Page 1

AllenĆBradley

High Resolution

Isolated Analog

Modules

(Cat. No. 1771ĆN Series)

User Manual

Page 2

N

T

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes

and standards. In no event will Rockwell Automation be responsible or

liable for indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout examples shown

in this publication are intended solely for purposes of example. Since

there are many variables and requirements associated with any particular

installation, Rockwell Automation does not assume responsibility or

liability (to include intellectual property liability) for actual use based

upon the examples shown in this publication.

Allen–Bradley publication SGI–1.1, Safety Guidelines for Application,

Installation, and Maintenance of Solid–State Control (available from

your local Rockwell Automation office), describes some important

differences between solid–state equipment and electromechanical

devices that should be taken into consideration when applying products

such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

part, without written permission of Rockwell Automation, is prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their accompanying

statements help you to identify a potential hazard. avoid a potential

hazard, and recognize the consequences of a potential hazard.

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTIO

Identifies information about practices or

circumstances that may lead to personal injury or

death, property damage, or economic loss.

!

Identifies information that is critical for

IMPORTAN

successful application and understanding of the

product.

Page 3

ATTENTION

!

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC publication

60664–1), at altitudes up to 2000 meters without

derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions, there

may be potential difficulties ensuring electromagnetic

compatibility in other environments due to conducted

as well as radiated disturbance.

This equipment is supplied as “open type” equipment.

It must be mounted within an enclosure that is suitably

designed for those specific environmental conditions

that will be present, and appropriately designed to

prevent personal injury resulting from accessibility to

live parts. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent

sections of this publication may contain additional

information regarding specific enclosure type ratings

that are required to comply with certain product safety

certifications.

ATTENTION

!

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for explanations of

the degrees of protection provided by different types of

enclosures. Also, see the appropriate sections in this

publication, as well as the Allen–Bradley publication

1770–4.1, (“Industrial Automation Wiring and

Grounding Guidelines”), for additional installation

requirements pertaining to this equipment.

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal

operation. Follow these guidelines when you handle

this equipment:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static–safe workstation.

• When not in use, keep modules in appropriate

static–safe packaging.

Page 4

Page 5

Using this Manual

Preface

Purpose of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your high resolution isolated

analog series input/output modules with an Allen-Bradley

programmable controller. It helps you install, program, calibrate, and

troubleshoot your modules.

You must be able to program and operate an Allen-Bradley

programmable controller (PLC) to make efficient use of your analog

module. In particular, you must know how to program block transfer

instructions.

We assume that you know how to do this in this manual. If you do

not, refer to the appropriate PLC programming and operations

manual before you attempt to program this module.

In this manual, we refer to:

• the individual module as the “module.”

• the programmable controller, as the “controller” or the

“processor.”

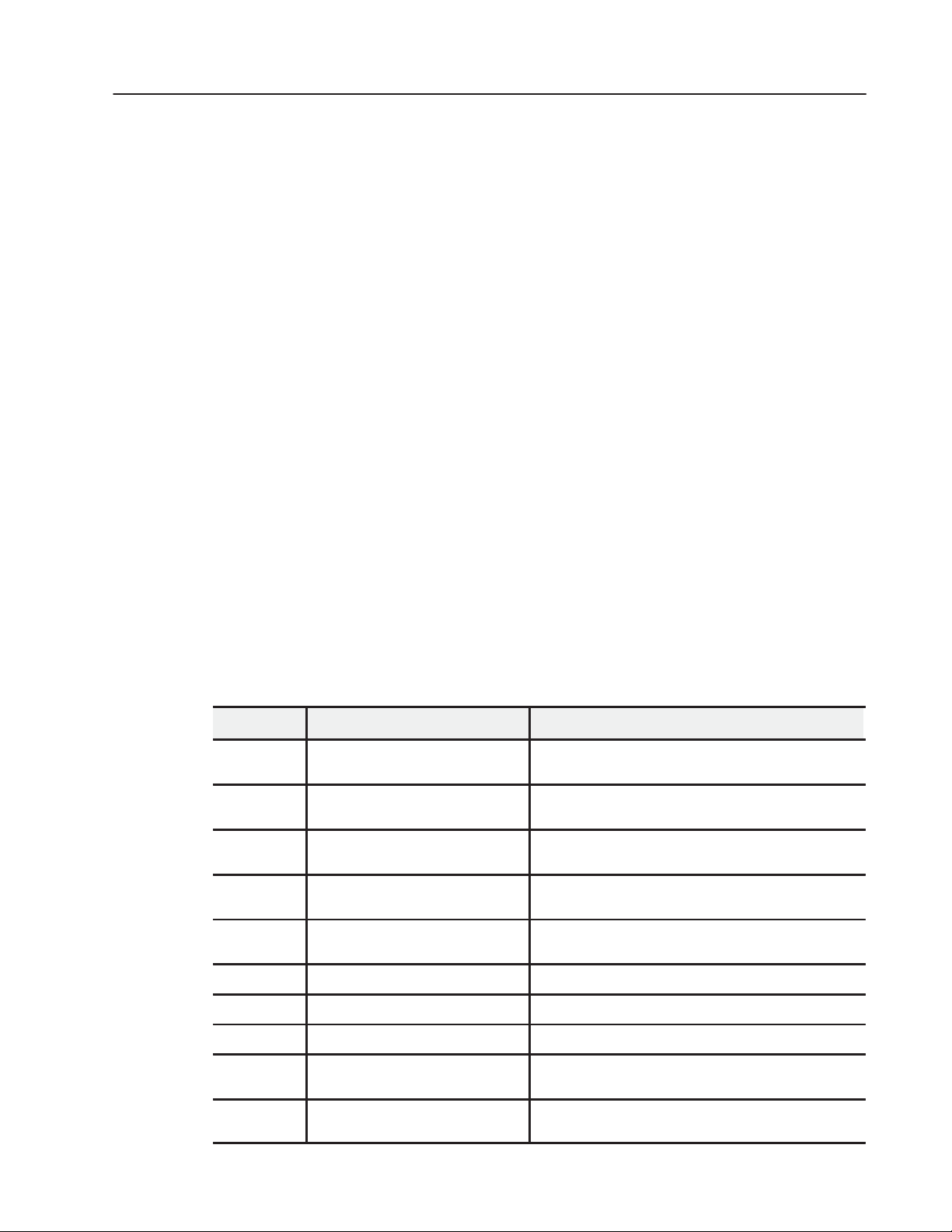

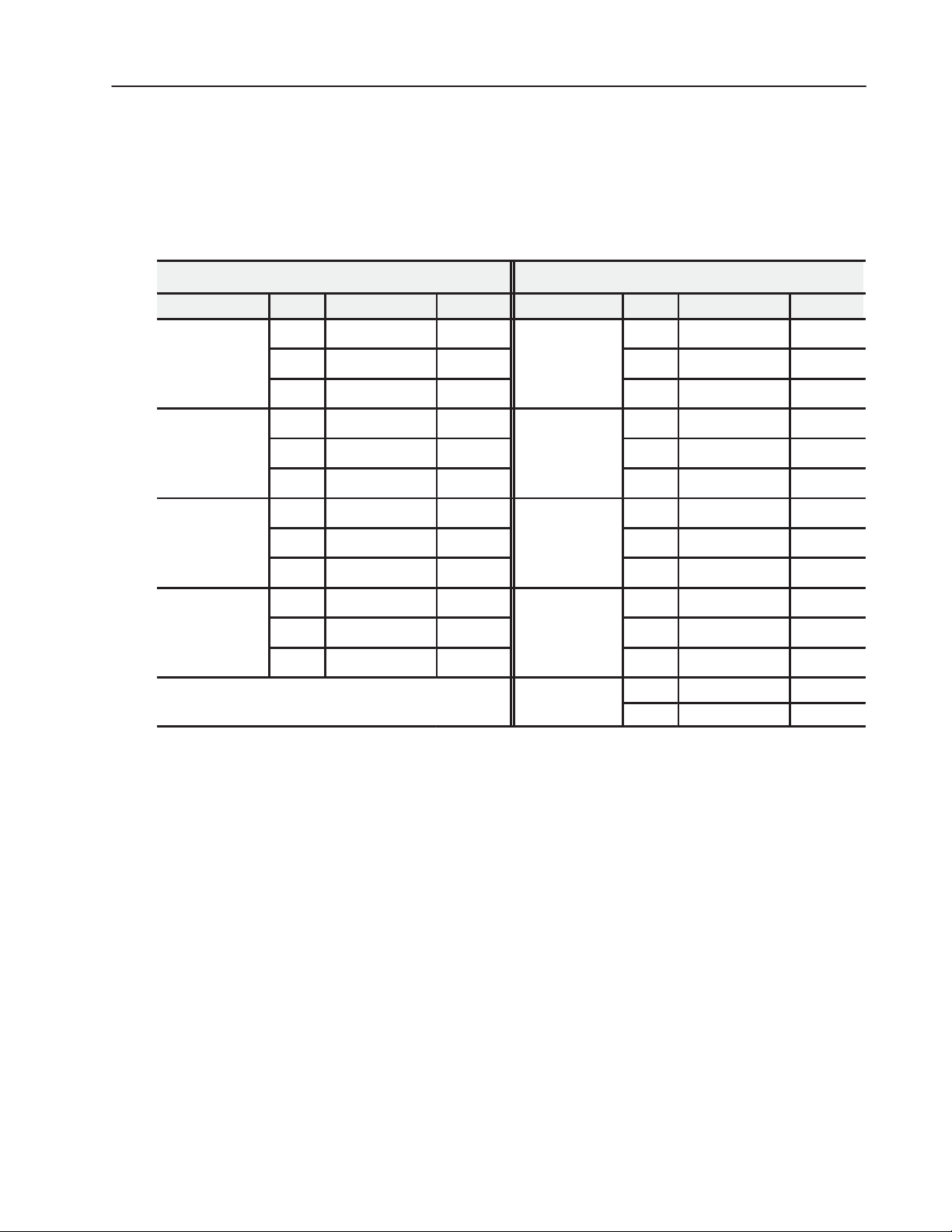

This manual is divided into seven chapters. The following chart

shows each chapter with its corresponding title and a brief overview

of the topics covered in that chapter.

Chapter Title Topics Covered

1

2 Installing the Module

3 Communicating with your Analog Module

4 Configuring the Module

5 Module Status and Input Data

6 Module Calibration How to calibrate your modules

7 Troubleshooting Diagnostics reported by the module

Appendix A Specifications Your module's specifications

Appendix B

Appendix C

Overview of the High Resolution Isolated

Analog Series Modules

Block Transfer Read and Write

Configurations for 0 out/8 in

Block Transfer Read and Write

Configurations for 8 out/0 in

Descriptions of the modules, including general and

hardware features

Module power requirements, keying, chassis location

Wiring of module and remote termination panel

How to program your programmable controller for this module

Sample programs

Hardware and software configuration

Module write block format

Reading data from your module

Module read block format

Description of BTR/BTW words.

Description of BTR/BTW words.

Publication 1771ĆUM127B-EN-P - December 2002

Page 6

Using this ManualP–2

Image

Image

Block

Block

Chassis

Topics CoveredTitleChapter

Appendix D

Appendix E

Appendix F

Appendix G

Appendix H

Appendix I

Appendix J

Appendix K

Appendix L UL/CSA Hazardous Location

Related Products

Block Transfer Read and Write

Configurations for 2 out/2 in

Block Transfer Read and Write

Configurations for 2 out/6 in

Block Transfer Read and Write

Configurations for 1 out/7 in

Block Transfer Read and Write

Configurations for 3 out/5 in

Block Transfer Read and Write

Configurations for 4 out/4 in

Block Transfer Read and Write

Configurations for 6 out/2 in

Block Transfer Read and Write

Configurations for 5 out/3 in

Block Transfer Read and Write

Configurations for 7 out/1 in

You can install your module in any system that uses Allen-Bradley

processors that support block transfer and the 1771 I/O structure.

Description of BTR/BTW words.

Description of BTR/BTW words.

Description of BTR/BTW words.

Description of BTR/BTW words.

Description of BTR/BTW words.

Description of BTR/BTW words.

Description of BTR/BTW words.

Description of BTR/BTW words.

