Page 1

Linear Positioning Module

Cat. No. 1771-QB

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation, the

Allen-Bradley Company, Inc. does not assume responsibility or liability (to

include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley Publication SGI-1.1, “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Control” (available from your local

Allen-Bradley office) describes some important differences between solid-state

equipment and electromechanical devices which should be taken into

consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted manual, in whole or in part,

without written permission of the Allen-Bradley Company Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attentions help you:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is especially important for

successful application and understanding of the product.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Page 3

Table of Contents

Preface P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Organization

Audience P2

Related

Related Software P2

Frequently Used Terms P3

of the Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introducing the Linear Positioning Module 11. . . . . . . . . . . .

What is the Linear Positioning Module? 11. . . . . . . . . . . . . . . . . . . .

Product

System Overview 14

Compatibility

Transducers 12

Servo and Proportional Valves 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Concepts 21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Axis

Motion

ClosedLoop

Linear Displacement Transducer 22

A

Simple Positioning Loop

Proportional

Feedforwarding 25

Integral Control (Reset Control) 25

Derivative Control (Rate Control) 26

Deadband 27

PID Band 27

Positioning

. . . . . . . . . . . . . . . . . . . . . . .

Gain

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23. . . . . . . . . . . . . . . . . . . . . . . . . . .

24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning with the Linear Positioning Module 31. . . . . . . . .

How

the Module Fits in a Positioning System

How the Module Interacts with a PLC 32

Read Operations 32

Write Operations 32

Axis Movement 32

Commanding

Setpoints 34

Jogging 35

Motion Blocks 35

Motion

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . .

34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Hardware Description 41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicators 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Arm Terminals 42

Transducer Interface 43

Determining

Discrete

Auto/Manual

Hardware

Hardware

Jog Forward Input 47

Jog Reverse Input 47

General Purpose Inputs 47

Analog

Discrete

OUTPUT 1 49

OUTPUT 2 49

Power Supplies 49

the Optimum Number of Circulations

Inputs

Start Input

Stop Input

Output Interface

Outputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43. . . . . . . . . . . . .

45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Linear Positioning Module 51. . . . . . . . . . . . . .

Before You Begin 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Avoiding Backplane Power Supply Overload 51

Planning Module Location 51

Electrostatic Discharge 52

Setting

Analog Output Switches

Keying 55

Inserting the Module 55

Wiring

Connecting the Transducer Interface 510

Connecting the Discrete Inputs 512

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines

Using Shielded Cables 56

Using Twisted Wire Pairs 58

Connecting AC Power 58

Power Supplies 510

Power Supply 511

Transducer Interface 512

Power Supply 514

Auto/Manual

Hardware

Hardware

Jog Forward Input 515

Jog Reverse Input 516

General Purpose Inputs 516

Connecting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

Start Input

Stop Input

Multiple Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

52. . . . . . . . . . . . . . . . . . . . . . . . . .

56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

514. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

516. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents iii

Connecting the Analog Outputs 518. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 519

Analog

Output

Connecting the Discrete Outputs 520

Power Supply 521

OUTPUT 1 521

OUTPUT 2 521

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

519. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interpreting ModuletoPLC Data (READS) 61. . . . . . . . . . . . .

PLC Communication Overview 61. . . . . . . . . . . . . . . . . . . . . . . . . .

Status Block 61

Word Assignment 62

Module Configuration Word (word 1) 62

Status Word 1 (words 2 and 6) 63

Status Word 2 (words 3 and 7) 67

Position/Error/Diagnostic Words 69

Active Motion Segment/Setpoint (words 10 and 11) 613

Measured Velocity (words 20 and 21) 614

Desired Velocity (words 22 and 23) 614

Desired Acceleration (words 24 and 25) 615

Desired Deceleration (words 26 and 27) 615

Percent Analog Output (words 28 and 29) 616

Maximum Velocity (words 30, 31 and 32, 33) 617

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

Formatting Module Data (WRITES) 71. . . . . . . . . . . . . . . . . . .

Data Blocks Used in Write Operations 71. . . . . . . . . . . . . . . . . . . . .

Parameter Block (Required) 71

Setpoint Block (Optional) 71

Command Block (Required) 71

Parameter Block 71

Parameter Control Word (word 1) 73

Analog Range (words 2 and 31) 75

Analog Calibration Constants (words 3, 4 and 32, 33) 76

Transducer Calibration Constant (words 5, 6 and 34, 35) 77

ZeroPosition

Software Travel Limits (words 9, 10 and 38, 39) 79

ZeroPosition and Software T

InPosition Band (words 11 and 40) 713

PID Band (words 12 and 41) 714

Deadband (words 13 and 42) 715

Excess Following Error (words 14 and 43) 716

Maximum PID Error (words 15 and 44) 716

Integral Term Limit (words 16 and 45) 717

Proportional Gain (words 17 and 46) 718

Gain Break Speed (words 18 and 47) 719

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Of

fset (words 7, 8 and 36, 37) 78. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . .

. . . . . . . . . . . .

ravel Limit Examples

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

710. . . . . . . . . .

Page 6

Table of Contentsiv

Gain Factor (words 19 and 48) 720. . . . . . . . . . . . . . . . . . . . . . . .

Integral Gain (words 20 and 49) 721

Derivative Gain (words 21 and 50) 722

Feedforward Gain (words 22 and 51) 722

Global Velocity (words 23 and 52) 723

Global Acceleration/Deceleration (words 24, 25 and 53, 54) 724

Velocity Smoothing (Jerk) Constant (words 26 and 55) 724

Jog Rate (Low and High) (words 27, 28 and 56, 57) 726

Reserved (words 29, 30 and 58, 59) 727

Setpoint Block 727

Setpoint Block Control Word (word 1) 729

Incremental/Absolute Word (word 2) 729

Setpoint

Local Velocity 731

Local Acceleration/Deceleration 732

Command Block 732

Axis Control Word 1 (words 1 and 8) 733

Axis Control Word 2 (words 2 and 9) 738

Setpoint 13 Words (words 3 to 7 and 10 to 14) 739

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

730. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

Initializing and Tuning the Axes 81. . . . . . . . . . . . . . . . . . . . .

Before You Begin 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Servo V

Initializing the Parameter Block 82

Verifying

Verifying Transducer Calibration Constants 87

Axis Tuning 810

Analog Output Polarity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Calibration Constants 810

Feedforward

PID Loop Gains 812

Update the Application Program 813

alve Nulls

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Gain

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

82. . . . . . . . . . . . . . . . . . . . . . . . . .

87. . . . . . . . . . . . . . . . . . . . . . . . .

811. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Features 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion Block 91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion Block Control Word 94

Programmable

Programmable

Default

Motion Segments 98

Motion Segment Control Words 98

Desired

and Local Deceleration Words 911

Trigger V

The Command Block and the Motion Block 911

The Status Block and the Motion Block 911

Input and Output

I/O Control W

I/O Configuration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position, Local V

elocity/Position W

. . . . . . . . . . . . . . . . . . . . . . . . . . .

95. . . . . . . . . . . . . . . . . . . . . . . . .

ord 95. . . . . . . . . . . . . . . . . . . . . . .

98. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

elocity, Local Acceleration

. . . . . . . . . . . . . . . . . . . . . .

ords 911. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents v

Using

the Motion Block

Sample Application Programs 101. . . . . . . . . . . . . . . . . . . . . .

912. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming

Block Transfer Sequencing 102

PLC5 Block Transfer Instructions 103

Application Program #1 103

Planning the Data Blocks for Application Program #1 105

Program Rungs for Application Program #1 108

Application Program #2 1011

Planning the Data Blocks for Application Program #2 1012

Program Rungs for Application Program #2 1016

Objectives

101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . .

Troubleshooting 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Indicators 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module

Loop Active Indicators 112

Indicator Troubleshooting Guide 112

Troubleshooting Feedback Faults 113

Troubleshooting Flowchart 114

Flowchart Notes 117

Fault Indicator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary of Terms & Abbreviations A1. . . . . . . . . . . . . . . . . .

Status Block B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Block C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setpoint Block D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Block E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motion Block F1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hexadecimal Data Table Forms G1. . . . . . . . . . . . . . . . . . . . .

Page 8

Table of Contentsvi

Data Formats H1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BCD H1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2's Complement Binary H1

Bit Inversion Method H2

Subtraction Method H2

Decimal

Implied

Position Format H3

Double Word Position Format H4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Specifications I1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

Preface

Preface

This manual explains how to install and configure the Linear Positioning

Module. It includes sample application programs to illustrate how to program a

PLC to work with the Linear Positioning Module.

Organization of the Manual

This manual contains eleven chapters and nine appendices that address the

following topics:

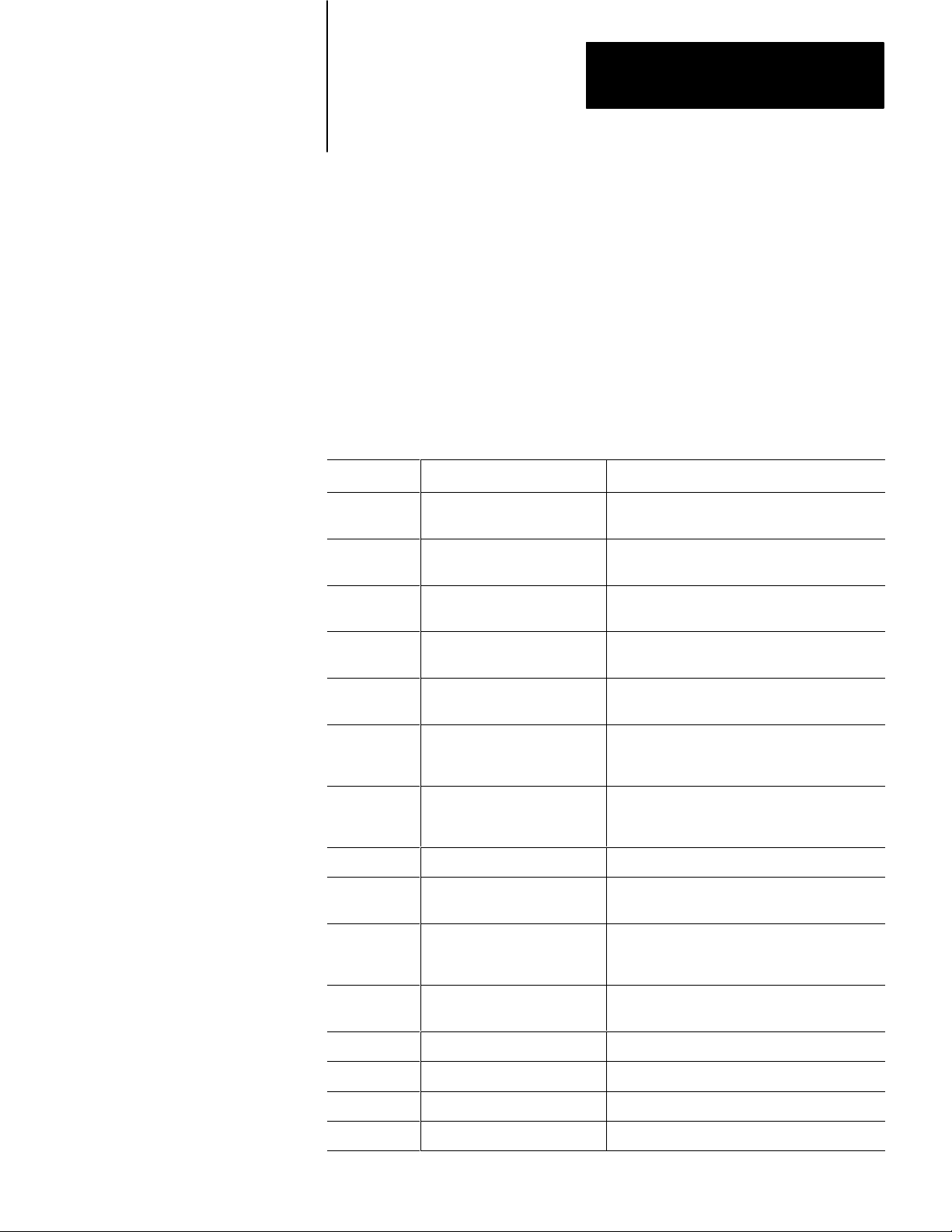

Chapter Title Describes:

1 Introducing the Linear Positioning

Module

2 Positioning Concepts concepts and principles of closedloop servo

3 Positioning with the Linear

Positioning Module

4 Hardware Description module hardware, module interfaces, and other

5 Installing the Linear Positioning

Module

6 Interpreting ModuletoPLC Data

(READS)

