Page 1

User Manual

EtherNet/IP to DeviceNet Linking Device

Catalog Number 1788-EN2DNR

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Studio 5000, Studio 5000 Logix Designer, RSNetWorx, RSLinx , and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Linking Device Overview

Install the Linking Device

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 1

About the Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Linking Device Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

EtherNet/IP Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DeviceNet Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

DeviceNet Standard and Safety I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Add I/O Online (Online Scanlist Changes Allowed in Run Mode). . . . . 8

Chapter 2

System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Required Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Required Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Connect the Linking Device to the EtherNet/IP Network. . . . . . . . . . . 10

Connect the Linking Device to the DeviceNet Network. . . . . . . . . . . . . 10

Set the DeviceNet Node Address and Data Rate . . . . . . . . . . . . . . . . . . . . 11

Set the DeviceNet Node Address and Data Rate by Using the

Rotary Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Set the DeviceNet Node Address and Data Rate

by Using RSNetWorx for DeviceNet Software. . . . . . . . . . . . . . . . . . 12

Set the Linking Device IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Set the Linking Device IP Address by Using the Rotary Switches . 12

Set the Linking Device IP Address by Using DHCP/BOOTP . . . 13

Set the Linking Device IP Address by Using RSLinx Software . . . . 15

Set the Linking Device IP Address by Using the Linking Device

Web Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Configure the Driver in RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Register the EDS File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Configure the Linking Device

Chapter 3

RSNetWorx for DeviceNet Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Set the DeviceNet Node Address and Data Rate . . . . . . . . . . . . . . . . 20

Enable/Disable Autobaud. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configure DeviceNet I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Add the Linking Device to a Logix Designer Application . . . . . . . . 28

Configure the Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Assembly Objects and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 3

Page 4

Table of Contents

Chapter 4

USB Cable

SD Card

Diagnostic Web Pages

Connect via USB to the Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Configure the USB Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 5

Install or Remove the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Load or Store to the SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Store to the SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Load from the SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Chapter 6

Diagnostic Web Pages—DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

DeviceNet Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Active Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Idle Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Faulted Nodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Invalid Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Node Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Diagnostic Web Pages—Ethernet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Diagnostic Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ethernet Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Ring Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Diagnostic Web Pages—Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Crash Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Heap Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Appendix A

Status Indicators

Linking Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Index

4 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 5

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

DeviceNet Media Design and Installation Guide,

publication DNET-UM072

DeviceNet Network Configuration User Manual,

publication DNET-UM004

DeviceNet Modules Installation Instructions,

publication DNET-IN001

EtherNet/IP Embedded Switch Technology Application

Guide, publication ENET-AP005

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides information about how to design, install and

troubleshoot a DeviceNet cable system.

Describes how to use DeviceNet modules with your

Logix5000 controller and communicate with various

devices on the DeviceNet network.

Describes how to install and start DeviceNet module

systems with Logix5000 controllers.

Describes how to install, configure and maintain linear

and device level ring (DLR) networks that use Rockwell

Automation EtherNet/IP devices with embedded switch

technology.

certification details.

You can view or download publications at

http:/www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 5

Page 6

Preface

Notes:

6 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 7

Linking Device Overview

Chapter 1

About the Linking Device

The 1788-EN2DNR EtherNet/IP-to-DeviceNet linking device lets you

seamlessly connect your information or control-level networks with your

device-level network.

The linking device provides full DeviceNet master functionality, so you can

connect up to 63 DeviceNet slave devices to an Ethernet TCP/IP interface that

supports the EtherNet/IP network and an HTTP web server. For example, you

could use the linking device to do the following:

• As a gateway to connect information or control-level networks to devicelevel networks for programming, configuration, control, or data collection

• As a router/bridge to connect the EtherNet/IP network to the DeviceNet

network

The linking device provides centralized data storage, or I/O tables, for data

shared between the DeviceNet and EtherNet/IP networks. Data is placed into

the I/O tables by one network interface, allowing the data to be read through the

other network interface.

The linking device appears as a single device on either network by using standard

protocol mechanisms. No special, or extended, protocol features are required for

the devices on either network to read or write the data flowing through the I/O

tables; all cross-network activity is transparent to the devices on either network.

The linking device also supports Device Level Ring (DLR) and CIP Safety

connections.

Phoenix connectors are provided for power and DeviceNet connections. Two

RJ45 style connectors are provided for EtherNet/IP connection.

The linking device can be mounted to a DIN rail.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 7

Page 8

Chapter 1 Linking Device Overview

Features

The 1788-EN2DNR module has the following features.

Linking Device Features

For Class 0 CIP Safety connections, 5 ms maximum delay from network to

network

EtherNet/IP Features

• The linking device supports these connections:

– 32 Class 0 connections (Safety)

– 21 Class 1 connections (1 excl. owner, 20 input only/listen only)

– 16 Class 3 connections

• Integrated web server

• Beacon-based DLR (Device Level Ring) support

DeviceNet Features

• 63 nodes on the DeviceNet network

• Master/scanner as well as slave/adapter functionality

• Safety I/O

• Scanner configuration using RSNetWorx™

• Autoscan

• ADR (Automatic Device Replacement) with a capacity of 256 kB

• Quick connect (as originator)

• I/O slave messaging (bit strobe, polling, cyclic, change of state)

for DeviceNet software

DeviceNet Standard and Safety I/O

Add I/O Online (Online Scanlist Changes Allowed in Run Mode)

8 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

The 1788-EN2DNR linking device features the possibility to bridge CIP safety

messages. It supports 32 CIP safety connections, with a maximum internal delay

of 5 ms.

The Online Scanlist Changes Allowed in Run (OSCAR) feature lets you

manipulate the DeviceNet scanner configuration while the scanner is in Run

mode. Configuration items that can be changed in Run mode include the

scanlist, ADR, and ISD (InterScan Delay). Safety I/O cannot be added to the

scanlist.

Page 9

Install the Linking Device

Chapter 2

System Requirements

The following hardware and software components are required to use the linking

device.

Required Hardware

• 1788-EN2DNR linking device

• Two 121 Ω (1%, 1/4 watt) termination resistors (shipped with the linking

device)

• DeviceNet cabling, power, and devices forming a DeviceNet network

• Ethernet cabling

• Computer with USB connection or access to the Ethernet network

• 24 V DC power to the linking device

DeviceNet power can be used; however, using DeviceNet power bypasses

the DeviceNet network isolation.

Required Software

• RSNetWorx for DeviceNet software, version 21 or later, to configure

DeviceNet devices and the linking device’s DeviceNet functionality

• RSLinx® software, version 3.51 or later

• RSLogix 5000 version 20 or Studio 5000 Automation Engineering &

Design Environment™, version 21 or later.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 9

