Page 1

Allen-Bradley

FLEX Integra Analog

Modules

(Cat. No. 1793-IE4, -IE4S, -OE2,

-OE2S, -IE2XOE1 and -IE2XOE1S)

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements,

including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown

in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death,

property damage or economic loss

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

DeviceNetManager, Allen-Bradley, FLEX I/O and FLEX Integra are trademarks of Rockwell Automation

ControlNet is a trademark of ControlNet International.

DeviceNet is a trademark of Open DeviceNet Vendor Association, Inc.

Page 3

Preface

Using This Manual

Purpose of this Manual This manual shows you how to use your FLEX Integra Analog modules

with Allen-Bradley programmable controllers. The manual helps you

install, program and troubleshoot your modules.

Audience You must be able to program and operate an Allen-Bradley programmable

controller to make efficient use of your FLEX Integra modules. In

particular, you must know how to program block transfers, and be familiar

with DeviceNet or ControlNet software.

Vocabulary We assume that you know how to do this in this manual. If you do not, refer

to the appropriate programming and operations manual before you attempt

to program your modules.

In this manual, we refer to:

– the analog input or analog output module as the “input module” or

“output module”

– the Programmable Controller as the “controller”

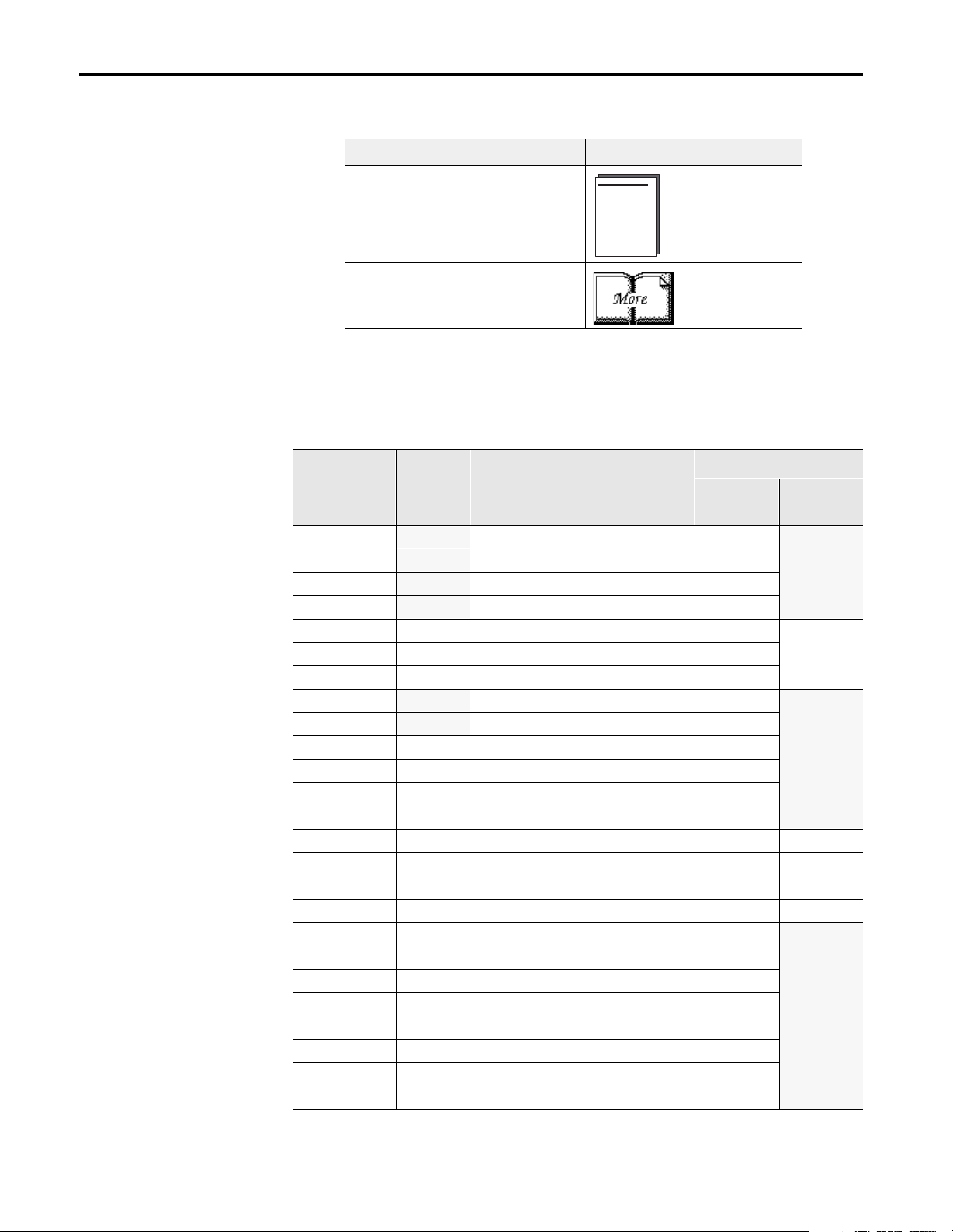

Manual Organization This manual is divided into five chapters. The following chart lists each

chapter with its corresponding title and a brief overview of the topics

covered in that chapter.

Chapter Title Contents

1 Overview of FLEX Integra and

Analog modules

2 How to Install Your Analog Module How to install and wire the modules

3 Module Programming Explains block transfer programming, sample programs

4 Writing Configuration to and

Reading Status From with a

Remote I/O Adapter

5 How Communication Takes Place

and I/O Image Table Mapping with

the DeviceNet Adapter

6 Input, Status, Output and

Configuration with ControlNet

Appendix Title Contents

A Specifications Specifications for the analog modules

Describes FLEX Integra Analog modules, features, and how

they function

Explains how to configure your modules and read status

information from your modules when using a remote I/O

adapter

Explains how you communicate with your modules, and

how the I/O image is mapped when using a DeviceNet

adapter

Explains how you communicate with your modules, and

how the I/O image is mapped when using ControlNet.

Publication 1793-6.5.1 - April 1999

Page 4

P-2 Using This Manual

Conventions We use these conventions in this manual:

In this manual, we show: Like this:

that there is more information about a topic

in another chapter in this manual

that there is more information about the topic

in another manual

For Additional Information For additional information on FLEX Integra and FLEX I/O systems and

modules, refer to the following documents:

