Page 1

MD65 PROFIBUS

Communications Module

M/N MDCOMM-PBUS

Instruction Manual

D2-3530

Page 2

The information in this manual is subject to change without notice.

Trademarks not belonging to Rockwell Automation are

property of their respective companies.

Throughout this manual, the following notes are used to alert you to safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal inj ury or death, property

damage, or economic loss.

!

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: The drive may contain high v oltages that can cause

injury or death. Remove all po wer from t he drive , and then v e rify

power has been removed before installing or removing a

!

PROFIBUS module. Failure to observe these precautions could

result in severe bodily injury or loss of life.

ATTENTION: Only qualified electrical personnel familiar with

drive and power products and the associated machinery should

plan or implement the installation, start up, configuration, and

subsequent maintenance of the product using a PROFIBUS

module. Read and understand this manual in its entirety before

proceeding. Failure to observ e these precautions could result

bodily injury and/or damage to equipment.

ATTENTION: MDI host products must not be directl y connected

together via RECBL-xxx cables. Unpredictable behavior due to

timing and other internal procedures can result if two or more

devices are connected in this manner. Failure to observe this

precaution could result bodily injury and/or damage to equipment.

ATTENTION: If the PROFIBUS module is transmitting control

I/O to the drive, the drive may fault when you reset the module.

Determine how your drive will respond bef ore resetting an module.

Failure to observe thi s precaution could result bodily injury

and/or damage to equipment.

ATTENTION: Comm Flt Action (parameter 9) and Idle Flt Action

(parameter 10) let you determine the action of the module and

connected drive if communications are disrupted. By default,

these parameters fault the drive. You can set these parameters

so that the drive continue s to run. Precautions should be tak en to

ensure that the settings of these parameters do not create a

hazard of injury or equipment damage. F ailure to observe this

precaution could result bodily injury and/or damage to equipment.

ATTENTION: When a system is configured f or the first time, there

may be unintended or incorrect machine motion. Disconnect the

motor from the machine or process during initial system testing.

Failure to observe thi s precaution could result bodily injury

and/or damage to equipment.

PROFIBUS is a trademark of the PROFIBUS Trade Organization.

Windows, Windows NT, and Microsoft are trademarks of Microsoft Corporation.

Reliance, MD65, VS Utilities, MDI, and SLC are trademarks of Rockwell

Automation.

©2004 Rockwell Automation. All rights reserved.

Page 3

CONTENTS

Chapter 1 Introduction

1.1 PROFIBUS Module Features ........................................ 1-1

1.2 Related Documentation.................................... .. ........... 1-2

1.3 Getting Assistance from Reliance Electric..................... 1-2

Chapter 2 Getting Started

2.1 PROFIBUS Module Components.................................. 2-1

2.2 Required Equipment......................................................2-2

2.3 Installation Checklist......................................................2-3

2.4 Modes of Operation.......................................................2-4

Chapter 3 Installing the PROFIBUS Module

3.1 Preparing for an Installation...........................................3-1

3.2 Commissioning the Module ...........................................3-1

3.3 Connecting the Module to the Network..........................3-4

3.4 Terminating the Network................................................ 3-7

3.5 Connecting the Module to the Drive .............................. 3-8

3.6 Applying Power............................................................3-10

Chapter 4 Configuring the PROFIBUS Module

4.1 Configuration Tools........................................................ 4-1

4.2 Using the LCD OIM to Configure the Module................ 4-2

4.3 Using V*S Utilities via MDCOMM-232........................... 4-3

4.4 Setting the Node Address.............................................. 4-4

4.5 Setting the I/O Configuration ......................................... 4-5

4.6 Setting a Fault Action..................................... ... .. ........... 4-6

4.6.1 Changing the Fault Action................................... 4-6

4.6.2 Setting the Fault Configuration Parameters ........ 4-7

4.6.3 Resetting the Module........................................... 4-7

4.7 Viewing the Module Configuration................................. 4-8

Chapter 5 Configuring the PROFIBUS Scanner

5.1 Configuring a Simple Network: An Example.................. 5-1

5.2 SST Profibus Configuration Software Tool.................... 5-2

5.3 Installing the MDCOMM-PBUS GSD File in the Software

Tool Library ...................................................................5-3

5.4 Configuring the SST-PFB-SLC PROFIBUS Scanner .... 5-5

Contents I

Page 4

Chapter 6 About I/O Messaging

6.1 About I/O Messaging .....................................................6-1

6.2 Understanding the I/O Image.........................................6-1

6.3 Using Logic Command/Status .......................................6-2

6.4 Using Reference/Feedback ...........................................6-3

Chapter 7 Using Explicit Messaging (Parameter Protocol)

7.1 About Explicit Messaging...............................................7-1

7.2 Running Explicit Messages............................................7-2

7.3 Parameter Protocol.................................................. .. ....7-3

7.3.1 Parameter Message Request..............................7-4

7.3.2 Parameter Message Response...........................7-5

Chapter 8 Using Multi-Drive Mode

8.1 Single Mode vs. Multi-Drive Mode.................................8-1

8.2 System Wiring................................................................8-4

8.3 Understanding the I/O Image.........................................8-5

8.4 Configuring the RS-485 Network...................................8-6

8.5 Multi- Mode Explicit Messaging .....................................8-7

8.6 Additional Information....................................................8-7

Chapter 9 Troubleshooting the PROFIBUS Module an d Network

9.1 Understanding the Status Indicators..............................9-1

9.1.1 DRIVE Status Indicator........................................9-2

9.1.2 MS Status Indicator .............................................9-3

9.1.3 NET A Status Indicator........................................9-4

9.2 Module Diagnostic Items in Single Drive Mode .............9-5

9.3 Module Diagnostic Items in Multi-Drive Mode................ 9-5

9.4 Viewing and Clearing Events.........................................9-7

Appendix A Technical Specifications.................................................... A-1

Appendix B PROFIBUS Module Parameters ........................................B-1

Appendix C Logic Command/Status Word.......................................... C-1

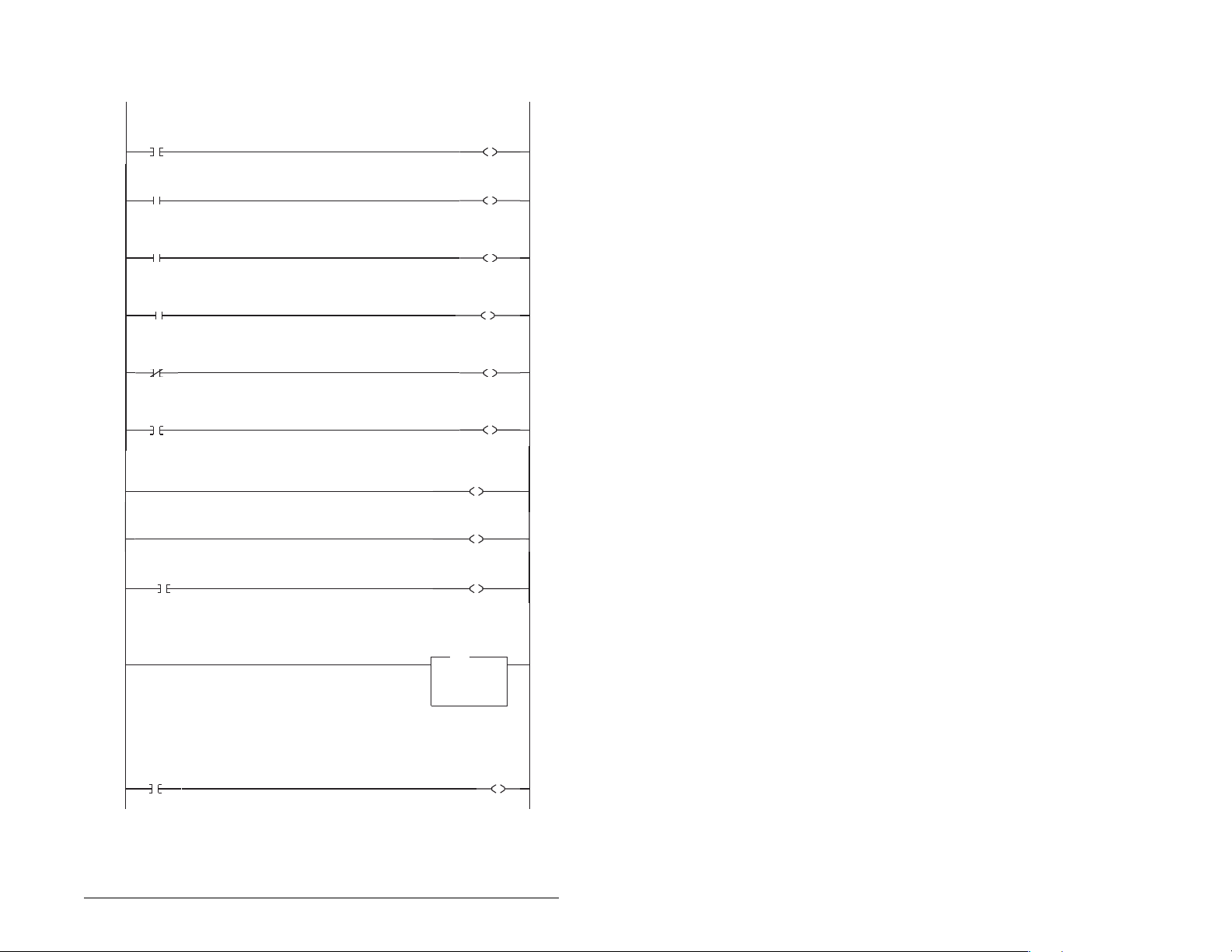

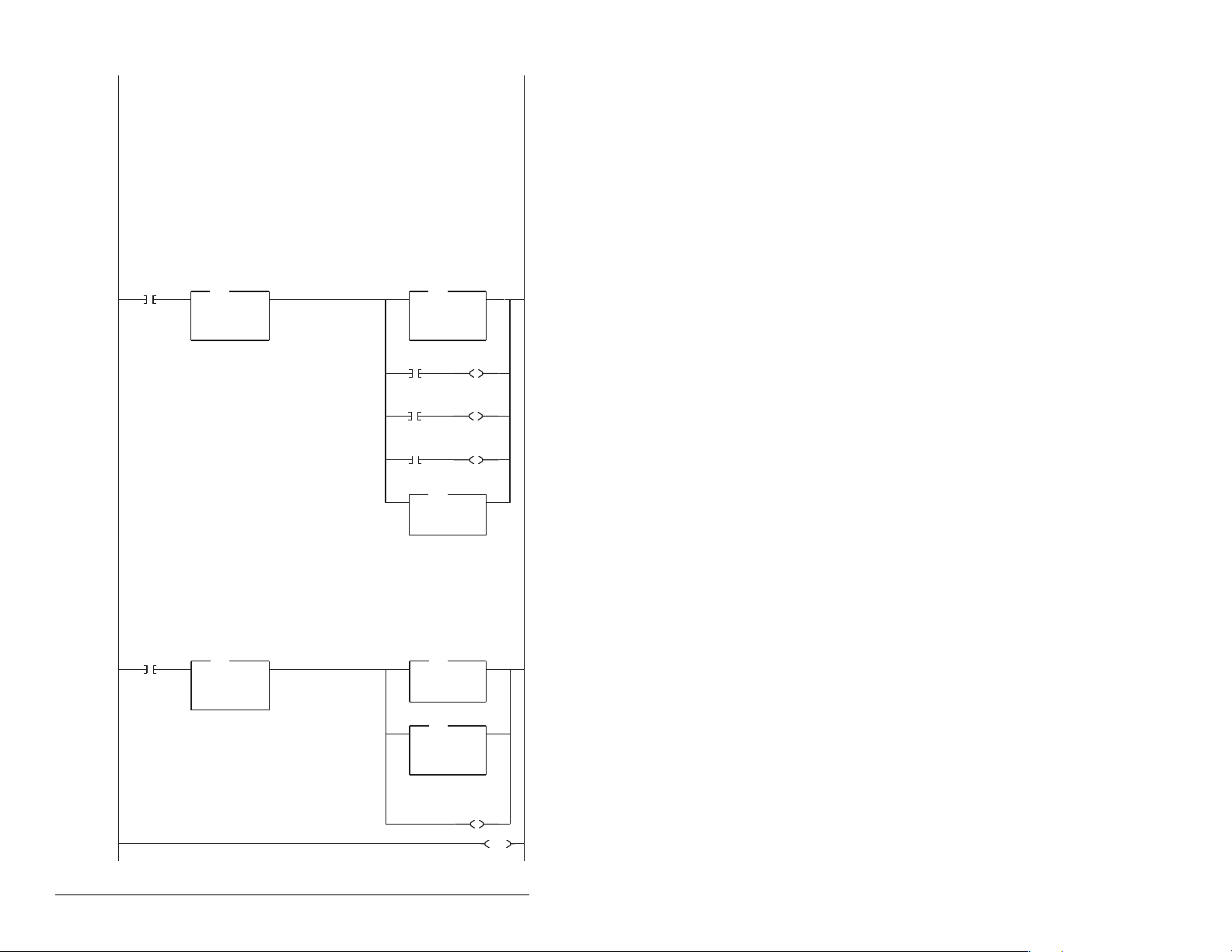

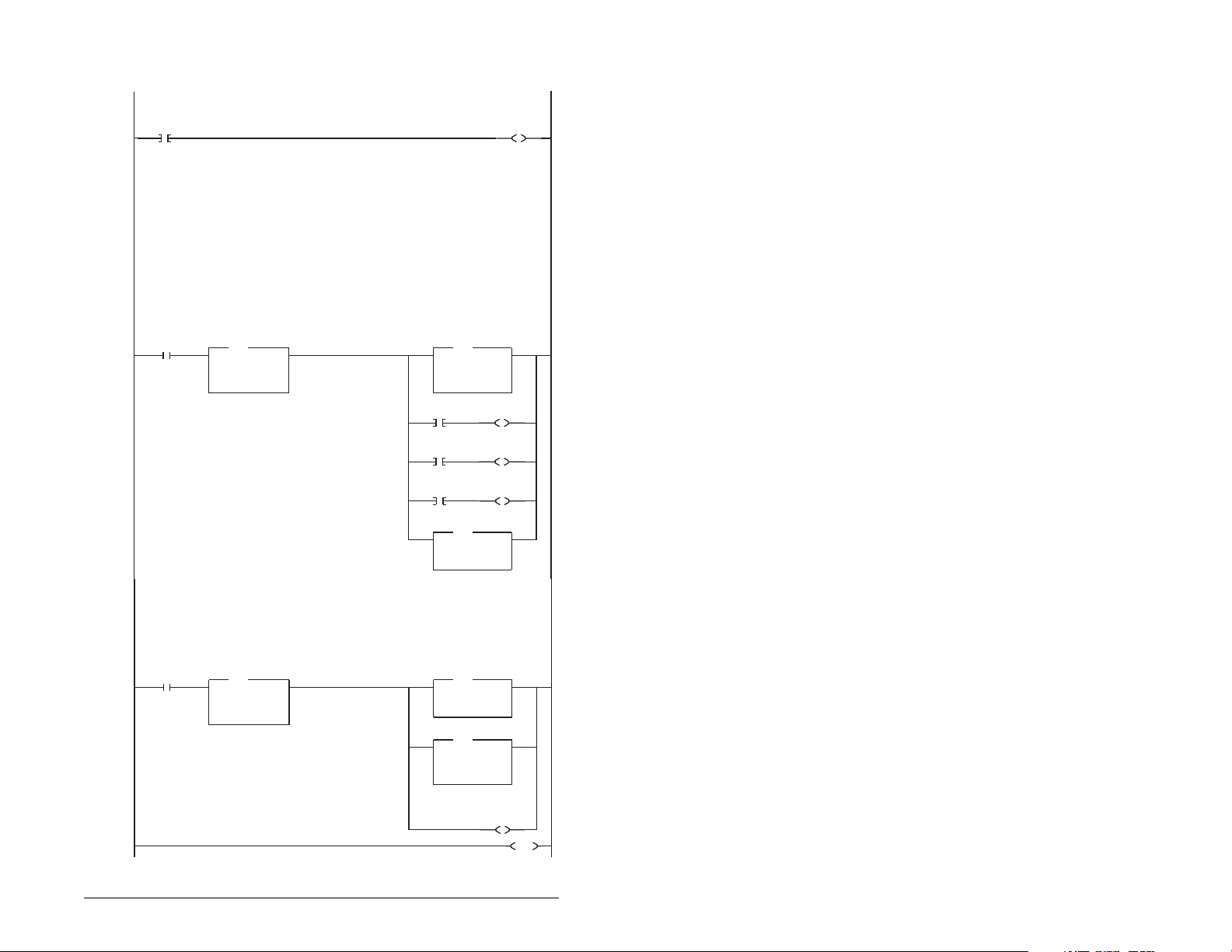

Appendix D SLC Ladder Logic Examples..............................................D-1

Glossary ........................................................... Glossary-1

Index ......................................................................Index-1

II PROFIBUS Communications Module

Page 5

List of Figures

Figure 2.1 – Components of the PROFIBUS Module................................. 2-1

Figure 2.2 – Status Indicators.....................................................................2-5

Figure 3.1 – Setting the Node Address....................................................... 3-2

Figure 3.2 – ERNI and Phoenix Subcon Connectors..................................3-5

Figure 3.3 – Network Wiring Diagram.........................................................3-5

Figure 3.4 – Optional Clamp-On Ferrite Cable Clamp................................ 3-6

Figure 3.5 – Connection for Terminating Resistors.................................... 3-7

Figure 3.6 – MDI Ports and Internal Interface Cables................................. 3-9

Figure 3.7 – Mounting the Adapter ........................................................... 3-10

Figure 4.1 – Using V*S Utilities................................................................... 4-3

Figure 4.2 – Setting the Node Address....................................................... 4-4

Figure 4.3 – Fault Action Screens on an LCD OIM.....................................4-6

Figure 4.4 – Reset Screen on an LCD OIM................................................4-8

Figure 5.1 – Example PROFIBUS Network................................................ 5-2

Figure 5.2 – SST PROFIBUS Configuration Software Tool........................ 5-2

Figure 5.3 – Standard Data Files................................................................ 5-3

Figure 5.4 – Add PROFIBUS Devices Applet Window............................... 5-4

Figure 5.5 – Adding the GSD File for the RECOMM-PBUS ....................... 5-4

Figure 5.6 – Masters/Slaves Library Window............................................. 5-5

Figure 5.7 – SST-SST-PFB-SLC Master (General) Dialog Box.................. 5-6

Figure 5.8 – Scan Cycle Times Dialog Box................................................5-6

Figure 5.9 – COM Port Default Settings..................................................... 5-7

Figure 5.10 – Scanner Network Window ....................................................5-7

Figure 5.11 – Reliance Electric Library Dialog Window..............................5-8

Figure 5.12 – Available Modules: Ctrl/Stat & Ref/Fdbk (2x2Bytes)

Window................................................................................ 5-8

Figure 5.13 – Modules: Ctrl/Stat & Ref/Fdbk Viewing Window................... 5-9

Figure 5.14 – Add Modules: Parameter Access Selection Window.......... 5-10

Figure 5.15 – Modules: Parameter Access Viewing Window ................... 5-10

Figure 5.16 – SLC Address: M1/M0 (Ctrl/Stat & Ref/Fdbk)...................... 5-11

Figure 5.17 – SLC Address: M1/M0 (Parameter Access)......................... 5-11

Figure 5.18 – Station 1 Network Window.................................................. 5-11

Figure 5.19 – Station 2 Network Window.................................................. 5-12

Figure 5.20 – Network Window Scanner Selection................................... 5-13

Figure 5.21 – Save As Dialog Window ..................................................... 5-13

Figure 6.1 – Single Drive Example of I/O Image......................................... 6-2

Figure 7.1 – Explicit Message Process.......................................................7-2

Figure 7.2 – Parameter Message Format................................................... 7-3

Contents III

Page 6

Figure 8.1 – Single Mode Example for Network..........................................8-1

Figure 8.2 – MDI Peripheral Devices for Single Mode Connection............. 8-2

Figure 8.3 – Multi-Drive Mode Example for Network..................................8-2

Figure 8.4 – AK-U0-RJ45-TB2P Terminal Block Connector.......................8-4

Figure 8.5 – Multi-Drive Mode Example for Network..................................8-4

Figure 8.6 – Multi-Drive Mode Example of I/O Image.................................8-5

Figure 9.1 – Status Indicators (Location on Drive May Vary)......................9-1

Figure 9.2 – Viewing and Clearing Events Using an LCD OIM...................9-7

IV ControlNet Communications Module

Page 7

List of Tables

Table 2.1 – Equipment Shipped with the PROFIBUS Module.................... 2-2

Table 2.2 – Required User-Supplied Equipment ........................................2-2

Table 2.3 – Status Indicator Descriptions...................................................2-5

Table 3.1 – SW8 Setting.............................................................................3-2

Table 3.2 – Node Address Switch Settings (UP = OPEN = 1).................... 3-3

Table 3.3 – Jumper Settings.......................................................................3-4

Table 3.4 – MDCOMM-PBUS DB-9 Pin Layout..........................................3-5

Table 4.1 – Configuration Tools.................................................................. 4-1

Table 4.2 – Using the LCD OIM or CopyCat Keypad ................................. 4-2

Table 4.3 – Selections for Drive Response to Communication Fault.......... 4-6

Table 4.4 – Fault Configuration Parameters...............................................4-7

Table 4.5 – Module Configuration Status Parameters................................ 4-8

Table 5.1 – Input/Output Size Configurations.............................................5-9

Table 5.2 – Station 1 Configurations.........................................................5-12

Table 5.3 – Station 2 Configurations.........................................................5-12

Table 7.1 – Parameter Message Request Data.......................................... 7-4

Table 7.2 – Parameter Message Response Data....................................... 7-5

Table 7.4 – Parameter Message Response Fault Numbers and

Descriptions...........................................................................7-6

Table 7.3 – Module Fault Code...................................................................7-6

Table 8.1 – Parameters for daisy-chained drives ....................................... 8-6

Table 8.2 – Parameters for MDCOMM-PBUS............................................ 8-6

Table 8.3 – Accessing Accel Time (Parameter 39)................................... ..8-7

Table 9.1 – DRIVE Status Indicator: State Definitions................................ 9-2

Table 9.2 – MS Status Indicator: State Definitions ..................................... 9-3

Table 9.3 – NET A Status Indicator: State Definitions................................ 9-4

Table 9.4 – Module Diagnostic Items for Single Drive Mode...................... 9-5

Table 9.5 – Module Diagnostic Items for Multi-Drive Mode........................9-5

Table 9.6 – Event Codes and Descriptions................................................. 9-7

Contents V

Page 8

VI PROFIBUS Communications Module

Page 9

CHAPTER 1

Introduction

This manual provides information about the PROFIBUS

Communications module (MDCOMM-PBUS) and using it with

MD65 drives. It is intended for qualified electrical personnel familiar

with installing, programming, and maintaining AC drives and

networks.

