Page 1

Design Guide

Motor Cables,

Interface Cables,

Connector Kits, and Other

Drive Accessories

Kinetix 6000

Servo Drives

Rotary Motion

Linear Motion

Kinetix 6200 and Kinetix 6500

Servo Drives

Kinetix 6000M

Integrated Drive-Motor

Systems

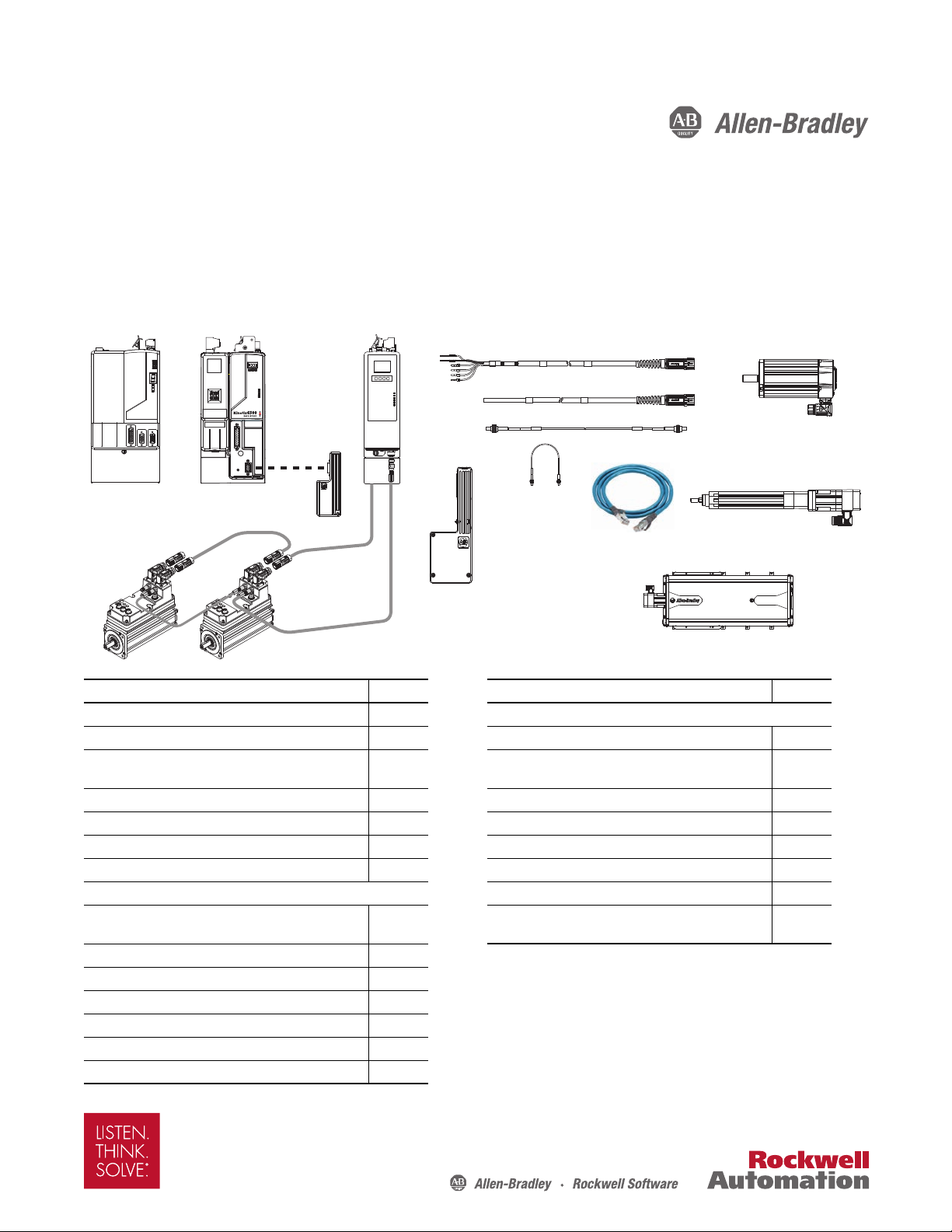

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Catalog Numbers 2094-ACxx-Mxx-S, 2094-BCxx-Mxx-S, 2094-AMxx-S, 2094-BMxx-S

2094-BCxx-Mxx-M, 2094-BMxx-M, 2094-SE02F-M00-Sx, 2094-EN02D-M01-Sx, 2094-SEPM-B24-S

Topic Page Topic, continued Page

Introduction 2 Linear Motion System Combinations

Kinetix 6000 and Kinetix 6200/6500 Drive Systems 3 LDAT-Series Integrated Linear Thrusters 65

Kinetix 6000 and Kinetix 6200/6500 System Examples 5

2090-Series Motor/Actuator Cables Overview 7 MP-Series Integrated Linear Stages 87

Kinetix 6000M Integrated Drive-Motor Systems 9 MP-Series Electric Cylinders 94

Kinetix 6000M Integrated Drive-Motor System Example 9 MP-Series Heavy Duty Electric Cylinders 97

Kinetix 6000M Integrated Drive-Motor System Performance 15 LDC-Series Linear Motors 104

Rotary Motion System Combinations LDL-Series Linear Motors 115

Kinetix 6000 Drive Rotary Performance Example with Peak

Enhancement Feature

MP-Series Low Inertia Motors 18

MP-Series Medium Inertia Motors 33

MP-Series Food Grade Motors 45

MP-Series Stainless Steel Motors 52

RDD-Series Direct Drive Motors 55

TL-Series (Bulletin TLY) Motors 61

17 Additional Resources 119

Kinetix 6000 Drive Linear Performance Example with Peak

Enhancement Feature

86

Page 2

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

IMPORTANT

Introduction

This publication assumes that your application uses the Kinetix® 6000, Kinetix 6200, or Kinetix 6500 drive family and that

you have already determined your motor/actuator series. To revisit those decisions, refer to the Kinetix Motion Control

Selection Guide, publication GMC-SG001

With Kinetix 6000 and Kinetix 6200 drive systems, Kinetix 6000M integrated drive-motor (IDM) systems are another

option. Cables between the IDM units and the IDM power interface module (IPIM) are unique to IDM systems.

Accessories shared with the Bulletin 2094 drive system include sercos fiber-optic cables and safe-off headers and cables.

The purpose of this publication is to assist you in identifying the drive system components and accessory items you’ll need

for your drive and motor/actuator combination or Kinetix 6000M integrated drive-motor system. Diagrams in this

publication illustrate how many of the common drive accessory items are used in a typical system, but refer to the Kinetix

Motion Accessories Technical Data, publication GMC-TD004

Also provided are drive/motor or drive/actuator system combinations that include the following:

• Motor/cable combinations table

• Drive and motor/actuator performance specification table

• Torque/speed curves with each motor matched to the drive with optimum performance

, or Motion Analyzer software.

, for detailed accessory descriptions and specifications.

Performance specification data and curves reflect nominal system performance of a typical system with motor/drive at

rated ambient temperature and line voltage. For additional information on ambients, line conditions, and valid

combinations not shown in this publication, refer to Motion Analyzer software.

These system combinations do not include all possible motor/drive combinations. Please refer to Motion Analyzer software to

verify compatibility. Download from http://www.ab.rockwellautomation.com/motion-control/motion-analyzer-software

.

Studio 5000 Environment

The Studio 5000™ Engineering and Design Environment combines engineering and design elements into a common

environment. The first element in the Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix™ 5000 software and will continue to be the product to program Logix5000™

controllers for discrete, process, batch, motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell Automation® engineering design tools and

capabilities. It is the one place for design engineers to develop all the elements of their control system.

2 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 3

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

For each Kinetix 6000, Kinetix 6200, or Kinetix 6500 drive system, you need to know the drive and motor/actuator catalog

numbers to determine the motor power and feedback cable catalog numbers. Interface cables, connector kits, and a Bulletin

2094 power rail are also required. Optional equipment includes the 2094 shunt module, slot-filler modules, line interface

module, AC line filter, and others. Example diagrams of the required equipment listed on this page are shown on page 5

.

For Kinetix 6000M integrated drive-motor system information including cables and torque/speed curves, refer to page 9

For Kinetix 6000 and Kinetix 6200/6500 (rotary motion) system combinations, refer to page 17

combinations, refer to page 86

.

. For linear motion system

.

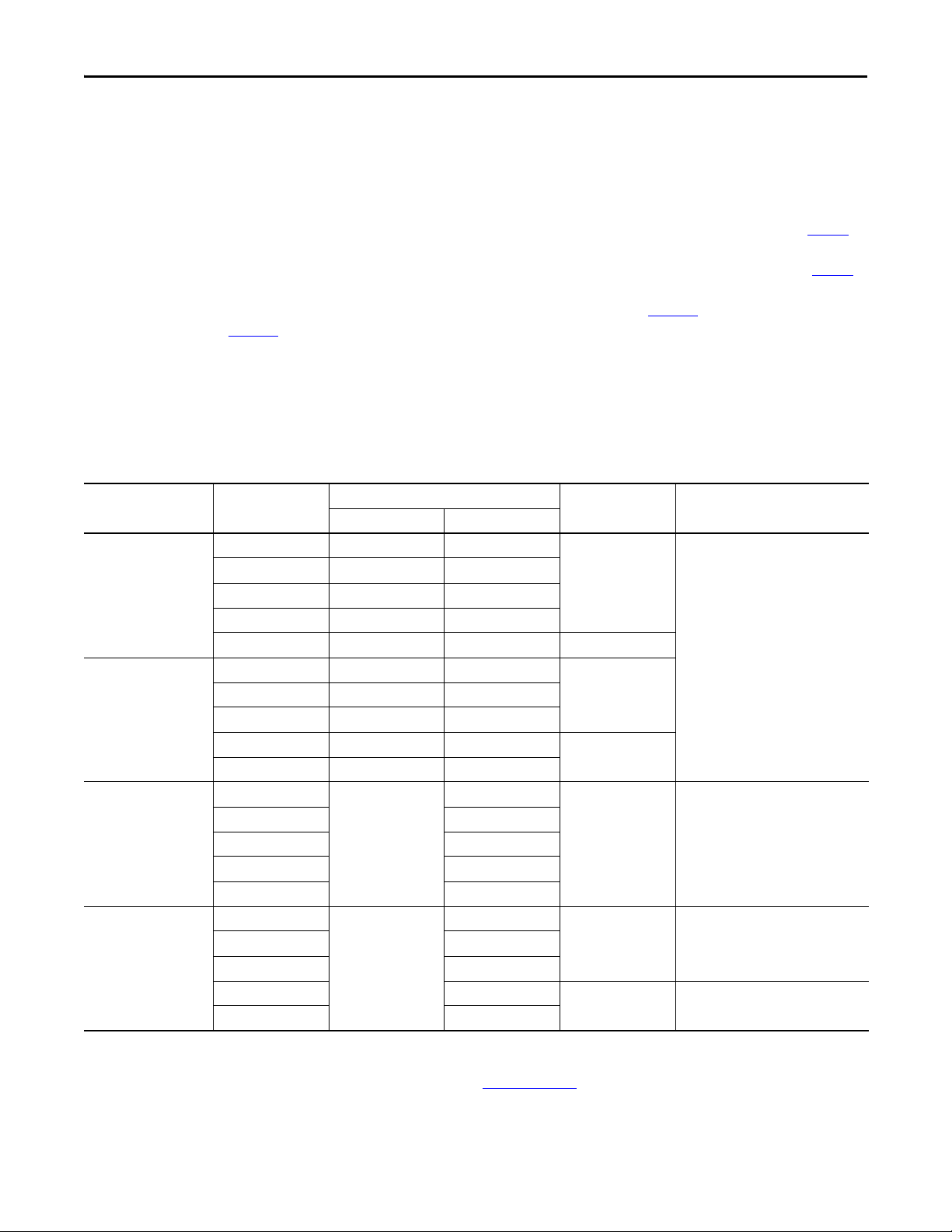

Determine What You Need

These tables list the drive modules and accessory items available for the Kinetix 6000 and Kinetix 6200/6500 drive systems.

Kinetix 6000 Drive Modules

Drive Module Drive Cat. No.

2094-AC05-MP5-S 3 kW, 10 A 1.2 kW, 5 A

2094-AC05-M01-S 3 kW, 10 A 1.9 kW, 9 A

Integrated axis module

(IAM) 200V-class

Integrated axis module

(IAM) 400V-class

Axis module (AM)

200V-class

Axis module (AM)

400V-class

2094-AC09-M02-S 6 kW, 19 A 3.4 kW, 15 A

2094-AC16-M03-S 11.3 kW, 36 A 5.5 kW, 25 A

2094-AC32-M05-S 22.5 kW, 71 A 11.0 kW, 49 A Double wide

2094-BC01-MP5-S 6 kW, 9 A 1.8 kW, 4.0 A

2094-BC02-M02-S 15 kW, 23 A 6.6 kW, 14.6 A

2094-BC04-M03-S 28 kW, 42 A 13.5 kW, 30 A

2094-BC07-M05-S 45 kW, 68 A 22.0 kW, 49 A

2094-AMP5-S

2094-AM01-S 1.9 kW, 9 A

2094-AM02-S 3.4 kW, 15 A

2094-AM03-S 5.5 kW, 25 A

2094-AM05-S 11.0 kW, 49 A

2094-BMP5-S

2094-BM02-S 6.6 kW, 14.6 A

2094-BM03-S 13.5 kW, 30 A

2094-BM05-S 22.0 kW, 49 A

(1)

Continuous Output Ratings

Converter (ADC) Inverter (A, 0-pk)

1.2 kW, 5 A

N/A

1.8 kW, 4.0 A

N/A

Slot Usage Quantity

Single wide

1 for each power rail

Single wide2094-BC01-M01-S 6 kW, 9 A 3.9 kW, 8.6 A

Double wide

Single wide Up to 7 for each 8-axis power rail

Single wide Up to 7 for each 8-axis power rail2094-BM01-S 3.9 kW, 8.6 A

Double wide Up to 3 for each 8-axis power rail

(1) The -S designator indicates safe-off functionality.

Refer to the Kinetix Servo Drives Technical Data, publication GMC-TD003, for detailed descriptions and additional

specifications for the Kinetix 6000 drive family.

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 3

Page 4

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

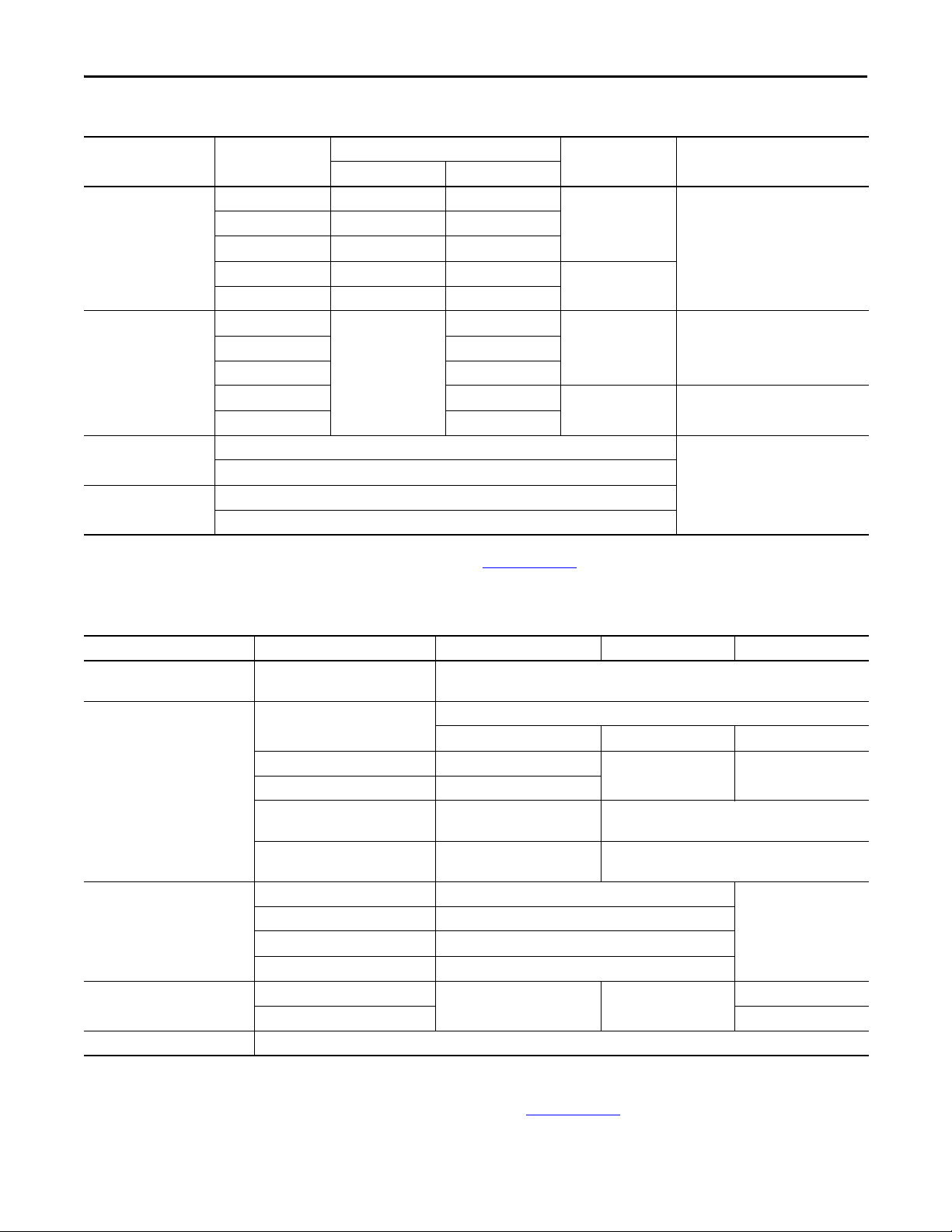

Kinetix 6200 and Kinetix 6500 Drive Modules

Drive Module Drive Cat. No.

2094-BC01-MP5-M 6 kW, 9 A 1.8 kW, 4.0 A

2094-BC01-M01-M 6 kW, 9 A 3.9 kW, 8.6 A

IAM power module

400V-class

AM power module

400V-class

Kinetix 6200 Control

module (sercos)

Kinetix 6500 Control

module (EtherNet/IP)

2094-BC02-M02-M 15 kW, 23 A 6.6 kW, 14.6 A

2094-BC04-M03-M 28 kW, 42 A 13.5 kW, 30 A

2094-BC07-M05-M 45 kW, 68 A 22.0 kW, 49 A

2094-BMP5-M

2094-BM02-M 6.6 kW, 14.6 A

2094-BM03-M 13.5 kW, 30 A

2094-BM05-M 22.0 kW, 49 A

2094-SE02F-M00-S0, Safe torque-off

2094-SE02F-M00-S1, Safe speed monitoring

2094-EN02D-M01-S0, Safe Torque-off

2094-EN02D-M01-S1, Safe speed monitoring

Continuous Output Ratings

Converter (A

N/A

)Inverter (A, 0-pk)

DC

Slot Usage Quantity

Single wide

1 for each power rail

Double wide

1.8 kW, 4.0 A

Single wide Up to 7 for each 8-axis power rail2094-BM01-M 3.9 kW, 8.6 A

Double wide Up to 3 for each 8-axis power rail

1 for each IAM and AM power module

Refer to the Kinetix Servo Drives Technical Data, publication GMC-TD003, for detailed descriptions and additional

specifications for the Kinetix 6200 and Kinetix 6500 drive families.

Required Drive Accessories

Drive Accessory Description Kinetix 6000 Systems Kinetix 6200 Systems Kinetix 6500 Systems

2094 power rail

Low-profile connector kits

(required for flying-lead cables)

Sercos fiber-optic cables

(required as needed)

Ethernet network cables

Motor power and feedback cables Refer to the specific drive/motor combination for the motor cables required for your system.

Backplane and mounting fixture for

Bulletin 2094 drive modules

Motor feedback connections

Auxiliary feedback connections 2090-K6CK-D15F

I/O connections 2090-K6CK-D26M

I/O, safety, and auxiliary feedback

connections

I/O and cascading safe torque-off

connections

Plastic, in-cabinet duty 2090-SCEPx-x

Plastic, on-machine duty 2090-SCNPx-x

Plastic, outdoor and conduit duty 2090-SCVPx-x

Glass, outdoor and conduit duty 2090-SCVGx-x

Double-ended, non-flex, shielded

Double-ended, high-flex, shielded 1585J-M8UBJM-x

2094-PRSx, available for 1, 2, 3, 4, 5, 7, and 8-axis drive systems

2090-K6CK-D15M

2090-K6CK-KENDAT

N/A 2090-K6CK-D44M

N/A 2090-K6CK-D44S0

N/A N/A

(1)

N/A N/A

N/A N/A

N/A

1585J-M8CBJM-x

(1) Applies to only Bulletin RDB direct-drive motors with EnDat encoder.

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these required servo drive accessories.