Page 10

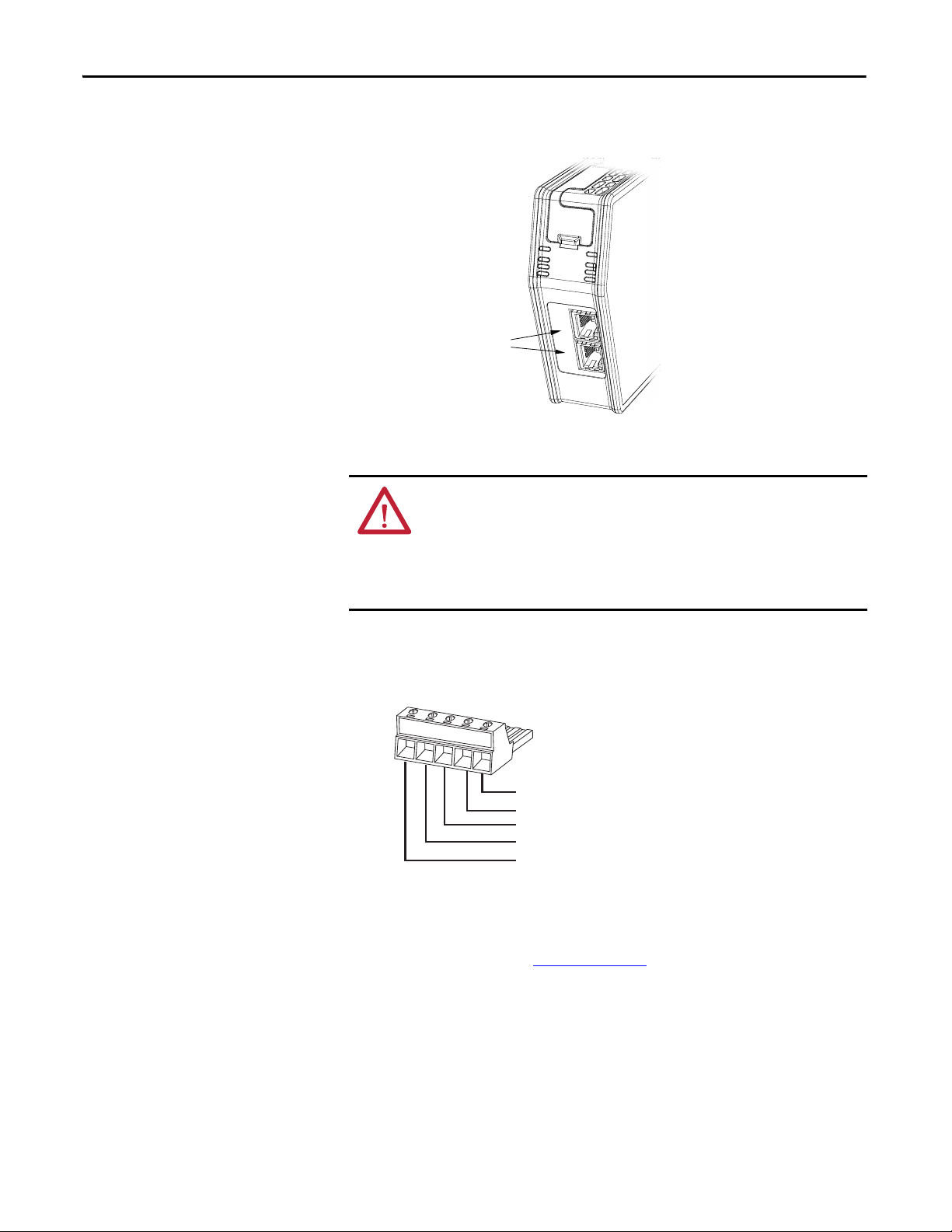

Chapter 2 Install the Linking Device

RJ45 Ports

TIP

31442-M

Connect the Linking Device to the EtherNet/IP Network

Connect the Linking Device to the DeviceNet Network

Connect the EtherNet/IP network cable to either of the two RJ45 ports on the

front of the linking device.

ATT EN TI ON : Do not wire more than two conductors on any single terminal. To

comply with the CE Low Voltage Directive (LVD), this equipment must be

powered from a source compliant with safety extra low voltage (SELV) or

protected extra low voltage (PELV). To comply with UL restrictions, this

equipment must be powered from a source compliant with Class 2 or Limited

Vol tage /Curren t.

1. With power to the linking device off, connect the DeviceNet network

cable to the DeviceNet connector on the linking device.

The female terminal block connector is provided with the linking device.

(Red) Net Power 24V DC

(White) CAN High +

CAN Shield

(Blue) CAN Low

(Black) Net Power 24V DC Common

The two 121 ? termination resistors that come with the linking device are

required for proper network termination at each end of the trunk line. See the

DeviceNet Specification (available from the Open DeviceNet Vendors

Association at http://www.odva.org

) for specific rules on DeviceNet

connections and termination.

10 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

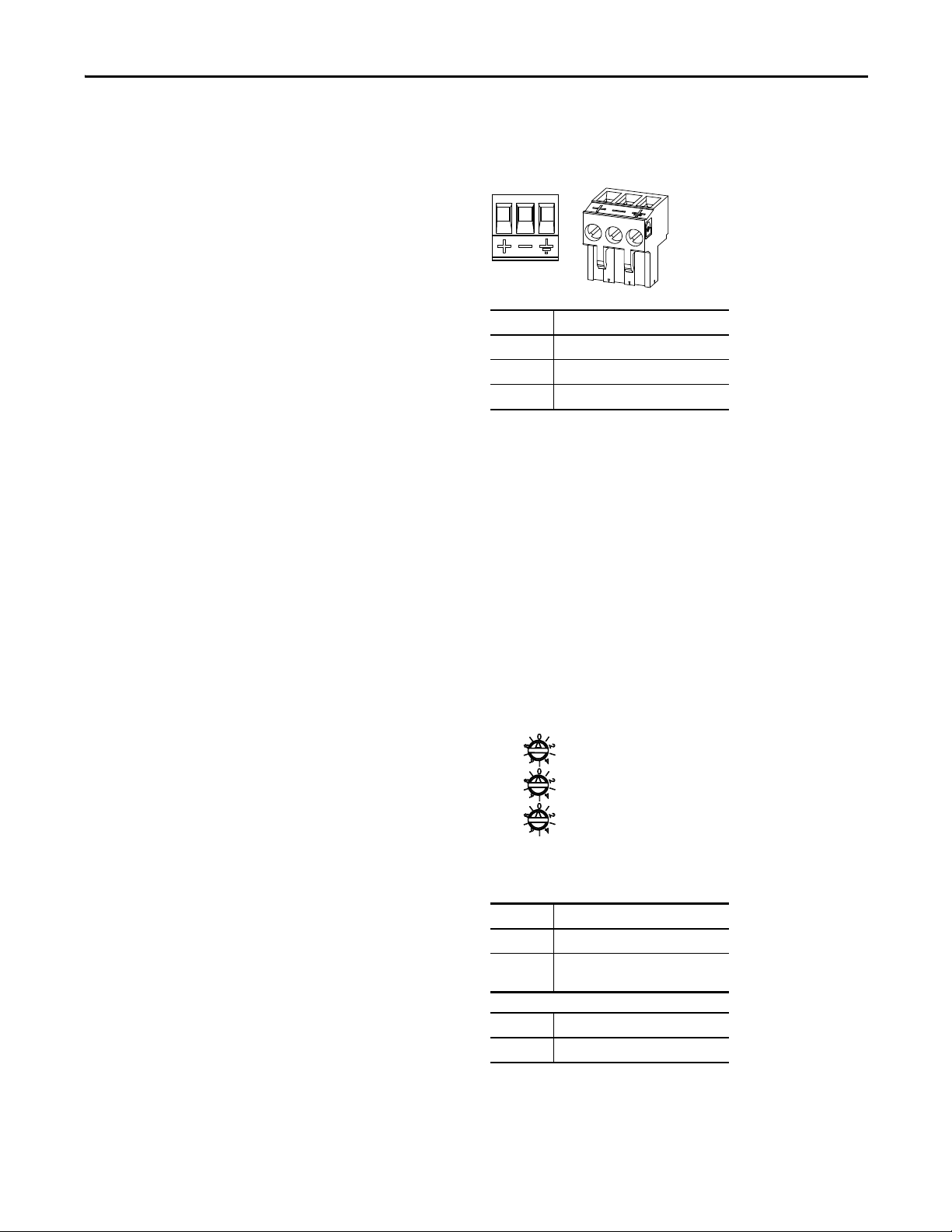

Page 11

Install the Linking Device Chapter 2

123

NA x10

NA x1

DATA RATE

2. Connect the power cable to the linking device.

The female terminal block connector is provided with the linking device.

Pin No. Description

1 +24 V DC

2GND

3PE (Protective Earth)

3. Apply power to the linking device and DeviceNet network.

Set the DeviceNet Node Address and Data Rate

Two methods can be used to set the DeviceNet node address and the data rate:

• Use the node address and data rate rotary switches on the side of the

linking device

• Use RSNetWorx for DeviceNet software

Set the DeviceNet Node Address and Data Rate by Using the Rotary Switches

The rotary switches are on the right side of the linking device.

Set the desired node address and data rate according to the table below.

Switch Node Address

00 - 63 DeviceNet node address

Other value Node address selected via RSNetWorx

software

Switch Data Rate

0 125 kbps

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 11

Page 12

Chapter 2 Install the Linking Device

x100

x10

x1

Switch Data Rate

1 250 kbps

2 500 kbps

Other value Data rate selected via RSNetWorx

software

Set the DeviceNet Node Address and Data Rate by Using RSNetWorx for DeviceNet Software

See Set the DeviceNet Node Address and Data Rate on page 20 for information

about using RSNetWorx software to set node address and data rate.

Set the Linking Device IP Address

Four methods can be used to set the linking device IP address:

• Use the IP address rotary switches on the side of the linking device

• Use the DHCP protocol

• Use RSLinx Software

• Use the web pages of the linking device

Set the Linking Device IP Address by Using the Rotary Switches

The rotary switches are on the right side of the linking device.

