIL PRESSURE

COOLAN

T

TEM

P

0.6

97

1

ENGINE SPEED

1500 R/MIN

OIL PRESSURE

0.6 BAR

COOLAN

T

TEM

P

97 C

VOLTAGE

16V

o

OK

341 614

When an alarm is generated, a warning is shown

in the display together with the alarm icon. At the

same time, an alarm signal sounds both in the analogue instrument panel and the digital display.

Acknowledge the alarm signal in the digital display by pressing button 3. If several alarms are

active, acknowledge one alarm at a time. See

figure A.

Each acknowledged alarm is then displayed as

an icon at the top right of the display as long as

the fault is active. The alarm is displayed regardless of which screen is active.

All alarms must be acknowledged before the

next screen will be displayed.

Alarm and fault code generation

The screen in figure B always has the same content.

If you press button 3 in figure B, you will return

to the screen displayed before the first alarm was

generated. See figure C.

©

Scania CV AB 2014, Sweden

OPM 500 en-GB 34

Page 35

External alarm signal

Output for external alarm

OIL PRESSURE

COOLANT

TEM

P

341 615

When an alarm is generated, pin 11 in the 12-pin

display connector is activated. The output can be

used to activate a warning lamp or suchlike. In

this case use pin 11 to ground a warning lamp.

Maximum current 200 mA. Use a relay if a higher current than 200 mA is required. See illustration.

Alarm and fault code generation

Fault code generation

There are several fault codes in the electrical system to help when a system fault or engine fault

occurs.

When a new active fault code is registered in the

system, it will be shown on the display as in figure A.

Acknowledge all active fault codes by pressing

button 3. The next screen then displays a fault

code icon at the top right as shown in figure B.

The icon is always displayed when at least one

fault code is active.

When starting the system, a dialogue box as in

figure A is always displayed if there is at least

one active fault code.

OPM 500 en-GB 35

©

Scania CV AB 2014, Sweden

Loading...

Loading...