01:02 Issue 10 en-GB

© Scania CV AB 2018, Sweden

Installation manual

Intake system and ventilation

Industrial engines

DC09, DC13, DC16

OC16

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

01:02 Issue 10 en-GB 2

Changes from the previous issue............................................................................3

Intake air ..................................................................................................................4

Intake air taken from outside engine room.......................................................... 5

Intake air taken from engine room ...................................................................... 8

Ventilation requirements for gas engines..............................................................9

Air cleaner..............................................................................................................10

Air cleaners with precleaner.............................................................................. 11

Air cleaners without precleaner......................................................................... 12

Crankcase ventilation............................................................................................13

Open crankcase ventilation ............................................................................... 13

Closed crankcase ventilation............................................................................. 14

Connection to turbocharger .................................................................................15

Cleanliness requirements................................................................................... 15

Charge air pipe .................................................................................................. 15

Stage IV/Tier 4f engines ................................................................................... 16

Important data.......................................................................................................20

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Changes from the previous issue

01:02 Issue 10 en-GB 3

Changes from the previous issue

The changes made in this document compared with the previous issue are marked

with a line in the left-hand margin. The changes are also described below.

• Max. permissible vacuum in the intake system has been changed to 40 mbar for

16 litre single-speed engines. See Intake air taken from outside engine room

.

• Max. permissible vacuum in the engine compartment for engines without fan

(1 mbar) has been removed. 2 mbar now applies to all engines. See Intake air tak-

en from engine room.

• Safety cartridges are no longer included with air cleaners with precleaners. Safety

cartridges can instead be purchased as an option. See Air cleaner

.

• Clearances for Air cleaners with precleaner

and Air cleaners without precleaner

have been corrected.

• Section Important data

has been added.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Intake air

01:02 Issue 10 en-GB 4

Intake air

If the intake line is located close to exhaust pipes or other hot parts, radiation protection should be used to limit unnecessary heating of the intake air.

REQUIREMENT!

The intake air temperature may not exceed the ambient temperature by more than

5°C for Stage IV/Tier 4f engines, or 10°C for other engines.

Measure the temperature when the installation is complete. Refer to 01:08 Measur-

ing instructions for installation inspection.

If the intake air temperature upstream of the turbocharger continuously exceeds

30°C, then engine power may drop. If the engine is enclosed in some manner, make

sure that there is an adequate flow of intake air.

