Page 1

Dual Fuel Range

Installation manual

NY63*875**

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 1 2020-03-27 11:10:00

Page 2

Contents Contents

WARNING

If the information in this manual is not followed exactly, a re or

explosion may result causing property damage, personal injury or death.

• DO NOT store or use gasoline or other ammable vapors and liquids

Before you begin 3

in the vicinity of this or any other appliance.

Contents

• WHAT TO DO IF YOU SMELL GAS:

Important safety information 3

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch.

- DO NOT use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the re department.

• Installation and service must be performed by a qualied installer,

service agency, or the gas supplier.

Anti-tip device

WARNING

ALL RANGES CAN TIP, RESULTING IN PERSONAL INJURY.

TIPPING RANGES CAN CAUSE BURNS FROM SPILLS, PERSONAL

INJURY, AND/OR DEATH.

INSTALL AND CHECK THE ANTI-TIP BRACKET FOLLOWING THE

INSTRUCTIONS AND TEMPLATE SUPPLIED WITH THE BRACKET.

• To prevent accidental tipping of the range, attach an approved

anti-tip device to the oor. (See Installing the Anti-Tip Device in the

Installation Instructions.) Check for proper installation by carefully

tipping the range forward. The anti-tip device should engage and

prevent the range from tipping over.

• If the range is pulled out away from the wall for any reason, make

sure the anti-tip device is reengaged after the range has been pushed

back into place.

• Follow the installation instructions found in the Installation Manual.

Failure to follow these instructions can result in death, serious

personal injury, and / or property damage.

Dual fuel range components 9

What’s in the box 9

Installation requirements 11

Location requirements 11

To avoid breakage 13

Gas requirements 14

Special gas requirements (gas models sold in Massachusetts) 14

Electrical requirements 15

Installation instructions 16

Installing your dual fuel range 16

Step 1. Unpack the range 16

Step 2. Meeting electrical connection requirements 16

Step 3. Accessing the power cord connection 17

Step 4. Installing the power cord 18

Step 5. Installing the conduit 19

Step 6. Replacing the access cover 21

Step 7. Connect the range to gas supply 21

Step 8. Convert to LP gas (optional) 22

Step 9. Install the anti-tip device 23

Step 10. Plug in and place 23

Step 11. Level the range 24

Step 12. Assemble the surface burners 24

Step 13. Check the ignition of surface burners 25

Step 14. Final installation checklist 26

• To prevent accidental tipping of the range, DO NOT step, sit, or lean

on the door or drawer.

• Be sure your appliance is properly installed and grounded by a

qualied technician.

2 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 2 2020-03-27 11:10:00

Page 3

Before you begin

Important safety information

ABOUT THIS MANUAL

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY.

IMPORTANT NOTE TO THE INSTALLER

• Read all instructions contained in these installation instructions before

installing the range.

• Remove all packing materials from the oven compartments before connecting

the electric and gas supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

• Installation of this appliance requires basic mechanical skills.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not covered under the Warranty.

IMPORTANT NOTE TO THE CONSUMER

Keep these instructions with your user manual for future reference.

• As when using any appliance generating heat, there are certain safety

precautions you should follow.

• Be sure your range is installed and grounded properly by a qualied installer

or service technician.

• Make sure the wall coverings around the range can withstand the heat

generated by the range.

• Cabinet storage space above the surface burners should be a minimum of

30 in (76.2 cm).

READ ALL INSTRUCTIONS BEFORE USING THIS

APPLIANCE

• All electrical and gas equipment with moving parts can be dangerous. Please

read the important safety instructions for this appliance in this manual. The

instructions must be followed to minimize the risk of injury, death, or property

damage.

• Save this manual. Please Do Not Discard.

SYMBOLS USED IN THIS MANUAL

WARNING

Hazards or unsafe practices that may result in severe personal injury or death.

CAUTION

Hazards or unsafe practices that may result in electric shock, personal injury, or

property damage.

NOTE

Useful tips and instructions.

These warning icons and symbols are here to prevent injury to you and others.

Please follow them explicitly. After reading this section, keep it in a safe place for

future reference.

CALIFORNIA PROPOSITION 65 WARNING

Before you begin

IMPORTANT NOTE TO THE SERVICER

The electrical diagram is in an envelope attached to the back of the range.

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 3 2020-03-27 11:10:00

WARNING

Cancer and Reproductive Harm - www.P65Warnings.ca.gov

English 3

Page 4

Important safety information

Important safety information

COMMONWEALTH OF MASSACHUSETTS

• This product must be installed by a licensed plumber or gas tter qualied

or licensed by the State of Massachusetts. When using ball-type gas shut-off

valves, you must use the T-handle type. Multiple exible gas lines must not be

connected in series.

GENERAL SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

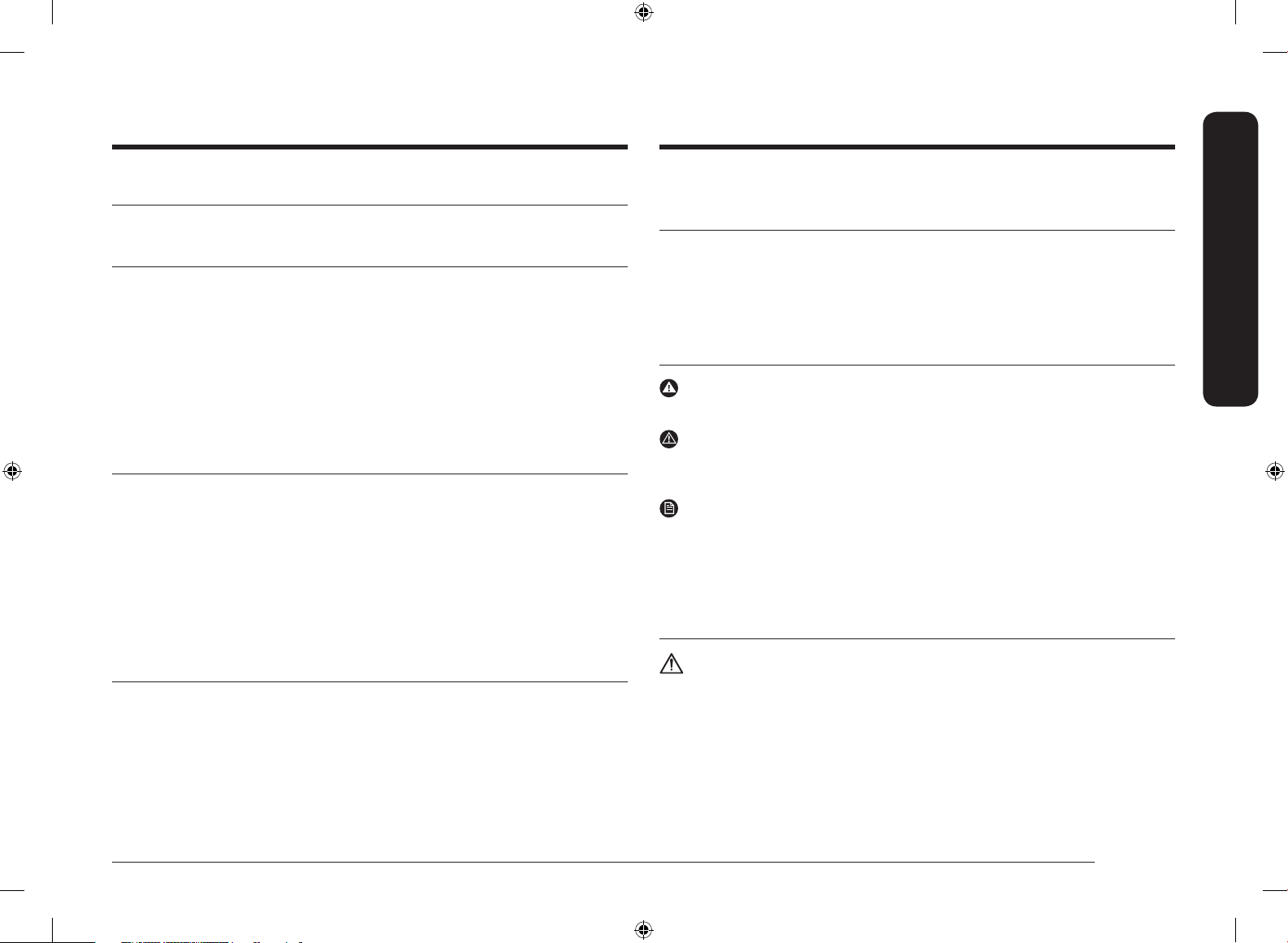

• Do not touch any part of the range,

including but not limited to, oven

burners, surface burners, or interior

surfaces during or immediately after

cooking.

• Know the location of the gas shut-off

valve and how to shut it off.

• Make sure the anti-tip device is properly installed on the range. See the

installation instructions for more information.

• Do not let children near, in, or on the range. Do not let children play with the

range or any part(s) of the range. Do not leave children unattended in an area

where the range is in use. For children’s safety, we recommend utilizing the

control/door lockout feature.

• Remove all packaging materials from the range before operating to prevent

ignition of these materials. Keep all packaging materials out of children’s

reach. Properly dispose the packaging materials after the range is unpacked.

• Do not store any object of interest to children on the cooktop or backguard

of the range. Children climbing on the range to reach items could be killed or

seriously injured.

• Do not operate the range if the range or any part of the range is damaged,

malfunctioning, or missing parts.

• Do not use the range as a space heater. This range is to be used for cooking

purposes only.

• Do not use oven cleaners or oven liners in or around any part of the oven.

• Use only dry pot holders.

• Do not use the range to heat unopened food containers.

• Do not strike the oven glass.

• When disposing of the range, cut off the power cord and remove the door.

• Unplug or disconnect power before servicing.

• Make sure all meat and poultry is cooked thoroughly. Meat should always be

cooked to an internal temperature of 160 °F (71 °C). Poultry should always be

cooked to an internal temperature of 180 °F (82 °C).

FIRE SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

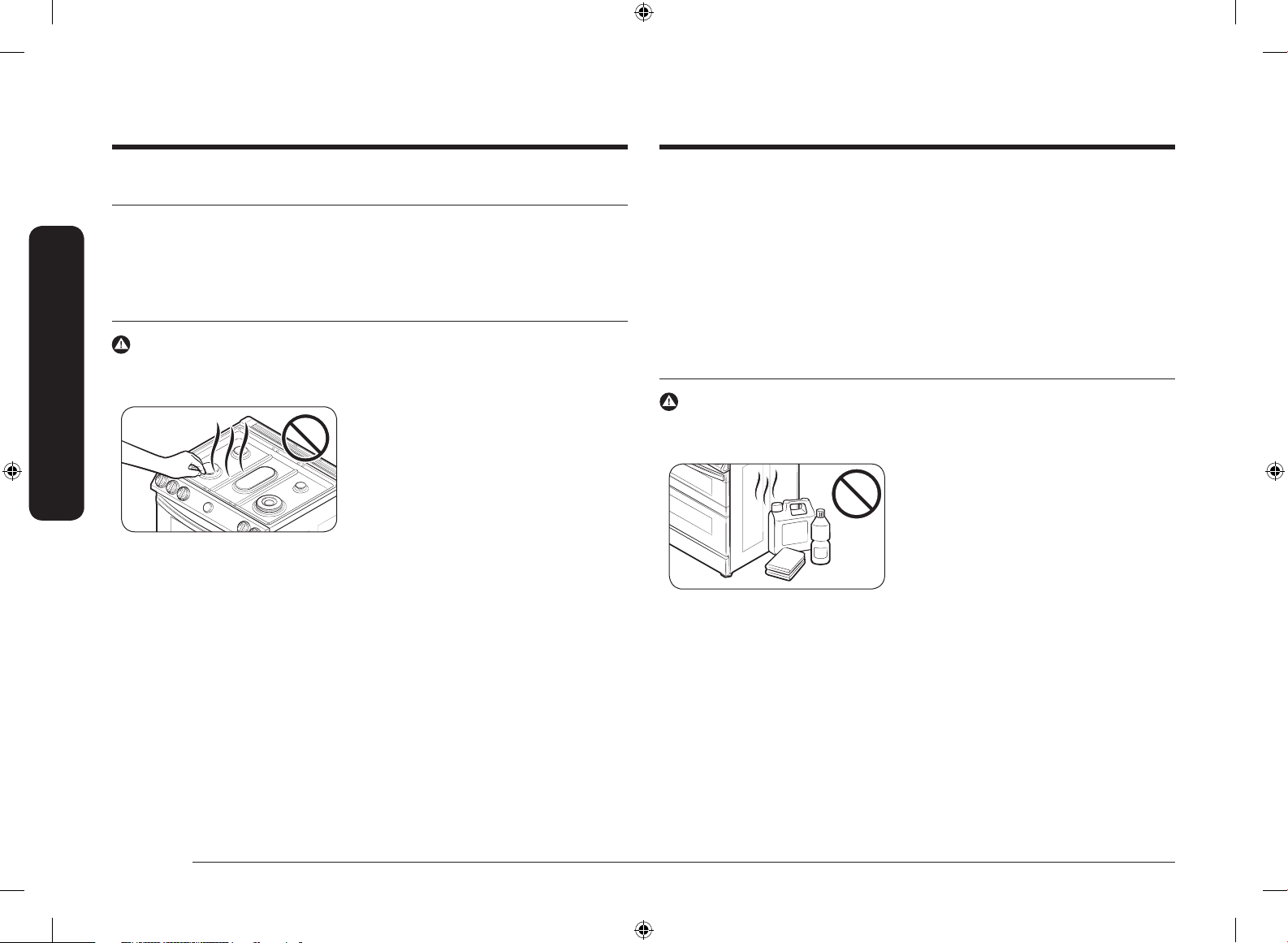

• Do not store, place, or use ammable

or combustible materials such as paper,

plastic, pot holders, linens, curtains,

gasoline or other ammable vapors or

liquids near the range.

• Do not wear loose tting or hanging

garments while using the range.

• To avoid grease buildup, regularly clean the vents.

• Do not let pot holders or other ammable materials touch a heating element.

Do not use a towel or other bulky cloths in place of a pot holder.

• Do not use water on a grease re. To put out a grease re, turn off the heat

source and smother the re with a tight-tting lid or use a multipurpose dry

chemical or foam-type re extinguisher.

• If a grease re should occur in the oven, turn off the oven by pressing the OFF

button. Keep the oven door closed until the re goes out. If necessary, use a

multipurpose dry chemical or foam-type re extinguisher.

• Do not heat unopened food containers - buildup of pressure may cause

container to burst and result in injury.

4 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 4 2020-03-27 11:10:01

Page 5

GAS SAFETY

ELECTRICAL AND GROUNDING SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

If you smell gas:

• Close the valve and do not use the range.

• Do not light a match, candle, or cigarette.

• Do not turn on any gas or electric appliances.

• Do not touch any electrical switches or plug a power cord into an outlet.

• Do not use any phone in your building.

• Evacuate the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

Checking for gas leaks

• Leak testing of the appliance shall be conducted according to the

manufacturer’s instructions. Do not use a ame to check for gas leaks. Use a

brush to spread a soapy water mixture around the area you are checking. If

there is a gas leak, you will see small bubbles in the soapy water mixture at

the leak point.

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Plug into a grounded 3-prong outlet.

• Do not remove the ground prong.

• Do not use an adapter or an extension

cord.

• Do not use a damaged power plug,

power cord, or loose power outlet.

• Do not modify the power plug, power cord, or power outlet in any way.

• Do not put a fuse in a neutral or ground circuit.

• Use a dedicated 240-volt, 60-Hz, 40-amp, AC, fused electrical circuit for this

range. A time-delay fuse or circuit breaker is recommended. Do not plug more

than one appliance into this circuit.

• Do not connect the ground wire to plastic plumbing lines, gas lines, or hot

water pipes.

• This range must be Earth grounded. In the event of a malfunction or

breakdown, grounding will reduce the risk of electrical shock by providing

a path for the electric current. This range is equipped with a cord having

a grounding plug. The plug must be rmly plugged into an outlet that is

properly installed and grounded in accordance with the local codes and

ordinances. If you are unsure whether your electrical outlet is properly

grounded, have it checked by a licensed electrician.

• Electrical service to the range must conform to local codes. Barring local

codes, it should meet the latest ANSI/NFPA No. 70 – Latest Revision (for the

U.S.) or the Canadian Electrical Code CSA C22.1 – Latest Revisions.

• It is the personal responsibility of the range owner to provide the correct

electrical service for this range.

Important safety information

English 5

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 5 2020-03-27 11:10:01

Page 6

Important safety information

Important safety information

INSTALLATION SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Have your range installed and properly

grounded by a qualied installer,

in accordance with the installation

instructions. Any adjustment and

service should be performed only by

qualied gas range installers or service

technicians.

