Page 1

NI-FBUS

Configurator

1788-FFCT

User Manual

Page 2

Page 3

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Rockwell Automation be

responsible or liable for indirect or consequential damage resulting

from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Rockwell Automation does not

assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware

of safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

!

ATTENTION

injury or death, property damage, or economic loss.

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

Identifies information that is critical for successful

application and understanding of the product.

Page 4

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

systems integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

first call your local Rockwell Automation representative, then:

• Post-sales Technical Support, 440.646.5800

• Web Links, http://www.ab.com

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the

How Are We Doing? form at the back of this manual.

Page 5

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . iii

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . iv

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . iv

Your Questions or Comments on this Manual . . . . . . . . . iv

Preface

Fieldbus Overview

Configuring a Fieldbus System

NI-FBUS Configurator Overview

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . ix

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Chapter 1

Introduction to Fieldbus . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Parts of a Fieldbus Network. . . . . . . . . . . . . . . . . . . . . . . . 1-1

Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Blocks and Parameters . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Linkages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Schedules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Chapter 2

Configuring a Typical Fieldbus System. . . . . . . . . . . . . . . . 2-1

Chapter 3

Introduction to

the NI-FBUS Configurator . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

NI-FBUS Configurator Features . . . . . . . . . . . . . . . . . . . . . 3-1

NI-FBUS Configurator Windows. . . . . . . . . . . . . . . . . . . . . 3-2

Configurator Main Window . . . . . . . . . . . . . . . . . . . . . 3-2

Project Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Help Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Status Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Chapter 4

Using the NI-FBUS Configurator

v Publication 1788-UM052B-EN-P - April 2002

Starting the NI-FBUS Configurator . . . . . . . . . . . . . . . . . . . 4-1

Configuring Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Importing Device Description Files . . . . . . . . . . . . . . . . . . 4-4

Setting Device or Block Tags . . . . . . . . . . . . . . . . . . . . . . . 4-5

Setting Device Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Resetting a Device to Factory Defaults . . . . . . . . . . . . . . . . 4-8

Formulating a Control Strategy. . . . . . . . . . . . . . . . . . . . . . 4-8

Function Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Adding Function Blocks . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Connecting Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Viewing and Editing Function Block Parameters. . . . . . . . . 4-19

Block Window Icons . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Block Window Toolbar . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Page 6

vi

Tabs of the Block Window. . . . . . . . . . . . . . . . . . . . . . 4-21

Editing Block Parameters . . . . . . . . . . . . . . . . . . . . . . . 4-23

Updating Block Parameter Values. . . . . . . . . . . . . . . . . 4-24

Using Menus and Methods . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Configuring Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Configuring Trends . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Viewing and Editing a Schedule. . . . . . . . . . . . . . . . . . . . . 4-27

Schedule Window Toolbar . . . . . . . . . . . . . . . . . . . . . . 4-28

Changing the Link Active Schedule. . . . . . . . . . . . . . . . 4-28

Multiple Loop Representation . . . . . . . . . . . . . . . . . . . . 4-29

Setting Network Parameters. . . . . . . . . . . . . . . . . . . . . . . . 4-30

Downloading a Configuration . . . . . . . . . . . . . . . . . . . . . . 4-31

Monitoring a Function Block Application . . . . . . . . . . . . . . 4-32

Verifying a Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Quick Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-33

Comparing Two Configurations . . . . . . . . . . . . . . . . . . 4-34

Viewing and Editing a Log. . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Replacing Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-35

Setting Preferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

Changing the Software Key . . . . . . . . . . . . . . . . . . . . . . . . 4-37

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-38

Error Messages and Warnings

Troubleshooting and Common

Questions

Appendix A

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Appendix B

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Missing Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Missing Symbolic Information. . . . . . . . . . . . . . . . . . . . B-2

Device Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Mode Transition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Reading and Writing Errors . . . . . . . . . . . . . . . . . . . . . B-5

Common Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

How can I speed up the control? . . . . . . . . . . . . . . . . . B-6

Why is my interface missing from the

Add Links dialog box? . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

Publication 1788-UM052B-EN-P - April 2002

Page 7

Preface

This manual gives an overview of fieldbus, describes the NI-FBUS

Configurator, and explains how to use the NI-FBUS Configurator.

The NI-FBUS Configurator is intended for use with Microsoft

Windows NT.

This manual assumes that you are already familiar with Windows NT.

Conventions Used in This Manual

Related Documentation

This manual uses the following conventions:

< > Angle brackets enclose the name of a key on the keyboard—for

example, <Enter>.

⇒ The ⇒ symbol leads you through nested menu items and dialog box

options to a final action. The sequence File

directs you to pull down the File menu, select the Page Setup item, and

select Options.

bold Bold text denotes parameters, menus, menu items, buttons or options.

monospace This font denotes the messages and responses that the computer

automatically prints to the screen.

italic Italic text denotes a key concept.

NI-FBUS In this manual, the term NI-FBUS refers to the NI-FBUS Communications

Manager.

These FOUNDATION Fieldbus Specification documents contain

information that you may find helpful as you read this manual:

• System Architecture, document FF-800

⇒ Page Setup ⇒ Options

• Function Block Application Process, Parts 1–3, documents

FF-890, FF-891, and FF-892.

These documents can be purchased from the Fieldbus Foundation as

part of the H1 Communications and User Layer Technical

Specification (hardcopy). For more information go to

http://www.foundationfieldbus.org/ProductsAndServices/FFProductCatalog/

and look under Final Specifications.

ix Publication 1788-UM052B-EN-P - April 2002

Page 8

Preface x

Publication 1788-UM052B-EN-P - April 2002

Page 9

Chapter

1

Fieldbus Overview

This chapter introduces fieldbus and the parts of a fieldbus network.

This chapter contains fieldbus information that will help you use the

NI-FBUS Configurator and solve problems with the configuration of

your fieldbus system. Refer to the Glossary for more explanation of

fieldbus terms and concepts. If you already have a basic knowledge

of fieldbus concepts, or if you want to start using the NI-FBUS

Configurator immediately, skip to Chapter 3, NI-FBUS

Configurator Overview.

Introduction to Fieldbus

Parts of a Fieldbus Network

The term fieldbus refers to an all-digital, two-way communication

system that connects control systems to instrumentation.

The Fieldbus Foundation is an organization that developed a fieldbus

network based on the work and principles of the ISA and IEC. The

goal of the Fieldbus Foundation is to help create products that use a

robust industrial network based on existing standards and other

proven technologies and to standardize using those sources.

F

OUNDATION Fieldbus, the communications network created by the

Fieldbus Foundation, is a protocol designed for robust, distributed

control in process control environments. Devices connected by

F

OUNDATION Fieldbus control a process by exchanging data.

There are six conceptual parts to a fieldbus network:

• links

• devices

• blocks and parameters

• linkages

• loops

• schedules

Descriptions of these parts can be found on the following pages.

