Page 1

User Manual

SoftLogix 5800 System

Catalog Numbers 1789-L10, 1789-L30, 1789-L60

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, RSLog ix, FactoryTalk, SoftLogix, R SLinx, ControlLogix, Studio 5000, Rockwell Automation, SLC, PLC-5, Logix5000, PhaseManager, ControlLogix, RSNetWorx, FlexLogix, PLC-2,

PLC-3, DH+, Integrated Architecture, Kinetix, Flex, PanelView, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

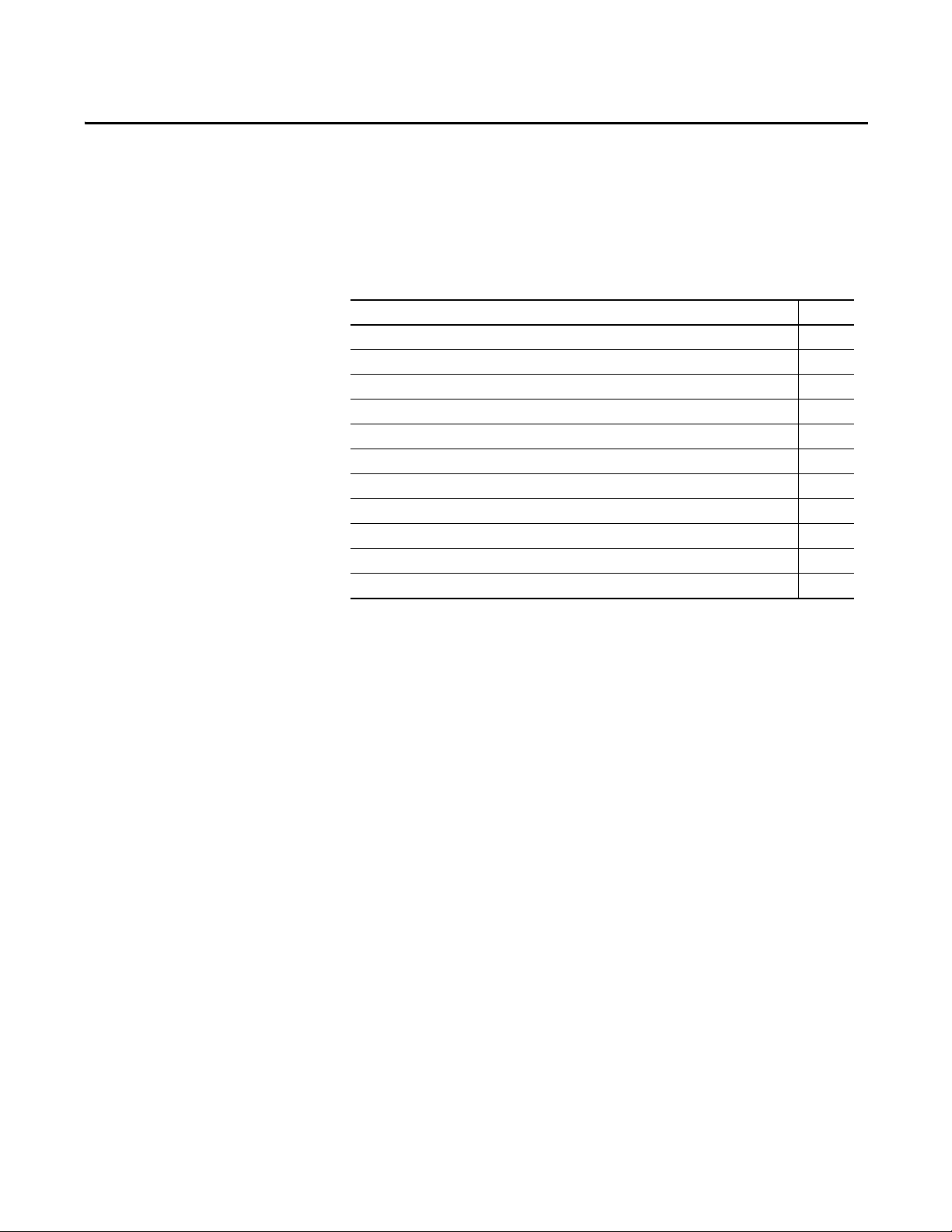

Summary of Changes

Introduction

Updated Information

The release of this document contains new and updated information. To find

new and updated information, look for change bars, as shown next to this

paragraph.

The document contains these changes. This table represents major topics. Make

sure to look for the change bars throughout this document.

Top ic Pa ge

Troubleshoot FactoryTalk Activations Link 17

Logix Designer software has now replaced RSLogix™ 5000 software Throughout

Studio 5000™ Logix Designer application is the rebranding of RSLogix 5000 software 11

DeviceNet is supported in SoftLogix software, Version 20 or earlier 159

ControlNet is supported in SoftLogix software, Version 20 or earlier 193

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 5

Table of Contents

Preface

What is the SoftLogix System?

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

About the SoftLogix 5800 Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install the SoftLogix 5800 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

FactoryTalk Activation Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Node-locked Activation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Concurrent Activation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Run the FactoryTalk Activation Manager . . . . . . . . . . . . . . . . . . . . . . 16

Activation Tools and Rehosting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshoot FactoryTalk Activations . . . . . . . . . . . . . . . . . . . . . . . . . 17

Configure the RSLinx Virtual-backplane Driver . . . . . . . . . . . . . . . . . . . . 18

Troubleshoot the SoftLogix 5800 Controller . . . . . . . . . . . . . . . . . . . 19

Chapter 2

SoftLogix System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SoftLogix System Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Set Up the Chassis Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Determine a Memory Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Specify a Periodic Save Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Configure the SoftLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Step 1: Create and Configure the Controller

in the SoftLogix Chassis Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Change the RSLinx Software Slot. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Step 2: Create the New Controller Project in

RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Step 3: Configure the Controller in the RSLogix 5000 Project . . . 32

Developing Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Configuring Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Determining Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Supporting Routines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Instruction Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

How the SoftLogix System Uses Connections . . . . . . . . . . . . . . . . . . . . . . 38

Connections for Produced and Consumed Tags . . . . . . . . . . . . . . . . . . . . 38

Connections for Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Connections for I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Total Connection Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Restart the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Online with the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Upload to the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Select a System Overhead Percentage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 5

Page 6

Table of Contents

Chapter 3

Communicate with Devices on an

Ethernet Network

Configure Your System for an Ethernet Network . . . . . . . . . . . . . . . . . . . 43

Step 1: Disable UDP Messages in RSLinx Classic Software . . . . . . . 44

Disabling the UDP option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Enabling the UDP option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Step 2: Create the Communication Card in

the SoftLogix Chassis Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Step 3: Configure the Communication Card as Part of the Project 50

Step 4: Configure the SoftLogix EtherNet/IP Module to

Communicate on an Ethernet Network. . . . . . . . . . . . . . . . . . . . . 53

Multiple EtherNet/IP Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Domain Interactions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Controller Connections over the EtherNet/IP Network. . . . . . . . . . . . . 55

Supported Functionality of the SoftLogix 5800

EtherNet/IP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Distributed Ethernet I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

I/O Configuration Order in the Project . . . . . . . . . . . . . . . . . . . . . . . . 56

Ethernet I/O Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Add a Remote Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Add a Consumed Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Check EtherNet/IP Statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Example 1: Workstation Remotely Connected

to a SoftLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Example 2: Send Messages over the EtherNet/IP Network. . . . . . . . . . . 68

Configure a MSG Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Example 3: Send Messages over the EtherNet/IP Network

to a PLC-5 Processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configure a MSG Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Example 4: Control Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Chapter 4

Communicate with Serial Devices

6 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Configure Your System for a Serial Device. . . . . . . . . . . . . . . . . . . . . . . . . . 75

Step 1: Configure the Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Change the COM Port Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Step 2: Configure the Serial Port of the Controller in the Project . 81

Controller Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Example 1: Workstation Directly Connected

to a SoftLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

DF1 Point-to-Point Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Example 2: Workstation Remotely Connected

to a SoftLogix Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Master and Slave Communication Methods . . . . . . . . . . . . . . . . . . . . 87

DF1 Slave Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

DF1 Master Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Example 3: SoftLogix Controller to a Bar Code Reader . . . . . . . . . . . . . . 90

Page 7

Configure and Use Simulated I/O

Table of Contents

Connect the ASCII Device to the Controller . . . . . . . . . . . . . . . . . . . 90

User Mode Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

ASCII Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Chapter 5

Configure Your System for a 1789-SIM Module . . . . . . . . . . . . . . . . . . . . 93

Step 1: Create the 1789-SIM Module in the SoftLogix Chassis

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Step 2: Configure the 1789-SIM module as Part of the Project . . . 97

Map I/O Data to the 1789-SIM Module . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Toggle Inputs and Monitor Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Turn On or Force a Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Example: Move Application Data into the 1789-SIM Tags . . . . . . . . . 103

Chapter 6

Execute External Routines

Develop External Routines

Configure Your System to Execute an External Routine . . . . . . . . . . . . 105

Add an External Routine to the Controller Organizer. . . . . . . . . . . . . . 106

How the Project Stores and Downloads an External Routine. . . . 111

Call an External Routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Jump to External Routine (JXR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Operands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Arithmetic Status Flags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Fault Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Execution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Type Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Chapter 7

Considerations For External Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

How the SoftLogix Controller Executes External Routines . . . . . . . . . 116

How the Project Stores and Downloads an External Routine. . . . 117

Create Synchronous, Single-threaded External Routines. . . . . . . . . . . . 117

Create a Visual Studio Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Project Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

RA_ExternalRoutines.h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

InlineExample.cpp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

InlineExample.h. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Create an HTML Resource . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Add Version Information to an External Routine DLL. . . . . . . . . . . . . 128

Build and Download External Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Update an Existing External Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Create Multi-threaded External Routines . . . . . . . . . . . . . . . . . . . . . . . . . 130

Sounds.cpp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Thread Priorities in a Multithreaded External Routine DLL . . . . 135

Debug External Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Set Up the Debug Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 7

Page 8

Table of Contents

Start a Debug Session . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Set Breakpoints in External Routine Code . . . . . . . . . . . . . . . . . . . . . 138

Data Type Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

ARRAY Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

INTEGER Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

STRUCTURE Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

STRING Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Packing in Structures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Parameter Type Checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Return Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Export Functions by Using C++ Export Style . . . . . . . . . . . . . . . . . . . . . 144

InlineExample.h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

InlineExample.cpp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Run dumpbin.exe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Edit XML Resource. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Other Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Pass Tags by Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

External Routine DLL that Uses Other DLLs. . . . . . . . . . . . . . . . . . 146

Program Windows Events to Monitor

and Change Controller Execution

Communicate with Devices on a

DeviceNet Network

Chapter 8

Use Outbound Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Programming Example: Outbound Events . . . . . . . . . . . . . . . . . . . . . 148

Configure Windows Events to Launch Tasks within the SoftLogix

Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Configure a Windows-event Task in the Controller . . . . . . . . . . . . 151

Trigger a Controller Task from a Windows Application . . . . . . . . 154

Programming Example: Windows Event. . . . . . . . . . . . . . . . . . . . . . . 154

Programmatically Saving the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Programming Example: Programmatic Save of Controller. . . . . . . 156

Appendix A

Configure Your System for a DeviceNet Network. . . . . . . . . . . . . . . . . . 160

Step 1: Install the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Step 2: Create the Communication Card in the SoftLogix Chassis

Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Step 3: Install the Communication Driver . . . . . . . . . . . . . . . . . . . . . 164

Step 4: Configure the Communication Card as Part of the Project . . .

