Page 1

Self-operated Regulators

Differential Pressure Regulators with

Flow Limitation

Type 42-34 · Type 42-38

Type 42-34

Type 42-38

Mounting and

Operating Instructions

EB 3013 EN

Edition July 2009

Page 2

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . . . . 4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Strainer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Shut-off valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Pressure gauge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Control line, equalizing tank and needle valve . . . . . . . . . . . . . . . . 8

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.1 Adjusting the differential pressure . . . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Adjusting the flow restriction . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2.3 Pressure conditions in the plant and regulator . . . . . . . . . . . . . . . . 12

3.3 Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Maintenance · Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Replacing the operating diaphragm . . . . . . . . . . . . . . . . . . . . 19

5 Nameplates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 Dimensions and weights. . . . . . . . . . . . . . . . . . . . . . . . . . 22

7 Customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Definitions of the signal words used in these instructions

WARNING!

WARNING indicates a hazardous situation

Note: Supplementary explanations, informa

tion and tips

which, if not avoided, could result in death or

serious injury.

NOTICE

NOTICE indicates a property damage

message.

2 EB 3013 EN

-

Page 3

Safety instructions

General safety instructions

The regulators must be installed, started up and serviced by fully trained and

4

qualified personnel only, observing the accepted industry codes and practi

ces. Make sure employees or third persons are not exposed to any danger.

The regulator complies with the requirements of the European Pressure Equip

4

ment Directive 97/23/EC. The declaration of conformity issued for a valve

bearing the CE marking includes information on the applied conformity as

sessment procedure.

The declaration of conformity can be provided on request.

For appropriate operation, make sure that the regulator is only used in appli

4

cations where the operating pressure and temperatures do not exceed the

operating values based on the sizing data submitted in the order.

Note that the manufacturer does not assume any responsibility for damage

4

caused by external forces or any other external factors.

Any hazards whichcould be causedin the regulatorby the processmedium or

4

operating pressure are to be prevented by means of appropriate measures.

Proper shipping and appropriate storage are assumed.

4

-

-

-

-

Note: Non-electric valve versions which do not have a valve body lined with an insulating coa

ting donot have theirown potential ignitionsource according tothe ignition risk assessment sti

pulated in EN 13463-1: 2001, section 5.2, even in the rare incident of an operating fault. The

refore, they do not fall within the scope of Directive 94/9/EC.

For the connection to equipotential bonding, observe section 6.3 in EN 60097-14: 1977

(VDE 0165, Part 1)

