SANDPIPER PB 1-4 User Manual

SERVICE & OPERATING MANUAL

Original Instructions

Model PB¼

Type 3

Air-Operated

Double Diaphragm Pump

See pages 2, 13 and 14 for ATEX ratings.

Table of Contents |

|

Engineering Data and Temperature Limitations |

.....................1 |

Performance Curve................................................................ |

1 |

Explanation of Pump Nomenclature....................................... |

2 |

Dimensions............................................................................ |

3 |

Metric Dimensions.................................................................. |

4 |

Principle of Pump Operation.................................................. |

5 |

Check Valve Servicing........................................................... |

5 |

Diaphragm Servicing.............................................................. |

5 |

Troubleshooting..................................................................... |

6 |

Warranty................................................................................. |

6 |

Recycling................................................................................ |

6 |

Important Safety Information.................................................. |

6 |

Material Codes....................................................................... |

7 |

Installation Guide................................................................... |

7 |

Composite Repair Parts Drawing........................................... |

8 |

Available Service and Conversion Kits.................................. |

8 |

Composite Repair Parts List.................................................. |

9 |

Grounding the Pump.............................................................. |

9 |

Solenoid Shifted Option Drawing......................................... |

10 |

Solenoid Shifted Air Valve Parts List.................................... |

10 |

Solenoid Shifted Options...................................................... |

11 |

Solenoid Connector Drawing............................................... |

11 |

CE Declaration of Conformity - Machinery........................... |

12 |

CE Declaration of Conformity - ATEX.................................. |

13 |

Explanatiion of ATEX Markings............................................ |

14 |

Wa rre n Rupp , Inc . , • A Uni t o f ID E X |

Corpo ratio n • 8 0 0 N . Ma i n St . , Mans f iel d , Oh i o 4 4 90 2 U S A |

Telephone (419) |

524-8388 • Fax (419) 522-7867 • warrenrupp.com |

pb025nmdl3sm-rev0614

Quality System

ISO 9001 Certified

Environmental Management System ISO

14001 Certified

See pages 2, 13 and 14 for ATEX ratings.

Model PB¼

Type 3

Air-Operated

Double Diaphragm Pump

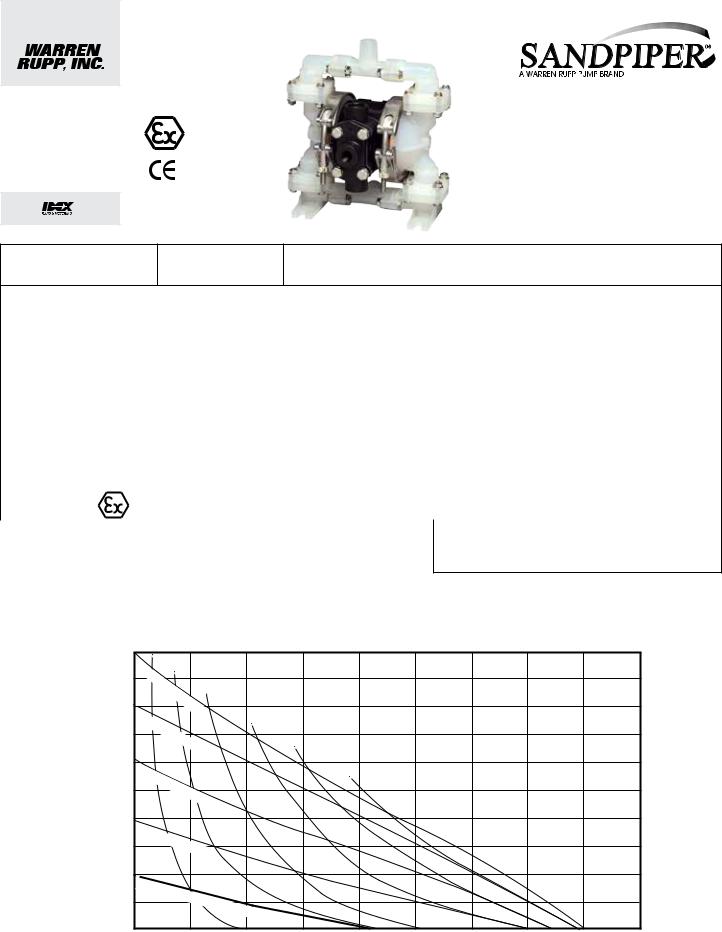

Engineering, Performance

& Construction Data

INTAKE/DISCHARGE PIPE SIZE

¼" NPT (internal) ½" NPT (external)

