Page 1

Allen-Bradley

Stepper

Positioning

User

Assembly

(Cat. No. 1771–QA)

Manual

Page 2

Important User

Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc.

is prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

Identify a hazard.

Avoid the hazard.

Recognize the consequences.

Important: Identifies information that is especially important for

successful application and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

Page 3

Table of Contents

Introduction

Assembly and Installation

Chapter 1

Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Understand Compliance to European Union Directives 1–2. . . . . . . . . .

EMC Directive 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Voltage Directive 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

General 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Considerations 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Considerations 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Power Supply 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Power Supply 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stepper Translator and Power Supply 2–3. . . . . . . . . . . . . . . . . . . .

Stepper Motor 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pulse Output Expander Module 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Disassembly 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Format (S1) 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Logic (S2) 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expander Module Address (S3) 2–6. . . . . . . . . . . . . . . . . . . . . . . .

Expander Module Output (S4, S5, S6) 2–7. . . . . . . . . . . . . . . . . . . .

Diagnostic Indicators 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stepper Controller Indicators 2–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Expander Module Indicators 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Grounding Considerations 2–10. . . . . . . . . . . . . . . . . . . . . .

Cable Considerations 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shield Connection 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Keying 2–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility 2–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Specifications 2–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming and

Operation

Chapter 3

General 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Concepts 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Definition 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moveset 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Positioning Modes 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single-Step Mode 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jog 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous Mode 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronization of Axes 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1771-UM002A–EN–P– May 2000

Page 4

Table of Contentsii

Independent Mode 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Block Concepts 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moveset Block 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moveset Control Word 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Offset Word 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preset Word 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialization Preset 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Preset 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Block 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Move Control Word 3–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Move Data 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ramp Time 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Rate 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decel 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Block 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Word 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Bits 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Position Words 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

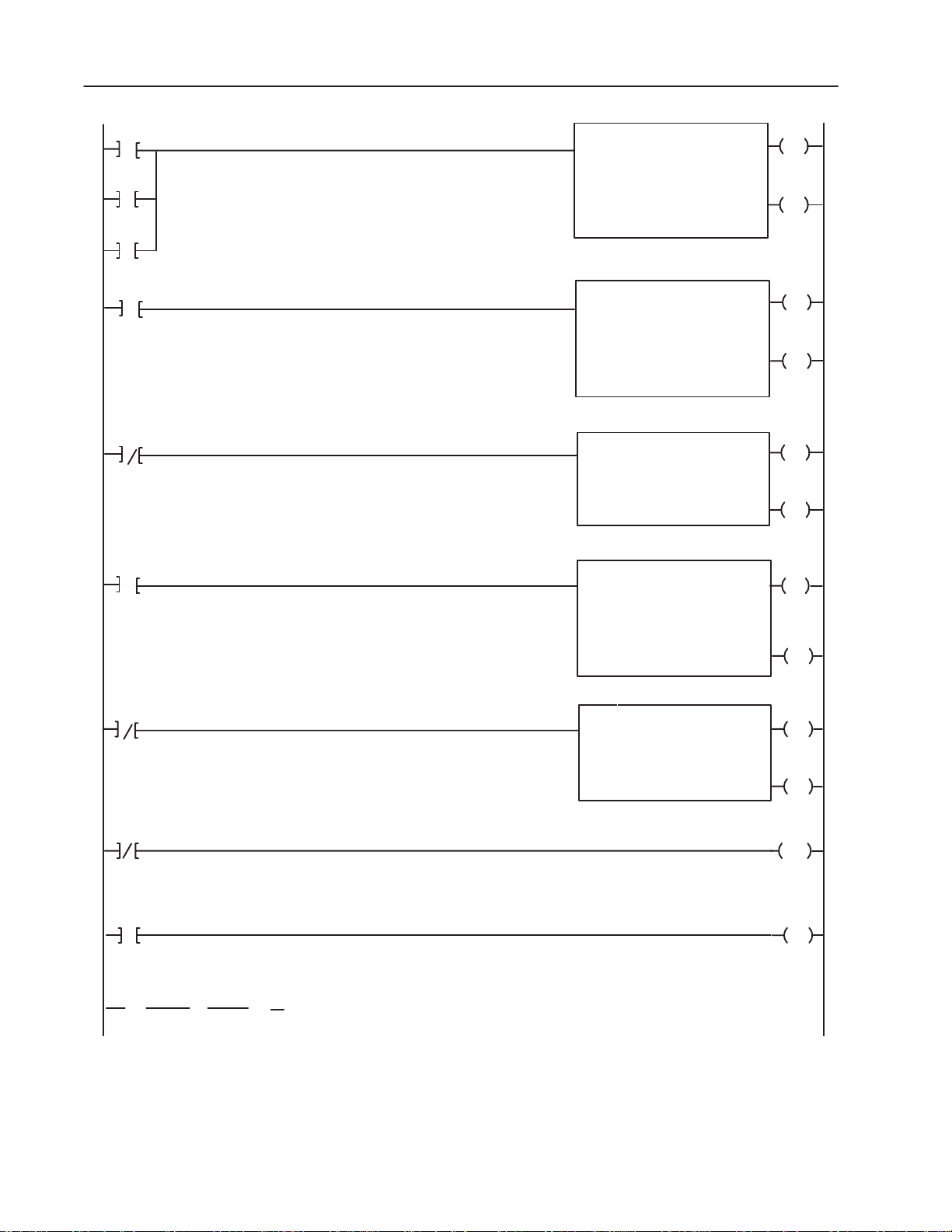

Block Transfer Programming 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Overview 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bidirectional Block Transfer 3–25. . . . . . . . . . . . . . . . . . . . . . . . .

Data Address and Module Address 3–25. . . . . . . . . . . . . . . . . . . .

Block Length 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multiple Writes of Different Block Lengths to One Module 3–27. . . .

File Addresses 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enable and Done bits 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Instructions 3–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Considerations 3–30. . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Strategy 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Length 3–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Commands 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table Sizing Considerations 3–33. . . . . . . . . . . . . . . . . . . . . . .

Data Table Documentation Forms 3–34. . . . . . . . . . . . . . . . . . . . .

Data Table Expansion 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handshaking 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Timing 3–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-2/30 (PLC-2/20) Remote System 3–38. . . . . . . . . . . . . . . . . .

PLC-2/30 Local System 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mini-PLC-2/15 Controller 3–42. . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Considerations 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Duration 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reversing Direction During a Continuous Sequence 3–48. . . . . . . . . .

Decel and Position Considerations for a 0Hz Rate Move 3–49. . . . . . .

Override Ramp Time Considerations 3–51. . . . . . . . . . . . . . . . . . . . .

Stepper Motor Acceleration Considerations 3–54. . . . . . . . . . . . . . . .

Publication 1771-UM002A–EN–P– May 2000

Page 5

Table of Contents iii

Resonant Frequency 3–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accuracy of Ramp and Decel Times 3–55. . . . . . . . . . . . . . . . . . . . .

Minimum Move Time 3–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example Programs

Troubleshooting

Specifications

Chapter 4

General 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-Axis Program 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming a 1-Axis Profile 4–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Preset and Jog Data 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Data 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ladder Diagram 1-Axis Program 4–1 1. . . . . . . . . . . . . . . . . . . . . .

Operational Summary 4–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-Axis Program 4–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming a 3-Axis Profile 4–18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Summary 4–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

General 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Tables 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Illegal Bit Combinations 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Pulse Output Expander Module Specifications (cat. no. 1771-OJ) A–1

Stepper Controller Module Specifications (cat. no. 1771-M1) A–2. . . .

CSA Hazardous Location

Approval

Appendix B

CSA Hazardous Location Approval B–1. . . . . . . . . . . . . . . . . . . . . . . .