The PROFIBUS module is an embedded communication option

for MDI AC drives, such as the MD65 drive. The module is

mounted in the drive and receives its required power from the drive.

The module can be used with other products that implement MDI, a

peripheral communication interface. Refer to the documentation for

your product for specific information about how it works with the

module.

1.1 PROFIBUS Module Features

The PROFIBUS module features the following:

• The low seven bits of 8-bit DIP switch let you set a node address,

and the MSB bit provides write access for the Flash update of

module firmware.

• Depending on the jumper position, “1X” or “5X”, the two operation

modes “Single” and “Multiple” are supported:

• In Single Drive Mode (default mode), the module

represents a single drive on one node and can support

one external peripheral (for example, an OIM) over MDI.

• In Multi-Drive Mode, the module represents up to 5 drives

on one node daisy-chained over the RS-485 interface. In

this case, the unit will not operate with MDI peripheral

devices such as the OIM or the MDCOMM-232.

• Status indicators that report the status of the drive

communications, module, and network.

• The I/O messages (i.e. Control/Status, Reference/Feedback) will

be exchanged with Profibus master in every bus cycle. I/O

configuration is fixed and Datalinks are not supported.

• The slave device’ s parameters on the PROFIBUS netw ork can be

configured and monitored using explicit messaging.

Introduction 1-1

Page 10

• User-defined fault actions determine how the module and MD65

drive respond to communication disruptions (faults) on the

network and controllers in idle mode.

• For Single Drive mode, the slave device’s parameters on the

Profibus network can be configured and monitored by the

software tool V*S Utilities.

1.2 Related Documentation

Refer to the following related publications as necessary for more

information. All of the publications are available from

http://www.theautomationbookstore.com or

http://www.reliance.com.

• D2-3519 MD65 AC Drive User Manual

• D2-3488 VS Utilities Getting Results Manual

Online help installed with the software

• 1747-6.2 SLC 500 Modular Hardware Style Installation and

Operation Manual

• 1747-6.15 SLC 500 and MicroLogix 1000 Instruction Set

Documentation about the scanner, SST-PFB-SLC User’s Guide,

V e rsion 2.03, can be obtained online at

http://www.mysst.com/download.

1.3 Getting Assistance from Reliance

Electric

If you have any questions or problems with the products described

in this instruction manual, contact your local Reliance Electric sales

office.

For technical assistance, call 1-864-284-5350. Before calling,

please review the troubleshooting chapter in this manual and check

the Reliance drives website for additional information. When you

call this number, you will be asked for the drive model number and

this instruction manual number.

1-2 PROFIBUS Communications Module

Page 11

CHAPTER 2

Getting Started

This chapter provides:

• A description of the PROFIBUS module components

• A list of parts shipped with the module and a list of user-supplied

parts required for installing the module

• An installation checklist

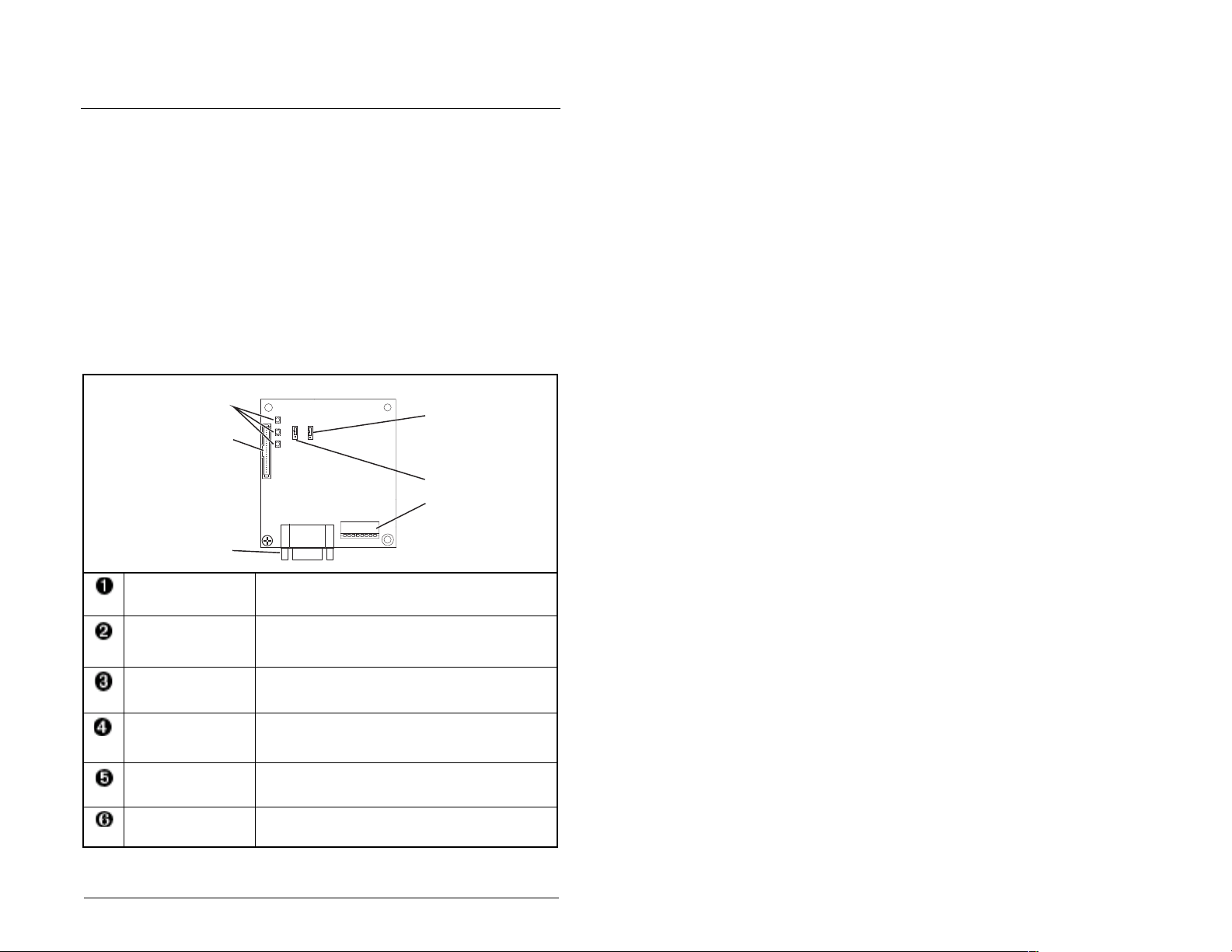

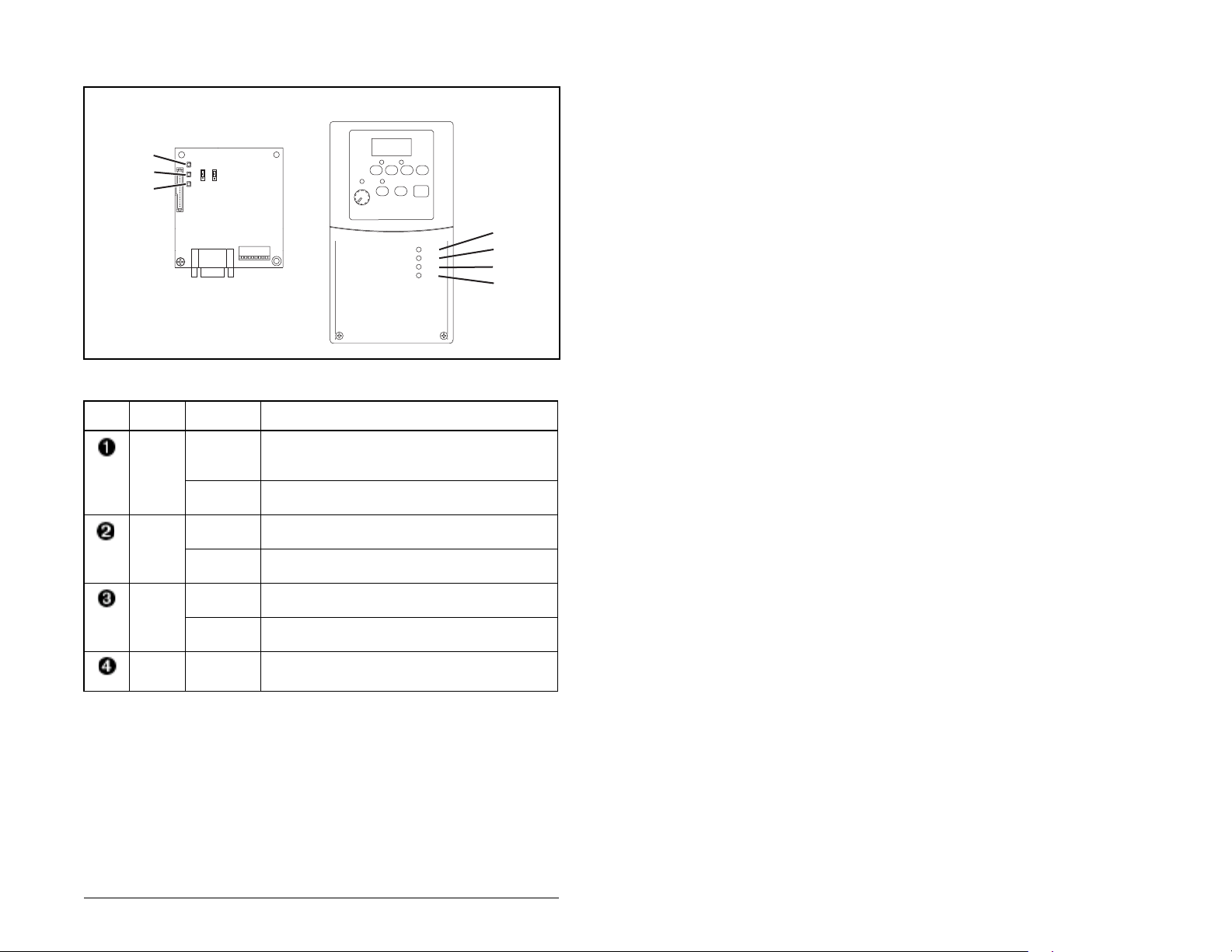

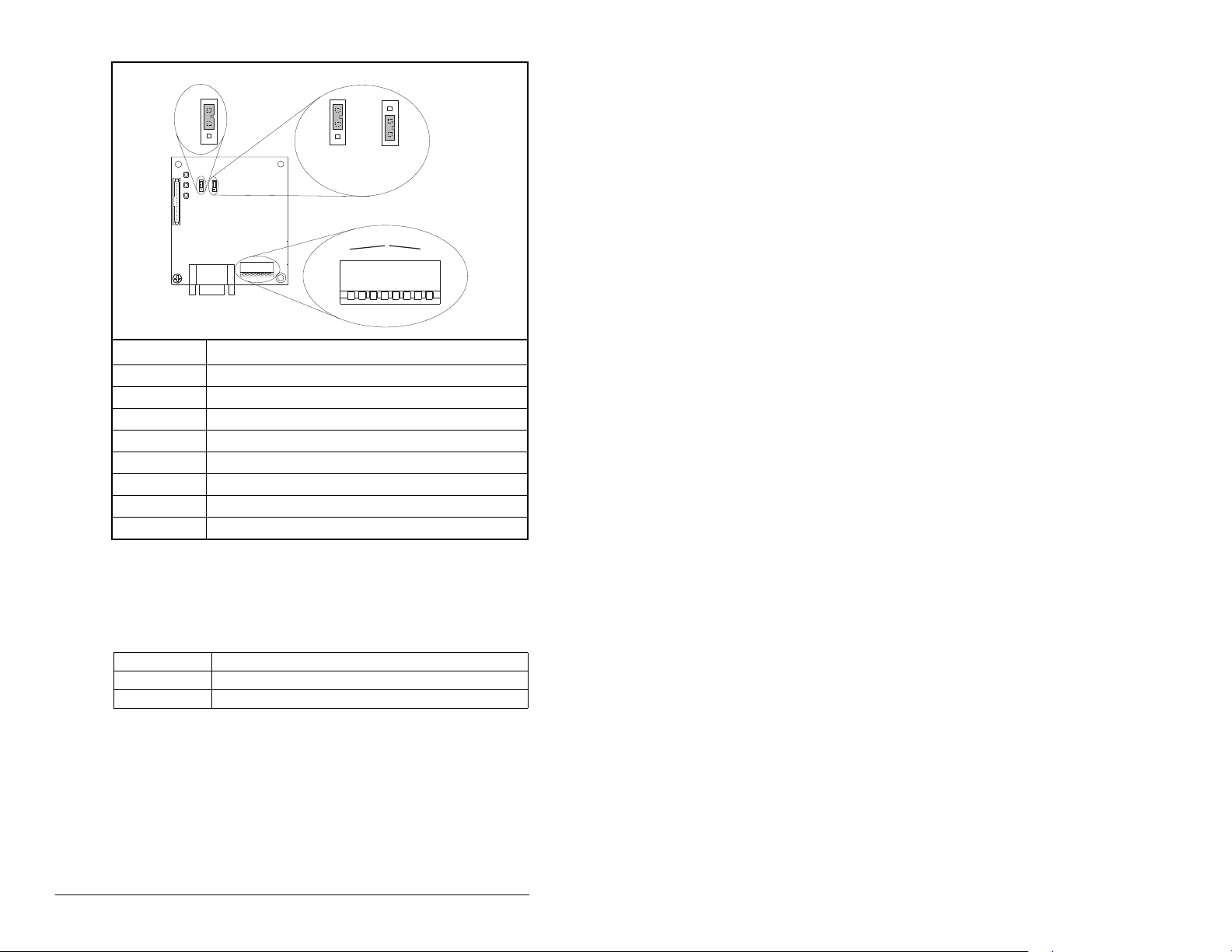

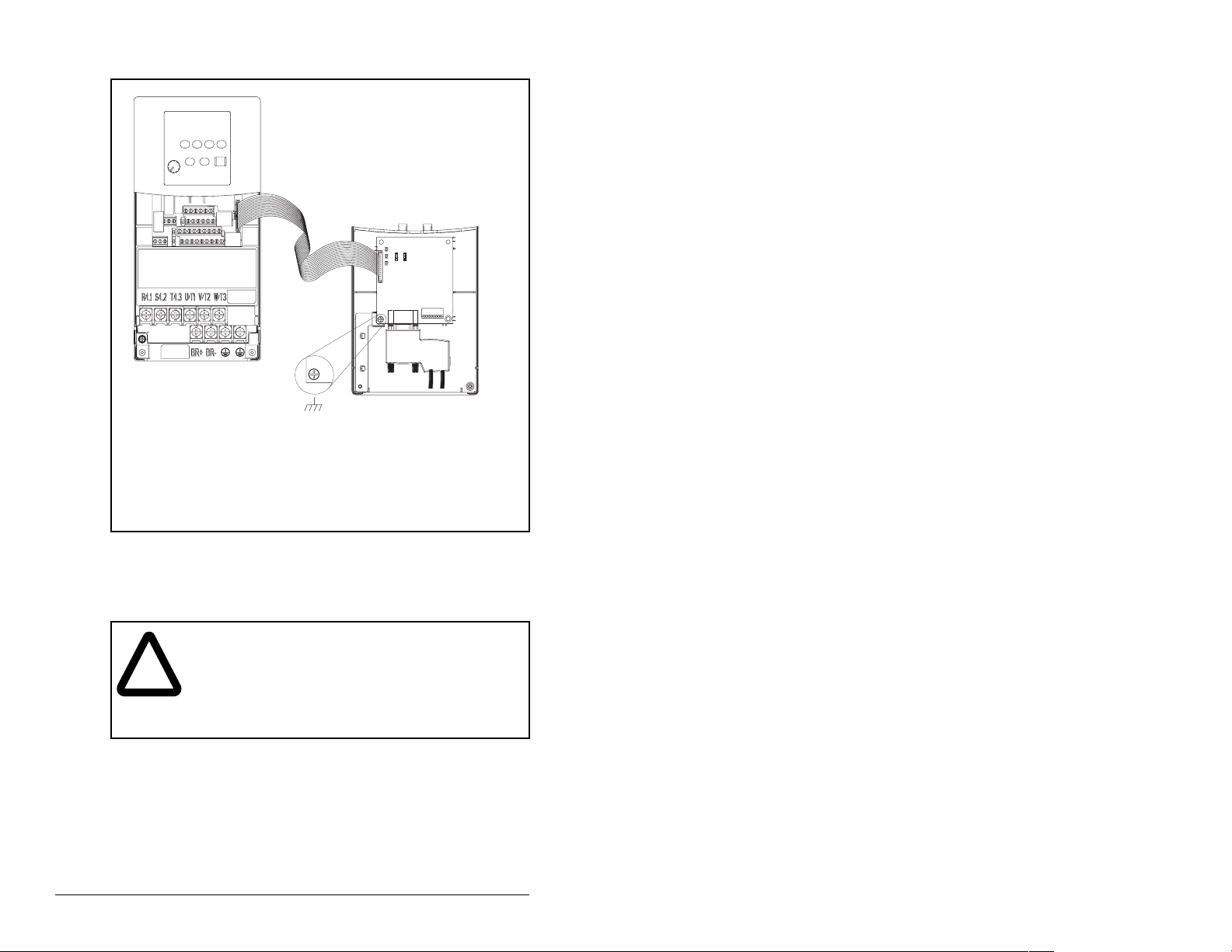

2.1 PROFIBUS Module Components

➊

➋

➌

Status Indicators Three LEDs to indicate the status of the

MDI Connector A 20-pin, single-row shrouded male header. An

PROFIBUS

Connector

Node Address

Switches/ Firmware

Update Switches

Mode Jumper (J2) Selects Single or Multi-Drive mode of

SWAP Jumper (J3) Determines the Intel or Motorola (SWAP) data

connected drive, module, and network.

Internal Interface cable connects to this

connector and a connector on the drive.

A 9-pin, female D-Sub connector.

Switches (SW1-7) for setting the node address

and SW8 for Firmware flash updating.

operation.

format for the corresponding PLC.

➎

❻

➍

Figure 2.1 – Components of the PROFIBUS Module

Getting Started 2-1

Page 12

2.2 Required Equipment

Table 2.1 lists the equipment shipped with the PROFIBUS module.

When you unpack the module, verify that the package includes all of

these items.