167

Step 5: Download the Project to the Controller . . . . . . . . . . . . . . . . 169

Step 6: Define the Scanlist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Perform DeviceNet Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Step 1: Start the Test Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Step 2: Configure the Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Step 3: Create a View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Step 4: Read Inputs and Write Outputs . . . . . . . . . . . . . . . . . . . . . . . 184

Step 5: Change the Scanner Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

8 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 9

Table of Contents

DeviceNet I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Determine How Often to Update Data . . . . . . . . . . . . . . . . . . . . . . . 187

Place the Communication Card in Run Mode . . . . . . . . . . . . . . . . . . . . . 188

CommandRegister Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

StatusRegister. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Status Data Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Example: SoftLogix Controller and DeviceNet I/O . . . . . . . . . . . . . . . . 191

Create Alias Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Appendix B

Communicate with Devices on a

ControlNet Network

Configure Your System for a ControlNet Network . . . . . . . . . . . . . . . . 193

Step 1: Install the Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Step 2: Create the Communication Card in the SoftLogix Chassis

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Step 3: Configure the Communication Card as Part of the Project. . .

198

Step 4: Add Remote Communication Devices for the Communication

Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Step 5: Download the Project to the Controller . . . . . . . . . . . . . . . . 207

Step 6: Schedule the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

ControlNet I/O Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Rack-optimized Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 216

Direct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Example 1: SoftLogix Controller and ControlNet I/O . . . . . . . . . . . . . 218

Controlling I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Total Connections Required by the SoftLogix Controller. . . . . . . 218

Example 2: SoftLogix Controller to SoftLogix Controller . . . . . . . . . . 219

Send a MSG Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Produce and Consume Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Total Connections Required by the Soft1 Controller. . . . . . . . . . . 224

Example 3: SoftLogix Controller to Other Devices. . . . . . . . . . . . . . . . . 224

Send a MSG Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Produce and Consume Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Total Connections Required by the Soft1 Controller. . . . . . . . . . . 229

Example 4: Use the SoftLogix Controller as a Gateway . . . . . . . . . . . . . 230

Program Virtual Motion

Appendix C

Virtual Motion Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Logic for Motion Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Motion Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Considerations When Running a Motion Application in Windows

Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 9

Page 10

Table of Contents

Appendix D

Windows Considerations

System Performance Tuning

Guidelines

Status Indicators

Observe Windows Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Additional Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Run a SoftLogix Controller on the Windows Operating System. . . . . 239

Dwell Time Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Periodic Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

System Overhead Timeslice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Multiple SoftLogix Controllers in the Virtual Chassis . . . . . . . . . . 243

HMI Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Personal Computer Hardware Considerations . . . . . . . . . . . . . . . . . . . . . 244

Appendix E

Pre-qualify Your Personal Computer for Soft Control . . . . . . . . . . . . . . 245

System Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

System Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Monitor Personal Computer Performance. . . . . . . . . . . . . . . . . . . . . . . . . 249

Appendix F

SoftLogix Controller Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Controller Status Indicator and Display . . . . . . . . . . . . . . . . . . . . . . . 254

SoftLogix EtherNet/IP Module Status Indicators . . . . . . . . . . . . . . . . . . 255

Link Status (LINK) Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

Network Status (NET) Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Module Status (OK) Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

SoftLogix 5800 Revision History

Index

Appendix G

SoftLogix 5800 Version 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

SoftLogix 5800 Version 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

10 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 11

Preface

Use this manual to become familiar with the SoftLogix™ 5800 controller and its

features.

Studio 5000 Environment

The Studio 5000 Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the Studio

5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix™ 5000 software and will continue to be

the product to program Logix5000™ controllers for discrete, process, batch,

motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. It is the one place for

design engineers to develop all of the elements of their control system.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 11

Page 12

Preface

IMPORTANT

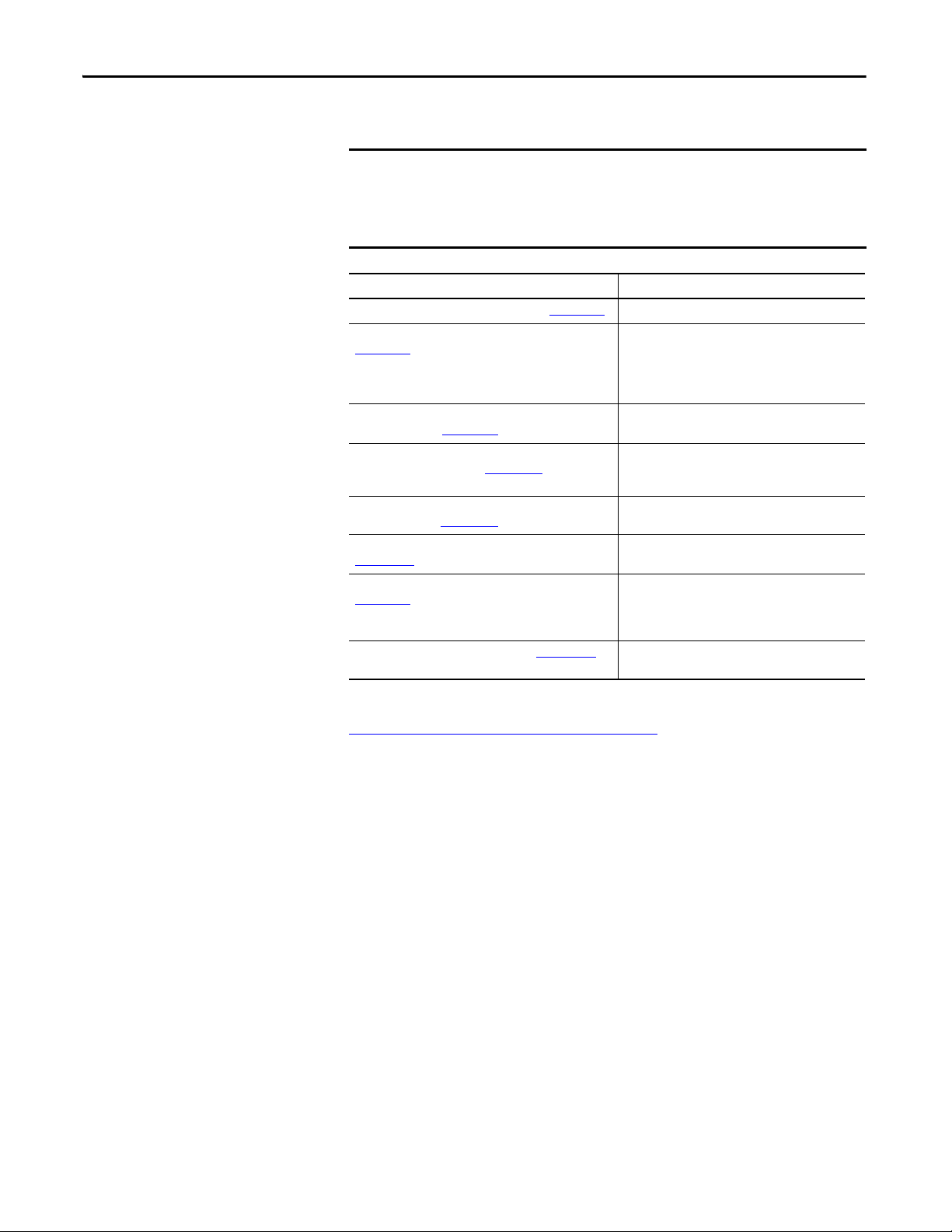

Additional Resources

These documents address the Logix5000™ family of controllers and networks.

We recommend that you read the appropriate release notes for software

requirements, compatible PCI cards and driver, and system requirements.

To locate the release notes for your system, search for 1789-RN in

Literature Library.

Resource Description

Logix5000 Controllers Quick Start, publication 1756-QS001 Explains how to set up a Logix5000 controller.

Logix5000 Controllers Common Procedures, publication

1756-PM001

Logix5000 Controllers General Instruction Set Reference

Manual, publication 1756-RM003

Logix5000 Controllers Process Control/Drives Instruction Set

Reference Manual, publication 1756-RM006

Logix5000 Controllers Motion Instruction Set Reference

Manual, publication 1756-RM007

Motion Modules in Logix5000 Control Systems, publication

LOG IX- UM0 02

EtherNet/IP Network Configuration User Manual, publication

ENET-UM001

PhaseManager™ User Manual, publication LOGIX-UM001

Describes how to complete standard tasks for

Logix5000 controllers. Program logic by using

sequential function chart (SFC), ladder diagram (LD),

structured text (ST), and function block diagram (FBD)

languages.

Program sequential applications, ladder diagram, and

structured text instructions.

Programming process control and drives applications

and function block

diagram instructions.

Describes ladder diagram motion instructions so you

can program motion applications.

Provides general information about motion modules.

Describes how to use EtherNet/IP communication

modules with your Logix5000 controller and

communicate with various devices on the Ethernet

network.

Describes how to set up a state model for your

controller.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

12 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 13

Chapter 1

IMPORTANT

SoftLogix 5800 System

Catalog Numbers 1789-L10, 1789-L30, 1789-L60

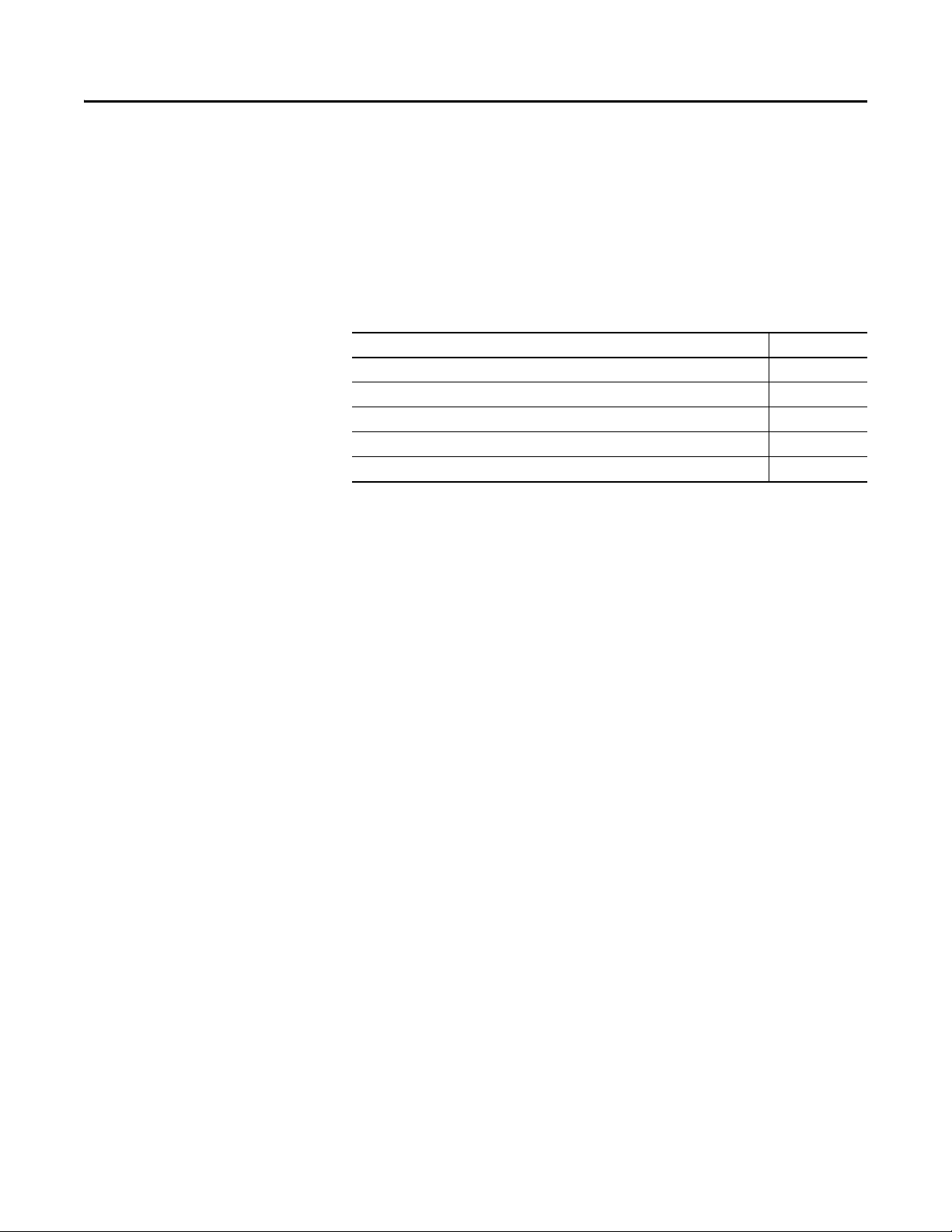

Top ic Pag e

About the SoftLogix 5800 Controller 13

Before You Begin 14

Install the SoftLogix 5800 Controller 15

FactoryTalk Activation Manager 15

Configure the RSLinx Virtual-backplane Driver 18

About the SoftLogix 5800 Controller

The type of SoftLogix™ 5800 controller you use determines how many slots are available in the

virtual chassis and how many devices you can install.

