SANDPIPER PULSE OUTPUT KIT User Manual

SERVICE AND OPERATING MANUAL

PULSE OUTPUT KIT

Design Level 5

WARNING!

WARNING!

Pulse Output Interface Kits cannot be

used if pump is to be submerged.

Pulse Output Interface

The Pulse Output Interface Kits are designed for easy field installation. The Kits are also available factory-installed on new pumps. The Pulse Output Interface Kit mounts on the pump and provides electrical pulses to operate the Warren Rupp Batch Control/Stroke Counter, or a customer-supplied control. The unit creates an electrical interface between the control and the air-powered pump. Pulse Output Kits can be purchased separately, for use in applications where a process controller is already present in a system. This provides a direct interface with the pump and the customer’s system.

Operation

Each pump stroke generates a signal through a proximity sensor (PNP) on either end of the air valve. As the air valve reciprocates back and forth during pump operation, targets on either end of the spool activate their respective proximity sensors. Each sensor signals the control to register one count on the stroke counter / batch control unit. This method provides a positive signal for every pump stroke, but with very few wearing parts.

Connecting a Factory-Installed Kit

Pulse Interface Kits are available factory-installed on new SANDPIPER and MARATHON diaphragm pumps. When installing, always refer to the service manual for pump installation and operation recommendations. After installing the pump, connect the interface to the control source. To connect the interface to the control source:

•

•

Install input cable according to the wiring diagram for your specific interface kit. Connect to Warren Rupp Batch Controller or existing system control.

Field Installation of Kit

Before adding an interface kit to an existing SANDPIPER or MARATHON pump, verify the compatibility of the pump model, kit number and voltage being used. A complete listing appears on page 3

Field Installation

•Remove the main air valve body assembly and gasket.

•Install the Pulse Output Kit,and pulse output pump adapter kit tighten and torque the screws according to the pump service manual instructions.

•Refer to the applicable wiring diagram when connecting to control source.

Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Mansfield, Ohio 44902 USA

Telephone (419) 524-8388 • Fax (419) 522-7867 • www.warrenrupp.com

pokdl5sm-rev0614 |

©Copyright 2014 Warren Rupp, Inc. All rights reserved. |

Replacing Proximity Sensors

• |

Shift the main air valve spool toward the sensor being replaced. |

CAUTION! |

• |

Lock the spool in place by inserting the safety clip |

Safety clip locks pump for |

|

(included in the kit) through the small hole of the opposite end cap. |

security or service. Pump |

• |

will NOT operate with safety |

|

Disconnect the sensors from terminal junction. |

clip in place. |

•Loosen the hex nut holding the proximity sensor in place.

•Remove the sensor from the end cap. Install the replacement sensor.

•Set the clearance between the sensor and the actuator pin to .015" (.38mm), using a feeler gauge or shim stock. The gauge or shim stock should slide freely, while making contact.

•Tighten the hex nut provided with the replacement proximity sensor to lock in place.

•Reattach terminal juction to proximity sensor

•Remove the safety clip from the end cap. The pump is now ready for use.

Pump Selection & Installation

Air-operated, double diaphragm pumps (AODD) are semi-positive displacement pumps designed with flexible diaphragms.

AODD have successfully been applied in metering and batching applications where system design allows for minimal variation of:

•Air Inlet Pressure

•Suction Head/Lift

•Discharge Head

•Pump Speed (Stroke Rate)

•Product Viscosity

•NPSH(a)

Variations of any of the above can result in variable, volumetric displacement per pumping stroke which normally holds to

+/- 1% to 3% repeatability. To verify actual displacement in your application, it is essential to follow a calibration procedure. This allows the batch control to be set for the actual average displacement per pump stroke. The larger the calibration volume, the more precise the average.

Sizing

Follow the normal pump sizing procedures using published data. DO NOT OVERSIZE THE PUMP. Select the smallest pump suitable for your use to ensure greater accuracy. The batch size from a SANDPIPER pump will be within +/- one stroke.

Installation

To ensure consistent repeating of the batch size, keep the suction piping short, straight, simple, and as large a diameter as is practical.

Differential pressure across the check valves of the pump will insure that the check valves seat properly and consistently. Discharge pressure must always be greater than the suction pressure in the application.

For consistent fluid displacement and system accuracy it is mandatory to keep the discharge line full of product from the pump to the point of discharge. A one-way check valve installed in the end of the discharge line will accomplish this.

In suction lift applications the pump must be kept primed at all times. Suction lift must be kept to a minimum and a foot valve may be required in the suction line to keep the pump primed.

