Page 1

Reference Manual

Bulletin 1606 Switched Mode Power Supplies

Catalog Numbers: 1606-XLS240E, 1606-XLS240EA, 1606-XLS240EC &

1606-XLS240E-D

Index

egaP

1.

Intended Use .......................................................3

2. Installation Requirements...................................3

3. AC-Input...............................................................4

4. DC-Input...............................................................5

5. Input Inrush Current ...........................................6

6. Output .................................................................7

7. Hold-up Time.......................................................9

8. DC-OK Relay Contact ..........................................9

9. Efciency and Power Losses..............................10

10. Reliability...........................................................11

11. Functional Diagram...........................................12

12. Terminals and Wiring........................................12

13. Front Side and User Elements...........................13

14. EMC....................................................................14

15. Environment ......................................................15

16. Protection Features ...........................................16

17. Safety Features..................................................16

18. Dielectric Strength ............................................16

19. Certications......................................................17

20. Environmental Compliance...............................18

2 Physical Dimensions and Weight......................18

21.

22. Accessories

22.1.

1606-XLB Wall Mounting Bracket ............19

22.2. 1606-XLSBUFFER24 Module ....................20

22.3. 1606-XLSRED Redundancy Module .......... 20

23. Application Notes............................................. 21

23.1. Repetitive Pulse Loading ..........................21

23.2. Peak Current Capability ...........................22

23.3. Back-feeding Loads ..................................22

23.4. External Input Protection .........................22

23.5. Charging Batteries ....................................23

23.6. Output Circuit Breakers ............................ 23

23.7. Parallel Use to Increase Output Power .... 24

23.8. Parallel Use for Redundancy ....................24

23.9. Daisy Chaining of Outputs .......................25

23.10. Series Operation .......................................25

23.11. Inductive and Capacitive Loads ................25

23.12. Operation on Two Phases ........................ 26

23.13. Use in a Tightly Sealed Enclosure ............ 26

23.14. Mounting Orientations ............................ 27

...................................................... 19

Terminology and Abbreviations

•PE and symbol—PE is the abbreviation for Protective Earth and has the same meaning as the symbol .

•Earth, Ground—This document uses the term “earth” which is the same as the U.S. term “ground”.

• T.b.d.—To be defined, value or description will follow later.

• AC 230V—A figure displayed with the AC or DC before the value represents a nominal voltage with standard tolerances (usually ±15%)

included. E.g.: DC 12V describes a 12V battery whether it is charged (13.7V) or discharged (10V).

• 230Vac—Afigure with the unit (Vac) at the end is a momentary figure without any additional tolerance included.

• 50Hz vs. 60Hz—Unless otherwise stated, AC 230V parameters are valid at 50Hz mains frequency.

•may—A key word indicating flexibility of choice with no implied preference.

• shall—A key word indicating a mandatory requirement.

•should—A key word indicating flexibility of choice with a strongly preferred implementation.

Page 2

Bulletin 1606 Switched Mode Power Supplies

Power Supply

AC 100-240V Wide-range Input

Width only 60mm

Efciency up to 93.5%

150% (360W) Peak Load Capability

Easy Fuse Tripping due to High Overload Current

Active Power Factor Correction (PFC)

Negligible low Inrush Current Surge

Short-term Operation down to 60Vac and up to 300Vac

Full Power Between -25°C and +60°C

DC-OK Relay Contact

Quick-connect Spring-clamp Terminals

3 Year Warranty

Description

The most outstanding features of the 1606-XLS DIN

rail power supplies are their high efciency and small

sizes, which are achieved by a synchronous

rectication and further design innovations. The 1606-XLS

series is part of Rockwell Automation's family of power

supplies, existing alongside lower featured power supplies.

With short-term peak power capability of 150% and

built-in large sized output capacitors, these features

help start motors, charge capacitors and absorb reverse

energy and often allow a unit of a lower wattage class

to be used.

High immunity to transients and power surges as well as

low electromagnetic emission makes usage in nearly

every environment possible.

The integrated output power manager, a wide range

input voltage design and virtually no input inrush

current make installation and usage simple. Diagnostics

are easy due to the dry DC-ok contact, a green DC-ok

LED and red overload LED.

Unique quick-connect spring-clamp terminals allow a

safe and fast installation and a large international

approval package for a variety of applications makes

this unit suitable for nearly every situation.

