Page 1

PowerFlex 700L

Active Converter Power Module

USER MANUAL

Firmware Version 3.xxx

Page 2

Important User

Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (Publication SGI-1.1 available from your local

Rockwell Automation sales office or online at

literature) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of

the wide variety of uses for solid state equipment, all persons responsible for applying

this equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of safety

considerations.

http://www.rockwellautomation.com/

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

Allen-Bradley, PowerFlex, DriveExplorer, DriveExecutive, and DPI are either registered trademarks or trademarks of Rockwell Automation, Inc.

PowerFlex 700L Active Converter Power Module User Manual

Page 3

Summary of Changes

The information below summarizes the changes resulting from the firmware

v3.001 upgrade to this manual since its last release (June, 2006):

Description of New or Updated Information Page(s)

To all pages, added a new footer containing:

• Publication description (1st line).

• Publication number hyperlink underlined in blue (2nd line) linking to the date of the

publication on the back cover.

The back cover publication date line hyperlinks to the newest version of the publication

on Rockwell Automation’s Literature Library web site.

Added new information about the Active Converter operating as a Coupled unit (DPI

SLAVE) or as a Stand Alone unit (DPI MASTER).

Changed the following for Parameter 051 - [Option Select]:

• Bit 6 changed from “Reserved” to “VC Inverter.”

• Bit 7 changed from “Reserved” to “Prechg Cntrl.”

• The default changed from “xxxx xxxx xx00 0001” to “xxxx xxxx 0000 0001.”

Added new Parameter 105 - [Regen I Lmt]. 3-9

Changed Parameter 153 - [CML Bandwidth] maximum value from “3000 Rad/sec” to

“4000 Rad/sec.”

Changed the description for Parameter 157 - [PF Bandwidth] to include that it should be

used only when unbalanced voltage compensation is enabled in Parameter 051 [Option Select].

Changed Parameter 162 - [Capacitance] maximum value from “32767 µF” to “65535 µF.” 3-12

Added new Parameter 170 - [Bus Capacitance]. 3-12

Added new Bit 11 (High DC Link) to Parameter 214 - [Start Inhibit]. 3-14

Changed Parameter 238 - [Fault Config] default from “xxxx xxx1 1110 1100” to

“xxxx xxx1 0110 1100.”

Added two new parameter groups which are only displayed and available in the

Communication File when the Converter is operated as a Stand Alone unit:

• Masks and Owners Group

– Parameter 340 - [Logic Mask]

– Parameter 341 - [Start Mask]

– Parameter 342 - [Fault Clr Mask]

– Parameter 343 - [Stop Owner]

– Parameter 344 - [Start Owner]

– Parameter 345 - [Fault Clr Owner]

• Security Group

– Parameter 346 - [Port Mask Act]

– Parameter 347 - [Write Mask Cfg]

– Parameter 348 - [Write Mask Act]

– Parameter 349 - [Logic Mask Act]

Added the following new fault codes:

• 70 – FiltCap Contactr

• 71 – Port 1 Adapter

• 72 – Port 2 Adapter

• 73 – Port 3 Adapter

• 74 – Port 4 Adapter

• 75 – Port 5 Adapter

• 76 – Port 6 Adapter

• 81 – Port 1 DPI Loss

• 82 – Port 2 DPI Loss

• 83 – Port 3 DPI Loss

• 84 – Port 4 DPI Loss

• 85 – Port 5 DPI Loss

• 86 – Port 6 DPI Loss

Throughout

Manual

1-6

3-6

3-11

3-11

3-15

3-18

4-3

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 4

soc-ii Summary of Changes

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 5

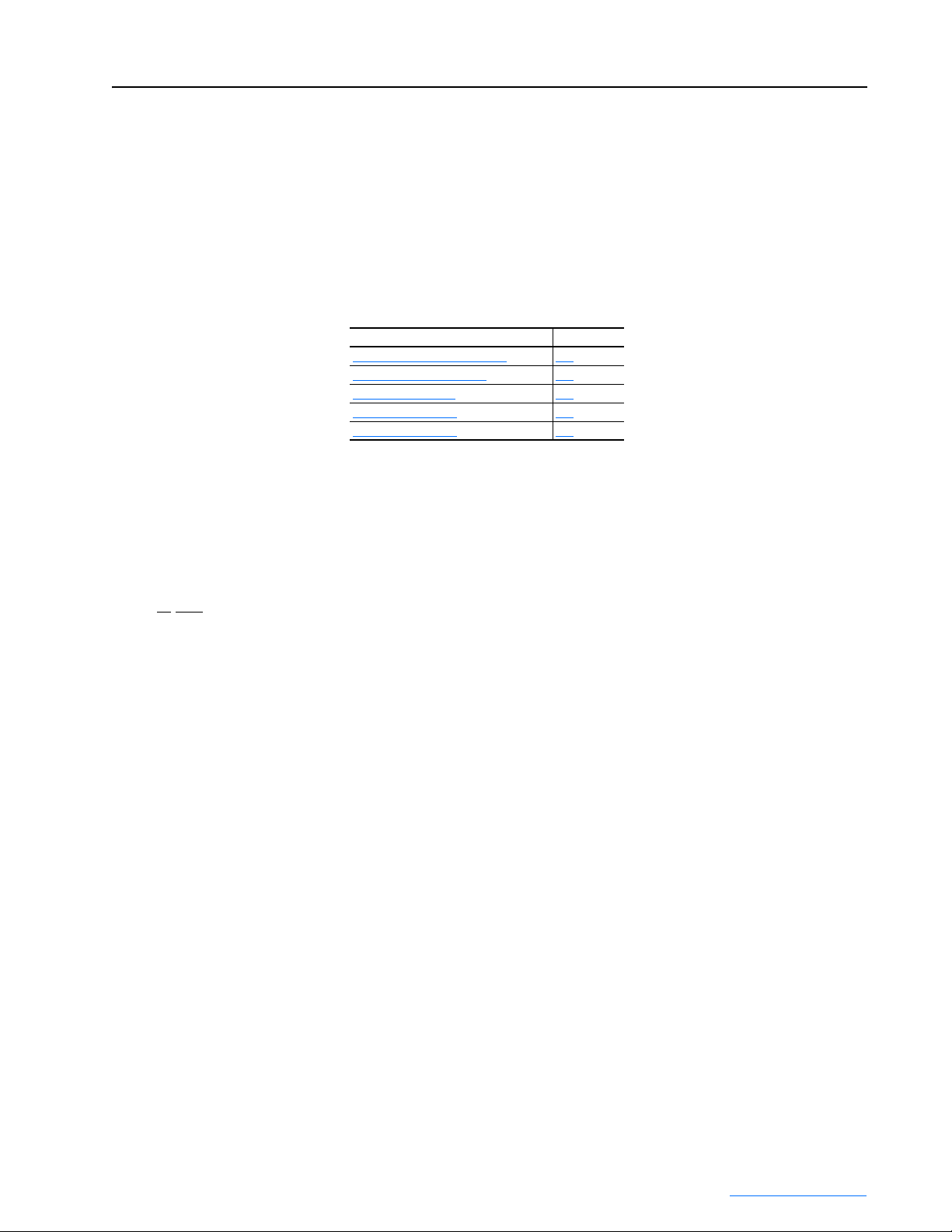

Preface Overview

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

What Is Not in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

LPM20 Liquid-Cooled AC Drive Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

PowerFlex 700L Liquid-Cooled AC Drive Information . . . . . . . . . . . . . . . . . . . . . . . P-1

PowerFlex 700 Vector Control Information (standard) . . . . . . . . . . . . . . . . . . . . . . . . P-1

PowerFlex 700S Phase II Control Information (optional) . . . . . . . . . . . . . . . . . . . . . . P-2

Reference Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Allen-Bradley Drives Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1 Installation/Wiring

Removing the Active Converter Power Module Covers . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Removing the Active Converter Control Cassette . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Frame 2 and 3A Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Frame 3B Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Wiring the Active Converter Control Cassette I/O Terminals . . . . . . . . . . . . . . . . . . . . . 1-4

I/O Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Using the Active Converter as a Coupled Unit vs. Standalone Unit. . . . . . . . . . . . . . . 1-6

Setting the DPI MASTER/SLAVE Switch (SW1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Connecting an Active Converter Power Module to an Inverter Power Module . . . . . . . . 1-8

Frame 2 and 3A Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Frame 3B Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Table of Contents

Chapter 2 Start Up

Establishing Communication as a Coupled Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Accessing Active Converter Power Module Parameters. . . . . . . . . . . . . . . . . . . . . . . . 2-1

Verifying Feedback Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Exchanging Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

CIP Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Establishing Communication as a Stand Alone Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Accessing Active Converter Power Module Parameters. . . . . . . . . . . . . . . . . . . . . . . . 2-8

Verifying Feedback Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Converter Sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Run On Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Run On PwrUp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Manual Cntrl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Start Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Sequencing Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Control Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Current Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Line Voltage Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Frequency Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Voltage Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Current Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

PWM Carrier Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 6

ii Table of Contents

Converter Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Converter Faults as a Coupled Unit (DPI SLAVE) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Displaying the Fault Text. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Resetting Converter Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Chapter 3 Programming and Parameters

About Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

How Parameters are Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

File-Group-Parameter Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Numbered List View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Monitor File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Command File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Limit Config File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Dynamic Control File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Utility File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Communication File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Inputs & Outputs File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Parameter Cross Reference – by Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

Parameter Cross Reference – by Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Chapter 4 Troubleshooting

Faults and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Manually Clearing Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Fault Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Clearing Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Alarm Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Index

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 7

Preface

Overview

The purpose of this manual is to provide you with the basic information

needed to wire and operate the PowerFlex 700 Active Converter Power

Module.

For information on ... See page ...

Who Should Use this Manual?

What Is Not in this Manual P-1

Reference Materials P-2

Manual Conventions P-2

General Precautions P-3

P-1

Who Should Use this Manual?

What Is Not in this Manual

This manual is intended for qualified personnel. You must be able to wire

and operate Adjustable Frequency AC Drive devices. In addition, you must

have an understanding of the parameter settings and functions.

This manual is designed to provide only basic active converter I/O wiring,

start-up, programming, and other related information.

LPM20 Liquid-Cooled AC Drive Installation

For information on installing LPM20 Liquid-Cooled AC drives, please refer

to LPM20 Liquid-Cooled Adjustable Frequency AC Drive Installation

Manual — (Publication No. 20N-IN001…).

PowerFlex 700L Liquid-Cooled AC Drive Information

For information on installing PowerFlex 700L Liquid-Cooled AC drives,

please refer to PowerFlex 700L Liquid-Cooled Adjustable Frequency AC

Drive User Manual — (Publication No. 20L-UM001…).

PowerFlex 700 Vector Control Information (standard)

For PowerFlex Liquid-Cooled AC drives equipped with standard PowerFlex

700 Vector Control, please refer to the PowerFlex 700 Adjustable Frequency

AC Drive User Manual — Series B (Publication No. 20B-UM002…) which

provides I/O wiring, start-up, programming, and vector control encoder

information.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 8

P-2 Overview

PowerFlex 700S Phase II Control Information (optional)

For PowerFlex Liquid-Cooled AC drives equipped with optional PowerFlex

700S Phase II Control, please refer to the PowerFlex 700S High

Performance AC Drive — Phase II Control User Manual (Publication No.

20D-UM006…) which provides I/O wiring, start-up, programming, and

other related information.

Reference Materials

Manual Conventions

Publications

Publications can be obtained online at

http://www.rockwellautomation.com/literature

The following manuals are recommended for general drive information:

Title Publication

Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives DRIVES-IN001…

Preventive Maintenance of Industrial Control and Drive System Equipment DRIVES-TD001…

Safety Guidelines for the Application, Installation, and Maintenance of Solid State

Control

A Global Reference Guide for Reading Schematic Diagrams 0100-2.10

Guarding Against Electrostatic Damage 8000-4.5.2

Allen-Bradley Drives Technical Support

Online: www.ab.com/support/abdrives

• In this manual we refer also to the PowerFlex 700 Active Converter

Power Module as Active Converter, converter or PowerFlex 700AC.

