Page 1

DeviceNet

Interface

Catalog Number 1761-NET-DNI

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

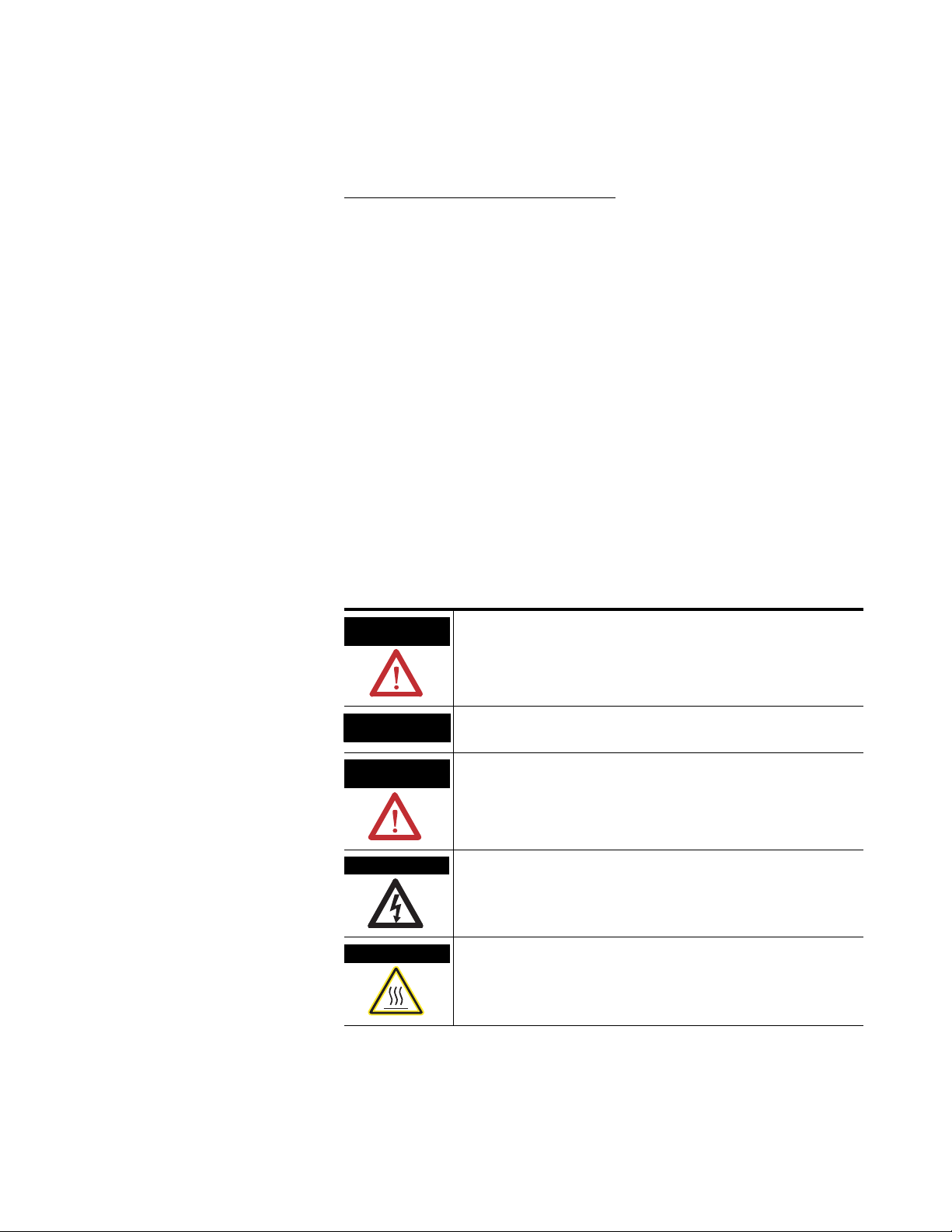

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Page 3

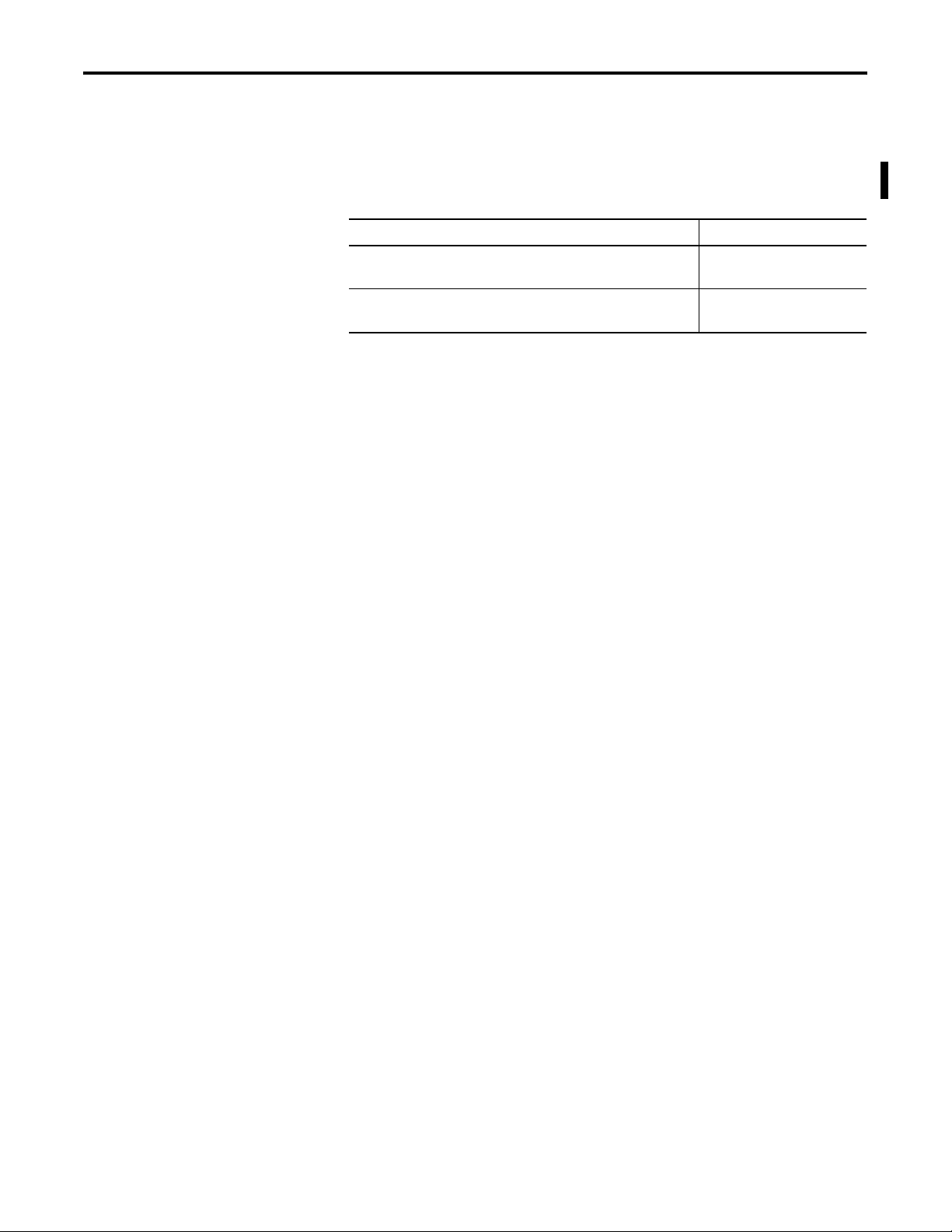

Summary of Changes

The information below summarizes the changes to this manual since

the last revision.

Revision bars in the margin identify updated information. The

following changes are included in this version of the document.

Change Page

Added note that programming over a DeviceNet network is

available only with RSLogix 5/500-based controllers.

21

Added note that remote access to a DeviceNet network is

available only with RSLogix 5/500-based controllers.

22

3 Publication 1761-UM005B-EN-P - October 2006

Page 4

4 Summary of Changes

Publication 1761-UM005B-EN-P - October 2006

Page 5

Overview

Quick Start

Operation

Table of Contents

Preface

About This Publication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Who Should Use This Publication . . . . . . . . . . . . . . . . . . . . . 7

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Device Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 2

Configure Peer-to-peer Messaging . . . . . . . . . . . . . . . . . . . . 11

Configuring Master/Slave I/O . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 3

Modes of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DeviceNet I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Network Configuration Software . . . . . . . . . . . . . . . . . . . . . 18

Messaging Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Programming Over the DeviceNet Network . . . . . . . . . . . . . 21

Installation and Wiring

DNI Configuration Parameters and

Programming Notes

Setup, Programming, and

Troubleshooting

Chapter 4

European Communities (EC) Directive Compliance . . . . . . . 23

Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Network Port Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cable Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 5

Information About DNI Series B . . . . . . . . . . . . . . . . . . . . . 27

EDS Parameters for the DNI . . . . . . . . . . . . . . . . . . . . . . . . 28

Programming Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Chapter 6

DNI Software Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Setting Up Network Configuration Software . . . . . . . . . . . . . 55

Commissioning the DNI . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Programming Over the DeviceNet Network . . . . . . . . . . . . . 59

Modifying DNI Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . 60

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fault Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

DNI Series A DeviceNet Class Codes . . . . . . . . . . . . . . . . . . 65

DNI Series B DeviceNet Class Codes . . . . . . . . . . . . . . . . . . 66

5 Publication 1761-UM005B-EN-P - October 2006

Page 6

Table of Contents 6

Application Examples

Explicit Messaging (DNI Series B

Only)

Specifications

Chapter 7

MicroLogix as I/O on the DeviceNet Network . . . . . . . . . . . 69

Example DNI Configuration Parameters . . . . . . . . . . . . . . . . 70

Example Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 8

Using DF1 Protocol for Explicit Messages Over a DeviceNet

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Routing Profile Configuration. . . . . . . . . . . . . . . . . . . . . . . . 79

Explicit Messaging Examples . . . . . . . . . . . . . . . . . . . . . . . . 80

Appendix A

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

DeviceNet Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Glossary

Interface Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Terms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Index

Publication 1761-UM005B-EN-P - October 2006

Page 7

Preface

About This Publication

Who Should Use This Publication

Conventions

This user manual introduces the DeviceNet Interface (DNI) and

explains the procedures you need to install, configure, and

commission the interface.

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use

Allen-Bradley controllers on a DeviceNet network.

You should have a basic understanding of Allen-Bradley

programmable controllers and DeviceNet technology. You should

understand programmable controllers and be able to interpret the

ladder logic instructions required to control your application. If you

do not, contact your local Allen-Bradley representative for information

on available training courses before using this product.

Text that is Identifies

Bold Emphasis, not used within programming text

Italic Software variables and configurable catalog numbers

courier

Example programming code, shown in a monospace font so

you can identify each character and space

7 Publication 1761-UM005B-EN-P - October 2006

Page 8

8 Preface

Additional Resources

Resource Description

MicroMentor, publication 1761-RM001 Information on understanding and applying micro

controllers.

AIC+ Advanced Interface Converter and DeviceNet

Interface Installation Instructions, publication 1761-IN002

MicroLogix 1000 Controllers User Manual,

publication 1761-UM003

MicroLogix 1500 Controllers User Manual,

publication 1764-UM001

SLC 500™ Modular Hardware Style User Manual,

publication 1747-UM011

PLC User Manual, publication 1785-UM001

SLC 500 and MicroLogix 1000 Instruction Set Reference

Manual, publication 1747-RM001

DeviceNet Manager Software User Manual,

publication 1787-UM053

1747 DeviceNet Scanner Installation Instructions,

publication 1747-IN058

1747 DeviceNet Scanner User Manual,

publication 1747-UM655

1771 DeviceNet Scanner Configuration Manual,

publication 1771-UM118

DeviceNet Cable System Planning and Installation

Manual, publication DNET-UM072

Mounting instructions for the DeviceNet Interface

Information on MicroLogix 1000 Controllers

Information on MicroLogix 1500 Controllers

Information on SLC Controllers

Information on PLC

A reference manual that contains status file data and

instruction set information

Information on DeviceNet Manager

Information on 1747 DeviceNet Scanner

Information on 1771 DeviceNet Scanner

Planning and installing a DeviceNet cable system

®

Controllers

Allen-Bradley Programmable Controller Grounding and

Wiring Guidelines, publication 1770-IN041

Allen-Bradley Industrial Automation Glossary,

publication AG-QR071

Publication 1761-UM005B-EN-P - October 2006

In-depth information on grounding and wiring

Allen-Bradley programmable controllers

A glossary of industrial automation terms and

abbreviations

Page 9

Overview

Chapter

1

Introduction

The DeviceNet interface is a standalone, DIN-rail or panel mounted,

intelligent DeviceNet-to-DF1 protocol-conversion device that lets

existing DF1 devices communicate on a DeviceNet network. The DF1

device exchanges I/O data with a Master device and originates and

receives DF1 encapsulated DeviceNet messages across a DeviceNet

network.

The DNI provides a single DeviceNet connection point and a single

RS-232 connection. The DeviceNet port is isolated from the DNI

digital logic and RS-232 port.

The primary functions of the DNI are:

• Collect or receive input data from the DF1 device connected on

its RS-232 port and forward that data to a connected master on

DeviceNet network.

• Monitor output data received from the DeviceNet master and

write that data to the DF1 device.

• Allow DF1 devices to send and receive messages across the

DeviceNet network.

Operating Modes

Device Compatibility

9 Publication 1761-UM005B-EN-P - October 2006

The DNI can be used in either or both of the following modes.

• Peer-to-peer

• DeviceNet slave

The DNI can be used to interconnect the following devices.

• MicroLogix controllers

• DF1 Full Duplex compliant products, for example: PLC-5

programmable controllers, operator interface devices, and SLC

5/03™ and higher processors

Page 10

10 Overview

Publication 1761-UM005B-EN-P - October 2006

Page 11

Chapter

2

Quick Start

This chapter can help you to get started using the 1761-NET-DNI

DeviceNet Interface (DNI). We base the procedures here on the

assumption that you have an understanding of MicroLogix products.

You should understand electronic process control and be able to

interpret the ladder logic instructions required to generate the

electronic signals that control your application.

