Page 1

CompactBlock LDX

RTD/Resistance

Input Module

1790D-4R0, 1790D-T4R0,

1790P-T4R0

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Allen-Bradley be responsible or

liable for indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

RSNetWorx, RSNetWorx for DeviceNet, RSLogix 500, and RSLogix 5000 are trademarks of Rockwell Automation.

Belden is a trademark of Belden, Inc.

Page 3

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

Rockwell Automation Support

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the troubleshooting information contained

in this publication first.

If the problem persists, call your local Rockwell Automation

representative or contact Rockwell Automation in one of the

following ways:

Phone United

States/Canada

Outside

United

States/Canada

Internet 1. Go to http://www.ab.com

1.440.646.5800

You can access the phone number for your

country via the Internet:

1. Go to http://www.ab.com

2. Click on Product Support

(http://support.automation.rockwell.com)

3. Under Support Centers, click on Contact

Information

2. Click on Product Support

(http://support.automation.rockwell.com)

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us by using the

enclosed How Are We Doing form.

Page 4

Page 5

Overview

Installation and Wiring

Module Data, Status, and Channel

Configuration for DeviceNet

Table of Contents

Chapter 1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

General Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Field Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Chapter 3

Module Memory Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Accessing Input Image File Data . . . . . . . . . . . . . . . . . . . . 3-1

Input Data File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Filter Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Channel Step Response . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Channel Cutoff Frequency . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Effective Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Determining Module Update Time. . . . . . . . . . . . . . . . . . . 3-9

DeviceNet RTD/Resistance Module (1790D-4R0/T4R0) . . . . 3-9

Configure DeviceNet RTD/Resistance Modules

Using RSNetWorx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Chapter 4

Diagnostics and Troubleshooting

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Module Operation vs. Channel Operation . . . . . . . . . . . . . 4-2

Power-up Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Channel Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Channel LED Indicator Operation . . . . . . . . . . . . . . . . . . . 4-5

Contacting Rockwell Automation . . . . . . . . . . . . . . . . . . . . 4-6

Chapter Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Appendix A

Specifications

i Publication 1790-UM002A-EN-P - May 2002

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . A-1

DeviceNet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

PROFIBUS DP Specifications . . . . . . . . . . . . . . . . . . . . . . . A-2

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

RTD/Resistance Specifications . . . . . . . . . . . . . . . . . . . . . . A-4

Page 6

Table of Contents ii

Two’s Complement Binary

Numbers

Module Configuration for

PROFIBUS

Appendix B

Positive Decimal Values . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Negative Decimal Values. . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Appendix C

Configure PROFIBUS RTD/Resistance Modules

(1790P-T4R0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Configure RTD/Resistance Modules Using the SST PROFIBUS

Configuration Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Save the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Download the Configuration . . . . . . . . . . . . . . . . . . . . . . . C-7

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Publication 1790-UM002A-EN-P - May 2002

Page 7

Chapter

1

Overview

This chapter describes the four-channel 1790D-4R0/T4R0 RTD/resistance

Input module and explains how the controller reads resistance

temperature detector (RTD) or direct resistance-initiated analog input data

from the module. Included is:

• a general description of hardware features

• an overview of module and system operation

• compatibility

General Description

The 1790D-4R0/T4R0 (1790P-T4R0) module supports RTD and direct

resistance signal measurement applications that require up to four

channels. The module digitally converts analog data and then stores the

converted data in its image table.

The module supports connections from any combination of up to four

input devices. Each channel is individually configurable via software for 2or 3-wire RTD or direct resistance input devices. Channels are compatible

with 4-wire sensors, but the fourth sense wire is not used. When

configured for RTD inputs, the module can convert the RTD readings into

linearized digital temperature readings in °C or °F. When configured for

resistance analog inputs, the module can convert voltages into linearized

resistance values in ohms. The module assumes that the direct resistance

input signal is linear prior to input to the module.

Each channel provides open-circuit (all wires) and over- and under-range

detection and indication.

IMPORTANT

The module accepts input from RTDs with up to 3 wires.

If your application requires a 4-wire RTD, one of the two

lead compensation wires is not used, and the RTD is

treated like a 3-wire sensor. The third wire provides lead

wire compensation. See Chapter 2, Installation and

Wiring, for more information.

1 Publication 1790-UM002A-EN-P

Page 8

1-2 Overview

The module supports the following filter frequencies:

• 10 Hz

• 25 Hz

• 50 Hz

• 60 Hz

• 100 Hz

• 250 Hz

• 500 Hz

The module uses five input words for data and status bits. Module

configuration is stored in the module memory. Configuration for

1790D-(T)4R0 is done via RSNetWorx for DeviceNet™ programming

software. See Chapter 3, Module Data, Status, and Channel

Configuration, for details on module configuration. Configuration for

1790P-T4R0 is done via PROFIBUS configuration software. See Appendix

C for details.

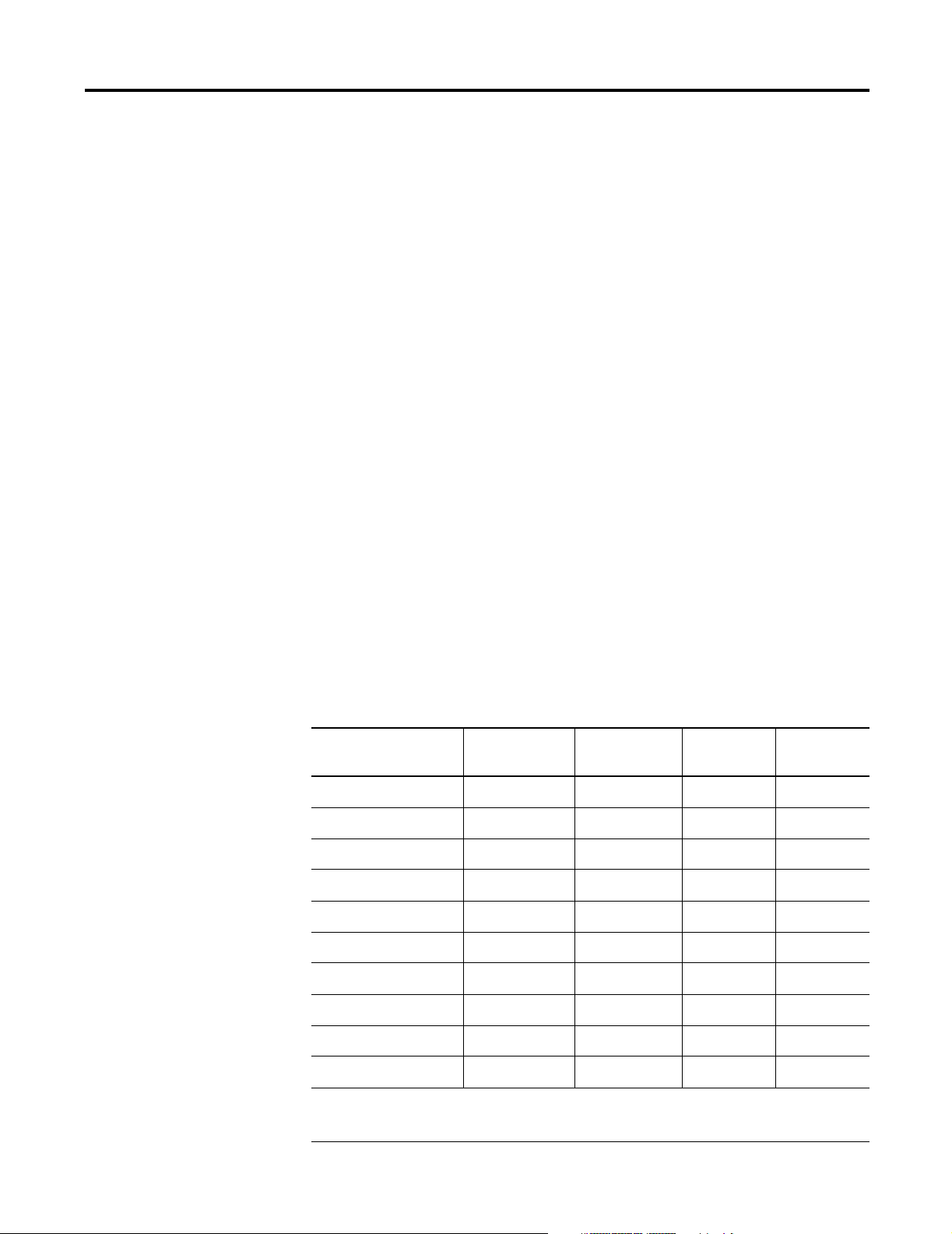

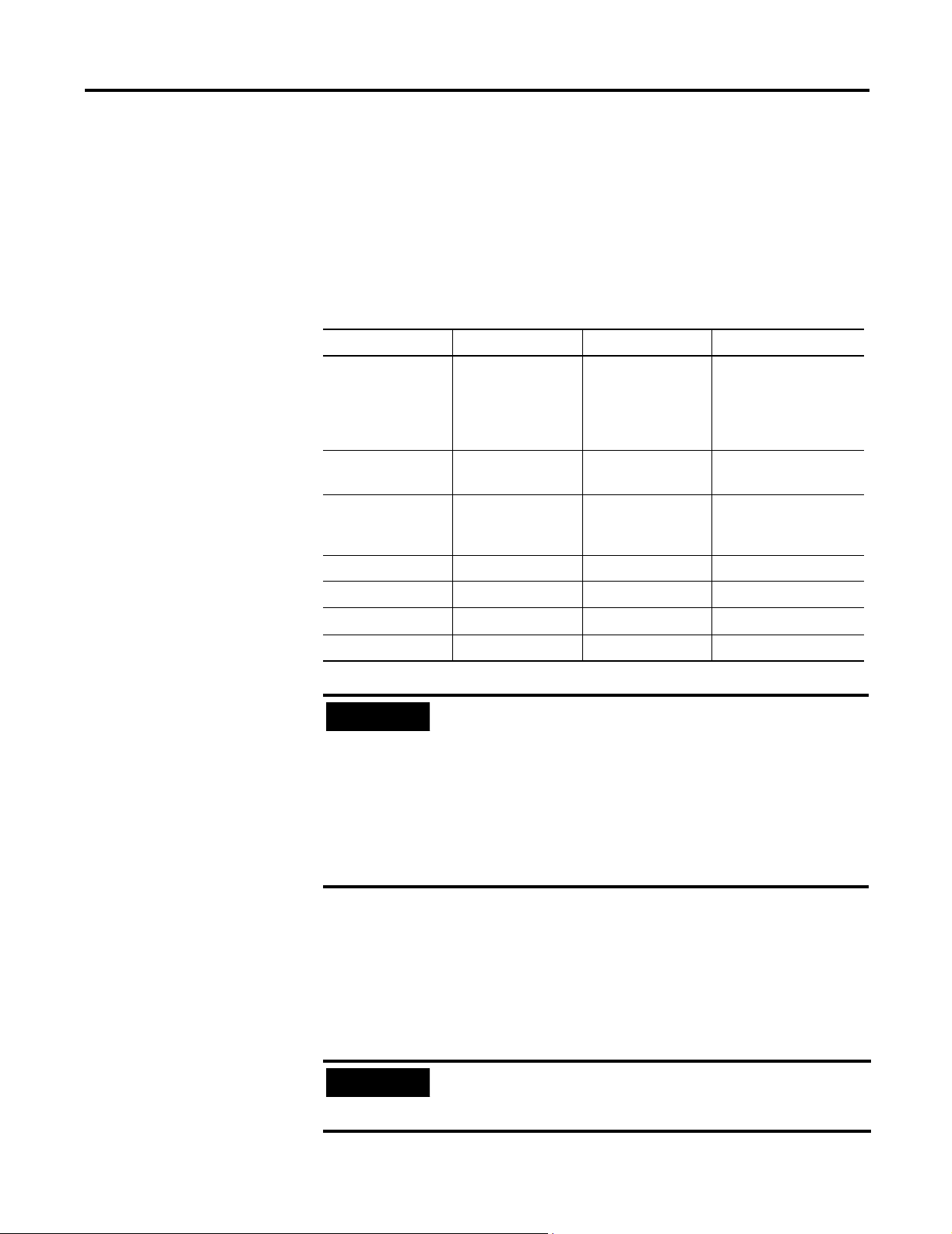

RTD Compatibility

An RTD consists of a temperature-sensing element connected by two,

three, or four wires that provide input to the module. The following table

lists the RTD types that you can use with the module, including their

temperature range, effective resolution, and accuracy.

Table 1.1 RTD Specifications

RTD Type Temperature

Range

100ohm Pt/α=0.00385 -200 to +850°C -2000 to +8500 0.1°C ±2.1°C

200ohm Pt/α=0.00385 -200 to +850°C -2000 to +8500 0.1°C ±2.1°C

500ohm Pt/α=0.00385 -200 to +650°C -2000 to +6500 0.1°C ±1.7°C

100ohm Pt/α=0.003916 -200 to +640°C -2000 to +6400 0.1°C ±1.68°C

200ohm Pt/α=0.003916 -200 to +640°C -2000 to +6400 0.1°C ±1.68°C

500ohm Pt/α=0.003916 -200 to +640°C -2000 to +6400 0.1°C ±1.68°C

100ohm Nickel -60 to 250°C -600 to 2500°C 0.1 °C ±0.62°C

120ohm Nickel -80 to 260°C -800 to 2600 0.1°C ±0.68°C

Scaling

(Counts)

Resolution* Accuracy**

(0 to 55°C)

Publication 1790-UM002A-EN-P

200ohm Nickel -60C to 250°C -600 to 2500 0.1°C ±1.62°C

500ohm Nickel -60 to 250°C -600 to 2500 0.1°C ±0.62°C

*Filter set for 10 Hz

**Module only

3

Page 9

Overview 1-3

Resister Device Compatibility

The following table lists the specifications for the resistance devices that

you can use with the module.