1 Publication 1788-UM052B-EN-P - April 2002

Page 10

1-2 Fieldbus Overview

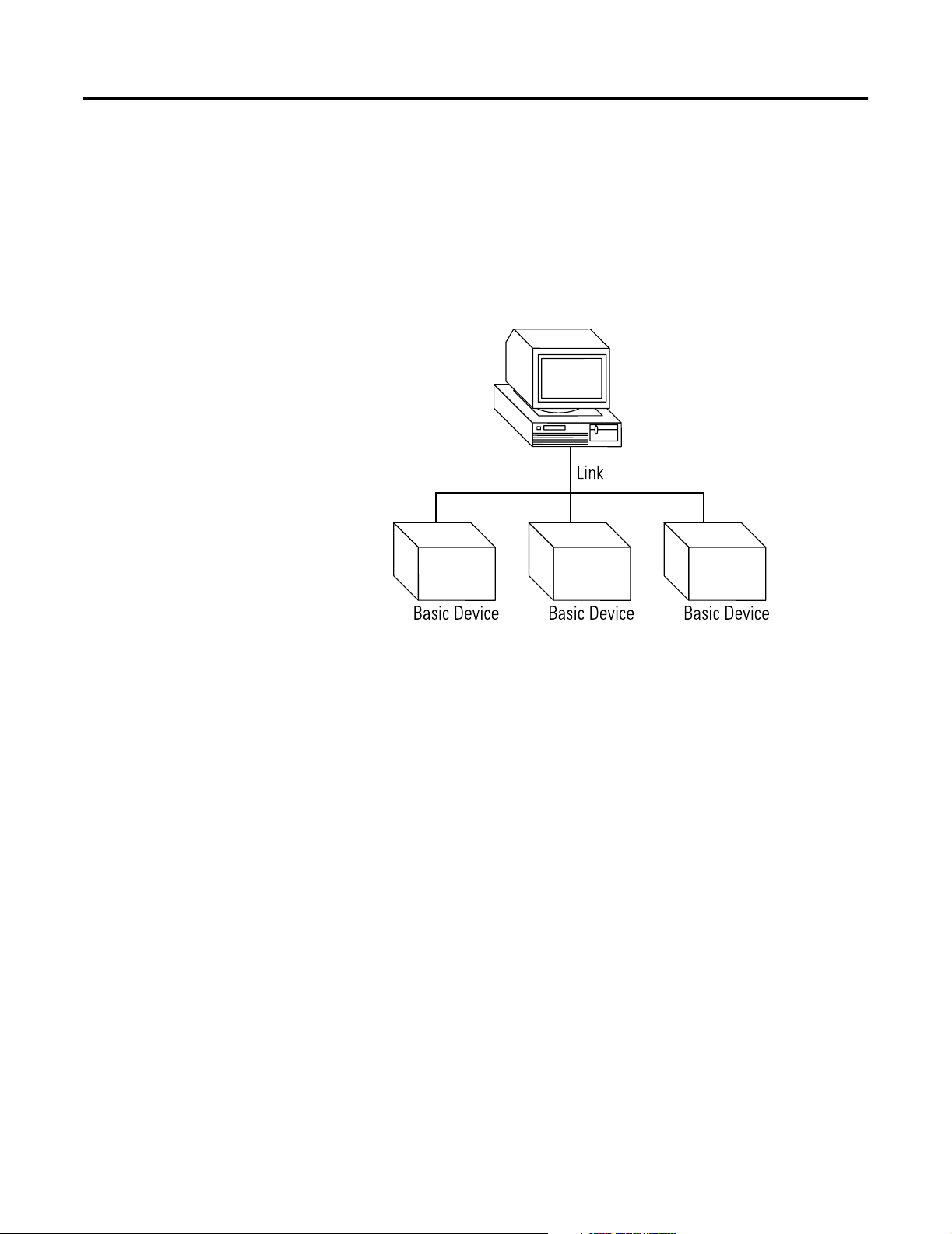

Links

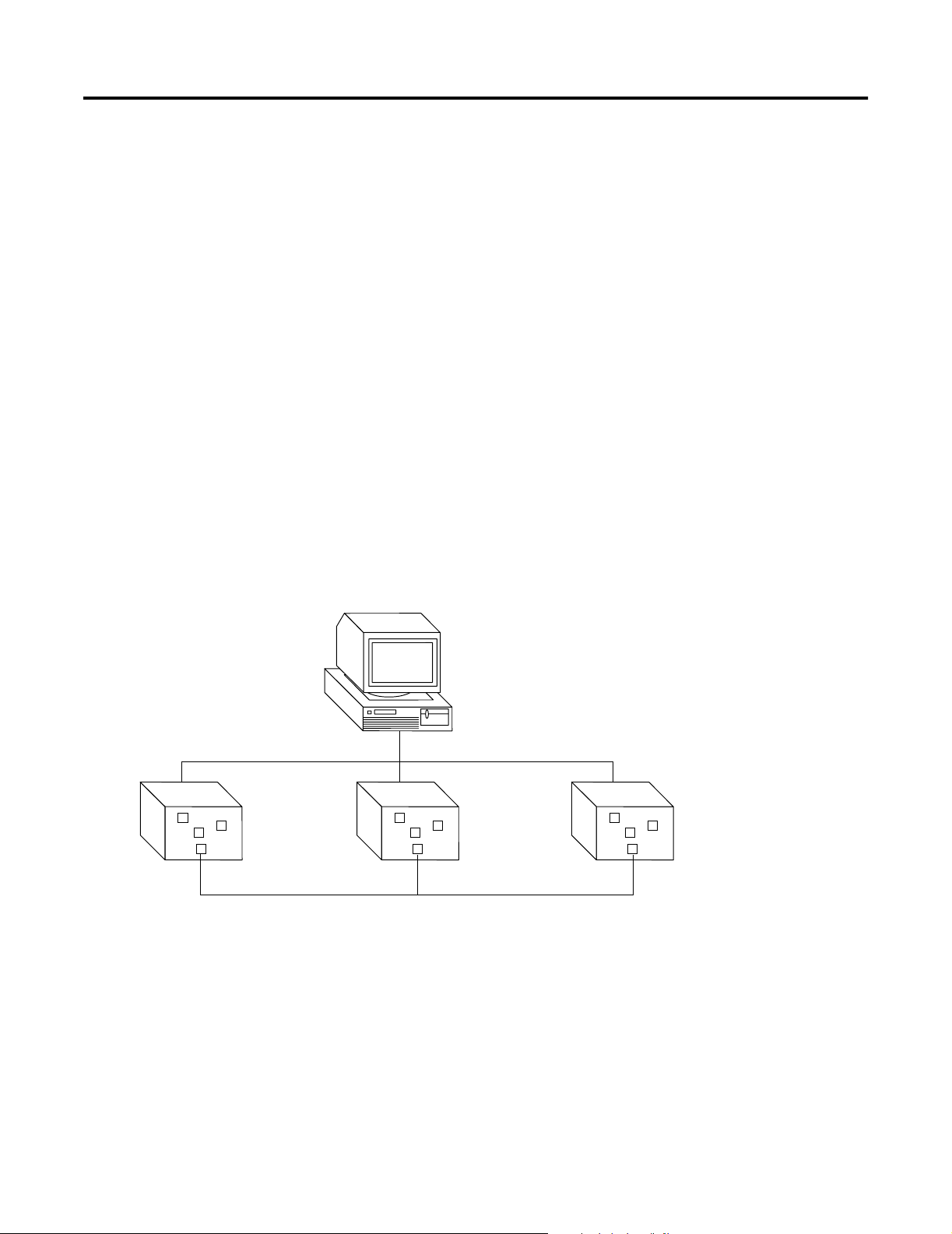

A FOUNDATION Fieldbus network is made up of devices connected by

a serial bus. This serial bus is called a link. Links can be separated by

special devices called bridges. Figure 1.1 shows a link in a fieldbus

network.

Figure 1.1 Fieldbus Network Link

43270

Publication 1788-UM052B-EN-P - April 2002

Page 11

Fieldbus Overview 1-3

Devices

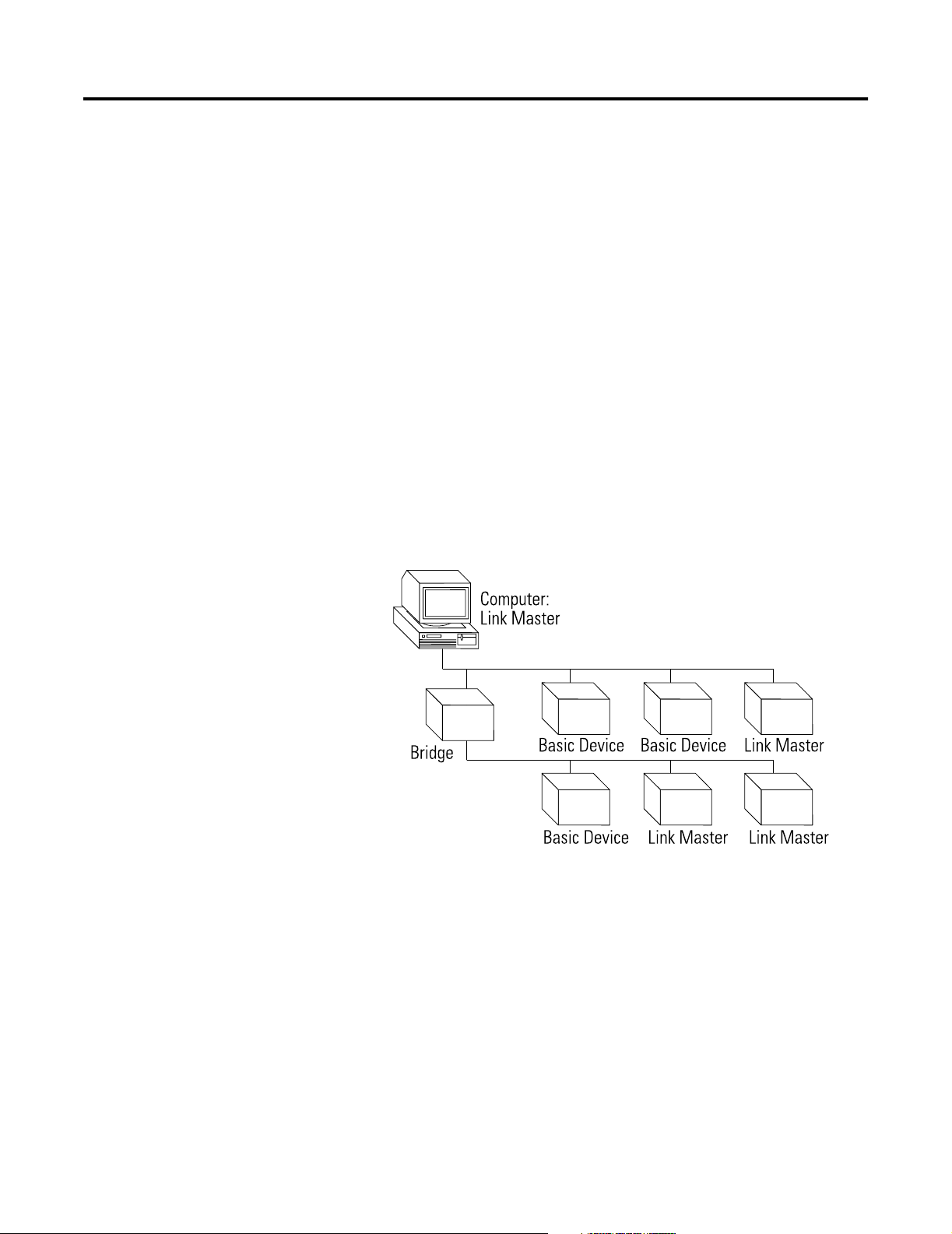

There are three types of devices on a fieldbus network: the link

master, basic devices, and bridges.

• Link master –A link master device controls the communications

traffic on a link. A link master prevents multiple devices from

communicating data at the same time. A link master can be a

Distributed Control System (DCS) or any other device, such as a

valve or a pressure transducer. There can be more than one link

master per link, but only one link master can be the Link Active

Scheduler (LAS) at any given time.

• Basic device –A basic device cannot become the LAS.

• Bridge –A bridge connects two or more links.

Figure 1.2 shows these three types of devices.

Figure 1.2 Fieldbus Network Devices

43271

Identifying Devices

Devices are uniquely identified on the fieldbus network by character

string name, or tag. The device tag is a configurable attribute of the

device that usually describes the type of the device. Device tags are

unique to each device on a fieldbus network.

Another unique identifier of a device is the device ID, which includes

a serial number unique to the device. The device ID is assigned by the

device manufacturer; you cannot configure it.

Publication 1788-UM052B-EN-P - April 2002

Page 12

1-4 Fieldbus Overview

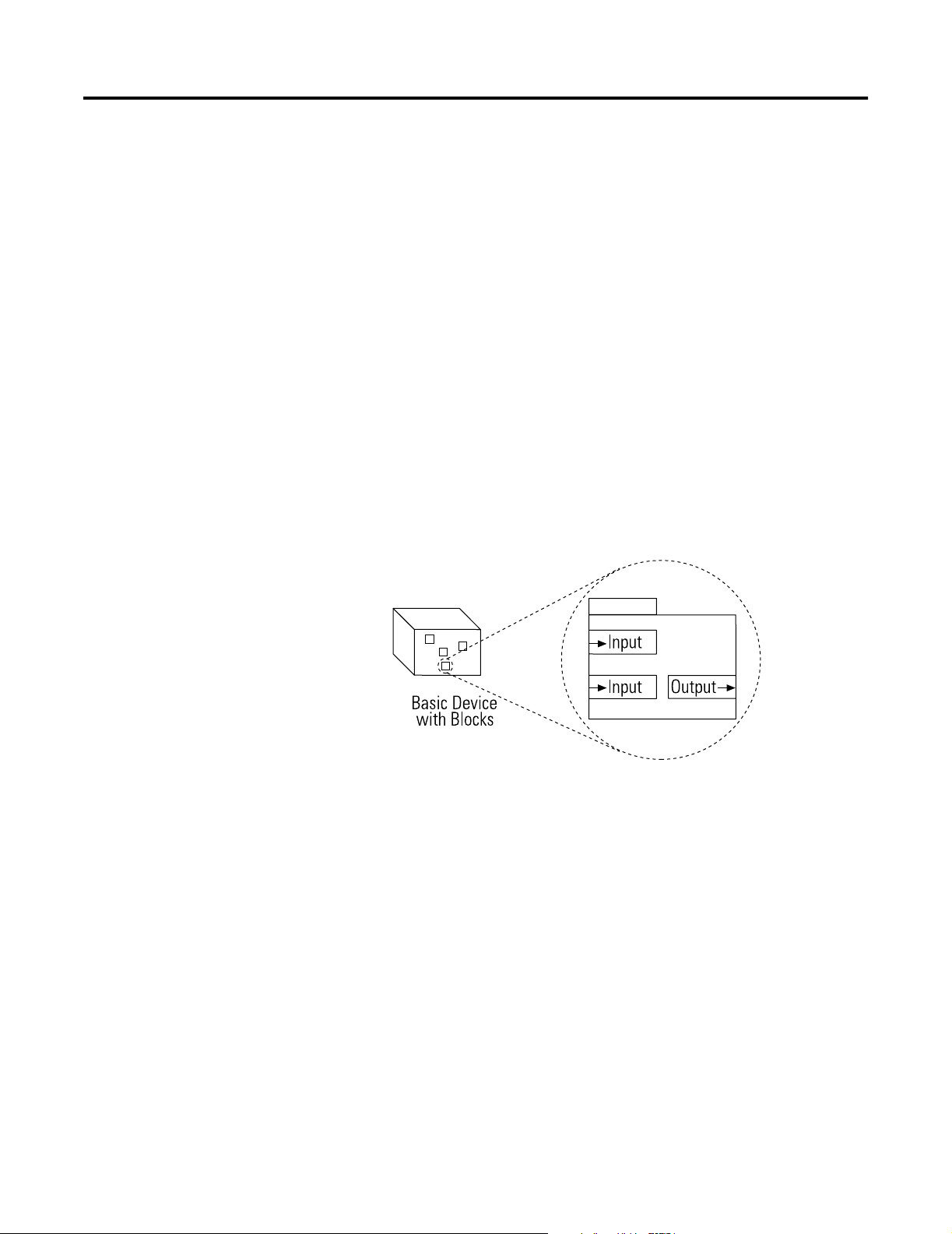

Blocks and Parameters

Functions that can be performed by a device are represented as

function blocks. Function blocks contain algorithms and

algorithm-controlling parameters. The 10 standard blocks and

algorithms include the following:

• Analog Input (AI)

• Analog Output (AO)

• Bias Gain (BG)

• Control Selector (CS)

• Discrete Input (DI)

• Discrete Output (DO)

• Proportional Derivative (PD)

• Proportional Integral Derivative (PID)

• Ratio Control (RC)

• Manual Loader (ML)