EB 3013 EN 3

-

-

-

Page 4

Design and principle of operation

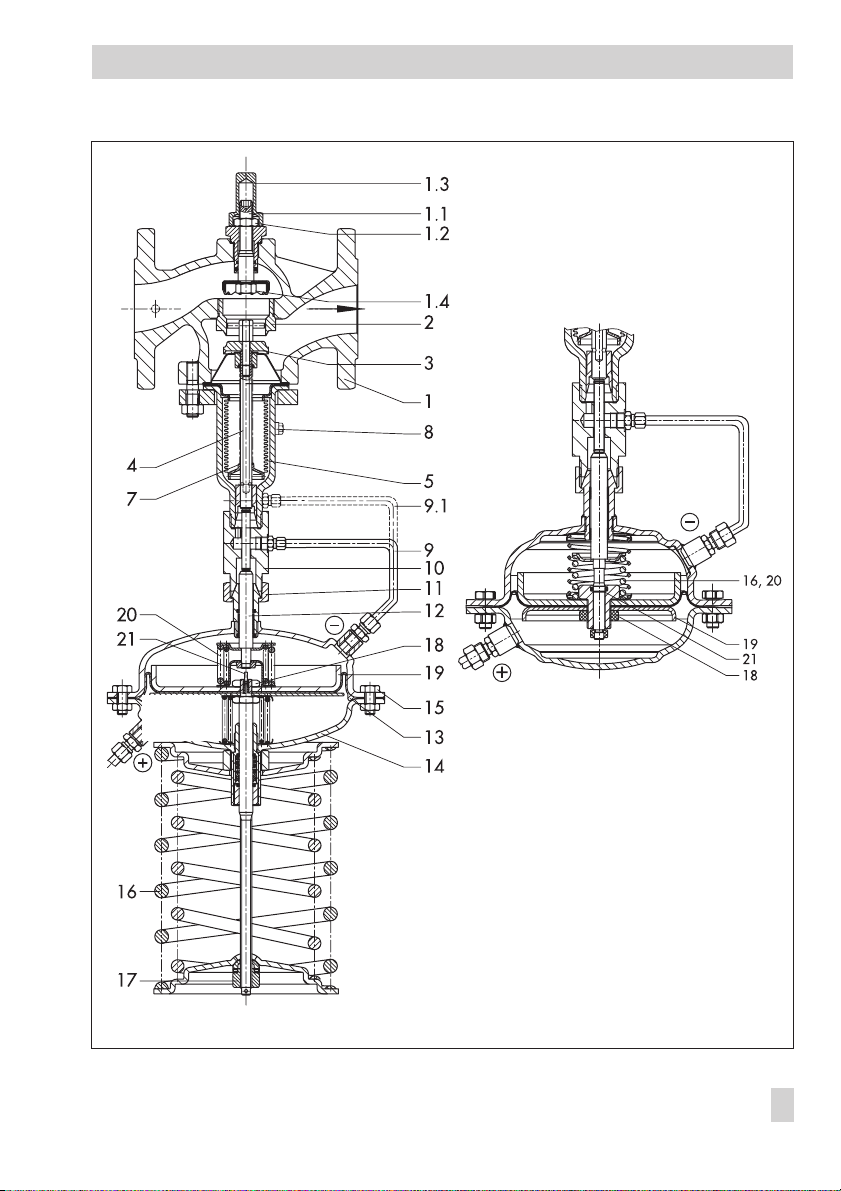

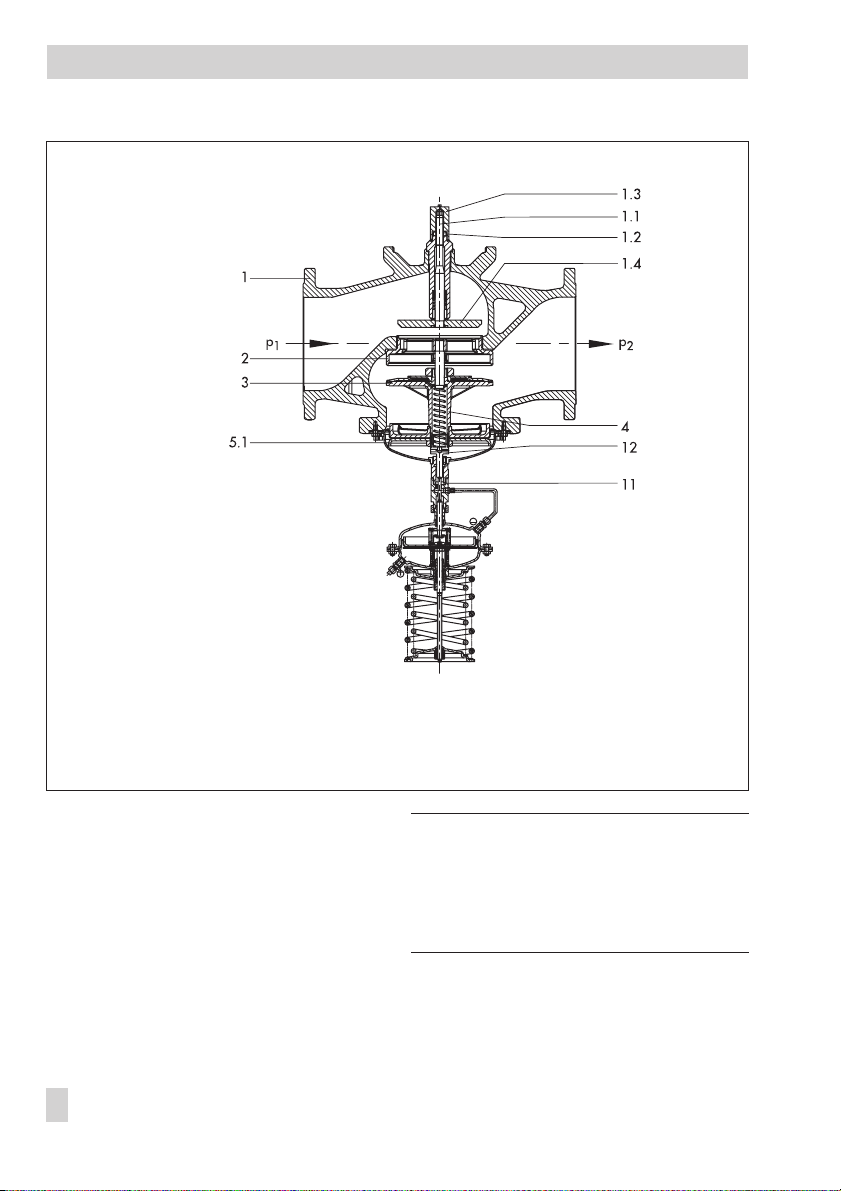

1 Design and principle of

operation

The differential pressure regulators are used

to maintain the differential pressure between

the high-pressure and the low-pressure pipe

at a set point which is either fixed (Type

42-38) or adjustable (Type 42-34). The re

striction built into the valve body allows for

limitation of the flow rate.

The regulators basically consist of a valve

with a seat, plug and restriction as well as a

closing actuator with an operating dia

phragm. The valve and actuator are deliv

ered in separate packaging and need to be

connected on siteusing the coupling nut(11).

The process medium flows through the valve

in the direction indicated by the arrow. The

free areasof flow releasedby the orifice(1.4)

and the valve plug (3) determine the flow rate

.

and the differential pressureΔp

V

the plant.

Fully balanced valves ensure that the up-

stream and downstream forces acting on the

valve plug are eliminated by a balancing bel

lows (5) or a balancing diaphragm (5.1). The

principle of operation of the regulators with

valves balanced by a bellows or by a dia

phragm only differ concerning their pressure

balancing. Valves balanced by a diaphragm

(DN 125 to 250 only) have a balancing dia

phragm instead of a balancing bellows (5).

The pressure downstream of the orifice (1.4)

acts on the outer surface of the metal bellows

plant

across

or balancing diaphragm and the down

stream pressure on the inside of the bellows

or diaphragm. As a result, the forces created

by the upstream and downstream pressures

acting on the valve plug are equally bal

anced.

The regulators in sizes DN 15 to 100 are

-

equipped witha connecting piece(10) forthe

low-pressure control line between the valve

and the actuator.

In differential pressure control, the high pres

sure (flow) of the plant is transmitted to the

bottom diaphragm chamber of the actuator

over the high-pressure control line. The pres

sure downstream of the orifice (1.4) acts on

the top diaphragm chamber over the hollow

plug stem and the connected low-pressure

control line. The differential pressure is converted into a positioning force at the diaphragm (13) and is used to change the position ofthe valve plug according to theforce of

the set point springs (16). Depending on the

version of the actuator, the set point springs

are installed in the actuator to provide a fixed

set point (Type 42-38), or they are located

outside to allow the set point tobe adjusted as

required (Type 42-34).

-

The restriction (1.1) is used to adjust the flow

limitation.