7 Formatting Module Data

(WRITES)

the functions and features of the Linear Positioning

Module

positioning

using the Linear Positioning Module in a positioning

system

hardware items you need for a positioning system

configuring the module's analog outputs and

installing the module in your system

monitoring module operation from a logic controller

by reading and interpreting data that the module

transfers to the logic controller's data tables

formatting parameter, move description, and control

data for block transfers to the Linear Positioning

Module

8 Initializing and Tuning the Axes bringing the module online

9 Advanced Features using the motion block to perform blended moves;

using programmable input and output operations

10 Sample Application Programs two application programs, one using basic concepts

and the other using advanced features, to control

and monitor the module

11 Troubleshooting using the module's indicators and the status block

to diagnose and remedy module faults and errors

Appendix A Glossary common terms and abbreviations

Appendix B Status Block status block word assignments

Appendix C Parameter Block parameter block word assignments

Appendix D Setpoint Block setpoint block word assignments

P1

Page 10

Preface

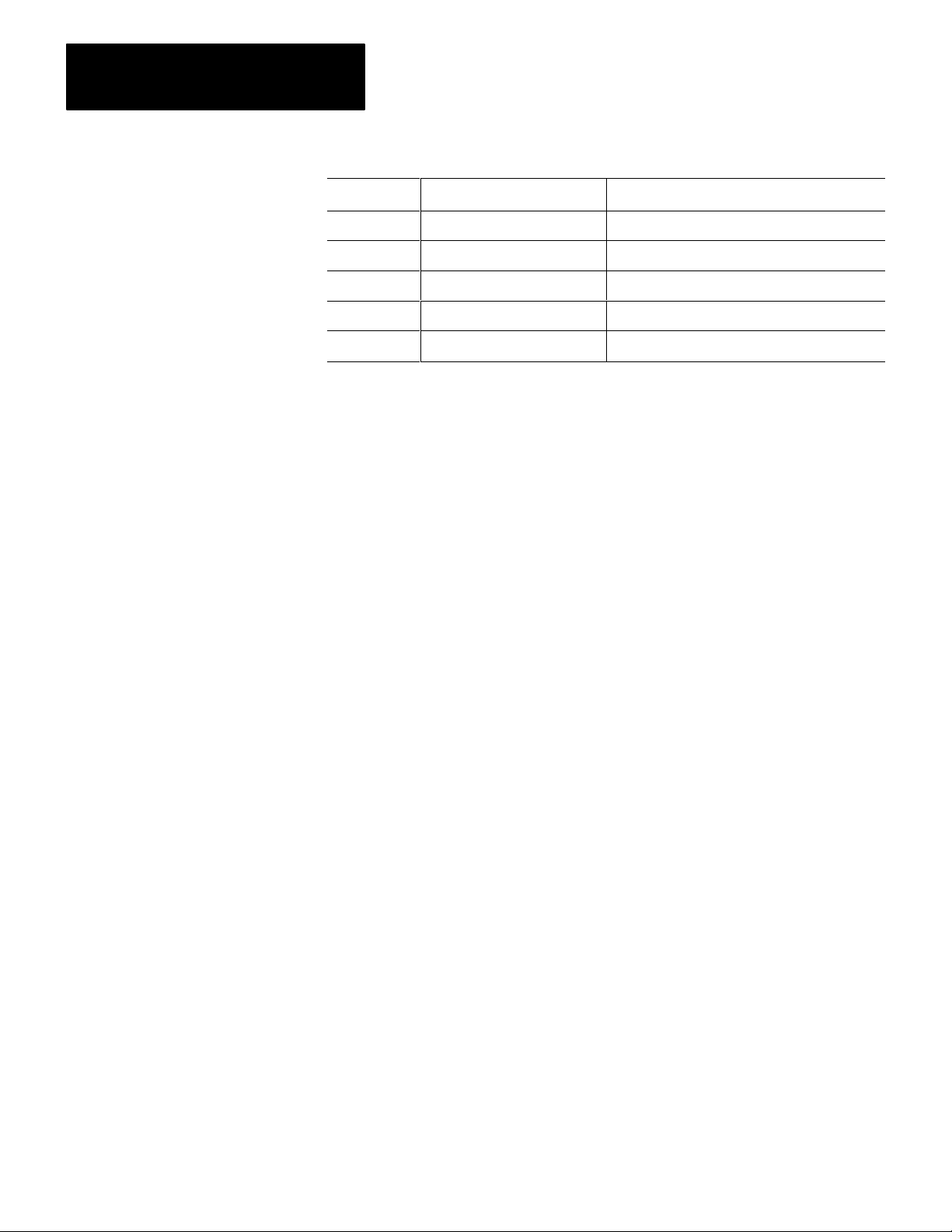

Chapter Describes:Title

Appendix E Command Block command block word assignments

Appendix F Motion Block motion block word assignments

Appendix G Hexadecimal Data Table Form hexadecimal data worksheets

Appendix H Data Formats valid data formats

Audience

Related Publications

Related Software

Appendix I

Product Specifications

1771QB product specifications

Read this manual if you intend to install or use the Linear Positioning Module

(Cat. No. 1771-QB).

To use the module, you must be able to program and operate an Allen-Bradley

PLC. In particular you must be able to program block transfer instructions.

In this manual, we assume that you know how to do this. If you don’t, refer to

the User Manual for the PLC you’ll be programming.

Consult the Allen-Bradley Industrial Computer Division Publication Index

(SD 499) if you would like more information about your modules or PLCs. This

index lists all available publications for Allen-Bradley programmable controller

products.

The Hydraulics Configuration and Operation Option (Cat. No. 6190-HCO)

operates within the ControlView Core (Cat. No. 6190-CVC) environment to

provide full configuration and realtime monitoring for the Linear Positioning

Module. Both software packages are available from:

P2

Allen-Bradley Company, Inc.

1201 South Second Street

Milwaukee, WI 53204

(414) 382-2000

Servo Analyzer is a software package that aids in tuning the axes by letting you

display an axis profile as you tune it. The resulting graphics may be plotted,

printed or saved to a file. The software is available from:

Computer Software Design

P.O. Box 962

Roseburg, OR 97470

(503) 673-8583

Page 11

Preface

Frequently Used Terms

Appendix A contains a complete glossary of terms and abbreviations used in

this manual.

To make this manual easier for you to read and understand, product names are

avoided where possible. The Linear Positioning Module is also referred to as

the “module”.

P3

Page 12

Chapter

1

Introducing the Linear Positioning Module

What is the Linear Positioning Module?

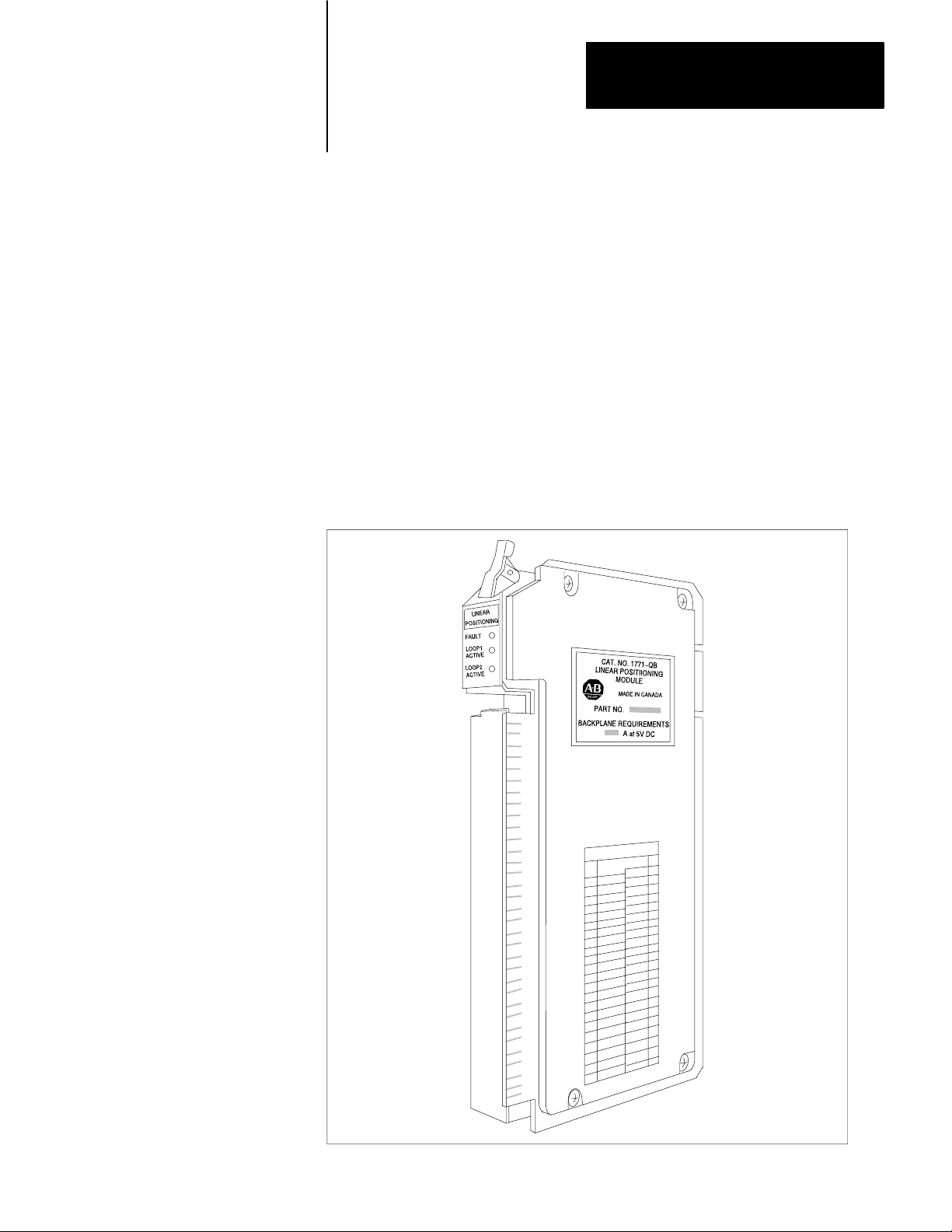

The Linear Positioning Module (Cat. No. 1771-QB) is a dual-loop position

controller occupying a single slot in the Allen-Bradley 1771 Universal I/O

chassis. It can control servo or proportional hydraulic valves, or some electric

servos. Position is measured with a linear displacement transducer. You use the

module to control and monitor the linear position of a tool or workpiece along

one or two axes.

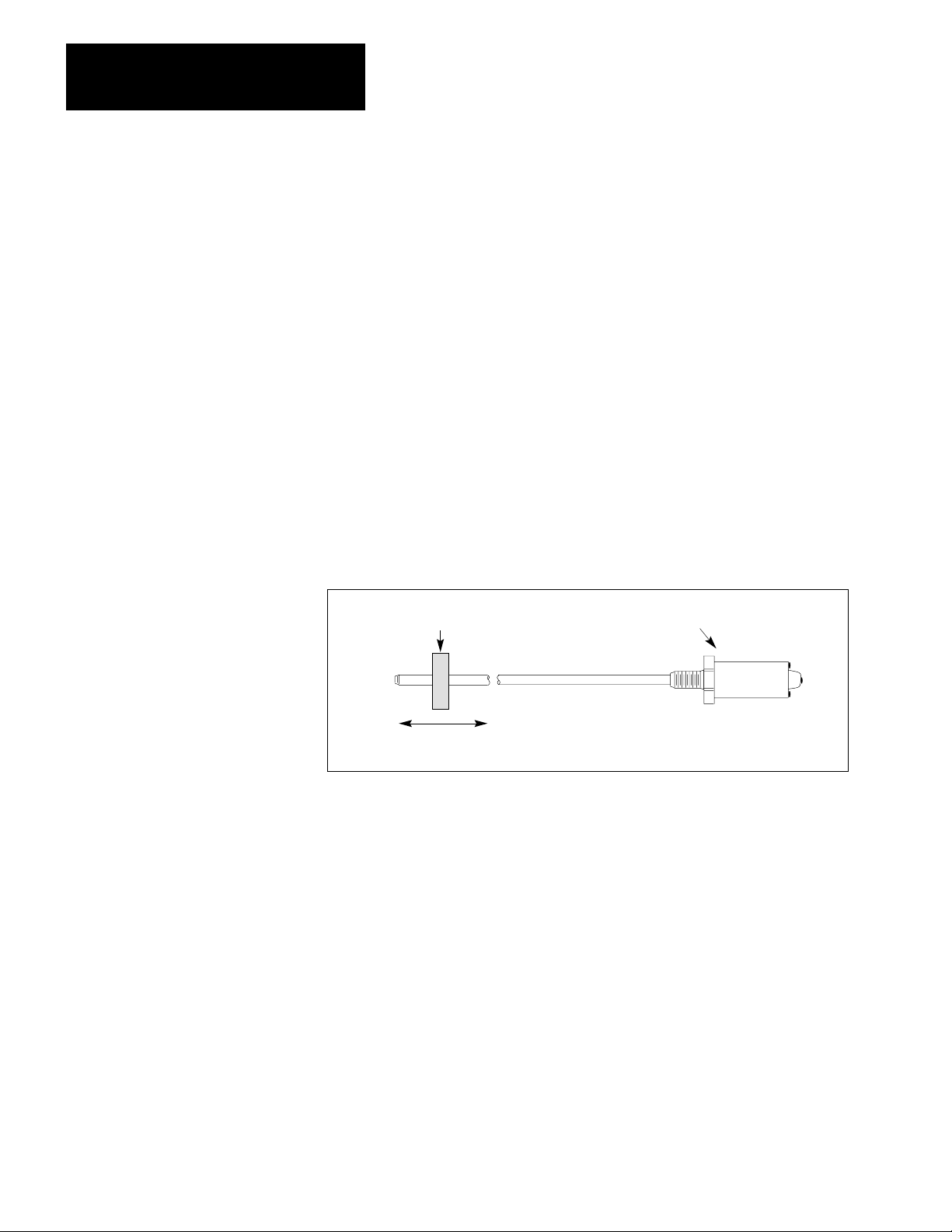

Figure 1.1

Positioning Module

Linear

50110

11

Page 13

Chapter 1

Introducing the Linear Positioning Module

Product Compatibility

PLCs

You can use the module with any Allen-Bradley PLC that uses block transfer

programming in local 1771 I/O systems including:

