Page 1

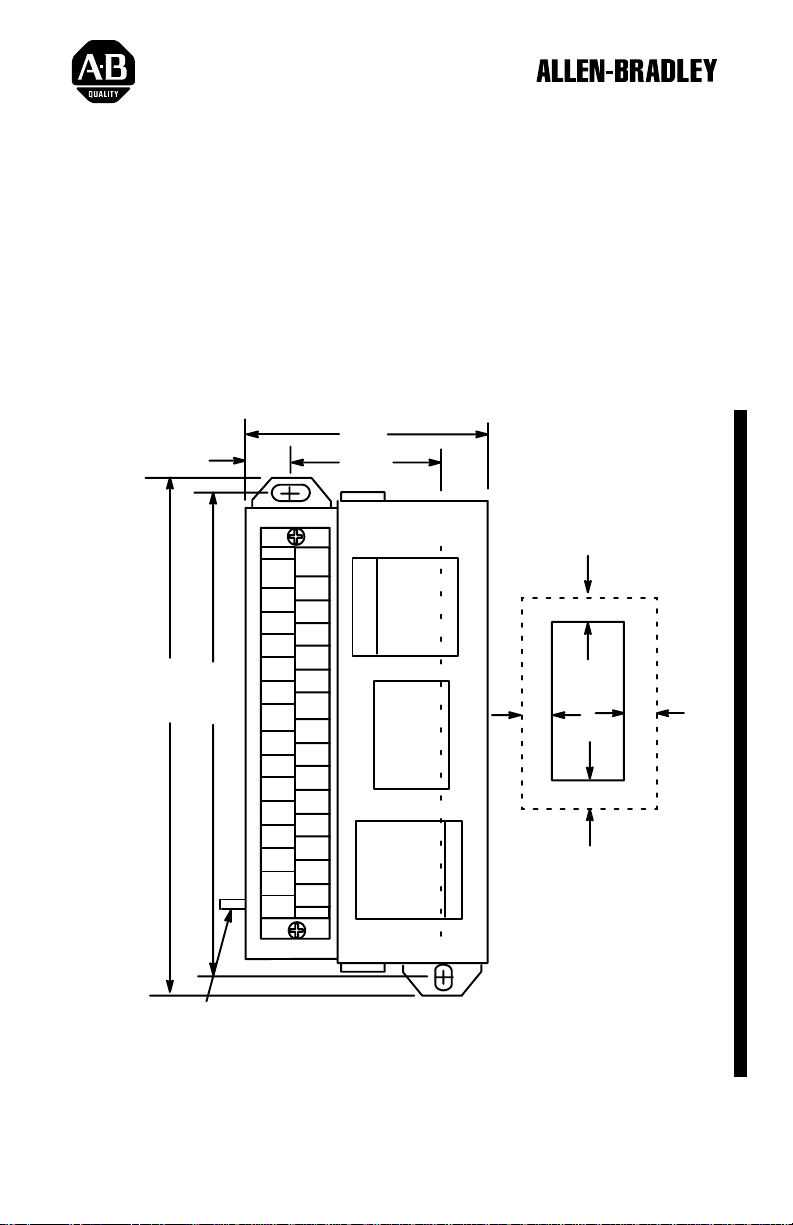

16 Input AC Block I/O Module

Cat. No. 1791-16A0 Series B

Installation

Mount the block I/O module in a vertical (recommended) or horizontal position.

Allow sufficient room around the block for cooling air flow through the block

module. Refer to Figure 1.

Figure 1

Mounting

Cat. No. 1791–16A0 Series B (PLC version shown)

Dimensions for the Block I/O Module

2.710

(68.8)

1.71

(43.4)

1791-16A0

120V

1

00

01

02

03

04

05

06

07

INPUT INPUT

00

01

02

03

04

05

06

07

ac INPUT

(12.7)

6.95

(176.5)

0.5

6.60

(167.6)

Inches

(Millimeters)

Dimensions

6.95H x 2.710W x 3.85D

(176.5H x 68.8W x 98D)

10

11

12

13

14

15

16

17

Block

Equipment

Grounding Stud

30

CAUTION:

10

11

12

13

14

15

16

17

2.0 (50.8) air gap

on all 4 sides.

