Page 1

"!

"

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes

and standards. In no event will Rockwell Automation be responsible or

liable for indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout examples shown

in this publication are intended solely for purposes of example. Since

there are many variables and requirements associated with any particular

installation, Rockwell Automation does not assume responsibility or

liability (to include intellectual property liability) for actual use based

upon the examples shown in this publication.

Allen–Bradley publication SGI–1.1, Safety Guidelines for Application,

Installation, and Maintenance of Solid–State Control (available from

your local Rockwell Automation office), describes some important

differences between solid–state equipment and electromechanical

devices that should be taken into consideration when applying products

such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their accompanying

statements help you to identify a potential hazard. avoid a potential

hazard, and recognize the consequences of a potential hazard.

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that may lead to personal injury or

death, property damage, or economic loss.

!

Identifies information that is critical for

IMPORTANT

successful application and understanding of the

product.

Page 3

ATTENTION

!

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC publication

60664–1), at altitudes up to 2000 meters without

derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions, there

may be potential difficulties ensuring electromagnetic

compatibility in other environments due to conducted

as well as radiated disturbance.

This equipment is supplied as “open type” equipment.

It must be mounted within an enclosure that is suitably

designed for those specific environmental conditions

that will be present, and appropriately designed to

prevent personal injury resulting from accessibility to

live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent

sections of this publication may contain additional

information regarding specific enclosure type ratings

that are required to comply with certain product safety

certifications.

ATTENTION

!

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of

the degrees of protection provided by different types of

enclosures. Also, see the appropriate sections in this

publication, as well as the Allen–Bradley publication

1770–4.1, (“Industrial Automation Wiring and

Grounding Guidelines”), for additional installation

requirements pertaining to this equipment.

FLEX I/O is grounded through the DIN rail to chassis

ground. Use zinc plated, yellow chromated steel DIN

rail to assure proper grounding. Using other DIN rail

material (e.g. aluminum, plastic, etc.) which can

corrode, oxidize or are poor conductors can result in

improper or intermittent platform grounding.

Page 4

ATTENTION

!

Preventing Electrostatic Damage

This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal

operation. Follow these guidelines when you handle

this equipment.

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch components inside the equipment.

• If available, use a static–safe workstation.

• When not in use, keep modules in appropriate

static–safe packing.

Page 5

The information below summarizes the changes to the Remote I/O

Adapter User Manual, publication 1794-UM009D–EN–P, since the

last release.

The series E adapter is capable of recognizing the safe state data for

the FLEX Integra analog modules, and allows use of 32 point FLEX

I/O modules. You must use a series D or later adapter when using

FLEX Integra analog modules in your system.

New Information

The following new information is included in this version of the

publication:

Corrected Switch Positions

Switch positions on S! and S2 were incorrectly identified in the

previous version of this publication. Corrections have been made on

page 2–11 of Chapter 2.

Additional FLEX I/O Modules

New modules available since the last version of this publication have

been added.

Change Bars

The areas in this manual which are different from previous editions

are marked with change bars (as shown to the right of this paragraph)

to indicate the addition of new or revised information.

Publication 1794ĆUM009D-EN-P - April 2004

Page 6

soc–ii Summary of Changes

Publication 1794ĆUM009D-EN-P - April 2004

Page 7

T

Using This Manual

Preface

Preface Objectives

Audience

Vocabulary

Read this preface to familiarize yourself with this manual and to

learn how to use it properly and efficiently.

Important:

You must use a series D or later adapter to

IMPORTAN

We assume that you have previously used an Allen–Bradley

programmable controller, that you are familiar with its features, and

that you are familiar with the terminology we use. If not, read the

user manual for your processor before reading this manual.

In this manual, we refer to:

communicate with FLEX Integra analog modules. You

must use a series E or later adapter to communicate

with 32 point FLEX modules.

• the individual adapter module as the “adapter.”

• the programmable controller as the “controller” or the

“processor.”

• input and output modules as the “module.”

What This Manual

Contains

The contents of this manual are as follows:

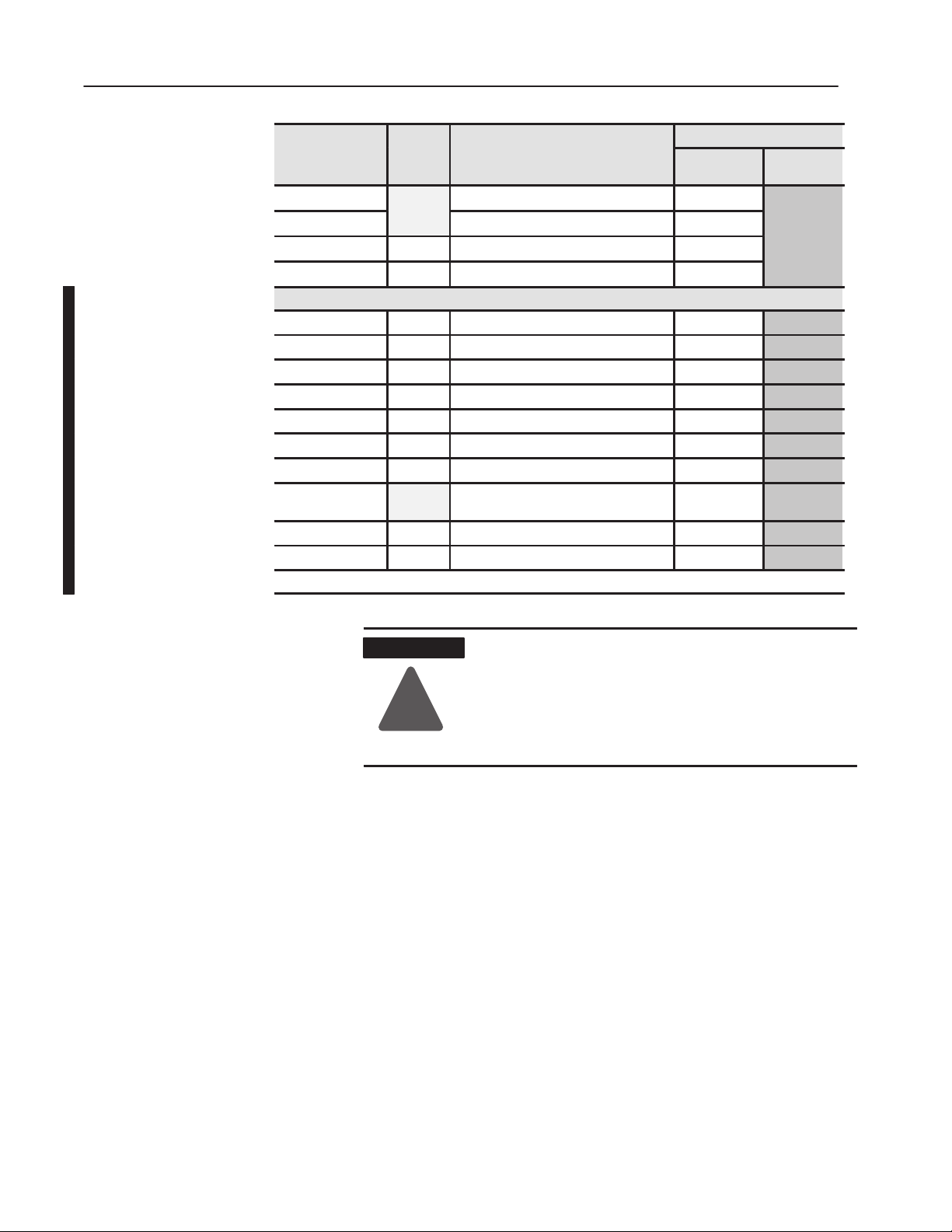

Table P. A

What This Manual Contains

Chapter Title What's Covered

1

2 Installing Your Remote I/O Adapter Procedures and guidelines for installing the module

3 Communicating with FLEX I/O Modules Hardware addressing and configuration options

4 Troubleshooting Troubleshooting aids

Appendix Title What's Covered

A Specifications Module specifications

B

C Safety Approvals

Overview of FLEX I/O and the Remote

I/O Adapter Module

Differences Between Series A, B, C, D

and E Remote I/O Adapters

Describes features, capabilities, and hardware

components.

Publication 1794ĆUM009D-EN-P - April 2004

Page 8

Using This ManualP–2

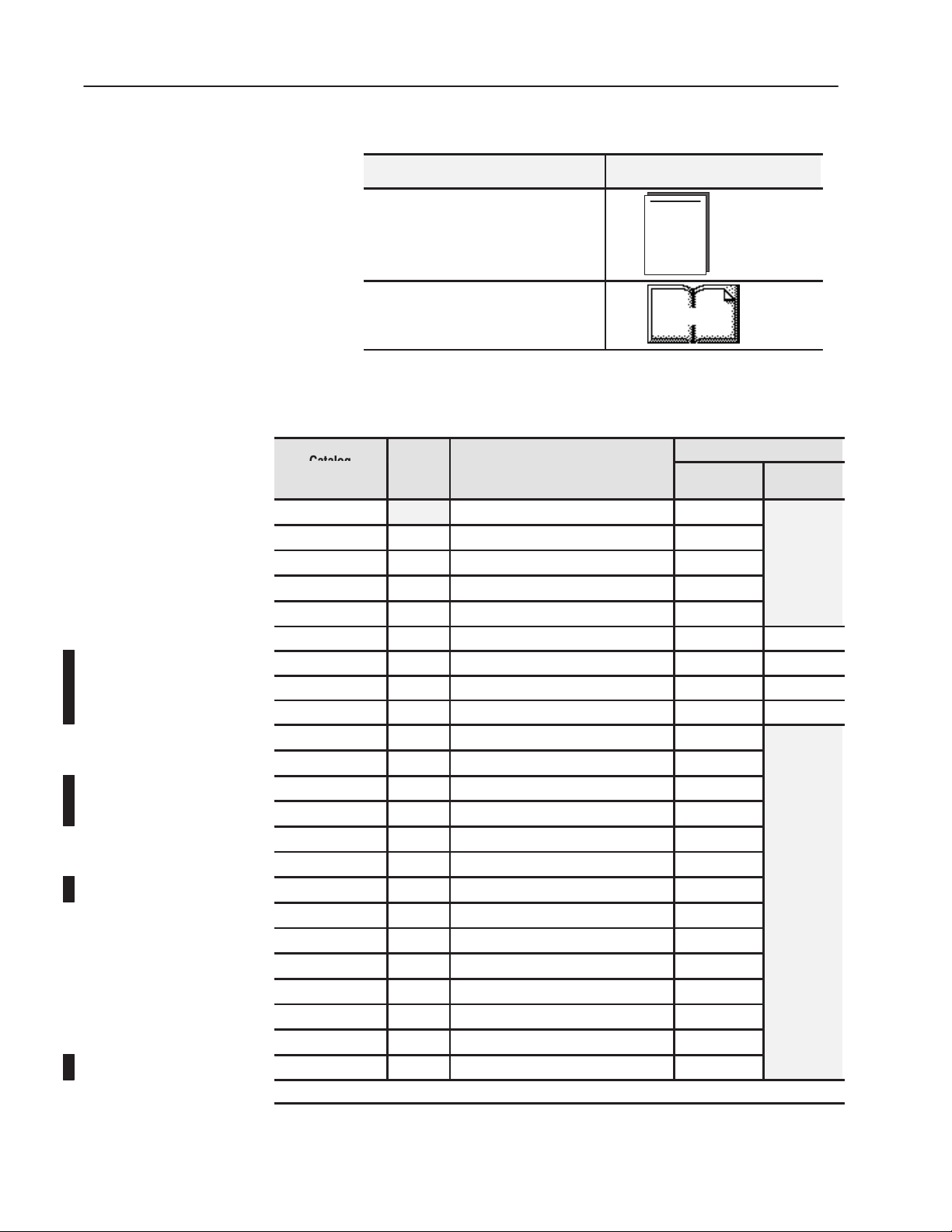

Catalog

Conventions

For Additional Information

1794ĆACNR 24V dc Redundant Media ControlNet Adapter

1794ĆACN15 24V dc ControlNet Adapter

1794ĆACNR15 24V dc Redundant Media ControlNet Adapter

1794ĆASB/E 24V dc Remote I/O Adapter 1794ĆIN046 1794ĆUM009

1794ĆASB2/D 24V dc 2ĆSlot Remote I/O Adapter 1794ĆIN044 1794ĆUM059

1794ĆOB16P 24V dc 16 Source Output Module

1794ĆOB32P 24V dc 32 Electronically Fused Output Module

1794ĆOB8EP 24V dc 8 Electronically Fused Output Module

1794ĆOV16P 24V dc 16 Electronically Fused Output Module

1794ĆIB10XOB6 24V dc 10 Input/6 Output Module

1794ĆIB16XOB16P 24V dc 16 Input/16 Output Module

We use these conventions in this manual:

