Page 1

Logix5000 Controllers

Catalog Numbers 1756 ControlLogix, 1756 GuardLogix,

1768 CompactLogix, 1768 Compact GuardLogix,

1769 CompactLogix, 1789 SoftLogix, PowerFlex with DriveLogix

Quick Start

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that

each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell

) describes some important differences

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage,

or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Allen-Bradley, Rockwell Automation, CompactLogix, ControlLogix, DriveLogix, FactoryTalk Batch, FactoryTalk View SE, PhaseManager, PowerFlex, RSLinx, RSLinx Classic, RSLogix 5000, SoftLogix, and

TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

This version of the quick start corresponds to revision 18 of the Logix5000

controller firmware.

Change Page

Descriptions of controller modes 32

Language switching 108

Additional information for finalizing edits in larger projects 124

Summary of Changes

3Publication 1756-QS001E-EN-P - October 2009 3

Page 4

Summary of Changes

Notes:

4 Publication 1756-QS001E-EN-P - October 2009

Page 5

Table of Contents

Preface

Program and Test a Simple Project

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Required Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Create a Project for the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Conventions for Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Add Your I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Look at Your I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Ladder Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Enter Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Enter a Function Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Create a Routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Call the Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Enter a Function Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configure a Function Block Instruction. . . . . . . . . . . . . . . . . . . . . 24

Assign Alias Tags for Your Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Show or Hide Alias Information. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Establish a Serial Connection to the Controller . . . . . . . . . . . . . . . . . . 28

Download a Project to the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . 30

Select the Operating Mode of the Controller . . . . . . . . . . . . . . . . . . . . 32

Organize a Project

Chapter 2

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Configure the Task Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Create Additional Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Create User-defined Data Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Define Your Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Define a Routine for Each Section of a Machine or Process . . . . 44

Identify the Programming Languages That Are Installed . . . . . . . 44

Assign a Programming Language to Each Routine . . . . . . . . . . . . 45

Divide Each Routine Into More Meaningful Increments . . . . . . . 46

Assign Main Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configure the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Configure I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5Publication 1756-QS001E-EN-P - October 2009 5

Page 6

Table of Contents

Program Add-On Instructions

Program an Equipment Phase

Chapter 3

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Insert an Add-On Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Copy an Add-On Instruction Definition . . . . . . . . . . . . . . . . . . . . . . . 53

Import an Add-On Instruction Definition . . . . . . . . . . . . . . . . . . . . . . 54

Access a Parameter That Is Not Visible . . . . . . . . . . . . . . . . . . . . . . . . 55

Function Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Ladder Logic and Structured Text . . . . . . . . . . . . . . . . . . . . . . . . . 55

Monitor or Change the Value of a Parameter of an

Add-On Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

View the Logic of an Add-On Instruction . . . . . . . . . . . . . . . . . . . . . . 57

Edit and Monitor an Add-On Instruction . . . . . . . . . . . . . . . . . . . . . . 58

Update an Add-On Instruction to a Newer Revision . . . . . . . . . . . . . 58

Chapter 4

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Create an Equipment Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Create a State Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Manually Step Through the States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Configure the Initial State for an Equipment Phase. . . . . . . . . . . . . . . 63

Open the Configuration for an Equipment Phase . . . . . . . . . . . . . . . . 64

Configure an Equipment Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Program a Project Offline

Chapter 5

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Enter Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Add a Rung or an Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Add a Branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Add a Level to a Branch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Delete an Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Use the Keyboard to Add an Element . . . . . . . . . . . . . . . . . . . . . . 70

Enter Logic Using ASCII Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Enable Quick Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Export/Import Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

When You Import Rungs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Export Rungs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Import Rungs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Check Alias Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

6 Publication 1756-QS001E-EN-P - October 2009

Page 7

Table of Contents

Enter a Function Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Use the Keyboard to Add an Element . . . . . . . . . . . . . . . . . . . . . . 78

Connect Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Resolve a Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Add Sheet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Use a Faceplate for a Function Block . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Set Up a Topic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Add a Faceplate to Microsoft Excel Software . . . . . . . . . . . . . . . . 83

Enter Structured Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Browse For an Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Assign Operands to an Instruction. . . . . . . . . . . . . . . . . . . . . . . . . 86

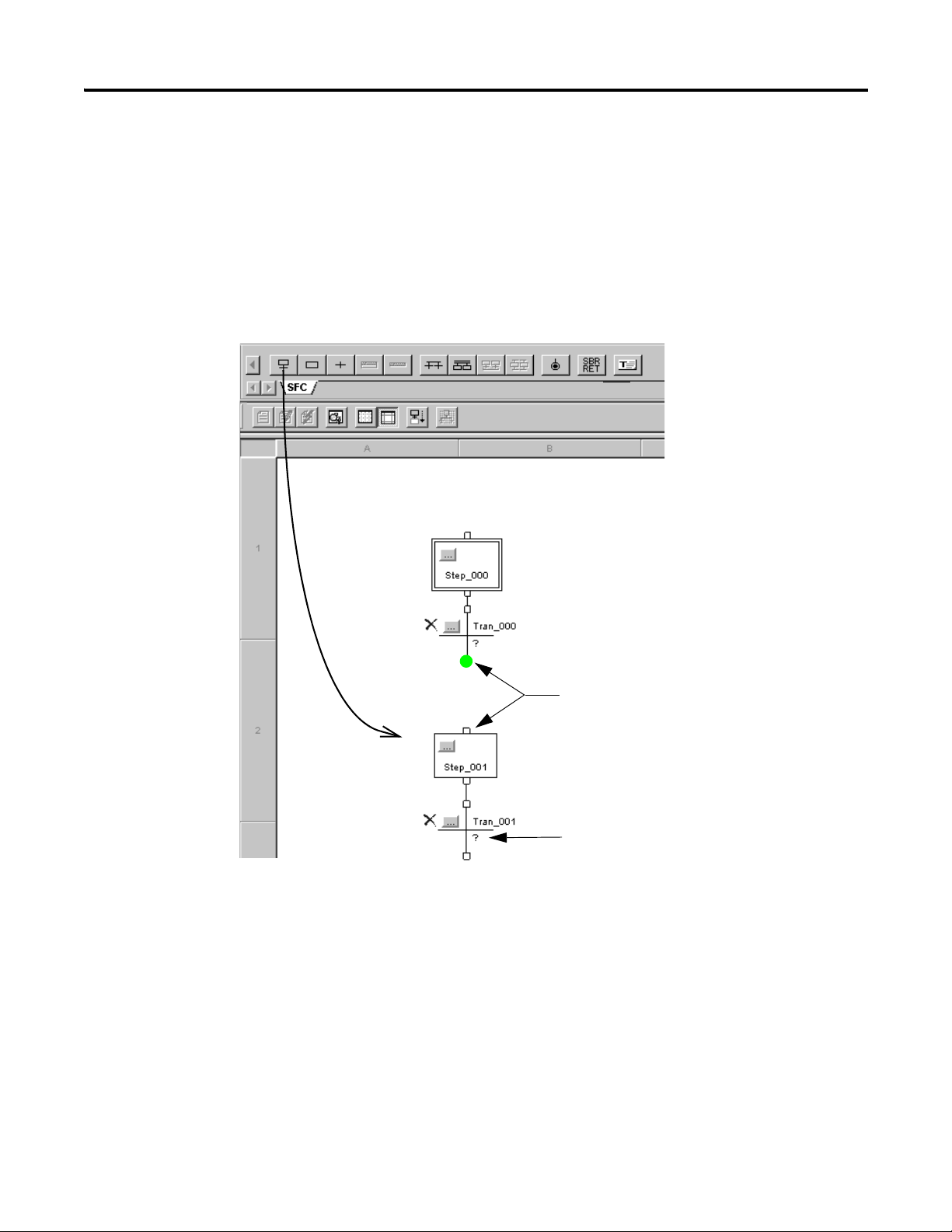

Enter a Sequential Function Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Enter an SFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Assign Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Create a Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Select an Existing Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

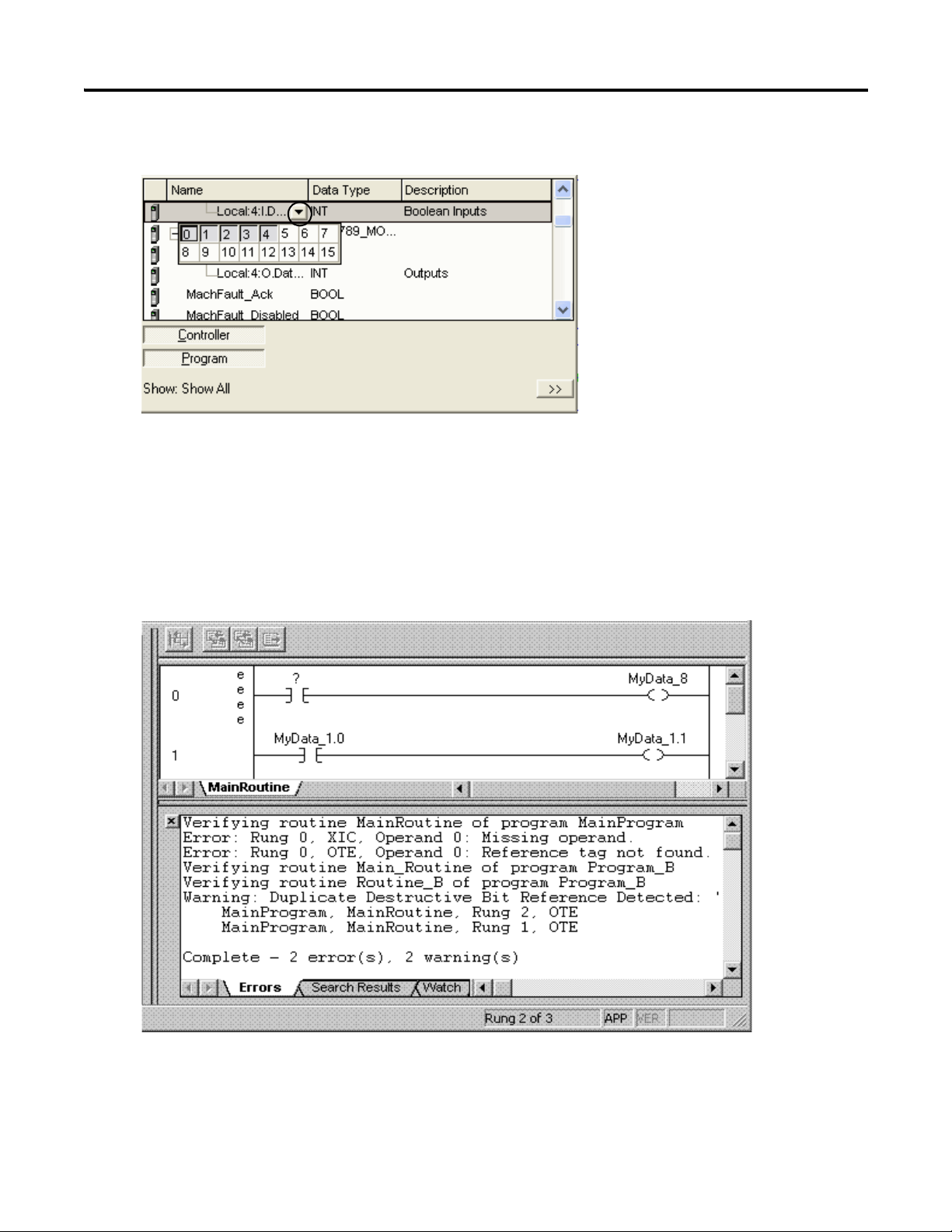

Verify a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Guidelines for Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Document a Project

Go Online to the Controller

Chapter 6

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

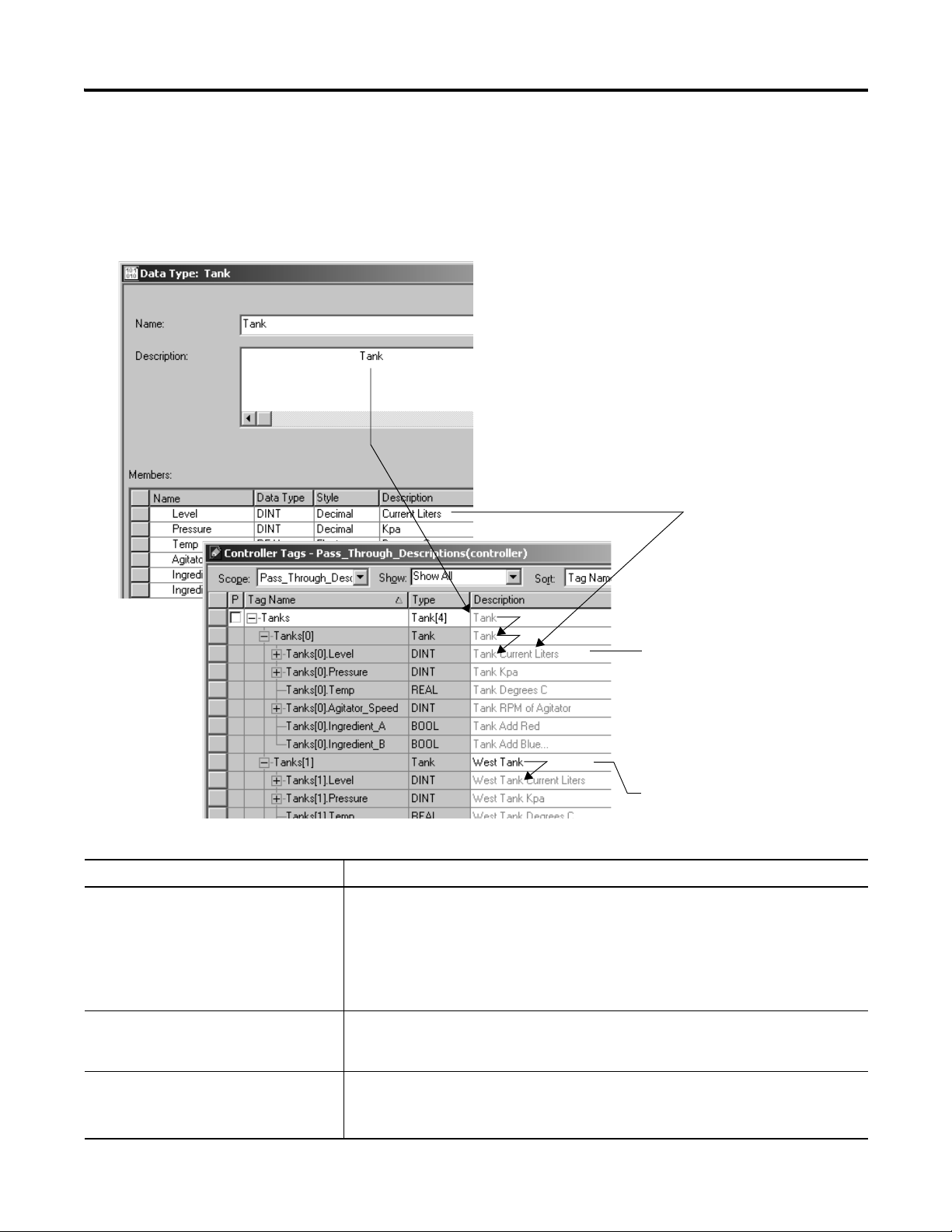

User-defined Data Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Turn Pass-Through and Append Descriptions On or Off . . . . . . 99

Paste a Pass-Through Description . . . . . . . . . . . . . . . . . . . . . . . . 100

Add Rung Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Rung Comments Using Microsoft Excel . . . . . . . . . . . . . . . . . . . . . . 102

Export the Existing Comments . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Edit the Export File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Import the New Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Comments in a Function Block Diagram or SFC . . . . . . . . . . . . . . . 105

Set the Word Wrap Option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Add a Text Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Comments in Structured Text . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Language Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Chapter 7

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Establish EtherNet/IP Communication with the Controller . . . . . . 110

Equipment and Information That You Need . . . . . . . . . . . . . . . 111

Connect Your EtherNet/IP Device and Computer . . . . . . . . . . 112

Assign an IP Address to the Controller or

Communication Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Assign an IP Address to Your Computer. . . . . . . . . . . . . . . . . . . 114

Publication 1756-QS001E-EN-P - October 2009 7

Page 8

Table of Contents

Program a Project Online

Troubleshoot the Controller

Index

Configure an Ethernet Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Online with a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

If Your Computer Has the Project For the Controller . . . . . . . . 117

If Your Computer Does Not Have the Project

For the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Chapter 8

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Edit Logic While Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Start a Pending Edit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Make and Accept Your Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Test the Edits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Assemble and Save the Edits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Finalize All Edits in a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Chapter 9

What You Need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Follow These Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Troubleshoot I/O Communication . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Clear a Major Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Search Functions in a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Search for All Occurrences of a Element. . . . . . . . . . . . . . . . . . . 128

Go to an Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Browse Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Forcing an I/O Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Install an I/O Force (Force an I/O Value. . . . . . . . . . . . . . . . . . 133

Remove an Individual Force . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Disable All I/O Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Data Trend (Histogram) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Run a Trend for a Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Add More Tags to the Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Save the Trend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

View Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

View Task Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

View Program Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

8 Publication 1756-QS001E-EN-P - October 2009

Page 9

Preface

About This Publication

Use this manual to get started programming and maintaining Logix5000 controllers.

This manual describes the necessary tasks to do the following.

• establish communication with a Logix5000 controller

• program a Logix5000 controller

• perform online maintenance tasks such a search and edit logic, run a histogram, clear faults, and force

I/O values.

Required Software

To complete this quick start, the following software is required:

• RSLogix 5000 software, version 18 or later

• RSLinx Classic software, version 2.51

9Publication 1756-QS001E-EN-P - October 2009 9

Page 10

Chapter Preface

Additional Resources

Resource Description

Logix5000 Controllers System Reference, publication 1756-QR107

Logix5000 Controllers Design Considerations Reference, publication

1756-RM094

Logix5000 Controllers Common Procedures, publication

1756-PM001

• Logix5000 Controllers General Instructions Reference

Manual, publication 1756-RM003

• Logix5000 Controllers Process and Drives Instructions

Reference Manual, publication 1756-RM006

• Logix5000 Controllers Motion Instruction Set Reference

Manual, publication MOTION-RM001

Logix5000 Controllers Import/Export Reference Manual, publication

1756-RM084

• 1768 CompactLogix Controller Quick Start and User Manual,

publication 1768-UM001

• 1769 CompactLogix System User Manual, publication

1769-UM007

• ControlLogix System User Manual, publication 1756-UM001

• DriveLogix Controller User Manual, publication 20D-UM002

• GuardLogix Controllers User Manual, publication

1756-UM020

• SoftLogix5800 System User Manual, publication

1789-UM002

EtherNet/IP Modules in Logix5000 Control Systems User Manual,

publication ENET-UM001

ControlNet Modules in Logix5000 Control Systems User Manual,

publication CNET-UM001

DeviceNet Modules in Logix5000 Control Systems User Manual,

publication DNET-UM004

Look up abbreviated information and procedures regarding

programming languages, instructions, communications, and status

Design and optimize a controller application.

Program a Logix5000 controller—detailed and comprehensive

information

Program a specific Logix5000 programming instruction

Import or export a Logix5000 project or tags from or to a text file

Integrate a specific Logix5000 controller within a system of

controllers, I/O modules, and other devices

Control devices over an EtherNet/IP network

Control devices over a ControlNet network

Control devices over a DeviceNet network

You can view or download publications a http://www.rockwellautomation.com/literature. To order paper

copies of technical documentation, contact your local Rockwell Automation distributor or sales

representative.

10 Publication 1756-QS001E-EN-P - October 2009

Page 11

Chapter

Program and Test a Simple Project

This chapter introduces the basic programming sequence for a Logix5000 controller.

• It covers the steps required to develop and test a ladder or function block diagram.

• The examples in the chapter show how to control a digital or analog output based on the state of a

digital or analog input.

