Page 1

Block I/O

Cat. No. 1791-IOBX and -IOVX

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc.

is prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

A

TTENTION:

procedures are not followed properly.

A

TTENTION:

or economic loss can occur if procedures are not

followed properly.

Attention helps you:

Identify a hazard.

Avoid the hazard.

Recognize the consequences.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

Tells readers where people may be hurt if

Tells readers where machinery may be damaged

Page 3

Using This Manual

Preface

Purpose

of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your Block I/O with an Allen-Bradley

programmable controller. It helps you:

install

program and

troubleshoot your module.

You must be able to program and operate an Allen-Bradley programmable

controller (PLC) to make efficient use of Block I/O modules.

We assume that you know how to do this in this manual. If you do not,

refer to the appropriate PLC programming and operations manual before

you attempt to program this module.

In this manual, we refer to:

the block I/O module as the “block” or the “module”

the programmable controller as the “controller” or “processor.”

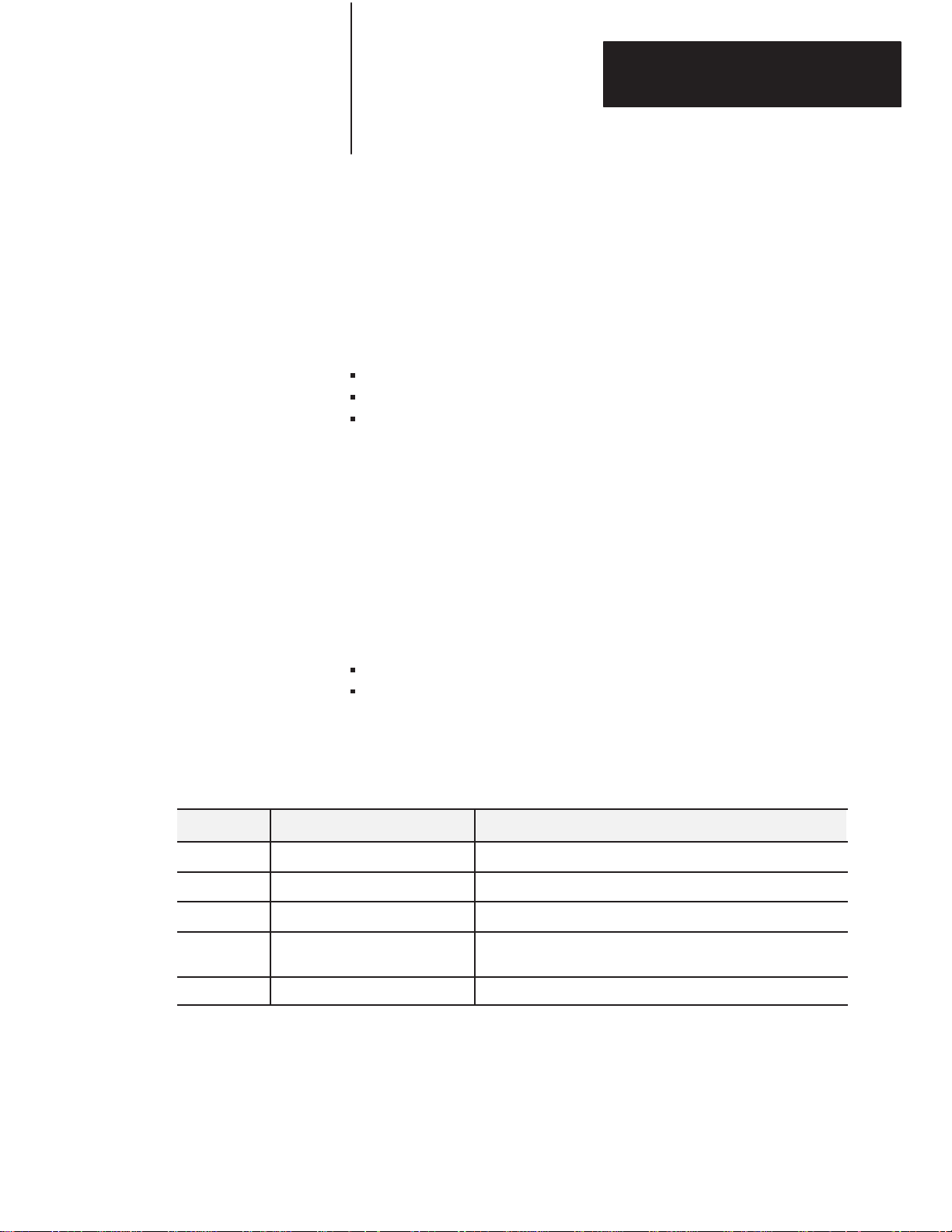

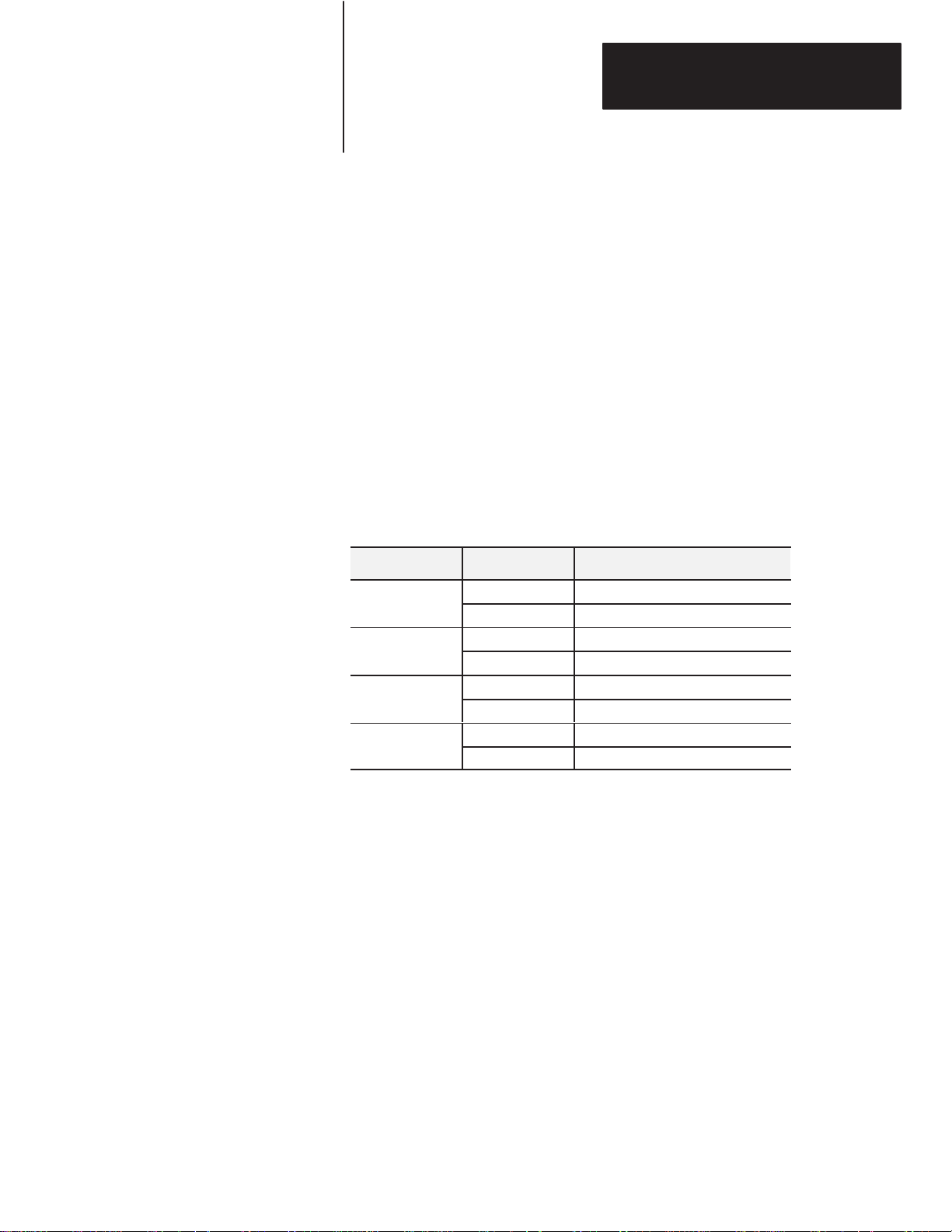

This manual is divided into 4 chapters. The following chart shows each

chapter with its corresponding title and brief overview of the topics

covered in that chapter.

Chapter Title Topics Covered

1 Introducing Block I/O Description of the module, including general and hardware features

2 Installing the Module Module power requirements, location, and wiring information

3 Configuring your block I/O How to set the configuration switches and address the block I/O.

4 Troubleshooting How to use the indicators to troubleshoot your block I/O module.

How to replace the fuse.

Appendix A Specifications Specifications for the block I/O.

P-1

Page 4

Preface

Using This Manual

About

Block I/O

Related Publications

Block I/O consists of small, self–contained remote I/O devices complete

with power supply, programmable controller interface, input/output

connections and signal conditioning circuitry.

This publication covers the 1791–IOBX and –IOVX block I/O modules.

The 1791–IOBX has 64 sinking inputs and 64 sourcing outputs; the

1791–IOVX has 64 sourcing inputs and 64 sinking outputs. In all other

aspects, they are identical.

For a list of publications with information on Allen-Bradley programmable

controller products, consult our publication index (SD499).

P-2

Page 5

Table of Contents

Introducing

Block I/O

Installing Block I/O

Configuring Y

our Block I/O

Chapter 1

Chapter Objectives

General Description 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How the Block I/O Fits in a PLC System 1-3. . . . . . . . . . . . . . . . . .

Summary 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives

Pre–installation Considerations

Installing the Block I/O 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting W

Remote I/O Link Wiring 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extended Node Capability 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility of 1771 I/O Products with

Extended Node Operation 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fusing 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iring 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives

Setting the Configuration Switches 3-1. . . . . . . . . . . . . . . . . . . . . . .

Summary 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Specifications

Chapter 4

Chapter Objectives

Indicators 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing a Fuse

Summary 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Page 6

Table of Contents

(This page left intentionally blank.)

II

Page 7

Introducing Block I/O

Chapter

1

Chapter

Objectives

General Description

In this chapter you will learn what block I/O is, its features, and how it

functions.

Block I/O consists of small, self-contained remote I/O devices complete

with power supply, programmable controller interface, input/output

connections and signal conditioning circuitry.

The 1791-IOBX 24V dc module has 64 sink input channels, and 64 source

output channels.

The 1791-IOVX 24V dc module has 64 source input channels, and 64 sink

output channels.

Complete specifications for these modules are contained in Appendix A.

The blocks are compatible with PLC-2

programmable controllers, and the SLC

used with PLC-2 family programmable controllers, a sub-scanner module

is used to communicate with the blocks. When used with PLC-3 and

PLC-5 family programmable controllers, they can be connected directly to

the controller or to a scanner module. When used with SLC 500

controllers, a 1747-SN remote I/O scanner is used to communicate with the

blocks.

, PLC-3, and PLC-5 family

500 modular controllers. When

A

TTENTION:

you must use a 1775-S5 or -SR5 scanner module. Do not use

1775-SR, -S4A or -S4B scanner modules.

Note: The 1791-IOBX and -IOVX block modules are not compatible with

the 1747-DSN scanner module.

Connections are made to removable terminal blocks mounted on the sides

of the block.