You can change or set the action of a block by changing the settings

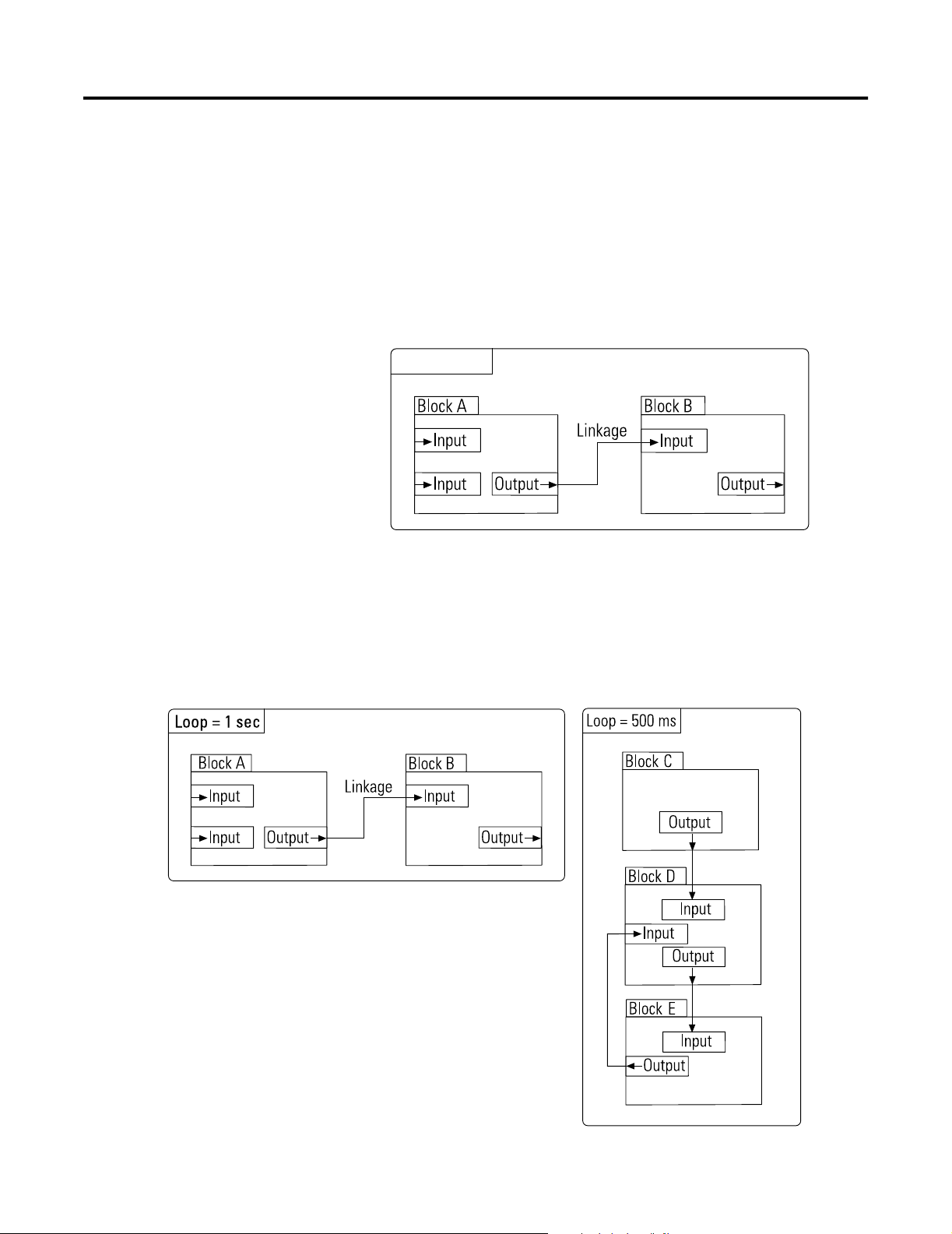

of its parameters. Figure 1.3 shows an example of a function block

and its input and output parameters.

Figure 1.3 Function Block Parameters

43272

Publication 1788-UM052B-EN-P - April 2002

Function block parameters are classified as follows:

• Input parameters receive data from other blocks.

• Output parameters send data to other blocks.

• Contained parameters do not receive or send data; they are

contained within the block.

Function block parameters are also classified as alarm, trend, or tuning

parameters. These classifications are independent of the input, output,

and contained classifications. For example, an input parameter can

also be an alarm, trend, or tuning parameter.

Page 13

Fieldbus Overview 1-5

Device Description Files

The vendor supplied Device Description (DD) files describe the

function and transducer blocks contained in a device. A DD file

includes symbolic information (such as names and help strings) and

functional information (such as menus and methods that you can use

with the device). DDs are used with the NI-FBUS Configurator to

configure a device.

Identifying Blocks

Blocks are uniquely identified on the fieldbus network by a character

string name, or tag, similar to the device tag. The block tag is an

attribute of a block that usually describes the purpose and location of

the block. You can change the block tag, but block tags must be

unique to each block on a fieldbus network.

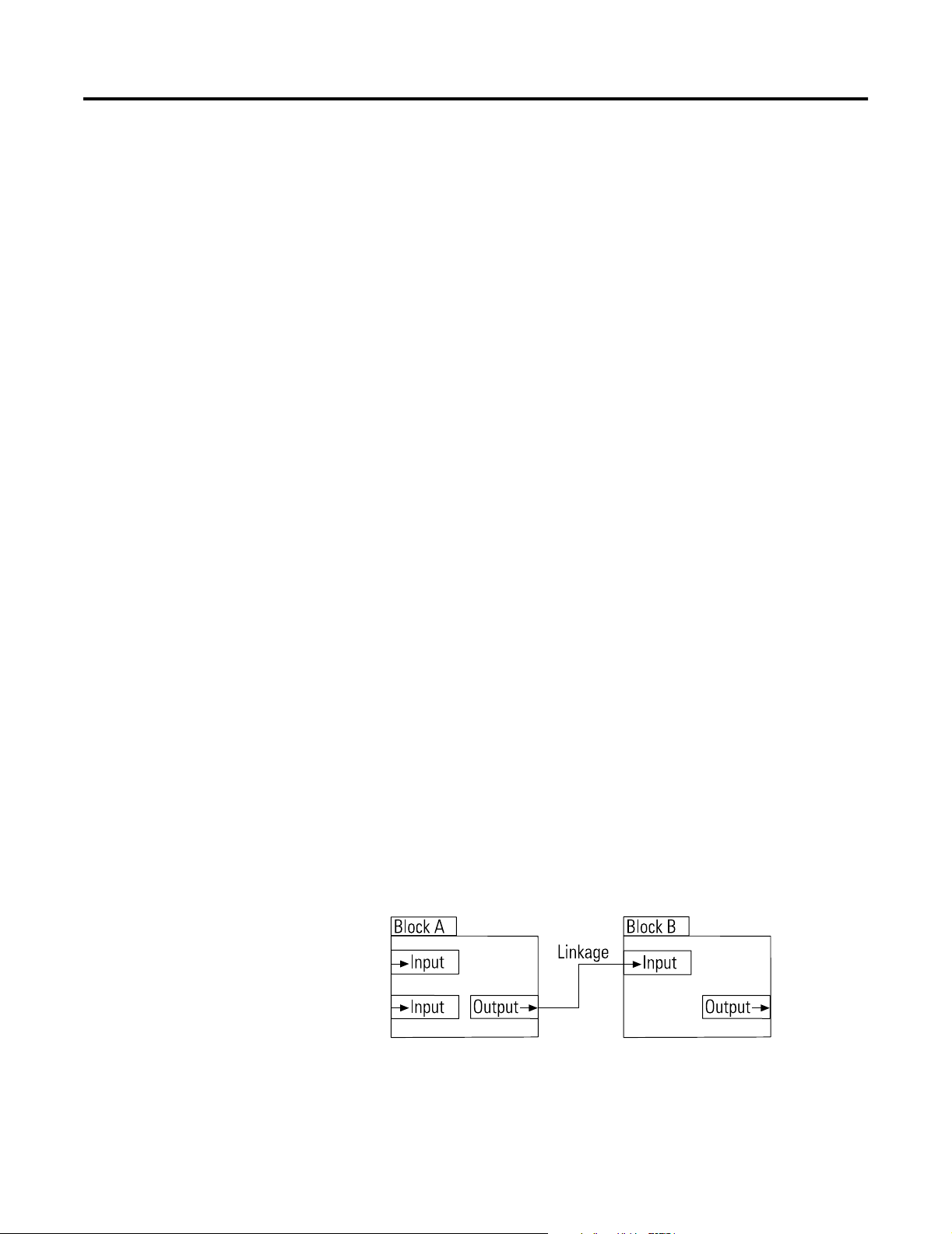

Linkages

The function blocks configured to control a process are linked, or

connected by configuration objects inside the devices. These linkages

allow you to send data from one block to the other. A linkage is

different from a link, in that a link is a physical wire pair that connects

devices on a fieldbus network, and a linkage is a logical connection

that connects two function blocks.

A block parameter that is written to the bus is referred to as a

published parameter. A block parameter that is receiving data is

referred to as a subscribed parameter. Figure 1.4 shows an example of

a linkage between blocks. In this example, the output parameter in

block A is the published parameter and the input parameter in block

B is the subscribed parameter. The blocks can be in the same device

or in different devices.

Figure 1.4 Linkage Between Function Blocks

43273

Publication 1788-UM052B-EN-P - April 2002

Page 14

1-6 Fieldbus Overview

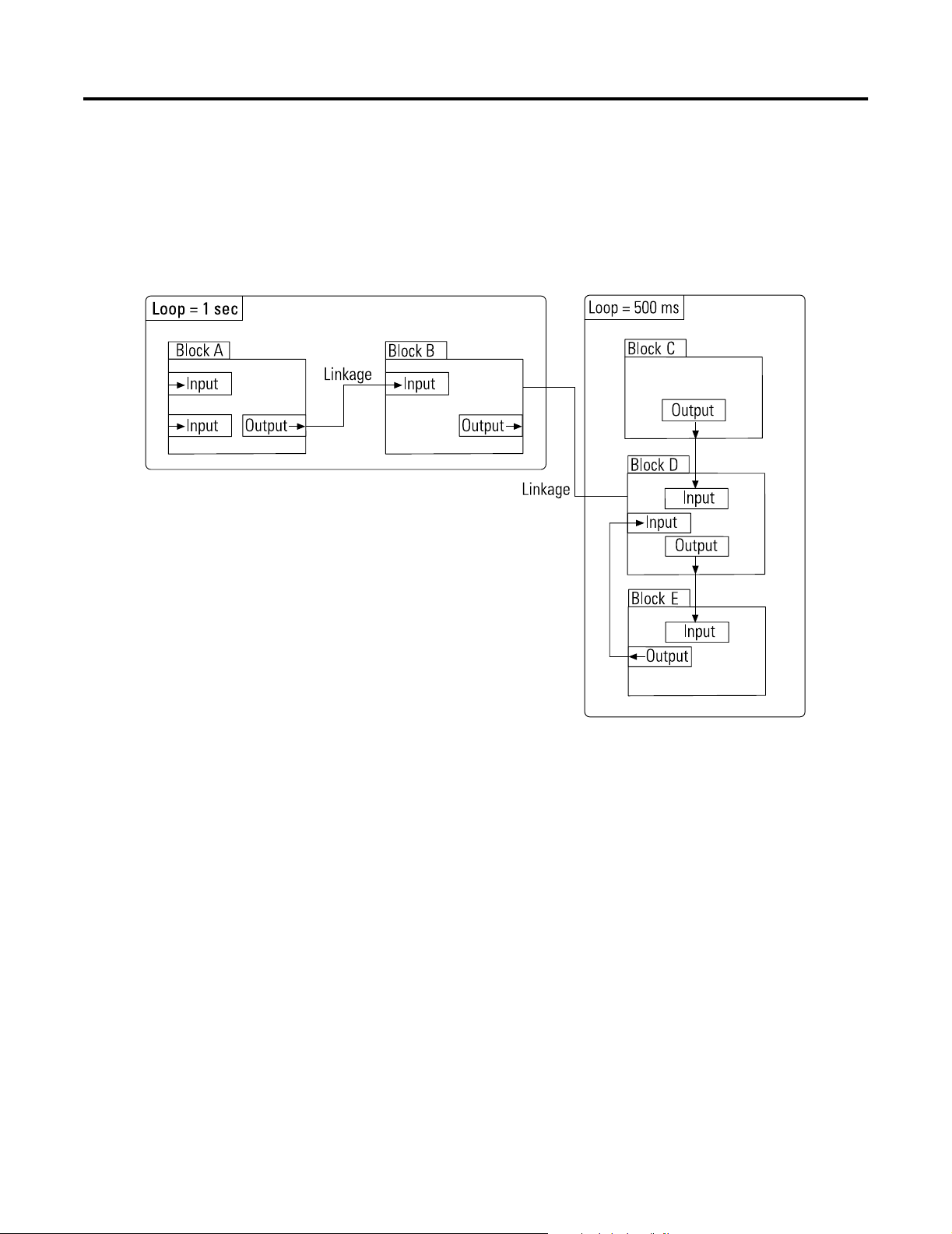

Loops

A loop or control loop is a group of function blocks connected by

linkages executing at a configured rate. Each block executes at the

configured rate and data moves across the linkages between the

blocks at the configured rate. Figure 1.5 shows an example of a

control loop.

Figure 1.5 Control Loop

Loop = 1 sec

43274

Multiple Loops

It is possible to have multiple loops running at different rates on a

link. Figure 1.6 shows an example of multiple loops.

Figure 1.6 Multiple Loops Running At Different Rates

Publication 1788-UM052B-EN-P - April 2002

43275

Page 15

Fieldbus Overview 1-7

Even if loops are running at different rates, they can send each other

data through linkages. Figure 1.7 shows an example of a linkage

between two loops. All loops on a link run within one macrocycle. A

macrocycle is the least common multiple of all the loop times on a

given link. For example, the macrocycle in Figure 1.7 is 1 second.