Catalog

Number

1793 Series

1793-IB4 4 Input Module 1793-5.1

1793-OB4P

1793-IB2XOB2P

1793-IE4 24V dc 4 Input Analog Module 1793-5.4

1793-IE2XOE1P 24V dc 2 In/1 Protected Output Analog Module 1793-5.6

1793-OW4

1794 1794 FLEX I/O Product Data 1794-2.1

1794-ACN 24V dc ControlNet Adapter 1794-5.8

1794-ACNR 24V dc Redundant Media ControlNet Adapter 1794-5.18

1794-ACN15 24V dc ControlNet Adapter 1794-5.47

1794-ACNR15 24V dc Redundant Media ControlNet Adapter 1794-5.48

1794-ADN 24V dc DeviceNet Adapter 1794-5.14 1794-6.5.5

1794-ASB/C & D 24V dc Remote I/O Adapter 1794-5.50 1794-6.5.9

1794-ASB2/B 24V dc 2-Slot Remote I/O Adapter 1794-5.44 1794-6.5.13

1794-APB 24V dc Profibus Adapter 1794-5.40 1794-6.5.6

1794-IB8 24V dc 8 Sink Input Module 1794-5.30

1794-OB8 24V dc 8 Source Output Module 1794-5.31

1794-IB16 24V dc 16 Sink Input Module 1794-5.4

1794-OB16 24V dc 16 Source Output Module 1794-5.3

1794-IV16 24V dc 16 Source Input Module 1794-5.28

1794-OV16 24V dc 16 Sink Output Module 1794-5.29

1794-OB8EP 24V dc 8 Electronically Fused Output Module 1794-5.20

1794-IB8S 24V dc Sensor Input Module 1794-5.7

Voltage Description

FLEX Integra Product Data 1793-2.1

4 Protected Output Module 1793-5.2

2 In/2 Protected Output Module 1793-5.3

4 Relay Output Module 1793-5.7

Publications

Installation

Instructions

User

Manual

1791-6.5.11793-OE2 24V dc 2 Protected Output Analog Module 1793-5.5

Publication 1793-6.5.1 - April 1999

Table continued on next page

Page 5

Using This Manual P-3

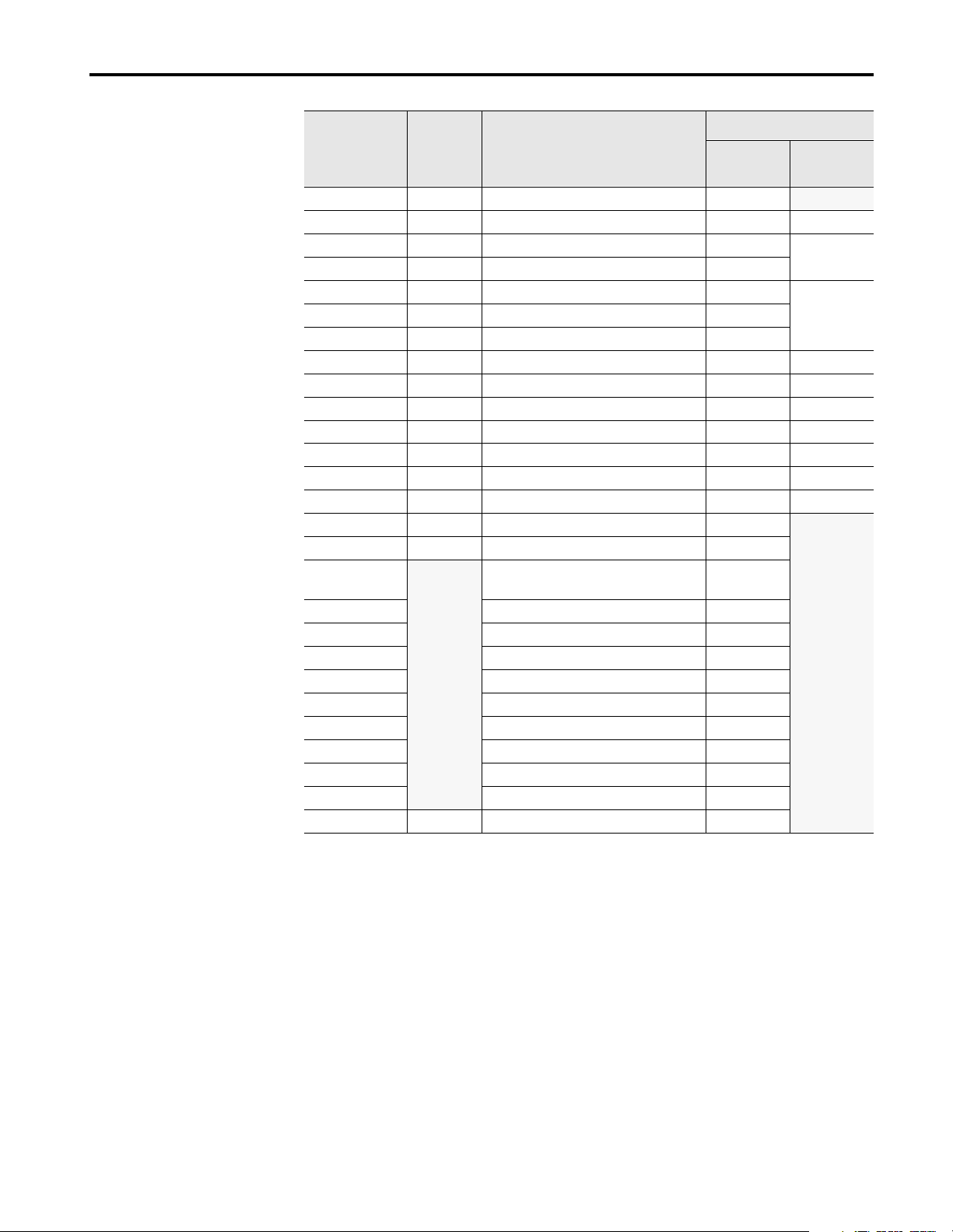

Catalog

Number

1794-IB10XOB6 24V dc 10 Input/6 Output Module 1794-5.24

1794-IE8 24V dc Selectable Analog 8 Input Module 1794-5.6 1794-6.5.2

1794-OE4 24V dc Selectable Analog 4 Output Module 1794-5.5

1794-IE4XOE2 24V dc 4 Input/2 Output Analog Module 1794-5.15

1794-OF4 24V dc 4 Output Isolated Analog Module 1794-5.37

1794-IF2XOF2 24V dc 2 Input/2 Output Isolated Analog Module 1794-5.39

1794-IR8 24V dc 8 RTD Input Analog Module 1794-5.22 1794-6.5.4

1794-IT8 24V dc 8 Thermocouple Input Module 1794-5.21 1794-6.5.7

1794-IRT8 24V dc 8 Thermocouple/RTD Input Module 1794-5.50 1794-6.5.12

1794-IJ2 24V dc 2 Frequency Input Module 1794-5.49 1794-6.5.11

1794-ID2 24V dc 2 Input Incremental Encoder Module 1794-5.63 1794-6.5.15

1794-IP4 24V dc 4 Input Pulse Counter Module 1794-5.64 1794-6.5.16

1794-VHSC 24V dc Very High Speed Counter Module 1794-5.67 1794-6.5.10

1794-IA8 120V ac 8 Input Module 1794-5.9

1794-OA8 120V ac Output Module 1794-5.10

1794-TB2

1794-TB3

1794-TBN Terminal Base Unit 1794-5.16

1794-TBNF Fused Terminal Base Unit 1794-5.17

1794-TB3T Temperature Terminal Base Unit 1794-5.41

1794-TB3S Spring Clamp Terminal Base Unit 1794-5.42

1794-TB3TS Spring Clamp Temperature Base Unit 1794-5.43

1794-TB3G Terminal Base Unit 1794-5.51

1794-TB3GS Spring Clamp Terminal Base Unit 1794-5.59

1794-CE1, -CE3 Extender Cables 1794-5.12

1794-NM1 Mounting Kit 1794-2.13

1794-PS1 24V dc Power Supply 1794-5.35

Voltage Description

2-wire Terminal Base

3-wire Terminal Base

Publications

Installation

Instructions

1794-5.2

User

Manual

1794-6.5.81794-IF4 24V dc 4 Input Isolated Analog Module 1794-5.38

Publication 1793-6.5.1 - April 1999

Page 6

Using This Manual

How to Install Your Analog

Module

Table of Contents

Preface

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

For Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Table of Contents

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Before You Install Your

Analog Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Compliance to

European Union Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Power Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Installing the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Connecting Wiring for the Analog Modules . . . . . . . . . . . . . . . . 2-5

Connecting Wiring for the 1793-IE4 Input Module. . . . . . . . 2-5

Connecting Wiring for the 1793-OE2 Output Module. . . . . . 2-6

Connecting Wiring for the 1793-IE2XOE1 Input/Output

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Module Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Module Programming

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Block Transfer

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Sample programs for FLEX Integra Analog Modules . . . . . . . . . 3-2

PLC-3 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

PLC-5 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

PLC-2 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Analog Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Publication 1793-6.5.1 - April 1999

Page 7

ii

Writing Configuration to and

Reading Status from Your

Module with a Remote I/O

Adapter

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Configuring Your Analog Module . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Range Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Safe State Value Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Reading Data From Your Module . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Mapping Data for the Analog Modules . . . . . . . . . . . . . . . . . . . . 4-2

Analog Input Module (1793-IE4 and -IE4S) Read . . . . . . . . . 4-3

Word/Bit Descriptions for the 1793-IE4 and -IE4S Analog Input

Module Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Analog Input Module (1793-IE4 and -IE4S) Write

Configuration Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Range Selection Bits for the 1793-IE4 and -IE4S Analog

Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Word/Bit Descriptions for the 1793-IE4 and -IE4S Analog Input

Module Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Analog Output Module (1793-OE2 and -OE2S) Read . . . . . . 4-6

Bit/Word Descriptions for the 1793-OE2 and -OE2S Analog

Output Module Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Analog Output Module (1793-OE2 and -OE2S) Write

Configuration Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Range Selection Bits for the 1793-OE2 and -OE2S Analog Output

Module (Word 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Word/Bit Descriptions for the 1793-OE2 and -OE2S Analog

Output Module Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Analog Combo Module (1793-IE4XOE1) Read . . . . . . . . . . . 4-8

Word/Bit Descriptions for the 1794-IE4XOE1 and -IE2XOE1S

Analog Combo Module Read . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Analog Combo Module (1793-IE2XOE1 and -IE2XOE1S) Write

Configuration Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Range Selection Bits for the 1793-IE2XOE1 and -IE2XOE1S

Analog Combo Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Word/Bit Descriptions for the 1793-IE2XOE1 and -IE2XOE1S

Analog Combo Module Write . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

How Communication Takes

Place and I/O Image Table

Mapping with the DeviceNet

Adapter

Publication 1793-6.5.1 - April 1999

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

About DeviceNetManager

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Polled I/O Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

System Throughput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Mapping Data into the

Image Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Page 8

Input, Status, Output and

Configuration Files using

ControlNet

iii

Chapter 6

What this Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

About the ControlNet Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Communication Over the

FLEX I/O Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Scheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Unscheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Module I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

I/O Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Adapter Input Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Safe State Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Device Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Communication Fault Behavior . . . . . . . . . . . . . . . . . . . . . . . 6-5

Idle State Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Input Data Behavior upon Module Removal . . . . . . . . . . . . . 6-5

Input Word/Bit Descriptions for the 1793-IE4 and -IE4S Analog

Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Range Selection Bits for the 1793-IE4 and -IE4S Analog Input

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Configuration Word/Bit Descriptions for the 1793-IE4 and -IE4S

Analog Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

ABit/Word Descriptions for the 1793-OE2 and -OE2S Analog

Output Module Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Range Selection Bits for the 1793-OE2 and -OE2S Analog

Output Module (Word 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Output Word/Bit Descriptions for the 1793-OE2 and -OE2S

Analog Output Module Write . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Configuration Word/Bit Descriptions for the 1793-OE2 and

-OE2S Analog Output Module Write . . . . . . . . . . . . . . . . . . . 6-9

Input Word/Bit Descriptions for the 1793-IE2XOE1and

-IE2XOE1S Analog Combo Module . . . . . . . . . . . . . . . . . . . 6-9

Range Selection Bits for the 1793-IE2XOE1and -IE2XOE1S

Analog Combo Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Output Word/Bit Descriptions for the 1793-IE2XOE1and

-IE2XOE1S Analog Combo Module . . . . . . . . . . . . . . . . . . 6-10

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Specifications

Data Table Formats

Appendix A

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B

Two’s Complement Binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Analog Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Publication 1793-6.5.1 - April 1999

Page 9

Chapter

1

Overview of FLEX Integra and your

Analog Modules

Chapter Objectives In this chapter, we tell you about:

• what the FLEX Integra system is and what it contains

• types of FLEX Integra analog modules

• how FLEX Integra analog modules communicate with programmable

controllers

• the features of your analog modules

The FLEX Integra System FLEX Integra is a small, modular I/O system for distributed applications

that performs all of the functions of rack-based I/O. The FLEX Integra

system contains the following components shown below:

Adapter

Flexbus connector

Remote I/O

Connector

• adapter/power supply – powers the internal logic for as many as eight

• I/O module with integral wiring terminals– contains the bus interface

24V dc field power

connection terminals

(externally provided)

I/O modules

and circuitry needed to perform specific functions related to your

application and connection terminals for connecting wiring.

Integra Module

Flexbus connector

Field wiring terminals

41480

Publication 1793-6.5.1 - April 1999

Page 10

1-2 Overview of FLEX Integra and your Analog Modules

Types of FLEX Integra Modules We describe the following FLEX Integra Analog modules in this user

manual:

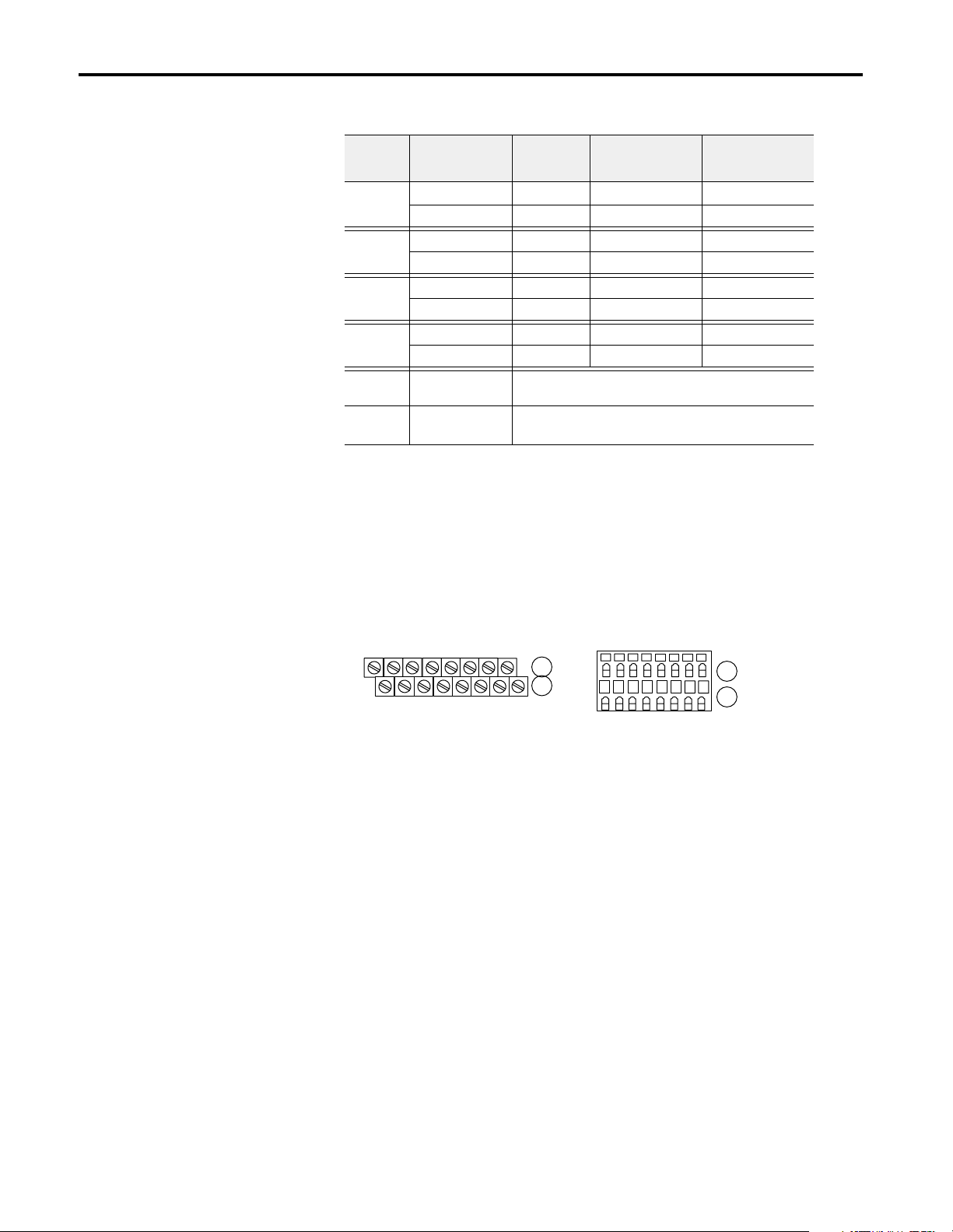

Catalog Number Voltage Inputs Outputs Description

1793-IE4 24V dc 4 –

1793-IE4S 24V dc 4 –

1793-OE2 24V dc – 2

1793-OE2S 24V dc – 2

1793-IE2XOE1 24V dc 2 1

1793-IE2XOE1S 24V dc 2 1

FLEX Integra analog input, output and combination modules are block

transfer modules that interface analog signals with any Allen-Bradley

programmable controllers that have block transfer capability. Block

transfer programming moves input from the module’s memory to a

designated area in the processor data table, and output data words from a

designated area in the processor data table to the module’s memory. Block

transfer programming also moves configuration words from the processor

data table to module memory.