• Do not attempt to service, modify, or replace your range or any part of your

range unless it is specically recommended in this manual. All other service

should be referred to a qualied technician.

• Always use new exible connectors when installing a gas appliance. Do not

use old exible connectors.

• Make sure the anti-tip device is properly installed on the range. See the

installation instructions for more information.

• Due to the size and weight of the range, have two or more people move the

range.

• Remove all tape and packaging materials.

• Remove all accessories from the cooktop, oven, and/or lower drawer. Grates

and griddles are heavy. Use caution when handling them.

• Make sure no parts came loose during shipping.

• Make sure your range is correctly installed and adjusted by a qualied service

technician or installer for the type of gas (natural or LP) you will use. For

your range to utilize LP gas, the installer must replace the 5 surface burner

orices and 2 oven orices with the provided LP orice set, and reverse

the GPR adapter. These adjustments must be made by a qualied service

technician in accordance with the manufacturer’s instructions and all codes

and requirements of the authority having jurisdiction. The qualied agency

performing this work assumes the gas conversion responsibility.

• Installation of this range must conform with local codes or, in the absence of

local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA.54, latest

edition. In Canada, installation must conform with the current Natural Gas

Installation Code, CAN/CGA-B149.1, or the current Propane Installation Code,

CAN/CGA-B149.2, and with local codes where applicable. This range has been

design-certied by ETL according to ANSI Z21.1, latest edition, and Canadian

Gas Association according to CAN/CGA-1.1, latest edition.

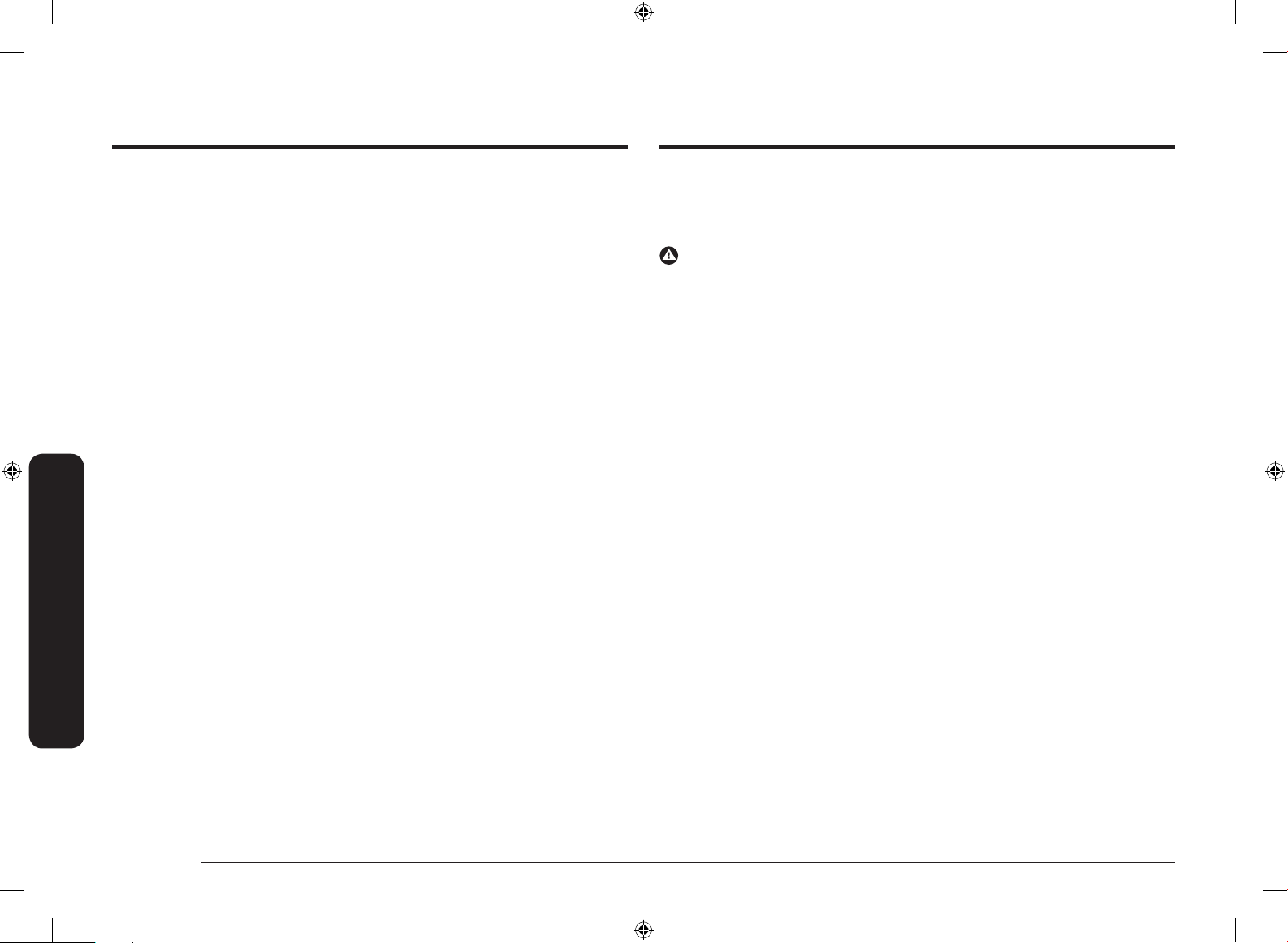

LOCATION SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• This range is for indoor, household use

only. Do not install the range in areas

exposed to the weather and/or water.

• Do not install the range in a place

which is exposed to a strong draft.

• Select a level, well-constructed oor that can support the range’s weight.

Synthetic ooring, such as linoleum, must withstand 180 °F (82 °C)

temperatures without shrinking, warping, or discoloring. Do not install

the range directly over interior kitchen carpeting unless a sheet of ¼ inch

plywood or a similar insulator is placed between the range and carpeting.

• Select a location where a grounded, 3- prong outlet is easily accessible.

• If the range is located near a window, do not hang long curtains or paper

blinds on that window.

• For the range to ventilate properly, make sure the range’s vents are not

blocked or covered, and that there is enough clearance at the top, back, sides,

and underneath the range. The vents allow the necessary exhaust for the range

to operate properly with correct combustion and get the good cooking result.

• Make sure the wall coverings around the range can withstand heat up to

194 °F (90 °C) generated by the range.

6 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 6 2020-03-27 11:10:01

Page 7

• Cabinet storage above the surface of the range should be avoided. If cabinet

storage above the range is necessary: allow a minimum clearance of 30 inches

(76.2 cm) between the cooking surface and the bottom of cabinets; or install a

range hood that projects horizontally a minimum of 5 inches (12.7 cm) beyond

the bottom of the cabinets.

COOKTOP SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Make sure all burners are off when not

in use.

• Do not use aluminium foil to line the

grates or any part of the cooktop.

• Do not leave burners unattended on

medium or high heat settings.

• Before igniting, make sure all burner caps are properly in place and all

burners are level.

• Always use the LITE position when igniting the burners and make sure the

burners have ignited. If ignition fails, turn the knob to OFF and wait until the

gas has dissipated.

• When you set a burner to simmer, do not turn the knob quickly. Make sure the

ame stays on.

• Do not place any objects other than cookware on the cooktop.

• This cooktop is designed to cook with a wok or wok ring attachment. If foods

are amed, they should only be amed under a ventilation hood that is on.

• Before removing or changing cookware, turn off the burners.

• Remove food and cookware immediately after cooking.

• Before removing any parts of the burner for cleaning, make sure the range is

off and completely cool.

• After cleaning the burner spreader, make sure it is completely dry before re-

assembling.

• Make sure the spark mark on the dual burner spreader is placed beside the

electrode when it is assembled.

• Please refer to the start guide how to install the burners.

• Checking the ame quality after installing all burner. Please refer to page 25.

• To avoid carbon monoxide poisoning, do not pour water into the cooktop well

while cleaning.

• Select cookware that is designed for top-range cooking. Use cookware that is

large enough to cover the burner grates. Adjust the burner ames so that the

ames do not extend beyond the bottom of the cookware.

• To avoid cookware discoloration, deformity, and/or carbon monoxide

poisoning, do not use cookware that is exceedingly larger than the grate.

• Make sure cookware handles are turned to the side or rear of the cooktop, but

not over other surface burners.

• Stand away from the range while frying.

• Always heat frying oils slowly, and watch as they heat. If you are frying foods

at high heat, carefully watch during the cooking process. If a combination of

fats or oils is to be used during frying, mix them together before heating.

• Use a deep-fryer thermometer whenever possible. This prevents overheating

the fryer beyond the smoking point.

• Use a minimum amount of oil when shallow pan-frying or deep-frying. Avoid

cooking unthawed food or food with excessive amounts of ice.

• Before moving cookware full of fats or oils, make sure it has completely cooled.

• To prevent delayed eruptive boiling, always allow heated liquids to stand at least

20 seconds after you have turned off the burner so that the temperature in the

liquid can stabilize. In the event of scalding, follow these rst aid instructions:

1) Immerse the scaled area in cool or lukewarm water for at least 10 minutes.

2) Do not apply any creams, oils, or lotions.

3) Cover with a clean, dry cloth.

Important safety information

English 7

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 7 2020-03-27 11:10:01

Page 8

Important safety information

Important safety information

OVEN SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Do not use the oven for non-cooking

purposes such as drying clothes or

storage. Use the oven for cooking

purposes only.

• Make sure the inner portion of the split

oven-rack is in the proper position

within the outer rack.

• Make sure the oven racks are placed on the same level on each side.

• Do not damage, move, or clean the door gasket.

• Do not spray water on the oven glass while the oven is on or just after you

have turned it off.

• Do not use aluminium foil or foil liners anywhere in the oven. Do not use

aluminium foil or like material to cover any holes or passages in the oven

bottom or to cover an oven rack.

• Stand away from the oven when opening the oven door.

• Keep the oven free from grease buildup.

• When repositioning the oven racks, make sure the oven is completely cool.

• Only use cookware that is recommended for use in gas ovens.

• To avoid damaging the burner control knobs, always bake and/or broil with

the oven door closed.

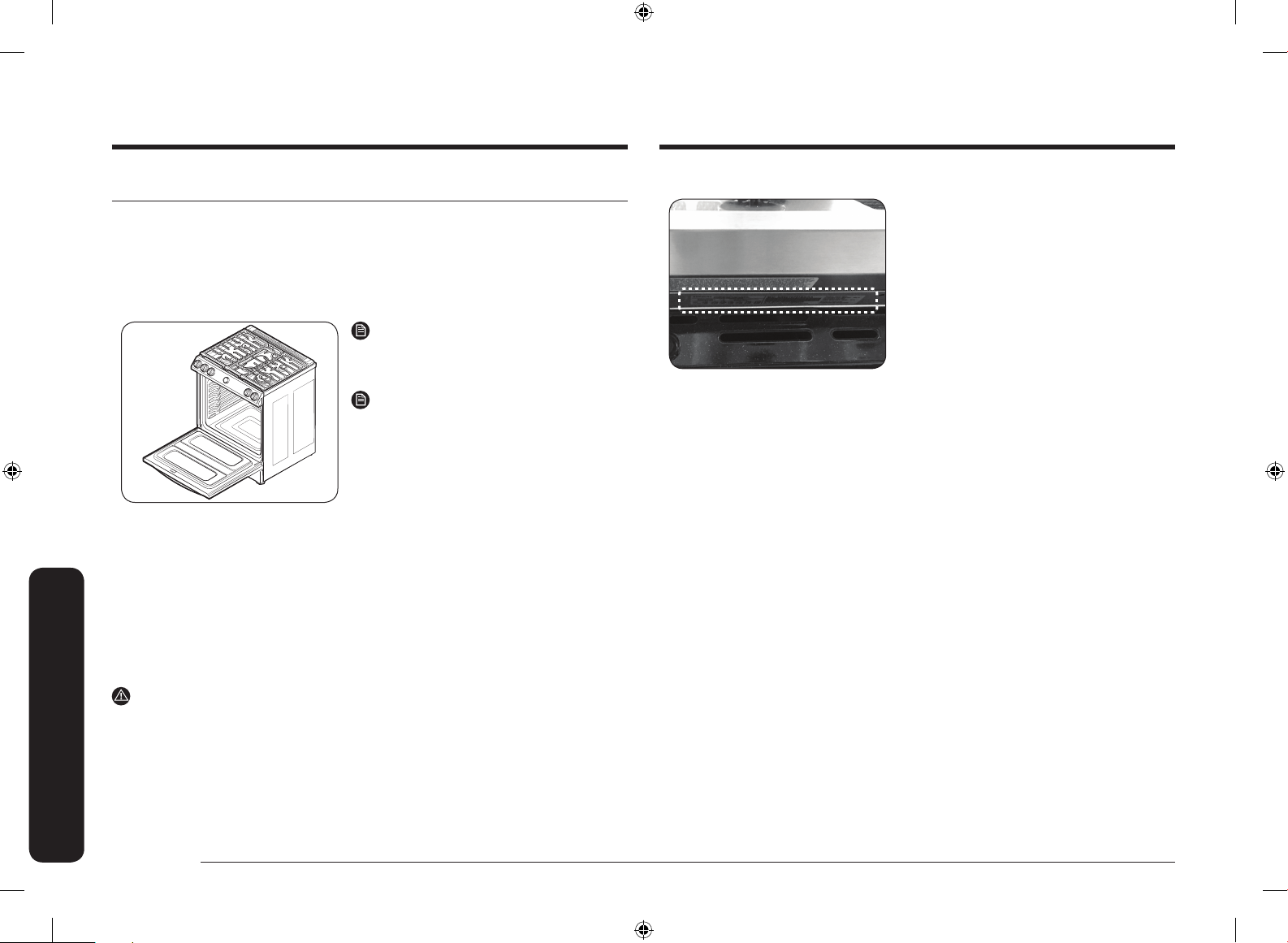

• Keep oven vent ducts unobstructed. The oven vent is located below the

control box. This area could become hot during oven use. Never block this

vent or place plastic or heat-sensitive items on it.

• When using cooking or roasting bags in the oven, follow the manufacturer’s

directions.

WARMING DRAWER SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• The warming drawer is designed to

keep hot foods at serving temperature.

Always start with hot food. Cold or

room temperature food cannot be

heated, warmed, or cooked in the

warming drawer. Bacteria will grow

very rapidly in food that is between

40 and 140 °F.

• Do not use the drawer for non-cooking purposes such as drying clothes or

storage. Use the drawer for cooking purposes only.

• Do not touch the interior drawer surface or heating element.

• To avoid steam burns, use caution when opening the drawer.

• Do not use aluminium foil to line the drawer.

• Do not use the drawer in the oven. Do not put the drawer in the oven during a

self-cleaning cycle.

• Do not leave containers of fat drippings in or near the drawer.

8 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 8 2020-03-27 11:10:01

Page 9

Dual fuel range components

SELFCLEANING OVEN SAFETY

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• The self-cleaning feature operates the

oven at temperatures high enough

to burn away food soils in the oven.

The range is extremely hot during a

self-cleaning cycle. Do not touch any

surfaces of the range during a selfcleaning cycle.

• Keep children away from the oven during a self-cleaning cycle.

• Before starting a self-cleaning cycle, remove all racks, cookware, and utensils

from the oven. Only porcelain-coated oven racks may be left in the oven.

• Before starting a self-cleaning cycle, wipe grease and food soils from the

oven.

• Do not put the lower drawer into the oven cavity when you run a self-

cleaning cycle.

• When opening the door after a self-cleaning cycle, stand away from the oven.

• If the self-cleaning cycle malfunctions, turn off the oven, disconnect the power

supply, and contact a qualied service technician.

