Page 1

Reference Manual

PowerFlex 750-Series AC Drives

Catalog Numbers 20F, 20G, 21G

Original Instructions

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

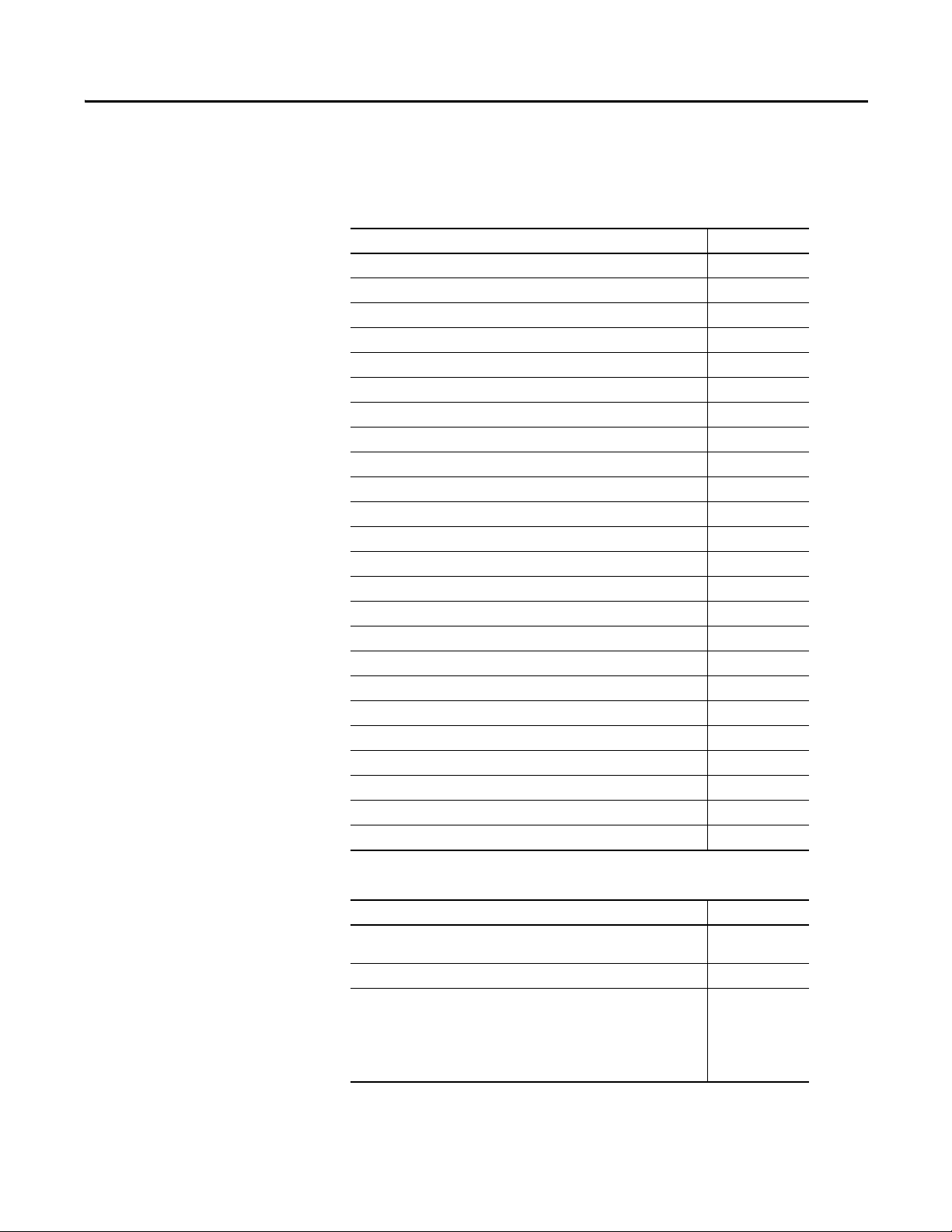

This manual contains new and updated information.

Summary of Changes

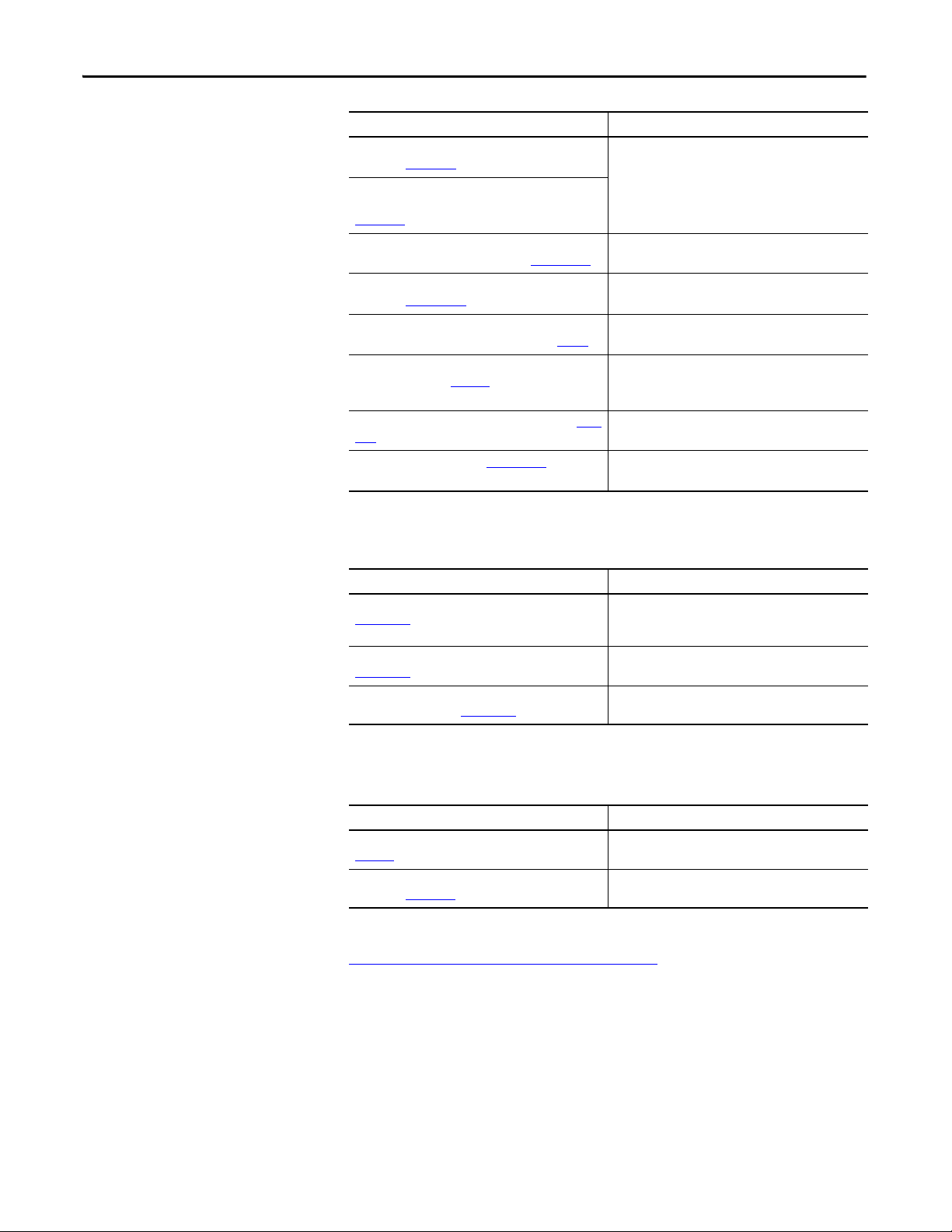

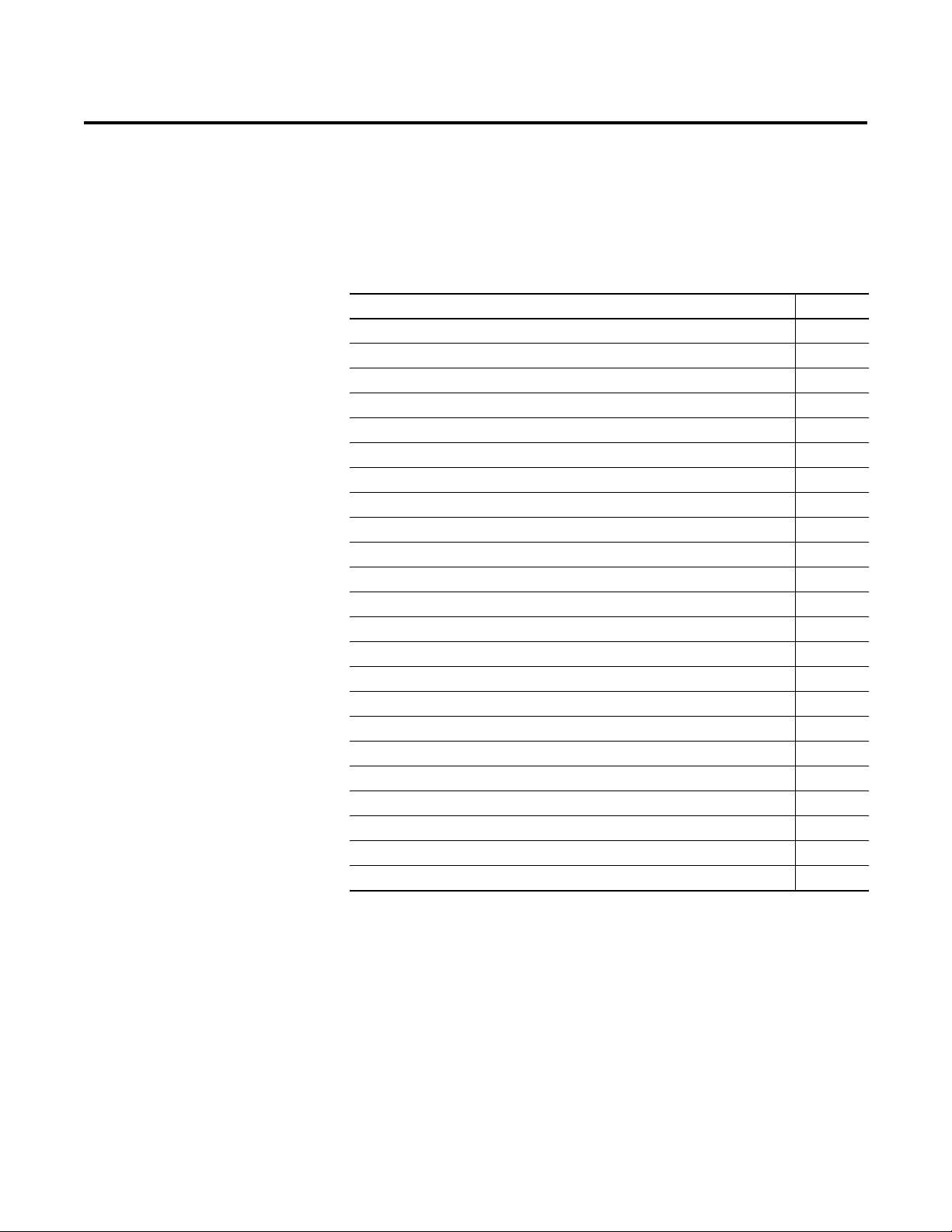

New and Updated Information

This table lists the topics added to this revision.

Top ic Pag e

Adjusta ble Voltage 17

Droop Feature 53

Owners 70

Process PID Loop 76

PTC Motor Thermistor Input 152

Alarms 155

Current Limi t 156

Drive Overload 158

Faul ts 162

Motor Overload 168

Pass word 173

Reflected Wave 179

Security 185

Shear Pin 188

Slip Compensation 192

Carrier (PWM) Frequency 196

Flux Braking 216

High Resolution Feedback 220

Inertia Adaption 221

Load Observer 225

Motor Control Modes 226

Motor Types 235

Torque Reference 262

Speed Torque Position 266

This table lists other changes made to this revision.

