Page 1

Programming Manual

Original Instructions

Logix 5000 Controllers Program Parameters

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069

CompactLogix, 5069 Compact GuardLogix, Studio 5000

Logix Emulate

Page 2

Logix 5000 Controllers Program Parameters

personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

temperatures.

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

ARC FLASH HAZARD:

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

2 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 3

Change

Topic

Updated branding.

Throughout

Summary of changes

This manual includes new and updated information. Use these reference tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

This table identifies changes that apply to all information about a subject in the manual and

the reason for the change. For example, the addition of new supported hardware, a software

design change, or additional reference material would result in changes to all of the topics

that deal with that subject.

Updated Legal notices. Legal notices on page 9

New or enhanced features

None in this version.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 3

Page 4

Page 5

Summary of changes

Connecting program

Directly accessing

program parameters

Table of Contents

Preface

parameters

Studio 5000 environment .......................................................................... 7

Additional resources ................................................................................... 7

Important terminology .............................................................................. 8

Legal notices ................................................................................................ 9

Chapter 1

Introduction ............................................................................................... 11

Program parameters .................................................................................. 11

Program parameter connection methods .......................................... 11

Program parameter connection syntax.............................................. 14

User-defined type sub-element connection considerations............. 14

Input parameters ....................................................................................... 15

Input parameter connection types and uses ..................................... 15

General rules for using Input parameters ......................................... 15

Connect an Input parameter to a controller scope tag ..................... 15

Output parameters ..................................................................................... 17

Output parameter connection types and uses ................................... 18

General rules for using Output parameters ....................................... 18

Connect an Output parameter to a controller scope tag ................... 18

Connect an Output parameter to another program.......................... 19

InOut parameters ....................................................................................... 21

InOut parameter connection types and uses ..................................... 21

General rules for using InOut parameters ........................................ 22

Connect an InOut parameter to a controller scope tag.................... 22

Public parameters.......................................................................................23

Public parameter connection types and uses ....................................23

General rules for using Public parameters ....................................... 24

Connect a Public parameter to another program ............................. 24

Safety program parameters ...................................................................... 26

General rules for connecting parameters for safety programs ....... 26

Program parameter connection rules...................................................... 26

Standard program to standard program connection rules ............. 27

Safety program to safety program connection rules ........................ 27

Safety program to standard program connection rules .................. 28

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 5

Chapter 2

Introduction .............................................................................................. 29

Direct access .............................................................................................. 29

Behavior of direct access in logic ....................................................... 29

Access program parameters when editing ladder logic ................... 29

Page 6

Table of Contents

Index

6 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 7

Resource

Description

Product Certifications webpage, available

Provides declarations of conformity, certificates,

Studio 5000 environment

Additional resources

Preface

This manual shows how to create and configure program parameters. This manual is one of a

set of related manuals that show common procedures for programming and operating Logix

5000 controllers.

For a complete list of common procedures manuals, refer to the

Logix 5000 Controllers

Common Procedures Programming Manual, publication 1756-PM001.

The term Logix 5000 controller refers to any controller based on the Logix 5000 operating

system.

The Studio 5000 Automation Engineering & Design Environment® combines engineering and

design elements into a common environment. The first element is the Studio 5000 Logix

Designer® application. The Logix Designer application is the rebranding of RSLogix 5000®

software and will continue to be the product to program Logix 5000™ controllers for discrete,

process, batch, motion, safety, and drive-based solutions.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 7

The Studio 5000® environment is the foundation for the future of Rockwell Automation®

engineering design tools and capabilities. The Studio 5000 environment is the one place for

design engineers to develop all elements of their control system.

These documents contain additional information concerning related Rockwell Automation

products.

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

at http://ab.rockwellautomation.com

Provides general guidelines for installing a Rockwell

Automation industrial system.

and other certification details.

View or download publications at http://www.rockwellautomation.com/literature. To order

paper copies of technical documentation, contact the local Rockwell Automation distributor

or sales representative.

Page 8

Preface

Term

Definition

structure, this behavior may be necessary.

change the value during execution of a program.

not change from external code or HMI interaction.

