Rockwell Automation 440R-N23132, 440R-N23130, 440R-N23129, 440R-C23139 Installation Instructions

Page 1

Reference Manual

Original Instructions

Minotaur Safety Relay (MSR) to Guardmaster Safety Relay

(GSR) Conversion – Phase 3

Bulletin Number 440R

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Table of Contents

Preface

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Introduction GSR Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Conversion Concerns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

CU2 Control Unit Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3

MSR7R and MSR7C Safety Relay Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maximum Input Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 4

MSR9T Safety Relay Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maximum Input Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Input Simultaneity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 5

MSR33 Safety Relay Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Input Simultaneity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 6

MSR35 Safety Relay Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 3

Page 4

Table of Contents

Chapter 7

MSR121RT Safety Relay Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 8

MSR124RT Safety Relay Terminal Location and PanelSpace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Wiring Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Output Load Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 5

Preface

A number of older Allen-Bradley Guardmaster® safety relays will be

discontinued and no longer be available for sale. This publication suggests

examples for how to convert these existing safety relay applications to safety

relays with the latest technologies.

The products that are described in this publication can be used in various ways.

Therefore, designers must verify that all steps have been taken to verify that

each application and use of this control equipment meets all performance and

safety requirements. Designers must consider applicable laws, regulations,

codes, and standards.

The wiring diagrams in this publication are intended as examples. Because

many variables and requirements are associated with any particular installation,

Rockwell Automation does not assume responsibility or liability for actual use

that is based on these examples.

This publication is intended for machine safeguarding system designers who

have been adequately trained in the design and use of safeguarding systems and

risk assessments.

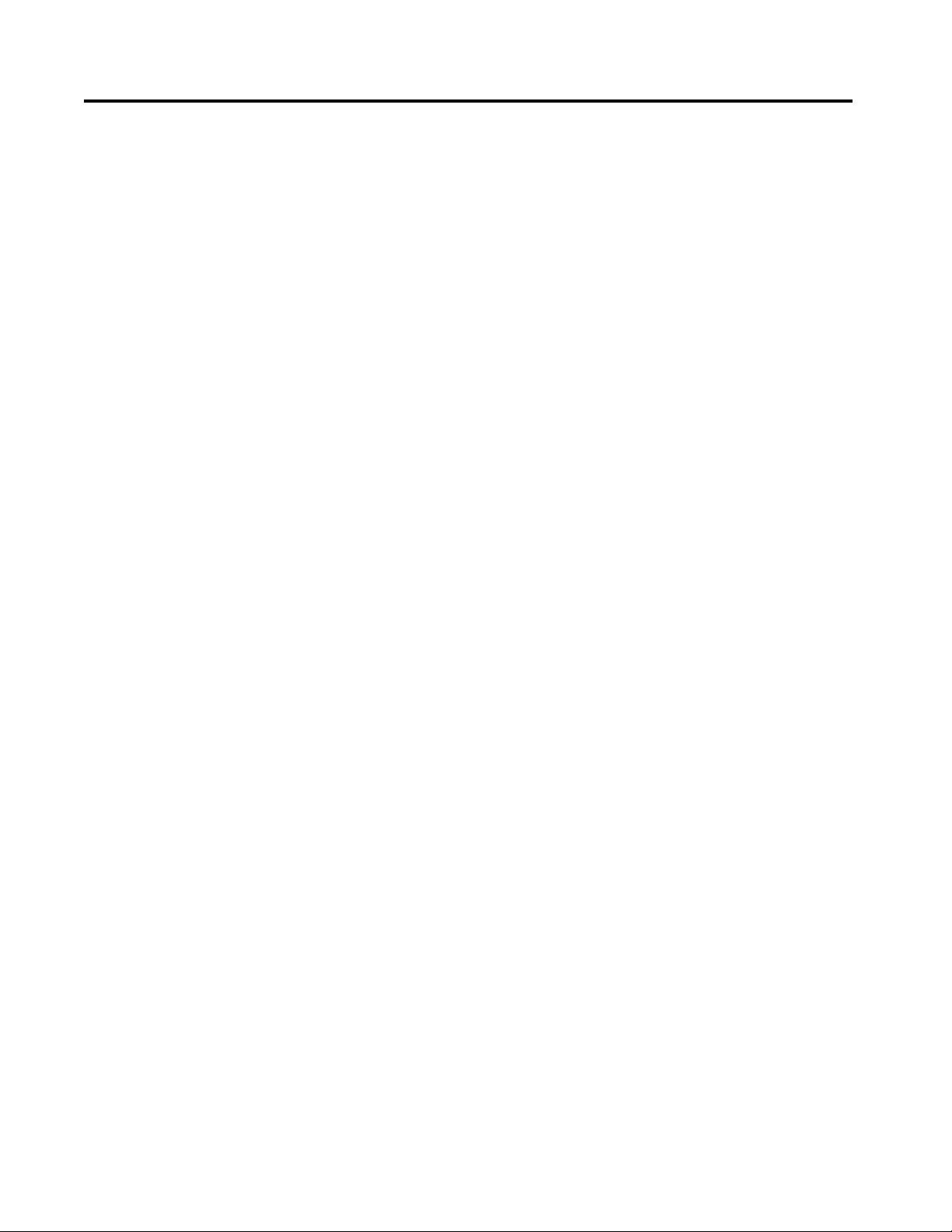

The following MSR safety relays will continue to be offered for the foreseeable

future (five, or more, years).

MSR Family Cat. No. MSR Family Cat. No. MSR Family Cat. No.

