Page 1

PowerFlex SCR Bus Supply

Firmware Version 1.xxx

User Manual

Page 2

Important User Information

!

!

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

http://

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

Allen-Bradley and PowerFlex are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

PowerFlex SCR Bus Supply User Manual

Page 3

Summary of Changes

The information below summarizes the changes made to this manual since

its last release (March 2011):

Description of Changes Page

In Chapter 1 in the “1000A SCR Bus Supply Flexibility” section:

• Added information and a table at the beginning to show which conversions are possible

and which are not possible.

• In the “Converting Master Unit to Slave Unit” subsection, added new steps 3 and 4.

• Deleted subsection “Converting Slave Unit to Master Unit” subsection.

In Appendix A in the “Accessories” section:

• Changed Table A.A cat. numbers for rows 256…509, and added new row for 939…1K0.

• Changed Table A.B cat. numbers for rows 256…509, and added new row for 939…1K0.

• Changed Table A.C cat. numbers for rows 256…509, and added new row for 939…1K0.

• Changed Table A.D cat. numbers for rows 256…509, and added new row for 939…1K0.

In Appendix A in the “HF Filter” section:

• Added new HF Filter Wiring Diagram Figure A.5.

• Added new subsection “Solid Ground Systems.”

• Added new subsection “Non-Solid Ground Systems.”

In Appendix A in the “Spare Parts” section:

• Added Important statement above Figure A.8.

• Added new “Availability” column to Table A.E

• Added Important statement above Figure A.9.

• Added new “Availability” column to Table A.F

• Added Important statement above Figure A.10.

• Added new “Availability” column and new footnote 1 to Table A.G

• Added new Figure A.11 to show locations of precharge and gate drive boards for 1000A

unit.

In Appendix A, revised Input Ratings “Operational AC Input Voltage Range” for catalog

number 20SF1K0… from “269…759V” to “528…759V.”

Added new Appendix B. B-1

1-16

1-16

A-7

A-8

A-9

A-10

A-11

A-12

A-12

A-14

A-15

A-16

A-17

A-18

A-19

A-19

A-1

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 4

soc-ii Summary of Changes

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 5

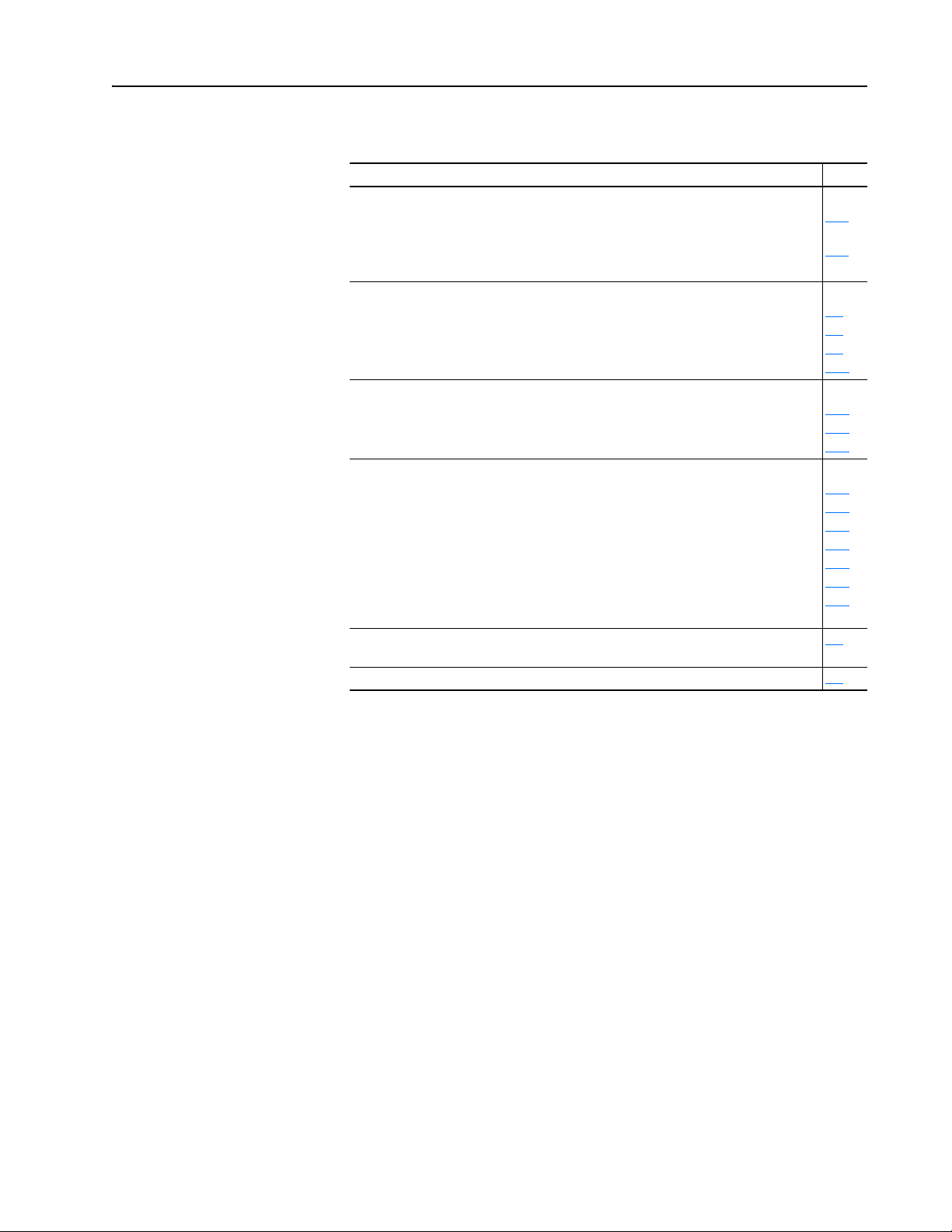

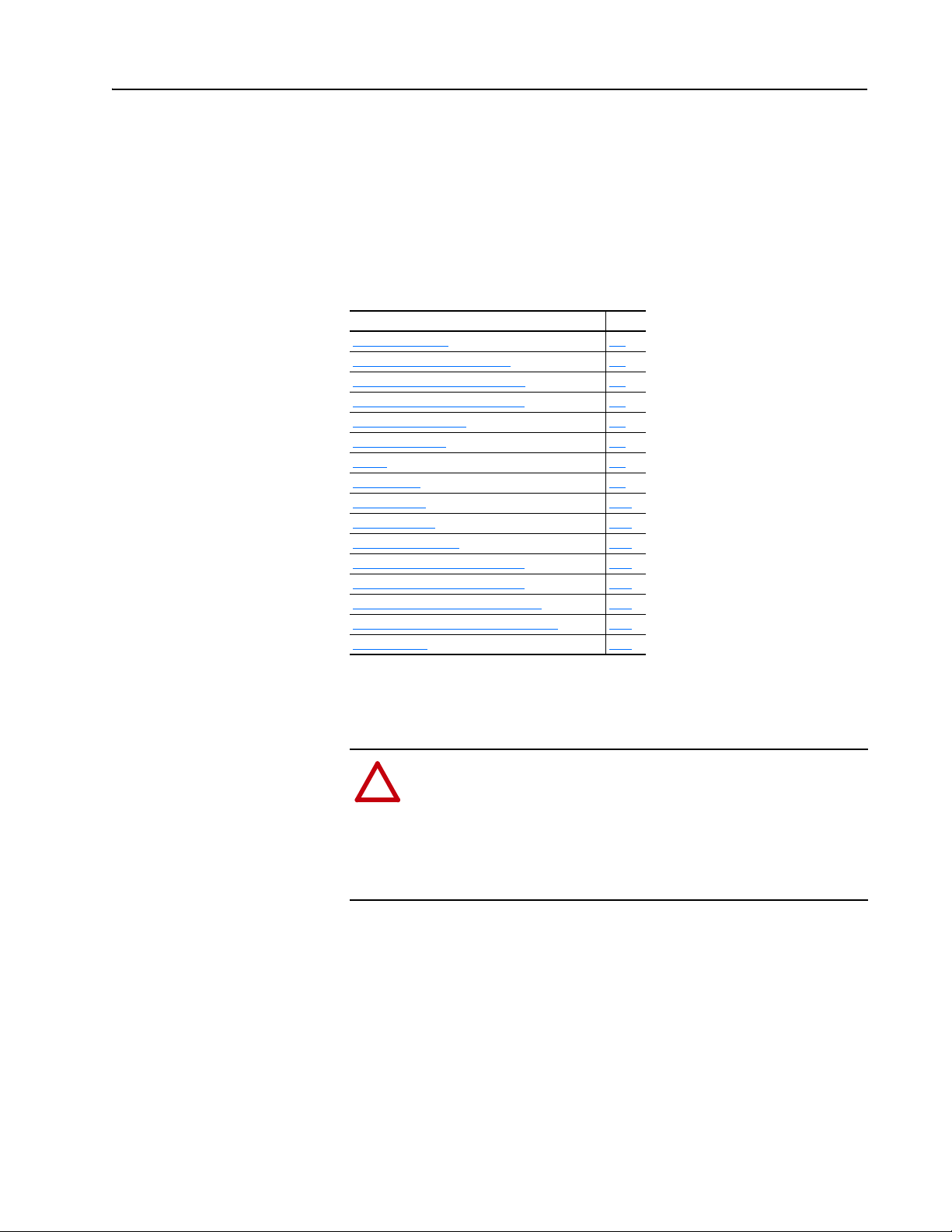

Preface Overview

Who Should Use this Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Reference Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Descriptions and Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-5

Chapter 1 Installation/Wiring

Opening the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Minimum Mounting Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

AC Supply Source Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

General Grounding Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Minimum Capacitance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Maximum Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Power Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Jumper Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Disconnecting MOVs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Parallel Connection of Slave Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

1000A SCR Bus Supply Flexibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1000A SCR Bus Supply Redundancy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

SCR Bus Supply 12-Pulse Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table of Contents

Chapter 2 Start Up/Troubleshooting

Start-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Precharge Board LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Appendix A Specifications

PowerFlex SCR Bus Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Bus Supply Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Appendix B History of Changes

20S-UM001F-EN-P, March 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Index

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 6

ii Table of Contents

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 7

Preface

Overview

The purpose of this manual is to provide you with the basic information

needed to install, start up, and troubleshoot the PowerFlex SCR Bus Supply.

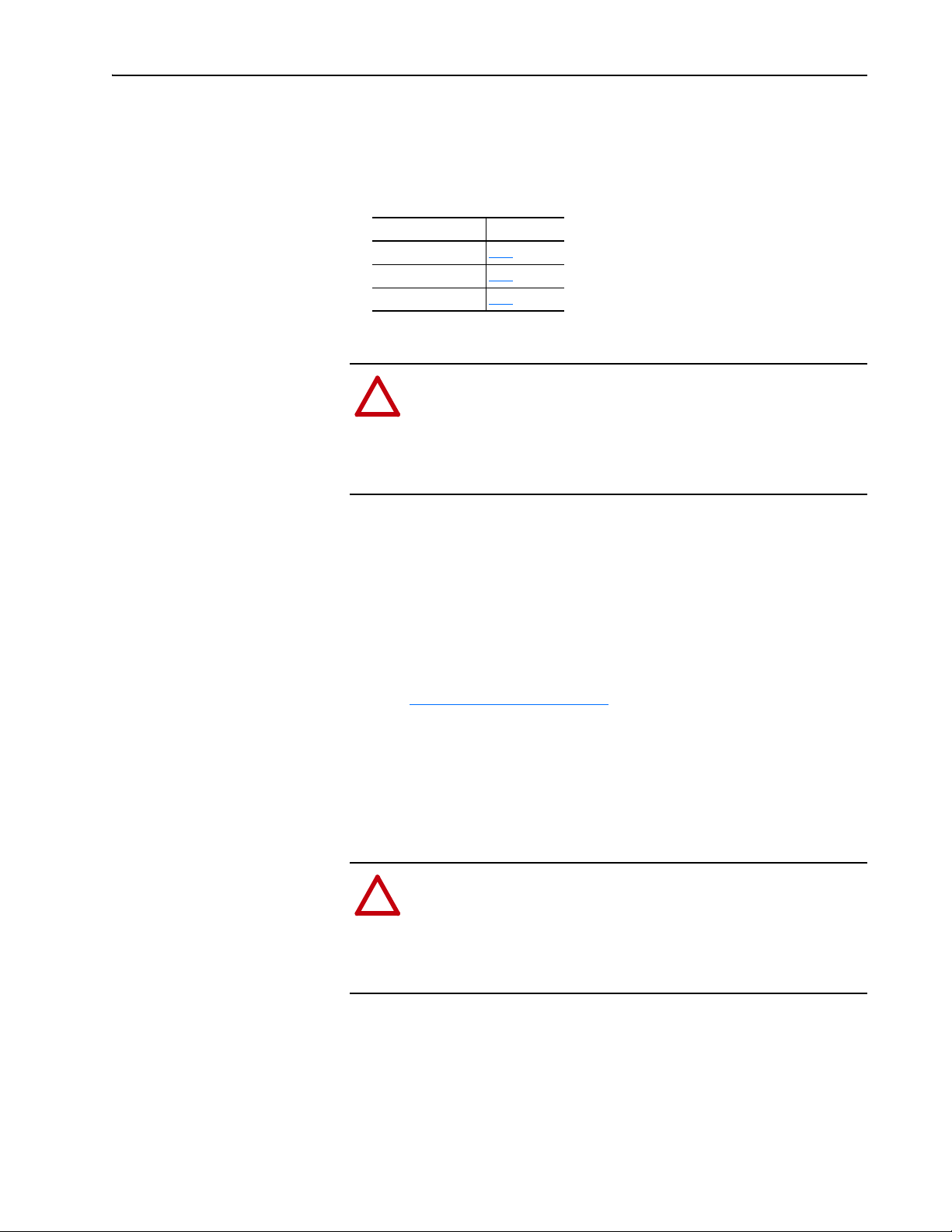

Topic Page

Who Should Use this Manual?