Publication 1771-UM002A–EN–P– May 2000

Page 6

Table of Contentsiv

Publication 1771-UM002A–EN–P– May 2000

Page 7

Chapter

1

Description

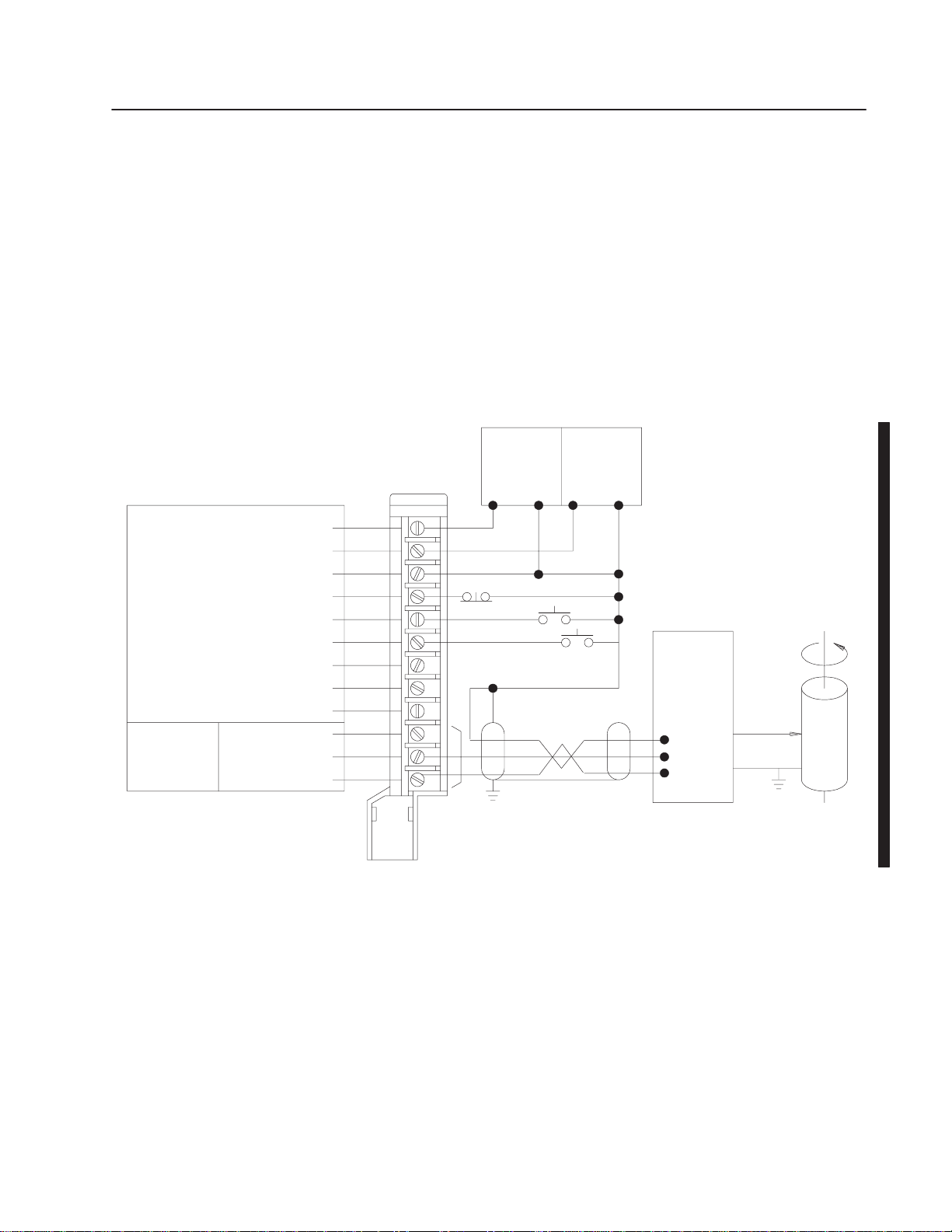

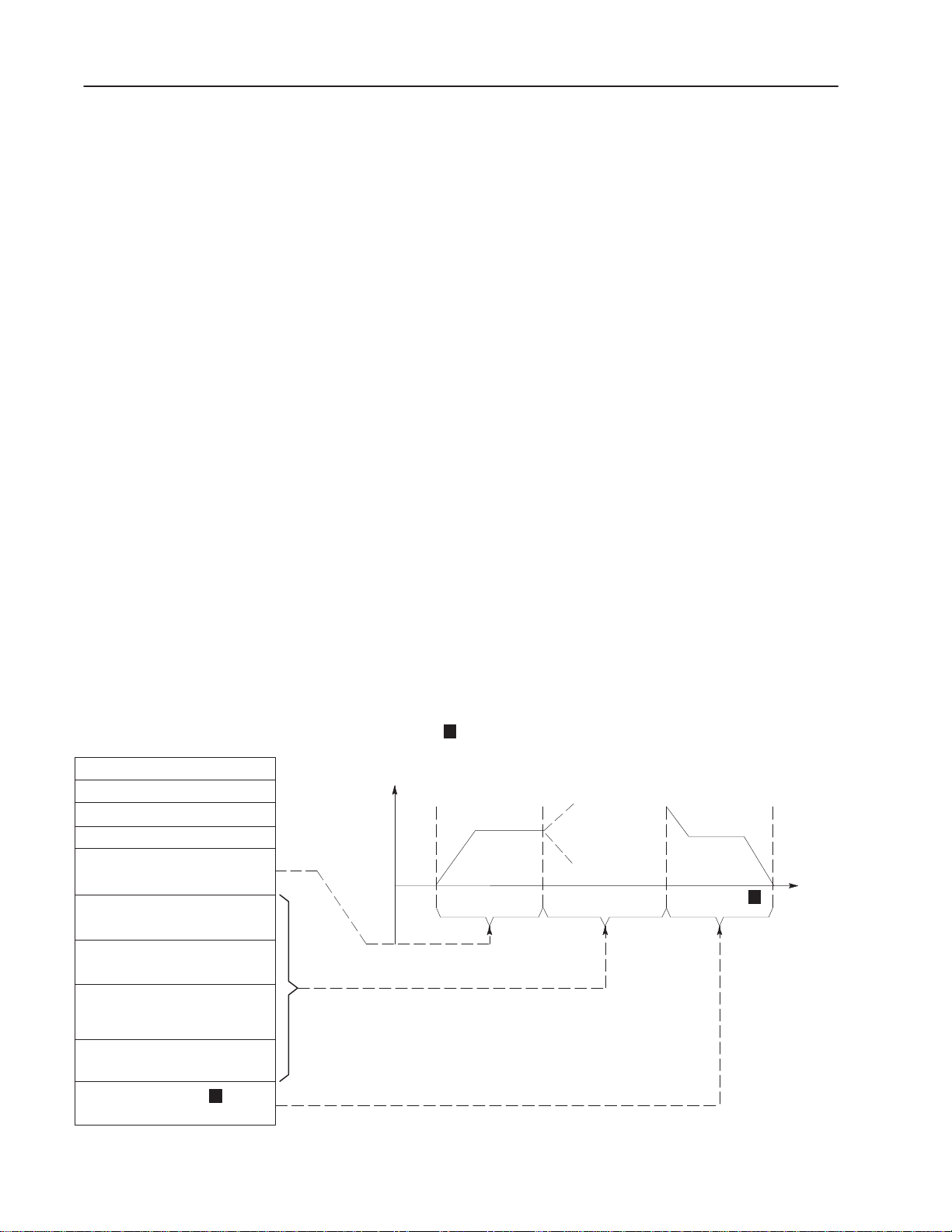

Processor

PC

Bi–Directional

Block Transfer

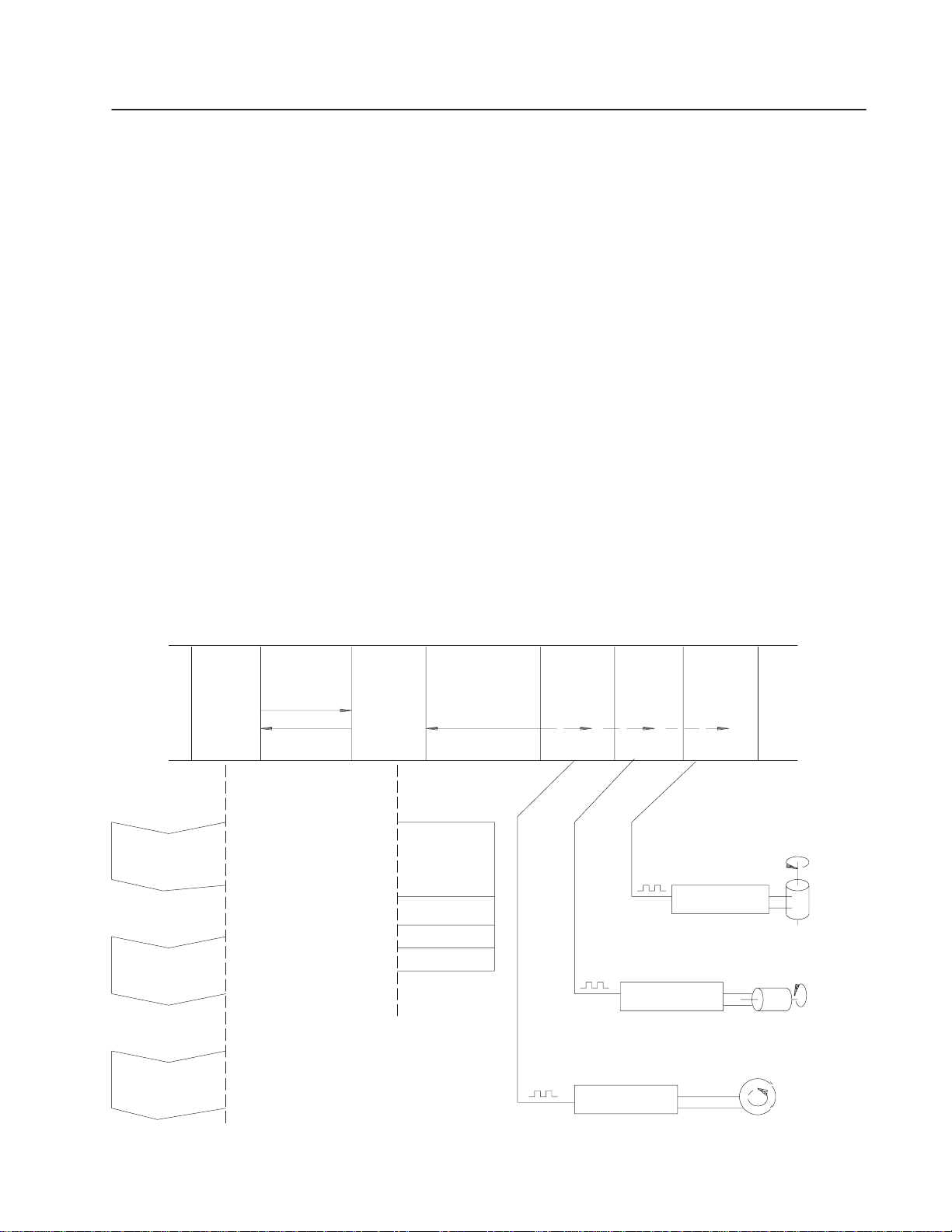

The Stepper Motor Positioning Assembly (cat. no. 1771-QA) allows

programmable control of stepper motors by Allen-Bradley

programmable controllers. Data and commands set to the stepper

positioning assembly are converted to a pulse output for a

user-supplied stepper motor translator which in turn provides the

proper voltage and current to the stepper motor to produce the

desired motion. The stepper motor positioning assembly consists of:

• 1 Stepper Controller Module (cat. no. 1771-M1)

• 1 Pulse Output Expander Module (cat. no. 1771-OJ)

• 1 Field Wiring Arm (cat. no. 1771-WB)

One stepper controller module can control up to three pulse output

expander modules. The system can be expanded modularly from

one to three axes per I/O chassis by placing from one to three output

expander modules in the chassis (Figure 1.1). The pulse output

expander modules can be located in any slot except the left-most slot

and in any order in the I/O chassis.

Figure 1.1

Typical System Block Diagram

1771 I/O Rack

1771–OJ 1771–OJ 1771–OJ

1771–M1

Stepper

Controller

Module

Backplane

Communications

Pulse

Output

Expander

#3

Pulse

Output

Expander

#2

Pulse

Output

Expander

#1

Move

Data

Axis #1

Move

Data

Axis #2

Move

Data

Axis #3

Status

Data

Axis #1

Axis #2

Axis #3

Translator

Translator

Translator

Axis #2

•

Axis #3

Publication 1771-UM002A–EN–P – May 2000

Stepper

Motor

Axis #1

Stepper

Motor

Stepper

Motor

10509

Page 8

1–2 Introduction

Stepper motor positioning assemblies can be used in applications

requiring more than three axes by using additional I/O chassis. The

stepper assemblies can be distributed throughout the plant using

remote I/O or data highway configurations.

Typically, each axis can control a linear slide although not limited to

that type of mechanical load. The axes can be controlled

independently or control of the axes can be synchronized.

Programming is based on a data block format where blocks of data

can be manipulated using block format instructions such as

file-to-file move and block transfer read and write instructions. The

stepper positioning assembly can be used with any Allen-Bradley

programmable controller that has block transfer capability and an

expandable data table except for Mini-PLC-2 (cat. no. 1772-LN3)

and PLC-2/20 (cat. no. 1772-LP1) Processors.

When using the PLC-2/20, programming will be more lengthy

because data must be transferred using repeated get/put (word)

transfer instructions.

Understand Compliance to

European Union Directives

The number of axes that can be controlled and the complexity of

motion will depend on the memory available for the positioning

program after the data table of the PC processor has been expanded

to store the data blocks.

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard,

Part 2 – Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard,

Part 2 – Industrial Environment

This product is intended for use in an industrial environment.

Publication 1771-UM002A–EN–P – May 2000

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

Page 9

1–3Introduction

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as “Industrial Automation Wiring

and Grounding Guidelines For Noise Immunity,” Allen-Bradley

publication 1770-4.1

Open style devices must be provided with environmental and safety

protection by proper mounting in enclosures designed for specific

application conditions. See NEMA Standards publication 250 and

IEC publication 529, as applicable, for explanations of the degrees of

protection provided by different types of enclosure.

Publication 1771-UM002A–EN–P – May 2000

Page 10

1–4 Introduction

Publication 1771-UM002A–EN–P – May 2000

Page 11

Chapter

Assembly and Installation

2

General

Rate

Fwd Dir

Rev Dir

+ DC Input Supply

+ DC Output Supply

Common

Stop Input

Jog Forward Input

Jog Reverse Input

Not Used

Not Used

Not Used

Not Used

Fwd Rate

Rev Rate

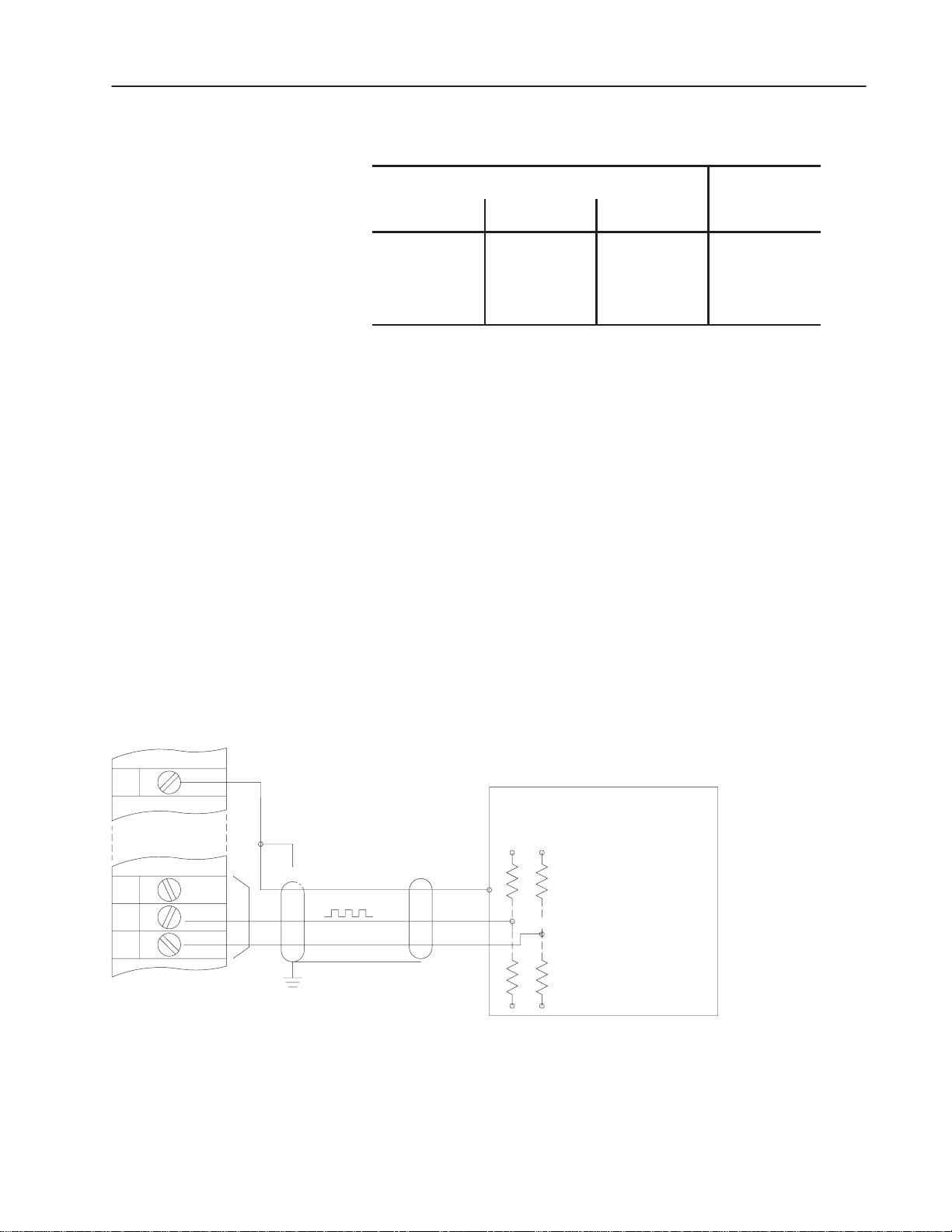

The stepper positioning assembly can be wired for 1-axis operation

with a stepper translator and motor as shown in Figure 2.1. One

stepper controller module can control up to three pulse output

expander modules installed in the same chassis. When the

application calls for 2-or 3-axis control, each additional expander

module should be wired as shown in Figure 2.1. No more than one

stepper controller module can operate in an I/O chassis.

Figure 2.1

Typical 1-Axis Connection Diagram

Pulse Output

Expander Module

Field Wiring Arm

1771–WB

1

2

3

4

5

6

7

8

9

10

11

12

Input

NEC Class 2

Power

Supply

+–+–

Rate Pulses/

Directional Signals

Output

NEC Class 2

Power

Supply

Stepper

Translator

and

Power

Supply

Mechanical

Load

Stepper

Motor

10510

Input Considerations

Pulse output expander modules can be controlled manually by the

use of switch inputs for stop, jog forward and jog reverse. The stop

switch will cause output pulses to the corresponding axis to cease

instantaneously. Jog switches are operational only when the

corresponding axis is at rest.

Publication 1771-UM002A–EN–P – May 2000

Page 12

2–2 Assembly and Installation

Input switch contacts should be compatible with the voltage and

current levels of the input circuits. The pulse output expander

module will accept inputs from open collector logic devices or

grounded switch contacts, and inputs from the Allen-Bradley

Encoder/Counter Module (cat. no. 1771-IJ, -IK). Refer to section

titled “Module Specifications” for additional input specifications.

Power Supply

Considerations

Each module in the I/O chassis including the processor or adapter

module draws power from the I/O (chassis) power supply. Some

modules require an additional power source.

I/O Power Supply

Power is supplied through the I/O chassis backplane from the 5V DC

I/O power supply. The stepper controller draws all of its power

(1.75A, maximum) from the I/O power supply. Each pulse output

expander module requires a current of 0.80A maximum. These

amounts (4.15A maximum for a 3-axis system) should be totalled

with the current requirements of all other modules in the chassis so

as not to exceed the maximum output current of the I/O chassis

power supply.

Auxiliary Power Supply

Pulse output expander modules require an additional power source

for switch inputs to the module and for pulse outputs to the stepper

translator and motor. The power source can be separate input and

output power supplies for one, two or three axes, a combined power

source for each axis, or a combined power source for up to three

axes. The power supply must be NEC Class 2 listed. Each input

switch draws 11mA maximum when closed. The maximum output

current for the pulse output expander module is 100mA. Refer to

Appendix A, Module Specifications” for additional information

concerning the auxiliary power supply requirements.

Publication 1771-UM002A–EN–P – May 2000

The supply voltage can be any value chosen from 5V DC to 30V DC

required by the user-selected stepper translator and/or the switch

input circuits. The variation in the DC voltage level due to ripple

should not exceed the input specification for the stepper translator

because the supply voltage ripple appears at the output terminals of

the pulse output expander module. Power supplies with 15mV

peak-to-peak ripple can be used. However, check the translator input

specification to ensure that the power supply specifications meet

translator input requirements. The supply may require input filtering

to guard against electrical noise.

Page 13

2–3Assembly and Installation

Stepper Translator and Power Supply

The stepper translator and power supply convert digital information

from the pulse output expander module into the proper voltage and

current for the precise control of a stepper motor. For compatibility

with the pulse output expander module, the translator must accept

low true logic. The programmed maximum pulse rate from the pulse

output expander module to the translator can be any value up to

20,000 pulses per second.

Stepper Motor

The stepper motor converts electrical pulses into mechanical

movements. The motor shaft rotates through a specific angular

rotation for each pulse. The movement is repeated precisely with

each pulse and the shaft rotates in fixed, repeatable increments.

When a threaded shaft is used to drive a linear slide, the velocity,

distance and direction of the slide can be precisely controlled.

Pulse Output Expander

Module

The stepper motor, stepper translator and translator power supply

should be grounded to guard against electrical noise interference in

accordance with the manufacturer’s specifications and guidelines.

Improper grounding can result in unwanted extra pulses occurring at

the stepper translator and/or stepper motor.

Prior to installation, a pulse output expander module must be

configured to correctly interface with the corresponding stepper

translator.

Adjustments are made using six switch assemblies. The functions of

the switches are summarized in Table 2.A and described in

subsequent paragraphs.

