Page 1

Rosemount Ultrasonic

3107 Level and 3108 Flow Transmitters

Reference Manual

00809-0200-4840, Rev BA

December 2014

Page 2

Page 3

Reference Manual

00809-0200-4840, Rev BA

Rosemount Ultrasonic

3107 and 3108 Transmitters

Title Page

December 2014

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Within the United States, Rosemount Inc. has two toll-free assistance numbers.

Customer Central: 1-800-999-9307 (7:00 a.m. to 7:00 p.m. CST)

Technical support, quoting, and order-related questions.

North American Response Center:

Equipment service needs.

1-800-654-7768 (24 hours a day – Includes Canada)

For equipment service or support needs outside the United States, contact your local

Rosemount representative.

The products described in this document are NOT designed for nuclear-qualified

applications.

Using non-nuclear qualified products in applications that require nuclear-qualified

hardware or products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Rosemount

Sales Representative.

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired

operation.

Page 4

Title Page

December 2014

Reference Manual

00809-0200-4840, Rev BA

Page 5

Reference Manual

00809-0200-4840, Rev BA

Table of Contents

1Section 1: Introduction

1.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.3 Service support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.4 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2Section 2: Transmitter Overview

2.1 Introduction to the transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.3 Components of the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.4 System architecture. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table of Contents

December 2014

3Section 3: Installation

3.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.2.1 Safety considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.2 Environmental considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.3.1 Consider liquid surface conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.2 Consider in-tank effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3.3 Mounting the transmitter above the liquid surface. . . . . . . . . . . . . . . . . .11

3.3.4 Open channel flow installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4 Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.1 Connecting the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

3.4.2 Remote temperature sensor (on 3108 only) . . . . . . . . . . . . . . . . . . . . . . .17

3.4.3 Wiring to allow HART communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.4.4 Lightning / surge protection and other loop devices . . . . . . . . . . . . . . . .18

4Section 4: Configuration

Tab le of C ontents

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Command parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.2.1 Base units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2.2 Set as empty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4.2.3 Present depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

TOC-i

Page 6

Table of Contents

December 2014

Reference Manual

00809-0200-4840, Rev BA

4.2.4 Learn false echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4.2.5 Auto tank map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.2.6 Simulation of PV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.2.7 Restart device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4.2.8 Load defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

4.2.9 Simulate current output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

4.2.10 Trim 4mA / Trim 20mA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4.3 Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3.1 Message (P000) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.3.2 Tag (P001). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

4.3.3 Descriptor (P002). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.3.4 Final assembly number (P004) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

4.3.5 Serial number (P005) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.3.6 Bottom reference (P010) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4.3.7 Upper blanking (P023) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

4.3.8 Lower blanking (P063) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

4.3.9 Distance offset (P060). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

4.3.10 Level offset (P069). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

4.3.11 Tank shape / non-linear profile (P011). . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4.3.12 Contents (volume) measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

4.3.13 Flow measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

4.3.14 Primary variable units (P012). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.3.15 Scale factor / K-factor (P013). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.3.16 Profile height / Power factor (P014) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.3.17 Profile points 1 to 10 (P030 to P039) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4.3.18 Upper range value (P015). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.3.19 Lower Range Value (P016) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.3.20 Damping (P020). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

4.3.21 Lost echo delay (P021) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4.3.22 Lost echo action (P022) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.3.23 Speed of sound (P024) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4.3.24 Temperature (P025) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

4.3.25 Set threshold (P026) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4.3.26 Transmit power control (P040) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

TOC-ii

4.3.27 Pulse repeat (P041) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

4.3.28 Echoes needed (P042) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

4.3.29 Threshold 1 time (P043). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Table of Contents

Page 7

Reference Manual

00809-0200-4840, Rev BA

5Section 5: Service and Troubleshooting

Table of Contents

December 2014

4.3.30 Threshold 1 size (P048). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4.3.31 Target pulses (P044) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

4.3.32 Target frequency (P045). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

4.3.33 Spike rejection (P049). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4.3.34 False echo data (P081 to P088). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

4.3.35 Clear false echoes (P089) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

4.3.36 Transducer material (P970) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

4.3.37 Poll address (D951) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

4.3.38 Maximum temperature (P046) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

4.3.39 Minimum temperature (P047) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

4.3.40 Date (P003). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.2 Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.3 Power failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.4 False echoes under certain ambient operating conditions. . . . . . . . . . . . . . . . . . 82

5.5 Monitoring and diagnostic parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.5.1 Process Value / Primary Variable (PV) (D900). . . . . . . . . . . . . . . . . . . . . . .84

5.5.2 Level / Secondary Variable (SV) (D901) . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

5.5.3 Distance / Tertiary Variable (TV) (D902) . . . . . . . . . . . . . . . . . . . . . . . . . . .86

5.5.4 Temperature / Fourth Variable (FV) (D903) . . . . . . . . . . . . . . . . . . . . . . . .87

5.5.5 % of current output (D905) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

5.5.6 Current output (D906) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

5.5.7 Distance (D910) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

5.5.8 Echo size (D911). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

5.5.9 Echo success (D912) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

5.5.10 Target echoes (D913) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

5.5.11 Speed of sound (D914) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

5.5.12 Temperature for SoS calculation (D915). . . . . . . . . . . . . . . . . . . . . . . . . . .94

5.5.13 Frequency (D916) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

5.5.14 Threshold in use (D917) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

5.5.15 Pulses in use (D918) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

5.5.16 Transmit power (D919) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Tab le of C ontents

5.5.17 Model code (D949) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.5.18 Hardware rev. (D952) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.5.19 Software revision (D953) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

TOC-iii

Page 8

Table of Contents

December 2014

Reference Manual

00809-0200-4840, Rev BA

5.5.20 Manufacturer (D960) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

5.5.21 Unique Device ID (D961) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5.5.22 HART revision (D962) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

5.5.23 Transmitter specific command rev. (D963) . . . . . . . . . . . . . . . . . . . . . . 106

5.5.24 Preambles (D964) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.5.25 Transmitter flags (D965) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.5.26 Primary variable trend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

5.5.27 Temperature trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.5.28 Distance and echo size trend . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . 109

AAppendix A: Reference Data

A.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.1.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.1.2 Measuring performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

A.1.3 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

A.1.4 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

A.1.5 Materials of construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A.1.6 Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A.1.7 Measuring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A.1.8 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

A.1.9 Temperature and pressure ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

A.1.10 Load limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

A.2 Dimensional drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

A.3 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

A.3.1 Spare parts and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

BAppendix B: Product Certifications

B.1 Safety messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

B.2 Approved manufacturing locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.3 European Union directive information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.4 MCERTS certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.5 Hazardous locations certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.5.1 American and canadian approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

B.5.2 European certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.5.3 Rest of the world certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

B.6 Approval drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

TOC-iv

Table of Contents

Page 9

Reference Manual

00809-0200-4840, Rev BA

CAppendix C: Rosemount 3490 Series Universal Control Unit

DAppendix D: Field Communicator

Table of Contents

December 2014

C.1 Menus and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

D.1 Menus and parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Tab le of C ontents

TOC-v

Page 10

Table of Contents

December 2014

Reference Manual

00809-0200-4840, Rev BA

TOC-vi

Table of Contents

Page 11

Reference Manual

00809-0200-4840, Rev BA

Section 1 Introduction

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1

Manual overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Service support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

1.1 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a caution symbol ( ). The external hot surface symbol ( ) is used when a surface

is hot and care must be taken to avoid possible burns. If there is a risk of an electrical shock the

( ) symbol is used. Refer to the safety messages listed at the beginning of each section before

performing an operation preceded by this symbol.

Section 1: Introduction

December 2014

Failure to follow these installation guidelines could result in death or serious injury.

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Explosions could result in death or serious injury.

Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations certifications.

Before connecting a HART

®

-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Electrical shock could cause death or serious injury.

Use extreme caution when making contact with the leads and terminals.

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution of

components etc., may also jeopardize safety and is under no circumstances allowed.

1

Page 12

Section 1: Introduction

December 2014

1.2 Manual overview

This manual provides installation, configuration, and maintenance information for the

Rosemount 3107 Level and 3108 Flow Transmitter.

Section 2: Transmitter Overview

Section 3: Installation

Section 4: Configuration

Section 5: Service and Troubleshooting

Section A: Reference Data

Section B: Product Certifications

Section C: Rosemount 3490 Series Universal Control Unit

Section D: Field Communicator

1.3 Service support

Reference Manual

00809-0200-4840, Rev BA

To expedite the return process outside of the United States, contact the nearest Emerson

Process Management representative.

Within the United States, call the Emerson Process Management Instrument and Valves

Response Center using the 1 800 654 7768 toll-free number. This center, available 24 hours a

day, will assist you with any needed information or materials.

The center will ask for product model and serial numbers, and will provide a Return Material

Authorization (RMA) number. The center will also ask for the process material to which the

product was last exposed.

Individuals who handle products exposed to a hazardous substance can avoid injury if they

are informed of, and understand, the hazard. If the product being returned was exposed to

a hazardous substance as defined by OSHA, a copy of the required Material Safety Data

Sheet (MSDS) for each hazardous substance identified must be included with the returned

goods.

1.4 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration. The product and

packaging should be disposed of in accordance with local and national legislation.

