Page 1

Quick Start

Logix5000 Control Systems: Connect Kinetix 350 Drives over

an EtherNet/IP Network

Catalog Numbers Logix5000 Controllers, Kinetix 350 Drives

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation

sales office or online at http://www.rockwellautomation.com/literature/) describes

some important differences between solid-state equipment and hard-wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, CompactLogix, Integrated Architecture, Kinetix, Logix5000 , MP-Series, PanelView, POINT I/O, Rockwell Software, Rockwell Automation, R SLogix, Stratix 200 0, and TechConnect are trademarks of

Rockwell Automation , Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Prepare the Kinetix 350

Drive Hardware

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Using This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Other Logix5000 Control System Quick Starts . . . . . . . . . . . . . . . . . . . . . . 8

Use Each Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Where to Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How Hardware is Connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Required Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Prepare the Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mount the Kinetix 350 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Ground the Kinetix 350 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Disable the Safe Torque-off Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wire the IOD Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wire the Back-up Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wire the Input Power Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wire the Motor Power Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Apply the Motor Cable Shield Clamp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wire the Motor Feedback Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connect the Kinetix 350 Drive to the EtherNet/IP Network . . . . . . . . 27

Assign an IP Address to the Kinetix 350 Drive . . . . . . . . . . . . . . . . . . . . . . 27

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Add a Kinetix 350 Drive to an

RSLogix 5000 Project

Index

Chapter 2

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

What You Need. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Add the Kinetix 350 Drive to the RSLogix 5000 Project. . . . . . . . . . . . . 34

Configure the Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Configure Axis Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Apply Power to the Kinetix 350 Drive System . . . . . . . . . . . . . . . . . . . . . . 41

Test the Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Tune an Axis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 3

Page 4

Table of Contents

Notes:

4 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 5

Preface

IMPORTANT

IMPORTANT

About This Publication

This quick start provides examples and procedures for integrating a Kinetix 350 drive into any

Logix5000

examples are not complex, and offer easy solutions to verify that devices are functioning and

communicating properly.

Before Using This Publication

controllers control system over an EtherNet/IP network. The programming

This publication describes basic example tasks you can complete when using a Kinetix 350 drive over an EtherNet/IP

network. The tasks described are not the only tasks you can complete with the drive on an EtherNet/IP network. You

will likely need to complete additional tasks when using a Kinetix 350 drive in a specific Logix5000 control system.

You can only complete the tasks described in this publication after first completing some

prequisite tasks with a Logix5000 controller. For example, before you can add a Kinetix 350

drive to an RSLogix

5000 project, as described on page 31, you must first create the project in a

Logix5000 controller.

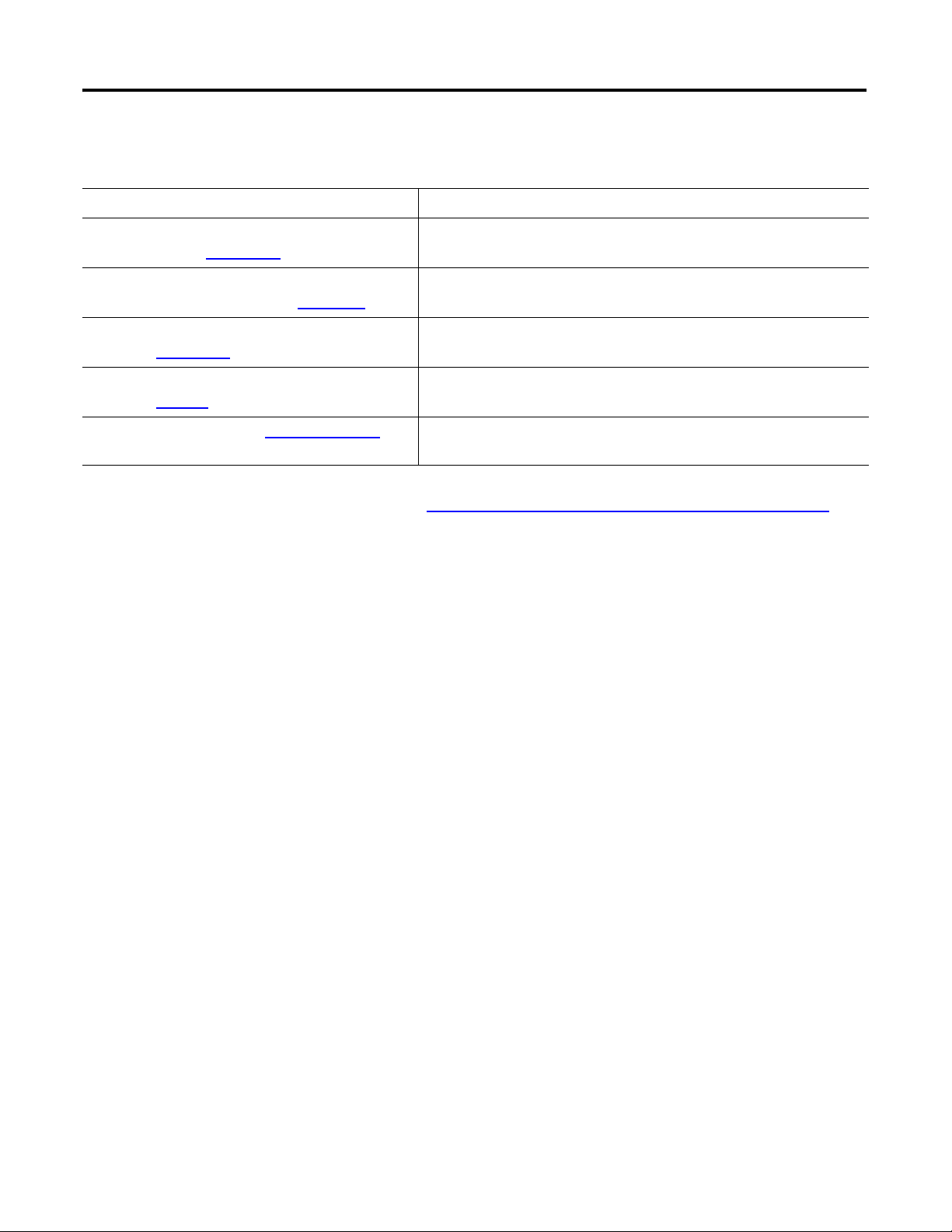

The example graphics shown in Table 1 - Required Tasks to Complete before Using This Quick Start on page 6 are for

CompactLogix 5370 L3 controllers. Depending on the Logix5000 controller you are using, the specific steps to

complete the tasks described in the table might vary.

For more information on how to complete these tasks with specific Logix5000 controllers, see