In flooded suction applications a back pressure device located in the discharge line may be required to insure sufficient differential pressure across the pump check valves. The one-way check valve mentioned above may provide sufficient back pressure to properly seat the pump check valves although additional means may be necessary in some applications.

Install an air line pressure regulator. This ensures a constant air pressure feed to the pump eliminating low to peak usage pressure spikes which will increase and or decrease the stroke rate of the pump resulting in variable (non-controlled) flow.

pokdl5sm-rev0614 |

Pulse Output Kit Page 2 |

IMPORTANT

Pulse Output Interface Kit Selection Instructions

Step 1 |

Determine the required system voltage and |

|

then chose one of the three Pulse Output |

|

Kits from Table 1. Each kit will include |

|

Proximity Sensor, Field Connector, and |

|

Terminal Junction |

Step 2 |

Determine the pump model being used and |

|

then choose the required Pulse Output |

|

Adapter Kit from Table 2. Each Kit include |

|

all parts required for field installation of kit, |

|

which may include Air Valve Assembly, |

|

Gaskets, Spacer Plate, and/or Hardware |

Step 3 |

Order the combination of the Pulse Output |

|

Kit and the Pulse Output Adapter Kit |

|

together to successfully field install a Pulse |

|

Output Interface. |

Note: |

When ordering a pump with a factory |

|

installed Pulse Output interface refer to |

|

Pump and Assecories Price Sheet for |

|

proper pump model number |

Assembly Notes

Pulse Output Adapter Kits do not not require an Adapter Kit to install Pulse Output kits to that particular pump. Order only the appropriate Pulse Output Kit (See Table 1)