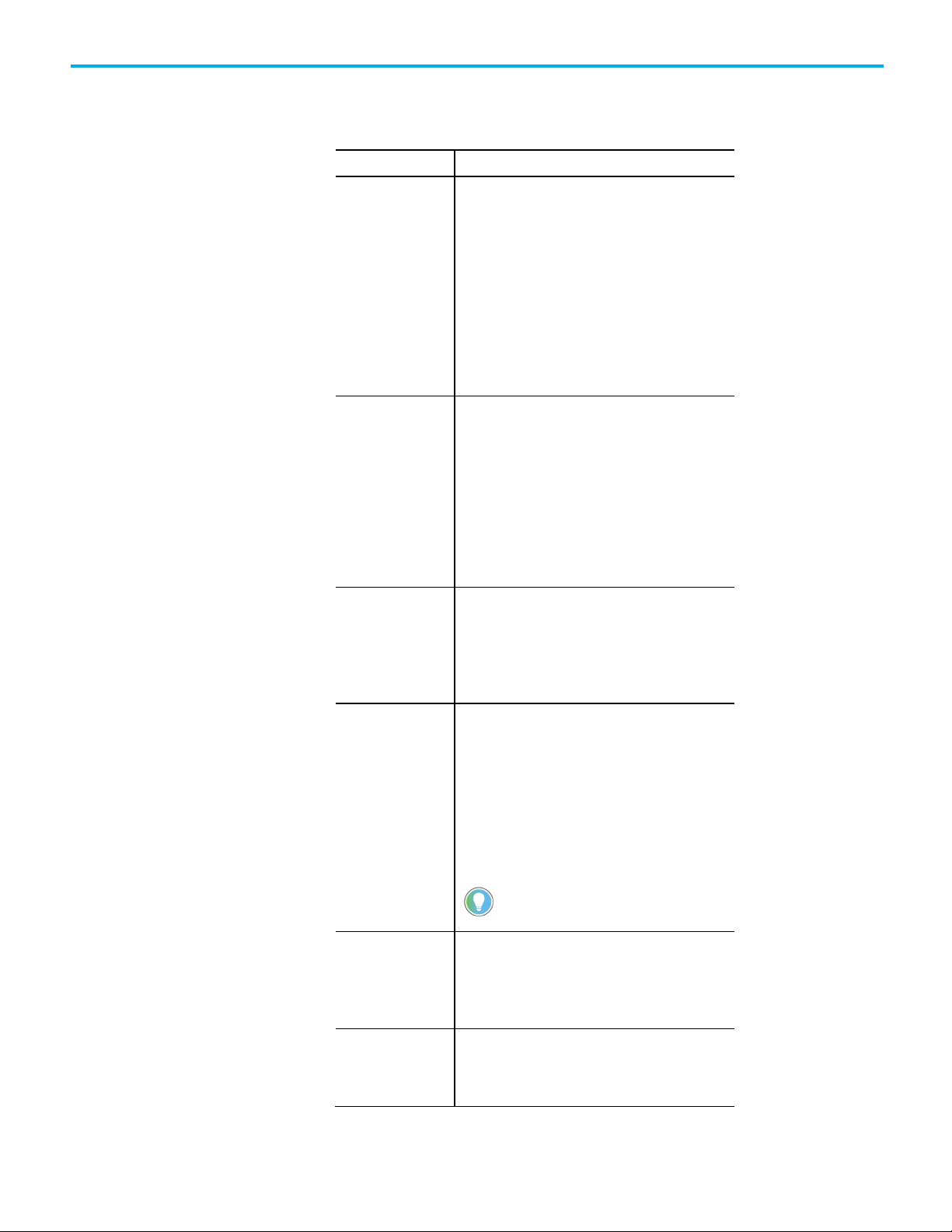

Important terminology

This table defines the terms that are important to understanding the concepts described in

this manual.

Argument An argument is assigned to a parameter and contains

the specification of the data used by an instruction in a

user program. An argument can contain the following:

• A simple tag (for example, L101)

• A literal value (for example, 5)

• A tag structure reference (for example,

Recipe.Temperature)

• A direct array reference (for example, Buffer[1])

• An indirect array reference (for example,

Buffer[Index+1])

•

A combination (for example, Buffer[Index+1].Delay)

InOut parameter An InOut parameter is a special usage program

parameter that represents a reference to data that can

be used both as input and output during the execution

of a program. Because InOut parameters pass by

reference rather than by value, they are merely a pointer

to the original data and closely resemble the behavior of

an alias tag. With that in mind, it is possible that the

InOut parameter values could change during the

execution of a program. Depending on your task

Input parameter An Input parameter is a parameter that defines the data

that is passed by value into an executing program. Since

Input parameters are passed by value, their values

cannot change from external sources during the

execution of the program. An Input parameter supports

a maximum of one sourcing connection.

Output parameter

An Output parameter is a parameter that

defines the data that is produced as a direct

result of executing a program. Since Output

parameters are always passed by value, their

values only change at the end of the scan of a

program when the copy of the parameters has

executed.

Tip: If using direct access another program

can be a source for an Output parameter.