2

Page 13

Reference Manual

B

E

E

20mA

4mA

F

D

D

C

A

G

00809-0200-4840, Rev BA

Section 2: Transmitter Overview

Section 2 Transmitter Overview

Introduction to the transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Theory of operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Components of the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

System architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

2.1 Introduction to the transmitters

The Rosemount 3107 and Rosemount 3108 are sealed 4–20 mA loop-powered liquid level

transmitters, and are designed for use in waste water and effluent treatment plant applications.

The 3108 is MCERTS certified for open flow channel applications.

These rugged UPVC transmitters are certified Intrinsically Safe for use in Zone 0 areas, and

factory fitted with up to 164 ft. (50 m) of two-core cable for simple low cost installation in

sumps, wet-wells and over open channel flow structures.

December 2014

The transmitters can be connected directly to a plant control system, or used with a Rosemount

3490 Series Control Unit for programmable control functionality.

Note

The Rosemount 3490 Series Control Unit software must be version 3.40 or later.

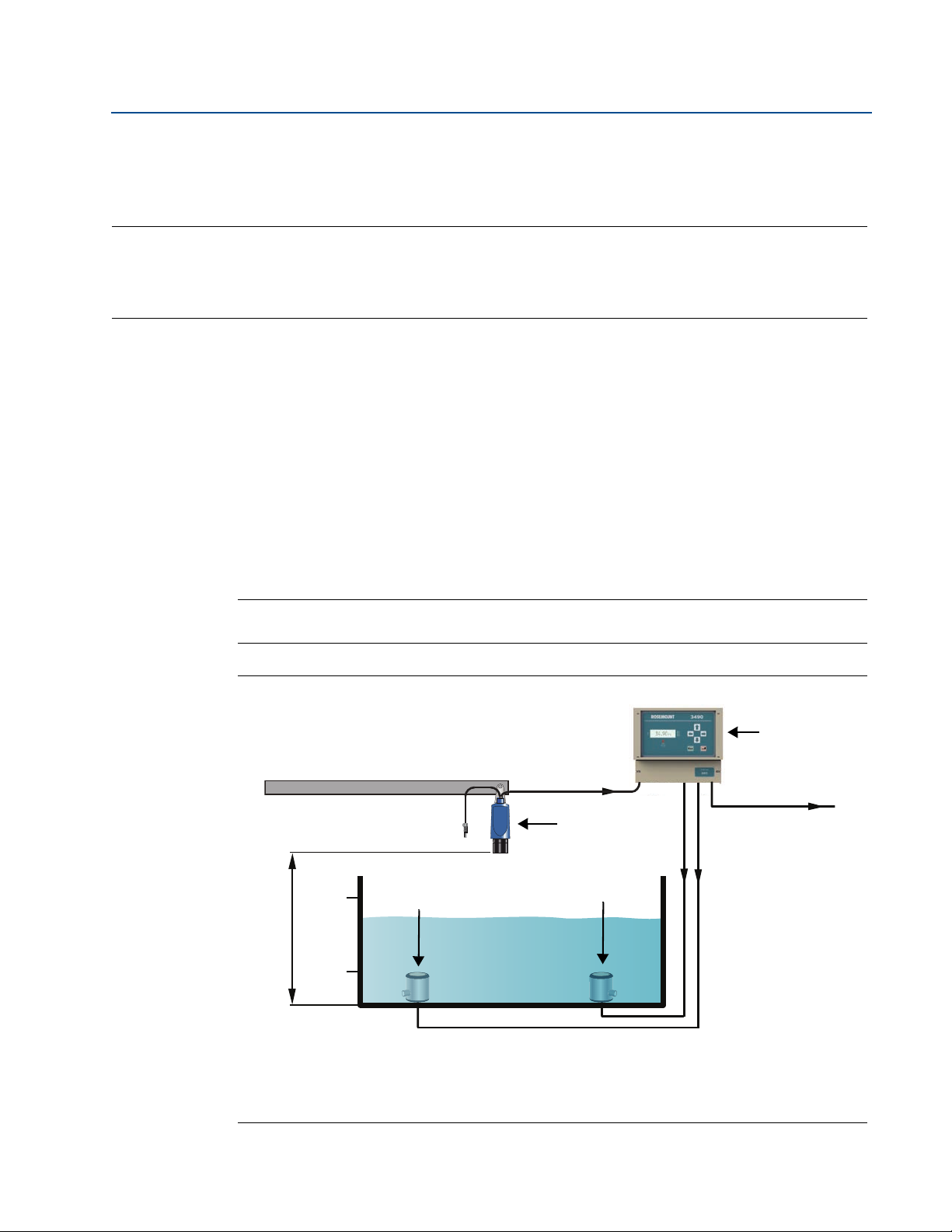

Figure 2-1. Typical application using a Rosemount 3108 flow transmitter

A. Rosemount 3108 Flow Transmitter E. Pump

B. Rosemount 3490 Series Control Unit F. Transmitter Bottom Reference

C. 4–20 mA signal output G. 4–20 mA and HART signal input

D. Relay

3

Page 14

Section 2: Transmitter Overview

D

C

E

B

A

D

December 2014

2.2 Theory of operation

The level transmitter is designed to be mounted above a liquid (Figure 2-1 on page 3), and uses

ultrasonic pulses to continuously measure the distance to the liquid surface. The electronics

calculate distance to the liquid level using the time delay between transmitting and receiving

signals.

When programmed with the bottom reference of the application – usually the bottom of a tank

– the transmitter calculates the liquid depth (level), and outputs the result as a 4–20 mA and

HART signal.

The 3108 and the 3107 can calculate contents (volume) or open channel flow when

programmed with further application information, and outputs the result as a 4–20 mA and

HART signal.

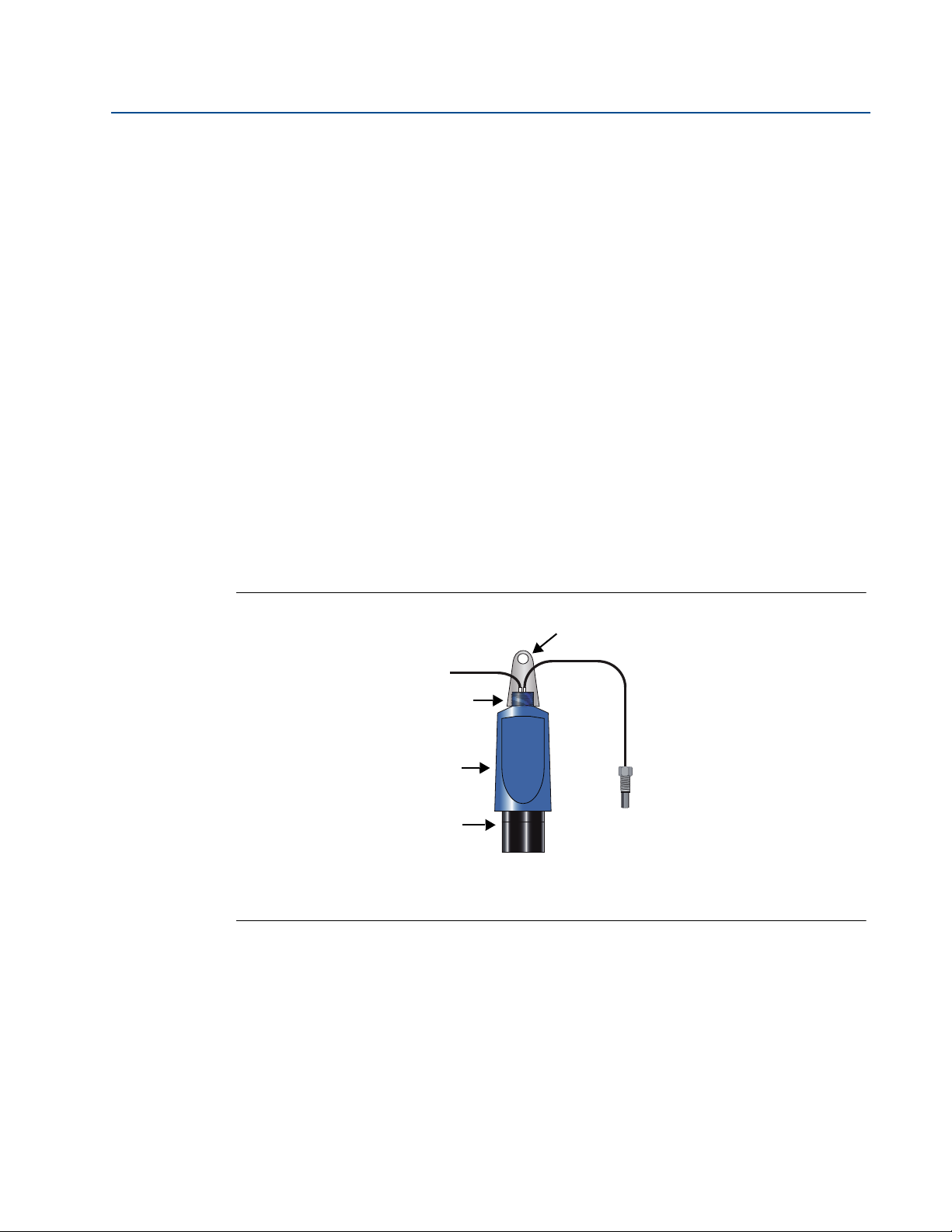

2.3 Components of the transmitter

Reference Manual

00809-0200-4840, Rev BA

The transmitter has a housing containing advanced electronics to generate ultrasonic pulses,

®

process the resultant signals, and provide a 4–20mA and HART

output.