Top ic Pag e

Studio 5000™ Logix Designer application is the rebranding of RSLogix™ 5000

software

Block diagrams updated to firmware revision 9.xxx. 375

Block diagrams added:

Position Control – Spindle Orient

11-Series Inputs and Outputs – Digital

11-Series Inputs and Outputs – Analog

11-Series Inputs and Outputs – ATEX

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 3

14

395

410

411

412

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 5

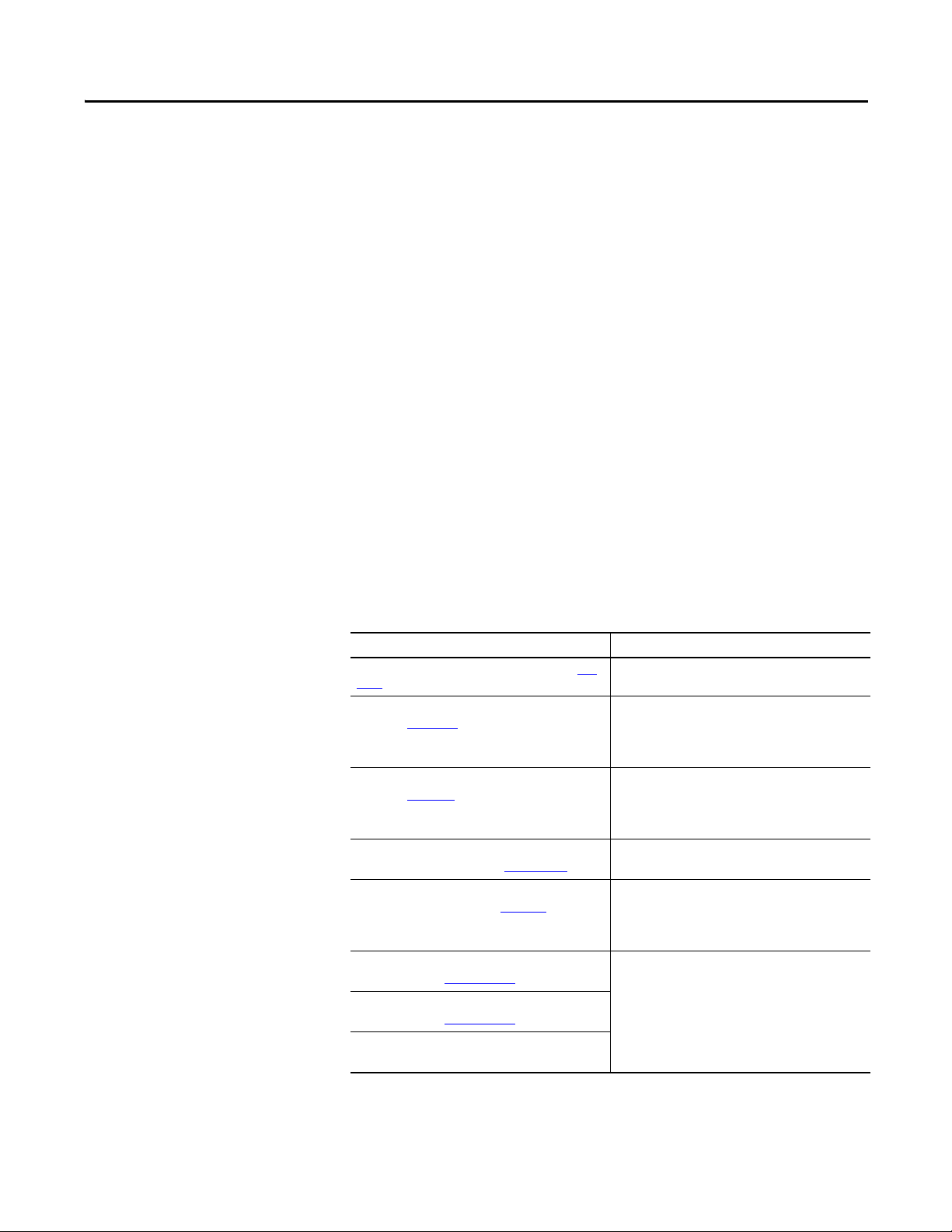

Overview

Table of Contents

Preface

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

What Is Not in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Allen-Bradley Drives Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 1

Drive Configuration

Accel/Decel Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Adjustable Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Auto Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Auto/Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Automatic Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Autotune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Auxiliary Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Bus Regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Configurable Human Interface Module Removal . . . . . . . . . . . . . . . . . . . 52

Droop Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Duty Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Feedback Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Flying Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Hand-Off-Auto. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Masks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Owners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Process PID Loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Reset Parameters to Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Sleep/Wake Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Start Permissives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Stop Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Voltage Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Feedback and I/O

Chapter 2

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

PTC Motor Thermistor Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 5

Page 6

Table of Contents

Chapter 3

Diagnostics and Protection

Motor Control

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Current Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

DC Bus Voltage/Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Drive Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Input Phase Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Motor Overload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Overspeed Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Reflected Wave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Shear Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Slip Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Slip Regulator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chapter 4

Carrier (PWM) Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Dynamic Braking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Flux Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Flux Regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Flux Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

High Resolution Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Inertia Adaption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Inertia Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Load Observer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Motor Control Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Motor Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Notch Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Regen Power Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Speed Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Speed Regulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Torque Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Speed Torque Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Chapter 5

Drive Features

6 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Energy Savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

High Speed Trending. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

Position Homing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Page 7

Chapter 6

Table of Contents

Integrated Motion on the EtherNet/

IP Network Applications for

PowerFlex 755 AC Drives

Additional Resources for Integrated Motion on the

EtherNet/IP Network Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

Coarse Update Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Control Modes for PowerFlex 755 Drives Operating on the Integrated

Motion on the EtherNet/IP Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Drive Nonvolatile (NV) Memory for Permanent Magnet Motor

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Dual Loop Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Dual-Port EtherNet/IP Option Module (ETAP) . . . . . . . . . . . . . . . . . . 315

Hardware Over Travel Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 316

Integrated Motion on EtherNet/IP Instance to PowerFlex 755 Drive

Parameter Cross-Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Motor Brake Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 338

Network Topologies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 341

PowerFlex 755 and Kinetix 7000 Drive Overload

Rating Comparison for Permanent Magnet Motor Operation. . . . . . . 345

PowerFlex 755 Drive Option Module

Configuration and Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346

Regenerative/Braking Resistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Safe Speed Monitor Option Module (20-750-S1) Configuration . . . . 350

Speed Limited Adjustable Torque (SLAT) . . . . . . . . . . . . . . . . . . . . . . . . 353

Supported Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 357

System Tuning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 363

Using an Incremental Encoder with an MPx Motor . . . . . . . . . . . . . . . . 372

PowerFlex 755 Integrated Motion on the

EtherNet/IP Network Block Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

Appendix A

Index

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 7

Page 8

Table of Contents

8 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 9

Overview

The purpose of this manual is to provide detailed information including

operation, parameter descriptions, and programming.

Preface

Who Should Use This Manual

What Is Not in This Manual

Additional Resources

This manual is intended for qualified personnel. You must be able to program

and operate Adjustable Frequency AC Drive devices. In addition, you must have

an understanding of the parameter settings and functions.

The purpose of this manual is to provide detailed drive information including

operation, parameter descriptions and programming.

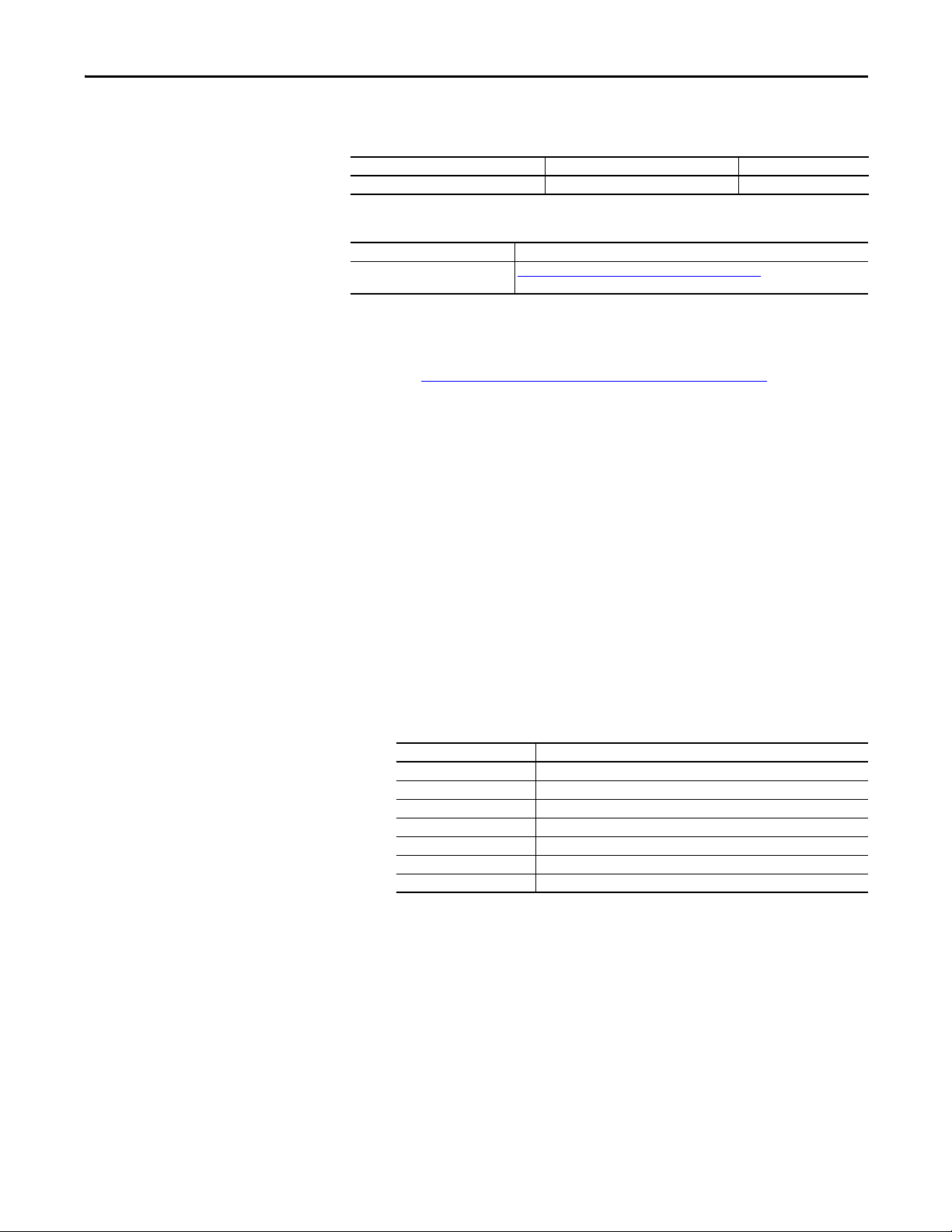

The following table lists publications that provide information about PowerFlex

750-Series drives.

Resource Description

PowerFlex 750-Series Drive Installation Instruction, 750-

IN001

PowerFlex 750-Series AC Drives Programming Manual,

publication 750-PM001

PowerFlex 750-Series AC Drives Technical Data,

publication 750-TD001

PowerFlex 20-HIM-A6 / -C6S HIM (Human Interface

Module) User Manual, publication 20HIM-UM001

PowerFlex 750-Series AC Drives Hardware Service Manual

- Frame 8 and Larger, publication 750-TG001

PowerFlex 755 Drive Embedded EtherNet/IP Adapter User

Manual, publication 750COM-UM001

PowerFlex 750-Series Drive DeviceNet Option Module User

Manual, publication 750COM-UM002

PowerFlex 7-Class Network Communication Adapter User

Manuals, publications 750COM-UMxxx

Provides the basic steps required to install a PowerFlex®

750-Series AC drive.

Provides detailed information on:

• I/O, control, and feedback options

• Parameters and programming

• Faults, alarms, and troubleshooting

Provides detailed information on:

• Drive specifications

• Option specifications

• Fuse and circuit breaker ratings

Provides detailed information on HIM components,

operation, features.

Provides detailed information on:

• Preventive maintenance

• Component testing

• Hardware replacement procedures

These publications provide detailed information on

configuring, using, and troubleshooting PowerFlex

750-Series communication option modules and adapters.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 9

Page 10

Preface

Resource Description

PowerFlex 750-Series Safe Torque Off User Manual,

publication 750-UM002

Safe Speed Monitor Option Module for PowerFlex

750-Series AC Drives Safety Reference Manual, publication

750-RM001

Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives, publication DRIVES-IN001

PowerFlex AC Drives in Common Bus Configurations,

publication DRIVES-AT002

Safety Guidelines for the Application, Installation and

Maintenance of Solid State Control, publication SGI-1.1

A Global Reference Guide for Reading Schematic

Diagrams, publication 100-2.10

Guarding Against Electrostatic Damage, publication 8000-

4.5.2

Product Certifications website, http://ab.com

These publications provide detailed information on

installation, set up, and operation of the 750-Series safety

option modules.

Provides basic information needed to properly wire and

ground PWM AC drives.

Provides basic information needed to properly wire and

ground common bus PWM AC drives.

Provides general guidelines for the application,

installation, and maintenance of solid-state control.

Provides a simple cross-reference of common schematic/

wiring diagram symbols used throughout various parts of

the world.

Provides practices for guarding against Electrostatic

damage (ESD)

Provides declarations of conformity, certific ates, and other

certification details.

The following publications provide necessary information when applying the

Logix Processors.

Resource Description

Logix5000 Controllers Common Procedures, publication

1756-PM001

Logix5000 Controllers General Instructions, publication

1756-RM003

Logix5000 Controllers Process Control and Drives

Instructions, publication 1756-RM006

This publication links to a collection of programming

manuals that describe how you can use procedures that

are common to all Logix5000 controller projects.

Provides a programmer with details about each available

instruction for a Logix-based controller.

Provides a programmer with details about each available

instruction for a Logix-based controller.

The following publications provide information that is useful when planning and

installing communication networks.

Resource Description

ContolNet Coax Tap Installation Instructions, publication

1786-5.7

ContolNet Fiber Media Planning and Installation Guide,

publication CNET-IN001

Provides procedures and specifications for the installation

of ControlNet coaxial taps.

Provides basic information for fiber cable planning and

installation.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

10 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 11

Preface

Allen-Bradley Drives Technical Support

Product Certification

Manual Conventions

Use one of the following methods to contact Automation and Control Technical

Support.

Online Email Telephone

www.ab.com/support/abdrives support@drives.ra.rockwell.com 262-512-8176

Title Online

Rockwell Automation Technical

Support

http://support.rockwellautomation.com/knowledgebase

Product Certifications and Declarations of Conformity are available on the

internet at www.rockwellautomation.com/products/certification

.

• In this manual we refer to PowerFlex 750-Series Adjustable Frequency AC

Drives as: drive, PowerFlex 750, PowerFlex 750 drive or PowerFlex 750

AC drive.

