Page 1

Quick Start

Redundant EtherNet/IP to FOUNDATION

Fieldbus Linking Device

Catalog Number

Topi c Pag e

About the Linking Device 1

Additional Resources 1

Installation Requirements 2

Configuration 3

Operation 5

1788-EN2FFR

About the Linking Device

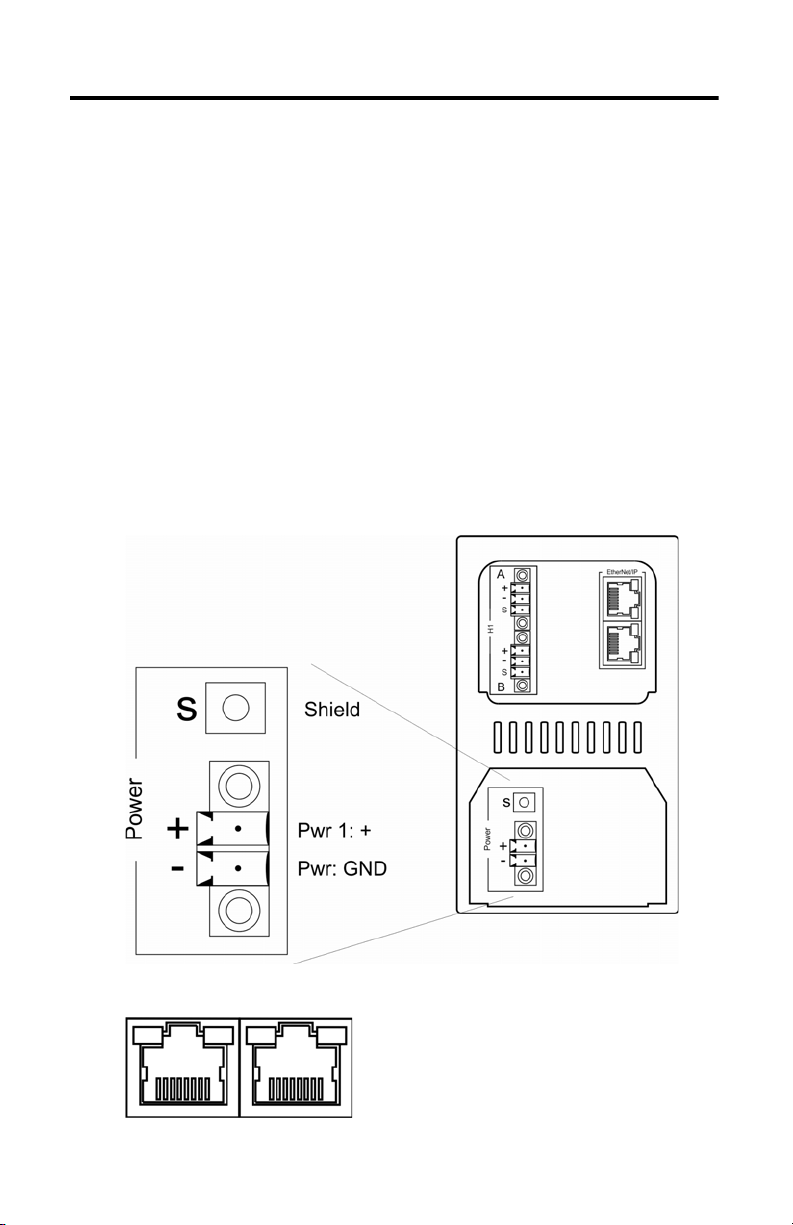

The 1788-EN2FFR linking device bridges an EtherNet/IP connection to a single

FOUNDATION Fieldbus H1 segment. The segment can support 16 Fieldbus devices. The

High-Speed Ethernet (HSE) layer is not supported.

The H1 segment is split between two hardware ports. Each port can provide 500 mA.

The linking device can support numerous redundant and simple topologies. Power conditioning

is built-in, and therefore, no external power conditioners are required.

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

EtherNet/IP and ControlNet to FOUNDATION Fieldbus

Linking Device User Manual, publication

1788-UM057

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

You can view or download publications at http://www.rockwellautomation.com/literature/

order paper copies of technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation® sales representative.

Provides details on how to install and operate the 1788-EN2FFR

EtherNet/IP to FOUNDATION Fieldbus and 1788-CN2FFR ControlNet to

FOUNDATION Fieldbus linking devices.

Provides general guidelines for installing a Rockwell Automation industrial

system.

. To

Page 2

2 Redundant EtherNet/IP to FOUNDATION Fieldbus Linking Device

Installation Requirements

The following software and hardware tools are required to successfully install and configure the

1788-EN2FFR linking device.

Software Requirements

The following software is required to configure the 1788-EN2FFR linking device:

• The RSLogix™ 5000 Add-on Profile (AOP) is required to configure and perform

diagnostics on the 1788-EN2FFR linking device.

• The Device Type Manager (catalog number 1788-EN2FFR DTM) is required for Asset

Management connectivity with field devices.