Motion, ControlNet, and DeviceNet modules not currently supported in SoftLogix software,

version 21.00.00 or later which runs on these 32 and 64-bit Windows operating systems:

– Win 7 Pro (32 & 64 bit)

– Win 7 Home Premium (32 & 64 bit)

– Server 2008 R2 Standard Edition w/SP1

Running the SoftLogix software in a Virtual Machine, for example, VMWare or VirtualBox, is not

supported.

Controller Type Maximum Available Slots

1789-L10 • One SoftLogix 5800 controller

• Memory size limit of 2 MB per controller

• One 1784-SIM module

• EtherNet/IP support

• No third-party virtual-backplane module suppor t

1789-L30 • Two SoftLogix 5800 controllers

• Memory size limit of 64 MB per controller

• Five PCI network interface cards

• Five 1784-SIM modules

• EtherNet/IP support

• Third-party virtual-backplane module suppor t

1789-L60 • Six SoftLogix 5800 controllers

• Memory size limit of 64 MB per controller

• Sixteen PC I network interface cards

• Sixteen 1784-SIM modules

• EtherNet/IP support

• Third-party virtual-backplane module suppor t

(1) As of version 12 of the SoftLogix 5800 controller, the 1789-L10 controller supports three slots in the virtual chassis.

(2) The number of available slots in th e virtual chassis is limited by activation level. You can have as many PCI communication

cards as you have available slots in the virtual chassis and in the personal computer.

(2)

(2)

3-slot virtual chassis

5-slot virtual chassis

16-slot virtual chassis

(1)

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 13

Page 14

Chapter 1

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

SoftLogix 5800 controllers and software do not support Integrated Motion on the EtherNet/IP

network. All motion PCI cards are not suppor ted by the Softlogix software, version 20.00.00 and

later.

PCI-based cards are not supported when using the Microsoft Windows 7 operating system. The

1784-PCIDS card is not supported when using the Microsoft Windows Vista or Windows 2008

Server operating system.

Before You Begin

Make sure you have the following software installed before you install SoftLogix software:

• Windows 7 operating system

• RSLinx® Classic software

We recommend that you read the appropriate release notes for software requirements,

compatible PCI cards and driver, and system requirements.

To locate the release notes for your system, search for 1789-RN in

Literature Library at http://www.rockwellautomation.com/literature

In Microsoft Windows Vista, Windows 2008 Server, and Windows 7 operating systems, when

RSlinx software is running as a service, the RSLinx® driver configuration GUI is not available.

To invoke the RSL inx GUI, remove a ll SoftLogix controllers from the chassis monitor and use the

RSLinx Control Panel to start RSLinx software as an application instead of a service.

.

Before you can install the SoftLogix 5800 controller, you need to perform the following steps.

1. Log into the Windows operating system under an account that is a member of the

Administrators user group on the computer where you are installing the SoftLogix 5800

controller.

To log in as a member of the Administrators group, your user account must be added to the

Administrators group on the computer. Ask your system administrator if you need help.

2. Install or verify that the following Windows services, required by the SoftLogix 5800

controller, are running.

The Workstation and Server services are automatically installed when you install Windows

Networking orRemote Access Service (RAS).

A machine running SoftLogix software does not support a remote desktop.

14 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 15

Chapter 1

IMPORTANT

Install the SoftLogix 5800 Controller

If you have a previous version of the SoftLogix 5800 controller already installed on the

computer, use Start>Control Panel>Programs and Features to remove that earlier version

before installing the current version.

When you insert the installation DVD into your CD ROM drive, the DVD automatically begins

the set-up program for the controller. If your computer meets the hardware and software

requirements for the controller, you can install the controller.

1. If RSLinx software is already running, shut it down before beginning this installation

procedure.

2. Insert the SoftLogix 5800 installation DVD.

3. From the installation window, click SoftLogix 5800 V21.00.

4. Follow the set-up wizard.

FactoryTalk Activation Manager

There are two types of FactoryTalk® activations to activate the SoftLogix 5800 controller license—

node-locked and concurrent.

Node-locked Activation

Node-locked activation can be used only on the computer where the activation is locked (on the

personal computer for which the license was purchased). It is always locked to a specific piece of

hardware, for example, an Ethernet card, a hard disk, or a USB dongle.

Concurrent Activation

Concurrent activation is used in a server-client environment and is a type of activation that lets

multiple computers across a network use Rockwell Automation software products concurrently. A

concurrent activation can ‘float’ to, or be borrowed temporarily from, an activation server for a

specific period of time before expiring and returning automatically to the pool of available

activations on the server. Concurrent activations can be borrowed only if your Rockwell Software®

product supports borrowed activations.

If you want to check out a concurrent activation from an activation server, you do not need to use

the Rockwell Software Activation website. You can use the FactoryTalk Activation Manager to

configure your client computer to recognize the activation server computer where concurrent

activations are stored.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 15

Page 16

Chapter 1

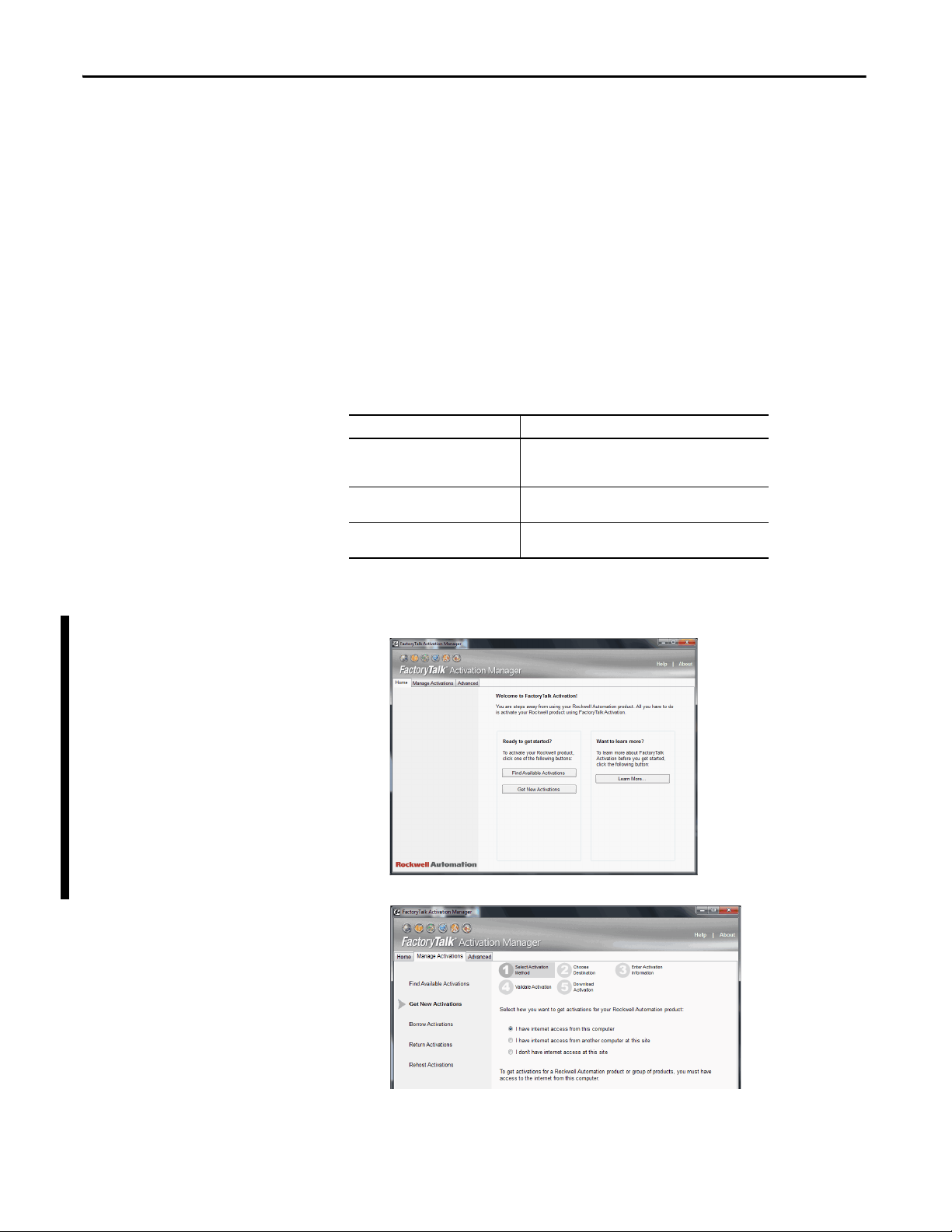

Run the FactoryTalk Activation Manager

When you install Studio 5000 environment, FactoryTalk Activation Manager is automatically

installed on the computer where the activation needs to reside. The FactoryTalk Activation

Manager software manages activations for the Rockwell Software products installed on the

computer. The FactoryTalk Activation Manager opens automatically when you install a new

Rockwell Software product.

You can also run the tool from the Windows Start menu by choosing Start>Programs>Rockwell

Software>FactoryTalk Activation>FactoryTalk Activation Manager.

For more information about the FactoryTalk Activation Manager, refer to the online help in the

software.

You need to have the following information available to activate your license:

• Host ID

• Serial Number

• Product Key

Item Description

Host ID This is found by using the FactoryTalk Activation Manager.

Serial Number This is a 10-digit number supplied to you when you purchased

Product Key This is usually found in a red envelope that is shipped with

Choose Start>Programs>Rockwell Software>FactoryTalk

Activation>FactoryTalk.

your product.

your product.

To start activation, follow these steps.

1. Click ‘Find Available Activations’ or ‘Get New Activations’.

2. Follow steps 1…5 in the FactoryTalk Activation Manager.

16 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 17

Activation Tools and Rehosting

For information on Activation Tools and Rehosting Activations, see the Rockwell Software

Activation website at https://activate.rockwellautomation.com

.

Troubleshoot FactoryTalk Activations

There could be several reasons you might have trouble installing

your activations:

• If you accidentally requested too few concurrent activations for a product, you can

download more new activations for the same Host ID. You cannot download more

activations than you have purchased.

To purchase additional activations, contact your local Rockwell Automation sales office.

• If you accidentally requested too many concurrent activations for a product, you must

rehost all of the activations, and then request the correct number of activations again.

For e xample, i f you have 50 con current activatio ns avai lable for a product, and you intended

to request 10 for a particular Host ID, but accidentally selected 13 in the Activations

Requested list, you cannot return just the three activations you didn't want. You must

rehost all 13 activations, and then download 10 activations to the correct Host ID.

• If you accidentally requested activations for the wrong Host ID (computer or dongle), you

must rehost all of the activations you downloaded accidentally, and then request the

activations again for the correct Host ID.

• If you accidentally requested activations for the wrong product, you must rehost all of the

activations for that product, and then request the activations again.

For example, if you accidentally requested five concurrent activations for Logix Designer

application instead of FactoryTalk View SE software, you must rehost the five activations

for Logix Designer application, and then download five activations for FactoryTalk View

SE software.

To obtain more information, go to the Rockwell Automation Activations Support website

at https://activate.rockwellautomation.com

.