4 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 5

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

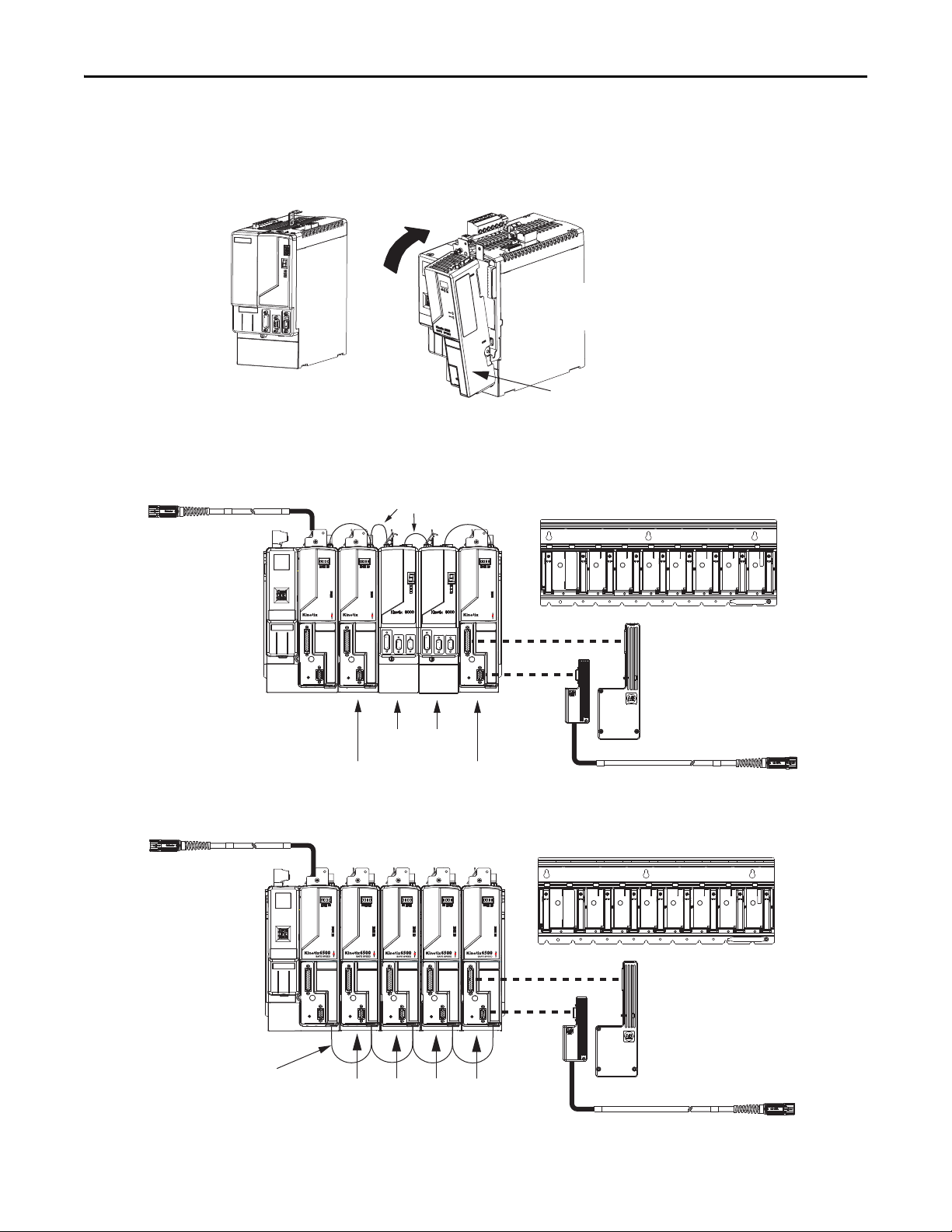

Kinetix 6200 or Kinetix 6500 Control Module

(2094-SE02F-M00-Sx module is shown)

Kinetix 6200 or Kinetix 6500

IAM or AM Power Module

(2094-BC02-M02-M IAM module is shown)

Kinetix 6000 IAM or AM Drive Module

(2094-BC02-M02-S IAM module is shown)

0.2 m

(7.1 in.)

62006200

SAFE SPEED

62006200

SAFE SPEED

62006200

SAFE SPEED

0.2 m

(7.1 in.)

0.1 m

(5.1 in.)

2090-SCxxx-x Sercos Fiber-optic

Drive-to-Drive Cables

2094-BMxx-S

AM Modules

2094-BMxx-M AM Power Modules with

2094-SE02F-M00-Sx Control Modules

2094-BCxx-Mxx-M

IAM Power Module

with

2094-SE02F-M00-Sx

Kinetix 6200 Control Module

2094-PRSx

Power Rail

2094-PRSx

Power Ra il

2094-K6CK-xxxx

Low-profile Connector Kits for

I/O, Safety, and Auxiliary Feedback

Bulletin 2090 Motor Feedback Cables

Bulletin 2090 Motor Power Cables

2094-BMxx-M Axis Modules (5) with

2094-EN02D-M01-Sx Control Modules (5)

2094-BCxx-Mxx-M

IAM Power Module

with

2094-EN02D-M01-Sx

Kinetix 6500 Control Module

1585J-M8CBJM-OM3

0.3 m (1.0 ft) Ethernet cable

for drive-to-drive connections.

2094-PRSx

Power Rail

2094-PRSx

Power Rail

2094-K6CK-xxxx

Low-profile Connector Kits for

I/O, Safety, and Feedback Connections

Bulletin 2090 Motor Feedback Cables

Bulletin 2090 Motor Power Cables

Kinetix 6000 and Kinetix 6200/6500 System Examples

These system examples illustrate how the required drive modules and accessories are used in a typical system.

Drive Module Examples

Kinetix 6000 and Kinetix 6200 Drive System Example (sercos interface)

Kinetix 6500 Drive System Example (EtherNet/IP network)

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 5

Page 6

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Shunt Module

MAIN VAC

Three-p hase

Input Power

115/230V Control Power

2090-XXLF-xxxx

AC Lin e Filter

(required for CE)

2094-xLxxS

Line Interface Module

(optional component)

2094-BSP2

Shunt Module

(optional component)

1394-SRxxxx

External Passive Shunt Module

(optional component)

2094-PRF

Slot Filler Module

(required to fill any

unused slots)

Optional Drive Accessories

Drive Accessory Description Kinetix 6000 Systems Kinetix 6200 Systems Kinetix 6500 Systems

2094 shunt module 200 W continuous shunt power 2094-BSP2

2094 slot-filler module Fills unused slots on the 2094 power rail 2094-PRF

2094 line interface module

Replaces many of the common input power

devices for your drive system

2090 AC line filters AC line conditioning for EMC 2090-XXLF-xxxx

1394 external passive shunt modules

Safety headers

Safety interface cables

(1)

(1)

Shunt capacity in addition to the 2094-BSP2

shunt module

Cascading safe-off connections from driveto-drive

Panel space-saving brackets that let you

2094 mounting brackets

mount the line filter behind the LIM module

or power rail

External auxiliary encoders

Connector sets

Resistive brake module (RBM)

Allen-Bradley® sine/cosine and incremental

external encoders

Replacement connectors for input power,

control power, motor power, and others

Physically and electrically separate the drive

power output from its corresponding motor

RBM interface cables Motor power, RBM to drive

8720MC regenerative power supply (RPS)

8720MC line reactors 8720MC-LRxx-xxxx

Power components required in regenerative

applications

2094-ALxxS, 2094-AL09,

2094-BLxxS, 2094-BL02,

2094-BLxxS, 2094-BL02, 2094-XL75S-Cx

2094-XL75S-Cx

1394-SRxxx

2090-XNSM-x N/A

1202-Cxx 2090-CS0DSDS-AAxx

2094-XNBRKT-1

Bulletin 842A, 844D, 845H, and 845T

2094-xxxCON, 2094-xxxINV, and 2094-XNSHT

2090-XBxxx-xx

2090-XXNRB-10F0P5

2090-XXNRB-8F0P6

8720MC-RPSxxx

(1) For drive system examples of safe-off headers and cables, refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004.

Kinetix 6000 and Kinetix 6200/6500 Power Accessories Example

Motor-end cable connector kits, for use when building your own cables, and panel-mounted breakout components are also

available. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

specifications of optional servo drive accessories.

For Kinetix 6000 and Kinetix 6200/6500 (rotary motion) system combinations, refer to page 17

combinations, refer to page 86

.

, for detailed descriptions and

. For linear motion system

6 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 7

2090-Series Motor/Actuator Cables Overview

IMPORTANT

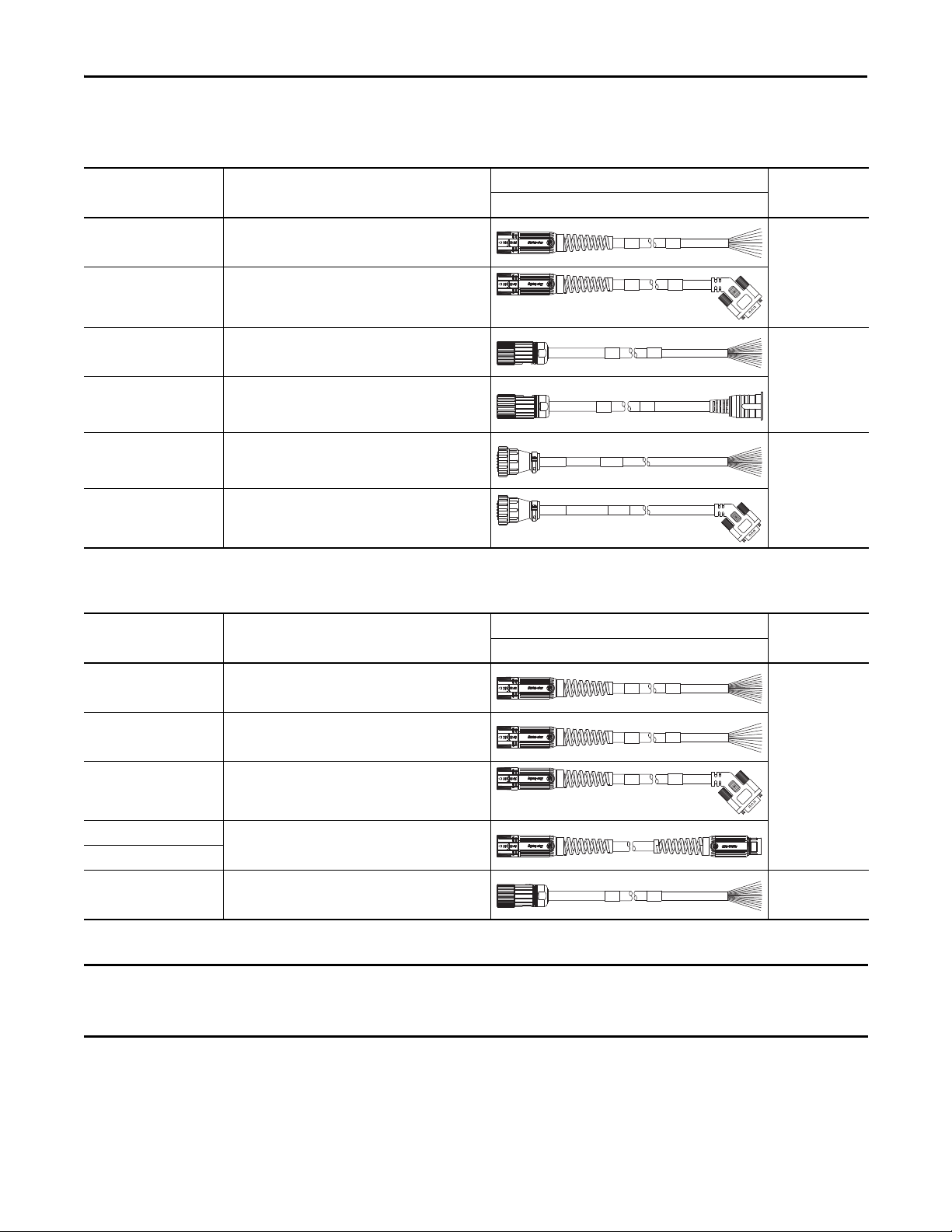

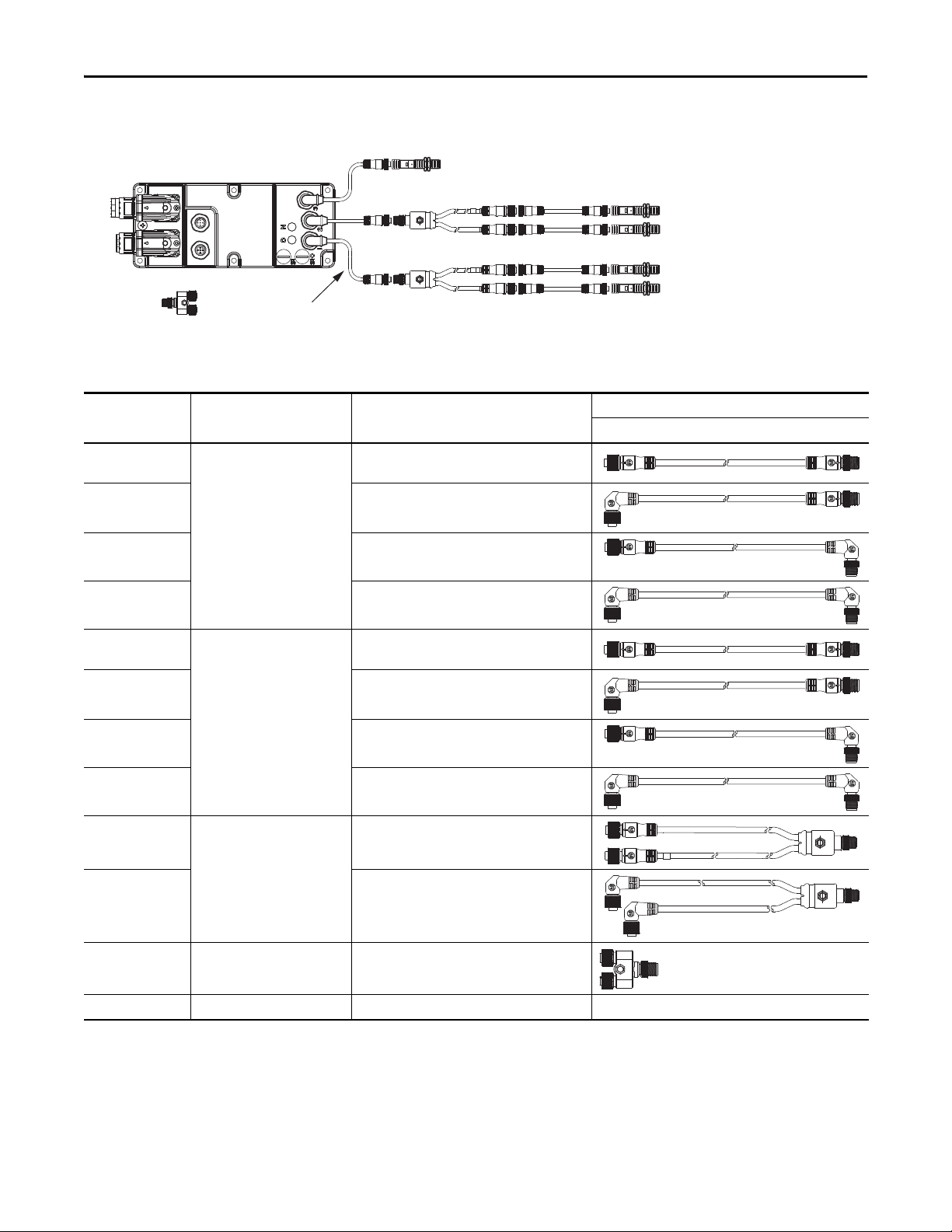

Feedback Cable Descriptions (standard, non-flex)

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Standard Cable

Cat. No.

2090-CFBM7DF-CEAAxx

2090-CFBM7DD-CEAAxx

2090-XXNFMF-Sxx

2090-CFBM4E2-CATR

2090-CFBM6DF-CBAAxx

2090-CFBM6DD-CCAAxx

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Description

• Drive-end flying-leads (DF)

• High-resolution or resolver applications (CE)

• Drive-end 15-pin connector (DD)

• High-resolution or resolver applications (CE)

• Drive-end flying-leads

• High-resolution or incremental applications

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• All feedback types (CA)

• Drive-end flying-leads (DF)

• High-resolution, battery backup or

Incremental applications (CB)

• Drive-end 15-pin connector (DD)

• Incremental applications only (CC)

Feedback Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

Description

Cable Configuration

Motor/Actuator End Drive End

(1)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Threaded DIN

(M4)

Circular Plastic

(M6)

Motor/Actuator

Connector

2090-CFBM7DF-CDAFxx

2090-CFBM7DF-CEAFxx

2090-CFBM7DD-CEAFxx

2090-CFBM7E7-CDAFxx

2090-CFBM7E7-CEAFxx

2090-CFBM4DF-CDAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

• Drive-end flying-leads (DF)

• High-resolution or incremental applications (CD)

• Drive-end flying-leads (DF)

• High-resolution or resolver applications (CE)

• Drive-end 15-pin connector (DD)

• High-resolution or resolver applications (CE)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

• Drive-end flying-leads

• High-resolution or incremental applications

(1)

Feedback cables with the CE designation, for example 2090-CFBM7DF-CEAAxx, are intended for high-resolution encoder or

resolver applications and have fewer conductors than feedback cables with the CD designation, for example

2090-CFBM7DF-CDAFxx, which are intended for high-resolution or incremental encoder applications.

SpeedTec DIN

(M7)

Threaded DIN

(M4)

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 7

Page 8

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

BR+

BR-

BR+

BR-

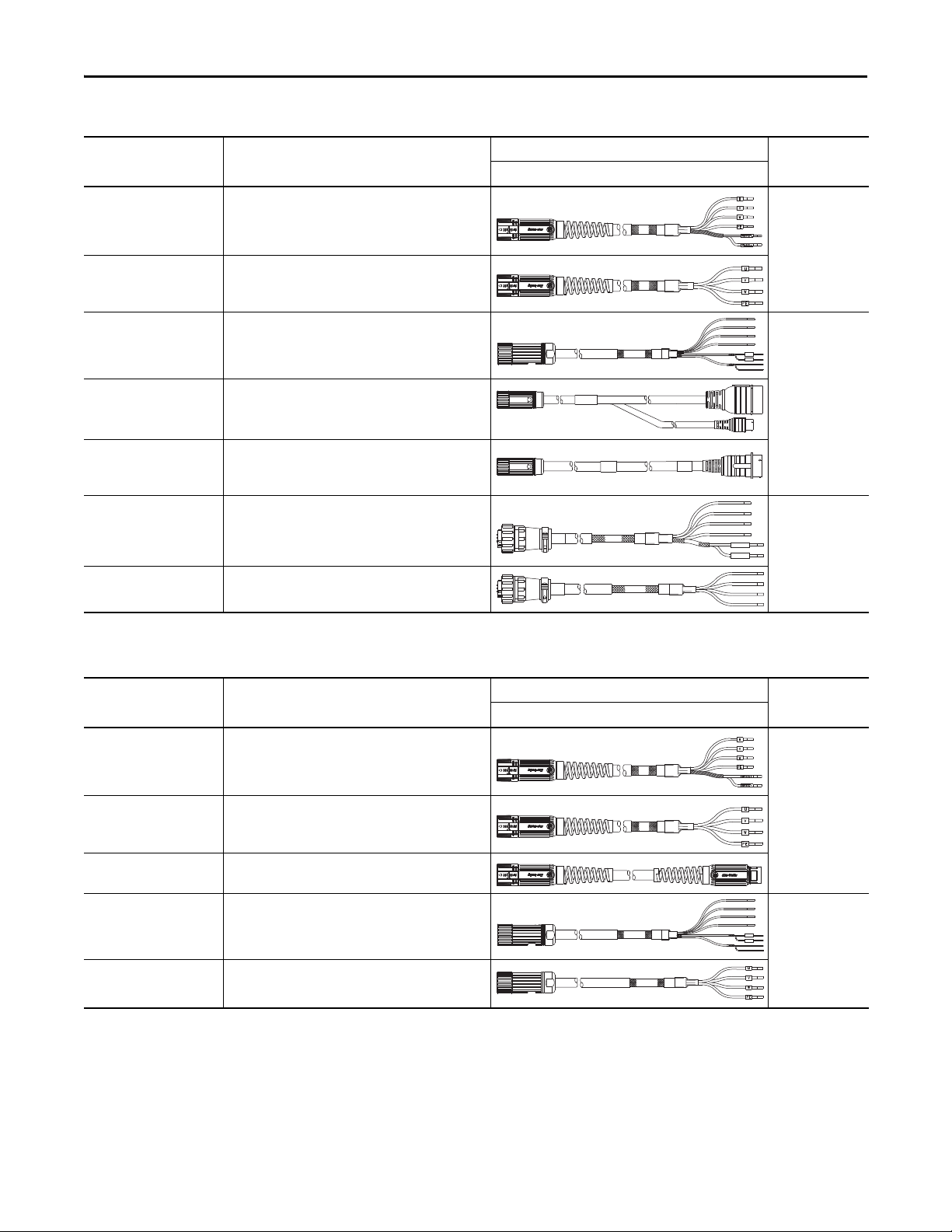

Power/Brake Cable Descriptions (standard, non-flex)

Standard Cable

Cat. No.

