SANDPIPER S1F User Manual

SERVICE & OPERATING MANUAL

Original Instructions

Certified Quality

Quality System

ISO 9001 Certified

Environmental Management System

ISO 14001 Certified

Warren Rupp, Inc.

A Unit of IDEX Corporation

800 N. Main St.,

Mansfield, Ohio 44902 USA

Telephone 419.524.8388

Fax 419.522.7867

SANDPIPERPUMP.COM

Model S1F

Metallic

Design Level 1

© Copyright 2014 Warren Rupp, Inc.

All rights reserved

3: EXP VIEW 2: INSTAL & OP 1: PUMP SPECS

4: AIR END

7: WARRANTY 6: OPTIONAL 5: WET END

sandpiperpump .com

Safety Information

IMPORTANT

IMPORTANT

Read the safety warnings and instructions in this manual before pump installation and start-up. Failure to comply with the recommendations stated in this manual could damage the pump and void factory warranty.

When the pump is used for materials that tend to settle out or solidify, the pump should be flushed after each use to

prevent damage. In freezing temperatures the pump should be completely drained between uses.

CAUTION

CAUTION

Before pump operation, inspect all fasteners for loosening caused by gasket creep. Retighten loose fasteners to prevent leakage. Follow recommended torques stated in this manual.

Nonmetallic pumps and plastic components are not UV stabilized. Ultraviolet radiation can damage these parts and negatively affect material properties. Do not expose to UV light for extended periods of time.

WARNING

Pump not designed, tested or certified to be powered by compressed natural gas. Powering the pump with natural gas will void the warranty.

WARNING

WARNING

When used for toxic or aggressive fluids, the pump should always be flushed clean prior to disassembly.

Before maintenance or repair, shut off the compressed air line, bleed the pressure, and disconnect the air line from the pump.

Be certain that approved eye protection and protective clothing are worn at all times. Failure to follow these recommendations may result in serious injury or death.

Airborne particles and loud noise hazards. Wear eye and ear protection.

In the event of diaphragm rupture, pumped material may enter the air end of the pump, and be discharged into the atmosphere. If pumping a product that is hazardous or toxic, the air exhaust must be piped to an appropriate area for safe containment.