In this manual, we show: Like this:

that there is more information about a topic

in another chapter in this manual

that there is more information about the

topic in another manual

More

For additional information on FLEX I/O systems and modules, refer

to the following documents:

Publications

Number

1794 1794 FLEX I/O Product Data

1794ĆACN 24V dc ControlNet Adapter

1794ĆADN 24V dc DeviceNet Adapter 1794Ć5.14 1794Ć6.5.5

1794ĆAPB 24V dc Profibus Adapter 1794ĆIN040 1794ĆUM057

1794ĆIB8 24V dc 8 Sink Input Module

1794ĆOB8 24V dc 8 Source Output Module

1794ĆIB16 24V dc 16 Sink Input Module

1794ĆIB32 24V dc 16 Source Output Module

1794ĆOB16 24V dc 16 Source Output Module

1794ĆIV16 24V dc 16 Source Input Module

1794ĆOV16 24V dc 16 Sink Output Module

1794ĆIB8S 24V dc Sensor Input Module

Voltage Description

Table continued on next page

Installation

Instructions

1794Ć2.1

1794Ć5.8

1794Ć5.18

1794Ć5.47

1794Ć5.48

1794Ć5.30

1794Ć5.31

1794ĆIN072

1794ĆIN084

1794Ć5.3

1794Ć5.45

1794ĆIN090

1794Ć5.28

1794Ć5.29

1794Ć5.20

1794Ć5.52

1794Ć5.7

1794Ć5.24

1794ĆIN083

User

Manual

Publication 1794ĆUM009D-EN-P - April 2004

Page 9

Using This Manual P–3

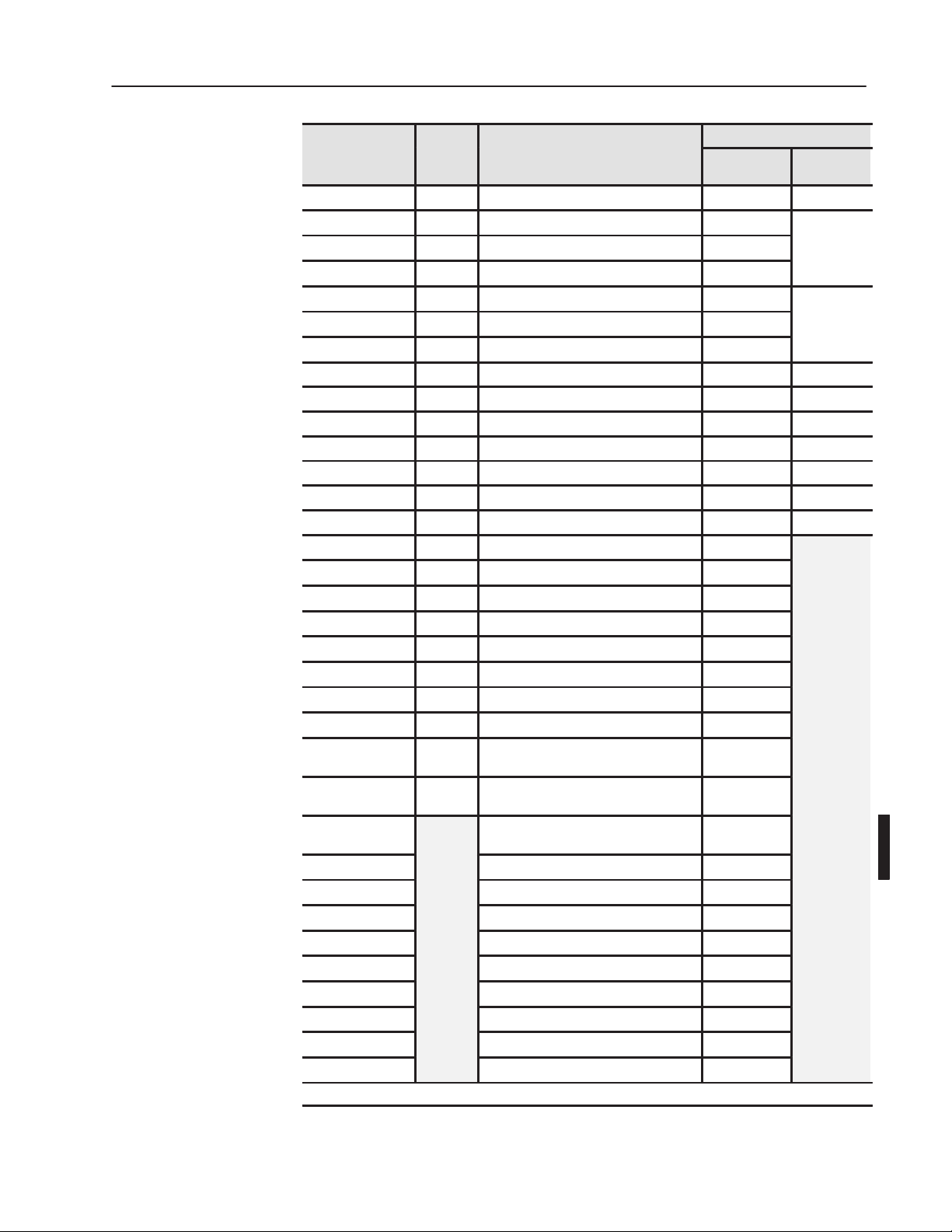

Catalog

Catalog

Number

Number

DescriptionVoltage

DescriptionVoltage

Publications

Installation

Instructions

User

Manual

1794ĆOW8 24V dc 8 Relay Output Module 1794Ć5.19

1794ĆIE8 24V dc Selectable Analog 8 Input Module

1794ĆOE4 24V dc Selectable Analog 4 Output Module

1794ĆIE4XOE2 24V dc 4 Input/2 Output Analog Module

1794ĆOF4I 24V dc 4 Output Isolated Analog Module

1794ĆIF4I 24V dc 4 Input Isolated Analog Module

1794ĆIF2XOF2I 24V dc 2 Input/2 Output Isolated Analog Module

1794Ć5.6

1794Ć5.5

1794Ć5.15

1794Ć5.37

1794Ć5.38

1794Ć5.39

1794Ć6.5.2

1794Ć6.5.8

1794ĆIR8 24V dc 8 RTD Input Analog Module 1794Ć5.22 1794Ć6.5.4

1794ĆIT8 24V dc 8 Thermocouple Input Module 1794Ć5.21 1794Ć6.5.7

1794ĆIRT8 24V dc 8 Thermocouple/RTD Input Module 1794Ć5.50 1794Ć6.5.12

1794ĆIJ2 24V dc 2 Frequency Input Module 1794Ć5.49 1794Ć6.5.11

1794ĆID2 24V dc 2 Channel Frequency Input Module 1794Ć5.63 1794Ć6.5.15

1794ĆIP4 24V dc 2 Channel Pulse Counter Module 1794Ć5.64 1794Ć6.5.16

1794ĆHSC 24V dc High Speed Counter Module 1794Ć5.67 1794Ć6.5.10

1794ĆIC16 48V dc 48V dc 16 Input Module

1794ĆOC16 48V dc 48V dc Output Module

1794ĆIA8 120V ac 8 Input Module

1794ĆOA8 120V ac 8 Output Module

1794ĆIA8I 120V ac Isolated 8 Input Module

1794ĆOA8I 120V ac Isolated Output Module

1794ĆIA16 120V ac 16 Input Module

1794ĆOA16 120V ac 16 Output Module

1794ĆIM8 220V

8 Input Module

ac/dc

1794ĆOM8 220V

8 Output Module

ac/dc

1794ĆTB2

1794ĆTB3

2Ćwire Terminal Base

3Ćwire Terminal Base

1794ĆTBN Terminal Base Unit

1794ĆTBNF Fused Terminal Base Unit

1794ĆTB3T Temperature Terminal Base Unit

1794ĆTB3S Spring Clamp Terminal Base Unit

1794ĆTB3TS Spring Clamp Temperature Base Unit

1794ĆTB3G Terminal Base Unit

1794ĆTB3GS Spring Clamp Terminal Base Unit

1794ĆTB32 Cage Clamp Terminal Base Unit

1794ĆTB32S Spring Clamp Terminal Base Unit

1794Ć5.53

1794Ć5.54

1794Ć5.9

1794Ć5.10

1794Ć5.55

1794Ć5.56

1794Ć5.60

1794Ć5.61

1794Ć5.57

1794Ć5.58

1794ĆIN070

1794ĆIN016

1794Ć5.17

1794Ć5.41

1794Ć5.42

1794Ć5.43

1794Ć5.51

1794Ć5.59

1794ĆIN085

1794ĆIN085

Table continued on next page

Publication 1794ĆUM009D-EN-P - April 2004

Page 10

Using This ManualP–4

Catalog

Catalog

Number

Number

1794ĆCE1, ĆCE3 Extender Cables

1794ĆNM1 Mounting Kit

1794ĆPS13 24V dc Power Supply

1794ĆPS3 24V dc Power Supply

1797ĆIBN16 See note 16 NAMUR Digital Input Module 1794ĆIN072

1797ĆOB4D See note 4 NI, Ex Source Digital Output Module 1794Ć5.6

1797ĆIE8 See note 8 Selectable Input Module 1794Ć5.5

1797ĆIE8NF See note 8 Selectable Filter Analog Input Module 1794Ć5.31

1797ĆOE4 See note Selectable Analog 4 Output Module 1794Ć5.3

1797ĆIRT8 See note 8 Thermocouple/RTD Input Module 1794Ć5.4

1797ĆIJ2 See note 2 Frequency Input Module 1794Ć5.9

1797ĆTB3

1797ĆTB3S

1797ĆBIC See note I.S. Bus Isolator 1797Ć5.13

1797ĆCEC See note FLEX Ex Bus Connector 1797Ć5.13

Note: Intrinsically Safe Voltage

3Ćwire Screw Clamp Terminal Base

3Ćwire Spring Clamp Terminal Base

DescriptionVoltage

DescriptionVoltage

FLEX Ex

Installation

Instructions

1794Ć5.12

1794Ć5.13

1794Ć5.35

1794Ć5.71

1797Ć5.1

1797Ć5.2

Publications

User

Manual

ATTENTION

!

FLEX I/O is grounded through the DIN rail to chassis

ground. Use zinc plated, yellow chromated steel DIN

rail to assure proper grounding. Using other DIN rail

materials (e.g. aluminum, plastic, etc.) which can

corrode, oxidize or are poor conductors can result in

improper or intermittent platform grounding.

Publication 1794ĆUM009D-EN-P - April 2004

Page 11

Using This Manual P–5

ATTENTION

!

WARNING

!

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static–safe workstation.

• When not in use, keep modules in appropriate

static–safe packaging.

Remove field-side power before removing or

inserting this module. This module is designed so

you can remove and insert it under backplane

power. When you remove or insert a module with

field-side power applied, an electrical arc may

occur. An electrical arc can cause personal injury or

property damage by:

• sending an erroneous signal to your system’s

field devices causing unintended machine motion

• causing an explosion in a hazardous environment

Repeated electrical arcing causes excessive wear to

contacts on both the module and its mating

connector. Worn contacts may create electrical

resistance.

Publication 1794ĆUM009D-EN-P - April 2004

Page 12

Using This ManualP–6

This preface gave you information on how to use this manual

efficiently. The next chapter introduces you to the remote I/O

adapter module.

Publication 1794ĆUM009D-EN-P - April 2004

Page 13

Table of Contents

Overview of FLEX I/O and

your Remote I/O Adapter

Module

Installing Your Remote I/O

Adapter Module

Chapter 1

Chapter Objectives 1-1...................................

The FLEX I/O System 1-1.................................

How FLEX I/O Modules Communicate with Programmable Controllers 1-2

Hardware Components 1-3................................

Diagnostic Indicators 1-3................................

Reset Pushbutton 1-4..................................

Remote I/O Wiring 1-4..................................

Power Wiring 1-4......................................

Address Switch Assemblies 1-4...........................

Chapter Summary 1-4....................................

Chapter 2

Chapter Objectives 2-1...................................

Power Requirements 2-3..................................

Mounting the Remote I/O Adapter 2-3.........................

Mounting on a DIN Rail before installing the terminal base units 2-3..

Mounting (or Replacing) the Adapter on an Existing System 2-4....

Mounting on a Wall or Panel 2-5...........................

Wiring 2-7.............................................

Setting the Switches 2-8..................................

Starting I/O Group 2-8..................................

I/O Rack Number 2-8...................................

Hold Inputs 2-8.......................................

Rack Fault Select Switch (RFS) 2-9........................

Addressing Mode Selection Switches 2-9....................

Communication Rate 2-10................................

Processor Restart Lockout (PRL) 2-10.......................

Hold Last State (HLS) 2-10...............................