MSR117 440R-B23211

440R-D23171 440R-N23129 440R-M23143

440R-D23170 440R-N23125 440R-M23143S

440R-D23169 440R-N23128 440R-M23141

MSR125

MSR126

MSR131

440R-D23168 440R-N23124 440R-M23140

440R-D23166 440R-N23127 440R-M23147

440R-D23164 440R-N23132 440R-M23147S

440R-D23163 440R-N23135 440R-M23145

440R-N23117 440R-N23132S 440R-M23144

440R-N23116 440R-N23135S 440R-M2315

440R-N23115 440R-N23131 440R-M23149

440R-N23114 440R-N23134 440R-M23148

440R-N23113 440R-N23130 440R-M23084

440R-N23112 440R-N23133 440R-M23082

440R-N23123 440R-N23213 440R-M23081

440R-N23122

440R-N23121 440R-E23192 440R-M23086

440R-N23120 440R-E23193 440R-M23085

440R-N23119 440R-E23194 440R-M23092

440R-N23118 440R-E23195 440R-M23090

440R-C23139 440R-E23097 440R-M23089

440R-C23139S 440R-E23159

440R-C23137 440R-E23160 440R-G23215

440R-C23136 440R-E23098 440R-G23216

MSR127

MSR132

440R-N23126

MSR138

440R-E23191 440R-M23088

MSR142

440R-E23161

440R-E23162

440R-M23080

440R-G23214

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 5

Page 6

Preface

Summary of Changes

Additional Resources

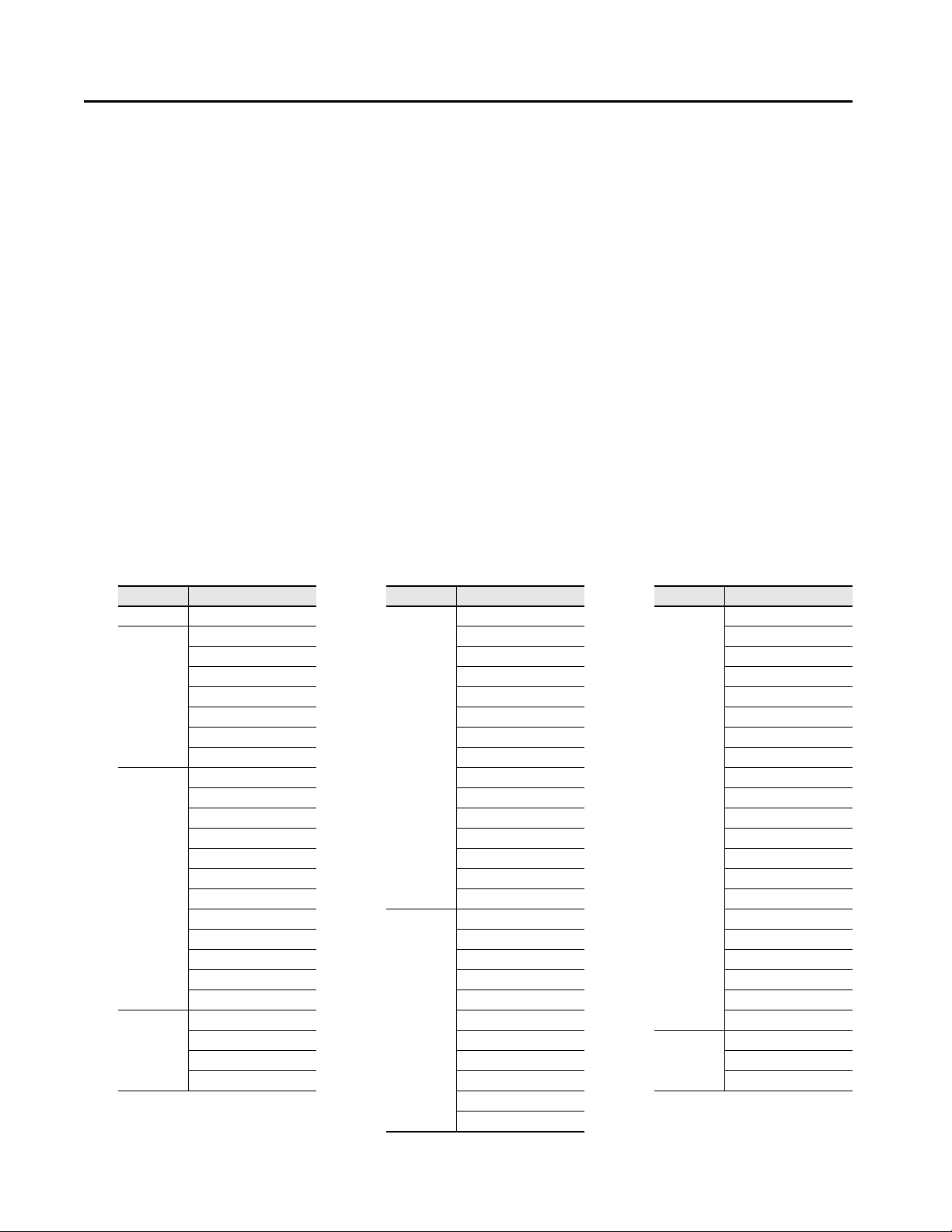

This publication contains new and updated information as indicated in the

following table.

Top ic Pag es

Updated series reference for CU2 Control Units 11

Updated AC voltage in Tab le 5

Updated text 40 and 41

footnote 19

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Guardmaster EtherNet/IP Network Interface User Manual,

publication 440R-UM009

Guardmaster Safety Relays User Manual, publication

440R-UM013

System Design for the Control of Electrical Noise Reference

Manual, publication GMC-RM001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://

www.rockwellautomation.com/global/certification/

overview.page

Provides detailed information to install, wire,

configure, troubleshoot, and use the EtherNet/IP™

module.

Provides detailed information to install, wire,

configure, troubleshoot, and use Guardmaster safety

relays.

Provides a thorough review of the installation and

grounding of noisy components and what can be done

to minimize thei r potential for injecting noise into the

system.

Provides general guidelines for installing a

Rockwell Automation® industrial system.

Provides declarations of conformity, certificates, and

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

.

6 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 7

Chapter 1

Introduction

The next generation Guardmaster safety relay (GSR) family is a high-quality

replacement for most of the Minotaur™ safety relay (MSR) family.

The consistent 22.5 mm (0.9 in.) wide housing design and configurable

functions for reset and logic of GSR modules let you consolidate various

functions of MSR modules with fewer relays. These features help you reduce

your stocking requirements.

The MSR family of safety relays typically offers one dedicated safety function,

for each safety circuit and actuator. MSR solutions have less connectivity to

each other than GSR modules. If you add additional safety circuits, those

circuits require additional safety relay modules and safety contacts for

cascading to maintain PLd or PLe safety ratings according to EN ISO 13849-1

or SIL 2 or SIL 3 according to IEC 62061.

The GSR family of safety relays offers configurable safety functions and

consolidated safety circuits, which result in fewer units, less space, and less cost.

Due to the unique capability to cascade single-wire safety (SWS), logic

combinations and zones are constructed quickly.

A replacement with GSR modules is meant to be more than just a swap out.

New Machinery Directives have changed machine designs over the years.

These changes have harmonized standards and demands of safety solutions

that contribute to productivity and flexibility.

This publication offers detailed information to help with your conversion from

the legacy MSR family to a smarter and cost-effective machine design in

compliance with the latest requirements of Machinery Directive and

harmonized standards.

For further assistance in replacing those devices contact Rockwell Automation

Support, your local Allen-Bradley distributor, or Rockwell Automation sales

office.

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 7

Page 8

Chapter 1 Introduction

GSR Benefits

Conversion Concerns

The GSR family of safety relays provides the following benefits:

• One or two (dual-channel) inputs

•Single wire safety (SWS) expansion

• Narrow package (less panel space)

• Configurable operation

• Cat 4 PLe and SIL 3 rating on most models

•RoHS compliance

It is widely recognized that product obsolescence is a part of the industrial

business cycle. This publication provides cost-effective recommendations for

converting your MSR family of safety relays to the state-of-the-art GSR family,

and considers the following major concerns.

Panel Space

Many control panel designers leave space in their panels for future expansion

and improvements. If that extra panel space gets used, then panel space can

become tight. With panel space in mind, the recommended conversion is

intended to maintain, or even reduce, panel space.

Wiring Terminal Location

A wire that is moved from the top of the old device to the bottom of the new

device in a control panel cannot be taken lightly. Each of the recommended

conversions shows the terminal locations of the old and new devices, so you can

plan the conversion appropriately.

Wiring Change

Example schematics that compare the older device and the recommended

newer device are provided for each of the applications that the older device can

provide.

Response Time

Response time is the time that is required to perform the safety function. For

each conversion, the comparable response time is provided. An increase in the

response time requires you to adjust the safety distance. This increase is not as

much of an issue when a safety gate must be opened manually. However, this

additional response time is likely to be an issue when presence-sensing devices

like light curtains and safety mats are used.

8 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 9

Introduction Chapter 1

S11

S12

S21

S22

S34A1 13

L11A2 142324

33

CR1 CR2

41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

CR1 CR2

K1 K2

L1

K1

K2

L2 L3

M

CR1 and CR2 consist of: 700-HPSXZ24 (relay)

700-HN123 (base)

700-AD1LR (diode and status indicator)

700-HN119 (retainer)