Reference Documentation P-1

Rockwell Automation Support P-2

Conventions Used in This Manual P-2

General Precautions P-3

Catalog Number Explanation P-4

Descriptions and Schematic Diagrams P-5

P-1

Who Should Use this Manual?

Reference Documentation

This manual is intended for personnel that are qualified to install, program,

and operate adjustable frequency drives and their use in common DC bus

systems.

General Drive Information

Title Publication

Wiring and Grounding Guidelines for PWM AC Drives DRIVES-IN001

AC Drives in Common Bus Configurations DRIVES-AT002

Preventive Maintenance of Industrial Control and Drive System Equipment DRIVES-TD001

Safety Guidelines for the Application, Installation and Maintenance of Solid State Control SGI-1.1

A Global Reference Guide for Reading Schematic Diagrams 0100-2.10

Guarding Against Electrostatic Damage 8000-4.5.2

1321 Power Conditioning Products Technical Data 1321-TD001

Specific Drive Information

For detailed drive information, including specifications, refer to the

following PowerFlex 70, PowerFlex 700, PowerFlex 700H, PowerFlex

700S, and PowerFlex 750-Series drive publications.

For: Refer to: Publication

PowerFlex

PowerFlex

PowerFlex

®

70/70EC Drive PowerFlex 70 User Manual

PowerFlex 70/700 Reference Manual

®

700/700VC Series A Drive

®

700VC Series B Drive

PowerFlex 70EC/700VC Reference Manual

PowerFlex 700 Series A User Manual

PowerFlex 700 Series B User Manual

PowerFlex 70/700 Reference Manual

PowerFlex 70EC/700VC Reference Manual

20A-UM001

PFLEX-RM001

PFLEX-RM004

20B-UM001

20B-UM002

PFLEX-RM001

PFLEX-RM004

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 8

P-2 Overview

For: Refer to: Publication

PowerFlex® 700H Drive PowerFlex 700H Installation Instructions

PowerFlex 700H Programming Manual

PowerFlex® 700S Drive PowerFlex 700S with Phase I Control Installation Manual (Frames 1…6)

PowerFlex

®

750-Series AC Drive PowerFlex 750-Series Drive Installation Instructions

PowerFlex 700S with Phase I Control Installation Manual (Frames 9 and 10)

PowerFlex 700S with Phase I Control User Manual (All Frame Sizes)

PowerFlex 700S with Phase I Control Reference Manual

PowerFlex 700S with Phase II Control Installation Manual (Frames 1…6)

PowerFlex 700S with Phase II Control Installation Manual (Frames 9…14)

PowerFlex 700S with Phase II Control Programming Manual (All Frame Sizes)

PowerFlex 700S with Phase II Control Reference Manual

PowerFlex 750-Series Drive Programming Manual

PowerFlex 750-Series Reference Manual

Documentation can be obtained online at http://

literature.rockwellautomation.com. To order paper copies of technical

documentation, contact your local Rockwell Automation distributor or sales

representative.

To find your local Rockwell Automation distributor or sales representative,

visit www.rockwellautomation.com/locations

.

PFLEX-IN006

20C-PM001

20D-IN024

PFLEX-IN006

20D-UM001

PFLEX-RM002

20D-IN024

PFLEX-IN006

20D-PM006

PFLEX-RM003

750-IN001

750-PM001

750-RM002

Rockwell Automation Support

Conventions Used in This Manual

For information such as firmware updates or answers to drive-related

questions, go to the Drives Service & Support web site at www.ab.com/

support/abdrives and click on the “Downloads” or “Knowledgebase” link.

Use the contacts below for PowerFlex SRC Bus Supply technical support.

Online… By Email… By Telephone…

www.ab.com/support/abdrives support@drives.ra.rockwell.com 262-512-8176

• In this manual we may refer to the PowerFlex SCR Bus Supply as SCR

Bus Supply or Bus Supply.

• The firmware release is displayed as FRN X.xxx. The “FRN” signifies

Firmware Release Number. The “X” is the major release number. The

“xxx” is the minor update number.

• The following words may be used throughout the manual to describe an

action:

Word Meani ng

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not Recommended

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 9

Overview P-3

!

!

!

!

!

!

!

General Precautions

ATTENTION: This Bus Supply contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with

static control procedures, refer to Allen-Bradley publication

8000-4.5.2, “Guarding Against Electrostatic Damage” or any other

applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed Bus Supply

can result in component damage or a reduction in product life.

Wiring or application errors, such as incorrect or inadequate AC

supply, or excessive ambient temperatures may result in

malfunction of the system.

ATTENTION: Only qualified personnel familiar with adjustable

frequency AC drives and associated machinery should plan or

implement the installation, start-up and subsequent maintenance of

the system. Failure to comply may result in personal injury and/or

equipment damage.

ATTENTION: Connect products with or without precharge

circuitry to the SCR Bus Supply common bus output terminals

within the minimum and maximum capacitance and load rating

guidelines.

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the DC bus terminals (which are connected to the DC

bus capacitors of the Inverter) has discharged before performing

any work on the Bus Supply. Measure the DC bus voltage at the

+DC and -DC output terminals. The voltage must be zero.

ATTENTION: A second source of power for the cooling blower

is present. To avoid an electric shock hazard or moving blades,

verify that the AC power supply has been removed prior to

performing any maintenance or repairs.

ATTENTION: National Codes and standards (NEC, VDE, BSI,

etc.) and local codes outline provisions for safely installing

electrical equipment. Installation must comply with specifications

regarding wire types, conductor sizes, branch circuit protection,

and disconnect devices. Failure to do so may result in personal

injury and/or equipment damage.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 10

P-4 Overview

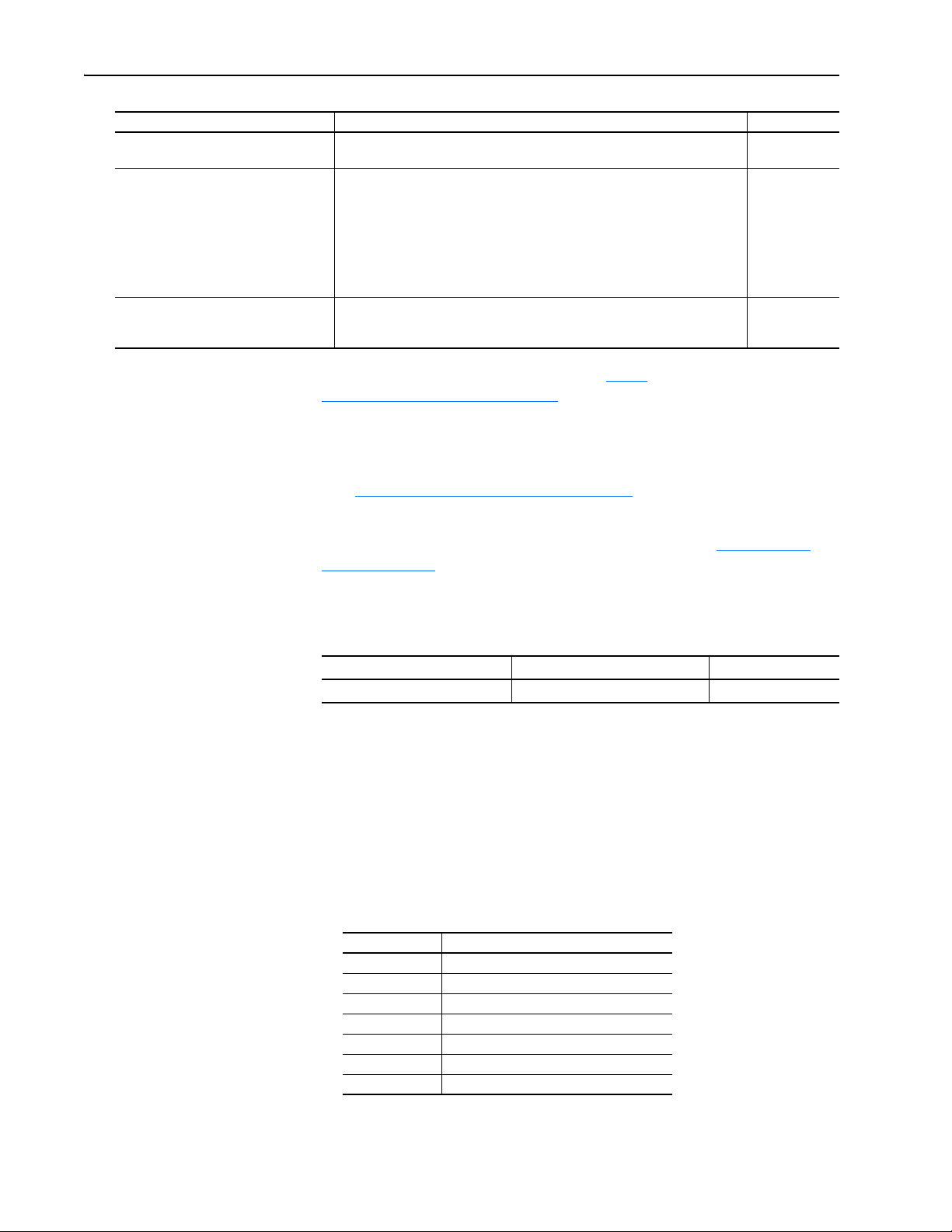

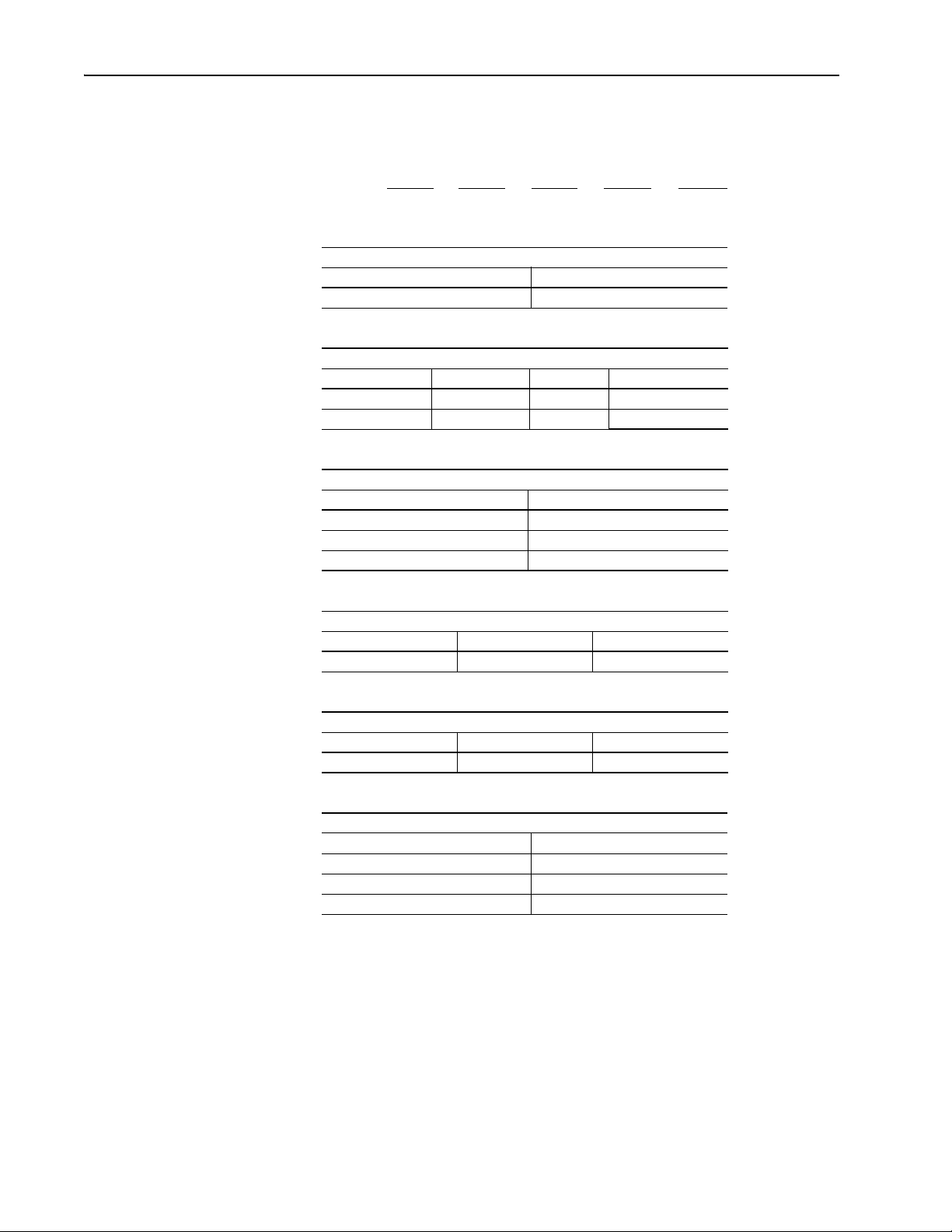

Catalog Number Explanation

Position Number

1-3 4 5-7 8 9 10

20S D 400 N E N

ab c d e f

a

Product

Code Type

20S PowerFlex SCR Bus Supply

b

Voltage Rating

Code Input Voltage Phase DC Output

D 400/480V AC 3 540 - 650V DC

F 600/690V AC 3 675 - 930V DC

c

Current Rating

Code Output

400 400A, 400/480V

600 600A, 400/480V

1k0 1000A, 400/480/600/690V

d

Enclosure

Code Rating Conformal Coating

N Open / IP00 No

e

Documentation & Shipping Carton

Code User Manual Carton

E English Yes

f

Configuration

Code Type

N Stand Alone

M Master (1000A only)