Figure 1.7 Linkage Between Two Loops

43276

Publication 1788-UM052B-EN-P - April 2002

Page 16

1-8 Fieldbus Overview

Schedules

A schedule of data traffic allows communication to be deterministic,

meaning that data is transferred between a given set of devices at the

same time during each loop.

The schedule can be divided into two parts: a function block schedule

that determines when a block executes, and a publishing schedule

that determines when data parameters are published over the fieldbus.

The function block schedule is downloaded to the device that

contains the function blocks, and the publishing schedule is usually

downloaded to a device or devices that have link master capability.

The link master running the publishing schedule, and therefore

controlling the process, is the LAS.

Downloading the schedule to multiple devices with link master

capability ensures that the process is controlled, even if the LAS fails.

If the LAS fails, another device with link master capability takes over

the bus and runs the schedule. Figure 1.8 shows the relationship of

the two schedules to the device, link, link master, and LAS.

Link

Basic Device

(Function Block

Schedule)

Linkage

Figure 1.8 Publishing and Function Block Schedules Relationships

LAS

(Publishing

Schedule)

Basic Device

(Function Block

Schedule)

(Function Block Schedule,

Link Master

Publishing Schedule)

43277

Publication 1788-UM052B-EN-P - April 2002

Page 17

Chapter

2

Configuring a Fieldbus System

This chapter contains brief instructions on how to configure a typical

fieldbus system.

Refer to Chapter, Fieldbus Overview, or the Glossary for an

explanation of fieldbus terms or concepts. Refer to Chapter 3,

NI-FBUS Configurator Overview, for information about a specific

control or window in the NI-FBUS Configurator.

Configuring a Typical Fieldbus System

IMPORTANT

The following is an example of a typical fieldbus system

configuration, using the NI-FBUS Configurator:

1. Connect the devices in a segment. You can connect devices in

one of two ways: online or offline.

• In the online mode, connect the devices to the fieldbus

segment and start the NI-FBUS Configurator.

• In the offline mode, the devices are not connected to the

fieldbus.

For instructions on how to connect devices, refer to the

Configuring Online section on page 4-2.

2. Import the Device Descriptions (DDs) of the connected devices

to the computer that runs the NI-FBUS Configurator.

Before you use the NI-FBUS Configurator, you must

install and configure your software and any fieldbus

interfaces, as instructed in your getting started

manual.

For instructions on how to import DDs, refer to the Starting the

NI-FBUS Configurator section on page 4-1.

1 Publication 1788-UM052B-EN-P - April 2002

Page 18

2-2 Configuring a Fieldbus System

3. Set addresses and tags.

• Each device has a physical device tag and a fieldbus network

address. You must assign a unique tag to each device. Each

address must be unique within a fieldbus segment.

• Each device has function blocks that perform control

functions, such as AI, AO, DI, DO, PID, and so on. Devices

also have transducer blocks that perform I/O with sensors

and actuators. You must assign a unique tag to function and

transducer blocks.

For instructions on how to set addresses and tags, refer to the

Setting Device or Block Tags and Setting Device Addresses

sections on pages 4-5 and 4-6, respectively.

4. Formulate a control strategy.

• To define your control strategy, identify the function blocks

and connect the relevant function blocks. For example, if you

are configuring a cascaded PID control, you must identify the

primary and secondary PIDs and their inputs and outputs.

• You must also configure loop times or cycle times. For

example, you can configure the primary loop in the cascade

to execute at a certain rate, and configure the secondary loop

to execute at a different rate.

For instructions on how to formulate a control strategy, refer to

the Formulating a Control Strategy section on page 4-8.

5. Schedule function blocks and communication.

Fieldbus schedules the execution of function blocks and the

communication between the connected function blocks. The

two schedules are synchronized to prevent oversampling.

For instructions on how to edit the schedule, Viewing and

Editing a Schedule section on page 4-27.

Publication 1788-UM052B-EN-P - April 2002

Page 19

Configuring a Fieldbus System 2-3

6. Configure alarms.

Using the NI-FBUS Configurator, you can configure fieldbus

devices to generate alarms. Thus, you do not need an HMI to

generate alarms. To configure alarms, identify the function

blocks that generate alarms and the hosts that receive the

alarms. You must also configure the alarm limits and priorities.

For instructions on how to configure alarms, refer to the

Configuring Alarms section on page 4-25.

7. Configure trends.

Fieldbus devices collect trend samples (value, status, and time

stamps) and broadcast them on the bus periodically. To

configure trends, identify the function block (or transducer

block) parameters that you want to trend, and configure the

sampling rates and types for each of them. You must also

identify which host or hosts receive the trend.

For instructions on how to configure trends, refer to the

Configuring Trends section on page 4-26.

8. Set static parameters.

For your control strategy to work, you must configure static

parameters, such as scaling parameters like XD_SCALE in AI/AO

blocks and PV_SCALE in PID blocks. For PID control, you must

also configure engineering units, control and I/O options, fault

state values for output blocks, and tuning parameters.

For instructions on how to set parameters, refer to the Viewing

and Editing Function Block Parameters section on page 4-19.

9. Configure input/output (I/O).

Sensor and actuator I/O is typically modeled as a transducer

block. Refer to your sensor or actuator documentation to

determine whether you can configure I/O.

For instructions on how to configure I/O, refer to the Viewing

and Editing Function Block Parameters section on page 4-19.

Publication 1788-UM052B-EN-P - April 2002

Page 20

2-4 Configuring a Fieldbus System

10. Set network parameters.

For communication and scheduling to function properly, you

must configure the fieldbus communication-specific network

parameters. An example of a network parameter is identifying

the primary time master and the primary Link Active Scheduler

(LAS) devices.

For instructions on how to set network parameters, refer to the

Setting Network Parameters section on page 4-30.

11. Download a configuration.

Make sure that all the devices are connected to the bus, and

download the configuration.

For instructions on how to download a configuration, refer to

the Downloading a Configuration section on page 4-31.

Publication 1788-UM052B-EN-P - April 2002

Page 21

Chapter

NI-FBUS Configurator Overview

This chapter introduces the NI-FBUS Configurator, lists some of its

main features, and describes the main windows of the application.

3

Introduction to

the NI-FBUS Configurator

NI-FBUS Configurator Features

You can use the NI-FBUS Configurator to configure a fieldbus network

and keep track of your configuration changes. The NI-FBUS

Configurator is an easy-to-use graphical environment for creating

linkages, loops, and a schedule based on the fieldbus concepts

described in Chapter, Fieldbus Overview.

Now that you are familiar with the basics of fieldbus communication,

you are ready to use the NI-FBUS Configurator. To use the NI-FBUS

Configurator immediately, continue to Chapter, Using the NI-FBUS

Configurator.

You can use the NI-FBUS Configurator to configure a fieldbus network

as follows:

• Set block and device tags

• Set device addresses

• Create and edit function block control strategies

(function block applications)

• Configure vendor-defined function and transducer blocks

• Create and edit schedules

• Read and write to function block control strategies

(function block applications)

• Invoke Device Description (DD) methods

• Display DD menus

• Download a configuration

• Verify a configuration and compare it to a saved configuration

• Monitor a downloaded configuration

• Replace devices

• Log project download changes

• Save and print a configuration

1 Publication 1788-UM052B-EN-P - April 2002

Page 22

3-2 NI-FBUS Configurator Overview

NI-FBUS Configurator Windows

The NI-FBUS Configurator has three moveable, dockable windows

within the Configurator Main window: the Project, Help, and Status

windows.

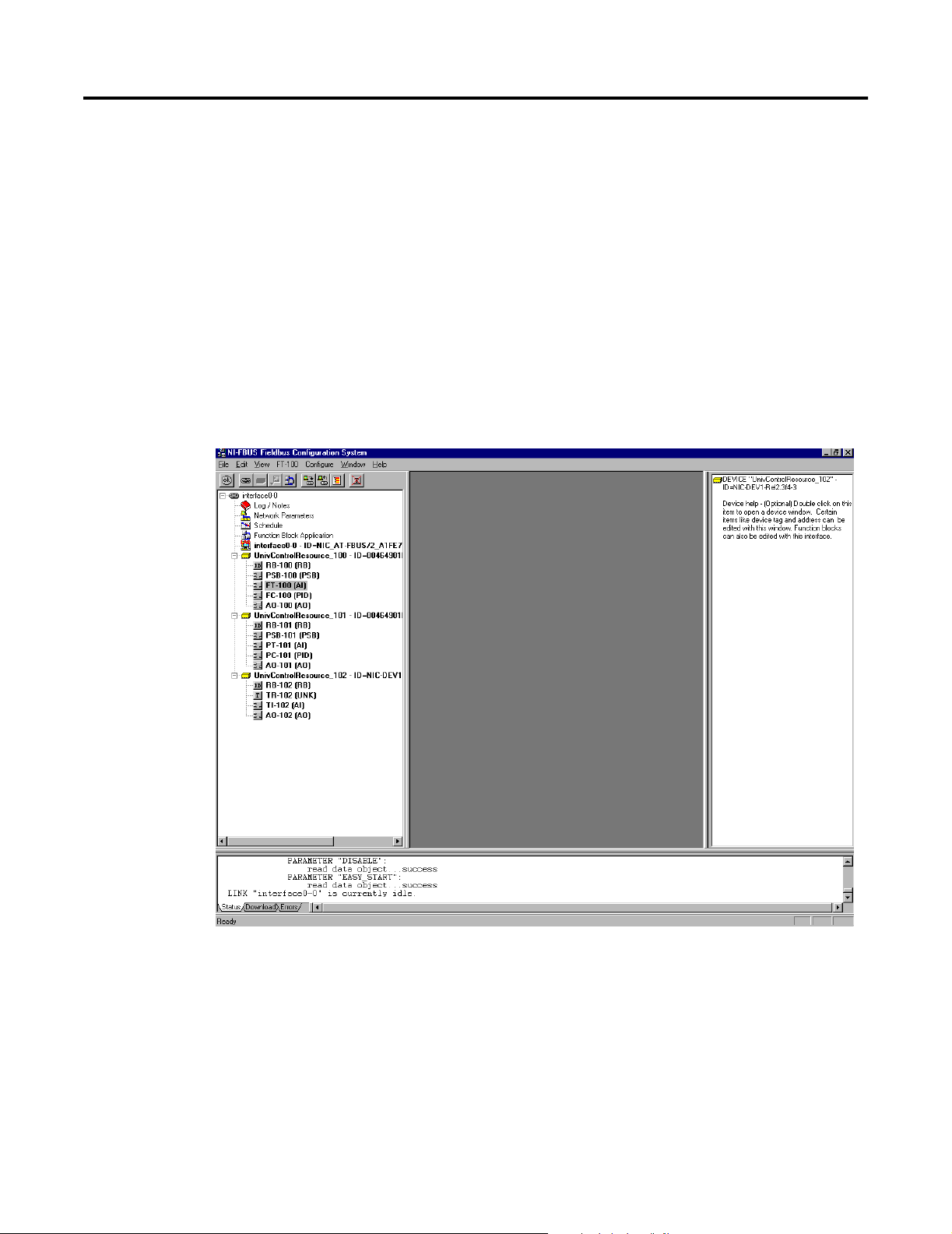

Configurator Main Window

The Configurator Main window has menus at the top, and contains

the windows described in the following sections. Figure 3.1 shows the

Project, Help, and Status windows within the Configurator Main

window.

