Page 1

Installation Instructions

P

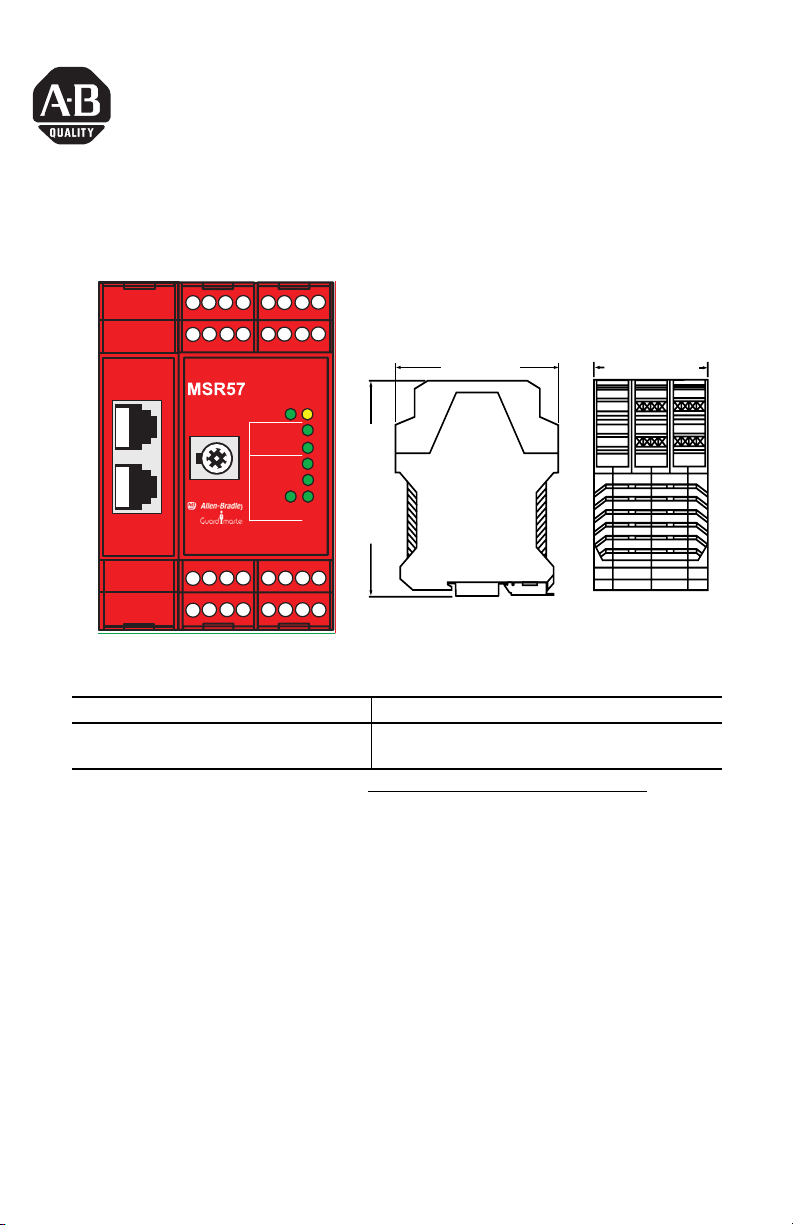

GuardMaster MSR57P Speed Monitoring Safety Relay

Catalog Number 440R-S845AER-NNL

Dimensions

S32 S52 S62S42 13 24 A114

S11 S12 S22S21 34515244

Encoder 1

Encoder 2

DPI

S72 X32X42S82 Y1 S34Y37Y2

Y31Y33 Y30Y3268Y35A278

PWR/Fault

InputsStatus

Limited Speed

Standstill

Safe Speed

Motion Power

Config

Lock

Stop

Door

114.5 mm (4.51 in.)

Additional Resources

Resource Description

GuardMaster MSR57P Speed Monitoring Safety

Relay User Manual, publication 440R-UM004

You can view or download publications at http://literature.rockwellautomation.com. To order

paper copies of technical documentation, contact your local Rockwell Automation distributor

or sales representative.

