Page 1

Long-range Inductive Sensors

with IO-Link Interface

Catalog Numbers 871TM-MxxNP8-xx, 871TM-NxxNP8-xx,

871TM-MxxNP18-xx, 871TM-NxxNP18-xx, 871TM-MxxNP12-xx,

871TM-NxxNP12-xx, 871TM-MxxNP30-xx, 871TM-NxxNP30xx

User Manual

Original Instructions

Page 2

Long-range Inductive Sensors with IO-Link Interface User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 3

Table of Contents

Preface

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1

Product Overview Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Correction Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 2

Installation User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

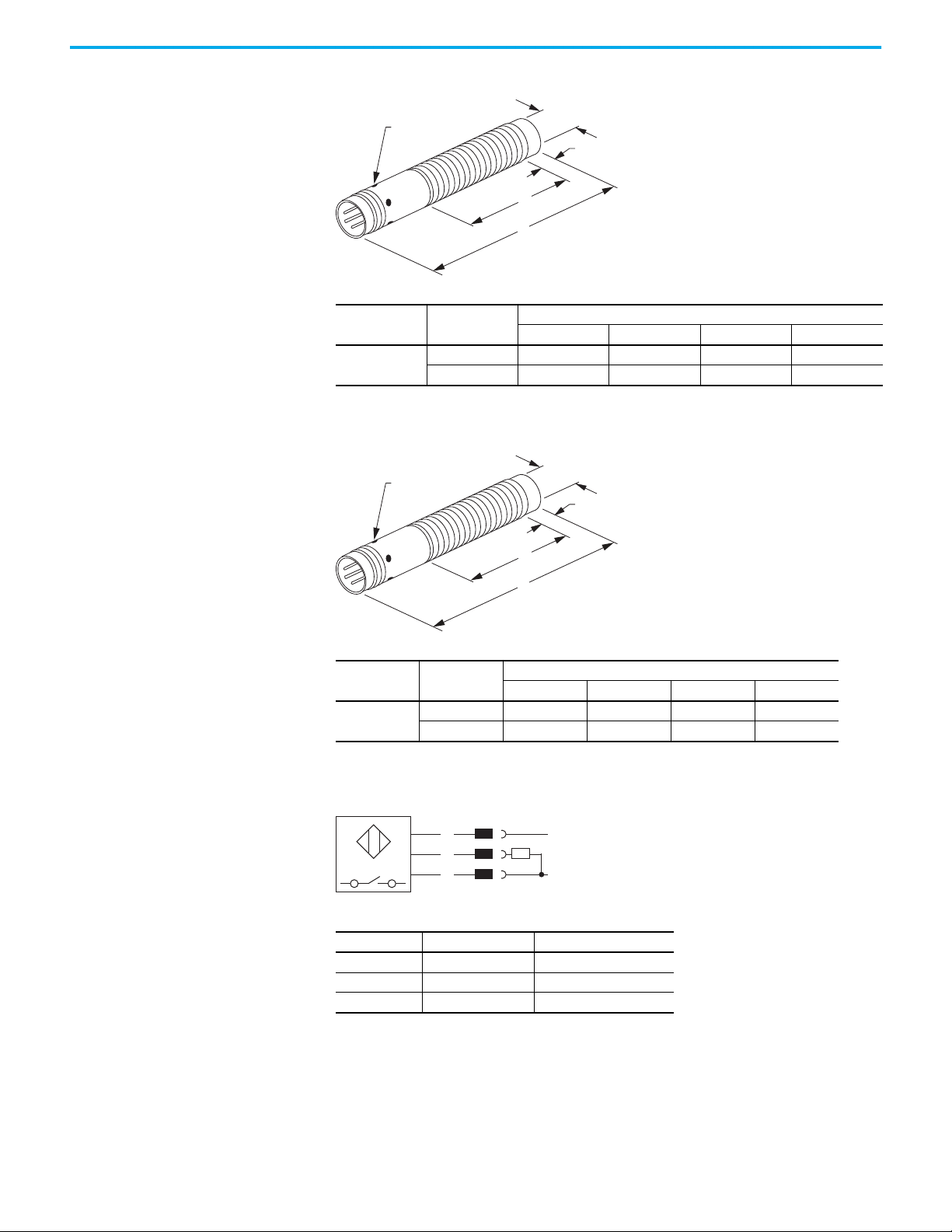

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cable Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Micro QD Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pico QD Style — 3-pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pico QD Style — 4-pin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

871TM Long-range Sensor with

IO-Link Overview

Chapter 3

What Is IO-Link?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Why IO-Link?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Seamless Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Real-time Diagnostics and Trending . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Sensor Health Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Device Profiles and Automatic Device Configuration. . . . . . . . . . . . 18

Descriptive Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How Does IO-Link Work?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transmission Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Transmission Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Response Time of the IO-Link System . . . . . . . . . . . . . . . . . . . . . . . . . 19

IO-Link Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Process Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Value Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Device Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Access IO-Link Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Cyclic Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Acyclic Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Start-up the I/O System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Assign Device Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rockwell Automation Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 3

Page 4

Table of Contents

Premier Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

871TM Sensor IO-Link Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Correlation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Automatic Device Configuration (ADC) . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Tag Naming for I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 4

Configure the 871TM Sensor for

IO-Link Mode

Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Example: Set up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 5

Create a Project Project Creation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chapter 6

Configure the IO-Link Master Configuration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

AOP Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 7

Connect the 871TM to the IO-Link

Connection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Master

Chapter 8

Register the 871TM IODD Registration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Chapter 9

Review the 1734-4IOL IO-Link

Add-on Profile

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Device Parameter Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Common Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Identification Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Parameter Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Switching Timer Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Diagnosis Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Controller Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 10

Configure the Sensor with the

Studio 5000 Environment

Sample Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Read the 871TM Configuration Via Explicit Message . . . . . . . . . . . . 61

Decipher the Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Write a New Configuration to the 871TM Via Explicit Message . . . 63

Reset the Sensor to Default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Chapter 11

Troubleshooting Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 5

Table of Contents

Appendix A

Install the Add-on Profile Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Perform the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix B

Device Parameters Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Process Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Appendix C

Error Codes Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Location of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 7

Preface

This manual is a reference guide for Bulletin 871TM inductive sensors with IOLink. It describes the procedures that you use to install, configure,

troubleshoot, and use these sensors. Use this manual if you are responsible for

these tasks for long-range inductive sensors with IO-Link.

Summary of Changes

Abbreviations

Additional Resources

This manual contains the following new and updated information:

• Updated Catalog Numbers on the front cover.

• Updated the URL for the Sample Code Library in Sample Code on

page 57.

The following abbreviations are used in this publication.

Abbreviation Definition

ADC Automatic Device Configuration

AOI Add-on Instruction

AOP Add-on Profile

ASN Application-specific name

IEC International Electrotechnical Commission

IODD I/O device description

NEC National Electric Code

QD Quick disconnect

SIO Standard I/O

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

871TM Extended Range User Manual,

publication 871TM-UM001

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website, rok.auto/

certifications.

Provides information to mount and install 871TM extended range

sensors.

Provides general guidelines for installing a Rockwell Automation

industrial system.

Provides declarations of conformity, certificates, and other

certification details.

You can view or download publications at rok.auto/literature

.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 7

Page 8

Preface

Notes:

8 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 9

Chapter 1

Product Overview

Product Description The Bulletin 871TM family of inductive sensors is the result of a unique

collection of enhancements—electrical and mechanical—that make these

sensors the optimal solution for harsh duty applications. The machined

stainless steel housing combines an unusually thick sensing face with onepiece construction. The result is a sensor that is exceptionally resistant to

abrasion and impervious to fluid ingress, a feature especially crucial in

applications that involve cutting fluids and chemical washdowns. The 871TM

sensor boasts sensing ranges two to three times greater than standard models,

and offers increased sensing distance for all metals, including copper and

brass.

The IO-Link interface enables consistent communication for diagnosing and

parameterizing through to the sensor level and makes the intelligence that is

already integrated in every 871TM inductive sensor fully available to you. This

design provides particular advantages in the service area (fault elimination,

maintenance, and device replacement), during commissioning (identification,

configuration, and during operation, continuous parameter monitoring, and

online diagnosis). The 871TM sensor operates as a standard discrete sensor on

pin four (black) or communicates via IO-Link on the same pin when connected

to an IO-Link master.

Operating Modes The sensor can operate in two modes:

Mode Description

Standard I/O

(SIO)

IO-Link

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 9

The sensor default operation mode. The sensor and its output act as a standard inductive sensor

without IO-Link functionality. This mode of operation is active when the sensor is connected to a

digital input device such as a PLC input module, a distribution box, or an input terminal connection.

This mode is automatically activated when the sensor is connected to an IO-Link enabled master

device. Upon entering this mode, the yellow status indicator on the sensor stays solid to indicate

that IO-Link communication has successfully been established with the master. The sensor

transmits parameter and diagnostic information that can be accessed via PLC process data. No user

intervention is required to enable this functionality within the sensor.

Page 10

Chapter 1 Product Overview

Features • 10…30V DC operating voltage

• Stainless steel housing

• Equal sensing for both steel and aluminum

•IP68/IP69K rated

• 3-wire operation

• IO-Link communication protocol helps minimize downtime and

increase productivity

• IO-Link sensors are forward/backward compatible with standard

sensors: the same sensors and same cables that are used in IO-Link and

non-IO-Link applications

•IO-Link provides

- Remote detection of the health of the sensor

- Margin status (low alarm)

-Timer function

Specifications

Attribute Value

Certifications c-UL-us Listed and CE Marked for all applicable directives

Load current <200 mA

Capacitive load 1 mF

Leakage current 0.1 mA

Operating voltage 10…30V DC

Voltage drop 2V DC at 200 mA

Repeatability 5% at constant temperature

Hysteresis 10% typical

Protection type

Enclosure type rating 12/18/30 barrel size: IP68/IP69K

Housing material Stainless steel face and barrel

Connection type

Status indicators

Operating temperature -25…+70 °C (-13…+158 °F)

Shock 30 g, 11 ms

Vibration 55 Hz, 1 mm amplitude, 3 planes

IO-Link

Protocol IO-Link V1.0

Interface type IO-Link

Mode COM2 (38.4 kBd)

Cycle time, min

SIO (Standard I/O) Supported (pin 4 for either IO-Link or SIO)

(1) These products have been tested to comply with IO-Link test specification IEC 61131-9. Environmental EMC and Physical

Layer testing have not been performed with the device running in IO-Link mode.

