Page 1

Quick Guide

Thank you for purchasing

Label Printer

CT400i Series

the SATO CT400i Series

barcode printer. Please

read this manual carefully

to ensure you understand

the CT400i Series

functions and how to

operate it properly.

CT400iTT Series

Thermal transfer type

203dpi/305dpi/600dpi

CT400iDT Series

Thermosensitive type

203dpi/305dpi/600dpi

EnglishGermanChineseKorean

* Be sure to use SATO genuine parts

(labels, ribbons).

Page 2

FCC WARNING

You ar e c autio ned that changes or modifi cations not expressly approved by

the party responsible for compliance could void your authority to operate the

equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject

EnglishGermanChineseKorean

to the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

AC power cord with ferrite core must be used for RF interference

suppression.

2

Page 3

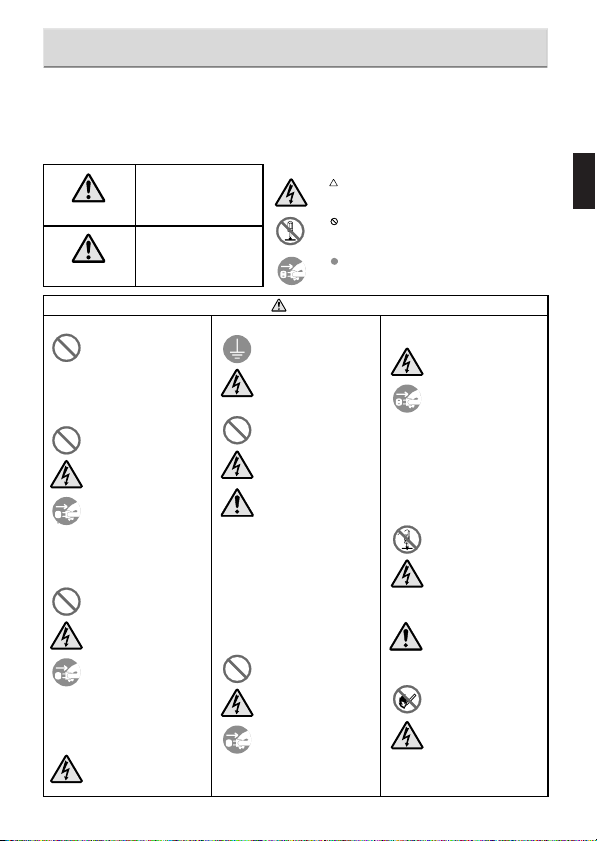

Safety Precautions

This section describes how to use the printer safely. Be sure to read it carefully before using the printer.

Pictographic Symbols

This instruction manual and the printer labels uses a variety of pictographic symbols to facilitate safe and correct use of the printer and to

prevent injury to others and property damage. The symbols and meanings for them are given below. Be sure to understand these symbols

well before reading the main text.

Ignoring the instructions

marked by this symbol and

erroneously operating the

Warning

Caution

Do not set on an unstable area

Do not place containers full of water

or other liquid on the printer.

Do not put objects inside the printer

Do not use other than

the specified voltage

Version 1 December 10, 2007 Q02073000

©2007 SATO CORPORATION

printer could result in death or

serious injury.

Ignoring the instructions

marked by this symbol and

erroneously operating the

printer could result in injury or

property damage.

• Do not set on an unstable area,

such as a wobbly table or

slanted area or an area subject

to strong vibration. If the printer

falls off or topples over, it could

injure someone.

• Do not place flower vases,

cups, or other containers

holding liquids, such as water

or chemicals, or small metal

objects near the printer. If they

are spilled and get inside the

printer, immediately turn off the

power switch, unplug the power

cord from the outlet, and

contact a store, dealer, or the

Support Center. Using the

printer in this condition could

cause a fire or electric shock.

• Do not insert or drop in metal

or burnable objects inside the

printer’s openings (cable

outlets, etc.). If foreign objects

do get inside the printer,

immediately turn off the power

switch, unplug the power cord

from the outlet, and contact a

store, dealer, or the Support

Center. Using the printer in this

condition could cause a fire or

electric shock.

• Do not use other than the

specified voltage. Doing so

could result in fire or electric

shock.

Example Pictographs

The pictograph means “Caution is required.” A specific

warning symbol is contained inside this pictograph (The symbol

at left is for electric shock).

The pictograph means “Should not be done.” What is

specifically prohibited is contained in or near the pictograph

(The symbol at left means “Disassembly prohibited”).

The pictograph means “Must be done.” What is specifically to

be done is contained in the pictograph (The symbol at left

means “Unplug the power cord from the outlet”).

Always ground the connections

Handling of the power cord

When the printer has been dropped

or broken

Warning

• Always connect the printer’s

ground wire to a ground. Not

grounding the ground wire

could result in electric shock.

• Do not damage, break, or

modify the power cord. Also, do

not place heavy objects on the

power cord, heat it, or pull it

because doing so could

damage the power cord and

cause a fire or electric shock.

• If the power cord becomes

damaged (core is exposed,

wires broken, etc.), contact a

store, dealer, or the Support

Center. Using the power cord in

this condition could cause a fire

or electric shock.

• Do not modify, excessively

bend, twist, or pull the power

cord. Using the power cord in

such a condition could cause a

fire or electric shock.

• If the printer is dropped or

broken, immediately turn off the

power switch, unplug the power

cord from the outlet, and

contact a store, dealer, or the

Support Center. Using the

printer in this condition could

cause a fire or electric shock.

Do not use the printer when

something is abnormal about it

• Continuing to use the printer in

the event something is

abnormal about it, such as

smoke or unusual smells

coming from it, could result in

fire or electric shock.

Immediately turn off the power

switch, unplug the power cord

from the outlet, and contact a

store, dealer, or the Support

Center for repairs. It is

dangerous for the customer to

try to repair it, so absolutely do

not attempt repairs on your

own.