analog – 4 input, single-ended, non-isolated;

screw-cage connectors

analog – 4 input, single-ended, non-isolated;

spring-clamp connectors

analog – 2 output, single-ended, non-isolated;

screw-cage connectors

analog – 2 output, single-ended, non-isolated;

spring-clamp connectors

analog – 2 input, single-ended, non-isolated

and 1 output, single-ended, non-isolated;

screw-cage connectiors

analog – 2 input, single-ended, non-isolated

and 1 output, single-ended, non-isolated;

spring-clamp connectors

How FLEX Integra Analog

Modules Communicate with

Programmable Controllers

The analog modules have selectable ranges as shown in the table below:

Voltage Current

0 to 10V dc 0 to 20mA

±10V dc 4 to 20mA

The adapter/power supply transfers data to the module (block transfer

write) and from the module (block transfer read) using BTW and BTR

instructions in your ladder diagram program. These instructions let the

adapter obtain input values and status from the module, and let you send

output values and establish the module’s mode of operation. Figure 1.1

describes the communication process.

Publication 1793-6.5.1 - April 1999

Page 11

Overview of FLEX Integra and your Analog Modules 1-3

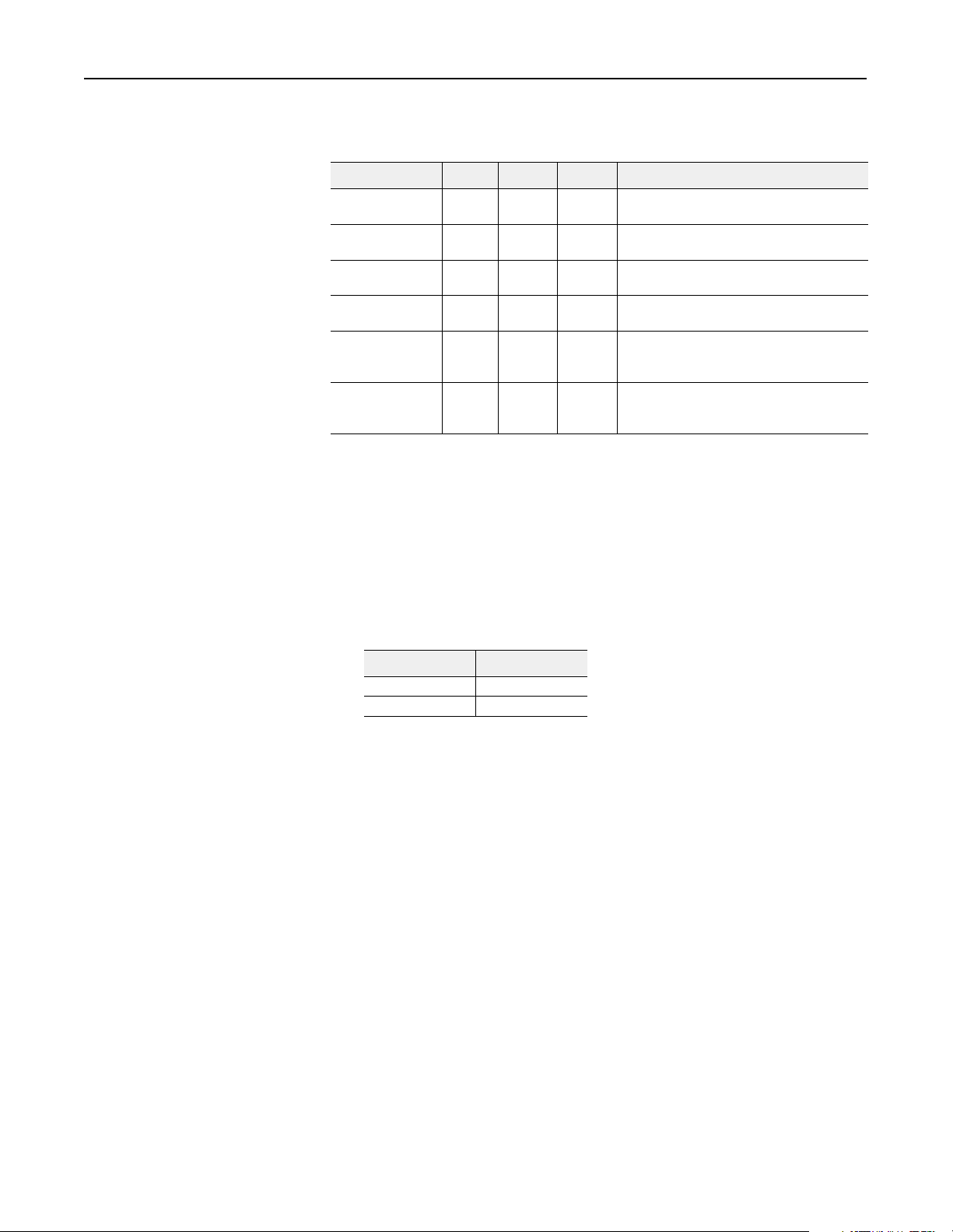

Figure 1.1

An Example of Communication Between an Adapter and an

Analog Input Module

ADAPTER

ACTIVE FAULT

Allen-Bradley

LOCAL

FAULT

1

The adapter transfers your configuration data

to the module using a BTW.

Flexbus

POWER SUPPLY

RIO ADAPTER

24VDC

1794-ASB

4

Your ladder program instructs the

adapter to perform a BTR of the values

and stores them in a data table.

5

The adapter and module determine

that the transfer was made without error

and input values are within specified

range.

6

Your ladder program can use and/or move the data

(if valid) before it is written over by the transfer of

new data in a subsequent transfer.

2

External devices transmit

analog signals to the module.

Allen-Bradley

3

The module converts analog signals

into binary format and stores these

values until the adapter requests their

transfer.

7

Your ladder program performs BTWs to the module when

you power it up, and any time you wish to reconfigure the module.

