Page 1

Temperature Regulators Series 43

Type 43-1

Type 43-2

Type 43-1 ⋅ Ver sio n w ith

female thread

Temperature regulator versions

Fig. 1

⋅

Type 43-2 ⋅ Ver si on wi th fl ang ed va lv e b od y

DN 32 to 50

Ty pe 4 3- 2 ⋅ Version with

weld-on fittings

Mounting and

operating instructions

EB 2171 EN

Edition August 2003

Page 2

Contents

Contents Page

1. Design and principle of operation

. . . . . . . . . . . . . . . . . . . . . .

1.1 Temperature regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Version with safety thermostat . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Version with double adapter and/or manual adustment . . . . . . . . . . . . 4

2. Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Installing the valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Additional installation instructions . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Installing the temperature sensor . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Capillary tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. Maintenance Replacing parts

. . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Cleaning or replacing the plug . . . . . . . . . . . . . . . . . . . . . . . . 8

5. Troubleshooting

6. Dimensions in mm and weights

7. Customer inquiries

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4

2

Typetesting

The Type 43-1 and Type 43-2 Temperature Regulators are typetested accord ing to DIN 3440 by the German technical surveillance association TÜV.

Register number available on request

EB 2171 EN

Page 3

Safety instructions

General safety instructions

The temperature regulators may only be mounted, started up or serviced by

fully trained and qualified personnel, observing the accepted industry codes

and practices. Make sure employees or third persons are not exposed to any

danger.

All safety instructions and warnings in these mounting and operating instruc tions, particularly those concerning assembly, start-up and maintenance, must

be observed.

The control valves fulfil the requirements of the European Pressure Equipment

Directive 97/23/EC. Valves with a CE marking have a declaration of con formity which includes information about the applied conformity assessment

procedure. The declaration can be viewed and downloaded on the Internet at

http://www.samson.de.

For appropriate operation, make sure that the temperature regulators are

only used in areas where the operating pressure and temperatures do not ex ceed the operating values which are based on the valve sizing data submitted

in the order. The manufacturer does not assume any responsibility for dam age caused by external forces or any other external influence!

Any hazards which could be caused in the temperature regulator by the pro cess medium, the operating pressure or by moving parts are to be prevented

by means of the appropriate measures.

Proper shipping and appropriate storage are assumed.

Caution!

Do not start up the temperature regulators before the valve and control

thermostat have been installed.

Prior to removing the regulator from the pipeline, make sure the relevant sec -

tion of the pipeline is depressurized and drained.

Allow the plant to fill up slowly on start-up.

Make sure regulators are frost protected when used to control freezing media.

If the sensor is used in combination with a thermowell, only SAMSON thermo-

wells should be used.