PLC-2 family

PLC-3 family

PLC-5 family

- PLC-5/10 (Cat. No. 1785-LT4)

- PLC-5/11 (Cat. No. 1785-LT11)

- PLC-5/12 (Cat. No. 1785-LT3)

- PLC-5/15 (Cat. No. 1785-LT)

- PLC-5/20 (Cat. No. 1785-L20)

- PLC-5/25 (Cat. No. 1785-LT2)

- PLC-5/30 (Cat. No. 1785-L30)

- PLC-5/40 (Cat. No. 1785-L40)

- PLC-5/60 (Cat. No. 1785-L60)

Transducers

The Linear Positioning (QB) Module is compatible with linear displacement

transducers manufactured by:

MTS Systems Corporation

Sensors Divisions

Box 13218, Research Triangle Park

North Carolina 27709

(919) 677–0100

Balluff Inc.

P.O. Box 937

8125 Holton Drive

Florence, KY 41042

(606) 727–2200

12

Page 14

Chapter 1

Introducing the Linear Positioning Module

Santest Co. Ltd.

c/o Ellis Power Systems

123 Drisler Avenue

White Plains, NY 10607

(914) 592-5577

Lucas Schaevitz Inc.

7905 N. Route 130

Pennsauken, NJ 08110-1489

(609) 662-8000

All four manufacturers provide versions of the transducer that connect directly

to the module’s wiring arm, without an external digital interface box. The

module may also be compatible with other linear displacement transducers.

Servo and Proportional Valves

The module provides current ranges of up to +100 mA for direct interface to

most servo valves, most proportional valves, and a +

compatibility with other devices, such as electric servo interfaces. The module

is compatible with valves supplied by the following manufacturers:

Moog, East Aurora NY servo/proportional

Parker Hannifin Corporation, Elyria OH servo/proportional

Robert Bosch Corporation proportional

Rexroth Corporation, Lehigh Valley PA servo/proportional

ATOS proportional

Atchley, Canaga Park CA servo

Pegasus servo

Vickers Inc., Grand Blanc, MI servo/proportional

The module may also be compatible with other valves.

Important: Some proportional valves with LVDT loop controllers may limit

the module’s output and thus prevent the module from providing optimal

control.

10 volt option for

13

Page 15

Chapter 1

Introducing the Linear Positioning Module

System Overview

PLC

Processor

D Status Block

D Parameter Block

D Setpoint Block

D Motion Block

D Command Block

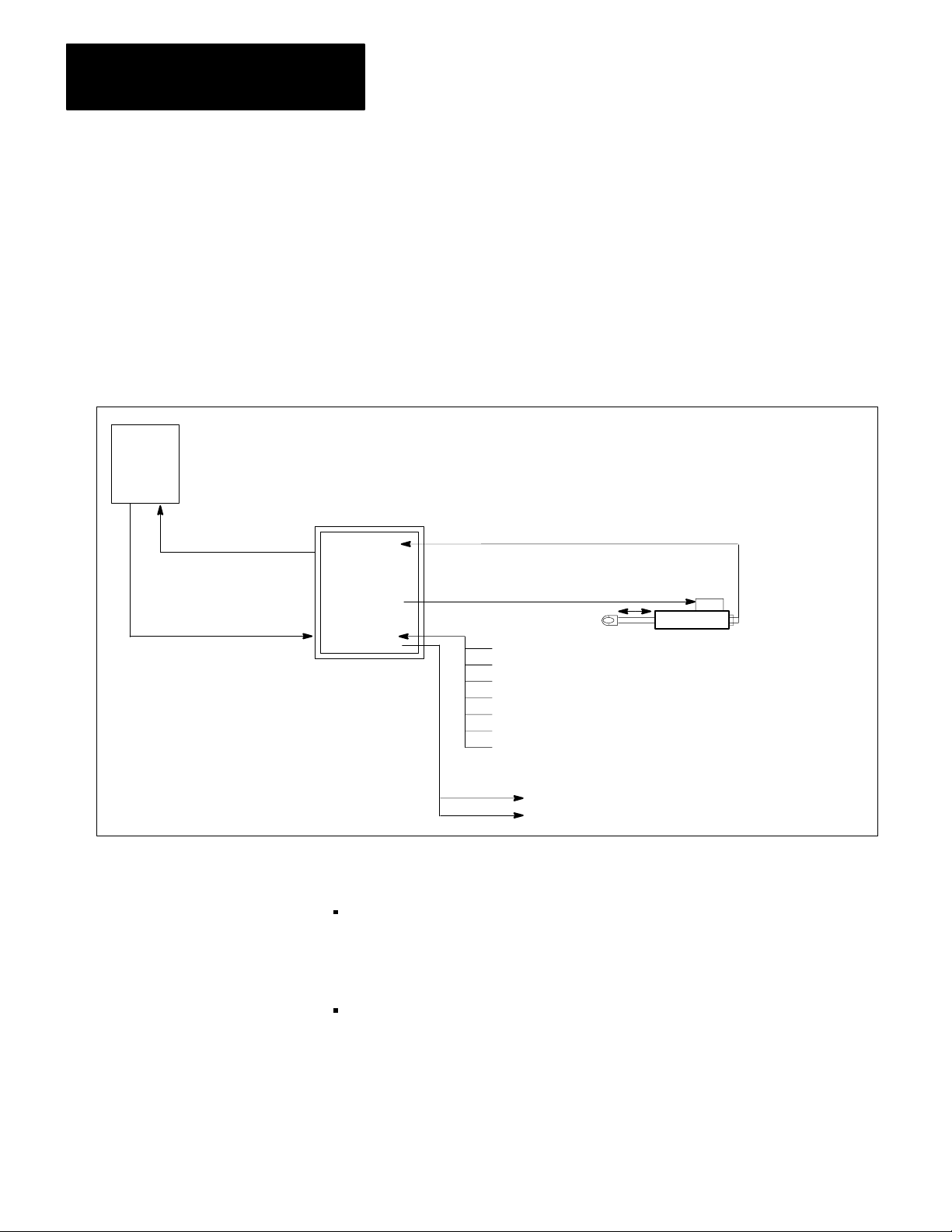

Figure 1.2 shows one of the module’s two control loops within a linear

positioning system for closed-loop axis control. The module communicates with

a programmable controller through the 1771 backplane.

The programmable logic controller sends commands and user-programmed data

from the data table to the module as directed by a block-transfer write

instruction.

Figure 1.2

Overview

System

Transducer

Interface

Linear

Positioning

Module

Discrete Inputs

D Jog Forward

D Jog Reverse

D Hardware Start

D Auto/Manual

D Hardware Stop

D Input 1

D Input 2

Discrete Outputs

D

Analog Output

D Output 1

D Output 2

Servo Valve

Linear Displacement

Transducer

PistonType

Cylinder

NOTE: All inputs and outputs are

duplicated for the second axis.

50033

14

Using PLC programming, you can:

send configuration and control parameters to the module via parameter,

setpoint, motion, and command blocks. With this data the module determines

axis parameters, calculates velocity curves, and commands axis

end-positions. (See Chapters 7 and 9.)

read status blocks to monitor axis position and status indicators in your

process control system. (See Chapter 6.)

The module’s analog outputs (one for each control loop) connect to servo or

proportional valves via wiring arm terminals. The module controls speed and

position by adjusting the voltage or current levels of the analog outputs 500

times each second.

Page 16

Chapter 1

Introducing the Linear Positioning Module

The module also connects to linear displacement transducers (one for each of

the two axes) via wiring arm terminals. The transducer senses the axis position

and feeds it back to the module, thereby closing the control loop.

The module’s built-in processor samples the linear displacement transducer

interfaces and determines positions along each of the two axes every two

milliseconds. The module then updates the analog outputs based on a

proprietary algorithm designed specifically to handle hydraulic actuators. This

rapid update rate provides repeatable positioning and superior control of

velocity without jerky movement.

Motion blocks provide for complex motions by allowing motion segments to be

blended or chained together. These motion segments may also be synchronized

using the hardware input triggers and outputs.

Cam emulation permits motion segments in one axis to start motion segments in

another axis. Articulated motions and axis sequencing may be easily

accomplished.

15

Page 17

Chapter

2

Positioning Concepts

This chapter explains concepts and principles of axis positioning. If you are

thoroughly familiar with the concepts of closed-loop servo positioning, you can

go on to Chapter 3.

Axis Motion

Electric

Control

Hydraulic

Fluid

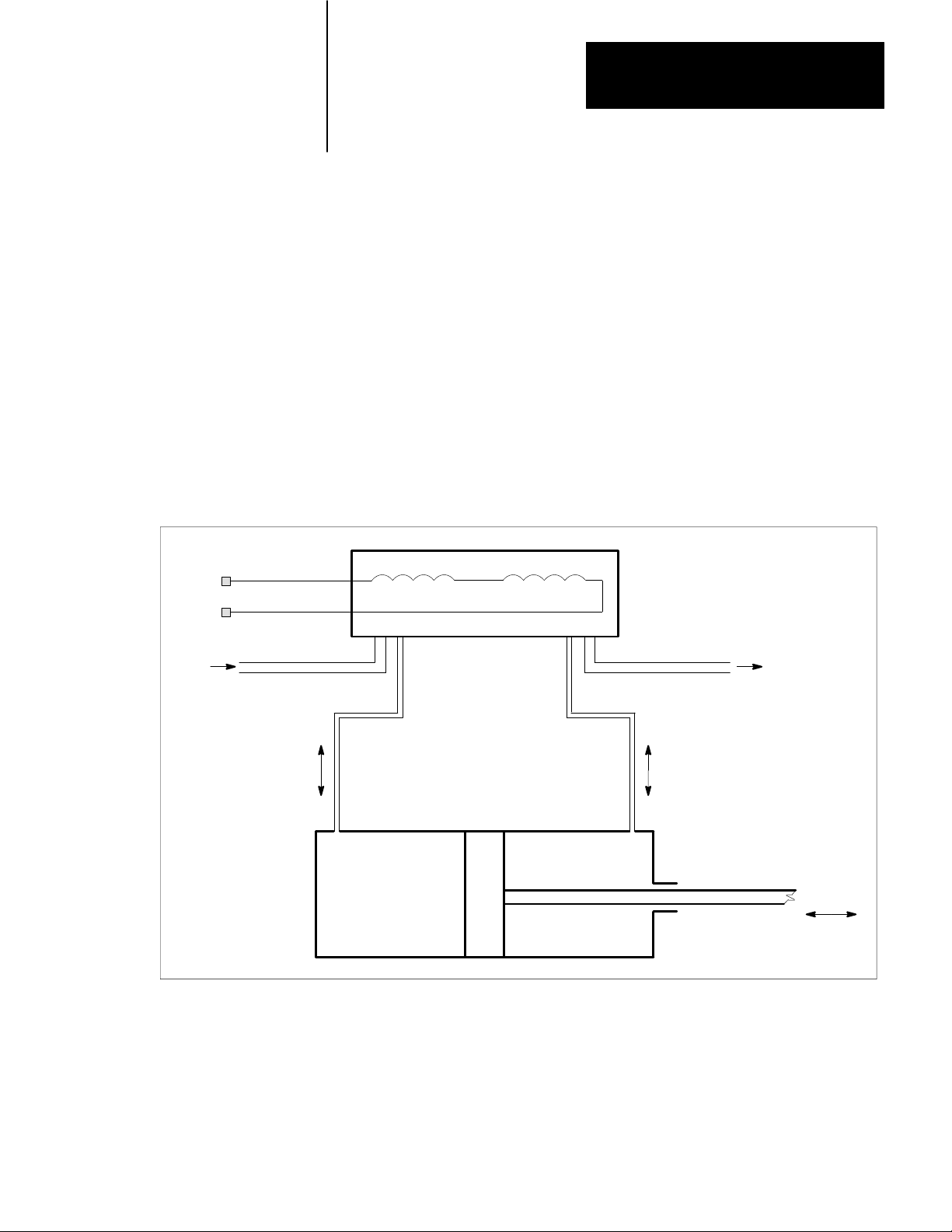

Figure 2.1 illustrates a typical method of converting the flow of fluid into a

linear displacement.