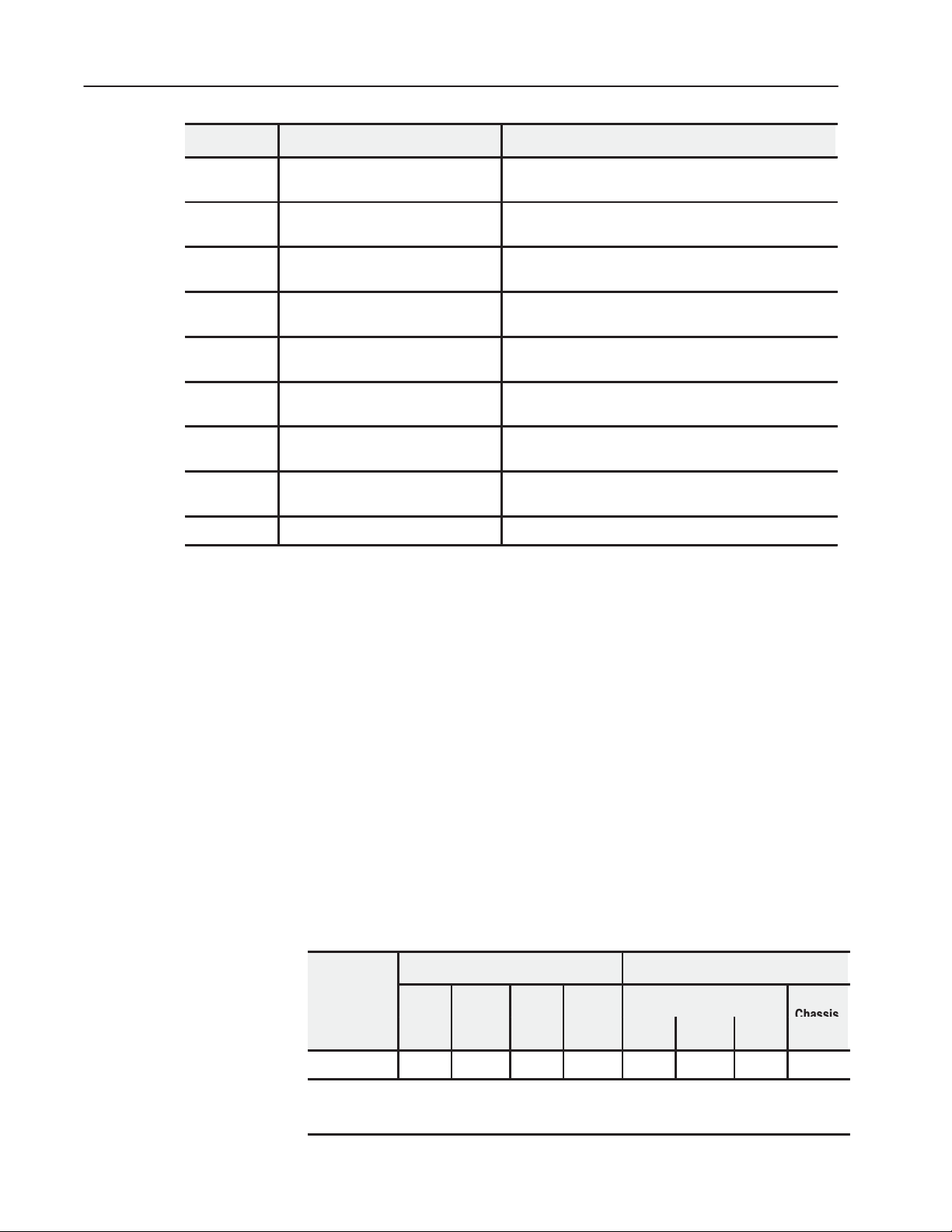

Product Compatibility

Contact your nearest Allen-Bradley office for more information

about your programmable controllers.

These modules can only be used with 1771-A1B, A2B, A3B, A3B1,

A4B or later 1771 I/O chassis and 1771-AM1, -AM2 chassis.

Communication between the analog module and the processor is

bidirectional. The processor block-transfers output data through the

output image table to the module and block-transfers input data from

the module through the input image table. The module also requires

an area in the data table to store the read block and write block data.

I/O image table use is an important factor in module placement and

addressing selection. Refer to the table below.

Compatibility and Use of Data Table

Use of Data Table Compatibility

Catalog

Number

1771ĆN Series 8 8 28 59 Yes Yes Yes B

A = Compatible with 1771ĆA1, A2, A4 chassis.

B = Compatible with 1771ĆA1B, A2B, A3B, A3B1,A4B, 1771ĆAM1, ĆAM2 chassis.

Yes = Compatible without restriction

No = Restricted to complementary module placement

Input

Bits

Output

Bits

Read

Words

Write

Words

Addressing

1/2Ćslot 1Ćslot 2Ćslot

Publication 1771ĆUM127B-EN-P - December 2002

Page 7

Using this Manual P–3

You can place your analog module in any I/O module slot of the

I/O chassis.

Do not put the analog module in the same module group as a digital

high density module unless you are using 1 or 1/2-slot addressing.

Avoid placing the analog module close to ac modules or high voltage

dc modules.

Related Publications

For a list of publications with information on Allen-Bradley

programmable controller products, consult our publication index

SD499.

Publication 1771ĆUM127B-EN-P - December 2002

Page 8

Using this ManualP–4

Publication 1771ĆUM127B-EN-P - December 2002

Page 9

Table of Contents

Overview of the High Resolution

Isolated Analog Modules

Installing the Module

Chapter 1

Chapter Objectives 1-1...................................

Module Description 1-1...................................

Features of the High Resolution Isolated Analog Series Modules 1-2...

Catalog/Channel Numbers 1-3..............................

How the High Resolution Isolated Analog Modules Communicate with

Processors 1-4......................................

Accuracy 1-4..........................................

Chapter Summary 1-4....................................

Chapter 2

Chapter Objectives 2-1...................................

Before You Install Your Analog Module 2-1.....................

Electrostatic Damage 2-1..................................

Calculate Power Requirements for the I/O Chassis 2-1.............

2-1..................................................

Determine Module Location in the I/O Chassis 2-2................

Install the Analog Module 2-2...............................

Install the Module in the Chassis and Connect the Cable 2-3.........

Connecting Wiring 2-5....................................

Connecting 4ĆWire Sensors 2-9.............................

Sourcing Input Analog Modules 2-10...........................

Making Your Own Cables 2-11...............................

Grounding the Field Devices 2-12.............................

Interpreting the Indicator Lights 2-13...........................

Chapter Summary 2-13....................................

Communicating With Your Analog

Module

Chapter 3

Chapter Objectives 3-1...................................

Block Transfer Programming 3-1............................

PLCĆ2 Programming 3-2..................................

PLCĆ3 Program Example 3-2...............................

PLCĆ5 and PLCĆ5/250 Program Example 3-3....................

Module Scan Time 3-4....................................

Programming Samples 3-4.................................

Sample Ladder Diagram Ć PLCĆ3 Family Processors 3-5...........

Sample Ladder Diagram Ć PLCĆ5 Family Processors 3-6...........

Setting Up the Data Table File 3-7............................

Chapter Summary 3-8....................................

Publication 1771ĆUM127B-EN-P - December 2002

Page 10

Table of Contentstoc-ii

Configuring the Module

Chapter 4

Chapter Objectives 4-1...................................

Configuring the High Resolution Isolated Analog Modules 4-1........

Default Configurations 4-2.................................

Module Level Programming Features 4-3......................

Module Configuration" Verification 4-3........................

Temperature Scale 4-3....................................

Data Format 4-3........................................

Two's Complement Binary 4-5..........................

Real Time Sampling 4-5...................................

Output Channel Programming Features 4-6.....................

Scaling 4-6............................................

Clamping 4-9..........................................

Ramping 4-10...........................................

Alarm Enable 4-10.......................................

Reset State 4-10.........................................

Reset Value 4-11........................................

Input Channel Programming Features 4-11......................

Scaling 4-11............................................

Alarms 4-11............................................

Alarm Deadband 4-12.....................................

Rate Alarm 4-13.........................................

Digital Filtering 4-13......................................

Thermocouple Type 4-14...................................

RTD Type 4-15..........................................

10 Ohm Offset 4-15.......................................

Configuration Block for a Block Transfer Write 4-15................

Block Transfer Write Configuration Data Header 4-15...............

Module Configuration Data Header 4-15....................

Bit/Word Description of Word 0 4-16.......................

Output Configuration Words 1 and 2 4-16...................

Bit/Word Description of Output Configuration Words 1 and 2 4-16..

Output Configuration Words 3 and 4 4-16...................

Bit/Word Description of Output Configuration Words 3 and 4 4-17..

Output Programming 4-17..............................

Output Configuration Words 5 through 10 4-17...............

Bit/Word Description of Output Configuration Words 5 through 10 4-18

Input Programming 4-19...............................

Bit/Word Description of Input Configuration Words 17 through 23 4-19

Chapter Summary 4-20....................................

Publication 1771ĆUM127B-EN-P - December 2002

Page 11

Table of Contents toc-iii

Module Status and Input Data

Module Calibration

Chapter 5

Chapter Objectives 5-1...................................

Reading Data from the Module 5-1...........................

Block Transfer Read Data Format 5-2.........................

Outputs Only" Block Transfer Read Data Header 5-2..............

Inputs Only" and Output/Input" Block Transfer Read Data Header 5-3.

Input Status Data 5-4.....................................

Bit/Word Description for Input Status Data Words 5-5..........

Output Status Data 5-6...................................

Bit/Word Description for Output Status Data Words 5-7.........

Chapter Summary 5-7....................................

Chapter 6

Chapter Objective 6-1....................................

Tools and Equipment 6-1..................................

Calibrating Your Module 6-2................................

Indicator Operation During Calibration 6-3......................

Manual Calibration 6-3....................................

Input Channel Calibration 6-3...............................

Output Channel Calibration 6-7..............................

Chapter Summary 6-8....................................

Troubleshooting

Specifications

Block Transfer Write and Block

Transfer Read Configurations

for 0 Output/8 Input 1771ĆN

Series Modules

Chapter 7

Chapter Objective 7-1....................................

Diagnostics Reported by the Module 7-1.......................

Troubleshooting with the Indicators 7-2........................

Status Reported by the Module 7-2...........................

Chapter Summary 7-4....................................

Appendix A

Specifications A-1.......................................

General Specifications A-1.................................

Appendix B

What This Appendix Contains B-1............................

Block Transfer Write Configuration Block for 8 Input Modules B-1.....

Block Transfer Write Bit/Word Descriptions for 8 Input Modules B-3....

Block Transfer Read Word Assignments for 8 Input Modules B-5......

Block Transfer Read Bit/Word Descriptions for 8 Input Modules B-7....

Publication 1771ĆUM127B-EN-P - December 2002

Page 12

Table of Contentstoc-iv

Block Transfer Write and Block

Transfer Read Configurations

for 8 Output/0 Input 1771ĆN

Series Modules

Block Transfer Write and Block

Transfer Read Configurations

for 2 Output/2 Input 1771ĆN

Series Modules

Block Transfer Write and Block

Transfer Read Configurations

for 2 Output/6 Input 1771ĆN

Series Modules

Appendix C

What This Appendix Contains C-1............................

Block Transfer Write Configuration Block for 8 Output Modules C-1....

Block Transfer Write Bit/Word Descriptions for 8 Output Modules C-3...

Block Transfer Read Word Assignments for 8 Output Modules C-5....

Block Transfer Read Bit/Word Description for 8 Output Module C-6....

Appendix D

What This Appendix Contains D-1............................

Block Transfer Write Configuration Block for the

2 Output/2 Input Modules D-1............................

Block Transfer Write Bit/Word Descriptions for

2 Output/2 Input Modules D-2............................

Block Transfer Read Word Assignments for 2 Output/2 Input Module D-5

Block Transfer Read Bit/Word Description for 2 Output/2 Input Module D-6

Appendix E

What This Appendix Contains E-1............................

Block Transfer Write Configuration Block for 2 Output/6 Input Modules E-1

Block Transfer Write Bit/Word Descriptions for

2 Output/6 Input Modules E-3............................

Block Transfer Read Word Assignments for 2 Output/6 Input Modules E-6

Block Transfer Read Bit/Word Description for

2 Output/6 Input Modules E-7............................

Block Transfer Write and Block

Transfer Read Configurations

for 1 Output/7 Input 1771ĆN

Series Modules

Block Transfer Write and Block

Transfer Read Configurations

for 3 Output/5 Input 1771ĆN

Series Modules

Appendix F

What This Appendix Contains F-1............................

Block Transfer Write Configuration Block for 1 Output/7 Input Modules F-1

Block Transfer Write Bit/Word Descriptions for

1 Output/7 Input Modules F-3............................

Block Transfer Read Word Assignments for 1 Output/7 Input Module F-6

Block Transfer Read Bit/Word Description for 1 Output/7 Input Module F-7

Appendix G

What This Appendix Contains G-1............................

Block Transfer Write Configuration Block for 3 Output/5 Input Modules G-1

Block Transfer Write Bit/Word Descriptions for

3 Output/5 Input Modules G-3............................

Block Transfer Read Word Assignments for 3 Output/5 Input Modules G-6

Block Transfer Read Bit/Word Descriptions for

3 Output/5 Input Modules G-7............................

Publication 1771ĆUM127B-EN-P - December 2002

Page 13

Table of Contents toc-v

Block Transfer Write and Block

Transfer Read Configurations

for 4 Output/4 Input 1771ĆN

Series Modules

Block Transfer Write and Block

Transfer Read Configurations

for 6 Output/2 Input 1771ĆN

Series Modules

Block Transfer Write and Block

Transfer Read Configurations

for 5 Output/3 Input 1771ĆN

Series Modules

Appendix H

What This Appendix Contains H-1............................

Block Transfer Write Configuration Block for 4 Output/4 Input Modules H-1

Block Transfer Write Bit/Word Descriptions for

4 Output/4 Input Modules H-3............................

Block Transfer Read Word Assignments for 4 Output/4 Input Modules H-6

Block Transfer Read Bit/Word Descriptions for

4 Output/4 Input Modules H-7............................

Appendix I

What This Appendix Contains I-1............................

Block Transfer Write Configuration Block for 6 Output/2 Input Modules I-1

Block Transfer Write Bit/Word Descriptions for

6 Output/2 Input Modules I-3............................

Block Transfer Read Word Assignments for 6 Output/2 Input Modules I-6

Block Transfer Read Bit/Word Descriptions for

6 Output/2 Input Modules I-8............................

Appendix J

What This Appendix Contains J-1............................

Block Transfer Write Configuration Block for

5 Output/3 Input Modules J-1............................

Block Transfer Write Bit/Word Descriptions for

5 Output/3 Input Modules J-3............................

Block Transfer Read Word Assignments for the

5 Output/3 Input Modules J-6............................

Block Transfer Read Bit/Word Descriptions for

5 Output/3 Input Modules J-7............................

Block Transfer Write and Block

Transfer Read Configurations

for 7 Output/1 Input 1771ĆN

Series Modules

CSA Hazardous Location

Appendix K

What This Appendix Contains K-1............................

Block Transfer Write Configuration Block for 7 Output/1 Input Modules K-1

Block Transfer Write Bit/Word Descriptions for

7 Output/1 Input Modules K-3............................

Block Transfer Read Word Assignments for 7 Output/1 Input Modules K-6

Block Transfer Read Bit/Word Descriptions for

7 Output/1 Input Modules K-7............................

Appendix L

CSA Hazardous Location L-1...............................