• Specific drives within the PowerFlex 750-Series can be referred to as:

– PowerFlex 753, PowerFlex 753 drive or PowerFlex 753 AC drive

– PowerFlex 755, PowerFlex 755 drive or PowerFlex 755 AC drive

• To help differentiate parameter names and LCD display text from other

text, the following conventions are used:

– Parameter Names appear in [brackets] after the Parameter Number.

For example: P308 [Direction Mode].

– Display text appears in “quotes.” For example: “Enabled.”

• The following words are used throughout the manual to describe an

action.

Word Meani ng

Can Possible, able to do something

Cannot Not possible, not able to do something

May Permitted, allowed

Must Unavoidable, you must do this

Shall Required and necessary

Should Recommended

Should Not Not recommended

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 11

Page 12

Preface

General Precautions

Qualified Personnel

ATT EN TI ON : Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation,

start-up and subsequent maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

Personal Safety

ATT EN TI ON : To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged completely before servicing. Check the DC bus

voltage at the Power Terminal Block by measuring between the +DC and -DC

terminals, between the +DC terminal and the chassis, and between the -DC

terminal and the chassis. The voltage must be zero for all three measurements.

Hazard of personal injury or equipment damage exists when using bipolar input

sources. Noise and drift in sensitive input circuits can cause unpredictable changes

in motor speed and direction. Use speed command parameters to help reduce

input source sensitivity.

Risk of injury or equipment damage exists. DPI or SCANport™ host products must

not be directly connected together via 1202 cables. Unpredictable behavior can

result if two or more devices are connected in this manner.

The drive start/stop/enable control circuitry includes solid state components. If

hazards due to accidental contact with moving machinery or unintentional flow of

liquid, gas or solids exists, an additional hardwired stop circuit may be required to

remove the AC line to the drive. An auxiliary braking method may be required.

Hazard of personal injury or equipment damage due to unexpected machine

operation exists if the drive is configured to automatically issue a Start or Run

command. Do not use these functions without considering applicable local,

national and international codes, standards, regulations or industry guidelines.

12 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 13

Product Safety

ATT EN TI ON : An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or appl ication errors such as under

sizing the motor, incorrect or inadequate AC supply, or excessive surrounding air

temperatures may result in malfunction of the system.

This drive contains ESD (Electrostatic Discharge) sensitive parts and assemblies.

Static control precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD control procedures

are not followed. If you are not familiar with static control procedures, reference

Guarding Against Electrostatic Damage, publication 8000-4.5.2, or any other

applicable ESD protection handbook.

Configuring an analog input for 0-20 mA operation and driving it from a voltage

source could cause component damage. Verify proper configuration prior to

applying input signals.

A contactor or other device that routinely disconnects and reapplies the AC line to

the drive to start and stop the motor can cause drive hardware damage. The drive is

designed to use control input signals to start and stop the motor. If an input device

is used, operation must not exceed one cycle per minute or drive damage will

occur.

Preface

Drive must not be installed in an area where the ambient atmosphere contains

volatile or corrosive gas, vapors or dust. If the drive is not going to be installed for a

period of time, it must be stored in an area where it will not be exposed to a

corrosive atmosphere.

Class 1 LED Product

ATT EN TI ON : Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into module ports or fiber optic cable connectors.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 13

Page 14

Preface

Studio 5000 Environment

The Studio 5000™ Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the Studio

5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix™ 5000 software and will continue to be

the product to program Logix5000™ controllers for discrete, process, batch,

motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. This environment is the

one place for design engineers to develop all of the elements of their control

system.

14 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 15

Chapter 1

Drive Configuration

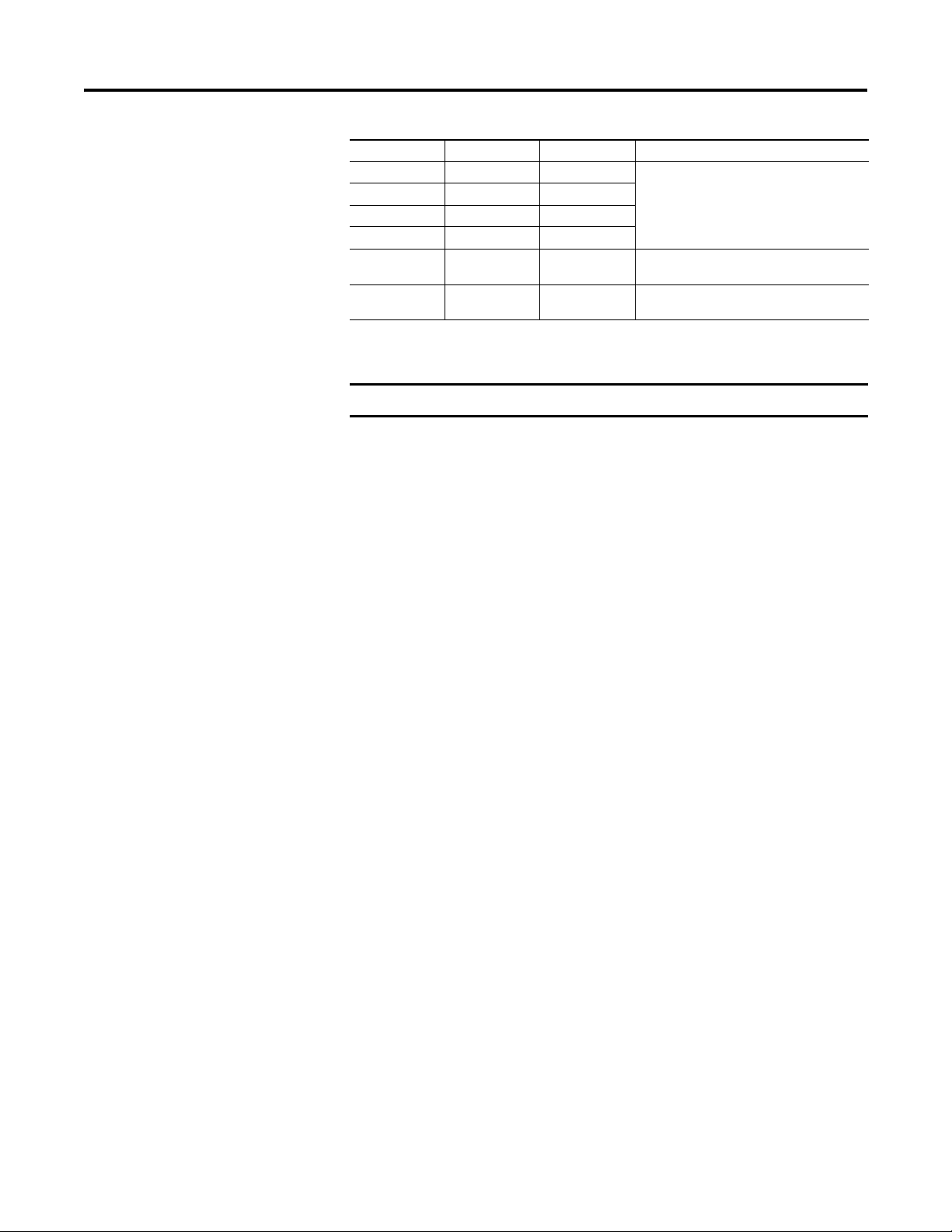

Top ic Pag e

Accel/Decel Time 16

Adjusta ble Voltage 17

Auto Restart 25

Auto/Manual 27

Automatic Device Configuration 34

Autotune 35

Auxiliary Power Supply 41

Bus Regulation 41

Configurable Human Interface Module Removal 52

Droop Feature 53

Duty Rating 53

Feedback Devices 54

Flying Star t 54

Hand-Off-Auto 64

Masks 67

Owners 70

Power Loss 72

Process PID Loop 76

Reset Parameters to Factor y Defaults 88

Sleep/Wake Mode 90

Start Permissives 94

Stop Modes 96

Vol tage Clas s 10 4

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 15

Page 16

Chapter 1 Drive Configuration

Accel/Decel Time

You can configure the drive’s acceleration time and deceleration time.

Acceleration Time

P535[Accel Time 1] and P536 [Accel Time 2] set the acceleration rate for all

speed changes. Defined as the time to accelerate from 0 to motor nameplate

frequency P27 [Motor NP Hertz] or to motor nameplate rated speed P28

[Motor NP RPM]. The setting of Hertz or RPM is programmed in P300 [Speed

Units]. Selection between Acceleration Time 1 and Acceleration Time 2 is

controlled by a digital input function (see Digin Functions in the PowerFlex 750Series Programming Manual, publication 750-PM001

(sent over a communication network or DeviceLogix™ software).

Adjustment range is 0.00 to 3600.00 seconds.

) or by Logic Command

Deceleration Time

P537 [Decel Time 1] and P538 [Decel Time 2] set the deceleration rate for all

speed changes. Defined as the time to decelerate from motor nameplate

frequency P27 [Motor NP Hertz] or from motor nameplate rated speed P28

[Motor NP RPM] to 0. The setting of Hertz or RPM is programmed in P300

[Speed Units]. Selection between Deceleration Time 1 and Deceleration Time 2

is controlled by a digital input function (see Digin Functions in the PowerFlex

750-Series Programming Manual, publication 750-PM001

Command (sent over a communication network or DeviceLogix software).

) or by Logic

Adjustment range is 0.00 to 3600.00 seconds.

16 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 17

Drive Configuration Chapter 1

Rated Voltage

Volt age

Frequenc y

Max Frequency

Adjustable Voltage

As standard AC drive applications are expanding into new markets, new control

methods are required to meet these market demands for electromagnetic

applications. Some of these applications, listed below, use non-motor or nonstandard motors that require independent control of load frequency and voltage.

• Vibration welding

• Induction heating

• Power supplies

• Vibratory feeders or conveyors

• Electromagnetic stirring

• Resistive loads

Standard inverter control modes consist of volts per hertz (V/Hz), with boost

selections, speed feedback selection, fan, pump, and economize, flux vector (FV),

with encoder and encoder less modes. The control of the output voltage/

frequency relationship of the variable frequency inverter must be maintained in

the linear and nonlinear (over-modulation) regions. Voltage linearity is achieved

by maintaining a constant voltage/frequency ratio over the entire operating

region. The variable frequency inverter must deliver an adjustable-frequency

alternating voltage whose magnitude is related to the output frequency. As the

linear-to-nonlinear transition begins, the control must compensate for the lost

voltage and deliver a linear output voltage profile.

In adjustable voltage control mode, the output voltage is controlled

independently from the output frequency. The voltage and frequency

components have independent references and acceleration/deceleration rates.

The adjustable voltage control mode operation enables separate control of the

output voltage and the output frequency for use on applications that are typically

non-motor types. The voltage and frequency components have independent

references and independent acceleration and deceleration rates. Both the voltage

and frequency can be set to any point within their respective range. The

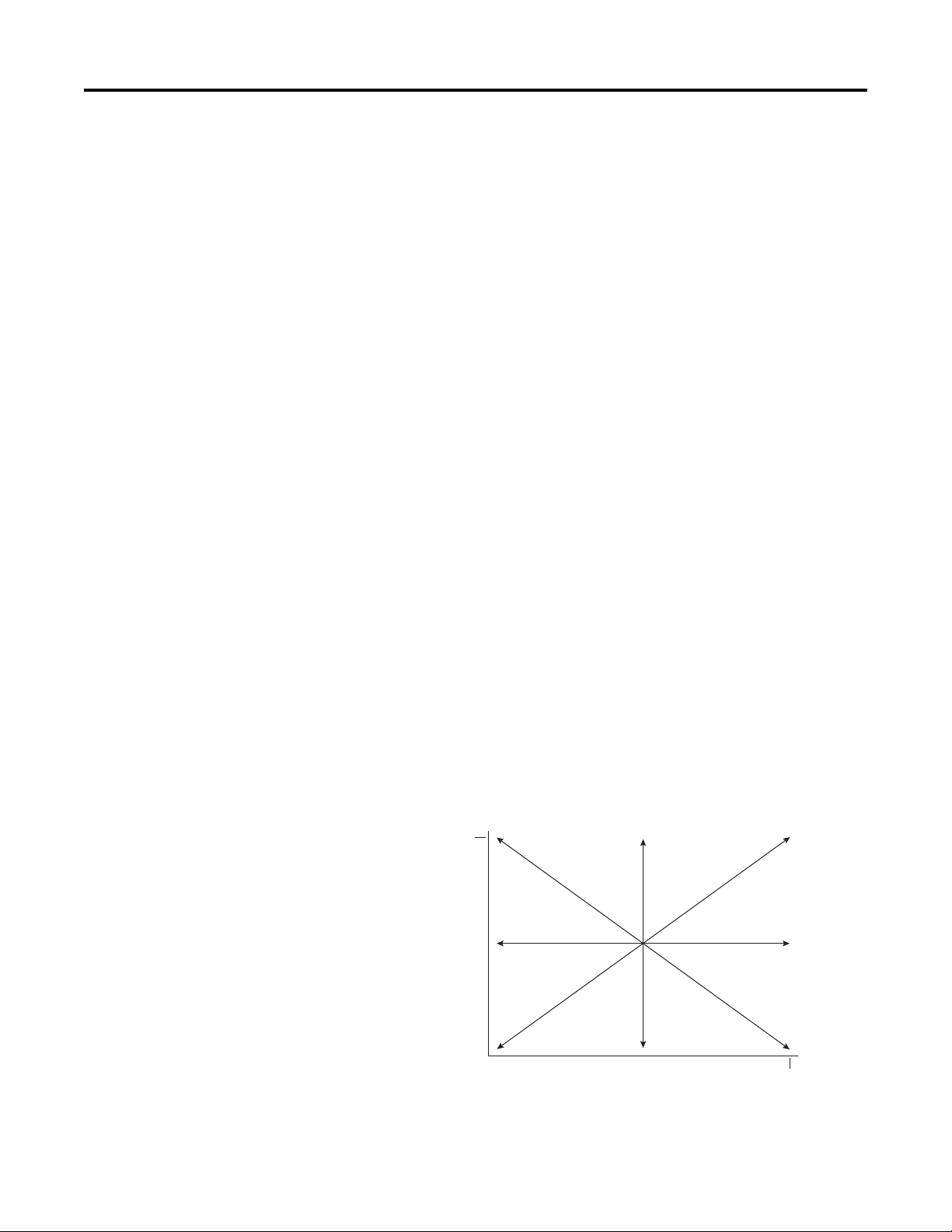

following graph illustrates these functional ranges.