Set the IP address according to the table below.

Switch IP Address

000 Administrative mode

The linking device uses the IP address that was used last startup

The web pages are available

001 - 254 192.168.1.XYZ where XYZ is the value of the three switches

888 Reset the linking device to initial out-of-box settings

Other value The linking device starts in operating mode, using the latest configured IP

address

12 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 13

Install the Linking Device Chapter 2

TIP

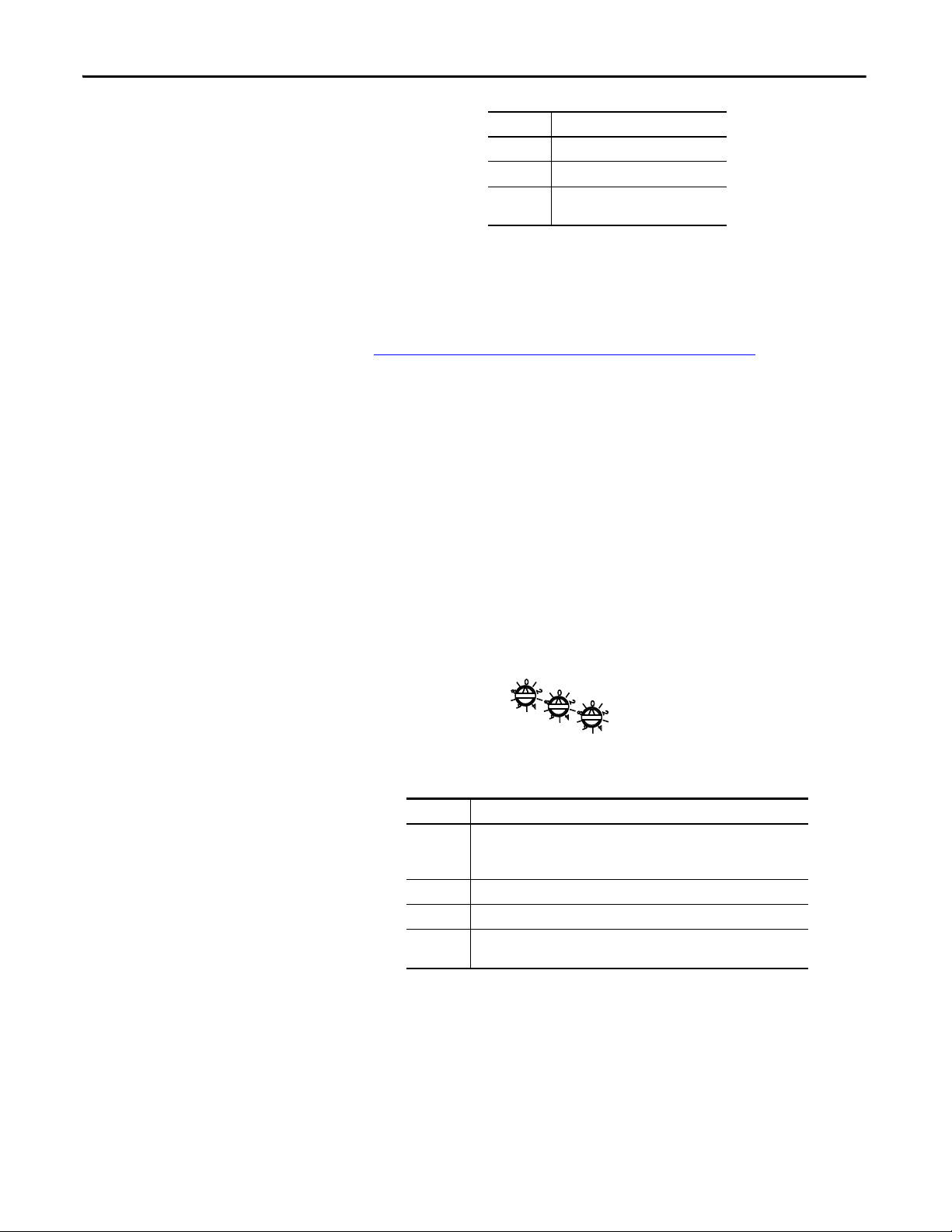

Set the Linking Device IP Address by Using DHCP/BOOTP

The use of DHCP is the default configuration for the linking device as shipped.

When DHCP/BOOTP is enabled and a DHCP or BOOTP server is found, the

IP address, subnet mask, and gateway address are automatically configured by the

DHCP server, as shown in the following figure.

Automatic Configuration

Launch a DHCP/BOOTP Server. If using the Rockwell Automation DHCP/

BOOTP server, then follow these steps to change the IP address, Subnet mask,

and Gateway address from this dialog box.

1. Click New.

The Properties dialog box appears.

2. Enter the appropriate values into the following boxes.

• Ethernet address (MAC ID) from the linking device product ID label

• IP address

• Subnet Mask

• Gateway (IP address)

3. Click OK.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 13

Page 14

Chapter 2 Install the Linking Device

TIP

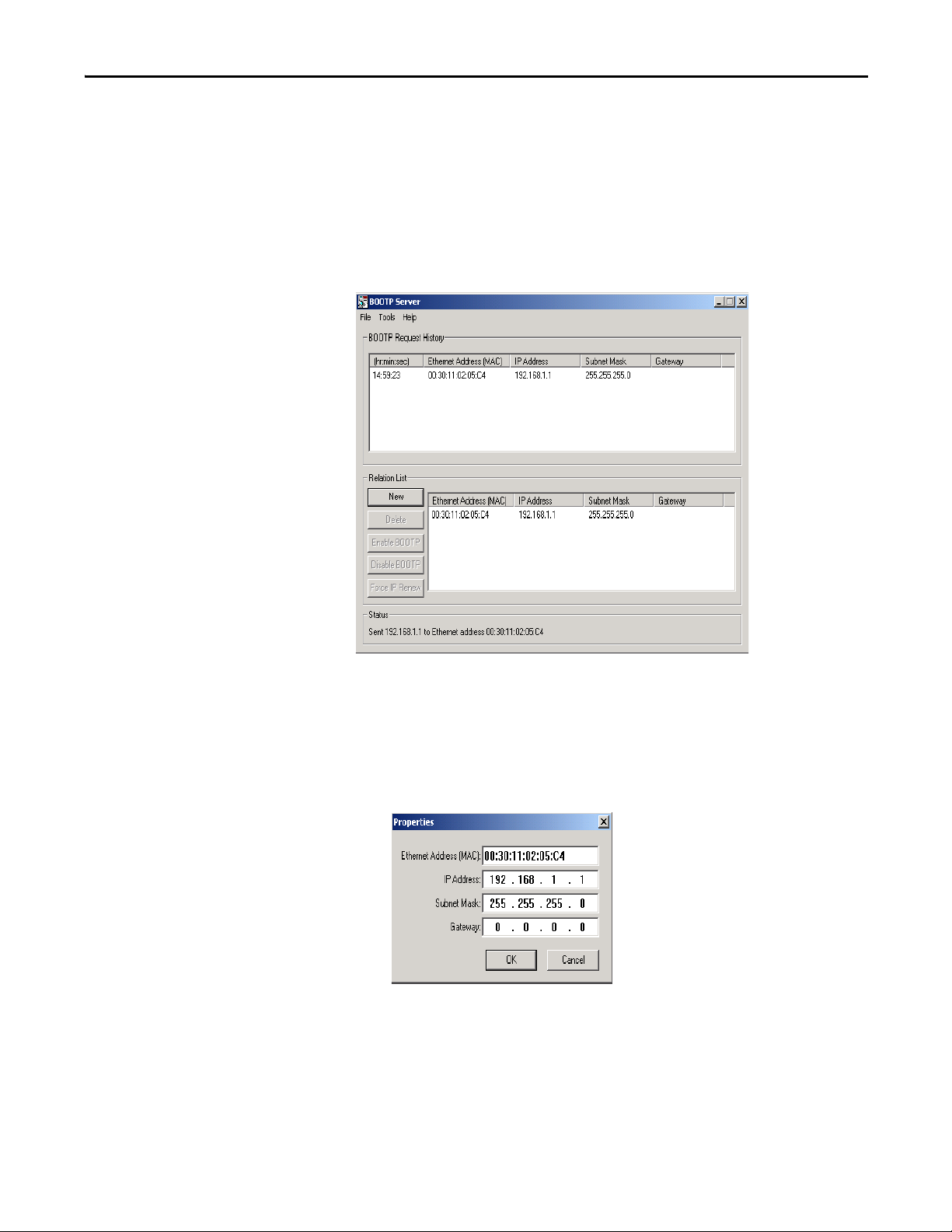

The following figure shows a flowchart describing how the IP configuration is

determined when the linking device is powered up.