• To help differentiate parameter names and LCD display text from other

text, the following conventions will be used:

.

SGI-1.1

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

– Parameter Names will appear in [brackets].

For example: [DC Bus Voltage].

– Display Text will appear in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an action:

Word Me aning

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Page 9

Overview P-3

General Precautions

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are

!

required when installing, testing, servicing or repairing this

assembly. Component damage may result if ESD control

procedures are not followed. If you are not familiar with static

control procedures, refer to Allen-Bradley publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life. Wiring

!

or application errors, such as, undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient temperatures may

result in malfunction of the system.

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

!

implement the installation, start-up, and subsequent maintenance

of the system. Failure to comply may result in personal injury and/

or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before performing

!

any work on the drive. After removing power to the drive, wait 5

minutes for the bus capacitors to discharge. Refer to the:

• LPM20 Liquid-Cooled Adjustable Frequency AC Drive

Installation Manual (Publication No. 20N-IN001…),

Figure 4.2, and measure the DC bus voltage at the locations

shown. The voltage must be zero.

• PowerFlex 700L Liquid-Cooled Adjustable Frequency AC

Drive User Manual (Publication No. 20L-UM001…), and

measure the DC bus voltage at the DC POSITIVE and DC

NEGATIVE test point sockets located on the front of the power

module. The voltage must be zero.

ATTENTION: Risk of injury or equipment damage exists. DPI

host products must not be directly connected together via 1202

!

cables. Unpredictable behavior can result if two or more devices

are connected in this manner.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 10

P-4 Overview

Notes:

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 11

Chapter 1

Installation/Wiring

This chapter provides information on installing and wiring the PowerFlex

700 Active Converter Power Module.

For information on… See page…

Removing the Active Converter Power Module Covers

Removing the Active Converter Control Cassette 1-2

Wiring the Active Converter Control Cassette I/O Terminals 1-4

Most start-up difficulties are the result of incorrect wiring. Every precaution

must be taken to assure that the wiring is done as instructed. All items must

be read and understood before the actual installation begins.

1-2

ATTENTION: The following information is merely a guide for

proper installation. Rockwell Automation, Inc. cannot assume

!

responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of

this drive or associated equipment. A hazard of personal injury

and/or equipment damage exists if codes are ignored during

installation.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 12

1-2 Installation/Wiring

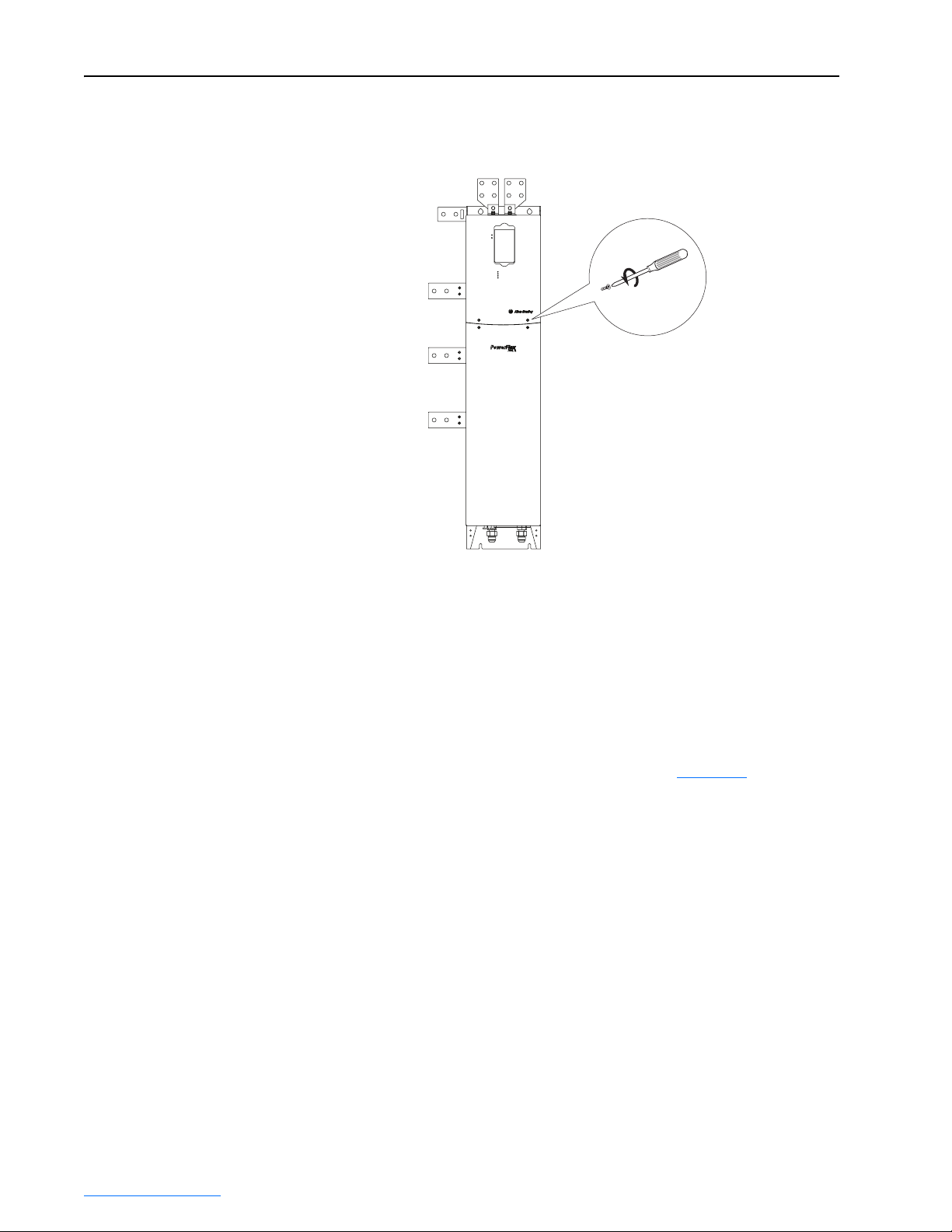

Removing the Active Converter Power Module Covers

All converter covers, regardless of drive frame size, are similarly removed

by unfastening the screws. A Frame 3B converter is shown as an example.

PORT

MOD

NET A

NET B

(4 Screws)

PowerFlex 700L

Liquid-Cooled AC Drive

Frame 3B Converter shown

Removing the Active Converter Control Cassette

Regenerative PowerFlex 700L Liquid-Cooled AC drives use an Active

Converter Power Module equipped with a converter control cassette.

Frame 2 and 3A Drives

PowerFlex 700L Liquid-Cooled Frame 2 and 3A drives combine the Active

Converter and Inverter into a single Power Module. Figure 1.1

location and removal of the Active Converter control cassette to access its

terminal blocks for control wiring. (The Inverter control cassette is located

just above the Active Converter control cassette.)

shows the

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 13

Installation/Wiring 1-3

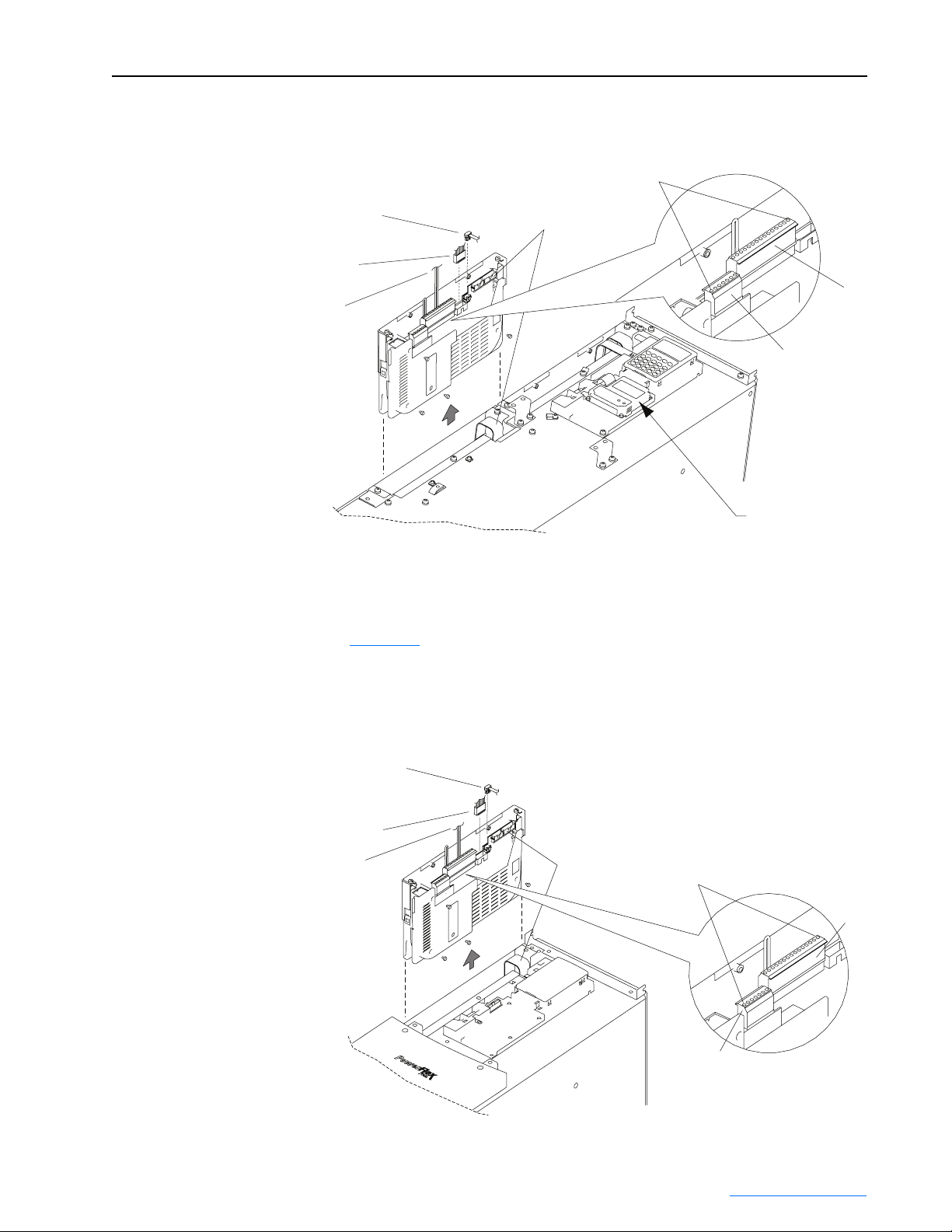

Figure 1.1 Removing the Frame 2 and 3A Active Converter Control Cassette

Synchronization Cable

(For use with 700S Phase II Control only)

Internal DPI Cable

Synchronization Cable

(For use with 700 Vector Control only)

