Page 1

User Manual

Kinetix 350 Single-axis EtherNet/IP Servo Drives

Catalog Numbers 2097-V31PR0-LM, 2097-V31PR2-LM,

2097-V32PR0-LM, 2097-V32PR2-LM, 2097-V32PR4-LM,

2097-V33PR1-LM, 2097-V33PR3-LM, 2097-V33PR5-LM, 2097-V33PR6-LM,

2097-V34PR3-LM, 2097-V34PR5-LM, 2097-V34PR6-LM

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

]Allen-Bradley, CompactLogix, ControlFLASH, ControlLogix , Kinetix, Logix5000, MP-Series, TL-S eries, RSLogix, Studio 5000 Logix D esign, Rockwell Automation, Rockwell Softw are, Stratix 2000, and Studi o 5000, and

are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

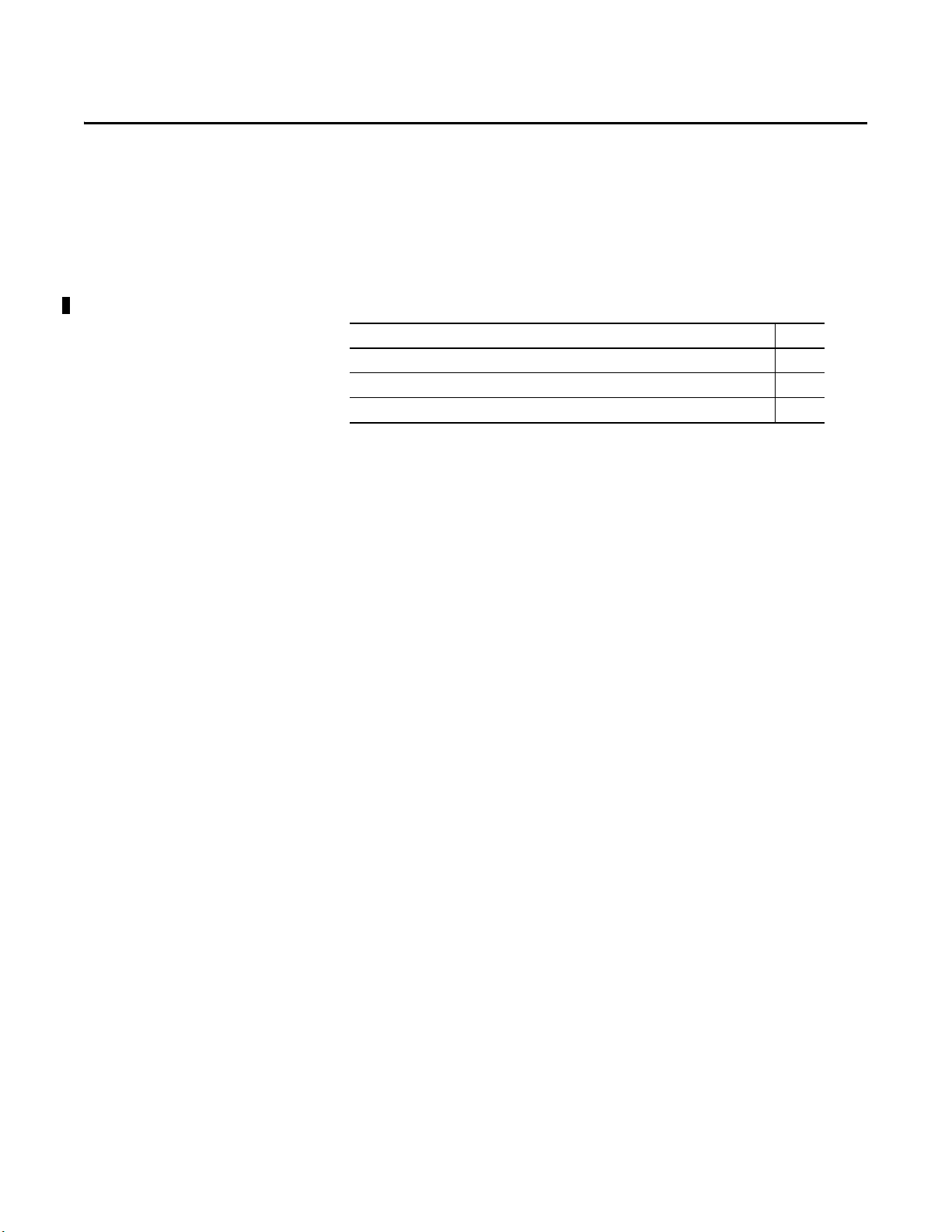

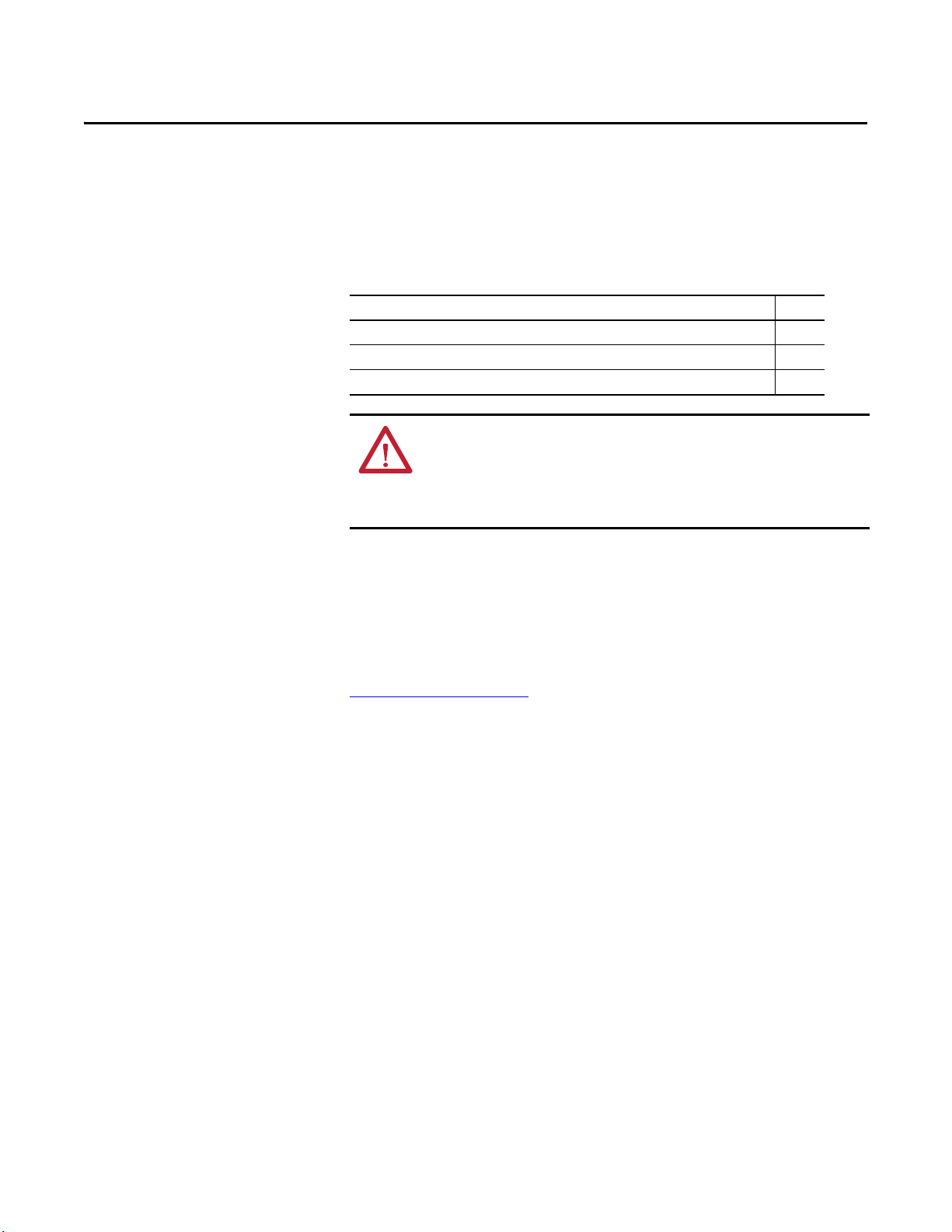

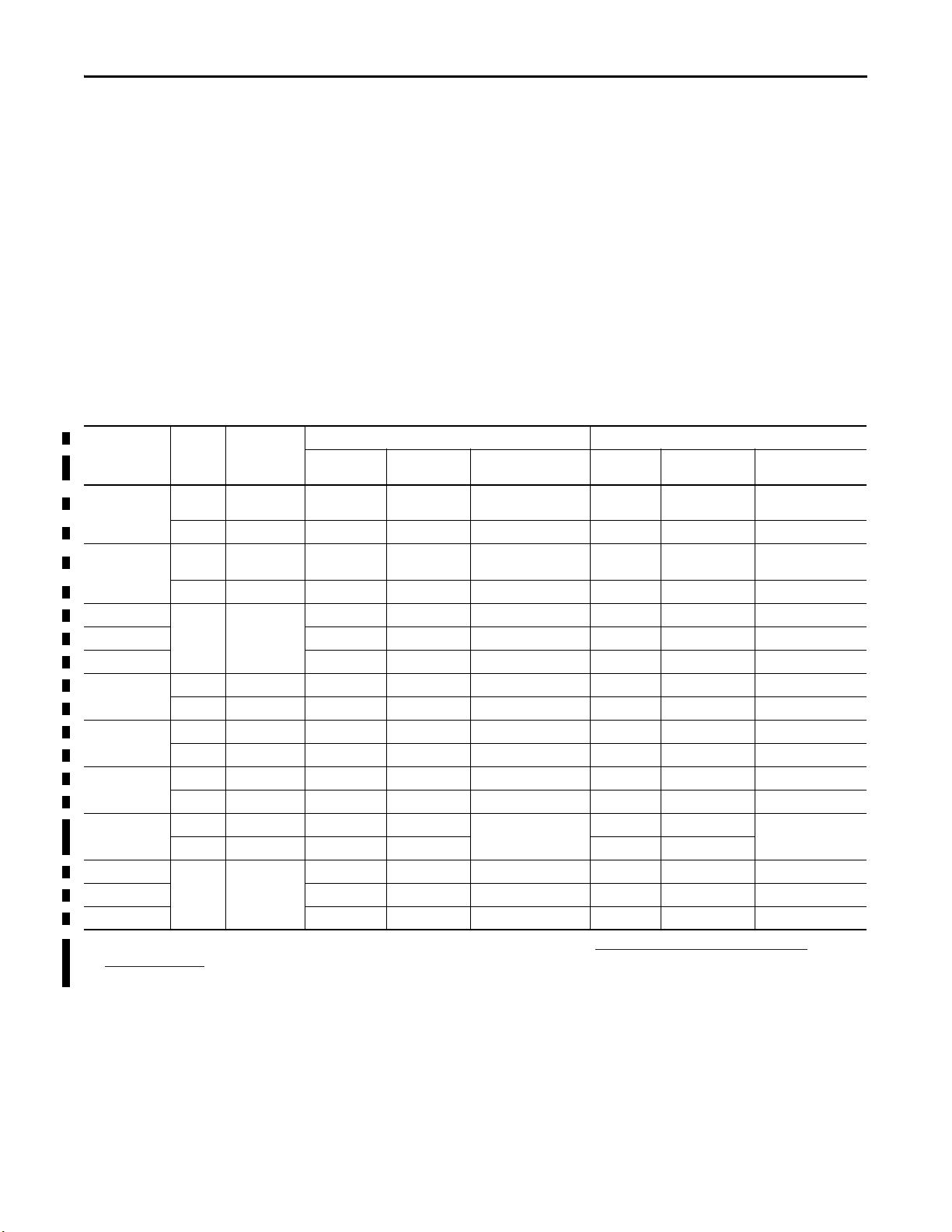

This table contains the changes made to this revision.

Top ic Page

Studio 5000 Logix Designer™ application is the rebranding of RSLogix™ 5000

software

Updated Kinetix® 350 Drive System Overview 12

Updated Typical Kinetix 350 Drive Installation 13

Updated catalog number explanation table 14

Updated the Fuse and Circuit Breaker Specifications table 20

Updated Shunt Resistor and DC connector description and signals names 36, 40, 60, 61,133

Updated motor brake pinout and specifications 44

Added vertical load and stored mechanical energy information to text and

attention statement

Updated Troubleshooting the Safe Torque-off Function attention statement 103

Updated Figure 48 Single-axis Relay Configuration (Stop Category 0) with

Automatic Reset

Added Error Codes for the Memory Module 113

Added troubleshooting for motor with a TTL encoder 122

Updated Figure 57 Kinetix 350 Drive with TL-Series™ (TLY-A) Motor high

resolution encoder cables

9

93, 97

108

135

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Page 5

Start

Table of Contents

Preface

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1

About the Kinetix 350 Drive System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CE Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Install the Kinetix 350 Drive System

Kinetix 350 Drive Connector Data

System Design Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Mounting Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Transformer Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Circuit Breaker/Fuse Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Circuit Breaker/Fuse Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Enclosure Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contactor Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Transformer Specifications for Input Power . . . . . . . . . . . . . . . . . . . . 23

Power Dissipation Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Minimum Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Electrical Noise Reduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bonding Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bonding Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Establishing Noise Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cable Categories for Kinetix 350 Drive Components. . . . . . . . . . . . 30

Noise Reduction Guidelines for Drive Accessories. . . . . . . . . . . . . . . 30

Mount Your Kinetix 350 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 3

Kinetix 350 Drive Connectors and Indicators . . . . . . . . . . . . . . . . . . . . . . 36

Safe Torque-off Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

I/O Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Motor Feedback (MF) Connector Pinout . . . . . . . . . . . . . . . . . . . . . . 39

Ethernet Communication Connector Pinout . . . . . . . . . . . . . . . . . . . 39

AC Input Power Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Back-up Power Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Shunt Resistor and DC Bus Connector Pinout . . . . . . . . . . . . . . . . . 40

Motor Power Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control Signal Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Motor Brake Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 5

Page 6

Table of Contents

Connect the Kinetix 350 Drive System

Ethernet Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . 45

24V DC Back-up Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 45

Motor Feedback Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Feedback Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Chapter 4

Basic Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Recommended Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Route Power and Signal Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Determine the Input Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . 52

Three-phase Power Wired to Three-phase Drives . . . . . . . . . . . . . . . 53

Single-phase Power Wired to Single-phase Drives . . . . . . . . . . . . . . . 54

Voltage Doubler Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Isolation Transformer in Grounded Power Configurations. . . . . . . 55

Three-phase Power Wired to Single-phase Drives . . . . . . . . . . . . . . . 55

Voiding of CE Compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Grounding Your Kinetix 350 Drive System. . . . . . . . . . . . . . . . . . . . . . . . . 58