The force limiter (20) as well as the internal

excess pressure limiter (21) are designed to

protect the seat (2) and plug (3) against over

load in caseof extreme operating conditions.

-

-

-

-

-

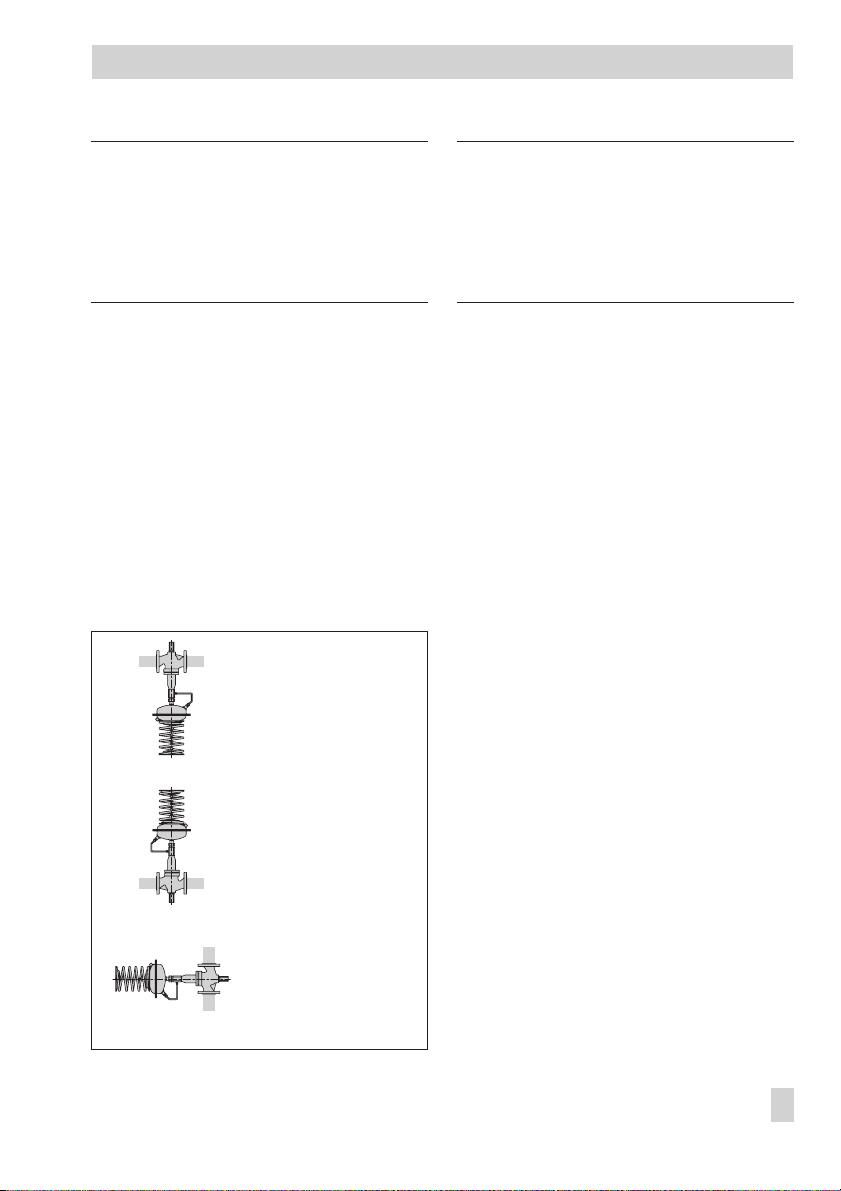

Table 1 · Regulator configuration

Controller = Valve + Actuator

Type 42-34 with connecting piece (

Type 42-38 with connecting piece Type 2423 Balanced Type 2428 Fixed set point

for DN 15 to 100) Type 2423 Balanced Type 2424 Adjustable set point

4 EB 3013 EN

Page 5

Design and principle of operation

Type 42-34

Type 42-34, Type 42-38 · Balanced by a bellows

DN 15 to 250

Type 2423 Valve

balanced by a bellows

Type 2424

Type 2428 Actuator

Actuator

1 Valve body

1.1 Restriction (for flow rate

set point adjustment)

1.2 Lock nut

1.3 Cap

1.4 Orifice

2 Seat

3 Plug

4 Plug stem

5 Balancing bellows

7 Spring

8 Venting

(DN 125 and larger)

Fig. 1 · Schematic diagrams of regulator with valve balanced by a bellows

Type 42-38

DN 15 to 100

9 Low-pressure control line

(up to DN 100)

9.1 Low-pressure control line

connection (DN 125 and larger)

10 Connecting piece (up to DN 100)

11 Coupling nut

12 Diaphragm stem

13 Operating diaphragm

14 Actuator housing

15 Screws

16 Set point springs

17 Set point adjustment (screw)

18 Nut

19 Diaphragm plate

20 Force limiter

21 Internal excess pressure limiter

EB 3013 EN 5

Page 6

Installation

Type 2423 Valve

balanced by a

diaphragm

Type 42-34 · Balanced by a diaphragm · DN 125 to 250

Type 2424

Actuator

1 Valve body

1.1 Restriction (for flow rate

set point adjustment)

1.2 Lock nut

1.3 Cap

1.4 Orifice

Fig. 2 · Schematic diagrams of regulator with valve balanced by a diaphragm

2 Installation

See Figs. 1 and 2

The regulator must be installed in the return

flow pipe as shown in the installation sche

matic in Fig. 5.

When choosing the place of installation, en

sure the regulator can be easily accessed af

2 Seat

3 Plug

4 Plug stem

5.1 Balancing diaphragm

11 Coupling nut

12 Diaphragm stem

-

-

-

NOTICE

The regulator mustbe installed freeof stress. If

necessary, support the piping near the con

nections. However, do not attach supports to

the valve or actuator.

ter completion of the plant.