Detailed information on wiring, configuring, and operating

an MSR57P relay, including safety requirements.

99 mm (3.9 in.)

67.5 mm (2.66 in.)

Publication 440R-IN016B-EN-P - November 2008

Page 2

2 GuardMaster MSR57P Speed Monitoring Safety Relay

Installation Instructions in Other Languages

English This instruction sheet is available in multiple languages at

http://rockwellautomation.com/literature

. Select publication language and type “MSR57P” in

the search field.

Deutsch Dieses Instruktionsblatt kann in mehreren Sprachen unter

http://rockwellautomation.com/literature

gelesen werden. Bitte Ihre Sprache anwählen und

“MSR57P” im Suchfeld eintippen.

Français Ces instructions sont disponibles dans différentes langues à l’adresse suivante:

http://rockwellautomation.com/literature

. Sélectionner la langue puis taper << MSR57P >> dans

le champ de recherche.

Italiano La presente scheda d’istruzione è disponibile in varie lingue sul sito

http://rockwellautomation.com/literature

. Selezionare la lingua desiderata e digitare “MSR57P”

nel campo di ricerca.

Español Puede encontrar esta hoja de instrucciones en varios idiomas en

http://rockwellautomation.com/literature

. Seleccione el idioma de publicación y escriba

“MSR57P” en el campo de búsqueda.

Português Esta folha de instruções está disponível em várias línguas em

http://rockwellautomation.com/literature

. Seleccione a língua de publicação e entre com

“MSR57P” no espaço de busca.

Polish Ta kartka z instrukcjami jest dostepna w wielu jezykach na stronie:

http://rockwellautomation.com/literature

. Wybierz jezyk publikacji i wpisz w polu poszukiwania

“MSR57P”.

Czech Tyto pokyny jsou k dispozici v nekolika jazycích na http://rockwellautomation.com/literature

Zvolte si jazyk publikace a do vyhledávacího polícka vepište “MSR57P”.

Swedish Detta instruktionsblad finns på olika språk på http://rockwellautomation.com/literature

. Välj

önskat språk och skriv “MSR57P” i sökrutan.

Dutch Dit instructieblad is beschikbaar in diverse talen op: http://rockwellautomation.com/literature

Kies taal van publicatie en tik “MSR57P” in het zoekveld.

Chinese

(complex)

從以下網頁可以獲得本說明書的多種語言的版本 :

請選擇出版物的語言 , 並在搜索欄輸入 “MSR57P”。

http://rockwellautomation.com/literature

Chinese

(simplified)

Japanese

从以下网页可以获得本说明书的多种语言的版本 :

请选择出版物的语言 , 并在搜索栏输入 “MSR57P 印

本説明書シートの多言語版は Web サイト

にて入手できます。出版言語を選択し、検索フィールドに 「

http://rockwellautomation.com/literature

http://rockwellautomation.com/literature

ٛ

MSR57P

」とタイプしてください。

.

.

。

。

Publication 440R-IN016B-EN-P - November 2008

Page 3

GuardMaster MSR57P Speed Monitoring Safety Relay 3

General Safety Information

Retain these instructions for future reference. Rockwell Automation cannot accept

responsibility or liability for a failure of this device if the product is used outside the

recommended specifications in this document.

ATTENTION

This device is intended to be part of the safety-related control system of a machine. Before

installation, a risk assessment should be performed to determine whether the specifications

of this device are suitable for all foreseeable operational and environmental characteristics

for the machine to which it is to be fitted. At regular intervals during the life of the machine,

check whether the characteristics foreseen remain valid.

ATTENTION

Safety Programmable Electronic Systems (PES)

Personnel responsible for the installation and application of safety-related programmable

electronic systems (PES) shall be aware of the safety requirements in the application of the

system and shall be trained in using the system.

Spacing Requirements

Adequate air space must be provided around the system (module cluster). Minimum

recommended clearances:

• 15 mm (0.6 in.) above

• 15 mm (0.6 in.) below

• 2…3 mm (0.08…0.12 in.) between modules at ambient temperatures higher

than 40 °C (104 °F).