S Slave (1000A only)

Important:PowerFlex SCR Bus Supply 1000A units with Master or Slave

configuration are available for 400/480 and 600/690 Volts.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 11

Overview P-5

>°C

V1 V3

V4 V2V6

F6-F8

G4

K4

G1

K1

K3

G3

K6

G6

G2

K2

G5

K5

F1

F2

F3

V5

4

5

6

7

5

4

6

PE

L1

L2

L3

GND

K1

A2

A1

1

X1

3

X3

X2

L1 L2 L3

1

1

8

7

5

4

2

5

4

3

2

6

M

N

GND

L1

X1

12

115

0

1

4

2

5

6

8

7

9

10

11

F12

K1

22

4321 3313

443414

F5

F4

➋

➌

➊

➑

➏

➍

➎

Precharge

Board

+DC

-DC

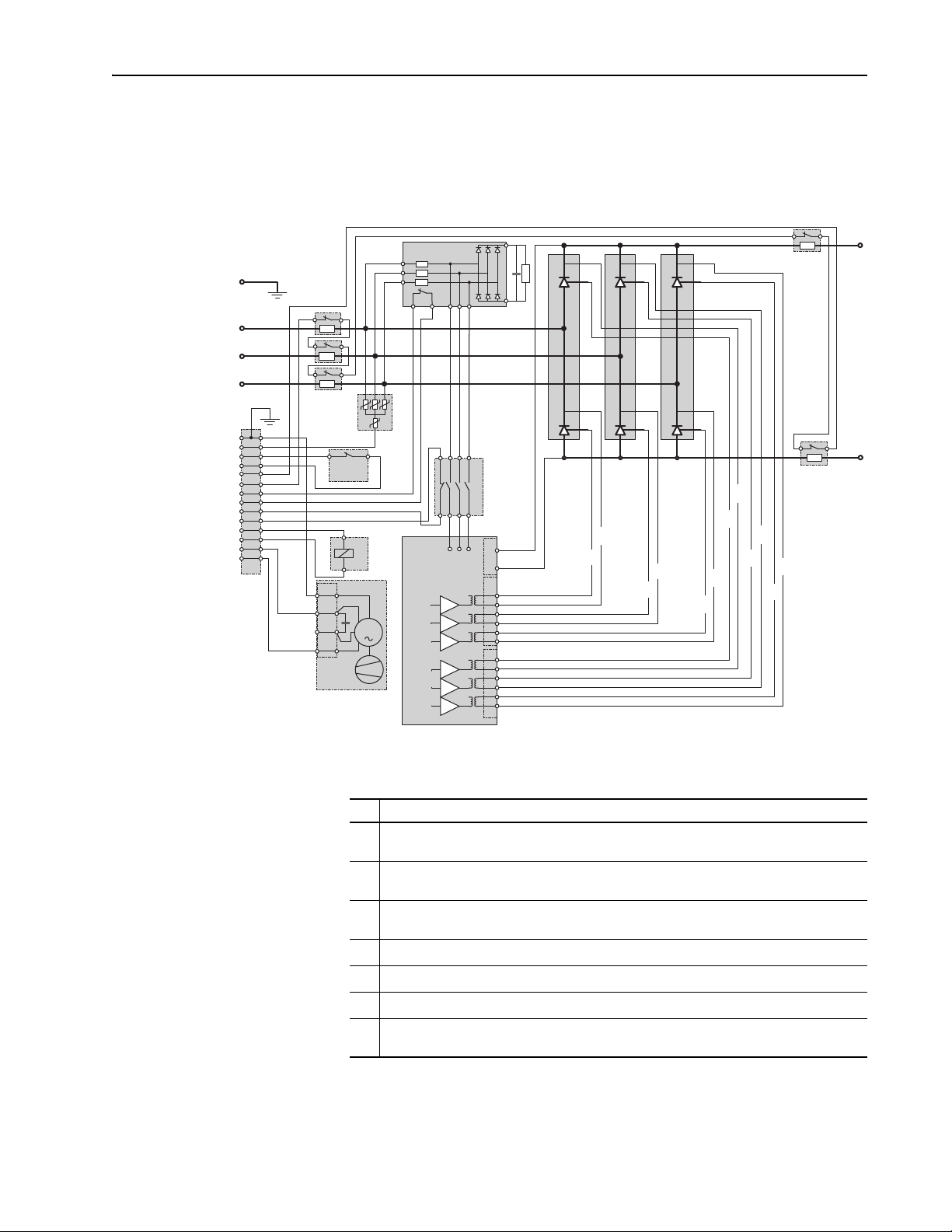

Descriptions and Schematic Diagrams

The SCR Bus Supply is a single-direction power converter for the front end

of common DC bus drive systems. It converts the incoming 3-phase AC line

voltage to a common DC bus voltage.

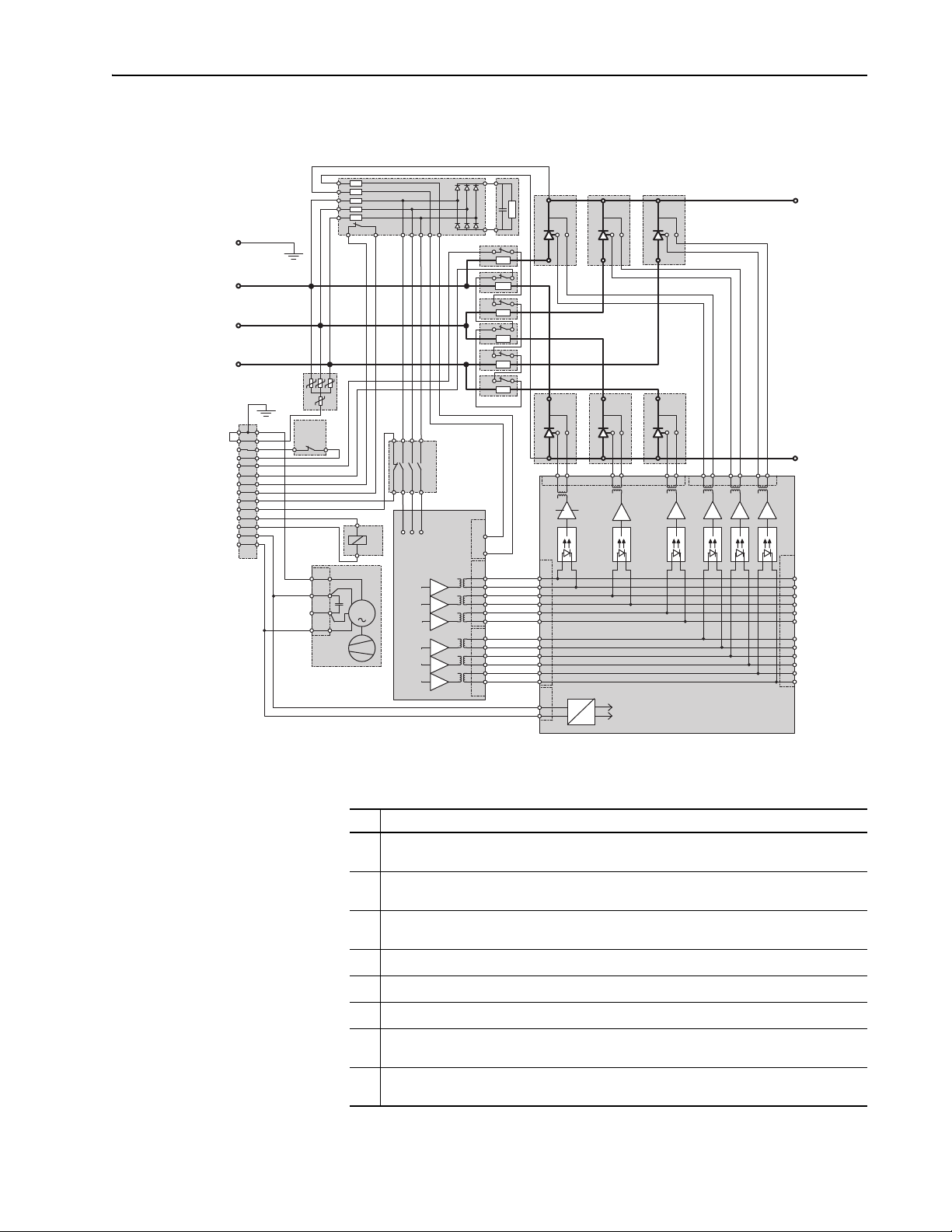

Figure P.1 400A and 600A SCR Bus Supply Schematic Diagram

The primary electrical components for the 400A and 600A SCR Bus Supply

are:

Item Description

➊

➋

➌

➍

➎

➏

➑

Six-Pulse, Full-Wave, 3-Phase SCR Bridge Rectifier Unit connected to the line input and DC

Bus output terminals through semi-conductor protection fuses with trip indicator switches.

Bus Supply Overtemperature Sensor located on the heat sink for thermal protection of the

SCR bridge rectifier.

RC snubber circuit routed to the three input phases through semi-conductor protection

fuses with trip indicator switches.

MOV snubber circuit routed to the three input phases.

Precharge Board

Enable Contactor (K1) for the precharge board.

Cooling Blower connected to a customer-supplied 115V AC Power Supply. The customer’s

controls must, at a minimum, command the blower to run whenever contactor K1 is enabled.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 12

P-6 Overview

PE

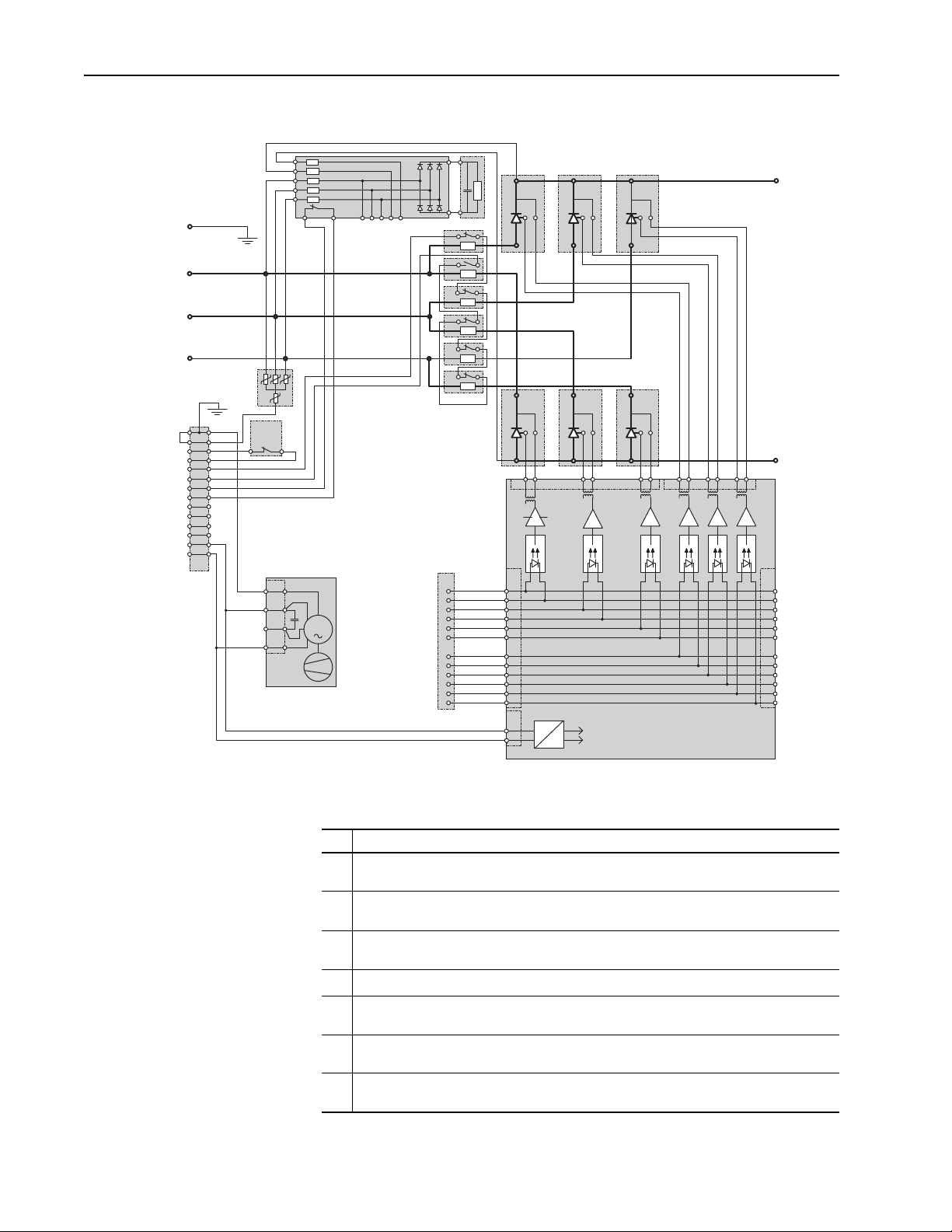

Figure P.2 1000A SCR Bus Supply Single Unit Schematic Diagram

➌

F7 - 11

L1 L4L5L3L2

2

V1

F1

3

2

V3

5

4

3

2

V5

5

4

5

4

3

+ DC

12

11

10

9

8

7

6

5

4

2

1

0

115

X1

L1

L2

L3

GND

➍

>°C

F12

➏

GND

N

L1

➑

➋

F4

F3

F6

F5

F2

2

V4

45

22

443414

K1

4321 3313

➎

X1

1

3

X3

1

2

4

5

7

8

1

2

3

4

5

6

X2

L1 L2L3

A2

K1

A1

Precharge

Board

M

3

G4

C4

➊

2

V6

3

G6

2

V2

45

C6

45

3

G1

C1

G3

G2

C2

- DC

C3

G5

C5

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

The primary electrical components for the 1000A SCR Bus Supply Single

Unit are:

Item Description

Six-Pulse, Full-Wave, 3-Phase SCR Bridge Rectifier Unit connected to the line input and DC

➊

Bus output terminals through semi-conductor protection fuses with trip indicator switches.