Setting the Mode Selection Switches 2-12.......................

Setting the Address Switches 2-13............................

Setting the Address Switches for Complementary I/O 2-15...........

Primary Rack 2-15.....................................

Complementary Rack 2-15................................

Chapter Summary 2-15....................................

Communicating with

FLEX I/O Modules

Chapter 3

Chapter Objectives 3-1...................................

FLEX I/O Module Data 3-1.................................

Addressing I/O 3-2......................................

Analog (Block Transfer) Modules 3-5.........................

Publication 1794ĆUM009D-EN-P - April 2004

Page 14

Table of Contentsii

Standard Addressing 3-6..................................

Standard - 32 Addressing 3-7..............................

Compact Addressing 3-8..................................

Compact Mode 3-8....................................

Complementary Addressing Mode 3-12........................

Complementary Mode - 16Ćpoint 3-12.......................

Complementary Mode - 8Ćpoint 3-13........................

Complementary - 32 Addressing 3-15.........................

Mapping Data into the Image Tables 3-16.......................

Determining Rack Size 3-16.................................

Operating Modes 3-18.....................................

Chapter Summary 3-18....................................

Troubleshooting

Specifications

Differences Between

Remote I/O Adapter Series

A, B, C, D and E

Safety Approvals

Chapter 4

Chapter Objectives 4-1...................................

Fault Conditions 4-1.....................................

Troubleshooting with the Indicator Lights 4-1....................

Chapter Summary 4-3....................................

Appendix A

Specifications A-1.......................................

Appendix B

Differences Between Remote I/O Adapter Series A, B, C, D and E B-1..

Appendix C

Safety Approvals C-1.....................................

Publication 1794ĆUM009D-EN-P - April 2004

Page 15

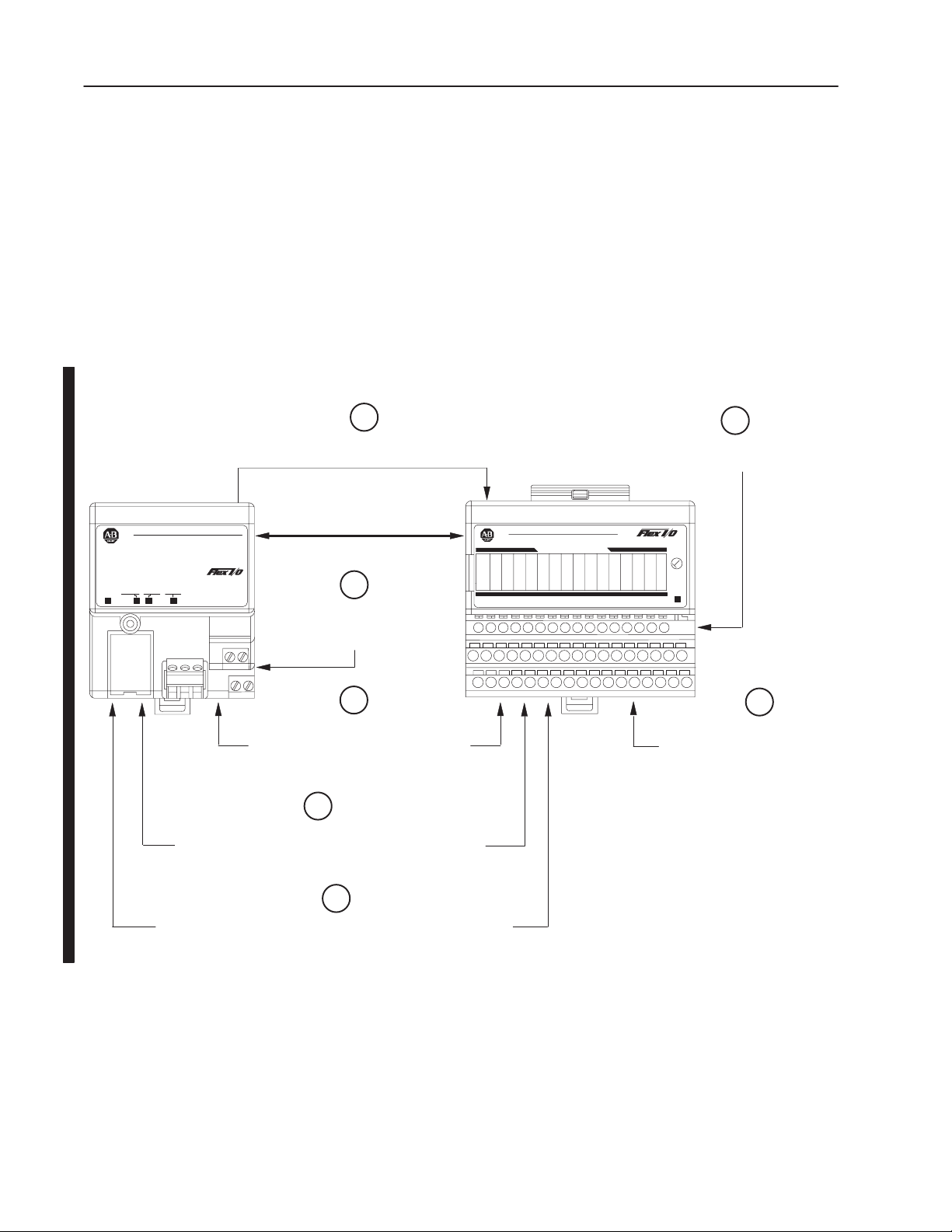

Overview of FLEX I/O and your

Remote I/O Adapter Module

Chapter Objectives

The FLEX I/O System

Adapter

In this chapter, we tell you about:

• what the FLEX I/O system is and what it contains

• how FLEX I/O modules communicate with programmable

controllers

• the features of your adapter module

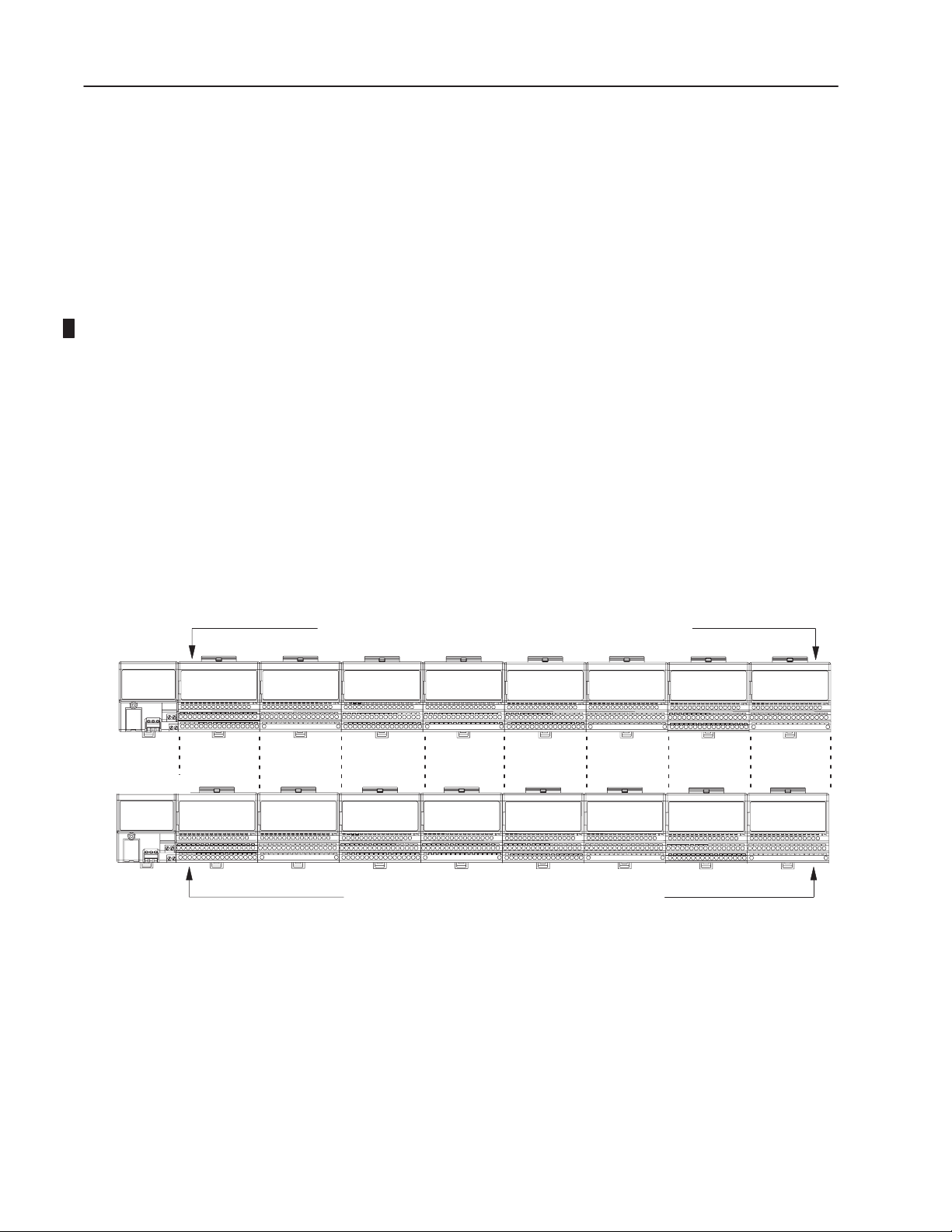

FLEX I/O is a small, modular I/O system for distributed

applications that performs all of the functions of rack-based I/O. The

FLEX I/O system contains the following components shown below:

Terminal Base

I/O Module

20125

• adapter/power supply – powers the internal logic for as many as

eight I/O modules

• terminal base – contains a terminal strip to terminate wiring for

two- or three-wire devices

• I/O module – contains the bus interface and circuitry needed to

perform specific functions related to your application

Publication 1794ĆUM009D-EN-P - April 2004

Page 16

1–2 Overview of FLEX I/O and your Remote I/O Adapter Module

How FLEX I/O Modules

Communicate with

Programmable Controllers

The adapter transfers your configuration data

PWR

ADAPTER

ACTIVE FAULT

LOCAL

FAULT

POWER SUPPLY

RIO ADAPTER

1794ĆASB

24VDC

Your ladder program instructs the

adapter to perform a BTR of the values

and stores them in a data table.

Data transfer to and from the remote I/O adapter/power supply and

discrete I/O modules occurs every flexbus scan. This provides the

controller with updated data.

The remote I/O adapter/power supply transfers data to the analog I/O

module (block transfer write) and from the analog I/O module (block

transfer read) using BTW and BTR instructions in your ladder

diagram program. These instructions let the adapter obtain input

values and status from the I/O module, and let you send output

values to establish the module’s mode of operation. The

communication process is described in the following illustration.

1

to the module using a BTW.

Flexbus

4

INPUT 0 INPUT 2 INPUT 4 INPUT 6INPUT 1 INPUT 3 INPUT 5 INPUT 7

IVIVIVIVIVIVIVI

ANALOG INPUT

2

External devices transmit

analog signals to the module.

1794-IE8

2

V

5

The adapter and module determine

that the transfer was made without error

and input values are within specified

range.

6

Your ladder program can use and/or move the data (if valid)

before it is written over by the transfer of new data in a

subsequent transfer.

7

Your ladder program performs BTWs to the module when you power

it up, and any time you wish to reconfigure the module.

3

The module converts analog signals

into binary format and stores these

values until the adapter requests their

transfer.