There is a factory-fitted cable for the signal output and connecting an external power supply.

The 3108 has a factory-fitted Remote Temperature Sensor.

Figure 2-2. Transmitter components

A. Mounting bracket D. UPVC wetted parts

B. Two-core cable E. Remote temperature sensor (3108 only)

C. 1-in. mounting thread

4

Page 15

Reference Manual

751 Display

Rosemount 3490

Series Controller

Field

Communicator

HART

Modem

AMS

™

Suite:

Intelligent Device Manager

Control System

Remote Temperature Sensor

(Rosemount 3108 only)

Rosemount

3107/3108

Tra ns mit te r

4–20 mA / HART

00809-0200-4840, Rev BA

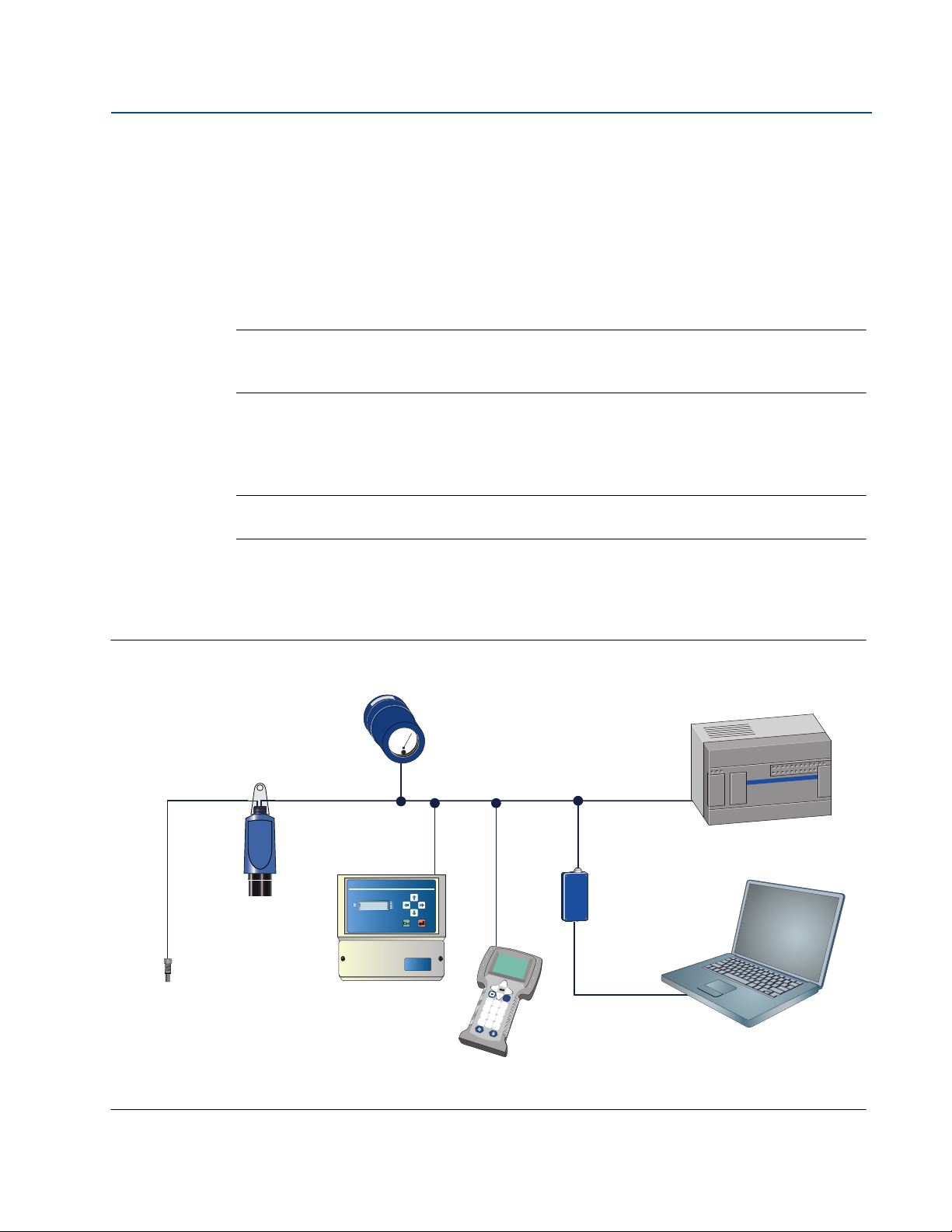

2.4 System architecture

The Rosemount 3107 and 3108 are loop-powered which means they use the same two wires for

both power supply and output signal.

The transmitter can be connected to any suitable direct current (dc) power source using the

factory-fitted two-core, shielded cable.

The output is a 4–20mA analog signal and a digital HART signal.

Note

It is possible to use the multidrop function with the HART protocol (see Figure 2-3). In

this case, communication is restricted to digital since the current is fixed to 4 mA.

The transmitters can easily be configured by using a Rosemount 3490 Series Control Unit.

Alternatively, a Field Communicator, or a PC with AMS

software, can be used to configure the transmitter.

Note

The Rosemount 3490 Control Unit software must be version 3.40 or later.

Section 2: Transmitter Overview

December 2014

™

Suite: Intelligence Device Manager

A comprehensive specification for the Rosemount 3107 and 3108 is in the section

“Specifications” on page 111.

Figure 2-3. System architecture

3490

Model type:

3491

Fn

1

2

3

4

5

6

7

8

9

.

0

-

5

Page 16

Section 2: Transmitter Overview

December 2014

Reference Manual

00809-0200-4840, Rev BA

6

Page 17

Reference Manual

00809-0200-4841, Rev BA

Section 3 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Considerations before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Mechanical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

3.1 Safety messages

Procedures and instructions in this manual may require special precautions to ensure the safety

of the personnel performing the operations. Information that raises potential safety issues is

indicated by a caution symbol ( ). The external hot surface symbol ( ) is used when a surface

is hot and care must be taken to avoid possible burns. If there is a risk of an electrical shock the

( ) symbol is used. Refer to the safety messages listed at the beginning of each section before

performing an operation preceded by this symbol.

Section 3: Installation

December 2014

Failure to follow these installation guidelines could result in death or serious injury

Make sure only qualified personnel perform the installation.

Use the equipment only as specified in this manual. Failure to do so may impair the

protection provided by the equipment.

Explosions could result in death or serious injury

Verify that the operating environment of the transmitter is consistent with the

appropriate hazardous locations certifications.

Before connecting a HART

®

-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Electrical shock could cause death or serious injury

Use extreme caution when making contact with the leads and terminals.

Any substitution of non-recognized parts may jeopardize safety. Repair, e.g. substitution of

components etc., may also jeopardize safety and is under no circumstances allowed.

Section 3: Installation

7

Page 18

Section 3: Installation

December 2014

3.2 Considerations before installation

The Rosemount 3107 and 3108 may be used for level and volume measurement in open or

closed tanks, or open channel flow measurement.

The transmitter must be installed in a location where it is protected from ultraviolet radiation to

prevent long term degradation of the plastics used in its construction e.g. shrouded from direct

sunlight.

It is important to correctly position the transmitter for reliable ultrasonic level measurement.

For maximum accuracy and stability of the level measurement reading, the transmitter should

always be shrouded from direct sunlight and radiated heat.

The transmitter may be site-tuned to deal with most application conditions, but it is

recommended that the following guidelines be adopted wherever relevant.

3.2.1 Safety considerations

Guidelines

Reference Manual

00809-0200-4841, Rev BA

1. Installation must be carried out by suitably trained personnel in accordance with the

applicable code of practice.

2. If the equipment is likely to come into contact with aggressive substances, it is the

responsibility of the user to take suitable precautions that prevent it from being

adversely affected, thus ensuring that the type of protection is not compromised.

Aggressive substances are acidic liquids or gases that may attack metals or solvents

that may affect polymeric materials.

Suitable precautions are regular checks as part of routine inspections, or establishing,

from the material's datasheet, that it is resistant to specific chemicals.

3. The equipment should only be cleaned with a damp cloth. Do not use solvents.

4. The equipment is not intended to be repaired by the user and is to be replaced by an

equivalent certified unit. Repairs should only be carried out by the manufacturer or

approved repairer.

5. The transmitter is Double Insulated, and therefore Protective Earthing is not required.

6. Note that if the equipment is used in a manner not specified by the manufacturer, the

protection afforded by the equipment may be impaired.

7. To ensure electro-magnetic compatibility in any European member state, it should not

be installed in a residential area.

Note

It is not advisable to mount the transmitter in close proximity to a source of electrical

noise such as a variable-speed drive, or other high-powered electrical device.

Section 3: Installation8

Page 19

Reference Manual

OKOK OK

00809-0200-4841, Rev BA

3.2.2 Environmental considerations

The Rosemount 3107 and 3108 ultrasonic transmitters are Intrinsically Safe (IS) approved for

hazardous area installations.

1. The 3107 is designed for open or closed tank installation. It is weatherproof and

protected against the ingress of dust

2. The 3108 is designed for open channel flow measurement. It is weatherproof and

protected against the ingress of dust

3. Avoid installing the 3107 and 3108 near heat sources

Figure 3-1. Environmental considerations

Section 3: Installation

December 2014

3.3 Mechanical installation

Guidelines

1. Mount the transmitter above the liquid using the 1-in. thread provided, but not closer

than 12 in. (0,3 m) to the surface. The transmitter does not detect any liquid surface

closer than 12 in. (0,3 m) to the transmitter face. (See “Mounting the transmitter above

the liquid surface” on page 11).