Chapter 1

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 17

Page 18

Chapter 1

IMPORTANT

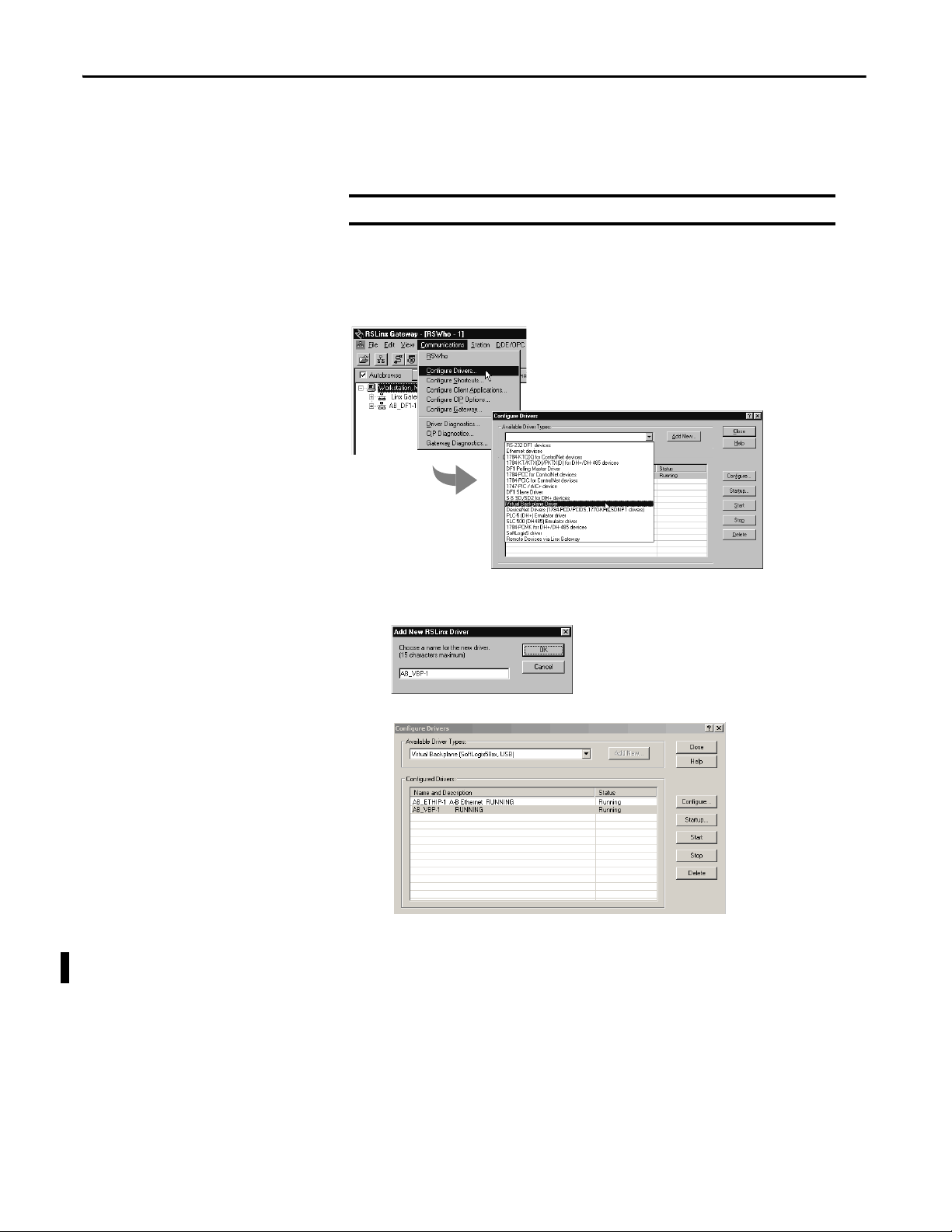

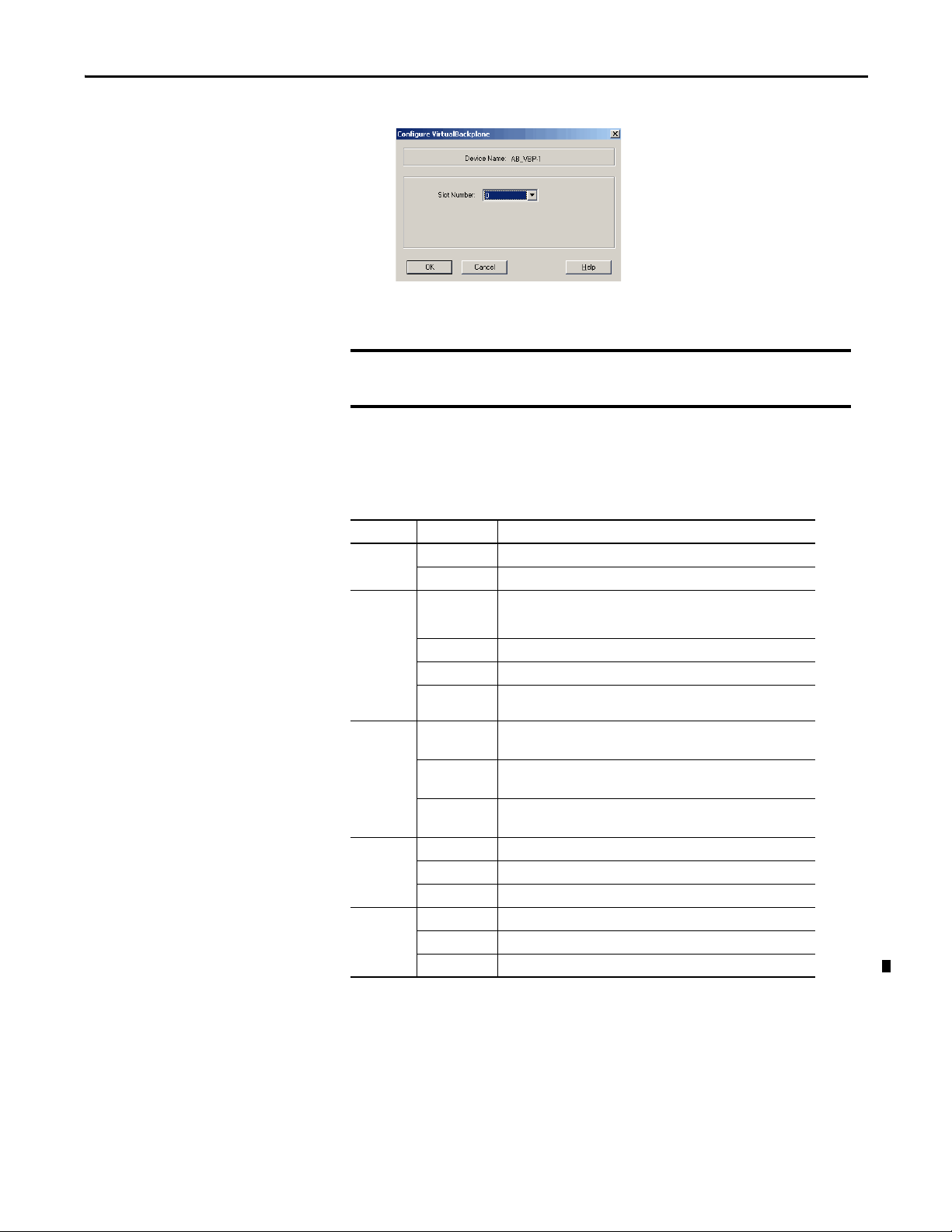

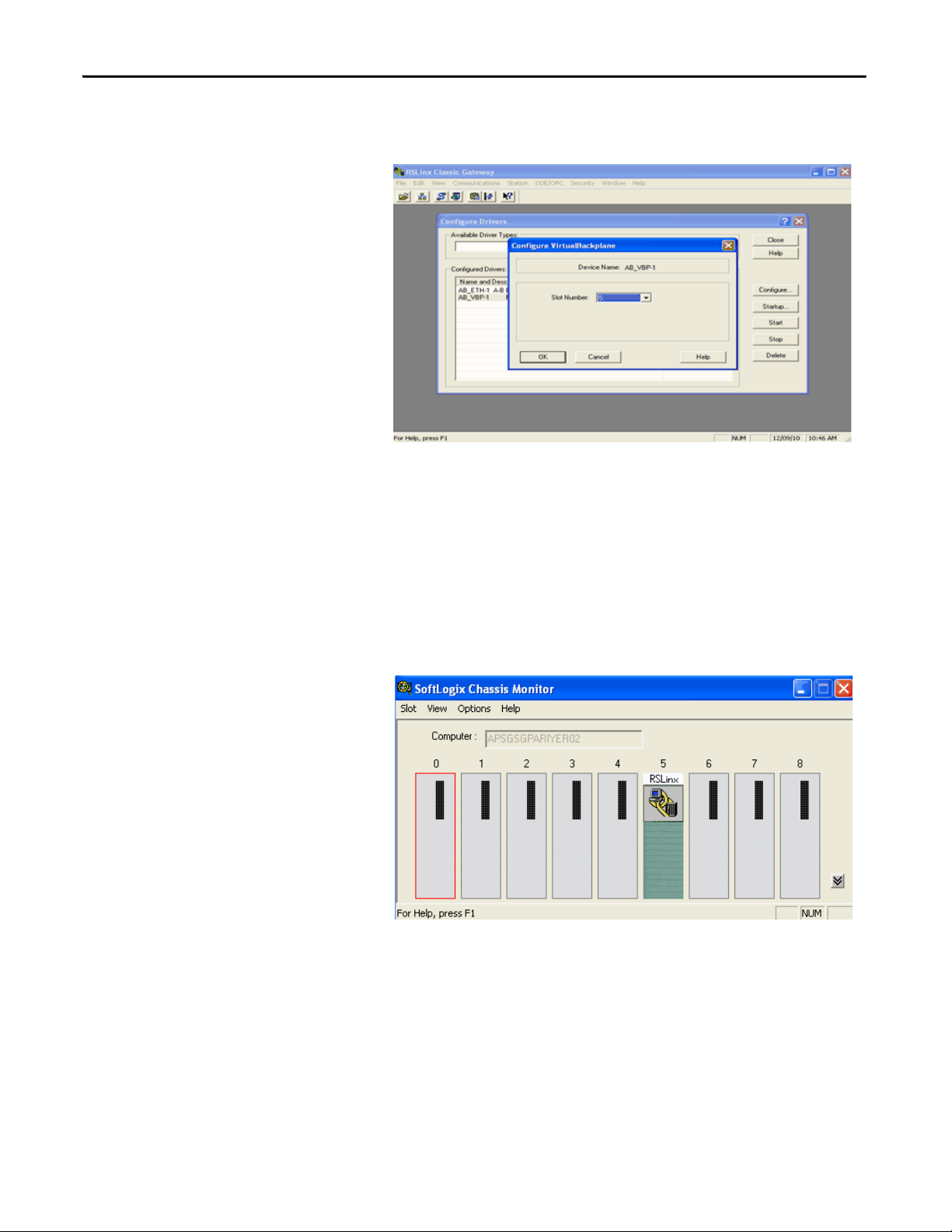

Configure the RSLinx Virtual-backplane Driver

Use RSLinx software to configure the virtual-backplane driver. You do this only once for the

computer.

The RSLinx virtual-backplane driver is required for SoftLogix software to operate.

To install the virtual-backplane driver, follow these steps.

1. In RSLinx software, from the Communications menu, choose Configure Drivers.

2. From the Available Driver Type pull-down menu, choose Virtual Backplane Driver.

3. Click Add New.

4. Type the driver name, such as AB_VBP-1, and click OK.

The Configure Drivers dialog box appears.

5. Click Configure.

The Configure VirtualBackplane dialog box appears. The Logix Designer application,

version 21.00.00, lets you insert a valid SoftLogix module into slot 0.

18 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 19

The RSLinx software module defaults in Slot 0 if not set up for another slot position.

IMPORTANT

6. From the Slot Number pull-down menu, choose a slot number.

7. Click OK and then click Close.

Even if you remotely program the controller over a ControlNet or Ethernet link, you must

add the virtual-backplane driver via RSLinx software. If you do not, the SoftLogix

application will not be restored when you restart the computer.