Passed by reference When an argument is passed to a parameter by

reference, the logic directly reads or writes the value

that the tag uses in controller memory. External code or

HMI interaction that changes the argument’s value can

Passed by value When an argument is passed to a parameter by value,

the value is copied in or out of the parameter during

execution of a program. The value of the argument does

8 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 9

Legal notices

Public parameter A Public parameter is an encapsulated version of a

controller scope tag, and typically it is used for large

data structures that need to be shared among programs.

Preface

Rockwell Automation publishes legal notices, such as privacy policies, license agreements,

trademark disclosures, and other terms and conditions on the Legal Notices

page of the

Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End User License Agreement (EULA) by opening the

license.rtf file located in your product's install folder on your hard drive.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\license.rtf.

Open Source Software Licenses

The software included in this product contains copyrighted software that is licensed under

one or more open source licenses.

You can view a full list of all open source software used in this product and their

corresponding licenses by opening the oss_license.txt file located your product's

OPENSOURCE folder on your hard drive. This file is divided into these sections:

• Components

Includes the name of the open source component, its version number,

and the type of license.

• Copyright Text

Includes the name of the open source component, its version number,

and the copyright declaration.

• Licenses

Includes the name of the license, the list of open source components

citing the license, and the terms of the license.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\Help\<product

name>\Release Notes\OPENSOURCE\oss_licenses.txt.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 9

You may obtain Corresponding Source code for open source packages included in this

product from their respective project web site(s). Alternatively, you may obtain complete

Corresponding Source code by contacting Rockwell Automation via the Contact form on the

Rockwell Automation website:

http://www.rockwellautomation.com/global/about-

us/contact/contact.page. Please include "Open Source" as part of the request text.

Page 10

Preface

10 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 11

Introduction

Program parameters

Program parameter

Chapter 1

Connecting program parameters

This chapter provides an overview of program parameters and then further defines each

type of program parameter. Explanations are provided on when to use each type of program

parameter and the general rules to follow, and example procedures are provided for

connecting each type of program parameter.

A program parameter is an argument that is exposed for external access by a program.

Unlike local tags, all program parameters are publicly accessible outside of the program.

Additionally, HMI external access can be specified for each parameter. Data sharing between

programs can be achieved either through pre-defined connections between parameters or

directly accessed through a special notation.

There are four types of program parameters.

• Input

• Output

• InOut

• Public

Among other benefits, program parameters allow you to clearly define the inputs to the

routines in a program, and the outputs from those routines. Input and Output parameters also

automatically buffer data, so that you do not need to create separate tags to buffer IO data

(although if desired, you can still buffer data using the Synchronous Copy File [CPS]

instruction).

connection methods

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 11

You can use any of the following methods to connect program parameters in the Logix

Designer application.

• Connections column on the Program Parameters and Local Tags

dialog box

Page 12

Chapter 1 Connecting program parameters

Tip: To show the Connections column click View > Toggle Columns > Connections.

