Page 1

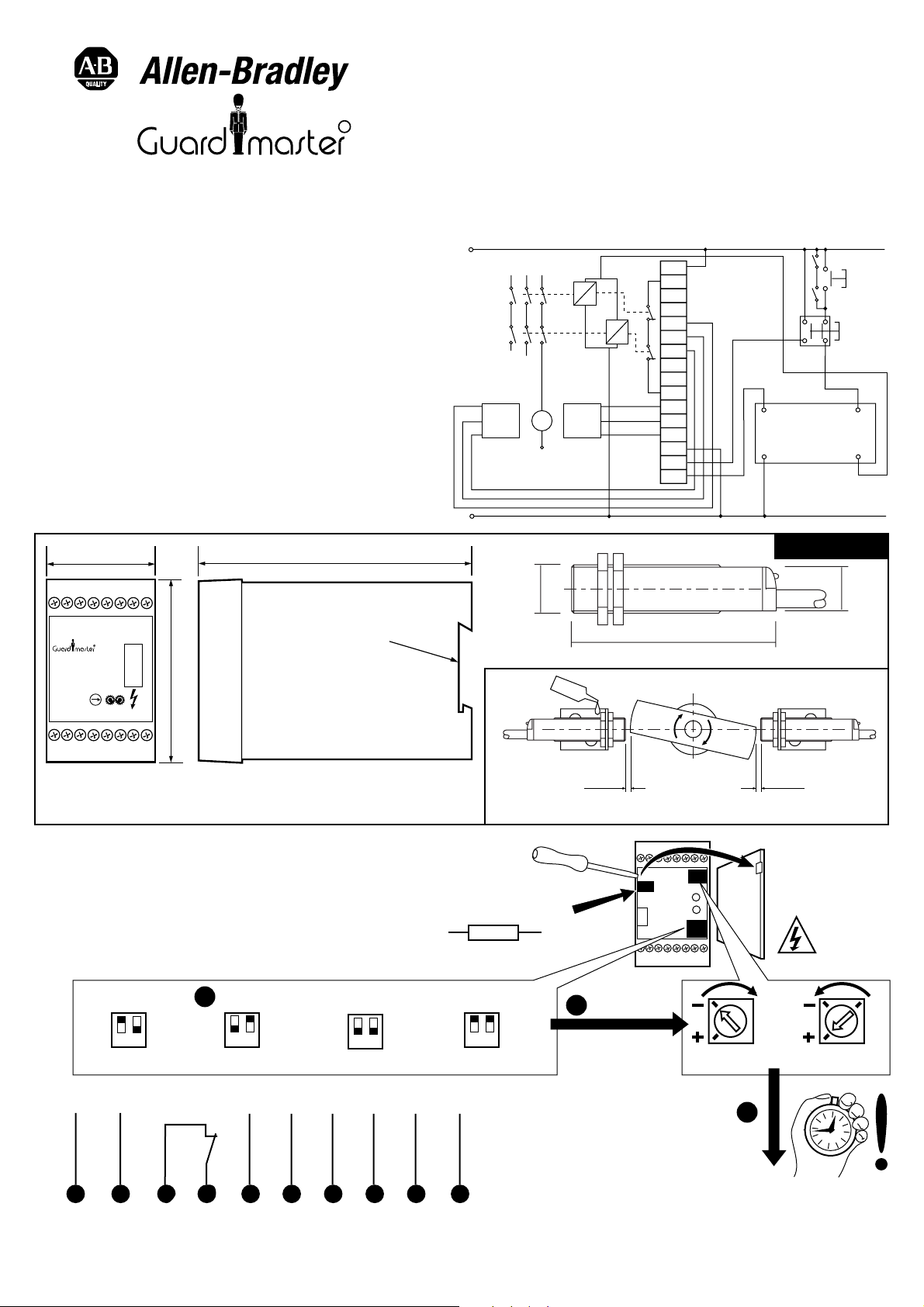

To gain access

to switches & fuse

flip off lid with

a small screwdriver.

Access to replaceable fuse

Isolate power

before opening.

Technical Specifications

CU2

STOP MOTION DETECTOR

TERMINAL CONNECTIONS

120

35mm DIN rail

mounting

45

73

Power supply:

Relay outputs:

Maximum switched:

current/voltage/load

Internal fuse:

Mounting:

Enclosure protection:

Terminal Isolation:

Ambient temperature:

Internal switches:

LED indication:

Standards conformity:

110/230V AC (Switch selectable)

or 24V AC/DC

2 N/O + 1N/C (TUV approved)

4A/250V AC/1000VA

2A/30V DC/60W

500mAT (replaceable)

35mm DIN Rail

IP 40 DIN 0470

IP 20 DIN 0470

-10°C to +55°C

110/230V AC selector

A, B, C, D timing range selector

Red = Power On

Red/Green LED : Red = Timing,

Green = Output

EN 60204, BS EN 292

SUPPLY

110/230

V AC

SELECTABLE

OR

24VAC/DC

13

23

3114

24

32A1 Y1

Y2

A2

TEST SAFETY

1

SAFETY

2

AUXILIARY

TIMER RANGE INTERNAL SWITCH SETTING

The CU2 provides a stopped motion detection system and is used together with CU2 sensors

to detect movement of a machine via the flywheel, gear or shaft etc. Upon energisation the

unit powers up (Red LED). When the sensor detects that the machine has stopped the CU2

integral timer operates and after the selected time delay the Signal LED turns Green. This

indicates that the safety outputs are closed and the CU2 will allow access to the machine,

typically via a solenoid operated guard interlocking switch with guard locking. In this way the

machine is at an ensured stop before access is possible. The auxiliary output is now "OFF".

The outputs and timer circuit are failsafe and cross monitored.

Time delay selection is a simple matter for a qualified person to set the DIP switches and fine

tune accordingly. In addition a replaceable plug-in 500mAT fuse is accessible behind the

removable panel (isolate the power before opening) preventing short circuits or overloads

from damaging the unit. Terminals YI - Y2 can be used to provide monitoring of the contactors

at power up of the CU2.

CU2 TIMER UNIT

CU2 SENSOR (2 REQUIRED)

500mA

Check time delay is set correctly

3

2 Fine tune

1 2

1 2

1 2

1 2

< 1 second to 10 seconds.

A

1 second to 39 seconds. 6 second to 5 mins 10 seconds. 48 second to 41 mins

BCD

1 Select general range

SUPPLY

SUPPLY

K1

K2

K1

K2

M

STOP

K1

K2

START

SOLENOID

LOCKING

SWITCH

A1

Y1

P

P

N

P

N

N

Y2

A2

14

13

NPN

INDUCTIVE

SENSOR

PNP

INDUCTIVE

SENSOR

NPN INDUCTIVE SENSOR

PNP INDUCTIVE SENSOR

L1 L2

L3

POWER

OUTPUT

MADE IN THE EC

Sicherheitstechnik

CU 2

EN60204

BS EN 292

A2 P N P Y2 14 24 32

A1 N P N Y1 13 23 31

SUPPLY

SUPPLY

Stop Motion Detection

BROWN BLACK BLUE

BROWN BLACK BLUE

M18

80

Ø16

DIMENSIONS

Minimum Maximum

SOLENOID

SAFETY

CONTACTS

6mm

max

6mm

max

LOCKTITE

THREADS

*

*

SENSOR INSTALLATION

Each sensor must have a separate

mounting bracket (not supplied)

Rotary movement

of machine

Part No: 70884

Change No. 13151 Issue 1

R

Loading...

Loading...