IP Configuration Flowchart

Start

No

Rotary

Switches = 000?

Yes

Admin Mode Operational Mode

No Yes

Fetch Stored Settings

No

Rotary

Switches

1 - 254?

Rotary

Switches = 888?

IP Address:

192.168.1.X

Yes

Factory Reset to DHCP

LED Indication

DHCP

Enabled?

No

IP Address:

Static Setting

Yes

Start up

You can enable these values by using the linking device’s IP Configuration web

page. Refer to Set the Linking Device IP Address by Using the Linking Device

Web Pages on page 16.

14 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Fetch IP Address

from Server

Page 15

Install the Linking Device Chapter 2

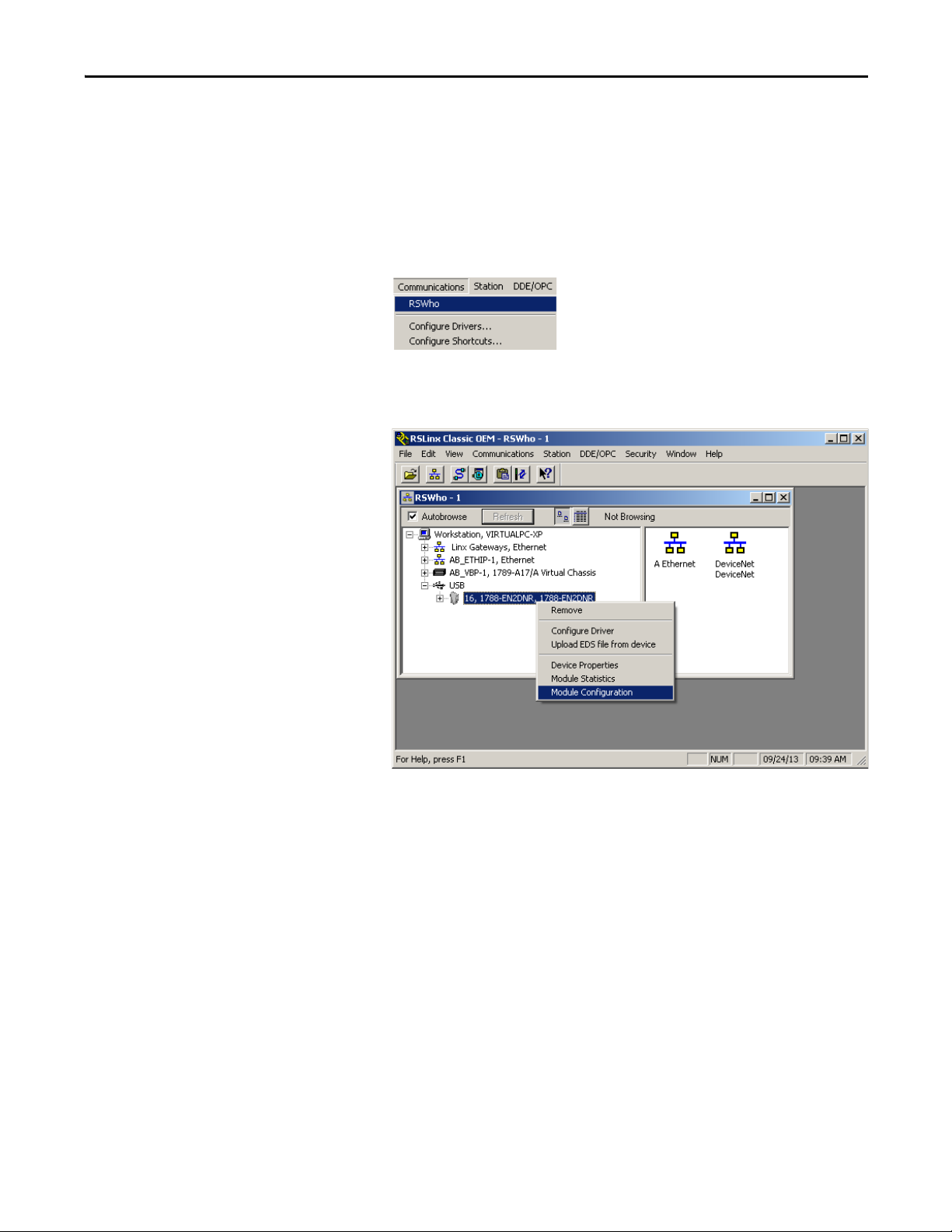

Set the Linking Device IP Address by Using RSLinx Software

To use RSLinx software to set the IP address of the linking device, follow these

steps.

1. Connect to the linking device using a USB cable.

2. From the Communications menu, choose RSWho.

3. Navigate to the USB port.

4. Right-click the linking device and choose Module Configuration.

5. Click the Port Configuration tab.

6. For Network Configuration Type, click Static to permanently assign this

configuration to the port.

7. Type the desired information in the appropriate boxes.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 15

Page 16

Chapter 2 Install the Linking Device

IMPORTANT

8. Configure the port settings.

To Th en

Use the default port speed and duplex

settings

Manually configure your port’s speed

and duplex settings

Consider the following when you configure the linking device’s port

settings:

• If the linking device is connected to an unmanaged switch, leave

Auto-negotiate port speed and duplex checked or the

communications to the linking device fails.

• If you are forcing the port speed and duplex with a managed

switch, the corresponding port of the managed switch must be

forced to the same settings or the linking device fails.

Leave Auto-negotiate port speed and duplex checked.

This setting determines the actual speed and duplex setting.

Follow these steps.

1. Clear the Auto-negotiate port speed and duplex checkbox.

2. From the Current Port Speed pull-down menu, choose a port

speed.

3. From the Current Duplex pull-down menu, choose the

appropriate Duplex value.