Optional flanges and bracket kits are available to help mounting.

(See “Spare parts and accessories” on page 120.)

2. The transmitter should be mounted vertically to ensure a good echo from the liquid

surface. The transmitter beam half angle is 6 degrees (See Figure 3-2 on page 10).

3. Obstructions in the tank, or well, may generate echoes which can be confused with the

real liquid surface echo. Obstructions within the beam angle generate strong false

echoes. Wherever possible, the transmitter should be positioned to avoid false echoes.

Section 3: Installation

9

Page 20

Section 3: Installation

A

C

B

December 2014

4. To avoid detecting unwanted objects in the tank or well, it is advisable to maintain a

5. No false echoes are generated if the transmitter is located near the side of the tank or

6. If the transmitter is mounted in an enclosed tank with a domed top, avoid mounting

7. Avoid applications where heavy condensation could form on the transmitter face.

8. If the transmitter is mounted in a stand-off or nozzle, the transmitter face should

9. If the transmitter is used in environments where direct sunlight can cause high surface

Reference Manual

00809-0200-4841, Rev BA

distance of at least 1.3 in. from the center line of the transmitter for every foot (11 cm

per meter) range to the obstruction.

well, and the wall is smooth and free of protrusions. However, there will still be a

reduction in the echo size. It is recommended that the transmitter be mounted no

closer than 12 in. (0,3 m) to the wall to avoid a large reduction in the echo size.

the transmitter in the center of the tank roof because this could act as a parabolic

reflector and create unwanted echoes.

protrude at least 0.2 in. (5 mm) into the tank.

temperatures on exposed instruments, a sun-shade is recommended.

Figure 3-2. Considerations when installing in a tank

A. Transmitter is mounted vertically (maximum deviation of 3°).

B. 6° beam half angle.

C. 1.3 in./ft. (11 cm/m). Minimum of 12 in. (0.3 m).

Section 3: Installation10

Page 21

Reference Manual

00809-0200-4841, Rev BA

3.3.1 Consider liquid surface conditions

Guidelines

1. Foaming liquids can reduce the size of the returned echo because foam is a poor

ultrasonic reflector.

Mount an ultrasonic transmitter over an area of clear liquid, such as near the inlet to a

tank or well. In extreme conditions, or where this is not possible, the transmitter may

be mounted in a vented stilling tube provided that the inside measurement of the

stilling tube is at least 4 in. (100 mm) and is smooth and free from joints or protrusions.

It is important that the bottom of the stilling tube stays covered to prevent the ingress

of foams.

2. Avoid mounting the transmitter directly over any inlet stream.

3. Liquid surface turbulence is not normally a problem unless it is excessive. The effects of

turbulence are minor, but excessive turbulence can be dealt with by fine-tuning the

transmitter on site, if necessary.

Section 3: Installation

December 2014

3.3.2 Consider in-tank effects

Guidelines

1. Stirrers or agitators can cause a vortex. Mount the transmitter off-center of any vortex

to maximize the return echo.

2. If stirrer blades become uncovered, they create echoes as they pass through the

ultrasonic beam. The transmitter can learn to ignore false echoes (see “Learn false

echo” on page 23).

3. In tanks with rounded or conical bottoms, mount the transmitter off-center. If needed,

a perforated reflector plate can be installed on the tank bottom directly under the

transmitter center line to ensure a satisfactory return echo.

4. Avoid detecting pump casings, as the liquid falls away, by not mounting the transmitter

directly above pumps. If this is not possible, fine-tuning of the transmitter on-site may

be required.

3.3.3 Mounting the transmitter above the liquid surface

A 1-in. thread is provided to mount the transmitter. The thread form is either BSPP (G1) or NPT,

and is marked below the mounting thread.

To help installation, flange accessories and bracket kits are available from Emerson Process

Management. The accessory flanges supplied are manufactured from PVC and are a full face

design. Care must be taken when installing to raised face mating flanges on the tank or vessel to

prevent distortion of the PVC flange by over-tightening the bolts. See “Spare parts and

accessories” on page 120 for ordering information.

Section 3: Installation

Note

Never suspend the transmitter by the cable.

11

Page 22

Section 3: Installation

December 2014

Bracket mounting

The transmitter is supplied with a purpose made 316 Stainless Steel mounting bracket which

should be used to mount the transmitter over the liquid surface. The bracket is designed to fit

over the threaded neck of the transmitter and is retained by a locknut (see “1-in. NPT/BSPP

bracket kits” on page 117 for dimensions).

Use a chain or wire through the hole provided in the bracket, which is shaped to ensure that the

transmitter will hang perpendicular to the liquid surface. Check that the material of the chain or

wire is corrosion resistant to the liquids and any vapors present.

The bracket may be bolted to a suitable cross member above the liquid surface. Ensure that the

transmitter is perpendicular to the liquid surface to maximise the return echo size.

Note

Check that the maximum liquid level will not enter the 12 in. (0.3 m) blanking zone of

To help with alignment, the echo size (signal strength) can be indicated on the

Reference Manual

00809-0200-4841, Rev BA

the transmitter.

Rosemount 3490 Series Control Unit or a Field Communicator.

Flange mounting

The instrument (accessory) flanges supplied by Emerson are manufactured from PVC and are a

full face design. Care must be taken when installing to a raised face mating flange on the tank or

vessel to prevent distortion of the PVC flange by over-tightening the bolts. See “Spare parts and

accessories” on page 120 for part numbers.

Mounting from a conduit

The 3107 and the 3108 can be mounted from a conduit using the optional adaptor

(03107-7003-0003 and 03107-7003-1004). See “Spare parts and accessories” on page 120.

3.3.4 Open channel flow installations

There are normally two distinct parts to an open channel flow measurement system; the

primary element (flow structure) and the secondary element (Head measurement instrumentation). For accurate open channel flow measurement, both parts of the system must be correctly

installed. This section explains the important parts of installing the transmitter (secondary

element). The flow structure (primary element) installation can be referenced in the British

(BS3680) or ISO International standards.

Note

The transmitter should be free from a situation where it is likely to 'drown' (refer to the

relevant standard for further information)

The Rosemount 3108 has a factory-fitted Remote Temperature Sensor.

See “Positioning of the remote temperature sensor (3108 only)” on page 14.

For some installations, the use of a calibration device is mandatory. Emerson offers the

Rosemount Head Verification Device (HVD) for this purpose. See “Spare parts and

accessories” on page 120 for further information.

Section 3: Installation12

Page 23

Reference Manual

A

B

C

D

A

C

B

00809-0200-4841, Rev BA

Positioning of the transmitter

The positioning is critical, and should be the correct distance upstream from the flow structure

as stated in the relevant standard for your country. For example, in the ISO standards, the

distance should be four to five times the maximum height of the water (Hmax) for a thin plate

weir, or three to four times Hmax for a flume. For optimum accuracy, position the transmitter’s

front face at a height equal to the sum of the maximum flow depth plus the transmitter

deadband of 12.2 in. (300 mm) plus an extra 2 in. (50 mm).