What You Need

You need these items to complete the tasks in this manual:

• Personal computer running RSLogix 5000 software, version 16 or later

• A layout of the system for which you are creating a project

1

11Publication 1756-QS001E-EN-P - October 2009 11

Page 12

Chapter 1 Program and Test a Simple Project

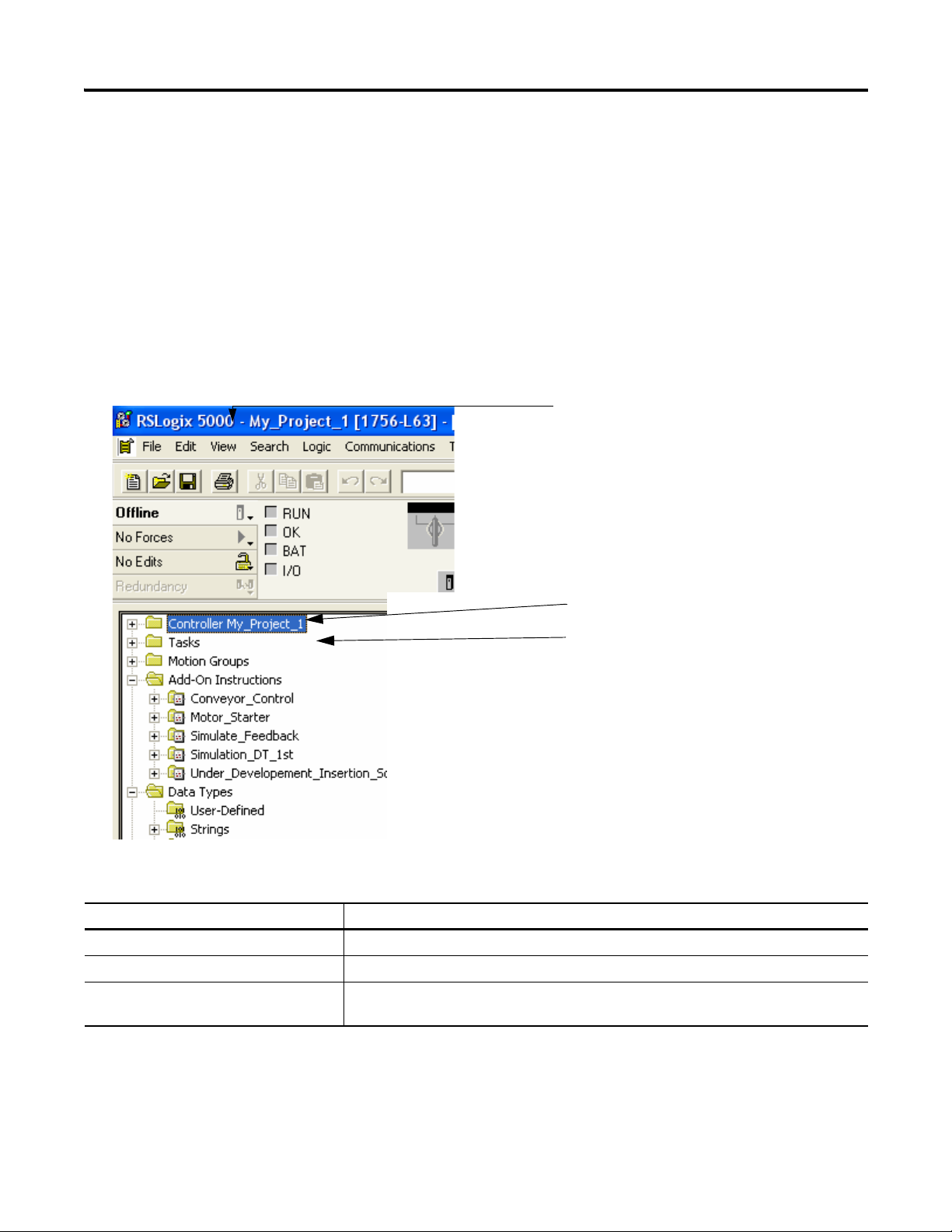

A

B

C

Before You Begin

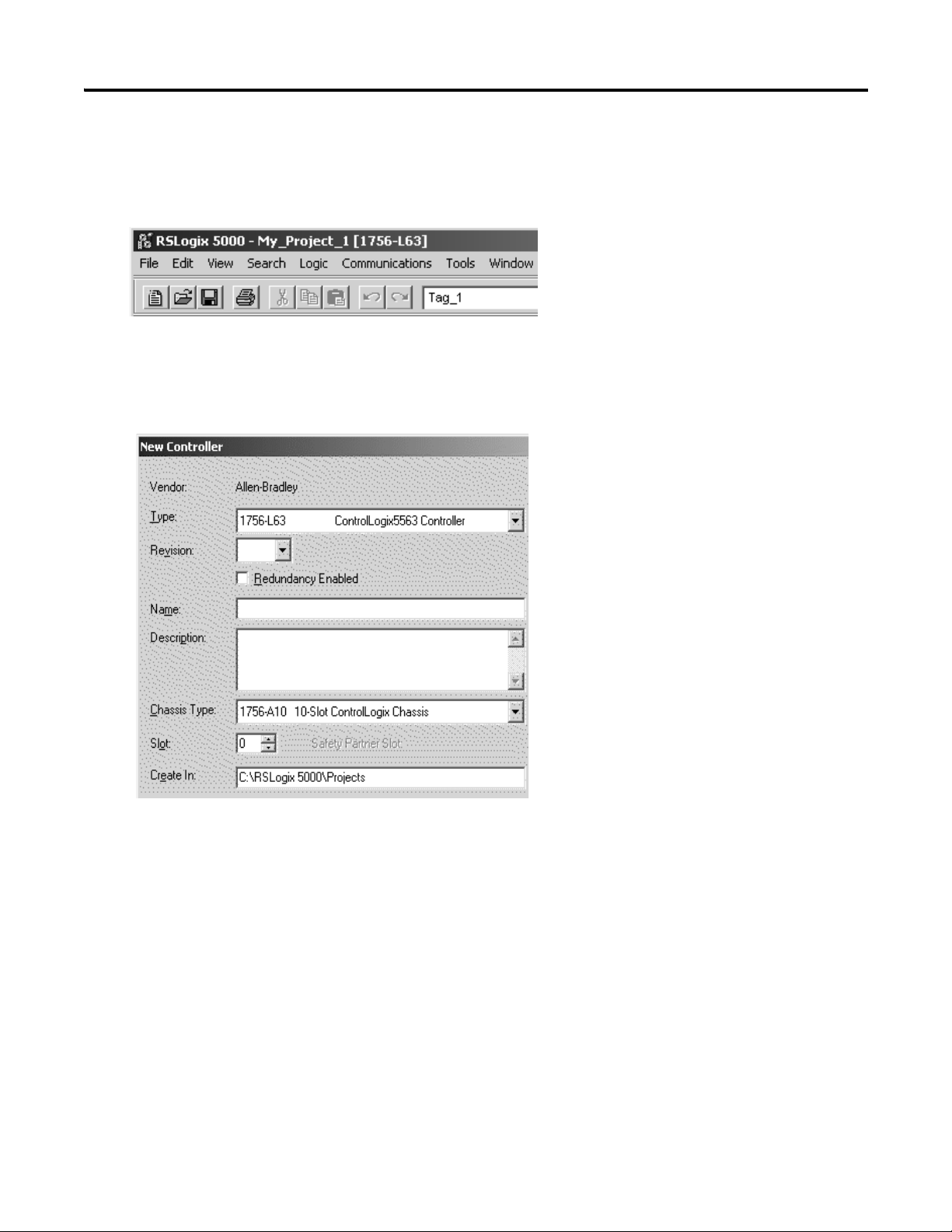

To configure and program a Logix5000 controller, you use RSLogix 5000 software to create and manage a

project for the controller. A project is the file on your workstation (or server) that stores the logic,

configuration, data, and documentation for a controller.

• The file for the project has an .ACD extension.

• When you create a project, the project name is the same as the name of the controller.

• The controller name is independent of the project name. You can rename either the project name or

the controller name.

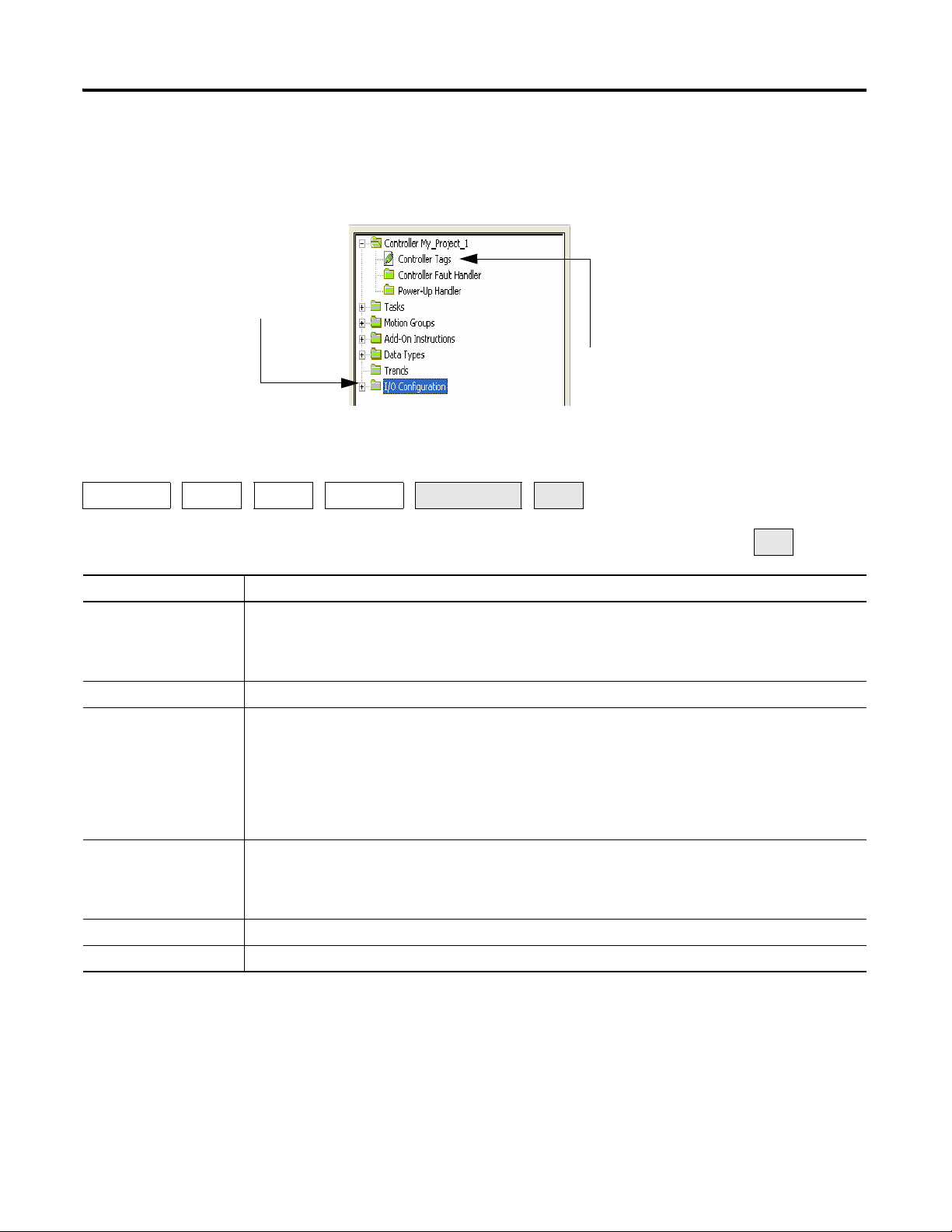

In an open project, there is this information:

Item Description

A Name of the project. If you rename the project or controller, both names are shown.

B Name of the controller.

C The controller organizer is a graphical overview of the project. Use the controller organizer

to navigate to the various components of a project.

To open a folder and show its contents, either:

• double-click the folder.

• click the + sign.

12 Publication 1756-QS001E-EN-P - October 2009

Page 13

Follow These Steps

1. Create a project for the controller (page 14).

2. Add I/O modules (page 15).

3. Look at I/O data (page 17).

4. Enter ladder logic (page 19).

5. Enter a function block diagram (page 21).

6. Assign alias tags for your devices (page 25).

7. Establish a serial connection to the controller (page 28).

8. Download a project to the controller (page 30).

Program and Test a Simple Project Chapter 1

9. Select the operating mode of the controller (page 32).

Publication 1756-QS001E-EN-P - October 2009 13

Page 14

Chapter 1 Program and Test a Simple Project

Create a Project for the Controller

1. Start RSLogix 5000 software.

2. Click New.

3. Specify the general configuration for the controller.

Specify these items (some items apply to only certain controllers):

• Type of controller.

• Major revision of firmware for the controller.

• Name for the controller.

• Chassis type for the controller.

• Slot number of the controller.

• The path where the project will be stored.

4. Click OK.

14 Publication 1756-QS001E-EN-P - October 2009

Page 15

Program and Test a Simple Project Chapter 1

TIP

CompactLogix

Controller

ControlLogix

Controller

Conventions for Names

Throughout a Logix5000 project, you define names for the different elements of the project, such as the

controller, data addresses (tags), routines, and I/O modules. As you enter names, follow these rules.

• Only letters, numbers, and underscores (_)

• Must start with a letter or an underscore

•≤ 40 characters

• No consecutive or trailing underscores

• Not case sensitive

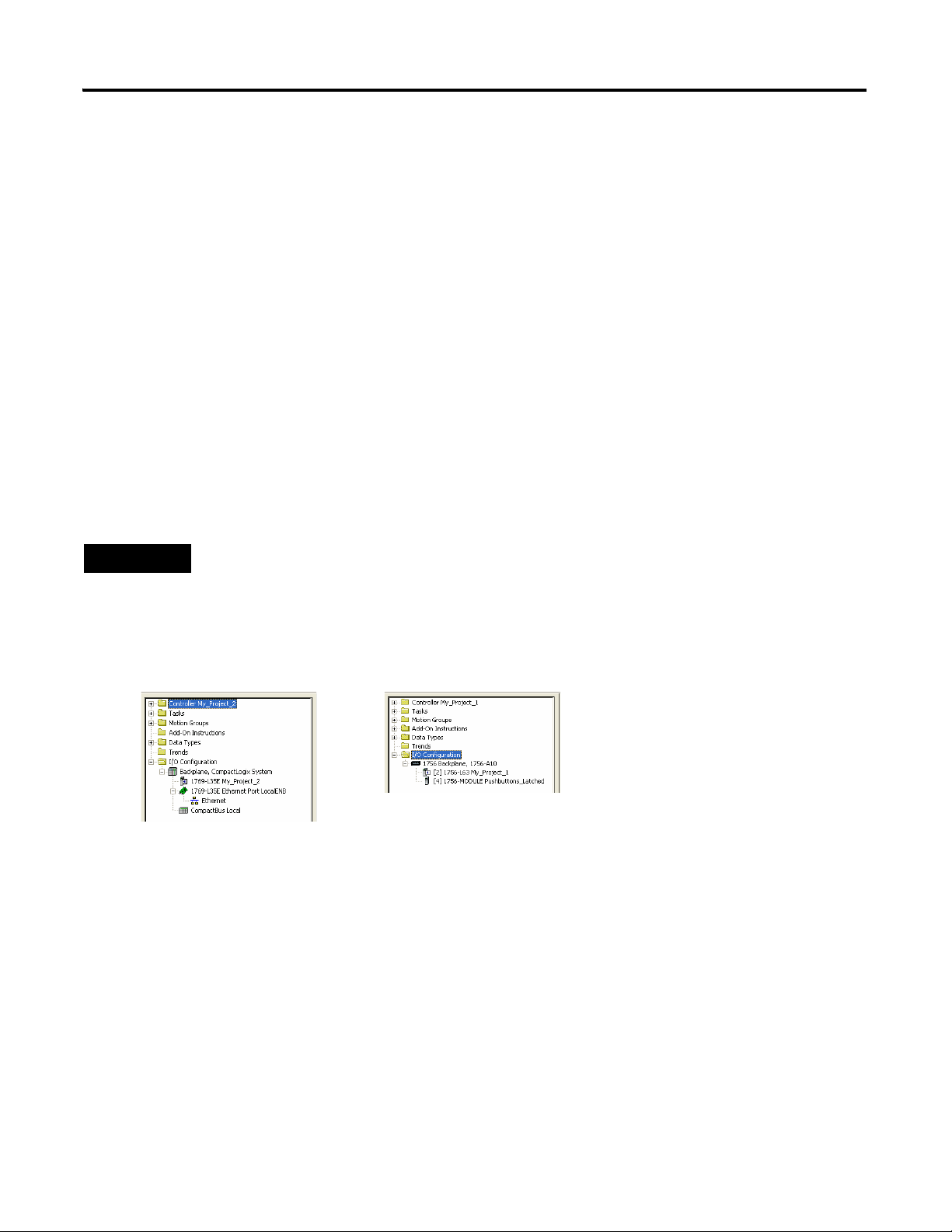

Add Your I/O Modules

To communicate with an I/O modules in your system, you add the modules to the I/O Configuration folder

of the controller. The properties you select for each module defines the behavior of the module.

The screens shown are representative of three types of controllers; other types are available, but are not

shown here.

1. Right-click the I/O Configuration folder and choose New Module.

Publication 1756-QS001E-EN-P - October 2009 15

Page 16

Chapter 1 Program and Test a Simple Project

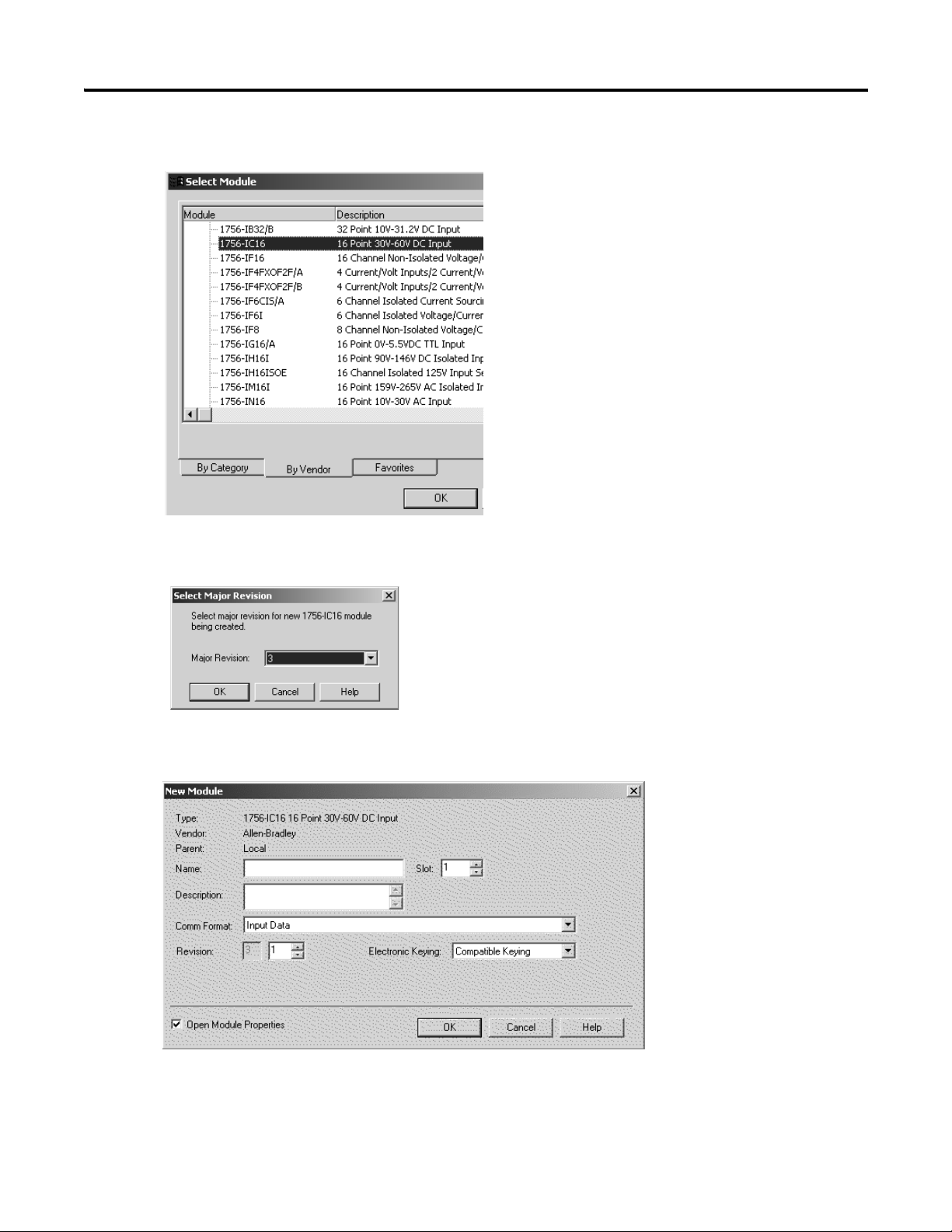

2. Select the module and click OK.

3. From the Major Revision pull-down menu, choose the revision of the module.

4. Define the module and click OK.

16 Publication 1756-QS001E-EN-P - October 2009

Page 17

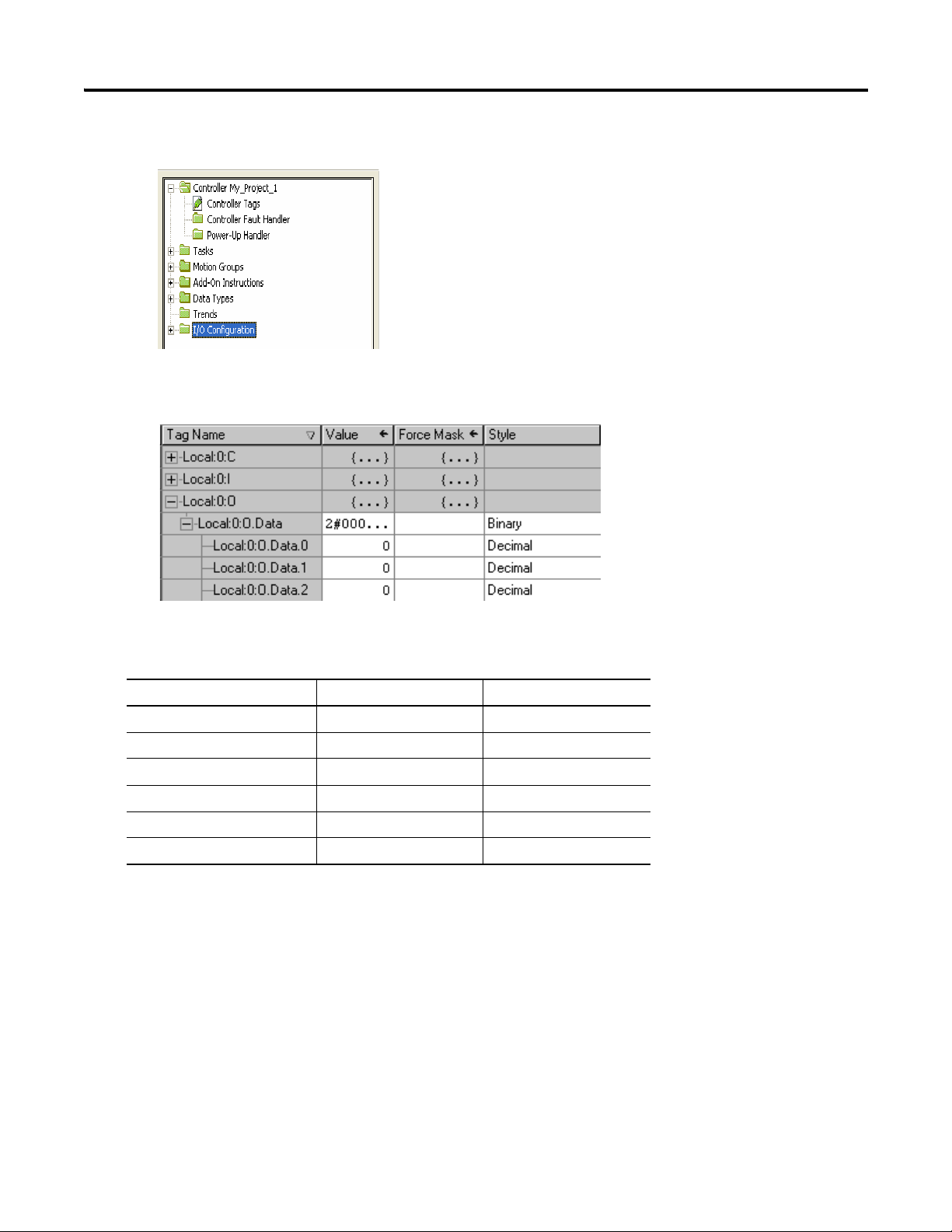

Look at Your I/O Data

When you add a module to the I/O

Configuration folder…

…the software automatically creates

controller-scoped tags for the module.