Frame 3B Drives

Pin 1

40-Pin

Ribbon Cable

SHLD

SHLD

Communications

Adapter Option

Detail

P1

P2

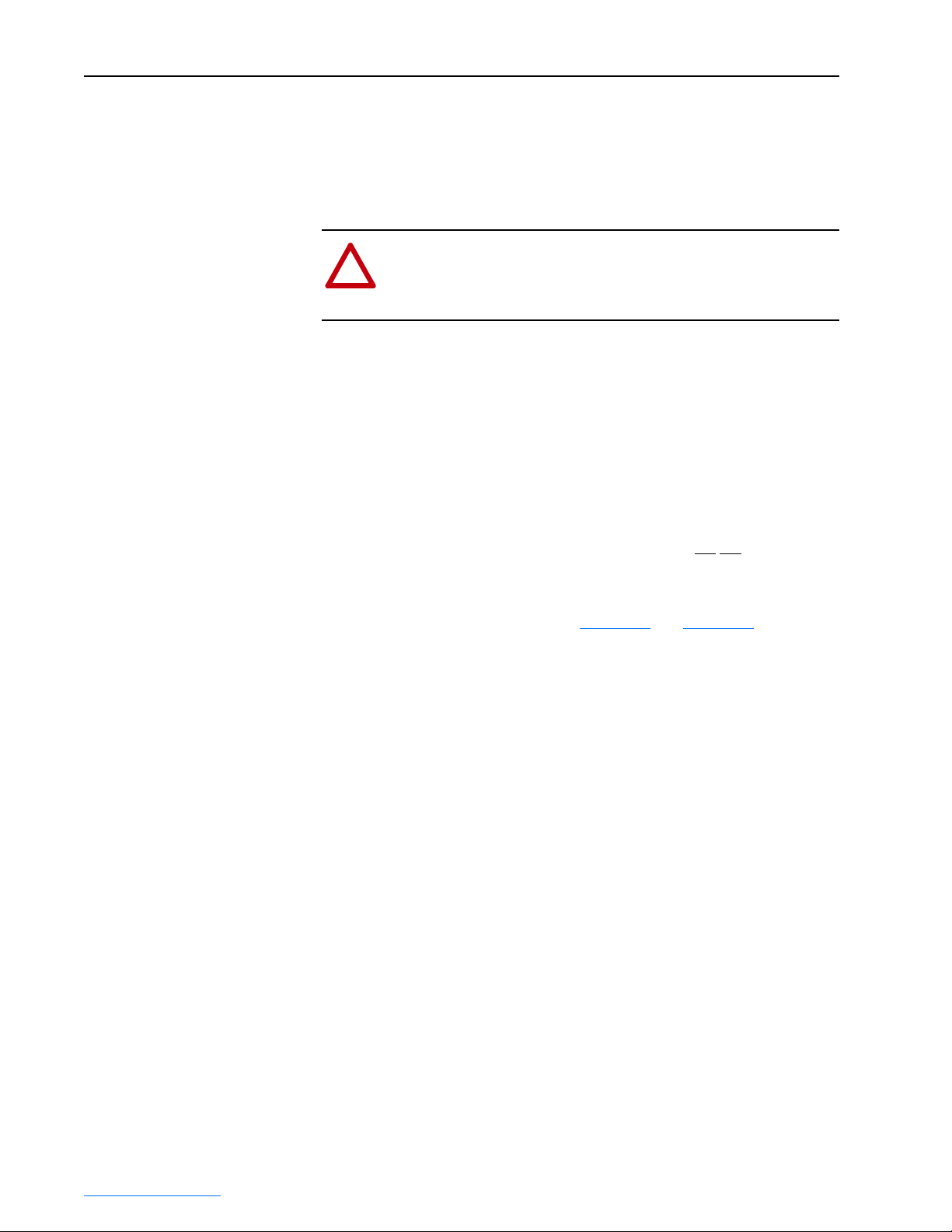

Figure 1.2 shows the location and removal of the Active Converter control

cassette to access its terminal blocks for control wiring. Frame 3B drives

have separate Converter Power Modules and Inverter Power Modules.

Figure 1.2 Removing the Frame 3B Active Converter Control Cassette

Synchronization Cable

(For use with coupled Inverter Power

Modules with 700S Phase II Control only)

Internal DPI Cable

Synchronization Cable

(For use with coupled Inverter Power

Modules with 700 Vector Control only)

40-Pin

Ribbon Cable

Pin 1

P2

P1

Detail

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 14

1-4 Installation/Wiring

Wiring the Active Converter Control Cassette I/O Terminals

All wiring should be installed in conformance with the applicable local,

national, and international codes (e.g., NEC/CEC). Signal wiring, control

wiring, and power wiring must be routed in separate conduits to prevent

interference with drive operation. Use grommets, when hubs are not

provided, to guard against wire chafing.

ATTENTION: Do not route signal and control wiring with

!

Important points to remember about I/O wiring:

• Use Copper wire only. Wire gauge requirements and recommendations

are based on 75 degrees C. Do not reduce wire gauge when using higher

temperature wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control and signal wires should be separated from power wires by at

least 0.3 meters (1 foot).

Important:I/O terminals labeled “(–)” or “Common” are

power wiring in the same conduit. This can cause interference

with drive operation. Failure to observe this precaution could

result in damage to, or destruction of, the equipment.

not referenced to

earth ground and are designed to greatly reduce common mode

interference. Grounding these terminals can cause signal noise.

Terminal blocks P1 and P2, shown in Figure 1.1

connection points for all inputs, outputs, and power connections to the

Active Converter control cassette.

1. Remove the terminal block plug from the socket, and make connections.

2. Reinstall the terminal block plug when wiring is complete. The terminal

blocks have keys, which make it difficult to insert a terminal block plug

into the wrong socket.

and Figure 1.3, contain

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 15

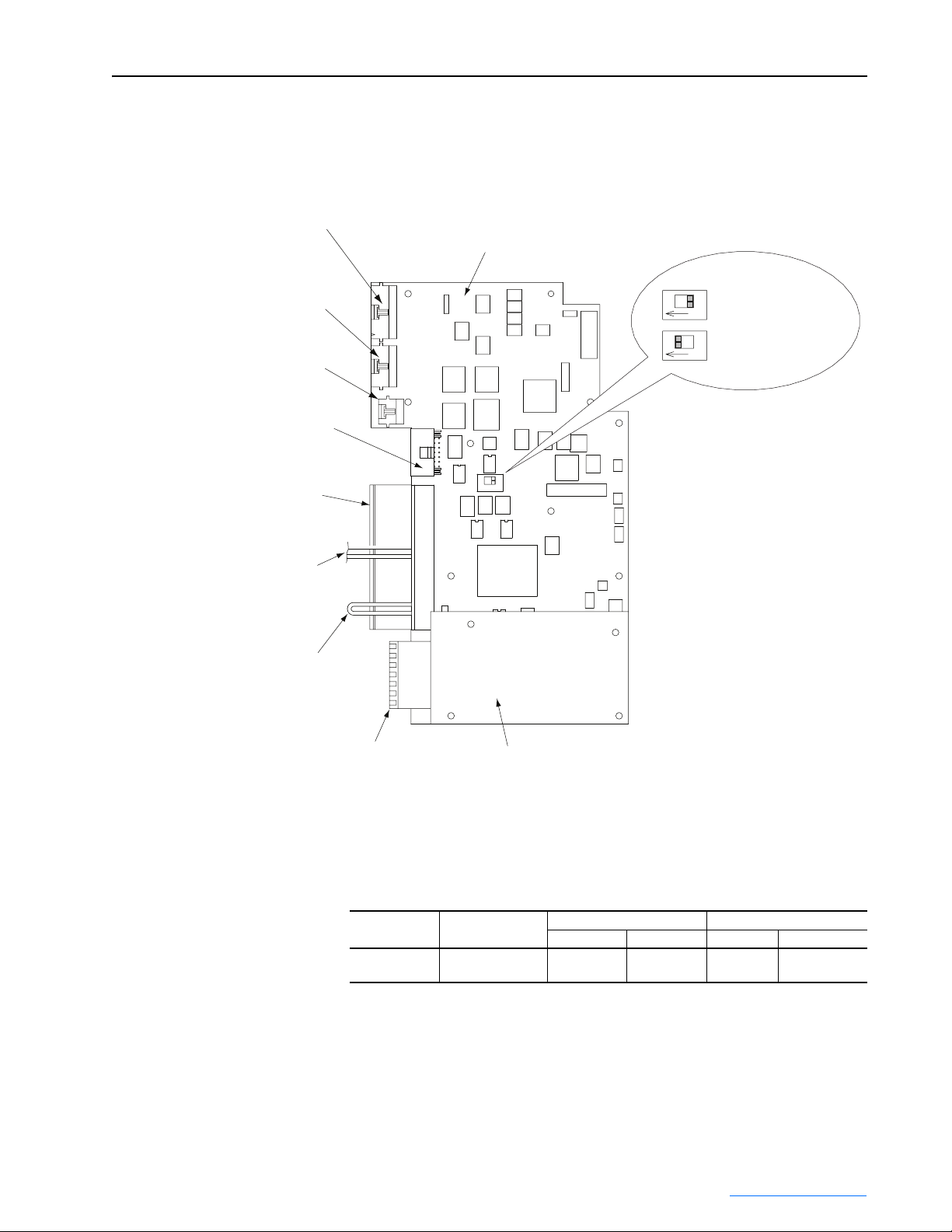

J1 40-Pin

Ribbon Cable

Header

Installation/Wiring 1-5

Figure 1.3 Active Converter Control Cassette I/O Terminal, Cable Connection, and

DPI SLAVE/MASTER Switch SW1 Locations

Active Converter

Control PCB Assembly

J2 30-Pin

Ribbon Cable

Header

J9 Synchronization

Cable Header

(700S Ph. II Control only)

J4 Internal DPI

Cable Header

P1 I/O Terminals

(see Table 1.B for

terminal descriptions)

P1-7 and P1-8

Synchronization

Cable Connection

(700 Vector Control only)

P1-13 and P1-14

Factory-Installed

Gate Kill Jumper

SW1

DPI SLAVE = OFF

ON

DPI MASTER = ON

ON

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

7

6

5

4

3

2

1

SW1

P2 I/O Terminals

(see Table 1.C for

terminal descriptions)

I/O Terminal Blocks

Table 1.A Active Converter Control Board I/O Terminal Block Specifications

Name Description

I/O Blocks Signal and power

(1)

Voltage Feedback

Resistor PCB Assembly

Wire Size Range

Maximum Minimum Maximum Recommended

2

connections

Maximum/minimum that the terminal block will accept - these are not recommendations.

1.5 mm

(16 AWG)

(1)

2

0.14 mm

(28 AWG)

PowerFlex 700L Active Converter Power Module User Manual

0.25 N-m

(2.2 lb.-in.)

Publication PFLEX-UM002D-EN-P

Torque

0.22 N-m

(1.9 lb.-in.)

Page 16

1-6 Installation/Wiring

Table 1.B Active Converter Control PCB Assembly P1 Terminal Descriptions

Pin Description

1Comm Out +

2Comm Out 3 SOC Out +

4 SOC Out 5 Comm In +

6 Comm In 7 SOC In +

8 SOC In 9Aux Out N.O.

10 Aux Out Common

11 Analog In Signal

12 Analog In Common

13 Gate Enable

14 24 Vdc

15 Aux Input

Table 1.C Voltage Feedback Resistor PCB Assembly P2 Terminal Descriptions

Pin Description

7L3

4L2

1L1

Specific pins on P1 and P2 terminals require control wiring connections to

the Input Filter Bay. For wiring information, please refer to the PowerF lex

700L Liquid-Cooled Adjustable Frequency AC Drive User Manual

(Publication No. 20L-UM001…).

Using the Active Converter as a Coupled Unit vs. Standalone Unit

Frame 3B converter power structures may be ordered as a unit Coupled to

an inverter (DPI SLAVE), or as a Stand Alone unit (DPI MASTER). Frame

2 and Frame 3A power structures are always wired for the converter to be a

Coupled unit.