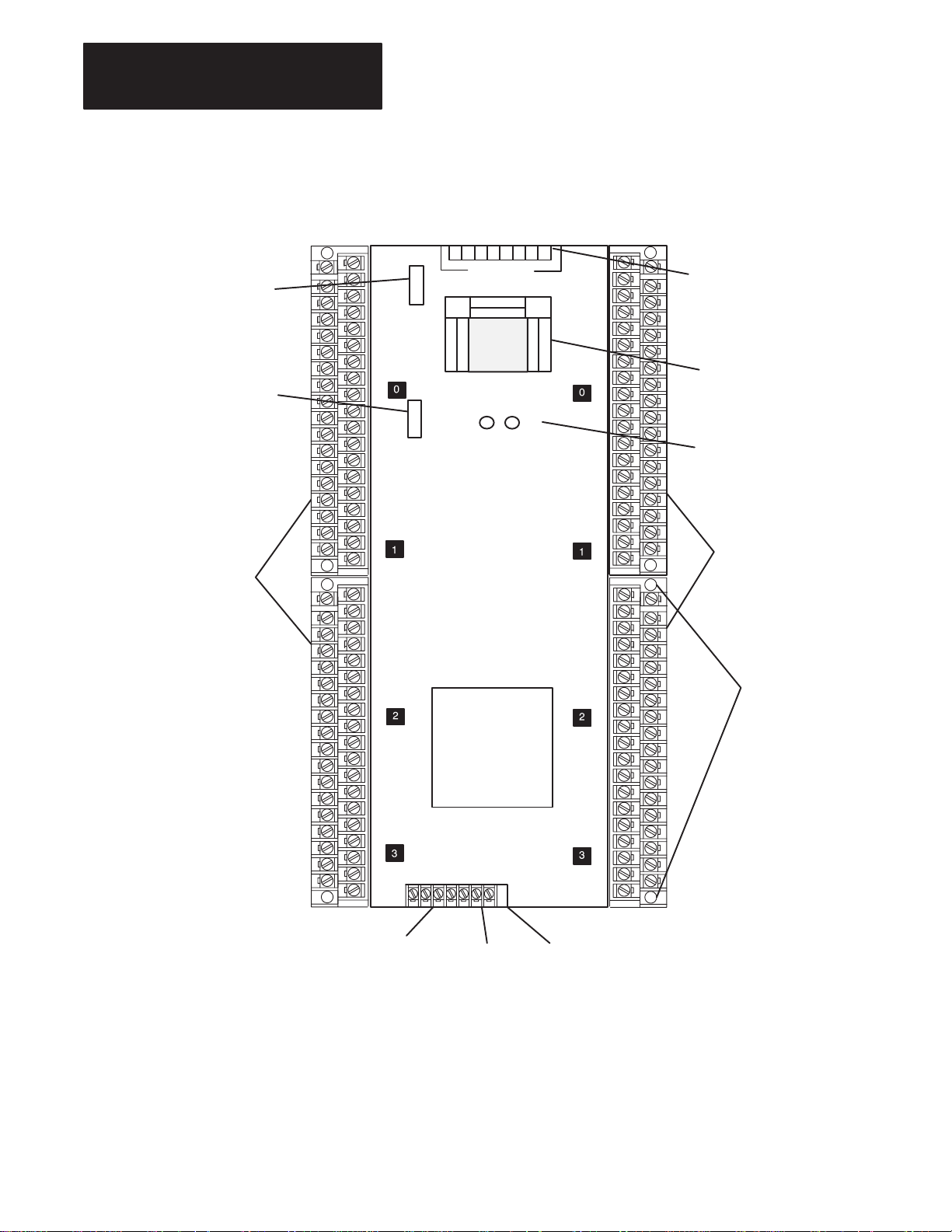

Physical features of the block I/O are shown in Figure 1.1.

When using PLC-3 programmable controllers,

1-1

Page 8

Chapter 1

Introducing Block I/O

Figure 1.1

Major

Features of the 1791-IOBX and -IOVX Block I/O Modules

(-IOBX shown)

Rack Address

Switch

, Active,

Power

Comm and Fuse

LED Indicators

Removable

Input Terminal

Blocks

87654321

CONFIGURATION

SWITCHES

RACK

ADDR

INPUT

DISPLAY

SELECT

OUTPUT

POWER

ACTIVE

COMM

FUSE

1791-IOBX

128

POINT

24V DC DISTRIBUTED

I/O MODULE

64

24VDC SINK INPUTS

64 24VDC SOURCE OUTPUTS

CONFIGURATION SWITCHES

Configuration Switches

(on top of unit)

Input/Output

Status LED

Array

Display Select

Pushbuttons

Removable

Output Terminal

Blocks

Terminal Block

Removal Screws

(same on all 4

terminal blocks)

1-2

GROUP

No.

RIO Wiring Block

+24V dc Power

GROUP No.

Termination

Resistor

Switch

10914-I

Wiring Terminals - The remote I/O field wiring is made to 4 separate

removable 37-pin terminal blocks mounted on the sides of the module.

Terminal assignments are shown in chapter 3.

A separate nonremovable terminal block is provided for connection of the

remote I/O link and external 24V dc power supply.

Page 9

Chapter 1

P

A

F

Introducing Block I/O

Switch Assemblies - Two DIP switches are provided for setting the I/O

configuration and rack address.

The configuration switch lets you select baud rate, last state, processor

restart lockout, last rack and I/O group.

The rack addr

ess switch

lets you select the system rack address for the

block.

A third switch is provided for selection of the termination resistor.

Status Indicators - Indicators are provided for power, active,

communication and fuse blown indications. An LED array provides

input/output status.

Status Indicators - Bi-color LED indicators provide power, active,

communication and fuse blown indications. An LED array provides

input/output status.

Indicator Indication

ower (green/wht)

ctive (green/red)

Comm (green/wht)

use (red/wht)

On (green) Customer voltage is present

Of

f (wht)

On (green) CPU operating correctly

Of

f (red)

On (green) Communication correctly established

Of

f (wht)

On (red) One of the 4 output fuses is open

Of

f (wht)

No customer voltage (less than 2V)

CPU not running

Communication not established

All fuses are intact

The I/O status array is an 8 by 8 array of 64 LEDs capable of displaying

the status of 32 inputs and 32 outputs at any one time. Pushbuttons are

provided to toggle the display between the lower 32 bits and the upper

32 bits.

How

the Block I/O Fits in a

PLC System

Block I/O is a complete I/O interface that includes the functionality of the

I/O rack, adapter, power supply, and I/O modules in a single unit. Simply

connect sensors and actuators to the module and use the remote I/O cable

to connect the block I/O to your programmable controller (Figure 1.6).

The 1791-IOBX block uses sinking inputs and sourcing outputs.

1-3

Page 10

Chapter 1

Introducing Block I/O

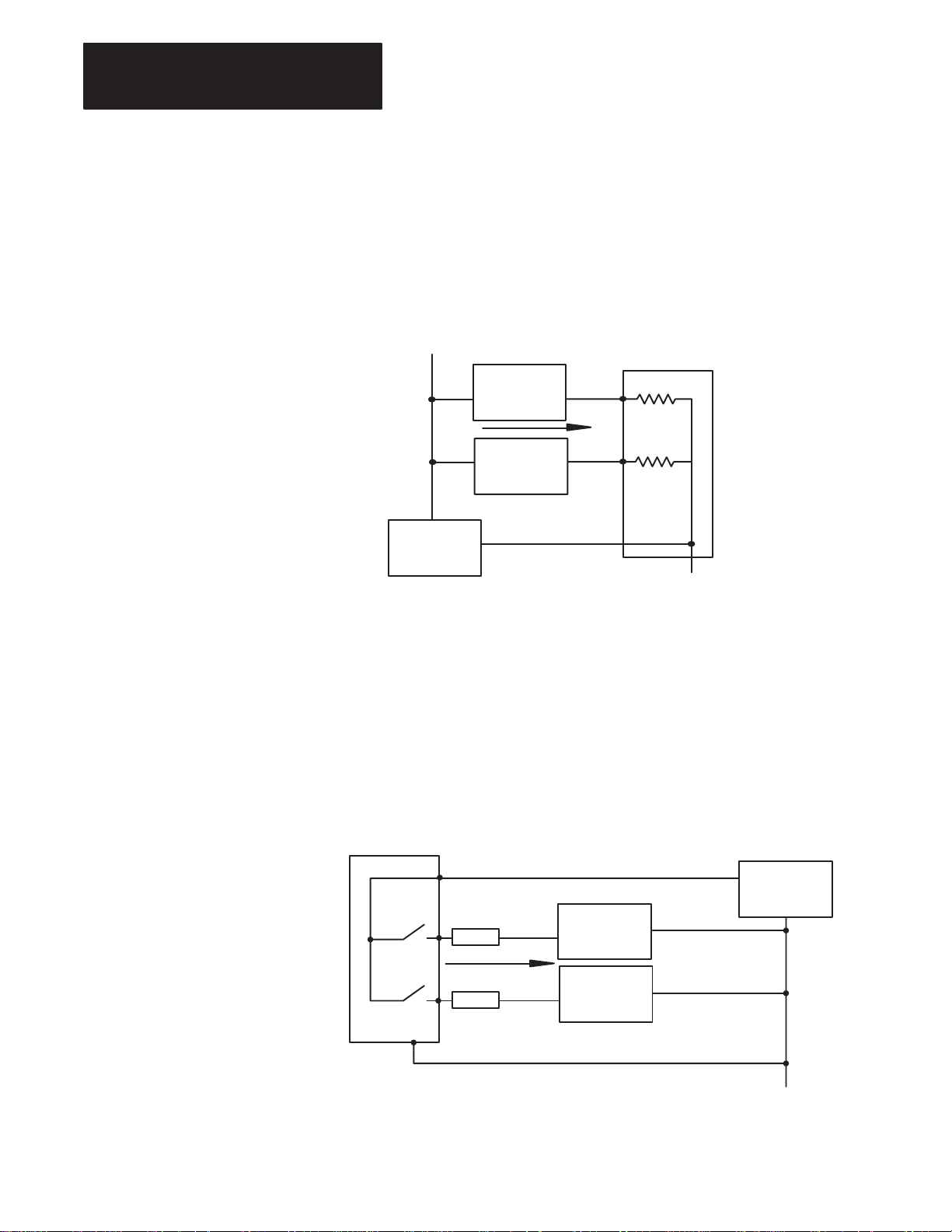

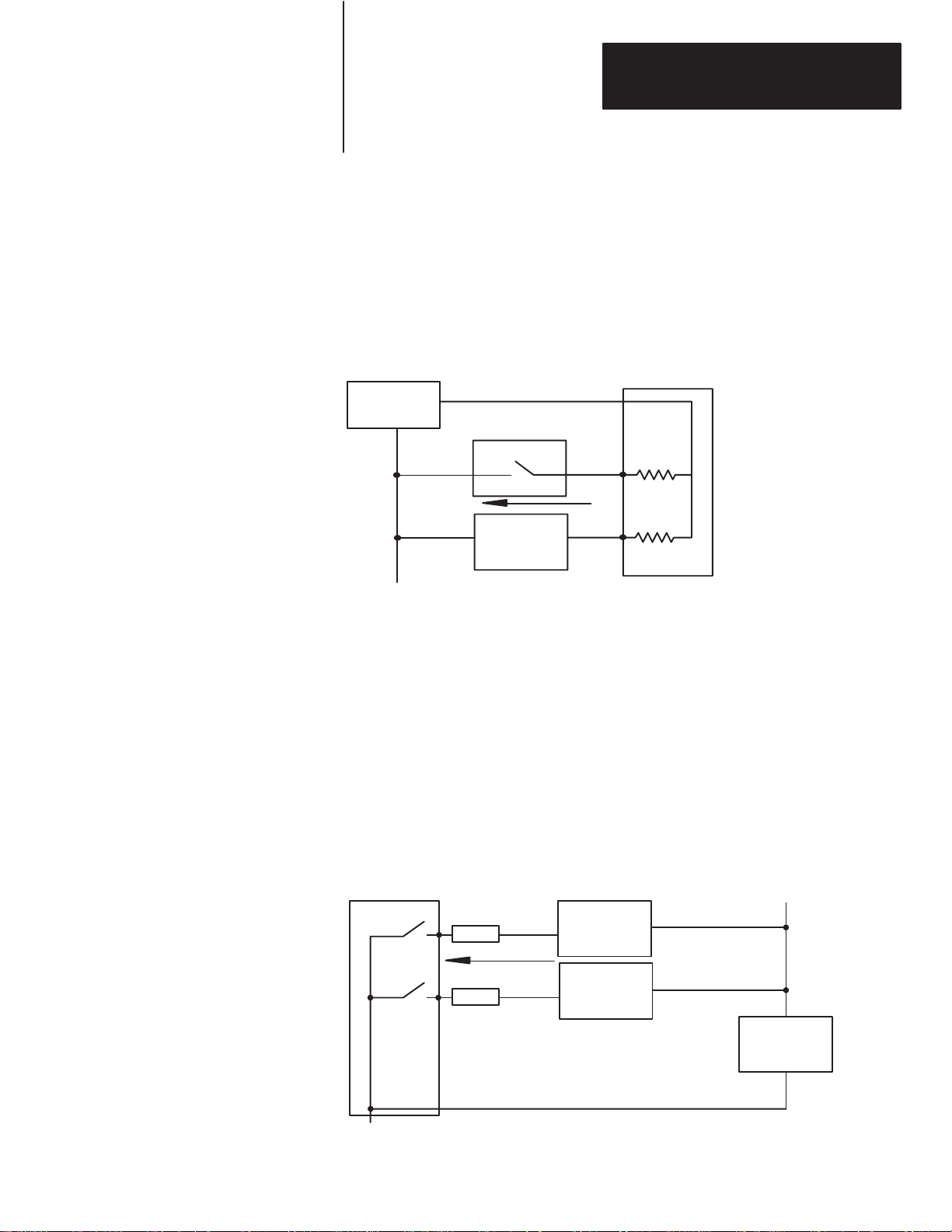

In sinking inputs, the dc common is bussed on the block. and the current is

sourced from the field device. The sourcing field device switches the hot

side of the power supply bus causing current to flow through the sourcing

device to the sinking input on the block. Refer to Figure 1.2.