2090-CPBM7DF-xxAAxx

2090-CPWM7DF-xxAAxx

2090-XXNPMF-xxSxx

2090-CPBM4E2-xxTR

2090-CPWM4E2-xxTR

2090-CPBM6DF-16AAxx

2090-CPWM6DF-16AAxx

Description

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (P W)

• Drive-end flying-leads

• Power /brake wires

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• Power /brake wires (PB)

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• Power wire s only (P W)

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (P W)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

(1)

Threaded DIN

(M4)

(1)

MBRK+

Circular Plastic

MBRK-

(M6)

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Power/Brake Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

2090-CPBM7DF-xxAFxx

2090-CPWM7DF-xxAFxx

2090-CPBM7E7-xxAFxx

2090-CPBM4DF-xxAFxx

2090-CPWM4DF-xxAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

Description

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (P W)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

• Drive-end flying-leads (DF)

• Power /brake wires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (P W)

(1)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Threaded DIN

(M4)

8 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 9

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

IMPORTANT

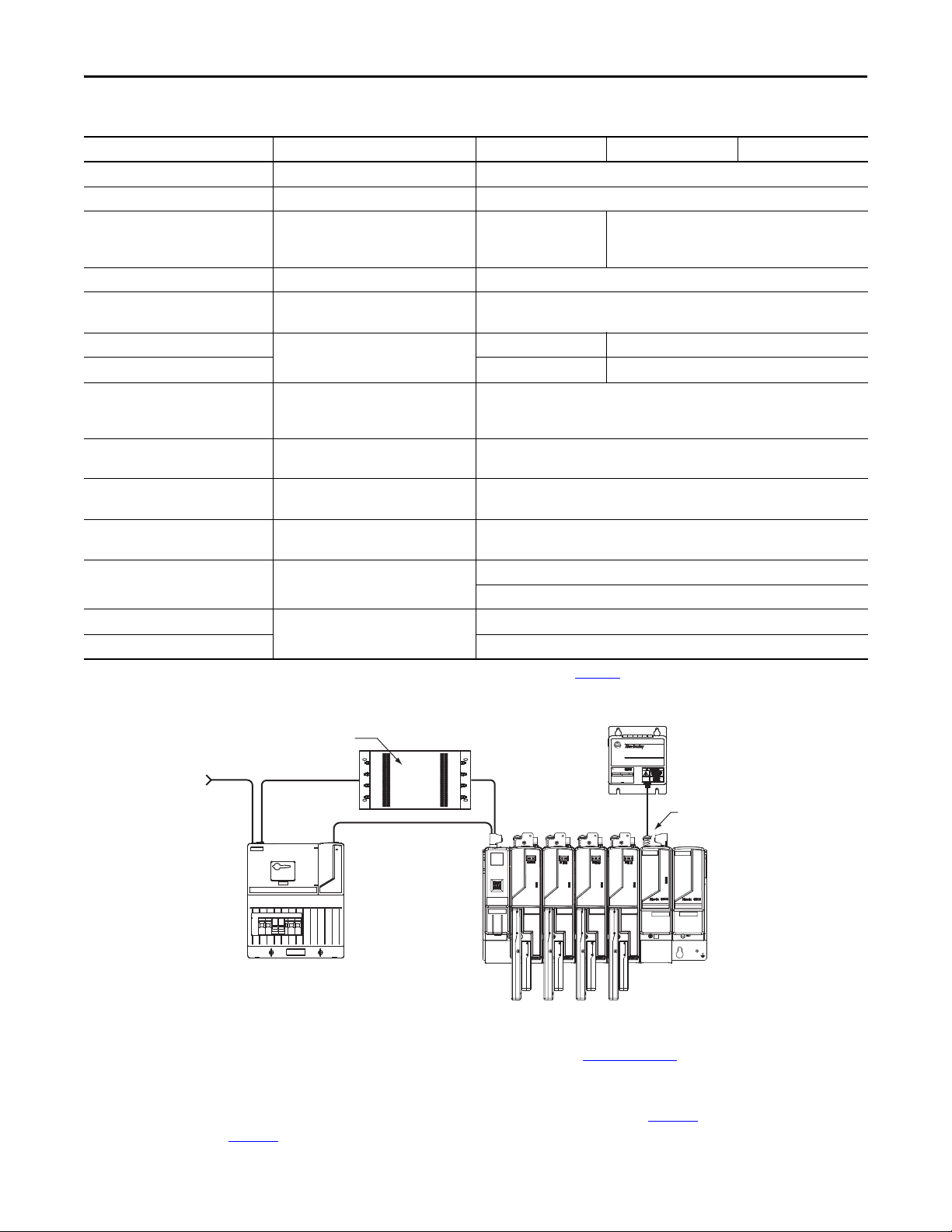

2090-CHBP8S8-12AAxx Hybrid Cable

(IDM unit-to-unit)

MDF-SBxxxxx-Qx8xB-S

IDM Units

2090-CNSxPxS-AAxx

Network Cables

2090-CNSSPxS-AAxx

Network Cable

2090-CHBIFS8-12AAxx Hybrid Cable

(IPIM module to first IDM unit)

2090-CTSRP Network Terminator

(last IDM unit only)

2090-CTHP8 Hybrid Terminator

(last IDM unit only)

2094-SEPM-B24-S

IPIM Module

Kinetix 6000 or Kinetix 6200

(400V-class) Servo Drive System

(Kinetix 6000 system is shown)

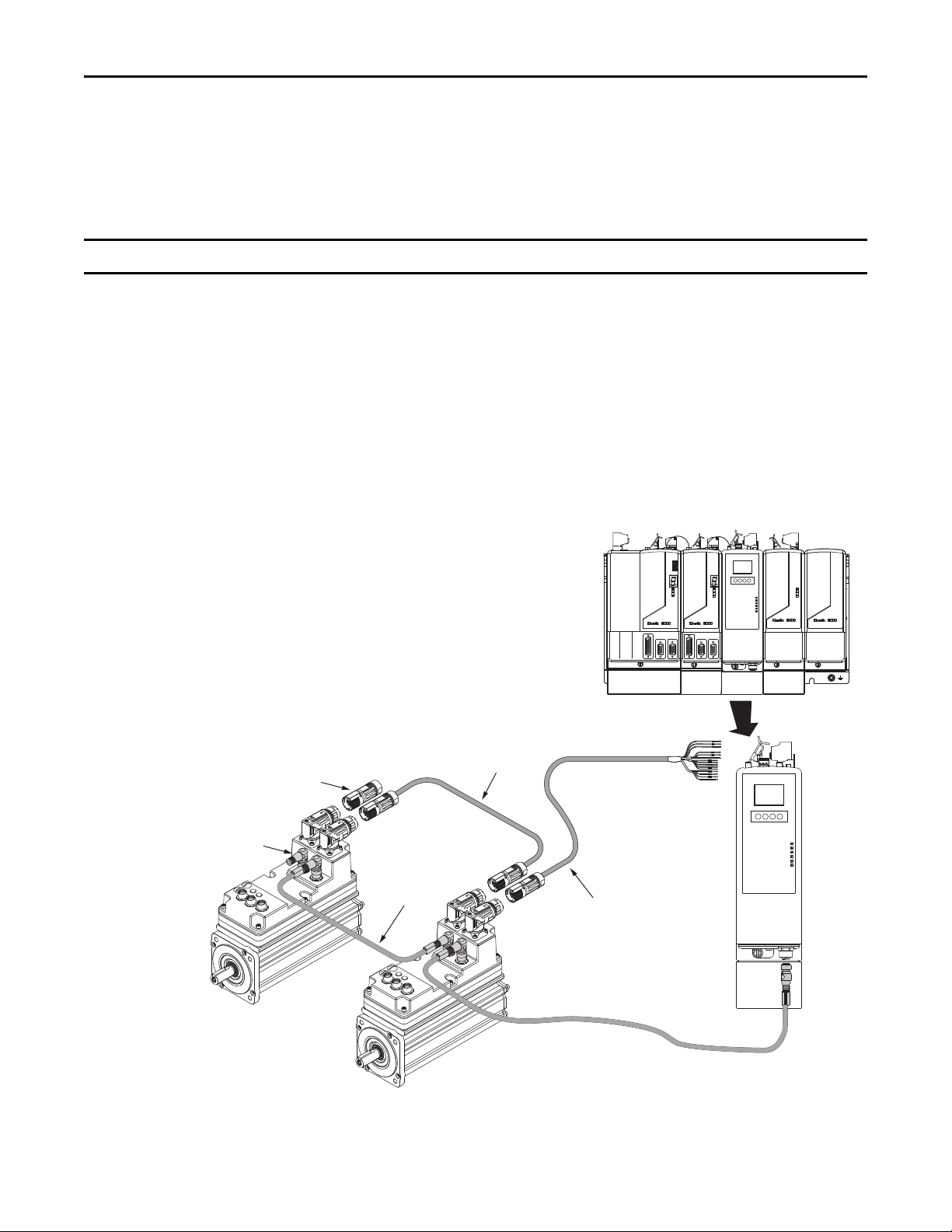

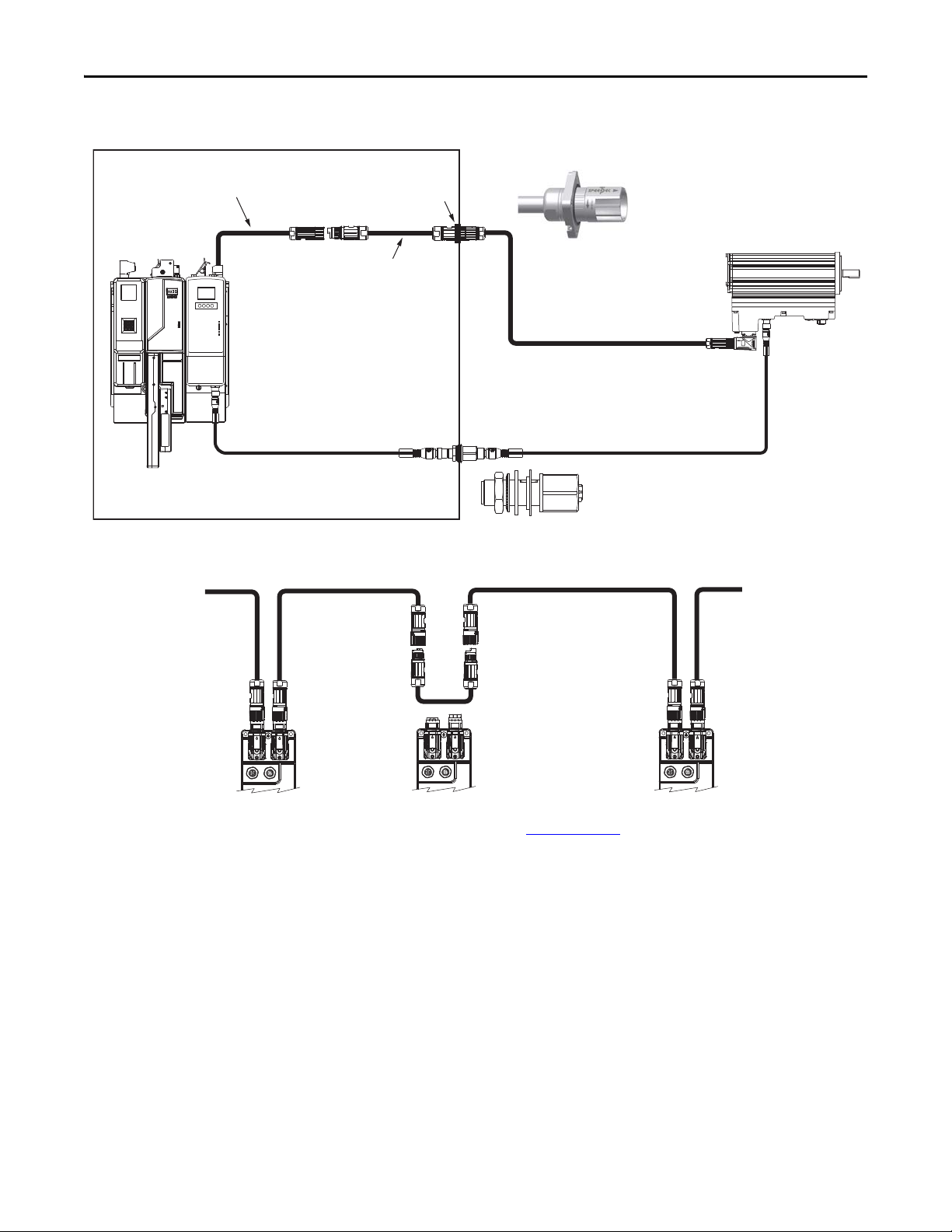

Kinetix 6000M Integrated Drive-Motor Systems

For each Kinetix 6000M integrated drive-motor system, you need to know the integrated drive-motor (IDM) unit and

IDM power interface module (IPIM) catalog numbers. The IPIM module is compatible with the Bulletin 2094 power rail

in any configuration with Kinetix 6000 or Kinetix 6200 (400V-class) drive systems.

Kinetix 6000 drives must be series B or series C.

You also need hybrid cables, network cables, and terminators. Optional equipment includes digital input cables, the hybrid

coupler cable, bulkhead adapter kits, the holding brake manual release cable, and Bulletin 2090 safe-off headers and

1202-Cxx safety cables.

Kinetix 6000M Integrated Drive-Motor System Example

This configuration illustrates the components needed to add Kinetix 6000M IDM units to a 400V-class Kinetix 6000 or

Kinetix 6200 multi-axis servo drive system. The IDM power interface module (IPIM) is mounted to the Bulletin 2094

power rail and connects to the sercos fiber-optic ring. The IDM units are wired to the IPIM module.

Typical Kinetix 6000M Integrated Drive-Motor System

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 9

Page 10

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Determine What You Need

These tables list the system components and accessory items available for the Kinetix 6000M IDM drive systems.

Kinetix 6000M Integrated Drive-Motor (IDM) Units

Cat. No. Speed Continuous Torque Peak Torque Features Quantity

MDF-SB1003P 5000 rpm 3.0 N•m (26.5 lb•in) 10.5 N•m (92.9 lb•in)

MDF-SB1153H 3500 rpm 4.8 N•m (42.5 lb•in) 18.5 N•m (164 lb•in)

MDF-SB1304F 3000 rpm 7.25 N•m (64.2 lb•in) 21.75 N•m (192 lb•in)

(1) Use Motion Analyzer software, version 6.00 or later, to determine the maximum number of IDM units to daisy-chain on each IPIM module.

Kinetix 6000M IDM Power Interface Module (IPIM)

Cat. No. Output Bus Voltage Continuous Output Peak Output Slot Usage Quantity

2094-SEPM-B24-S 650V DC 15 kW, 24 A, rms 60 A 1 Up to 4 on each power rail

(1) Use Motion Analyzer software, version 6.00 or later, to determine the maximum number of IPIM modules on a single power rail.

Refer to the Kinetix Rotary Motion Technical Data, publication GMC-TD001, for detailed descriptions and additional

specifications for the Kinetix 6000M integrated drive-motor (IDM) units and IPIM module.

• USDA compliant

food-grade paint

• 400V-class

• Safe-off

Up to 16 on each IPIM module

(1)

(1)

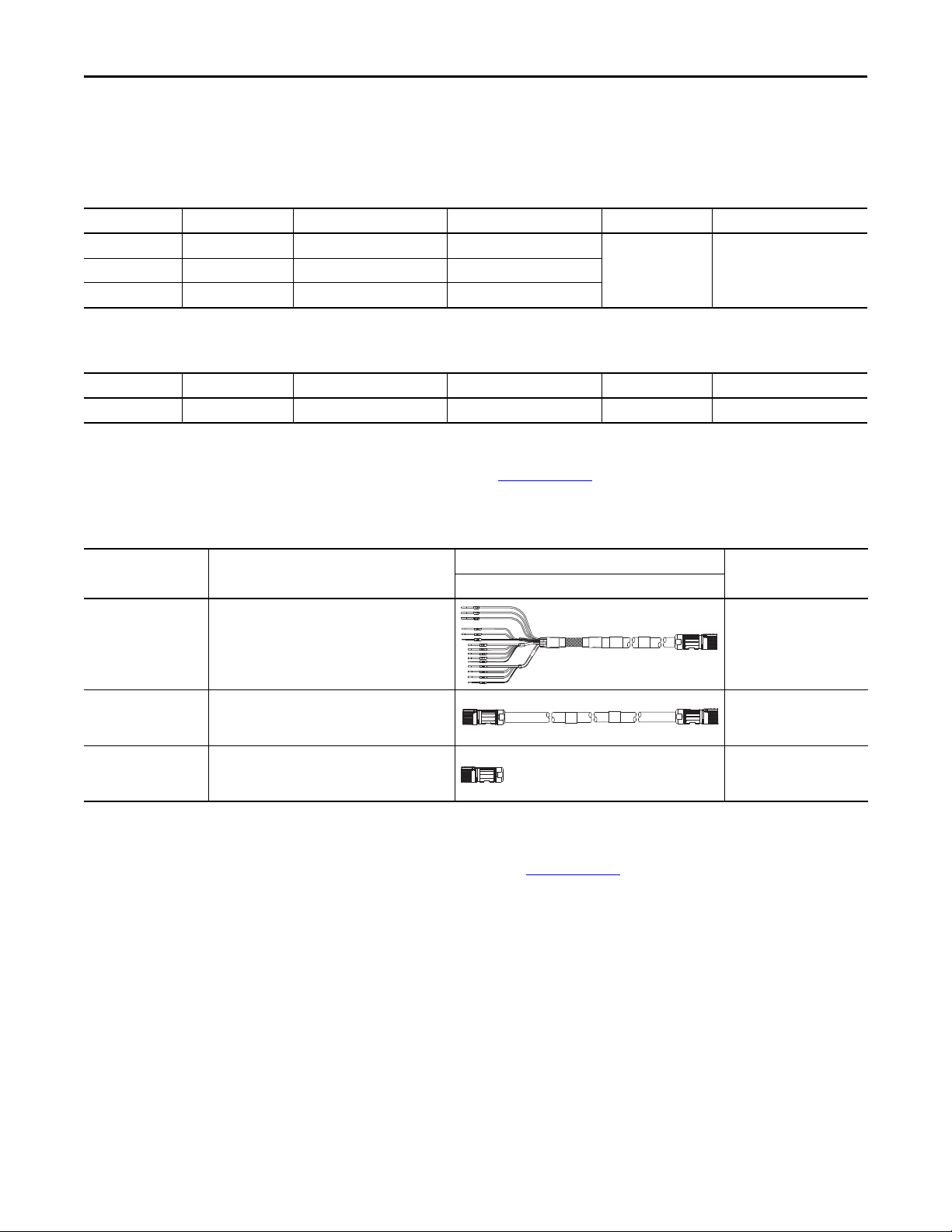

Required Hybrid Cables

Cat. No. Description

From IPIM module (flying-leads) to the first IDM unit

(1)

2090-CHBIFS8-12AAxx

2090-CHBP8S8-12AAxx

2090-CTHP8

(1) Cables are available in standard lengths of 1, 2, 3, 4, 5, 7, 9, 12, 15, 20, and 25 m (3.2, 6.6, 9.8, 13.1, 16.4, 22.9, 29.5, 39.3, 49.2, 65.5, and 82.0 ft).

(2) Cables are available in standard lengths of 0.5, 1, 2, 3, 4, 5, 7, 9, 12, 15, 20, and 25 m (1.6, 3.2, 6.6, 9.8, 13.1, 16.4, 22.9, 29.5, 39.3, 49.2, 65.5, and 82.0 ft).

• IPIM-end flying-leads (IF)

• SpeedTec connector, socket (S8)

IDM unit-to-unit connections

(2)

• SpeedTec connector, pin (P8)

• SpeedTec connector, socket (S8)

Hybrid (SpeedTec) terminator

• Required on last IDM unit, pin (P8)

• Included with each IPIM module

Flying-lead/Pin Socket

Cable Configuration

Quantity

1 required per system (IPIM

module to first IDM unit)

1 required for the second IDM

unit and each additional

downstream IDM unit

1 required per system

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these required accessories.

10 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 11

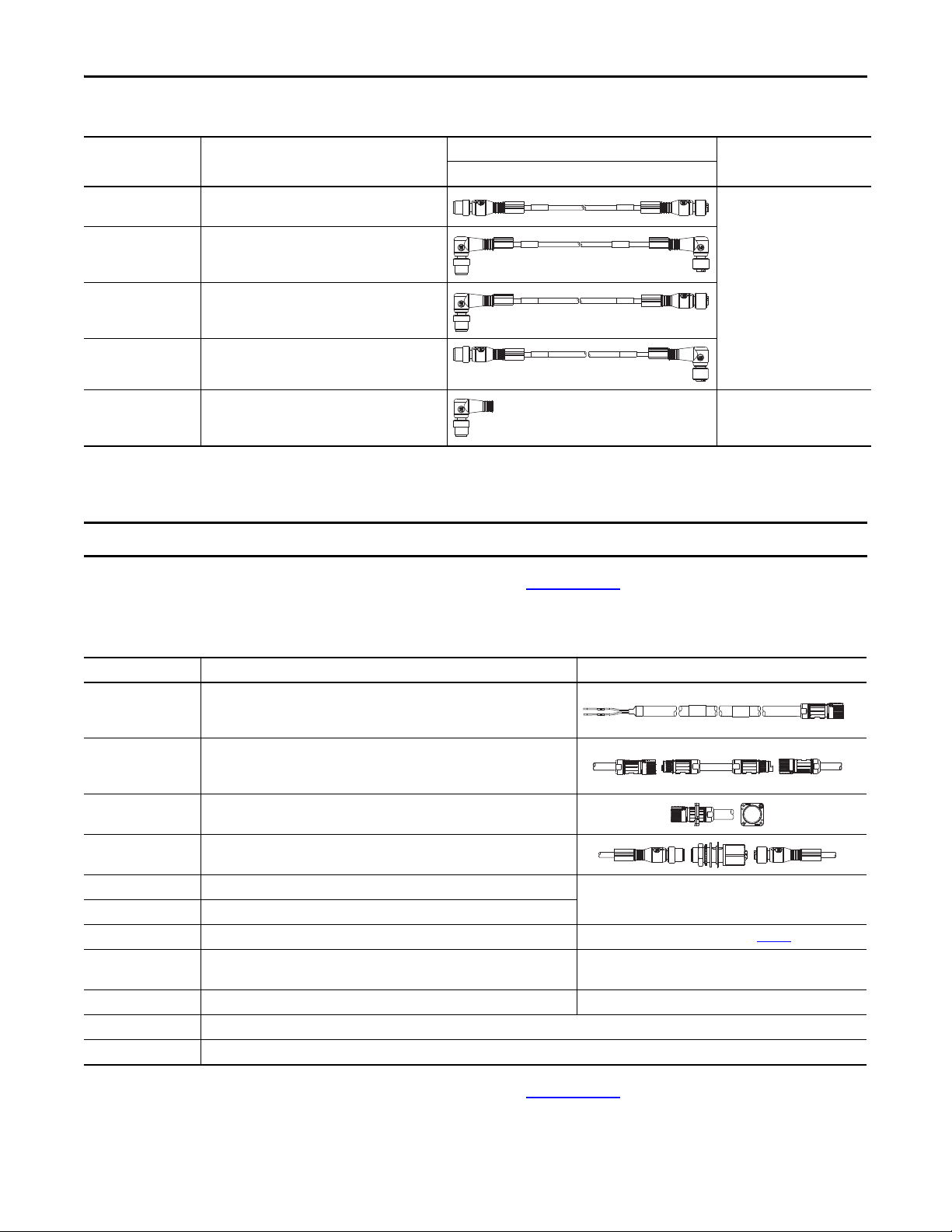

Required Network Cables

IMPORTANT

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Cat. No. Description

Cable Configuration

Quantity

Pin Socket

• Straight connector, pin (SP)

2090-CNSSPSS-AAxx

2090-CNSRPRS-AAxx

2090-CNSRPSS-AAxx

2090-CNSSPRS-AAxx

(1)

• Straight connector, socket (SS)

• Right-angle connector, pin (RP)

(1)

• Right-angle connector, socket (RS)

• Not compatible for connection to the IPIM module

• Right-angle connector, pin (RP)

(1)

• Straight connector, socket (SS)

• Not compatible for connection to the IPIM module

• Straight connector, pin (SP)

(1)

• Right-angle connector, socket (RS)

1 required per system (IPIM

module to first IDM unit)

Plus, 1 required for the second

IDM unit and each additional

downstream IDM unit

Network terminator

2090-CTSRP

• Required on last IDM unit, right-angle, pin (RP)

1 required per system

• Included with each IPIM module

(1) Cables are available in standard lengths of 0.5, 1, 2, 3, 4, 5, 7, 9, 12, 15, 20, and 25 m (1.6, 3.2, 6.6, 9.8, 13.1, 16.4, 22.9, 29.5, 39.3, 49.2, 65.5, and 82.0 ft).