Table 1.2 Resistance Device Specifications

Hardware Features

Resistance Type Range Scaling

Resolution* Accuracy (0 to 55°C)**

(Counts)

Resistance 100mΩ 1 to 650Ω 10 to 6250 100mΩ +

Resistance 10mΩ 1 to 327Ω 100 to 32700 10Ω +

1.25Ω

0.65Ω

*Filter set for 10 Hz

**Module only

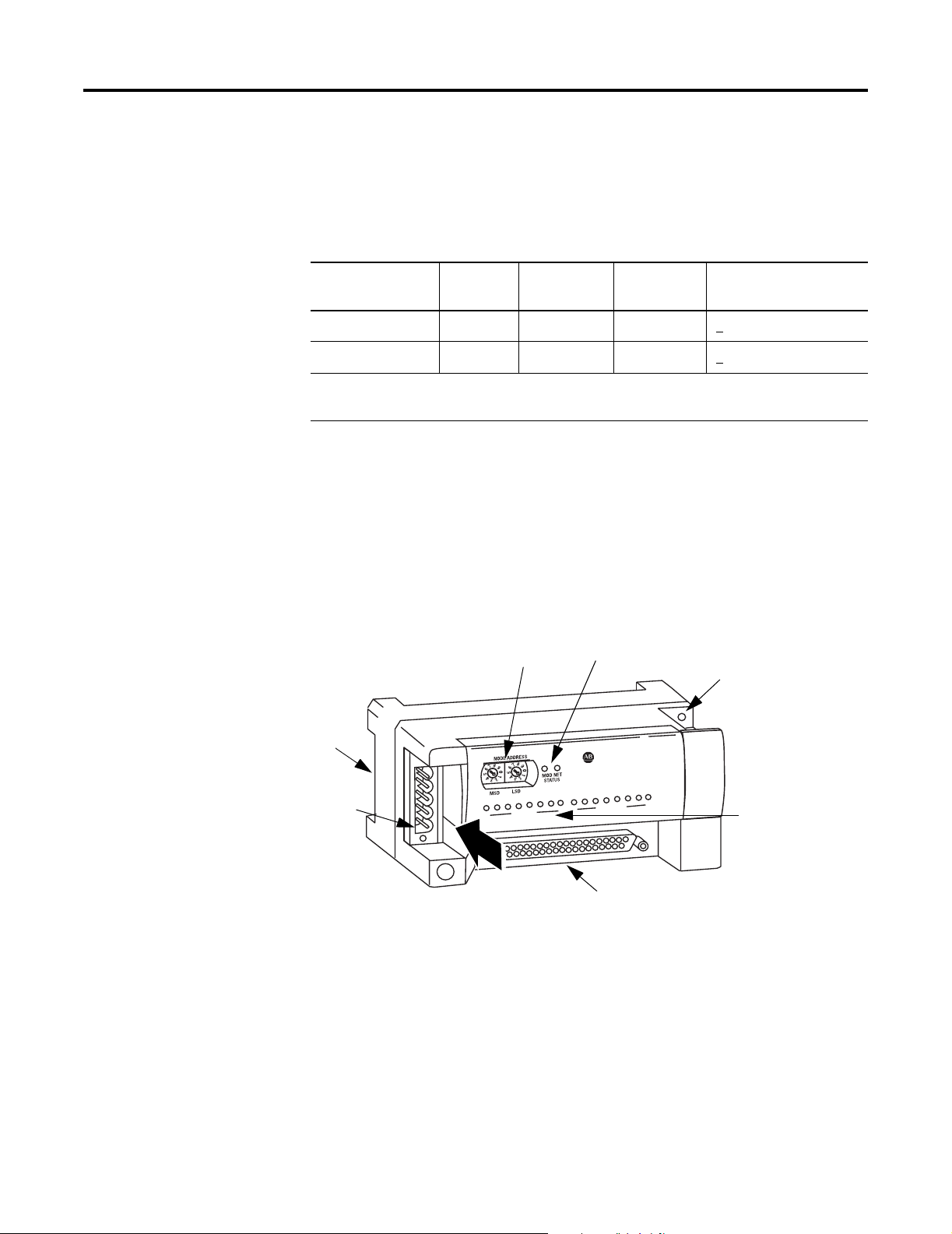

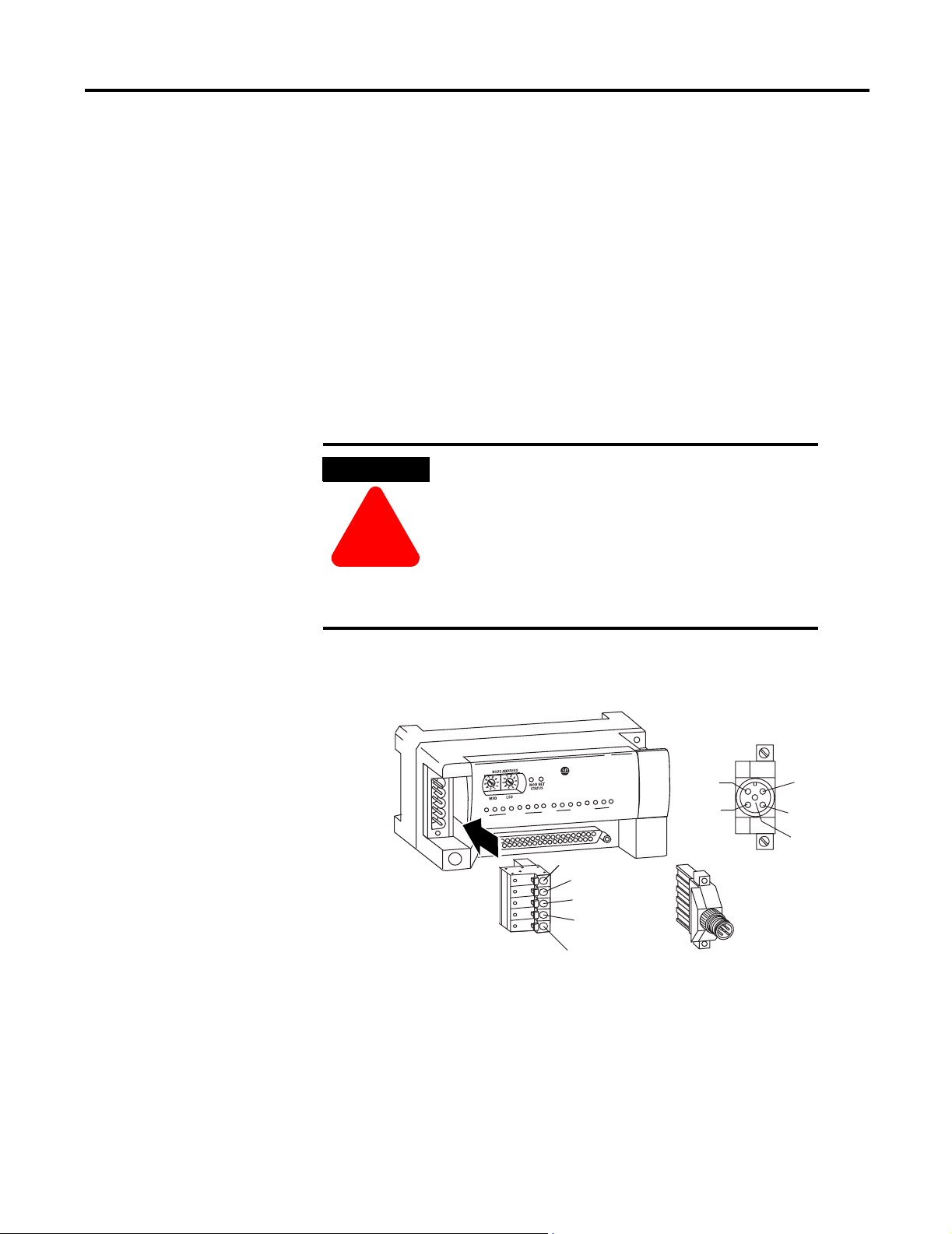

The RTD/resistance module contains either a fixed terminal block (or a

removable D-sub connector) providing connections for four 3-wire inputs

for any combination of RTD and resistance input devices. Channels are

wired as differential inputs. The illustration below shows the hardware

features of the module.

1790D-4R0/T4R0 DeviceNet Module

Node Address

Switches

Module and Network

Status Indicators

Panel Mount

Hole

DIN Rail Slot

DeviceNet Network

Connection

CompactBlock LDX

1790D-8BV8V

8 INPUTS/8OUTPUTS-DC POWER

0

0

7

7

RTD/resistance Connections

RTD/resistance

Channel Indicators

43223

(D-sub Connector shown)