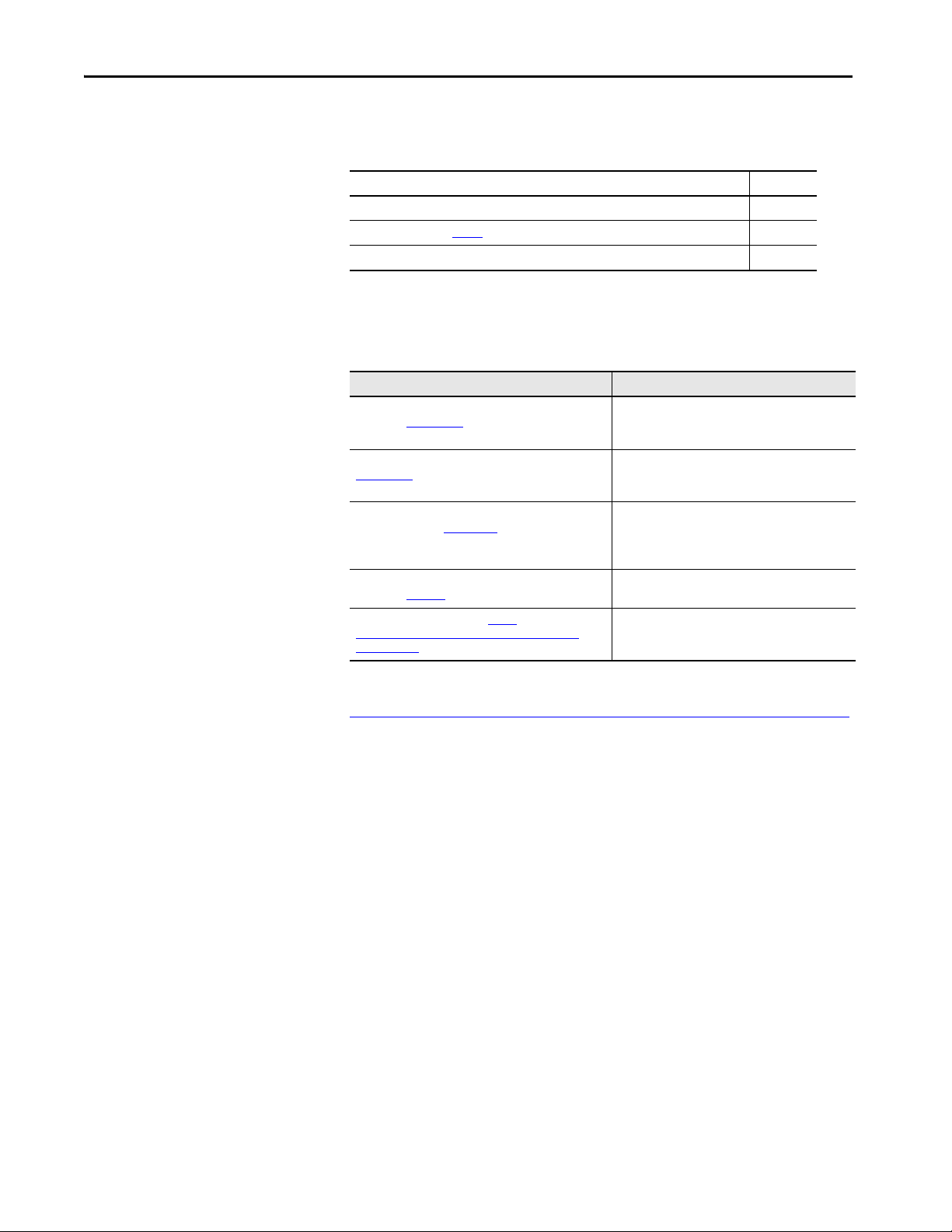

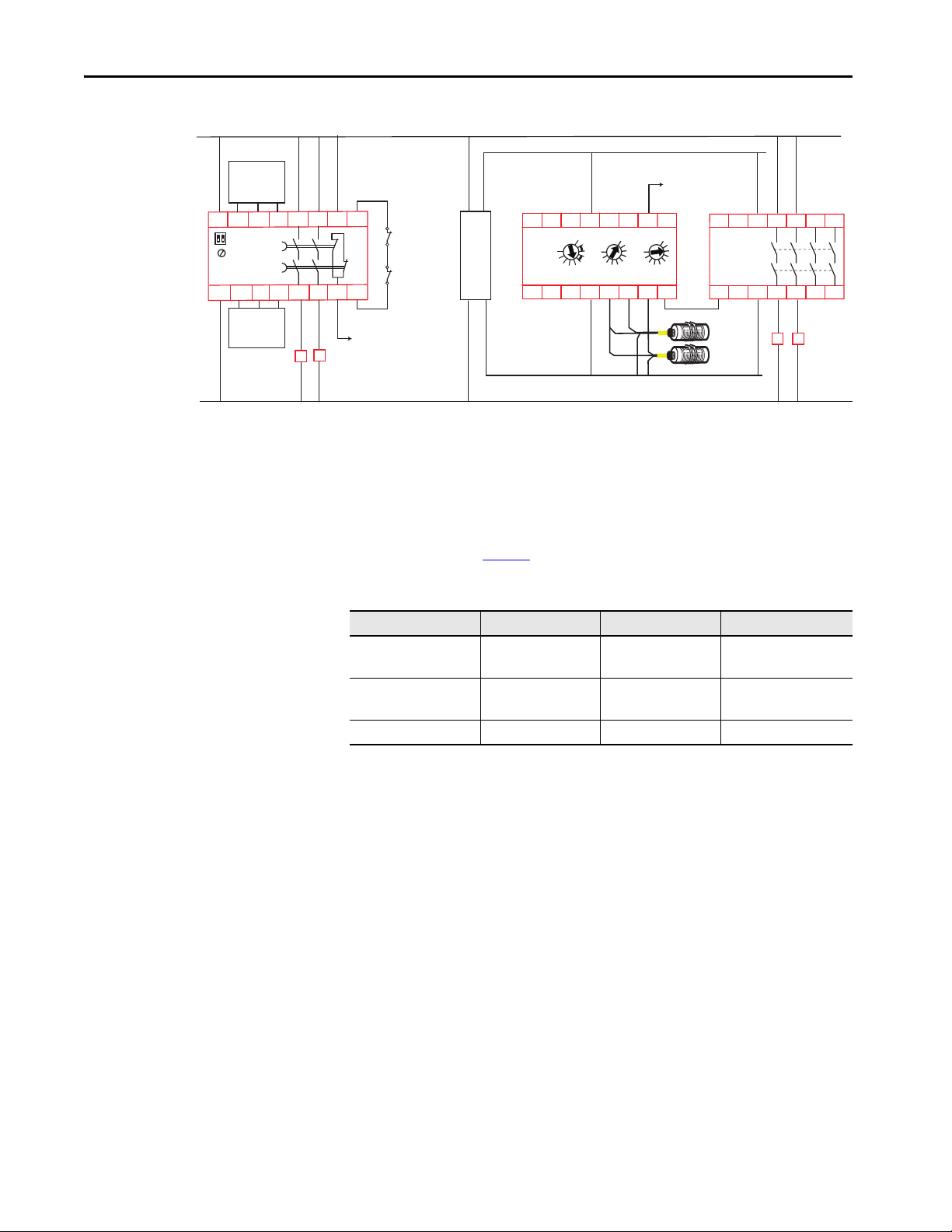

Output Load Capability

Every safety relay has limitations on the amount of current the relay can switch

or carry. When the load exceeds the rating of the safety relay, interposing relays

can be used as shown in Figure 1

Figure 1 - Output Load Capability Using Interposing Relays

.

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 9

Page 10

Chapter 1 Introduction

Notes:

10 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 11

CU2 Control Unit

Chapter 2

Figure 2 - CU2 Control Unit

We recommend replacing the CU2 control unit with a GLP (Series A 205 or

later) safety relay.

Both the CU2 control unit and GLP safety relay use two proximity sensors to

sense the motion of the hazard. The CU2 control unit uses one proximity

sensor with an NPN output and the second proximity sensor with a PNP

output. The GLP safety relay requires PNP outputs for both proximity sensors.

The GLP safety relay has a multi-position switch that lets you configure the

GLP safety relay functionality. Switch positions 5, 6, 7, and 8 reflect the

functionality of the CU2 control unit. Additional functionalities (Cat 1 stop,

safely-limited speed, single wire safety expansion, unlock request, reset, and

lock request) are achieved with logic settings 1, 2, 3, and 4.

The CU2 control unit offers automatic/manual reset with the Y1/Y2

terminals. When the GLP safety relay is configured for logic settings 5, 6, 7, or

8, the GLP safety relay ignores the S44 reset input and operates in automatic

mode.