Because this is a start-up guide for experienced users, this chapter

does not contain detailed explanations about the procedures listed. It

does, however, reference other chapters in this book where you can

get more information.

Configure Peer-to-peer Messaging

If you have any questions or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended documentation before

trying to apply the information.

Follow these steps to communicate with other controllers connected

to DNIs on a DeviceNet network.

1. Unpack and mount the DNI.

2. Connect the DNI to the DeviceNet network.

When power is first applied to the DNI, it resides at node 63 on

the network. The DNI out-of-box configuration is defaulted to

Autobaud; it synchronizes to the DeviceNet network baud rate.

3. Connect a DF1 device to the DNI.

The DF1 connection automatically enters the Autobaud mode; it

synchronizes to the attached DF1 device.

4. Connect to the DNI with your network configuration tool

(software such as the DNI Configuration Utility, RSNetWorx, or

DeviceNet Manager) and set the DNI to the desired node

number. This is called commissioning the DNI.

See Commissioning the DNI on page 58 for more details.

11 Publication 1761-UM005B-EN-P - October 2006

Page 12

12 Quick Start

IMPORTANT

If your network consists entirely of DNIs (no master is present),

you must disable Autobaud on at least one DNI. It is

recommended that all DNIs be manually set to a specific baud

rate. This is to prevent multiple DNIs from hunting for a baud

rate at power-up.

5. To exchange data with other controllers over a DeviceNet

network, configure a message instruction inside each controller’s

program.

See Programming Over the DeviceNet Network on page 21 for

more information.

6. To send data to a specific controller on the network, enter the

destination DNI’s DeviceNet node address into the destination

parameter of a message instruction. Think of each

DNI/Controller pair as one unit.

EXAMPLE

To send a message from controller A (plugged into DNI number

5) to controller B (plugged into DNI number 10), controller A

must have a message instruction with a destination node

address of 10.

See the application example MicroLogix as I/O on the

DeviceNet Network on page 69 for an example ladder program.

Publication 1761-UM005B-EN-P - October 2006

Page 13

Configuring Master/Slave

Quick Start 13

I/O

IMPORTANT

Follow these steps to configure a DNI connected to a MicroLogix 1000

controller as a slave device to a DeviceNet master.

1. Unpack and mount the DNI.

2. Connect the DNI to the DeviceNet Network.

When power is first applied to the DNI, it resides at node 63 on

the network. The DNI out-of-box configuration is defaulted to

Autobaud; it synchronizes to the DeviceNet network baud rate.

3. Connect to the DNI with your network configuration tool

(software such as DeviceNet Manager or RSNetWorx) and set the

DNI to the desired node number. This is called node

commissioning.

4. Double-click on the DNI icon to open the DNI’s EDS.

You must have the DNI’s EDS (electronic data sheet) file and

bitmap file (or icon) loaded into your configuration software.

See DNI Software Files on page 53 and Setting Up Network

Configuration Software on page 55 for more information.

5. For DNI Series A: set DNI Mode (parameter 17) to Standby mode

(0).

For DNI Series B: set I/O Scan Enable (parameter 12) to disable

(0) (default).

6. Click Save to Device.

Publication 1761-UM005B-EN-P - October 2006

Page 14

14 Quick Start

To configure a MicroLogix 1000 controller as a slave device to a

DeviceNet master, set the parameters as shown in the following table.

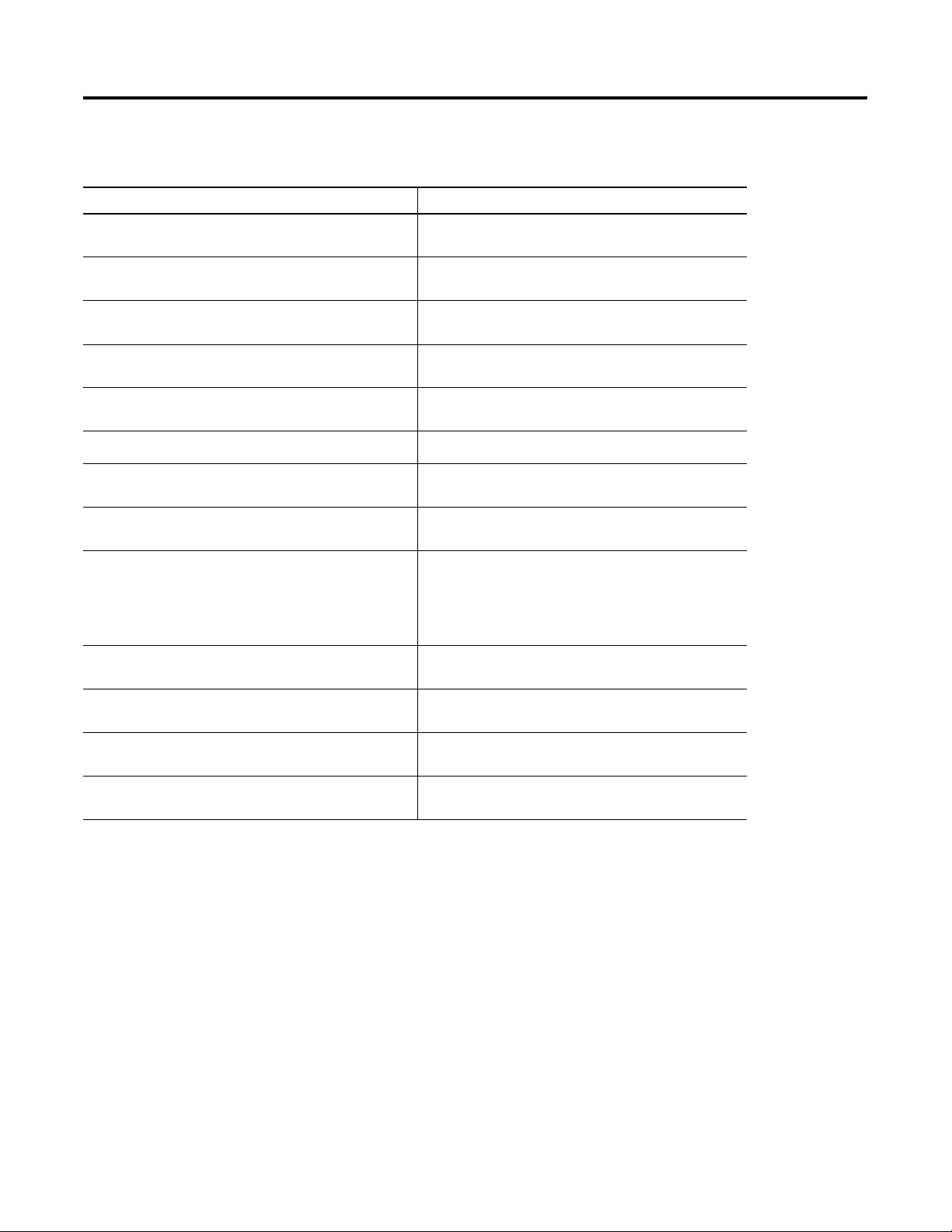

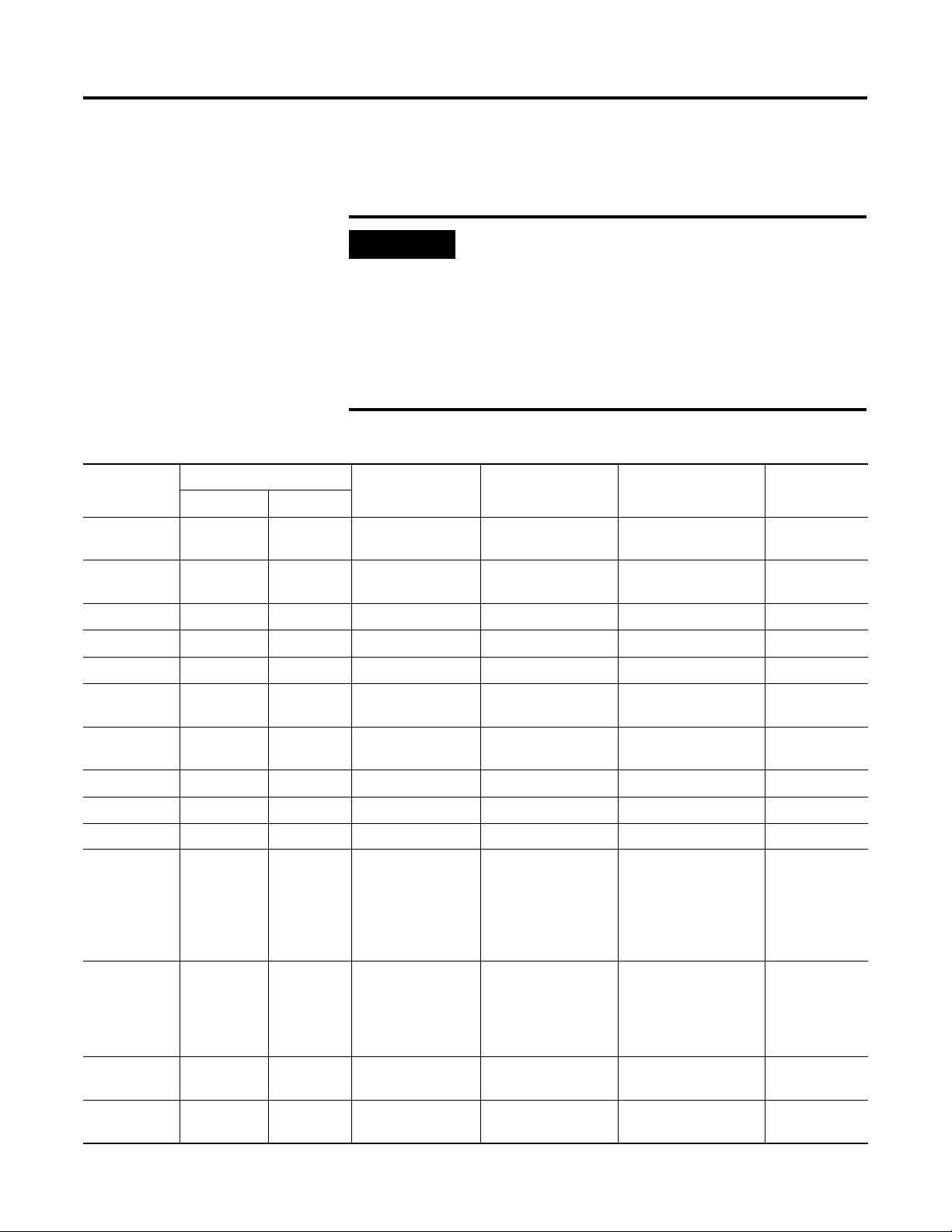

MicroLogix 1000 Controller Parameter Settings

Parameter Number Description Range Default Value For this Example,

Series A Series B

4 1 Input Size Series A: 1…16

Series B: 1…32

Not Applicable 2 Input Split Point 1…32 1 word 2 words

5 3 Input Type Bit or Integer File Integer File Integer File

6 4 Input Data File 3…254 7 7

7 5 Input Word Offset 0…254 0 90

8 6 Output Size Series A: 1…16

Series B: 1…32

9 8 Output Type Bit or Integer File Integer File Integer File

10 9 Output Data File 3…254 7 7

11 10 Output Word Offset 0…254 1 95

14 11 DF1 Device 0…3:

0: Other

1: PLC

2: SLC/ Other

MicroLogix

3: MicroLogix 1000

312DNI Series A:

Data Enable

DNI Series B:

I/O Scan Enable

(Polling Enable)

12 13 DF1 Heartbeat Series A: 2…10

13 14 Data Scan Delay

(Polling Delay)

2 15 Message Timeout 0…2500 ms 0 ms 0 ms

Not Applicable 16 DF1 Substitute Address 0…64 64 = Disabled 64 = Disabled

15 17 DF1 Autobaud Disabled (0) or Enabled

16 18 DF1 Baud Rate 0…5:

1 19 DeviceNet Autobaud Disabled (0) or Enabled

17 Not

Applicable

DNI Mode Standby (0) or

Disabled (0) or Enabled

(1)

Series B: 1…10

20…3000 ms 50 ms 100 ms

(1)

0: 38,400

1: 19,200

2: 9600

3: 4800

4: 2400

5: 1200

(1)

Operational (1)

1 word 2 words

1 word 2 words

3 = MicroLogix 1000 3 = MicroLogix 1000

Disabled (0) Enabled (1)

22

Enabled (1) Enabled (1)

Series A: 2 = 9600

Series B: 1 = 19,200

Enabled (1) Enabled (1)

Operational (1) Operational (1)

ENTER

n/a

Publication 1761-UM005B-EN-P - October 2006

Page 15

Quick Start 15

7. Click Modified Parameter, then OK.

8. Save to the configuration to the DNI.

In this configuration, the DNI provides two words (32 bits) of data.

The data is scanned (read), starting at address N7:90 of the attached

MicroLogix 1000 controller, at 100 msec intervals.

Data received (DeviceNet master output) is written to the MicroLogix

1000 controller whenever new (changed) data is detected by the DNI.

Two words of data will be written to Integer file 7, starting at word 95.

IMPORTANT

You must have the following rung programmed into the

MicroLogix 1000 controller:

N7:95

7

N7:90

7

At this point, the DNI is configured to be a slave on DeviceNet, but it

is not part of (owned by) a DeviceNet master/scanner.

To configure your DeviceNet scanner, refer to its manual. For the

1747-SDN, refer to the SLC 500 DeviceNet Scanner user manual,

publication 1747-UM655. For the 1771-SDN, refer to the PLC-5

DeviceNet Scanner user manual, publication 1771-UM118.

Publication 1761-UM005B-EN-P - October 2006

Page 16

16 Quick Start

Publication 1761-UM005B-EN-P - October 2006

Page 17

Operation

Chapter

3

Modes of Use

DeviceNet I/O

The DeviceNet Interface has three primary features.

• DeviceNet I/O

• Explicit Messaging

• Programming over DeviceNet network

IMPORTANT

The DNI is capable of being owned by a master on DeviceNet. This

functionality on DeviceNet is part of the I/O class of services, and

allows a master device to exclusively manage (own) another device’s

(a different node number) data and resources. This type of

relationship is functionally the same as a PLC with remote I/O. A PLC

uses the remote I/O chassis as distributed inputs and outputs. The

master/slave relationship on DeviceNet is exactly the same, except it

is being done over DeviceNet.