Publication 1771ĆUM127B-EN-P - December 2002

Page 14

Table of Contentstoc-vi

Publication 1771ĆUM127B-EN-P - December 2002

Page 15

Overview of the High

T

Resolution Isolated

Analog Modules

Chapter 1

Chapter Objectives

Module Description

This chapter gives you information on:

• features of the input/output modules

• how the modules communicate with programmable controllers

The high resolution isolated analog modules are intelligent block

transfer modules that interface analog signals with Allen-Bradley

PLC-3 and PLC-5 family programmable controllers that have block

transfer capability. Block transfer programming moves input data

words from the module’s memory to a designated area in the

processor data table in a single scan. It also moves configuration

words and output data from the processor data table to module

memory.

The N-series family includes modules with both analog inputs and

outputs on the same module. The modules use 16-bit

analog-to-digital converters and 14-bit digital-to-analog converters

for high resolution and accuracy. All of these modules require only a

single slot in the I/O chassis, and do not require an external power

supply.

Since the N-series modules are combination modules, with input and

output capabilities on the same module, block transfer reads from the

module are structured differently from dedicated input or output

modules. Normally, block transfer read information is contiguous,

and is stored in contiguous locations in the data block. N-series

modules transmit channel data on an individual basis with status

information in between. This results in non-contiguous blocks of

data in non-contiguous data locations. Care must be taken when

transferring this information. Additional programming may be

required.

Use with PLC-2 family programmable

IMPORTAN

Input data is converted to a specified data type in a digital format to

be transferred to the processor’s data table on request. Output data is

converted to analog signals and sent to the appropriate output

channels. If real time sampling is selected, block transfer reads will

only occur at the time selected. Consequently, the minimum interval

between block transfer reads is the same as the total input update

time for each analog input module (25ms).

controllers is not recommended. Refer to

chapter 3, page 3-2.

Publication 1771ĆUM127B-EN-P - December 2002

Page 16

1–2 Overview of the High Resolution Isolated Analog Modules

The modules have either four or eight channels, each electrically

isolated from each other and from the backplane. Input and output

terminations are made through prefabricated cables which connect to

remote termination panels (RTP). The modules are compatible with

all 1771-A1B, A2B, A3B, A3B1, A4B, and later 1771 universal

I/O chassis. In addition, they can be used in 1771-AM1, and -AM2

chassis.

Features of the High

Resolution Isolated

Analog Series Modules

The analog modules are comprised of modular analog signal

conditioning blocks that are plugged into a common circuit board.

These signal conditioning blocks provide the following:

• 4–20mA output range

• 0–50mA output range

• +10V output (scalable +5V, 0-5V, 0-10V, etc.)

• thermocouple input (+100mV)

• +5V input (+20mA with resistor RTP)

• +10V input (+20mA with resistor RTP)

• 4–20mA input with sourcing/sinking input

• 1–650 ohm RTD input

Your particular module may have a combination of the above

conditioning blocks.

The N-Series analog modules feature:

• scaling of data to engineering units

• self-calibration (external reference required)

• software configuration

• user-selectable high and low alarms with deadband (hysteresis)

• self diagnostics

• input open circuit detection

• programmable ramped outputs

Publication 1771ĆUM127B-EN-P - December 2002

Specific analog modules have these additional features:

• Thermocouple input channels

– input channels configurable for thermocouple input ranges —

Types B, E, J, K, R, S and T thermocouples (1771-NT2 also

includes types C and N)

– cold junction compensation

– scaling to selected temperature range in

o

C or oF

– temperature resolution —

o

up to 0.03

up to 0.1

up to 0.07

C/0.06°F (E, J, K, T, N)

o

C/0.2°F (B, R, S)

o

C/0.1°F (C)

– millivolt resolution up to 1 microvolt

Page 17

1–3Overview of the High Resolution Isolated Analog Modules

• RTD input channels

– reports

10Ω copper sensors

o

C, oF, or ohms for 100Ω platinum, 120Ω nickel, or

– reports ohms for other types of sensors

o

– 0.1

C/0.1oF resolution on 100Ω platinum sensor

– resistance resolution to 10mΩ

• +5V and +10V input channels — can be used with remote

termination panel

resistor to achieve a nonsourcing current input

• 4-20mA input with internal loop power supply

• ±10V output channels

• 0-25mA output channels

• 0-50mA output channels

Catalog/Channel Numbers

The following are standard catalog numbers and their respective

channel configurations:

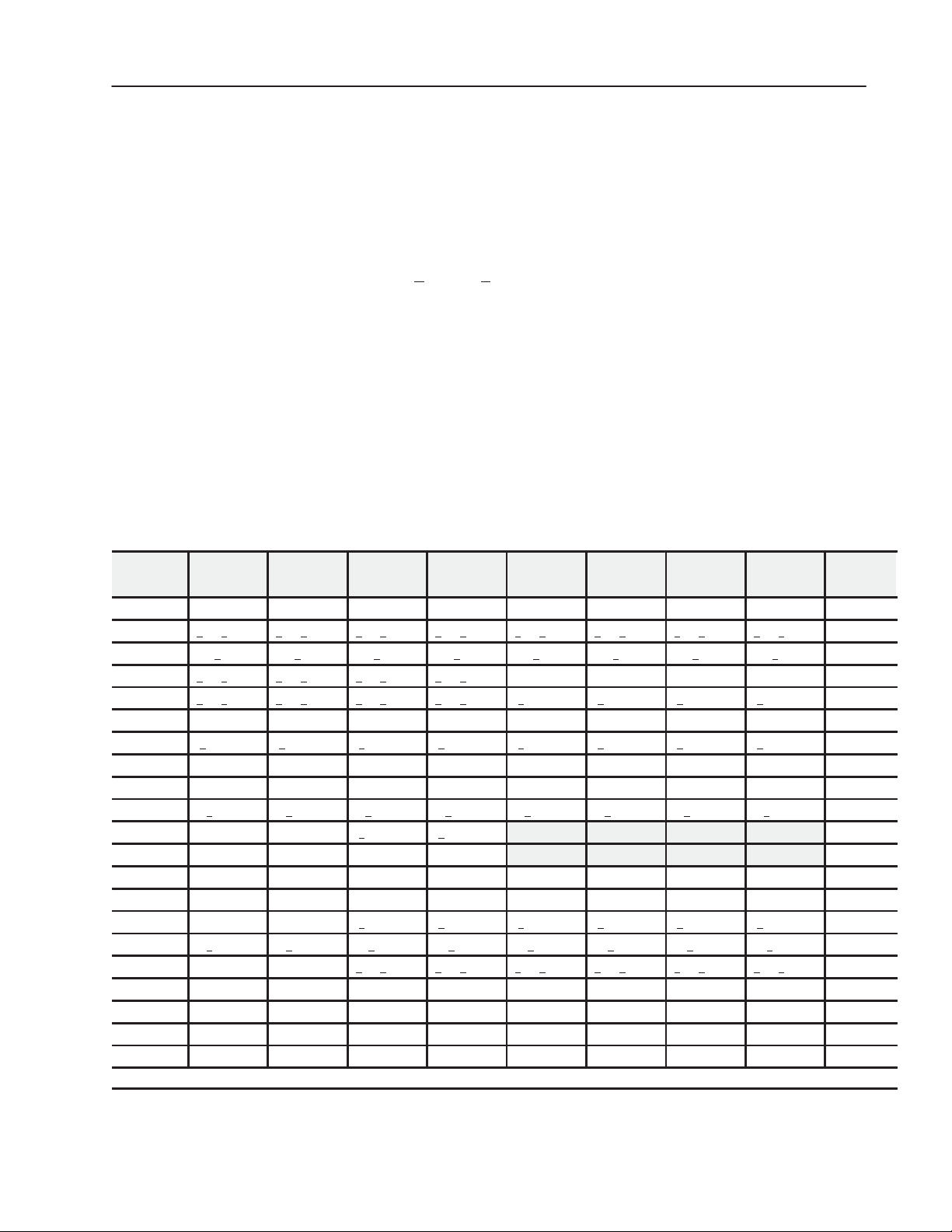

Module Channel 1 Channel 2 Channel 3 Channel 4 Channel 5 Channel 6 Channel 7 Channel 8

1771ĆNIS 4-20mA 4-20mA 4-20mA 4-20mA 4-20mA 4-20mA 4-20mA 4-20mA B

1771ĆNIV +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) B

1771ĆNIV1 +10V +10V +10V +10V +10V +10V +10V +10V B

1771ĆNIVR +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) RTD RTD RTD RTD B

1771ĆNIVT +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +100mV/TC +100mV/TC +100mV/TC +100mV/TC B

1771ĆNR RTD RTD RTD RTD RTD RTD RTD RTD B

1771ĆNT1 +100mV/TC +100mV/TC +100mV/TC +100mV/TC +100mV/TC +100mV/TC +100mV/TC +100mV/TC B

1771ĆNT2 -5/+55mV/TC -5/+55mV/TC -5/+55mV/TC -5/+55mV/TC -5/+55mV/TC -5/+55mV/TC -5/+55mV/TC -5/+55mV/TC B

1771ĆNOC 0-25mA out 0-25mA out 0-25mA out 0-25mA out 0-25mA out 0-25mA out 0-25mA out 0-25mA out C

1771ĆNOV +10V out +10V out +10V out +10V out +10V out +10V out +10V out +10V out C

1771ĆNB4T 0-25mA out 0-25mA out +100mV/TC +100mV/TC D

1771ĆNB4S 0-25mA out 0-25mA out 4-20mA 4-20mA D

1771ĆNBSC 0-25mA out 0-25mA out 4-20mA 4-20mA 4-20mA 4-20mA 4-20mA 4-20mA E

1771ĆNBRC 0-25mA out 0-25mA out RTD RTD RTD RTD RTD RTD E

1771ĆNBTC 0-25mA out 0-25mA out +100mV/TC +100mV/TC +100mV/TC +100mV/TC +100mV/TC +100mV/TC E

1771ĆNBV1 +10V out +10V out +10V in +10V in +10V in +10V in +10V in +10V in E

1771ĆNBVC 0-25mA out 0-25mA out +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) +5V (+20mA) E

1771ĆNX1 0-50mA out 0-25mA out 0-50mA out 0-25mA out 0-25mA out RTD RTD 100mV/TC F

1771ĆNX2 0-50mA out 0-25mA out 0-50mA out 0-25mA out RTD RTD 100mV/TC 100mV/TC G

1771ĆNX3 0-50mA out 0-25mA out 0-50mA out 0-25mA out RTD RTD RTD 100mV/TC G

1771ĆNX4 0-50mA out 0-25mA out 0-25mA out 0-25mA out 0-25mA out 0-25mA out RTD 100mV/TC H

Note: Appendices I thru L cover other variations of the 1771ĆN series module.

Refer to

Appendix

Publication 1771ĆUM127B-EN-P - December 2002

Page 18

1–4 Overview of the High Resolution Isolated Analog Modules

How the High Resolution

Isolated Analog Modules

Communicate with

Processors

5

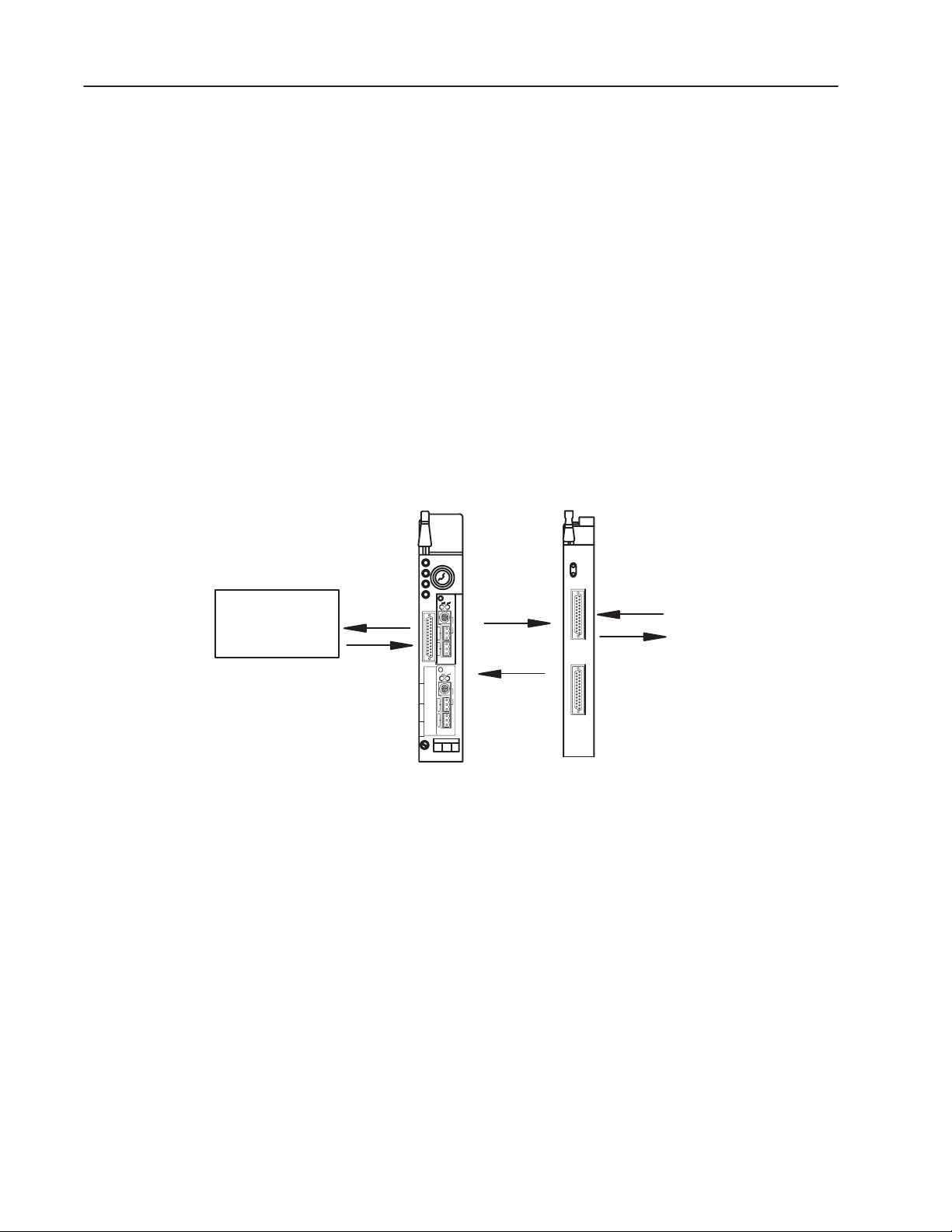

The processor transfers data to and from the module using BTW

(block transfer write) and BTR (block transfer read) instructions in

your ladder diagram program. These instructions let the processor

obtain input values and status from the module, and let you establish

the module’s mode of operation (Figure NO TAG).

