SANYO Sanmotion F5 User Manual

5-PHASE STEPPING SYSTEMS

Ver.3

1

Load:JL:0.6×10

-4

kg・m

2

(2050.3×10

-4

lb・in

2

)

F series driver

2 4 6 8 10

Rise time

(

ms

)

0

200

400

600

800

1000

Reduced 10%

Current model

Number of rotations(min

-1

)

5-phase STEPPING SYSTEMS

F series DRIVER

F series MOTOR

M series MOTOR

Extensive lineup

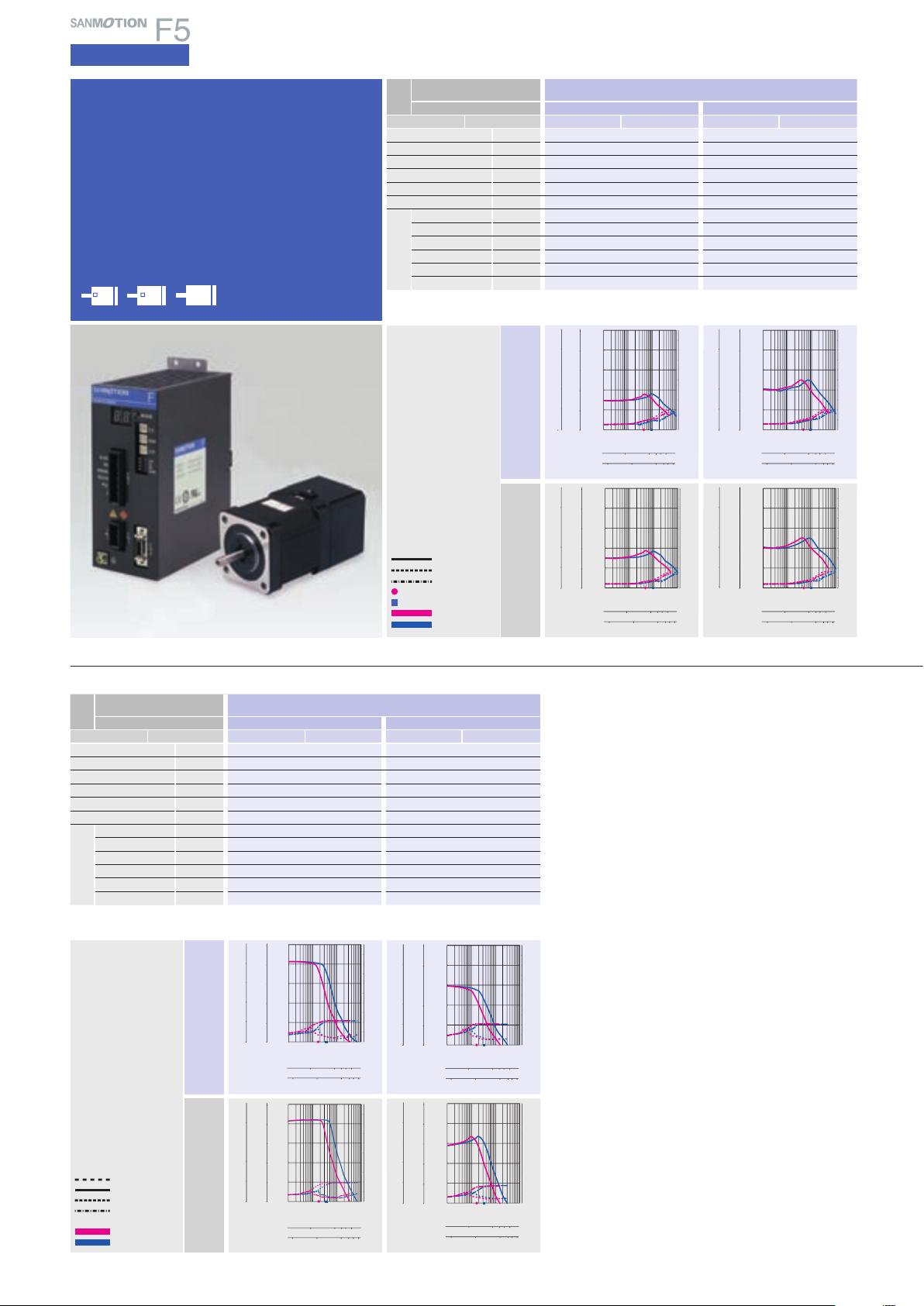

F series driver features

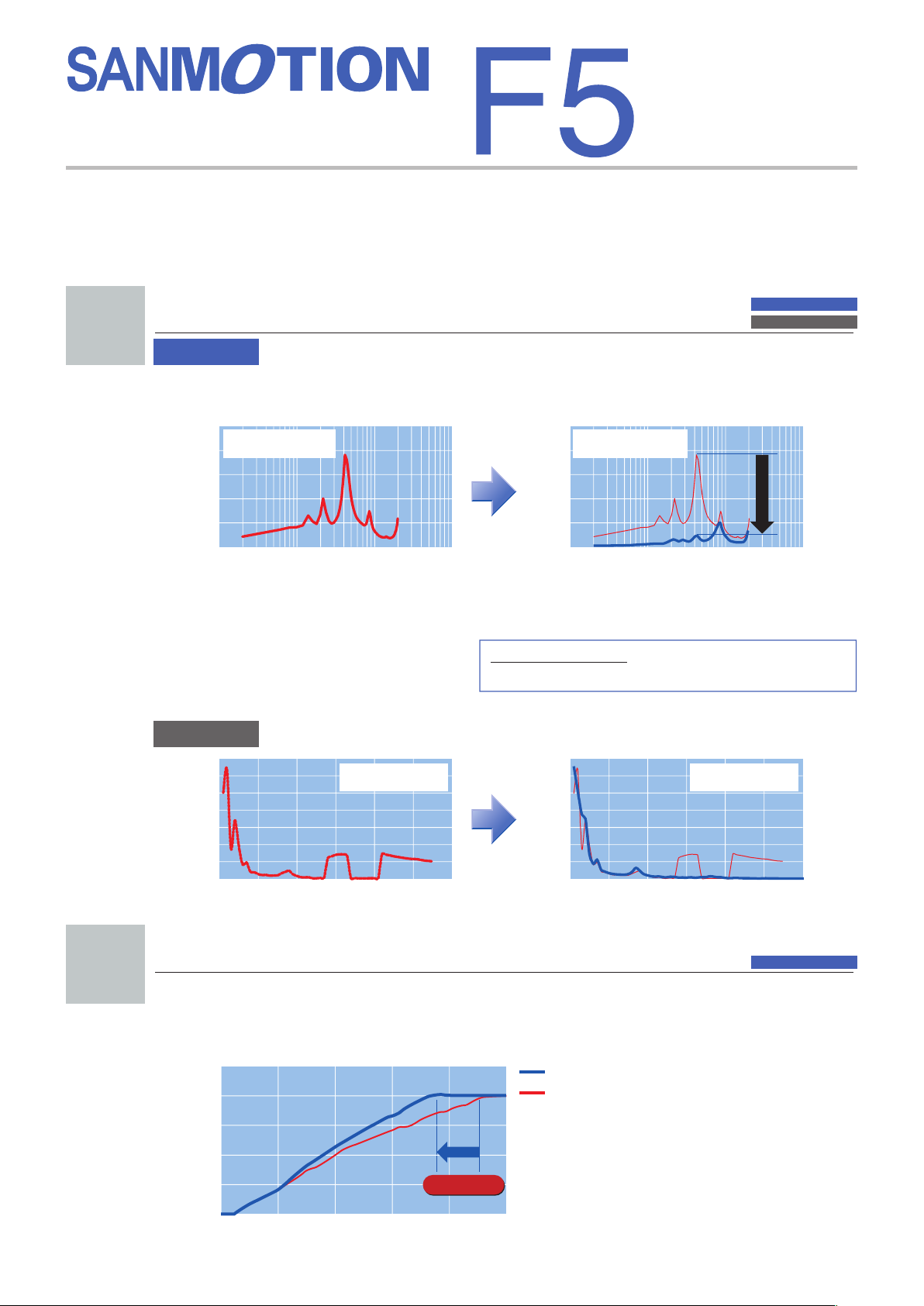

Lower vibration

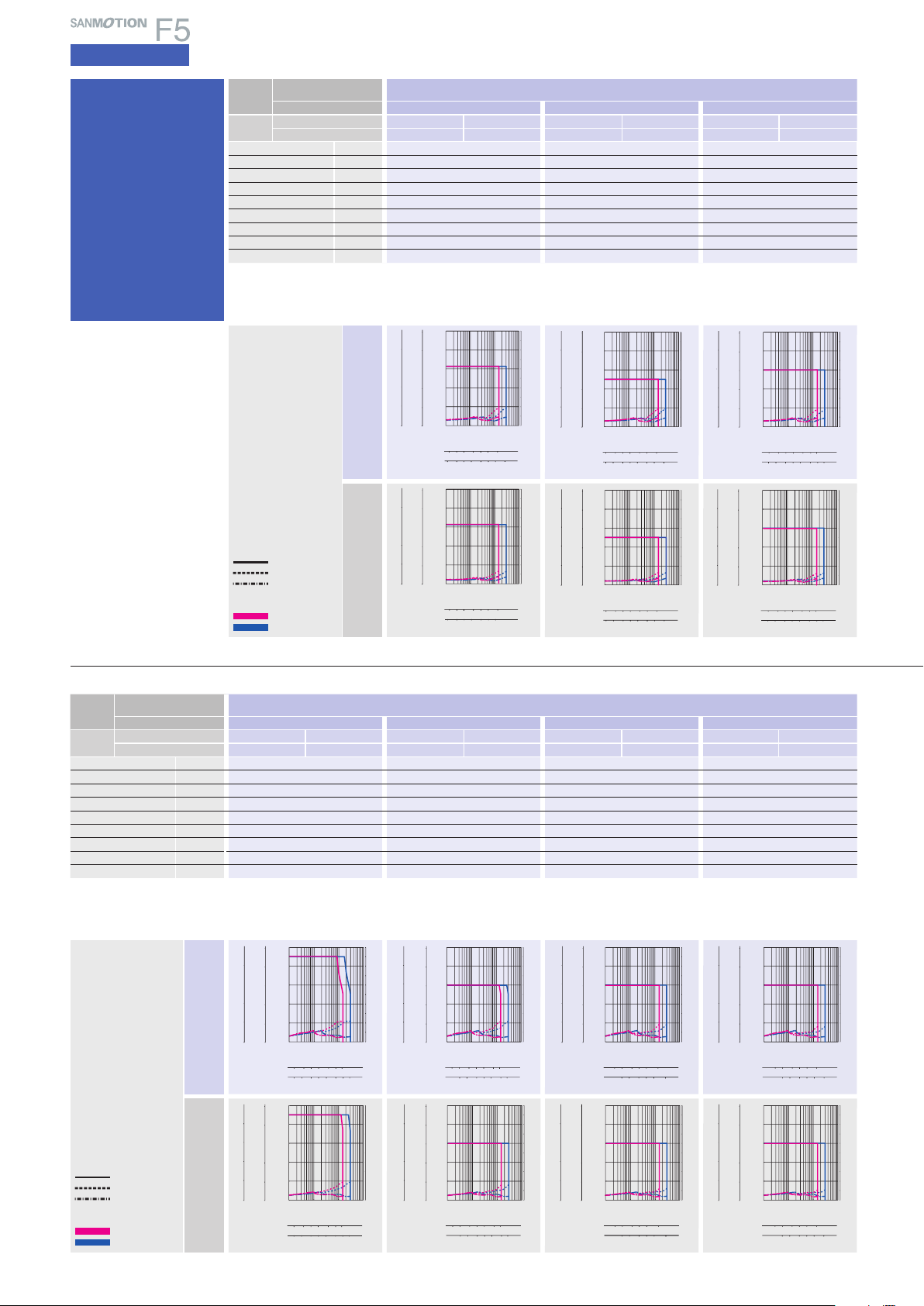

1

Shoter cycle time

■

Improved response

(

up to 10% compared to current models

)

shortens the machine cycle

time for repetitive operations.

2

Rotation-vibration characteristics

(

Full-step

)

0.01

0.1

1 10

Number of rotations(S

1

)

Motor : 103F7851-7041

Power source voltage

: 100V AC

Winding current : 0.75A/phase

0

0.2

0.4

0.6

0.8

1

(Vrms) (Vrms)

Rotation-vibration characteristicsx

(

1 / 250

)

Current model

New model

0.01 0.1 1 10

Number of rotations(S

1

)

Motor : 103F7851-7041

Power source voltage

: 100V AC

Winding current : 0.75A/phase

0

0.2

0.4

0.6

0.8

1

0

50

100

150

200

250

300

350

0123 45 6

Number of rotations

(

S

1

)

Motor : 103F7852-8241

Power source voltage:DC24V

Excitation method:Half-step

0

50

100

150

200

250

300

350

0123 45 6

Number of rotations

(

S

1

)

Speed variation(%)

Speed variation(%)

TG ripple voltage

TG ripple voltage

Motor : 103F7852-8241

Power source voltage:DC24V

Excitation method:Half-step

0.72

1 to 250 divisions

=

0.72 to 0.00288degrees/pulse

AC input

DC input

AC input

DC input

■

Automicro function

Vibration suppression is executed internally and independently from the controller.

AC input

■

Automicro function and microstepping system enables further reduction of vibration

compared to current models.

■

Microstepping system

The basic step angle is divided by a maximum of

1 / 250 using 16 selectable resolution levels to enable

smooth and vibration-free operation.