Operating temperature in air

gap below module must not

ALLENĆBRADLEY

exceed 60oC (140oF).

2

mounting holes

for #8 screws

When tightening grounding stud nut, do not exceed 15 in-lbs.

12381–I

1

Page 2

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

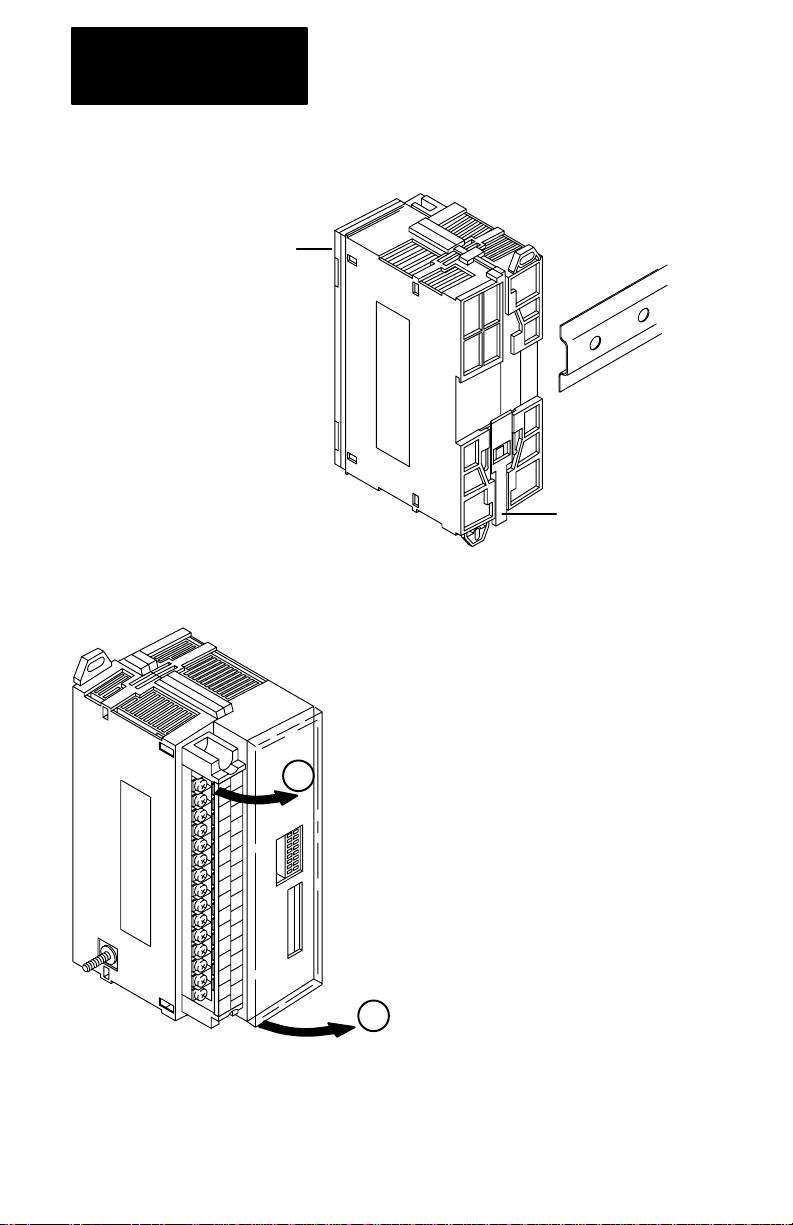

Figure 2

Mounting

1.

2. While pressing block against rail,

3. When block is flush against rail,

on a DIN Rail

Block

Hook top of slot over DIN rail.

pull down on locking lever

push up on locking lever to secure

block to rail.

.

Figure 3

Inserting

Labels

DIN Rail

A-B Pt. No. 199-DR1

46277-3

EN 50022

(35 x 7.5mm)

Locking Lever

12382–I

A set of labels is supplied with your module. Select the

proper module designation labels (PLC or SLC) for the front

door and terminal strip.

1.

Remove die-cut labels from package. Select correct

labels for your application. (PLC label is numbered

2

00–07 and 10–17. SLC label is numbered 00–07

and 08–15.)

2.

Remove plastic cover on terminal strip by flexing

in middle. Slip the terminal designation label into

built-in holders in terminal strip cover

slightly to install.