False pulse, transient noise, reverse polarity, short circuit (trigger at 340 mA

typical), overload

Cable: 2 m (6.5 ft) length;

Quick-Disconnect: 4-pin micro style

Yellow: Output energized/360° status indicator visibility; flashing status

indicator indicates target that is located between 80…100% of rated sensing

distance

(1)

8 ms

10 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 11

Chapter 1 Product Overview

Correction Factors To determine the sensing distance for materials other than the standard mild

steel, a correction factor is used. The correction factors are used as a general

guideline for determining the de-rated sensing distance, if applicable.

Instructions for unshielded sensor: To determine the appropriate correction

factor, use Table 1

sensing range to determine de-rated sensing distance, if applicable.

Instructions for shielded sensor: To determine the appropriate correction

factor, use Table 1

factor based on the type and the target material. Then, in Table 2

result from Table 1

the final correction factor.

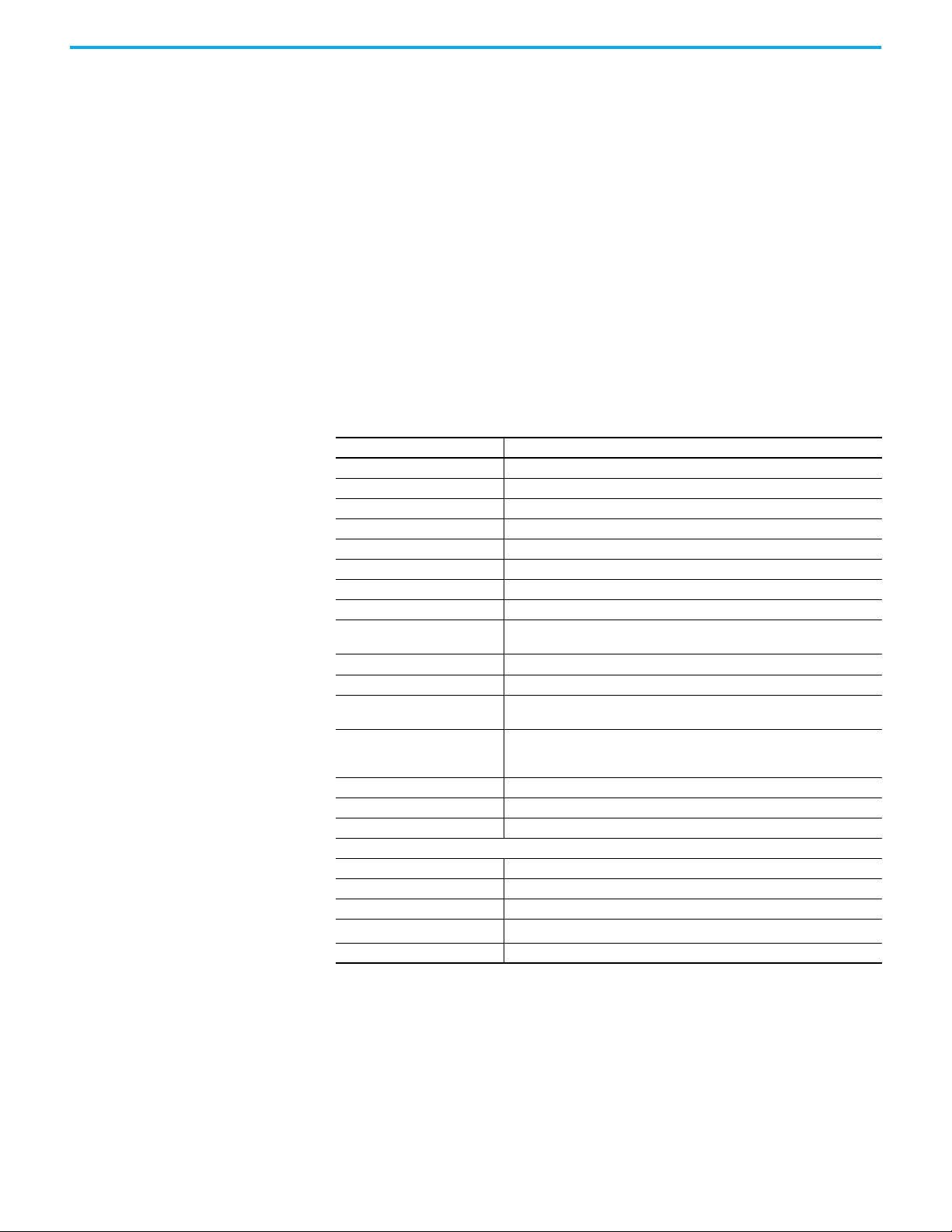

Table 1 - Correction Factor

. Multiply the sensor type with the target material by the

and Table 2. In Table 1, determine the appropriate correction

, multiply the

by the material the sensor is mounted in. This number is

Target Material

(No Surrounding

Metal)

(Shielded)

Steel 111111

Copper 0.85 0.8 0.8 0.9 0.9 0.9

Aluminum111111

Brass 1.3 1.4 1.2 1.35 1.3 1.2

Stainless Steel

1 mm/2 mm thick

(1) No detection.

M12 M18 M30

6 mm

(Unshielded)

0.5/0.9

Barrel Size and Nominal Sensing Range

10 mm

(1)

/0.65

10 mm

(Shielded)

0.5/0.9 0.2/0.7 0.35/0.7

20 mm

(Unshielded)

20 mm

(Shielded)

40 mm

(Unshielded)

(1)

/0.25

Table 2 - Surrounding Material

Surrounding Material Type

Steel 1 0.7 0.75 0.9

Aluminum 0.9 1.15 0.9 0.7

Brass 0.9 1.05 0.75 0.6

Stainless Steel 1 0.8 0.8 1.3

8 mm Dia.,

Shielded

12 mm Dia.,

Shielded

18 mm Dia.,

Shielded

30 mm Dia.,

Shielded

The following table indicates the protrusion distance from the mounting

device for the unshielded sensor face.

Unshielded Sensor

Distance from Mounting

Device [mm (in.)]

Steel 15 (0.59) 22 (0.87) 36 (1.41) 18 (0.71)

Aluminum 9 (0.35) 13 (0.51) 22 (0.87) 34 (1.34)

Brass 10 (0.39) 15 (0.59) 22 (0.87) 34 (1.34)

8 mm Dia. 12 mm Dia. 18 mm Dia. 30 mm Dia.

Unshielded

See table

Stainless Steel 14 (0.55) 21 (0.83) 43 (1.69) 18 (0.71)

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 11

Page 12

Chapter 1 Product Overview

Notes:

12 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 13

Installation

Chapter 2

User Interface

Mounting

Table 3 - Standard I/O Operation

Status Indicator State Condition

OFF Output is OFF

Yel lo w

Blinking (margin indication) Target is 80…100% of the maximum sensing range

Table 4 - IO-Link Operation

Status Indicator Color State Condition

Yel low

Securely mount the sensor on a firm, stable surface, or support for reliable

operation. Mounting is subject to excessive vibration or shifting could cause

intermittent operation. Once securely mounted, the sensor can be wired per

the wiring instructions in the next section.

You may need to adjust the sensor in the mounting due to the location of the

target in relation to the sensor face. The 871TM sensor offers margin

indication through the yellow status indicator. The status indicator blinks

when the target is 80% of the maximum sensing distance or farther from the

sensor face. It is recommended that you adjust the sensor to be closer to the

target.

ON Sensor output is triggered ON

OFF Power is OFF

Solid Sensor is connected to IO-Link master

IMPORTANT

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 13

When the sensor is connected to IO-Link, the status indicators do not

indicate margin status. The margin status is shown as a process bit in

the Studio 5000® controller tag.

Page 14

Chapter 2 Installation

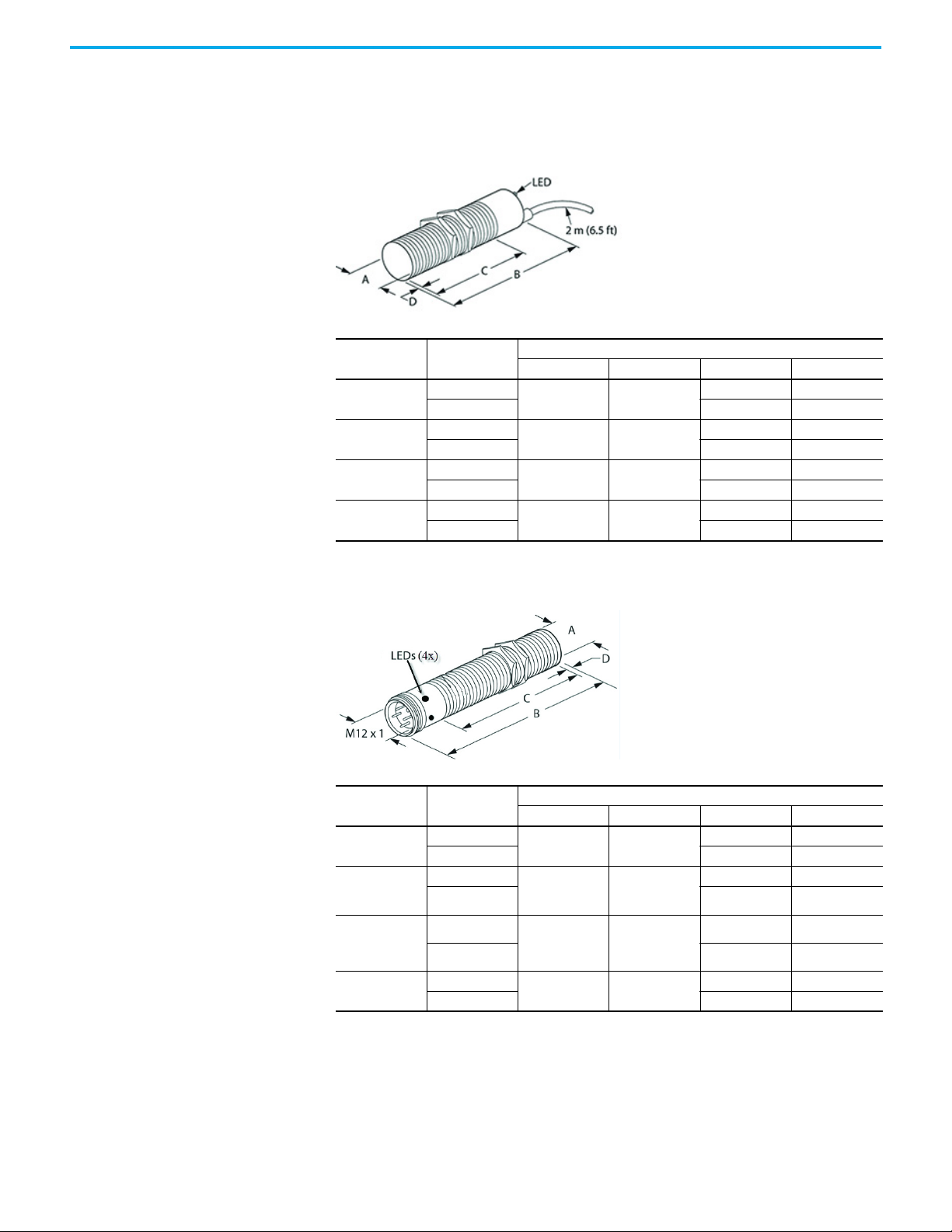

Dimensions The following illustrations show the relevant device dimensions.