All input and output comments are referenced from

the perspective of the DeviceNet Master.

The amount of data available between devices that implement I/O

master/slave services is determined by the design of each device, and

is not a function of DeviceNet.

The DNI on DeviceNet is capable of handling 32 I/O words of data

with a DeviceNet I/O master for DNI Series A (64 for DNI Series B).

This is broken up into two data images: the input image and the

output image.

17 Publication 1761-UM005B-EN-P - October 2006

Page 18

18 Operation

Input Image

The input image is a configurable array of 16-bit data words. The

image is configurable from 1…16 data words for DNI Series A (1…32

data words for DNI Series B). The actual data that resides in the input

image is delivered to the DeviceNet master by one of three

mechanisms.

• Polled: Where the DeviceNet Master sends a poll request with

output data and the DNI responds with its current input data.

• COS (Change of State): Where the DNI detects that data has

changed within the input image and automatically sends the

data to the DeviceNet Master.

• Cyclic: The DNI continuously sends the input image data to the

master at a user/scanner-defined time interval, regardless of

whether the data has changed.

Network Configuration Software

Output Image

The output image is a configurable array of 16-bit data words. The

image is configurable from 1…16 data words for DNI Series A (1…32

data words for DNI Series B). The actual data that resides in the

output image is delivered to the DNI from the master by one of two

mechanisms:

• Polled: Where the DeviceNet Master sends a poll request with

output data and the DNI responds with its current input data.

• COS (Change Of State): Where the DeviceNet Master detects that

data has changed within its output image and automatically

sends the data to the DNI.

• Cyclic: The DNI continuously receives the output image data

from the master at a user/scanner-defined time interval,

regardless of whether the data has changed.

All DNI I/O parameters are configured with software such as the DNI

Configuration Utility, RSNetWorx, or DeviceNet Manager and stored as

part of the network configuration.

Publication 1761-UM005B-EN-P - October 2006

Configuration software is covered in Setup, Programming, and

Troubleshooting on page 53.

Individual settings of the DNI are covered in DNI Configuration

Parameters and Programming Notes on page 27.

Page 19

Operation 19

Messaging Services

The capabilities of each individual device determine what level of

messaging is supported. The types of messaging supported are:

• I/O Assembly Messaging (DNI responds)

• PCCC encapsulated DeviceNet Messaging (peer-to-peer)

• Explicit Assembly Messaging (DNI initiates, DNI Series B Only)

See Explicit Messaging (DNI Series B Only) on page 77 for more

information.

I/O Assembly Messaging

Two conditions must be met to access the I/O assemblies.

• Data Enable (DNI Series A) or I/O Scan Enable (DNI Series B)

must be enabled.

• The DF1 Device must be servicing the Heartbeat.

See DF1 Heartbeat on page 43 for information on using the

Heartbeat.

The following sections describe additional conditions based on the

DNI Series.

DNI Series A

DNI Series A supports explicit messaging to the master I/O assemblies

over DeviceNet at a minimal level. If the DNI is not owned by a

DeviceNet master, the DNI responds to explicit messaging gets and

accepts explicit messaging sets to the master I/O assembly. If the DNI

is owned by a DeviceNet master, it responds to gets, but cannot

accept sets. In either case, the data size must be 16 words, even if the

I/O size is smaller.

See page 65 to address DNI Series A assemblies.

DNI Series B

DNI Series B provides the above described functionality, except the

data size is equal to the configured I/O size. Additionally, DNI Series

B can respond to explicit messages over DeviceNet to its explicit I/O

assemblies whether it is owned by a DeviceNet master or not.

See page 66 to address DNI Series B assemblies.

DNI Series B can also perform get/set services with its new DeviceNet

messaging capability.

See page 77 for Explicit Messaging (DNI Series B Only).

Publication 1761-UM005B-EN-P - October 2006

Page 20

20 Operation

Programmable Controller Communications Commands (PCCC) DeviceNet Messaging/ DF1 (peer-to-peer)

Allen-Bradley controllers with RS-232 ports communicate via PCCC

messaging. The DNI encapsulates the PCCC messages to allow PCCC

messaging to operate over DeviceNet. This is an open,

non-proprietary protocol that can be implemented by anyone who

needs to exchange information with an Allen-Bradley controller.

The DNI is capable of receiving the DF1 protocol, and sending or

receiving it over DeviceNet. This enables any existing Allen-Bradley

device that is capable of DF1 communications to an Allen-Bradley

controller to use the DNI to communicate over DeviceNet.

For DNI Series A, the only stipulation is that the device has to be

capable of entering a destination node address (For DNI Series B, this

stipulation has been removed with the addition of the DF1 Substitute

Address parameter.). The DNI uses the DF1 destination node address

that is embedded in the DF1 packet to determine where on DeviceNet

it needs to send the information.

This DF1-to-DeviceNet capability lets you configure a peer-to-peer

network. By programming standard ladder logic message instructions,

with the destination address the same as the destination DNI (when

not using DNI Series B address substitution), the message is routed

across DeviceNet by the DNI. The following diagram illustrates the

types of messaging.

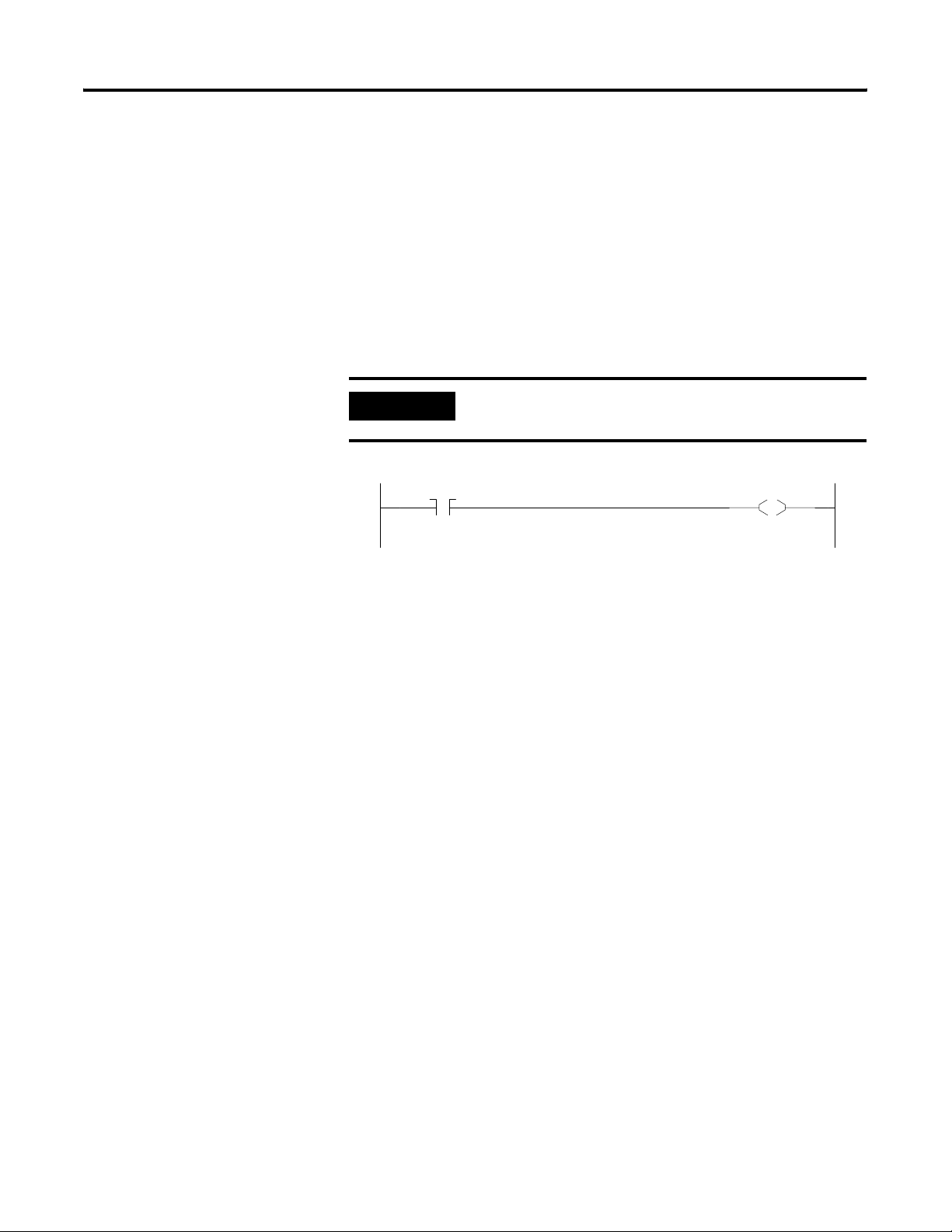

Messaging Overview

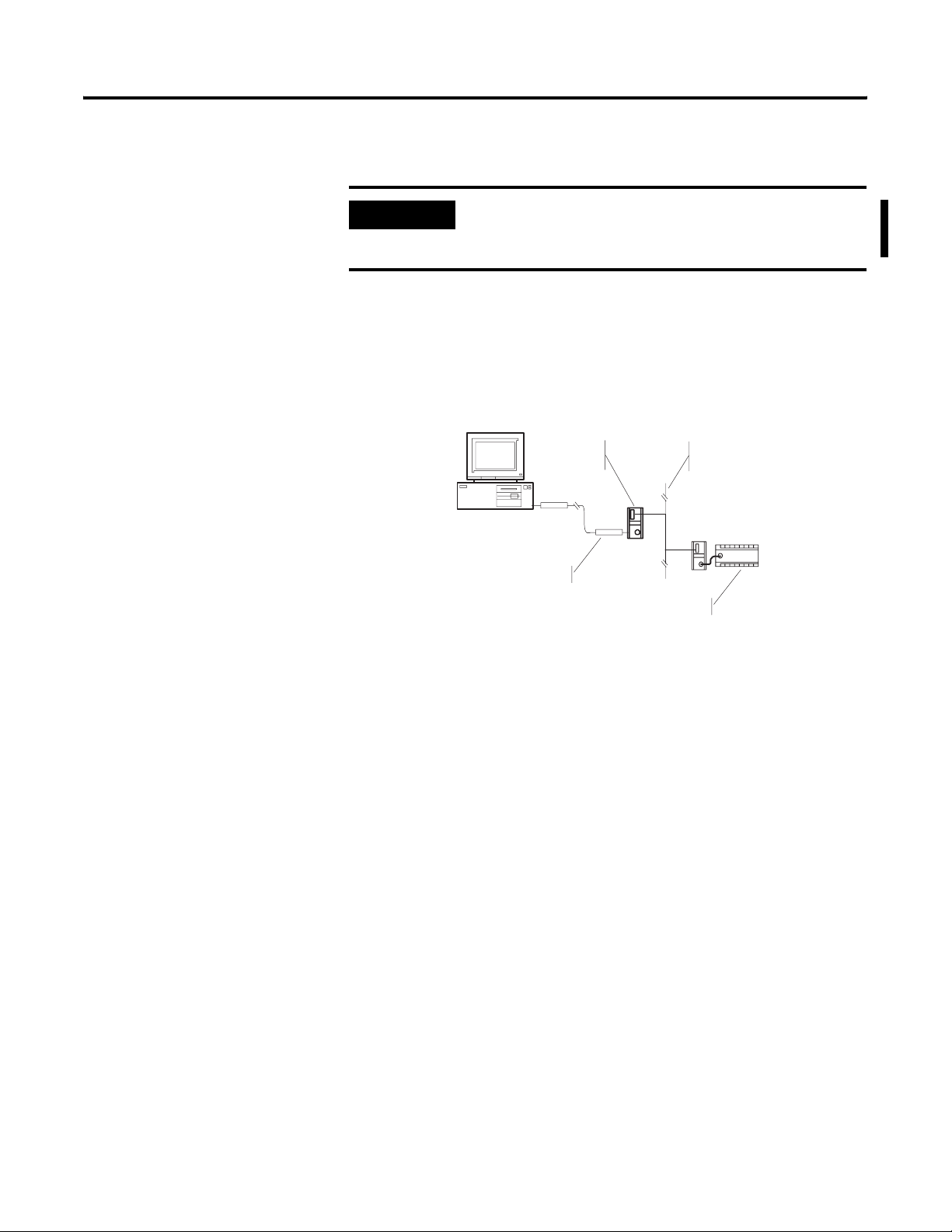

Running RSLogix 500

and/or DeviceNet

Manager

:

IBM Compatible

SLC

Rack

Node 3

KFD

1747-SDN

5/0x

Master/Slave I/O

Peer-to-Peer Messaging

DeviceNet Network

DNI Module

Node 1

Publication 1761-UM005B-EN-P - October 2006

Node 2

Also see Explicit Messaging (DNI Series B only) on page 80 for DNI

Series B.

Page 21

Operation 21

Programming Over the DeviceNet Network

IMPORTANT

Programming over a DeviceNet network via the DNI

is available only with RSLogix 5/500-based

controllers such as PLC-5, SLC, and MicroLogix.

