Page 1

User Manual

Kinetix 6000M Integrated Drive-Motor System

Catalog Numbers 2094-SEPM-B24-S, MDF-SB1003P, MDF-SB1153H, MDF-SB1304F

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, Kinetix, On-Machine, ControlLogix, CompactLogix, SoftLogix, RSLinx, RSLogix, DriveExplorer, ControlFLASH and TechConnect are trademarks of

Rockwell Automation , Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Start

Planning the Kinetix 6000M System

Installation

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

About the Kinetix 6000M System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Typical Hardware Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Typical Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Catalog Number Explanations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Component Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

CE Requirements (system without LIM module). . . . . . . . . . . . . . . . 19

CE Requirements (system with LIM module). . . . . . . . . . . . . . . . . . . 19

Chapter 2

Cable Length Restrictions and System Sizing . . . . . . . . . . . . . . . . . . . . . . . 21

IPIM Module Design Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System Mounting Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Circuit Breaker/Fuse Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Enclosure Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Minimum Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

IDM Unit Design Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Minimum Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Electrical Noise Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cable Categories for Kinetix 6000M System . . . . . . . . . . . . . . . . . . . . 28

Mounting the Kinetix 6000M System

Chapter 3

Mounting the IPIM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Using the 2094 Mounting Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installing the 2094 Power Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Determine Mounting Order. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mount the IPIM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installing the IDM Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Aligning the IDM Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Mount and Connect the IDM Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 3

Page 4

Table of Contents

Chapter 4

Kinetix 6000M System Connector

Data

Connecting the Kinetix 6000M

System

IPIM Module Connectors and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 38

IPIM Module Connector and Signal Descriptions . . . . . . . . . . . . . . . . . . 39

Hybrid Cable DC Bus Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Hybrid Cable Communication Signals Connector . . . . . . . . . . . . . . 39

Safe Torque-off Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Sercos Fiber-optic Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Enable Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

EtherNet/IP Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

IPIM Module Network Connector Pinouts. . . . . . . . . . . . . . . . . . . . . 42

IDM Unit Connectors and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

IDM Unit Connector and Signal Descriptions. . . . . . . . . . . . . . . . . . . . . . 44

Hybrid Cable Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

IDM Network Input and Output Connector Pinouts . . . . . . . . . . . 45

Digital Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Power Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Brake Override Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Peak Duty Cycle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Feedback Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Absolute Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 5

Basic Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Routing the Power and Signal Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Grounding the IDM System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Apply the Cable Shield Clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

General IDM System Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Hybrid Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Network Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

How to Bypass an IDM Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

The Sercos Fiber-optic Ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Ethernet Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 5

Chapter 6

Table of Contents

Configuring the Kinetix 6000M

System

Configure the Kinetix 6000M Integrated Drive-motor System . . . . . . . 65

Understanding the IPIM Module Display . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Information Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Tools Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring the IPIM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Setting the IPIM Module Network Address . . . . . . . . . . . . . . . . . . . . 69

Configuring the IDM Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Setting the Node Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Add-on Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Configure the Logix Sercos Interface Module . . . . . . . . . . . . . . . . . . . . . . . 73

Configure the Logix Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Configure the Logix Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Configure the IDM Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configure the Motion Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configure Axis Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Download the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Apply Power to the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Test and Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Test the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Troubleshooting the Kinetix 6000M

System

Removing and Replacing the

Kinetix 6000M IPIM Module

Chapter 7

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

IDM System Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Reading the Fault Status of the IPIM Module. . . . . . . . . . . . . . . . . . . 88

Interpret Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

IPIM Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

IDM Unit Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

General System Anomalies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

IPIM Module Fault Diagnosis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

IPIM Module Fault Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

IDM Unit Fault Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Logix Controller/IDM Unit Fault Behavior . . . . . . . . . . . . . . . . . . . . 95

Use a Web Browser to Monitor System Status . . . . . . . . . . . . . . . . . . . . . . 97

Chapter 8

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Remove the IPIM Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Replace the IPIM Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 5

Page 6

Table of Contents

Appendix A

Using the Safe Torque-off Feature

with the Kinetix 6000M System

Interconnect Diagram

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Category 3 Requirements According to EN ISO 13849-1 . . . . . . . 104

Stop Category Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Performance Level (PL) and Safety Integrity Level (SIL) . . . . . . . . 104

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Troubleshooting the Safe Torque-off Function . . . . . . . . . . . . . . . . 105

PFD, PFH, and MTTFd Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

PFD, PFH, and MTTFd Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Wiring Your Safe Torque-off Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

European Union Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

IDM Safe Torque-off Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Safe Torque-off Feature Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

IDM System Safe Torque-off Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Cascading the Safe Torque-off Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Safe Torque-off Signal Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Appendix B

Upgrading the Kinetix 6000M System

Firmware

Kinetix 6000M System Sizing

Index

Appendix C

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Configure Logix Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

IPIM Module Firmware Upgrade. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

IDM Unit Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Verify the Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Appendix D

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Manually Sizing the Kinetix 6000M System . . . . . . . . . . . . . . . . . . . . . . . 128

6 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 7

Preface

About This Publication

Conventions Used in This Manual

This manual provides detailed installation instructions for mounting, wiring, and

troubleshooting the Kinetix® 6000M Integrated Drive-Motor (IDM) system

including the IDM Power Interface Module (IPIM).

For information on wiring and troubleshooting the safe-off feature on your

integrated drive-motor system, refer to Appendix A

.

This manual is intended for engineers or technicians directly involved in the

installation, wiring, and programming of the Kinetix 6000M integrated drivemotor system.

If you do not have a basic understanding of the Kinetix drives, contact your local

Rockwell Automation sales representative for information on available training

courses.

The conventions listed below are used throughout this manual.

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Acronyms for the Kinetix 6000 and Kinetix 6200 system components and

Kinetix 6000M integrated drive-motor are shown in the table below and

are used throughout this manual.

Additional Resources

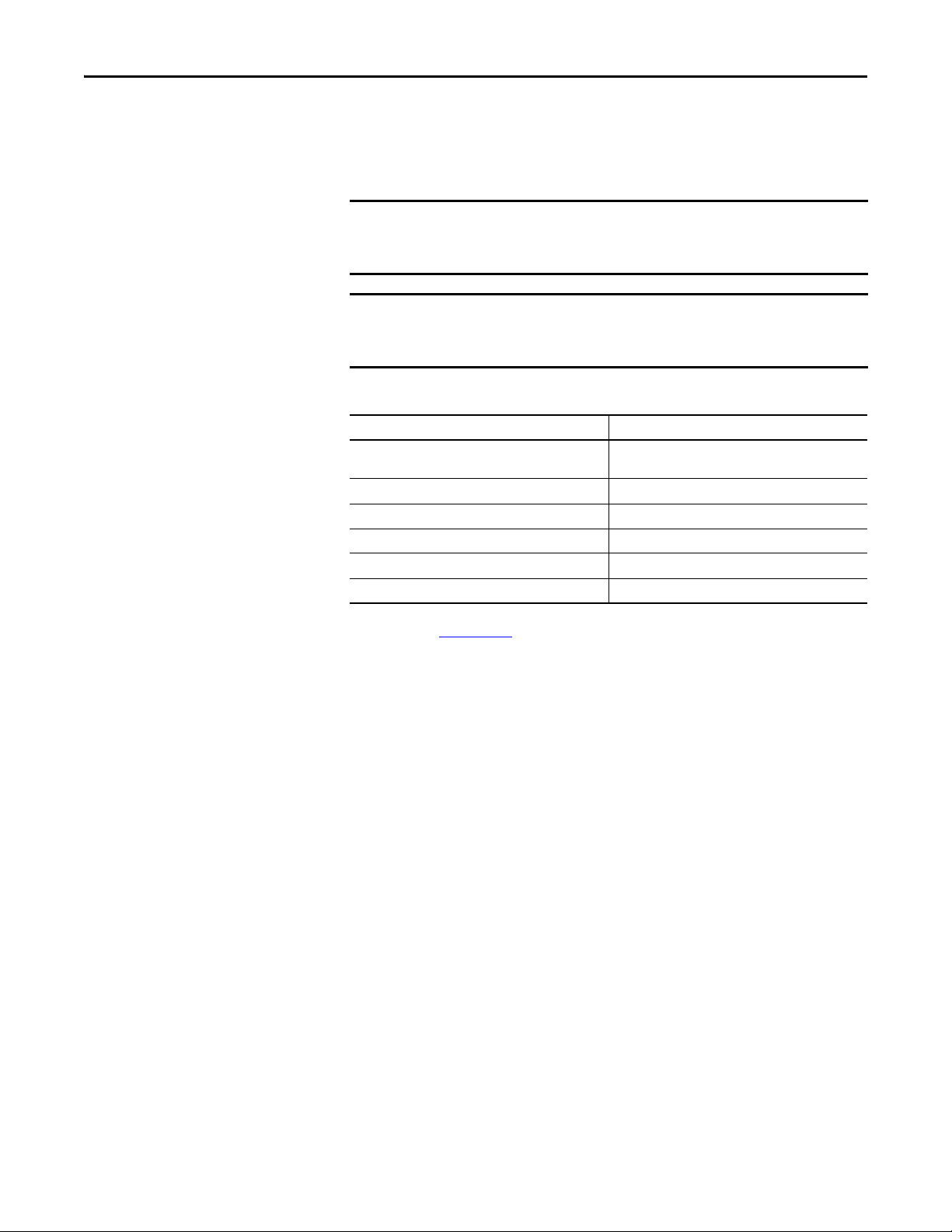

Acronym Kinetix Modules Cat. No.

IDM Integrated drive-motor MDF-SBxxxxx-Qx8xA-S

IPIM IDM power interface module 2094-SEPM-B24-S

IAM Integrated axis module 2094-BCxx-Mxx-x

AM Axis module 2094-BMxx-x

LIM Line interface module 2094-BLxx and 2094-BLxxS-xx

These documents contain additional information concerning related

Rockwell Automation products.

Resource Description

Kinetix 6000M IPIM-to-IDM Hybrid Cable Installation Instructions,

publication 2090-IN031

Kinetix 6000M IDM-to-IDM Hybrid Cable Installation Instructions,

publication 2090-IN032

Kinetix 6000M IDM Network Cable Installation Instructions,

publication 2090-IN034

Kinetix 6000M Manual Brake Release Cable Installation

Instructions, publication 2090-IN037

Provides detailed cable information.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 7

Page 8

Preface

Resource Description

Kinetix 6000M IPIM Hybrid Terminator Installation Instructions,

publication 2090-IN035

Kinetix 6000M Network Terminator Installation Instructions,

publication 2090-IN036

Kinetix 6000M Hybrid Power Coupler Installation Instructions,

publication 2090-IN038

Kinetix 6000M Bulkhead Cable Adapter Kit Installation

Instructions, publication 2090-IN039

Kinetix 6000M Integrated Drive-Motor Installation Instructions,

publication MDF-IN001

Kinetix 6000M Integrated Drive-Motor Power Interface Module

Installation Instructions, publication 2094-IN016

Kinetix 6000 Multi-axis Servo Drives User Manual, publication

2094-UM001

Kinetix 6200 and Kinetix 6500 Modular

Multi-axis Servo Drives User Manual, publication 2094-UM002

Fiber-optic Cable Installation and Handling Instructions,

publication 2090-IN010

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

EMC Noise Management DVD, publication GMC-SP004

Kinetix Rotary Motion Specifications, publication GMC-TD001 Provides IPIM module and IDM unit specifications.

Kinetix Motion Accessories Specifications, publication GMC-TD004

Kinetix Safe-off Feature Safety Reference Manual, publication

GMC-RM002

Kinetix Motion Control Selection Guide, publication GMC-SG001 Provides specifications, motor/servo-drive system

Sercos and Analog Motion Configuration User Manual, publication

MOTION-UM001

Motion Coordinate System User Manual, publication

MOTION-UM002

SoftLogix Motion Card Setup and Configuration Manual,

publication 1784-UM003

Rockwell Automation Industrial Automation Glossary, publication

AG-7. 1

Rockwell Automation Configuration and Selection Tools website:

http://www.rockwellautomation.com/en/e-tools

Rockwell Automation Product Certification website:

http://www.rockwellautomation.com/products/certification

Provides detailed terminator information.

Provides installation information for the Hybrid

Power Coupler.

Provides installation information for the Bulkhead

Cable Adapter.

Provides installation information for the IDM unit.

Provides information on the installation of the IPIM

module.

Provides detailed information about the Kinetix

6000 drives.

Provides detailed information about the Kinetix

6200 drives.

Provides information on proper handling, installing,

testing, and troubleshooting fiber-optic cables.

Provides information, examples, and techniques

designed to minimize system malfunctions caused

by electrical noise.

Provides product specifications for Bulletin 2090

motor and interface cables, low-profile connector

kits, drive power components, and other servo drive

accessory items.

Provides information on wiring and

troubleshooting your Kinetix 6000 servo drives with

the safe-off feature.

combinations, and accessories for Kinetix motion

control products.

Provides information on configuring and

troubleshooting your ControlLogix®,

CompactLogix™, and SoftLogix™ sercos interface

modules.

Provides information to create a motion coordinate

system with sercos or analog motion modules.

Provides information on configuring and

troubleshooting SoftLogix PCI cards.

A glossary of industrial automation terms and

abbreviations.

Motion Analyzer application analysis software for

drive/motor sizing.

Online product selection and system configuration

tools, including AutoCAD (DXF) drawings.

For declarations of conformity (DoC ) currently

available from Rockwell Automation.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

8 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

. To order paper copies of

Page 9

Chapter 1

Start

Use this chapter to become familiar with the design and installation requirements

for the Kinetix 6000M integrated drive-motor system.