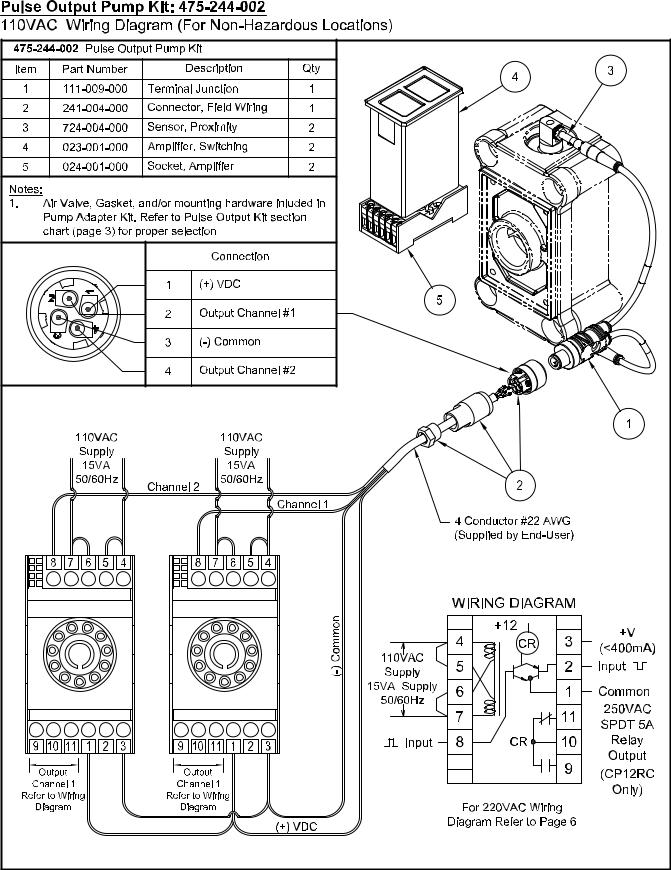

Table 1

Pulse Output Kits

|

|

System Voltage |

|

Kit Number |

Comment |

|

Standard 10-30VDC |

|

|

|

475-244-001 |

Refer to Page 4 |

|

Standard 110VAC |

|

|

|

475-244-002 |

Refer to Page 5 |

|

Standard 220VAC |

|

|

|

475-244-002 |

Refer to Page 6 |

|

Intrinsically Safe 10-30VDC, 110VAC, & 220VAC |

|

475-244-003 |

Refer to Page 7 |

|||

Table 2 |

|

|

|

|

|

|

|

|

|

Pulse Output Adapter Kits |

|

||

Pump Class |

|

Size |

Pump Model |

Kit Number |

Comment |

|

|

|

1/4" |

PB1/4-A / MP01P |

|

475-245-001 |

Refer to Page 8 |

|

|

1/2" |

S05 / M05 |

|

475-245-002 |

Refer to Page 9 |

|

|

3/4" |

S07 / M07 |

|

475-245-002 |

Refer to Page 9 |

Standard Duty |

|

1" |

S10 / M10 |

|

475-245-002 |

Refer to Page 9 |

Non-Metallic |

|

S1F / M1F |

|

475-245-003 |

Refer to Page 10 |

|

|

|

|

||||

|

|

1 1/2" |

S15 / M15 |

|

475-245-003 |

Refer to Page 10 |

|

|

2" |

S20 / M20 |

|

475-245-003 |

Refer to Page 10 |

|

|

3" |

S30 / M30 |

|

475-245-003 |

Refer to Page 10 |

|

|

1/2" |

S05 / M05 |

|

475-245-002 |

Refer to Page 9 |

Standard Duty |

|

1" |

S1F / M1F |

|

475-245-003 |

Refer to Page 10 |

|

1 1/2" |

S15 / M15 |

|

475-245-003 |

Refer to Page 10 |

|

Metallic |

|

|

||||

|

2" |

S20 / M20 |

|

475-245-003 |

Refer to Page 10 |

|

|

|

|

||||

|

|

3" |

S30 / M30 |

|

475-245-003 |

Refer to Page 10 |

Pump Class |

|

Size |

Pump Model |

Mid-Section |

Kit Number |

Comment |

|

|

1" |

SB1 / SB25 |

|

475-245-004 |

Refer to Page 11 |

|

|

1 1/2" |

HDB1 1/2 / HDB40 |

Aluminum |

475-245-005 |

Refer to Page 12 |

|

|

Cast Iron |

475-245-006 |

Refer to Page 13 |

||

|

|

|

|

|||

Heavy Duty Ball |

|

2" |

HDB2 |

Aluminum |

475-245-005 |

Refer to Page 12 |

|

|

Cast Iron |

475-245-006 |

Refer to Page 13 |

||

|

|

|

|

|||

|

|

3" |

HDB3 |

|

475-245-007 |

Refer to Page 14 |

|

|

4" |

HDB4 |

|

475-245-007 |

Refer to Page 14 |

|

|

1" |

HDF1 / HDF25 |

|

475-245-004 |

Refer to Page 11 |

|

|

2" |

HDF2 |

Aluminum |

475-245-005 |

Refer to Page 12 |

|

|

Cast Iron |

475-245-006 |

Refer to Page 13 |

||

|

|

|

|

|||

Heavy Duty Flap |

|

3" |

HDF3-M |

|

475-245-007 |

Refer to Page 14 |

|

|

HDF3-A |

|

475-245-008 |

Refer to Page 15 |

|

|

|

|

|

|||

|

|

4" |

HDF4-M |

|

475-245-007 |

Refer to Page 14 |

|

|

HDF4-A |

|

475-245-008 |

Refer to Page 15 |

|

|

|

|

|

|||

|

|

1" |

ST1 / ST25 |

|

|

Refer to Note 1 |

|

|

ET1-M / MP04D |

|

|

Refer to Note 1 |

|

|

|

|

|

|

||

|

|

|

ET1 1/2-SM / MP05D |

|

|

Refer to Note 1 |

Containment Duty |

|

1 1/2" |

ET1 1/2-M / MP07D |

|

|

Refer to Note 1 |

|

|

|

ST1 1/2 / ST40 |

|

475-245-009 |

Refer to Page 15 |

|

|

2" |

ET2-M / MP08D |

|

|

Refer to Note 1 |

|

|

3" |

ET3-M / MP12D |

|

|

Refer to Note 1 |

|

|

|

MSB2 |

|

475-245-005 |

Refer to Page 12 |

|

|

2" |

MSA2 |

|

475-245-005 |

Refer to Page 12 |

Special Duty |

|

|

W09-2 |

|

|

Refer to Note 1 |

|

3" |

W09-3 |

|

|

Refer to Note 1 |

|

|

|

|

|

|||

|

|

W15-3 |

|

|

Refer to Note 1 |

|

|

|

|

|

|

||

|

|

4" |

W15-4 |

|

|

Refer to Note 1 |

pokdl5sm-rev0614 |

Pulse Output Kit Page 3 |

pokdl5sm-rev0614 |

Pulse Output Kit Page 4 |

pokdl5sm-rev0614 |

Pulse Output Kit Page 5 |

pokdl5sm-rev0614 |

Pulse Output Kit Page 6 |

Loading...

Loading...