Bus Supply Overtemperature Sensor located on the heat sink for thermal protection of the

➋

SCR bridge rectifier.

RC snubber circuit routed to the three input phases through semi-conductor protection

➌

fuses with trip indicator switches.

MOV snubber circuit routed to the three input phases.

➍

Precharge Board

➎

Enable Contactor (K1) for the precharge board.

➏

Cooling Blower connected to a customer-supplied 115V AC Power Supply. The customer’s

➑

controls must, at a minimum, command the blower to run whenever contactor K1 is enabled.

NOTE: There is no DC output fuse protection in the 1000A SCR unit.

Page 13

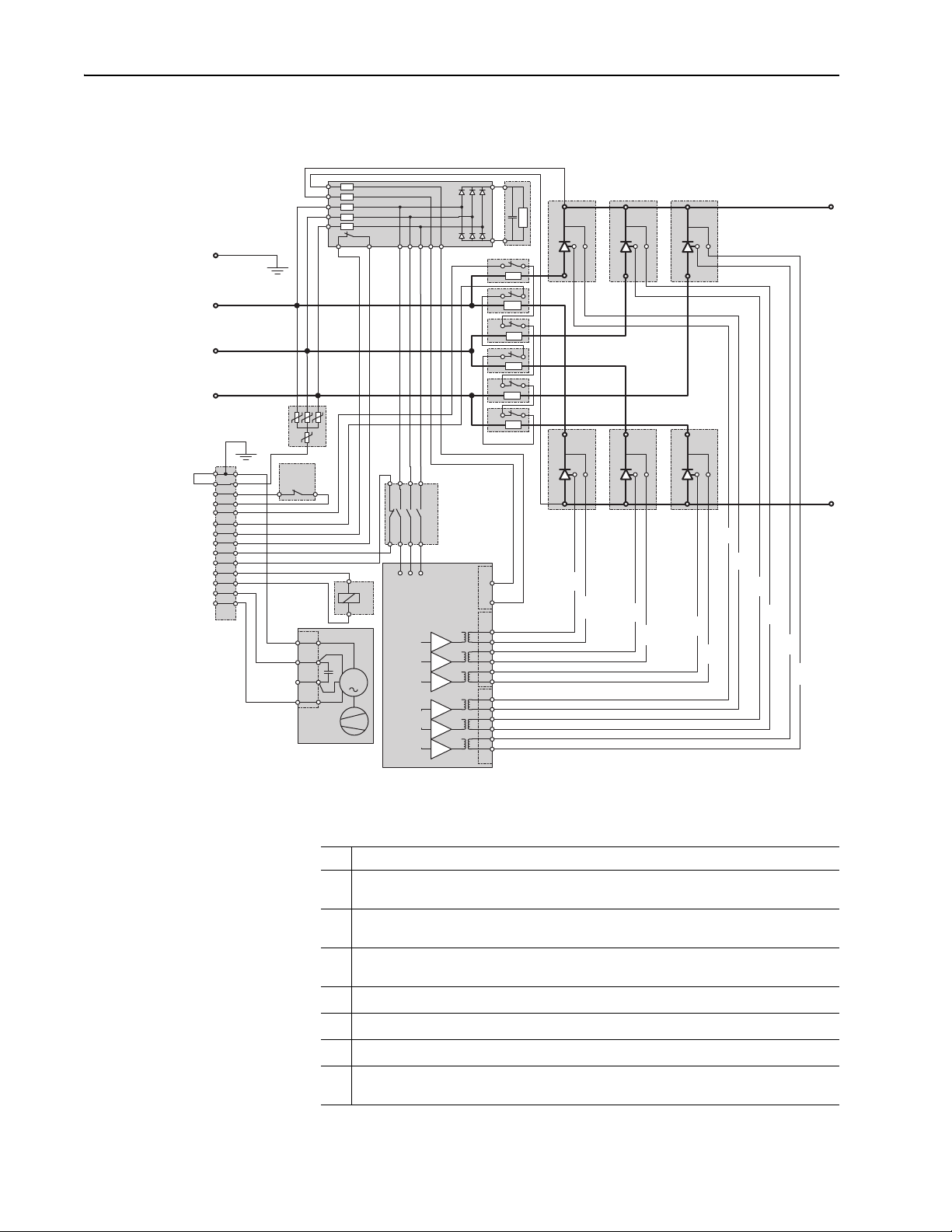

Figure P.3 1000A SCR Bus Supply Master Unit Schematic Diagram

>°C

F12

K1

A2

A1

F6

F2

F1

F4

F5

F3

F7-11

L1 L4L5L3L2

K1

22

4321 3313

443414

X1

GND

12

115

0

1

4

2

5

6

8

7

9

10

11

3

2

V3

45

3

2

V5

45

3

2

V1

45

3

2

V4

45

3

2

V6

45

3

2

V2

45

L1

L2

L3

PE

+

-

+

+

-

X3

X4

X6

2

1

X1

3

X3

X2

L1 L2 L3

1

1

8

7

5

4

2

X5

5

4

3

2

6

1

3

4

5

6

7

9

12

11

10

8

12 7854126543X2

7

8

9

10

11

12

1

2

3

4

5

6

1

5

M

N

GND

L1

Precharge

Board

Gate Driver Board

➋

➌

➊

➑

➐

➏

➍

➎

+DC

-DC

To Gate

Driver X4

on the Slave

(Figure P.4)

Overview P-7

The primary electrical components for the 1000A SCR Bus Supply Master

Unit are:

Item Description

➊

➋

➌

➍

➎

➏

➐

➑

NOTE: There is no DC output fuse protection in the 1000A SCR unit.

Six-Pulse, Full-Wave, 3-Phase SCR Bridge Rectifier Unit connected to the line input and DC

Bus output terminals through semi-conductor protection fuses with trip indicator switches.

Bus Supply Overtemperature Sensor located on the heat sink for thermal protection of the

SCR bridge rectifier.

RC snubber circuit routed to the three input phases through semi-conductor protection

fuses with trip indicator switches.

MOV snubber circuit routed to the three input phases.

Precharge Board

Enable Contactor (K1) for the precharge board.

Gate Driver Board. The DC power supply is connected to a customer-supplied 115V AC Power

Supply.

Cooling Blower connected to a customer-supplied 115V AC Power Supply. The customer’s

controls must, at a minimum, command the blower to run whenever contactor K1 is enabled.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 14

P-8 Overview

>°C

F12

F6

F2

F1

F4

F5

F3

F7-11

L1 L4L5L3L2

X1

GND

12

0

1

4

115

2

5

6

8

7

9

10

11

3

2

V3

45

3

2

V5

45

3

2

V1

45

3

2

V4

45

3

2

V6

45

3

2

V2

45

L1

L2

L3

PE

+

-

+

+

-

X3

X4

X6

2

X6

1

1

8

7

5

4

2

X5

5

4

3

2

6

1

3

4

5

6

7

9

12

11

10

8

1

2

7854126543X2

7

8

9

10

11

12

1

2

3

4

5

6

1

5

M

N

GND

L1

+DC

-DC

Gate Driver Board

From Gate

Driver X6

on the Master

(Figure P.3 or

previous Slave)

➋

➌

➊

➑

➐

➒

➍

To Gate

Driver X4

on the next

Slave

Figure P.4 1000A SCR Bus Supply Slave Unit Schematic Diagram

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

The primary electrical components for the 1000A SCR Bus Supply Slave

Unit are:

Item Description

➊

➋

➌

➍

➐

➑

➒

NOTE: There is no DC output fuse protection in the 1000A SCR Unit.

Six-Pulse, Full-Wave, 3-Phase SCR Bridge Rectifier Unit connected to the line input and DC

Bus output terminals through semi-conductor protection fuses with trip indicator switches.

Bus Supply Overtemperature Sensor located on the heat sink for thermal protection of the

SCR bridge rectifier.

RC snubber circuit routed to the three input phases through semi-conductor protection

fuses with trip indicator switches.

MOV snubber circuit routed to the three input phases.

Gate Driver Board. The DC power supply is connected to the customer-supplied 115V AC

Power Supply.

Cooling Blower connected to a customer-supplied 115V AC Power Supply. The customer’s

controls must, at a minimum, command the blower to run whenever contactor K1 is enabled.

Connection Cable (1 m) connects the gate firing pulses from the Master to the first Slave or

between any two Slaves (maximum 4).

Page 15

!

Chapter 1

Installation/Wiring

This chapter provides information on the installation and wiring of the

PowerFlex SCR Bus Supply.

Topic Page

Opening the Cover

Minimum Mounting Clearances 1-3

AC Supply Source Considerations 1-4

General Grounding Requirements 1-5

Minimum Capacitance 1-6

Maximum Loading 1-6

Fusing 1-7

Power Wiring 1-7

Control Wiring 1-11

Jumper Settings 1-12

Disconnecting MOVs 1-14

Parallel Connection of Slave Units 1-15

1000A SCR Bus Supply Flexibility 1-16

1000A SCR Bus Supply Redundancy 1-17

SCR Bus Supply 12-Pulse Configuration 1-18

CE Conformity 1-19

1-2

Most start-up difficulties are the result of incorrect wiring. Every precaution

must be taken to assure that the wiring is done as instructed. All items must

be read and understood before the actual installation begins.

ATTENTION: The following information is merely a guide for

proper installation. Rockwell Automation, Inc. cannot assume

responsibility for the compliance or the noncompliance to any

code, national, local or otherwise for the proper installation of this

product or associated equipment. A hazard of personal injury and/

or equipment damage exists if codes are ignored during

installation.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 16

1-2 Installation/Wiring

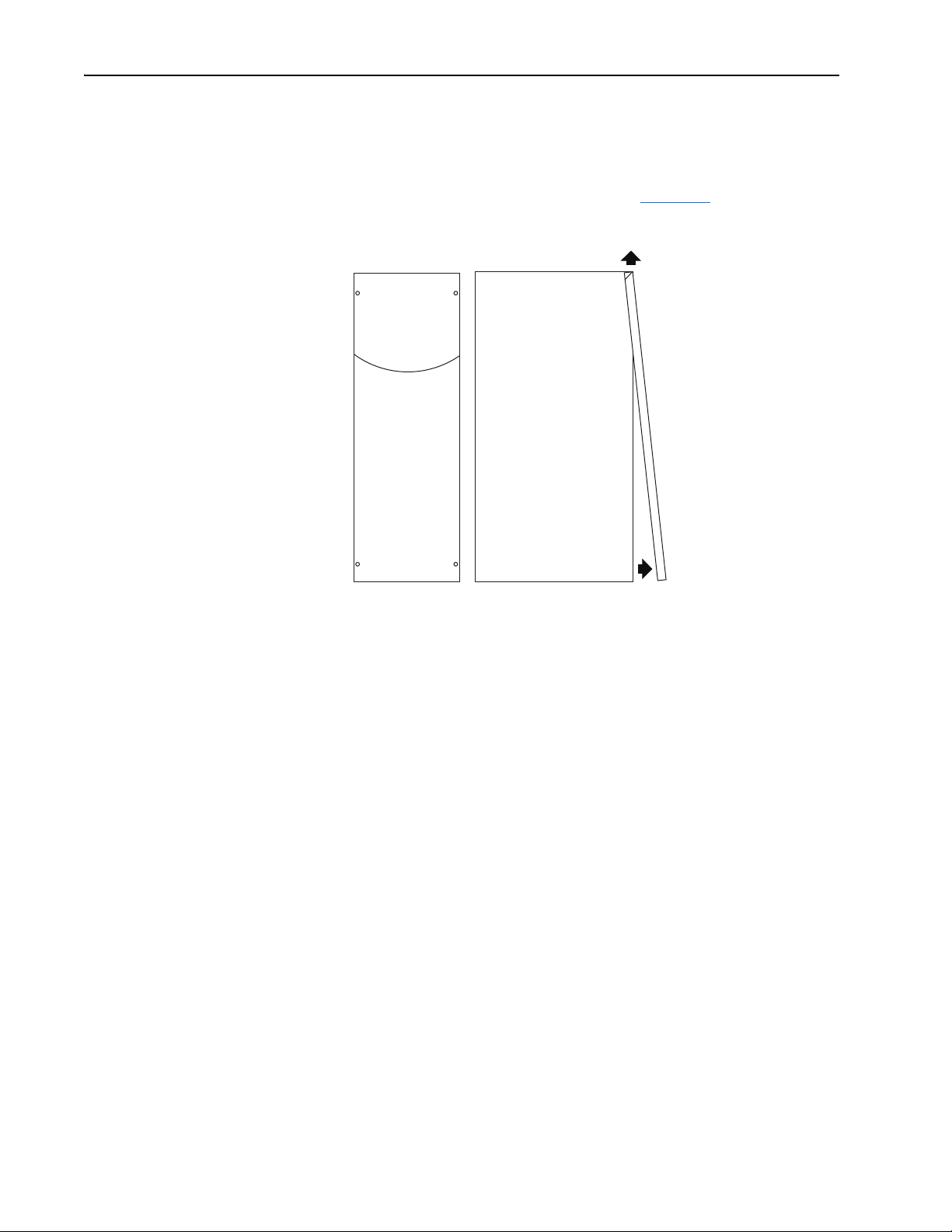

Opening the Cover

1. Remove the four fastening screws. (The steel sheet cover will stay in

place, even in the vertical position.)