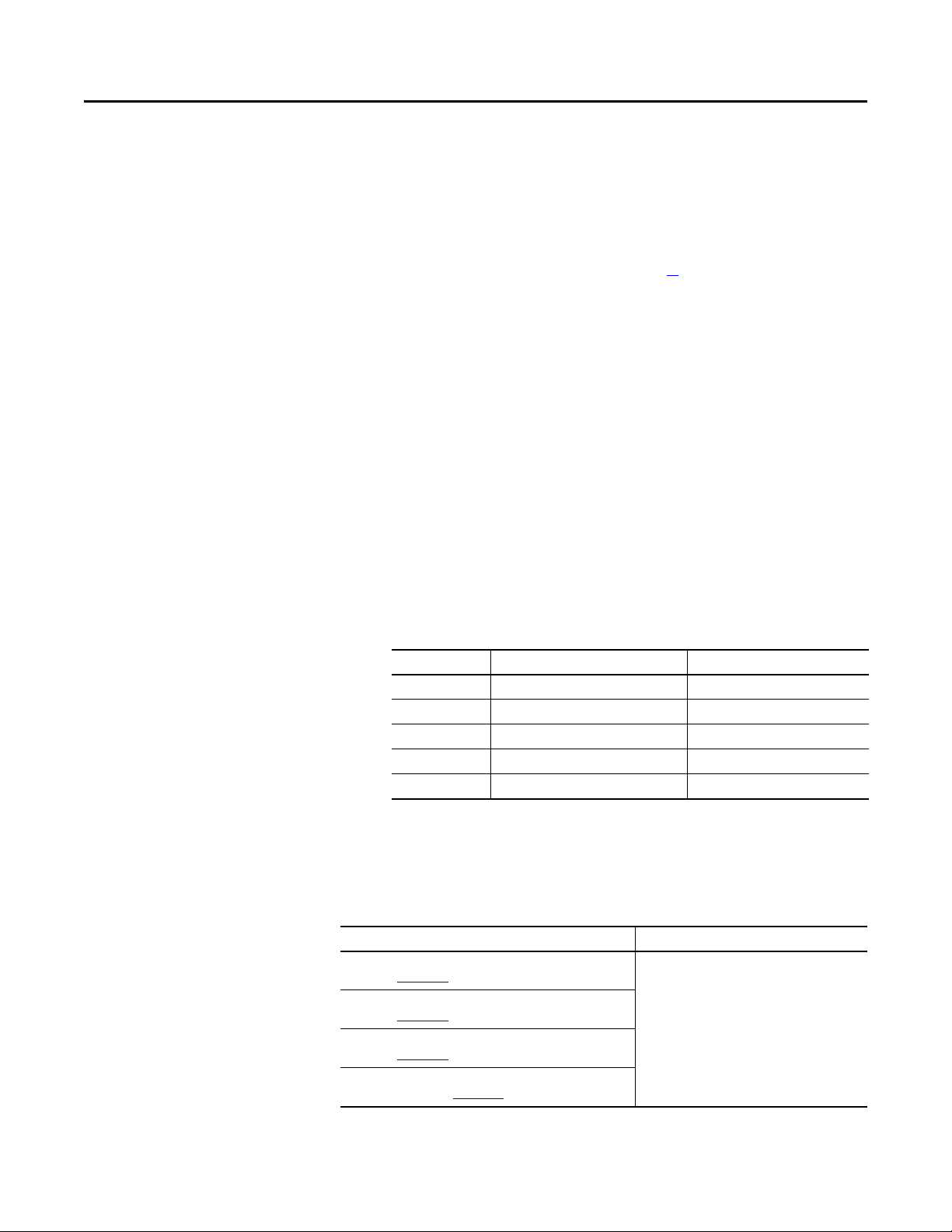

Top ic Pa ge

About the Kinetix 6000M System 9

Typical Ha rdware Configurations 11

Typical Communication Configurations 16

Catalog Number Explanations 17

Component Compatibility 18

Agenc y Compliance 19

About the Kinetix 6000M System

The Kinetix 6000M integrated drive-motor system is designed to provide a

Kinetix Integrated Motion solution for your applications. Ta b l e 1

lists the

components that can be used to build an integrated solution.

Table 1 - System Component Overview

System Component Cat. No. Description

IDM Unit MDF-SBxxxxx-Qx8xA-S Integrated drive-motor (IDM) unit with the safe -off feature. The unit contains a servo drive and motor.

IDM Power Interface

Module (IPIM)

IDM Hybrid Cables From the IPIM module to the first IDM unit:

IDM Network Cables From the IPIM module to the first IDM unit:

Integrated Axis Module 2094-BCxx-Mxx-S (Kinetix 6000)

Axis Module 2094-BMxx-S (Kinetix 6000)

Shunt Module 2094-BSP2 The Bulletin 2094 shunt module mounts to the power rail and provides additional shunting capability in

2094-SEPM-B24-S 460V AC integrated drive-motor power interface module that resides on the power rail and provides

2090-CHBIFS8-12AAxx

From IDM unit to IDM unit:

2090-CHBP8S8-12AAxx

2090-CNSSPRS-AAxx,

2090-CNSSPSS-AAxx

From IDM unit to IDM unit:

2090-CNSSPRS-AAxx,

2090-CNSSPSS-AAxx,

2090-CNSRPSS-AAxx,

2090-CNSRPRS-AAxx

2094-BCxx-Mxx-M (Kinetix 6200)

2094-BMxx-M (Kinetix 6200)

power and communications to the IDM units. The module also monitors power output and provides

overload protection.

Hybrid cable provides power and inter-module communication to each IDM unit via daisy chain.

Required to daisy chain the Kinetix 6000M network.

460V Integrated Axis Modules (IAM) contains an inverter and converter section.

Axis Modules (AM) are a shared DC-bus inverter rated for 460V input power. The AM module must be

used with an IAM module.

regenerative applications.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 9

Page 10

Chapter 1 Start

System Component Cat. No. Description

Power Rail 2094-PRSx The Bulletin 2094 power rail consists of copper bus bars and a circuit board with connectors for each

module. The power rail provides power and control signals from the converter section to adjacent

inverters. The IPIM, IAM and AM power modules, shunt module, slot-filler modules mount to the power

rail.

Power Rail Slot-filler

Module

Logix Controller Platform 1756-Mxx SE CompactLogix module

2094-PRF The Bulletin 2094 slot-filler module is used when one or more slots on the power rail are empty after all

the other power rail modules are installed. One slot-filler module is required for each empty slot.

The network interface module/PCI card serves as a link between the ControlLogix/CompactLogix/

1768-M04SE ControlLogix module

1784-PM16SE PCI option card

SoftLogix platform and the Kinetix 6000 drive system. The communication link uses the IEC 61491 Serial

Real-time Communication System (sercos) protocol over a fiber-optic cable.

RSLogix 5000 Software 9324-RLD300ENE RSLogix 5000 software provides support for programming, commissioning, and maintaining the Logix

family of controllers. Version 20 or later is required when using the Kinetix 6000M integrated drive-

motor system.

Line Interface Modules 2094-BLxxS

2094-XL75S-Cx

Line interface modules (LIM) include the circuit breakers, AC line filter (catalog number 2094-BL02

only), power supplies, and safety contactor required for Kinetix 6000 operation. The LIM module does

not mount to the power rail. You can purchase individual components separately in place of the LIM

module.

IDM Unit Digital Input

Cables

889D DC Micro Allows use of sensors (see Digital Input Connectors

Quick Selection Guide, public ation CNSYS-BR001, or the On-Machine™ Connectivity Catalog, publication

on page 45). Also refer to the Connection Systems

M117-CA001.

Safe-Off Wiring

(1)

Headers

For first drive in multiple safety drive

configurations: 2090-XNSM-W

Required for various installations of the IPIM module into the Kinetix 6000 servo drive systems.

Middle header for drive-to-drive connections in

multiple safety drive configurations with three

or more drives:

2090-XNSM-M

Safe-off te rminating header for the last drive in

multiple safety drive configurations:

2090-XNSM-T

Sercos Interface Cables Network fiber-optic plastic cables, regular duty:

2090-SCEPx-x

Required for various installations of the IPIM module into the Kinetix 6000 and Kinetix 6200 servo drive

systems.

2090-SCVPx-x

2090-SCNPx-x (harsh duty)

Network fiber-optic glass cables:

2090-SCVGx-x

Network fiber optic cable bulkhead adapter:

2090-S-BLHD (2 per pack)

EtherNet/IP Interface

Cables

RJ45-to-RJ45:

1585J-M8CBJM-xx:

Required for various installations of the IPIM module into the Kinetix 6200 servo drive systems.

RJ45 Insulation Displacement Connector:

1585J-M8CC-H

Cable, shielded: 1585-C8CB-Sxxx

Cascaded Safety Cables 1202-Cxx (xx = length) Required accessory to support cascaded safety wiring across multiple modules on the 2094 power rail.

Bulkhead Adapter Kits Network cable: 2090-CBUSPSS Provides wall-mount connectors for hybrid and network cables. The connector kit allows signals to pass

Hybrid cable: 2090-KPB47-12CF

through a cabinet wall or other physical barrier.

(1) Refer to Appendix A for safety information.

10 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 11

Start Chapter 1

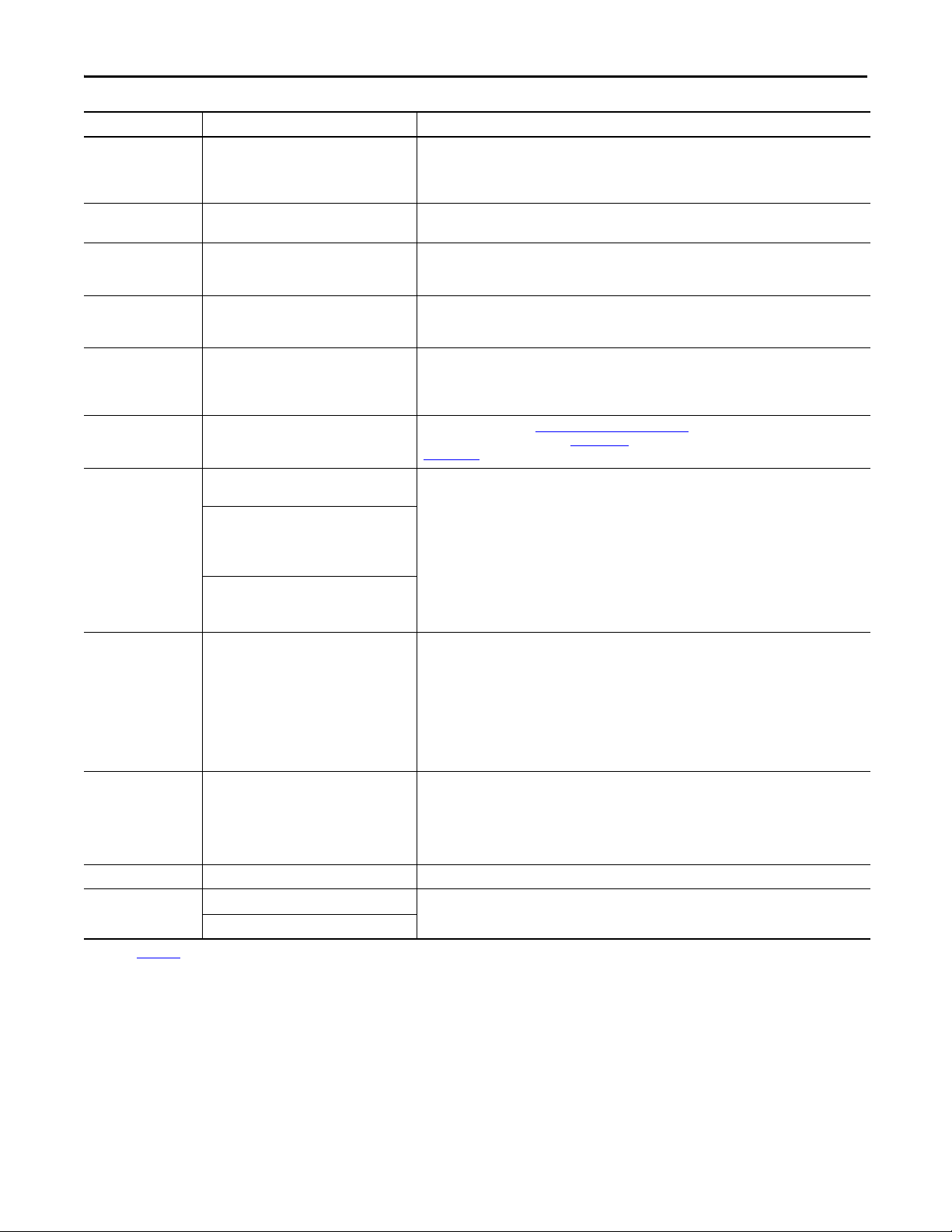

PORT 1 PORT 2 NETWORK

IDM-to-IDM Hybrid Cable

(2090-CHBP8S8-12AAxx)

IPIM Module

(2094-SEPM-B24-S)

IDM Unit

(MDF-SBxxxx)

Network Terminator

Last IDM Unit

(2090-CTSRP)

Network Cable

(2090-CNSxPxS)

Network Cable to

First IDM Unit

(2090-CNSSPxS)

Ter m in at o r

Last IDM Unit

(2090-CTHP8)

IPIM-to-IDM Hybrid Cable

(2090-CHBIFS8-12AAxx)

Catalog numbers are in parenthesis

IDM Unit

(MDF-SBxxxx)

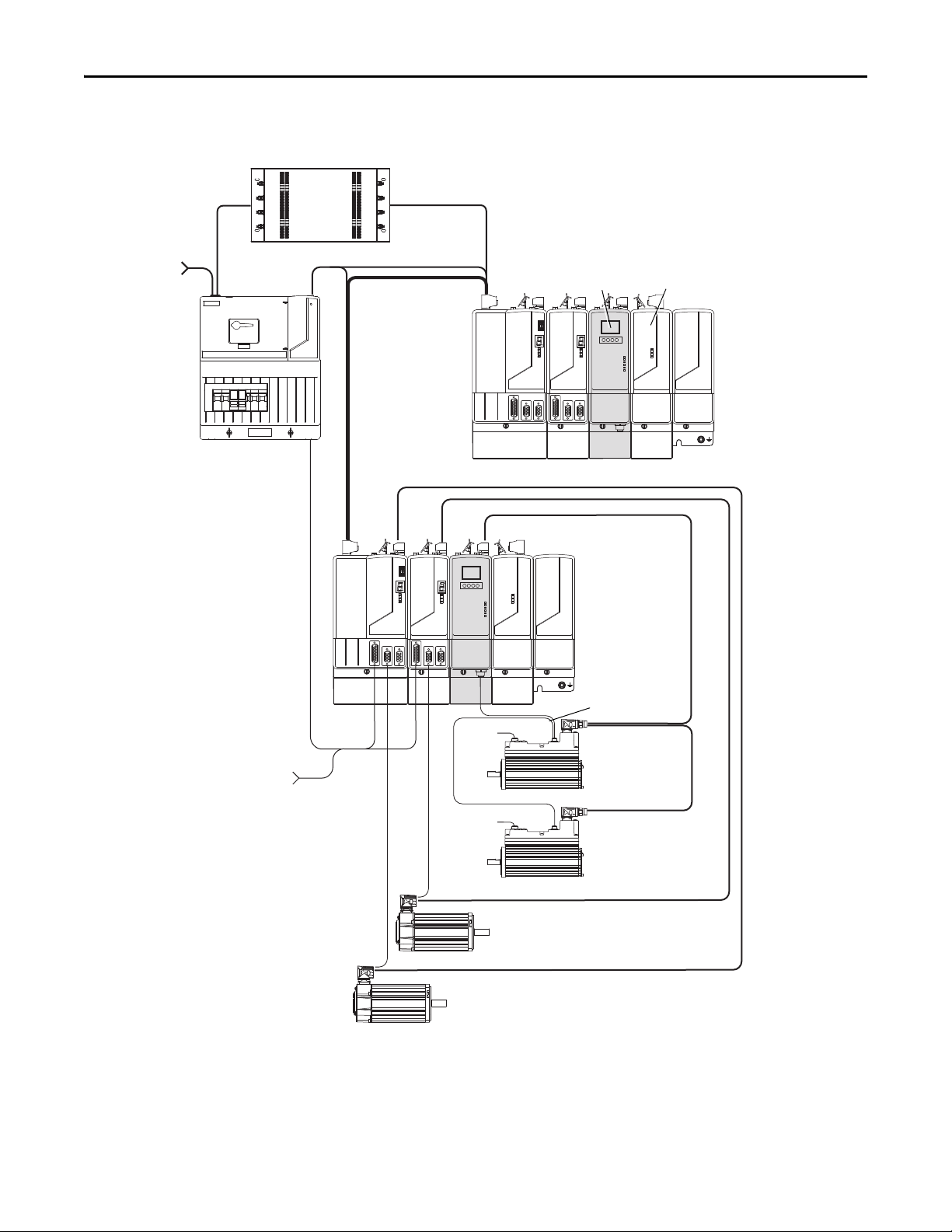

Typical Hardware Configurations

SHOCK HAZARD: To avoid personal injury due to electrical shock, place a

2094-PRF slot-filler module in all empty slots on the power rail.