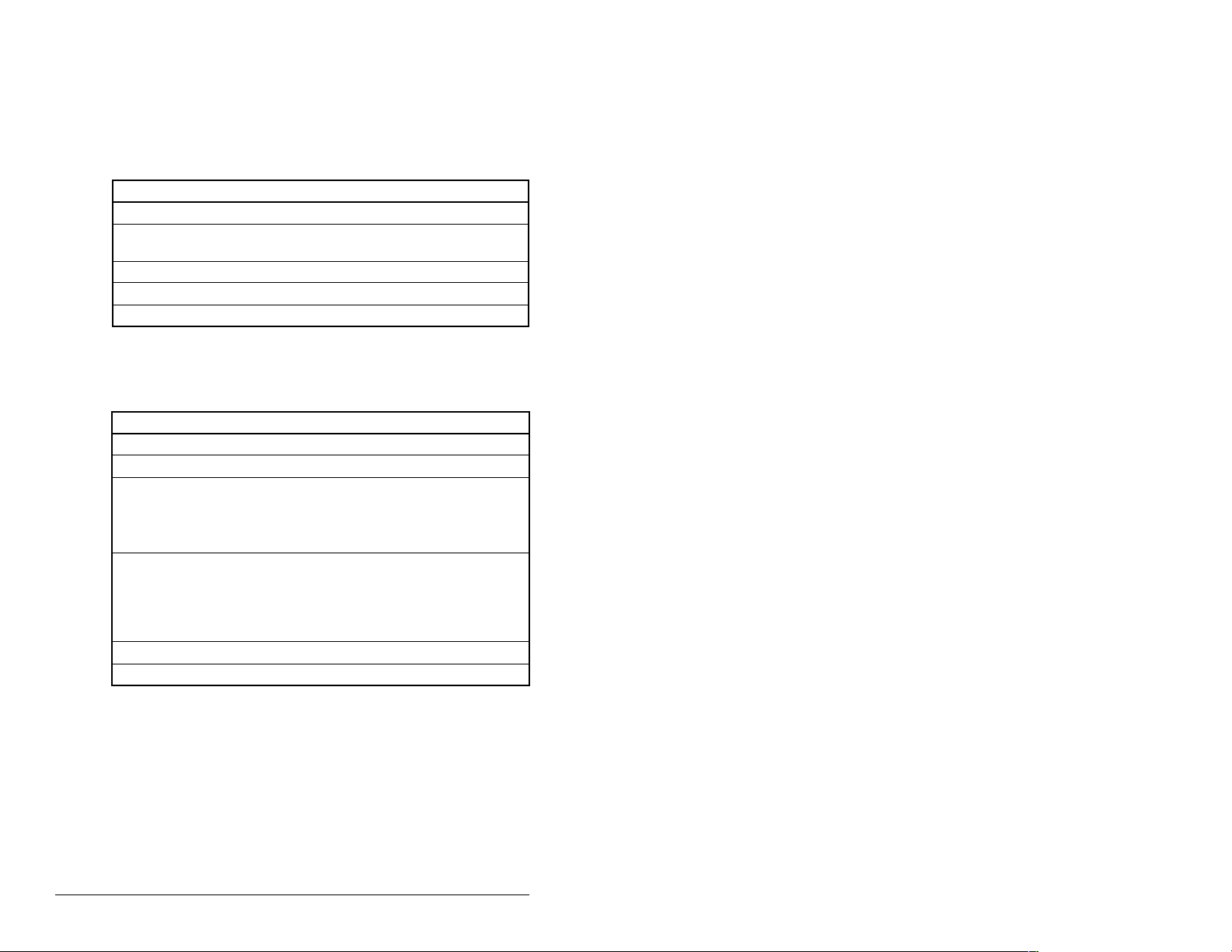

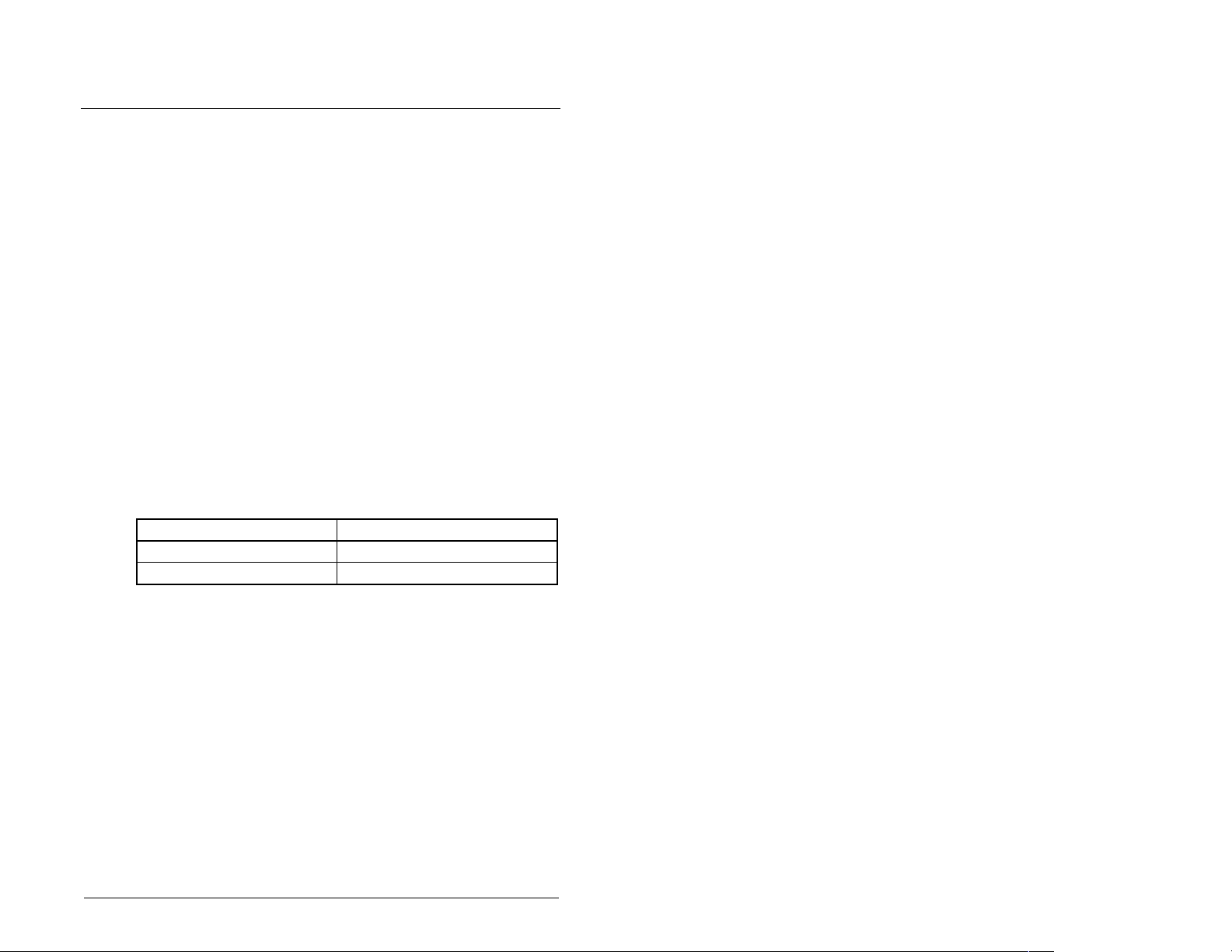

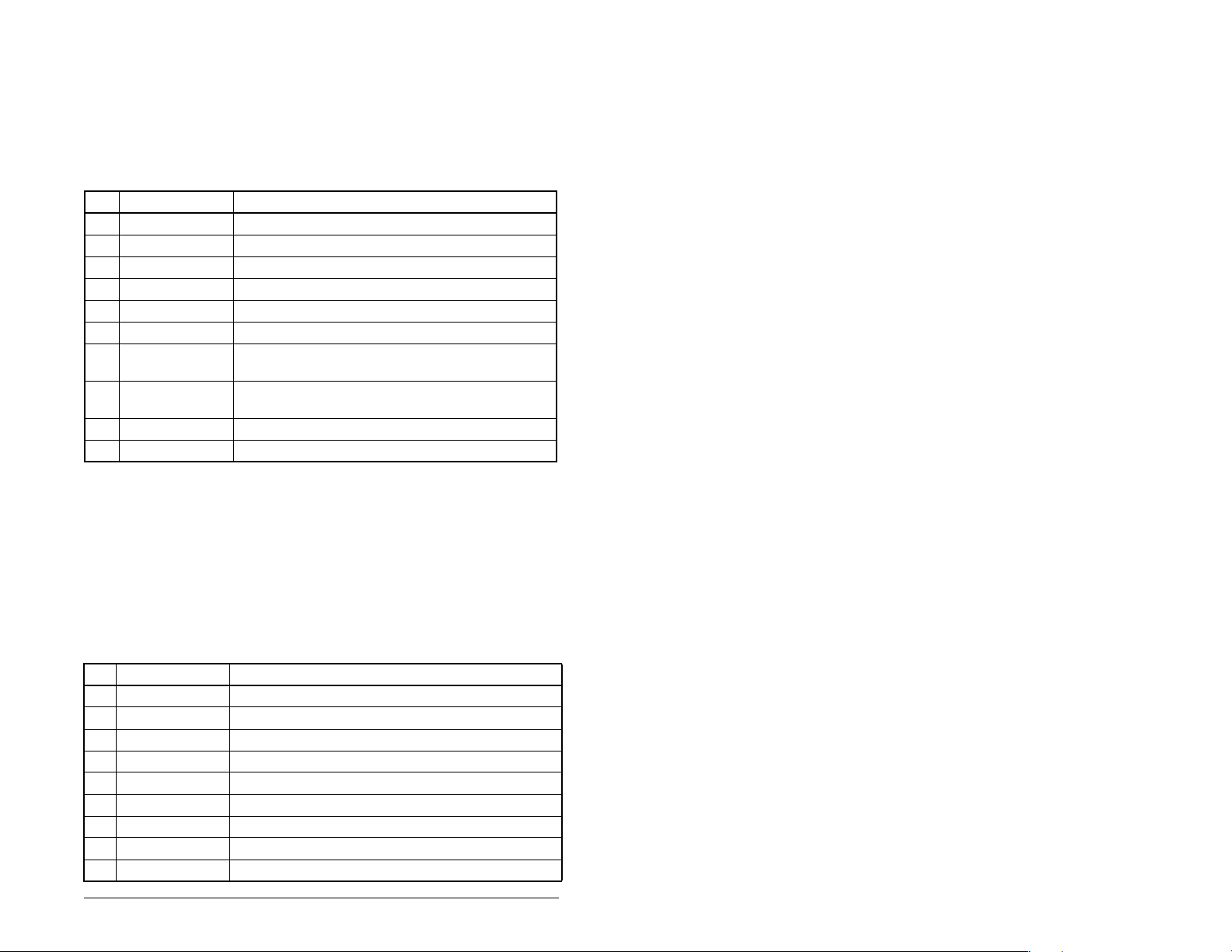

Table 2.1 – Equipment Shipped with the PROFIBUS Module

Item Description

One MDCOMM-PBUS PROFIBUS module

A 2.54 cm (1 in) and a 12.7 cm (5 in) Internal Interface cable (only

one cable is needed to connect the module to the drive)

One grounding wrist strap

One floppy disc with GSD file

PROFIBUS Module User Manual (D2-3530)

Table 2.2 lists user-supplied equipment also required to install and

configure the PROFIBUS mo du l e.

Table 2.2 – Required User-Supplied Equipment

Item Description

Small flathead screwdriver

PROFIBUS cable

One 9-pin, male D-Sub PROFIBUS connector.

Note: PROFIBUS connectors are available from a variety of

sources and in various sizes. As such, there may be mechanical

limitations that prohibit the use of some connectors.

Configuration tool, such as:

• LCD OIM

• VS Utilities

• with MDCOMM-232 Serial Converter

PROFIBUS configuration software

Controller configuration software

2-2 PROFIBUS Communications Module

Page 13

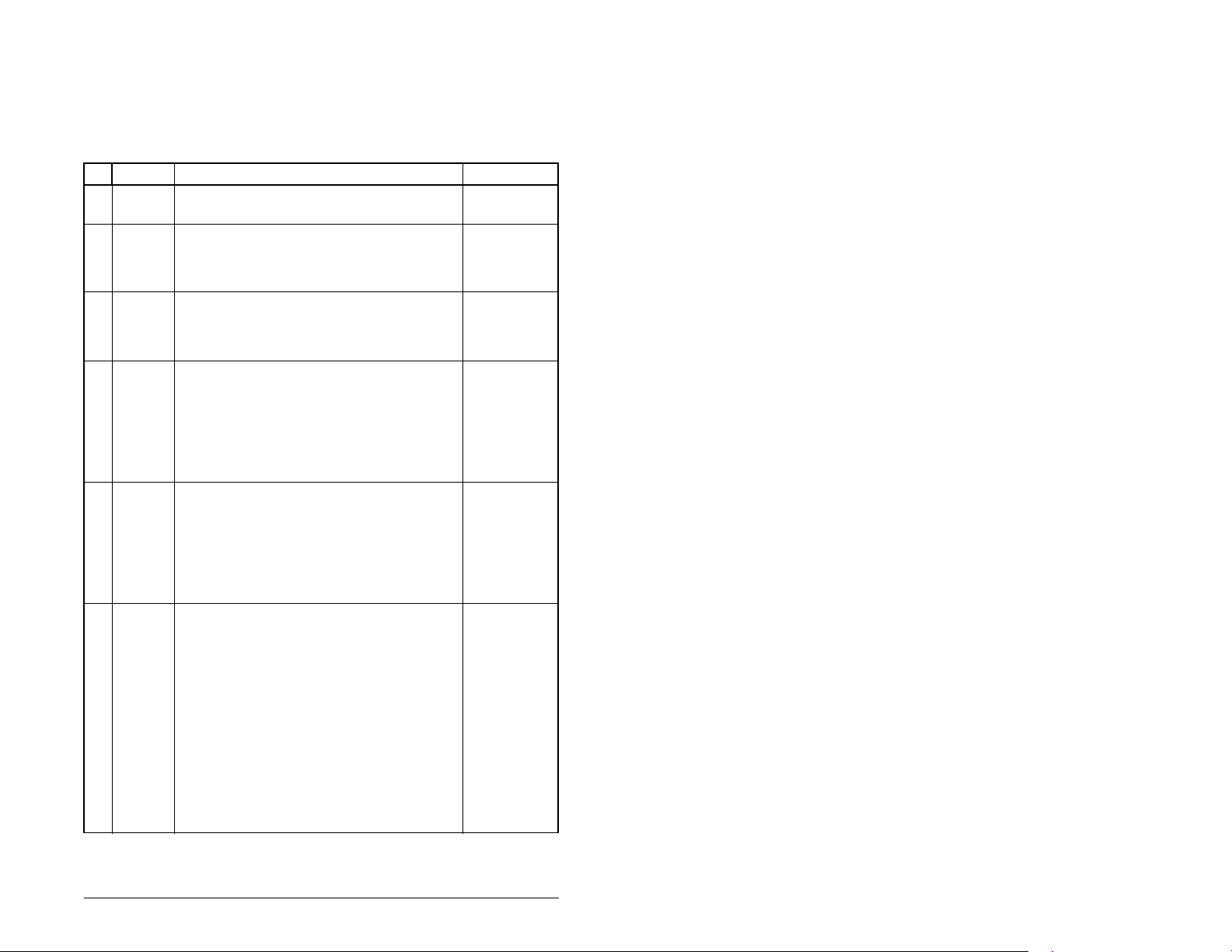

2.3 Installation Checklist

This section is designed to help experienced users start using the

PROFIBUS module. If you are unsure about how to complete a

step, refer to the referenced chapter.

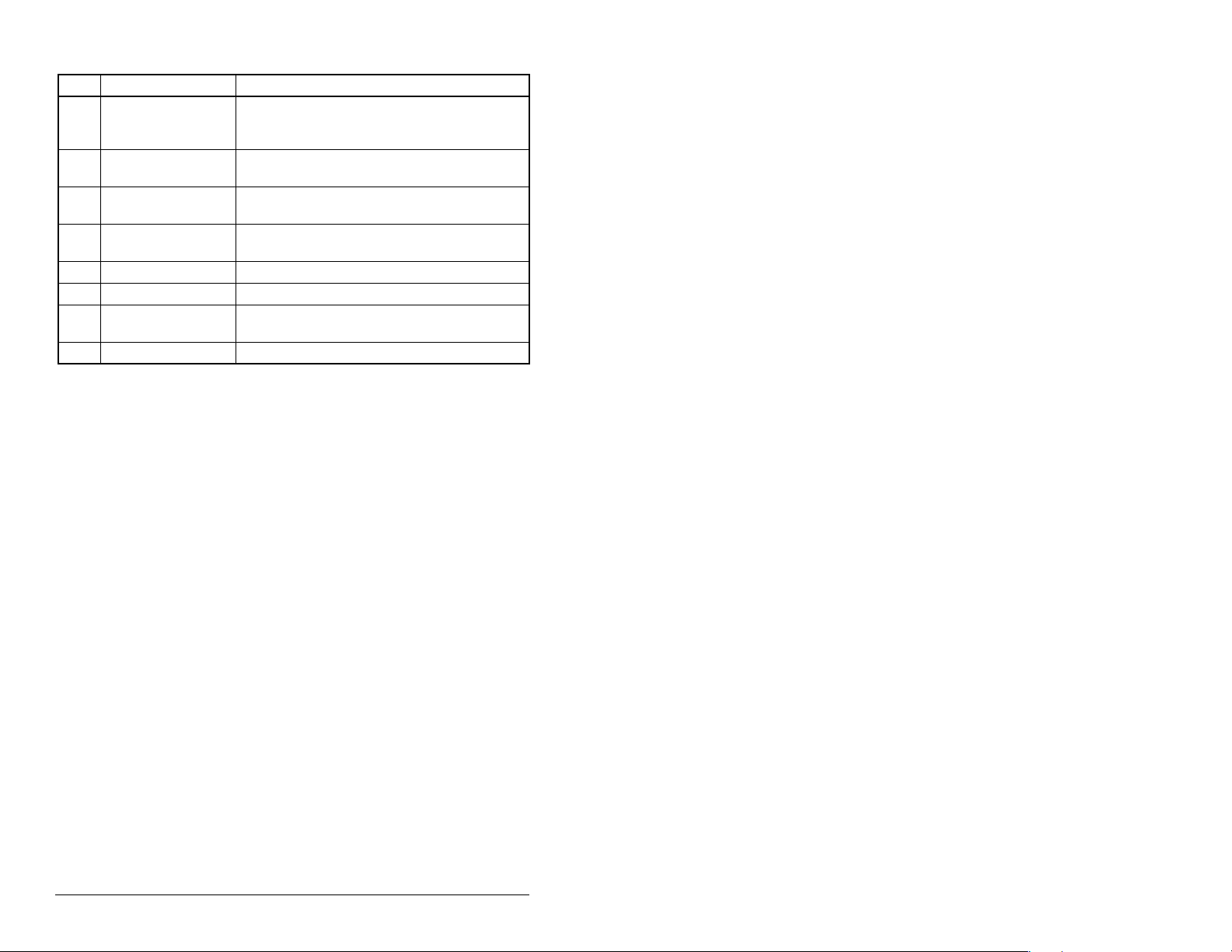

4 Step Action Refer to:

❒

❒

❒

❒

❒

❒

1 Review the safety precautions for the

module.

2 Verify that the MD65 drive is properly

installed.

3 Commission the module.

Set a unique node address using the DIPswitch for Bit 1 to 7 on the module.

4 Install the module.

Verify that the drive and PROFIBUS network

are not powered. Then, connect the module

to the network using a PROFIBUS cable and

to the drive using the Internal Interface cable.

Use the captive screws to secure and ground

the module to the drive.

5 Apply power to the module.

Apply power to the drive and to the network.

The module receives power from the drive.

The status indicators should be green. If they

flash red, there is a problem. Refer to chapter

9, Troubleshooting the PROFIBUS Module

and Network.

6 Set up the drive parameters.

Before starting, configuring and working with

the Profibus module, the following

parameters must be set:

• Start Source (P036) to 5

“RS485(MDI) port” if Start is

controlled from the network.

• Speed Reference (P038) to 5

“RS485(MDI) port” if the Speed

Reference is controlled from the

network.

For Multi-Drive mode, the following drive

parameters must be set: A103, A104, A107.

Throughout

this manual

MD65 AC

Drive User

Manual

(D2-3519)

Chapter 3,

Installing the

PROFIBUS

Module

Chapter 3,

Installing the

PROFIBUS

Module

Chapter 3,

Installing the

PROFIBUS

Module

Chapter 4,

Configuring

the

PROFIBUS

Module

Getting Started 2-3

Page 14

4 Step Action Refer to:

❒

7 Configure the module for your

application.

Set the parameters for the following features

as required by your application:

Chapter 4,

Configuring

the

PROFIBUS

Module

• Node address

• I/O configuration

• Fault actions

❒

❒

8 Apply power to the PROFIBUS master and

other devices on the network.

Verify that the master and network are

installed and functioning in accordance with

PROFIBUS standards, and then apply power

to them.

9 Configure the scanner to communicate

with the module.

Use a network tool for PROFIBUS to

configure the master on the network.

Be sure to:

Chapter 5,

Configuring

the

PROFIBUS

Scanner

• Set up the scan list.

• Map the module data to the scan list.

• Save your PROFIBUS configuration to the

scanner and a file.

10 Create a ladder logic program.

❒

Use a programming tool such as RS Lo g i x to

create a ladder logic program that enables

you to do the following:

• Control the module and connected drive.

• Monitor or configure the drive using Explicit

Messages.

Chapter 6,

Using I/O

Messaging.

Chapter 7,

Using Explicit

Messaging

(Parameter

Protocol)

2.4 Modes of Operation

The PROFIBUS module uses three status indicators to report its

operating status. They can be viewed through the drive cover.

2-4 PROFIBUS Communications Module

Page 15

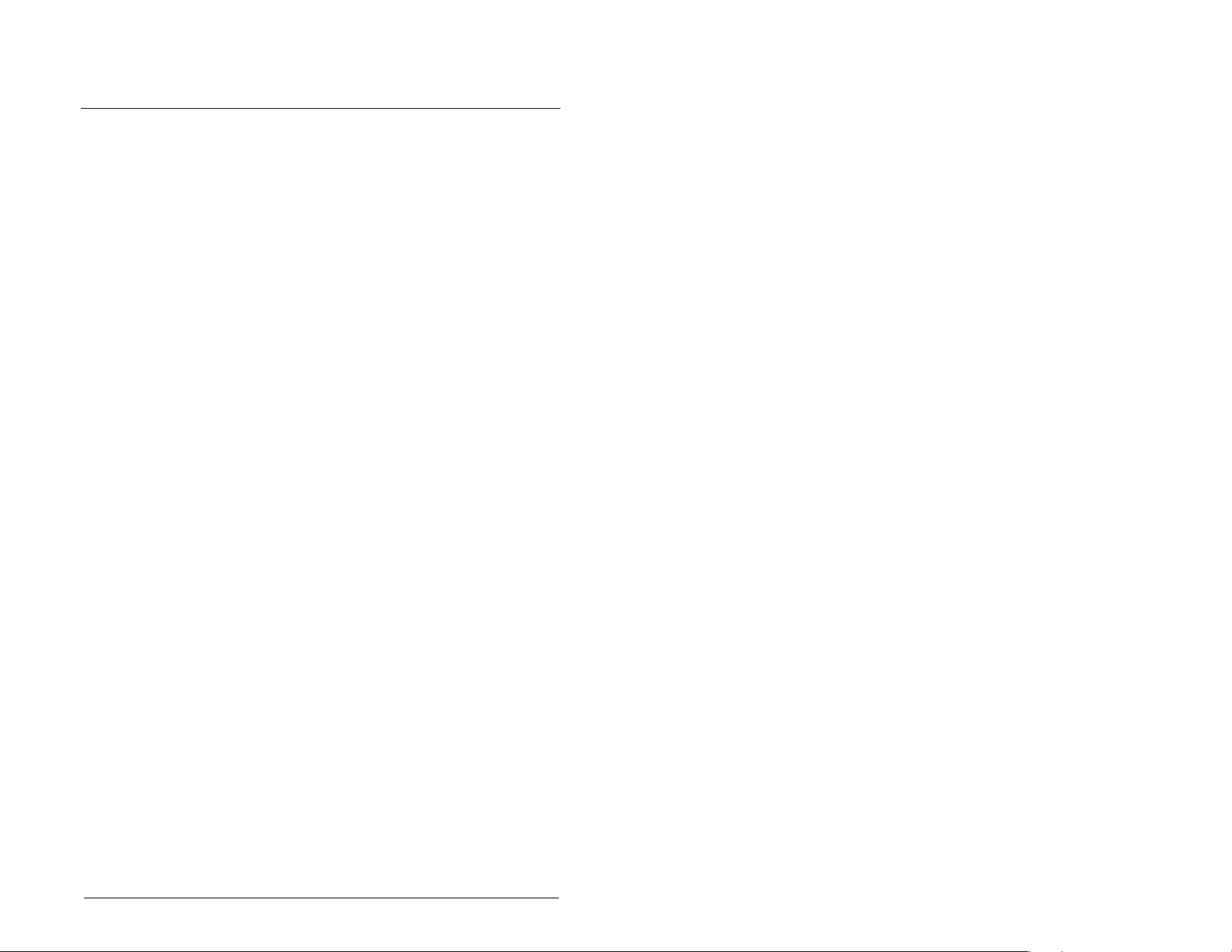

Table 2.3 describes the status indicators shown in figure 2.2.

➊

➋

➌

DRIVE

MS

NET A

NET B

Figure 2.2 – Status Indicators

Table 2.3 – Status Indicator Descriptions

Item Status

Indicator

Status

1

Description

DRIVE Green Normal Operation. The module is properly

connected and is communicating with the

drive.

Flashing

Not used.

Green

MS Green Normal Operation. The module is operational

and is transferring I/O data.

Flashing

Green

Normal Operation. The module is operational

but is not transferring I/O data.

NET A Green Normal Operation. The module is properly

connected and communicating on the network.

Flashing

Not used.

Green

NET B Off Not used for Profibus module.

➊

➋

➌

➍

1. If all status indicators are off, the module is not receiving power. Refer to Chapter 3,

Installing the PROFIBUS Module for installation instructions. For other conditions,

refer to Chapter 9, Troubleshooting the PROFIBUS Module and Network.

Getting Started 2-5

Page 16

2-6 PROFIBUS Communications Module

Page 17

CHAPTER 3

Installing the

PROFIBUS Module

Chapter 3 provides instructions for installing the PROFIBUS module

in a MD65 drive.

3.1 Preparing for an Installation

Before installing the PROFIBUS module, verify that you have all

required equipment. Refer to chapter 2, Getting Started.

3.2 Commissioning the Module

To commission the module, you must set a unique node address

and check the data rate that is used by the network and set in the

GSD-file.

Important: New settings are recognized only when power is

applied to the module. If you change a setting, cycle

power.