Publication 1790-UM002A-EN-P

Page 10

1-4 Overview

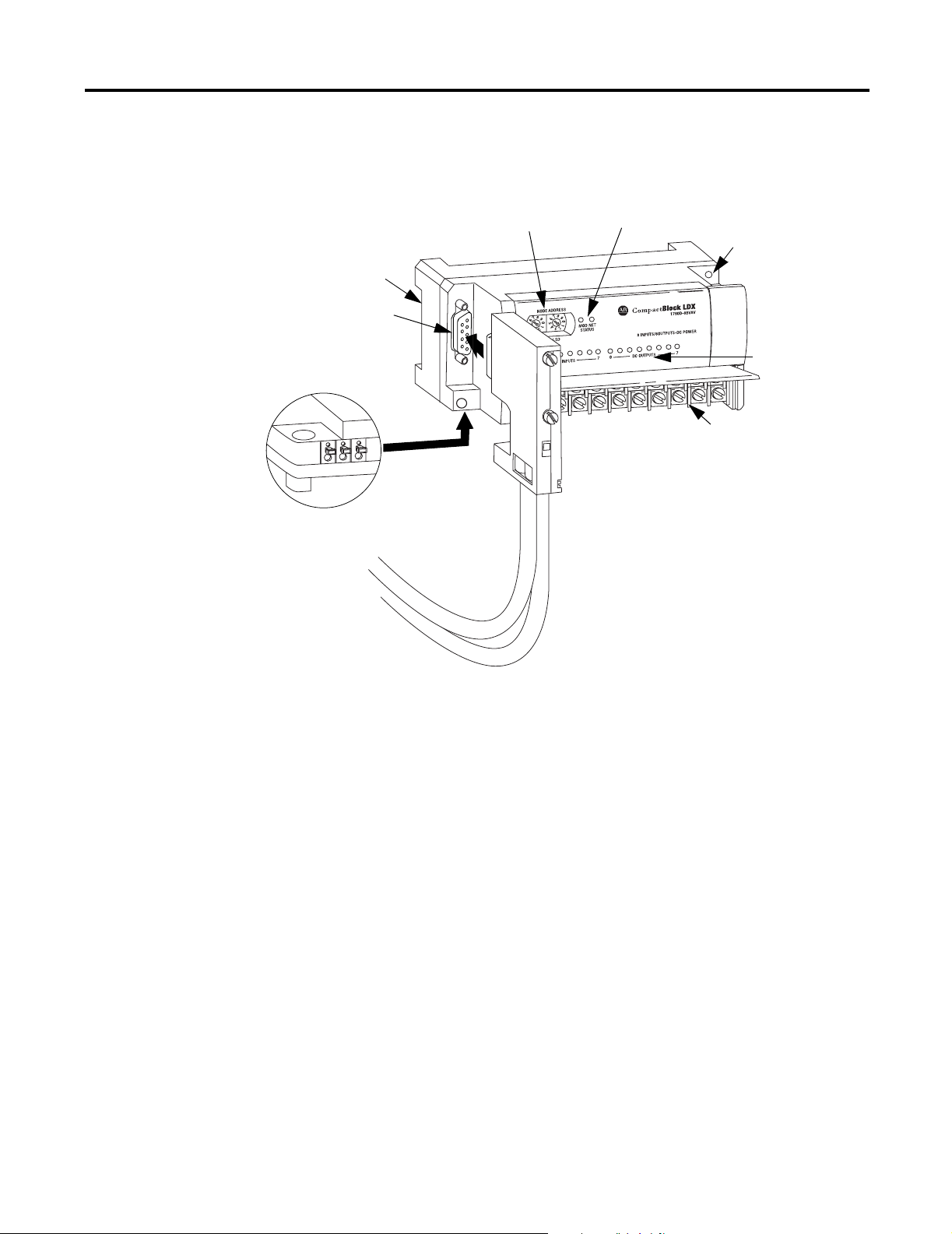

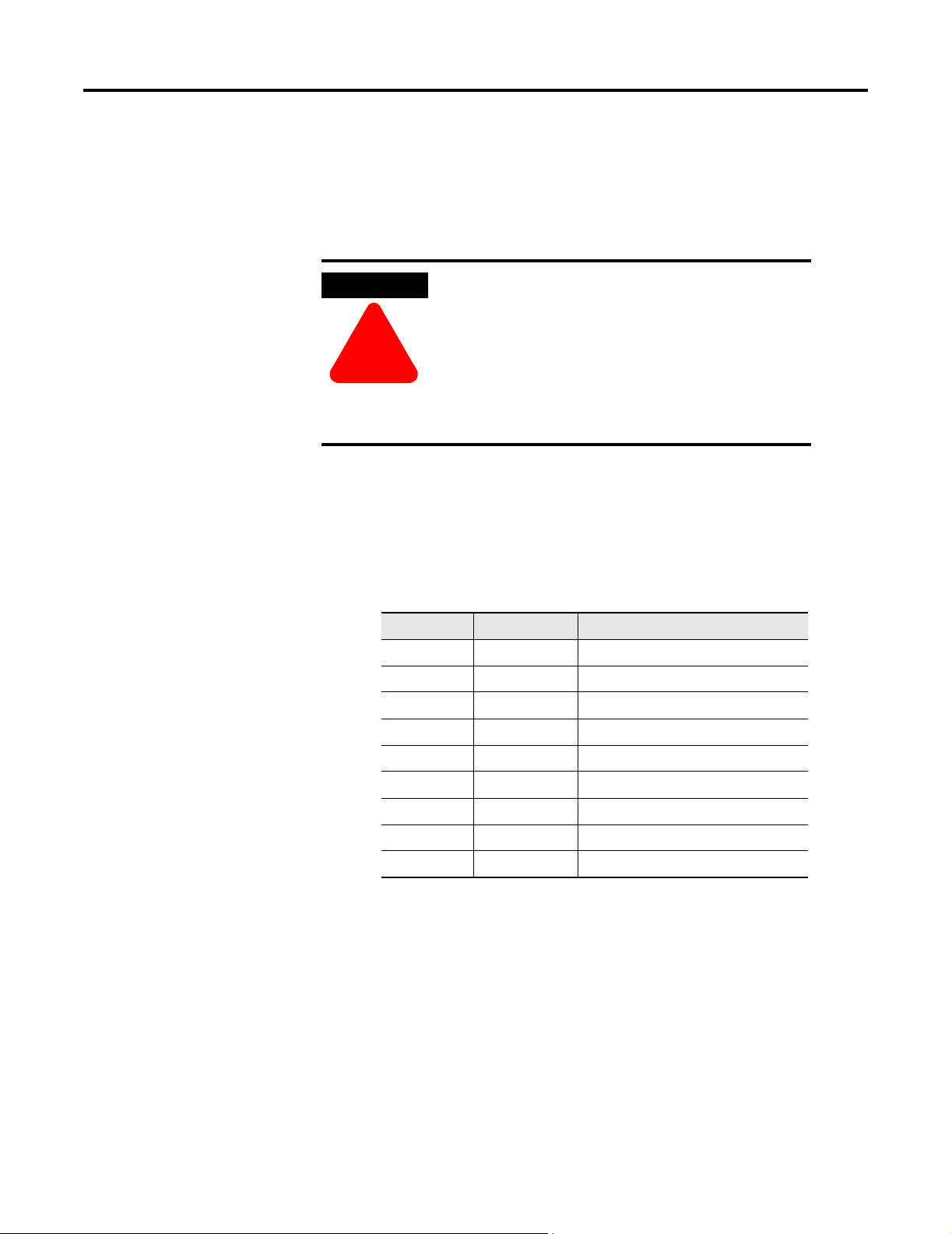

1790P-T4R0 PROFIBUS DP Module

DIN Rail Slot

PROFIBUS Network

Connector

Module Power Connector

(underneath module)

Node Address

Switches

Module and Network

Status Indicators

PROFIBUS

Connector

Panel Mount

Hole

RTD/resistance

Channel Indicators

RTD/resistance Connections

(Terminal block)

31341-M

System Overview

General Diagnostic Features

Module, network, and channel LEDs help you identify the source of

problems that may occur during power-up or during normal channel

operation. The LEDs indicate both status and power. See Chapter 4,

Diagnostics and Troubleshooting, for details on power-up and channel

diagnostics.

The modules communicate to the controller or network scanner via the

DeviceNet™ or PROFIBUS network. The modules also receive 24V dc

power through DeviceNet. An external 24V dc auxiliary source is required

to power the RTD/resistance channels.

System Operation

At power-up, the module performs a check of its internal circuits,

memory, and basic functions. If no faults are found during power-up

diagnostics, the module status LED is turned on (green).

Publication 1790-UM002A-EN-P

Page 11

Overview 1-5

Once a channel is properly configured and enabled, the module

continuously converts the RTD or resistance input to a value within the

range selected for that channel.

Each time the module reads an input channel, it tests the data for a fault

(over- or under-range or open-circuit condition). If it detects a fault, the

module sets a unique bit in the channel status word. See Input Data File

on page 3-2. The module sends two’s compliment binary converted RTD/

resistance data out over the network. See Appendix B for a description of

two’s compliment binary numbers.

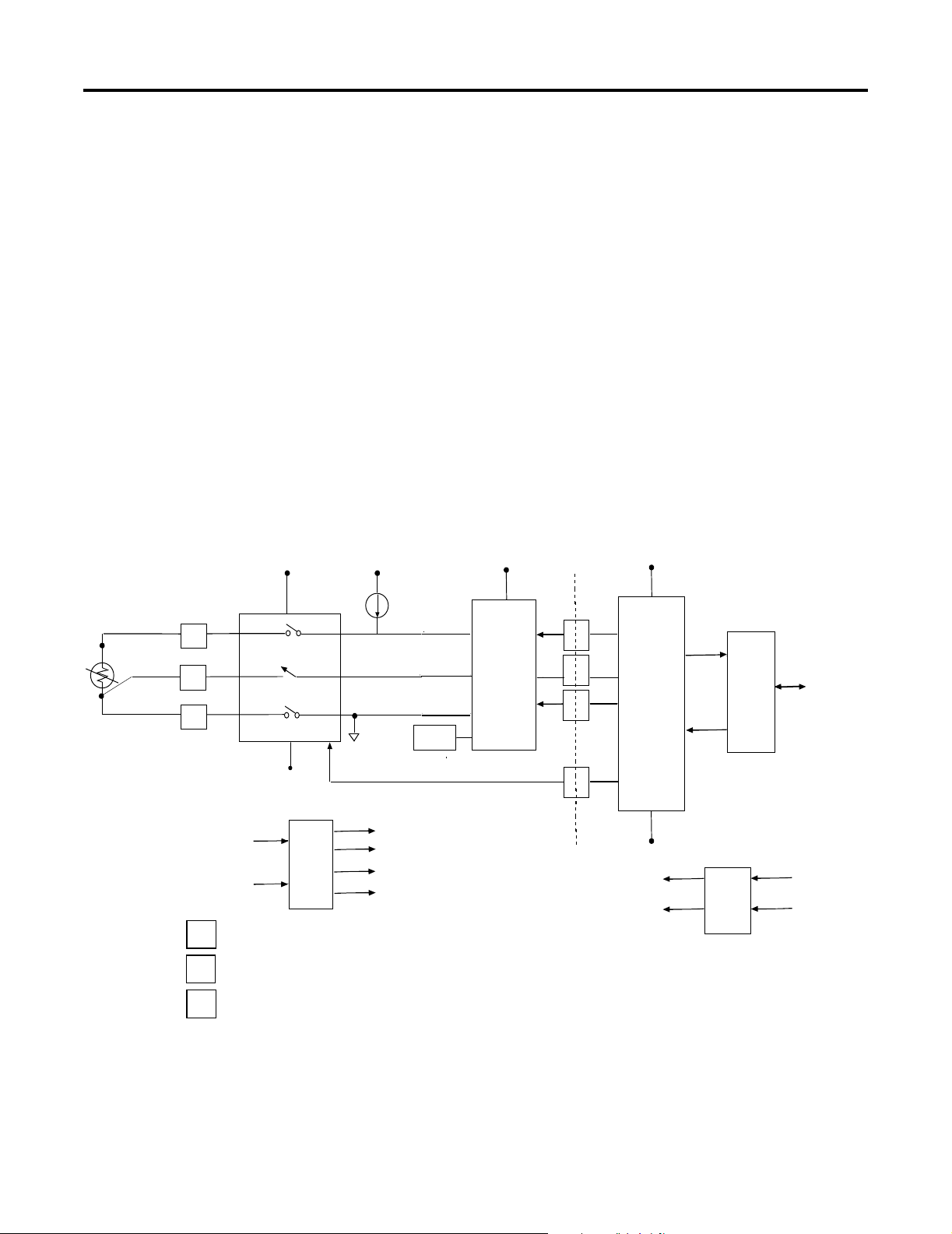

Module Operation - DeviceNet Example

As shown in the block diagram below, each input channel of the module

consists of an RTD/resistance connection that accepts excitation current; a

sense connection that detects lead wire resistance; and a return

connection. The signals are multiplexed to an A/D converter that reads

the RTD or resistance value and the lead wire resistance.

Input

EXC0

SENSE0

RTN0

VA2

CH0

A

B

COM

Auxiliary

24Vdc

Power

1

2

3

Multiplexer

VDC

GND

Channels 1 through 3 same as

channel 0 above.

VA3

Analog

Power

Supply

VA1 VA1

EXC

Current

AIN+1

A/D

AIN+2

A-GND

VA1

VA2

VA3

A-GND

AIN-

VREFVref

Channel Select

Optical

Isolation

43224

Vcc

Micro Controller

GND

Vcc

GND

Transmit

Receive

Power

Supply

Network

DeviceNet

24Vdc

Power

From the readings taken by the converter, the module sends RTD or

resistance data through the microcontroller to the DeviceNet network.

The PROFIBUS block diagram is similar.

Publication 1790-UM002A-EN-P

Page 12

1-6 Overview

Chapter Summary

In this chapter, you learned about the 1790D/4R0/T4R0 and 1790P-TR40

RTD/resistance modules. See Chapter 2 to learn how to install and wire

the modules.

Publication 1790-UM002A-EN-P

Page 13

Installation and Wiring

Chapter

2

Before You Begin

Power Requirements

This chapter tells you how to:

• determine the power requirements for the modules

• avoid electrostatic damage

• install the module

• wire the module’s terminal block

1790D-4R0/T4R0

The module receives system power from the DeviceNet network. An

auxiliary field supply provides power for the RTD/resistance channels.

Table 2.1 1790D-4R0/T4R0 Power Specifications

Power Specification

DeviceNet Supply voltage - 24V dc nominal

Voltage range - 11-28.8V dc

Power dissipation - 1.2W maximum @ 28.8V dc

Field Supply voltage - 24V dc nominal

Voltage range - 21.6-26.4V dc (+

Power dissipation - 1.5W maximum @ 26.4V dc

10%)

1790P-T4R0

The module requires external supplies for both system power and for the

RTD/resistance channels.

Table 2.2 1790P-T4R0 Power Specifications

Power Specification

PROFIBUS Supply voltage - 24V dc nominal

Voltage range - 19.2-28.8V dc

Power dissipation - 2W maximum @ 28.8V dc

Field Supply voltage - 24V dc nominal

Voltage range - 21.6-26.4V dc (+

Power dissipation - 1.5W maximum @ 26.4V dc

1 Publication 1790-UM002A-EN-P

10%)

Page 14

2-2 Installation and Wiring

General Considerations

The modules are suitable for use in a commercial or light industrial

environment when installed in accordance with these instructions.

Specifically, this equipment is intended for use in clean, dry environments

(1)

(Pollution degree 2

(2)

Category II

(IEC 60664-1).

) and to circuits not exceeding Over Voltage

(3)

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D

or non-hazardous locations only. The following WARNING statement

applies to use in hazardous locations.

WARNING

ÿ

EXPLOSION HAZARD

• Substitution of components may impair suitability for

Class I, Division 2.

• Do not replace components or disconnect equipment

unless power has been switched off or the area is

known to be non-hazardous.

• Do not connect or disconnect components unless

power has been switched off or the area is known to be

non-hazardous.

• This product must be installed in an enclosure.

• All wiring must comply with N.E.C. article 501-4(b).

Publication 1790-UM002A-EN-P

(1)

Pollution Degree 2 is an environment where, normally, only non-conductive pollution occurs except that occasionally

a temporary conductivity caused by condensation shall be expected.

(2)

Over Voltage Category II is the load level section of the electrical distribution system. At this level transient voltages

are controlled and do not exceed the impulse voltage capability of the product’s insulation.

(3)

Pollution Degree 2 and Over Voltage Category II are International Electrotechnical Commission (IEC) designations.

Page 15

Installation and Wiring 2-3

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC publication

60664-1), at altitudes up to 2000 meters without

derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions, there

may be potential difficulties ensuring electromagnetic

compatibility in other environments due to conducted

as well as radiated disturbance.