Specication Quick Reference

Output voltage DC 24V

Adjustment range 24 - 28V

Output current 10 – 9A continuous

15 – 13.5A for typ. 4s

Output power 240W continuous

360W for typ. 4s

Output ripple < 50mVpp 20Hz to 20MHz

Input voltage AC 100-240V ±15%

Mains frequency 50-60Hz ±6%

AC Input current 2.22 / 1.22A at 120 / 230Vac

Power factor 0.98 / 0.92 at 120 / 230Vac

AC Inrush current typ. 4 / 7A peak at 120 / 230Vac

Efciency 92.6 / 93.5% at 120 / 230Vac

Losses 19.1 / 16.7W at 120 / 230Vac

Temperature range -25°C to +70°C operational

Derating 6W/°C +60 to +70°C

Hold-up time typ. 27 / 28ms at 120 / 230Vac

Dimensions 60x124x117mm WxHxD

Catalog Numbers

Power Supply

1606-XLS240E

1606-XLS240E-D

1606-XLS240EA

1606-XLS240EC

24-28V Standard unit

Extended DC-input

ATEX approved unit

Conformal coated unit

Accessories 1606-XLB Wall mount bracket

1606-XLSRED Redundancy module

1606-XLSBUFFER24 Buffer module

Certication Marks

IND. CONT. EQ.

UL 508

UL 60950-1

Class I Div 2

ATEX

II 3G Ex nAC II T4

Marine

EMC, LVD

GOST R

Marine RINA

C-Tick

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

2 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

Page 3

Bulletin 1606 Switched Mode Power Supplies

Intended Use

• This device is designed for installation in an enclosure and is intended for the general professional use such as in industrial control, office,

communication, and instrumentation equipment.

• Do not use this power supply in aircraft, trains, nuclear equipment or similar systems where malfunction may cause severe personal injury or

threaten human life.

• This device is designed for use in hazardous, non-hazardous, ordinary or unclassified locations.

Installation Requirements

• This device may only be installed and put into operation by qualified personnel.

• This device does not contain serviceable parts. The tripping of an internal fuse is caused by an internal defect.

• Should damage or malfunction occur during installation or operation, turn power off immediately and send unit to the factory for inspection.

• Mount the unit on a DIN rail so that the terminals are located on the bottom of the unit. For other mounting orientations, refer to derating

requirements in this document. Refer to section 24.14.

• This device is designed for convection cooling and does not require an external fan. Do not obstruct airflow and do not cover ventilation grid

(e.g. cable conduits) by more than 30%!

• Keep the following installation clearances: 40mm on top, 20mm on the bottom, 5mm on the left and right sides are recommended when the

device is loaded permanently with more than 50% of the rated power. Increase this clearance to 15mm in case the adjacent device is a heat

source (e.g. another power supply).

SHOCK HAZARD: Do not use the power supply without proper grounding (Protective Earth). Use the terminal on the input

block for earth connection and not one of the screws on the housing.

- Turn power off before working on the device. Protect against inadvertent re-powering

- Make sure that the wiring is correct by following all local and national codes

- Do not modify or repair the unit

- Do not open the unit as high voltages are present inside

- Use caution to prevent any foreign objects from entering the housing

- Do not use in wet locations or in areas where moisture or condensation can be expected

- Do not touch during power-on, and immediately after power-off. Hot surfaces may cause burns.

WARNING: EXPLOSION HAZARDS!

Substitution of components may impair suitability for this environment. Do not disconnect the unit or operate the voltage adjustment or S/P jumper unless

power has been switched off or the area is known to be non-hazardous.

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 3

Page 4

Bulletin 1606 Switched Mode Power Supplies

3. AC-Input

AC input nom. AC 100-240V suitable for TN-, TT- and IT mains networks

AC input range min. 85-276Vac continuous operation

min. 60-85Vac full power for 200ms, no damage between 0 and 85Vac

min. 276-300Vac < 500ms

Allowed voltage L or N to earth max. 276Vac continuous, IEC 62103

Input frequency nom. 50–60Hz ±6%

Turn-on voltage typ. 81Vac steady-state value, see Fig. 3-1

Shut-down voltage typ. 63Vac steady-state value, see Fig. 3-1

typ. 55Vac dynamic value

AC 100V AC 120V AC 230V

Input current typ. 2.65A 2.22A 1.22A at 24V, 10A, see Fig. 3-3

Power factor *) typ. 0.99 0.98 0.92 at 24V, 10A, see Fig. 3-4

Crest factor **) typ. 1.65 1.67 1.85 at 24V, 10A

Start-up delay typ. 800ms 650ms 340ms see Fig. 3-2

Rise time typ. 8ms 8ms 8ms 0mF, 24V, 10A, see Fig. 3-2

typ. 15ms 15ms 15ms 10mF, 24V, 10A, see Fig. 3-2

Turn-on overshoot max. 100mV 100mV 100mV see Fig. 3-2

*) The power factor is the ratio of the true (or real) power to the apparent power in an AC circuit.