(2) This cable must be either 2090-CNSSPSS-AAxx or 2090-CNSSPRS-AA xx. Only straight, pin (SP) connectors fit properly at the IPIM module.

(3) Use of straight or right-angle connectors depends on application.

Right-angle (pin) connectors are not compatible for connection to the IPIM module. Only straight (pin) connectors fit properly.

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these required accessories.

(2)

(3)

Optional Accessories

Cat. No. Accessory Item Description

Manual brake release cable

2090-CBKS8-16AA03

2090-CCPP8S8

2090-KPB47-12CF

2090-CBUSPSS

2090-XNSM-x Safe-off headers

1202-Cxx Safety cables

Bulletin 889D and 879D DC micro-style patchcords, V-cables, and splitters for digital input connections Refer to Digital Input Cable Examples on page 12

2094-XNIPIM-1 Connector set

2094-SEPM-FUSE Replacement fuses for the IPIM module, 6 each Bussmann part number FWP-50A14Fa

MDF-SB-NODECVR Replacement covers for the node address switches on the IDM units

1485A-M12 Replacement covers for the digital input connectors on the IDM units

• Brake release wires (BK)

• SpeedTec connector, socket (S8)

Hybrid coupler cable connects between two hybrid cables to bypass an IDM unit

• SpeedTec connector, pin (P8)

• SpeedTec connector, socket (S8)

• The hybrid bulkhead adapter secures cables as they pass through the cabinet

• Mating cable attaches on the other side

• The network cable bulkhead adapter feeds signals through the cabinet wall

• Network cables attach on either side

Cascading safe-off connections from drive-to- drive (applies to

Kinetix 6000 drive systems)

Includes hybrid power (DC bus), hybrid communication, safe-off,

and enable input replacement connectors for the IPIM module

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these optional accessories.

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 11

Page 12

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

889D-x4ACDx-x

Patch cords

Input Assignments:

1 = Overtravel- (NC)

2 = Overtravel+ (NC)

3 = Home (NO)

Digital Inputs

(1, 2, 3)

Input Assignments:

1 = Registration 2 (NO)

2 = Registration 1 (NO)

MDF-SBxxxxx

IDM Units

Sensors

1 2 3

1 2

Digital Input Cable Examples

Kinetix 6000M IDM units have three 5-pin, M12, digital input connectors. Allen-Bradley (Bulletin 889D and 879D)

DC micro-style patchcords, splitters, and V-cables are available with straight and right-angle connectors for making

connections from the IDM unit to input sensors.

For the most popular patchcord specifications, refer to the Connection Systems Quick Selection Guide, publication

CNSYS-BR001

Digital Inputs Used for Home and Overtravel Functions

. For complete information, refer to On-Machine™ Connectivity, publication M117-CA001.

Digital Input Accessories Items

Cat. No. Item Type Description

889D-F4ACDM-x

889D-R4ACDM-x

Digital input patchcords

889D-F4ACDE-x

889D-R4ACDE-x

871TS-N12BP18-D4 Sensor (example) Proximity N/A

(1) Patchcords are available in standard lengths of 2, 5, and 10 m (6.6, 16.4, and 32.8 ft).

12 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

(IDM unit to NC and NO sensors)

(1)

• Straight connector, socket (F)

• Straight connector, pin (M)

• Right-angle connector, socket (R)

• Straight connector, pin (M)

• Straight connector, socket (F)

• Right-angle connector, pin (E)

• Right-angle connector, socket (R)

• Right-angle connector, pin (E)

Socket Pin (IDM unit)

Cable Configuration

Page 13

Digital Inputs Used for Home, Overtravel, and Registration Functions

879D-F4DM

Splitter

Digital Inputs

(1, 2, 3)

Input Assignments:

2A = Registration 1 (NO)

2B = Overtravel+ (NC)

1A = Overtravel- (NC)

1B = Registration 2 (NO)

MDF-SBxxxxx IDM Unit

889D-x4ACDx-x

Patch cords

Sensors

889D-x4ACDx-x (NO) or

889D-x4ACDx-Vx (NC)

Patch cords

879D-x4ACDM-x

V-ca ble

Input Assignment:

3 = Home (NO)

Digital Input Accessories Items

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Cat. No. Item Type Description

889D-F4ACDM-x

889D-R4ACDM-x

Digital input patchcords

(1)

• Straight connector, socket (F)

• Straight connector, pin (M)

• Right-angle connector, socket (R)

• Straight connector, pin (M)

• IDM unit to NC and NO sensors

889D-F4ACDE-x

889D-R4ACDE-x

889D-F4ACDM-Vx

889D-R4ACDM-Vx

889D-F4ACDE-Vx

889D-R4ACDE-Vx

879D-F4ACDM-x

879D-R4ACDM-x

• IDM unit to V-cable

• V-ca ble to NO se nsors

Digital input patchcords

(V-cable to NC sensor)

(2)

V-ca bles

(1)

• Straight connector, socket (F)

• Right-angle connector, pin (E)

• Right-angle connector, socket (R)

• Right-angle connector, pin (E)

• Straight connector, socket (F)

• Straight connector, pin (M)

• Right-angle connector, socket (R)

• Straight connector, pin (M)

• Straight connector, socket (F)

• Right-angle connector, pin (E)

• Right-angle connector, socket (R)

• Right-angle connector, pin (E)

• Straight connectors, socket (F)

• Straight connector, pin (M)

• Right-angle connectors, socket (R)

• Straight connector, pin (M)

Cable Configuration

Socket Pin (IDM unit)

879D-F4DM Splitter

(3)

• Straight connectors, socket (F)

• Straight connector, pin (M)

871TS-N12BP18-D4 Sensor (example) Proximity N/A

(1) Patchcords are available in standard lengths of 2, 5, and 10 m (6.6, 16.4, and 32.8 ft).

(2) V-cables are available in standard lengths of 0.3, 1, 2, and 5 m (1.0, 3.2, 6.6, and 16.4 ft).

(3) Splitter can be used in place of the V-cable.

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 13

Page 14

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

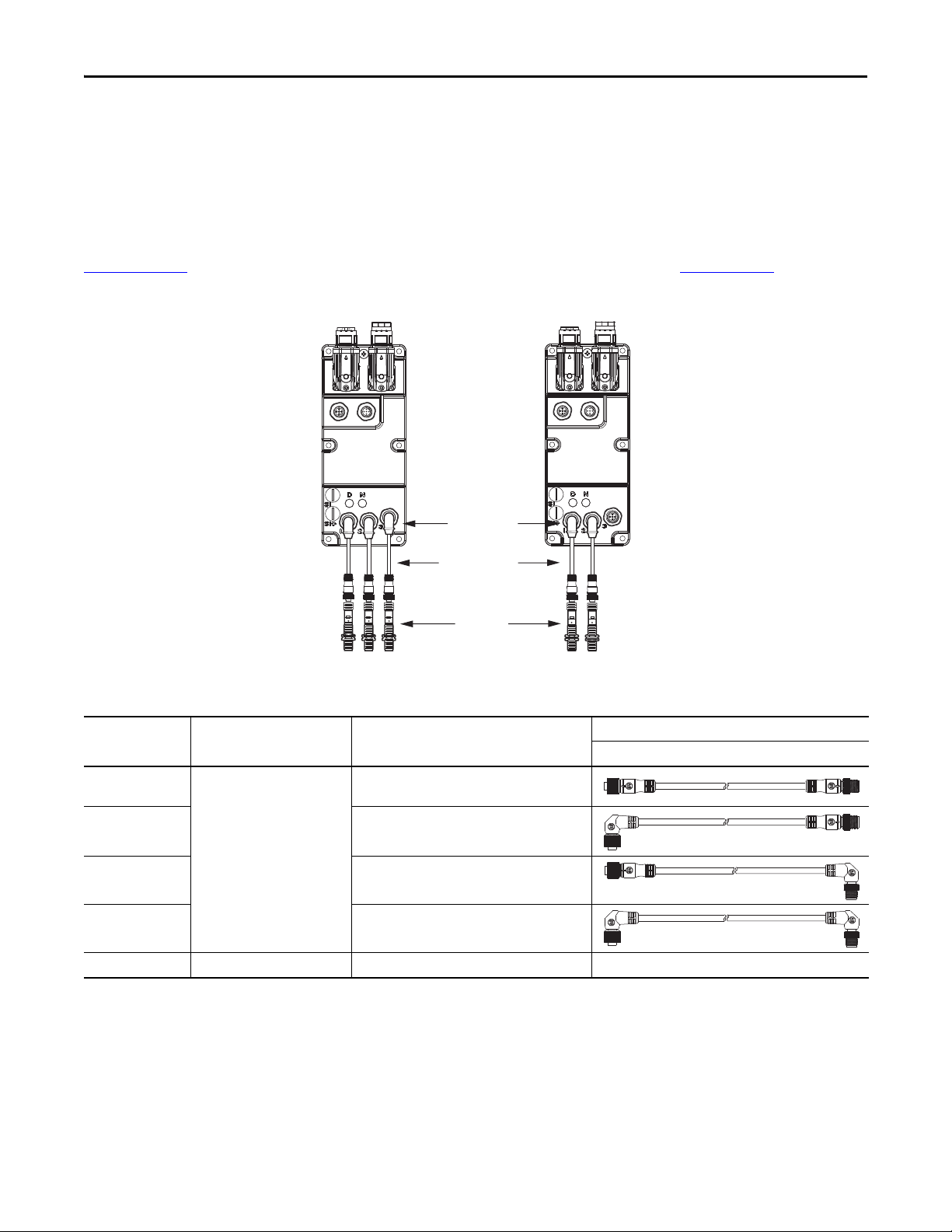

2090-CHBIFS8-12AAxx

Hybrid Cable

2090-CNSSPSS-AAxx

Network Cable

2090-KPB47-12CF

Hybrid Cable Bulkhead Adapter

2090-CNSSPSS-AAxx

Network Cable

2090-CBUSPSS

Network Cable Bulkhead Adapter

2094 Servo Drive System

(Kinetix 6200 drive system is shown)

2094-SEPM-B24-S

IPIM Module

Enclosure

2090-CHBP8S8-12AAxx

Hybrid Cable

MDF-SBxxxxx IDM Unit

Mounted on the Machine

2090-CCPP8S8

Hybrid Coupler Cable

2090-CCPP8S8 Hybrid Coupler Cable

(IDM unit bypass)

IDM Unit 3

IDM Unit 2

(removed for servicing)

IDM Unit 1

2090-CHBP8S8-12AAxx

Hybrid Cable

2090-CHBP8S8-12AAxx

Hybrid Cable

Bulkhead Adapter Examples

Hybrid Coupler Cable Example

Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004, for detailed descriptions and

specifications of these optional accessories.

14 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 15

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

IMPORTANT

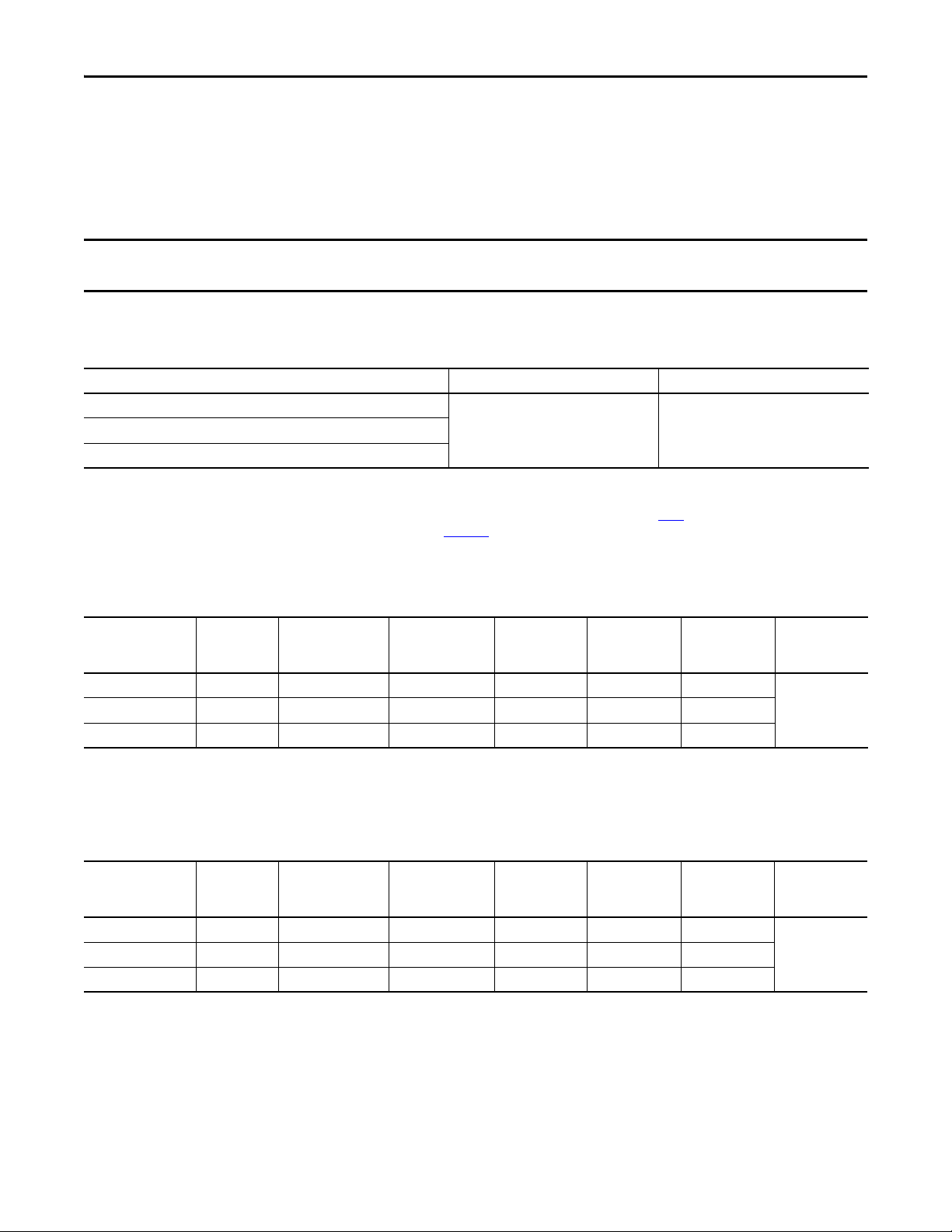

Kinetix 6000M Integrated Drive-Motor System Performance

This section provides system performance information for the Bulletin MDF integrated drive-motor units. Included are

hybrid power and network cable catalog numbers, system performance specifications, and the optimum torque/speed

curves.

The Kinetix 6000M integrated drive-motor systems are compatible with Kinetix 6000 and Kinetix 6200 (400V-class) power rail

configurations. Kinetix 6000 drives must be series B or series C.

Kinetix 6000M (Bulletin MDF) Integrated Drive-Motor Cable Combinations

Motor Cat. No. (400V-class) Hybrid Cables

MDF-SB1003P

2090-CHBIFS8-12AAxx and

2090-CHBP8S8-12AAxx

MDF-SB1304F

(1) Hybrid terminator (catalog number 2090-CTHP8) is included with the IPIM module.

(2) Network terminator (catalog number 2090-CTSRP) is included with the IPIM module.

For cable configuration illustrations and feature descriptions, by catalog number, refer to the Kinetix 6000M Integrated Drive-Motor System Example on page 9.

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

(1)

, for standard cable lengths.

Network Cables

2090-CNSxPxS-AAxxMDF-SB1153H

(2)