Do not disassemble the printer

• Do not disassemble or modify

the printer. Doing so could

result in fire or electric shock.

Ask the store, dealer, or the

Support Center to conduct

internal inspections,

adjustments, and repairs.

Regarding the cutter

• Do not touch the cutter with

your hands or do not put

something into the cutter. Doing

so could result in an injury.

Using the head cleaning fluid

• Use of flame or heat around the

head cleaning fluid is

prohibited. Absolutely do not

heat it or subject it to flames.

•Keep the fluid out of reach of

children to prevent them from

accidentally drinking it. If the

fluid is drunk, immediately

consult with a physician.

EnglishGermanChineseKorean

3

Page 4

Safety Precautions

Do not place in areas with high humidity

• Do not place the pr inter in

areas with high humidity or

where condensation forms. If

condensation forms,

EnglishGermanChineseKorean

immediately turn off the power

switch and do not use the

printer until it dries. Using the

printer while condensation is on

it could result in electric shock.

Carrying the Printer

•When moving the printer,

always unplug the power cord

from the outlet and check to

make sure all external wires

are disconnected before

moving it. Moving the printer

with the wires still connected

could damage the cords or

connecting wires and result in a

fire or electrical shock.

• Do not carry the printer with

paper loaded in it. The paper

could fall out and cause an

injury.

•When setting the printer on the

floor or a stand, make sure not

to pinch your fingers or hands

under the printer feet.

Power supply

• Do not operate the power

switch or plug in/unplug the

power cord with wet hands.

Doing so could result in electric

shock.

Caution

Power cord

•Keep the power cord away from

hot devices. Getting the power

cord close to hot devices could

cause the cord’s covering to

melt and cause a fire or

electrical shock.

•When unplugging the power

cord from the outlet, be sure to

hold it by the plug. Pulling it by

the cord could expose or break

the core wires and cause a fire

or electric shock.

• The power cord set that comes

with the printer is especially

made for this printer. Do not

use it with any other electrical

devices.

Cover

• Be careful not to pinch your

fingers when opening or closing

the cover. Also be careful the

cover does not slip off and

drop.

Thermal head

• The thermal head is hot after

printing. Be careful not to get

burned when replacing paper

or cleaning immediately after

printing.

•Touching the edge of the

thermal head with bare hands

could result in injury. Be careful

not to become injured when

replacing paper or cleaning.

• The customer should not

replace the thermal head.

Doing so could result in injury,

burns, or electric shock.

Opening and closing the thermal head

•When opening or closing the

thermal head, make sure

nothing other than paper gets

in it. Debris getting in could

cause injury or damage.

Loading paper

•When loading roll paper, be

careful not to get your fingers

pinched between the paper roll

and the supply unit.

• Be careful not to become

injured when opening the fanfolded paper loading slot

window.

When not using the printer

for a long time

•When not using the printer for a

long time, unplug the power

cord from the outlet to maintain

safety.

During maintenance and cleaning

•When maintaining and cleaning

the printer, unplug the power

cord from the outlet to maintain

safety.

(1)

Reproduction in any manner of all or part of this document is prohibited.

(2)

The contents of this document may be changed without prior notice.

(3)

Great care has been taken in the preparation of this document, but if any problems, mistakes, or

omission are found, please contact the store or dealer where you purchased the printer.

Caution

4

Page 5

Accessories Check

The following items are packed together with the main unit in the

box. Be sure to check to make sure nothing is missing. If something

is missing, contact the store or dealer where you purchased the

product.

EnglishGermanChineseKorean

¡

Quick Guide¡Safety manual

¡

Manual (for RoHS) ¡GWP leaflet

¡Test labels and ribbons

¡Dial adjustment screwdriver

* Attached to the printer unit.

The power cord set included with this printer is only for use with this printer.

Do not use it with other electrical products.

Caution

¡Power cord and AC adapter

¡USB cable

¡Ribbon adapter

* The test ribbons and ribbon adapter

come with the thermal transfer model.

5

Page 6

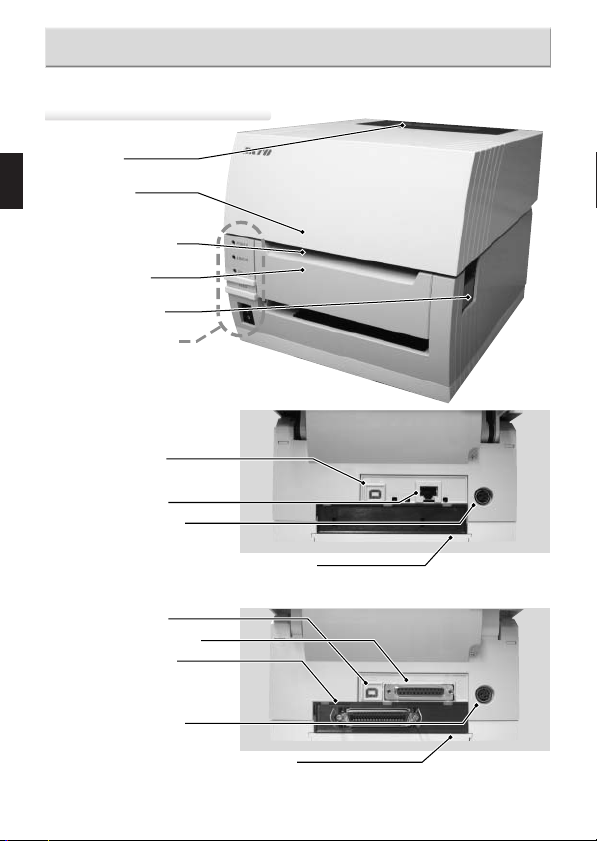

Names of Parts

Printer unit [unit exterior]

¡Window

¡Top cover

EnglishGermanChineseKorean

¡Label discharge

outlet

¡Front cover

¡Opening lever

¡Operation panel

[Back (USB + LAN interface)]

¡USB interface

¡LAN interface

¡DC input power

terminal

(Power connector)

[Back (USB + RS-232C interface)]

¡USB interface

¡RS-232C interface

¡Interface board

The interface can be

changed using an optional

interface board.