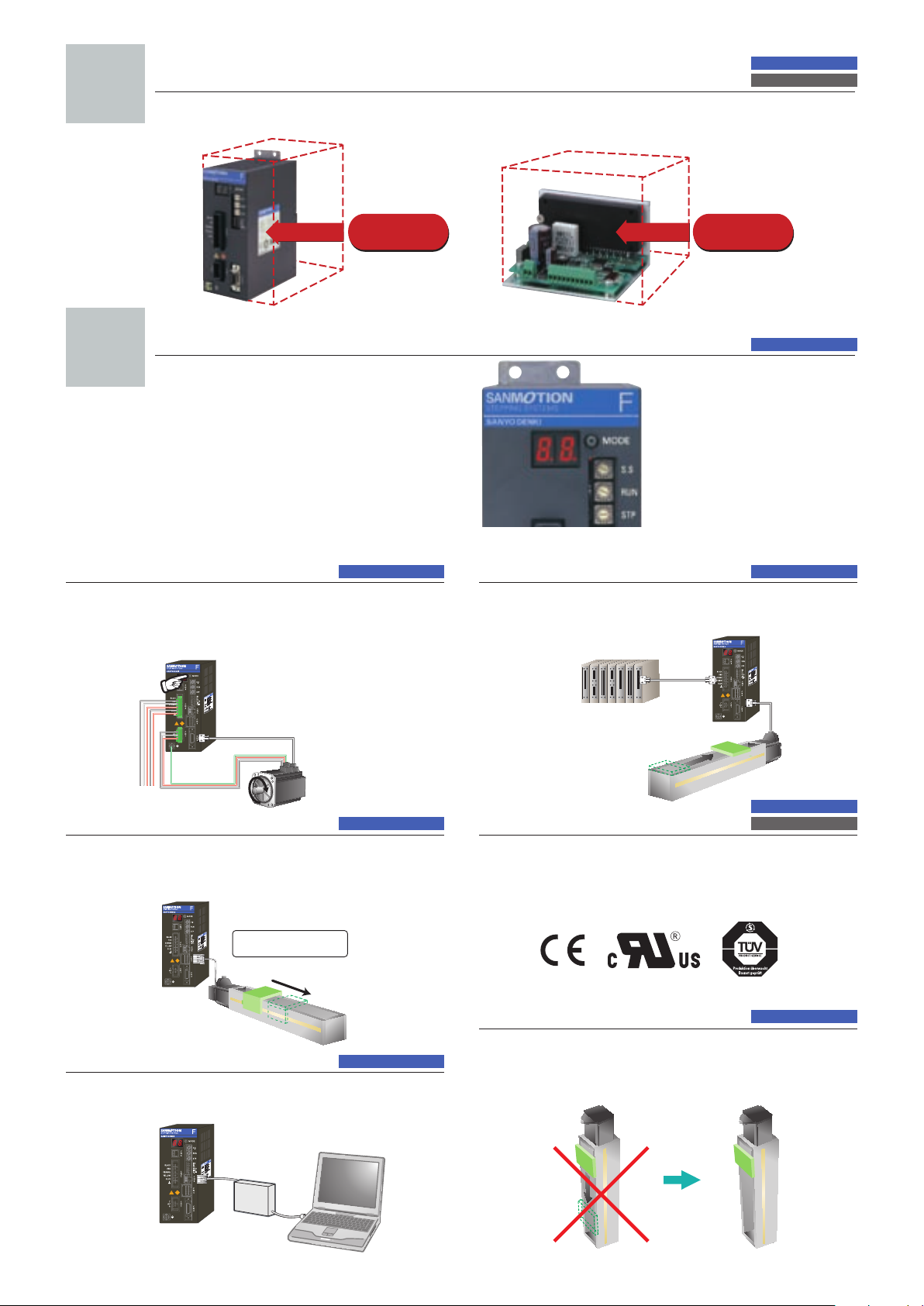

2

Control panel space is reduced

■

Volume is reduced by up to 50% for AC input types and 45% for DC input types compared

to current models.

3

Easy maintenance

■

2-digit 7-segment LED displays

operating status and alarm for

easy troubleshooting and

faster system recovery.

4

50% reduction

for 200V types

Test run function

(

JOG

)

With built-in positioning func tion

On-board JOG operation function is available for testing motor

and amplifier connection without the need to connect to host

device.

Encoder I/F Control

With built-in positioning func tion

Motor stall detection is possible by connecting a motor encoder. 500P/

R

(

1000/2000 multiplier function

)

line driver method.

PC-based setup monitor

With built-in positioning func tion

Parameter and program settings can be made from the bundled

setup software.

Capable of JOG operation

without connecting to host

device

PLC

F motor

Designate

program

number”1”

Load

Highly precise positioning

is possible

Parameter

(

position, speed

)

Program settings

AC input

AC input

DC input

AC inputAC input

AC input

AC input

AC input

DC input

45% reduction

for 24V types

AC input

F motor

Tare weight

General-purpose I/O input

for positioning

With built-in positioning func tion

System positioning is easily executed by using general-purpose

I/O from an upper-level controller

(

PLC

)

to designate preset

program numbers.

Compliance with

international standards

Th e standard spe cifi cation S ANMOTION F series s tep ping

driver complies with UL and EN safety standards . Step ping

motors complying with UL an

d EN standards are available upon

r

equest. EMC filters are also available to comply with the EMC

directive.

Brake control

Automatic brake activation timing control is available when

using electromagnetic brake motors.

• Internal power source for brake

(

FP type

)

3

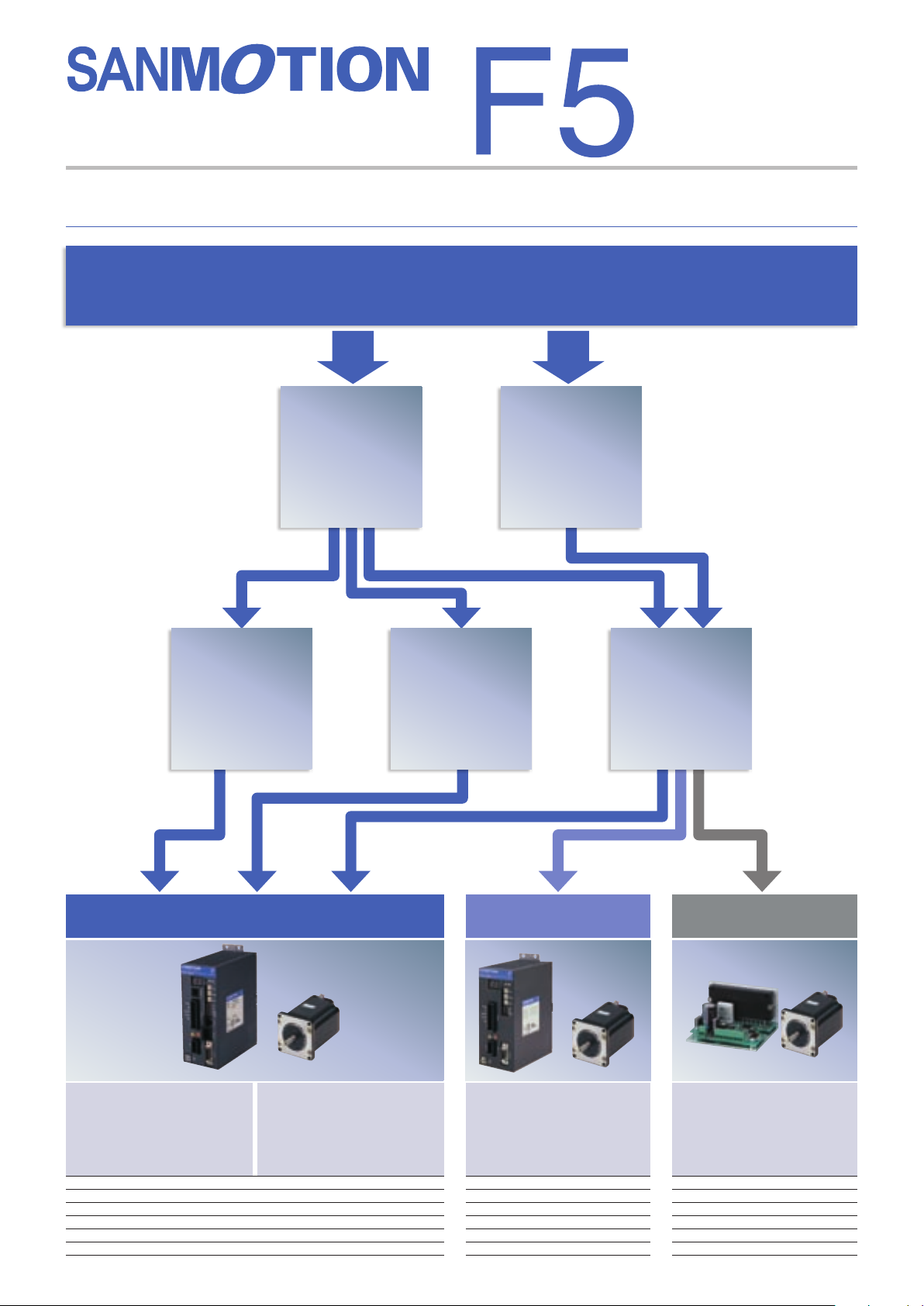

5-phase STEPPING SYSTEMS

F series DRIVER

F series MOTOR

M series MOTOR

How do you want to control the equipment ?

The F series offers the choice of 3 different control methods

Control method

Point command

control using

PLC I/O

Network control

using serial

communication

(

RS-485

)

Control using a

pulse generator

AC power

source

DC power

source

AC input

with built-in positioning function

Startup via I/O :

Initiate program c ont aining

speed, acceleration/deceleration,

and travel distance commands

stored in the driver via the I/O.

Startup via serial

communication:

Control by sending data for

speed, acceleration/deceleration,

and travel distance commands

via serial communication.

System confi guration diagram P7

Set part number nomenclature P9

Motor specifi cations P47 to 58

General specifi cations P 25

・

26, 60

Motor dimension drawing P61 to 67

Driver dimension drawing P68

AC input

standard type

Motion is generated by pulse

input commands from an

upper-level controller.

System confi guration diagram P5

Set part number nomenclature P9

Motor specifi cations P47 to 58

General specifi cations P23

・

24, 60

Motor dimension drawing

P61 to 67

Driver dimension drawing P68

DC input

Motion is generated by pulse

input commands from an

upper-level controller.