the Integrated Architecture

publication IASIMP-QR024

: Logix5000 Control Systems Quick Starts Quick Reference,

.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 5

Page 6

Preface

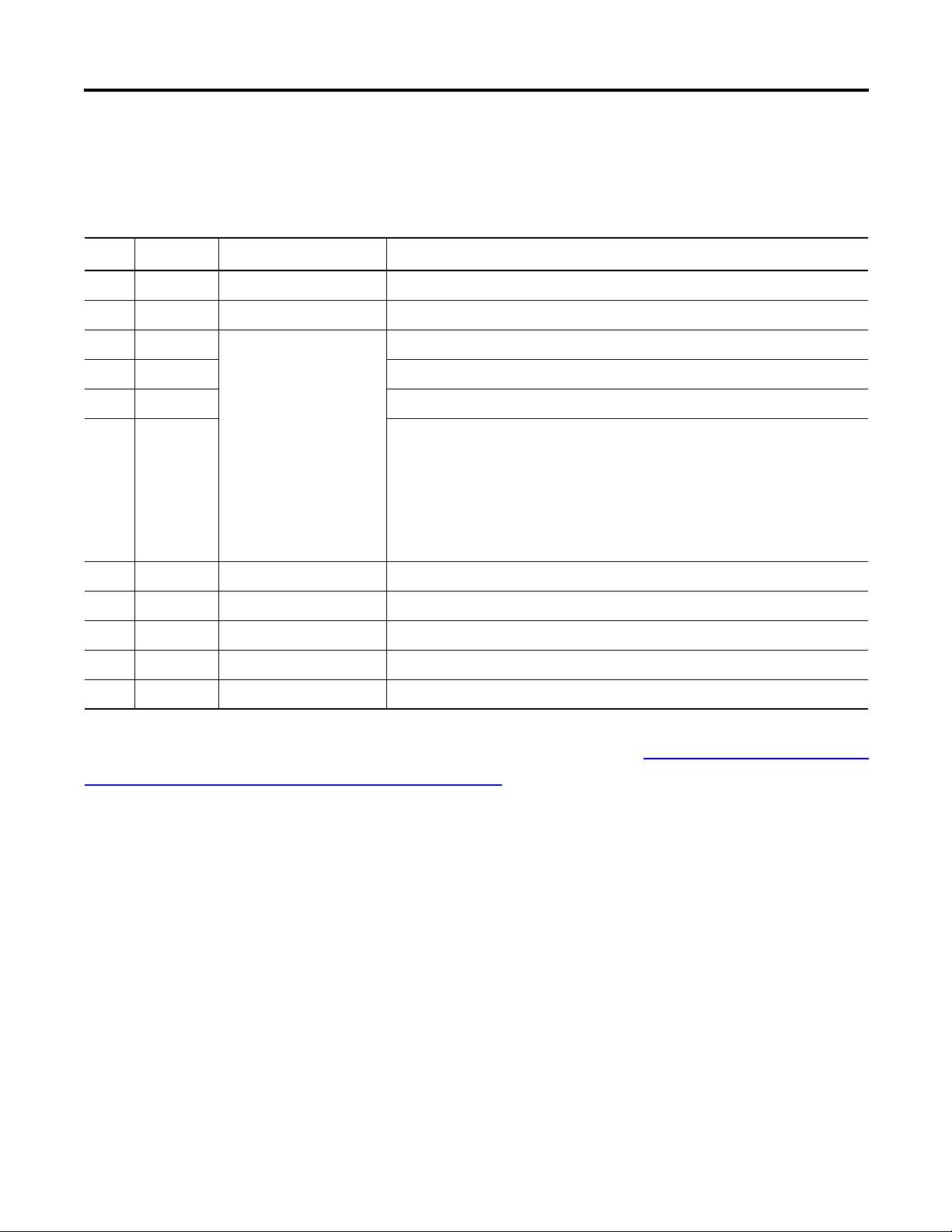

Table 1 - Required Tasks to Complete before Using This Quick Start

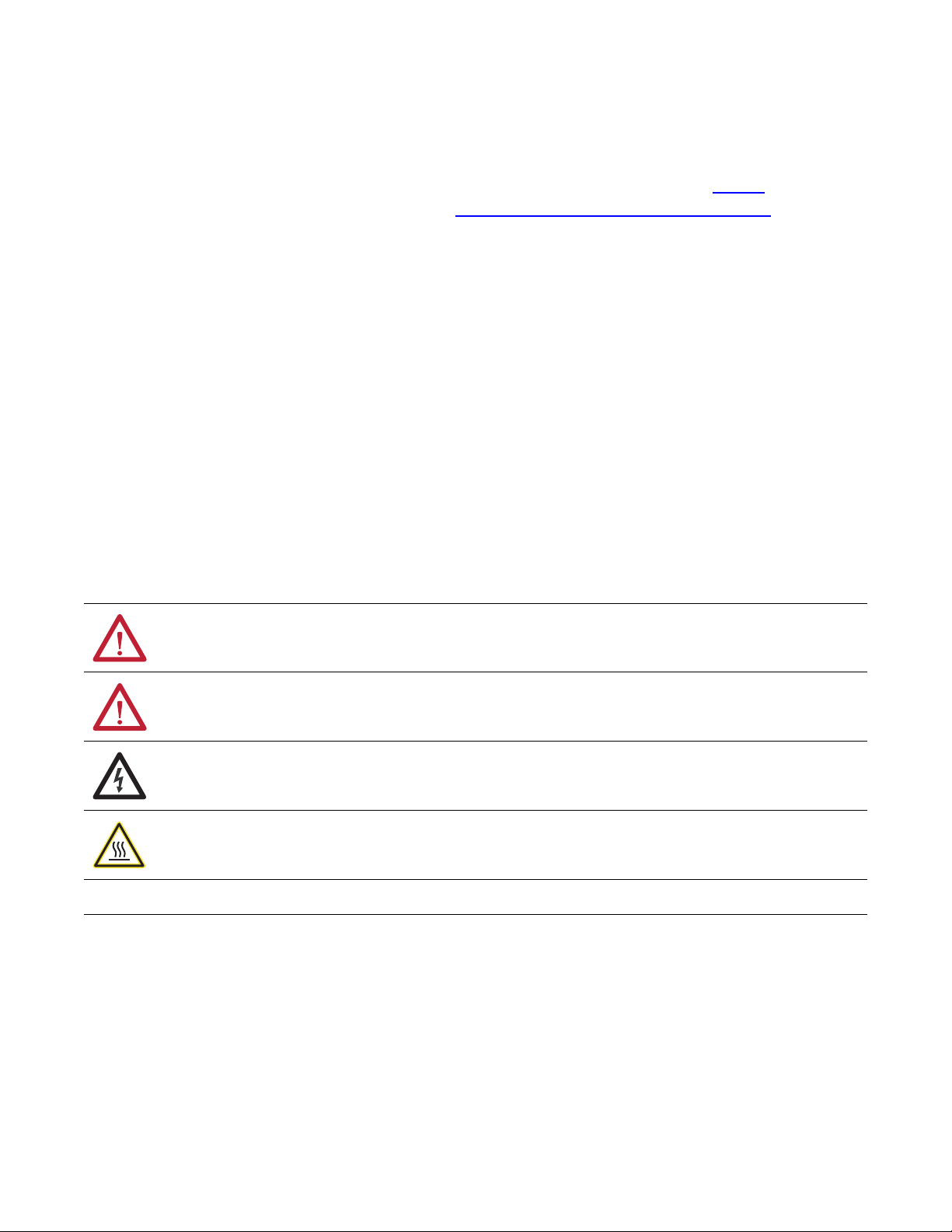

Task Description

Prepare the Logix5000

control system

hardware

Assemble the control system and connect to necessary communication networks. Some components, for

example, the Logix5000 controller and system power supply, are required. Other components, for example, a

network communication module, are optional.

These example graphics show the assembly of one Logix5000 controller.

1 (Front)

2 (Rear)

IMPORTANT: This task does not include installation of specific hardware components, for example,

Kinetix 350 drives, used over the networks included in your application.

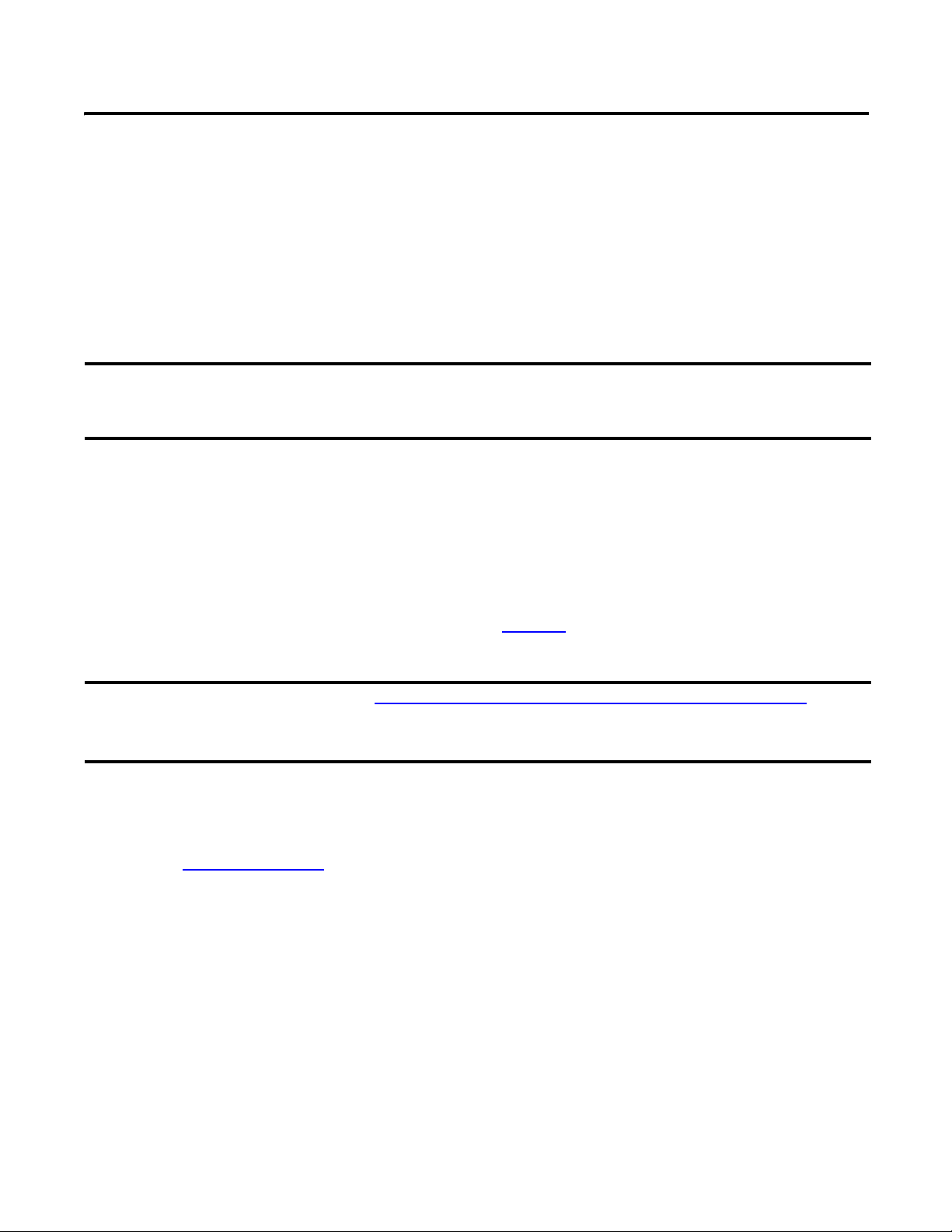

Prepare the computer Install necessary software on your complete. Some software, for example, RSLogix 5000 software.

6 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 7

Table 1 - Required Tasks to Complete before Using This Quick Start

Task Description

Preface

Configure the

networks

Create an

RSLogix 5000 project

Complete required tasks associated with the networks used in your application, such as assigning an IP address

to the controller’s communication port or communication module in your Logix5000 control system.

Create a project to be used with your Logix5000 controller. A project includes all desired control system

components and necessary programming. For example, add ladder logic to test tasks associated with individual

system components.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 7

Page 8

Preface

Other Logix5000 Control System Quick Starts

This quick start describes how to use one device on one network in a Logix5000 control system.

Typically, though, a Logix5000 control system includes more than the controller and one device

on one network.

For example, if a Logix5000 control system operates on an EtherNet/IP network, in addition to

a controller, power supply, and communication modules, the system might use remote I/O

modules, drives, and HMI terminals.

Other quick starts describe how to use different devices on different networks in Logix5000

control systems. For more information, see the Integrated Architecture: Logix5000 Control

Systems Quick Starts Quick Reference, publication IASIMP-QR024

.

Use Each Chapter

The beginning of each chapter contains the following information. You should read these

sections before beginning work in each chapter:

• Before You Begin - This section lists the tasks you must complete before starting

the chapter.

• What You Need - This section lists the tools that are required to complete the tasks in

the chapter.

• Follow These Steps - This section illustrates the steps in the current chapter.