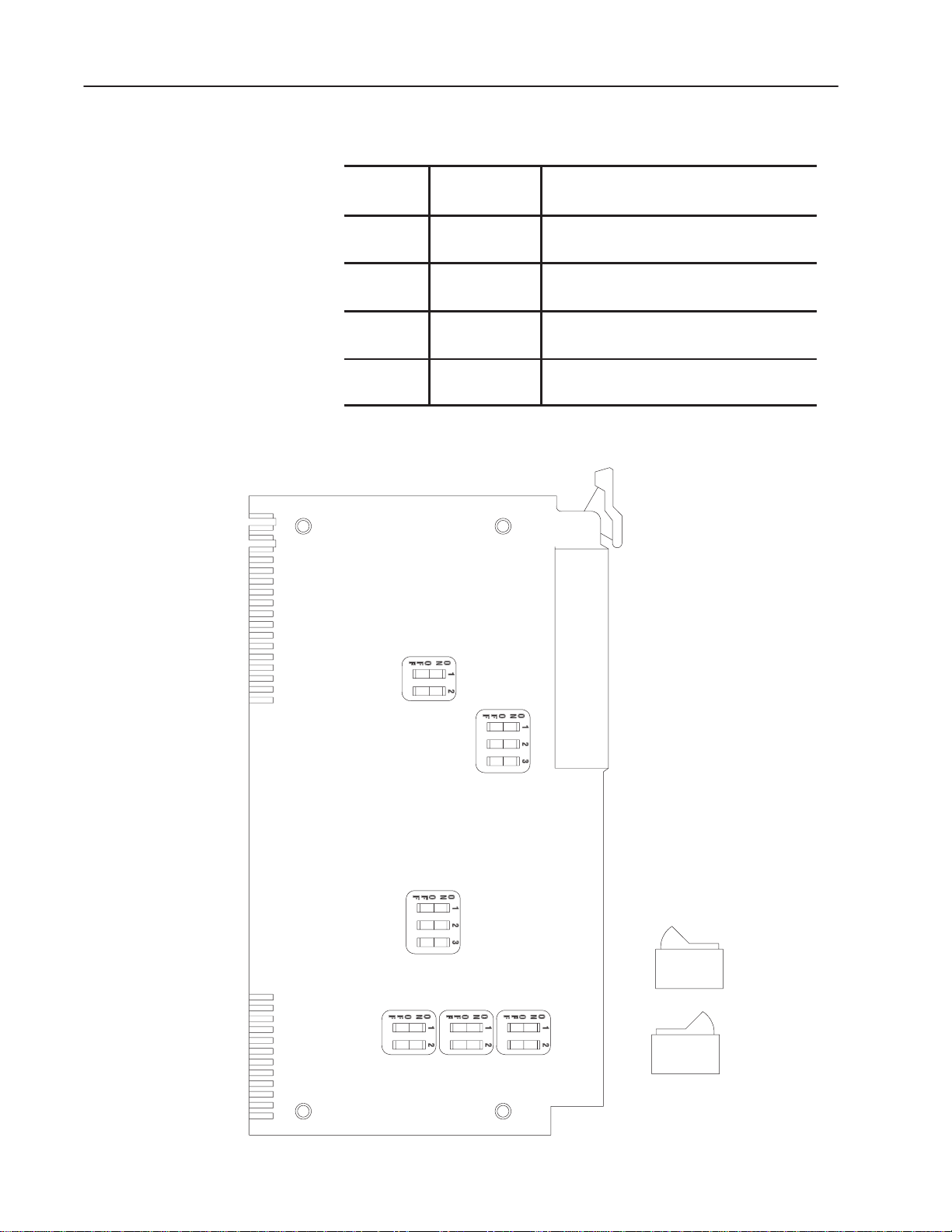

Module Disassembly

The switch assemblies are located on the module printed circuit

board. They are accessed as follows:

1. Remove the four screws from the upper and lower edges of the

labeled cover.

2. Remove the printed circuit board from the covers and set it

solder-side down.

3. Locate the switch assemblies labeled S1 through S6 as shown in

Figure 2.2.

Publication 1771-UM002A–EN–P – May 2000

Page 14

2–4 Assembly and Installation

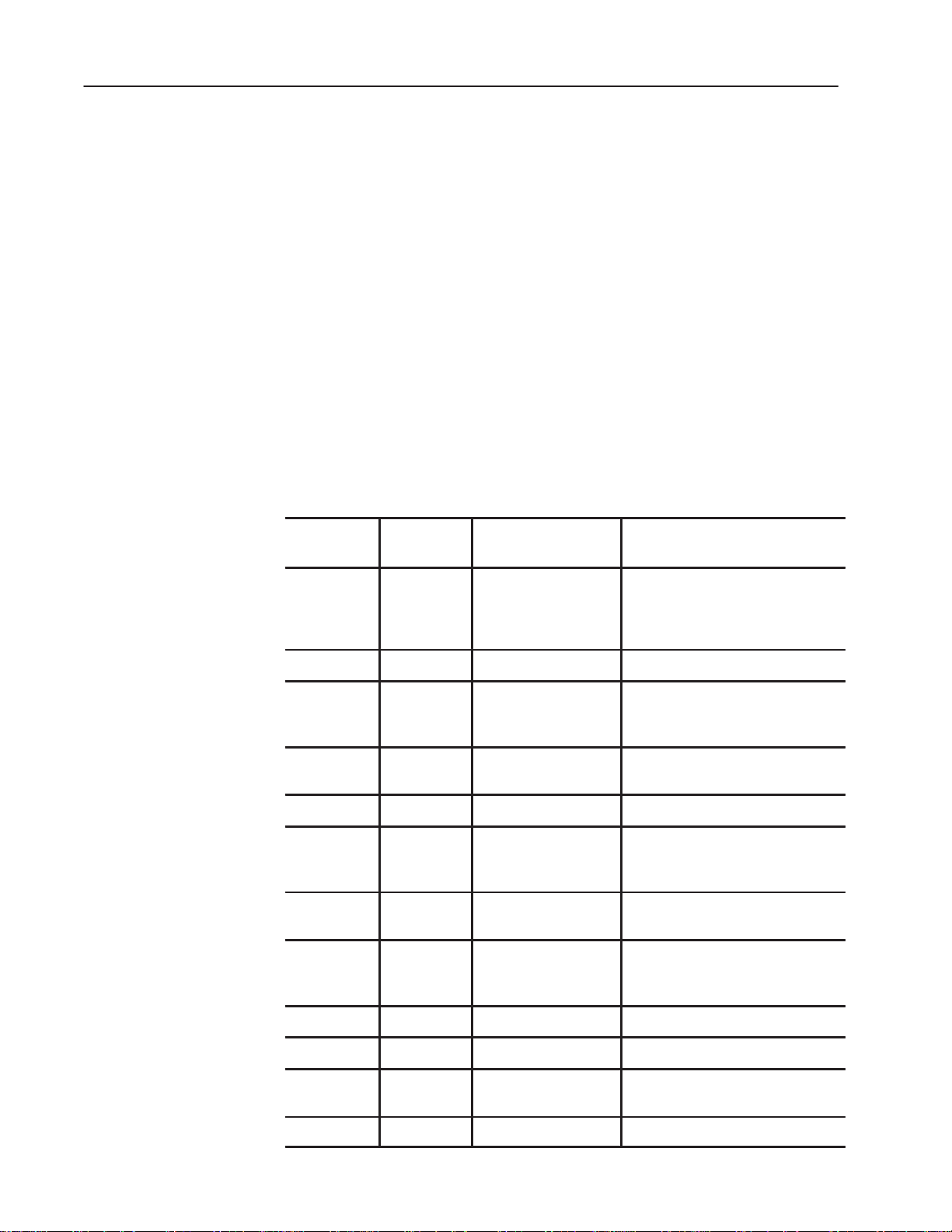

Table 2.A

Summary of Internal Switch Functions

Switch

Assembly Function Description

1 Output Format Separate forward and reverse pulse outputs,

or Pulse out, direction output

2 Input Logic low = true or

high = true

3 Expander Module

Address

Each expander module must have a different

binary address, either 1, 2 ,or 3.

4, 5, 6 Module Output Push-Pull or Current Source (open emitter), or

Current Sink (open collector).

Figure 2.2

Location of Dip Switch Assemblies

S1

S2

Publication 1771-UM002A–EN–P – May 2000

S3

S4 S5 S6

OFF

OFF

OFF

ON

ON

ON

10511

Page 15

2–5Assembly and Installation

4. Set the switches as described in the following sections. Some

switches are labeled on/off. Others may be labeled open for the

off position.

5. Reassemble the module. Start all four screws before tightening to

facilitate alignment of the covers and printed circuit board.

Output Format (S1)

The output format that determines forward or reverse motion differs

between translators. Therefore, the output terminals of the pulse

expander module are user-selectable to match the required pulse

input configuration of the translator. There are two basic translator

input configurations.

Some translators are designed to receive a pulse train at either one of

two terminals, depending on the direction of rotation desired in the

stepping motor. With this type of translator, a pulse train sent from

the pulse output expander module to one of the translator terminals

causes the stepping motor to rotate in the forward direction. An

identical pulse train sent from the module to the other translator

terminal causes the stepping motor to rotate in the reverse direction.

Output terminals on the pulse output expander module can be

selected in accordance with Table 2.B.

Table 2.B

Output Format (S1)

Switch Assembly S1

Switch 1 Switch 2

either ON

or OFF

OFF ON 10

ON ON 10

Note: Low = true logic

OFF 10

Output

Terminal

11

12

11

12

11

12

Active Output

Configurations &

Logic Levels

High

Forward Pulse train

Reverse Pulse train

Pulse train

Low High

(Forward) (Reverse)

High Low

Pulse train

Low High

(Forward) (Reverse)

High Low

Logic

Level

When

Stopped

High

High

High

High

Last State

Last State

High

High

High

Publication 1771-UM002A–EN–P – May 2000

Page 16

2–6 Assembly and Installation

Other translators are designed to receive only one pulse train at a

single “pulse” terminal. These translators usually have a separate

terminal for direction information. If a high (or low) signal is sent to

the “direction” terminal, the stepping motor rotates in the reverse

direction. If a low (or high) signal is sent to this terminal, the

stepping motor rotates in the forward direction. The rate of rotation

(in either direction) is controlled by the pulse train at the “pulse”

terminal.

The status of the pulse output expander module’s outputs when

motion has stopped is also user-selectable.

The settings of switch assembly S1 for the output format are

summarized in Table 2.B.

Input Logic (S2)

The choice of low true or high true logic for manual control of the

pulse output expander module’s hardware inputs is user-selectable.

The S2 switch assembly settings are summarized in Table 2.C.

Table 2.C

Input Logic (S2)

Switch

Number Motion Control Input Logic

1 STOP OFF = High true

ON = Low true

2 JOG

FORWARD

3 JOG

REVERSE

OFF = High true

ON = Low true

OFF = High true

ON = Low true

Expander Module Address (S3)

Each pulse output expander module must have its own (binary)

address for communication with the stepper controller module.

Allowable addresses are 1 (001), 2 (010) or 3 (011). They can be set

using switches 1 and 2. Switch 3 is always off. No other

combinations of the S3 switch assembly settings are valid. Refer to

Table 2.D.

Publication 1771-UM002A–EN–P – May 2000

Page 17

2–7Assembly and Installation

Table 2.D

Expander Module Address (S3)

Switch Assembly S3 Expander

Switch 1 Switch 2 Switch 3 Address

ON OFF OFF 1

OFF ON OFF 2

ON ON OFF 3

Expander Module Output (S4, S5, S6)

The choice of pulse output expander module output, either push-pull,

current source (open emitter) or current sink (open collector), is

user-selectable to best match the input characteristics of the stepper

translator.

PUSH-PULL-OPEN The push-pull output is compatible with many

stepper translators. The expander module output is wired to the

translator input as shown in Figure 2.1.

3

10

11

12

Expander Module

Common

Direction

CURRENT SOURCE or CURRENT SINK-OPEN When using the

expander module as a current source or sink for the output pulses, it

may be necessary to use a pull-down or pull-up resistor, respectively

(Figure 2.3) Refer to the translator input specifications and

installation instructions for correct use of this resistor if it is required.

Figure 2.3

Output Source or Sink Connections

+Supply

Pull–Up

Resistors

(Current Sink)

or

Pull–Down

Resistors

(Current Source)

–Supply

Translator

10512

The positive (+) and negative (-) terminals of the output power

supply must be connected to the + DC OUTPUT SUPPLY and

COMMON terminals, respectively, of the module field wiring arm

regardless of the choice of module output.

Publication 1771-UM002A–EN–P – May 2000

Page 18

2–8 Assembly and Installation

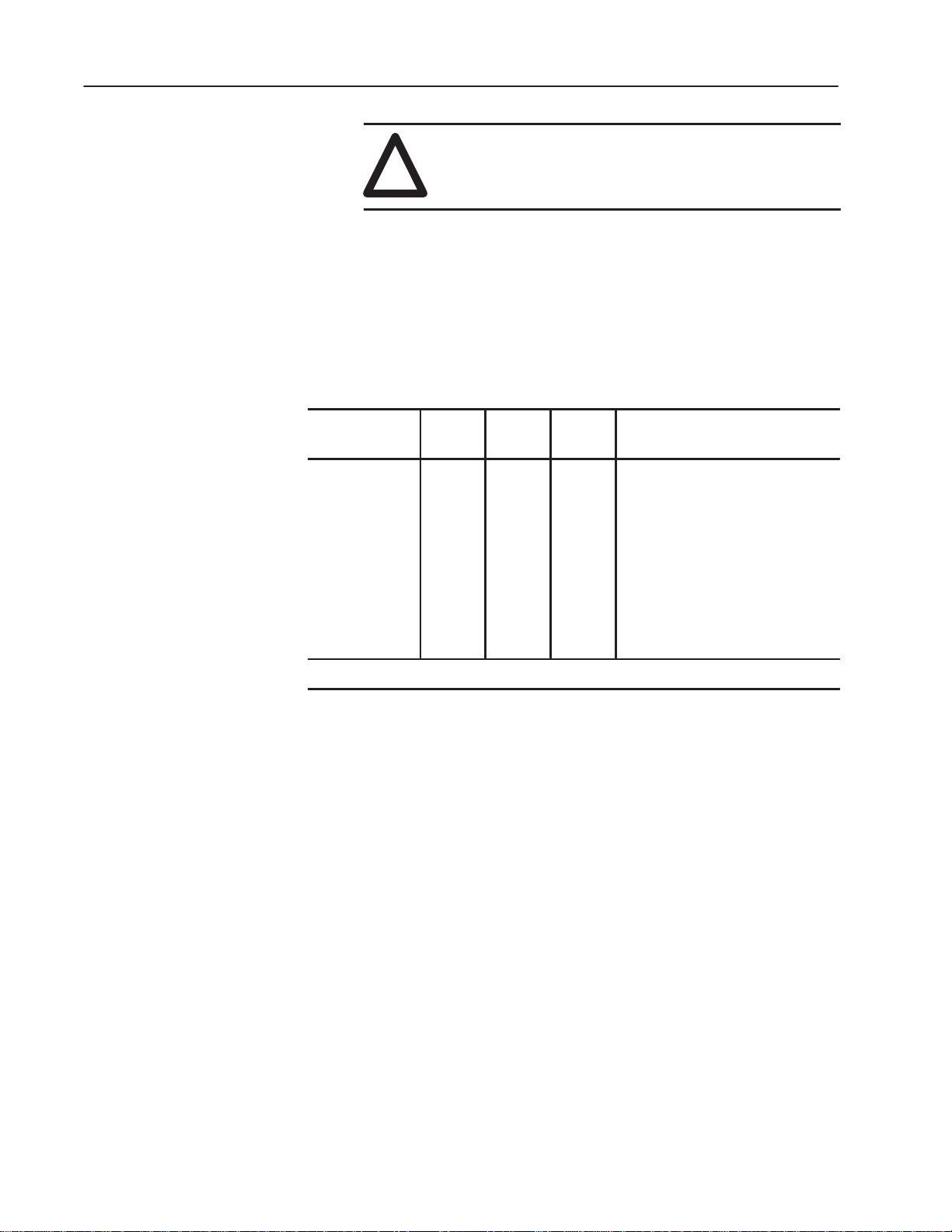

ATTENTION: Avoid shorting any of the output

terminals to ground, to the common terminal, or to the

!

positive (+) terminal of a power supply. Damage to the

module could occur.