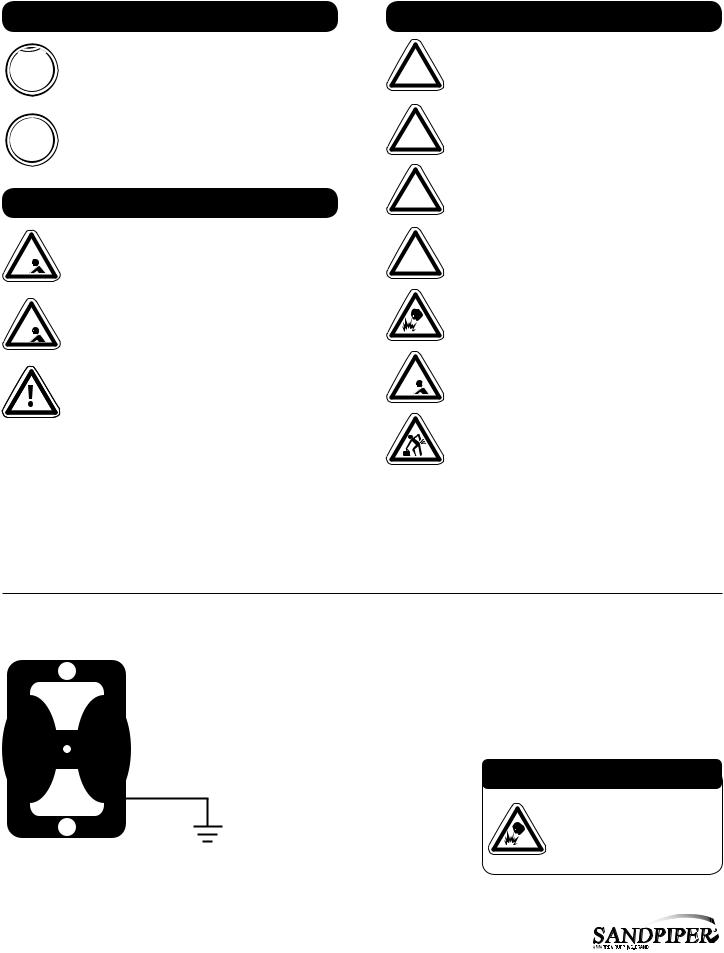

Take action to prevent static sparking. Fire or explosion can result, especially when handling flammable liquids. The pump, piping, valves, containers and other miscellaneous equipment must be properly grounded.

This pump is pressurized internally with air pressure during operation. Make certain that all fasteners are in good condition and are reinstalled properly during reassembly.

Use safe practices when lifting

Grounding the Pump

To be fully groundable, the pumps must be ATEX Compliant. Refer to the nomenclature page for ordering information.

Optional 8 foot long (244 centimeters) Ground Strap is available for easy ground connection.

To reduce the risk of static electrical sparking, this pump must be grounded. Check the local electrical code for detailed grounding instruction and the type of equipment required.

Refer to nomenclature page for ordering information.

WARNING

WARNING

Take action to prevent static sparking.

Fire or explosion can result, especially when handling flammable liquids. The pump, piping, valves, containers or other miscellaneous equipment must be grounded.