6 EB 3013 EN

-

Page 7

Installation

Note: Install a strainer (e.g. SAMSON

Type 2 N/2 NI) upstream of the regulator to

prevent sealing particles, welding spatter or

other impurities carried along by the process

medium from impairing the proper function

ing of the valve, especially tight shut-off.

2.1 Mounting position

See Fig. 3 for permissible mounting positions.

Standard installation · Install the valve with

out the actuator in a horizontal pipeline with

the connection for the actuator facing downwards. Make sure the medium flows through

the valve in the direction indicated by the arrow. Then connect the actuator (and the connecting piece (10) for versions in sizes DN 15

to 100) to the valve using the coupling nut

(11).

–

Standard mountingposition

– all versions –

–

All versions

up to max. 80 °C

NOTICE

Protect the regulator when it is used to control

freezing process media.

On shutting down the plant in areas not free

from frost, depressurize and empty the regu

lator and remove it from the pipeline.

2.2 Strainer

A strainer installed in the flow pipe (Fig. 5)

prevents foreign matter and dirt particles in

the medium from entering the regulator. The

SAMSON product range includes the

Type 2 N/2 NI Strainer (refer to Data Sheet

T 1010 EN).

Install the strainer upstream of the regulator.

Make sure the direction of medium flow corresponds with the direction indicated by the

arrow on the strainer. The filter element must

be suspended downwards. Remember to

leave enough space to remove it.

2.3 Shut-off valve

We recommend installing a hand-operated

shut-off valve (Fig. 5) both upstream of the

strainer and at the outlet of the return flow

pipe to be able to shut down the plant for

cleaning and maintenance, and when the

plant is not used for longer periods of time.

-

–

Only versions with fixed

plug guide and

up to max. 80 °C

Fig. 3 · Permissible mounting positions

2.4 Pressure gauge

To monitor the pressures in the plant, install a

pressure gauge both upstream and down

stream of the regulator (Fig. 5).

EB 3013 EN 7

-

Page 8

Installation

2.5 Control line, equalizing tank

and needle valve

Control lines · After mounting the actuator,

fasten the supplied high-pressure control line

to the regulator (standard: 8 mm pipe diame

ter) routing it from the bottom diaphragm

chamber to the high-pressure line (flow pipe)

of the plant. Attach the low-pressure control

line to the regulator as shown in Figs. 1 and

2.

The controlline to be installed on site for pres

sure tapping at the pipeline must be at least

three times the nominal size (DN) away from

pipe fittings or instruments thatcause flow tur

bulence (e.g. pipe bends, manifolds,pressure

measuring points or other valves) (see Fig.

4.1). How the lines are routed generally de-

pends on the installation location. Preferably

connect the control line at the side of the main

pipeline (Fig. 4.4).

Do not change the pipe diameter of the main

pipeline so that it is off-center!

Control line kit · A control line kit for tapping

pressure directly at the valve body is avail

able as an accessory from SAMSON. Refer to

Data Sheet T 3095 EN.

Equalizing tank · An equalizing tank is re

quired for liquids above 150 °C. Install an

equalizing tank in the control line directly

downstream of the pressure tapping point.

The mounting position of the equalizing tank

is indicated by an adhesive label on the tank

itself as well as by an arrow and the word

"top" stamped onto the top of the tank. Ad

here to the mounting position and distances

prescribed, otherwise the safe functioning of

the regulator cannot be guaranteed.

Correct!

-

4.4 · Connection at the side – correct

Incorrect!

-

4.3 · Connection at the top – incorrect

-

Incorrect!

4.2 · Connection at the bottom – incorrect

-

-

-

DN = Nominal size

4.1 · Control line connection, depending on how

the pipeline is routed

Fig. 4 · Control line connection

8 EB 3013 EN

Page 9

Operation

Needle valve · If the regulator tends to hunt,

we recommend installing a SAMSON needle

valve in the control line installed on site at the

actuator connection.

Note: Needle valves, equalizing tanks and

compression-type screw fittings can be sup

plied as required. These accessories are listed

in the Data Sheet T 3095 EN.

1 Shut-off valve

2 Strainer

3 Differential pressure regulator

4 Equalizing tank (optional)

5 Pressure gauge

6 Needle valve (optional)

7 Motorized valve

Fig. 5 · Typical installation, Type 42-34/42-38

installed in the return flow pipe

3 Operation

See Figs. 1 and 2.

3.1 Start-up

CAUTION!

First start up the regulator after mounting all

the components, e.g. valve, actuator andcon

trol line.

Make sure the control line (and needle valve)

is open and correctly connected before

start-up.

For media temperatures above 150 °C, fill

the equalizing tank with the process medium

(water) before start-up.

Note: On filling the plant, make sure the

orifice (1.4) is open byunscrewing the restriction (1.1) counterclockwiseas far asit will go.

Open all the valves on the consumer side.

4

Slowly open the shut-off valves starting on

the return flow pipe first. In case of valves

balanced by a bellows in DN 125 or

larger, vent the bellows housing at the

stopper (8) located at the side of the bel

lows housing.

Rinsing the plant · After filling the plant, first

completely open the consumers. At the regu

lator, openthe restriction counterclockwise as

far as it will go and adjust the maximum dif

ferential pressure by tensioning the set point

springs to the maximum. Rinse out the pipe

line at full flow ratefor several minutes. Check

the installed strainer (e.g. by measuring the

pressure drop) afterwards. Clean the strainer,

if necessary.

-

-

-

-

-

EB 3013 EN 9

Page 10

Operation · Set point adjustment

NOTICE

When testing the pressure of the plant when

the regulatoris already installed, the pressure

must not exceed the nominal pressure of the

valve by 1.5times nor themaximum permissi

ble differential pressure in the actuator (final

value of set point range by 1.5 times).