2. Hold the cover with both hands at the bottom, and lift it upward about 2

cm (0.8 in.) and away from the enclosure (Figure 1.1

Figure 1.1 Opening the Cover

).

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 17

Installation/Wiring 1-3

Refer to Appendix A for detailed dimension information.

below fan

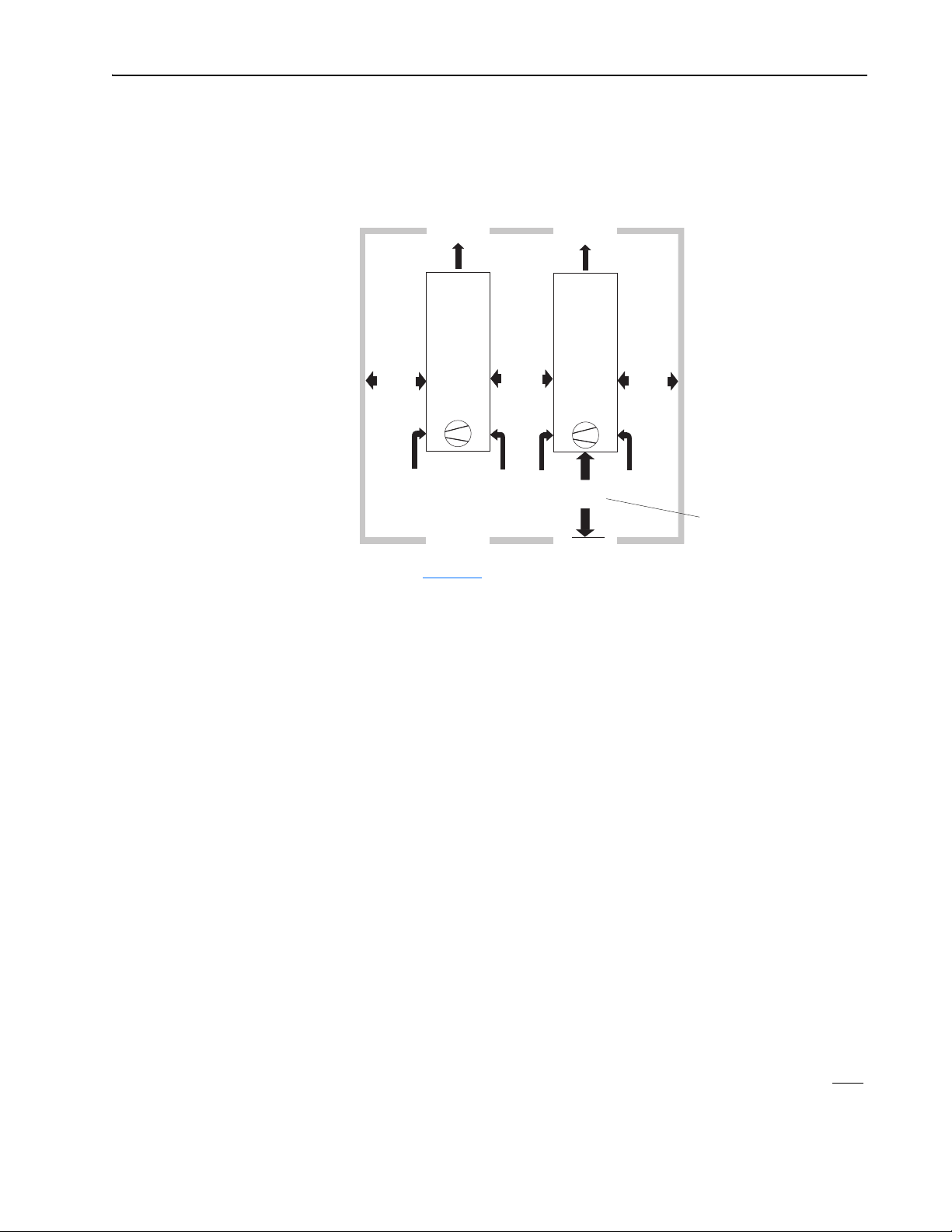

Minimum Mounting Clearances

The cabinet air inlet and outlet areas for each SCR Bus Supply must be a

minimum of 200 cm

4:1.

Figure 1.2 Mounting Clearances

Air Outlet

PowerFlex

Bus Supply

120 mm

(4.7 in.)

SCR

2

(31 in.2). The length-to-width ratio must not exceed

Air Outlet

PowerFlex

SCR

Bus Supply

150 mm

(6 in.)

Air Flow Air FlowAir Flow

300 mm

(12 in.)

Air InletAir Inlet

120 mm

(4.7 in.)

Ambient Operating Temperatures

The PowerFlex SCR Bus Supply is designed to operate at 0…40 °C

(32…104 °F) ambient without derating. For operation in ambients above

40 °C up to 50 °C (104 °F up to 122 °F), the PowerFlex SCR Bus Supply

output Amps must be derated by 1.2% per 1 °C for 400A unit, and by 1.0%

per 1 °C for 600A and 1000A units.

Ensure that proper cooling is provided to the SCR Bus Supply to maintain

the 40 °C rated specification. If the ambient temperature is exceeded, apply

the proper derate factors. Add exhaust fans to the front or top of the

enclosure bay and provide a filtered opening at the bottom of the cabinet

bay.

The SCR Bus Supply watt losses (from specification section) are 1200W at

400A, 1600W at 600A, 2700W at 480V 1000A, and 2800W at 690V

1000A. The three-phase AC line reactor watt losses are listed in the 1321

Power Conditioning Products Technical Data (publication 1321-TD001).

Because of the internal design of the SCR Bus Supply, it is NOT

recommended to rely on an air dam surrounding the SCR Bus Supply.

It is recommended that the system integrator completes a thermal evaluation

to ensure adequate cooling to maintain proper operating conditions for each

cabinet or bay. A minimum air exchange of 725 CFM per SCR Bus Supply

is recommended.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 18

1-4 Installation/Wiring

!

AC Supply Source Considerations

The PowerFlex SCR Bus Supply is suitable for use on a circuit capable of

delivering a short circuit rating up to a maximum of 85,000 rms

symmetrical amperes.

If a Residual Current Detector (RCD) is used as a system ground fault

monitor, only Type B (adjustable) devices should be used to avoid nuisance

tripping.

Line Reactors

A minimum 3% rated three-phase AC line reactor must be installed for

minimum voltage drop unless the closest supply transformer is matched to

the kVA rating of the PowerFlex SCR Bus Supply. For recommended line

reactors, see Line Reactors

Install one three-phase AC line reactor for each

is recommended to maintain cable length symmetry between the

three-phase AC line reactors and the SCR Bus Supply connections. One

method is to mount the three-phase AC line reactors on the cabinet floor

under the SCR Bus Supply.

Important:It is recommended to keep all wired or bus bar connections

identical in size and length. This includes the AC line

connection to the three-phase AC line reactors and from the

three-phase AC line reactors to the SCR Bus Supply.

on page A-7.

SCR Bus Supply module. It

Unbalanced or Non-Solid Grounded Distribution Systems

Where the potential exists for abnormally high phase-to-ground voltages (in

excess of 125% of nominal), or the supply system is non-solid grounded,

refer to the Wiring and Grounding Guidelines for Pulse Width Modulated

(PWM) AC Drives (publication DRIVES-IN001).

ATTENTION: The PowerFlex SCR Bus Supply contains

protective MOVs that are referenced to ground. The MOVs should

be disconnected from ground if the SCR Bus Supply is installed on

any non-solid grounded power distribution system (IT-network).

For jumper location, see Figure 1.7 on page 1-11

.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 19

Installation/Wiring 1-5

Ground Grid, Girder or Ground

Rod (Building Ground Potential)

General Grounding Requirements

The Safety Ground terminal (PE) must be connected to the building

grounding scheme. Ground impedance must conform to the requirements

of national and local industrial safety regulations and/or electrical codes.

The integrity of all ground connections should be periodically checked.

For installations within a cabinet, a single safety ground point or ground bus

bar connected directly to building steel should be used. All circuits

including the AC input ground conductor should be grounded

independently and directly to this point/bar.

Figure 1.3 Typical Grounding

R (L1)

S (L2)

T (L3)

SCR

Bus Supply

PE

+DC

- DC

Safety Ground Terminal - PE

The Bus Supply safety ground (PE) must be connected to the customer

grounding scheme or earth ground. This is the safety ground for the Bus

Supply that is required by code. This point must be connected to adjacent

building steel (girder, joist), a floor ground rod, bus bar or building ground

grid. Grounding points must comply with national and local industrial

safety regulations and/or electrical codes.

RFI Filter Grounding

Using an external RFI filter may result in relatively high ground leakage

currents. Therefore, the filter must only be used in installations with

grounded AC supply systems and be permanently installed and solidly

grounded (bonded) to the building power distribution ground. Ensure that

the incoming supply neutral is solidly connected (bonded) to the same

building power distribution ground. Grounding must not rely on flexible

cables and should not include any form of plug or socket that would permit

inadvertent disconnection. Some local codes may require redundant ground

connections. The integrity of all connections should be periodically

checked. Refer to the instructions supplied with the filter.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 20

1-6 Installation/Wiring

Minimum Capacitance

Maximum Loading

In order to commission and test the SCR Bus Supply, a minimum

capacitance is required. The design of the final installation must assure that

the minimum capacitance is connected whenever the bus supply is to be

enabled. If this minimum capacitance is not present, the bus supply internal

fault detection circuit will interpret the condition as a DC bus short and stop

pulse firing. The minimum capacitance (110 µF per SCR bus supply) may

be provided by an external capacitor bank (recommended) or a drive (as

long as the drive remains connected to the DC bus). NOTE: A capacitance

of 110 µF is typical of a 5 HP or 3.7 kW drive. To find DC bus capacitances

for specific PowerFlex drives, refer to Appendix A tables in the Powe rF lex

AC Drives in Common Bus Configurations Application Guidelines

(publication DRIVES-AT002).

To avoid overloading the Bus Supply, the following requirement applies:

The DC Input current sum (Normal Duty rating at 40 °C/104 °F) of the

connected drive(s) must not exceed the Bus Supply continuous DC Bus

output current rating.

For the DC Input Current values of the drives, see tables in the respective

drive documentation.

Table 1.A

SCR Bus Supply. No overload capability is built into the tables.

Important:See “Output Ratings

When an overload is being utilized in connected drives or products, that

overload current must be accounted for in the calculation to properly size

the SCR Bus Supply.

Table 1.A Normal Duty ND (110%, 1 minute; 150%, 3 seconds)

Drive Rating Drive Output Current Drive DC Input Current SCR Bus Supply

DC

Volt ag e

540V 3 x 110 kW

650V 3 x 60 HP

(1)

Drive Rating Drive Output Current Drive DC Input Current SCR Bus Supply

DC

Volt ag e

540V 3 x 90 kW 3 x 170 = 510A 510A 3 x 192.3 = 577A 577A 600A 400V

ND

Power

1 x 45 kW

1 x 30 HP

No overload capability.

Table 1.B Heavy Duty HD (150%, 1 minute; 200%, 3 seconds)

HD

Power

and Table 1.B provide guidance on the nominal operation of the

” in Appendix A for overload capability.

ND Output

Currents

3 x 205 = 615A

1 x 85 = 85A

3 x 77 = 231A

1 x 40 = 40A

HD Output

Currents

ND Output

Current Sum

700A 3 x 226 = 678A

271A 3 x 84.5 = 253.5A

HD Output

Current Sum

ND DC Input

Currents

1 x 95 = 95A

1 x 42.9 = 42.9A

HD DC Input

Currents

ND DC Input

Current Sum

773A 1000A 400V

297A 400A 480V

HD DC Input

Current Sum

Maximum DC

Output Amps

Maximum DC

Output Amps

(1)

AC Input

Vol ta ge

(1)

AC Input

Vol ta ge

(1)

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

No overload capability.

Page 21

Installation/Wiring 1-7

!

!

Fusing

Power Wiring

The 400A and 600A PowerFlex SCR Bus Supplies have built-in AC line

and DC bus fuses. The 1000A unit has six in-path fuses which

simultaneously protect AC and DC paths. All units are equipped with fuse

trip indicator switches. For a list of recommended replacement fuses, refer

to these pages.