• Ellipses button (...) in the Connections cell on the Program

Parameters and Local Tags dialog box

12 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 13

Chapter 1 Connecting program parameters

• Properties pane on the Program Parameters and Local Tags dialog

box

• Parameters tab on the Program Properties dialog box

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 13

Page 14

Chapter 1 Connecting program parameters

Program parameter

User-defined type sub-

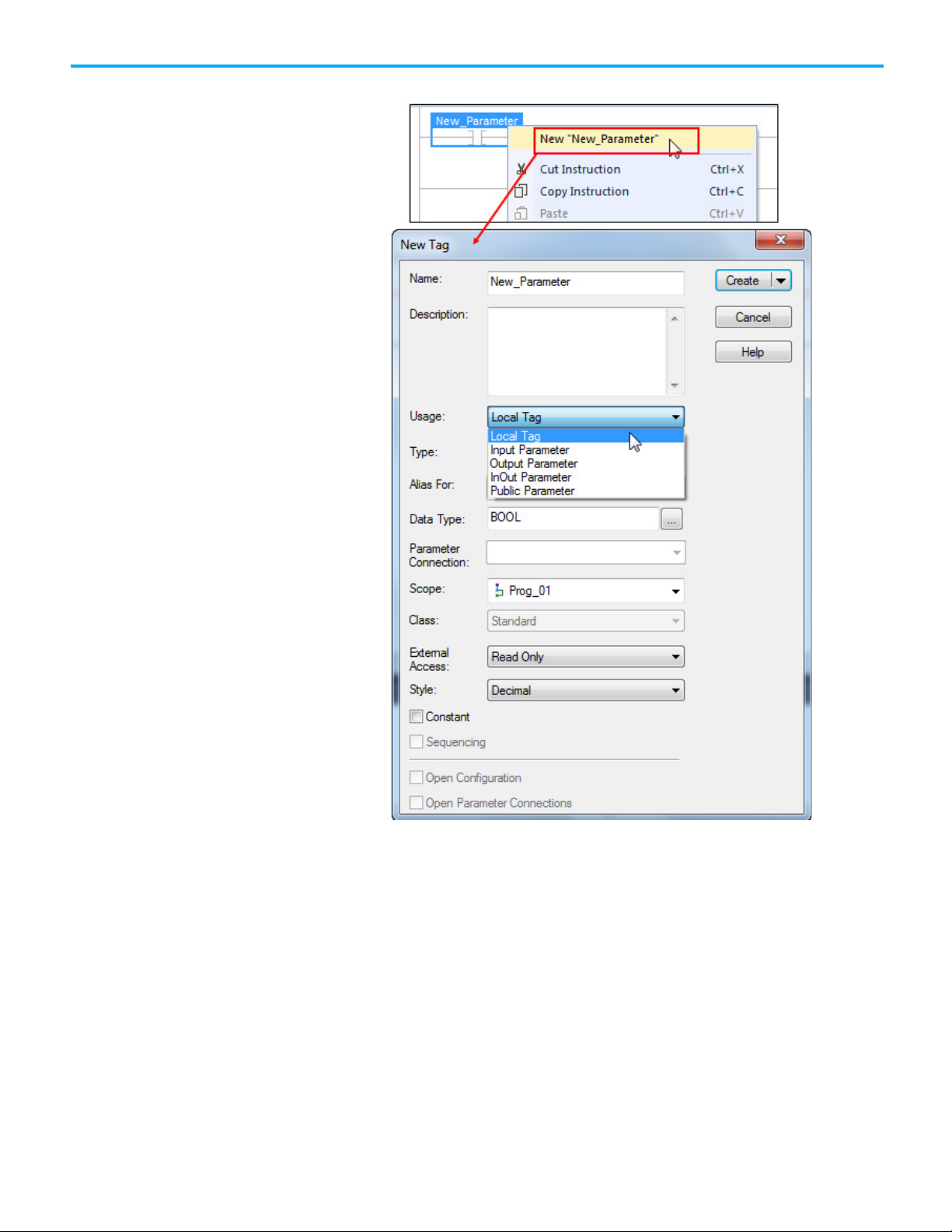

• New Parameter or Tag dialog box

connection syntax

element connection

considerations

14 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

The syntax {x:y} is used to connect program parameters where:

x = the number of full connections, meaning connections at the word or user-defined

type level

y = the number of partial connections, meaning connections at the bit or member

level

User-defined types (UDTs) used as parameters can contain member-specific connections. To

ensure proper data flow, the base Usage can only be specified at the base of the UDT, and

not at the member level, as the following example shows.

Page 15

methods shown in Program parameter connection methods on page 11.

Input parameters

Input parameter connection

types and uses

General rules for using

Connect an Input parameter

An Input parameter is a parameter that defines the data that is passed by value into an

executing program. Since Input parameters are passed by value, their values cannot change

from external sources during the execution of the program. An Input parameter supports a

maximum of one sourcing connection.

Input parameters can be connected to Output parameters, Public parameters, InOut

parameters, and controller scope tags. This makes Input parameters a great option for

connecting input card data to a code module or object. It also is a good option for code

module or object commands that are point-to-point.

The following are general rules when using Input parameters.

Chapter 1 Connecting program parameters

Input parameters

to a controller scope tag

• Input parameters (including members) can only support one sourcing

connection. This means that only one source can be delivering the

value to the input parameter.

• Input parameter values are refreshed before each scan of a program.

The values do not change during the logic execution, so you do not

need to write code to buffer inputs.

• A program can write to its own Input parameters.

• Data values for Output parameters that are connected to controller

scope tags or Public parameters are copied after the scan of a program.

In a project with multiple tasks, the data copy for a parameter that is of

type BOOL, SINT, INT, DINT, LINT, or REAL will not be interrupted.

The data copy from an Output parameter to a controller scope tag or

Public parameter or any other predefined or user-defined data type

may be interrupted by a task switch.

For more information on the Input parameter connections that can be made, see

parameter connection rules on page 26.

A parameter can be connected to another parameter or controller scope tag. As an example,

connecting an Input parameter to an Output parameter ensures that data is copied to the

Input parameter from the Output parameter on every scan. The following procedure explains

how to connect an Input parameter to a controller scope tag.