Publication 1793-6.5.1 - April 1999

Page 12

1-4 Overview of FLEX Integra and your Analog Modules

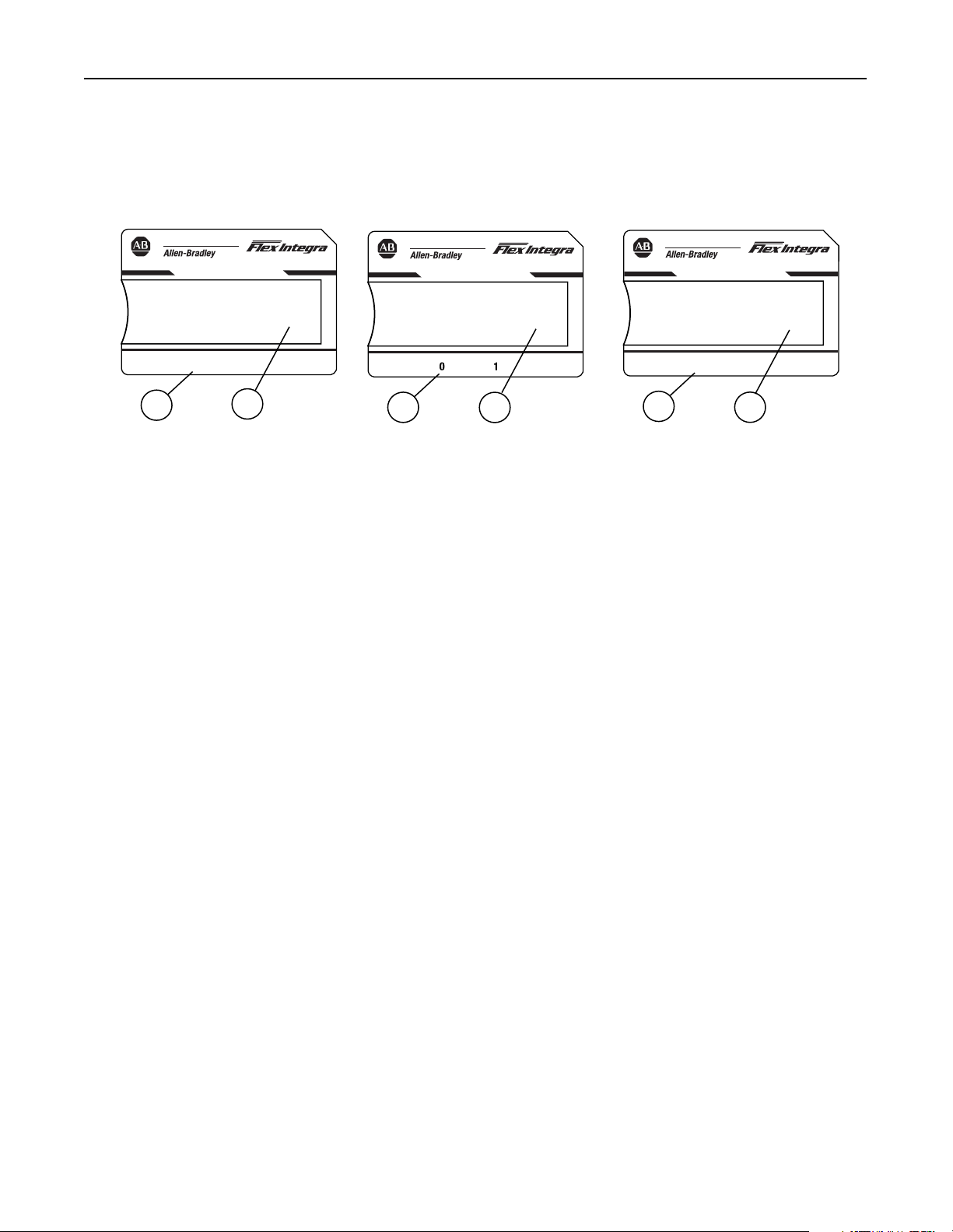

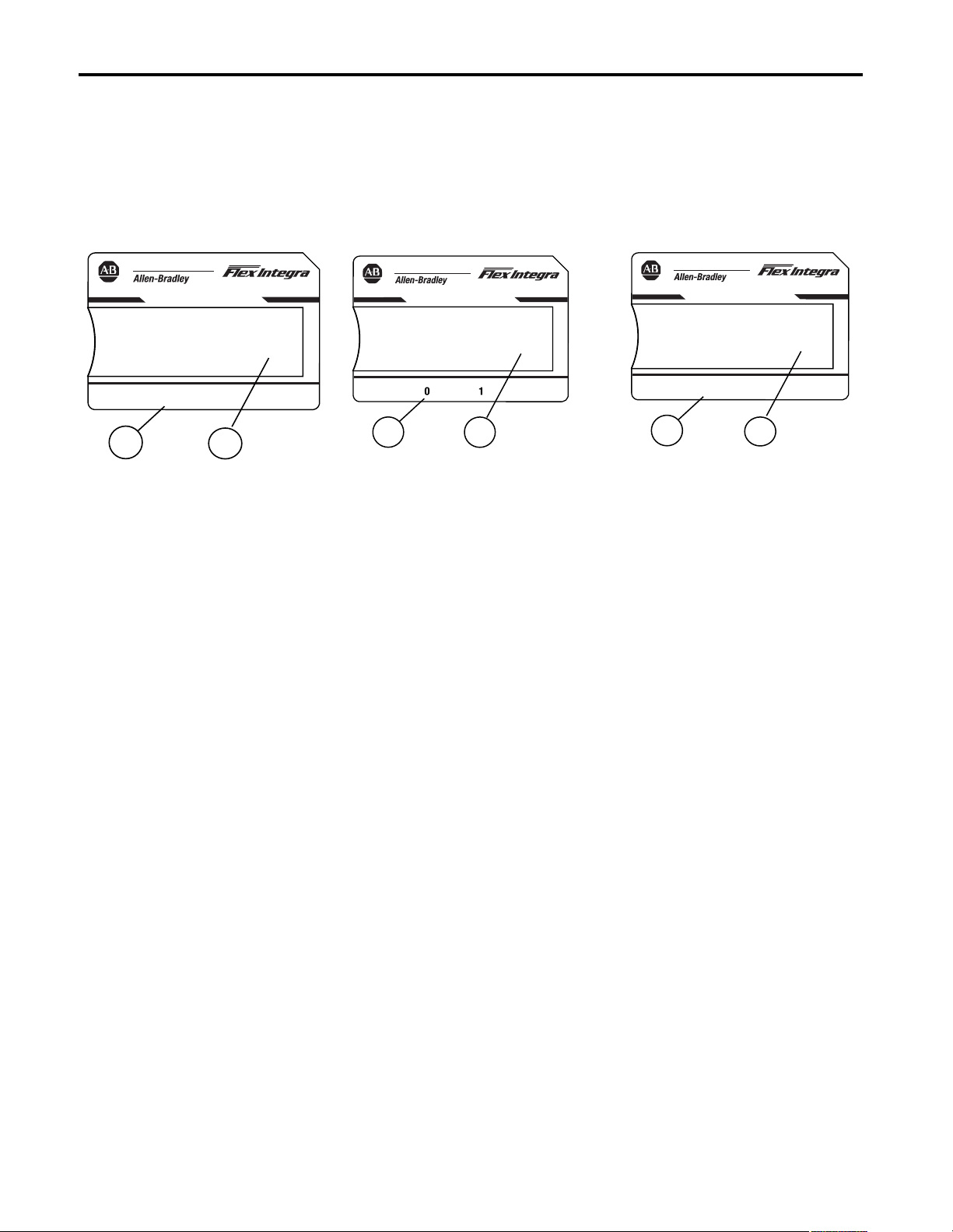

Features of your Analog

Modules

Each module has a unique label identifying its wiring and module type. A

removable label provides space for writing individual designations per

your application.

A

4 INPUT ANALOG

INPUT

0

123

1793-IE4S

B

41350

2 CH ANALOG OUTPUT

A

1793-OE2

41368

B

2 INPUT/1 OUTPUT ANALOG

INPUT

0

1

A

1793-IE2XOE1

OUTPUT

0

B

41491

A = status indicator

B = insertable label

Chapter Summary In this chapter you learned about the FLEX I/O system and the types of

analog modules and how they communicate with programmable

controllers.

Publication 1793-6.5.1 - April 1999

Page 13

Chapter 2

How to Install Your Analog Module

Chapter Objectives

Before You Install Your

Analog Module

In this chapter, we tell you about:

• how to install your module

• how to wire your module

• the indicators

Before installing your analog module in the I/O chassis:

You n e e d to: As described under:

Calculate the power requirements of all

modules in each chassis.

ATTENTION: +24V dc power must be applied to your

module before operation. If power is not applied, the module

position will appear to the adapter as an empty slot in your

chassis. If the adapter does not recognize your module after

installation is completed, cycle power to the adapter.

Power Requirements, page 2-2

Compliance to

European Union Directives

If this product has the CE mark it is approved for installation within the

European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 – Industrial

Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

This product is intended for use in an industrial environment.

Publication 1793-6.5.1 - April 1999

Page 14

2-2 How to Install Your Analog Module

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage,

by applying the safety requirements of EN 61131-2 Programmable

Controllers, Part 2 – Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For Noise

Immunity, publication 1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Power Requirements

Installing the Module

The wiring of the module is determined by the current draw through the

terminals. Make certain that the current draw does not exceed 10A.

ATTENTION: Total current draw through the module

wiring terminals is limited to 10A. Separate power

connections may be necessary.

ATTENTION: Do not daisy chain power or ground from

an analog module to any ac or dc discrete module.

Installation of the analog module consists of:

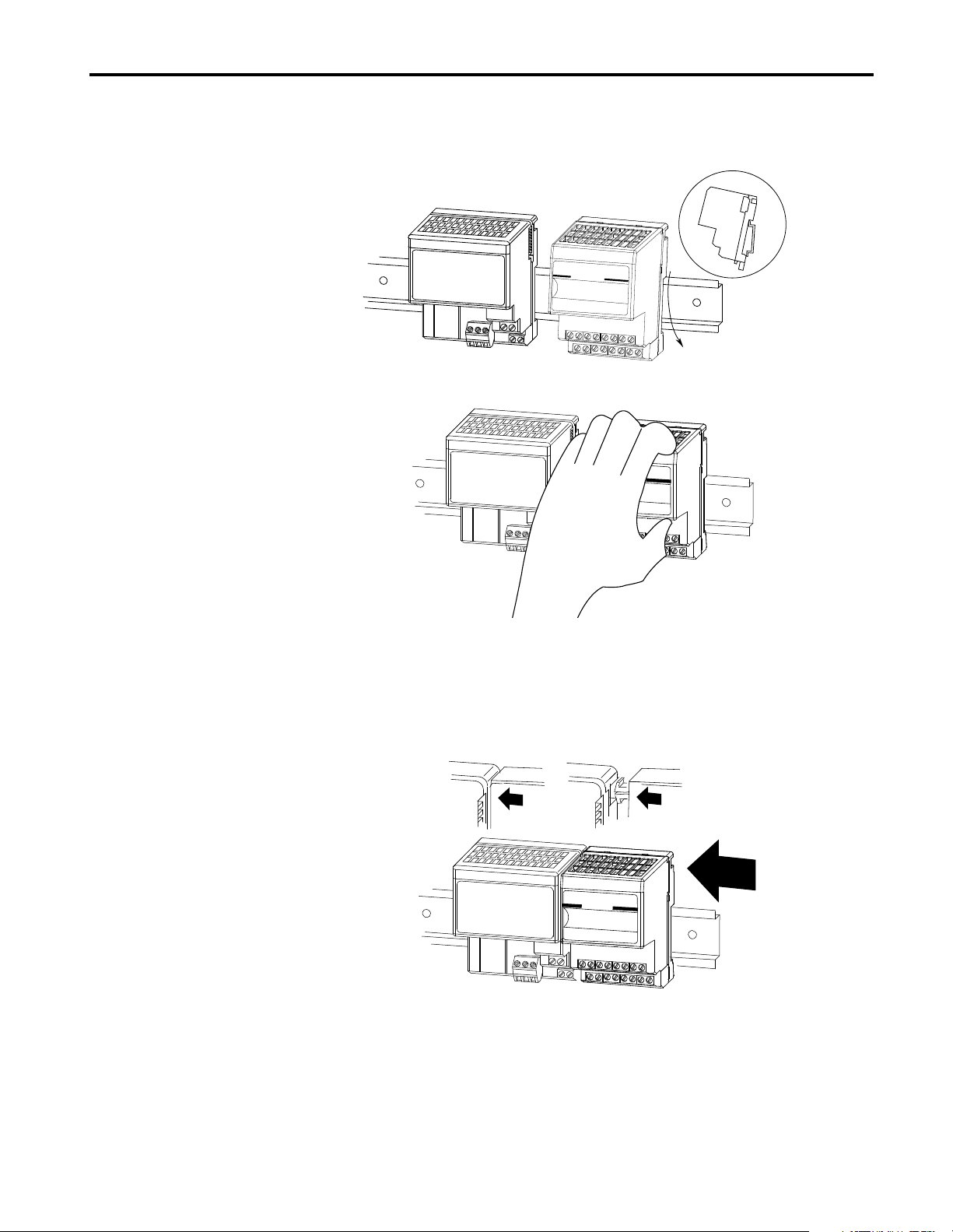

This module mounts on a DIN rail. It connects to an adapter or another

FLEX I/O or Integra module. Note: If using this module with FLEX I/O

modules, do not mount between FLEX I/O modules. Mount Integra

modules to the right of the FLEX I/O modules. To mount this module::

1. Remove the cover plug (if used) in the male connector of the unit to

which you are connecting this module.

Publication 1793-6.5.1 - April 1999

Page 15

How to Install Your Analog Module 2-3

2. Position the module on the 35 x 7.5mm DIN rail A (A-B pt. no.

199-DR1). Rotate the module onto the DIN rail with the top of the rail

hooked under the lip on the rear of the module.

A

A

30720-M

3. Press down to lock the module on the DIN rail.l

A

41377

If the module does not lock in place, use a screwdriver of similar device

to move the locking tab down, press the module flush with the DIN rail

and release the locking tab to lock the module in place

4. Firmly push the module into the adjacent module/terminal base until the

units lock together.