**) The crest factor is the mathematical ratio of the peak value to RMS value of the input current waveform.

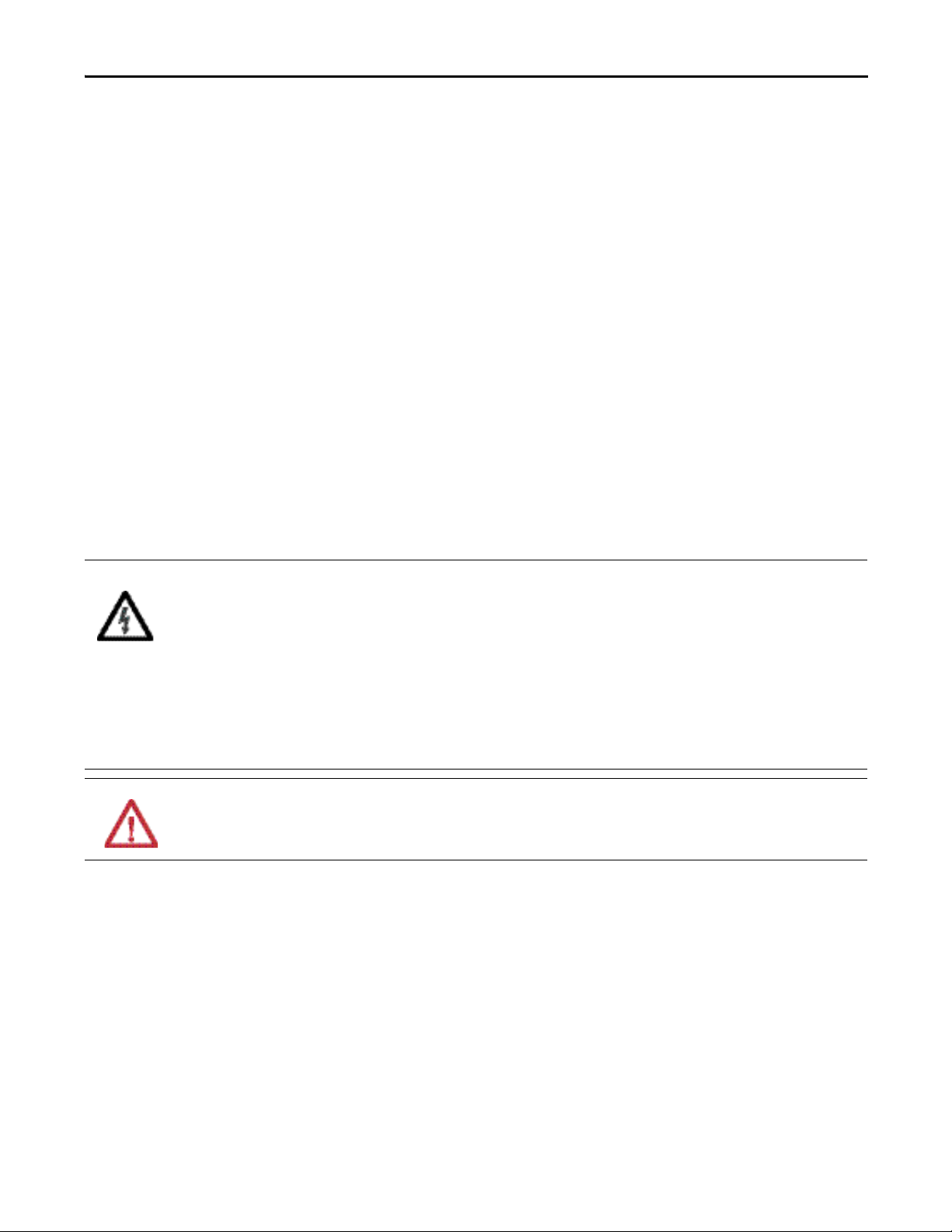

Fig. 3-1 Input voltage range Fig. 3-2 Turn-on behavior, denitions

Turn-on

85V

Rated

input range

max.