Ground Your Drive to the System Subpanel . . . . . . . . . . . . . . . . . . . . 58

Ground Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Power Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Wiring Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Wiring the Kinetix 350 Drive Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . 63

Wire the Safe Torque-off (STO) Connector . . . . . . . . . . . . . . . . . . . . 63

Wire the Back-up Power (BP) Connector. . . . . . . . . . . . . . . . . . . . . . . 63

Wire the Input Power (IPD) Connector. . . . . . . . . . . . . . . . . . . . . . . . 64

Wire the Motor Power (MP) Connector . . . . . . . . . . . . . . . . . . . . . . . 65

Apply the Motor Cable Shield Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Feedback and I/O Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Flying-lead Feedback Cable Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Wiring the Feedback and I/O Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . 73

Wire the I/O Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Wire the Low-profile Connector Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Shunt Resistor Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Ethernet Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter 5

Configure and Start Up the

Kinetix 350 Drive System

6 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Keypad Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configure the Kinetix 350 Drive Ethernet IP Address . . . . . . . . . . . . . . . 81

Ethernet Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Kinetix 350 Drive Ethernet Port Configuration . . . . . . . . . . . . . . . . . 81

Obtain the Kinetix 350 Drives’ Current Ethernet Settings . . . . . . . 81

Configure the IP Address Manually (static address). . . . . . . . . . . . . . 82

Configure the IP Address Automatically (dynamic address) . . . . . . 83

Configure the Logix5000 EtherNet/IP Controller . . . . . . . . . . . . . . . . . . 84

Configure the Logix5000 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Page 7

Kinetix 350 Drive Safe Torque-off

Feature

Table of Contents

Configure the Kinetix 350 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Configure the Motion Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Configure Axis Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Download the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Apply Power to the Kinetix 350 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Test and Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Test the Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Disable EnableInputChecking by Using a Logix

Designer Message Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 6

Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Safety Category 3 Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Stop Category Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Performance Level and Safety Integrity Level (SIL) CL2 . . . . . . . . 102

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Troubleshooting the Safe Torque-off Function . . . . . . . . . . . . . . . . 103

PFD and PFH Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

PFD and PFH Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Safe Torque-off Connector Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

STO Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Wiring Your Safe Torque-off Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

European Union Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Safe Torque-off Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . 106

Kinetix 350 Drive Safe Torque-off Feature . . . . . . . . . . . . . . . . . . . . . . . . 107

Safe Torque-off Feature Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Kinetix 350 Drive Safe Torque-off Wiring Diagrams. . . . . . . . . . . . . . . 108

Safe Torque-off Signal Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Troubleshoot the Kinetix 350 Drive

Chapter 7

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Interpret Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Four-digit Display Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

General System Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Logix5000 Controller and Drive Behavior . . . . . . . . . . . . . . . . . . . . . . . . 123

Kinetix 350 Drive Exception Behavior . . . . . . . . . . . . . . . . . . . . . . . . 123

Web Server Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 7

Page 8

Table of Contents

Appendix A

Interconnect Diagrams

Upgrade the Kinetix 350 Drive

Firmware

Interconnect Diagram Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Power Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Shunt Resistor Wiring Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Kinetix 350 Drive/Rotary Motor Wiring Examples . . . . . . . . . . . . . . . . 134

Kinetix 350 Drive/Actuator Wiring Examples . . . . . . . . . . . . . . . . . . . . . 136

Motor Brake Currents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Appendix B

Upgrade Drive Firmware with ControlFLASH Software . . . . . . . . . . . 143

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Configure Logix5000 Communication . . . . . . . . . . . . . . . . . . . . . . . . 144

Upgrade Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Verify the Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

8 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Page 9

Preface

About This Publication

Conventions

Studio 5000 Environment

This manual provides detailed installation instructions for mounting, wiring, and

troubleshooting your Kinetix

motor combination with a Logix5000™ controller.

The conventions starting below are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

The Studio 5000™ Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the Studio

5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix 5000 software and continues to be the

product to program Logix5000 controllers for discrete, process, batch, motion,

safety, and drive-based solutions.

350 drive; and system integration for your drive/

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. This environment is the

one place for design engineers to develop all of the elements of their control

system

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 9

Page 10

Preface

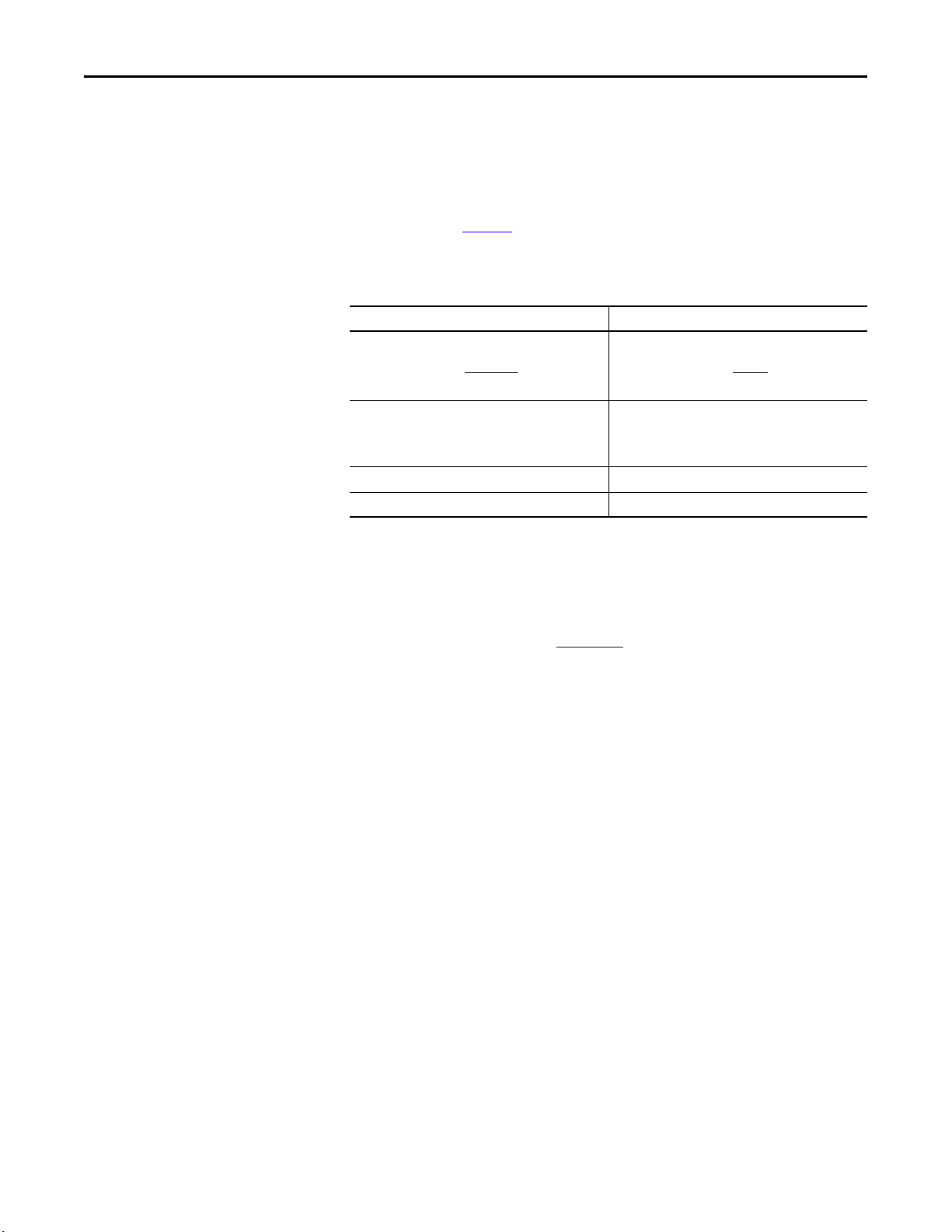

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Kinetix 350 Single-axis EtherNet/IP Servo Drive Installation Instructions,

publication 2097-IN008

Kinetix 300 Shunt Resistor Installation Instructions, publication 2097-IN002 Information on installing and wiring the Kinetix 300 shunt resistors.

Kinetix 300 AC Line Filter Installation Instructions, publication 2097-IN003 Information on installing and wiring the Kinetix 300 AC line filter.

Kinetix 300 I/O Terminal Expansion Block Installation Instructions,

publication 2097-IN005

CompactLogix L3ER Controllers User Manual, publication 1769-UM021 Information on installing, configuring, programming, and operating a

Stratix 2000 Ethernet Unmanaged Switches Installation Instructions,

publication 1783-IN001

Ethernet/IP Benefits of Industrial Connectivity in Industrial Apps White Paper, publication 1585-

WP001A

Industrial Ethernet Media, publication 1585-BR001 This brochure provides connectivity solutions for Ethernet networks and

Guidance for Selecting Cables for EtherNet/IP Networks White Paper,

publication ENET-WP007

Integrated Motion on SERCOS and EtherNet/IP Systems - Analysis and Comparison White Paper,

publication MOTION-WP007

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

EMC Noise Management DVD, publication GMC-SP004

Kinetix Motion Control Selection Guide, publication GMC-SG001 Specifications, motor/servo-drive system combinations, and accessories for

Kinetix Servo Drives Specifications Technical Data, publication GMC-TD003 Specifications for Kinetix ser vo drive motion control products.

Motion Analyzer software, download at http://www.ab.com/e-tools Drive and motor sizing with application analysis software.

ControlLogix Controllers User Manual, publication 1756-UM001 Information on installing, configuring, programming, and operating a

CIP Motion Configuration and Startup User Manual,

publication MOTION-UM003

842E-CM Integrated Motion Encoder on EtherNet/IP

User Manual. Publication 842E-UM002A

ControlFLASH Firmware Upgrade Kit User Manual, publication 1756-QS105 For ControlFLASH™ information not specific to any drive family.

Rockwell Automation Configuration and Selection Tools,

website http://www.ab.com/e-tools

Rockwell Automation Product Certification,

website http://www.rockwellautomation.com/products/certification

National Electrical Code, published by the National Fire Protection Association of B oston, MA An article on wire sizes and types for grounding electrical equipment.

Rockwell Automatio n Industrial Automation Glossary, publication AG-7 .1 A glossary of industrial automation terms and abbreviations.

Information on installing your Kinetix 350 drive system.

Information on installing and wiring the Kinetix 300 I/O terminal expansion

block.

Compac tLogix© system.

Information on installing and operating a Stratix 2000“ Ethernet Switches.

Provides general guidelines and theory for Ethernet/IP industrial systems.

integrated architecture.

This guide is arranged to help you select cabling based on the application,

environmental conditions, and mechanical requirements

This white paper compares and contrasts SERCOS and EtherNet/IP with a

ControlLogix® controller.

system.

Information, examples, and techniques designed to minimize system failures

caused by electrical noise.

Kinetix motion control products.

ControlLogix system.

Information on configuring and troubleshooting your ControlLogix and

CompactLogix EtherNet/IP network modules.

Information on installing, wiring, and troubleshoot a integrated motion encoder

on EtherNet /IP.

Online product selection and system configuration tools, including AutoCAD

(DXF) drawings.

For declarations of conformity (DoC) currently available from

Rockwell Automation.

You can view or download publications at

http://www.rockwellatuomation.com/literature. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

10 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Page 11

Chapter 1

Start

Top ic Page

About the Kinetix 350 Drive System 12

Catalog Number Explanation 14

Agenc y Compliance 15

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 11

Page 12

Chapter 1 Start

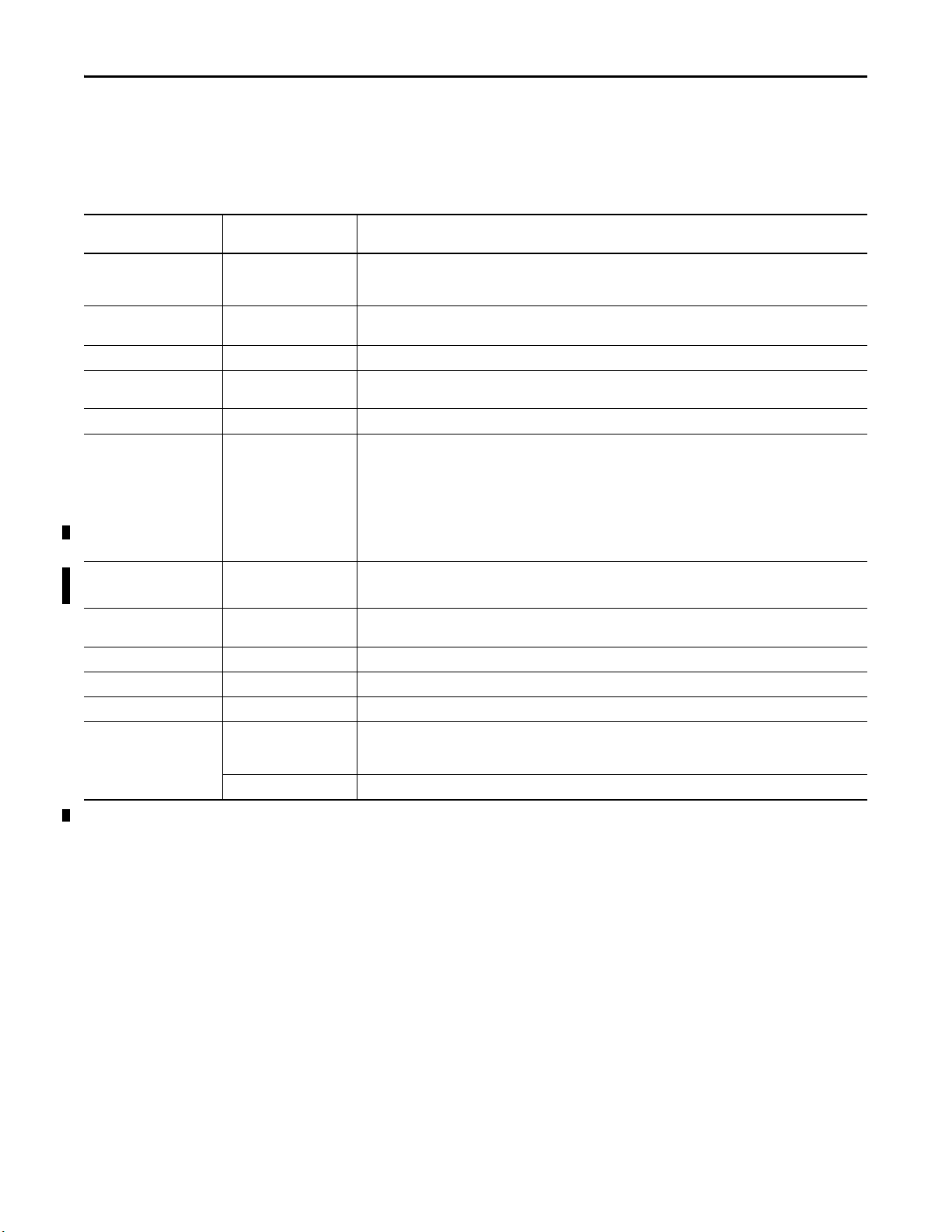

About the Kinetix 350 Drive System

The Kinetix 350 single-axis EtherNet/IP servo drive is designed to provide a

solution for applications with output power requirements between 0.4…3.0 kW

(2…12 A rms).