Publication 1794ĆUM009D-EN-P - April 2004

Page 17

1–3Overview of FLEX I/O and your Remote I/O Adapter Module

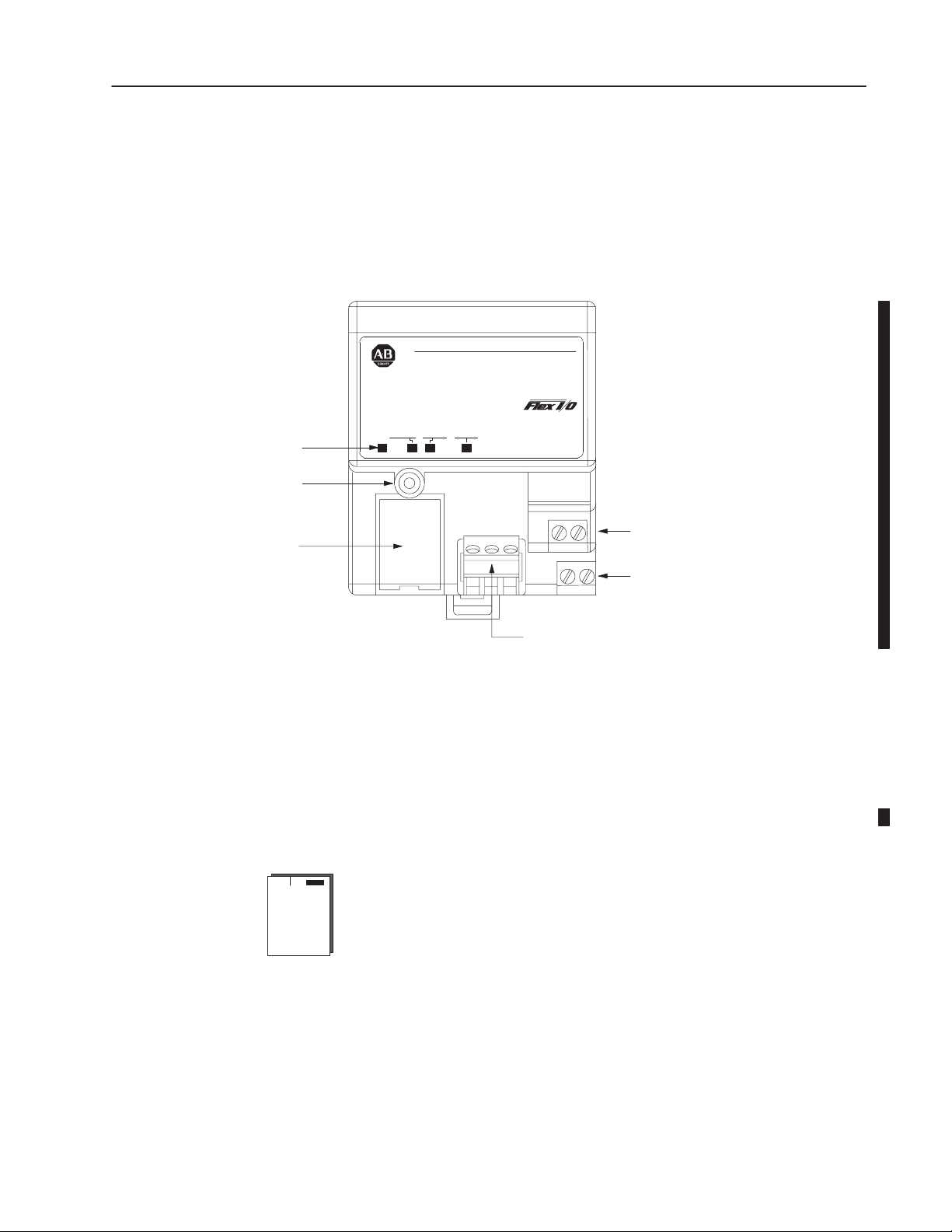

Hardware Components

Diagnostic Indicators

Reset Pushbutton

Address/Group Switches

The adapter module consists of the following major components:

• diagnostic indicators

• reset pushbutton

• remote I/O wiring connections

• 24V dc power wiring connections

• address/group switch assemblies

AllenĆBradley

ADAPTER

ACTIVE FAULT

PWR

LOCAL

FAULT

24 VDC

POWER SUPPLY

RIO ADAPTER

1794-ASB

24V dc Common Wiring Connections

+24V dc Wiring Connections

Remote I/O Wiring Connections (connector part no. 942029-03)

Diagnostic Indicators

Diagnostic indicators are located on the front panel of the adapter

module. They show both normal operation and error conditions in

your remote I/O system. The indicators are:

• Power ON (green)

• Adapter ACTIVE (green)

• Adapter FAULT (red)

• LOCAL FAULT (red)

A complete description of the diagnostic indicators and how to use

them for troubleshooting is explained in chapter 4.

Publication 1794ĆUM009D-EN-P - April 2004

Page 18

1–4 Overview of FLEX I/O and your Remote I/O Adapter Module

Reset Pushbutton

Use the reset pushbutton to reset the adapter module and resume

communication when a communication error occurs. (The adapter’s

processor restart lockout switch (PRL) must be in the “locked out”

position.) If the adapter is not locked out by the PRL switch, it

will be automatically reset via special commands sent over the

communication link.

Important: Do not cycle power to the adapter to clear a fault. All

queued block transfer instructions will be lost.

Remote I/O Wiring

The remote I/O wiring termination is made to a plug-in connector on

the front of the adapter module. Refer to Chapter 2 for information

on wiring the connector.

FlipĆopen

cover

ON

S1

Power Wiring

Connections are provided for connecting the required 24V dc power

to the front of the module. The power wiring can be daisy-chained to

the terminal base unit located next to the adapter to supply power to

the module installed in that base unit. Wiring information is shown in

Chapter 2.

Address Switch Assemblies

Multi-position switches are provided for:

• starting I/O group

• I/O rack number

• hold inputs

• mode switches for mode 0, mode 1, mode 2, mode 3 and mode 4

• rack fault

87654321

87654321

• communication rate

• processor restart lockout (PRL)

• hold last state (outputs)

These switches are accessed by lifting the hinged cover on the front

ON

S2

of the module. Refer to Chapter 2 for switch settings.

Chapter Summary

Publication 1794ĆUM009D-EN-P - April 2004

In this chapter you learned about the FLEX I/O system and features

of the remote I/O adapter module.

Page 19

Installing Your Remote I/O

Adapter Module

Chapter Objectives

This chapter describes the procedures for installing your remote I/O

adapter module. These include:

• power requirements

• mounting the remote I/O adapter

• setting the module switches

ATTENTION

!

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC

publication 60664–1), at altitudes up to 2000

meters without derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring

electromagnetic compatibility in other

environments due to conducted as well as radiated

disturbance.

This equipment is supplied as “open type”

equipment. It must be mounted within an

enclosure that is suitably designed for those

specific environmental conditions that will be

present, and appropriately designed to prevent

personal injury resulting from accessibility to live

parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent

sections of this publication may contain additional

information regarding specific enclosure type

ratings that are required to comply with certain

product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations

of the degrees of protection provided by different

types of enclosures. Also, see the appropriate

sections in this publication, as well as the

Allen–Bradley publication 1770–4.1, (“Industrial

Automation Wiring and Grounding Guidelines”),

for additional installation requirements pertaining

to this equipment.

Publication 1794ĆUM009D-EN-P - April 2004

Page 20

2–2 Installing Your Remote I/O Adapter Module

ATTENTION

!

ATTENTION

!

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static–safe workstation.

• When not in use, keep modules in appropriate

static–safe packaging.

Remove field-side power before removing or

inserting this module. This module is designed so

you can remove and insert it under backplane

power. When you remove or insert a module with

field-side power applied, an electrical arc may

occur. An electrical arc can cause personal injury

or property damage by:

ATTENTION

!

• sending an erroneous signal to your system’s

field devices causing unintended machine

motion

• causing an explosion in a hazardous environ-

ment

Repeated electrical arcing causes excessive wear

to contacts on both the module and its mating

connector. Worn contacts may create electrical

resistance.

FLEX I/O is grounded through the DIN rail to

chassis ground. Use zinc plated, yellow chromated

steel DIN rail to assure proper grounding. Using

other DIN rail materials (e.g. aluminum, plastic,

etc.) which can corrode, oxidize or are poor

conductors can result in improper or intermittent

platform grounding.

Publication 1794ĆUM009D-EN-P - April 2004

Page 21

2–3Installing Your Remote I/O Adapter Module

Power Requirements

Mounting the Remote I/O

Adapter

A

The Remote I/O adapter module requires a current of 450mA at

24V dc from an external power supply for flexbus operation. This is

sufficient to support the flexbus current requirements of 8 modules.

Remember to add this amount to current requirements for other

modules using the same 24V supply.

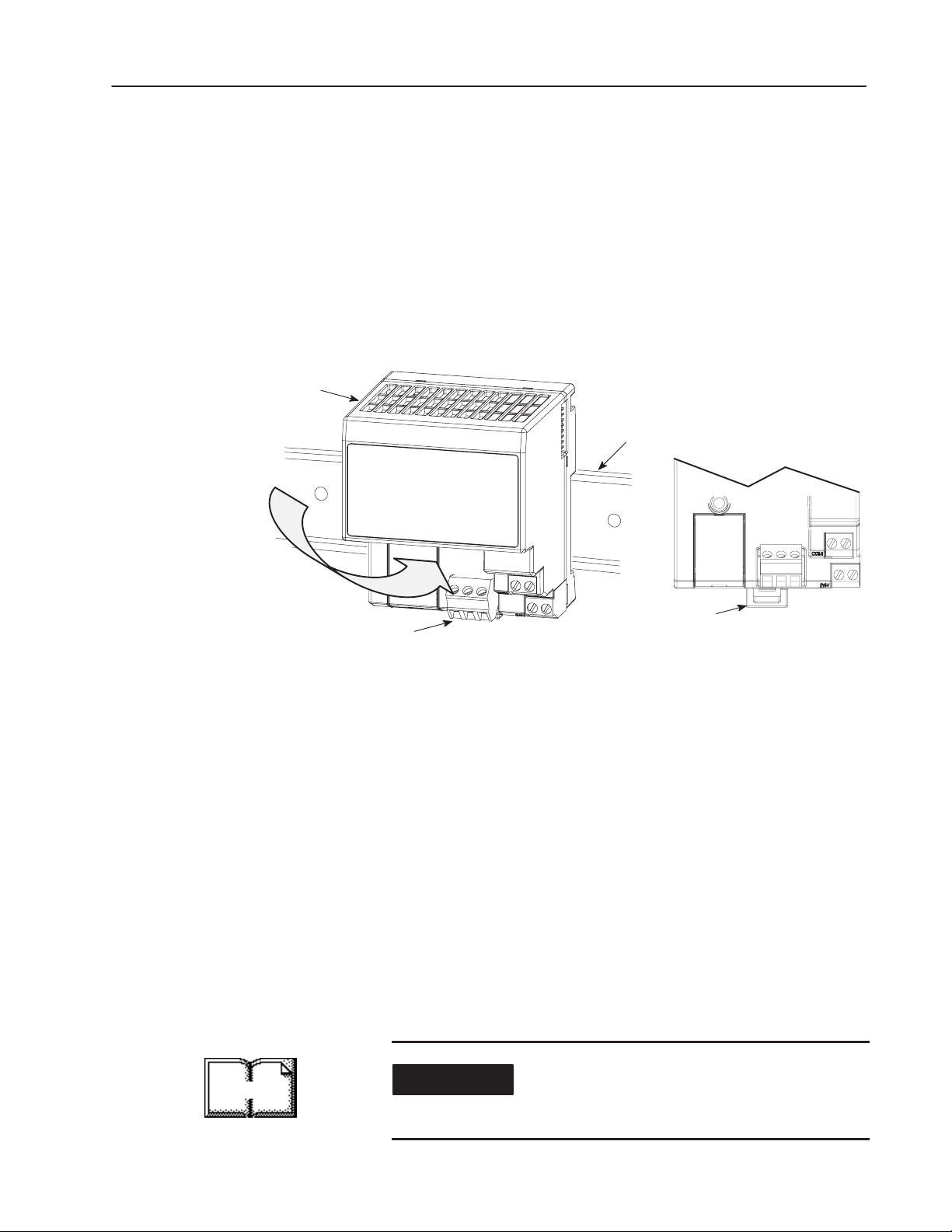

The remote I/O adapter module can be DIN rail or wall/panel

mounted. Refer to the specific method of mounting below.