1. The processor transfers your configuration data, output data and

calibration values to the module using a block transfer write

instruction.

2. External input devices generate analog signals that are transmitted

to the module. Internal output circuitry generates analog signals

that drive field devices.

3. The module converts the analog signals into binary or BCD

format and stores theses values until the processor requests their

transfer.

Table 1.A

Communication Between the Processor and the Module

3

1

Accuracy

Memory

User Program

PLC Processor

(PLCĆ5/40 Shown)

BTW

BTR

4

High Resolution

Isolated Analog

Module

From input devices

To output devices

2

12933ĆI

4. When instructed by your ladder program, the processor performs

a read block transfer of the values and stores them in a data table.

5. The processor and module determine that the transfer was made

without error, and that input values are within specified range.

6. Your ladder program can use and/or move the data (if valid)

before it is written over by the transfer of new data in a

subsequent transfer.

See chapter 4, “Configuring the Module,” for more information.

The accuracy of each of the high resolution isolated analog modules

is described in Appendix A.

Chapter Summary

Publication 1771ĆUM127B-EN-P - December 2002

In this chapter you read about the functional aspects of the analog

modules and how they communicate with programmable controllers.

Page 19

Installing the Module

Chapter 2

Chapter Objectives

Before You Install Your

Analog Module

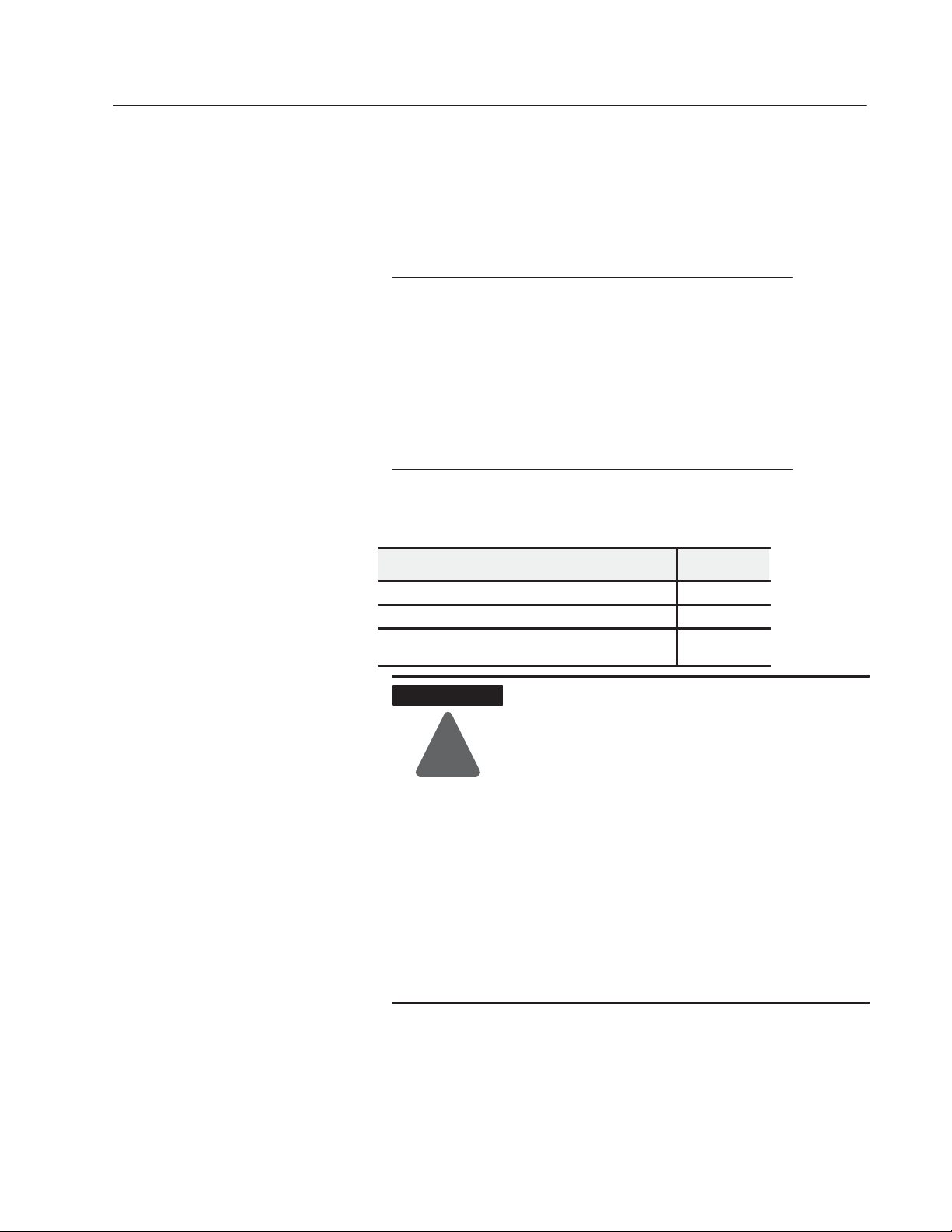

This chapter gives you information on:

For information on See page

Before You Install Your Module . ......................

Determining Power Requirements . ................... 2-1

Determining Module Location in the Chassis . ............ 2-2

Installing the Module . ............................. 2-2

Connecting Wiring . ............................... 2-5

Connecting 4-wire sensors . ........................ 2-9

Sourcing input Analog Modules . ..................... 2-10

Making Your Own Cables . .......................... 2-11

Grounding Field Devices . .......................... 2-12

Module Indicators . .................

Before installing your module in the I/O chassis you must:

Action required: Refer to:

Calculate power requirements for the I/O chassis. page 2-1

Determine module location in the I/O Chassis page 2-2

Connect the cable and make wiring connections to the

remote termination panel

page 2-3

2-1

2-13

Electrostatic Damage

Calculate Power

Requirements for the

I/O Chassis

ATTENTION

!

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge potential

static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static–safe workstation.

• When not in use, keep modules in appropriate

static–safe packaging.

Your module receives its power through the 1771 I/O chassis

backplane from the chassis power supply. The maximum current

drawn by the module from this supply ranges from 1.5 to 3.3A,

dependent upon the particular type of module. Refer to the

specifications in appendix A for standard modules.

Publication 1771ĆUM127B-EN-P - December 2002

Page 20

2–2 Installing the Module

N

N

Add this value to the requirements of all other modules in the I/O

chassis to prevent overloading the chassis backplane and/or

backplane power supply.

Determine Module

Location in the I/O Chassis

Install the Analog Module

Place your module in any slot of the I/O chassis except for the

extreme left slot. This slot is reserved for processors or adapter

modules.

Group your modules to minimize adverse affects from radiated

electrical noise and heat. We recommend the following.

• Group analog and low voltage dc modules away from ac modules

or high voltage dc modules to minimize electrical noise

interference.

• Do not place this module in the same I/O group with a discrete

high-density I/O module when using 2-slot addressing. This

module uses a byte in both the input and output image tables for

block transfer.

To install your module in an I/O chassis:

1. First, turn off power to the I/O chassis:

ATTENTIO

!

Remove power from the 1771 I/O chassis

backplane and disconnect the cable from the

module before removing or installing an I/O

module.

• Failure to remove power from the backplane

could cause injury or equipment damage due to

possible unexpected operation.

• Failure to remove power from the backplane

could cause module damage, degradation of

performance, or injury.

Publication 1771ĆUM127B-EN-P - December 2002

ATTENTIO

!

Observe the following precautions when inserting

or removing keys:

• insert or remove keys with your fingers

• make sure that key placement is correct

Incorrect keying or the use of a tool can result in

damage to the backplane connector and possible

system faults.

Page 21

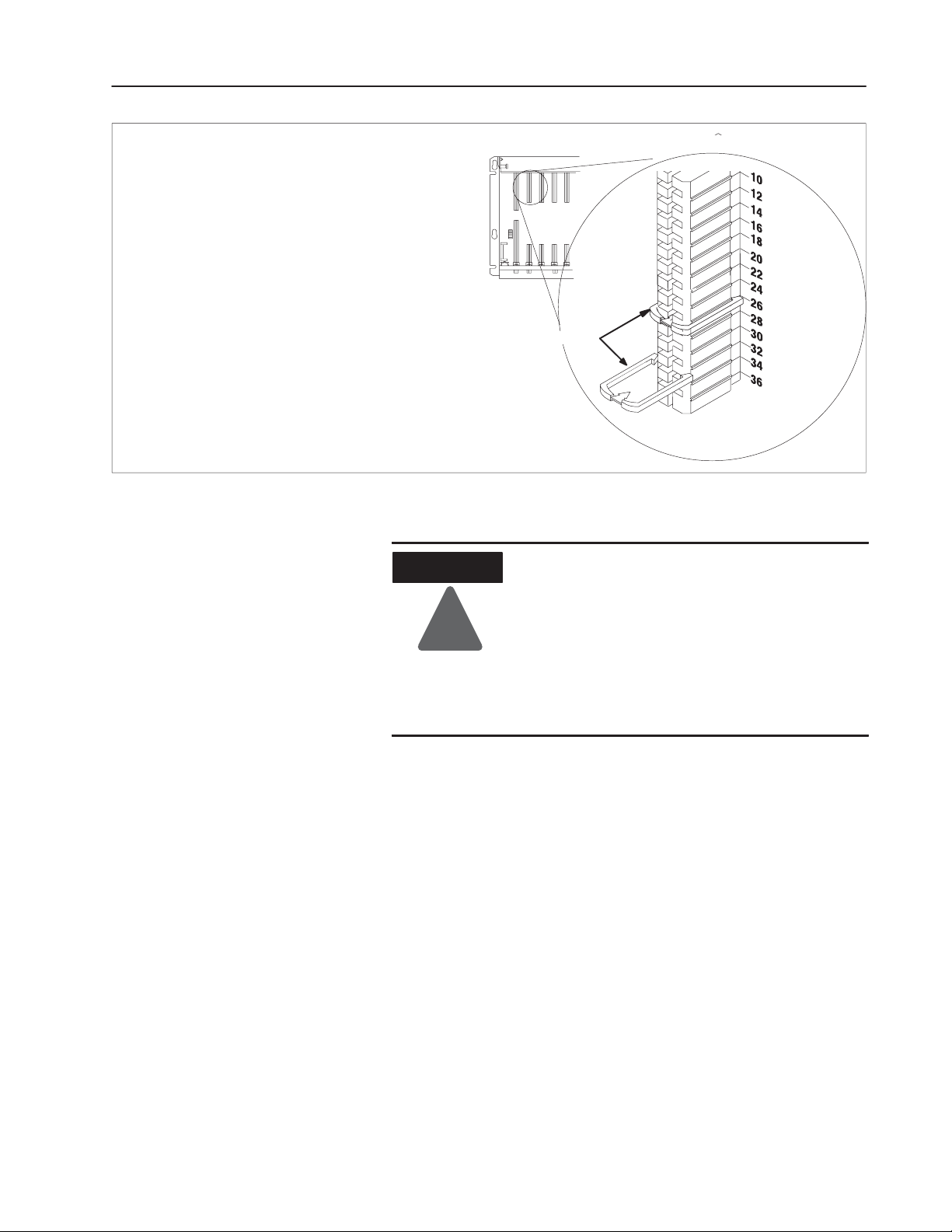

Key the Backplane Connector

N

Place your module in any slot in the chassis

except the leftmost slot which is reserved for

processors or adapters.

Position the keying bands in the backplane connectors

to correspond to the key slots on the module.

Place the keying bands:

between 26 and 28

between 32 and 34

You can change the position of these bands if

subsequent system design and rewiring makes

insertion of a different type of module necessary.

2–3Installing the Module

I/O chassis

Keying Bands

Install the Module in the

Chassis and Connect the

Cable

ATTENTIO

Upper Connector

Remove power from the 1771 I/O chassis

backplane and field wiring arm before removing

or installing an I/O module.

11022ĆI

• Failure to remove power from the backplane or

!

wiring arm could cause module damage, degradation of performance, or injury.

• Failure to remove power from the backplane

could cause injury or equipment damage due to

possible unexpected operation.