Ta b l e 1

shows the recommended conversions. With 110/230V AC supply

voltages, many other Bulletin 1606 power supplies can be used. If voltage-free

contacts are needed, the single wire safety signal from the GLP safety relay can

drive the EM safety relay.

Table 1 - Conversion Table

Supply Voltage CU2 Cat. No. GLP Cat. No. EM Cat. No.

24V AC/DC 440R-S07139 440R-GL2S2P

110/230V AC 440R-S07140

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 11

440R-GL2S2P with

1606-XLP15E

440R-EM4R2

Page 12

Chapter 2 CU2 Control Unit

Terminal Location and

PanelSpace

The CU2 control unit is 45 mm (1.8 in.) wide and has one row of terminals at

the top and bottom. The GLP safety relay is only 22.5 mm (0.9 in.) wide and

has two rows of terminals at the top and bottom.

Figure 3 - DC Powered Terminals and Panel Space [mm (in.)]

22.5 (0.88)

45 (1.89)

S12 S22 AP S54

A1 A2 P12 P22

A1 N P N Y1 13 23 31

CU 2

A2 P N P Y2 14 24 32

73

(2.87)

GLP

L12 L11 Y32 S44

X14 X24 51 L61

119

(4.79)

The CU2 control unit can also be ordered with a 110/230V AC power supply.

Because the GLP safety relay is DC powered, a power supply (catalog number

1606-XLP15E) must be used to convert the AC supply to 24V DC. This

configuration occupies the same amount of space as one CU2 control unit.

Figure 4 - AC Powered Terminals and Panel Space [mm (in.)]

67.5 (2.66)

45 (1.89)

45 (1.89)

GLP

33 34 43 44

A1 A2

EM

L12 L11 X32

13 14 23 24

A1 N P N Y1 13 23 31

CU 2

A2 P N P Y2 14 24 32

73

(2.87)

+

DC 24-28V 15W

1606-

XLP15E

AC 100-240V

N L

S12 S22 AP S54

A1 A2 P12 P22

L12 L11 Y32 S44

X14 X24 51 L61

119

(4.79)

12 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 13

CU2 Control Unit Chapter 2

12

22

21 33

34

11

TLS1-GD2

41

42

53

54A1

A2

K1 (aux)

K2 (aux)

Guard Closed

& Locked

Start

Stop

P

PP

N

Y1

Y2

A1

NPN

Proximity

Sensor

N

N

13

A2

1423243132

CU2

440R-S07139

+24V DC

24V Com

To PLC

To PLC

PNP

Proximity

Sensor

K2

K1

LOGIC SLS1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

SLS2/TIME

0

1

2

3

4

5

6

7

8

9

GLP

440R-GL2S2P

A2S12 S22 L11

L12

L61

51

P12 P22

A1X14 X24 S44S54APY32

12

22

21 33

34

11

TLS1-GD2

41

42

53

54A1

A2

K1 (aux)

K2 (aux)

K1

K2

Guard Closed

& Locked

Start

Stop

K2

K1

Brown

Black

Black

Blue

Blue

Two PNP

Proximity

Sensors

L1

K1

K2

L2 L3

M

L1 L2 L3

M

12

22

21 33

34

11

TLS1-GD2

41

42

53

54A1

A2

K1 (aux)

K2 (aux)

Guard Closed

& Locked

Start

Stop

L1

115V AC

230V AC

+24V DC

L+

N-

24V Com

1606XLP15E

NPN

Proximity

Sensor

PNP

Proximity

Sensor

Two PNP

Proximity

Sensors

P

PP

N

Y1

Y2

A1 N

N

13

A2

1423243132

CU2

440R-S07139

N

To PLC

To PLC

K2

K1

LOGIC SLS1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

SLS2/TIME

0

1

2

3

4

5

6

7

8

9

GLP

440R-GL2S2P

A2S12 S22 L11

L12

L61

51

P12 P22

A1X14 X24 S44S54APY32

12

22

21 33

34

11

TLS1-GD2

41

42

53

54A1

A2

K1 (aux)

K2 (aux)

K1

K2

Guard Closed

& Locked

Start

Stop

K2

K1

Brown

Black

Black

Blue

Blue

L1

K1

K2

L2 L3

M

L1 L2 L3

M

Wiring Schematics

The following schematics compare the wiring of your existing MSR module to

the recommended newer devices for each application that the existing device

provides.

DC Powered

Figure 5 - DC Powered Schematic

AC Powered

Figure 6 - AC Powered Schematic

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 13

Page 14

Chapter 2 CU2 Control Unit

NPN

Proximity

Sensor

PNP

Proximity

Sensor

Two PNP

Proximity

Sensors

L1

115V AC

230V AC

+24V DC

L+

N-

24V Com

1606XLP15E

P

PP

N

Y1

Y2

A1 N

N

13

A2

1423243132

CU2

440R-S07139

N

K1

K2

To PLC

To PLC

K2

K1

LOGIC SLS1

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

SLS2/TIME

0

1

2

3

4

5

6

7

8

9

GLP

440R-GL2S2P

A2S12 S22 L11

L12

L61

51

P12 P22

A1X14 X24 S44S54APY32

K2

K1

Brown

Black

Black

Blue

Blue

A1

L11

X32

L12 14 344424

13 33 4323

A2

EM

440R-EM4R2

Figure 7 - AC Powered Loads Schematic

Output Load Capability

The CU2 control unit has voltage-free output contacts, while the GLP safety

relay has solid-state outputs. The GLP safety relay can easily expand its output

capability with the single wire safety connection to an EM expansion relay,

which has voltage-free contacts. Use an interposing relay if additional current

capability is needed. Ta b l e 2

Table 2 - Current Capability

Load Type CU2 GLP EM

AC Inductive

DC

Thermal (non-switching) 4 A 0.5 A 1 x 6 A

shows the current capability of the three relays.

B300, AC-15

5 A/120,250V

DC-13

3 A/24V DC

—

0.5 A/24V DC

B300 AC-15

1.5 A / 250V AC

DC13

2 A/24V DC (0.1 Hz)

14 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 15

MSR7R and MSR7C Safety Relay

Chapter 3

Figure 8 - MSR7R and MSR7C Safety Relay

We recommend replacing both the MSR7R and MSR7C safety relays with the

MSR125H/HP safety relay. The replacement catalog numbers are shown in

Ta b l e 3

. The MSR125H/HP safety relay is one of the MSR relays that will

remain available for five or more years.

The MSR7R and MSR7C safety relays are logic units for monitoring and

interfacing two-hand control devices with a safety-related circuit. The MSR7R

safety relay is for use with mechanical switches and Bulletin 800Z Zero-Force

Touch Buttons™. The MSR7C safety relay is for use with electronic-sensing (for

example, capacitive or photoelectric) palm buttons because the MSR7C safety

relay does not turn its output ON if a power interruption occurs while hands

are on the buttons.

Table 3 - Conversion Table

MSR125 Cat. No.

Type Supply Voltage MSR7 Cat. No.

24V DC

440R-D23021

440R-D23024

MSR7R

MSR7C

24V AC 440R-D23165

110/115V AC 440R-D23022 440R-D23164 440R-D23169

230V AC 440R-D23023 440R-D23163 440R-D23168

24V DC

24V AC 440R-D23165

110/115V AC 440R-D23025 440R-D23164 440R-D23169

230V AC 440R-D23026 440R-D23163 440R-D23168

Fixed Terminals Removable Terminals

440R-D23166 440R-D23171

440R-D23171 or

440R-D23170

440R-D23166 440R-D23171

440R-D23171 or

440R-D23170

ATT EN TI ON : A risk assessment must be performed when converting MSR7C

safety relay to MSR125 safety relay. The risk assessment must include an

evaluation of a hands-on-the-buttons during a power interruption.