Any power rail connector without a module installed will disable the 3-phase

power; however, control power is still present.

Figure 1 - Typical Kinetix 6000M Integrated Drive-motor System

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 11

Page 12

Chapter 1 Start

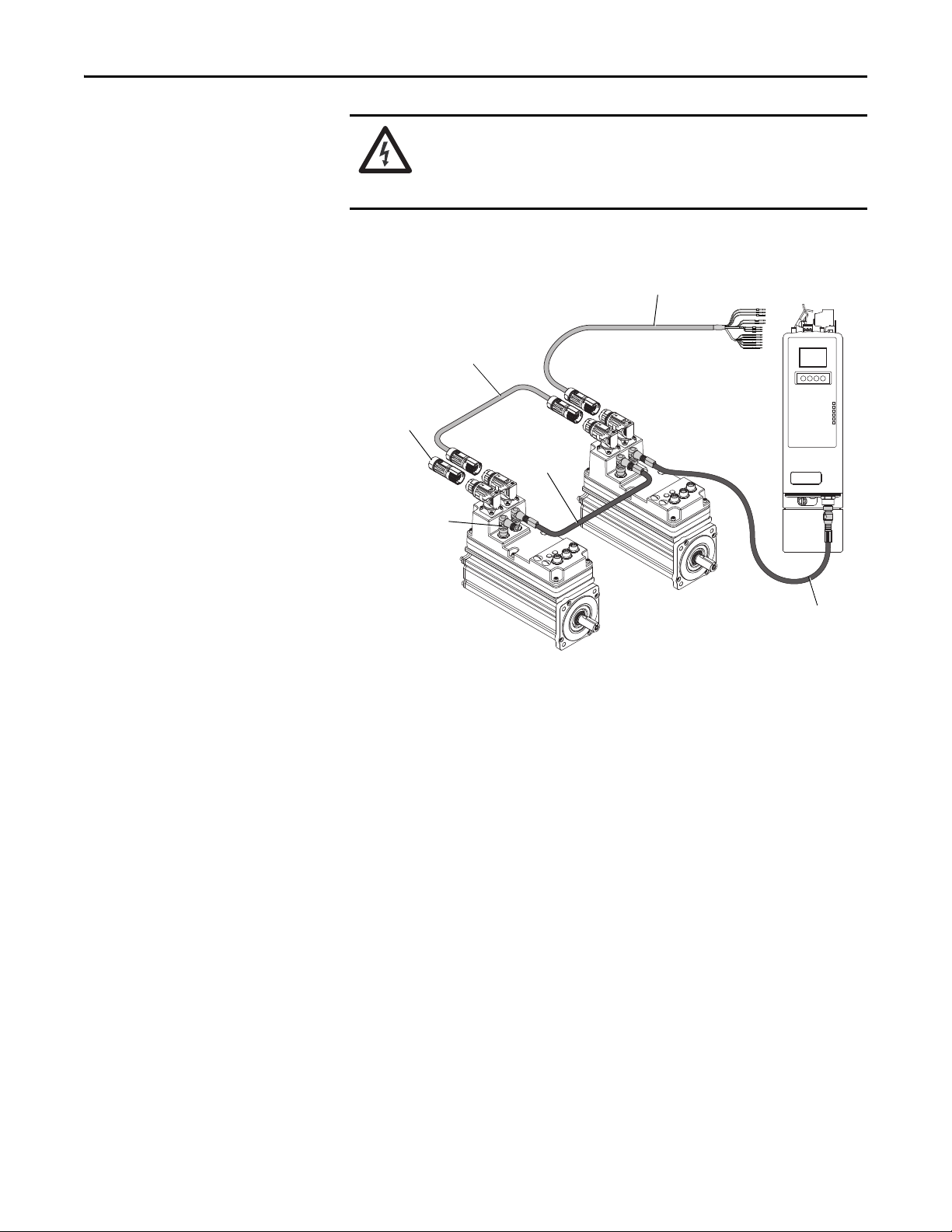

2094-BLxxS

Line Interface Module

(optional component)

3-Phase

Input Power

2094-BSP2

Shunt Module

(optional component)

2090-XXLF-xxxx

AC Lin e Filter

(required for CE)

2094-PRSx

Power Rail

2094-PRF

Slot-filler Module

(required for

unused slots)

To Input Sensors

and Control String

Control Power

2090-K6CK-Dxxxx

Low Profile Connector

Kits for I/O, Motor

Feedback, and Aux

Feedba ck

Bulletin 2090

Motor Feedback Cables

Bulletin 2090

Hybrid Cables

Bulletin 2090

Network Cables

2094-SEPM-B24-S

IPIM Module

Bulletin 2090

Motor Power Cables

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

Digital

Inputs

Digital

Inputs

Digital

Inputs

Digital

Inputs

2094 Drive System

(Kinetix 6000 shown)

2090-CTHP8, 2090-CTSRP terminators required on last IDM unit.

Figure 2 - Typical 2094 Power Rail with Kinetix 6000M System (with LIM)

MAIN VAC

12 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 13

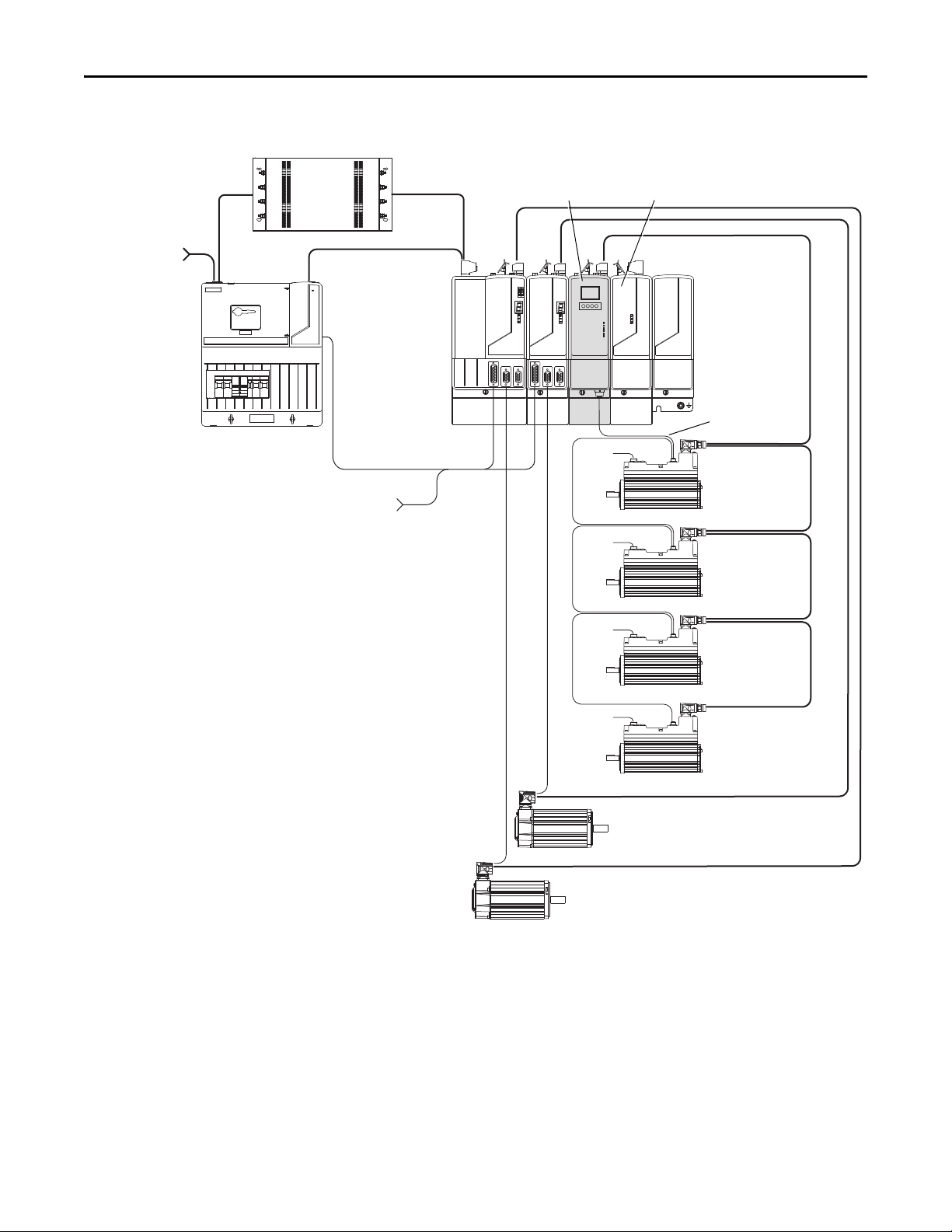

3-Phase Input Power

Line

Disconnect

Device

Input

Fusing

Magnetic

Contactor

2094-BSP2

Shunt Module

(optional component)

2094-PRF

Slot-filler Module

(required for

unused slots)

To Input Sensors

and Control String

Control

Power

2090-K6CK-Dxxxx

Low Profile Connector Kits for I/O,

Motor Feedback, and Aux Feedback

Bulletin 2090

Motor Feedback Cables

2094-SEPM-B24-S

IPIM Module

Bulletin 2090

Motor Power Cables

Digital

Inputs

2090-XXLF-xxxx

AC Lin e Filter

(required for CE)

2090-XXLF-xxxx

Line Filter

(required for CE)

Digital

Inputs

Digital

Inputs

Digital

Inputs

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

2094-PRSx

Power Rai l

2094 Drive System

(Kinetix 6000 shown)

Bulletin 2090

Hybrid Cables

Bulletin 2090

Network Cables

2090-CTHP8, 2090-CTSRP terminators required on last IDM unit.

Start Chapter 1

Figure 3 - Typical 2094 Power Rail with Kinetix 6000M System (without LIM)

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 13

Page 14

Chapter 1 Start

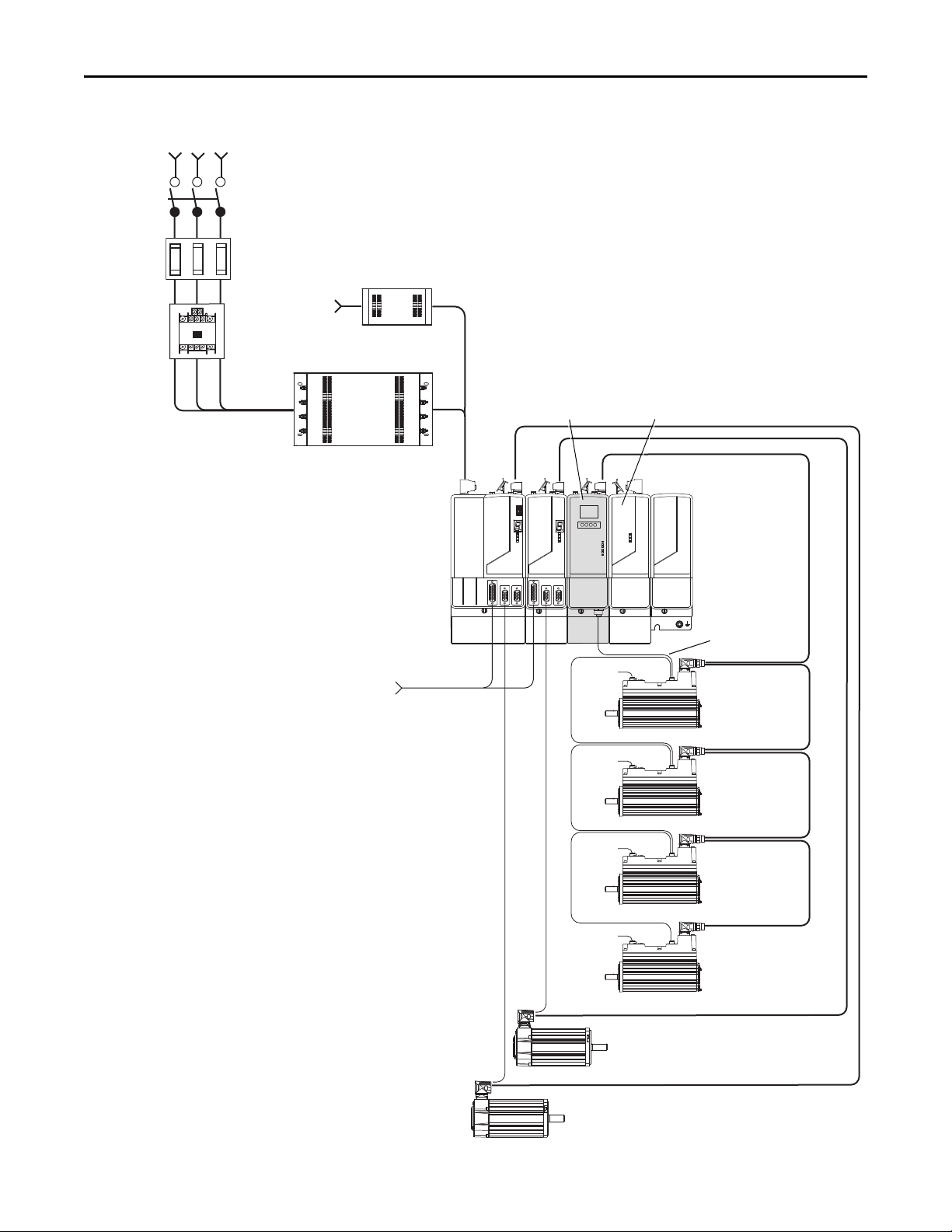

IMPORTANT

In the following example, the leader IAM module is connected to the follower

IAM module via the DC common-bus. When planning your panel layout, you

must calculate the total bus capacitance of your DC common-bus system to be

sure that the leader IAM module is sized sufficiently to pre-charge the entire

system.

Refer to the Kinetix 6000 Multi-axis Servo Drives User Manual, publication

2094-UM001,

Drives User Manual, publication 2094-UM002

or the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo

, for further information.

If total bus capacitance of your system exceeds the leader IAM module precharge rating and input power is applied, the IAM module status indicator will

display an error code.