I/O information is presented as a set of tags.

An I/O address follows this format.

Location :Slot :Type .Member .SubMember .Bit

Program and Test a Simple Project Chapter 1

= Optional

Where Is

Location Network location

LOCAL = same chassis or DIN rail as the controller

ADAPTER_NAME = identifies remote communication adapter or bridge module

Slot Slot number of I/O module in its chassis or DIN rail

Type Type of data

I = input

O = output

C = configuration

S = status

Member Specific data from the I/O module; depends on what type of data the module can store.

• For a digital module, a Data member usually stores the input or output bit values.

• For an analog module, a Channel member (CH#) usually stores the data for a channel.

SubMember Specific data related to a Member.

Bit Specific point on a digital I/O module; depends on the size of the I/O module (0-31 for a 32-point module)

Publication 1756-QS001E-EN-P - October 2009 17

Page 18

Chapter 1 Program and Test a Simple Project

1. Right-click Controller Tags and choose Monitor Tags.

The Tag Monitor displays the tags.

Values are shown in the following styles.

Style Base Notation

Binary 2 2#

Decimal 10 NA

Hexadecimal 16 16#

Octal 8 8#

Exponential NA 0.0000000e+000

Float NA 0.0

A blue arrow indicates that when you change the value, it immediately takes effect.

2. To see a value in a different style, select the desired style.

3. To change a value, click the Value cell, type the new value, and click Enter.

4. To expand a tag and show its members, click the + sign.

18 Publication 1756-QS001E-EN-P - October 2009

Page 19

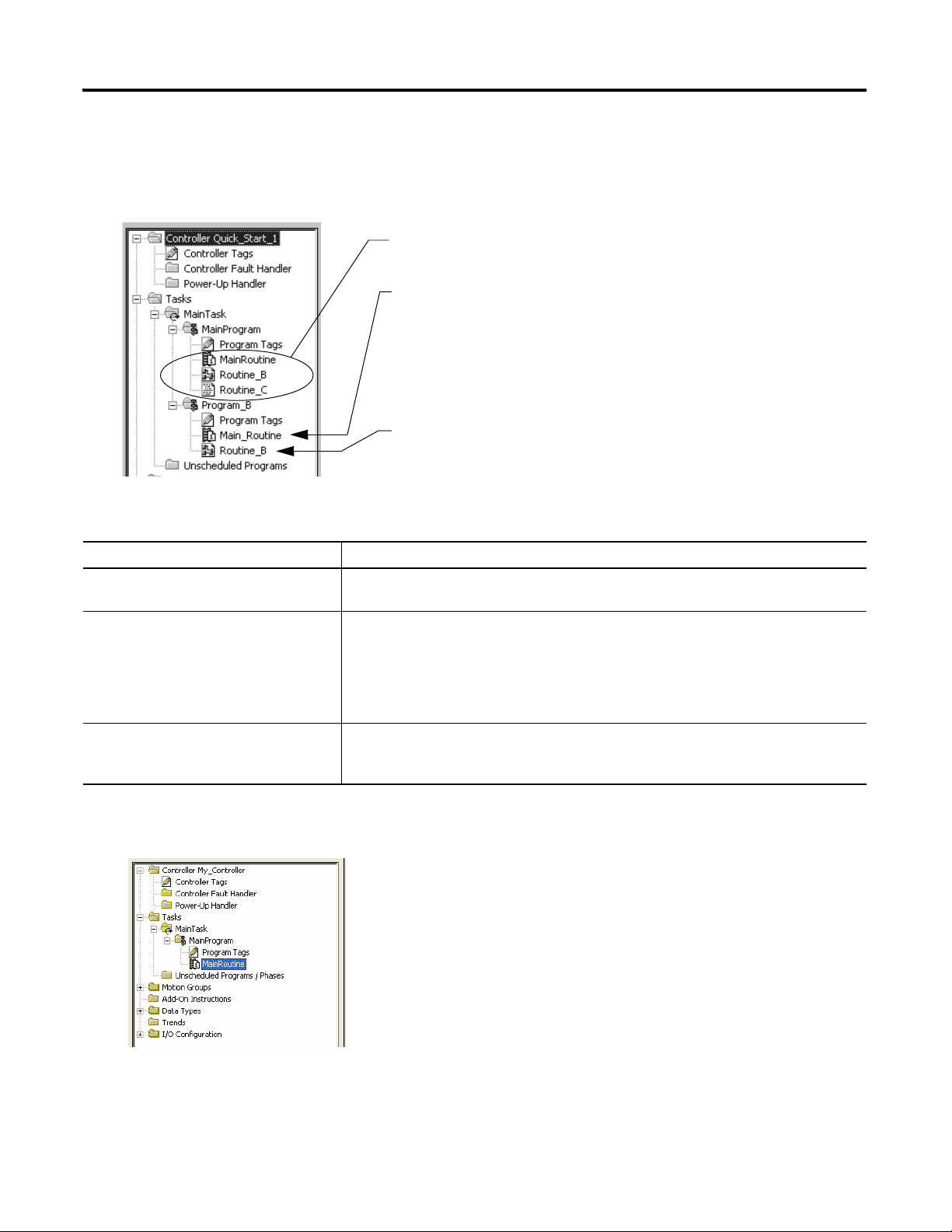

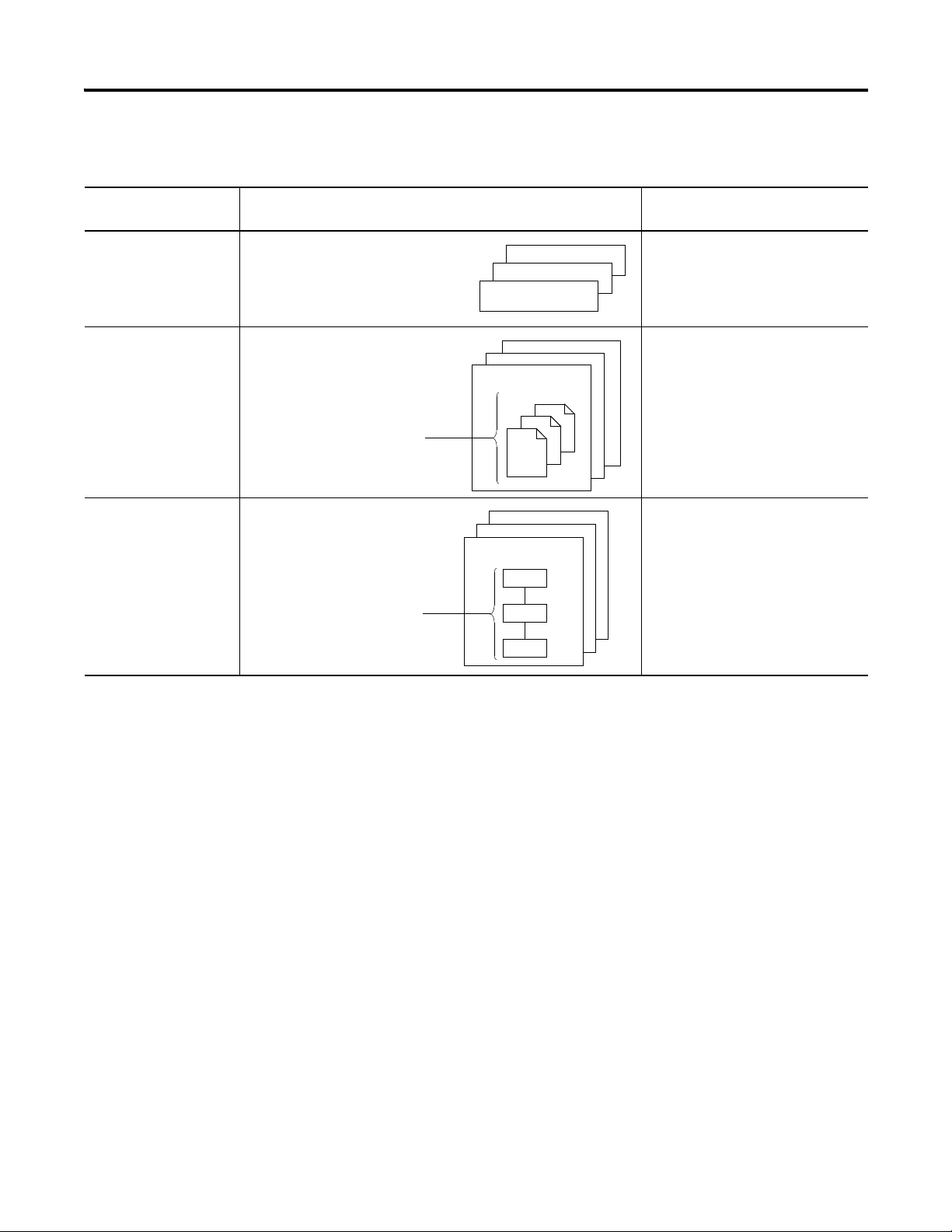

Ladder Logic

A

B

C

For a Logix5000 controller, you enter your logic in routines.

Program and Test a Simple Project Chapter 1

Item Description

A A routine provides the executable code (logic) for a program (similar to a program file in a

PLC or SLC controller).

B There is one main routine you assign for each program.

• When the program executes, its main routine automatically executes.

• Use the main routine to control the execution of the other routines in the program.

• To call (execute) another routine (subroutine) within the program, use a Jump to

Subroutine (JSR) instruction.

C A subroutine is any routine other than the main routine or fault routine. To execute a

subroutine, use a Jump to Subroutine (JSR) instruction in another routine, such as the main

routine.

When you create a project, the software automatically creates a main routine that uses the ladder diagram

programming language.

Publication 1756-QS001E-EN-P - October 2009 19

Page 20

Chapter 1 Program and Test a Simple Project

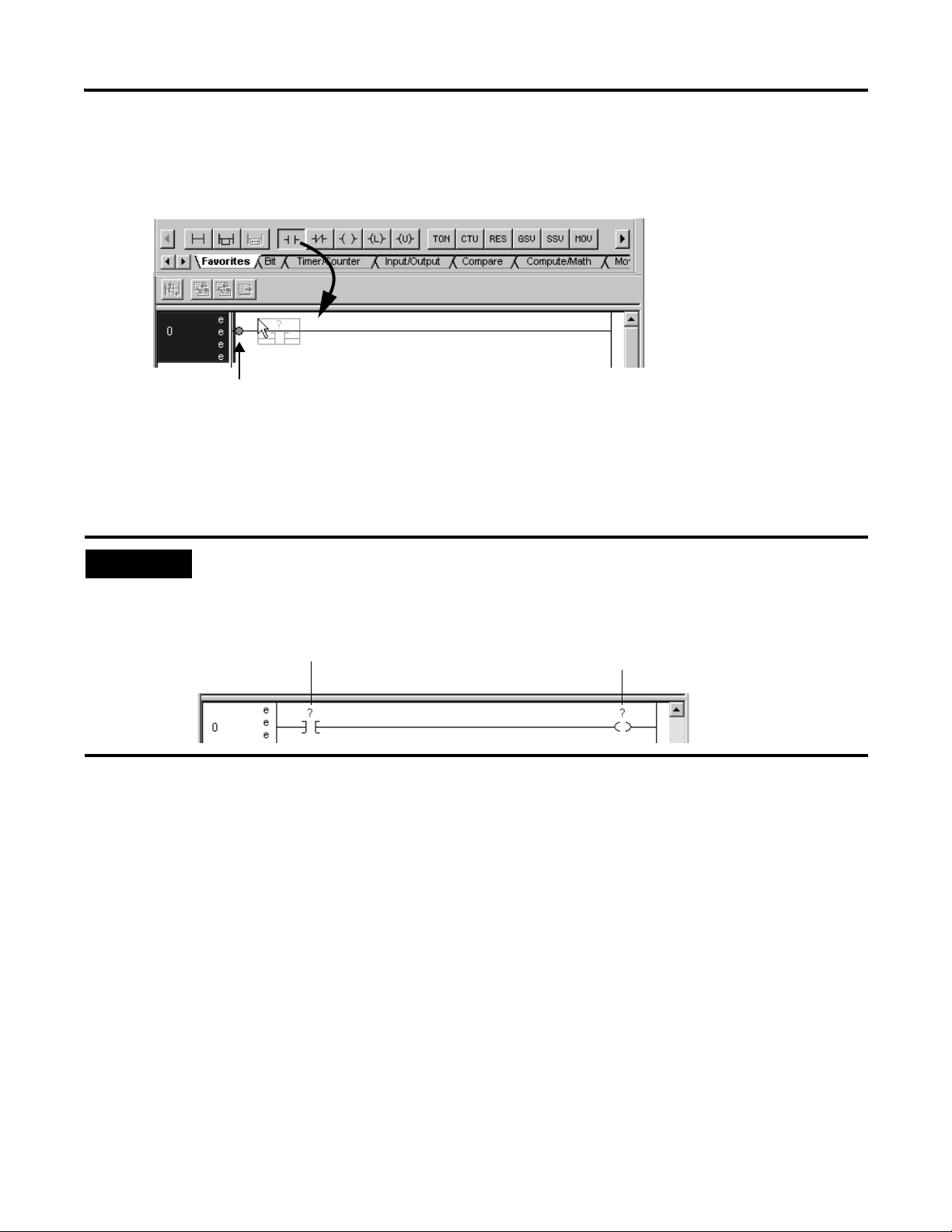

EXAMPLE

A green dot shows a valid placement location

(drop point).

XIC

If this bit is on…

OTE

…turn on this bit. Otherwise,

turn off this bit.

Enter Ladder Logic

One way to enter logic is to drag buttons from a toolbar to the desired location.

To add ladder logic, drag the button for the rung or instruction directly to the desired location. You can enter

your logic and leave the operands undefined. After you enter a section of logic, go back and assign the

operands.

In the following example, an Examine If Closed (XIC) instruction checks the on/off state of a pushbutton. If

the pushbutton is on, the Output Energize (OTE) instruction turns on a light.

20 Publication 1756-QS001E-EN-P - October 2009

Page 21

Program and Test a Simple Project Chapter 1

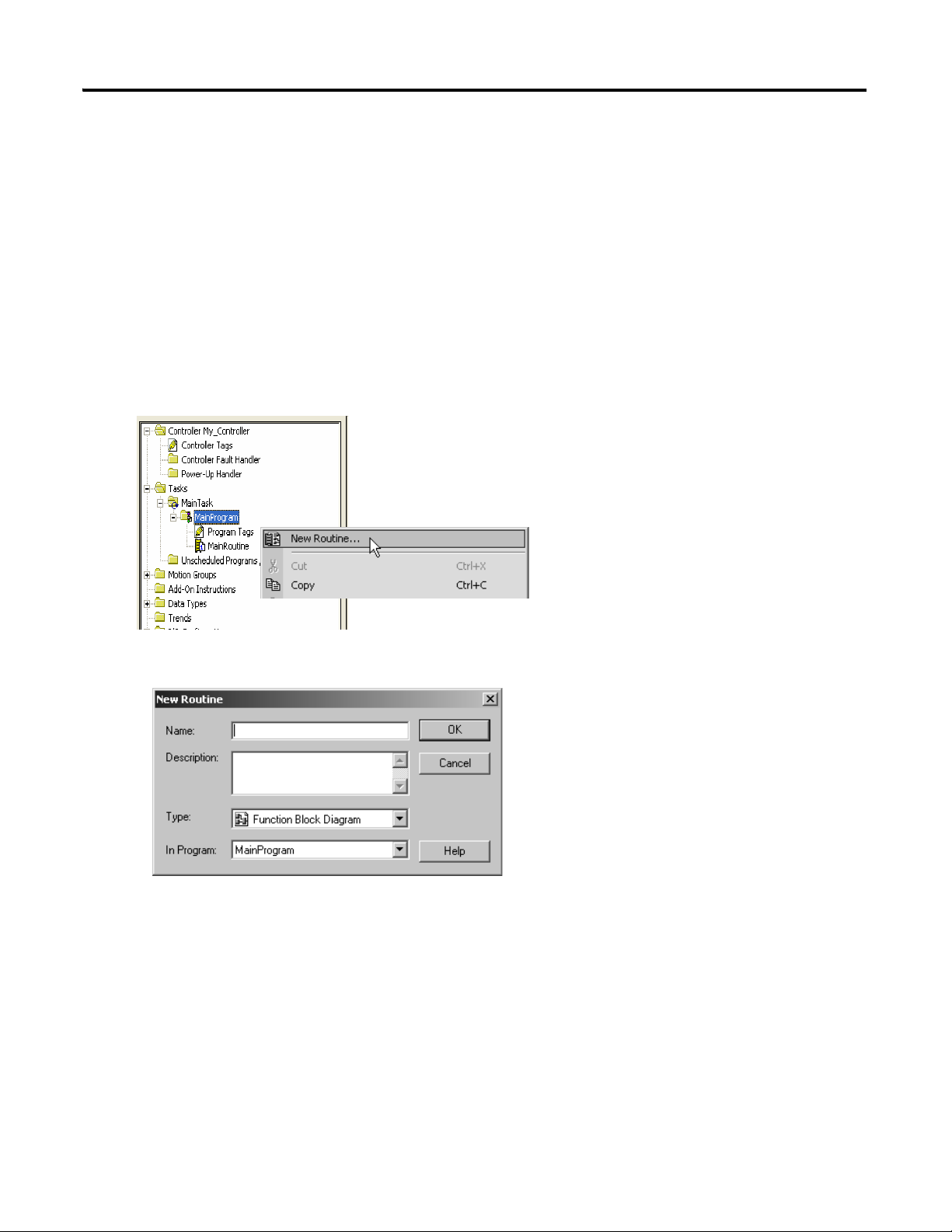

Enter a Function Block Diagram

Follow these steps to add a function block diagram to your project.

Create a Routine

Each routine in your project uses a specific programming language. To program in a different language, such

as function block diagram, create a new routine.

1. Right-click MainProgram and choose New Routine.

2. Type a name for the routine.

3. Choose the programming language.

4. Click OK.

Publication 1756-QS001E-EN-P - October 2009 21

Page 22

Chapter 1 Program and Test a Simple Project

Call the Routine

To execute a routine other than the main routine, use a Jump to Subroutine (JSR) instruction to call the

routine.

1. Add a rung.

2. On the Program Control tab, add a JSR instruction.

3. In the Routine Name field of the JSR instruction, type the name of the routine that you want to

execute.

4. To simply call the routine, remove the rest of the parameters for the JSR instruction. To remove a

parameter, right-click the parameter and choose Remove Instruction Parameter.

22 Publication 1756-QS001E-EN-P - October 2009

Page 23

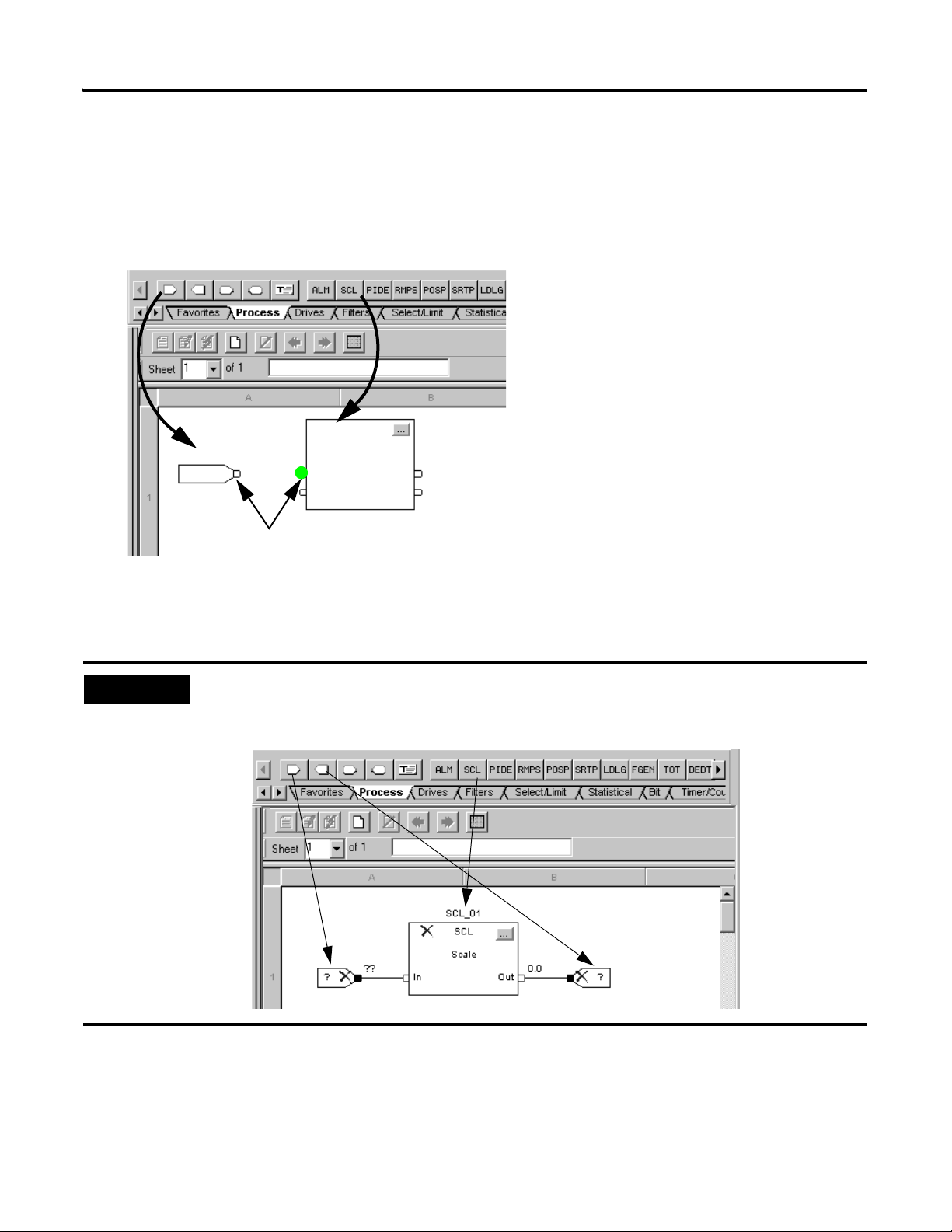

Enter a Function Block Diagram

EXAMPLE

Enter function block diagram instructions in a function block routine.