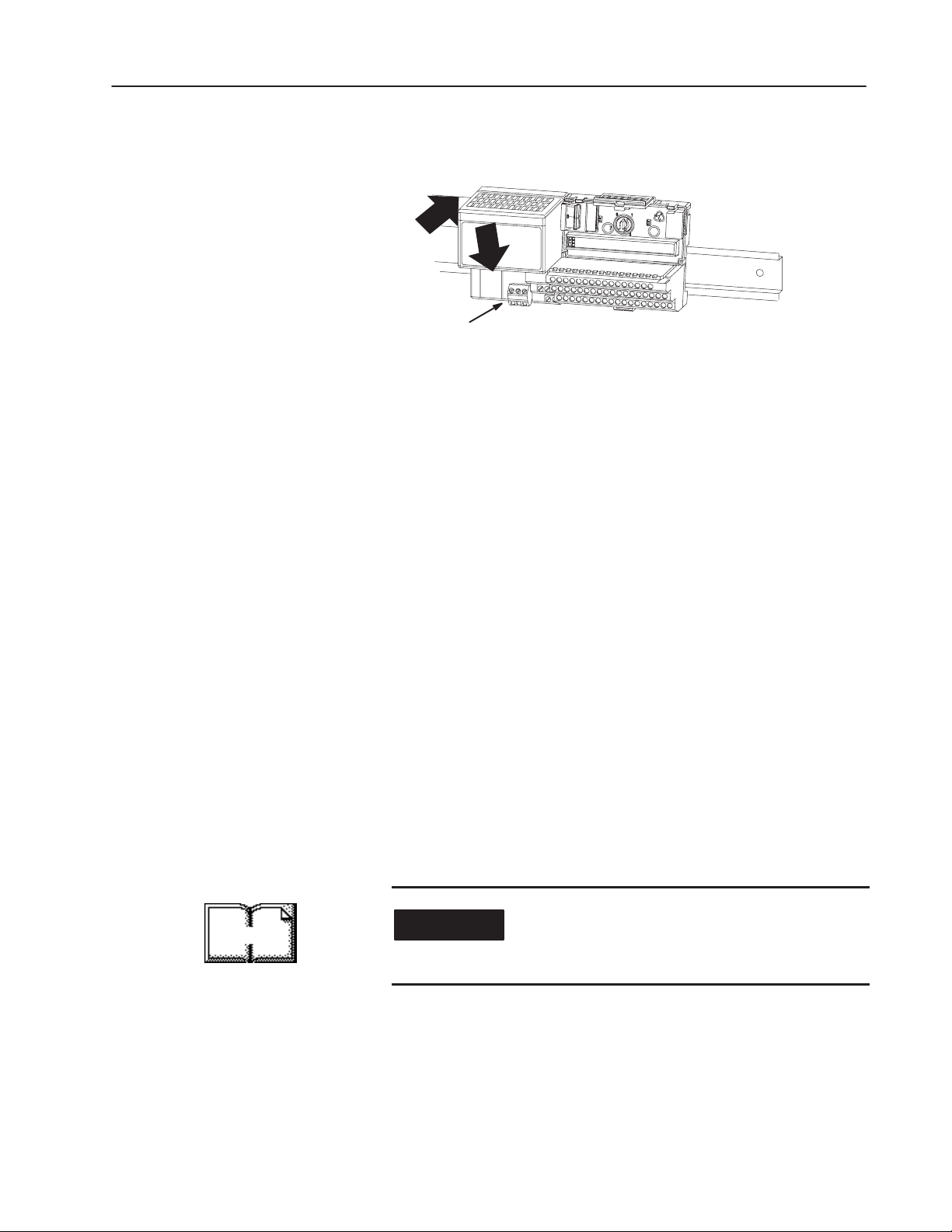

Mounting on a DIN Rail before installing the terminal base units

B

C

C

1. Position the remote I/O adapter module A on a 35 x 7.5mm DIN

rail B (A-B pt. no. 199-DR1; 46277-3; EN 50022) at a slight

angle.

2. Rotate the adapter module onto the DIN rail with the top of the

rail hooked under the lip on the rear of the adapter module.

3. Press the adapter module down onto the DIN rail until flush.

Locking tab (C) will snap into position and lock the adapter

module to the DIN rail.

If the adapter module does not lock in place, use a screwdriver or

similar device to move the locking tab down while pressing the

adapter module flush onto the DIN rail and release the locking tab

to lock the adapter module in place. If necessary, push up on the

locking tab to lock.

4. Connect the adapter wiring as shown under “Wiring” later in this

document.

Make certain that the DIN rail is properly

IMPORTANT

grounded to the panel. Refer to “Industrial

Automation Wiring and Grounding Guidelines,”

publication 1770-4.1.

Publication 1794ĆUM009D-EN-P - April 2004

Page 22

2–4 Installing Your Remote I/O Adapter Module

Mounting (or Replacing) the Adapter on an Existing System

ATTENTION

!

1. Remove the RIO plug-in connector from the front of the adapter.

2. Disconnect any wiring connected to the adjacent terminal base.

3. Using a screwdriver or similar tool, open the lock and remove the

module from the base unit to which the adapter will be attached.

4. Push the flexbus connector toward the right side of the terminal

base to unplug the backplane connection.

ATTENTION

!

If you connect or disconnect wiring while the field

side power is on, an electrical arc can occur. This

could cause an explosion in hazardous location

installations. Be sure that power is removed or the

area is nonhazardous before proceeding.

Make certain that the flexbus connector is

completely clear of the adapter. The slide must be

completely to the right and the raised spot on the

slide visible.

5. Release the locking tab and remove the adapter.

6. Before installing the new adapter, notice the notch on the right

rear of the adapter. This notch accepts the hook on the terminal

base unit. The notch is open at the bottom. The hook and adjacent

connection point keep the terminal base and adapter tight

together, reducing the possibility of a break in communication

over the backplane.

ATTENTION

!

7. Place the adapter next to the terminal base unit and push down to

mate the hook into slot.

Make certain that the hook on the terminal base is

properly hooked into the adapter. Failure to lock

the hook into the adjacent base/adapter can result

in loss of communication on the backplane.

Publication 1794ĆUM009D-EN-P - April 2004

Page 23

2–5Installing Your Remote I/O Adapter Module

T

8. With the hook on the terminal base inside the notch on the

adapter, and the lip on the rear of the adapter hooked over the

DIN rail, press in and down to lock the adapter onto the DIN rail.

C

If the adapter module does not lock in place, use a screwdriver or

similar device to move the locking tab down while pressing the

adapter module flush onto the DIN rail and release the locking tab

(C) to lock the adapter module in place. If necessary, push up on

the locking tab to lock.

9. Gently push the flexbus connector into the side of the adapter to

complete the backplane connection.

10.Reinstall the module into the terminal base unit.

11. Reconnect the adapter wiring as shown under “Wiring.”

Mounting on a Wall or Panel

To mount the remote I/O adapter module on a wall or panel, you

must have the 1794-NM1 mounting kit. The kit contains a special

plate and screws necessary for wall/panel mounting. Proceed as

follows:

Install the mounting plate on a wall or panel as follows:

1. Lay out the required points on the wall/panel as shown in the

drilling dimension drawing.

2. Drill the necessary holes for #6 self-tapping mounting screws.

3. Mount the mounting plate (1) for the adapter module using two

#6 self-tapping screws (18 included).

Make certain that the mounting plate is properly

IMPORTAN

grounded to the panel. Refer to “Industrial

Automation Wiring and Grounding Guidelines

for Noise Immunity,” publication 1770-4.1.

4. Hold the adapter (2) a slight angle and engage the top of the

mounting plate in the indention on the rear of the adapter module.

5. Press the module down flush with the panel until the locking

lever locks.

Publication 1794ĆUM009D-EN-P - April 2004

Page 24

2–6 Installing Your Remote I/O Adapter Module

Inches

(Millimeters)

3.2

(80)

3.4

(87)

.83 (21)

A

1.4

(35)

2.7

(68)

1794 Adapters

3.4H x 2.7W x 2.7D

(87H x 68W x 69D)

2.3

(59)

1794 Terminal Base Units

3.7H x 3.7W x 2.7D

(94H x 94W x 69D)

(35)

3.7

(94)

1.4

3.7

(94)

= Mounting hole dimensions for optional

A

0.9

(23)

mounting kit

6. Position the termination base unit up against the adapter and push

the female bus connector into the adapter.

7. Secure to the wall with two #6 self-tapping screws.

2.0

(50)

1.2

(30)

3.7

(94)

3.2

(80)

2 - Remote I/O Adapter Module

8. Repeat for each remaining terminal base unit.

Note: The adapter is capable of addressing eight modules. Do not

exceed a maximum of eight terminal base units in your system.

1.4

(35.5)

1 - Adapter Mounting Plate

Mounting Screws(18) -

2 for the mounting plate

and 2 each for the 8

possible modules

Publication 1794ĆUM009D-EN-P - April 2004

Page 25

2–7Installing Your Remote I/O Adapter Module

Wiring

Connect external wiring to the remote I/O adapter as shown below.

AllenĆBradley

ADAPTER

LOCAL

ACTIVE FAULT

PWR

SH

1

Termination resistor (if required)

2

82Ω or 150Ω (refer to your processor

documentation for size and usage)

FAULT

24 VDC

POWER SUPPLY

RIO ADAPTER

1794-ASB

BC

COM

A

24V

20131

1. Connect the remote I/O cable to the removable plug-in remote

I/O connector.

Connect To

Blue Wire - RIO 1

Shield Wire - RIO SH

Clear Wire - RIO 2

D

For Example:

DaisyĆchaining

24V dc

ATTENTION

If this is the last adapter in your FLEX I/O

system, or the last adapter on the remote I/O link,

you must use a termination resistor across

!

terminals 1 and 2 on the remote I/O connector.

Refer to the information supplied with the

processor being used for information on the size

of the resistor.

2. Connect +24V dc input to the left side of the lower connector

terminal A.

3. Connect 24V common to the left side of the upper connector

terminal B.

4. Connections C and D are used to pass 24V dc power and

common to the next module in the series (if required).

Wiring when total current draw is less than 10A

Note: Modules must be either all analog or all discrete. Do not mix analog

and discrete modules when using the daisyĆchain wiring scheme.

Note: Refer to the individual instructions for each module for actual wiring information.

Publication 1794ĆUM009D-EN-P - April 2004

Page 26

2–8 Installing Your Remote I/O Adapter Module

Setting the Switches

The remote I/O adapter module has two 8-position switch assemblies

which you set for:

• starting I/O group

• I/O logical rack number

• hold inputs

• addressing modes

• last chassis

• communication rate

• processor restart lockout (PRL)

• hold last state (outputs)

WARNING

!

The switch settings on the series E adapter are not

the same as on the series A, B, C or D adapter. If

you are replacing an earlier series adapter with

this series E adapter, make certain that the

switches are set correctly for your application.

Starting I/O Group

Chapter

An I/O group is an addressing unit that can contain up to 16 input

terminals and 16 output terminals. The starting I/O group is the

first group of input and output circuits that correspond to one word in

both the input and output image tables. These starting I/O groups are

numbered 0, 2, 4 and 6. The number of modules that make up an I/O

group varies with the mode of addressing.

I/O Rack Number

One logical I/O rack is 8 I/O groups. You cannot have more than 2

logical racks per adapter. Refer to “Determining Rack Size” on page

3–16 for examples.

Hold Inputs

When hold inputs is enabled (S2-7 on), the adapter will retain the

last memory image present when you remove a discrete input

module from its base. These inputs are held until the correct module

is placed back in the base. If the same type of module is reinserted

into the base, its inputs will be transferred. If a different type of

module is inserted in the base, its memory image will go to zero.

Any associated outputs will also go to zero.

Publication 1794ĆUM009D-EN-P - April 2004

Page 27

2–9Installing Your Remote I/O Adapter Module

Rack Fault Select Switch (RFS)

The rack fault select allows the user to determine what action the

adapter takes if communication is lost with one or more I/O modules

ATTENTION

!

When RFS is disabled (S2–6 on), module removal and insertion

under power (RIUP) is possible. If an I/O module stops responding,

the adapter declares a local fault and flashes the Local Fault

indicator. The adapter also resets the output data (if any) for the

module not responding. All other modules remain active.

When the RFS is enabled (S2-6 off), communication error

detection is extended to the I/O module level. If an I/O module stops

responding, the adapter declares a local fault, flashes the Local Fault

indicator and causes the scanner to declare a Rack Fault. The adapter

resets the output data (if any) for the module not responding and

commands all other outputs to go to the state determined by the Hold

Last State switch (S2–1).

ATTENTION

If an I/O module stops responding to the adapter

due to a module being removed under power, a

problem with the flexbus, or a problem with an

I/O module, the adapter declares a Local fault.

Module removal and insertion under power

(RIUP) will cause a rack fault when Rack Fault

Select is enabled.

!

Addressing Mode Selection Switches

The addressing mode switches are used to select the addressing

modes of the adapter: standard, 8-pt compact, 16-pt compact, 8-pt

complementary, 16-pt complementary, 32 standard, and 32

complimentary. Refer to the table on page2–12 for information on

the interaction of these switches.

Mode switch S1-1 provides different functions. In standard mode, it

acts as part of the rack address, providing backward compatibility

with the series A or B adapters. In compact mode, it determines 8 or

16-point density. In complementary mode, it specifies whether the

rack has a complementary rack at the same address.

Publication 1794ĆUM009D-EN-P - April 2004

Page 28

2–10 Installing Your Remote I/O Adapter Module

Communication Rate

You set these switches (S2-3 and S2-4) for the desired

communication rate (in bits/s). Selections are:

57.6k bits/s

115.2k bits/s

230.4k bits/s

Autobaud (used in 32-pt modes)

Processor Restart Lockout (PRL)

When PRL is disabled (switch S2-2 on), the programmable

controller can restart communication with the adapter in the event of

a communication fault.

Reset

Pushbutton

When PRL is enabled (switch S2-2 off), the programmable controller

cannot restart communication with the adapter in the event of a

communication fault. In this case, you must press the restart

pushbutton on the front of the adapter module to restart

communication.

Hold Last State (HLS)

The hold last state option allows the user to determine what action

the outputs take in the event of a communication error.