Figure 1.2

Sinking

Input Example

+V

Bus

DC Power

Supply

Field

Device

Field

Device

-V

Block I/O

Sinking

Input

Common

10826-I

Sourcing outputs have the power bussed in the block. When the output is

on, current is supplied to the field control device, which sinks the current.

The field circuit and the equipment remain at ground potential until the

output is turned on. Refer to Figure 1.3.

Note: The outputs must be externally fused to protect the device output

against overcurrent or short circuit conditions.

1-4

Figure 1.3

Sourcing

Block I/O

Common

Output Example

+V

Fuse

Fuse

Field

Device

Field

Device

Common

DC Power

Supply

-V

Bus

The 1791-IOVX block uses sourcing inputs and sinking outputs.

10827-I

Page 11

Chapter 1

Introducing Block I/O

In sourcing input modules (Figure 1.4), the +V on dc circuits is bussed on

the module supplying (sourcing) the current for each input circuit. The

field device switches the circuit to the common (side of the power supply,

sinking the circuit and causing current to flow from the module’s input.

Figure 1.4

Sourcing

Input Example

DC Power

Supply

-V

+V

Block

I/O

Field

Device

Input

dc Common Bus

10917-I

In sinking outputs (Figure 1.5), the current flow is reversed. The dc

common is bussed on the module and the current is sourced from the field

device being actuated. When an output is turned on, the output switch in

the module sinks the circuit, causing current to flow from the +V bus

through the field device to the module.

Note: The outputs must be externally fused to protect the device output

against overcurrent or short circuit conditions.

Figure 1.5

Sinking

Output Example

Block I/O

Fuse

Fuse

Field

Device

Field

Device

+V

Bus

Common

Common

DC Power

Supply

-V

10918-I

1-5

Page 12

Chapter 1

Introducing Block I/O

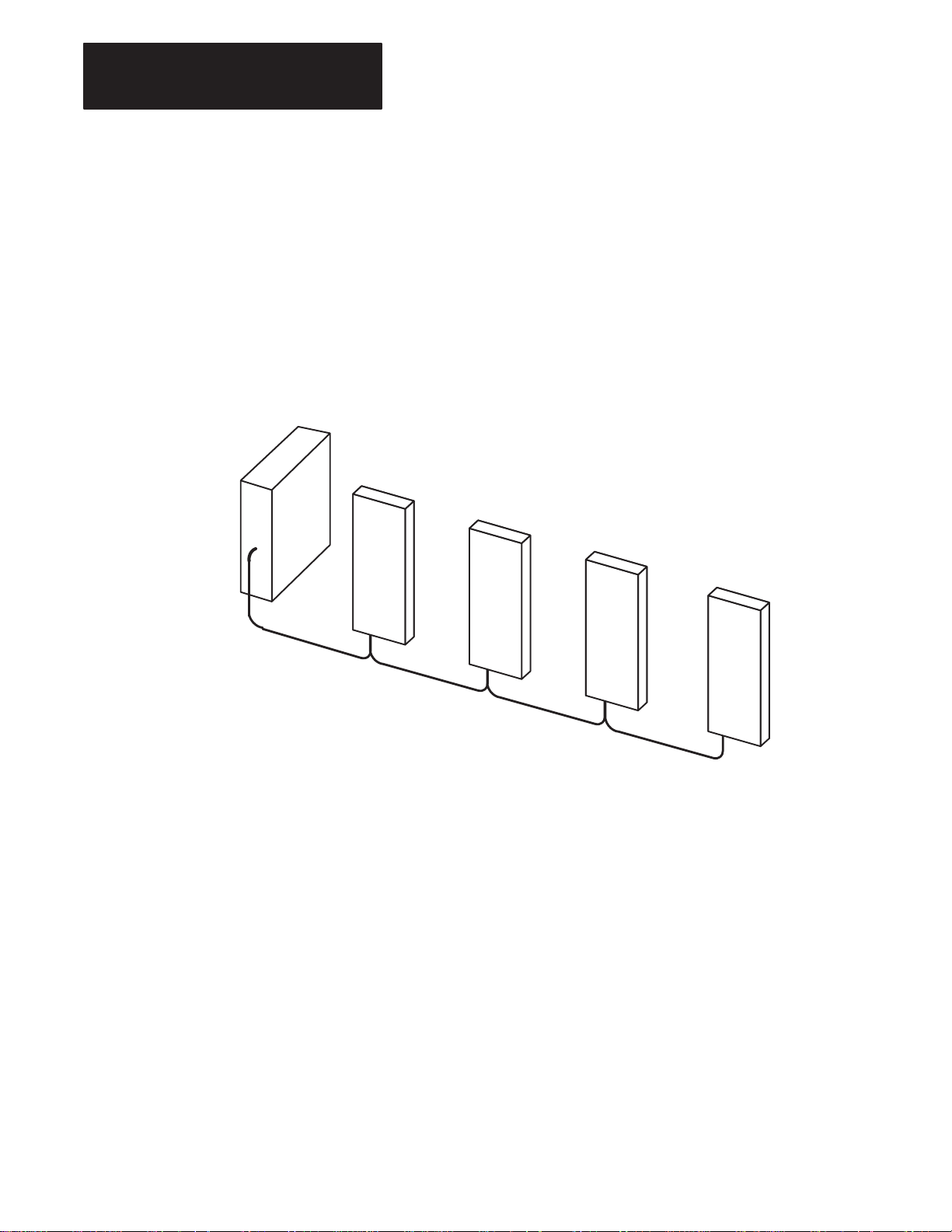

Block I/O functions exactly like any Allen-Bradley remote I/O product.

Input and output data is scanned asynchronously and transferred back and

forth between the block and the controller input and output image table.

You connect the block I/O to your remote I/O link as you would any other

device. The block looks like a 1/2 I/O rack to the processor, and uses 4

words of input image table memory and 4 words of output image table

memory. The block is addressed directly on the remote I/O link.

Figure 1.6

Block

I/O Connection in a PLC System

Blocks are daisy-chained to

a programmable controller

or scanner.

,

Programmable Controller,

or Scanner

Summary

Block I/O - each block

is 1/2 I/O rack.

10915-I

In this chapter you learned what block I/O is, its features and

how it functions.

1-6

Page 13

Installing Block I/O

Chapter

2

Chapter

Pre-installation

Considerations

Installing the Block I/O

Objectives

In this chapter you will learn how to mount the block, how to connect the

remote I/O link, how to connect the input and output wiring to the block,

and how to terminate the remote I/O link.

Before installation, you must determine:

the number of blocks desired

the total distance of the installation

transmission rate desired

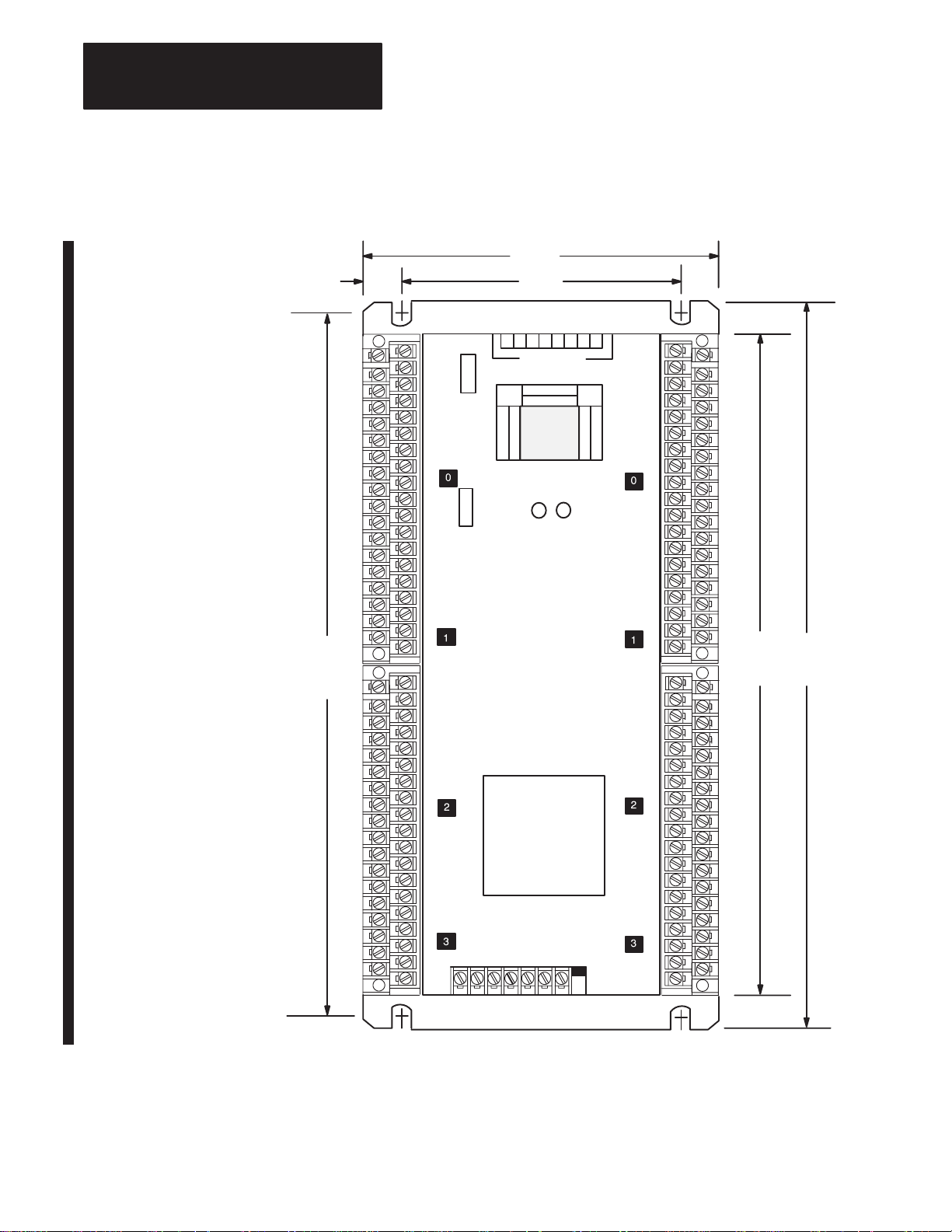

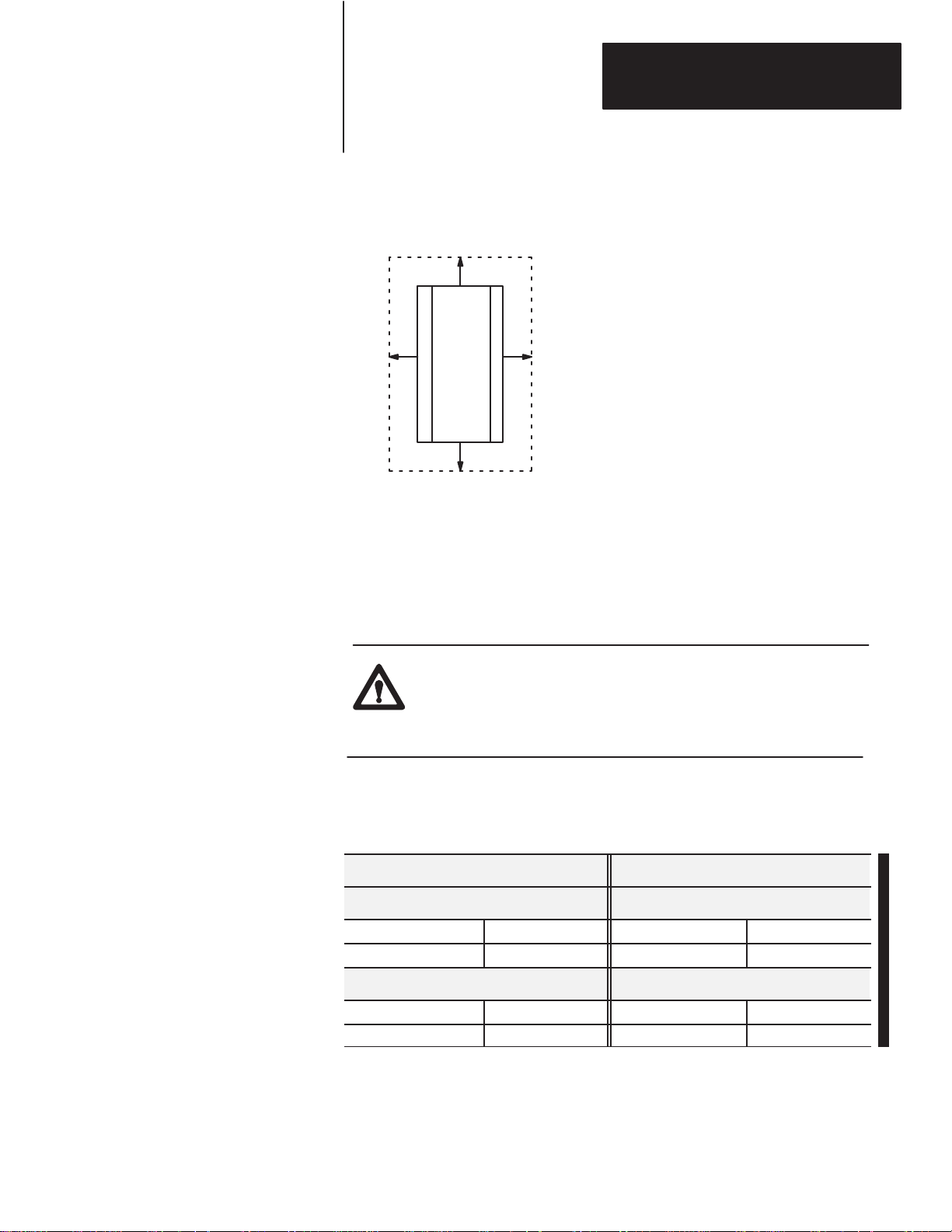

Mounting dimensions for the block I/O module are shown in Figure 2.1.

Mount the blocks horizontally with a minimum of 2” between blocks. This

air gap is necessary to maintain proper cooling air flow through the block.

2-1

Page 14

Chapter 2

Installing Block I/O

0.67

(17.105)

Figure 2.1

Mounting

and -IOVX)

Dimensions for the Block I/O Module (Cat. No. 1791-IOBX

6.15

(156.21)

4.8

(122.0)

87654321

CONFIGURATION

SWITCHES

RACK

ADDR

Dimensions:

6.15W x 13.0H x 1.72D

(156.21W x 334.0H x 43.7D)

Inches

(Millimeters)

12.7

(322.0)

GROUP

POWER

ACTIVE

COMM

FUSE

INPUT OUTPUT

1791-IOBX

128 POINT

24V DC

DISTRIBUTED

I/O MODULE

CONFIGURATION SWITCHES

No.

DISPLAY

SELECT

GROUP No.

12.28

(312.0)

13.0

(334.0)

2-2

10916-I

The operating temperature in the air gap between block I/O modules must

not exceed 60

o

C (140oF). The dimensions of the air gap required are

shown in Figure 2.2.

Page 15

Figure 2.2

Clearance

Chapter 2

Installing Block I/O

Required for Block I/O Modules

2

(50.8)

Connecting Wiring

2

(50.8)

2

(50.8)

2

(50.8)

Inches

(Millimeters)

10919-I

Connections to the block I/O module are made to the removable terminal

blocks on each side of the module. Input connections are on the left side,

and output connections are on the right side. The input terminal blocks are

keyed differently than the output blocks to prevent incorrect insertion.

TTENTION:

A

Both input terminal blocks are keyed alike. If

removed for wiring, or module replacement, make certain that

the terminal blocks are placed in their proper position

when reinstalling.

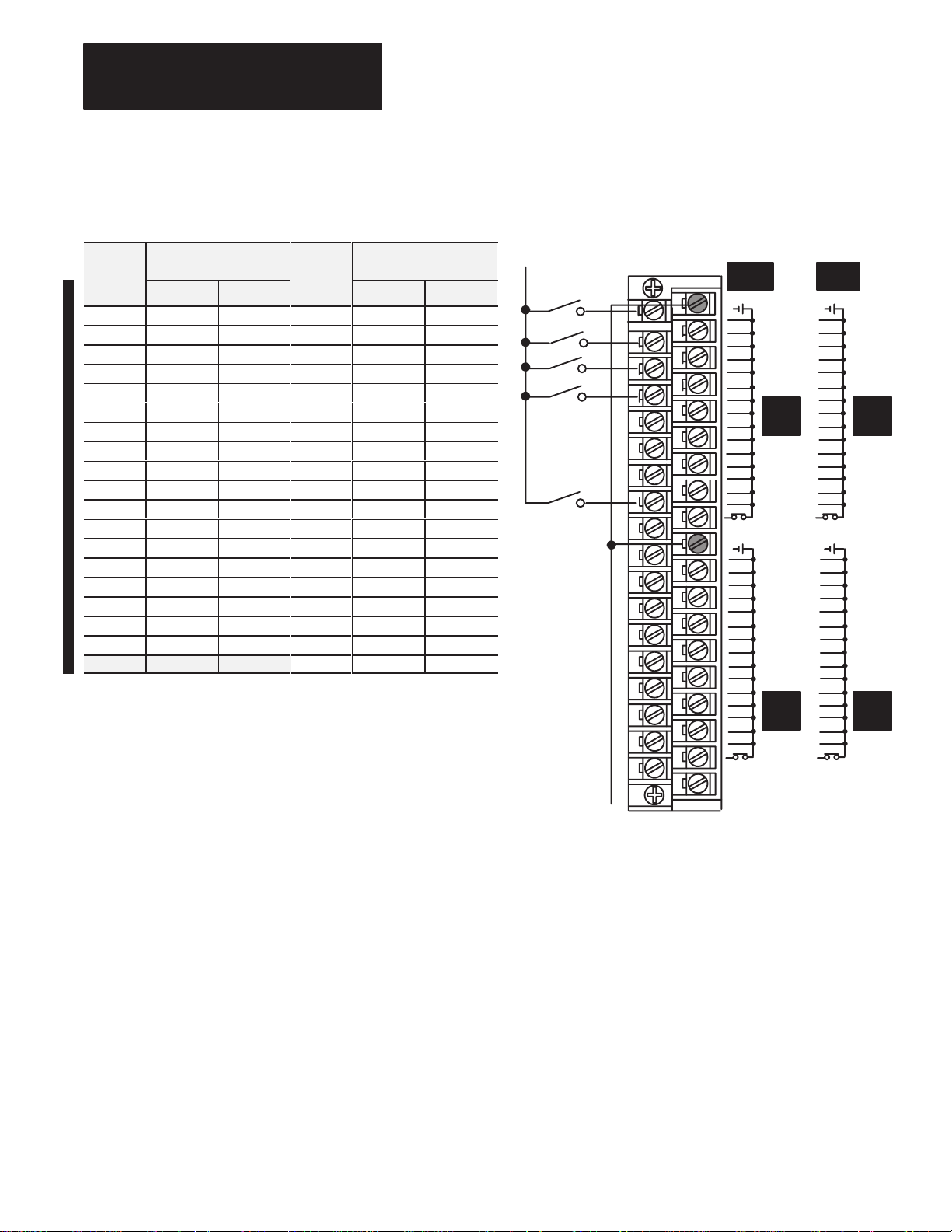

Wiring connections for the 1791-IOBX and -IOVX are shown in Tables

2.A through 2.H.

Catalog Number 1794-IOBX Catalog Number 1794-IOVX

Input Terminal Wiring Input Terminal Wiring

Groups 0 and 1 (TRM1) Table 2.A, page 2-4 Groups 0 and 1 (TRM1) Table 2.E, page 2-8

Groups 2 and 3 (TRM2) Table 2.B, page 2-5 Groups 2 and 3 (TRM2) Table 2.F, page 2-9

Output Terminal Wiring Output Terminal Wiring

Groups 0 and 1 (TRM3) Table 2.C, page 2-6 Groups 0 and 1 (TRM3) Table 2.G, page 2-10

Groups 2 and 3 (TRM4) Table 2.D, page 2-7 Groups 2 and 3 (TRM4) Table 2.H, page 2-11

Remote I/O link wiring connections are shown in Figure 2.3.

2-3

Page 16

Chapter 2

Numb

Numb

Installing Block I/O

T

able 2.A

1791-IOBX

Input T

erminal W

iring for Groups 0 and 1 (TRM1) for PLC

Family Controllers and SLC Processors

Terminal

er

Input Assignment

Group 0

PLC SLC

Terminal

er

Input Assignment

Group 1

PLC SLC

1 Common A Common A 19 Common B Common B

2 Input 00 Input 00 20 Input 00 Input 00

3 Input 01 Input 01 21 Input 01 Input 01

4 Input 02 Input 02 22 Input 02 Input 02

5 Input 03 Input 03 23 Input 03 Input 03

6 Input 04 Input 04 24 Input 04 Input 04

7 Input 05 Input 05 25 Input 05 Input 05

8 Input 06 Input 06 26 Input 06 Input 06

9 Input 07 Input 07 27 Input 07 Input 07

10 Input 10 Input 08 28 Input 10 Input 08

11 Input 11 Input 09 29 Input 11 Input 09

12 Input 12 Input 10 30 Input 12 Input 10

13 Input 13 Input 11 31 Input 13 Input 11

14 Input 14 Input 12 32 Input 14 Input 12

15 Input 15 Input 13 33 Input 15 Input 13

16 Input 16 Input 14 34 Input 16 Input 14

17 Input 17 Input 15 35 Input 17 Input 15

18 N.C. N.C. 36 N.C. N.C.

37 N.C. N.C.

+V

PLC SLC

1

2

INPUT

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

NC

INPUT

COM

00

01

02

03

04

05

06

0

1

07

0

08

09

10

11

12

13

14

15

NC

COM

00

01

02

03

04

05

06

07

08

09

10

11

12

1

13

14

15

NC

NC

2-4

Common

36 37

12490-I

Page 17

Chapter 2

Numb

Numb

Installing Block I/O

T

able 2.B

1791-IOBX

Input T

erminal W

iring for Groups 2 and 3 (TRM2) for PLC

Family Programmable Controllers and SLC Processors

Terminal

er

Input Assignment

Group 2

PLC SLC

Terminal

er

Input Assignment

Group 3

PLC SLC

1 Common C Common C 19 Common D Common D

2 Input 00 Input 00 20 Input 00 Input 00

3 Input 01 Input 01 21 Input 01 Input 01

4 Input 02 Input 02 22 Input 02 Input 02

5 Input 03 Input 03 23 Input 03 Input 03

6 Input 04 Input 04 24 Input 04 Input 04

7 Input 05 Input 05 25 Input 05 Input 05

8 Input 06 Input 06 26 Input 06 Input 06

9 Input 07 Input 07 27 Input 07 Input 07

10 Input 10 Input 08 28 Input 10 Input 08

11 Input 11 Input 09 29 Input 11 Input 09

12 Input 12 Input 10 30 Input 12 Input 10

13 Input 13 Input 11 31 Input 13 Input 11

14 Input 14 Input 12 32 Input 14 Input 12

15 Input 15 Input 13 33 Input 15 Input 13

16 Input 16 Input 14 34 Input 16 Input 14

17 Input 17 Input 15 35 Input 17 Input 15

18 N.C. N.C. 36 N.C. N.C.

37 N.C. N.C.

+V

1

2

PLC SLC

COM

NC

NC

00

02

04

06

10

12

14

16

COM

00

02

04

06

10

12

14

16

01

03

05

07

11

13

15

17

01

03

05

07

11

13

15

GROUP

17

NC

COM

00

01

02

03

04

05

06

07

08

09

10

11

12

13

2

14

2

15

NC

COM

00

01

02

03

04

05

06

07

08

09

10

11

12

13

No.