EB 2171 EN

3

Page 4

Design and principle of operation

1. Design and principle of operation

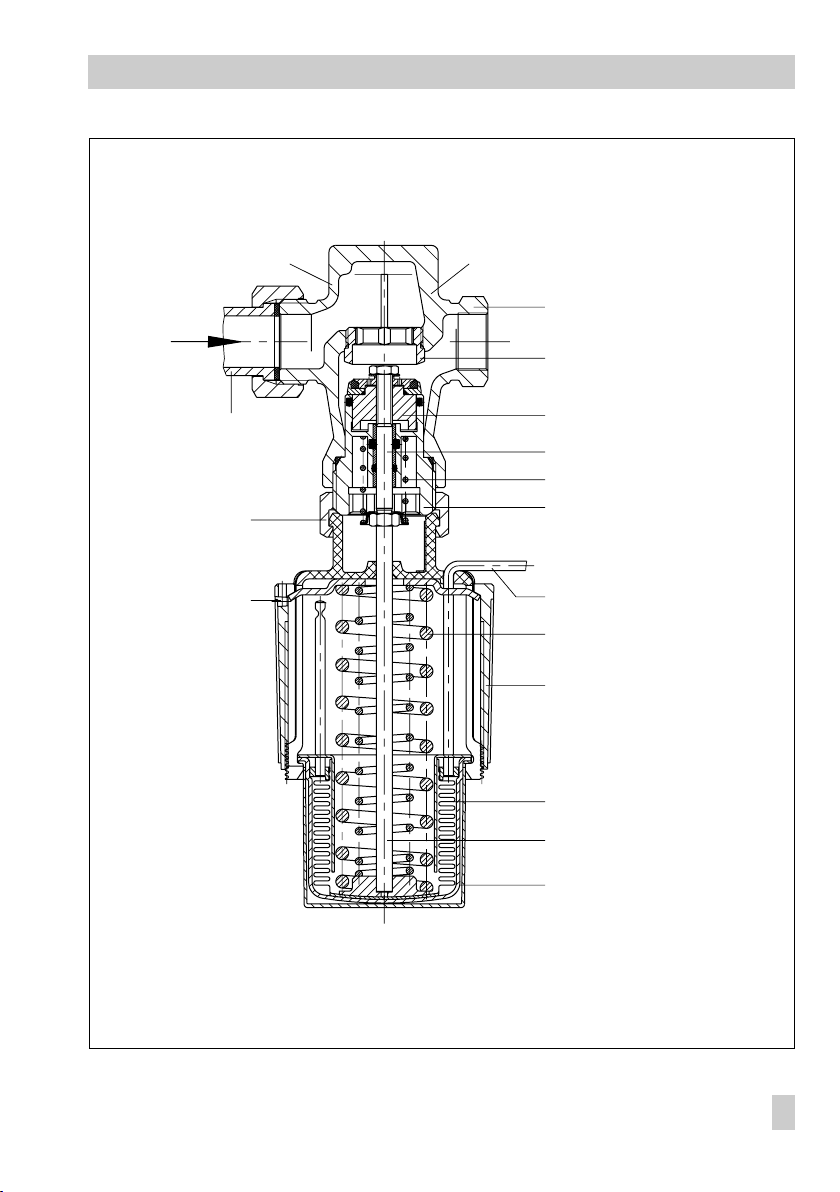

1.1 Temperature regulator

The temperature regulators consist of a

valve with the Type 2430 K Thermostat

screwed onto it.

The valve consists of a valve body, seat and

a pressure-balanced plug. The thermostat

contains a positioning bellows, set point

spring, capillary tube and temperature sensor.

1.2 Version with safety thermostat

When a Type 2439 K/ 2403 K Safety

Thermostat is attached to the valve or regulator, these versions are used as safety temperature limiters STL or safety temperature

monitors STM.

Refer to the mounting and operating instructions EB 2185 EN for more details.

1.3 Version with double adapter

and/or manual adjustment

The temperature regulator can be equipped

with a double adapter and/or manual adjustment to control a further control variable.

Refer to the mounting and operating instructions EB 2176 EN for more details.

Principle of operation:

The temperature regulator functions according to the adsorption principle. The tempera ture of the medium to be controlled creates

a pressure in the sensor which corresponds

with the temperature measured. This press ure is transferred over the capillary tube

(10) to the operating element (13) where it

is converted into a positioning force.

The force acts over the positioning bellows

(9) and pin of the operating element (12)

on the plug stem and plug (3).

By turning the set point adjuster (8), the

point of response over the spring (7) is

changed. As a result, the valve plug moves

through its full travel range within a higher

or lower temperature range measured by

the sensor.

Note:

Thermostats that function according to the

vapor pressure principle are described in

EB 2430-3 EN.

4

EB 2171 EN

Page 5

Design and principle of operation

Type 43-2

Type 2432 K Valve

1.1

15

(20 Nm)

14

Type 2439 K Thermostat

Type 43-1

Type 2431 K Valve (female thread)

1

2

3

4

5

3

10

7

8

9

12

13

1Valve body

1.1 Connection nut with

gasket and weld-on

fitting

2Seat

3Plug

4Plug stem

5 Valve spring

7 Positioning spring

8 Set point adjuster

9Positioning bellows

10 Capillary tube

12 Pin of operating element

13 Operating element

14 Lead-sealed bore

15 Coupling nut

Fig. 2 ⋅Sectional drawing

EB 2171 EN

5

Page 6

Installation

2. Installation

Make sure that the permissible ambient temperature of 80 °C is not exceeded.