¡DC input power

terminal

(Power connector)

6

¡I/F Cover

¡I/F Cover

*Handling of an I/F Cover:

Please close with an I/F Cover after shutting off a

power supply and attaching or removing an I/F

board, in case an I/F Cover is opened.

Page 7

When top cover is opened

[For CT400iDT Series]

¡ Thermal head

¡ Paper holder

¡ Paper sensor

¡ Platen roller

¡ Paper holder

slide lever

[For CT400iTT Series]

¡ Ribbon unit

¡ Paper holder

Names of Parts

EnglishGermanChineseKorean

¡ Paper sensor

¡ Platen roller

¡ Paper holder

slide lever

7

Page 8

Names of Parts

When top cover is opened

[Cutter Type]

¡Cutter top knife

EnglishGermanChineseKorean

¡Paper holder

¡Paper sensor

¡Platen roller

¡Paper holder

slide lever

¡Cutter bottom knife

¡Cutter unit

[Separation Type]

¡Paper holder

¡Paper sensor

¡Platen roller

¡Paper holder

slide lever

¡Backing paper

discharge outlet

(When front cover is open)

(When front cover is open)

¡Separation unit

8

Page 9

Names of Parts

[Operation Panel]

¡ [POWER] lamp

Illuminates (green) when the power switch is on.

¡ [ERROR] lamp

Illuminates or flashes (red) when an error occurs.

¡ [ON LINE] lamp

Illuminates (green) when reception is possible.

¡ [ON LINE] key

This is press to stop/restart and

to terminate data reception.

¡ [FEED] key

This feeds the paper when pressed

while the printer is online.

¡ Power switch

[When the front cover is opened]

¡Separator connector

¡Cutter connector

¡Error display lamp

EnglishGermanChineseKorean

¡Adjustment dial

¡Dip switches

(DSW1)

9

Page 10

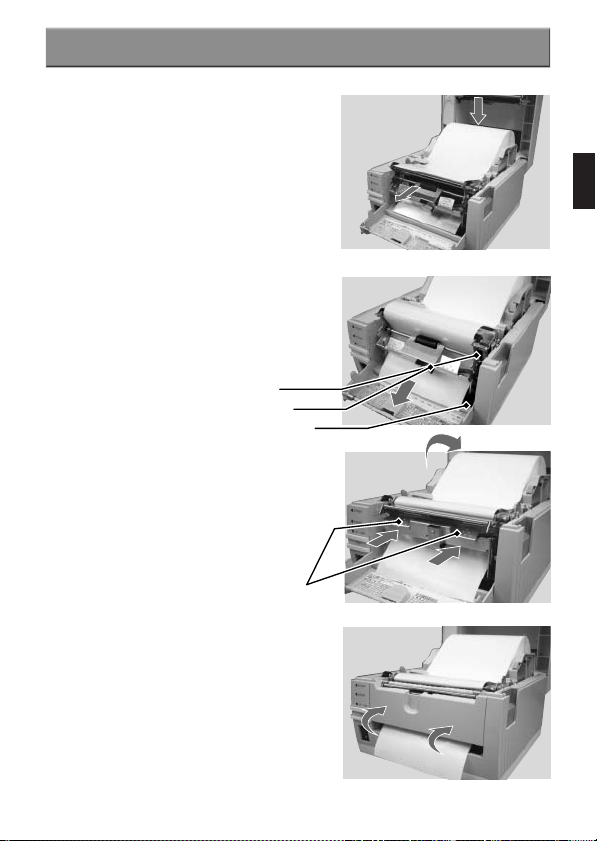

Loading the Roll Paper [Continuous, Cutter, Linerless types]

Press down the opening

lever (1) on the right side

1

of the printer to release

the lock and open the top

cover (2).

EnglishGermanChineseKorean

While pressing the paper

holder slide lever (1),

2

adjust the paper holder to

match the paper size (2).

Load the paper into the

paper holder.

3

(2)

(1)

(1)

(2)

After pulling out the

paper, pass the paper

4

through the paper sensor.

10

Paper sensor

Page 11

Loading the Roll Paper [Continuous, Cutter, Linerless types]

Close the top cover.

5

At this time, press on the

top where shown by the

arrows to close the cover

until you hear the lock

engage.

(1) Press the [FEED] key

to feed the leading edge

6

of the paper.

(2) Finally, press the [ON

LINE] key to bring the

printer online.

After printing, the thermal head and surrounding area are hot. Be careful not

to get burned when replacing paper immediately after printing.

Touching the thermal head with bare hands could result in an injury.

Be careful not to become injured when replacing paper.

Caution

Be careful not to pinch your fingers when closing the top cover.

(2)

(1)

EnglishGermanChineseKorean

11

Page 12

Loading fan-folded paper [Continuous, Cutter types]

Open the window from

the back edge.

1

EnglishGermanChineseKorean

Press down on the

open lever (1) on the

2

right side of the printer

to release the lock and

then open the top

cover (2).

Pass the paper through

the opened window.

3

Window

(2)

(1)

12

Page 13

Loading fan-folded paper [Continuous, Cutter types]

While pressing the paper

holder slide lever (1), adjust

4

the paper holder to match

the paper size (2).

Paper sensor

(1)

After pulling out the paper,

pass it through the paper

sensor.

Close the top cover.

5

At this time, press on the

top where shown by the

arrows to close the cover

until you hear the lock

engage.

(1) Press the [FEED] key to

feed the leading edge of the

6

paper.

(2) Finally, press the [ON

LINE] key to bring the

printer online.