Table 1 - Kinetix 350 Drive System Overview

Kinetix 350 System

Component

Kinetix 350 integrated

motion on EtherNet/IP Servo

Drive

AC Line Filters 2090

Shunt Module 2097-Rx Bulletin 2097 shunt resistors connect to the drive and provide shunting capability in regenerative applications.

Terminal block for I/O

connector

Stratix 2000 Ethernet Switch 1783-US05T An Ethernet switch divides an Ethernet network into segments and directs network traffic efficiently.

Logix5000 Controller

Platform

Studio 5000 Environment

Rotary Servo Motors MP-Series™, TL-Series Compatible rotary motors include the MP-Series (Bulletin MPL, MPM, MPF, and MPS) and TL-Series (Bulletin TLY)

Linear Stages MP-Series (Ballscrew) Compatible stages include MP-Series (Bulletin MPAS) Integrated Linear Stages.

Electric Cylinders MP-Series, TL-Series Compatible electric cylinders include MP-Series and TL- Series (Bulletin MPAR, TLAR, and MPAI) Electric Cylinders.

Encoder 842E-CM Integrated Motion Encoder on EtherNet/IP

Cables Motor/brake and feedback

Cat. No. Description

2097-V3xPRx-LM Kinetix 350 integrated motion on EtherNet/IP drives with safe torque-off feature are available with 120/240V or

2097-Fx

2097-TB1 50-pin terminal block. Use with IOD connector for control inter face connections.

1769-L18ERM-BB1B

1769-L27ERM-QBFC1B

1769-L33ERM

1769-L36ERM

1769-L30ERM

(1)

1756-L6x

1756-L7x

N/A

cables

Communication cables 1585J-M8CBJM-x (shielded) or 1585J-M8UBJM-x (high-flex shielded) Ethernet cable.

480V AC input power.

Bulletin 2090 and Bulletin 2097-Fx AC line filters are required to meet CE with Kinetix 350 drives without an

integrated line filter. Bulletin 2097 filters are available in foot mount and side mount.

CompactLogix controller with integrated dual-port Ethernet/IP interface serves as communication link with the

Kinetix 350 drive system. The communication link uses EtherNet/IP protocol over a copper cable.

The Studio 5000 Logix Designer application provides support for programming, commissioning, and maintaining the

Logix5000 family of controllers.

motors.

Motor power/brake and feedback cables include SpeedTec and threaded DIN connectors at the motor. Power/brake

cables have flying leads on the drive end and straight connectors that connect to servo motors. Feedback cables have

flying leads that wire to low-profile connector kits on the drive end and straight connectors on the motor end.

(1) 1756-L6x CompactLogix controller requires RSLogix 5000 software version 17.01.02 or later.

12 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 13

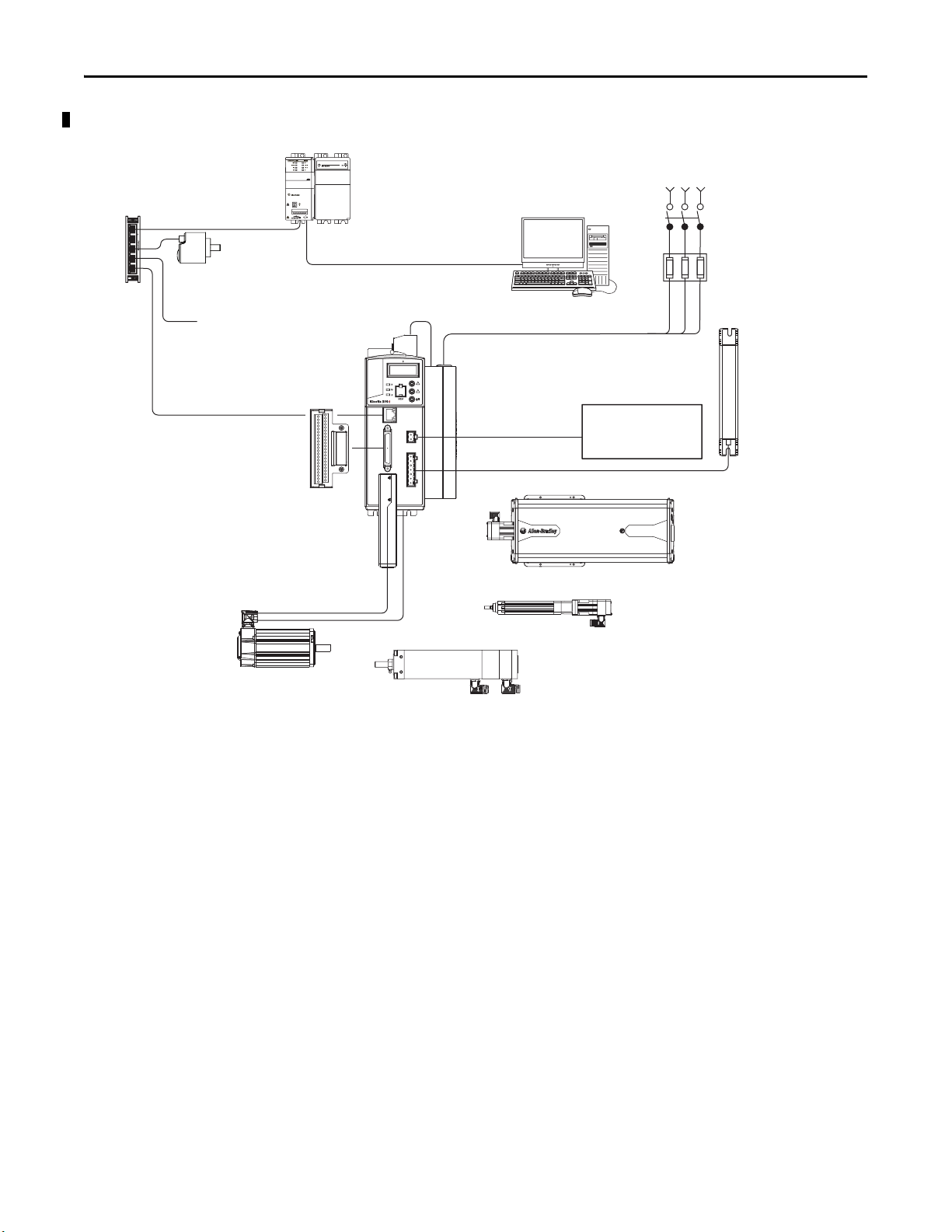

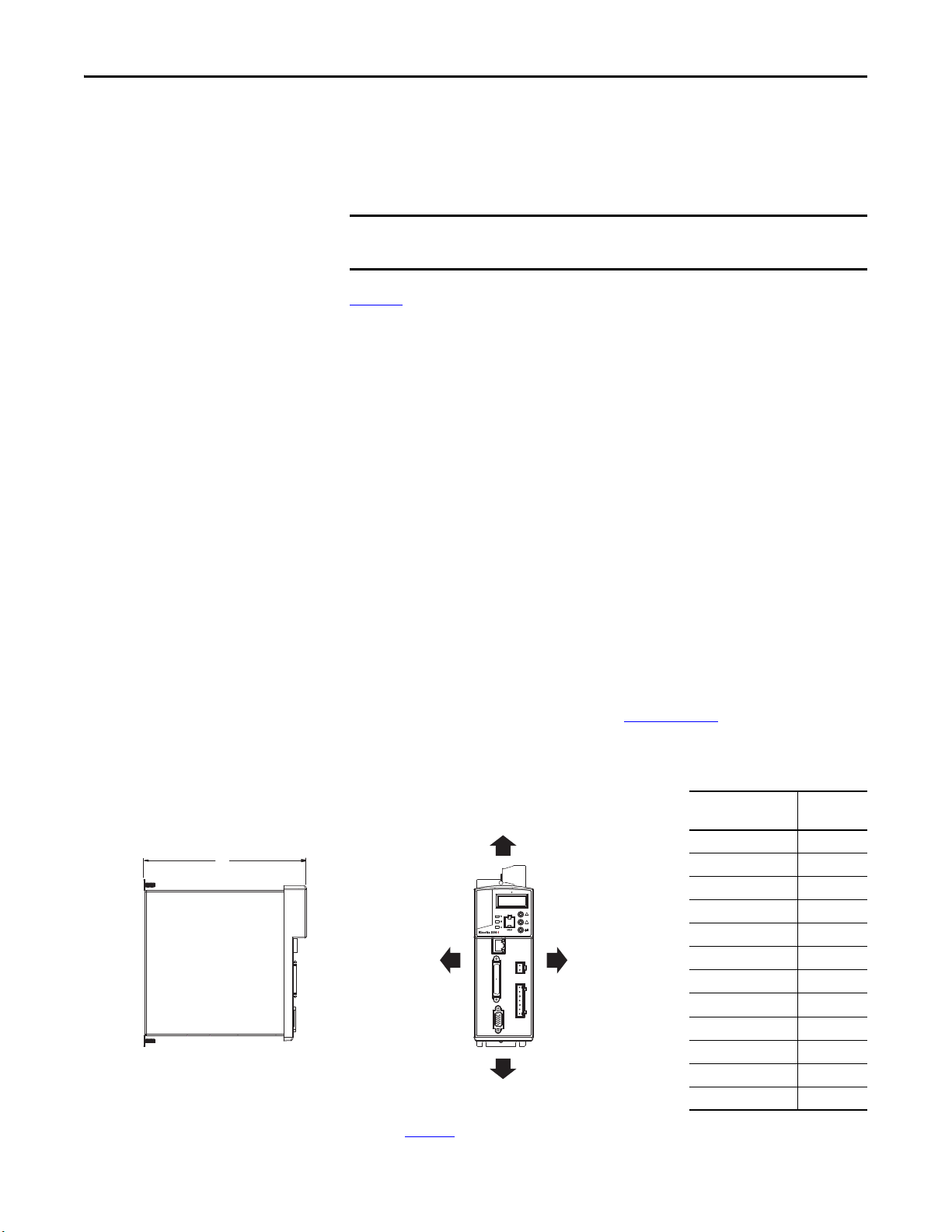

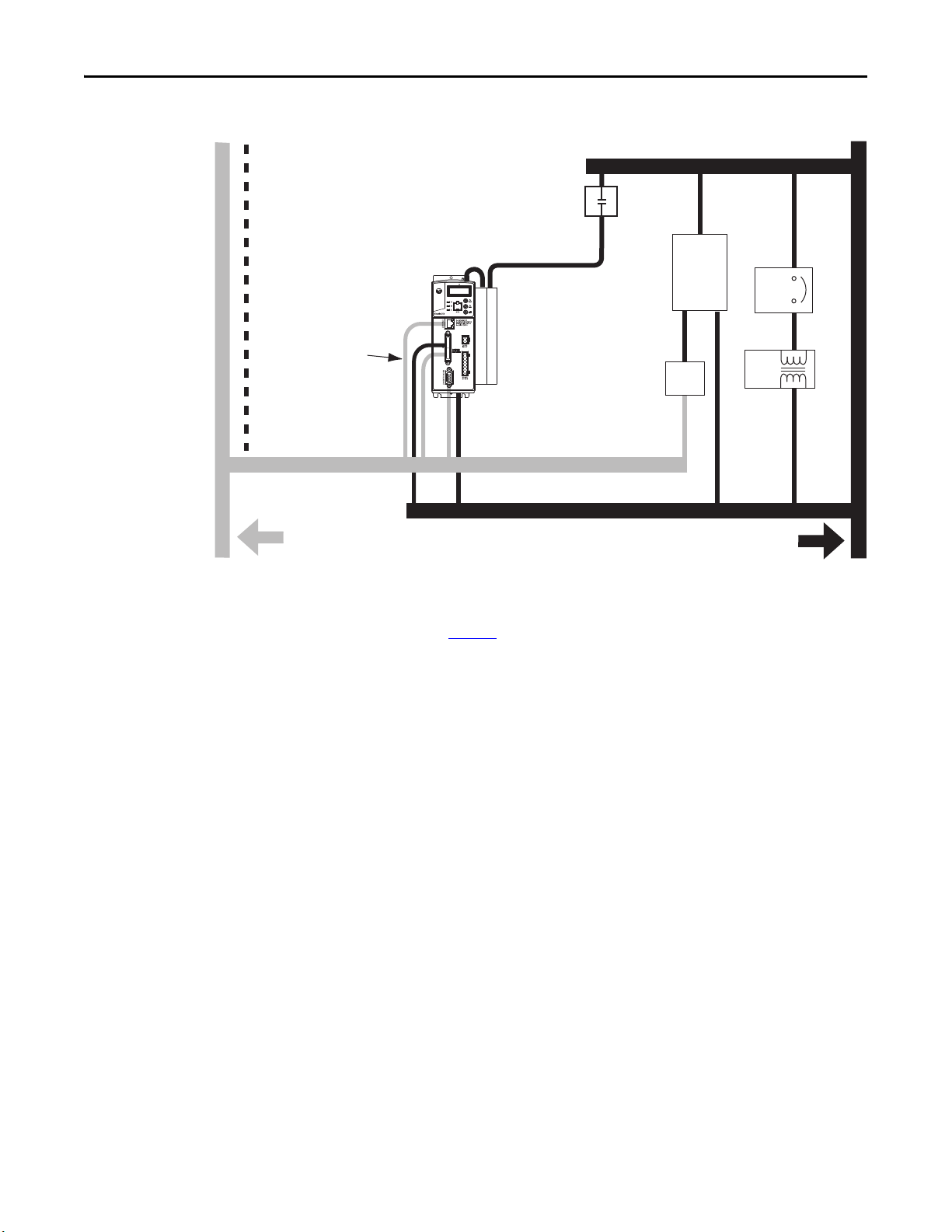

Figure 1 - Typical Kinetix 350 Drive Installation

2

3

5

4

1

R

W

P

2097-V3xxxx-LM

Kinetix 350 Drive

2097-Fx

AC Line Filter (optional equipment)