8 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 9

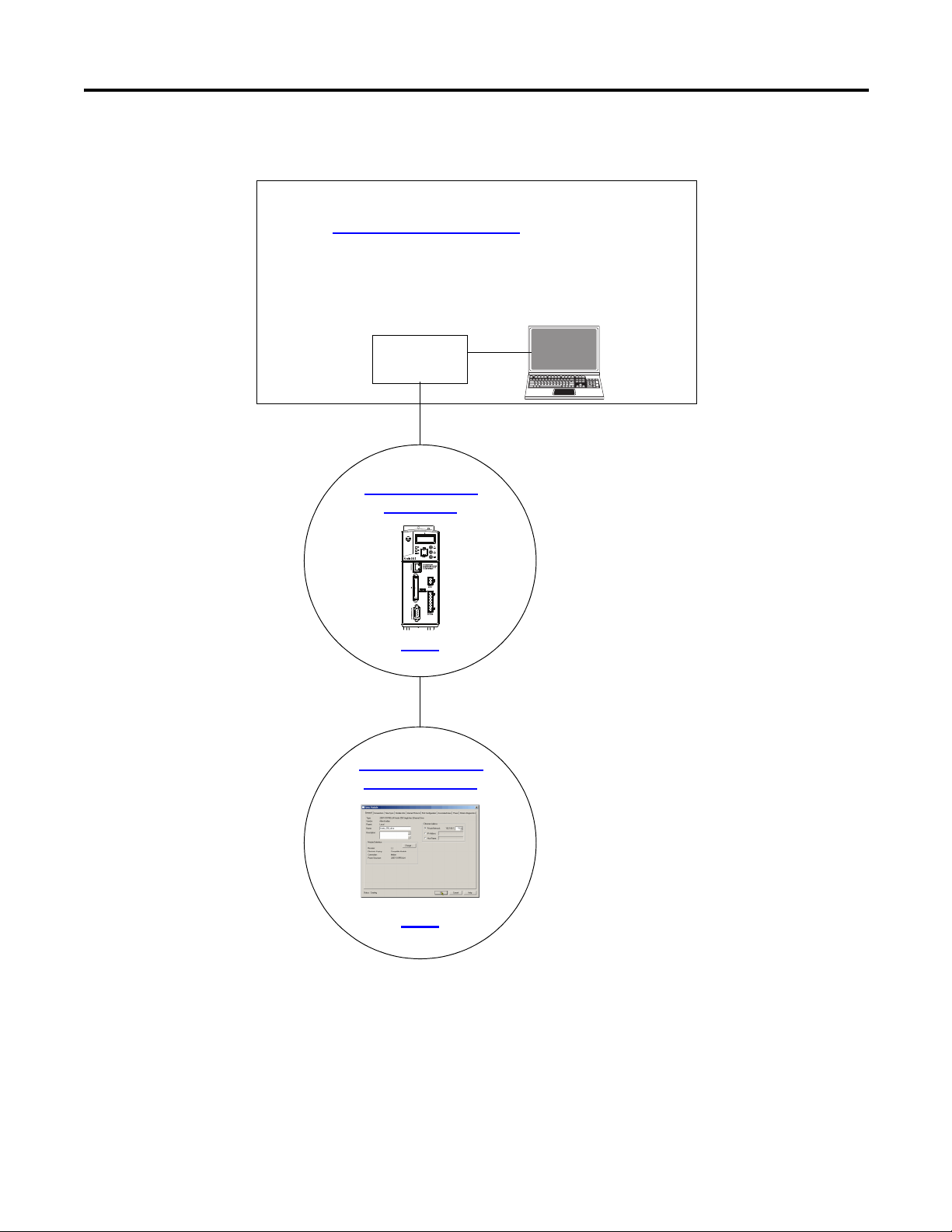

Where to Start

Prepare the Kinetix 350

Drive Hardware

page 13

Prerequisite Tasks

Described in Before Using This Publication

on page 5.