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 15

Page 16

Chapter 3 MSR7R and MSR7C Safety Relay

A1 S13 S24 X1 41 13 13 33

A2 S14 S23 X2 42 14 24 34

45 (1.8)

MSR7

A1 S11 S12 S13

Y1 Y2 13 23

14 24

S21 S22 S23 A2

MSR125

22.5 (0.9)

99

(3.9)

73

(2.9)

23

S21 A2 Y214S22 S23

S11

A1S12 S13 13 Y1

24

MSR125

440R-D231**

24/110/230V

K1

K2

S1

S2

S1

S2

Ground

23

S13 A2 X214 34S14

33 41

42

S23

A1S24 13 X1

24

MSR7R

440R-D230**

K1 K2 K1 K2

K1

K2

Terminal Location and

PanelSpace

Wiring Schematics

The MSR7 safety relay is 45 mm (1.8 in.) wide and has one row of terminals at

the top and bottom. The MSR125 safety relay is only 22.5 mm (0.9 in.) wide

with two rows of terminals on the top and bottom.

The MSR125 safety relay is available with wither fixed or removable terminals;

the MSR7 safety relay only has fixed terminals.

Figure 9 - Terminals and Panel Space [mm (in.)]

The MSR7 and MSR125 safety relays are available in the following power

supplies:

• 24V AC

• 24V DC

• 110V AC

• 230V AC

The wiring schematics are the same for each voltage supply.

MSR7R

Figure 10 - MSR7R Schematic

16 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 17

MSR7C

23

S21 A2 Y214S22 S23

S11

A1S12 S13 13 Y1

24

MSR125

440R-D231**

24/110/230V

K1

K2

S1

S2

S1

S2

Ground

23

S13 A2 X214 34S14

33 41

42

S23

A1S24 13 X1

24

MSR7C

440R-D230**

K1 K2

K1 K2

23

S13 A2 X214 34S14

33 41

42

S23

A1S24 13 X1

24

MSR7R

440R-D23021

or

440R-D23024

23

S21 A2 Y214S22 S23

S11

A1S12 S13 13 Y1

24

MSR125

440R-D23171

or

440R-D23166

24V DC

K1 K2 K3

S1

S2

Aux

S1

S2

Ground

K1 K2 K1 K2

K1

K2

K3

K3

Aux

K3

23

A2 X2 14 34 44

33 43 51 61

52 62

A1 13X1

24

MSR132E

440R-E23191

or

440R-E23097

Figure 11 - MSR7C Schematic

MSR7 — All Contacts Used

MSR7R and MSR7C Safety Relay Chapter 3

Maximum Input Impedance

Figure 12 - MSR125 with Expansion Relay

The MSR7 safety relay can tolerate up to 500 ohms of resistance on its input

circuits. The MSR125 safety relay is limited to 40 ohms. This difference is not

likely to be an issue as the typical cable resistance of 18 AWG (0.75 mm2) wire

is 20.95 ohms per 1000 meters (6.4 ohms per 1000 feet).

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 17

Page 18

Chapter 3 MSR7R and MSR7C Safety Relay

Response Time

Output Load Capability

Response time applies when at least one hand is removed from the two-hand

controls and the operator reaches towards the hazard.

If the MSR132 expansion relay is not used, the response time of the MSR125

safety relay is faster than the MSR7 safety relay, and the distance from the twohand controls to the hazard can remain unchanged.

If the MSR132 expansion relay is used, the response time of the relay is 20 ms

longer; the safety distance must be recalculated and the two-hand controls may

have to be moved further away from the hazard. Using the standard speed

constant of 1600 mm/sec (63 in./sec), the additional 20 ms requires an

additional 32 mm (1.25 in.) of spacing from the hazard.

Safety Relay Response Time

MSR7 50 ms

MSR125 20 ms

MSR132 50 ms

The MSR125 safety relay has a higher current capability than the MSR7

safety relay.

Table 4 - Current Capability

Load Type MSR7 MSR125 MSR132

AC Inductive

DC

Thermal (non-switching) 4 A

BC300, AC-15

4 A

P300, DC-13

2 A/24V DC

B300, AC-15

6 A

P300, DC-13

3 A/24V DC

1 x 6 A

2 x 4 A

AC-15

6 A

DC-13

3 A/24V DC

2 x 6 A

4 x 4 A

18 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 19

MSR9T Safety Relay

Chapter 4

Figure 13 - MSR9T Safety Relay

Terminal Location and

PanelSpace

We recommend replacing the MSR9T safety relay with a Sipha™ 2 controller.

The replacement catalog numbers are shown in Ta b l e 5

.

The MSR9T safety relay was used in older applications, where the input device

employed the diversity concept of one normally closed contact and one

normally open contact. The Sipha 2 controller employs the same diversity

approach and can easily be applied to contact-type switches and the Sipha noncontact switches.

These controllers are similar in the type of inputs and the number of outputs.

Table 5 - Conversion Table

Supply Voltage MSR9T Cat. No. Sipha 2 Cat. No.

(1)

24V AC/DC

110/230V AC 440R-F23028

(1) For 24V, the Sipha 2 controller can only operate at 24V DC. When the MSR9T is powered by

115/230V AC, you must provide an AC/DC converter.

440R-F23027

440N-S32021

The MSR9T safety relay and Sipha 2 controller are both 45 mm (1.8 in.) wide

and have one row of terminals at the top and bottom.

There is a significant difference in the location of the terminals for the power,

inputs, outputs, and monitoring. Numerous wires must be moved from the top

of the relay to the bottom and vice versa.

Figure 14 - Terminals and Panel Space [mm (in.)]

45 (1.8)

A1 A2 X1 X2

MSR9T Sipha 2

31 32 13 14 23 24 S21 S22

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 19

S13 S14 A1 + X1 2 1 13 23 31

45 (1.8)

230/

24V

110

AC/DC

230/

24V

110

AC/DC

A2 - X2 3 4 14 24 32

Page 20

Chapter 4 MSR9T Safety Relay

Sipha 2

440N-S32021

23

3

A2 X2144

31

32

1

A1 +213X1

24

MSR9

440R-F23027

23

S13 A2 X214S14

31

32

S21

A1S22 13 X1

24

Closed

24V DC

Ground

K1

K2

Open

K1 K2

Closed

K1

K2

Open

K1 K2

Sipha 2

440N-S32021

23

3

A2 X2144

31

32

1

A1 +213X1

24

MSR9

440R-F23028

23

S13 A2 X214S14

31

32

S21

A1S22 13 X1

24

Closed

110/115/230V AC

Neutral

115

230

K1

K2

Open

K1 K2

Closed

K1

K2

Open

K1 K2

110

230

Wiring Schematics

The following schematics compare the wiring of your existing MSR module to

the recommended newer devices for each application that the existing device

provides.

24V AC/DC Powered

When powered by 24V AC/DC, the power supply connections are made to +

and – terminals of the Sipha controller; the A1 and A2 terminals must have no

connections.

Figure 15 - 24V AC/DC Powered Schematic

110/115/230V AC Powered

An internal, user-selectable switch is used to set the input voltage of both the

MSR9 safety relay and Sipha 2 controller. Remove the front cover and set the

switch to either 110/115V or 230V AC. Figure 16

schematics; in this case the power to the relay is connected to A1 and A2.

Figure 16 - AC Powered

shows the conversion

20 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 21

MSR9T Safety Relay Chapter 4

Maximum Input Impedance

Input Simultaneity

The MSR9T tolerates up to 500 ohms of resistance on its input circuits. The

Sipha 2 controller tolerates 200 ohms on terminals 1…4 and 150 ohms on

terminals 2…3. This difference is not likely to be an issue as the typical cable

resistance of 18 AWG (0.75 mm2) wire is 20.95 ohms per 1000 meters

(6.4 ohms per 1000 feet).

Input simultaneity is a measure of the difference in time between the change in

state of the two channels to enable the relay to energize its outputs.