2097-F1 Filter Shown

1783-US05T

Stratix 2000 Switch

CompactLogix Controller Platform

1769-L33ERM Shown

Line

Disconnect

Device

Input

Fusing

Three- phase

Input Power

24V DC Control Back-up

Power Supply

(optional equipment)

MP-Series and TL-Series

Rotary Motors

(MPL-Bxxxx motors shown)

Bulletin 2090

Motor Feedback Cables

Bulletin 2090

Motor Power Cables

1585J-M8CBJM-x (shielded) or

11585J-M8UBJM-x (high-flex shielded)

Ethernet Cable

2097-TB1 Terminal

Expansion Block

2097-Rx

Shunt Resistor

(optional equipment)

MP-Series and TL-Series Electric Cylinders

(MPAR-Bxxxx electric cylinders shown)

MP-Series Integrated Linear Stages

(MPAS-B9xxx ballscrew shown)

MP-Series Heavy Duty Electric Cylinders

(MPAI-Bxxxx electric cylinders shown)

2090-K2CK-D15M

Low-profile Connector Kit

Other Ethernet/IP

Compat ible Dri ves

842E-CM Integrated Motion

Encoder on EtherNet/IP

Logix Designer

Application

Start Chapter 1

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 13

Page 14

Chapter 1 Start

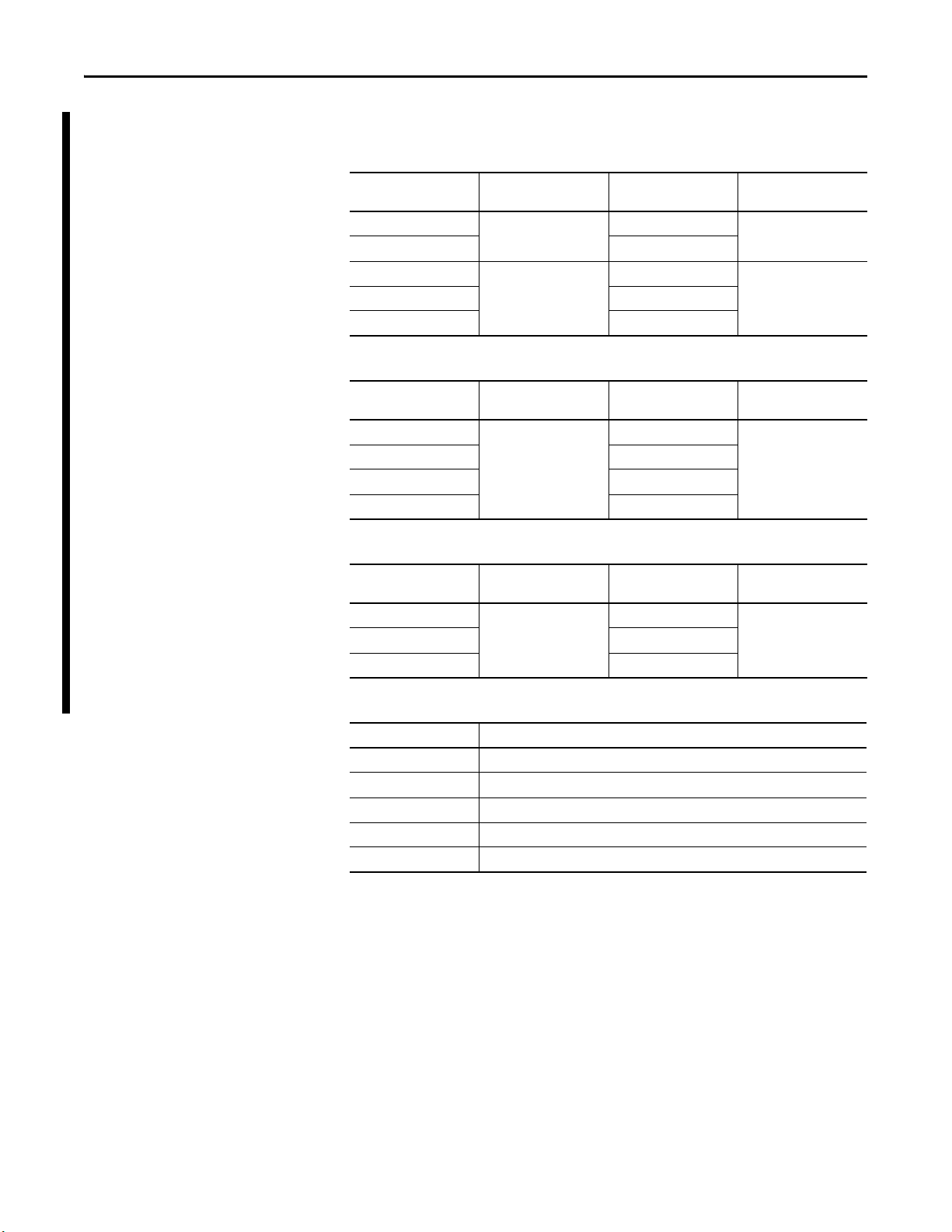

Catalog Number Explanation

Kinetix 350 drive catalog numbers and descriptions are listed in these tables.

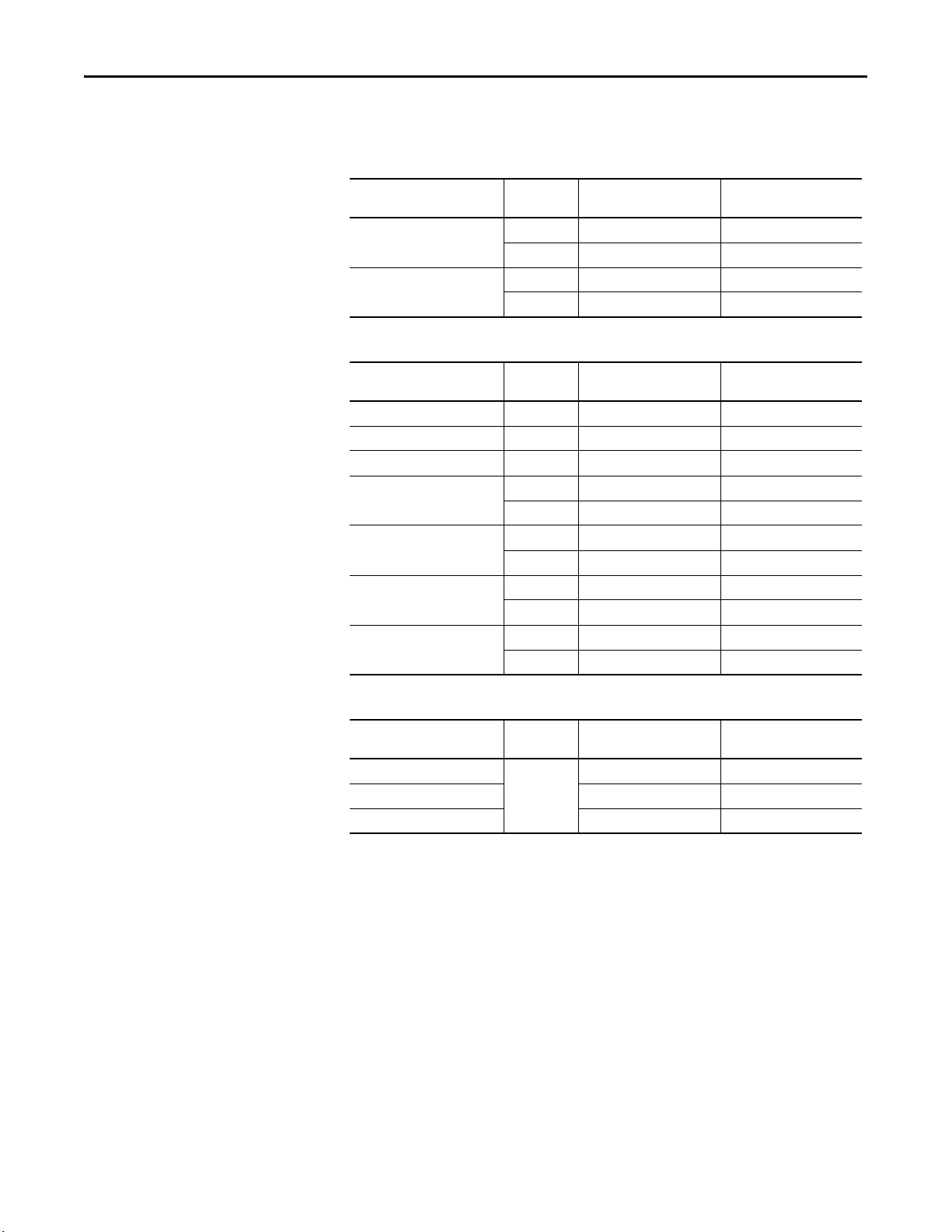

Table 2 - Kinetix 350 Drives (single-phase)

Cat. No. Input Voltage

2097-V31PR0-LM

2097-V31PR2-LM 5.7

2097-V32PR0-LM

2097-V32PR2-LM 5.7

2097-V32PR4-LM 11.3

120V, 1 Ø

240V, 1 Ø

240V, 1 Ø

Table 3 - Kinetix 350 Drives (single/three-phase)

Cat. No. Input Voltage

2097-V33PR1-LM

2097-V33PR3-LM 5.7

2097-V33PR5-LM 11.3

2097-V33PR6-LM 17.0

120V, 1 Ø

240V, 1 Ø

240V, 3 Ø

Table 4 - Kinetix 350 Drives (three-phase)

Continuous Output

Current A (0-pk)

2.8

2.8

Continuous Output

Current A (0-pk)

2.8

Featu res

• 120V Doubler mode

• Safe Torque-off

• Integrated AC line filter

• Safe Torque-off

Featu res

Safe Torque-off

Cat. No. Input Voltage

2097-V34PR3-LM

480V, 3 Ø

2097-V34PR6-LM 8.5

Table 5 - Kinetix 350 Drive Accessories

Cat. No. Drive Components

2097-Fx AC lin e filter s

2097-TB1 Terminal block for I/O connector

2097-Rx Shunt resistors

2097-PGMR Memory module programmer

2097-MEM Memory modules 12 pack

Continuous Output

Current A (0-pk)

2.8

Featu res

Safe Torque-off2097-V34PR5-LM 5.7

14 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 15

Start Chapter 1

Agency Compliance

If this product is installed within the European Union and has the CE mark, the

following regulations apply.

ATT EN TI ON : Meeting CE requires a grounded system. The method of

grounding the AC line filter and drive must match. Failure to do this renders the

filter ineffective and can cause damage to the filter.

For grounding examples, refer to Grounding Your Kinetix 350 Drive System on

page 58.

For more information on electrical noise reduction, refer to the System Design

for Control of Electrical Noise Reference Manual, publication

GMC-RM001.

CE Requirements

To meet CE requirements, these requirements apply:

• Install an AC line filter (Bulletin 2090 or 2097) as close to the drive as

possible.

• Use 2090 series motor power cables or use connector kits and terminate

the cable shields to the subpanel with clamp provided.

• Use 2090 series motor feedback cables or use connector kits and properly

terminate the feedback cable shield. Drive-to-motor power and feedback

cables must not exceed 20 m (65.6 ft).

• Install the Kinetix 350 system inside an enclosure. Run input power wiring

in conduit (grounded to the enclosure) outside of the enclosure. Separate

signal and power cables.

• Segregate input power wiring and motor power cables from control wiring

and motor feedback cables. Use shielded cable for power wiring and

provide a grounded 360° clamp termination.

Refer to Appendix A on page 129 for interconnect diagrams, including input

power wiring and drive/motor interconnect diagrams.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 15

Page 16

Chapter 1 Start

Notes:

16 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 17

Chapter 2

Install the Kinetix 350 Drive System

Top ic Page

System Design Guidelines 17

Electrical Noise Reduction 25

Mount Your Kinetix 350 Drive 33

ATT EN TI ON : Plan the installation of your system so that you can perform all

cutting, drilling, tapping, and welding with the system removed from the

enclosure. Because the system is of the open type construction, be careful to

keep any metal debris from falling into it. Metal debris or other foreign matter

can become lodged in the circuitry, which can result in damage to components.

System Design Guidelines

Use the information in this section when designing your enclosure and planning

to mount your system components on the panel.

For on-line product selection and system configuration tools, including

AutoCAD (DXF) drawings of the product, refer to

http://www.ab.com/e-tools.

System Mounting Requirements

• To comply with UL and CE requirements, the Kinetix 350 system must be

enclosed in a grounded conductive enclosure offering protection as

defined in standard EN 60529 (IEC 529) to IP4X such that they are not

accessible to an operator or unskilled person. A NEMA 4X enclosure

exceeds these requirements providing protection to IP66.

• The panel you install inside the enclosure for mounting your system

components must be on a flat, rigid, vertical surface that won’t be subjected

to shock, vibration, moisture, oil mist, dust, or corrosive vapors.

• Size the drive enclosure so as not to exceed the maximum ambient

temperature rating. Consider heat dissipation specifications for all drive

components.

• Segregate input power wiring and motor power cables from control wiring

and motor feedback cables. Use shielded cable for power wiring and

provide a grounded 360° clamp termination.

• Use high-frequency (HF) bonding techniques to connect the enclosure,

machine frame, and motor housing, and to provide a low-impedance

return path for high-frequency (HF) energy and reduce electrical noise.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 17

Page 18

Chapter 2 Install the Kinetix 350 Drive System

IMPORTANT

• Use 2090 series motor feedback cables or use connector kits and properly

terminate the feedback cable shield. Drive-to-motor power and feedback

cables must not exceed 20 m (65.6 ft).

System performance was tested at these cable length specifications. These

limitations are also a CE requirement.

Refer to the System Design for Control of Electrical Noise Reference Manual,

publication

GMC-RM001, to better understand the concept of electrical noise

reduction.

18 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 19

Install the Kinetix 350 Drive System Chapter 2

IMPORTANT

IMPORTANT

Transformer Selection

The Kinetix 350 drive does not require an isolation transformer for three-phase

input power. However, a transformer can be required to match the voltage

requirements of the controller to the available service.

To size a transformer for the main AC power inputs, refer to Circuit Breaker/

Fuse Specifications on page 20 and Transformer Specifications for Input Power

on page 23.

If you are using an autotransformer, make sure that the phase to neutral/

ground voltages do not exceed the input voltage ratings of the drive.

Use a form factor of 1.5 for single and three-phase power (where form factor is

used to compensate for transformer, drive, and motor losses, and to account for

utilization in the intermittent operating area of the torque speed curve).

For example, sizing a transformer to the voltage requirements of catalog

number 2097-V34PR6-LM = 3 kW continuous x 1.5 = 4.5 KVA transformer.