To correct this condition, you must replace the leader IAM module with a larger

module or decrease the total bus capacitance by removing AM or IPIM modules.

14 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 15

MAIN VAC

3-phase

Input Power

Control Power

2094-BCxx-Mxx-S

IAM Module

Common Bus Leader

2094-PRSx Power R ail

2094-BCxx-Mxx-S

IAM Module

Common Bus Follower

2094-PRF

Slot-filler Module

(required to fill

unused slots)

2094-BLxxS

Line Interface Module

(optional component)

DC Common Bus

2090-XXLF-xxxx

AC Line Filter (required for CE)

2094-BSP2

Shunt Module

(optional component)

To I nput Se nso rs

and Control String

2094-SEPM-B24-S

IPIM Module

Bulletin 2090

Motor Feedback Cables

Bulletin 2090

Motor Power Cables

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

Bulletin 2090

Hybrid Cables

Bulletin 2090

Network Cables

Digital

Inputs

Digital

Inputs

2090-CTHP8, 2090-CTSRP terminators required on last IDM unit.

Start Chapter 1

Figure 4 - Typical Kinetix 6000 with Kinetix 6000M System Common Bus

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 15

Page 16

Chapter 1 Start

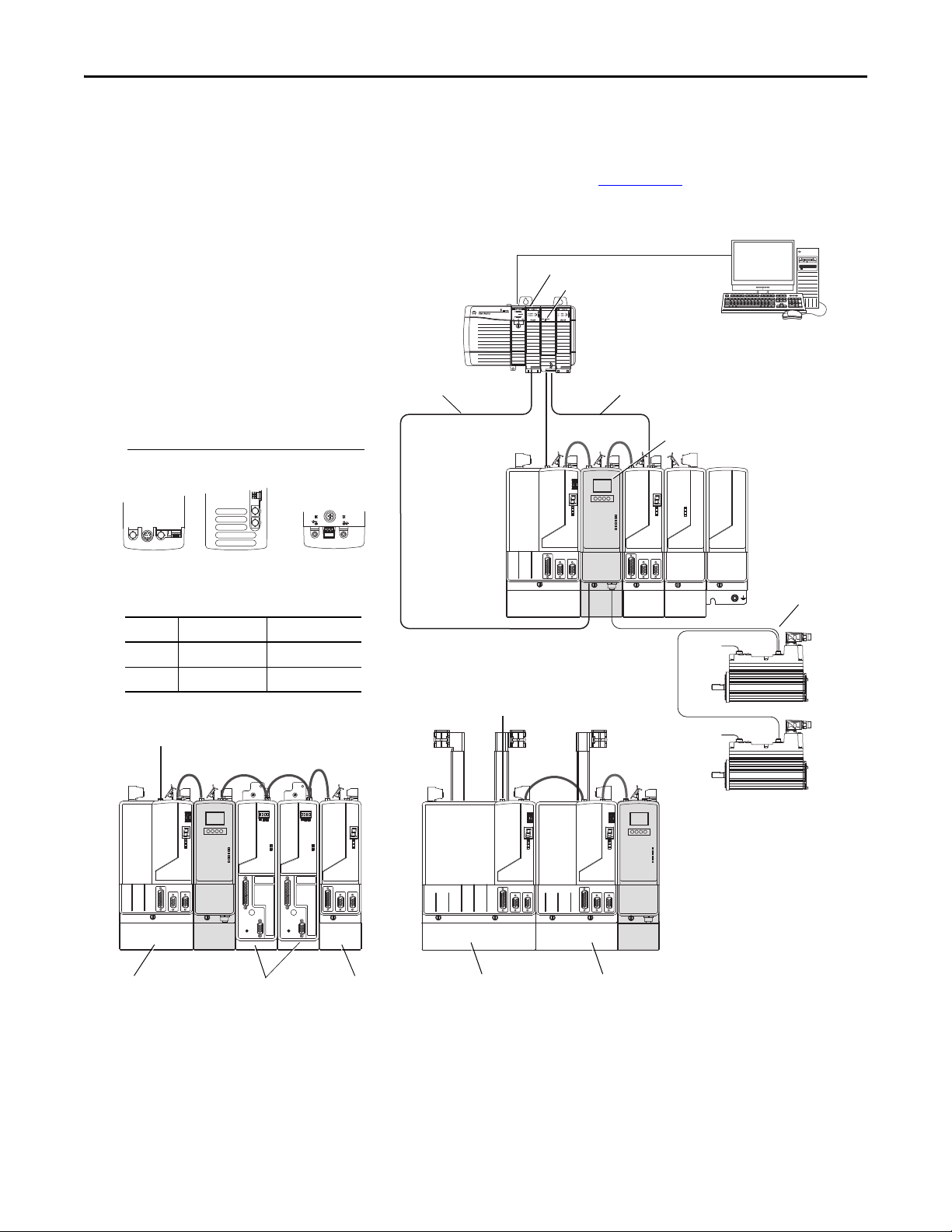

SERCOS interface

Tx (rear)

Rx (front)

OK

CP

TXRX

TX

RX

TXRX

Logix Sercos Interface Module

Logix Platform

(Control Logix is shown)

RSLogix 5000

Software

Bulletin 2090

Sercos Fiber-optic Cable

Logix Controller Programming Network

2094-BCxx-Mxx-S

IAM Module

Single-wide

2094-BCxx-Mxx-S

IAM Module

Kinetix 6000 Double-wide

2094-BCxx-Mxx-S

IAM Module

2094-BMxx-S Double-wide

AM Module

2094-BMxx-S

Single-wide AM

Module

Kinetix 6200

Kinetix 6000

2094-PRSx

Power Rail

2094-SEPM-B24-S

IPIM Module

IPIM Module

Network Connectors (top view)

➋➊➋

➊

➊➋

Recommended Fiber-optic Cables

Number Cable Length Catalog Number

➊ 0.1 m (5.1 in.) 2090-SCxx0-1

➋ 0.2 m (7.1 in.) 2090-SCxx0-2

➊➊

MDF-SBxxxxx

IDM Unit

MDF-SBxxxxx

IDM Unit

Bulletin 2090

Network Cables

Digital

Inputs

Digital

Inputs

EtherNet/IP Module

Bulletin 1585

Ethernet (shielded) Cable

2094-BMxx-M Single-wide

AM Power Modules with

2094-SE02F-M00-Sx

Control Modules

Typical Communication Configurations

The Kinetix 6000M IPIM module uses the EtherNet/IP network to report

diagnostics to the controller and for firmware upgrades via ControlFLASH™

software. For more information on Ethernet cables, refer to the Industrial

Ethernet Media Brochure, publication 1585-BR001

Figure 5 - Typical Kinetix 6000M, Kinetix 6000 and Kinetix 6200 Network Configuration

.

16 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 17

Start Chapter 1

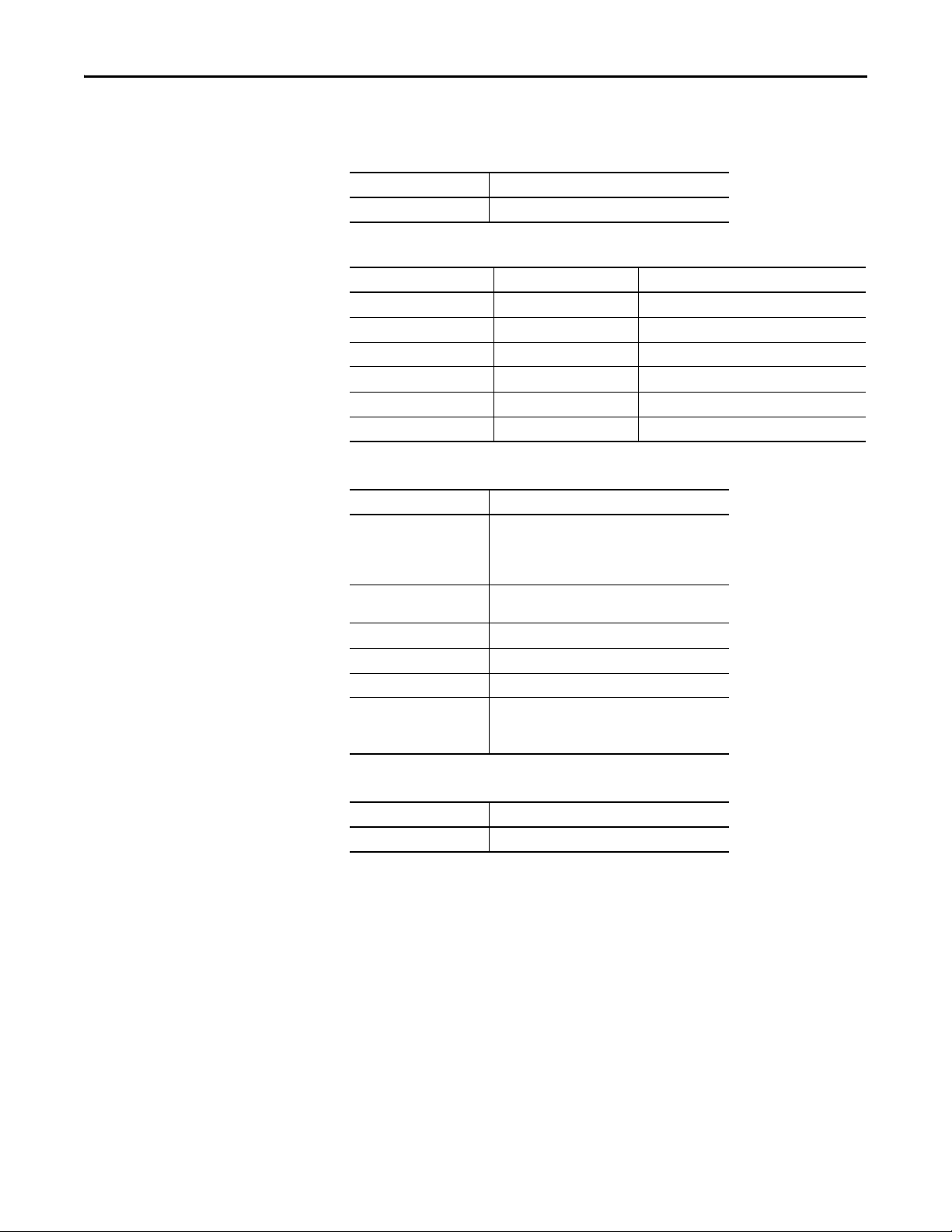

Catalog Number Explanations

Kinetix 6000M catalog numbers and descriptions are listed in the tables below.

Table 2 - Power Interface Module (IPIM)

Cat. No. Description

2094-SEPM-B24-S 460V IDM Power Interface Module (IPIM) w/Safe-off

Table 3 - Integrated Drive-motor (IDM)

Cat. No. (No Brake) Cat. No. (with Brake) Description

MDF-SB1003P-QJ82A-S MDF-SB1003P-QJ84A-S 460V, IEC 100 mm, 5000 rpm, Keyed

MDF-SB1003P-QK82A-S MDF-SB1003P-QK84A-S 460V, IEC 100 mm, 5000 rpm, Smooth

MDF-SB1153H-QJ82A-S MDF-SB1153H-QJ84A-S 460V, IEC 115 mm, 3500 rpm, Keyed

MDF-SB1153H-QK82A-S MDF-SB1153H-QK84A-S 460V, IEC 115 mm, 3500 rpm, Smooth

MDF-SB1304F-QJ82A-S MDF-SB1304F-QJ84A-S 460V, IEC 130 mm, 3000 rpm, Keyed

MDF-SB1304F-QK82A-S MDF-SB1304F-QK84A-S 460V, IEC 130 mm, 3000 rpm, Smooth

Table 4 - Replacement Parts

Cat. No. Description

Shaft seal kit for:

MPF-SST-A3B3

MPF-SST-A4B4

MPF-SST-A45B45

2094-XNIPIM IPIM module connectors; includes hybrid DC bus,

2094-SEPM-FUSE Fuses for IPIM module, 6 each.

MDF-SB-NODECVR IDM unit node address switch covers.

1485-M12 IDM unit digital input connector covers.

2090-CTHP8

2090-CTSRP

MDF-SB1003

MDF-SB1153

MDF-SB1304

hybrid communication, safe-off, and enable.

Ter m in at o r:

Hybrid

Network

Table 5 - Accessories

Cat. No. Description

MPS-AIR-PURGE Positive air pressure kit.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 17

Page 18

Chapter 1 Start

IMPORTANT

IMPORTANT

Component Compatibility

The Kinetix 6000M integrated drive-motor system is compatible with:

• 400V-class Series B Kinetix 6000 drive systems

• 400V-class Kinetix 6200 drive systems

Kinetix 6500 EtherNet/IP control modules (catalog numbers 2094-EN02DM01-Sx) are not compatible with the Kinetix 6000M IPIM or Kinetix 6000/

Kinetix 6200 IAM and AM modules on the same Bulletin 2094 power rail.

The IDM system cannot be accessed with DriveExplorer™ or a human interface

module (HIM). However, all IDM units will respond to a Stop command from a

HIM.

Table 6 - IDM System Compatibility

Component Requires

RSLinx® software version RSLinx version 2.59 or greater will fully support the IPIM

RSLogix™ 5000 software 20.01

IPIM AOP (Add-On Profile) 1.x

Kinetix 6000 drive firmware 1.123 or later

Kinetix 6200 drive firmware 1.045 or later

ControlLogix EtherNet/IP modules All 1756 Ethernet modules; 1756-ENBT, 1756-EN2T

module after installation of an appropriate EDS file

(1)

or later

(1) Version 20.00 may be used if the motion database is updated to version 8.12. For detailed information about updating the motion

database, refer to RA Knowledgebase

article 490160.

18 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 19

Start Chapter 1

Agency Compliance

If this product is installed within the European Union and has the CE mark, the

following regulations apply.

ATT EN TI ON : Meeting CE requires a grounded system, and the method of

grounding the AC line filter and IDM must match. Failure to do this renders the

filter ineffective and may cause damage to the filter.

Refer to Grounding the IDM System

For more information on electrical noise reduction, refer to the System Design

for Control of Electrical Noise Reference Manual, publication GMC-RM001

on page 54.

.

CE Requirements (system without LIM module)

To meet CE requirements when your system does not include the LIM module,

these requirements apply:

• Install an AC line filter (catalog number 2090-XXLF-xxxx) as close to the

IAM module as possible.

• Use line filters for 3-phase input power and single-phase control power.

• Use 2090 series cables.

• Use 889 series sensor cables.

• Combined motor power cable length for all axes on the same power rail

must not exceed 240 m (787 ft).

• Combined cable length for all IDM units connected to a single IPIM

module is 100 m (328 ft).

• Install the Kinetix 6x00 system inside an enclosure. Run input power

wiring in conduit (grounded to the enclosure) outside of the enclosure.

Separate signal and power cables.

Refer to the Kinetix 6000 Multi-axis Servo Drives User Manual, publication

2094-UM001

Drives User Manual, publication 2094-UM002

including input power wiring.