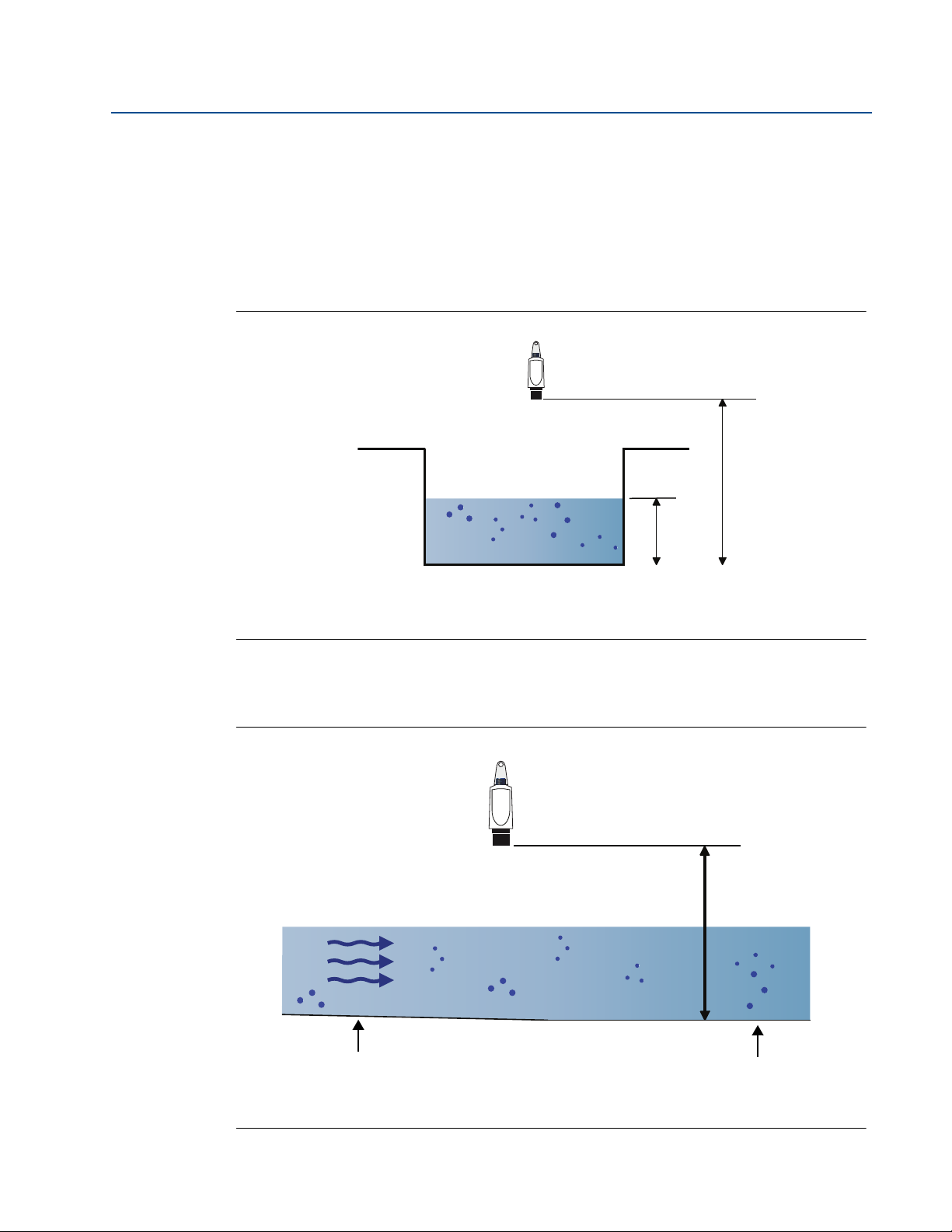

Figure 3-3. Choosing the height position above a flow

Section 3: Installation

December 2014

A. Transmitter front face

B. Hmax

C. Transmitter bottom reference = Hmax + 12.2 in. (300 mm) + 2 in. (50 mm)

It is important that the bottom reference of the transmitter should be related to the datum of

the primary measuring device (Figure 3-4).

Figure 3-4. Bottom Reference of a flume or weir

Section 3: Installation

A. Transmitter bottom reference C. Approach channel

B. Primary element (e.g. flume, weir) invert D. Flow

13

Page 24

Section 3: Installation

B

A

December 2014

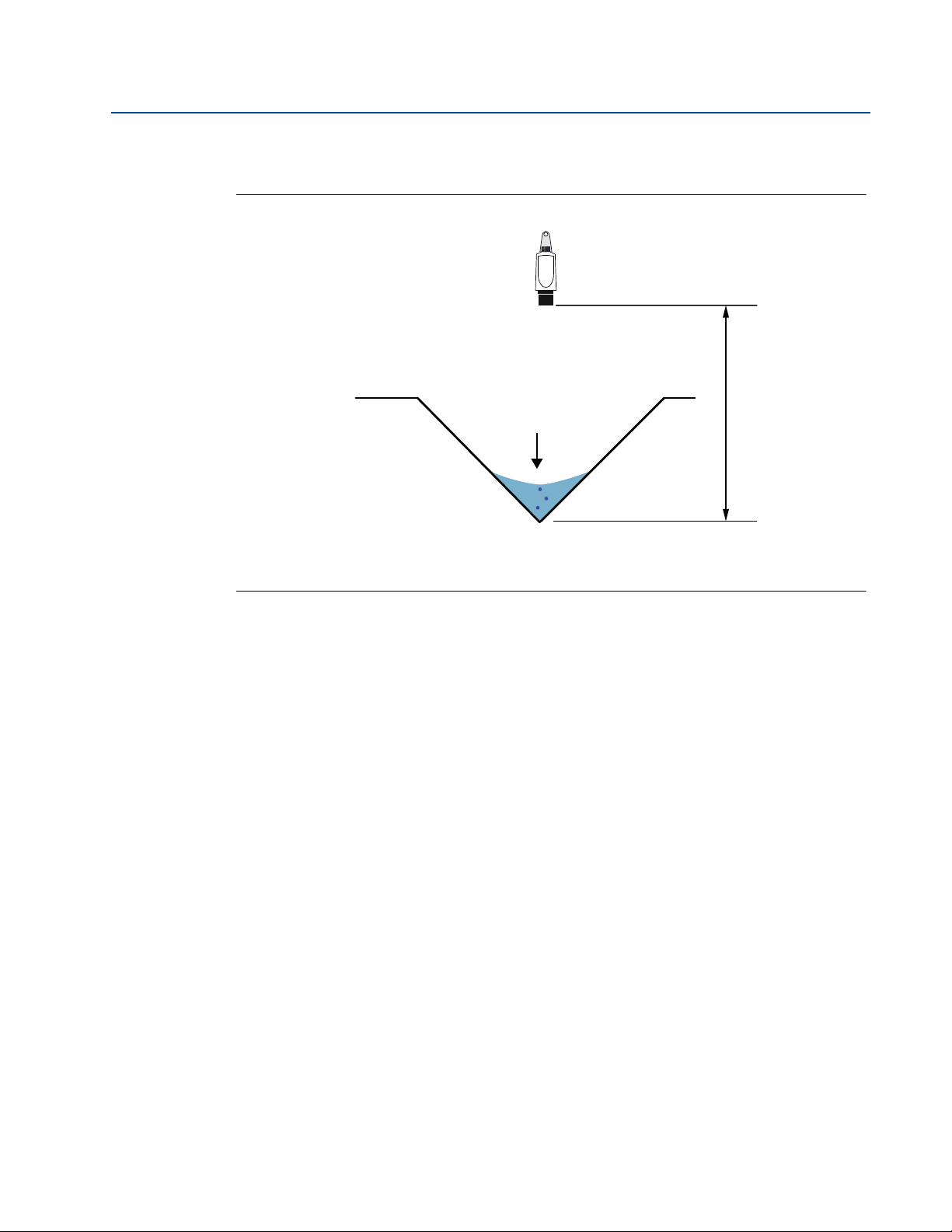

When setting the bottom reference on a ‘V’ notch weir, it is important the true invert is used and

not the meniscus level (Figure 3-5).

Figure 3-5. Bottom reference of a ‘V’ notch weir

Reference Manual

00809-0200-4841, Rev BA

A. Transmitter bottom reference (i.e. true invert)

B. Meniscus level

Positioning of the remote temperature sensor (3108 only)

The Rosemount 3108 transmitter has a factory fitted remote temperature sensor. The

temperature sensor is enclosed in a M8 x 1.5 threaded stainless steel body.

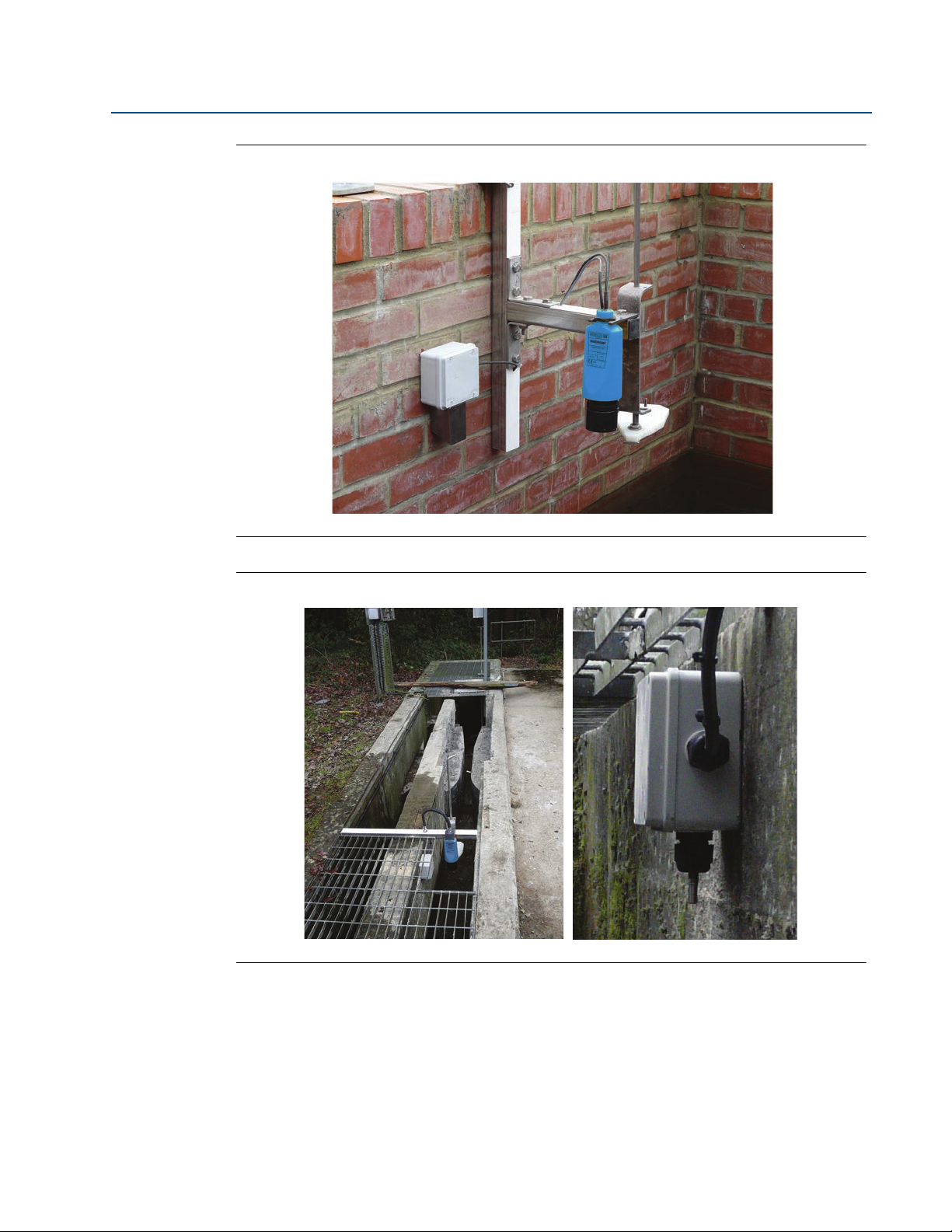

Figure 3-6 and Figure 3-7 on page 15 show two typical arrangements for installing the

temperature sensor in an open or enclosed chamber. The sensor may be installed in a suitable

plastic conduit box and clamped in place using a suitable compression type cable gland.