500ms

V

IN

P

OUT

60V 300Vac276V

Shut-down

full

power

for

200ms

Start-up

delay

Rise

Time

Overshoot

- 5%

Output

Voltage

Input

Voltage

Fig. 3-3 Input current vs. output load at 24V Fig. 3-4 Power factor vs. output load

10A

123456789

0

0.4

0.8

1.2

1.6

2.0

2.4

2.8A

Output Current

Input

Current, typ.

2

3

0

V

a

c

1

2

0

V

a

c

1

0

0

V

a

c

Power Factor, typ.

12345678910A

0.75

0.8

0.85

0.9

0.95

1.0

Output Current

100Vac

120Vac

2

3

0

V

a

c

4 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 5

Bulletin 1606 Switched Mode Power Supplies

4. DC-Input

1606-XLS240E, 1606-XLS240EA, 1606-XLS240EC:

DC input nom. DC 110-150V -20%/+25%

DC input range min. 88-187Vdc continuous operation

DC input current typ. 2.37A 110Vdc, at 24V, 10A

1606-XLS240E-D:

DC input nom. DC 110-300V -20%/+25%

DC input range min. 88-375Vdc continuous operation

DC input current typ. 2.37/ 0.85A 110/300Vdc, at 24V, 10A

All units:

Allowed Voltage L/N to Earth max. 375Vdc continuous, IEC 62103

Turn-on voltage typ. 80Vdc steady state value

Shut-down voltage typ. 55Vdc steady state value

Fig. 4-1 Wiring for DC Input

Instructions for DC use:

+

-

Load

L

PE

+

-

Power Supply

AC

Battery

N

DC

a) Use a battery or similar DC source.

For other sources, contact Rockwell Automation.

b) Connect +pole to L and –pole to N.

c) Connect the PE terminal to a earth wire or to the machine

ground.

d) A supply from the intermediate DC-bus of a frequency

converter is not recommended and can cause a

malfunction or damage the unit.

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 5

Page 6

Bulletin 1606 Switched Mode Power Supplies

5. Input Inrush Current

An active inrush limitation circuit limits the input inrush current after turn-on of the input voltage and after short

input voltage interruptions.

The charging current into EMI suppression capacitors is disregarded in the rst microseconds after switch-on.