The settings of switch assemblies S4, S5 and S6 for the desired

module output are summarized in Table 2.E.

Set all switch positions in assemblies S4, S5 and S6 to the same

output configuration.

Table 2.E

Expander Module Output (S4, S5, S6)

Diagnostic Indicators

Switch

Assembly

S6

S5

S4 ON

Set all switch positions in assemblies S6, S5, and S4 to the same output configuration.

Switch 1Switch2Output

ON

OFF

ON

ON

OFF

ON

OFF

ON

OFF

ON

ON

OFF

ON

ON

OFF

ON

ON

Terminal Module Output

10

11

12 Current Source (Open Emitter)

Current Source (Open Emitter)

Current Sink (Open Collector)

Push-Pull

Current Source (Open Emitter)

Current Sink (Open Collector)

Push-Pull

Current Sink (Open Collector)

Push-Pull

The stepper controller and pulse output expander modules have LED

indicators. Their color and function are described in the following

paragraphs.

Stepper Controller Indicators

Publication 1771-UM002A–EN–P – May 2000

Three LED indicators are located on the upper front panel of the

stepper controller module. They perform the following functions.

• PC COMMUNICATIONS FAULT (Red)

This indicator is normally off. If a communications fault between

the stepper controller module and the PC processor is detected, or

a stepper controller module hardware fault is detected, this

indicator will illuminate.

Page 19

• EXPANDER COMMUNICATIONS FAULT (Red)

This indicator is normally off. If a communications fault between

the stepper controller module and any one of the pulse output

expander modules is detected, or a hardware fault in any one of

the pulse output expander modules is detected, this indicator will

illuminate.

Important: If both red indicators illuminate simultaneously at

power-up, the stepper controller module has a hardware

fault.

• ACTIVE (Green)

This indicator illuminates unless a hardware fault on the stepper

controller module is detected causing it to turn off. At power-up

this LED will not illuminate until the PC processor is in run

mode. This indicator will flash on/off if, after power-up, an

invalid expander address is detected, no expander module is

present and/or another stepper controller module is detected in the

same I/O rack.

2–9Assembly and Installation

Expander Module Indicators

Five LED indicators are located on the upper front panel of the pulse

output expander module (Figure 2.4). They perform the following

functions:

• MODULE FAULT (Red)

This LED is normally off. If an expander module hardware fault

is detected, it will illuminate.

• OUTPUT PULSE RATE (Green)

This LED is normally on or flashing at the output pulse rate

whenever an output is present.

• STOP INPUT (Orange)

This LED illuminates when a hardware stop input is asserted.

• JOG FORWARD (Orange)

This LED illuminates when a hardware jog forward input is

asserted.

• JOG REVERSE (Orange)

This LED illuminates when a hardware jog reverse input is

asserted.

Installation

The stepper positioning system is susceptible to electrical noise

unless the equipment is properly grounded, the cabling is properly

shielded and the power supply(ies) is properly filtered. If not, an

incorrect number of position pulses could result.

Publication 1771-UM002A–EN–P – May 2000

Page 20

2–10 Assembly and Installation

System Grounding Considerations

The following should be connected to earth ground:

• Ground prong of all AC line cords

• Negative (-) or common terminal of the I/O power supply(ies)

• One I/O chassis mounting stud

Ground the drain wire of the cable connecting the pulse output

expander module to the stepper translator. This cable should be

grounded either at the translator or at the I/O chassis, but not both.

See Shield Connection below.

The stepper translator, power supply and motor should be grounded

in accordance with the manufacturer’s instructions.

ATTENTION: Improper system grounding can result

in additional unwanted pulses occurring at the stepper

!

translator and/or stepper motor. Unpredictable

machine motion could occur with possible damage to

equipment and/or injury to personnel.

Cable Considerations

The stepper translator should be wired to the field wiring arm using a

twisted 3-conductor shielded cable (Belden 8771). The cable

distance between the pulse output expander module and the stepper

translator generally should not exceed 40 feet.

Shield Connection

Belden 8771 cable has a foil shield with a bare drain wire. The

shield should be connected to earth ground at one end of the cable

only. This can be at the customer end of the cable or at an I/O

chassis mounting bolt or stud. At the other end of the cable, the

shield should be cut short, bent back and taped to insulate it from any

electrical contact. This practice helps to guard against unwanted

radiated electrical noise and ground current loops.

Module Keying

Plastic keying bands shipped with each I/O chassis provide an easy

method for keying an I/O slot to accept only one type of module. Use

of the keying bands is strongly recommended.

Publication 1771-UM002A–EN–P – May 2000

Page 21

2–11Assembly and Installation

The module is slotted in two places on its rear edge. The position of

the keying bands on the backplane connector must correspond to the

slots to allow insertion of the module so that only the desired module

will fit in this slot.

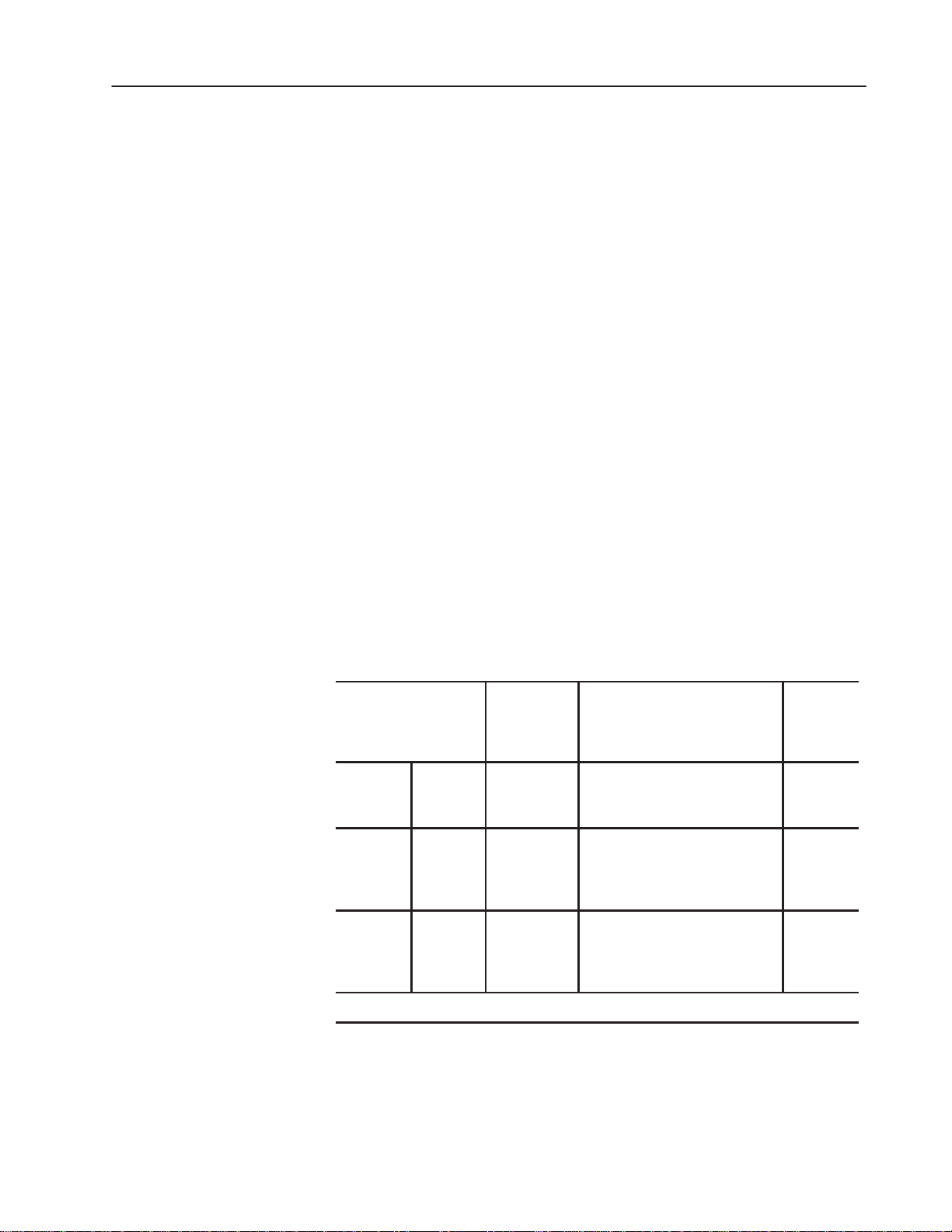

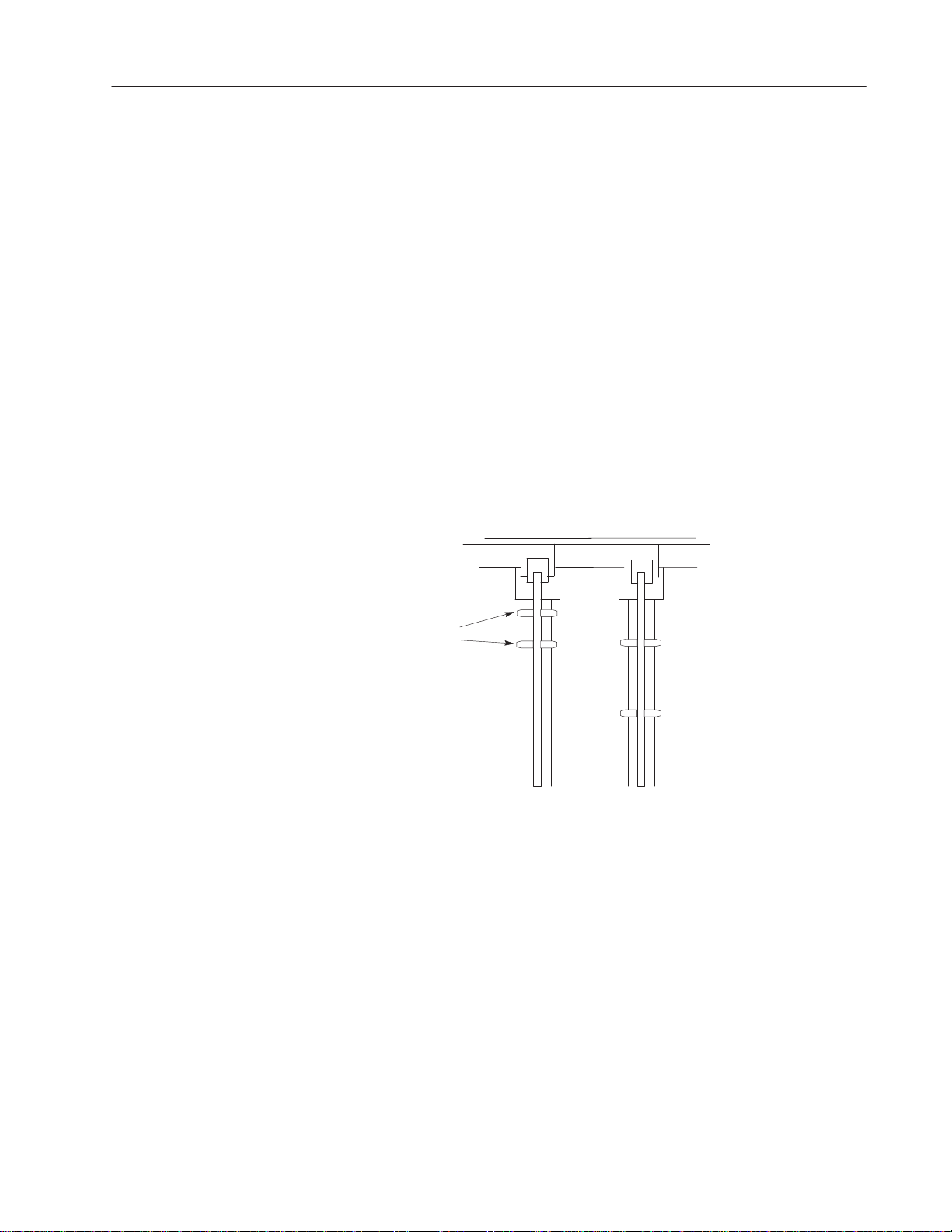

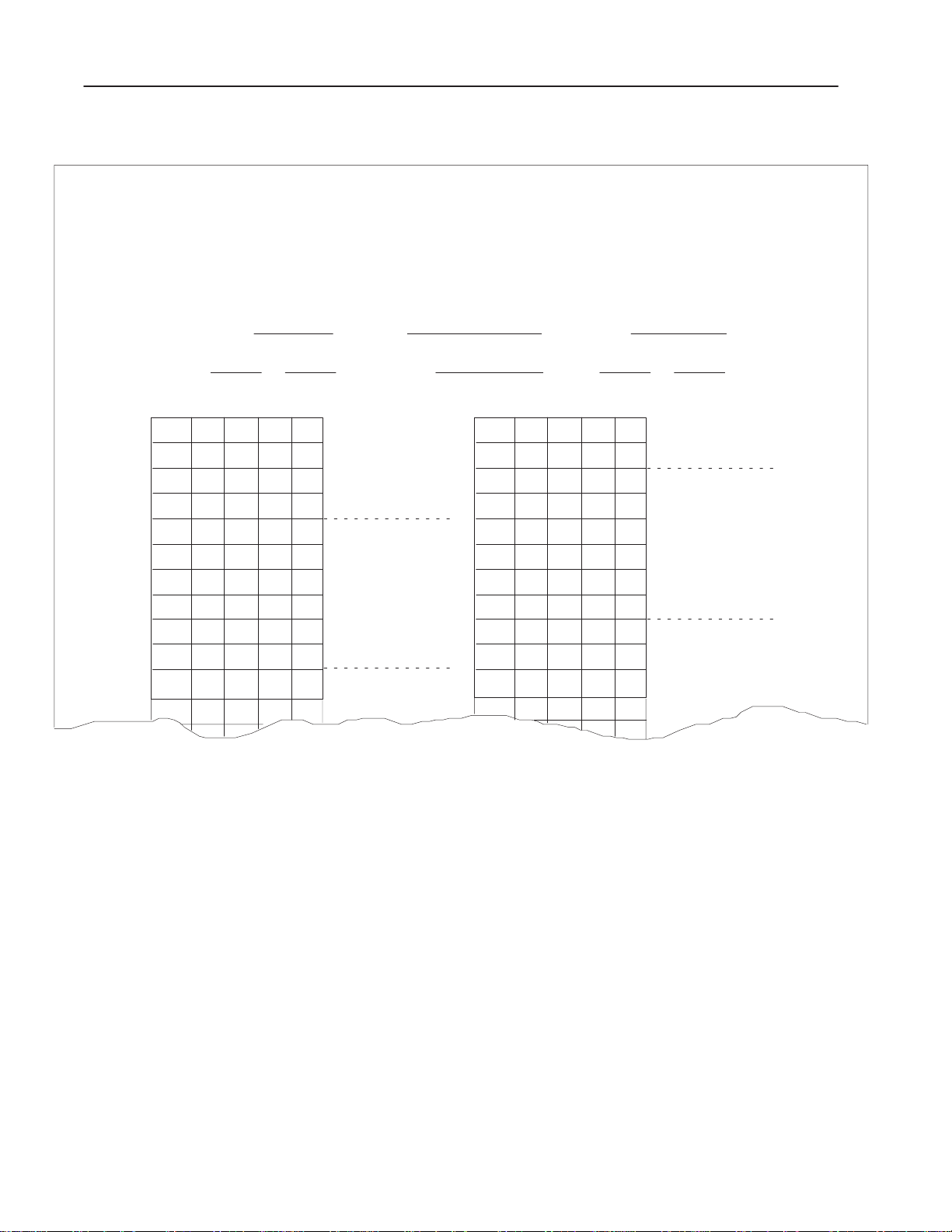

Refer to Figure 2.4. Snap the keying bands on the upper backplane

connectors between these numbers printed on the backplane:

Stepper Controller

2 and 4

8 and 10

Expander Module

8 and 10

22 and 24

Needle-noise pliers can be used to insert or remove keying bands.