ATTENTION: The PROFIBUS module contains

ESD- (Electrostatic Discharge) sensitive parts that

!

Step 1. Set the node address switches as shown in figure 3.1.

The PROFIBUS Node address/Firmware Update State is set

through the use of an 8-bit DIP switch. The low seven bits let you set

a node address and the valid address allows binary coding 1

through 125. New settings of node address are recognized only

when power is applied to the module, cycle power, or a Reset

Module Command. The MSB bit provides write access for the

module flash firmware update. In normal operating state, SW8

should be set to 1.

Installing the PROFIBUS Module 3-1

can be damaged if you do not follow ESD control

procedures. Static control precautions are required

when handling the module. Failure to observe these

precautions could result in damage to equipment.

Page 18

J3

SWAP

J2

Single Drive

Operation

J2

Multi-Drive

Operation

NODE

ADDRESS SWITCHES

2

1

3

4

2

1

3

4

UP = OPEN = 1

Description

5

7

6

8

5

7

6

8

Switches

J4

J1

1

SW1 Least Significant Bit (LSB) of Node Address

SW 2 Bit 1 of Node Address

SW 3 Bit 2 of Node Address

SW 4 Bit 3 of Node Address

SW 5 Bit 4 of Node Address

SW 6 Bit 5 of Node Address

SW 7 Most Significant Bit (MSB) of Node Address

SW 8 SW8 Firmware Update

Figure 3.1 – Setting the Node Address

1. The factory default states of all switches are UP, and have the default

address of 3.

Table 3.1 – SW8 Setting

SW 8 Setting Description

0 Write Access Firmware Update

1 Normal Operating State

3-2 PROFIBUS Communications Module

Page 19

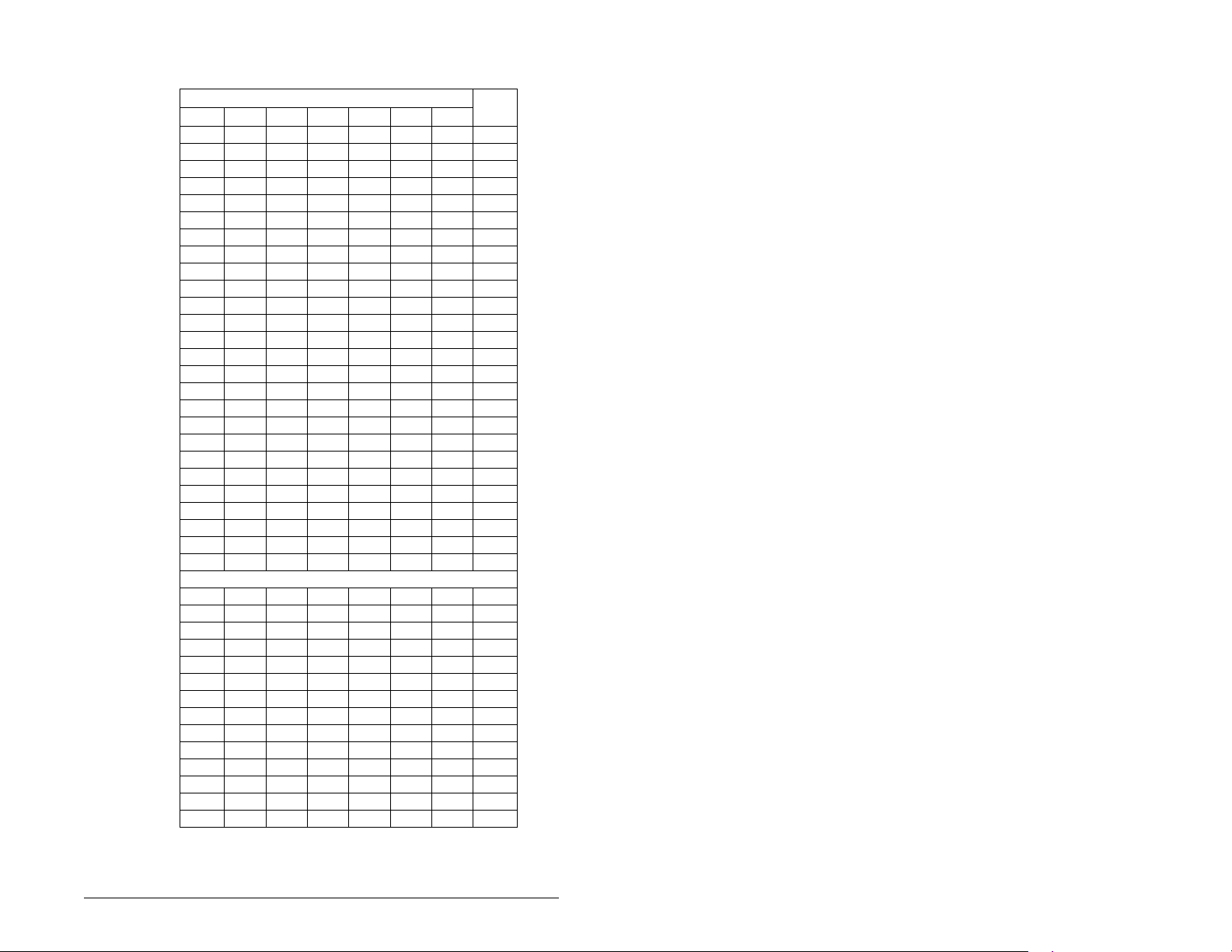

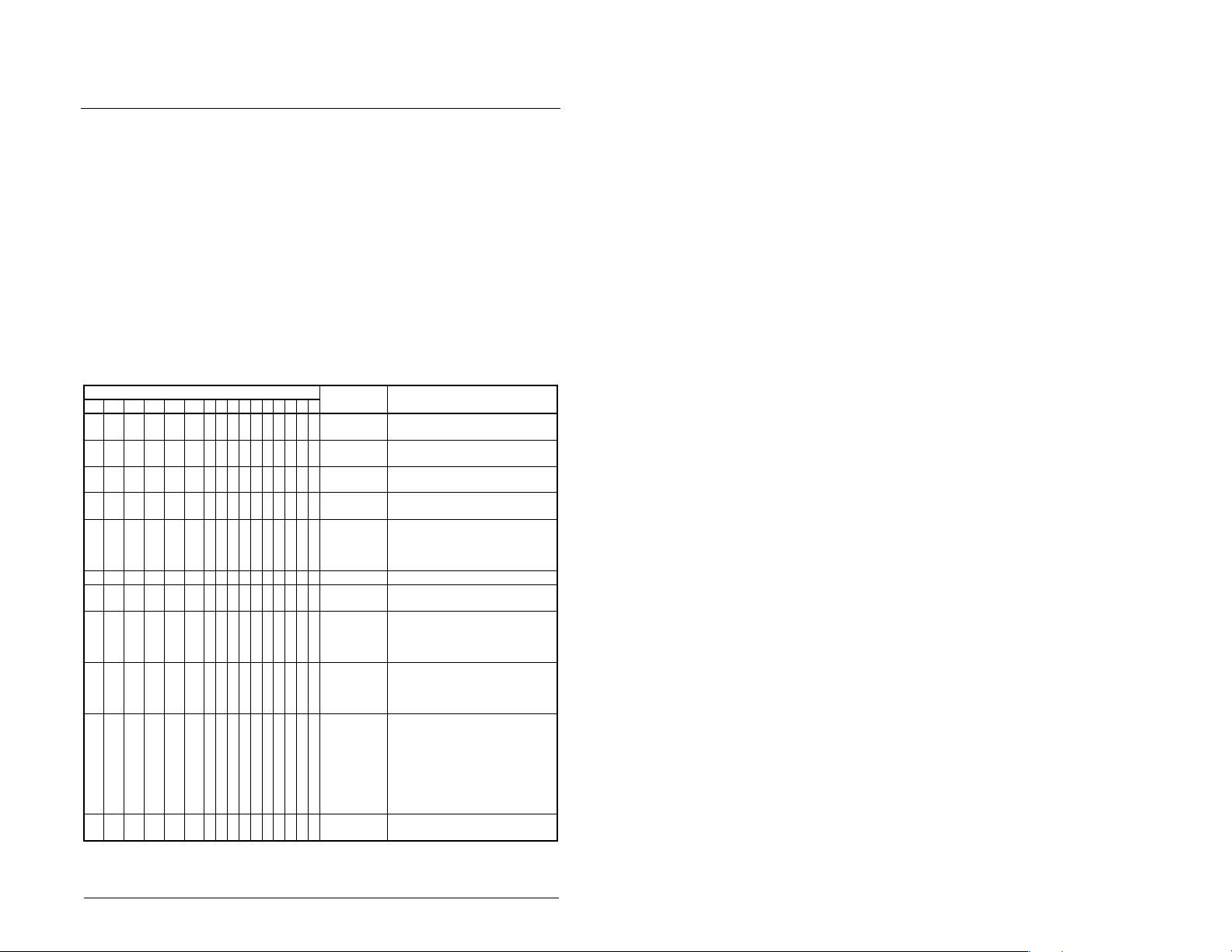

Table 3.2 – Node Address Switch Settings (UP = OPEN = 1)

Switch Setting Node

SW 1 SW 2 SW 3 SW 4 SW 5 SW 6 SW 7 Addr

00000000

10000001

01000002

11000003

00100004

10100005

01100006

11100007

00010008

10010009

010100010

110100011

001100012

101100013

011100014

111100015

000010016

100010017

010010018

110010019

001010020

101010021

011010022

111010023

000110024

100110025

-0000111112

1000111113

0100111114

1100111115

0010111116

1010111117

0110111118

1110111119

0001111120

1001111121

0101111122

1101111123

1101111124

1011111125

Installing the PROFIBUS Module 3-3

Page 20

Step 2. Verify the Network Baud rate, which is set by the network

master and depends on cable length.

The MDCOMM-PBUS module uses the Auto-Baud and

supports the following different data rates: 9.6 kpbs, 19.2

kpbs, 45.45 kpbs, 93.75 kpbs, 187.5kpbs, 500 kpbs, 1.5

Mpbs, 3 Mpbs, 6 Mpbs, and 12 Mpbs.

The Auto-Baud function allows the module to recognize

the current baud rate and sets itself to the transmission

rate by the master automatically. After detecting the

correct baud rate, the baud rate that was found is

monitored continuously. Auto-Baud is always active.

Step 3. Set the Byte Swap jumper J3, which determines the Intel

or Motorola (position SWAP) data format depending on

the corresponding PLC. See Figure 3.1.

Step 4. Verify that the jumper J2 is in position “1X” for Single

Jumper Setting Description

Right position or

jumper missing

Left position Sets the module for Multi-Drive operation mode

Drive operation, or set J2 in “5X” for Multi Drive operation.

Table 3.3 – Jumper Settings

Sets the module for Single drive mode (default

setting) using a single drive connection.

Important:In this mode, connections to multiple

drives must be removed since all

powered and connected hosts will

respond to any message sent by the

module.

using up to 5 different drives. MDI peripherals do

not operate with the modul e in th i s mod e.

3.3 Connecting the Module to the

Network

ATTENTION: The drive may contain high voltages

that can cause injury of death. Remove all power

!

Step 1. Remove power from the drive.

Step 2. Use static control precautions.

Step 3. Remove the drive cover.

3-4 PROFIBUS Communications Module

from the drive, and then verify power has been

removed before installing or removing a PR OFIBUS

module. F ailure to observe th ese precautions co uld

result in severe bodily injury or loss of life.

Page 21

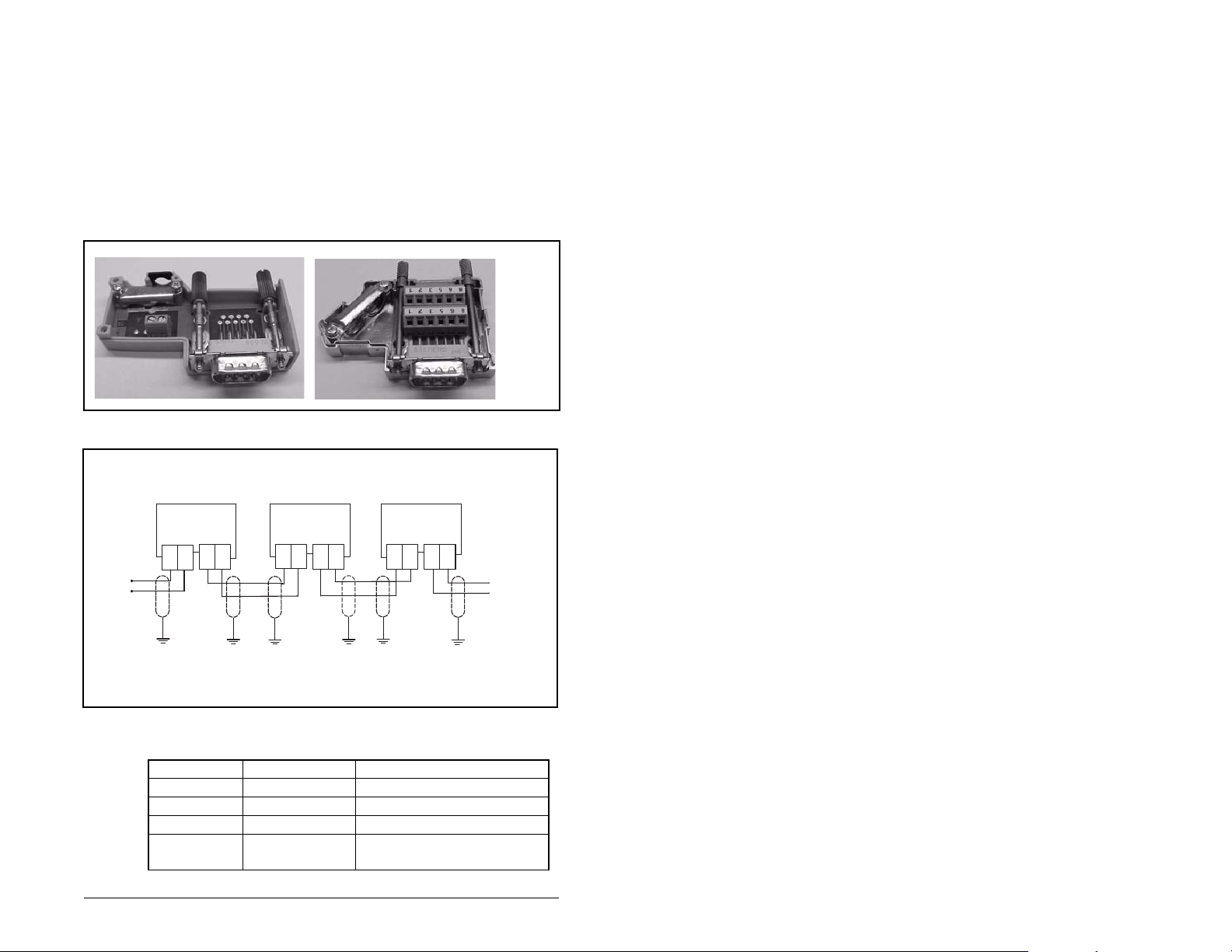

Step 4. Connect a PROFIBUS connector to the cable. Only use

cable that conforms to Profibus cable standards. Belden

#3079A Profibus cable or equivalent is recommended.

Note: PROFIBUS connectors are available from a v ariety

of sources and in various sizes. As such, there may be

mechanical limitations that prohibit the use of some

connectors. Phoenix Subcon Plus M1 (Part # 2761826) or

ERNI PROFIBUS vertical (Node Part # 103658 and

Termination Part # 103659 connectors) are

recommended for use with MD65 and other Reliance

Electric MDI-based drives.

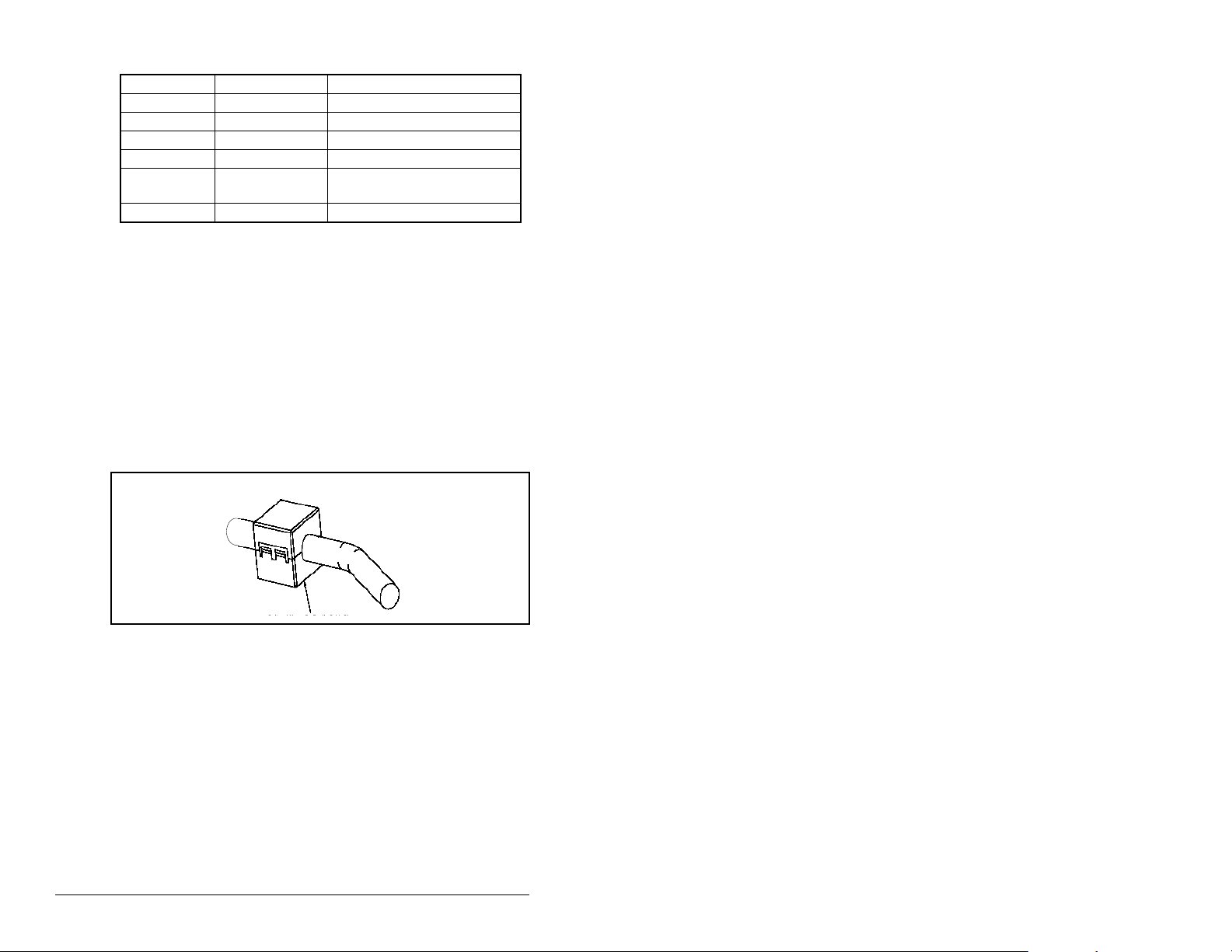

Figure 3.2 – ERNI and Phoenix Subcon Connectors

A

B

B

A

B

A

A

B

AB

A

B

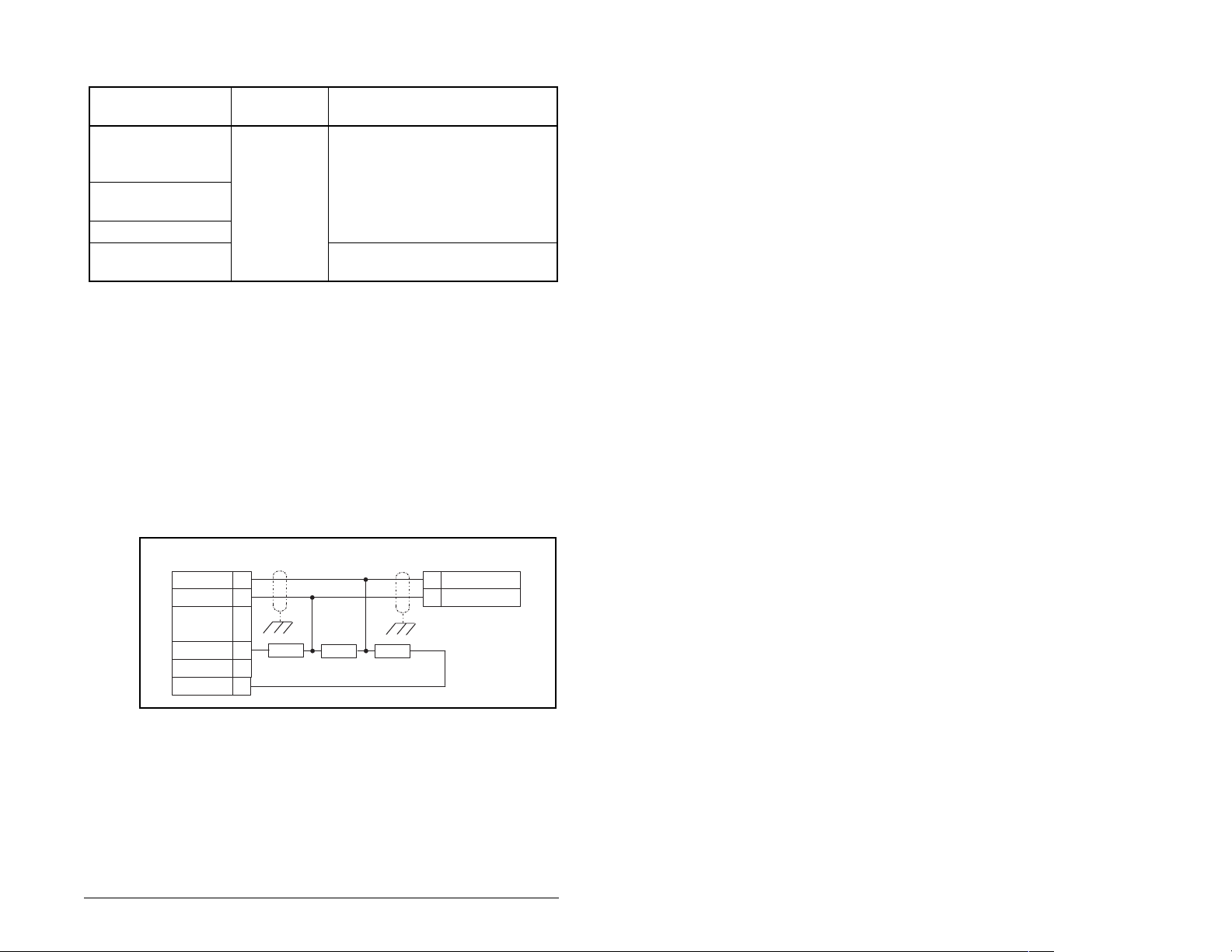

Figure 3.3 – Network Wiring Diagram

Table 3.4 – MDCOMM-PBUS DB-9 Pin Layout

Terminal Signal Function

Housing Shield

1 Not connected

2 Not connected

3 B-LINE Positive RxD/TxD, according

to RS485 specification

Installing the PROFIBUS Module 3-5

Page 22

Table 3.4 – MDCOMM-PBUS DB-9 Pin Layout (Continued)

Terminal Signal Function

4RTS

5 GND BUS Isolated GND from bus

6 +5V BUS Isolated +5V from bus

7 Not connected

8 A-LINE Negative RxD/TxD according

to RS485 specification

9 Not connected

Step 5. Connect the PROFIBUS cab le to the module, secure it

with the two screws on the connector, and route it through

the bottom of the MD65 drive. See figure 3.3.