AC 100V AC 120V AC 230V

Inrush current max. 10A

peak

10A

peak

10A

peak

over entire temperature range

typ. 5A

peak

4A

peak

7A

peak

over entire temperature range

Inrush energy max. 4A

2

s 4A2s 4A2s over entire temperature range

Inrush delay (A) typ. 650ms 520ms 250ms see (A) in Fig. 5-1

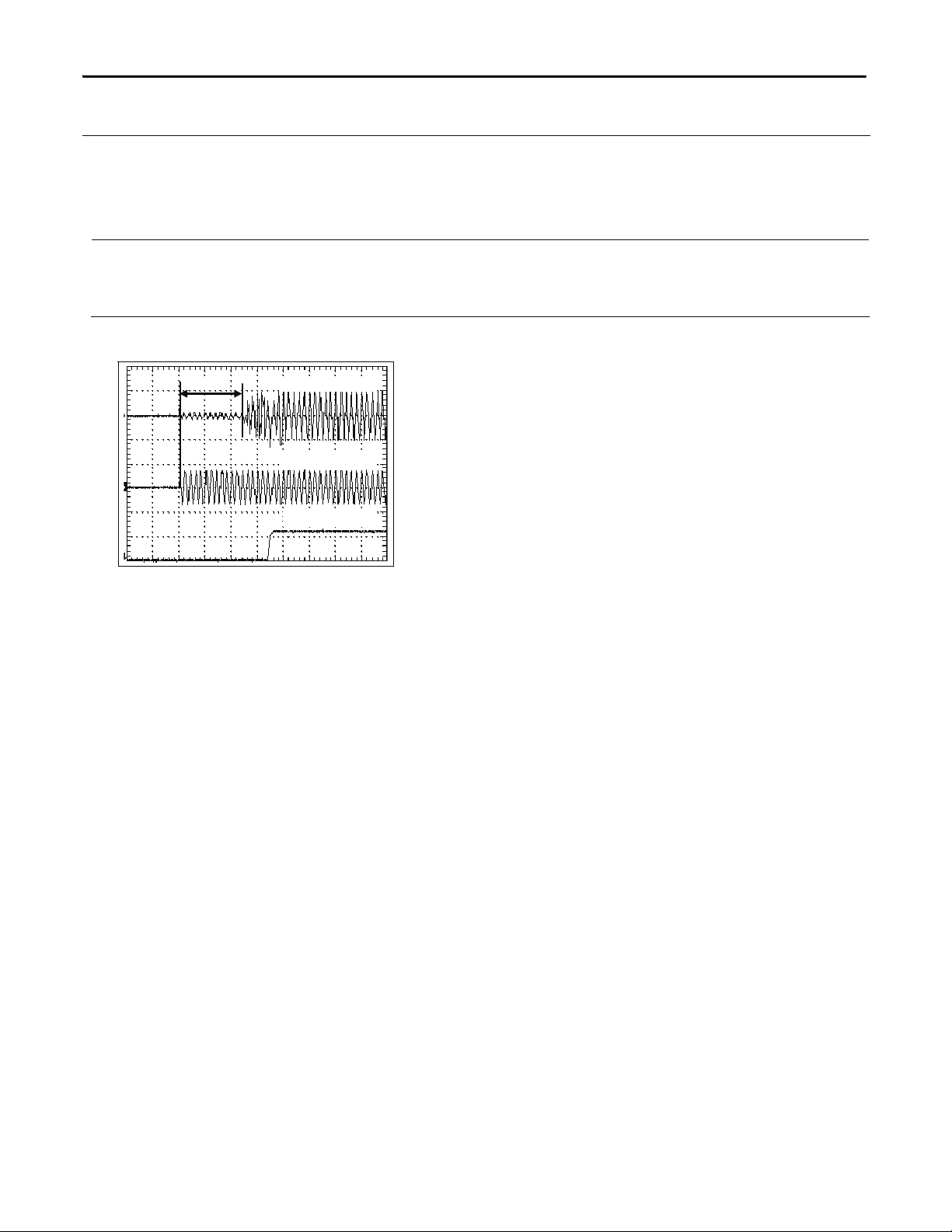

Fig. 5-1 Input inrush current, typical behavior

Input Current

Input Voltage

Output Voltage

A

A…. Inrush delay

Input: 230Vac

Output: 24V, 10A

Ambient: 25°C

Upper curve: Input current 2A / DIV

Middle curve: Input voltage 500V / DIV

Lower curve: Output voltage 20V / DIV

Time basis: 100ms / DIV

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

6 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

Page 7

Bulletin 1606 Switched Mode Power Supplies

6. Output

Output voltage nom. 24V

Adjustment range min. 24-28V guaranteed

max. 30V

Factory setting typ. 24.1V ±0.2%, at full load, cold unit

Line regulation max. 10mV 60-300Vac

Load regulation max. 100mV static value, 0A 10A

Ripple and noise voltage max. 50mVpp 20Hz to 20MHz, 50Ohm

Output current nom. 10A continuously available at 24V, see Fig. 6-1

nom. 9A continuously available at 28V, see Fig. 6-1

nom. 15A

nom. 13.5A

Output power nom. 240W / 252W continuously available at 24V / 28V

nom. 360W / 378W *) short term available BonusPower

®

BonusPower

time typ. 4s duration until the output voltage dips, see Fig. 6-2

min. 3s

max. 5s

®

BonusPower

recovery time typ. 7s overload free time to reset power manager, see Fig. 6-3

Overload behaviour cont. current

Short-circuit current min. 8A

max. 12.5A

min. 21A

max. 27A

max. 15A

Output capacitance typ. 7 000μF included inside the power supply

*) BonusPower, short term power capability (up to typ. 4s)

The power supply is designed to support loads with a higher short-term power requirement without damage or shutdown. The shortterm duration is hardware controlled by an output power manager. BonusPower is repeatedly available. Detailed information

can be found in section 23.1. If the power supply is loaded longer with the BonusPower than shown in the Bonus-time diagram (see

Fig. 6-2), the max. output power is automatically reduced to 240/252W.

**) Discharge current of output capacitors is not included.

***) This is the maximum output voltage which can occur at the clockwise end position of the potentiometer due to tolerances. There is no

guarantee this value can be achieved. The typical value is about 28.6V.

Peak current capability (up to several milliseconds)

The power supply can deliver a peak current which is higher than the specied short term current. This helps to start

current demanding loads or to safely operate subsequent circuit breakers.

The extra current is supplied by the output capacitors inside the power supply. During this event, the capacitors will be

discharged and causes a voltage dip on the output. Detailed curves are provided in section 23.2.