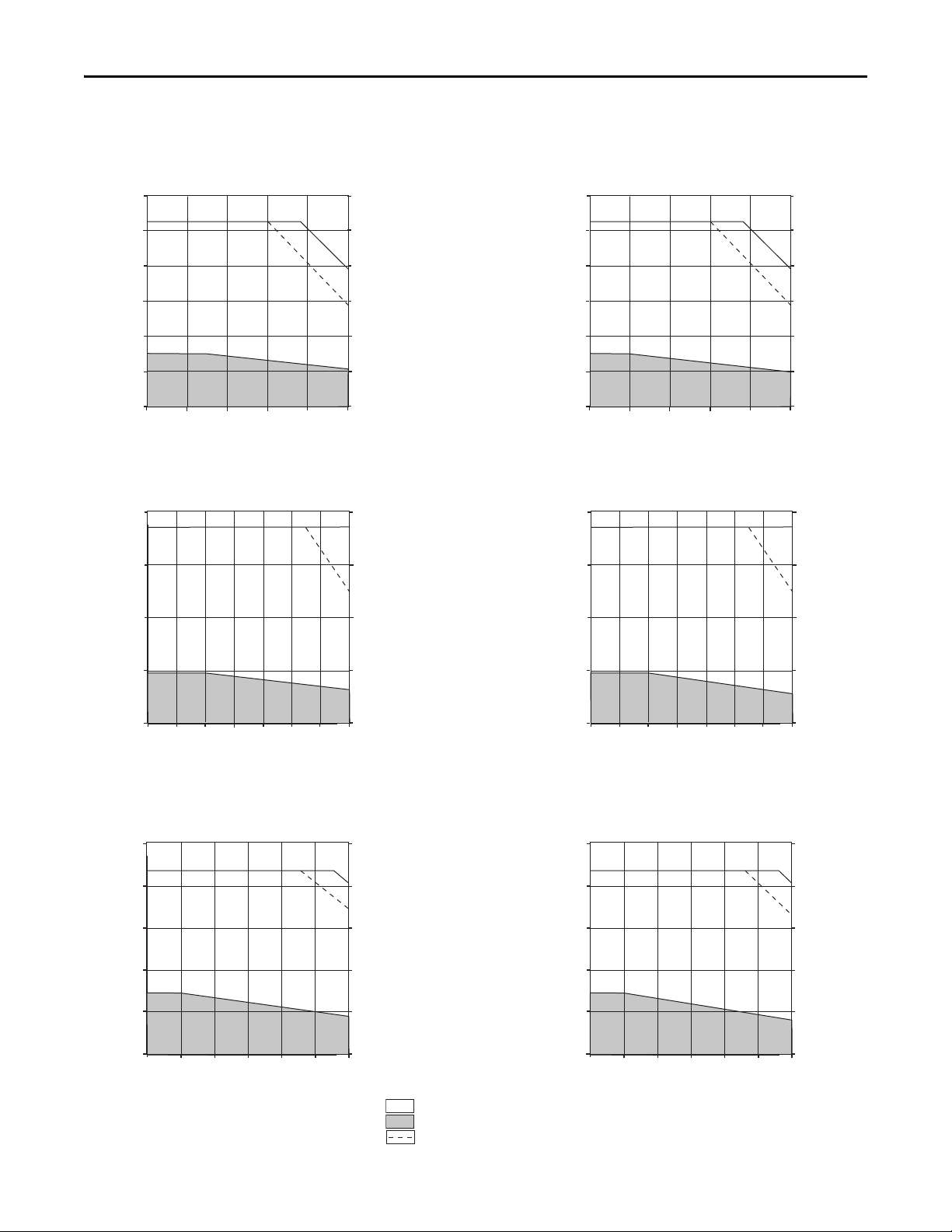

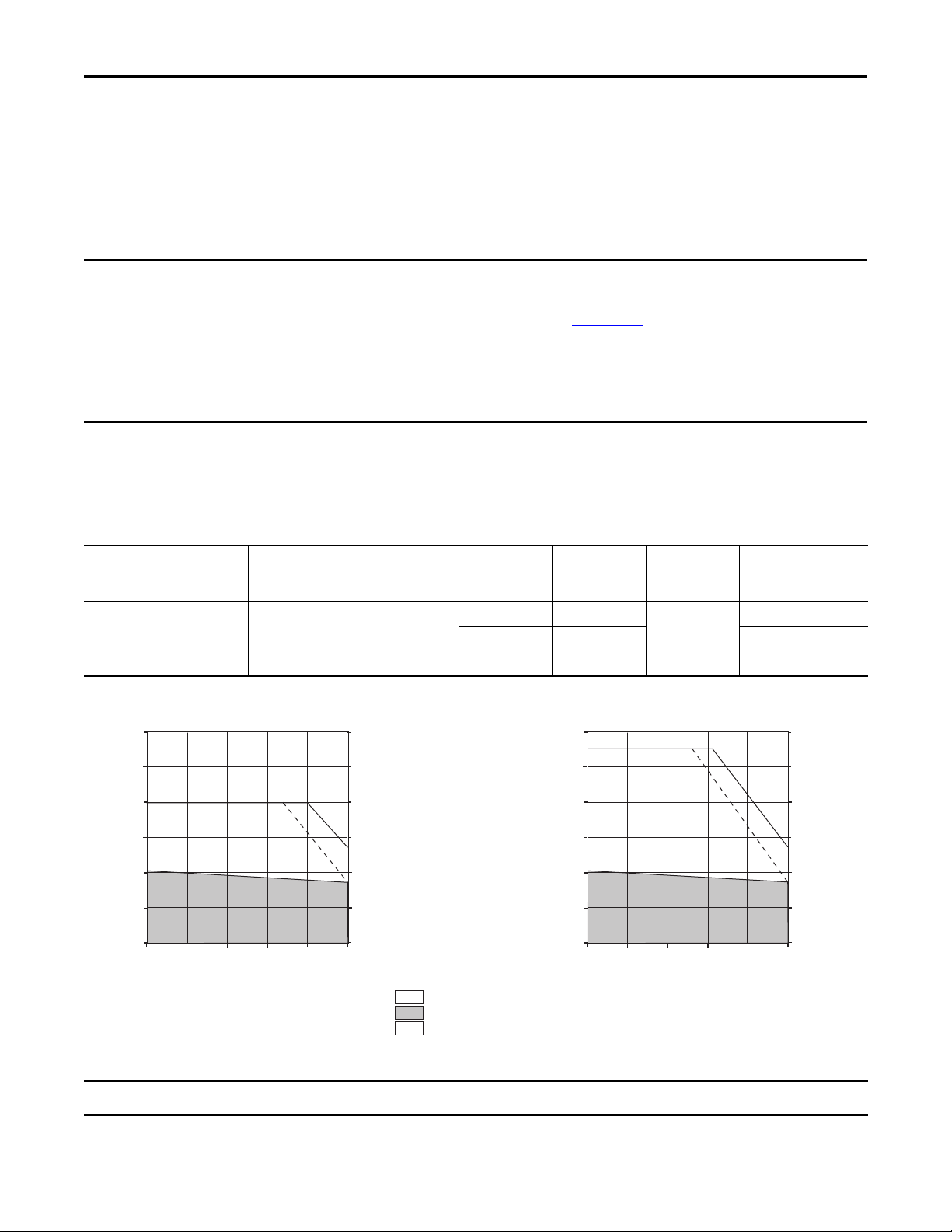

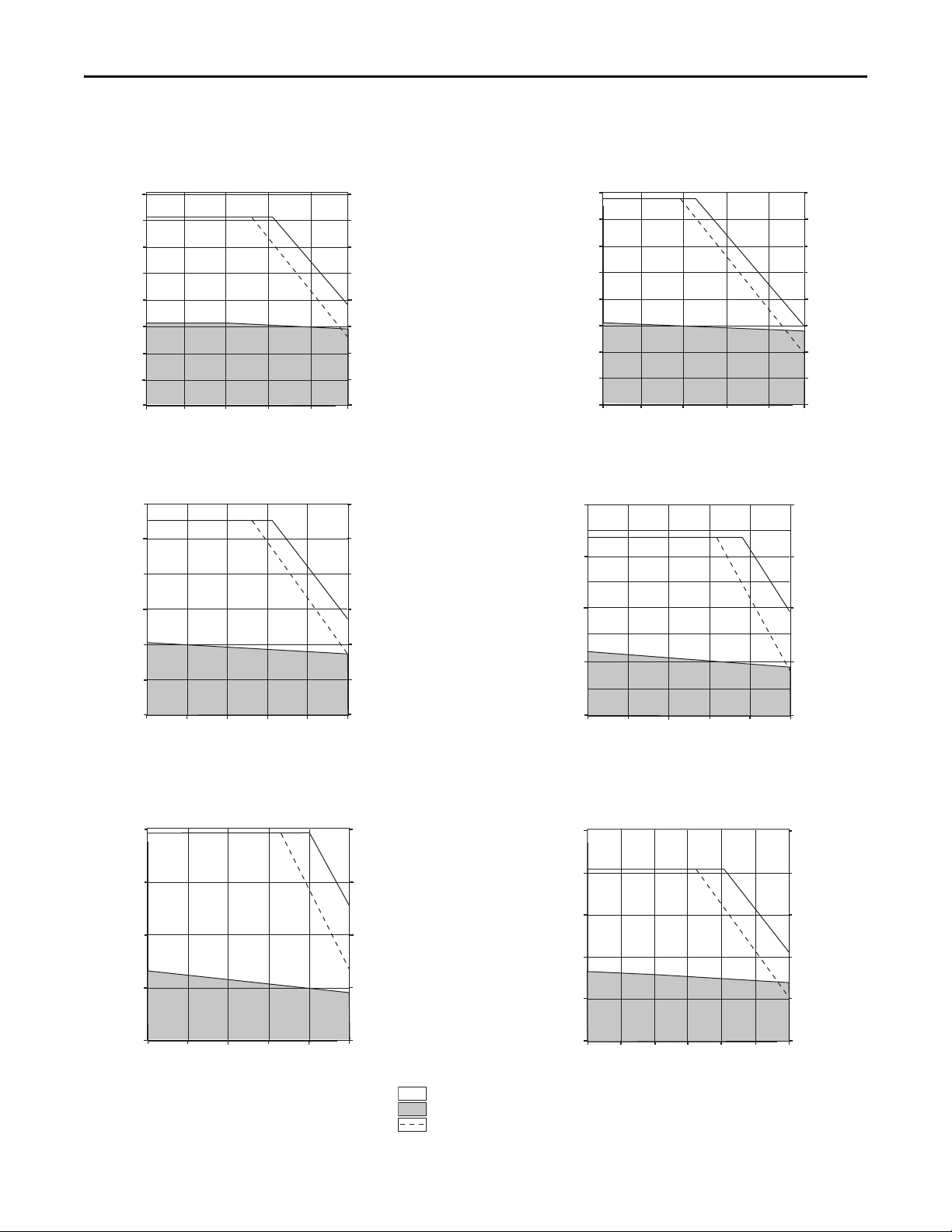

Performance Specifications with Kinetix 6000M (non-brake) Motors

IDM Drive-Motor

Unit

MDF-SB1003P-xxx2x-S 5000 4.03 3.00 (26.5) 19.0 10.50 (92.9) 1.10

MDF-SB1304F-xxx2x-S 3000 5.80 7.25 (64.2) 20.0 21.75 (192) 1.39

Performance specification data and curves reflect nominal system performance of a typical system at 40 °C (104 °F) ambient and rated line voltage. For additional information on ambient and line conditions,

refer to M otion Analy zer software.

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 6000M

IPIM Module

2094-SEPM-B24-SMDF-SB1153H-xxx2x-S 3500 4.50 4.80 (42.5) 20.0 18.50 (164) 1.15

Performance Specifications with Kinetix 6000M (brake) Motors

IDM Drive-Motor

Unit

MDF-SB1003P-xxx4x-S 5000 4.03 3.00 (26.5) 19.0 10.50 (92.9) 1.02

MDF-SB1304F-xxx4x-S 3000 5.80 7.25 (64.2) 20.0 21.75 (192) 1.24

Performance specification data and curves reflect nominal system performance of a typical system at 40 °C (104 °F) ambient and rated line voltage. For additional information on ambient and line conditions,

refer to M otion Analy zer software.

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 15

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 6000M

IPIM Module

2094-SEPM-B24-SMDF-SB1153H-xxx4x-S 3500 4.50 4.80 (42.5) 20.0 18.50 (164) 1.00

Page 16

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

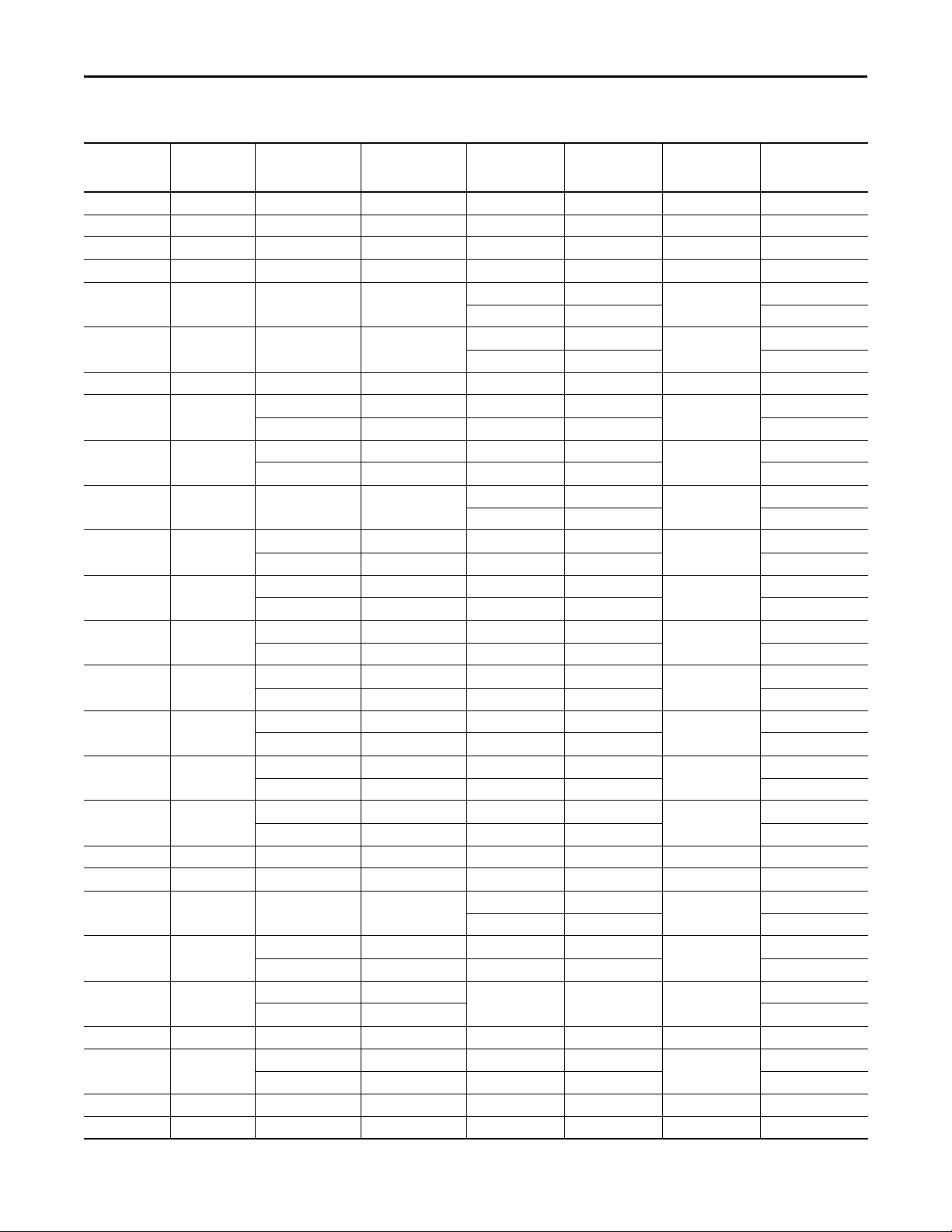

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

2000

4000

30001000

5000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

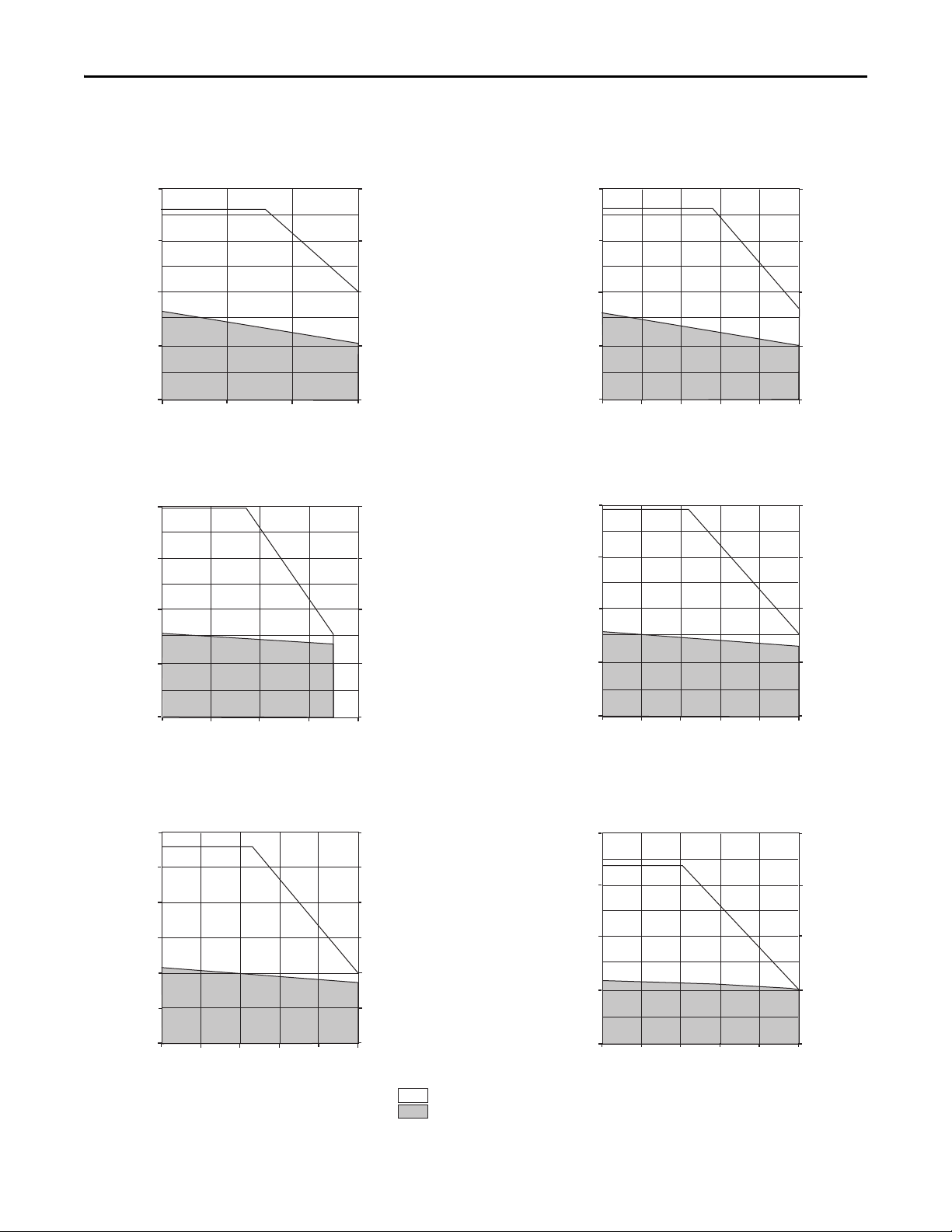

2094 Power Rail with 2094-SEPM-B24-S

and MDF-SB1003P

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

2000

4000

30001000

5000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

2094 Power Rail with 2094-SEPM-B24-S

and MDF-SB1003P (brake)

Torque

(N•m)

Torque

(lb•in)

2094 Power Rail with 2094-SEPM-B24-S

and MDF-SB1153H

0

0

5

10

15

44

88

133

20

177

Speed (rpm)

0

2500

3500

30001000

2000

500

1500

Torque

(N•m)

Torque

(lb•in)

2094 Power Rail with 2094-SEPM-B24-S

and MDF-SB1153H (brake)

0

0

5

10

15

44

88

133

20

177

Speed (rpm)

0

2500

3500

30001000

2000

500

1500

Torque

(N•m)

Torque

(lb•in)

0

0

5

10

15

25

20

44.2

88.5

133

177

221

2094 Power Rail with 2094-SEPM-B24-S

and MDF-SB1304F

Speed (rpm)

0

1000

2000

1500500

3000

2500

Torque

(N•m)

Torque

(lb•in)

0

0

5

10

15

25

20

44.2

88.5

133

177

221

2094 Power Rail with 2094-SEPM-B24-S

and MDF-SB1304F (brake)

Speed (rpm)