The MSR9T safety relay is specified to have input simultaneity of 500 ms; the

dual-inputs must change state with 500 ms of each other. The Sipha 2

controller has historically been specified with a minimum approach speed of

17 mm/s (0.67 in./s).

The following describes how a Sipha 2 controller works:

• If the N.O. contact opens first, then the N.C. contact can close at any

time afterwards.

• If the N.C. contact closes first, then the N.O. contact must open within

1.4 seconds.

Response Time

Output Load Capability

Because the response time of the Sipha 2 controller is faster than the MSR9T

safety relay, the safety distance calculation does not require recalculation.

Safety Relay Response Time

MSR9T 50 ms

Sipha 2 40 ms

Ta b l e 6 compares the output load capability of the MSR9T to the replacement

relays. See Output Load Capability on page 9

for a wiring example of using

interposing relays for applications where the load exceeds the capability of the

replacements.

Table 6 - Current Capability

Load Type MSR9T Sipha 2

AC Inductive

DC

Thermal (non-switching) 4 A —

B300, AC-15

4 A/250V AC

4 A/120V AC

P300, DC-13

3 A/24V DC

B300, AC-15

4 A/250V AC

P300, DC-15

2 A/24V DC

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 21

Page 22

Chapter 4 MSR9T Safety Relay

Notes:

22 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 23

MSR33 Safety Relay

Chapter 5

Figure 17 - MSR33 Safety Relay

Terminal Location and

PanelSpace

We recommend replacing the MSR33 safety relay with a Sipha 2 controller.

The MSR33 safety relay is offered with either fixed or removable terminals.

The Sipha 2 controller only has fixed terminals. The MSR33 safety relay has

solid-state outputs, while the Sipha 2 controller has electromechanical outputs.

The MSR33 safety relay has a feature that is called Startup Test. The wiring

configures the startup test. Upon initial power-up, the input device must be

cycled once to energize the safety outputs. The Sipha 2 controller does not

support this feature.

Table 7 - Conversion Table

Ter min al s MSR33 Cat. No. Sipha 2 Cat. No.

Fixed 440R-F23199

Removable 440R-F23200

440N-S32021

(only fixed terminals)

The Sipha 2 controller requires twice as much panel space as its width is 45 mm

(1.8 in.) compared to the 22.5 mm (0.9 in.) for the MSR33 safety relay. The

difference in relay height must be considered but is not significant.

The terminal locations for the inputs, outputs, and monitoring circuits require

movement of the wiring from the top to the bottom of the relay and vice versa.

Figure 18 - Terminals and Panel Space [mm (in.)]

22.5 (0.9)

45 (1.8)

A1 Y41 S11 S34

99

MSR33

A2 S12 S22 Y32

14 24 S21 Y2

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 23

(3.9)

A1 + X1 2 1 13 23 31

230/

24V

110

AC/DC

Sipha 2

230/

24V

110

AC/DC

A2 - X2 3 4 14 24 32

73

(2.9)

Page 24

Chapter 5 MSR33 Safety Relay

Sipha 2

440N-S32021

23

3

A2 X2144

31

32

1

A1 +213X1

24

MSR33

440R-F23***

Y41

S12 A2 14S22

Y2

Y32

S11 A1

S21 S34

24

Closed

24V DC

Ground

K1

Reset

K2

Open

K1 K2

Closed

K1

K2

Open

K1 K2

Reset

Sipha 2

440N-S32021

23

3

A2 X2144

31

32

1

A1 +213X1

24

MSR33

440R-F23***

Y41

S12 A2 14S22

Y2

Y32

S11

A1S21 S34

24

Closed

24V DC

Ground

K1

K2

Open

K1 K2

Closed

K1

K2

Open

K1 K2

Wiring Schematics

The following schematics compare the wiring of your existing MSR module to

the recommended newer devices for each application that the existing device

provides.

Manual Reset

In the manual reset examples, the MSR33 safety relay has monitored reset,

where the Reset button must be pressed and released. The reset action occurs

when the button is released. With the Sipha 2 controller, the reset occurs when

the button is pressed.

Figure 19 - Manual Reset

Automatic Reset

Figure 20 - Automatic Reset

24 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 25

MSR33 Safety Relay Chapter 5

Auxiliary Output

The auxiliary output of the MSR33 is normally open. When the safety outputs

are OFF, the auxiliary output is OFF.

The Sipha 2 auxiliary output is normally closed. When the safety outputs are

open (OFF), the auxiliary output is closed (ON).

Input Simultaneity

Response Time

Input simultaneity is a measure of the difference in time between the changes

in state of the two channels to enable the relay to energize its outputs.

The MSR33 safety relay allows an infinite amount of time between the

changes of state of the two inputs. The Sipha 2 controller has historically been

specified with a minimum approach speed of 17 mm/s (0.67 in./s).

The following describes how a Sipha 2 controller works:

• If the N.O. contact opens first, then the N.C. contact can close at any

time afterwards.

• If the N.C. contact closes first, then the N.O. contact must open with

1.4 seconds.

ATT EN TI ON : Because the response time of the MSR33 safety relay is 25 ms

faster than the Sipha 2 controller, the safety distance must be examined

closely and adjusted, if necessary.

Safety Relay Response Time

MSR33 15 ms

Sipha 2 40 ms

Output Load Capability

The load capability table only compares DC loads because the MSR33 safety

relay can only accommodate DC loads.

Table 8 - Current Capability

Load Type MSR33 Sipha 2

DC 2 A/24V DC 2 A/24V DC

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 25

Page 26

Chapter 5 MSR33 Safety Relay

Notes:

26 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 27

MSR35 Safety Relay

A1 Y41 S11 S34

14 24 S21 Y2

A2 S12 S22 Y32

MSR35

22.5 (0.9)

99

(3.9)

A1 S11 S12 S13

Y1 Y2 13 23

14 24

S21 S22 S23 A2

MSR125

22.5 (0.9)

99

(3.9)

Chapter 6

Figure 21 - MSR35 Safety Relay

Terminal Location and

PanelSpace

We recommend replacing the MSR35 safety relay with an MSR125 safety

relay. The MSR125H/HP safety relay is one of the MSR relays that will remain

available for five or more years.

The MSR35H/HP safety relay is an electronic two-hand control relay that is

offered with either fixed or removable terminals. It is only available with

24V DC power.

Table 9 - Conversion Table

Ter min al s MSR35 Cat. No. MSR125 Cat. No.

Fixed 440R-D23201 440R-D23171

Removable 440R-D23202 440R-D23166

The MSR35RT safety relay has a 22.5 mm (0.9 in.) wide body, with two rows

of terminals at the top and bottom. The MSR125 safety relay also has two rows

of terminals at the top and bottom and is 22.5 mm (0.9 in.) wide.

Figure 22 - Terminals and Panel Space [mm (in.)]

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 27

Page 28

Chapter 6 MSR35 Safety Relay

23

S21 A2 Y214S22 S23

S11

A1S12 S13 13 Y1

24

MSR125

440R-D231**

24V DC

K1

K2

S1

S2

Ground

K1 K2

S1

S2

MSR35

440R-D232**

Y41

S12 A2 14S22

Y2

Y32

S11 A1

S21 S34

24

K1

K2

K1 K2

Wiring Schematics

The output is a significant difference between the two relays. The MSR35

safety relay has solid-state outputs, while the MSR125 safety relay has

voltage-free contacts.

Category IIIC

Figure 23 - Category IIIC Per EN574

24V DC

K1

S1

S2

Ground

S11 A1

S21 S34

MSR35

440R-D232**

S12 A2 14S22

K1 K2

Y41

24

K2

Y2

Y32

S1

S11

MSR125

440R-D231**

S21 A2 Y214S22 S23

S2

A1S12 S13 13 Y1

23

24

K1 K2

K1

K2

Category IIIA

Figure 24 - Category IIIA Per EN574

28 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 29

MSR35 Safety Relay Chapter 6

Response Time

Output Load Capability

ATT EN TI ON : Because the response time of the MSR35RT is faster than the

MSR125 relay, the safety distance must be examined closely and adjusted if

necessary.