, or the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo

, for interconnect diagrams,

CE Requirements (system with LIM module)

To meet CE requirements when your system includes the LIM module, follow all

the requirements as stated in CE Requirements (system without LIM module)

and these additional requirements as they apply to the AC line filter.

• Install the LIM module (catalog numbers 2094-BL02) as close to the IAM

module as possible.

• Install the LIM module (catalog numbers 2094-BLxxS, or 2094-XL75S-

Cx) with line filter (catalog number 2090-XXLF-xxxx) as close to the

IAM module as possible.

When the LIM module (catalog numbers 2094-BLxxS, or 2094-XL75SCx) supports two IAM modules, each IAM module requires an AC line

filter installed as close to the IAM module as possible.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 19

Page 20

Chapter 1 Start

Notes:

20 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 21

Chapter 2

Planning the Kinetix 6000M System Installation

This chapter describes system installation guidelines used in preparation for

mounting your Kinetix 6000M components.

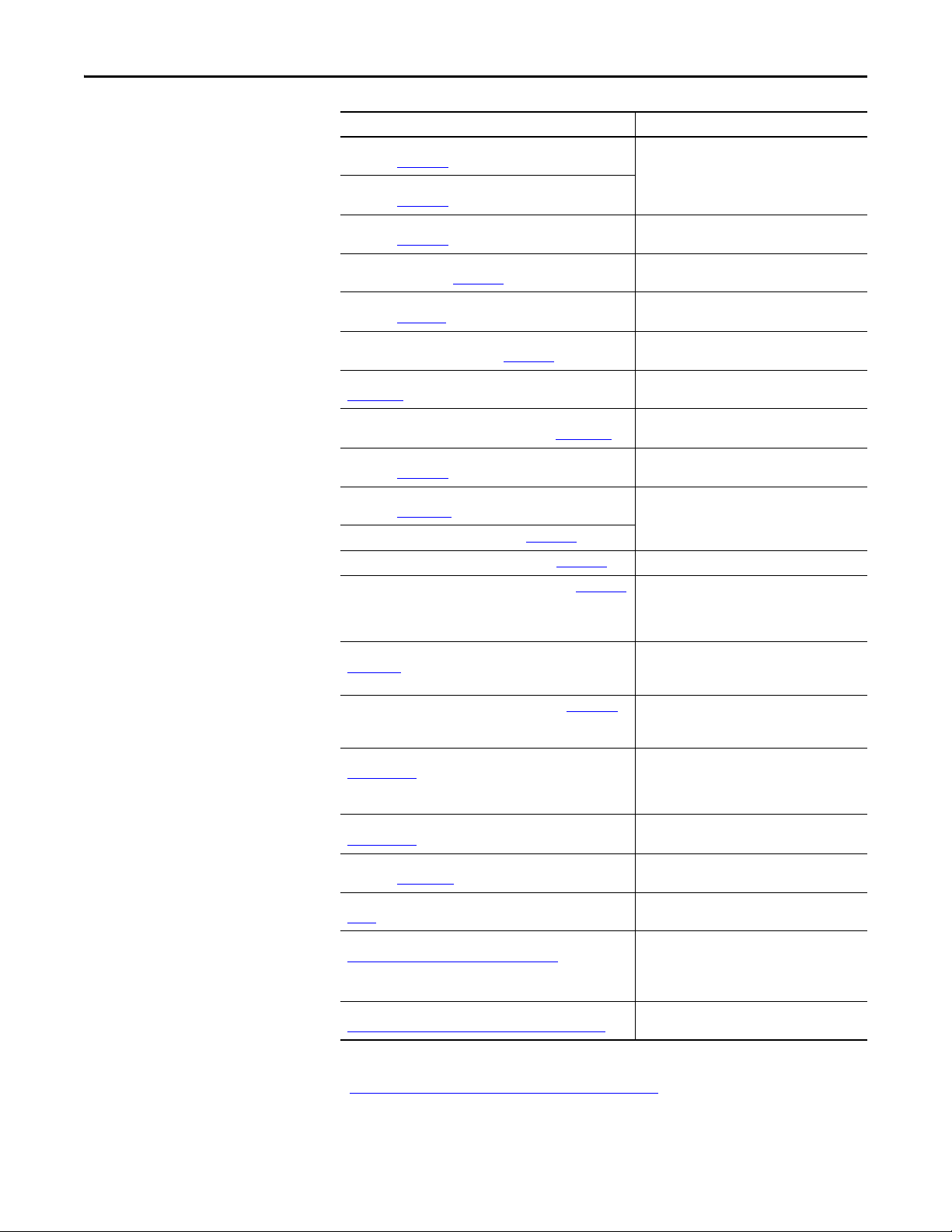

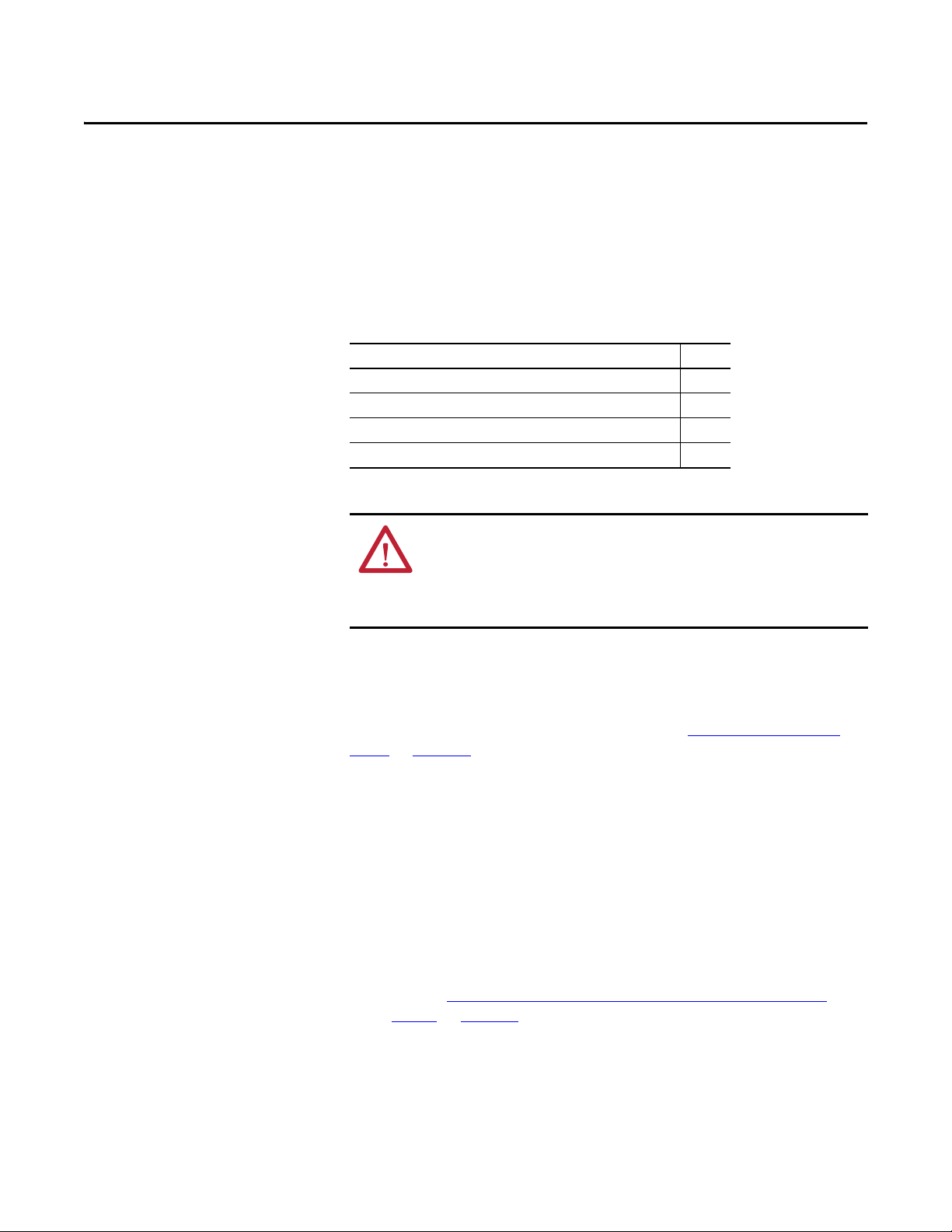

Top ic Pag e

Cable Length Restrictions and System Sizing 21

IPIM Module Design Guidelines 22

IDM Unit Design Guidelines 26

Electrical Noise Reduction 27

ATT EN TI ON : Plan the installation of your system so that you can perform all

cutting, drilling, tapping, and welding with the system removed from the

enclosure. Because the system is of the open type construction, be careful to

keep any metal debris from falling into it. Metal debris or other foreign matter

can become lodged in the circuitry, which can result in damage to components.

Cable Length Restrictions and System Sizing

This section provides guidelines for sizing an IDM system. For accurate, detailed

sizing, use Motion Analyzer software version 6.000 or later. For additional

information and a sizing estimation method, refer to Kinetix 6000M System

Sizing on page 127.

When sizing your system, please note the following:

• Motion Analyzer software (version 6.000 or later), should be used for

sizing your system.

• Maximum cable length between IDM units is 25 m (82 ft).

• Combined cable length for all IDM units connected to a single IPIM

module is 100 m (328 ft).

• Combined motor power and hybrid cable length for all axes on the same

power rail must not exceed 240 m (787 ft).

• The number of IDM units also depends on the use of the safe-off function.

Refer to Using the Safe Torque-off Feature with the Kinetix 6000M

System on page 103 for details.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 21

Page 22

Chapter 2 Planning the Kinetix 6000M System Installation

IMPORTANT

The following items limit the number of IDM units that can be used in a system.

1. The IDM unit control power load which consists of three load sources:

• internal load (constant)

• parking brake load

• digital input loading.

These items also affect the total control power load:

• The cable lengths between IDM units

• IDM units with brakes and their location in the daisy chain

• IDM units that use digital inputs.

2. The continuous and intermittent load on the DC bus of all AM modules

and IDM units.

The Kinetix 6000 or Kinetix 6200 IAM module supplying DC bus power to the

IDM units should be sized to support all IDM units connected to the power rail.

Motion Analyzer software (version 6.000 or later) sizing analysis accounts for

control power and DC bus power.

IPIM Module Design Guidelines

3. The total number of axes connected in the safe-off circuit.

Use the information in this section when designing your enclosure and planning

to mount your system components.

For on-line product selection and system configuration tools, including

AutoCAD (DXF) drawings of the product, refer to

http://www.rockwellautomation.com/en/e-tools

.

System Mounting Requirements

• To comply with UL and CE requirements, the Kinetix 6000M power

interface module must be part of a Kinetix 6000 or Kinetix 6200 system

that is enclosed in a grounded conductive enclosure offering protection as

defined in standard EN 60529 (IEC 529) to IP2X such that they are not

accessible to an operator or unskilled person. A NEMA 4X enclosure

exceeds these requirements providing protection to IP66.

• The panel you install inside the enclosure for mounting your system

components must be on a flat, rigid, vertical surface that won’t be subjected

to shock, vibration, moisture, oil mist, dust, or corrosive vapors.

• Size the enclosure so as not to exceed the maximum ambient temperature

rating. Consider heat dissipation specifications for all components.

• Use high-frequency (HF) bonding techniques to connect the modules,

enclosure, machine frame, and motor housing, and to provide a lowimpedance return path for high-frequency (HF) energy and reduce

electrical noise.

22 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 23

Planning the Kinetix 6000M System Installation Chapter 2

IMPORTANT

• Combined motor power cable lengths for all axes and hybrid cable lengths

for all IDM units on the same DC bus must not exceed 240 m (787 ft)

with 400V-class systems. Drive-to-motor power cables must not exceed

90 m (295.5 ft).

System performance was tested at these cable length specifications. These

limitations also apply when meeting CE requirements.

Refer to the System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

reduction.

, to better understand the concept of electrical noise

Circuit Breaker/Fuse Options

The 2094-SEPM-B24-S IPIM module and the MDF-SBxxxxx IDM units use

internal solid-state motor short-circuit protection and when protected by

suitable branch circuit protection, are rated for use on a circuit capable of

delivering up to 200,000 A. Fuses or circuit breakers, with adequate withstand

and interrupt ratings, as defined in NEC or applicable local codes, are permitted.

The 2094-BL02 LIM module contains supplementary protection devices and,

when protected by suitable branch circuit protection, are rated for use on a

circuit capable of delivering up to 5000 A. When these modules are used,

protection on the line side of the LIM module is required. Fuses must be class J or

CC only.

The 2094-BLxxS, and 2094-XL75S-Cx LIM modules contain branch circuit

rated devices suitable for use on a circuit capable of delivering up to 65,000 A

(400V-class).

Refer to the Line Interface Module Installation Instructions, publication 2094-

IN005, for power specifications and more information on using the LIM

module.

