Page 1

Installation Instructions

PHOTOSWITCH Bulletin 42FT SelfĆTeach Fiber Optic

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Description

The 42FT is a compact, DIN Rail Mount Fiber Optic

Photoelectric sensor with sophisticated part detection,

diagnostic, and self-teach capabilities.

Five LED indicators provide diagnostic and alignment

information. A dynamic diagnostic output signals when margin

levels are below a predetermined threshold for seven

successive detections.

The self-teach capability allows the Bulletin 42FT to determine

an optimum sensitivity and hysteresis setting for a specific

application. The remote lockout feature can be used to help

prevent unauthorized changes to these adjustments. A switch

selectable 50ms off-delay (“pulse stretcher”) is useful in high

speed applications where the output pulse must be lengthened

to allow time for the machine logic to respond.

42FT sensors are designed for DIN rail mounting. For

installation convenience, a steel mounting bracket is supplied

for separate mounting.

42FT sensors are designed for use with 2.2mm diameter

plastic fiber optic cables. An adaptor is supplied with the

sensor to use 1.25mm diameter plastic fiber optic cables. Fiber

optic cables are held in place by a rotating collar. No tools are

required to attach or remove fiber optic cables. Special glass

fiber optic cables are also available. Over 40 compatible

standard plastic and glass fiber optic cables are available,

please refer to page 1–232 of the C112 Sensor catalog.

Features

S Pico quick-disconnect available

S (5) LED indicators: 0.8X to 1.6X margin and output

S Manual or Self-Teach sensitivity adjustment

S Manual or Self-Teach hysteresis adjustment

S Stability output

S Visible red, green, or blue light sources

S Selectable light or dark operate

Features (continued)

S Selectable 50ms off-delay output (pulse stretcher)

S Can be DIN rail mounted or separately mounted

S No tools required to attach or remove Fiber Optic cables

General Specifications

Output Protection Short circuit, Reverse polarity, False pulse, Transient noise

Housing Materials ABS resin, polycarbonate cover

Cable Construction 2m (6.5ft) 500V PVC jacketed 24AWG multiĆconductor

Supplied

Accessories

Operating

Environment

Vibration 10-55Hz, 1mm amplitude, Meets or exceeds IEC 947-5-2

Ambient

Temperature

Relative

Humidity

Approvals UL listed and CSA certified, and CE marked for applicable

Emitter LED Visible red 660nm: 42FT-F2LNA-XX

Connections Cable:

cable

Adjustment screwdriver, 1.25mm diameter fiber optic cable

adaptors

NEMA 1, 4X, 12, 13 and IP66 (IEC 529) (Mounting bracket

not NEMA 4X)

Shock 30G, Meets or exceeds IEC 947-5-2

-25°C to +55°C (-13°F to +131°F)

85%

directives

Visible green 565nm: 42FT-F3LNA-XX

Visible blue 450nm: 42FT-F6LNA-XX

5Ćconductor PVC 3Ćpin pico quickĆ

jacketed cable 2m (6.5ft) disconnect style

42FT-F2LNA-A2 42FT-F2LNA-Y3

42FT-F2LPA-A2 42FT-F2LPA-Y3

42FT-F3LNA-A2 42FT-F3LNA-Y3

42FT-F3LPA-A2 42FT-F3LPA-Y3

42FT-F6LNA-A2 42FT-F6LNA-Y3

42FT-F6LPA-A2 42FT-F6LPA-Y3

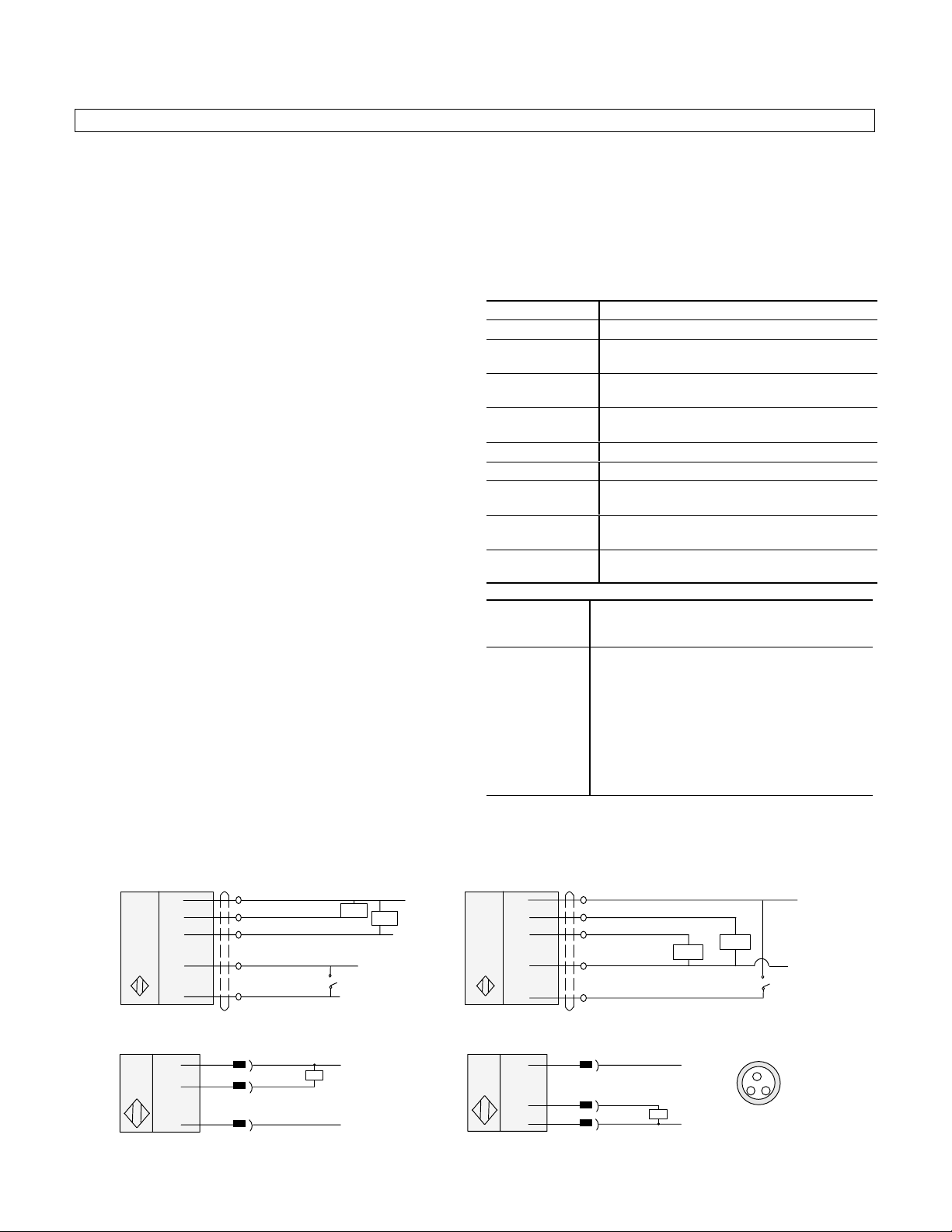

Wiring

NPN Output

Cable

Cable

Brown: 12V-24V DC

Black: Output

Orange: Stability Output

Blue: -DC

Pink: External Set

Load

Load

Remote Self

Teach Activate

QuickĆDisconnect

1

4

3

Note: Details regarding connection of Allen-Bradley Bulletin 42FT photoelectric sensors to Allen-Bradley Program m able Controllers

can be found in publication 42-2.0.

Brown

Black

Blue

PNP Output

Cable

1

4

3

Brown: 12V-24V DC

Black: Output

Orange: Stability Output

Blue: -DC

Pink: External Set

Brown

Black

Blue

Load

Load

Pic

o

4

13

Remote Self

Teach Activate

1

Page 2

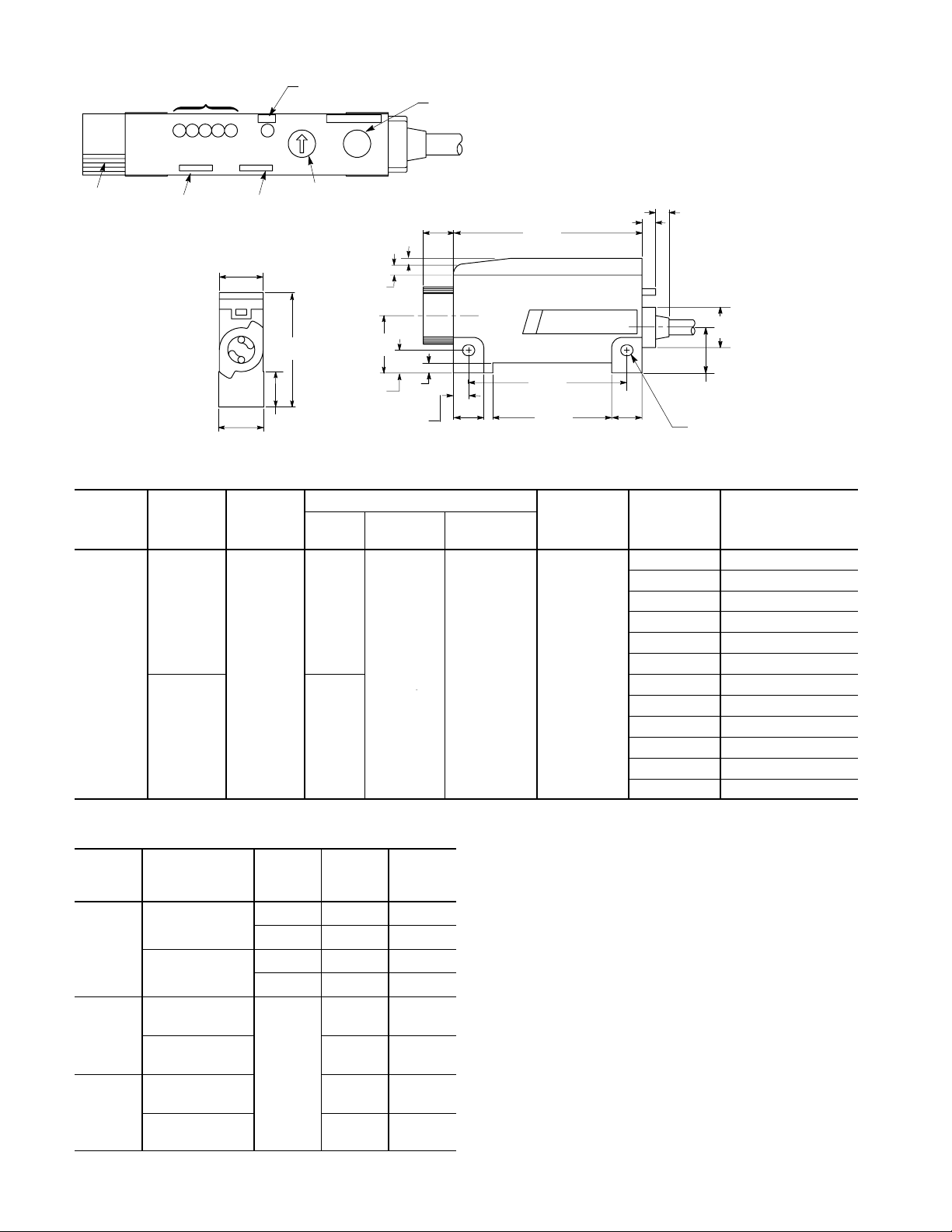

Dimensions—mm (inches)

12-24V DC

Light/Dark

100mA

y

Diffuse

Transmitted Beam

Light Level

(Margin) Indicator

Light

-

1

1

Set Indicator (Flashes During

Automatic Sensitivity Setting)

Set Self Teach+3+2+

Self Teach Button

(Steps Sensitivity or Hysteresis Up or

Down Depending on Mode Switch

Selection)

Cable Clamp

Normal/Off

Delay Switch

Light Operate/Dark

Operate Switch

13

(0.511

)

13.5

(0.413)

(0.531)

Mode Switch (Run, Set,

Auto, Hysteresis, Sensitivity)

34

(1.338)

10.5

Visible Red, Green, or Blue Fiber Optic

Operating

Voltage

12-24V DC Light/Dark

±10%

Supply

Current

Output

Energized

60mA PNP

Selectable

50mA NPN

Type

9

(0.354)

2

(0.078)

3

(0.118)

17

(0.669)

3

6.7

(0.118)

(0.263)

4.5

(0.177)

9

(0.354)

Output Characteristics

Max Load

Current

Output:

100mA

Stability:

50mA

Max Leakage

Current

56

(2.204)

47

(1.850)

35.3

(1.389)

Response

Time

0.5mA 500µs

4

(0.157)

(0.354)

9

4

(0.157)

12

(0.472)

13.5

(0.531)

Dia. 3.2 x 3.6

(0.126 x 0.142) 2 Places

Emitter LED Catalog Number

Red 42FT-F2LPA-A2

Red 42FT-F2LPA-Y3

Green 42FT-F3LPA-A2

Green 42FT-F3LPA-Y3

Blue 42FT-F6LPA-A2

Blue 42FT-F6LPA-Y3

Red 42FT-F2LNA-A2

Red 42FT-F2LNA-Y3

Green 42FT-F3LNA-A2

Green 42FT-F3LNA-Y3

Blue 42FT-F6LNA-A2

Blue 42FT-F6LNA-Y3

Typical Glass Fiber Optic Cable Selection—mm (in)

2

LED Sensing Mode

Diffuse

(Bifurcated Fiber)

Red

Transmitted Beam

(Individual Fiber)

Diffuse

(Bifurcated Fiber)

Green

Transmitted Beam

(Individual Fiber)

Diffuse

(Bifurcated Fiber)

Blue

Transmitted Beam

(Individual Fiber)

Plastic

Fiber

Diameter

Typical

Fiber

Model

MaxiĆ

mum

Range

1 (0.040) 99-94 110 (4.3)

0.5 (0.020) 99-808 30 (1.2)

1 (0.040) 99-90 350 (13.2)

0.5 (0.020) 99-822 95 (3.7)

99-94 13 (0.5)

99-90 35 (1.4)

1 (0.040)

99-94 18 (0.7)

99-90 60 (24)

Mode Switch

AUTO (Factory Setting)

Allows Self-Teach to be initiated with the pushbutton on the

sensor (Local) or through an external connection (Remote).

Sensor indicators and outputs are active and function normally.

Sensors may be operated in AUTO mode. Sensors must be

operated in AUTO mode when Remote Self-Teach is required.

SET

Allows self-teach to be initiated with the pushbutton on the

sensor (Local) only. The external Self-Teach connection

(Remote) is ignored. Sensor indicators function normally. Both

sensor and stability outputs are inhibited.

RUN

RUN mode is recommended for sensor operation in all

applications where Remote Self-Teach will not be used.

Sensor indicators and outputs are active and function normally.

No adjustments, Local or Remote, are possible while the

sensor is in RUN mode.

Page 3

Two RUN switch positions are provided. For applications in

close proximity, alternate sensors should be set to alternate

RUN positions to reduce the possibility of crosstalk.

SENS

Allows Sensitivity to be increased (+) or decreased (–)

manually. See Manual Adjustment section for information.

Self-Teach

Self-Teach can be initiated using the pushbutton on the sensor

(Local) or through an external input (Remote) in the AUTO

mode. Only Local Self-Teach is possible in the SET mode.

Refer to the Mode Switch section for a description of each

Mode Switch setting.

HYS

Allows Hysteresis to be increased (+) or decreased (–)

manually. See Manual Adjustment section for information.

D.O./L.O. Switch

Selects Dark Operate or Light Operate sensor output.

OFF DLY/NORMAL Switch

OFF DLY position enables a 50ms off-delay on the sensor

output (“pulse-stretcher”). NORMAL disables the off-delay.

Indicators

As more light is detected, more indicators will illuminate.

Green “–1” 0.8X margin

Red “LIGHT” 1.0X margin

The Sensor Output changes state whenever

this indicator turns ON or OFF

Green “+1” 1.2X margin

Green “+2” 1.4X margin

Green “+3” 1.6X margin

Green “SET” Verifies adjustment inputs.

Alignment

All Sensing Modes—Mount the sensor securely. Attach the

fiber optic cable(s) to the sensor and fasten the sensing end

tip(s) loosely at the point where the target object is to be

sensed. Apply power to the sensor. Set the mode switch to

SET.

Diffuse Sensing—Place the target object in the position

where it is to be sensed. Watch the margin indicators and pan

the light source fiber optic cable up and down, left and right to

center it on the target. Secure the sensing end tip at the point

yielding the greatest margin.

Transmitted Beam Sensing—Secure the “receiver” firmly in

position. Watch the margin indicators and pan the “light

source” fiber optic cable up and down, left and right to center it

on the “receiver” fiber optic cable. Secure the “light source”

sensing end tip at the point yielding the greatest margin.

Retroreflective Sensing—Watch the margin indicators and

pan the fiber optic cable end tip up and down, left and right to

center it on the reflector. Mount the sensing end tip at the point

yielding the greatest margin.

Alignment Aid

A special alignment assistance feature visibly increases the

brightness of the sensor light source, as seen at the tip of the

fiber optic cable, whenever the amount of light received by the

sensor is sufficient for stable operation.

Reducing the Potential for Crosstalk

Crosstalk can occur when the fiber optic cables of two sensors

are positioned to sense at points close to each other. Adjust

each sensor independently while the other sensor is not

powered. Once adjusted set each sensor to a different RUN

position on the Mode Switch. (Note that two positions on the

Mode Switch are labeled RUN.)

Local Self-Teach

Moving Target Objects

1. Set Mode Switch to AUTO or SET.

2. Press and hold the SET button. The SET indicator flashes

rapidly for three seconds while the sensor prepares to

monitor the passing target objects then flashes more

slowly as the sensor actually monitors the light received

as the target objects pass. The sensor monitors the light

received as long as the button remains pressed.

3. Allow at least one target object to pass completely while

the SET indicator flashes slowly before releasing the

button. Automatic Sensitivity adjustment is complete.

(Note: Self-Teach will not occur if the button is released

early.)

4. Set Mode Switch to AUTO or one of the RUN positions

(see the description of operation in the Mode Switch

section.)

Stationary Target Objects

1. Set Mode Switch to AUTO or SET.

2. Remove the target object and press and release the SET

button. The SET indicator flashes continuously to confirm

that the “no target” signal is stored.

3. With the target object in its sensing position press and

release the SET button. The SET indicator stops flashing

to confirm that Local Self-Teach is complete.

4. Set Mode Switch to AUTO or one of the RUN positions

(see the description of operation in the Mode Switch

section).

Remote Self-Teach

1. Set Mode Switch to AUTO. An external signal or switch

closure can be used to automatically adjust sensitivity and

hysteresis via the pink External Set wire (refer to wiring

diagrams).

2. The adjustment procedure is the same as described in the

Manual Self-Teach section except that the external signal

or switch closure takes the place of manually pressing

SET button. The duration of External Set signal or switch

closure must be at least 100ms. The Stability Output

pulses to provide a verification signal which duplicates the

blinking of the SET indicator as described above.

3. Set Mode Switch to AUTO or one of the RUN positions

(see the description of operation in the Mode Switch

section.)

Manual Adjustment

Setting Maximum Sensitivity

1. Set Mode Switch to AUTO or SET.

2. Diffuse Sensing

Remove the target object and press and release the SET

button twice.

Transmitted Beam or Retroreflective Sensing

Completely block the beam from source to receiver or

3

Page 4

from fiber optic cable to reflector. Press and release the

SET button twice.

The SET indicator blinks OFF, briefly, after each press of

the SET button to confirm the Sensor has been set to

maximum sensitivity.

3. Set Mode Switch to AUTO or one of the RUN positions

(see the description of operation in the Mode Switch

section).

Adjusting Sensitivity

Increase—Set the Mode Switch to SENS +.

Decrease—Set the Mode Switch to SENS –.

1. Press and release the SET button. Sensitivity is increased

(or decreased) each time the SET button is pressed and

released. Press and release the SET button until the

desired sensitivity is reached. The SET indicator turns off

once, briefly, each time until the limit of the adjustment

range is reached. The SET indicator no longer blinks

when the upper or lower limit has been reached.

2. Set Mode Switch to AUTO or one of the RUN positions

(see the description of operation in the Mode Switch

section).

Adjusting Hysteresis

Increase—Set the Mode Switch to HYS +.

Decrease—Set the Mode Switch to HYS –.

1. Press and release the SET button. Hysteresis is increased

(or decreased) each time the SET button is pressed and

released. Press and release the SET button until the

desired hysteresis is reached. The emitted light at the fiber

tip and the SET indicator turn off once, briefly, each time

until the limit of the adjustment range is reached. The

emitted light at the fiber tip and the SET indicator no

longer blink when the upper or lower limit has been

reached.

2. Set Mode Switch to AUTO or one of the RUN positions

(see the description of operation in the Mode Switch

section).

Self Diagnostic/Stability Output

Self Diagnostic Upon Power Up

The sensor has a built-in self diagnostic program. Upon power

up, this program verifies that sufficient input light is being

detected.

Upon power up the light received by the sensor is measured

for 3 seconds. If the light is below +1 (1.2X margin), the

stability output signal is turned on.

Application Quality Verification

In diffuse applications, it is desirable to have a margin of less

than 0.8X when the target is absent and a margin of greater

than 1.2X when the target is present.

In transmitted beam and retroreflective applications, it is

desirable to have a margin of greater than 1.2X when the

target is absent and a margin of less than 0.8X when a target

is present.

The diagnostic output of the 42FT will turn on when application

margin levels are not less than 0.8X or greater than 1.2X for

seven successive detections.

If seven consecutive input signals are below the +1 level (1.2X

margin), the stability output signal turns on to indicate that the

application is not stable (see Ê).

If seven consecutive input signals are above the –1 level (0.8X

margin), the stability output signal turns on to indicate that the

application is not stable (see Ë).

Stability Output

Input Signal

Level

Level +1

1.2:1

On

1:1

Off

0.8:1

Level -1

Stability Output

Ê 7 Low Margin Detections

Trip Stability Output

Ë 7 High Margin Detections

Trip Stability Output

OffOff

Instability

Range

OnOn

Publication 75009–056–01(E)

May 1999

Printed in Japan

4

Loading...

Loading...