2.1 Installing the valve

The valve must be installed in a horizontal

pipeline with the thermostat suspended

downwards. Other installation positions are

also possible for temperatures lower than

110 °C.

The direction of flow must correspond with

the arrow on the valve body.

2.1.1 Strainer

Install a strainer (SAMSON Type 1 or

Type 2, refer to Data Sheet T 1010 EN and

1015 EN) upstream of the valve to prevent

any sealing parts, weld spatter or other impurities carried along by the process medium from impairing the proper functioning

of the valve, particularly tight shut-off.

The filter element of the strainer must be sus pended downwards.

Make sure sufficient space is left to allow

the filter element to be removed.

1123 54

1Shut-off valve

2Strainer

3Temp. regulator

Fig. 3 ⋅Example of installation in a water-heated boiler

4 Thermometer

5 Temperature sensor

2.1.2 Additional installation instructions

We recommend installing a hand-operated

shut-off valve both upstream of the strainer

and downstream of the regulator to be able

to shut down the plant for cleaning and

maintenance, and when the plant is not

used for long periods of time.

For checking the adjusted set point, it is ad visable to install a thermometer which is sub mersed in the controlled medium close to

the sensor.

2.2 Installing the temperature sensor

The Type 2430 K Temperature Sensor can

be installed in any position. The instructions

of the corresponding mounting and operating instructions must be observed for the

Type 2430 K-3 Vapor Pressure Sensor. The

entire length of the sensor must be immersed

in the medium which is being controlled. Select a point of installation where overheating

and considerable delays cannot occur. Weld

in a welding sleeve with G 1/2 or G 3/4 female thread at the point of installation.

Seal the screw gland or thermowell into the

welded-in sleeve. Insert the sensor and fix

into place using a clamping screw.

To prevent damage caused by corro-

Note:

sion, make sure that the same kinds of materials are used when installing the sensor

or thermowell. For example, do not use a

temperature sensor or thermowell made of

non-ferrous metal in a stainless steel heat exchanger. In this case, use a stainless steel

thermowell for the sensor.

6

EB 2171 EN

Page 7

2.2.1 Capillary tube

The capillary tube must be run without bending or twisting it. The smallest bending

radius should not be less than 50 mm.

Do not damage or shorten the capillary

tube. Roll up any excess tube to form a ring.

Make sure no considerable temperature fluctuations occur along the entire length of the

tube.