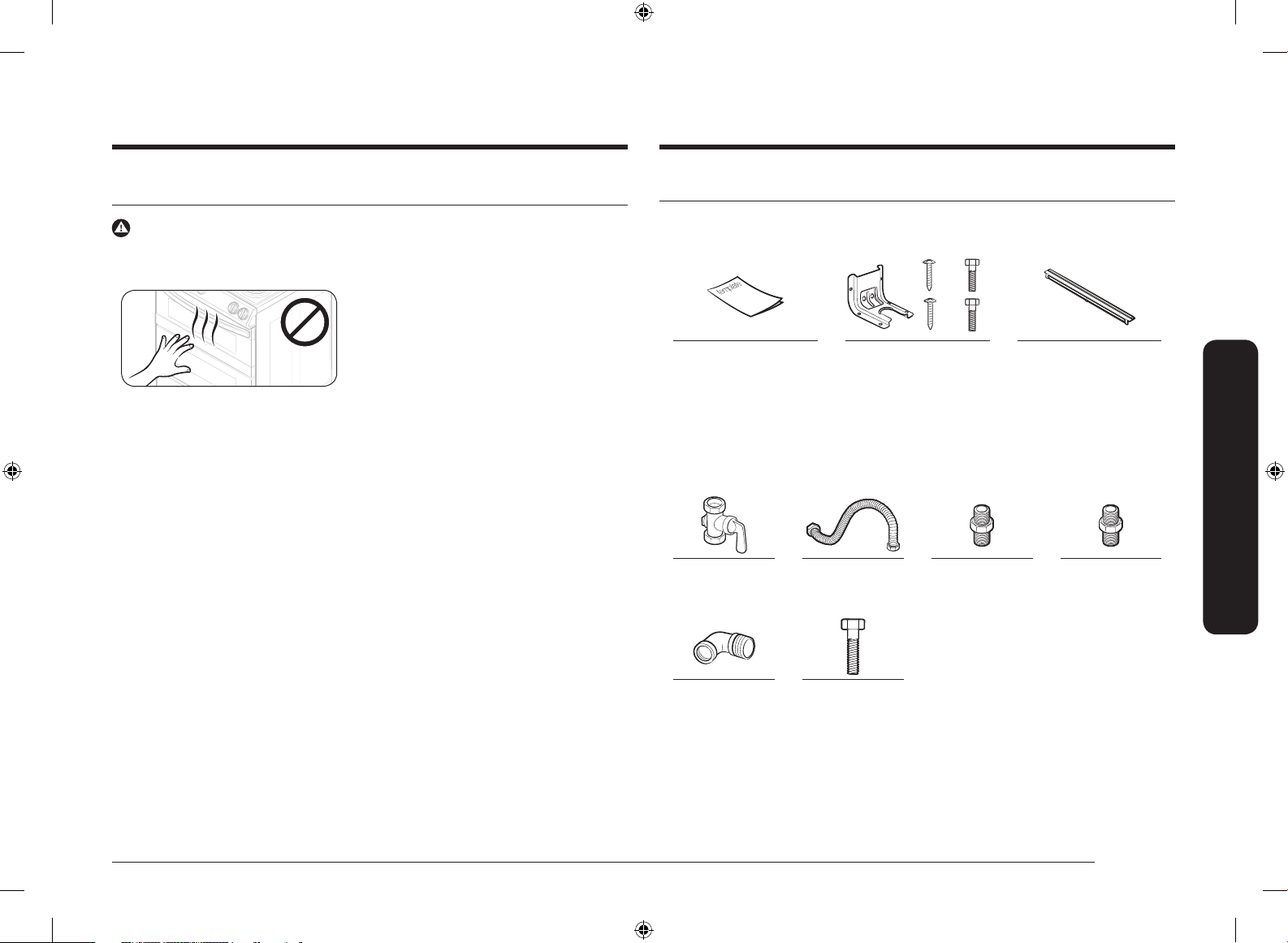

What’s in the box

Parts supplied

Template Anti Tip Bracket (1) /

Screws (4)

• Make sure you have received all of the supplied parts shown above.

• If your range was damaged during shipping or you do not have all of the

supplied parts, contact your local retailer.

Parts needed

Gas line shut-off

valve

Flexible metal

appliance connector

½ in (ID) x 5 ft

Flare union adapter

¾ in or ½ in (NPT)

x ½ in (ID)

Filler Kit (1) & Screws (2)

Flare union adapter

½ in (NPT)

x ½ in (ID)

Dual fuel range components

135-degree elbow

(optional)

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 9 2020-03-27 11:10:02

Lag bolt or ½-in

(OD) sleeve anchor

English 9

Page 10

Dual fuel range components

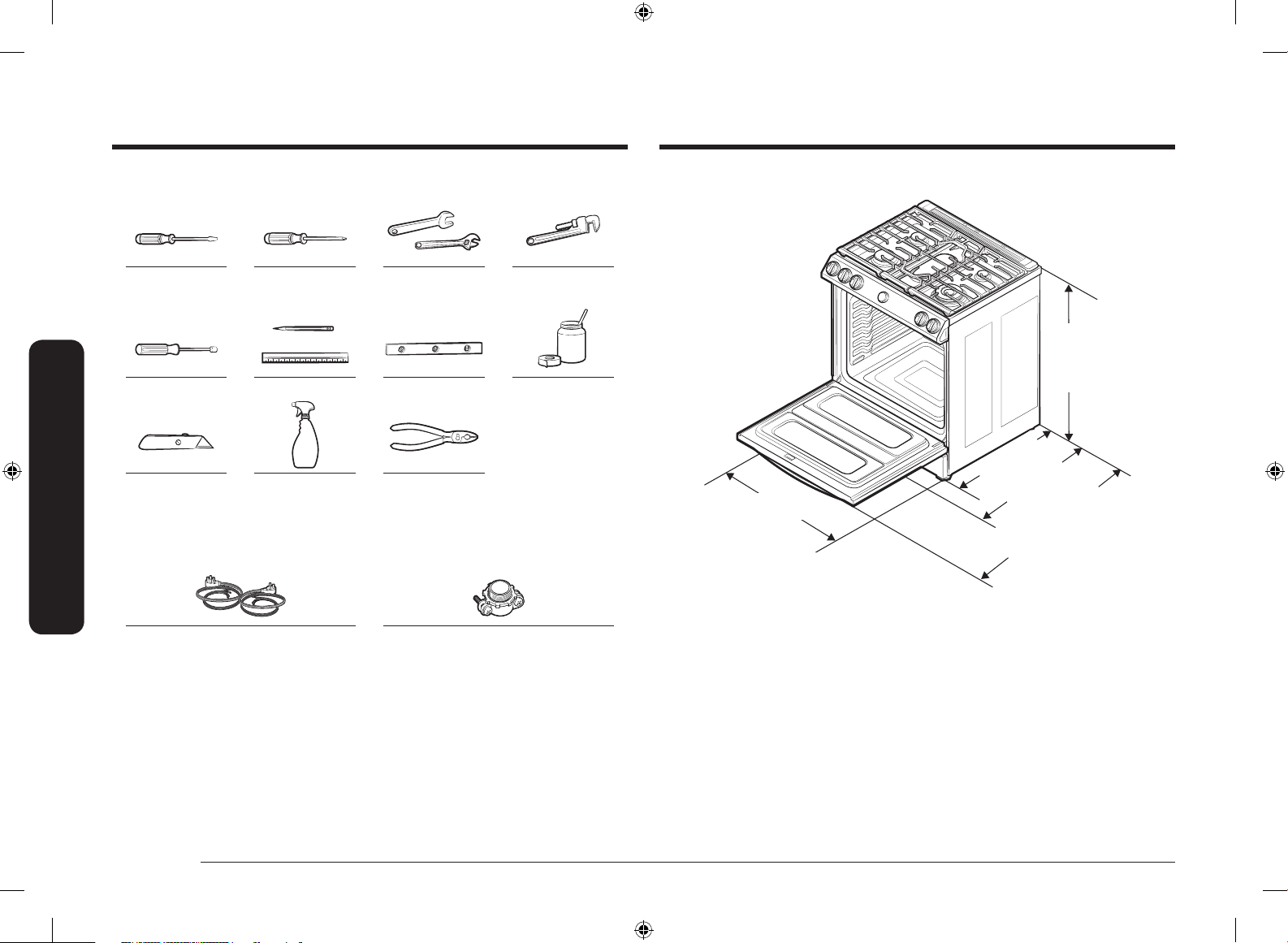

Tools needed

Flat-blade

screwdriver

Dual fuel range components

¼” Nut driver Pencil and ruler Level Pipe joint compound

Utility knife Soapy water

What’s not included

4-Wire Cord or 3-Wire Cord

(UL Approved 40 or 50 AMP)

Phillips screwdriver Open-end or

adjustable wrench

Pliers

solution

Strain Relief

(For Conduit Installation Only)

Pipe wrench (2)

2915/16 in

(761.0 mm)

in

16

7

/

26

16

/

11

(671.7 mm)

28

(728.6 mm)

With handle

in (1250.3 mm)

4

1

/

49

Door fully open

361/4 in

(921.2 mm) Min.

37 in

(939.8mm) Max.

in

* For Canada only

10 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 10 2020-03-27 11:10:04

Page 11

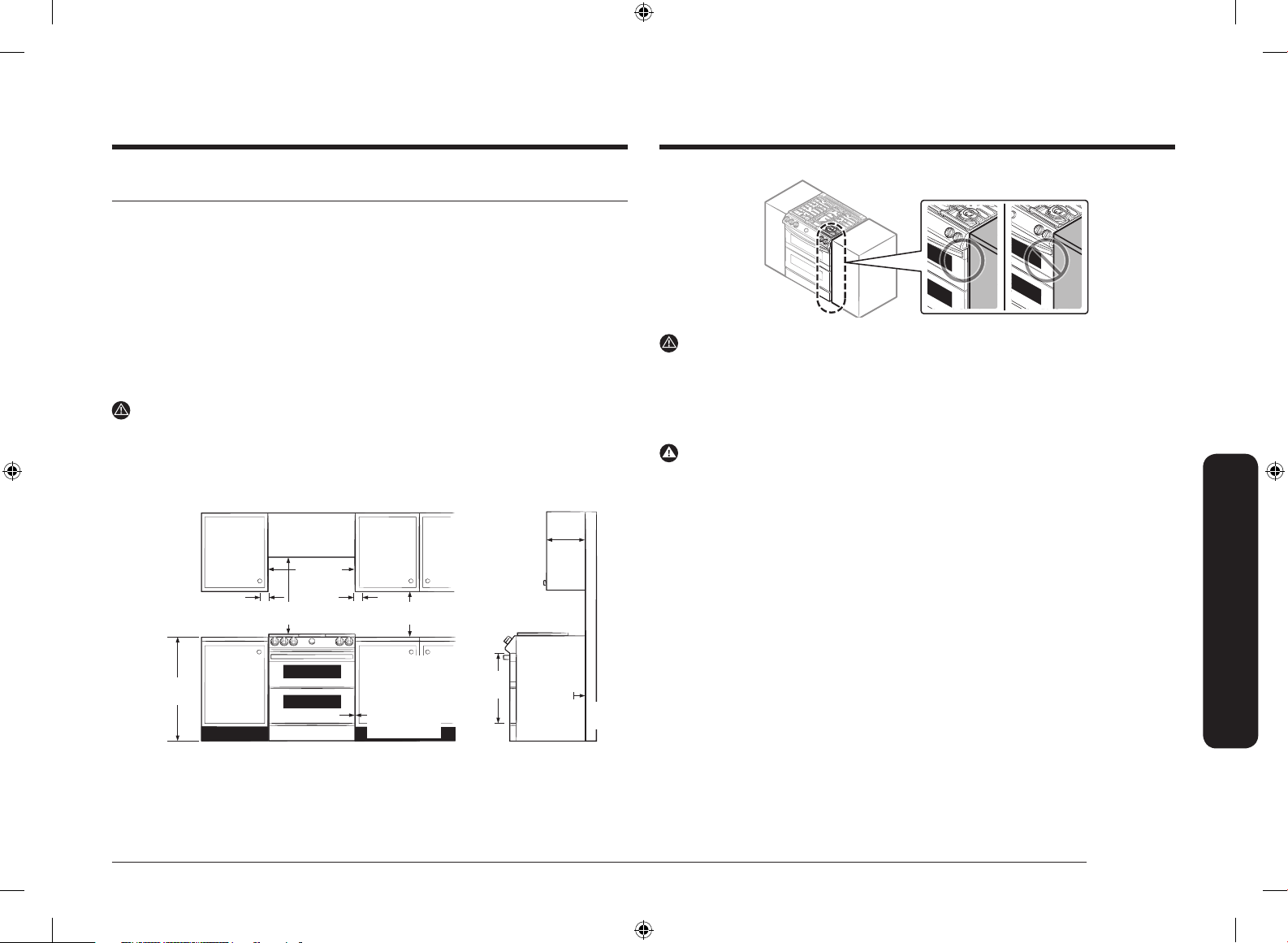

Installation requirements

Location requirements

Clearances and dimensions

BEFORE YOU BEGIN to install this appliance, refer to the following information,

dimensions, and clearances. Do not locate the range where it may be subject

to strong drafts. Provide adequate clearances between the range and adjacent

combustible surfaces. These dimensions must be met for safe use of the range.

The location of the electrical outlet and gas piping may be adjusted to meet the

following dimensions and clearances.

For installation in Canada, a free-standing range is not to be installed closer than

4.7 in (12 cm) from any adjacent surface.

CAUTION

This range has been designed to comply with the maximum allowable wood

cabinet temperature of 194 °F (90 °C). Make sure the wall covering, countertops,

and cabinets around the range can withstand the heat (up to 194 °F [90 °C])

generated by the range. If not, discoloration, delamination, or melting may occur.

Side Clearance

Above Cooking

Surface to Wall

36 in

(91.4 cm)

(10.2 cm)

24 in

(61 cm)

Lower

Cabinet

Depth

Minimum from

top of cooktop to

4 in

(76.2 cm)

cabinets

(76.2 cm)

30 in

30 in

6 in

(15.2 cm)

Below Cooking

Top and at Rear

18 in

(45.7 cm)

0 in (0 cm)

Clearance

and Sides of

Range

13 in (33 cm)

Overhead

Cabinet

Depth

24.2 in

(61.5 cm)

0 in

(0 cm)

CAUTION

DO NOT install the oven so that the door is ush with the cabinet.

For OTR over Gas Stove, please follow local GAS CODE.

Minimum dimensions

WARNING

If overhead cabinets are provided, a range hood should also be provided that

projects horizontally a minimum of 5 in (12.7 cm) beyond the front of the cabinets.

This will dissipate any heat buildup in the overhead cabinets to prevent death,

personal injury, and/or re hazard. The ventilating hood must be constructed of

sheet metal not less than 0.0122” thick. Install above the cooktop with a clearance

of not less than ¼” between the hood and the underside of the combustible

material or metal cabinet. The hood must be at least as wide as the appliance

and centered over the appliance. Clearance between the cooking surface and the

ventilation hood surface must never be less than 24 inches.

Exception 1 : Installation of a listed microwave oven or cooking appliance over the

cooktop shall conform to the installations packed with that appliance.

• 30-in (76.2-cm) minimum clearance between the top of the cooking surface

and the bottom of an unprotected wood or metal cabinet; or If no 30-in

(76.2-cm) minimum clearance, 24-in (61-cm) minimum when the bottom of

the wood or metal cabinet is protected by not less than 0.25-in (0.64-cm)

ame-retardant millboard covered with not less than no. 28 MSG sheet steel,

0.015-in (0.038-cm) stainless steel, 0.024-in (0.061-cm) aluminum, or 0.020-in

(0.051-cm) copper.

• 18-in (45.7-cm) minimum between the countertop and the adjacent cabinet

bottom.

Installation requirements

English 11

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 11 2020-03-27 11:10:04

Page 12

Installation requirements

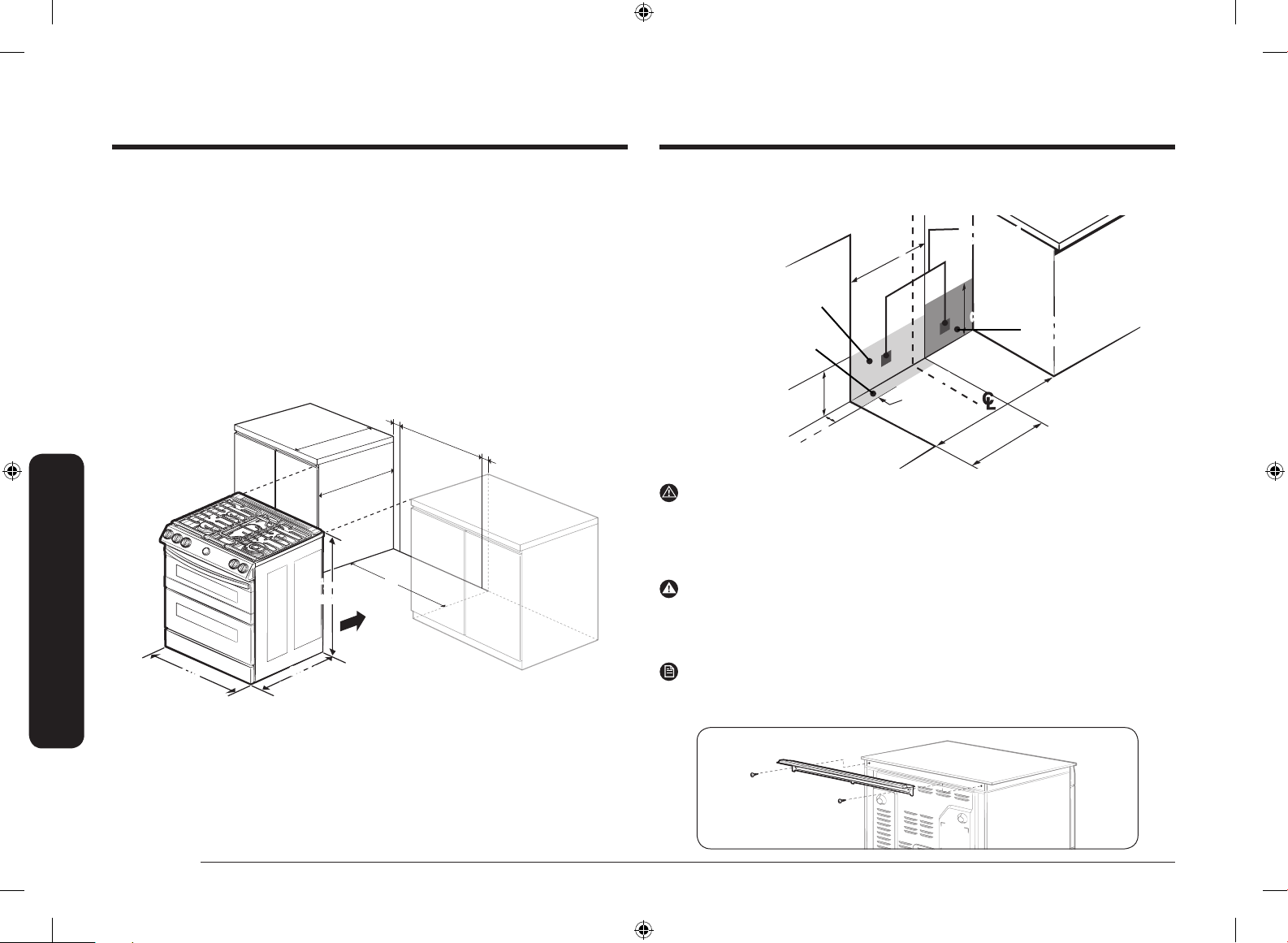

Exception 2 : For island installation, maintain 2-½” minimum from cutout to back

edge of countertop and 4” minimum from cutout to side edges of countertop.