41371

41370

5. Repeat the above steps to install the next Integra module.

Publication 1793-6.5.1 - April 1999

Page 16

2-4 How to Install Your Analog Module

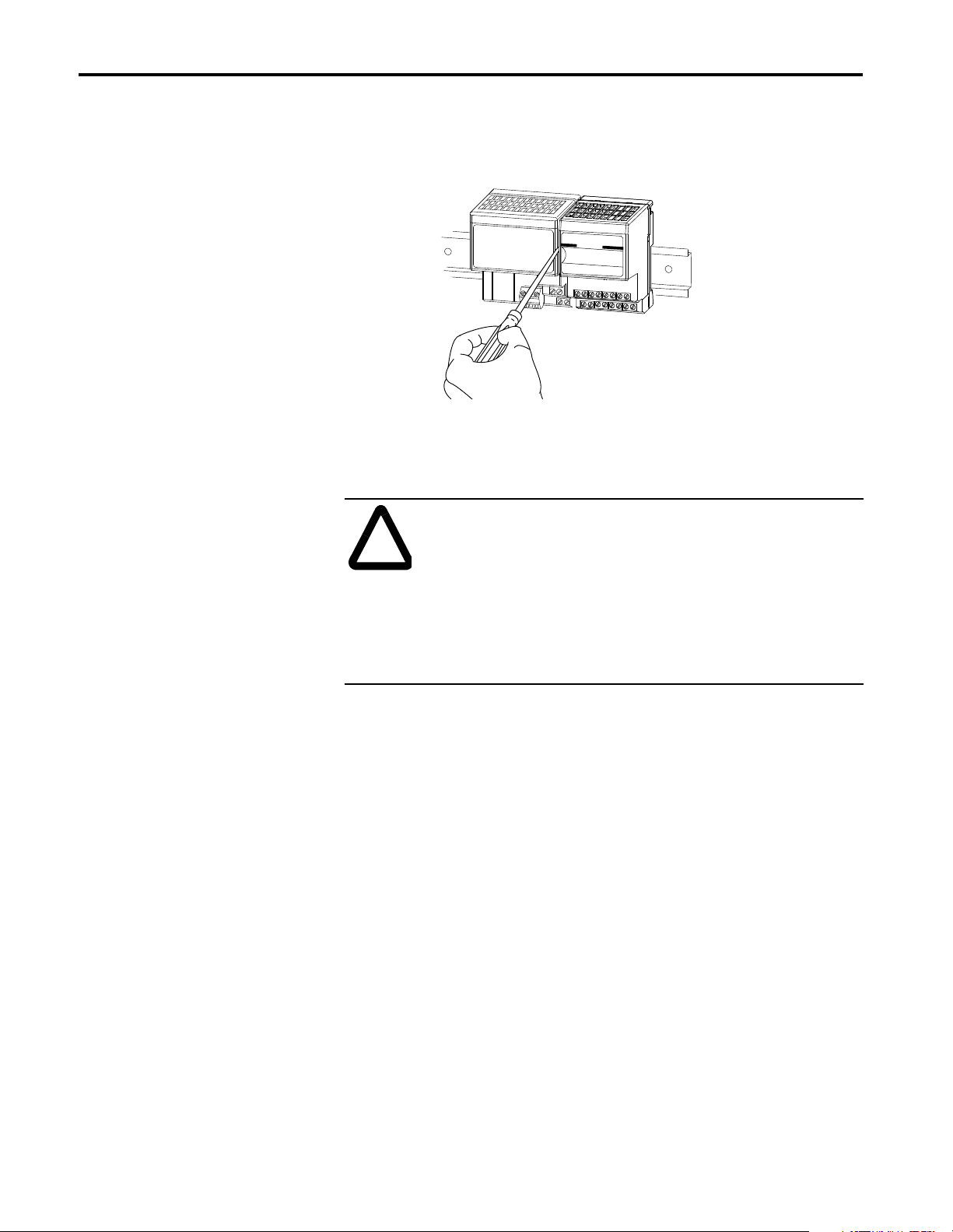

6. To remove an Integra module, you must work from the right side and

remove one module at a time. To disengage a module from its neighbor,

place a common flat-bladed screwdriver between the 2 modules and turn

1/4 turn to separate the modules.

41373

7. Then slide the module away from its left neighbor, and release the

locking lever to remove the module from the DIN rail.

ATTENTION: Do not remove this module under power.

Removing this module under power will break the electrical

backplane (flexbus) connections. This can cause personal injury

or property damage by:

• sending an erroneous signal to your system’s field devices

causing unintended machine motion

• causing an explosion in a hazardous environment

• breaking communication to modules beyond this module

Publication 1793-6.5.1 - April 1999

Page 17

How to Install Your Analog Module 2-5

Connecting Wiring for the

Analog Modules

Connecting Wiring for the 1793-IE4 Input Module

This module is available with 2 styles of connectors; screw-cage and spring

clamp. Refer to the wiring figure below.

1793-IE4

Ch 0 Ch 1

CC

01234567

8 9 10 11

CCVV

Ch 2 Ch 3

Where: C = 24V dc common, V = 24V dc power, In = current in, Vn = voltage in

I1I0 V0 V1

I3I2 V2 V3

C

A

B

13 14 1512

41470

C

1. Connect individual analog channel signal wiring to terminals on row A

and row C. Use Belden 8761 cable for signal wiring..

ATTENTION: Connect only 1 current or 1

voltage signal per channel. Do not connect both

current and voltage on 1 channel.

1793-IE4S

Ch 0 Ch 1

CC

V1 V2I2I1

CC

0 1234567

A

B

8 9 10 11 12 13 14 15

VVCC

V3 V4I4I3

Ch 2 Ch 3

41471

2. Connect the associated channel common to common terminals 1, 6, 9 or

14 according to the wiring table on the next page.

3. Connect +24V dc to terminal 8 on row B.

4. Connect 24V dc common to terminal 0 on row A.

5. If daisy-chaining +24V dc from this module to the next FLEX Integra

module, connect a jumper from terminal 15 to terminal 8 on the next

FLEX Integra module.

6. If daisy-chaining 24V dc common from this module to the next FLEX

Integra module, connect a jumper from terminal 7 on this module to

terminal 0 on the next Integra module.

Publication 1793-6.5.1 - April 1999

Page 18

2-6 How to Install Your Analog Module

Table 2.A Wiring connections for the 1793-IE4 Analog Module

Channel Signal Type

0

1

2

3

Current I 2 1

Voltage V 3 1

Current I 4 6

Voltage V 5 3

Current I 10 9

Voltage V 11 9

Current I 12 14

Voltage V 13 14

24V dc Common

+24V dc power

Label

Markings

Signal Return

Terminals 0, 1, 6, 9, and 14 are connected together in

the module.

Terminals 8 and 15 are internally connected in the

module.

Connecting Wiring for the 1793-OE2 Output Module

. This module is available with 2 styles of connectors; 1793-OE2 screw-cage and 1793-OE2S - spring clamp. Refer to the figure below.

1793-OE4 1793-OE4S

Out Ch 0 Out Ch 1

01234567

8 9 10 11

Where: C = common; V = +24V dc power;

I = current output; V = voltage output

I1 V1Io VoCVCCC

13 14 1512

41358

VCC

A

B

Ch0 Ch1

CC

V0I0 V1I1

CC

0 1234567

A

B

8 9 10 11 12 13 14 15

CVVC

41359

1. Connect individual analog output channel signal wiring as follows:

Channel 0 - Current output - connect output signal to terminal 2

(current output) on row A. Connect the associated channel common

to terminal 1 on row A.

Channel 0 - voltage output - connect output signal to terminal 3

(current output) on row A. Connect the associated channel common

to terminal 1 on row A.

Channel 1 - Current output - connect output signal to terminal 4

(current output) on row A. Connect the associated channel common

to terminal 6 on row A.

Channel 0 - voltage output - connect output signal to terminal 5

(current output) on row A. Connect the associated channel common

to terminal 6 on row A.

Publication 1793-6.5.1 - April 1999

1RWH8VH%HOGHQFDEOHIRUVLJQDOZLULQJ

Page 19

How to Install Your Analog Module 2-7

$77(17,21 &RQQHFWRQO\YROWDJHRUFXUUHQWVLJQDO

SHUFKDQQHO'RQRWFRQQHFWERWKYROWDJHDQGFXUUHQWRQRQH

FKDQQHO

2. Connect +24V dc to terminal 8 on row B

3. Connect 24V common to terminal 0 on row A.

4. If daisy-chaining +24V dc from this module to the next FLEX Integra

module, connect a jumper from terminal 15 to terminal 8 on the next

FLEX Integra module.

5. If daisy-chaining 24V dc common from this module to the next FLEX

Integra module, connect a jumper from terminal 7 on this module to

terminal 0 on the next Integra module.

ATTENTION: Total current draw through the

module’s 24V dc terminals is limited to 10A.

Separate power connections to the module may be

required.

$77(17,21'RQRWUHPRYHWKLVPRGXOHXQGHUSRZHU

5HPRYLQJWKLVPRGXOHXQGHUSRZHUZLOOEUHDNWKHHOHFWULFDO

EDFNSODQHIOH[EXVFRQQHFWLRQV7KLVFDQFDXVHSHUVRQDO

LQMXU\RUSURSHUW\GDPDJHE\

VHQGLQJDQHUURQHRXVVLJQDOWR\RXUV\VWHPVILHOG

GHYLFHVFDXVLQJXQLQWHQGHGPDFKLQHPRWLRQ

FDXVLQJDQH[SORVLRQLQDKD]DUGRXVHQYLURQPHQW

EUHDNLQJFRPPXQLFDWLRQWRPRGXOHVEH\RQGWKLV

PRGXOH

ATTENTION: Connect only one current or one voltage

signal per channel. Do not connect both current and voltage

on one channel.

Publication 1793-6.5.1 - April 1999

Page 20

2-8 How to Install Your Analog Module

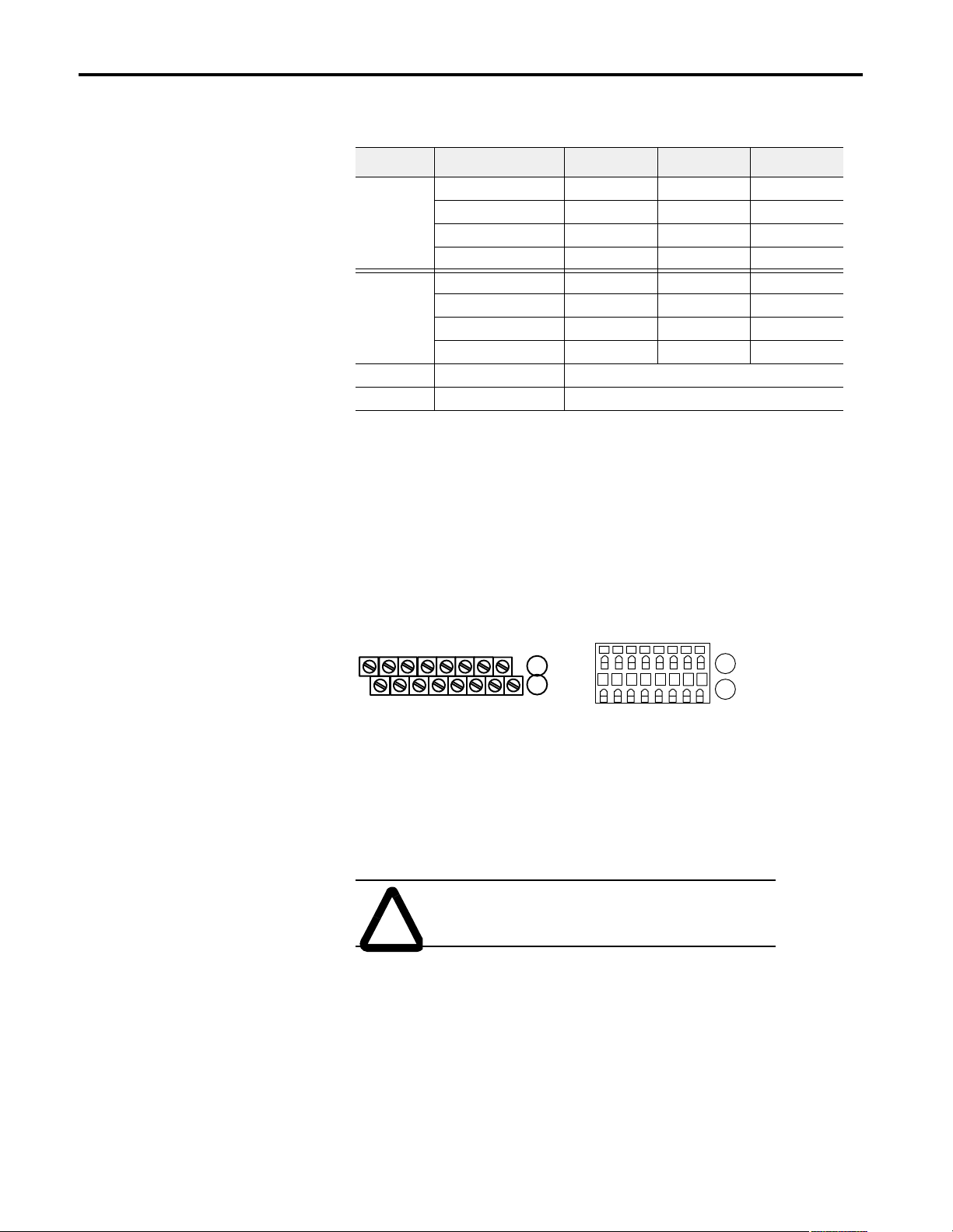

Tabl e 2.B

Wiring connections for the 1793-OE2 Analog Module

Channel Type Label Marking Signal Return

Current Signal I 2

0

Current Common RET 1

Voltage Signal V 3

Voltage Common RET 1

Current Signal I 4

1

Current Common RET 6

Voltage Signal V 5

Voltage Common RET 6

24V dc Common Terminals 0, 1, 6, 7, 9 and 14

+24V dc Terminals 8 and 15 are internally connected to +V.