1. Prepare the Logix5000 control system hardware

2. Prepare the computer

3. Configure the networks

4. Create an RSLogix 5000 project

Logix5000

Control ler

Add a Kinetix 350 Drive to

an RSLogix 5000 Project

page 31

Preface

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 9

Page 10

Preface

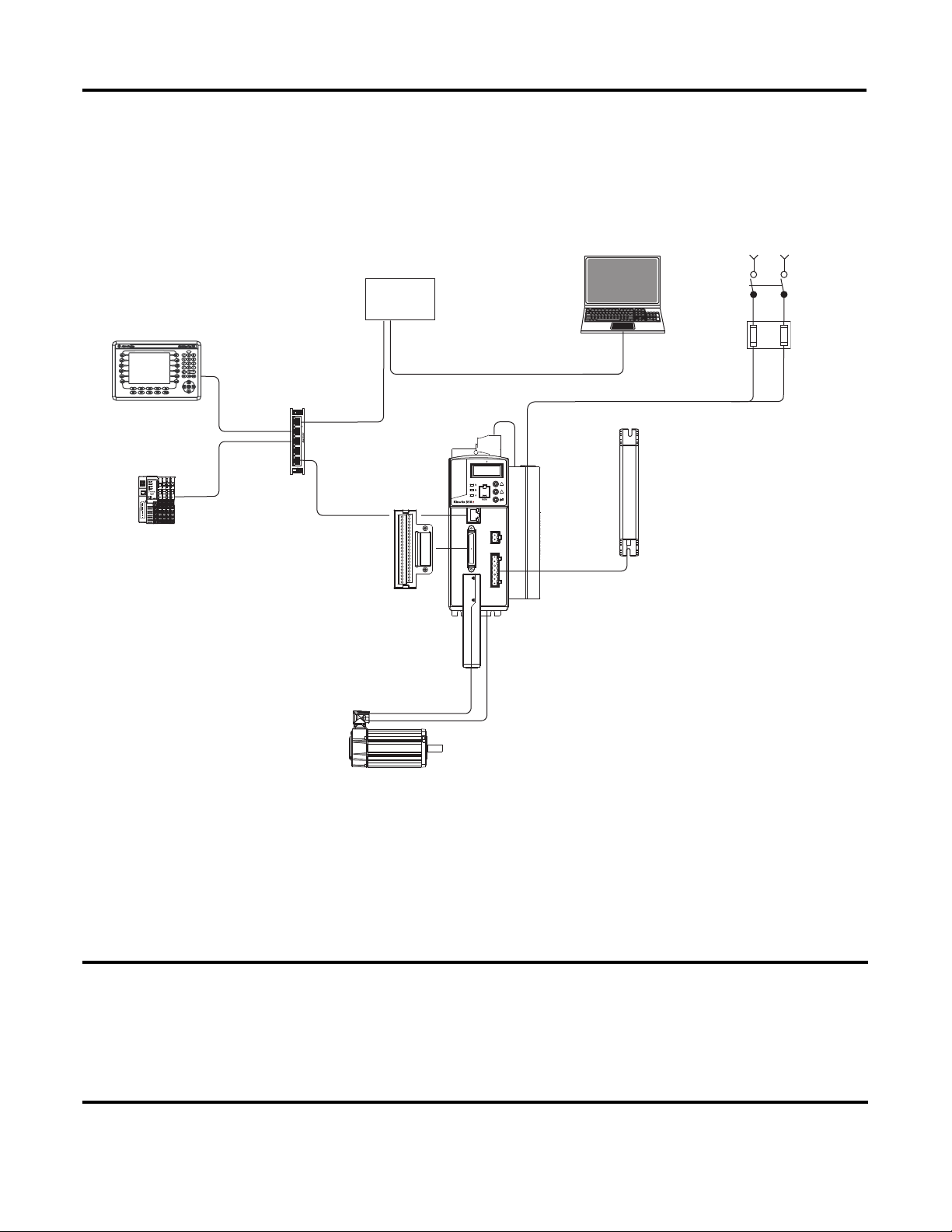

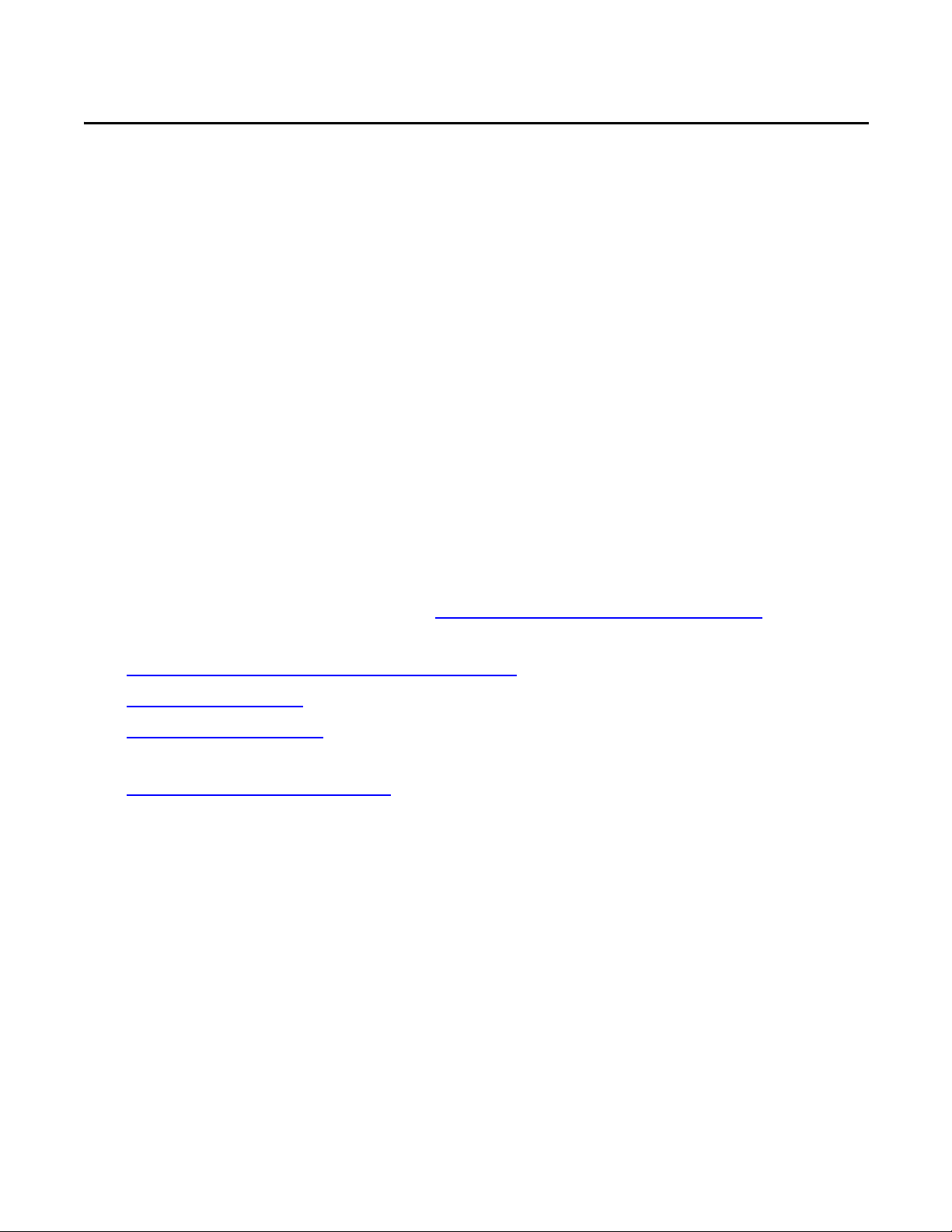

IMPORTANT

2

3

5

4

1

R

W

P

Logix5000

Controller

Stratix 2000

Switch

Computer with

RSLogix 5000 Software

MP-Series

Rotary Motor

Single-phase Input Power

Shunt

Resistor

Motor Feedback Cable

Kinetix 350

Drive

Terminal Expansion Block

1734 POINT I/O

Modules

Pane lView

Plus Terminal

AC Line Filter

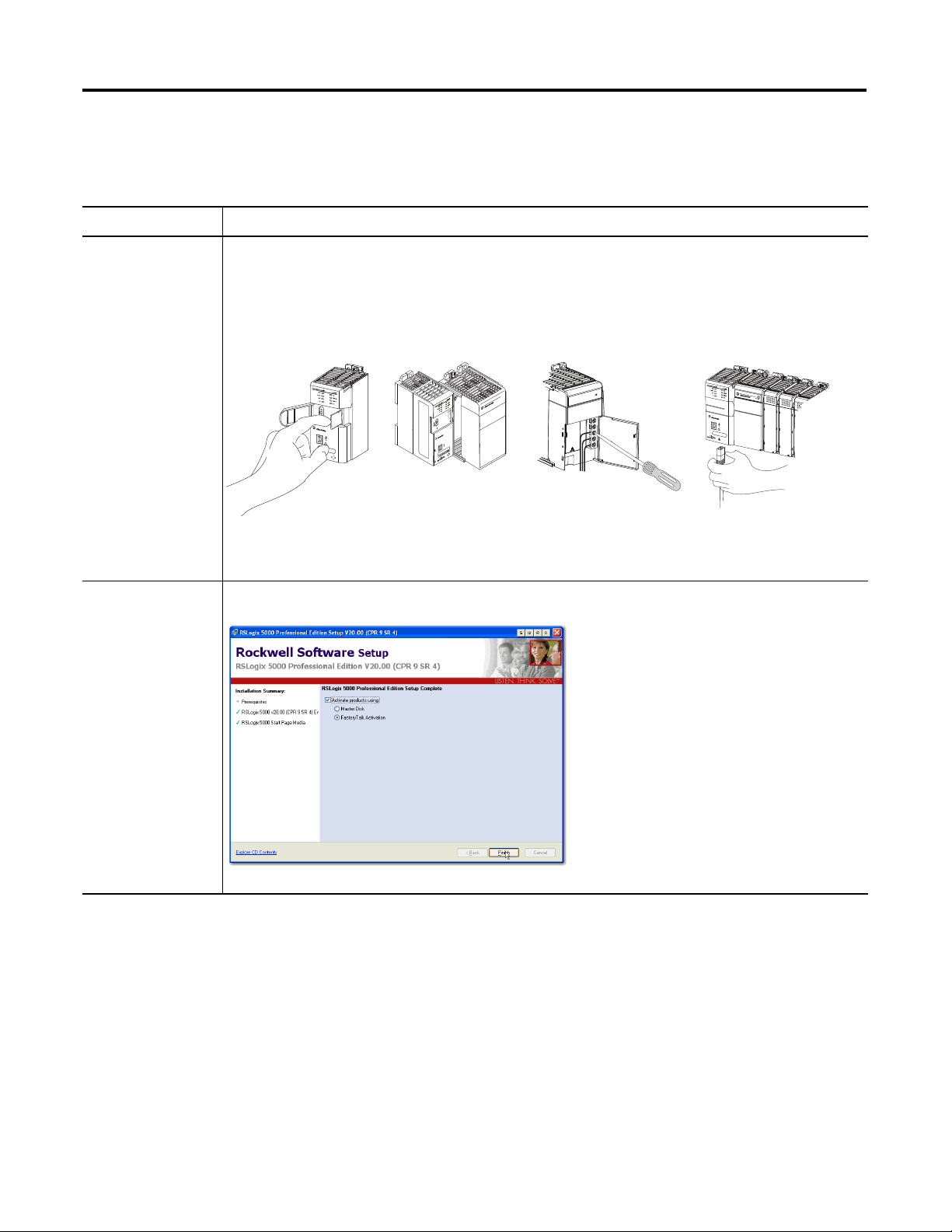

How Hardware is Connected

This graphic shows an example control system that uses a Kinetix 350 drive.

Required Software

To complete examples in this quick start, you need RSLogix 5000 software. RSLogix 5000

software is required to create or change RSLogix 5000 projects that use Kinetix 350 drives.

This quick start uses RSLogix 5000 software, version 20.00.00 or later, because the example Logix5000 controller, and

associated tasks, described herein are completed in a CompactLogix 5370 L3 control system. CompactLogix 5370 L3

control systems require RSLogix 5000 software, version 20.00.00 or later.

If you connect a Kinetix 350 drive over an EtherNet/IP network in a Logix5000 control system that uses a different

Logix 5000 controller, the minimum version may differ.

10 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 11

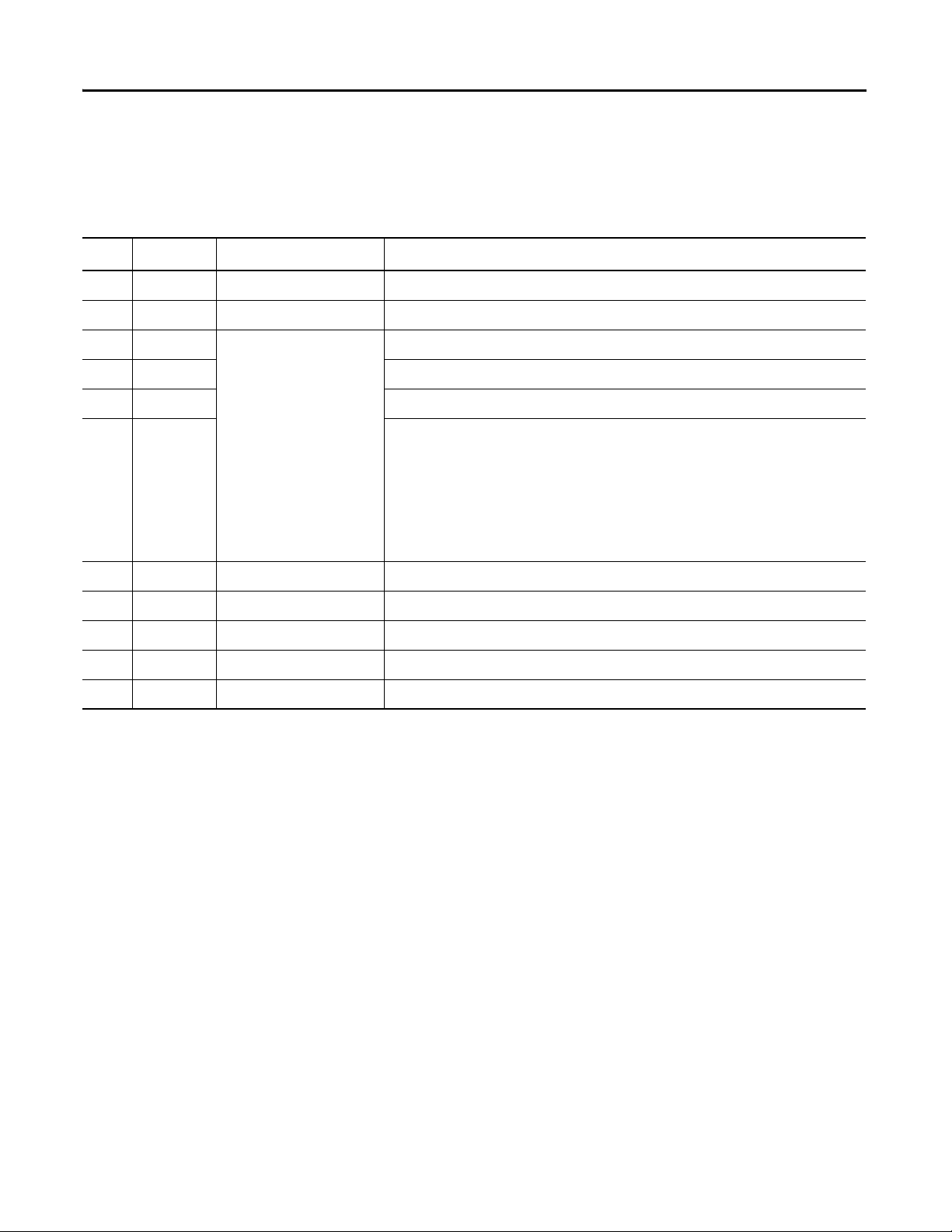

Parts List

You need these parts to complete the tasks described in this quick start.