Model S1F Metallic |

sandpiperpump.com |

s1fmdl1sm-rev0614

Table of Contents

SECTION 1: PUMP SPECIFICATIONS................ |

1 |

•Explanation of Nomenclature

•Performance

•Materials

•Dimensional Drawings

SECTION 2: INSTALLATION & OPERATION......5

•Principle of Pump Operation

•Recommended Installation Guide

•Troubleshooting Guide

SECTION 3: EXPLODED VIEW........................... |

8 |

•Composite Repair Parts Drawing

•Composite Repair Parts List

•Material Codes

SECTION 4: AIR END....................................... |

11 |

•Air Distribution Valve Assembly

•Air Valve with Stroke Indicator Assembly

•Pilot Valve Assembly

•Intermediate Assembly

SECTION 5: WET END...................................... |

18 |

•Diaphragm Drawings

•Diaphragm Servicing

SECTION 6: OPTIONAL CONFIGURATIONS.... |

20 |

• Solenoid Shifted Air Valve |

|

SECTION 7: WARRANTY & CERTIFICATES..... |

21 |

• Warranty |

|

• CE Declaration of Conformity - Machinery |

|

• ATEX Declaration of Conformity |

|

• ATEX Summary of Markings |

|

sandpiperpump.com

3: EXP VIEW 2: INSTAL & OP 1: PUMP SPECS

4: AIR END

7: WARRANTY 6: OPTIONAL 5: WET END

Model S1F Metallic

s1fmdl1sm-rev0614

1: PUMP SPECS

Explanation of Pump Nomenclature

Your Model #: |

S |

|

____ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

__ |

|

|

____ |

|

||||||||||||

(fill in from pump |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

nameplate) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pump |

|

Pump |

Check |

Design |

Wetted |

Diaphragm/ |

Check Valve |

Non-Wetted |

Porting |

Pump |

Pump |

|

Kit |

||||||||||||||||||||||||||||||||

|

Brand |

|

Size |

Valve |

Level |

Material |

Check Valve |

Seat |

Material |

Options |

Style |

Options |

Options |

|||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model #: |

S |

|

XX |

X |

X |

X |

X |

X |

X |

X |

X |

X |

|

XX |

||||||||||||||||||||||||||||||||

Pump Brand |

Non-Wetted Material Options |

|||

S |

SANDPIPER® |

A |

Painted Aluminum |

|

Pump Size |

I |

Cast Iron |

||

Y |

Painted Aluminum with |

|||

1F |

1" |

|||

|

Stainless Steel Hardware |

|||

Check Valve Type |

Z |

|||

Cast Iron with |

||||

B |

Ball |

|

Stainless Steel Hardware |

|

Design Level |

Porting Options |

|||

1 |

Design Level |

N |

NPT Threads |

|

Wetted Material |

B |

BSP (Tapered) Threads |

||

R |

Raised Face 150# |

|||

A |

Aluminum |

|||

|

Threaded ANSI Flange |

|||

I |

Cast Iron |

W |

Welded Raised Face 150# ANSI Flanged Manifolds |

|

S |

Stainless Steel |

|

|

|

H |

Alloy C |

|

|

|

X |

Unpainted Aluminum |

Pump Style |

||

Diaphragm/Check Valve Materials |

S |

Standard |

||

Pump Options |

||||

1 |

Santoprene/Santoprene |

|||

0 |

None |

|||

2 |

PTFE Santoprene/PTFE |

|||

1 |

Sound Dampening Muffler |

|||

B |

Nitrile/Nitrile |

|||

2 |

Mesh Muffler |

|||

C |

FKM/PTFE |

|||

3 |

High temperature Air |

|||

I |

EPDM/Santoprene |

|||

|

Valve w/Encapsulated Muffler |

|||

G |

PTFE-Neoprene/PTFE |

4 |

||

High temperature Air |

||||

H |

Hytrel/Hytrel |

|||

|

Valve w/Sound |

|||

N |

Neoprene/Neoprene |

|

||

|

Dampening Muffler |

|||

Z |

One-Piece Bonded/PTFE |

5 |

||

High temperature Air |

||||

|

|

|||

Check Valve Seat |

6 |

Valve w/Mesh Muffler |

||

Metal Muffler |

||||

A |

Aluminum |

|||

7 |

Metal Muffler with |

|||

C |

Carbon Steel |

|||

|

Grounding Cable |

|||

S |

Stainless Steel |

|

||

|

|

|||

T |

PTFE |

|

|

|

W |

UHMW |

|

|

|

Kit Options

00. None

P0. 10.30VDC Pulse Output Kit

P1. Intrinsically-Safe 5.30VDC, 110/120VAC 220/240 VAC Pulse Output Kit

P2. 110/120 or 220/240VAC Pulse Output Kit

E0. Solenoid Kit with 24VDC Coil

E1. Solenoid Kit with 24VDC Explosion-Proof Coil

E2. Solenoid Kit with 24VAC/12VDC Coil

E3. Solenoid Kit with 12VDC Explosion-Proof Coil

E4. Solenoid Kit with 110VAC Coil

E5. Solenoid Kit with 110VAC Explosion-Proof Coil

E6. Solenoid Kit with 220VAC Coil

E7. Solenoid Kit with 220VAC Explosion-Proof Coil

E8. Solenoid Kit with 110VAC, 50 Hz Explosion-Proof Coil

E9. Solenoid Kit with 230VAC, 50 Hz Explosion-Proof Coil

SP. Stroke Indicator Pins

A1. Solenoid Kit with 12 VDC ATEX Compliant Coil

A2. Solenoid Kit with 24 VDC ATEX Compliant Coil

A3. Solenoid Kit with 110/120 VAC 50/60 Hz ATEX Compliant Coil A4. Solenoid Kit with 220/240 VAC 50/60 Hz ATEX Compliant Coil

Your Serial #: (fill in from pump nameplate)_ _____________________________________

ATEX Detail

(1) |

II 1G c T5 |

Models equipped with Wetted Options I, S or H, Non-Wetted |

|

II 3/1 G c T5 |

Options I or Z Pump Options 6 or 7, and Kit Option 0. |

||

|

II 1D c T100°C Note: See ATEX Explanation of EC-Type Certificate |

||

|

I M1 c |

|

|

|

I M2 c |

|

|

|

|

|

|

|

II 2G c T5 |

Models equipped with Wetted Options A, I, S, or H, Non-Wetted |

|

|

II 3/2 G c T5 |

Options A, I,Y, or Z, Pump Options 6 or 7, and Kit Option 0. |

|

|

II 2D c T100°C |

Note: See page 19 for ATEX Explanation of Type Examination |

|

|

|

Certificate |

|

(3) |

II 3/2 2G EEx m c II T5 |

|

II 2G EEx m c II T5 |

II 2D c IP65 T100°C

Note: Pumps ordered with the options listed in (1) to the left are ATEX compliant when ordered with kit option A1, A2, A3, or A4. Compressed Air Temperature Range: Maximum Ambient Temperature to plus 50°C.