9. Click OK.

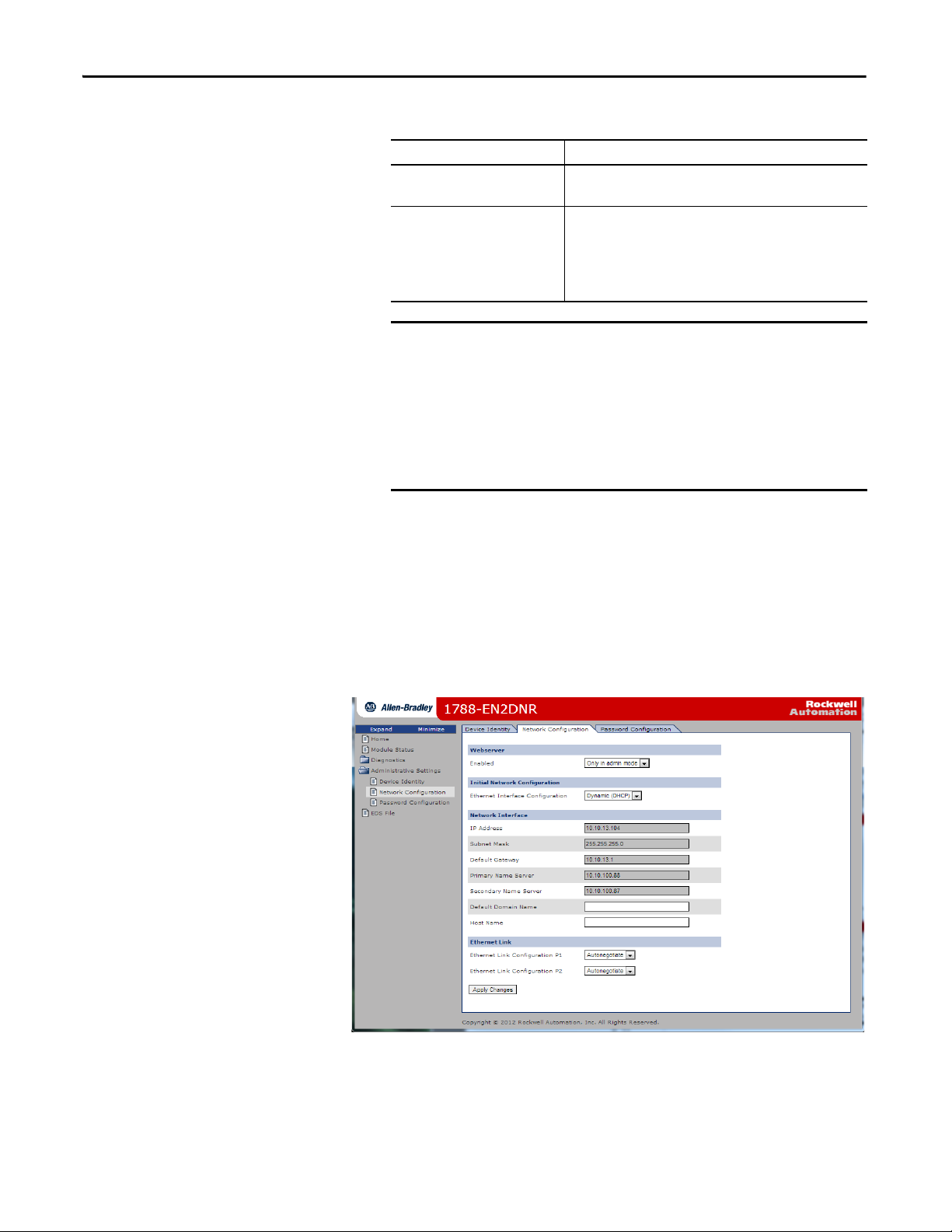

Set the Linking Device IP Address by Using the Linking Device Web Pages

The EtherNet/IP address can also be configured by using the Network

Configuration web page on the linking device, as shown in the following figure.

16 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 17

Install the Linking Device Chapter 2

IMPORTANT

The IP address can be set with the web page only if the linking device already has

a valid IP address. One way that you can do this is by using the rotary switch to

force the linking device to use the IP address from the switches after you cycle

power. Follow these steps to configure the IP address with the web page.

Because the rotary switches setting overrides other IP address configurations,

be sure to set the rotary switches to the 0 position before continuing.

1. Browse to the linking device by entering the IP address set by the switches

in your web browser’s address bar and press Enter.

2. In the left pane, click Network Configuration.

The Enter Network Password dialog box appears.

3. In the User Name box, type Administrator.

4. In the password box, type the default password, which is the serial number

of the linking device in hexadecimal format, upper case.

The serial number can be found on the 1788-EN2DNR web page.

5. Click OK.

The Network Configuration dialog box appears.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 17

Page 18

Chapter 2 Install the Linking Device

6. In the Network Configuration dialog box, enter the following values.

Description Type

IP Address Any valid value. See your system administrator for a

valid IP address.

Subnet Mask Any valid value.

Default Gateway

Primar y Name Server

Secondary Name Server

Default Domain Name

Host Name

7. Click Apply Changes.

8. Follow the on-dialog box prompts.

9. Cycle power to the linking device.

Configure the Driver in RSLinx Software

Register the EDS File

1. In RSLinx software, choose Communications > Configure Drivers.

2. From the Available Driver Types pull-down menu, choose EtherNet/IP

Driver.

3. Click Add New.

4. In the Add New RSLinx Drivers dialog box, click OK.

5. In the Configure Driver window, select the EtherNet/IP network

interface, and click OK.

6. Click Close.

The EDS file for the linking device is accessible and downloadable with RSLinx.

To register the EDS file in RSLinx software, follow these steps.

1. In RSLinx software, right-click the linking device.

2. Select Upload EDS File from Device.

3. Click Next or Finish for the remaining dialog boxes.

18 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 19

Configure the Linking Device

Chapter 3

RSNetWorx for DeviceNet Software

1. In RSNetWorx for DeviceNet software, choose Network > Online.

2. In the left pane, click the RSLinx Ethernet driver you added previously.

See Configure the Driver in RSLinx Software on page 18

3. In the left pane, click the + next to the 1788-EN2DNR linking device

icon.

4. In the left pane, choose DeviceNet, DeviceNet.

.

5. When asked to upload from the network, click OK to perform a single

pass browse.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 19

Page 20

Chapter 3 Configure the Linking Device

Set the DeviceNet Node Address and Data Rate

Note that, to be able to set the node address and the data rate from RSNetWorx

software, the rotary switches must be set to any value other than 0 - 63.

1. In RSNetWorx for DeviceNet software, choose Tools > Node

Commissioning.

The Node Commissioning dialog box appears.

2. On the Node Commissioning dialog box, click Browse.

The Device Selection dialog box appears.

3. In the left pane, click the + next to the RSLinx driver for the

1788-EN2DNR linking device.

20 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 21

Configure the Linking Device Chapter 3

4. In the left pane of the dialog box, click the + next to the IP address for the

1788-EN2DNR linking device.

5. In the left pane, click the + next to the DeviceNet network.

You see the 1788-EN2DNR linking device in the left pane.

6. Click the 1788-EN2DNR linking device in the left pane.

The linking device appears in the right pane.

7. Click OK.

8. If a warning text box asking you if you wish to continue appears, click Yes.

9. Enter the desired node address or data rate, then click Apply.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 21

Page 22

Chapter 3 Configure the Linking Device

IMPORTANT

TIP

10. Click Close.

The linking device automatically restarts the DeviceNet network if a

new node address is entered. If the communication rate is changed,

you must cycle power to the linking device before the new

communication rate takes effect.

Note: Data rate changes can cause bus-off errors. Do not change the

data rate during live network performance.

11. Restart RSNetWorx for DeviceNet software and go online.

If you are using the linking device as a network gateway, you need to

restart RSNetWorx for DeviceNet software before continuing.

22 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 23

Configure the Linking Device Chapter 3

IMPORTANT

Enable/Disable Autobaud

Autobaud is disabled by default. You can turn it on or off by following the

procedure below.

1. In RSNetWorx for DeviceNet software, click the linking device icon.

2. From the Device pull-down menu, choose Class Instance.

3. If a warning dialog box appears, click Yes.

The Class Instance Editor dialog box appears.

4. From the Description pull-down menu, choose Set Single Attribute.

5. Choose the appropriate options in the Class Instance Editor dialog box.

In This Box Choose

Object Address

Class

Instance

Attribute

Data Sent to Device 00 to enable Autobaud

Tra nsm it D ata Size By te

3

1

64h

01 to disable Autobaud

Make sure the Values in Decimal checkbox is cleared.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 23

Page 24

Chapter 3 Configure the Linking Device

IMPORTANT

6. Click Execute.

A message in the ‘Data received from device’ box indicates that the

execution was completed.

7. Click Close.

Changes to the autobaud option configuration do not take effect until

you cycle power to the linking device. You may also have to cycle power

to the slave devices.

If the linking device is the only master on the DeviceNet network, do

not enable autobaud. Automatic detection requires traffic on the

network. There is typically no traffic until a master attempts to

establish a connection.

Enable autobaud only if there are three or more devices on the

network, including the linking device.

24 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 25

Configure the Linking Device Chapter 3

IMPORTANT

IMPORTANT

TIP

IMPORTANT

Configure DeviceNet I/O

Steps 8 and 9 are required only if the linking device is used as an I/O scanner.

The linking device can function as a gateway/bridge for explicit messaging and

safety I/O routing, even if no I/O is configured.

I/O Mapping

The DeviceNet I/O configuration defines the format of the Input and Output

tables, or the mapping of DeviceNet slaves’ I/O data to the I/O tables. As slaves

are added to the linking device’s DeviceNet scanner configuration, the location in

the I/O tables of each part of the slave’s I/O data is determined and stored.

The organization of the I/O tables is very important. I/O tables define the

format of the data that is provided to the EtherNet/IP scanner. Plan and

document the Input and Output table formats to be sure the EtherNet/IP

scanner is working with the correct data from the DeviceNet network.

The size of the I/O data that can be exchanged with the EtherNet/IP scanner

(and, hence, the size of the I/O tables) is restricted as explained below:

• The Input table size cannot be larger than 496 bytes.

• The Output table size cannot be larger than 492 bytes.

• Either table can be empty (0 bytes).

To configure standard DeviceNet I/O, use RSNetWorx for DeviceNet software

to set the linking device’s scan list and I/O table mapping.

To configure CIP Safety I/O, see the following:

• GuardLogix User manual: 1756-UM020H-EN-P - April 2012

• 1791DS User manual: 1791DS-UM001J-EN-P - May 2013

Automap is used in this example for simplicity. In some cases, if you want to

organize the I/O data in other ways, use the Advanced data table editor in the

Input and Output tabs. Refer to RSNetWorx online help for complete details.