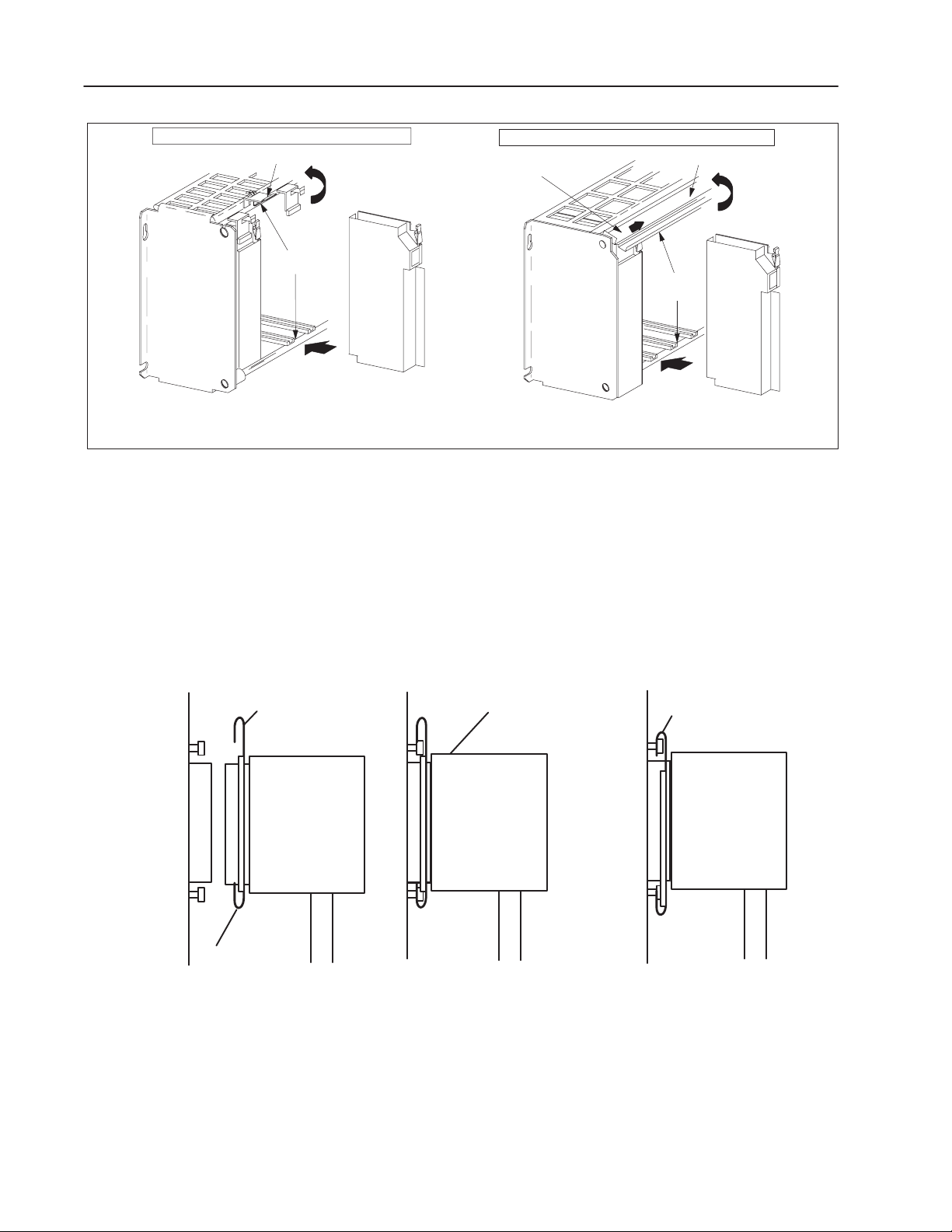

1. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

2. Do not force the module into its backplane connector. Apply firm

even pressure on the module until it is firmly seated in the

chassis. Note: The chassis locking bar will not close if all

modules are not seated properly.

Publication 1771ĆUM127B-EN-P - December 2002

Page 22

2–4 Installing the Module

1771ĆA1B, ĆA2B, ĆA3B, ĆA3B1, ĆA4B I/O chassis

locking tab

card guides

module

Snap the chassis latch over

the top of the module to secure it.

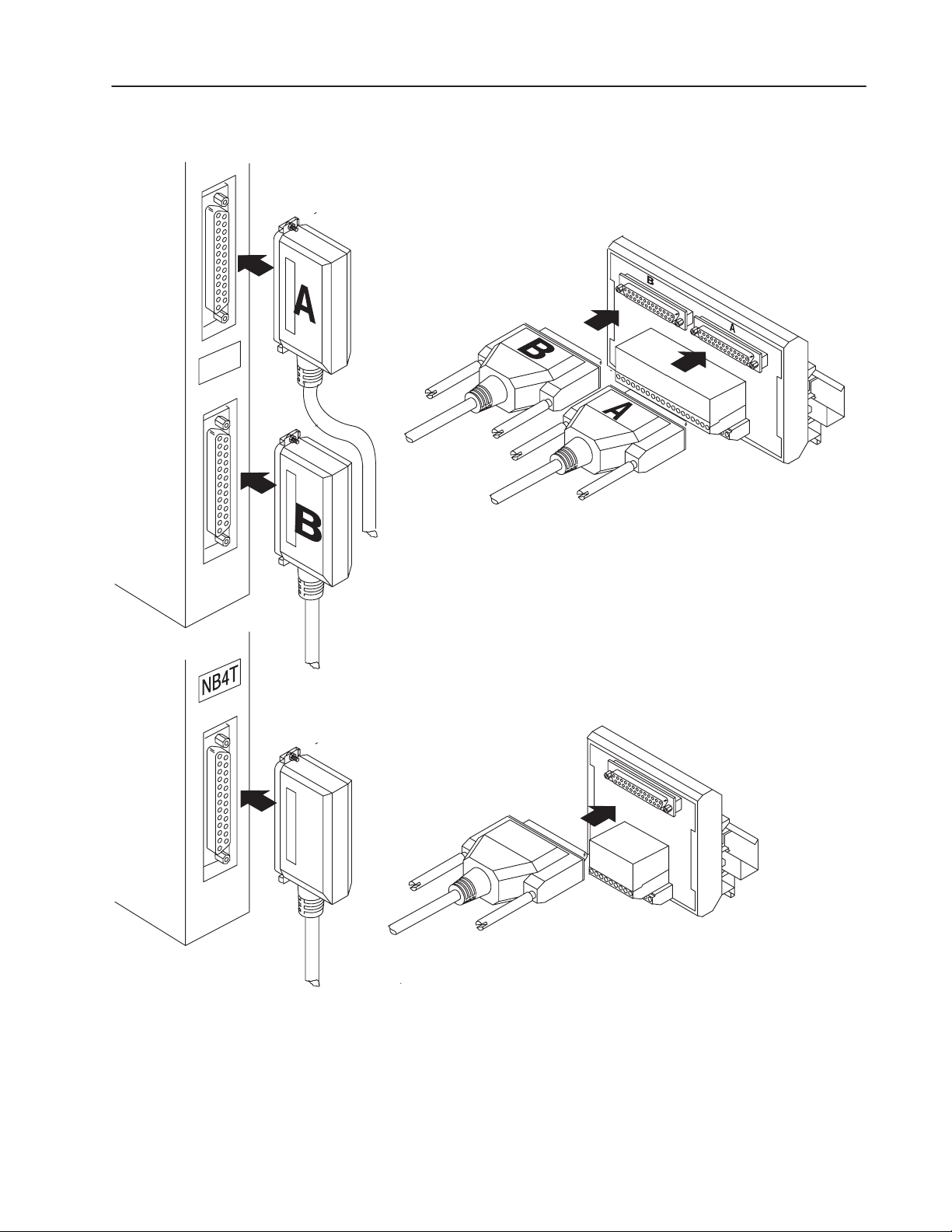

3. Connect the 1771-NC cable to the module as shown in Figure 2.1.

A. Slide the locking bar up.

B. Insert the cable connector into the mating connector on the

1771ĆA1B, ĆA2B, ĆA3B1, ĆA4B Series B I/O chassis

locking bar pin

Swing the chassis locking bar down into place to secure

the modules. Make sure the locking pins engage.

front of the module.

locking bar

card guides

module

19809

Module Connector

1. Position locking bar in up position.

Cable Connector

Locking bar

C. Slide the locking bar down over the mating pins on the

module to lock the connector onto the module.

Figure 2.1

Connecting the Cable to the Front of the Module

2. Insert connector into mating connector.

3. Slide locking bar down to lock.

11023ĆI

Publication 1771ĆUM127B-EN-P - December 2002

Page 23

2–5Installing the Module

Connecting Wiring

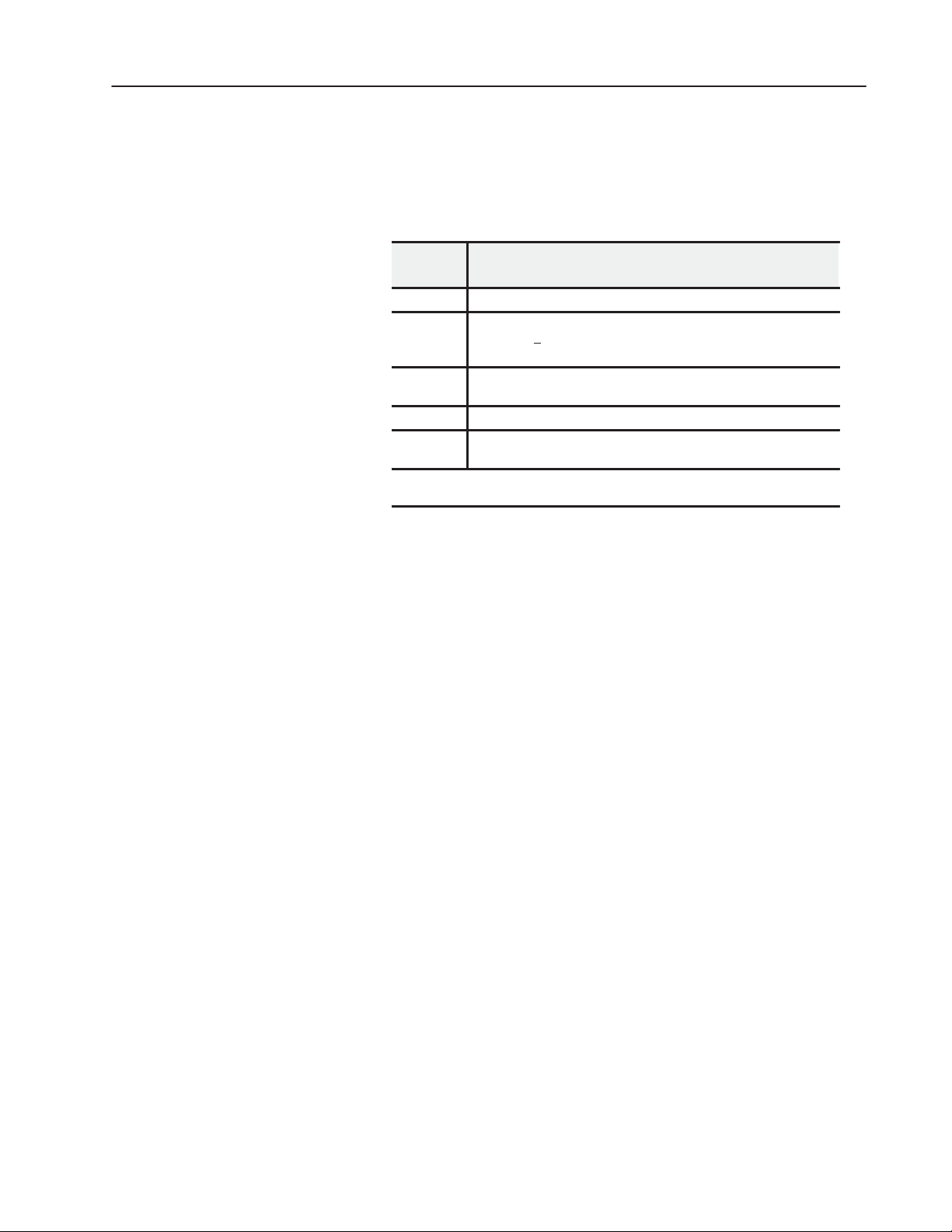

The N-series modules are cable-connected to a remote termination

panel using cat. no. 1771-NC6 (6 ft) or -NC15 (15 ft) cables.

Variations of remote termination panels are used, depending on the

type of module used. These are:

Catalog

Number

1771ĆRTP1 has cold junction compensation for thermocouples

1771ĆRTP3 incorporates resistors and fuses; used primarily for 4Ć20mA inputs

when using +

such as Bussmann GMA-1/4, 250V/250mA.)

1771ĆRTP4 a generalĆuse block with straightĆthru wiring that can be used for all

applications except thermocouples

1771ĆRT41 a 4Ćchannel block with cold junction compensation for thermocouples

1771ĆRT44 a generalĆuse 4Ćchannel block with straightĆthru wiring that can be

used for all applications except thermocouples

1

RTP4 and RT44 can be used withthermocouples if a method of cold junction compensation is provided at

the interface of thermocouple and copper wires within the system.

5V inputs (Uses 5mm x 20mm fast acting 1/4A fuses

Description

1

1

The remote termination panels are designed for mounting on

standard DIN 1 or DIN 3 mounting rails.