CAPACITY

0 to 4 gallons per minute (0 to 15 liters per minute)

AIR VALVE |

SOLIDS-HANDLING |

HEADS UP TO |

DISPLACEMENT/STROKE |

No-lube, no-stall |

Up to 1/32" (1mm) |

100 psi or 231 ft. of water |

.01 US Gallons / .04 liters |

design |

|

(7 bar or 70 meters) |

|

|

|

|

|

CAUTION! Operating temperature limitations are as follows: |

Operating Temperatures |

||

Materials |

|||

Maximum |

Minimum |

||

Santoprene® Injection molded thermoplastic elastomer with no fabric layer. Long mechanical flex life. |

275°F |

-40°F |

|

Excellent abrasion resistance. |

135°C |

-40°C |

|

Hytrel®: Good on acids, bases, amines and glycols at room temperatures only. |

220°F |

-20°F |

|

|

104°C |

-29°C |

|

Virgin PTFE Chemically inert, virtually impervious. Very few chemicals are known to react chemically |

220°F |

-35°F |

|

with PTFE: molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such |

|||

104°C |

-37°C |

||

as chlorine trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures. |

|||

|

|

|

|

PVDF |

250°F |

0°F |

|

|

121°C |

-18°C |

|

Polypropylene |

180°F |

32°F |

|

|

82°C |

0°C |

|

Conductive Acetal |

190°F |

-20°F |

|

|

88°C |

-29°C |

|

For specific applications, always consult the Warren Rupp “Chemical Resistance Chart”

CAUTION: Nonmetallic pumps and plastic components are not UV stabilized. Ultraviolet radiation can damage these parts and negatively affect material properties. Do not expose to UV light for extended periods of time.

Maximum and Minimum Temperatures are the limits for which these materials can be operated. Temperatures coupled with pressure affect the longevity of diaphragm pump components. Maximum life should not be expected at the extreme limits of the temperature ranges.

HEAD

BAR |

|

PSI |

|

7 |

|

100 |

|

|

|||

6 |

90 |

||

|

|

||

80 |

|||

|

|||

5 |

|

|

|

70 |

|||

|

|||

4 |

|

60 |

|

50 |

|||

|

|||

3 |

|

|

|

40 |

|||

|

|||

2 |

|

30 |

|

|

|||

1 |

20 |

||

|

|

||

10 |

|||

|

|||

0 |

|

|

|

0 |

|||

|

|||

Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions.

The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%. 1(1.7) AIR CONSUMPTION SCFM (M3/hr)

100 |

2(3.4) |

|

||

PSI |

|

3(5.1) |

||

|

|

(6 |

||

|

|

|

|

|

|

|

|

. |

|

|

|

|

8 |

|

80 |

|

|

Bar) |

|

PSI (5. |

|

|||

|

|

|||

|

|

|

44 |

Bar) |

|

|

|

|

|

60 |

|

PSI (4. |

|

|

|

|

|

||

|

|

|

08 |

Bar) |

|

|

|

|

|

4(6.8)

5(8.5)

6(10.2)

40 |

PSI (2. |

|

|

|

|

|

72 |

Bar) |

|

|

|

20 |

PSI |

|

|

(1.36 |

Bar) |

|

|

Air |

|

|

Inlet |

|

|

Pressure |

0 |

.5 |

1.0 |

1.5 |

2.0 |

|

2.5 |

|

3.0 |

|

3.5 |

|

4.0 |

4.5 |

||||||

|

|

|

|

|

|

|

U.S. Gallons per minute |

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

2 |

4 |

6 |

8 |

10 |

12 |

14 |

|

16 |

|

|||||||||

Liters per minute

(SANDPIPER® pumps are designed to be powered only by compressed air)

pb025nmdl3sm-rev0614 |

Page 1 |

Explanation of Pump Nomenclature

MATERIALS OF CONSTRUCTION

To order a pump or replacement parts, first enter the Model Number PB1/4, followed by the Type Designation listed below in the far left column.