1. In RSNetWorx for DeviceNet software, from the Network menu, choose

Online.

2. From the Network menu, choose Single Pass Browse.

Wait for browsing to complete.

3. From the Network menu, choose Upload from Network.

Wait for the device information to be uploaded from the network.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 25

Page 26

Chapter 3 Configure the Linking Device

4. Double-click the linking device icon to open the Module Description

dialog box.

Several tabs appear on the top of the dialog box.

5. Click the Scanlist tab.

6. In the informational dialog box that appears, click Upload.

The dialog box shows two columns. On the left is a list of available devices

that can be added to the scan list. On the right is a list of devices that are

configured in the scan list.

7. Check AutoMap on Add.

8. Select the I/O devices on the left side of the dialog box and click > to move

it to the right side of the dialog box.

9. Click the Input tab.

26 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 27

The Input mapping dialog box appears.

TIP

The top portion of this dialog box lists the

devices in the scan list from which the linking

device receives input data. The bottom shows

the location in the Input table where the data

is placed for each device. This shows the

format of the Input table of the linking

device. This is the format of the input data

that is sent to the EtherNet/IP scanner.

The top portion of this dialog box lists the

devices in the scan list from which the linking

device sends output data. The bottom shows

the location in the Output table where the

data is placed for each device. This shows the

format of the Output table of the linking

device. This is the format of the output data

that is sent to the linking device from the

EtherNet/IP scanner.

10. Click the Output tab.

The Output mapping dialog box appears.

Configure the Linking Device Chapter 3

11. Click Apply, and click Yes to download the scan list to the linking device.

The linking device starts scanning as soon as it finds entries in its scan list.

However, in Idle mode, output data is not sent to the devices.

12. Click OK.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 27

Page 28

Chapter 3 Configure the Linking Device

Studio 5000 Environment

These procedures explain how to work with the linking device in the

Studio 5000® environment.

Add the Linking Device to a Logix Designer Application

1. In the Studio 5000 Logix Designer™ application, from the File menu,

choose New to create a new project.

The New Controller dialog box appears.

2. From the Type pull-down menu, choose the controller type.

3. From the Revision pull-down menu, choose the controller version.

4. In the Name box, type a name for the controller project.

5. Click OK.

A project is created.

Configure the Linking Device

1. In the left pane, right-click I/O Configuration.

2. Click New Module.

3. From the Select Module Type dialog box, select any EtherNet/IP bridge

module (such as the 1756-EN2TR module) and click Create.

The New Module dialog box appears.

4. In the Slot Number pull-down, choose the slot number in which the device

resides.

5. Click OK.

6. In the right pane, right-click the EtherNet/IP module you just added to

your project and choose New Module.

28 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 29

Configure the Linking Device Chapter 3

7. From the Select Module Type dialog box, select 1788-EN2DNR 1788

Ethernet to DeviceNet Linking Device and click Create.

The AOP needs to be installed for the linking device to show up in the list.

The AOP is available here: https://download.rockwellautomation.com/

esd/download.aspx?downloadid=addonprofiles

The New Module dialog box appears.

8. In the Name box, enter a module name.

9. Click IP Address and type the IP address for which the linking device is

configured.

10. Click the Connection tab.

11. Enter the Requested Packet Interval (RPI or update rate) in a range from

2…750 ms.

12. Click the RSNetWorx tab.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 29

Page 30

Chapter 3 Configure the Linking Device

TIP

13. If an RSNetWorx for DeviceNet configuration file (filename *.dnt) already

exists for the linking device, enter or browse to the appropriate filename.

Doing so lets RSNetWorx for DeviceNet software launch directly from the

Studio 5000 environment.

14. Click OK.

You can now use the linking device as both a bridge and a scanner.

15. Write a user program to use the linking device on the network.

Consult Rockwell Automation Technical Support or your Rockwell

Automation representative for assistance in writing the program.

16. To view information specific to the Logix Designer application tags that

pertain to the linking device, do the following.

a. In the left pane, click Controller Tags.

In the right pane, you see the 1788-EN2DNR linking device controller

tags.

b. Click the + to the left of the tag name to expand it.

c. Review data in the boxes that appear for each tag, as described in the

section entitled Assembly Objects and Connections on page 31

30 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

.

Page 31

Configure the Linking Device Chapter 3

IMPORTANT

Assembly Objects and Connections

Three Assembly Object instances are accessible from the EtherNet/IP network:

input, output and status. The input and output assemblies are linked to the input

and output tags created in the Studio 5000 environment. The status assembly

provides current status information about the linking device.

With a specific 1788-EN2DNR profile, I/O tags are mapped without an offset.

For example, the Logix Designer application input tag EN2DNR:I:Data[0]

corresponds to word 0 of the RSNetWorx for DeviceNet software input mapping

table.

The assembly instances associated with these three assemblies are listed in the

following tables.

Input Assembly

The input assembly contains a 32-bit status register followed by the data in the

linking device’s input data table.

Input Assembly Format

DINT

Offset

0 1 Status register EN2DNR:I.Status Register

1 Up to 123 Input data EN2DNR:I.Data[0 …123]

Size in DINTs Description Studio 5000 Environment Version 21or Later

Example Tags

The input data format and content is determined by the DeviceNet scanner

configuration. The data appears in the table as it is mapped from the DeviceNet

input connections. The input data in the assembly is 124 DINTs long ; however,

only the size of the input data table is used. The remaining space is filled with the

value 0 (zero).

Output Assembly

The output assembly contains a 32-bit command register followed by the data in

the linking device’s output data table.

Output Assembly Format

DINT

Offset

0 1 Command register EN2DNR:O.CommandRegister

1 Up to 124 Output data EN2DNR:O.Data[0 …122]

Size in DINTs Description Studio 5000 Environment Version 21or Later

Example Tags

The output data format and content is determined by the DeviceNet scanner

configuration. The data appears in the table as it is mapped to the DeviceNet

output connections. The output data in the assembly is 123 DINT long;

however, only the size of the output data table is used. The remaining space is

ignored.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 31

Page 32

Chapter 3 Configure the Linking Device

IMPORTANT

Status Assembly

The status assembly is a collection of status and diagnostic information for the

linking device’s DeviceNet network interface. The information in the assembly is

updated once a second.

All information in the status assembly is stored in little endian format. The

least significant byte of multibyte values is stored first.

Status Assembly Format

Byte

Offset

0 4 UDINT ScanCounter The number of DeviceNet I/O scans that

4 8 SINT[8] DeviceFailureRegister Indicates which DeviceNet slaves are

12 8 SINT[8] AutoVerifyFailure

20 8 SINT[8] DeviceIdleRegister Indicates which DeviceNet slaves are in

28 8 SINT[8] ActiveNodeRegister Indicates which DeviceNet nodes are

36 4 SINT[4] StatusDisplay Mimics a 4-character alpha-numeric

40 1 USINT ScannerAddress The DeviceNet MAC ID of the linking

41 1 USINT ScannerStatus The current status of the DeviceNet

42 1 USINT ScrollingDevice

43 1 USINT

64 64 USINT[64] DeviceStatus The current status of each DeviceNet slave

Size in

Bytes

Data Type Name (Studio 5000

environment version

21or later)

Register

AddressAndStatus

Description

have taken place since power was applied

to the linking device.

faulted. Each bit represents the status of

the slave at the corresponding MAC ID.

Indicates which DeviceNet slaves are the

incorrect device type. Each bit represents

the status of the s lave at the

corresponding MAC ID.

Idle mode. Each bit represents the status

of the slave at the corresponding MAC ID.

configured in the 1788-EN2DN’s scan list.

Each bit represents the status of the slave

at the corresponding MAC ID.

display. If there are no faults, the display

shows the linking device’s MAC ID and its

Run/Idle status.

If there are faults, the display scrolls

through the MAC IDs of the faulted nodes

and display the error code associated with

each.

device.

scanner.

The scrolling address and status fields

scroll through the address and status of all

DeviceNe t slaves that are faulted. This

scrolling includes the linking device

scanner itself.

If there are no faulted nodes, both the

scrolling address and status are set to 0.

The scrolling fields change once a second.

node. Each array element is the status of

the node at the corresponding MAC ID.

If a node is not configured in the linking

device scan list, the status value is set to 0.