Safety Relay Response Time

MSR35 15 ms

MSR125 20 ms

The MSR125 safety relay has a higher current capability than the

MSR35H/HP safety relay, as shown in Ta b l e 1 0

Table 10 - Current Capability

Load Type MSR35 MSR125

DC 2 A/24V DC 3 A/24V DC

.

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 29

Page 30

Chapter 6 MSR35 Safety Relay

Notes:

30 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 31

MSR121RT Safety Relay

Chapter 7

Figure 25 - MSR121RT Safety Relay

Terminal Location and

PanelSpace

We recommend replacing the MSR121RT safety relay with a CI safety relay.

The MSR121RT safety relay can be wired for automatic or monitored reset.

The CI safety relay is configured for automatic or monitored reset by a rotary

switch on its front face.

The MSR121RT safety relay is only available with a 24V AC/DC power

supply.

Table 11 - Conversion Table

Supply Voltage MSR121RT Cat. No. CI Cat. No.

(1)

24V AC/DC

(1) For 24V, the CI safety relays can only operate at 24V DC. When the MSR121RT is powered by

24V AC, you must provide an AC/DC converter.

440R-J23102 440R-S13R2

The MSR121RT safety relay has a 55 mm (2.17 in.) wide body, with one row

of terminals at the top and one at the bottom. The CI safety relay has a

22.5 mm (0.9 in.) wide body with two rows of terminals at the top and bottom.

Figure 26 - Terminals and Panel Space [mm (in.)]

22.5 (0.9)

55 (2.17)

13 23 33 41

A1 S11 S12 L11

A1 S11 S52 S12 Y31 Y32 13 23 33 41

MSR121R/T

S21 S22 X5 S33 S34 14 24 34 42 A2

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 31

75

(2.95)

CI

S21 S22 S34 A2

14 24 34 42

119

(4.69)

Page 32

Chapter 7 MSR121RT Safety Relay

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

Reset

K1

K2

Reset

S11

S12

S21

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

K1

K2

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

S11

S12

S21

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Stop

Start

K1

K2

Stop

Start

K1

K2

K1

K2

K1 K2

Wiring Schematics

The following schematics compare the wiring of your existing MSR module to

the recommended newer devices for each application that the existing device

provides.

Dual Channel Input

Figure 27 - Monitored Reset

Figure 28 - Automatic Reset

32 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 33

Single Channel Input

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

S11

S12

S21

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Reset

K1

K2

Reset

K1

K2

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

S11

S12

S21

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Stop

Start

K1

K2

Stop

Start

K1

K2

K1

K2

K1 K2

Figure 29 - Monitored Reset

Figure 30 - Automatic Reset

MSR121RT Safety Relay Chapter 7

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 33

Page 34

Chapter 7 MSR121RT Safety Relay

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

Reset

S11

S21

S12

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

K1

K2

Reset

K1

K2

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

S11

S21

S12

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

Stop

Start

K1

K2

Stop

Start

K1

K2

K1

K2

K1 K2

OSSD Input

Figure 31 - Monitored Reset

Figure 32 - Automatic Reset

34 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 35

Safety Mat Input

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

Reset

S11

S21

S12

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Safety

Mat

Safety

Mat

K1

K2

Reset

K1

K2

S11 S12

S21

S52

S22

S34

S33

A1

X5

13Y31

A2 142324

33 41

34 42Y32

MSR121RT

440R-J23102

S11

S21

S12

S22

S34A1 13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

+24V DC

24V Com

K2K1 K2K1

Safety

Mat

Safety

Mat

Stop

Start

K1

K2

Stop

Start

K1

K2

K1

K2

K1 K2

Figure 33 - Monitored Reset

MSR121RT Safety Relay Chapter 7

Response Time

Figure 34 - Automatic Reset

ATT EN TI ON : Because the response time of the MSR121RT safety relay is

faster than the CI safety relay, the safety distance must be examined closely

and adjusted if necessary.

Safety Relay Response Time

MSR121RT 15 ms (24V AC/DC)

CI 35 ms (mechanic al and OSSD inputs);

45 ms (safety mat inputs)

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 35

Page 36

Chapter 7 MSR121RT Safety Relay

Output Load Capability

The MSR121RT safety relay has a higher current capability than the CI safety

relay, as shown in Ta b l e 1 2

. See Output Load Capability on page 9 for a wiring

example of using interposing relays for applications where the load exceeds the

CI safety relay capability.

Table 12 - Current Capability

Load Type MSR121RT CI

AC Inductive

DC

Thermal (non-switching) 6 A 2 A

B300, AC-15

6 A/250V AC

R300, DC-13

6 A/240V DC

C300, AC-15

1.5 A

2 A @ 24V DC

36 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 37

MSR124RT Safety Relay

Chapter 8

Figure 35 - MSR124RT Safety Relay

We recommend replacing the MSR124RT safety relay with a CI and EM

safety relay.

The MSR124RT has the following design characteristics:

•Single- or dual-channel inputs

• Can accommodate mechanical and OSSD (light curtain) inputs

• Five electromechanical safety outputs

• One solid-state auxiliary output

• Reset can operate automatically or monitored manual.

The MSR124RT safety relay is a safety monitoring relay that provides versatile

inputs and monitoring capability with many safety outputs in a 100 mm

(3.93 in.) package.

The MSR124RT safety relay can be connected as either a single- or dualchannel safety gate or E-stop. It can also be connected to a light curtain that

provides cross fault detection.

The wiring configuration determines the Reset and output monitoring.

Automatic/manual reset can use a jumper or can be used to check operation of

the contacts. Monitored manual requires the use of a manually operated

normally open momentary switch to activate the outputs.

The outputs include five normally open safety rated outputs and one auxiliary

output. The safety outputs have independent and redundant internal contacts

to help verify the safety function. The auxiliary output is not safety rated and

must only be used for indication purposes.

Table 13 - Conversion Table

Supply Voltage MSR124 Cat. No. CI Cat. No. EM Cat. No.

24V AC/DC

115V AC/ 24V DC 440R-G23108

230V AC/24V DC 440R-G23107

(1) For 24V, the C I and EM safet y relays can o nly operate at 2 4V DC. When the M SR124RT is powe red by 24V AC, you must provide a n

AC/DC converte r.

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 37

(1)

440R-G23110

440R-S13R2 440R-EM4R2

Power Supply

Cat. No.

—

1606-XLP15E

Page 38

Chapter 8 MSR124RT Safety Relay

100 (3.93)

75

(2.95)

13 23 33 41

A1 S11 S12 L11

S21 S22 S34 A2

14 24 34 42

CI

1606-

XLP15E

MSR124RT

A1 S11 S12 S21 S23 S22 S12

A3+

13 23 33 43 53 81 A4

PE

Y1 Y2 (-) X1 X2

X5 X6 14 24 34 44 54 82 A2

45 (1.89)

119

(4.79)

67.5 (2.66)

33 34 43 44

A1 A2

L12 L11 X32

13 14 23 24

EM

+

N L

AC 100-240V

DC 24-28V 15W

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

+24V DC

24V Com

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23110

434453

54

Reset

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

Reset

Terminal Location and

PanelSpace

For DC applications, the combination of the CI and EM safety relay is smaller

than the MSR124RT safety relay. For AC applications, a 1606-XLP15E power

supply can be used; this combination still occupies less panel space than an

MSR124RT safety relay.

Figure 36 - Terminals and Panel Space [mm (in.)]

Wiring Schematics

38 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

The following schematics compare the wiring of your existing MSR module to

the recommended newer devices for each application that the existing device

provides.