IMPORTANT:

To eliminate the risk of burns or re caused by reaching over heated surface

Recommended locations for gas piping and electrical outlets

(For models NY63*875**)

Recommended

17 in

(43.2 cm)

position

units, avoid having cabinet storage space located above the surface units. If you

have cabinet storage space over the heating elements, you can reduce the risk by

installing a range hood that projects horizontally a minimum of 5 inches beyond

the bottom of the cabinets.

Installation guide

3"

25"

24"

24"

3"

Recommended area for

through-the-wall and through-

the-oor connection of gas

pipe stub and shut-off valve.

Gas Wall Area

9 in

(22.9 cm)

2 in

(5.1 cm)

Gas Floor Area

30 in (76.2 cm)

12 in

(30.5 cm)

Cabinet Opening

Recommended area for

120V electrical outlet

on rear wall

17 in (43.2 cm)

CAUTION

Installation requirements

You must use the rear ller kit to install the range in a freestanding cutout cabinet.

For more information, see “Optional rear ller kit” as shown below.

Optional rear ller kit

36 1/4"-37"

(921.2 mm)

29 15/16"

(761.0 mm)

26 7/16"

(671.7 mm)

A: Cabinet opening 30" (76.2)

IMPORTANT: If your cabinet have height over 37", this range cannot be installed

without supporting unit like hard block.

A

WARNING

Used to ll gap between the range back and wall. Adds a ller strip to the rear

of the range. This kit can only be used when the opening in the countertop is 25"

deep.

NOTE

If the countertop depth is greater than 25", there will be a gap between the ller

kit and the back wall.

12 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 12 2020-03-27 11:10:05

Page 13

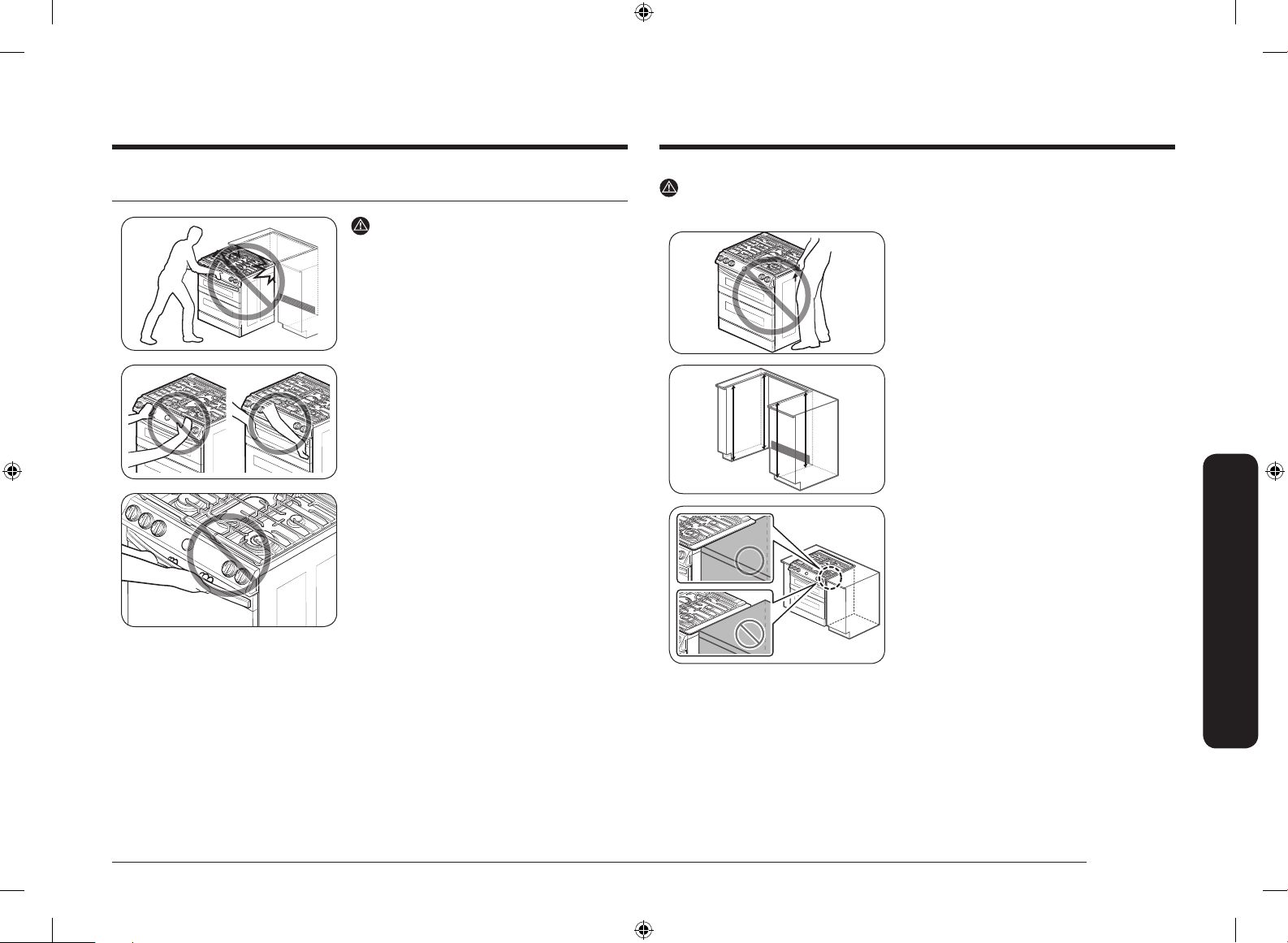

To avoid breakage

CAUTION

Please DO NOT push the unit strongly when

you install. These actions can cause the

damage to the unit.

Please DO NOT push the burner knobs when

installing the range.

(Grasp the L/R door area to push the unit.)

Do not grasp and push handle when you

install.

CAUTION

Do NOT lift or handle the unit by the cooktop frame.

1. The counter top around the cut-out

should be at and leveled (See hatched

area on Fig. 1).

2. Before installing the unit, measure

the heights of the two cabinet sides

(C1~C4), front and back (See Fig. 1)

from the oor to the top of the counter.

3. Level the range using the four leveling

legs so that the height from the oor

to the underside of the cooktop frame

is greater than the tallest cabinet

measurement by at least /".

4. Slide the unit into the cabinet (DO NOT

Fig. 1

PUSH THE UNIT HARD). Make sure the

center of the unit aligns with the center

of the cabinet cut-out.

5. The metal ange under each side of

the cooktop MUST be placed over the

cabinet countertop for proper unit

support. The cooktop should NOT rest

directly on the countertop or else it

could cause damage to the cooktop

voiding the warranty. Level the unit if

needed.

Installation requirements

English 13

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 13 2020-03-27 11:10:05

Page 14

Installation requirements

Gas requirements

Provide adequate gas supply

This range is designed to operate at a pressure of 5 in (13 cm) of water column on

natural gas or 10 in (25 cm) of water column on LP gas (propane or butane).

Make sure you are supplying your range with the type of gas for which it is

designed.

Do not attempt to convert the appliance from the gas specied in this manual to a

different gas without consulting the gas supplier.

This range is convertible for use on natural or propane gas. If you decide to use

this range on LP gas, conversion must be made by a qualied LP installer before

attempting to operate the range.

For proper operation, the pressure of natural gas supplied to the regulator must be

between 5 in and 13 in (13 cm and 33 cm) of water column.

For LP gas, the pressure supplied must be between 10 in and 13 in (25 cm and

33 cm) of water column.

When checking for proper operation of the regulator, the inlet pressure must be at

Installation requirements

least 1 in (2.5 cm) greater than the operating (manifold) pressure as given.

The pressure regulator located at the inlet of the range manifold must remain in

the supply line regardless of whether natural or LP gas is being used.

A exible-metal appliance connector used to connect the range to the gas supply

line should have an I.D. of 0.5 in (1.3 cm) and be 5 ft (152 cm) in length for ease of

installation. In Canada, exible connectors must be single-wall metal connectors no

longer than 6 ft (183 cm) in length.

Do not kink or damage the exible metal tubing when moving the range.

Special gas requirements (gas models sold in Massachusetts)

COMMONWEALTH OF MASSACHUSETTS REQUIREMENTS:

WARNING

Gas leaks may occur in your system, creating a dangerous situation.

- Gas leaks may not be detected by smell alone.

- Gas suppliers recommend you purchase and install a UL-approved

gas detector. Gas detector should be installed in accordance with the

manufacturers instructions.

• Range must be installed by a qualied plumber or gas tter by the State of

Massachusetts.

• A T-handle manual gas valve MUST be installed in the gas supply line to your

range.

• If a exible gas connector is used to install your range, multiple exible gas

lines must not be connected in series.

14 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 14 2020-03-27 11:10:06

Page 15

Electrical requirements

WARNING

To reduce the risk of re, electric shock, or personal injury:

All ranges

• Do not use an extension cord or adapter plug with this range.

• This range must be properly grounded.

• Check with a qualied electrician if you are in doubt as to whether your range

is properly grounded.

• Do not modify the plug provided with your range—if it doesn’t t the outlet,

have a proper outlet installed by a qualied electrician.

• All wiring and grounding must be done in accordance with local codes or, in

the absence of local codes, with the National Electrical Code, ANSI/NFPA

No. 70 – Latest Revision (for the U.S.) or the Canadian Electrical Code CSA

C22.1 – Latest Revisions and local codes and ordinances.

• Wiring diagram is located on the back of the range. (Inside of the cover back

wire)

• This range is equipped with an electronic ignition system that will not operate

if plugged into an outlet that is not properly polarized.

Gas models

• Canada gas models are equipped with a power cord with an equipmentgrounding conductor and a grounding plug.

(The power cord is not provided in US model.)

• A 240-Volt, 60-Hz, AC, approved electrical service with 40-amp circuit breaker

or time-delay fuse is required for all U.S. and Canadian models.

• Check for ¾-in (1.9-cm) UL-listed strain relief where the power cord comes out

of the range cabinet.

• Do not reuse a power supply cord from an old range or other appliance.

• The power cord electric supply wiring must be retained at the range cabinet

with a suitable UL-listed strain relief.

• A time-delay fuse or circuit breaker is also recommended.

Grounding

• All ranges must be grounded for personal safety.

• All gas models have a power cord with an equipment-grounding conductor

and a grounding plug.

• Do not use a damaged power plug or loose wall outlet.

• Do not use an extension cord or adapter with this appliance.

• Do not, under any circumstances, cut, modify, remove, or otherwise defeat the

grounding (third) prong from the power cord. If the plug and the outlet do not

match or you have any doubt, have a qualied electrician install the proper

outlet.

The customer should have the wall receptacle and circuit checked by a

qualied electrician to make sure the receptacle is properly grounded.

Ground Fault Circuit Interrupters (GFCIs) are not required or recommended for

gas range receptacles.

• NEVER connect ground wire to plastic plumbing lines, gas lines, or water

pipes.

CAUTION

Failure to follow these instructions can result in death, re, or electrical shock.

Additional installation requirements for mobile homes

The installation of appliances designed for mobile home installation must conform

with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part

3280 (formerly the Federal Standard for Mobile Home Construction and Safety,

Title 24, HUD, Part 280) or, when such standard is not applicable, the Standard

for Manufactured Home Installations, latest edition (Manufactured Home Sites,

Communities and Set-Ups), ANSI A225.1, latest edition, or with local codes. In

Canada, mobile home installation must be in accordance with the current CAN/CSA

Z240/MH Mobile Home Installation Code.

Installation requirements

English 15

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 15 2020-03-27 11:10:06

Page 16

Installation instructions

Installation instructions

Installing your dual fuel range

IMPORTANT:

Please read the following instructions, as well as the Important Safety Instructions

section at the front of this manual, completely and carefully BEFORE installing

and/or operating the gas range. Improper installation, adjustment, service, or

maintenance can cause personal injury or property damage.

NOTE

To order parts or accessories, contact your

local retailer or refer to the last page.

NOTE

To ensure proper installation, we strongly

recommend that you hire a professional

installer.

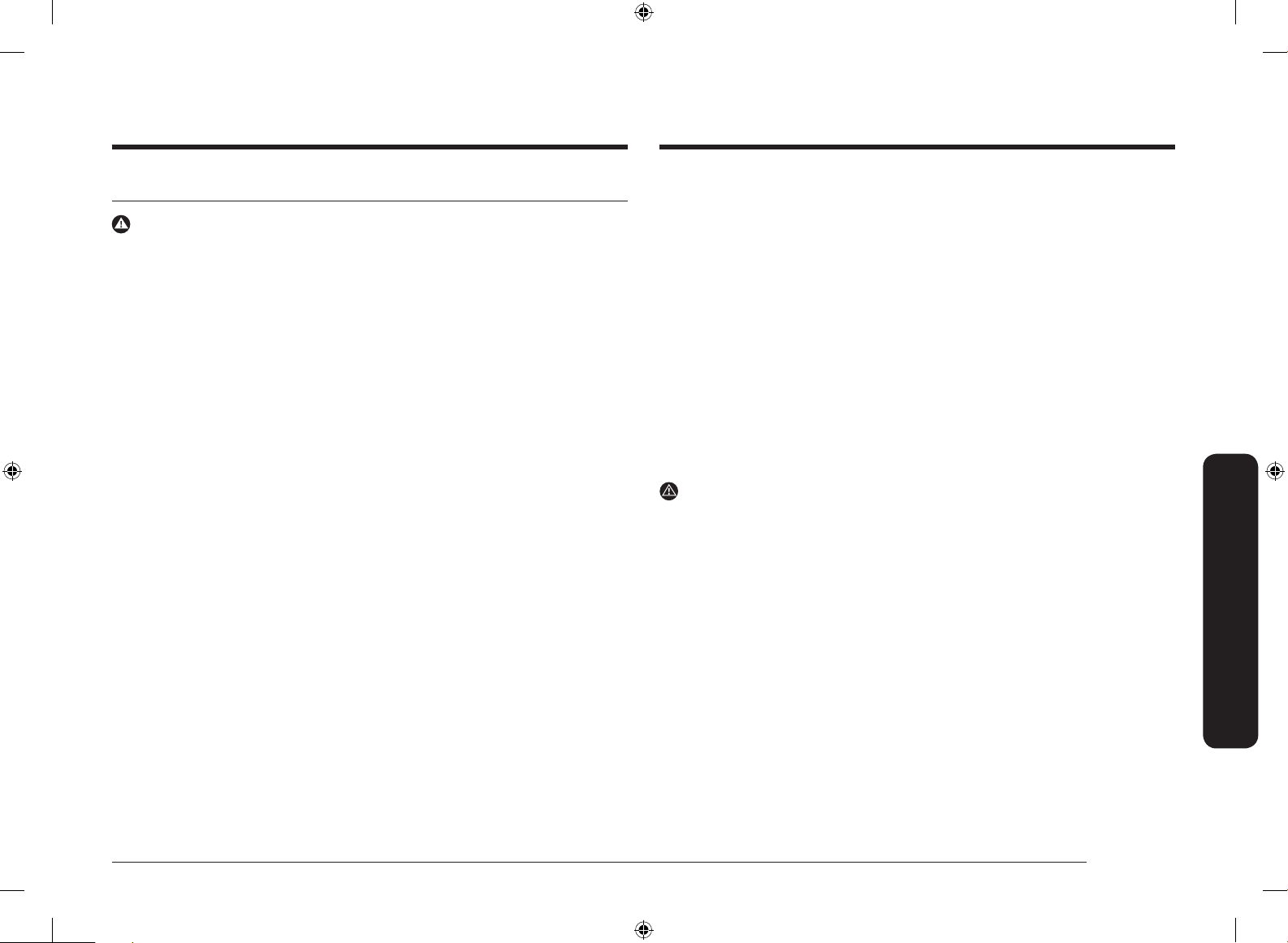

Step 1. Unpack the range

Remove all packaging materials. Failure to remove packaging materials could

result in damage to the appliance.