The linking device scanner status appears

at the entry associated with the linking

device MAC ID.

32 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 33

USB Cable

Chapter 4

Connect via USB to the Linking Device

To use the USB port of the linking device, you must have RSLinx software,

version 2.56 or later, installed on your workstation. Use a USB cable to connect

your workstation to the USB port of the linking device.

With this connection, you can configure the linking device and the DeviceNet

network or upgrade the linking device’s firmware, directly from your workstation.

ATT EN TI ON : The USB port is intended only for temporary connections. The USB

cable is not to exceed 3.0 m (9.84 ft) and must not contain hubs.

WARNING: Do not use the USB port in hazardous locations.

The USB port is on the front of the linking device.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 33

Page 34

Chapter 4 USB Cable

TIP

Configure the USB Driver

To configure RSLinx software to use a USB port, you need to configure a USB

driver.

To configure a USB driver, perform this procedure.

1. Connect the linking device and your workstation by using a USB cable.

The Found New Hardware Wizard appears.

2. Click any of the Windows Update connections options and click Next.

If the software for the USB driver is not found and the installation is

cancelled, verify that you have installed RSLinx Classic software,

version 2.57 or later.

3. Click Install the software automatically (Recommended) and click Next.

The software is installed.

34 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 35

USB Cable Chapter 4

4. Click Finish to set up your USB driver.

To browse to the linking device in RSLinx software, click the RSWho

icon.

The RSLinx Workstation organizer appears.

The linking device appears under two different drivers, a virtual chassis

and the USB port. You can use either driver to browse to the linking

device.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 35

Page 36

Chapter 4 USB Cable

Notes:

36 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 37

SD Card

IMPORTANT

Unlocked

Locked

Chapter 5

Install or Remove the SD Card

Complete these steps to install or remove the Secure Digital (SD) card in the

linking device.

WARNING: When you insert or remove the SD card while power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is turned off or the area is nonhazardous before proceeding.

• Verify that the SD card status indicator is off and that the card is not in use

before removal.

• We recommend that you do the following:

- Leave an SD card installed.

- Use the SD cards available from Rockwell Automation (catalog number

1784-SD1 or 1784-SD2).

• While other SD cards can be used with the linking device, Rockwell

Automation has not tested the use of those cards with the linking device. If

you use an SD card other than those available from Rockwell Automation,

there is a possibility of data corruption or loss.

• Also, SD cards not provided by Rockwell Automation do not have the same

industrial, environmental, and certification ratings as those available from

Rockwell Automation.

1. Verify that the SD card is locked or unlocked according to your preference.

For more information about the lock/unlock memory settings, see Load or

Store to the memory card on page 38

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 37

.

Page 38

Chapter 5 SD Card

2. Open the latch situated on the linking device and insert or remove the

SD card.

3. Close the SD card latch.

Load or Store to the SD Card

Using RSLogix 5000, the SD card can be used to load or store the linking device’s

configuration. Note that the SD card does not store the scan list created by

RSNetworx for DeviceNet.

Store to the SD Card

To store the linking device’s configuration to the SD card, the SD card must be

correctly inserted and unlocked.

Clicking Store to SD Card produces this warning:

Clicking Yes stores the current configuration of the linking device to the SD card.

38 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 39

SD Card Chapter 5

Load from the SD Card

To load the configuration currently on the SD card to the linking device, the

inserted SD card can be either locked or unlocked.

The image below shows a locked SD card.

Clicking Load to Module produces this warning:

Clicking Yes loads the configuration stored on the SD card to the linking device.

Any configuration currently stored in the linking device is overwritten.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 39

Page 40

Chapter 5 SD Card

Notes:

40 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 41

Diagnostic Web Pages

Chapter 6

Diagnostic Web Pages— DeviceNet

The following sections explain the diagnostic web pages for the DeviceNet

network.

DeviceNet Status

The DeviceNet Status page presents information about the DeviceNet network

and general DeviceNet diagnostics.

Active Nodes

The Active Nodes page indicates which DeviceNet nodes are currently online on

the DeviceNet network. Nodes that are listed in the scan list are marked ‘Active’.

Nodes that are not in the scan list, but still part of the network, are marked

‘Online’.

Idle Nodes

The Idle Nodes page indicates which DeviceNet nodes are currently in the Idle

state. If a node is Idle, the page displays ‘Idle’ next to the node’s MAC ID. Note

that only nodes configured as slaves to the linking device and the linking device

itself are updated on this page.

Faulted Nodes

The Faulted Nodes page indicates which DeviceNet nodes are currently in a

faulted state. If a node is faulted, the page displays ‘Faulted’ next to the node’s

MAC ID. Note that only nodes configured as slaves to the linking device and the

linking device itself are updated on this page.

A node is considered faulted if the linking device has lost communication or is

unable to establish communication with the node. The actual problem can be

determined by viewing the Node Status web page.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 41

Page 42

Chapter 6 Diagnostic Web Pages

Invalid Nodes

The Invalid Nodes page indicates which DeviceNet nodes are not the correct

device type. If a node’s device type is different than that configured in the scan

list, the page displays ‘Invalid’ next to the node’s MAC ID. Note that only nodes

configured as slaves to the linking device are updated on this page.

Node Status

The Node Status page displays the current status of all DeviceNet nodes that are

configured as slaves to the linking device and the linking device itself. The status

of each node is displayed next to the node’s MAC ID. Note that only nodes

configured as slaves to the linking device and the linking device itself are updated

on this page.

The page displays the status textually for many of the common status values.

However, to save web page size, many of the status values are displayed only

numerically. The table below describes the meaning of each status value.

Node Status Codes

Status Code Description Action

0OK Do nothing.

60 Duplicate MAC ID test in progress Do nothing.

65 Autoscan active Do nothing. The scanner’s autoscan

70 Module failed Duplicate Node Address check Change the module address to another

71 Illegal data in scan list table Reconfigure the scan list table and remove

72 Slave device stopped communicating Inspect the field devices and verify

73 Device’s identity information does not match

electronic key in scan list table entry

74 Data overrun on port detected Modify your configuration and check for

75 No traffic detected on the net work Check the network configuration.

76 No direct network traffic for module detected None. The module hears other network

77 Data size expected by the device does not

match scan list entry

78 Slave device in scan list table does not exist Add the device to the network, or delete the

79 Module has failed to transmit a message Make sure that your module is connected to

functionality is ac tive.

available one. The node address you

selected is already in use on that network.

any illegal data.

connections.

Verify that the correct device is at this node

number. Make sure that the device at the

scrolling node address matches the desired

electronic key (such as vendor, product code,

and product type).

invalid data. Check network communication

traffic.

communication .

Reconfigure your module for the correct

transmit and receive data sizes.

scan list entry for that device.

a valid network.

Check for disconnected cables.

42 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 43

Node Status Codes (Continued)

Status Code Description Action

80 Module is in IDLE mode Put controller in RUN mode. Enable RUN bit

81 Module is in FAULT mode Check Module Command Register for fault

82 Error detected in sequence of fragmented I/O

messages from device

83 Slave dev ice is return ing error resp onses when

module attempts to communicate with it

84 Module is initializing the DeviceNet network None. This code clears itself once module

85 Data size was incorrect for this device at

runtime

86 Device is producing zero length data (idle

state) while module is in Run mode

87 The primary owner has not allocated the slave Put the primary owner on line.

88 The connection choices (such as polled or

strobed) between the primar y connection and

the shared input only connection do not

match

89 Slave device initialization using Auto Device

Replacement parameters failed

90 User has disabled communication port Check Module Command Register for

91 Bus-off condition detected on comm port.

Module is detecting communication errors

92 No network power detected on

communication port

95 Application nonvolatile memory update in

progress

96 COMM port in Test mode Do nothing.

97 Module operation halted by user command Check Module Command Register for HALT

98 General firmware error Replace module.

99 System failure Replace module.

in module command register.

bit set.

Check scan list table entry for slave device to

make sure that input and output data

lengths are correct. Check slave device

configuration.

Check accuracy of scan list tabl e entry. Check

slave device configuration. Slave device can

be in another master’s scan list. Reboot slave

device.

attempts to initialize all slave devices on the

network.

Slave device is transmitting incorrect length

data. Try replacing the device.

Check device configuration and slave node

status.

Reconfigure the shared input only

connection's choices to be the same as, or a

subset of, the primary connection's

choice(s).

Put the slave device into configurable mode.