1. Click the tab for the desired instructions.

Program and Test a Simple Project Chapter 1

2. Drag elements from the toolbar to the sheet.

3. To connect elements, click corresponding pins (green dot = valid connection point).

In the following example, an Input Reference (IREF) reads the value of an analog input and sends the value

to a Scale (SCL) instruction. The SCL instruction converts the value to engineering uses and sends it to an

Output Reference (OREF). The OREF writes the value to an analog output.

Publication 1756-QS001E-EN-P - October 2009 23

Page 24

Chapter 1 Program and Test a Simple Project

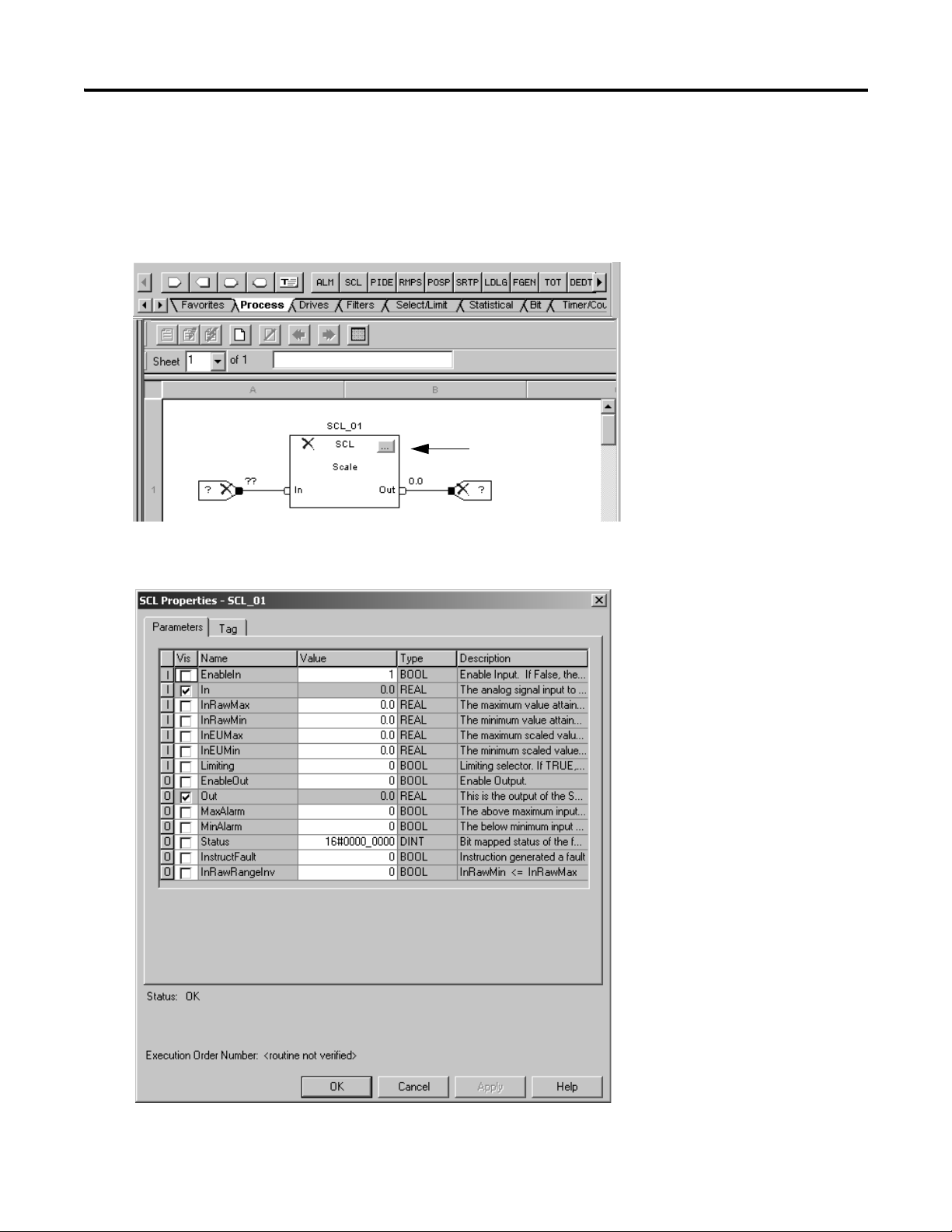

Configure a Function Block Instruction

Assign specific values (parameters) to configure a function block instruction.

1. Click the configuration button.

2. To change the value of a parameter, click the value cell, type the new value, and click Enter.

24 Publication 1756-QS001E-EN-P - October 2009

Page 25

Program and Test a Simple Project Chapter 1

For example, in the SCL instruction, specify the following parameters:

• InRawMax – maximum input value

• InRawMin – minimum input value

• InEUMax – maximum engineering value

• InEUMin – minimum engineering value

3. Click OK.

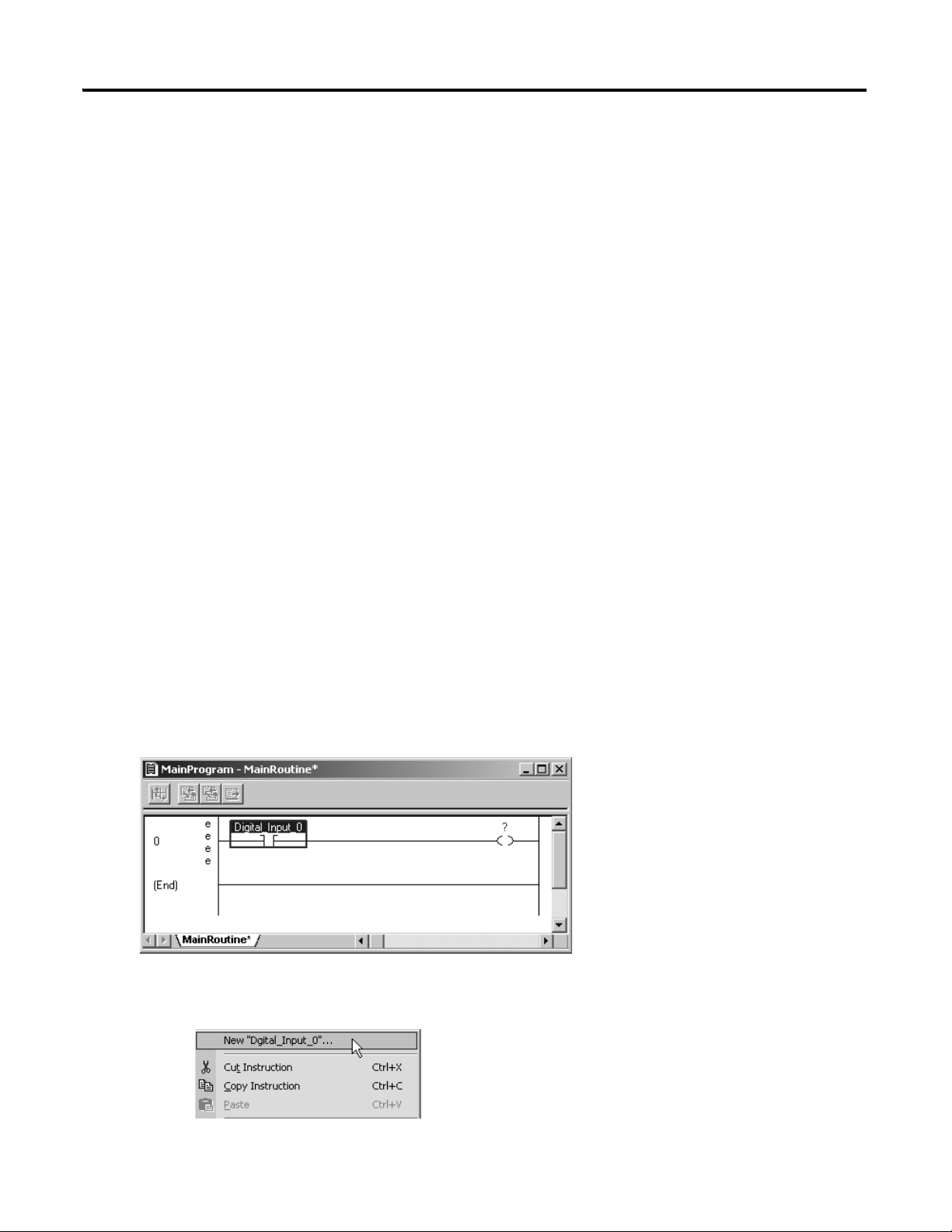

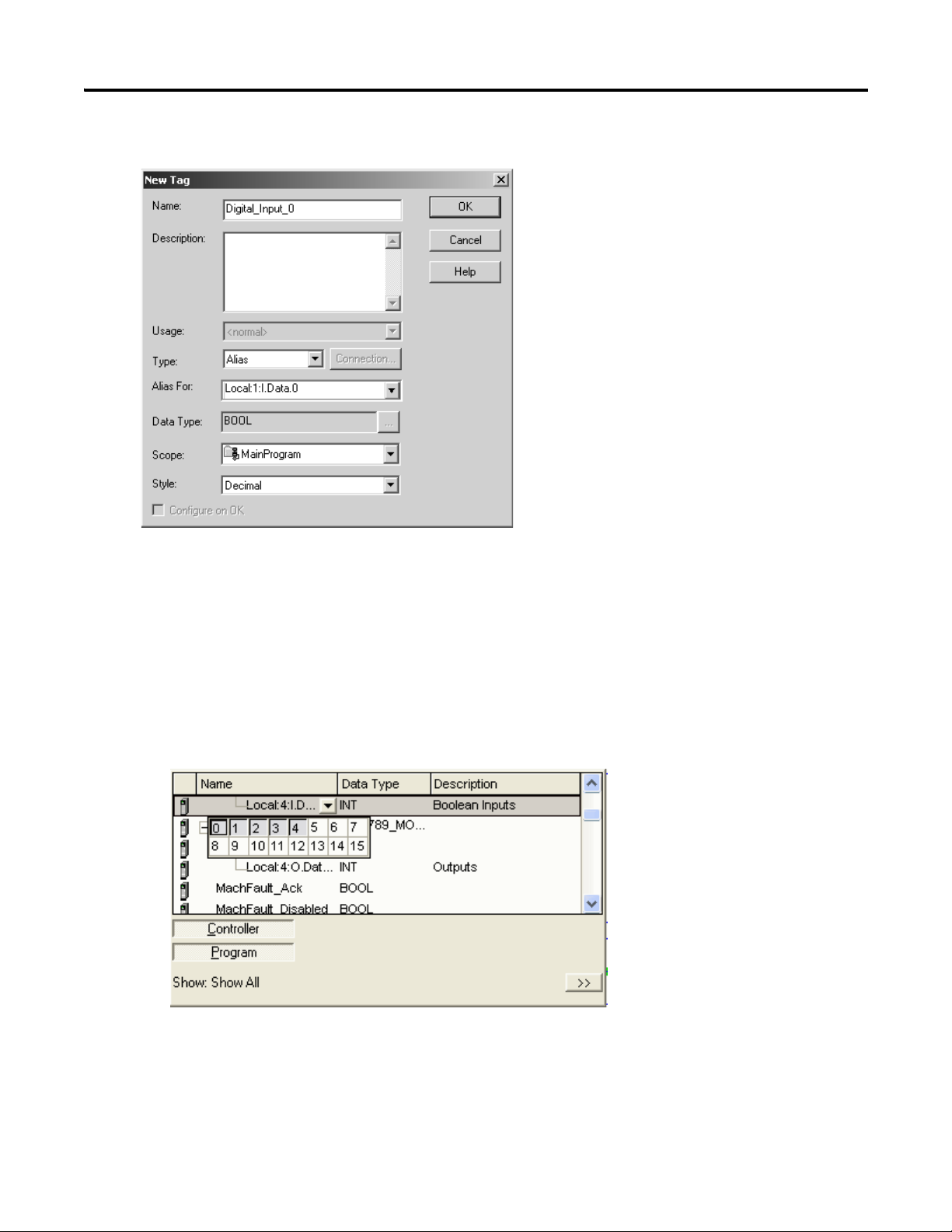

Assign Alias Tags for Your Devices

While you can use the input and output tags of a module directly in your logic, it is easier to use alias tags. An

alias tag is a tag that represents another tag.

• Both tags share the same data.

• When the data changes, both tags change.

• An alias tag provides a descriptive name for data, such as DeviceNet input or output data.

• If the location of the data changes, simply point the alias tag goes to the new location without editing

your logic.

As an option, create tags that describe each device without pointing them to the actual addresses of the

devices. Later, convert the tags to aliases for the data of the devices.

1. Enter the logic.

2. Type a descriptive tag name for the device.

3. Right-click the tag name and choose New…

Publication 1756-QS001E-EN-P - October 2009 25

Page 26

Chapter 1 Program and Test a Simple Project

4. Select Alias from the menu.

5. Select the tag that this alias tag represents.

6. Select the scope for the alias tag.

7. Click OK.

8. Select the address of the data.

To select a bit, click the b button.

26 Publication 1756-QS001E-EN-P - October 2009

Page 27

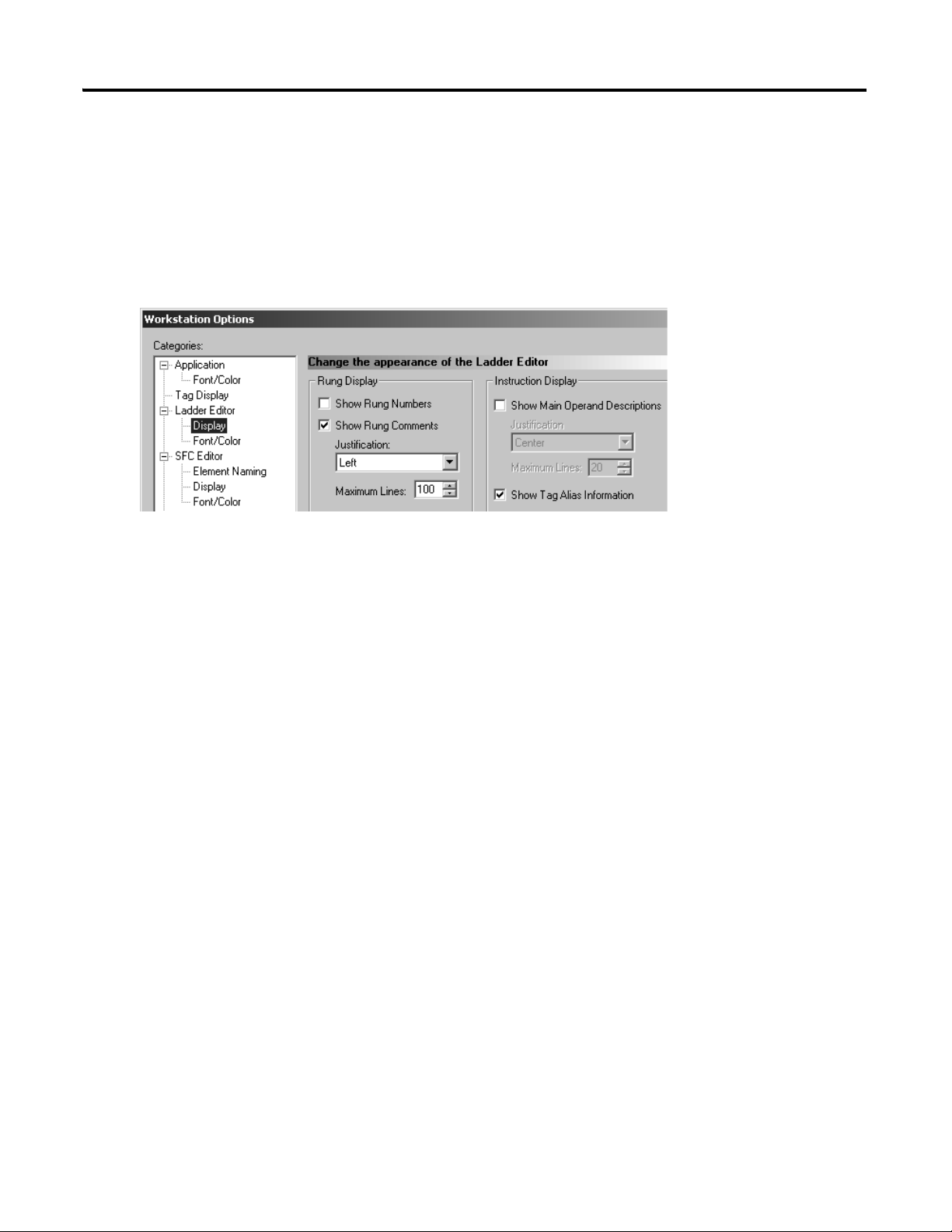

Show or Hide Alias Information

Show or hide alias information for a tag.

1. From the Tools menu, choose Options.

2. Select the Ladder Editor Display category.

Program and Test a Simple Project Chapter 1

3. Check or uncheck Show Tag Alias Information.

4. Click OK.

Publication 1756-QS001E-EN-P - October 2009 27

Page 28

Chapter 1 Program and Test a Simple Project

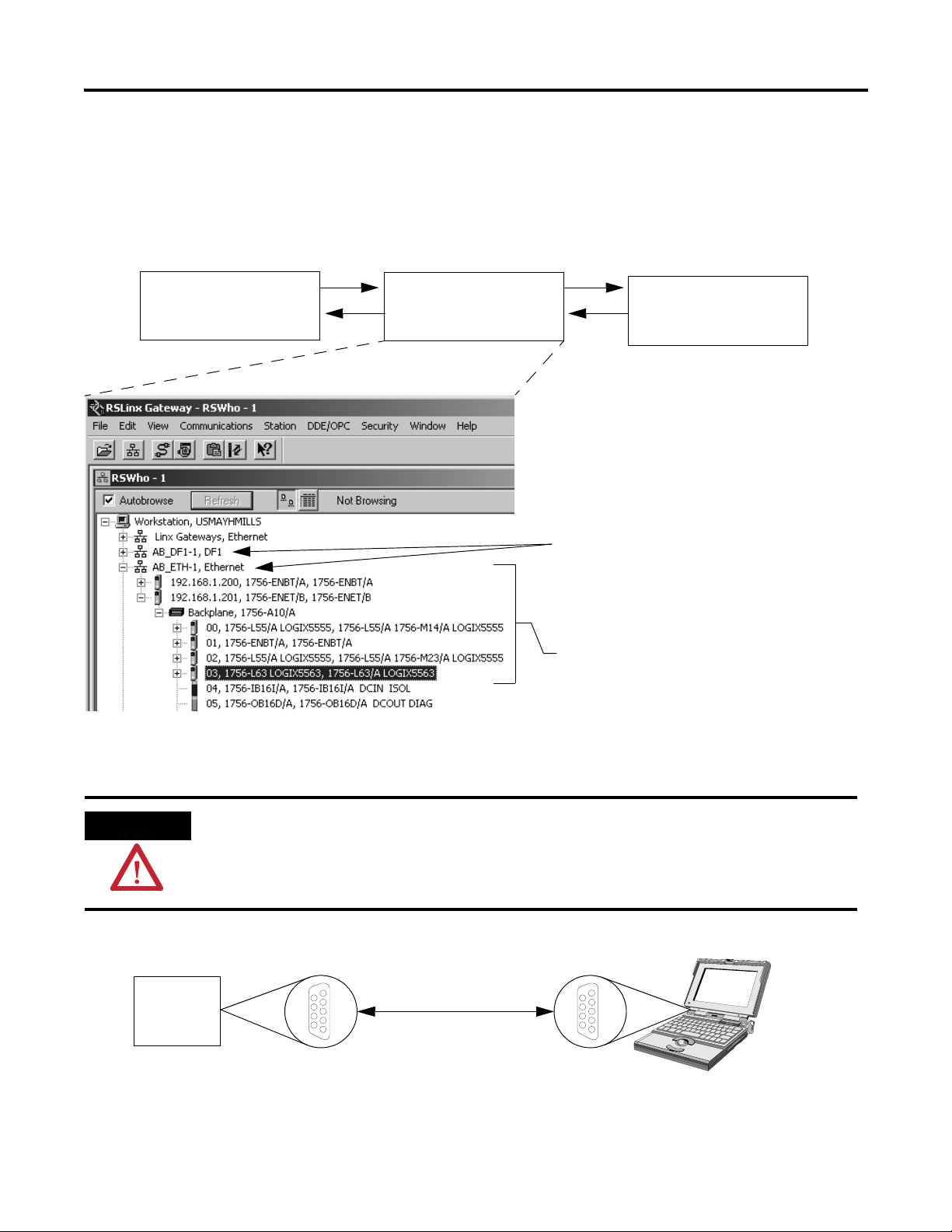

WARNING

Logix5000 Controller

RSLinx Classic Software

RSLogix 5000 Software

Driver – establish communication over a specific

network.

Path – communication route to a device. To define a

path, you expand a driver and select the device.

Logix5000

Controller

1756-CP3 or 1747-CP3 serial cable

Establish a Serial Connection to the Controller

RSLinx Classic software handles communication between Logix5000 controllers and your software

programs, such as RSLogix 5000 software. To communicate with a controller (for example, download,

monitor data), configure RSLinx Classic software for the required communication.