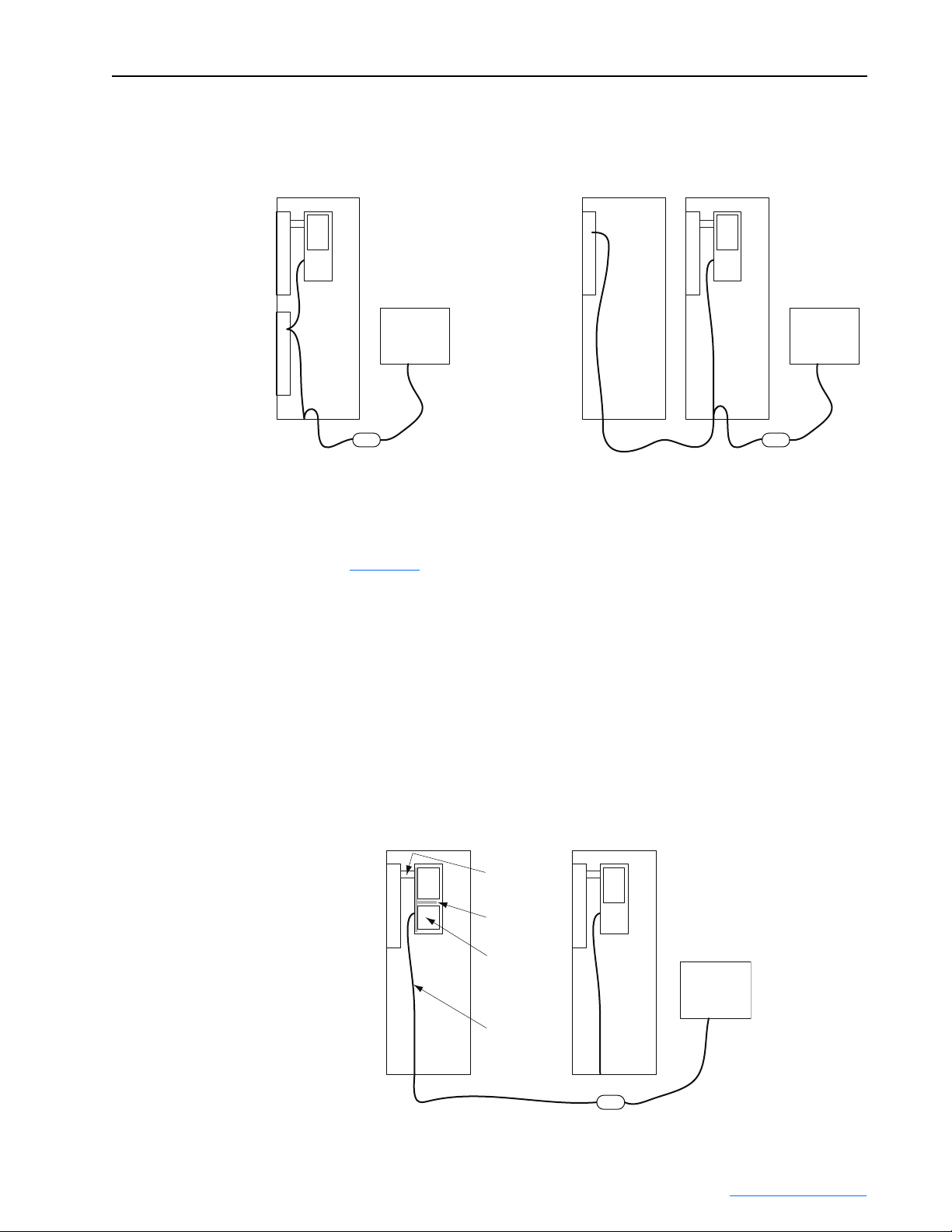

Coupled

Figure 1.4

(DPI SLAVE). In this configuration, the Converter is connected to a

PowerFlex 700L Inverter through DPI Port 6. When configured for "Run On

Start," the Converter is able to start and stop automatically as the Inverter is

started and stopped.

shows the Active Converter wired to operate as a Coupled unit

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 17

Installation/Wiring 1-7

Figure 1.4 Active Converter Operating as a Coupled Unit (DPI SLAVE)

Frame 3A with Converter as a

Coupled Unit (DPI SLAVE)

I

n

HIM HIM

v

e

r

t

e

r

C

o

n

v

e

r

t

e

r

1203-USB or 1203-SSS

Serial Converter

Personal

Computer

Stand Alone

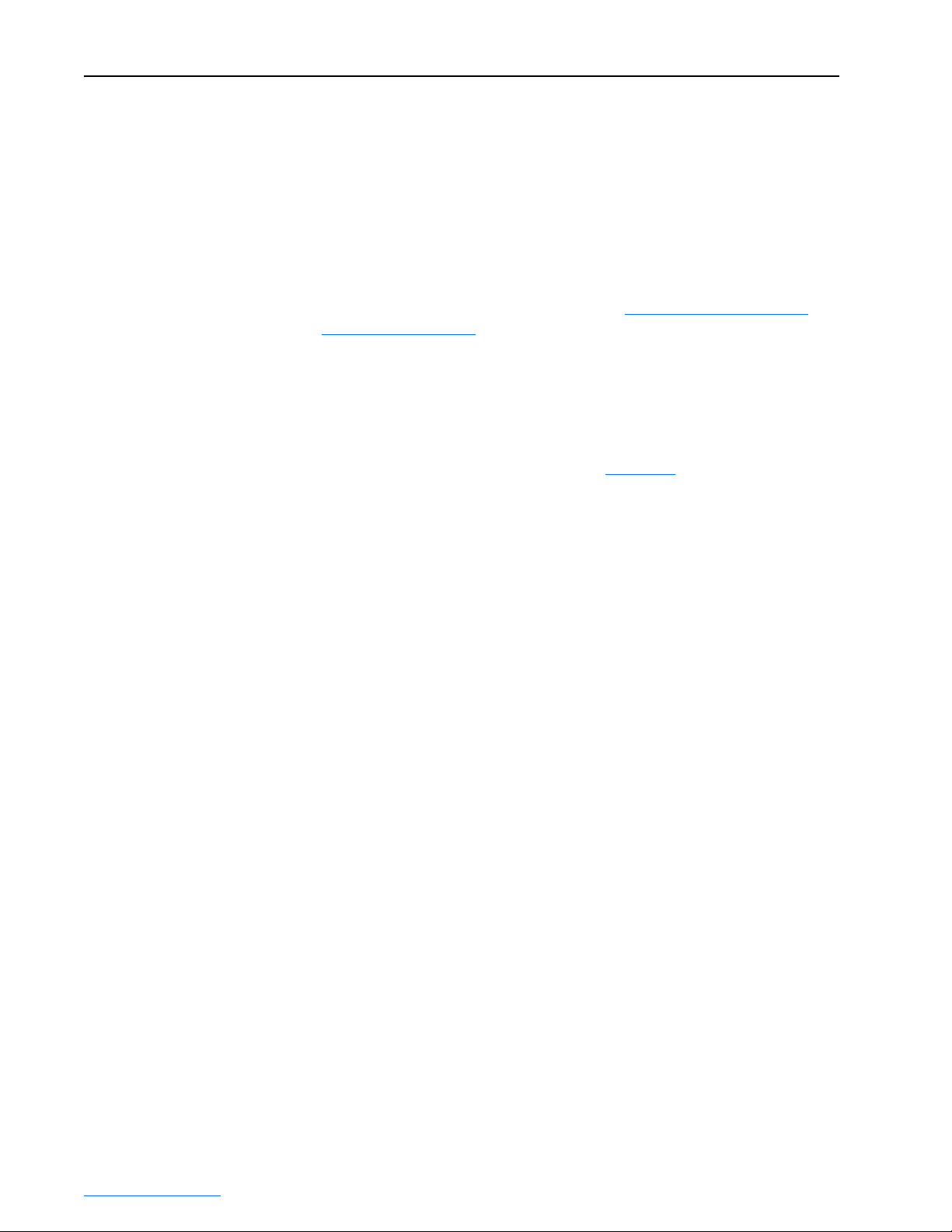

Figure 1.5

unit (DPI MASTER). In this configuration, the Converter may have a HIM

or any PowerFlex 7-Class network communication adapter (20-COMM-x)

connected. This may be preferred when the converter is to supply the DC

bus for a set of common bus inverters. When configured for "Run On Start,"

the precharge bypass contactor may be configured to close when the power

is turned on and the DC Bus voltage is stable (see Parameter 51 - [Option

Select]). The Converter starts and stops with commands from the HIM, the

1203-USB or 1203-SSS serial converter, or a 20-COMM-x network

communication adapter.

Frame 3B with Converter as a

Coupled Unit (DPI SLAVE)

C

o

n

v

e

r

t

e

r

I

n

v

e

r

t

e

r

1203-USB or 1203-SSS

Serial Converter

Personal

Computer

shows the Active Converter wired to operate as a Stand Alone

Figure 1.5 Active Converter Operating as a Stand Alone Unit (DPI MASTER)

Frame 3B with Converter as a

Stand Alone Unit (DPI MASTER)

C

o

HIM

n

v

e

r

t

e

r

196755-C01

193136

20-COMM-x

181046-C01

I

n

HIM

v

e

r

t

e

r

1203-USB or 1203-SSS

Serial Converter

PowerFlex 700L Active Converter Power Module User Manual

Personal

Computer

Publication PFLEX-UM002D-EN-P

Page 18

1-8 Installation/Wiring

The Frame 3B Active Converter power module is ordered as a Stand Alone

unit (DPI SLAVE) by specifying equipment type P in the catalog number

(refer to the catalog number explanation in the PowerFlex 700L User

Manual).

The Stand Alone (DPI SLAVE) Active Converter is supported with Active

Converter firmware revision 3.001 (or higher).

To operate the Frame 3B Active Converter as a Stand Alone unit (DPI

SLAVE) the DPI MASTER/SLAVE switch (SW1) on the Active Converter

control board must be properly set. Refer to Setting the DPI MASTER/

SLAVE Switch (SW1) below for details.

Setting the DPI MASTER/SLAVE Switch (SW1)

Active Converters with version 2.006 (or lower) firmware are always

operated as a peripheral on DPI port 6. In this case, switch SW1 on the

Active Converter control PCB assembly (Figure 1.3

SLAVE). Do not use the ON setting. For Active Converters with version

3.001 (or higher) firmware, switch SW1 is used to select between converter

operation as a Coupled unit (DPI SLAVE position) or as a Stand Alone unit

(DPI MASTER position).

) is set to OFF (DPI

Connecting an Active Converter Power Module to an Inverter Power Module

Frame 2 and 3A Drives

Coupling a Frame 2 or 3A Power Module is achieved by using two cables: a

DPI cable and a control synchronization cable. These cables are factory

installed.

Frame 3B Drives

Coupling a Frame 3B Active Converter Power Module to a Frame 3B

Inverter Power Module is achieved by using two cables: a DPI cable and a

control synchronization cable. For the Complete Drive equipment type,

these cables are factory installed. When Power Modules are purchased

separately, these cables are user installed. For information regarding these

cables and their installation, please refer to the PowerFlex 700L

Liquid-Cooled Adjustable Frequency AC Drive User Manual (Publication

No. 20L-UM001…), Chapter 3 in the “Synchronization Connections for

Frame B” section.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 19

Chapter 2

Start Up

The start-up procedure built into the HIM addresses only the start up of the

inverter. This chapter describes how to start up the PowerFlex 700 Active

Converter Power Module.

For information on… See page…

Establishing Communication as a Coupled Unit

Establishing Communication as a Stand Alone Unit 2-8

Converter Sequencing 2-12

Control Setup 2-14

Converter Faults 2-17

2-1

Establishing Communication as a Coupled Unit

When the Converter is set to operate as a Coupled unit (DPI SLAVE), the

first step after turning on power is to verify that you are able to

communicate with the unit and that it properly displays selected data.

Data is exchanged between the Inverter Power Module and Active

Converter Power Module to pass control and status information.

An example is given for how to communicate with the Active Converter

Power Module using a CIP message from a ControlLogix controller.

Accessing Active Converter Power Module Parameters

The Active Converter operates as a DPI peripheral on port 6. This section

describes how to access parameters in the Active Converter.