Figure 3.1 Configurator Main Window

Publication 1788-UM052B-EN-P - April 2002

Page 23

NI-FBUS Configurator Overview 3-3

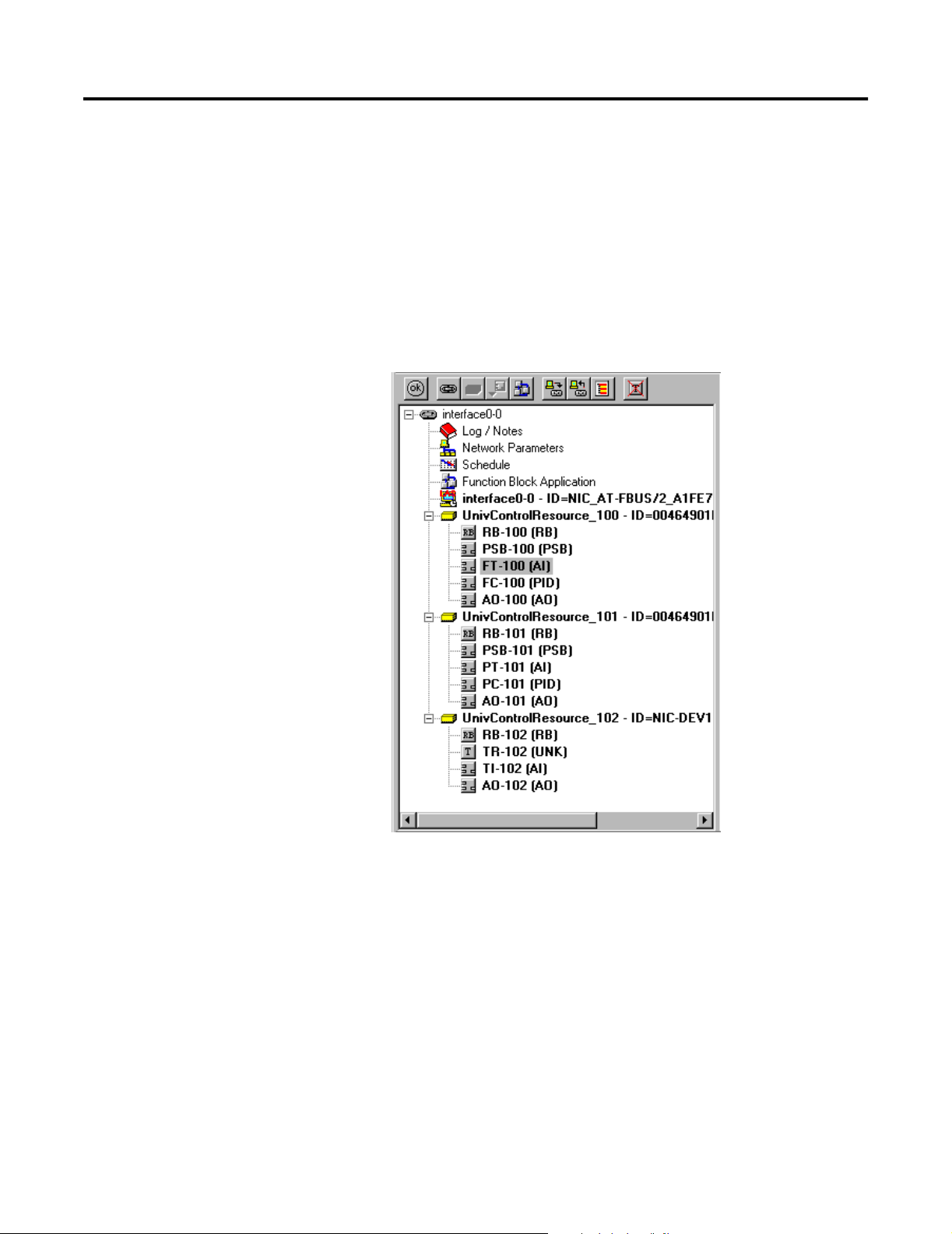

Project Window

The Project window, which appears to the left of the Configurator

Main window by default, displays the configurable objects of the link

connected to the NI-FBUS Configurator. To configure each object,

double-click these objects in the Project window; doing so opens the

correct interface to use to configure the object. Figure 3.2 shows the

Project window.

Figure 3.2 Project Window

Publication 1788-UM052B-EN-P - April 2002

Page 24

3-4 NI-FBUS Configurator Overview

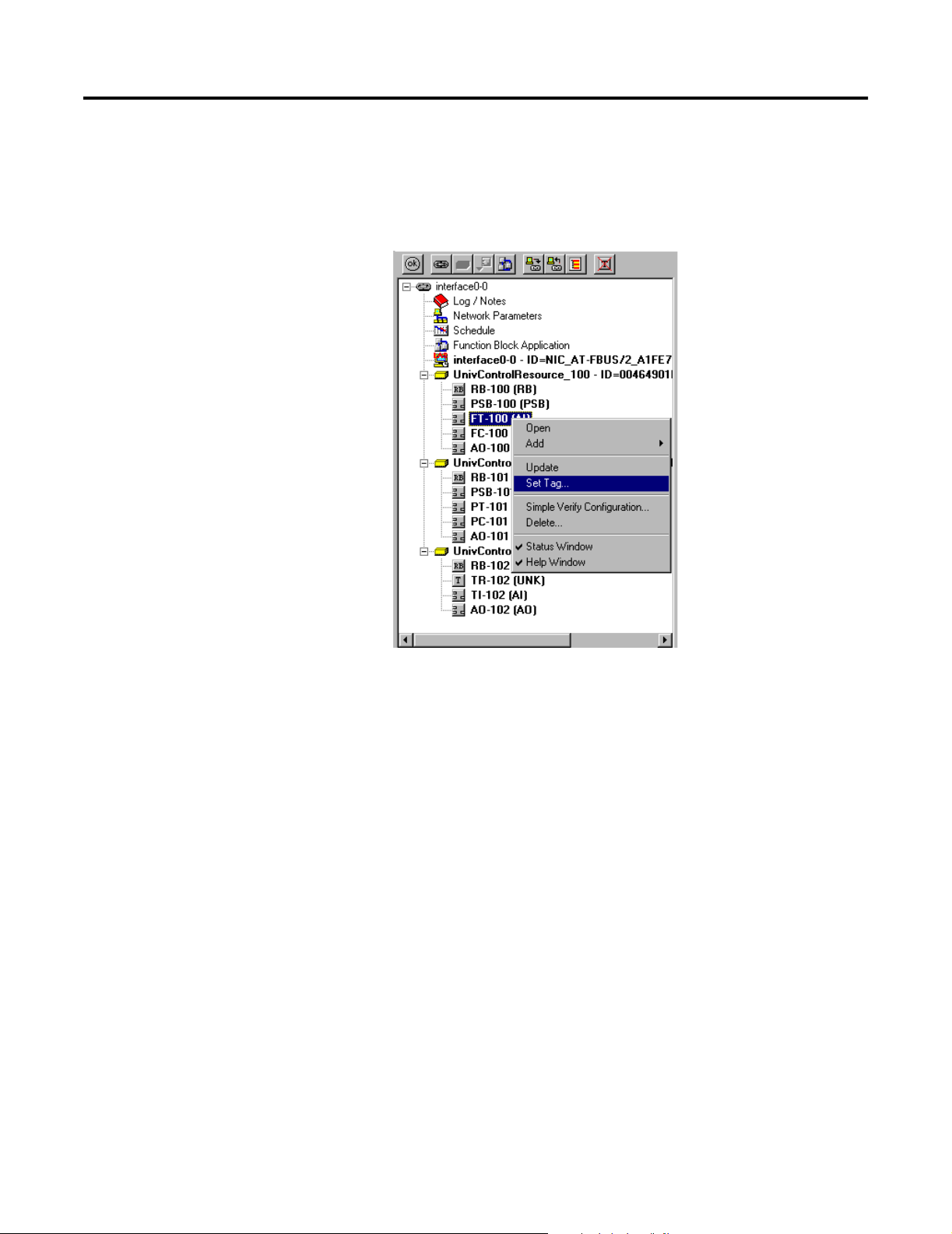

Each object in the Project window has its own menu that appears on

the main taskbar when you select the object. You can also view the

menu by right-clicking the object, as shown in Figure 3.3.

Figure 3.3 Project Window Pop-Up Menu

Conventions

The NI-FBUS Configurator uses the following standard user interface

conventions:

• Double-click an object to open the configuration interface.

• Right-click an objewct to display a popup menu that lists actions

related to that object.

• Single-click an object to select it and display a popup menu in

the menu bar at the top of the Main window.

• Single-click an object to select it and hover the cursor over the

object to view the help information for that object. The

appropriate help information appears in the Help window.

• Drag and drop icons (block or device) from one window and

into another.

Publication 1788-UM052B-EN-P - April 2002

Page 25

NI-FBUS Configurator Overview 3-5

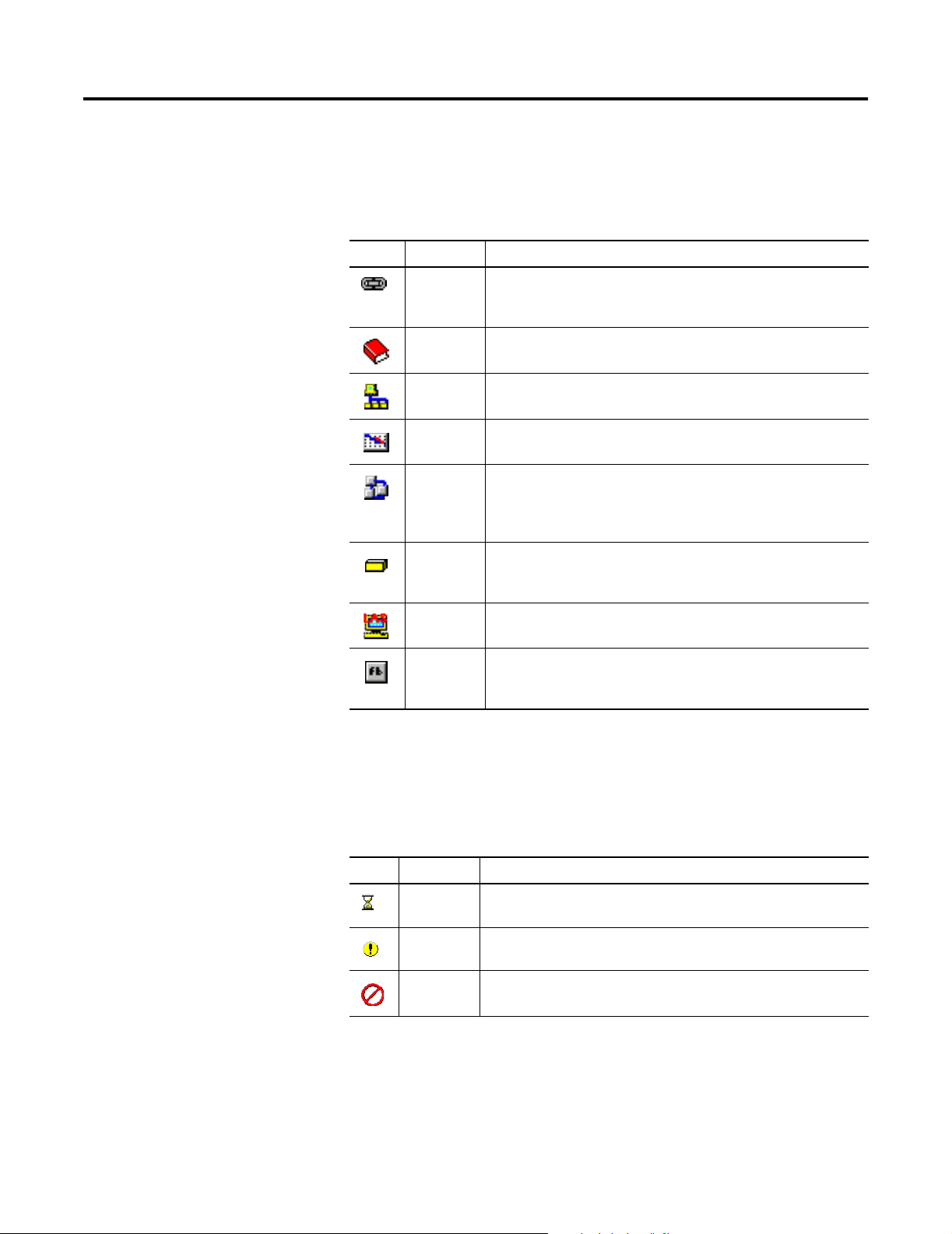

Icons

Descriptions of the project icons that appear in the Project window

follow:

Icon Name Description

Link This icon represents the fieldbus segment to which your PC is

connected. Double-click this icon to open the Network Parameters

window.

Log/Notes Double-click this icon to see a summary of all the changes you

have made to the project link.

Network

Parameters

Schedule Double-click this icon to see the schedule of function block

Function

Block

Application

Editor

Device This icon represents a fieldbus device, followed by the device tag

Host Device This icon represents the device (PC) that hosts the NI-FBUS

Function

Block

Double-click this icon to open the Network Parameters window

and change the low-level configuration parameters for the link.

executions and data transmissions for the entire link.

Double-click this icon to use the Function Block Application Editor

to wire function blocks together into a function block application.

You can add multiple function block applications to your project.

and its unique serial identifier. Double-click this icon to open the

Device window.

Configurator. Double-click this icon to open the Device window.

This icon represents a fieldbus function block, followed by the

block tag and its type (in parentheses). Double-click this icon to

open the Block window.

State Icons

During the initial scan of the bus, state icons sometimes overlap the

project icons. Descriptions of the state icons used in the Project

window follow:

Icon Name Description

Updating This icon appears when the NI-FBUS Configurator is reading or

writing to the object.

Error This icon appears when the NI-FBUS Configurator detects or

encounters an error with the object.

Invalid This icon appears when the indicated object is not responding to

the NI-FBUS Configurator scan.