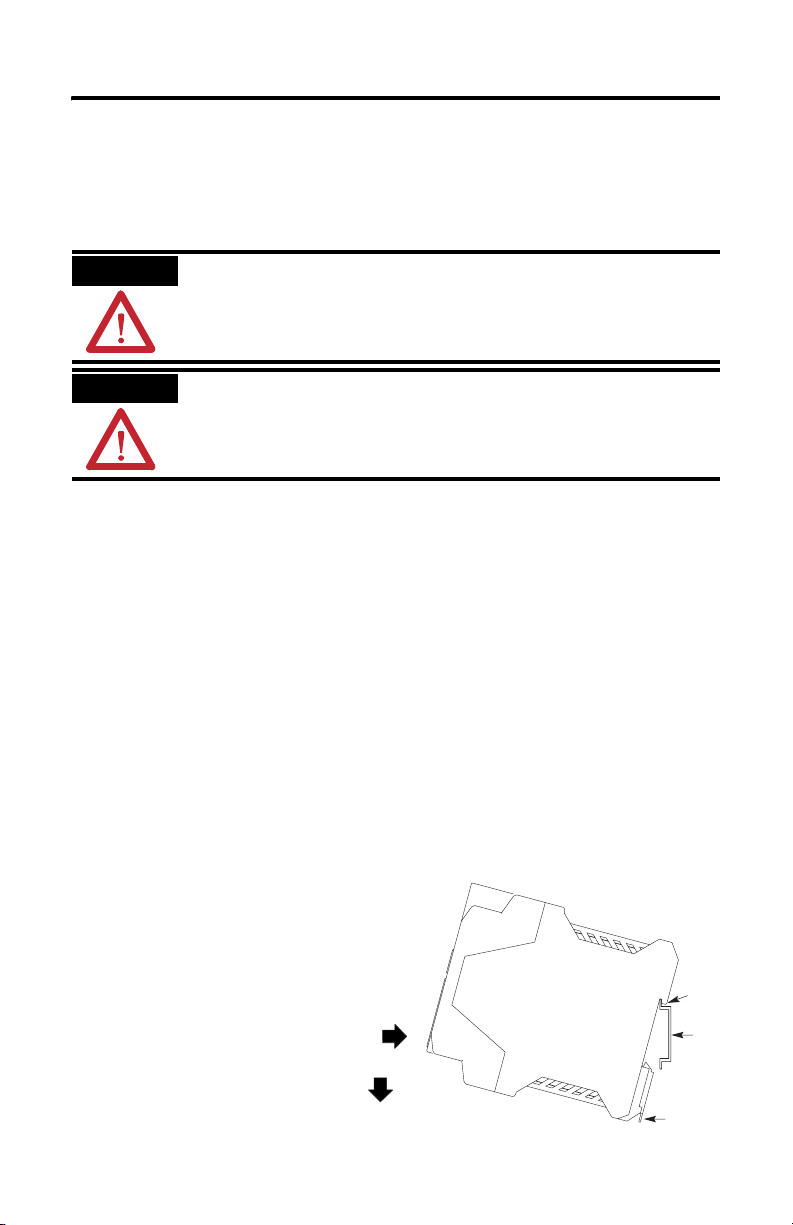

Mount the MSR57P Relay

Follow these steps to mount the MSR57P relay to an EN50022 -35 x 7.5 DIN rail.

1. Hook the top slot over the DIN

rail.

2. Snap the bottom of the device

into position while pressing the

device down against the top of

the rail.

3. Attach end plates on each end

of the DIN rail.

To remove the device from the DIN rail,

use a flathead screwdriver to pull down

the latch and lift the device from the rail.