*Note: See page 16 for Special Conditions For Safe Use.

(2) |

II 3/2 G Ex ia c IIC T5 |

|

II 2G Ex ia c IIC T5 |

II 2D Ex c ia 20 IP67 T100°C

Note: Pumps ordered with the options listed in (1) to the left are ATEX compliant when ordered with kit option P1.

Special condition for safe use:

Conductive polypropylene, conductive acetal, or conductive PVDF pumps are not to be installed in applications where the pumps may be subjected to oil, greases and hydraulic liquids.

1• Model S1F Metallic

(4)  IEC EEX m T4

IEC EEX m T4

Note: Pump models equipped with these explosion-proof solenoid kit options E1, E3, E5, E7, E8 or E9, are certified and approved by the above agencies. They are NOT ATEX compliant.

sandpiperpump.com

s1fmdl1sm-rev0614

Performance

S1F METALLIC

SUCTION/DISCHARGE PORT SIZE

• 1" NPT (internal) |

|

BAR |

|

• 1" BSP Tapered (internal) |

|

||

|

7 |

||

• 1" ANSI 150# Raised Face Flanges |

|||

|

|||

CAPACITY |

|

6 |

|

• 0 to 45 gallons per minute |

|

||

|

|

||

(0 to 170 liters per minute) |

|

5 |

|

AIR DISTRIBUTION VALVE |

|

||

|

|

||

• No-lube, no-stall design |

HEAD |

4 |

|

• Up to .25 in. (6mm) |

|||

3 |

|||

SOLIDS-HANDLING |

|

|

|

HEADS UP TO |

|

|

|

• 125 psi or 289 ft. of water |

|

2 |

|

(8.6 Kg/cm2 or 86 meters) |

|

|

|

DISPLACEMENT/STROKE |

|

1 |

|

• .11 Gallon / .42 liter |

|

0 |

|

MAXIMUM OPERATING PRESSURE |

|||

• 125 psi (8.6 bar) |

|

|

|

SHIPPING WEIGHT

•Aluminum 28 lbs. (13kg)

•Cast Iron 46 lbs. (21kg)

•Stainless Steel 43 lbs. (20kg)

