Page 1

Temperature Regulator Series 43

Type 43-2 N

Fig. 1 ⋅Type 4 3-2 N

Mounting and

operating instructions

EB 2186 EN

Edition July 2001

Page 2

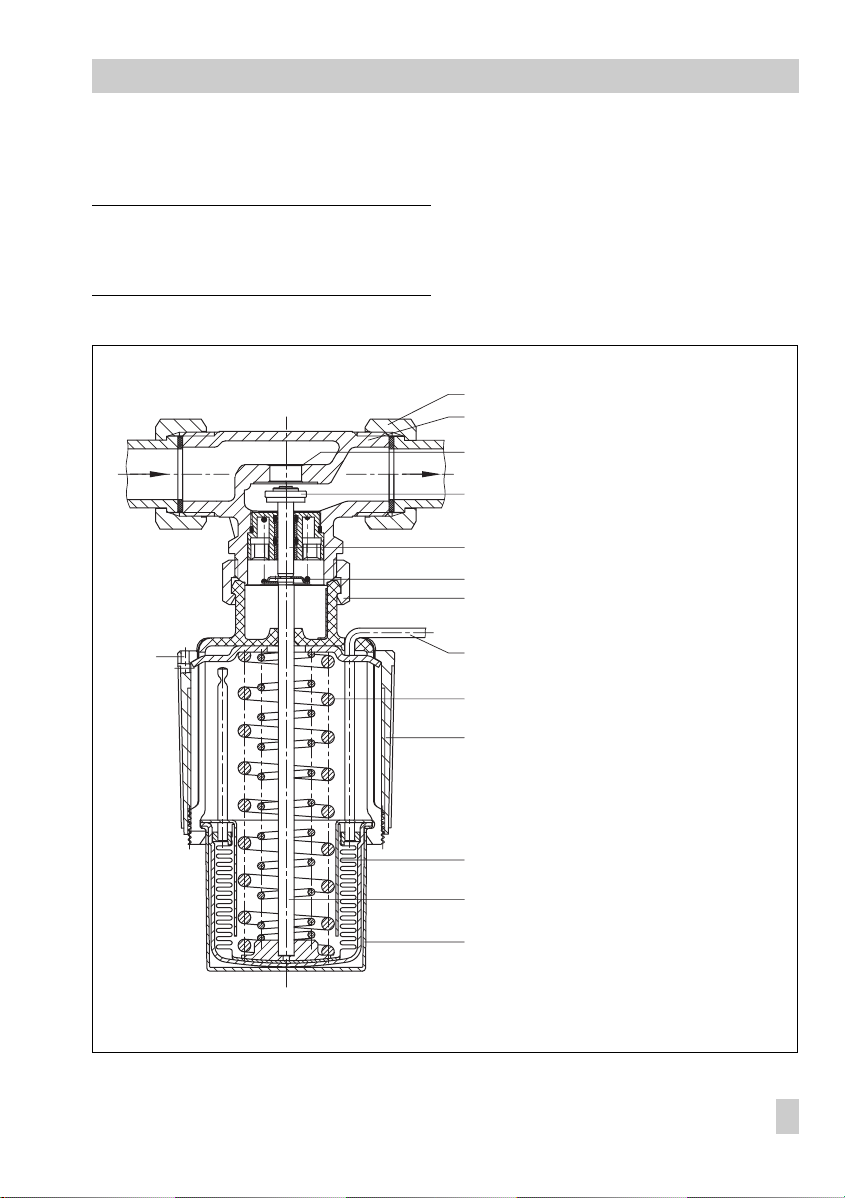

Design and principle of operation

1. Design and principle of operation

1.1 Temperature regulator

The temperature regulator consists of the

valve and the Type 2430 K Thermostat

which are screwed together.

The valve comprises the valve body, seat

and plug, the thermostat comprises operating bellows, set point spring, capillary tube

and temperature sensor.

1.2 Version with double adapter

and/or manual adjuster

For measurement of an additional process

variable, the temperature regulator can be

equipped with a double adapter plus an addi-

The device may only be assembled, started up and operated by trained and

experienced personnel familiar with this product.

According to these mounting and operating instructions, trained personnel is

referred to as individuals who are able to judge the work they are assigned to

and recognize possible dangers due to their specialized training, their knowledge and experience as well as their knowledge of the applicable standards.

Any hazards which could be caused by the process medium, the signal press-

ure and moving parts of the control valve are to be prevented by means of appropriate measures.

In addition, it is necessary to make sure that the control valve is only used in

areas where the operating pressure and temperatures do not exceed the operating values which are based on the valve sizing data submitted in the order.

Proper shipping and appropriate storage are assumed.

tional thermostat, or with a manual adjuster.

For further details, refer to EB 2176 EN.

Principle of operation:

The temperature regulator works according

to the adsorption principle. The temperature

of the process medium produces a pressure

in the sensor, which is proportional to the

actual value. This pressure is transmitted via

the capillary tube (10) to the operating element (13) and converted into a positioning

force.

This force acts upon the operating bellows

(9) and the operating element pin (12) and

is passed on to the plug stem and plug (3).

Turning the set point adjuster (8) changes

the regulators point of response via the

spring (7). As a result, the valve plug passes

through its travel range within a higher or

2

EB 2186 EN

Page 3

lower temperature range sensed by the sensor.