Check the slave's EDS file, if the slave is

configured offline.

Check to see if the slave device has been

replaced with an incompatible device.

DISABLE bit set.

Check DeviceNet connections and physical

media integrity. Check system for failed

slave devices or other possible sources of

network interference.

Provide network power. Make sure that

module drop cable is providing network

power to module comm port.

Do nothing. Do not disconnect the module

while application nonvolatile memory

update is in progress. You lose any existing

data in the module’s memory.

bit set.

Diagnostic Web Pages Chapter 6

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 43

Page 44

Chapter 6 Diagnostic Web Pages

Diagnostic Web Pages— Ethernet

The following sections explain the diagnostic web pages for Ethernet.

Diagnostic Overview

General Ethernet information of the linking device, containing the information

below:

• CPU load

• Number of TCP connections

• Web server statistics

• CIP connections statistics

• I/O packet information

Network Settings

Settings for the Ethernet network are presented here. This includes network

address information and status for each of the two Ethernet ports.

The current setup for the IP address switches is also displayed.

Ethernet Statistics

This section contains information about the current Ethernet settings, as well as

detailed packet statistics. The most commonly monitored fields are described in

the tables that follow.

Ethernet Port 1/Port 2

Field Description

Link Status Whether the port is blocked for DLR protocol frames.

Speed Whether the Ethernet port is operating at 10 or 100 Mbps.

Duplex Whether the Ethernet port is operating at half duplex or full duplex.

Autonegotiate Status Whether the port speed and Duplex mode were determined via autonegotiation or

whether they were manually configured.

44 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 45

Diagnostic Web Pages Chapter 6

Media Counters Port 1/Port 2

Field Description

Alignment Errors A frame containing bits that do not total an integral multiple of eight.

FCS Errors A frame containing eight bits, at least one of which has been corrupted.

Single Collisions The number of outgoing packets that encountered only one collision during

Multiple Collisions The number of outgoing packets that encountered 2...15 collisions during

Excessive Collisions The number of frames that experience 16 consecutive collisions.

MAC Transmit Errors Frames for which transmission fails due to an internal MAC sublayer transmit error.

Frame Too Long The number of incoming packets that exceed the maximum Ethernet packet size.

MAC Receive Errors Frames for which reception on the Ethernet interface failed due to an internal MAC

transmission.

transmission.

sublayer receive error.

Ring Statistics

This section contains information about the topology of the network, and

specific ring information.

Diagnostic Web Pages— Miscellaneous

The following sections explain the miscellaneous sections of the diagnostic web

pages.

Crash Display

This is the hexadecimal dump of the current fatal event log, that is stored in the

linking device. If no crash has ever occurred, the contents are all zero.

Heap Statistics

This information is only for support issues.

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 45

Page 46

Chapter 6 Diagnostic Web Pages

Notes:

46 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 47

Linking Device

Status Indicators

Indicator Status Description

MS

(Module Status)

SD

(SD card Status)

Off

Green

Flashing green

Red

Flashing red

Alternating red/green

Orange

Repeating one flash orange

Repeating two flashes orange

Repeating three flashes orange

Flashing green

Flashing red

Power off

Normal operation

The module is not configured

Unrecoverable error

Recoverable error

Power-on self-test (POST)

Unrecoverable error: firmware has crashed

Unrecoverable error

Unrecoverable error

Unrecoverable error: firmware is not started

Accessing SD card

Fai lure

Appendix A

EtherNet/IP Network

DeviceNet Network

Indicator Status Description

EN NS

(EtherNet/IP Status)

LNK 1, LNK 2

(Ethernet Link 1, 2)

Indicator Status Description

DN NS

(DeviceNet Status)

Off

Green

Flashing green

Red

Flashing red

Alternating green/red

Off

Flashing green

Flashing yellow

Off

Green

Flashing green

Red

Flashing red

Alternating green/red

Power off, or no IP address

Conne cted

Not connected

Duplicate IP address

Connection timeout

Power-on self-test (POST)

No link

Receiving/transmitting Ethernet packets at 100

Mbit

Receiving/transmitting Ethernet packets at 10

Mbit

No power

Online, connected

Online, not connected

Unrecoverable fault

Recoverable fault

Communication faulted

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 47

Page 48

Appendix A Status Indicators

Notes:

48 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

Page 49

Index

A

active nodes 41

apply power to linking device

assembly

input

31

output

31

status

Autobaud 23

32

11

C

cable, USB 33

CIP safety

connections

messages

configuration file

configuration file, RSNetWorx for DeviceNet

configure

DeviceNet I/O

driver

IP address

port settings 16

USB driver

connectors

Phoenix

RJ45 7

USB cable

8

8

30

30

25

18

14

34

7

33

D

data rate 11, 20

data storage

DeviceNet I/O

DeviceNet network

disable Autobaud

driver

7

25

connect to linking device

connectors

data storage

diagnostic web pages

linking device features

scanner configuration

set data rate

set node address 11

status

status indicators

7

7

11

41

10

41

8

8

47

23

configure USB

configure via RSLinx software

34

18

EtherNet/IP network

connect to linking device

connectors

diagnostic web pages 44

linking device features

status

status indicators

faulted nodes 41

features

DeviceNet network

EtherNet/IP network 8

linking device

online scanlist changes allowed in Run mode

safety I/O

hardware requirements 9

I/O mapping 25

idle nodes

indicators, status

input assembly

install

linking device

power to linking device

Secure Digital (SD) card

invalid nodes 42

IP address

configuration flowchart

set via RSLinx software

set via web pages

IP configuration

LED indicators 47

7

10

7

8

44

47

F

8

8

8

8

H

I

41

47

31

9

11

37

12

14

15

16

14

L

E

EDS file 18

enable Autobaud

Ethernet statistics

Rockwell Automation Publication 1788-UM059A-EN-P - August 2014 49

23

44

Page 50

Index

linking device

add to Logix Designer application

configure port settings

configure via Logix Designer application 28

configure via RSNetWorx for DeviceNet

connect to DeviceNet network

connect to EtherNet/IP network

DeviceNet diagnostic web pages

EtherNet/IP diagnostic web pages 44

features

install

IP configuration 14

overview

power

register EDS file 18

rotary switches

set IP address via DHCP

set IP address via rotary switches

set IP address via RSLinx software

set IP address via web pages

status indicators 47

USB cable

load

Secure Digital (SD) card

Logix Designer application 28

software

8

9

7

11

33

16

19

10

10

41

11, 12

12

16

38

M

mapping, I/O 25

messages, CIP safety

8

N

Network Configuration web page 16

node address

node status

nodes

active

faulted

41

idle

invalid

status

11, 20

42

41

41

42

42

12

28

15

R

register EDS file 18

remove

Secure Digital (SD) card

requirements

hardware

9

power source

software 9

RJ45

connectors

ports

rotary switches 11, 12

RSLinx software

configure driver

set IP address

RSNetWorx for DeviceNet software

set data rate

set DeviceNet node address

10

7

10

12

37

18

15

12

S

safety I/O 8

safety messages

Secure Digital (SD) card

install

load 38

remove

store

set

DeviceNet data rate

DeviceNet node address

IP address via RSLinx software

IP address via web pages 16

linking device IP address

software requirements

statistics, Ethernet

status assembly

status indicators

store

Secure Digital (SD) card

Studio 5000 environment

8

37

37

38

11

11

15

12

9

44

32

47

38

28

19

O

Online Scanlist Changes Allowed in Run

(OSCAR)

8

output assembly

31

P

Phoenix connectors 7

port

RJ45

10

16

settings

USB

33

power cable

power source requirements

50 Rockwell Automation Publication 1788-UM059A-EN-P - August 2014

11

10

U

UL restrictions 10

USB cable

33

W

web pages

diagnostic

set IP address

41

16

Page 51

Page 52

Rockwell Automation Support

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

software service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

updates, support chats and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more

information, contact your local distributor or Rockwell Automation representative, or visit

http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this

manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwi de Lo cato r

Rockwell Automation representative.

at http://www.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

New Product Satisfaction Return

you can find technical and application notes, sample code, and links to

for software

.

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the

manufacturing facility. However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this

document, complete this form, publication RA-DU002

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

, available at http://www.rockwellautomation.com/literature/.

.

Publication 1788-UM059A-EN-P - August 2014

Copyright © 2014 Rockwell Auto mation, Inc. All rights reserved. Pr inted in the U.S.A.

Loading...

Loading...