Using the HIM

1. On power up, the HIM displays the main menu and communicates with

the Inverter.

F-> Stopped Auto

0.0 RPM

Main Menu:

Diagnostics

Parameter

Device Select

2. As you scroll down to “Device Select,” the HIM shows the following

indication. With “Device Select” highlighted, press the Enter key.

F-> Stopped Auto

0.0 RPM

Main Menu:

Parameter

Device Select

Memory Storage

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 20

2-2 Start Up

3. The HIM displays that it is currently communicating with the Inverter on

DPI Port 0.

F-> Stopped Auto

0.0 RPM

Device: Port 0

PowerFlex 700S 2

PowerFlex 700 AC

4. Press the Down arrow to scroll to “PowerFlex 700 AC.”

F-> Stopped Auto

0.0 RPM

Device: Port 6

PowerFlex 700S 2

PowerFlex 700 AC

5. With “PowerFlex 700 AC” highlighted as shown in Step 4, press the

Enter key to start communicating with the Active Converter on DPI Port

6.

Port 6 Device

PowerFlex 700AC

Main Menu:

Diagnostics

Parameter

Device Select

– To examine the fault queue in the Active Converter, press the Up

Arrow to scroll to “Diagnostics” and press the Enter key.

– To begin examining parameters (with “Parameters” highlighted),

press the Enter key.

– To resume communication with the Inverter, press the Down Arrow to

scroll to “Device Select” and press the Enter key.

6. After accessing the Parameter menu, the display shows the File menu.

Press the Up or Down Arrow to select the desired file and press the Enter

key.

Port 6 Device

PowerFlex 700AC

FGP: File

Monitor

Command

Limit Config

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 21

Start Up 2-3

7. The display then shows the groups of parameters in the selected file.

Press the Up or Down Arrow to select the desired group and press the

Enter key.

Port 6 Device

PowerFlex 700AC

FGP: Group

Current

Vol ta ge

Power & Ti me

8. The display then shows the parameters in the selected group. Press the

Up or Down Arrow to select the desired parameter and press the Enter

key.

Port 6 Device

PowerFlex 700AC

FGP: Parameter

Rated Amps

Input Current R

Input Current S

9. The display then shows the value of the selected parameter and allows

for entry of a new value for parameters that are read/write.

Port 6 Device

PowerFlex 700AC

FGP: Par 1

Rated Amps

705.0 Amps

[Alt] [View] - > Limits

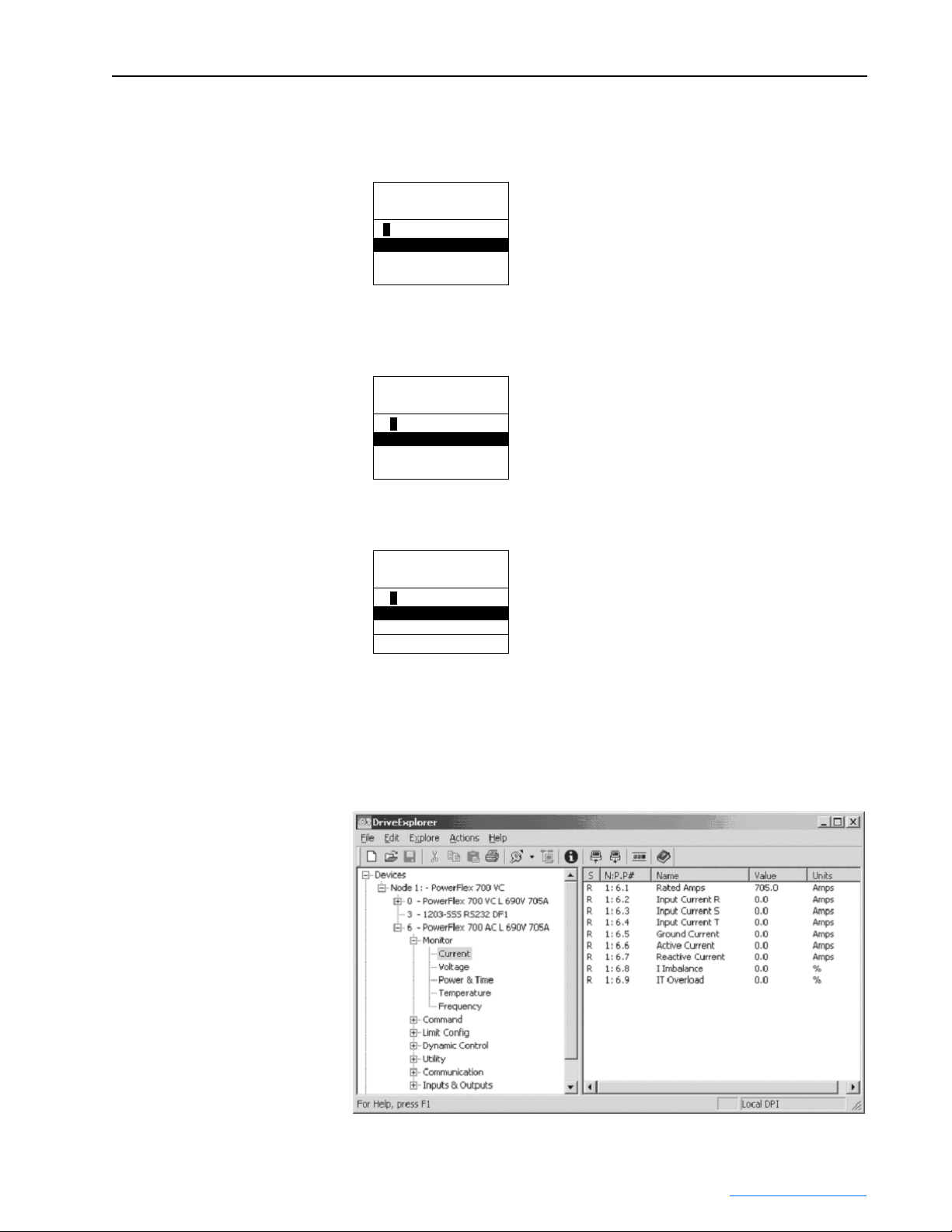

Using DriveExplorer

When using DriveExplorer, the window shows the files and groups for the

Active Converter (left pane) and the parameters for the selected group (right

pane). Double-click a parameter in the right pane to edit it

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 22

2-4 Start Up

Using DriveExecutive

When using DriveExecutive, the Active Converter parameters are displayed

in a linear list. Uploading reads parameter values from all DPI peripherals

but downloading parameters only write to the Inverter. To download

parameter values to the Active Converter, you must first select the

Converter.

Verifying Feedback Parameters

Using the HIM, DriveExplorer or DriveExecutive, verify that reasonable

values are displayed for the following parameters in the Active Converter

Power Module:

• Line to Line Voltage – Verify converter parameters 11 - [Input Voltage

RS], 12 - [Input Voltage ST], and 13 - [Input Voltage TR] display a

reasonable Line to Line RMS Voltage. Verify the voltage imbalance

displayed in parameter 16 - [V Imbalance] does not exceed 5.0%.

• DC Link Voltage – Verify converter parameter 14 - [DcLink Voltage]

displays a reasonable DC Link Voltage.

• AC Line Frequency – Verify converter parameter 40 - [Line Frequency]

displays a reasonable AC Line Frequency.

• Ambient Temperatures – Verify converter parameter 30 - [Ambient

Temp] displays a reasonable ambient temperature. Verify parameter 32 [IGBT Junction Temp] displays the temperature of the liquid being

pumped through the coldplate.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 23

Start Up 2-5

Exchanging Data

DPI Type 3 communication is used to exchange control and status

information between the Inverter and the Converter. This provides a

mechanism to start and stop the Converter as the Inverter is started and

stopped. It also transfers the minimum DC Link voltage required for the

given motor voltage to the Converter, and any Converter fault codes back to

the Inverter so all faults are maintained in the Inverter’s fault queue. The

data exchanged is displayed in these Active Converter parameters:

• 70 - [Converter Control] • 72 - [Converter Min Vdc]

• 71 - [Converter Status] • 73 - [Converter Fault]

No setup is required to configure the Type 3 communication. The Converter

requests a Type 3 connection at power up and, when the connection is

complete, Converter parameter 320 - [Connect Status] shows which

communication types are active. The use of Type 3 communication for

exchange of data is important in that none of the normal data links are used

for this communication. By default, all four sets of DPI data links remain

available for use in a 20-COMM-* adapter.

The automatic starting and stopping of the Active Converter requires the

Converter to be configured for “0 = Run On Start” using Converter

parameter 50 - [Start Config]. In this case, when the Inverter is started or

jogged, the Converter is enabled and the Inverter sequencing delays running

the Inverter for up to 500 milliseconds, allowing the Converter to close the

precharge bypass contactor. When the Inverter is stopped, the Converter

continues to run for the time configured in Converter parameter 53- [Turn

Off Delay]. On a subsequent start or jog, the Inverter does not need to wait

for the precharge to close if the Converter is still running.

Start Jog

Inverter

Functions

Inverter

Communications

Converter

Communications

PF700 AC

Parameters

AC 70 - [Converter Control]

AC 72 - [Converter Min Vdc]

Inverter Sequencing

Inverter DPI Type 3

Producer / Consumer

Converter DPI Type 3

Producer / Consumer

AC 71 - [Converter Status]

AC 73 - [Converter Fault]

Converter

Functions

Converter Sequencing

Precharge

Contactor

PowerFlex 700L Active Converter Power Module User Manual

Converter

Enable

Publication PFLEX-UM002D-EN-P

Page 24

2-6 Start Up

In addition to Type 3 communication, the 700S may optionally use DPI data

links to control the sequencing of the Converter from a Logix processor as

shown below. This requires the Converter to be configured for Manual

Control in Converter parameter 50 - [Start Config]. The reference for the

voltage loop may also be controlled by a Logix processor when Converter

parameter 160 - [Voltage Loop Sel] is set to Manual Ref.

The DPI data links between the Inverter and Converter are enabled by

setting Converter parameters 300 - [Data In A1] through 317 - [Data Out

D2] to the parameter number of the data to send or receive. When a DPI

data link is used by the Converter, that channel cannot be used by a different

communication card. The following example illustrates using DPI data links

between the Inverter and Converter.

Suppose Inverter parameter 666 is linked to Converter parameter 52 [Manual Control], Inverter parameter 667 is linked to Converter parameter

60 - [DcLink Reference], and Converter parameter 71 - [Converter Status] is

linked to Inverter parameter 657. This requires Converter data links to be

configured as follows:

• Active Converter parameter 306 [Data In D1] = 52

• Active Converter parameter 307 [Data In D2] = 60

• Active Converter parameter 316 [Data Out D1] = 71

This example shows Data Link D being used to communicate with the

Converter. The Converter supports DPI Data Links A, B, C, and D so any

group could be used as needed.

All the options for starting and stopping the Converter are explained in

greater detail in Converter Sequencing

Logix

PF700 S

Parameters

Inverter

Communications

Converter

Communications

PF700 AC

Parameters

S 667 - [DPI Data Out D2]

AC 52 - [Manual Control]

AC 60 - [DcLink Reference]

on page 2-12.

S 657 - [DPI Data In D1]S 666 - [DPI Data Out D1]

Inverter DPI Data Link

Producer / Consumer

Converter DPI Data Link

Producer / Consumer

AC 71 - [Converter Status]

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Converter

Functions

Converter Sequencing

Precharge

Contactor

Converter

Enable

Page 25

Start Up 2-7

CIP Messages

Parameters in the Converter may be accessed by a Logix processor using a

CIP message block. To read or write a parameter value you must

respectively perform a Get Attribute Single or Set Attribute Single message

to the DPI Parameter Object (Class 0x93). The Converter is in DPI Port 6,

so the instance is 22528 plus the parameter number. The value of the

parameter is accessed through Attribute 0x9 or 0xA. The example shown

below reads the value of Converter parameter 30 - [Ambient Temp].