Use a serial cable to establish a point-to-point connection between the serial ports on your computer and

controller.

If you connect or disconnect the serial cable with power applied to this module or the serial device on the

other end of the cable, an electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Connect a serial cable to your controller and computer.

28 Publication 1756-QS001E-EN-P - October 2009

Page 29

Program and Test a Simple Project Chapter 1

2. Start RSLinx Classic software.

3. Click .

4. Select RS-232 DF1 devices and click .

5. From the Comm Port pull-down menu, choose the COM port of your computer.

6. From the Device pull-down menu, choose Logix 5550/CompactLogix.

7. Click .

8. When the auto-configuration completes, click OK.

The driver is successfully configured and running.

Publication 1756-QS001E-EN-P - October 2009 29

Page 30

Chapter 1 Program and Test a Simple Project

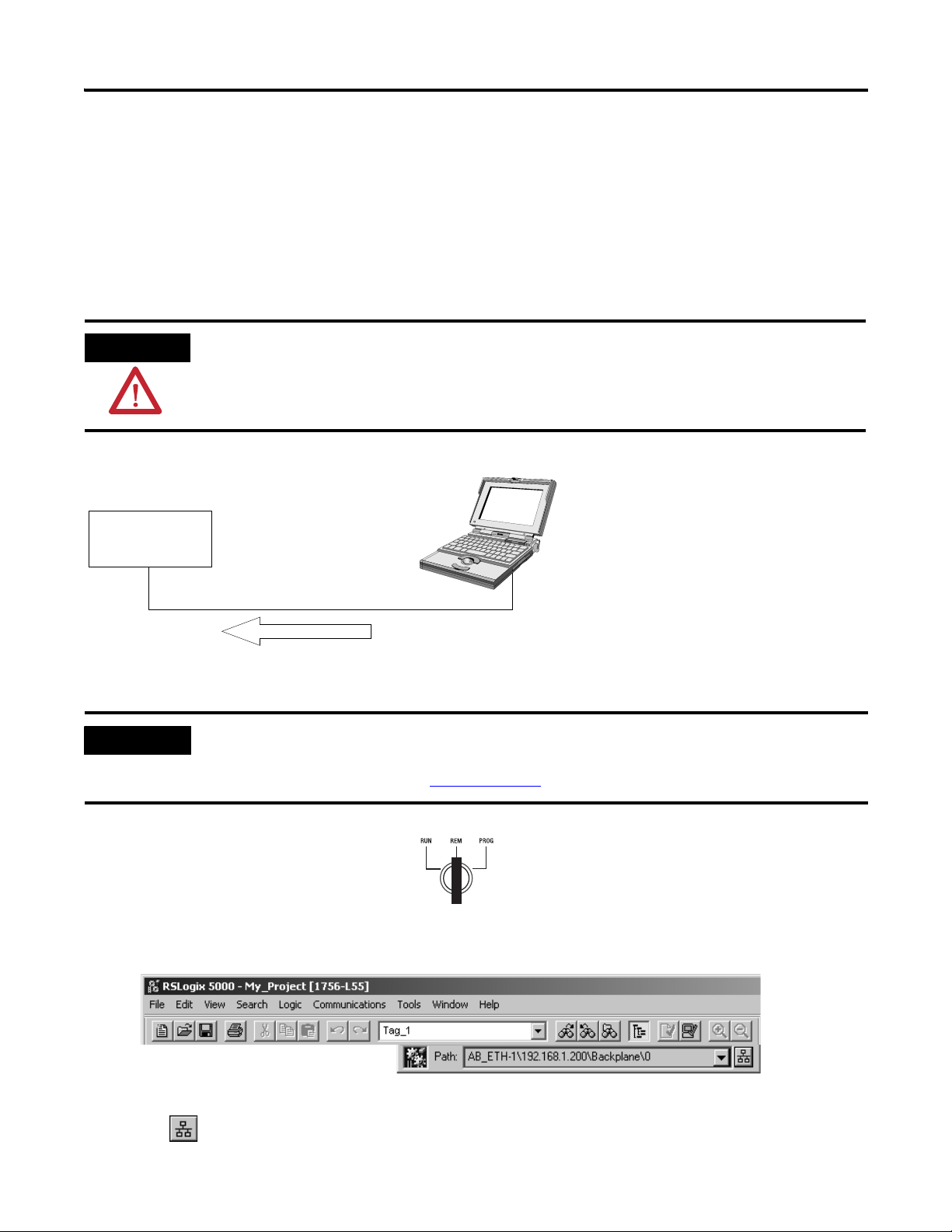

ATTENTION

IMPORTANT

Logix5000

Controller

Project

Download

Download a Project to the Controller

To execute a project in a controller, download the project to the controller to transfer a project from your

computer to the controller so you can run the project. When you download a project, you lose the project

and data that is currently in the controller, if any. If the revision of the controller does not match the revision

of the project, you are prompted to update the firmware of the controller. RSLogix 5000 software lets you

update the firmware of the controller as part of the download sequence.

When you download a project or update firmware, all active servo axes are turned off. Before you

download a project or update firmware, make sure that this will not cause any unexpected movement of an

axis.

To update the firmware of a controller, first install a firmware upgrade kit.

• An upgrade kit ships on a supplemental CD along with RSLogix 5000 software.

• To download an upgrade kit, go to http://www.ab.com

. Choose Product Support. Choose Firmware Updates.

1. Turn the keyswitch of the controller to .

2. Open the RSLogix 5000 project that you want to download.

3. Click .

30 Publication 1756-QS001E-EN-P - October 2009

Page 31

Program and Test a Simple Project Chapter 1

4. Browse to the controller.

5. To download the project, click .

If the process failed to download to the controller. The revision of the offline project and controller’s

firmware are not compatible.

1. Choose .

2. Select the revision for the controller.

3. Choose and then .

Publication 1756-QS001E-EN-P - October 2009 31

Page 32

Chapter 1 Program and Test a Simple Project

Do you want to execute the

logic in the controller?

Choose Program mode.

Yes

Choose Run mode.

No

No

Yes

Choose Test mode.

Do you want the logic to

control the output devices?

RUN REM PROG

Select the Operating Mode of the Controller

To execute or stop executing the logic in a controller, change the operating mode of the controller.

1. Determine which mode you want for the controller.

2. Turn the keyswitch to

3. Go online with the controller.

4. Select the mode.

32 Publication 1756-QS001E-EN-P - October 2009

Page 33

Program and Test a Simple Project Chapter 1

Mode Description

Program Logic is not executing, outputs are not controlled, and editing operations are available.

If you are configuring an output module, the owner controller is in Program Mode. Newly

received output values are ignored and all outputs will transition to their Program mode

state (which you can configure on the Configuration tab). The output module’s health LED

will flash green when in Program mode.

Input modules are always in Run mode and always report back input data to the controller. It

does not matter whether the owner controller is in Run or Program mode. The input

module’s health indicator is always solid green if a connection exists to it.

Run Logic is executing, inputs are read, logic is scanned, and outputs are controlled by the

application program and changes made through the data monitor or the I/O force table. The

actual I/O modules accept the output results of the application and set the outputs

accordingly. The keyswitch must be in the Remote or Run position.

Test Logic is executing, inputs are read, logic is scanned, and outputs are controlled by the

application program and changes made through the data monitor or the I/O force table. The

actual I/O modules will ignore the output results of the application. Some editing operations

are restricted. The keyswitch must be in the Remote position.

When going into Test mode:

• Input modules continue to update in Test mode.

• Produce/consume tags continue to update in Test mode.

• Test mode places all outputs in the project in the Program mode state (as configured

in the Configuration tab for module properties).

Publication 1756-QS001E-EN-P - October 2009 33

Page 34

Chapter 1 Program and Test a Simple Project

Notes:

34 Publication 1756-QS001E-EN-P - October 2009

Page 35

Chapter

2

Organize a Project

This chapter provides more detailed information on how to organize the program layout and data structures

for the controller.

What You Need

You need these items to complete the tasks in this manual:

• Personal computer running RSLogix 5000 software, version 16 or later

• A layout of the system for which you are creating a project

Before You Begin

A new project contains a default task for the execution of your logic. Before you can create programs, you

must first configure the task execution. A task defines scheduling and priority information for the execution

(scan) of your logic.

35Publication 1756-QS001E-EN-P - October 2009 35

Page 36

Chapter 2 Organize a Project

Execution of

Logic

task automatically

restarts

task automatically

restarts

task automatically

restarts

task automatically

restarts

period expires

task restarts

period expires

task restarts

Execution of

Logic

task finishestask finishestask finishes

Follow These Steps

1. Configure the task execution (page 36).

2. Create additional programs (page 38).

3. Create user-defined data types (page 40).

4. Define your routines (page 43).

5. Assign main routines (page 47).

6. Configure the controller (page 48).

7. Configure I/O modules (page 49).

Configure the Task Execution

In this quick start, we limit the project to a single task with one of the following types of execution.

If you want to execute your logic Then configure the task for this type of

execution

All of the time

At a specific period

Continuous

This is the default configuration of

MainTask.

Periodic

You define the period at which the task

executes.

36 Publication 1756-QS001E-EN-P - October 2009

Page 37

1. Right-click MainTask and choose Properties.

2. Click the Configuration tab.

3. From the Type pull-down menu, choose Periodic.

Organize a Project Chapter 2

4. Type the period for the task and click OK.

To use multiple tasks or execute a task when a specific event (trigger) occurs, see Logix5000 Controllers

Common Procedures, publication 1756-PM001

.

Publication 1756-QS001E-EN-P - October 2009 37

Page 38

Chapter 2 Organize a Project

A

B

C

Controller Tags (Global Data)

Program_A

Other routines

Main Routine

Ta g_ 4

Ta g_ 5

Ta g_ 6

Program Tags

(Local Data)

Tag _1

Tag _2

Tag _3

Program_B

Other Routines

Main Routine

Ta g_ 4

Ta g_ 5

Ta g_ 6

Program Tags

(Local Data)

Data

Create Additional Programs

A Logix5000 controller lets you divide your application into multiple programs, each with its own tags (data).

Item Description

A Tag stores data. There is no fixed data table or numeric format for data addresses. The tag

name is the address (no cross-reference to a physical address). You create the tags that you

want to use.

B Program isolates logic and data from other logic and data. Each program contains one or

more logic routines as associated data.

C Scope defines whether a tag is accessible to all programs (controller tag) or limited to a

specific program (program tag). Data at the program scope is isolated from other programs.

There is no need to manage conflicting tag names between the programs.

All programs have access to data that is at the controller scope. Data at the program scope is isolated from

other programs.

• Routines cannot access data that is at the program scope of another program.

• You can re-use the tag name of a program-scoped tag in multiple programs.

• For example, both Program_A and Program_B can have a program tag named Tag_4.

38 Publication 1756-QS001E-EN-P - October 2009

Page 39

Organize a Project Chapter 2

TIP

If you have multiple machines, stations, or processes that use identical logic but different data, create a

program for each machine, station, or process.

• You can re-use both code and tag names in the programs.

• There is no need to manage conflicting tag names between the programs.

1. Right-click MainTask and choose New Program.

2. Type a name for the program and click OK.

Names follow these conventions:

• Only letters, numbers, and underscores (_)

• Must start with a letter or an underscore

•≤ 40 characters

• No consecutive or trailing underscores

• Not case-sensitive

Certain tags must be controller scope.

If you want to use a tag Use this scope

In more than one program in the project

In a Message (MSG) instruction

To produce or consume data

To communicate with a PanelView terminal

In a single program only Program Tags for the program

Publication 1756-QS001E-EN-P - October 2009 39

Controller Tags

Page 40

Chapter 2 Organize a Project

A

D

F

E

C

B

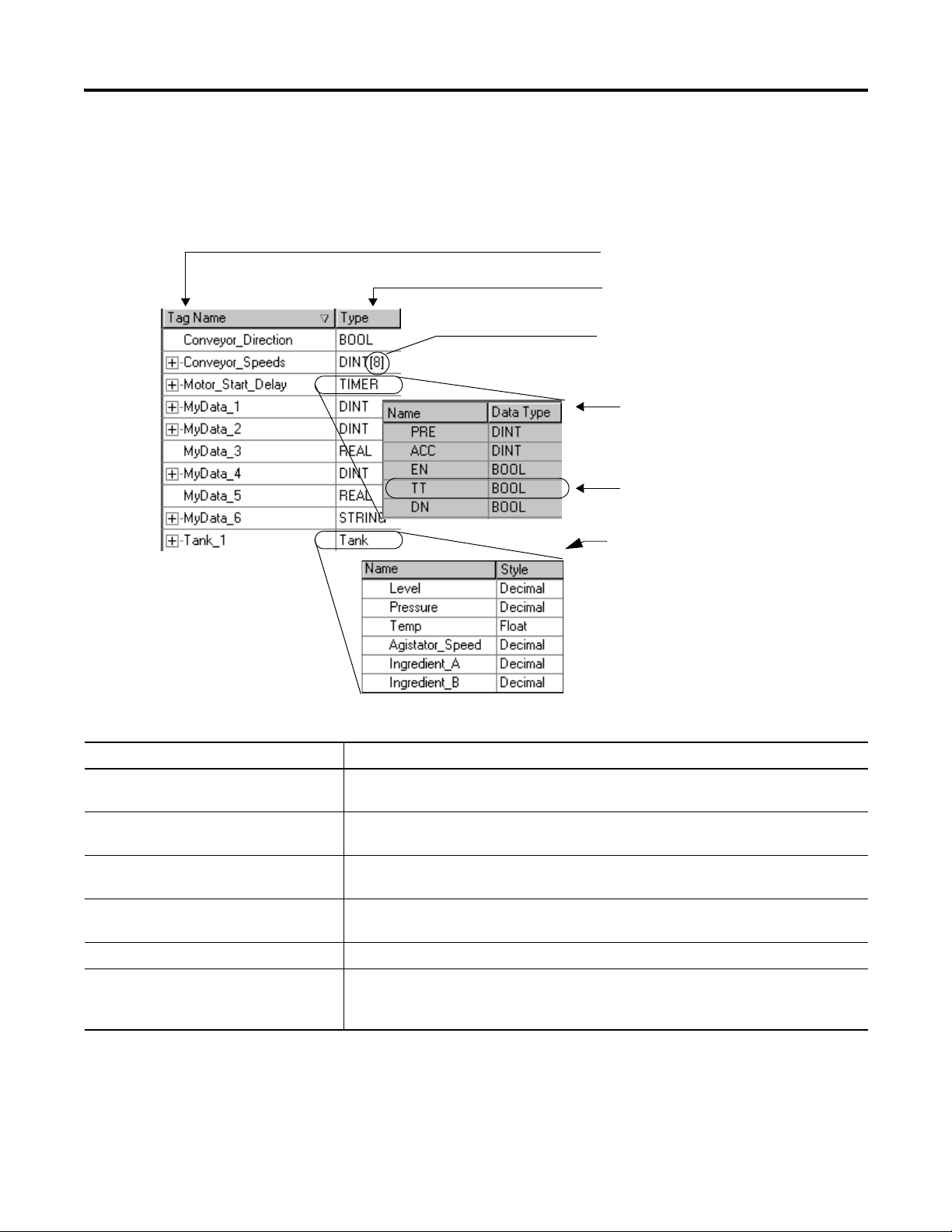

Create User-defined Data Types

User-defined data types let you organize your data to match your machine or process. This streamlines

program development and creates self-documenting code that is easier to maintain.

Item Description

A Tag stores data. There is no fixed data table or numeric format for data addresses. The tag

name is the address. You create the tags that you want to use.

B Data type defines the type of data that a tag stores, such as a bit, integer, floating-point

value, or string.

C Array defines a block of data (file). The entire block uses the same data type. It can have 1,

2, or 3 dimensions.

D Structure combines a group of data types into a re-usable format (template for tags). Use a

structure as the basis for multiple tags with the same data layout.

E Member describes an individual piece of data within a structure.

F User-defined data type defines your own data structure. A user-defined data type stores all

the data related to a specific aspect of your system. This keeps related data together and

easy to locate, regardless of its data type.

40 Publication 1756-QS001E-EN-P - October 2009

Page 41

As you create user-defined data types, follow these guidelines.

More Efficient

BOOL

BOOL

BOOL

DINT

DINT

Less Efficient

BOOL

DINT

BOOL

DINT

BOOL

Guideline Details

Consider the pass-through of descriptions. See User-defined Data Type on page 98

Data that represents an I/O device requires

additional programming.

If you include an array as a member, limit

the array to a single dimension.

If you include members that represent I/O devices, you must use logic to copy the data

between the members in the user-defined data type and the corresponding I/O tags.

Multi-dimension arrays are not permitted in a user-defined data type.

Organize a Project Chapter 2

.

When you use the BOOL, SINT, or INT data

types, place members that use the same

Logix5000 controllers allocate memory in 4-byte chunks. If you sequence smaller data

types together, the controller packs as many as it can fit into a 4-byte chunk.

data type in sequence:

Follow these steps to create a user-defined data type.

1. Right-click Data Types and choose New Data Type.

2. Type a name for the data type (not the name of a tag that will use the data type).

Publication 1756-QS001E-EN-P - October 2009 41

Page 42

Chapter 2 Organize a Project

3. Enter the members.

As an option, type a description for each member.

4. Click OK.

Follow these steps to create a tag that uses a user-defined data type.

1. Right-click the scope that you want for the tag and choose Edit Tags.

2. Type a name for the tag.

3. Type the name of the user-defined data type.

42 Publication 1756-QS001E-EN-P - October 2009

Page 43

Organize a Project Chapter 2

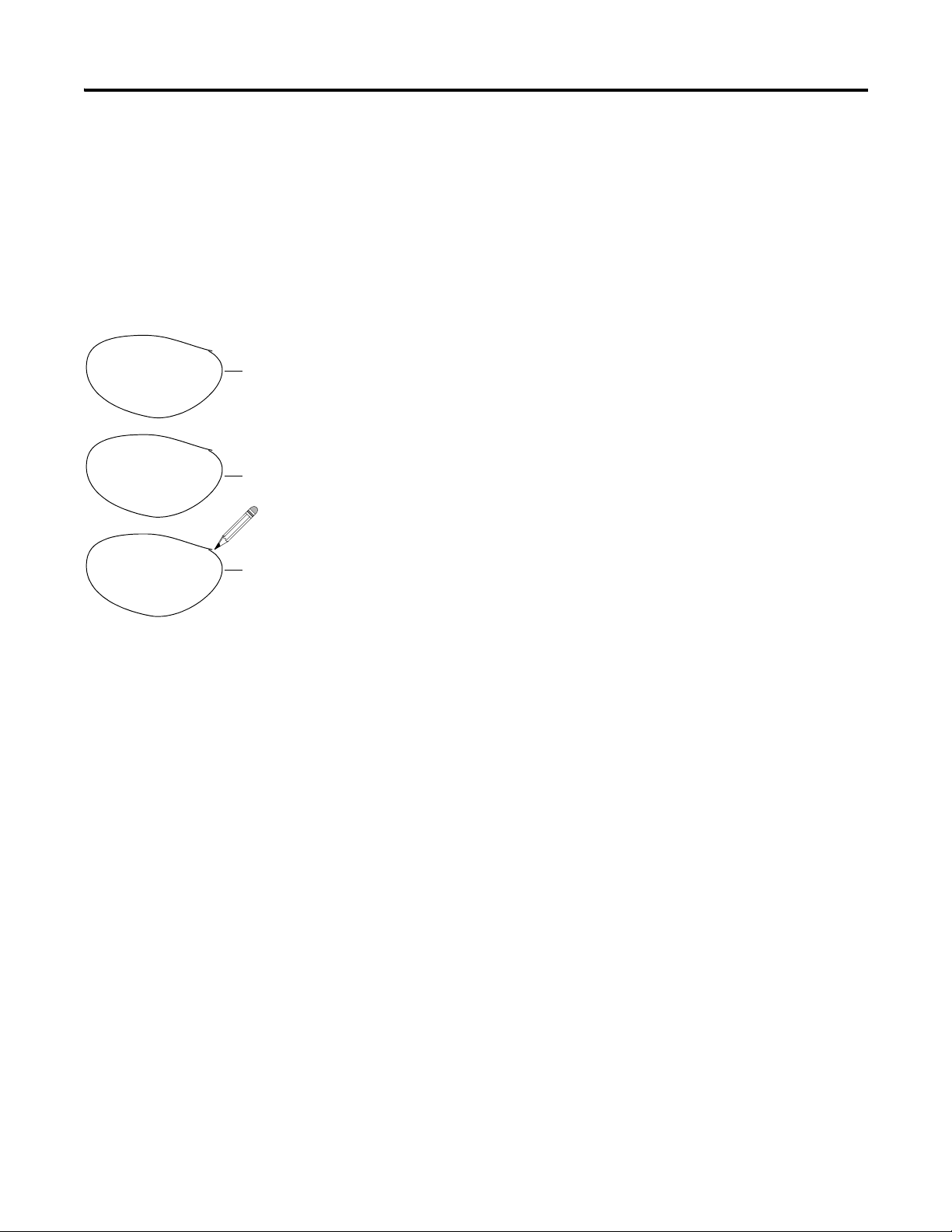

A

B

C

4. Do the following if you want the tag to be an array (multiple instances of the data type).

a. Select the data type and click .

b. Specify the array dimensions and click OK.