Connecting Wiring for the 1793-IE2XOE1 Input/Output Module

This module is available with 2 styles of connectors; screw-cage and spring

clamp. Refer to the wiring figure below.

1793-IE2XOE1

In Ch 1

In Ch 0

CC

01234567

Where: C = common; V = +24V dc power; I

V

= voltage in; Io = current out; Vo = voltage out

0,1

V0 V1I1I0

8 9 10 11

CCVV

Out Ch 0

C

A

B

13 14 1512

VoIo

41473

C

= current in;

0,1

1793-IE2XOE1S

In Ch 1

In Ch 0

CC

V0 V1I1I0

CC

0 1234567

A

B

I

8 9 10 11 12 13 14 15

VVCC

VoIo

Out Ch 0

41472

1. Connect individual analog input channel signal wiring to terminals on

row A. Use terminals 2 (channel 0) and 4 (channel 1) for current and

terminals 3 and 5 for current. Use Belden 8761 cable for signal wiring..

$77(17,21 &RQQHFWRQO\FXUUHQWRUYROWDJHVLJQDO

SHUFKDQQHO'RQRWFRQQHFWERWKFXUUHQWDQGYROWDJHRQ

FKDQQHO

2. Connect the associated channel common to common terminals 1 and 6

according to the wiring table on the next page.

3. Connect individual analog output channel signal wiring to terminals 10

or 11 on row B. (Use terminal 10 for current, or terminal 11 for voltage not both.)

4. Connect the associated channel common to common terminal 9

according to the wiring table on the next page.

Publication 1793-6.5.1 - April 1999

Page 21

How to Install Your Analog Module 2-9

5. Connect +24V dc to terminal 8 on row B

6. Connect 24V dc common to terminal 0 on row A.

7. If daisy-chaining +24V dc from this module to the next FLEX Integra

module, connect a jumper from terminal 15 to terminal 8 on the next

FLEX Integra module.

8. If daisy-chaining 24V dc common from this module to the next FLEX

Integra module, connect a jumper from terminal 7 on this module to

terminal 0 on the next Integra module.

ATTENTION: Total current draw through the terminal

base unit is limited to 10A. Separate power connections to

the terminal base unit may be necessary.

Tabl e 2.C

Wiring connections for the 1794-IE4XOE2 Analog Module

Channel Signal Type

Input

0 Current I 2 1

Voltage V 3

1 Current I 4 6

Voltage V 5

Output

0 Current I 10 9

Voltage V 11

+24V dc Terminals 8 and 15 are internally connected to +V.

24V dc

common

Terminals 0, 1, 6, 7, 9, 14 are internally connected together

in the module.

ATTENTION: Use a 100Ω, 25W or greater,

resistor when connecting to a low-impedence

device, i.e., panel meter. Failure to do so can

result in damage to output circuitry.

Label

Markings

Signal Return

Publication 1793-6.5.1 - April 1999

Page 22

2-10 How to Install Your Analog Module

Module Indicators

4 INPUT ANALOG

iNPUT

0

123

A

The analog modules have status indicators that are on when power is

applied to the module An insertable label is supplied to identify your inputs

and outputs.

1793-IE4S

B

41350

2 CH ANALOG OUTPUT

A

1793-OE2

41368

B

2 INPUT/1 OUTPUT ANALOG

INPUT

0

1

A

1793-IE2XOE1

OUTPUT

0

B

41491

A = status indicator

B = insertable label

Chapter Summary

In this chapter you learned how to install and wire your analog module in an

existing programmable controller system.

Publication 1793-6.5.1 - April 1999

Page 23

Module Programming

Chapter

3

Chapter Objectives

Block Transfer

Programming

In this chapter, we tell you about:

• analog data format

• block transfer programming

• sample programs for the PLC-3 and PLC-5 processors

Your module communicates with the processor through bidirectional block

transfers. This is the sequential operation of both read and write block

transfer instructions.

A configuration block transfer write (BTW) is initiated when the analog

module is first powered up, and subsequently only when the programmer

wants to enable or disable features of the module. The configuration BTW

sets the bits which enable the programmable features of the module, such as

scaling, alarms, ranges, etc. Block transfer reads are performed to retrieve

information from the module.

Block transfer read (BTR) programming moves status and data from the

module to the processor’s data table. The processor user program initiates

the request to transfer data from the module to the processor. The

transferred words contain module status, channel status and input data from

the module.

ATTENTION: If the analog module is not powered up

before the remote I/O adapter, the adapter will not recognize

the module. Make certain that the analog module is installed

and powered before or simultaneously with the remote I/O

adapter. If the adapter does not establish communication with

the module, cycle power to the adapter.

The following sample programs are minimum programs; all rungs and

conditioning must be included in your application program. You can disable

BTRs, or add interlocks to prevent writes if desired. Do not eliminate any

storage bits or interlocks included in the sample programs. If interlocks are

removed, the program may not work properly.

Your program should monitor status bits, block transfer read and block

transfer write activity.

Publication 1793-6.5.1 - April 1999

Page 24

3-2 Module Programming

Sample programs for FLEX

Integra Analog Modules

The following sample programs show you how to use your analog module

efficiently when operating with a programmable controller.

These programs show you how to:

• configure the module

• read data from the module

• update the module’s output channels (if used)

These programs illustrate the minimum programming required for

communication to take place.

PLC-3 Programming

Block transfer instructions with the PLC-3 processor use one binary file in a

data table section for module location and other related data. This is the

block transfer control file. The block transfer data file stores data that you

want transferred to your module (when programming a block transfer write)

or from your module (when programming a block transfer read). The

address of the block transfer data files are stored in the block transfer

control file.

The same block transfer control file is used for both the read and write

instructions for your module. A different block transfer control file is

required for every module.

Program Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module if the power - up bit

is set.

Thereafter, the program continuously

performs read block transfers.

Note: You must create the data file

for the block transfers before you

enter the block transfer instructions.

The pushbutton allows the user to

manually request a block transfer write to

configure the module.

A sample program segment with block transfer instructions is shown in

Figure 3.1, and described below.

Figure 3.1

PLC-3 Family Sample Program Structure for a 1793-IE4 Module

Block Transfer

Read Done Bit

B3:0

1

15

Block Transfer

Write Done Bit

Pushbutton

2

Power-up Bit

1

Power-up bit included in Series B modules only.

1

B4:8

15

B3:0

05

BTR

BLOCK XFER READ

RACK: 7

GROUP: 0

MODULE: 0

CONTROL: #B3:0

DATA FILE: #B4:0

LENGTH: 9

BTW

BLOCK XFER WRITE

RACK: 7

GROUP: 0

MODULE: 0

CONTROL: #B3:0

DATA FILE: #B5:0

LENGTH: 1

Enable

EN

12

Done

DN

15

Error

ER

13

Enable

EN

02

Done

DN

05

Error

ER

03

Publication 1793-6.5.1 - April 1999

Page 25

Program Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module and send data

values.

Thereafter, the program continuously

performs read block transfers and write

block transfers.

Note: You must create the data file

for the block transfers before you

enter the block transfer instructions.

Module Programming 3-3

Figure 3.2

PLC-3 Family Sample Program Structure for a 1793-OE2 Module

BTR

Block Transfer

Read Done Bit

1

2

B6:0

15

Block Transfer

Write Done Bit

B6:0

05

BLOCK XFER READ

RACK: 7

GROUP: 1

MODULE: 0

CONTROL: #B6:0

DATA FILE: #B7:0

LENGTH: 1

BTW

BLOCK XFER WRITE

RACK: 7

GROUP: 1

MODULE: 0

CONTROL: #B6:0

DATA FILE: #B8:0

LENGTH: 14

Enable

EN

12

Done

DN

15

Error

ER

13

Enable

EN

02

Done

DN

05

Error

ER

03

Program Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module and send data values

Thereafter, the program continuously

performs read block transfers and write

block transfers.

Note: You must create the data file

for the block transfers before you

enter the block transfer instructions.

Figure 3.3

PLC-3 Family Sample Program Structure for a 1793-IE2XOE1 Module

BTR

Block Transfer

Read Done Bit

B9:0

1

15

Block Transfer

Write Done Bit

B9:0

2

05

BLOCK XFER READ

RACK: 7

GROUP: 2

MODULE: 0

CONTROL: #B9:0

DATA FILE: #B10:0

LENGTH: 5

BTW

BLOCK XFER READ

RACK: 7

GROUP: 2

MODULE: 0

CONTROL: #B9:0

DATA FILE: #B11:0

LENGTH: 8

Enable

EN

12

Done

DN

15

Error

ER

13

Enable

EN

02

Done

DN

05

Error

ER

03

Publication 1793-6.5.1 - April 1999

Page 26

3-4 Module Programming

Program Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module if the power-up bit

is set.

Thereafter, the program continuously

performs read block transfers to configure

the module.

The pushbutton allows the user to

manually request a block transfer write.

1

Power-up bit included in Series B modules only.

PLC-5 Programming

The PLC-5 program is very similar to the PLC-3 program with the

following exceptions:

• block transfer enable bits are used instead of done bits as the conditions

on each rung.

• separate block transfer control files are used for the block transfer

instructions.

Figure 3.4

PLC-5 Family Sample Program Structure for the 1793-IE4

N12:0

15

BTR Enable Bit

N12:0

15

BTW Enable Bit

N12:5

15

BTR

BLOCK TRANSFER READ

RACK: 2

GROUP: 1

MODULE: 0

CONTROL: N12:0

DATA FILE: N13:0

LENGTH: 9

CONTINUOUS: N

BTW

BLOCK TRANSFER WRITE

RACK: 2

GROUP: 1

MODULE: 0

CONTROL: N12:5

DATA FILE: N13:20

LENGTH: 1

CONTINUOUS: N

EN

DN

ER

EN

DN

ER

1

2

Pushbutton

Power-up

1

Bit

N13:8

15

BTW Enable Bit

N12:5

15

BTR Enable Bit

Program Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module and send data values.

Thereafter, the program continuously

performs read block transfers and write block

transfers.

Publication 1793-6.5.1 - April 1999

Figure 3.5

PLC-5 Family Sample Program Structure for the 1793-OE2

BTR Enable Bit

N14:0

1

15

BTW Enable Bit

N14:5

2

15

BTW Enable Bit

N14:5

15

BTR Enable Bit

N14:0

15

BTR

BLOCK TRANSFER READ

RACK: 2

GROUP: 2

MODULE: 0

CONTROL: N14:0

DATA FILE: N15:0

LENGTH: 1

CONTINUOUS: N

BTW

BLOCK TRANSFER WRITE

RACK: 2

GROUP: 2

MODULE: 0

CONTROL: N14:5

DATA FILE: N15:5

LENGTH: 14

CONTINUOUS: N

EN

DN

ER

EN

DN

ER

Page 27

Module Programming 3-5

Figure 3.6

PLC-5 Family Sample Program Structure for the 1793-IE2XOE1

Program Action

At power-up in RUN mode, or when the

processor is switched from PROG to RUN,

the user program enables a block transfer

read. Then it initiates a block transfer write

to configure the module and send data

values.

Thereafter, the program continuously

performs read block transfers and write block

transfers.