Publication 1771ĆUM127B-EN-P - December 2002

Page 24

2–6 Installing the Module

1

3.0

(75.0)

Figure 2.2

Mounting Dimensions for the Remote Termination Panels

RTP1, RTP3, RTP4

AB

Inches

(Millimeters)

2.3

(58.4)

2.3

(58.4)

3.0

(75.0

)

J8

J7

J6

J5

J1

J2

J3

J4

5.30

(134.6)

RT41, RT44

J1

J2

J3

J4

2.3

(58.4)

Dimensions to

3.5

(88.9)

back of DIN rail

19366

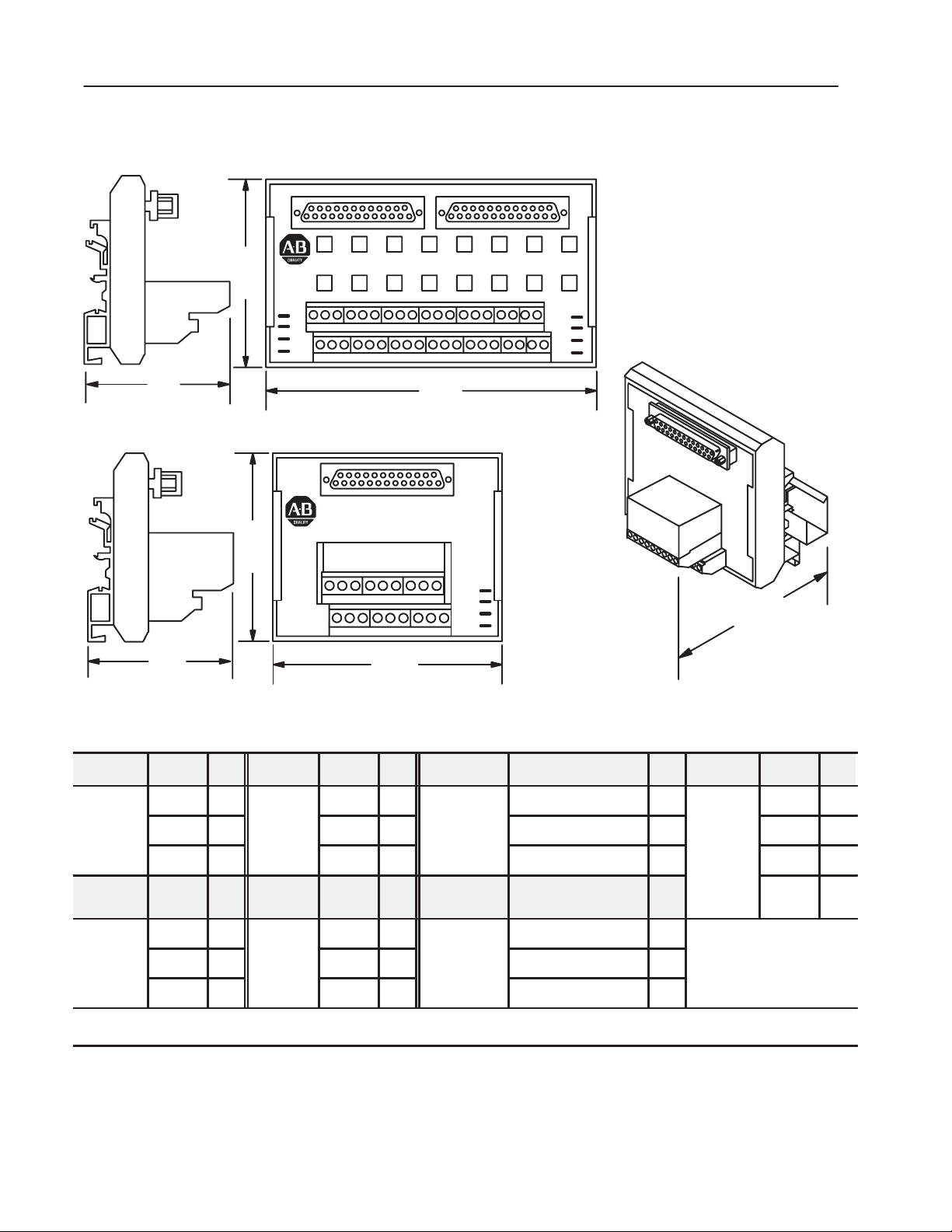

Table 2.A

Remote Termination Panel Connection Points for Field Devices (Channel 1 shown)

Input Type Connect To Input Type Connect To Input Type Connect To Input Type Connect To

Voltage

Output

Type

Voltage

+ I1

Ć

Shield S1

Connect To

R1

Current

(with

external

resistor)

Output

Type

+ O1 + O1

R1

Current

Ć

+ I1 + I1 + I1

Ć R1

Shield S1 Shield S1

Connect To Input Type Connect To

Thermocouple

Ć R1

Current

(Source/

Sink)

Shield S1

Power

Excitation (A) O1

Ć R1

RTD

Lead Compensation (B) I1

Shield S1 Shield S1 Common (C) R1

1

When using 4Ćwire RTD, leave the 4th wire open.

2

Not used when NĆSeries module is supplying loop power. Refer to Figure 2.6 in this document.

Publication 1771ĆUM127B-EN-P - December 2002

Ć

Loop

2

R1

O1

Page 25

Figure 2.3

Remote Termination Panel Wiring

2–7Installing the Module

Module End of

1771ĆNC cable

Example:

Channel 1 Connections

R1 = Return 1

I1 = Input 1

O1 = Output 1

S1 = Shield 1

RTP End of

1771ĆNC cable

Channel 1 Connections

R1 = Return 1

I1 = Input 1

O1 = Output 1

S1 = Shield 1

Note: Terminals W1, W2 and W3 are

spares.

Do not use terminals CR and CL.

RTP1

DIN Rail

Note: Terminals W1, W2 and W3 are

spares.

Do not use terminals CR and CL.

Module End of

1771ĆNC cable

RT41

RTP End of

1771ĆNC cable

DIN Rail

11024ĆI

Publication 1771ĆUM127B-EN-P - December 2002

Page 26

2–8 Installing the Module

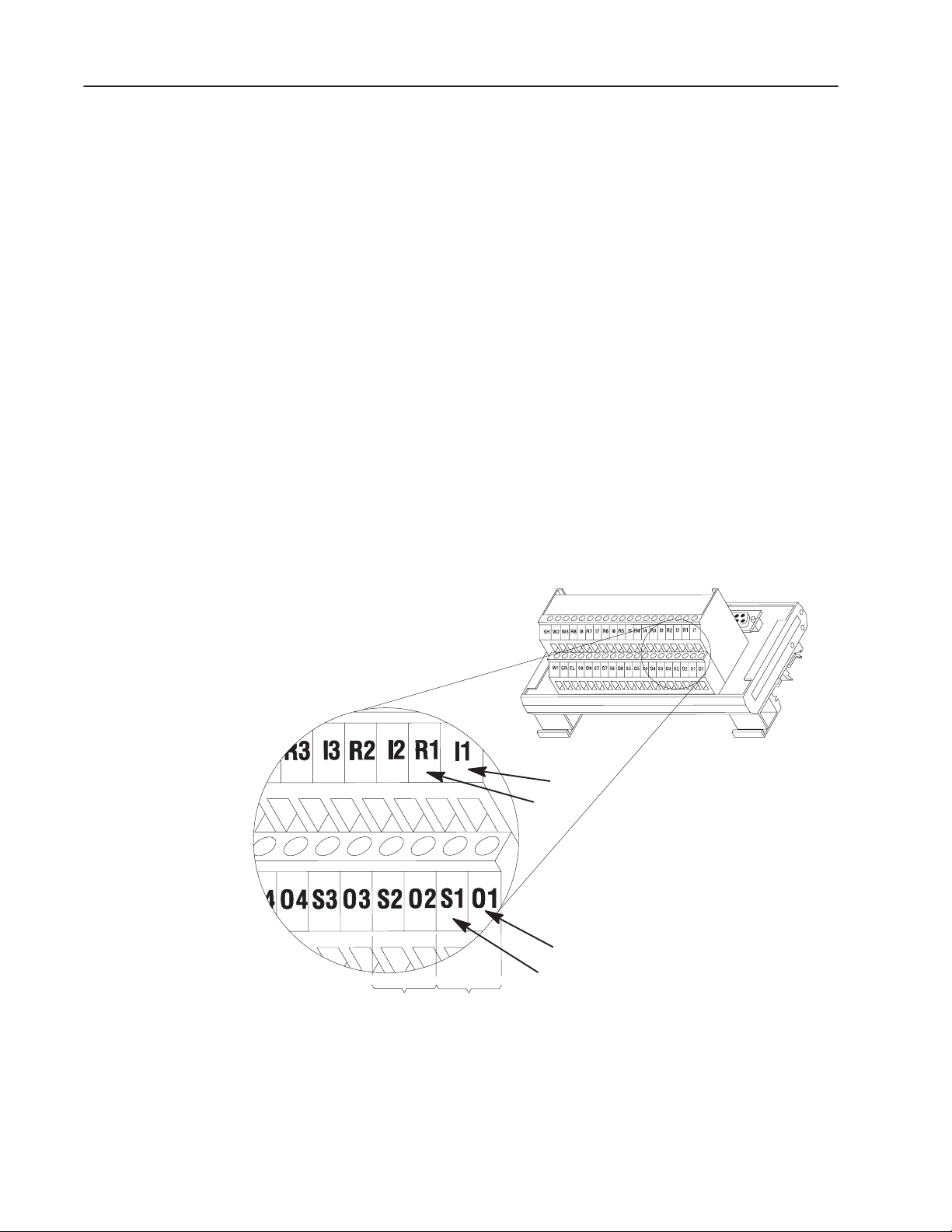

Field wiring to the remote termination panel is the same for all

remote termination panel variations. Refer to Figure 2.4.

Each channel has 4 connections: R, I, O, and S.

• R = return

• I = input

• O = output

• S = shield

Channel 1 would use R1, I1, O1, and S1; channel 2 would use R2,

I2, O2, and S2; and so on for the remaining channels.

To connect field wiring to the remote termination panel:

1. Strip 3/8 inch (9.25 mm) of insulation from the 22-12 AWG wire.

2. Insert the wire into the open connector slot.

3. Tighten the screw to 4.4–5.2 lb–in. (0.5–0.6Nm) to clamp the

wire.

Figure 2.4

Connecting Wire to the Remote Termination Panel

Each channel has four connections: R, I, O, and S.

Field wiring to the RTP is the same for all RTP variations.

Channel 1 uses R1, I1, O1, and S1; channel 2 uses R2, I2,

O2, and S2; and so on for the remaining channels.

Remote

Termination

Panel (RTP)

I = input

R = return

Field Wiring

O = output

S = shield

Publication 1771ĆUM127B-EN-P - December 2002

channel 2

channel 1

19621

Page 27

2–9Installing the Module

Connecting 4ĆWire

Sensors

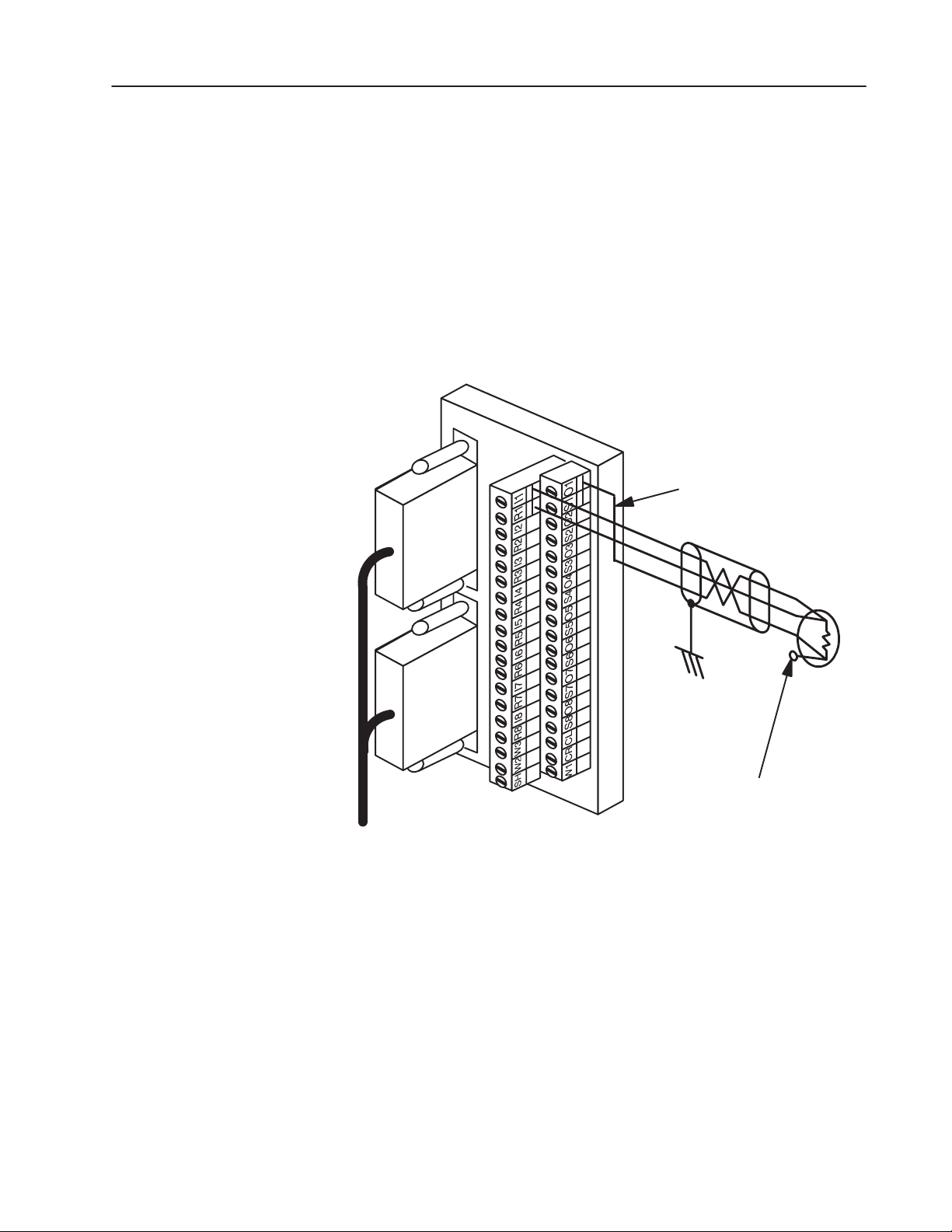

Figure 2.5 shows how to connect 4-wire sensors to the remote

termination panel. A 4-wire sensor has two pairs of leads; one pair

for each resistor junction. One wire of the four is not used (it does

not matter which one). This leaves three wires – one pair and one

single wire. You must connect the single wire to the terminal marked

“O_”. You connect the remaining pair of wires to terminals “I_” and

“R_”. It doesn’t matter which wire of the pair connects to terminal

“I_” and which wire connects to terminal “R_” so long as all three

wires are the same AWG gauge.