3. Operation

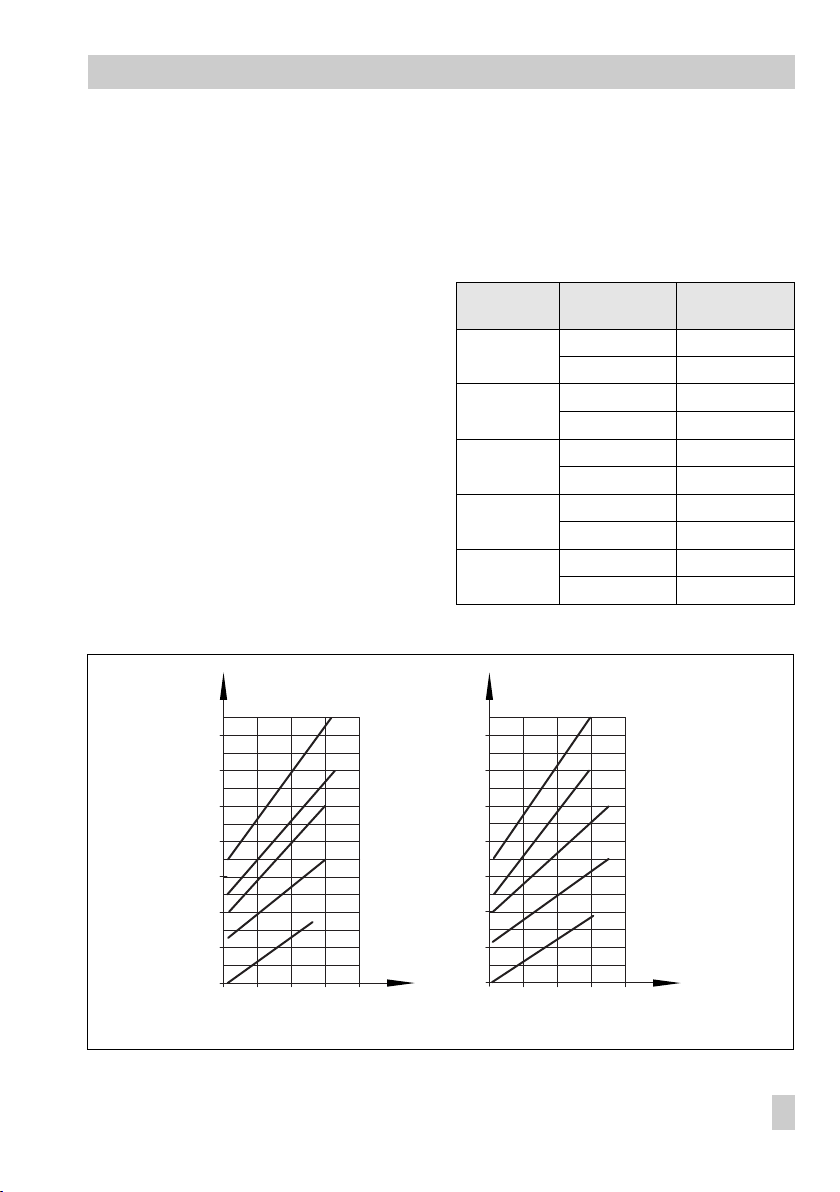

3.1 Set point adjustment

Use the black plastic ring (set point adjus-

ter 8) to set the set point while watching

the reference thermometer.

The adjustment diagrams are intended to

help you find a rough initial value.

Operation

Turning the adjuster clockwise results in

a lower temperature and turning it

counterclockwise a higher temperature.

The adjusted value can be lead-sealed at

the bore (14) in the set point adjuster.

Set point range°CChange in set

0 to 35

25 to 70

40 to 100

50 to 120

70 to 150

po in t p er tu rn

2.5 9.5

216

39.5

216

49.5

316

49.5

4.5 16

4.5 9.5

516

Sensor

diameter

Set point ranges for DN 15 to 25

with sensor Ø 9.5

˚C

150

140

120

100

80

60

40

20

0

01234

Fig. 4 ⋅Adjustment diagrams

˚C

70...150

50...120

40...100

25...70

0...35

Tu r ns ( s c a le m a r ki n g s )

150

140

120

100

80

60

40

20

Set point ranges for DN 32 to 50

with sensor Ø 16

0

01234

70...150

50...120

40...100

25...70

0...35

EB 2171 EN

7

Page 8

Maintenance - Replacing parts

4. Maintenance - Replacing parts

The temperature regulator is maintenance

free. Nevertheless, it is subject to natural

wear, particularly at the seat and plug.

Depending on the operating conditions, the

regulator needs to be checked at regular in tervals to avoid possible malfunctions.

If the valve does not shut off tightly, this may

be due to dirt on the seat and plug, or the

valve seat and plug have become untight

due to natural wear.

The valve can be removed from the pipeline

to repair it.

Note

If you intend carrying out maintenance work on the temperature regulator, first relieve the corresponding

plant section of pressure and, depending on the process medium,

drain it as well.

Let the plant section cool down to

reach ambient temperature, if

necessary.

We recommend removing the regulator from the pipeline.

To replace the seat, a special tool is

Note:

additionally required. Refer to the

EB 029 EN (formerly WA 029 EN) for the

product numbers 2710 to 2730 (also available on the Internet at http://www.samson.de/pdf_en/e00290en.pdf).

1. Unscrew the coupling nut (15) and take

the control thermostat off the valve.