BTW Enable Bit

N16:5

1

15

BTR Enable Bit

N16:0

2

15

PLC-2 Programming

BTR Enable Bit

N16:0

15

BTW Enable Bit

N16:5

15

BTR

BLOCK TRANSFER READ

RACK: 2

GROUP: 3

MODULE: 0

CONTROL: N16:0

DATA FILE: N17:0

LENGTH: 5

CONTINUOUS: N

BTW

BLOCK TRANSFER WRITE

RACK: 2

GROUP: 3

MODULE: 0

CONTROL: N16:5

DATA FILE: N17:5

LENGTH: 8

CONTINUOUS: N

EN

DN

ER

EN

DN

ER

Analog Data Format

The 1793 analog I/O modules are not recommended for use with PLC-2

family programmable controllers due to the number of digits needed for

high resolution. In addition, the data returned from the analog-to-digital

converter in the module is 12-bit resolute. This value is left-justified into a

16-bit field, reserving the most significant bit for a sign bit. Refer to

Appendix B for more information.

The data returned from the analog-to-digital converter in the module is

12-bit resolute. This value is left-justified into a 16-bit field, reserving the

most significant bit for a sign bit.

A/D Unipolar Data

Analog Value

Input

A/D Bipolar Data

Analog Value

D/A Data

Output

Analog Value

11 10 09 08 07 06 05 04 03 02 01 00

14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

0*

= Always positive

*

10 09 08 07 06 05 04 03 02 01 00

S

14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

S

11 10 09 08 07 06 05 04 03 02 01 00

S

14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

S

Publication 1793-6.5.1 - April 1999

Page 28

3-6 Module Programming

Refer to Appendix B for a table of values for various current and voltage

modes.

Appendix B also includes an example of scaling.

Chapter Summary

In this chapter, you learned how to program your programmable controller.

You were given sample programs for your PLC-3 and PLC-5 family

processors.

Publication 1793-6.5.1 - April 1999

Page 29

Writing Configuration to and

Reading Status from Your Module

with a Remote I/O Adapter

Chapter

4

Chapter Objectives

Configuring Your Analog

Module

In this chapter, we tell you about:

• configuring your module’s features

• entering your data

• reading data from your module

• read block format

Note: You must use a 1794-ASB series D or later remote I/O adapter to

communicate with the 1793 FLEX Integra analog modules.

Because of the many analog devices available and the wide variety of

possible configurations, you must configure your module to conform to the

analog device and specific application that you have chosen. The module is

configured using a group of data table words that are transferred to the

module using a block transfer write instruction.

The software configurable features available are:

• input/output range selection, including full range and bipolar

• safe state operating value (customer selected analog values the module

will maintain in the event of a network communication error)

Note: PLC-5 family programmable controllers that use 6200 software

programming tools can take advantage of the IOCONFIG utility to

configure these modules. IOCONFIG uses menu-based screens for

configuration without having to set individual bits in particular locations.

Refer to your 6200 software literature for details.

Publication 1793-6.5.1 - April 1999

Page 30

4-2 Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter

Range Selection

Safe State Value Selection

Individual input channels are configurable to operate with the following

voltage or current ranges:

Bit Settings

Ranges

0-10V dc/0-20mA 0 1

4-20mA 1 0

–10 to +10V dc 1 1

Off 0 0

1

When configured to Off, individual output channels will drive 0V/0mA.

Configure

Select

Full Range

You can select individual channel ranges using the designated words of the

write block transfer instruction. Refer to the Bit/Word description for your

particular module for word and bit numbers.

You can select the analog values that your output module will maintain in

the event of a network communication error. When the multiplex control

bits (M) are cleared simultaneously by a communication error, (or by the

user), the analog outputs will automatically switch to the values set in the

safe state analog words. This allows you to define a safe operating state for

controlled devices which depend on the analog output from the module.

Data Format

Reading Data From Your

Module

Mapping Data for the

Analog Modules

The data returned from the analog-to-digital converter in the module is

12-bit resolute. This value is left-justified into a 16-bit field, reserving the

most significant bit for a sign bit. The 4-20mA mode scales in the module

and uses all 16 bits.

Refer to Appendix C for a table of values for various current and voltage

modes, and an example of scaling to engineering terms.

Read programming moves status and data from the module to the

processor’s data table. The processor’s user program initiates the request to

transfer data from the input module to the processor.

The following read and write words and bit/word descriptions describe the

information written to and read from the analog modules. Each word is

composed of 16 bits.

Publication 1793-6.5.1 - April 1999

Page 31

Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter 4-3

8 Input Analog Module (Cat. No. 1793-IE4 and -IE4S)

Module Image

Input Data Channel 0

I/O Image

Input Size

1 to 9 Words

PU

Output Size

0 or 1 Word

Analog Input Module (1793-IE4 and -IE4S) Read

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Reserved

Reserved

Reserved

Reserved

Underrange

Configure select

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 0 S Analog Value Channel 0

Word 1 S Analog Value Channel 1

Word 2 S Analog Value Channel 2

Word 3 S Analog Value Channel 3

Word 4 S Reserved

Word 5 S Reserved

Word 6 S Reserved

Word 7 S Reserved

Word 8 PU Not used – set to zero U3 U2 U1 U0

Where: S = sign bit (in 2’s complement)

U = Underrange bits for 4-20mA inputs

PU = Power up bit

Publication 1793-6.5.1 - April 1999

Page 32

4-4 Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter

Word/Bit Descriptions for the 1793-IE4 and -IE4S Analog Input Module Read

Word

Read Word 0

Word 1

Word 2

Word 3

Words 4-7 Reserved

Word 8

Decimal Bit

(Octal Bit)

Bits 00-14

(00-16)

Bits 15 (17) Channel 0 analog data sign bit.

Bits 00-14

(00-16)

Bits 15 (17) Channel 1 analog data sign bit.

Bits 00-14

(00-16)

Bits 15 (17) Channel 2 analog data sign bit.

Bits 00-14

(00-16)

Bits 15 (17) Channel 3 analog data sign bit.

Bits 00-03

Bits 04-14

(04-16)

Bit 15 (17)

Channel 0 analog data – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Channel 1 analog data – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Channel 2 analog data – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Channel 3 analog data – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Underrange bits (U) for individual channels (4-20mA current input only)Bit 00 corresponds to input channel 0, bit 01 corresponds to input channel 1,

and so on. When set (1), indicates either a broken or open input wire, or input

current at or below 4mA.

Not used – set to 0.

Power Up bit .- This bit is set to 1 when all bits in the configuration

register (write word 0) are 0 (unconfigured state). The configuration

register can be cleared by either a reset, or by the user writing all zeroes to it.

Definition

Analog Input Module (1793-IE4 and -IE4S) Write Configuration Block

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Write Word 0 Reserved C3 C2 C1 C0 Reserved F3 F2 F1 F0

Where: C = Configure select bit

F = Full range bit

Publication 1793-6.5.1 - April 1999

Page 33

Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter 4-5

Range Selection Bits for the 1793-IE4 and -IE4S Analog Input Module

Channel No. Channel 0 Channel 1 Channel 2 Channel 3

F0 C0 F1 C1 F2 C2 F3 C3

Decimal Bits

(Octal Bits)

00

08

(10)

01

09

(11)

02

0-10V dc/0-20mA 1 0 1 0 1 0 1 0

4-20mA 0 1 0 1 0 1 0 1

–10 to +10V dc 1 1 1 1 1 1 1 1

1

Off

C = Configure select bit

F = Full range bit

1

When configured to off, individual channels will return 0000H on Series B modules, and 4

to 20mA on Series A modules.

0 0 0 0 0 0 0 0

Word/Bit Descriptions for the 1793-IE4 and -IE4S Analog Input Module Write

Word Decimal Bit (Octal Bit) Definition

Full range bits (F) for individual channels – Bit 00 corresponds to input channel

0, bit 01 corresponds to input channel 1, and so on.

Configure select bits (C) for individual channels – Bit 08 corresponds to input

channel 0, bit 09 corresponds to input channel 1, and so on. Refer to Range Bit

Write

Word 0

Bits 00-03

Bits 04-07 Reserved

Bits 08-11 (10-13)

Selections.

Bits 12-15 (14-17) Reserved

2 Output Analog Module (Cat. No. 1793-OE2 and -OE2S)

10

(12)

03

11

(13)

Read

Write

I/O Image

Input Size

0 or 1 Word

Output Size

1 to 12 Words

Module Image

PU

Not used Not used

Config. Select Full Range

Not used

Analog Data Channel 0

Analog Data Channel 1

Reserved

Reserved

Not used

Not used

Not used

Not used

Not used

Channel 0 Safe State

Channel 1 Safe State

Diagnostics

M

Publication 1793-6.5.1 - April 1999

Page 34

4-6 Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter

Analog Output Module (1793-OE2 and -OE2S) Read

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 0 PU Not used – set to 0 W1 W0

Where: W = Diagnostic bits for current output wire broken or load resistance high. (Not used on voltage outputs.)

PU = Power up bit

Bit/Word Descriptions for the 1793-OE2 and -OE2S Analog Output Module Read

Word

Decimal Bit

(Octal Bit)

Definition

Current outputs only – When set (1), the wire on the output is broken or the

Bits 00-01

load resistance is too high. Bit 00 corresponds to channel 0, bit 01

corresponds to channel 2, and so on.

Read

Word 0

Bits 02-14

(02-16)

Not used – set to 0

Power Up bit. - This bit is set to 1 when all bits in the configuration

Bit 15 (17)

register (write word 5) are 0 (unconfigured state). The configuration

register can be cleared by either a reset, or by the user writing all zeroes to it.

Analog Output Module (1793-OE2 and -OE2S) Write Configuration Block

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Write Word 0 S Analog Data – Channel 0

Word 1 S Analog Data – Channel 1

Word 2 S Reserved

Word 3 S Reserved

Word 4 0 Not used – set to 0 M1 M0

Word 5 0 Not used – set to 0 C1 C0 Not used – set to 0 F1 F0

Word 6 thru 9 Not used – set to 0

Word 10 S Safe State Value – Channel 0

Word 11 S Safe State Value – Channel 1

Word 12 S Reserved

Word 13 S Reserved

Where: S = Sign bit (in 2’s complement)

M = Multiplex control

C = Configure select bit

F = Full range bit

Publication 1793-6.5.1 - April 1999

Page 35

Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter 4-7

Range Selection Bits for the 1793-OE2 and -OE2S Analog Output Module (Word 5)

Channel No. Channel 0 Channel 1

F0 C0 F1 C1

Decimal Bits (Octal Bits) 00 08 (10) 01 09 (11)

4-20mA 0 1 0 1

0-10V dc/0-20mA 1 0 1 0

–10 to +10V dc 1 1 1 1

1

Off

C = Configure select bit

F = Full range bit

1

When configured to off, individual channels will send 0V or 0mV on

Series B modules. On Series A modules, 2V or 4mA is output until the

module is configured.

0 0 0 0

Word/Bit Descriptions for the 1793-OE2 and -OE2S Analog Output Module Write

Word

Write Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Words 6 thru 9

Word 10

Word 11

Decimal Bit

(Octal Bit)

Bits 00-14

(00-16)

Channel 0 analog data – 12-bit left justified two’s complement number; unused

lower bits are zero; 4-20mA uses all 16 bits.

Definition

Bits 15 (17) Channel 0 analog data sign bit.

Bits 00-14

(00-16)

Channel 1 analog data – 12-bit left justified two’s complement number; unused

lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 1 analog data sign bit.

Bits 00-14

(00-16)

Channel 2 analog data – 12-bit left justified two’s complement number; unused

lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 2 analog data sign bit.

Bits 00-14

(00-16)

Channel 3 analog data – 12-bit left justified two’s complement number; unused

lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 3 analog data sign bit.