Latch

Slot

DIN

Rail

Publication 440R-IN016B-EN-P - November 2008

Page 4

4 GuardMaster MSR57P Speed Monitoring Safety Relay

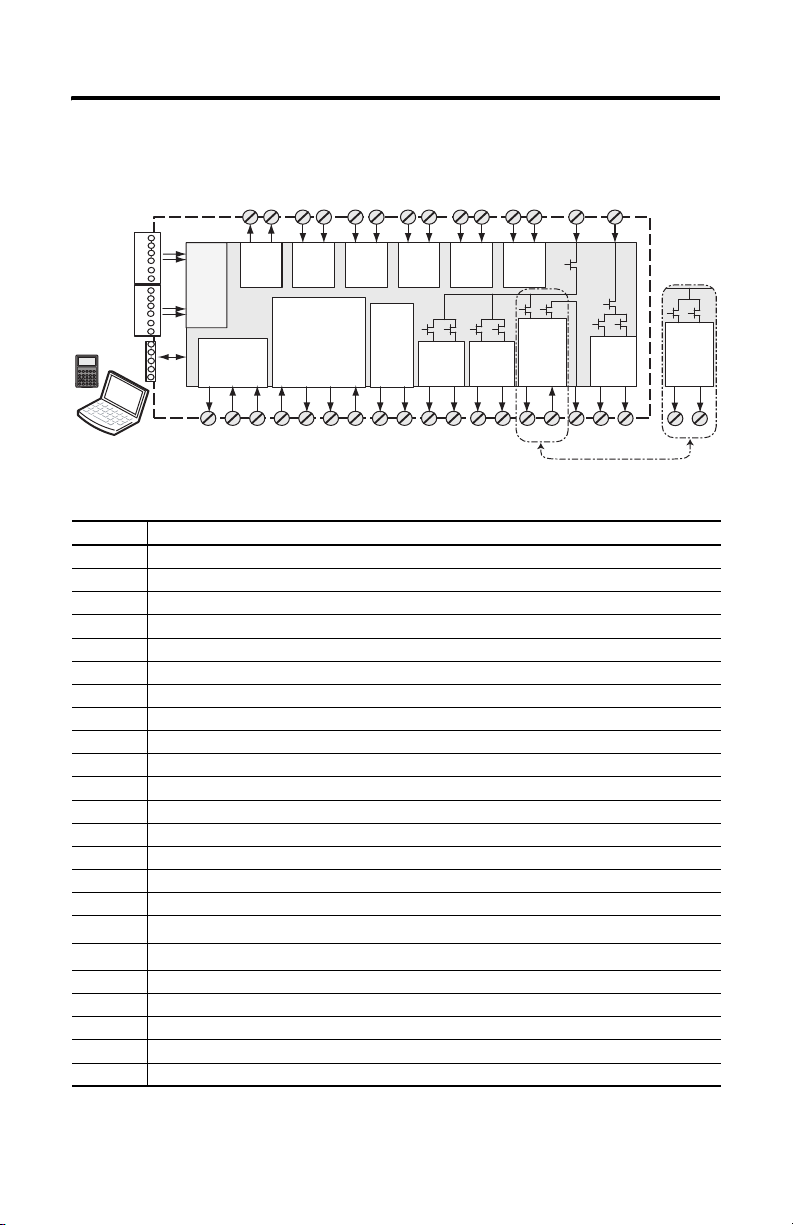

Circuit Diagram

S72

Enabling

Switch

(ESM_In)

Fault_Status

Y37Y35

S82

SS_Out

(Cascade)

2 OSSD

34

S32 S42

Door

Monitor

(DM_In)

44

SLS_Out

(Cascade)

2 OSSD

X32 X42

Lock

Monitor

(LM_In)

7868

Door Lock

Control

(DC_Out)

bipolar

Hi

51 A252

13

A1

Door Lock

Motion

Power

(MP_Out)

Lo

2 OSSD

14

Control

(DC_Out)

Cascade

Hi

Hi

24

51 52

HIM

Encoder 1Encoder 2

RJ45-1

RJ45-2

DPI

Mini-DIN

Monitor

Encoder

PS

24V dc

Y1

S11

Outputs

Reset_In

S34 Y2

Pulse

Tes t

Feedback

S21

(RL_In)

S22

S12

Safe

Stop

(SS_In)

Isolated Outputs

24V dc

Stop_Command

Y32 Y33

Y31

SLS_Command

S52 S62

Safe

Limited

Speed

(SLS_In)

GND

Y30

Diag.