System confi guration diagram P29

Set part number nomenclature P31

Motor specifi cations P47 to 58

General specifi cations P43

・

44, 60

Motor dimension drawing

P61 to 67

Driver dimension drawing P68

4

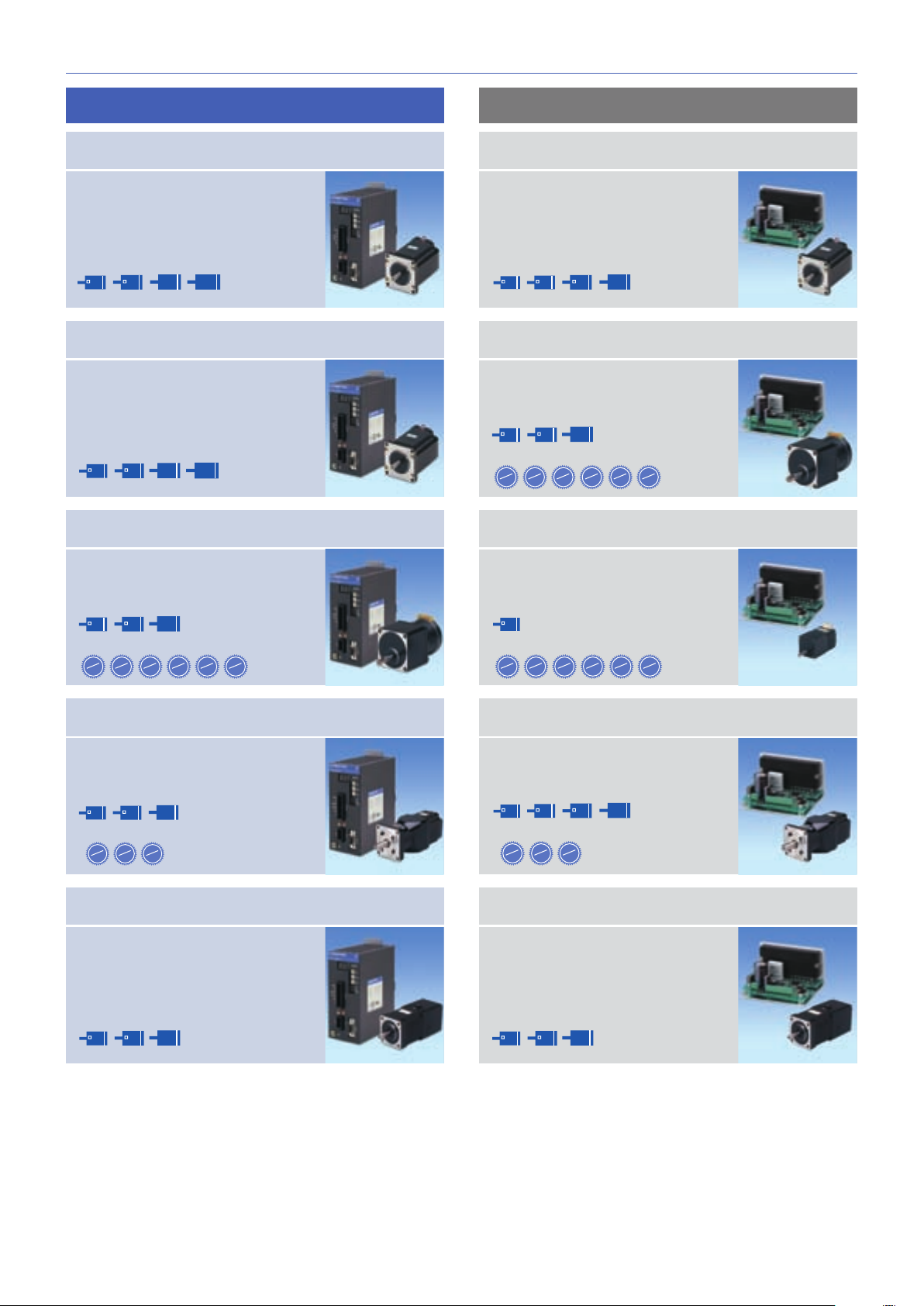

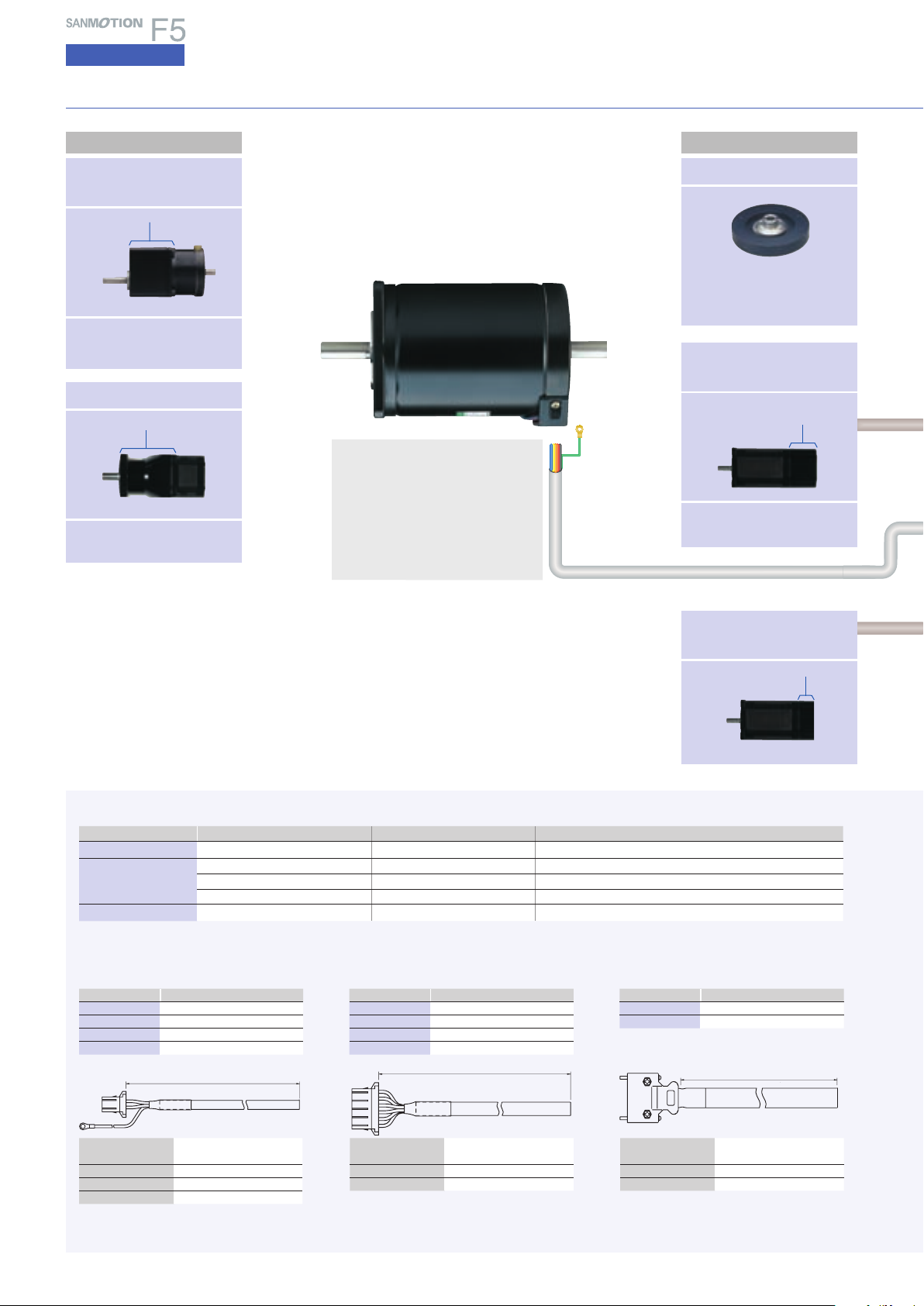

Motor flange size

Reduction gear ratios

30

1

50

1

100

1

42

60

ø

86

(

□

1.65inch)(

□

2.35inch)(

ø

3.39inch)

Harmonic gear model

This set utilizes a harmonic gear.

42

60

ø

86

Motor flange size

(

□

2.35inch)(

□

1.65inch) (

ø

3.39inch)

Electromagnetic brake model

This set utilizes a non-excitation

electromagnetic brake to maintain

position in vertical load applications

and hold load even during power off.

42

60

ø

86

Motor flange size

3.6

1

7.2

1

10

1

20

1

30

1

36

1

Reduction gear ratios

(

□

1.65inch)(

□

2.35inch)(

ø

3.39inch)

Low-backlash gear model

This set includes a low backlash gear that

uses tapered hobbed gears to engage the

final stage of the speed reduction mechanism.

42

60

ø

86

ø

106

Motor flange size

(

□

1.65inch)(

□

2.35inch)(

ø

3.36inch)(

ø

4.17inch)

CE / UL model

The UL/CE set includes a F Series

driver and a M Series motor.

Set model

DC inputAC input

Motor flange size

42

60

ø

86

ø

106

(

□

1.65inch)(

□

2.35inch)(

ø

3.39inch)(

ø

4.17inch)

Standard model

The standard set includes a F series

driver and a F series motor.

P.19

P.21

28

Motor flange size

3.6

1

7.2

1

10

1

20

1

30

1

50

1

Reduction gear ratios

(

□

1.10inch)

Spur gear model

This set utilizes a spur gear in the

speed reduction mechanism.

28 42

60

ø

86

Motor flange size

Reduction gear ratios

30

1

50

1

100

1

(

□

1.65inch)(

□

1.10inch) (

□

2.35inch)(

ø

3.39inch)

Harmonic gear model

This set utilizes a harmonic gear.

42

60

ø

86

Motor flange size

(

□

2.35inch)(

□

1.65inch) (

ø

3.39inch)

Electromagnetic brake model

This set utilizes a non-excitation

electromagnetic brake to maintain

position in vertical load applications

and hold load even during power off.

P.35

42

60

ø

86

Motor flange size

3.6

1

7.2

1

10

1

20

1

30

1

36

1

Reduction gear ratios

(

□

1.65inch)(

□

2.35inch)(

ø

3.39inch)

Low-backlash gear model

This set includes a low backlash gear that

uses tapered hobbed gears to engage the

final stage of the speed reduction mechanism.

P.33

Standard model

The standard set includes a F series

driver and a F series motor.

P.38

P.39

P.41

28 42

60

ø

86

ø

106

Motor flange size

(

□

1.65inch)(

□

1.10inch) (

□

2.35inch)(

ø

3.39inch

)(

ø

4.17inch)

P.12

P.14

P.16

5

5-phase STEPPING SYSTEMS

System configuration

AC input

Standard type

Harmonic gear model

Motor flange size

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

Harmonic gear

Low-backlash gear

model

Low backlash gear

Motor flange size

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

Brake power source

(

DC24V

)

Electromagnetic

brake model

Damper

End-cap side

Motor flange size

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

Electromagnetic brake

Magnetic dampers can be

selected according to the

required inertia.

Required for brake-equipped

stepping motor models.

●

A

AC power cable

■

Optional cables

●

B

Motor cable

L

( feet)

+50 mm

− 0 mm

+.16

− 0

L

( feet)

+50 mm

− 0 mm

+.16

− 0

L

(

feet

)

+50 mm

− 0 mm

+.16

− 0

●

C

I/O signal cable

Standard model : F series motor

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

/

φ

106mm

(

φ

4.17inch

)

CE / UL model : M series motor

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

φ

3.39inch

)

/

φ

106mm

(

φ

4.17inch

)

●

Motors are available in standard or vacuum

types.

●

Motor cable

(

optional

)

B

L : m

(

feet

)

Part number

10

(

32.81

)

PM-C03P1000-05

5

(

16.40

)

PM-C03P0 500-05

3

(

9.84

)

PM-C03P0300-05

1

(

3.28

)

PM-C03P0100-0 5

Leadwire

600V vinyl cab tire cable

3-c ore AWG16

(

1.25mm

2

)

Housing 1-178128-2

(

AMP

)

Contact 1-175218-5

(

AMP

)

Round-type crimp contact

1.25M4

(

J.S.T. Mfg Co.

)

Connec tor typ e Housing Contac t Applicable moto r flange size

●

AC power connector

1-178128-2

(

AMP

)

1-175218-5

(

AMP

)

─

●

Motor connec tor

1-178128-6

(

AMP

)

1-175216-5

(

AMP

)

□

42mm

(

□

1.65inch

)

1-178128-6

(

AMP

)

1-175217-5

(

AMP

)

□

60mm

(

□

2.35inch

)

,

φ

86mm

(

φ

3.39inch

)

1-178128-6

(

AMP

)

1-175218-5

(

AMP

)

φ

106mm

(

φ

4.17inch

)

●

I/O signal connector

10314-52A0-008

(

3M

)

10114-3000PE

(

3M

)

─

■

Bundled connectors

(

set models only

)

1

2

3

●

Cables 10m

(

32.81 feet

)

or longer are available

upon request.

L : m

(

feet

)

Part number

10

(

32.81

)

PM-C06M1000-11

5

(

16.40

)

PM-C06M0500 -11

3

(

9.84

)

PM-C06M0300 -11

1

(

3.28

)

PM-C06M0100-11

L : m

(

feet

)

Part number

2

(

6.56

)

PM-C14S0200-03

1

(

3.28

)

PM-C14S0100-03

●

Cables 10m

(

32.81 feet

)

or longer are available

upon request.

Leadwire

600V vinyl cab tire cable

6-core AWG16

(

0.75mm

2

)

Housing 1-178128-6

(

AMP

)

Contact 1-175218-5

(

AMP

)

Leadwire

7-pair PVC shielded cable

AWG28

(

0.08mm

2

)

Shell 10314 -52 A0- 008

(

3M

)

Plug 10114-3000PE

(

3M

)

Flange side

6

AC inputInput / Output signal standardDC inputStepping motorDimensions

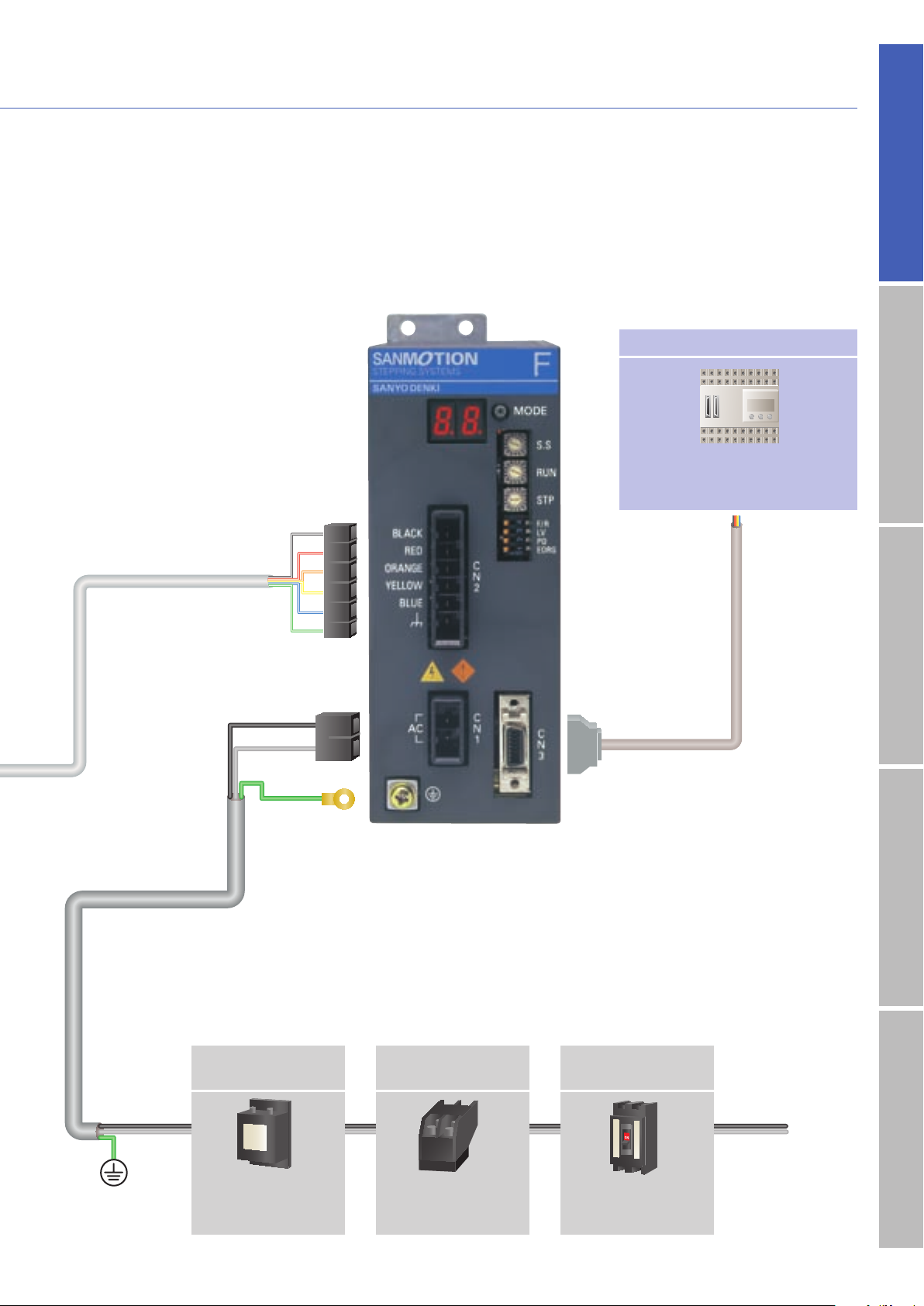

Host Devices

PLC and controllers are available as

the host device.

Single

phase

AC100V

to

AC230V

(

t

)

(

r

)

●

I/O signal connector

(

bundled

)

●

I/O signal cable

(

optional

)

C

3

●

Motor connector

(

bundled

)

2

●

AC power connector

(

bundled

)

1

●

AC power cable

(

optional

)

A

Molded case

circuit breaker

Noise filter

Electromagnetic

contactor

Switches driver power

on/off. Use together

with a surge protector.

Filters out incoming

noise from power line

Protects the power line.

Cuts off circuit in the

event of overcurrent.