|

|

|

|

|

|

|

|

|

Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions. |

||||||||

PSI |

|

|

|

|

|

|

|

|

|

The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. |

|||||||

5(8.5) |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

100 |

|

10(17) |

|

|

|

|

|

|

|

||||||||

|

PSI |

(6. |

|

15(25.5) |

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

8 |

Bar) |

20(34) |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

80 |

|

|

|

|

|

|

|

|

|

25(42.5) |

|

|

|

|

|

|

|

80 |

PSI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

(5. |

|

|

|

|

30(51) |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

44 |

Bar) |

35(59.5) |

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

60 |

PSI |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

(4.08 |

Bar) |

|

|

|

|

|

40(68) |

|||||||||

|

|

|

|||||||||||||||

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

40 |

PSI (2. |

72 |

Bar) |

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

20 PSI |

(1.36 |

Bar) Air |

|||||||||||||||

|

|||||||||||||||||

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

Inlet Pressure |

|||||||

NPSHR |

1: PUMP SPECS |

|

FEET |

METERS |

|

30 |

|

9.1 |

|

||

25 |

|

7.6 |

20 |

|

6 |

|

||

15 |

|

4.5 |

10 |

|

3 |

|

||

0 0 |

|

|

|

|

|

|

|

|

|

5 |

1.5 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

|

|

|

|

|

|

U.S. Gallons per minute |

|

|

|

|

|

||

0 |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

|

160 |

180 |

|

Liters per minute

CAPACITY

Materials

Material Profile: |

|

Operating |

|

CAUTION! Operating temperature limitations are as follows: |

Temperatures: |

||

Max. |

Min. |

||

Conductive Acetal: Tough, impact resistant, ductile. Good |

190°F |

-20°F |

|

abrasion resistance and low friction surface. Generally inert, with |

88°C |

-29°C |

|

good chemical resistance except for strong acids and oxidizing |

|

|

|

agents. |

|

|

|

EPDM: Shows very good water and chemical resistance. Has |

280°F |

-40°F |

|

poor resistance to oils and solvents, but is fair in ketones and |

138°C |

-40°C |

|

alcohols. |

|

|

|

FKM: (Fluorocarbon) Shows good resistance to a wide range |

350°F |

-40°F |

|

of oils and solvents; especially all aliphatic, aromatic and |

177°C |

-40°C |

|

halogenated hydrocarbons, acids, animal and vegetable oils. |

|

|

|

Hot water or hot aqueous solutions (over 70°F(21°C)) will |

|

|

|

attack FKM. |

|

|

|

Hytrel®: Good on acids, bases, amines and glycols at room |

220°F |

-20°F |

|

temperatures only. |

|

104°C |

-29°C |

Neoprene: All purpose. Resistance to vegetable oils. Generally |

200°F |

-10°F |

|

not affected by moderate chemicals, fats, greases and many |

93°C |

-23°C |

|

oils and solvents. Generally attacked by strong oxidizing acids, |

|

|

|

ketones, esters and nitro hydrocarbons and chlorinated aromatic |

|

|

|

hydrocarbons. |

|

|

|

Nitrile: General purpose, oil-resistant. Shows good solvent, oil, |

190°F |

-10°F |

|

water and hydraulic fluid resistance. Should not be used with |

88°C |

-23°C |

|

highly polar solvents like acetone and MEK, ozone, chlorinated |

|

|

|

hydrocarbons and nitro hydrocarbons. |

|

|

|

Nylon: 6/6 High strength and toughness over a wide |

180°F |

32°F |

|

temperature range. Moderate to good resistance to fuels, oils |

82°C |

0°C |

|

and chemicals. |

|

|

|

Ambient temperature range: |

-20°C to +40°C |

|

|

Process temperature range: |

-20°C to +80°C for models rated as category 1 equipment |

||

|

-20°C to +100°C for models rated as category 2 equipment |

||

Polypropylene: A thermoplastic polymer. Moderate tensile |

180°F |

32°F |

and flex strength. Resists stong acids and alkali. Attacked by |

82°C |

0°C |

chlorine, fuming nitric acid and other strong oxidizing agents. |

|

|

PVDF: (Polyvinylidene Fluoride) A durable fluoroplastic with |

250°F |

0°F |

excellent chemical resistance. Excellent for UV applications. |

121°C |

-18°C |

High tensile strength and impact resistance. |

|

|

Santoprene®: Injection molded thermoplastic elastomer with |

275°F |

-40°F |

no fabric layer. Long mechanical flex life. Excellent abrasion |

135°C |

-40°C |

resistance. |

|

|

UHMW PE: A thermoplastic that is highly resistant to a broad |

180°F |

-35°F |

range of chemicals. Exhibits outstanding abrasion and impact |

82°C |

-37°C |

resistance, along with environmental stress-cracking resistance. |

|

|

Urethane: Shows good resistance to abrasives. Has poor |

150°F |

32°F |

resistance to most solvents and oils. |

66°C |

0°C |

Virgin PTFE: (PFA/TFE) Chemically inert, virtually impervious. |

220°F |

-35°F |

Very few chemicals are known to chemically react with PTFE; |

104°C |

-37°C |

molten alkali metals, turbulent liquid or gaseous fluorine and |

|

|

a few fluoro-chemicals such as chlorine trifluoride or oxygen |

|

|

difluoride which readily liberate free fluorine at elevated |

|

|

temperatures. |

|

|

Maximum and Minimum Temperatures are the limits for which these materials can be operated. Temperatures coupled with pressure affect the longevity of diaphragm pump components. Maximum life should not be expected at the extreme limits of the temperature ranges.