After printing, the thermal head and surrounding area are hot. Be careful not

to get burned when replacing paper immediately after printing.

Touching the thermal head with bare hands could result in an injury.

Caution

Be careful not to become injured when replacing paper.

Be careful not to pinch your fingers when closing the top cover.

(2)

(1)

(2)

EnglishGermanChineseKorean

13

Page 14

Loading Roll Paper [Separator]

Press down on the open

lever (1) on the right side of

1

the printer to release the lock

and then open the top cover

(2).

EnglishGermanChineseKorean

Open the front cover forward.

2

While pushing on the [PUSH

DOWN] mark on the

3

separator unit, tilt it forward

(1) to open the separator

unit (2).

[PUSH DOWN] mark

When the separator unit is

opened, the separator bar

4

will automatically open in the

direction shown by the

arrow.

(2)

(1)

(1)

(2)

Separator bar

Separator bar

14

Page 15

Loading Roll Paper [Separator]

Peel off labels to expose 15

cm of only the backing paper

5

and then load the paper into

the paper holder.

After pulling out the paper,

pass it through the paper

sensor.

Pass the backing paper

between the separator unit

6

and the platen roller.

Set the backing paper so

that it is below the separator

plate.

Press on the [PUSH DOWN]

mark on the separator unit in

7

the direction shown by the

arrows to close it.

If the backing paper is slack,

turn the labels to wind it up

and remove the slack.

Platen roller

Separator unit

Separator plate

[PUSH DOWN] mark

EnglishGermanChineseKorean

Close the front cover.

8

15

Page 16

Close the top cover.

At this time, press on the top

9

where shown by the arrows

to close the cover until you

hear it lock closed.

EnglishGermanChineseKorean

Loading Roll Paper [Separator]

(1) Press the [FEED] key to

feed the leading edge of the

10

paper.

(2) Finally, press the [ON

LINE] key to bring the printer

online.

After printing, the thermal head and surrounding area are hot. Be careful not

to get burned when replacing paper immediately after printing.

Touching the thermal head with bare hands could result in an injury.

Caution

Be careful not to become injured when replacing paper.

Be careful not to pinch your fingers when closing the top cover.

16

(2)

(1)

Page 17

Printing Position Adjustment

▲

Printing Standard Position

The printing standard position when using labels is the top of the label.

The printing standard position when using fan folded paper is the top of the match mark on the back of

the fan folded paper.

Label

Match mark

Label

Paper feed direction

Standard position (Vertical position 1 dot)

Fan folded paper

Match mark

Fan folded paper

Paper feed direction

Standard position (Vertical position 1 dot)

If the printing standard position is not at the correct position, open the top cover and used the flat head

end of the dial adjustment screwdriver that comes with the printer to adjust the printing standard

position.

Turn left: Moves the printing position forward relative

to the printing direction.

Turn right: Moves the printing position backward relative

to the printing direction.

(Use the dial adjustment screwdriver.)

EnglishGermanChineseKorean

17

Page 18

Cut Position Adjustment

▲

Label Cut

The cut position when using labels is the designated cut position between labels on the blank area (the

area where there is only backing paper).

Labels

EnglishGermanChineseKorean

If the cut position is not the prescribed position, open the top cover and use the Philips head end of the

dial screwdriver attached to the printer unit to adjust the cut position.

Absolutely do not cut on top of the labels because the adhesive will stick to the cutter knife and cause

poor cutting.

Turn left: Stops the label behind the printing direction.

Turn right: Stops the label in front of the printing direction.

(Use the dial adjustment screwdriver.)

▲

Cutting paper with perforated lines

For paper with perforated lines, cutting on or in front of the perforated lines is prohibited.

Cutting in those locations could cause the printer to malfunction.

If cutting on or in front of the perforated line, use the Philips head end of the dial screwdriver

attached to the printer unit to adjust the [OFFSET] so that the cut is behind the perforated line.

The following items are specifications for paper that can be used by this printer, so check them

before using the printer.

(1) Paper thickness (including the backing paper) is 0.08 mm to 0.19 mm. For details contact

the store, dealer, or Support Center.

(2) Cut accuracy is ±1.5 mm.

(3) The cutter unit has a valid cut pitch of 20 to 400 mm. However, the cut size may be

restricted depending on the usage conditions.

(4) The perforated line +1 mm is the cut prohibited zone (Fig. 1).

(5) The folded perforated line +4 mm to +25 mm of fan folded paper is the cut prohibited zone

(Fig.2).

(6) After adjusting the volume, issue about 2 to 5 labels to stabilize the cut position.

Cut prohibited

zone

Backing

paper

Cut position

(Fig. 1) (Fig. 2)

25mm

4mm

Folded perforated

line

Perforated

18

(Fig. 1)

line

(Fig. 2)

Page 19

Loading the Carbon Ribbon

[Loading the Carbon Ribbon]

Press down on the open

lever (1) on the right side of

1

the printer to release the

lock and open the top cover

(2).

(2)

(1)

EnglishGermanChineseKorean

Pull the ribbon unit’s [PULL]

mark to pull the ribbon unit

2

forward.

If the carbon ribbon width is over 92 mm and under 76 mm, use

Steps 3 to 6 to set the carbon ribbon.

For a carbon ribbon with a

width greater than 92 mm,

load the carbon ribbon

directly into the ribbon unit.

For a carbon ribbon with a

width under 76 mm, use a

ribbon adapter to load it into

the ribbon unit.

Ribbon adapter

[PULL] mark

19

Page 20

Loading the Carbon Ribbon

[Loading carbon ribbons with a width greater than 92 mm]

After setting the carbon

ribbon in the right side of

3

the ribbon supply unit (1),

EnglishGermanChineseKorean

press the core guide (2).

(1)

(2)

After setting the ribbon core

in the right side of the

4

ribbon windup unit (1),

press the core guide (2).