0

0

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 17

Page 18

Chapter 1 Drive Configuration

Overview

Adjustable voltage control is enabled by setting P35 [Motor Ctrl Mode] to

option 9 “Adj VltgMode.” This feature provides either three-phase and singlephase output voltage. The default mode is three-phase output voltage and is

selected by P1131 [Adj Vltg Config]. In single-phase mode the drive is not

designed to operate single phase motors, but rather the output load is considered

to have a lagging or unity power factor consisting of resistance and inductance for

specially designed motor or non-motor application.

Input reference sources can be configured from P1133 [Adj Vltg Select]. The

input source can be scaled and upper when lower limits are applied. A trim source

can be selected reference from P1136 [Adj Vltg TrimSel] with the trim voltage

added or subtracted from the voltage reference.

The scalar frequency selection and scalar frequency ramp are the same

components as used in all other control modes. The exception being the

frequency command and ramp are decoupled from the voltage generation for the

adjustable voltage control mode to provide an independent frequency ramp.

Acceleration and deceleration rates and S Curve are the same as used in all other

modes. Upper and lower limits are applied to the value of the output command

frequency.

The adjustable voltage control voltage ramp provides an independent voltage

ramp decoupled from the scalar frequency ramp and controlled by user selectable

acceleration and deceleration ramp times. There is also an adjustable percent S

Curve feature.

The current limit function reduces the output voltage when the current limit is

exceeded. Minimum and maximum voltage limits are applied so the output

voltage is never operated outside that range.

Adjustable Voltage Control Setup

The following examples of setups for the Adjustable Voltage Control mode are a

starting point for configuration. Applications can be unique and require specific

parameter settings. These examples are base case only.

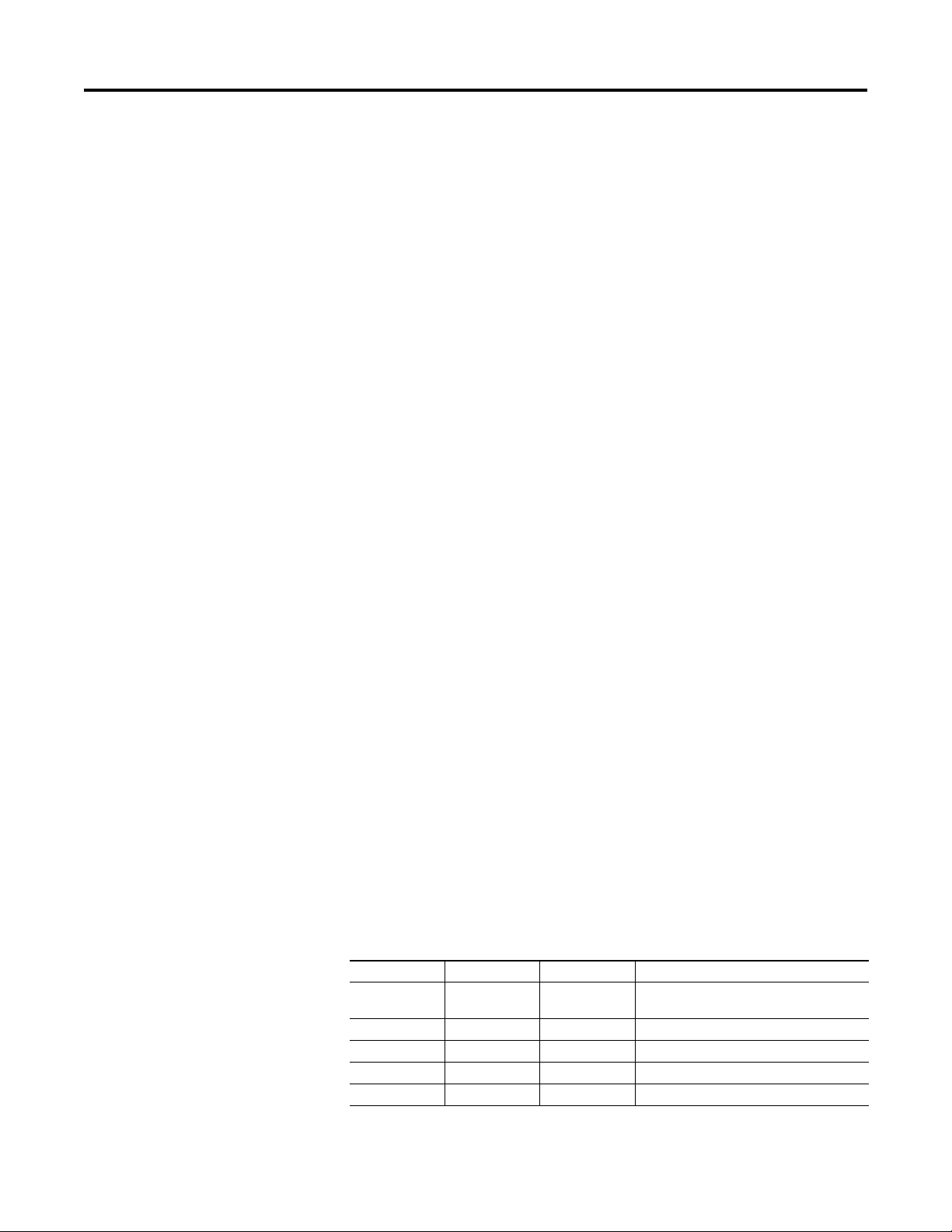

Table 1 - Basic Adjustable Voltage Control Parameters

Parameter No. Parameter Name Setting Description

35 Motor Ctrl Mode 9 “Adj VltgMode” Adjustable Voltage feature is used in non-motor

1131 Adj Vltg Config 1 1 = 3-Phase Operation, 0 = 1-Phase Operation

1133 Adj Vltg Select Preset 1

1134 Adj Vltg Ref Hi 100 Percent

1140 Adj Vltg AccTim e n Secs Application dependent

applications.

18 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 19

Drive Configuration Chapter 1

Parameter No. Parameter Name Setting Description

1141 Adj Vltg DecTime n Secs Application dependent

1142 Adj Vltg Preset1 n VAC Application dependent

1153 Dead Time Comp n % Vary from 0% to 100%. Dead Time Comp is best set

to 0% when output of the Sine wave Filter is fed

into a transformer, to prevent or minimize DC Offset

voltage s.

Refer to the PowerFlex 750-Series Programming Manual, publication 750-

PM001, for parameter descriptions and defaults.

When using sine wave or dv/dt filters, the PWM frequency must match the filter

design. The drive’s thermal protection changes the PWM frequency if over

temperature conditions are detected. Set P420 [Drive OL Mode] to option 1

“Reduce CLmt” and P38 [PWM Frequency] to the filter instructions.

Additional Parameter Changes

When using adjustable voltage control it is necessary to change additional

parameters beyond the feature itself. Use this table to assist in setting these

parameters.

Table 2 - Adjustable Voltage Applications Parameter Settings

Parameter No. Parameter Name Setting Description

38 PWM Frequency 2 kHz or 4 kHz Match the setting with filter tuning.

40 Mtr Options Cfg Bit 5 = 0 Reflected wave is turned off so that there are no

Bit 8 = 1 AsyncPWMLock is on because the filter is tuned to

Bit 9 = 1 PWM Freq Lock is on because the filter is tuned to

Bit 11 = 0 The “Elect Stab” bit affects angle stability and

Bit 12 = 0 Transistor diagnostics is turned off because that

43 Flux Up Enable 0 Leave at the “Manual” setting.

44 Flux Up Time Default Leave at 0.0000 seconds.

missing pulses in the output voltage waveform and

to minimize any offsets that can appear.

the carrier frequency. The carrier frequency must be

fixed, if it changes the filter will not work. Also, set

the PWM frequency match filter tuning, either 2 kHz

or 4 kHz.

the carrier frequency. The carrier frequency must be

fixed, if it changes the filter will not work. Also, set

the PWM frequency match filter tuning, either 2 kHz

or 4 kHz.

voltage stability.

Angle stability gain is set for 0 so it does not

compensate for the current going into the filter’s

caps. Voltage stability gain is set for 0 for the same

reason.

sequence of turning transistors on and off charges

the caps in the filter and can cause an IOC trip.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 19

Page 20

Chapter 1 Drive Configuration

IMPORTANT

Parameter No. Parameter Name Setting Description

60 Start Acc Boost 0 Set if there are DC offset voltages at load

61 Run Boost 0

62 Break Voltage 0

63 Break Frequency 0

420 Drive OL Mode 1 “Reduce CLmt” Drive OL mode is set for reduce current limit, and

1154 DC Offset Ctrl 1 “Enable” This turns off any offset control programmed in the

transformer input windings.

not the PWM frequency as it must remain fixed.

firmware.

Modulation mode is default at space vector only because 2-phase modulation will

degrade the filter’s performance.

Do not autotune.

Application Considerations

Whatever the device the user wants to connect to the drive by using the

adjustable voltage feature, that device has some type of rating associated with it.

As a minimum it needs to have a current rating and voltage rating. Drive selection

is based on those ratings.

Sizing

First, consider the voltage rating of the drive. Determine what the available line

voltage is and select a drive voltage rating to match. Next, select a drive that

supplies the current necessary for the device’s rating.

Single Phase Output

Consult Rockwell Automation before configuring a drive for single phase

adjustable voltage output. Derating of the drive is necessary because of stress on

the DC bus capacitor or the IGBT switching losses. When PWM is applied to a

resistor, the current changes state following the voltage. For each PWM voltage

pulse the current is pulsing the same way. This rapid change in current is not

designed into the IGBT selection for the drive. Therefore, some sort of derating

needs to be applied. Somewhere around 67% derating. When in this mode, actual

losses must be measured to determine a derating percentage. Adding a reactor in

series with the resistor can help by adding inductance and rounding off the

corners of the current pulses. Depending on how much inductance is added, the

waveform can look like a sine wave.