PLC

7

5-phase STEPPING SYSTEMS

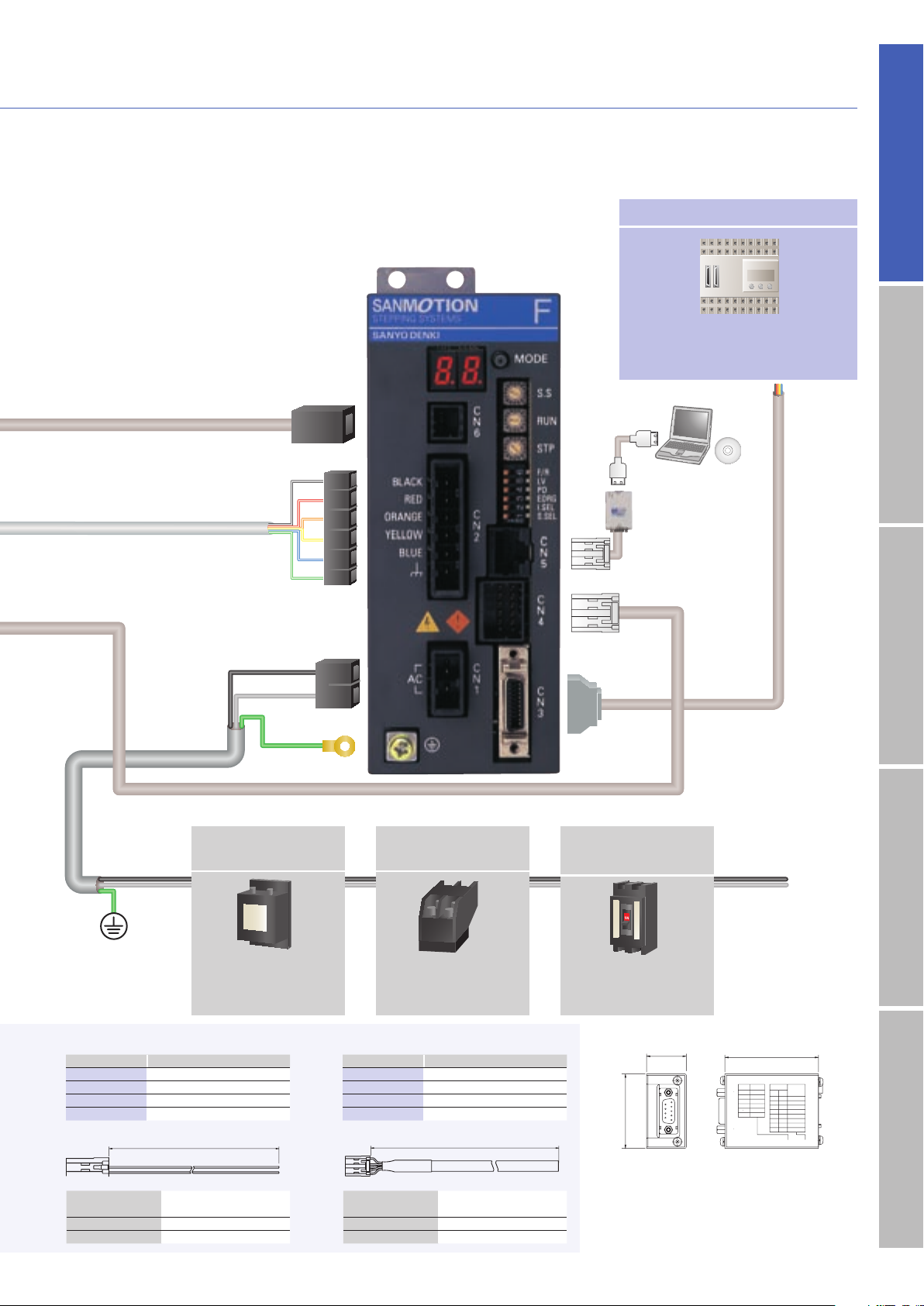

System configuration

AC input

Damper

Electromagnetic

brake model

End - cap side

With built-in positioning function

Motor flange size

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

Harmonic gear model

Motor flange size

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

Harmonic gear

Low-backlash gear

model

Low backlash gear

Motor flange size

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

Electromagnetic brake

●

A

AC power cable

■

Optional cables

●

B

Motor cable

●

C

I/O signal cable

Flange side

Magnetic dampers can be

selected according to the

required inertia.

Encoder equipped

model

Optional

Encoder

L

( feet)

+50 mm

− 0 mm

+.16

− 0

L

( feet)

+50 mm

− 0 mm

+.16

− 0

L

(

feet

)

+50 mm

− 0 mm

+.16

− 0

Standard model : F series motor

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

/

φ

106mm

(

φ

4.17inch

)

CE / UL model : M series motor

□

42mm

(

□

1.65inch

)

/

□

60mm

(

□

2.35inch

)

/

φ

86mm

(

φ

3.39inch

)

/

φ

106mm

(

φ

4.17inch

)

●

Motors are available in standard or vacuum

types.

●

Option cable for motor

B

L : m

(

feet

)

Part number

10

(

32.81

)

PM-C03P1000-05

5

(

16.40

)

PM-C03P0 500-05

3

(

9.84

)

PM-C03P0300-05

1

(

3.28

)

PM-C03P0100-0 5

L : m

(

feet

)

Part number

10

(

32.81

)

PM-C06M1000-11

5

(

16.40

)

PM-C06M0500 -11

3

(

9.84

)

PM-C06M0300 -11

1

(

3.28

)

PM-C06M0100-11

L : m

(

feet

)

Part number

2

(

6.56

)

PM-C 20S0200- 01

1

(

3.28

)

PM-C 20S0100-01

Leadwire

600V vinyl cab tire cable

3-c ore AWG16

(

1.25mm

2

)

Housing 1-178128-2

(

AMP

)

Contact 1-175218-5

(

AMP

)

Round-type crimp tool

1.25M4

(

J.S.T.

)

●

Cables 10 m

(

32.81 feet

)

or longer are available

upon request.

Leadwire

600V vinyl cab tire cable

6-core AWG16

(

0.75mm

2

)

Housing 1-178128-6

(

AMP

)

Contact 1-175218-5

(

AMP

)

Leadwire

10-pair PVC shielded cable

AWG28

(

0.08mm

2

)

Shell 10320-52A0-0 08

(

3M

)

Plug 10120-3000PE

(

3M

)

Connec tor typ e Housing Contac t Applicable moto r flange size

●

AC power connector

1-178128-2

(

AMP

)

1-175218-5

(

AMP

)

─

●

Motor connec tor

1-178128-6

(

AMP

)

1-175216-5

(

AMP

)

□

42mm

(

□

1.65inch

)

1-178128-6

(

AMP

)

1-175217-5

(

AMP

)

□

60mm

(

□

2.35inch

)

,

φ

86mm

(

φ

3.39inch

)

1-178128-6

(

AMP

)

1-175218-5

(

AMP

)

φ

106mm

(

φ

4.17inch

)

●

I/O signal connector

10314-52A0-008

(

3M

)

10114-3000PE

(

3M

)

─

■

Bundled connectors

(

set models only

)

1

2

3

●

Cables 10 m

(

32.81 feet

)

or longer are available

upon request.

8

AC inputInput / Output signal standardDC inputStepping motorDimensions

RS485

RS232C

Molded case

circuit breaker

Noise filter

Electromagnetic

contactor

Switches driver power

on/off. Use together

with a surge protector.

Filters out incoming

noise from power line.

Protects the power line.

Cuts off circuit in the

event of overcurrent.

Single

phase

AC100V

to

AC230V

(

t

)

(

r

)

●

Encoder cable

E

●

Motor connector

(

bundled

)

2

●

AC power

connector

(

bundled

)

1

●

AC power cable

(

optional

)

A

L

( feet)

+50 mm

− 0 mm

+.16

− 0

●

D

Brake cable

L

(

feet

)

+50 mm

− 0 mm

+.16

− 0

●

E

Cable for encoder use

●

I/O Signal

Connector

(

bundled

)

3

●

I/O signal cable

(

optional

)

C

●

Brake connector

2

●

Brake cable

D

63.5(2.52)

27(1.06)

50(1.77)

B3

C N 2

C N 1

57600

Term

2

F.Dup

Func Parity

C N 3

bps

UseNone

No.

1

toGND

Echo

to+5V

91

19200

9600

80

38400

A2

3

6,7

4,5

307200

F7

None

D5

128000

115200

C4

153600

E6

8

DSWRSWRX TX

●

F

Part number for RS232C-RS485 converter :

232485CFP01-01

●

G

RS232 cable is supplied by user.

●

H

Part number for FP communications cable :

PM-C08S0100-05

●

J

Part number for bundled software :

SFPA1W-01

(

please download from website

)

●

F

Converter [unit : mm

(

inch

)

]

●

Cable

H

●

Converter

F

●

G

●

Software

J

L : m

(

feet

)

Part number

10

(

32.81

)

PM-C03B1000-01

5

(

16.40

)

PM-C03B0500-01

3

(

9.84

)

PM-C03B0300-01

1

(

3.28

)

PM-C03B0100-01

Leadwire

PVC cable

AWG22

(

0.3mm

2

)

Housing 1-1318120-3

(

AMP

)

Contact 1318107-1

(

AMP

)

Leadwire

4-pair PVC shielded cable

AWG22

(

0.3mm

2

)

Housing 1-1318118-6

(

AMP

)

Plug 1318107-1

(

AMP

)

L : m

(

feet

)

Part number

10

(

32.81

)

PM-C12S1000-01

5

(

16.40

)

PM-C12S0500-01

3

(

9.84

)

PM-C12S0300-01

1

(

3.28

)

PM-C12S0100-01

Host Devices

PLC and controllers are available as

the host device.

PLC

9

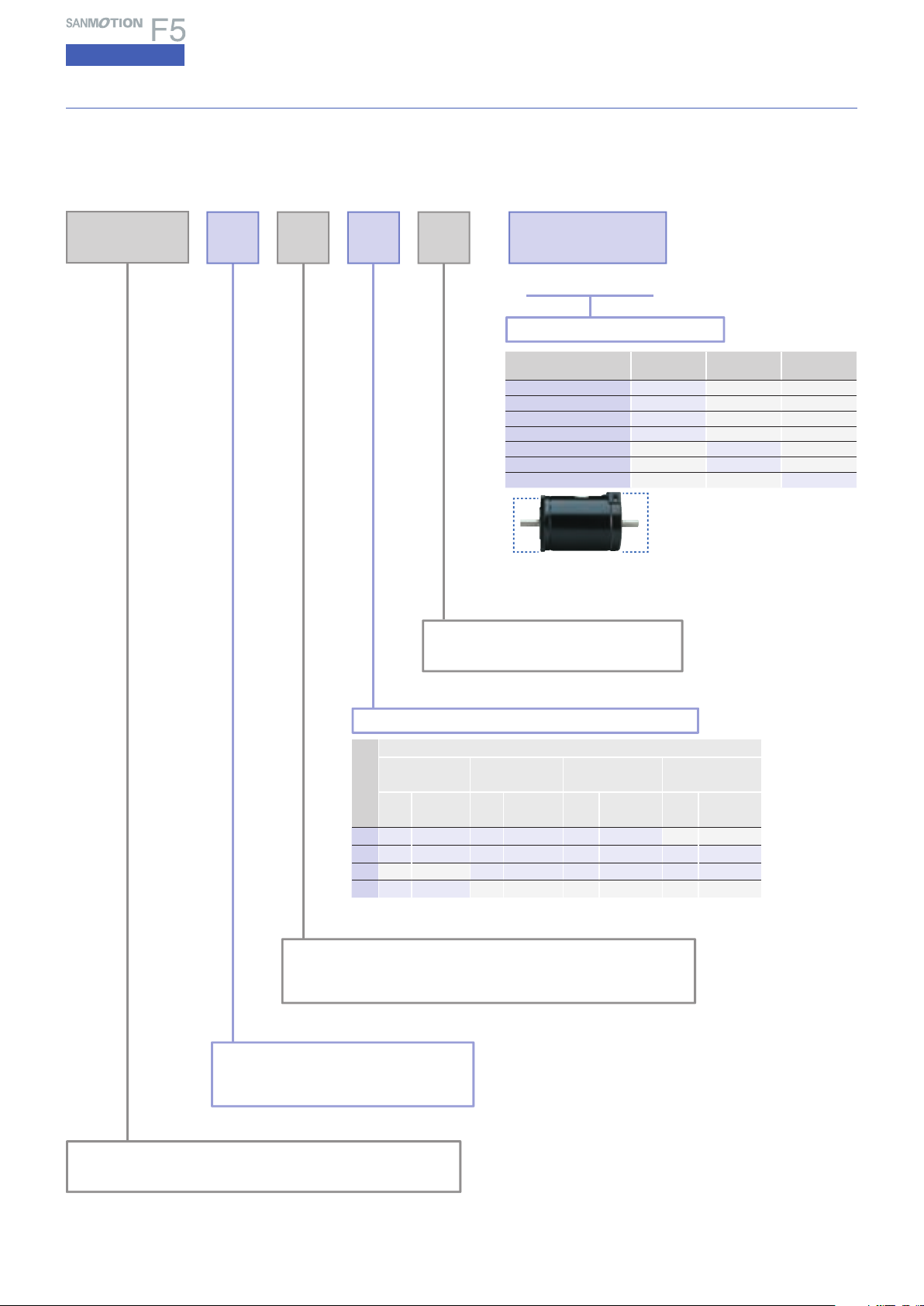

5-phase STEPPING SYSTEMS

AC input

Part number convention

The following part number specifies a system with an F series driver

(

type code : FS1W075P

)

and a single

shaft F series motor

(

type code : 103F7851-7041

)

,

□

60mm

(

□

2.36inch

)

square flange, and 46.5mm

(

1.83inch

)

motor length, equipped with low-backlash gear

(

reduction ratio of 1/3.6

)

.