Pass the carbon ribbon

from the ribbon supply unit

5

beneath the thermal head

and to the ribbon windup

unit. Affix the carbon ribbon

to the ribbon core using

tape, etc., and wind it up

several times in the

direction shown by the turn

arrow.

Be sure to pass the carbon

ribbon between the thermal

head and the label restraint.

Do not pass it beneath the

label restraint.

20

Ribbon supply unit core guide

(1)

(2)

Ribbon windup unit core guide

Label restraint

Page 21

Loading the Carbon Ribbon

[Loading carbon ribbon with a width under 76 mm]

For carbon ribbon with a width of 76 mm or 59 mm, set the ribbon

adapter hooks at the bottom. From this state, turn the hooks in

3

the direction shown by the arrow to set it at the bottom. If the

carbon ribbon width is 45 mm, use it in that state.

For 76 mm or 59 mm For 45 mm

Set the carbon ribbon in the ribbon adapter.

4

For 76 mm or 59 mm For 45 mm

EnglishGermanChineseKorean

Set the ribbon adapter in which the

carbon ribbon (1) is loaded from the

5

right side of the ribbon supply unit.

Set the ribbon adapter in which the

ribbon core is set from the right

side of the ribbon windup unit (2).

Pass the carbon ribbon from the

ribbon supply unit under the

6

thermal head and to the ribbon

windup unit. Affix the carbon ribbon

to the ribbon core with tape, etc.,

and turn the core several times in

the direction shown by the arrow.

(1)

(2)(2)

Label restraint

21

Page 22

EnglishGermanChineseKorean

Set the ribbon unit in the top

cover and return the cover to its

7

original position.

Closing the top cover after closing the

ribbon unit could prevent the top

cover from closing properly. Always

Caution

put the ribbon unit in the top cover.

Loading the Carbon Ribbon

10

22

For the cutter type, be careful not to

cut your hand on the top cutter knife

when putting the ribbon unit into the

Caution

top cover.

Set the paper in the paper

holder.

8

After pulling out the paper, pass

the paper between the paper

sensors.

Close the top cover.

At this time, press on the top

9

where shown by the arrows to

close the cover until you hear it

lock closed.

(1) Press the [FEED] key to feed

the leading edge of the paper.

(2) Finally, press the [ON LINE]

key to bring the printer online.

The thermal head and surrounding area is hot after printing. When replacing

the carbon ribbon immediately after printing, be careful not to get burned.

Touching the thermal head with bare hands could result in an injury.

Be careful not to get injured when replacing the carbon ribbon.

Caution

Be careful not to pinch your fingers when closing the top cover.

For cutter type printers, be careful not to cut your hands.

Paper sensor

(2)

(1)

Page 23

Connecting to a Computer

[Standard Interface]

¡USB + LAN type

USB interface

LAN interface

(1)When using a USB interface, set DSW 1-8 inside the front cover

to OFF.

When using a LAN interface, set DSW 1-8 inside the front cover

to ON.

(2)To set the USB interface printing support settings or LAN

interface reception mode settings, set DSW 3-2 of the circuit

board on the bottom of the printer.

For details regarding dip switch settings, refer to [Dip Switch

Settings].

/Page 29~31

¡USB + RS-232C type

USB interface

RS-232C interface type

(1)When using a USB interface, set DSW 1-8 inside the front cover

to OFF.

When using an RS-232C interface type, set DSW 1-8 inside the

front cover to ON.

(2)To set the RS-232C interface conditions, set DSW2 of the circuit

board on the bottom of the printer.

(3)To set the USB interface printing support settings, set DSW 3-2 of

the circuit board on the bottom of the printer.

For details regarding dip switch settings, refer to [Dip Switch

Settings].

/Page 29~31

EnglishGermanChineseKorean

23

Page 24

[Extension Interface(Option)]

¡IEEE 1284 interface

Connecting to a Computer

EnglishGermanChineseKorean

IEEE 1284 interface

(1)When using an IEEE 1284 interface, set DSW 3-1 of the circuit

board on the bottom of the printer to ON.

(2)To set the printing support for the IEEE 1284 interface setting, set

DSW3-2 of the circuit board on the bottom of the printer.

For details regarding dip switch settings, refer to [Dip Switch

Settings].

/Page 29~31

¡Wireless LAN2 interface

Wireless LAN2 interface

No

Operation when the dip switch is ON and the printer power is turned on ((1) to (3)).

(1)

Not used

Wireless LAN2 interface board setting information initialization

(2)

(3)

Wireless LAN2 interface board setting information print/Self-diagnostic print

(Prints the setting information, such as IP address, and the wireless LAN2 interface

board diagnostic results.)

(4)

Communication mode

(For wireless LAN operation)

When the LAN cable is connected and the power is turned on, the LAN interface starts up.

When the LAN cable is not connected and the power is turned on, the wireless LAN

interface starts up.

24

Wireless LAN2 interface board Dip Switch Table

OFF: Ad hoc

ON: Infrastructure

ON

(1)(2)(3)(4)

Page 25

Connecting to a Computer

(1)When using the wireless LAN2 interface, set DSW 3-1 of the

circuit board on the bottom of the printer to ON.

(2)When setting the wireless LAN2 interface setting to the reception

mode, set DSW 3-2 of the circuit board on the bottom of the

printer.

For details regarding dip switch settings, refer to [Dip Switch

Settings].

/Page 29~31

¡Bluetooth interface

Bluetooth interface

The Bluetooth interface board is contained

inside the printer and cannot be seen from

outside.

(1)When using the Bluetooth interface, set DSW 3-1 of the circuit

board on the bottom of the printer to ON.

For details regarding dip switch settings, refer to [Dip Switch

Settings].

/Page 29~31

EnglishGermanChineseKorean

25

Page 26

Turning On the Power

Plug the AC adapter/power cord into the printer and turn on the power.