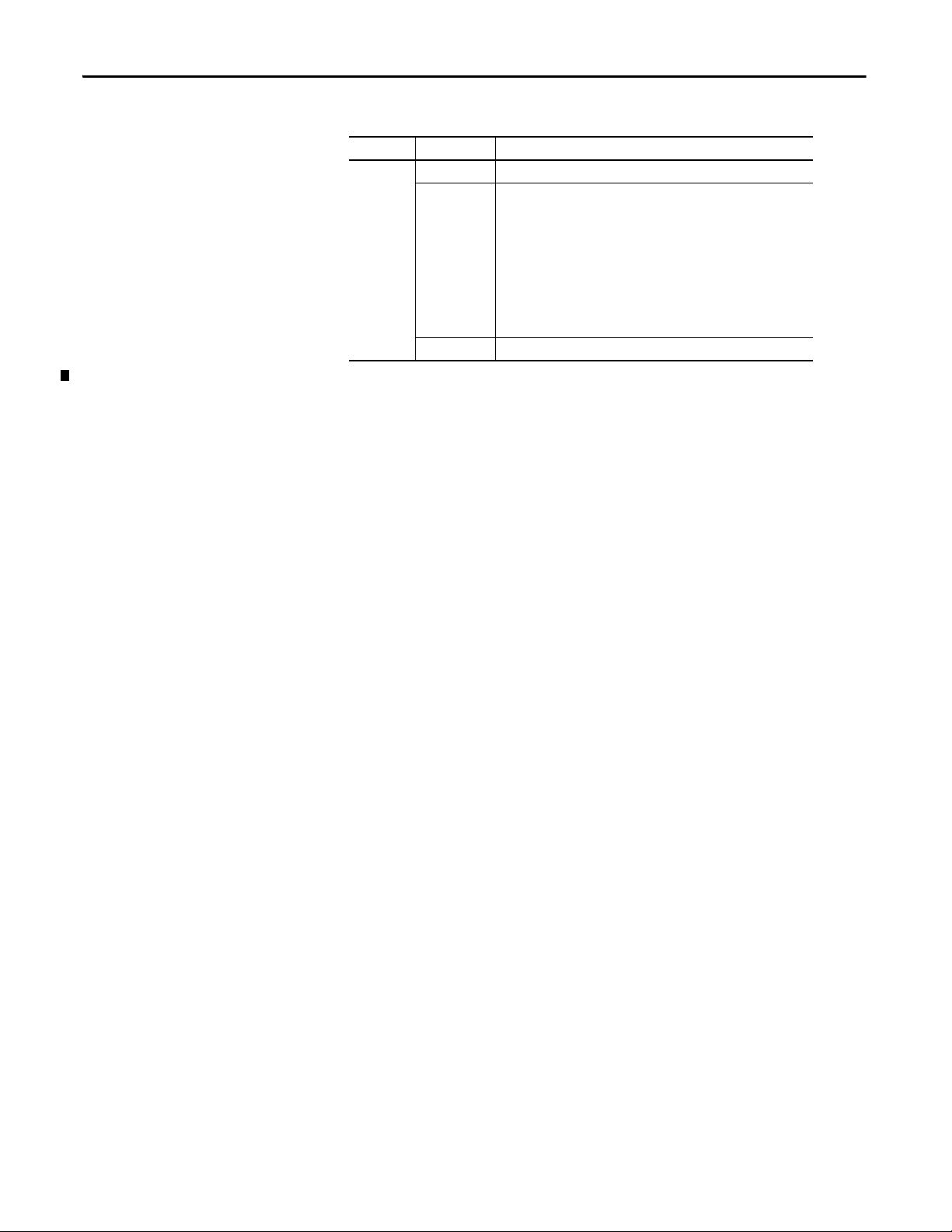

Troubleshoot the SoftLogix 5800 Controller

This table describes the status of the controller.

Table 1 - Troubleshooting the Controller

Chapter 1

Indicator Status Description

RUN Off The controller is in Program or Test mode.

Green The controller is in Run mode.

I/O Off Either of these is true:

Green The controller is communicating with all the devices in its I/O configuration.

Green flashing One or more devices in the I/O configuration of the controller are not responding.

Red flashing A virtual chassis error was detected. Contact your Rockwell Automation

FRC Off No tags contain force values.

Flashing At least one tag contains a force value.

Green Forces are active (enabled).

(1)

RS232

BAT

(1)

Off No COM port was selected.

Green The selected COM port was successfully assigned to channel 0 on the controller.

Red There is a COM port conflict or you selected an invalid COM port number.

Off Normal operation.

Amber flashing The controller is in Power-up mode.

Red Persistent storage for the controller has failed.

• There are no devices in the I/O configuration.

• The controller does not contain a project (controller memory is empt y).

representative or local distributor.

Forces are inactive (disabled).

Force values are inactive (disabled).

Force values may or may not exist.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 19

Page 20

Chapter 1

Table 1 - Troubleshooting the Controller (continued)

Indicator Status Description

OK R ed flashing Recoverable fault.

Red Nonrecoverable fault.

Complete the following to correc t.

1. Remove the controller from the virtual chassis and then reinstall the

controller.

2. Download the project.

3. Place the controller in Run mode.

If the problem continues to occur, contact your Rockwell Automation sales

representative or local Allen-Bradley distributor.

Green The controller is OK.

(1) Note that these status indicators func tion slightly different than the same status indicators on a ControlLogix® controlle r.

20 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 21

Chapter 2

What is the SoftLogix System?

Top ic Pag e

SoftLogix System Components 22

Set Up the Chassis Monitor 24

Configure the SoftLogix Controller 27

Developing Programs 34

How the SoftLogix System Uses Connections 38

Connections for Produced and Consumed Tags 38

Connections for Messages 38

Connections for I/O Modules 40

Total Connection Requirements 40

Restart the Controller 41

Select a System Overhead Percentage 42

This chapter discusses SoftLogix controller options and characteristics.

Procedures include how to configure your SoftLogix controller in the virtual

chassis monitor for the first time and how to create your SoftLogix project in the

Logix Designer application.

The SoftLogix system is a ‘soft’ control system that runs in Microsoft operating

systems. The system resides on a computer, as opposed to a physical module in a

hard chassis. For a list of the supported Windows operating systems, see the

System Requirements section of the current release notes. The SoftLogix

controller is part of the Logix environment and is a software-based controller that

supports Logix instructions.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 21

Page 22

Chapter 2 What is the SoftLogix System?

SoftLogix System Components

A SoftLogix system can consist of these components, depending on your needs:

• The Chassis Monitor resides in the SoftLogix Virtual Chassis. It is a virtual

‘soft’ chassis as opposed to a physical chassis. It lets you create, delete,

monitor, and configure controllers, communication interface cards, and

motion cards in your SoftLogix System.

• The Studio 5000 environment supports every Logix controller. It provides

the flexibility to program (online or offline) in ladder logic, function block

diagram, structured text, and sequential function chart. It provides

complete axis configuration and motion programming support.

• A SoftLogix 5800 controller is based on the Logix platform and takes the

control functions normally found in a dedicated programmable controller,

encapsulates them in software, and runs them on a commercial operating

system. The SoftLogix controller contains a high-speed motion task,

which executes ladder motion commands and generates position and

velocity profile information. The controller sends this profile information

to one or more motion cards. Each controller can control up to 32 axes of

motion. There are several controllers to choose from in the SoftLogix

family, depending on your needs.

• A commercially available Ethernet port for messaging and controlling I/O

over an EtherNet/IP network.

• RSNetWorx™ software is a configuration tool that lets you control and

schedule your network. RSNetWorx software can be used with a

ControlNet network, a DeviceNet network, and an EtherNet/IP network.

• RSLinx software is a communication server that lets you configure

communication devices for networks.

• IOLinx software lets the SoftLogix controller read I/O data.

22 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 23

What is the SoftLogix System? Chapter 2

Analog

Analog Drives

EtherNet/IP Connection

SoftLogix

IMPORTANT

SoftLogix System Description

The same RSLogix 5000 software supports program development for all Logix

controllers. The system can make a connection through a 1784-PCICS card via

the ControlNet network, through a 1784-PCIDS card via the DeviceNet

network, and through a standard EtherNet port via the EtherNet/IP network.

SoftLogix supports two types of motion cards; the 1784-PM02AE analog

motion card and the 1784-PM16SE SERCOS motion card.

Figure 1 - The SoftLogix System at a Glance

Regardless of the product you have, choose 1789-L60/A in RSLogix 5000

software when you specify a controller type.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 23

Page 24

Chapter 2 What is the SoftLogix System?

IMPORTANT

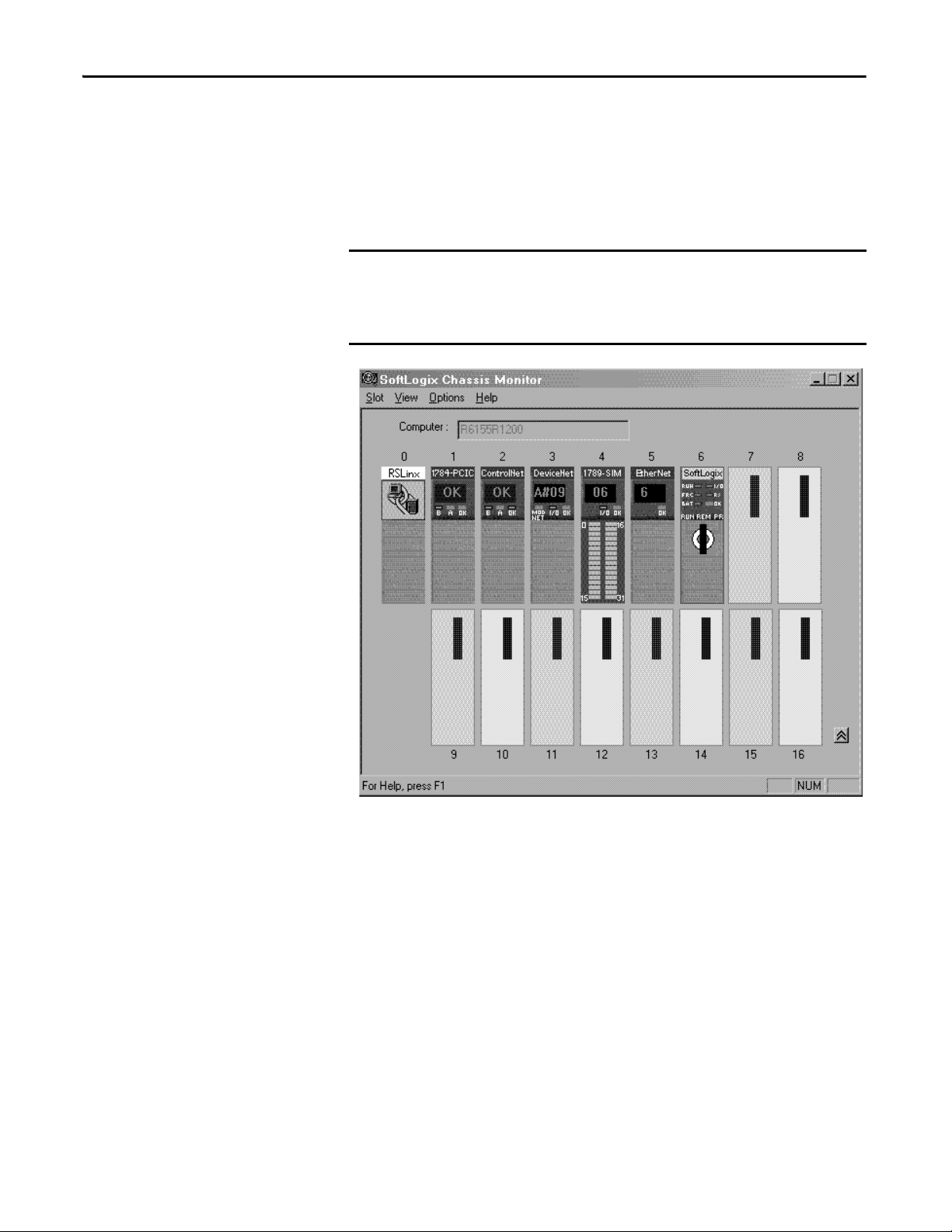

Set Up the Chassis Monitor

The Chassis Monitor is your window into the SoftLogix system that lets you

configure and monitor the system components. The Chassis Monitor models a

physical chassis, but is virtual, or ‘soft.’ You install virtual devices in the virtual

chassis to represent the controller and cards in your system.