F 78 1 S - C X 3.6

Stepping motor flange size

55

:

□

42mm

(

□

1.65inch

)

85

:

φ

86mm

(

φ

3.39inch

)

78

:

□

60mm

(

□

2.36inch

)

89

:

φ

106mm

(

φ

4.17inch

)

Stepping motor total length

(

Standard model

)

Stepping motor shaft spec

S : Single shaft

D : Double shaft

System spec

Code

Motor flange size

□

42mm

(

□

1.65inch

)

□

60mm

(

□

2.36inch

)

φ

86mm

(

φ

3.39inch

)

φ

106mm

(

φ

4.17inch

)

Type

code

Motor length :

mm

(

inch

)

Type

code

Motor leng th :

mm

(

inch

)

Type

code

Motor leng th :

mm

(

inch

)

Type

code

Motor leng th :

mm

(

inch

)

1 5505 34

(

1.34

)

7851 46.5

(

1.83

)

8581 62.2

(

2.45

)

2 5508 40

(

1.57

)

7852 55

(

2.17

)

8582 92.2

(

3.63

)

89582

163.3

(

6.43

)

3 7853 87.5

(

3.44

)

8583 125.9

(

4.96

)

89583 221.3

(

8.71

)

4 5510 49

(

1.93

)

System type

Ⅰ Ⅱ Ⅲ

(

Flange side

)

(

End cap side

)

(

Reduction ratio

)

Spur gear

G

─ ─

Low-backlash gear

C

─ ─

Harmonic gear

H

─ ─

No system at Flange side

X

─ ─

Electromagnetic brake

─

B

─

No system at End cap side

─

X

─

Gear ratio

─ ─

3.6 to 100

▲

Ⅰ

▲

Ⅱ

▲

Ⅲ

(

Flange side

) (

End cap side

)

●

Spur gear

●

Low-backlash gear

●

Harmonic gear

●

Electromagnetic

FS : AC Power source Standard type

FP : AC Power positioning-function-included type

Stepping motor series name

F

:

F series motor

M

:

M series motor

(

CE/UL

)

F S

10

AC inputInput / Output signal standardDC inputStepping motorDimensions

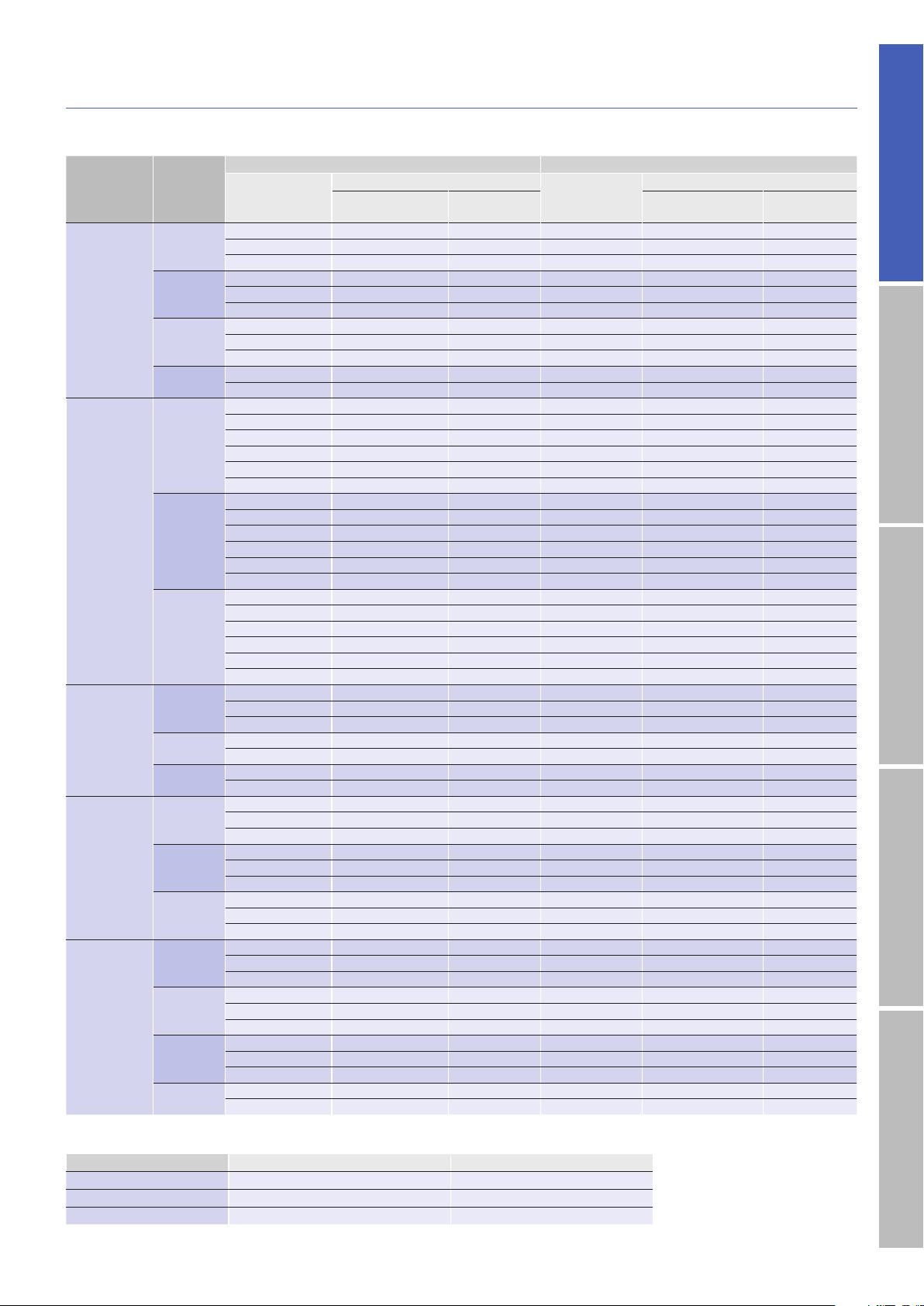

Packaged Sale Model Configuration

AC pulse input type

Bundled driver model number

:

FS1W075P00

Step angle

/

0.72

°

Rated current 0.75A

Model

Motor

flange size

Single shaft Double shafts

Set part

number

Set accessories

Set part

number

Set accessories

Motor model

number

Connector

number

Note)

Motor model

number

Connector

number

Note)

Standard

model

□

42mm

FSF551S 103F5505-7041 PM-AP-065 FSF551D 103F5505-7011 PM-AP-065

FSF552S 103F5508-7041 PM-AP-065 FSF552D 103F5508-7011 PM-AP-065

FSF554S 103F5510-7041 PM-AP-065 FSF554D 103F5510-7011 PM-AP-065

□

60mm

FSF781S 103F7851-7041 PM-AP-064 FSF781D 103F7851-7011 PM-AP-064

FSF782S 103F7852-7041 PM-AP-064 FSF782D 103F7852-7011 PM-AP-064

FSF783S 103F7853-7041 PM-AP-064 FSF783D 103F7853-7011 PM-AP-064

φ

86mm

FSF851S 103F8581-7041 PM-AP-064 FSF851D 103F8581-7011 PM-AP-064

FSF852S 103F8582-7041 PM-AP-064 FSF852D 103F8582-7011 PM-AP-064

FSF853S 103F8583-7041 PM-AP-064 FSF853D 103F8583-7011 PM-AP-064

φ

106mm

FSF892S 103F89582-7041 PM-AP-063 FSF892D 103F89582-7011 PM-AP-063

FSF893S 103F89583-7041 PM-AP-063 FSF893D 103F89583-7011 PM-AP-063

Low-backlash

gear model

□

42mm

FSF551S-CX3.6 103F5505-70CXA4 PM-AP-065 FSF551D-CX3.6 103F5505-70CXA1 PM-AP-065

FSF551S-CX7.2 103F5505-70CXB4 PM-AP-065 FSF551D-CX7.2 103F5505-70CXB1 PM-AP-065

FSF551S-CX10 103F5505-70CXE4 PM-AP-065 FSF551D-CX10 103F5505-70CXE1 PM-AP-065

FSF551S-CX20 103F5505-70CXG4 PM-AP-065 FSF551D-CX20 103F5505-70CXG1 PM-AP-065

FSF551S-CX30 10

3F5505-70CXJ4 PM-AP-065 FSF551D-CX30 103F5505-70CXJ1

PM-AP-065

FSF551S-CX36 103F5505-70CXK4 PM-AP-065 FSF551D-CX36 103F5505-70CXK1 PM-AP-065

□

60mm

FSF781S-CX3.6 103F7851-70CXA4 PM-AP-064 FSF781D-CX3.6 103F7851-70CXA1 PM-AP-064

FSF781S-CX7.2 103F7851-70CXB4 PM-AP-064 FSF781D-CX7.2 103F7851-70CXB1 PM-AP-064

FSF781S-CX10 103F7851-70CXE4 PM-AP-064 FSF781D-CX10 103F7851-70CXE1 PM-AP-064

FSF781S-CX20 103F7851-70CXG4 PM-AP-064 FSF781D-C

X20 103F7851-70CXG1 PM-AP-064

F

SF781S-CX30 103F7851-70CXJ4 PM-AP-064 FSF781D-CX30 103F7851-70CXJ1 PM-AP-064

FSF781S-CX36 103F7851-70CXK4 PM-AP-064 FSF781D-CX36 103F7851-70CXK1 PM-AP-064

φ

86mm

FSF851S-CX3.6 103F8581-70CXA4 PM-AP-064 FSF851D-CX3.6 103F8581-70CXA1 PM-AP-064

FSF851S-CX7.2 103F8581-70CXB4 PM-AP-064 FSF851D-CX7.2 103F8581-70CXB1 PM-AP-064

FSF851S-CX10 103F8581-70CXE4 PM-AP-064 FSF851D-CX10 103F8581-70CXE1 PM-AP-064

FSF8

51S-CX20 103F8581-70CXG4

PM-AP-064 FSF851D-CX20 103F8581-70CXG1 PM-AP-064

FSF851S-CX30 103F8581-70CXJ4 PM-AP-064 FSF851D-CX30 103F8581-70CXJ1 PM-AP-064

FSF851S-CX36 103F8581-70CXK4 PM-AP-064 FSF851D-CX36 103F8581-70CXK1 PM-AP-064

Harmonic

gear model

□

42mm

FSF551S-HX30 103F5505-70HXJ5 PM-AP-065 FSF551D-HX30 103F5505-70HXJ2 PM-AP-065

FSF551S-HX50 103F5505-70HXL5 PM-AP-065 FSF551D-HX50 103F5505-70HXL2 PM-AP-065

FSF551S-HX100 103F550

5-70HXM5 PM-AP-065 F

SF551D-HX100 103F5505-70HXM2 PM-AP-065

□

60mm

FSF781S-HX50 103F7851-70HXL4 PM-AP-064 FSF781D-HX50 103F7851-70HXL1 PM-AP-064

FSF781S-HX100 103F7851-70HXM4 PM-AP-064 FSF781D-HX100 103F7851-70HXM1 PM-AP-064

φ

86mm

FSF851S-HX50 103F8581-70HXL4 PM-AP-064 FSF851D-HX50 103F8581-70HXL1 PM-AP-064

FSF851S-HX100 103F8581-70HXM4 PM-AP-064 FSF851D-HX100 103F8581-70HXM1 PM-AP-064

Electromag-

netic brake

model

□

42mm

FSF551S-XB 103F5505-70XB41 PM-AP-065

− − −

FSF552S-XB 103F5508-70XB41 PM-AP-065

− − −

FSF554S-XB 103F5510-70XB41 PM-AP-065

− − −

□

60mm

FSF781S-XB 103F7851-70XB41 PM-AP-064

− − −

FSF782S-XB 103F7852-70XB41 PM-AP-064

− − −

FSF783S-XB 103F7853-70XB41 PM-AP-064

− − −

φ

86mm

FSF851S-XB 103F8581-70XB41 PM-AP-064

− − −

FSF852S-XB 103F8582-70XB41 PM-AP-064

− − −

FSF853S-XB 103F8583-70XB41 PM-AP-064

− − −

CE / UL

model

□

42mm

FSM551S 103M5505-7041 PM-AP-065 FSM551D 103M5505-7011 PM-AP-065

FSM552S 103M5508-7041 PM-AP-065 FSM552D 103M5508-7011 PM-AP-065

FSM554S 103M5510-7041 PM-AP-065 FSM554D 103M5510-7011 PM-AP-065

□

60mm

FSM781S 103M7851-7041 PM-AP-064 FSM781D 103M7851-7011 PM-AP-064

FSM782S 103M7852-7041 PM-AP-064 FSM782D 103M7852-7011 PM-AP-064

FSM783S 103M7853-7041 PM-AP-064 FSM783D 103M7853-7011 PM-AP-064

φ

86mm

FSM851S 103M8581-7041 PM-AP-064 FSM851D 103M8581-7011 PM-AP-064

FSM852S 103M8582-7041 PM-AP-064 FSM852D 103M8582-7011

PM-AP-064

FSM853S 103M8583-7041 PM-AP-064 FSM853D 103M8583-7011 PM-AP-064

φ

106mm

FSM892S 103M89582-7041 PM-AP-063 FSM892D 103M89582-7011 PM-AP-063

FSM893S 103M89583-7041 PM-AP-063 FSM893D 103M89583-7011 PM-AP-063

Note) Includes a driver connector set (power supply connector, input/output signal connector) and a motor connector.

Connector model number Driver connector set model number Motor connector model number

PM-AP-063 PM-AP-078 4838971-1

PM-AP-064 PM-AP-078 4837994-1

PM-AP-065 PM-AP-078 4835758-1

This is a set comprising a driver,

motor and connectors.