Circuit Breaker/Fuse Selection

The Kinetix 350 drives use internal solid-state motor short-circuit protection

and, when protected by suitable branch circuit protection, are rated for use on a

circuit capable of delivering up to 100,000 A. Fuses or circuit breakers that are

adequate and can withstand interrupt ratings, as defined in NEC or applicable

local codes, are permitted.

The Bulletin 140M and 140U products are another acceptable means of

protection. As with fuses and circuit breakers, you must make sure that the

selected components are properly coordinated and meet applicable codes

including any requirements for branch circuit protection. When applying the

140M/140U product, evaluation of the short circuit available current is critical

and must be kept below the short circuit current rating of the 140M/140U

product.

In most cases, class CC, J, L, and R fuses selected to match the drive input current

rating meets the NEC requirements or applicable local codes, and provide the full

drive capabilities. Use dual element, time delay (slow-acting) fuses to avoid

nuisance trips during the inrush current of power initialization.

See Kinetix 350 Drive Power Specifications in Kinetix Servo Drives

Specifications Technical Data, publication

inrush current specifications for your Kinetix 350 drive.

GMC-TD003 for input current and

Refer to Circuit Breaker/Fuse Specifications on page 20 for recommended circuit

breakers and fuses.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 19

Page 20

Chapter 2 Install the Kinetix 350 Drive System

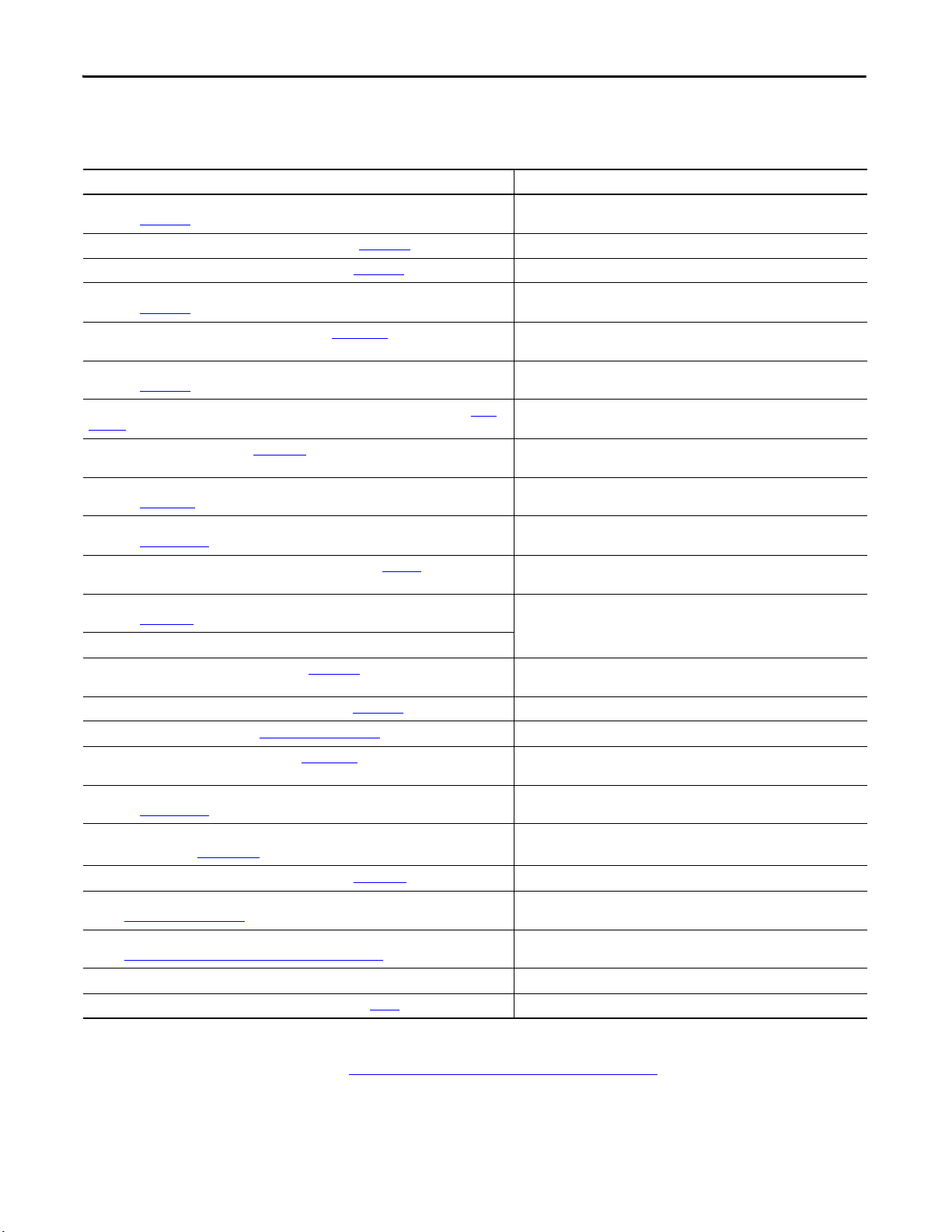

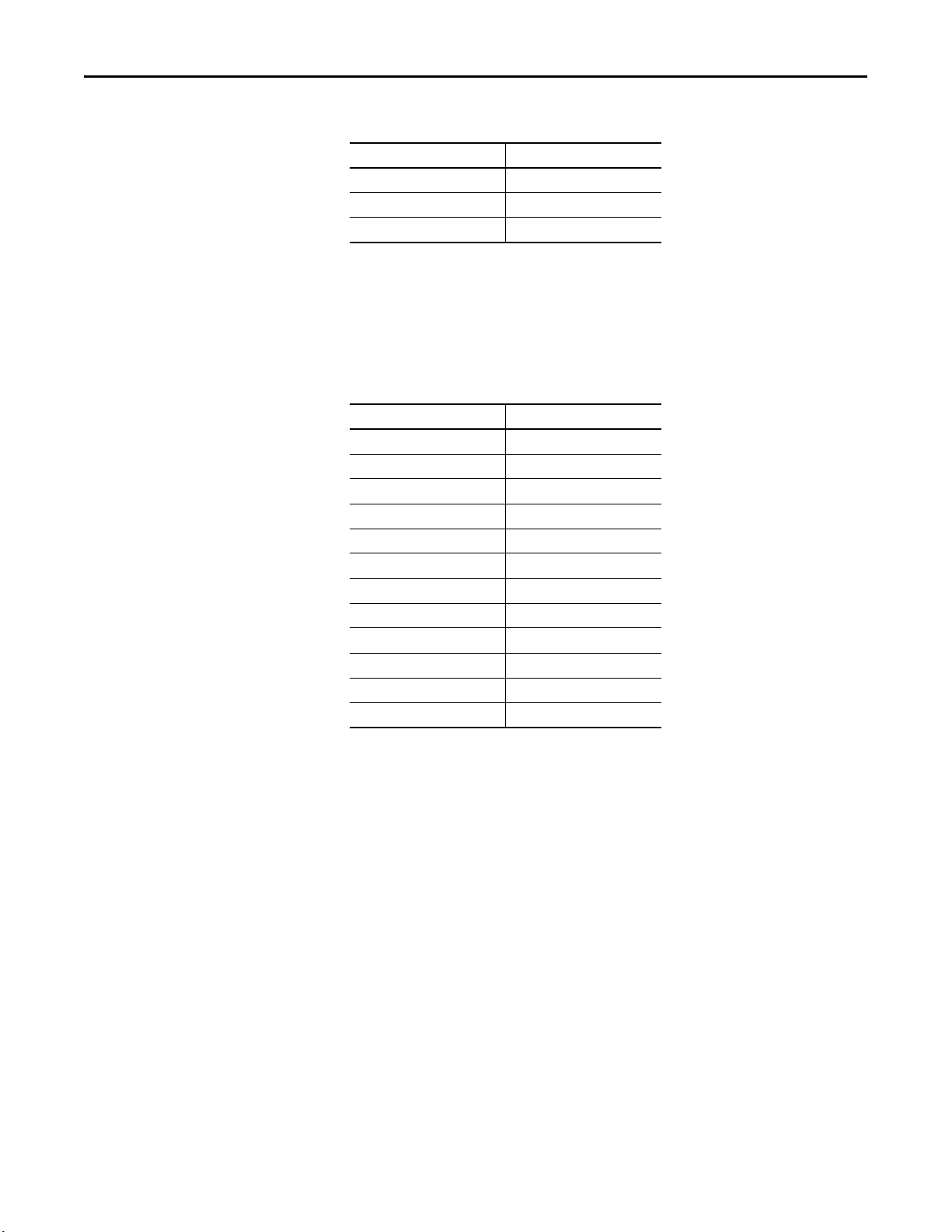

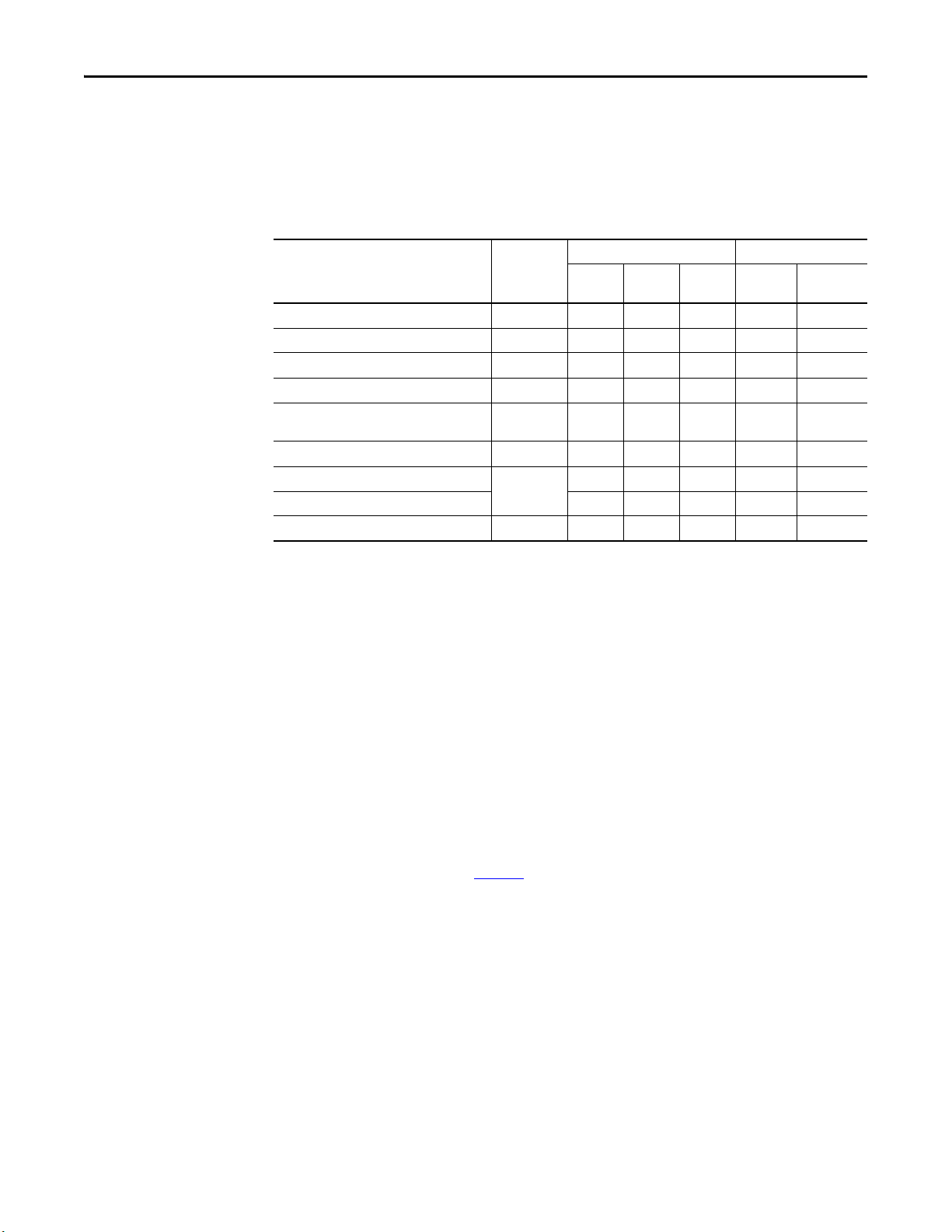

Circuit Breaker/Fuse Specifications

While circuit breakers offer some convenience, there are limitations for their use.

Circuit breakers do not handle high current inrush as well as fuses.

Make sure the selected components are properly coordinated and meet

acceptable codes including any requirements for branch circuit protection.

Evaluation of the short-circuit available current is critical and must be kept below

the short-circuit current rating of the circuit breaker.

Use class CC or T fast-acting current-limiting type fuses, 200,000 AIC,

preferred. Use Bussmann KTK-R, JJN, JJS or equivalent. Thermal-magnetic type

breakers preferred. The following fuse examples and Allen-Bradley circuit

breakers are recommended for use with Kinetix 350 drives.

Figure 2 - Fuse and Circuit Breaker (CB) Specifications

Drive Cat. No.

2097-V31PR0-LM

2097-V31PR2-LM

2097-V32PR0-LM

2097-V32PR2-LM KTK-R-20 (20 A) 1489-A1C200 140M-D8E-C20 20 1492-SP 1D200 140 M-D8E-C20

2097-V32PR4-LM KTK-R-30 (30 A) 1489-A1C300 140M-F8E-C32 32 1492-SP 1D320 140 M-F8E-C32

2097-V33PR1-LM

2097-V33PR3-LM

2097-V33PR5-LM

2097-V33PR6-LM

2097-V34PR3-LM

2097-V34PR5-LM KTK-R-10 (10 A) 1489-A3C100 140M-C2E-C10 10 1492-SP3D100 140M-C2E-C10

2097-V34PR6-LM KTK-R-20 (20 A) 1489-A3C200 140M-D8E-C20 20 1492-SP 3D200 140 M-D8E-C20

Drive

Voltage

120V

120/240V Single-phase KTK-R-10 (10 A) 1489-A1C100 140M-C2E-C10 10 1492-SP1D100 140M-C2E-C10

120V

120/240V Single-phase KTK-R-20 (20 A) 1489-A1C200 140M-D8E-C20 20 1492-SP1D2 00 140 M-D8E-C20

240V Single-phase

120/240V Single-phase KTK-R-20 (20 A) 1489-A1C200 140M-D8E-C20 20 1492-SP1D2 00 140 M-D8E-C20

240V Three-phase KTK-R-15 (15 A) 1489-A3C150 140M-D8E-C16 16 1492-SP 3D150 140 M-D8E-C16

120/240V Single-phase KTK-R-20 (20 A) 1489-A1C200 140M-D8E-C20 20 1492-SP1D2 00 140 M-D8E-C20

240V Three-phase KTK-R-15 (15 A) 1489-A3C150 140M-D8E-C16 16 1492-SP 3D150 140 M-D8E-C16

120/240V Single-phase KTK-R-30 (30 A) 1489-A1C300 140M-F8E-C32 32 1492-SP1D3 00 140 M-F8E-C32

240V Three-phase KTK-R-20 (20 A) 1489-A3C200 140M-D8E-C20 20 1492-SP 3D200 140 M-D8E-C20

120/240V S ingle-phase LPJ-40SP N/A

240V Three-phase KTK-R-30 (30 A) 1489-A3C300 32 1492-SP3D3 00

480V Three-phase

Phase

Single-phase

(voltage doubler)

Single-phase

(voltage doubler)

Fuses

(Bussmann)

KTK-R-20 (20 A) 1489-A1C200 140M-D8E-C20 20 1492-SP1D2 00 140 M-D8E-C20

KTK-R-30 (30 A) 1489-A1C300 140M-F8E-C32 32 1492-SP1D3 00 140 M-F8E-C32

KTK-R-15 (15 A) 1489-A1C150 140M-D8E-C16 16 1492-SP1D1 50 140 M-D8E-C16

KTK-R-10 (10 A) 1489-A3C100 140M-C2E-C10 10 1492-SP3D100 140M-C2E-C10

UL Applications IEC (non UL) Applications

Miniature CB

Cat. No.