20 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 21

Drive Configuration Chapter 1

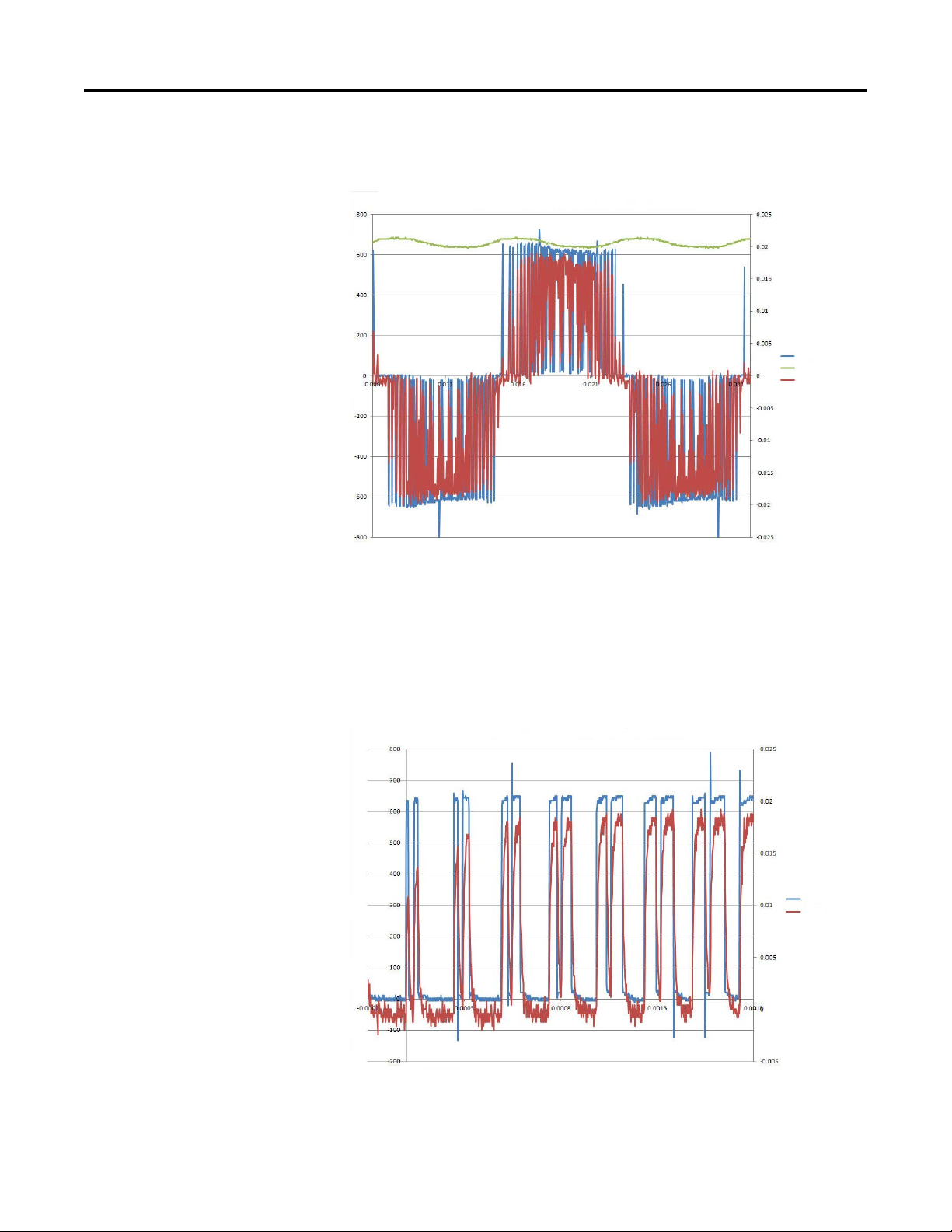

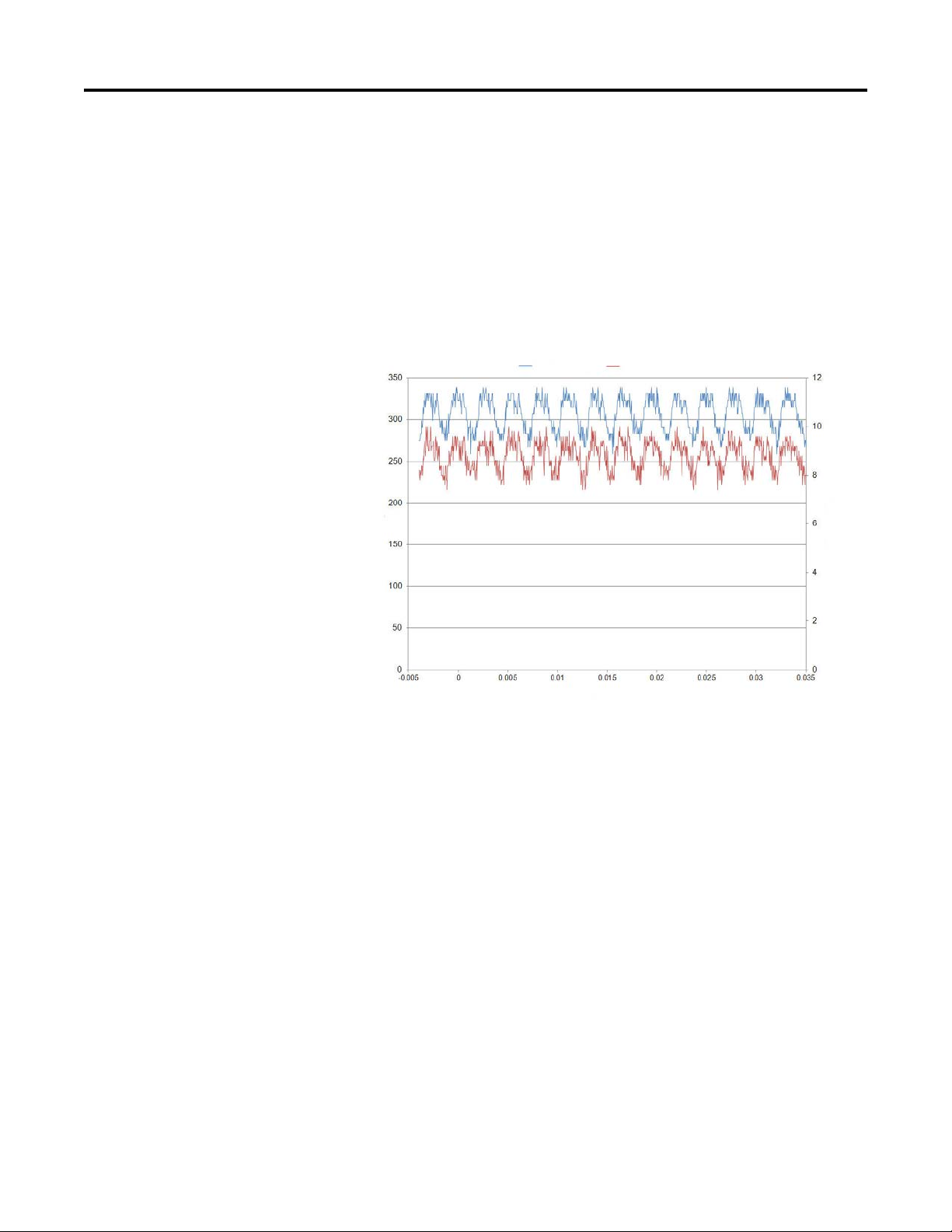

Single Phase - PWM into Resistor - No Reactor

Vol tag e

DC Bus

Curren t

Single Phase - PWM into Resistor - No Reactor

Vol tag e

Curren t

This is a plot showing output voltage, output current, and DC Bus voltage. Here

you can see the current following the voltage in a typical PWM output.

This plot enlarges some of the pulses to see the current and its shape.

Notice the tops have an abrupt change to them. Any rounding of the wave form

at the top is due to the type of resistor used. The resistors used for this plot are the

grid type resistors where the resistor element is coiled along its length, adding a

certain amount of inductance. This inductance helps round over the leading edge

of the current.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 21

Page 22

Chapter 1 Drive Configuration

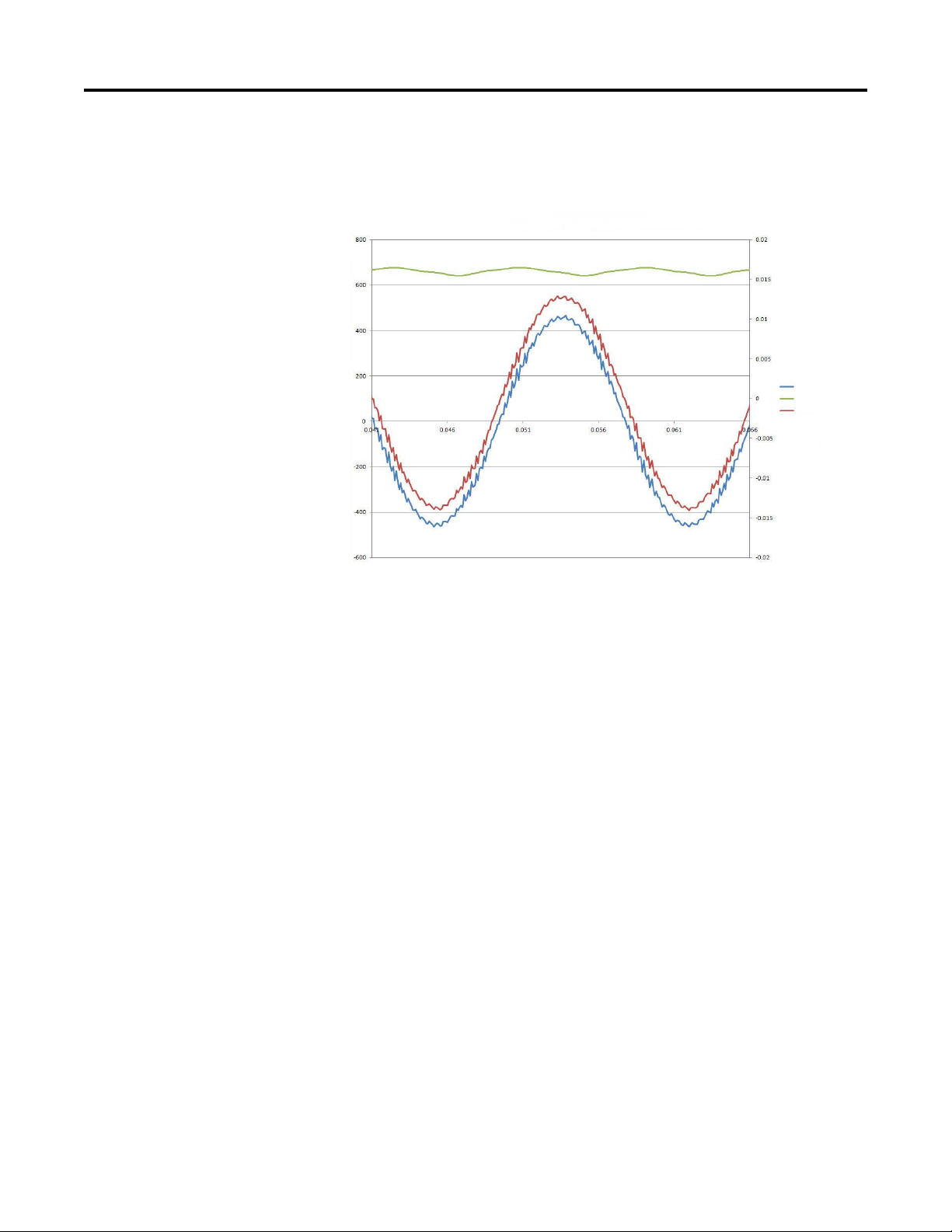

Single Phase - PWM into Resistor - No Reactor

Vol tag e

DC Bus

Curren t

Below is the same plot with a reactor added in series. These waveform look like a

sine wave and that is a function of how much inductance is added. However, the

increased voltage drop must be accounted for.

Another option is to have a sine wave filter in the circuit. This lets unshielded

cable to be used without the worry of PWM generated noise being injected into

the facility. The cost of shielded cable versus a sine wave filter, Among other

factors, has to be weighed.

When using single phase operation, connect the load to the U and V phases. The

W phase is energized but is not used.

Enter your maximum current into the Motor NP Amps parameter. Also use this

value in the Current Limit parameter. When started the drive attempts to ramp

to the commanded voltage. If current limit is hit, the drive levels off or reduce the

voltage to satisfy the current limit.

Notice the DC Bus voltage ripple in two of the plots above. If this ripple is high

enough in magnitude, it can cause the drive to trip on an Input Phase Loss fault.

This is due to the drive monitoring the bus ripple and if a certain delta between

max volts and min volts exists for a certain amount of time, the drive assumes an

input phase was lost. This fault can be disabled by setting P462 [InPhase

LossActn] to option 0 “Ignore.”

Three Phase Output

If you are driving as resistive load, configure it in a three phase arrangement to

avoid using the single phase mode of adjustable voltage. Use a sine wave filter to

keep PWM off the resistors. If the resistors are of the ceramic type, it is possible to

crack the resistor using PWM.

22 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 23

Drive Configuration Chapter 1

XL 2 pi× f× H×=

XL12pi× 60× 1.2 1000⁄()× 0.45ohm==

XL22pi× 60× 5 1000⁄()× 1.88ohm==

XL32pi× 60× 5 1000⁄()× 1.88ohm==

XL42pi× 60× 3 1000⁄()× 1.13ohm==

IVXL 3×()⁄=

VIXL× 3×=

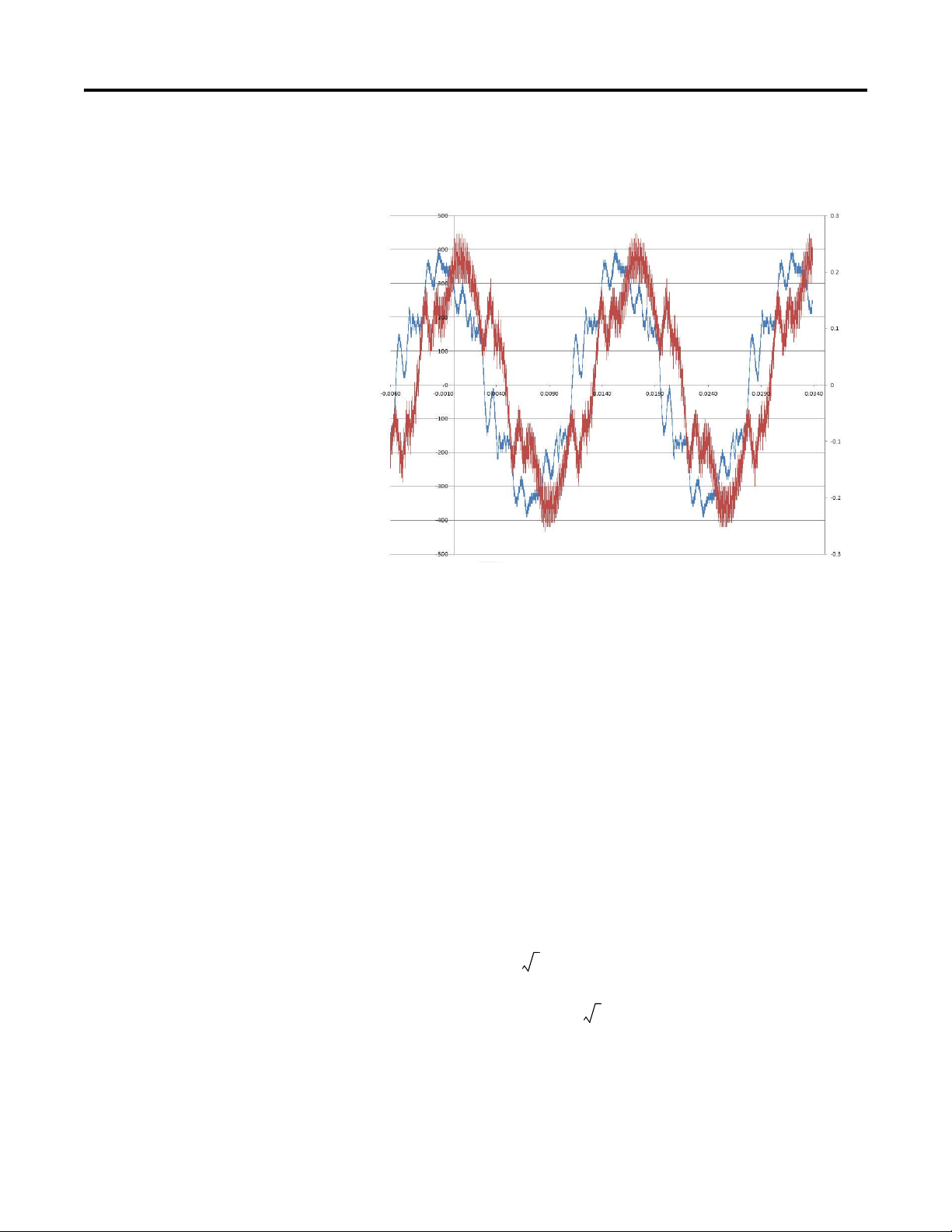

The following is a plot of voltage and current at the reactor. The output of the

drive is sent through a sine wave filter then to the reactor. The shape of the

waveform is determined by the amount of capacitance in the sine wave filter.