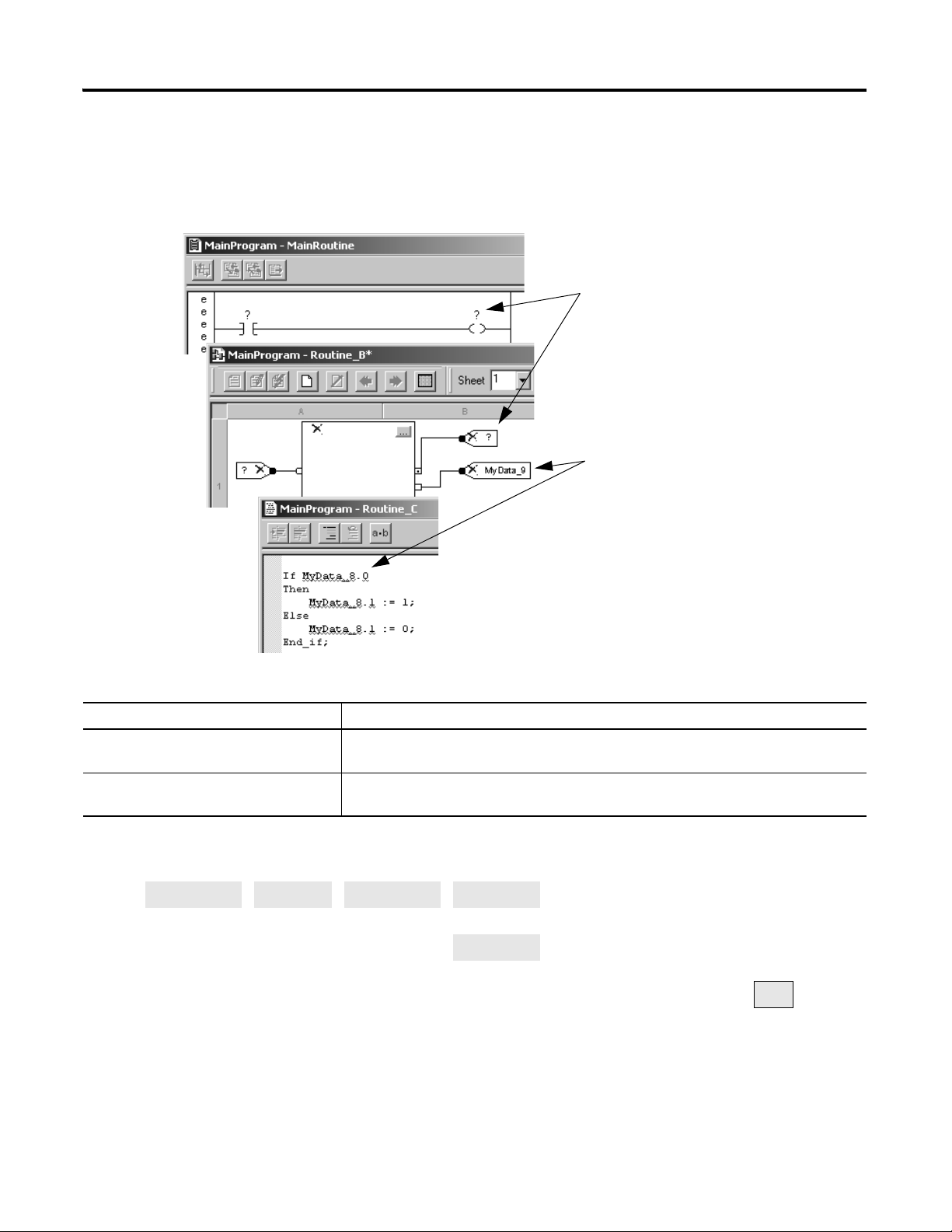

Define Your Routines

Once your project has the required programs, you have to define and create the routines for each program.

Item Description

A Routine provides the executable code (logic) for a program (similar to a program file in a PLC

or SLC controller).

B Main routine is required each program.

• When the program executes, its main routine automatically executes.

C Subroutine is any routine other than the main routine or fault routine. To execute a

• Use the main routine to control the execution of the other routines in the program.

• To call (execute) another routine (subroutine) within the program, use a Jump to

Subroutine (JSR) instruction.

subroutine, use a Jump to Subroutine (JSR) instruction in another routine, such as the main

routine.

Publication 1756-QS001E-EN-P - October 2009 43

Page 44

Chapter 2 Organize a Project

Description of Your Machine or Process

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

Xxxxx xxxxx xxx

First Section = Routine 1

Second Section = Routine 2

Third Section = Routine 3

Define a Routine for Each Section of Your Machine or Process

To make your project easier to develop, test, and troubleshoot, divide it into routines (subroutines).

1. Identify each physical section of your machine or process.

2. Assign a routine for each of those sections.

Identify the Programming Languages That Are Installed

Follow these steps to determine which programming languages are installed on your version of RSLogix 5000

software.

1. Start RSLogix 5000 software.

2. From the Help menu, choose About RSLogix 5000.

44 Publication 1756-QS001E-EN-P - October 2009

Page 45

Organize a Project Chapter 2

Assign a Programming Language to Each Routine

For each routine, choose a programming language.

• Logix5000 controllers let you use the following languages:

– Ladder logic

– Function block diagram

– Sequential function chart

– Structured text

• Use any combination of the languages in the same project.

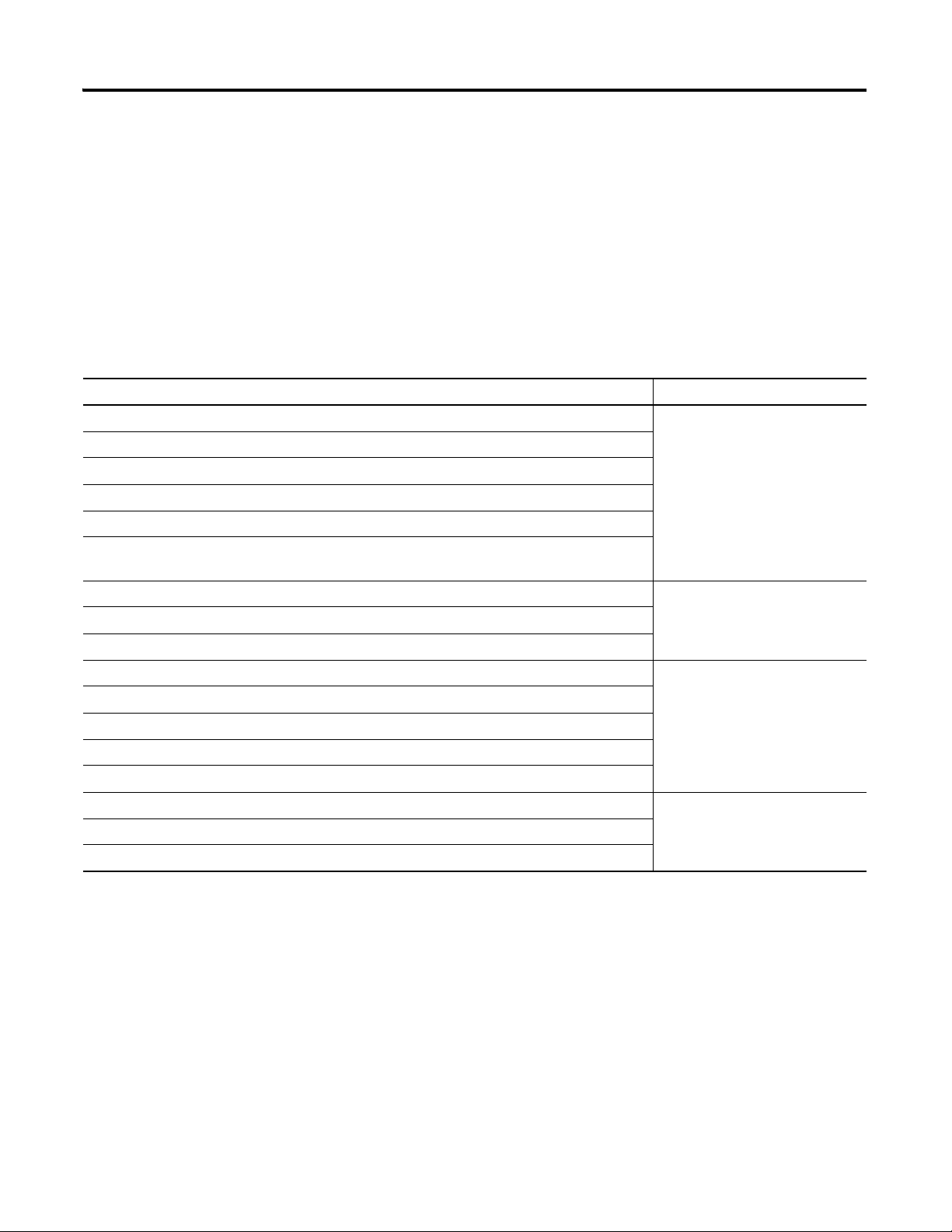

In general, if a routine represents Use this language

Continuous or parallel execution of multiple operations (not sequenced) Ladder logic

Boolean or bit-based operations

Complex Logical operations

Message And Communication Processing

Machine interlocking

Operations that service or maintenance personnel may have to interpret in order to troubleshoot the

machine or process.

Continuous process and drive control Function block diagram (FBD)

Loop control

Calculations in circuit flow

High-level management of multiple operations Sequential function chart (SFC)

Repetitive sequences of operations

Batch process

Motion control using structured text

State machine operations

Complex mathematical operations Structured text

Specialized array or table loop processing

ASCII string handling or protocol processing

Publication 1756-QS001E-EN-P - October 2009 45

Page 46

Chapter 2 Organize a Project

routine

routine

Within the FBD routine, make

a sheet for each functional

loop for a device, such as a

motor or valve.

sheet

routine

step

step

step

Break the SFC into steps.

Divide Each Routine Into More Meaningful Increments

If a routine uses this

language

Ladder logic

Structured text

Function block diagram

(FBD)

Sequential function chart

(SFC)

Then Example

Break up large routines into several

smaller routines

To continuously execute several

complex boolean operations…

…create a separate routine for each

operation.

To control 4 valves, where each valve

requires feedback that it is in its

commanded position…

…make a separate sheet for each

valve.

To perform the following sequence:

1. Fill a tank.

2. Mix the ingredients in the

3. Empty the tank…

…make each section (fill, mix, empty)

a separate step.

tank.

46 Publication 1756-QS001E-EN-P - October 2009

Page 47

Organize a Project Chapter 2

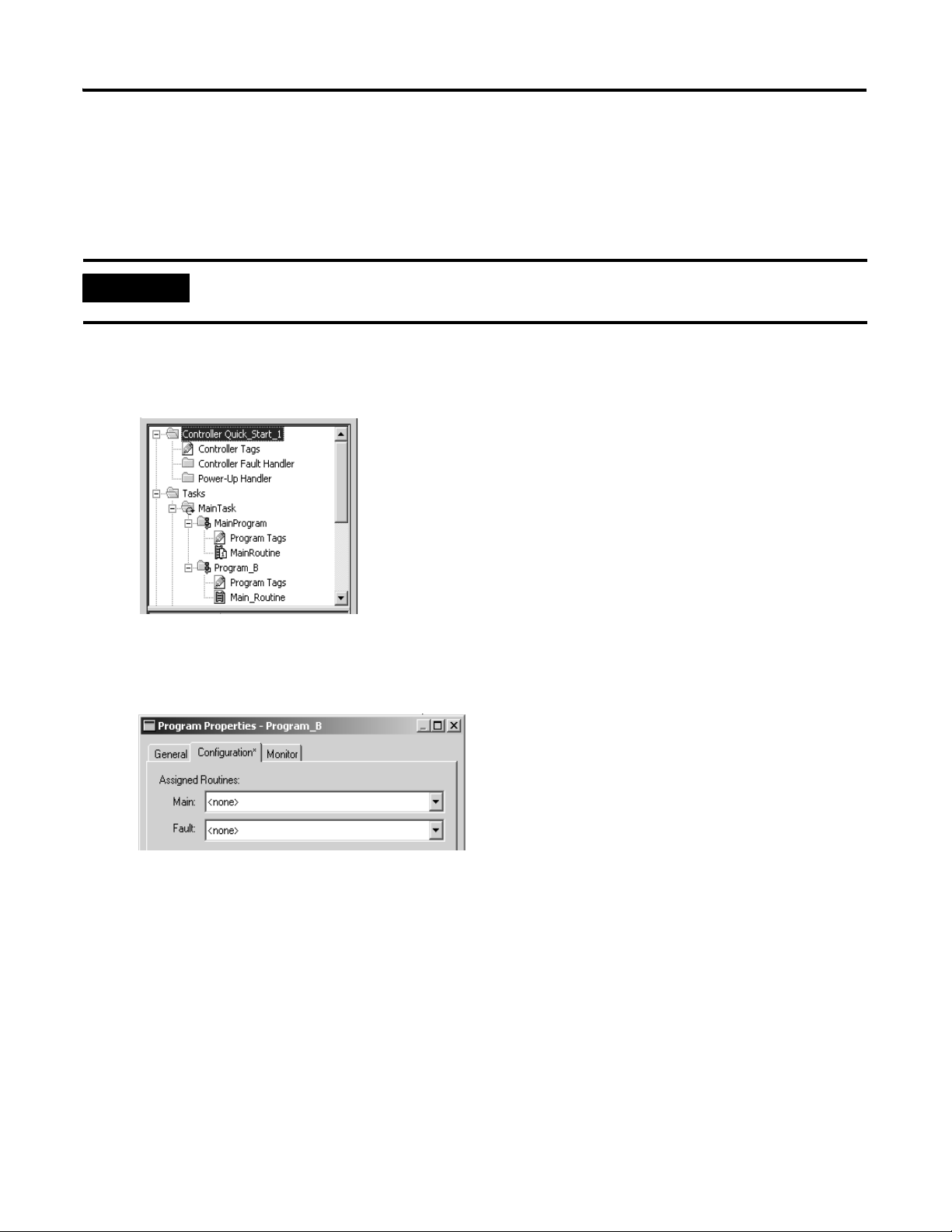

IMPORTANT

Assign Main Routines

Each program requires a main routine. Once you create your routines, assign a main routine for each

program.

In the default project, MainProgram already has a main routine (MainRoutine). You have to assign a main

routine only for each additional program that you create.

Follow these steps to assign a main routine.

1. Right-click the program folder and choose Properties.

2. Click the Configuration tab.

3. Select the main routine and click OK.

Publication 1756-QS001E-EN-P - October 2009 47

Page 48

Chapter 2 Organize a Project

Configure the Controller

If you want to change the configuration of the controller, such as name, chassis size, or slot number, use the

Controller Properties dialog box.

1. Click the Controller Properties button.

2. Change the required properties (some items apply only to certain controllers) and click OK.

48 Publication 1756-QS001E-EN-P - October 2009

Page 49

Organize a Project Chapter 2

Configure I/O Modules

To change the behavior of a module, use the Module Properties window for the module. The configuration

options vary from module to module.

1. Right-click the module and choose Properties.

2. To change the name or slot number, use the General tab.

3. To change the configuration, click the Configuration tab.

Some modules have several configuration tabs.

Publication 1756-QS001E-EN-P - October 2009 49

Page 50

Chapter 2 Organize a Project

Notes:

50 Publication 1756-QS001E-EN-P - October 2009

Page 51

Chapter

3

Program Add-On Instructions

With version 16 of RSLogix 5000 programming software, you can design and configure sets of commonly

used instructions to increase project consistency. Similar to the built-in instructions contained in Logix5000

controllers, these instructions you create are called Add-On Instructions.

With Add-On Instructions, you can:

• insert your own instruction.

• copy an Add-On Instruction definition from another RSLogix 5000 project.

• import an Add-On Instruction definition from another RSLogix 5000 project.

What You Need

You need these items to complete the tasks in this manual:

• Personal computer running RSLogix 5000 software, version 16 or later

• A layout of the system for which you are creating a project

Follow These Steps

4. Insert an Add-On Instruction (page 52).

5. Copy an Add-On Instruction definition (page 53

6. Import an Add-On Instruction definition (page 54).

7. Access a parameter that is not visible (page 55).

8. Monitor or change the value of a parameter (page 56

9. View the logic of an Add-On Instruction (page 57

).

).

).

10. Edit and monitor an Add-On Instruction (page 58

11. Update an Add-On Instruction to a newer revision (page 58).

51Publication 1756-QS001E-EN-P - October 2009 51

).

Page 52

Chapter 3 Program Add-On Instructions

TIP

Insert an Add-On Instruction

You can create an Add-On Instruction in a ladder, function block, or structured text routine.

1. Open the routine that will use the instruction.

2. Click the Add-On tab of the Language Element toolbar.

3. Drag the instruction from the toolbar to the routine.

4. Enter the parameters.

Routine Type Parameters

Ladder Single question mark — Required parameter. Enter a tag.

Single and double question marks — Required parameter. Enter a

tag.

Only double question marks — Not a required parameter. You can

either:

• leave it blank and use the default value.

• if it’s an input value, enter a different value.

Function block Nub on the end of a pin — Required parameter. Wire the pin to an

IREF, OREF, connector, or another block.

Single question mark — Required parameter. Enter a tag.

No nub on the end of a pin — Not a required parameter.

Structured text The instruction takes only the required parameters. Enter a tag for

each parameter.

For help with an instruction, select the instruction and then press [F1]. In structured text, make sure the

cursor is in the blue instruction name.

52 Publication 1756-QS001E-EN-P - October 2009

Page 53

Program Add-On Instructions Chapter 3

Copy an Add-On Instruction Definition

You can copy an Add-On Instruction from within another RSLogix 5000 project.

1. Open the RSLogix 5000 project that has the Add-On Instruction definition.

2. Find the definition in the Add-On Instructions folder.

3. Right-click the definition and choose Copy.

4. Go to the project that gets the definition.

5. Right-click the Add-On Instructions folder and choose Paste.

Publication 1756-QS001E-EN-P - October 2009 53

Page 54

Chapter 3 Program Add-On Instructions

Import an Add-On Instruction Definition

You can add the definition of an Add-On Instruction that was exported from another RSLogix 5000 project.

Does the RSLogix 5000 project already have a revision of this Add-On Instruction?

• No — use this procedure to import the instruction.

• Yes — see Update an Add-On Instruction to a Newer Revision on page 58

1. Right-click the Add-On Instructions folder and choose Import Add-On Instruction.

2. Find the instruction.

3. Select the instruction and click Import.

54 Publication 1756-QS001E-EN-P - October 2009

Page 55

Program Add-On Instructions Chapter 3

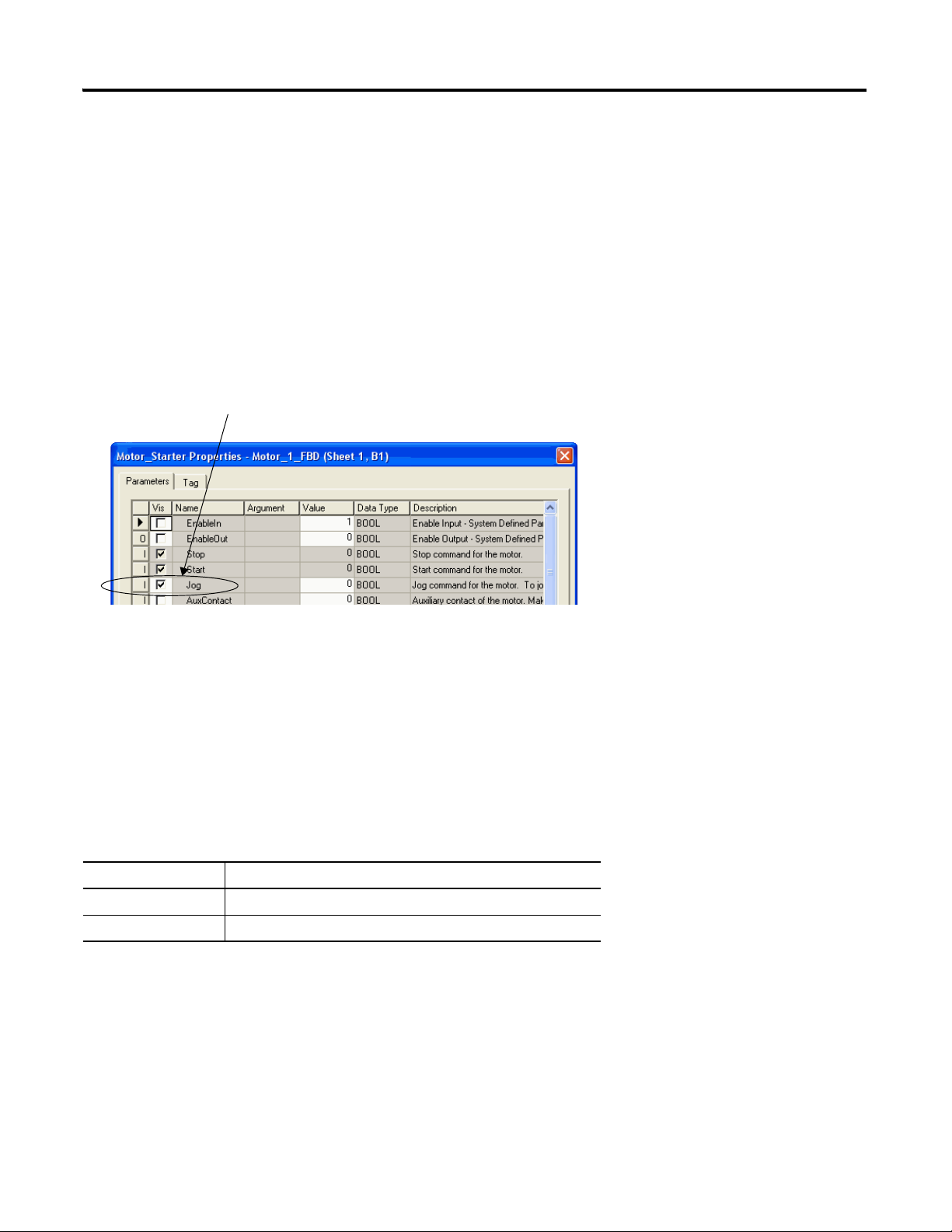

Access a Parameter That Is Not Visible

How you read or write to a parameter of an Add-On Instruction that is not visible depends on the

programming language.

Function Block

1. Click the Properties button for the instruction.

2. Check the Vis box for the parameter and click OK.

3. Wire to the pin for the parameter.

Ladder Logic and Structured Text

Use another instruction, an assignment, or an expression to read or write to the tag name of the parameter.