Note: The screws on some connectors tie the PROFIBUS

cable ground/shield to the metal of the socket. In some

cases, PROFIBUS will not operate correctly without this

connector.

Keep communication wiring away from high noise

sources such as motor cables.

Step 6. Depending on the switching frequency of the MD65, it is

optional to use the ferrite cable clamp around the

communication cables next to the D-Sub connector, to

reduce high frequency emission. See figure 3.4.

Figure 3.4 – Optional Clamp-On Ferrite Cable Clamp

3-6 PROFIBUS Communications Module

Page 23

To meet the requirements of EN55011 Class A or B, the conditions

listed below must be satisfied.

Switching

Frequency of MD65

EN55011

Class A EN55011 Class B

4 kHz Use one ferrite Ferrishield (part No.

HI28B2039) or Fair-Rite (part No.

0443164151)

6 kHz No ferrite

required

8 kHz

16 kHz Use three clip ferrites TDK, type

ZCAT 3035-1330

Note: For the conditions to satisfy the essential

requirements for CE compliance on MD65 drives. please

refer to the MD65 manual, D2-3519.

In applications where first environment, unrestricted

distribution is requested (EN55011 group 1, class B), the

installation requires a shielded enclosure.

3.4 Terminating the Network

The first and last node on the PROFIBUS network needs to be

terminated by using a PROFIBUS connector with terminating

resistors. See figure 3.5.

R x D / T x D - N 8

R x D / T x D - P 3

V c c 6

3 9 0 2 2 0 3 9 0 O h m

G N D 5

Figure 3.5 – Connection for Terminating Resistors

A

B

8 R x D / T x D - N

3 R x D / T x D - P

Some connector manufacturers offer standard terminating

connectors, such as the yellow ERNI PROFIBUS termination

vertical connector (Part # 103659). Standard PROFIBUS node

connectors, such as the Phoenix Subcon Plus M1 (Part #2761826),

can be configured as a terminating connector by adding resistors.

Installing the PROFIBUS Module 3-7

Page 24

3.5 Connecting the Module to the Drive

Step 1. Remove power from the drive.

Step 2. Use static control precautions.

Step 3. Mount the module on the required special dr ive cover

(ordered separately).

• C Frame: Use the module screw to secure the module to

the cover.

• B F rame: Disregard the screw and snap the module in

place.

Important:For C Frame drives , tighten the module’s low er left screw

Step 4. Connect the Internal Interface cable to the MDI port on

to ground the module. For B Frame drives, install the

special drive cover onto the drive using both cover

fasteners to ground the module.

the drive and then to the MDI connector on the module.

3-8 PROFIBUS Communications Module

Page 25

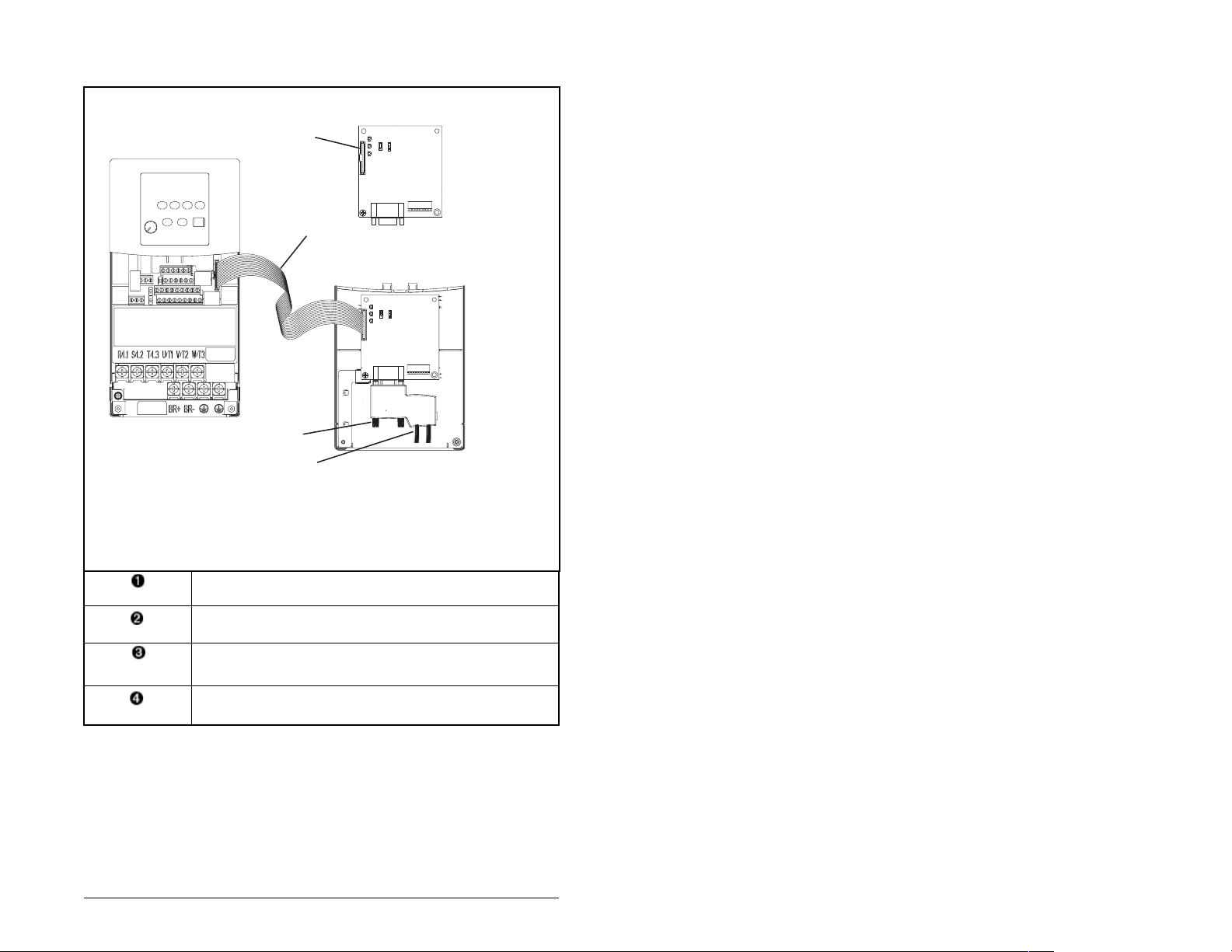

Profibus Module

➊

➋

MD65 Drive

B and C Frames

(cover removed)

➍

➌

Back of Cover

Back of Required Special Drive Cover

(ordered separately):

Part Number 6MD-COMMCVRB for B Frame

Part Number 6MD-COMMCVRC for C Frame

MDI Connector

15.24 cm (6 in) Internal Interface cable

PROFIBUS cable

Retaining screws

Figure 3.6 – MDI Ports and Internal Interface Cables

Installing the PROFIBUS Module 3-9

Page 26

MD65 Drive

B and C Frames

(cover removed)

Ground for C Frame Drives

For B Frame drives, the lower left module

screw does not ground the module. To

ground the module, install the special drive

cover onto the drive using both cover fasteners.

Figure 3.7 – Mounting the Adapter

3.6 Applying Power

ATTENTION: Unpredictable operation may occur if

parameter settings and switch settings are not

!

compatible with your application. V erify that settings

are compatible with your application before applying

power to the drive. Failure to observe these

precautions could result in severe bodily injury or

loss of life.

Module Mounted

on Back of Cover

Step 1. Install the required special cover on the drive. The status

indicators can be viewed on the front of the drive after

power has been applied.

Step 2. Ensure that the module will have a unique address on the

network. If a new address is needed, reset its switches.

See section 3.2, Commissioning the Module.

3-10 PROFIBUS Communications Module

Page 27

Step 3. Apply power to the drive. The module receives its power

from the connected drive and the network. When you

apply power to the product and network for the first time,

the status indicators should be green after an

initialization. If the status indicators are red, there is a

problem. Refer to chapter 8, Troubleshooting the

PROFIBUS Module and Network.

Step 4. Apply power to the master device and other devices on

the network.

Installing the PROFIBUS Module 3-11

Page 28

Installing the PROFIBUS Module 3-12

Page 29

CHAPTER 4

Configuring the

PROFIBUS Module

Chapter 4 provides instructions and information for setting the

parameters in the module.

For a complete list of parameters, refer to Appendix B, PROFIBUS

Module Parameters. For definitions of terms in this chapter, refer to

the Glossary.

4.1 Configuration Tools

The PROFIBUS module stores parameters and other information in

its own non-volatile memory. Therefore, you must access the

module to view and edit its parameters. Table 4.1 lists the tools that

can be used to access the module parameters.

Table 4.1 – Configuration Tools

Tool Refer to:

VS Utilities Software VS Utilities online help

LCD OIM Section 4.2

Configuring the PROFIBUS Module 4-1

Page 30

4.2 Using the LCD OIM to Configure the

Module

Use the procedure in figure 4.1 to access the parameters on the

PROFIBUS module using the LCD OIM. If you are unfamiliar with

the operation of the LCD OIM, refer to the MD65 AC Drive User

Manual (D2-3519) for more information.

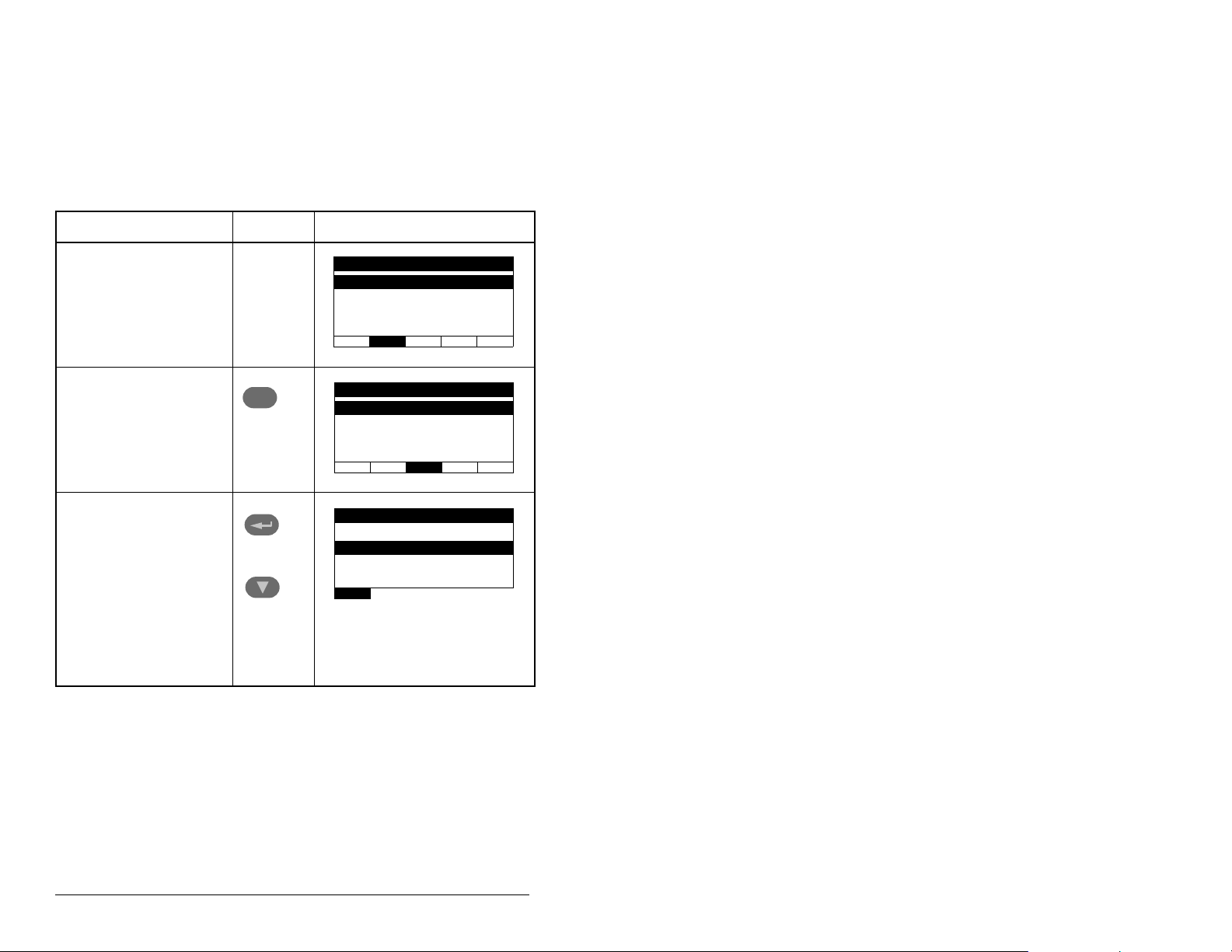

Table 4.2 – Using the LCD OIM or CopyCat Keypad

Step Key(s) Example Screens

1. Po wer up the drive.

Plug the OIM or

CopyCat Keypad into

the drive. The

Parameters menu for

the drive will be

displayed.

2. Press Sel key once to

display the Device

Select menu.

3. Press Enter to display

the MDI Devices

menu. Press Down

Arrow to scroll to

MDCOMM-PBUS.

Sel

and

Parameters

Groups

Linear List

Changed Params

DIAG PA R AM DSEL MEM SEL X

Device Selected

MDI Devices

DIAG PARAM DSEL MEM SEL X

MDI Devices

MD65

MDCOMM-PBUS

4-2 PROFIBUS Communications Module

Page 31

Table 4.2 – Using the LCD OIM or CopyCat Keypad

Step Key(s) Example Screens

4. Press Enter to select

the Profibus module.

The Parameters menu

for the module will be

Parameters

Linear List

Changed Params

displayed.

DIAG PA R AM DSEL MEM SEL X

5. Press Enter to access

the parameters. Edit

the module parameters

using the same

techniques that you

use to edit parameters.

Mode RO

Parameter: #

Single Drive 0

VAL UE LIMITS SEL X

001

4.3 Using V*S Utilities via MDCOMM-232

V*S Utilities can be used to access parameters in the module. Use

V*S Utilities (version 4.0) and the MDCOMM-232 (version 2.001 or

higher). For more information on V*S Utilities, see instruction

manual D2-3488.

Step 1. Connect the MDCOMM-232 to the MD65 and to a PC

Step 2. Open V*S Utilities and press the “Connect Serial” button

serial COM port, then apply power to the MD65 drive.

in the toolbar. In the left window under “Devices,” “Node 1:

MD65” appears. There are three configurable devices: the

MD65, the Profibus module and the serial module

MDCOMM-232.

Figure 4.1 – Using V*S Utilities

Configuring the PROFIBUS Module 4-3

Page 32

4.4 Setting the Node Address

The PROFIBUS Node address/Firmware Update State is set

through the use of an 8-bit DIP switch. The low seven bits let you set

a node address and the valid address allows binary coding 1

through 125. New settings of node address are recognized only

when power is applied to the module, cycle power, or a Reset

Module Command. The MSB bit provides write access for the

module flash firmware update. In normal operating state, SW8

should be set to 1.

J3

SWAP

J2

Single Drive

Operation

J2

Multi-Drive

Operation

J4

Switches

J1

1

NODE

ADDRESS SWITCHES

2

1

3

4

2

1

3

4

UP = OPEN = 1

Description

5

7

6

8

5

7

6

8

SW1 Least Significant Bit (LSB) of Node Address

SW 2 Bit 1 of Node Address

SW 3 Bit 2 of Node Address

SW 4 Bit 3 of Node Address

SW 5 Bit 4 of Node Address

SW 6 Bit 5 of Node Address

SW 7 Most Significant Bit (MSB) of Node Address

SW 8 SW8 Firmware Update

Figure 4.2 – Setting the Node Address

1. The factory default states of all stitches are UP. The fault address is 3.

SW 8 Setting Description

0 Write Access Firmware Update

1 Normal Operating State

Refer to section 3.2, Commissioning the Module, for more

information.

4-4 PROFIBUS Communications Module

Page 33

4.5 Setting the I/O Configuration

The I/O configuration determines the number of drives that will be

represented on the network as one node by the module. If the Mode

Jumper is set to the Single mode position, only one drive is

represented by the module and MDI I/O Cfg (parameter 11) has no

effect. If the Mode Jumper J2 is set to the Multi-Drive position, up to

five drives can be represented as one node by the module.

Step 1. Set the value in MDI I/O Cfg (parameter 11):

MDI I/O Cfg

Para meter : #

Drive 0 0

VAL UE LIMITS SEL X

Drive 0 is the MD65 with the MDCOMM-PBUS module installed.

Drives 0-1 through 0-4 are MD65 and/or MD60 drives that multidrop to the RJ45 (RS-485) port on Drive 0. Refer to Chapter 8,

Using Multi-Drive Mode, for more information.

Step 2. If a drive is enabled, configure the parameters in the drive

to accept the Logic Command and Reference from the

module. For example, set Start Source (parameter 36)

and Speed Reference (parameter 38) in a MD65 drive to

“MDI Port 5.”

Step 3. Reset the module. Refer to section 4.6.2, Resetting the

Module.

Value Description

011

0 Drive 0 (Default) ✓✓

1Drives 0-1 ✓

2Drives 0-2 ✓

3Drives 0-3 ✓

4Drives 0-4 ✓

Mode Jumper Position

Single Multi-Drive

The module is ready to receive I/O from the master (i.e., scanner).

You must now configure the scanner to recognize and transmit I/O

to the module. Refer to chapter 5, Configuring the PROFIBUS

Scanner, for more information.

Configuring the PROFIBUS Module 4-5

Page 34

4.6 Setting a Fault Action

ATTENTION: Comm Flt Action (parameter 9) and

Idle Flt Action (parameter 10) let you determine the

!

By default, when communications are disrupted (for example, a

cable is disconnected) or the master is idle, the drive responds by

faulting if it is using I/O from the network. You can configure a

different response to communication disruptions using Comm Flt

Action (parameter 9) and a different response to an idle scanner

using Idle Flt Action (parameter 10).

4.6.1 Changing the Fault Action

Set the values of Comm Flt Action (parameter 9) and Idle Flt Action

(parameter 10) to the desired responses as shown in table 4.3.

Table 4.3 – Selections for Drive Response to Communication Fault

Value Action Description

0 Fault (default) The drive is faulted and stopped (Default).

1 Stop The drive is stopped, but not faulted.

2 Zero Data The drive is sent 0 for output data after a

3 Hold Last The drive continues in its present state after a

4 Send Flt Cfg The drive is sent the data that you set in the

action of the module and connected drive if

communications are disrupted or the scanner is idle.

By default, these parameters fault the drive. You can

set these parameters so that the drive continues to

run. Precautions should be taken to ensure that the

settings of these parameters do not create a risk of

injury or equipment damage.

communications disruption. This does not

command a stop.

communications disruption.

fault configuration parameters 13 and 14 (Flt

Cfg Logic and Flt Cfg Ref).

Comm Flt Action

Para meter : #

Faul t 0

VAL UE LIMITS SEL X

Figure 4.3 – Fault Action Screens on an LCD OIM

009

Idle Flt Action

Para meter : #

Fault 0

VALU E LIMITS SEL X

010

4-6 PROFIBUS Communications Module

Page 35

Changes to these parameters take effect immediately. A reset is not

required.

If Multi-Drive mode is used, the same fault action is used by the

module for all of the drives it controls (Drive 0, Drives 0-1 to Drives

0-4).

4.6.2 Setting the Fault Configuration Parameters

If you set module Comm Flt Action (parameter 9) or module Idle Flt

Action (parameter 10) to “Send Flt Cfg,” the values in the

parameters shown in table 4.4 are sent to the drive after a

communications fault and/or idle fault occurs. You must set these

parameters to values required by your application.

Table 4.4 – Fault Configuration Parameters

Number Name Description

13 Flt Cfg Logic A 16-bit value sent to the drive

for Logic Command

14 Flt Cfg Ref A 16-b it value sent to the dr ive

as a Reference

Changes to these parameters take effect immediately. A reset is not

required.

4.6.3 Resetting the Module

Changes to switch settings or some module parameters require that

you reset the module before the new settings take effect. You can

reset the module by cycling po wer to the drive or by using Rese t

Module (parameter 8).

ATTENTION: If the module is transmitting control

I/O to the drive, the drive may fault when you reset

!

Configuring the PROFIBUS Module 4-7

the module. Determine how your drive will respond

before resetting a connected module. Failure to

observe this precaution could result in bodily injury

or damage to equipment.

Page 36

Set parameter 8 (Reset Module) to “Reset Module.” See figure 4.4.

Reset Module

Param ete r: #

Ready 0

VAL UE LIMITS SEL X

Figure 4.4 – Reset Screen on an LCD OIM

Value Description

008

0 Ready (Default)

1 Reset Module

2 Set Defaults

When you enter 1 (“Reset Module”), the module will be

immediately reset. When you enter 2 (“Set Defaults”), the module

will set all module parameters to their factory-default settings. The

value of this parameter will be restored to 0 (“Ready”) after the

module is reset.

4.7 Viewing the Module Configuration

The parameters in table 4.5 provide information about how the

module is configured. You can view these parameters at any time.

Table 4.5 – Module Configuration Status Parameters

No. Name Description

01 Mode Displays the Single or Multi-Drive operating mode selected

with the jumper J2 on the module.

Values

0 = Single drive operation

1 = Multi-Drive operation

04 P-DP Addr

Actual

05 P-DP Rate

Actual

12 MDI I/O

Actual

PROFIBUS Node Address actually used by the module.

PROFIBUS actual operating data rate.

Displays the Drives that are active in the Multi-Drive mode:

Bit Values

0 = Drive 0 Active

1 = Drives 0-1 Active

2 = Drives 0-2 Active

3 = Drives 0-3 Active

4 = Drives 0-4 Active

4-8 PROFIBUS Communications Module

Page 37

CHAPTER 5

Configuring the

PROFIBUS Scanner

PROFIBUS scanners are available from several manufacturers,

including SST. SST PROFIBUS scanners come with a software tool

for configuring the scanner (see figure 5.2).