SCR Bus Supply See Page…

400A A-15

600A A-17

1000A A-19

ATTENTION: National Codes and standards (NEC, VDE, BSI,

etc.) and local codes outline provisions for safely installing

electrical equipment. Installation must comply with specifications

regarding wire types, conductor sizes, and disconnect devices.

Failure to do so may result in personal injury and/or equipment

damage.

To maintain balanced impedance, and thus balance current in the SCR Bus

Supply, it is recommended to keep all wired or bus bar connections identical

in size and length. This includes the AC line connection to three-phase AC

line reactors and from the three-phase AC line reactors to the SCR Bus

Supply.

EMC Compliance

Refer to CE Conformity on page 1-19 for details.

Cable Trays and Conduit

If cable trays or large conduits are to be used, refer to guidelines in the

Wiring and Grounding Guidelines for Pulse Width Modulated (PWM) AC

Drives (publication DRIVES-IN001).

ATTENTION: To avoid a possible shock hazard caused by

induced voltages, unused wires in the conduit must be grounded at

both ends. For the same reason, if a drive sharing a conduit is being

serviced or installed, all drives using this conduit should be

disabled. This will help minimize the possible shock hazard from

“cross coupled” motor leads.

DC Bus Wiring Guidelines

For DC Bus wiring guidelines, refer to AC Drives in Common Bus

Configurations (publication DRIVES-AT002).

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 22

1-8 Installation/Wiring

Power Connection Bus Bars and Terminals

Figure 1.4 400A Unit Bus Bar and Terminal Locations for Customer Wiring

➋

DC-

DC+

L1

➍

Table 1.C 400A Unit Power Connection Specifications

Item Description Copper Bus Bars

AC Line Input

➊

L1, L2, L3

DC Bus

➋

DC+, DC-

Protective Earth PE M8 x 25 mm (0.98 in.) stud;

➌

Control Terminal Block See Tabl e 1. F

➍

(1)

Input/output power bus bar connections require the use of either lug type connectors to terminate field-installed

conductors or bus bars.

L2

L3

40 x 5 mm (1.57 x 0.2 in.) with

single 14 mm (0.55 in.) diameter

hole for customer terminal

40 x 5 mm (1.57 x 0.2 in.) with

single 14 mm (0.55 in.) diameter

hole for customer terminal

torque to 6 N•m (54 lb•in)

➊

➌

Recommended Minimum Size

(1)

Bus Bar Wire

40 x 5 mm 120 mm

(or 2 x 50 mm

40 x 5 mm 150 mm2

(or 2 x 70 mm

Size per NEC or local code

2

2

)

2

)

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 23

Installation/Wiring 1-9

DC+

DC-

➋

L1

L2

L3

➊

➍

➌

Figure 1.5 600A Unit Bus Bar and Terminal Locations for Customer Wiring

Table 1.D 600A Unit Power Connection Specifications

Recommended Minimum Size

Item Description Copper Bus Bars

AC Line Input

➊

L1, L2, L3

DC Bus

➋

DC+, DC-

Protective Earth PE M12 x 25 mm (0.98 in.) stud;

➌

Control Terminal Block See Table 1.F

➍

50 x 5 mm (1.97 x 0.2 in.) with

two 14 mm (0.55 in.) diameter

holes for customer terminal

50 x 5 mm (1.97 x 0.2 in.) with

two 14 mm (0.55 in.) diameter

holes for customer terminal

torque to 15 N•m (133 lb•in)

(1)

Bus Bar Wire

50 x 5 mm 240 mm

(or 2 x 95 mm

60 x 5 mm 300 mm2

(or 2 x 120 mm

Size per NEC or local code

2

2

)

2

)

(1)

Input/output power bus bar connections require the use of either lug type connectors to terminate field-installed

conductors or bus bars.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 24

1-10 Installation/Wiring

DC+

DC-

L1

L2

L3

➋

➊

➍

➌

Figure 1.6 1000A Unit Bus Bar and Terminal Locations for Customer Wiring

Table 1.E 1000A Unit Power Connection Specifications

Recommended Minimum Size

Item Description Copper Bus Bars

AC Line Input

➊

L1, L2, L3

DC Bus

➋

DC+, DC-

Protective Earth PE M12 x 25 mm (0.98 in.) stud;

➌

Control Terminal Block See Ta b l e 1 . F

➍

(1)

Input/output power bus bar connections require the use of either lug type connectors to terminate field-installed

conductors or bus bars.

50 x 10 mm (1.97 x 0.39 in.) with

two 14 mm (0.55 in.) diameter

holes for customer terminal

60 x 10 mm (2.36 x 0.39 in.) with

two 14 mm (0.55 in.) diameter

holes for customer terminal

torque to 15 N•m (133 lb•in)

(1)

Bus Bar Wire

50 x 10 mm

(or 80 x 5 mm)

60 x 10 mm

(or 100 x 5 mm)

Size per NEC or local code

2 x 240 mm2

2 x 300 mm2

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 25

Installation/Wiring 1-11

12

11

10

9

8

7

6

5

4

2

1

0

115

GND

12

11

10

9

8

7

6

5

4

2

1

0

115

GND

Control Wiring

Important points to remember about control wiring:

• Use Copper wire only. Wire gauge requirements and recommendations

are based on 75 °C (168 °F). Do not reduce wire gauge when using

higher temperature wire.

• Wire with an insulation rating of 600V or greater is recommended.

• Control wires outside the cabinet should be separated from power wires

by at least 0.3 meters (1 foot).

Table 1.F Control Terminal Specifications

Wire Size Range

Item Name

Control Terminals 2.5 mm2

➍

(1)

Maximum/minimum sizes that the terminals will accept - these are not

recommendations.

Figure 1.7 Control Terminal Arrangement

(14 AWG)

(1)

0.25 mm2

(22 AWG)

TorqueMaximum Minimum

0.8 N•m

(7 lb•in)

Terminal Bus Supply Description Notes

115 and 0 All units 115V AC

Supply Input

1 and 2

4 and 5

6 and 7 400A and 600A

8 and 9 400A and 600A

10 and 11 All units NC Contact

12 and GND All units Jumper MOVs

(1)

(1)

units

1000A units Opens if any of the snubber circuit fuses or DC

units

1000A units Opens if any of the line input branch circuit fuses

Contactor Coil

115V AC

NC Contact

(2)

Output

NC Contact

(2)

Output

NC Contact

(2)

Output

(2)

Output

to Ground

For cooling blower (and power supply on the

Gate Driver Board - on Master and Slave Units)

Contactor must be energized to enable the

controller

Opens if the Enable Contactor is energized

Opens if any of the snubber circuit fuses

(F6…F8) trip

bus feedback fuses (F7…F11) trip

Opens if any of the line input or DC bus branch

circuit fuses (F1…F5) trip

(F1…F6) trip

Opens at power stack heat sink overtemperature

Disconnects MOVs from ground by removing this

jumper. (See Disconnecting MOVs

for details.)

on page 1-14

(1)

Not used on Slave Units.

(2)

Refer to Appendix A for contact rating.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 26

1-12 Installation/Wiring

NOTE: Optional HF Filter

(see page A-11

)

Drive Run Interlock

To protect the Bus Supply from overtemperature, the normally closed

contacts (Bus Supply Overtemperature - terminals 10 and 11) should be

wired to either the AC line input contactor for the Bus Supply or the Run

interlock circuit (enable input) of each connected drive. This ensures that

the drives are stopped in case of Bus Supply Overtemperature.

Control Wiring Example

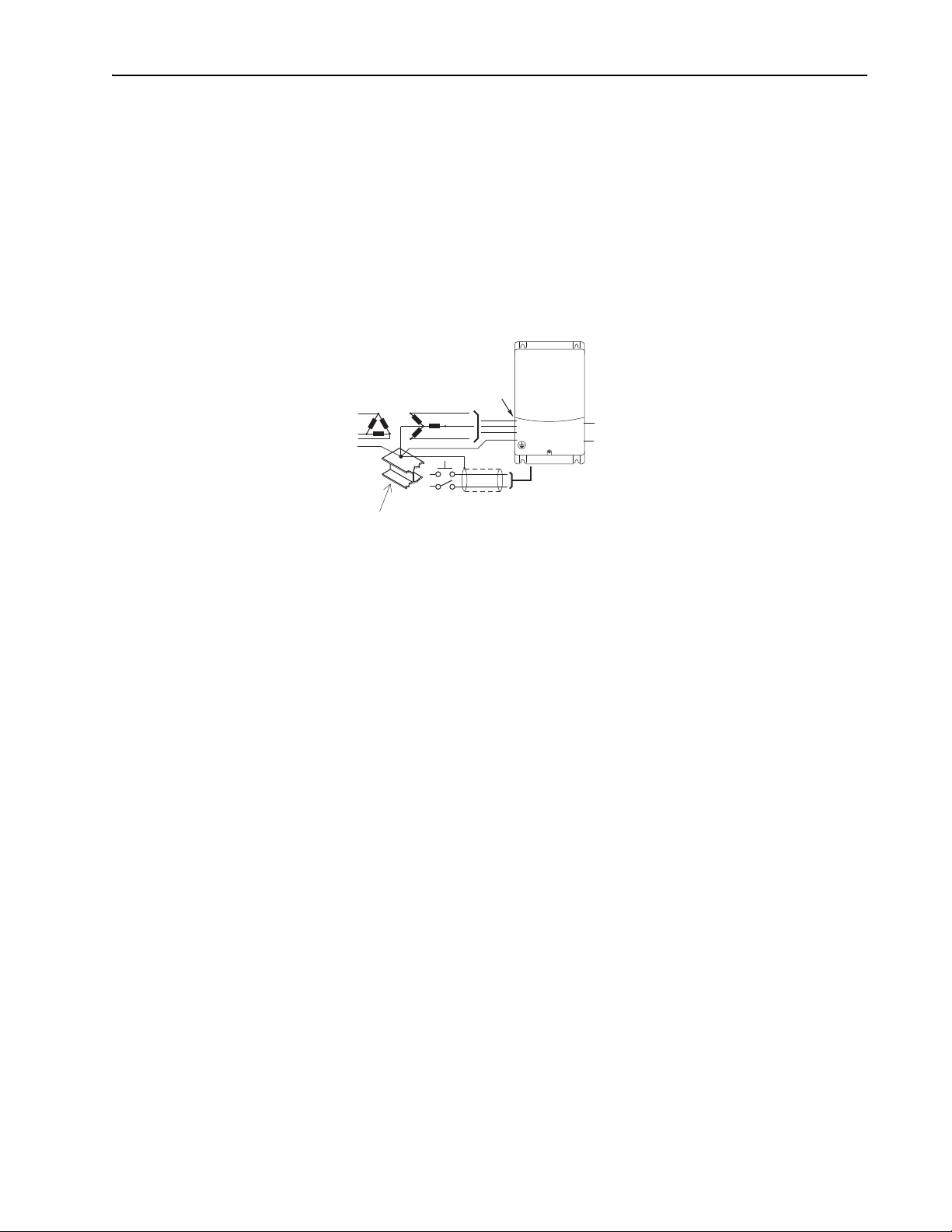

Figure 1.8 Example of SCR Bus Supply, 1000A Single with Multiple Drives Using

Drive Run Interlocks, Running Simultaneous

115 VAC

K1M

K1M

Stop

Run

K1M

115

1

4

5

6

7

8

9

10

11

K1 *

F7-11

Precharge

*

M

0

AC Drive

110 kW

205A

-

M

3

Board

f

F1-6

>°C

2

K1M K1M K1M K1M

RC

F7-F9

f

AC Drive

110 kW

205A

-

M

3

L1

PowerFlex

SCR Bus

Supply

F1-F6

DC Bus

f

* The customer’s controls

must, at a minimum,

command the blower

to run whenever contactor

K1 is enabled.