Preface

Quantity Cat. No. Description

1 2097-V31PR2-LM Kinetix 350 Single Axis Ethernet/IP Servo Drive

1 MPL-A310P-MJ72AA MP-Series Low-inertia Servo Motor

1 The connectors required to

1 6-pin Motor Power (MP) Connector

1 24V DC Back-up Power (BP) Connector

1 4- pin General-purpose AC Input Power (IPD) Connector

1 2097-TB1 Bulletin 2097 I/O Terminal Expansion Block - 50-pin SCSI I/O (IOD) Connector

1 2090-CPWM7DF-16AA03 6-pin Standard Power Cable with SpeedTec DIN Connector Type 923

1 2090-CFBM7DD-CEAA03 Standard Feedback Cable with SpeedTec DIN Connector Type 623

1 1585J-M8PBJM-2 RJ45 to RJ45 patchcord Ethernet cables

3 Jumper wires

use Kinetix 350 drives vary

by drive catalog number.

The specific connectors to

be used with your

2097-V31PR2-LM drive

ship with the drive.

You do not need to order

this part separately.

6-pin Safe Torque Off (STO) Connector

For a list of parts required to complete the prerequisite tasks listed in Tab le 1 -

Required Tasks to

Complete before Using This Quick Start on page 6, see the documentation describing those

tasks.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 11

Page 12

Preface

Additional Resources

Resource Description

Kinetix 350 Single-axis EtherNet/IP Servo Drives User

Manual, publication 2097-UM002

Kinetix 350 Single-axis EtherNet/IP Servo Drives

Installation Instructions, publication 2097-IN008

EtherNet/IP Modules in Logix5000 Control Systems,

publication ENET-UM001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other certification

Describes how to install, wire, configure, operate, and troubleshoot your

Kinetix 350 drive.

Describes how to install and wire your Kinetix 350 drive.

Describes how to install, configure, and operate EtherNet/IP modules.

Provides general guidelines for installing a Rockwell Automation industrial

system.

details.

You can view or download publications at http://www.rockwellautomation.com/literature/. To

order paper copies of technical documentation, contact your local Allen-Bradley

distributor or

Rockwell Automation sales representative.

12 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 13

Chapter

Prepare the Kinetix 350 Drive Hardware

In this chapter, you learn how to complete the following tasks:

• Mount a 2097-V31PR2-LM drive.

• Make multiple connections, for example, power, feedback and resistor connections to

the drive.

• Configure EtherNet/IP communication for the drive.

1

Before You Begin

You must complete these tasks described in Before Using This Publication on page 5 before using

this chapter:

• Prepare the Logix5000 control system hardware

• Prepare the computer

• Configure the networks - The tasks described in this chapter require an

EtherNet/IP network.

• Create an RSLogix 5000 project

The example RSLogix 5000 project used in this chapter uses a

CompactLogix 5370 L3 controller.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 13

Page 14

Chapter 1 Prepare the Kinetix 350 Drive Hardware

What You Need

This table lists the products you need to complete the tasks described in this chapter.

Quantity Cat. No. Description

1 2097-V31PR2-LM Kinetix 350 Single Axis Ethernet/IP Servo Drive

1 MPL-A310P-MJ72AA MP-Series Low-inertia Servo Motor

1 The connectors required to

1 6-pin Motor Power (MP) Connector

1 24V DC Back-up Power (BP) Connector

1 4- pin General-purpose AC Input Power (IPD) Connector

1 2097-TB1 Bulletin 2097 I/O Terminal Expansion Block - 50-pin SCSI I/O (IOD) Connector

1 2090-CPWM7DF-16AA03 6-pin Standard Power Cable with SpeedTec DIN Connector Type 923

1 2090-CFBM7DD-CEAA03 Standard Feedback Cable with SpeedTec DIN Connector Type 623

1 1585J-M8PBJM-2 RJ45 to RJ45 patchcord Ethernet cables

3 Jumper wires

use Kinetix 350 drives vary

by drive catalog number.

The specific connectors to

be used with your

2097-V31PR2-LM drive

ship with the drive.

You do not need to order

this part separately.

6-pin Safe Torque Off (STO) Connector

14 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 15

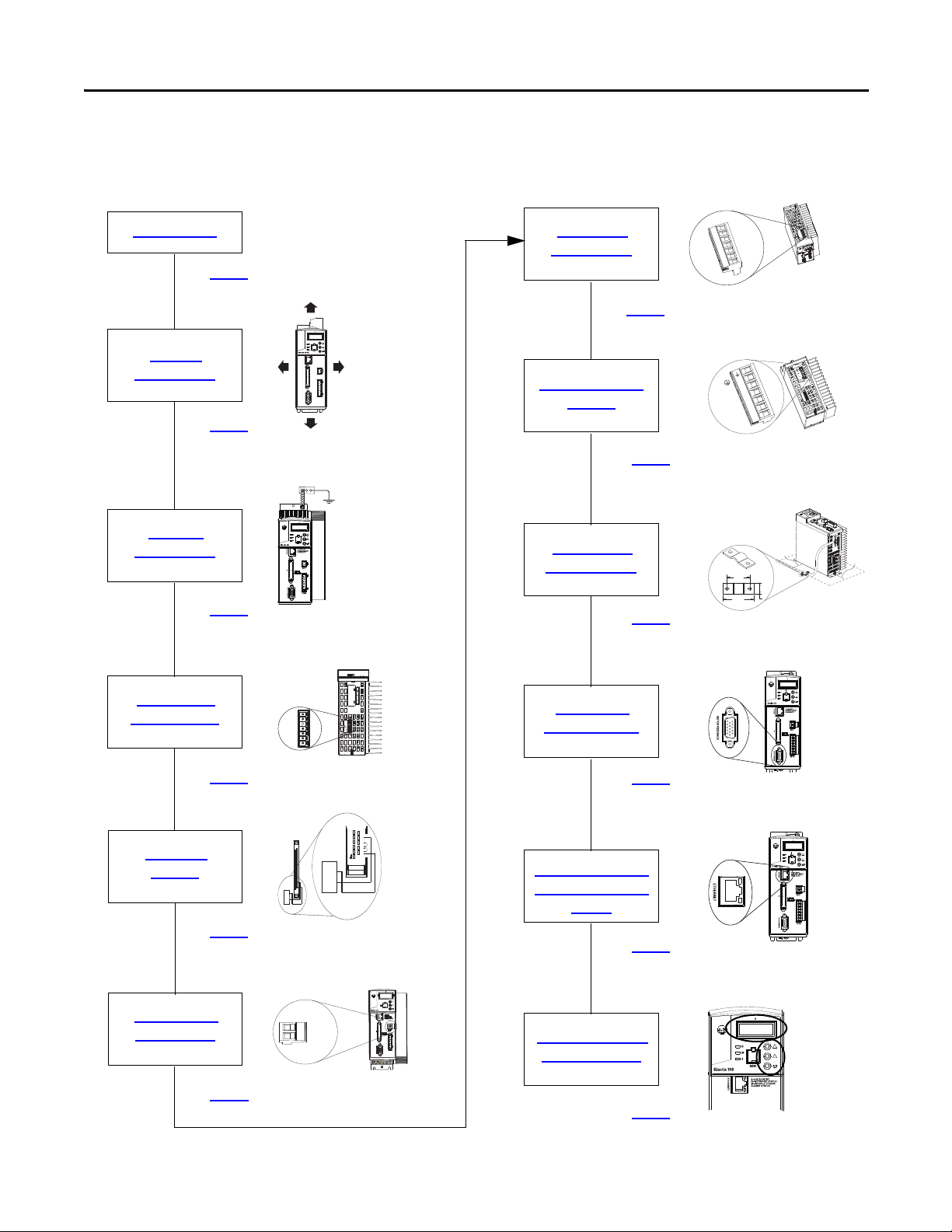

Follow These Steps

Prepare the Panel

Ground the

Kinetix 350 Drive

page 16

page 17

Mount the

Kinetix 350 Drive

page 17

Apply the Motor

Cable Shield Clamp

page 25

Wire the Motor

Feedback Connector

page 26

Connect the Kinetix 350

Drive to the EtherNet/IP

Network

page 27

Disable the Safe

Torque-off Feature

page 18

Wire the Motor Power

Conne ctor

page 24

Assign an IP Address to

the Kinetix 350 Drive

page 27

Wire the IOD

Conne ctor

page 20

Pin 26

Pin 25

Pin 46

Pin 47

Pin 48

Pin 49

Pin 50

Pin 29

Pin 28

Pin 27

+

-

Wire the Back- up

Power Connector

page 22

Wire the Input

Power Connector

page 23

Prepare the Kinetix 350 Drive Hardware Chapter 1

1 2 3 4 5 6

STO

PE

W

W

V

V

U

U

+

+24V DC

24

-24V DC

-

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 15

Page 16

Chapter 1 Prepare the Kinetix 350 Drive Hardware

25.0 mm (1.0 in.)

3 mm (0.12 in.)

3 mm (0.12 in.)

25.0 mm (1.0 in.)

Prepare the Panel

You must install the 2097-V31PR2-LM drive on a grounded panel. This quick start assumes you

installed a panel when you fulfilled the prerequisite task of installing the Logix5000 control

system hardware:

• If you have already installed a painted, grounded panel, move to section Mount the Kinetix

350 Drive.

• If you have not already installed a painted, grounded panel, do so before proceeding to the

next section.

For more information on properly installing a panel that you can use with a Kinetix 350

drive, see the Kinetix 350 Single-axis EtherNet/IP Servo Drives User Manual,

publication 2097-UM002

Mount the Kinetix 350 Drive

1. Verify that you have at least the

minimum clearance to mount your

2097-V31PR2-LM drive on

the panel.

.

16 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 17

Prepare the Kinetix 350 Drive Hardware Chapter 1

238 mm

(9.37 in.)