Peak current voltage dips typ. from 24V to 20.5V at 20A for 50ms, resistive load

typ. from 24V to 18V at 50A for 2ms, resistive load

typ. from 24V to 14V at 50A for 5ms, resistive load

***)

at clockwise end position of potentiometer

*)

short term available BonusPower

at 24V, for typical 4s, see Fig. 6-1

*)

short term available BonusPower

at 28V, for typical 4s, see Fig. 6-1

**)

continuous, load impedance 100mOhm, see Fig. 6-1

**)

continuous, load impedance 100mOhm, see Fig. 6-1

**)

during BonusPower

**)

during BonusPower

**)

continuous, load impedance <10mOhm, see Fig. 6-1

*)

, load impedance 100mOhm

*)

, load impedance 100mOhm

*)

,

*)

,

*)

at 24V / 28V

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 7

Page 8

Bulletin 1606 Switched Mode Power Supplies

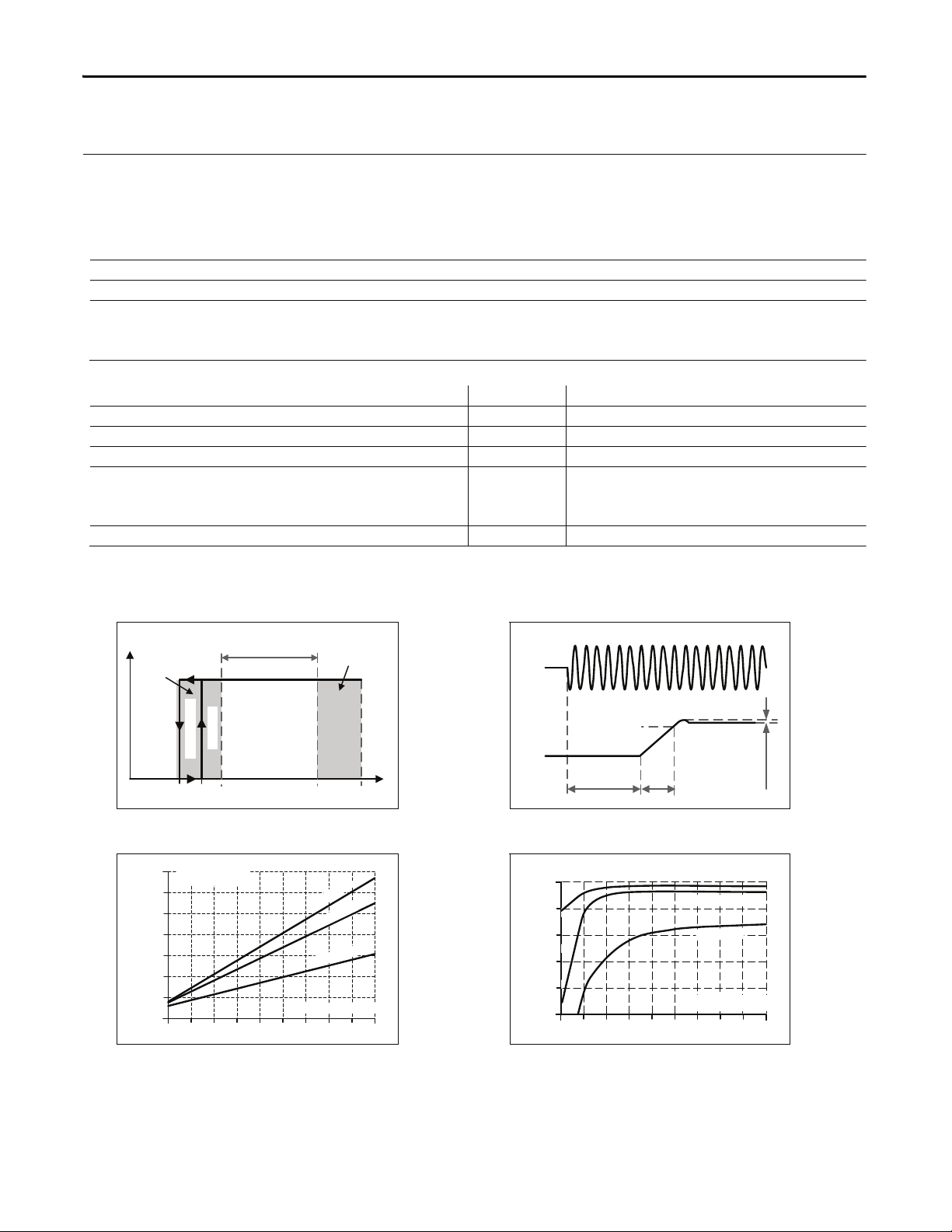

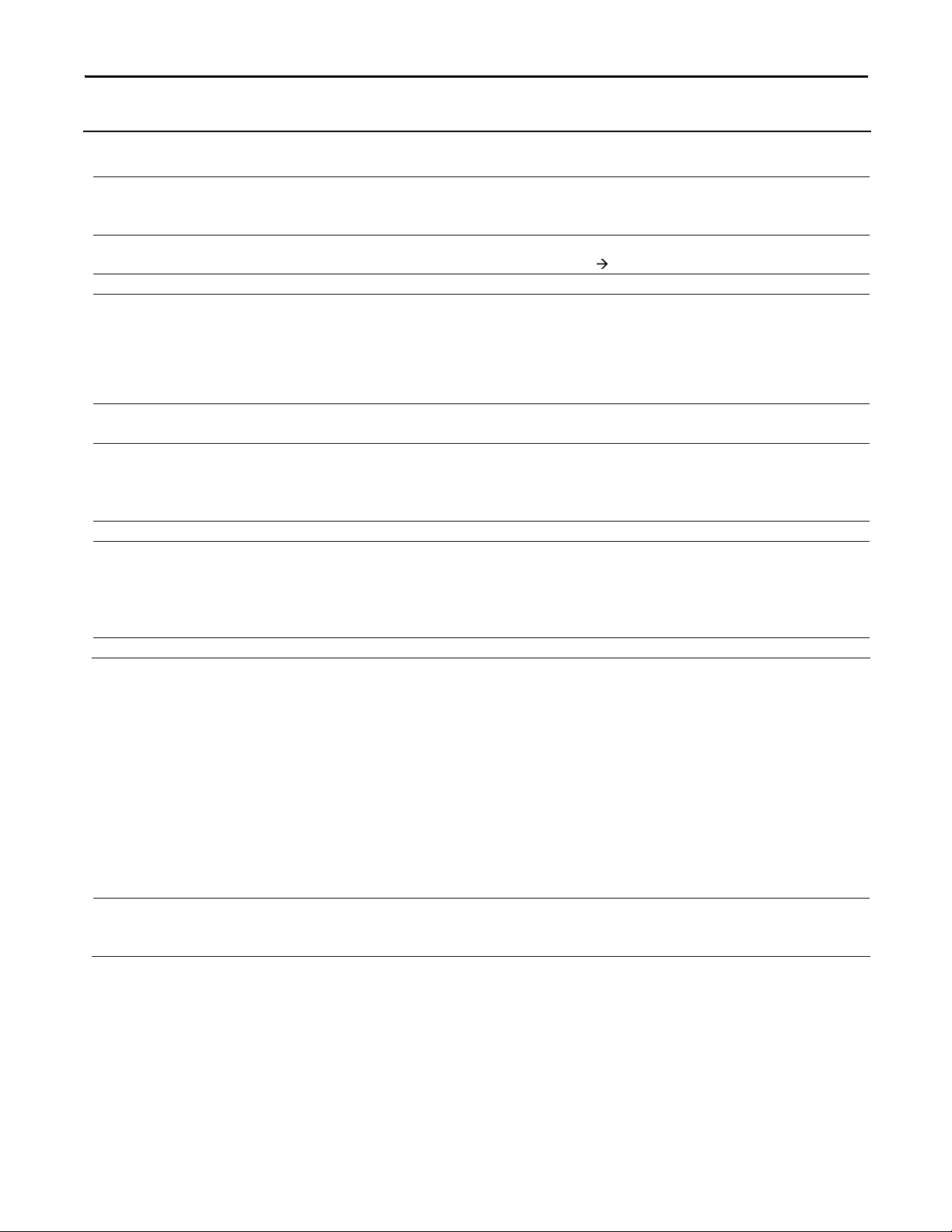

Fig. 6-1 Output voltage vs. output current,

typ.

Fig. 6-2 Bonus time vs. output power

c

on

t

i

n

uo

u

s

Output Voltage

0

0 5 10 15 20

4

8

12

28V

16

20

24

25

A

Output Current

s

h

or

t

-

t

e

r

m

Adjustment

Range

Bonus Time

0

110 120 130 140 150

160%

1

2

3

7

4

5

6

8

9

10s

m

i

n

m

a

x

typ

Output Power

Fig. 6-3 BonusPower recovery time

Power

Demand

100%

t

t

Limitation by

Power Manager

Output

Voltage

Bonus Power disabled

Bonus

Time

Recovery Time

BonusPower is available as soon as power comes on and immediately after the end of an output short circuit or

output overload.