Figure 2.1

PistonType

Hydraulic Cylinder

SERVO VALVE

Hydraulic

Fluid

Axis

Motion

Hydraulic fluid Hydraulic fluid

50032

The servo valve controls the flow of hydraulic fluid into or out of the hydraulic

cylinder. Adding fluid to the left side of the cylinder extends the rod; adding

fluid to the right side retracts it.

21

Page 18

Chapter 2

Positioning Concepts

ClosedLoop Positioning

Closed-loop positioning is a precise means of moving an object from one

position to another. In a typical application, a positioning device activates a

servo valve controlling the movement of fluid in a hydraulic system. The

movement of fluid translates into the linear motion of a hydraulic cylinder. A

transducer monitors this motion and feeds it back to the positioning device. The

positioning device, in turn, calculates a positioning correction and feeds it back

to the servo valve.

Important: Throughout this manual we refer to servo valves, but you can also

use the analog outputs to control proportional valves or an electric servo.

Linear Displacement Transducer

A linear displacement transducer (see Figure 2.2) is a device that senses the

position of an external magnet to measure displacements.

Figure 2.2

Displacement T

Linear

Magnet

ransducer

Transducer

Head

22

Magnet mounted to

the piston of actuator

50034

The transducer sends a signal through the transducer wave guide where a

permanent magnet generates the return pulse. You can use the time interval

between the transducer’s signal and the return pulse to measure axis

displacement.

Circulations

Some linear displacement transducers provide circulations or recirculation to

improve resolution. (See Figure 2.3.) This technique stretches the pulse by a

factor of two or more and results in finer resolution in the circuitry monitoring

the pulse width.

Page 19

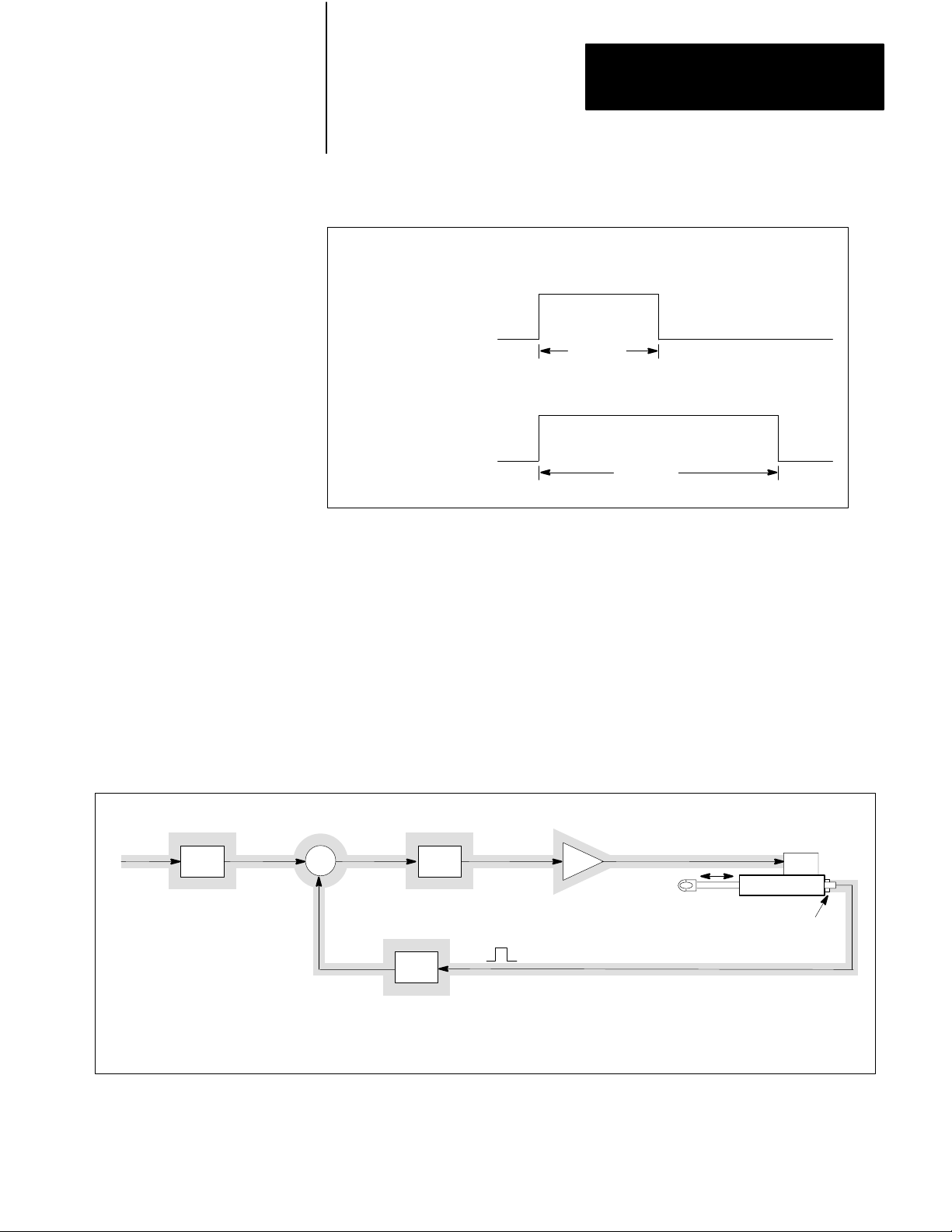

Figure 2.3

Circulations

Gate

(received from transducer)

Gate

(received from transducer)

Chapter 2

Positioning Concepts

resolution = 0.002

Duration

(1 circulation)

resolution = 0.001

Duration

(2 circulations)

50035

Desired

Velocity

dt

s

Integrator

Position

Command

A Simple Positioning Loop

To move a specified distance along an axis, you can command the hydraulic

device to move at a specific velocity for a specific length of time. However, this

method can be imprecise. To control the position of the hydraulic device

accurately you need a loop to monitor actual position. Figure 2.4 shows a

simple positioning loop.

Figure 2.4

Positioning

Following

Error

+

Actual

Position

Loop

dt

s

Kp

D/A

Velocity

Command

Axis

Servo Valve

Linear

Displacement

Transducer

50036

23

Page 20

Chapter 2

Positioning Concepts

In Figure 2.4:

desired velocity is the desired speed of axis motion from one position to

another

position command equals the integration of velocity over time

actual position value (transducer feedback) is the actual position of the

axis as measured by the LDT

following error equals position command minus actual position

velocity command is generated by amplifying the following error and

converting the result into an analog output

D/A (Digital to Analog convertor) generates the analog output controlling the

servo valve

KP (proportional gain) is the component that causes an output signal to

change as a direct ratio of the error signal variation

Proportional Gain

The following error is a function of the velocity command divided by the

proportional gain (K

following error by the proportional gain. Proportional gain can be expressed in

ips/mil (where 1 mil = 0.001 inches) or mmps/mil (where 1 mil = 0.001 mm).

For example, with a velocity of 12 ips and a gain of 1 ips/mil, the following

error is:

Following Error = Velocity/Gain

When you increase the gain, you decrease the following error and decrease the

cycle time of the system. However, the capabilities of the system limit the gain.

Too large a gain causes instability.

). To generate the velocity command, multiply the

P

= 12 ips/(1 ips/mil)

= 12 mil

24

Page 21

Chapter 2

Positioning Concepts

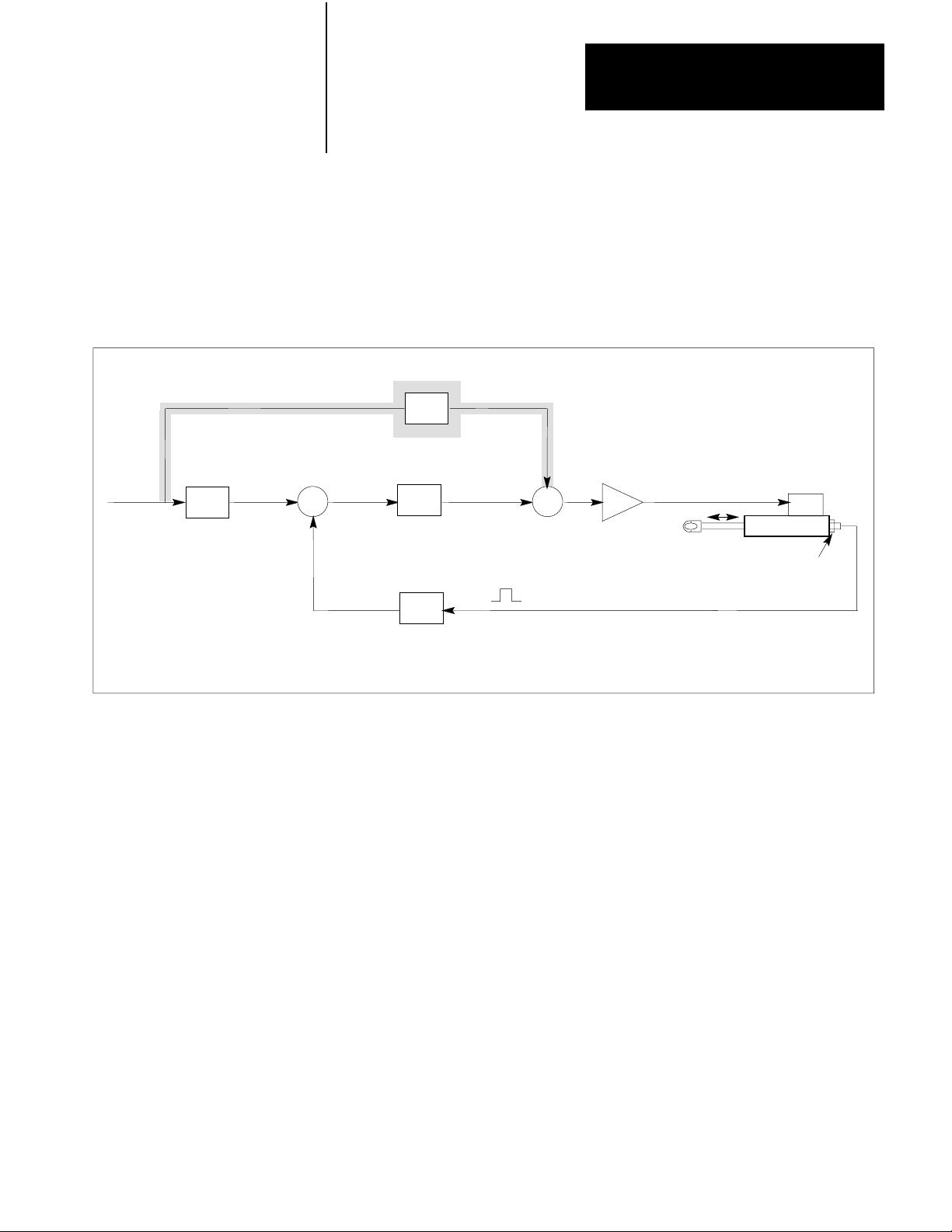

Feedforwarding

To decrease the following error without increasing the gain, you can add a

feedforward component. (See Figure 2.5.)

Desired

Velocity

dt

s

Integrator

Position

Command

Figure 2.5

Loop with Feedforwarding

Feed

Forward

+

+

Kp

s

K

F

dt

Velocity

Command

D/A

Axis

+

-

Positioning

Following

Error

Actual

Position

Feedforwarding requires an additional summing point and an amplifier.

Multiply the desired velocity by the feedforward gain K

to produce a

F

feedforward value. The feedforward value, added to a multiplication of the

following error by the proportional gain (K

), generates the velocity command.

P

Servo Valve

Linear

Displacement

Transducer

50037

Without feedforwarding, axis motion does not begin until the following error is

large enough to overcome friction and inertia. The feedforward component

generates a velocity command to move the cylinder almost immediately. This

immediate response keeps the actual position closer to the desired position and

thereby reduces the following error.

Integral Control (Reset Control)

You can increase the positioning accuracy of the control loop by adding an

integral component. (See Figure 2.6.)

To achieve the integral component of the positioning loop, integrate the

following error over time and amplify it to produce an integral value. Then add

this integral value to the proportional component and the feedforward value to

generate the velocity command.

25

Page 22

Chapter 2

Positioning Concepts

Without integral control, the axis responds only to the size of the positioning

error, not its duration. Integral control responds to both the size and duration of

the positioning error. Thus, the integral term continues to adjust the velocity

command until it achieves an exact correction.

Desired

Velocity

dt

s

Integrator

Position

Command

When you increase the integral gain (K

), you increase the rate at which the

I

positioning loop responds to a following error. However, the capabilities of the

system limit gain K

Figure 2.6

Integral

Following

Error

+

-

Actual

Position

Control

s

K

K

Kp

dt

Too large a gain causes instability.