If you wanted to know what voltage you can expect at the three phase reactor,

consider an example where the user has four reactors in series. The inductance of

each is 1.2mH, 5mH, 5mH and 3mH. First item to calculate is XL for each

reactor. .

Now total it. XL1 + XL2 + XL3 + XL4 = 5.35 ohm.

For a three phase reactor the current is represented by the

equation,

Isolate the voltage.

The current value can be what the least rating of the reactors are or if the rating

are greater than the drive rating, use the drive rating. In this case the drive is rated

for 14 amps.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 23

Page 24

Chapter 1 Drive Configuration

V 14 5.35× 1.73× 129.8==

DC Voltage

Resistor Current

Times

DC Voltage

Resistor Current

So plug in the numbers.

So 14 amps is realized when the voltage is 129.8 on the output. A drive with a

voltage rating of 240V AC could be selected.

Below is a waveform of voltage and current at a resistor. The output of the drive

runs through a sine wave filter. Then this is connected to a one to one

transformer. This output is then sent to a bridge rectifier giving us pure DC.

With the use of a feedback board and the drives PI loop, the voltage at the resistor

was steady even if the resistance changed while running.

Other

Setting the frequency acceleration time to zero results in the drive outputting a

DC voltage waveform.

If the frequency accel time is set between 0 and 1, this could trigger and anomaly

24 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

where the drive outputs a frequency not equal to the commanded frequency. The

Page 25

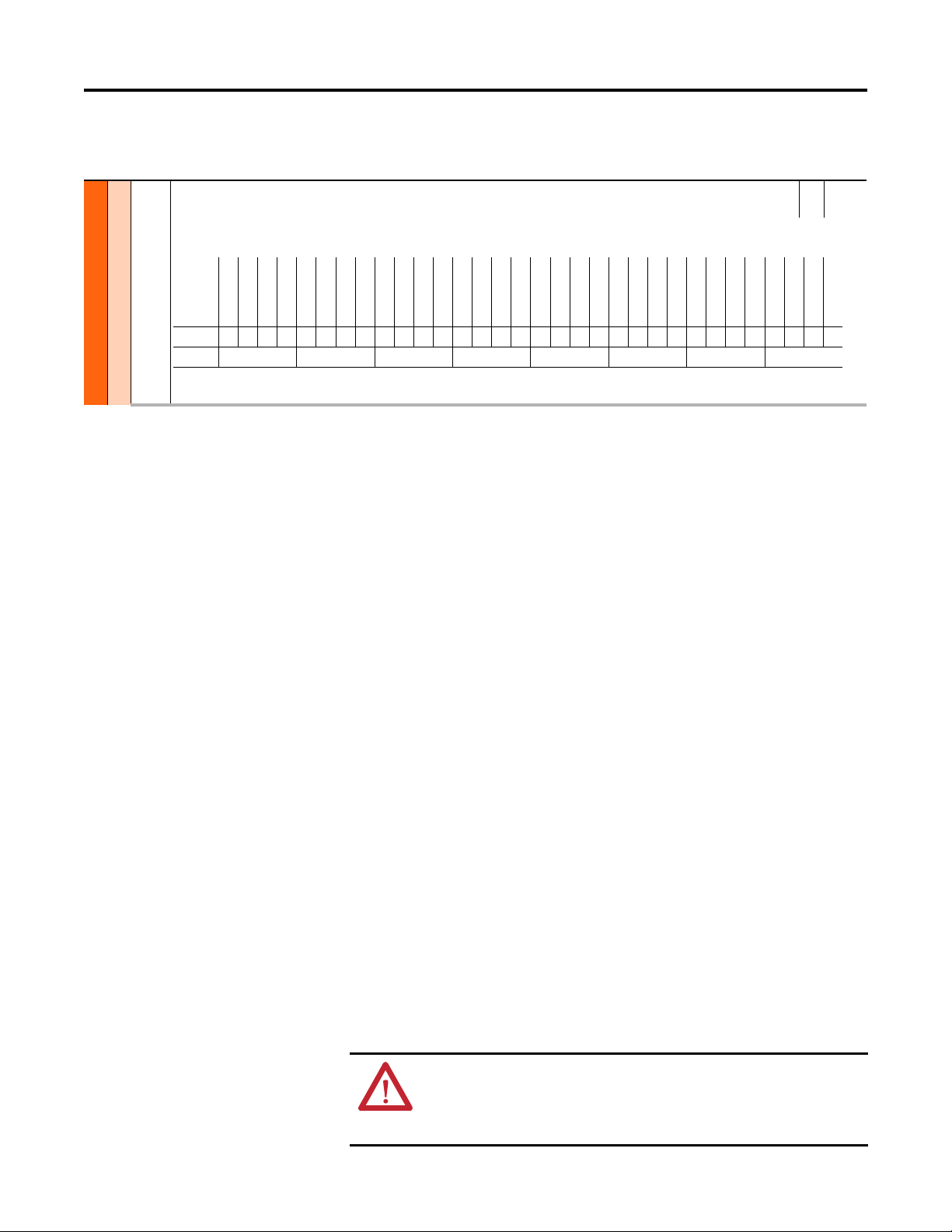

40 Mtr Options Cfg

Options

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Jerk Select

Not Used

Common Mode

Xsistor Diag

Elect Stab

DB WhileStop

PWM FreqLock

AsyncPWMLock

PWM Type Sel

RS Adaption

Reflect Wave

Mtr Lead Rev

EnclsTrqProv

(1)

(1) 755 drives only.

Trq ModeJog

Trq ModeStop

Zero TrqStop

Default00000000000000000001100011100111

Bit 323029282726252423222120191817161514131211109876543210

Mtr Ctrl Options

MOTOR CONTROL

Drive Configuration Chapter 1

cause of this anomaly is the introduction of the jerk function. This bit needs to be

off during this condition.

RW 32-bit

Motor Options Configuration

Configuration of motor control-related functions. For motors abo ve 200 Hz, a carrier frequency of 8 kHz or higher is recommended. Consider drive derate and motor

lead distance restrictions.

Integer

When using single phase operation, connect the load to the U and V phases. The

W phase is energized but is not used.

Using a DC output can result in thermal issues. The drive may need to be

derated.

Auto Restart

Investigate Possible Derating

Derate drive for sine wave filter.

Motor or drive overload is not affected by adjustable voltage mode.

The Auto Restart feature provides the ability for the drive to automatically

perform a fault reset followed by a start attempt without user or application

intervention. Provided the drive has been programmed with a 2 wire control

scheme and the Run signal is maintained. This enables remote or unattended

operation. Only certain faults are allowed to be reset. Faults listed as NonResettable in the programming manual indicate possible drive component

malfunction and are not resettable.

Use caution when enabling this feature, because the drive attempts to issue its

own start command based on user selected programming.

Configuration

Setting P348 [Auto Rstrt Tries] to a value greater than zero enables the Auto

Restart feature. Setting the number of tries equal to zero disables the feature.

ATT EN TI ON : Equipment damage and/or personal injury may result if this

parameter is used in an inappropriate application. Do not use this function

without considering applicable local, national and international codes,

standards, regulations or industry guidelines.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 25

Page 26

Chapter 1 Drive Configuration

P349 [Auto Rstrt Delay] sets the time, in seconds, between each reset/run

attempt.

The auto reset/run feature supports the following status information.

• P936 [Drive Status 2] Bit 1 “AuRstrCntDwn” provides indication that an

Auto Restart attempt is presently counting down and the drive attempts to

start at the end of the timing event.

• P936 [Drive Status 2] Bit 0 “AutoRstr Act” indicates that the auto restart

has been activated.

Operation

The typical steps performed in an Auto Reset/Run cycle are as follows.

1. The drive is running and an Auto Reset Run fault occurs, thus initiating

the fault action of the drive.

2. After the number of seconds in P349 [Auto Rstrt Delay], the drive

automatically performs an internal Fault Reset, resetting the faulted

condition.

3. The drive then issues an internal Start command to start the drive.

4. If another Auto Reset Run fault occurs, the cycle repeats itself up to the

number of attempts set in P348 [Auto Rstrt Tries].

5. If the drive faults repeatedly for more than the number of attempts set in

P348 [Auto Rstrt Tries] with less than five minutes between each fault, the

Auto Reset/Run is considered unsuccessful and the drive remains in the

faulted state.

6. If the drive remains running for five minutes or more because the last

reset/run without a fault, or is otherwise stopped or reset, the Auto Reset/

Run is considered successful. The Auto Restart status parameters are reset,

and the process repeats if another auto resettable fault occurs.

See Aborting an Auto-Reset/Run Cycle for information on how the

Reset/Run cycle can be aborted.

Beginning an Auto-Reset/Run Cycle

The following conditions must be met when a fault occurs for the drive to begin

an Auto Reset/Run cycle:

• The fault type must be Auto Reset Run.

• P348 [Auto Rstrt Tries] setting must be greater than zero.

• The drive must have been running, not jogging, not auto tuning, and not

stopping, when the fault occurred. (A DC Brake state is part of a stop

sequence and therefore is considered stopping.)

26 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 27

Drive Configuration Chapter 1

Aborting an Auto-Reset/Run Cycle

During an Auto Reset/Run cycle the following actions/conditions abort the

reset/run attempt process.

• A stop command is issued from any source. (Removal of a 2-wire run-fwd

or run-rev command is considered a stop assertion.)

• A fault reset command is issued from any source.

• The enable input signal is removed.

• P348 [Auto Rstrt Tries] is set to zero.

• A Non-Resettable fault occurs.

• Power to the drive is removed.

• The Auto Reset/Run Cycle is exhausted.

After all [Auto Rstrt Tries] have been made and the drive has not successfully

restarted and remained running for five minutes or more, the Auto Reset/Run

cycle is considered exhausted and therefore unsuccessful. In this case the Auto

Reset/Run cycle terminates and an F33 “AuRsts Exhaust” fault is indicated by

P953 [Fault Status B] Bit 13 “AuRstExhaust.”

Auto/Manual

The purpose of the Auto/Manual function is to permit temporary override of

speed control and/or exclusive ownership of logic (start, run, direction) control.

A manual request can come from any port, including HIM, digital input or other

input module. However, only one port can own manual control and must release

the drive back to auto control before another port can be granted manual control.

When in Manual mode, the drive receives its speed reference from the port that

requested manual control, unless otherwise directed by the Alternate Manual

Reference Select.

The HIM can request Manual control by pressing the Controls key followed by

the Manual key. Manual control is released by pressing the Controls key followed

by Auto. When the HIM is granted manual control, the drive uses the speed

reference in the HIM. If desired, the auto speed reference can be automatically

preloaded into the HIM when entering HIM manual control, so that the

transition is smooth.

Manual control can also be requested through a digital input. To do this, a digital

input has to be set to request Manual control through P172 [DI Manual Ctrl].

Digital Input Manual control requests can be configured to use their own

alternative speed reference to control the drive. Digital inputs can also be used in

conjunction with Hand-Off-Auto Start to create a three way HOA switch that

incorporates Manual mode.

The Safe Speed Monitor Option Module uses Manual mode to control the speed

of the drive when entering Safe Limited Speed monitoring.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 27

Page 28

Chapter 1 Drive Configuration

Auto/Manual Masks

The port configuration of the Auto/Manual feature is performed through a set of

masks. Together, these masks set which ports can control the speed and/or logic

control of the drive as well as which ports can request Manual control. The masks

are configured by setting a 1 or 0 in the bit number that corresponds to the port

(Bit 1 for port 1, Bit 2 for port 2, and so forth). Digital Inputs are always

configured through Bit 0, regardless of what port the module physically resides

in. If both [Manual Ref Mask] and [Manual Cmd Mask] for a particular port are

set to 0, that port is unable to request manual control.

P324 [Logic Mask]

Logic Mask enables and disables the ports from issuing logic commands (such as

start and direction) in any mode. Stop commands from any port are not masked

and still stop the drive.

P325 [Auto Mask]

Auto Mask enables and disables the ports from issuing logic commands (such as

start and direction) while in Auto mode. Stop commands from any port are not

masked and still stop the drive.