1. Open weir chamber (Figure 3-6 on page 15)

Mount the remote temperature sensor so that it is representative of the mean air

temperature in the chamber and is in a shaded area away from direct sunlight and solar

radiation.

2. Enclosed or partially covered flume chamber (Figure 3-7 on page 15)

Mount the remote temperature sensor in the approach channel, in a shaded area away

from direct sunlight and solar radiation. In Figure 3-7 on page 15, the sensor is partially

covered by grating which helps prevent solar gain. (Full grating is removed for clarity.)

The temperature sensor should be positioned in the weir chamber or flume approach channel so

the average air temperature can be accurately measured. The temperature sensor must be

protected at all times from direct sunlight and any radiated heat.

In extreme high temperatures, for the best accuracy and stability of level measurement reading,

the transmitter should be shrouded to prevent the incidence of direct sunlight and solar

radiation. If the flow structure permits, mount the transmitter within the flow channel or

chamber.

Section 3: Installation14

Page 25

Reference Manual

00809-0200-4841, Rev BA

Figure 3-6. Open weir chamber arrangement with Rosemount Head Verification Device

Section 3: Installation

December 2014

Figure 3-7. Enclosed or partially covered flume chamber arrangement

Section 3: Installation

15

Page 26

Section 3: Installation

December 2014

3.4 Electrical installation

3.4.1 Connecting the transmitter

The Rosemount 3490 Series is a two-wire loop-powered transmitter accepting power supplies

as follows:

12 to 40 Vdc in a non-hazardous area (ordinary location)

12 to 30 Vdc in a hazardous area (classified location)

Note

To comply with the CSA requirements, the transmitters must be powered from a

Rosemount 3490 Series Control Unit or class 2 or separate extra-low voltage (SELV)

source.

Other devices may reset if connecting the transmitter to a multi-drop system while the

loop is powered. De-energize the loop to avoid devices being reset.

Reference Manual

00809-0200-4841, Rev BA

Each transmitter is supplied with a factory-fitted PVC sheathed, two-core, shielded cable for

communications and external power supply connections. There are no cable conduit entries

and no covers to remove. The cable may be cut to length on site or may be extended using a

junction box and suitable extension cable.

See “Wiring to allow HART communication” on page 18 if HART digital communication is

required.

Installation in a non-hazardous area (ordinary location)

The 3107 and the 3108 are suitable for non-hazardous (ordinary location) applications.

To connect the transmitter:

1. Make sure that the power supply is disconnected.

2. Connect the cable wires as shown in Figure 3-8 on page 17, taking note of the required

voltage of 12 to 40 Vdc for non-hazardous (ordinary location) applications.

Installation in a hazardous area (classified location)

The 3107 and the 3108 are suitable for Intrinsically Safe (IS) applications. Appendix B: Product

Certifications has the safety approval information and control drawings.

When the transmitters are used with a Rosemount 3490 Series Control Unit, no additional

safety barriers are required as the control unit output is Intrinsically Safe.

If powering the transmitter from any other source, ensure a suitable Intrinsically Safe (IS) barrier

is fitted in the non-hazardous area. The barrier must be chosen such that its output parameters

Uo, Io and Po are less than Ui, Ii and Pi of the transmitter (see Appendix B: Product Certifications

for the parameter values). In addition, the sum of the capacitance and the inductance of the

transmitter and any extra cable fitted must not exceed the maximum specified for the barrier.

Suitable barriers include the MTL products 706, 706S, 787, and 787S.

Section 3: Installation16

Page 27

Reference Manual

A

C

B

D

00809-0200-4841, Rev BA

To connect the transmitter:

1. Make sure that the power supply is disconnected.

2. Connect the cable wires (see Figure 3-8 on page 17), taking note of the restricted

Note

Other devices may reset if connecting the transmitter to a multi-drop system while the

Make sure that the instruments in the loop are installed according to intrinsically-safe

Figure 3-8. Wiring diagram

Section 3: Installation

December 2014

voltage of 12 to 30 Vdc for hazardous area (classified location) applications.

loop is powered. De-energize loop to avoid devices being reset.

field wiring practices and control drawings, when applicable.

A. Black: 0 Vdc

B. Red: 12 to 40 Vdc (for non-hazardous area) or 12 to 30 Vdc from protective barrier (for hazardous area)

C. Non-hazardous area: connect cable screen to standard ground (earth) or

hazardous area: connect cable screen to intrinsically safe ground (earth)

D. Remote temperature sensor (3108 only)

3.4.2 Remote temperature sensor (on 3108 only)

The factory-fitted remote temperature sensor on the 3108 may be installed in a hazardous area

without the need for any additional protection or barriers.

Note

See also “Positioning of the remote temperature sensor (3108 only)” on page 14.

Section 3: Installation

17

Page 28

Section 3: Installation

December 2014

3.4.3 Wiring to allow HART communication

If HART communications is required, a 250 Ohm (minimum), 0.25 W load resistor must be

installed in the loop. (See “Load limitations” on page 114).

Note

When the transmitter is used with a Rosemount 3490 Series Control Unit, there is no

need to install an external load resistor in the loop because a suitable resistor is built in

to the control unit.

If the transmitter is being supplied through a safety barrier, ensure the type chosen will pass

HART information.

After the load resistor is installed, a Field Communicator can be connected across the load

resistor, or across the loop at any point downstream of the load resistor. It is the responsibility

of the installer to ensure that any Field Communicator used in the hazardous area is

suitably certified.

Note

Make sure that the instruments in the loop are installed according to intrinsically-safe

field wiring practices and control drawings, when applicable.

Reference Manual

00809-0200-4841, Rev BA

3.4.4 Lightning / surge protection and other loop devices

If the area is prone to lightning strikes or voltage surges, a suppressor device may be installed

between the transmitter and the control unit.

If an additional loop-powered device or separately powered device is included in the two-wire

loop, ensure the transmitter receives a minimum voltage of 12 Vdc (see “Load limitations” on

page 114).

Section 3: Installation18

Page 29

Reference Manual

00809-0200-4840, Rev BA

Section 4 Configuration

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 19

Command parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page 20

Configuration parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 31

4.1 Overview

The Rosemount 3107 and Rosemount 3108 support HART communications, which may be used

to program or interrogate the transmitters from any point on the two-wire loop.

This section contains information on configuring the transmitters using a

Field Communicator, PC with AMS, or Rosemount 3490 Series Control Unit.

Rosemount 3490 Series control unit

Section 4: Configuration

December 2014

The product manual 00809-0100-4841 provides detailed instructions on installation and

operation of the control unit.

A full menu map showing how to access transmitter parameters using the control unit’s menu

system is in Appendix Appendix C: Rosemount 3490 Series Universal Control Unit.

For convenience, the parameter identification numbers (P*** and D***) are used in parameter

headings and descriptions in this configuration section.

When using the control unit, use the Enter ( ) key to start editing a configuration parameter

and then use the arrow keys to change the setting. Changes are confirmed by pressing the Enter

key, or abandoned by pressing the Esc key. Commands e.g. Set As Empty are run using the

Enter () key.

Note

The Rosemount 3490 Control Unit software must be version 3.40 or later.

Field Communicator and AMS

For convenience, Field Communicator fast key sequences are labeled

“Fast Keys” for each software function below the appropriate headings.

Example software function

Fast Keys

1, 2, 3, etc.

Section 4: Configuration

When using a Field Communicator, some configuration changes are sent to the transmitter by

pressing “SEND”. AMS configuration changes are implemented when the “Apply” button is

clicked.

Connect the Field Communicator leads to the transmitter, and turn on the Field Communicator

by pressing the ON/OFF key. The Field Communicator will search for a HART-compatible device

19

Page 30

Section 4: Configuration

Set Base Units (ft)

m

ft

in

ft

ENTER

ABORT

(Field Communicator Screen)

Base Units

Esc=Quit =Edit

metric

(Rosemount 3491 Screen)

December 2014

and indicate when the connection is made. If the Field Communicator fails to connect, it

indicates that no device was found. If this occurs, check the lead connections and re-try.

A full menu map showing how to access transmitter parameters using the Field Communicator

is in Appendix Appendix D: Field Communicator.

4.2 Command parameters

4.2.1 Base units

Reference Manual

00809-0200-4840, Rev BA

Fast Keys

3, 4, 3, 3

When the transmitter is shipped from the factory, the default factory setting for Base Units is

“metric” or “imperial ft” depending on the model order code (see “Ordering information” on

page 118).