Inventory all loose parts against the Parts supplied components listed on page 9.

Check for shipping damage and/or missing parts. Any damage and/or missing

parts should be reported to your local retailer.

This appliance must be supplied with

the proper voltage and frequency, and

connected to an individual properly

grounded branch circuit, protected by a

circuit breaker or fuse having amperage

as specied on the rating plate. The rating

plate is located on the bottom side of the

control panel.

We recommend you have the electrical

wiring and hookup of your range connected

by a qualied electrician. After installation,

have the electrician show you where your

main range disconnect is located.

Check with your local utilities for electrical

codes which apply in your area. Failure

to wire your oven according to governing

codes could result in a hazardous condition.

If there are no local codes, your range

must be wired and fused to meet the

requirements of the National Electrical Code,

ANSI/NFPA No. 70–Latest Edition. You can

get a copy by writing:

National Fire Protection Association

Batterymarch Park

Quincy, MA 02269

Step 2. Meeting electrical connection requirements

CAUTION

For personal safety, do not use an extension cord with this appliance. Remove

house fuse or open circuit breaker before beginning installation.

16 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 16 2020-03-27 11:10:06

Effective January 1, 1996, the National Electrical Code requires that new

construction (not existing) utilize a 4-conductor connection to an electric range.

When installing an electric range in new construction, follow Steps 2 and 3 for

4-wire connection.

You must use a 3-wire or 4-wire, single-phase A.C. 208Y/120 Volt or 240/120 Volt,

60 hertz electrical system.

If the electrical service provided does not meet the above specications, have a

licensed electrician install an approved outlet.

Page 17

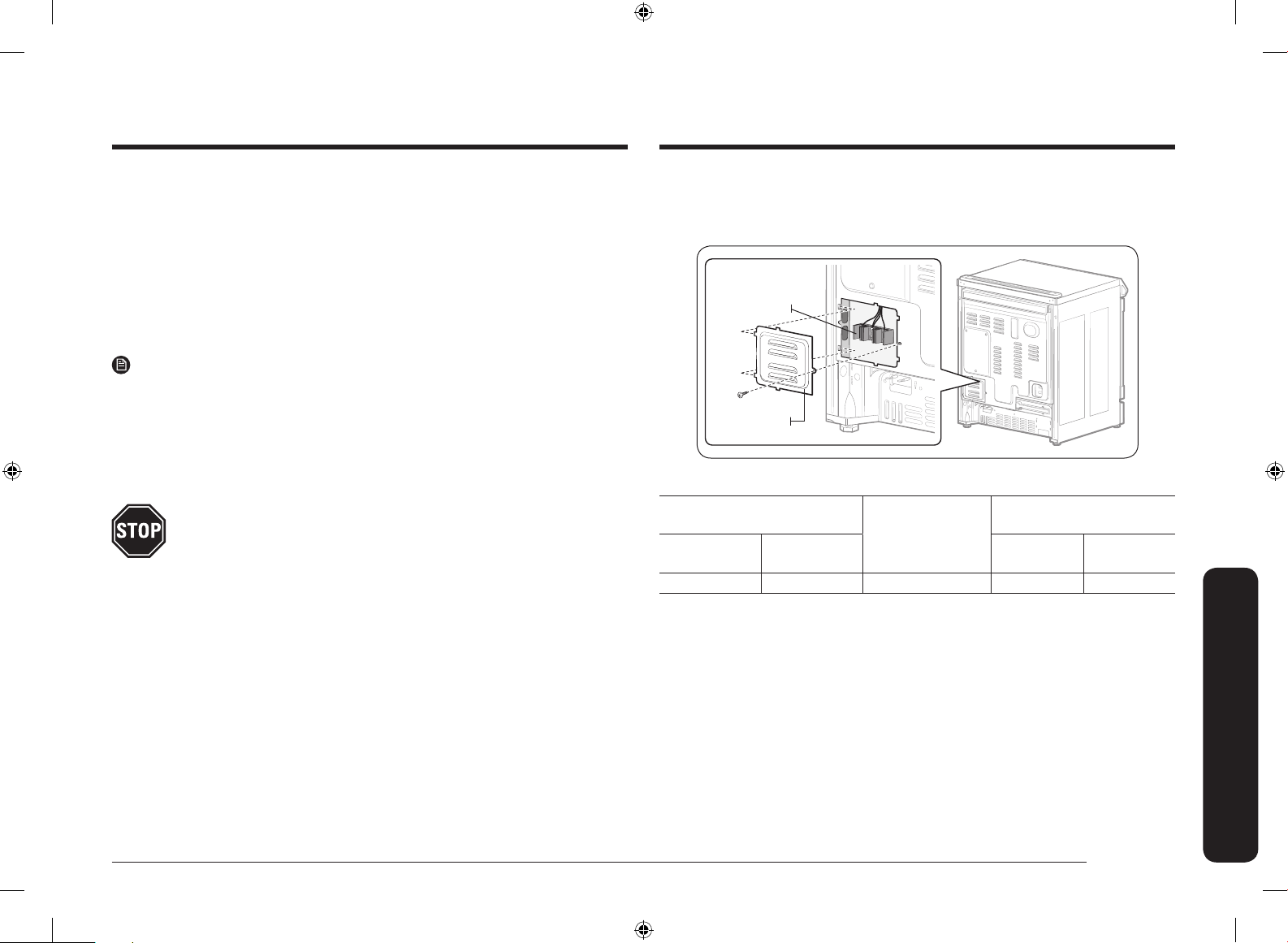

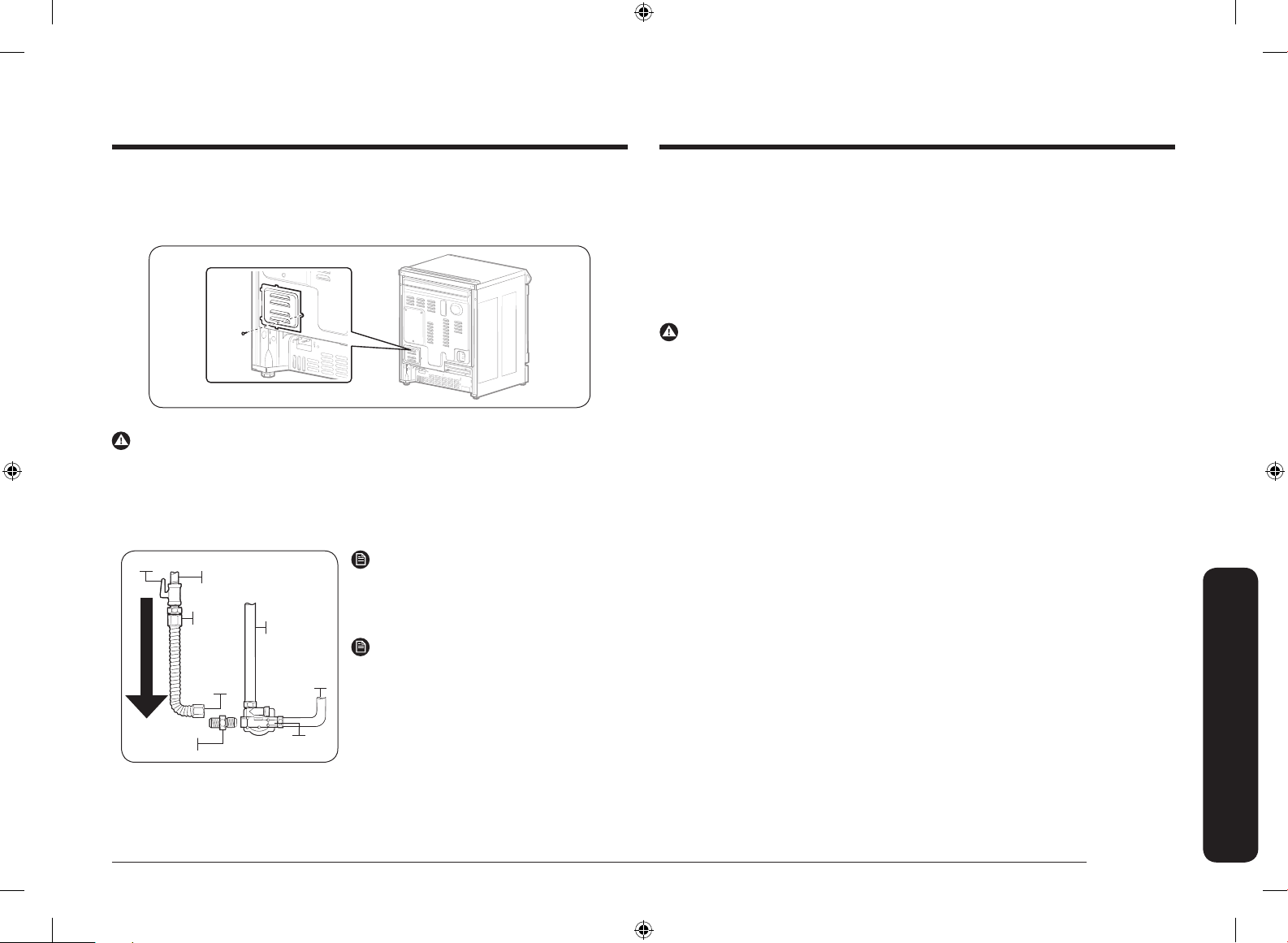

Access cover

Terminal block

Use only a 3-conductor or a 4-conductor UL-listed range cord. These cords may be

provided with ring terminals on wire and a strain relief device.

A range cord rated at 40 amps with 125/250 minimum volt range is required.

A 50 amp range cord is not recommended but if used, it should be marked for

use with nominal 1⅜" diameter connection openings. Care should be taken to

center the cable and strain relief within the knockout hole to keep the edge from

damaging the cable.

• Because range terminals are not accessible after range is in position, exible

service conduit or cord must be used.

NOTE

• If conduit is being used, go to Step 5 on pages 19 ~ 20.

• If the power connection is plugged in improperly, the following message

appears on the display.

• LCD, PMOLED : Wire installation fail

• LED : bAd LinE

• Reconnect the power connection properly, and the message disappears.

ALL NEW BRANCH-CIRCUIT CONSTRUCTIONS, MOBILE HOMES,

RECREATIONAL VEHICLES AND INSTALLATIONS WHERE LOCAL

CODES DO NOT ALLOW GROUNDING THROUGH NEUTRAL, REQUIRE A

4-CONDUCTOR UL-LISTED RANGE CORD.

Step 3. Accessing the power cord connection

Remove the rear access cover and loosen the screw with a screwdriver. The

terminal block will then be accessible.

Specied power-supply-cord kit rating

Range rating, watts

120/240

volts 3-wire

120/208

volts 3-wire

Specied rating

of power-supplycord kit, amperes

8750 - 16500 7801 - 12500 40 or 50A 1⅜" 1⅛"

Diameter (inches) of range

connection opening

Power cord Conduit

Installation instructions

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 17 2020-03-27 11:10:06

English 17

Page 18

Installation instructions

Ground strap

Neutral

terminal

Black

White

Red

Black

White

Red

Strain relief

Power cord

Conduit connection

plate

Installation instructions

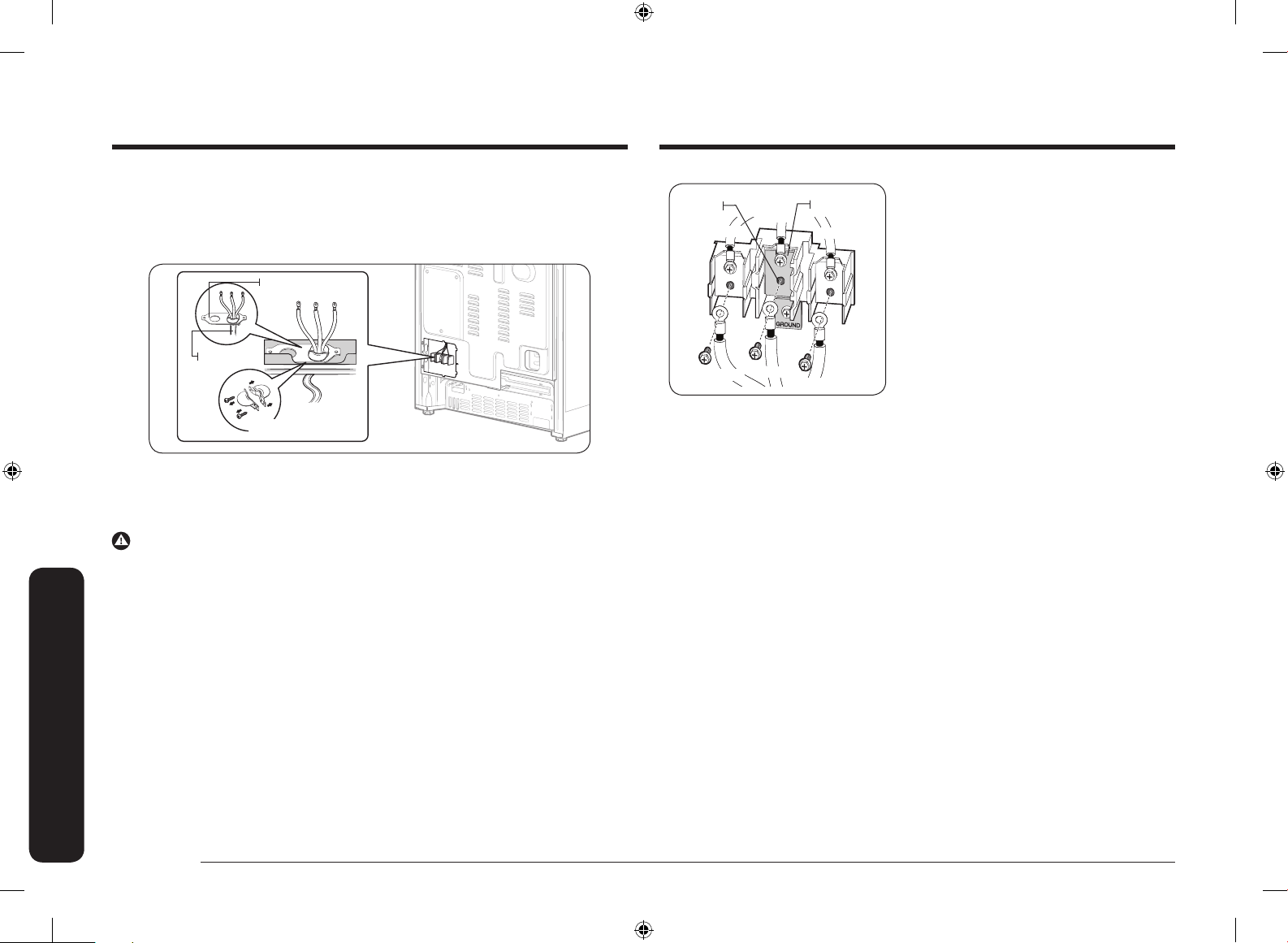

Step 4. Installing the power cord

For power cord installations, hook the strain relief over the power cord hole (1⅜")

located below the rear of the drawer body. Insert the power cord through the

strain relief and tighten the device.

• You must install the power cord with a strain relief.

• Attach the strain relief to the 1⅜" opening in conduit connection plate.

Installing a 3-wire power cord

WARNING

The neutral or ground wire of the power cord must be connected to the neutral

terminal located in the center of the terminal block. The power leads must be

connected to the lower left and the lower right terminals of the terminal block.

1. Remove the 3 lower terminal screws

from the terminal block.

2. Insert the 3 terminal screws through

each power cord terminal ring and into

the lower terminals of the terminal

block. Be certain that the center wire

(white/neutral) is connected to the

center lower position of the terminal

block.