Publication 1788-UM052B-EN-P - April 2002

Page 26

3-6 NI-FBUS Configurator Overview

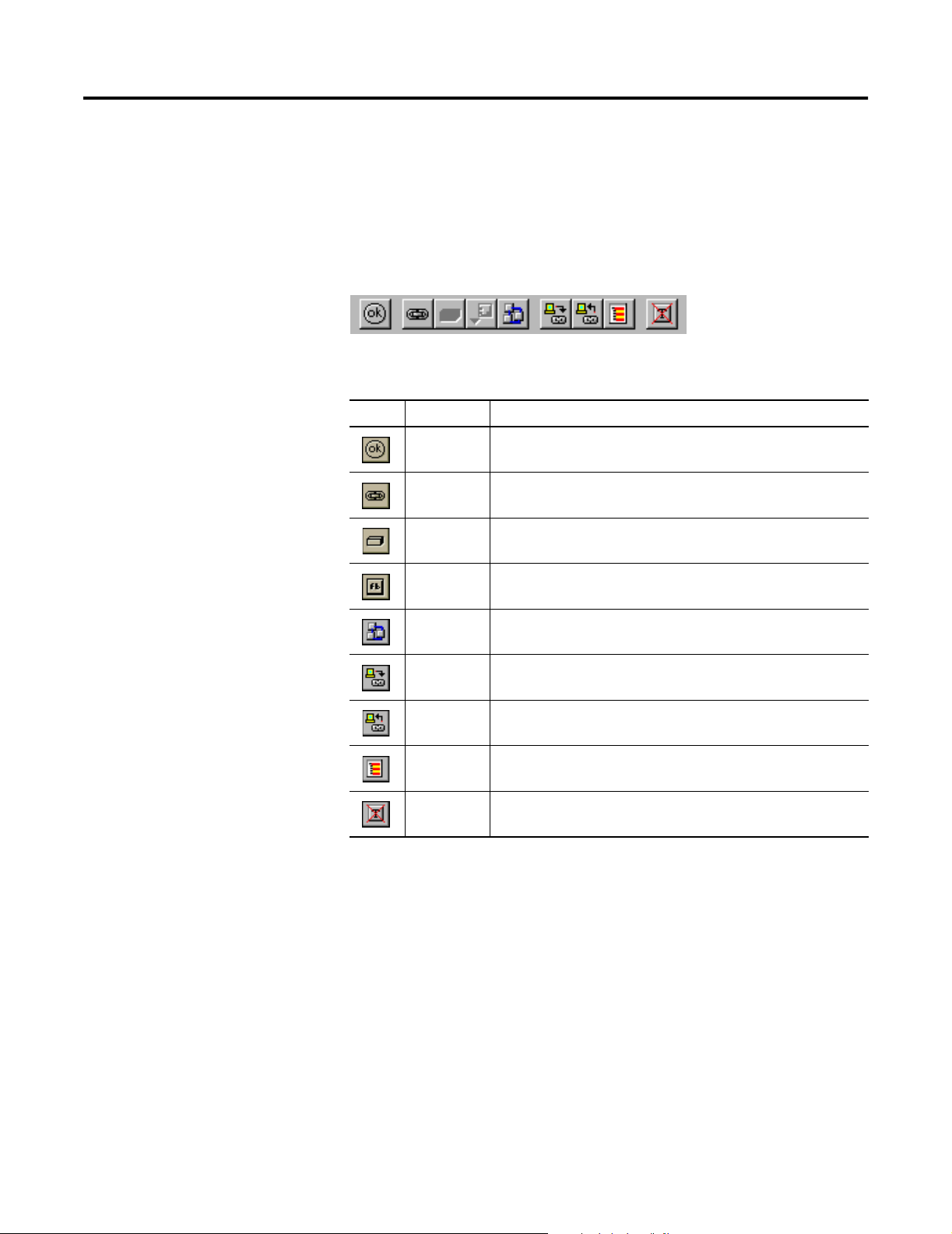

Toolbar

The toolbar at the top of the Project window helps you perform basic

operations on your project. Figure 3.4 shows the Project window

toolbar.

Figure 3.4 Project Toolbar

Descriptions of the buttons on the Project toolbar follow:

Button Name Description

Errors Click this button to validate the project.

New Link Click this button to add another link to the project.

New Device Click this button to add another device to the project.

New Block Click this button to add another block to the project.

New FBAP Click this button to add another Function Block Application Editor

window to the project.

Download

Project

Upload

Project

Verify and

Diff

Show/Hide

Transducers

Click this button to open the Download Configuration dialog box.

Click this button to reread the configuration.

Click this button to upload your current configuration and

compare it to the saved project.

Click this button to hide the transducer blocks from the Project

window.

Publication 1788-UM052B-EN-P - April 2002

Page 27

NI-FBUS Configurator Overview 3-7

Help Window

The Help window, which appears to the right of the Configurator

Main window by default, displays help information for the object over

which you place your cursor. The text is generated from the NI-FBUS

Configurator and Device Description (DD) files. To hide the Help

window, select Window

Figure 3.5 Help Window

⇒ Help Window.

Status Window

The Status window, which appears at the bottom of the Configurator

Main window by default, displays the current status of the NI-FBUS

Configurator. When you read, write, scan, or download data to the

bus, the Status window shows the steps that the NI-FBUS Configurator

takes to accomplish the task on the Status tab.

The Status window also contains Download and Error tabs. The

Download tab is updated only when a configuration is downloaded to

the bus. The Errors tab shows any errors in the current project. To

hide the Help window, select Window

Status Tab

The Status tab shows live updates of what the NI-FBUS Configurator

does on the fieldbus. For example, the Status tab shows when the

NI-FBUS Configurator is reading, writing, and configuring. The Status

tab automatically appears on top when you start the NI-FBUS

Configurator.

⇒ Status Window.

Publication 1788-UM052B-EN-P - April 2002

Page 28

3-8 NI-FBUS Configurator Overview

Download Tab

The Download tab shows all the status information for the last

configuration download of the bus. The NI-FBUS Configurator retains

this information until the next download. The Download tab

automatically appears on top when you begin to download your

configuration. The status information on the Download tab is also in

the Log/Notes window.

Errors Tab

The Errors tab, shown in Figure 3.6, displays all recent I/O errors,

project configuration errors, and warnings. To fix an error,

double-click the error to open the window containing the error. Some

error messages give hints about how to solve the problem. For a list of

errors, refer to Appendix, Error Messages and Warnings.

Figure 3.6 Errors Tab

Publication 1788-UM052B-EN-P - April 2002

The Errors tab has a drop-down list attached to the upper left corner

of the window. Use this list to select the errors you want to see. The

All Errors selection shows all I/O and project errors, and the Project

Errors selection shows only project errors.

When you download your configuration, the NI-FBUS Configurator

checks for errors in your project. If you have a project error, the

NI-FBUS Configurator warns you and allows you to cancel the

download.

The NI-FBUS Configurator automatically regenerates error information

each time you change the project. However, you can force the

NI-FBUS Configurator to revalidate the project by clicking the OK

toolbar button in any window.

Page 29

Chapter

4

Using the NI-FBUS Configurator

The following sections describe how to use the NI-FBUS Configurator

to configure your fieldbus system.

Starting the NI-FBUS

Configurator

Before you use the NI-FBUS Configurator, you must install and

configure your software and any fieldbus interfaces, as instructed in

your getting started manual.

To start the NI-FBUS Configurator, complete the following steps:

1. Select Start

The Add Links window opens.

2. To open an existing project, click Cancel.

⇒ Programs ⇒ NIFBUS ⇒ NI-FBUS Configurator.

OR

To create a new project, select the interface that you want to

connect to from the Added Link(s) checklist and click OK.

1 Publication 1788-UM052B-EN-P - April 2002

Page 30

4-2 Using the NI-FBUS Configurator

Configuring Online

When you start the NI-FBUS Configurator, or when you create a new

project, the Add Links window opens.

To add new links at any other time, click the Link button in the

toolbar.

TIP

You can edit saved configuration files without

connecting to the fieldbus. To open a saved

configuration, click Cancel to close the Add Links

window that opens. Select File

⇒ Open and

browse to your saved configuration files, which

have a .fcp extension.

To connect to a specific fieldbus interface, complete the following

steps:

1. In the Add Links window that opens, select the interface you

want to connect to from the Added Link(s) checklist.

2. Click OK to create a new project that is connected to the links

you checked.

The NI-FBUS Configurator scans the fieldbus network and

checks addresses and object tags. If a device is missing either an

address or a tag, the NI-FBUS Configurator assigns one. If the

NI-FBUS Configurator detects duplicate tags, it renames the

device or block, appending the original device or block tag with

a numeric identifier.

After you complete the preceding steps, the NI-FBUS

Configurator creates a new project so you can develop your

configuration. The Project window opens, displaying all the

fieldbus objects on the link or links to which your PC is

connected.

Publication 1788-UM052B-EN-P - April 2002

Page 31

Using the NI-FBUS Configurator 4-3

Figure 4.1 shows the Project window with an example list of fieldbus

objects. For more information about the parts of the Project window,

refer to the Project Window section on page 3-3.

Figure 4.1 Fieldbus Object List in the Project Window

Publication 1788-UM052B-EN-P - April 2002

Page 32

4-4 Using the NI-FBUS Configurator

Importing Device Description Files

To use Device Description (DD) files with the NI-FBUS Configurator,

you must import the DD files:

1. Select Start

the Interface Configuration utility.

2. Click DD Info.

The DD Info window opens.

3. Type the base directory for your DD files in the first field.

⇒ Programs ⇒ NI-FBUS ⇒ Interface Config to run

4. If necessary, click Browse to select your standard text

dictionary.

5. Click Import DD.

The Import DD window opens.

6. Click Browse and browse to the .ffo DD file path and click OK.

For more information about DD files, refer to the Device Description

Files section on page 1-5.

Publication 1788-UM052B-EN-P - April 2002

Page 33

Using the NI-FBUS Configurator 4-5

Setting Device or Block Tags

Setting a device or block tag may affect how other host machines on

an (online) operating network access the device.

IMPORTANT

To set a tag, complete the following steps:

1. In the Project window, select the device or block whose tag you

want to change.

2. Right-click the device or block, or select Object Name from the

main menu bar.

3. Select Set Tag from the pop-up menu that opens.

The Set Tag window opens.

The operating control system must not be using the

device or function block when you set tags. When

you set the device tag, the device loses all linkage

and communication configuration information and

loses control of the process.

4. In the New Tag field, type the tag you want to assign to the

object.

5. Select the Set to OOS Mode checkbox. Doing so sets the block

to OOS mode, which prevents the device from operating in its

current control system.

6. Click Set.

The NI-FBUS Configurator sets the block or device to OOS

mode before setting the new tag. If the device or block does not

go to OOS mode, the NI-FBUS Configurator notifies you and

you must determine whether to continue setting the tag.

Publication 1788-UM052B-EN-P - April 2002

Page 34

4-6 Using the NI-FBUS Configurator

7. After you successfully set the tag, use the Block window to

change the block from OOS mode to a desired mode.

Setting Device Addresses

IMPORTANT

Complete the following steps to set the device address:

1. In the Project window, select the desired device.

2. Right-click the device or select Devices from the main

menu bar.

The operating control system must not be using the

device when you set the address. When you set the

address, the device deletes all communication

information.

Publication 1788-UM052B-EN-P - April 2002

Page 35

Using the NI-FBUS Configurator 4-7

3. Select Set Address from the pop-up menu that opens.

The Set Address window opens.

4. In the New Address field, select the desired address from the

drop-down list.

5. Select the Set to OOS Mode checkbox. Doing so sets the block

to OOS mode, which prevents the device from operating in its

current control system.

6. Click Set.

The NI-FBUS Configurator sets the device resource block to out

of service (OOS) mode before setting the new address. If the

device does not go to OOS mode, the NI-FBUS Configurator

notifies you and you must determine whether to continue setting

the address.

7. After you successfully set the address, you can set the resource

block to the desired mode (typically NORMAL_MODE).

Publication 1788-UM052B-EN-P - April 2002

Page 36

4-8 Using the NI-FBUS Configurator

Resetting a Device to Factory Defaults

Formulating a Control Strategy

You can clear a device so that it is reset to a state appropriate for

shipping. To do so, right-click on the device name in the Project

window and select Set to Factory Defaults from the popup menu

that opens.

The NI-FBUS Configurator clears the device and function block tags,

along with the device address. In addition, it clears all communication

information in the device.

The Function Block Application Editor, shown in Figure 4.2, is the

graphical interface you use to create your fieldbus control strategy in

the NI-FBUS Configurator.