AC Drive

110 kW

205A

-

M

3

f

AC Drive

45 kW

85A

-

3

f

M

Jumper Settings

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

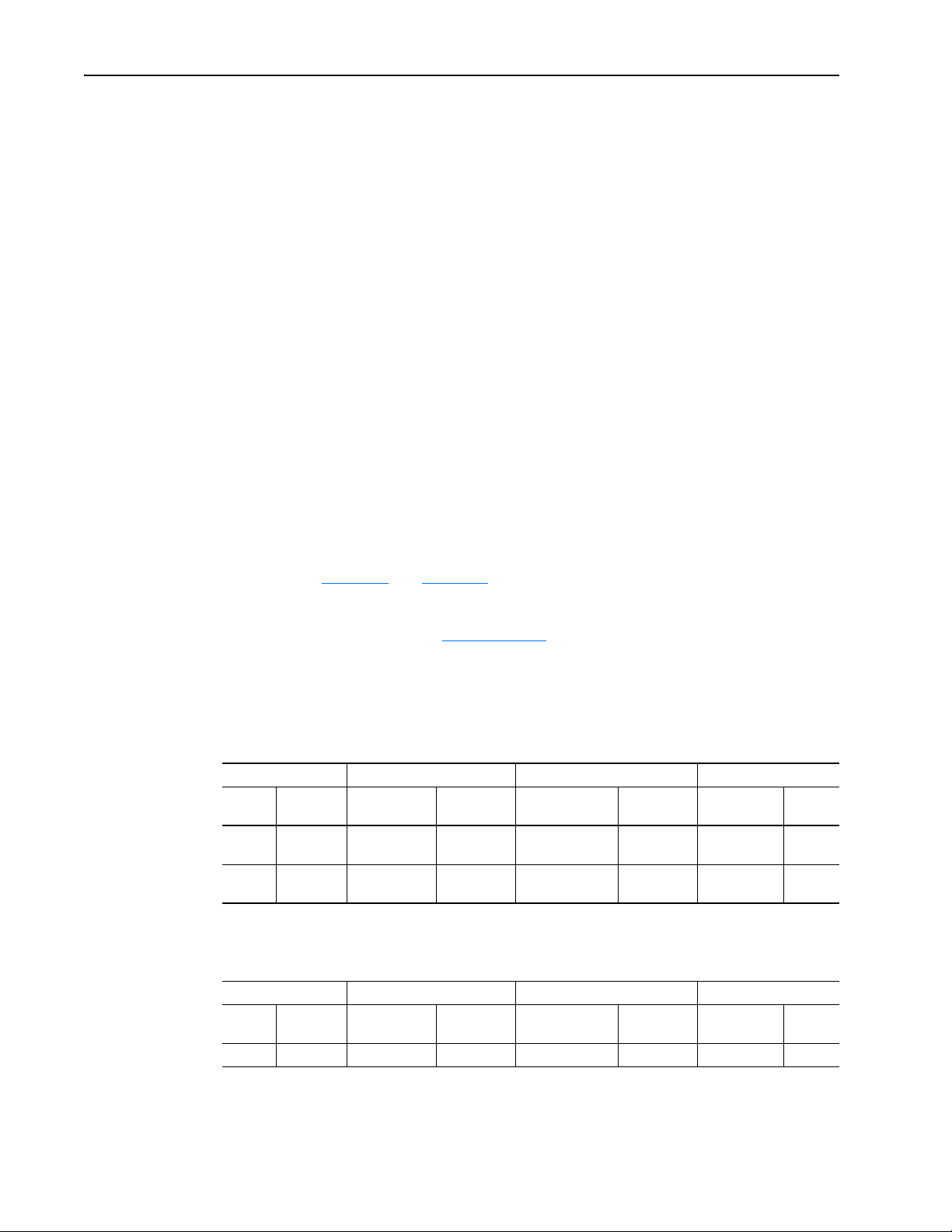

The PowerFlex SCR Bus Supply precharge board has three jumpers. See

Figure 1.9 on page 1-13

for jumper locations and positions.

• LINE TYPE Jumper: Always set to the “3-ph” default right-side position

(towards the board edge).

• SPARE 1 Jumper: For board firmware version 1.21 (or earlier), this

jumper is non-functional. For firmware version 1.22 (or later), the SCR

Bus Supply is shipped with this jumper in the right (default) inactive

state position. When the jumper is placed in the left (RGU/AFE) or

active position, the firmware is active for SCR and RGU/AFE parallel

operation on common bus systems, where the SCR is in parallel with an

Page 27

Installation/Wiring 1-13

active front end that is used only as a regenerative brake unit. The

PowerFlex SCR Bus Supply will then deliver the required motoring

power and the RGU/AFE will provide the possibility to feed the

regenerative energy back to the AC power line. The auto-voltage

limitation (allowing the SCRs to phase back) associated with high AC

line will be disabled. The left (RGU/AFE) jumper position provides the

best protection for parellel SCR and RGU/AFE operation.

• SPARE 2 Jumper: For board firmware version 1.21 (or earlier), this

jumper is non-functional. For firmware version 1.22 (or later), this

jumper is used for slow ramp-up, which slows the DC bus voltage charge

up time (from 0.2 to 1.3 seconds). Slow ramp-up should be used when

the connected DC bus capacitance is greater

following table.

than the values shown in the

Max. Bus Capacitance

SCR Bus Supply

400A 40,000 µF 200,000 µF

600A 60,000 µF 300,000 µF

1000A @ 480V 100,000 µF 500,000 µF

1000A @ 690V 50,000 µF 250,000 µF

(1)

It is recommended to derate the capacitance value by 20% in master/slave configurations.

To operate the SCR Bus Supply with a slow ramp-up, set the SPARE 2

jumper to the left (SLOW) position.

For standard applications where only the PowerFlex SCR Bus Supply

provides the required common DC power, make sure the SPARE 1 and

SPARE 2 jumpers are in their default settings (right side—towards the

board edge) shown in Figure 1.9

Figure 1.9 Location of LED Indicators and Jumpers on the Precharge Board

Precharge Board

Firmware Version Label

with Normal Ramp

.

(1)

Max. Bus Capacitance

with Slow Ramp

(Ramp-Up)

(SCR and

RGU/AFE

Paralleling)

SPARE

SPARE

LINE

TYPE

(1)

2

Slow Norm

1

Yes No

1-ph 3-ph

POWER

OK

ALARM LEDs

FAULT

default positions

Jumpers shown in

TIP: To identify the firmware version, remove the SCR Bus Supply cover

and check the firmware version label on the Precharge Board (Figure 1.9

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

).

Page 28

1-14 Installation/Wiring

!

Disconnecting MOVs

The PowerFlex SCR Bus Supply contains protective MOVs that are

referenced to ground. To prevent damage, the MOVs should be

disconnected from ground if the Bus Supply is installed on any

non-solid grounded distribution system where the line-to-ground voltages

on any phase could exceed 125% of the nominal line-to-line voltage. To

disconnect the MOVs from ground, remove the jumper (12-GND) on the

control terminal block shown in Figure 1.7 on page 1-11

non-solid grounded systems are defined in Table 1.G

Table 1.G Recommended MOV Configurations

MOV/Input Filter

Capacitors

Connected • UL compliance

Disconnected • Helps avoid severe equipment

(2)

Power Source Type

Solid Grounded

• AC fed, solidly grounded

• DC fed from passive rectifier which

has an AC source and solid ground

Non-Solid Grounded

• AC fed ungrounded

• Impedance grounded

• High resistive ground

• B phase ground

• Regenerative unit (common DC bus

supply and brake)

• DC fed from an active converter

(1)

It is highly recommended to accurately determine the power source type and then configure appropriately.

(2)

When MOVs are disconnected, the power system must have its own transient protection to ensure known and

controlled voltages.

(1)

Benefits of Correct Power Source

Type Configuration

• Reduced electrical noise

• Most stable operation

• EMC compliance

• Reduced voltage stress on

components and motor bearings

damage when ground fault occurs

. Solid and

.

For more information on non-solid grounded system installation, see Wiring

and Grounding Guidelines for Pulse Width Modulated (PWM) AC Drives

(publication DRIVES-UM001).

ATTENTION: To avoid an electric shock hazard, verify that the

voltage on the bus capacitors has discharged before removing the

jumper. Measure the DC bus voltage at the +DC and –DC output

terminals. The voltage must be zero.

Table 1.H Jumper Removal

Item Jumper Jumper Location Removes…

12 and GND Control Terminals

➍

(1)

For control terminal location, see Figure 1.4, Figure 1.5 or Figure 1.6.

(1)

MOVs from Ground

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 29

Installation/Wiring 1-15

DC Bus

Power

Input

Master Unit Slave Unit #1 Slave Unit #n

Precharge

Board

Enable

Contactor

Gate

Driver

Gate

Driver

Gate

Driver

Cable Cable

Main Switch or

Main Input Contactor

Up to 5 Units Maximum

(4750A Maximum DC Bus Current

without altitude or ambient derating)

Aux. Supply

115 VAC

Parallel Connection of Slave Units

Up to four 1000A PowerFlex SCR Bus Supply Slave units may be

connected in parallel with one 1000A Master. The derate for each additional

slave is 5% plus 5% for the master. Thus, the maximum possible output

rating without altitude or ambient derating is 4750 Amps (0.95 x 5 x 1000

amps) at 40 °C.

Figure 1.10 Example for Master-Slave Configuration

(shown without circuit protection for clarity)

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 30

1-16 Installation/Wiring

1000A SCR Bus Supply Flexibility

The 1000A SCR Bus Supply can be converted in the following ways.

1000A SCR Bus Supply

Convert from: Standalone

Master Yes

Slave No No

Because of numerous internal changes (components, cables, and hardware)

the following conversions are not allowed:

• Standalone to master

• Standalone to slave

• Slave to standalone

• Slave to master

NOTE: See Figure A.11 on page A-19

Converting Master Unit to Standalone Unit

No changes are required to run a master (without slave units) as a

standalone SCR Bus Supply.

Convert to…

Standalone Master Slave

No No

Ye s

for circuit board location.

Converting Master Unit to Slave Unit

It is possible to reconfigure a master SCR Bus Supply to run as a slave SCR

Bus Supply. To convert a master unit to a slave, perform these steps.

1. Remove the cables between the precharge board connectors (X2 and

X3) and the gate driver printed circuit board connector X4 (see

Figure P.3 on page P-7

2. Connect a cable from the gate driver printed circuit board connector

(X4) to the new master SCR Bus Supply or another slave SCR Bus

Supply gate connector (X6, see Figure P.4 on page P-8

precharge board does not need to be removed from the converted SCR

Bus Supply.

3. Ensure that the precharge relay is not energized (terminal

block…terminal 1 and 2, see page 1-11

4. Place a label near the data nameplate stating that the SCR bus supply

has been converted to catalog # 20Sx1K0NES, where x is the voltage

class of the unit.

).

). Note that the

).

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 31

Installation/Wiring 1-17

1000A SCR Bus Supply Redundancy

It is not recommended to install parallel master SCR Bus Supplies. The

reason is that there is nothing to synchronize the SCR gate firing between

the precharge printed circuit boards in separate SCR Bus Supplies. Each

precharge board has circuitry designed to energize the DC bus, which has

little to no impedance to limit the inrush current. This DC bus charging

synchronization could lead to power device failure.

If redundancy of the SCR Bus Supply master is required by the application,

there are two options.

• A microcontroller or other electronically or manually-controlled switch

or contact network can be used to reconfigure the wire harnesses

between the redundant master SCR Bus Supplies. Basically, one SCR

Bus Supply becomes the master and the other becomes the slave by the

logic selection of the controlling or steering network. One example of

numerous possible configurations is shown in Figure 1.11

Figure 1.11 Basic Master/Slave Redundancy System Configuration

Enable

Control Logic

* Only one Master enabled.

.

Master

Precharge

PCB

Gate

PCB

• Although not recommended, synchronization differences might be

minimized by using the slower ramp time available in precharge printed

circuit boards with firmware version 1.22 (or later). The standard ramp

time is for the rise of DC bus to phase full on in approximately 0.2

seconds, while the slower ramp time will take approximately 1.3

seconds. This will help to limit the inrush current in the system.

For additional recommendations about SCR Bus Supply redundancy,

contact Rockwell Automation Technical Support.

Slave Slave

Gate

PCB

Slave

Gate

PCB

Gate

PCB

Master

Precharge

PCB

Gate

PCB

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 32

1-18 Installation/Wiring

Y

Reactor

Standalone

or

Master

SCR Bus

Supply

Reactor

Fuses*

Gate

Harness

Fuses*

Enable

Slave

Reactor

12-Pulse

Transformer

Slave

Reactor

AC Line

Standalone

or

Master

SCR Bus

Supply

Gate

Harness

Fuses* Fuses*

* Fuses are optional.

DC Bus

SCR Bus Supply 12-Pulse Configuration

Standalone or master/slave SCR Bus Supplies can be used on applications

that use a 12-pulse transformer to minimize power line harmonics.

Important:Be sure to select the slow ramp time (see Jumper Settings

page 1-12).

Figure 1.12

optional slave SCR Bus Supplies.

Figure 1.12 12-Pulse System Configuration

shows a recommended 12-pulse system configuration with

on

For additional recommendations about SCR Bus Supply 12-pulse

configurations, contact Rockwell Automation Technical Support.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 33

Installation/Wiring 1-19

CE Conformity

Conformity with the Low Voltage (LV) Directive and Electromagnetic

Compatibility (EMC) Directive has been demonstrated using harmonized

European Norm (EN) standards published in the Official Journal of the

European Communities. The PowerFlex SCR Bus Supply complies with the

EN standards listed below when installed according to the User Manual.

CE Declarations of Conformity are available online at:

http://www.ab.com/certification/ce/docs

Low Voltage Directive (73/23/EEC)

• EN50178 Electronic equipment for use in power installations

EMC Directive (89/336/EEC)

• EN61800-3 Adjustable speed electrical power drive systems Part 3:

EMC product standard including specific test methods.

Harmonic Emissions

Electronic converters such as the Bus Supply can cause conducted low

frequency disturbances (harmonic emissions) to the supply network. The

mandatory three-phase AC line reactors will substantially reduce harmonic

currents produced by the Bus Supply. However, the magnitude of the

harmonic currents and resulting harmonic voltages depends upon the

network impedance at the point where the unit is connected to the network.

Currently there are no mandatory harmonic emission limits related to CE

compliance for equipment connected to private power networks. Upon

request, Rockwell Automation can provide information regarding harmonic

emissions from the SCR Bus Supply.

General Notes

• The DC bus cable to the inverter(s) should be kept as short as possible to

avoid electromagnetic emission and capacitive currents. Therefore the

inverter(s) should be located in the same cabinet as the Bus Supply or

next to the cabinet with the Bus Supply. If the connection leads between

DC bus and inverter(s) are leaving the cabinet, shielded cables must be

used.

• Use of line filters in non-solid grounded systems is not recommended.