3. Tighten screws securely into the

terminal block. DO NOT remove the

ground strap connection.

4. Go to step 6 on page 21 and proceed

with the installation.

18 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 18 2020-03-27 11:10:07

Page 19

1⅛" 1⅜"

1⅛"1⅜"

Conduit connection plate

Strain relief

Ring

Body

Figure 2

1"

3½"

⅜" 1"

3½"

3 wire 4 wire

Knockout surface

Figure 1

⅜"

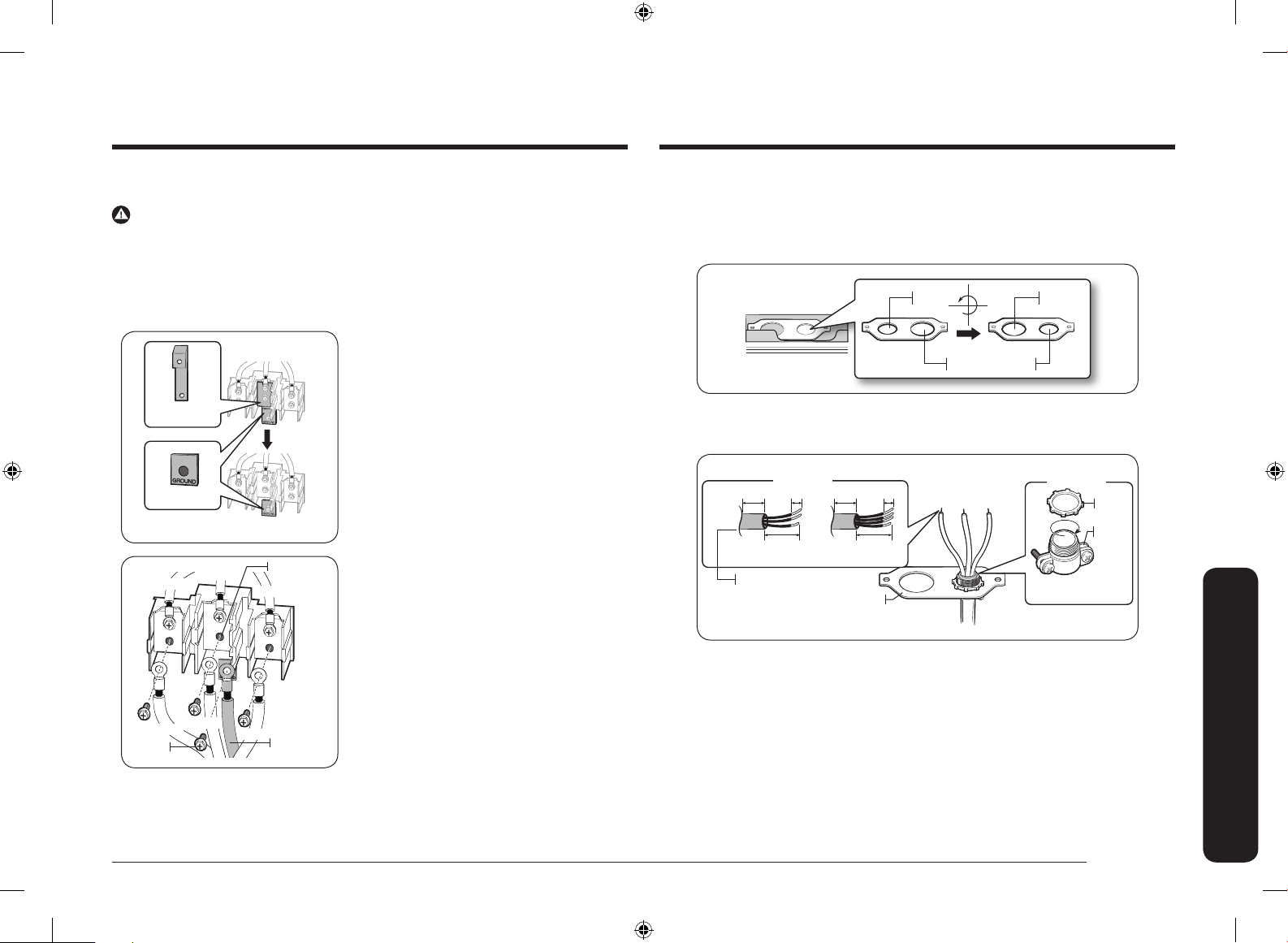

Installing a 4-wire power cord

Ground strap

Ground plate

Ground

screw

Neutral

terminal

Ground wire

(Green)

White

Black

Red

Black

White

Red

WARNING

The neutral wire of the supply circuit must be connected to the neutral terminal

located in the lower center of the terminal block. The power leads must be

connected to the lower left and the lower right terminals of the terminal block. The

4th grounding lead must be connected to the frame of the range with the ground

plate and the ground screw.

1. Remove the 3 lower terminal screws

from the terminal block. Remove the

ground screw and ground plate and

retain them.

2. Cut and discard the ground strap. Do

not discard any screws.

3. Insert the one ground screw into the

power cord ground wire terminal ring,

through the ground plate, and into the

frame of the range.

4. Insert the 3 terminal screws (removed

earlier) through each power cord

terminal ring and into the lower

terminals of the terminal block. Be

certain that the center wire (white/

neutral) is connected to the center

lower position of the terminal block.

Tighten screws securely into the

terminal block.

5. Go to step 6 on page 21 and proceed

with the installation.

Step 5. Installing the conduit

Remove the conduit connection plate from the rear of the drawer body and rotate

it as shown below.

The conduit hole (1⅛") must be used.

1. Prepare the conduit cord shown in Figure 1.

2. Install the conduit cord as shown in Figure 2.

Installation instructions

For conduit installations, insert the strain relief (not included) into the conduit hole

(1⅛"). Then thread the conduit cord through the body of the strain relief and fasten

the ring. Reinstall the bracket.

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 19 2020-03-27 11:10:07

English 19

Page 20

Installation instructions

Ground strap

Ground plate

White

Black

Red

Neutral

terminal

Ground wire

(Green)

Wire

tips

White

Black

Red

White

Black

Red

Ground

strap

Neutral

terminal

Wire tips

Red

White

Black

Installation instructions

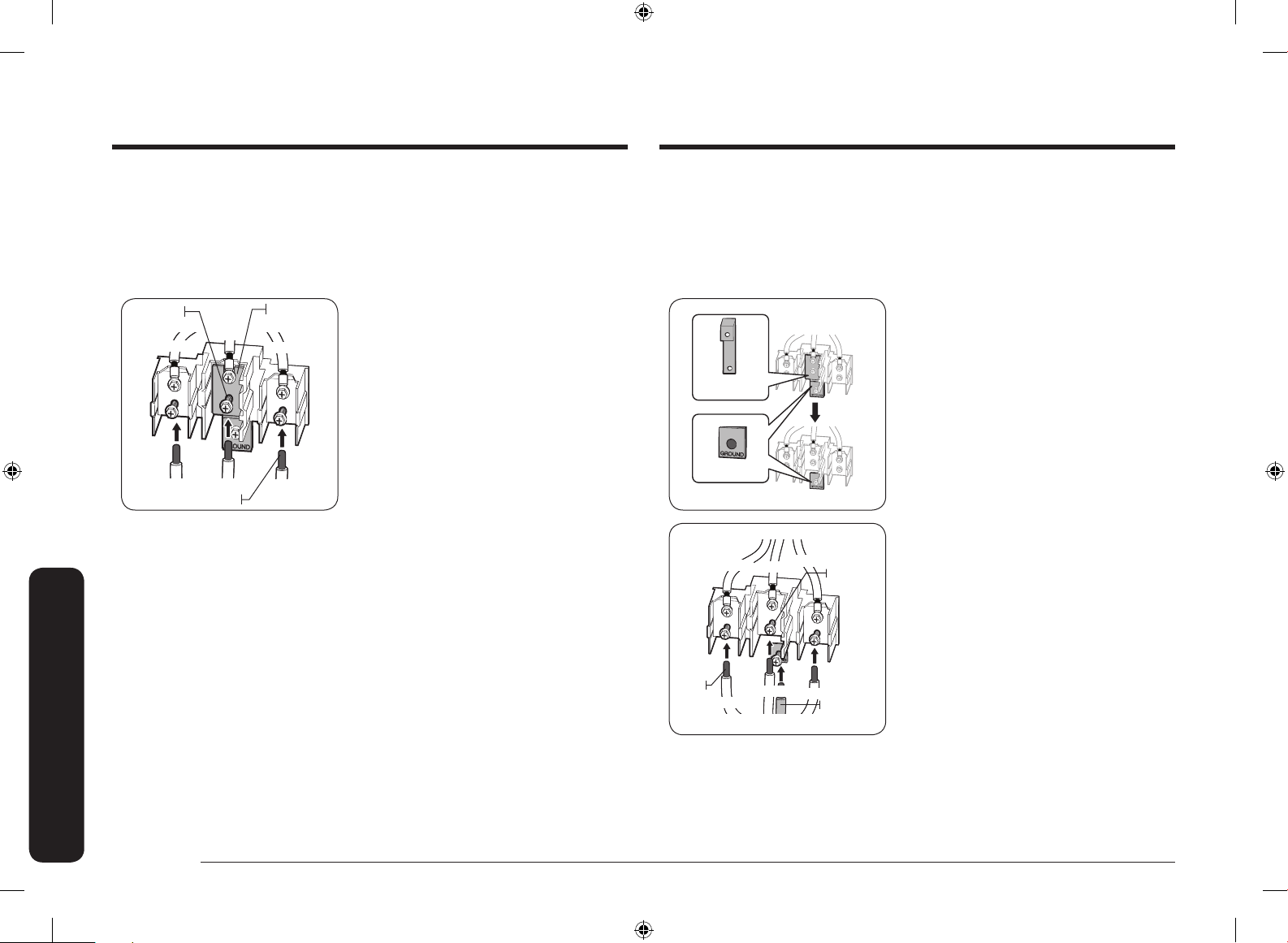

Installing a 3-wire conduit

• Aluminum building wire may be used but it must be rated for the correct

amperage and voltage to make the connection. Connect wires according to

Step 4 depending on the number of wires.

• Wire used, location and enclosure of splices, etc., must conform to good wiring

practices and local codes.

1. Loosen the 3 lower terminal screws

from the terminal block.

2. Insert the center bare wire (white/

neutral) tip through the bottom center

terminal block opening. On certain

models, the wire will need to be

inserted through the ground strap

opening and then into the bottom

center block opening.

3. Insert the two side bare wire tips into

the lower left and the lower right

terminal block openings.

4. Tighten the screws until the wire is

rmly secured (35 to 50 inch-lbs.). Do

not over-tighten the screws since it

could damage the wires.

5. Go to step 6 on page 21 and proceed

with the installation.

Installing a 4-wire conduit

• Aluminum building wire may be used but it must be rated for the correct

amperage and voltage to make the connection. Connect wires according to this

Step 4 depending on the number of wires.

• Wire used, location and enclosure of splices, etc., must conform to good wiring

practices and local codes.

1. Loosen the 3 lower terminal screws

from the terminal block. Remove the

ground screw and ground plate and

retain them.

2. Cut and discard the ground strap. Do

not discard any screws.

3. Insert the ground bare wire tip between

the range frame and the ground plate

(removed earlier) and secure it in

place with the ground screw (removed

earlier).

4. Insert the bare wire (white/neutral)

tip through the bottom center of the

terminal block opening.

5. Insert the two side bare wire tips into

the lower left and the lower right

terminal block openings.

6. Tighten the screws until the wire is

rmly secured (35 to 50 inch-lbs.). Do

not over-tighten the screws since it

could damage the wires.

7. Go to step 6 and proceed with the

installation.

20 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 20 2020-03-27 11:10:08

Page 21

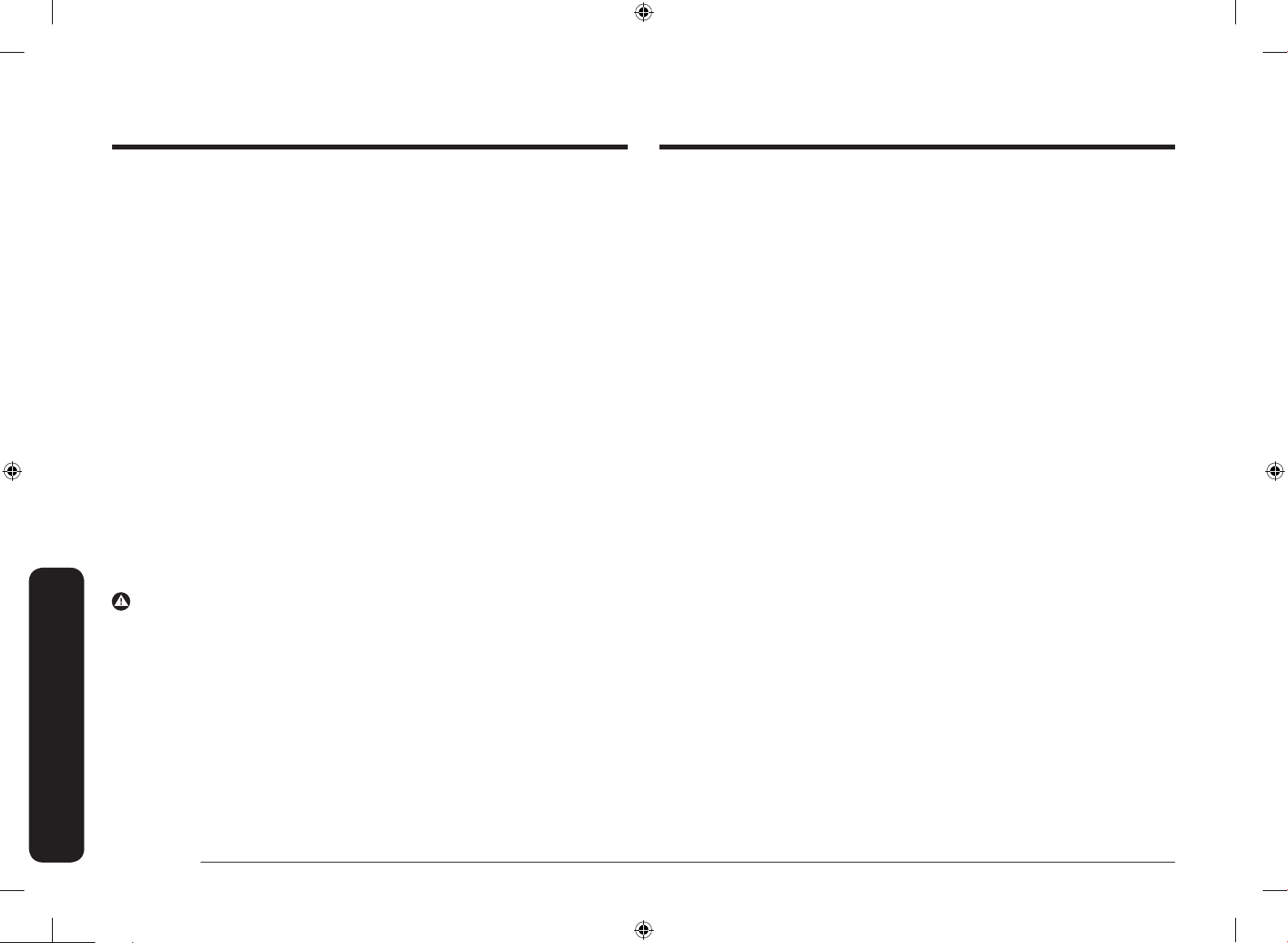

Adapter

Flex

Connector

(6-ft max.)

Adapter

Gas Shut-Off Valve

0.5-in or 0.75-in Gas Pipe

Tubing Line

to Oven

Burner

Control Valve

Gas Flow into Range

Pressure

Regulator

Tubing Line

to Cooktop

Control

Manifold

Step 6. Replacing the access cover

Replace the access cover on the range back. To replace the wire cover, insert

double projections in the pockets located below the opening and tighten the screw.

WARNING

Do not exceed 25 ft-lbs of torque when making gas line connections.

Overtightening may crack the pressure regulator resulting in a gas leak.

Flexible connector hookup

Installer: Inform the consumer of the location of the gas shut-off valve.

NOTE

If your area requires a rigid pipe hookup,

contact a qualied installer, service agency,

or gas supplier.

NOTE

The gas shut-off valve should be installed

in an accessible location in the gas piping,

external to the appliance, for the purpose

of turning on or shutting off the gas to the

appliance.

Step 7. Connect the range to gas supply

Shut off the main gas supply valve before disconnecting the old range and leave

it off until the new hookup has been completed. Don’t forget to relight the pilot on

other gas appliances when you turn the gas back on.

Because hard piping restricts movement of the range, the use of a CSA

International-certied exible metal appliance connector is recommended unless

local codes require a hard-piped connection.