[Power Setting]

When installation is

completed, set the power as

1

shown below.

EnglishGermanChineseKorean

Connect the power cord to

the AC adapter.

2

The plug of the included

power cord is a 3-pronged

plug.

3-prong type outlets use one

of the prongs as a ground.

When the outlet is a 3-prong

type, plug the power cord

directly into it.

Connect the printer → AC

adapter → power cord.

3

When plugging the power

cord into the printer’s power

connector, make sure the

power cord connector is

oriented properly. When

plugging in the power cord

to the printer, use one hand

to hold the printer while

using the other hand to plug

in the cord.

Plug the included AC

adapter into the print and the

4

power cord into the outlet.

When the power outlet is the

2-prong type, use the

included 2-pronged adapter

to plug the power cord into

the power outlet.

Be sure to connect the ground

wire to a ground. Not connecting

the ground wire could result in

Caution Caution

electrical shock.

26

The power cord set included

with this printer is only for use

with this printer. Do not use it

with other electrical products.

Page 27

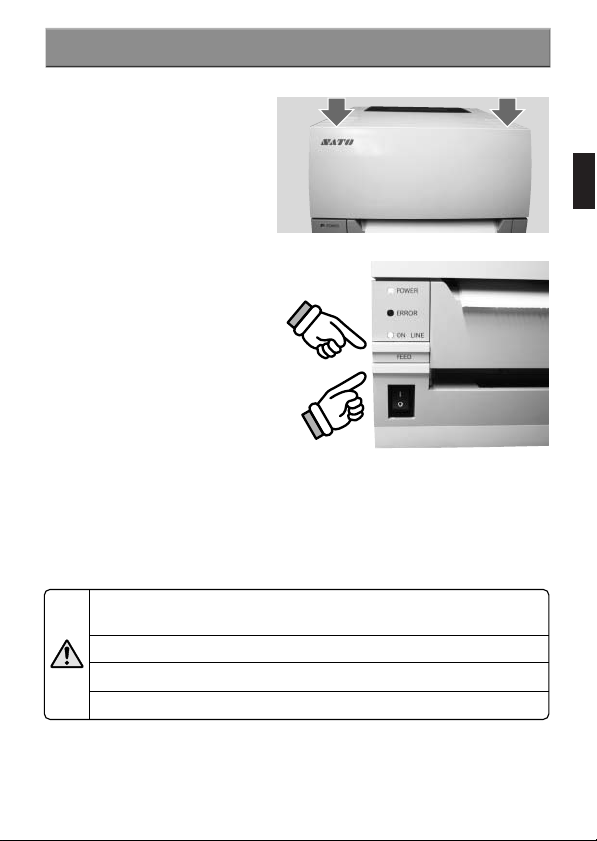

Turning On the Power

[Turning On the Power]

Turn on the power switch at the front

of the printer.

Switch it to the “ ” symbol.

When the power switch is turned on,

the POWER lamp will illuminate. (The

ONLINE lamp also illuminates.)

Check to make sure this happens.

POWER lamp

ERROR lamp

ONLINE lamp

[ONLINE] key

Power switch

EnglishGermanChineseKorean

Caution

Do not operate the power switch or plug in/unplug the power cord with wet hands.

Doing so could result in electric shock.

[If you think something is wrong...]

When preparation does not go well as it has before, the ONLINE LINE lamp or the

POWER lamp will not illuminate. When preparation is not performed properly, the

ERROR lamp will illuminate or flash. If the ERROR lamp illuminates or flashes, redo

the preparation.

[Turning Off the Power]

After making sure the printer is operating properly, turn off the power.

Do not suddenly turn off the power before making sure the printer is ready to have

the power turned off.

▲

Check the following before turning off the power.

Press the [ONLINE] key and confirm the ONLINE lamp has turned off.

After the ONLINE lamp turns off, turn off the power.

Switch the switch to the “ ” symbol.

[FEED] key

27

Page 28

Printing Operation Confirmation and Error Number Display

[Printer Status Print]

This prints the status of the printer.

The current settings information is printed, so check the settings

printout.

EnglishGermanChineseKorean

Turn on the power while

pressing the [FEED] key.

1

The buzzer will sound, so

then press the following

2

key.

Press the [ON LINE] key

to print a large size.

Press the [FEED] key

to print a small size.

Pressing the [FEED] key during

printing will stop/restart

printing.

The printer setting information is

printed out.

3

Check if the printed information is the

settings values.

28

[ON LINE] key

[FEED] key

(1)(2)(3)(4)(5)(6)(7)(8)

Page 29

Printing Operation Confirmation and Error Number Display

[Dip Switch Settings]

Suitable settings have been made to match the printer’s operating environment,

but in the event the settings are different, please reset the dip switches.

*A detailed explanation of the dip switches is given on the explanation sticker affixed

to the printer.

¡Dip Switch Settings Table DSW1 (Inside the front cover)

USB + LAN type

Mode Change

Continuous

Tear off

Cutter

Separator

Liner less

Par tial cut

Font download

DSW1-1

OFF

ON

OFF

ON

OFF

ON

OFF

USB + RS-232C type

Mode Change

Continuous

Tear off

Cutter

Separator

Liner less

Par tial cut

Font download

DSW1-1

OFF

ON

OFF

ON

OFF

ON

OFF

DSW1-2

OFF

OFF

ON

ON

OFF

ON

ON

DSW1-2

OFF

OFF

ON

ON

OFF

ON

ON

Printing Method

DSW1-3

Direct thermal

OFF

OFF

Thermal transfer

OFF

Head check

OFF

Disable

ON

Enable

ON

VR1 adjustment selection

ON

Offset adjustment

Print density adjustment

DSW1-3

Printing Method

OFF

Direct thermal

OFF

Thermal transfer

OFF

Head check

OFF

Disable

ON

Enable

ON

VR1 adjustment selection

ON

Offset adjustment

Print density adjustment

DSW1-4

OFF

ON

DSW1-5

OFF

ON

DSW1-6

OFF

ON

DSW1-4

OFF

ON

DSW1-5

OFF

ON

DSW1-6

OFF

ON

Dump Mode

Disable

Enable

Interface Change

USB

LAN

Dump Mode

Disable

Enable

Interface Change

USB

RS-232C

DSW1-7

DSW1-8

DSW1-7

DSW1-8

OFF

ON

OFF

ON

OFF

ON

OFF

ON

EnglishGermanChineseKorean

* The head check is a head disconnection guideline and is not a function

warranted for the barcode reader. Check the barcode reader periodically.