(1)

Motor Protection CB

Cat. No.

140M-F8E-C32

(1)(2)

DIN gG Fuses

Amps, max

40 N/A

Miniature CB

Cat. No.

(1)

Motor Protection CB

Cat. No.

140M-F8E-C32

(1)

(1) Bulletin 1492 circuit protection devices have lower short-circuit current ratings than Bulletin 140M devices. Refer to http://ab.rockwellautomation.com/allenbradley/

productdirector y.page? for product literature with specific short-circuit ratings.

(2) For UL applications, Bulletin 140M devices are applied as self-protected combination motor controllers.

20 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 21

Install the Kinetix 350 Drive System Chapter 2

A =

4.08Q

T - 1.1

A =

0.38 (416)

1.8 (20) - 1.1

= 4.53 m

2

Enclosure Selection

This example is provided to assist you in sizing an enclosure for your

Bulletin

planned for your enclosure to calculate the enclosure size. See

Specifications on page 23 for your drive.

With no active method of heat dissipation (such as fans or air conditioning)

either of the following approximate equations can be used

2097 drive system. You need heat dissipation data from all components

Power Dissipation

.

Metric Standard English

0.38Q

A =

1.8T - 1.1

Where T is temperature difference between inside air and

outside ambient (°C), Q is heat generated in enclosure

(Watts), and A is enclosure surface area (m2). The exterior

surface of all six sides of an enclosure is calculated as

A = 2dw + 2dh + 2wh A = (2dw + 2dh + 2wh) /144

Where d (depth), w (width), and h (height) are in meters. Where d (depth), w (width), and h (height) are in inches.

Where T is temperature difference between inside air and

outside ambient (°F), Q is heat generated in enclosure

(Watts), and A is enclosure surface area (ft2). The exterior

surface of all six sides of an enclosure is calculated as

If the maximum ambient rating of the Kinetix 350 drive system is 40 °C (104 °F)

and if the maximum environmental temperature is 20 °C (68

°F), then T=20. In

this example, the total heat dissipation is 416 W (sum of all components in

enclosure). So, in the equation below, T=20 and Q=416.

In this example, the enclosure must have an exterior surface of at least 4.53 m2. If

any portion of the enclosure is not able to transfer heat, do not include heat in the

calculation.

Because the minimum cabinet depth to house the Kinetix 350 system (selected

for this example) is 332 mm (13 in.), the cabinet needs to be approximately 2000

x 700 x 332 mm (78.7 x 27.6 x 13.0 in.) HxWxD.

2 x (0.332 x 0.70) + 2 x (0.332 x 2.0) + 2 x (0.70 x 2.0) = 4.59 m

2

Because this cabinet size is considerably larger than what is necessary to house the

system components, it can be more efficient to provide a means of cooling in a

smaller cabinet. Contact your cabinet manufacturer for options available to cool

your cabinet.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 21

Page 22

Chapter 2 Install the Kinetix 350 Drive System

Contactor Ratings

Table 6 - Kinetix 350 Drives (120/240V)

Cat. No.

2097-V31PR0-LM

2097-V31PR2-LM

Drive

Volt age

120V 100-C23x10 100-C23Zx10

240V 100-C12x10 100-C12Zx10

120V 100-C30x10 100-C30Zx10

240V 100-C23x10 100-C23Zx10

AC Coil Contactor DC Coil Contactor

Table 7 - Kinetix 350 Drives (240V)

Cat. No.

2097-V32PR0-LM 240V 100-C23x10 100-C23Zx10

2097-V32PR2-LM 240V 100-C23x10 100-C23Zx10

2097-V32PR4-LM 240V 100-C30x10 100-C30Zx10

2097-V33PR1-LM

2097-V33PR3-LM

2097-V33PR5-LM

2097-V33PR6-LM

Drive

Volt age

120V 100-C23x10 100-C23Zx10

240V 100-C16x10 100-C16Zx10

120V 100-C23x10 100-C23Zx10

240V 100-C16x10 100-C16Zx10

120V 100-C30x10 100-C30Zx10

240V 100-C23x10 100-C23Zx10

120V N/A N/A

240V 100-C30x10 100-C30Zx10

AC Coil Contactor DC Coil Contactor

Table 8 - Kinetix 350 Drives (480V)

Cat. No.

2097-V34PR3-LM

2097-V34PR5-LM 100-C12x10 100-C12Zx10

2097-V34PR6-LM 100-C23x10 100-C23Zx10

Drive

Volt age

480V

AC Coil Contactor DC Coil Contactor

100-C12x10 100-C12Zx10

22 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 23

Install the Kinetix 350 Drive System Chapter 2

Transformer Specifications for Input Power

Attribute Value (460V system)

Input volt-amperes 750VA

Input voltage 480V AC

Output voltage 120…240V AC

Power Dissipation Specifications

This table shows the maximum power dissipation of each drive. Use this table to

size an enclosure and calculate required ventilation for your Kinetix

system.

Cat. No. Power D issipat ion, W

2097-V31PR0-LM 28

2097-V31PR2-LM 39

2097-V32PR0-LM 28

2097-V32PR2-LM 39

2097-V32PR4-LM 67

2097-V33PR1-LM 28

2097-V33PR3-LM 39

2097-V33PR5-LM 67

2097-V33PR6-LM 117

2097-V34PR3-LM 39

2097-V34PR5-LM 58

2097-V34PR6-LM 99

350 drive

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 23

Page 24

Chapter 2 Install the Kinetix 350 Drive System

IMPORTANT

A

25.0 mm (1.0 in.) Clearance

for Airflow and Installation

3 mm (0.12 in.)

Side Clearance

3 mm (0.12 in.)

Side Clearance

25.0 mm (1.0 in.) Clearance

for Airflow and Installation

Drive

Cat. No.

A

2097-V31PR0-LM 185 (7.29)

2097-V31PR2-LM 185 (7.29)

2097-V32PR0-LM 230 (9.04)

2097-V32PR2-LM 230 (9.04)

2097-V32PR4-LM 230 (9.04)

2097-V33PR1-LM 185 (7.29)

2097-V33PR3-LM 185 (7.29)

2097-V33PR5-LM 185 (7.29)

2097-V33PR6-LM 230 (9.04)

2097-V34PR3-LM 185 (7.29)

2097-V34PR5-LM 185 (7.29)

2097-V34PR6-LM 230 (9.04)

Minimum Clearance Requirements

This section provides information to assist you in sizing your cabinet and

positioning your Kinetix

Mount the module in an upright position as shown. Do not mount the drive

module on its side.

Figure 3 illustrates minimum clearance requirements for proper airflow and

installation:

• Additional clearance is required depending on the accessory items

installed.

• An additional 9.7 mm (0.38 in.) clearance is required left of the drive if the

I/O expansion terminal block is used.

• An additional 26 mm (1.0 in.) clearance is required right of the drive when

the heatsink is present.

• An additional 36 mm (1.42 in.) is required right of the drive when the

side-mount line filter is present. An additional 50 mm (2.0 in.) is required

behind the drive when the rear-mount line filter is present.

• An additional 5.0 mm (0.19 in.) clearance is required in front of the drive

when the 2090-K2CK-D15M feedback connector kit is used.

• Additional clearance is required for the cables and wires connected to the

top, front, and bottom of the drive.

• An additional 150 mm (6.0 in.) is required when the drive is mounted

adjacent to noise sensitive equipment or clean wireways.

350 system components.

Refer to Kinetix 350 Drive Power Specifications in Kinetix Servo Drives

Specifications Technical Data, publication

dimensions.

Figure 3 - Minimum Clearance Requirements

Refer to page 23 for power dissipation specifications.

24 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

GMC-TD003 for Kinetix 350 drive

Page 25

Install the Kinetix 350 Drive System Chapter 2

IMPORTANT

Electrical Noise Reduction

This section outlines best practices that minimize the possibility of noise-related

failures as they apply specifically to Kinetix

information on the concept of high-frequency (HF) bonding, the ground plane

principle, and electrical noise reduction, refer to the System Design for Control

of Electrical Noise Reference Manual, publication

350 system installations. For more

GMC-RM001.

Bonding Drives

Bonding is the practice of connecting metal chassis, assemblies, frames, shields,

and enclosures to reduce the effects of electromagnetic interference (EMI).

Unless specified, most paints are not conductive and act as insulators. To achieve

a good bond between drive and the subpanel, surfaces need to be paint-free or

plated. Bonding metal surfaces creates a low-impedance return path for highfrequency energy.

To improve the bond between the drive and subpanel, construct your subpanel

out of zinc plated (paint-free) steel.

Improper bonding of metal surfaces blocks the direct return path and lets highfrequency energ y travel elsewhere in the cabinet. Excessive high-frequency energy

can effect the operation of other microprocessor controlled equipment.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 25

Page 26

Chapter 2 Install the Kinetix 350 Drive System

Stud-mounting the Subpanel

to the Enclosure Back Wall

Subpanel

Star Washer

Nut

Back Wall of

Enclosure

Weld ed St ud

Use a wire brush to remove paint from

threads to maximize ground connection.

Use plated panels or scrape paint on

front of panel.

Nut

Star Washer

Welded Stud

Flat Washer

Stud-mounting a Ground Bus

or Chassis to the Subpanel

Scrape Paint

Flat Washer

If the mounting bracket is coated with

a non-conductive material (anodized

or painted), scrape the material around

the mounting hole.

Mounting Bracket or

Ground Bus

Subpanel

Subpanel

Nut

Nut

Star Washer

Flat Washer

Star Washer

Star Washer

Scrape paint on both sides of

panel and use star washers.

Tapped Hole

Bolt

Flat Washer

Ground Bus or

Mounting Bracket

If the mounting bracket is coated with

a non-conductive material (anodized

or painted), scrape the material around

the mounting hole.

Bolt-mounting a Ground Bus or Chassis to the Back-panel

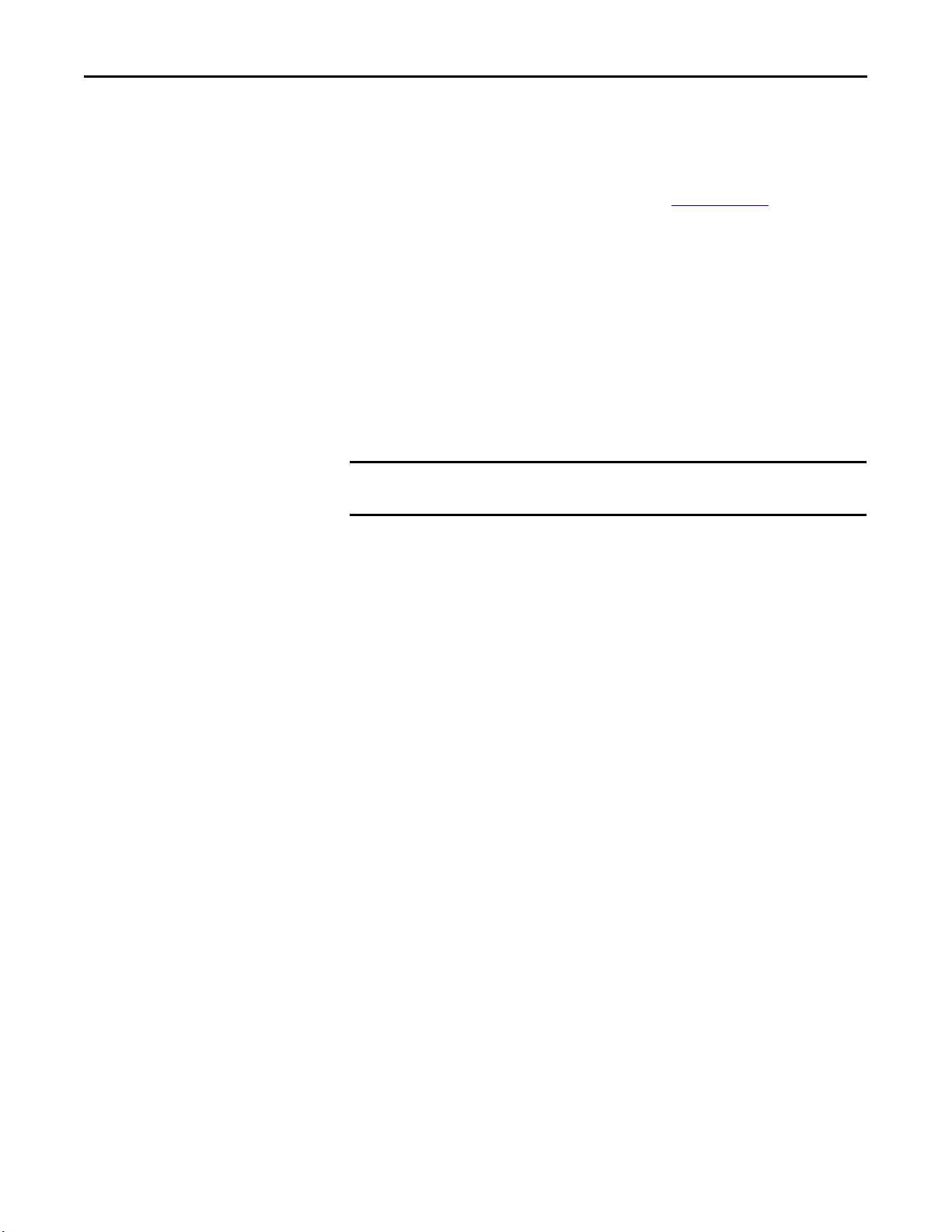

These illustrations show recommended bonding practices for painted panels,

enclosures, and mounting brackets.