I.

Feed

F

I

Forward

Integrator

dt

s

+

+

+

+

Velocity

Command

D/A

Axis

Servo Valve

Linear

Displacement

Transducer

26

50038

Derivative Control (Rate Control)

Proportional and integral gains can cause instability in a positioning loop. The

cylinder can overshoot its programmed endpoints and oscillate or hunt around

them. You can increase the stability of the positioning loop by adding a

derivative component. (See Figure 2.7.)

Derivative control operates on the rate of change of positioning error. It helps to

stabilize the system by opposing changes in positioning error. However, a

derivative gain that is too large can cause instability. Derivative control is also

very susceptible to electrical noise.

Page 23

Chapter 2

Positioning Concepts

Desired

Velocity

dt

s

Integrator

Position

Command

Figure 2.7

Derivative

Following

Error

+

-

Actual

Position

Control

K

K

Kp

K

s

I

D

dt

F

Feed

Forward

Integrator

dt

s

Derivative

d

dt

D/A

Velocity

Command

Servo Valve

Axis

Linear

Displacement

Transducer

50039

+

+

+

+

+

Deadband

Most systems have friction and play in their mechanical linkages. These

characteristics can cause a cylinder to oscillate around a programmed

endpoint–especially if you use an integral term. You can use a deadband to

reduce these oscillations.

A deadband is an area surrounding the programmed endpoint where the error is

ignored. Outside the deadband, error is reduced by one half the width of the

deadband.

If you apply a deadband to an integral term, the integral output remains constant

while the axis is within the deadband. This reduces oscillations around the

endpoint. However, if the deadband is too large, it can also reduce the

positioning accuracy of the system.

PID Band

Integral and derivative control can cause undesirable results when the axis

moves from one position to another. The integral term can cause the axis to

overshoot the programmed endpoint. The derivative term opposes changes in

error, and thereby changes in position.

27

Page 24

Chapter 2

Positioning Concepts

You can control the integral and derivative components by defining a PID

(proportional, integral and derivative) band. The PID band is a region

surrounding the programmed endpoint where the system enables integral or

derivative terms. As a result, the integral and derivative components affect only

the final positioning of the axis.

28

Page 25

Chapter

3

Positioning with the Linear Positioning Module

This chapter explains how the Linear Positioning Module interacts with a

programmable controller to control axis movement within a linear positioning

system.

How the Module Fits in a Positioning System

1771-QB MODULE

Desired

Velocity

Integrator

s

Position

Command

dt

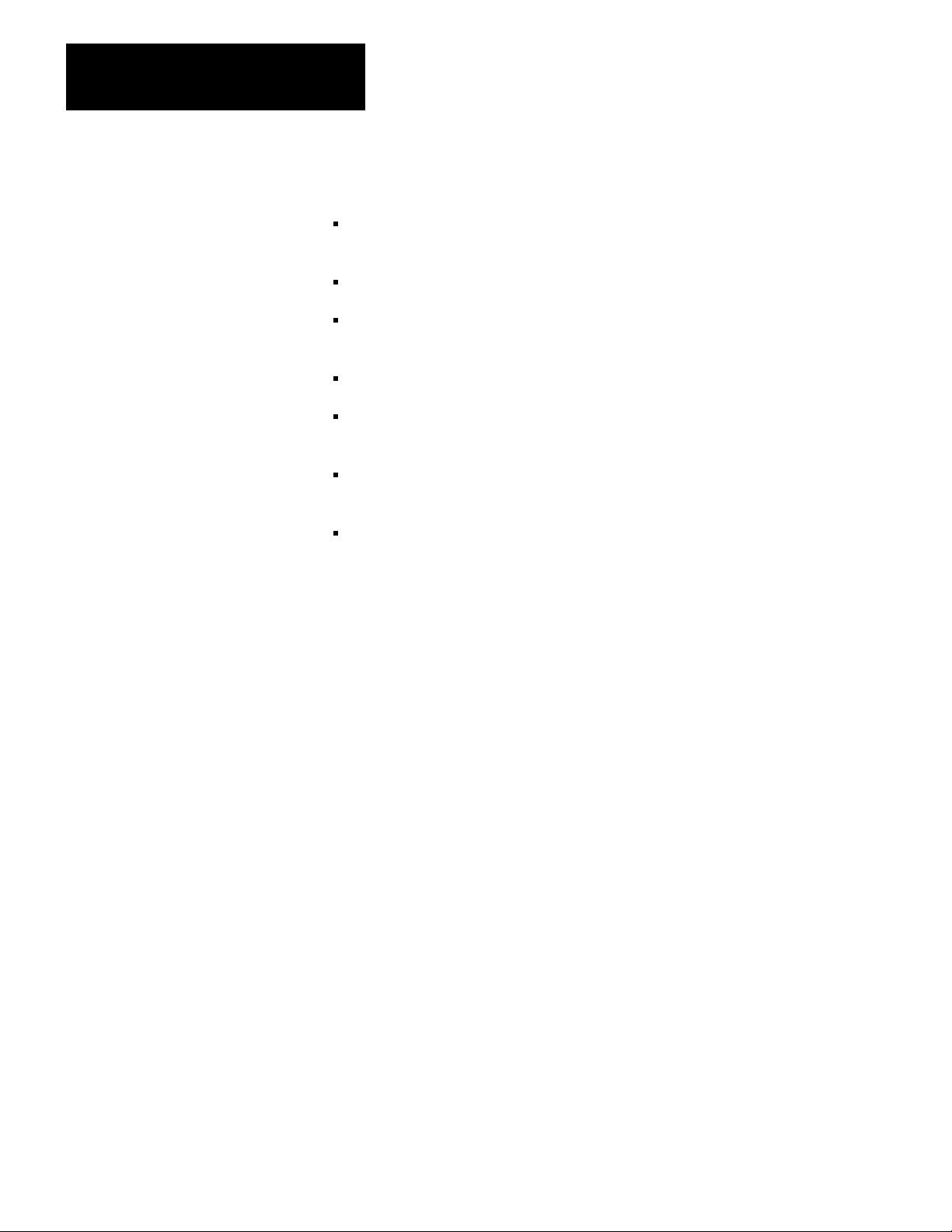

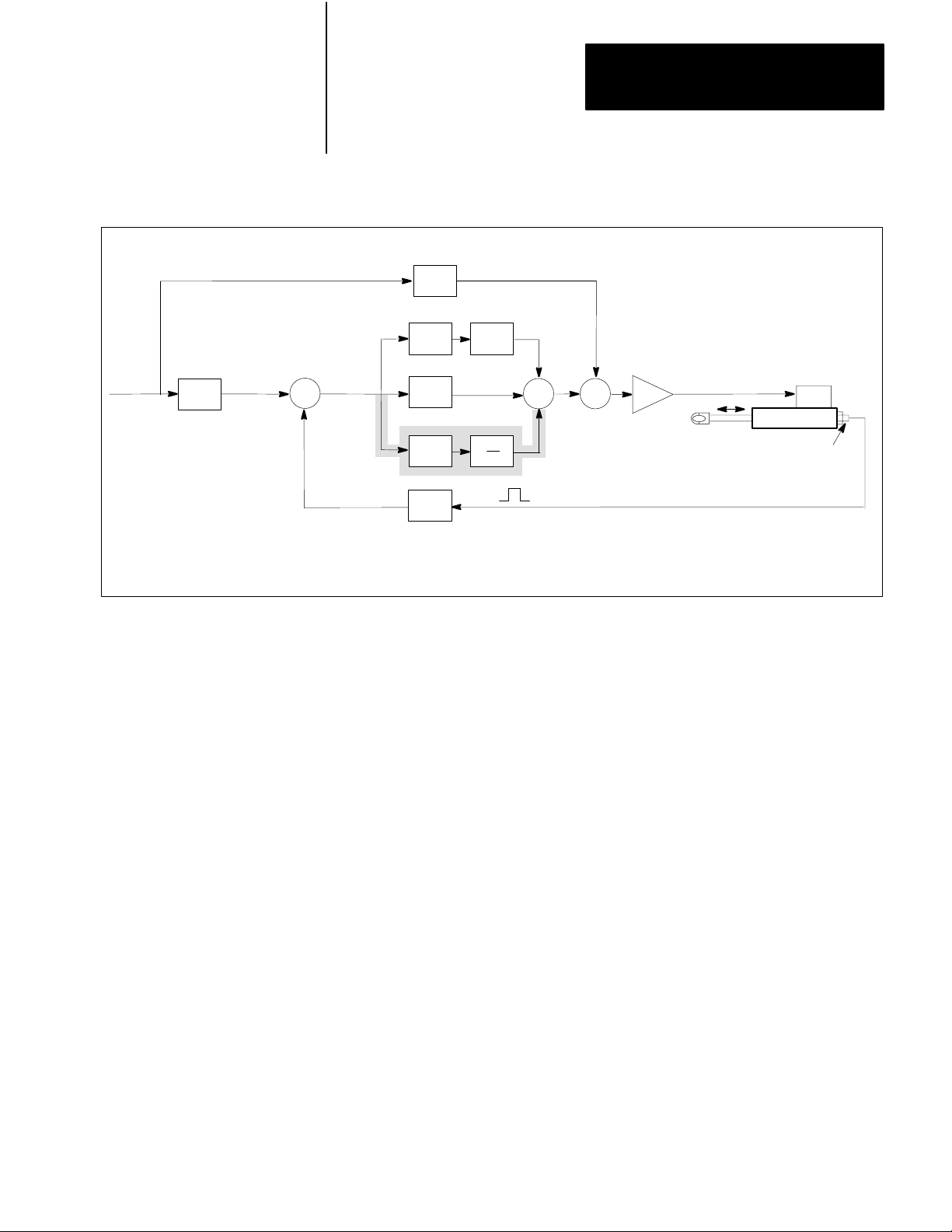

Figure 3.1 shows how the module functions in a typical positioning system.

Note that the positioning loop closes in the module and functions independently

of the programmable controller’s I/O scan rate. The fast loop update time of

2 ms is possible, because the module has a built-in microprocessor.

Figure 3.1

Module in a Positioning System

The

Feed

K

F

K

s

I

Kp

K

D

dt

Following

Error

+

-

Actual

Position

Forward

Integrator

dt

s

Derivative

d

dt

+

+

+

+

+

D/A

Velocity

Command

Axis

Servo Valve

Linear

Displacement

Transducer

50040

31

Page 26

Chapter 3

Positioning with the Linear Positioning

Module

How the Module Interacts with a PLC

The module is a dual-loop position controller, occupying a single slot in the

Allen-Bradley 1771 universal I/O chassis. The module communicates with the

PLC through the 1771 backplane. There are two kinds of transfers–read

operations and write operations. By programming the PLC you can transfer

parameter, setpoint, motion and command blocks to the module to control the

two axes. You can also use the PLC to monitor the status of the module’s two

loops through block read operations. For more details on block transfers, see

Chapters 6 and 7.

Read Operations

Read operations enable the programmable logic controller to monitor the status

of both axes through the status block. The status block includes detailed

information on the two axes: fault conditions, current axis position, positioning

error, and diagnostic information.

Write Operations

The following four types of write operations enable the programmable

controller to control axis movement:

Axis Movement

Parameter Block - defines the module’s operating parameters for each axis.

These parameters include calibration constants, software travel limits,

zero-position offset, in-position and PID bands, PID gains, maximum

velocities, jog rates, maximum accelerations and decelerations and more.

Setpoint Block - defines up to 12 setpoints for each axis with optional

acceleration, deceleration and velocity parameters for each setpoint move.

The programmable controller selects from among the 12 setpoints using the

command block.

Motion Block - permits complex profiles to be executed by the module. This

advanced feature can be used to blend or chain multiple motion segments in a

single, continuous motion.

Command Block - you use the command block to select the next setpoint or

motion segment to which the axis will move; to set a delayed start, software

stop or reset; to set jog bits; to select jog rate (low or high); to set

auto/manual, to enable/disable integral control and to define a 13th setpoint.

When the module receives a setpoint command, motion segment command, jog

command, or a discrete jog input, it automatically calculates the velocity curve

for the requested axis movement using parameters that you define for the move.