Figure 2.4

Keying Diagram

Stepper Expander

Controller Module(s)

Keying

Bands

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

10513

Compatibility

An I/O chassis that contains a stepper controller module may not

contain another “master” intelligent I/O module.

Module Specifications

The pulse output expander module specifications and stepper

controller module specifications are listed in Appendix A.

Publication 1771-UM002A–EN–P – May 2000

Page 22

2–12 Assembly and Installation

Publication 1771-UM002A–EN–P – May 2000

Page 23

Chapter

Programming and Operation

3

General

The desired motion of the stepper motor can be accelerated,

decelerated or maintained at constant rate by controlling the pulse

rate from the pulse output expander module. Motion can be

rotational such as used to position an indexing table, or can be linear

such as obtained when a linear slide is driven forward or backward

by turning a threaded shaft. In either case, the position at any given

moment is defined by the number of pulses sent to the stepper motor.

It can result in some number of degrees of rotation or linear units of

travel.

The motion can be programmed by manipulating data table words

(control blocks) arranged in a convenient format. Blocks of data are

also used to indicate that commands were received and desired

motion was implemented (status block). Control and status blocks

are communicated bidirectionally between the PC processor and

stepper controller module by block transfer programming.

The task of programming requires that control and status block be

assigned in the data table and that control data be entered using the

industrial terminal. Control blocks sent to the stepper controller

module by write block transfers govern acceleration, deceleration,

final rate and final position. Control blocks also contain control

words. Bits in control words must be set according to the particular

application and desired motion.

Positioning Concepts

The stepper controller module sends status blocks of data to the PC

processor using read block transfers. Status blocks contain current

position information and diagnostic bits set by the stepper

positioning assembly.

The format of the data blocks and the function of status and control

bits will be covered later in this chapter.

There are three stepper positioning concepts which should be

understood before learning how the stepper positioning assembly is

programmed. They are:

• Move Definition

• Moveset

• Positioning Modes

Publication 1771-UM002A–EN–P – May 2000

Page 24

3–2 Programming and Operation

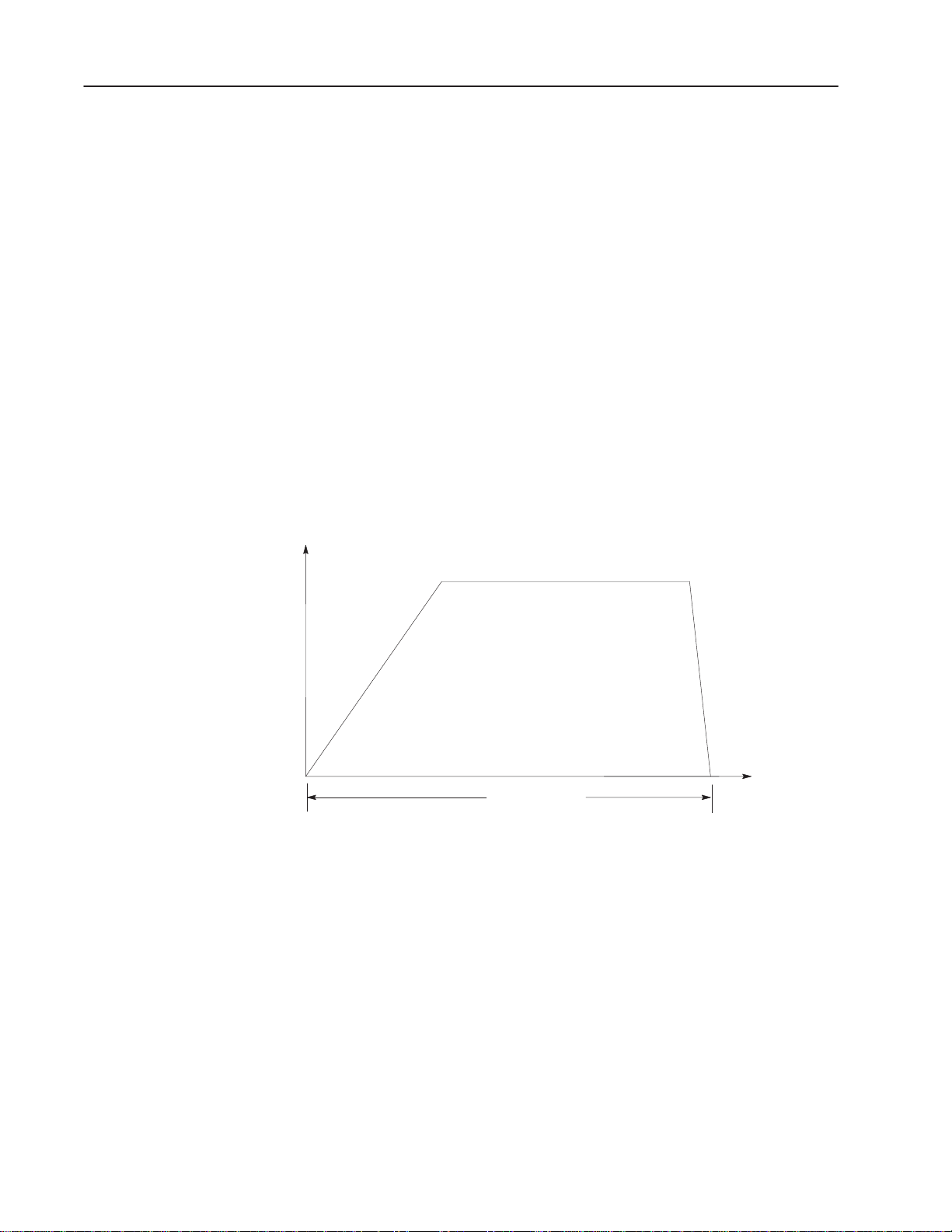

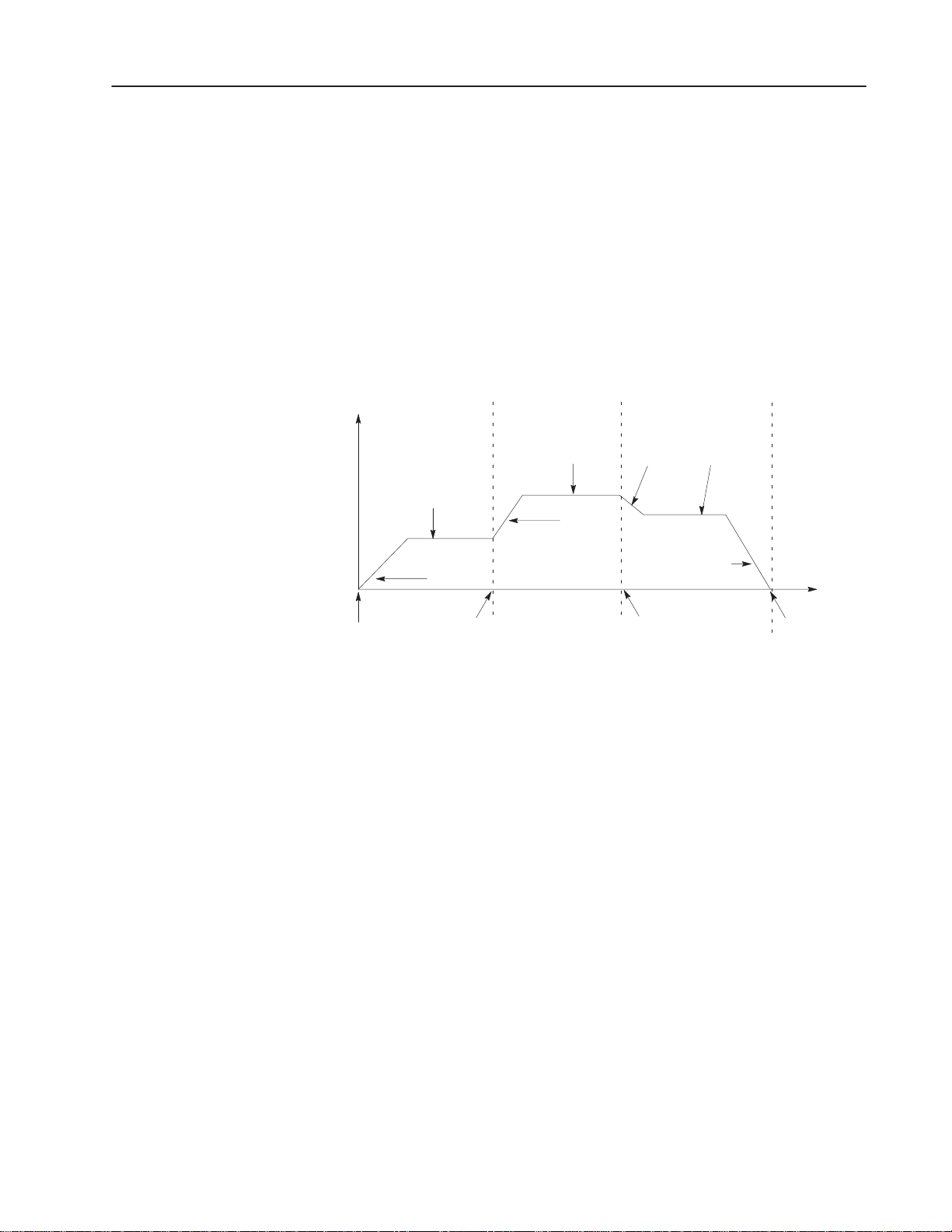

Move Definition

A move in its simplest form consists of an acceleration of the stepper

motor axis, a final rate, a deceleration to zero and a final position

(Figure 3.1). The value for an acceleration is the time required to

achieve a final rate. Values can be chosen from 0-9.99 seconds. The

final rate determines the constant speed of machine motion. The

final rate value can vary from 1 to 20,000 pulses per second. The

decel value, any value from 0-9.99 seconds, is the time required to

decelerate to zero pulses per second from a final rate.

The final position of a move is the number of pulses between 0 and

999,999 to be achieved by the move. The physical location will

depend on the resolution (pulses per degree of rotation or pulses per

inch of travel, etc.) of the stepper translator/motor configuration and

the specific application (gearing threads per inch of the linear axis,

etc.).

Figure 3.1

Move Definition

Rate

Ramp (Accel)

(0-9.99 Sec)

Final Rate

(1–20,000 Pulse/Sec)

Decel

(0-9.99 Sec)

Final Position

0–999,999 Pulses

Position

10514

Moveset

A moveset refers to the data used to control from 1 to 10 moves.

Sequential moves can be blended to form a continuous move profile

or can be implemented one move at a time where motion stops

between moves. A moveset can be executed using a minimum of

ladder diagram programming.

Publication 1771-UM002A–EN–P – May 2000

Two or more movesets can be implemented sequentially as if they

were a single large moveset. The stepper positioning assembly can

store two movesets simultaneously for up to three axes. When one

moveset is in operation (working moveset), the next moveset is in

storage (storage moveset). In the continuous mode, the last move of

the working moveset is blended with the first move of the storage

moveset.

Page 25

3–3Programming and Operation

In any mode, when the working moveset is finished, the storage

moveset automatically becomes the next working moveset. Then

another (storage) moveset can be block transferred to the stepper

positioning assembly.

In the continuous and independent modes of operation, the storage

moveset must be received by the stepper controller module before

the third from last move of the working moveset is complete (for

example, move 8 of 10 moves). In the single-step mode, the storage

moveset must be received before the second from last move of the

working moveset is completed. Skipped moves (section titled

“Move Block,” Bit 02) are not counted. The use of multiple

movesets allows long and complex positioning profiles or long

sequences of single moves to be performed with little additional

programming. The moveset is further defined in section titled

“Moveset Block.”

Positioning Modes

The stepper positioning assembly can be programmed for operation

that is tailored to the application requirements. The positioning

modes determine the type of positioning profile and the manner in

which the axes of two or three stepper motors can be coordinated.

The stepper positioning assembly can also be operated manually

using hardware or software jog inputs.