Cable Style

Thread Size Shielded

M8 x 1

M12 x 1

M18 x 1

M30 x 1.5

Micro QD Style

Thread Size Shielded

M8 x 1

M12 x 1

[mm (in.)]

ABCD

Yes

No — 4 (0.16)

Yes

No 45 (1.77) 5 (0.19)

Yes

No 43 (1.69) 7 (0.27)

Yes

No 40 (1.57) 10 (0.39)

Yes

No 46 (1.81) 4 (0.16)

Yes

No 36 (1.42) 5 (0.19)

8 (0.31) 45 (1.77)

12 (0.47) 50 (1.96)

18 (0.71) 50 (1.96)

30 (1.18) 50 (1.96)

[mm (in.)]

ABCD

8 (0.31) 66 (2.60)

12 (0.47) 60 (2.36)

——

50 (1.96) —

50 (1.96) —

50 (1.96) —

46 (1.81) —

41 (1.61) —

M18 x 1

M30 x 1.5

14 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Yes

No 35.5 (1.40) 7 (0.27)

Yes

No 32.5 (1.28) 10 (0.39)

18 (0.71) 63.5 (2.5)

30 (1.18) 66.3 (2.61)

42.5 (1.67) —

42.5 (1.67) —

Page 15

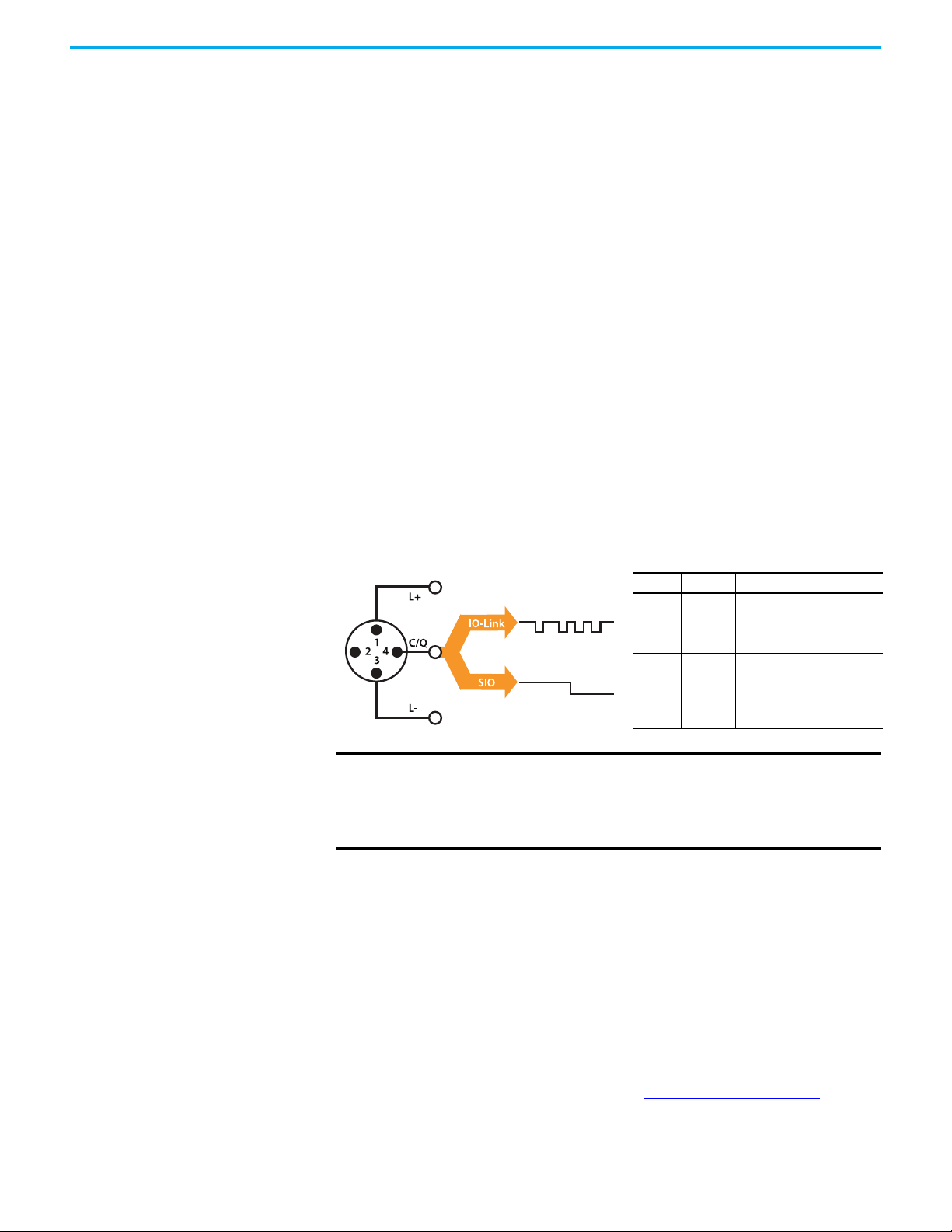

Pico QD Style — 3-pin

Brown

Black

Blue

1

4

3

+

DC

-

(Cable N.O. source)

Chapter 2 Installation

4 Status

Indicators

Thread Size Shielded

M8 x 1

Yes 8 (0.31) 60 (2.36) 51.5 (2.03) —

No 8 (0.31) 60 (2.36) 51.5 (2.03) 4 (0.16)

Pico QD Style — 4-pin

4 Status

Indicators

A

D

C

B

[mm (in.)]

ABCD

A

D

C

Wiring

B

Thread Size Shielded

M8 x 1

Yes 8 (0.31) 66 (2.59) 51.5 (2.03) —

No 8 (0.31) 66 (2.59) 51.5 (2.03) 4 (0.16)

ABCD

[mm (in.)]

Pin Signal Description

1 10…30V DC Device supply

3GNDGND for device

4 LOAD IO-Link/Output/SIO

We recommend the use of Bulletin 889 cordsets and patchcords for quickdisconnect (QD) model sensors. All external wiring must conform to the

National Electric Code and all applicable local codes.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 15

Page 16

Chapter 2 Installation

Notes:

16 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 17

Chapter 3

871TM Long-range Sensor with IO-Link Overview

What Is IO-Link? IO-Link technology is an open point-to-point communication standard and

was launched as (IS) IEC 61131-9. IO-Link is now the first globally standardized

technology for sensor and actuator communication with a field bus system.

This technology provides benefits to both OEMs and end users.

IO-Link provides communications-capable sensors to the control level by a

cost-effective point-to-point connection. IO-Link provides a point-to-point

link between the I/O module and sensor that is used for transferring detailed

diagnostics, device identity information, process data, and parameterization.

IO-Link communication is based on a master-slave structure in which the

master controls the interface access to the sensor. The option of using the

intelligence that is integrated into the sensor provides you with new methods

to commission your sensor. Benefits range from reduced installation time

during startup to increased diagnostics over the lifetime of the machine.

Benefits of IO-Link technology include:

• Reduced inventory and operating costs

• Increased uptime/productivity

• Simplified design, installation, configuration, and maintenance

• Enhanced flexibility and scalability

• Detailed diagnostic information for preventative maintenance

Why IO-Link? IO-Link offers a full range of advanced features and functions.

Seamless Integration

• Forward and backward compatible, sensor catalog numbers remain the

same

• No special cables required

• Connectivity options remain the same

• Access IO-Link functionality by simply connecting an IO-Link enabled

device to an IO-Link master

Real-time Diagnostics and Trending

• Real-time monitoring of the entire machine down to the sensor level

• Optimized preventative maintenance—identify and correct issues

before failures can occur

• Detect sensor malfunctions/failure

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 17

Page 18

Chapter 3 871TM Long-range Sensor with IO-Link Overview

Sensor Health Status

Real-time monitoring verifies that sensors are operating correctly

Device Profiles and Automatic Device Configuration

• Golden device configurations are stored in the IO-Link master module

• Within minutes instead of hours, modify sensor parameters to produce

different finished goods

Descriptive Tags

• Faster programming during initial setup

• More efficient troubleshooting process data tags are named based on the

information they provide

• Easily monitor sensor data though intuitive tag names

How Does IO-Link Work? IO-Link delivers data over the same standard field cabling used today. By

connecting an IO-Link sensor to an IO-Link master, the field-device data and

diagnostics are accessible. So, go beyond product detection on the machine—

now the health of the machine can be monitored as it runs.

Pin Signal Remark

1L+ 24V

2 Out Depends on sensor

3L- Ground

4C/Q

Communication/

switching signal

IMPORTANT The response time of an IO-Link system may not be fast enough for

high-speed applications. In this case, it may be possible to monitor/

configure the sensor through IO-Link on pin 4 of the sensor while

connecting pin 2 (if the sensor offers a second output) of the sensor to

a standard input card.

Transmission Rates

Three communication rates are specified for the IO-Link device:

•COM 1 = 4.8 kBd

•COM 2 = 38.4 kBd

• COM 3 = 230.4 kBd

An IO-Link device typically supports only one of the specified transmissions

rates, while the IO-Link V1.1 specifications requires an IO-Link master to

support all three communication rates. (See Specifications on page 10

communication rates.)