3. Open clear front door

label into slots that secure it to the door

. Insert module designation

. Flex cover

3

.

12384–I

2

Page 3

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

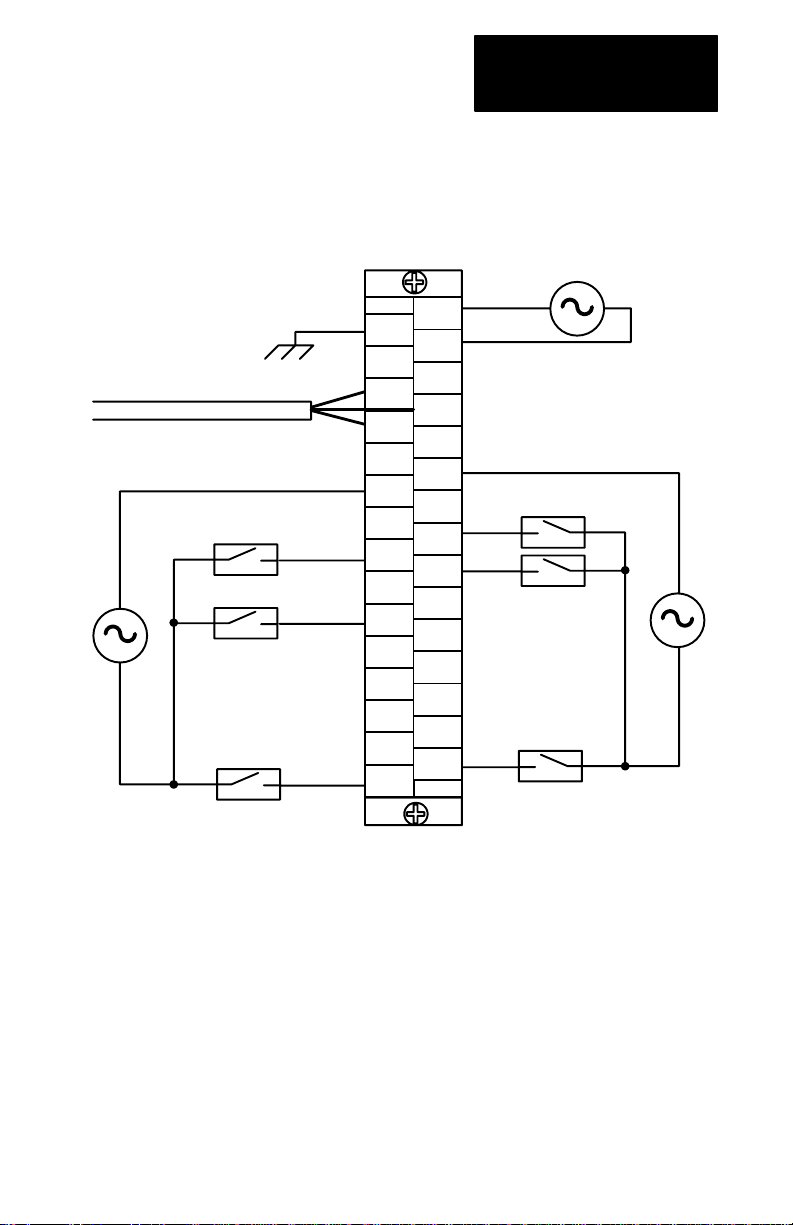

Connect wiring as shown in Figure 4 or Figure 5.

Figure 4

Wiring

Connections with PLC Family Programmable Controllers (refer

to T

able

A)

PLC

RIO

L2/N

L1

GND

NOT

USED

BLU

CLR

COM

1

COM

1

COM

00

in

in 01

in 02

in 03

in 04

in 05

in 06

in 07

30

1

L1

N

NOT

USED

SHD

COM

2

COM

2

COM

2

1

in 10

in 1

1

in 12

in 13

in 14

in 15

in 16

in 17

L1

NOTE: COM 1 connections are internally connected together.

COM 2 connections are internally connected together.