Chapter 5 provides instructions on how to utilize the SST

PROFIBUS configuration software tool to:

• Install the MDCOMM-PBUS GSD file in the software tool library.

• Configure the SST-PFB-SLC PROFIBUS scanner.

Important:The configuration of other manufacturer’s scanners may

differ significantly from this example. Please ref er to y our

scanner manufacturer’s documentation.

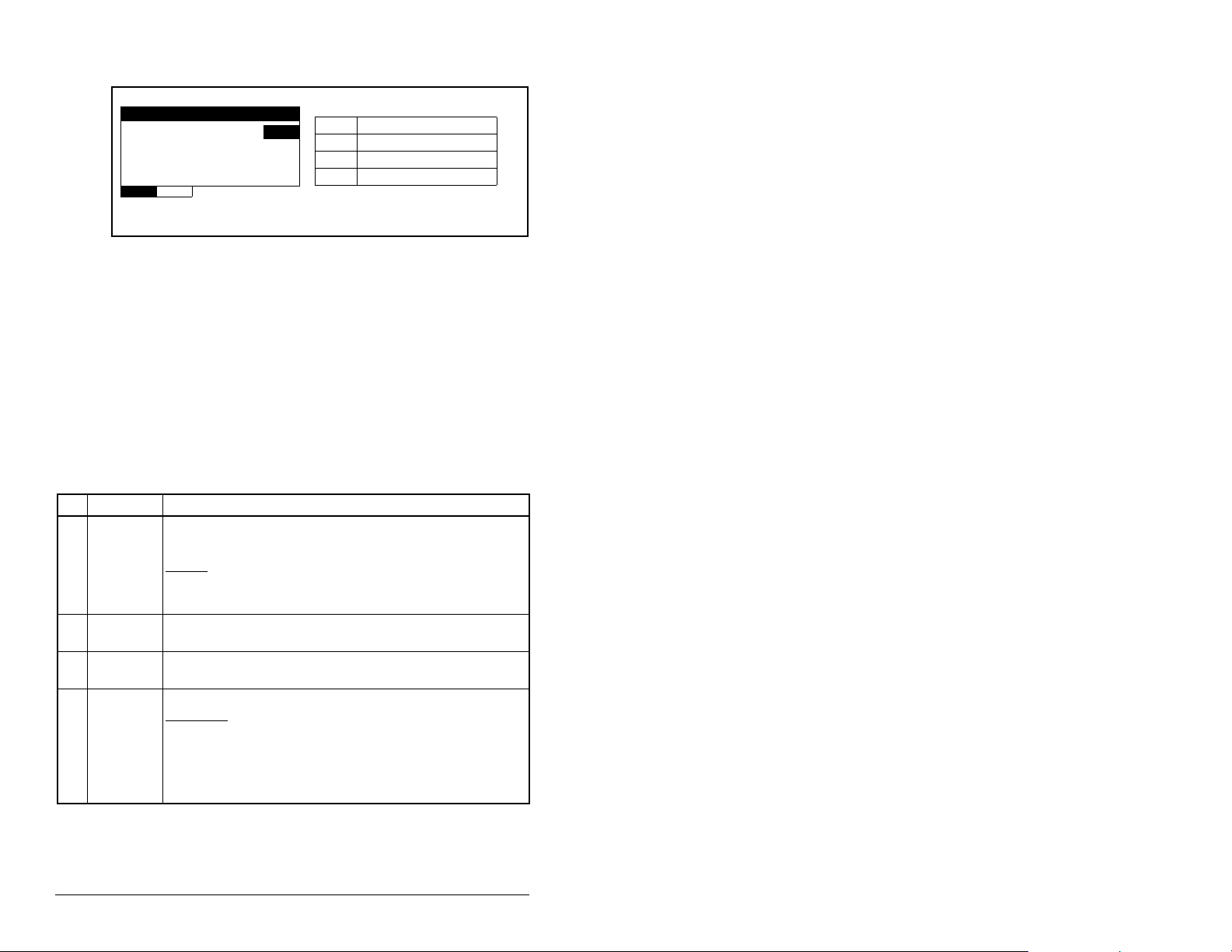

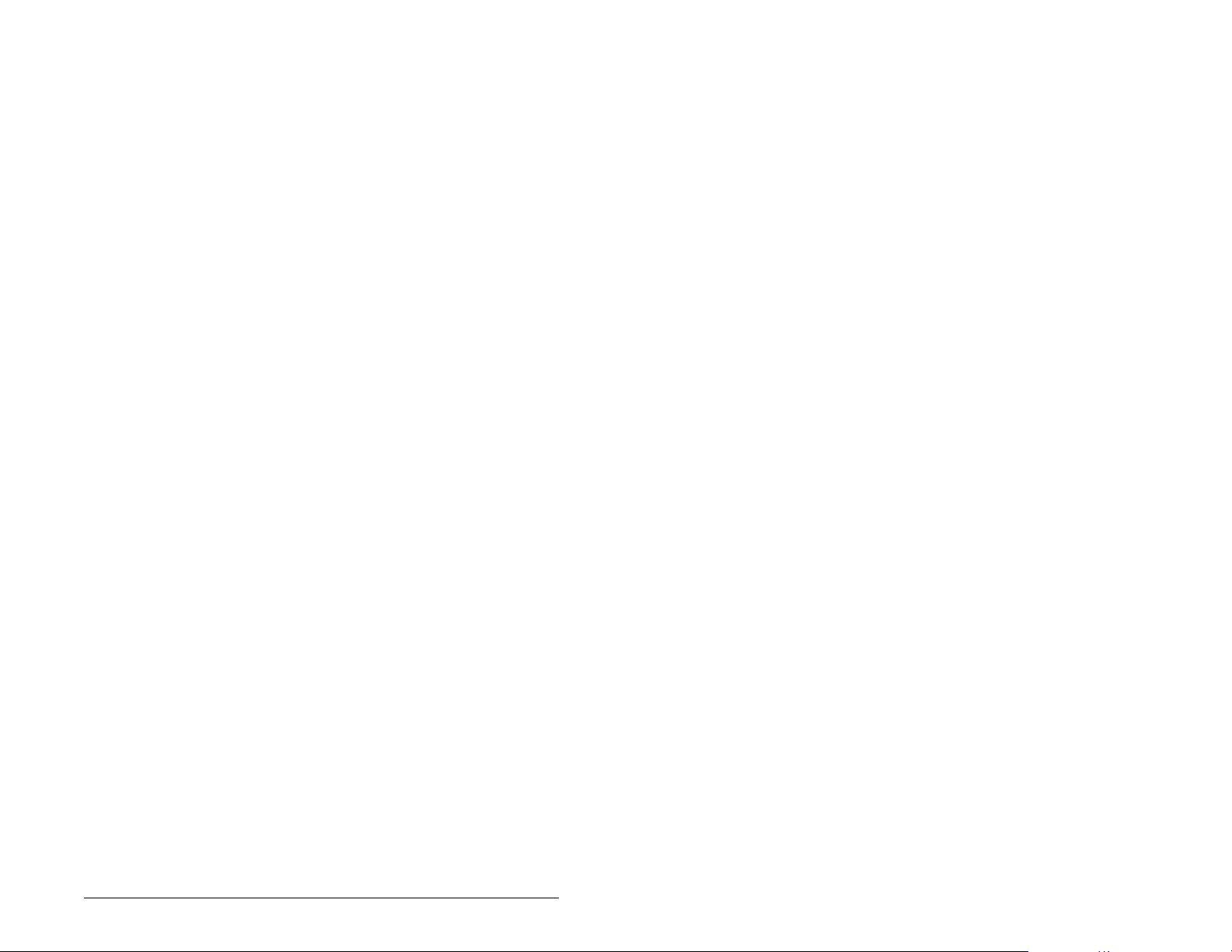

5.1 Configuring a Simple Network: An

Example

In this example, we will be configuring two MD65 drives to be

Station 1 and Station 2 on a PROFIBUS network. This will be the

configuration used throughout the manual, including the ladder

examples. Apart from the node address and scanner mapping, they

will have identical configurations. This chapter describes the steps

to configure a simple network like the network in figure 5.1.

Configuring the PROFIBUS Scanner 5-1

Page 38

Station 0

n

COMM

LED

SYS LED

Config Port

Front Label

PROFIBUS Port

MD65

Station 1

Figure 5.1 – Example PROFIBUS Network

MD65

Station 2

5.2 SST Profibus Configuration Software

Tool

SST Profibus Scanners come with a software tool for configuring

the scanner. See figure 5.2.

Device

Library

window

Online

Browse

window

Network

Configuratio

window

Figure 5.2 – SST PROFIBUS Configuration Software Tool

5-2 PROFIBUS Communications Module

Page 39

5.3 Installing the MDCOMM-PBUS GSD

File in the Software Tool Library

GSD files are used by software tools to configure the network, in

other words, to map and define the I/O in a PROFIBUS scanner. A

GSD file is required for each type of module on the network.

For example: The MDCOMM-PBUS GSD file is “R_E_07FF.gsd”

and a copy of the file is provided on a floppy disk with each

MDCOMM-PBUS PROFIBUS module. The file can also be

downloaded from the Internet by going to: www.reliance.com.

Follow the steps outlined below only when a new GSD file needs to

be added to the SST PROFIBUS Configuration Software Tool.

Typically, this is only done once, after the software tool is initially

installed or if configuring a MDCOMM-PBUS on the network for the

very first time with this software tool.

The software tool comes with standard data files as shown in figure

5.3. Additional data files, such as the MDCOMM-PBUS GSD file,

will need to be added to configure the MDCOMM-PBUS in the

scanner.

Figure 5.3 – Standard Data Files

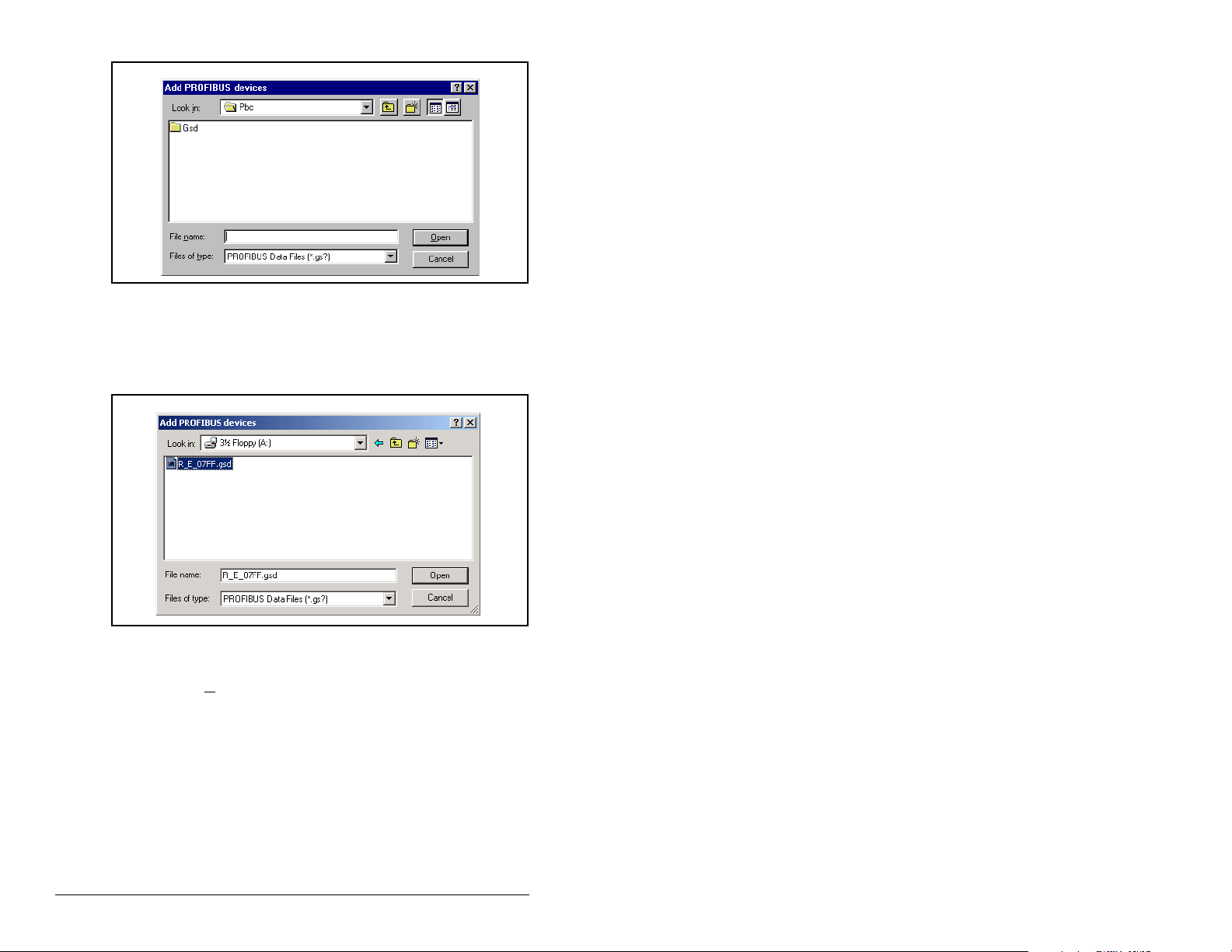

Step 1. Click on the “New Device” icon to add GSD files to

the software library tool.

Step 2. An “Add PROFIBUS devices” applet window will appear

Configuring the PROFIBUS Scanner 5-3

(see figure 5.4). Prompts for the location of the

PROFIBUS data files to be added to the library will follow.

Page 40

Figure 5.4 – Add PROFIBUS Devices Applet Window

Step 3. Find the directory location of the data file(s) you wish to

add (typically, the source location is a floppy disk in drive

A:). “R_E_07FF.gsd” is the GSD file for the

MDCOMM-PBUS as shown in figure 5.5.

Figure 5.5 – Adding the GSD File for the RECOMM-PBUS

Step 4. Select “R_E_077FF.gsd” for the MDCOMM-PBUS and

click O

pen.

5-4 PROFIBUS Communications Module

Page 41

Step 5. Click on the (+) sign of the Slaves folder as shown in

The software tool will automatically create a Reliance Electric

sub-folder (in the Slaves folder) if it does not already exist. The

MDCOMM-PBUS is now shown in the library and the software tool

is now ready to configure a MDCOMM-PBUS on a PROFIBUS

network.

figure 5.6.

Figure 5.6 – Masters/Slaves Library Window

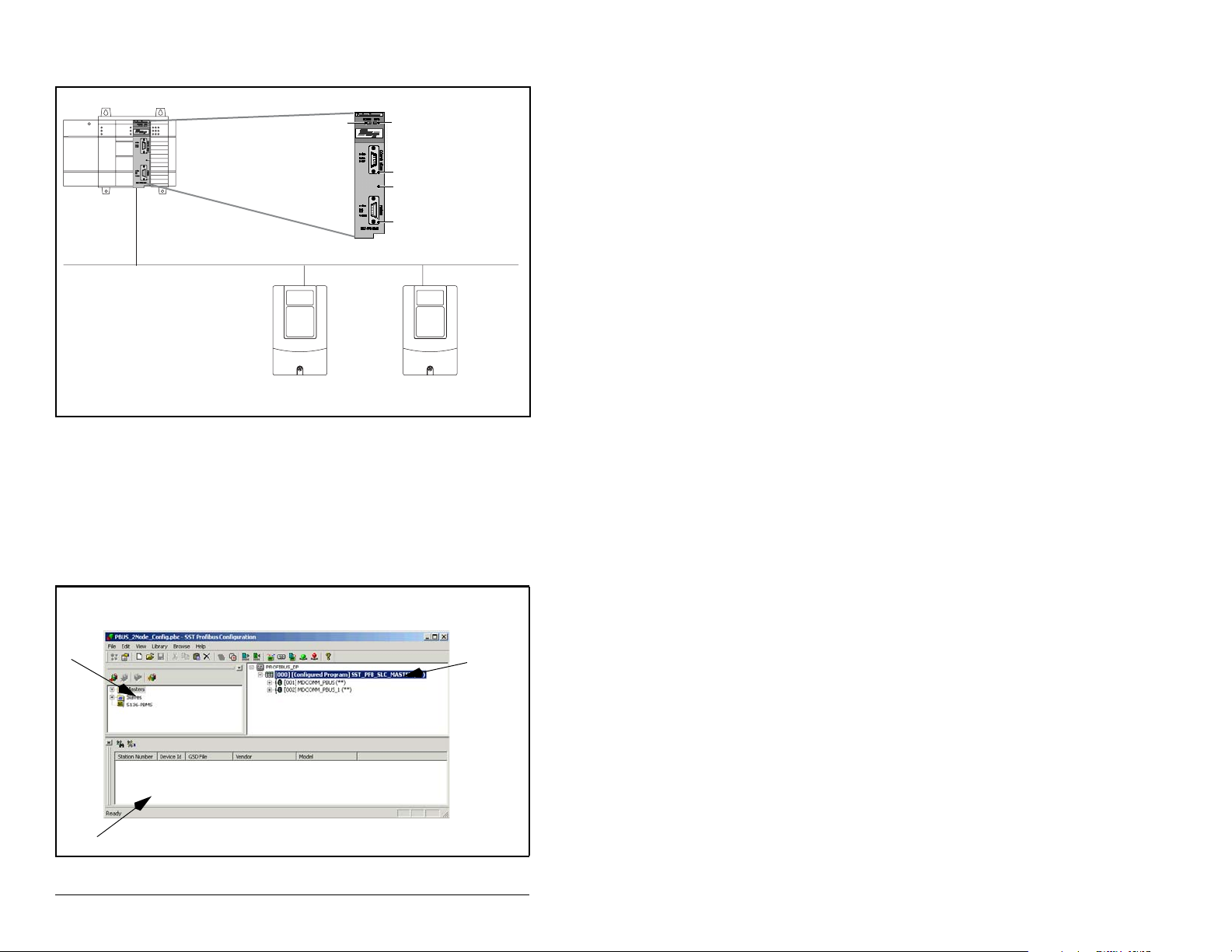

5.4 Configuring the SST-PFB-SLC

PROFIBUS Scanner

The following steps are performed to configure the SST-PFB-SLC

scanner using the SST PROFIBUS Configuration Software Tool. In

our example, the PROFIBUS network will consist of a SLC master

and two MD65 drives working in Single drive mode. The

configuration example is as follows:

• Drive 0: Ctrl/Stat & Ref/Fdbk enabled - Parameter Access

enabled

• Drive 1: Ctrl/Stat & Ref/Fdbk enabled - Parameter Access

enabled

The SLC processor must be in Program mode to configure the

scanner.

Step 1. Click on the (+) sign of the Masters folder in the Library

Configuring the PROFIBUS Scanner 5-5

window to open the SST sub-folder. A v ailable Profib us DP

masters are displayed in this sub-fold er.

Page 42

Step 2. Click on the (+) sign of the Slaves folder in the Library

window and the Reliance Electric sub-folder to display

the available Profibus DP slaves or the RECOMM-PBUS

slave. Refer to figure 5.6.

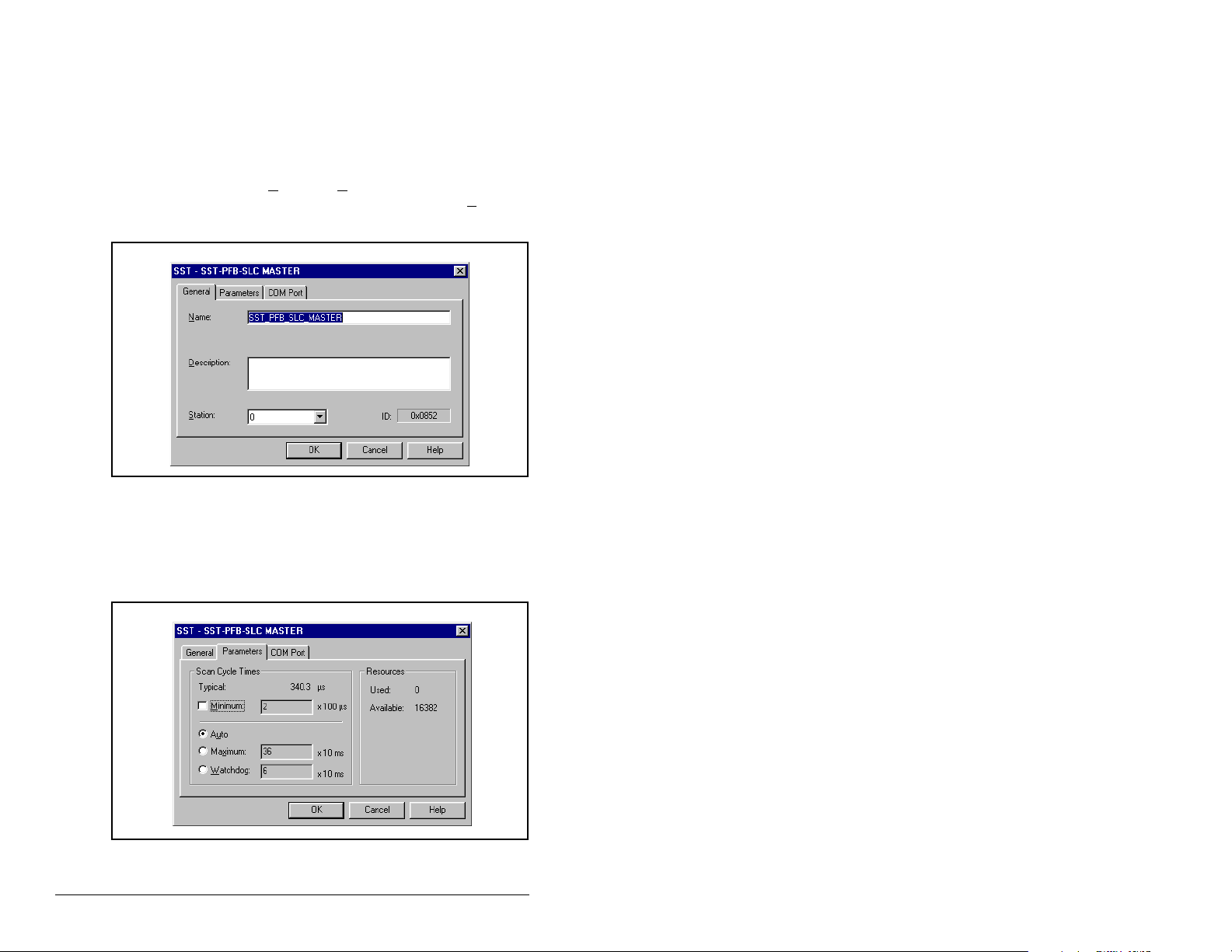

Step 3. Double-click the SST-PFB-SLC MASTER in the Masters

folder in the Library window to add the scanner to the

network.