18 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

for

Page 19

Chapter 3 871TM Long-range Sensor with IO-Link Overview

Transmission Quality

The IO-Link communication system operates at a 24V level. If a transmission

fails, the frame is repeated two more times. If the transmission fails on the

second try, the IO-Link master recognizes a communication failure and

signals it to the controller.

Response Time of the IO-Link System

The device description file (IODD) of the device contains a value for the

minimum cycle time of the device. This value indicates the time intervals at

which the master may address the device. The value has a large influence on

the response time. In addition, the master has an internal processing time that

is included in the calculation of the system response time.

Devices with different minimum cycle times can be configured on one master.

The response time differs accordingly for these devices. When configuring the

master, you can specify a fixed cycle time and the device-specific minimum

cycle time that is stored in the IODD. The master then addresses the device

that is based on this specification. The typical response time for a device

therefore results from the effective cycle time of the device and the typical

internal processing time of the master. (See Specifications on page 10

minimum cycle time.)

for

IO-Link Data Types There are four data types available through IO-Link:

Process data → Cyclic data

Value status → Cyclic data

Device data → Acyclic data

Events → Acyclic data

Process Data

The process data of the devices are transmitted cyclically in a data frame in

which the device specifies the size of the process data. Depending on the

device, 0…32 bytes of process data are possible (for each input and output). The

consistency width of the transmission is not fixed and is thus dependent on

the master.

Some devices can support multiple process data modes, which allow you to

select different cyclic process data themes.

Value Status

The value status indicates whether the process data is valid or invalid. The

value status can be transmitted cyclically with the process data.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 19

Page 20

Chapter 3 871TM Long-range Sensor with IO-Link Overview

Device Data

Device data supports device-specific configurable parameters, identification

data, and diagnostic information. They are exchanged acyclically and at the

request of the IO-Link master. Device data can be written to the device (Write)

and also read from the device (Read).

Events

When an event occurs, the device signals the presence of the event to the

master. The master then reads out the event. Events can be error messages and

warnings/maintenance data. Error messages are transmitted from the device

to the controller via the IO-Link master. The transmission of device

parameters or events occurs independently from the cyclic transmission of

process data (see Appendix C on page 79

associated codes).

for device-specific events and

Access IO-Link Data Cyclic Data

To exchange the cyclic process data between an IO-Link device and a

controller, the IO-Link data from the IO-Link master is placed on the address

ranges assigned beforehand. The user program on the controller accesses the

process values using these addresses and processes them. The cyclic data

exchange from the controller to the IO-Link device (that is, IO-Link sensor) is

performed in reverse.

Acyclic Data

Acyclic data, such as device parameters or events, are exchanged using a

specified index and subindex range. The controller accesses these using

Explicit Messaging. The use of the index and subindex ranges allows targeted

access to the device data (that is, for reassigning the device or master

parameters during operation).

Start-up the I/O System If the port of the master is set to IO-Link mode, the IO-Link master attempts to

communicate with the connected IO-Link device. To do so, the IO-Link master

sends a defined signal (wake up pulse) and waits for the IO-Link device to

reply.

The IO-Link master initially attempts to communicate at the highest defined

data transmission rate. If unsuccessful, the IO-Link master then attempts to

communicate at the next lower data transmission rate.

If the master receives a reply, the communication begins. Next, it exchanges

the communication parameters. If necessary, parameters that are saved in the

system are transmitted to the device. Then, the cyclic exchange of the process

data and value status begins.

20 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 21

Chapter 3 871TM Long-range Sensor with IO-Link Overview

Assign Device Parameters Configuration of a device for a specific application requires changes to

parameter settings. The device parameters and setting values are contained in

the IODD of the device.

I/O Device Description (IODD) files contain information about the device

identity, parameters, process data, diagnostic data, and communication

properties. These files are required to establish communication with the

sensors via IO-Link.

The IODD consists of multiple data files; the main file and several optional

language files are in XML-format and graphic files are in PNG format

(portable network graphics). These files adhere to the IO-Link open standard,

which means that they can be used with any IO-Link masters.

IODD files are assigned using the Studio 5000 environment and the 1734-4IOL

Add-on Profile (when using the 1734-4IOL IO-Link master module).

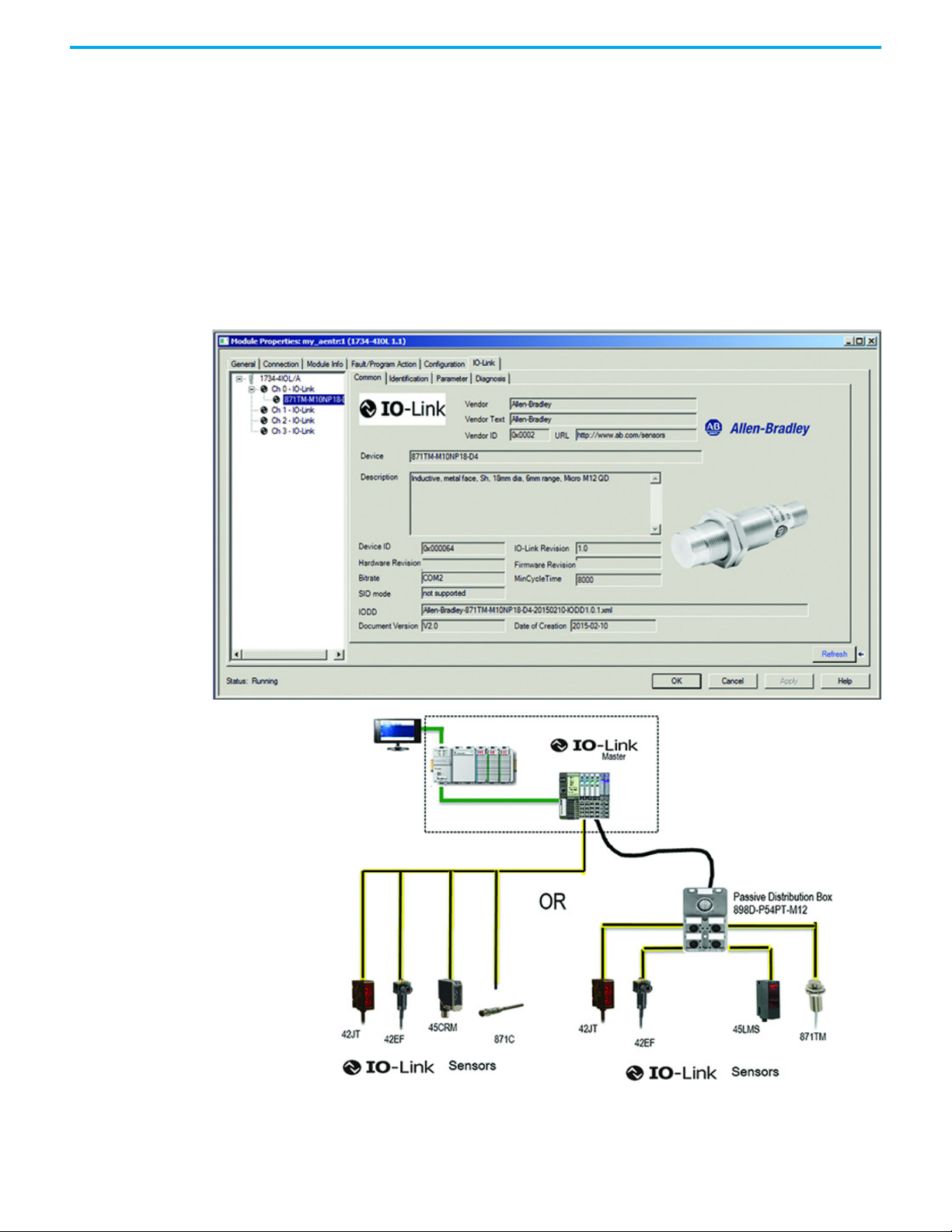

Rockwell Automation Solution

Rockwell Automation is the only supplier who provides every piece of the

Connected Enterprise solution from top to bottom. Plus, exclusive features

and Premier Integration between Allen-Bradley® components and an

Integrated Architecture® system allow for a seamless connection and

commission of control components. Empowering the ability to reap the

benefits of an IO-Link solution with access to more detailed and customized

plant-floor information than other solutions can offer.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 21

Page 22

Chapter 3 871TM Long-range Sensor with IO-Link Overview

Premier Integration The Studio 5000 Logix Designer® environment combines design and

engineering elements in one interface, which enables you to access I/O and

configuration data across the Integrated Architecture system. Use of a

Rockwell Automation solution, provides a smooth, consistent integration of

Allen-Bradley IO-Link enabled devices into the system.

To simplify the integration of the Allen-Bradley IO-Link devices to the

Rockwell Automation architecture, there is an IO-Link Add-on Profile (AOP)

available for the 1734-4IOL master module. The use of an AOP simplifies the

setup of devices by providing the necessary fields in an organized manner that

allows you to build and configure their systems in a quick and efficient

manner.

22 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 23

Chapter 3 871TM Long-range Sensor with IO-Link Overview

871TM Sensor IO-Link Features

The following features are available in the 871TM sensor:

Feat ure Des cript ion

Triggered

Polarity

Margin Status

Switching Timer Mode

The process data bit that communicates the change in state of the 871TM sensor upon the

detection of a target. The status of the triggered bit can be viewed in a Studio 5000

controller tag.

Changes the operation of the triggered parameter. It performs the same function as

normally open or normally closed in standard I/O (SIO) mode.

The process data bit that communicates the target is within or beyond 80% of the

maximum sensing range of the sensor. The margin status bit can be viewed in Studio

5000 controller tag.

Ability to manipulate the output of the sensor in relation to timing. It is useful for precision

applications where the output of the needs to be precisely triggered at a certain time.