ATTENTION

ÿ

This equipment is supplied as "open type" equipment. It

must be mounted within an enclosure that is suitably

designed for those specific environmental conditions

that will be present and appropriately designed to

prevent personal injury resulting from accessibility to

live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections

of this publication may contain additional information

regarding specific enclosure type ratings that are

required to comply with certain product safety

certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of the

degrees of protection provided by different types of

enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication

1770-4.1 ("Industrial Automation Wiring and Grounding

Guidelines"), for additional installation requirements

pertaining to this equipment.

Publication 1790-UM002A-EN-P

Page 16

2-4 Installation and Wiring

ATTENTION

ÿ

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal

operation. Follow these guidelines when you handle

this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate

static-safe packaging.

WARNING

ÿ

If you insert or remove the module while power is on,

an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Selecting a Location

Reducing Noise

Most applications require installation in an industrial enclosure to reduce

the effects of electrical interference. RTD inputs are highly susceptible to

electrical noise. Electrical noise coupled to the RTD inputs will reduce the

performance (accuracy) of the module.

Group your modules in the enclosure to minimize adverse effects from

radiated electrical noise and heat. Consider the following conditions when

selecting a location for the module. Position the module:

• away from sources of electrical noise such as hard-contact switches,

relays, and AC motor drives

Publication 1790-UM002A-EN-P

• away from modules which generate significant radiated heat.

In addition, route shielded, twisted-pair wiring away from any high

voltage I/O wiring.

Page 17

Installation and Wiring 2-5

Protecting the Circuit Board from Contamination

The printed circuit boards of analog modules must be protected from dirt,

oil, moisture, and other airborne contaminants. To protect these boards,

the system must be installed in an enclosure suitable for the environment.

The interior of the enclosure should be kept clean and the enclosure door

should be kept closed whenever possible.

Installing CompactBlock LDX I/O

Follow these steps to install the block:

1. Set the node address on the base block.

2. Mount the base block.

3. Wire the terminal blocks.

4. Connect the network cable.

These steps are explained in detail in the following procedures for

both the 1790D-4R0/T4R0 DeviceNet and 1790P-T4R0 PROFIBUS DP

modules.

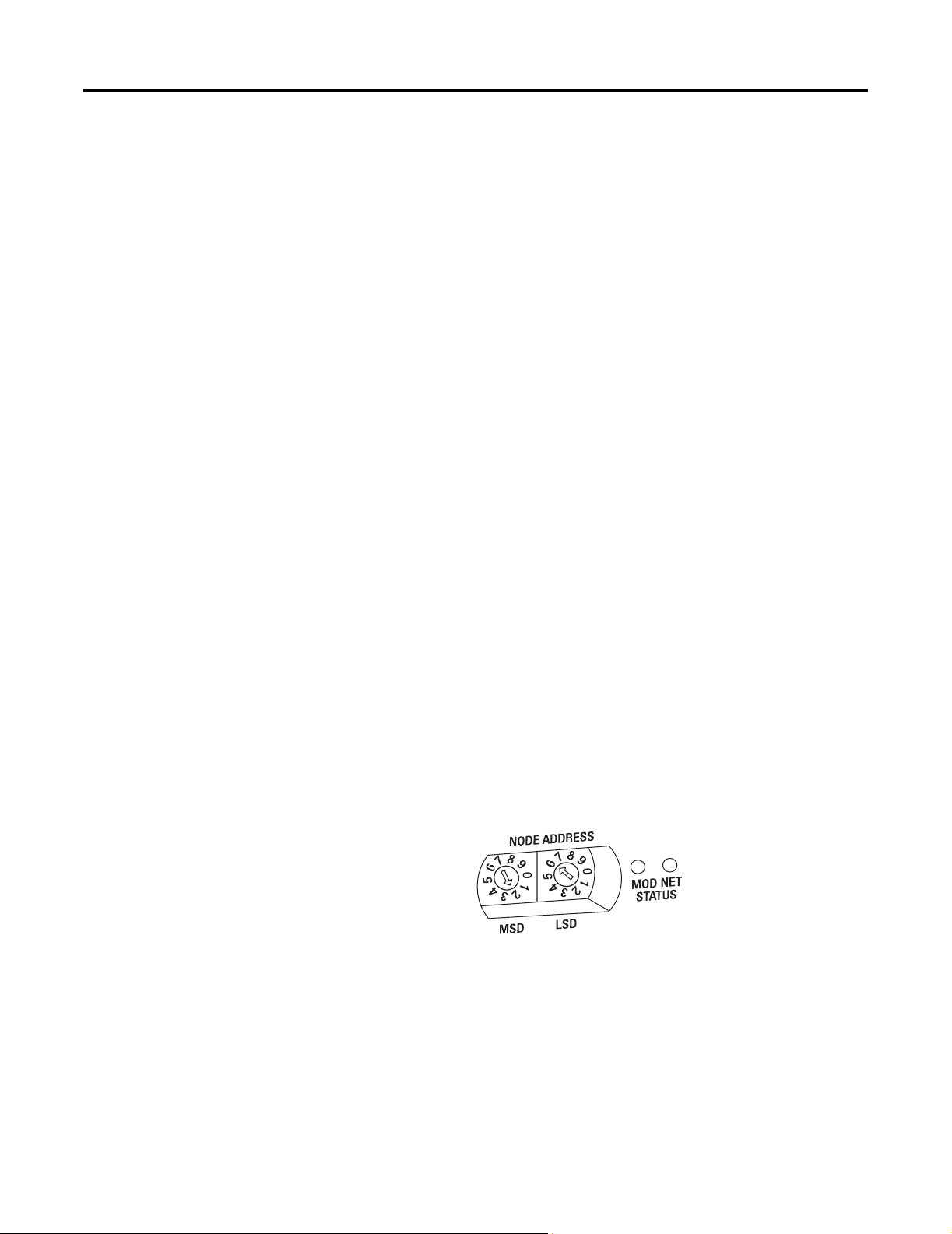

Set the Node Address on the DeviceNet 1790D-4R0/T4R0 Base Block

Each base block comes with its internal program set for node address 63.

To reset the node address, adjust the switches on the front of the block.

The two switches are most significant digit (MSD) and least significant

digit (LSD). The switches can be set between 00 and 63.

The rotary switches are read at block power up only. Switch settings

between 64 and 99 cause the block to use the last valid node address

stored internally.

Example: Node

Address is set at 26

The node address may also be set through RSNetWorx for DeviceNet or a

similar configuration tool. When software configuration is used for the

node address, the switches must be set between 64 and 99.

43230

Publication 1790-UM002A-EN-P

Page 18

2-6 Installation and Wiring

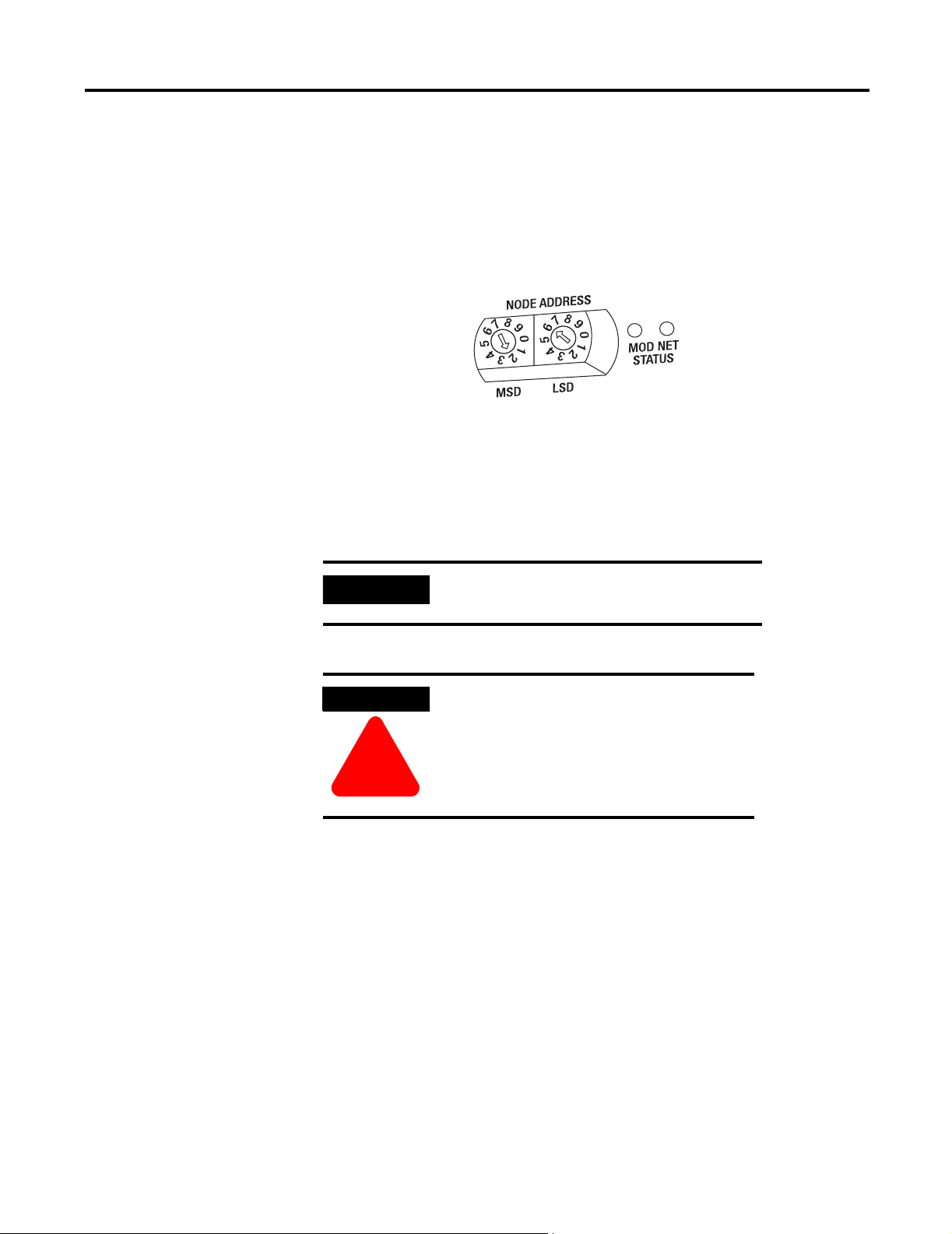

Set the Station Address on the 1790P-T4R0 PROFIBUS DP Base Block

To set the station address, adjust the switches on the front of the base

block. The two switches are most significant digit (MSD) and least

significant digit (LSD). The switches can be set between 00 and 99.

Mounting

The rotary switches are read at base block power up only

Example: Node

Address is set at 26

43230

.

Mount the Base Block

You can mount the base block to a panel or DIN rail. We recommend that

you ground the panel or DIN rail before mounting the block.

IMPORTANT

WARNING

ÿ

The RTD and thermocouple base modules

do not support any expansion blocks.

When used in a Class I, Division 2,

hazardous location, this equipment must

be mounted in a suitable enclosure with

proper wiring method that complies with

the governing electrical codes.

Publication 1790-UM002A-EN-P

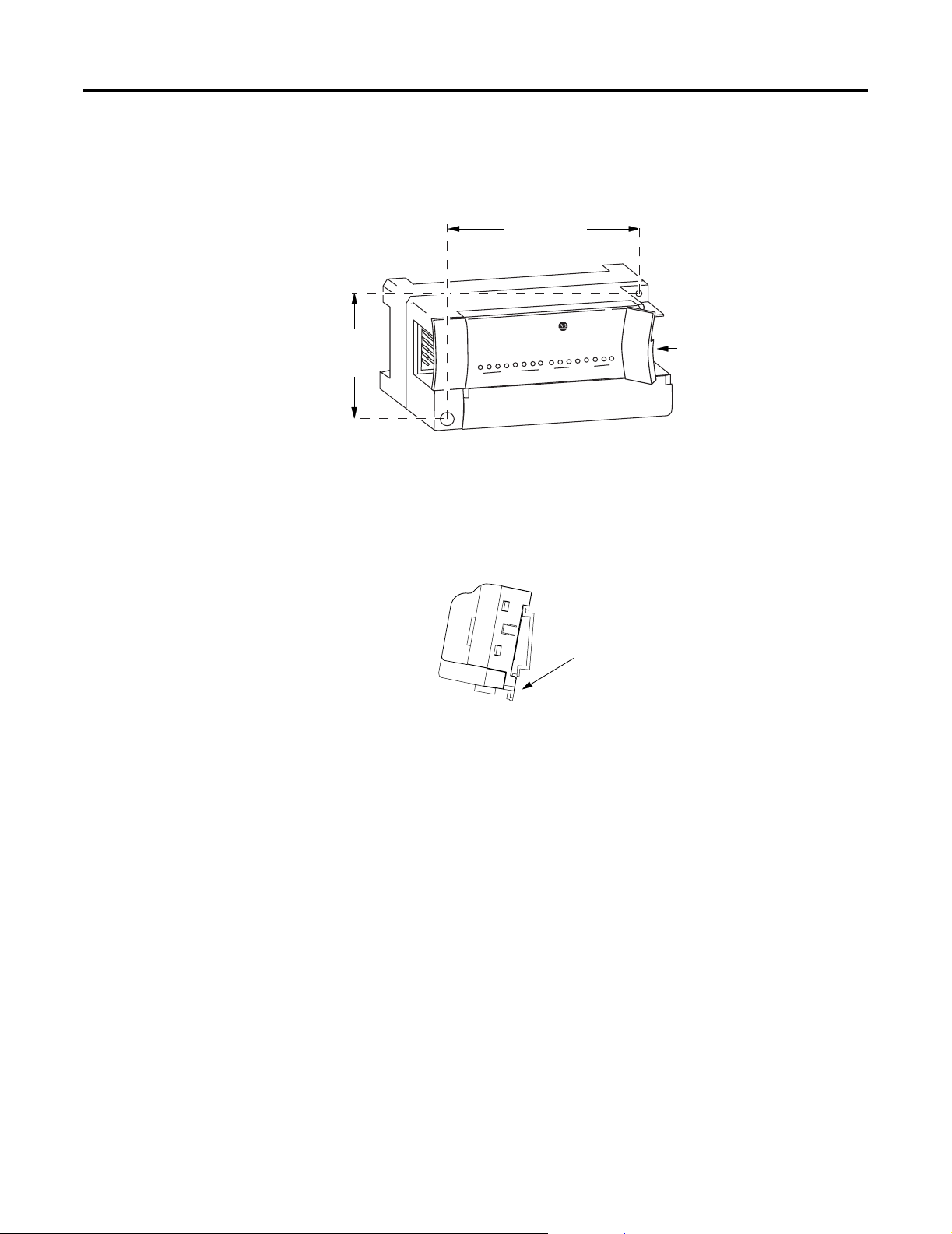

Panel Mounting

1. Place the block against the panel where you want to mount it.

2. Gently pull and position the expansion cover to the left.

3. Place a center punch, nail or similar device through the mounting

holes in the block and make two marks on the panel (lower left and

upper right corners of the module).