0

1000

2000

1500500

3000

2500

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

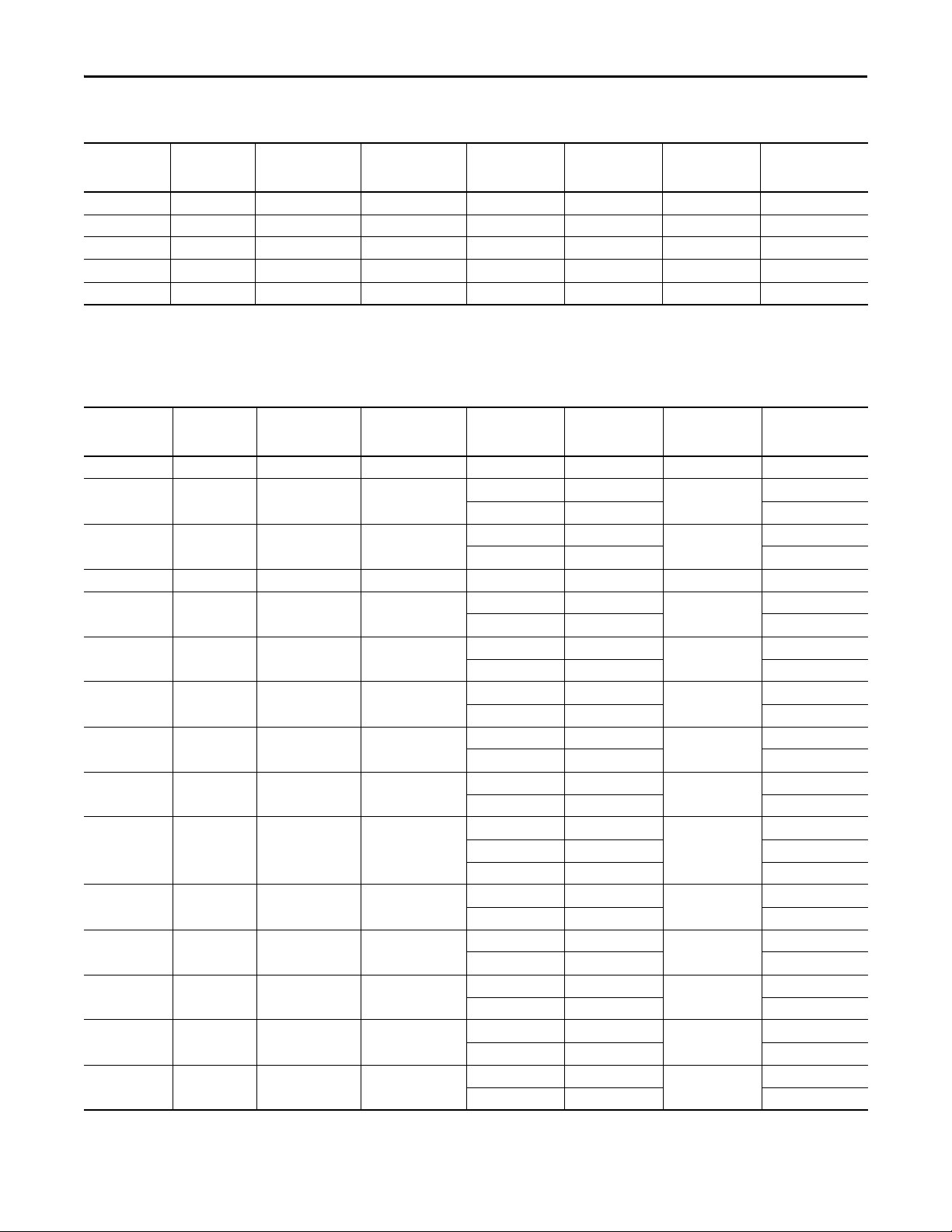

Kinetix 6000M Integrated Drive-Motor (400V-class) System Performance Curves

16 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 17

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

IMPORTANT

IMPORTANT

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

2000

4000

30001000

5000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

2094-BM01-S @ 150% and MPL-B330P

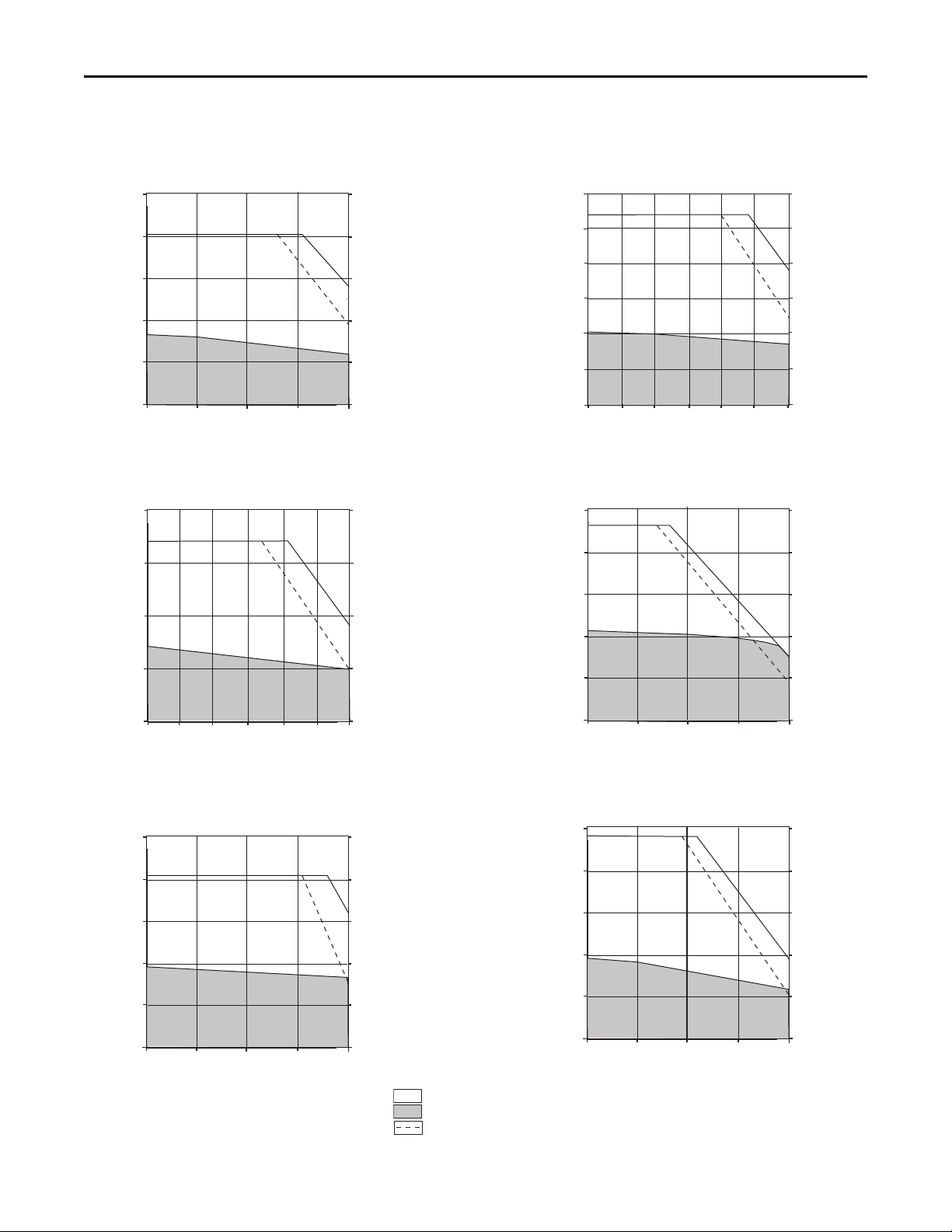

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

2094-BM01-S @ 250% or 2094-BM02-S @ 150%

and MPL-B330P

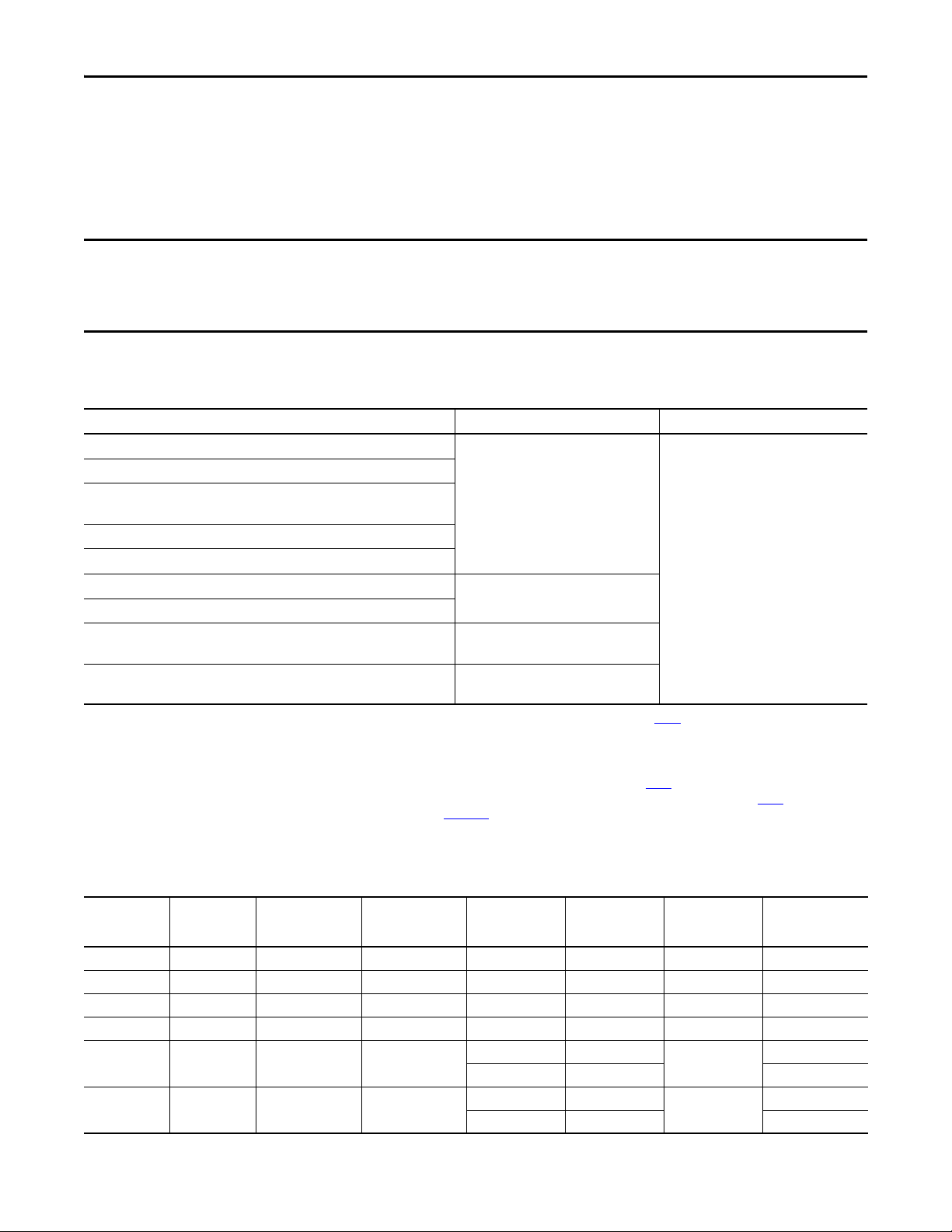

Kinetix 6000 Drive Rotary Performance Example with Peak Enhancement Feature

The peak current ratings of the Kinetix 6000 AM modules (series A, B, and C) are configured at the factory as 150% of continuous

current. You can program 400V-class (series B and C) AM modules, and the equivalent IAM (inverter) modules, to operate with up to

250% of continuous inverter current. Refer to

information.

Before your Kinetix 6000 drive can deliver enhanced-peak performance, you must enable the peak enhancement feature by

configuring your drive by using DriveExplorer™ or RSLogix 5000 software, or the Studio 5000 Logix Designer application.

Refer to the Kinetix 6000 Multi-axis Servo Drive User Manual, publication 2094-UM001

deceleration limit values, and paste them into the appropriate Axis Properties dialog box in RSLogix 5000 software or the

Logix Designer application.

For sizing your drive/motor combination when using series B or C drives with the peak enhancement feature, use Motion Analyzer

software, version 4.6 or later.

In this example, the MPL-B330P motor, usually paired with the 2094-BM02 (series A) AM module, is shown paired with

the 2094-BM01-S (series B or C) AM module. The two curves illustrate how the 2094-BM01-S (series B or C) drive, when

configured for 250% peak, can achieve full motor performance.

the Kinetix Servo Drives Technical Data, publication GMC-TD003, for more

, to recalculate torque and acceleration/

Rotary Motor Performance Specifications Example with Kinetix 6000 Drives

Motor

MPL-B330P 5000 6.10 4.18 (37)

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

13.0 8.0 (71)

19.0 11.1 (98)

System Peak

Stall Torque

N•m (lb•in)

12.0

Torque

(N•m)

10.0

8.0

6.0

4.0

2.0

0

0

Motor Rated

Output

kW

1.8

30001000

2000

Speed (rpm)

Kinetix 6000

400V-class Drives

2094-BM01-S @ 150%

2094-BM01-S @ 250%

2094-BM02-S @ 150%

106

88.5

70.8

53.1

35.4

17.7

0

5000

4000

Torque

(lb•in)

The 2094-BC07-M05-S and 2094-BM05-S (series B and C) modules are limited to 200% of continuous inverter current.

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 17

Page 18

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

IMPORTANT

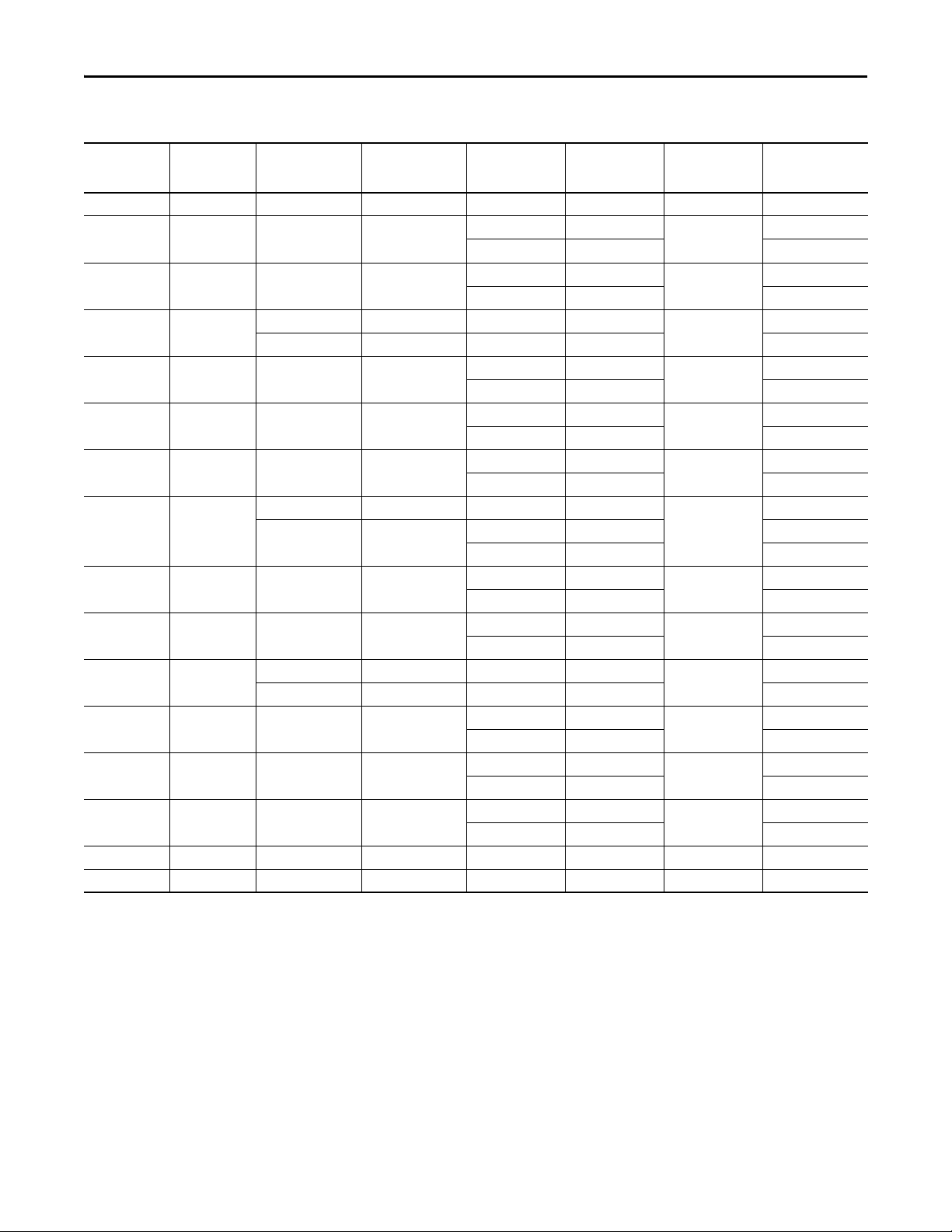

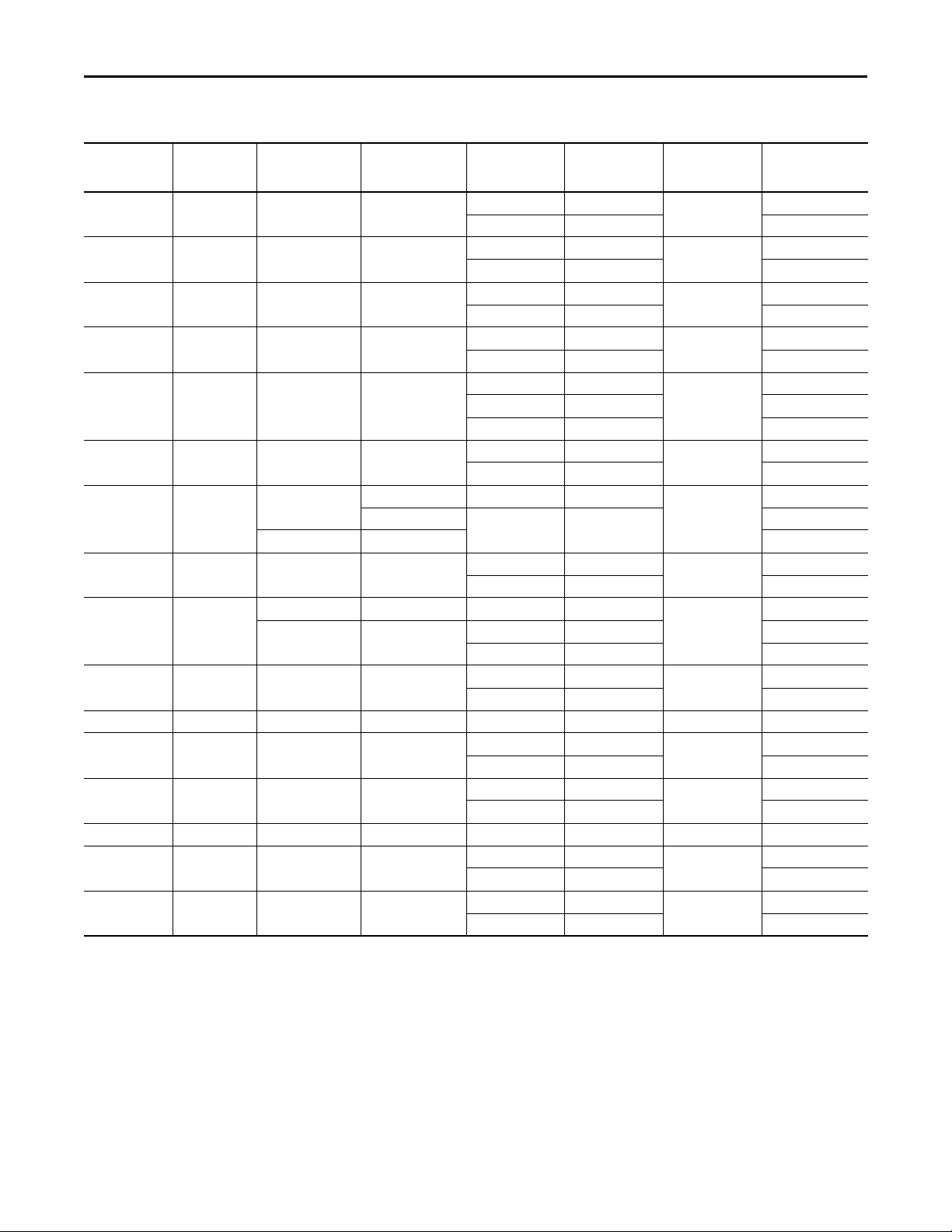

Kinetix 6000 (200V-class) Drives with MP-Series Low Inertia Motors

This section provides system combination information for the Kinetix 6000 (200V-class) drives when matched with

MP-Series™ low-inertia motors. Included are motor power/brake and feedback cable catalog numbers, system performance

specifications, and the optimum torque/speed curves.

The MP-Series low-inertia motors on this page are equipped with DIN connectors (specified by 7 in the catalog number) and are

not compatible with cables designed for motors equipped with bayonet connectors (specified by 2 in the catalog number). The

motors with bayonet connectors (for example, MPL-A310P-xx2xAA) are being discontinued and require 2090-XXNxMP (bayonet)

cables. For help with migration or to select bayonet cables, contact your Rockwell Automation sales representative.

Bulletin MPL Motor Cable Combinations

Motor Cat. No. (200V-class) Motor Power/Brake Cable Motor Feedback Cable

MPL-A1510V-xx7xAA, MPL-A1520U-xx7xAA, MPL-A1530U-xx7xAA

MPL-A210V-xx7xAA, MPL-A220T-xx7xAA, MPL-A230P-xx7xAA

MPL-A310F-xx7xAA, MPL-A310P-xx7xAA,

MPL-A320H-xx7xAA, MPL-A320P,-xx7xAA, MPL-A330P-xx7xAA

MPL-A420P-xx7xAA, MPL-A430H-xx7xAA

MPL-A4530F-xx7xAA, MPL-A4540C-xx7xAA

MPL-A430P-xx7xAA

MPL-A4530K-xx7xAA, MPL-A4540F-xx7xAA, MPL-A4560F-xx7xAA

MPL-A520K-xx7xAA

MPL-A540K-xx7xAA, MPL-A560F-xx7xAA

(1) Use low-profile connector kit (catalog number 2090-K6CK-D15M) with flying-lead cables on the drive end. Refer to Required Drive Accessories on page 4.

(2) Applies to Kinetix 6000 drives and MPL-A3xxx-M/S…MPL-A5xxx-M/S motors with absolute high-resolution feedback.

(3) Applies to Kinetix 6000 drives and MPL-A15xxx-V/E…MPL-A2xxx-V/E motors with absolute high-resolution feedback.

(4) Applies to Kinetix 6000 drives and MPL-A15xxx-H…MPL-A45xxx-H motors with incremental feedback.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Motor-end connector kits, and panel-mounted breakout components (drive end), are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPxM7DF-16AAxx (standard, non-flex)

2090-CPxM7DF-16AFxx (continuous-flex)

2090-CPxM7DF-14AAxx (standard, non-flex)

2090-CPxM7DF-14AFxx (continuous-flex)

2090-CPxM7DF-10AAxx (standard, non-flex)

2090-CPxM7DF-10AFxx (continuous-flex)

20

M7DF-08AAxx (standard, non-flex)

90-CPx

2090-CPxM7DF-08AFxx (continuous-flex)

, for standard cable lengths.

2090-CFBM7DF-CEAAxx or

2090-CFBM7DD-CEAAxx (standard, non-flex)

2090-CFBM7DF-CEAFxx or

2090-CFBM7DD-CEAFxx (continuous-flex)

Absolute High-resolution Feedback

2090-XXNFMF-Sxx (standard, non-flex)

2090-CFBM7DF-CDAFxx (continuous-flex)

Incremental Feedback

(1)

(2) (3)

(4)

.

Bulletin MPL Motor Performance Specifications with Kinetix 6000 (200V-class) Drives

Rotary Motor

MPL-A1510V 8000 1.05 0.26 (2.3) 3.40 0.77 (6.8) 0.16 2094-AMP5-S

MPL-A1520U 7000 1.80 0.49 (4.3) 6.10 1.58 (13.9) 0.27 2094-AMP5-S

MPL-A1530U 7000 2.82 0.90 (8.0) 10.1 2.82 (24.9) 0.39 2094-AMP5-S

MPL-A210V 8000 3.09 0.55 (4.8) 10.2 1.52 (13.4) 0.37 2094-AMP5-S

MPL-A220T 6000 4.54 1.61 (14.2)

MPL-A230P 5000 5.40 2.10 (18.6)

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

18 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

10.5 3.45 (30.0)

15.5 4.74 (41.9) 2094-AM01-S

17.0 8.0 (70.8)

23.0 8.2 (73.0) 2094-AM02-S

System Peak

Stall Torque

N•m (lb•in)

Motor Rated Output

kW

0.62

0.86

Kinetix 6000

200V-class Drives

2094-AMP5-S

2094-AM01-S

Page 19

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Bulletin MPL Motor Performance Specifications with Kinetix 6000 (200V-class) Drives (continued)

Rotary Motor

MPL-A310F 3000 3.24 1.58 (14.0) 9.30 3.61 (31.9) 0.46 2094-AMP5-S

MPL-A310P 5000 4.91 1.58 (14.0)

MPL-A320H 3500 6.10 3.05 (27.0)

MPL-A320P 5000

MPL-A330P 5000 12.0 4.18 (37.0)

MPL-A420P 5000 12.9 4.79 (42.3)

MPL-A430H 3500 12.2 6.21 (55.0)

MPL-A430P 5000

MPL-A4530F 2800 13.40 8.36 (74 .0)

MPL-A4530K 4000 19.50 8.13 (71.9)

MPL-A4540C 1500

MPL-A4540F 3000 18.40 10.19 (90.1)

MPL-A4560F 3000 22.0 14.1 (125)

MPL-A520K 4000 15.0 10.77 (9 5.2)

MPL-A540K 4000 41.5 19.42 (1 71) 73.4 31.3 (277) 5.5 2094-AM05-S

MPL-A560F 3000 42.0 27.39 (242) 73.4 39.6 (350) 5.3 2094-AM05-S

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

8.50 2.88 (25.5) 17.0 5.07 (44.8)

9.00 3.05 (27.0) 29.5 7.91 (70.0) 2094-AM02-S

15.0 5.35 (47.3) 30.0 9.99 (88.3)

16.80 5.99 (52.9)

8.50 9.15 (80.9) 17.0 16.9 (150)

9.55 10.30 (91.1) 29.0 27.1 (239) 2094-AM02-S

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

10.5 2.90 (25.6)

14.0 3.61 (31.9) 2094-AM01-S

17.0 7.13 (63.0)

19.3 7.91 (70.0) 2094-AM02-S

30.0 9.10 (80.5)

38.0 11.1 (98.2) 2094-AM03-S

30.0 9.67 (85.5)

46.0 13.6 (119) 2094-AM03-S

30.0 13.9 (123)

45.0 19.8 (175) 2094-AM03-S

49.0 15.4 (136) 2094-AM03-S

67.0 19.8 (175) 2094-AM05-S

30.0 15.8 (139)

42.0 20.3 (179) 2094-AM03-S

49.0 17.0 (150)

62.0 20.3 (179) 2094-AM05-S

49.0 23.6 (208)

58.0 27.1 (239) 2094-AM05-S

49.0 27.0 (239)

66.0 34.4 (305) 2094-AM05-S

49.0 19.3 (171)

65.0 24.2 (214) 2094-AM05-S

System Peak

Stall Torque

N•m (lb•in)

