Page 1

Installation Instructions

PowerFlex® 700L Spare Parts

ATTENTION: This drive contains ESD (Electrostatic Discharge)

sensitive parts and assemblies. Static control precautions are

!

required when installing, testing, servicing or repairing this

assembly. Component damage may result if ESD control

procedures are not followed. If you are not familiar with static

control procedures, refer to Allen-Bradley publication 8000-4.5.2,

“Guarding Against Electrostatic Damage” or any other applicable

ESD protection handbook.

ATTENTION: An incorrectly applied or installed drive can

result in component damage or a reduction in product life. Wiring

!

or application errors, such as undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient temperatures may

result in malfunction of the system.

Finding Specific Information

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

!

implement the installation, start-up, and subsequent maintenance

of the system. Failure to comply may result in personal injury and/

or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged completely before

!

servicing. After removing power to the drive, wait 5 minutes for

the bus capacitors to discharge. Measure the DC bus voltage at the

DC+ and DC- TESTPOINT sockets on the front of the power

module. The voltage must be zero.

ATTENTION: Risk of injury or equipment damage exists. DPI

host products must not be directly connected together via 1202

!

cables. Unpredictable behavior can result if two or more devices

are connected in this manner.

Installation information for this part can be found in one of the following

PowerFlex 700L Hardware Service Manuals which are written for the frame

size of the drive being serviced:

PowerFlex 700L Drive Hardware Service Manual

Frame 2 20L-TG002…

Frame 3A and 3B 20L-TG001…

Consult the Rockwell Automation Literature Library web site at:

www.rockwellautomation.com/literature

Page 2

A

A

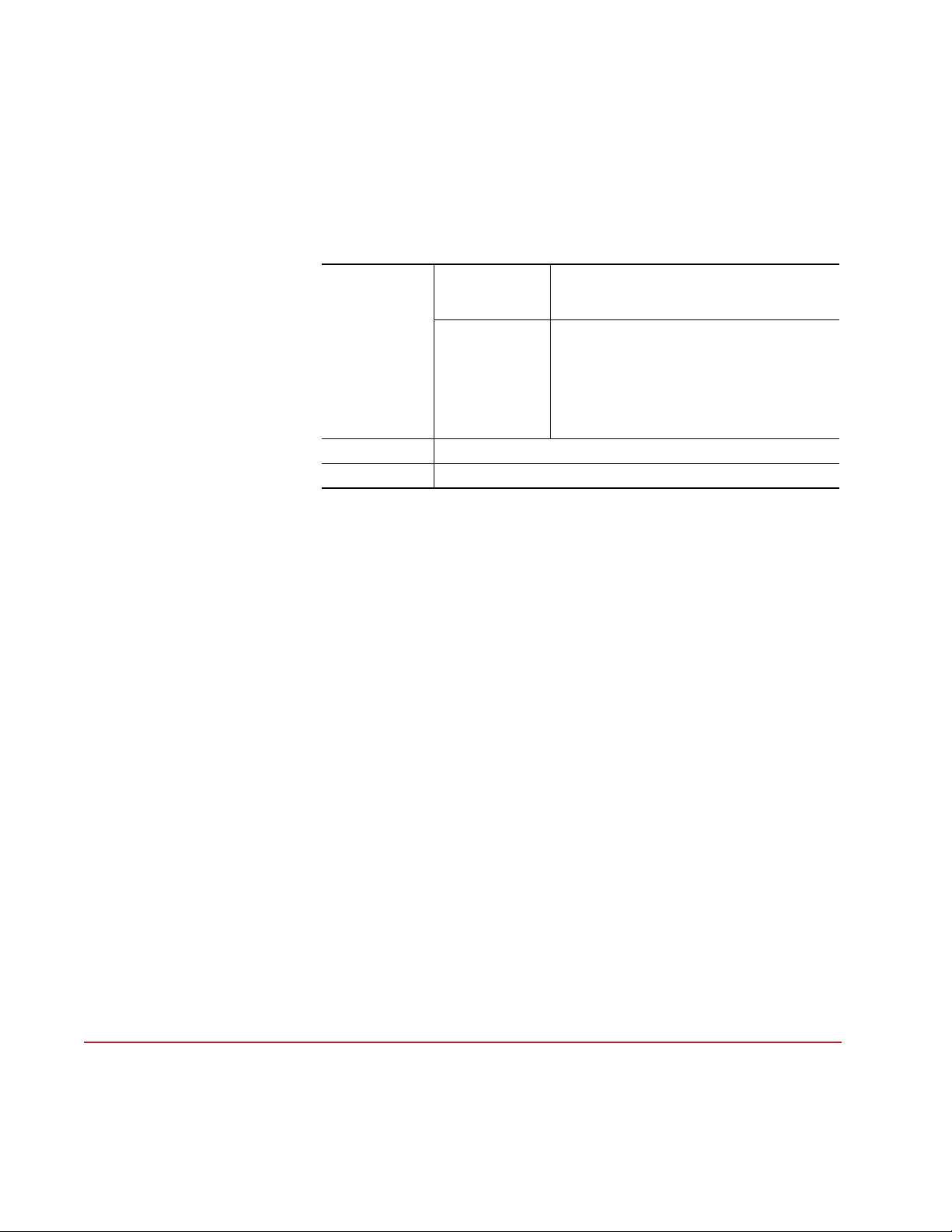

Rockwell Automation Support

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the troubleshooting information contained in the

supporting product publications first (e.g. Hardware Service Manual,

Installation Instructions, Programming Manual, etc.).

If the difficulty persists, call your local distributor or contact Rockwell

Automation in one of the following ways:

Phone United States/

Canada

Outside United

States/Canada

Internet Go to http://www.ab.com/support/abdrives/

E-mail support@drives.ra.rockwell.com

Be prepared to provide the following information when you contact

support:

• Product Catalog Number

• Product Serial Number

• Firmware Revision Level

1.262.512.8176 (7 AM - 6 PM CST)

1.440.646.5800 (24 hour paid support available

through the TechConnect Support Program)

You can access the phone number for your country via

the Internet:

Go to http://www.ab.com

Click on Support

(http://support.rockwellautomation.com/)

Under Contact Customer Support, click on Phone

Support

U.S. Allen-Bradley Drives Technical Support - Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

www.rockwellautomation.com

Power, Control and Information Solutions Headquarters

mericas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation, Vorstlaan/Boulevard du Souverain 36, 1170 Brussels, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

sia Pacific: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 20L-IN005A-EN-P – December 2006 P/N 181729-P01

Copyright © 2006 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...