Figure 4 - Recommended Bonding Practices for Painted Panels

26 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 27

Install the Kinetix 350 Drive System Chapter 2

Wire B raid

25.4 mm (1.0 in.) by

6.35 mm (0.25 in.)

Remove paint

from cabinet.

Ground bus

bonded to the

subpanel.

Wire Br aid

25.4 mm (1.0 in.) by

6.35 mm (0.25 in.)

Bonding Multiple Subpanels

Bonding multiple subpanels creates a common low impedance exit path for the

high frequency energy inside the cabinet. Subpanels that are not bonded together

can not share a common low impedance path. This difference in impedance can

affect networks and other devices that span multiple panels:

• Bond the top and bottom of each subpanel to the cabinet by using

25.4

mm (1.0 in.) by 6.35 mm (0.25 in.) wire braid. As a rule, the wider

and shorter the braid is, the better the bond.

• Scrape the paint from around each fastener to maximize metal-to-metal

contact.

Figure 5 - Multiple Subpanels and Cabinet Recommendations

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 27

Page 28

Chapter 2 Install the Kinetix 350 Drive System

Clean Wireway

24V Motor

Brake PS

Circuit

Breaker

Contactors

Kinetix 350

Drive

I/O

(1)

, Ethernet, and

Feedback Cables

Very Dirty Zone

Segregated (not in wireway)

Route 24V DC I/O

Shielded Cable

Ethernet

(shielded)

Cable

I/O

(1)

, Motor Power, and Safety Cables

(4)

(3)

Dirty Wireway

XFMR

DC

Filter

Bulletin 2090

AC Line Filte r

(optional)

Route encoder/analog/registration

shielded cables.

DD

VD

VD

D

C

C

No sensitive

equipment within 150

mm (6.0 in.).

(2)

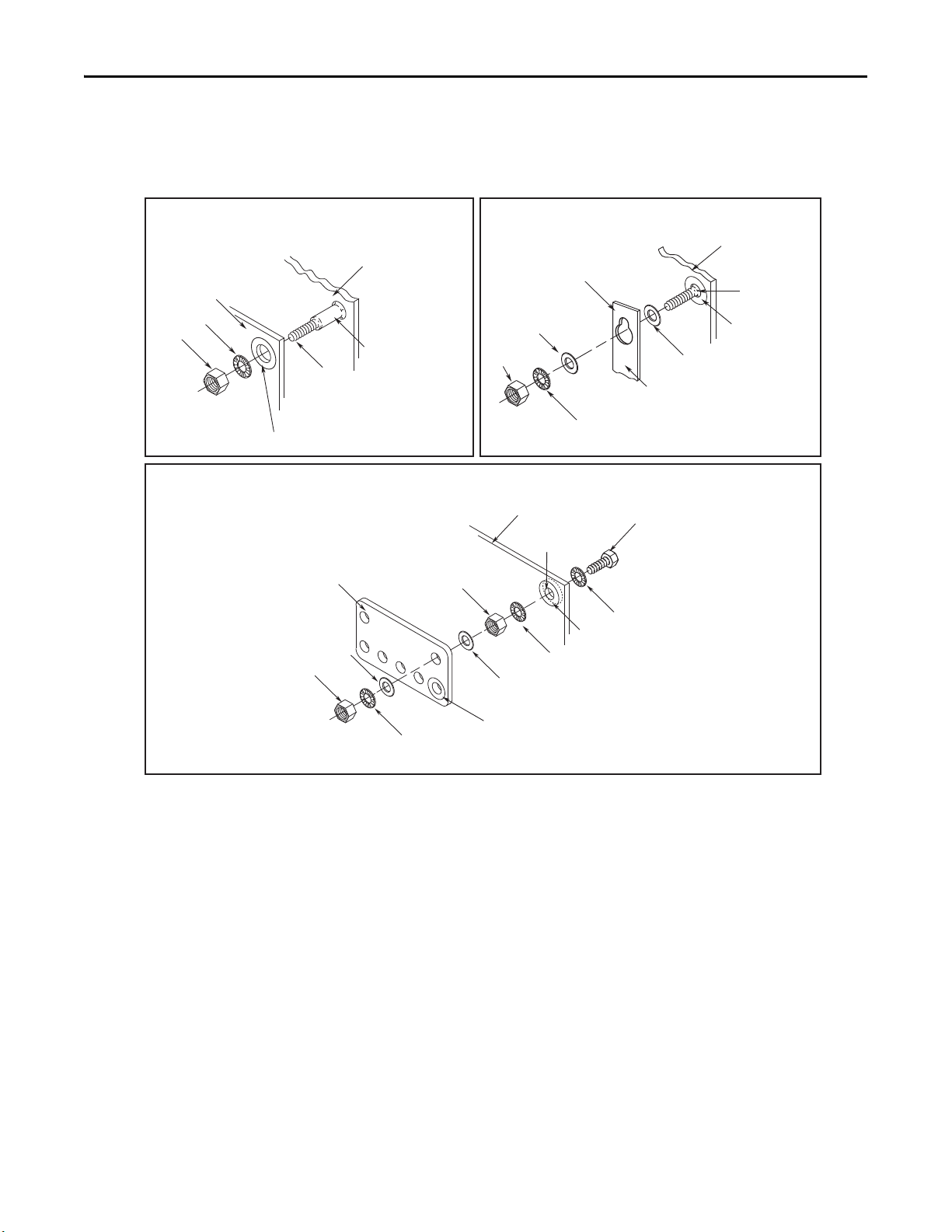

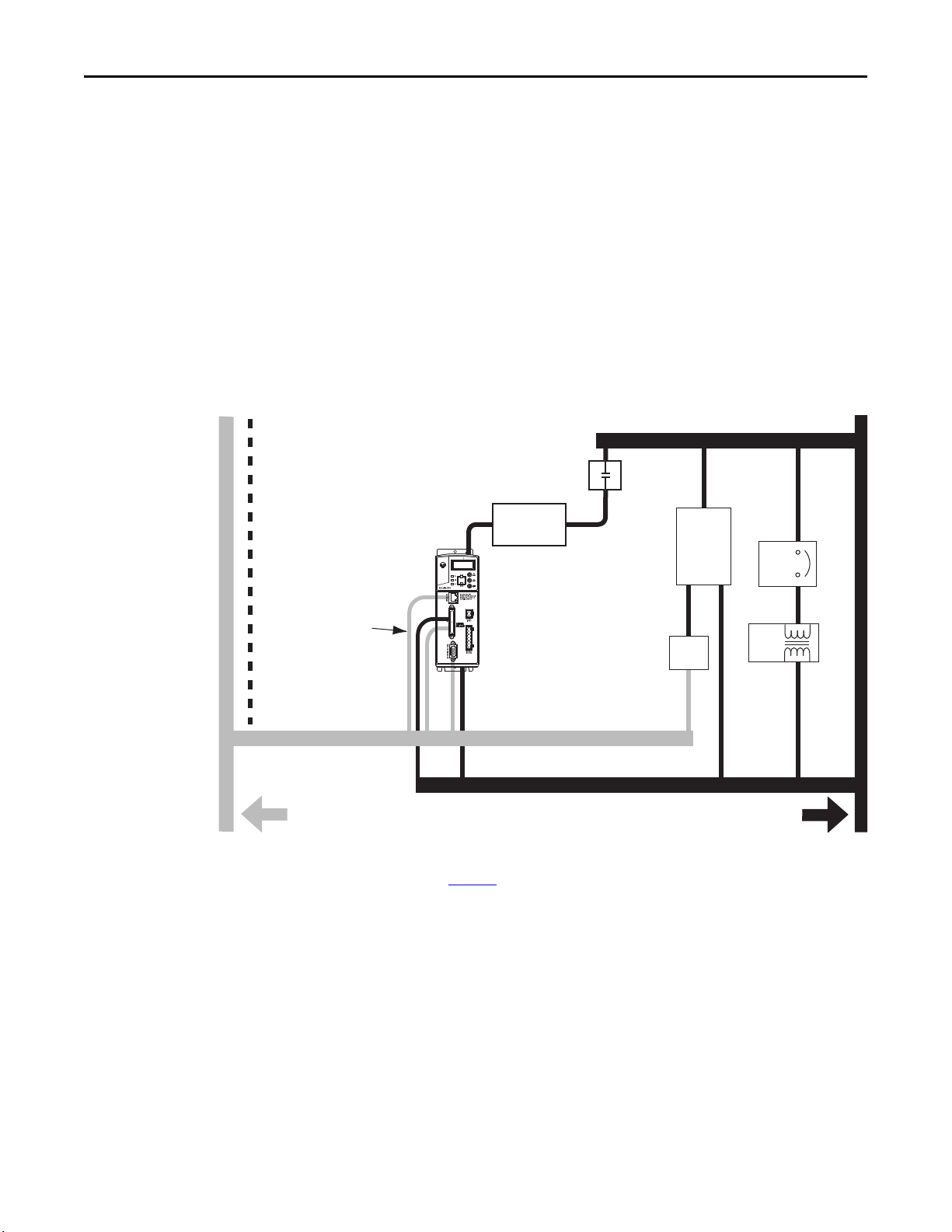

Establishing Noise Zones

Observe these guidelines when individual input power components are used in

the Kinetix

• The clean zone (C) exits left of the Kinetix 350 system and includes the I/

• The dirty zone (D) exits right of the Kinetix 350 system (black wireway)

• The very dirty zone (VD) is limited to where the AC line (EMC) filter

Figure 6 - Noise Zones (Bulletin 2090 AC line filters)

350 system:

O wiring, feedback cable, Ethernet cable, and DC filter (gray wireway).

and includes the circuit breakers, transformer, 24V DC power supply,

contactors, AC line filter, motor power, and safety cables.

VAC output jumpers over to the drive. Shielded cable is required only if

the very dirty cables enter a wireway.

(1) If drive system I/O cable contains (dirty) relay wires, route cable in dir ty wireway.

(2) For tight spaces use a grounded steel shield. For examples, refer to the System Design for Control of Electrical Noise Reference

Manual, publication

(3) This is a clean 24V DC available for any device that requires it. The 24V enters the clean wireway and exits to the left.

(4) This is a dirty 24V DC available for motor brakes and contactors. The 24V enters the dirty wireway and exits to the right.

GMC-RM001.

28 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 29

Figure 7 - Noise Zones (Bulletin 2097 AC line filters)

Clean Wireway

24V Motor

Brake PS

Circuit

Breaker

Contactors

Kinetix 350

Drive

I/O

(1)

, Ethernet, and Feedback Cables

Very Dirty Zone

Segregated (not in wireway)

Route 24V DC I/O

Shielded Cable

Ethernet

(shielded)

Cable

I/O

(1)

, Motor Power, and Safety Cables

(4)

(3)

Dirty Wireway

XFMR

DC

Filter

Route encoder/analog/registration

shielded cables.

D

D

VD

VD

D

C

C

Bulletin 2097 AC line

filters mount to side,

as shown, or behind

the drive.

No sensitive

equipment within 150

mm (6.0 in.).

(2)

Install the Kinetix 350 Drive System Chapter 2

(1) If drive system I/O cable contains (dirty) relay wires, route cable in dir ty wireway.

(2) For tight spaces use a grounded steel shield. For examples, refer to the System Design for Control of Electrical Noise Reference

Manual, publication

GMC-RM001.

(3) This is a clean 24V DC available for any device that requires it. The 24V enters the clean wireway and exits to the left.

(4) This is a dirty 24V DC available for motor brakes and contactors. The 24V enters the dirty wireway and exits to the right.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 29

Page 30

Chapter 2 Install the Kinetix 350 Drive System

Wire/Cable Connector

L1, L2, L3 (unshielded cable) IPD X

U, V, W ( motor power) MP X X

B+-, B-, BR (shunt resistor) BC X

24V DC BP X

Control COM, 24V DC control, safety enable, and

feedback signals for safe-off feature

Motor feedback MF X X

Registration

Others X

Ethernet Port 1 X X

Cable Categories for Kinetix 350 Drive Components

These table indicate the zoning requirements of cables connecting to the

Kinetix

Table 9 - Kinetix 350 Drive Components

350 drive components.

STO X

IOD

Very

Dirty

Zone Method

Dirty Clean

Ferrite

Sleeve

X X

Shielded

Cable

Noise Reduction Guidelines for Drive Accessories

Refer to this section when mounting an AC line filter or shunt resistor module

for guidelines designed to reduce system failures caused by excessive electrical

noise.

AC Line Filters

If you are using a Bulletin 2090 line filter, mount the filter on the same panel as

the Kinetix

Observe these guidelines when mounting your AC line filter:

• Good HF bonding to the panel is critical. For painted panels, refer to the

• Segregate input and output wiring as far as possible.

350 drive, and as close to the drive as possible.

examples on

page 26.

30 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 31

Install the Kinetix 350 Drive System Chapter 2

Contactor

Dirty Wireway

Custom er-sup plied

Metal Enclosure

150 mm (6.0 in.)

clearance (min) on all four

sides of the shunt module.

Very dirty connections

Shunt Wiring Methods:

Twisted pair in conduit (first choice).

Shielded twisted pair (second choice).

Twisted pair, two twists per foot (min) (third choice).

Metal Conduit

(where re quired

by local code)

Ethernet

(shielded)

Cable

No sensitive

equipment within 150

Route 24V DC I/O

Shielded Cable

24V Motor

Brake PS

Enclosure

Clean Wireway

Circuit

Breaker

I/O

(1)

, Ethernet, and

Feedback Cables

DC

Filter

Kinetix 350 Drive

Route Encoder/Analog/Registration

Shielded Cables

D

VD

D

C

C

I/O

(1),

Motor Power and Safety Cables

XFMR

D

AC Line

Filter

VD

Shunt Resistors

Observe these guidelines when mounting your shunt resistor outside the

enclosure:

• Mount shunt resistor and wiring in the very dirty zone or in an external

shielded enclosure.

• Mount resistors in a shielded and ventilated enclosure outside the cabinet.

• Keep unshielded wiring as short as possible. Keep shunt wiring as flat to

the cabinet as possible.

Figure 8 - Shunt Resistor Outside the Enclosure

(1) If drive system I/O cable contains (dirty) relay wires, route cable in dirt y wire way.