Motor Rated Output

kW

0.73

1.0

1.3

1.8

2.0

1.8

2.2

1.9

2.5

1.5

2.6

3.0

3.5

Kinetix 6000

200V-class Drives

2094-AMP5-S

2094-AM01-S

2094-AM01-S

2094-AM02-S

2094-AM02-S

2094-AM02-S

2094-AM02-S

2094-AM02-S

2094-AM03-S

2094-AM01-S

2094-AM03-S

2094-AM03-S

2094-AM03-S

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 19

Page 20

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

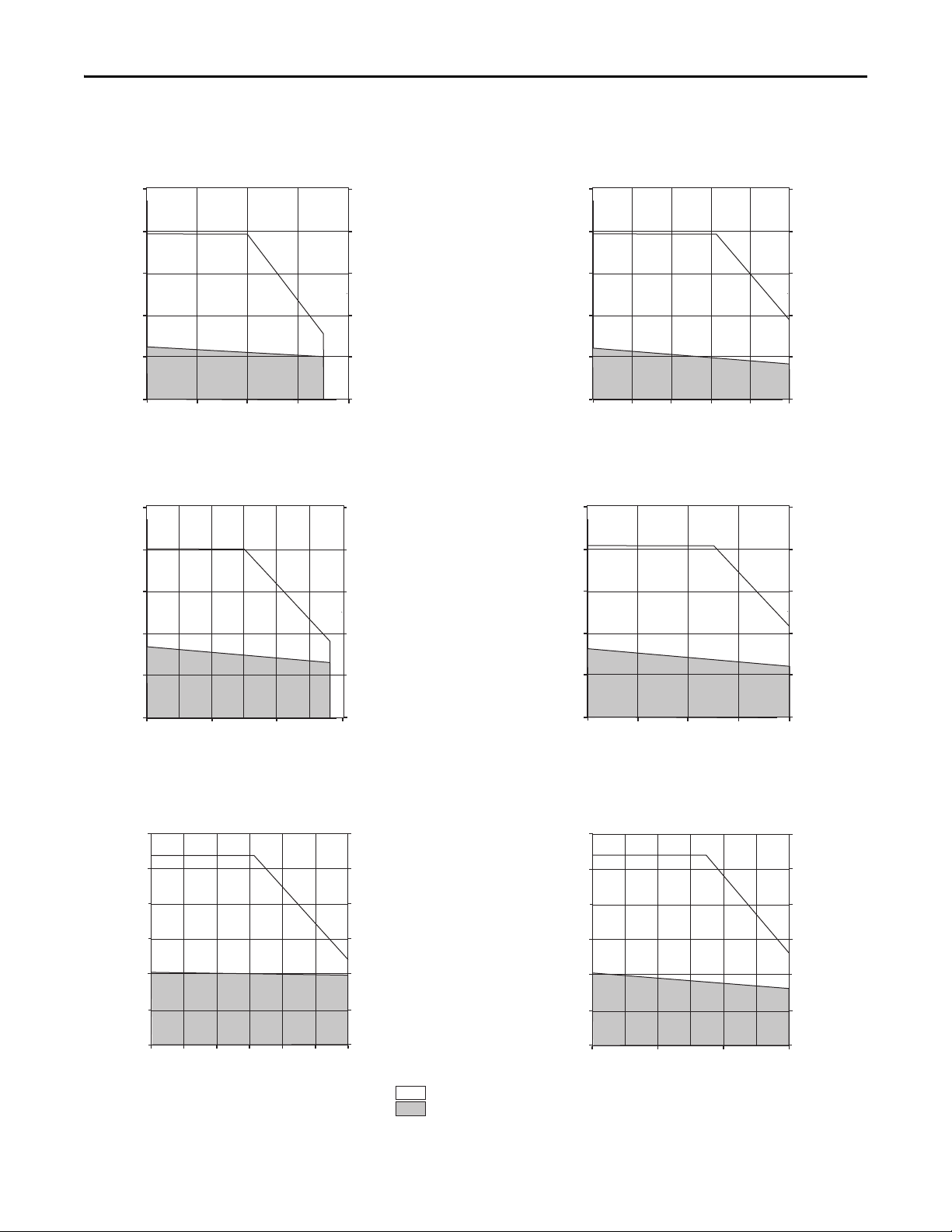

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-AMP5-S and MPL-A1510V

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0

7.08

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-AMP5-S and MPL-A1520U

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-AMP5-S and MPL-A1530U

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0

35.4

30.9

26.5

22.1

17.7

13.3

8.84

4.42

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-AMP5-S and MPL-A210V

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2094-AM01-S and MPL-A220T

Speed (rpm)

1000

2000 3000 40000 5000 6000

Torque

(N•m)

Torque

(lb•in)

2094-AM02-S and MPL-A230P

0

0

2.0

4.0

6.0

35.4

53.1

70.8

8.0

88.5

Speed (rpm)

0

3000

5000

40001000

2000

10.0

1.77

= Intermittent operating region

= Continuous operating region

Kinetix 6000 (200V-class) Drives/MP-Series Low Inertia Motor Curves

20 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 21

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

2094-AMP5-S and MPL-A310F

35.4

26.5

17.7

8.85

0

4.0

3.0

2.0

1.0

0

Speed (rpm)

30001000

2000

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2094-AM02-S and MPL-A320H

70.8

53.1

35.4

17.7

0

0

2000

4000

8.0

6.0

4.0

2.0

0

30001000

Torque

(N•m)

Torque

(lb•in)

2094-AM03-S and MPL-A330P

Speed (rpm)

0

2000

4000

30001000

5000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

Torque

(N•m)

Torque

(lb•in)

141

106

70.8

35.4

0

16.0

12.0

8.0

4.0

0

2094-AM03-S and MPL-A420P

Speed (rpm)

0

2000

4000

30001000

5000

= Intermittent operating region

= Continuous operating region

Kinetix 6000 (200V-class) Drives/MP-Series Low Inertia Motor Curves (continued)

2094-AM01-S and MPL-A310P

Torque

(N•m)

4.0

35.4

Torque

(lb•in)

Torque

(N•m)

3.0

2.0

1.0

8.0

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

0

2094-AM02-S and MPL-A320P

0

0

30001000

2000

Speed (rpm)

30001000

2000

Speed (rpm)

4000

4000

5000

5000

26.5

17.7

8.8.5

0

70.8

61.9

53.1

44.2

35.4

26.5

17.7

8.85

0

Torque

(lb•in)

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 21

Page 22

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

0

0

5

10

15

25

20

44.2

88.5

133

177

221

Speed (rpm)

0

2000

4000

30001000

2094-AM03-S and MPL-A430H

Torque

(N•m)

Torque

(lb•in)

0

0

5

10

15

25

20

44.2

88.5

133

177

221

Speed (rpm)

30001000

2000

0

2094-AM03-S and MPL-A4530F

Torque

(N•m)

Torque

(lb•in)

2094-AM02-S and MPL-A4540C

30

25

20

15

10

5

0

265

221

177

133

88.5

44.2

0

Speed (rpm)

0 15001000500 1250750250

Torque

(N•m)

Torque

(lb•in)

2094-AM05-S and MPL-A4540F

30

25

20

15

10

5

0

265

221

177

133

88.5

44.2

0

Speed (rpm)

0 300020001000

= Intermittent operating region

= Continuous operating region

Kinetix 6000 (200V-class) Drives/MP-Series Low Inertia Motor Curves (continued)

2094-AM05-S and MPL-A430P

25

Torque

(N•m)

20

221

177

Torque

(lb•in)

Torque

(N•m)

15

10

5

0

0

2094-AM05-S and MPL-A4530K

25

20

15

10

5

0

0

30001000

2000

Speed (rpm)

2000

Speed (rpm)

4000

30001000

5000

4000

133

88.5

44.2

0

221

177

133

88.5

44.2

0

Torque

(lb•in)

22 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 23

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

0

0

10

20

30

50

40

88.5

177

265

354

443

Speed (rpm)

0 300020001000

2094-AM05-S and MPL-A4560F

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2094-AM05-S and MPL-A540K

0

2000

4000

32

24

16

8

0

30001000

283

212

141

70.8

0

= Intermittent operating region

= Continuous operating region

Kinetix 6000 (200V-class) Drives/MP-Series Low Inertia Motor Curves (continued)

2094-AM05-S and MPL-A520K

Torque

(N•m)

30

25

265

221

Torque

(lb•in)

Torque

(N•m)

4000

177

133

88.5

44.2

0

443

354

265

177

88.5

Torque

(lb•in)

20

15

10

5

0

0

2094-AM05-S and MPL-A560F

50

40

30

20

10

2000

Speed (rpm)

30001000

0

0 300020001000

Speed (rpm)

0

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 23

Page 24

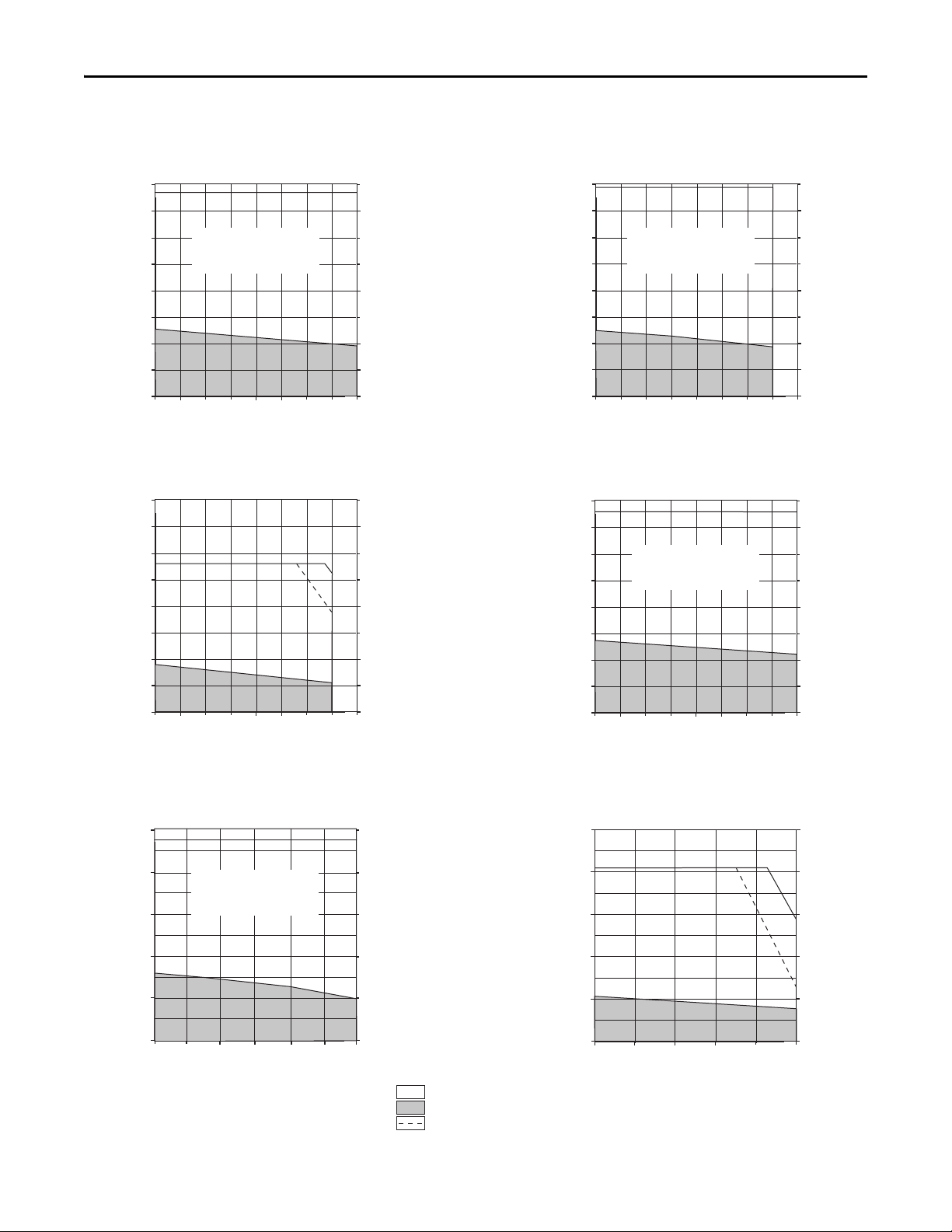

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

IMPORTANT

IMPORTANT

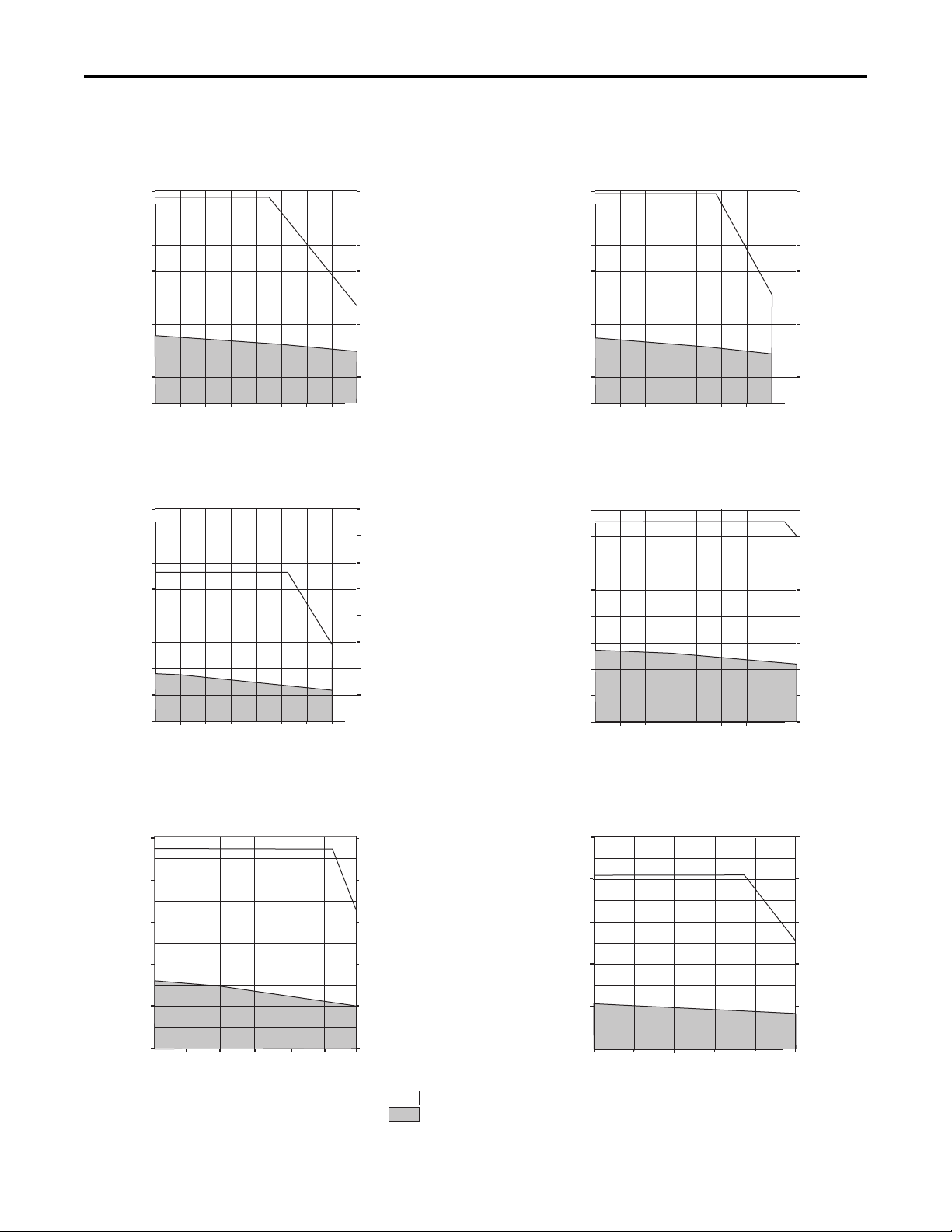

Kinetix 6000 and Kinetix 6200/6500 (400V-class) Drives

with MP-Series Low Inertia Motors

This section provides system combination information for the Kinetix 6000 and the Kinetix 6200/6500 (400V-class)

drives when matched with MP-Series low-inertia motors. Included are motor power/brake and feedback cable catalog

numbers, system performance specifications, and the optimum torque/speed curves.

When using Kinetix 6000 (series B or C) drives, configured for enhanced peak performance, you can usually achieve full motor

performance with a smaller drive. Kinetix 6200 and Kinetix 6500 drives are configured for enhanced peak performance by default.

Expect the same peak performance from Kinetix 6200/6500 drives as you get from Kinetix 6000 (series B or C) drives configured for

enhanced peak performance.

Refer to Kinetix Servo Drives Specifications Technical Data, publication GMC-TD003

The MP-Series low-inertia motors on this page are equipped with DIN connectors (specified by 7 in the catalog number) and are

not compatible with cables designed for motors equipped with bayonet connectors (specified by 2 in the catalog number). The

motors with bayonet connectors (for example, MPL-A310P-xx2xAA) are being discontinued and require 2090-XXNxMP (bayonet)

cables. For help with migration or to select bayonet cables, contact your Rockwell Automation sales representative.

, for more information.

Bulletin MPL Motor Cable Combinations

Motor Cat. No. (400V-class) Motor Power/Brake Cable Motor Feedback Cable

MPL-B1510V-xx7xAA, MPL-B1520U-xx7xAA, MPL-B1530U-xx7xAA

MPL-B210V-xx7xAA, MPL-B220T-xx7xAA, MPL-B230P-xx7xAA

MPL-B310P-xx7xAA, MPL-B320P-xx7xAA, MPL-B330P-xx7xAA

MPL-B420P-xx7xAA, MPL-B430P-xx7xAA

MPL-B4530F-xx7xAA, MPL-B4530K-xx7xAA,

MPL-B4540F-xx7xAA, MPL-B4560F-xx7xAA

MPL-B520K-xx7xAA

MPL-B540D-xx7xAA, MPL-B540K-xx7xAA, MPL-B560F-xx7xAA

MPL-B580F-xx7xAA, MPL-B580J-xx7xAA,

MPL-B640F-xx7xAA

MPL-B660F-xx7xAA, MPL-B680D-xx7xAA,

MPL-B960B-xx7xAA, MPL-B980B-xx7xAA

MPL-B680F-xx7xAA, MPL-B680H-xx7xAA,

MPL-B860D-xx7xAA, MPL-B880C-xx7xAA

MPL-B880D-xx7xAA 2090-CPxM7DF-04AAxx (standard, non-flex)

(1) Use low-profile connector kit (catalog number 2090-K6CK-D15M) with flying-lead cables on the drive end. Refer to Required Drive Accessories on page 4.

(2) Applies to Kinetix 6000 drives and MPL-B3xxx-M/S…MPL-B9xxx-M/S motors with absolute high-resolution feedback.

(3) Applies to Kinetix 6000 drives and MPL-B15xxx-V/E…MPL-B2xxx-V/E motors with absolute high-resolution feedback.

(4) Applies to Kinetix 6000 drives and MPL-B15xxx-H…MPL-B45xxx-H motors with incremental feedback.

(5) Applies to Kinetix 6000 drives and MPL-B3xxx-R…MPL-B45xxx-R motors with resolver feedback.

For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Motor/Actuator Cables Overview beginning on page 7.

Motor-end connector kits, and panel-mounted breakout components (drive end), are available for motor power/brake and feedback cables. Refer to Optional Drive Accessories on page 6

Cable len gth xx is in meters. Refer to the Kinetix Motion Accessories Technical Data, publication GMC-TD004

2090-CPxM7DF-16AAxx (standard, non-flex)

2090-CPxM7DF-16AFxx (continuous-flex)

2090-CPxM7DF-14AAxx (standard, non-flex)

2090-CPxM7DF-14AFxx (continuous-flex)

2090-CPxM7DF-10AAxx (standard, non-flex)

2090-CPxM7

2090-CPxM7DF-08AAxx (standard, non-flex)

2090-CPxM7DF-08AFxx (continuous-flex)

2090-CPxM7DF-06AAxx (standard, non-flex)

DF-10AFxx (

, for standard cable lengths.

continuous-flex)

2090-CFBM7DF-CEAAxx or

2090-CFBM7DD-CEAAxx (standard, non-flex)

2090-CFBM7DF-CEAFxx or

2090-CFBM7DD-CEAFxx (continuous-flex)

Absolute High-resolution Feedback

2090-XXNFMF-Sxx (standard)

2090-CFBM7DF-CDAFxx (continuous-flex)

Incremental Feedback

2090-CFBM7DF-CEAAxx (standard, non-flex)

2090-CFBM7DF-CEAFxx (continuous-flex)

Resolver Feedback

(1)

(2) (3)

(4)

(5)

.