Program

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 15

Tip: This procedure demonstrates the use of the Properties pane on the Program Parameters

and Local Tags dialog box. You can alternatively connect parameters using any of the other

Page 16

Chapter 1 Connecting program parameters

To connect an Input parameter to a controller scope tag

1. In the Controller Organizer, expand the folder for the program for

which you are connecting an Input parameter, and doubleclick Parameters and Local Tags.

2. On the Program Parameters and Local Tags dialog box, choose the

Input parameter that you want to connect.

3. On the right, in the Properties pane, expand Parameter Connections.

4. Click New Connection.

16 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 17

Output parameters

Chapter 1 Connecting program parameters

5. Click the Browse (...) button.

6. In the Tag box, choose the drop-down arrow.

7. In the Tag Browser, locate and expand the desired controller scope tag.

8. Click to the right of the desired tag, and click the drop-down arrow.

9. Click the bit that you want to associate with this Input parameter.

10. In the Tag box, verify that the resulting information is correct, and

click OK. Notice that the first number in the brackets next

to Parameter Connections has incremented by one, indicating that the

number of connections to the parent tag have increased by one.

An Output parameter is a parameter that defines the data that is produced as a direct result

of executing a program. Since Output parameters are always passed by value, their values

only change at the end of the scan of a program when the copy of the parameters has

executed.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 17

Tip: If using direct access another program can be a source for an Output parameter.

Page 18

Chapter 1 Connecting program parameters

connected to the InOut parameter is used.

Program parameter connection methods on page 11.

Output parameter

General rules for using

Connect an Output

Output parameters can be connected to one or more Input parameters, Public parameters,

InOut parameters (constants), and controller scope tags, which makes Output parameters a

connection types and uses

great option for connecting a code module or object to an output card. It also is a good

option for configuring a code module or object to invoke operations (such as commands and

settings) in other code modules or objects. Additionally, multiple connections can be

configured for an Output parameter (known as fanning), which allows one code module or

object to send multiple commands to multiple modules or objects using one Output

parameter.

The following are general rules when using Output parameters.

Output parameters

parameter to a

controller scope tag

• Output parameters, including members, can support multiple

connections. For example, assume you have a BOOL Input parameter

in Program_A named Input1a, and a BOOL Input parameter in

Program_B named Input1b. You are allowed to connect a single Output

parameter in Program_C to both Input1a and Input1b. This is known

as fanout.

• Output parameter values are refreshed after each scan of a program.

They maintain the value from the previous scan until the program

execution is complete.

• Output parameters connected to Public parameters or controller scope

tags are copied (pushed) at the end of the program execution.

• An Output parameter can only be connected to an InOut parameter if

the InOut parameter is configured as a constant.

Tip: InOut parameters are passed by reference, which means they point to the base tag.

That is, when an InOut parameter is used in logic, the current value of the parameter

For more information on the Output parameter connections that can be made, see Program

parameter connection rules on page 26.

The following procedure explains how to connect an Output parameter to a controller scope

tag.

Tip: This procedure demonstrates the use of the Parameters tab on the Program Properties

dialog box. You can alternatively connect parameters using any of the other methods shown in

18 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 19

Tip: This procedure demonstrates the use of the Properties pane on the Program Parameters

Connect an Output

Chapter 1 Connecting program parameters

To connect an Output parameter to a controller scope tag

1. In the Controller Organizer, double-click the folder for the program

for which you are creating an Output parameter connection.

2. On the Program Properties dialog box, click the Parameters tab.

3. In the Name box, click the name of the Output parameter for which

you want to add a connection.

parameter to

another program

4. In the Connections area, click New Connection.

5. In the New Connection box, type the tag to which you want to connect

this Output parameter, and click Apply.

6. Click OK to close the Program Properties dialog box.

The following procedure explains how to connect an Output parameter to another program.

and Local Tags dialog box. You can alternatively connect parameters using any of the other

methods shown in

Program parameter connection methods on page 11.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 19

Page 20

Chapter 1 Connecting program parameters

To connect an Output parameter to another program

1. In the Controller Organizer, expand the folder for the program for

which you are creating an Output parameter connection, and doubleclick Parameters and Local Tags.

2. On the Program Parameters and Local Tags dialog box, choose the

Output parameter that you want to connect.

3. On the right, in the Properties pane, expand Parameter Connections.

20 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 21

InOut parameters

InOut parameter connection

Chapter 1 Connecting program parameters

4. Click New Connection.

5. Click the Browse (...) button.

6. In the Tag box, choose the drop-down arrow.

7. (optional) On the Tag Browser, clear one or more of the check boxes to

limit the number of available parameters that appear in the list.

types and uses

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 21

8. In the Show parameters from other program list, choose the program

to which you want to connect this Output parameter.