WARNING

If the information in this manual is not followed exactly, a re or explosion may

result, causing death, personal injury, or property damage.

- Do not store or use gasoline or other ammable vapors and liquids in the

vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• DO NOT light a match, candle, or cigarette.

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

- Installation and service must be performed by a qualied installer, service

agency, or gas supplier.

English 21

Installation instructions

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 21 2020-03-27 11:10:08

Page 22

Installation instructions

Installation instructions

Never use an old connector when installing a new range. If the hard-piping method

is used, you must carefully align the pipe; the range cannot be moved after the

connection is made.

To prevent gas leaks, apply pipe-joint compound or wrap pipe-thread tape with

Teon on all male (external) pipe threads.

1. Install a manual gas line shut-off valve in the gas line in an easily accessed

location outside of the range.

Make sure everyone operating the range knows where and how to shut off

the gas supply to the range.

2. Install male 0.5-in (1.3-mm) are union adapter to the 0.5-in (1.3-mm) NPT

internal thread at the regulator inlet. Use a backup wrench on the regulator

tting to avoid damage.

When installing the range from the front, remove the 90 ° elbow for easier

installation.

3. Install male 0.5-in (1.3-mm) or 0.75-in (1.9-mm) are union adapter to the

NPT internal thread of the manual shut-off valve, taking care to back up the

shut-off valve to keep it from turning.

4. Connect exible metal appliance connector to the adapter on the range.

Position range to permit connection at the shut-off valve.

5. When all connections have been made, make sure all range controls are in the

off position and turn on the main gas supply valve. Use a liquid leak detector

at all joints and connections to check for leaks in the system.

WARNING

To prevent death, personal injury, explosion, and/or re hazard, DO NOT use a

ame to check for gas leaks.

When using test pressures greater than ½ psig to pressure-test the gas supply

system of the residence, disconnect the range and individual shut-off valve from

the gas supply piping. When using test pressures of ½ psig or less to test the gas

supply system, simply isolate the range from the gas supply system by closing the

individual shut-off valve.

Step 8. Convert to LP gas (optional)

All new gas ranges are shipped from the factory set up to use natural gas. Any

Samsung gas range can be converted to use LP gas. Refer to page 57 in the User

Manual to contact a qualied service technician.

The conversion process should only be performed by a qualied LP gas installer.

Conversion instructions and LP orices will be supplied with the LP conversion kit.

The conversion to LP requires all burner orices to be changed (5 surface burners).

In addition, the nozzle on the gas pressure regulator needs to be reversed. All

replaced orices must be left with the consumer, including the instructions and

retrot sizes and orice indication.

Checking the ame quality all burner after converting to LP gas.

22 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 22 2020-03-27 11:10:08

Page 23

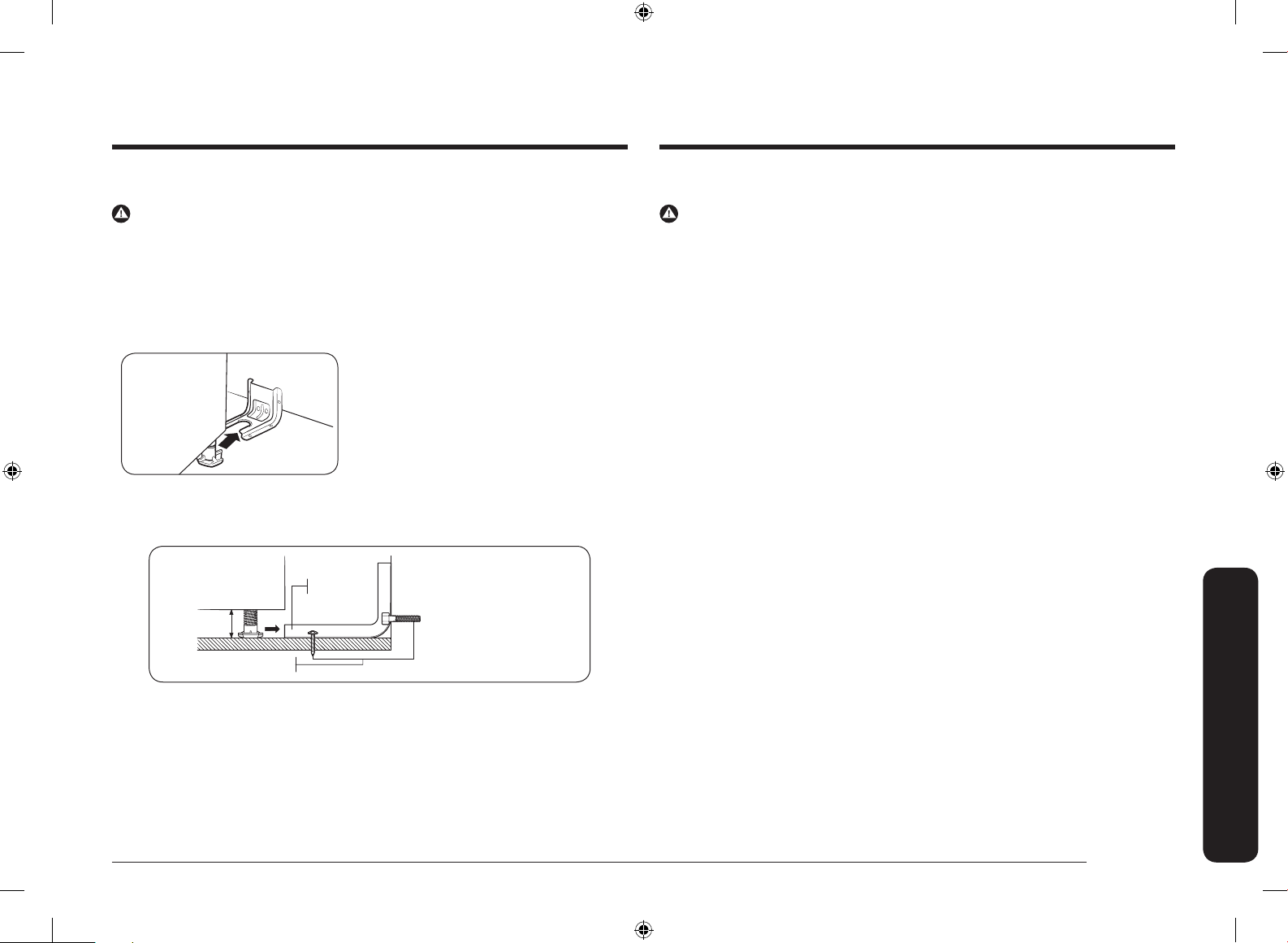

Step 9. Install the anti-tip device

Anti-Tip

bracket

*approximately

/" (16.5 mm)

Screw must enter

wood or concrete

*NOTE: To install the Anti-Tip

bracket, release the leveling leg.

A minimum clearance of /"

(16.5 mm) is required between

the range bottom and the kitchen

oor.

Step 10. Plug in and place

WARNING

To reduce the risk of tipping, the appliance must be secured by properly installing

the anti-tip device packed with the appliance.

• All ranges can tip, resulting in personal injury.

• Tipping ranges can cause burns from spills, personal injury, and/or death.

• To prevent accidental tipping, install and check the anti-tip bracket following

the instructions and template supplied with the bracket.

An anti-tip bracket and screws, installation

instructions, and template are shipped

with every range (PN DG94-00870B). The

instructions include information necessary to

complete the installation of the anti-tip bracket.

Read and follow the instructions on the sheet

and use the template for anti-tip bracket

installation. If not properly installed, the range

could be tipped by you or a child standing,

sitting, or leaning on an open oven door.

WARNING

BEFORE OPERATING OR TESTING, follow the grounding requirements on pages

15 ~ 16 in this manual. Improper connection of the grounding plug can result in a

risk of electric shock.

• All Dual Fuel ranges come with a power cord. The power cord is connected to

the rear of the range. Please review "Electrical requirements" on pages

15 ~ 16.

• The electrical system, including the power cord, is preinstalled and prewired at

the factory. Altering any part of this system may result in a short or overload.

1. Plug in the power cord. Make sure the outlet meets local or national electrical

codes as referenced on pages 15 ~ 16.

2. Slide the range into place.

3. Check the gas supply line to make sure it did not get damaged and it stayed

connected during positioning.

4. Check to make sure the back leg of the range has slid into the anti-tip bracket.

Carefully tip the range forward to ensure that the anti-tip bracket engages the

back brace and prevents tip-over.

Installation instructions

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 23 2020-03-27 11:10:08

To check if the bracket is installed and engaged properly, remove storage drawer

and look underneath the range to see that the leveling leg is engaged in the bracket.

Carefully tip the range forward. The bracket should stop the range within 4 inches

(10.2 cm) of tipping. If it does not, the bracket must be reinstalled.

If the range is pulled from the wall for any reason, always repeat this procedure to

verify the range is properly secured by the anti-tip bracket. Never completely remove

the leveling legs or the range will not be secured to the anti-tip device properly.

English 23

Page 24

Installation instructions

Leveling leg

Installation instructions

Step 11. Level the range

1. Make sure the range is positioned

where you want it.

2. Using a wrench, level the range by

turning the front leveling legs in or

out as necessary. Counterclockwise

shortens the leg and lowers the range.

Clockwise lengthens the leg and raises

the range.

NOTE

• Adjusting the two front legs is usually

sufcient, but adjust all four legs if

necessary.

• Adjust the leveling legs only as far as

necessary to level the range. Extending

the leveling legs more than necessary

or removing legs can cause the range

to be unstable.

3. If range is next to or between cabinets,

make sure the cooktop (without the

surface burner grates) is level with the

countertops.

4. Position an oven rack in the center rack

position.

5. Check the level of the range with a

carpenter level using the two positions

shown at right.

6. After the range becomes level, slide the

range away from the wall so that the

anti-tip bracket can be installed.

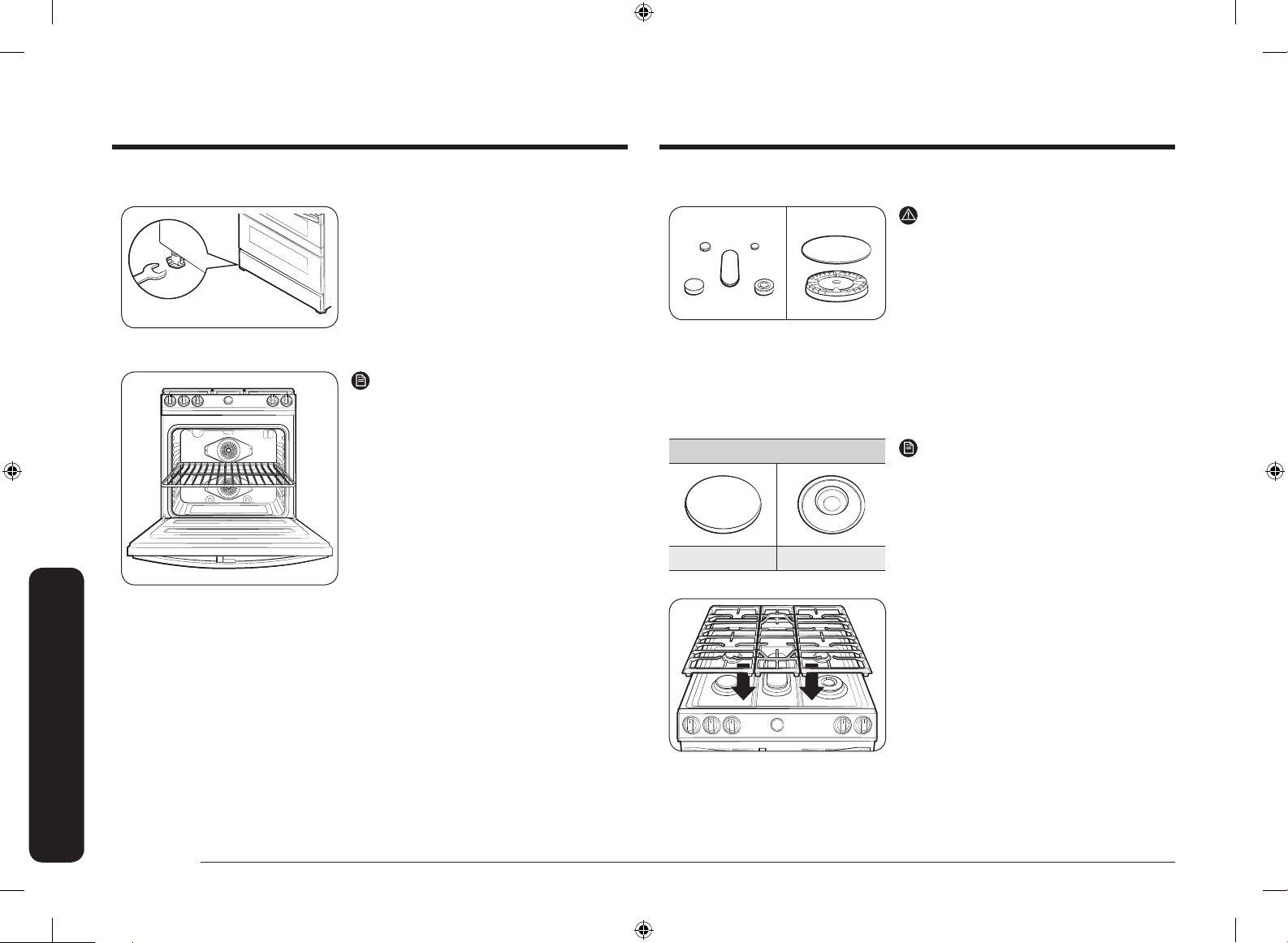

Step 12. Assemble the surface burners

Do not operate the surface burners without

all burner parts in place.

1. Position surface burner heads on top of

2. Place the matching size caps on top of

Precise Simmer Burner (RR)

The caps on Precise simmer burner

(RR) and inside Dual Burner (RF) can be

interchangeably used.

Flat surface Concave line

3. Place the left, center, and right surface

CAUTION

the surface burner manifolds as shown

at right. The electrodes will t into the

slot in the bottom of the heads. Make

sure the surface burner heads are at

and parallel with the cooktop.

each surface burner head.

NOTE

burner grates on the cooktop. The

edges of the grates should match up

with the edges of the cooktop.

24 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 24 2020-03-27 11:10:09

Page 25

2

3

1

Step 13. Check the ignition of surface burners

2

1

Check the operation of all cooktop and oven burners after the range has been

installed and assembled, gas supply lines have been carefully checked for leaks,

and electrical power cord has been plugged in.

All surface and oven burners have electronic ignition.

To turn on a surface burner:

1. Push in and turn the control knob for

that surface burner to the LITE position.

The "clicking" sound indicates the

electronic ignition system is operating

properly. The burner will light in about

4 seconds, after the air has been

purged from the supply line.

2. After the burner lights, turn the control

knob to the desired setting. The

"clicking" sound will stop and the ame

height will change from Max. to Min.

during turning the control knob.

3. Repeat steps 1 and 2 to check the

operation of each surface burner in

succession.

NOTE

Place food in the oven after preheating

if the recipe calls for it. Preheating is

important for good baking results. After

the oven has reached the desired cooking

temperature, it will beep 6 times.

Checking the ame quality:

All combustion ames need to be visually checked to determine their ame

quality.

1. Soft blue ames—Normal for natural

gas operation.

2. Yellow tips on outer cones—Normal for

LP gas operation.

3. Yellow ames—Abnormal for any gas

operation; call for service.

NOTE

If burner ame looks like 3, the range

should not be used until it is serviced. Call

for service. Normal burner ames shall look

like 1 or 2, depending on the gas type you

use.

