Page 1

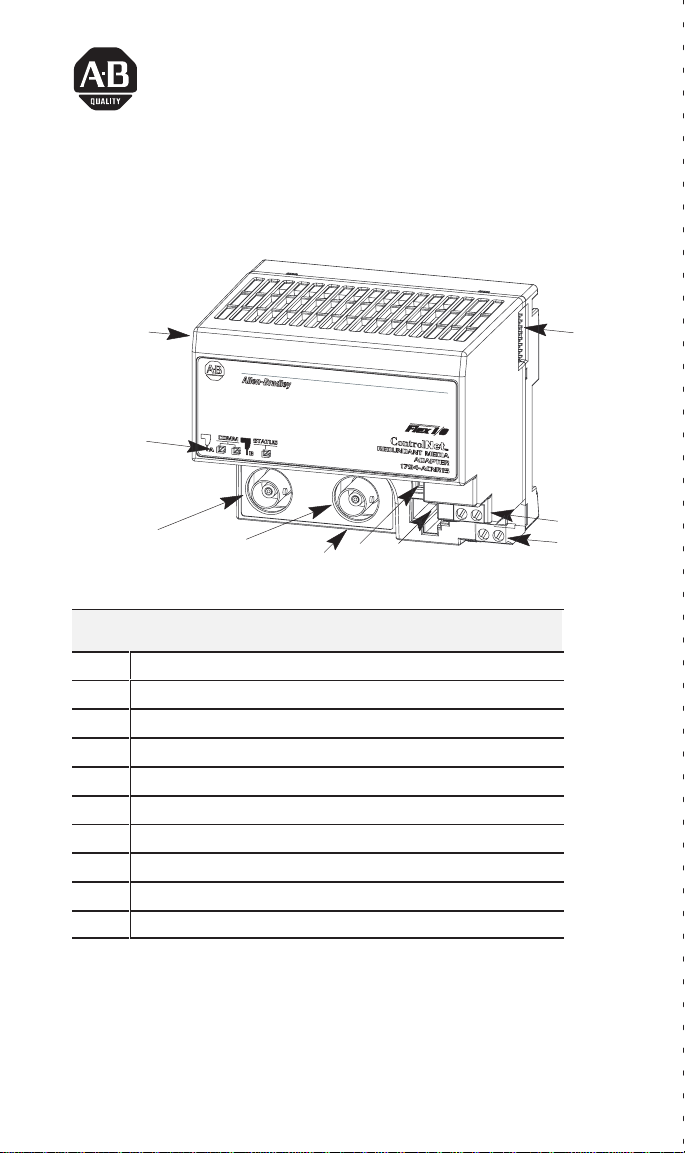

Installation Instructions

FLEX I/O ControlNet Redundant Media

Adapter

(Cat. No. 1794-ACNR)

1

2

3a

1 ControlNet

2 Indicators

3a

ControlNet network cable BNC connector A

3b

ControlNet network cable BNC connector B (1794-ACNR15 only)

4

ControlNet Node selection thumbwheel switches

5

ControlNet programming terminal connector port

6

Module locking tab

7 +24V dc connections

8

24V common connections

9

Flexbus connector

3b

6

Component Identification

Adapter module

45

9

8

7

FLEX I/O is a trademark of Rockwell Automation.

Publication

1794-5.18 – September 1996

Page 2

FLEX I/O ControlNet Redundant Media Adapter2

European

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

Union Directive Compliance

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 – Industrial

Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

This product is intended for use in an industrial environment.

Low V

oltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131–2 Programmable

Controllers, Part 2 – Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

This equipment is classified as open equipment and must be mounted in

an enclosure during operation to provide safety protection.