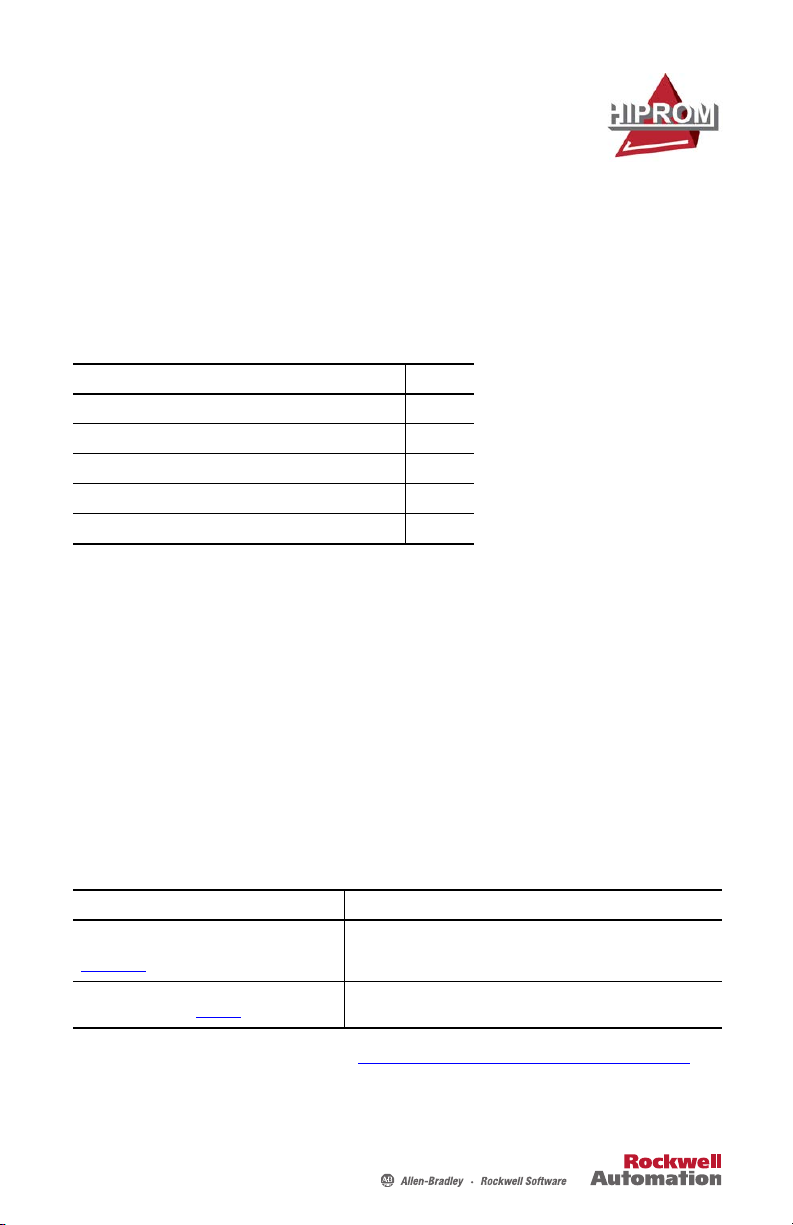

Hardware Requirements

The following hardware is required to install and configure the 1788-EN2FFR linking device:

• A 24…32V DC power supply

• An EtherNet/IP connection via a RJ45 connector

Publication 1788-QS006A-EN-P - October 2012

Page 3

Redundant EtherNet/IP to FOUNDATION Fieldbus Linking Device 3

• An H1 network using IEC 61158-2 cable color coding

Configuration

Complete the following instructions to configure the 1788-EN2FFR linking device.