Figure 2.5

Connecting a 4ĆWire Sensor to the Remote Termination

Panel

Single lead connects

to terminal O

Note: In this illustration:

Terminal O is the 1mA excitation (A) sourcing current

Terminal I is the lead compensation (B) sense input

Terminal R is common (C)

Chassis

Ground

RTD

Leave 1 lead open

12935-I

Publication 1771ĆUM127B-EN-P - December 2002

Page 28

2–10 Installing the Module

Sourcing Input Analog

Modules

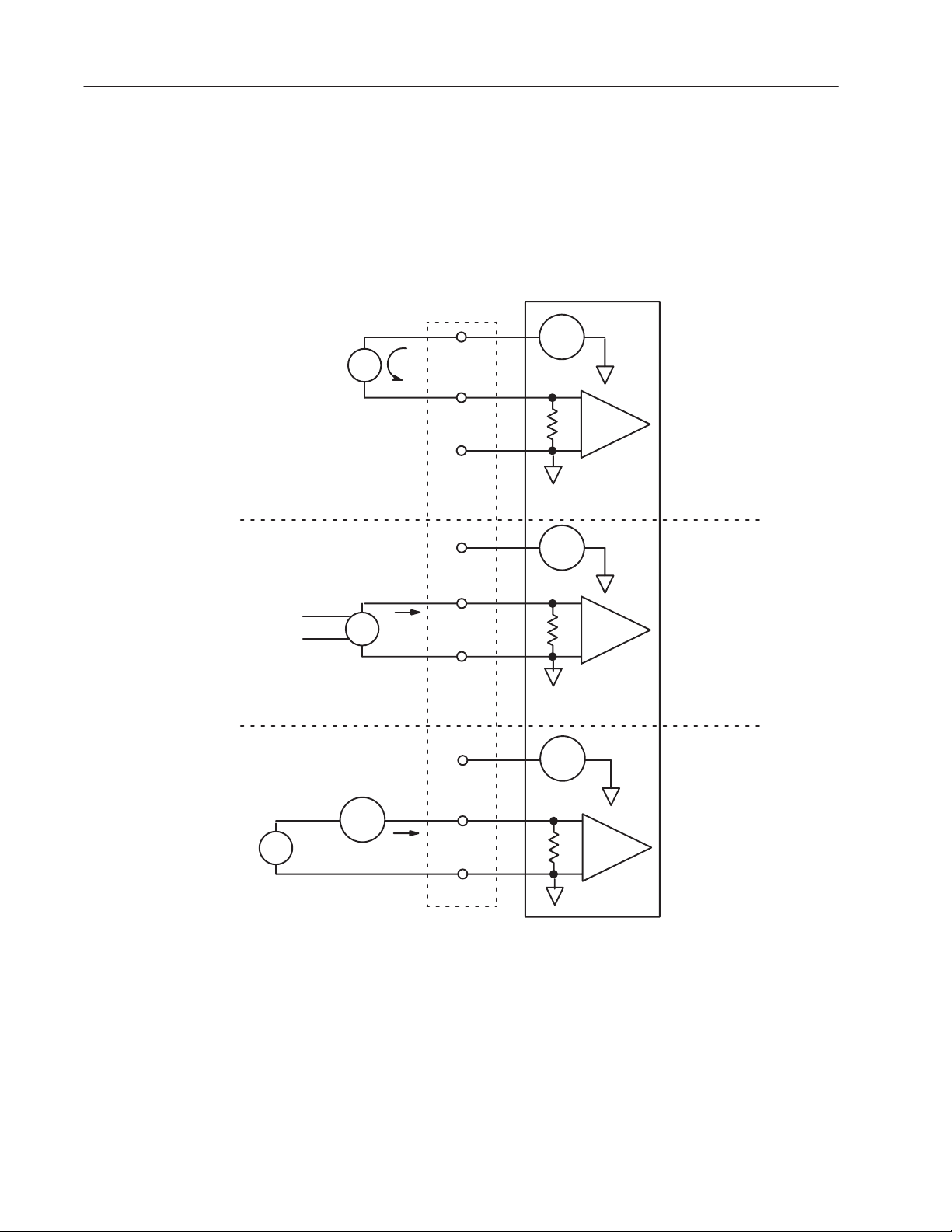

The 1771-NIS, 1771-NBSC and 1771-NB4S modules are

sourcing/sinking input modules. These modules can supply the

necessary loop power for 2-wire transmitters connected to the input.

All loop power functionality is contained within the analog module.

Examples of typical configurations are shown in Figure 2.6.

No external resistors are required.

Figure 2.6

Examples of Sourcing/Sinking Input Modules

2ĆWire Transmitter

4ĆWire Transmitter

RTP4

i

Output

Input

Return

Output

24V dc

24V dc

Input

Module supplies loop power

(sourcing)

24V dc

2ĆWire Transmitter

i

24V dc

i

Input

Return

Output

Input

Return

24V dc

Input

Input

User supplies loop power

with 4Ćwire transmitter

(sinking)

User supplies loop power

(sinking)

Inputs can be configured as sourcing or sinking inputs. For sourcing

inputs, the N-series module supplies the loop power. For sinking

inputs, you supply the loop power.

When the loop power is supplied externally, the 16-bit resolution

provides 65535 counts over the 0–20mA current range. This

provides about twice the resolution of voltage inputs with external

resistors.

Publication 1771ĆUM127B-EN-P - December 2002

Page 29

2–11Installing the Module

Thermistor

Making Your Own Cables

Module Top Connector Module Bottom Connector

Channel Number Signal 37ĆPin Connector Wire Color Channel Number Signal 37ĆPin Connector Wire Color

I1 20 Blk I5 20 Blk

1

2

3

O1

R1 21 Wht/Blk R5 21 Wht/Blk

I2 24 Orn I6 24 Orn

O2

R2 25 Wht R6 25 Wht

I3 29 Grn I7 29 Grn

O3

R3 30 Grn/Wht R7 30 Grn/Wht

If you are not using thermocouples, you can terminate the analog

module to a terminal block by cutting the 25-pin RTP end connector

off the standard cable and wiring to your terminal block. Refer to

Table 2.B for wire termination designations.

Table 2.B

Wire Termination Designations

22 Blk/Wht

26 Orn/Blk

31 Grn/Blk

5

6

7

O5 22 Blk/Wht

O6 26 Orn/Blk

O7 31 Grn/Blk

I4 33 Blu I8 33 Blu

4

O4

R4 34 Blu/Wht R8 34 Blu/Wht

35 Blu/Blk

8

Cold Junction

O8 35 Blu/Blk

36 Red

37 Red/Wht

Publication 1771ĆUM127B-EN-P - December 2002

Page 30

2–12 Installing the Module

Grounding the Field

Devices

When using shielded cable or shielded thermocouple extension wire,

ground the foil shield and drain wire only at one end of the cable.

We recommend that you wrap the foil shield and drain wire together

and connect them to the “S” connection on the RTP for the particular

channel. All shield connections are internally connected together in

the RTP so that only one wire is required to ground the entire remote

termination panel. Connect a wire from the “SH” connection on the

RTP to a ground stud on the metal cabinet in which the remote

termination panel is mounted.

If you do not want to ground a particular shield at the RTP, you can

remove the jumper for that particular channel. This will allow the

shield to float at the RTP end. To remove a jumper, you must cut it

out. Once the jumper is removed it cannot be replaced. Clip as

close to the circuit board as possible at both ends to completely

remove it. The jumpers (Figure 2.7) are labeled J1 through J8,

corresponding to channels 1 through 8 respectively.

Figure 2.7

Jumper Positions

Jumpers for channels

5 through 8

J8

J7

J6

J5

J1

J2

J3

J4

Jumpers for channels

1 through 4

Refer to publication 1770-4.1, Programmable Controller Wiring and

Grounding Guidelines, for additional information.

Publication 1771ĆUM127B-EN-P - December 2002

Page 31

2–13Installing the Module

Interpreting the

Indicator Lights

The front panel of the analog module contains two bi-color

indicators: a red/green RUN/FLT (fault) indicator and a red/green

CAL/COM indicator (Figure 2.8).

Figure 2.8

Diagnostic Indicators

Run/Fault indicator. This indicator will flash green

until the first valid block transfer write has been

RUN/FLT

CAL/COM

received. If a fault is found initially or occurs later, the

RUN/FLT indicator turns red.

Calibrate/communication indicator. This indicator will

flash green when doing block transfers. It will flash red

during calibration.

10528ĆI

At power-up, an initial module self-check occurs. The RUN/FLT

indicator will be green when the check is completed satisfactorily. It

will flash green until the first valid block transfer write has been

received. If a fault is found initially or occurs later, the RUN/FLT

indicator turns red.

Chapter Summary

The bottom indicator is the calibrate/communication indicator. This

indicator will flash green when doing block transfers. It will flash red

during calibration.

Possible module fault causes and corrective action are discussed in

Chapter 7, “Troubleshooting.”

In this chapter you learned how to install your module in an existing

programmable controller system and how to wire to the remote

termination panel.

Publication 1771ĆUM127B-EN-P - December 2002

Page 32

2–14 Installing the Module

Publication 1771ĆUM127B-EN-P - December 2002

Page 33

Chapter 3

Communicating With Your

Analog Module

Chapter Objectives

Block Transfer

Programming

configure the module

send data to the output channels

of those modules having outputs

In this chapter, we describe

• block transfer programming

• quick-startup sample programs for the PLC-3 and PLC-5

processors

• module scan time issues

Your module communicates with the processor through bidirectional

block transfers. This is the sequential operation of both read and

write block transfer instructions.

For the 1771-N series modules, block transfer writes (BTWs) can

perform two different functions.

If you want to: Description This type of BTW is called:

This involves setting the bits which enable the

programmable features of the module, such as

scaling, alarming, real time sampling, etc.

This type of BTW is generally shorter in length

than the configuring BTW because it does not

configure the module each time it is initiated.

the configuration BTW”

the output update BTW"

A configuration BTW is initiated when the analog module is first

powered up, and subsequently only when the programmer wants to

enable or disable features of the module.

An output update BTW is initiated when the programmer wants the

output channels on the module to change value. This shortened

version of the BTW allows faster response time from the output

channels.

The following example programs are minimum programs; all rungs

and conditioning must be included in your application program. You

can disable BTRs, or add interlocks to prevent writes if desired. Do

not eliminate any storage bits or interlocks included in the sample

programs. If interlocks are removed, the program may not work

properly.

Publication 1771ĆUM127B-EN-P - December 2002

Page 34

3–2 Communicating With Your Analog Module

Your analog module works with a default configuration upon

powerup as long as a block transfer write (BTW) has not been

initiated. See the configuration default section in chapter 4 to

understand what this configuration looks like. Refer to the sample

programs in this chapter to get started.

Your program should monitor status bits (such as overrange,

underrange, alarms, etc.) and block transfer read activity.

The following example programs illustrate the minimum

programming required for the 1771-N series module to powerup and

operate.

PLCĆ2 Programming

PLCĆ3 Program Example

Due to the number of digits required for high resolution readings, the

1771-N series modules normally read input values in 2’s complement

binary. Binary coded decimal (BCD) can be used, but with lower

resolution. As a result, the 1771-N series modules are not

recommended for use with PLC-2 family programmable controllers.

Block transfer instructions with the PLC-3 processor use three data

table files. A binary file is used for module location and other related

data. This is the block transfer control file. Two separate block

transfer data files store data that you want transferred to the module

(when programming a block transfer write) or from the module

(when programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The industrial terminal prompts you to create a control file when a

block transfer instruction is being programmed. The same block

transfer control file is used for both the read and write

instructions for your module. A different block transfer control file

is required for every module.

An example program segment with block transfer instructions is

shown in Figure 3.1, and described below.

Publication 1771ĆUM127B-EN-P - December 2002

Page 35

Figure 3.1

PLCĆ3 Family Sample Program Structure

3–3Communicating With Your Analog Module

Program Action

At powerup, the user program enables a

block transfer read. Then it initiates a

block transfer write to configure module.

Thereafter, the program continuouslyperĆ

forms read and write block transfers.

PLCĆ5 and PLCĆ5/250

Program Example

BTR

BLOCK XFER READ

Block Transfer

1

Read Done Bit

Block Transfer

2

Write Done Bit

RACK:

GROUP:

MODULE:

DATA:

LENGTH:

CNTL:

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

DATA:

LENGTH:

CNTL:

X = XXXX

XXXX:XXXX

XXXX:XXXX

X = XXXX

XXXX:XXXX

XXXX:XXXX

XXX

XXX

Enable

EN

12

X

Done

DN

15

00

Error

ER

13

Enable

EN

02

Done

X

DN

05

Error

00

ER

03

This program is very similar to the PLC-3 program with the

following exceptions:

• Block transfer enable bits are used instead of done bits as the

conditions on each rung.

• Separate block transfer control files are used for the block

transfer instructions.

Program Action

At powerup, the user program enables a

block transferread. Thenit initiatesa block

transfer write to configure module.

Thereafter, the program continuously perĆ

forms read and write block transfers.

Figure 3.2

PLCĆ5 Family Sample Program Structure

1

2

BTR Enable

BTR

Enable

BTW Enable

BTW

Enabl

e

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

XXX:XX

XXX:XX

XXX:XX

XXX:XX

EN

X

X

DN

X

ER

00

N

EN

X

X

DN

X

ER

00

N

Publication 1771ĆUM127B-EN-P - December 2002

Page 36

3–4 Communicating With Your Analog Module

Module Scan Time

Scan time is defined as the amount of time it takes for the module to

read the input channels and place new data into the data buffer

and/or read the data buffer and write new data to the output channels.

Scan time for your module is shown in Figure 3.3.

Figure 3.3

Block Transfer Time

End of Block

Transfer Write

Block

Transfer

Write

Time

1 2 3 456

Internal scan time = 25ms

Configure

Time

Module available

to perform block transfer

1st Scan 2nd Scan 3rd Scan

The following description references the sequence numbers in

Figure 3.3.

Following a block transfer write (1) the module inhibits

communication until after it has configured the data and loaded

calibration constants (2), scanned the inputs and/or outputs (3), and

filled the data buffer (4). Configuration block transfers, therefore,

should only be performed when the module is being configured or

calibrated.

10529ĆI

Programming Samples

Any time after the buffer is filled (4), a block transfer read (BTR)

request can be acknowledged.

When operated in the default mode, new data will be available for a

BTR every 25 milliseconds. When operated in real time sample

mode

(RTS = T), BTRs will be ignored by the module for “T”

milliseconds, at which time a single BTR will be allowed.

The following are sample programs for using your modules more

efficiently when operating with the PLC-3 or PLC-5 family

processors.

These programs show you how to configure the module and read

data from the module, and efficiently update the output channels on

those modules with outputs.

Refer to the proper PLC-3 or PLC-5 documentation for additional

information on processor programming and data entry.

Publication 1771ĆUM127B-EN-P - December 2002

Page 37

3–5Communicating With Your Analog Module

The differences between the types of 1771-N series modules is

related to the number of output channels each module has. A module

with only inputs (no outputs) requires one BTW after powerup.