Use this format for the tag name of the parameter.

Add_On_Tag.Parameter

Where Is

Add_On_Tag Add-on-defined tag for the add-on instruction

Parameter Name of the parameter

Publication 1756-QS001E-EN-P - October 2009 55

Page 56

Chapter 3 Program Add-On Instructions

Motor_Starter(Motor_St

arter_ST,Stop_PB,Start

_PB,Motor_Out_ST);

Monitor or Change the Value of a Parameter of an Add-On Instruction

Use the Properties dialog to monitor or change a parameter value of an Add-On Instruction.

Routine Type Parameters

Ladder logic or function block Click the Properties button for the instruction.

Structured text Right-click the instruction and choose Properties.

1. Click and type the new value.

2. Click Apply.

3. Click OK.

56 Publication 1756-QS001E-EN-P - October 2009

Page 57

Program Add-On Instructions Chapter 3

Motor_Starter(Motor_St

arter_ST,Stop_PB,Start

_PB,Motor_Out_ST);

View the Logic of an Add-On Instruction

It’s possible to protect an Add-On Instruction so that you can’t see its logic. You can determine whether an

Add-On Instruction is protected.

1. Select the add-on instruction.

2. Look in the Quick View pane for Source Protection.

If it isn’t listed, then the routine isn’t protected.

To view the logic, right-click the instruction and choose Open Instruction Logic.

Publication 1756-QS001E-EN-P - October 2009 57

Page 58

Chapter 3 Program Add-On Instructions

IMPORTANT

Edit and Monitor an Add-On Instruction

You can:

• see the logic as it executes.

• see tag values.

• change tag and parameter values.

You cannot:

• edit logic online.

• edit logic for just this instruction.

To edit the logic, you must edit the definition.

Update an Add-On Instruction to a Newer Revision

You can update the definition of an Add-On Instruction to a newer revision.

Before you change the definition of an add-on instruction, make sure the change won’t cause problems

with existing instances of that instruction. When you change the definition of an add-on instruction, the

change affects all the instances of that instruction in your project.

For example, if a project uses a certain Add-On Instruction 5 times, update the definition so that all 5

instances change when you change the definition.

1. Right-click the Add-On Instructions folder and choose Import Add-On Instruction.

2. Find the instruction and choose Import.

3. Decide how to handle the conflict with the existing revision (probably overwrite).

4. Use a cross-reference list to check each use of the instruction in your logic.

58 Publication 1756-QS001E-EN-P - October 2009

Page 59

Chapter

4

Program an Equipment Phase

Use PhaseManager software to create an equipment phase and change the default settings for the equipment

phase.

What You Need

You need these items to complete the tasks in this manual:

• Personal computer running RSLogix 5000 software, version 16 or later

• A layout of the system for which you are creating a project

Follow These Steps

5. Create an equipment phase (page 60).

6. Create a state routine (page 60).

7. Manually step through the states (page 61).

8. Configure the initial state for an equipment phase (page 63).

9. Open the configuration for an equipment phase (page 64

10. Configure an equipment phase (page 64).

).

59Publication 1756-QS001E-EN-P - October 2009 59

Page 60

Chapter 4 Program an Equipment Phase

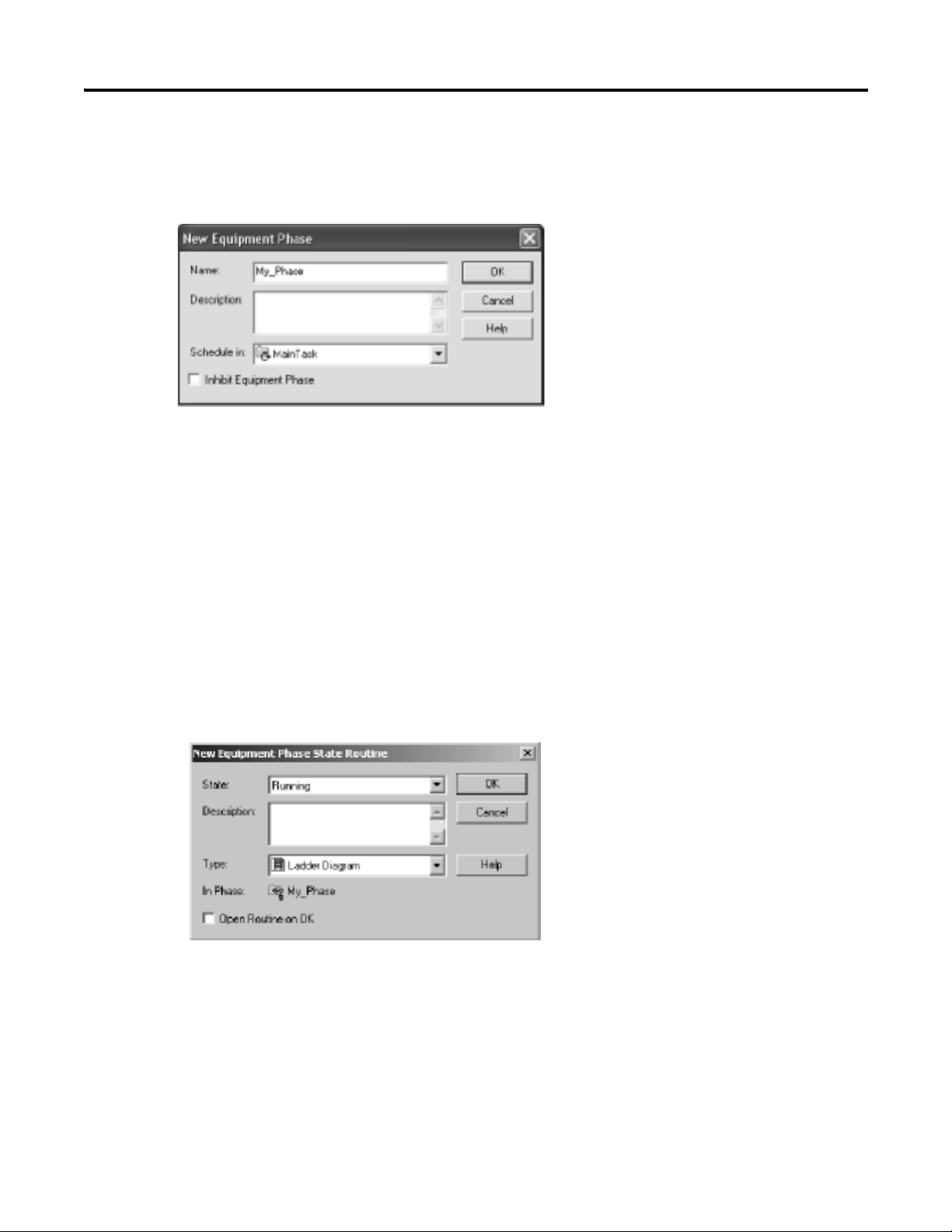

Create an Equipment Phase

1. Right-click Main Task and choose New Equipment Phase.

2. Type a name for the equipment phase and click OK.

Create a State Routine

1. Right-click Main Task and choose the equipment phase.

2. Choose New Phase State Routine.

3. Type a name for the state routine.

4. Select the programming language and click OK.

60 Publication 1756-QS001E-EN-P - October 2009

Page 61

Manually Step Through the States

Before you step through states, do the following:

• Download the project to the controller.

• Put the controller in run or remote run mode.

1. Right-click the equipment phase and choose Monitor Equipment Phase.

2. Click the Ownership and then Yes.

Use this window to step through the states.

Program an Equipment Phase Chapter 4

3. Click Start.

The equipment phase goes to the Running state. Any code in the Running state routine starts running.

This is where you put the code for the normal production sequence of your equipment.

Publication 1756-QS001E-EN-P - October 2009 61

Page 62

Chapter 4 Program an Equipment Phase

4. Click Stop.

The equipment phase goes to the Stopped state.The Running state routine stops running. The Stopping

state routine is optional. Without it, the equipment phase goes directly to the Stopped state.

5. Click Reset.

The equipment phase goes to the Idle state. The Resetting state routine is optional. Without it, the

equipment phase goes directly to the Idle state.

62 Publication 1756-QS001E-EN-P - October 2009

Page 63

Program an Equipment Phase Chapter 4

6. Click Ownership.

This releases the equipment phase from control by this window.

Configure the Initial State for an Equipment Phase

The initial state is the first state to which the equipment phase goes after you apply power.

1. Right-click the equipment phase and choose Properties.

2. Choose the Configuration tab.

3. Choose the Initial State and click OK.

Publication 1756-QS001E-EN-P - October 2009 63

Page 64

Chapter 4 Program an Equipment Phase

current state

routine

prestate routine

Open the Configuration for an Equipment Phase

1. Right-click the equipment phase and choose Properties.

2. Click the Configuration tab.

Configure an Equipment Phase

Use the following settings to configure an equipment phase.

Setting Choices

Prestate

The prestate routine runs all the time, even when the equipment phase is in the idle state.

It runs before each scan of a state.

Do you want to run a prestate routine?

• Yes — Select the routine that you want to run.

• No — Leave this box set to <none>

64 Publication 1756-QS001E-EN-P - October 2009

Page 65

Program an Equipment Phase Chapter 4

Setting Choices

Fault A fault routine lets you clear a major fault made by an instruction.

Do you want to set up a fault routine for the instructions in this equipment phase?

• Yes — Select the routine that you want as your fault routine.

• No — Leave this box set to <none>

Inhibit Equipment Phase Do you want the controller to inhibit this equipment phase?

• Yes — Check this box.

• No — Leave this box unchecked or uncheck it.

Initial State Which state do you want the equipment phase to go to when you turn on the controller?

• Idle

• Complete

• Stopped

• Aborted

Complete State Immediately If not

Implemented

Do you want the equipment phase to skip any states that you aren’t using?

• Yes — Leave this box checked or check it.

• No — Uncheck this box.

Initial Step Index Are any of the state routines in ladder diagram or structured text?

• No — Skip this box.

• Yes — Go to the next question.

Do any of those state routines use step numbers?

• Yes — Type the number for the first step of each state.

• No — Skip this box.

The tag for the equipment phase has a StepIndex number. The controller resets the

StepIndex each time the equipment phase changes states. The controller resets the

StepIndex to the number you put in the Initial Step Index box.

External Sequencer Loss of Communication

Command

Are you using FactoryTalk Batch software to command this equipment phase?

• No — Skip this box.

• Yes — Go to the next question.

If the controller loses communication with FactoryTalk Batch software, what do you want

the equipment phase to do?

• Continue in its current state — Select None.

• Go to aborting — Select Abort.

• Go to holding — Select Hold.

• Go to stopping — Select Stop.

The equipment phase must still follow the state model. For example, it goes to holding only

if it is in running or restarting when communication fails.

Publication 1756-QS001E-EN-P - October 2009 65

Page 66

Chapter 4 Program an Equipment Phase

Setting Choices

External Request Hold Action Are you using any PXRQ instructions?

• No — Skip this box.

• Yes — Go to the next question.

What do you want to do if an equipment phase goes to holding while a PXRQ instruction is

in process?

• Nothing — Select None.

• Stop the request — Select Clear.

66 Publication 1756-QS001E-EN-P - October 2009

Page 67

Chapter

5

Program a Project Offline

This chapter provides more detailed information on how to program the logic for a routine and create tags

for the logic.

What You Need

You need these items to complete the tasks in this manual:

• Personal computer running RSLogix 5000 Software, version 16

• A plan for the project you are programming

Before You Begin

In this chapter, you program the project while offline. Online programming requires additional steps. See

chapter Chapter 8, Program a Project Online.

Follow These Steps

1. Enter ladder logic (page 68).

2. Export/import ladder logic (page 73).

3. Enter a function block diagram (page 77

4. Use a faceplate for a function block (page 81).

5. Enter structured text (page 84

6. Enter a sequential function chart (page 87

).

).

).

7. Assign operands (page 89

8. Verify a project (page 92).

9. Review guidelines for tags (page 94

67Publication 1756-QS001E-EN-P - October 2009 67

).

).

Page 68

Chapter 5 Program a Project Offline

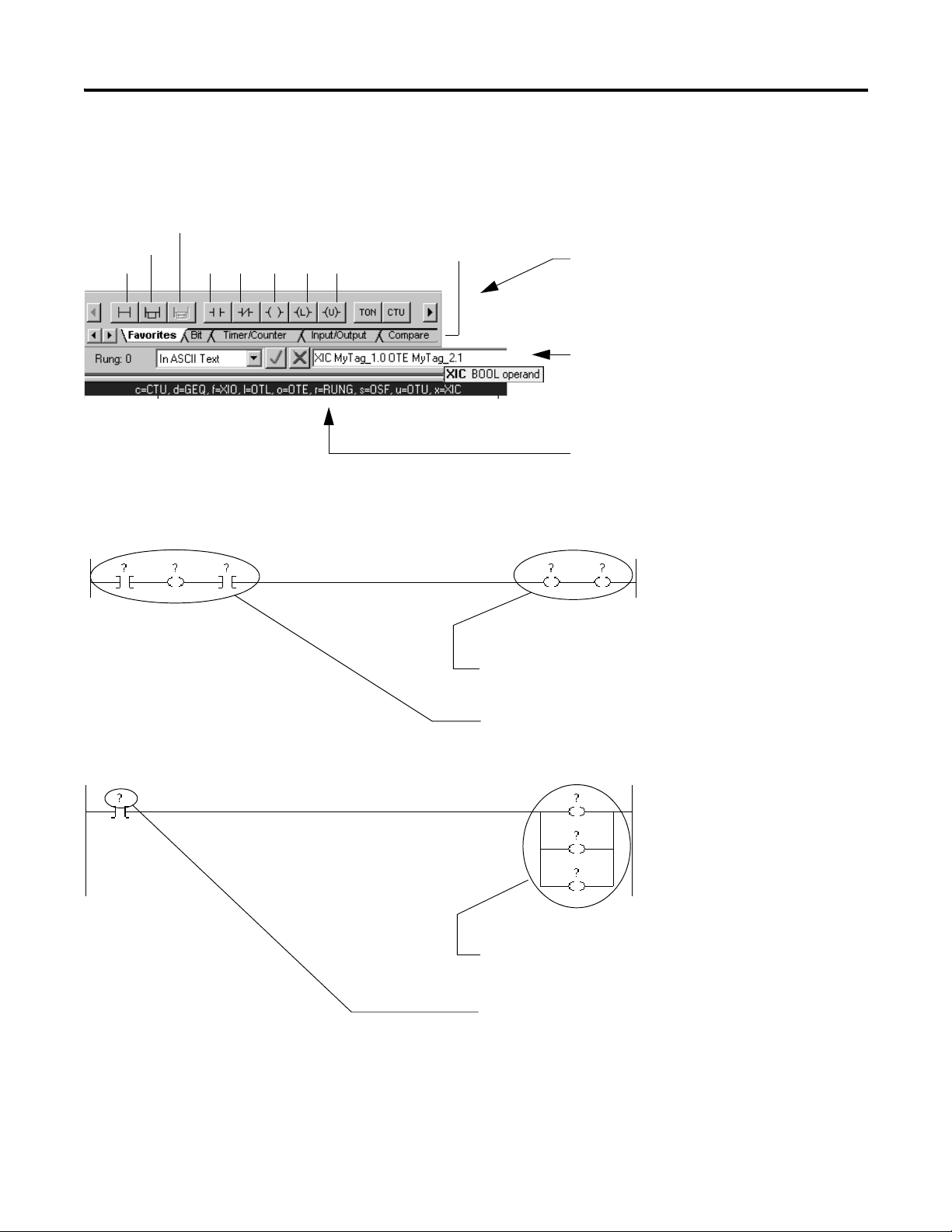

Quick keys – Assign a logic element (rung,

branch, instruction) to a keyboard key. To add an

element to the right or below the cursor, press the

designated key for the element.

ASCII text – Use ASCII text to enter or edit logic.

A tool tip helps you enter the required operands.

ASCII text typically uses the following format:

mnemonic operand_1 operand_2

Rung

XIC

Branch

Branch Level

XIO OTE OTU OTL

More Instructions

Drag and drop logic elements – Use the

Language Element toolbar to drag and drop a rung,

branch, or instruction to your routine.

Interlace input and output instructions – The last instruction

on the rung must be an output instruction.

Outputs in series – Place multiple output instructions in

sequence (serial) on a rung.

Leave operands undefined – enter logic without defining

operands. RSLogix 5000 software lets you enter and save logic

without assigning operands. This lets you develop your logic in

iterations and save libraries of code for re-use.

Parallel branches – No limit to the number of parallel branches

on a rung (nest up to 6 levels).

Enter Ladder Logic

To enter ladder logic, you have the following options:

68 Publication 1756-QS001E-EN-P - October 2009

Page 69

Program a Project Offline Chapter 5

Add a Rung or an Instruction

Drag the button for the rung or instruction directly to the desired location. A green dot shows a valid

placement location (drop point).

Add a Branch

1. Drag the branch button to where the branch starts.

A green dot shows a valid placement location (drop point).

2. Drag a branch rail to the desired location.

Add a Level to a Branch

Right-click the branch and choose Add Branch Level.

Publication 1756-QS001E-EN-P - October 2009 69

Page 70

Chapter 5 Program a Project Offline

Delete an Element

1. Click the element.

2. Click Delete.

Use the Keyboard to Add an Element

You can add elements by using the computer keyboard.

1. Press Insert.

2. Type the mnemonic for the instruction or type Rung, Branch, or Branch Level.

3. Press Enter.

70 Publication 1756-QS001E-EN-P - October 2009

Page 71

Program a Project Offline Chapter 5

4. To move an instruction, branch, or rung to a different location, use the mouse to drag it there.

A green dot shows a valid placement location (drop point).

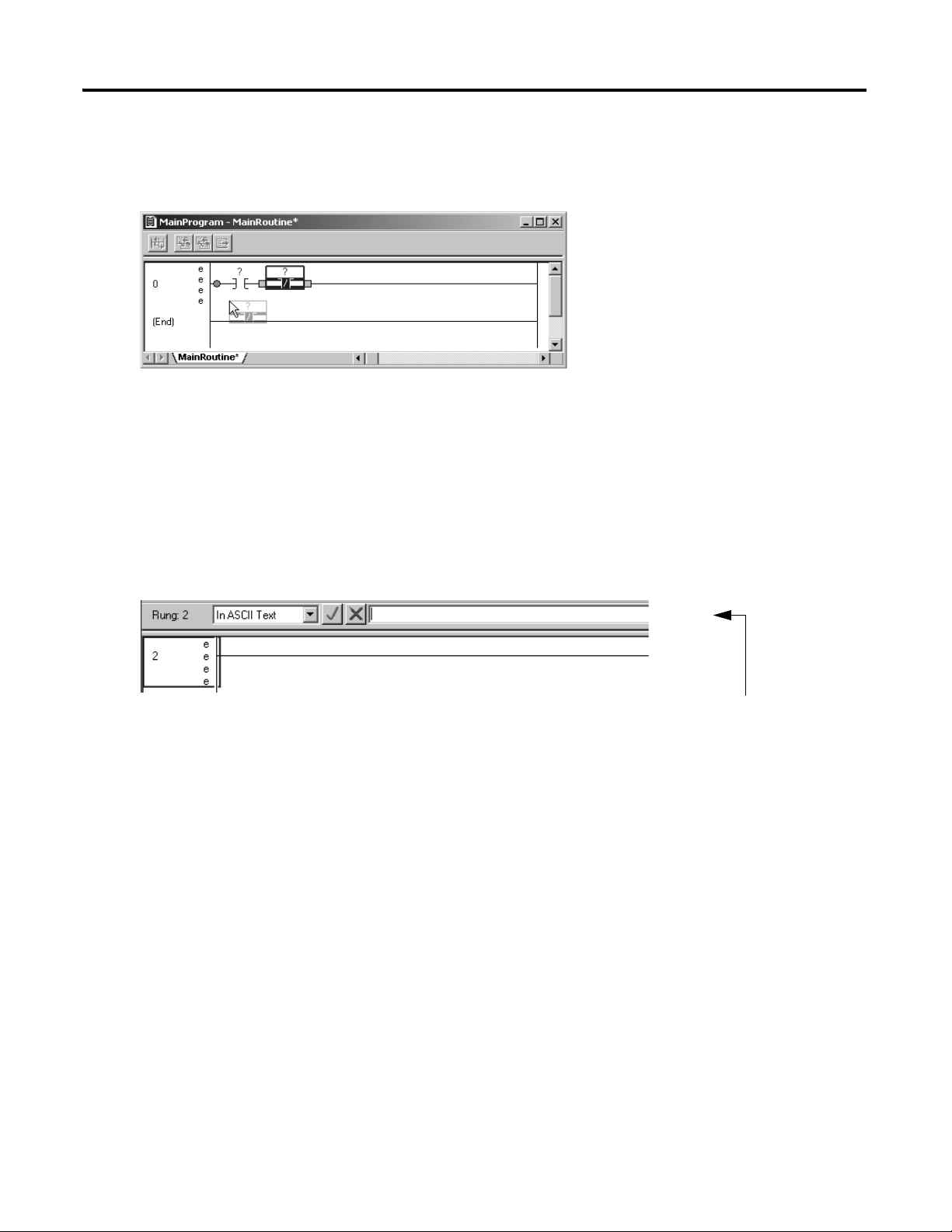

Enter Logic Using ASCII Text

You can add elements by using the typing their ASCII equivalents.