A

B

C

Publication

1794-5.18 – September 1996

Page 3

FLEX I/O ControlNet Redundant Media Adapter 3

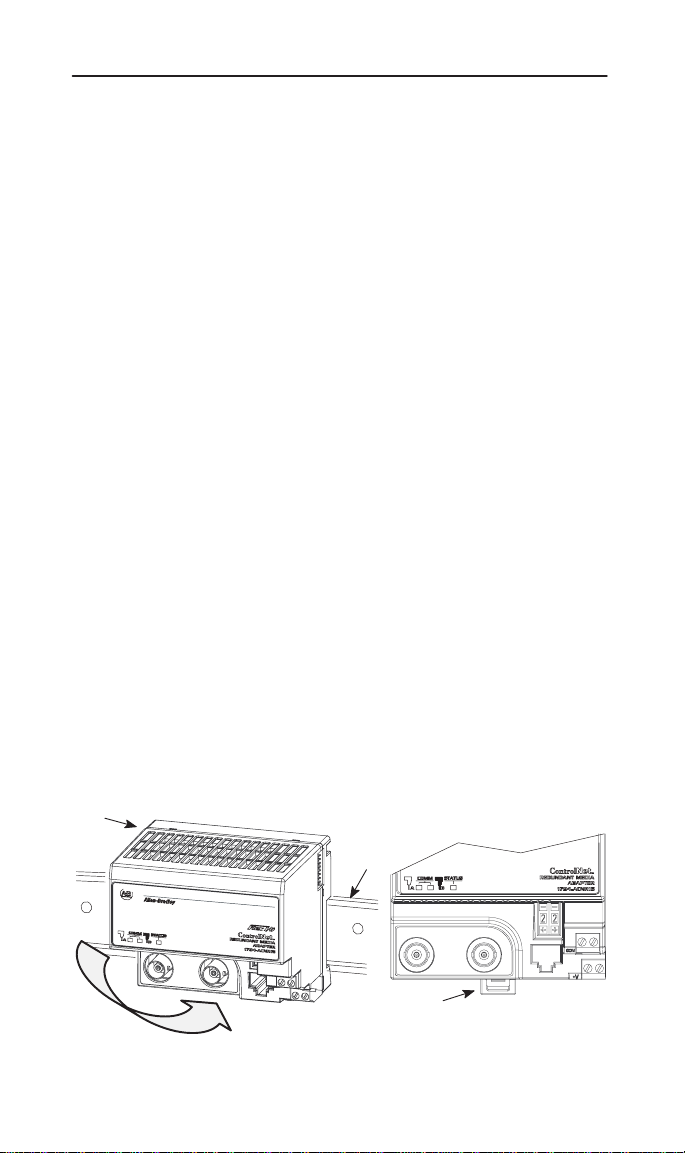

1. Position the ControlNet adapter module (A) on a 35 x 7.5mm DIN rail

(B) (A-B pt. no. 199-DR1; 46277-3; EN 50022) at a slight angle.

2. Hook the lip on the rear of the adapter (A) onto the top of the DIN rail

(B), and rotate the adapter module onto the rail.

3. Press the adapter module down onto the DIN rail until flush. Locking

tab (C) will snap into position and lock the adapter module to the DIN

rail.

4. If the adapter module does not lock in place, use a screwdriver or

similar device to move the locking tab down while pressing the

adapter module flush onto the DIN rail and release the locking tab to

lock the adapter module in place. If necessary, push up on the locking

tab to lock.

5. Connect the adapter wiring as shown under “Wiring” later in this

document.

ATTENTION: Make certain that the hook on the

terminal base is properly hooked into the adapter. Failure

!

6. Complete the adapter mounting as shown below.

to lock the hook into the adjacent base/adapter can result

in loss of communication on the backplane.

Publication

1794-5.18 – September 1996

Page 4

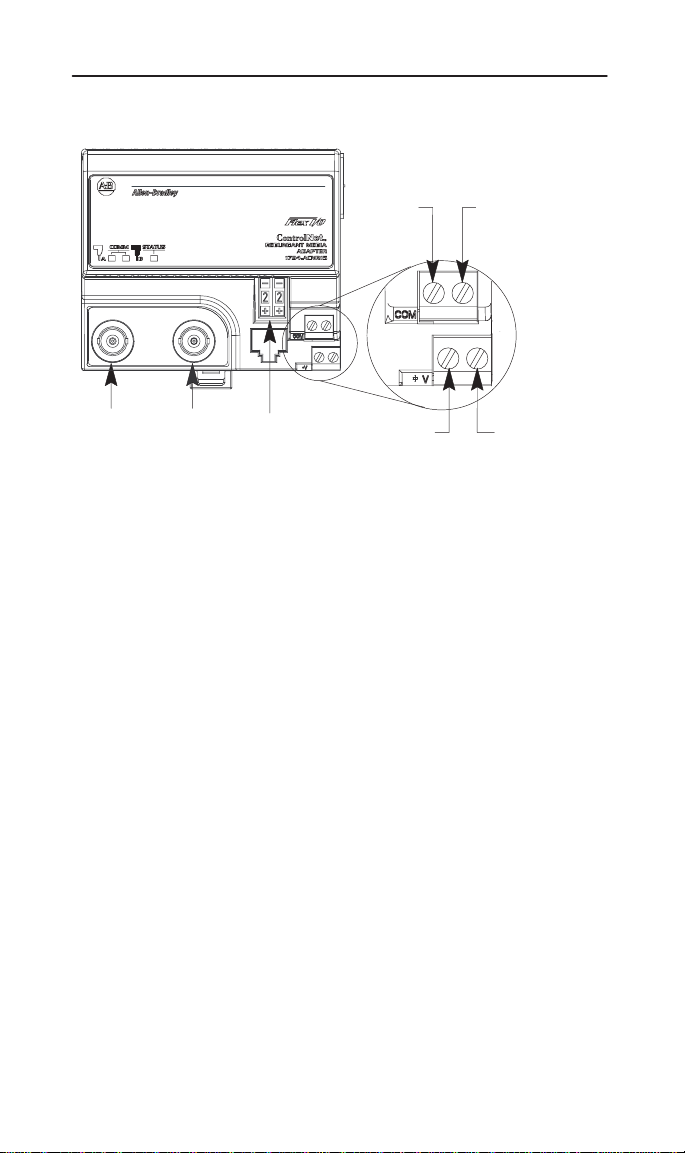

Wiring

FLEX I/O ControlNet Redundant Media Adapter4

C

AG

1. Connect the ControlNet network cable to connector, terminal A.

2. Connect the redundant ControlNet network cable to connector B.

3. Connect 24V common to the left side of the upper connector,

terminal C.