29

Page 30

Printing Operation Confirmation and Error Number Display

¡Dip Switch Settings Table DSW2 (RS-232C Interface Settings)

Only for the USB + RS-232C type

To change the dip switch DSW2 settings to make the RS-232C interface

settings, set them as shown below.

EnglishGermanChineseKorean

(1) Turn off the printer power and disconnect the power cord.

(2) Disconnect the connected interface cable.

(3) Remove the paper set in the printer.

(4) Open the cover on the bottom of the printer.

Make the ON/OFF setting for dip switch DSW2 that is on the circuit board and

then switch to the RS-232C interface settings.

(1)(2)(3)(4)(5)(6)(7)(8)

No.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

30

Function Explanation

Data bit length

Parity bit

Stop bit

Baud rate

Communication protocol

OFF: 8 bit

ON: 7 bit

DSW2-2

OFF

OFF

ON

ON

OFF: 1 bit

ON: 2 bit

DSW2-5

OFF

OFF

ON

ON

DSW2-7

OFF

OFF

ON

ON

DSW2-3

OFF

ON

OFF

ON

DSW2-6

OFF

ON

OFF

ON

DSW2-8

OFF

ON

OFF

ON

Parity bit

None

Even number

Odd number

Not used

Baud rate

9600bps

19200bps

38400bps

57600bps

Protocol

READY/BUSY

XON/XOFF

Status 3 return

Status 4 return

ON

Page 31

Printing Operation Confirmation and Error Number Display

¡

Dip Switch Settings Table DSW3 (Standard/Extension Interface Settings)

To change the dip switch DSW3 settings to make the standard/extension interface

change, set them as shown below.

(1) Turn off the printer power and disconnect the power cord.

(2) Disconnect the connected interface cable.

(3) Remove the paper set in the printer.

(4) Open the cover on the bottom of the printer.

Make the ON/OFF setting for dip switch DSW3 that is on the circuit board and

then switch the standard/extension interface settings.

ON

EnglishGermanChineseKorean

USB + LAN type

No.

(1)

(2)

Function Explanation

Not used

Interface settings

USB + RS-232C type

No.

(1)

(2)

Function Explanation

Standard/extension

Interface change

Interface settings

(1)(2)

Normally OFF

USB interface (DSW1-8 OFF)

DSW3-2

OFF

ON

LAN interface (DSW1-8 ON)

DSW3-2

OFF

ON

OFF :

Standard interface

When DSW1-8 is OFF, USB interface

When DSW1-8 is ON, RS-232C interface

ON :

Extension interface (option)

USB interface (DSW1-8 OFF, DSW3-1 OFF)

DSW3-2

OFF

ON

IEEE 1284 interface (DSW3-1 ON)

DSW3-2

OFF

ON

Wireless LAN2 interface (DSW3-1 ON)

DSW3-2

OFF

ON

Printing port

SATO port

Standard printing port

Reception mode

Periodic response status

ENQ response status

Printing port

SATO port

Standard printing port

Printing port

SATO port

Standard port

Reception mode

Periodic response status

ENQ response status

31

Page 32

¡

Error Messages

Error

Code

0

EnglishGermanChineseKorean

2

FLASH ROM read/write overflow

or write count overflow.

Defective circuit board

Printing Operation Confirmation and Error Number Display

Resolution MethodCause

Contact the store, dealer, or support center.

Contact the store, dealer, or support center.

EEPROM error

3

Thermal head is disconnected

4

or broken.

Top cover is not locked.

5

The paper is dead.

6

Sensor type does not match, or

7

sensor level does not match.

The cutter is not connected, or

the cutter is not operating

8

9

A

b

c

d

r

32

1

normally.*

The ribbon is dead. or ribbon is

2

broken.*

The amount of data sent from

the computer is too high.

There is a problem with the computer’s

communication conditions settings.

Abnormal read/write from the

RFID tag.

Contact the store, dealer, or support center.

Contact the store, dealer, or support center.

Press on both sides of the top of the top cover

until you hear the cover lock in place.

Load new paper

Contact the store, dealer, or support center.

Contact the store, dealer, or support center.

*1 For cutter, linerless, ad partial cutter types.

Correctly load the ribbon.

*2 For thermal transfer printers

Turn the power off and on again. Adjust the

computer’s software data amount to match the

communication conditions. If this does not resolve

the error, check the communication conditions.

Set a new RFID.

Page 33

Basic Specifications

Model name

Printing method

Head density

Printing effective range

Printing speed

Paper

Paper thickness

Shape type

Label size

(Backing paper and

thick paper size)

Sheet capacity

Roll paper

Fan-folded paper

Carbon ribbon

Width

Length

Base material

thickness

Color

Winding direction

Label feed

Dimensions

CT408iDT/CT408iTT

Thermal transfer (DT)/ Thermosensitive (TT)

8-dot/mm (203 dpi)

104 mm wide x 400 mm pitch

Printing is not possible for 1.5 mm from both edges, and printing is not

possible in the I-mark range.

Maximum 6 inchs (Approx. 150 mm/s) Maximum 4 inchs (Approx. 100mm/s)

Note: However, there are times when there are restrictions depending on

Only use paper manufactured and specified by SATO.