Additional clearance below the

connector kit is necessary to

provide the recommended

cable bend radius.

Dimensions are in mm (in.)

Braided Ground Strap Bonded Cabinet Ground Bus

Ground Grid or Power

Distribution Ground

Ground Stud

2. Use the dimensions shown to make sure your mounting holes are in the correct location.

A

5.0

(0.19)

238

(9.37)

7.1

(0.28)

9.7

(0.38)

6.6

(0.26)

11.8

(0.46)

30.8

(1.21)

38.1

(1.5)

182

(7.18)

190

(7.50)

Ø 4.57

(0.18) 3x

B

3. Attach the drive to the cabinet using M4 (#6-32) steel machine screws torqued to 1.1 N

(9.8 lb

in) beginning with the upper mounting slots and then the lower slots.

4. Tighten all mounting fasteners.

Ground the Kinetix 350 Drive

Use a braided ground strap or 4.0 mm2

(12 AWG) solid copper wire 100 mm

(3.9 in.) long to ground the

2097-V31PR2-LM drive to the bonded

cabinet ground bus, as shown.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 17

m

Page 18

Chapter 1 Prepare the Kinetix 350 Drive Hardware

IMPORTANT

1 2 3 4 5 6

STO

Safe Torque-off

(STO) Connector

Bottom View of Drive

STO-1

STO-2

STO-3

STO-4

STO-5

STO-6

Motion-allowed

Jumpers

Disable the Safe Torque-off Feature

The safe torque-off feature is used in applications used in safety conditions. This feature safely

removes power from the gate firing circuits of the drives output power devices (IGBTs). The

feature is enabled by default when the Kinetix 350 drive ships from the factory.

If your application, for example, the one used in this quick start, does not require the use of safety

options, you disable the safe torque-off feature. You use jumper wires, as shown, to disable the

safe torque-off feature. The tasks in this quick start are not completed in an environment that

includes safety conditions. You can disable the safe torque-off feature.

Complete these steps to disable the safe torque-off feature.

1. Remove the STO connector from

the drive.

2. Install STO Motion-allowed

jumpers at the termination points

as shown.

3. Insert the STO connector into the

bottom of the drive.

For more information about

using the safe torque-off

feature in an environment

that includes safety

conditions, see the Kinetix

350 Single-axis EtherNet/IP

Servo Drive User Manual,

publication 2097-UM002.

18 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 19

Prepare the Kinetix 350 Drive Hardware Chapter 1

IMPORTANT

Bonded Cabinet

Ground Bus

Single-phase AC

Input 120V rms AC,

50/60 Hz

User-supplied

+24V DC

Main Single-phase

AC Input (IPD)

Connector

Back-up Power

(BP) Connector

Motor Power

(MP) Connector

Ground Stud

L2/N

L1

Contactor

Coil

Input

Fusing

Fuse

Disconnect

or Circuit

Breakers

Cable Shield

Clamp

AC Line Filter

(Opti onal)

PE

N

L1

L2/N

Pin 26

Pin 29

Pin 27

Pin 28

User-supplied 24V

DC Power Supply

I/O (IOD)

Conne ctor

+

-

Wiring Diagram

You can wire 120V or 240V single-phase input power to your Kinetix 2097-V31PR2-LM drive.

When completing the tasks described in this quick start, you use 120V single-phase power.

The following graphic shows how to wire connectors on your Kinetix 2097-V31PR2-LM drive

for 120V single-phase power. More detailed descriptions of how to wire each connector are

included later in this chapter.

Keep in mind, the following graphic does not show all the possible connections to your

Kinetix 2097-V31PR2-LM drive. It only describes the connections required to complete the tasks

described in this quick start.

For more complete information on how to wire your Kinetix 350 drive see the Kinetix 350 Single-axis

EtherNet/IP Servo Drives User Manual, publication 2097-UM002.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 19

Page 20

Chapter 1 Prepare the Kinetix 350 Drive Hardware

Wire the IOD Connector

The 2097-V31PR2-LM drive ships from the factory with the drive ENABLE functionality

enabled. In addition to this configuration, you must wire the 2097-TB1 I/O terminal expansion

block to complete the tasks described in this quick start, for example, the tasks described in Your

control system can execute drive actions, such as the Hookup test described on Te st th e Ax is

page 44.

To use your Kinetix drive with the drive ENABLE functionality in the enabled state, you must

connect a user-supplied, external 24V DC power supply to the drive via the IOD connector.

Complete these steps to use the IOD connector.

1. Verify the user-supplied, external power supply is not powered.

on

2. Connect a wire from a -24V DC terminal on the external power supply to pin 26 (+/-

Overtravel, enable and home common) on the IOD connector.

3. Jumper a wire from pin 27 (Negative hardware overtravel) to pin 28 (Positive hardware

overtravel) on the IOD connector.

4. Jumper a wire from pin 28 (Positive hardware overtravel) to pin 29 (Drive enable) on the

IOD connector.

20 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 21

Prepare the Kinetix 350 Drive Hardware Chapter 1

IMPORTANT

Pin 26

Pin 25

Pin 46

Pin 47

Pin 48

Pin 49

Pin 50

Pin 29

Pin 28

Pin 27

+

-

User-supplied

24V DC Power

Supply

I/O Connection

5. Connect a wire from a +24V DC terminal on the external power supply to pin 29

(ENABLE signal) on the IOD connector.

6. Insert the IOD connector into the

drive in the location shown in this

graphic.

Do not connect power to the

external power supply.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 21

Page 22

Chapter 1 Prepare the Kinetix 350 Drive Hardware

IMPORTANT

Wire the Back-up Power Connector

You need a user-supplied, external 24V DC power supply to provide back-up power to the drive.

Complete these steps to wire the BP connector.

1. Verify the user-supplied, external power supply is not powered.

2. Remove the BP connector from

the drive.

3. Remove approximately 6 mm (0.25

in.) insulation from two 1.5 mm

(16 AWG) copper wires.

2

+

24

-

+24V DC

-24V DC

4. Connect a wire from a +24V DC

terminal on the external power

supply to the +24V DC terminal

on the BP connector.

5. Connect a wire from a -24C DC terminal on the external power supply to the -24V DC

terminal on the BP connector.

6. Insert the connector plug into the drive in the location shown above.

Do not connect power to the external power supply.

22 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 23

Prepare the Kinetix 350 Drive Hardware Chapter 1

IMPORTANT

L2/N

L1

N

PE

Top View of Drive

Wire the Input Power Connector

You can use a 120V AC or 240V DC power source to connect input power to the

2097-V31PR2-LM drive via the IPD connector. In this quick start, we describe how to connect a

120V AC power source to the drive.

Complete these steps to wire the IPD connector.

1. Verify the 120V AC power source is not powered.

2. Remove the IPD connector plug

from the top of the drive.

3. Remove approximately 7 mm

(0.28 in.) insulation from four

2

2.5 mm

copper wires.

(14 AWG)

4. Insert the wires from the 120V

AC power source cable into the

IPD connector positions

according to the following table.

Power Cable Wire Terminal

Black L1

White N

Green PE

The L2/N connector is not used when connecting input power from a 120V AC

power source.

5. Insert the connector plug into the location shown above.

Do not connect power to the external power supply.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 23

Page 24

Chapter 1 Prepare the Kinetix 350 Drive Hardware

Bottom View of Drive

Wire the Motor Power Connector

This publication uses a 2090-CPWM7DF-16AA03 standard power cable with SpeedTec DIN

connector type 923 to wire power from the 2097-V31PR2-LM drive to the motor.

Complete these steps to wire the power cable to the MP connector.

1. Remove the MP connector from the bottom of the drive.

2. Remove approximately 7 mm

(0.28 in.) insulation from four

2

2.5 mm

copper wires.

3. Insert the wires into the

appropriate connector positions

according to the following table.

MP-Series Servo

Motor Wire

(14 AWG)

Terminal

PE

W

W

V

V

U

U

Green/

yellow

W/Blue W

V/Black V

U/Brown U

PE

4. Insert the MP connector into the module as shown above.

5. Connect the other end of the 2090-CPWM7DF-16AA03 cable to the motor.

24 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 25

Prepare the Kinetix 350 Drive Hardware Chapter 1

25 mm

(1.0) in.

If panel is painted, remove paint to

provide metal-to-metal contact.

34 mm

(1.34) in.

Motor Power Ground Shield Clamp

12.7 mm

(0.50) in.

50…75 mm

(2…3 in.)

50…75 mm

(2…3 in.)

Apply the Motor Cable Shield Clamp

Complete these steps to apply the motor cable shield clamp.

1. Locate a position for installing the cable shield clamp within 50…75 mm (2…3 in.) of

the drive.

2. Lay out and drill holes for the cable clamp.

ATTENTION: Plan the installation of your system so that you can perform all cutting, drilling,

tapping, and welding with the system removed from the enclosure. Because the system is of

the open type construction, be careful to keep any metal debris from falling into it. Metal debris

or other foreign matter can become lodged in the circuitry, which can result in damage to

components.

3. Locate the position on the motor power cable that comes under the clamp and remove

about an inch of the cable jacket to expose the shield braid.

4. Position the exposed portion of the cable braid directly in line with the clamp.

5. Clamp the exposed shield to the panel by using the clamp and two #6-32 x 1 screws

provided with your drive.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 25

Page 26

Chapter 1 Prepare the Kinetix 350 Drive Hardware

Wire the Motor Feedback Connector

This publication describes how to use a

2090-CFBM7DD-CEAA03 standard

feedback cable with SpeedTec DIN

connector type 623 to wire feedback

from the motor to the drive.

Complete these steps to wire the

MFconnector.

1. Plug the premolded feedback cable

into the MF connector on the

front of the drive.

2. Tighten the fastening screws at the top and bottom of the motor feedback connector to

secure the connection.

3. Connect the other end of the cable to the MPL-A310P-MJ72AA motor.

26 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 27

Prepare the Kinetix 350 Drive Hardware Chapter 1

IMPORTANT

Buttons

Display

Connect the Kinetix 350 Drive to the EtherNet/IP Network

Complete these steps to connect the 2097-V31PR2-LM drive to the EtherNet/IP network.