11

AC input

Specifications

5-phase STEPPING SYSTEMS

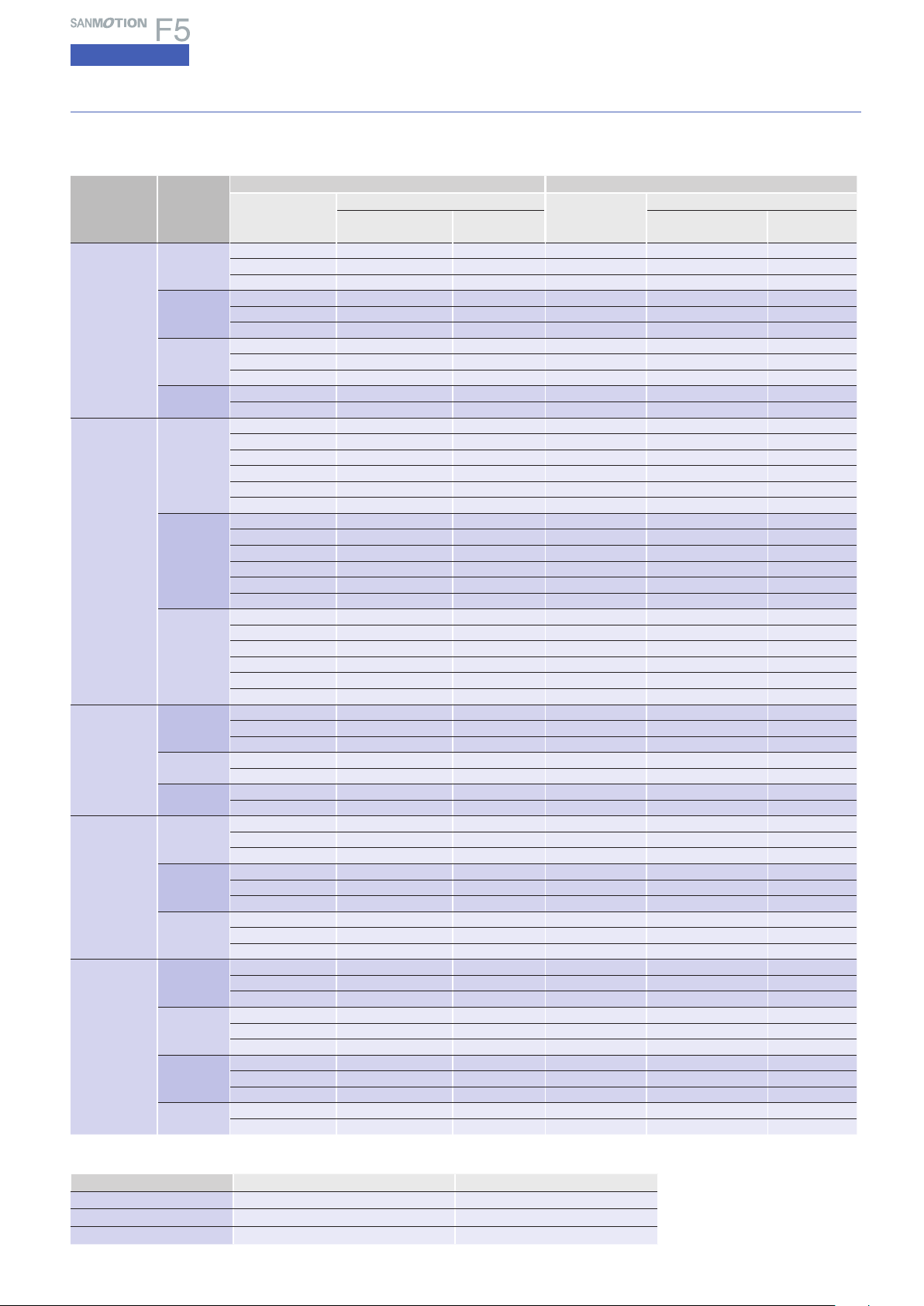

Type with built-in AC positioning function

Bundled driver model number : FP1W075P00

Step angle

/

0.72

°

Rated current 0.75A

Model

Motor

flange size

Single shaft Double shafts

Set part

number

Set accessories

Set part

number

Set accessories

Motor model

number

Connector

number

Note)

Motor model

number

Connector

number

Note)

Standard

model

□

42mm

FPF551S 103F5505-7041 PM-AP-074 FPF551D 103F5505-7011 PM-AP-074

FPF552S 103F5508-7041 PM-AP-074 FPF552D 103F5508-7011 PM-AP-074

FPF554S 103F5510-7041 PM-AP-074 FPF554D 103F5510-7011 PM-AP-074

□

60mm

FPF781S 103F7851-7041 PM-AP-073 FPF781D 103F7851-7011 PM-AP-073

FPF782S 103F7852-7041 PM-AP-073 FPF782D 103F7852-7011 PM-AP-073

FPF783S 103F7853-7041 PM-AP-073 FPF783D 103F7853-7011 PM-AP-073

φ

86mm

FPF851S 103F8581-7041 PM-AP-073 FPF851D 103F8581-7011 PM-AP-073

FPF852S 103F8582-7041 PM-AP-073 FPF852D 103F8582-7011 PM-AP-073

FPF853S 103F8583-7041 PM-AP-073 FPF853D 103F8583-7011 PM-AP-073

φ

106mm

FPF892S 103F89582-7041 PM-AP-072 FPF892D 103F89582-7011 PM-AP-072

FPF893S 103F89583-7041 PM-AP-072 FPF893D 103F89583-7011 PM-AP-072

Low-backlash

gear model

□

42mm

FPF551S-CX3.6 103F5505-70CXA4 PM-AP-074 FPF551D-CX3.6 103F5505-70CXA1 PM-AP-074

FPF551S-CX7.2 103F5505-70CXB4 PM-AP-074 FPF551D-CX7.2 103F5505-70CXB1 PM-AP-074

FPF551S-CX10 103F5505-70CXE4 PM-AP-074 FPF551D-CX10 103F5505-70CXE1 PM-AP-074

FPF551S-CX20 103F5505-70CXG4 PM-AP-074 FPF551D-CX20 103F5505-70CXG1 PM-AP-074

FPF551S-CX30 10

3F5505-70CXJ4 PM-AP-074 FPF551D-CX30 103F5505-70CXJ1

PM-AP-074

FPF551S-CX36 103F5505-70CXK4 PM-AP-074 FPF551D-CX36 103F5505-70CXK1 PM-AP-074

□

60mm

FPF781S-CX3.6 103F7851-70CXA4 PM-AP-073 FPF781D-CX3.6 103F7851-70CXA1 PM-AP-073

FPF781S-CX7.2 103F7851-70CXB4 PM-AP-073 FPF781D-CX7.2 103F7851-70CXB1 PM-AP-073

FPF781S-CX10 103F7851-70CXE4 PM-AP-073 FPF781D-CX10 103F7851-70CXE1 PM-AP-073

FPF781S-CX20 103F7851-70CXG4 PM-AP-073 FPF781D-C

X20 103F7851-70CXG1 PM-AP-073

F

PF781S-CX30 103F7851-70CXJ4 PM-AP-073 FPF781D-CX30 103F7851-70CXJ1 PM-AP-073

FPF781S-CX36 103F7851-70CXK4 PM-AP-073 FPF781D-CX36 103F7851-70CXK1 PM-AP-073

φ

86mm

FPF851S-CX3.6 103F8581-70CXA4 PM-AP-073 FPF851D-CX3.6 103F8581-70CXA1 PM-AP-073

FPF851S-CX7.2 103F8581-70CXB4 PM-AP-073 FPF851D-CX7.2 103F8581-70CXB1 PM-AP-073

FPF851S-CX10 103F8581-70CXE4 PM-AP-073 FPF851D-CX10 103F8581-70CXE1 PM-AP-073

FPF8

51S-CX20 103F8581-70CXG4

PM-AP-073 FPF851D-CX20 103F8581-70CXG1 PM-AP-073

FPF851S-CX30 103F8581-70CXJ4 PM-AP-073 FPF851D-CX30 103F8581-70CXJ1 PM-AP-073

FPF851S-CX36 103F8581-70CXK4 PM-AP-073 FPF851D-CX36 103F8581-70CXK1 PM-AP-073

Harmonic

gear model

□

42mm

FPF551S-HX30 103F5505-70HXJ5 PM-AP-074 FPF551D-HX30 103F5505-70HXJ2 PM-AP-074

FPF551S-HX50 103F5505-70HXL5 PM-AP-074 FPF551D-HX50 103F5505-70HXL2 PM-AP-074

FPF551S-HX100 103F550

5-70HXM5 PM-AP-074 F

PF551D-HX100 103F5505-70HXM2 PM-AP-074

□

60mm

FPF781S-HX50 103F7851-70HXL4 PM-AP-073 FPF781D-HX50 103F7851-70HXL1 PM-AP-073

FPF781S-HX100 103F7851-70HXM4 PM-AP-073 FPF781D-HX100 103F7851-70HXM1 PM-AP-073

φ

86mm

FPF851S-HX50 103F8581-70HXL4 PM-AP-073 FPF851D-HX50 103F8581-70HXL1 PM-AP-073

FPF851S-HX100 103F8581-70HXM4 PM-AP-073 FPF851D-HX100 103F8581-70HXM1 PM-AP-073

Electromag-

netic brake

model

□

42mm

FPF551S-XB 103F5505-70XB41 PM-AP-074

− − −

FPF552S-XB 103F5508-70XB41 PM-AP-074

− − −

FPF554S-XB 103F5510-70XB41 PM-AP-074

− − −

□

60mm

FPF781S-XB 103F7851-70XB41 PM-AP-073

− − −

FPF782S-XB 103F7852-70XB41 PM-AP-073

− − −

FPF783S-XB 103F7853-70XB41 PM-AP-073

− − −

φ

86mm

FPF851S-XB 103F8581-70XB41 PM-AP-073

− − −

FPF852S-XB 103F8582-70XB41 PM-AP-073

− − −

FPF853S-XB 103F8583-70XB41 PM-AP-073

− − −

CE / UL

model

□

42mm

FPM551S 103M5505-7041 PM-AP-074 FPM551D 103M5505-7011 PM-AP-074

FPM552S 103M5508-7041 PM-AP-074 FPM552D 103M5508-7011 PM-AP-074

FPM554S 103M5510-7041 PM-AP-074 FPM554D 103M5510-7011 PM-AP-074

□

60mm

FPM781S 103M7851-7041 PM-AP-073 FPM781D 103M7851-7011 PM-AP-073

FPM782S 103M7852-7041 PM-AP-073 FPM782D 103M7852-7011 PM-AP-073

FPM783S 103M7853-7041 PM-AP-073 FPM783D 103M7853-7011 PM-AP-073

φ

86mm

FPM851S 103M8581-7041 PM-AP-073 FPM851D 103M8581-7011 PM-AP-073

FPM852S 103M8582-7041 PM-AP-073 FPM852D 103M8582-7011

PM-AP-073

FPM853S 103M8583-7041 PM-AP-073 FPM853D 103M8583-7011 PM-AP-073

φ

106mm

FPM892S 103M89582-7041 PM-AP-072 FPM892D 103M89582-7011 PM-AP-072

FPM893S 103M89583-7041 PM-AP-072 FPM893D 103M89583-7011 PM-AP-072

Note) Includes a driver connector set (power supply connector, input/output signal connector) and a motor connector.

Connector model number Driver connector set model number Motor connector model number

PM-AP-072 PM-AP-079 4838971-1

PM-AP-073 PM-AP-079 4837994-1

PM-AP-074 PM-AP-079 4835758-1

Packaged Sale Model Configuration

This is a set comprising a driver,

motor and connectors.