4. Remove the block and drill two holes in the panel to accommodate

each of the mounting screws.

Page 19

Installation and Wiring 2-7

5. Replace the block on the panel and place a screw through each of the

two mounting holes. Tighten the screws until the block is firmly in

.

place

95 mm

3.74 in

CompactBlock LDX

41 mm

1.6 in

EXPANSION UNIT

0

0

7

1790-16BVOX

16 INPUTS-DCPOWER

7

Expansion

Cover

43242

DIN Rail Mounting

1. Hook the top slot of the block over the DIN Rail.

2. Pull down on the locking lever while pressing the block against the

.

rail

ÿ

Locking Lever

43243

3. Push up on the locking lever to secure the block to the rail when the

block is flush against the rail.

Publication 1790-UM002A-EN-P

Page 20

2-8 Installation and Wiring

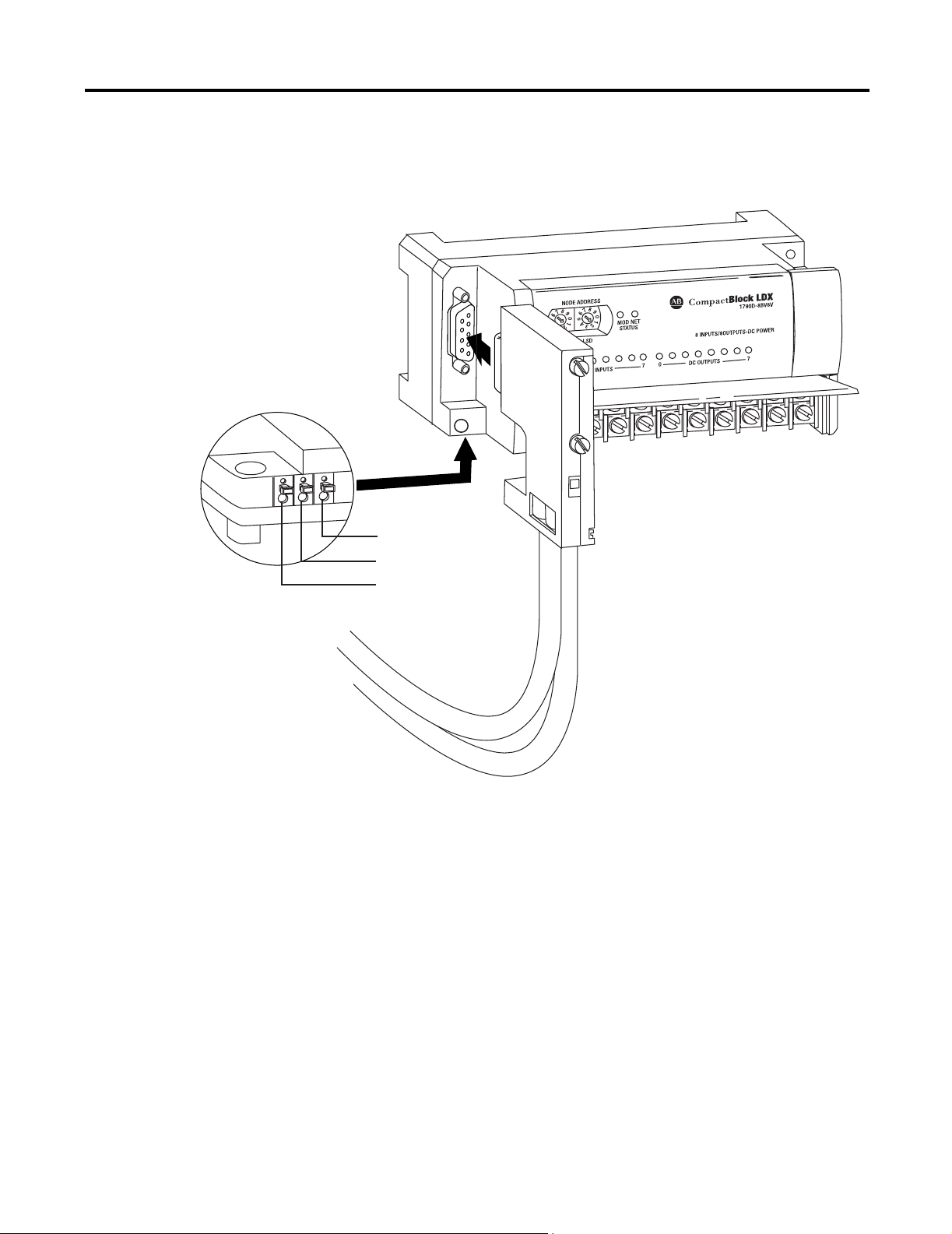

Connect the DeviceNet Cable to the 1790D-4R0/T4R0 Base Block

Follow these procedures when connecting the DeviceNet cable to the

base block.

The required DeviceNet connector is not supplied with the block - you

must purchase it separately. There are three types of connectors that you

can order directly from Rockwell Automation or your local distributor:

• 1799-DNETCON - 5-position open style connector

• 1799-DNETSCON - 5-position open style connector with locking

screws

• 1799-DNC5MMS - 5-position open style to 5-pin micro male connector

with locking screws

WARNING

If you connect or disconnect the DeviceNet cable

with power applied to this module or any device

on the network, an electrical arc can occur. This

could cause an explosion in hazardous location

ÿ

installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Connect the DeviceNet wiring (drop line) to one of the DeviceNet

connectors as shown below. A color-coded wiring diagram is also printed

next to the connector on the left side of the module

CompactBlock LDX

Wiring Diagram for

1799-DNETCON

1790D-8BV8V

8 INPUTS/8OUTPUTS-DC POWER

0

0

7

7

V+ Red

Can_H White

Drain/Shield

Can_L Blue

V- Black

V+ Red

V- Black

Wiring Diagram for

1799-DNC5MMS

Drain/Shield

Can_H White

Can_L Blue

43245

Publication 1790-UM002A-EN-P

Page 21

Installation and Wiring 2-9

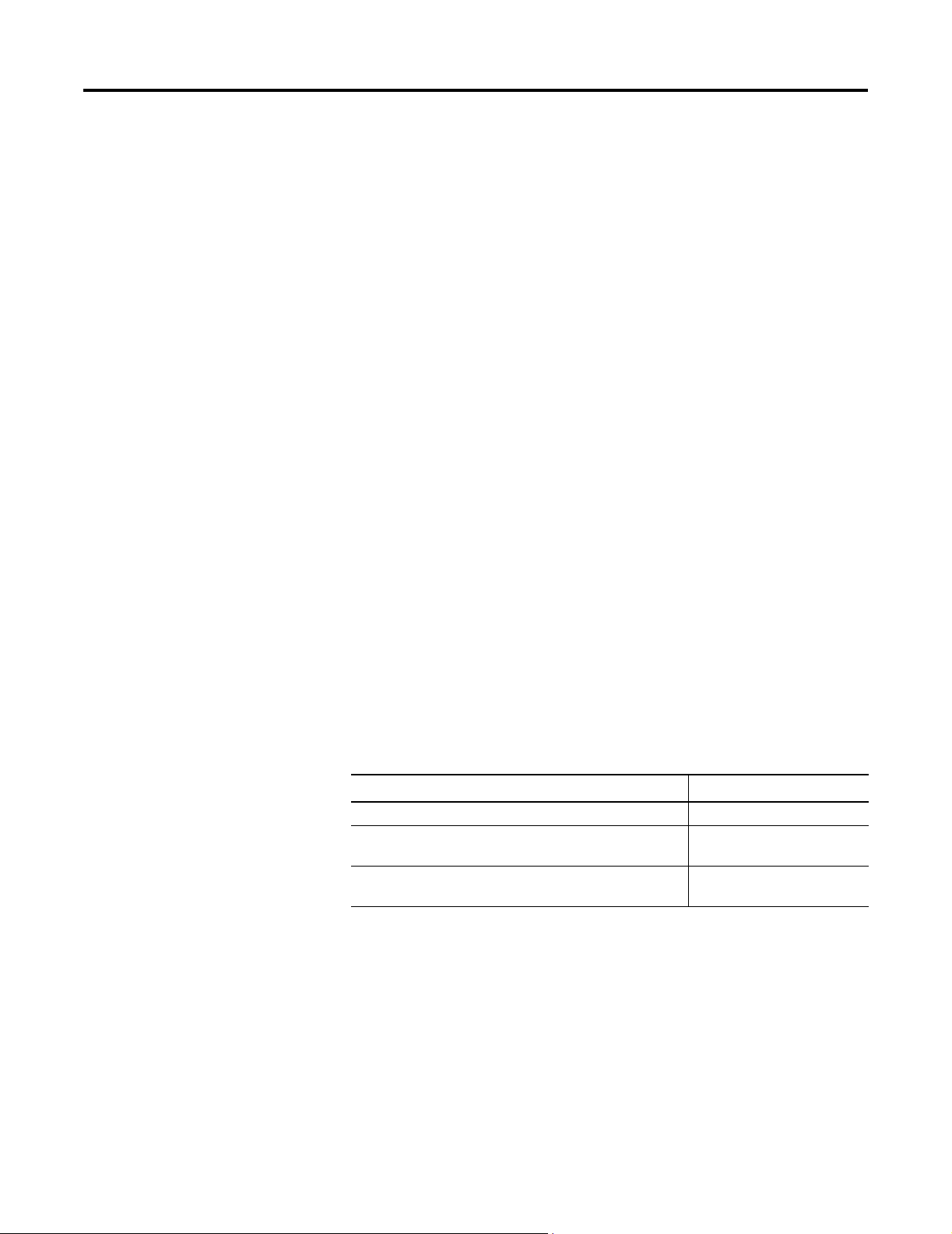

Connect the PROFIBUS DP Terminal Connector to the 1790P-T4R0 Base Block

Follow these procedures to connect the PROFIBUS DP terminal connector

to the base block.

WARNING

ÿ

The required PROFIBUS female 9-pin D-sub connector is not supplied

with the base block - you must purchase it separately.

Before you connect female 9-pin D-sub connector to the base block,

make sure it is wired correctly as shown in the following table.

Pin Number: Name: Description:

1 shield Shield, Protective Ground

2 M24V Minus 24V Output Voltage

3 RxD/TxD-P Receive/Transmit-Data-P

4 CNTR-P Control-p

5 DGND Data Ground

If you connect or disconnect the PROFIBUS

cable with power applied to this module or any

device on the network, an electrical arc can

occur. This could cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is

nonhazardous before proceeding.

Table 2.3 Wiring Descriptions for 9-Pin D-Sub Connector

6 VP Voltage-Plus

7 P24V Plus 24V Output Voltage

8 RxD/TxD-N Receive/Transmit-Data-N

9 CNTR-N Control-N

Publication 1790-UM002A-EN-P

Page 22

2-10 Installation and Wiring

Module Power Connector

(underneath module)

Once you have properly wired the connector, attach it to the base block

as shown below. Use the locking screws on the connector to fasten it to

the base block.

PROFIBUS Connector

Green - GRD

Black - COM

Red - +24V dc

43249

Connect Power to the 1790P-T4R0 Block

To apply power to the block, refer to the above illustration.

Publication 1790-UM002A-EN-P

Page 23

Installation and Wiring 2-11

Field Wiring Connections

System Wiring Guidelines

Consider the following when wiring your system:

General

• This product is intended to be mounted to a well-grounded mounting

surface such as a metal panel. Additional grounding connections from

the module’s mounting tabs or DIN rail (if used) are not required

unless the mounting surface cannot be grounded.