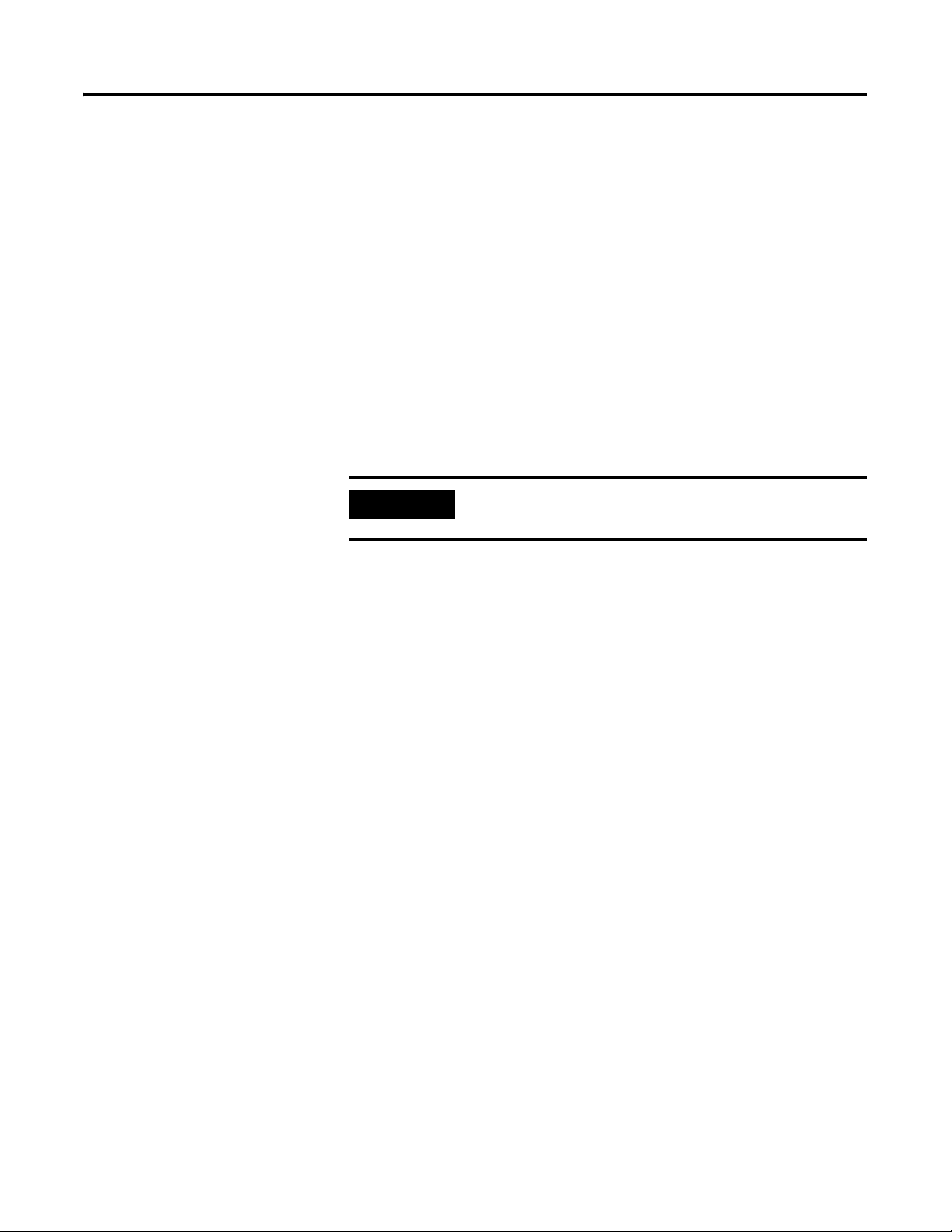

Local Access to a DeviceNet Network

PCCC/DF1 messaging allows programming devices to connect to a

DeviceNet network, and upload/download/monitor and even edit

programs if the controller attached to the destination DNI supports

that functionality. Rockwell Software RSLogix 500/RSLinx (version 2

and higher) users can connect directly to the DeviceNet network using

a KFD, PCD, or PCI interface.

DeviceNet

KFD

PC

Upload/Download

Monitoring

DNI Configuration

Cable

MicroLogix

Controller

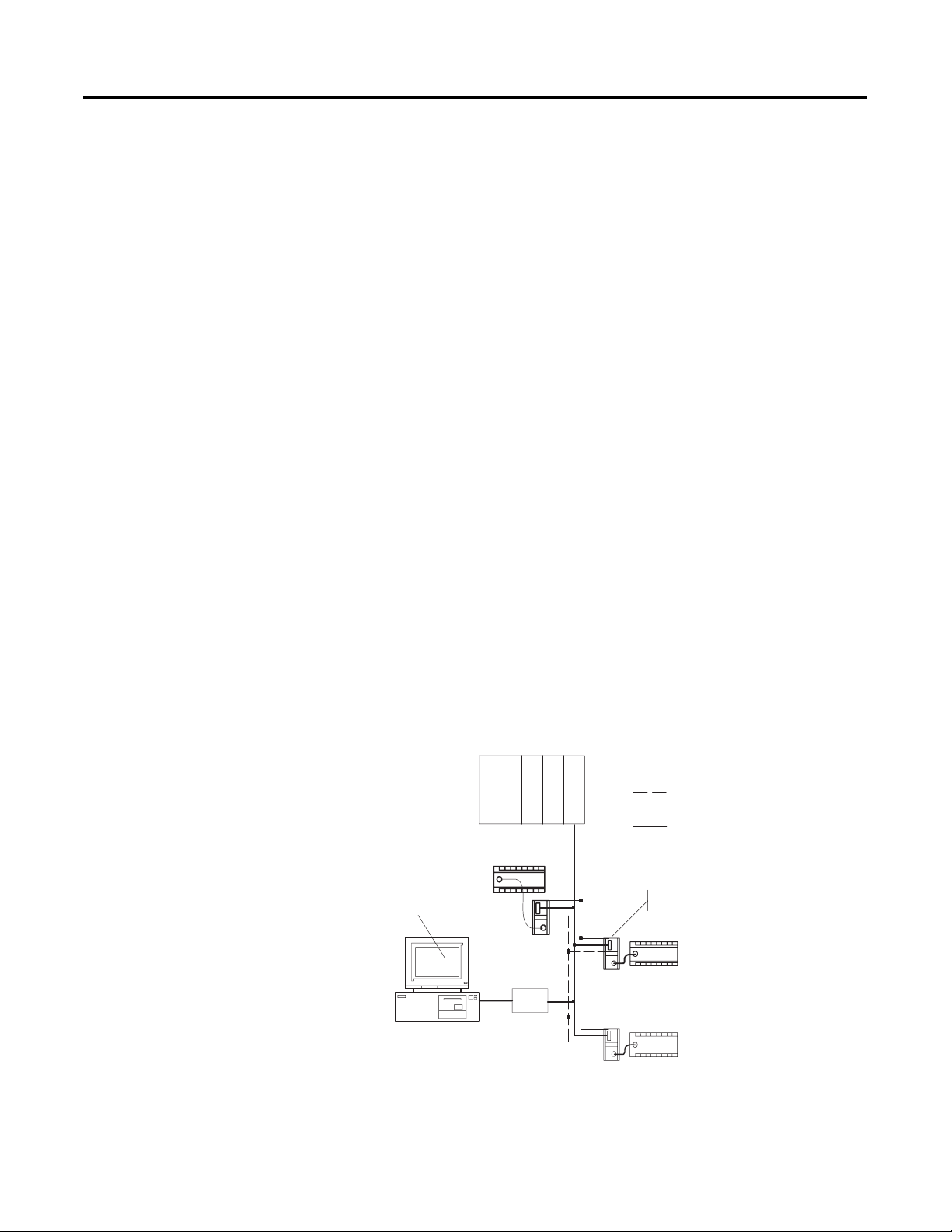

You can also use a DNI connected to the computer’s RS-232 port to

upload/download to other controllers connected to DNIs on a

DeviceNet network.

RS-232 Port DeviceNet Connection

RS-232

DF1

PC

Upload/Download

Monitoring

DNI Configuration

DeviceNet

Cable

DNI Module

MicroLogix

Controller

Publication 1761-UM005B-EN-P - October 2006

Page 22

22 Operation

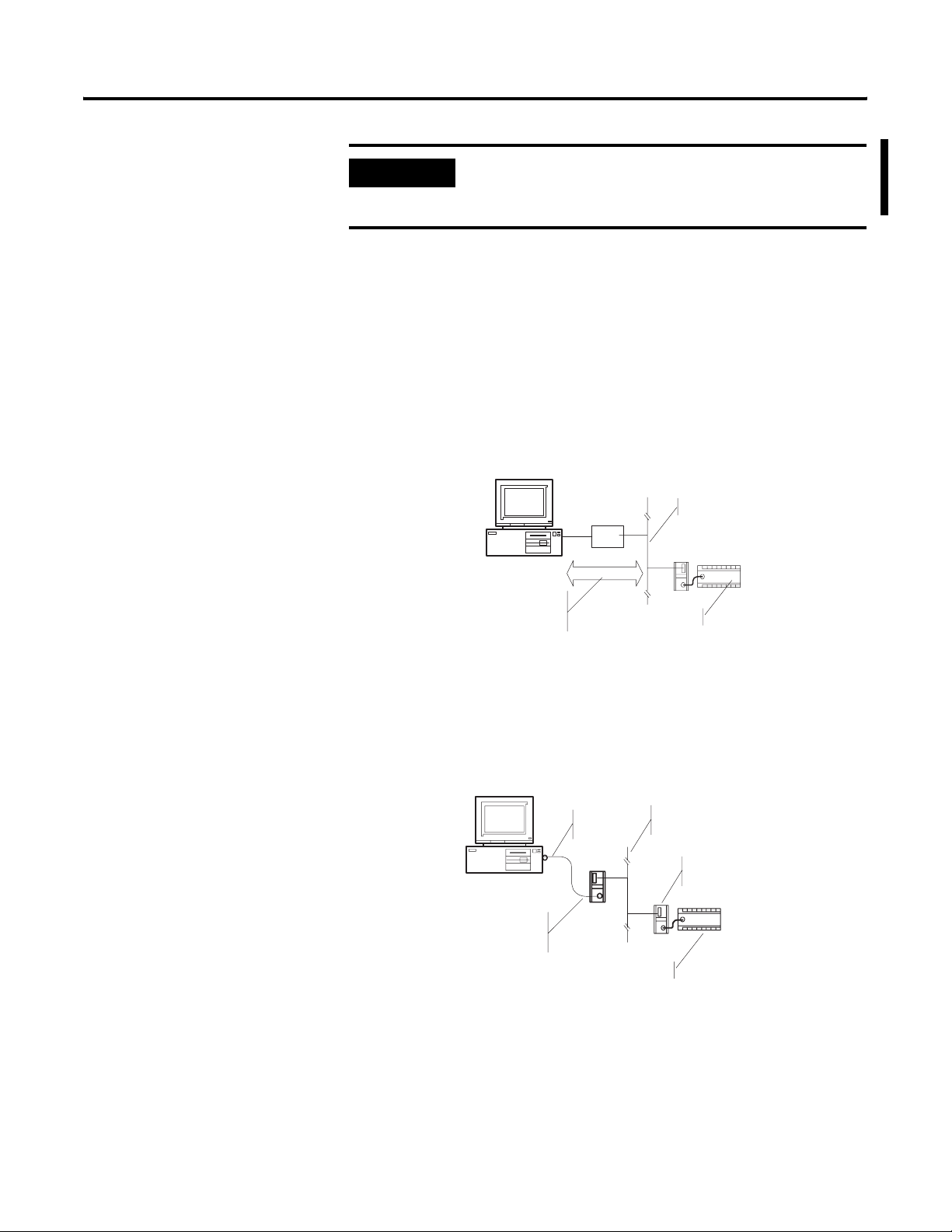

Remote Access to DeviceNet (Modems)

IMPORTANT

Remote access to a DeviceNet network via the DNI is

available only with RSLogix 5/500-based controllers

such as PLC-5, SLC, and MicroLogix.

If users need to dial into a DeviceNet network and have access to

controllers connected to DNIs, they can plug a DNI into a modem.

Now users can dial into the modem and have access to all

DNI/controllers from a remote site.

Remote Access to DeviceNet

DNI Module

PC

Modem

DeviceNet

Cable

MicroLogix

Controller

Publication 1761-UM005B-EN-P - October 2006

Page 23

Installation and Wiring

Chapter

4

European Communities (EC) Directive Compliance

This product has the CE mark and is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following additional directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests. For specific information required by EN 61131-2, see the

appropriate sections in this publication, as well as the Allen-Bradley

publication Industrial Automation Wiring and Grounding Guidelines

For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted

in an enclosure during operation to provide safety protection.

23 Publication 1761-UM005B-EN-P - October 2006

Page 24

24 Installation and Wiring

Safety Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B,

C, D, or non-hazardous locations only.

ATTENTION

Use only the following communication cables and replacement

connectors in Class I, Division 2, Hazardous Locations.

Environment Classification Communication Cables

Class I, Division 2 Hazardous Environment 1761-CBL-PM02 Series C (or later)

Explosion Hazard

Substitution of components may impair suitability for

Class I, Division 2.

Do not replace components unless power has been

switched off and the area is known to be

non-hazardous.

Do not disconnect connectors unless power has

been switched off and the area is known to be

non-hazardous.

1761-CBL-HM02 Series C (or later)

1761-CBL-AM00 Series C (or later)

1761-CBL-AP00 Series C (or later)

1761-RPL-00 DeviceNet Connector

Mounting

The DNI can be mounted in the vertical or horizontal position. There

are no spacing requirements except as necessary for DIN rail latch

movement.

See Physical Specifications on page 85 for operating temperature

specifications.