1. Double-click the rung.

2. Enter the ASCII text for the rung.

Publication 1756-QS001E-EN-P - October 2009 71

Page 72

Chapter 5 Program a Project Offline

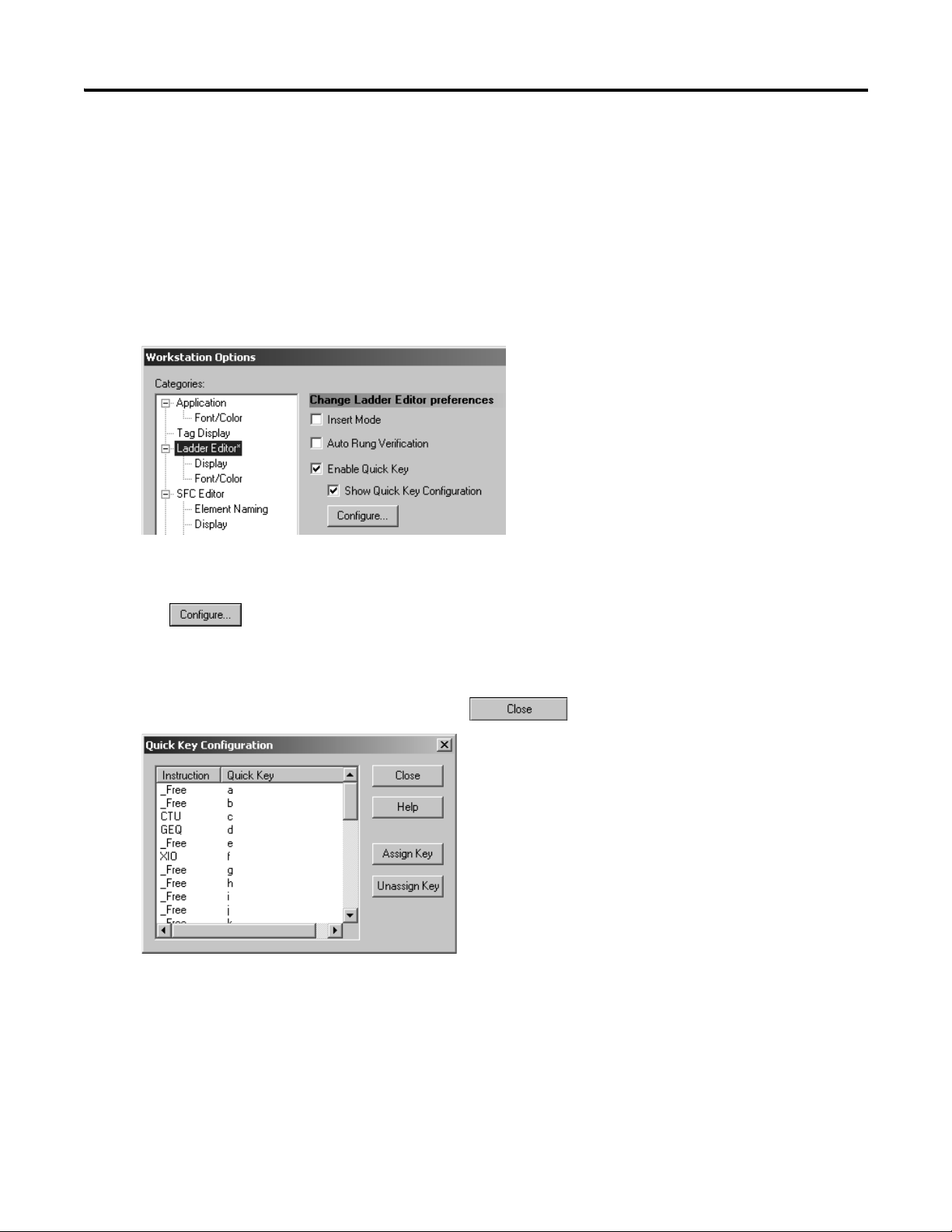

Enable Quick Keys

Enable quick keys to use shortcuts when editing.

1. From the Tools menu, choose Options.

2. Click Ladder Editor.

3. Check these checkboxes.

To assign a key to an element:

1. Click .

2. For the desired key, select the element.

3. When you have assigned the desired keys, click .

72 Publication 1756-QS001E-EN-P - October 2009

Page 73

Program a Project Offline Chapter 5

L5X file

rungs

tags

data types

comments

Project A

Export

Import

Project B

If you place the variables for the rungs in a user-defined data

type, you have less tags to manage.

If desired, you can rename a tag to

make it fit the project better.

If a tag already exists in the project,

you can either:

• use the existing tag, which

discards the tag in the library file

and binds the logic to the existing

tag.

• rename the tag, which creates a

new one.

If an I/O tag already exists in the project, the import operation uses this tag for

any aliases to that tag name. Once you import a project, make sure you check

the alias tags for accuracy.

No new I/O tags are created.

The Operation column shows what will happen to each tag and data type during

the import. The software either creates it, uses an existing one in the project, or

discards it (does not import it).

Export/Import Ladder Logic

If you want to re-use ladder logic from another project, simply export the logic to an L5X file and import it

into the required project. The L5X file contains all that you need for the logic except I/O modules.

When You Import Rungs

When you import rungs, RSLogix 5000 software shows a list of the tags and user-defined data types that go

along with the rungs. Use the list to manage the tags and data types that are created during the import

operation.

Publication 1756-QS001E-EN-P - October 2009 73

Page 74

Chapter 5 Program a Project Offline

Export Rungs

1. Select the rungs to export.

If rungs are Do this

In sequence Click the first rung and then Shift + click the last rung.

Out Of sequence Click the first rung and then Ctrl + click each additional rung.

2. Right-click the selection and choose Export Rung.

3. Choose a location and name for the file.

4. Create the file.

74 Publication 1756-QS001E-EN-P - October 2009

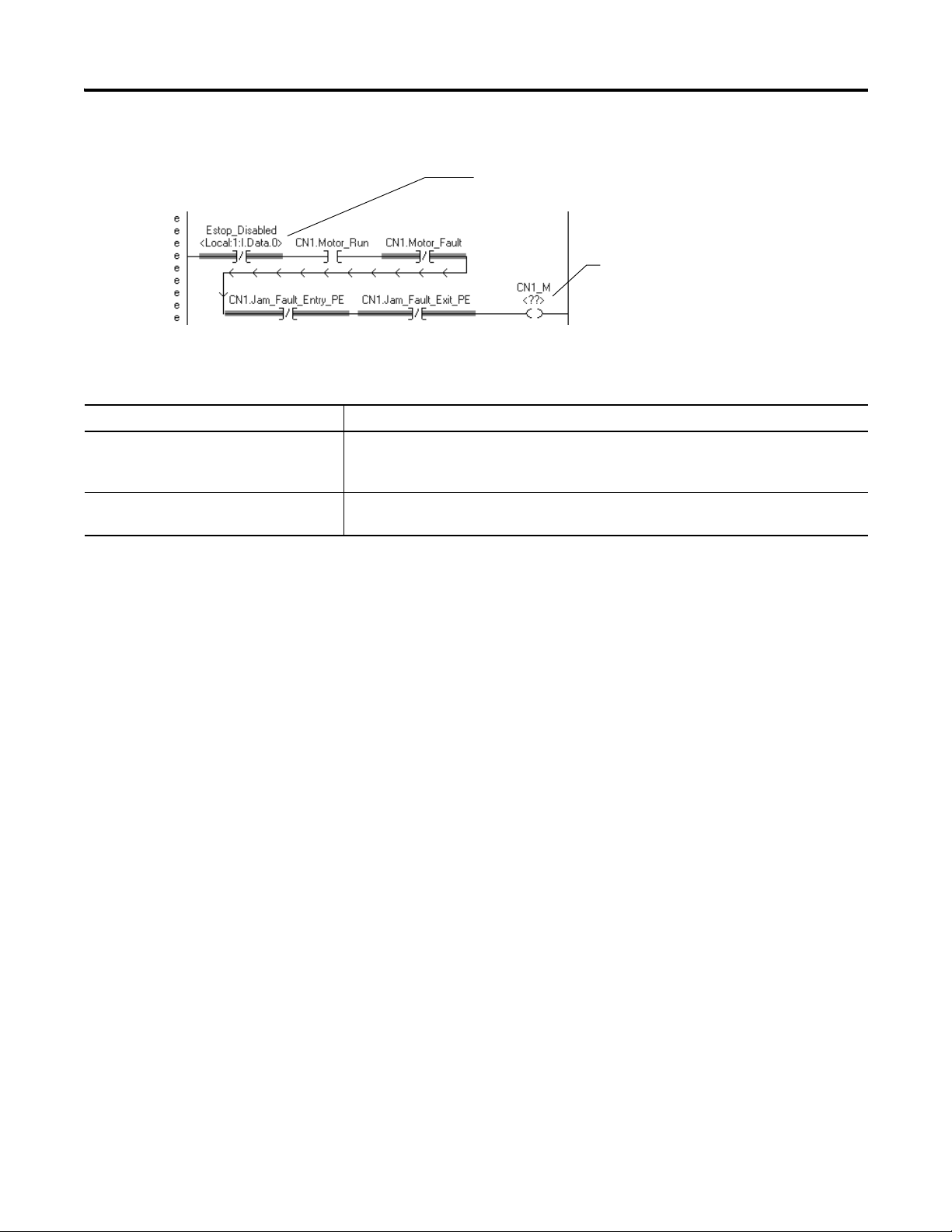

Page 75

Import Rungs

1. Right-click the location for the rungs and choose Import Rung.

2. Select the file to import and click Import.

Program a Project Offline Chapter 5

3. Check for conflicts in names.

4. Click OK.

Publication 1756-QS001E-EN-P - October 2009 75

Page 76

Chapter 5 Program a Project Offline

A

B

Check Alias Tags

Check the alias tags in the rungs you import.

Item Description

A If you import an alias tag, make sure it points to the correct base tag. When a tag is an alias

for a tag that already exists in the project, the software sets up the relationship between

the alias and base tags.

B If the project does not have the base tag, you have to either create the base tag or point the

alias to a different base tag.

76 Publication 1756-QS001E-EN-P - October 2009

Page 77

Program a Project Offline Chapter 5

A

D

F

E

G

C

B

Enter a Function Block Diagram

A function block diagram lets you visually define the flow of data between instructions. The data flow then

drives the execution order of the instructions.

Item Description

A Sheet divides the diagram into sections without affecting execution. When the routine

executes, all sheets execute.

B Input reference (IREF) reads a value from a tag or set a constant value

C Wire transfers a value between elements

D Instruction produces output values based on input values

E Output reference (OREF) writes a value to a tag

F Output wire connector (OCON) writes a value to one or more ICONs

G Input wire connector (ICON) reads a value from an OCON on the same sheet or a different

sheet in the routine. To read a value from another routine, use an OREF/IREF combination.

Publication 1756-QS001E-EN-P - October 2009 77

Page 78

Chapter 5 Program a Project Offline

12 3

H

Item Description

H Assume data available indicator defines the data flow within the loop. The arrow indicates

that the data serves as input to the first block in the loop.

If a group of blocks are in a loop, you have to identify which block to execute first. Use the

Assume Data Available indicator to mark the input wire that creates the loop (the feedback

wire).

This input pin uses the output that block 3 produced on the previous scan.

Use the Keyboard to Add an Element

You can add function block elements by using the computer keyboard.

1. Press Insert.

2. Type the mnemonic for the element and press Enter.

78 Publication 1756-QS001E-EN-P - October 2009

Page 79

3. Drag the element to the desired location.

Program a Project Offline Chapter 5

Connect Elements

To connect elements, click corresponding pins (green dot = valid connection point).

Publication 1756-QS001E-EN-P - October 2009 79

Page 80

Chapter 5 Program a Project Offline

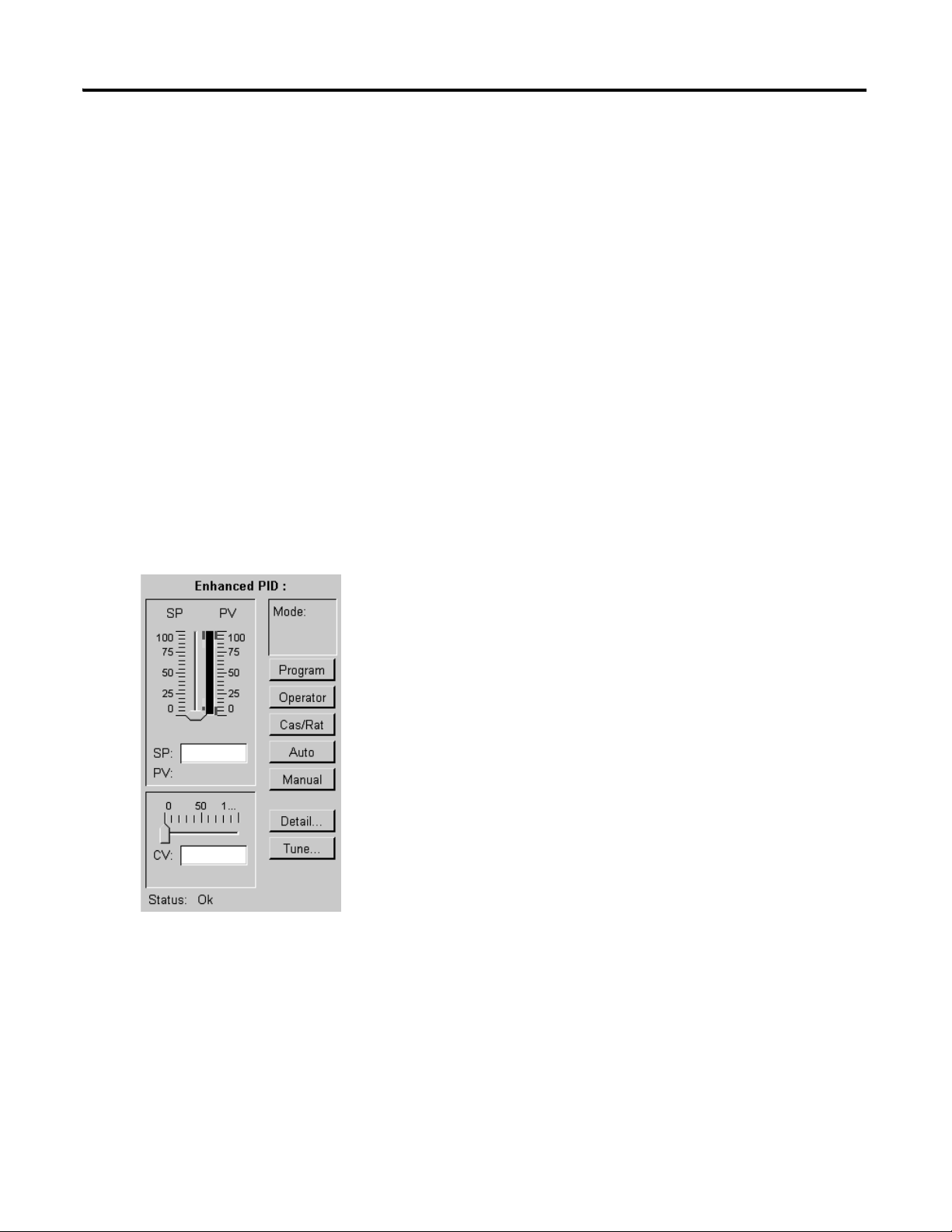

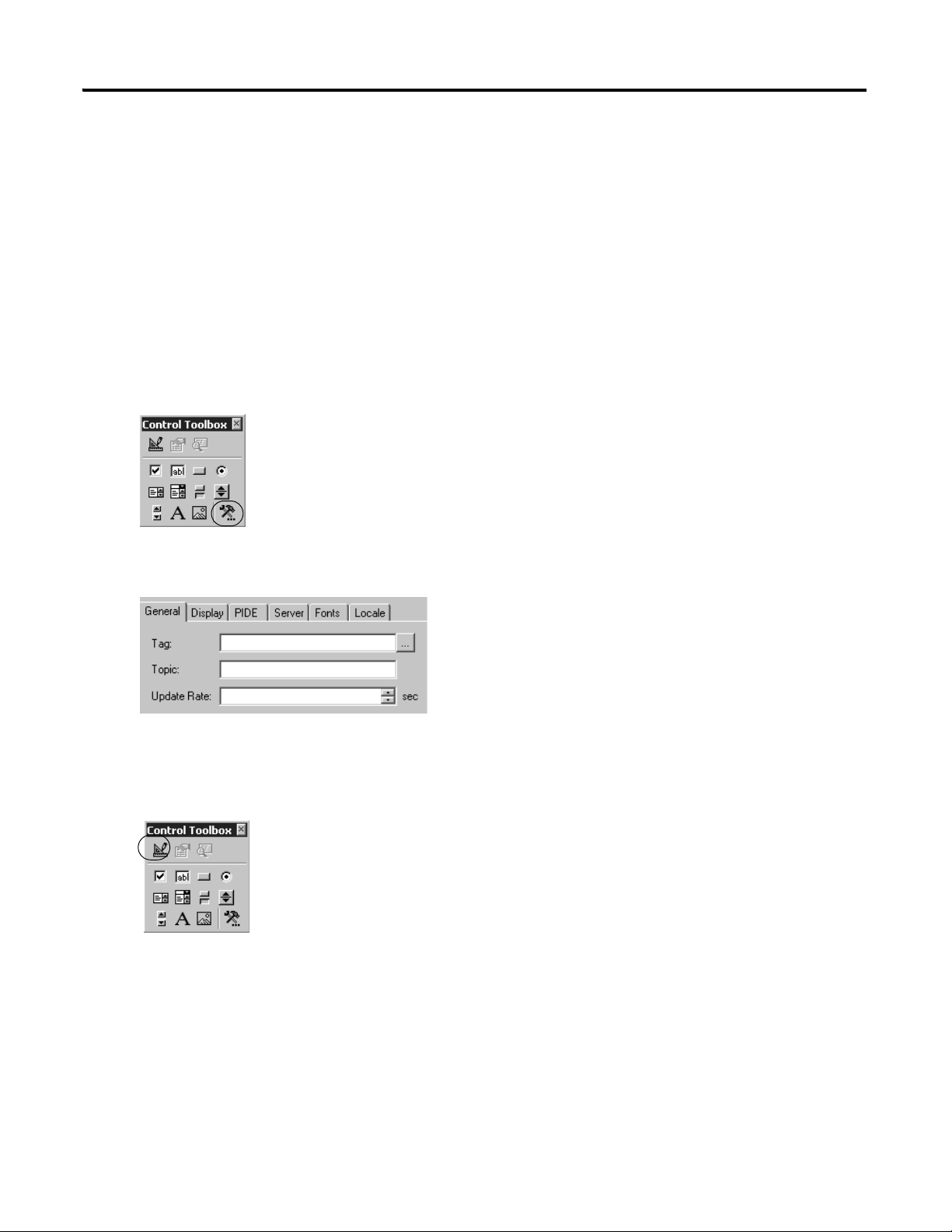

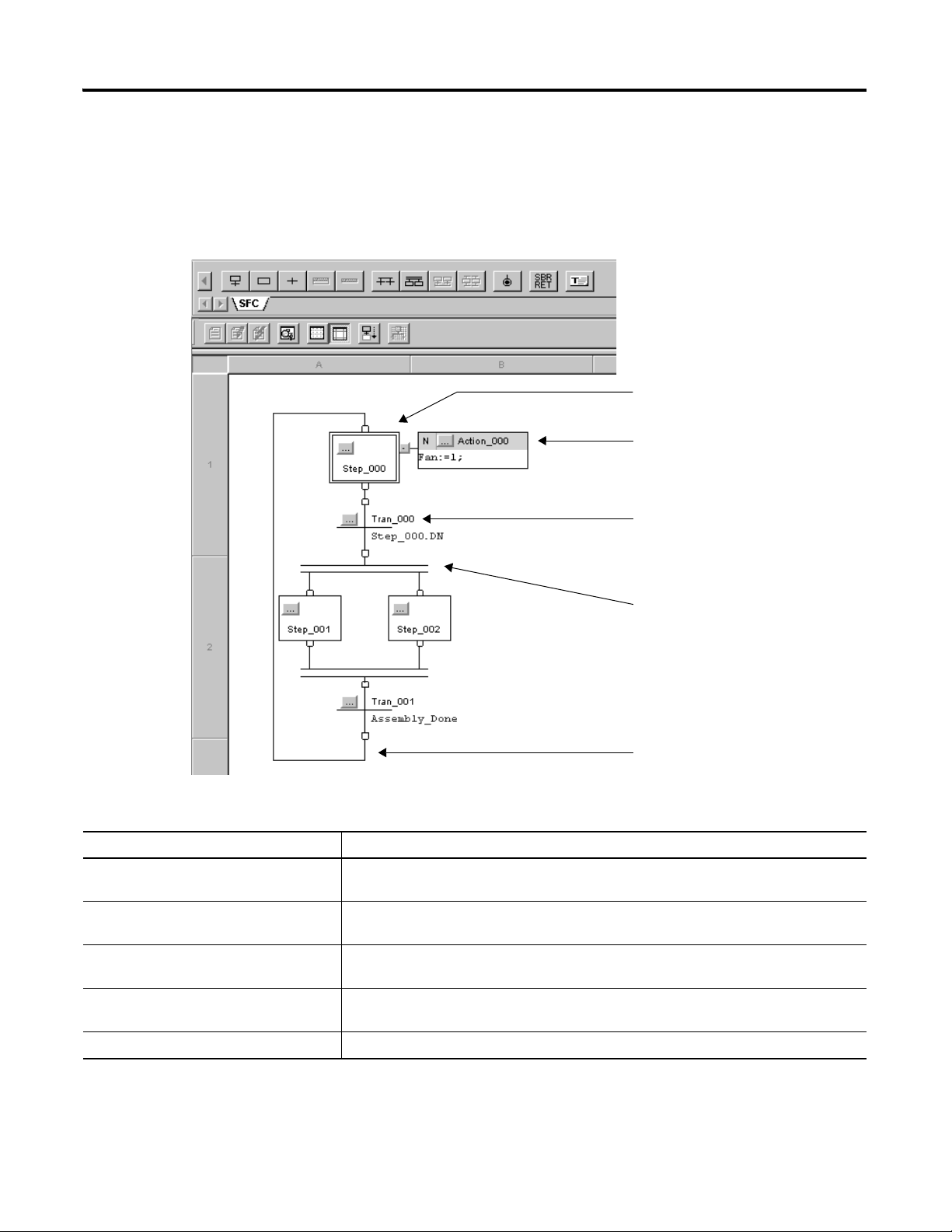

Resolve a Loop