L2/N

L2/N

L1

12386–I

3

Page 4

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

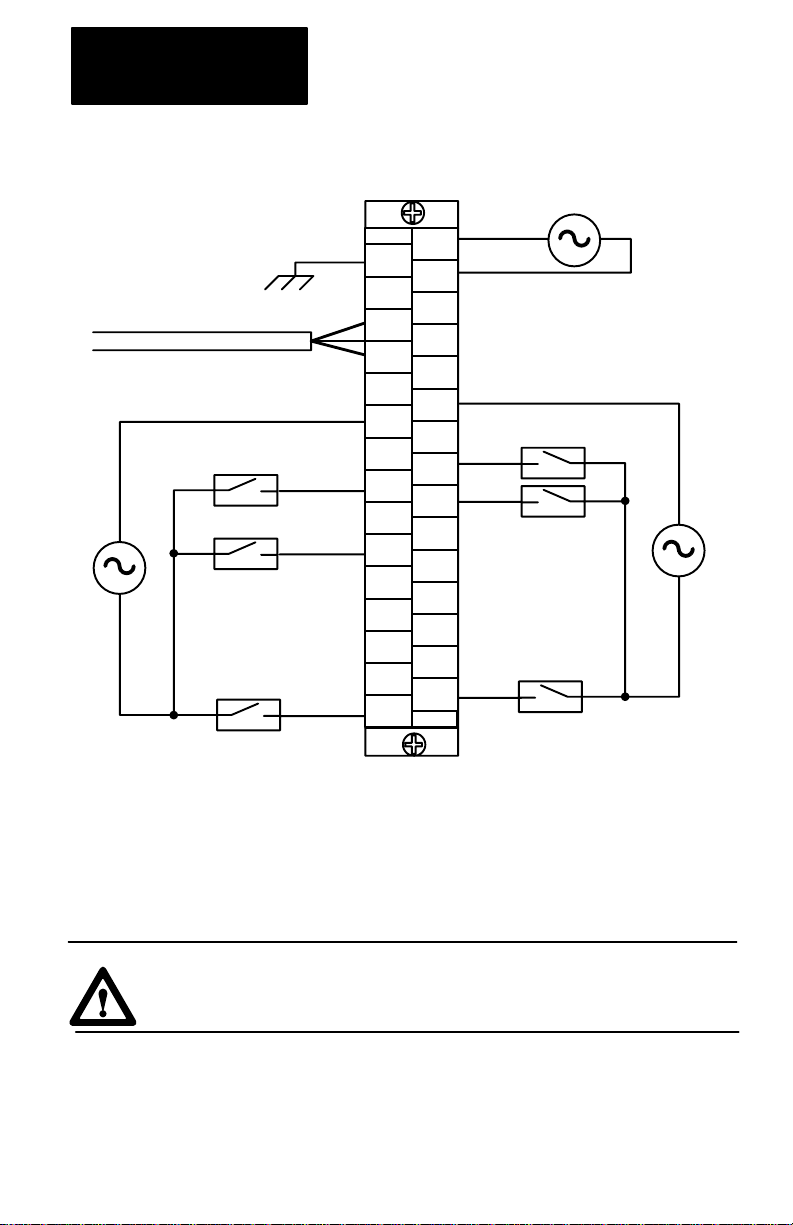

Figure 5

Wiring

Connections with SLC Family Processors (refer to T

able

A)

SLC

RIO

L2/N

L1

GND

NOT

USED

BLU

CLR

COM

1

COM

1

COM

00

in

in 01

in 02

in 03

in 04

in 05

in 06

in 07

30

1

L1

N

NOT

USED

SHD

COM

2

COM

2

COM

2

1

in 08

in 09

in 10

in 1

1

in 12

in 13

in 14

in 15

L1

L2/N

L2/N

L1

NOTE: COM 1 connections are internally connected together.

COM 2 connections are internally connected together.

12389–I

The block I/O module has an equipment grounding stud on the lower left side of

the module. Connect this grounding stud to your equipment ground. Torque the

nut to 15 in-lbs maximum when connecting to your equipment ground.

ATTENTION: Do not overtighten the nut on the grounding stud

when connecting the wire. Damage to the module could result.

Refer to “Programmable Controller Wiring and Grounding Guidelines”

(1770-4.1) for further information.

4

Page 5

T

s

Power

Remote I/O

able

A

Block Designations

Wiring

Connection

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

1791–16A0 Series B

Designation Description Terminal No.