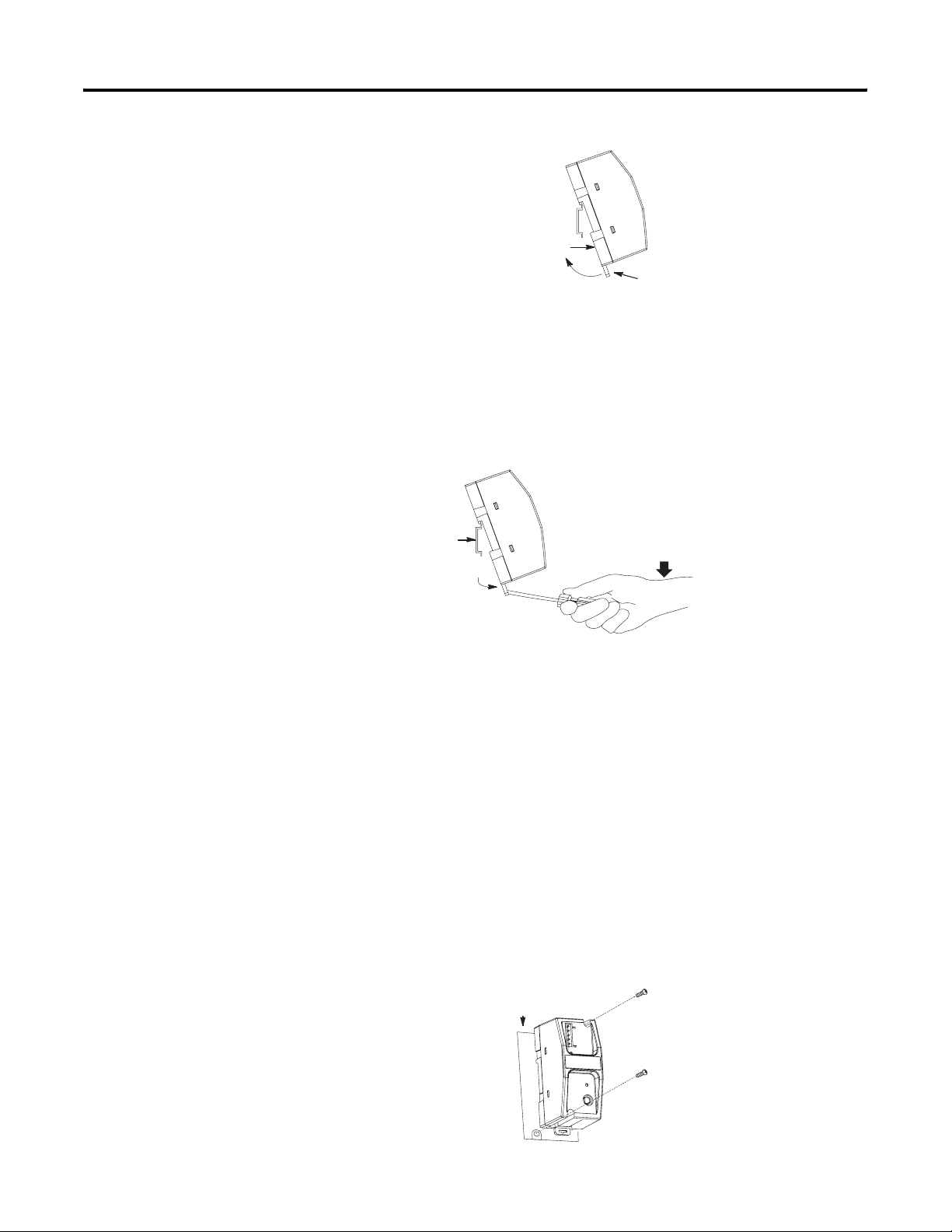

DIN Rail Mounting

Follow these steps to mount the DNI on a DIN rail.

1. Mount your DIN rail.

2. Snap the DIN rail latch into the closed position.

3. Hook the top slot over the DIN rail.

4. While pressing the unit against the rail, snap the unit into

position.

Publication 1761-UM005B-EN-P - October 2006

Page 25

Installation and Wiring 25

Side

View

DIN

Rail

Latch

Follow these steps to remove the DNI from the DIN rail.

1. Place a screwdriver in the DIN rail latch at the bottom of the

unit.

2. Holding the unit, pry downward on the latch until the unit is

released from the DIN rail.

Side

DIN Rail

View

Panel Mounting

Follow these steps to mount the DNI on a panel.

1. Remove the mounting template from Appendix A of this

document.

2. Secure the template to the mounting surface.

3. Drill holes through the template.

4. Remove the mounting template.

5. Mount the unit.

Mounting Template

Publication 1761-UM005B-EN-P - October 2006

Page 26

26 Installation and Wiring

Network Port Wiring

DeviceNet Network

To properly design your DeviceNet network, see DeviceNet Media

Design Installation Guide, publication DNET-UM072. This document

provides design guidelines concerning wiring practices, connectors,

grounding and power budgeting.

This publication is available from your Allen-Bradley distributor, or

from the Internet at www.literature.rockwell.com.

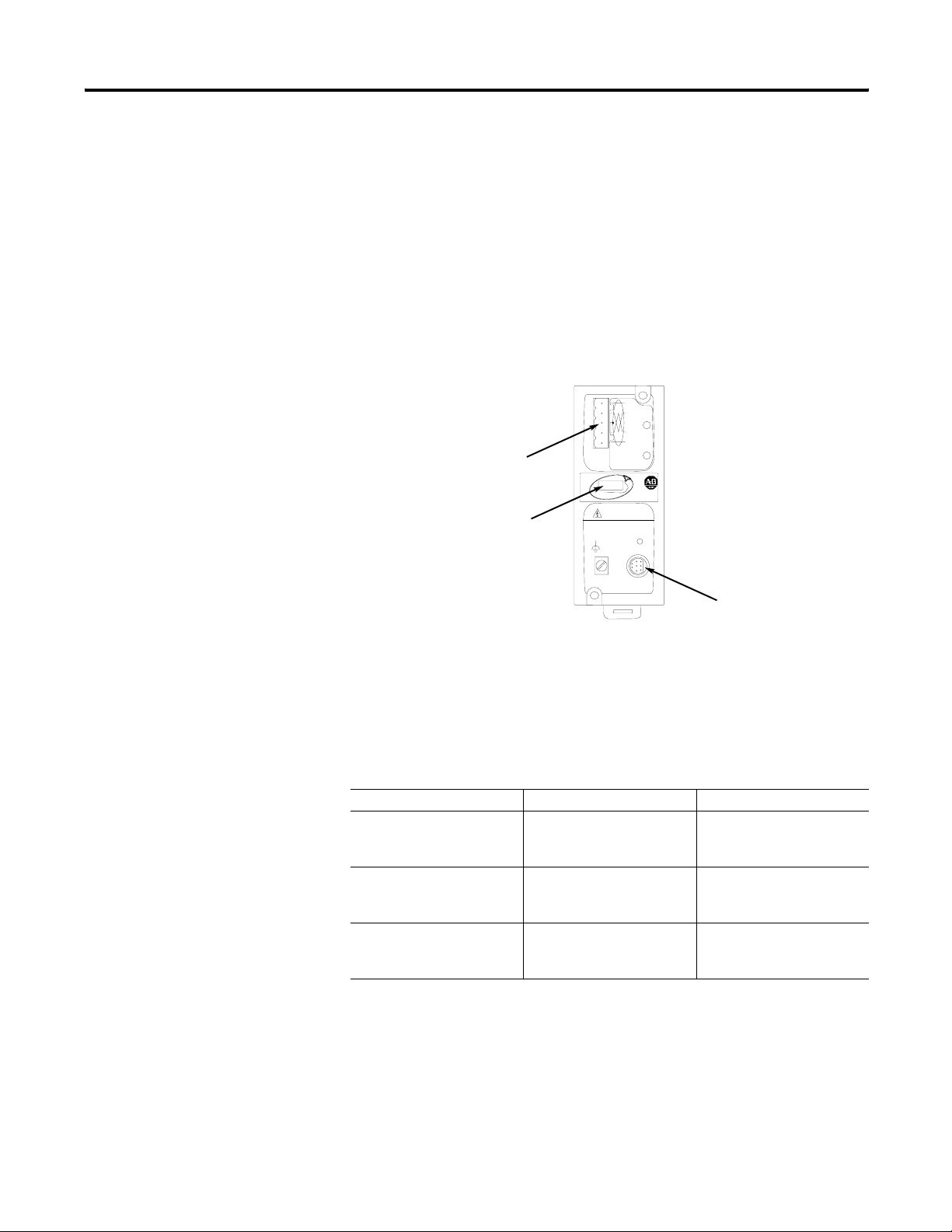

Port Identification

NODE

DANGER

GND

V–

CAN_L

SHIELD

CAN_H

V+

TX/RX

NET

MOD

DeviceNet Network

(Port 1) (Replacement

connector part no.

1761-RPL-0000)

Use this write-on

area to mark the

DeviceNet node

Address.

Cable Selection Guide

RS-232 (Port 2)

Port 2 of the DNI is an 8-pin mini-DIN RS-232 port that provides

connection to DF1 compatible RS-232 devices. The table below

describes the RS-232 compatible cables.

RS-232 Devices

DNI Connected to: Catalog Number Use Cable

MicroLogix (all series) 1761-CBL-AM00

1761-CBL-HM02

SLC 5/03, SLC 5/04, or

SLC 5/05 Channel 0

1761-CBL-AP00

1761-CBL-PM02

PLC 5 1761-CBL-AP00

1761-CBL-PM02

Mini DIN to Mini DIN

45cm (17.7 in)

2m (6.5 ft.)

Mini DIN to D-Shell

45cm (17.7 in)

2m (6.5 ft.)

Mini DIN to D-Shell

45cm (17.7 in)

2m (6.5 ft.)

Publication 1761-UM005B-EN-P - October 2006

Page 27

Chapter

DNI Configuration Parameters and Programming Notes

5

Information About DNI Series B

The following changes have been made which affect the EDS file.

• The Standby/Operational parameter has been removed from the

EDS file. The operating mode is now controlled by the I/O Scan

Enable parameter.

• Three new parameters have been added to the EDS file. The

parameters are:

– DF1 Substitution Address - The DF1 Substitution Address

allows any DF1 device, such as the MicroView, to

communicate to A-B controllers over the DeviceNet network.

– Input Split Point and Output Split Point - The split point

parameters are used to define how much data is configured

as Master/Slave I/O and how much data is configured for

explicit I/O assembly messaging.

ATTENTION

DNI Series A configurations are not compatible with

DNI Series B. You must manually re-enter the Series

A parameters into the Series B DNI. This step is

required because of the enhanced functionality of

DNI Series B.

TIP

27 Publication 1761-UM005B-EN-P - October 2006

DNI Series A stopped shipping in June of 1999. DNI

Series B started shipping in July of 1999.

Page 28

28 DNI Configuration Parameters and Programming Notes

EDS Parameters for the DNI

The following list shows the available parameters for configuring the

DNI. Parameter definitions and usage information are provided in the

sections following the table.

IMPORTANT

When modifying most DNI parameters, you must

first disable polling (Set the Data Enable parameter

to disable for DNI Series A. Set the I/O Scan Enable

parameter to disable for DNI Series B). You can

enable polling after setting your configuration.

For information on how to set up and modify

parameters, see Setup, Programming, and

Troubleshooting on page 53.