1. Connect one end of the 1585J-

M8PBJM-2, RJ45 to RJ45

patchcord Ethernet cables to the

Ethernet connector on the front of

the Kinetix 350 drive.

2. Connect the other end of the

Ethernet cable to the EtherNet/IP

network.

Assign an IP Address to the Kinetix 350 Drive

You can assign an IP address to the 2097-V31PR2-LM drive manually via the drive keypad or

dynamically via a DHCP-enabled server. Because this publication describes tasks intended to be

completed on a private network, you assign an IP address via the drive keypad.

The graphic shows which buttons to

push on the keypad to make changes.

Before assigning the IP address

manually, disable the DHCP mode.

If you do not disable the DHCP

mode before assigning the IP

address manually, the next

time power is cycled to the

drive, the drive will lose the IP

address that had been

assigned previously.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 27

Page 28

Chapter 1 Prepare the Kinetix 350 Drive Hardware

Complete these steps to assign an IP address to your 2097-V31PR2-LM drive.

1. Apply power to the drive via the 120V AC power source described in Wire the Input Power

Connector on page 23.

Do not apply power to the BP connector yet.

2. Press .

3. Use to access parameter DHCP.

The display indicates each parameter as you use the up/down arrows to scroll all options.

4. Check this parameter is set to a value of 0.

5. If the DHCP parameter is set to 1, then use and to set to 0.

6. Cycle power to the drive.

The change takes effect. Unless DHCP mode is enabled in the future, each time power is cycled

to the drive, it uses the IP address that was manually assigned.

Your 2097-V31PR2-LM drive ships from the factory with its IP address set at 192.168.124.200.

To complete the tasks described in this quick start, you must change the IP address to

192.168.1.5.

28 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 29

Complete these steps to assign an IP address for your drive.

1. Press .

2. Use to access parameter IP_1.

3. Press .

4. Use to set the value for parameter IP_1.

5. Press .

Prepare the Kinetix 350 Drive Hardware Chapter 1

6. Repeat step 1

through step 5 to change the values for the remaining IP address parameters,

that is, IP_2, IP_3 and IP_4.

7. Cycle power to the drive.

8. Apply back-up power to the drive via the BP connector.

Additional Resources

For a list of additional resources that might assist you when preparing the Kinetix 350 drive

hardware, see page 12

.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 29

Page 30

Chapter 1 Prepare the Kinetix 350 Drive Hardware

Notes:

30 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 31

Chapter

Add a Kinetix 350 Drive to an RSLogix 5000 Project

In this chapter, you learn how to complete the following tasks:

• Add a 2097-V31PR2-LM drive to an RSLogix 5000 project and configure it.

• Download the project to the controller.

• Verify communication with the drive by applying power to the drive and testing an axis.

2

Before You Begin

You must complete these tasks before using this chapter:

• The tasks described in Before Using This Publication on page 5, include the following:

– Prepare the Logix5000 control system hardware

– Prepare the computer

– Configure the networks - The tasks described in this chapter require an

EtherNet/IP network.

– Create an RSLogix 5000 project

The example RSLogix 5000 project used in this chapter uses a

CompactLogix 5370 L3 controller.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 31

Page 32

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

• The tasks described in Chapter 1, Prepare the Kinetix 350 Drive Hardware on page 13,

include the following:

– Prepare the Panel

– Mount the Kinetix 350 Drive

– Ground the Kinetix 350 Drive

– Disable the Safe Torque-off Feature

– Wire the Back-up Power Connector

– Wire the Input Power Connector

– Wire the Motor Power Connector

– Apply the Motor Cable Shield Clamp

– Wire the Motor Feedback Connector

– Connect the Kinetix 350 Drive to the EtherNet/IP Network

– Assign an IP Address to the Kinetix 350 Drive

What You Need

You need RSLogix 5000 software to complete the tasks described in this chapter.

32 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 33

Follow These Steps

Add the Kinetix

350 Drive to the

RSLogix 5000

Project

page 34

Configure the

Motion Group

page 37

Configure Axis

Properties

page 39

Apply Power to the

Kinetix 350

Drive System

page 41

Tes t the A xi s

page 44

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 33

Page 34

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

IMPORTANT

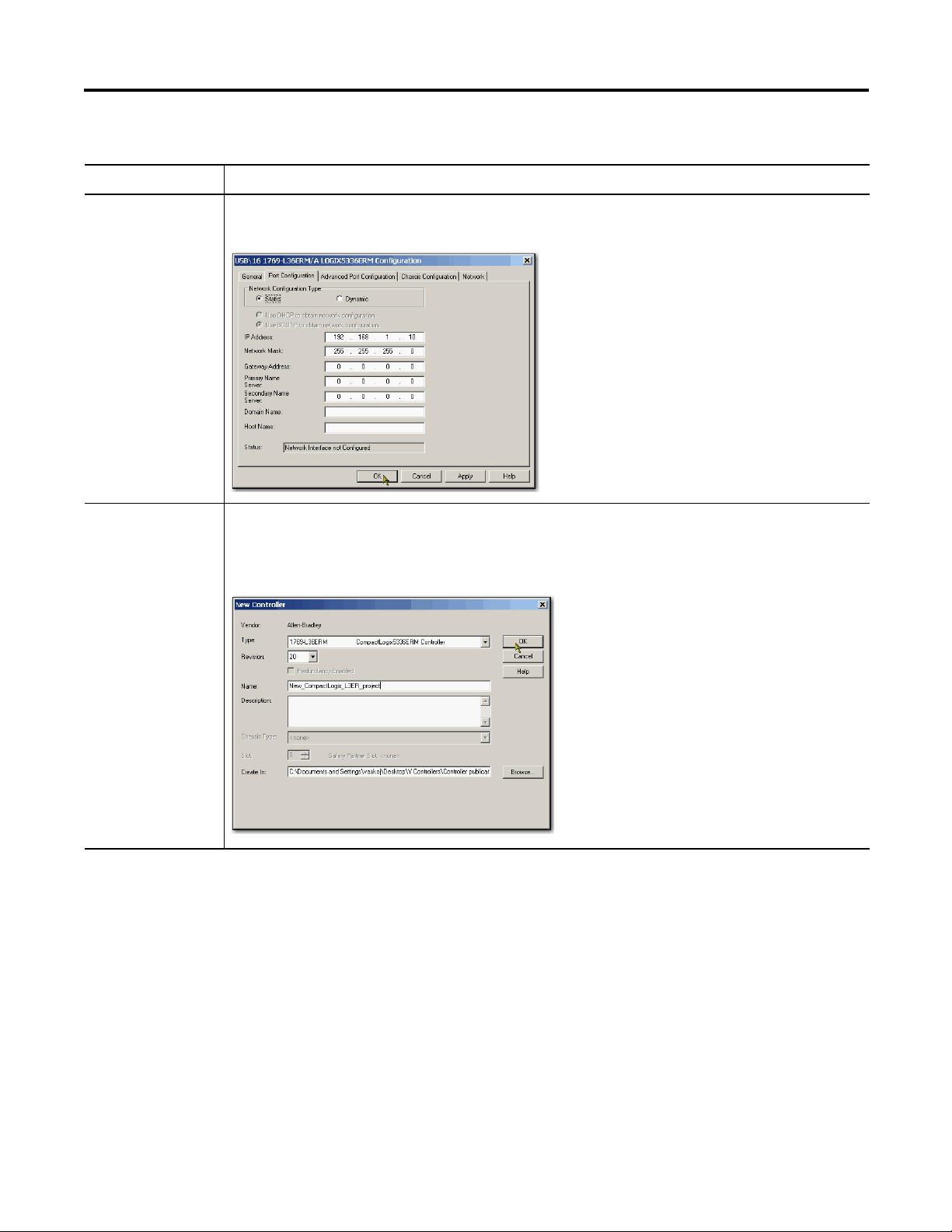

Add the Kinetix 350 Drive to the RSLogix 5000 Project

The tasks described in this section use an RSLogix 5000 project for a CompactLogix 5370 L3 controller.

CompactLogix 5370 L3 controllers require that you use RSLogix 5000, version 20.00.00 or later.

If you are using a different Logix5000 controller, your project’s RSLogix 5000 software version requirement might

be different.

1. Verify that the 2097-V31PR2-LM drive is not powered at the IPD connector nor the

BPconnector.

2. Verify the following about your RSLogix 5000 project:

• The project is offline.

• The controller is configured such that Time Synchronization is enabled.

The Enable Time Synchronization feature is on the Date/Time tab of the Controller

Properties dialog box.

3. Verify the Logix5000 controller

mode switch is in the PROG

mode position.

RUN

REM

PROG

4. Right-click your network port and

choose New Module.

34 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 35

5. Select the Kinetix 350 drive and

click Create.

The Select Module Type dialog

box may appear differently

depending on which Logix5000

controller your application uses

and, thus, what version of

RSLogix 5000 software is used.

The New Module dialog

boxopens.

6. Configure the new drive.

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

a. Type the drive Name.

b. Click an Ethernet Address

option.

In this example, the Private

Network address is selected.

c. Enter the IP address of your

EtherNet/IP drive.

The IP address must match the

IP address used in Assign an IP

Address to the Kinetix 350

Drive on page 27.

7. Click Change in the Module Definition area.

The Module Definition dialog box opens.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 35

Page 36

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

IMPORTANT

8. From the Electronic Keying

pull-down menu, choose

Disable Keying.

The Disable Keying

selection ensures that

you will easily complete

the taks. In typical

applications, we

recommend you avoid

using Disable Keying

whenever possible.

9. Click OK twice to close the Module Definition dialog box and the Module Properties

dialog box successively.

10. Right-click the 2097-V31PR2-LM

drive and choose Properties.

The Module Properties dialog

boxopens.

11. Click the Associated Axes tab.

12. Click New Axis.

The New Tag dialog box opens.