Step 4. A user-defined N

the scanner. In our example, the scanner will be S

ame and Description can be given to

tation 0

on the network, as shown in figure 5.7.

Figure 5.7 – SST-SST-PFB-SLC Master (General) Dialog Box

Step 5. Click on the Parameters tab to view the Scan Cycle

Times.

In our example, use the default settings as shown in

figure 5.8.

Figure 5.8 – Scan Cycle Times Dialog Box

5-6 PROFIBUS Communications Module

Page 43

Connection and Baud Rate settings configure how the software tool

will communicate with the CONFIG RS232 port on the scanne r.

Step 6. Click on the COM Port tab.

Step 7. Accept the settings in our example (COM1 on the PC at

115200 bps baud rate), as shown in figure 5.9.

Figure 5.9 – COM Port Default Settings

Step 8. The scanner will appear in the network window as shown

in figure 5.10. Double-click on the scanner in the network

window.

Figure 5.10 – Scanner Network Window

Step 9. Double-click on the MDCOMM-PBUS listed in the

Reliance Electric library folder. A user-defined N

D

escription can be given to this MDCOMM-PBUS.

Reliance Electric RECOMM-PBUS

In our example, this device will be S

tation 1 on the network. Other

ame and

stations may be chosen by using the arrow to display a drop-down

list in the S

Configuring the PROFIBUS Scanner 5-7

tation window.

Page 44

Figure 5.11 – Reliance Electric Library Dialog Window

Logic Command / Status, Reference / Feedback, Datalinks and

Parameter Access (explicit messaging) modules are added using

the Modules tab.

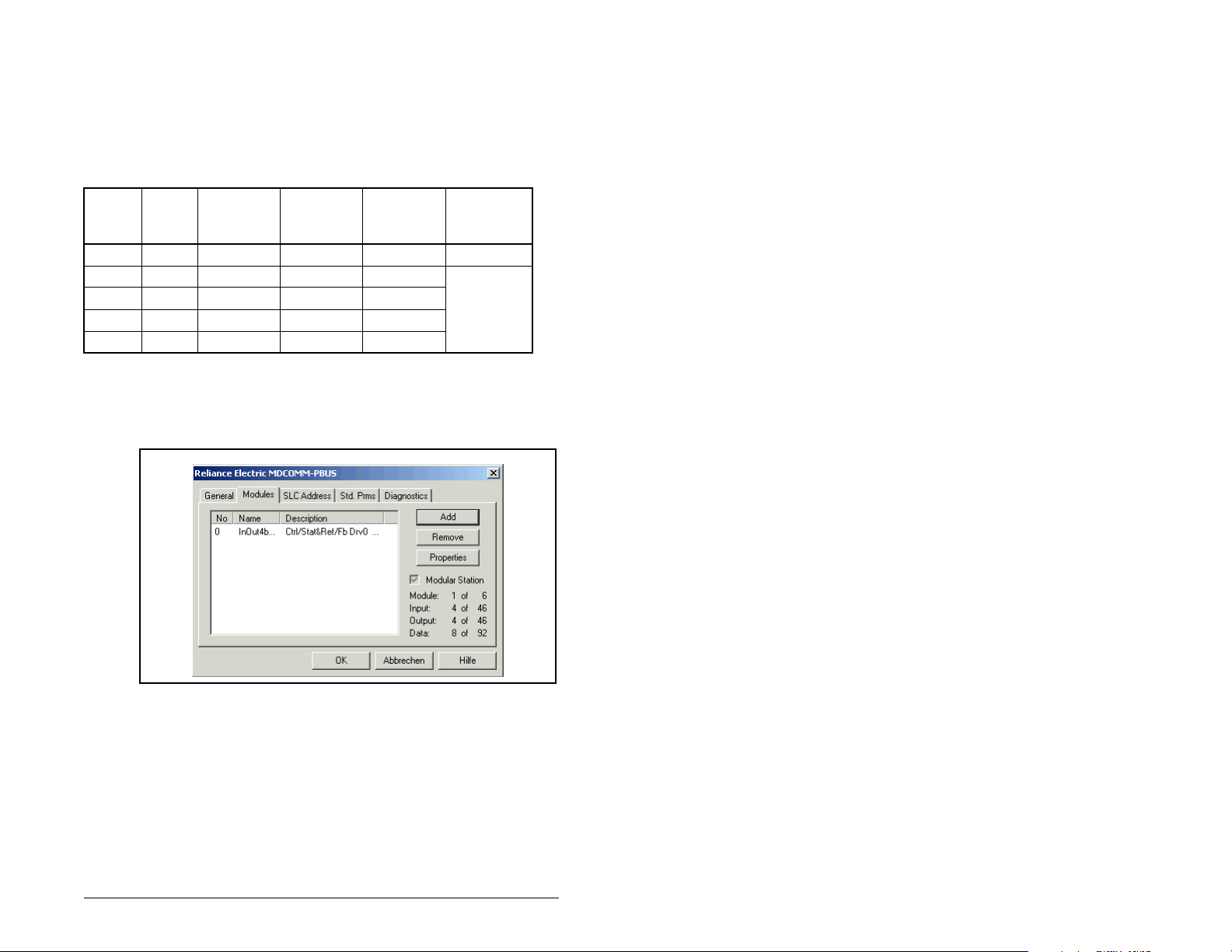

Step 10. Click on the Modules tab. Click A

dd to view the choice of

modules.

Figure 5.12 – Available Modules: Ctrl/Stat & Ref/Fdbk (2x2Bytes) Window

5-8 PROFIBUS Communications Module

Page 45

In our example, Station 1 will be controlled using Logic Command /

Status and Reference / Feedback. The Parameter Access will also

be used. Because the Mode Jumper J2 on the module is set to “1X”

for Single Drive (default) and MDI I/O Cfg (parameter 11) is set to

Drive 0. Logic Command/Reference uses 4 bytes and Logic

Status/Feedback uses 4 bytes.

Table 5.1 – Input/Output Size Configurations

Logic

Input

Size

Output

Size

44

88

12 12

16 16

20 20

Command/

Feedback

✔✔Drive 0 Single

✔✔Drives 0-1 Multi-Drive

✔✔Drives 0-2

✔✔Drives 0-3

✔✔Drives 0-4

Reference/

Feedback

MDI I/O

Cfg (11) Mode (1)

Step 11. Select “Ctrl/Stat & Ref/Fdbk (2+2bytes)” from the

“Availab le Modules” list as shown in figure 5.13. Click OK.

The “Ctrl/Stat & Ref/Fdbk” (2+2 bytes) module has now

been added as shown in figure 5.13.

Figure 5.13 – Modules: Ctrl/Stat & Ref/Fdbk Viewing Window

Configuring the PROFIBUS Scanner 5-9

Page 46

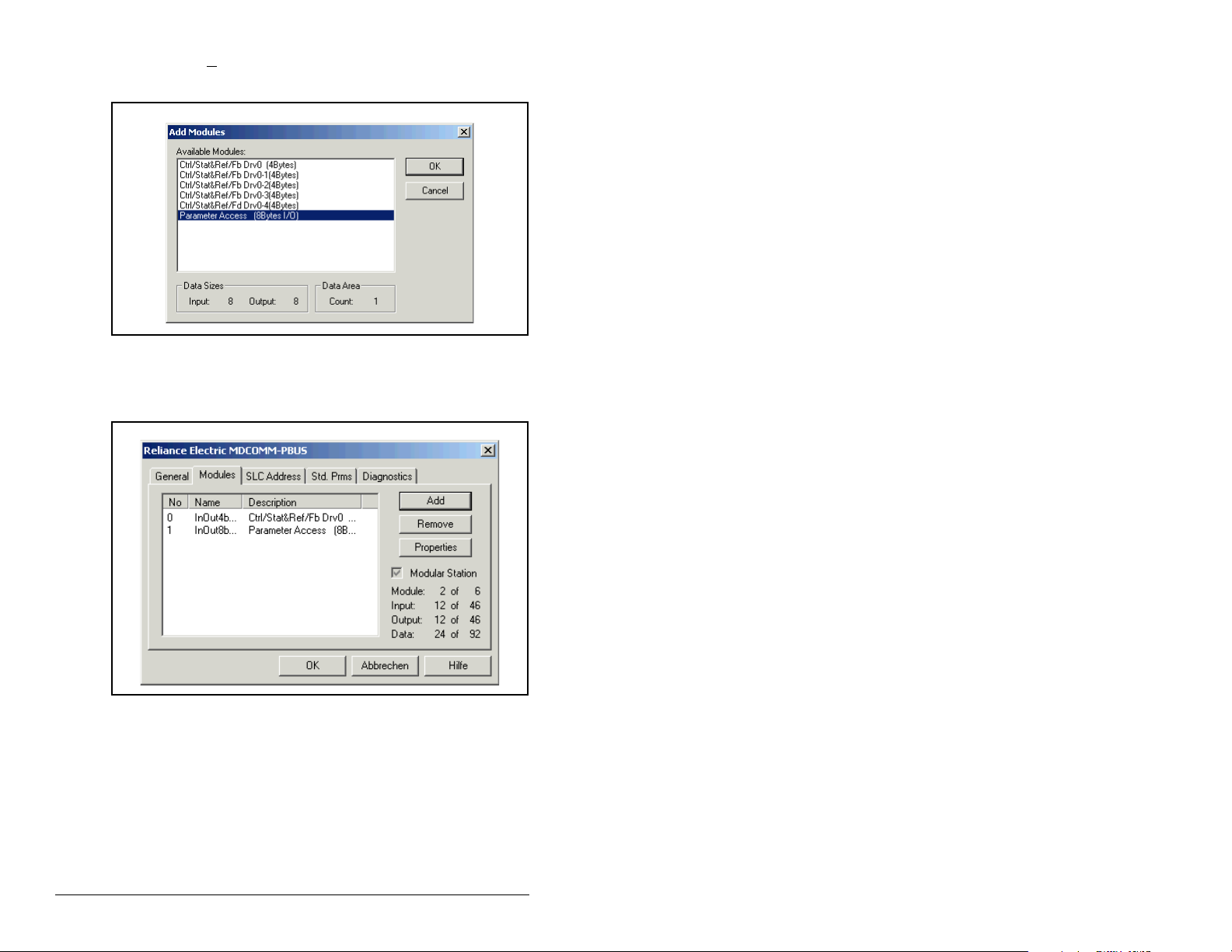

Step 12. Click Add to continue adding modules. Select “P arameter

Access” and click OK.

Figure 5.14 – Add Modules: Parameter Access Selection Window

Step 13. The “Parameter Access” module has now been added as

shown in figure 5.15.

Figure 5.15 – Modules: Parameter Access Viewing Window

Settings can be chosen to map Station models to SLC addresses.

In our example M1/Mo files are used for Input / Output.

Note that the Reference/Feedback (Ctrl/Stat & Ref/Fdbk) start at

word 0.

5-10 PROFIBUS Communications Module

Page 47

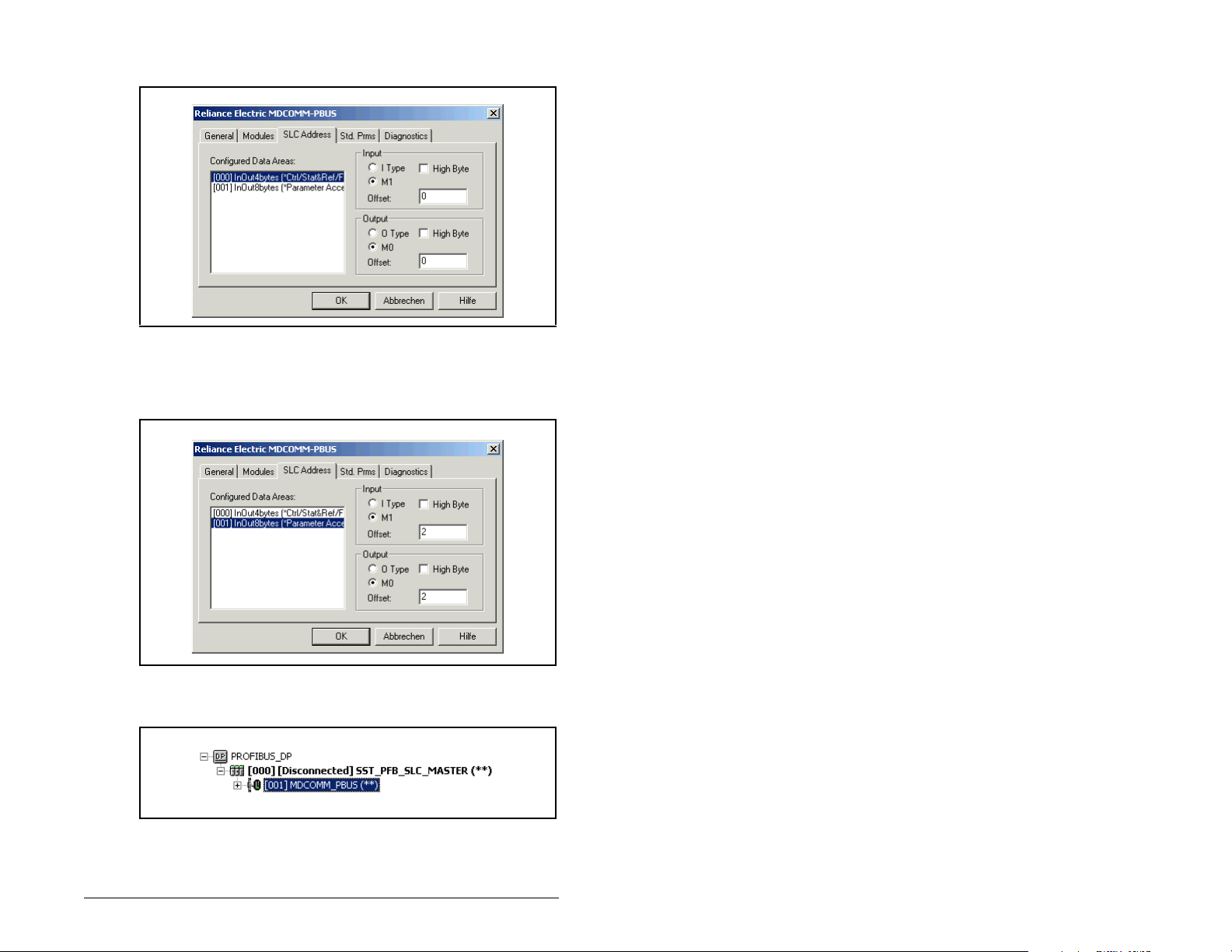

Step 14. Click on the SLC Address tab as shown in figure 5.16.

Figure 5.16 – SLC Address: M1/M0 (Ctrl/Stat & Ref/Fdbk)

Step 15. Parameter Access starts at word 10 in the M1/M0 files.

Note that Parameter Access utilizes 4 words. Click OK

when finished.

Figure 5.17 – SLC Address: M1/M0 (Parameter Access)

Step 16. Station 1 is now displayed in the network window.

Figure 5.18 – Station 1 Network Window

Configuring the PROFIBUS Scanner 5-11

Page 48

Station 1 is configured as follows:

Table 5.2 – Station 1 Configurations

Module M1/M0 Word

Ctrl/Stat & Ref Fdbk Drive 0 0

Parameter Access 2

Note that Station 1 occupies 6 words.

Step 17. The same steps for configuring Station 1 will be used to

configure Station 2. Refer to previous steps (beginning

with step 9) for Configuring the SST-PFB-SLC PROFIBUS

Scanner Station 2. Refer to figure 5.19.

Figure 5.19 – Station 2 Network Window

Station 2 is configured as follows:

Table 5.3 – Station 2 Configurations

Module M1/M0 Word

Ctrl/Stat & Ref Fdbk Drive 0 6

Parameter Access 8

Note that Station 2 occupies 6 words.

Step 18. Use the null modem cable that came with the scanner to

connect COM1 on the PC and the CONFIG RS232 port

on the scanner.

Important:The processor needs to be in program mode before

proceeding.

Step 19. Right-click on the scanner in the network window and

select “Connect”. Then right-click again on the scanner in

the network window and select “Load Configuration”. If a

minimum cycle time attention window pops up, clic k OK to

continue. After the configuration has been loaded into the

5-12 PROFIBUS Communications Module

Page 49

scanner, “Configured Program” will be displayed in the

message window (see figure 5.20).

Figure 5.20 – Network Window Scanner Selection

Step 20. Click F

ile and Save As from the tool bar, as a unique File

N

ame. The configuration of the scanner is now complete.

Note that cycling power to the scanner is recommended.

See figure 5.21.

Figure 5.21 – Save As Dialog Window

Summary of the example scanner configuration:

M0 / M1 Addressing

Module

Station 1 Station 2

Logic Command / Status 0 6

Reference / Feedback 1 7

Parameter Access 2 8

Configuring the PROFIBUS Scanner 5-13

Page 50

5-14 PROFIBUS Communications Module

Page 51

CHAPTER 6

Using I/O Messaging

Chapter 6 provides information and examples that explain how to

use I/O Messaging to control an MD65 drive.

ATTENTION: The examples in this publication are

intended solely for purposes of example. There are

!

6.1 About I/O Messaging

I/O messaging is used to transfer the data which controls the MD65

drive and sets its Reference.

many variables and requirements with any

application. Rockwell Automation does not assume

responsibility or liability (to include intellectual

property liability) for actual use of the examples

shown in this publication. Failure to observe this

precaution could result in bodily injury or damage to

equipment.

The PROFIBUS module provides options for configuring and using

I/O, including the size of the I/O, which can be configured by

selecting the number or attached drives (Single or Multi-Drive

mode).

Chapter 4, Configuring the PROFIBUS Module, and chapter 5,

Configuring the PROFIBUS Scanner, discuss how to configure the

module and scanner on the network for these options. The Glossary

defines the different options. This chapter discusses how to use I/O

after you have configured the module and scanner.

6.2 Understanding the I/O Image

The terms input and output are defined from scanner’s point of

view. Therefore, Output I/O is data that is output from the scanner

and consumed by the PROFIBUS module. Input I/O is the data that

is produced by the module and consumed as input by the scanner.

Using I/O Messaging 6-1

Page 52

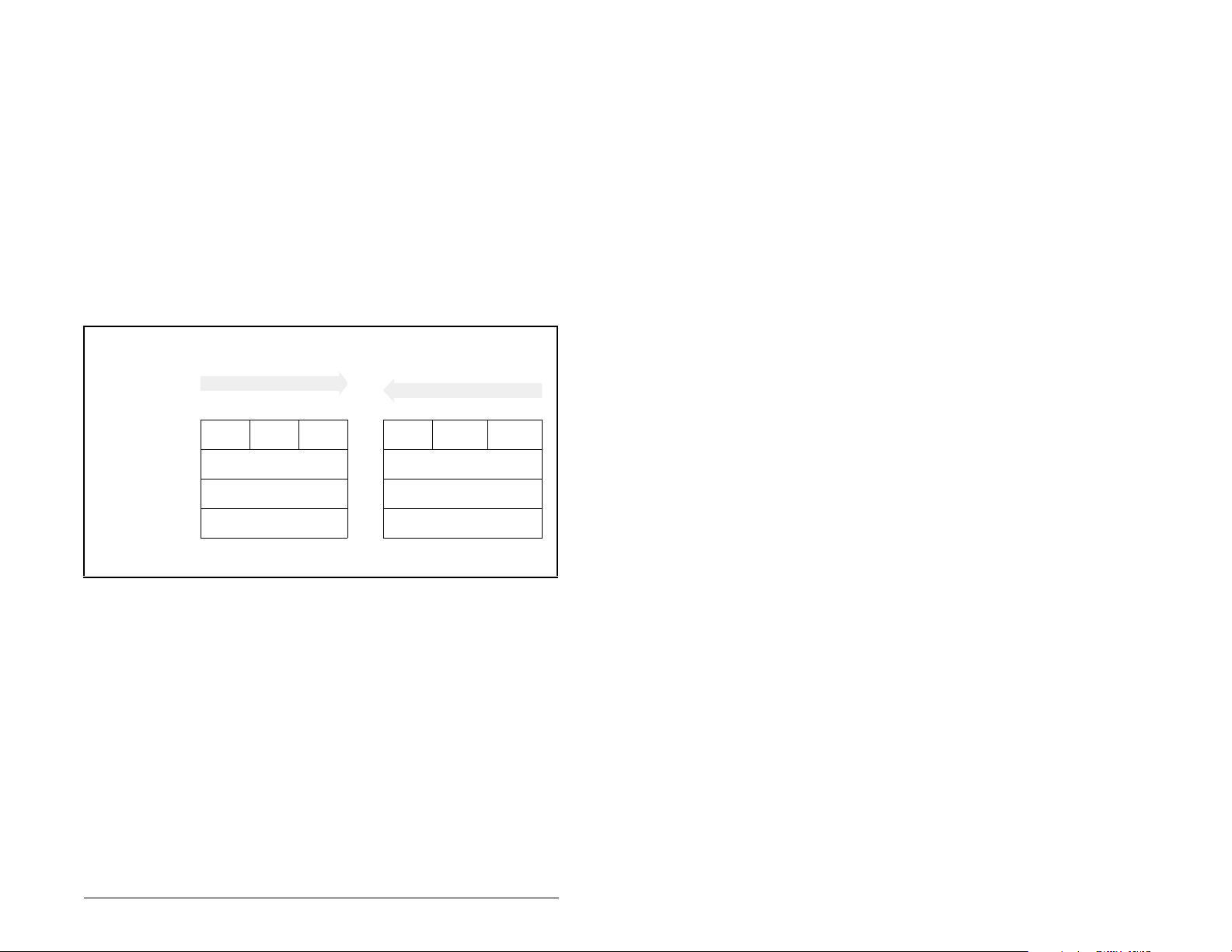

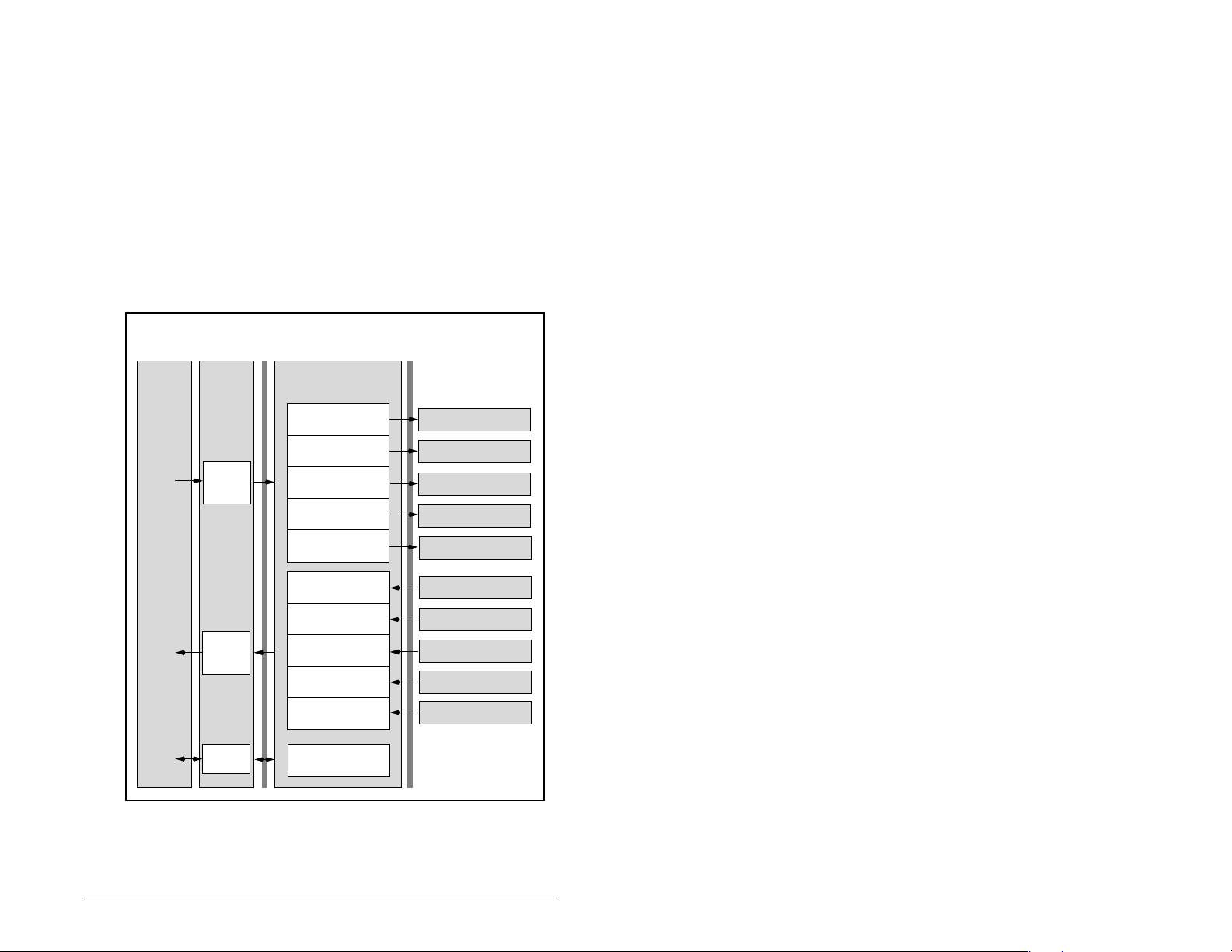

The I/O image table will vary based on the configuration of the

Mode Jumper (J2) on the module and MDI I/O Cfg (parameter 11).