Power

Connections

L1 ac hot 1

N

ac neutral 3

GND Chassis ground 2

Remote I/O

Connections

BLU Blue wire – RIO 6

CLR

Clear wire – RIO 8

SHD Shield – RIO 7

I/O Connections

Input in 00 thru in 07 Input 00 thru 07

COM 1 L2/N Input Common 10, 12, 14

COM 2 L2/N Input Common 9, 11, 13

Input

PLC: in 10 thru in 17

SLC: in 08 thru in 15

Not used

1

Connect chassis ground to equipment grounding stud. These are not internally connected.

2

T

erminals 10, 12 and 14 are internally connected.

3

T

erminals 9, 11 and 13 are internally connected.

T

able B

PLC: Input 10 thru Input 17

SLC: Input 08 thru Input 15

For internal test only; not for

customer use.

Acceptable Wiring Cables for Block I/O Connection

1

16, 18, 20, 22,

24, 26, 28, 30

2

3

15, 17, 19, 21,

23, 25, 27, 29

4, 5

Use Cable Type

Remote I/O link Belden 9463

Input and output wiring

Up to 14AWG (2mm2) stranded with

3/64 inch (1.2mm) insulation

5

Page 6

Installation Instructions

Not use

Block I/O

Cat. No. 1791-16A0 Series B

Figure 6

Switch

Settings

1791-16A0

120V

1

ac INPUT

Default Switch

Settings = 0

87654321

SW2–8

d

SW2–7

Not used

INPUT INPUT

00

01

02

03

04

05

06

07

10

11

12

SW2

13

14

15

16

17

01

SW1

30

01

Open cover to

access switches

Position = 1Position = 0

End View of Switch

ATTENTION: Cycle power to the module after

setting the switches.

Only block I/O modules with all inputs or

all outputs can use complementary I/O.

NOTE: Set switch SW2–3 to 0 if this rack will have a

unique address (not complemented). If this rack

address is a duplicate of another I/O block or

chassis, set the switch to 1 for primary or 0 for

complementary. Refer to Table C for the

complementary I/O rack address.

Series A block I/O modules do not support

complementary I/O. If using series A

modules, set switch SW2–3 to 0.

6

SW2–6 Last I/O Group

0 Not last rack

1 Last rack

SW2–5

87654321

0 Processor Restart

Processor

Restart/Lockout (PRL)

1 Processor Lockout

SW2–4 Hold Last State

0 Reset Outputs

1 Hold Last State

SW2–3 Complementary I/O

0 Non-Complemented System

0 Complementary Rack

1 Primary Rack

1

See note.

Communication Rate

SW2–2 SW2–1 Bits/s

0 0 57.6 K

0 1 115.2 K

1 0 230.4 K

1 1 230.4 K

Starting Quarter

SW1–2 SW1–1

0 0 0 (1st)

0 1 2 (2nd)

1 0 4 (3rd)

1 1 6 (4th)