12

AC inputInput / Output signal standardDC inputStepping motorDimensions

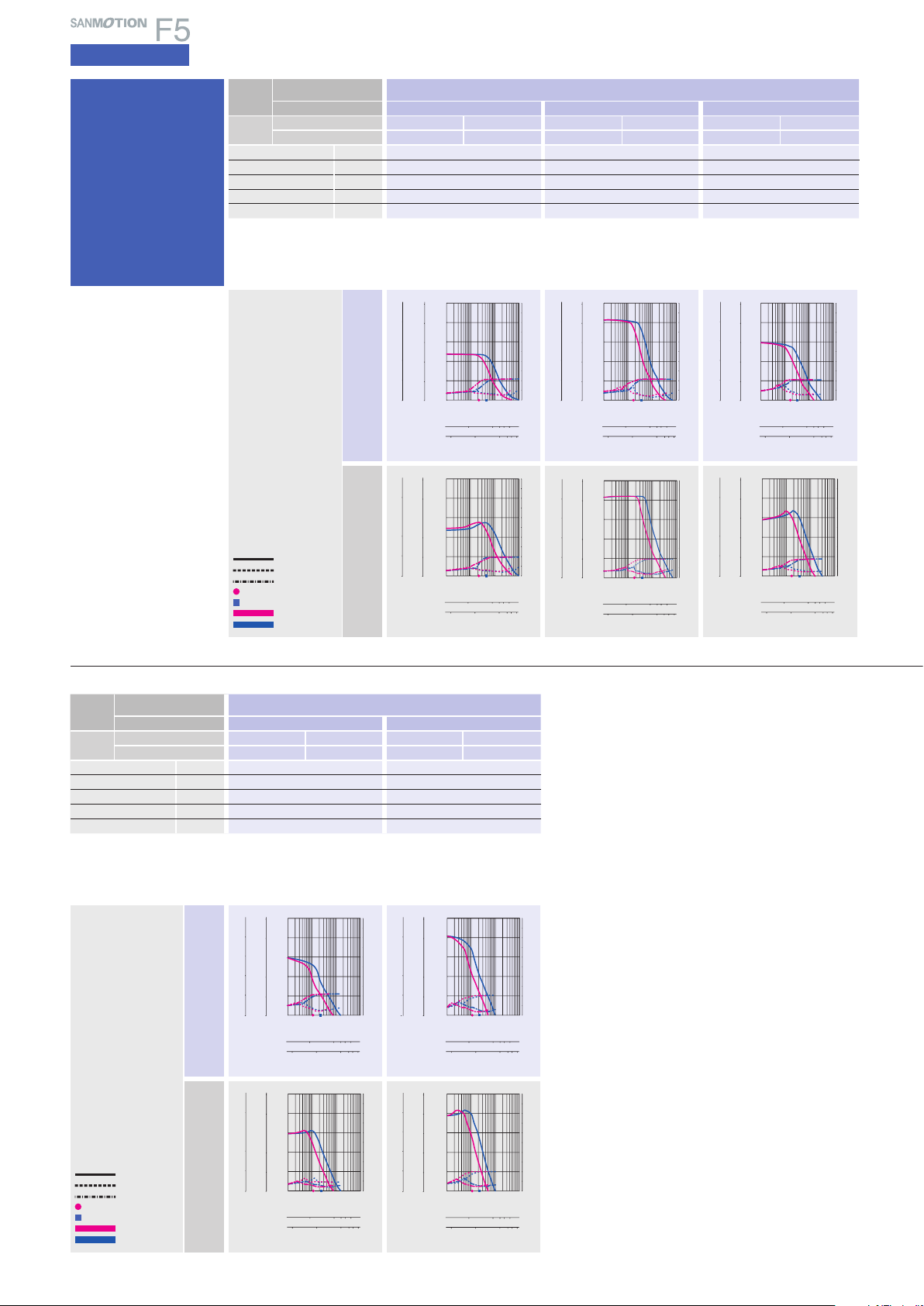

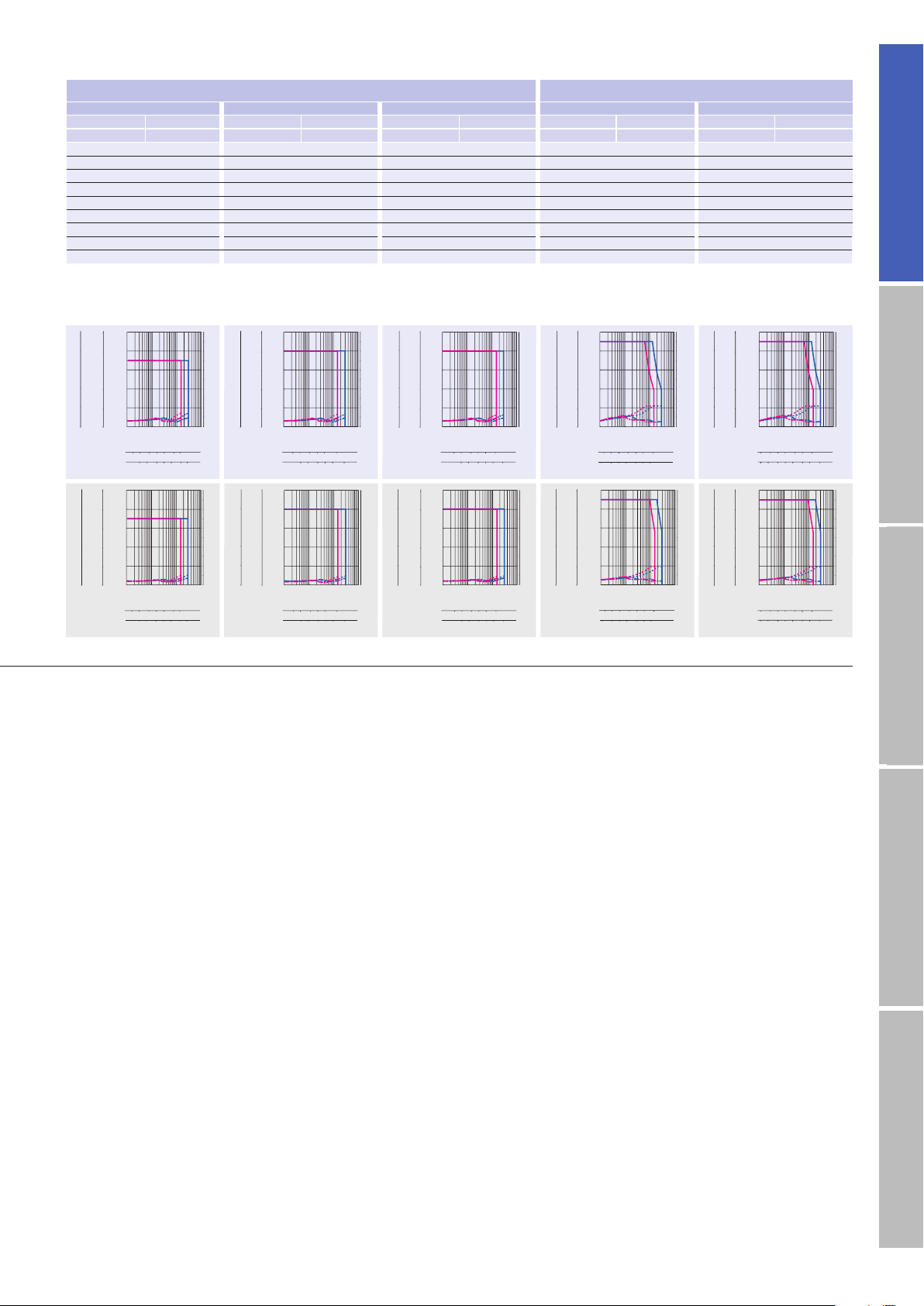

Size

Motor flange size

□

42

mm

(

□

1.65

inch

)

□

60

mm

(

□

2.36

inch

)

Motor leng th

49mm

(

1.93inch

)

46.5mm

(

1.83inch

)

55mm

(

2.17inch

)

87.5mm

(

3.45inch

)

Set par t

number

Single shaft

FSF55 4S FPF554S FSF781S FPF781S FSF782S FPF782S FSF783S FPF783S

Double shaft

FSF55 4D FPF554D FSF781D FPF781D FSF782D FPF782D FSF782D FPF783D

Holding torque N

・

m

(

oz

・

in

)

0.26

(

36.82

)

0.6

(

85.0

)

0.93

(

131.7

)

1.79

(

253.5

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

0.065

(

0.36

)

0.275

(

1.50

)

0.4

(

2.19

)

0.84

(

4.60

)

Mass

(

Weight

)

kg

(

lbs

)

0.37

(

0.81

)

0.6

(

1.32

)

0.78

(

1.72

)

1.36

(

3.0

)

Allowable thrust load N

(

lbs

)

10

(

2.25

)

20

(

4.5

)

20

(

4.5

)

20

(

4.5

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

35

(

8.75

)

80

(

18

)

80

(

18

)

80

(

18

)

AC100V

AC200V

Standard model

F series driver + F series motor

42

60

86

106

φ φ

(

φ

4.17inch)(

φ

3.39inch)(

□

2.35inch)(

□

1.65inch)

Size

Motor flange size

□

42

mm

(

□

1.65

inch

)

Motor leng th

34mm

(

1.34inch

)

40mm

(

1.57inch

)

Set par t

number

Single shaft

FSF551S FPF551S FSF552S FPF552S

Double shaft

FSF551D FPF551D FSF552D FPF552D

Holding torque N

・

m

(

oz

・

in

)

0.13

(

18.41

)

0.18

(

25.49

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

0.03

(

0.16

)

0.053

(

0.29

)

Mass

(

Weight

)

kg

(

lbs

)

0.23

(

0.50

)

0.28

(

0.62

)

Allowable thrust load N

(

lbs

)

10

(

2.25

)

10

(

2.25

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

35

(

8.75

)

35

(

8.75

)

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

Motor flange size

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.2

0.4

0.6

0.8

1.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

10

8

6

4

2

8

6

4

2

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

Source current (A)

0

0

0.2

0.4

0.5

0.8

1.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

10

8

6

4

2

8

6

4

2

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.4

0.8

1.2

1.6

2.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

20

16

12

8

4

16

12

8

4

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.4

0.8

1.2

1.6

2.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

20

16

12

8

4

16

12

8

4

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

AC100V

AC200V

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

The data a re measured und er the drive c ondition of o ur company. Th e drive

torque may ver y depending on the acc uracy of cust omer-side e quipment.

The data a re measured und er the drive c ondition of o ur company. Th e drive torque m ay very dep ending on th e accuracy o f customer-s ide equipm ent.

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

13

AC input

Specifications

5-phase STEPPING SYSTEMS

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.11 10 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

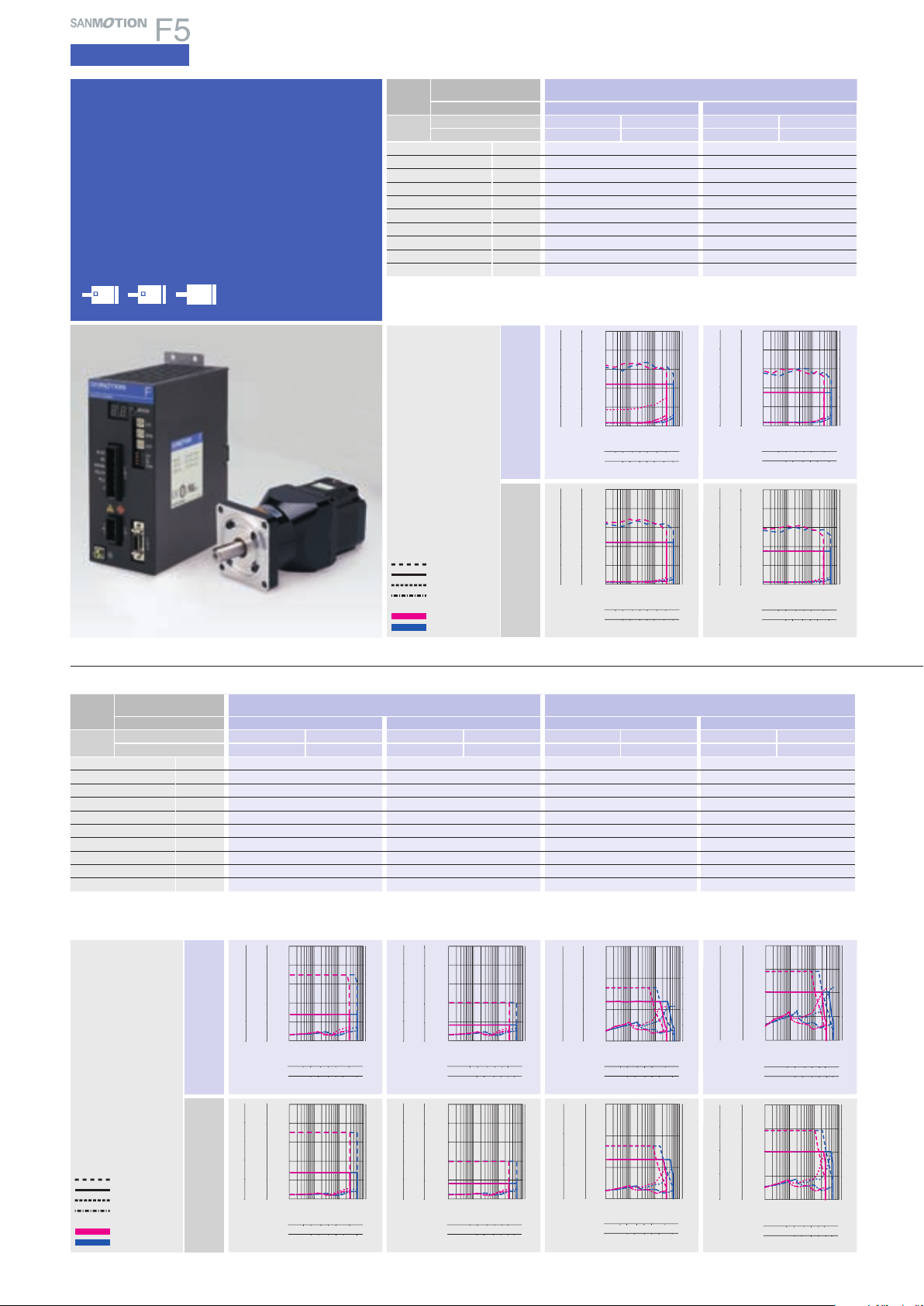

AC100V

AC200V

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

0

0

2

4

6

8

10

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

100

80

60

40

20

80

60

40

20

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

2

4

6

8

10

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

100

80

60

40

20

80

60

40

20

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

1-division

2-division

Number of rotations (min

-1

)

0

1

2

3

4

5

0

1

2

3

4

5

6

7

8

9

10

0.1 110 100

100 1000 2000 30005000

10 100 1000 200030005000

0

50

40

30

20

10

40

30

20

10

Torque( kgf・cm )

0

Torque( lb-in )

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

1

2

3

4

5

0.11 10 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

AC100V

AC200V

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

Size

Motor flange size

φ

106

mm

(

φ

4.17

inch

)

Motor leng th

163.3mm

(

6.43inch

)

221.3mm

(

8.71inch

)

Set par t

number

Single shaft

FSF892S FPF892S FSF893S FPF893S

Double shaft

FSF892D FPF892D FSF893D FPF893D

Holding torque N

・

m

(

oz

・

in

)

10.8

(

1529.4

)

16

(

2265.7

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

14.6

(

79.83

)

22

(

120.28

)

Mass

(

Weight

)

kg

(

lbs

)

7.5

(

16.5

)

10.5

(

23.1

)

Allowable thrust load N

(

lbs

)

100

(

22.5

)

100

(

22.5

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

360

(

81

)

360

(

81

)

Size

Motor flange size

φ

86

mm

(

φ

3.39

inch

)

Motor leng th

62.15mm

(

2.47inch

)

92.2mm

(

3.63inch

)

125.85mm

(

4.95inch

)

Set par t

number

Single shaft

FSF851S FPF851S FSF852S FPF852S FSF853S FPF853S

Double shaft

FSF851D FPF851D FSF852D FPF852D FSF853D FPF8 53D

Holding torque N

・

m

(

oz

・

in

)

2.06

(

291.7

)

4.02

(

569. 3

)

6.17

(

873.7

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

1.45

(

7.93

)

2.9

(

15.86

)

4.4

(

24.06

)

Mass

(

Weight

)

kg

(

lbs

)

1.5

(

3.3

)

2.5

(

5.5

)

3.5

(

7.7

)

Allowable thrust load N

(

lbs

)

60

(

13.5

)

60

(

13.5

)

60

(

13.5

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

220

(

49.5

)

220

(

49.5

)

220

(

49.5

)

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

The data a re measured und er the drive c ondition of o ur company. Th e drive

torque may ver y depending on the acc uracy of cust omer-side e quipment.

The data a re measured und er the drive c ondition of o ur company. Th e drive torque m ay very dep ending on the a ccuracy o f customer-s ide equipm ent.