P326 [Manual Cmd Mask]

Manual Command Mask enables and disables the ports from exclusively

controlling logic commands (such as start and direction) while in Manual mode.

If a port assumes Manual control, and the corresponding bit for the port in the

[Manual Cmd Mask] is set, no other port is able to issue logic commands. Stop

commands from any port are not masked and still stops the drive.

P327 [Manual Ref Mask]

Manual Reference Mask enables and disables the ports from controlling the

speed reference while in Manual mode. If a port assumes manual control, and the

corresponding bit for the port in the [Manual Ref Mask] is set, the drive is

commanded to the speed reference from that port. An alternate speed reference

can be commanded using P328 [Alt Man Ref Sel]. If the respective bit for the

manual control port is not set, then the drive follows its normal automatic speed

reference, even in Manual mode.

Alternate Manual Reference Select

By default, the speed reference used in Manual mode comes from the port that

requested manual control (For example, if a HIM in port 1 requests manual

control, the speed reference in Manual mode comes from port 1). If instead it is

desired to use an a different speed reference, P328 [Alt Man Ref Sel], can be used.

The port selected in the parameter is used for manual reference regardless of

which port requested manual control, as long as the port in manual control is

allowed to set the manual reference per P327 [Manual Ref Mask]. If P328 [Alt

Man Ref Sel] is an analog input, the maximum and minimum speeds can be

configured through P329 [Alt Man Ref AnHi] and P330 [Alt Man Ref AnLo].

28 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 29

Drive Configuration Chapter 1

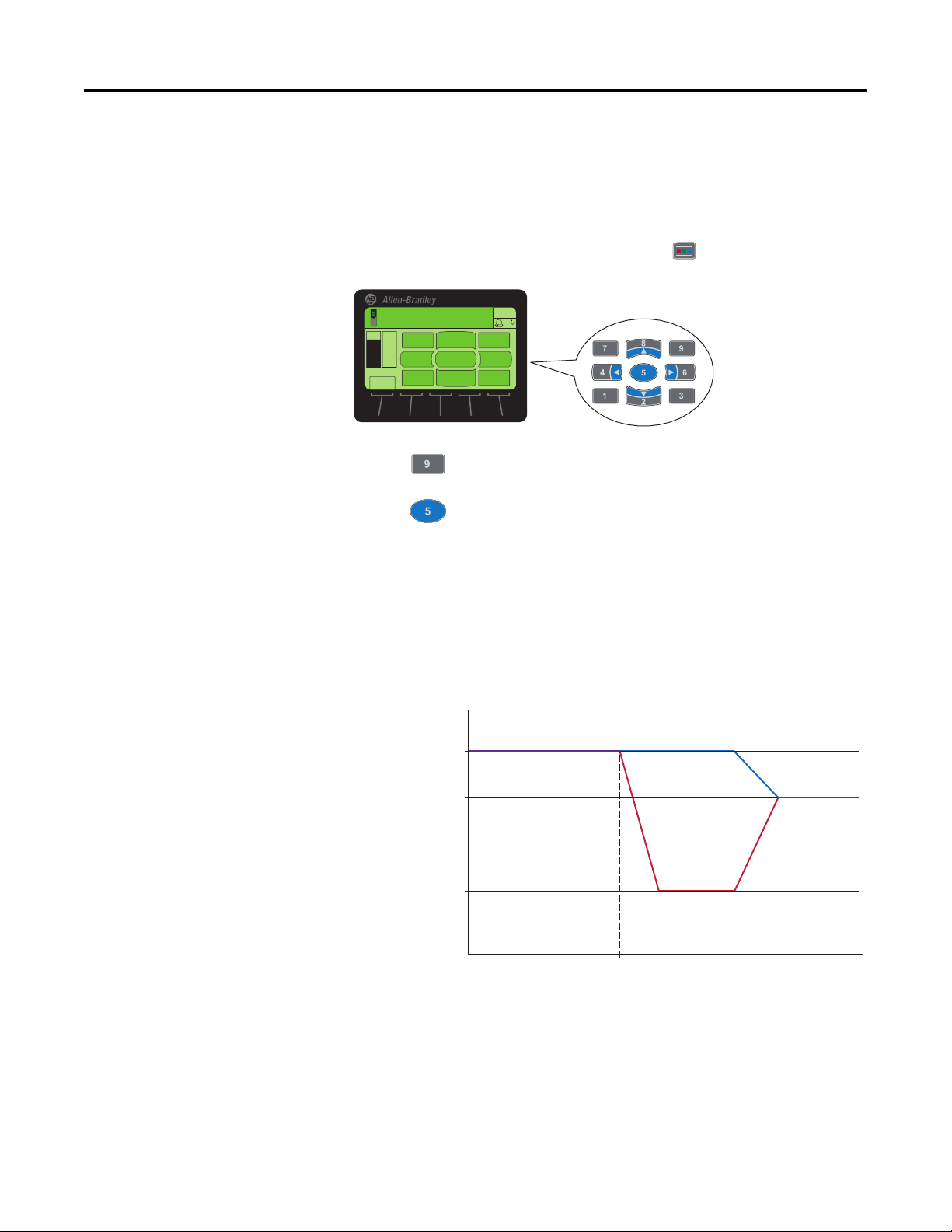

ESC

REF

MANUAL

FBKREF

REMOVE

HIM

EDIT

REF

FWDREV

REF

JOG HELP

Control Sc reen Key Functio n Map

corresponds to Navigation/Number Keys

Stopped

0.00 Hz

AUTO

F

Stopped

0.00 Hz

MAN

F

00

Stopped

0.00 Hz

AUTO

Host Drive

240V 4.2A

20G...D014

ESC REF TEXT

F

PAR#

For analog input between the minimum and maximum, the drive derives the

speed from these parameters through linear interpolation.

The P328 [Alt Man Ref Sel] manual reference overrides all other manual speed

references, including P563 [DI ManRef Sel].

HIM Control

Manual Control can be requested through an HIM device attached to port 1, 2,

or 3. The proper bits must be set in the masks (P324 [Logic Mask], P326

[Manual Cmd Mask], and P327 [Manual Ref Mask]) for the port that the HIM

is attached. To request control through the HIM, press the (Controls) key

to display the Control screen.

Press the (Manual) key.

Press the (Edit) key to confirm that you want to switch to Manual mode.

If the request is accepted, the HIM displays “MAN” in the top right corner. The

display does not indicate if the drive is in Manual, but rather if that particular

HIM has Manual control. A HIM still displays “AUTO” if it does not have

ownership of the Manual mode, even if the drive itself is in Manual mode. To see

if the drive is in Manual mode, check P935 [Drive Status 1] Bit 9.

When a HIM has Manual control of the drive, the drive uses the speed reference

from the HIM unless overridden by P328 [Alt Man Ref Sel]. To change the speed

reference on the HIM, navigate to the Status screen and press the middle soft key

labeled REF.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 29

Page 30

Chapter 1 Drive Configuration

ESC

REF

MANUAL

FBKREF

REMOVE

HIM

EDIT

REF

FWDREV

REF

JOG HELP

Control Scre en Key Function Map

corresponds to Navigation/Number Keys

Stopped

0.00 Hz

AUTO

F

Current Speed

With Manual Preload

Without Manual Preload

Desired Speed

Set in HIM

Manual Mode

Requested

Desired Manual Speed

Last Speed Used in HIM

If the request is not accepted, a message indicates that “Manual Control is not

permitted at this time.” The most likely causes are that manual control is disabled

for the port or that another port currently has manual control. To check which

port has manual control, look at P924 [Manual Owner].

To release Manual mode from the HIM, press the (Controls) key to display

the Control screen.

Press the (Auto) key.

Press the (Edit) key to confirm that you want to switch to Auto mode.

HIM Preload

Before taking a manual control speed reference from a HIM, the drive can

preload its current speed into the HIM to provide a smooth transition. Without

this feature, the drive immediately transitions to whatever speed was last used in

the HIM, before the operator has a chance to make their adjustment. With this

feature, the drive maintains its current speed until the operator sets the speed to

the desired manual reference.

30 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

The Auto/Manual HIM Preload is configured through P331 [Manual Preload].

Ports 1, 2, and 3 can be configured to have the speed reference preloaded into the

HIM by setting bits 1, 2, and 3 respectively.

Page 31

Drive Configuration Chapter 1

Manual Speed Reference HIM (DPI Port 1)

Manual Control (Port 5, Input 3)

Automatic Speed Reference (Port 14)

Example Scenario

The drive has a HIM in port 1 and a 24V DC I/O module in port 5. You want to

select manual control from a digital input 3 on the I/O module. You want the

embedded EtherNet/IP port to be the source for the speed reference in

Automatic mode, and the HIM to be the source for the speed reference in

Manual mode.

Required Steps

1. Set P172 [DI Manual Ctrl] to Port 5-I/O Module > 1-Dig In Sts > 3 –

Input 3.

2. Set P328 [Alt Man Ref Sel] = 871 Port 1 Reference 3. Set P331 [Manual

Preload] = 0000 0000 0000 0010, Bit 1 enables the preloading of the

speed feedback value to the HIM at port 1 when the HIM is granted

manual control.

Digital Input Control

A Digital Input can be configured to request manual control through P172 [DI

Manual Ctrl]. When setting up the Auto/Manual masks, digital inputs are

configured through Bit 0, regardless of what port the module physically resides

in.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 31

Page 32

Chapter 1 Drive Configuration

+24V

+10V

HA

O

XOO

OOX

XOO

DI 0: Stop

DI 1: HOA Start and

Manual Control

Analog IN 0: DI Manual

Speed Reference

Speed Potentiometer

A speed reference for Manual mode from a digital input can be set by selecting a

port in P328 [Alt Man Ref Sel]. This however causes all manual requests to use

that port as a reference, whether the request was from the digital input or from a

HIM. A separate manual reference port for use only when the request comes

from a digital input can be configured through P563 [DI ManRef Sel]. (To see

P564 [DI ManRef AnlgHi], set P301 [Access Level] to 1 “Advanced.”) If P328

[Alt Man Ref Sel] is configured, it overrides P563 [DI ManRef Sel] and provides

the manual reference.

If P563 [DI ManRef Sel] is an analog input, the maximum and minimum speeds

can be configured through P564 [DI ManRef AnlgHi] and P565 [DI ManRef

AnlgLo]. For analog input between the minimum and maximum, the drive

derives the speed from these parameters through linear interpolation.

Hand-Off-Auto

The Auto/Manual feature can be used in conjunction with a Hand-Off-Auto

Start to create a H-O-A switch that starts the drive and requests manual control

at the same time, allowing for a local speed reference to control the drive. See

Hand-Off-Auto

on page 64 for more details on the Hand-Off-Auto Start feature.

In the circuit below, a speed potentiometer was added to the analog input to

provide a speed reference to the drive. When the H-O-A switch is moved from

Auto to Hand, the digital input block requests manual control and issues a start

command to the drive. If the digital input port receives manual control, the drive

accelerates to the reference speed from the analog input. All attempts to change

the speed except from the analog input are blocked. If the drive is stopped while

in Hand, switch the H-O-A switch to Off and then back to Hand to restart the

drive.

If another port has manual control of the drive, but does not have exclusive

ownership of the logic commands (due to P326 [Manual Cmd Mask]), turning

the switch to Hand causes the drive to begin moving but for the analog input to

have no control over the speed.

32 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 33

Drive Configuration Chapter 1

For this circuit, set the following parameters (P301 [Access Level] must be set to

1 “Advanced” to see P563 [DI ManRef Sel]).

Number Parameter Name Value

158 DI Stop Digital Input 0

172 DI Manual Ctrl Digital Input 1

176 DI HOA Start Digital Input 1

324 Logic Mask xxxxxxxxxxxxxxx1 (Digital In)

326 Manual Cmd Mask xxxxxxxxxxxxxxx1 (Digital In)

327 Manual Ref Mask xxxxxxxxxxxxxxx1 (Digital In)

563 DI ManRef Sel Anlg In0 Value

The drive requests Manual mode, start, and tracks the reference speed coming

from the Analog Input when the H-O-A switches to Hand. (The HIM still reads

Auto. This display changes only when the HIM has control of Manual mode).

Safe Limited Speed

Safe Limited Speed through the PowerFlex Safe Speed Monitor option module

uses Manual mode to control the speed of the drive. When Safe Limited Speed

monitoring is enabled, the safety module requests manual control of the drive. If

the drive does not reach a safe speed, as defined on the option module by P55

[Safe Speed Limit] and within P53 [LimSpd Mon Delay], the drive faults.

While the option module uses the Manual mode, it has no way to provide a speed

reference or start the drive. The following parameters must thus be configured.

P326 [Manual Cmd Mask]

Turn off the bit corresponding to the safety option’s port to allow modules

installed in other ports to continue to control the drive when it is operating in

Manual mode. For example, if the safety option is installed in port 6, then turn

off Bit 6 in this parameter.

P327 [Manual Ref Mask]

Turn on the bit corresponding to the safety option’s port to allow the safety

option to command the drive to use its Manual Speed Reference when it is

operating in Manual mode. For example, if the safety option is installed in port 6,

then turn on Bit 6 in this parameter.

P328 [Alt Man Ref Sel]

Set this parameter to select the desired speed reference when the drive is

operating in Manual mode. For example, set this parameter to the value Port 0:

Preset Speed 1 to configure the drive to use P571 [Preset Speed 1] as the Manual

Speed Reference. In this case, P571 [Preset Speed 1] must be less than P55 [Safe

Speed Limit] in the safety option to avoid causing an SLS Speed Fault.