An example of the SoftLogix Chassis Monitor is shown here.

Treat the computer running a SoftLogix controller like an industrial

controller and not a personal computer. A personal computer can perform

many operations that are incompatible with the real-time operations

required by a SoftLogix controller.

The Chassis Monitor is your SoftLogix controller interface. You use the

simulated status indicators to view the status of the controllers in your system.

You use the virtual chassis to do the following:

• Add and configure controllers

• Add and configure communication cards

• Change processor mode

• Monitor controller and associated module status

• Monitor motion performance

24 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 25

What is the SoftLogix System? Chapter 2

IMPORTANT

Table 1 - Chassis Motor Characteristic

Characteristic Description

Startup mode Specify how the controller should behave when its service is star ted. Select Remote Program (default) or

Memory size Specify the memory size (KB) to allow for the controller. The maximum limit depends on the controller type. See page 25

Periodic save interval Specify whether you want to save the current controller information (tag data values and configuration information)

Continuous task dwell time (ms) Specify the dwell time (0…1000 ms) made available for all other Windows applications. The default is 10 ms.

CPU affinity If your computer has multiple Pentium CPUs, choose which CPU to use for this controller. The default is CPU 0.

Channel 0 serial port Choose which COM port to use for serial communication. Choose COM1, COM2, COM3, or COM4. The default is none.

Last Controller State.

more information.

periodically, and if so, specify how often (minutes). Specify an interval between 0.5…30 minutes. Online edits to the

program are saved instantly, regardless of Periodic Save interval. The default is enabled for 10 minutes.

See page 26

The dwell time is the time between the end of the continuous task and the start of the next execution of the continuous

task. This setting has an impact on overall system performance, see Appendix E

about this setting’s impact on overall system performance.

.

Determine a Memory Size

for

The memory size you specify is the amount of RAM in your computer that

you want to allocate to the SoftLogix controller. The maximum memory size

per controller is determined by the controller type.; see page 25

information. This allocated RAM is not available to the Windows operating

system or any other application.

These equations provide an estimate of the memory needed for a controller.

Each of these numbers includes a rough estimate of the associated user

programming. Depending on the complexity of your application, you might

need additional memory.page 22

Controller tasks _____ * 4000 = _____ bytes (min 1 needed)

Discrete I/O points _____ * 400 = _____ bytes

Analog I/O points _____ * 2600 = _____ bytes

Communication modules _____ * 2000 = _____ bytes

Motion axis _____ * 8000 = _____ bytes

Tot al = _____ bytes

If you want to change the amount of memory you specified for a controller, you

must first remove the controller from the SoftLogix chassis monitor, then

reinstall the controller and specify the new memory size.

for more

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 25

Page 26

Chapter 2 What is the SoftLogix System?

Specify a Periodic Save Interval

The periodic save task executes at a priority of ‘user-mode high’. This means that

the control process running within the SoftLogix 5800 controller will not be

impacted by a periodic save, but other user applications will be impacted if they

run at a priority lower than ‘user-mode high’. Most HMI applications run at a

‘user-mode normal’ priority. If these applications run on the same computer as

the SoftLogix 5800 controller, these applications will be starved of CPU cycles

while the periodic save is in progress. If you run an HMI application remotely

and gather data from a SoftLogix 5800 controller via OPC, the performance of

the HMI may also be impacted during a periodic save. The controller handles

both the periodic save ‘tag value upload’ and HMI OPC requests through the

same communication mechanism.

When the periodic save task executes, it performs these actions:

• For every tag defined within the controller, the current tag value is read

from the controller.

The larger the amount of data, the longer the periodic save takes and the

greater the impact on HMI responsiveness.

• The current tag values read earlier, along with the current program file, are

saved to the computer disk drive.

The larger the archive file, the longer the periodic saves takes and the

greater the impact on HMI responsiveness. However, tag data size has

more of an impact than archive file size.

To maintain better HMI responsiveness, you can do the following:

• Turn off the periodic save interval.

Even with the periodic save interval disabled, a periodic save occurs if a

remote terminal performs an upload. This makes sure that the most

current tag data values and archive file are uploaded.

If you disable the periodic save, you can still initiate a save manually by

using the Save menu item on the controller from the Chassis Monitor or

programmatically from an external routine or application.

(See Chapter 7

).

• Increase the periodic save interval so that it occurs less frequently.

• Use a dual CPU computer.

On a dual CPU computer, the Windows operating system automatically

balances the periodic save and HMI applications across the CPUs.

For more information on system tuning and the periodic save interval,

see Appendix E

26 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

.

Page 27

What is the SoftLogix System? Chapter 2

Configure the SoftLogix Controller

You must first create and configure your SoftLogix controller, that is, catalog

number 1789-L10, 1789-L30, or 1789-L60, in the virtual chassis monitor.

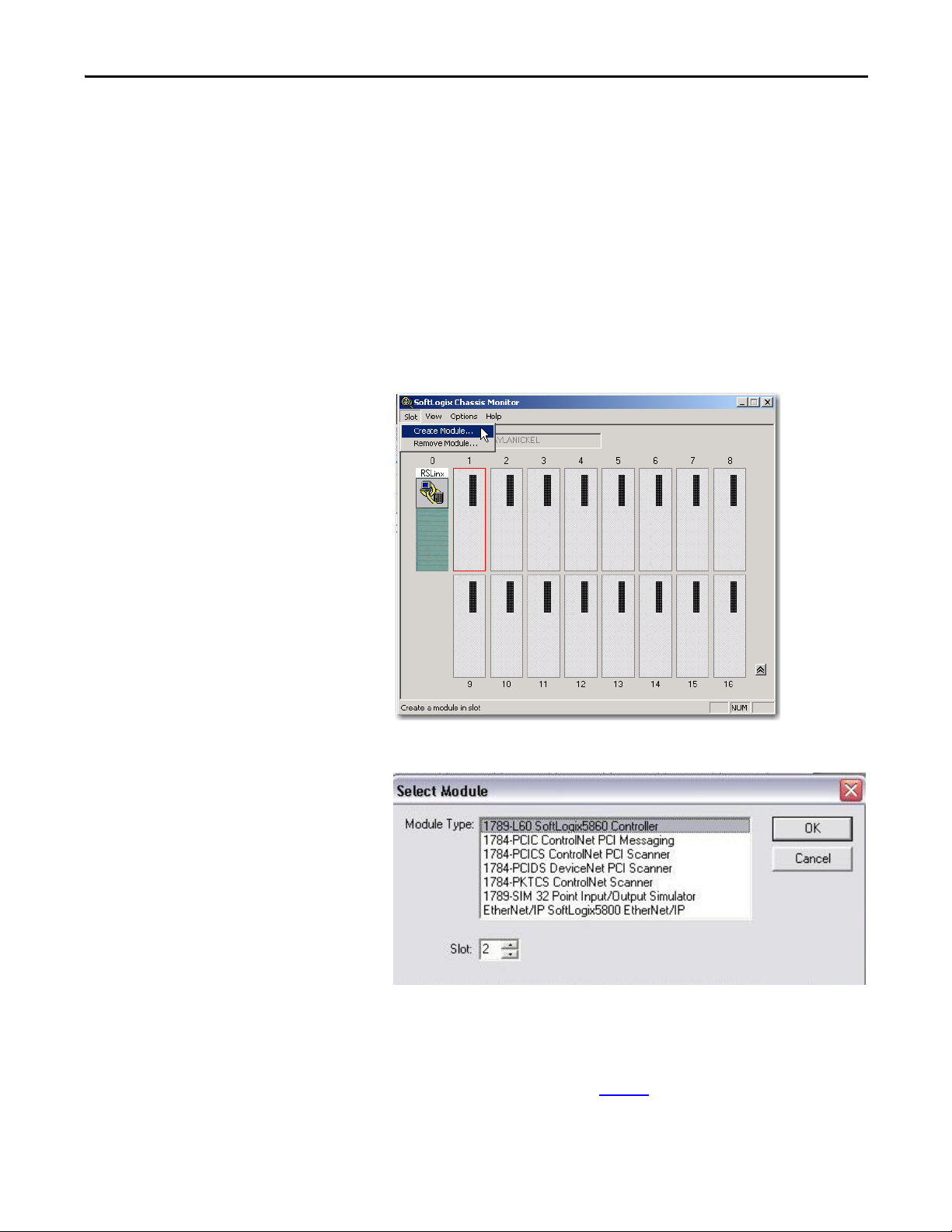

Step 1: Create and Configure the Controller in the SoftLogix Chassis Monitor

When you install a controller, the Chassis Monitor lets you configure specific

characteristics about the controller. To configure the controller in the Chassis

Monitor, follow these steps.

1. In the SoftLogix Chassis Monitor, from the Slot menu, choose

Create Module.

The Select Module dialog box appears.

2. In the Select Module dialog box, select your module type and enter the

Slot number.

RSLinx software defaults to slot 0, but you can move it to another slot if

set up for this functionality. See page 29

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 27

.

Page 28

Chapter 2 What is the SoftLogix System?

For this example, we will enter slot 1 for the 1789-L60

SoftLogix controller.

3. Click OK.

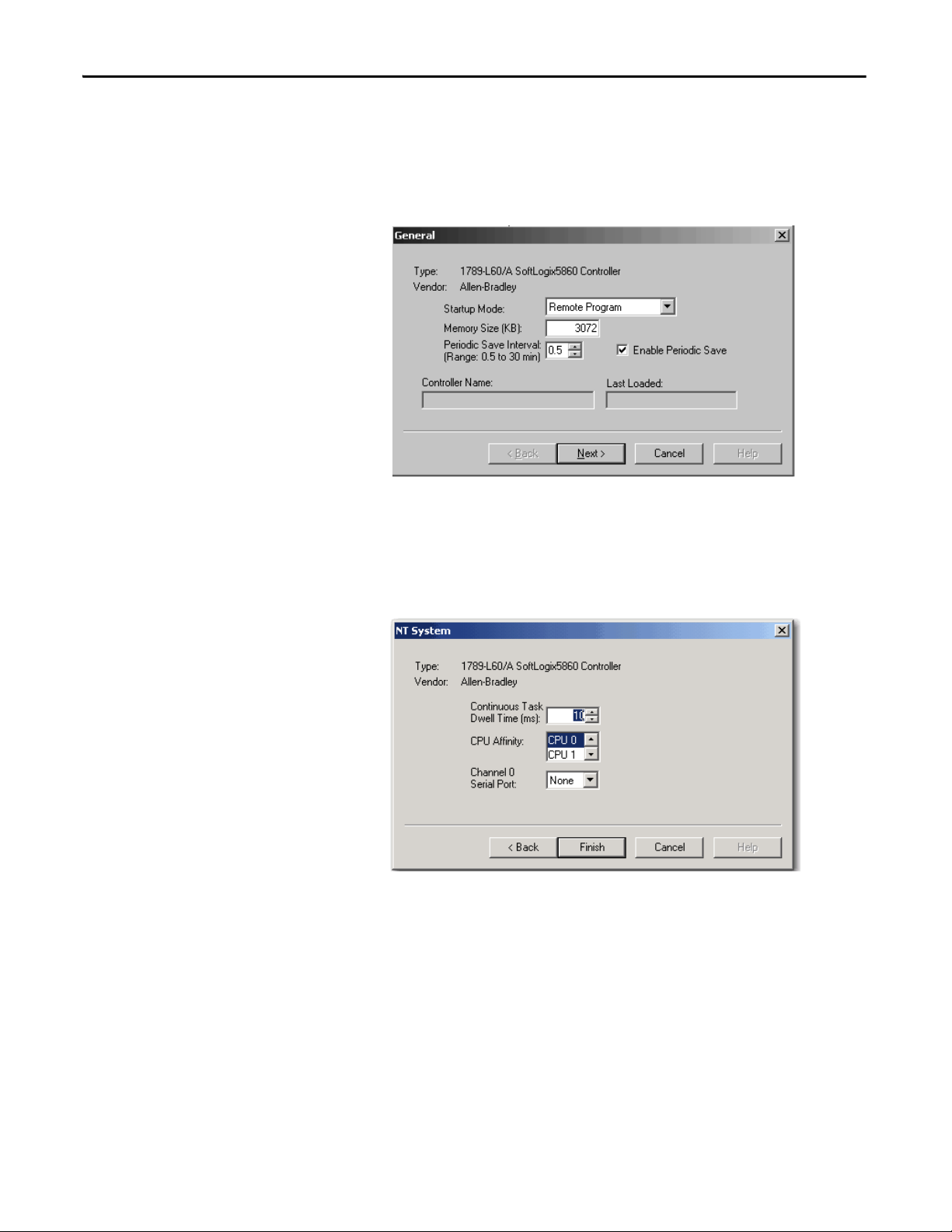

The General dialog box appears.