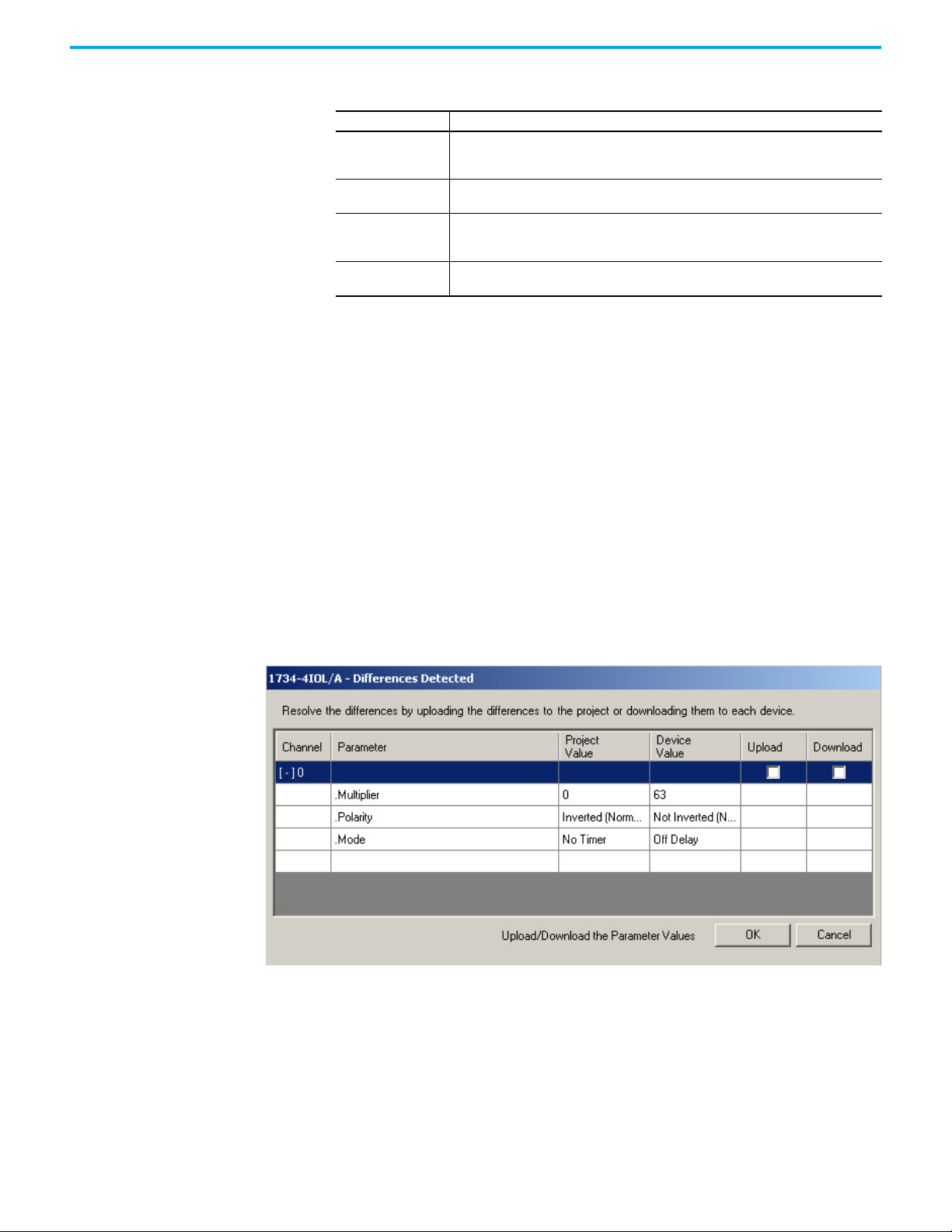

Correlation

The AOP reads all configuration read-write (R.W.) parameters directly from the

connected IO-Link devices and compares the values to ones stored in the

controller. This action determines if there are differences (note that the

correlation does not work for read-only (R.O.) in the parameters or for

competitive sensors.). This feature is for Allen-Bradley enabled IO-Link devices

only and is an online only function that runs when opening up the AOP.

• No differences: There are no differences, so you go directly into the AOP.

• Differences: If there are differences, the user is provided with a

differences dialogue that identifies the IO-Link parameters that, do not

match for each channel. You can then choose, on a channel by channel

basis (where differences exist) to upload the parameters that are currently

in the device and store them in the controller. Alternatively, you can

choose to download the parameters that are stored in the controller to the

connected IO-Link device.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 23

Page 24

Chapter 3 871TM Long-range Sensor with IO-Link Overview

Automatic Device Configuration (ADC)

Replacement of damaged sensors is easy. Simply remove the old Allen-Bradley

sensor and connect the new sensor (with the same catalog number) — the

controller automatically sends the configuration to the new sensor.

ADC capability within the sensor and controller enable flexibility and reliability

in your application. When the sensor becomes damaged or fails and must be

replaced, replace it with the exact same catalog number of the existing sensor.

When the damaged sensor is removed and the new sensor is plugged in, the

existing

Link Master. No additional steps are required on the sensor or in the controller.

No personal computer is required and reteaching the sensor is not required.

configuration

is automatically stored in the sensor through the IO-

Tag Naming for I/O Data

Rockwell Automation system solutions provide tag names that are based on

the Allen-Bradley sensor connected. I/O data is converted, formatted, and

named based on the Allen-Bradley sensor applied. Reduces commissioning

time by the OEM and reduces troubleshooting time by the end user when

searching for sensor data. Consistent naming techniques used.

The Triggered and Margin Status that is previously shown are examples of

consistent tag names that are used across all Allen-Bradley sensors. These tags

give insightful and descriptive meaning to the operation of the sensor output.

The tags may change depending on the type of sensor being used and the

functionality within the sensor.

24 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 25

Chapter 4

Configure the 871TM Sensor for IO-Link Mode

This chapter shows the physical hardware and software that is required to

configure the 871TM sensor through IO-Link and provides a simple guide to

setting up the hardware.

The products that are required include the following hardware and software.

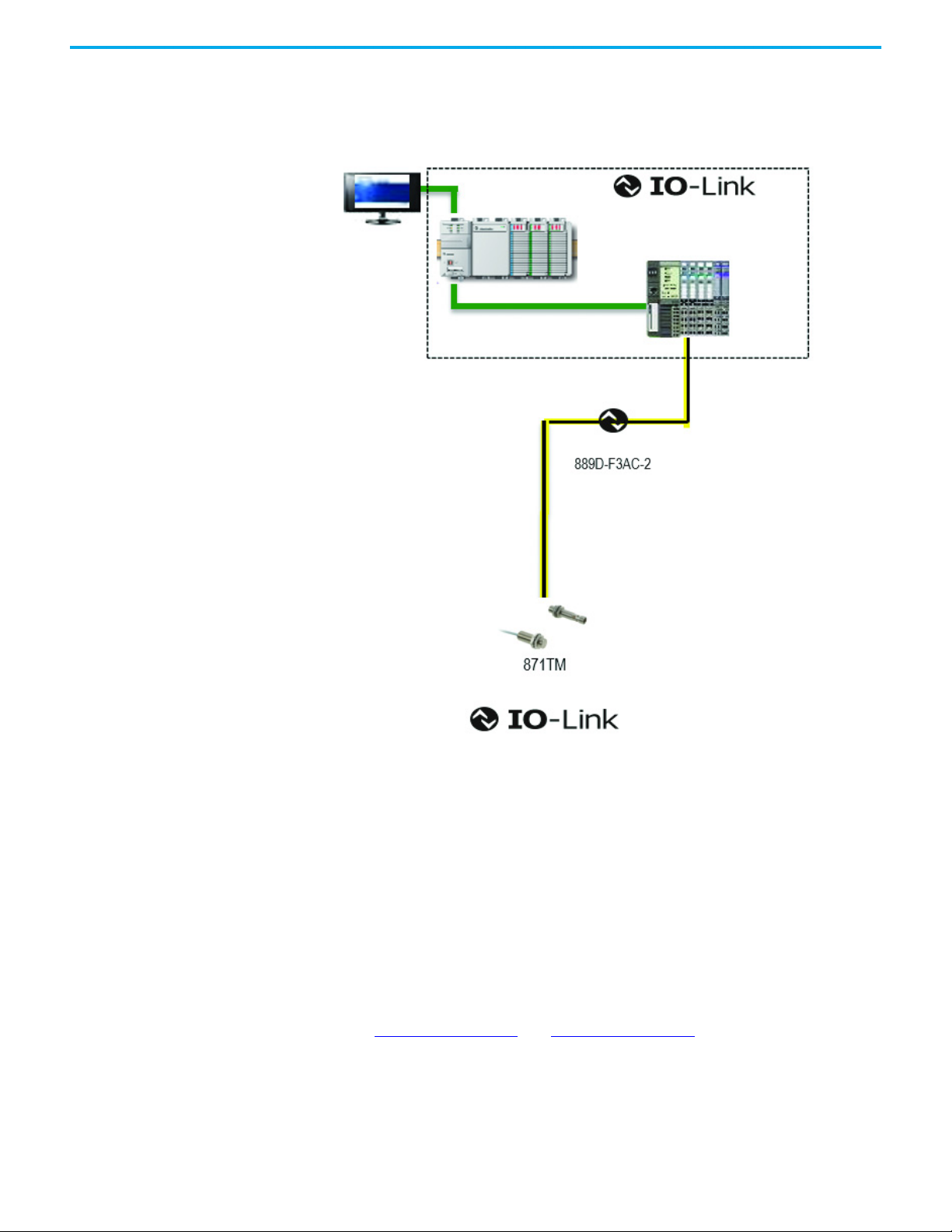

Hardware •871TM-xx (compatible sensors are N.O. PNP) with 12 mm or 18 mm barrel

diameter

• CompactLogix™ or ControlLogix® PLC Platform

• POINT I/O™ Communications Interface: 1734-AENTR

• POINT I/O IO-Link Master Module: 1734-4IOL

•POINT I/O Terminal Base: 1734-TB

• RJ45 network cable for EtherNet/IP™ connectivity:

1585J-M8TBJM-1M9xx

• 889D cordsets (optional): 889D-F3AC-2xx (IO-Link maximum acceptable

cable length is 20 m [65.6 ft])

Software • Studio 5000® environment, version 20 and higher

• Sensor-specific IODD

• 1734-4IOL IO-Link Add-on Profile (AOP)

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 25

Page 26

Chapter 4 Configure the 871TM Sensor for IO-Link Mode

Example: Set up the Hardware

In this example, a POINT I/O™ chassis is shown with a 1734-AENTR adapter

and a 1734-4IOL IO-Link master module in the first slot. The 1734-AENTR

adapter is communicating with a CompactLogix controller via an EtherNet/IP

network.