Metals:

Alloy C: Equal to ASTM494 CW-12M-1 specification for nickel and nickel alloy.

Stainless Steel: Equal to or exceeding ASTM specification A743 CF-8M for corrosion resistant iron chromium, iron chromium nickel and nickel based alloy castings for general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

For specific applications, always consult the Chemical Resistance Chart.

In addition, the ambient temperature range and the process temperature range do not exceed the operating temperature range of the applied non-metallic parts as listed in the manuals of the pumps.

sandpiperpump.com |

Model S1F Metallic • 2 |

s1fmdl1sm-rev0614

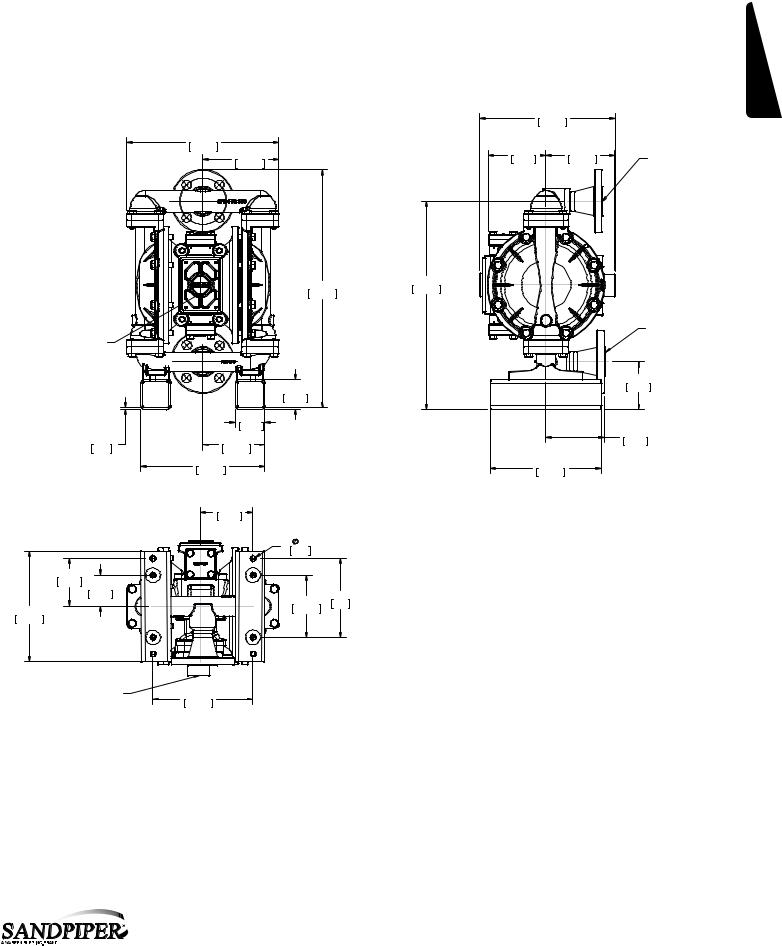

1: PUMP SPECS

Dimensional Drawings

S1F Metallic - NPT

Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm)

The dimensions on this drawing are for reference only. Acertified drawing can be requested if physical dimensions are needed.