Dual Channel

Figure 37 - Monitored Reset, DC Powered

Page 39

Figure 38 - Automatic Reset, DC Powered

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

+24V DC

24V Com

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23110

434453

54

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

+24V DC

24V Com

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23110

434453

54

Reset

Reset

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

+24V DC

24V Com

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23110

434453

54

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

Single Channel

Figure 39 - Monitored Reset, DC Powered

MSR124RT Safety Relay Chapter 8

Figure 40 - Automatic Reset, DC Powered

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 39

Page 40

Chapter 8 MSR124RT Safety Relay

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

+24V DC

24V Com

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23110

434453

54

Reset

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

Reset

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

+24V DC

24V Com

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23110

434453

54

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

Light curtain

Safezone, SC300

SensaGuard

OSSD1 OSSD2

120V or

240V AC

V AC Com

S11

S12

S21

S22

S34A1

K1

K2

K3K4

K5

13

L11A2 142324

33 41

34 42Y32

GSR CI

440R-S13R2

RESET

0

MM

AM

S11PES12 S22S21

Y1 X5 X6

X1

K1

K2

K3

K4

K5

A1S23

To PLC

A3+ 13

A4-A2Y2 142324

33 81

34 82 X2

MSR124RT

440R-G23108

440R-G23107

434453

54

Reset

K3 K4 K5K1 K2

To PLC

A1

L11

X32

L12 14 34 4424

13 33 4323

A2

GSR EM

440R-EM4R2

K1 K2 K3

K4 K5

Reset

+24V DC

L+

N-

24V Com

1606XLP15E

OSSD Inputs

Figure 41 - Monitored Reset, DC Powered

Figure 42 - Automatic Reset, DC Powered

40 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

AC Powered

A Bulletin 1606-XLP15E power supply can be used to provide the 24V DC to

power the CI and EM safety relays.

Figure 43 - AC Powered

Page 41

MSR124RT Safety Relay Chapter 8

Ambient Temperature (°C)

Current² x number of contacts paths, (A²)

Response Time

Output Load Capability

ATT EN TI ON : Because the MSR124RT safety relay is faster than the CI and EM

safety relays, the safety distance must be examined closely and adjusted if

necessary.

Safety Relay Response Time

MSR124RT 20 ms

CI 35 ms for the inputs, and 25

EM 35 ms

ms for the SWS to the EM

For example, the total response time of the EM safety relay is 25 + 35 = 60 ms.

The outputs of the CI safety relay may require interposing relays, depending in

the load being switched by the MSR124RT safety relay. See Output Load

Capability on page 9 for a wiring example of using interposing relays for

applications where the load exceeds the capability of the CI or EM safety relay.

Table 14 - Current Capability

Load Type MSR124RT CI EM

AC Inductive

DC

Thermal (non-switching)

A300, AC-15

5 A/250V AC

N300, DC-13

4 A @ 24V DC

10 A (max in one circuit)

See current limit curve in

Figure 4 4

C300, AC-15

1.5 A/250V AC

DC-13

2 A/24V DC

1 x 6 A 2 A

2 x B300, AC-15

4 A/250V AC

P300, DC-13

2 A/24V DC

The current through all contacts in the MSR124RT safety relay must be

adjusted to its current limit curve, which is shown in Figure 44

Figure 44 - Current Limit Curve

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 41

.

Page 42

Chapter 8 MSR124RT Safety Relay

Notes:

42 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 43

Index

B

benefit

8

GSR

C

capability

output load

change

8

wiring

concern

conversion

control unit

CU2

conversion

concern

CU2

control unit

current capability

CU2

MSR121RT 36

MSR124RT

MSR33

MSR35 29

MSR7C

MSR7R

MSR9T 21

8

11

8

11

14

41

25

18

18

M

MSR121RT

response time

safety relay

MSR124RT

response time

safety relay 37

9

MSR33

input simultaneity

response time

safety relay 23

MSR35

response time

safety relay

MSR7C

input impedance

response time

safety relay

MSR7R

input impedance

response time

safety relay

MSR9T

input impedance

input simultaneity

response time

safety relay 19

35

31

41

25

25

29

27

17

18

15

17

18

15

21

21

21

G

GSR

8

benefit

I

input impedance

17

MSR7C

MSR7R

17

MSR9T

MSR33

MSR9T

21

25

21

7

input simultaneity

introduction

L

location

wiring terminal

CU2

12

MSR121RT

MSR124RT 38

MSR33

MSR35

MSR7C 16

MSR7R

MSR9T

19

23

27

16

O

output load capability 9

14

CU2

MSR121RT

MSR124RT 41

MSR33

MSR35

MSR7C 18

MSR7R

MSR9T

36

25

29

18

21

P

panel space 8

12

CU2

MSR121RT

MSR124RT 38

MSR33

MSR35

8

31

MSR7C 16

MSR7R

MSR9T

31

23

27

16

19

Rockwell Automation Publication 440R-RM002B-EN-P - November 2018 43

Page 44

Index

R

response time 8

MSR121RT

MSR124RT

MSR33

25

29

MSR35

MSR7C

18

MSR7R

18

MSR9T 21

S

safety relay

MSR121RT

MSR124RT 37

MSR33

23

MSR35

27

MSR7C 15

MSR7R

15

MSR9T

wiring

CU2

MSR121RT

MSR124RT 38

MSR33

MSR35

MSR7C 16

MSR7R

MSR9T

8

panel

CU2

MSR121RT

MSR124RT 38

MSR33

MSR35

MSR7C 16

MSR7R

MSR9T

19

schematic

space

13

12

35

41

31

24

28

16

20

23

27

16

19

32

31

T

terminal location

12

CU2

MSR121RT

MSR124RT

MSR33

MSR35

MSR7C

MSR7R 16

MSR9T

time

response

31

38

23

27

16

19

8

W

wiring

8

change

terminal location

wiring schematic

13

CU2

AC powered

DC powered

MSR121RT 32

dual channel input

OSSD input

safety mat input 35

single channel input

MSR124RT

MSR33

MSR35

MSR7C

MSR7R

MSR9T 20

38

AC powered 40

dual channel

OSSD inputs

single channel 39

24

automatic reset

auxiliary output 25

manual reset

28

category IIIA 28

category IIIC

16

16

110/115/230V AC powered

24V AC/DC powered

8

13

13

32

34

33

38

40

24

24

28

20

20

44 Rockwell Automation Publication 440R-RM002B-EN-P - November 2018

Page 45

Page 46

Rockwell Automation Support

Use the following resources to access support information.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the

How Are We Doing? form at http://literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf

.

Technical Support Center

Knowledgebase Articles, How-to Videos, FAQs, Chat, User

Forums, and Product Notification Updates.

https://rockwellautomation.custhelp.com/

Local Technical Support Phone Numbers Locate the phone number for your country. http://www.rockwellautomation.com/global/support/get-support-now.page

Direct Dial Codes

Find the Direct Dial Code for your product. Use the code to

route your call directly to a technical support engineer.

http://www.rockwellautomation.com/global/support/direct-dial.page

Literature Library

Installation Instructions, Manuals, Brochures, and

Technical Data.

http://www.rockwellautomation.com/global/literature-library/overview.page

Product Compatibility and Download

Center (PCDC)

Get help determining how products interact, check

features and capabilities, and find associated firmware.

http://www.rockwellautomation.com/global/support/pcdc.page

.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation maintains current product environmental information on its website at http://ww w.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.

Allen-Bradley, Guardmaster, Minotaur, Rockwell Automation, Rockwell Software, Sipha, and Zero-Force Touch Buttons are trademarks of Rockwell Automation, Inc.

EtherNet/IP is a trademark of ODVA, Inc.

Trademarks not belonging to Rockwell Automation are property of their resp ective companies.

Publication 440R-RM002B-EN-P - November 2018

Supersedes Publication 440R-RM002A-EN-P – July 2018 Copyright © 2018 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...