Thereafter, it sends back input data and module status by way of

BTRs.

A module with outputs requires BTWs to configure it and update its

output data. BTRs are required to send back input data and module

status.

Sample Ladder Diagram Ć PLCĆ3 Family Processors

The following PLC-3 program can be used for all 1771-N series

modules. The program can be altered to effectively address modules

with or without output channels.

Figure 3.4

PLCĆ3 Family Example Program Structure

Rung 1

Rung 2

Rung 3

Rung 4

BTR

07

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE

LENGTH:

MOV

SOURCE:

DESTINATION:

MOV

SOURCE:

DESTINATION:

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE

LENGTH:

0

0

0

#B1:10

#N1:0

0

0000000000111011

0000000000001001

0000000000001001

0000000000001001

0

0

0

#B1:10

#N1:100

9

Block Transfer

Read Error Bit

B1:10

13

Pushbutton

I0:2

00

Power-up Bit

N1:1

17

Pushbutton

I0:2

00

Block Transfer

Write Error Bit

B1:10

03

Block Transfer

Read Done Bit

B1:10

15

Block Transfer

Write Done Bit

Power-up Bit

N1:1

17

Block Transfer

Write Done Bit

B1:10

05

B1:10

07

Block Transfer

Write Done Bit

B1:10

This program changes the length of the block transfer write from 59 words at powerup

or when reconfigured, to 9 words at all other times.

Enable

EN

12

Done

DN

15

ER

13

B1:0

B1:15

B1:1

B1:15

Enable

EN

Done

DN

Error

ER

03

Error

02

05

Publication 1771ĆUM127B-EN-P - December 2002

Page 38

3–6 Communicating With Your Analog Module

o

Modules without output channels do not require rungs 2 and 3.

Instead, move the input condition instructions from rung 2 to the

front of rung 4, and specify the BTW length equal to 59.

Sample Ladder Diagram Ć PLCĆ5 Family Processors

The following PLC-5 program is very similar to the preceding

PLC-3 program with the following exceptions:

• You use enable bits instead of done bits as the conditions on each

rung.

• A separate control file must be selected for each of the block

transfer instructions.

Figure 3.5

PLCĆ5 Family Example Program Structure

For the following example, assume the analog module is physically located at rack address 01, module group 00, module sl

and the input module connected to the pushbutton is located at rack address 00, module group 7, slot 6. The block transfer

data files correspond to the example on the following pages.

BTR Enable

1

2

3

4

N10:0 N10:5

15

Pushbutton

I:007 N10:5

00 15

Powerup Bit

N10:11

15

Pushbutton

I:007 N10:5

00 15

BTR

Enable

N10:0 N10:5

15 15

BTW Enable

Powerup Bit

N10:11

15

* Length = (number of outputs + 1) words.

For 2 output/6 input modules, this would be equal to 3.

Modules without output channels do not require rungs 2 and 3. Instead, move

the input

condition instructions (pushbutton and powerup) from rung 2 to the front of rung

4, and specify the BTW length equal to 59.

BTR

BLOCK XFER READ

RACK:

15

BTW

Enable

BTW

Enable

BTW

Enable

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

CPT

COMPUTE

DEST

EXPRESSION

CPT

COMPUTE

DEST

EXPRESSION

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

N10:10

N10:80

N10:0

N10:6

N10:6

N10:5

EN

01

00

DN

0

ER

00

N

59

9

EN

01

00

DN

0

ER

*

N

Publication 1771ĆUM127B-EN-P - December 2002

Page 39

3–7Communicating With Your Analog Module

Setting Up the Data

Table File

Channel 1 400/2000 0/0 1.6 Minimum Ye s N/A

Channel 2 Ć1000/1000 Ć900/900 8.0 User Ye s 100

Channel 3 0/0 25000/26000 17 Ye s 20.0 0.5 N/A N/A B

Scale Value

Low/High

(counts)

Scale Value

Low/High

(counts)

If you use a 1771-NBTC module with the parameters listed below,

the PLC-5 data table file screen on an industrial terminal screen

would look similar to Figure 3.6.

Overall Module Functions Chosen

Number of outputs: 2

Verify mode: Disabled

Temperature Scale: Fahrenheit

BCD Select Bit: 2's complement binary data format

Cold Junction Temperature Alarm: Enabled

Real Time Sampling Rate: 200 milliseconds

Clamp Value

Low/High

(counts)

Alarm Value

Low/High

(counts)

Max Output

Ramp Rate

(mA/sec)

Input Rate

Alarm

o

F/sec)

(

Reset

State

Alarm

Enable

Alarm

Enable

Alarm

Deadband

o

F)

(

Reset

Value

(mA)

Filter

Time

(sec)

10 Ohm

Offset

RTD

TypeTCType

Channel 4 0/0 10000/10500 1.7 Yes 10.0 1.0 N/A N/A E

Channel 5 0/0 20000/20500 1.7 Yes 10.0 1.5 N/A N/A J

Channel 6 0/0 10000/10500 1.7 Yes 10.0 2.0 N/A N/A K

Channel 7 0/0 20000/21000 N/A Ye s 20.0 2.5 N/A N/A R

Channel 8 0/0 30000/31000 N/A Ye s 20.0 3.0 N/A N/A S

The above configuration for the 2 output/6 input module (cat. no.

1771-NBTC) would be set up using the following PLC-5 data table

file (Figure 3.6).

Publication 1771ĆUM127B-EN-P - December 2002

Page 40

3–8 Communicating With Your Analog Module

Figure 3.6

Sample PLCĆ5 Data File (Hexadecimal Data) for a

2 Output/6 Input Module

0

Address

N10:0

N10:10

N10:20

N10:30

N10:40

N10:50

N10:60

N10:70

N10:80

N10:90

N10:100

N10:110

N10:120

N10:130

C684

8800

8010

0062

0000

0000

0000

0000

8820

0000

6590

2000

2710

19C8

1

0000

2000

0C71

0062

0000

0000

0000

0000

04B0

FC18

80AA

0000

2904

5000

Press a function key or enter a

value.

N10:25 =

Rem Prog Forces: None

2

001C

000A

8000

02EC

8010

0EA4

0005

0005

0000

0000

0000

0000

0000

0000

0000

0000

0000

8002

03E8

FC7C

05C8

1000

0000

4E20

1464

801

1

0000

0000

Data: Hex/BCD Addr: Decimal 5/25 Addr 11 APL_NBTC

4

3

000A

6404

0000

39A9

8010

1288

0005

0005

0000

0000

0000

0000

0000

0000

0000

0000

00C8

0190

0384

E032

0000

0000

5014

8011

0000

4000

7918

7530

6

5

003B

0000

39C1

0000

4045

8010

0005

0005

0000

0000

0000

0000

0000

0000

0000

0000

0000

07D0

0000

0064

2904

2710

3000

0E64

0000

4E20

8000

1DC8

8

7

000A

642C

8000

44E6

8010

0000

0000

0000

0000

0000

A00A

0000

61A8

0000

0A64

8011

0000

0000

5208

8000

6000

0000

9

0050

0000

0000

0000

0000

0000

Chapter Summary

Change

Radix

F1

Specify

Address

F5

The block transfer read data file is located at N10:10 thru N10:37.

The block transfer write data file is located at N10:80 thru N10:138.

In this chapter, you learned how to program your programmable

controller. You were given sample programs for your PLC-3 and

PLC-5 family processors, and shown what the data file for a module

looks like.

You also read about module scan time.

Next

File

F7

Prev

File

F8

Publication 1771ĆUM127B-EN-P - December 2002

Page 41

Chapter 4

Configuring the Module

Chapter Objectives

Configuring the High

Resolution Isolated

Analog Modules

In this chapter you will read how to:

• configure your module’s features

• condition your inputs and outputs and

• enter your data.

Because of the many analog devices available and the wide variety

of possible configurations, you must configure your module to

conform to the analog device and specific application that you have

chosen. Data is conditioned through a group of data table words that

are transferred to the module using a block transfer write instruction.

Configure your module for its intended operation by means of your

programming terminal and write block transfers.

Note: Programmable controllers that use 6200 software (release 4.2

or higher) programming tools can take advantage of the IOCONFIG

Addendum utility to configure this module. IOCONFIG Addendum

uses menu-based screens for configuration without having to set

individual bits in particular locations. You must have block

transfer read and block transfer write rungs in your program

before using IOCONFIG software. Refer to your 6200 software

literature for details.

Important: It is strongly recommended that you use IOCONFIG to

configure this module. The IOCONFIG utility greatly

simplifies configuration. If the IOCONFIG is not

available, you must enter data directly into the data

table. Use this chapter as a reference when performing

this task.

Note: Programmable controllers that use process configuration and

operation software (cat. no. 6190-PCO) can take advantage of those

development and runtime tools used for the application of

programmable controllers in process control. The PCO worksheets

and the menu-driven configuration screens and faceplates let you

configure, test/debug and operate the I/O module. Refer to your

6190-PCO software literature for details.

During normal operation, the processor transfers from 1 to 59 words

to the module when you program a BTW instruction to the module’s

address. The BTW file contains configuration words, high and low

channel alarm settings, and calibration values that you enter for each

channel.

Publication 1771ĆUM127B-EN-P - December 2002

Page 42

4–2 Configuring the Module

When making entries in the configuration block, use binary or

hexadecimal only.

Default Configurations

The modules can be operated in a default mode by using zeroes in all

but the first word of the BTW data file. The first word must identify

the number of outputs on the module. For example, the first word

for the 8 output module (cat. no. 1771-NOC) would be 8880

hexadecimal; the first word for the 2 out/6 input module (cat. no.

1771-NBVC, -NBTC, -NBRC) would be 8820 hexadecimal; and the

first word for the 8 input module (cat. no. 1771-NIV, -NT1, -NR)

would be 8800 hexadecimal.

First Word in BTW file

8880 hexadecimal 8

8870 hexadecimal 7

8860 hexadecimal 6

8850 hexadecimal 5

8840 hexadecimal 4

8830 hexadecimal 3

8820 hexadecimal 2

8810 hexadecimal 1

8800 hexadecimal 0

Number of

Outputs

The default scaling values that apply to the inputs and outputs are

listed in the specifications in appendix A. In default mode, all

programmable features (alarming, filtering, real time sampling, etc.)

are disabled.

Publication 1771ĆUM127B-EN-P - December 2002

Page 43

4–3Configuring the Module

Module Level

Programming Features

Module level programming features include:

• module “configuration” verification

• temperature scale

• data format

• real time sample

Module Configuration" Verification

The verify bit 00 in the block transfer write word 3 allows you to

compare the configuration information the module is using to the

configuration information contained in a block transfer write (BTW).

You set the verify bit in the BTW you wish to check, and download

the BTW to the module. After the BTW is completed, request a BTR

from the module. The program verify field in the BTR (bits 09-10

decimal, bits bits 11-12 octal, word 1) will contain either of two

values: 10 (binary) indicates the verify failed; 11 (binary) indicates

the verify succeeded.

If the verify bit is set, configuration information in the BTW data file

will not be used by the module regardless of the success or failure of

the verify.

Temperature Scale

You select the temperature scale that the module will use when

returning temperature to the processor using bit 01, word 3 of the

block transfer write data file. If the bit is set to 0, the temperature is

in degrees C; if the bit is set to 1, the temperature is in degrees F.

Data Format

Use bit 02, word 3 of the block transfer write data file to select a data

format. If this bit is 0, all data fields will be in two’s complement

binary format. If the bit is 1, all fields will be in BCD format. In

BCD, the most significant bit is the sign bit for all signed fields. This

sign bit applies to both BTW and BTR words.

NOTE: Available resolution is poor when using BCD format.

The 4-digit BCD format uses an arrangement of 16 binary digits to

represent a 4-digit decimal number from 0000 to 9999 (Figure 4.1).

The BCD format is used when the input values are to be displayed

for operator viewing. Each group of four binary digits is used to

represent a number from 0 to 9. The place values for each group of

0

digits are 2

group of four binary digits is determined by multiplying the binary

digit by its corresponding place value and adding these numbers.

, 21, 22 and 23 (Table 4.A). The decimal equivalent for a

Publication 1771ĆUM127B-EN-P - December 2002

Page 44

4–4 Configuring the Module

The 1771-N series modules use 15-bit signed magnitude BCD. The

maximum range value available then becomes +

Figure 4.1

4ĆDigit Binary Coded Decimal

Sign Bit Ć

0=+

1X22=4

1

=2

1X2

0

1X2

=1

0111100110011001

Sign

Bit

7

99

1=Ć

7

1X2

0X2

0X2

1X2

3

=8

2

=0

=0

=1

1X2

0X2

0X2

1X2

9

3

=8

2

=0

1

=0

0

=1

1

0

7999.

9

3

1X2

=8

2

0X2

=0

9

1

=0

0X2

0

1X2

=1

9

10

12955ĆI

Table 4.A

BCD Representation

3

(8) 22(4) 21(2) 20(1)

2

Place Value

0 0 0 0 0

0 0 0 1 1

0 0 1 0 2

0 0 1 1 3

0 1 0 0 4

0 1 0 1 5

0 1 1 0 6

0 1 1 1 7

1 0 0 0 8

1 0 0 1 9

Decimal

Equivalent

Publication 1771ĆUM127B-EN-P - December 2002

Page 45

4–5Configuring the Module

Two's Complement Binary

Two’s complement binary is used with PLC-3 processors when

performing mathematical calculations internal to the processor. To

complement a number means to change it to a negative number. For

example, the following binary number is equal to decimal 22.

10110

= 22

2

10

First, the two’s complement method places an extra bit (sign bit) in

the left-most position, and lets this bit determine whether the number

is positive or negative. The number is positive if the sign bit is 0 and

negative if the sign bit is 1. Using the complement method:

0 10110 = 22

To get the negative using the two’s complement method, you must

invert each bit from right to left after the first “1” is detected.

In the above example:

0 10110 = +22

Its two’s complement would be:

1 01010 = -22

Note that in the above representation for +22, starting from the right,