• Route field wiring away from any other wiring and as far as possible

from sources of electrical noise, such as motors, transformers,

conductors, and ac devices. As a general rule, allow at least 15.2 cm (6

in.) of separation for every 120V of power.

• Routing field wiring in a grounded conduit can reduce electrical noise.

• If field wiring must cross ac or power cables, ensure that they cross at

right angles.

• To ensure optimum accuracy, limit overall cable impedance by

keeping your cable as short as possible. Locate the I/O system as

close to your sensors or actuators as your application will permit.

• Tighten terminal screws with care. Excessive tightening can strip a

screw.

Shield Grounding

• Use Belden shielded, twisted-pair wire to ensure proper operation

and high immunity to electrical noise. Refer to the following table and

the RTD Wiring Considerations below.

Table 2.4 Belden Shielded Wiring

Configuration

2-wire Belden™ 9501 or equivalent

3-wire

less than 30.48 m (100ft.)

3-wire

greater than 30.48 m (100 ft.) or high humidity conditions

(1) For additional information, see Table 2.5.

Recommended Cable

Belden 9533 or equivalent

Belden 83503 or equivalent

• Under normal conditions, the drain wire and shield junction should be

connected to earth ground, via a panel or DIN rail mounting screw at

the module end.

• Keep shield connection to ground as short as possible.

• If noise persists for a device, try grounding the opposite end of the

cable. (You can only ground one end at a time.)

• Refer to Industrial Automation Wiring and Grounding Guidelines,

Allen-Bradley publication 1770-4.1, for additional information.

(1)

Publication 1790-UM002A-EN-P

Page 24

2-12 Installation and Wiring

RTD Wiring Considerations

Because the operating principle of the RTD module is based on the

measurement of resistance, take special care when selecting your input

cable. For 2-wire or 3-wire configurations, select a cable that has a

consistent impedance throughout its entire length. Cable specifications are

noted below.

Table 2.5 Cable Specifications

Description Belden #9501 Belden #9533 Belden #83503

When used? For 2-wire RTDs and

potentiometers

Conductors 2, #24 AWG tinned

copper (7 x 32)

Shield Beldfoil aluminum

polyester shield with

copper drain wire

Insulation PVC S-R PVC Teflon

Jacket Chrome PVC Chrome PVC Red Teflon

Agency Approvals NEC Type CM NEC Type CM NEC Art-800, Type CMP

Temperature Rating 80°C 80°C 200°C

IMPORTANT

The RTD module requires three wires to compensate for

lead resistance error. We recommend that you do not

For 3-wire RTDs and

potentiometers.

Short runs less than

100 feet and normal

humidity levels.

3, #24 AWG tinned

copper (7 x 32)

Beldfoil aluminum

polyester shield with

copper drain wire

For 3-wire RTDs and

potentiometers. Long

runs greater than 100

feet or high humidity

levels.

3, #24 AWG tinned

copper (7 x 32)

Beldfoil aluminum

polyester shield with

tinned drain wire

use 2-wire RTDs if long cable runs are required, as it

reduces the accuracy of the system. However, if a

two-wire configuration is required, reduce the effect of

the lead wire resistance by using a lower gauge wire for

the cable (for example, use AWG #16 instead of AWG

#24). The module’s terminal block accepts two AWG #14

gauge wires.

Publication 1790-UM002A-EN-P

When using a 3-wire configuration, the module compensates for

resistance error due to lead wire length. For example, in a 3-wire

configuration, the module reads the resistance due to the length of one of

the wires and assumes that the resistance of the other wire is equal. If the

resistances of the individual lead wires are much different, an error may

exist. The closer the resistance values are to each other, the greater the

amount of error that is eliminated.

IMPORTANT

To ensure temperature or resistance value accuracy, the

resistance difference of the cable lead wires must be

equal to or less than 0.01

Ω .

Page 25

Installation and Wiring 2-13

To insure that the lead values match as closely as possible:

• Keep lead resistance as small as possible

.

• Use quality cable that has a small tolerance impedance rating.

• Use a heavy-gauge lead wire which has less resistance per foot.

Wire Size and Terminal Screw Torque

Each terminal accepts up to two wires with the following restrictions:

Table 2.6 Wire Size and Terminal Screw Torque

Wire Type Wire Size Terminal Screw

Torque

Solid Cu-90°C (194°F) #14 to #22 AWG 0.68 Nm (6 in-lbs) 0.46 Nm (4.1 in-lbs)

Stranded Cu-90°C (194°F) #16 to #22 AWG 0.68 Nm (6 in-lbs) 0.46 Nm (4.1 in-lbs)

Retaining Screw

To rq ue

Wiring the Modules

ATTENTION

To prevent shock hazard, care should be taken when

wiring the module to analog signal sources. Before

wiring any module, disconnect power from the system

power supply and from any other source to the module.

ÿ

After the module is properly installed, follow the wiring procedure below

and the RTD and potentiometer wiring diagrams on pages 2-15 through

2-16. To ensure proper operation and high immunity to electrical noise,

always use Belden shielded, twisted-pair or equivalent wire.

Cut foil shield

and drain wire

signal wire

Cut foil shield

and drain wire

signal wires (3)

signal wire

43250

signal wire

signal wire

signal wire

signal wire

signal wire

drain wire

drain wire

cable

foil shield

cable

foil shield

Publication 1790-UM002A-EN-P

Page 26

2-14 Installation and Wiring

To wire your module follow these steps.

1. At each end of the cable, strip some casing to expose the individual

wires.

2. Trim the signal wires to 2-inch (5 cm) lengths. Strip about 3/16 inch (5

mm) of insulation away to expose the end of the wire.

ATTENTION

Be careful when stripping wires. Wire fragments that fall

into a module could cause damage at power up.

ÿ

3. At the module end of the cable, twist the drain wire and foil shield

together, bend them away from the cable, and apply shrink wrap.

Then earth ground via a panel or DIN rail mounting screw at the end

of the module. Keep the length of the drain wire as short at possible.

4. At the other end of the cable, cut the drain wire and foil shield back to

the cable and apply shrink wrap.

5. Connect the signal wires to the terminal block as described for each

type of input. See Wiring RTDs below or Wiring Resistance Devices

(Potentiometers) on page 2-15.

6. Connect the other end of the cable to the analog input device.

7. Repeat steps 1 through 6 for each channel on the module.

Wiring RTDs

Three types of RTDs can be connected to the module:

• 2-wire RTD, which is composed of an RTD EXC (excitation) lead wire

and a RTN (return) lead wire.

• 3-wire RTD, which is composed of a Sense and 2 RTD lead wires

(RTD EXC and RTN).

• 4-wire RTD, which is composed of a Sense and 2 RTD lead wires

(RTD EXC and RTN). The second sense wire from the 4-wire RTD is

left open.

Publication 1790-UM002A-EN-P

Page 27

2-Wire RTD Configuration

Installation and Wiring 2-15

Add Jumper

CHO_A

CHO_B

COM

3-Wire RTD Configuration

CHO_A

CHO_B

COM

Cable Shield (to Ground)

RTD EXC

Return

Cable Shield (to Ground)

RTD EXC

Sense

Return

RTD EXC

Return

43251

RTD EXC

Sense

Return

43252

4-Wire RTD Configuration

Leave this sensor wire open

RTD EXC

Sense

Return

43253

CHO_A

CHO_B

COM

Cable Shield (to Ground)

RTD EXC

Sense

Return

Wiring Resistance Devices (Potentiometers)

Potentiometer wiring requires the same type of cable as that for the RTDs.

Potentiometers can be connected to the module as a 2-wire or 3-wire

connection as shown in the following figure.

Publication 1790-UM002A-EN-P

Page 28

2-16 Installation and Wiring

2-Wire Potentiometer Interconnection

Add Jumper

Cable Shield (to Ground)

Potentiometer

CHO_A

CHO_B

COM

Add Jumper

CHO_A

CHO_B

COM

TIP

RTD EXC

Return

Cable Shield (to Ground)

RTD EXC

Return

Potentiometer

43254

The potentiometer wiper arm can be connected to

either the EXC or return terminal depending on

whether you want increasing or decreasing resistance.

3-Wire Potentiometer Interconnection

Cable Shield (to Ground)

RTD EXC

CHO_A

CHO_B

COM

CHO_A

CHO_B

COM

Return

Cable Shield (to Ground)

RTD EXC

Sense

Return

Potentiometer

Run Return and sense wires from the module to

potentiometer terminal and tie terminal to one point.

Potentiometer

43255

Run Return and sense wires from the module to

potentiometer terminal and tie terminal to one point.

Publication 1790-UM002A-EN-P

Page 29

Installation and Wiring 2-17

Wiring the Terminal Blocks

The following figures show how to wire the terminal blocks.

1790D-4R0-RTD Input Module D-Shell Wiring

+24V

19

+24V

37

GND

18

+24V

36

GND

17

35

GND

NC

16

NC

CH0_B

12

31

COM

CH1_A

30

COM

CH1_B

11

29

COM

NC

NC

CH0_A

15

13

14

34

33

32

NC

NC

10

COM

NC

CH2_B

25

CH3_A

6

24

COM

CH3-B

5

23

COM

NC

CH2_A

9

8

7

28

27

26

COM

COM

COM

Wire pins 17, 18, 19 to Field Power (+) 24V dc

Wire pins 35, 36, 37 to Field Power (-) GND

1790D-T4R0 and 179P-T4R0 RTD Input Module D-Shell Wiring

+24V

1

CH0_A

3

2

GND

CH0-B

CH1_A

5

4

CH1_B

COM

7

6

COM

CH2_A

CH3_A

9

8

10

CH2_B

COM

11

13

12

CH3_B

NC

14

COM

15

NC

17

16

NC

4

COM

18

NC

22

NC

NC

19

3

COM

21

20

NC

43257

NC

2

COM

NC

1

20

43256

Publication 1790-UM002A-EN-P

Page 30

2-18 Installation and Wiring

Chapter Summary

In this chapter, you learned how to install and wire your modules. See

Chapter 3 to learn about module data, status, and channel configuration

with DeviceNet.

Publication 1790-UM002A-EN-P

Page 31

Chapter

3

Module Data, Status, and Channel Configuration

for DeviceNet

After installation of the RTD/resistance input module, you must configure

it for operation, usually using the programming software compatible with

the controller (for example, RSLogix 500™ or RSLogix 5000™) or scanner

(RSNetWorx for DeviceNet). Once configuration is complete and reflected

in ladder logic, you will need to get the module up and running and then

verify its operation. This chapter includes information on the following:

• module memory map

• accessing input image file data

• configuring channels

• running the module

Module Memory Map

Input Image

File

Accessing Input Image File Data

The module uses five input words for data and status bits (input image).

Memory Map

Word 0

Word 1

Word 2

Word 3

Word 4

43258

Input Image

5 words

Channel 0 Data Word

Channel 1 Data Word

Channel 2 Data Word

Channel 3 Data Word

Status Bits

Input Image

The input image file represents data words and status words. Input words

0 through 3 hold the input data that represents the value of the analog

inputs for channels 0 through 3. These data words are valid only when

the channel is enabled and there are no errors. Input word 4 holds status

bits.

Five words of the processor input image table are reserved for the

module’s image data. You can access the information in the input image

file using the programming software configuration screen.

1 Publication 1790-UM002A-EN-P

Page 32

3-2 Module Data, Status, and Channel Configuration for DeviceNet

Input Data File

The input data table lets you access RTD input module read data for use

in the control program, via word and bit access. The data table structure is

shown in the tables below.

Table 3.1 Input Data Table

Word/

Bit

0 RTD Input Data Channel 0

1 RTD Input Data Channel 1

2 RTD Input Data Channel 2

3 RTD Input Data Channel 3

4 Not Used

Word Decimal Bit Description

Read Word 0 Bits 00-15 Channel 0 input data

Read Word 1 Bits 00-15 Channel 1 input data

Read Word 2 Bits 00-15 Channel 2 input data

Read Word 3 Bits 00-15 Channel 3 input data

Read Word 4

15141312111098 6543210

S11 S10 S9 S8 Not Used S3 S2 S1 S0

Table 3.2 Input Data Table

Underrange for individual channels - Bit 00 corresponds to input

Bits 00-03

Bits 04-07 Not used: Set to 0

Bits 08-11 Overrange for individual channels - Bit 08 corresponds to input

Bit 12-15 Not used: Set to 0.

channel 0, bit 01 corresponds to input channel 1 and so on.

When set (1), the input signal is below the input channel’s

minimum range.

channel 0, bit 09 corresponds to input channel 1 and so on.

When set (1), the input signal is above the input channel’s

maximum range, or open RTD is detected.

7

Publication 1790-UM002A-EN-P

Input Data Values

Data words 0 through 3 correspond to channels 0 through 3 and contain

the converted analog input data from the input device.

Under-Range Flag Bits (S0 to S3)

Over-range bits for channels 0 through 3 are contained in word 4, bits 0-3.

When set (1), the under-range flag bit indicates an RTD temperature that

is less than the minimum allowed temperature. The module automatically

resets (0) the bit when the data value is again within the normal operating

range.