Note

Keep a record of your programmed settings. Changing base units resets parameters to

their default factory settings in the appropriate units.

Field Communicator

To view or change the transmitter base units:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Maintenance.

3. Select 3: Utilities.

4. Select 3: Set Base Units.

5. Use the up and down navigation keys to select new base units, and then save the

selection by pressing “ENTER”.

20

6. Press “ENTER” to select 1: Yes (in response to “Are you sure?”).

7. Use the left navigation key to return to the previous menu.

Note

When messages appear, take appropriate action if needed and press “OK”.

Rosemount 3490 Series Control Unit

To view or change the transmitter base units:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM.

Section 4: Configuration

Page 31

Reference Manual

Select:

1. Present Depth

2. Set as Empty

3. Exit

2. Set as Empty

ENTER

ABORT

(Field Communicator Screen)

00809-0200-4840, Rev BA

4. Select Base Units.

5. Follow on-screen instructions to select and confirm the new base units.

6. Select “Quit” to exit to the previous menu.

7. To get the same base units on the control unit, switch the power off and then on again.

The control unit prompts for the transmitter’s Bottom Reference value (page 35) in

the new base units.

Note

The display units (reported units) of the transmitter’s PV (Process Value) can be

changed to metric or imperial measurement units using the parameter Primary

Variable Units (page 51), but this does not automatically re-scale the PV.

4.2.2 Set as empty

Section 4: Configuration

December 2014

Fast Keys

2, 2, 2, 3, 2

If the bottom reference is unknown and the tank is empty, the transmitter can change the

Bottom Reference value (page 35) to the Distance measurement with the tank empty.

P010 = (D910 - P060)

Where:

P010 = Bottom Reference setting.

D910 = Distance measurement (see page 90).

P060 = Distance Offset setting (see page 40).

Field Communicator

To select the Set As Empty command:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Level.

4. Select 3: Present Depth.

5. Select 2: Set as Empty, and then press “ENTER”.

Section 4: Configuration

Note

When messages appear, take appropriate action if needed and press “OK”.

Set As Empty is also available at Fast Key sequence 2, 1, 2.

21

Page 32

Section 4: Configuration

(Rosemount 3491 Screen)

(Field Communicator Screen)

December 2014

Rosemount 3490 Series Control Unit

Reference Manual

00809-0200-4840, Rev BA

To select the Set As Empty command:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY.

4. Select SET AS EMPTY.

5. Follow on-screen instructions to perform the Set As Empty action.

(If prompted to change the mode to off-line, press the Enter key).

6. Select “Quit” to exit to the previous menu.

4.2.3 Present depth

Fast Keys

If the Bottom Reference is unknown but the present liquid depth is known, the transmitter can

set the Bottom Reference value using the Present Depth value, the live distance measurement,

and optional offsets:

P010 = (Depth + D910) - (P060 + P069)

Where:

SET AS EMPTY

Esc=Quit =Start

2, 2, 2, 3, 1

P010 = Bottom Reference (see page 35).

Depth = Present Depth setting (live level value snapshot but can be edited).

D910 = Distance measurement (see page 90).

P060 = Distance Offset (see page 40).

P069 = Level Offset (see page 41).

Field Communicator or AMS

To use the Present Depth action:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 2: Level.

4. Select 3: Present Depth.

5. Select 1: Present Depth, and then press “ENTER”.

6. Follow the on-screen instructions to input the

present depth, which will then change the

transmitter’s bottom reference using the

calculation.

7. Press “ENTER” to confirm the input present depth.

Select:

1. Present Depth

1. Present Depth

2. Set as Empty

3. Exit

ABORT

ENTER

22

Section 4: Configuration

Page 33

Reference Manual

(Rosemount 3491 Screen)

(Field Communicator Screen)

00809-0200-4840, Rev BA

Note

When messages appear, take appropriate action if needed and press “OK”.

Present Depth is also available at Fast Key sequence 2, 1, 2.

Rosemount 3490 Series Control Unit

To select the Set As Empty command:

Section 4: Configuration

December 2014

1. From the Main Menu screen, select SETUP

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY.

4. Select Present Depth.

5. Follow the on-screen instructions to input the present depth, which will then change

the transmitter’s bottom reference using the calculation.

(If prompted to change the mode to “off-line”, press the Enter key).

6. Select “Quit” to exit to the previous menu.

4.2.4 Learn false echo

Fast Keys

The transmitter can be manually told the live Distance (on page 90) is being calculated from a

false target echo and that echo can therefore be ignored.

If there is another false target echo, repeat the learning process again. A maximum of four false

echoes can be learnt.

Field Communicator or AMS

To ignore a false target echo:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

2, 2, 6, 6

Present Depth

1.045m

Esc=Quit =Edit

1. Number of False Echoes

2. Distance D910

3. Echo Size D911

4. Target Echoes D913

5. Clear False Echoes

6. Learn False Echo

6. Learn False Echo

7. Auto Tank Map

8. False Echo Data

HELP

SAVE

HOME

10.674 ft

75 %

0

5

Section 4: Configuration

3. Select 6: False Echoes.

4. Select 6: Learn False Echo.

5. Wait three seconds while the transmitter learns to ignore the false echo.

Note

When messages appear, take appropriate action if needed and press “OK”.

23

Page 34

Section 4: Configuration

(Rosemount 3491 Screen)

False Echoes

1. Number of False Echoes

2. Distance D910

3. Echo Size D911

4. Target Echoes D913

5. Clear False Echoes

6. Learn False Echo

7. Auto Tank Map

8. False Echo Data

7. Auto Tank Map

SAVE

HOME

HELP

0

10.674 ft

75 %

5

(Field Communicator Screen)

December 2014

Rosemount 3490 Series Control Unit

Reference Manual

00809-0200-4840, Rev BA

To ignore a false target echo:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select ENGINEERING.

4. Select FALSE ECHO ACTION.

5. Select Learn False Echo.

6. Follow the on-screen instruction (“Start”) to ignore a false echo.

(Press the Enter ( ) key if prompted to change the mode to “off-line”).

7. Select “Quit” to exit to the previous menu.

Note

To clear all learned false echoes, see Clear False Echoes on page 75.

To edit existing false echo data, see False Echo Data on page 74.

Use the “Auto Tank Map” feature for automatic learning (page 24).

4.2.5 Auto tank map

LEARN FALSE ECHO

Esc=Quit =Start

Fast Keys

2, 2, 6, 7

The transmitter can automatically map up to four echoes from false targets within an empty

tank. The tank needs to be empty so that echoes from all false targets are exposed.

Note

Set the Bottom Reference (page 35) before using Auto Tank Map.

Field Communicator or AMS

To automatically map up to four echoes from

false targets:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 6: False Echoes.

4. Select 7: Auto Tank Map.

5. Wait while the transmitter learns about the empty tank to ignore the false echoes. This

process takes less than one minute.

24

Note

When messages appear, take appropriate action if needed and press “OK”.

Section 4: Configuration

Page 35

Reference Manual

Esc=Quit =Start

AUTO TANK MAP

(Rosemount 3491 Screen)

00809-0200-4840, Rev BA

Rosemount 3490 Series Control Unit

To automatically map up to four echoes

from false targets:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select ENGINEERING.

4. Select FALSE ECHO ACTION.

5. Select Auto Tank Map.

6. Follow the on-screen instruction (“start”) to ignore a false echo.

7. Wait while the transmitter learns about the empty tank to ignore the false echoes. The

Section 4: Configuration

December 2014

(Press the Enter key if prompted to change the mode to “off-line”).

process takes less than one minute.

8. Select “Quit” to exit to the previous menu.

Note

To clear all learned false echoes, see Clear False Echoes on page 75.

To edit existing false echo data, see False Echo Data on page 74.

Use the “Learn False Echo” feature manual learning (page 23).

4.2.6 Simulation of PV

Fast Keys

The transmitter simulations automatically cycle the PV between the bottom of the tank and the

nearest measurable distance. The cycle direction is given by the name of the simulation mode

selected.

Simulation modes are:

“Run up” – cycles up, and then down, repeatedly until stopped.

“Run down” – cycles down, and then up, repeatedly until stopped.

“Run from Zero” – as “Run up” except the PV initially starts from 0.

A single cycle takes 100 seconds to complete. The Current Output responds according to the PV.

3, 5, 1

Section 4: Configuration

The cycling may be paused with the “pause” mode, and then re-started by selecting another

simulation mode.

To stop the cycling, select the “normal” mode.

25

Page 36

Section 4: Configuration

1. Simulation Enabled

2. Change Mode

3. Primary Variable D900

4. Current Output D906

5. Percentage Current D905

2. Change Mode

SAVE

HOME

HELP

OFF

35.0078 ft

14.40 mA

19.0 %

(Field Communicator Screen Shown)

(Rosemount 3491 Screen)

December 2014

Field Communicator or AMS

To use the simulation tool:

1. From the Home screen, select 3: Service Tools.

2. Select 5: Simulate.

3. Select 1: Primary Variable.

4. Select 2: Change Mode.

5. Select a simulation mode e.g. 2: Run Up.

6. The simulation is now running, and Simulation

7. Monitor the parameters Primary Variable (PV), Current Output, and Percentage of

8. When finished, change the mode to “Normal”.

Reference Manual

00809-0200-4840, Rev BA

Enabled is “ON”.

Current Output on the LCD screen.

Note

When messages appear, take appropriate action if needed and press “OK”.