10.25 |

9.09 |

260.35 |

|

5.13 |

230.80 |

130.18 |

DISCHARGE PORT |

|

|

|

1" NPT |

|

|

AIR INLET |

|

|

|

1/2 NPT |

|

12.88 |

|

12.03 |

|

327.09 |

|

305.56 |

|

6.40 |

1.22 |

6.39 |

|

162.43 |

162.31 |

||

30.96 |

|||

|

|

||

1" NPT EXHAUST PORT |

.41 |

|

|

10.32 |

1.63 |

||

|

|

||

|

SUCTION PORT |

41.28 |

|

|

1" NPT |

|

|

|

|

5.00 |

|

|

|

127 |

|

|

6.75 |

|

|

4X R.16 |

171.45 |

|

|

|

|

||

3.97 |

|

|

3.87 |

5.00 |

98.35 |

127 |

8.16

207.19

3• Model S1F Metallic |

sandpiperpump.com |

s1fmdl1sm-rev0614

Dimensional Drawings

S1F Metallic - ANSI Flange

Dimensions in inches (mm dimensions in brackets). Dimensional Tolerance:±1/8" (± 3mm)

The dimensions on this drawing are for reference only. Acertified drawing can be requested if physical dimensions are needed.

10.25

260.35

5.13

130.18

16.04 |

14.04 |

|

356.50 |

||

407.30 |

||

|

1" NPT EXHAUST PORT

|

|

2.00 |

|

|

|

50.80 |

|

|

|

2.00 |

|

|

|

50.80 |

|

|

.13 |

4.18 |

|

|

3.18 |

106.29 |

|

|

|

8.37 |

|

|

|

212.71 |

|

|

|

3.54 |

|

|

|

89.81 |

|

|

|

4X .38 MOUNTING HOLES |

|

|

|

9.53 |

|

3.22 |

|

|

|

81.76 |

2.09 |

|

|

|

|

|

|

|

53.18 |

4.19 |

5.31 |

|

|

135 |

|

7.44 |

|

106.43 |

|

|

|

||

188.98

AIR INLET

1/2" NPT 6.73

171.07

BOTTOM VIEW

1: PUMP SPECS

9.10

231.14

3.874.64

98.17 |

117.73 |

DISCHARGE PORT |

|

|

1" 150# ANSI RF FLANGE |

SUCTION PORT

1" 150# ANSI RF FLANGE

3.22

81.76

3.93

99.89

7.44

188.98

sandpiperpump.com |

Model S1F Metallic • 4 |

s1fmdl1sm-rev0614

Principle of Pump Operation

& OP |

Air Line |

INSTAL2: |

Discharged |

|

Fluid |

Discharge |

Suction |

Stroke |

Stroke |

Primed

Fluid

Air-Operated Double Diaphragm (AODD) pumps are powered by compressed air or nitrogen.

The main directional (air) control valve distributes compressed air to an air chamber, exerting uniform pressure over the inner surface of the diaphragm . At the same time, the exhausting air from behind the opposite diaphragm

is directed through the air valve assembly(s) to an exhaust port .

As inner chamber pressure (P1) exceeds liquid chamber pressure (P2), the rod connected diaphragms shift together creating discharge on one side and suction on the opposite side. The discharged and primed liquid’s directions are controlled by the check valves (ball or flap) orientation.

The pump primes as a result of the suction stroke. The suction stroke lowers the chamber pressure (P3) increasing the chamber volume. This results in a pressure differential necessary for atmospheric pressure (P4) to push the fluid through the suction piping and across the suction side check valve and into the outer fluid chamber .

Suction (side) stroking also initiates the reciprocating (shifting, stroking or cycling) action of the pump. The suction diaphragm’s movement is mechanically pulled through its stroke. The diaphragm’s inner plate makes contact with an actuator plunger aligned to shift the pilot signaling valve. Once actuated, the pilot valve sends a pressure signal to the opposite end of the main directional air valve, redirecting the compressed air to the opposite inner chamber.

SUBMERGED ILLUSTRATION

MUFFLER

1" DIAMETER AIR LIQUID EXHAUST PIPING LEVEL

SUCTION

LINE

Pump can be submerged if the pump materials of construction are compatible with the liquid being pumped. The air exhaust must be piped above the liquid level. When the pumped product source is at a higher level than the pump (flooded suction condition), pipe the exhaust higher than the product source to prevent siphoning spills.

5• Model S1F Metallic |

sandpiperpump.com |

s1fmdl1sm-rev0614

Loading...

Loading...