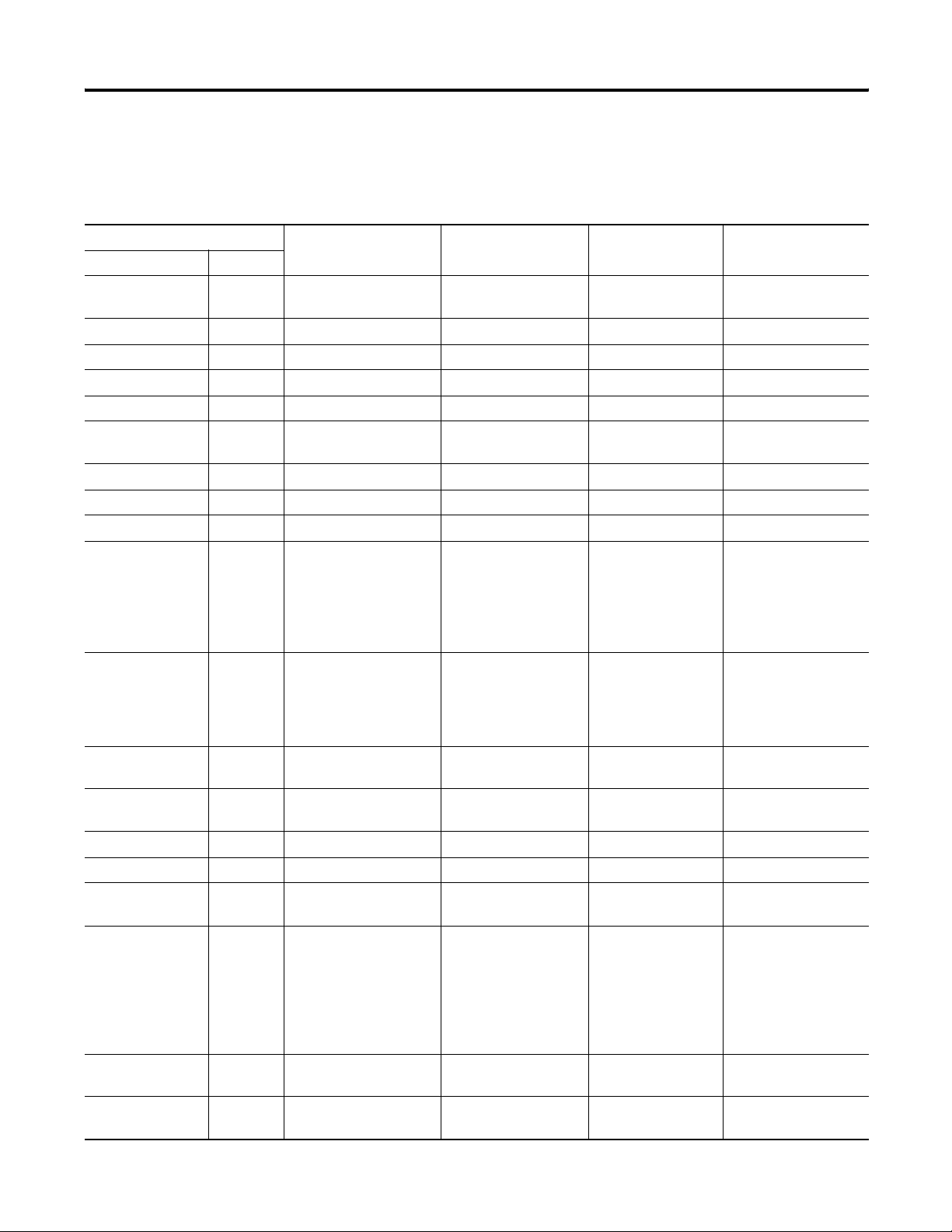

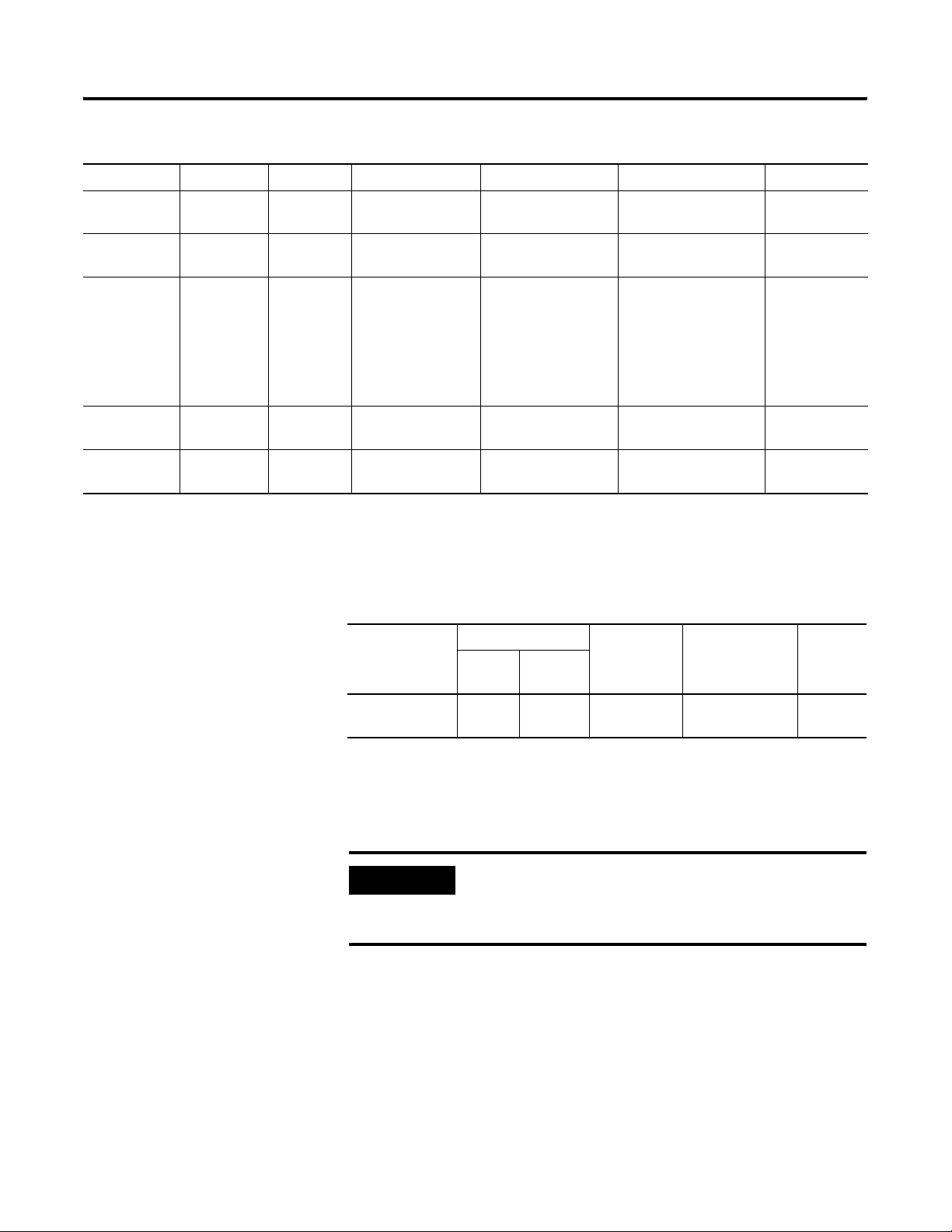

EDS Parameters for the DNI

Parameter

Ty pe

I/O 4 1 Input Size Series A: 1…16

I/O Not

I/O 5 3 Input Type Bit or Integer File Integer File 33

Parameter Number Description Range Default Value For More

Series A Series B

1 word 29

Series B: 1…32

2 Input Split Point 1…32 1 word 30

Applicable

Information

I/O 6 4 Input Data File 3…254 7 33

I/O 7 5 Input Word Offset 0…254 0 34

I/O 8 6 Output Size Series A: 1…16

Series B: 1…32

I/O Not

Applicable

I/O 9 8 Output Type Bit or Integer File Integer File 38

I/O 10 9 Output Data File 3…254 7 39

I/O 11 10 Output Word Offset 0…254 1 39

I/O 14 11 DF1 Device 0…3:

I/O 3 12 DNI Series A: Data

I/O 12 13 DF1 Heartbeat Series A: 2…10

7 Output Split Point 1…32 1 word 36

0: Other

1: PLC

2: SLC/ Other

MicroLogix

3: MicroLogix 1000

Disabled (0) or

Enable

DNI Series B: I/O

Scan Enable

(Polling Enable)

Enabled (1)

Series B: 1…10

1 word 35

3 = MicroLogix 1000 41

Disabled (0) 41

243

I/O 13 14 Data Scan Delay

(Polling Delay)

Publication 1761-UM005B-EN-P - October 2006

20…3000 ms 50 ms 45

Page 29

DNI Configuration Parameters and Programming Notes 29

EDS Parameters for the DNI

Messaging 2 15 Message Timeout 0…2500 ms 0 ms 46

Messaging Not

Applicable

DF1 15 17 DF1 Autobaud Disabled (0) or

DF1 16 18 DF1 Baud Rate 0…5:

DeviceNet 1 19 DeviceNet Autobaud Disabled (0) or

Device 17 Not

16 DF1 Substitute

Address

DNI Mode Standby (0) or

Applicable

0…64 64 = Disabled 47

Enabled (1)

0: 38,400

1: 19,200

2: 9600

3: 4800

4: 2400

5: 1200

Enabled (1)

Operational (1)

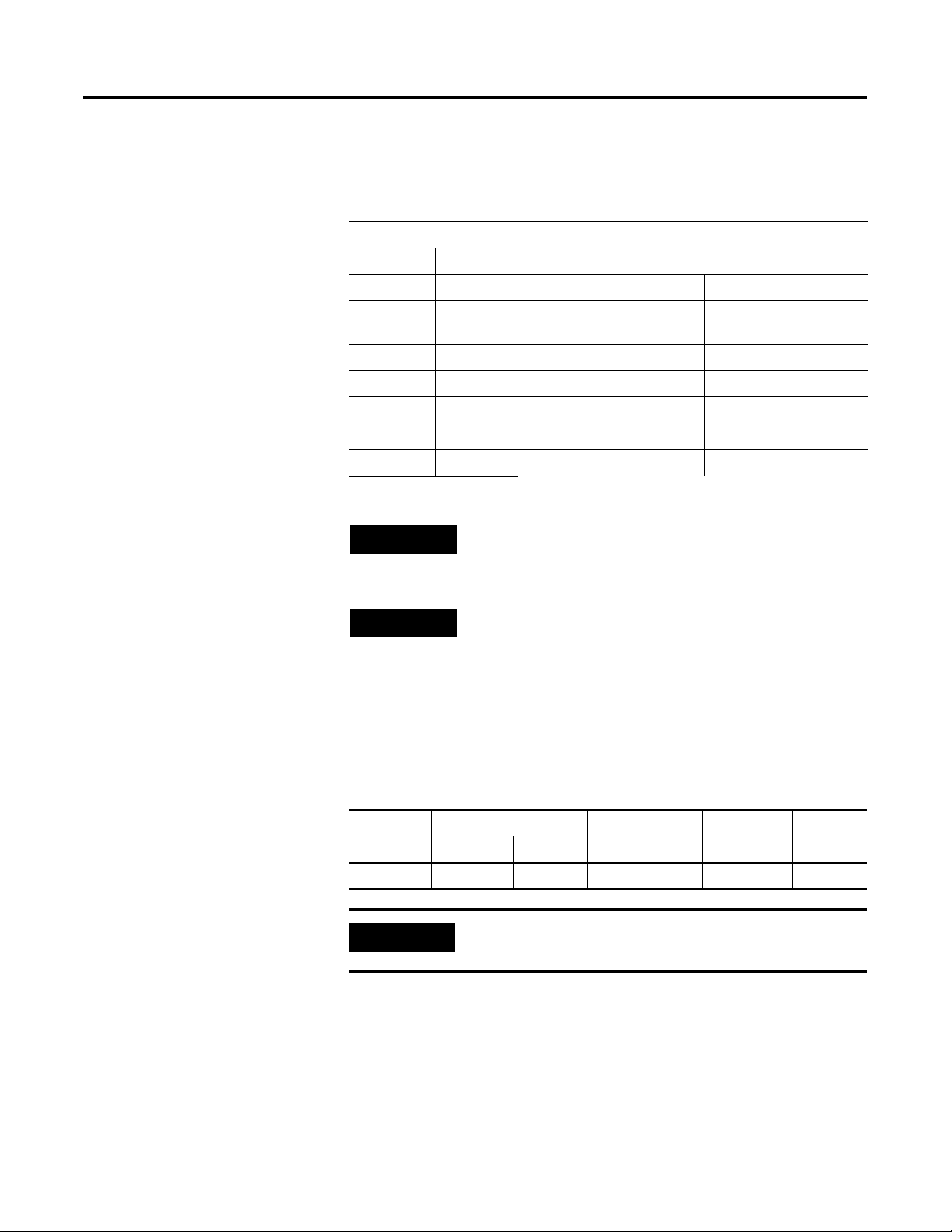

Input Size

Input Size Parameter Definition

Parameter

Ty pe

Parameter Number Description Range Default

Series ASeries B

Enabled (1) 47

Series A: 2 = 9600

Series B: 1 = 19,200

Enabled (1) 48

Operational (1) 49

48

Value

I/O 4 1 Input Size Series A: 1…16

Series B: 1…32

1

This parameter identifies the size, in words, of the data array that is

read from the controller attached to the DNI’s RS-232 port.

IMPORTANT

For DNI Series B, you must also configure the Input

Split Point.

See Input Split Point on page 30.

The array may contain up to 16 (16-bit) words of data for DNI Series A

(32 words for DNI Series B) from a contiguous block within the

attached controller.

Publication 1761-UM005B-EN-P - October 2006

Page 30

30 DNI Configuration Parameters and Programming Notes

The first byte (byte 0) of the first word contains the status byte and is

not available to the user.

Input Size Sample Data Array

Series A Series B

0 0 Data (8 bits) Status

1 1 Data Most Significant Byte

2 2 Data MSB Data LSB

3 3 Data MSB Data LSB

↓↓↓ ↓

14 30 Data MSB Data LSB

15 31 Data MSB Data LSB

Word Input Image

(MSB)

Data Least Significant

Byte (LSB)

TIP

TIP

Byte 1 (MSB) of word 0 is available for user data.

For information on the Status Byte (byte 0), see the

Status Byte section on page 50.

Input Split Point

Input Split Point Parameter Definition

Parameter

Ty pe

I/O n/a 2 Input Split Point 1…32 1

IMPORTANT

Paremeter Number Description Range Default

Series A Series B

The Input Split Point parameter cannot be used with

DNI Series A.

Value

Publication 1761-UM005B-EN-P - October 2006

The Input File Size within the DNI is configurable from 1…32 words.

The Input Split Point defines how much data is configured as

Master/Slave I/O and how much data is configured for explicit

assembly messaging.

Page 31

DNI Configuration Parameters and Programming Notes 31

Organization of Input Data

The following diagram describes how the Split Point parameter affects

the data in the DF1 Device. The split point represents the last word of

the Master data. Words above the split point are Explicit data.

Organization of Input Data

DNI Device

Explicit\

Input

Assembly

Master

Input

Assembly

Split

Point

DF1 Device

most significant word

Explicit

Inputs

least significant word

most significant word

Master’s

Inputs

least significant word

Higher

Addresses

Input

File

Size

Lower

Addresses

Input Split Point Example

We need 4 (3.5 data + 0.5 status) words of slave data that the master

will own, and we need to configure an additional 15 words so that

other DeviceNet products can read data.

• Input Size = 19

• Input Split Point = 4

Publication 1761-UM005B-EN-P - October 2006

Page 32

32 DNI Configuration Parameters and Programming Notes

The DNI’s input image will consist of:

Word Instance ID

DNI’s Input Image

0 Master’s Slave Data and

Status

1 Master’s Slave Data

2 ↓

3 Master’s Slave Data

Split Point

4 Explicit Input Data 0x70 You can use 0x66

5 ↓ 0x71

6 ↓ 0x72

7 ↓ 0x73

8 ↓ 0x74

9 ↓ 0x75

10 ↓ 0x76

11 ↓ 0x77

12 ↓ 0x78

13 ↓ 0x79

14 ↓ 0x7A

15 ↓ 0x7B

0x64

to access the

entire configured

explicit assembly.

16 ↓ 0x7C

17 ↓ 0x7D

18 ↓Explicit Input Data 0x7E

The minimum value allowed for the split point is 1, if the Input Size

parameter is 32 (the maximum), the resulting range of explicit input

words would be 0x70 to 0x8E.

See Input Assembly Data (Explicit, Split Point, and Slave) on page 67

for more information.

Publication 1761-UM005B-EN-P - October 2006

Page 33

Input Type

DNI Configuration Parameters and Programming Notes 33

Parameter

Ty pe

I/O 5 3 Input Type Bit or Integer File Integer File

Parameter Number Description Range Default

Series A Series B

Value

This parameter is used to identify the type of data to be read within

the controller. The DNI supports data exchange with either bit or

integer files.

Input Data File

Parameter

Ty pe

I/O 6 4 Input Data File 3…254 7

This parameter is used to identify the data file to be read within the

controller. The following table shows the files within Allen-Bradley

controllers.

Parameter Number Description Range Default Value

Series A Series B

Controller Input Data Files Number Values

MicroLogix 1000 Bit 3

Integer 7

SLC/Other MicroLogix Bit 3, 10-255

Integer 7, 9-255

PLC Bit 3, 10-999

Integer 7, 9-999

TIP

The DNI can access only files 3…254.

Publication 1761-UM005B-EN-P - October 2006

Page 34

34 DNI Configuration Parameters and Programming Notes

Input Word Offset

Parameter

Ty pe

I/O 7 5 Input Word Offset 0…254 0

Parameter Number Description Range Default Value

Series A Series B

This parameter identifies the starting word within the input file

identified by the parameter Input Data File. The value entered is the

first word of data that is read from the controller attached to the DNI.