4. Connect +24V dc input to the left side of the lower connector,

terminal D.

5. Connections E and F are used to pass 24V dc power (F) and 24V

common (E) to the next module in the series (if required).

6. Set the network address using the 2-position thumbwheel switch G.

Valid settings range from 01 to 99. Press either the + or – buttons to

change the number.

B

D

E

F

Indicators

Publication

1794-5.18 – September 1996

Page 5

FLEX I/O ControlNet Redundant Media Adapter 5

Comm B

Comm A

Status Indicators Probable Cause

Comm A and Comm B Simultaneously

Off No

Red

Red/Grn – (flashing alternately) Adapter self-test

Red/Of

f – (flashing alternately)

power

, or reset

Adapter inoperative

Bad node configuration (duplicate address)

Comm A or Comm B (individually)

Off Channel disabled

Green

Flashing Grn/Off T

Flashing Red/Off

Flashing Red/Grn

Channel operational

emporary network errors

Cable fault, broken cable, redundancy warning

Bad network configuration

Status

Status Indicator

Off Channel disabled

Flashing Grn

Green On-line, link okay

Flashing Red

Red

1794-ACNR

I/O

Capacity

Specifications

On-line but not connected

Recoverable fault

Critical – adapter failure

8 modules

Publication

, connected

1794-5.18 – September 1996

Page 6

FLEX I/O ControlNet Redundant Media Adapter6

Power Supply

Input V

oltage Rating

Input Voltage Range

Communication Rate

Indicators

Flexbus Output Current

Isolation Voltage

Power Consumption

Power Dissipation

Thermal Dissipation

Environmental Conditions

Operational T

Storage T

emperature

emperature

Relative Humidity

Shock Operating

Non-operating

Vibration

ControlNet Cable

Power Conductors

Wire Size

Category

Specifications continued on next page

Note:

In order to comply with CE Low V

oltage

Directives, you must use a Safety Extra Low

V

oltage (SEL

V

oltage (PELV) power supply to power this

V) or a Protected Extra Low

adapter.

24V dc nominal

19.2V to 31.2V dc (includes 5% ac ripple)

5M Bits/s

Comm A – red/grn

Comm B – red/grn

I/O Status – red/grn

640mA maximum @ 5V dc

100% tested at 850V dc for 1s between user

power and flexbus

400mA maximum from external 24V supply

4.6W maximum @ 19.2V dc

15.7 BTU/hr @ 19.2V dc

0 to 55oC (32 to 131oF)

–40 to 85oC (–40 to 185oF)

5 to 95% noncondensing

30 g peak acceleration, 1

50 g peak acceleration, 1

T

ested 5 g @ 10–500Hz per IEC 68-2-6

1(+

1)ms pulse width

1(+

1)ms pulse width

Belden RG-6/U

12 gauge (4mm2) stranded maximum

3/64 inch (1.2mm) insulation max.

1

2

Publication

1794-5.18 – September 1996

Page 7

FLEX I/O ControlNet Redundant Media Adapter 7

Wiring T

erminal Screw T

Requirement

Agency Certification

(when product or packaging is

marked)

1 Use

this conductor category information for planning conductor routing. Refer to publication

1770-4.1, “Industrial Automation Wiring and Grounding Guidelines.”

orque

7-9 inch-pounds

•

CSA certified

• CSA Class I, Division 2

Groups A, B, C, D certified

•

UL listed

•

CE marked for all applicable directives

Mounting

Dimensions

Inches

(Millimeters)

3.2

(80)

3.4

(87)

A

=

DIN rail

B

= Secure DIN rail approximately every 200mm

3.7

(94)

1794-ACNR

3.4H x 3.7W x 2.7D

(87H x 94W x 69D)

B

2.0

(50)

1.2

(30)

A

Publication

1794-5.18 – September 1996

Page 8

FLEX I/O ControlNet Redundant Media Adapter8

With major offices worldwide.

World

Headquarters,

Allen-Bradley

1201 South Second Street,

Milwaukee, WI 53204 USA,

T

el: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 1794-5.18 – September 1996

Publication

,

1794-5.18 – September 1996

Copyright

1996 Allen-Bradley Company, Inc. Printed in USA

PN955117–39

Loading...

Loading...