Out

SLS_Status

Terminal Connections

Terminal Function

A1 +24V dc, user supply

A2 Common, user supply

S11, S21 Test_Out_0, Test_Out_1, pulse test outputs for safety functions

S12, S22 SS_In_Ch0, SS_In_Ch1, Safe Stop (SS) dual-channel input

S72, S82 ESM_In_Ch0, ESM_In_Ch1, Enabling Switch Monitor (ESM) dual-channel input

S52, S62 SLS_In_Ch0, SLS_In_Ch1, Safe Limited Speed (SLS) dual-channel input

S32, S42 DM_In_Ch0, DM_In_Ch1, Door Monitor (DM) dual-channel input

X32, X42 LM_In_Ch0, LM_In_Ch1, Lock Monitor (LM) dual-channel input, solenoid position

Y1 24V dc output for reset (S34) and for feedback (Y2)

S34 Reset_In

Y2 RL_In, feedback input

Y35 SLS_Status output

Y37 Fault_Status output

13 Supply power for Motion Power (MP) safety outputs 14 and 24

14, 24 MP_Out_Ch0, MP_Out_Ch1, Motion Power (MP) outputs

68, 78 SLS_Out_Ch0, SLS_Out_Ch1, Safe Limited Speed (SLS) outputs

51

52

DC_Out_Ch0 (High Side), Door Control output [door switch solenoid, bipolar or cascading

DC_Out_Ch1 (Low Side), Door Control output [door switch solenoid, bipolar or cascading

34, 44 SS_Out_Ch0, SS_Out_Ch1, cascading Safe Stop outputs

Y31 24V dc power for isolated outputs

Y32 Stop_Command, isolated output

Y33 SLS_Command, isolated output

Y30 GND for isolated outputs

(1) The DC_Out output may also be configured as cascading (2 Channel Source). For information on using this configuration in

limited applications, refer to the GuardMaster Speed Monitoring Safety Relay User Manual, publication 440R-UM004.

(1)

]

(1)

]

Publication 440R-IN016B-EN-P - November 2008

Page 5

GuardMaster MSR57P Speed Monitoring Safety Relay 5

Status Indicators

Indicator Status Description

(1)

PWR/Fault

Config Lock

Stop Green/On The Safe Stop (SS) input is closed.

Limited

Speed

Motion Power Green/On The Motion Power (MP) output is ON.

Door Green/On The door is closed.

Safe Speed Green/On Safe Limited Speed is being actively monitored and is below the

Standstill Green/On Standstill Speed has been detected.

(1) PWR/Fault green indicator and Config Lock indicator flash in synch when the device is in Program mode.

When you apply power to the device, the red/green indicators flash alternate colors twice and

the Config Lock indicator flashes on and off twice before all indicators except for the

PWR/Fault indicator turn off. The PWR/Fault indicator remains flashing until the device

enters Run or Program mode.

Green/On The device is operating normally and is in Run mode.

Red/Flashing A recoverable fault has occurred.

Red/On A nonrecoverable fault has occurred.

Red/Green Flashing The configuration is being downloaded or a firmware upgrade is in

progress.

(1)

Yellow/On The device’s configuration is locked.

Yellow/Flashing The device’s configuration is unlocked.

Red/On The SS input is open or pressed.

Red/Flashing The SS input has a fault.

Green/On The Safe Limited Speed (SLS) input is closed for normal Run

Green/Flashing The SLS input is open for a safe speed request to allow access to

Off The SLS function is not configured.

Red/Flashing The SLS input has a fault.

Off The MP output is OFF.

Red/Flashing The MP output has a fault.

Red/On The door is open.

Red/Flashing Door Monitor or Lock Monitor input switch has a fault.

Off Door monitoring is not configured.

Off Safe Limited Speed is not being monitored.

Red/Flashing An SLS Speed Fault has occurred.

Off Speed is greater than the configured Standstill Speed.

Red/Flashing Motion has been detected after stopped condition or a Stop Speed

operation.

the machine (Maintenance operation).

configured Safe Limited Speed value after an SLS request has

been made.