24 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 25

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Bulletin MPL Motor Performance Specifications with Kinetix 6200/6500 (400V-class) Drives

Rotary Motor

MPL-B1510V 8000 0.95 0.26 (2.3) 3.10 0.77 (6.8) 0.16 2094-BMP5-M

MPL-B1520U 7000 1.80 0.49 (4.3) 6.10 1.58 (13.9) 0.27 2094-BMP5-M

MPL-B1530U 7000 2.0 0.90 (8.0) 7.20 2.82 (24.9) 0.39 2094-BMP5-M

MPL-B210V 8000 1.75 0.55 (4.9) 5.80 1.52 (13.4) 0.37 2094-BMP5-M

MPL-B220T 6000 3 .30 1.61 (14.2)

MPL-B230P 5000 2.60 2.10 (18.6)

MPL-B310P 5000 2.4 1.6 (14.1) 7 .10 3.6 (32) 0.77 2094-BMP5-M

MPL-B320P 5000

MPL-B330P 5000

MPL-B420P 5000 6.3 4.74 (42)

MPL-B430P 5000

MPL-B4530F 3000

MPL-B4530K 4000

MPL-B4540F 3000

MPL-B4560F 3000

MPL-B520K 4000

MPL-B540D 2000

MPL-B540K 4 000 20.4 19.4 (171) 60.0 48.6 (430) 5.4 209 4-BM03-M

MPL-B560F 3000 20.6 26.8 (237) 6 8.0 67.8 (600) 5.5 2094-BM03-M

MPL-B580F 3000 26.0 34.0 (300)

MPL-B580J 3800

MPL-B640F 3000

MPL

0F 3000 38.5 48.0 (425) 96.0 101 (895) 6.1 2094-BM05-M

-B66

MPL-B680D 2000

MPL-B680F 3000 47.9 60.0 (531) 9 6.0 108 (960) 7.5 2094-BM05-M

MPL-B680H 3500 48.9 58.0 (513) 9 7.8 107 (947) 7.5 2094-BM05-M

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

4.0 2.7 (23.9) 9.90 5.9 (52.2)

4.5 3.10 (27) 14.0 8.2 (72.5) 2094-BM01-M

4.0 2.7 (23.9) 9.90 6.8 (60.2)

6.1 4.18 (37) 19.0 11.1 (98) 2094-BM01-M

8.6 6.2 (54.9) 21.6 13.9 (123)

9.2 6.55 (58) 32.0 19.8 (175) 2094-BM02-M

4.0 4.9 (43.3) 9.90 11.0 (97.3)

6.7 8.36 (74) 21.0 20.3 (180) 2094-BM01-M

8.6 7.1 (62.8) 21.6 15.1 (133)

9.9 8.25 (73) 31.0 20.3 (179) 2094-BM02-M

8.6 9.5 (84.1) 21.6 20.9 (185)

9.1 10.20 (90) 29.0 27.1 (240) 2094-BM02-M

8.6 10.5 (92.9) 21.6 22.7 (201)

11.8 14.0 (124) 36.0 34.4 (304) 2094-BM02-M

8.6 7.9 (69.9) 21.6 16.6 (147)

11.5 10.7 (95) 33.0 23.2 (205) 2094-BM02-M

8.6 15.8 (139) 21.6 37.9 (335)

10.5 19.4 (172) 23.0 41.0 (362) 2094-BM02-M

30.0 31.7 (280) 75.0 67.0 (592)

32.0 34.0 (301) 94.0 81.0 (716) 2094-BM05-M

30.0 34.4 (304)

32.0 36.7 (325) 2094-BM05-M

30.0 55.4 (490) 75.0 125 (1105)

34.0 62.8 (556) 94.0 154 (1365) 2094-B M05-M

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

9.90 4.12 (36.4)

11.3 4.74 (41.9) 209 4-BM01-M

9.90 7.24 (64.0)

11.3 8.20 (73.0) 209 4-BM01-M

21.6 13.1 (116)

22.0 13.5 (119) 2094-BM02-M

75.0 74.6 (660)

94.0 87.0 (770) 2094-BM05-M

65.0 72.3 (640) 6.1

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

0.62

0.86

1.5

1.8

1.9

2.2

2.1

2.6

2.6

3.2

3.5

3.4

7.1

7.9

9.3

Kinetix 6200/

Kinetix 6500

400V-class Drives

2094-BMP5-M

2094-BMP5-M

2094-BMP5-M

2094-BMP5-M

2094-BM01-M

2094-BM01-M

2094-BMP5-M

2094-BM01-M

2094-BM01-M

2094-BM01-M

2094-BM01-M

2094-BM01-M

2094-BM03-M

2094-BM03-M

2094-BM03-M

2094-BM03-M

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 25

Page 26

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Bulletin MPL Motor Performance Specifications with Kinetix 6200/6500 (400V-class) Drives (continued)

Rotary Motor

MPL-B860D 2000 47.3 83.0 (735) 95.5 152 (1350) 12.5 2094-BM05-M

MPL-B880C 1500 47.5 11 0 (973) 97.5 203 (1800) 12.6 2094-BM05-M

MPL-B880D 2000 48.9 79.9 (706) 96.0 147 (1300) 12.6 2094-BM05-M

MPL-B960B 1200 42.5 130 (1150) 94.0 231 (2050) 12.7 2094-BM05-M

MPL-B980B 1000 40.0 162 (1440) 94.0 278 (2460) 15.2 2094-BM05-M

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW

Kinetix 6200/

Kinetix 6500

400V-class Drives

Bulletin MPL Motor Performance Specifications with Kinetix 6000 (400V-class) Drives

Rotary Motor

MPL-B1510V 8000 0.95 0.26 (2.3) 3.10 0.77 (6.8) 0.16 BMP5-S @ 150 %

MPL-B1520U 7000 1.80 0.49 (4.3)

MPL-B1530U 7000 2.0 0.90 (8.0)

MPL-B210V 8000 1.75 0.55 (4.9) 5.80 1.52 (13.4) 0.37 BMP5-S @ 150%

MPL-B220T 6000 3.30 1.61 (14.2)

MPL-B230P 5000 2.60 2.10 (18.6)

MPL-B310P 5000 2.4 1.6 (14)

MPL-B320P 5000 4.5 3.10 (27)

MPL-B330P 5000 6.1 4.18 (37)

MPL-B420P 5000 6.3 4.74 (42)

MPL-B430P 5000 9.2 6.55 (58)

MPL-B4530F 3000 6.7 8.36 (74)

MPL-B4530K 4000 9.9 8.25 (73)

MPL-B4540F 3 000 9.1 10.20 (90)

MPL-B4560F 3 000 11.8 14.0 (124)

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

5.90 1.53 (13.3)

6.10 1.58 (13.9) BMP5-S @ 250%

5.90 2.34 (20.7)

7.20 2.82 (24.9) BMP5-S @ 250%

9.90 4.12 (36.4)

11.3 4.74 (41.9) BM01-S @ 150%

9.90 7.24 (64.0)

11.3 8.20 (73.0) BM01-S @ 150%

5.90 3.2 (28)

7.10 3.6 (32) BMP5-S @ 250%

13.0 7.5 (66)

14.0 8.2 (72.5) BM01-S @ 250%

13.0 8.0 (71)

19.0 11.1 (98) BM01-S @ 250%

13.0 13.1 (116)

21.8 13.4 (118) BM02-S @ 150%

22.0 13.5 (119) BM02-S @ 250%

21.8 14.4 (127)

32.0 19.8 (175) BM02-S @ 250%

13.0 13.9 (123)

21.0 20.3 (180) BM01-S @ 250%

21.8 15.5 (137)

31.0 20.3 (179) BM02-S @ 250%

21.8 21.4 (189)

29.0 27.1 (240) BM02-S @ 250%

21.8 23.3 (206)

36.0 34.4 (304) BM02-S @ 250%

System Peak

Stall Torque

N•m (lb•in)

Motor Rated Output

kW

0.27

0.39

0.62

0.86

0.77

1.5

1.8

1.9

2.2

2.1

2.6

2.6

3.2

Kinetix 6000

400V-class Drives

BMP5-S @ 150%

BMP5-S @ 150%

BMP5-S @ 250%

BMP5-S @ 250%

BMP5-S @ 150%

BM01-S @ 150%

BM01-S @ 150%

BM01-S @ 250%

BM02-S @ 150%

BM01-S @ 150%

BM02-S @ 150%

BM02-S @ 150%

BM02-S @ 150%

26 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

Page 27

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Bulletin MPL Motor Performance Specifications with Kinetix 6000 (400V-class) Drives (continued)

Rotary Motor

MPL-B520K 4000 11.5 10.7 (95)

MPL-B540D 2000 10.5 19.4 (172)

MPL-B540K 4000 20.4 19.4 (171)

MPL-B560F 3000 20.9 26.8 (237)

MPL-B580F 3000 26.1 34.0 (300)

MPL-B580J 3800 32.0 34.0 (301)

MPL-B640F 3000

MPL-B660F 3000 38.5 48.0 (425)

MPL-B680D 2000

MPL-B680F 3000 47.9 60.0 (531)

MPL-B680H 3500 48.9 58.0 (513) 97.8 107 (947) 7.5 B M05-S @ 200%

MPL-B860D 2000 47.3 83.0 (735)

MPL-B880C 1500 47.5 110 (973)

MPL-B880D 2000 48.9 79.9 (706) 96.0 147 (1300) 12.6 BM05-S @ 200%

MPL-B960B 1200 42.5 130 (1150)

MPL-B980B 1000 40.0 162 (1440)

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

30.0

32.0 36.7 (325) BM05-S @ 150%

30.0 55.4 (490) 75.0 125 (1105)

34.0 62.8 (556)

System Continuous

Stall Torque

N•m (lb•in)

34.4 (304) 4 5.0 50.4 (446)

34.4 (304)

System Peak

Stall Current

A 0-pk

21.8 17.0 (150)

33.0 23.2 (205) BM02-S @ 250%

21.8 38.8 (343)

23.0 41.0 (362) BM02-S @ 250%

45.0 38.1 (337)

60.0 48.6 (430) BM03-S @ 250%

45.0 49.3 (436)

68.0 67.8 (600) BM03-S @ 250%

75.0 74.6 (660)

73.4 73.5 (650) BM05-S @ 150%

94.0 87.0 (770) BM05-S @ 200%

73.4 66.6 (589)

94.0 81.0 (716) BM05-S @ 200%

65.0 72.3 (640)

73.4 81.0 (716)

96.0 101 (895) BM05-S @ 200%

73.4 124 (1098) BM05-S @ 150%

94.0 152 (1350) BM05-S @ 200%

73.4 85.4 (755)

96.0 108 (960) BM05-S @ 200%

73.4 120 (1065)

95.5 152 (1350) BM05-S @ 200%

73.4 157 (1387)

97.5 203 (1800) BM05-S @ 200%

73.4 190 (1684)

94.0 231 (2050) BM05-S @ 200%

73.4 235 (2077)

94.0 278 (2460) BM05-S @ 200%

System Peak

Stall Torque

N•m (lb•in)

Motor Rated Output

kW

3.5

3.4

5.4

5.5

7.1

7.9

6.1

6.1

9.3

7.5

12.5

12.6

12.7

15.2

Kinetix 6000

400V-class Drives

BM02-S @ 150%

BM02-S @ 150%

BM03-S @ 150%

BM03-S @ 150%

BM03-S @ 250%

BM05-S @ 150%

BM03-S @ 150%

BM03-S @ 250%

BM05-S @ 150%

BM03-S @ 250%

BM05-S @ 150%

BM05-S @ 150%

BM05-S @ 150%

BM05-S @ 150%

BM05-S @ 150%

Performance specification data and curves reflect nominal sys tem performance of a typical system with motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient and rated line voltage. For additional

information on ambient and line conditions, refer to Motion Analyzer software.

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 27

Page 28

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

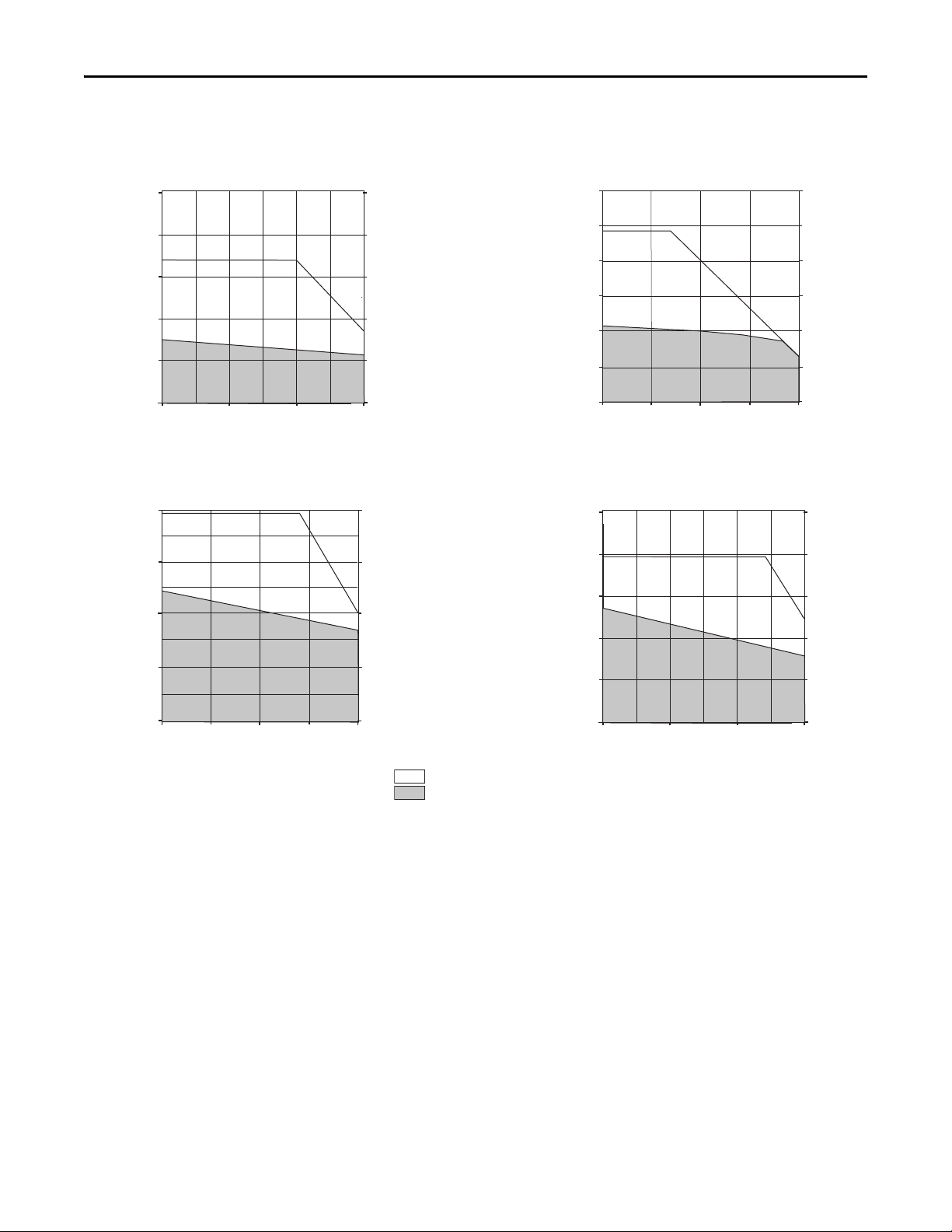

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-BMP5-S @ 150% or 2094-BMP5-M

and MPL-B1510V

0.800

0.700

0.600

0.500

0.400

0.300

0.200

0.100

0

7.08

6.19

5.31

4.42

3.54

2.65

1.77

0.88

0

Peak curve represents

460V and 400V inputs

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-BMP5-S @ 250% or 2094-BMP5-M

and MPL-B1530U

4.00

3.50

3.00

2.50

2.00

1.50

1.00

0.50

0

35.4

30.9

26.5

22.1

17.7

13.3

8.84

4.42

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2000 4000 6000 80000

2094-BMP5-S @ 150% or 2094-BMP5-M

and MPL-B210V

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

Peak curve represents

460V and 400V inputs

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2094-BM01-S @ 150% or 2094-BM01-M

and MPL-B220T

Speed (rpm)

1000

2000 3000 40000 5000

6000

Peak curve represents

460V and 400V inputs

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 6000 and Kinetix 6200/6500 (400V-class) Drives/MP-Series Low Inertia Motor Curves

2094-BMP5-S @ 250% or 2094-BMP5-M

and MPL-B1520U

Peak curve represents

460V and 400V inputs

2000 4000 6000 80000

Speed (rpm)

Torque

(N•m)

1.600

1.400

1.200

1.000

0.800

0.600

0.400

0.200

0

14.1

12.4

10.6

8.85

7.08

5.31

3.54

1.77

0

Torque

(lb•in)

Torque

(N•m)

28 Rockwell Automation Publication GMC-RM003C-EN-P - September 2013

2094-BM01-S @ 150% or 2094-BM01-M

and MPL-B230P

10.0

8.0

6.0

4.0

2.0

0

0

2000

Speed (rpm)

3000

88.5

Torque

(lb•in)

70.8

53.1

35.4

1.77

0

5000

40001000

Page 29

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

1000 2000 3000 4000

0

0

0

17.7

35.4

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.42

8.85

13.3

22.1

26.5

31.0

5000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

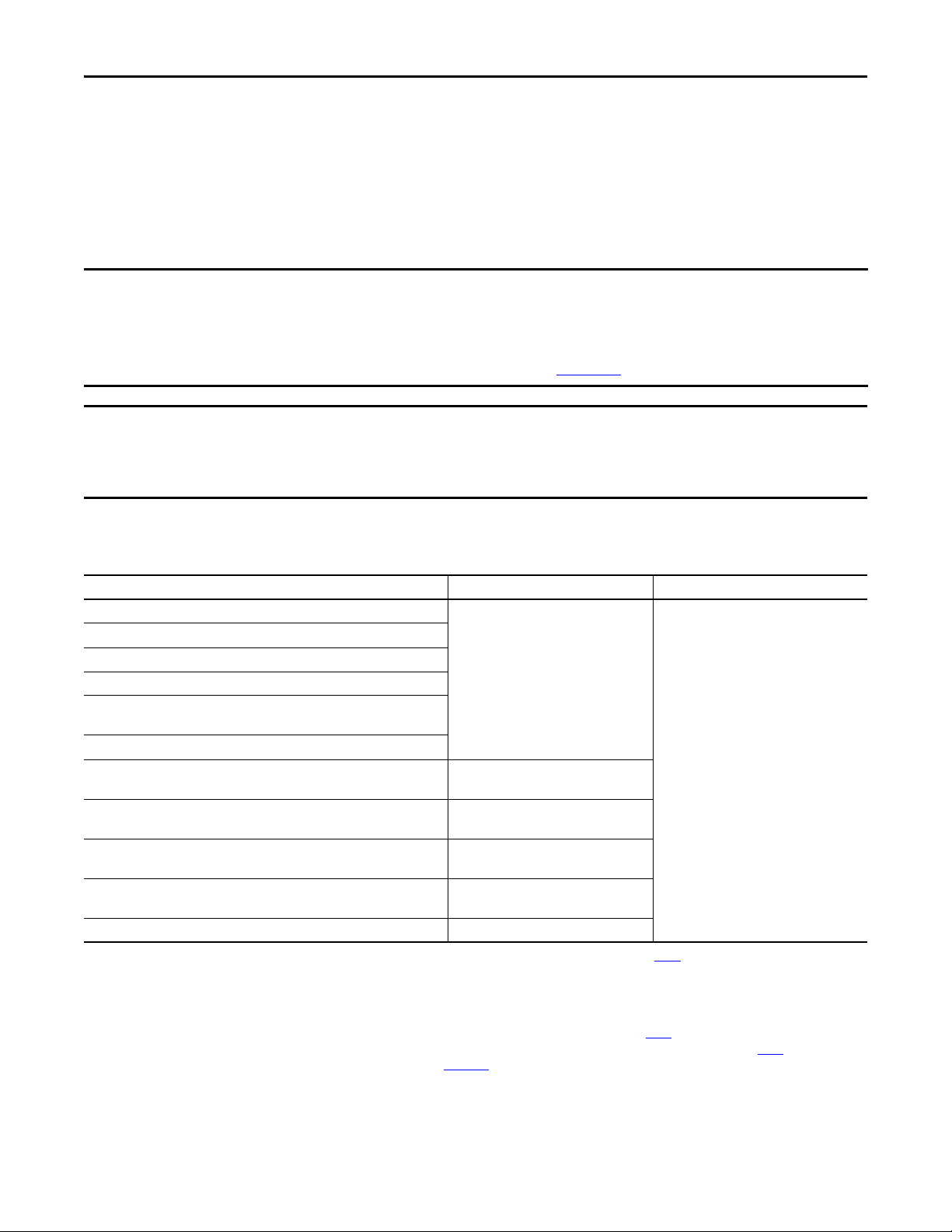

2094-BMP5-S @ 250% or 2094-BMP5-M

and MPL-B310P

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

0

2000

4000

30001000

5000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

2094-BM01-S @ 250% or 2094-BM01-M

and MPL-B330P

Torque

(N•m)

Torque

(lb•in)

2094-BM02-S @ 250% or 2094-BM02-M

and MPL-B430P

0

0

5

10

15

44

88

133

20

177

Speed (rpm)

0

3000

5000

40001000

2000

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 6000 and Kinetix 6200/6500 (400V-class) Drives/MP-Series Low Inertia Motor Curves (continued)

2094-BM01-S @ 250% or 2094-BM01-M

Torque

(N•m)

8.0

and MPL-B320P

7.0

70.8

61.9

Torque

(lb•in)

Torque

(N•m)

6.0

5.0

4.0

3.0

2.0

1.0

0

1000 2000 3000 4000

0

Speed (rpm)

2094-BM02-S @ 250% or 2094-BM02-M

16

12

8

4

and MPL-B420P

5000

141

106

70.8

35.4

53.1

44.2

35.4

26.5

17.7

8.85

0

Torque

(lb•in)

0

0

2094-BM01-S @ 250% or 2094-BM01-M

25

Torque

(N•m)

20

15

10

Rockwell Automation Publication GMC-RM003C-EN-P - September 2013 29

5

0

and MPL-B4530F

500

1000 1500 20000 2500

30001000

2000

Speed (rpm)

Speed (rpm)

4000

0

5000

221

177

133

88.5

44.2

0

3000

Torque

(lb•in)

Page 30

Kinetix 6000 and Kinetix 6200/6500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

0

0

5

10

15

25

20

44.2

88.5

133

177

221

2094-BM02-S @ 250% or 2094-BM02-M

and MPL-B4530K

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

2094-BM02-S @ 250% or 2094-BM02-M

and MPL-B4560F

0

0

10

20

30

88.5

177

265

40

354

Speed (rpm)

500

1000 1500 20000 2500

3000

Torque

(N•m)

Torque

(lb•in)

0

0

5

10

15

25

20

44.2

88.5

133

177

221

2094-BM02-S @ 250% or 2094-BM02-M

and MPL-B520K

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

10

20

30

50

40

88.5

177

265

354

2094-BM02-S @ 250% or 2094-BM02-M

and MPL-B540D

442

Speed (rpm)

0

1000

2000

1500500

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 6000 and Kinetix 6200/6500 (400V-class) Drives/MP-Series Low Inertia Motor Curves (continued)

2094-BM02-S @ 250% or 2094-BM02-M

Torque

(N•m)

30

and MPL-B4540F

25

265

221

Torque