Fig. 6-4 BonusPower after input turn-on Fig. 6-5 BonusPower after output short

100%

Output

Voltage

Input

Voltage

Bonus

Power

150%

Output

Power

Short of

Output

100%

Output

Voltage

Bonus

Power

Output

Power

150%

8 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 9

Bulletin 1606 Switched Mode Power Supplies

7. Hold-up Time

AC 100V AC 120V AC 230V

Hold-up Time typ. 51ms 53ms 55ms at 24V, 5A, see Fig. 7-1

typ. 26ms 27ms 28ms at 24V, 10A, see Fig. 7-1

Fig. 7-1 Hold-up time vs. input voltage Fig. 7-2 Shut-down behavior, denitions

10

20

30

40

50

60ms

85 120 155 190 230Vac

Input Voltage

2

4

V

,

5

A,

m

i

n

.

2

4

V

,

5

A

,

t

y

p

.

2

4

V

,

1

0

A

,

m

i

n

.

2

4

V

,

1

0

A,

t

y

p

.

Hold-up Time

- 5%

Hold-up Time

Zero Transition

Output

Voltage

Input

Voltage

8. DC-OK Relay Contact

This feature monitors the output voltage, which is produced by the power supply itself. It is independent of a back-fed

voltage from a unit connected in parallel to the power supply output.

Contact closes As soon as the output voltage reaches the adjusted output voltage level.

Contact opens As soon as the output voltage dips more than 10% below the adjusted output voltage.

Short dips will be extended to a signal length of 250ms. Dips shorter than 1ms will be ignored.

Contact re-closes As soon as the output voltage exceeds 90% of the adjusted voltage.

Contact ratings max 60Vdc 0.3A, 30Vdc 1A, 30Vac 0.5A resistive load

min 1mA at 5Vdc min. permissible load

Isolation voltage See dielectric strength table in section 18.

Fig. 8-1 DC-ok relay contact behavior

250ms

0.9* V

ADJ

<

1ms

10%

V

OUT

= V

ADJ

>

1ms

open openclosed closed

Note: The DC-ok feature requires that the output voltage reaches the nominal (=adjusted) level after turn-on in order to function according

to specication. If this level cannot be achieved, the overload lamp will be on and the DC-ok contact will be open. The overload signal

will only shut off as soon as the adjusted voltage is reached. This is an important condition to consider particularly if the load is a

battery, if the power supply is used in parallel or if the power supply is used for N+1 redundant systems.

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 9

Page 10

Bulletin 1606 Switched Mode Power Supplies

9. Efciency and Power Losses

AC 100V AC 120V AC 230V

Efciency typ. 91.5% 92.6% 93.5% at 24V, 10A

Average efciency *) typ. 91.7% 92.4% 92.4% 25% at 2.5A, 25% at 5A, 25%

at 7.5A. 25% at 10A

Power losses typ. 4.4W 4.9W 6.1W at 24V, 0A

typ. 22.4W 19.1W 16.7W at 24V, 10A

*) The average efciency is an assumption for a typical application where the power supply is loaded with 25% of the nominal load for 25%

of the time, 50% of the nominal load for another 25% of the time, 75% of the nominal load for another 25% of the time and with 100%

of the nominal load for the rest of the time.

Fig. 9-1 Efciency vs. output current at 24V,

typ

Fig. 9-2 Losses vs. output current at 24V, typ.

Efciency

23456789

10A

86

87

88

89

90

91

Output Current

92

93

94%

A

.

.

.

1

0

0

V

a

c

B

.

.

.

1

2

0

V

a

c

C

.

.

.

2

3

0

V

a

c

A

B

C

Power Losses

01234567 10A

0

3

12

15

18

Output Current

21

24W

89

A

B

C

6

9

A

.

.

.

1

0

0

V

a

c

B

.

.

.

1

2

0

V

a

c

C

.

.

.

2

3

0

V

a

c

Fig. 9-3 Efciency vs. input voltage at 24V,

10A, typ.

Fig. 9-4 Losses vs. input voltage at 24V, 10A,

typ.

Efciency

85 120

155

190 225 260Vac

88

89

90

91

Input Voltage

92

93

94%

Power Losses

9

12

15

18

21

Input Voltage

24

27W

85 120

155

190 225 260Vac

10 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 11

Bulletin 1606 Switched Mode Power Supplies

10. