Page 1

Mounting Clips

Catalog Number 2711-NP1

Installation Instructions

Inside...

English ..............................................................................................................3

Français.............................................................................................................4

Deutsch.............................................................................................................5

Español .............................................................................................................6

Italiano..............................................................................................................7

1 Publication 2711-2.12

Page 2

2 Mounting Clips

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Publication 2711-2.12

Page 3

Installation Instructions

Mounting Clips

Catalog Number 2711-NP1

English

The package of mounting clips (Catalog No. 2711–NP1) contains 10

clips. Use these clips to mount the following:

• PanelView 1400 Operator Terminal (requires 10 clips)

• 6180 Industrial Computer (requires 10 clips)

• 14 inch Industrial Monitors (requires 6 clips)

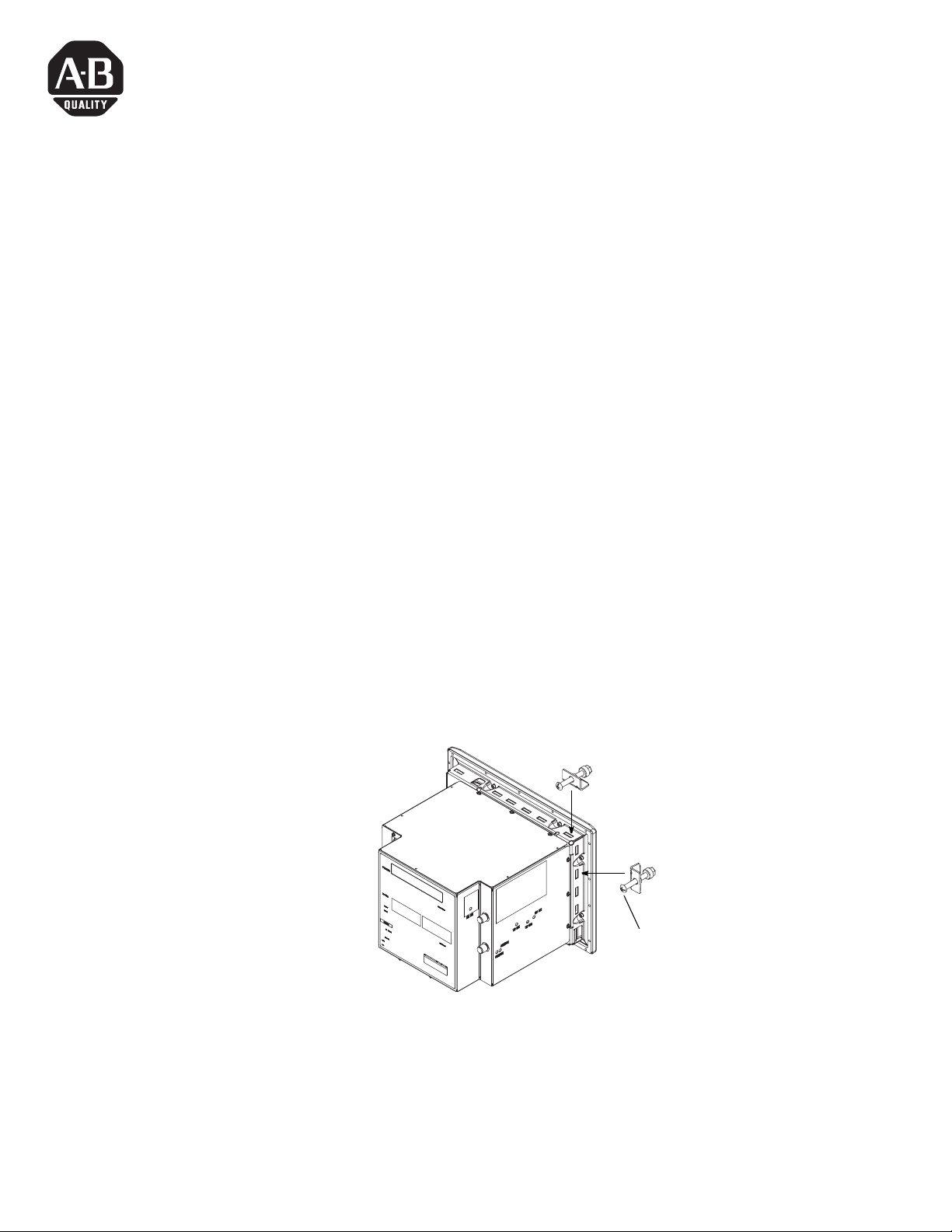

Mounting Clip Installation

1. Refer to the installation instructions provided with the operator

terminal, monitor, or industrial computer.

2. Clips are positioned in the chassis mounting slots. Tighten the

mounting clip using the screwdriver slot on the clip. Refer to the

device’s installation instructions for specific torque values and

tightening sequences.

Screwdriver slot for tightening clip

Aquí se muestra el PanelView 1400, otros dispositivos son

similares

3 Publication 2711-2.12

Page 4

Notice d’installation

Attaches de fixation

Catalog Number 2711-NP1

Français

Ce paquet d’attaches de fixation (référence 2711-NP1) contient dix

attaches. Utiliser ces attaches pour le montage d’un :

• ordinateur industriel 6180 (10 attaches)

• ordinateur industriel 6180 (10 attaches)

• moniteur industriel avec écran de 14 pouces (6 attaches)

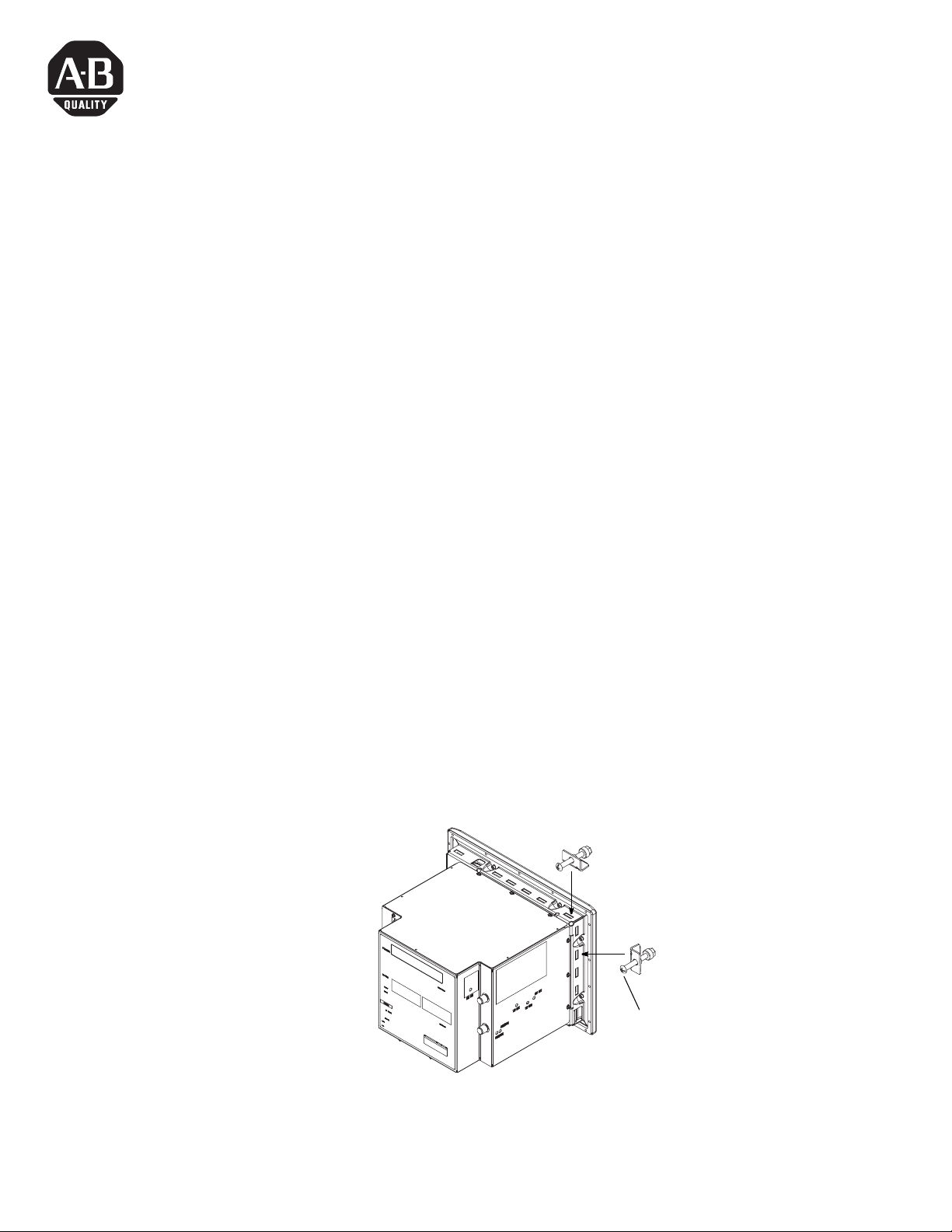

Installation des attaches de fixation

1. Se reporter à la notice d’installation fournie avec le terminal

opérateur, le moniteur ou l’ordinateur industriel.

2. Les attaches sont placées dans les encoches du châssis. Elles

sont munies d’une tête fendue pour le serrage. Se reporter aux

notices d’installation des appareils pour les valeurs spécifiques

de couple et d’ordre de serrage.

Tête fendue pour le serrage

Ici, PanelView 1400. Similaire pour les autres appareils.

4 Publication 2711-2.12

Page 5

Installationsanleitung

Montageklammern

Catalog Number 2711-NP1

Deutsch

Dieses Paket mit Montageklammern (Katalognr. 2711–NP1) enthält 10

Klammern. Diese Klammern werden für die Montage der folgenden

Geräte verwendet:

• PanelView 1400 Bedienerterminal (benötigt 10 Klammern)

• 6180 Industrie-Computer (benötigt 10 Klammern)

• 14 Zoll Industrie-Monitor (benötigt 6 Klammern)

Installation der Montageklammern

1. Beziehen Sie sich auf die Installationsanweisungen, die Sie mit

dem Bedienerterminal, Monitor oder Industrie-Computer

bekommen.

2. Die Klammern werden in den Chassismontageschlitzen

positioniert. Befestigen Sie die Montageklammern mit

Verwendung des Schraubendreher- schlitzes auf der Klammer.

Beziehen Sie sich auf die Installations- anweisungen des Gerätes

für ein spezifisches Drehmoment und die

Befestigungsreihenfolge.

Schraubendreherschiltz zur Befestigung

der Klammer.

PanelView 1400 gezeigt (andere Geräte sind ähnlich)

5 Publication 2711-2.12

Page 6

Instrucciones de instalación

Clips de montaje

Catalog Number 2711-NP1

Español

El paquete de clips de montaje (No. de catálogo 2711–NP1) contiene

10 clips. Usar estos clips para montar lo siguiente

• Terminal de operador PanelView 1400 (requiere 10 clips)

• Computadora industrial 6180 (requiere 10 clips)

• Monitor industrial de 14 pulgadas (requiere 6 clips)

Instalando los clips de montaje

1. Refiérase a las instrucciones de instalación proporcionadas con

el terminal de operador, monitor o computadora industrial.

2. Los clips se posicionan en las ranuras de montaje del chasis.

Apretar los clips de montaje usando la ranura de destornillador

del clip. Refiérase a las instrucciones de instalación para valores

específicos de torsión y secuencias de apretar.

Ranura de destomillador para apretar

el clip

PanelView 1400 shown, other devices are similar.

6 Publication 2711-2.12

Page 7

Istruzioni per l’installazione

Ganci di montaggio

Catalog Number 2711-NP1

Italiano

La confezione con i ganci di montaggio (N. Catalogo 2711–NP1)

contiene 10 ganci. Usare questi ganci per montare i seguenti terminali:

• Terminale Operatore PanelView 1400 (richiede 10 ganci)

• Computer industriale 6180 (richiede 10 ganci)

• Monitor industriali da 14 pollici (richiedono 6 ganci)

Installazione dei ganci di montaggio

1. Consultare la guida per l’installazione fornita con il terminale

operatore, il monitor, o il computer industriale.

2. I ganci vengono posizionati nelle fessure di montaggio del

telaio. Stringere i ganci di montaggio servendosi dell’apposita

fessura per il cacciavite. Consultare la guida per l’installazione

del dispositivo, per avere le specifiche sequenze e i valori di

serraggio.

Fessura per il cacciavite

PanelView 1400, altri dispositivi sono simili

7 Publication 2711-2.12

Page 8

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using its products. At

http://support.rockwellautomation.com, you can find technical manuals, a knowledge base of FAQs, technical and

application notes, sample code and links to software service packs, and a MySupport feature that you can customize

to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer

TechConnect Support programs. For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation, please review the

information that's contained in this manual. You can also contact a special Customer Support number for initial help

in getting your module up and running:

United States 1.440.646.3223

Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned:

United States Contact your distributor. You must provide a Customer Support case number (see phone number

above to obtain one) to your distributor in order to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for return procedure.

Publication 2711-2.12 - March 1997 8 PN 40061-212-01(D)

Supersedes Publication 2711-2.12 - October 1995 Copyright © 1997 Rockwell Automation, Inc . All rights reserved. Printed in the U.S.A.

ö

Loading...

Loading...