See the Safe Speed Monitor Option Module for PowerFlex 750-Series AC Drives

Safety Reference Manual, publication 750-RM001

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 33

, for more information.

Page 34

Chapter 1 Drive Configuration

Automatic Device Configuration

Automatic Device Configuration (ADC) supports the automatic download of

configuration data to a Logix controller that has an EtherNet/IP connection to a

PowerFlex 755 drive (firmware 4.001 or later) and its associated peripherals

ADC is supported in the following:

• RSLogix 5000 software, version 20 or later

• Studio 5000 environment, version 21 or later

Project files (.ACD files) created with this software contain the configuration

settings for PowerFlex drives in the project. When the project is downloaded to

the controller, the configuration settings are transferred to controller memory.

Earlier programming software required a manual process to download

configuration settings to the controller.

ADC can also work in tandem with Firmware Supervisor. If Firmware Super visor

is set up and enabled for a drive (Exact Match keying must be used), the drive/

peripheral is automatically upgraded (if necessary) prior to any ADC operation

for that port.

Information on Automatic Device Configuration (ADC) can be found in the

PowerFlex 755 Embedded EtherNet/IP Adapter User Manual, publication

750COM-UM001

topics:

• Description of the ADC functionality

• How the Drive Add-On Profiles (AOPs) affect ADC

• Configuring a PowerFlex 755 Drive (firmware 4.001 or later) for ADC

• ADC and Logix Memory

• Storing the Drive’s and Peripherals’ Firmware in the Logix Controller

(Firmware Supervisor)

• Special Considerations When Using a DeviceLogix software Program

• Special Considerations When Using a 20-750-S1 Safe Speed Monitor

Module

• Monitoring the ADC Progress

• Examples of potential issues and solutions

, Chapter 4, Configuring the I/O includes the following

34 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 35

Drive Configuration Chapter 1

Autotune

The Autotune feature is used to measure motor characteristics. The Autotune

feature is made up of several individual tests, each of which is intended to identify

one or more motor parameters. These tests require motor nameplate information

to be entered into the drive parameters. Although some of the parameter values

can be changed manually, measured values of the motor parameters provide the

best performance. Each motor control mode requires its own set of tests to be

performed. The information obtained from these measurements is stored in the

drives non volatile memory for use during operation of the drive. The feature lets

these tests to be separated into tests that don’t require motor rotation (Static

Tune), all tests within the selected control mode (Rotate Tune), or if the control

mode requires the Inertia (Inertia Tune).

The Autotune tests are selected through the P70 [Autotune]. The feature

provides a manual or automatic method for setting P73 [IR Voltage Drop], P74

[Ixo Voltage Drop] and P75 [Flux Current Ref ]. Valid only when P35 [Motor

Ctrl Mode] is set to 1 “Induction SV,” 2 “Induct Econ,” or 3 “Induction FV.”

Other motor control modes such as Permanent Magnet and Interior Permanent

magnet, populate other parameters associated with those control modes. See the

autotune parameter set below.

Tes ts

Four Autotune selections are available in the PowerFlex 755 drive control. All

four selections are selected from the Autotune parameter.

P70 [Autotune]

• 0 = Ready

• 1 = Calculate

• 2 = Static Tune

• 3 = Rotate Tune

• 4 = Inertia Tune

Ready

Parameter returns to this setting following a Static Tune or Rotate Tune, at which

time another start transition is required to operate the drive in Normal mode. It

also permits manually setting P73 [IR Voltage Drop], P74 [Ixo Voltage Drop],

and P75 [Flux Current Ref ].

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 35

Page 36

Chapter 1 Drive Configuration

IMPORTANT

Calcula te

When the Autotune parameter is set to Calculate (default), the drive uses motor

nameplate data to automatically set P73 [IR Voltage Drop], P74 [Ixo Voltage

Drop], P75 [Flux Current Ref ] and P621 [Slip RPM at FLA].

P73 [IR Volt Drop], P87 [PM IR Voltage], P79 [Encdrlss VltComp], P74 [Ixo

Voltage Drop], P75 [Flux Current Ref ], P93 [PM Dir Test Cur], and the Slip

Frequency parameters are updated based on nameplate parameter values. When a

nameplate parameter value is changed, the Autotune parameters are updated

based on the new nameplate values.

When using Calculate, updated values come from a lookup table.

Static Tune

When the Autotune parameter is set to Static, only tests that do not create motor

movement are run. A temporary command that initiates a non-rotational motor

stator resistance test for the best possible automatic setting of P73 [IR Voltage

Drop] in all valid modes and a non-rotational motor leakage inductance test for

the best possible automatic setting of P74 [Ixo Voltage Drop] in a Flux Vector

(FV) mode. A start command is required following initiation of this setting.

Used when motor cannot be rotated.

Rotate Tune

The actual tests performed when Static and Rotate Tune selections are made,

differ for the available motor control modes, Feedback Type and motor type

selected. The tests performed are dependent on the settings of P35 [Motor Ctrl

Mode], P125 [Pri Vel Fdbk Sel], and P70 [Autotune]. The parameters that are

updated are then dependent on the tests run and in some cases calculated values

for some parameters are used to update other parameters. Refer to Ta b l e 3

A temporary command initiates a Static Tune and is then followed by a rotational

test for the best possible automatic setting of P75 [Flux Current Ref ]. In Flux

Vector (FV) mode, with encoder feedback, a test for the best possible automatic

setting of P621 [Slip RPM at FLA] is also run. A start command is required

following initiation of this setting.

If using rotate tune for a Sensorless Vector (SV) mode, uncoupled the motor from the

load or results can be invalid. With a Flux Vector (FV) mode, either a coupled or

uncoupled load produces valid results. Caution must be used when connecting the

load to the motor shaft and then performing an autotune. Rotation during the tune

process can exceed machine limits.

.

36 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 37

Drive Configuration Chapter 1

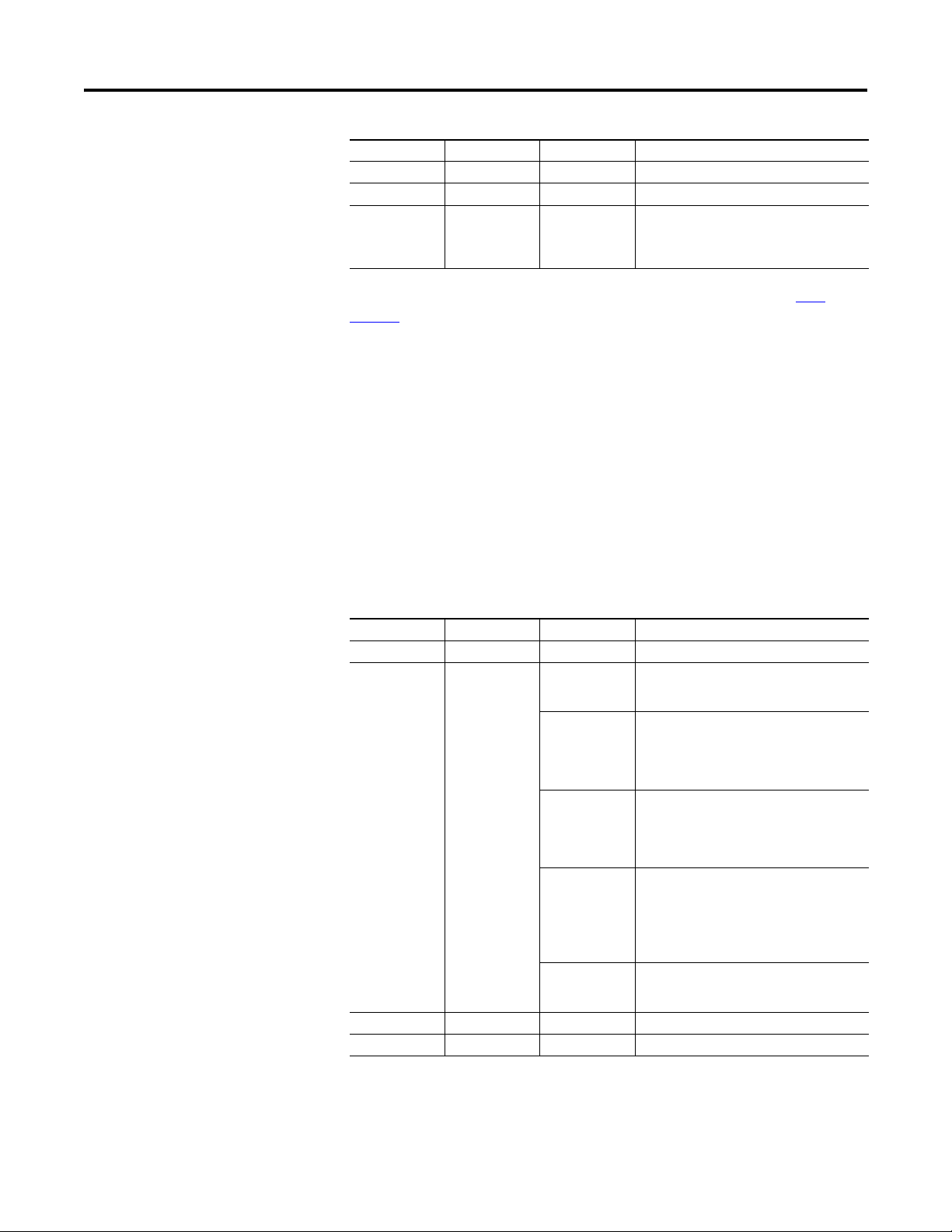

Table 3 - Autotune Value Source

Control

Mode

VF Induction NA Static ON OFF OFF OFF OFF ON OFF OFF OFF OFF

FV Induction Encoder Static ON ON ON OFF OFF OFF OFF OFF OFF OFF

Motor

Type

PM NA Static ON OFF OFF OFF OFF OFF OFF OFF OFF OFF

Reluctance NA Static ON OFF OFF OFF OFF OFF OFF OFF OFF OFF

PM Encoder Static OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Reluctance Encoder Static OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Feedback

Select

EncoderlessStaticONONONONOFFOFFOFFOFFOFFOFF

Encoderless Static ON ON OFF OFF OFF OFF OFF OFF OFF OFF

Encoderless Static OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Autotune Rs Xo Idlt Rslt Id Rsld Slip Encrls Cemf PmOffset

Dynamic ON OFF OFF OFF ON ON OFF OFF OFF OFF

Dynamic ON OFF OFF OFF OFF OFF OFF OFF OFF OFF

Dynamic ON OFF OFF OFF ON OFF OFF OFF OFF OFF

Dynamic ON ON OFF OFF ON OFF ON OFF OFF OFF

DynamicONONONONONONOFFONOFFOFF

Dynamic ON ON OFF OFF OFF OFF OFF OFF ON ON

Dynamic ON ON OFF OFF OFF OFF OFF OFF ON OFF

Dynamic OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Dynamic OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Inertia Tune

The Inertia Autotune selection involves only one test. Several parameters are

updated from the test results. Refer to the tables in the Individual Tests section.

A temporary command initiates an inertia test of the motor/load combination.

The motor ramps up and down while the drive measures the amount of inertia.

This option applies only to FV modes selected in P35 [Motor Ctrl Mode].

Obtain final test results with the load coupled to the motor as long as the rotation

won’t damage the machine.

Test Dependencies

When running the flux test, the selected accel rate is used unless it is less than 10

seconds. In this case, 10 seconds is forced. In the case of the Inertia test, a 0.1

second accel rate is used. The selected direction used during normal operation is

used for all rotation tests. Also, during any rotate test, the normal speed limits are

enforced.

The thermal manager is always being run in the 2 ms loop, which provides

protection during all of the Autotune tests.

Rockwell Automation Publication 750-RM002B-EN-P - September 2013 37

Page 38

Chapter 1 Drive Configuration

Tacc

WK2ΔN×

308 t()

-------------------------=

WK

2

Tacc 308 t()××

ΔN

--------------------------------------=

Individual Tests

Some of the following tests are executed during an Autotune.

Resistance Test

This test is a Static test whether Static or Rotate is selected. Used to measure

Stator resistance.

Inductance Tests

This test is a Static test whether Static or Rotate is selected. One test is used for

Induction motors and a another is used for PM motors. The result from the

Induction test is placed into the Ixo parameter and the PM test is placed into the

IXd and IXq parameters.

Flux Test

This test is a Rotate test that measures the current under a no load condition. The

results are used for the flux current. If a Static test is used, the resulting value is

from a lookup table.

Slip Test

This test is a Rotate test that measures the difference between the rotor speed and

the stator speed. This measurement is taken during acceleration.

PM Offset Test

This test can create a small amount of motor movement so it needs to be

performed with the Rotate selection. The test reads the encoder position when

the drive outputs zero hertz.

Inertia Test

This test is a stand alone test that is used to measure the system inertia.

The drive sets this value in P76 [Total Inertia] as seconds of inertia. This reflects

the time it takes to accelerate the load at 100% torque to base speed. This

2

information can be very useful in determining the total inertia (in lb•ft

connected to a motor shaft.

) that is

Using the following formula,

and rearranging it to

38 Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Page 39

Drive Configuration Chapter 1

HP

T Speed×

5252

-------------------------=

T

HP 5252×

Speed

-----------------------=

T

10 5252×

1785

------------------- -=

WK

2

Tacc 308× t()×

ΔN

--------------------------------------=

we have a formula that isolates the connected inertia.