Rosemount 3490 Series Control Unit

To use the simulation tool:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM.

4. Select Simulation.

5. Select a simulation mode.

6. When finished, select “Quit” to exit to the previous menu.

SIMULATION

Normal

Esc=Quit =Edit

26

Section 4: Configuration

Page 37

Reference Manual

Utilities

1. Restart Device

2. Load Defaults

3. Set Base Units

1. Restart Device

SAVE

HOME

HELP

(Field Communicator Screen)

(Rosemount 3491 Screen)

00809-0200-4840, Rev BA

4.2.7 Restart device

Section 4: Configuration

December 2014

Fast Keys

3, 4, 3, 1

This re-starts the transmitter as if the power has been interrupted.

Field Communicator or AMS

To restore the original factory configuration:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Maintenance.

3. Select 3: Utilities.

4. Select 1: Restart Device.

5. When the message “About to restart the transmitter” appears, press “OK” to continue

(or “ABORT” to not continue).

6. Select 1: Yes to restart the transmitter.

Note

When messages appear, take appropriate action if needed and press “OK”.

Rosemount 3490 Series Control Unit

RESTART DEVICE

Section 4: Configuration

To restore the original factory configuration:

1. From the Main Menu screen, select SETUP.

Esc=Quit =Start

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM, and then select RESTART DEVICE.

4. Follow the on-screen instruction (“Start”) to restart the transmitter.

(Press the Enter ( ) key if prompted to change the mode to “off-line”).

5. Select “Quit” to exit to the previous menu.

27

Page 38

Section 4: Configuration

Utilities

1. Restart Device

2. Load Defaults

3. Set Base Units

2. Load Defaults

SAVE

HOME

HELP

(Field Communicator Screen)

LOADS FACTORY

DEFAULT VALUES

Esc=Quit =Start

DEFAULTS

(Rosemount 3491 Screen)

December 2014

4.2.8 Load defaults

Reference Manual

00809-0200-4840, Rev BA

Fast Keys

3, 4, 3, 2

This restores the transmitter parameters to the factory default values for the selected base

units. This is sometimes necessary, particularly if the data held in the transmitter is in doubt.

Note

Restoring the factory defaults values overwrites all site entered data.

After loading the factory defaults, the transmitter automatically re-starts and

communication is interrupted until the re-start is complete.

Field Communicator or AMS

To restore the factory default settings of the transmitter:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Maintenance.

3. Select 3: Utilities.

4. Select 2: Load Defaults.

5. When the message “About to restore factory defaults” appears, press “OK” to continue

(or “ABORT” to not continue).

6. Select 1: Yes to restore the factory defaults.

Note

When messages appear, take appropriate action if needed and press “OK”.

Rosemount 3490 Series Control Unit

To restore the factory default settings of the transmitter:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM, and then select DEFAULTS.

4. Follow the on-screen instructions (select “Start” and answer “Yes”)

to restore the factory defaults.

(Press the Enter ( ) key if prompted to change the mode to “off-line”).

5. Select “Quit” to exit to the previous menu.

28

Section 4: Configuration

Page 39

Reference Manual

Choose analog output level

1. 4mA

2. 20mA

3. Other

4. End

1. 4mA

ENTER

ABORT

(Field Communicator Screen)

Fix Current

0.000

Esc=Quit =Edit

(Rosemount 3491 Screen)

00809-0200-4840, Rev BA

4.2.9 Simulate current output

Section 4: Configuration

December 2014

Fast Keys

3, 5, 2, 1

This forces a fixed output current in the range 4 to 20 mA. This feature temporarily overrides the

normal function of the transmitter’s PV driving the 4–20mA Current Output until exiting to the

previous menu.

Note

The simulation is automatically cancelled after 20 minutes, and the output current

returns to representing the transmitter’s PV.

Field Communicator or AMS

To fix the output current:

1. From the Home screen, select 3: Service Tools.

2. Select 5: Simulate.

3. Select 2: Loop Current.

4. Select 1: Loop Test.

5. Select the required output current e.g. 1: 4mA.

6. When a message appears saying the output current is fixed, press “OK”.

Section 4: Configuration

7. Select 4: End to exit and restore the output current to normal.

Note

When messages appear, take appropriate action if needed and press “OK”.

Rosemount 3490 Series Control Unit

To fix the output current:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM, and then select TRIM.

4. Select Fix Current.

5. Follow on-screen instructions to input the required output current.

(Press the Enter ( ) key if prompted to change the mode to “off-line”).

6. When finished, select “Quit” to exit to the previous menu.

29

Page 40

Section 4: Configuration

Analog Calibration

1. D/A Trim

1. D/A Trim

SAVE

HOME

HELP

(Field Communicator Screen)

(Rosemount 3491 Screen)

December 2014

4.2.10 Trim 4mA / Trim 20mA

Reference Manual

00809-0200-4840, Rev BA

Fast Keys

3, 4, 1, 1

This is for calibrating the 4mA and 20mA output current from the transmitter. The output

current is temporarily set to 4mA and 20mA. Measure the actual output current and then input

that mA value to re-calibrate. The output current resumes normal operation after exiting.

Note

The re-calibration procedure is automatically cancelled after 20 minutes of inactivity,

and the previous calibration is restored.

Field Communicator or AMS

To re-calibrate the 4mA and 20mA output current:

1. From the Home screen, select 3: Service Tools.

2. Select 4: Maintenance,

3. Select 1: Analog Calibration.

4. Select 1: D/A Trim.

5. Follow the instruction “Connect reference

meter”, and then press “OK”.

6. Input the measured mA from the reference meter, and press “ENTER”.

7. Select 1: Yes.

8. Select “OK” to continue to calibrate the 20mA output current.

9. Input the measured mA from the reference meter, and press “ENTER”.

10. Select 1: Yes. (The output current now returns to normal operation).

Note

When messages appear, take appropriate action if needed and press “OK”.

Rosemount 3490 Series Control Unit

To re-calibrate the 4mA output current:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM, select TRIM, and then select Tr im

4mA.

4. Connect a reference meter.

Esc=Quit =Start

TRIM 4mA

30

Section 4: Configuration

Page 41

Reference Manual

Esc=Quit =Start

TRIM 20mA

(Rosemount 3491 Screen)

Message P000

MESSAGE

MESSAGE

ESC

DEL ENTER

HELP

wsq

a

z

Lock

Shift

@ &

á ü

x

e

d

c

r

f

v

t

g

b

y

h

n

u

j

m

*

+

/

.

0

7

4

1

8

5

2

9

6

3

iko

l

FN

(Field Communicator Screen)

00809-0200-4840, Rev BA

5. Follow the on-screen instructions to start the re-calibration feature.

6. Input the measured mA from the reference meter, and select “Save”.

7. Select the “Quit” instruction to exit.

To re-calibrate the 20mA output current:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select SYSTEM, select TRIM,

4. Follow the on-screen instructions to start the re-calibration feature.

5. Measure the actual output current, and input that new value.

Section 4: Configuration

December 2014

(Press the Enter ( ) key if prompted to change the mode to “off-line”).

and then select Trim 20mA.

(Press the Enter ( ) key if prompted to change the mode to “off-line”).

6. Select “Quit” to exit to the previous menu.

4.3 Configuration parameters

4.3.1 Message (P000)

Fast Keys

This allows a general 32-character message to be edited (12 characters if using a Rosemount

3490 Series Control Unit). It can be used for any purpose, such as recording the initials of the

person who programmed it, a support contact number, details of last programming change,

etc.

Field Communicator or AMS

To view or change the message:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: HART / Identity.

4. Select 1: Identity.

2, 2, 4, 1, 3

Section 4: Configuration

5. Select 3: Message P000.

6. Input the new message, and then press “ENTER” to save it.

7. Press “SEND” to update the transmitter.

31

Page 42

Section 4: Configuration

Message

MESSAGE

Esc=Quit =Edit

P000

(Rosemount 3491 Screen)

Tag P001

3107

3107

ESC

DEL ENTER

HELP

wsq

a

z

Lock

Shift

@ &

á ü

x

e

d

c

r

f

v

t

g

b

y

h

n

u

j

m

*

+

/

.

0

7

4

1

8

5

2

9

6

3

iko

l

FN

(Field Communicator Screen)

Tag P001

3107

Esc=Quit =Edit

(Rosemount 3491 Screen)

December 2014

Rosemount 3490 Series Control Unit

To view or change the message:

1. From the Main Menu screen, select SETUP.

2. Select the transmitter (e.g. “Tx1: 3107”).

3. Select DUTY, and then select IDENTITY.

4. Select Message.

5. Follow on-screen instructions to input and save the message.

6. Select “Quit” to exit to the previous menu.

4.3.2 Tag (P001)

Reference Manual

00809-0200-4840, Rev BA

Fast Keys

2, 2, 4, 1, 1

This is for editing an electronic ‘label’ of up to 8 characters for the transmitter. The tag is

typically a reference number, but it can also be used to identify the location or duty of the

transmitter in plant item terms.

Note

This tag helps identify the transmitter being interrogated when using a HART Master

Device such as the Rosemount 3490 Series Control Unit.

Field Communicator or AMS

To view or change the tag:

1. From the Home screen, select 2: Configure.

2. Select 2: Manual Setup.

3. Select 4: HART / Identity.

4. Select 1: Identity.

5. Select 1: Tag P001.

6. Input the new tag, and then press “ENTER” to save it.