3

GROUP No.

14

15

NC

3

NC

Common

36 37

12490-I

2-5

Page 18

Chapter 2

Numb

Numb

Installing Block I/O

T

able 2.C

1791-IOBX

Output T

erminal W

iring for Groups 0 and 1 (TRM3) for PLC

Family Programmable Controllers

Terminal

er

Output Assignment

Group 1

PLC SLC

Terminal

Output Assignment

er

PLC SLC

Group 0

1 N.C. N.C. 20 Common A Common A

2 Common B Common B 21 Output 17 Output 15

3 Output 17 Output 15 22 Output 16 Output 14

4 Output 16 Output 14 23 Output 15 Output 13

5 Output 15 Output 13 24 Output 14 Output 12

6 Output 14 Output 12 25 Output 13 Output 11

7 Output 13 Output 11 26 Output 12 Output 10

8 Output 12 Output 10 27 Output 11 Output 09

9 Output 11 Output 09 28 Output 10 Output 08

10 Output 10 Output 08 29 Output 07 Output 07

11 Output 07 Output 07 30 Output 06 Output 06

12 Output 06 Output 06 31 Output 05 Output 05

13 Output 05 Output 05 32 Output 04 Output 04

14 Output 04 Output 04 33 Output 03 Output 03

15 Output 03 Output 03 34 Output 02 Output 02

16 Output 02 Output 02 35 Output 01 Output 01

17 Output 01 Output 01 36 Output 00 Output 00

18 Output 00 Output 00 37 VDC A VDC A

19 VDC B VDC B

OUTPUT

0

1

+VDC

+VDC

05

07

09

11

13

15

COM

NC

PLCSLC

3637

+VDC

OUTPUT

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

COM

00

L

01

02

03

04

06

08

10

12

14

00

L

01

02

03

04

05

06

07

10

11

12

13

14

15

0

16

17

COM

+VDC

00

L

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

COM

1

NC

1

2

Field

Device

Field

Device

Field

Device

Field

Device

Common

12491-I

2-6

Page 19

T

Numb

Numb

able 2.D

1791-IOBX

Output T

Family Programmable Controllers

Terminal

er

Group 3

PLC SLC

Terminal

1 N.C. N.C. 20 Common C Common C

2 Common D Common D 21 Output 17 Output 15

3 Output 17 Output 15 22 Output 16 Output 14

4 Output 16 Output 14 23 Output 15 Output 13

5 Output 15 Output 13 24 Output 14 Output 12

6 Output 14 Output 12 25 Output 13 Output 11

7 Output 13 Output 11 26 Output 12 Output 10

8 Output 12 Output 10 27 Output 11 Output 09

9 Output 11 Output 09 28 Output 10 Output 08

10 Output 10 Output 08 29 Output 07 Output 07

11 Output 07 Output 07 30 Output 06 Output 06

12 Output 06 Output 06 31 Output 05 Output 05

13 Output 05 Output 05 32 Output 04 Output 04

14 Output 04 Output 04 33 Output 03 Output 03

15 Output 03 Output 03 34 Output 02 Output 02

16 Output 02 Output 02 35 Output 01 Output 01

17 Output 01 Output 01 36 Output 00 Output 00

18 Output 00 Output 00 37 VDC C VDC C

19 VDC D VDC D

Output Assignment

Output Assignment

er

PLC SLC

Group 2

erminal W

Chapter 2

Installing Block I/O

iring for Groups 2 and 3 (TRM4) for PLC

PLCSLC

3637

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

2

COM

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

2

3

COM

NC

+VDC

00

L

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

2

COM

+VDC

00

L

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

2

3

COM

NC

1

2

+VDC

Field

Device

Field

Device

Field

Device

Field

Device

Common

12491-I

2-7

Page 20

Chapter 2

nal

N

nal

N

Installing Block I/O

T

able 2.E

1791-IOVX

Family Programmable Controllers

Input Assignment

Terminal

umber

Group 0

Terminal

umber

PLC SLC

1 VDC A VDC A 19 VDC B VDC B

2 Input 00 Input 00 20 Input 00 Input 00

3 Input 01 Input 01 21 Input 01 Input 01

4 Input 02 Input 02 22 Input 02 Input 02

5 Input 03 Input 03 23 Input 03 Input 03

6 Input 04 Input 04 24 Input 04 Input 04

7 Input 05 Input 05 25 Input 05 Input 05

8 Input 06 Input 06 26 Input 06 Input 06

9 Input 07 Input 07 27 Input 07 Input 07

10 Input 10 Input 08 28 Input 10 Input 08

11 Input 11 Input 09 29 Input 11 Input 09

12 Input 12 Input 10 30 Input 12 Input 10

13 Input 13 Input 11 31 Input 13 Input 11

14 Input 14 Input 12 32 Input 14 Input 12

15 Input 15 Input 13 33 Input 15 Input 13

16 Input 16 Input 14 34 Input 16 Input 14

17 Input 17 Input 15 35 Input 17 Input 15

18 N.C. N.C. 36 N.C. N.C.

Input Assignment

Group 1

PLC SLC

37 N.C. N.C.

Input T

erminal W

iring for Groups 0 and 1 (TRM1) for PLC

PLC SLC

+VDC

1

2

INPUT

+VDC

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

+VDC

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

NC

0

1

INPUT

+VDC

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

NC

+VDC

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

NC

NC

0

15

1

36 37

12493-I

2-8

Page 21

T

nal

N

nal

N

able 2.F

1791-IOVX

Input T

erminal W

iring for Groups 2 and 3 (TRM2) for PLC

Family Programmable Controllers

Chapter 2

Installing Block I/O

Terminal

umber

Input Assignment

Group 2

PLC SLC

Terminal

umber

Input Assignment

Group 3

PLC SLC

1 VDC C VDC C 19 VDC D VDC D

2 Input 00 Input 00 20 Input 00 Input 00

3 Input 01 Input 01 21 Input 01 Input 01

4 Input 02 Input 02 22 Input 02 Input 02

5 Input 03 Input 03 23 Input 03 Input 03

6 Input 04 Input 04 24 Input 04 Input 04

7 Input 05 Input 05 25 Input 05 Input 05

8 Input 06 Input 06 26 Input 06 Input 06

9 Input 07 Input 07 27 Input 07 Input 07

10 Input 10 Input 08 28 Input 10 Input 08

11 Input 11 Input 09 29 Input 11 Input 09

12 Input 12 Input 10 30 Input 12 Input 10

13 Input 13 Input 11 31 Input 13 Input 11

14 Input 14 Input 12 32 Input 14 Input 12

15 Input 15 Input 13 33 Input 15 Input 13

16 Input 16 Input 14 34 Input 16 Input 14

17 Input 17 Input 15 35 Input 17 Input 15

18 N.C. N.C. 36 N.C. N.C.

37 N.C. N.C.

+VDC

1

2

PLC SLC

+VDC

00

01

02

03

04

05

06

07

10

11

12

13

14

2

15

16

17

NC

+VDC

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

3

NC

+VDC

00

02

04

06

08

10

12

14

NC

+VDC

00

02

04

06

08

10

12

14

NC

01

03

05

07

09

11

2

13

15

01

03

05

07

09

11

13

15

3

NC

36 37

12493-I

2-9

Page 22

Chapter 2

Numb

Numb

Installing Block I/O

T

able 2.G

1791-IOVX

Output T

erminal W

iring for Groups 0 and 1 (TRM3) for PLC

Family Programmable Controllers

Terminal

er

Output Assignment

Group 1

PLC SLC

Terminal

Output Assignment

Group 0

er

PLC SLC

1 N.C. N.C. 20 Common A Common A

2 Common B Common B 21 Output 17 Output 15

3 Output 17 Output 15 22 Output 16 Output 14

4 Output 16 Output 14 23 Output 15 Output 13

5 Output 15 Output 13 24 Output 14 Output 12

6 Output 14 Output 12 25 Output 13 Output 11

7 Output 13 Output 11 26 Output 12 Output 10

8 Output 12 Output 10 27 Output 11 Output 09

9 Output 11 Output 09 28 Output 10 Output 08

10 Output 10 Output 08 29 Output 07 Output 07

11 Output 07 Output 07 30 Output 06 Output 06

12 Output 06 Output 06 31 Output 05 Output 05

13 Output 05 Output 05 32 Output 04 Output 04

14 Output 04 Output 04 33 Output 03 Output 03

15 Output 03 Output 03 34 Output 02 Output 02

16 Output 02 Output 02 35 Output 01 Output 01

17 Output 01 Output 01 36 Output 00 Output 00

18 Output 00 Output 00 37 VDC A VDC A

19 VDC B VDC B

SLC PLC

OUTPUT

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

0

15

-COM

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

1

15

-COM

NC

OUTPUT

+VDC

01

03

05

07

11

13

15

0

17

-COM

+VDC

01

03

05

07

11

13

15

1

17

-COM

NC

3637

00

L

02

04

06

10

12

14

16

00

L

02

04

06

10

12

14

16

+VDC

Field

Device

Field

Device

Field

Device

Field

Device

Common

2

1

12494-I

2-10

Page 23

T

Numb

Numb

R

able 2.H

1791-IOVX

Output T

erminal W

iring for Groups 2 and 3 (TRM4) for PLC

Family Programmable Controllers

Chapter 2

Installing Block I/O

Terminal

er

Output Assignment

Group 3

PLC SLC

Terminal

Output Assignment

Group 2

er

PLC SLC

1 N.C. N.C. 20 Common C Common C

2 Common D Common D 21 Output 17 Output 15

3 Output 17 Output 15 22 Output 16 Output 14

4 Output 16 Output 14 23 Output 15 Output 13

5 Output 15 Output 13 24 Output 14 Output 12

6 Output 14 Output 12 25 Output 13 Output 11

7 Output 13 Output 11 26 Output 12 Output 10

8 Output 12 Output 10 27 Output 11 Output 09

9 Output 11 Output 09 28 Output 10 Output 08

10 Output 10 Output 08 29 Output 07 Output 07

11 Output 07 Output 07 30 Output 06 Output 06

12 Output 06 Output 06 31 Output 05 Output 05

13 Output 05 Output 05 32 Output 04 Output 04

14 Output 04 Output 04 33 Output 03 Output 03

15 Output 03 Output 03 34 Output 02 Output 02

16 Output 02 Output 02 35 Output 01 Output 01

17 Output 01 Output 01 36 Output 00 Output 00

18 Output 00 Output 00 37 VDC C VDC C

19 VDC D VDC D

SLC PLC

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

12

13

14

2

15

-COM

+VDC

00

L

01

02

03

04

05

06

07

08

09

10

11

2

3

12

13

14

15

-COM

NC

3637

+VDC

00

L

01

02

03

04

05

06

07

10

11

12

13

14

15

16

2

17

-COM

+VDC

00

L

01

02

03

04

05

06

07

10

11

12

13

2

3

14

15

16

17

-COM

NC

Field

Device

Field

Device

Field

Device

Field

Device

Field

Device

+VDC

T

able 2.I

Wiring

Block Designations

Connector Designation Description

1 (BLU) Blue wire - RIO

2 (CLR) Clear wire - RIO

Shield Shield - RIO

emote I/O Connector

Chassis GND

Chassis Ground

24VDC RET +24V ground

24VDC +24V dc

Input Terminals 1 thru 37 See Tables

Output Terminals 1 thru 37 See Tables

2

1

Common

12494-I

2-11

Page 24

Chapter 2

Installing Block I/O

Power Supply Requirements

An external 24V dc (+10/-25%) power supply is required to power the

block. Total current required to power the block is equal to 300mA.

In addition, the external power supply should have current limiting

capabilities. The voltage range must not exceed 18.0-26.4V dc.

Wiring Requirements

Wiring cable requirements are shown in Table 2.J.

T

able 2.J

Acceptable Wiring Cables for Block I/O Connection

Use Cable Type With

Remote I/O Link Belden 9463

Input and Output wiring

Up to 14AWG (2mm

with 3/64 inch (1.2mm) insulation

Figure 2.3

Remote

GROUP

No.

2

(CLR)

I/O Link W

Shield

1

(BLU)

iring

Chassis

GND

24VDC

RET

2)

Stranded

24VDC

PLC-2, PLC-3, PLC-5 family programmable

controllers and SLC controllers

All

GROUP No.