9. In the list of available parameters, double-click the desired parameter.

10. Click OK.

An InOut parameter is a special usage program parameter that represents a reference to

data that can be used both as input and output during the execution of a program. Because

InOut parameters pass by reference rather than by value, they are merely a pointer to the

original data and closely resemble the behavior of an alias tag. With that in mind, it is

possible that the InOut parameter values could change during the execution of a program.

Depending on your task structure, this behavior may be necessary.

InOut parameters can be connected to Input parameters, Public parameters, Output

parameters (if InOut is constant), and controller scope tags.

An example of how InOut parameters are advantageous is an application that contains

multiple tasks with different priority assignments. In this scenario, a lower priority task is

interrupted by a higher priority task. If the higher priority task is referencing data in the lower

priority task, the InOut parameter allows the higher priority task to point directly to a tag’s

Page 22

Chapter 1 Connecting program parameters

methods shown in Program parameter connection methods on page 11.

General rules for using

Connect an InOut parameter

value in the lower priority task. This ensures that the higher priority task is using the most

up-to-date value of a tag.

Another useful scenario for InOut parameters is for instructions whose tags can only be

placed at the controller scope, such as the Message (MSG) instruction. InOut parameters can

connect directly to the MSG instruction tags in the controller scope.

Finally, InOut parameters are useful for programs that have a large data structure, and you do

not want to pass the whole structure by value.

The following are general rules when using InOut parameters.

InOut parameters

to a controller scope tag

• InOut parameters can only support one connection. You cannot

configure connections to any member of an InOut parameter.

• An InOut parameter can only be connected to an Output parameter if

the InOut parameter is configured as a constant.

• InOut parameters are passed by reference, which means they point to

the base tag. In other words, when an InOut parameter is used in logic,

the current value of the parameter connected to the InOut parameter

is used.

• Connections to InOut parameters cannot be changed online, unless

using the Partial Import Online (PIO) functionality.

For more information on the InOut parameter connections that can be made, see

Program

parameter connection rules on page 26.

The following procedure explains how to connect an InOut parameter to a controller scope

tag.

Tip: This procedure demonstrates the use of the Properties pane on the Program Parameters

and Local Tags dialog box. You can alternatively connect parameters using any of the other

22 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

To connect an InOut parameter to a controller scope tag

1. In the Controller Organizer, expand the folder for the program for

which you are creating an InOut parameter connection, and doubleclick Parameters and Local Tags.

Page 23

Public parameters

Public parameter

Chapter 1 Connecting program parameters

2. On the Program Parameters and Local Tags dialog box, choose the

InOut parameter that you want to connect.

3. On the right, in the Properties pane, expand Parameter Connections,

and click New Connection.

4. Click the Browse (...) button.

5. In the Tag box, choose the drop-down arrow.

6. (optional) On the Tag Browser, clear all but the Show controller tags

check box to limit the number of available parameters that appear in

the list.

7. In the list of available parameters, double-click the desired parameter.

8. Click OK.

A Public parameter is an encapsulated version of a controller scope tag, and typically it is

used for large data structures that need to be shared among programs.

connection types and uses

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 23

Public parameters can be connected to Input parameters, Output parameters, and InOut

parameters. Public parameters function like controller scope tags, but are at the program

level. The key benefit to using Public parameters over controller scope tags is better

encapsulation. It is an excellent option for code modules or objects that contain data that

must be globally available to other code modules.

Page 24

Chapter 1 Connecting program parameters

General rules for using

Connect a Public parameter

Public parameters are updated as the source updates, so higher priority tasks that interrupt a

program during execution have access to any updated values in the lower priority task.

Additionally, fan-in is supported with Public parameters, which is useful in situations where a

code module or object could receive a command from many modules or objects. Input

parameters can be used, but an individual Input parameter is required for each connection. In

other words, if a code module or object had a command that could be invoked by 10 different

code modules or objects then 10 input parameters are required. However, if the command is

configured as a Public parameter, then all 10 code modules or objects could have an Output

parameter connected to a single Public parameter.

The following are general rules when using Public parameters.

Public parameters

to another program

• Public parameters can support multiple connections. You can

configure connections to the base Public parameter or any member of

a Public parameter, including User-defined structures.

• Public parameters are updated when the source is updated. In other

words, when a Public parameter value updates, it is immediately

available to any higher priority tasks that are connected to that

parameter.