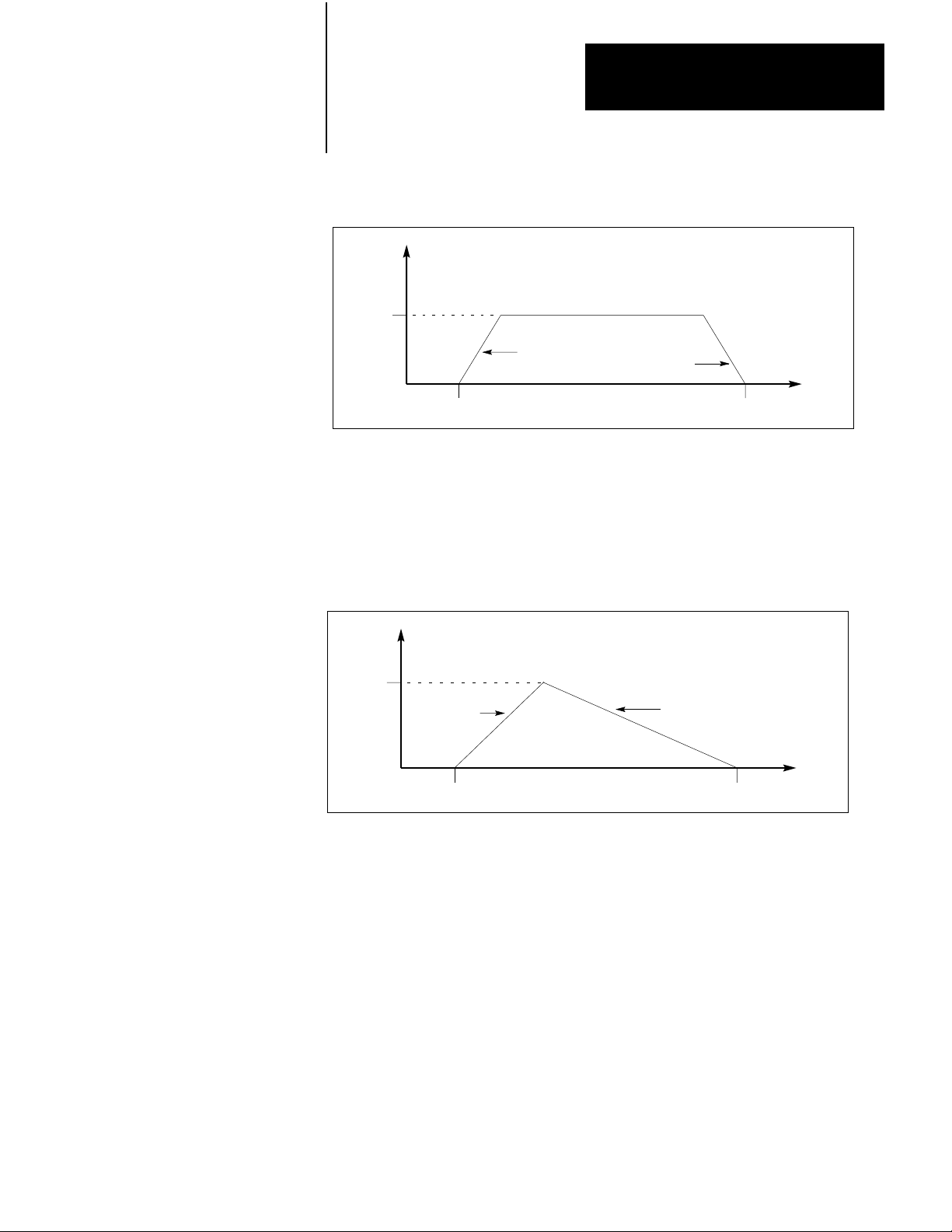

(See Figure 3.2.)

32

Page 27

Chapter 3

Positioning with the Linear Positioning

Module

Figure 3.2

Trapezoidal

Velocity

Final

Velocity

Axis Movement

Constant

Velocity

Acceleration

Start

0 Finish

Deceleration

Time

50002

The actuator may not reach the final velocity during a short move which may

only consist of acceleration and deceleration phases without a constant velocity

phase. This produces a ramp movement. (See Figure 3.3.)

Figure 3.3

Movement

Ramp

Velocity

Peak

Velocity

Acceleration

Start

0 Finish

Deceleration

Time

50003

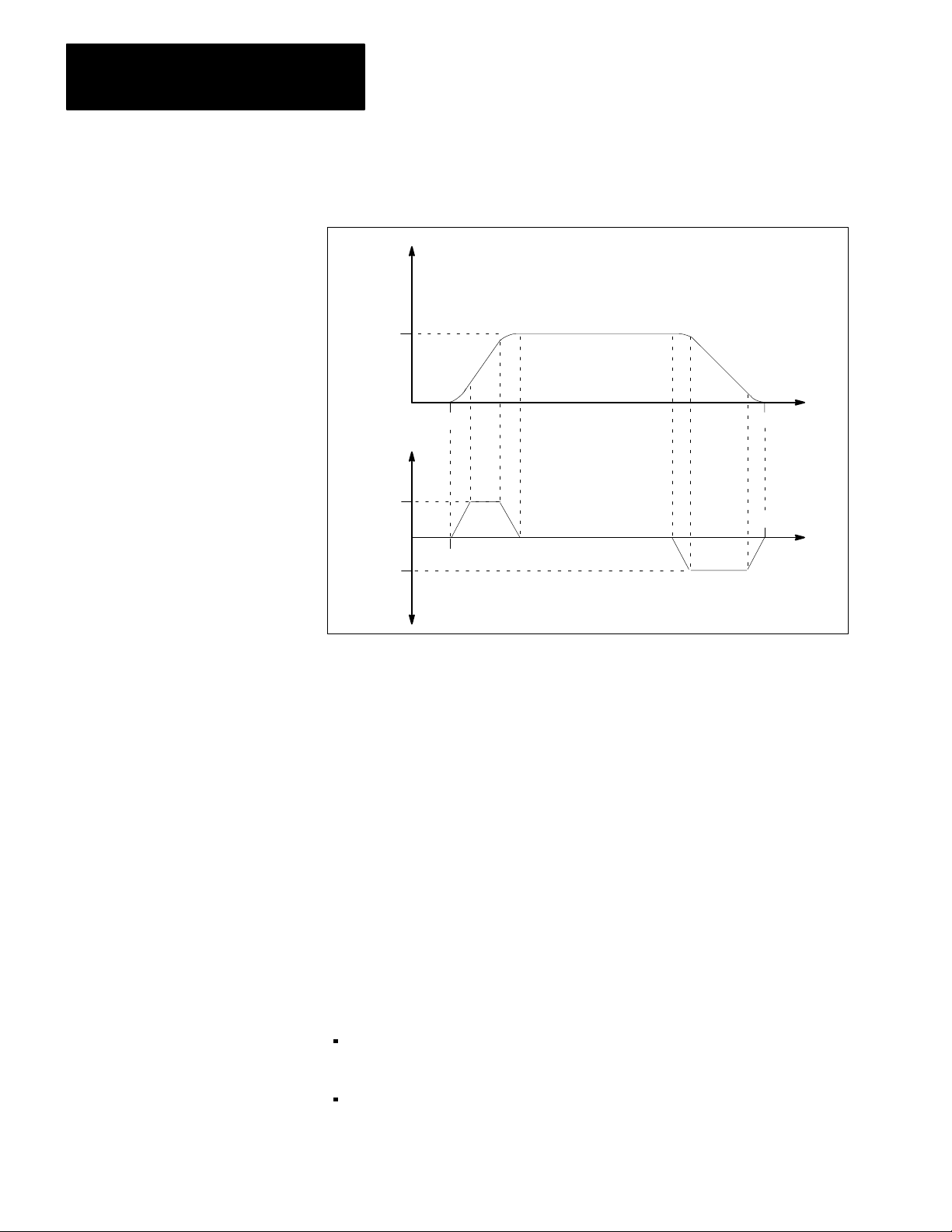

The module employs a technique called velocity curve smoothing to shape the

velocity curve into an “S curve”. To achieve this smoothing, acceleration and

deceleration rates are changed to provide more gradual application and removal

of force, thus reducing mechanical wear. The velocity smoothing constant that

you set in the parameter block determines how quickly acceleration and

deceleration change. The lower the value of the velocity smoothing constant,

the more slowly acceleration and deceleration change, producing a smoother

transition. Figure 3.4 shows the effect of velocity curve smoothing on the axis

movement.

33

Page 28

Chapter 3

Positioning with the Linear Positioning

Module

Figure 3.4

Movement with Velocity Curve Smoothing

Axis

Velocity

Final

Velocity

Acceleration

Final

Accel

Final

Decel

Acceleration Deceleration

Start0 Finish

0

Start

Constant

Velocity

Time

Finish

Time

Commanding Motion

Deceleration

50004

There are three ways to specify module axis motion: by setpoints, by jogging or

by motion blocks. All motion must be started using the command block and/or

hardware inputs.

Setpoints

The module must have the axis controller in auto mode if you are using setpoint

moves. You can switch between modes using the auto/manual bit in the

command block or the auto/manual discrete input.

Important: The auto/manual bit and the auto/manual input must both be high

to enter auto mode.

In the auto mode, you position the actuator by commanding desired setpoints

using the command block. You can:

define up to 12 setpoints through the setpoint block. You can define the 13th

setpoint within the command block.

34

specify acceleration, deceleration, and velocity for each setpoint move.

Page 29

Chapter 3

Positioning with the Linear Positioning

Module

turn on a hardware start enable bit (using the command block), which causes

the module to delay movement to the commanded setpoint. The delay ends

and movement starts when you activate the hardware start input or send a

software start command in the command block.

command a setpoint while the axis is moving towards another setpoint. If the

new setpoint is in the opposite direction of travel, the axis decelerates to zero

speed (at the current deceleration rate) and then moves in the opposite

direction. If the new setpoint is in the same direction of travel, the old

setpoint is abandoned and the axis movement accelerates or decelerates to the

specified velocity and continues toward the new setpoint.

Jogging

In the manual mode, you position the actuator by jogging, i.e., directly

commanding movement in one direction or the other. You make these

movement commands by turning on forward or reverse jog bits (via the

command block) or activating forward or reverse hardware jog inputs (typically

via momentary action switches).

If you command a jog, the axis movement continues until the actuator reaches

the software travel limit or until you turn off the jog bit or jog input, whichever

occurs first.

Jog Rates

You define two jog rates (high and low) through the parameter block. You select

between low and high jog rates through the jog rate select bit in the command

block.

If you change jog rates (from high to low or from low to high) during a jog

movement, the axis decelerates/accelerates to the new rate.

Important: Jog commands are ignored in auto mode.

Motion Blocks

A motion block contains information similar to that which the setpoint block

uses to define axis movement. In addition, a motion block also contains trigger

conditions that will initiate a subsequent axis movement, thus changing the

motion of the axis without the intervention of the programmable controller. See

Chapter 9 for a full explanation of motion blocks.

35

Page 30

Chapter

4

Hardware Description

This chapter describes the Linear Positioning Module hardware, as well as other

hardware required for a positioning system.

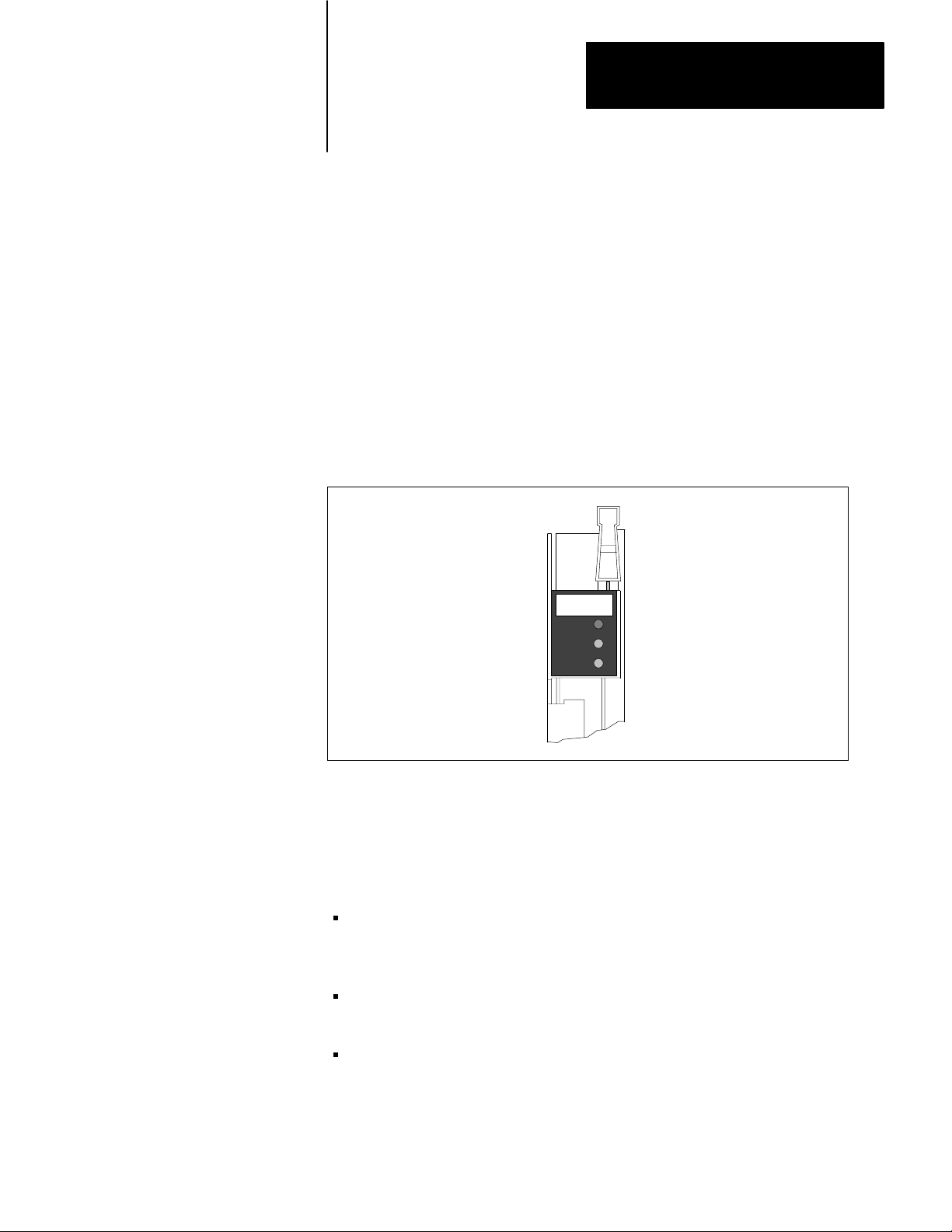

Indicators

Figure 4.1 shows the three indicators on the module.