When HLS is enabled (S2–1 off), all digital outputs, and 1794-OE4

and 1794-IE4XOE2 analog modules remain in their last state. All

other analog outputs take their configured safe state action

When HLS is disabled (S2–1 on), all digital outputs are reset. All

analog outputs take their configured safe state action

ATTENTION

!

Only 1794-OE4 and 1794-IE4XOE2 analog

modules hold their last state when Hold Last State

is enabled. Refer to the respective module

publications for information about configuring

analog output safe state actions.

Publication 1794ĆUM009D-EN-P - April 2004

The switch assemblies are located under a flip-open cover on the

front of the adapter module.

Page 29

2–11Installing Your Remote I/O Adapter Module

Starting I/O Group

1

S1-8 S1-7 I/O group

ON ON 0 (1st quarter)

OFF ON 2 (2nd quarter)

ON OFF 4 (3rd quarter)

OFF OFF 6 (4th quarter)

1 In 32 point mode, starting quarter must be 0

(S1-8 and S1-7 on).

I/O Rack Number

S1-6 thru S1-1

Refer to page 2-13

S2-8 Mode Switch 0

Refer to Mode Selection Switches, 2-12

S2-7 Hold Inputs

ON Hold Inputs

OFF Reset Inputs

S2-6 Rack Fault

ON Not Enabled (default)

OFF Enabled

Starting

I/O Group

I/O Rack

Number

Mode

Switch 2

ON

S1

FlipĆopen

cover

87654321

87654321

ON

S2

S2-5 Mode Switch 1

Refer to Mode Selection Switches, 2-12

Communication Rate/

32-pt Mode Select

S2-4 S2-3 Bits/s

ON ON 57.6k

OFF ON 115.2k

ON OFF 230.4k

OFF OFF Autobaud (use only with 32Ćpt

1

Cycle power to the 1794ĆASB/E or push the reset

button when baud rate is changed in the scanner.

1

mode

) Use these switches to put

the adapter in 32-pt mode and

perform autobaud.

Processor Restart Lockout (PRL)

S2-2 Processor:

ON Restart

OFF Locked out

Hold Last State (HLS)

S2-1 Processor will:

ON Reset outputs

OFF Hold last state

ON

S1

87654321

87654321

Mode Switch 0

Hold Inputs

Rack Fault

Mode Switch 1

Mode Switch 4

Communication Rate/Mode switches 3 and 4

Mode Switch 3

Processor Restart Lockout

Hold Last State

ON

S2

Publication 1794ĆUM009D-EN-P - April 2004

Page 30

2–12 Installing Your Remote I/O Adapter Module

2

8Ćpoint modules

2

16Ćpoint modules

2

Setting the Mode Selection

Switches

When Using this

Addressing Mode

Standard

Compact

Complementary See Complementary Rack Addressing Table, page2-15

Primary chassis

Complementary chassis

Complementary See Complementary Rack Addressing Table, page 2-15

Primary chassis

Complementary chassis

1

In standard mode, this switch retains its function as switch position 1 of rack addressing. In Standard mode, the module is functionally

interchangeable with a 1794ĆASB series A or B adapter.

2

In compact mode, 32-point modules appear as 8 or 16-point modules.

3

When programming block transfers, address analog modules as module 0 if switch S1Ć1 is on; module 1 if switch S1Ć1 is off.

Set the mode selection switches for the desired mode as follows.

1. Lift the hinged switch cover on the front of the adapter to expose

the switches.

2. Set the switches as shown below.

3. Cycle power to the adapter to activate the settings.

And

1

8 and/or 16Ć point

modules

Mode Switch 2

S1Ć1

See note 1 ON ON

8Ćpoint modules OFF ON OFF

16Ćpoint modules ON ON OFF

Ć

Ć

OFF OFF ON

ON OFF ON

OFF OFF OFF

ON OFF OFF

Mode Switch 1

S2Ć5

Mode Switch 0

S2Ć8

When Using this

Addressing Mode

Standard - 32

1

And

8, 16 and/or 32Ć

point modules

Complementary - 32

Primary chassis

Complementary - 32

Complementary chassis

1

In Standard - 32 mode, any module in the chassis occupies 32 input points and 32 output points in the Input/Output data table.

2

In Complementary - 32 mode, any module in the chassis occupies 32 input points or 32 output points in the Input/Output data table. If using an 8 point or 16 point module, the unused

points in the data table are zeroed out.

2

8, 16 and/or 32Ć

point modules

2

Mode Switch 0

S2-8

Mode Switch 1

S2Ć5

Mode Switch 2

S1-1

Mode Switch 3

S2-3

ON ON See note 1 OFF OFF

OFF OFF OFF OFF OFF

OFF OFF ON OFF OFF

Mode Switch 4

S2Ć4

Publication 1794ĆUM009D-EN-P - April 2004

Page 31

2–13Installing Your Remote I/O Adapter Module

only available in standard and standard 32

Setting the Address

Switches

Use the following table to set your address switches. (Refer to page

2–15 to set address switches when in complementary mode.)

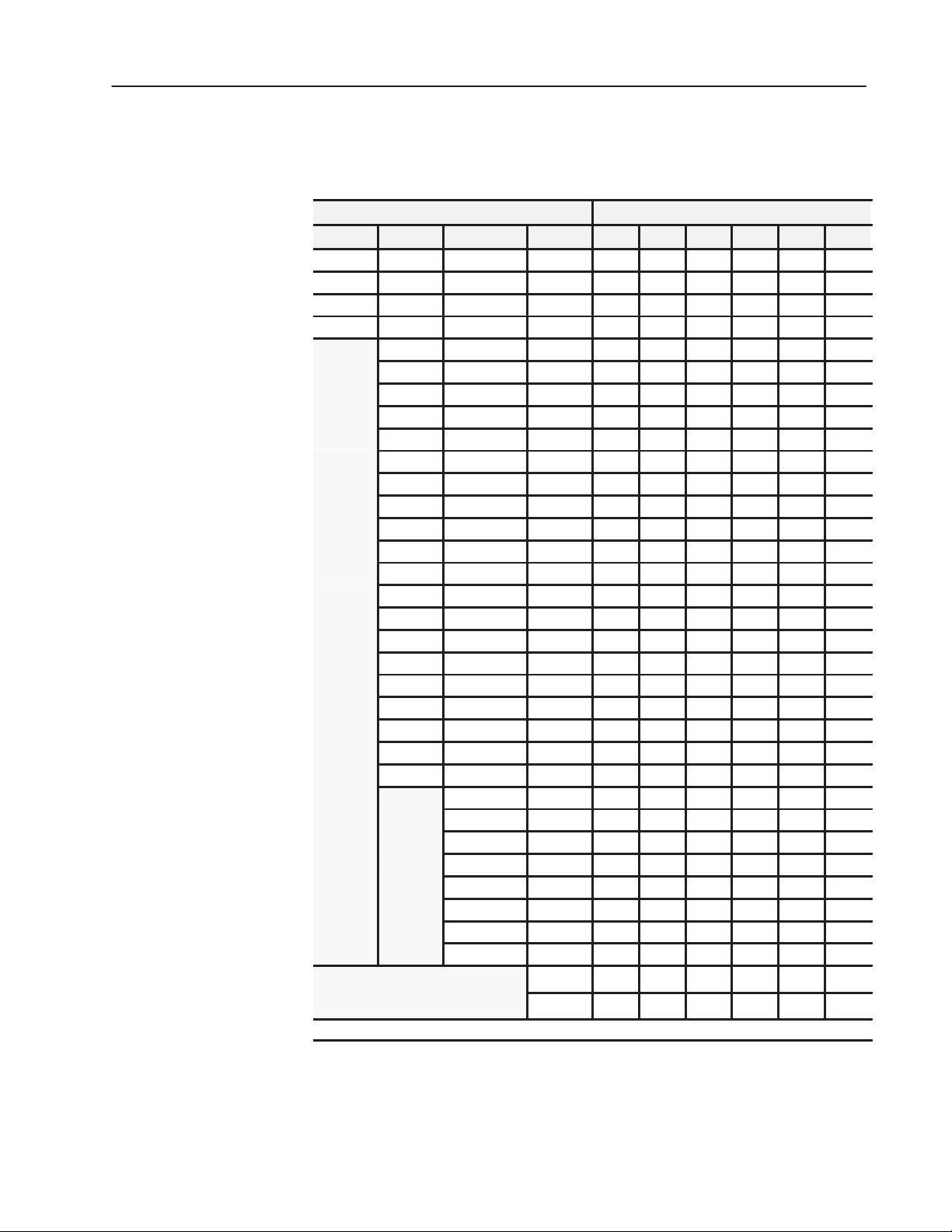

Rack Number S1 Switch Position

1747ĆSN PLCĆ5 PLCĆ5/250 PLCĆ3 6 5 4 3 2 1

Rack 0 Not Valid Rack 0 Rack 0 ON ON ON ON ON ON

Rack 1 Rack 1 Rack 1 Rack 1 OFF ON ON ON ON ON

Rack 2 Rack 2 Rack 2 Rack 2 ON OFF ON ON ON ON

Rack 3 Rack 3 Rack 3 Rack 3 OFF OFF ON ON ON ON

Rack 4 Rack 4 Rack 4 ON ON OFF ON ON ON

Rack 5 Rack 5 Rack 5 OFF ON OFF ON ON ON

Rack 6 Rack 6 Rack 6 ON OFF OFF ON ON ON

Rack 7 Rack 7 Rack 7 OFF OFF OFF ON ON ON

Rack 10 Rack 10 Rack 10 ON ON ON OFF ON ON

Rack 11 Rack 11 Rack 11 OFF ON ON OFF ON ON

Rack 12 Rack 12 Rack 12 ON OFF ON OFF ON ON

Rack 13 Rack 13 Rack 13 OFF OFF ON OFF ON ON

Rack 14 Rack 14 Rack 14 ON ON OFF OFF ON ON

Rack 15 Rack 15 Rack 15 OFF ON OFF OFF ON ON

Rack 16 Rack 16 Rack 16 ON OFF OFF OFF ON ON

Rack 17 Rack 17 Rack 17 OFF OFF OFF OFF ON ON

Rack 20 Rack 20 Rack 20 ON ON ON ON OFF ON

Rack 21 Rack 21 Rack 21 OFF ON ON ON OFF ON

Rack 22 Rack 22 Rack 22 ON OFF ON ON OFF ON

Rack 23 Rack 23 Rack 23 OFF OFF ON ON OFF ON

Rack 24 Rack 24 Rack 24 ON ON OFF ON OFF ON

Rack 25 Rack 25 Rack 25 OFF ON OFF ON OFF ON

Rack 26 Rack 26 Rack 26 ON OFF OFF ON OFF ON

Rack 27 Rack 27 Rack 27 OFF OFF OFF ON OFF ON

Rack 30 Rack 30 ON ON ON OFF OFF ON

Rack 31 Rack 31 OFF ON ON OFF OFF ON

Rack 32 Rack 32 ON OFF ON OFF OFF ON

Rack 33 Rack 33 OFF OFF ON OFF OFF ON

Rack 34 Rack 34 ON ON OFF OFF OFF ON

Rack 35 Rack 35 OFF ON OFF OFF OFF ON

Rack 36 Rack 36 ON OFF OFF OFF OFF ON

Rack 37 Rack 37 OFF OFF OFF OFF OFF ON

See note 1 - Rack addresses 40 thru 76 are-Rack 40 ON ON ON ON ON OFF

modes.

Continued on next page

Rack 41

OFF ON ON ON ON OFF

Publication 1794ĆUM009D-EN-P - April 2004

Page 32

2–14 Installing Your Remote I/O Adapter Module

Rack address 77 is an illegal configuration.

PLCĆ5/11 processors can scan rack 03.

PLCĆ5/15 and PLCĆ5/20 processors can scan racks 01-03.

PLCĆ5/25 and PLCĆ5/30 processors can scan racks 01-07.

PLCĆ5/40 and PLCĆ5/40L processors can scan racks 01-17.

PLCĆ5/60 and PLCĆ5/60L processors can scan racks 01-27.

PLCĆ5/250 processors can scan racks 00-37.

PLCĆ3 processors can scan racks 00-76.

Note1-Whenusing a 1794ĆASB series C (or later) adapter module, rack addresses 40 to 76 are only available in Standard and

Standard-32 modes.