Fault has occurred.

Publication 440R-IN016B-EN-P - November 2008

Page 6

6 GuardMaster MSR57P Speed Monitoring Safety Relay

Specifications

GuardMaster MSR57P Speed Monitoring Safety Relay – 440R-S845AER-NNL

Attribute Value

Standards IEC/EN60204-1, ISO12100, IEC 61800-5-2

Safety category Cat. 4 and PL e per EN ISO 13849-1; SIL CL1 to CL3 per IEC 61508/EN62061

Power supply

Aggregate current of

24V dc, 0.8…1.1 x rated voltage

10.4 A max. @ terminal A1 + 13

MSR57P

Power consumption 5 W

Outputs 14, 24, 68, 78 24V dc, 2 A, short-circuit protected

Outputs 34, 44 24V dc, 100 mA, short-circuit protected

Outputs Y35, Y37 24V dc, 50 mA, short-circuit protected

(1)

Door switches 51, 52

24V dc, short-circuit protected

• 1.5 A, bipolar (Power to Release/Power to Lock) configuration

• 20 mA, cascading (2 Channel Source) configuration

Outputs Y32, Y33 24V dc, 100 mA, short-circuit protected

Output Y1 24V dc, 20 mA, short-circuit protected

Pulse outputs S11, S21 24V dc, 100 mA, short-circuit protected

Pulse inputs S12, S22,

11 mA per input, max

S32, S42, S52, S62,

S72, S82, X32, X42

Inputs S34, Y2 11 mA per input, max

Power-on delay, max 3 s

Response time

User-configurable.

(4)

Pollution degree 2

Enclosure protection IP40

Terminal protection IP20

Wire Type Use copper that will withstand 60/75 °C (140/167 °F)

(2)

Conductor size

0.2…2.5 mm2 (12…24 AWG)

Terminal screw torque 0.6…0.8 Nm (5…7 lb-in)

Case material Polyamide PA 6.6

Mounting 35 mm DIN rail

Weight, approx. 350 g (0.77 lb)

(1) For information on using these outputs in bipolar or cascading configurations, refer to the GuardMaster Speed Monitoring

Safety Relay, publication 440R-UM004.

(2) Refer to Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1.

(3) Safety outputs need additional fuse for reverse voltage protection of the control circuit. Install a 6 A slow-blow or 10 A

fast-acting fuse.

(4) Refer to the GuardMaster MSR57P Speed Monitoring Safety Relay User Manual, publication 440R-UM004 for details.

(3)

PELV/SELV

Publication 440R-IN016B-EN-P - November 2008

Page 7

GuardMaster MSR57P Speed Monitoring Safety Relay 7

Environmental Specifications

Attribute Value

Temperature, operating -5…55 °C (23…131 °F)

Relative humidity 90% RH noncondensing

Vibration 10…55 Hz, 0.35 mm displacement

Shock, operating 10 g, 16 ms, 100 shocks

ESD immunity 4 kV contact discharges; 8 kV air discharges

Radiated RF immunity

EFT/B immunity Power, dc: ±2 kV

Surge transient immunity Power, dc: ±0.5 kV line-line and ±0.5 kV line-earth

Conducted RF immunity 10V rms from 150 kHz…80 MHz

10 V/m from 80…1000 MHz; 3 V/m from 1.4…2.0 GHz;

I/O signal lines: ±1 kV

I/O signal lines: ±1 kV line-earth

1V/m from 2.0…2.7GHz

Certifications

(1)

Certification

c-UL-us UL Listed, certified for US and Canada.

CE

C-Tick Australian Radiocommunications Act, compliant with:

TÜV TÜV Certified for Functional Safety: SIL CL1 to CL3, according to IEC 61508/EN62061;

(1) When product is marked. See the Product Certification link at http://ab.com for Declarations of Conformity, Certificates, and

other certifications details.

Value

European Union 2004/108/EC EMC Directive, compliant with:

• EN 61000-6-4; Industrial Emissions.

• EN 61131-2 Programmable Controllers (Clause 8, Zone A & B).