If higher test pressures are used, unscrew the

control lines connected to the actuator and

seal openings atthe actuator andcontrol lines

with stoppers.

3.2 Set point adjustment

3.2.1 Adjusting the differential

pressure

Type 42-34 only · Set the required differen-

tial pressure by turning the set point screw

(17) when the plant is almost closed and the

orifice (1.4) is completely open. Then adjust

the value for the flow restriction.

–

Turn clockwise= Tensioning thesprings

To increase the set point

–

Turn counterclockwise = Relieving the

springs of tension→To reduce the set

point.

How to proceed

Close motorized valve!

4

Unscrew cap (1.3) and undo lock nut

4

(1.2).

Turn the restriction (1.1) counterclockwise

4

as far as it will go (completely opening it)

to deactivate the flow restriction.

Relieve the set point springs (16) of ten

4

sion.

Open motorized valve slightly (approx.

4

10 % travel).

-

Adjust the differential pressure by

4

tensioning the set point springs at the set

point screw (17).

3.2.2 Adjusting the flow restriction

Open control and shut-off valvesas well as all

the consumers (minimum plant resistance) to

achieve the maximum flow rate.

Close the bypass, if applicable.

Adjust the desired flow limitation by turning

the restriction (1.1),monitoring the flow meter

in the heat meter (see Table 2 · Flow rate set

points for water).

Note: Always start the set point adjustment

based on a closed restriction.

–

→

Turn clockwise to close the restriction

Reduces the flow rate.

–

Turn counterclockwise to open the restric

tion→Increases the flow rate.

How to proceed

Completely close the restriction (1.1) to

4

block the flow rate

Completely open motorized valve.

4

Open restriction (1.1), turning it counter

4

clockwise, until the desired flow rate is

reached.

Initially open the restriction by one turn at

4

a time, while monitoring the flow rate at

-

→

-

-

10 EB 3013 EN

Page 11

Operation · Set point restriction

the flow meter in the heat meter. Then ad

just it in small steps until the required flow

rate is constant (generally,±2 % devia

tions are acceptable).

If therequired flow rate is not reached,the

4

differential pressure set point must be in

creased (see section 3.2.1).

When the required flow rate is reached,

4

secure the setting of the restriction (1.1)

with the lock nut (1.2). Screw back on cap

(1.3).

Lead-seal the set point setting at the set

4

point adjuster (17) and cap (1.3).

If the pressure drop in the plant is known, the

adjustment diagrams for water in Figs. 7 to

10 (pages 14 to 17) can also be used.

Example:

Adjusting the flow restriction

Determining the adjustment values using the

adjustment diagram in Fig. 7.

A Type 42-34 Regulator, DN 25, set point

range 0.25 to 3.5 m³/h, is to be used in a

plant to limit the flow rate to 3.0 m³/h.

The pressure dropacross the plant is0.4 bar.

To which value do you have to adjust the dif

ferential pressure set point and how many

turns of the set point screw at the restriction

will be required?

Solution:

-

Follow the sequence from A to E in the dia

gram in Fig. 7.

The pressure dropΔp across the plant serves

as a basis. This value must be known!

AssumingΔp = 0.4 bar, this value corre

sponds to point A in the diagram. Add the

upper differential pressure across the restric

tionΔp

A horizontal line corresponding to this value

is drawn from A to the right-hand side, result

ing in point B. Point B is located on the

straight line associated with the differential

pressureΔp to be adjusted =0.6 bar (see section 3.2.1).

From point B, the line is further drawn vertically downward to the desired limiting curve

for the flow rate (3.0 m³/h), resulting in point

C.

Then, plot the line from point C straight to the

curve associated with the nominal size and

you will reach point D.

The vertical line above point D which meets

point E shows the required number of turns of

the set point screw.

Result: approx. 1.9 times

Based on a closed restriction, the set point

-

screw must be turned counterclockwise

approx. 1.9 times.

, assumed to be 0.2 bar.

restriction

-

-

-

-

EB 3013 EN 11

Page 12

Operation

3.2.3 Pressure conditions in the plant and regulator

When selecting the differential pressure set point or set point range, it is important to observe

that the differential pressure set pointΔp

across the completely open plantΔp

tion)Δp

restriction

.

plant

Table 2 list the flow rates with the known upper differential pressure value at the restriction for

Type 2423 Valves balanced by a bellows and balanced by a diaphragm.

set point

=Δp

p

Δ

The minimum required differential pressureΔp

is calculated as follows:

=Δp

p

Δ

min

Fig. 6 shows a schematic diagram of the plant’s pressure conditions.

Δp

is calculated from the known pressure drop

set point

and the pressure drop directly at the orifice (restric

+Δp

set point

Δp

Δp

set point

plant

plant

min

min

restriction

between the flow pipe and return flow pipe

2

&

⎛

⎞

V

⎜

⎟

+

⎜

⎟

K

VS

⎝

⎠

Δp

restriction

-

p

1

p

Δ

p

Δ

p

Δ

Fig. 6 · Pressure conditions in the plant

Minimum differential pressure between

min

flow and return flow pipes in bar

Pressure drop at restriction in bar

restriction

Differential pressure set point adjusted

set point

at the regulator in bar

12 EB 3013 EN

p

2

Type 42-34

or

Type 42-38

p

Δ

&

V

K

VS

Differential pressure (pressure drop) across

plant

a completely open plant in bar

Flow rate adjusted in m³/h

Valve flow coefficient in m³/h

Page 13

Operation

Table 2 · Flow rate set points for water in m³

/h

Type 2423 Valve balanced by a bellows

p

p

p

Δ

Δ

set p.

plant

0.2

0.1

bar

bar

0.5

0.3

bar

bar

1.0

0.5

bar

bar

Max. perm. diff. pressureΔp

DN ... 15 20 25 32 40 50 65 80 100 125 150 200 250

Δ

restr.