S1 Switch PositionRack Number

123456PLCĆ3PLCĆ5/250PLCĆ51747ĆSN

Rack 42 ON OFF ON ON ON OFF

Rack 43 OFF OFF ON ON ON OFF

Rack 44 ON ON OFF ON ON OFF

Rack 45 OFF ON OFF ON ON OFF

Rack 46 ON OFF OFF ON ON OFF

Rack 47 OFF OFF OFF ON ON OFF

Rack 50 ON ON ON OFF ON OFF

Rack 51 OFF ON ON OFF ON OFF

Rack 52 ON OFF ON OFF ON OFF

Rack 53 OFF OFF ON OFF ON OFF

Rack 54 ON ON OFF OFF ON OFF

Rack 55 OFF ON OFF OFF ON OFF

Rack 56 ON OFF OFF OFF ON OFF

Rack 57 OFF OFF OFF OFF ON OFF

Rack 60 ON ON ON ON OFF OFF

Rack 61 OFF ON ON ON OFF OFF

Rack 62 ON OFF ON ON OFF OFF

Rack 63 OFF OFF ON ON OFF OFF

Rack 64 ON ON OFF ON OFF OFF

Rack 65 OFF ON OFF ON OFF OFF

Rack 66 ON OFF OFF ON OFF OFF

Rack 67 OFF OFF OFF ON OFF OFF

Rack 70 ON ON ON OFF OFF OFF

Rack 71 OFF ON ON OFF OFF OFF

Rack 72 ON OFF ON OFF OFF OFF

Rack 73 OFF OFF ON OFF OFF OFF

Rack 74 ON ON OFF OFF OFF OFF

Rack 75 OFF ON OFF OFF OFF OFF

Rack 76 ON OFF OFF OFF OFF OFF

Not Valid OFF OFF OFF OFF OFF OFF

Publication 1794ĆUM009D-EN-P - April 2004

Page 33

2–15Installing Your Remote I/O Adapter Module

Setting the Address

Switches for

Complementary I/O

Use the following table to set your address switches for

complementary I/O when using a PLC-5 processor. For all other

processors, refer to the programming manual for that specific

processor.

Primary Rack

Rack Number S1 Switch Position

1747ĆSN PLCĆ5 6 5 4 3 2 1

Rack 0 Not Valid ON ON ON ON ON OFF

Rack 1 Rack 1 OFF ON ON ON ON OFF

Rack 2 Rack 2 ON OFF ON ON ON OFF

Rack 3 Rack 3 OFF OFF ON ON ON OFF

Rack 4 ON ON OFF ON ON OFF

Rack 5 OFF ON OFF ON ON OFF

Rack 6 ON OFF OFF ON ON OFF

Rack 7 OFF OFF OFF ON ON OFF

Complementary Rack

Rack Number S1 Switch Position

1747ĆSN PLCĆ5 6 5 4 3 2 1

Rack 0 Not Valid ON ON ON OFF ON ON

Rack 1 Rack 1 OFF ON ON OFF ON ON

Rack 2 Rack 2 ON OFF ON OFF ON ON

Rack 3 Rack 3 OFF OFF ON OFF ON ON

Rack 4 ON ON OFF OFF ON ON

Rack 5 OFF ON OFF OFF ON ON

Rack 6 ON OFF OFF OFF ON ON

Rack 7 OFF OFF OFF OFF ON ON

Chapter Summary

In this chapter you learned how to install your adapter module and

set your switches. Chapter 3 tells you how to communicate with your

system.

Publication 1794ĆUM009D-EN-P - April 2004

Page 34

2–16 Installing Your Remote I/O Adapter Module

Publication 1794ĆUM009D-EN-P - April 2004

Page 35

Communicating with

FLEX I/O Modules

Chapter Objectives

FLEX I/O Module Data

In this chapter, we tell you about:

• FLEX I/O module data

• selecting an addressing type

• selecting an addressing mode

• determining rack size

• mapping data into the image tables

• operating modes

There are 2 types of data associated with FLEX I/O modules: input

data and output data.

• input data – data read from the module by the processor

• output data – data written to the module by the processor

Some digital I/O modules have both input and output data associated

with them. Digital I/O modules map input data and output data to the

input and output image tables in the processor. Input and output data

can be defined as:

• real I/O data – data that represents the actual state of

hardwired inputs and outputs (input data on input modules,

output data on output modules)

• configuration/status data – data written to configure the

module (such as delay times); and status information (such as

a fuse blown indication)

For FLEX analog modules, input and output data is only accessible

by the processor using block transfer instructions. The data is

contained in block transfer write (BTW) and block transfer read

(BTR) data files, not in the input and output image tables. A byte of

input image and a byte of output image is required for the module

status byte (MSB) and the module control byte (MCB). The MSB

uses input image, and the MCB uses output image. These bytes are

required for block transfer command communications.

Publication 1794ĆUM009D-EN-P - April 2004

Page 36

3–2 Communicating with FLEX I/O Modules

Addressing I/O

The 1794-ASB series E adapter supports 5 different modes of

addressing: standard, compact, complementary, standard–32 and

complementary–32.

For digital modules, the mode of addressing determines what type of

data is available to the processor from the module.

• standard addressing – input and output data is available for each

digital module connected to the adapter

• compact addressing – either input or output data (not both) is

available for each digital module connected to the adapter

• complementary addressing – either input or output data (not both)

is available for each digital module connected to the adapter

Analog modules can be used in any mode of addressing with no loss

of data because data is not stored in the input and output image table,

with the exception of the MCB and MSB. Analog data is stored in

BTW and BTR data files.

The following table helps you to select an addressing mode based on

the kind of modules you want to use, and the features you need from

those modules. The table also lists both advantages and

disadvantages of using each addressing type.

Addressing Mode Use this addressing scheme when: Advantages Disadvantages

Standard •you need full FLEX I/O module

functionality, including combination

modules (1794ĆIB10XOB6), settable

input delay times on input modules

(1794ĆIB16, ĆIB8S), and fuse blown

indication (1794ĆOB8EP) for

example. Will work with 32-pt.

modules with 16 in and 16 out

(1794-IB16XOB16P).

Compact •you don't need full FLEX I/O module

functionality, including combination

modules (1794ĆIB10XOB6), settable

input delay times on input modules

(1794ĆIB16, ĆIB8S), and fuse blown

indication (1794ĆOB8EP), for

example.

•you can locate equal numbers of

input and output modules in a single

chassis

•User has access to 1 word of input, 1

word of output for each digital module.

•Eight modules equal 1 logical rack.

•No restrictions on module placement

•Maximum use of configuration/status and

combination modules

•Eight 8 point modules equal 1/4 logical

racks (when input and output modules are

installed in alternate slots).

•Eight 16 point modules equal 1/2 logical

racks (when input and output modules are

installed in alternate slots).

•Provides maximum use of I/O image table

by a single FLEX chassis (when input and

output modules are installed in alternate

slots).

•Inefficient I/O image table

utilization

•You must configure all modules

in the chassis as either 8Ćpoint

orĆ16 point.

•No combination modules

allowed

•Configuration/status data is not

accessible to user

Publication 1794ĆUM009D-EN-P - April 2004

Page 37

3–3Communicating with FLEX I/O Modules

Complementary •you need full FLEX I/O module

functionality, including combination

modules (1794ĆIB10XOB6), settable

input delay times on input modules

(1794ĆIB16, ĆIB8S), and fuse blown

indication (1794ĆOB8EP), for

example.

•you can locate equal numbers of

input and output modules in

separate chassis

Standard - 32 •you need full FLEX I/O module

functionality, including 32 point

modules, combination modules

(1794ĆIB10XOB6), settable input

delay times on input modules

(1794ĆIB16, ĆIB8S), and fuse blown

indication (1794ĆOB8EP) for

example.

Complementary - 32 •you need full FLEX I/O module

functionality, including combination

modules (1794ĆIB10XOB6), settable

input delay times on input modules

(1794ĆIB16, ĆIB8S), and fuse blown

indication (1794ĆOB8EP), for

example.

•you can locate equal numbers of

input and output modules in

separate chassis

•Eight 8 point modules in each chassis

equal 1/2 logical rack (when input

modules are installed in 1 chassis, and

output modules are installed in the

complementary chassis).

•Eight 16 point modules in each chassis

equal 1 logical rack (when input modules

are installed in 1 chassis, and output

modules are installed in the

complementary chassis).

•Provides maximum use of I/O image table

in 2 FLEX chassis (when input modules

are installed in 1 chassis, and output

modules are installed in the

complementary chassis).

•User has access to 2 words of input, 2

words of output for each digital module.

•Four modules equal 1 logical rack.

•No restrictions on module placement

•Maximum use of configuration/status and

combination modules

•Eight modules in each chassis equal 2

logical racks

•Provides maximum use of I/O image table

in 2 FLEX chassis (when input modules

are installed in 1 chassis, and output

modules are installed in the

complementary chassis).

•You must configure all modules

in both chassis as either 8Ćpoint

or 16Ćpoint.

•No combination modules

allowed

•Configuration/status data is not

accessible to user

•Inefficient I/O image table

utilization

•All digital I/O modules are

configured as 32Ćpoint.

•No combination modules

allowed

•Configuration/status data may

not be accessible to user

(depending on module type).

The amount of data accessible to the processor in the 5 addressing

modes is illustrated below. Note that the shaded areas represent data

not accessible by the processor.

Publication 1794ĆUM009D-EN-P - April 2004

Page 38

3–4 Communicating with FLEX I/O Modules

Digital I/O Modules

Input Module Example Output Module Example

Input Word

Output Word

8 Bits 8 Bits

8 Bits8 Bits

Note: If 32 pt. modules are used in standard

mode, only the lower word (16 bits) will be sent

to the processor. All 32 bits of the 32-pt

combo module are available.

8 Bits 8 Bits

8 Bits8 Bits

Standard Mode

16 bits of input AND

16 bits of output available

Input Word 0

Input Word 1

Output Word 0

Output Word 1

Input Word

Output Word

Input Word

Output Word

Input Module Example

8 Bits 8 Bits

8 Bits8 Bits

8 Bits 8 Bits

8 Bits8 Bits

Input Module Example Output Module Example

8 Bits 8 Bits

8 Bits8 Bits

Note: If 32 pt. modules are used in 16 pt.

compact mode, only the low word (16 bits)

will be sent to the processor.

Input Module Example Output Module Example

8 Bits 8 Bits

8 Bits8 Bits

Note: If 16Ćpt or 32Ćpt modules are used in 8Ćpt

compact addressing, only the information in

the lowest byte (8 bits) will be sent to the

processor.

Output Module Example

8 Bits 8 Bits

8 Bits8 Bits

8 Bits 8 Bits

8 Bits8 Bits

8 Bits 8 Bits

8 Bits8 Bits

8 Bits 8 Bits

8 Bits8 Bits

Standard - 32 Mode

32 bits of input AND

32 bits of output available

Compact Mode

16Ćpt Density

16 bits of input OR

16 bits of output available

Compact Mode

8Ćpt Density

8 bits of input OR

8 bits of output available

16Ćbit Input modules complemented by 16Ćbit output modules

Input Module Example Output Module Example

Input Word

Output Word

Input Word

Output Word

Publication 1794ĆUM009D-EN-P - April 2004

8 Bits 8 Bits

Input Module Example Output Module Example

8 Bits 8 Bits

Primary Chassis

8 Bits 8 Bits

8 Bits8 Bits

Complement Chassis

8 Bits8 Bits

8 Bits 8 Bits

8 Bits8 Bits

Note: If 32Ćpt modules are used in 16Ćpt complimentary addressing,

only the information in the lower word will be sent to the processor.

8 Bits8 Bits

Complementary Mode

16Ćpt Density

16 bits of input OR

16 bits of output available

Page 39

Input Word

Output Word

Input Word

Output Word

Input Word 0

Input Word 1

Output Word 0

Output Word 1

8Ćbit Input modules complemented by 8Ćbit output modules

Primary Chassis

Input Module Example Output Module Example

8 Bits 8 Bits

8 Bits8 Bits

Complement Chassis

Input Module Example Output Module Example

8 Bits 8 Bits

8 Bits8 Bits

Note: If 16Ćpt or 32Ćpt modules are used in 8Ćpt complementary addressing,

only the information in the lowest byte will be sent to the processor.

8 Bits 8 Bits

8 Bits8 Bits

8 Bits 8 Bits

8 Bits8 Bits

32Ćbit Input modules complemented by 32Ćbit output modules

Primary Chassis

Input Module Example Output Module Example

8 Bits 8 Bits

8 Bits8 Bits

8 Bits

8 Bits

8 Bits

8 Bits

8 Bits

8 Bits

8 Bits 8 Bits

8 Bits

8 Bits

8 Bits8 Bits

3–5Communicating with FLEX I/O Modules

Complementary Mode

8Ćpt Density

8 bits of input OR

8 bits of output available

Complementary - 32 Mode

32-pt density

32 bits of input OR

32 bits of output available

Input Module Example Output Module Example

Input Word 0

Input Word 1

Output Word 0

Output Word 1

8 Bits

8 Bits

8 Bits 8 Bits

Note: Shaded areas represent data not accessible by the processor.