The image table always uses consecutive words starting at word 0.

Figure Figure 6.1 illustrates an example of a drive I/O image (16-bit

words).

MDI

MD65 Drive

Logic Command

Reference

Logic Status

Feedback

Message

Handler

Controller

PROFIBUS

Scanner

Output

Image

(Write)

Input

Image

(Read)

Message

Handler

Figure 6.1 – Single Drive Example of I/O Image

Adapter

Word and I/O

0 Logic Command

1 Reference

0 Logic Status

1 Feedback

Message

Buffer

Single drive mode is the typical configuration, where one node

consists of a MD65 drive with a MDCOMM-PBUS module.

For Multi-Drive mode, where one node can consist of up to five

drives, refer to chapter 8, Using Multi-Drive mode.

6.3 Using Logic Command/Status

When enabled, the Logic Command/Status word is always word 0 in

the I/O image. The Logic Command is a 16-bit word of control

produced by the scanner and consumed by the module. The Logic

Status is a 16-bit word of status produced by the module and

consumed by the scanner.

This manual contains the bit definitions for compatible products

available at the time of publication in Appendix C, Logic Command/

Status Words. For other products, refer to their documentation.

6-2 PROFIBUS Communications Module

Page 53

6.4 Using Reference/Feedback

When enabled, Reference/Feedback alwa ys begins at word 1 in the

I/O image. The Reference (16 bits) is produced by the controller

and consumed by the module. The Feedback (16 bits) is produced

by the module and consumed by the controller.

Size Valid Values

16-bit 0.0 to 4000

1

In I/O Image Example

Word 1 Figure 6.1

0.0 to 240.0 Hz (MD60) or

0.0 to 400.0 Hz (MD65)

1

The Reference for a MD65 or MD60 is set in Hz. For example, “300”

equates to 30.0 Hz (the decimal point is always implied).

Using I/O Messaging 6-3

Page 54

6-4 PROFIBUS Communications Module

Page 55

CHAPTER 7

Using Explicit Messaging

(Parameter Protocol)

Chapter 7 provides information and examples that explain how to

use Explicit Messaging to monitor and configure the module and

connected MD65 drive, as well as other peripherals.

ATTENTION: The examples in this publication are

intended solely for purposes of example. There are

!

many variables and requirements with any

application. Rockwell Automation does not assume

responsibility or liability (to include intellectual

property liability) for actual use of the examples

shown in this publication. Failure to observe this

precaution could result in bodily injury or damage to

equipment.

ATTENTION: If Explicit Messages are programmed

to write parameter data to Non-Volatile Storage

(NVS) frequently , the NVS will quickly exceed its lif e

cycle and cause the drive to malfunction. Do not

create a program that frequently uses Explicit

Messages to write parameter data to NVS. Datalinks

do not write to NVS and should be used for frequently

changed parameters. Failure to observe this

precaution could result in damage to, or destruction

of, equipment.

7.1 About Explicit Messaging

Explicit Messaging is used to transfer data that does not require

continuous updates. With Explicit Messaging, you can configure

and monitor a slave device’s parameters on the PROFIBUS

network.

To be able to use the parameter protocols in the PROFIBUS

module, the Parameter Access module must be added to the

master configuration when configuring the network.

Using Explicit Messaging (Parameter Protocol) 7-1

Page 56

Refer to step 21 in chapter 5 to view the procedure for adding the

“Parameter Access” module to a configuration. This maps four

words input and output to the end of the I/O configuration, which is

used as the request/response in the parameter message format

(figure 7.2).

7.2 Running Explicit Messages

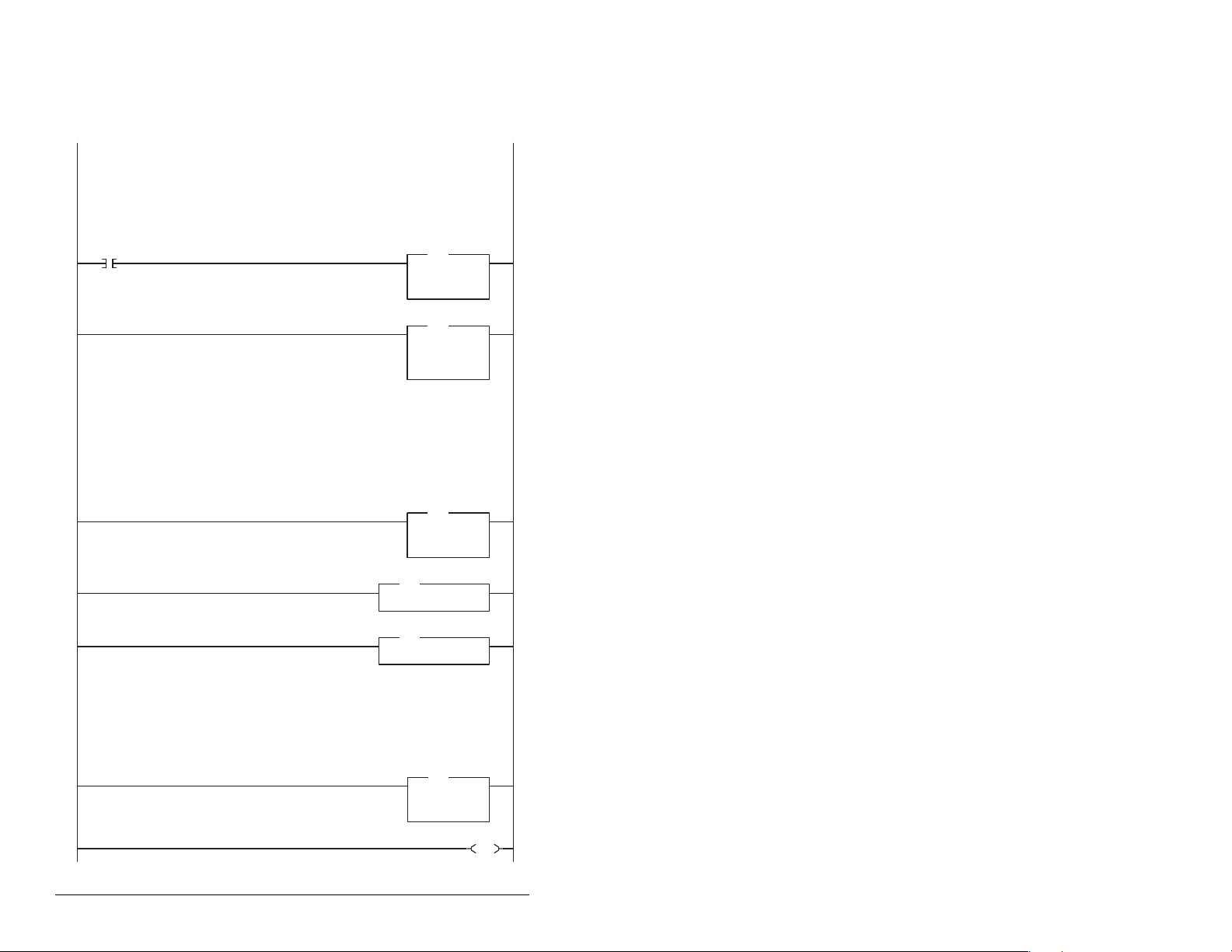

There are five basic events in the Explicit Messaging process

defined in figure 7.1. The details of each step will vary depending on

the controller. Refer to the documentation for your controller.

Important: There must be a request message and a response

Complete Parameter

Data Exchange

Retrieve Parameter

Data Exchange Response

message for all Explicit Messages, whether you are

reading or writing data.

Set up and send

Parameter Data

Format the required data and set up the ladder

logic program to send an Explicit Message request

to the scanner module (download).

The scanner module transmits the Explicit

Message Request to the slave device over the

PROFIBUS network.

The slave device transmits the Explicit Message

Response back to the master.

The controller retrieves the Explicit Message

Response.

The Explicit Message is complete.

Figure 7.1 – Explicit Message Process

7-2 PROFIBUS Communications Module

Page 57

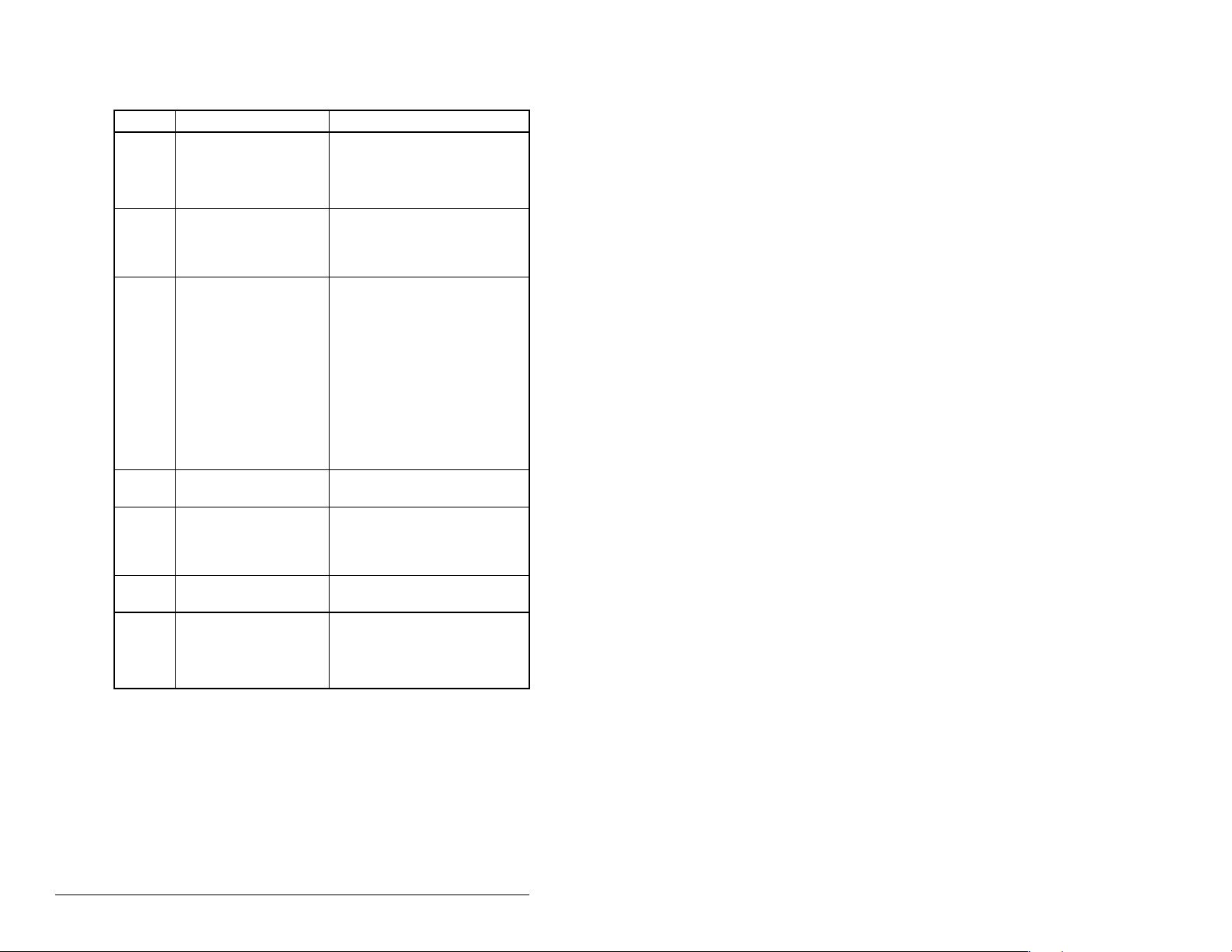

7.3 Parameter Protocol

This protocol uses four words in the PROFIBUS I/O area. Requests

and responses are a handshake procedure and cannot be batched,

meaning that if the master sends a request, it has to wait for the

response before sending a new request.

With this protocol you can:

• Read 8-bit or 16-bit parameters from any MDI port

• Write 8-bit or 16-bit parameters to any MDI port

• Read the Module Fault Code

• Read Events

• Read Diagnostic Items

Request

Bit 15-12 11 10-0 15-12 11 10-0

Parameter Access

Word 1 (PCA)

Parameter Access

Word 2 (IND)

Parameter Access

Word 3 (PVA)

Parameter Access

Word 4 (PVA)

Refer to sections 7.3.1 and 7.3.2 for a description of the data that is

required in each word.

RC SPM PNU RC SPM PNU

Subindex Subindex

Spare Spare

Parameter value Parameter value

Figure 7.2 – Parameter Message Format

Response

Using Explicit Messaging (Parameter Protocol) 7-3

Page 58

7.3.1 Parameter Message Request

Table 7.1 – Parameter Message Request Data

Word Description

1 PNU - Parameter Number (Bit 0-10)

The parameter number determines which parameter to

access in the selected peripheral. Parameters 1-1023 can

be accessed.

Parameter numbers 1024 - 2047 are used to access the

fault object. Parameter 1024 is equal to the latest fault, 1025

to the prior fault, and so on.

Bit Definitions

1-1023 Parameters (Drive or Module)

1024 Module Fault Code

1025-1056 Module Events

1280-1289 Diagnostic Items (Single Drive)

1280-1304 Diagnostic Items (Multi-Drive)

SPM - Spontaneous Message (Bit 11)

Reserved - Should always be set to 0.

RC - Request/Response Code (Bit 12-15)

One of the following codes have to be used:

0 = No request

1 = Request parameter value

2 = Change parameter value (8-bit & 16-bit word)

3 = Spare

4 = Parameter minimum

5 = Parameter maximum

6 = Default Value

7 - 15 = Reserved

7-4 PROFIBUS Communications Module

Page 59

Table 7.1 – Parameter Message Request Data

Word Description

2 IND - Index

The IND is used to specify which drive will receive a

message.

0-2 bits = MDI port

Bit Definitions

000 Drive 0 single drive mode

001 Drives 0-1 multi-drive mode

010 Drives 0-2 multi-drive mode

011 Drives 0-3 multi-drive mode

101 Drives 0-4 multi-drive mode

3 - 15 = Reserved

3 PVA - Parameter value

Spare

4 PVA - Parameter value (8-bit & 16-bit word).

Read Request: Not used

Write Request: Contents the write value for a 8-bit or 16-bit

parameter.

7.3.2 Parameter Message Response

Table 7.2 – Parameter Message Response Data

Word Description

1 PNU - Parameter Number (Bit 0-10)

Requested parameter number.

SPM - Spontaneous Message (Bit 11)

Reserved - is always set to 0.

RC - Request/Response Code (Bit 12-15)

One of the following codes will be sent:

0 = No request

1 = Transfer parameter value (8-bit & 16-bit word)

2 = Spare

3-6 = Reserved

7 = Request rejected (including Module Fault Code and

Parameter Message Fault Code, see table below)

9-15 = Reserved

Using Explicit Messaging (Parameter Protocol) 7-5

Page 60

Table 7.2 – Parameter Message Response Data

Word Description

2 IND - Index

Port ID of requested parameter

3 PVA - Parameter value

Spare

4 PVA - Parameter value (8-bit & 16-bit word).

Read Response: Contents the value from a 8-bit or 16-bit

parameter or the Fault Code (if RC = 7).

Write Response: Confirms the write value for a 8-bit or 16bit parameter or the Fault Code (if RC = 7).

Table 7.3 – Module Fault Code

Fault Code Description

51 MDI Port watchdog

52 Profibus network loss

53 Not compatible product

54 MDI time-out or additional MDI master connected

Table 7.4 – Parameter Message Response Fault Numbers and Descriptions

Fault

Number Description

101 Service not supported (i.e., set service to a read-only

parameter)

102 Service not valid

104 Parameter does not exist (i.e., parameter

number>max number of parameters)

106 Data value out of range (i.e., set value is out of range)

107 State conflict (i.e., parameter is not changeable while

the product is in an operating state)

7-6 PROFIBUS Communications Module

Page 61

CHAPTER 8

Using Multi-Drive Mode

Chapter 8 provides information to explain how to use Multi-Drive

mode.

ATTENTION:The examples in this publication are

intended solely for purposes of example. There are

!

8.1 Single Mode vs. Multi-Drive Mode

The MDI interface provides a means to connect up to five drives on

one node daisy-chained over the RS-485. Two different operation

modes, single and multiple drive modes, are possible.

many variables and requirements with any

application. Rockwell Automation, Inc. does not

assume responsibility or liability (to include

intellectual property liability) for actual use of the

examples shown in this publication. Failure to

observe these precautions could result in bod il y

injury and/or damage to equipment.

Single mode is a typical network installation, where a single

Profibus node consists of a single drive with a MDCOMM-PBUS

module. In this mode, the module can talk to one host, and the host

can support one additional external peripheral (OIM or MDCOMM-

232) over MDI.

1 drive per node

Profibus

MD65 with

MDCOMM-PBUS

Figure 8.1 – Single Mode Example for Network

Using Multi-Drive Mode 8-1

MD65 with

MDCOMM-PBUS

MD65 with

MDCOMM-PBUS

Page 62

Figure 8.2 shows that the Single Drive mode provides the possibility

of connecting one additional external peripheral.

MDI

LANG DISP

Esc

PROG

7 8 9

4 5 6

1 2 3

.

DEL

ALT

JOG

0

+/-

LANG DISP

Prog

ALT

JOG

Figure 8.2 – MDI Peripheral Devices for Single Mode Connection

Multi-Drive mode is an alternative to the typical network installation,

where a single Profibus node can consist of one to five drives (see

figure 8.3). The first drive must be a MD65 with a MDCOMM-PBUS

module. The remaining drives can be MD65 or MD60 drives that are

daisy-chained over RS-485 with the first drive.

Profibus

MD65

up to 5 drives per node

Up to 4 MD65 or MD60 Drives

MDCOMM-PBUS

AK-U0-RJ45-TB2P

Connector with 3rd Party

Terminating Resistor

AK-U0-RJ45-TB2PRS-485

AK-U0-RJ45-TB2P

Connector with 3rd Party

Terminating Resistor

Figure 8.3 – Multi-Drive Mode Example for Network

8-2 PROFIBUS Communications Module

Page 63

The multiple drive connectivity, up to five drives with at least one

MD65 drive, for example , one MD65 and four MD60 drives, provides

a low cost Profibus solution in the industry for multiple drives.

Important: In Multi-Drive mode, the unit will not operate with MDI

peripheral devices such as the OIM or the MDCOMM232 and the application of any other peripheral will be

prohibited.

Benefits of Multi-Drive mode include:

• Lower hardware costs. Only one MDCOMM-PBUS module is

needed for up to five drives. The MD60 can also be used for the

daisy-chained drives instead of MD65 drives.

• Reduces the network node count. For example, in Single mode

30 drives would consume 30 nodes. In Multi-Drive mode, 30

drives can be connected in 6 nodes.

• Provides a means to put MD60 drives on Profibus (MD60 drives

do not have an internal communications module slot).

• Controller can control, monitor, and read/write parameters for all

five drives.

The trade-offs of Multi-Drive mode include:

• If the MD65 drive with the MDCOMM-PBUS module is powered

down, then communications with the daisy-chained drives is

disrupted and the drives will take the appropriate communications

loss action set in each drive.

• Communications throughput to the daisy-chained drives will be

slower than if each drive was a separate node on Profibus (Single

mode). This is because the MDCOMM-PBUS module must take

the Profibus data for the other drives and sequentially send the

respective data to each drive over RS-485.

• Since the RS-485 ports are used for daisy-chaining the drives,

there is no connection for a peripheral device such as an OIM.

The AK-U0-RJ45-SCI MDI Splitter Cable cannot be used to add a

connection for a peripheral device.

Using Multi-Drive Mode 8-3

Page 64

8.2 System Wiring

To daisy-chain the drives of the MD65 with the MDCOMM-PBUS

module (Drive 0), the AK-U0-RJ45-TB2P terminal block connector

(Figure 8.4) can be used for easy installation.

Figure 8.4 – AK-U0-RJ45-TB2P Terminal Block Connector

The wiring diagram for using AK-U0-RJ45-TB2P terminal block

connectors is shown in figure 8.5.

To