Figure 4.1

Indicators

LINEAR

POSITIONING

FAULT

LOOP1

ACTIVE

LOOP2

ACTIVE

50009

When you first power up the module, all three indicators turn on for about one

second. Next, the LOOP 1 ACTIVE and LOOP 2 ACTIVE indicators turn off

while the module performs diagnostics. If the diagnostics discover a module

fault, the red FAULT indicator stays on and the module remains inactive. When

the programmable controller is in run mode, the indicators behave as follows:

FAULT - a red indicator that is normally off. The indicator turns on if there

is a module fault in one loop or both loops. See Chapter 11 for more

information on module faults.

LOOP 1 ACTIVE - a green indicator that is on when loop 1 is active. The

indicator blinks if a fault occurs on loop 1 and turns off if loop 1 is inactive.

LOOP 2 ACTIVE - a green indicator that is on when loop 2 is active. The

indicator blinks if a fault occurs on loop 2 and turns off if loop 2 is inactive.

41

Page 31

Chapter 4

Hardware Description

Wiring Arm Terminals

Transducer

Interface

Discrete

Inputs

Analog

Outputs

Discrete

Outputs

The module draws power for its internal circuitry and communicates with the

programmable controller through the 1771 universal I/O chassis. You make all

other connections through the wiring arm terminals. Cable length can be up to

200 feet for these connections, depending on the gauge used. See Chapter 5 for

wiring guidelines. Figure 4.2 shows the wiring arm terminals for both control

loops.

Figure 4.2

Arm T

+ GATE

- GATE

START

STOP

erminals

LINEAR

POSITIONING

FAULT

LOOP1

ACTIVE

LOOP2

ACTIVE

LOOP 1

+ GATE

- GATE

+ INTERR

- INTERR

+5 VDC

UNUSED

AUTO/MAN

START

STOP

JOG FWD

JOG REV

INPUT 1

INPUT 2

I/P SUPPLY

+ ANALOG

- ANALOG

+ 15 VDC

- 15 VDC

OUTPUT 1

OUTPUT 2

NO.

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

1

3

5

7

9

Transducer

Interface

Discrete

Inputs

Analog

Outputs

Discrete

Outputs

Wiring

NO.

2

4

6

8

+5 COMMON

10

12

14

16

18

20

22

24

26

I/P COMMON

28

30

32

34

± 15 COMMON

36

38

40

O/P SUPPLY

LOOP 2

+ INTERR

- INTERR

UNUSED

AUTO/MAN

JOG FWD

JOG REV

INPUT 1

INPUT 2

+ ANALOG

- ANALOG

OUTPUT 1

OUTPUT 2

42

50010

The input and output terminals of each of the module’s control loops are in four

groups. Each group is electrically isolated from the 1771 backplane and from

the three other groups:

transducer interface terminals

discrete input terminals

Page 32

Chapter 4

Hardware Description

analog output interface terminals

discrete output terminals

The terminals for these four groups are divided between loop 1 and loop 2. Odd

number terminals are for loop 1; even numbered terminals apply to loop 2.

Transducer Interface

Determining the Optimum Number of Circulations

Terminals 1 through 8 on the module’s wiring arm provide connection points for

the transducer interface. The module is designed to work with the linear

displacement transducers (LDT) listed in Chapter 1.

The transducer interface circuit is electrically isolated from the 1771 I/O

chassis. This protects the 1771 backplane from noise and current surges in the

transducer circuits. The transient isolation exceeds 1,500 volts RMS. The

transducer interface is also isolated from the other module interfaces and

external power supplies.

The module supports a transducer length of up to 15 feet (4572 mm), and can

resolve the signal from the transducer to within two thousandths of an inch with

one circulation. You can achieve a higher accuracy by configuring the

transducer for more circulations. For example, the resolution for 60 inches

(1524 mm) is better than one thousandth of an inch if two recirculations are

used.

Every two milliseconds, the module sends an interrogate signal to the

transducer. The transducer returns a pulse width that is proportional to the axis

position. The maximum pulse width that can be measured without overflowing

the counter is about 1680 microseconds (1.680 milliseconds).

The pulse width returned to the module depends on the transducer stroke length

and the number of circulations. Each doubling of the number of circulations

doubles the width of the gate pulse and the resolution of the position reading.

Doubling the gate pulse length, however, effectively halves the maximum

transducer length supported by the module, because the maximum pulse width

is still determined by the size of the module’s counter. Overflowing the counter

causes a feedback fault. Is is recommended that you configure the digital

interface box for the highest number of circulations that still allows a long

enough stroke length for your application. Increasing the number of circulations

reduces the effect of noise and improves resolution.

43

Page 33

Chapter 4

Hardware Description

Use these equations to determine the maximum length and positioning

resolution for the transducer:

maximum length = 1680/(T x N)

resolution = 1/(58.5 x T x N)

where:

T = transducer constant stamped on transducer head (typically

9.0500 microseconds per inch)

N = number of circulations

The following table gives several maximum transducer lengths assuming a

transducer constant of 9.0500 microseconds per inch. Resolutions may be

limited by the physical capabilities of the transducer. See Chapter 8 for a

description of a procedure for verifying the transducer constant.

Number of

Circulations

1

2

3

4

5

6 0.0003 30.9

7 0.0003 26.5

8 0.0002 23.2

9 0.0002 20.6

10 0.0002 18.6

Resolution

(Inches)

0.002

0.001

0.0006

0.0005

0.0004

Maximum Transducer Length

(Inches)

185.6

92.8

61.9

46.4

37.1

Important: Apply a 10% to 20% margin when determining the maximum

transducer length. The available stroke length will be less than indicated above

due to the null space (typically 2 inches) near the transducer head.

44

Page 34

Chapter 4

Hardware Description

Discrete Inputs

Terminals 13 through 26 on the module’s wiring arm provide connection points

for discrete input signals. Seven terminals (for each loop) connect to seven

discrete inputs.

The use of these inputs is optional. If you do not want to use them, you can

disable them through the parameter block. (See Chapter 7.) If you disable the

inputs:

the hardware stop input is deactivated (you do not have to tie it high)

the auto/manual input defaults to auto

the programmable controller programs can still read the status of the discrete

inputs in the status block

Because the programmable controller programs can still read the status of the

discrete inputs, by disabling them you can redefine them for your own purposes.

Here are the requirements of the discrete inputs:

low signal 0 to 4 VDC

high signal 10.0 to 30.0 VDC

peak input current 8 mA at 12 VDC

16 mA at 24 VDC

The discrete inputs are configured as current sinks. To reduce heat dissipation,

the module turns the discrete input currents off between samples at a 20% duty

cycle every 2 ms.

Each discrete input has an internal pull-down resistor. If the device that you

have connected to an input provides a high signal, the device must source

current through the pull-down resistor. Figure 4.3 is a simplified schematic of a

discrete input circuit.

45

Page 35

Chapter 4

Hardware Description

Figure 4.3

Simplified

Schematic of a Discrete Input

1771 - QB MODULE

+ 5V

10K

3.3K

27

INPUT SUPPLY

DISCRETE INPUT

(e.g. JOG FWD)

28

INPUT COMMON

50041

Auto/Manual Input

The module accepts the signal at the AUTO/MAN terminal (13/14) as the

auto/manual input. Use this input in conjunction with block transfers to set the

operation mode for the axis. A high input means auto mode and a low input

means manual mode. The auto/manual input defaults to auto mode if the inputs

are disabled via the parameter block.

Important: To set the mode of the axis to auto, you must set both the

auto/manual input and the auto/manual bit in the command block high. If either

the bit or the input is low, the mode is manual.

Hardware Start Input

In the auto mode, the module accepts a transition from low to high at the

START terminal (15/16) as a high-true hardware start input signal.

If the axis is in auto mode, and if the hardware start has been enabled via the

command block, the module waits for a transition from low to high at the

START terminal before it will start axis movement to a previously commanded

setpoint. If you don’t want to use this feature, disable the hardware start via the

command block.

Important: Because of the module’s built-in switch debouncing, the

low-to-high transition must follow a minimum 16 ms low signal.

46

Page 36

Chapter 4

Hardware Description

Hardware Stop Input

The module accepts the signal at the STOP terminal (17/18) as a low-true

hardware stop input. A low signal at the hardware stop input disables the analog

output and stops axis movement. Unless the discrete inputs are disabled via the

parameter block, this input must be high for normal operation. If the connection

breaks, axis movement stops.

Example: If the loop fault output of one axis is connected to the hardware stop

input of another axis, the movement of both axes will stop if a fault occurs.

Jog Forward Input

In manual mode, the module accepts a high signal at the JOG FWD terminal

(19/20) as a high-true jog forward signal. When the module receives this signal,

it moves the tool or workpiece forward until it reaches the software limit or

until the input goes low. Forward is the direction of positive movement relative

to the zero-position offset. Chapter 7 explains how to define the zero-position

offset in the parameter block.

Analog Output Interface

Jog Reverse Input

In manual mode, the module accepts a high signal at the JOG REV terminal

(21/22) as a high-true jog reverse signal. When the module receives this signal,

it moves the tool or workpiece in the reverse direction until it reaches the

software limit or until the input goes low. Reverse is the direction of negative

movement relative to the zero-position offset.

Important: If the module detects a feedback fault, the jog inputs will perform

open-loop jogs only. This means that the module can send velocity commands

to the servo valve (at the low jog rate), but can’t monitor axis position.

Therefore, software travel limits are ignored.

General Purpose Inputs

There are two general purpose inputs for each control loop of the module at

terminals INPUT 1 (23/24) and INPUT 2 (25/26). You can monitor the state of

the signal at these terminals through the status block. These inputs can also be

configured as programmable as described in Chapter 9.

The module’s analog outputs, terminals 29 through 32, connect to a hydraulic

valve for each axis that the module controls. These outputs supply up to +

mA for direct servo valve control or up to +

amplifiers or other voltage controlled devices.

10 V for proportional valve

100

47

Page 37

Chapter 4

Hardware Description

The analog output interface circuit is electrically isolated from the 1771 I/O

chassis. This feature protects other devices on the 1771 backplane from noise

and current surges in the analog output circuit. An internal relay automatically

shuts off these outputs in the event of a module fault. For details on connecting

the servo valve interface, see Chapter 5.

Important: Throughout this manual we refer to servo valves, but you can also

use the analog outputs to control proportional valves. All references to servo

valves also apply to proportional valves.