.

0.05 0.15 0.25 0.4 0.6 0.9 2 3.5 6.5 11 18 20 26

min

0.1

V

bar

0.2

bar

0.5

bar

V

V

1.4 2.1 2.4 4.9 7.7 11.2 19 28 44 56 84 126 154

max

.

2 3 3.5 7 11 16 28 40 63 80 120 180 220

max

.

3 4.5 5.3 9.5 16 24 40 58 90 120 180 260 300

max

25 bar 20 bar 16 bar 12bar 10 bar

Type 2423 Valve balanced by a diaphragm

Nominal size DN 125 150 200 250

Flow rate set points in m³/h with

Δ

Max. perm. diff. pressureΔp

p

restriction

= 0.2 bar

11 to 120 18 to 180 20 to 320 26 to 350

12 bar 10 bar

3.3 Decommissioning

Preferably close the shut-off valves starting

from the flow pipe side and then return flow

pipe side.

EB 3013 EN 13

Page 14

Operation

p (bar)

Δ

Pressure drop across the plant

Differential pressure set point

(fixed for Type 42-38, adjustable Type 42-34)

1.6

1.4

Turns of the set point adjuster

3

2

E

DN 15

DN 20

DN 25

DC

1.2

1.0

1.2

0.8

1.0

0.6

0.4

A

0.2

1

0.1

0.2

0.8

B

0.6

0.4

1.6

1.4

1.8

0.6

1.2

1.8

2.4

3.0

3.6

4.2

4.8

5.4

˚

V

max

3

m

/h

Adjustment diagram based on water!

Fig. 7 · Adjustment diagram DN 15 to 25

14 EB 3013 EN

0.2 0.4

0.5

Upper diff. pressureΔp

Page 15

p (bar)

Δ

Pressure drop across the plant

Differential pressure set point

(fixed for Type 42-38, adjustable Type 42-34)

1.6

1.4

Operation

Turns of the set point adjuster

6

4

DN 40

DN 50

DN 32

1.2

1.0

1.2

0.8

1.0

0.6

0.4

0.2

0.2

2

0.1

0.8

0.6

0.4

1.6

1.4

1.8

˚

V

3

m

3.0

6.0

9.0

12.0

15.0

18.0

21.0

24.0

27.0

max

/h

Adjustment diagram based on water!

Fig. 8 · Adjustment diagram DN 32 to 50

0.2 0.4

0.5

Upper diff. pressureΔp

EB 3013 EN 15

Page 16

Operation

p (bar)

Δ

Pressure drop across the plant

Turns of the set point adjuster

8765 32110 9

DN 65

DN 80

4

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.1

0.2

Differential pressure set point

(fixed for Type 42-38,

adjustable Type 42-34)

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

˚

V

max

3

m

/h

8

16

24

32

40

48

56

64

72

80

90

Adjustment diagram based on water!

DN 100

Fig. 9 · Adjustment diagram DN 65, DN 80 and DN 100

16 EB 3013 EN

0.2 0.4

0.5

Upper diff. pressureΔp

Page 17

p (bar)

Δ

Pressure drop across the plant

Operation

Differential pressure set point

(fixed for Type 42-38, adjustable Type 42-34)

1.6

1.4

Turns of the set point adjuster

12

8

DN 125

DN 150

1.2

1.0

1.2

0.8

1.0

0.6

0.4

0.2

0.2

4

0.1

0.8

0.6

0.4

1.6

1.4

1.8

˚

V

m

20

40

60

80

100

120

140

160

180

200

max

3

/h

Adjustment diagram based on water!

Fig. 10 · Adjustment diagram DN 125 and DN 150

0.2 0.4

0.5

Upper diff. pressureΔp

EB 3013 EN 17

Page 18

Maintenance · Troubleshooting

4 Maintenance ·

Troubleshooting

The regulators are maintenance free. Never

theless, they are subject to natural wear, par

ticularly at the seat, plug and operating dia

phragm.

Depending on the operating conditions, the

regulator needs to be checked at regular in

tervals to avoid possible malfunctions.

CAUTION!

On performing any work on the regulator,

make sure the relevant section of the pipeline

-

is depressurized and, depending on the pro

-

cess medium, drained as well.

-

For high temperatures, allow the regulator to

cool down to ambient temperature before

starting any work on it.

-

Interrupt or shut off the control line to avoid

any hazards which could be caused by mov

ing parts.

As valves are not free of cavities, remember

that residual process medium might still be

contained in the valve.

We recommend to remove the valve from the

pipeline after it has been depressurized and

drained. Make sure that all the plant sections

connected to the control line are also

depressurized. If this is not the case, shut off

the control line.

Details on malfunctions and the recommended action can be found in the Ta-

ble 3 · Troubleshooting.

Proceed as described in section 4.1 if the op

erating diaphragm is defective.

-

-

-

18 EB 3013 EN

Page 19

Maintenance · Troubleshooting

Table 3 · Troubleshooting

Malfunction Possible reasons Recommended action

Remove valve from pipeline. Clean seat and plug.

Flow rate or

differential

pressure

exceeds the flow

.

or

rate

V

differential

pressure set

point.

Flow rate or

differential

pressure does

not reach the

flow rate

.

or

V

differential

pressure set

point.

Control loop

hunts

Seat and plug leak

Operating diaphragm defective

Control line blocked

Valve too large to regulate the

flow rate or too small to regulate

the differential pressure

Wrong set point range selected

Safety equipment, e.g. pressure

limiter, has been triggered

Insufficient pressure drop across

the plantΔp

Strainer blocked Drain and clean filter of the strainer.

Direction of flow, valve incorrect-

ly installed

Valve too large for control task

Restriction (or needle valve) is

missing in a control line to dam

pen pulsation

Replace plug, if necessary. Otherwise send the

regulator to SAMSON for repair.

Replace diaphragm (see section 4.1) or send the

regulator to SAMSON for repair.

Remove control line and clean it.

Check and clean the screw joint with orifice plate.

Recalculate K

for further action.

coefficient and contact SAMSON

VS

Check set point range and contact SAMSON for

further action.

Check plant and unlock safety equipment.

Compare existing differential pressure across the

plant with the plant’s drag:

Min. differential pressure across the plant

p

=Δp

Δ

min

restriction

+ (

.

VK

/

2

+Δp

)

VS

Install the valve so that the direction of flow is the

same as indicated by the arrow.

Recalculate K

for further action.

coefficient and contact SAMSON

VS

Install a needle valve in the control line and start

-

to close it until the control loop becomes stable.

NOTICE Do not completely close needle valve.

Contact SAMSON if the malfunction cannot be remedied using the above table.

plant.

4.1 Replacing the operating

diaphragm

See Figs. 1 and 2.

If just the operating diaphragm is defective, it

can bereplaced without having to remove the

valve from the pipeline. Relieve the relevant

section of the pipeline of pressure and drain

it. Unscrew the control lines and separate the

actuator from the valve.

EB 3013 EN 19

Page 20

Maintenance · Troubleshooting

Type 2428 Actuator

1. Place actuator upside down.

2. Undo screws (15) at the actuator. Pull out

the top cover (+ chamber) together with

diaphragm plate (19) and diaphragm

(13) as wellas the diaphragm stem(12).

3. Unscrew nut (18), while holding the dia

phragm stem stationary using a suitable

tool.

4. Lift off diaphragm plate (19) and pull out

diaphragm (13).

5. Check the diaphragm stem (12) for scor

ing and replace it with a new one, if nec

essary.

NOTICE

The stem surface is roller-burnished. Never

regrind the stem!

6. Insert a new diaphragm.

7. Proceed in the reverse order to reassemble the actuator. Secure nut (18) from

turning with suitable adhesive (e.g.

8121-0230 from SAMSON). Use lubri

cant from SAMSON (8150-0111).

8. Check screw fittings for dirt and clean

them, if necessary.

Start up as described in section 3.1.

Type 2424 Actuator

1. Place actuator upside down.

2. Relieve set point springs (16) completely

of tension byturning the setpoint adjuster

(17) counterclockwise.

3. Take off set point springs (16) and set

point adjuster (17).

4. Undo screws (15) at the actuator. Re

move topcover (+ chamber)and take out

inner springs in the + chamber.

5. Lift out diaphragm plate (19) together

-

-

-

with diaphragm (13), diaphragm stem

(12) and excess pressure limiter unit . Re

move forcelimiter (20) together with stem

(12).

6. Check stem (12) for scoring and replace

it with a new one, if necessary.

NOTICE

The stem surface is roller-burnished. Never

regrind the stem! When exchanging the diaphragm stem, the nipple (guide bushing) in

the actuator cover must also be replaced.

7. Unscrew nuts (18) and pull out diaphragm stem.

8. Remove diaphragm (13) and insert a

new diaphragm.

9. Insert diaphragm stem. Tighten nuts (18)

to fix diaphragm, diaphragm plate and

washer into place. Secure nut (18) from

turning with suitable adhesive (e.g.

8121-0230 from SAMSON).

10. Proceed in the reverse order to reassem

ble the actuator. Use lubricant

(8150-0111).

11.Check screw fittings for dirt and clean

them, if necessary.

Start up as described in section 3.1.

-

-

-

20 EB 3013 EN

Page 21

5 Nameplates

Nameplates

Valve nameplates

DIN version

ANSI version

Actuator nameplate

Valve

1 Valve type

2 Model number

3 Model number index

4 Order number or order date

coefficient

5K

VS

8 Nominal size

9 Nominal pressure

10 Perm. differential pressure in bar

11 Perm. temperature in °C

12 Body material

ANSI version

5 Nominal size

8 Perm. differential pressure in psi

9 Perm. temperature in °F

10 Body material

V coefficient (K

11 C

12 ANSI Class (pressure rating)

Actuator

1 Model number

2 Model number index

3 Order number or order date

4 Effective diaphragm area

5 Labeling acc. to DIN

6 Labeling acc. to ANSI

7 Max. perm. pressure

8 Nominal size

9 Differential pressure at restriction

10 Set point range

11 Diaphragm material

12 Year of production

VS

x 1.17)

Fig. 11 · Nameplates

EB 3013 EN 21

Page 22

Dimensions and weights

6 Dimensions and weights

Valve balanced by a bellows

Type 42-38

Valve balanced by a bellows

– see Table 5 on p. 23 –

Fig. 12 · Dimensions, valve balanced by a bellows

Valve balanced by a diaphragm

Type 42-34 ·

Valve balanced by a bellows

– see Table 5 on p. 23 –

Table 4 · Dimensions in mm and weights

Type 42-34 · Valve balanced by a diaphragm

Nom. size DN 125 150 200 250

Length L

Height H1

Height H2

Weight in kg

1)

With 640 cm² actuator

Fig. 13 · Dimensions, valve balanced by a diaphragm

400 480 600 730

720 745 960

295 325 345 375

95 115

1)

2901)305

22 EB 3013 EN

1)

Type 42-34 · Balanced by a diaphragm

Page 23

Dimensions and weights

Table 5 · Dimensions in mm and weights · Type 24-34, Type 24-38 · Balanced by a bellows