When adding a 871TM sensor to the 1734-4IOL master module, complete the

following steps:

1. Provide power to the 1734-AENTR adapter.

2. Set the node address on 1734-AENTR adapter.

3. Connect the 1734-AENTR adapter to the Allen-Bradley controller with the

recommended RJ45 Ethernet cable.

4. Wire the sensor cable to the desired location on the IO-Link master (in

this example, we are showing the sensor that is wired to the channel 0).

5. Connect the 871TM sensor to the other end of the sensor cable.

6. After connecting the sensor, you must create/open a project in the Studio

5000 environment to establish communication with the Allen-Bradley

controller that is being used. You must also add the 1734-AENTR adapter

and 1734-4IOL IO-Link master module to Controller Organizer Tree (see

Chapter 6 on page 31

26 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

and Chapter 7 on page 35 for detailed instructions).

Page 27

Chapter 5

Create a Project

Project Creation To begin a new Studio 5000® project, follow the steps in this chapter.

If there is an existing project within the Studio 5000 environment with

CompactLogix™ or ControlLogix® hardware that is installed and

communicating online, go directly to Chapter 6 on page 31

1. Double-click the Studio 5000 environment icon.

2. Click New Project.

.

3. In the New Project dialog box, select the controller for your project, name

the project, and click Next.

In this example, the project is named 1769 L24ER CompactLogix 5370

controller.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 27

Page 28

Chapter 5 Create a Project

4. After selecting the controller, name the project and click Next.

In this example, the project name is “Project871TM.”

5. To verify communication, set the IP address by clicking the browsing

icon.

Project871TM opens.

28 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 29

Chapter 5 Create a Project

6. Select the controller that is being used for the project and click Go Online

to start communication.

In this example, we are using a 1769-L24ER-QB1B CompactLogix.

The next step is to Configure the IO-Link Master on page 31

.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 29

Page 30

Chapter 5 Create a Project

Notes:

30 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 31

Chapter 6

Configure the IO-Link Master

Configuration Procedure 1. Make sure that the controller is offline to configure the IO-Link Master.

2. In the controller organizer tree, find Ethernet under I/O Configuration

and right-click to add New Module.

The module window pops up and shows the available modules.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 31

Page 32

Chapter 6 Configure the IO-Link Master

3. Select the “1734-AENTR, 1734 Ethernet adapter, 2-port, twisted-pair

media” and click Create.

4. Name the Ethernet adapter (in this example our adapter name is

“adapter”), set the chassis size, check the module revision, and configure

the adapter Ethernet address. Click OK and then Close.

32 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 33

Chapter 6 Configure the IO-Link Master

5. The 1734-AENTR adapter appears in the Controller Organizer tree.

6. Right-click the 1734-AENTR/B Adapter, and click New Module.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 33

Page 34

Chapter 6 Configure the IO-Link Master

7. Select “1734 IO-Link Module Profiles” and click Install.

The IO-Link Configuration screen appears.

8. Name the IO-Link Master and click OK.

The 871TM sensor can now be configured. To configure the sensor, a sensorspecific IODD (I/O Device Description) file is required. The next steps show

how to register the IODD file.

AOP Installation Verify that the Studio 5000® environment contains the 1734-4IOL IO-Link AOP.

Version 20 or higher of Studio 5000 environment supports this module and

AOP. To verify that the 1734-4IOL module is installed, verify that the 1734AENTR adapter contains the 1734-4IOL in the library. If the AOP is required to

be downloaded, see Appendix A on page 71

34 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

for more information.

Page 35

Chapter 7

Connect the 871TM to the IO-Link Master

Connection Procedure Once the IO-Link master is configured, connect the sensor to the IO-Link

master. Take the controller offline to add a device to the IO-Link master.

1. Go to the IO-Link tab and click Change.

2. Choose the IO-Link channel number that you want to add a sensor to and

click the Change Device column.

A window that contains a library of all sensors that are currently

registered in the IO-Link Device Library appears.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 35

Page 36

Chapter 7 Connect the 871TM to the IO-Link Master

3. Select the appropriate sensor and click Create.

If the sensor does not appear in the library, see Chapter 8 on page 41

learn how to Register the IODD.

to

The sensor is now in the channel configuration window.

36 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 37

Chapter 7 Connect the 871TM to the IO-Link Master

4. You can change the Application Specific Name, Electronic Keying, and

Process Data Input configuration while the project is in the offline mode.

IMPORTANT

The 871TM IO-Link does not support Application Specific Name or

Process Data Input configuration.

Modify the information:

• Application Specific Name (ASN): The purpose of the Application

Specific Name is to add theme naming to distinguish the sensors

within a machine and the associated project profile in the Add-on

Profile (AOP). The ASN allows for easier maintenance and operation

since the device is further identified by how it is used on the machine/

project.

• Electronic Keying Information: Select Exact Match or Disabled from

the pull-down menu. The Exact Match and Disabled keying options in

this dialog correspond to the Compatible and No Check keying options

in IO-Link terminology, respectively.

When Exact Match is selected, the connected IO-Link device must

have the same Vendor ID, Device ID, and Revision information that

has been configured for that channel. If they do not match, IO-Link

communications are not established and a Keying Fault status bit is

set. When Disabled is selected, key check is not performed.

• Process Data Input: Select the input data from the pull-down menu

(for devices that support multiple layouts of input data).

Click OK.

5. Click Yes to confirm the sensor changes.

The module properties screen appears on the General Tab.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 37

Page 38

Chapter 7 Connect the 871TM to the IO-Link Master

6. Click the IO-Link tab.

7. Locate the sensor that you added in the organization tree and select it.

The sensor can now be configured through the AOP.

38 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 39

Chapter 7 Connect the 871TM to the IO-Link Master

8. Click Go Online to communicate with the controller and sensor.

Proceed to Chapter 9 on page 49

for a description of each tab that is associated

with the 1734 AOP and a description of how the AOP can be used to configure

the sensor.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 39

Page 40

Chapter 7 Connect the 871TM to the IO-Link Master

Notes:

40 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 41

Chapter 8

Register the 871TM IODD

If you are not able to locate the 871TM in the IO-Link Sensor Library (as shown

in the previous chapter), then you must register the IODD of the sensor. By

default, the IODDs are already located in the Add-on Profile (AOP), but as new

products are released it is necessary to add products to the library.

The I/O Device Description (IODD) files contain the information that is related

to the sensor, integrated into the system environment. To initialize a sensor on

an IO-Link Master, you must register the IODD of the sensor.

If the IODD file for the sensor cannot be located in the library, it can be

downloaded from rok.auto/pcdc

to register the IODD again unless it is manually deleted from the Master Tree.

. Once the IODD is registered, there is no need

Registration Procedure 1. Double-click 1734-4IOL in the Controller Organizer Tree.

2. Click the IO-Link tab.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 41

Page 42

Chapter 8 Register the 871TM IODD

3. On the IO-Link screen, click Change.

4. Click in the Change Device column for the IO-Link channel number that

the sensor is added to.

5. In the IO-Link Device Library window, click Register IODD.

42 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 43

Chapter 8 Register the 871TM IODD

6. Click Register IODD in the following dialog box.

7. Locate the IODD XML file and double-click it. Then, click Open.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 43

Page 44

Chapter 8 Register the 871TM IODD

8. Click Exit.

The 871TM is now visible in the IO-Link Device Library.

44 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 45

Chapter 8 Register the 871TM IODD

9. Select the appropriate sensor and click Create.

10. Verify that the sensor appears in the channel configuration window and

click OK.

You can change the Application Specific Name, Electronic Keying, and

Process Data Input configuration while the project is in the offline mode.

IMPORTANT

The 871TM IO-Link does not support Application Specific Name or

Process Data Input configuration.

Modify the information:

• Application Specific Name (ASN): The purpose of the Application

Specific Name is to add theme naming to distinguish the sensors

within a machine and the associated project profile in the AOP. The

ASN allows for easier maintenance and operation since the device is

further identified by how it is used on the machine/project.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 45

Page 46

Chapter 8 Register the 871TM IODD

• Electronic Keying Information: Select Exact Match or Disabled from

the pull-down menu. The Exact Match and Disabled keying options in

this dialog correspond to the Compatible and No Check keying options

in IO-Link terminology, respectively.

When Exact Match is selected, the connected IO-Link device must

have the same Vendor ID, Device ID, and Revision information that

has been configured for that channel. If they do not match, IO-Link

communications is not established and a Keying Fault status bit is set.

When Disabled is selected, key check is not performed.

• Process Data Input: Select the input data from the pull-down menu

(for devices that support multiple layouts of input data).

Click OK.

11. Click Yes to confirm the sensor changes.

The module properties screen appears on the General Tab.

12. Click the IO-Link tab and navigate to the sensor that was added. The

sensor can now be programmed through the AOP.

46 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 47

Chapter 8 Register the 871TM IODD

13. Click Go Online to communicate with the controller and sensor.

The IODD registration and connection to the IO-Link master is complete.

Proceed to Chapter 9 on page 49

for a description of each tab that is associated

with the 1734 AOP and a description of how the AOP is used to configure the

sensor.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 47

Page 48

Chapter 8 Register the 871TM IODD

Notes:

48 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 49

Review the 1734-4IOL IO-Link Add-on Profile

Overview Device Parameter Behavior

IO-Link parameters are shown in the Add-on Profile (AOP) only for IO-Link

devices with IODD Advanced integration. Each parameter can have an

attribute of read-only (ro), read-write (rw), or write only (wo). The behavior of

parameters and the source for their values differ whether you are offline or

online.

Table 5 - IO-Link Device Parameter Behavior

Attribute Offline Online

Read-only (ro) Parameters are blank. Parameter values are read from the connected IO-Link device.

Read-write (r w) Parameter values are read from the IODD file

when the IO-Link device is added.

Changes made to the parameters are

applied when the OK and Apply buttons are

clicked.

Write only (wo) Parameter buttons are disabled. Parameter buttons that could potentially alter the Process Data

Chapter 9

Parameters show “??” when communication breaks.

Parameter values can be edited and changes made to the

parameters are applied when the OK and Apply buttons are

clicked.

Changes are sent to the Master Module, which then writes the

changes to the connected IO-Link device.

are disabled.

Other parameter buttons that are enabled, result in commands

being sent to the connected IO-Link device.

The 1734-4IOL AOP offers four different tabs to describe the sensor

functionality and operation. These tabs are:

• Common Tab: General product information about the sensor

specifications and IO-link IODD information.