Class Code

Hexadecimal Decimal

0x93 147

Instances

Instances (Hex.) (Dec.) Device

0x0000 – 0x3FFF 0 – 16383 Host

0x4000 – 0x43FF 16384 – 17407 Adapter

0x4400 – 0x47FF 17408 – 18431 DPI Port 1

0x4800 – 0x4BFF 18432 – 19455 DPI Port 2

0x4C00 – 0x4FFF 19456 – 20479 DPI Port 3

0x5000 – 0x53FF 20480 – 21503 DPI Port 4

0x5400 – 0x57FF 21504 – 22527 DPI Port 5

0x5800 – 0x5BFF 22528 – 23551 DPI Port 6

Attributes

ID Rule Name Data Type Description

0x9 Get/Set Parameter Value Various Value in NVS

0xA Get/Set Parameter Value Various Value in RAM

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 26

2-8 Start Up

Establishing Communication as a Stand Alone Unit

When the Converter is set to operate as a Stand Alone unit (DPI MASTER),

the first step after turning on power is to verify that you are able to

communicate with the unit and that it properly displays selected data.

Accessing Active Converter Power Module Parameters

Using the HIM

1. On power up, the HIM displays the AC Line Frequency, the Active

Current, and the DC Bus Voltage. The status text will display one of five

indications: Faulted, Start Inhibit, Ready, Running or Ride Through.

F-> Ready Auto

59.97 Hz

0.00 Amps

664.20 Bus VDC

2. Access the parameters of the Converter by selecting Parameter on the

Main Menu.

F-> Ready Auto

59.97 Hz

Main Menu:

Diagnostics

Parameter

Device Select

3. Parameters may then be accessed with the File, Group, Parameter menu,

F-> Ready Auto

59.97 Hz

FGP: File

Monitor

Command

Limit Config

or with a Numbered List.

F-> Ready Auto

59.97 Hz

Parameter : #

Rated Amps

650.0 Amps

[Alt] [View] - > Limits

The start and stop buttons may start and stop the Converter. The stop button

may also be used to reset a fault in the Converter. The speed, jog, forward/

reverse, and auto/manual buttons are not functional.

F-> Ready Auto

FGP: File

Current

Voltage

Power & Time

1

59.97 Hz

F-> Ready Auto

59.97 Hz

FGP: File

Rated Amps

Input Current R

Input Current S

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 27

Start Up 2-9

Using DriveExplorer or DriveExecutive

When using DriveExplorer or DriveExecutive, the Converter parameters are

displayed under Port 0 and are organized into the normal menu of Files,

Groups, and Parameters. The control bar can be opened to show a stop and

start push button.

Verifying Feedback Parameters

Using the HIM, DriveExplorer or DriveExecutive, verify that reasonable

values are displayed for the following parameters in the Active Converter

Power Module:

• Line to Line Voltage – Verify converter parameters 11 - [Input Voltage

RS], 12 - [Input Voltage ST], and 13 - [Input Voltage TR] display a

reasonable Line to Line RMS Voltage. Verify the voltage imbalance

displayed in parameter 16 - [V Imbalance] does not exceed 5.0%.

• DC Link Voltage – Verify converter parameter 14 - [DcLink Voltage]

displays a reasonable DC Link Voltage.

• AC Line Frequency – Verify converter parameter 40 - [Line Frequency]

displays a reasonable AC Line Frequency.

• Ambient Temperatures – Verify converter parameter 30 - [Ambient

Temp] displays a reasonable ambient temperature. Verify parameter 32 [IGBT Junction Temp] displays the temperature of the liquid being

pumped through the coldplate.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 28

2-10 Start Up

Using a 20-COMM-x Adapter

When a 20-COMM-x network communication adapter is connected to the

Converter, the Product Logic Command bits may be used to start and stop

the Converter and to reset a fault. All other bits are reserved. The Product

Logic Status bits may be used to determine the state of the Converter.

Converter Logic Command Word

Logic Bits

1514131211109876543210Command Description

x Stop 0 = Not Stop

x Start 0 = Not Start

x Reserved

x Fault Reset 0 = Not Fault Reset

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

1 = Stop

1 = Start

1 = Fault Reset

Converter Logic Status Word

Logic Bits

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 Status Description

x Ready 0 = Not Ready

x Running 0 = Not Running

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

x Reserved

The reference value from the 20-COMM-x adapter that is often used to

select the speed is not used in the Converter. The Converter is always

xAlarm0 = No Alarm

x Fault 0 = No Fault

1 = Ready

1 = Running

1 = Alarm

1 = Fault

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 29

Start Up 2-11

synchronized to the AC line frequency and does not have a speed reference.

The feedback value sent to the 20-COMM-x adapter is the measured AC

line frequency, where a value of 32767 corresponds to 100.00 Hz.

The Converter supports 16-bit data links so if all data links are configured in

the 20-COMM-x then the Connection Parameters in the Logix Processor

must be setup as shown here. This defines twelve 16-bit words sent from the

20-COMM-x to the Logix, and ten 16-bits words sent from the Logix to the

20-COMM-x.

The data is utilized as shown below:

Logix to 20-COMM-x 20-COMM-x to Logix

Word Output I/O Word Input I/O

1 Logic Command 1 Not Used

2 Reference (not used) 2 Not Used

3 Datalink In A1 3 Logic Status

4 Datalink In A2 4 Feedback (AC line frequency)

5 Datalink In B1 5 Datalink Out A1

6 Datalink In B2 6 Datalink Out A2

7 Datalink In C1 7 Datalink Out B1

8 Datalink In C2 8 Datalink Out B2

9 Datalink In D1 9 Datalink Out C1

10 Datalink In D2 10 Datalink Out C2

11 Datalink Out D1

12 Datalink Out D2

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 30

2-12 Start Up

Converter Sequencing

The condition when to start and stop the Converter must be configured in

parameter 50 - [Start Config]. There are three ways to operate the

Converter: Run On Start, Run On Power Up, and Manual Control. This also

configures how the precharge bypass contactor operates.

Run On Start

When Converter parameter 50 - [Start Config] is set to “0 = Run On Start,”

the operation changes when the Converter is set as a Coupled unit (DPI

SLAVE) or a Stand Alone unit (DPI MASTER) using SW1 (Figure 1.3

Coupled Unit (DPI SLAVE Setting)

When set as a Coupled unit (DPI SLAVE) and Run on Start is selected, then

starting and stopping the Converter is coordinated with starting and

stopping the Inverter. When the Inverter is started or jogged, the Converter

is enabled to turn on. When the Inverter is stopped or jog is released, the

Converter is stopped.

Stand Alone Unit (DPI MASTER Setting)

When set as a Stand Alone unit (DPI MASTER) and Run on Start is

selected, then the Converter may be started and stopped from the buttons on

a HIM, or by the Logic Command bits transmitted by a 20-COMM-x

adapter or 1203-USB or 1203-SSS device. The logic masks determine

which DPI ports are allowed to take control.

).

Precharge Bypass Operation

In Run On Start, the precharge can be configured to operate in one of two

ways as selected by parameter 51 - [Option Select], Bit 7 (Precharge

Control). By default, this option bit is turned off so the precharge bypass

contactor will be commanded to close at the time the Converter is

commanded to start, and the bypass contactor opens after the Converter is

commanded to stop. If the option bit is set, then the bypass contactor is

closed at power up after the DC bus is at steady state.

If there is a fault in the Converter, the precharge bypass contactor will open.

If the option bit is set, the bypass contactor is closed when the fault is reset.

The option bit also selects how long the Converter continues to run after it is

commanded to stop. If the option bit is turned off, then parameter 53 - [Turn

Off Delay] selects the time delay between the stop command and the time

when the converter is stopped and the bypass is opened. If the option bit is

turned on, then the Converter stops without a delay.

As a Coupled unit (DPI SLAVE), Run On Start with the precharge option

bit turned off is recommended for applications where the drive is left

powered up but the drive is not run for extended periods of time. With the

precharge bypass contactor open, the fan cooling the input reactor is turned

off.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 31

Start Up 2-13

Run On PwrUp

When Converter parameter 50 - [Start Config] is set to “1 = Run On

PwrUp,” the precharge bypass contactor is automatically closed and the

Converter is enabled shortly after power is turned on.

The precharge will close as soon as the DC Link voltage is above the

minimum required level and it has reached steady state. The precharge will

remain closed when there is a fault in the Converter. When the fault is reset,

the Converter will go back into run. In this configuration, the coolant

circulating loop must be enabled when the Converter is enabled, even if the

Inverter is not in run. The auxiliary contacts on the precharge bypass could

be used to enable the circulating pump.

This mode of operation is recommended for applications where the drive is

powered down when it is to be stopped for an extended period of time.

Manual Cntrl

When Converter parameter 50 - [Start Config] is set to “2 = Manual Cntrl,”

the operation of the precharge bypass contactor and enabling of the

Converter is controlled by two bits in Converter parameter 52 - [Manual

Control]. The bits are normally level sensitive. Turning the bits on closes the

bypass contactor and enables the Converter. Turning the bits off opens the

bypass contactor and disables the Converter.

The exception is that if there is a fault, the bypass contactor is not allowed to

close. After a fault, the fault must be reset, and then a rising edge on bit 1 in

parameter 52 - [Manual Control] is required to re-enable the Converter. The

value in parameter 52 is not retentive; it is reset to zero on power up.

When operating as a Coupled unit (DPI SLAVE), the Inverter is not allowed

to start with the precharge open and the Inverter will fault if it started with

the Converter stopped. When operating as a Stand Alone unit (DPI

MASTER), the value in parameter 52 - [Manual Control] may be written by

a datalink and the value in parameter 72 - [Converter Status] may be read

with a datalink and used as part of the interlocks with Inverters.

Start Inhibit

If the Converter does not start when expected, refer to Converter parameter

214 - [Start Inhibit] to display the Start Inhibit conditions.

Sequencing Precautions

When operating as a Coupled unit (DPI SLAVE) that is supplying power to

a single Inverter, the built-in interlocks will not allow the Inverter to start

unless the Converter is running, and the Converter will not stop when the

Inverter is running. However, when the Converter is operated as a Stand

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 32

2-14 Start Up

Alone unit (DPI MASTER) and is supplying power to a common bus, extra

precaution must be taken.

ATTENTION: When operating as a Stand Alone unit (DPI

MASTER) or supplying power to a common bus, external logic

!

must be used to make sure the precharge bypass contactor is

closed and the Converter is running before running an Inverter.

Likewise, all Inverters must stop if the precharge opens or the

Converter stops.

Operating an Inverter with the precharge bypass open will overheat the

precharge resisters. Operating an Inverter with the Converter stopped will

draw non-sinusoidal current with peak current greater than rated and will

have significant harmonic distortion.

Control Setup

The following topics discuss parameters that should be reviewed when

starting up an Active Converter.

Current Limits

Converter parameter 100 - [Active I Lmt] defines the limit on active current.

This parameter defaults to 150% of Converter rated current. Current limit

for regeneration is set in parameter 105 - [Regen I Lmt]. This defaults to

-150% of Converter rated current. When in current limit, the Converter is

unable to regulate the DC link voltage. If the drive is motoring and the

Converter is in current limit, then the DC link will drop to the peak of the

AC line. If the drive is regenerating and the Converter is in current limit, the

DC link will rise and it is up to the Inverter to limit its regenerating current

to avoid a high bus fault.

The Converter parameter 71 - [Converter Status] word bit 4 (Bus Reg Ena)

turns on when the Converter is in current limit to command the Inverter to

enable its bus voltage regulators. When the Converter is active and Bus Reg

Ena is turned off, the bus voltage regulators in the Inverter are turned off.