Page 33

Module Data, Status, and Channel Configuration for DeviceNet 3-3

Over-Range Flag Bits (S8 to S11)

Under-range bits for channels 0 through 3 are contained in word 4, bits

8-11. When set (1), the over-range flag bit indicates an RTD temperature

that is greater than the maximum allowed temperature, a resistance input

that is greater than the maximum allowed resistance for the module or an

open channel is detected. The module automatically resets (0) the bit

when the data value is again within the normal operating range.

Data Format

RTD/resistance data is presented in engineering units x1. The engineering

units data format represents real temperature or resistance data provided

by the module. RTD data is reported in either degrees C or degrees F.

Table 3.3 RTD Data Format

Data Format

RTD Input Type Range

100Ω Platinum 385 -200 to +850°C -2000 to +8500 -3280 to +15620

200Ω Platinum 385 -200 to +850°C -2000 to +8500 -3280 to +15620

500Ω Platinum 385 -200 to +650°C -2000 to +6500 -3280 to +12020

100Ω Platinum 3916 -200 to +640°C -2000 to +6400 -3280 to +1184

200Ω Platinum 3916 -200 to +640°C -2000 to +6400 -3280 to +1184

500Ω Platinum 3916 -200 to +640°C -2000 to +6400 -3280 to +1184

100Ω Nickel -60 to +250°C -600 to +2500 -760 to +4820

120Ω Nickel -80 to +260°C -800 to +2600 -1120 to +5000

Engineering Units x1

0.1°C 0.1°F

200 Nickel -60C to 250°C -600 to +2500 -760 to +4820

500 Nickel -60 to 250°C -600 to +2500 -760 to +4820

Table 3.4 Resistance Data Format

Resistance Input Range

Resistance 100mΩ 1 to 625Ω 10 to 6250

Resistance 10mΩ 1 to 327Ω 100 to 32700

Data Format

Engineering Units x1

Publication 1790-UM002A-EN-P

Page 34

3-4 Module Data, Status, and Channel Configuration for DeviceNet

The module scales input data to the actual temperature values for the

selected RTD type per RTD standard. It expresses temperatures in 0.1

degree units, either degrees C or degrees F, depending on which

temperature scale is selected. For resistance inputs, the module expresses

resistance in 0.1

scale.

Negative temperatures are returned in 16-bit two’s complement binary

format. See Appendix B for a detailed explanation of two’s complement

binary numbers.

Ω units for the 100mΩ scale and in 0.01Ω units for the 10mΩ

Filter Frequency

The module supports filter selections corresponding to filter frequencies

of 10Hz, 25Hz, 50 Hz, 60 Hz, 100 Hz, 250 Hz, and 500 Hz. Your filter

frequency selection is determined by the desired range for the input type,

and the required effective resolution, which indicates the number of bits

in the input data that do not vary due to noise. Also consider the required

module update time when choosing a filter frequency. For example, the

10 Hz filter provides the greatest attenuation of 50 and 60 Hz noise and

the greatest resolution, but also provides the slowest response speed.

The choice that you make for filter frequency will affect:

• noise rejection characteristics for module input

• channel step response

• channel cutoff frequency

• effective resolution

• module update time

Effects of Filter Frequency on Noise Rejection

The filter frequency that you choose for the module determines the

amount of noise rejection for the inputs. A smaller filter frequency (e.g.

10Hz) provides the best noise rejection and increases effective resolution,

but also increases channel update time. A larger filter frequency (e.g. 500

Hz) provides lower noise rejection, but also decreases the channel update

time and effective resolution.

Publication 1790-UM002A-EN-P

When selecting a filter frequency, be sure to consider channel cutoff

frequency and channel step response to obtain acceptable noise rejection.

Choose a filter frequency so that your fastest-changing signal is below that

of the filter’s cutoff frequency.

Page 35

Module Data, Status, and Channel Configuration for DeviceNet 3-5

Common mode noise rejection for the module is better than 110 dB at 50

Hz (50 Hz filter) and 60 Hz (60 Hz filter). The module performs well in

the presence of common mode noise. Improper earth ground can be a

source of common mode noise.

Channel Step Response

NOTE

Transducer power supply noise, transducer circuit noise,

and process variable irregularities can also be sources of

common mode noise.

Another module characteristic determined by filter frequency is channel

step response, as shown in the following table. The step response is the

time required for the analog input signal to reach 100 percent of its

expected final value, given a full-scale step change in the input signal.

Thus, if an input signal changes faster than the channel step response, a

portion of that signal will be attenuated by the channel filter. The channel

step response is calculated by a settling time of 3 x (1 / filter frequency).

Table 3.5 Filter Frequency vs. Channel Step Response

Filter Frequency Step Response

10 Hz 300 ms

25 Hz 120 ms

50 Hz 60 ms

60 Hz 50 ms

100 Hz 30 ms

250 Hz 12 ms

500 Hz 6 ms

Publication 1790-UM002A-EN-P

Page 36

3-6 Module Data, Status, and Channel Configuration for DeviceNet

Channel Cutoff Frequency

The channel cutoff frequency (-3 dB) is the point on the input channel

frequency response curve where frequency components of the input

signal are passed with 3 dB of attenuation. The following table shows

cutoff frequencies for the supported filters.

Table 3.6 Filter Frequency vs. Channel Cutoff Frequency

Filter Frequency Channel Cutoff Frequency

10 Hz 2.62 Hz

25 Hz 6.55 Hz

50 Hz 13.1 Hz

60 Hz 15.7 Hz

100 Hz 26.2 Hz

250 Hz 65.5 Hz

500 Hz 131 Hz

All frequency components at or below the cutoff frequency are passed by

the digital filter with less than 3 dB of attenuation. All frequency

components above the cutoff frequency are increasingly attenuated, as

shown in the graphs below for several of the input filter frequencies.

NOTE

Channel cutoff frequency should not be confused with

channel update time. The cutoff frequency simply

determines how the digital filter attenuates frequency

components of the input signal.

Publication 1790-UM002A-EN-P

Page 37

Module Data, Status, and Channel Configuration for DeviceNet 3-7

Frequency Response Graphs

Gain (dB)

Gain (dB)

–20

–40

–60

–80

-100

-120

-140

-160

-180

- 200

- 200

0

–20

–40

–60

–80

-100

-120

-140

-160

-180

0

2.62 Hz

0

0

1 5 .72 Hz

10 Hz Input Filter Frequency

–3 dB

10

20

60 Hz Input Filter Frequency

–3 dB

60

120

30

40

Frequency (Hz)

180

Frequency (Hz)

240

0

–20

–40

–60

–80

-100

-120

Gain (dB)

-140

-160

-180

50

60

- 200

13. 1 Hz

–3 dB

0

50

100

150

200

250

300

Frequency (Hz)

250 Hz Input Filter Frequency

50 Hz Input Filter Frequency

300

360

0

–20

–40

–60

–80

-100

Gain (dB)

-120

-140

-160

-180

- 200

0

65 .5 Hz

–3 dB

900

Frequency (Hz)

1300

1150750500250

500 Hz Input Filter Frequency

0

–20

–40

–60

–80

-100

-120

Gain (dB)

-140

-160

-180

- 200

131 Hz

–3 dB

2000

Frequency (Hz)

30000 250015001000500

43259

Publication 1790-UM002A-EN-P

Page 38

3-8 Module Data, Status, and Channel Configuration for DeviceNet

Effective Resolution

Input Type Range 10 Hz 25 Hz 50/60 Hz 100 Hz 250 Hz 500 Hz

100 ohm Pt α=385 -200/850°C Sign + 14

200 ohm Pt α=385 -200/850°C Sign + 14

500 ohm Pt α=385 -200/650°C Sign + 13

100 ohm Pt α=3916 -200/640°C Sign + 13

200 ohm Pt α=3916 -200/640°C Sign + 13

500 ohm Pt α=3916 -200/640°C Sign + 13

100 ohm Nickel -60/250°C Sign + 12

The table below identifies the number of significant bits used to represent

the input data for each available filter frequency. The number of

significant bits is defined as the number of bits that will have little or no

jitter due to noise, and is used in defining the effective resolution.

Table 3.7 Input Effective Resolution Versus Input Filter Selection

bits 0.1°C

bits 0.1°C

bits 0.1°C

bits 0.1°C

bits 0.1°C

bits 0.1°C

bits 0.1°C

Sign + 14

bits 0.1°C

Sign + 14

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 14

bits 0.1°C

Sign + 14

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 14

bits 0.1°C

Sign + 14

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 13

bits 0.2°C

Sign + 13

bits 0.2°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 13

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 11

bits 0.5°C

Sign + 11

bits 0.5°C

Sign + 11

bits 0.4°C

Sign + 11

bits 0.4°C

Sign + 11

bits 0.4°C

Sign + 11

bits 0.4°C

Sign + 11

bits 0.2°C

120 ohm Nickel -80/260°C Sign + 12

bits 0.1°C

200 ohm Nickel -60/250°C Sign + 12

bits 0.1°C

500 ohm Nickel -60/250°C Sign + 12

bits 0.1°C

Resistance 100mΩ 1/625 Ω Sign + 13

bits 0.1Ω

Resistance 100mΩ 1/327 Ω Sign + 15

bits 0.1Ω

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 13

bits 0.1Ω

Sign + 15

bits 0.1Ω

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 13

bits 0.1Ω

Sign + 15

bits 0.1Ω

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 13

bits 0.1Ω

Sign + 15

bits 0.1Ω

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 12

bits 0.1°C

Sign + 13

bits 0.1Ω

Sign + 13

bits 0.04Ω

Sign + 11

bits 0.2°C

Sign + 11

bits 0.2°C

Sign + 11

bits 0.2°C

Sign + 13

bits 0.4Ω

Sign + 11

bits 0.2Ω

Publication 1790-UM002A-EN-P

Page 39

Module Data, Status, and Channel Configuration for DeviceNet 3-9

Determining Module Update Time

The module update time is defined as the time required for the module to

sample and convert the input signals. The module sequentially samples

the channels in a continuous loop. Module update time is dependent on

the number of input channels and the input filter selection.

The fastest update time occurs with the 500Hz filter enabled. The

following table shows update times for all filter frequencies.

Table 3.8 Module Update Time

Filter

Frequency

10 Hz 2.2 seconds

25 Hz 840 milliseconds

50 Hz 420 milliseconds

60 Hz 348 milliseconds

100 Hz 224 milliseconds

250 Hz 88 milliseconds

500 Hz 48 milliseconds

Module Update Time

DeviceNet RTD/ Resistance Module (1790D-4R0/T4R0)

Configuring 1790D-4R0/T4R0 RTD/resistance modules is as easy as

pointing and clicking. RSNetWorx™ lets you simply identify the network

and configure the I/O modules with easy-to-use Electronic Data Sheets

(EDS) files - just point to the field and click on your selection.

To obtain the EDS files you need to configure the modules, go to the

following website: http:/www.ab.com/networks/eds.

EDS files for blocks with matching catalog numbers (for D-Shell and

terminal block versions) are the same. Thus, on the website or in

RSNetWorx for DeviceNet, there may be only one catalog number listed

for both versions.

When using 3rd party configuration software, simply load the EDS files

into the software and follow the vendor’s instructions.

The following example takes you through configuring your RTD/

resistance module with RSNetWorx for DeviceNet, version 3.00 or later.

NOTE

Refer to Appendix C to configure the 1790P-T4R0

PROFIBUS module.

Publication 1790-UM002A-EN-P

Page 40

3-10 Module Data, Status, and Channel Configuration for DeviceNet

Configure DeviceNet RTD/Resistance Modules Using RSNetWorx

Online Browse

Button

Following the steps below to configure 1790D-4R0/T4R0 RTD/resistance

modules.

1. Open RSNetWorx for DeviceNet.

2. Using the selections on the left of the window below, construct you

system. (If your network is up, just click on the Online Browse

button.)

Publication 1790-UM002A-EN-P

Page 41

Module Data, Status, and Channel Configuration for DeviceNet 3-11

3. After setting up your system, double-click on the module you want to

configure. (If you are online, upload the configuration and existing

parameters from the module display.) A window similar to the

following appears.

Click the device

Parameters tab to

display the screen in

which you can set

parameters.

RTD/resistance modules will have parameters similar to the following.

If you see a lock next to

an entry, this indicates

that you cannot change

that parameter.

On this screen, you see all the parameters for the module. These include Autobaud,

RTD Input value, combined temperature units/filter frequency, module status and

Input RTD/resistance type.

Publication 1790-UM002A-EN-P

Page 42

3-12 Module Data, Status, and Channel Configuration for DeviceNet

Module configuration parameters include Temperature Units/Notch

Filter frequency, RTD/resistance Input type and Autobaud.

Select the desired

temperature units (in

degrees C or F) and notch

filter frequency. ALL four

channels will be

configured identically.

Select the RTD/

resistance input type for

each channel from the

dropdown list.

Select to have Autobaud

either Enabled or

Disabled.

Publication 1790-UM002A-EN-P

Page 43

Module Data, Status, and Channel Configuration for DeviceNet 3-13

n

Once module configuration is

complete, click either the

Download or Apply button

and click Yes for the popup

question.

Then click OK to close the

module properties window.

RTD/resistance module parameters may be monitored real time. The

most convenient way to monitor module parameters is to:

a. Click the Groups checkbox.

b. Close the No Group Specified folder

c. Open the I/O Input Values and I/O Input Status folders.

d. Click the Monitor button.