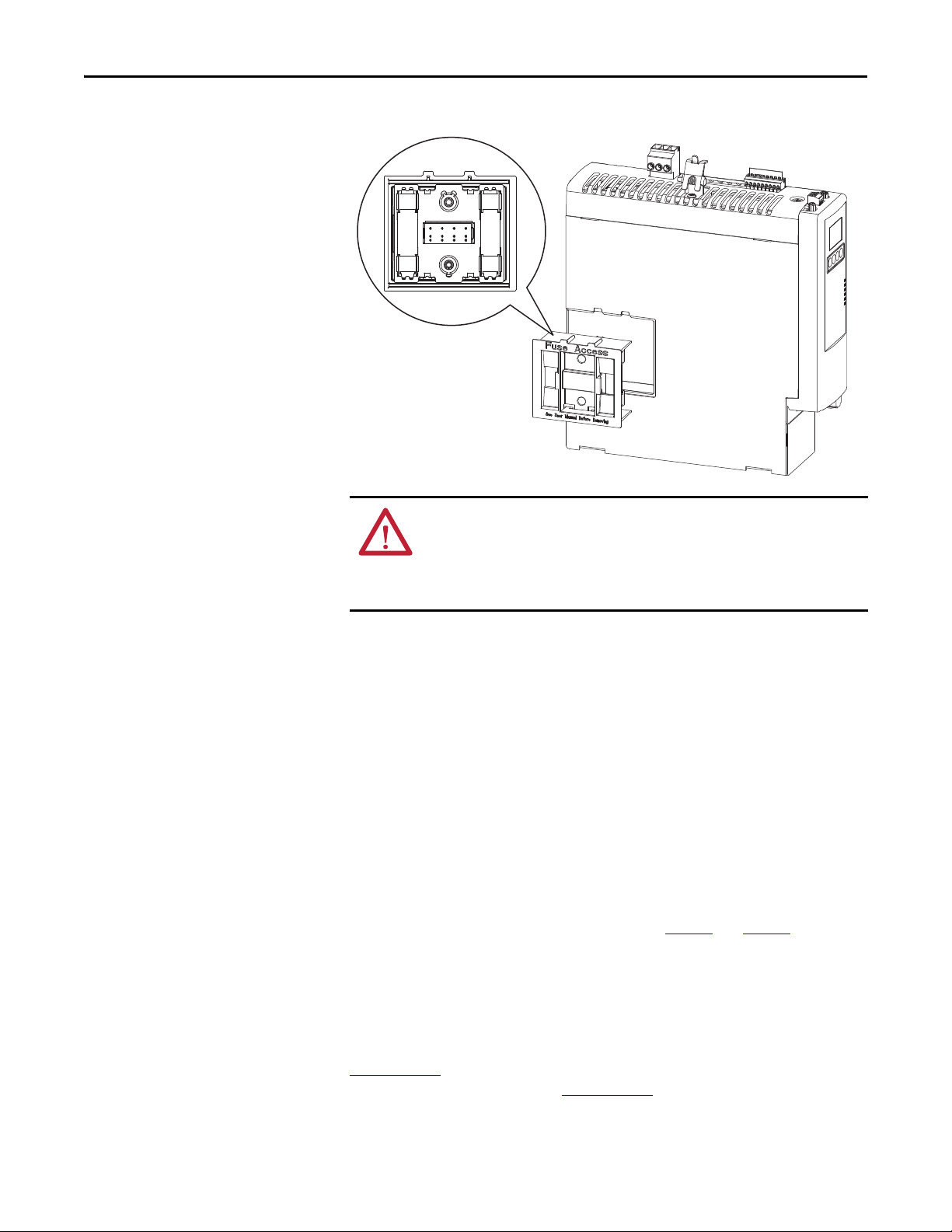

Fuse Location and Replacement

The IPIM module uses internal fuses (see Figure 6) for short-circuit protection

of the DC bus. The recommended fuse is Bussmann FWP-50A14Fa. A fuse

replacement kit (catalog number 2094-SEPM-FUSE) is also available.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 23

Page 24

Chapter 2 Planning the Kinetix 6000M System Installation

Figure 6 - IPIM Fuse Location

ATT EN TI ON : Capacitors on the DC bus may retain hazardous voltages after

input power has been removed. Before working on the IDM system, measure

the DC bus voltage to verify it has reached a safe level or wait the full time

interval as indicated in the warning on the IPIM module. Failure to observe this

precaution could result in severe bodily injury or loss of life.

To replace the fuses, follow these steps.

1. Ensure that all power to the power rail has been removed.

2. Measure the DC bus voltage to verify it has reached a safe level or wait the

full time interval as indicated in the warning on the IPIM module.

3. Loosen the captive screws.

4. Grasp the top and bottom edges of the fuse holder and pull straight out.

5. Replace the fuses.

Enclosure Selection

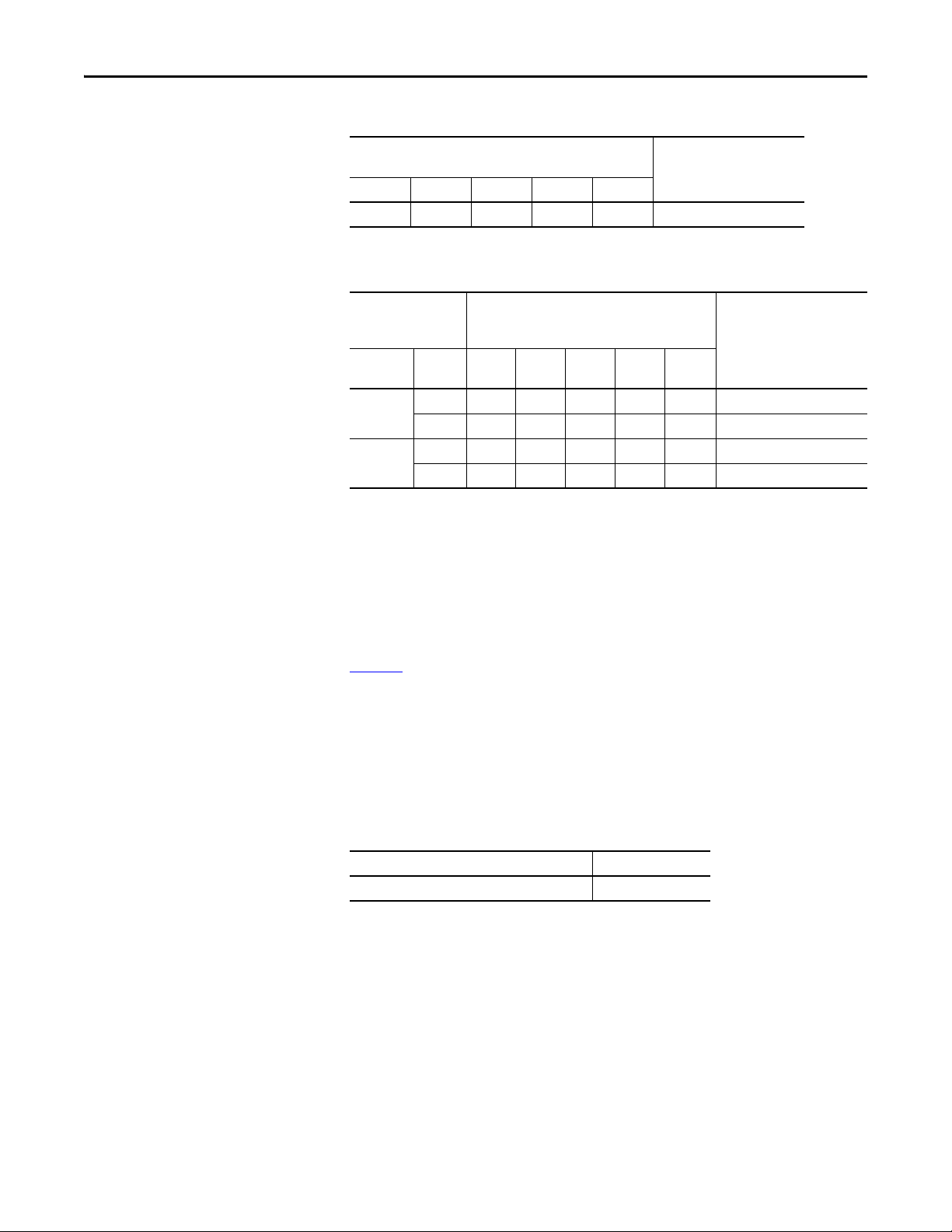

Heat dissipation of the IPIM module is shown in Ta b l e 7 and Ta b l e 8 . To size the

enclosure you will need heat dissipation data from all equipment inside the

enclosure (such as the Logix controller, LIM module, IAM). Once the total

amount of heat dissipation (in watts) is known, you can calculate the minimum

enclosure size.

Refer to the Kinetix 6000 Multi-axis Servo Drives User Manual, publication

2094-UM001

, or the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo

Drives User Manual, publication 2094-UM002

24 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

, for further information.

Page 25

Planning the Kinetix 6000M System Installation Chapter 2

Table 7 - Power Dissipation Specifications - Percent of DC Bus Current

Power Dissipation as % of DC Bus Current Output Rating

Watts

20% 40% 60% 80% 100%

2 7 142538Y = 33.95x2 + 3.18x

(1) x is percent of DC bus current output rating: any value between 0.0 and 1.0.

Heat Dissipation Formula

Table 8 - Power Dissipation Specifications - Percent of IPIM Module Control Power

(1)

Power Dissipation as % of IPIM Module Control

Control Power Input

Frequenc yHzVolt age

AC 20% 40% 60% 80% 100%

50

60

(1) x is percent of IPIM module control power output rating: any value between 0.0 and 1.0.

120V 22 29 38 48 61 Y = 23.76x

240V 34 42 52 63 76 Y = 18.56x

120V 23 27 32 39 46 Y = 14.57x2 + 11.40x + 20.01

240V 38 49 62 76 92 Y = 19.63x2 + 43.22x + 28.75

Power Out put Rati ng

Watts

Heat Dissipatio n Formulas

2

+ 20.73x + 16.54

2

+ 30.19x + 27.41

Minimum Clearance Requirements

This section provides information to assist you in sizing your cabinet and

positioning your IDM unit.

Figure 7

installation:

illustrates minimum clearance requirements for proper airflow and

• Additional clearance is required for the cables and wires connected to the

top and front of the module.

• Additional clearance left and right of the power rail is required when the

module is mounted adjacent to noise sensitive equipment or clean

wireways.

(1)

Table 9 - Minimum Cabinet Depth

Cat. No. Cabinet Depth, Min

2094-SEPM-B24-S 272 mm (10.7 in.)

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 25

Page 26

Chapter 2 Planning the Kinetix 6000M System Installation

Clearance right of the

module is not required

(1)

50.8 mm (2.0 in.) clearance for

airflow and installation

Clearance left of the

module is not required

(1)

Power Rail

(2094-PRSx)

50.8 mm (2.0 in.) clearance for

airflow and installation

(1) The power rail (slim), catalog number 2094-PRSx, extends left and right of the first and last module 5.0 mm (0.20

in.). The Bulletin 2094-PRx power rail extends approximately 25.4 mm (1.0 in.) left of the IAM module and right of

the last module mounted on the rail.

(2) Dimension applies to the following modules:

IPIM module 2094-SEPM-B24-S

IAM module (Series B) 2094- BC01-Mxx-x and 2094-BC02-M02-x

AM module (Series B) 2094-BMP5-x, 2094-BM01-x, 2094-BM02-x

287 mm

(11.3 in.)

(2)

Figure 7 - Minimum IPIM Module Clearance Requirements

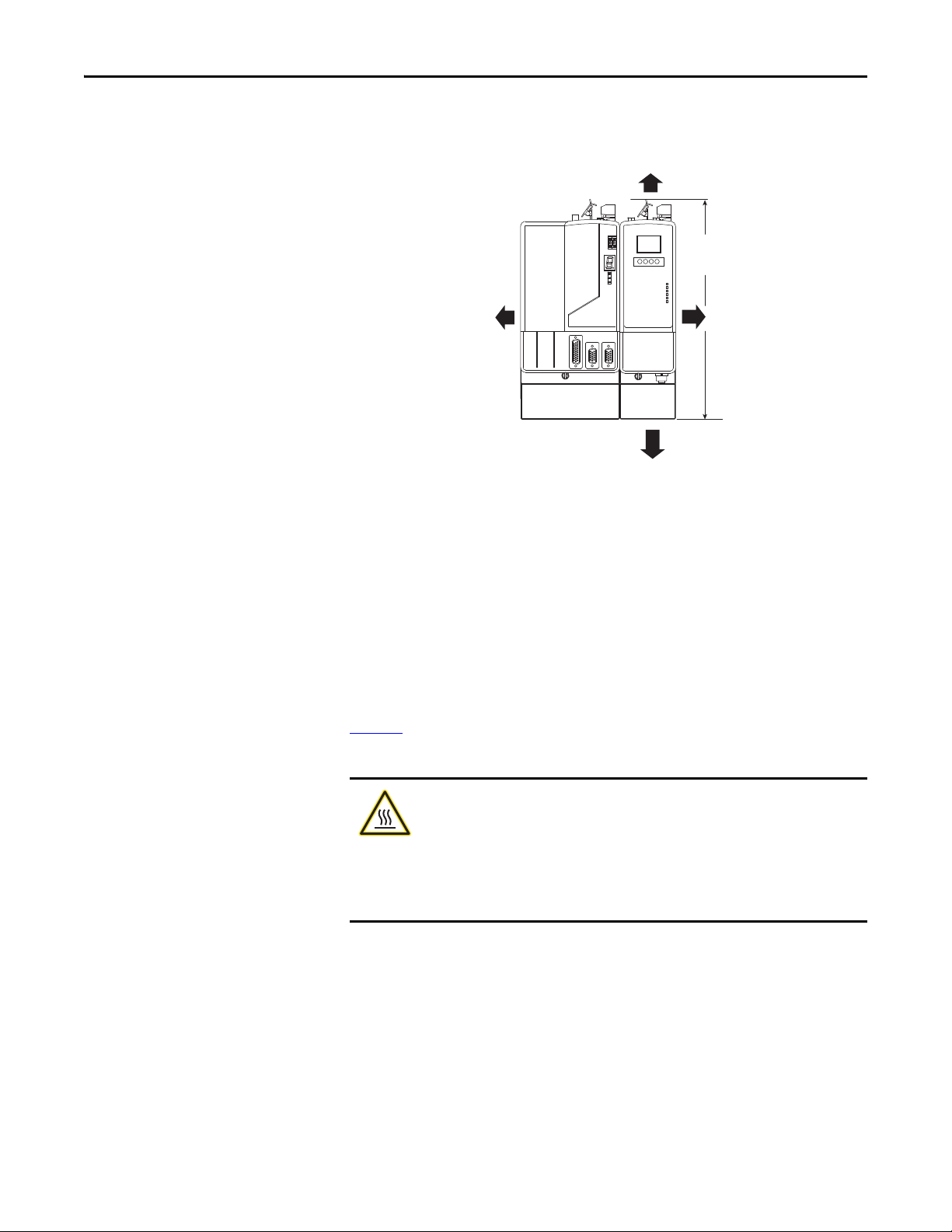

IDM Unit Design Guidelines

Minimum Clearance Requirements

Figure 8 illustrates minimum IDM unit clearance requirements for proper

airflow and installation.

BURN HAZARD: Outer surfaces of the motor can reach high temperatures,

125 °C (275 °F), during motor operation.

Take precautions to prevent accidental contact with hot surfaces. Consider IDM unit

surface temperature when selecting motor mating connections and cables.

Failure to observe these safety procedures could result in personal injury or

damage to equipment.

Additionally, consider the following items:

• Obtain the specified motor thermal rating by mounting the motor on a

surface with heat dissipation equivalent to a 304.8 x 304.8 x 12.7 mm

(12 x 12 x 0.5 in.) aluminum heatsink.

• Do not install the motor in an area with restricted airflow, and keep other

heat producing devices away from the motor.