TERMINATION

RESISTOR

-

150 OHM

-OFF

- 82 OHM

2-12

2

1

(CLR)

Connection

Clear

wire X

(BLU)

Shield

Blue wire X

Shield wire X

10928-I

Page 25

Chapter 2

Installing Block I/O

Remote

I/O Link W

iring

Blocks must be wired in series as shown in Figure 2.4. Do not attempt to

wire any block in parallel.

The number of blocks used depends not only on the user requirements but

also on the system used.

Figure 2.4

Series

Connection for Block I/O Using PLC-2, PLC-3 or PLC-5 Family

Programmable Controllers

To Programmable Controller

or I/O Scanner Module

1 I/O Rack

Install terminating resistor on last block.

1 I/O Rack

1 I/O Rack

1 I/O Rack

10929-I

2-13

Page 26

Chapter 2

Installing Block I/O

Termination Resistor

A termination resistor must be used on the last block in the series. A 150

ohm and 82 ohm termination resistors are built into the unit. To select the

termination resistor, position the switch to the desired position as shown in

Figure 2.5.

Figure 2.5

Installing

the T

ermination Resistor

Extended

Node Capability

2

(CLR)

Shield

1

(BLU)

24VDC

Chassis

GND

Position

across 1 and 2 as follows:

150 ohm - position switch at top;

82 ohm - position switch at bottom;

OFF - no resistor - position switch in middle.

24VDC

RET

switch to connect termination resistor

TERMINATION

RESISTOR

150 OHM

-

-OFF

- 82 OHM

10930-I

If this is the last remote I/O adapter on the RIO link in a PLC system, you

must use a terminating resistor to terminate both ends of the remote I/O

link (scanner end and last block end). The size of the terminator is

determined by the system configuration.

Older configurations can use a 150 ohm resistor at both ends. With newer

devices that can support it, you can use an 82 ohm termination resistor at

both ends. The 82 ohm terminators provide “extended node” capability

which allows you to have up to 32 physical devices on the RIO link. (The

number of logical racks capable of being addressed by the scanner is

not affected.)

2-14

A

TTENTION:

Devices that are operating at 230.4K baud must

have 82 ohm terminators in place for proper operation.

Page 27

Chapter 2

2.4A

Installing Block I/O

Compatibility

of 1771 I/O

Products with Extended

Node Operation

Certain products are not compatible with extended node capabilities

obtained with the use of 82 ohm terminators. The following table lists

those products that are not compatible.

Device Series

Scanners -1771-SN All

1772-SD All

1772-SD2 All

1

1775-SR

1775-S4A

1775-S4B

Adapters - 1771-AS All

1771-ASB Series A

1771-DCM All

Miscellaneous - 1771-AF All

1771-AF1 All

1

When

using PLC-3 programmable controllers, you must use a

1775-S5 or -SR5 scanner module.

or -S4B scanner modules.

1

1

Do not use

All

All

All

1775-SR, -S4A

Fusing

Summary

1791 high-density block I/O modules (64 and 128 input/output) have

internal fusing. Each group of 16 output points is protected by a 5.0A fuse.

These fuses protect the user output devices. They do not protect each

individual output from overload. It is recommended that individual outputs

be fused externally to protect the individual output circuit.

Catalog Number Voltage

1791-IOBX

1791-IOVX

24V dc

24V dc

Maximum Output Rating at:

o

C 60oC

30

300mA per point

2.4A continuous per 16 point group

continuous per 16 point group

maximum surge current 1.0A for 25ms

1 pulse per second maximum

Maximum Surge Current

Consult the factory for fuse recommendations.

In this chapter you learned how to physically mount your block I/O, make

power wiring connections, how to make the input/output wiring

connections to the block, and how to terminate the remote I/O link.

2-15

Page 28

Chapter 2

Installing Block I/O

(This page left intentionally blank.)

2-16

Page 29

Chapter

Configuring Your Block I/O

3

Chapter

Objectives

Setting the Configuration

Switches

In this chapter you will learn how to configure your block I/O when used

with PLC family programmable controllers. This includes the following:

setting the configuration switches

addressing the block I/O

To learn how to configure your block I/O when used with SLC 500

processors, refer to the publication for the 1747-SN Remote I/O Scanner

Module.

Each block I/O module has multiple-position switches for setting:

transmission (baud) rate - used to set the communication rate chosen

for the remote I/O link

last state - when last state is enabled, a processor reset will keep the

outputs in their present (last) state; when last state is disabled, the

outputs will reset

pr

ocessor r

the programmable controller cannot automatically start up the module’s

communications if the power has been cycled to either the module or

the programmable controller. Press Input and Output pushbuttons

simultaneously to reset PRL.

estart lockout (PRL) - when PRL is enabled (switch 4 on),

last rack - used to identify if the module contains the highest numbered

I/O group for the associated rack number

I/O group address - used to identify which module group (0-3 or 4-7)

the module should assign to its inputs/outputs

rack address - used to select the rack address of the module

RIO termination resistor - used to connect an internal resistor

(82 ohm, 150 ohm, or no resistor) across LINE 1 and 2 on the remote

I/O terminals

These switches are all accessible on the front or top of the module, as

shown in Figure 3.1.

3-1

Page 30

Chapter 3

Configuring Your Block I/O

Figure 3.1

Switch

Setting Locations (1791-IOBX shown)

Configuration Switch

Rack Address Switch

Termination Resistor Switch

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

NC

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

NC

87654321

CONFIGURATION

SWITCHES

RACK

ADDR

POWER

ACTIVE

COMM

FUSE

INPUT

1791-IOBX

128

24V DC DISTRIBUTED

I/O MODULE

64 24VDC SINK INPUTS

64 24VDC SOURCE OUTPUTS

CONFIGURATION SWITCHES

BAUD

GROUP

RATE

57.6K BPS

115.2KBPS

230.4KBPS

UNUSED

PRL

NO OFF

YES ON

No.

1 2

OFF OFF

ON OFF

OFF ON

ON ON

LAST

RACK

4

NO OFF

YES ON

DISPLAY

SELECT

POINT

5

OUTPUT

LAST

STATE

LATCH

RESET

NOT

USED

GROUP

Termination

I/O

0 to 3

4 to 7

3

OFF

ON

7 8

6

OFF

ON

Resistor

150 Ohm

Off

82 Ohm

GROUP No.

+VDC

03

05

07

11

13

15

17

COM

+VDC

03

05

07

11

13

15

17

COM

+VDC

03

05

07

11

13

15

17

+VDC

03

05

07

11

13

15

17

COM

L

01

02

04

06

10

12

14

16

00

L

01

02

04

06

10

12

14

16

NC

00

01

02

04

06

10

12

14

16

COM

00

01

02

04

06

10

12

14

16

NC

00

3-2

10931-I

Page 31

Rack Address Switch

(Refer to Table 3.A)

ON

134256

Figure 3.2

Configuration

Chapter 3

Configuring Your Block I/O

Switch Settings (PLC designations shown)

COM

00

02

04

06

10

12

14

01

03

05

RACK

ADDR

07

11

13

15

8

87654321

CONFIGURATION

SWITCHES

Configuration Switch

(Top View of Switch)

7

654321

ON

+VDC

03

05

07

11

13

15

00

L

01

02

04

06

10

12

14

Not Used -

set to off

Group

L

RACK

I/O

0 to 3

4 to 7

AST

7 8

6

OFF

ON

5

NO OFF

YES ON

Last Rack Switch 5

PLC-2

- When module

OFF

numbered I/O group for the associated rack number

ON

- When module

numbered I/O group for the associated rack number

PLC-3

switch must always be set to “OFF

This

PLC-5

This switch not used.

does not

contain the highest

does

contain the highest

.”

3

OFF

ON

OFF

ON

OFF

ON

1 2

OFF

OFF

ON

ON

Last

State Switch 3

CAUTION:

BAUD

R

ATE

57.6kbps

115.2kbps

230.4kbps

Unused

LAST

STATE

Latch

Reset

Set switch 3 to the ON position to

deenergize outputs wired to this module when

a fault is detected. If switch 3 is set to the

OFF position, outputs connected to this

module remain in their last state when a fault

.

.

Disabled OFF

Enabled ON

PRL

4

Processor Restart Lockout (PRL) Switch 4

occurs and machine motion may continue

after fault detection.

-

When PRL is enabled (on), the programmable

controller cannot automatically start up the module’

s

communications if the power has been cycled to

either the module or the programmable controller

10932-I

3-3

Page 32

Chapter 3

Rack

Rack

Rack

Rack

Rack

Rack

Configuring Your Block I/O

T

able 3.A

Rack

Address Switch Settings

1747-SN

Number

Rack

Rack 1 Rack 2 Rack 2 Rack 1 Rack 1 Rack 1

Rack 2 Rack 3 Rack 3 Rack 2 Rack 2 Rack 2

Rack 3 Rack 4 Rack 4 Rack 3 Rack 3 Rack 3

1771-SN

Number

0

Rack 1 Rack 1

Rack 5 Rack 5 Rack 4 Rack 4 Rack 4

Rack 6 Rack 6 Rack 5 Rack 5 Rack 5

Rack 7 Rack 7 Rack 6 Rack 6 Rack 6

PLC-2

Number

PLC-5

Number

Not V

Rack 7 Rack 7 Rack 7

Rack 10 Rack 10 Rack 10

Rack 1

Rack 12 Rack 12 Rack 12

Rack 13 Rack 13 Rack 13

Rack 14 Rack 14 Rack 14

Rack 15 Rack 15 Rack 15

Rack 16 Rack 16 Rack 16

Rack 17 Rack 17 Rack 17

Rack 20 Rack 20 Rack 20

Rack 21 Rack 21 Rack 21

Rack 22 Rack 22 Rack 22

Rack 23 Rack 23 Rack 23

Rack 24 Rack 24 Rack 24

Rack 25 Rack 25 Rack 25

Rack 26 Rack 26 Rack 26

Rack 27 Rack 27 Rack 27

PLC-5/250

Number

alid

1

Number

Rack 0 Rack 0

Rack 1

1

Rack 30 Rack 30

Rack 31 Rack 31

Rack 32 Rack 32

Rack 33 Rack 33

Rack 34 Rack 34

Rack 35 Rack 35

Rack 36 Rack 36

Rack 37 Rack 37

PLC-3

Rack Address Switch Position

6 5 4 3 2 1

0 0 0 0 0 0

0 0 0 0 0 1

0 0 0 0 1 0

0 0 0 0 1 1

0 0 0 1 0 0

0 0 0 1 0 1

0 0 0 1 1 0

0 0 0 1 1 1

0 0 1 0 0 0

Rack 1

1 0 0 1 0 0 1

0 0 1 0 1 0

0 0 1 0 1 1

0 0 1 1 0 0

0 0 1 1 0 1

0 0 1 1 1 0

0 0 1 1 1 1

0 1 0 0 0 0

0 1 0 0 0 1

0 1 0 0 1 0

0 1 0 0 1 1

0 1 0 1 0 0

0 1 0 1 0 1

0 1 0 1 1 0

0 1 0 1 1 1

0 1 1 0 0 0

0 1 1 0 0 1

0 1 1 0 1 0

0 1 1 0 1 1

0 1 1 1 0 0

0 1 1 1 0 1

0 1 1 1 1 0

0 1 1 1 1 1

Rack 40

Rack 41

Rack 42

Rack 43

Rack 44

Rack 45

Rack 46

Rack 47

Rack 50

Rack 51

Rack 52

Rack 53

Rack 54

Rack 55

Rack 56

Rack 57

Rack 60

Rack 61

Rack 62

1 0 0 0 0 0

1 0 0 0 0 1

1 0 0 0 1 0

1 0 0 0 1 1

1 0 0 1 0 0

1 0 0 1 0 1

1 0 0 1 1 0

1 0 0 1 1 1

1 0 1 0 0 0

1 0 1 0 0 1

1 0 1 0 1 0

1 0 1 0 1 1

1 0 1 1 0 0

1 0 1 1 0 1

1 0 1 1 1 0

1 0 1 1 1 1

1 1 0 0 0 0

1 1 0 0 0 1

1 1 0 0 1 0

3-4

Page 33

Chapter 3

Configuring Your Block I/O

1747-SN

1747-SN

Rack

Rack

Number

Number

Rack address 77 is an illegal configuration.

PLC-5/1

PLC-5/15 and PLC-5/20 processors can scan racks 01-03.