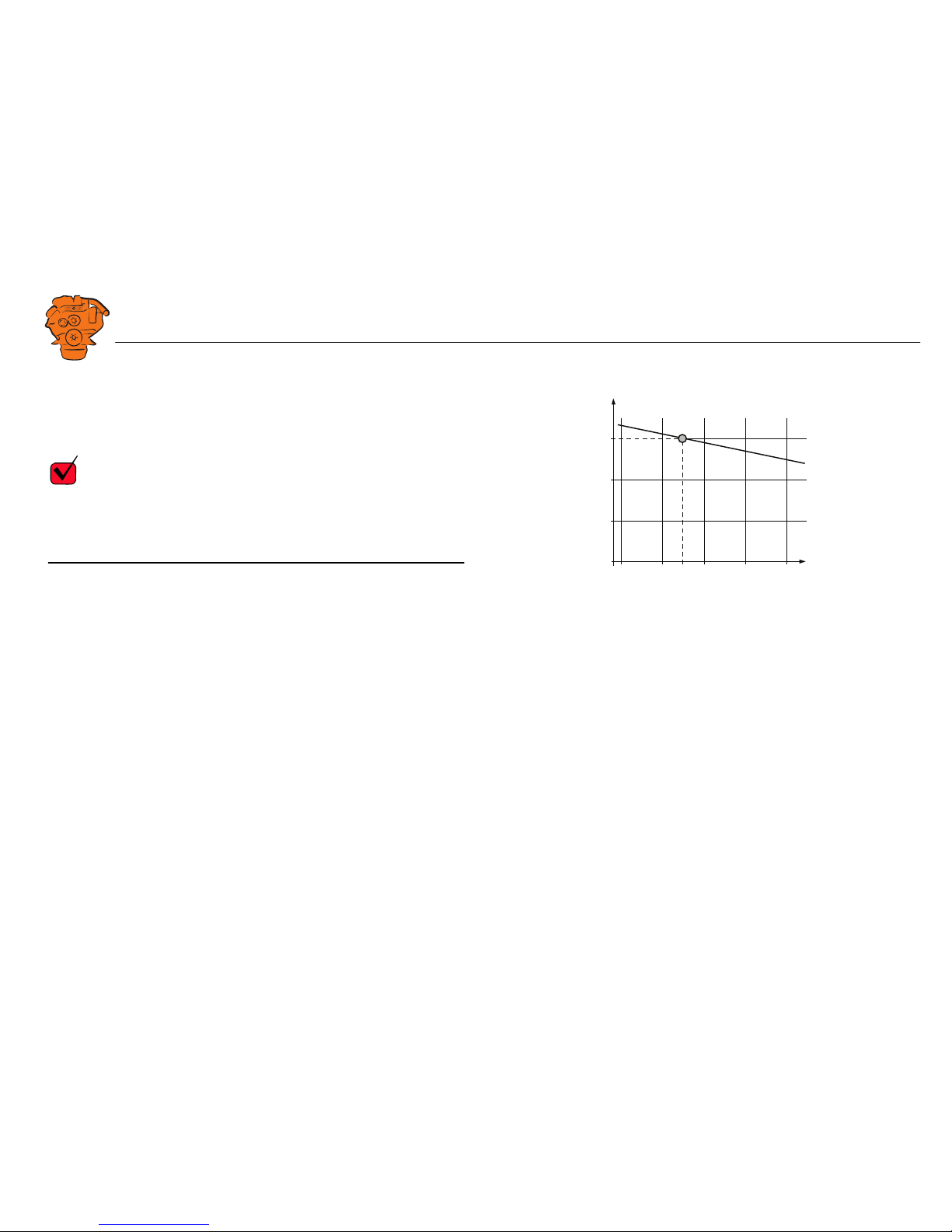

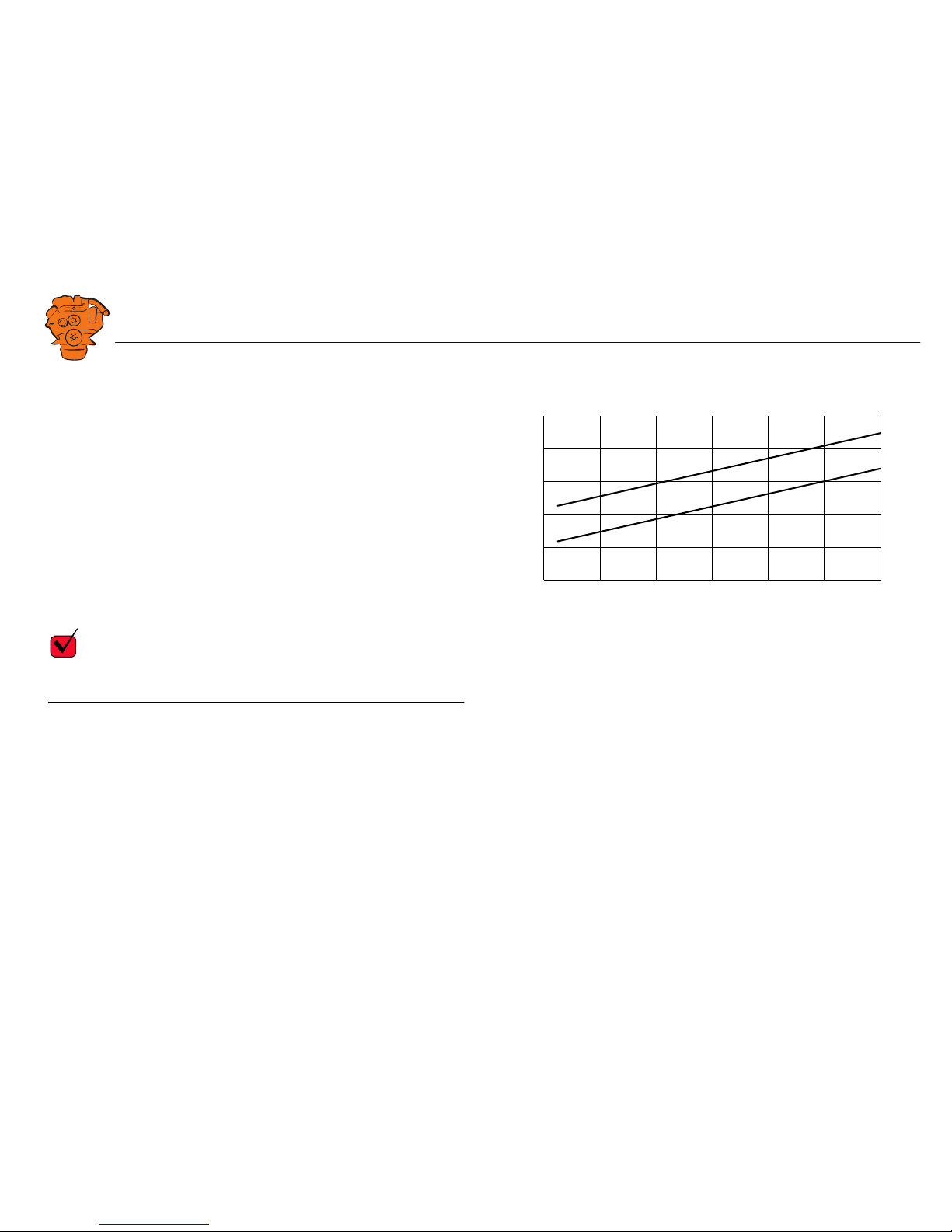

The dependence of the engine power on intake air temperature is shown in the chart

on the right. This diagram is only valid for DC engines. 100% engine power is shown

under actual test conditions at the factory.

Gas engines can be subject to significant power loss if the intake air to the turbocharger has a high temperature in combination with the fuel having a low MN value

(knock-sensitive fuel).

The engine air consumption in kg/min at full power and at different engine speeds is

indicated in the tables showing the air consumption and radiated heat for the relevant

engine type in 01:06 Technical data.

100

95

90

%

A

B

10 20 302540 50

°C

340 422

Engine power dependence on intake air temperature. 100 % at 25°C, 1,000 mbar, engine power setting not corrected.

This diagram is only valid for DC engines.

A = Engine power.

B = Intake air temperature.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Intake air