(2) When space does not permit 150 mm (6.0 in.) clearance, install a grounded steel shield between the drive and clean wireway. For

examples, refer to the System Design for Control of Electrical Noise Reference Manual, publication

GMC-RM001.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 31

Page 32

Chapter 2 Install the Kinetix 350 Drive System

Shunt Wiring Methods:

Twisted pair in conduit (first choice).

Shielded twisted pair (second choice).

Twisted pair, two twists per foot (min) (third choice).

Contac tor

Dirty Wireway

Very dirty zone

segregated (not in wireway).

Ethernet

(shielded)

Cable

No sensitive

equipment within 150

mm (6.0 in.).

(2)

Route 24V DC I/O

Shielded Cable

24V Motor

Brake PS

Circuit

Breaker

I/O

(1)

, Ethernet, and Feedback

Cables

DC

Filter

Kinetix 350

Drive

Route Encoder/Analog/Registration

Shielded Cables

D

VD

C

I/O

(1)

, Motor Power, and Safety Cables

XFMR

D

D

AC Line

Filter

VD

D

C

Clean Wireway

Enclosure

When mounting your shunt module inside the enclosure, follow these additional

guidelines:

• Mount the shunt resistor anywhere in the dirty zone, but as close to the

Kinetix

350 drive as possible.

• Shunt wires can be run with motor power cables.

• Keep unshielded wiring as short as possible. Keep shunt wiring as flat to

the cabinet as possible.

• Separate shunt wires from other sensitive, low-voltage signal cables.

Figure 9 - Shunt Resistor inside the Enclosure

(1) If drive system I/O cable contains (dirty) relay wires, route cable in dirt y wire way.

(2) When space does not permit 150 mm (6.0 in.) clearance, install a grounded steel shield between the drive and clean wireway. For

examples, refer to the System Design for Control of Electrical Noise Reference Manual, publication

Motor Brake

The brake is mounted inside the motor and how you connect to the drive

depends on the motor series.

Refer to Kinetix 350 Drive/Rotary Motor Wiring Examples beginning on

page 134 for the interconnect diagram of your drive/motor combination.

32 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

GMC-RM001.

Page 33

Install the Kinetix 350 Drive System Chapter 2

IMPORTANT

Mount Your Kinetix 350 Drive

This procedure assumes you have prepared your panel and understand how to

bond your system. For installation instructions regarding other equipment and

accessories, refer to the instructions that came with those products.

ATT EN TI ON : This drive contains electrostatic discharge (ESD) sensitive parts

and assemblies. You are required to follow static control precautions when you

install, test, service, or repair this assembly. If you do not follow ESD control

procedures, components can be damaged. If you are not familiar with static

control procedures, refer to Guarding Against Electrostatic Damage, publication

8000-4.5.2, or any other applicable ESD Protection Handbook.

Follow these steps to mount your Kinetix 350 drive.

1. Lay out the position for the Kinetix 350 drive and accessories in the

enclosure.

Refer to Establishing Noise Zones on page 28 for panel layout

recommendations. Mounting hole dimensions for the Kinetix 350 drive

are shown in Kinetix Servo Drives Specifications Technical Data,

publication number

2. Attach the Kinetix 350 drive to the cabinet, first by using the upper

mounting slots of the drive and then the lower.

GMC-TD003.

The recommended mounting hardware is M4 (#6-32) steel machine

screws torqued to 1.1 N•m (9.8 lb•in). Observe bonding techniques as

described in

3. Tighten all mounting fasteners.

Bonding Drives on page 25.

To improve the bond between the Kinetix 350 drive and subpanel,

construct your subpanel out of zinc plated (paint-free) steel.

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013 33

Page 34

Chapter 2 Install the Kinetix 350 Drive System

Notes:

34 Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Page 35

Chapter 3

Kinetix 350 Drive Connector Data

Top ic Page

Kinetix 350 Drive Connectors and Indicators 36

Control Signal Specifications 41

Motor Feedback Specifications 46

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 35

Page 36

Chapter 3 Kinetix 350 Drive Connector Data

3

5 0

Kinetix 350 Drive, Front View

(2097-V33PR5-LM drive is shown)

Kinetix 350 Drive, Bottom View

(2097-V33PR5-LM drive is shown)

Kinetix 350 Drive, Top View

(2097-V33PR5-LM drive is shown)

Kinetix 350 Drive Connectors and Indicators

Although the physical size of the Kinetix 350 drives vary, the location of the

connectors and indicators is identical.

Figure 10 - Kinetix 350 Drive Connector and Indicators

2

3

4

5

6

7

8

1

9

0

10

13

14

12

15

11

10

Item Description Item Description

1 Mains (IPD) connector 9 Motor feedback (MF) connector

2 Data status indicator and diagnostic display 10 Ground lug

3 Memory module socket 11 Shunt resistor and DC bus (BC) connector

4 Network status indicator 12 Back-up power (BP) connector

5 Module status indicator 13 Display control push buttons (3)

6 Axis status indicator 14 Motor power (MP) connec tor

7 Ethernet communication port (Port 1) 15 Safe torque-off (STO) connector

8 I/O (IOD) connector

Table 10 - Kinetix 350 Drive Connectors

Designator Description Connector

IPD AC input power 3-position or 4-position plug/header

PORT1 Ethernet communication port RJ45 Ethernet

IOD I/O SCSI 50 pin high density connector

MF Motor feedback 15-pin high-density D-shell (male)

BP Back-up power 2-pin quick-connect terminal block

BC Shunt Resistor and DC Bus 7-pin quick-connect terminal block

MP Motor power 6-pin quick-connect terminal block

STO Safe torque off (STO) Terminal 6-pin quick-connect terminal block

36 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Page 37

Kinetix 350 Drive Connector Data Chapter 3

1 2 3 4 5 6

+24 V DC control

Control COM

Safety status

Safety input 1

Safety COM

Safety input 2

Bottom view of the Kinetix 350 drive.

(2097-V33PR5-LM drive is shown)

Wiring Plug Header

Safe Torque-off

(STO) Connector

IMPORTANT

Safe Torque-off Connector Pinout

The Kinetix 350 drive ships with the (6-pin) wiring-plug header that connects

your safety circuit to the Kinetix

your system does not use the safe torque-off feature, follow instructions in

To rqu e -o ff Fe at ur e B yp a ss starting on page 107 to wire the drive with motion-

allowed jumpers.

Figure 11 - Safe Torque-off Connector

350 drive safe torque-off (STO) connector. If

Safe

Table 11 - Kinetix 350 Drive Safe Torque-off Connector Pinout

STO Pin Description Signal

1 +24V DC output from the drive +24V DC control

2 +24V DC output common Control COM

3 Safety status Safety Status

4 Safety input 1 (+24V DC to enable) Safety Input 1

5 Safety common Safety COM

6 Safety input 2 (+24V DC to enable) Safety Input 2

Use only pins STO-1 (+24V DC Control) and STO-2 (Control COM) of the motionallowed jumpers to enable the drive when the safe torque-off function is not

used. When the safe torque-off function is in operation, the 24V supply must

come from an external source.

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 37

Page 38

Chapter 3 Kinetix 350 Drive Connector Data

1

25

50

26

I/O Connector Pinout

IOD Pin Description Signal

1…25 Reserved Reserved

26 +/- Overtravel, enable, and home common COM

27 Negative hardwa re overtravel NEG_OT

28 Positive hardware overtravel POS_OT

29 Drive enable ENABLE

30 Home switch HOME_SW

31…35 Reserved —

36 Registration common REG_COM

37…38 Reserved —

39 Registration input REG

40…42 Reserved —

43 Motor brake release positive MT R_B RAKE +

44 Motor brake release negative MTR_ BRAK E-

44…50 Reserved —

Figure 12 - Pin Orientation for 50-pin SCSI I/O (IOD) Connector

38 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Page 39

Kinetix 350 Drive Connector Data Chapter 3

IMPORTANT

Pin 11

Pin 6

Pin 15

Pin 1

Pin 10

Pin 5

1

8

Motor Feedback (MF) Connector Pinout

MF Pin Description Signal MF Pin Description Signal

1

2

3

4

5

6 Comm on ECOM 14 Encoder power (+5V) EPWR_5V

7 Encoder power (+9V) EPWR_9V

8

(1) Not applicable unless motor has integrated thermal protection.

(2) Encoder power supply uses either 5V or 9V DC based on encoder/motor used.

Sine differential input+

AM+ differential input+

Sine differential inputAM- differential input-

Cosine differential input+

BM+ differential input+

Cosine differential inputBM- differential input-

Data differential input +

Index pulse+

Single-ended 5V Hall effect

commutation

SIN+

AM+

SINAM-

COS+

BM+

COSBM-

DATA+

IM+

S3

9

10

11

12

13

(2)

15 Reserved —

Reserved

Data differential input Index pulse-

Motor thermal switch

(normally closed)

Single-ended 5V Hall effect

commutation

Single-ended 5V Hall effect

commutation

(1)

—

DATAIM-

TS

S1

S2

(2)

Drive-to-motor power and feedback cable length must not exceed 20 m

(65.6 ft). System performance was tested at these specifications and also

apply when meeting CE requirements.

Figure 13 - Pin Orientation for 15-pin Motor Feedback (MF) Connector

Ethernet Communication Connector Pinout

Port 1 Pin Description Signal Port 1 Pin Description Signal

1 Transmit port (+) data terminal + TX 5 — —

2 Transmit port (-) data terminal - TX 6 Receive port (-) data terminal - RX

3 Receive port (+) data terminal + RX 7 — —

4 — — 8 — —

Figure 14 - Pin Orientation for 8-pin Ethernet Communication (port 1) Port

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 39

Page 40

Chapter 3 Kinetix 350 Drive Connector Data

AC Input Power Connector Pinout

IPD

Designator

L2/N AC power in (non-doubler operation) L2/N L2 AC powe r in L2

L1 AC power i n L1 L1 AC power in L1

N AC power neutral (only 120V doubler) N PE Protective earth (ground) PE

PE Protective earth (ground) PE

Description

(2097-V31PRx-LM drives)

Signal

IPD

Designator

IPD

Designator

L3 AC power in (three-phase models) L3

L2 AC powe r in L2

L1 AC powe r in L1

PE Protective earth (ground) PE

Description

(2097-V32PRx-LM drives)

Description

(2097-V33PRx-LM, and 2097V34PRx-LM drives)

Back-up Power Connector Pinout

BP

Designator

+24V Positive 24V DC +24V DC

-24V 24V DC power supply return Return

Description Signal

Signal

Signal

Shunt Resistor and DC Bus Connector Pinout

BC

Designator

+

+ +

SH Shunt resistor SH

-

- -

Description Signal

+

Positive DC bus and shunt resistor

-

Negative DC bus

Motor Power Connector Pinout

MP

Designator

PE Protective earth (ground) PE

W Motor power out W

V Motor power out V

U Motor power out U

Description Signal

40 Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Page 41

Kinetix 350 Drive Connector Data Chapter 3

IMPORTANT

IMPORTANT

Control Signal Specifications

IOD Pin Signal Description

IOD-29 ENABLE

IOD-30 HOME

IOD-39 REG

IOD-27

IOD-28

NEG_OT

POS_OT

Optically isolated, single-ended active high signal. Current loading is nominally 9 mA. A 24V

DC input is applied to this terminal to enable the axis.

Optically isolated, single-ended active high signal. Current loading is nominally 9 mA. Home

switch (normally open contact) inputs axis require 24V DC (nominal).

Fast registration inputs are required to inform the motor interface to capture the positional

information with less than 5 μs uncertainty. Optically isolated, single-ended active high

signal. Current loading is nominally 9 mA. A 24V DC input is applied to this terminal to enable

axis.

Overtravel detection is available as an optically isolated, single-ended active high signal.

Current loading is nominally 9 mA per input. The positive/negative limit switch (normally

closed contact) inputs for axis require 24V DC (nominal).

This section provides a description of the Kinetix 350 drive I/O (IOD),

communication, shunt resistor and DC bus (BC), and back-up power (BP)

connectors.

Digital Inputs

Five fixed inputs are available for the machine interface on the Kinetic 350 drive.

To improve registration input EMC performance, refer to the System Design for

Control of Electrical Noise Reference Manual, publication

Over-travel limit input devices must be normally closed.

The five digital inputs (IOD-27…IOD-30 and IOD-39) have fixed pin

assignments.

Table 12 - Understanding Digital Inputs

GMC-RM001.

Capture

Time

0.5 ms Level

0.5 ms Edge

5 μs Ed ge

1 ms Level

Edge/Level

Sensitive

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013 41

Page 42

Chapter 3 Kinetix 350 Drive Connector Data

Function Description Behavior

If the controller configuration specifies checking of the enable input, an

active state enables the power electronics to control the motor and an

inactive state prevents motion.

The drive generates an exception if the input is inactive when the

Enable

Home

Registration

Positive O ver-travel

Negative Over-travel

controller commands motion and has authorized checking. The drive

behavior in this situation is programmable.

An active state indicates to a homing sequence that the referencing

sensor has been seen. Typically, a transition of this signal is used to

establish a reference position for the machine axis.

An inactive-to-active transition (also known as a positive transition) or

active-to-inactive transition (also known as a negative transition) is

used to latch position values for use in registration moves.

If the controller configuration specifies checking of the hardware overtravel inputs, an inactive state indicates that a position limit has been

exceeded in the positive direction.

The drive generates an exception if the input is inactive when the

controller authorizes checking. The drive behavior in this situation is

programmable.

If the controller configuration specifies checking of the hardware

overtravel inputs, an inactive state indicates that a position limit has

been exceeded in the negative direction.

The drive generates an exception if the input is inactive when the

controller authorizes checking. The drive behavior in this situation is

programmable.

Table 13 - Understanding Digital Input Functions

By default drive enable input checking is enabled. If the checking is

authorized and the input is disabled the drive issues a Drive Enable

Start Inhibit and you are not be able to issue a Servo On instruction

from the controller.

To disable the Enable function:

• Tie input to 24V DC

• Write a Logix Designer message instruction that changes

enableInputChecking or Attribute 736 to zero, see instructions

on page 100

The function is always inactive unless armed by the controller.

The function is always active.

To disable function:

• Tie input to 24V

• Set to only Fault Status

Table 14 - Digital Input Specifications

Attribute Value

Typ e Active high, single-ended, current sinking

Funct ions

Input current (with 24V applied) 9 mA, max

On-state input voltage 4.2…24V @ 2…9 mA total

Off-state input voltage 0…2.5V

Pulse reject filtering (only Registration functions) 120 ns, nom

Pulse reject filtering, default (all other input functions, can be configured) 1.0 ms, nom

Propagation delay (only Registration function) 5 μs

Registration repeatability 200 ns

Input reaction time (Disable) 2 ms, max