Installation instructions

English 25

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 25 2020-03-27 11:10:09

Page 26

Installation instructions

Installation instructions

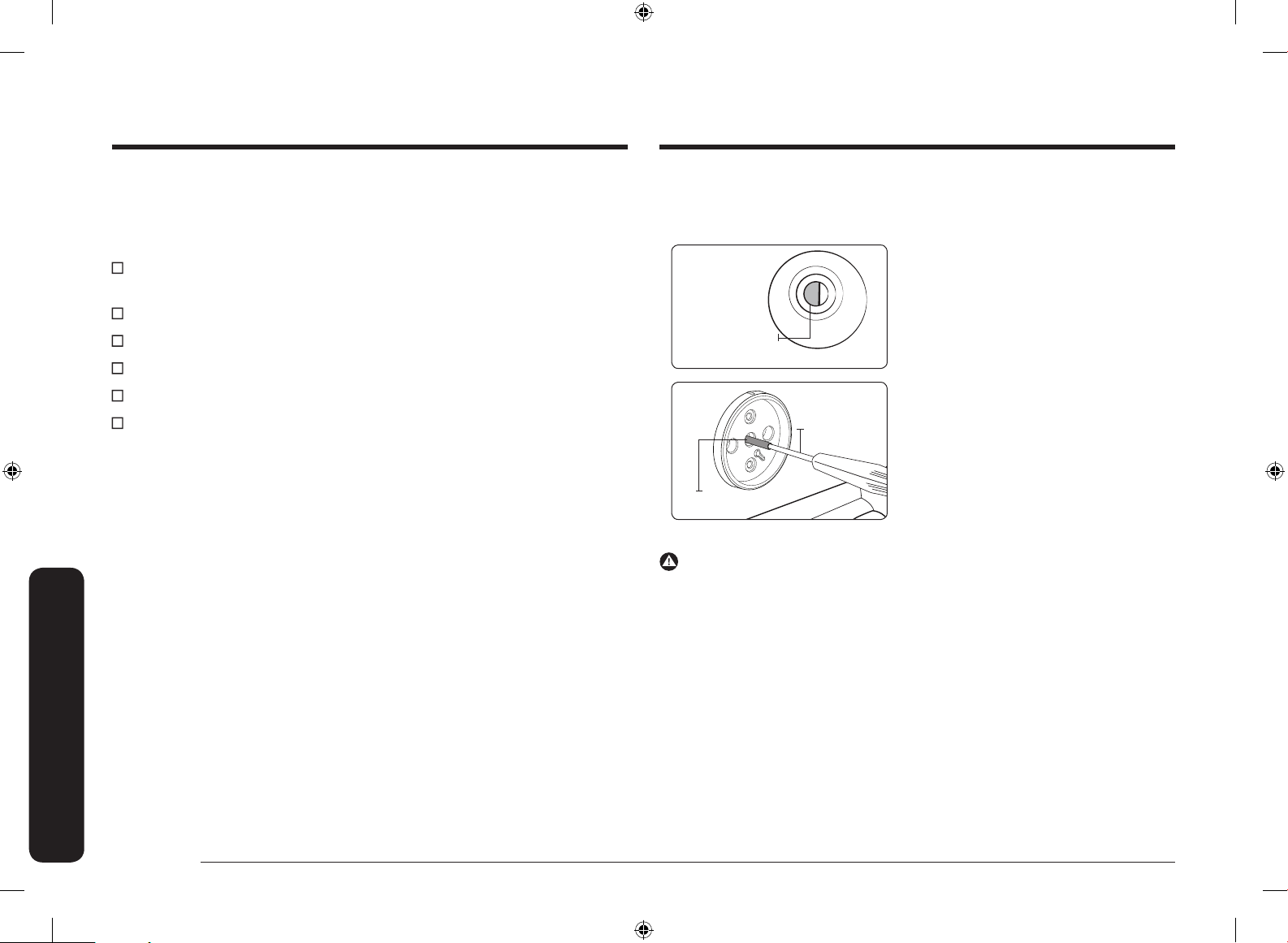

Step 14. Final installation checklist

You have just completed installing your range. Make sure all controls are in the off

position and the ow of ventilation air to the range is unobstructed. The following

is a checklist to conrm your range is safely installed and ready for operation.

Gas line has been properly connected to the range. The gas has been turned

on. All connections have been checked for leaks.

Range is plugged into the properly grounded electrical receptacle.

Approved anti-tip bracket is properly installed and engaged with the range.

Range is leveled and is rmly sitting on a solid, level oor.

Gas surface burners have been properly assembled.

All burners have been tested for proper operation.

To adjust ame low setting

Identify which burner is exhibiting too high or too low of simmer rate via manifold

panel graphics.

1. Rotate a knob to LO position and

remove the knob from the valve stem

while the ame is lit.

Simmer Set

Screw

Small

Screwdriver

Valve Stem

WARNING

1. Do not completely remove the valve set screw from the valve stem. The valve

set screw is an integral part of the gas valve assembly. Removing the valve

set screw will cause gas to leak.

2. After adjusting the valve set screw, inspect the assembly for gas leaks.

2. Carefully push the screw driver into

the stem of the valve, until it hits

the simmer set screw. Make sure the

screwdriver athead is seated into the

set screw groove.

3. Rotate valve set screw clockwise to

decrease LO setting ame output, or

rotate set screw counter clockwise to

increase LO setting ame output.

26 English

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 26 2020-03-27 11:10:10

Page 27

Memo

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 27 2020-03-27 11:10:10

Page 28

Scan the QR code* or visit

www.samsung.com/spsn

to view our helpful

How-to Videos and Live Shows

* Requires reader to be installed on your

QUESTIONS OR COMMENTS?

COUNTRY CALL OR VISIT US ONLINE AT

U.S.A

Consumer Electronics

CANADA 1-800-SAMSUNG(726-7864)

1-800-SAMSUNG (726-7864) www.samsung.com/us/support

www.samsung.com/ca/support (English)

www.samsung.com/ca_fr/support (French)

smartphone

DG68-01242A-00

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 28 2020-03-27 11:10:10

Page 29

Estufa de combustible dual

Manual de instalación

NY63*875**

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 1 2020-03-27 11:10:11

Page 30

Contenido

Contenido Contenido

ADVERTENCIA

Si no se sigue la información de este manual con exactitud, podrían producirse

incendios o explosiones que causen daños a la propiedad, lesiones personales o muerte.

• NO debe almacenarse ni utilizarse gasolina u otros líquidos y vapores

Antes de comenzar 3

inamables cerca de este u otros artefactos.

• QUÉ HACER SI HAY OLOR A GAS:

- NO intente encender ningún electrodoméstico.

- NO toque ningún interruptor eléctrico.

- NO utilice ningún teléfono dentro del edicio.

- Llame inmediatamente al proveedor de gas desde el teléfono de un vecino.

Información importante de seguridad 3

Componentes de la estufa de combustible dual 9

Contenido de la caja 9

Siga las instrucciones del proveedor de gas.

- Si no puede comunicarse con el proveedor de gas, llame al departamento

de bomberos.

• La instalación y el servicio técnico deben ser realizados por un instalador

calicado, agencias de servicio técnico o el proveedor de gas.

Dispositivo anti inclinación

ADVERTENCIA

TODAS LAS ESTUFAS PUEDEN INCLINARSE, LO QUE PUEDE TENER COMO

RESULTADO LESIONES PERSONALES.

LAS ESTUFAS INCLINADAS PUEDEN CAUSAR QUEMADURAS POR

DERRAMES, LESIONES PERSONALES O LA MUERTE.

INSTALE Y VERIFIQUE LA MÉNSULA ANTI INCLINACIÓN SEGÚN LAS

INSTRUCCIONES Y LA PLANTILLA PROVISTA CON LA MÉNSULA.

• Para evitar que se incline la estufa, je al piso un dispositivo anti inclinación aprobado.

(Consulte Instalación del dispositivo anti inclinación en las Instrucciones de instalación.)

Incline cuidadosamente la estufa hacia adelante para vericar que la instalación se haya

realizado correctamente. El dispositivo anti inclinación debe conectarse y evitar que la

estufa se incline.

• Si por alguna razón se separa la estufa de la pared, asegúrese de que vuelva a conectarse

el dispositivo anti inclinación luego de volver a colocar la estufa en su lugar.

• Siga las instrucciones de instalación que se encuentran en el Manual de instalación. No

seguir estas instrucciones puede ocasionar muerte, lesiones personales graves o daños a

la propiedad.

• Para evitar la inclinación accidental de la estufa, NO se pare, siente o apoye sobre la

puerta ni el cajón.

• Asegúrese de que su electrodoméstico sea correctamente instalado y conectado a tierra

por un técnico calicado.

Requisitos de instalación 11

Requisitos de ubicación 11

Para evitar la rotura 13

Requisitos para el gas 14

Requisitos especiales para el gas (modelos a gas vendidos en Massachusetts) 14

Requisitos eléctricos 15

Instrucciones de instalación 16

Instalación de la estufa de combustible dual 16

Paso 1. Desembalaje de la estufa 16

Paso 2. Cumplimiento de los requisitos de conexión eléctrica 16

Paso 3. Acceso a la conexión del cable de alimentación 17

Paso 4. Instalación del cable de alimentación 18

Paso 5. Instalación del conducto 19

Paso 6. Colocación de la cubierta de acceso 21

Paso 7. Conexión de la estufa al suministro de gas 21

Paso 8. Conversión a gas LP (opcional) 22

Paso 9. Instalación del dispositivo anti inclinación 23

Paso 10. Enchufe y ubicación 23

Paso 11. Nivelación de la estufa 24

Paso 12. Montaje de los quemadores superiores 24

Paso 13. Vericación del encendido de los quemadores superiores 25

Paso 14. Lista de vericación nal de la instalación 26

2 Español

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 2 2020-03-27 11:10:11

Page 31

Antes de comenzar

Información importante de seguridad

ACERCA DE ESTE MANUAL

LEA ESTAS INSTRUCCIONES EN SU TOTALIDAD Y CUIDADOSAMENTE.

NOTA IMPORTANTE PARA EL INSTALADOR

• Lea todas las instrucciones contenidas en este manual antes de instalar la estufa.

• Retire todos los materiales de empaque de los compartimientos del horno antes de

conectar la alimentación eléctrica y el suministro de gas a la estufa.

• Cumpla todos los códigos y ordenanzas exigidos por las autoridades pertinentes.

• Asegúrese de dejar estas instrucciones al usuario.

• La instalación de este artefacto requiere conocimientos mecánicos básicos.

• La instalación adecuada es responsabilidad del instalador.

• La falla del producto debido a una instalación inadecuada no está cubierta por la Garantía.

NOTA IMPORTANTE PARA EL USUARIO

Conserve estas instrucciones con el manual del usuario para consultas futuras.

• Como con cualquier artefacto que genera calor, existen ciertas precauciones de seguridad

que se deben cumplir.

• Asegúrese de que su electrodoméstico sea correctamente instalado y conectado a tierra

por un técnico calicado.

• Asegúrese de que los revestimientos de las paredes alrededor de la estufa pueden

soportar el calor que ésta genera.

• Los gabinetes de almacenamiento deben colocarse un mínimo de 30 pulgadas (76.2 cm)

por encima de la supercie de los quemadores.

NOTA IMPORTANTE PARA EL SERVICIO TÉCNICO

El diagrama eléctrico se encuentra en un sobre jado a la parte trasera de la estufa.

LEA TODAS LAS INSTRUCCIONES ANTES DE USAR ESTE

ARTEFACTO

• Todos los equipos eléctricos y a gas con piezas móviles pueden ser peligrosos. Lea las

instrucciones de seguridad importantes para este electrodoméstico que se incluyen en

este manual. Se deben seguir las instrucciones a n de minimizar el riesgo de lesión,

muerte o daño a la propiedad.

• Guarde este manual. No lo deseche.

SÍMBOLOS USADOS EN ESTE MANUAL

ADVERTENCIA

Prácticas peligrosas o inseguras que pueden provocar lesiones personales graves o la muerte.

PRECAUCIÓN

Prácticas peligrosas o inseguras que pueden provocar descargas eléctricas, lesiones personales

o daños a la propiedad.

NOTA

Instrucciones y sugerencias útiles.

Estos iconos y símbolos de advertencia se incluyen para evitar que usted u otras personas

sufran lesiones. Sígalas explícitamente. Una vez que haya leído esta sección, consérvela en un

lugar seguro para consultas futuras.

CALIFORNIA PROPOSICIÓN 65 ADVERTENCIA

ADVERTENCIA

Cáncer y Daño Reproductivo - www.P65Warnings.ca.gov

Antes de comenzar

Español 3

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 3 2020-03-27 11:10:12

Page 32

Información importante de seguridad

Información importante de seguridad

MANCOMUNIDAD DE MASSACHUSETTS

• Este producto debe ser instalado por un plomero con licencia o un gasista matriculado

o con licencia del Estado de Massachusetts. Cuando se utilicen válvulas de bola para

el cierre del gas, se debe usar una manija en forma de "T". No deben conectarse varios

conductos exibles de gas en serie.

SEGURIDAD GENERAL

ADVERTENCIA

Para reducir el riesgo de incendio, descarga eléctrica, lesiones personales y muerte, obedezca

las siguientes precauciones.

• No toque ninguna parte de la estufa,

incluyendo, entre otros, los quemadores

del horno, los quemadores superiores o

las partes internas durante la cocción o

inmediatamente después de cocinar.

• Debe conocer la ubicación de la válvula de

cierre del gas y cómo cerrarla si es necesario.

• Asegúrese de que el dispositivo anti inclinación esté correctamente instalado en la estufa.

Consulte las instrucciones de instalación para obtener más información.

• No permita que los niños se acerquen a la estufa ni que se metan o se paren sobre

ella. No permita que los niños jueguen con la estufa ni con ninguna parte de la estufa.

Los niños no deben quedar sin vigilancia en el lugar donde se utiliza la estufa. Para la

seguridad de los niños, recomendamos utilizar la función de control/bloqueo de la puerta.

• Quite todos los materiales de empaque de la estufa antes de utilizarla para evitar que se

prendan fuego. Mantenga todos los materiales de empaque fuera del alcance de los niños.

Deseche adecuadamente los materiales de empaque luego de desembalar la estufa.

• No guarde ningún objeto que resulte de interés para los niños sobre la cubierta o el

protector posterior de la estufa. Los niños que se trepen a la estufa para alcanzar un

objeto podrían morir o resultar seriamente lesionados.

• No opere la estufa si esta o alguna de sus partes se encuentran dañadas, no funcionan

correctamente o si falta alguna pieza.

• No utilice la estufa como calefactor del ambiente. Esta estufa se debe usar exclusivamente

para cocinar.

• No utilice limpiadores para horno ni revestimientos de horno dentro o cerca de ninguna

parte del horno.

• Utilice únicamente agarradores aislantes secos.

• No utilice la estufa para calentar recipientes cerrados con alimentos.

• No golpee el vidrio del horno.

• Al desechar la estufa, corte el cable de alimentación y quite la puerta.

• Desenchufe o desconecte la alimentación antes de realizar tareas de mantenimiento o

reparación.

• Asegúrese de que todas las carnes de res y de ave se cocinen bien. La carne de res debe

cocinarse siempre a una temperatura interna de 160 °F (71 °C). La carne de ave debe

cocinarse siempre a una temperatura interna de 180 °F (82 °C).

SEGURIDAD CONTRA INCENDIOS

ADVERTENCIA

Para reducir el riesgo de incendio, descarga eléctrica, lesiones personales y muerte, obedezca

las siguientes precauciones.

• No guarde, coloque ni use materiales

inamables o combustibles como papel,

plástico, agarradores aislantes, ropa de cama,

cortinas, gasolina u otros vapores o líquidos

inamables cerca de la estufa.

• No lleve prendas amplias o colgantes

mientras utiliza la estufa.

• Para evitar la acumulación de grasa, limpie regularmente las ventilaciones.

• No permita que agarradores aislantes u otros materiales inamables entren en contacto

con el elemento calentador. No utilice una toalla u otras telas voluminosas como

agarrador aislante.

• No eche agua sobre la grasa prendida fuego. Para extinguir el fuego de la materia grasa,

apague la fuente de calor y sofoque el fuego con una tapa que ajuste bien o utilice un

extinguidor de incendios de polvo químico seco o de espuma para usos diversos.

4 Español

Install_NY63T8751S_DG68-01242A-00_EN+MES+CFR.indb 4 2020-03-27 11:10:12

Page 33

• Si la grasa llegara a prenderse fuego, presione el botón OFF (APAGAR) para apagar

el horno. Mantenga cerrada la puerta del horno hasta que se extinga el fuego. De ser

necesario, utilice un extinguidor de incendios de polvo químico seco o de espuma para

usos diversos.

• No caliente recipientes cerrados con alimentos. La acumulación de presión puede causar

que el recipiente explote y provocar lesiones.

SEGURIDAD DEL GAS

ADVERTENCIA

Para reducir el riesgo de incendio, descarga eléctrica, lesiones personales y muerte, obedezca

las siguientes precauciones.

Si hay olor a gas:

• Cierre la válvula y no use la estufa.

• No encienda cerillos, velas ni cigarrillos.

• No encienda ningún artefacto eléctrico o a gas.

• No toque ningún interruptor eléctrico ni enchufe el cable de alimentación en un

tomacorriente.

• No utilice ningún teléfono dentro del edicio.

• Evacue a todos los ocupantes del ambiente, edicio o área.

• Llame inmediatamente al proveedor de gas desde el teléfono de un vecino. Siga las

instrucciones del proveedor de gas.

• Si no puede comunicarse con el proveedor de gas, llame al departamento de bomberos.

Vericación de pérdidas de gas

• La prueba de pérdidas del artefacto debe ser realizada de acuerdo con las instrucciones

del fabricante. No utilice una llama para vericar si hay fugas de gas. Utilice un cepillo