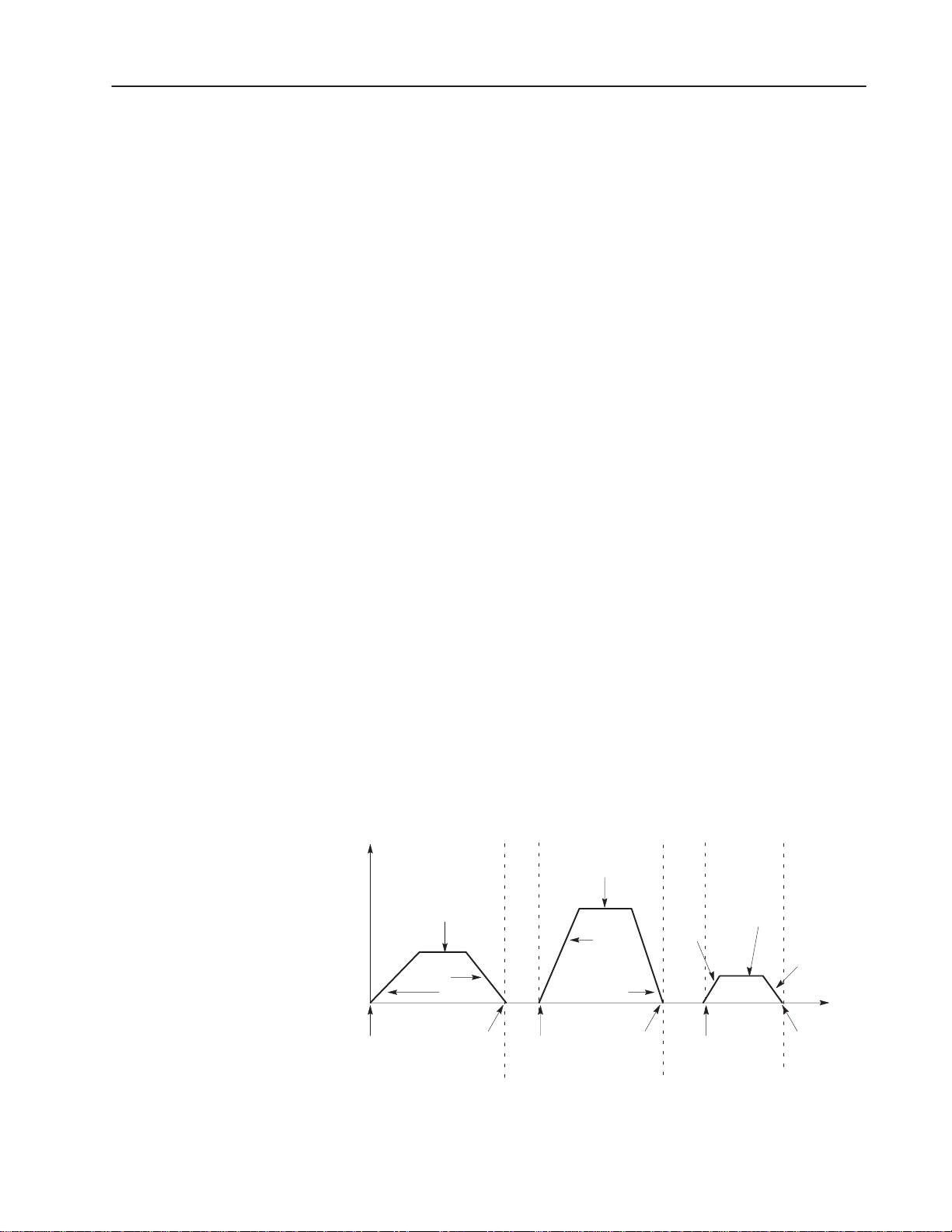

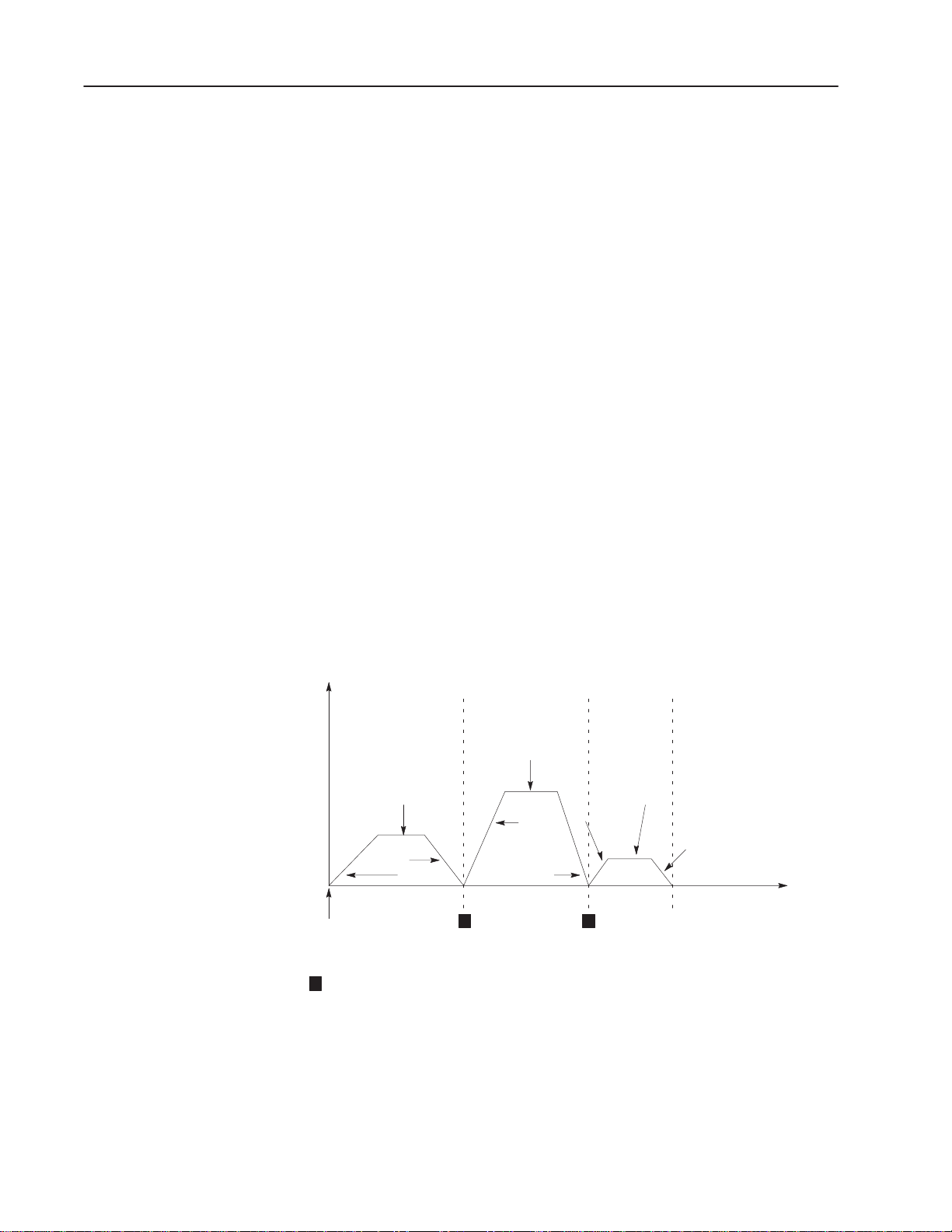

Single-Step Mode

In the single-step mode, a moveset allows the individual moves to be

controlled one at a time. A start command from the PC processor

starts the first move of the sequence. After the move is completed,

the stepper motor axis stops and a done bit is set. In order for the

next move to begin, the PC processor must transfer another start

command to the stepper controller module (Figure 3.2).

Figure 3.2

Single Step Mode

Rate

Final

Rate

Start

Command

Final

Rate

Ramp

Decel

Ramp

Move 1 Move 2 Move 3

Final

Position

Start

Command

Decel

Final

Position

Ramp

Final

Rate

Start

Command

Decel

Time

Final

Position

Done Bit

is set

Note: Jogging between moves causes a system fault..

Done Bit

is set

Publication 1771-UM002A–EN–P – May 2000

Done Bit

is set

10515

Page 26

3–4 Programming and Operation

Jog

A jog allows an axis to be manually controlled by an operator

independent of other axes in the system. This can be done at any

time except when a positioning profile is in progress. A jog can be

initiated by a hardware or software input to the stepper positioning

assembly.

Jog data is one move block that controls one axis. The job move

block typically is contained in a separate 1-move (10-word) moveset.

The jog move block can also be contained in a moveset with other

moves. If so, the jog must be the first move of the moveset. The

remaining moves will be ignored as a result of the stepper controller

module processing the jog move block. After the jog has been

executed as needed, the remaining moves can be initiated by again

transferring the same moveset to the stepper controller module. This

time a skip bit must be set in the jog data and the jog load bit must be

cleared. (These bits are described in section titled “Move Block,”

Bit 02 and 03). The positioning profile will then start with move two

and ignore the jog data.

The jog can be initiated by jog forward or jog reverse user-supplied

input switches or by ladder diagram logic. An axis must be at rest

before a jog can be initiated. As long as the jog input is asserted, the

jog will continue at the specified rate.

Once released (off) the jog will decelerate to a zero rate over the time

defined by the decel value programmed in the jog move. If desired,

the final position value can serve as an upper (or lower) limit of jog

travel. The jog will automatically decelerate to reach a zero rate at

the programmed final position if the jog input is held on.

If the final position value of the jog is programmed as zero, the limit

of travel will be 999,999 pulses. If the decel value is programmed as

zero, the jog rate will cease instantly when the jog input is turned off.

ATTENTION: Avoid damage to the stepper motor

and machine by selecting jog final rate and decel

!

values which are compatible with the stepper

motor/machine dynamics.

Publication 1771-UM002A–EN–P – May 2000

Page 27

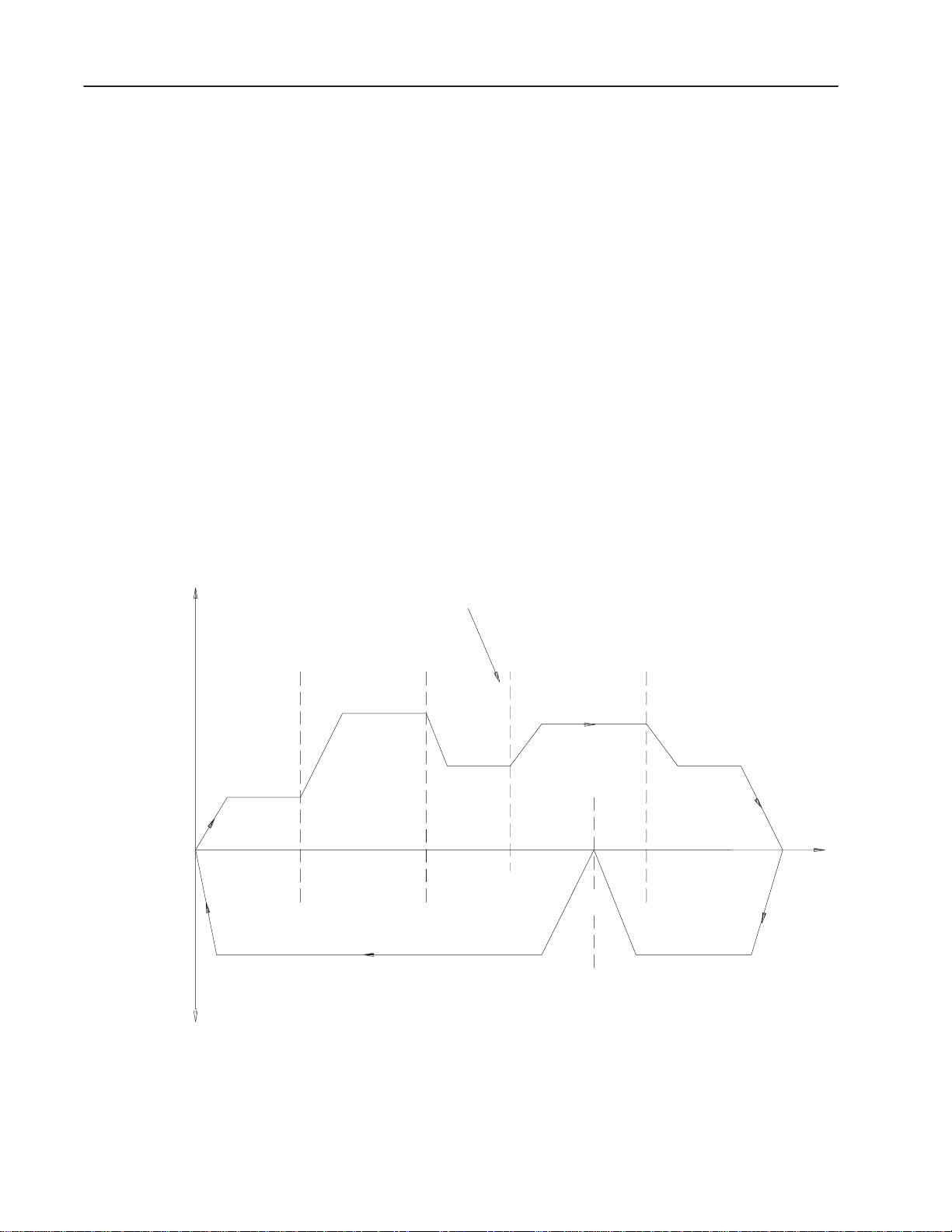

Continuous Mode

The continuous mode allows moves of the moveset to be blended

continuously into a move profile with fully programmed

accelerations and decelerations. One start command is required for

the entire positioning profile. A done bit is set at completion. Each

move is defined as having a ramp, a final rate and a final position.

The last move of the profile, in addition to the ramp, final rate and

final position, contains a deceleration to zero (Figure 3.3). The decel

value does not affect the positioning profile in any move except the

last move.

Figure 3.3

Continuous Mode

Rate

3–5Programming and Operation

Final

Rate 3

Decel 3

Done Bit

is set

Start

Command

Final

Rate 2

Final

Rate 1

Ramp 2

Ramp 1

Move 1 Move 2 Move 3

Final

Position 1

Ramp 3

Final

Position 2

Synchronization of Axes

All axes (up to three) can be synchronized move-by-move in the

single-step and independent modes. Each axis must complete a

given move before any axis is allowed to begin the next move.

Coordination is independent of PC processor scan time. If two axes

are synchronized, then the third axis, if used, must also be

synchronized. Synchronized axes must operate in the same

positioning mode.

Position

Final

Position 3

10515

A start command can be programmed for only one of the

synchronized axes. In the single-step positioning mode, this must be

done for each move of the moveset. Start commands received during

a move will be ignored. Done bits for all axes must be set before a

start command is executed. In the continuous and independent

modes, one start command is required at the beginning of the

synchronized profiles.

Publication 1771-UM002A–EN–P – May 2000

Page 28

3–6 Programming and Operation

A done bit is set for each axis at completion of each positioning

profile. If all axes (up to three) are not synchronized, then the

control of any axis is completely independent of the other(s). Three

different single-axis machines could be controlled by one stepper

controller module and three pulse output expander modules in one

I/O chassis.

Independent Mode

The independent mode allows a chain of single-step moves to be

sequentially executed. Each move is defined as having a ramp, final

rate, decel (to 0Hz rate) and a final position. Typically there is a

pause of 10-30ms from the end of one move to the beginning of the

next (dwell at 0Hz rate). Refer to Figure 3.4. One start command is

required for the entire positioning profile. A done bit is set at the

completion of each move.

Important: Done bits which are set between moves in the

independent mode should not be used because they

remain set for too short a time. Only the done bit of the

last move should be examined. This can be achieved by

examining the number that identifies the last move

(status bit 10-13) and the done bit in the same rung.

Figure 3.4

Independent Mode

Rate

Final

Rate

Final

Rate

Ramp

Decel

Ramp

Move 1 Move 2 Move 3

Start

Command

1

The done bit remains set until the start of the next move (10msec dwell time, nominal)

1

Decel

Ramp

1

Final

Rate

Decel

Done Bit

is set

Position

10517

Publication 1771-UM002A–EN–P – May 2000

Page 29

When using the independent mode and the axes are synchronized, all

but the last axis to finish the move in process will stop motion when

finished and wait for the last axis to complete its move. All axes will

then begin the next move simultaneously as soon as the last axis has

finished its move. The process then repeats for each move in the

positioning profile (Figure 3.5).

Figure 3.5

Synchronized Axes (Independent Mode)

Rate

Done Bit

is set

Expander

# 1

1

3–7Programming and Operation

Expander

# 2

Expander

# 3

Rate

Rate

Start

Command

Move 1 Move 2

Done Bit

is set

1

Move 1 Move 2

Done Bit

is set

2

Move 1 Move 2

1

Done bit remains set until start of next move.

Done bit dwell time, 10msec, nominal.

2

Time

Time

Time

10518

Publication 1771-UM002A–EN–P – May 2000

Page 30

3–8 Programming and Operation

Data Block Concepts

Words that control the motion of the stepper motor axis, record

position or monitor move diagnostics are stored in data table files.

These words are grouped into the following three kinds of data

blocks.

• Moveset Block

• Move Block

• Status Block

In addition to move data, the blocks contain special control or status

words. The bits in these words affect how the motion is controlled

or verify that the move commands and the move data were received

and implemented.

Moveset Block

The moveset block is a data table file for storing data and controlling

the motion of one stepper motor axis. It allows move data to be

stored in consecutive data table words to control up to 10 moves of a

positioning profile. Each axis must have at least one moveset block.