01:02 Issue 10 en-GB 5

Intake air taken from outside engine room

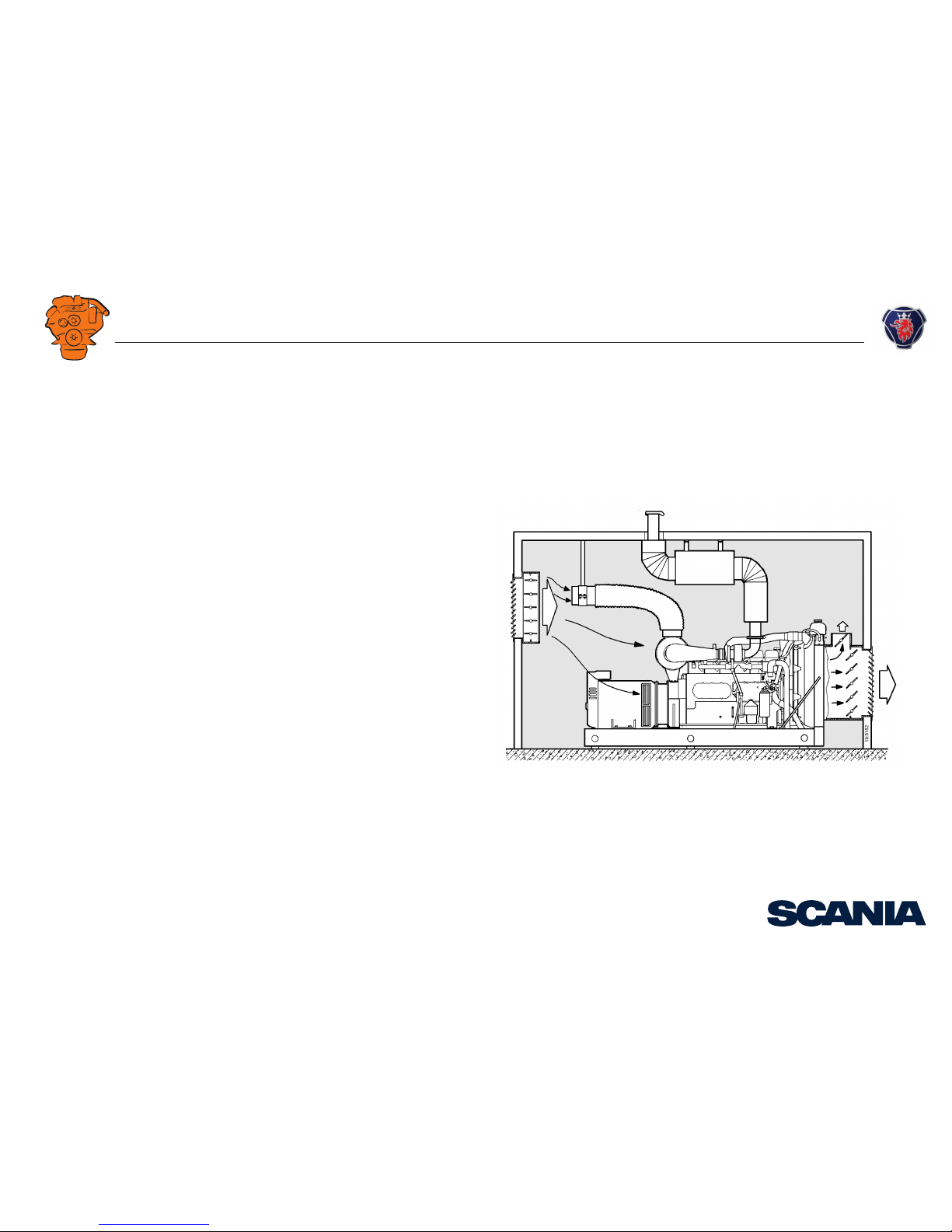

In engine systems where the engine intake air comes from outside the engine room

and is led via a fresh air line to the engine, the vacuum for the intake system should

be measured.

The air intake should be located so that the intake air is as clean as possible and so

that neither the engine exhaust gases nor heated air from the engine room can mix

with the intake air. The air intake should be designed to exclude water, snow and contamination.

The intake air must not contain chemical pollutants, such as CFCs.

REQUIREMENT!

The maximum permissible vacuum in the intake system is 30 mbar. For 16 litre single-speed engines, a vacuum of 40 mbar is permissible. This value includes the vacuum in the new air filter, connected coarse filter and in the fresh air line.

Measure the vacuum when the installation is complete. Refer to 01:08 Measuring in-

structions for installation inspection.

INSTALLATION

MANUAL

© Scania CV AB 2018, Sweden

Intake air

01:02 Issue 10 en-GB 6

The following applies to the fresh air line:

• The fresh air line must not be routed with any sharp bends.

• The inside of the fresh air line must be flat and even.

• If a hose is used as a fresh air line, it must be rigid enough that it does not collapse

onto itself.

It is not necessary to check the vacuum in the following cases:

• If the intake system is comprised of air hoses and air pipes from Scania's standard

range.

• If the fresh air line is maximum 5 m and has an inside diameter of at least 160 mm

for DC09 or 210 mm for DC13 and DC16, respectively.

If the planned fresh air line is longer than 5 m, the required diameter must be calculated as illustrated. The vacuum upstream of the turbocharger must then be measured.

Refer to 01:08 Measuring instructions for installation inspection.

REQUIREMENT!

The total vacuum in the intake system with a blocked air filter must not exceed

65 mbar.

Engine damage will not occur up to 100 mbar, but fuel consumption and smoke will

increase. Above 100 mbar there is a risk that the air volume to the engine will be inadequate, resulting in breakdowns.

B (kg/min)

365 744

A (mm)

500

400

300

200

100

0

0

10 20 30 40 50 60

25 m

50 m

Calculation of minimum diameter of the intake line.

A = Intake line diameter.

B = Air consumption.

Loading...

Loading...