26 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 27

Planning the Kinetix 6000M System Installation Chapter 2

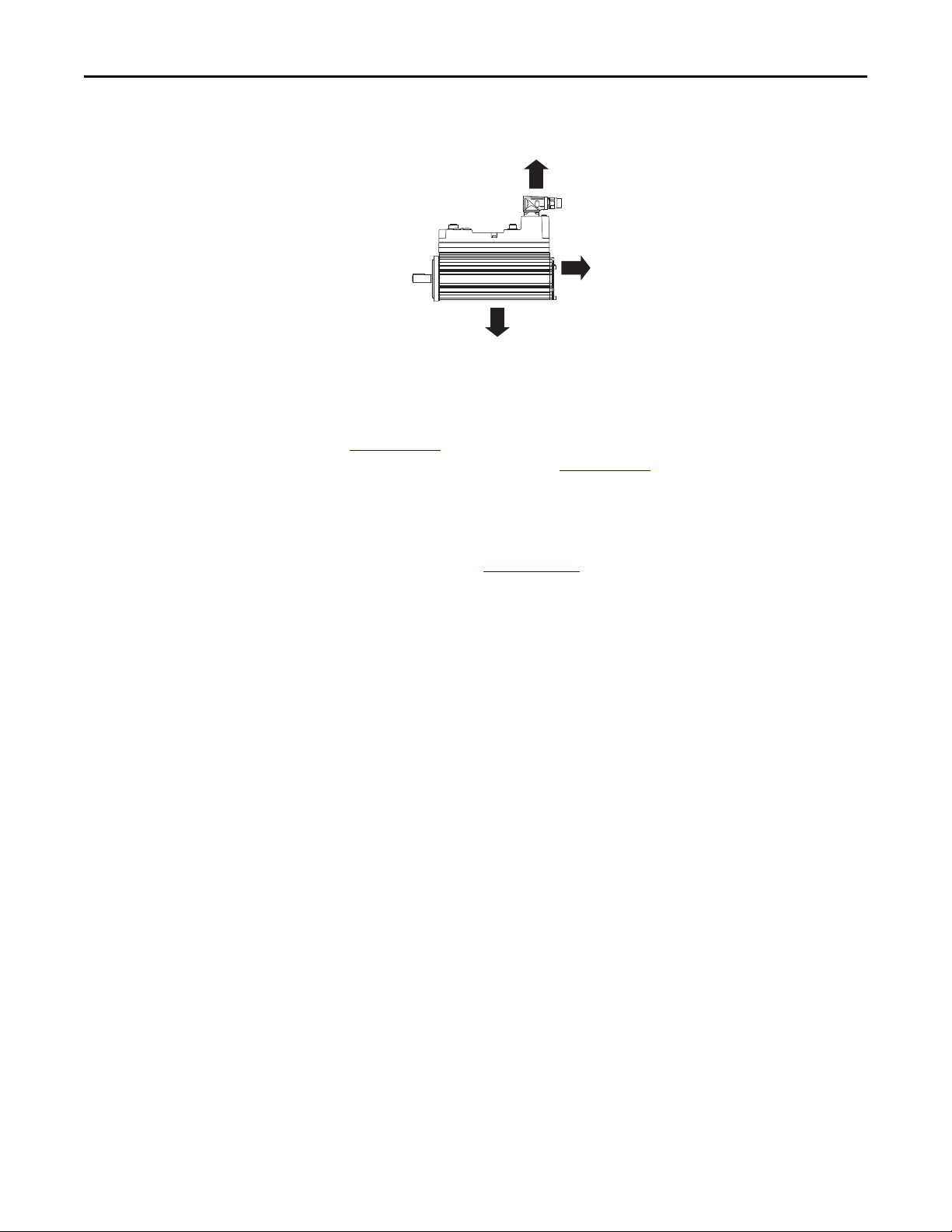

100.0 mm (3.9 in.)

100.0 mm (3.9 in.)

100.0 mm (3.9 in.)

Figure 8 - Minimum IDM Unit Clearance Requirements

Electrical Noise Reduction

Refer to the Kinetix 6000 Multi-axis Servo Drives User Manual, publication

2094-UM001

Drives User Manual, publication 2094-UM002

, or the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo

, for information on best practices

that minimize the possibility of noise-related failures as they apply specifically to

Kinetix 6000 system installations. For more information on the concept of highfrequency (HF) bonding, the ground plane principle, and electrical noise

reduction, refer to the System Design for Control of Electrical Noise Reference

Manual, publication GMC-RM001

.

Observe these guidelines when your system includes the 2094-SEPM-B24-S

IPIM module. In this example, a 2094-BL02 LIM module is used in the Bulletin

2094 system and mounted left of the IAM module:

• Establish clean (C) and dirty zones (D) similar to other Bulletin 2094

drive systems.

• The sercos fiber-optic cables are immune to electrical noise, but due to

their delicate nature, route them in the clean zone.

• IPIM communication wires are noise sensitive and belong with the fiberoptic cables in the clean zone.

• Ethernet cables are noise sensitive and belong in the clean zone.

• IDM network cables, although noise sensitive by nature, are shielded and

designed to be routed with the hybrid cable outside of the enclosure.

• The Bulletin 2090 hybrid cable is dirty and belongs in the dirty zone.

This layout is preferred due to the reduced size of the very dirty zone.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 27

Page 28

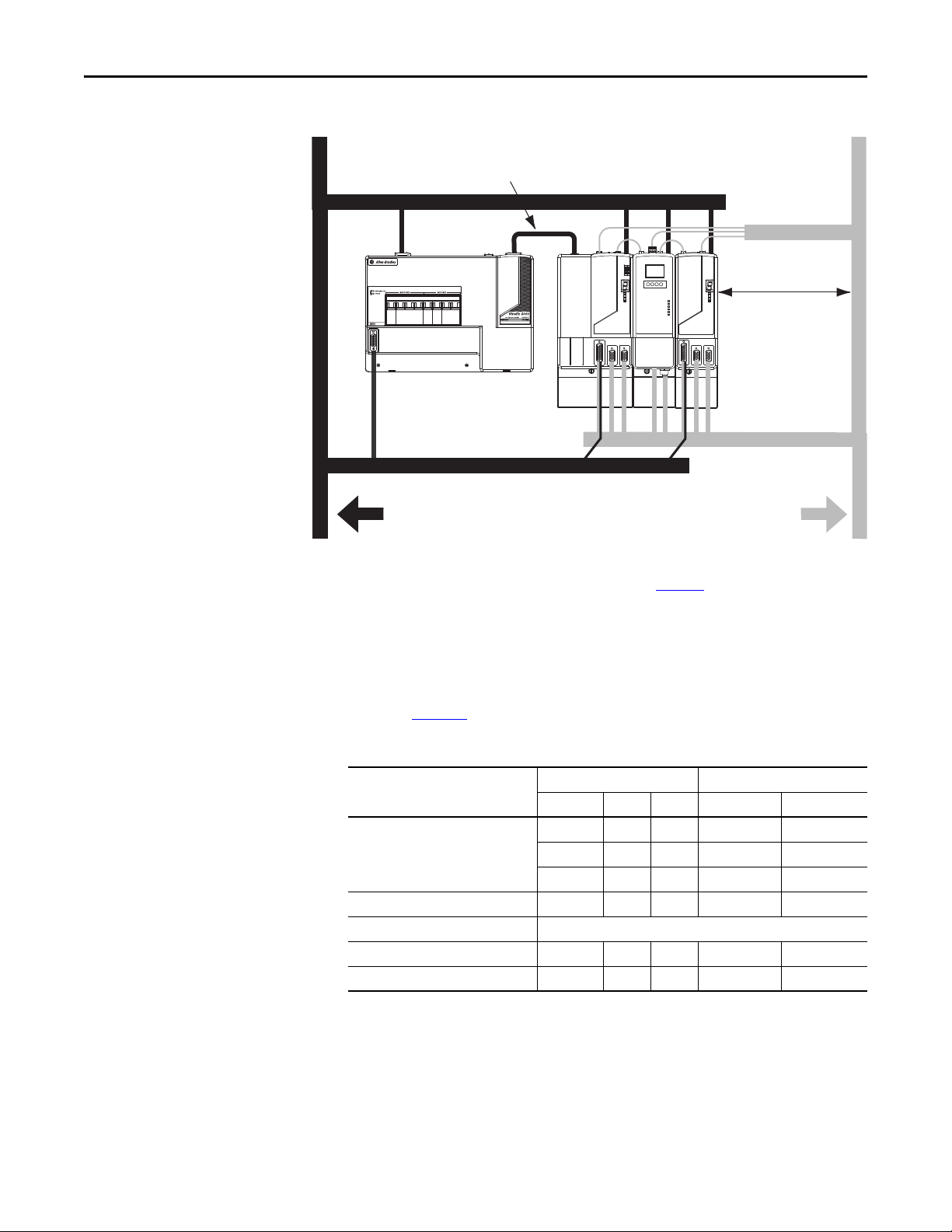

Chapter 2 Planning the Kinetix 6000M System Installation

2094-BL02 or 2094-BLxxS

Line Interface Module

Kinetix 6000

System

Dirty Wireway

Clean Wireway

I/O

(1)

, Feedback, and

Network Cables

Motor and Hybrid Cables

Very Dirty Filter/IAM Connections

Segregated (not in wireway)

Route 24V DC I/O

shielded cable.

Route encoder/analog/registration

shielded cables.

Fiber-optic Cables and

IPIM Communication Wires

No sensitive

(2)

equipment within

150 mm (6.0 in.).

D

Figure 9 - Noise Zones (Bulletin 2094 power rail with IPIM module)

D

D

(1) If drive system I/O cable contains (dirty) relay wires, route cable with LIM module I/O c able in dirty wireway.

(2) When space does not permit the 150 mm (6.0 in.) segregation, use a grounded steel shield instead. For examples, refer to the

System Design for Control of Electrical Noise Reference Manual, publication GMC-RM001

VD

D

D

CC

.

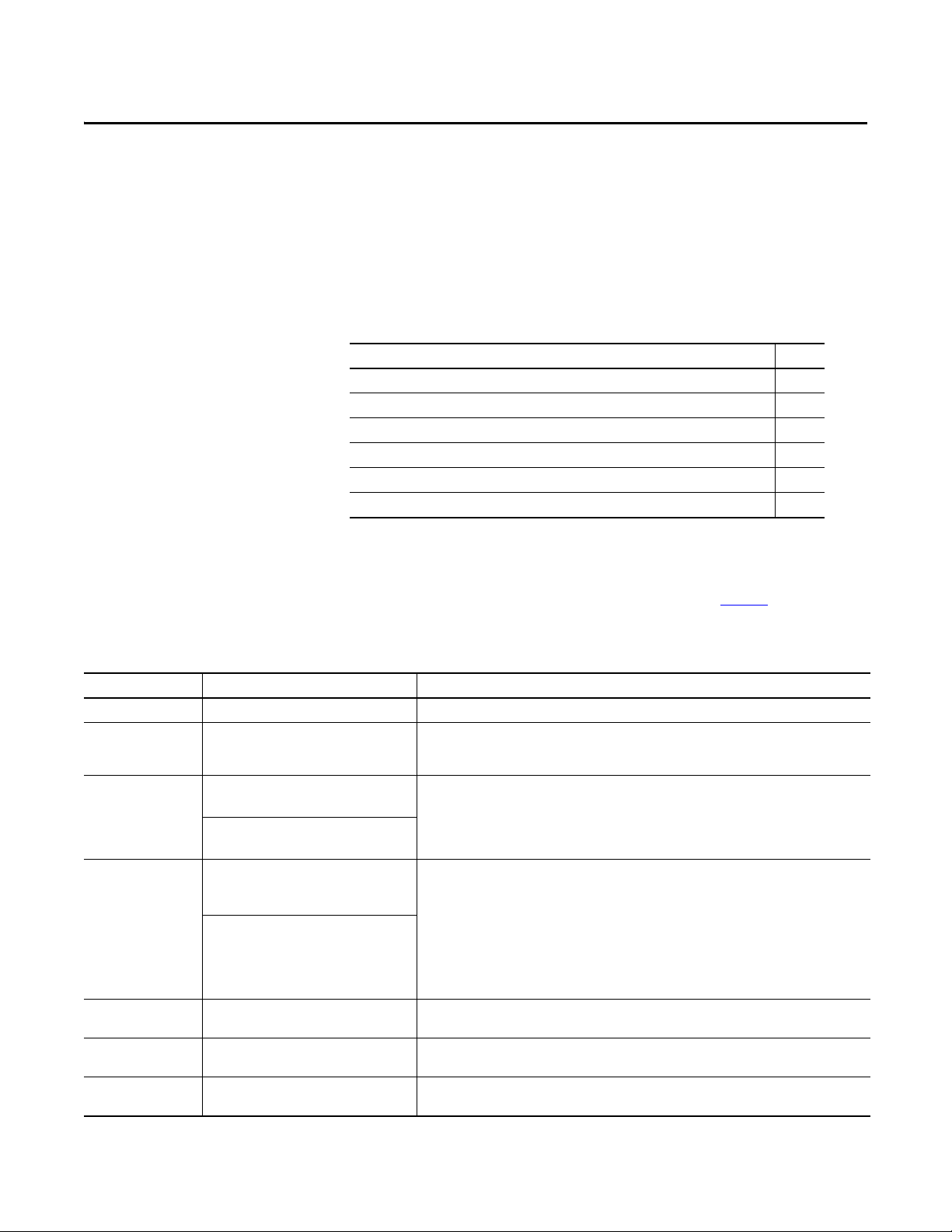

Cable Categories for Kinetix 6000M System

C

Zoning requirements of cables connecting to the IDM system components are

shown in Ta b l e 1 0

Table 10 - IPIM Module Zoning Requirements

Wire/Cable

Hybrid DC bus power, control power,

inter-module communication, and safe-

(1)

off

Enable input X X

Fiber-optic No restrictions

Ethernet network X X

IDM network

(1) There is no option for making your own hybrid or IDM network cables.

(1)

.

Zone Method

Very Dirty Dirty Clean Ferrite Sleeve Shielded Cable

XX

XX

X

XX

28 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 29

Chapter 3

Mounting the Kinetix 6000M System

This chapter provides the system installation procedures for mounting your

Kinetix 6000M integrated drive-motor (IDM) unit and your power interface

module (IPIM).

Top ic Pa ge

Mounting the IPIM Module 30

Installing the IDM Unit 33

This procedure assumes you have prepared your panel, mounted your Bulletin

2094 power rail, and understand how to bond your system. For installation

instructions regarding equipment and accessories not included here, refer to the

instructions that came with those products.

SHOCK HAZARD: To avoid hazard of electrical shock, perform all mounting and

wiring of the Bulletin 2094 power rail and modules prior to applying power.

Once power is applied, connector terminals may have voltage present even

when not in use.

ATT EN TI ON : Plan the installation of your system so that you can perform all

cutting, drilling, tapping, and welding with the system removed from the

enclosure. Because the system is of the open type construction, be careful to

keep any metal debris from falling into it. Metal debris or other foreign matter

can become lodged in the circuitry, which can result in damage to components.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 29

Page 30

Chapter 3 Mounting the Kinetix 6000M System

Mounting the IPIM Module

Using the 2094 Mounting Brackets

You can use Bulletin 2094 mounting brackets to mount the power rail or LIM

module over the AC line filter. Refer to the 2094 Mounting Brackets Installation

Instructions, publication 2094-IN008

, when using mounting brackets with your

system.

Installing the 2094 Power Rail

The Bulletin 2094 power rail comes in lengths to support one IAM module and

up to seven additional modules. A maximum of four IPIM modules can be

mounted to a single power rail. The connector pins for each slot are covered by a

protective cover. The cover is designed to protect the pins from damage and make

sure that no foreign objects lodge between the pins during installation. Refer to

the Kinetix 6000 Power Rail Installation Instructions, publication 2094-IN003

when installing your power rail.