2. Use the socket wrench to unscrew the

entire plug section.

3. Thoroughly clean the seat and plug.

If the seat is damaged, use the seat

wrench (EB 029 EN) to replace the

seat.

If the plug is damaged, the entire plug

section as well as the seal ring in the

body must be replaced with new ones.

4. Proceed in the reverse order to reas semble the valve.

Insert a new seal ring for the plug sec tion in the body.

Apply a drop of "Omnifit 222" before

screwing on the plug section (tightening

torque 80 Nm).

Tighten the coupling nut of the thermostat on the valve with 20 Nm.

4.1 Cleaning or replacing the plug

To change the plug section (3), a special

socket wrench is needed:

For DN 15 to 25 Order no. 1280-3001,

For DN 32 to 50 Order no. 1280-3007.

For nominal sizes DN 15 to 25, this wrench

can be made, for example, from a

GEDORE screwdriver bit (IN 19-19) by drill ing a hole into the 19 mm hexagon bit as

shown in Fig. 5.

8

EB 2171 EN

19 mm hexagon bit

17

Ø 17

SW 19

Fig. 5 ⋅Socket wrench

Page 9

5. Troubleshooting

Problem Possible source Remedy

The value at

the sensor

exceeds or falls

below the set

point

The value at

the sensor

exceeds the

set point

Control loop

is unstable

Leakage at the seat and

plug

Valve is too small or too

big for the control task

Sensor is installed in the

wrong place

Safety device, e.g. STL

or STM has been

triggered

Insufficient cooling or

warming energy

available

Thermostat defective Send the thermostat to SAMSON for repair.

Strainer is blocked Empty strainer filter and clean it.

The medium flows

through the valve in the

opposite direction than

indicated by the arrow

Valve is too big for the

control task

Time constant is too

large for the control

loop

Remove the valve. Clean the seat and plug.

Contact SAMSON after-sales service if the

regulator is defective.

Recalculate the K

SAMSON.

Check whether the entire length of the sensor

is immersed in the medium or whether it is installed where delays can occur or heat can

accumulate.

Check the plant and unlock safety device.

Draw up an energy balance.

Remove the valve and reinstall it so that the

medium flows through the valve in the

direction indicated by the arrow.

Recalculate K

Fill the thermowell with conductive paste, or

remove thermowell or use a sensor with a

smaller time constant.

Troubleshooting

value and contact

VS

value and contact SAMSON.