Multiplex control bits (M) for individual channels. These bits control the safe

state analog outputs. – Bit 00 corresponds to output channel 0, bit 01

corresponds to output channel 1, and so on.

Bits 00-03

1 = use words 0 or 1 as directed by channel number n

0 = use words 10 or 11 as directed by channel number n

When bits 00-01 are all cleared (0) simultaneously by a communication error or

user choice thru the programmable controller program, word 5 full range and

configure select bits are preserved at their last setting.

Bits 04-15 (04-17) Not used – set to 0.

Bits 00-01

Full range bits (F) for individual channels – Bit 00 corresponds to output channel

0, and bit 01 corresponds to output channel 1.

Bits 02-07 Not used – set to 0.

Bits 08-09 (10-11)

Configure select bits (C) for individual channels – Bit 08 corresponds to output

channel 0, and bit 09 corresponds to output channel 1.

Bits 10-15 (12-17) Not used – set to 0.

Bits 00-15

(00-17)

Bits 00-14

(00-16)

Not used – set to 0.

Channel 0 Safe State analog value – 12-bit left justified two’s complement

number; unused lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 0 Safe State analog data sign bit.

Bits 00-14

(00-16)

Channel 1 Safe State analog value – 12-bit left justified two’s complement

number; unused lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 1 Safe State analog data sign bit.

Publication 1793-6.5.1 - April 1999

Page 36

4-8 Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter

Word

Words 12-13

Decimal Bit

(Octal Bit)

Bits 00-15

(00-17)

Definition

Reserved

2 Input/1 Output Analog Combo Module (Cat. No. 1793-IE2XOE1 and -IE2XOE1S)

Module Image

Read

Write

I/O Image

Input Size

0 to 5 Words

Output Size

0 to 7 Words

PU

Not used Full Range and Configure Select

Input Data Channel 0

Input Data Channel 1

Reserved

Reserved

Underrange & Diag.

Output Data Channel 0

Reserved

Not used

Not used

Not used

Output Channel 0 Safe State

M

Analog Combo Module (1793-IE4XOE1) Read

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 0 S Analog Value Input Channel 0

Word 1 S Analog Value Input Channel 1

Word 2 S

Word 3 S

Word 4 PU Not used – set to 0 W1 W0

Where: S = sign bit (in 2’s complement)

W = Diagnostic bits for current output wire broken or load resistance high. (Not used on voltage outputs.)

PU = Power up bit

Word/Bit Descriptions for the 1794-IE4XOE1 and -IE2XOE1S Analog Combo

Module Read

Word

Read

Word 0

Word 1

Words 2

and 3

Decimal Bit

(Octal Bit)

Bits 00-14

(00-16)

Channel 0 analog data – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 0 analog data sign bit.

Bits 00-14

(00-16)

Channel 1 analog data – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Bits 15 (17) Channel 1 analog data sign bit.

Reserved

Definition

Publication 1793-6.5.1 - April 1999

Page 37

Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter 4-9

Word

Word 4

Decimal Bit

(Octal Bit)

Bits 00-01

Definition

Underrange bits (U) for individual channels (4-20mA current input only)-

Bit 00 corresponds to input channel 0, bit 01 corresponds to input channel 1.

When set (1), indicates either a broken or open input wire, or input current at

or below 4mA.

Bits 02-03 Reserved

Wire Off bits (W) – Current outputs only – When set (1), the wire on the

Bits 04

current output is broken or the load resistance is too high. Bit 00 corresponds

to channel 0.

Bits 05-14

(05-16)

Reserved

Power Up bit - This bit is set to 1 when all bits in the configuration

Bit 15 (17)

register (write word 3) are 0 (unconfigured state). The configuration

register can be cleared by either a reset, or by the user writing all zeroes to it.

Analog Combo Module (1793-IE2XOE1 and -IE2XOE1S) Write Configuration Block

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Write Word 0 S Analog Data – Output Channel 0

Word 1 S Reserved

Word 2 0 Not used – set to 0 M0

Word 3 Not used C5 C4 C3 C2 C1 C0 0 0 0 F4 0 0 F1 F0

Words 4 and 5 Not used – set to 0

Word 6 S Safe State Value – Output Channel 0

Word 7 S Reserved

Where: M = Multiplex control bits

S = Sign bit (in 2’s complement)

C = Configure select bit

F = Full range bit

Publication 1793-6.5.1 - April 1999

Page 38

4-10 Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter

Range Selection Bits for the 1793-IE2XOE1 and -IE2XOE1S Analog Combo Module

Channel No.

Decimal Bits

(Octal Bits)

0-10V dc/0-20mA 1 0 1 0 1 0

–10 to +10V dc 1 1 1 1 1 1

C = Configure select bit

F = Full range bit

1

When configured to off, individual channels will return 0000H.

Word/Bit Descriptions for the 1793-IE2XOE1 and -IE2XOE1S Analog Combo

Module Write

Word

Write

Word 0

Word 1 Bits 00-15

Word 2

Word 3

Decimal Bit

(Octal Bit)

Bits 00-14

(00-16)

Bits 15

(17)

(00-17

Bit 00

Bits 01-15 (01-17) Not used – set to 0.

Bits 00-01, 04

Bits 02, 03, 05-07 Not used – set to 0.

Bits 08-09, 12 (10,

11, 13-15)

Bits 14-15 (16-17) Not used – set to 0.

Input

Channel 0

Input

Channel 1

Output

Channel 0

F0 C0 F1 C1 F4 C4

00

08

(10)

01

09

(11)

04

12

(14)

4-20mA 0 1 0 1 0 1

Off

1

0 0 0 0 0 0

Definition

Channel 0 analog data – 12-bit left justified two’s complement number; unused

lower bits are zero; 4-20mA uses all 16 bits.

Channel 0 analog data sign bit.

Reserved

Multiplex control bits (M) for individual channel. This bit controls the safe state

analog outputs– Bit 00 corresponds to output channel 0.

1 = use words 0 (analog value) as directed by channel number n

0 = use words 6 (safe state analog value) as directed by channel number n

When bit 00 is cleared (0) simultaneously by a communication error or user choice

thru the programmable controller program, word 3 full range and configure select

bits are preserved at their last setting.

Full range bits (F) for individual channels – Bit 00 corresponds to input channel 0,

bit 01 corresponds to input channel 1, and bit 04 corresponds to output channel 1.

Refer to Range Bit Selections.

Configure select bits (C) for individual channels – Bit 08 corresponds to input

channel 0, bit 09 (11) corresponds to input channel 1, bit 12 (14) corresponds to

output channel 0. Refer to Range Bit Selections.

Publication 1793-6.5.1 - April 1999

Page 39

Writing Configuration to and Reading Status from Your Module with a Remote I/O Adapter 4-11

Chapter Summary

Word

Words 4

and 5

Word 6

Word 7

Decimal Bit

(Octal Bit)

Not used – set to 0.

Bits 00-14

(00-16)

Bits 15 (17) Channel 0 Safe State analog data sign bit.

Bits 00-14

(00-16)

Bits 15 (17) Channel 1 Safe State analog data sign bit.

Channel 0 Safe State analog value – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Channel 1 Safe State analog value – 12-bit left justified two’s complement number;

unused lower bits are zero; 4-20mA uses all 16 bits.

Definition

In this chapter you learned how to configure your module’s features and

enter your data.

Publication 1793-6.5.1 - April 1999

Page 40

How Communication Takes Place

and I/O Image Table Mapping

with the DeviceNet Adapter

Chapter

5

Chapter Objectives

About DeviceNetManager

Software

Polled I/O Structure

In this chapter, we tell you about:

• DeviceNetManager software

• I/O structure

• image table mapping

• factory defaults

DeviceNetManager software is a tool used to configure your FLEX I/O

DeviceNet adapter and its related modules, including any FLEX Integra

modules. This software tool can be connected to the adapter via the

DeviceNet network.

You must understand how DeviceNetManager software works in order to

add a device to the network. Refer to the DeviceNetManager Software User

Manual, publication 1787-6.5.3.

Output data is received by the adapter in the order of the installed I/O

modules. The Output data for Slot 0 is received first, followed by the

Output data for Slot 1, and so on up to slot 7.

The first word of input data sent by the adapter is the Adapter Status Word.

This is followed by the input data from each slot, in the order of the

installed I/O modules. The Input data from Slot 0 is first after the status

word, followed by Input data from Slot 2, and so on up to slot 7.

Network READ

Network WRITE

DeviceNet Adapter

Read Data

Adapter Status

Slot 0 Input Data

Slot 1 Input Data

...

...

Slot 7 Input Data

Write Data

Slot 0 Output Data

Slot 1 Output Data

...

...

Slot 7 Output Data

Read

Write

I/O Module

Slot 0

I/O Module

Publication 1793-6.5.1 - April 1999

Slot 1

...

I/O Module

Slot 7

Page 41

5-2 How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

Adapter Input Status Word

The input status word consists of:

• I/O module fault bits – 1 status bit for each slot

• node address changed – 1 bit

• I/O status – 1 bit

10 through 15

15Bit: 012345678

9

I/O Module Fault Bits

Not Used

I/O State Bit

Node Address Changed Bit

Slot 7

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Slot 1

Slot 0

The adapter input status word bit descriptions are shown in the following

table.

Bit Description Bit Explanation

0 This bit is set (1) when an error is detected in slot position 0.

1 This bit is set (1) when an error is detected in slot position 1.

2 This bit is set (1) when an error is detected in slot position 2.

I/O Module Fault

Node Address Changed 8

I/O State 9

3 This bit is set (1) when an error is detected in slot position 3.

4 This bit is set (1) when an error is detected in slot position 4.

5 This bit is set (1) when an error is detected in slot position 5.

6 This bit is set (1) when an error is detected in slot position 6.

7 This bit is set (1) when an error is detected in slot position 7.

This bit is set (1) when the node address switch setting has been

changed since power up.

Bit = 0 – idle

Bit = 1 – run

10 thru 15 Not used – sent as zeroes.

Publication 1793-6.5.1 - April 1999

Possible causes for an I/O Module Fault are:

• transmission errors on the Flex I/O backplane

• a failed module

• a module removed from its terminal base

• incorrect module inserted in a slot position

• the slot is empty

The node address changed bit is set when the node address switch setting

has been changed since power up. The new node address does not take

affect until the adapter has been powered down and then powered back up.

Page 42

How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter 5-3

System Throughput

Mapping Data into the

Image Table

System throughput, from analog input to backplane, is a function of:

• the data format selected

• the type and mode of sensors selected

• whether filtering is selected

The A/D converter which converts channel 0 through 7 analog data to a

digital word provides a programmable single low pass filter. You can set the

frequency of this filter during module configuration. The selection

influences the A/D output data rate, thus affecting system throughput.

FLEX Integra analog input module data table mapping is shown below.

4 Input Analog Module (Cat. No. 1793-IE4 and -IE4S)

Module Image

Input Data Channel 0

I/O Image

Input Size

1 to 9 Words

PU

Output Size

0 or 6 Words

Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Reserved

Reserved

Reserved

Reserved

Underrange

Configure select

Reserved

Reserved

Reserved

Reserved

Reserved

Publication 1793-6.5.1 - April 1999

Page 43

5-4 How Communication Takes Place and I/O Image Table Mapping with the DeviceNet Adapter

Analog Input Module (1793-IE4 and -IE4S) Read

Word/Dec. Bit 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Word/Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Read Word 1 S Analog Value Channel 0

Word 2 S Analog Value Channel 1

Word 3 S Analog Value Channel 2

Word 4 S Analog Value Channel 3

Word 5 S Reserved

Word 6 S Reserved

Word 7 S Reserved

Word 8 S Reserved