ATT EN TI ON : To avoid damage to the power rail during installation, do not

remove the protective covers until the module for each slot is ready for

mounting.

,

Determine Mounting Order

Refer to the Module Mounting Order Example diagram on page 31 and mount

the modules in the order (left to right) shown. Install modules according to

power utilization (highest to lowest) from left to right starting with the highest

power utilization. If power utilization is unknown, position modules (highest to

lowest) from left to right based on the IPIM or AM continuous power rating

(kW).

Power utilization is the average power (kW) consumed by a servo axis. If the

servo axis has been sized by using Motion Analyzer software, version 6.000 or

later, the calculated axis power required can be used for power utilization. If the

servo axis has not been sized in Motion Analyzer, use Ta b l e 1 1

maximum continuous power for IPIM and AM modules, to determine the

desired location on a power rail.

Table 11 - Module Type and Continuous Power Output

2094-BM05-S

Axis Module

22.0 kW 15.0 kW 13.5 kW 6.6 kW 3.9 kW 1.8 kW

2094-SEPM-B24-S

IPIM Module

2094-BM03-S

Axis Module

2094-BM02-S

Axis Module

The IPIM module may be installed on a power rail with an IAM module

configured as a common bus follower, but you will be responsible for configuring

the leader for the appropriate additional capacitance in the follower power rail,

including the IPIM module.

, showing the

2094-BM01-S

Axis Module

2094-BMP5-S

Axis Module

30 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 31

Figure 10 - Module Mounting Order Example

IMPORTANT

Highest Power Utilization Lowest Power Utilization

Integrated Axis

Module

Shunt

Module

Slot Filler

Module

IPIM Module Axis Modules

The IAM must be positioned in the leftmost slot of the power rail. Position your

other modules to the right of the IAM module.

Mount modules according to power utilization (highest to lowest) from left to

right starting with the highest power utilization. If power utilization is

unknown, position modules (highest to lowest) from left to right based on

continuous power rating (kW). Refer to page 30

The shunt module must be installed to the right of the last module. Only slotfiller modules may be installed to the right of the shunt module.

Do not mount the shunt module on power rails with a follower IAM module.

Common bus follower IAM modules disable the internal, rail mounted, and

external shunt modules.

Mounting the Kinetix 6000M System Chapter 3

.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 31

SHOCK HAZARD: To avoid personal injury due to electrical shock, place a

2094-PRF slot-filler module in all empty slots on the power rail. Any power rail

connector without a module installed will disable the drive system; however,

control power will still be present.

Page 32

Chapter 3 Mounting the Kinetix 6000M System

Slots for Additional Modules

Power Rail Sl ot

Mounting Bracket

Power Rail

Fuse Access

See User Manual Before Removing

Guide Pin Hole

Rear View

Side View

Power Rai l

Guide Pin

Pivot module

downward and align

with pin

Mount the IPIM Module

All modules mount to the power rail using the same technique.

1. Determine the next available slot and module for mounting. Refer to

Determine Mounting Order

2. Remove the protective covers from the power rail connectors.

3. Inspect the module connector pins and power rail connectors and remove

any foreign objects.

ATTENTION: To avoid damage to the pins located on the back of each

module and to make sure that module pins mate properly with the

power rail, hang modules as explained below.

The power rail must be mounted vertically on the panel before hanging

modules on the power rail.

4. Hang the module mounting bracket from the slot on the power rail.

on page 30.

5. Pivot module downward and align the guide pin on the power rail with the

guide pin hole in the back of the module.

6. Gently push the module against the power rail connectors and into the

32 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

final mounting position.

Page 33

Mounting the Kinetix 6000M System Chapter 3

Power Rail

Bracket secured in slot

Flat

2.26 N•m (20 lb•in)

7. Tighten the mounting screws.

8. Repeat the above steps for each module being installed.

Installing the IDM Unit

ATT EN TI ON : Do not attempt to open or modify the IDM unit. This manual

describes modifications that you can perform in the field. Do not attempt other

changes. Only a qualified Allen-Bradley employee can service an IDM unit.

Failure to observe these safety procedures could result in personal injury or

damage to equipment.

ATT EN TI ON : Damage may occur to the bearings and the feedback device if a

sharp impact is applied to the shaft during installation of couplings and pulleys,

or to remove the shaft key. Damage to the feedback device also may result from

applying leverage from the faceplate to remove devices mounted on the shaft.

Do not strike the shaft, key, couplings, or pulleys with tools during installation or

removal. Use a wheel puller to apply pressure from the user end of the shaft to

remove any friction fit or stuck device from the shaft.

Failure to observe these safety procedures could result in damage to the IDM unit.

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 33

Page 34

Chapter 3 Mounting the Kinetix 6000M System

Aligning the IDM Unit

The IDM unit can be mounted in any position and has a mounting pilot that aids

in aligning the unit on a machine. A shaft seal that helps protect the motor

against fine dust and fluids is factory installed and should be replaced at regular

intervals.

Preferred fasteners are stainless steel. The installation must comply with all local

regulations. The installer also must use equipment and installation practices that

promote electromagnetic compatibility and safety.

ATT EN TI ON : Unmounted IDM units, disconnected mechanical couplings, loose

shaft keys, and disconnected cables are dangerous, if power is applied.

Disassembled equipment should be appropriately identified (tagged-out) and

access to electrical power restricted (locked-out).

Before applying power, remove the shaft key and other mechanical couplings that

could be thrown from the shaft.

Failure to observe these safety procedures could result in personal injury or

damage to equipment.

Mount and Connect the IDM Unit

To install the IDM unit, follow these procedures and recommendations.

ATT EN TI ON : Arcing or unexpected motion can occur if cables are connected or

disconnected while power is applied to the IDM system. Before working on the

system, disconnect power and wait the full time interval indicated on the IPIM

module warning label or verify the DC bus voltage at the IPIM module measures

less than 50V DC.

Failure to observe this precaution could result in severe bodily injury or loss of life,

and damage to the product will occur.

ATT EN TI ON : Do not strike the shaft, couplings, or pulleys with tools during

installation or removal.

Damage may occur to the motor bearings and the feedback device if you apply a

sharp impact to the shaft during installation of couplings and pulleys, or a shaft

key.

Failure to observe these safety procedures could result in damage to the motor and

its components.

ATT EN TI ON : The IDM unit is not for direct connection to an AC power line.

IDM units are designed for connection to an IPIM module that controls the

application of power.

Failure to observe these safety precautions could result in damage to the motor

and equipment.

34 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 35

Mounting the Kinetix 6000M System Chapter 3

TIP

1. Allow sufficient clearances around the IDM unit for it to stay within its

specified operating temperature range. See page 27

for details.

BURN HAZARD: Outer surfaces of the IDM unit can reach high temperatures,

125 °C (275 °F), during motor operation.

Take precautions to prevent accidental contact with hot surfaces. Consider IDM

unit surface temperature when selecting motor mating connections and cables.

Failure to observe these safety procedures could result in personal injury or

damage to equipment.

2. Determine the radial and axial shaft load limitations of your motor. Refer

to the Kinetix Rotary Motion Specifications Technical Data, publication

GMC-TD001

, for specifications.

3. Set the node address for the IDM unit. Refer to Setting the Node Address

on page 70

.

4. If sufficient mounting clearance is provided, rotate the hybrid cable

connectors into position prior to installing. If the mounting clearance is

restricted, rotate after installing.

ATT EN TI ON : Connectors are designed to be rotated into a fixed position during

motor installation, and remain in that position without further adjustment.

Strictly limit the applied forces and the number of times the connector is

rotated to make sure that connectors meet the specified IP ratings.

Apply force only to the connector and cable plug. Do not apply force to the cable

extending from the cable plug. No tools, for example pliers or vise-grips, should be

used to assist with the rotation of the connector.

Failure to observe safety precautions could result in damage to the IDM unit and its

components.

5. Position the IDM unit on the machine in any position.

IDM units with a brake may require use of the manual brake release

cable to release the brake prior to rotating the shaft so the IDM unit

will align with the machine mounts.

Refer to the Manual Brake Release Cable Installation Instructions,

publication 2090-IN037

, for details on using this cable.

6. Properly mount and align the IDM unit using stainless steel bolts. Refer to

the Kinetix Rotary Motion Specifications Technical Data, publication

GMC-TD001

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 35

, for dimensions.

Page 36

Chapter 3 Mounting the Kinetix 6000M System

Notes:

36 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 37

Chapter 4

Kinetix 6000M System Connector Data

This chapter provides connector locations and signal descriptions for your

Kinetix 6000M integrated drive-motor system.

Top ic Pa ge

IPIM Module Connectors and Indicators 38

IPIM Module Connector and Signal Descriptions 39

IDM Unit Connectors and Indicators 43

IDM Unit Connector and Signal Descriptions 44

Power Specifications 50

Feedback Specifications 52

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 37

Page 38

Chapter 4 Kinetix 6000M System Connector Data

➋

➊

➌

➏

➍

➎

➒

➑

➐

➓

IPIM Module Connectors and Indicators

Figure 11 - Module Connectors and Indicators

SH1

42+

42-

SH2

CN-

CN+

OUT

RTN

SH3

SE1

SE-

SE2

ETHERNET 1

ETHERNET 2

NETWORK

Item Description See page

➊ Hybrid cable DC bus connector Termination point for +/- DC and PE 39

➋ Hybrid cable communication signals

connector

Connection point for IDM unit power and

communication

39

➌ Safe- off connector Termination point for safety signals 40

➍ Enable connector Enable input to the IDM system 41

➎ Sercos fiber-optic connectors Transmit and receive fiber-optic connectors 41

➏ LCD display Allows ethernet configuration and system status 66

➐ Navigation buttons Four buttons provide access and navigation

66

when using the LCD display

➑ Status indicators

DC Bus

Control Bu s

Port 1 and Port 2

Module Status

Network Status

DC bus status

Control bus status (present, faulted)

Communication status of the EtherNet/IP ports

IPIM module status (operating, standby, faulted)

Indicates IDM system network status

90

➒ EtherNet/IP ports Two Ethernet ports are provided 42

➓ IDM network cable connector Connection point for network cable to first IDM

42

unit

38 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 39

Kinetix 6000M System Connector Data Chapter 4

1

DC-

DC+

IPIM Module Connector and Signal Descriptions

Hybrid Cable DC Bus Connector

This connector supplies the DC bus voltage. Three wires from the

hybrid power and communication cable (catalog number 2090CHBIFS8-12AAxx) are used to extend this voltage to the first

IDM unit.

Strip

Length

Terminal Description Signal

1 DC bus supply (-) DC- DC- 9.7 (0.38) 0.75 (6.6)

2 Chassis ground

3 DC bus supply (+) DC+ DC+

Hybrid Cable Communication Signals Connector

mm (in.)

1

SH1

The hybrid communication connector extends control

power, communication, and safety signals to the first

IDM unit. The 2090-CHBIFS8-12AAxx cable

interfaces with this connector.

42+

42-

SH2

Tor que

N•m (lb•in)

CN-

CN+

OUT

RTN

SH3

SE1

SE-

SE2

Strip

Length

Terminal Description Signal

1 Shield – SH1 6.4 (0.25) 0.235 (2.0)

2 Control Power +42V DC 42V + 42+

3 Control Power -42V DC 42V COM 424 CAN Bus Shield IDM CAN SHIELD SH2

5 IDM CAN Bus Lo IDM CAN LO CN6 IDM CAN Bus Hi IDM CAN HI CN+

7 System OK out to IDMs IDM SYSOKOUT OUT

8 System OK return from IDMs IDM SYSOKRTN RTN

9 Safety Shield SAFETY SHIELD SH3

10 Safety Enable Input 1 SAFETY ENABLE 1+ SE1

11 Safety Enable Common SAFETY ENABLE- SE12 Safety Enable Input 2 SAFETY ENABLE 2+ SE2

mm (in.)

Tor que

N•m (lb•in)

Rockwell Automation Publication 2094-UM003A-EN-P - May 2012 39

Page 40

Chapter 4 Kinetix 6000M System Connector Data

IMPORTANT

IMPORTANT

Remove the motionallowed jumper before

connecting any safety

devices.

Wiring P lug Hea der

Safe Torque-off Connector

This connector provides a termination

point for connecting safety devices such

as: emergency stop switches, light

1

F2+

F2-

F1+

F1-

SE2

SE-

SE1

24+

24-

curtains, and floor mats. The redundant

safety device outputs should be connected

to Safety Enable Input 1 and 2 with

reference to Safety Enable Common.

Each IPIM module ships with the wiring-plug header and motion-allowed

jumper installed in the safe torque-off connector.

With the motion-allowed jumper installed, the safe torque-off function is

.

defeated

Pins 8 and 9 (24V+) are used only by the motion-allowed jumper. When

wiring to the wiring-plug header, the 24V supply (for an external safety

device that triggers the safe torque-off request) must come from an

external source, otherwise system performance will be jeopardized.

This connector extends the safe-off signals for use in wiring single and multiple

safe torque-off configurations, or to bypass (not use) the safe torque-off function.

Refer to page 107

for further information.

Strip

Length

Terminal Description Signal

(2)

24+

24V COM

(1)

(1)

(1)

(1)

(2)

1 Feedback Monitoring 2+ FDBK2+

2 Feedback Monitoring 2- FDBK23 Feedback Monitoring 1+ FDBK1+

4 Feedback Monitoring 1- FDBK15 Safety Enable Input 2 SAFETY ENABLE 2+ SE2

6 Safety Enable Common SAFETY ENABLE- SE7 Safety Enable Input 1 SAFETY ENABLE 1+ SE1

8 Safety Bypass S upply, +24V

DC, 320 mA max

9 Safety Bypass supply,

Common

(1) Feedback monitoring terminals are provided for compatibility with the Kinetix 6000 safety connector only.

(2) Refer to page 107 for information on the proper use of these terminals.

(3) Maximum/minimum that the connector will accept—these are not recommendations.

mm (in.)

F2+ 7.0

(0.275)

F2F1+

F1-

24+

24-

Tor que

N•m (lb•in)

0.235 (2.0) 0.14…1.5

Min/Max

Wire Size

mm2 (AWG)

(30…14)

(3)

40 Rockwell Automation Publication 2094-UM003A-EN-P - May 2012

Page 41

Kinetix 6000M System Connector Data Chapter 4

TransmitReceive

Sercos Fiber-optic Connectors

The sercos fiber-optic ring is connected by using

the sercos receive (RX) and transmit (TX)

connectors.

ATT EN TI ON : To avoid damage to the sercos RX and TX connectors use only

finger-tight torque when attaching the fiber-optic cables. Do not use a wrench

or any other mechanical assistance. For more information, refer to Fiber-optic

Cable Installation and Handling Instructions, publication 2090-IN010

Table 12 - Sercos Specifications

Attribute Value

Data rates 8 Mbps (fixed)

Light intensity Adjustable, low or high power, selectable via the keypad/LCD display (see page 68

Cyclic update period 500 μs, minimum