• While Public parameters cannot be connected to controller scope tags,

they can be aliased to controller scope tags. If this functionality is

desired, it is important to remember that the alias updates

asynchronous to program execution. The Public parameter contains

the real-time value of the controller scope tag.

For more information on the Public parameter connections that can be made, see

Program

parameter connection rules on page 26.

The following procedure explains how to change an existing tag to a Public parameter, and

then connect a Public parameter to another program.

Tip: This procedure demonstrates the use of the Properties pane on the Program Parameters

and Local Tags dialog box. You can alternatively connect parameters using any of the other

methods shown in Program parameter connection methods on page 11

.

24 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 25

Chapter 1 Connecting program parameters

To connect a Public parameter to another program

1. In the Controller Organizer, expand the folder for the program for

which you are creating a Public parameter connection, and doubleclick Parameters and Local Tags.

2. On the Program Parameters and Local Tags dialog box, click the Edit

Tags tab.

3. Locate the tag you want to change to a Public parameter, and in

the Usage box, choose Public Parameter.

4. On the right, in the Properties pane, expand Parameter Connections,

and click New Connection.

5. Click the Browse (...) button.

6. In the Tag box, choose the drop-down arrow.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 25

Page 26

Chapter 1 Connecting program parameters

General rules for

Program parameter

7. On the Tag Browser, in the Show parameters from other program list,

choose the program to which you want to connect this Public

parameter.

8. In the list of available parameters, double-click the desired parameter.

9. Click OK.

Safety program parameters

connecting parameters for

safety programs

Special considerations apply when using program parameters within safety programs.

The following are general rules when connecting parameters for safety programs.

• A safety parameter cannot connect to a standard parameter or

controller scoped tag of standard class; the controller scope must be of

class safety.

• A safety parameter can source a standard parameter, as shown in the

following image.

• Safety Output parameters cannot connect to a standard class InOut

parameter.

• Safety local tags can alias safety class controller scope tags.

• Safety Public parameters can alias safety class controller scope tags.

connection rules

26 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

The following tables summarize the program parameter connection rules.

Page 27

Tip: The connection rules for programs also apply to Equipment Phases.

(Standard)

Program_B

Input

Output

InOut

Public

Controller Scope Tag

Input

—

Yes — Yes

Yes

Output

InOut

—

Yes*

—

Yes

Yes

Public

Controller Scope Tag

(Standard Class)

(Safety)

Program_B

Input

Output

InOut

Public

Controller Scope Tag

Input

—

Yes — Yes

Yes

Output

InOut

—

Yes* — Yes

Yes

Public

Yes

Yes

Yes — Alias

Controller Scope Tag

Standard program to

Safety program to safety

standard program

connection rules

Chapter 1 Connecting program parameters

The following table summarizes the rules for using program parameters to connect two

standard programs.

(Standard)

program connection rules

Program_A

(Standard Class)

Yes — Yes* Yes Yes

Yes Yes Yes — Alias

Yes Yes Yes Alias Alias

• * An InOut parameter can only be connected to an Output parameter if

the InOut parameter is configured as a constant.

• An Input parameter from Program_A can connect to an Output

parameter of Program_A (wrap around).

• Parameters of the same type cannot be connected together.

• Public tags can only bind to controller scope tags using an alias.

The following table summarizes the rules for using program parameters to connect two

safety programs.

Tip: The connection rules for programs also apply to Equipment Phases.

(Safety)

(Safety Class)

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 27

Program_A

(Safety Class)

Yes — Yes* Yes Yes

Yes Yes Yes Alias Alias

• * An InOut parameter can only be connected to an Output parameter if

the InOut parameter is configured as a constant.

• An Input parameter from Program_A can connect to an Output

parameter of Program_A (wrap around).

Page 28

Chapter 1 Connecting program parameters

Tip: The connection rules for programs also apply to Equipment Phases.

(Safety)

Program_B

Input

Output

InOut

Public

Controller Scope Tag

Input

—

Yes — Yes

Yes

Output

InOut

Public

Controller Scope Tag

(Safety Class)

Safety program to standard

The following table summarizes the rules for using program parameters to connect a safety

program connection rules

program to a standard program.

• Safety mapping must be used to connect standard class tags to safety

class tags/parameters.

• Standard class tags cannot alias safety class tags.

Program_A

(Standard)

— — — — —

— — — — —

— — — — —

Yes Yes Yes Alias Alias

(Safety Class)

• An Input parameter from Program_A can connect to an Output

parameter of Program_A (wrap around).

• Safety mapping must be used to connect standard class tags to safety

class tags/parameters.

• Standard class tags cannot alias safety class tags.