Line Voltage Limits

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

The limits on line voltage may need to be adjusted to indicate abnormal

conditions. At low line voltages, the Converter will deliver greater amps to

produce the same power. If the possible range of input voltage would result

in a condition that would exceed the rated current, then the voltage limits

must be set to guard against this condition. The low voltage and high

voltage limits have timers associated with each limit to allow brief

excursions outside of normal operating conditions. See Converter

parameters 112 -[Low Vac Lmt] through 115 - [High Vac Time].

Page 33

Start Up 2-15

Frequency Limits

The PWM Carrier Frequency is fixed at 4 kHz and cannot be changed.

If operating on a generator, the normal range of acceptable AC line

frequencies may need to be expanded. The limit of the rate of change may

also need to be adjusted to allow the line synchronization to properly track

the changes in frequency. See Converter parameters 131 - [AC Low Freq

Lmt] through 135 - [AC Maximum dF/dt].

Voltage Loop

The voltage major loop uses Vdc Reference and Vdc Feedback to calculate

the required active current to maintain a constant DC bus voltage.

Voltage Reference Selection

Converter parameter 160 - [Voltage Loop Sel] selects the value used for the

DC Link voltage reference. One of two values may be chosen at this time;

“0 = Optimized Ref” and “1 = Manual Ref.” The Regen Only option is

reserved for future enhancements, and the Open Loop option is reserved for

manufacturing tests. A password must be entered to use the Open Loop

option.

When “0 = Optimize Ref” is selected, the value for the DC Link reference is

calculated as the minimum value for the given operating condition to reduce

switching losses and increase efficiency. The base value for DC Link

reference is 1.44 times the RMS AC line. For a 480 volt line, the DC link

reference starts at 692 Vdc. This is 2% above the peak of the AC line. In

applications where the maximum motor voltage is greater than the AC line,

the Converter can boost the DC link to a higher level. The Inverter

calculates the minimum required DC link for the present motor voltage and

transmits that value to Converter parameter 72 - [Converter Min Vdc]. As

the line voltage goes up and down and as the Inverter’s motor voltage goes

up and down, the DC Link reference goes up and down to match the

operating conditions.

This option is most useful when there are significant changes in the line

voltage. This option is not recommended for common bus applications

where multiple Inverters operate at different speeds.

When “1 = Manual Ref” is selected, the value for DC Link reference is the

value in parameter 60 - [DcLink Reference]. If the peak of the AC line

becomes greater than the entered value, then the AC line will over-ride to

keep the DC link reference at least 1.44 times the RMS AC line. This option

is intended for operating at a specific DC Link voltage, or in situations were

the Converter is regulating a common bus for multiple Inverters and an

external controlling device is calculating the required DC Link voltage.

The currently commanded DC Link voltage is displayed in parameter 161 [DcLink Command].

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 34

2-16 Start Up

Voltage Loop Tuning

The tuning of the voltage loop is a function of Converter parameter 162 [Capacitance], parameter 163 - [VML bandwidth], and parameter 164 [VML Damping]. In most cases, the default values for these three

parameters should not need to be adjusted. When multiple Inverters are on a

common bus, the combined DC link capacitance of the additional inverters

must be entered into parameter 170 - [Bus Capacitance].

Current Loop

The current minor loops regulate the active current as requested by the

voltage major loop, and the reactive current to produce the desired kVAR.

kVAR Control

KVAR Control can be used for power factor compensation.

When parameter 61- [kVAR Reference] is set to zero, the Converter will

regulate reactive current to maintain unity power factor. When a nonzero

value is entered, it requests the amount of kVAR to command. Negative

values are a lagging power factor and positive values are a leading power

factor. When no real current is being delivered by the Converter, the full

current rating of the Converter may be used to produce kVAR. As real

current increases, motoring or regenerating, the reactive current limit is

automatically reduced. The reactive current limit is displayed in parameter

158- [Reactive I Lmt]. The reactive current that is being commanded is

displayed in parameter 159- [Reactive I Cmd].

Current Loop Tuning

The tuning of the current loop is a function of Converter parameter 152 [Inductance], parameter 153 - [CML Bandwidth], and parameter 154 [CML Damping]. In most cases, the default values for these three

parameters should not need to be adjusted. If a non-standard input filter is

used, the new inductance needs to be entered. When the AC line voltage has

greater than 5% impedance, the CML bandwidth may need to be reduced.

PWM Carrier Synchronization

The converter has the option to synchronize its PWM carrier frequency to

the PWM carrier frequency of the inverter to reduce the common mode

voltage on the motor. This requires the Inverter carrier frequency to be set to

4 kHz.

PWM carrier synchronization is enabled by setting parameter 51- [Option

Select] bit 3 (PWM SyncRecv). After carrier synchronization is completed,

the Converter sets parameter 71 - [Converter Status] bit 9 (PWM

SyncLock). When PWM SyncRecv is set and sync is not locked, the

Converter is inhibited from starting. If sync is lost while the Converter is in

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 35

Start Up 2-17

run, a fault is generated. This fault can be disabled in parameter 238 - [Fault

Config] bit 7 (PWM SyncLost).

When operating as a Stand Alone unit (DPI MASTER) and PWM Carrier

Synchronization is enabled, the Converter needs to know if it should

synchronize to a 700VC or a 700S. This selection is done in parameter 51 [Option Select] Bit 6 (700VC Invtr). This bit must be set for a 700VC and

cleared for a 700S. PWM carrier synchronization can only be done with one

inverter, so any other inverters on the common bus will have higher

common mode voltage.

Converter Faults

When set to operate as a Coupled unit (DPI SLAVE), any fault in the

Converter is passed to the Inverter so all the faults are recorded in the

Inverter fault queue. When set to operate as a Stand Alone unit (DPI

MASTER), the Converter maintains its own fault queue.

Converter Faults as a Coupled Unit (DPI SLAVE)

When using PowerFlex 700 Vector Control, the fault from the Converter is

added to a base number of 300, so all the Converter faults are numbered 301

to 399. The pop-up window on the HIM alerts the user to look at the fault

log in the PF700AC to get the specific fault text.

- Fault - F 340

F340 See PF700AC

Time Since Fault

00000:00:01

When using PowerFlex 700S Phase II Control, the faults from the Converter

are all combined into one fault code (F110) in the Inverter. The pop-up

window on the HIM alerts the user to look at the fault log in the PF700AC

to get the specific fault text.

- Fault - F 110

700L Cnv Faulted

Time Since Fault

00000:00:01

For a complete listing of Converter faults, descriptions, and actions, please

refer to Fault Descriptions on page 4-1

Displaying the Fault Text

To view the fault queue in the Converter with a HIM, begin by using the

Device Select menu as described in Accessing Active Converter Power

Module Parameters on page 2-1.

.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 36

2-18 Start Up

1. Rather than selecting Parameters, use the Up arrow to select

“Diagnostics” and press the Enter key.

Port 6 Device

PowerFlex 700AC

Main Menu:

Diagnostics

Parameter

Device Select

2. The HIM then displays the Diagnostics menu. With “Events” selected,

press the Enter key.

Port 6 Device

PowerFlex 700AC

Diagnostics:

Events

Status Info

Device Version

3. The HIM then displays the Diag: Events menu. With “View Event

Queue” selected, press the Enter key.

Port 6 Device

PowerFlex 700AC

Diag: Events

View Event Queue

Clear Events

Clr Event Queue

4. The HIM then displays the Event queue where the specific fault text is

displayed. In this example screen, the Converter faulted because the AC

was lost and power dip ride through was not enabled.

Port 6 Device

PowerFlex 700AC

EvtQ#1: E# 40

AC Line Lost

Accum:

0:00:00.001

Resetting Converter Faults

In most cases, faults in the Converter are reset by resetting the Inverter. If

the condition causing the fault is still present, then a second fault is

generated and recorded in the fault queue. The only exception is a

checksum fault in the Converter. A checksum fault in the Converter is reset

by doing a reset defaults in the Converter, and then reset the fault in the

Inverter.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Clearing the fault queue in the Inverter does not affect the event queue in the

Converter. The Converter event queue is cleared independently of the

Inverter fault queue.

Page 37

Chapter 3

Programming and Parameters

This chapter provides a complete listing and description of the Active

Converter Power Module parameters. The parameters can be configured

(viewed/edited) using an LCD HIM (Human Interface Module). As a

convenient alternative, programming can also be performed using

DriveExecutive™ or DriveExplorer™ software and a personal computer.

For information on… See page…

About Parameters

How Parameters are Organized 3-2

Monitor File 3-4

Command File 3-6

Limit Config File 3-9

Dynamic Control File 3-11

Utility File 3-13

Communication File 3-17

Inputs & Outputs File 3-20

3-1

About Parameters

To configure the Active Converter Power Module to operate in a specific

way, parameters may have to be set. Three types of parameters exist:

• ENUM Parameters

ENUM parameters allow a selection from 2 or more items. The LCD

HIM will display a text message for each item.

• Bit Parameters

Bit parameters have individual bits associated with features or

conditions. If the bit is 0, the feature is off or the condition is false. If the

bit is 1, the feature is on or the condition is true.

• Numeric Parameters

These parameters have a single numeric value (i.e. 0.1 Volts).

The example on the following page shows how each parameter type is

presented in this manual.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 38

3-2 Programming and Parameters

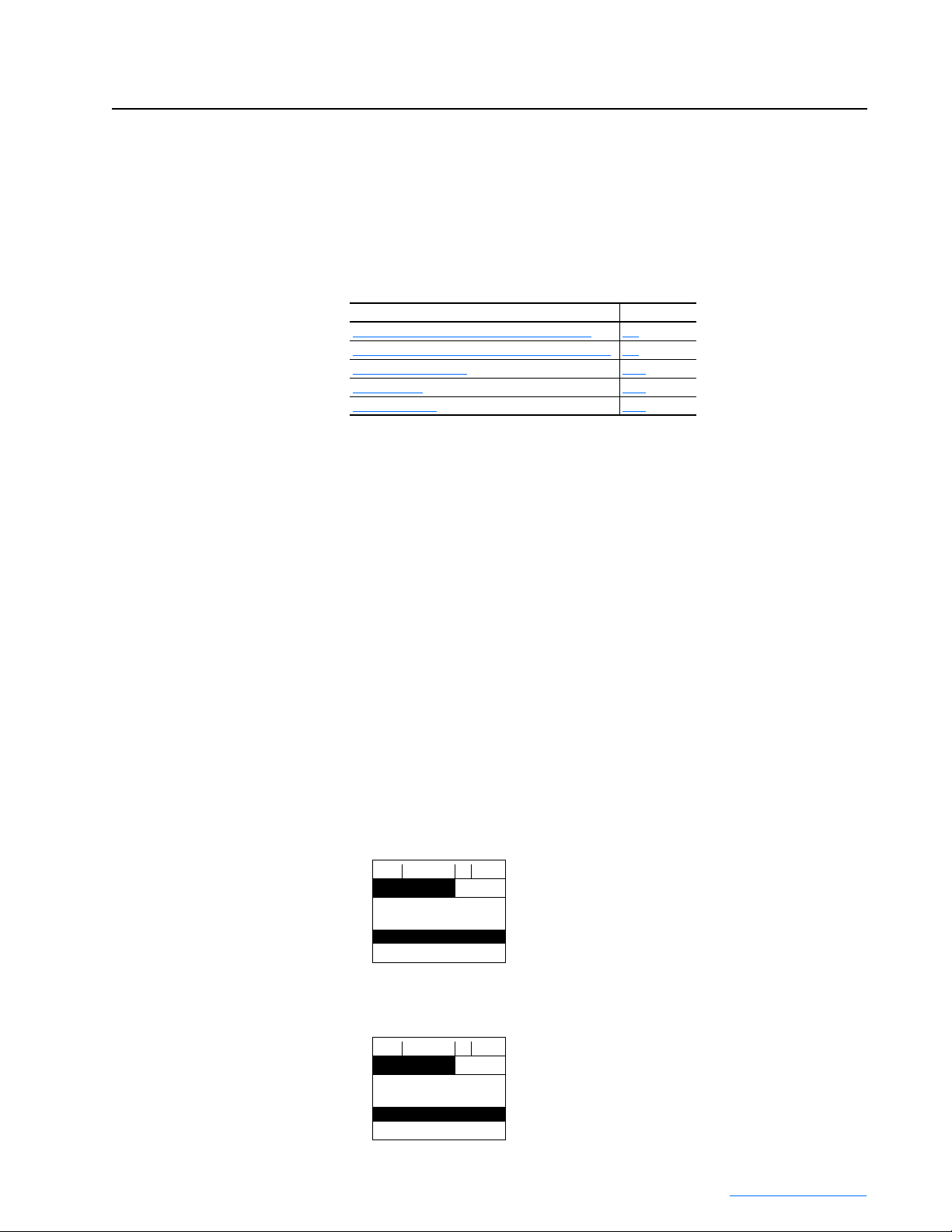

➊➌➋

File

LIMIT…

UTILITY

➍

No. Parameter Name & Description Values

Group

100 [Active I Lmt]]

Sets the current limit used when the IGBT overload is less than 90% of the IT fault

Current

threshold.