Nominal size DN 15 20 25 32 40 50 65 80 100 125 150 200 250

Length L

Height H1

Height H2

Other materials

Forged steel

Type 42-34 Differential Pressure Regulator with Flow Limitation · Balanced by a bellows

Set point

range

0.1 to

0.6 bar

Height H

Actuator

Weight

1)

Height H

Set point

range

0.2 to 1 bar

Set point

range

0.5 to

1.5 bar

Actuator

Weight

Height H

Actuator

Weight

1)

1)

Type 42-38 Differential Pressure Regulator with Flow Limitation · Balanced by a bellows

Height H

Set point

range

0.2 0.3

0.4 · 0.5 bar

Actuator

Weight

1)

in kg

1)

The weight is based on the version made of EN-JL1040/PN 16 (GG-25). +10 % for other materials

2)

Optionally with 320 cm² actuator

130 150 160 180 200 230 290 310 350 400 480 600 730

285 360 415 460 590 730

115 135 195 220 265 295 400

113 − 130 − 155 161 −−−−−−−

670 745 800 990 1120 1260

Ø D = 285 mm

Ø D = 225 mm ⋅ A = 160 cm²

16 16.5 17.5 24 24.5 27 46 51 65 135 185 425 485

in kg

2)

A = 320 cm²

Ø D = 390 mm

A = 640 cm²

670 745 800 990 1120 1260

Ø D = 225 mm ⋅ A = 160 cm²

16 16.5 17.5 24 24.5 27 42 47 61 135 185 425 485

in kg

2)

Ø D = 390 mm

A = 640 cm²

670 745 800 880 1040 1210

Ø D = 225 mm ⋅ A = 160 cm²

16 16.5 17.5 24 24.5 27 42 47 61 125 175 415 475

in kg

2)

Ø D = 285 mm

A = 320 cm²

450 525 585

Ø D = 225 mm ⋅ A = 160 cm²

Ø D = 285 mm

A = 320 cm²

11.5 12 13 19.5 20 22.5 38 43 57

−

EB 3013 EN 23

Page 24

Customer service

7 Customer service

Should any malfunctions or any defect occur, SAMSON's After-Sales Service is prepared to

help you on site.

You can also send the defective regulator directly to your local SAMSON representative for re

pair. Addresses of SAMSON subsidiaries, agencies and service centers are listed in the prod

uct catalogs and in the Internet at www.samson.de.

To allow SAMSON to find the fault and to have an idea of the installation situation, specify the

following details (refer to the nameplate):

Type and nominal size of the valve

4

Order number and model number

4

Upstream and downstream pressure

4

Flow rate in m³/h

4

Has a strainer been installed?

4

Sketch of the installation

4

8 Technical data

-

-

Table 6 · Type 42-34, Type 42-38

Valve balanced by a bellows

Type 42-34 42-38

Nominal size

Nominal pressure

Valve body

Max. perm.

temperature

Pressure at which the internal excess

pressure limiter responds, depending

on diaphragm area A

Set point ranges

Leakage rate

1)

Higher temperatures on request

Actuator

1)

DN 15 to 250 DN 15 to 100

PN 16, 25 or 40 (acc. to DIN EN 12516-1)

See pressure-temperature diagram in T 3013 EN

With equalizing tank: Liquids up to 220 °C

Without equalizing tank: Liquids up to 150 °C

Air and gases up to 80 °C

160 cm² = 1.2 bar

320 cm² = 0.6 bar

640 cm² = 0.3 bar

0.1 to 0.6 bar ⋅ 0.2 to 1 bar

0.5 to 1.5 bar

0.05 % of K

≤

160 cm² = 0.6 bar

320 cm² = 0.3 bar

0.2 ⋅ 0.3 ⋅ 0.4 ⋅ 0.5 bar

coefficient

VS

24 EB 3013 EN

Page 25

Technical data

Valve balanced by a diaphragm

Type 42-34

Nominal size

Nominal pressure

Valve body

Max. perm.

temperature

Actuator

1)

Pressure at which the internal excess

pressure limiter responds, depending on

diaphragm area A

Set point ranges

Leakage rate

1)

Higher temperatures on request

PN 16, 25 or 40 (acc. to DIN EN 12516-1)

See pressure-temperature diagram in T 3013 EN

With equalizing tank: Liquids up to 220 °C

Without equalizing tank: Liquids up to 150 °C

0.1 to 0.6 bar ⋅ 0.2 to 1 bar · 0.5 to 1.5 bar

DN 125 to 250

Air and gases up to 80 °C

160 cm² = 1.2 bar

320 cm² = 0.6 bar

640 cm² = 0.3 bar

0.05 % of K

≤

coefficient

VS

Table 7 · Data for Type 2423 Valve

Valve balanced by a bellows · KVScoefficients, z values and max. perm. differential pressures

Nominal size DN 15 20 25 32 40 50 65 80 100 125 150 200 250

Travel

K

coefficient m³/h

VS

z value

Max. perm. diff.

pressureΔp

4 6.3 8 16 20 32 50 80 125 190 280 420 500

0.65 0.6 0.55 0.45 0.4 0.35 0.3

10 mm 16 mm 22 mm

25 bar 20 bar 16 bar 12bar 10 bar

Valve balanced by a diaphragm · KVScoefficients and max. perm. differential pressures

Nominal size DN 125 150 200 250

K

VS

m³/h

coefficient

22 mm travel

35 mm travel

Max. perm. diff. pressureΔp

190 290 550 600

250 380 650 800

12 bar 10 bar

See Table 2 on page 13 for the flow rate set points for both valve versions.

EB 3013 EN 25

Page 26

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 3013 EN

S/Z 2009-09

Loading...

Loading...