• The PowerFlex SCR Bus Supply with external Line Reactor and HF

filter satisfies CE EMC emission limits for the industrial environment. If

used in a residential or domestic environment it may cause radio

interference. The user is required to take measures to prevent

interference, in addition to the essential requirements for CE compliance

listed below, if necessary.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 34

1-20 Installation/Wiring

• Conformity of the drive with CE EMC requirements does not guarantee

an entire machine installation complies with CE EMC requirements.

Many factors can influence total machine/installation compliance.

Essential Requirements for CE Compliance

Conditions 1…5 listed below must be satisfied for the PowerFlex SCR Bus

Supply to meet the requirements of EN61800-3.

1. Bus Supply and inverter must be PowerFlex type and CE compatible.

2. Externally mounted Line Reactor and HF filter (specified in

Appendix

Figure 1.8 on page 1-12

3. Review important precaution/attention statements throughout this

document before installing the drive(s).

A) must be connected to the line input as shown in

.

4. Grounding as described in General Grounding Requirements

page 1-5.

5. Control wiring and DC bus wiring leaving the cabinet must be braided,

shielded cable with a coverage of 75% or better, metal conduit or

equivalent attenuation.

For additional conditions, refer to the respective drive Reference Manual.

on

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 35

!

!

!

Chapter 2

Start Up/Troubleshooting

This chapter provides the necessary information for the start up and

troubleshooting of the PowerFlex SCR Bus Supply.

Topic Page

Start-Up

Precharge Board LED Indicators 2-4

Troubleshooting 2-6

ATTENTION: Power must be applied to the SCR Bus Supply

and the Inverter to perform the following start-up procedure. Some

of the voltages present are at incoming line potential. To avoid

electric shock hazard or damage to equipment, only qualified

service personnel should perform the following procedure.

Thoroughly read and understand the procedure before beginning.

If an event does not occur while performing this procedure, do not

proceed. Remove power including user-supplied control voltages.

User-supplied voltages may exist even when main AC power is not

applied to the Bus Supply. Correct the malfunction before

continuing.

2-2

ATTENTION: When operating the SCR Bus Supply, a minimum

of one 7.5 kW (10 HP) PowerFlex 700/700S Inverter must be

connected to the DC bus—otherwise the internal fault detection

circuit will interpret the condition as an Output Voltage Loss and

stop pulse firing. This is indicated on the Precharge Board by the

Alarm LED (7 flashes) and after 30 seconds by the Fault LED (2

flashes). Refer to Table 2.A

ATTENTION: Second source of power for cooling blower is

present. To avoid an electric shock hazard or moving blades, verify

the AC power supply has been removed prior to performing any

maintenance or repairs.

and Table 2.B.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 36

2-2 Start Up/Troubleshooting

Start-Up

Before Applying Power to the Bus Supply

❏ 1. Verify that the minimum of one Inverter is connected to the DC bus.

❏ 2. Confirm that all inputs are connected to the correct terminals and are

properly torqued.

❏ 3. Using an ohmmeter or other continuity testing device, verify that shorts

do not exist between Source 1 and Source 2:

Source 1 Source 2 Checkmark Below if No Short Exists

L1 L2

L1 L3

L2 L3

L1 PE

L2 PE

L3 PE

L1 DC+ Bus

L2 DC+ Bus

L3 DC+ Bus

L1 DC- Bus

L2 DC- Bus

L3 DC- Bus

DC+ Bus DC- Bus

DC+ Bus PE

DC Bus PE

❏ 4. Verify that AC line power at the disconnect device is within the rated

value of the Bus Supply. See Appendix

❏ 5. Verify that control power voltage is correct.

❏ 6. Verify that the enable contactor coil K1 (not used on Slave units) is

correctly wired.

❏ 7. Verify that these four outputs are correctly wired:

❏ 8. Verify that the “Line Type” jumper on the Precharge Board shown in

– Bus Supply Overtemperature

– Rectifier Fuse Trip

– Snubber/DC feedback Fuse Trip

– Enable Contactor Feedback (not used on Slave units)

These normally closed contact outputs are used to set alarms and to stop

the drive(s). Verify that they have been wired correctly according to the

user’s specification. Refer to the control wiring example shown in

Figure 1.8 on page 1-12

Figure 2.1

is set to the “3-ph” position (default).

.

A.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 37

Start Up/Troubleshooting 2-3

❏ 9. Verify that the SPARE 1 and SPARE 2 jumpers on the Precharge Board

shown in Figure 2.1

(Refer to Jumper Settings

more information).

❏ 10. Verify that the jumper between control terminals 12 and GND (Figure

1.7 on page 1-11) is present on grounded supply lines (default) or is

removed on non-solid grounded supply lines. (Refer to Disconnecting

MOVs on page 1-14 for more information).

Applying AC Power to the Bus Supply

❏ 1. Apply AC power and control voltage (115V AC) to the Bus Supply.

The green POWER OK LED on the Precharge Board should be on if

power is applied to terminals L1 (R), L2 (S), L3 (T) and the enable

contactor for the precharge board (not used on Slave units) is energized.

are set to appropriate positions for the application.

on page 1-12 and Figure 1.9 on page 1-13 for

❏ 2. If the green POWER OK LED is off at this point, refer to Table 2.B

.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 38

2-4 Start Up/Troubleshooting

!

SPARE

2

(Ramp-Up)

Precharge Board

Firmware Version Label

(SCR and

RGU/AFE

Paralleling)

Slow Norm

Yes No

1-ph 3-ph

SPARE

1

LINE

TYPE

POWER

OK

ALARM LEDs

Jumpers shown in

default positions

FAULT

Precharge Board LED Indicators

The three LEDs on the Precharge Board are visible through a small slot in

the SCR Bus Supply cover. The 400A unit cover has one slot. The 600A

unit cover has two slots but only the lower slot is used to view the LEDs.

Since the Precharge Board for the 1000A unit is mounted either on the

lower carrier plate (on Single Units) or on the upper carrier plate (on Master

Units), the corresponding lower or upper slot is used to view the LEDs. For

slot locations, see Figure A.1 on page A-3

ATTENTION: The SCR Bus Supply LEDs are only operational

when the unit is energized. Servicing energized equipment can be

hazardous. Severe injury or death can result from electrical shock,

burn, or unintended actuation of the controlled equipment. Follow

safety-related practices of NFPA 70E, Electrical Safety For

Employee Workplaces. DO NOT work alone on energized

equipment!

Figure 2.1 Location of LED Indicators and Jumpers on the Precharge Board

.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 39

Pause

0.3

sec.

0.3

sec.

0.9 sec.

Start Up/Troubleshooting 2-5

Table 2.A Precharge Board LED Indicators

Name Color State Description

POWER OK Green Steady Illuminates when precharge board power supply is operational.

ALARM Yellow Flashing The number [n] of flashes (see flashing pattern in Figure 2.2

indicates one of the following alarms

[1]

Low Line Voltage (< 90%)

Low Line Voltage (< 65%) for SCR and RGU/AFE paralleling

mode

Very Low Line Voltage (< 50%)

[2]

Low Phase (One phase < 80% of line voltage), or

[3]

Low Phase Voltage (One phase < 56% of line voltage) for SCR

and RGU/AFE paralleling mode

Freq. out of range or asymmetry (Line synchronization failed)

[4]

Low DC Bus Voltage (triggers ride-through operation)

[5]

Input Frequency momentarily out of range (40…65 Hz)

[6]

DC Bus Short Circuit testing active (repetitive for appr. 120 s) or

[7]

no inverter connected to the bus

FAULT Red Flashing The number [n] of flashes (see flashing pattern in Figure 2.2

(1)

The ALARM indicator LED will continue the flashing pattern as long as the alarm condition exists. An alarm

might trigger internal actions which may stop SCR gate firing.

(2)

If a fault occurs, the FAULT indicator LED will continue the flashing pattern, even if the fault condition no longer

exists. Power must be cycled to clear the fault.

indicates one of the following faults

[2]

DC Bus Short (Udc < 2% after 20ms)

[4]

Line Synchronization failed or Low Line (Uac < 50% Unom)

[5]

Jumper setting wrong

(1)

:

(2)

:

)

)

Figure 2.2 Flashing Pattern for ALARM and FAULT LEDs

Example: Flashing pattern for ALARM LED showing a Low Phase alarm (where n = 3 flashes)

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 40

2-6 Start Up/Troubleshooting

Troubleshooting

Table 2.B Possible Faults and Corrective Actions

Fault Cause Corrective Action

Heat sink

Overtemperature

DC Output

Voltage Loss

Heat sink temperature

exceeds maximum rating

DC bus:

- Short Circuit FAULT [2] or

- Low Line FAULT [4] or

- No Load ALARM [7]

Refer to Table 2 . A

Loss of 115V AC power 1. Check 115V AC supply input voltage at control

.

Jumper setting

wrong

Wrong jumper settings:

Single phase (1-ph) line

type and one or both of the

SPARE 1 or SPARE 2

jumpers set to their

respective left positions.

1. Verify that maximum ambient temperature has

not been exceeded.

2. Check Overtemperature Switch (N.C. contacts)

at control terminals 10 and 11.

3. Check 115V AC supply input voltage at control

terminals 0 and 115.

4. Check blower for correct operation.

5. Check for excess load on the bus supply.

6. Check for minimum mounting clearance around

the bus supply.

7. Contact your local RA sales office.

1. Check 3-phase AC incoming power for

undervoltage or phase loss.

2. Check all Bus Supply fuse trip indicator switches.

3. Verify the Inverter is connected.

4. Verify the power of the connected Inverter(s) is

minimum 7.5 kW (10 HP). Refer to the 2nd

Attention statement on page 2-1

5. Contact your local RA sales office.

terminals 0 and 115.

2. Check Enable Contactor function.

3. Contact your local RA sales office.

1. Check the jumper setting(s).

2. Set the jumper(s) correctly.

.

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 41

Start Up/Troubleshooting 2-7

Important:Complete the tests listed in Table 2.C without power applied to

the SCR Bus Supply.

Table 2.C Control Terminal Block Continuity Test Conditions

Test Condition Possible Cause Corrective Action

N.C. contact on

control terminals

6 and 7 is open

N.C. contact on

control terminals

8 and 9 is open

N.C. contact on

control terminals

10 and 11 is open

400A and 600A Unit: Open

snubber fuse (F6…F8).

1000A Unit: Open snubber

fuse or open DC bus fuse

(F7…F11).

400A and 600A Unit: Open

AC line fuse or open DC bus

fuse (F1…F5).

1000A Unit: Open AC line

fuse (F1…F6).

Open heat sink

Overtemperature Switch

1. Check for evidence of power module failure (see

Step 3 in Start-Up

2. Check for evidence of failure in snubber circuit.

Check the snubber pcb diodes and snubber

resistor and capacitor.

3. Replace entire SCR Bus Supply if any device

has failed.

4. If there is no evidence of a failure, check for open

fuse and replace.

1. Check for evidence of power module failure (see

Step 3 in Start-Up

2. Replace entire SCR Bus Supply if any device

has failed.

3. If there is no evidence of power module failure,

check for open fuse and replace.

1. Verify that maximum ambient temperature is not

exceeded.

2. Replace the Overtemperature Switch.

on page 2-2).

on page 2-2).

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 42

2-8 Start Up/Troubleshooting

Notes:

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 43

Appendix A

Specifications

This appendix provides electrical, environmental, functional and physical

specifications for the PowerFlex SCR Bus Supply, and selection tables for

AC input devices.

Topic Page

PowerFlex SCR Bus Supply

Bus Supply Dimensions A-3

Accessories A-7

Spare Parts A-14

A-1

PowerFlex SCR Bus Supply

Category Specification

Input

Ratings

Output

Ratings

(1)

Includes appropriate AC line reactor.

Specifications Dependent on Power and Voltage

SCR Bus Supply Catalog Number

20SD400… 20SD600… 20SD1K0… 20SF1K0…

Nominal AC Input Voltage: 400/480V 600/690V

Frequency: 47…63 Hz 47…63 Hz

Operational AC Input Voltage Range: 187…528V 528…759V

Input Current (Max. Continuous rms): 355 521 843 843

Input kVA at Max. Continuous rms Amps: 246/295 361/433 584/700 876/1007

DC Bus Amps Normal Duty/Heavy Duty

Continuous:

1 minute:

3 Sec. every minute:

Max. Continuous DC Bus Amps

without Overload:

Power Dissipation

Maximum Continuous Amps:

The derate for each additional slave is 5% plus 5% for the master. See

Parallel Connection of Slave Units

(1)

— Watts at

300/240

330/360

450/480

400 600 1000 1000

1200 1600 2700 2800

on page 1-15.

500/400

550/600

750/800

800/720

880/1080

1200/1440

800/720

880/1080

1200/1440

Specifications Dependent on Voltage

AC Input

Vol ta ge

400V 540V 750V

480V 650V 750V

600V 810V 1080V

690V 930V 1080V

DC Bus Voltage

Nominal Maximum

PowerFlex SCR Bus Supply User Manual

Publication 20S-UM001G-EN-P

Page 44

A-2 Specifications

Specifications Common to All SCR Bus Supplies

Category Specification

Input/Output

Ratings

Control Input Enable Contactor Coil: Single Phase 115V AC, 30 VA (pick-up), 4.5 VA (hold)

Control

Output

Approvals and

Standards

Compliance

Voltage Tolerance: –10% of minimum, +10% of maximum

Frequency Tolerance: 47…63 Hz.

Displacement Power Factor: 0.92 lagging (entire load range)

Efficiency: 99.5% at rated amps, nominal line volts