PB¼ |

|

Outer |

Outer |

Inner |

Intermediate |

Diaphragm |

Hardware |

Valve |

Diaphragm |

Ball Valve |

Air |

Cap |

Options |

Shipping |

Manifold |

Diaphragm |

Diaphragm |

Weight |

|||||||||||

|

|

Chamber |

Plate |

Plate |

Housing |

Rod |

|

Seat |

|

Material |

Valve |

|

|

(lbs.) |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TS3PP. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

PP* |

PP* |

- |

4 |

TU3PP. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

T |

PP* |

PP* |

- |

4 |

TT3PP. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

T |

T |

PP* |

PP* |

- |

4 |

TS3K. |

K |

K |

K |

2011-AL |

PP* |

416SS |

301/302SS |

K |

S |

S |

PP* |

PP* |

- |

5 |

TU3K. |

K |

K |

K |

2011-AL |

PP* |

416SS |

301/302SS |

K |

S |

T |

PP* |

PP* |

- |

5 |

TT3K. |

K |

K |

K |

2011-AL |

PP* |

416SS |

301/302SS |

K |

T |

T |

PP* |

PP* |

- |

5 |

TS3CA. |

CA |

CA |

CA |

2011-AL |

CA* |

416SS |

301/302SS |

AC |

S |

S |

CA* |

CA* |

- |

4 |

TU3CA. |

CA |

CA |

CA |

2011-AL |

CA* |

416SS |

301/302SS |

AC |

S |

T |

CA* |

CA* |

- |

4 |

TT3CA. |

CA |

CA |

CA |

2011-AL |

CA* |

416SS |

301/302SS |

AC |

T |

T |

CA* |

CA* |

- |

4 |

TS3PPE0. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E0 |

4 |

TS3PPE1. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E1 |

4 |

TS3PPE2. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E2 |

4 |

TS3PPE3 |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E3 |

4 |

TS3PPE4. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E4 |

4 |

TS3PPE5. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E5 |

4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TS3PPE6. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E6 |

4 |

TS3PPE7. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E7 |

4 |

TS3PPE8. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E8 |

4 |

TS3PPE9. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

E |

PP* |

E9 |

4 |

TS3PPP0. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

PP |

PP* |

P0 |

4 |

TS3PPP2. |

PP |

PP |

PP |

2011-AL |

PP* |

416SS |

301/302SS |

PP |

S |

S |

PP |

PP* |

P2 |

4 |

Horizontal suction and vertical discharge are standard. All combinations of suction and discharge are available.

Meanings of Abbreviations:

AC = Acetal |

Kit Options |

E4.= Solenoid Kit w/110VAC Coil |

|

AL = Aluminum |

00.= None |

E5.= Solenoid Kit w/110VAC |

|

CA = Conductive Acetal** |

P0.= 10-30VDC Pulse Output Kit |

Explosion-Proof Coil |

|

K |

= PVDF |

P2.= 110/120 or 220/240VAC |

E6.= Solenoid Kit w/220VAC Coil |

PP = Polypropylene |

Pulse Output Kit |

E7.= Solenoid Kit w/220VAC |

|

SS = Stainless Steel |

E0.= Solenoid Kit w/24VDC Coil |

Explosion-Proof Coil |

|

T |

= PTFE |

E1.= Solenoid Kit w/24VDC |

E8.= Solenoid Kit with 110VAC, 50 Hz |

S |

= Santoprene |

Explosion-Proof Coil |

Explosion-Proof Coil |

R |

= Hytrel |

E2.= Solenoid Kit w/24VAC/12VDC Coil |

E9.= Solenoid Kit with 230VAC, 50 Hz |

|

|

E3.= Solenoid Kit w/12VDC Coil |

Explosion-Proof Coil |

|

|

Explosion-Proof |

SP.= Stroke Indicator Pins |

ATEX Compliant ONLY with no options.

ATEX Compliant ONLY with no options.

*Designates Glass Filled

**Note: Only Conductive Acetal equipped pumps with no options are ATEX compliant

Conductive Acetal Models equipped with Integral Mufflers:

II 2 G c T5

II 3/2 G c T5

II 2 D c T100 C

I M2 c

Conductive Acetal Models equipped with a metal muffler:

II 1 G c T5

II 3/1 G c T5

II 1 D c T100 C

I M1 c

Ambient temperature range |

-20 C to +40 |

C |

Process temperature range |

-20 C to +80 |

C for models rated as category 1 equipment |

|

-20 c to +100 C for model rated as category 2 equipment |

|

In addition, the ambient temperature range and the process temperature range do not exceed the operating temperature range of the applied non-metallic parts as listed in the manuals of the pumps.

pb025nmdl3sm-rev0614 |

Page 2 |

Dimensions: PB¼ Non-Metallic

Dimension |

A |

B |

C |

Standard |

7" |

3 1/8" |

5 1/2" |

|

|

|

|

Pulse Output Kit |

7" |

3 1/8" |

5 1/2" |

pb025nmdl3sm-rev0614 |

Page 3 |

Loading...

Loading...