VS

EB 2171 EN

9

Page 10

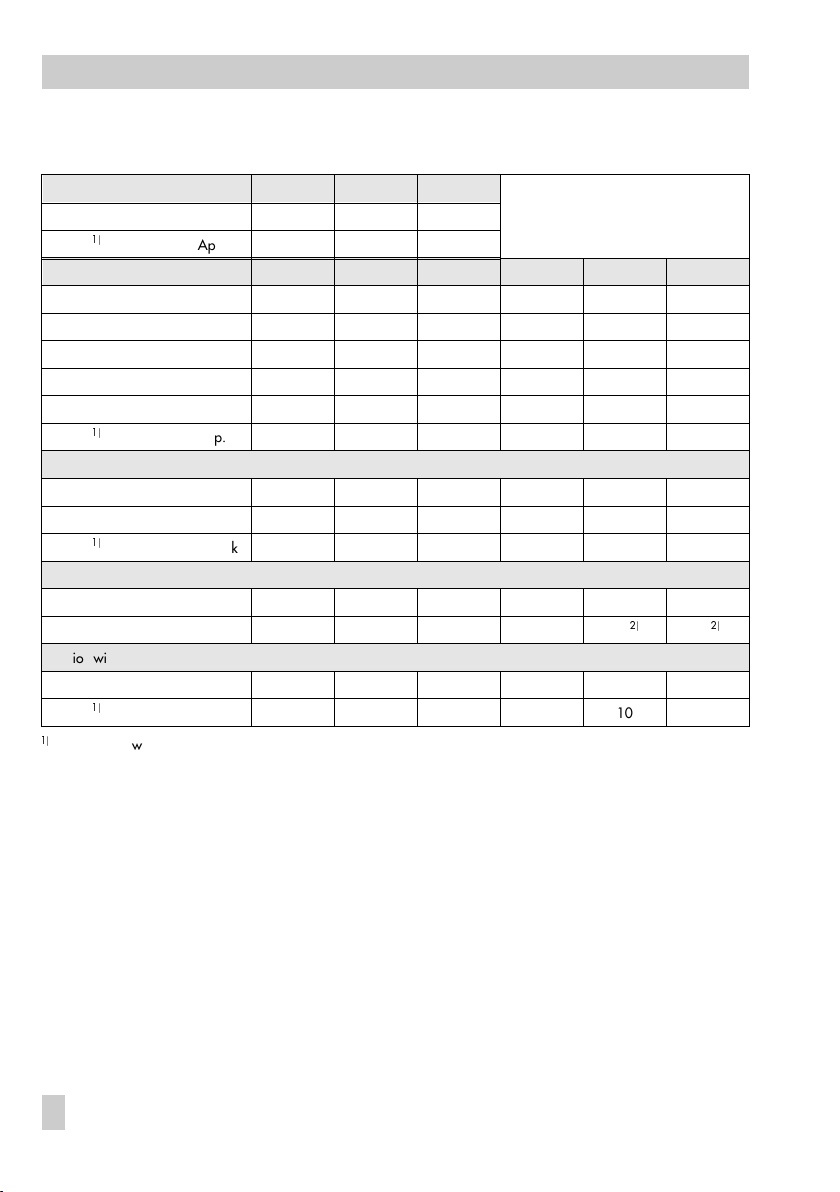

Dimensions in mm and weights

6. Dimensions in mm and weights

Type 43-1

Nom. size G 1/2 3/4 1

Length L 65 75 90

Wei ght

Type 43-2

Nom. sizeDN152025324050

Pipe Ød 21.3 26.8 33.7 42 48 60

R G 3 /4 G 1 G 1 1 /4 G 1 3/ 4 G 2 G 2 1 /2

Width across flats SW 303646596582

Length L 65 70 75 100 110 130

L1 with weld-on fittings 210 234 244 268 294 330

Wei ght

Special version with threaded ends (male thread)

Length L2 129 144 159 180 196 228

Ma le thr ea d A G 1 /2 G 3/ 4 G 1 G 1 1/ 4 G 1 1 /2 G 2

Wei ght

Special version with flanges PN 16/25

Length L3 130 150 160 180 200 230

Weight App. kg 3.1 4 4.8 7.6 9.1

Version with flanged valve body

L3 200 230

Wei ght

App. kg 10 13.2

For versions with bulb sensor and thermowell, versions without thermowell: minus 0.2 kg

App kg 1.4 1.5 1.6

App. kg1.7 2 2.34.45.15.9

App. kg1.7 2 2.34.45.15.9

11

10

EB 2171 EN

Page 11

Typ e 43 -2

30

(55)

with threaded ends

L1

L

Values in parentheses for DN 32 to 50

G½

(G¾)

R

d

Dimensions in mm and weights

Type 43-2

with flanged valve body

L3

SW

180

(230)

Ø12(19) Ø9.5(16)

30180

Type 43-1

L

Bul b s en so r w ith t he rm ow el l o r

screwed gland

Type 43-2

A

7. Customer inquiries

Should you have any questions, please submit the following details (see nameplate):

Type and nominal size

Product and order numbers

Pressures upstream and downstream of

the valve

Process medium and temperature

Minimum and maximum flow rate

Has a strainer been installed?

Installation drawing

220

185(220)

SW

185(220)

with weld-on fittings with flanges

L2

220

SW

Sensor with

Ø 16 only

L3

EB 2171 EN

11

Page 12

SAMSON AG ⋅ MESS- UND REGELTECHNIK

Weismüllerstraße 3 ⋅ 60314 Frankfurt am Main ⋅ Germany

Phone: +49 69 4009-0 ⋅ Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 2171 EN

S/Z 2003-09

Loading...

Loading...