4. In the General dialog box, enter Startup Mode, Memory Size and Periodic

Save Interval values.

5. Click Next.

The NT System dialog box appears.

6. In the NT System dialog box, enter Continuous Task Dwell Time, CPU

Affinity, and Channel Serial Port values.

7. Click Finish.

28 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 29

What is the SoftLogix System? Chapter 2

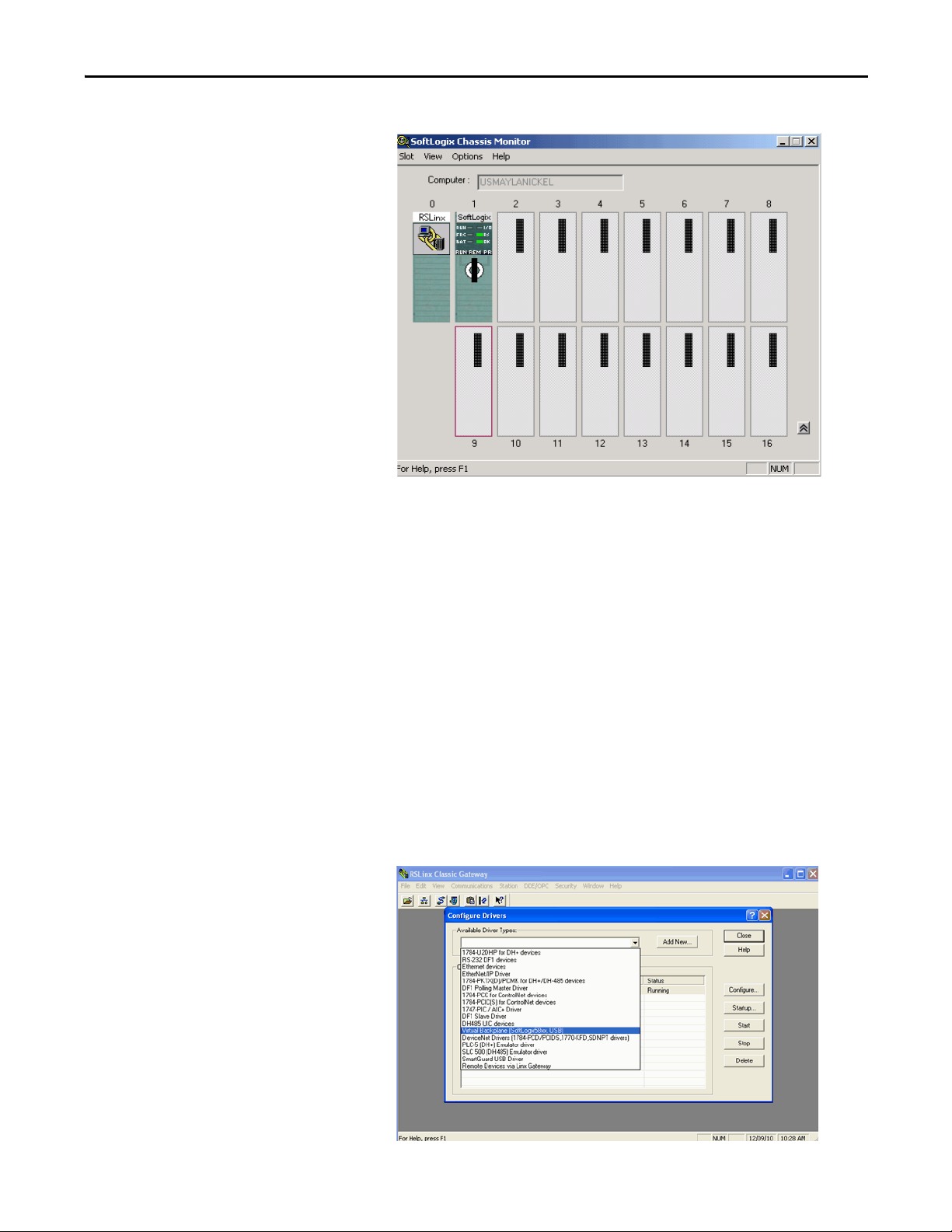

This SoftLogix Chassis Monitor now shows our new controller in slot 1.

Change the RSLinx Software Slot

The RSLinx software module automatically defaults to Slot 0 in the chassis. But

you can program the virtual backplane to use the RSLinx module in another slot

before starting up the SoftLogix application. This flexibility allows a SoftLogix

module to be used in Slot 0 if so desired.

Complete these steps to set up RSLinx software, version 2.59.00 or later, in the

chassis.

1. In RSLinx software, from the Communications menu, choose

Configure Drivers.

The Configure Drivers dialog box appears.

2. From the Available Driver Types pull-down menu, choose

Virtual Backplane.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 29

Page 30

Chapter 2 What is the SoftLogix System?

3. Click Add New and click OK.

4. Select AB-VBP-1 RSLinx Classic Driver from the list and click Configure.

The driver must be running if SoftLogix is used. If the driver is deleted

while SoftLogix is running after choosing a slot other than zero for the

RSLinx module, RSLinx chooses the next available slot in the

chassis monitor.

5. From the Slot Number pull-down menu, choose the slot for the

RSLinx module.

6. Click OK and then click Close.

This SoftLogix Chassis Monitor now shows the RSLinx module in slot 5.

In addition to configuring your controller in the SoftLogix Chassis

Monitor, you must create the controller as part of your RSLogix 5000

project before you can configure and program it.

30 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 31

What is the SoftLogix System? Chapter 2

Step 2: Create the New Controller Project in RSLogix 5000 Software

1. In RSLogix 5000 software, from the File menu, choose New.

The New Controller dialog box appears.

2. In the New Controller dialog box, from the Type pull-down menu, choose

your SoftLogix controller.

3. Enter the controller Name, Chassis Type, and Slot Number to create the

new controller project.

The example above shows the 1789-L60 controller in slot 1.

For RSLogix 5000 software version 20.00.00 or later, slot 0 can

be selected.

4. Click OK.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 31

Page 32

Chapter 2 What is the SoftLogix System?

RSLogix 5000 Controller

Organizer

You now see the new controller in the Controller Organizer’s

I/O Configuration section of RSLogix 5000 software.

Step 3: Configure the Controller in the RSLogix 5000 Project

1. To configure the controller, in the Controller Organizer, from the I/O

Configuration folder, right-click the new controller you just created and

choose Properties.

32 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 33

What is the SoftLogix System? Chapter 2

The Controller Properties dialog box appears.

2. In the Controller Properties dialog box, set controller configuration

information for the open project, and when online—for the attached

controller.

The tabs that appear are particular to the type of controller you have

selected.

3. Click OK when you are done configuring each tab for your controller.

For a complete description of each tab and the appropriate configuration

settings for your SoftLogix controller, see the SERCOS and Analog

Motion Configuration and Startup User Manual,

publication MOTION-UM001.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 33

Page 34

Chapter 2 What is the SoftLogix System?

Figure 2 - Control Application

Controller Fault Handler

Tas k 32

Tas k 1

Confi guration

Status

Watc hdo g

Program 32

Program 1

Main Routine

Fault Ro utine

Program (local)

Tag s

Other Routines

Controller (global) Tags I/O Data System-shared Data

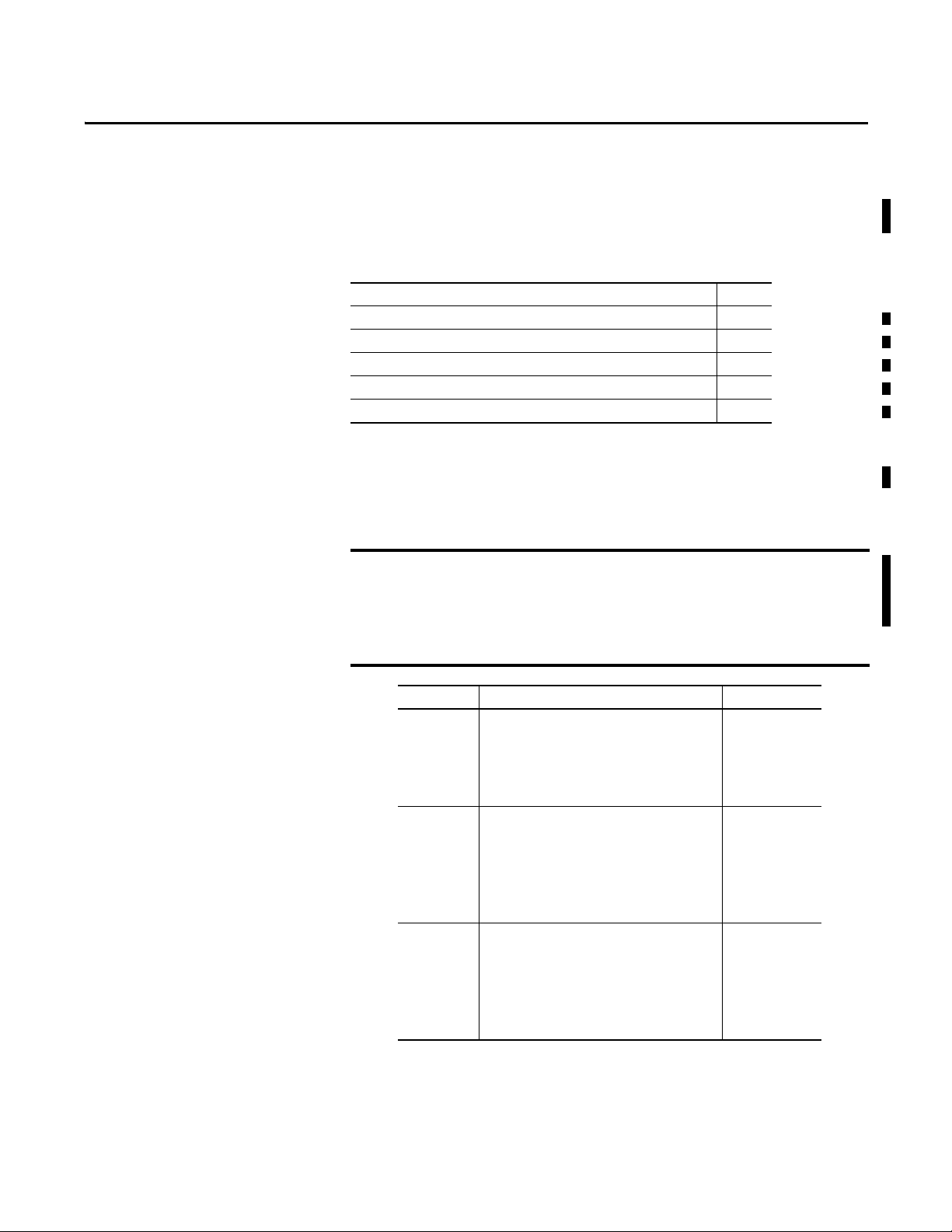

Developing Programs

The controller’s execution model is a preemptive, multitasking system that is

IEC 1131-3 compliant. This environment provides the following:

• Tasks to configure controller execution

• Programs to group data and logic

• Routines to encapsulate executable code written in a single

programming language

Configuring Tasks

A task provides scheduling and priority information for a set of one or more

programs. You can configure tasks as either continuous or periodic. The

SoftLogix controller supports as many as 32 tasks, only one of which can

be continuous.