28 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 29

Introduction

Direct access

Behavior of direct

Access program

Chapter 2

Directly accessing program parameters

This chapter provides an overview of direct access and an example procedure for directly

accessing program parameters when working within code editors.

Direct access lets you reference the program parameters from another program in logic

without configuring parameters in the local program. The syntax used for direct access is

\ProgramName.ParameterName. For example, assume Program_A has an output parameter

called Tank_Level. Without creating a corresponding input parameter to connect to

Program_A, Program_B can reference the Tank_Level parameter in logic using the syntax

\A.Tank_Level.

Program local tags cannot be accessed using direct access.

access in logic

parameters when editing

ladder logic

Input, Output, and Public parameters can all be directly accessed in logic.

• When direct access is implemented in Output parameters, values are

updated when the program that contains the Output parameter

completes execution.

• When direct access is implemented in Input and Public parameters,

the values of the referenced parameters are updated in real time. This

means that higher priority tasks are using parameter values that are up

to date, thus minimizing the risk of performing actions on stale data.

• Direct access to an Input parameter counts toward fan-in. You cannot

have both a connection and a direct access sourcing an Input

parameter. You can however still use direct access to read the value.

• Using direct access of Input parameters is a good way to circumvent

the one connection limit of Input parameters. If you create an Input

parameter but do not configure any connections for that Input

parameter, you can directly reference it from multiple programs.

The following procedure explains how to access program parameters when editing ladder

logic.

Tip: While this example is specific to ladder logic, the notation is the same for all programming

languages.

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 29

Page 30

Chapter 2 Directly accessing program parameters

To access program parameters when editing ladder logic

1. In the Controller Organizer, expand the folder for the program that

2. In the Ladder Editor Routine, locate the instruction for which you

3. Double-click the existing tag name (it appears as ? if currently

contains the ladder logic routine that contains instructions for which

you are configuring direct access, and double-click the routine.

want to add a reference to a program parameter that is in another

program.

unassigned), and choose the drop-down arrow.

4. (optional) On the Tag Browser, clear or select the check boxes to focus

the list of available parameters that appear to what you need.

5. In the Show parameters from other program list, choose the program

to which you want to connect this instruction.

6. In the list of available parameters, double-click the desired parameter.

30 Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Page 31

Index

A

argument 8

C

connect

InOut parameter 22

Input parameter 15

Output parameter 18, 19

Public parameter 24

connection methods 11

Index

passed by value 8

program parameter

connect 11

connection methods 11

connection of UDT sub-elements 14

connection syntax 14

Public parameter

connect to another program 24

connection types and uses 23

general connection rules 24

overview 23

S

safety program parameters

general connection rules 26

overview 26

U

D

direct access

behavior 29

overview 29

use 29

I

InOut parameter

connect to a controller scope tag 22

connection types and uses 21

general connection rules 22

overview 21

Input parameter

connect to a controller scope tag 15

connection types and uses 15

general connection rules 15

overview 15

O

Output parameter

connect to a controller scope tag 18

connect to another program 19

connection types and uses 18

general connection rules 18

overview 17

UDT sub-elements 14

P

passed by reference 8

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020 31

Page 32

Technical Support Center

Find help with how-to videos, FAQs, chat, user forums, and product notification

rok.auto/support

Knowledgebase

Access Knowledgebase articles.

rok.auto/knowledgebase

Local Technical Support Phone Numbers

Literature Library

Product Compatibility and Download Center

Rockwell Automation support

Use these resources to access support information.

updates.

Locate the telephone number for your country. rok.auto/phonesupport

Find installation instructions, manuals, brochures, and technical data publications. rok.auto/literature

(PCDC)

Get help determining how products interact, check features and capabilities, and

find associated firmware.

rok.auto/pcdc

Documentation feedback

Your comments help us serve your documentation needs better. If you have any suggestions on how to improve our content, complete the form

at rok.auto/docfeedback

.

Waste Electrical and Electronic Equipment (WEEE)

At the end of life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation maintains current product environmental information on its website at rok.auto/pec.

Allen-Bradley, expanding human possibility, Logix, Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomayson Ticaret A.Ş. Kar Plaza İş Merkezi E Blok Kat:6 34752, İçerenkÖy, İstanbul, Tel: +90 (216) 5698400 EEE YÖnetmeliğine Uy gundur

Rockwell Automation Publication 1756-PM021D-EN-P - September 2020

Supersedes Publication 1756-PM021C-EN-P - February 2018 Copyright © 2020 Rockwell A utomation Technologies, Inc. All Rights Rese rved. Printed in the U.S.A.

Loading...

Loading...