Analog (Block Transfer)

Modules

Complement Chassis

8 Bits

8 Bits

8 Bits8 Bits

8 Bits 8 Bits

8 Bits

8 Bits

8 Bits

8 Bits

8 Bits8 Bits

Complementary - 32 Mode

32 bits of input OR

32 bits of output available

Analog modules use block transfers, which require 1 byte (8 bits) of

input image for the module status byte, and 1 byte (8 bits) of output

image for the module control byte. This is true for any addressing

mode selected.

Input Word

Output Word

Input or Output Example

8 Bits

8 Bits

MSB

MCB

Any Mode

Block transfers require

8 bits of input image and

8 bits of output image

Publication 1794ĆUM009D-EN-P - April 2004

Page 40

3–6 Communicating with FLEX I/O Modules

Standard Addressing

Standard Addressing

Input Output Input Output Analog Analog Output Input

Adapter

Use standard addressing when:

• you need full FLEX I/O module functionality, such as delay time

selection on input modules, fuse-blown indication on the

1794-OB8EP, etc.

• using combination modules, such as the 1794-IB10XOB6 10 in/6

out module

In standard mode, each module position equals one I/O group – 1

word of input image and 1 word of output image. If 32-pt input or

output modules are used, only the lower 16 bits are available. All 32

bits of the 32–pt combination modules are available.

Any combination of digital or analog modules.

Eight terminal bases per adapter (maximum)

Each terminal base represents 1 I/O group

20128

Standard Addressing Example

I/O Group 0 I/O Group 1 I/O Group 2 I/O Group 3

M0 M1 M2 M3 M4 M5 M6 M7

ASB/E

IL = Input Low Byte

IH = Input High Byte

OL = Output Low Byte

OH = Output High Byte

IH IL IH IL

OH OL OH OL OH OL

IB16 IB16IB16

I/O Group

IH IL IH IL IH IL

OH OL

MCB = Module Control Byte (output data)

MSB = Module Status Byte (input data)

0

1

2

3

4

5

6

7

- 8 modules = 1 logical rack = 8 I/O groups

I/O Group 4 I/O Group 5 I/O Group 6 I/O Group 7

MSB

OH OL

OB16

Legal Module Placement in Standard Addressing

Any module in any slot

1 module position is an I/O group

Input Image Table Output Image Table

00071017 00071017

M0ĆIH

M1ĆIH

M0ĆIL

M1ĆIL

M2ĆILM2ĆIH M2ĆOLM2ĆOH

M3ĆILM3ĆIH

M4ĆMSB

M5ĆMSB

M6ĆILM6ĆIH

M7ĆILM7ĆIH

MCB

IE8 IE8

MSB

MCB

M0ĆOH

M1ĆOH

M4ĆMCB

M5ĆMCB

M6ĆOH

M7ĆOH

IH IL

OH OL

OB16OB16

M0ĆOL

M1ĆOL

M3ĆOLM3ĆOH

M6ĆOL

M7ĆOL

Publication 1794ĆUM009D-EN-P - April 2004

Page 41

3–7Communicating with FLEX I/O Modules

Standard - 32 Addressing

Use standard 32 point addressing when:

• you use 32 point modules in your system

• you need full FLEX I/O module functionality, such as delay time

selection on input modules, fuse-blown indication on the

1794-OB8EP, etc.

• using combination modules, such as the 1794-IB16XOB16 16

in/16 out module

In standard – 32 mode, each module position equals two I/O groups

– 2 words of input image and 2 words of output image.

Standard 32 Addressing Example - 8 modules = 2 logical racks, N and N+1 = 16 I/O groups

Rack N RackN+1

M0 M1 M2 M3 M4 M5 M6 M7

Gr. 0

Gr. 1 Gr. 2 Gr. 3 Gr. 4 Gr. 5 Gr. 6 Gr. 7

IHH IHL

ILH ILL IH IL

ASB/E

OLH

OLL

OHH OHL

ILH ILL

IHH IHL

OH OL OLL

OHH OHLOLH OLL

ILH ILL

OHH OHLOLH OLL

IB32 OB32IB16 IB32 Analog Analog IB8OB32

Note: Shaded areas represent data which is not available.

Eight terminal bases per adapter (maximum)

Each terminal base represents 2 I/O groups.

ILL, OLL = Bits 0 thru 7 for input and output words of 32 point modules

ILH, OLH = Bits 8 thru 15 for input and output words of 32 point modules

IHL, OHL = Bits 16 thru 23 for input and output words of 32 point modules

IHH, OHH = Bits 24 thru 32 for input and output words of 32 point modules

IL, OL = Bits 0 thru 7 for input and output words for 16 and 8 point modules

IH, OH = Bits 8 thru 15 for input and output words for 16 point modules

MCB = Module Control Byte (output data)

MSB = Module Status Byte (input data)

Input Image Table for Rack N Output Image Table for Rack N

Input Image Table for Rack N Output Image Table for Rack N

I/O Group

I/O Group

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

M0ĆILH

M0ĆILH

M0ĆIHH

M0ĆIHH

M1ĆILH M1ĆOLLM1ĆOLLM1ĆOLHM1ĆOLH

M1ĆILH

M1ĆIHH

M1ĆIHHM1ĆIHH

M2ĆIH

M2ĆILHM2ĆILH

M2ĆIHHM2ĆIHH

M3ĆILH

M3ĆILHM3ĆILH

M3ĆIHH

M3ĆIHH

M0ĆILLM0ĆILL

M0ĆILL

M0ĆIHLM0ĆIHL

M1ĆILLM1ĆILL

M1ĆILL

M1ĆIHL

M1ĆIHLM1ĆIHL

M2ĆILLM2ĆILL

M2ĆIHLM2ĆIHL

M3ĆILL

M3ĆILLM3ĆILL

M3ĆIHL

M3ĆIHLM3ĆIHL

00071017 00071017

00071017 00071017

M2ĆIL

Gr. 0 Gr. 1 Gr. 2 Gr. 3 Gr. 4 Gr. 5 Gr. 6 Gr. 7

IHH IHL ILH

MSB

MCB

Legal Module Placement in Standard Addressing

Any module in any slot

1 module position is 2 I/O groups

I/O GroupI/O Group

I/O GroupI/O Group

00

00

11

11

22

22

33

33

44

44

55

55

66

66

77

77

MSB

MCB

M0ĆOLH

M0ĆOLH

M0ĆOHH

M0ĆOHH

M1ĆOLH

M1ĆOHH

M2ĆOLHM2ĆOLH

M2ĆOH

M2ĆOHHM2ĆOHH

M3ĆOLH

M3ĆOLH

M3ĆOHH

M3ĆOHH

OL

M0ĆOLL

M0ĆOLL

M0ĆOHL

M0ĆOHL

M1ĆOLL

M1ĆOHL

M1ĆOHLM1ĆOHLM1ĆOHHM1ĆOHH

M2ĆOLH

M2ĆOL

M2ĆOHL

M3ĆOLL

M3ĆOLL

M3ĆOHL

M3ĆOHL

OLH

ILL

IHH

IHL

OHH

OHL

IL

I/O Group

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

Input Image Table for Rack N+1 Output Image Table for Rack N+1

00071017 00071017

M4ĆMSB

M1ĆILH M1ĆOLLM1ĆOLLM1ĆOLHM1ĆOLH

M1ĆIHHM1ĆIHH

M2ĆILHM2ĆILH

M2ĆIHHM2ĆIHH

M7ĆILH

M3ĆILHM3ĆILH

M7ĆIHH

M3ĆIHH

M5ĆMSB

M1ĆILLM1ĆILL

M1ĆIHLM1ĆIHL

M6ĆIL

M2ĆILLM2ĆILL

M2ĆIHLM2ĆIHL

M7ĆILL

M3ĆILLM3ĆILL

M7ĆIHL

M3ĆIHLM3ĆIHL

I/O Group

00

00

11

11

22

22

33

33

44

44

55

55

66

66

77

77

M4ĆMCB

M0ĆOLH

M0ĆOHH

M0ĆOLL

M0ĆOHL

M5ĆMCB

M1ĆOHLM1ĆOHLM1ĆOHHM1ĆOHH

M2ĆOLHM2ĆOLH

M2ĆOHHM2ĆOHH

M7ĆOLH

M3ĆOLH

M3ĆOHH

M7ĆOHH

Publication 1794ĆUM009D-EN-P - April 2004

M6ĆOL

M2ĆOLH

M2ĆOHL

M7ĆOLL

M3ĆOLL

M3ĆOHL

M7ĆOHL

Page 42

3–8 Communicating with FLEX I/O Modules

Compact Addressing

Use compact addressing when:

• you are not using combination modules

• you are using only digital input, digital output and analog

modules

• you don’t need all the features of digital FLEX I/O modules (You

can only access the input word on an input module, or the output

word of an output module. Any status information/configuration

information in the corresponding input/output word is not

accessible.)

• you can locate equal numbers of input and output modules in a

single chassis

• you want more efficient use of the input/output data table

Compact Mode

Compact mode maximizes single chassis I/O image table usage when

using either 8- or 16-point modules and block transfer modules.

Compact mode allows more than 1 module to occupy a single I/O

group. How many modules depends on the density selected (16- or

8-point).

In compact mode, with 16-point density, 2 digital modules (1 input

and 1 output module) can occupy 1 I/O group. In addition, 2 block

transfer modules can occupy 1 I/O group. If higher density modules

are used, only the lowest 16 bits will be available.

In compact mode, with 8-point density, 4 digital modules (2 input

and 2 output modules) mounted in module pairs can occupy 1 I/O

group. In addition, 2 block transfer modules can occupy 1 I/O group.

If higher density modules are used, only the lowest 8 bits will be

available.

Publication 1794ĆUM009D-EN-P - April 2004

Page 43

3–9Communicating with FLEX I/O Modules

16Ćpoint Compact Addressing

Group 0 Group 1 Group 2 Group 3

Input Output Input Output Output InputAnalog Analog

Adapter

Compact 16Ćpoint Addressing Example

I/O Group 0 I/O Group 1 I/O Group 2 I/O Group 3

M0 M1 M2 M3 M4 M5 M6 M7

ASB/E

IL = Input Low Byte

IH = Input High Byte

OL = Output Low Byte

OH = Output High Byte

Note: Shaded areas represent unavailable data

IH IL IH IL

OH OL

IB16 IB16IB16

MCB = Module Control Byte (output data)

MSB = Module Status Byte (input data)

Input modules and Output modules in pairs, or analog modules.

Eight terminal bases per adapter (maximum)

Each module represents 1/2 of an I/O group

2 modules represent 1 I/O group

8 modules = 1/2 I/O rack

- 8 modules = 1/2 logical rack = 4 I/O groups

OH OL

OB16

MSB

MCB

IE8 IE8

Legal Module Placement in 16Ćpt Compact Addressing

A 16Ćpoint input module and a 16Ćpoint output module

(or an empty slot) in an I/O group.

A 16Ćpt output module and a 16Ćpt input module

(or an empty slot) in an I/O group.

A block transfer module with another block transfer module

(or an empty slot) in an I/O group.

An empty slot with any module, or another empty

slot in an I/O group.

2 module positions = an I/O group

MSB

MCB

20128

IH IL

OH OL

OB16OB16

Input Image Table Output Image Table

I/O Group

0

1

2

3

4

5

6

7

Note: When using block transfer modules in 16Ćpt compact addressing, address module positions

M0, M2, M4 and M6 as module 0" in a block transfer instruction block; address module positions

M1, M3, M5 and M7 as module 1" in a block transfer instruction block.

M0ĆIH

M2ĆIH

M5ĆMSB

M7ĆIH

M4ĆMSB

I/O groups 4-7 are available for another adapter.

00071017 00071017

M0ĆIL

M2ĆIL

M7ĆIL

M1ĆOH

M3ĆOH

M5ĆMCB

M6ĆOH

M1ĆOL

M3ĆOL

M4ĆMCB

M6ĆOL

Publication 1794ĆUM009D-EN-P - April 2004

Page 44

3–10 Communicating with FLEX I/O Modules

8Ćpoint Compact Addressing - Digital Modules

Input modules and Output modules in the same group.

Group 0 Group 1

Input Output Input Output Output Input

Adapter

Eight terminal bases per adapter (maximum)

Each module represents 1/4 of an I/O group

4 modules represent 1 I/O group

Compact 8Ćpoint Addressing Example - 8 digital modules = 1/4 logical rack

I/O Group 0 I/O Group 1

M0 M1 M2 M3 M4 M5 M6 M7

ASB/E

IL = Input Low Byte

IH = Input High Byte

OL = Output Low Byte

OH = Output High Byte

Note: Shaded areas represent unavailable data

IL IL

OL

IA8 IA8IA8

OL

OW8

Legal Module Placement in 8Ćpoint Compact Addressing

Two 8Ćpoint input modules and two 8Ćpoint output modules (or empty

slots) in an I/O group. Module type must alternate within an I/O group:

input, output, etc.