PLC-5/25 and PLC-5/30 processors can scan racks 01-07.

PLC-5/40 and PLC-5/40L processors can scan racks 01-17.

PLC-5/60 and PLC-5/60L processors can scan racks 01-27.

PLC-5/250 processors can scan racks 00-37.

PLC-3 processors can scan racks 00-76.

1771-SN

1771-SN

Rack

Rack

Number

Number

1 processors can scan rack 03.

PLC-2

PLC-2

Rack

Rack

Number

Number

PLC-5

PLC-5

Rack

Rack

Number

Number

Each block uses 4 words of output image table memory and 4 words of

input image table memory. Each block occupies 1/2 rack of data table, with

2 blocks comprising 1 logical rack. Image table usage for one assigned

rack number is shown in Figure 3.3. An example of image table usage is

shown in Figure 3.4.

PLC-5/250

PLC-5/250

Rack

Rack

Number

Number

PLC-3

PLC-3

Rack

Rack

Number

Number

Rack

63

Rack 64

Rack 65

Rack 66

Rack 67

Rack 70

Rack 71

Rack 72

Rack 73

Rack 74

Rack 75

Rack 76

Not V

alid 1 1 1 1 1 1

Rack Address Switch Position

1 1 0 0 1 1

1 1 0 1 0 0

1 1 0 1 0 1

1 1 0 1 1 0

1 1 0 1 1 1

1 1 1 0 0 0

1 1 1 0 0 1

1 1 1 0 1 0

1 1 1 0 1 1

1 1 1 1 0 0

1 1 1 1 0 1

1 1 1 1 1 0

123456

1

Rack 1

2 1791-IOBX or 1791-IOVX per rack

1st 1/2 rack = module group 0-3

2nd 1/2 rack = module group 4-7

Figure 3.3

I/O

2

1791-IOVX1791-IOBX

Image T

able for One Assigned Rack Number

Block 1

Inputs

Block 2

Inputs

Block 1

Outputs

Block 2

Outputs

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

Input Image

710

Output Image

710

017

017

10933-I

3-5

Page 34

Chapter 3

Exampl

Configuring Your Block I/O

Figure 3.4

Input Table Usage Example for One Starting I/O Group with 1791-IOBX

and -IOVX

Starting

I/O Group

0

(Configuration

Switch 6 = OFF)

110

111

112

113

010

011

012

013

T

ype of I/O

1 = Input

0 = Output

I/O Rack Number

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

e

11100

I/O Bit

I/O Group Number

111076543210

11107654321

111076543210

11107654321

111076543210

11107654321

111076543210

11107654321

0

Input

0

0

Output Image

0

Image

Starting

I/O Group

4

(Configuration

Switch 6 = ON)

114

115

116

117

014

015

016

017

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

17 16 15 14 13 12

111076543210

11107654321

0

111076543210

11107654321

0

111076543210

11107654321

0

111076543210

11107654321

0

Input

Image

Output Image

10934-I

3-6

Page 35

T

able 3.B

1791-IOBX

Chapter 3

Configuring Your Block I/O

Input T

erminal Addressing for Groups 0 and 1 (TRM1)

Terminal

Number

Input

Assignment

Group 0

Program

Address

Terminal

Number

Input

Assignment

Group 1

1 Common A 19 Common B

2 Input 00 1XY00 20 Input 00 1X(Y+1)00

3 Input 01 1XY01 21 Input 01 1X(Y+1)01

4 Input 02 1XY02 22 Input 02 1X(Y+1)02

5 Input 03 1XY03 23 Input 03 1X(Y+1)03

6 Input 04 1XY04 24 Input 04 1X(Y+1)04

7 Input 05 1XY05 25 Input 05 1X(Y+1)05

8 Input 06 1XY06 26 Input 06 1X(Y+1)06

9 Input 07 1XY07 27 Input 07 1X(Y+1)07

10 Input 10 1XY10 28 Input 10 1X(Y+1)10

11 Input 11 1XY11 29 Input 11 1X(Y+1)11

12 Input 12 1XY12 30 Input 12 1X(Y+1)12

13 Input 13 1XY13 31 Input 13 1X(Y+1)13

14 Input 14 1XY14 32 Input 14 1X(Y+1)14

15 Input 15 1XY15 33 Input 15 1X(Y+1)15

16 Input 16 1XY16 34 Input 16 1X(Y+1)16

17 Input 17 1XY17 35 Input 17 1X(Y+1)17

18 N.C. 36 N.C.

37 N.C.

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

2

1

INPUT

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

NC

COM

00

02

04

06

10

12

14

16

NC

0

17

01

03

05

07

11

13

15

1

17

NC

36 37

10935-I

3-7

Page 36

Chapter 3

Configuring Your Block I/O

T

able 3.C

1791-IOBX Input Terminal Addressing for Groups 2 and 3 (TRM2)

Terminal

Number

Input

Assignment

Group 2

Program

Address

Terminal

Number

1 Common C 19 Common D

2 Input 00 1X(Y+2)00 20 Input 00 1X(Y+3)00

3 Input 01 1X(Y+2)01 21 Input 01 1X(Y+3)01

4 Input 02 1X(Y+2)02 22 Input 02 1X(Y+3)02

5 Input 03 1X(Y+2)03 23 Input 03 1X(Y+3)03

6 Input 04 1X(Y+2)04 24 Input 04 1X(Y+3)04

7 Input 05 1X(Y+2)05 25 Input 05 1X(Y+3)05

8 Input 06 1X(Y+2)06 26 Input 06 1X(Y+3)06

9 Input 07 1X(Y+2)07 27 Input 07 1X(Y+3)07

10 Input 10 1X(Y+2)10 28 Input 10 1X(Y+3)10

11 Input 11 1X(Y+2)11 29 Input 11 1X(Y+3)11

12 Input 12 1X(Y+2)12 30 Input 12 1X(Y+3)12

13 Input 13 1X(Y+2)13 31 Input 13 1X(Y+3)13

14 Input 14 1X(Y+2)14 32 Input 14 1X(Y+3)14

15 Input 15 1X(Y+2)15 33 Input 15 1X(Y+3)15

16 Input 16 1X(Y+2)16 34 Input 16 1X(Y+3)16

17 Input 17 1X(Y+2)17 35 Input 17 1X(Y+3)17

18 N.C. 36 N.C.

37 N.C.

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Input

Assignment

Group 3

Program

Address

2

1

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

NC

COM

00

02

04

06

10

12

14

16

17

01

03

05

07

11

13

15

17

2

GROUP

2

3

No.

3-8

NC

NC

36 37

10936-I

Page 37

T

able 3.D

1791-IOBX

Output T

Chapter 3

Configuring Your Block I/O

erminal Addressing for Groups 0 and 1 (TRM3)

Terminal

Number

Output

Assignment

Group 1

Program

Address

Terminal

Number

Output

Assignment

Group 0

1 N.C. 20 Common A

2 Common B 21 Output 17 0XY17

3 Output 17 0X(Y+1)17 22 Output 16 0XY16

4 Output 16 0X(Y+1)16 23 Output 15 0XY15

5 Output 15 0X(Y+1)15 24 Output 14 0XY14

6 Output 14 0X(Y+1)14 25 Output 13 0XY13

7 Output 13 0X(Y+1)13 26 Output 12 0XY12

8 Output 12 0X(Y+1)12 27 Output 11 0XY11

9 Output 11 0X(Y+1)11 28 Output 10 0XY10

10 Output 10 0X(Y+1)10 29 Output 07 0XY07

11 Output 07 0X(Y+1)07 30 Output 06 0XY06

12 Output 06 0X(Y+1)06 31 Output 05 0XY05

13 Output 05 0X(Y+1)05 32 Output 04 0XY04

14 Output 04 0X(Y+1)04 33 Output 03 0XY03

15 Output 03 0X(Y+1)03 34 Output 02 0XY02

16 Output 02 0X(Y+1)02 35 Output 01 0XY01

17 Output 01 0X(Y+1)01 36 Output 00 0XY00

18 Output 00 0X(Y+1)00 37 VDC A

19 VDC B

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

OUTPUT

+VDC

0

+VDC

1

03

05

07

11

13

15

17

L

01

03

05

07

11

13

15

17

COM

NC

L

01

COM

00

02

04

06

10

12

14

16

3637

00

02

04

06

10

12

14

16

2

1

10937-I

3-9

Page 38

Chapter 3

Configuring Your Block I/O

T

able 3.E

1791-IOBX Output Terminal Addressing for Groups 2 and 3 (TRM4)

Terminal

Number

Output

Assignment

Group 3

Program

Address

Terminal

Number

Output

Assignment

Group 2

1 N.C. 20 Common C

2 Common D 21 Output 17 0X(Y+2)17

3 Output 17 0X(Y+3)17 22 Output 16 0X(Y+2)16

4 Output 16 0X(Y+3)16 23 Output 15 0X(Y+2)15

5 Output 15 0X(Y+3)15 24 Output 14 0X(Y+2)14

6 Output 14 0X(Y+3)14 25 Output 13 0X(Y+2)13

7 Output 13 0X(Y+3)13 26 Output 12 0X(Y+2)12

8 Output 12 0X(Y+3)12 27 Output 11 0X(Y+2)11

9 Output 11 0X(Y+3)11 28 Output 10 0X(Y+2)10

10 Output 10 0X(Y+3)10 29 Output 07 0X(Y+2)07

11 Output 07 0X(Y+3)07 30 Output 06 0X(Y+2)06

12 Output 06 0X(Y+3)06 31 Output 05 0X(Y+2)05

13 Output 05 0X(Y+3)05 32 Output 04 0X(Y+2)04

14 Output 04 0X(Y+3)04 33 Output 03 0X(Y+2)03

15 Output 03 0X(Y+3)03 34 Output 02 0X(Y+2)02

16 Output 02 0X(Y+3)02 35 Output 01 0X(Y+2)01

17 Output 01 0X(Y+3)01 36 Output 00 0X(Y+2)00

18 Output 00 0X(Y+3)00 37 VDC C

19 VDC D

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

GROUP

2

No.

2

3

+VDC

L

03

05

07

11

13

15

17

+VDC

L

01

03

05

07

11

13

15

17

COM

NC

3637

00

01

02

04

06

10

12

14

16

COM

00

02

04

06

10

12

14

16

3-10

2

1

10938-I

Page 39

T

able 3.F

1791-IOVX

Chapter 3

Configuring Your Block I/O

Input T

erminal Addressing for Groups 0 and 1 (TRM1)

Terminal

Number

Input

Assignment

Group 0

Program

Address

Terminal

Number

Input

Assignment

Group 1

1 VDC A 19 VDC B

2 Input 00 1XY00 20 Input 00 1X(Y+1)00

3 Input 01 1XY01 21 Input 01 1X(Y+1)01

4 Input 02 1XY02 22 Input 02 1X(Y+1)02

5 Input 03 1XY03 23 Input 03 1X(Y+1)03

6 Input 04 1XY04 24 Input 04 1X(Y+1)04

7 Input 05 1XY05 25 Input 05 1X(Y+1)05

8 Input 06 1XY06 26 Input 06 1X(Y+1)06

9 Input 07 1XY07 27 Input 07 1X(Y+1)07

10 Input 10 1XY10 28 Input 10 1X(Y+1)10

11 Input 11 1XY11 29 Input 11 1X(Y+1)11

12 Input 12 1XY12 30 Input 12 1X(Y+1)12

13 Input 13 1XY13 31 Input 13 1X(Y+1)13

14 Input 14 1XY14 32 Input 14 1X(Y+1)14

15 Input 15 1XY15 33 Input 15 1X(Y+1)15

16 Input 16 1XY16 34 Input 16 1X(Y+1)16

17 Input 17 1XY17 35 Input 17 1X(Y+1)17

18 N.C. 36 N.C.

37 N.C.

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

2

1

INPUT

+VDC

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

NC

+VDC

00

02

04

06

10

12

14

16

NC

0

17

01

03

05

07

11

13

15

1

17

NC

36 37

10939-I

3-11

Page 40

Chapter 3

Configuring Your Block I/O

T

able 3.G

1791-IOVX Input T

erminal Addressing for Groups 2 and 3 (TRM2)

Terminal

Number

Input

Assignment

Group 2

Program

Address

Terminal

Number

Input

Assignment

Group 3

1 VDC C 19 VDC D

2 Input 00 1X(Y+2)00 20 Input 00 1X(Y+3)00

3 Input 01 1X(Y+2)01 21 Input 01 1X(Y+3)01

4 Input 02 1X(Y+2)02 22 Input 02 1X(Y+3)02

5 Input 03 1X(Y+2)03 23 Input 03 1X(Y+3)03

6 Input 04 1X(Y+2)04 24 Input 04 1X(Y+3)04

7 Input 05 1X(Y+2)05 25 Input 05 1X(Y+3)05

8 Input 06 1X(Y+2)06 26 Input 06 1X(Y+3)06

9 Input 07 1X(Y+2)07 27 Input 07 1X(Y+3)07

10 Input 10 1X(Y+2)10 28 Input 10 1X(Y+3)10

11 Input 11 1X(Y+2)11 29 Input 11 1X(Y+3)11

12 Input 12 1X(Y+2)12 30 Input 12 1X(Y+3)12

13 Input 13 1X(Y+2)13 31 Input 13 1X(Y+3)13

14 Input 14 1X(Y+2)14 32 Input 14 1X(Y+3)14

15 Input 15 1X(Y+2)15 33 Input 15 1X(Y+3)15

16 Input 16 1X(Y+2)16 34 Input 16 1X(Y+3)16

17 Input 17 1X(Y+2)17 35 Input 17 1X(Y+3)17

18 N.C. 36 N.C.

37 N.C.

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

2

1

+VDC

00

01

02

03

04

05

06

07

10

11

12

13

14

15

17

03

05

07

11

13

15

17

NC

2

GROUP

3

No.