A task can have as many as 32 separate programs, each with its own executable

routines and program-scoped tags. Once a task is activated, all of the programs

assigned to the task execute in the order in which they are grouped. Programs can

appear only once in the Controller Organizer and cannot be shared by

multiple tasks.

34 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 35

What is the SoftLogix System? Chapter 2

Setting Task Priorities

Each task in the controller has a priority level. The controller uses the priority

level to determine which task to execute when multiple tasks are triggered. There

are 3 configurable priority levels for periodic tasks that range from 1…3, with 1

being the highest priority and 3 being the lowest priority. A higher priority task

will interrupt any lower priority task. The continuous task has the lowest priority

and is always interrupted by any periodic task.

The continuous-task dwell time determines how much time to allow for other

Windows programs, running at a normal priority, to execute. The dwell time is

the time between the end of the continuous task and the start of the next

execution of the continuous task. The dwell time does not affect periodic tasks.

Periodic tasks execute as scheduled, regardless of the dwell time. By default, the

dwell time is 10 ms. This setting has an impact on overall system performance,

see Appendix E

.

Tasks Based on Other Events

The SoftLogix controller supports an additional Windows event trigger. This

trigger lets you monitor Windows events in Windows 2000 or Windows XP

operating systems so that applications outside of the SoftLogix controller can

cause a task within the SoftLogix controller to execute. For more information,

see Chapter 7

.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 35

Page 36

Chapter 2 What is the SoftLogix System?

Tas k 1

Tas k 2

Continuous

Tas k

Dwell

Time

Table 2 - Task Execution Order for Application with Periodic Tasks and Continuous Task

Task Priority Level Task Type Actual Execution Time Worst Case

1 1 20 ms periodic task 2 ms 2 ms

2 2 10 ms periodic task 4 ms 6 ms

N/A None (lowest) Continuous task 25 ms 35 ms

N/A None Dwell time 10 ms 14 ms

Execution Time

Tas k De scr ipt ion

A The highest priority task interrupts all lower priority tasks.

B A lower priority task can be interrupted multiple times by a higher priority task.

C The continuous task runs at the lowest priority and is interrupted by all other tasks.

D The dwell time starts when the continuous task completes. The dwell time does not affect periodic tasks.

Periodic tasks execute as scheduled, regardless of the dwell time.

E The continuous t asks restart, when the dwell time completes, unless a higher priority task is running.

Determining Programs

Each program contains program tags, a main executable routine, other routines,

and an optional fault routine. Each task can schedule as many as 100 programs

(including equipment phases).

The scheduled programs within a task execute to completion from first to last.

Programs that are not attached to any task appear as unscheduled programs. You

must specify (schedule) a program within a task before the controller can scan

the program.

36 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 37

What is the SoftLogix System? Chapter 2

Supporting Routines

A routine is a set of logic instructions in a single programming language, such as

ladder logic. Routines provide the executable code for the project in a controller.

A routine is similar to a program file or subroutine in a PLC or SLC™ processor.

Each program has a main routine. This is the first routine to execute when the

controller triggers the associated task and calls the associated program. Use logic,

such as the JSR instruction, to call other routines.

You can also specify an optional program-fault routine. The controller executes

this routine if it encounters an instruction-execution fault within any of the

routines in the associated program.

The SoftLogix controller supports routines developed with the relay ladder and

function block editors of RSLogix 5000 software. You can edit relay ladder and

function block routines either offline or online. You can also develop C/C++

routines and incorporate them into your project.

See Chapter 5

Chapter 6

for information on adding external routines to a project; see

for information on developing external routines.

Instruction Execution

When performing a math operation, the SoftLogix controller handles INT to

REAL conversions differently than hardware-based Logix controllers. The

SoftLogix controller completes the math operation by using the INT data and

then converts the result to REAL data, which is more consistent with how math

operations occur on personal computers. The hardware-based Logix controllers

first convert INT data to REAL data and then perform the math operation.

The SoftLogix controller also handles the conversion of single-float values to

double-float values differently than the ControlLogix controller. The personal

computer processor calculates conversions to more decimal points than the

ControlLogix controller. This can result in instructions operating differently

between SoftLogix and ControlLogix controllers. For example, when calculating

cam (MAPC) position with the MAPC instruction, the.PC bit can get set

slightly sooner or later in a ControlLogix controller than in a SoftLogix

controller. Factors that affect the time the .PC bit is set are as follows:

• Direction of travel

• Axis scaling constants of the two axes being used for the camming

instruction

• The start and end point values used in the cam

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 37

Page 38

Chapter 2 What is the SoftLogix System?

How the SoftLogix System Uses Connections

Connections for Produced and Consumed Tags

The SoftLogix system uses a connection to establish a communication link

between two devices. Connections can be any of the following:

• Controller to local I/O modules or local communication modules

• Controller to remote I/O or remote communication modules

• Controller to remote I/O (rack-optimized) modules

• Produced and consumed tags

• Messages

You indirectly determine the number of connections the controller uses by

configuring the controller to communicate with other devices in the system.

Connections are allocations of resources that provide more reliable

communication between devices than unconnected messages.

The SoftLogix controller supports the ability to produce (multicast) and

consume (receive) system-shared tags. System-shared data is accessible by

multiple controllers over an EtherNet/IP network. Produced and consumed tags

each require scheduled connections.

Tag Type Required Connection

Produced By default, a produced tag allows two other controllers to consume the tag, which means that as

many as two controllers can simultaneously receive the tag data. The local controller (producing)

must have one connection for the produced tag and the first consumer and one more connection

for each additional consumer (heartbeat). The default produced tag requires two connections.

As you increase the number of controllers that can consume a produced tag, you also reduce the

number of connections the controller has available for other operations, like communication and I/

O.

Consumed Each consumed tag requires one connection for the controller that is consuming the tag.

The SoftLogix controller supports a maximum of 127 consumed connections.

For two controllers to share produced or consumed tags, both controllers must be

attached to the same network. You cannot bridge produced and consumed tags

between two networks.

Connections for Messages

38 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Messages transfer data to other devices, such as other controllers or operator

interfaces. Some messages use unscheduled connections to send or receive data.

These connected messages can leave the connection open (cache) or close the

Page 39

What is the SoftLogix System? Chapter 2

connection when the message is done transmitting. This table shows which

messages use a connection and whether you can cache the connection.

Message Type Communication Method Connection

CIP data table read or write CIP

PLC-2®, PLC-3®, PLC-5®, or SLC (all types) CIP

CIP with source ID

DH+™

CIP generic N/A

Connected messages are unscheduled connections on both ControlNet and

EtherNet/IP networks.

If a message executes repeatedly, cache the connection. This keeps the connection

open and optimizes execution time. Opening a connection each time the message

executes increases execution time.

If a message executes infrequently, do not cache the connection. This closes the

connection upon completion of the message, which frees up that connection for

other uses.

Each message uses one connection, regardless of how many devices are in the

message path. To conserve connections, you can configure one message to read

from or write to multiple devices.

You can cache as many as 16 messages (a combination of any type, not including

block-transfer) at one time. If you try to cache more than 16, the controller

determines the 16 most-currently used messages and caches those. If there are 16

messages cached, and a message is triggered that is currently not cached, the

controller drops the connection of the oldest-cached message to make room for

the new message.

In addition to 16 cached messages, you can also cache as many as 16 blocktransfer messages. The same conditions apply to caching block-transfer messages

as described above for caching other types of messages.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 39

Page 40

Chapter 2 What is the SoftLogix System?

Connections for I/O Modules

Connection Description

Direct A direct connection is a real-time, data transfer link between the controller and an I/O module. The controller maintains and

Rack-optimized For digital I/O modules, you can choose rack-optimized communication. A rack-optimized connection consolidates

The SoftLogix system uses connections to transmit I/O data. These connections

can either be direct connections or rack-optimized connections.

monitors the connection between the controller and the I/O module. Any break in the connection, such as a module fault or

the removal of a module while under power, causes the controller to set fault status bits in the data area associated with the

module.

connection usage between the controller and all of the digital I/O modules on a rack (or DIN rail). Rather than having

individual, direct connections for each I/O module, there is one connection for the entire rack (or DIN rail).

To conserve the number of connections that are available, place digital

I/O modules together in the same location and use a rack-optimized connection.

To choose a rack-optimized connection, choose a ‘rack-optimized’ option for the

communication format when you add the communication device and

I/O modules to the controller project in RSLogix 5000 software.

If you have analog I/O modules, or want a direct connection to specific

I/O modules, you do not have to create the rack-optimized connection to the

communication device. To use direct connections to I/O modules, choose ‘none’

for the communication format of the communication device.

Total Connection Requirements

Table 3 - Connections

Connection Type Device Quantity Connections Per

Remote EtherNet/IP communication device (such as a 1794-AENT or 1756-ENBT

module):

• Configured as a direct (none) connection

• Configured as a rack-optimized connection

Remote I/O device over the EtherNet/IP network (direct connection) 1

Produced and consumed tag:

• Produced tag and one consumer

• Each additional consumer

Consumed tag 1

Cached message 1

Total

The SoftLogix controller supports 250 connections. Each 1784-PCICS

ControlNet communication card supports 128 total connections, 127 of which

can be scheduled. Do not configure more connections than the controller can

support. Use this table to tally ControlNet connections.

Total Connections

Device

0

1

1

1

40 Rockwell Automation Publication 1789-UM002J-EN-P - December 2012

Page 41

What is the SoftLogix System? Chapter 2

Restart the Controller

You restart the controller by either of these methods:

• Restarting the computer

• Removing and reinserting the controller in the virtual chassis

After restarting the controller, you must upload or download from

RSLogix 5000 software before you can go online with the controller. This is

because the RSLogix 5000 project file (.ACD) contains explicit knowledge of the

physical memory addresses used by the controller. When you restart the

controller, all of the physical addresses for the controller are regenerated. Note

that as long as the controller is not restarted, you can go online and offline as

many times as required.

Online with the Controller

You must save the RSLogix 5000 project after a download completes, or you will

not be able to go online with the controller. After downloading, the physical

address information has changed. RSLogix 5000 software prompts you to save

and indicates that a change has occurred even though you might not have made

changes to the project. Saving the project stores the physical address information

into the ACD file.

An upload recovers all of the information that was downloaded to the controller,

including documentation. This is because of the persistent storage feature that

you enable by specifying a periodic save interval (see page 26

the persistent storage copies the entire project file to the controller. The

controller opens and goes online with the project file so that any edits made by

RSLogix 5000 workstations are saved into the persistent image (the controller's

copy of the project file). Online edits are saved to the persistent image

immediately; tag data values are saved to the persistent image at every periodic

save interval (10 min default). If the periodic save is disabled, tag data values are

not saved, but online edits are still saved to the persistent image.

The SoftLogix controller maintains a change log that holds 999 entries. This

means that as you edit an RSLogix 5000 project file, you must save the project file

before you make 999 changes. If you make more than 999 changes to a project,

you will not be able to go back online without performing an upload or

a download.

). On a download,

Upload to the Controller

If your project has edits and you want to upload the project to the controller,

RSLogix 5000 software prompts you to save the project before uploading.

Regardless of your choice, the edits are saved before the upload occurs. This

happens because the edits are already stored in the controller as you make

the edits.

Rockwell Automation Publication 1789-UM002J-EN-P - December 2012 41

Page 42

Chapter 2 What is the SoftLogix System?

Select a System Overhead Percentage

The Controller Properties dialog box lets you specify a percentage of controller

time (excluding the time for periodic tasks) that is devoted to communication

and background functions.

1. In the RSLogix 5000 software, from the Controller Organizer, right-click

the controller and choose Properties.