A moveset block must contain the following move data (Figure 3.6).

64–Word Moveset Block in

Data Table

Moveset Control Word

Offset word

MS Preset Word

LS Preset Word

Move Block # 1

Move Block # 2

Move Block # 3

• Moveset Control Word

• Offset and Preset Words

• One or more Moves

Figure 3.6

Moveset Block and Positioning Profile

1

The 64-word moveset block may

contain from 1 to 10 move blocks. If using less than

Rate

10 move blocks, fill all unused words with zeros or

a programming error results.

Move # 1 Interim Moves Move # 10

1

Position

Move Block # 9

Move Block # 10

Publication 1771-UM002A–EN–P – May 2000

1

10519

Page 31

3–9Programming and Operation

Moveset Control Word

A moveset block must contain a moveset control word as the first

word in the block. Each of the bits of the moveset control word

serves a function in the control of a stepper motor axis. Bit functions

of the moveset control word are defined below and summarized in

Figure 3.7.

Figure 3.7

Moveset Control Word

MCW

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Override

Moveset

Jog Forward

Jog Reverse

Offset

Not Used (Must be zero)

Axis Address

Axis Address

2

Axis Addr.

1

2

3

Start

Profile Mode Select

Profile Mode Select

Synchronized Axes

Reset

Global/Axis

2

2

Bit 11

0

1

1

Bit 10 Mode

1

0

1

1

Continuous

Independent

Single Step

Bit 02

0

1

N/A

Stop

Decel/Instantaneous

Bit 01

0

0

1

Bit 00 Start Command Bit.

When this bit is set, the stepper controller module will start to

execute the first move of a continuous or independent mode

sequence or the next single step move.

Bit 01, 02 Mode Select Bits.

These two bits are used to determine the type of positioning profile.

Bit 01=0, Bit 02=0: Continuous Mode (Figure 3.3)

Bit 01=0, Bit 02=1: Independent Mode (Figure 3.4)

Bit 01=1, Bit 02=1 or 0: Single-Step Mode (Figure 3.2)

1

1

10520

Refer to section titled “Positioning Modes” for mode descriptions.

Publication 1771-UM002A–EN–P – May 2000

Page 32

3–10 Programming and Operation

Bit 03 Synchronized Axes Bit.

If this bit is set for any axis, it must be set for the other axes so that

all (two or three) axes controlled by the stepper positioning assembly

are synchronized. Synchronized axes must be operating in the same

positioning mode. (Bits 01, 02, and 03 must be set identically in the

moveset control words of the synchronized axes.) Refer to

“Synchronization of Axes.”

Bit 04 Reset Command Bit.

A reset command can be limited to a single axis or can reset all axes

(up to three) depending on the logic state of the global/axis bit (bit

05). With the exception of the done bit and reset bit, all status and

position information and all moveset data are cleared in the stepper

controller module when the reset command bit is set. The reset bit

and done bit are reset in the status word at the start of the first move

in the next moveset. The user program should clear the reset bit after

the reset has been executed as indicated by reset bit 05 in the status

word. Refer to section titled “Status Block.”

Bit 05 Global/Axis

Bit (for stop or reset commands, only).

When this bit is set, all axes controlled by the stepper positioning

assembly are stopped or reset with one command. (The

notation

refers to a low logic state.)

When this bit is zero, only the axis of the moveset defined by the

axis address bits (bits 10 and 11) is stopped or reset.

The function of this bit should be considered whenever the stop bit

(bit 06) or the reset bit (bit 04) is programmed.

Bit 06 Stop Command Bit.

When this bit is set, output pulses will cease either in a controlled

decel or instantly, depending on how the decel/instantaneous bit (bit

07) is set. A stop command can be limited to a single axis or can

apply to all axes (up to three) depending on how the global/axis (bit

05) is set.

All move profile data is cleared, but position and status information

remains the same in the stepper controller module when this bit is

set.

The user program should clear the stop bit after the stop command

has been executed as indicated by reset bit 05 in the status word.

Refer to section titled “Status Block.”

Publication 1771-UM002A–EN–P – May 2000

Bit 07 Decel/Instantaneous Bit.

When this bit is set, the output pulse rate will decelerate to zero in

accordance with the decel value in the move block that was being

executed when a software stop command was received.

Page 33

3–11Programming and Operation

When the decel/instantaneous bit is zero, output pulses will cease

instantly when a software stop command is received.

A hardware stop input in instantaneous, independent of the

decal/instantaneous bit.

This bit is generally set when a stop bit is set.

Bits 10, 11 Axis Address Bits.

These bits define the axis to be controlled by the data and/or

commands in the moveset block. The address in the moveset control

word of the moveset block must be identical to the settings of the

address switch assembly (S3) of the corresponding pulse output

expander module. The address bits of the moveset block are

generally set when the profile is initially programmed using the

industrial terminal. The setting of bits 11 and 10 respectively are 01

= axis 1, 10 = axis 2, 11 = axis 3.

Bit 12 Must always be zero.

Bit 13 Offset Command Bit.

When set, the value contained in the offset word (described below)

will be added to or subtracted from the final position value(s) of all

moves of the moveset blocks residing in the stepper controller

module memory. In all modes, the final position of each move is

shifted by the offset amount and direction.

Bit 17 of the offset word determines the direction of the shift, 1 for

subtracted or 0 for added.

Important: The present move being executed and the move

following may not be affected by the offset command in

all but the single step mode. In the single step mode,

only the present move will not be affected.

The user program should clear the offset bit and allow the stepper

controller module to see the bit cleared before another offset for that

axis is enabled.

Bit 14 Software Jog Reverse Command Bit.

The axis will move in the direction indicated for as long as this bit is

set or until the final position programmed in the jog move is reached.

Hardware jog inputs are disabled during this time. The jog will

follow the ramp, rate, decel and final position values programmed in

the jog move block.

In large systems or systems using remote I/O, the software jog

timing will depend on block transfer timing. Refer to section titled

“Handshaking.”

Publication 1771-UM002A–EN–P – May 2000

Page 34

3–12 Programming and Operation

The load jog command bit (bit 03 of the single move control word,

defined in section titled “Move Block”) must be set to identify jog

move block data.

The user program should clear the software jog reverse command bit

and allow the stepper controller module time to see the bit cleared

before another jog to that axis is enabled.

Bit 15 Software Jog Forward Command Bit.

Same as bit 14. See software jog reverse command bit.

Bit 16 Moveset Bit.

Successive movesets can be programmed for continuous execution

using the moveset bit. This bit can be used to label each block

transfer of move data as moveset 0 or moveset 1. When movesets

are alternately labeled 1 for the first, 0 for the second, 1 for the third,

etc., user program logic can sequence the movesets without

interruption as if they were one large moveset. The number of

successive movesets is limited only by processor memory.

Once a positioning profile has begun, none of the moves of the

working moveset can be updated. However, the storage moveset in

the stepper controller module can be updated provided that the

moveset bit in the transferred (updated) moveset has the same setting

(0 or 1) as the storage moveset bit. Refer to section titled

“Movesets.”

In large systems or systems using remote I/O, moveset timing will

depend upon block transfer timing. Refer to “Handshaking,” page

3–35, for more information.

Bit 17 Override Command Bit.

The override bit is set in the moveset containing the override data.

When the override command is enabled, the override bit causes the

current moveset to be interrupted and the override moveset to be

blended immediately. The first move of the override moveset is

blended with the interrupted move in progress. Refer to section

titled “Override Ramp Time Considerations” to ensure that the first

move of the override moveset will be compatible with any worst

case move in progress.

Generally, bits of the moveset control word are set by user program

logic. A command to the stepper controller module should be

cleared and the stepper controller module allowed sufficient time to

see the bit cleared before the next command is transferred. See the

section titled “Handshaking.”

Publication 1771-UM002A–EN–P – May 2000

Page 35

3–13Programming and Operation

Avoid sending multiple commands to the stepper controller module

at the same time. A programming error could result or the

data/command could be ignored.

All bits must be set carefully to tailor the move profile(s) to the

application requirements and to avoid illegal bit combinations. If

only one command is transferred at a time with proper handshaking,

no difficulty should be encountered. An illegal bit combination will

cause a programming error when data is received by the stepper

controller module or when move data is processed for execution.

Once the definitions of the bit functions have been learned, the table

of illegal bit combinations found in section titled “Illegal Bit

Combinations,” can be consulted as an aid in avoiding programming

errors when programming the required move profile(s).

Offset Word

The position offset allows an entire positioning profile (all moves of

the profile) to be shifted to compensate for machine wear without

reprogramming the profile (Figure 3.8). The offset value between 0

and 7,999 pulses, can be added to or subtracted from the final

position of each move in the moveset(s).

Rate

Figure 3.8

Offset

Offset

–+

0

Move 1

Move 2

–+

Move 3

–+

Position

10521

The offset value is entered in BCD in bits 00-16 of the offset word.

Bit 17 is the control bit that determines whether the offset will be

added to or subtracted from the final position (Figure 3.9). The

value entered in the figure is the maximum allowable value of offset.

Refer to offset command bit 13 of the moveset control word

described earlier in this section

Publication 1771-UM002A–EN–P – May 2000

Page 36

3–14 Programming and Operation

17 10 07 00

Figure 3.9

Offset and Preset Words

Data Table

MCW

0 = Add

1 = Subtract

1 = Assert

Initialization

Preset

0 = Move

Preset

0

0

0000

7

00

1

0

1

999

999

999

Offset

MS Preset

LS Preset

10522

The moves affected by the offset will be those stored in the working

and storage moveset when the command is received. If additional

movesets have been programmed, the offset command must be

re-enabled when additional movesets are transferred to the stepper

controller module.

Preset Word

The preset word can store values that serve two functions. One

function, initialization preset, is used by the stepper controller

module to define the starting point value of the positioning profile.

The other function, move preset, can be used to extend one or more

moves of the profile beyond the 999,999 pulse (position) limit of the

stepper controller module. In either case, the preset word can be

loaded with the necessary value, the function enabled and another

value loaded as needed. When used, the preset value becomes the

new position reference of the profile.

Publication 1771-UM002A–EN–P – May 2000

The preset can be any value between 0 and 999,999. Preset data is

contained in two words, one for the most significant (MS) 3 digits,

the other for the least significant (LS) 3 digits (Figure 3.9). Preset

values are entered in BCD in bits 00-13. Bits 14-17 in the LS preset

word and bits 14-16 in the MS preset word are undefined and must

be loaded with zeros. Bit 17 of the MS preset word is the assert bit

for the initialization preset.

Page 37

3–15Programming and Operation

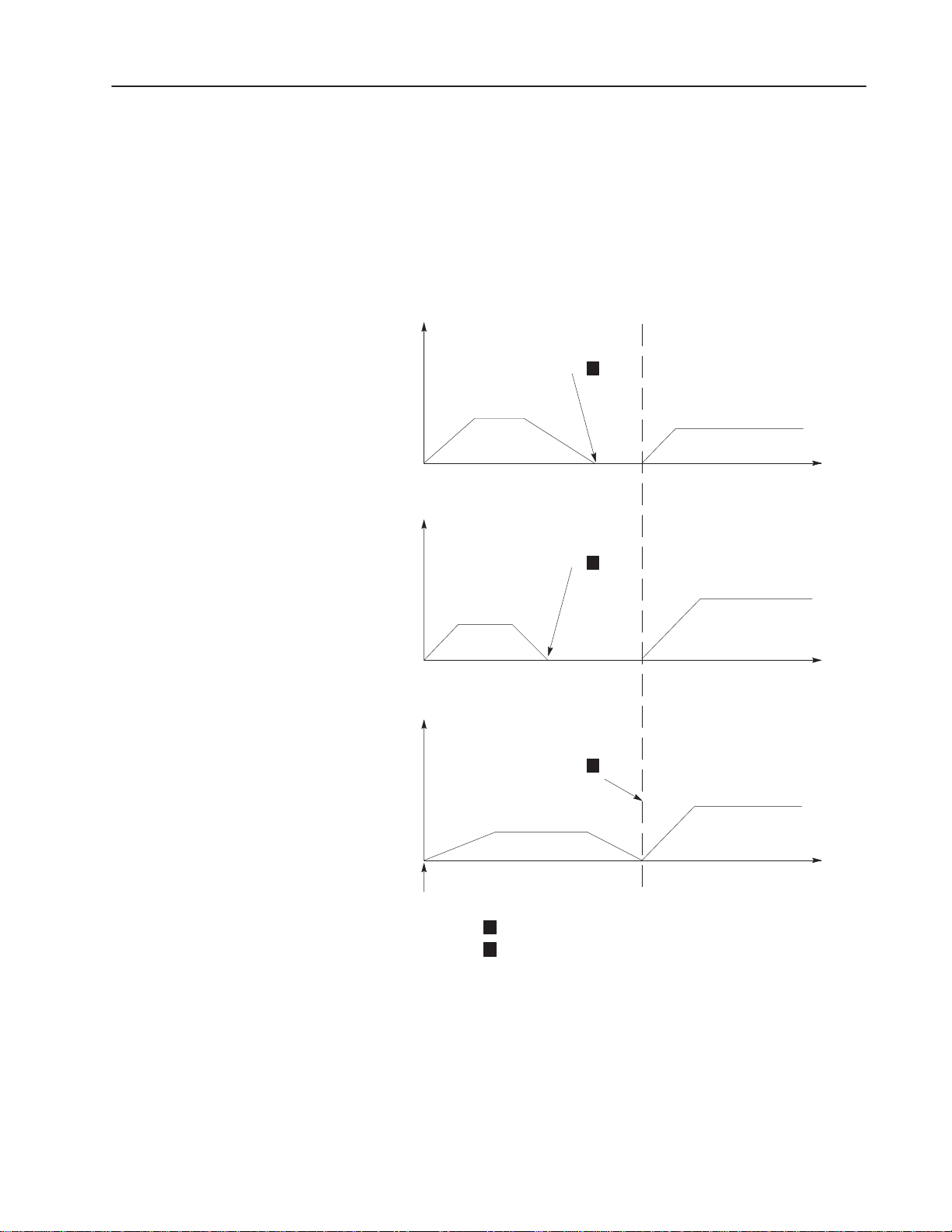

Initialization Preset

Typically it may be necessary to jog the machine to a starting

position before the positioning profile(s) is (are) started. The

position register of the stepper controller module will read some

number of position pulses representing the machine starting position.

The initialization preset can be used to reset the value of the position

register to zero, or to any value that would be used as the profile

starting value.

If the preset value were not set equal to zero (or not equal to the

profile starting value), when started, the first move(s) of the profile

would be shortened or lengthened. The amount would be the

difference between the initialization preset and the starting point

value: shortened if the preset exceeded the starting point value or

lengthened if the value were less than the starting point value

(Figure 3.10).

ATTENTION: All moves must achieve a final rate

for a minimum duration of 20ms or a programming

!

error and a system fault will result. The minimum

duration of a move is covered in section titled

“Application Considerations.”

Rate

Figure 3.10

Initialization Preset and Starting Value

Preset > Starting Value

Preset = Starting Value

Preset < Starting Value

Initialization Preset

1

Final rate must be mainained for 20ms, minimum

Bit 17 of the MS preset word is the assert bit for the initialization

preset. When this bit is set, the preset value will be written over

whatever value is in the position register of the stepper controller

module. Once the positioning profile has been started, bit 17 must

not be set or a programming error will occur.