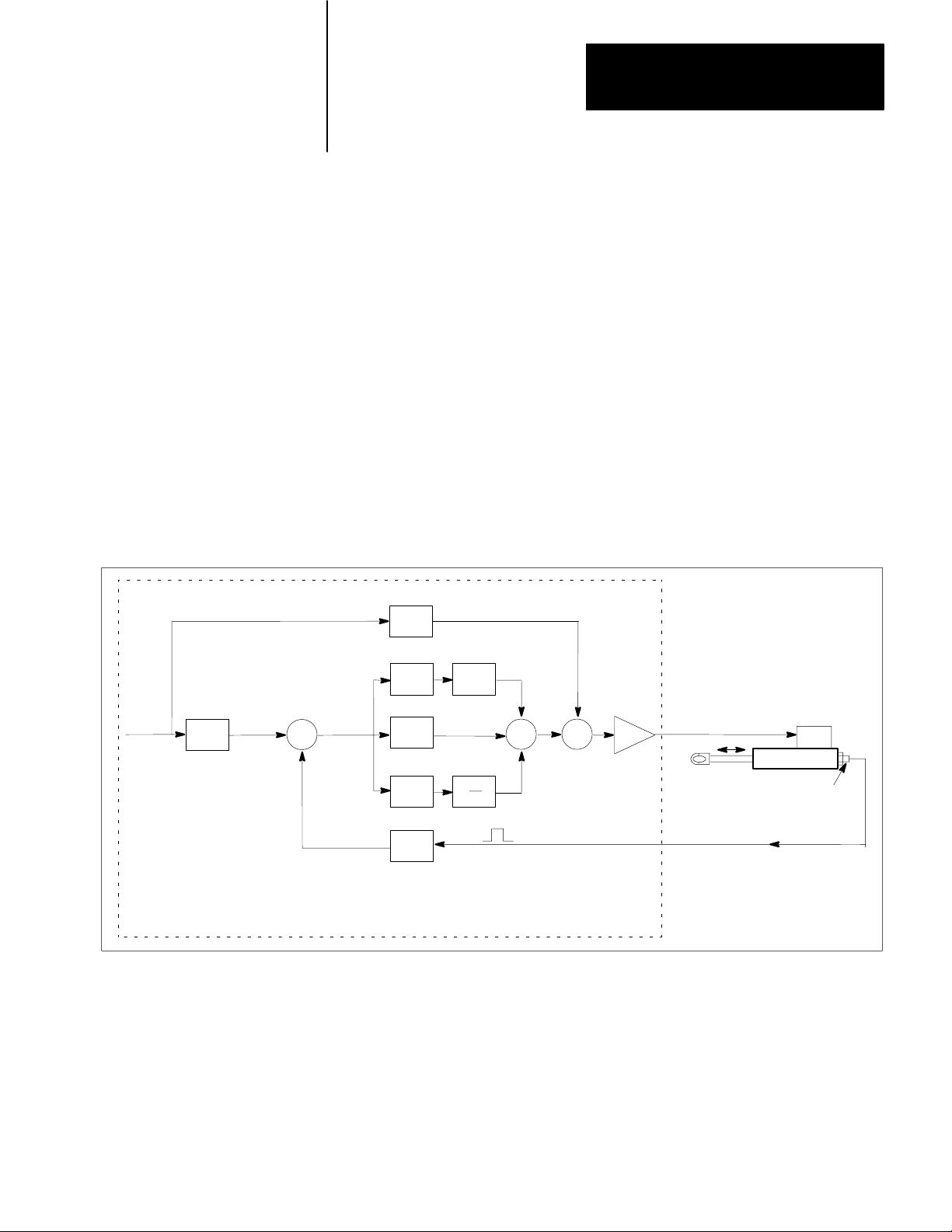

Discrete Outputs

Terminals 36 through 39 on the module’s wiring arm provide connection points

for discrete output signals. Each axis has two discrete outputs: Output 1 which

can be configured to be either an in-position or programmable output, and

Output 2 which can be configured to be either a loop fault or programmable

output. (See Chapter 9.) The default configuration is in-position and loop fault.

The discrete outputs are current sources. Figure 4.4 gives a simplified schematic

of a discrete output circuit.

Figure 4.4

Simplified

Schematic of a Discrete Output

1771 QB MODULE

3.9

40

OUTPUT SUPPLY

37

OUTPUT 1

48

Here are the characteristics of the discrete outputs:

Low no voltage applied to the output

High output supply voltage applied to output

Maximum Current 100 mA

Voltage Drop 1.6 VDC maximum (at 100 mA) between the

discrete output power supply (terminal 40) and the

discrete outputs

5

0

0

4

2

50042

Page 38

Chapter 4

Hardware Description

Important: If you want to connect a discrete output of one axis to the discrete

input of another axis, the minimum discrete output supply voltage is 11.6 VDC.

This accounts for the voltage drop of 1.6 VDC shown above and provides the

minimum voltage required to drive a module discrete input (10 VDC).

ATTENTION: The discrete outputs can withstand a short circuit for

a few seconds. However, a continuous short circuit will damage the

module’s discrete output transistor.

OUTPUT 1

When OUTPUT 1 (terminals 36/37) is configured as an in-position output, it

turns off when axis movement toward a commanded endpoint begins and turns

on when the axis enters the in-position band (defined in the parameter block).

You can connect an in-position output to a hardware start input to provide a

simple form of axis coordination.

Power Supplies

When this output is configured as a programmable output, its state is

determined by the configuration information provided in the motion blocks.

(See Chapter 9.)

OUTPUT 2

When OUTPUT 2 (terminal 38/39) is configured as a loop fault output, it is

high under normal axis operation. When the module detects a fault in the axis,

the loop fault output goes low.

You can connect the loop fault output to the hardware stop input of other control

loops so all axis movement will stop if a fault occurs. The loop fault output then

provides the low signal required by the hardware stop input of the other axis.

As with OUTPUT 1, OUTPUT 2 can be configured as a programmable output

and its state determined by information in the motion blocks.

You must provide external DC power for the input and output circuits. You

could use a single supply, but you’ll maintain maximum separation and keep

noise to a minimum by using four separate power supplies. In less critical

applications, you could power two or three circuits from the same supply.

49

Page 39

Chapter 4

Hardware Description

to power the: supply:

Transducer interface +5 VDC 9, 10

Discrete inputs +24 VDC (max) 27, 28

Servo valve interface +15 VDC 33, 34, 35

Discrete outputs +30 VDC (max) 40

to these terminals:

All power connections must be made for the transducer, servo valve, and

discrete outputs. The power supply for discrete inputs may be left unconnected

if the discrete input disable bit has been set in the parameter block.

410

Page 40

Chapter

5

Installing the Linear Positioning Module

Before You Begin

This chapter tells you how to install the module in the I/O chassis and how to

configure the module’s analog outputs by setting DIP switches. Before you

install the module:

make sure your power supply is adequate

plan your module’s location in the I/O chassis

take steps to avoid electrostatic discharge

Avoiding Backplane Power Supply Overload

Make sure your power supply can handle the extra load before installing the

module in your I/O chassis. Add the module’s current requirement, listed on the

module’s label, to the currents required by other modules inserted in the I/O

chassis. If the backplane power supply rating is less than the total current

required, you’ll need a larger power supply.

Here are the current ratings for the various Allen-Bradley power supply

modules.

This Power Supply Module:

Is Rated at:

1771P1

1771P2

1771P4 8A

1771P5

1771P7

6.5A

6.5A

8A

16A

Planning Module Location

The module requires one I/O chassis slot. You can install it in any slot in the I/O

chassis. The module uses both the output image table byte and the input image

table byte that corresponds to its location address.

51

Page 41

Chapter 5

Installing the Linear Positioning Module

Electrostatic Discharge

Under some conditions, electrostatic discharge can degrade performance or

damage the module. Observe the following precautions to guard against

electrostatic damage:

use a static-free workstation if one is available

touch a grounded object to discharge yourself before handling the module

don’t touch the backplane connector or connector pins

when you set the analog output switches, don’t touch other circuit

components inside the module

keep the module in a static-shielded bag when it’s not in use

Setting Analog Output Switches

You set the analog output DIP switches to define the range of output voltage or

output current for the analog output of each control loop.

There are two switch assemblies for each control loop: a single switch assembly

that selects voltage or current output and a dual switch assembly that sets the

current range. The current range switch has no effect if you choose a voltage

output. You must limit the voltage range through the analog range word in the

parameter block if you require a voltage range of less than +

Chapter 7.)

If the analog output will be controlling a current controlled device, such as a

servo valve, set the single switch for current and set the current range to match

the device. If your device requires a range that falls between those provided,

select the next higher range and reduce the range using the analog range word in

the parameter block.

Important: Although you can set the current range with the analog range word

in the parameter block, you’ll improve analog output resolution by first limiting

the range with the current range DIP switch.

To set the switches:

1. Lay the module on its side and locate the switches using Figure 5.1. All

switches are accessible from the right edge of the module without

removing the module cover.

10 VDC. (See

52

Page 42

Chapter 5

Installing the Linear Positioning Module

Figure 5.1

Locating

the Analog Configuration Switches

LOOP 2

LOOP 1

CURRENT RANGE

VOLTAGE/CURRENT

CURRENT RANGE

VOLTAGE/CURRENT

2. Use a blunt pointed instrument (such as a ballpoint pen) to set the

switches.

ATTENTION: Don’t use a pencil to set switches. Lead can jam the

switch.

50043

53

Page 43

Chapter 5

Installing the Linear Positioning Module

3. Set the current/voltage switch for each control loop as shown in

Figure 5.2.

Figure 5.2

Configuring

SLIDEONROCKERONTOGGLE

the Analog Outputs

TYPES OF SWITCHES

ON

C1

12

C2

±100mA

± 50mA

± 20mA

LOOP 1

1 2

OPEN

12

C2

12

C2

12

C2

C1

C1

C1

LOOP 2

C1

12

C2

1 2

OPEN

2

1

OPEN

2

1

OPEN

OPEN

1 2

1771QB

Chassis

54

2

C1

1

2

C2

1

OPEN

± 10V

The range selection switches have no

effect when ±10V is selected.

50044

4. If you have selected a current output, set the current range switch to +100

mA, +

50 mA, or +20 mA as shown in Figure 5.2. If your device requires a

range that falls between those provided, select the next higher range and

reduce the range using the analog range word in the parameter block.

ATTENTION: If your switch setting does not provide enough

current, the servo valve may not operate to its full capability. On the

other hand, excessive currents may damage the servo valve.

Page 44

Chapter 5

Installing the Linear Positioning Module

Keying

A package of plastic keys (Cat. No. 1771-RK) is provided with every I/O

chassis. When properly installed, these keys prevent the seating of anything but

the module in the keyed I/O chassis slot. Keys also help to align the module

with the backplane connector.

Each module is slotted at its rear edge. Position the keys on the chassis

backplane connector, corresponding to the slots on the module’s rear edge.

Insert the keys into the upper backplane connectors. Position the keys between

the numbers at the right of the connectors, as shown in Figure 5.3.

Figure 5.3

Keying

Module

2

4

6

8

10

12

Keying

Positions

Between

D pins 16 and 18

D pins 30 and 32

14

16

18

20

22

24

26

28

30

32

34

36

Inserting the Module

50045

After setting analog output switches and setting the keying positions, you’re

ready to insert the module into a slot in the I/O chassis.

To insert the module, follow this procedure:

1. Remove all power from the I/O chassis and from the module’s wiring arm

before inserting or removing a module.

55

Page 45

Chapter 5

Installing the Linear Positioning Module

2. Open the module locking latch on the I/O chassis and insert the module

into the slot keyed for it.

3. Press firmly to seat the module into the backplane connector.

4. Secure the module with the module locking latch.

ATTENTION: Don’t force a module into the backplane connector.

If you can’t seat a module with firm pressure, check the alignment

and keying. Forcing a module can damage the backplane connector

and the module.

Wiring Guidelines

Through the module’s terminals, you connect the module to external devices.

The exact wire gauge and maximum allowable length depends upon the devices

being connected. Here are some general rules to follow when you connect the

terminals:

don’t use wire with too large a gauge. The maximum practical wire gauge is

14 AWG.

keep low level conductors separate from high level conductors. Follow the

practices outlined in Publication 1770-980 P2LC Grounding and Wiring

Guidelines.

keep your power supply cables as short as possible–less than 50 feet is

preferable.

Using Shielded Cables

For many connections, you are instructed to use shielded cables. Using shielded

cables and properly connecting their shields to ground protects against

electromagnetic noise interfering with the signals transmitted through the

cables. Connect each shield to ground at one and only one end. At the other end,

cut the shield foil and drain wire short and cover them with tape. This will

protect them against accidentally touching ground. Keep the length of leads

extending beyond the shield as short as possible.

56

Figure 5.4 shows shielded cable connections for one control loop. Mount a

ground bus directly below the I/O chassis to provide a connection point for the

cable shield drain wires and the common connections for the input and output

circuits. Connect the I/O chassis ground bus through 8 AWG wire to the central

ground bus to provide a continuous path to ground.

Page 46

Chapter 5

Installing the Linear Positioning Module

Transducer

Supply

Figure 5.4

Shielded

4

Cable Grounding Connections

5

LINEAR

POSITIONING

FAULT

LOOP1

ACTIVE

LOOP2

ACTIVE

Transducer

1

2

Discrete

2

Input

Supply

3

Analog

Supply

Discrete

Output

Supply

2

5

2

Shielded cables are not

required for these discrete

inputs and outputs.

However, they can

improve noise immunity.

I/O Chassis Ground Bus

8 AWG wire to

central ground bus

1

Belden 8723 or equivalent (50 ft. max.), Belden 8227, Belden 9207, Belden 1162A, or equivalent (200 ft. max.)

2

Belden 8761 or equivalent (50 ft. max.)

3

Belden 8761 or equivalent (200 ft. max.)

4

Belden 8761 or equivalent (25 ft. max.), Belden 9318 or equivalent (50 ft. max.)

5

Belden 8723 or equivalent (50 ft. max.)

Servo Valve

50026

57

Page 47

Chapter 5

Installing the Linear Positioning Module

Using Twisted Wire Pairs

It is recommended you use twisted wire pairs for a signal and its return path to