The sizes of compatible data files within Allen-Bradley controllers vary

based on the DFI device selected.

Compatible Data File Sizes

Controller Input Data Files File Size

MicroLogix 1000 Bit 32 Words

Integer 105 Words

SLC/Other MicroLogix Bit 255 Words

Integer 255 Words

PLC Bit 999 Words

Integer 999 Words

TIP

IMPORTANT

The DNI can only access files 3 through 254.

You must have sufficient room in the file that you

select. Make sure the Input Word Offset plus the

Input Size does not exceed the boundary of the

controller’s data file. For example, a MicroLogix 1000

controller has 32 words in its bit file; therefore, you

could not use a Input Word Offset of 30 and a Input

Size of 5 because this exceeds the file size.

Publication 1761-UM005B-EN-P - October 2006

Page 35

DNI Configuration Parameters and Programming Notes 35

IMPORTANT

If you use RSNetWorx or DeviceNet Manager to

configure/commission the DNI, it is up to you to

select the correct values for:

• Input Size

• Input Split Point (DNI Series B only)

• Input Type

• Input Data File

• Input Word Offset

Only the DNI Configuration Software Utility

performs checks on the information entered.

Output Size

Parameter

Ty pe

I/O 8 6 Output Size Series A: 1…16

Parameter Number Description Range Default

Series A Series B

Series B: 1…32

Value

1

IMPORTANT

For DNI Series B, you must also configure the

Output Split Point. See page 36.

This parameter identifies the size, in words, of the data array that will

be written to the controller attached to the DNI’s RS-232 port. The

array may contain up to 16 (16-bit) words of data for DNI Series A

(32 words for DNI Series B) from a contiguous block within the

attached controller.

Publication 1761-UM005B-EN-P - October 2006

Page 36

36 DNI Configuration Parameters and Programming Notes

The first byte (byte 0) of the first word contains the status byte and is

not available to the user. A sample of the data array is shown below.

Sample Data Array

Word Output Image

Series A Series B

0 0 Data (8 bits) Status

1 1 Data Most Significant Byte

2 2 Data MSB Data LSB

3 3 Data MSB Data LSB

ØØØ Ø

14 30 Data MSB Data LSB

15 31 Data MSB Data LSB

(MSB)

Data Least Significant

Byte (LSB)

TIP

TIP

Byte 1 (MSB) of word 0 is available for user data.

For information on the Status Byte (byte 0), see the

Status Byte section on page 50.

Output Split Point

Parameter

Ty pe

I/O n/a 7 Output Split Point 1…32 1

IMPORTANT

The Output Size within the DNI is configurable from 1…32 words.

The Output Split Point defines how much data is configured as

Master/Slave I/O and how much data is configured for explicit

assembly messaging.

Parameter Number Description Range Default

Series A Series B

Value

The Output Split Point parameter cannot be used

with DNI Series A.

Publication 1761-UM005B-EN-P - October 2006

Page 37

DNI Configuration Parameters and Programming Notes 37

Organization of Output Data

The following diagram describes how the Split Point parameter affects

the data in the DF1 Device. The split point represents the last word of

the Master data. Words above the split point are Explicit data.

Output Data Organization

DNI Device

Explicit

Output

Assembly

Master

Output

Assembly

Split

Point

DF1 Device

most significant word

Explicit

Outputs

least significant word

most significant word

Master’s

Outputs

least significant word

Higher

Addresses

Output

File

Size

Lower

Addresses

Output Split Point Example

We need 4 (3.5 data + 0.5 status) words of slave data that the master

will own, and we need to configure an additional 15 words so that

other DeviceNet products can write data.

• Output Size = 19

• Output Split Point = 4

Publication 1761-UM005B-EN-P - October 2006

Page 38

38 DNI Configuration Parameters and Programming Notes

The DNI’s output image will consist of:

Word Instance ID

0 Master’s Slave Data and Status 0x65

1 Master’s Slave Data

2 ↓

3 Master’s Slave Data

Split Point

4 Explicit Output Data 0x90 You can use

5 ↓ 0x91

6 ↓ 0x92

9 ↓ 0x93

8 ↓ 0x94

9 ↓ 0x95

10 ↓ 0x96

11 ↓ 0x97

12 ↓ 0x98

13 ↓ 0x99

14 ↓ 0x9A

15 ↓ 0x9B

16 ↓ 0x9C

17 ↓ 0x9D

18 Explicit Output Data 0x9E

DNI’s Output Image

0x67 to access

the entire

configured

explicit

assembly.

The minimum value allowed for the Split Point is 1. If the Output Size

is 32 (maximum), the resulting range of explicit output words would

be 0x90 to 0xAE.

See Output Assembly Data (Explicit, Split Point, and Slave) on page 68

for more information.

Output Type

Parameter

Ty pe

I/O 9 8 Output Type Bit or Integer File Integer File

This parameter is used to identify the type of data to be written to the

controller. The DNI supports data exchange with either bit or integer

files.

Parameter number Description Range Default

Series A Series B

Value

Publication 1761-UM005B-EN-P - October 2006

Page 39

Output Data File

DNI Configuration Parameters and Programming Notes 39

Parameter

Ty pe

I/O 10 9 Output Data File 3…254 7

Parameter Number Description Range Default

Series A Series B

Value

This parameter is used to identify the target data file where data will

be written within the controller.

The sizes of compatible data files within Allen-Bradley controllers vary

based on the DFI device selected.

Controller Data Files

Controller Output Data Files File Sizes

MicroLogix 1000 Bit 3

Integer 7

SLC/Other MicroLogix Bit 3, 10-255

Integer 7, 9-255

PLC Bit 3, 10-999

Integer 7, 9-999

TIP

The DNI can access only files 3…254.

Output Word Offset

Parameter

Ty pe

I/O 11 10 Output Word Offset 0…254 1

This parameter identifies the starting word within the output file

identified by the Output Data File parameter. The value entered is the

first word of data that is written to the controller attached to the DNI.

Parameter Number Description Range Default

Series A Series B

Value

Publication 1761-UM005B-EN-P - October 2006

Page 40

40 DNI Configuration Parameters and Programming Notes

The sizes of compatible data files within Allen-Bradley controllers vary

based on the DFI device selected.

Controller Data Files

Controller Output Data Files File Sizes

MicroLogix 1000 Bit 32 Words

SLC/Other MicroLogix Bit 255 Words

PLC Bit 999 Words

Integer 105 Words

Integer 255 Words

Integer 999 Words

TIP

IMPORTANT

IMPORTANT

The DNI can only access files 0…254.

You must have sufficient room in the file that you

select. Make sure the Output Word Offset plus the

Output Size does not exceed the boundary of the

data file. For example, a MicroLogix 1000 controller

has 32 words in its bit file; therefore, you could not

use a Output Word Offset of 30 and a Output Size of

5 because this exceeds the file size.

If you use RSNetWorx or DeviceNet Manager to

configure/commission the DNI, it is up to the user to

select the correct values for:

• Output Size

• Output Split Point (DNI Series B only)

• Output Type

• Output Data File

• Output Word Offset

Only the DNI Configuration Software Utility

performs checks on the information entered.

Publication 1761-UM005B-EN-P - October 2006

Page 41

Device Type

Device Type Parameter Definition

DNI Configuration Parameters and Programming Notes 41

Parameter

Typ e

I/O 14 11 DF1 Device 0…3:

Parameter Number Description Range Default

Series A Series B

0: Other

1: PLC

2: SLC/ Other

MicroLogix

3: MicroLogix

1000

Value

3 = MicroLogix

1000

Select the device connected to the DNI’s RS-232 port. If you are

connecting an Allen-Bradley controller as a DeviceNet I/O slave

device, this selection is used by the DNI to determine the type of

communication commands used to read and write data.

To achieve the best communications performance you should use

these recommended combinations.

Recommended Combinations

RS-232 Device DF1 Device

Value

MicroLogix 1000 3 N (integer) 7

SLC 5/03 or higher

Other MicroLogix (MicroLogix 1500)

2 N (integer) 9

File Type File Number

TIP

If you do not want to communicate with these

specific data files, RS-232 port communications

throughput will suffer marginally.

I/O Scan Enable

Parameter

Ty pe

I/O 3 12 DNI Series A:

This parameter enables the DNI to scan/exchange I/O data with DF1

devices. If the DNI is being used in an application that does not use

this feature, disabling this parameter improves the DNI’s messaging

Parameter Number Description Range Default

Series A Series B

Disabled (0) or

Data Enable

DNI Series B:

I/O Scan Enable

(Polling Enable)

Publication 1761-UM005B-EN-P - October 2006

Enabled (1)

Value

Disabled (0)

Page 42

42 DNI Configuration Parameters and Programming Notes

performance. When this parameter is disabled, PCCC messaging still

operates.

IMPORTANT

IMPORTANT

Enable this parameter to use explicit messaging to

assemblies.

When modifying most DNI parameters, you must

first disable polling (Set the Data Enable parameter

to disable for DNI Series A. Set the I/O Scan Enable

parameter to disable for DNI Series B). You can

enable polling after setting your configuration.

For information on how to set up and modify

parameters, see Setup, Programming, and

Troubleshooting on page 53.

Publication 1761-UM005B-EN-P - October 2006

Page 43

DNI Configuration Parameters and Programming Notes 43

DF1 Heartbeat

DF1 Heartbeat Parameter Definition

Parameter

Ty pe

I/O 12 13 DF1 Heartbeat Series A: 2…10

Parameter Number Description Range Default

Series A Series B

Series B: 1…10

Value

2

The DF1 data heartbeat is used to detect a valid communications path

between the controller and the DNI and also to detect if the

connected controller is scanning its ladder logic.

The heartbeat is enabled when:

• DNI Series A: Data Enable is enabled and DNI Mode is

operational

• DNI Series B: I/O Scan Enable is enabled

The heartbeat consists of a bit in the first byte (byte 0, bit 7) of the

data packet that is exchanged with the controller. The DNI sets this bit

in the output data being sent to the controller. The user must move

this bit, using ladder logic, to the corresponding bit position in the

input data area where the bit is then read from the controller by the

DNI.

At the heartbeat rate, once the DNI sees the bit return in its correct

state, it toggles the bit to the opposite state and sends it back to the

controller (this is a round robin process). If the bit state does not

change, it is detected as a communication/controller error and

reported to the DNI master as a zero-length packet. Refer to your

scanner or master controller documentation to determine how this is

detected in the master logic.

This bit should also be monitored by the controller attached to the

DNI, and if the bit does not change in the output image at the

heartbeat rate, it can be used within the controller to detect a problem

with the DNI/DeviceNet Master.

Publication 1761-UM005B-EN-P - October 2006

Page 44

44 DNI Configuration Parameters and Programming Notes

DF1 Heartbeat Rotation Example

The value entered for the heartbeat determines how often the DNI

will rotate the heartbeat bit. The table below illustrates the heartbeat

rotation with the default setting of two (heartbeat checked on every

other read).

DF1 (RS-232) Port A DEF A

DNI’s Read Sequence

DNI’s Write Sequence

A. DNI gets (reads) data from controller

B. DNI checks heartbeat and toggles bit

C. DNI sets (writes) data to controller

D. Data Scan Delay period

BC BC

E. DNI gets (reads) data from controller

F. Data Scan Delay (period)

IMPORTANT

The example above does not represent accurate

timing relationships.

Consider the following with the above list.

• B is done inside the DNI and is completed extremely fast,

typically less than a millisecond.

• D is the only consistent time variable; the DNI waits for the

amount of time specified by the Data Scan Delay parameter.

• A, C, and E are variable; the time associated with each is

dependent on a number of factors: baud rate, communication

errors/retries.

• If you are monitoring the heartbeat bit in the controller to

determine communications integrity, as a general rule, multiply

the Data Scan Delay by the DF1 Heartbeat plus 1 to determine

the preset time value for the heartbeat timer.

• DF1 Heartbeat determines how many input reads are done

between heartbeat checks and toggles (step B). When the DF1

Heartbeat is set to 2, this occurs on every other read; when the

DF1 Heartbeat is set to 3, this occurs on every third read.

Publication 1761-UM005B-EN-P - October 2006

See the application example DF1 Heartbeat (Bit 7) on page 51 and

MicroLogix as I/O on the DeviceNet Network on page 69 for more

information about using the DF1 Heartbeat.

Page 45

DNI Configuration Parameters and Programming Notes 45

Data Scan Delay

Data Scan Delay Parameter Definition

Parameter

Ty pe

I/O 13 14 Data Scan

Parameter Number Description Range Default

Series A Series B

20…3000 ms 50 ms

Delay

(Polling Delay)

Value

When Data Enable (parameter 3) is enabled (DNI Series A) or I/O

Scan Enable (parameter 12) is enabled (DNI Series B), the value

entered for Data Scan Delay defines the amount of time that the DNI

will delay between communications. This value does not identify how

often communications take place; it defines the delay between the

completion (end) of one communication sequence and the beginning

of the next.

IMPORTANT

It is important not to set this value too low. Setting

Data Scan Delay too low limits access to the

controller from other devices on the network. If this

value is too low, programming terminals, other

controllers, and any other devices attempting to

communicate with this controller are unable to due

so, because the RS-232 port communications link

bandwidth is being consumed by the I/O scan

feature of the DNI.

IMPORTANT

To move data from the controller to the DeviceNet

master as quickly as possible, use the DNI’s input

messaging feature.

See input messaging on page 49.

See the application example MicroLogix as I/O on the DeviceNet

Network on page 69 for more information about using the Data Scan

Delay.

Publication 1761-UM005B-EN-P - October 2006

Page 46

46 DNI Configuration Parameters and Programming Notes

Message Timeout

Message Timeout Parameter Definition

Parameter

Ty pe

Messaging 2 15 Message Timeout 0…2500 ms 0 MS

Parameter Number Description Range Default

Series A Series B

Value

The Message Timeout is the amount of time that a DeviceNet explicit

connection is held open after message completion. The Message

Timeout allows the DNI to hold open a connection with another

device over the DeviceNet network. On a DeviceNet network, a

connection means that two devices have established a

communications path. Each time communications need to occur

between devices, a connection is established; when the

communications have completed, the connection is released.

