Page 1

User Manual

Guardmaster® EtherNet/IP Network Interface

Catalog Numbers 440R-ENETR

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, ControlLogix, CompactLogix, Guardmaster, SoftLogix, Rockwell Software, Rockwell Automation, RSLogix, RSLinx, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

• conventions used in this manual

Who Should Use this Manual

Use this manual if you are responsible for designing, installing, programming, or

troubleshooting control systems that use the 440R-ENETR Guardmaster®

EtherNet/IP network interface.

Purpose of this Manual

This manual is a reference guide for the 440R-ENETR Guardmaster

EtherNet/IP network interface, communications interface for Guardmaster

Safety Relays. It describes the procedures you use to install, wire, configure,

troubleshoot, and use these modules.

ATT ENTI ON: You must use firmware version 2 or later Guardmaster

Safety Relays equipped with the optical bus with the interface.

Firmware version 1 Guardmaster Safety Relays do not work with the

interface.

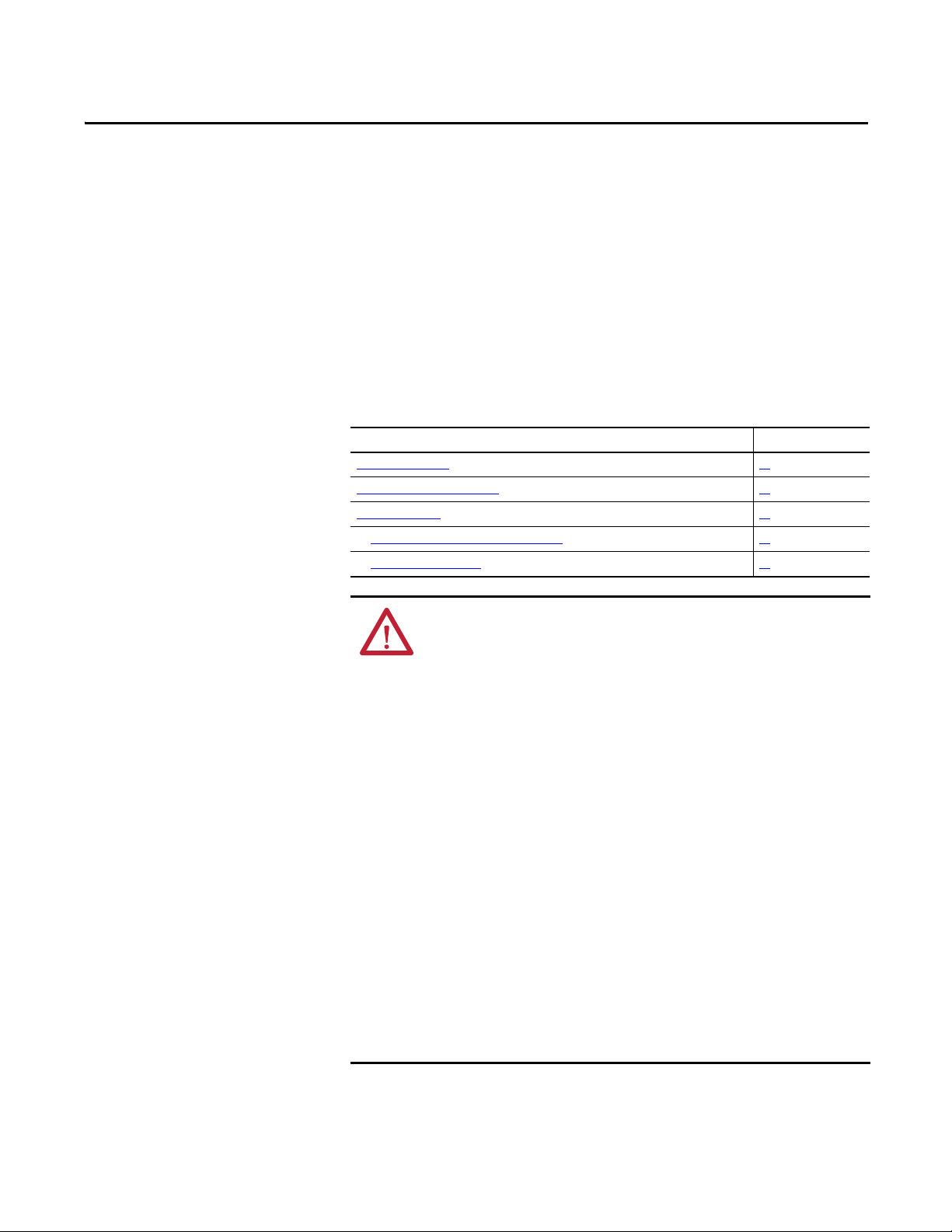

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

For Information About See This Publication Publication Number

Next Generation Safety Relays (GSR) Next Generation Safety Relays Overview Brochure EUSAFE-BR009A

Using EtherNet/IP for industrial control EtherNet/IP Design Considerations Reference Manual ENET-RM002

ControlLogix Ethernet communication interface modules ControlLogix EtherNet/IP Bridge Module Installation Instructions 1756-IN019

EtherNet/IP Modules in Logix5000 Control Systems User Manual ENET-UM001

ControlLogix chassis and power supplies installation ControlLogix Chassis and Power Supplies Installation Instructions 1756-IN005

ControlLogix systems ControlLogix System User Manual 1756-UM001

RSLinx RSLinx Classic Getting Results Guide LINX-GR001

440R-ENETR interface installation Guardmaster Ethernet/IP Network Interface Installation Instructions 440R-IN078

Installing an EtherNet/IP network EtherNet/IP Media Planning and Installation Manual ODVA

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 3

Page 4

Preface

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

Rockwell Software products contain extensive tutorials and help screens. We

recommend that you use these tutorials and help screens to learn about the

products.

For more information about Rockwell Software products, visit the Rockwell

Software website at

http://www.rockwellautomation.com/software/.

4 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 5

Preface

About the Interface

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Important Interface Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Up a System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RIUP Situations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Interface Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

What the Interface Does. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hardware/Software Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Use of the Common Industrial Protocol (CIP) . . . . . . . . . . . . . . . . . . . . . 10

Understand the Producer/Consumer Model . . . . . . . . . . . . . . . . . . . . . . . 10

Specify the Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . . 11

Support of Data Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Install a Guardmaster EtherNet/IP

Network Interface

Configure the Interface for Your

EtherNet/IP Network

Chapter 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mount the Interface on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Wiring Requirements and Recommendations. . . . . . . . . . . . . . . . . . . 16

Grounding Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Configuration Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Gateway Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Set the Network Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Set the Network Address for Guardmaster EtherNet/IP Interface 23

Use the Rockwell BootP/DHCP Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Save the Relation List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Use DHCP Software to Configure Your Interface . . . . . . . . . . . . . . . . . . 27

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Rockwell Automation Publication 440R-UM009A-EN-P - February 2014 5

Page 6

Table of Contents

Chapter 4

Automation Controller

Communications

Troubleshoot the Interface

EtherNet/IP Network Interface

Specifications

Interface Web Dialogs

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ethernet Messaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

I/O Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Logix Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

EtherNet/IP Network Configuration with Add-on Profiles . . . . . . 30

Accessing Module Data with Add-on Profiles . . . . . . . . . . . . . . . . . . . 32

Explicit Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Interpret the Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Status Indicators for the Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Appendix B

Work with the Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Work with the Browse LSR Devices Page. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Work with the Administrative Settings Pages . . . . . . . . . . . . . . . . . . . . . . . 42

Use the Network Configuration Page . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Use the E-mail Configuration Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Configure the RSLinx Ethernet

Communication Driver

Tag Definitions

Appendix C

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install the RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Configure the AB_ETH Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Configure the AB_ETH/IP Driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Appendix D

Tag Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Rockwell Automation Publication 440R-UM009A-EN-P - February 2014

Page 7

About the Interface

Chapter 1

Overview

This chapter provides an overview of the Guardmaster EtherNet/IP Network

Interface, its primary features, and how to use it.

You need to understand the concepts discussed in this chapter to configure your

interface and use it in an EtherNet/IP control system.

This table lists where to find specific information.

Top ic Pa ge

Important Interface Considerations 7

About the Interface 8

Power Up a System 8

RIUP Situations 8

Interface Features 8

What the Interface Does 9

Hardware/ Software Compatibility 9

Use of the Common Industrial Protocol (CIP) 10

Understand the Producer/Consumer Model 10

Specify the Requested Packet Interval (RPI) 11

Support of Data Connections 11

Important Interface Considerations

Before you begin using your interface, note the following important

considerations.

ATTENTION: You must use firmware version 2 or later Guardmaster Safety

Relays equipped with the optical bus with the interface. Firmware version 1

Guardmaster Safety Relays do not work with the interface.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 7

Page 8

Chapter 1 About the Interface

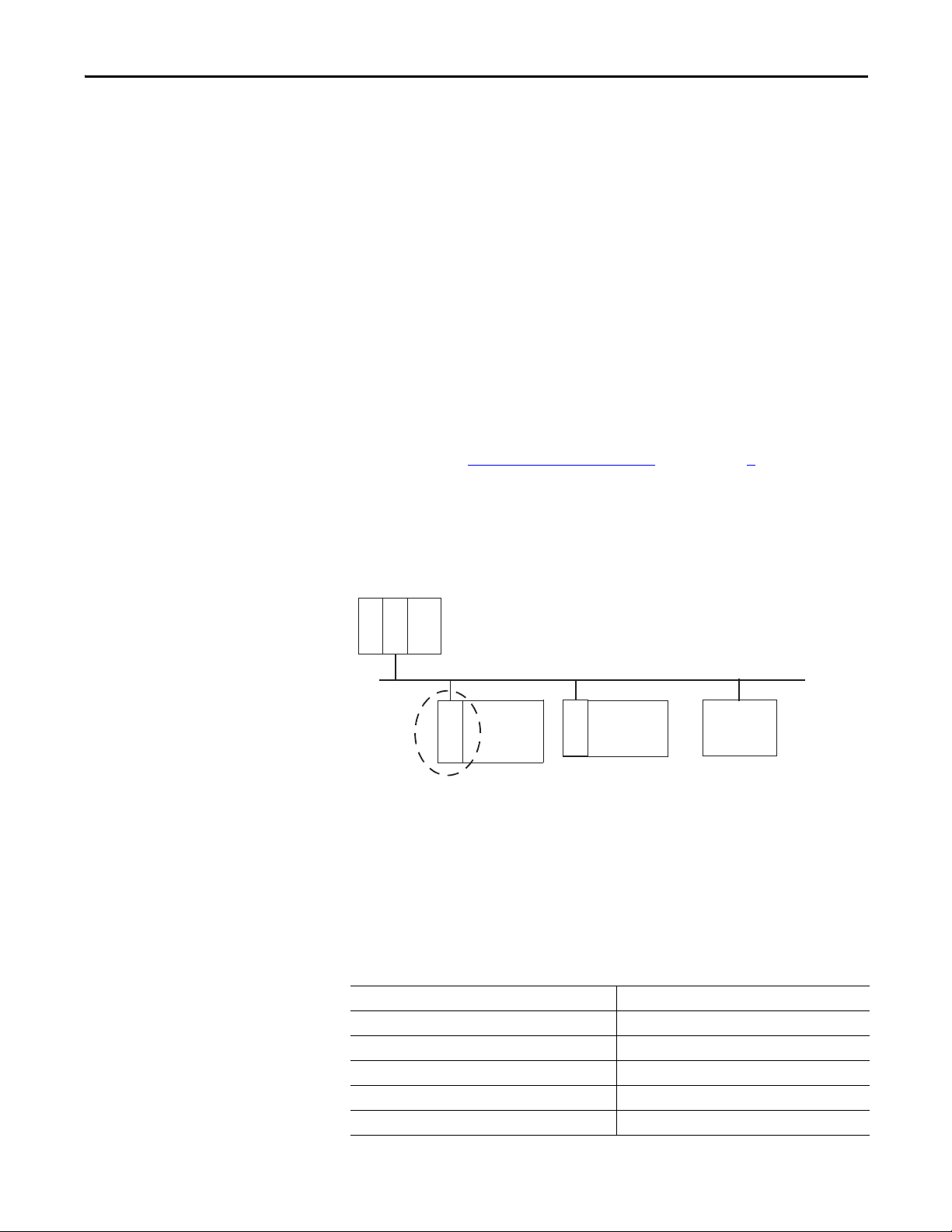

About the Interface

The Guardmaster EtherNet/IP Network Interface provide connectivity to

EtherNet/IP networks for Guardmaster Safety Relays.

The interface is for the optical bus backplane that provides connectivity through

two RJ-45 connectors for 2-port pass-through support of daisy chain or ring, and

the existing star and tree network topologies.

Power Up a System

Each time the interface is powered up, the adapter compares the number of I/O

modules present on its backplane to the chassis size value from non-volatile

memory. The adapter does not allow any I/O connection until the number of

I/O modules present equals the chassis size value minus one for the adapter itself.

On power up, the interface assigns an address to every Guardmaster Safety Relay

(up to six) in the backplane. The addressing starts from left to right with the

Guardmaster Safety Relay to the immediate right of the interface taking the first

address of 1.

RIUP Situations

Interface Features

You must observe the following rules for Guardmaster Safety Relay system

construction and the

• Actual Guardmaster Safety Relay identification (such as, electronic

keying) is done when connection establishment requests are received from

the controller or controllers. The interface will not allow any I/O

connections until the number and type of Guardmaster Safety Relays

match the configuration in the connection request.

• A Guardmaster Safety Relay removed under power disrupts

communication of the other Guardmaster Safety Relays in the system.

Connections to all safety relays are disallowed until the entire system,

including the interface, is power cycled to initiate re-addressing the system.

• If safety relays of different types are removed and returned to the wrong

locations, attempts to connect to these safety relays will fail during

verification of the electronic ID (providing that keying has not been

disabled).

• If safety relays of the same type are removed and returned to the wrong

locations, they accept connections from the controller or controllers once

they pass their electronic keying check.

Features of the interface include:

• Use of EtherNet/IP messages encapsulated within standard TCP/UDP/

IP protocol

• Common application layer with ControlNet and DeviceNet networks

• Interfacing via Category 5 rated twisted pair cable

removal and reinsertion of safety relays.

8 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 9

About the Interface Chapter 1

EtherNet/IP Network

Other

Network

Devices

ControlLogix

I/O

Guardmaster

Safety

Relays

L

7

X

E

N

B

T

E

N

E

T

R

E

N

B

T

• Half/full duplex 10 Mbit or 100 Mbit operation

• DIN Rail mounting for 440R-ENETR interface

• Communication from Guardmaster Safety Relays on the same DIN Rail

(mounted immediately to the right of the interface) as the 440R-ENETR

interface (when each safety relay is mounted to the right of the interface

and each unit is within 5 mm of the next) to controllers on the EtherNet/

IP network

• Communication supported by RSLinx® software

• IP address assigned via standard BootP or DHCP tools

• Configuration via RSLogix 5000 software

• No network scheduling required

• No routing tables required

• Support of connections from multiple controllers simultaneously

You must use RSLogix 5000 to configure these features. For more details on

configuration, see Configuration Requirements

on in chapter 3.

What the Interface Does

The interface performs the following primary tasks:

• Real-time input data (also known as implicit messaging) - the interface

serves as a bridge between Guardmaster Safety Relays and the network

• Support of messaging data for programming information (also known as

explicit messaging)

Hardware/Software Compatibility

The interface and the applications described in this manual are compatible with

the following firmware versions and

software releases.

Contact Rockwell Automation if you need software or firmware upgrades to use

this equipment

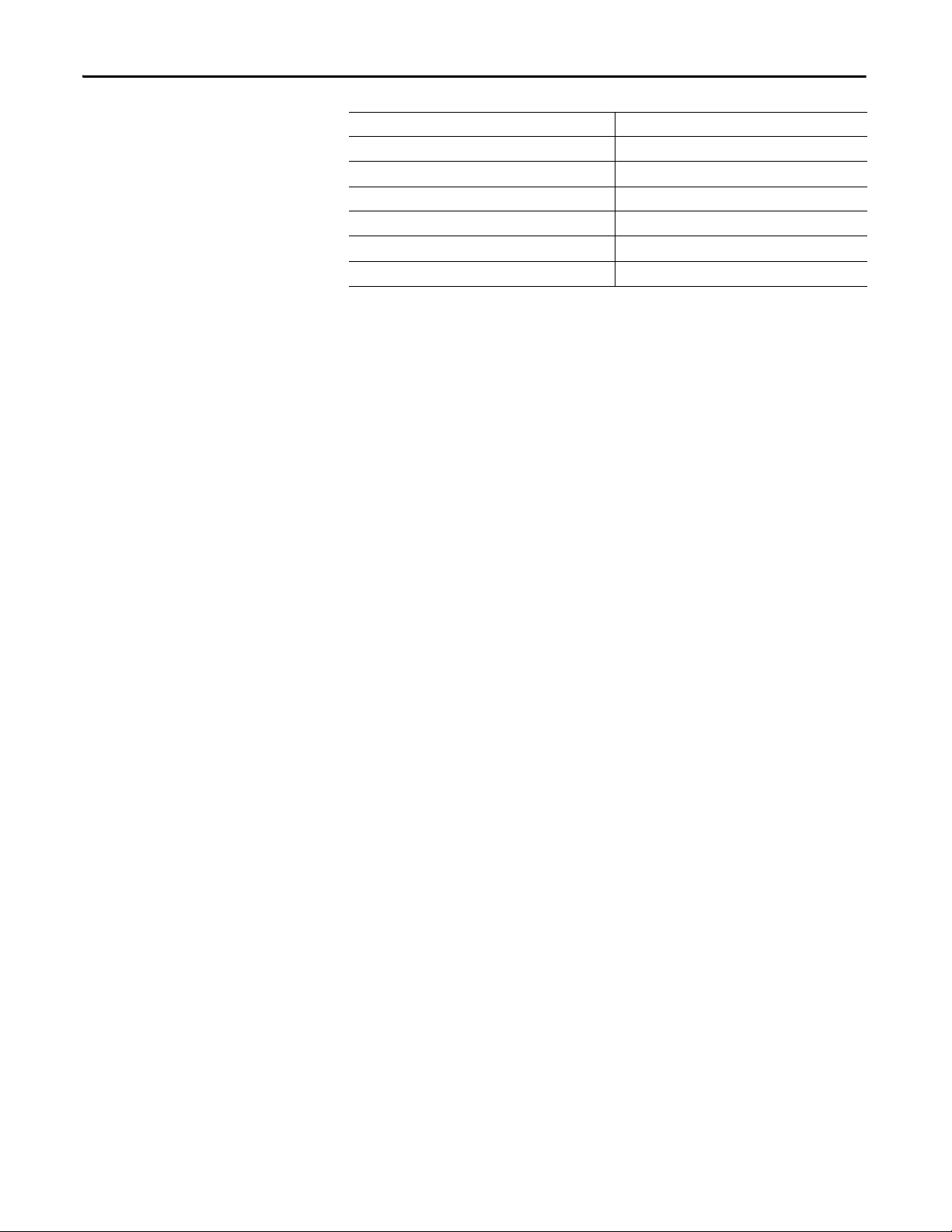

Product Firmware Revision/ Software Release

440R-ENETR interface 1.xx or later

1756-ENBT 2.3 or later

Logix controller 19 or later

RSLogix 5000 software 19 or later

RSLinx software 2.52 or later

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 9

Page 10

Chapter 1 About the Interface

Product Firmware Revision/ Software Release

GSR DI (Catalog number 440R-D22R2) 2 or later

GSR DIS (Catalog number 440R-D22S2) 2 or later

GSR EM (Catalog number 440R-EM4R3) 2 or later

GSR EMD (Catalog number 440R-EM4R2D) 2 or later

GSR GLP (Catalog number 440R-GL2S1P) 2 or later

GSR GLT (Catalog number 440R-GL2S2T) 2 or later

Use of the Common Industrial Protocol (CIP)

Understand the Producer/ Consumer Model

The adapter uses the Common Industrial Protocol (CIP). CIP is the application

layer protocol specified for EtherNet/IP, the Ethernet Industrial Protocol, as well

as for ControlNet and DeviceNet networks. It is a message-based protocol that

implements a relative path to send a message from the producing device in a

system to the consuming devices.

The producing device contains the path information that steers the message

along the proper route to reach its consumers. Since the producing device holds

this information, other devices along the path simply pass this information; they

do not store it.

This has the following significant benefits:

• You do not need to configure routing tables in the bridging modules,

which greatly simplifies maintenance and module replacement.

• You maintain full control over the route taken by each message, which

enables you to select alternative paths for the same end device.

The CIP producer and consumer networking model replaces the old source and

destination (master and slave) model. The producer and consumer model reduces

network traffic and increases speed of transmission. In traditional I/O systems,

controllers poll input modules to obtain their input status. In the CIP system,

input modules are not polled by a controller. Instead, they produce (multicast or

unicast) their data either upon a change of state (COS) or periodically.

Multicast is the default mode for version 17 Logix and earlier controllers and

unicast is the default for version 18 with multicast as a selectable option.

The frequency of update depends upon the options chosen during configuration

and where on the network the input module resides. The input module,

therefore, is a producer of input data, and the controller is a consumer of the data.

The controller also produces data for other controllers to consume. The

produced and consumed data is accessible by multiple controllers and other

devices over the EtherNet/IP network. This data exchange conforms to the

producer and consumer model.

10 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 11

About the Interface Chapter 1

Specify the Requested Packet Interval (RPI)

Support of Data Connections

The Requested Packet Interval or RPI is the update rate specified for a particular

piece of data on the network. The RPI can be specified for the interface and

include all of the Guardmaster Safety Relays in the system.

When you add an interface to the I/O configuration of a controller, you must

enter the RPI as a parameter. This value specifies how often to produce the data

for that device. For example, if you specify an RPI of 50 ms, it means that every

50 ms the device should send its data to the controller and the controller should

send the consumed (output) data to the device.

Use RPIs only for devices that exchange data. For example, a ControlLogix

EtherNet/IP bridge module in the same chassis as the controller does not require

an RPI, because it is not a data-producing member of the system. Its use is only as

a bridge to remote racks.

TheGuardmaster EtherNet/IP Network Interface supports data connections.

A data connection to the interface is a grouping of data from one or more

Guardmaster Safety Relays into a single block of data sent over a single

connection at the same data rate.

Chapter Summary

See the EtherNet/IP Design Considerations Reference Manual,

publicationENET-RM002

In this chapter, you were introduced to the features of the Guardmaster

EtherNet/IP Network Interface, and considerations for installation and usage.

for more information on connections.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 11

Page 12

Chapter 1 About the Interface

Notes:

12 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 13

Install a Guardmaster EtherNet/IP Network Interface

Chapter 2

Overview

This chapter describes how to physically install a Guardmaster EtherNet/IP

network interface; and how to mount the interface to DIN Rail.

This table lists where to find specific information.

Top ic Pag e

Installation Summary 14

Mount the Interface on a DIN Rail 15

Install the Interface 16

Wiring Requirements and Recommendations 16

Grounding Considerations 17

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in IEC

60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is not intended for use in residential environments and may

not provide adequate protection to radio communication services in such

environments.

This equipment is supplied as open-type equipment. It must be mounted

within an enclosure that is suitably designed for those specific environmental

conditions that will be present and appropriately designed to prevent

personal injury resulting from accessibility to live parts. The enclosure must

have suitable flame-retardant properties to prevent or minimize the spread

of flame, complying with a flame spread rating of 5VA or be approved for the

application if nonmetallic. The interior of the enclosure must be accessible

only by the use of a tool. Subsequent sections of this publication may contain

additional information regarding specific enclosure type ratings that are

required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-

4.1, for additional installation requirements

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of

protection provided by enclosures

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 13

Page 14

Chapter 2 Install a Guardmaster EtherNet/IP Network Interface

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause

internal damage and affect normal operation.

Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static

• Wear an approved grounding wrist strap

• Do not touch connectors or pins on component boards

• Do not touch circuit components inside the equipment

• Use a static-safe workstation, if available

• Store the equipment in appropriate static-safe packaging when not in use

Installation Summary

Do these steps to install a network interface.

1. Mount the Interface on a DIN Rail.

2. Install the Interface.

SHOCK HAZARD: To prevent electrical shock, disconnect the EtherNet/IP

network interface from it power source before installing or servicing. Install in

suitable enclosure. Keep free from contaminants.

ATTENTION: An incorrectly applied or installed EtherNet/IP network

interface can result in damage to the components or reduction in product

life. Wiring or application errors (e.g. supplying incorrect or inadequate

supply voltage or operating/storing in excessive ambient temperatures) may

result in malfunction of the product.

ATTENTION: Only personnel familiar with the EtherNet/IP network interface

and associated machinery should plan to install, set up, and maintain the

system. Failure to comply may result in personal injury and/or equipment

damage.

ATTENTION: This is a Class A product. In a domestic environment, this

product may cause radio interference in which case the user may be required

to take adequate measures.

14 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 15

Install a Guardmaster EtherNet/IP Network Interface Chapter 2

5

1

2

3

4

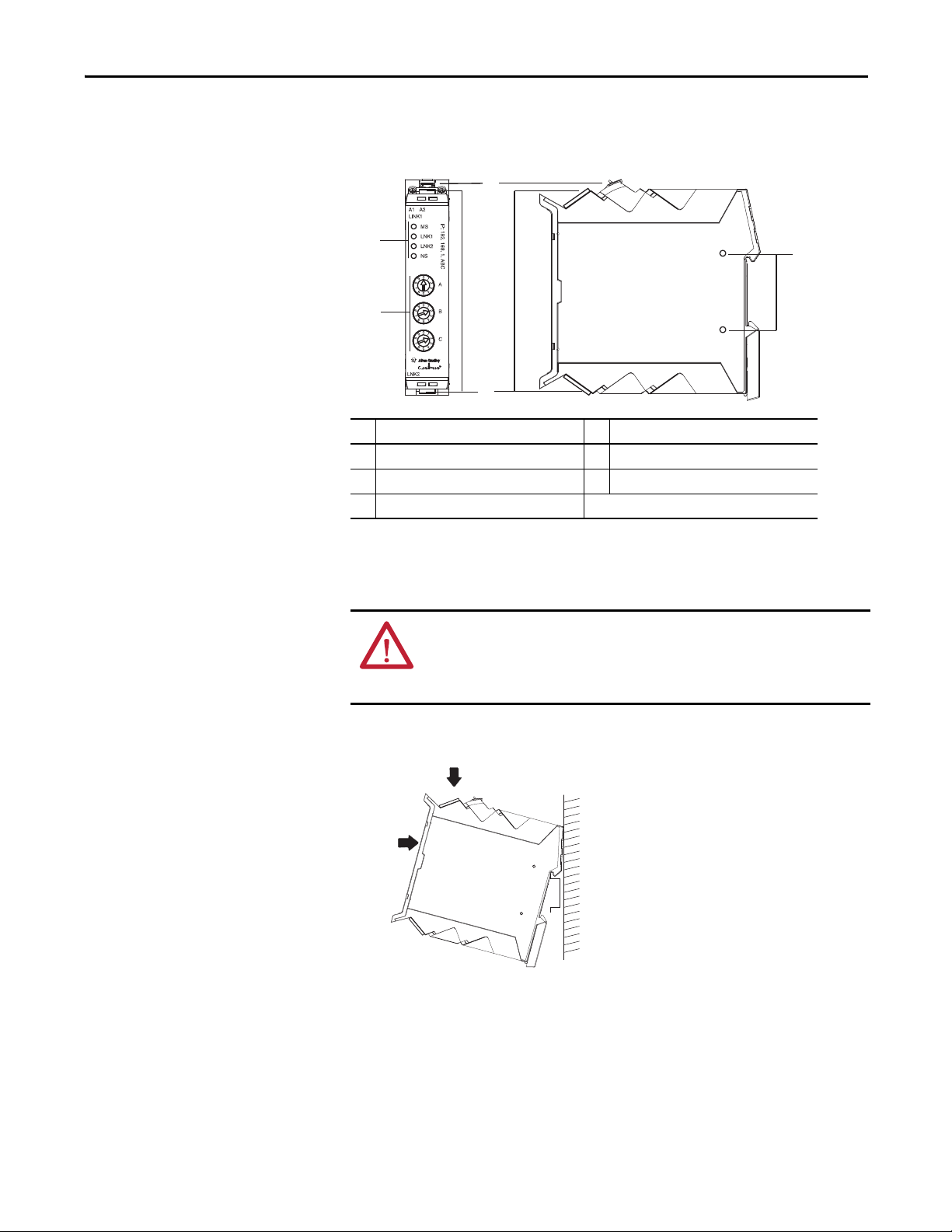

Use the figure to identify the external features of your interface.

Figure 1 - Physical Features of the 440R-ENETR Interface

Description Description

1 Removable terminal block 4 Network address rotary switches

2 Status indicators 5 Ethernet network RJ-45 connectors

3 Optical communications link

Mount the Interface on a DIN Rail

Follow these steps to mount the interface on a DIN Rail.

ATTENTION: To avoid overheating, the unit must be mounted vertically and

requires 37.4mm (1.5in.) of clearance at the top and the bottom to allow

adequate ventilation. The temperature ratings for the unit will be derated if

not mounted in this manner.

1. Position the adapter vertically above an IEC standard (35x7.5x1 mm) tophat DIN Rail at a slight angle (DIN Rail: Cat. No. 199-DR1; 46277-3).

2. Press down firmly to install the interface on the DIN Rail.

3. Set the network address switches to the desired value. See Set the Network

Address in chapter 3 for more details on setting the IP address.

To remove your interface from the DIN Rail, pry the DIN Rail latch downwards

until there is separation from the latch and the DIN Rail.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 15

Page 16

Chapter 2 Install a Guardmaster EtherNet/IP Network Interface

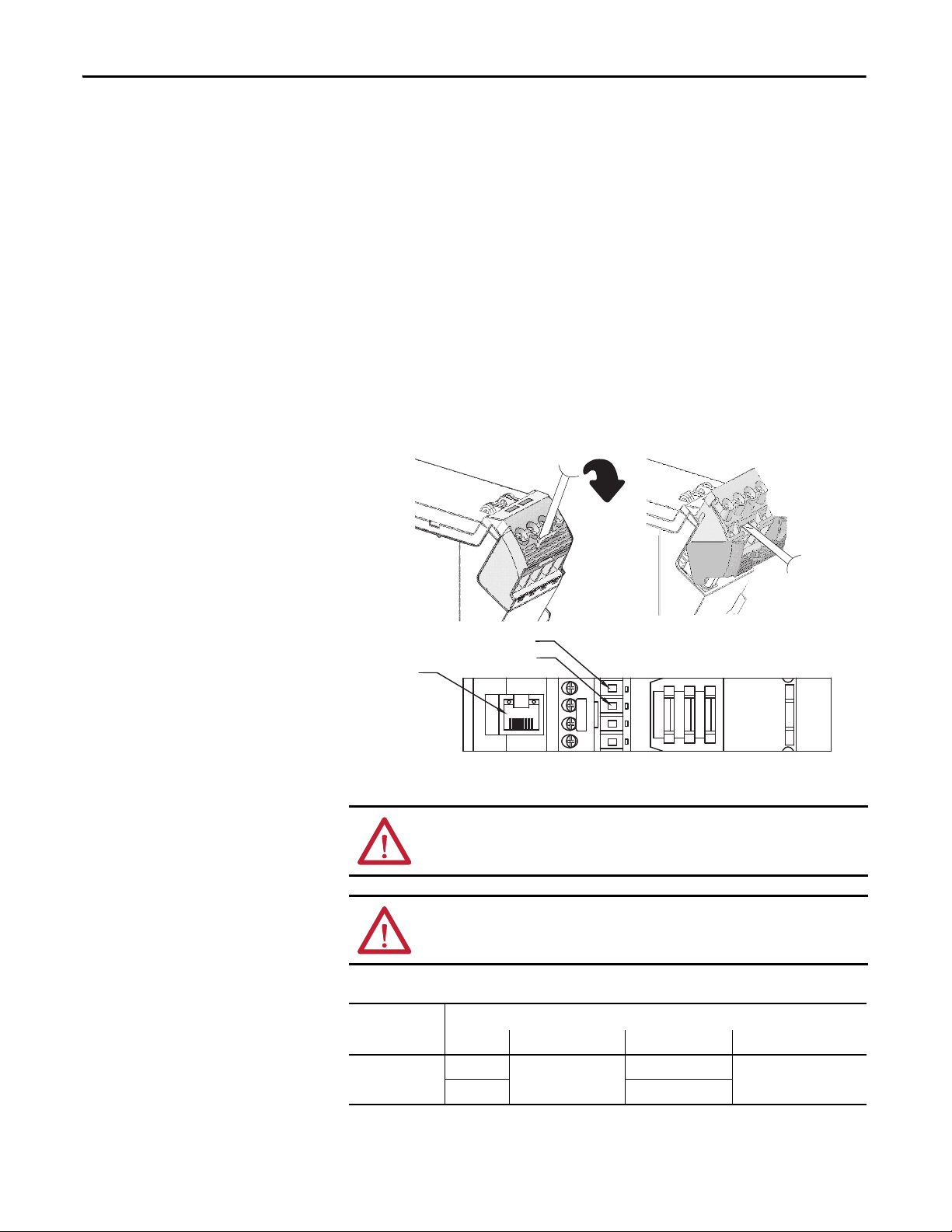

Install the Interface

Install the interface to the left of Guardmaster Safety Relays equipped with an

optical communication bus. There must be no more than 5 mm horizontal

separation between two adjacent relays for the optical communication bus to

operate properly.

Wiring Requirements and Recommendations

• Allow for at least 50 mm (2 in.) between I/O wiring ducts or terminal

strips and the interface.

• Separate wiring by signal type. Bundle wiring with similar electrical

characteristics together.

• Label wiring to all devices in the system. Use tape, shrink-tubing, or other

dependable means for labeling purposes. In addition to labeling, use

colored insulation to identify wiring based on signal characteristics. For

example, you may use blue for DC wiring and red for AC wiring.

Refer to the following illustration to wire the interface.

A1 = Supply

Ethernet

RJ-45

connector

A2 = Common

ATTENTION: Do not connect 120/240V AC power to the A1/A2 DC supply.

ATTENTION: Do not wire more than two conductors on any single terminal.

Table 1 - Wire Requirements

Type Min Max

440R- ENETR

Solid 0.14 mm2 (26 AWG) 2.5 mm2 (14 AWG) Rated @ 90 ºC (194 ºF)

Stranded 1.5 mm

TOP VIEW

Wire Size

2

(16 AWG)

insulation max

16 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 17

Install a Guardmaster EtherNet/IP Network Interface Chapter 2

Grounding Considerations

The grounding and bonding must be of equal potential between all devices in the

communication coverage area.

ATTENTION: If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

Chapter Summary

In this chapter, you learned how to install and wire your Guardmaster EtherNet/

IP network interface. The following chapter describes how to configure your

Guardmaster EtherNet/IP network interface to communicate on the EtherNet/

IP network by providing an IP address, gateway address, and Subnet mask.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 17

Page 18

Chapter 2 Install a Guardmaster EtherNet/IP Network Interface

Notes:

18 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 19

Chapter 3

Configure the Interface for Your EtherNet/ IP Network

Overview

Before using your interface in an EtherNet/IP network, you need to configure it

with an IP address, subnet mask, and optional Gateway address. This chapter

describes these configuration requirements and the procedures for providing

them. Here are ways you can do this:

• Use the Rockwell BootP/DHCP utility, version 2.3 or later, that ships

with RSLogix 5000 or RSLinx software.

– You can also use this utility to reconfigure a device with an IP address

you must change.

• Use a

• Use the Network Address rotary switches.

• Have your network administrator configure the interface via the network

See the table for a list of where to find information in this chapter.

Top ic Pa ge

Configuration Requirements 20

IP Address 20

Gateway Address 21

Subnet Mask 22

Set the Network Address 23

Set the Network Address for Guardmaster EtherNet/IP Interface 23

Use the Rockwell BootP/DHCP Utility 24

Save the Relation List 26

Use DHCP Software to Configure Your Interface 27

third party DHCP server.

DHCP server.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 19

Page 20

Chapter 3 Configure the Interface for Your EtherNet/IP Network

Class A

Class B

Class C

Network ID

Host ID

Host ID

Host ID

0

0

0

10

0

110

78

15 16

31

31

3123 24

Network ID

Network ID

EXAMPLE

Configuration Requirements

Before you can use your interface, you must configure its IP address, its subnet

mask, and, optionally, a gateway address. You can use the Rockwell BootP utility,

version 2.3 or later, to perform the

configuration. You can also use a DHCP

server or the network address switches to configure these parameters.

ATTENTION: You must use firmware version 2 or later Guardmaster Safety

Relays equipped with the optical bus with the interface. Firmware version 1

Guardmaster Safety Relays do not work with the interface.

If you need to reset the interface to factory defaults, set the network address

rotary switches to 888 and perform a power cycle to the device.

IP Address

The IP address identifies each node on the IP network (or system of connected

networks). Each TCP/IP node on a network (including the interface) must have

a unique IP address.

The IP address is 32 bits long and has a Network ID part and Host ID part.

Networks are classified A, B, C, (or other). The class of the network determines

how an IP address is formatted

.

You can distinguish the class of the IP address from the first integer in its dotteddecimal IP address as follows:

Range of first integer Class Range of first integer Class

0 1…127 A 192…223 C

128…191 B 224… 255 other

Each node on the same physical network must have an IP address of the same

class and must have the same network ID. Each node on the same network must

have a different Host ID thus giving it a unique IP address.

IP addresses are written as four decimal integers (0…255) separated by periods

where each integer gives the value of one byte of the IP address

For example, the 32-bit IP address:

10000000 00000001 00000000 00000001 is written as

128.1.0.1

20 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

.

Page 21

Configure the Interface for Your EtherNet/IP Network Chapter 3

Network 1

Network 2

128.1.0.1

128.2.0.1 128.2.0.2 128.2.0.3

128.1.0.2

A

B

G

C

Gateway Address

This section applies to multi-network systems. If you have a single network

system, refer to the next section.

The Gateway Address is the default address of a network. It provides a single

domain name and point of entry to the site. Gateways connect individual physical

networks into a system of networks.

When a node needs to communicate with a node on another network, a gateway

transfers the data between the two networks. The figure shows gateway G

connecting Network 1 with Network 2.

When host B with IP address 128.2.0.1 communicates with host C, it knows

from C’s IP address that C is on the same network. in an Ethernet environment,

B can then resolve C’s IP address into a hardware address (MAC address) and

communicate with C directly.

When host B communicates with host A, it knows from A’s IP address that A is

on another network (the network IDs are different). In order to send data to A, B

must use the IP address of the gateway connecting the two networks. In this

example, the gateway’s IP address on Network 2 is 128.2.0.3.

The gateway has two IP addresses (128.1.0.2 and 128.2.0.3). The first must be

used by hosts on Network 1 and the second must be used by hosts on Network 2.

To be usable, a gateway of a host must be addressed using a network ID matching

its own.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 21

Page 22

Chapter 3 Configure the Interface for Your EtherNet/IP Network

EXAMPLE

These two bits of the Host ID are used to extend the

netdwork ID.

Network 1

Network 2.1

Network 2.2

A

BC

DE

128.1.0.2

128.1.0.1

128.2.64.3

128.2.128.2

128.2.64.1 128.2.64.2

128.2.128.3

128.2.128.1

G2

G

Subnet Mask

The subnet mask is used for splitting IP networks into a series of subgroups, or

subnets. The mask is a binary pattern that is matched up with the IP address to

turn part of the Host ID address field into a field for subnets

Two bits of the Class B host ID are used to extend the network ID. Each unique

combination of bits in the part of the Host ID where subnet mask bits are 1

specifies a different physical network.

.

Take Network 2 (a Class B network) in the previous

example and add another physical network. Selecting the

following subnet mask would add two additional

network ID bits, allowing for four physical networks:

11111111 11111111 11

000000 00000000 = 255.255.192.0

The new configuration is:

A second network with Hosts D and E was added. Gateway G2 connects

Network 2.1 with Network 2.2.

Hosts D and E will use Gateway G2 to communicate with hosts not on

Network 2.2.

Hosts B and C will use Gateway G to communicate with hosts not on

Network 2.1.

When B is communicating with D, G (the configured Gateway for B) will route

the data from B to D through G2.

22 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 23

Configure the Interface for Your EtherNet/IP Network Chapter 3

This example shows the network address set

at 163.

Set the Network Address

The interface ships DHCP-enabled and with the switches set to 999. To change

the network address, do the following.

Set the Network Address for Guardmaster EtherNet/IP Interface

• Adjust the switches in front of the module

• Use a Dynamic Host Configuration Protocol (DHCP) server such as

Rockwell Automation BootP/DHCP

• Retrieve the IP address from non-volatile memory

The interface reads the switches first to determine if the switches are set to a valid

number. Set the network address by adjusting the three switches on the front of

the interface.

Figure 2 - Network Address Example

A

0

1

9

8

7

2

3

4

6

5

B

0

1

9

8

7

2

3

4

6

5

0

9

8

7

6

5

Use a small blade screwdriver to rotate the switches. Line up the small notch on

the switch with the number setting you wish to use. Valid settings range from

001…254.

When you use the switches to assign an address and set it to 001, the interface

gateway address is set to 0.0.0.0. and the subnet mask is 255.255.255.0 . When

you use the switches to assign an address and set it to a valid number between

002...254, the interface gateway address is set to 192.168.1.1.

If the switches are set to an invalid number (for example, 000 or a value greater

than 254 excluding 888), the interface checks to see if DHCP is enabled. If

DHCP is enabled, the interface requests an address from a DHCP server. The

DHCP server also assigns other Transport Control Protocol (TCP) parameters.

If DHCP is not enabled, the interface uses the IP address, along with other TCP

configurable parameters, stored in non-volatile memory.

C

1

2

3

4

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 23

Page 24

Chapter 3 Configure the Interface for Your EtherNet/IP Network

Use the Rockwell BootP/ DHCP Utility

The Rockwell BootP/DHCP utility is a standalone program that incorporates

the functionality of standard BootP software with a user friendly graphical

interface. It is located in the Utils directory on the RSLogix5000 software

installation CD. The interface must have DHCP enabled (factory default and

the network address switches set to an invalid value) to use the utility.

To configure your interface using the BootP utility, perform the following steps:

1. Run the BootP software.

In the BOOTP Request History panel you see the hardware addresses of

devices issuing BootP requests.

24 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 25

Configure the Interface for Your EtherNet/IP Network Chapter 3

2. Double-click the hardware address of the device you want to configure.

The New Entry dialog appears with the device’s Ethernet Address (MAC).

3. Enter the IP Address you want to assign to the device and click OK. The

device is added to the Relation List, displaying the Ethernet Address

(MAC) and corresponding IP Address, Hostname, and Description (if

applicable).

When the address displays in the IP Address column in the Request History

section, the IP address assignment has been made.

4. To make this configuration static in the device, highlight the device in the

Relation List panel, and click the Disable BOOTP/DHCP button.

When power is cycled to the device, it uses the configuration saved in nonvolatile memory and will not issue a DHCP request.

5. To enable DHCP for a device with DHCP disabled, highlight the device

in the Relation List, and click the Enable DHCP button.

You must have an entry for the device in the Relation List panel to reenable DHCP.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 25

Page 26

Chapter 3 Configure the Interface for Your EtherNet/IP Network

Save the Relation List

You can save the Relation List for later use. To save the Relation List, perform the

following steps:

1. Select Save As... from the File menu.

The Save As dialog appears.

2. Select the folder where you want to save the Relation List.

3. Enter a File name for the Relation List, for example, control system

configuration, and click Save.

You can leave the Save as type at the default setting: Bootp Config Files

(*.bpc).

You now have the option to open the file containing the Relation List at a

later session.

26 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 27

Configure the Interface for Your EtherNet/IP Network Chapter 3

Use DHCP Software to Configure Your Interface

DHCP (Dynamic Host Configuration Protocol) software automatically assigns

IP addresses to client stations logging onto a TCP/IP network.

DHCP is based on BootP and maintains some backward compatibility. The

main difference is that BootP was designed for manual configuration, while

DHCP allows for dynamic allocation of network addresses and configurations to

newly attached devices.

Be cautious about using DHCP software to configure your interface. A DHCP

server typically assigns a finite lease time to the offered IP address.

When 50% of the leased time has expired, the interface attempts to renew its IP

address with the DHCP server.

The possibility exists that the interface will be assigned a different IP address,

which would cause the interface to cease communicating with the ControlLogix

controller.

ATTENTION: To avoid unintended control or loss of control, the interface

must be assigned a fixed IP address. A dynamically provided IP address

should be used only at initial configuration. If a DHCP server is used, it must

be configured to assign the same IP address to your interface.

Failure to observe this precaution may result in unintended machine motion or

loss of process control.

Chapter Summary

This chapter provided instructions on how to configure Guardmaster

EtherNet/IP Interface modules through the RSLogix 5000 software and

included information on configuration requirements and setting the network

address.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 27

Page 28

Chapter 3 Configure the Interface for Your EtherNet/IP Network

Notes:

28 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 29

Automation Controller Communications

Chapter 4

Overview

Ethernet Messaging

This chapter describes and gives examples of how each type of EtherNet/IP

messaging, I/O messaging and Explicit messaging, is used.

Top ic Pag e

Ethernet Messaging

I/O Messaging 29

Logix Configuration 29

EtherNet/IP Network Configuration with Add-on Profiles 30

Accessing Module Data with Add-on Profiles 32

Explicit Messaging 33

The Guardmaster EtherNet/IP network interface supports two types of

EtherNet/IP messaging.

• I/O Messaging – Used for deterministic EtherNet/IP communications

with ControlLogix®, CompactLogix™, SoftLogix™, and EtherNet/IP

scanners. Its primary use is to read and write I/O data for control purposes.

• Logic Explicit Messaging – Used for non-deterministic communications

in which data is not critical for control. Logic explicit messages have a

lower priority compared to I/O messages and are used to read and write

non-critical data.

29

I/O Messaging

RSLogix™ 5000 software is used to configure I/O messaging between an

automation controller and a Guardmaster EtherNet/IP network interface on an

EtherNet/IP network.

The following example provides the steps necessary to configure a Logix

controller for I/O messaging.

Logix Configuration

An Add-on Profile is available for the Guardmaster EtherNet/IP network

inferface and can be used with RSLogix 5000 version 19 and higher. The profile

can be downloaded from:

http://support.rockwellautomation.com/controlflash/LogixProfiler.asp

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 29

Page 30

Chapter 4 Automation Controller Communications

An existing project can be used or a new project can be created to configure

EtherNet/IP I/O messaging. To create a new project, perform the following

steps.

1. Select File > New from the RSLogix 5000 menu bar.

2. Select the controller type. Then, enter a name for the project and click

Next.

3. Select the Security Authority and enter a description. Then, click Finish.

EtherNet/IP Network Configuration with Add-on Profiles

After the controller configuration, the Guardmaster EtherNet/IP Network

Interface has to be added to the I/O Configuration.

1. Right-click on the EtherNet/IP bridge within the I/O Configuration

folder, then select New Module to open the Select Module Type window

30 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 31

Automation Controller Communications Chapter 4

2. Select the 440R-ENETR, then click Create.

3. Enter a name for the Guardmaster EtherNet/IP network interface. The

name will create tags in RSLogix 5000 that can be used to read data from

the Guardmaster Safety Relays being scanned by the Guardmaster

EtherNet/IP network interface.

4. Enter the IP address of the Guardmaster EtherNet/IP network interface.

5. Select Change to configure the Guardmaster safety relays monitored by

the Guardmaster EtherNet/IP network interface.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 31

Page 32

Chapter 4 Automation Controller Communications

6. Right-click on an <Empty Slot> in the Module Definition dialog box and

select the Guardmaster Safety Relay that is physically located in that slot

position next to the Guardmaster EtherNet/IP network interface.

Note: Empty slots between Guardmaster Safety Relays are not supported

by the Guardmaster EtherNet/IP network interface at run-time. Your

configuration must represent the actual Safety Relays present beginning

with the first slot and without any empty slots.

7. Once all Guardmaster Safety Relays monitored by the Guardmaster

EtherNet/IP network interface have been added, Click OK.

8. Click OK at the next window to have RSLogix 5000 create the predefined

tags. The Guardmaster EtherNet/IP network interface will now show as a

module in the I/O Configuration folder.

Accessing Module Data with Add-on Profiles

With both the Logix controller and the EtherNet/IP network configured, the

Logix controller can exchange data with the Guardmaster EtherNet/IP network

interface.

1. Open the Controller tags window.

2. Select the Monitor Tags tab.

In the previous example, predefined input tags were created for the GSR

DIS module in slot 1 of the configuration. For detailed information on the

individual tag members and their meaning, see Appendix D

.

32 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 33

Automation Controller Communications Chapter 4

Explicit Messaging

Data can be accessed from the Guardmaster EtherNet/IP network interface by

non-Logix automation controllers that support EtherNet/IP explicit messaging.

This example shows the configuration of an explicit message from a MicroLogix™

1100 controller to the Guardmaster EtherNet/IP network interface:

1. Set up the MSG instruction to read the data assembly from the

Guardmaster EtherNet/IP network interface by configuring the following

fields.

– Channel: 1 (Integral) (this is the Ethernet port)

– Communication Command: CIP Generic

– Data Table Address (Receive): N7:0 (choose an address that supports

60 bytes)

– Size in Bytes (Receive): 60

– Extended Routing Info File(RIX): RIX10:0

– Service: Read Assembly

– Class: 04

– Instance: 100 (64h)

– Attribute: 03

2. Set the Ethernet network address of the Guardmaster EtherNet/IP

network interface as the target of the message instruction:

Appendix D

describes the individual members of the data returned from

the message instruction.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 33

Page 34

Chapter 4 Automation Controller Communications

Notes:

34 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 35

Troubleshoot the Interface

Module Status

Link 1 Activity/Status

Network Status

Link 2 Activity/Status

Chapter 5

Overview

Interpret the Status Indicators

This chapter describes the different status indicators available in the Guardmaster

EtherNet/IP network interface and how to interpret these indicators to help

troubleshoot the module.

The following table lists where to find specific information

Top ic Pa ge

Interpret the Status Indicators

Status Indicators for the Interface 35

Read this chapter to learn about what the LED status indicators mean for the

Guardmaster EtherNet/IP Network Interface.

35

Status Indicators for the Interface

The following describes the status indicators on the 440R-ENETR.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 35

Page 36

Chapter 5 Troubleshoot the Interface

Table 2 - Status Indicators for 440R-ENETR Interface

Status Description

Module status Off No power applied to device

Solid green Device operating normally

Flashing green Device needs commissioning due to missing, incomplete, or incorrect configuration.

Flashing red/green Module self-test

Flashing red Recoverable fault.

Solid red Unrecoverable fault, may require device replacement.

Network status Off Device is not online

Flashing green Device is online but has no CIP connections in the established state.

Solid green Device online and has CIP connections in the established state.

Flashing red One or more CIP connections in timed-out state.

Solid red Duplicate IP address detected.

Link 1 or Link 2 Activity / Status Off No link established.

Solid green One of the following conditions exist:

Flashing green Transmit or receive activity present on indicated port @ 100 Mbps.

Solid yellow One of the following conditions exist:

Flashing yellow Transmit or receive activity present on indicated port @ 10 Mbps.

Complete firmware update, verify address switches. Check for monitored safety relay fault.

- Device has not completed Dup_MAC_ID test.

- Device not powered - check module status indicator.

Check for Guardmaster safety relay failure and controller operation.

Verify IP address setting and correct, as needed.

• A 100 Mbps (full or half duplex) link exists.

• The ring network is operating normally.

• A 10 Mbps (full or half duplex) link exists.

• The ring network is operating normally.

36 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 37

Appendix A

EtherNet/IP Network Interface Specifications

Specifications

Following are specifications for the Guardmaster EtherNet/IP Network Interface

Table 3 - General Specifications – Guardmaster EtherNet/IP Network Interface

Specification Description

Indicators 2 red/green status indicators:

Power consumption, max 2.2 W @ 26.4V DC

Power dissipation, max 0.8 W @ 26.4V DC

Thermal dissipation, max 2.7 BTU/hr @ 26.4V DC

Dimensions (HxWxD), approx. 111.4 x 22.5 x 113.6 mm

Enclosure type rating None (open-style)

Terminal base screw torque 0.8 N•m (7 lb•in)

Weight, approx. 180 g (0.4 lb)

Wiring c ategor y

Wire s ize Power connections:

North American temp code T6

IEC temp code T6

(1)

– Module status

– Network status (Ports 1 and 2 combined)

2 green/yellow status indicators:

– Link 1 status

– Link 2 status

(4.39 x 0.89 x 4.47 in.)

1 – on power ports

2 – on communications ports

0.34... 2.1 mm2 (22...14 AWG) solid or stranded copper wire

rated @ 75 °C (167 °F) or greater, 1.2 mm (3/64 in.) insulation max.

Ethernet wiring:

RJ45 connector according to IEC 60603-7, 2 or 4 pair

Category 5e min cable according to TIA 568-B.1 or

Category 5 cable according to ISO/IEC 24702.

(1) Use this conductor category information for planning conductor routing. Refer to publication 1770-IN041, Industrial Automation

Wiring and Grounding Guidelines.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 37

Page 38

Appendix A EtherNet/IP Network Interface Specifications

Table 4 - Environmental Specifications

Specification Description

Temperature, operating IEC 60068-2-1 (Test Ad, Operating Cold),

Tem pe rat ure , su rr oun di ng

air, max

Temperature, nonoperating IEC60068-2-1 (Test Ab, Unpackaged Nonoperating Cold)

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

Vibration IEC 60068-2-6 (Test Fc, Operating):

Shock, operating IEC60068-2-27 (Test Ea, Unpackaged Shock):

Emissions CISPR 11:

ESD immunity IEC61000-4-2:

Radiated RF immunity IEC 61000-4-3:

EFT/B immunity IEC 61000-4-4:

Surge transient immunity IEC 61000-4-5:

Conducted RF immunity IEC61000-4-6:

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20...+55 °C (-4...+131 °F)

55 °C (131 °F)

IEC60068-2-2 (Test Bb, Unpackaged Nonoperating Dry Heat)

IEC60068-2-14 (Test Na, Unpackaged Nonoperating Thermal Shock):

-40...+85 °C (-40...+185 °F)

5...95% non-condensing

5 g @ 10...500 Hz

15 g

Group 1, Class A

6 kV contact discharges

8 kV air discharges

10V/m with 1 kHz sine-wave 80% AM from 80...2000 MHz

10V/m with 200 Hz 50% Pulse 100% AM @ 900 MHz

10V/m with 200 Hz 50% Pulse 100% AM @ 1890 MHz

10V/m with 1 kHz sine-wave 80% AM from 2000...2700 MHz

±4 kV @ 5 kHz on power ports

±2 kV @ 5 kHz on communications ports

±1 kV line-line (DM) and ±2 kV line-earth (CM) on power ports

±2 kV line-earth (CM) on communications ports

10V rms with 1 kHz sine-wave 80% AM from 150 kHz...80 MHz

Table 5 - Certifications

Certifications (when

product is marked)

cULus

(1)

Value

UL Listed Industrial Control Equipment, certified for US and

Canada. See UL File E65584.

CE

European Union 2004/108/EC EMC Directive, compliant with:

EN 61326-1; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

EtherNet/IP

(1) See the Product Certification link at http://www.rockwellautomation.com/products/certification/ for Declaration of Conformity,

Certificates, and other certification details.

38 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

ODVA conformance tested to EtherNet/IP specifications

Page 39

Appendix

Interface Web Dialogs

.

For Information About Page

Work with the Home Page

Work with the Browse LSR Devices Page 41

Work with the Administrative Settings Pages 42

Use the Network Configuration Page 43

Use the E-mail Configuration Page 44

39

B

Work with the Home Page

Use the interface diagnostics home page to access other interface diagnostics web

pages and see the following information.

• 440R-ENETR

– Revision

– Device IP address

– Ethernet address (MAC)

– Serial number

• Status

– GSR connection status

– GSR faults

– Rotary switch status

– Interface connection status

• Software versions

– EtherNet/IP FW revision

– Controller FW revision

• Configuration

– Switch setting (startup/current)

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 39

Page 40

Appendix B Interface Web Dialogs

IMPORTANT

Enter the interface IP address

to see the home page.

To display and work with the interface diagnostics home page, follow these

procedures.

Make sure that your PC Internet LAN setting and your TCP/IP

settings are configured to access the subnet on which your

interface communicates.

1. From your web browser, enter the interface IP address to see the Home

page.

2. From the Home page, complete one of these, as desired.

• Click one of the following to access www.ab.com

.

– Allen-Bradley logo at the top of the page

– Visit

ab.com for additional information statement under Resources

• Click Rockwell Automation at the top right to go to

www.rockwellautomation.com

.

• Click the following to see additional diagnostics web pages.

– Browse LSR devices

– Administrative Settings: Network and Email Configuration

40 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 41

Interface Web Dialogs Appendix B

Work with the Browse LSR Devices Page

To work with the Browse LSR devices options, follow these procedures.

1. From the Home page, click Browse LSR Devices page. The Browse LSR

Devices page opens.

2. In the Refresh Rate field, you can type a refresh rate, noting that the default

rate is 15 seconds.

3. From the Browse LSR devices page, view the following:

• Overview

– Port type/series

– Bus running

– Number of GSR devices found on bus

– Number of GSR devices found on bus

– Error Counters

□ UART framing/parity error

□ UART or receive buffer overrun

□ UART break error

□ Receive timeout error

□ Frame timing error

□ CRC error

□ Unexpected/wrong data received

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 41

Page 42

Appendix B Interface Web Dialogs

IMPORTANT

• LSR device #N (where N is 1-6 monitored safety relays)

– Device type

– Firmware version

– Running

– Has recoverable fault

– Has non-recoverable fault

– Operation state 1

– Operation state 2

– Recoverable fault processor 1

– Non-recoverable fault processor 1

– Recoverable fault processor 2

– Non-recoverable fault processor 2

– Communication errors

– Communication retries

– Non recoverable error count

– Recoverable error count

Work with the Administrative Settings Pages

To work with the Administrative Settings pages, follow these procedures.

Administrative mode must be enabled to make changes to the

Administrative pages. To enable Administrative mode set the network

address rotary switches to the value 000.

1. From the Home page, click Administrative Settings or Expand to see the

Administrative options, if needed.

2. From the Administrative Settings list, click one of these:

• Network Configuration

• E-mail Configuration

3. Refer to the section of this manual that describes which of these you

clicked: Network Configuration, E-mail Configuration.

42 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 43

Interface Web Dialogs Appendix B

Use the Network Configuration Page

To use the Network Configuration page to make entries for enabling or disabling

DHCP and setting TCP/IP parameters and Ethernet link operation, follow this

procedure:

1. From the Web page, click the Network Configuration tab at the top of the

page or panel on the left. You see the Network Configuration page.

2. From the Network Configuration tab, complete these entries.

• For Initial Network Configuration DHCP

– Static

– DHCP enabled

• For Network Interface, select form these choices.

– IP Address

– Subnet Mask

– Default Gateway

– Primary Name Server

– Secondary Name Server

– Default Domain Name

– Host Name

• For Ethernet Link, select from these choices

– Ethernet Link Configuration P1

□ Auto

□ 10 HDX

□ 10 FDX

□ 100 HDX

□ 100 FDX

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 43

Page 44

Appendix B Interface Web Dialogs

– Ethernet Link Configuration P2

□ Auto

□ 10 HDX

□ 10 FDX

□ 100 HDX

□ 100 FDX

Use the E-mail Configuration Page

To use the E-mail Configuration page to configure the interface to send e-mail

messages and text notifications for different communication events, follow this

procedure:

1. From the Web page, click the E-mail Configuration tab at the top of the

page or panel on the left. You see the E-mail Configuration page.

2. From the E-mail Configuration tab, complete these entries.

• For E-mail trig configuration select:

– Send an e-mail message when a non-recoverable fault is reported from

a safety relay

– Send an e-mail message when a recoverable fault is reported from a

safety relay

– Send an e-mail message when there is a safety relay communication

fault

• For E-mail client configuration

– E-mail Recipient

– E-mail Sender

– SMTP Server

– SMTP Username

– SMTP Password

3. Click Apply Changes to save the modified values.

44 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 45

Configure the RSLinx Ethernet Communication Driver

Appendix

C

Overview

Install the RSLinx Software

To communicate with your adapter over your network, you must configure the

RSLinx Ethernet Communication Driver (AB_ETH) or the EtherNet/IP driver

(AB-ETHIP). You can configure the AB_ETH driver with the IP addresses of all

the Ethernet devices on your system. You need one of these drivers to download

the example application programs in this manual.

See the table for a list of the contents of this appendix.

For Information About Page

Install the RSLinx Software 45

Configure the AB_ETH Driver 46

Configure the AB_ETH/IP Driver 48

Use this procedure to install the RSLinx software on your computer.

1. Insert the CD in the CD-ROM drive.

Note that the CD-ROM supports Windows Autorun. Once inserted into

the CD-ROM drive, if you have Autorun configured, the installation

automatically starts at the first setup screen.

If Autorun is not configured for your CD-ROM drive, go to step 2.

2. From the Start menu, choose Run. The Run dialog opens.

3. Type D:/setup (if it does not appear automatically), where D: is your CD-

ROM drive letter.

4. Click OK.

The progress bar, followed by the welcome screen opens.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 45

Page 46

Appendix C Configure the RSLinx Ethernet Communication Driver

Configure the AB_ETH Driver

To configure the AB-ETH Ethernet communication driver perform the

following steps:

1. Start the RSLinx software.

2. From the Communications menu, select Configure Drivers.

3. Select Ethernet Devices from the list and click Add/New...

4. Select the default driver name (for example, AB_ETH-1) or type in a

name and click OK.

The Configure driver dialog opens.

46 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 47

Configure the RSLinx Ethernet Communication Driver Appendix C

5. Click Add New and enter the IP address or Host Name of your Ethernet

device (for example, 10.88.70.4, Pump1).

6. Repeat step 6 for each additional Ethernet device you need to access.

7. After entering the IP addresses, click Apply.

8. Click OK to close the Configure driver dialog.

The new driver appears in the list of configured drivers. Your list displays

the drivers you configured on your workstation.

9. Close the RSLinx software

.

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 47

Page 48

Appendix C Configure the RSLinx Ethernet Communication Driver

Configure the AB_ETH/IP Driver

To configure the AB-ETHIP Ethernet communication driver, perform the

following steps.

1. Start the RSLinx software.

2. From the Communications menu, select Configure Drivers.

3. Select EtherNet/IP Devices from the list and click Add/New...

48 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 49

Configure the RSLinx Ethernet Communication Driver Appendix C

The Configure Driver dialog box opens.

Make sure the Browse Local Subnet button is selected.

The RSLinx software browses your local subnet and automatically reads

the IP address.

4. Click OK.

The AB-ETHIP driver is now configured and appears in the configured

drivers window.

5. Close the RSLinx software

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 49

.

Page 50

Appendix C Configure the RSLinx Ethernet Communication Driver

Notes:

50 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Page 51

Appendix D

Tag Definitions

Table 6 - GSR DI(S) Module Input Tags

Name Data Type Definition

Slotx_GSR_DIS_IN01 BOOL IN01 Status - Indicates whether input circuit 1 is On or Off.

Slotx_GSR_DIS_IN02 BOOL IN02 Status - Indicates whether input circuit 2 is On or Off.

Slotx_GSR_DIS_SingleWireSafetyIn BOOL Single Wire Safety Input Status - Indicates whether the

Slotx_GSR_DIS_ResetRequired BOOL Reset Required Indication - This indication turns On (1)

Slotx_GSR_DIS_CrossLoopOK BOOL Cross Loop OK - Indicates whether the safety relay is

Slotx_GSR_DIS_SafetyOutput BOOL Safety Output Status – Indicates whether the safety

Slotx_GSR_DIS_RecoverableFault BOOL Recoverable Fault Status – Toggles On (1) for one scan

Slotx_GSR_DIS_NonRecoverableFault BOOL Non-Recoverable Fault Status – Toggles On (1) for one

Slotx_GSR_DIS_S12 BOOL S12 Status – Indicates whether terminal S12 of circuit IN01

Slotx_GSR_DIS_S22 BOOL S22 Status – Indicates whether terminal S22 of circuit IN02

Slotx_GSR_DIS_S32 BOOL S32 Status – Indicates whether terminal S32 of circuit IN02

0 = The input channel is Off.

1 = The input channel is On.

0 = The input channel is Off.

1 = The input channel is On.

Single Wire Safety input (L12) is On or Off.

0 = The Single Wire Safety input signal is Off.

1 = The Single Wire Safety input signal is On.

when all monitored input conditions are On and the safety

relay Output is Off (0).

detecting a cross loop fault on one of the input circuits.

0 = Cross loop fault

1 = No fault

output channels are On or Off.

0 = The safety output channels are Off.

1 = The safety input channels are On.

when the safety relay has detected unexpec ted operation of

a monitored safety device. See S12 OpenWire, S22

OpenWire, S32 OpenWire, S42 OpenWire, Cross Loop Fault,

Invalid Switch Setting, and Reset Held On (page 52

details.

0 = No fault

1 = Fault

scan when the safety relay has detected unexpected

internal operation or failed a pulse check. See

NonRecoverableFault_A and NonRecoverableFault_B (page

52) for details.

0 = No fault

1 = Fault

is On or Off.

0 = The terminal is Off.

1 = The terminal is On.

is On or Off.

0 = The terminal is Off.

1 = The terminal is On.

is On or Off.

0 = The terminal is Off.

1 = The terminal is On.

) for

Rockwell Automation Publication 440R-UM009B-EN-P - February 2014 51

Page 52

Appendix D Tag Def ini tio ns

Table 6 - GSR DI(S) Module Input Tags

Name Data Type Definition

Slotx_GSR_DIS_S42 BOOL S42 St atus – Indicates whether terminal S42 of circuit IN02

Slotx_GSR_DIS_L12 BOOL L12 Status – Indicates whether terminal L12 is On or Off.

Slotx_GSR_DIS_S34 BOOL S34 Status – Indicates whether term inal S34 is On or Off.

Slotx_GSR_DIS_NonRecoverableFaul t_A SINT Non-Recoverable Fault Processor A – Indicates a

Slotx_GSR_DIS_NonRecoverableFaul t_B SINT Non-Recoverable Fault Processor B – Indicates a

Slotx_GSR_DIS_S12OpenWire BOOL S12 Open Wire - Indicates S12 open (0) and closed (1)

Slotx_GSR_DIS_S22OpenWire BOOL S22 Open Wire - Indicates S22 open (0) and closed (1)

Slotx_GSR_DIS_S32OpenWire BOOL S32 Open Wire - Indicates S32 open (0) and closed (1)

Slotx_GSR_DIS_S42OpenWire BOOL S42 Open Wire - Indicates S42 open (0) and closed (1)

Slotx_GSR_DIS_CrossLoopFault BOOL Cross Loop Fault – Indicates whether the safety relay has

Slotx_GSR_DIS_InvalidSwitchSetting BOOL Invalid Switch Settings – Indicates the switch settings

Slotx_GSR_DIS_ResetHeldOn BOOL Reset Held O n Fault – Indicates the reset signal On (1) for

is On or Off.

0 = The terminal is Off.

1 = The terminal is On.

0 = The terminal is Off.

1 = The terminal is On.

0 = The terminal is Off.

1 = The terminal is On.

nonrecoverable fault has been recorded by Safet y Processor

A. See Table 7 on page 52 for a list of non-recoverable fault

codes.

nonrecoverable fault has been recorded by Safet y Processor

B. See Table 7 on page52

codes.

while S22 remained closed (1).

while S12 remained closed (1).

while S42 remained closed (1).

while S32 remained closed (1).

detected a cross loop fault on one of the input circuits.

0 = No fault

1 = Cross loop fault

changed after power-up of the safety relay.

0 = No fault

1 = Fault

longer than the maximum time of 3000 ms.

0 = No fault

1 = Fault

for a list of non-recoverable fault

Table 7 - GSR DI(S) NonRecoverableFault_A and NonRecoverableFault_B Fault Codes

Faul t

Code

00H No fault None

01H RAM test fault

02H Stack over-/under-flow

03H Configuration mismatch between

04H Internal timing fault

05H EEPROM read/write failure

52 Rockwell Automation Publication 440R-UM009B-EN-P - February 2014

Description Corrective Action

Do one of the following:

• Power cycle the safety relay.

• Reconfigure the safety relay.

Processors A and B

• Validate the electrical installation and appropriate

measures to reduce noise and suppress surges are taken.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

Page 53

Tag Def in iti ons Appendix D

Table 7 - GSR DI(S) NonRecoverableFault_A and NonRecoverableFault_B Fault Codes

Faul t

Code

06H Safety mat wiring detected on one of

07H Mismatch between current switch

09H SPI compare fault

0BH ROM test failure

0CH Terminal S12 hardware input fault

0DH Terminal S22 hardware input fault

0EH Terminal S32 hardware input fault

0FH Terminal S42 hardware input fault

10H Terminal S34 hardware input fault

11H Pulse test fault on main transistor Do one of the following:

12H Pulse test fault of transistor for safety

13H Pulse test fault of transistor for safety

14H-1EH Internal plausibilit y test fault

1FH Different Single Wire Safety input signal

20H, 21H Internal program fault

22H, 23H Rotary switch read error

24H Cross fault at processor pins for safety

25H Under voltage detected Do one of the following:

26H Fault detected in the other Processor If viewing the NonrecoverableFault_A tag, refer to

Description Corrective Action

the input pairs while the safety relay is

configured for ‘OR’ logic

settings and setting stored during

power-up

output channel 1

output channel 2

detected at Processor A than Processor B

outputs

Do one of the following:

• If there are no safety mats, check the input wiring (safety

mat wiring is crossed from normal dual-channel device

wiring)

• Change the safety relay to ‘AND’ logic.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

Do one of the following:

• Change the switch settings to the correct values.

• Power cycle the safety relay.

• Reconfigure the safety relay.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

Do one of the following:

• Power cycle the safety relay.

• Reconfigure the safety relay.

• Validate the electrical installation and appropriate

measures to reduce noise and suppress surges are taken.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

• Check wiring for shorts to 24V or other channels.

• Power cycle the safety relay.

• Reconfigure the safety relay.

• Validate the electrical installation and appropriate

measures to reduce noise and suppress surges are taken.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

Do one of the following:

• Power cycle the safety relay.

• Reconfigure the safety relay.

• Validate the electrical installation and appropriate

measures to reduce noise and suppress surges are taken.

If the fault persists, contact your local Rockwell Automation

technical support representative. For contact information, see:

http://rockwellautomation.com/support

• Validate the electrical installation and appropriate supply

voltage is provided.

• Power cycle the safety relay.

• Reconfigure the safety relay.