For thermostats working according to

Note:

the vapor pressure principle, refer to

EB 2430-3 EN.

Design and principle of operation

1.1

1

2

3

4

5

15

(20Nm)

7

Fig. 2 ⋅Sectional drawing

10

7

8

9

12

13

1 Valve body

1.1 Coupling nut with gasket and

accessory weld-on fittings

(must be ordered separately)

2Seat

3Plug

4Plug stem

5Valve spring

7Set point spring

8 Set point adjuster

9 Operating bellows

10 Capillary tube

12 Pin of operating element

13 Operating element

14 Lead bore

15 Coupling nut

EB 2186 EN

3

Page 4

Installation

2. Installation

On installing the regulator, make sure that

the permissible ambient temperature does

not exceed 80 °C.

2.1 Installing the valve

The valve may be installed in any desired

position, however, we recommend that the

valve be installed in a horizontal pipeline

with the thermostat vertically suspended.

The medium must flow through the valve in

direction indicated by the arrow on the

valve body.

2.1.1 Strainer

A strainer (SAMSON Type 1 NI) must be installed upstream of the relevant valve, since

sealing particles, globules or other impurities carried along by the process medium could impair the proper functioning of

the valve, especially tight shut-off.

The filter element must be vertically suspended.

Ensure that ample space is available to

remove the filter.

2.1.2 Additional installation instructions

Ideally, hand-operated shut-off valves

should be installed both upstream of the

strainer and downstream of the regulator.

This allows the plant to be shut down for

cleaning and maintenance routines, or

when the plant is not operated for extended

periods.

To check the adjusted set point, we recommed that a thermometer be installed

near the sensor immersed in the medium to

be controlled.

2.2 Installing the temperature sensor

The temperature sensor may be installed in

any desired position. Its entire length must

be immersed in the medium to be controlled.

When choosing the point of installation,

make sure that the sensor is installed in a lo-

1123 54

Fig. 3 ⋅Installation example in a water-heated boiler

4

EB 2186 EN

1Shut-off valves

2Strainer

3Regulator

4 Thermometer

5 Temperature sensor

Page 5

Adjusting the set point

cation where overheating and considerable

idling times do not occur.

A welding socket with a G 1/2 female

thread connection should be welded where

the sensor is to be installed.

Seal the screw gland or thermowell into

the welding socket.

Insert the sensor and tighten it with the

clamping screw.

CAUTION!

To prevent damage caused by corrosion, it

is important to make sure on installing the

sensor or thermowell that only the same

kind of materials are used together. For example, do not use a sensor or thermowell

made of non-ferrous metal in a stainless

steel heat exchanger. In this case, the sensor should be used together with a stainless

steel thermowell.

2.2.1 Capillary tube

The capillary tube should be routed without

bends or twists. The smallest bending radius

is 50 mm. Roll up any extra length to form

a ring. Do not bend or shorten.

The ambient temperature around the tube

should be kept as even as possible.

3. Operation

3.1 Adjusting the set point

To adjust the set point value, use the black

plastic ring (set point adjuster 8) while watching the reference thermometer.

The adjustment diagrams below can be used

as a guide to find the first approximate value.

The adjustment is infinitely variable. Turning

the ring clockwise reduces the temperature

and counterclockwise turning increases it.

The temperature can be fixed at an adjusted

value by lead-sealing the bore (14) in the set

point adjuster.

Set point

range °C

0 to 35 2.5 9.5

25 to 70 3 9.5

40 to 100 4 9.5

100

80

C

˚

Set point change

per turn

Sensor

diameter

40...100

60

40

20

0

01234

Turns of adjuster (scale marking)

Fig. 4 ⋅Set point adjustment

25...70

0...35

EB 2186 EN

5

Page 6

Adjusting the set point

4. Troubleshooting

Should the temperature exceed the set point

adjusted, the cause could be either contamination of seat and plug or wear and tear of

the seat and plug no longer ensuring tight

shut-off.

For remedy, the valve can be disassembled

after shutting down the plant.

5. Customer inquiries

Should you have any inquiries regarding

the temperature regulator, please submit the

following details:

(see also nameplate)

Type and nominal size

Order no. and product no.

Upstream and downstream pressure

Type of process medium and temperature

Max. and min. flow rate

Has a strainer been installed?

Installation drawing

6

EB 2186 EN

Page 7

6. Dimensions in mm

Dimensions in mm

65

G½

ISO 228/1 - G¾B

150

Ver si on wi th thr ea de d e nd s

129

SW30

65

Version with weld-on fittings

with thermowell or with screw gland

210

Bulb sensor

G½

185

Ø12 Ø9.5

Soldered ends

107 for ∅di =15, 103 for ∅di =18

di

Ø21.3

SW30

185

Ø21.3

SW30

EB 2186 EN

7

Page 8

SAMSON AG ⋅ MESS- UND REGELTECHNIK

Wei smü lle rst raß e 3 ⋅ D-60314 Frankfurt am Main

Telefon (0 69) 4 00 90 ⋅ Telefax (0 69) 4 00 95 07

Internet: http://www.samson.de

EB 2186 EN

S/C 2001-07

Loading...

Loading...