The number of connections that each device can support depends on

the design/capabilities of each device. The DNI has five connections

available for messaging. The Message Timeout allows the user to tune

how a connection behaves after communications have completed.

You may want to dedicate a connection to a specific node/device to

maintain a connection. This reduces the amount of time needed to

re-establish communications with the device.

It is recommended that this value only be changed (from the default)

if communications with another node is constant. When the timeout is

set, the connection is not released back to the system until the timeout

expires (where 0 ms means close immediately after use).

Publication 1761-UM005B-EN-P - October 2006

IMPORTANT

An open connection between devices over

DeviceNet does not limit or inhibit communications

over the network. If two devices maintain a

connection, other devices continue to communicate.

Page 47

DNI Configuration Parameters and Programming Notes 47

DF1 Substitute Address

DF1 Substitute Address Parameter Definition

Parameter

Ty pe

Messaging n/a 16 DF1 Substitute

IMPORTANT

Parameter Number Description Range Default Value

Series A Series B

0…64 64 = Disabled

Address

The DF1 Substitute Address parameter cannot be

used with DNI Series A.

If the device that is connected to the DNI is not capable of selecting a

DF1 destination address of 0…63, by entering a value in this

parameter, the DNI automatically routes all DF1 communications to

this address with the following exceptions:

• Responses to poll requests are sent to the configured address.

• COS/Cyclic I/O data messages are sent to the configured device.

For example, when using a MicroView operator interface over

DeviceNet, DF1 Substitute Address defines the device (node number)

that the MicroView exchanges data with.

TIP

A value of 64 (default) disables this feature.

DF1 Autobaud

Parameter

Ty pe

DF1 15 17 DF1 Autobaud Disabled (0)

The DNI’s RS-232 baud rate is set up to automatically synchronize to

the attached RS-232 device. If you want to lock the RS-232 baud rate,

disable this parameter. If this parameter is disabled (0), the DNI’s

RS-232 port baud rate is set to the value specified by the DF1 Baud

Rate parameter.

Parameter Number Description Range Default Value

Series A Series B

Enabled (1)

or

Enabled (1)

Publication 1761-UM005B-EN-P - October 2006

Page 48

48 DNI Configuration Parameters and Programming Notes

DF1 Baud Rate

DF1 Baud Rate Parameter Definition

Parameter

Ty pe

DF1 16 18 DF1 Baud

Parameter Number Description Range Default Value

Series A Series B

Series A: 2 = 9600

Series B: 1 = 19,200

Rate

0…5:

0: 38,400

1: 19,200

2: 9600

3: 4800

4: 2400

5: 1200

This parameter defines the baud rate for the RS-232 port when DF1

Autobaud is disabled.

DeviceNet Autobaud

DeviceNet Autobaud Parameter Definition

Parameter

Ty pe

DeviceNet 1 19 DeviceNet

Parameter Number Description Range Default Value

Series A Series B

Autobaud

Disabled (0) or

Enabled (1)

Enabled (1)

The DNI automatically synchronizes to the DeviceNet network that it

is attached to (125K, 250K, or 500K baud). To disable this feature, set

DeviceNet Autobaud to disable (0).

When set to disable, the DNI uses the DeviceNet baud rate configured

during the node commissioning process. Therefore, when the

DeviceNet Autobaud is disabled, the baud rate the DNI is set to may

be different than the DeviceNet network baud rate.

IMPORTANT

When parameter is disabled (0), the baud rate is set

using the node commissioning utility in your

network configuration software, and is not set by the

DNI’s EDS file.

IMPORTANT

Power cycle the DNI for baud rate changes to take

effect.

Publication 1761-UM005B-EN-P - October 2006

Page 49

DNI Mode

DNI Mode Parameter Definition

DNI Configuration Parameters and Programming Notes 49

Programming Notes

Parameter

Typ e

Device 17 n/a DNI Mode Standby (0) or

IMPORTANT

Parameter Number Description Range Default Value

Series A Series B

Operational (1)

Operational (1)

The DNI Mode parameter only applies to DNI Series

A. For DNI Series B, the operating mode is controlled

by the I/O Scan Enable parameter.

This parameter defines the mode of the DNI. You must set this mode

to Standby (0) when you want to change a number of DNI

parameters. Once you have made the necessary changes, set this

value to Operational (1).

Input Messaging

The DNI is capable of accepting an unsolicited Input Data Message

from the DF1 device. This capability allows the controller to update

the DNI’s input data whenever it detects a change in its input data.

With this capability, a user can increase the value of the data scan

delay; this reduces the amount of communications traffic over the

RS-232/DF1 port, but still maintains very high I/O throughput

performance.

To utilize this feature, simply program a message instruction in the

controller with a destination address of 254. The DNI accepts the

message and when it sees the 254 address (which is invalid on

DeviceNet), it recognizes that the message is input data. All data

received by message instruction with address 254 is automatically

routed to the DNI’s input data area.

See the application example MicroLogix as I/O on the DeviceNet

Network on page 69 for more information about input messaging.

Publication 1761-UM005B-EN-P - October 2006

Page 50

50 DNI Configuration Parameters and Programming Notes

Input Messaging Considerations

• You cannot write to a specific word in the DNI’s input area.

• The destination offset value in the controller’s message

• The message length must equal the size specified by the Input

• For MicroLogix 1000 controllers, use N7 as the destination file

instruction is ignored. Data always starts at word 0.

Size parameter. For DNI Series B only, both the Master’s Slave

data and the Explicit Assembly are considered to be input. For

more information, see:

– Input Split Point on page 30.

– Input Assembly Data (Explicit, Split Point, and Slave) on

page 67.

type.

– For other controllers, see the recommended file number on

page 41.

Status Byte

The first byte (bits 0…7) of the first word of I/O data is set aside as

status information. The second byte (bits 8…15) of the first word of

I/O is available for user data. The DNI Input/Output Image is shown

below:

Word Input/Output Image

Series A Series B

0 0 Data (bits 8…15) Status Byte (bits 0…7)

1 1 Data Most Significant Byte (MSB) Data Least Significant Byte (LSB)

2 2 Data MSB Data LSB

3 3 Data MSB Data LSB

↓↓↓ ↓

14 30 Data MSB Data LSB

15 31 Data MSB Data LSB

Input Status to Master Device

Publication 1761-UM005B-EN-P - October 2006

The Input Status Byte provides the following information.

Function n/a Output Buffer Overdrive n/a

Bit Number76 543210

Page 51

DNI Configuration Parameters and Programming Notes 51

Output Buffer Overdrive (Bit 6, written by the DNI)

This bit is set (1) when Master Outputs arrive at a rate faster than the

DNI can forward the data to the DF1 device. When the Buffer

Overdrive bit is set, the output image is being overwritten before it

can be sent to the DF1 device. To resolve this, limit the data

production rate in the scanner until this bit stays clear (0).

Output Status to DF1 Device

The Output Status Byte provides the following information.

Function Heartbeat Valid Data DeviceNet Node Number

Bit Number7 6 543210

DeviceNet Node Number (Bits 0 - 5)

Whenever the DNI sets (writes) output data to the DF1 device, these

six bits contain the DeviceNet address that the DNI is assigned on

DeviceNet. If the user program needs to know what node number its

DNI is configured for, program a masked move (MVM) instruction in

the ladder logic to move the node number out of this byte. The MVM

should have:

• its destination address located in the controller’s integer file

• a masked value of 003F

• the source address should match the location identified by the

Output Word Offset parameter.

DeviceNet Valid Data (Bit 6)

The DNI sets this bit (1) to the DF1 device whenever it detects that the

DNI’s DeviceNet master is on-line/operational. The ladder logic

program in the controller should monitor this bit and take any

necessary control action.

DF1 Heartbeat (Bit 7)

The DNI writes the status of this bit to the controller, using the interval

set by the DF1 Heartbeat parameter. The DNI expects the controller to

move the status of bit 7 from the output data area to the input data

area. The easiest way to accomplish this is by programming an XIC

instruction in series with an OTE instruction as shown in the following

example.

Publication 1761-UM005B-EN-P - October 2006

Page 52

52 DNI Configuration Parameters and Programming Notes

Example

With the starting output word at N7:95 (Output Word Offset), and the

starting input word at N7:90 (Input Word Offset), you need to

program this rung in the controller’s program to move the heartbeat

bit.

N7:95

7

N7:90

7

Your program should also monitor N7:95/7 for activity. If activity is

lost, it represents a problem with the connection to the DNI, or the

DNI has some type of error or problem.

See the application example MicroLogix as I/O on the DeviceNet

Network on page 69 for more information about using the DF1

Heartbeat.

Publication 1761-UM005B-EN-P - October 2006

Page 53

Chapter

Setup, Programming, and Troubleshooting

6

DNI Software Files

To configure the DNI as an I/O slave device on a DeviceNet network,

you may need to obtain two software files. These two files provide

your network configuration software with the information it needs to

interface with the DNI.

DNI Series A Information

RSNetWorx and DeviceNet Manager (version 3.0 and higher) include

the files necessary for DNI Series A.

DNI Series B Information

To configure the Series B DNI, you must have the Series B DNI EDS

file installed in your DeviceNet configuration software. RSNetWorx

DeviceNet Network Management software version 2.11.36 or higher

includes all Series B DNI files. You can also download the new files

from http://www.ab.com/micrologix.

The following table shows the old and new file filenames:

Series B DNI Files

1761-NET-DNI File Description File Name

Series B DNI Electronic Data Sheet 1761DNI3.EDS

DNI Configuration Software Utility DNIUTIL1.EXE (Rev. 2.0 or higher)

DNI Icon for Configuration Software 1761DNI.ICO or 1761DNIB.BMP

Series A DNI Electronic Data Sheet 1761DNI2.EDS

DNI Configuration Software Utility DNIUTIL1.EXE

DNI Icon for Configuration Software 1761DNI.BMP

ATTENTION

53 Publication 1761-UM005B-EN-P - October 2006

DNI Series A configurations are not compatible with

DNI Series B. You must manually re-enter the Series

A parameters into the Series B DNI. This step is

required because of the enhanced functionality of

DNI Series B.

Page 54

54 Setup, Programming, and Troubleshooting

TIP

DNI Series A stopped shipping in June of 1999. DNI

Series B started shipping in July of 1999.

File Descriptions

File Description

DNI Electronic Data

Sheet

DNI Icon for

Configuration

Software

DNI Configuration

Software Utility

This is a text file that is compatible with A-B network configuration

software. This file, along with the 1761DNI.BMP (or 1761DNI.ICO)

file, must be installed using the EDS import utility built into your

network configuration software.

This is a bitmap that is used to graphically illustrate the DNI in your

configuration software. For RSNetWorx, use 1761BMP.ICO. For

DeviceNet Manager, use 1761DNI.BMP. The DNI Configuration

Software Utility includes the DNI icon files.

The 1761-NET-DNI configuration utility can be used to configure all

1761-NET-DNI parameters, and also to commission (set node

number and baud rate) of other DeviceNet compatible products for

operation on a DeviceNet Network. This utility makes configuring a

1761-NET-DNI easier through the use of intuitive screens and

Wizards.

Obtaining the Files

These files are routinely incorporated into your network configuration

software. If they are not in your version of configuration software,

these files are available from a number of sources:

• Local Allen-Bradley distributor

• Local Allen-Bradley Sales Office

• Via the Internet at http://www.ab.com/micrologix

Publication 1761-UM005B-EN-P - October 2006

Page 55

Setup, Programming, and Troubleshooting 55

Setting Up Network Configuration Software

To configure the DNI, you must set up your network configuration

software and follow the configuration procedures. The initial set up is

only performed once. After the files have been saved by your network

configuration software, they are stored on the computer.

Setting Up DNI Configuration Software Utility

No initial set up is required to use the DNI Configuration Software

Utility.

Setting Up RSNetworx

With RSNetworx open, install 1761DNI2.EDS for DNI Series A

(1761DNI3.EDS for DNI Series B) and 1761DNI.ICO using the EDS

install utility (in the Utilities menu of RSNetworx).

Follow these steps to load both DNI files into RSNetWorx.

1. Start RSNetWorx.

2. With RSNetWorx open, select the View Tools Menu.

3. Select EDS Wizard.

4. Select Register an EDS file and follow the prompts.

RSNetWorx is now set up to recognize and configure the DNI.

5. To locate 1761-NET-DNI in RSNetWorx file list, double-click on

the following folders:

– Rockwell Automation - Allen-Bradley Company

Publication 1761-UM005B-EN-P - October 2006

Page 56

56 Setup, Programming, and Troubleshooting

– Communications Adapter

Publication 1761-UM005B-EN-P - October 2006

Page 57

Setup, Programming, and Troubleshooting 57

Setting Up DeviceNet Manager

With DeviceNet Manager open, install 1761DNI2.EDS for DNI Series A

(1761DNI3.EDS for DNI Series B) and 1761DNI.BMP for DNI Series A

(1761DNIB.BMP for DNI Series B) using the EDS install utility (in the

Utilities menu of DeviceNet Manager).

Follow these steps to load both DNI files into DeviceNet Manager.

1. Start DeviceNet manager.

2. With DeviceNet manager open, select the Utilities Menu.

3. Select Install EDS Files.

4. Locate 1761DNI2.EDS for DNI Series A (1761DNI3.EDS for DNI

Series B) on your computer.

5. Highlight and load electronic data sheet into the software.

6. Confirm the prompt to attach a bitmap.

7. Locate 1761DNI.BMP (1761DNIB.BMP for DNI Series B) on your

computer.

8. Highlight and load bitmap into the software. DeviceNet manager

is now set up to recognize and configure the DNI.

9. To locate 1761-NET-DNI in DeviceNet managers file list,

double-click on the following folders:

– Communications Adapter

– Allen-Bradley Company

Publication 1761-UM005B-EN-P - October 2006

Page 58

58 Setup, Programming, and Troubleshooting

Commissioning the DNI

Your configuration software handles all interface issues for connection

to a DNI over a DeviceNet network. You use exactly the same

procedures to connect to a DNI as you do any other DeviceNet

product.

The DNI draws power from the DeviceNet connector. When the DNI