• EN 61326-3-1; Meas./Control/Lab., Industrial Requirements.

• EN 61000-6-2; Industrial Immunity.

AS/NZS CISPR 11; Industrial Emissions.

Category 1 to 4 and Performance Level e, according to EN ISO 13849-1, when used as

described in the GuardMaster MSR57P Speed Monitoring Safety Relay User Manual,

publication 440R-UM004.

Publication 440R-IN016B-EN-P - November 2008

Page 8

8 GuardMaster MSR57P Speed Monitoring Safety Relay

Application Example 1

This example is configured for Safe

Stop 1. The control cabinet

contains an MSR57P relay, a

PowerFlex 70 AC Drive with

Safe-Off function, as well as a

PanelView terminal. The MSR57P

relay monitors speed via a TTL

encoder connected to the

PowerFlex 70 drive.

The control panel lets the operator

select Run or Maintenance speeds.

The door has an interlock switch

with guardlocking to limit access

to the machine when the machine

is operating at normal Run speed.

A towerlight indicates machine

status.

Example 1: System Layout

PowerFlex 70 Drive With Safe-Off

Encoder Cable

1585J-M8RB-2M5

Stopped

Safe Speed

Running

Safe

Stop

E-Stop

Reset

Run Maintenance

Mode

SLS

Request

Configuration Tools

S32 S52 S62S42 13 24 A114

S11 S12 S22S21 34 51 5244

Encoder 1

DPI

Encoder 2

S72 X32 X42S82 Y1 S34 Y37Y2

Y31 Y33 Y30Y32 68 Y35 A278

MSR57P Relay

Motor

Power

Cable

M

Encoder

Feedback

Cable

Encoder

Input 1

Start/Stop Command

and Motion Power

Outputs

Primary Encoder

(Example, Catalog Number:

845T-HZ42EEN)

Publication 440R-IN016B-EN-P - November 2008

20-HIM-A3

-OR-

20-HIM-H10

1203-USB or

1203-SSS(B)

PC

P

Config

Lock

PWR/Fault

Stop

InputsStatus

Limited Speed

Standstill

Safe Speed

Motion Power

Door

Guardlocking

Switch

TLS3-GD2

Page 9

GuardMaster MSR57P Speed Monitoring Safety Relay 9

V

d

Example 1: System Wiring

c

+24

Remove two

34

33

22

21

12

11

Release

Power to

SLS Request

800FM-KM23

800F-MX02V

SS

Request

52

51

42

41

A2

A1

E-Stop

800FM-MT44

800F-MX02V

L1 L2 L3

Power

Supply

DriveGuard

PowerFlex 70

AC Drive with

8 DC Comm

9 24V dc

Gate Control

(1)

Safe-Off Option

1

3

4 SLS Input

2 Start

1 Stop

7 Dig Comm

internal jumpers

TLS3-GD2

440G-T27260

Gate

Circuit

Control

Remove jumpers

6 Enable

4

2

13

SLS

Output

and Power

Motion

24V

Stop

SLS

Feed-

Fault

SLS

68 7834 44

14 24

Power Out

dc

GND

Cmd

Cmd

Reset

back

S34Y1A2 Y2 Y30 Y31Y33 Y32Y35 Y37

Reset

RL

Feed

SS Output

Status

Status

800FM-F6MX10

S42

S32

X32 X42

51 52

S62 S72 S82S21

S52S11

S22S12

A1

Door

Lock

Door Lock

ESM

SLS

SS

Pulse Test

Monitor

Monitor

Control

Input

Input

Input

Outputs

A1

MSR57P Relay

RJ45

RJ45

Isolated Diagnostics

DPI

Input 2

Encoder

Input 1

Encoder

Motor

24V dc Com

Aux. Signals

to PLC

Proper configuration is required for inputs 1, 2, 4, and 6 on the PowerFlex 70 Drive.

(1) Digital input 4.