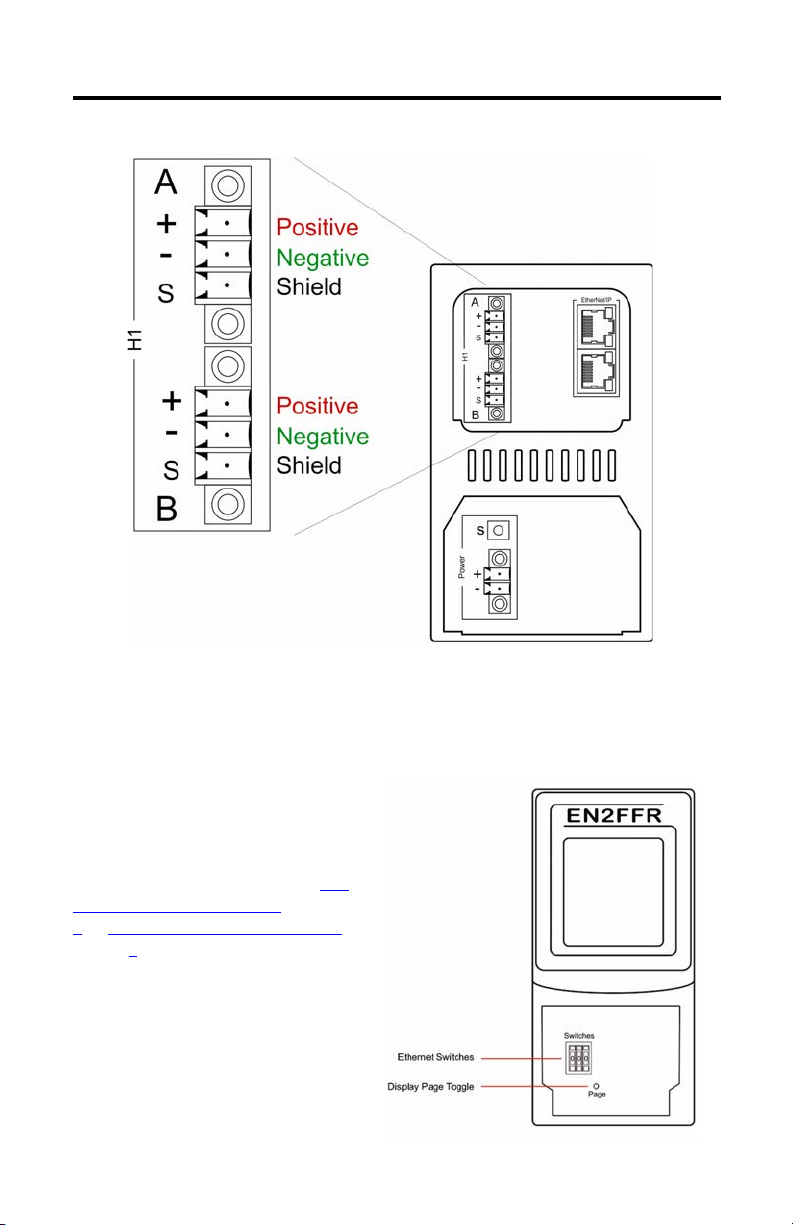

Configure the Ethernet Address

The module has BOOTP enabled when

shipped. You can set an address via a

BOOTP server or set the hardware

switches to a specific IP address. See Use

BOOTP to Set the IP Address on page

4, or Use Switches to Set the IP Address

on page 4

found under the front cover of the

module.

for details. The switches can be

Publication 1788-QS006A-EN-P - October 2012

Page 4

4 Redundant EtherNet/IP to FOUNDATION Fieldbus Linking Device

Use BOOTP to Set the IP Address

1. Set the Ethernet switches to 888 (factory default).

2. Apply power to the linking device.

3. Set the IP address by using any BOOTP server.

4. Once the new IP address has been set, power down the linking device.

5. Return the switches to 000.

6. Apply power to the linking device.

Use Switches to Set the IP Address

To set the IP address of the linking device to the 192.168.1.xxx sub net, set the switches to the

required last three digits.

Add a 1788-EN2FFR Module in RSLogix 5000 Software

The module must be added to the RSLogix 5000 I/O tree by selecting the 1788-EN2FFR

module (under a Rockwell Automation Ethernet bridge, for example EN2T).

1. Right-click the Ethernet bridge and choose New Module.

2. Expand the Hiprom Technologies option and select 1788-EN2FFR.

The Module Properties dialog box appears.

3. Type the module's Name, Description, IP Address, and RPI.

4. Click OK.

Publication 1788-QS006A-EN-P - October 2012

Page 5

Redundant EtherNet/IP to FOUNDATION Fieldbus Linking Device 5

5. Open the 1788-EN2FFR linking device’s Module Properties dialog box and click the

Configuration Tab.

6. Configure the linking device by setting the required Topology mode, Max Scan Address,

and MacroCycle time.

7. Download the configuration to your controller.

8. Go online with the controller to see all attached field devices, which will appear in the

Configuration tree on the left side below the Master.

Field devices can now be configured.

Operation

The following features can be used to view the data and status of the field devices connected to

the 1788-EN2FFR linking device.

Publication 1788-QS006A-EN-P - October 2012

Page 6

6 Redundant EtherNet/IP to FOUNDATION Fieldbus Linking Device

RSLogix 5000 Software

The data and status for each field device can be found in FieldDevice tags of the profile as shown

here.

Status Indicators

The LCD displays the status of the Master and each field device. More detail can be seen by

pressing the Page button under the front cover on the device.

Display Communication Quality

>>> 95+

>> 80+

> 60+

XXX Below 6 0

??? Unknown

OOS Allocated, Online, not compelling data

Off Allocated, Offline

Err Allocated, Online, not producing compelled data

Publication 1788-QS006A-EN-P - October 2012

Page 7

Notes:

Redundant EtherNet/IP to FOUNDATION Fieldbus Linking Device 7

Publication 1788-QS006A-EN-P - October 2012

Page 8

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

links to software service packs, and a MySupport feature that you can customize to make the best use of these tools. You can also visit

our Knowledgebase at http://www.rockwellautomation.com/knowledgebase

forums, software updates, and to sign up for product notification updates.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/support/americas/phone_en.html

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all o f its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

, you can find technical manuals, technical and application notes, sample code and

for FAQs, technical information, support chat and

SM

.

at

, or contact your local

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Allen-Bradley, Rockwell Software, Rockwell Automation, and Te chConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 1788-QS006A-EN-P - October 2012

Copyright © 2012 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

Loading...

Loading...