1

1

1

Module

Group

12391–I

Page 7

Installation Instructions

Ra

Ra

Ra

Ra

Ra

Ra

Block I/O

Cat. No. 1791-16A0 Series B

1747-SN

Number

Rack

Rack 1 Rack 2 Rack 2 Rack 1 Rack 1 Rack 1

Rack 2 Rack 3 Rack 3 Rack 2 Rack 2 Rack 2

Rack 3 Rack 4 Rack 4 Rack 3 Rack 3 Rack 3

1771-SN

ck

Number

0

Rack 1 Rack 1

Rack 5 Rack 5 Rack 4 Rack 4 Rack 4

Rack 6 Rack 6 Rack 5 Rack 5 Rack 5

Rack 7 Rack 7 Rack 6 Rack 6 Rack 6

PLC–2

ck

Number

PLC–5

ck

PLC–5/250

ck

Number

Not V

alid

Rack 7 Rack 7 Rack 7

Rack 10 Rack 10 Rack 10

Rack 1

1

Rack 12 Rack 12 Rack 12

Rack 13 Rack 13 Rack 13

Rack 14 Rack 14 Rack 14

Rack 15 Rack 15 Rack 15

Rack 16 Rack 16 Rack 16

Rack 17 Rack 17 Rack 17

Rack 20 Rack 20 Rack 20

Rack 21 Rack 21 Rack 21

Rack 22 Rack 22 Rack 22

Rack 23 Rack 23 Rack 23

Rack 24 Rack 24 Rack 24

Rack 25 Rack 25 Rack 25

Rack 26 Rack 26 Rack 26

Rack 27 Rack 27 Rack 27

PLC–3

ck

Number

Rack 0 Rack 0

Rack 1

Rack 30 Rack 30

Rack 31 Rack 31

Rack 32 Rack 32

Rack 33 Rack 33

Rack 34 Rack 34

Rack 35 Rack 35

Rack 36 Rack 36

Rack 37 Rack 37

Number

1

Rack 1

Rack 40

Rack 41

Rack 42

Rack 43

Rack 44

Rack 45

Rack 46

Rack 47

Rack 50

ck

SW1 Switch Position

8 7 6 5 4 3

0 0 0 0 0 0

0 0 0 0 0 1

0 0 0 0 1 0

0 0 0 0 1 1

0 0 0 1 0 0

0 0 0 1 0 1

0 0 0 1 1 0

0 0 0 1 1 1

0 0 1 0 0 0

1 0 0 1 0 0 1

0 0 1 0 1 0

0 0 1 0 1 1

0 0 1 1 0 0

0 0 1 1 0 1

0 0 1 1 1 0

0 0 1 1 1 1

0 1 0 0 0 0

0 1 0 0 0 1

0 1 0 0 1 0

0 1 0 0 1 1

0 1 0 1 0 0

0 1 0 1 0 1

0 1 0 1 1 0

0 1 0 1 1 1

0 1 1 0 0 0

0 1 1 0 0 1

0 1 1 0 1 0

0 1 1 0 1 1

0 1 1 1 0 0

0 1 1 1 0 1

0 1 1 1 1 0

0 1 1 1 1 1

1 0 0 0 0 0

1 0 0 0 0 1

1 0 0 0 1 0

1 0 0 0 1 1

1 0 0 1 0 0

1 0 0 1 0 1

1 0 0 1 1 0

1 0 0 1 1 1

1 0 1 0 0 0

7

Page 8

Installation Instructions

Ra

Ra

Block I/O

Cat. No. 1791-16A0 Series B

Rack

Rack

PLC–5/250

PLC–5/250

1747-SN

1747-SN

Rack

Rack

Number

Number

Rack address 77 is an illegal configuration.

PLC-5/1

PLC-5/15 and PLC-5/20 processors can scan racks 01–03.

PLC-5/25 and PLC-5/30 processors can scan racks 01–07.

PLC-5/40 and PLC-5/40L processors can scan racks 01–17.

PLC-5/60 and PLC-5/60L processors can scan racks 01–27.

PLC-5/250 processors can scan racks 00–37.

1771-SN

1771-SN

Rack

Rack

Number

Number

1 processors can scan rack 03.

PLC–2

PLC–2

Rack

Rack

Number

Number

PLC–5

PLC–5

Number

Number

Rack

Rack

Number

Number

PLC–3

PLC–3

Rack

Rack

Number

Number

Rack

51

Rack 52

Rack 53

Rack 54

Rack 55

Rack 56

Rack 57

Rack 60

Rack 61

Rack 62

Rack 63

Rack 64

Rack 65

Rack 66

Rack 67

Rack 70

Rack 71

Rack 72

Rack 73

Rack 74

Rack 75

Rack 76

Not V

alid 1 1 1 1 1 1

SW1 Switch Position

1 0 1 0 0 1

1 0 1 0 1 0

1 0 1 0 1 1

1 0 1 1 0 0

1 0 1 1 0 1

1 0 1 1 1 0

1 0 1 1 1 1

1 1 0 0 0 0

1 1 0 0 0 1

1 1 0 0 1 0

1 1 0 0 1 1

1 1 0 1 0 0

1 1 0 1 0 1

1 1 0 1 1 0

1 1 0 1 1 1

1 1 1 0 0 0

1 1 1 0 0 1

1 1 1 0 1 0

1 1 1 0 1 1

1 1 1 1 0 0

1 1 1 1 0 1

1 1 1 1 1 0

345678

T

able C

PLC–2

and PLC–5 With Complementary I/O

PLC–2

Number

Rack

Rack 2 Rack 1

Rack 3 Rack 2

Rack 4 Rack 3

Rack 5 Rack 4

Rack 6 Rack 5

Rack 7 Rack 6

ck

PLC–5

ck

Number

1

Not V

alid 0 0 1 0 0 0

Rack 7

SW1 Switch Position

8 7 6 5 4 3

0 0 1 0 0 1

0 0 1 0 1 0

0 0 1 0 1 1

0 0 1 1 0 0

0 0 1 1 0 1

0 0 1 1 1 0

0 0 1 1 1 1

8

When

configured as complementary I/O,:

PLC-2 can scan racks 01–07

PLC-5/1

1 can scan rack 03

PLC-5/20, PLC-5/30, PLC-5/40, PLC-5/60

can scan racks 01–07

NOTE:

Remote rack numbers which can

have a complementary rack are rack

numbers 01 thru 07 only

.

Page 9

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

The SLC 500 controllers communicate with the block I/O using an I/O Scanner

module (cat. no. 1747-SN series A). Refer to the user manual for the 1747-SN/A

Scanner module for more information.

Note: This block I/O module is not compatible with the 1747-DSN Distributed

I/O Scanner module.

Termination Resistor

A

termination resistor must be installed on the last block in a series. Connect the

resistor as shown in Figure 7.

Figure 7

Installing

Connect

terminals 6 (BLU) and 8 (CLR).

150 ohm – 57.6K and 115.2K baud

82 ohm – 230.4K baud

the T

ermination Resistor

termination resistor across

Termination

Resistor

BLU

CLR

SHD

12392–I

ATTENTION: Devices that are operating at 230.4K baud must have

82 ohm terminators in place for proper operation.

9

Page 10

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

Indicators

PLC SLC

INPUT INPUT

00

01

02

03

04

05

06

07

COMM

STATUS

10

11

12

13

14

15

16

17

Indicator Description

COMM OFF

ON

Flashing

STATUS OFF

ON

Flashing

COMM

and STATUS will alternately flash when processor restart lockout is selected, a fault has occurred and the processor

is communicating with the block.

Communications not established

Communication established

Processor in Program mode

Normal

Error (hardware or software), block power low

COMM F

AIL – Communication cable of

than 255 valid frames between valid frames addressed to block, 20ms idle time

exceeded.

INPUT INPUT

00

01

02

03

04

05

06

07

COMM

STATUS

f, 100ms between valid frames, no more

08

09

10

11

12

13

14

15

12394–I

Fusing

The block I/O module is internally fused to protect the module. No external

power fusing is required.

10

Page 11

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

1791-16A0 Series B Specifications

Input Specifications

Inputs per Block 16 (2 groups of 8)

Nominal Input Current 11.0mA

Nominal Input Voltage 120V ac

On–state Voltage Range 79–132V ac, 47–63Hz

Off-state Voltage Maximum 35V

On-state Current Minimum 5mA @ 79V, 60Hz

Off-state Current Minimum 2.3mA (60Hz)

Input Impedance Maximum 15K ohms @ 60Hz

Input Signal Delay Off to on

On to off

General Specifications

External Power (Internally protected

- no external fuse required)

Voltage

Current

Dimensions Inches

Millimeters

Isolation Power supply to RIO

I/O Group-to-Group

I/O Group-to-Logic

Power Dissipation Maximum 8.9 Watts

Thermal Dissipation Maximum 30.35 BTU/hr

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Conductors Wire Size

Category

1

You

use this conductor category information for planning conductor routing as described in the

system level installation manual.

1.0ms

26ms (maximum) (allows for 1/2 cycle dropout)

85–132V ac, 47–63Hz

150mA

6.95H X 2.7W X 3.85D

176.5H X 68.8W X 98D

500V ac

1250V ac

1250V ac

0 to 60oC (32 to 140oF)

–40 to 85oC (–40 to 185oF)

5 to 95% noncondensing

14 gauge (2mm2) stranded maximum

3/64 inch (1.2mm) insulation maximum

1

1

11

Page 12

Installation Instructions

Block I/O

Cat. No. 1791-16A0 Series B

Publication 1791-5.24 – May 1995

Supersedes publication 1791-2.24 – March 1994

12

Copyright 1995 Allen-Bradley Company, Inc. Printed in USA

PN 955122–59

Loading...

Loading...