Publication 440R-IN016B-EN-P - November 2008

Page 10

10 GuardMaster MSR57P Speed Monitoring Safety Relay

Application Example 2

This example is configured for Safe

Stop 1. The control cabinet

contains an MSR57P relay, a

Kinetix 6000 drive with Safe-Off

function, as well as a PanelView

terminal. The MSR57P relay

monitors speed via a Sin/Cos

encoder connected to the

Kinetix 6000 drive.

The control panel lets the operator

select Run or Maintenance speeds.

The door has an interlock switch

with guardlocking to limit access to

the machine when the machine is

operating at normal Run speed.

In addition, an enabling switch is

required to be held in the middle

position while operators are within

the machine environment to keep

the machine running at safe speed.

A towerlight indicates machine

status.

Stopped

Safe Speed

Running

E-Stop

Reset

Run Maintenance

Mode

Example 2 System Layout

Kinetix 6000 or Kinetix 7000

With Safe-Off

Low Profile

Connector

2090-K6CK-D15M

Encoder

Feedback

Cable

MP-Series Bulletin MPL

Servo Motors

Publication 440R-IN016B-EN-P - November 2008

Safe

Stop

Encoder Cable

1585J-M8RB-2M5

Encoder Input 1

Motor

Power

Cable

SLS Request

Encoder 1

Encoder 2

MSR57P Relay

Enabling Switch

S32 S52 S62S42 13 24 A114

S11 S12 S22S21 34515244

P

Config

Lock

PWR/Fault

Stop

DPI

InputsStatus

Limited Speed

Standstill

Safe Speed

Motion Power

Door

S72 X32X42S82 Y1 S34Y37Y2

Y31Y33 Y30Y3268Y35A278

Start/Stop Command

to Logix Controll er

Motion Power Outputs and

Feedback Monitoring From the

MSR57P Relay to Kinetix Safe-Off

Interface

Configuration Tools

20-HIM-H10

-OR1203-USB or

1203-SSS(B)

Guardlocking

Switch

TLS3-GD2

20-HIM-A3

PC

Page 11

Example 2: System Wiring

V

d

GuardMaster MSR57P Speed Monitoring Safety Relay 11

Enable

FDBK2

Motor

24V dc Com

Aux.Signals

to Logix Controller

Reset

Aux. Signals

to Logix Controller

800FM-F6MX10

TLS3-GD2

L1 L2 L3

Gate

Circuit

Control

R2

Gate Control

Power Supply

Safety

Monitor

R1

R2

GuardMotion

AC Drive with

Kinetix 6000 and 7000

440G-T27260

SAFETY EN-

SAFETY EN1+

SAFETY EN2+

R1

R1

FDBK1

Gate

FDBK1

Control

R2

FDBK2

13

SLS

Output

and Power

Motion

Power Out

dc

24V

GND

Cmd

Stop

SLS

Cmd

back

Feed-

Reset

RL

Feed

SS Output

Fault

Status

SLS

Status

68 7834 44

14 24

S34Y1A2 Y2 Y30 Y31Y33 Y32Y35 Y37

S42

S32

X32 X42

51 52

S62 S72 S82S21

S52S11

S22S12

A1

Door

Lock

Door Lock

ESM

SLS

SS

Pulse Test

A1

Monitor

Monitor

Control

Isolated Diagnostics

Input

MSR57P Relay

Input

DPI

Input

RJ45

Input 2

Encoder

Outputs

RJ45

Input 1

Encoder

c

+24

Remove two

internal jumpers

Release

Power to

SLS Request

800FM-KM23

SS

800F-MX02V

34

33

22

21

12

11

Request

52

51

42

41

A2

A1

3

4

1

2

440J-N21TNPM

Enabling Switch

E-Stop

800FM-MT44

800F-MX02V

Publication 440R-IN016B-EN-P - November 2008

Page 12

Rockwell Automation, Allen-Bradley, GuardMaster, PowerFlex, Kinetix, PanelView, DriveExplorer, DriveGuard, GuardMotion,

and MP-Series are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 440R-IN016B-EN-P - November 2008 PN 95302398

Copyright © 200 8 Rockwell Automation, Inc . All rights reserved. Pri nted in Germany.

Loading...

Loading...