The module parameters are sequentially updated.

Check Groups

Click the Monitor butto

Open these

folders

Close this folder

Publication 1790-UM002A-EN-P

Page 44

3-14 Module Data, Status, and Channel Configuration for DeviceNet

Chapter Summary

In this chapter, you learned how to setup and configure your module. See

Chapter 4 to learn how to troubleshoot using the module indicators.

Publication 1790-UM002A-EN-P

Page 45

Chapter

4

Diagnostics and Troubleshooting

This chapter describes module troubleshooting, containing information

on:

• safety considerations when troubleshooting

• module vs. channel operation

• the module’s diagnostic features

• critical vs. non-critical errors

• module condition data

• contacting Rockwell Automation for assistance

Safety Considerations

Safety considerations are an important element of proper troubleshooting

procedures. Actively thinking about the safety of yourself and others, as

well as the condition of your equipment, is of primary importance.

The following sections describe several safety concerns you should be

aware of when troubleshooting your control system.

ATTENTION

ÿ

Never reach into a machine to actuate a switch because

unexpected motion can occur and cause injury.

Remove all electrical power at the main power disconnect

switches before checking electrical connections or inputs/

outputs causing machine motion.

Indicator Lights

When the green MOD and NET LED on the thermocouple module are

illuminated, it indicates that power is applied to the module, that it has

passed its internal tests and that the module is communicating on the

network.

Activating Devices When Troubleshooting

When troubleshooting, never reach into the machine to actuate a device.

Unexpected machine motion could occur.

1 Publication 1790-UM002A-EN-P

Page 46

4-2 Diagnostics and Troubleshooting

Stand Clear of the Equipment

When troubleshooting any system problem, have all personnel remain

clear of the equipment. The problem could be intermittent, and sudden

unexpected machine motion could occur. Have someone ready to operate

an emergency stop switch in case it becomes necessary to shut off power.

Program Alteration

There are several possible causes of alteration to the user program,

including extreme environmental conditions, Electromagnetic Interference

(EMI), improper grounding, improper wiring connections, and

unauthorized tampering. If you suspect a program has been altered,

check it against a previously saved master program.

Safety Circuits

Circuits installed on the machine for safety reasons, like over-travel limit

switches, stop push buttons, and interlocks, should always be hard-wired

to the master control relay. These devices must be wired in series so that

when any one device opens, the master control relay is de-energized,

thereby removing power to the machine. Never alter these circuits to

defeat their function. Serious injury or machine damage could result.

Module Operation vs. Channel Operation

The module performs diagnostic operations at both the module level and

the channel level. Module-level operations include functions such as

power-up, configuration, and communication with a controller.

Channel-level operations describe channel related functions, such as data

conversion and over- or under-range detection.

Internal diagnostics are performed at both levels of operation. When

detected, module error conditions are indicated by the module status LED.

Channel over-range or under-range conditions are reported in the

module’s input data table.

Publication 1790-UM002A-EN-P

Page 47

Diagnostics and Troubleshooting 4-3

Power-up Diagnostics

Power-up diagnostics includes module status and network status.

Module Status

At module power-up, a series of internal diagnostic tests are performed.

These diagnostic tests must be successfully completed. The following

table shows module status LED indictor operation.

Table 4.1 Module Status Power-up Diagnostics

1790D-4R0/T4R0, 1790P-T4R0

LED Indicator: Status: Description:

Module Status Solid Red Unrecoverable fault

Flashing Red Recoverable fault

Solid Green Normal operation - OK

Flashing Green Standby

Off No power

Network Status

The network status LED indicator shows the condition of the network

connection. The following tables show network status LED indicator

operation.

Table 4.2 Network Status Power-up Diagnostics for 1790D-4R0/T4R0)

1790D-4R0/T4R0

LED Indicator: Status: Description:

Network Status Solid Red Unrecoverable communication fault

Flashing Red Recoverable communication fault

Solid Green Communication path complete - OK

Flashing Green Communication path incomplete

Off Device not online or not powered

Table 4.3 Network Status Power-up Diagnostics for the 1790P-T4R0

1790P-4R0

LED Indicator: Status: Description:

Network Status Solid Green Communication path complete - OK

Flashing Green Communication path incomplete

Off No power or baud rate search

Publication 1790-UM002A-EN-P

Page 48

4-4 Diagnostics and Troubleshooting

Channel Diagnostics

When an input channel is enabled, the module performs a diagnostic

check to see that the channel has been properly configured. In addition,

the channel is tested on every scan for configuration errors, over-range

and under-range, and broken input conditions.

Non-critical module errors are typically recoverable. Channel errors

(over-range or under-range errors) are non-critical. Non-critical error

conditions are indicated in the module input data table.

Out-of-Range Detection

When the input signal data received at the channel word is out of the

defined operating range, an over-range or under-range error is indicated

in input data word 4.

Possible causes for an out-of-range condition include:

• The temperature is too hot or too cold for the RTD being used.

• The wrong RTD is being used for the input type selected, or for the

configuration that you have programmed.

• The input device is faulty.

• The signal input from the input device is beyond the scaling range.

Open-Wire Detection

The module performs an open-circuit input test on all channels on each

scan. Whenever an open-circuit condition occurs, the overrange input bit

for that channel is set in input data word 4.

Possible causes of a broken input condition include:

• the input device is broken

• a wire is loose or cut

• the input device is not installed on the configured channel

• an RTD is internally shorted

• an RTD is not installed correctly

Module Error Definition Table

RTD/resistance module errors are expressed on a channel basis in input

read word 4. The structure of the status data is shown in the following

table.

Publication 1790-UM002A-EN-P

Page 49

Diagnostics and Troubleshooting 4-5

Table 4.4 Word Bit Position

Word Bit Description

1514131211109876543210

4 Not Used S11 S10 S9 S8 Not Used S3 S2 S1 S0

Table 4.5 Word/Bit Description

Word Decimal Bit Description

Bits 00-03 Underrange for individual channels. Bit 00 corresponds to input

channel 0, bit 01 corresponds to input channel 1 and so on.

When set (1), the input signal is below the input channel’s

minimum range

Read Word 4

Bits 04-07 Not used: Set to 0

Bit 08-11 Overrange for individual channels. Bit 08 corresponds to input

channel 0, bit 09 corresponds to input channel 1 and so on.

When set (1), the input signal is above the input channel’s

maximum range, or open RTD is detected

Bit 12-15 Not used: Set to 0

Channel LED Indicator Operation

Individual channel LED indicator operation is shown in the following

table.

Table 4.6 Individual Channel LEDs Indicator

I/O Channel LED Status Indicator

Status: Description

Flashing Green/Red Power up

Off Off line

Red On line and no field power

Red DeviceNet connection and no field power

Flashing Red Field power and open wire

Green Field power and valid input

Flashing Red Input over range, open input

Flashing Red Input under range

Flashing Red Recoverable fault

Publication 1790-UM002A-EN-P

Page 50

4-6 Diagnostics and Troubleshooting

Contacting Rockwell Automation

Chapter Summary

If you need to contact Rockwell Automation for assistance, please have

the following information available when you call:

• a clear statement of the problem, including a description of what the

system is actually doing. Note the LED state; also note input and

output image words for the module.

• a list of remedies you have already tried

• processor type and firmware number (See the label on the processor)

• hardware types in the system, including all I/O modules

• fault code if the processor is faulted

In this chapter, you learned how to perform diagnostic and

troubleshooting on the 1790D/4R0/T4R0 and 1790P-TR40 RTD/resistance

modules. See the appendixes for module specifications, binary number

information, and module configuration for PROFIBUS.

Publication 1790-UM002A-EN-P

Page 51

Environmental Specifications

Appendix

Specifications

Environmental Specifications

Operating Temperature 0 to 55°C (32 to 131°F)

IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock)

Storage Temperature -40 to 85°C (-40 to 185°F)

IEC 60068-2-1 (Test Ab, Un-packaged Non-operating Cold),

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating Thermal Shock)

Relative Humidity 5-90% non-condensing

IEC 60068-2-30 (Test Db, Un-packaged Non-operating)

Operating Altitude 2000m

Vibration I2g @ 10-500Hz

EC60068-2-6 (Test Fc, Operating)

Shock: Operating

Non-operating

Emissions Group 1, Class A

ESD Immunity 8kV air discharges

Radiated RF Immunity 10V/m with 1kHz sine-wave 80%AM from 80MHz to 1000MHz

EFT/B Immunity +

Surge Transient

Immunity

Conducted RF Immunity 10Vrms with 1kHz sine-wave 80%AM from 150kHzto 80MHz

Enclosure Type Rating None (open style)

Mounting DIN rail or screw

Dimensions 52 x 104 x 42mm (2.03 x 4.07 x 1.64in)

Weight 0.3lb (0.1kg)

I0g

30g

IEC60068-2-27 Test Ea, (Unpackaged Shock)

CISPR 11

IEC 61000-4-2

10V/m with 200Hz 50% Pulse 100%AM @ 900Mhz

IEC 61000-4-3

1kV @ 5kHz on power ports

+2kV @ 5kHz on signal ports

2kV @ 5kHz on communications ports

+

IEC 61000-4-4

1kV line-line(DM) and +2kV line-earth(CM) on power ports

+

1kV line-line(DM) and +2kV line-earth(CM) on signal ports

+

2kV line-earth(CM) on shielded ports

+

IEC 61000-4-5

IEC 61000-4-6

A

1 Publication 1790-UM002A-EN-P

Page 52

A-2 Specifications

DeviceNet Specifications

PROFIBUS DP Specifications

Specification Value

Network protocol I/O Slave messaging:

- Poll command

- Bit Strobe command

- Cyclic command

- COS command

Network length 500 meters maximum @ 125Kbps

100 meters maximum @ 500Kbps

Indicators 1 red/green module status

1 red/green network status

Number of nodes 64 maximum - rotary switch type node address setting

Communication rate 125Kbps, 250Kbps, 500Kbps - auto baud rate selection

Isolation Type test 1250Vac rms for 60 seconds between field power and

DeviceNet (I/O to logic)

Wiring Refer to publication DN-6.7.2

PROFIBUS DP Specifications

Network Protocol PROFIBUS-DP (EN50170)

Communication of the slave with a Class 1 master

Communication of the slave with a Class 2 master

Redundancy Not supported

Repeater Control Signal RS485 signal

Implementation Type DPC31

Freeze Mode Supported

Sync Mode Supported

Auto Baud Rate Supported

Fail Safe Mode Supported

Station Type Slave

FMS Support Not supported

Indicators 1 red/green module status

1 red/green network status

Number of nodes 100 maximum - rotary switch type node address setting (0-99)

Network Length/

Communication rate

Isolation Type test 1250Vac rms for 60 seconds between field power and

9.6Kbps @ 1000m (3280ft)

19.2Kbps @ 1000m (3280ft)

45.45Kbps @ 1000m (3280 ft)

93.75Kbps @ 1000m (3280ft)

187.5Kbps @ 1000m (3280ft)

500Kbps @ 400m (1312ft)

1.5mbps @ 200m (656ft)

3mbps @ 100m (328ft)

6mbps @ 100m (328ft)

12mbps @ 100m (328ft)

PROFIBUS (I/O to logic)

Publication 1790-UM002A-EN-P

Page 53

General Specifications

Specifications A-3

яюэюьыъщшчюцхфхцыухтэс

Wiring Category

Product Certifications

(when product or

packaging is marked)

1

2

c-UL-us UL Listed for Class I, Division 2 Group A,B,C,D Hazardous

Locations, certified for U.S. and Canada

CE

2

European Union 89/336/EEC EMC Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN61326; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

2

C-Tick

Australian Radiocommunications Act, compliant with:

AS/NZS 2064; Industrial Emissions

ODVA ODVA conformance tested to ODVA DeviceNet

specifications

DeviceNet Power Supply voltage - 24V dc nominal

Voltage range - 11-28.8V dc

Power dissipation - 1.2W maximum @ 28.8V dc

PROFIBUS Power Supply voltage - 24V dc nominal

Voltage range - 19.2-28.8V dc

Power dissipation - 2W maximum @ 28.8V dc

Field Power Supply Voltage - 24Vdc nominal

Voltage Range - 21.6-26.4V dc (+

10%)

Power Dissipation - 1.5W maximum @ 26.4V dc

Isolation I/O to logic: photocoupler isolation

Isolation voltage: Type Test 1250V ac rms for 60 seconds

DeviceNet to logic: non-isolated

Field power: non-isolated

Indicators 4 red/green I/O status

Wiring

1790D-4R0

1790D-T4R0

1

Refer to publication 1770-4.1,

2

See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates and other certification details.

37-pin D-Shell connector

Terminal block connector screw torque: 7 inch pounds maximum

Programmable Controller Wiring and Grounding Guidelines.

IMPORTANT

This module does not support any expansion modules.

Publication 1790-UM002A-EN-P

Page 54

A-4 Specifications

RTD/Resistance Specifications

RTD/resistance Specifications

Inputs per module 4 channel, RTD/Resistance Input

Input Range 1-625

Sensors Supported Sensor Type Degree Counts Resolution

Resistance 100mΩ 1 to 625Ω 10 to 6250 100mΩ