• Identification Tab: Sensor cat. no., series letter, general product

description including the current product firmware, and hardware

revisions.

• Parameter Tab: Different configurable parameters available in the

871TM.

• Diagnosis Tab: Monitor IO-Link communication characteristics.

For a complete listing of all sensor parameters and parameter definitions, see

Device Parameters on page 77

.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 49

Page 50

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

Common Tab The common tab is automatically generated to give general information about

the sensor. The tab contains:

•

Vendor

•

Vendor ID

•

URL

• Device and

•Device

•IO-Link

• Hardware and Firmware Revision

•

Bitrate

•MinCycle

•

IODD

•Document

•Date of

Description

ID

Revision

Time

Version

creation

50 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 51

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

Identification Tab The Identification tab shows device information such as specific Vendor ID

and Device ID for the exact sensor that is configured. These fields are

automatically populated according to the sensor information. These fields are

Read Only (ro).

Parameter Tab

The Parameter tab allows changes to the behavior of the output of the sensor.

The IO-Link master uses these parameters for validation purposes.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 51

Page 52

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

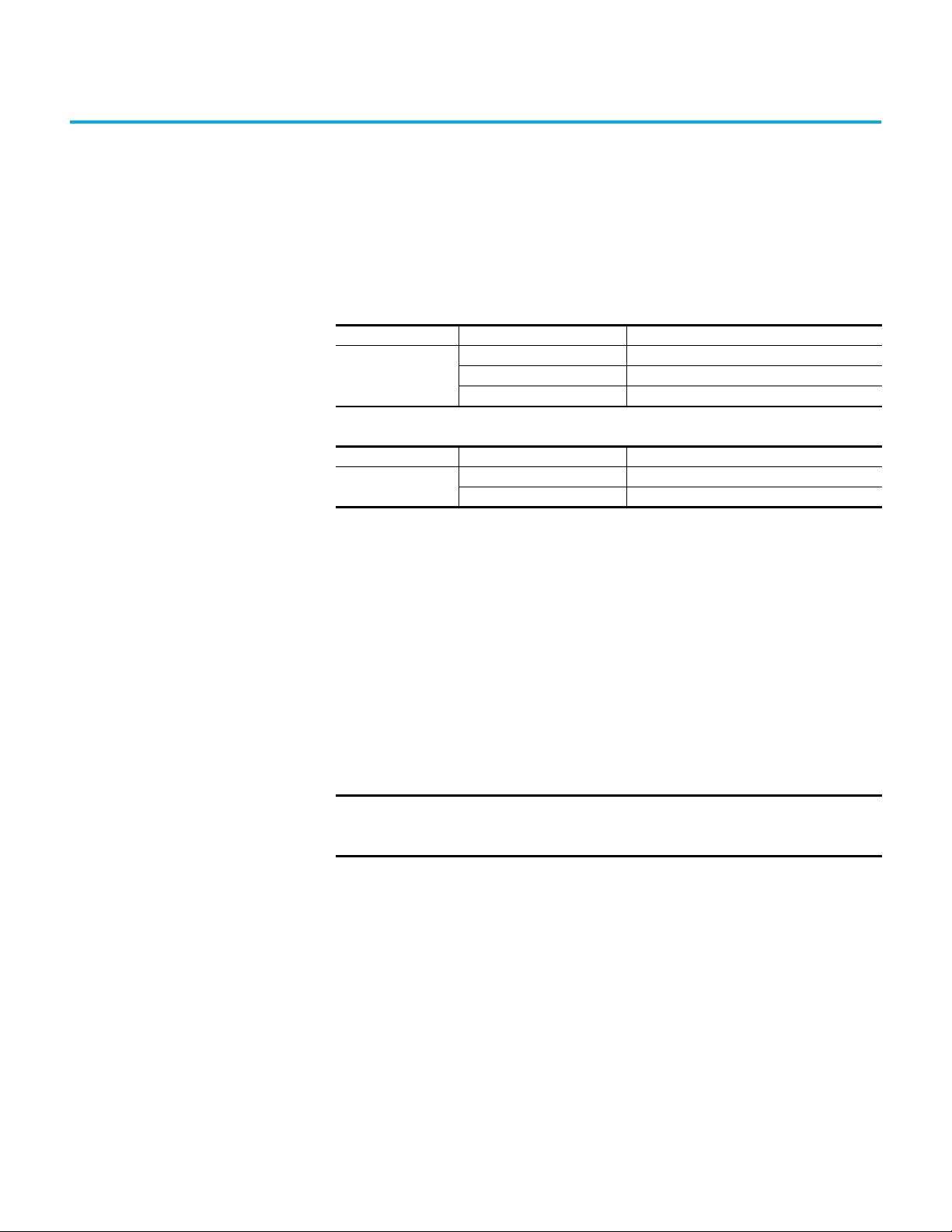

Polarity

The 871TM sensor features the ability to change the output switching mode.

The factory default mode is Not Inverted (normally open). With the sensor in

IO-Link mode, you can change the polarity parameter to Inverted (normally

closed). The sensor cannot operate in Inverted (normally closed) mode while

operating in IO-Link mode. Therefore, to use the Inverted (normally closed)

functionality, the sensor must be disconnected from IO-Link and used as a

standard input/output (SIO) device.

If you want to change the sensor back to “Not Inverted” (normally open), you

must connect the sensor back to the IO-Link master and change the setting

under the polarity parameter.

Switching Timer Mode

The switching timer is a useful function for manipulating the output of the

sensor in relation to timing. It is useful for precision applications where the

output of the sensor must be precisely triggered at a certain time. It is

important to note that the lowest time base must be used and that there is a

tolerance error of approximately ±15%.

IMPORTANT The enable parameter must be ON to enable the switching timer mode.

The 871TM sensor uses a time base with an associated offset value along with a

multiplier to create a delay value when using the switching timer mode

function. It is important that the smallest time base and multiplier is used to

create the delay. By using the smallest time base and multiplier, the tolerance

error of ±15% can be reduced. An example is provided to understand the

relationship between the different input values. The maximum delay that can

be entered is 537.6 ms.

Desired Time Delay= (Time Multiplier) (Time Base) + Offset Value

Time Base Offset Value (ms) Timer Multiplier (ms)

0 = 0.1 ms 0 0…63 ms

1 = 0.4 ms 6.4

2 = 1.6 ms 32

3 = 6.4 ms 134.4

For example: To achieve a delay of approximately24 milliseconds, you must use a time

base of 1 (0.4 ms) and 44 milliseconds for a timer base multiplier. This value does not

factor in the tolerance error of ±15%.

24 ms = (44) (0.4) + 6.4 ms

No Timer = sensor performs without any delays with the output before or after

the target in presented in front of the sensor

Off Delay = sensor triggered bit stays ON after the target is removed from the

face of the sensor. The time the output is triggered ON after the target is

removed as dictated by the time base set and the multiplier used.

52 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 53

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

No Target

Present

Tar ge t

Present

O-Delay

Target not

Present

Triggered ON

24 ms

O Delay

Time

1

0

No Target

Present

On Delay Target

Present

Tar ge t

Present

Triggered ON

24 ms

On Delay

Time

1

0

For example: Using the example above, implement an off delay of 24 ms.

On Delay = target is presented in front of the sensor, sensor triggered bit stays

OFF until switching time base and the multiplier time period have elapsed.

Once that time frame has elapsed, the trigger bit turns ON.

For example: Using the example above, implement an On Delay of 24 ms.

On Delay and Off Delay = Target is presented in front of the sensor, sensor

triggered bit stays OFF until switching time base and the multiplier have

elapsed. Once that time frame has elapsed, the trigger bit turns ON as long as

target is present. The sensor triggered bit stays ON after the target is removed

from the face of the sensor. The time the output is triggered ON after the target

is removed as dictated by the time base set and the multiplier used.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 53

Page 54

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

For example: Using the example above, implement an On Delay and Off Delay of 24ms.

On Delay and O Delay

No Target

Present

1

On Delay Target

Present

Tar ge t

Present

O Delay Target

not Present

Triggered ON

Diagnosis Tab

0

24 ms

24 ms

Time

The Diagnosis tab shows the user communication characteristics such as cycle

time and IO-Link Revision ID.

54 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 55

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

Controller Tags The controller tags have two process data tags that show the status of the sensor

concerning the output and the margin status.

Triggered: This process bit turns toggles to (1) when the sensor detects the

target and to (0) when the sensor does not detect the target. The sensor

operates as normally open when connected to IO-Link regardless of whether it

is normally closed.

Margin Status: The bit can be used as a low margin warning indicator to detect

the target is beyond the recommended working range of the sensor. This

process bit toggles to High (1) when the sensor detects a target AND the target

is between 0…80% of the operating range of the sensor. The process bit toggles

to Low (0) when the sensor detects a target beyond 80% of the specified

operating range of the sensor.

The recommended working range of the sensor is less than 80% of the specified

or nominal sensing range. Operation within the working range of the sensor

helps sustain stable operation with typical environmental

and supply voltage fluctuations and differences due to the manufacturer

tolerances.

temperature,

load,

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 55

Page 56

Chapter 9 Review the 1734-4IOL IO-Link Add-on Profile

Notes:

56 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 57

Chapter 10

Configure the Sensor with the Studio 5000

Environment

This chapter provides detailed instructions on the configuration of the 871TM

sensor using message instructions in the Studio 5000® environment. The

example code that is shown allows you to:

• Read the sensor configuration

• Set the time delay multiplier

Sample Code To download the sample code that is shown in this chapter, find the IO-Link

871TM Explicit Messaging Example from the Sample Code Library

(rockwellautomation.com/en-us/support/product/product-downloads/

application-code-library/sample-code.html) and follow these steps:

1. Save and Extract PROX_871_TM.L5X to a folder of your choice.

2. Within your Logix Studio program, right-click Main program and click

Import Routine.

3. Browse to the folder that contains the routine that is extracted in step 1

Select and click Import.

.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 57

Page 58

Chapter 10 Configure the Sensor with the Studio 5000 Environment

4. In Import Configuration window, click OK to accept the default settings.

5. From within the MainRoutine, create a rung of code that runs the

subroutine PROX_871_TM.

6. Open the 871_TM subroutine. On rung 0 within the MSG instruction,

click the square button to open the message configuration.