197 [Reset to Defaults]

Resets all values in the Converter to the factory defaults.

“Ready” = A new value may be entered.

Drive…

“Factory” = Parameters are reset.

238 [Fault Config]

A set of bits that select which conditions may generate faults.

Bit

Definition

Inverter Flt

PWM SyncLost

V Imbalance

I Imbalance

High dFdt

Ac High Freq

Ac Low Freq

Ac High Volt

Ac Low Volt

Default xxxxxxx101101100

Bit 1514131211109876543210

• Bit 0 (Ac Low Volt) – When this bit is set, Low AC Line Voltage will generate a fault.

• Bit 1 (Ac High Volt) – When this bit is set, High AC Line Voltage will generate a fault.

Fault Queue

• Bit 2 (Ac Low Freq) – When this bit is set, Low AC Line Frequency will generate a fault.

• Bit 3 (Ac High Freq) – When this bit is set, High AC Line Frequency will generate a fault.

• Bit 4 (High dFdt) – When this bit is set, High dF/dt will generate a fault.

• Bit 5 (I Imbalance) – When this bit is set, high current imbalance will generate a fault.

• Bit 6 (V Imbalance) – When this bit is set, high voltage imbalance will generate a fault.

• Bit 7 (PWM SyncLost) - When this bit is set, loss of PWM synchronization will generate a fault.

• Bit 8 (Inverter Flt) - When this bit is set, the Converter will fault when the Inverter faults.

0 = Disabled

1 = Enabled

x = Reserved

➎

Default:

Min/Max:

Units:

Default:

Options:00

Rated Amps*1.5

Rated ÷ 4/Rated*1.5 Amps

0.1 Amps

“Ready”

“Ready”

1

“Factory”

No. Description

File – Lists the major parameter file category.

➊

Group – Lists the parameter group within a file.

➋

No. – Parameter number. = Parameter value cannot be changed until Converter is stopped.

➌

Parameter Name & Description – Parameter name as it appears on an LCD HIM, with a brief description of the parameters function.

➍

Val ues – Defines the various operating characteristics of the parameter. Three types exist.

➎

ENUM Default:

Options:

Bit Bit: Lists the bit place holder and definition for each bit.

Numeric Default:

Min/Max:

Units:

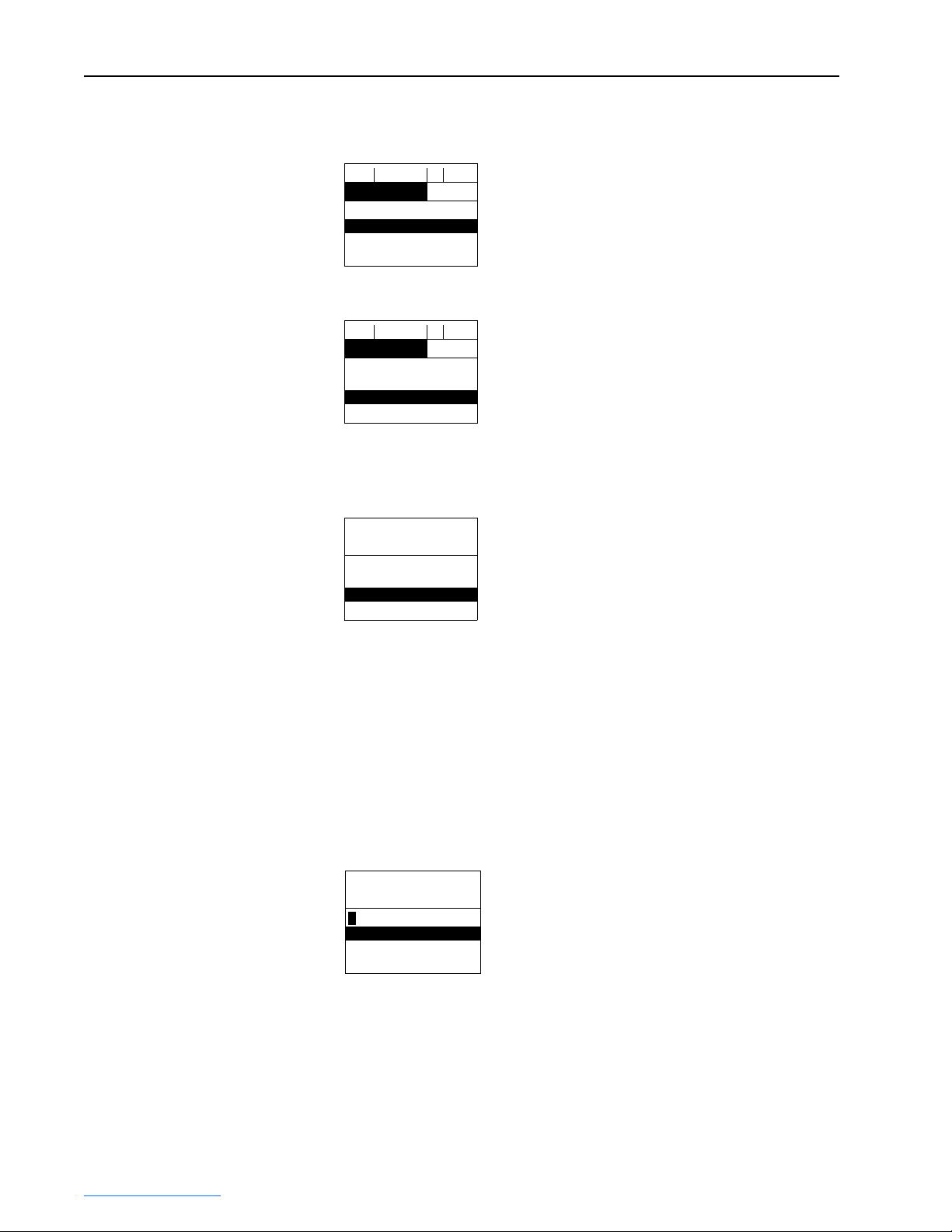

How Parameters are Organized

Lists the value assigned at the factory. “Read Only” = no default.

Displays the programming selections available.

Lists the value assigned at the factory. “Read Only” = no default.

The range (lowest and highest setting) possible for the parameter.

Unit of measure and resolution as shown on the LCD HIM.

The LCD HIM displays parameters in a File-Group-Parameter or Numbered

List view order. To switch display mode, access the Main Menu, press ALT,

then Sel while cursor is on the parameter selection.

File-Group-Parameter Order

This simplifies programming by grouping parameters that are used for

similar functions. The parameters are organized into 7 files. Each file is

divided into groups, and each group contains a set of parameters related to a

specific purpose.

PowerFlex 700L Active Converter Power Module User Manual

Publication PFLEX-UM002D-EN-P

Page 39

Programming and Parameters 3-3

File Group Parameters

Monitor Current Rated Amps 001

M

onitor

Command Start/Stop Start Config 050 Option Select 051 Manual Control 052 Turn Off Delay 053

Command

Limit Config Current Active I Lmt 100

Limit Config

Dynamic Control Current Loop Reduce Ilmt Sel 150

Dynamic Control

Utility Drive Memory Param Access Lvl 196

Utility

Communication Datalinks Data In A1 300

Communication

Inputs & Outputs Mux’ed Temps IGBT NTC Temp1 330

Inputs &

O

utputs

Input Current R 002

Input Current S 003

Voltage Rated Volts 010

Power & Time Rated Power 020

Temperature Ambient Temp 030 IGBT Base Temp 031 IGBT Junct Temp 032

Frequency Line Frequency 040

Setpoints DcLink Reference 060

Data Exchange Converter Control 070 Converter Status 071 Converter Min Vdc 072 Converter Fault 073

AC Line Voltage Ride Through Ena 110

Temperature Ambnt Temp Alrm 120

Frequency PWM Frequency 130

Voltage Loop Voltage Loop Sel 160

Diagnostics Alarm Status 211

Fault Queue Fault Config 238

DPI Status Connect Status 320

Masks & Owners Logic Mask 340

Security Port Mask Act 346 Write Mask Cfg 347 Write Mask Act 348 Logic Mask Act 349

Digital Inputs Dig In Status 350 Dig In Frc Mask 351 Dig In Frc Data 352

Digital Outputs Dig Out Status 360 Dig Out Frc Mask 361 Dig Out Frc Data 362

Input Voltage RS 011

AC Line kW 021

Motoring kWh 022

Min Line Freq 041

kVAR Reference 061

Active OL I Lmt 101

Ride Through Sec 111

Ambnt Te m p Tr ip 121

AC Low Freq Lmt 131

Active I Cmd 151

Inductance 152

DcLink Command 161

Capacitance 162

Reset to Defaults 197

Start Inhibit 214

Fault Frequency 220

Fault Amps R 221

Fault Amps S 222

Fault Clear 239

Power Up Mar ker 24 2

Data In A2 301

Data In B1 302

Data In B2 303

DPI Error Out 321

CS Msg Rx Cnt 322

Start Mask 341

IGBT NTC Temp2 331

IGBT NTC Temp3 332

Input Current T 004

Ground Current 005

Active Current 006

Input Voltage ST 012

Input Voltage TR 013

Regen kWh 023

Lifetime kWh 024

Elapsed Run Time 025

Max Line Freq 042

Min Max Persist 043

Extern Cml Ref 062

Modulation Index 063

Reactive RateLmt 102

I Imbalance Lmt 103

Low Vac Lmt 112

Low Vac Time 113

Base Temp Alrm 122

Base Te m p Tr ip 123

AC Low Freq Time 132

AC High Freq Lmt 133

CML Bandwidth 153

CML Damping 154

CML Ki 155

VML Bandwidth 163

VML Damping 164

VML Ki 165

Reset Meters 200

Language 201

Fault Amps T 223

Fault Amps Q 224

Fault Amps D 225

Fault Volts RS 226

Fault Volts ST 227

Fault 1 Code 243

Fault 1 Time 244

Fault 2 Code 245

Data In C1 304

Data In C2 305

Data In D1 306

Data In D2 307

CS Msg Tx Cnt 323

CS Timeout Cnt 324

CS Msg Bad Cnt 325

Fault Clr Mask 342

Stop Owner 343

IGBT NTC Temp4 333

Coldplate Temp1 334

IGBT NTC Temp5 335

Reactive Current 007

I Imbalance 008

IT Overload 009