36 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 37

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

13. Type the axis Name.

AXIS_CIP_DRIVE is the default

Data Type.

14. Change the Scope to your

controller project.

In this case, the Scope is

Kinetix_350_project.

15. Click Create and Close.

16. When the Module Properties dialog box appears, the new axis appears in the Axis 1: field.

17. Click OK.

Configure the Motion Group

Complete these steps to configure the motion group.

1. Right-click Motion Groups in the

Controller Organizer and choose

New Motion Group.

The New Tag dialog box opens.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 37

Page 38

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

2. Type the new motion group Name.

3. Click Create and Close.

The new motion group appears

under the Motion Groups folder.

4. Right-click the new motion group

and choose Properties.

The Motion Group Properties

dialog box opens.

5. Click the Axis Assignment tab and

move the axis you created

beginning at step 12

from

Unassigned to Assigned.

6. Click OK.

38 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 39

Configure Axis Properties

Complete these steps to configure the

properties for Axis_1.

1. Right-click Axis_1 in the

Controller Organizer and

choose Properties.

The Axis Properties dialog

boxopens.

2. Click the Motor category.

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

The Motor Device Specification

dialog box opens.

3. From the Data Source pull-down

menu, choose Catalog Number.

4. Click Change Catalog.

The Change Catalog Number

dialog box opens.

5. Select the motor catalog number.

This quick start uses the

MPL-A310P-MJ72AA, MP-series

motor. The correct catalog number

to choose is MPL-A310P-M.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 39

Page 40

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

6. Click OK to close the Change Catalog Number dialog box.

Motor data specific to your motor appears in the Motor category.

7. Click Apply.

Motor data specific to your MPL-A310P-MJ72AA motor appears in the Motion category.

You do not need to change the parameters in the other categories to complete the tasks

described in this quick start.

8. Click OK to close the Axis Properties dialog box.

9. Save the file and download it to the controllers.

10. Verify the controller is in the Remote Run mode.

40 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 41

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

Four- charact er

Status Indicators

Data Entry Status

Indicator

Apply Power to the Kinetix 350 Drive System

Before beginning this section, verify that you have wired and configured your Kinetix 350 drive

and your controller’s EtherNet/IP network port correctly.

SHOCK HAZARD: To avoid hazard of electrical shock, perform all mounting and wiring of the

Bulletin 2097 drive prior to applying power.

Once power is applied, connector terminals may have voltage present even when not in use.

Complete these steps to apply power to the Kinetix 350 drive system.

1. Disconnect the load to the MPL-A310P-MJ72AA motor.

ATTENTION: To avoid personal injury or damage to equipment, disconnect the load to the

motor. Make sure each motor is free of all linkages when initially applying power to the system.

2. Apply 120V AC main input power to the 2097-V31PR2-LM drive’s IPD connector.

3. Verify the four-character status indicator is initially 00 and then transitions to scrolling the

drive’s IP address.

If so, proceed to the next step.

If the status indicator is blank,

return to step 2

.

4. Apply 24V DC power to the

2097-V31PR2-LM drive’s BP

connector.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 41

Page 42

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

5. Observe the status indicators on

the 2097-V31PR2-LM drive.

The indicators include

the following:

• N - Network

• M- Module

• A - Axis

The network and module status indicators should be in the steady green state and the axis

status indicator should be in the flashing green state. If the status indicators are not in these

states you must determine what condition is preventing it.

Use the following table to diagnose and correct potential issues with your system.

Table 2 - Drive Status Indicators

Status Indicator Condition Status

Network Off No power or no IP address.

Alternating green/red Self-test mode (power-up diagnostics). Wait for steady green.

Flashing green Standby - Drive is either not configured or no connections are

established.

Steady green Drive is ready for network communication.

Flashing red Recoverable minor fault or connection timeout.

Steady red Non-recoverable fault or duplicate IP address.

Module Off No power. Apply power.

Alternating green/red Self-test mode (power-up diagnostics). Wait for steady green.

Flashing green Standby - Drive is either not configured or no connections are

established.

Steady green Drive is operating correctly.

Flashing red Recoverable fault. A four-digit fault message scrolls across

the display.

For more information on drive faults, see the Kinetix 350

Single-axis EtherNet/IP Servo Drives User Manual,

publication 2097-UM002.

Steady red Non-recoverable fault. A four-digit fault message scrolls

across the display.

For more information on drive faults, see the Kinetix 350

Single-axis EtherNet/IP Servo Drives User Manual,

publication 2097-UM002.

42 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 43

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

Table 2 - Drive Status Indicators

Status Indicator Condition Status

Axis Off One of the following conditions exists:

• Off

• Initialization is in process - Bus not operating

• Shutdown is in process - Bus not operating

• Pre-charge is in process - Bus not operating

Flashing red/green Self-test (power-up diagnostics) in process

Flashing green One of the following conditions exists:

• Initialization is in process- Bus is operating

• Axis is stopped.

Flashing amber One of the following conditions exists:

• Shutdown is in process - Bus is operating

• Start is inhibited.

Steady green One of the following conditions exists:

• Axis is stopping.

• Axis is starting.

• Axis is running.

• Axis is testing.

Flashing red One of the following conditions exists:

• Axis is aborting.

• Axis experienced a major fault.

Steady red One of the following conditions exists:

• Axis is aborting.

• Axis experienced a major fault.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 43

Page 44

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

IMPORTANT

Test the Axis

This section assumes that your 2097-V31PR2-LM drive’s status indicators show that drive is

operating as expected.

If the status indicators do not reflect a fully operational drive state, as described in Table 2 on

page 42, use the table to address any issues with regard to the drive’s stater before proceeding with

this section.

Complete these steps to test the axes.

1. Remove the load from Axis_1.

2. Right-click Axis_1 in your Motion

Group folder and choose

Properties.

The Axis Properties dialog box

opens.

3. Click the Hookup Tests category.

4. Click the Motor and Feedback tab.

5. Type 2.0 as the number of

revolutions for the Motor and

Feedback test.

The Motor and Feedback test

verifies the motor power and

feedback connections are wired

correctly as you command the

motor to rotate.

6. Apply 24V DC power to the 2097-V31PR2-LM drive’s IOD connector.

7. Click Start.

44 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 45

The RSLogix 5000 - Motor and

IMPORTANT

Feedback Test dialog box opens.

The Test State is Executing.

During this time, the shaft

on your motor should be

turning. Additionally, the

axis status indicator

should be in a steady

green state.

When the test completes

successfully, the Test State changes

from Executing to Passed.

8. Click OK.

Add a Kinetix 350 Drive to an RSLogix 5000 Project Chapter 2

A dialog box opens to confirm that

the shaft’s direction was correct.

9. Click Yes.

10. When prompted, click to accept

test results.

If the test fails, this dialog box opens.

1. Click OK.

2. Return to Add the Kinetix 350

Drive to the RSLogix 5000 Project

on page 34 and verify that you completed each steps correctly.

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 45

Page 46

Chapter 2 Add a Kinetix 350 Drive to an RSLogix 5000 Project

Tune an Axis

For the purposes of this quick start, you do not need to tune the axis. Some applications,

however, require the use of tuning to improve the application’s use of Integrated Motion on an

EtherNet/IP network. Tuning conditions and parameters are defined by each individual

application.

For more information about tuning in an application that uses a Kinetix 350 drive, see the

Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual, publication 2097-UM002

.

Additional Resources

For a list of additional resources that might assist you when adding the Kinetix 350 drive to an

RSLogix 5000 project, see page 12

.

46 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 47

Index

A

axis properties

39-40

configure

C

configure

axis properties

motion group 37-38

connections

apply motor cable shield clamp

apply power to drive

drive to EtherNet/IP network 27

hardware

wire input power connector

wire motor feedback connector

wire motor power connector

wire safe torque-off connector

39-40

10, 18-27

D

drive preparation

16-17

mount

E

EtherNet/IP network

connect drive

27

H

hardware

example control system

ground drive

input power connector 23

motor cable shield clamp

motor feedback connector

motor power connector

mount drive

preparation

safe torque-off connector

use to assign IP address to drive

hookup test

17

16-17

13-29

44-45

I

input power connector

23

wire

IP address

assign to drive

27

41

10

24

25

18

26

23

24

18

25

26

27

M

mode switch 34, 40

motion group

37-38

configure

motor cable shield clamp

motor feedback connector

26

wire

motor power connector

24

wire

25

P

parts

required to complete tasks

power

connect to drive

wire input power connector

wire motor power connector

prerequisite tasks

41

5-7

Q

quick starts

for devices in Logix5000 control systems

R

requirements

hardware preparation

parts 11

prerequisite tasks

software

10

RSLogix 5000 software

add drive to project

configure axis properties 39-40

configure motion group

requirements

44-45

test axis

13-29

5-7

34-37

37-38

10

S

safe torque-off connector 18

software

configure motion group

RSLogix 5000 10, 34-37

37-38

T

test axes

hookup test

44-45

11

23

24

8

L

Logix5000 controllers

prerequisite tasks

Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012 47

5-7

Page 48

Index

Notes:

48 Rockwell Automation Publication IASIMP-QS032A-EN-P - March 2012

Page 49

Page 50

Page 51

Page 52

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Support

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa : Rockwell Automation NV, Pegas us Park, De Kleetlaan 12a, 1831 Diegem, Belg ium, Tel : (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

Rockwell Automation provides technical information on the Web to assist you in using its products.

http://www.rockwellautomation.com/support/, you can find technical manuals, a knowledge base of FAQs, technical and

At

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

Tec hConnec t

representative, or visit

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwide Locat or

New Product Satisfaction Return

SM

support programs. For more information, contact your local distributor or Rockwell Automation

http://www.rockwellautomation.com/support/.

Automation representative.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact your local Rockwell

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication

RA-DU002, available at http://www.rockwellautomation.com/literature/.

Publication IASIMP-QS032A-EN-P - March 2012

Copyright © 2012 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...