58 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 59

Chapter 10 Configure the Sensor with the Studio 5000 Environment

7. In the Message configuration window, click the Communication Tab and

then click Browse.

8. Browse the Ethernet network to the 1734-AENTR/B adapter and select the

1734-4IOL Master. Click OK.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 59

Page 60

Chapter 10 Configure the Sensor with the Studio 5000 Environment

Notice that the path is now set to My_4IOL in the communication path.

Click Apply and then click OK.

9. Repeat step 8

for the Message instructions on rung 12 (Write_Index_1).

10. Verify that the routine is free of Errors.

11. Press Download to download the Program to the controller.

60 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 61

Chapter 10 Configure the Sensor with the Studio 5000 Environment

12. Click Yes to put the Controller back to Run mode.

Operation

The 871TM sensor conforms to V1.0 of the IO-Link standard. The parameters of

the sensor are defined in Index 1. Index 1 consists of 128 bits of data. Data

starts at an offset of 80 bits. When using explicit messages to read and change

the sensor, configuration of the whole index must be read/written to.

Open the Controller Tag viewer and locate the tag that is named

Sensor_Channel. Set this tag to equal the channel number the 871TM sensor is

connected to on the 1734-4IOL module.

Read the 871TM Configuration Via Explicit Message

Toggle the Read_Index contact on rung 1. This action runs the Message

instruction to read the data that is contained in Index 1.

Select the contact and press Ctrl-T to toggle contacts.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 61

Page 62

Chapter 10 Configure the Sensor with the Studio 5000 Environment

The sensor configuration is read back into the Read_Assembly array. Open the

controller tags from within the controller organizer. Expand the

Read_Assembly array. The configuration is detailed in Read_Assembly[4] and

[5].

Decipher the Data

Read_Assembly[4] Contains the Hex equivalent of the time delay in

milliseconds. Use Table 6

to convert the value to milliseconds.

Table 6 - Hex Value Conversion

Delay

Value

Hex

Value

(ms)

0 0 2.6 1A 5.2 4D 12 5E 22.4 8E 54.4 A2 96 CF 243.2 E6

0.1 01 2.7 1B 5.3 35 12.4 5F 22.8 79 56 A3 97.6 BD 249.6 E7

0.2 02 2.8 47 5.4 36 12.8 C2 23.2 7A 57.6 C9 99.2 BE 256 E8

0.3 03 2.9 1D 5.5 37 13.2 61 23.6 7B 59.2 A5 100.8 BF 262.4 E9

0.4 41 3 1E 5.6 4E 13.6 62 24 8F 60.8 A6 102.4 D0 268.8 EA

0.5 05 3.1 1F 5.7 39 14 63 24.4 7D 62.4 A7 108.8 D1 275.2 EB

0.6 06 3.2 82 5.8 3A 14.4 89 24.8 7E 64 CA 115.2 D2 281.6 EC

0.7 07 3.3 21 5.9 3B 14.8 65 25.2 7F 65.6 A9 121.6 D3 288 ED

0.8 42 3.4 22 6 4F 15.2 66 25.6 C4 67.2 AA 128 D4 294.4 EE

0.9 09 3.5 23 6.1 3D 15.6 67 27.2 91 68.8 AB 134.4 D5 300.8 EF

1 0A 3.6 49 6.2 3E 16 8A 28.8 92 70.4 CB 140.8 D6 307.2 F0

1.1 0B 3.7 25 6.3 3F 16.4 69 30.4 93 72 AD 147.2 D7 313.6 F1

1.2 43 3.8 26 6.4 C1 16.8 6A 32 C5 73.6 AE 153.6 D8 320 F2

1.3 0D 3.9 27 6.8 51 17.2 6B 33.6 95 75.2 AF 160 D9 326.4 F3

1.4 0E 4 4A 7.2 52 17.6 8B 35.2 96 76.8 CC 166.4 DA 332.8 F4

1.5 0F 4.1 29 7.6 53 18 6D 36.8 97 78.4 B1 172.8 DB 339.2 F5

1.6 81 4.2 2A 8 85 18.4 6E 38.4 C6 80 B2 179.2 DC 345.6 F6

1.7 11 4.3 2B 8.4 55 18.8 6F 40 99 81.6 B3 185.6 DD 352 F7

1.8 12 4.4 4B 8.8 56 19.2 C3 41.6 9A 83.2 CD 192 DE 358.4 F8

1.9 13 4.5 2D 9.2 57 19.6 71 43.2 9B 84.8 B5 198.4 DF 364.8 F9

2 45 4.6 2E 9.6 86 20 72 44.8 C7 86.4 B6 204.8 E0 371.2 FA

2.1 15 4.7 2F 10 59 20.4 73 46.4 9D 88 B7 211.2 E1 377.6 FB

2.2 16 4.8 83 10.4 5A 20.8 8D 48 9E 89.6 CE 217.6 E2 384 FC

2.3 17 4.9 31 10.8 5B 21.2 75 49.6 9F 91.2 B9 224 E3 390.4 FD

2.4 46 5 32 11.2 87 21.6 76 51.2 C8 92.8 BA 230.4 E4 396.8 FE

2.5 19 5.1 33 11.6 5D 22 77 52.8 A1 94.4 BB 236.8 E5 403.2 FF

Delay

Value

(ms)

Hex

Value

Delay

Value

(ms)

Hex

Valu e

Delay

Value

(ms)

Hex

Valu e

Delay

Valu e

(ms)

Hex

Valu e

Delay

Value

(ms)

Hex

Valu e

Delay

Value

(ms)

Hex

Valu e

Delay

Value

(ms)

Hex

Value

62 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 63

Chapter 10 Configure the Sensor with the Studio 5000 Environment

Read_Assembly[5] contains the Hex equivalent of the sensors configuration.

The individual bits within this byte define the configuration of the timer being

enabled, Sensor Output, and On/Off Delay.

Normally Closed Normally Open Timer Disabled Timer Enabled

Mode: On Delay

Off Delay

Mode: On Delay Mode: Off Delay Mode: No Timer Hex Value

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

Write a New Configuration to the 871TM Via Explicit Message

1. The sensors configuration (NO/NC and Delay type) can be set by toggling

the required contacts on rungs two through nine.

2. If you use a time delay, use Table 6 on page 62

to determine the required

time delay Hex value.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 63

Page 64

Chapter 10 Configure the Sensor with the Studio 5000 Environment

64 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 65

Chapter 10 Configure the Sensor with the Studio 5000 Environment

3. Within the Logic on rung three, double-click the numerical field below

‘Time_Delay_ms’ and enter the new hex value for the time delay. Then,

press Enter.

Leave the 16# ahead of your entry.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 65

Page 66

Chapter 10 Configure the Sensor with the Studio 5000 Environment

4. Toggle the ‘Write_Index’ contact to write new configuration to the

871TM.

IMPORTANT The whole index has to be written to the sensor, it is required that both

5. After writing to the index, perform a read index and validate that the

sensor settings have been changed from the Controller Tag viewer.

Additionally, open up the Master by clicking the 1734-4IOL Master in the

I/O Configuration. RS Studio detects there is a difference between the

actual configuration of the sensor and the configuration in the project. A

popup box is displayed. Expand the ‘+’ sign and the differences are

shown.

bytes be populated. If only one of the values must be changed, enter the

value that you initially read into the other field.

66 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 67

Chapter 10 Configure the Sensor with the Studio 5000 Environment

Reset the Sensor to Default

1. Toggle the ‘Default_Sensor_Config’ contact. Default settings are

normally open, no timer, off delay, and no multiplier

2. Then toggle the ‘Write_Index’ contact on rung 11.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 67

Page 68

Chapter 10 Configure the Sensor with the Studio 5000 Environment

Notes:

68 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 69

Checklist

Chapter 11

Troubleshooting

This guide is meant to help resolve common issues that occur when

configuring the 871TM sensor.

Error Cause Remedy

Status indicator does not

light up

Status indicator does not

light up

Status indicator does not

light up

Status indicator does not

light up

No IO-Link connection to

the device

The power supply is switched off.

The 4-pin M12 plug is not

connected to the connector on

the sensor

Wiring fault in the splitter or

control cabinet.

Supply cable to the sensor is

damaged.

No power supply

Check to see if there is a reason for it to be

switched off (installation or maintenance work, and

so on). Switch on the power supply if appropriate.

Connect the 4-pin M12 plug to the sensor and

tighten the cap nut by hand.

Check the wiring carefully and repair any wiring

faults.

Replace the damaged cable.

See error “Operating Indicator” status indicator

does not light up.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 69

Page 70

Chapter 11 Troubleshooting

Notes:

70 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 71

Appendix A

Install the Add-on Profile

Introduction This appendix shows how to install the IO-Link Add-on Profile (AOP) with the

RSLogix 5000® program. AOPs are files that users add to their

Rockwell Automation library. These files contain the pertinent information for

configuring a device that is added to the Rockwell Automation network.

The AOP simplifies the setup of devices because it presents the necessary fields

in an organized fashion. The AOP allows you to install and configure their

systems in a quick and efficient manner.

The AOP is a folder that contains numerous files for the device. It comes as an

installation package.

Perform the Installation 1. Download the latest IO-Link AOP file from the Add-on Profiles website.

https://download.rockwellautomation.com/esd/

download.aspx?downloadid=addonprofiles

2. Extract the AOP zip file, open the folder, and execute the “MPSetup”

application file.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 71

Page 72

Appendix A Install the Add-on Profile

3. Click Next to install the IO-Link module profiles.

4. Accept the license agreements and click Next. Follow the module profiles

installation wizard.

72 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 73

Appendix A Install the Add-on Profile

5. Verify that the Install option is selected and click Next.

6. Review the install details and click Install.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 73

Page 74

Appendix A Install the Add-on Profile

7. The installation process begins. This process can take several minutes.

8. Once completed, click Next.

74 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 75

Appendix A Install the Add-on Profile

9. Click Finish and review the release notes for any additional information.

The IO-Link AOP installation is completed.

Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021 75

Page 76

Appendix A Install the Add-on Profile

Notes:

76 Rockwell Automation Publication 871TM-UM002D-EN-P - February 2021

Page 77

Identification

Appendix B

Device Parameters

When using Explicit Messages to Read/Write parameter values from/to the

871TM, you must know the Index Number, Data Type, and Size of the Data that