1

Position

Move 1

10523

Publication 1771-UM002A–EN–P – May 2000

Page 38

3–16 Programming and Operation

Move Preset

The move preset can be used to adjust the starting point value of any

move in a moveset whenever necessary. For example, the move

preset can extend one or more moves of the profile beyond the

999,999 pulse limit of the stepper controller module.

The move preset is enabled by bit 00 in the single move control word

(see section titled “Move Block”). When this bit is set, the position

register of the stepper controller module and the starting point value

of the move block will become the value stored in the preset words.

The final position value of the move block and all subsequent move

blocks will be referenced to this new starting point value.

If a move profile extends beyond 999,999 pulses and the application

calls for a return to the home position, it may be necessary to change

the preset value and again set the move preset bit (Figure 3.11).

When necessary, this must be done before the move to home position

is started. Reverse travel to the home position can require two

moves if the total travel exceeds 999,999 pulses.

Rate

Forward

Rate

Reverse

Figure 3.11

Move Preset

Move Preset

000,000

0

0

999k

Move Preset

999,999 (to return)

Position

10524

Publication 1771-UM002A–EN–P – May 2000

Page 39

3–17Programming and Operation

Move Block

A move block contains ramp, final rate, final position and

deceleration data that characterize a move. A moveset block must

contain from 1 to 10 move blocks. A move block contains the

following words (Figure 3.12):

• Single Move Control Word

• Move Data

Figure 3.12

Single Move Control Word

17 16 SMCW 03 02 01 00

110000000000

Always 1 to

identify the SMCW

Single Move Control Word

The single move control word is the first word in each move block.

The word contains two identification bits (bits 16, 17) and four bits

which affect the operation of the move (bits 00-03). The function of

each bit is defined below and summarized in Figure 3.12.

Bit 00 Move Preset Bit.

This bit, when set, causes the value contained in the preset words of

the moveset block to become the starting point value for that move.

The position register becomes this value. The preset value can be

changed and re-enabled as needed to further extend the position limit

or to allow the profile to return to the home position. Refer to

“Move Preset.”

Always Zero

Move Preset

Rate Multiplier

Move Skip

Load Jog

10526

Bit 01 Rate Multiplier Bit.

When the rate multiplier bit is set, final rates can be selected in 10

pulses per second increments between 0 and 20,000 pulses per

second.

When this bit is zero, any final rate from 1 to 9,999 pulses per

second can be selected in 1 pulse per second increments.

This bit would typically be set when ramp, rate and decel values are

initially set in the data table using the data monitor mode of the

industrial terminal.

Publication 1771-UM002A–EN–P – May 2000

Page 40

3–18 Programming and Operation

Bit 02 Skip Bit.

The skip bit allows one or more moves of a moveset to be ignored

without reprogramming. When this bit is set, the corresponding

move block is skipped over. When operating in the continuous

mode, the move preceding the skipped move and the move following

the skipped move are blended automatically. Refer to section titled

“Application Considerations” to ensure that the blend is achievable

without a programming error. When operating in the independent

mode, the move following the skipped move begins as soon as the

one preceding the skipped move is done. Skip bits can be set

initially in the data table when move data is entered or they can be

set by user program logic. Skip bits must be set before the moveset

is transferred to the stepper controller module. Once the moveset is

transferred, additional skip bits cannot be set in that moveset.

Bit 03 Load Jog Bit.

This bit is set to identify the accompanying move block as jog data.

Bit 14 software jog reverse command or bit 15 software jog forward

of the moveset control word can be programmed to initiate the jog.

Jog data (with the load jog bit set) can be transferred to the stepper

controller module with the software jog forward or reverse command

(bit 15 or 14), or jog data can be transferred to the stepper controller

module in advance. See software jog forward and reverse command

bits 15 and 14 of the moveset control word described earlier in this

section. Refer to the section titled “Jog.”

An axis reset command will clear any previously transferred jog data

for that axis.

Bit 04-15 Must always be zero.

Bit 16, 17 Identification Bits.

Both bits must be set to identify each single move control word.

Otherwise, a programming error will occur.

Generally, bits of the single move control word are set by user

program logic. A command to the stepper controller module should

be cleared and the stepper controller module allowed sufficient time

to see the bit cleared before the next command is transferred. See

“Handshaking.”

Avoid sending multiple commands to the stepper controller module

at the same time. A programming error could result or the

data/command could be ignored.

Publication 1771-UM002A–EN–P – May 2000

Page 41

SMCW

3–19Programming and Operation

Move Data

Move data is contained in the remaining five words of the move

block (Figure 3.13). Values are entered in BCD. Those shown in

Figure 3.13 are the maximum allowable values. Undefined bits (bits

14-17) in the words specifying the ramp, decel and position must be

filled with zeros.

Figure 3.13

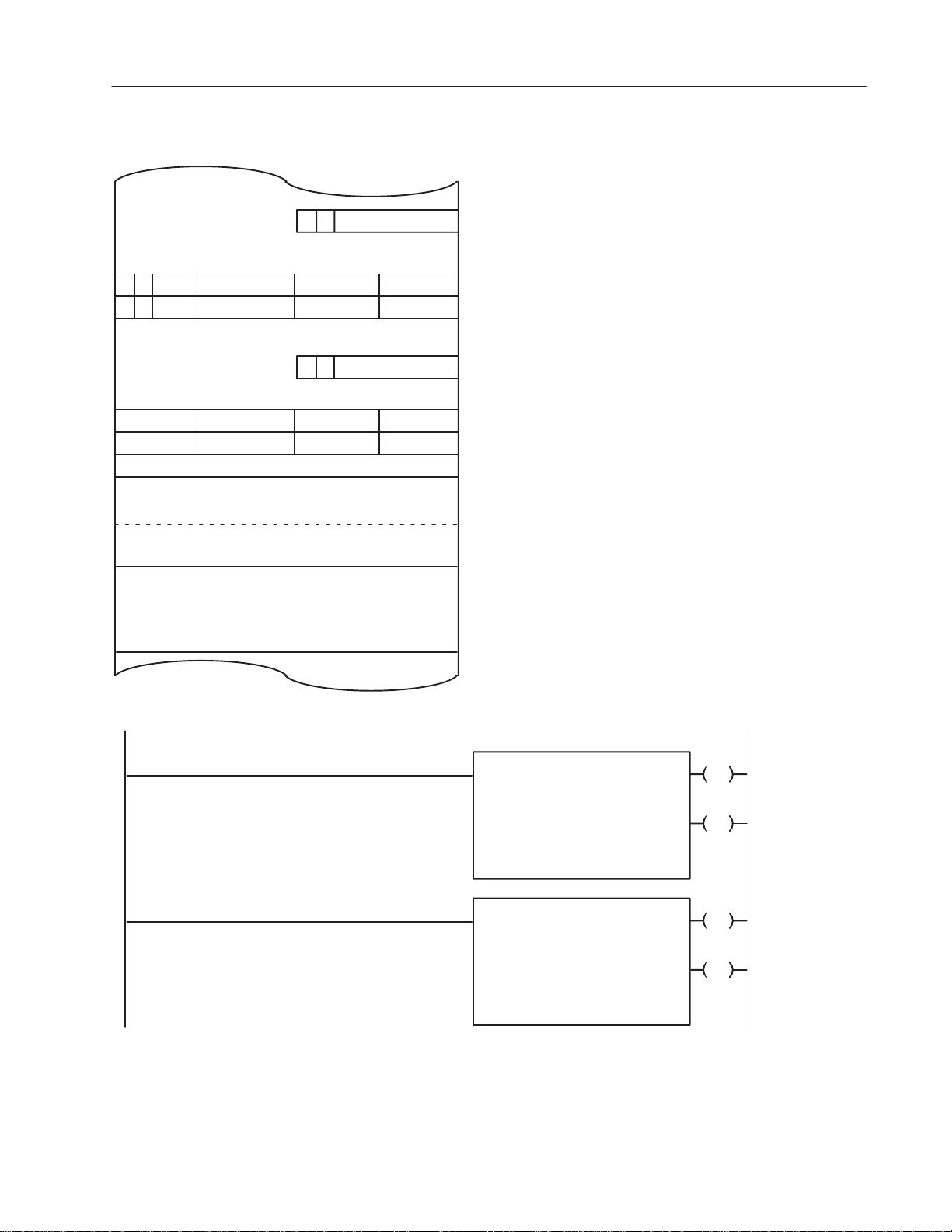

Move Block

Data Table

17 10 07 00

Single Move Control Word

Ramp

Rate

Decel

MS Position

LS Position

0000

9

0000

999

999

999

9990000

9990000

0 – 9.99 Seconds

0 – 9,999 x 1

0 – 2,000 x 10

0 – 9.99 seconds

0 – 999,999 Pulses

10525

Pulses per

second

Ramp Time

The ramp value is the number of seconds the positioning assembly

will take to reach a (new) final rate. In the continuous mode, the

final rate can be greater than or less than the starting rate. Ramp

time can be any value between 0 and 9.99 seconds. Refer to section

titled “Application Considerations.”

Final Rate

The final rate value determines the constant speed of the move. The

rate can be any value between 0 and 9,999 pulses per second or in

increments of 10 pulses per second between 0 and 20,000 pulses per

second. Refer to section titled “Application Considerations.”

Important: When the rate multiplier bit (bit 01) of the single move

control word is set, the resulting rate will be equal to the

programmed rate value times ten.

Decel

The deceleration value is the number of seconds the positioning

assembly will take to decelerate to zero pulses per second. It should

not be confused with a ramp to a lower final rate other than zero.

The decel is an active part of the move profile in the single step and

independent modes.

Publication 1771-UM002A–EN–P – May 2000

Page 42

3–20 Programming and Operation

In the continuous mode, the decel value is not used in the move

profile except for the last move. However, the decel value has a

special purpose in the continuous mode: it allows a controlled decel

to 0Hz rate under two conditions:

1. If a system fault is detected, the move in progress will decel to a

0Hz rate (come to a stop) in the time defined by the decel value.

2. If a software stop command is received by the stepper controller

module, a controlled decel to a 0Hz rate will occur during the

move in progress. This will happen only if the

decel/instantaneous bit of the moveset control word is set.

Otherwise the stop will be instantaneous.

ATTENTION: Select a decel value for a controlled

stop that is compatible with the stepper motor and

!

system dynamics in order to avoid damage to the

equipment. Refer to section titled “Application

Considerations.”

Position

The position value defines the final position of any particular move.

It is the number of position pulses from a reference value such as the

beginning of the move profile. When the number of pulses defined

in the position words of a move block equals the number of pulses

sent from the pulse output expander module to the stepper translator,

that particular move is done.

The most significant digits of the position value are contained in the

MS position word, the least significant digits in the LS position

word. Use leading zeros when necessary.

Status Block

The status block is a data table file used to store position and

diagnostic information received from the stepper controller module.

The status block contains the following word storage for each pulse

output expander module (axis).

• Status Word

• Position Word

Publication 1771-UM002A–EN–P – May 2000

Page 43

Pulse

Output

Expander

Module #1

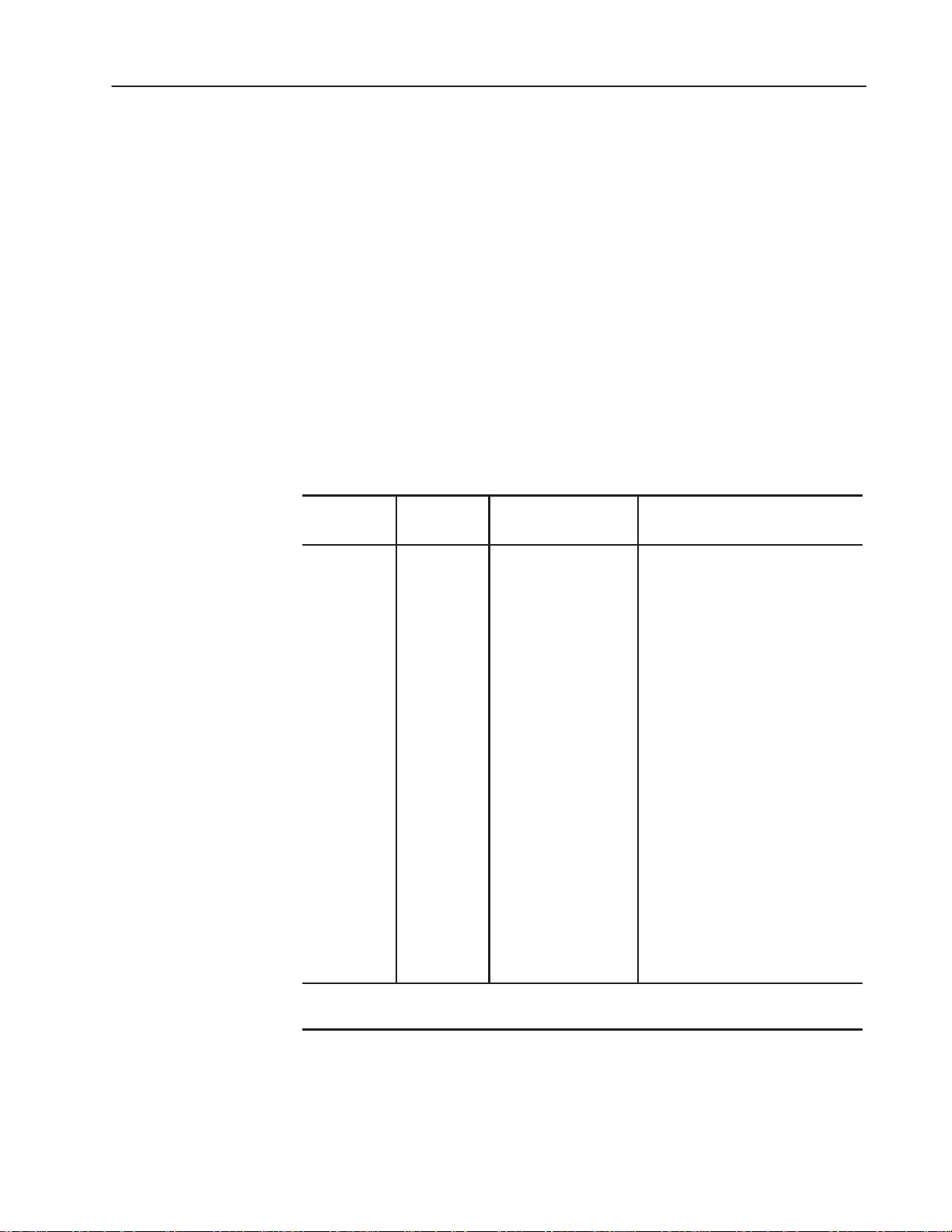

The first word in the status block is reserved for future use (Figure

3.14). Each expander module then uses three words, the first of

which is the status word. The remaining two are position words.

The number of status and position words returned to the PC

processor depends on the highest numbered axis in the stepper

positioning assembly, not on the number of axes used. The status

block must contain four words if only axis 1 is in the system, seven

words if axis 2 is the highest numbered axis, and ten words if axis 3

is in the system.

Figure 3.14

Status Block

Data Table

17 10 07 00

Reserved For Future Use

Status Word, Axis 1

0

000

*

1

0000

999

999

3–21Programming and Operation

MS Position

LS Position

Pulse