Figure 4.2 Function Block Application Editor

You can open the Function Block Application Editor by

double-clicking on its icon in the Project window.

The toolbar at the top of the Function Block Application Editor,

shown in Figure 4.3, displays the various tools used for function

blocks.

Figure 4.3 Function Block Application Editor Toolbar

Publication 1788-UM052B-EN-P - April 2002

Page 37

Descriptions of the items on this toolbar follow:

Table 4.1 Function Block Application Toolbar Descriptions

Toolbar Item Name Description

FBAP Name This field shows the name of the function block application.

Loop Execution Time This field shows the default execution rate of the process loop.

Stale Limit This field shows the number of consecutive duplicate values that a function block

accepts before it labels the input data as stale (old data).

Errors Click this button to perform error checking, regenerate the schedule of the application,

and remove bad wires.

Pointer Click this button to drag and highlight objects on the screen.

Wiring Click this button to make connections between valid inputs and outputs. When you try

to make a connection, the NI-FBUS Configurator checks the data type of the input and

output you are trying to connect, and highlights the connection if it is valid.

Loop Click this button to isolate certain function blocks from the default execution time. The

default execution time on the toolbar is the execution rate for all blocks on the

Function Block Application Editor. However, you can define multiple loops that run at

rates other than the default execution time. The Loop tool helps you to assign a

special execution rate to a group of function blocks. For more information about

running loops at different rates, refer to the Defining Multiple Loops section of this

chapter.

Using the NI-FBUS Configurator 4-9

Block Click this button to show the block menu.

Monitor FBAP Click this button to enable graphical monitoring of the process.

Text Click this button to type additional information about the application to the screen and

change text in fields.

Zoom Click this button to zoom in and out. To zoom in, drag a rectangle around the area you

want to enlarge. To zoom out, right-click on the background of the Function Block

Application Editor window.

Execution Order Click this button to choose the order of execution for blocks. The NI-FBUS Configurator

automatically decides the order of the blocks, but you can change the default order by

using the Execution Order tool to click on the blocks in the order you want them to

execute.

Fill Click this button to fill objects on the screen with a color.

Fill Color Click this button to select a color to be used with the Fill tool.

TIP

To switch between the major tools you are using,

press <Tab>. To switch between the pointer and the

wiring tool, press the spacebar.

Publication 1788-UM052B-EN-P - April 2002

Page 38

4-10 Using the NI-FBUS Configurator

Function Blocks

As stated in the Blocks and Parameters section of Chapter 1, function

blocks contain an algorithm and several parameters to control a

process. The input and output parameters of this function block are

displayed on the block, as in Figure 4.4.

Figure 4.4 Input and Output Parameters on a Function Block

The pointers on the outside of the parameters show the direction of

the data flow. By default, the block tag is at the top, the inputs are on

the left, and the outputs are on the right.

You can resize the block and move the tags relative to the block.

To change the tag, double-click the block tag to open the edit box, or

right-click and select Set Tag from the drop-down list.

Adding Function Blocks

To add function blocks, complete the following steps:

1. To open the Function Block Application Editor, double-click the

Function Block Application Editor icon in the Project window.

2. Drag blocks from the Project window to the Function Block

Application Editor until all the blocks you want to use are in the

Function Block Application Editor. A block looks like the

following while you drag it from the Project window:

3. If you want to change the names of the blocks, double-click a

tag or use the Text tool on the Function Block Application

Editor toolbar.

Publication 1788-UM052B-EN-P - April 2002

Page 39

Using the NI-FBUS Configurator 4-11

You can also add function blocks as follows:

1. Right-click on the background of the Function Block Application

Editor or click the Block button.

2. Select the device from the menu that opens, then select the

block you want to place on the screen from the menu of

function blocks.

TIP

You can use a function block on a fieldbus network

only once. After you use a function block in a

Function Block Application Editor window, the

function block is grayed out on the menu and in the

Project window.

Figure 4.5 shows how the Function Block Application Editor looks

with function blocks dragged onto it.

Figure 4.5 Added Function Blocks

Publication 1788-UM052B-EN-P - April 2002

Page 40

4-12 Using the NI-FBUS Configurator

Connecting Blocks

To send data from one block to another, you must connect the blocks

through wiring. You can wire blocks manually or use a template.

Wiring Blocks Manually

To wire blocks manually, complete the following steps:

1. Click the Wiring tool on the Function Block Application Editor

toolbar.

2. Click the input or output you want to connect.

3. Click on the background of the Function Block Application

Editor window to guide the connection to the input or output to

which you want to attach the wiring.

TIP

To toggle the direction of the connection you are

dragging, press the spacebar while wiring.

4. Click the input or output to which you want to wire.

When you click the Wiring tool, the NI-FBUS Configurator performs

type checking and highlights valid inputs and outputs when you move

the cursor over them.

Figure 4.6 shows the BKCAL IN of the PID block being wired to the

BKCAL OUT of the AO block.

Figure 4.6 Wiring to a Block Input

Publication 1788-UM052B-EN-P - April 2002

Page 41

Using the NI-FBUS Configurator 4-13

You can also drag devices from the Project window into the Function

Block Application Editor to configure alarms and trends, as described

in the Configuring Alarms and Configuring Trends sections on pages

4-25 and 4-26, respectively.

Using Pre-Wired Templates

Templates are predefined, pre-wired control loops that you can drag

into the Function Block Application Editor to use as a model for your

function block application. The NI-FBUS Configurator includes several

types of templates.

You can also save your own template as a file by selecting File

⇒

Save Template. The NI-FBUS Configurator saves all templates in the

c:\Nifb\fcs\templates directory. If a template is in that directory, it

automatically opens in the template menu.

To access templates, do one of the following:

• Right-click on the background of the Function Block Application

Editor and select FBAP Templates.

or

• Select File

⇒ Open Template.

The NI-FBUS Configurator includes the following templates:

• PID Feedback Control

• Manual Control with PV Indication

• PD Feedback Control

• Track Feedforward Control

• Cascade Control

• Ratio Control

• Override Control

Publication 1788-UM052B-EN-P - April 2002

Page 42

4-14 Using the NI-FBUS Configurator

Figure 4.7 shows an example of a template.

Figure 4.7 Example Template

If template blocks are grayed out, as shown on the left in Figure 4.7,

you have not assigned a function block to the template block. To

assign a function block to the template block, complete the following

steps:

1. Double-click the template block to view all the blocks that

match this block type in your project. You can also right-click

the block and select Replace from the popup menu that opens.

2. Select the desired block from the list that opens.

Your application is not complete until you replace all the template

blocks with function blocks from your project, as shown on the Right

in Figure 4.7.

Publication 1788-UM052B-EN-P - April 2002

Page 43

Using the NI-FBUS Configurator 4-15

Defining Multiple Loops

A loop is a group of connected function blocks that execute at a

specified rate. You can define many loops in one Function Block

Application Editor window.

Figure 4.8 shows an example of two separate loops running at the

same rate.

Figure 4.8 Multiple Loops

Publication 1788-UM052B-EN-P - April 2002

Page 44

4-16 Using the NI-FBUS Configurator

Defining Multiple Loops Running at Different Rates

The loop execution time shown on the Function Block Application Editor

toolbar is the default execution time for all function blocks on the

window not isolated in a loop structure. For example, the AI and PID

blocks in Figure 4.9 execute at a rate of once every second, but the

AI-PID-AO loop can be set to execute at another time by modifying the

time at the top of the shaded area.

Figure 4.9 Two Loops Running at Different Rates

Publication 1788-UM052B-EN-P - April 2002

Page 45

Using the NI-FBUS Configurator 4-17

You can use the loop structure shown in Figure 4.10 to isolate a group

of function blocks to run at a different execution rate than the rate on

the Function Block Application Editor toolbar.

Figure 4.10 Loop Structure

To create a loop structure, complete the following steps:

1. Click the Loop tool on the Function Block Application Editor

toolbar.

2. On the background of the Function Block Application Editor,

click and drag a loop around the blocks you want to put in the

loop.

3. To change the loop execution time, type the new time in the

box at the upper left of the loop.

Publication 1788-UM052B-EN-P - April 2002

Page 46

4-18 Using the NI-FBUS Configurator

Changing the Block Execution Order

To change the execution order of the blocks, complete the following

steps:

1. In the Function Block Application Editor, click the Change

Execution Order button. Numbers appear on the blocks,

indicating their current order.

Publication 1788-UM052B-EN-P - April 2002

2. Click on the blocks in the order that you want them to execute.

3. When you are done, click on the background of the Function

Block Application Editor window or select another tool.

Page 47

Using the NI-FBUS Configurator 4-19

Viewing and Editing Function Block Parameters

Each function block in your application has a Block window that you

can use to change block parameters and other settings. When you

read or write data on a block, the Status window shows the status of

the transactions.

To open the Block window for a block, do one of the following:

• Double-click on the name of the function block in the Project

window.

OR

• Double-click on a function block in the Function Block

Application Editor.

Figure 4.11 Block Window

Publication 1788-UM052B-EN-P - April 2002

Page 48

4-20 Using the NI-FBUS Configurator

Block Window Icons

As shown in Figure 4.11, an icon to the left of each parameter name

color-codes and symbolically represents the class of the parameter.

Table 4.2 describes the classes of the parameter.

Table 4.2 Block Window Icons

Shape Color Description

Circle Alarms—Green Represents contained parameters.

Tuning—Light blue

Others—Black

Right arrow Red Represents output

Left arrow Blue Represents input

Contained parameters cannot be linked to

other parameters; they are contained in the

block.

Block Window Toolbar

The toolbar at the top of the Block window provides an interface for

reading and writing parameters. Figure 4.12 shows this toolbar.

Figure 4.12 Block Window Toolbar

Publication 1788-UM052B-EN-P - April 2002

Page 49

Descriptions of the icons on this toolbar follow:

Toolbar Item Name Description

Device Tag This field shows the function block tag. To change the block tag, click the field.

Write Changes Click this button to write only changed parameters to the block on the device, including

changed block tags.

Write All Click this button to write all parameters, including changed block tags, to the block on the

device.

Read Selected Click this button to read a selected parameter.

Read All Click this button to read all parameters.

Refresh Click this button to update the screen.

Customize Click this button to add, delete, or rename tabs for this type of block.

Spaced View Click this button to add space between parameter listings.

Using the NI-FBUS Configurator 4-21

Simple View Click this button to display only the Parameter and Value columns.

Detailed View Click this button to display the Parameter, Value, Type & Range, and Help columns.

Tabs of the Block Window

The Block window groups the parameters by functional category. For

example, parameters related to alarms appear on the Alarms tab, and

parameters related to tuning appear on the Tuning tab.

Uncategorized parameters appear on the Others tab.

You can also customize the tabs of the Block window. You can add or

delete tabs, change the order in which they appear in the window,

and add or remove any block parameters.

TIP

When you customize a tab of the Block window, that

customization applies to all blocks of the same type.

In other projects, blocks of the same type will have

the same tab configuration.

Publication 1788-UM052B-EN-P - April 2002

Page 50

4-22 Using the NI-FBUS Configurator

Adding Tabs

To add a tab to the Block window, complete the following steps:

1. Click the Add or Delete Custom Tab button in the Block

window toolbar.

The Add & Delete Custom Tabs window opens.

2. Click the section where you want to add the tab.

3. Click Add and type the name of the new tab in the edit control

that opens.

4. Click OK to generate the new tab.

Removing Tabs

To remove a tab from the Block window, complete the following

steps:

1. Click the Add or Delete Custom Tab button in the Block

window toolbar.

The Add & Delete Custom Tabs window opens.

2. Select the name of the tab that you want to remove.

3. Click Delete.

Customizing Parameters

Publication 1788-UM052B-EN-P - April 2002

To customize the parameters on a Block window tab, right-click

on the tab in the Block window to display the popup menu and

select Customize Parameters.

Page 51

Using the NI-FBUS Configurator 4-23

Editing Block Parameters

The Block window displays the parameters in the order that they

appear in the block. Parameters with a plus sign beside them are

records or arrays (structures) that contain more than one entry. To

expand the record or array, click the plus sign, or to collapse the

structure, click the minus sign.

To edit a block parameter value, complete the following steps:

1. In the Function Block Application Editor, double-click a function

block to open the Block window.

2. To see the values of the record or array parameters in the Block

window, click the plus signs.

3. To change a paramter value, select the value and type in the

new value. If a parameter value is grayed out, it is read-only and

you cannot change it. After you change a parameter value, an

asterisk (*) appears by the parameter name.

4. To make your changes effective immediately, click the Write

changes button on the Block window toolbar. If you do not

click the Write changes button, your changes will not take effect

until you download the configuration.