0.08 to 0.19 mm

Roll paper, fan-folded paper

Standard

Tear off

Separated

Cutter

linerless

Par tial cut

There may be restrictions depending on the number issued and the paper size and type.

However, there may be restrictions on size depending on the usage conditions.

Max. outside diameter: 110 mm (Approx. 50 m/roll) Using 40 mm paper core

Surface wound (However, linerless is for surface wound only)

Max. folded height: 100 mm (Supplied from outside the printer.)

Refer to “Fan-folded Paper Settings.” / page 12

Only use carbon ribbon manufactured and specified by SATO.

45, 59, 76, 92, 111mm

The carbon ribbon width should be wider than the paper being used.

100 m/roll

4.5

µ

Black (standard)

However, colored ribbon is available.

Surface winding

Continuous, tear off, separated, cutter, linerless, par tial cut

198 W

CT400i Series

CT412iDT/CT412iTT CT424iDT/CT424iTT

12-dot/mm (305 dpi) 24-dot/mm (600 dpi)

Max. 3 inchs (Approx. 75 mm/sec)

the printing layout, paper, and type of carbon ribbon.

Width:

25 to 115 mm (28 to 118 mm)

Pitch:

15 to 397 mm (18 to 400 mm)

Width:

25 to 115 mm (28 to 118 mm)

Pitch:

27 to 397 mm (30 to 400 mm)

Width:

25 to 115 mm (28 to 118 mm)

Pitch:

20 to 120 mm (23 to 123 mm)

Width:

25 to 115 mm (28 to 118 mm)

Pitch:

20 to 397 mm (23 to 400 mm)

Width:

25 to 118 mm

Pitch:

23 to 123 mm

Width:

25 to 115 mm (28 to 118 mm)

Pitch:

20 to 397 mm (23 to 400 mm)

m

×

247 D × 181 H mm (standard)

33

EnglishGermanChineseKorean

Page 34

Basic Specifications

Weight

3.0 kg (standard) Excluding AC adapter,battery

Power supply

AC adapter

Input voltage

Output voltage

Power consumption

EnglishGermanChineseKorean

Environmental

conditions

AC 100 to 240V (1.5A) 50/60 Hz

DC 25V (2.0A)

Print ratio 30% 180VA 120W

Maximum 280VA 180W

During standby 30VA 15W

Operation ambient temperature: 5 to 35°C

Storage ambient temperature : -5 to 60

Excluding paper and carbon ribbon

Humidity: 30 to 80% (However, no dew formation)

Humidity: 30 to 90% (However, no dew formation)

°

C

External interface

Standard interface

USB + LAN type

USB (Full Speed)

LAN (10BASE-T/100BASE-TX automatic switching)

USB + RS-232C type

USB (Full Speed)

RS-232C

Extension interface

Operation panel

Keys

Switches

lamp

Adjustment dials

USB + RS-232C type

Parallel (IEEE 1284)

Wireless LAN2 (LAN: 10BASE-T/100BASE-TX automatic switching,

Wireless LAN: IEEE 802.11 b/g)

Bluetooth (Bluetooth Specification Ver. 1.1 Class 2)

LINE, FEED

POWER switch, DIP switch

POWER, ONLINE, ERROR, 7SEG lamp

Paper sensor adjustment, printing position adjustment, printing density

adjustment, tear off/separated/cutter stop position adjustment.

However, printing density adjustment and tear off/separated/cutter stop

position adjustment are switched using DSW1-6.

Sensor Paper sensor reflection type, transparent type

Printing format Transfer from host (computer)(with format registration function)

34

Page 35

Basic Specifications

Contained fonts

Standard

Barcode

2D Barcode

Composite Symbol

Magnification

Rotation

Characters

Barcode

Barcode ratio 1:2, 1:3, 2:5, Free specification

Self-diagnostic function

Noise standard

Emitted noise FCC, CE, CCC, MIC (If differs in each destination)

Options Separation unit, cutter unit, Linerless unit, RFID unit, interface board

XU 5 × 9 dots (alphanumeric, symbol)

XS 17 × 17 dots (alphanumeric, symbol)

XM 24 × 24 dots (alphanumeric, symbol)

XB 48 × 48 dots (alphanumeric, symbol)

XL 48 × 48 dots (alphanumeric, symbol)

Outline font (alphanumeric, symbol)

OCR-A 15×22 dots

(alphanumeric, symbol)

×

OCR-B 20

(alphanumeric, symbol)

24 dots

UPC-A/UPC-E, JAN/EAN, CODE39, CODE93, CODE128,

GS1-128(UCC/EAN-128), CODABAR(NW-7), ITF, Industrial 2of5,

Matrix 2of5, BOOKLAND, MSI, POSTNET, GS1 DataBar(RSS)

QR Code, Micro QR, PDF417, Micro PDF, MAXI Code,

GS1 DataMatrix(ECC200)

Composite Symbol(JAN/EAN, UPC-A/UPC-E,

GS1-128, GS1 DataBar(RSS))

Ve rtical

×

1 to ×12, horizontal ×1 to ×12 (characters)

1 to 12L (barcode)

0

°

, 90°, 180°, 270

Parallel 1, Serial 1, Parallel 2, Serial 2

Head check, head/cover open, paper end, ribbon end, test print

(Parallel (IEEE 1284), Wireless LAN2 (LAN: 10BASE-T/100BASE-TX

automatic switching, Wireless LAN: IEEE 802.11 b/g), Bluetooth)

OCR-A 22

(alphanumeric, symbol)

OCR-B 30

(alphanumeric, symbol)

°

×

33 dots

×

36 dots

OCR-A 44

×

(alphanumeric, symbol)

OCR-B 60

(alphanumeric, symbol)

66 dots

×

72 dots

EnglishGermanChineseKorean

Notice regarding the registered trademarks and trademarks of other companies

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

35

Loading...

Loading...