16

NC

+VDC

00

01

02

04

06

10

12

14

16

NC

3-12

36 37

10940-I

Page 41

T

able 3.H

Terminal

Number

Output

Assignment

Group 1

Program

Address

1791-IOVX

Terminal

Number

Output T

Output

Assignment

Group 0

erminal Addressing for Groups 0 and 1 (TRM3)

1 N.C. 20 Common A

2 Common B 21 Output 17 0XY17

3 Output 17 0X(Y+1)17 22 Output 16 0XY16

4 Output 16 0X(Y+1)16 23 Output 15 0XY15

5 Output 15 0X(Y+1)15 24 Output 14 0XY14

6 Output 14 0X(Y+1)14 25 Output 13 0XY13

7 Output 13 0X(Y+1)13 26 Output 12 0XY12

8 Output 12 0X(Y+1)12 27 Output 11 0XY11

9 Output 11 0X(Y+1)11 28 Output 10 0XY10

10 Output 10 0X(Y+1)10 29 Output 07 0XY07

11 Output 07 0X(Y+1)07 30 Output 06 0XY06

12 Output 06 0X(Y+1)06 31 Output 05 0XY05

13 Output 05 0X(Y+1)05 32 Output 04 0XY04

14 Output 04 0X(Y+1)04 33 Output 03 0XY03

15 Output 03 0X(Y+1)03 34 Output 02 0XY02

16 Output 02 0X(Y+1)02 35 Output 01 0XY01

17 Output 01 0X(Y+1)01 36 Output 00 0XY00

18 Output 00 0X(Y+1)00 37 VDC A

19 VDC B

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

Chapter 3

Configuring Your Block I/O

37

OUTPUT

+VDC

00

L

01

02

03

04

05

06

07

10

11

12

13

14

15

17

+VDC

01

03

05

07

11

13

15

17

-COM

NC

16

-COM

00

L

02

04

06

10

12

14

16

0

1

36

12

10941-I

3-13

Page 42

Chapter 3

Configuring Your Block I/O

T

able 3.I

1791-IOVX Output Terminal Addressing for Groups 2 and 3 (TRM4)

Terminal

Number

Output

Assignment

Group 3

Program

Address

Terminal

Number

Output

Assignment

Group 2

1 N.C. 20 Common C

2 Common D 21 Output 17 0X(Y+2)17

3 Output 17 0X(Y+3)17 22 Output 16 0X(Y+2)16

4 Output 16 0X(Y+3)16 23 Output 15 0X(Y+2)15

5 Output 15 0X(Y+3)15 24 Output 14 0X(Y+2)14

6 Output 14 0X(Y+3)14 25 Output 13 0X(Y+2)13

7 Output 13 0X(Y+3)13 26 Output 12 0X(Y+2)12

8 Output 12 0X(Y+3)12 27 Output 11 0X(Y+2)11

9 Output 11 0X(Y+3)11 28 Output 10 0X(Y+2)10

10 Output 10 0X(Y+3)10 29 Output 07 0X(Y+2)07

11 Output 07 0X(Y+3)07 30 Output 06 0X(Y+2)06

12 Output 06 0X(Y+3)06 31 Output 05 0X(Y+2)05

13 Output 05 0X(Y+3)05 32 Output 04 0X(Y+2)04

14 Output 04 0X(Y+3)04 33 Output 03 0X(Y+2)03

15 Output 03 0X(Y+3)03 34 Output 02 0X(Y+2)02

16 Output 02 0X(Y+3)02 35 Output 01 0X(Y+2)01

17 Output 01 0X(Y+3)01 36 Output 00 0X(Y+2)00

18 Output 00 0X(Y+3)00 37 VDC C

19 VDC D

Where: X = Rack Number (1, 2, 3 ...)

Y = Module Group (0-7)

Program

Address

GROUP

2

No.

2

3

+VDC

01

03

05

07

11

13

15

17

-COM

+VDC

01

03

05

07

11

13

15

17

-COM

NC

3637

00

L

02

04

06

10

12

14

16

00

L

02

04

06

10

12

14

16

Summary

3-14

2

1

10942-I

In this chapter you learned how to set the configuration switches and the

rack addresses for input and output terminals.

Page 43

Troubleshooting

Chapter

4

Chapter

Objectives

Indicators

In this chapter you will learn about the indicators on the block I/O module,

and how to use them to troubleshoot the unit.

Each block I/O module has indicators (Figure 4.1) which provide

indication of specific functions. Each module has the following:

Status Indicators - Indicators are provided for power, active,

communication and fuse blown indications. An LED array provides

input/output status.

POWER Indicator -

- green -on continuously if customer voltage is present;

off if power is not applied or there is an internal power supply

problem.

ACTIVE Indicator -

- red if the CPU is not running;

green if the CPU is operating correctly.

COMM Indicator - indicates the status of the RIO link.

- green when communication is correctly established;

off when communication is not established;

flashing when programmable controller is in PROG mode.

FUSE Indicator - indicates the status of the 4 output fuses.

- off if all 4 fuses are intact;

red if any one of the fuses opens.

The I/O status array is an 8 by 8 array of 64 LEDs capable of displaying

the status of 32 inputs and 32 outputs at any one time. Pushbuttons are

provided to toggle the display between the lower 32 bits and the upper

32 bits.

Refer to Table 4.A below for status indications reported by the indicators.

4-1

Page 44

Chapter 4

Troubleshooting

Figure 4.1

Indicators

shown)

on the 1791-IOBX and -IOVX Block I/O Modules (PLC labels

POWER

ACTIVE

COMM

FUSE

INPUT

0:1 2:3

COM

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

17

NC

COM

00

01

02

03

04

05

06

07

10

11

12

LED

RACK

ADDR

87654321

POWER

ACTIVE

COMM

FUSE

0:1 2:3GROUP

CONFIGURATION

SWITCHES

DISPLAY

SELECT

INPUT

OUTPUT

OUTPUT

+VDC

03

05

07

11

13

15

17

COM

+VDC

03

05

07

11

00

01

02

04

06

10

12

14

16

00

01

02

04

06

10

4-2

00

01

02

03

04

05

06

07

INPUT

10

11

12

13

14

15

16

17

DISPLAY

SELECT

10

00

11

01

12

02

13

03

14

04

15

05

16

06

17

07

OUTPUT

10

00

10

00

11

01

11

01

12

02

12

02

13

03

13

03

14

04

14

04

15

05

15

05

16

06

16

06

17

07

17

07

indicates LED off - lower 32 bits are displayed

indicates LED on - upper 32 bits are displayed

Press Input and Output pushbuttons simultaneously

to reset Processor Restart Lockout.

10943-I

Page 45

Chapter 4

P WER

ACTIVE

FUSE

Troubleshooting

T

able 4.A

Troubleshooting

Indication Probable Cause Corrective Action

Chart

POWER

(green)

COMM

(green)

(green)

ACTIVE

(green/red)

FUSE

(red)

Green

I/O status on/off

Off

Solid green

Off

Flashing green

Green

Red

Red

Off

Normal indication None required

No 24V dc power connected, or hardware fault. Check 24V dc power to block

Normal indication - module is communicating with

the programmable controller

No communication with adapter, scanner etc.

Reset command (or output disable bit for SLC) has

been issued by processor, scanner or adapter.

SLC or programmable controller not in run mode.

Normal indication None

Internal CPU fault Return module for repair

One or more fuses are open Replace blown fuse

Normal indication None required

None required

Check that power LED is on. Make sure that

proper number of blocks are configured.

Check program. Correct as necessary.

Place in run mode.

Replacing

a Fuse

The block I/O module has one fuse for each group of outputs. To replace a

fuse, proceed as follows.

1. Remove power to the block I/O module.

TTENTION:

A

Remove power to the block I/O module before

attempting to replace the fuse.

Failure to remove power from the block I/O module could

cause injury or equipment damage due to possible

unexpected operation.

Failure to remove power from the module could cause

module damage, degradation of performance or injury.

2. Remove the 5 screws securing the cover to the block I/O module.

3. Locate and remove the blown fuse.

4-3

Page 46

Chapter 4

Troubleshooting

4. Replace the blown fuse with a 5.0A slow blow fuse.

5. Reinstall cover and secure with 5 screws removed in step 2.

6. Reapply power to the module.

Summary

In this chapter you learned what the LED indicators represent, and how to

interpret them.

4-4

Page 47

Specifications

General Specifications

Appendix

A

External power

Power Dissipation 25.2 Watts (maximum); 15.2 Watts (typical)

Thermal Dissipation 86.2 BTU/hr (maximum); 51.9 BTU/hr (typical)

Remote I/O Isolation 850V dc (transformer) for 1 second

Interconnect cable length

PLC or SLC

Cable requirements RIO – Belden 9463

Dimensions

Conductors Wire Size

Category

Environmental Conditions

Operating Temperature

Storage Temperature

Relative Humidity

Operating

Non-operating

1

Refer

to publication 1770–4.1, Programmable Controller Wiring and Grounding Guidelines

Range: 18 to 26.4V dc

300mA @ 24V dc; initial surge 2.0A for 10msec

RIO: 57.6K 10,000 cable–feet

115.2K 5,000 cable–feet

230.4K 2,500 cable–feet

Inches: 6.15W x 13.0H x 1.72D

Millimeters: 156.21W x 334.0H x 43.7D

14 gauge (2mm2) stranded (maximum)

3/64 inch (1.2mm) insulation (maximum)

1

2

32 to 140oF (0 to 60oC)

–40 to 185oF (–40 to 85oC)

5 to 95% noncondensing

5 to 80% noncondensing

Input Specifications

Number of Inputs 64 (4 groups of 16)

Input type 1791–IOBX – Sinking; 1791–IOVX – Sourcing

On-state voltage range 12.0 to 26.4V dc

On–state input current 1.56mA (minimum)

Off–state voltage 7.0V dc (maximum)

Off–state current 1.0mA dc (maximum)

Turn On time 10msec (maximum) (+4msec)

Turn Off time 10msec (maximum) (+4msec)

Input to System Isolation 1500V ac (opto) for 1 second

Group to Group Isolation 1500V ac (air gap) for 1 second

A-1

Page 48

Appendix

A

Specifications

Output Specifications

Number of outputs 64 (4 groups of 16)

Output type 1791–IOBX – Source; 1791–IOVX – Sink

Maximum output range 18.0 to 26.4V dc @ 300mA resistive

Maximum on–state voltage drop 1.5V dc maximum @ 25oC at rated current

Maximum on–state current 300mA per point (maximum)

Minimum on–state current 5mA (minimum)

Output Current per output group 2.4A maximum continuous

Surge Current 1.0A for 25ms (maximum), 1 pulse per second max.

Off–state voltage 26.4V dc (maximum)

Off–state leakage current 0.5mA (maximum)

Turn on time 2.0ms (maximum)

Turn off time 2.0ms (maximum)

Fuse Type 5.0A slow blow (5 X 20mm size) – one per group