Publication 1788-UM052B-EN-P - April 2002

Page 52

4-24 Using the NI-FBUS Configurator

Updating Block Parameter Values

You can update block parameter values manually or automatically,

as described below:

Manually

To update each block parameter value manually, select the parameter

and click the Read Selected button on the Block window toolbar.

To update all of the block parameter values, click the Read All

button.

Automatically

To update the block parameter values automatically, complete these

steps:

1. At the top of the Block window, select the Periodic Updates

checkbox.

2. Select the poll rate from the drop-down list to the right of the

Periodic Updates checkbox.

The NI-FBUS Configurator updates the block parameter values

periodically, based on the poll rate you choose.

Publication 1788-UM052B-EN-P - April 2002

Page 53

Using the NI-FBUS Configurator 4-25

Using Menus and Methods

If you double-click a function block in the Project window and the

block has menus and methods associated with it, a menu bar opens

above the Block window toolbar and the Methods tab opens in the

Block window.

To invoke a method, select it from the menu bar.

Figure 4.13 Methods pull-down menu

Configuring Alarms

To configure a device, such as a PC, to receive alarms generated by

function blocks complete the following steps:

1. Locate the Project window icon for the device or interface to

which you want to send the alarm. Drag this icon from the

Project window to the Function Block Application Editor.

2. Wire the Alarms output of the block that you want to generate

the alarm to the device you want to receive the alarm. The

following an example of a configured alarm.

Publication 1788-UM052B-EN-P - April 2002

Page 54

4-26 Using the NI-FBUS Configurator

3. Double-click the function block that you want to generate the

alarm.

The Block window opens.

4. Select the Alarms tab to view or change alarm information,

such as the high and low limits of an alarm condition, alarm

priorities, and so on.

Configuring Trends

You can configure a device, such as a PC, to receive trends from

fieldbus devices. To configure trends, complete the following steps:

1. Find the Project window icon for the device or interface to

which you want to send the trend. Drag this icon from the

Project window to the Function Block Application Editor.

2. Double-click the function block from which you want to send a

trend.

The Block window opens.

3. Select the Trends tab.

4. Select the checkbox in the Trend column next to the parameter

you want to trend.

5. Set the sample Interval of the trend in loops/sample.

6. Set the Sample Type. To do so, select Instant or Average from

the Sample Type drop-down list. Instant trends the actual value.

Average trends all samples.

Publication 1788-UM052B-EN-P - April 2002

7. Wire the Trends output of the block to the device you want to

receive the trend. The following is an example of a configured

trend.

Page 55

Using the NI-FBUS Configurator 4-27

Viewing and Editing a Schedule

The NI-FBUS Configurator automatically determines the execution

order and timing of the schedule based on your control strategy,

network and device factors, and on the loop execution rate you

choose. The NI-FBUS Configurator also automatically optimizes the

schedule. Double-click the Schedule icon in the Project window to

view or edit the link active schedule.

The NI-FBUS Configurator combines the link active schedule and

function block schedules into one diagram, as shown in Figure 4.14.

Figure 4.14 Schedule Window

In the Schedule window, a key of the scheduled objects appears on

the left. The timing diagram on the right displays the execution times

of the function blocks, and when data is transmitted on the bus.

The blue bars on the screen correspond to the function block

execution times and the red bars correspond to the data transmission

times, which consist of LAS notification time and transmission time.

TIP

To change the execution time for a loop, click the Loop Time next to

the loop icon and type in the new time.

An optimized schedule can show that the

transmission time overlaps the end time for the

function block because the transmission time

includes the time that the LAS uses to tell the device

to send the data.

Publication 1788-UM052B-EN-P - April 2002

Page 56

4-28 Using the NI-FBUS Configurator

Schedule Window Toolbar

Figure 4.15 shows the toolbar for the Schedule window.

Figure 4.15 Schedule Toolbar

Descriptions of the icons on the Schedule window toolbar follow:

Toolbar Item Name Description

Primary LAS This field displays the name of the device

that is the primary LAS for the system.

Scale This field displays the time and divisions

on the timing diagram.

Errors Click this button to validate the schedule.

Pointer Use this tool to drag the time bars around

on the timing diagram.

Zoom Click this button to zoom in and out on the

view.

Optimize

Schedule

Click this button to rerun the optimization

routine.

Changing the Link Active Schedule

You do not need to alter the schedule if the function block execution

times in the device are correct. If the times in the device are incorrect,

you might have to tune the execution times by dragging the execution

time bars on the screen. Automatic optimization is shut off when you

drag the bars to tune. If you want to reoptimize, click the Optimize

Schedule button.

If the function block execution times in a device are incorrect, or if

your control application needs a different schedule, you might want to

change the schedule by completing the following steps:

Publication 1788-UM052B-EN-P - April 2002

1. Double-click the Schedule icon in the Project window.

The Schedule window opens.

2. Use the cursor to move the function blocks in the schedule as

needed.

Page 57

Using the NI-FBUS Configurator 4-29

Multiple Loop Representation

Figure 4.16 shows how the NI-FBUS Configurator displays multiple

loops in the Schedule window.

Figure 4.16 Multiple Loops in a Schedule

The loops are separated by white dividers. Select the checkbox by the

loop time shown above the colored bars to lock the loop and prevent

you and the NI-FBUS Configurator from changing the schedule until

you uncheck the box.

Publication 1788-UM052B-EN-P - April 2002

Page 58

4-30 Using the NI-FBUS Configurator

Setting Network Parameters

To change network parameters such as the Link Active Scheduler

(LAS) and primary time master, double-click the Network

Parameters icon in the Project window, or click the Link Masters

button in the Download Configuration window.

The Network Parameters window opens.

This window lists all devices capable of being link master. Every

device you select in this window receives the Link Active Schedule

when you download your configuration. Thus, if the primary LAS is

unavailable, one of these devices will execute the fieldbus schedule.

To review or modify the details of the link settings, select a device and

then select the Link Settings (Advanced) tab.

The specific parameters are displayed.

These paramters can be modified as required. Suggested values can

be viewed by clicking on the box above the parameters.

Publication 1788-UM052B-EN-P - April 2002

Page 59

Using the NI-FBUS Configurator 4-31

Downloading a Configuration

When you download a configuration, the NI-FBUS Configurator

configures the following items:

• Function block linkages between devices

• Function block schedule

• Alarms configuration

• Trends configuration

• Static parameters

• Communication schedule for the LAS

To download your configuration, complete the following steps:

1. Click the Download button in the Project window toolbar or

select Configure

The Download Configuration window opens.

⇒ Download Configuration.

2. Select the configuration object to download.

3. Click Link Masters... to set link masters to receive the LAS, the

primary LAS, and the primary time master of the link.

The Network Parameters window opens.

4. (Optional) To write all of the contained parameters of function

blocks in the project, select the Write Contained Block

Parameters checkbox.

5. (Optional) If you want to make sure that the device does not

have any communication configuration information that

connects to devices outside the configuration you are

downloading, you can reset or clear all of the communication

connections from the devices on the bus. To do so, select the

Clear Devices checkbox.

Publication 1788-UM052B-EN-P - April 2002

Page 60

4-32 Using the NI-FBUS Configurator

6. (Optional) If you want the NI-FBUS Configurator to switch

function blocks in the configuration to OOS mode and back to

the desired mode automatically, select the Automatic Mode

Handling checkbox.

If you do not select this checkbox, you are responsible for

changing the modes during the download process.

7. To download your fieldbus configuration changes to the

network, click Download.

The Download Status progress bar shows what percentage of

the configuration is complete.

While downloading, the NI-FBUS Configurator displays and

updates the Download tab in the status window. It shows what

devices are configured, their settings, and whether it was

successfully configured.

8. If you did not check the Automatic Mode Handling checkbox,

click Set All Targets to OOS to switch the function blocks to

OOS mode. After the configuration downloads, you can set the

blocks back to their normal mode of operation.

Monitoring a Function Block Application

You can configure how the NI-FBUS Configurator displays the

graphical representation of the updates of I/O parameters and mode

parameters of function blocks. To do so, complete the following steps:

1. On the Function Block Application Editor toolbar, click the

Monitor button.

The Monitor window opens.

2. In the Monitor window, select the items you want the NI-FBUS

Configurator to monitor and display.

3. After you download your configuration, click Start Monitoring

to monitor the application.

Publication 1788-UM052B-EN-P - April 2002

Page 61

Using the NI-FBUS Configurator 4-33

Verifying a Configuration

This section describes two ways to verify your configuration: a quick

verification and a comparison of the configuration to a saved project.

Quick Verification

You can perform a quick check to verify that the parameters on the

bus match those in the project. To verify the configuration of a link,

device, or function block, complete the following steps:

1. Right-click the object to display the popup menu and select

Verify Configuration.

The Verification Test window opens.

2. Click Verify.

The NI-FBUS Configurator compares the function blocks and

project settings, and displays the results in the Result field.

3. If the function blocks do not match the project settings, you can

click Upload Changes to upload the function block parameters

to the project.

4. Click Done.

Publication 1788-UM052B-EN-P - April 2002

Page 62

4-34 Using the NI-FBUS Configurator

Comparing Two Configurations

You can upload your current bus configuration and compare it against

a saved project. To do so, click the Veri f y a nd D if f button in the

Project window toolbar. You can also select Configure

Diff Configuration.

The NI-FBUS Configurator uploads device parameter values, function

block schedules, trend and alarm connections, and function block

application linkages, and compares them with the saved

configuration. The NI-FBUS Configurator shows which components

are different, as shown in Figure 4.17.

Figure 4.17 Diff Window

⇒ Ver ify and

Publication 1788-UM052B-EN-P - April 2002

Page 63

Using the NI-FBUS Configurator 4-35

Viewing and Editing a Log

The Log/Notes window keeps track of the last downloaded

configuration status output. The Log/Notes window shows the same

output as the Download Log tab of the Status window plus the time

and date of the last change and previous downloads of the current

project.

To open the Log/Notes window, double-click the Log/Notes icon in

the Project window. Figure 4.18 shows the Log/Notes window.

Figure 4.18 Log/Notes Window

Double-click a log entry to see the download log for that session. You

can also add notes at the bottom of the download log for each

session, and the NI-FBUS Configurator automatically saves them with

the project for future reference.

Replacing Devices

Complete the following steps to substitute a new device for a missing

device in the configuration:

1. From the Configure menu, select Replace Devices or

right-click a device and select Replace Devices from the popup

menu that opens.

2. In the Missing Device field, select the device you want to

replace from the drop-down list.

Publication 1788-UM052B-EN-P - April 2002

Page 64

4-36 Using the NI-FBUS Configurator

3. In the Correct Device field, select the new device from the

drop-down list to replace the Missing Device.

4. After you select the desired devices, click Done.

The NI-FBUS Configurator replaces the Missing Device with the

Correct Device. When you download your changes, the new

configuration, including linkages, tags, and parameter values, is

written to the Correct Device.

Setting Preferences

To set your preferences in the NI-FBUS Configurator, select View ⇒

Preferences.

The Preferences window opens.

Descriptions of the tabs follow:

Tab Description

Fonts Use this tab to change the font types and sizes on the display.

Publication 1788-UM052B-EN-P - April 2002

Parameter Views Use this tab to configure the default view for parameters:

• Show Detailed View–Click this checkbox to show additional type

and help strings for the view.

• Show Spaced View–Click this checkbox to add space between

parameters.

General Use this tab to select which windows appear when you start the

NI-FBUS Configurator.

Links Use this tab to change the software key, as described in the following

section, Changing the Software Key.

Page 65

Using the NI-FBUS Configurator 4-37

Changing the Software Key

The NI-FBUS Configurator software license has a default number of

links that you can configure. If you purchase additional licenses to

access more than the default number of links, contact National

Instruments to obtain a new software key.

After you obtain a new key, complete the following steps to change

the key:

1. Select View

⇒ Preferences and select the Links tab.

2. Click Show About Dialog.

The About window opens.

3. Click Set SW Key, enter the new key, and click OK.

4. Click OK to close the About window.

The number of Links Allowed changes based on the new

software key.

5. Click OK to close the Preferences window.

Publication 1788-UM052B-EN-P - April 2002

Page 66

4-38 Using the NI-FBUS Configurator

Printing

You can print your configured project in the form of text, graphical

diagrams, and text explanations of the diagrams.

To print your project, select File

⇒ Print.

The Print window opens.

Under What to Print, you can choose to print the Entire

Configuration or only Specific Configuration Items.

Descriptions of the checkboxes in the Print window follow:

Checkbox Description

Print Minimum

Amount of

Configuration

Information

Print Graphical

Diagrams

Print Text

Interpretations of

Graphical Diagrams

Click this checkbox to print only the minimum amount of