Standard

model

F series driver + F series motor

14

AC inputInput / Output signal standardDC inputStepping motorDimensions

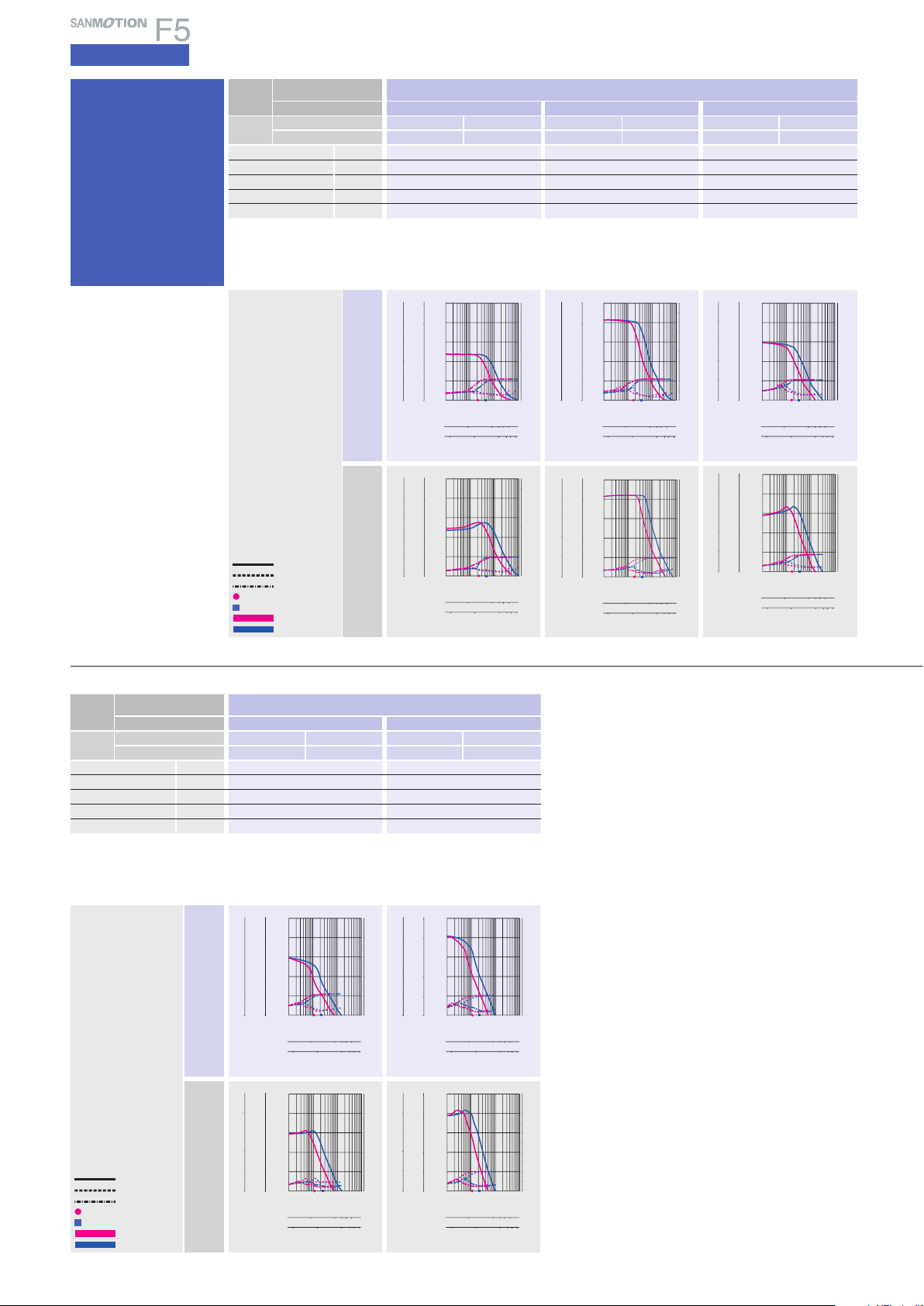

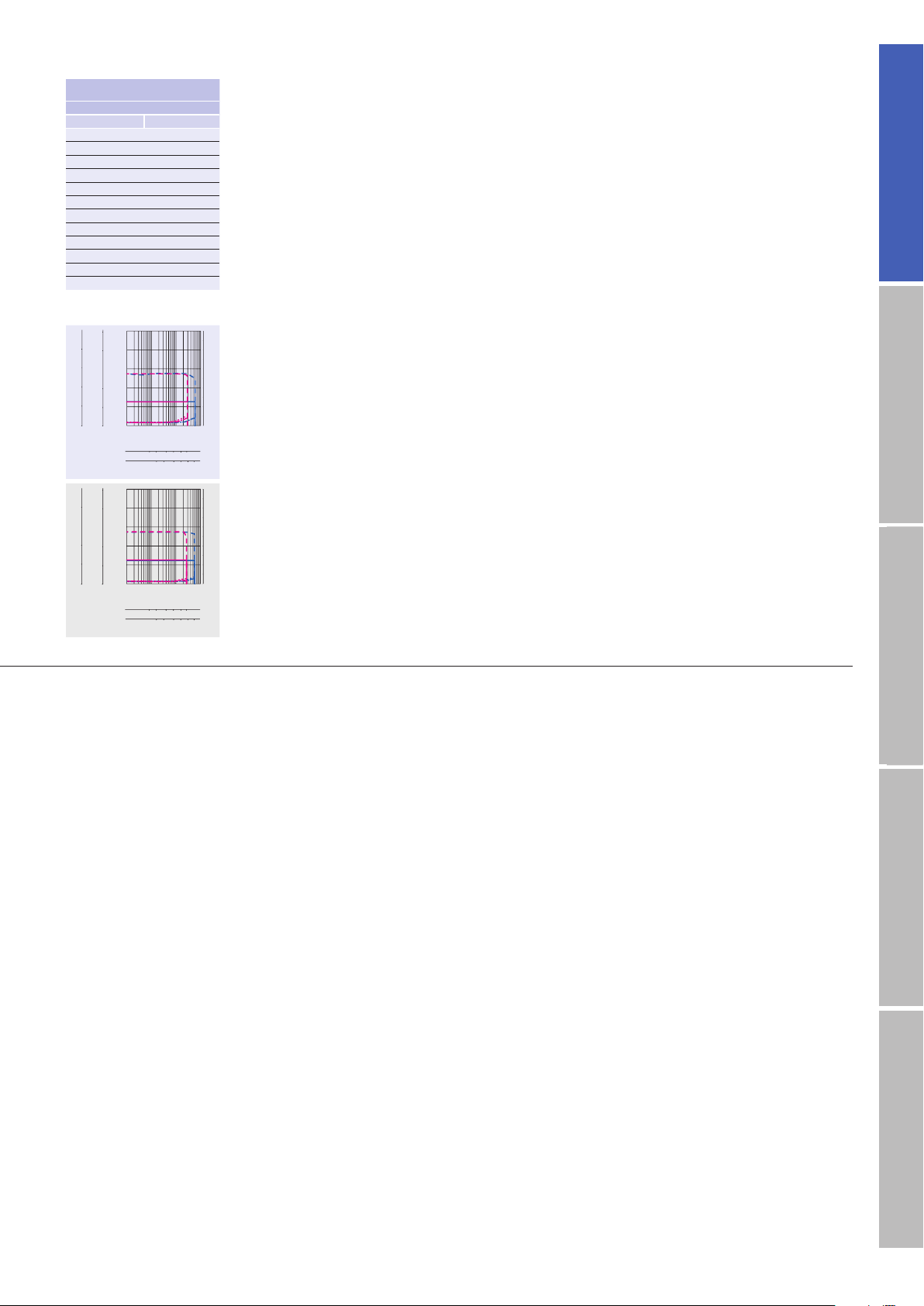

CE / UL model

F series driver + M series motor

Size

Motor flange size

□

42

mm

(

□

1.65

inch

)

Motor leng th

31mm

(

1.22inch

)

50.5mm

(

1.99inch

)

Set par t

number

Single shaft

FSM551S FPM551S FSM552S FPM552S

Double shaft

FSM551D FPM551D FSM552D FPM552D

Holding torque N

・

m

(

oz

・

in

)

0.13

(

18.41

)

0.18

(

25.49

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

0.03

(

0.16

)

0.053

(

0.29

)

Mass

(

Weight

)

kg

(

lbs

)

0.23

(

0.51

)

0.28

(

0.62

)

Allowable thrust load N

(

lbs

)

10

(

2.25

)

10

(

2.25

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

35

(

8.75

)

35

(

8.75

)

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

42

60

86

106

φ φ

(

φ

4.17inch)(

φ

3.39inch)(

□

2.35inch)(

□

1.65inch)

Motor flange size

AC100V

AC200V

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.1

0.2

0.3

0.4

0.5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

5

4

3

2

1

4

3

2

1

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.2

0.4

0.6

0.8

1.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

10

8

6

4

2

8

6

4

2

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.2

0.4

0.6

0.8

1.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

10

8

6

4

2

8

6

4

2

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.4

0.8

1.2

1.6

2.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

20

16

12

8

4

16

12

8

4

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

0.4

0.8

1.2

1.6

2.0

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

20

16

12

8

4

16

12

8

4

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

The data a re measured und er the drive c ondition of o ur company. Th e drive

torque may ver y depending on the acc uracy of cust omer-side e quipment.

AC100V

AC200V

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

Size

Motor flange size

□

42

mm

(

□

1.65

inch

)

□

60

mm

(

□

2.36

inch

)

Motor leng th

49mm

(

1.93inch

)

46.5mm

(

1.83inch

)

55mm

(

2.17inch

)

87.5mm

(

3.44inch

)

Set par t

number

Single shaft

FSM554S FPM554S FSM781S FPM781S FSM782S FPM782S FSM783S FPM783S

Double shaft

FSM554D FPM554D FSM781D FPM781D FSM782D FPM782D

FSM783D FPM78 3D

Holding torque N

・

m

(

oz

・

in

)

0.26

(

36.82

)

0.6

(

85.0

)

0.065

(

9.20

)

1.79

(

253.5

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

0.065

(

0.36

)

0.275

(

1.50

)

0.016

(

0.09

)

0.84

(

4.59

)

Mass

(

Weight

)

kg

(

lbs

)

0.37

(

0.81

)

0.6

(

1.32

)

0.2

(

0.44

)

1.36

(

3.0

)

Allowable thrust load N

(

lbs

)

10

(

2.25

)

20

(

4.5

)

3

(

0.68

)

20

(

4.5

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

35

(

8.75

)

80

(

18

)

34

(

7.65

)

80

(

18

)

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

The data a re measured und er the drive c ondition of o ur company. Th e drive torque m ay very dep ending on th e accuracy o f customer-s ide equipm ent.

15

AC input

Specifications

5-phase STEPPING SYSTEMS

The data a re measured und er the drive c ondition of o ur company. Th e drive

torque may ver y depending on the acc uracy of cust omer-side e quipment.

Size

Motor flange size

φ

106

mm

(

φ

4.17

inch

)

Motor leng th

163.3mm

(

6.43inch

)

221.3mm

(

8.71inch

)

Set par t

number

Single shaft

FSM892S FPM892S FSM893S FPM8 93S

Double shaft

FSM892D FPM892D FSM893D FPM893D

Holding torque N

・

m

(

oz

・

in

)

10.8

(

1529.4

)

16

(

2265.7

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

14.6

(

79.83

)

22

(

120.28

)

Mass

(

Weight

)

kg

(

lbs

)

7.5

(

16.5

)

10.5

(

23.1

)

Allowable thrust load N

(

lbs

)

100

(

22.5

)

100

(

22.5

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

360

(

81

)

360

(

81

)

(

Note1

)

When loa d is applied at 1/ 3 length from output s haft edge .

AC100V

AC200V

Pull-out torque

Source current (load applied)

Source current (no load)

Fs:

Maximum self-start

frequency when not loaded

1-division

2-division

Operating current:

0.75A/phase

1-division fs

2-division fs

0

0

1

2

3

4

5

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

50

40

30

20

10

40

30

20

10

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

1-division

2-division

Number of rotations (min

-1

)

0

1

2

3

4

5

0

1

2

3

4

5

6

7

8

9

10

0.1 110 100

100 1000 2000 30005000

10 100 1000 200030005000

0

50

40

30

20

10

40

30

20

10

Torque( kgf・cm )

0

Torque( lb-in )

0

0

2

4

6

8

10

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

100

80

60

40

20

80

60

40

20

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

2

4

6

8

10

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

100

80

60

40

20

80

60

40

20

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

0

200

160

120

80

40

160

120

80

40

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

Torque( kgf・cm )

0

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

0

0

4

8

12

16

20

0.1 110 100

0

1

2

3

4

5

6

7

8

9

10

200

160

120

80

40

160

120

80

40

0

Torque( kgf・cm )

Torque( lb-in )

Torque(N・m )

Source current (A)

Pulse rate (kpulse/s)

100 1000 2000 3000 5000

Number of rotations (min

-1

)

1-division

2-division

10 100 1000 2000 3000 5000

The data a re measured und er the drive c ondition of o ur company. Th e drive torque m ay very dep ending on th e accuracy o f customer-s ide equipm ent.

Size

Motor flange size

φ

86

mm

(

φ

3.39

inch

)

Motor leng th

62.15mm

(

2.47inch

)

92.2mm

(

3.63inch

)

125.85mm

(

4.95inch

)

Set par t

number

Single shaft

FSM851S FPM851S FSM852S FPM852S FSM8 53S FPM853S

Double shaft

FSM851D FPM851D FSM852D FPM852D FSM853D FPM853D

Holding torque N

・

m

(

oz

・

in

)

2.06

(

291.7

)

4.02

(

569. 3

)

6.17

(

873.7

)

Rotor iner tia

×10

-4

kg・m

2

(oz・in

2

)

1.45

(

7.93

)

2.9

(

15.86

)

4.4

(

24.06

)

Mass

(

Weight

)

kg

(

lbs

)

1.5

(

3.3

)

2.5

(

5.5

)

3.5

(

7.7

)

Allowable thrust load N

(

lbs

)

60

(

13.5

)

60

(

13.5

)

60

(

13.5

)

Allowable radial l oad

(

Note 1

)

N

(

lbs

)

220

(

49.5

)

220

(

49.5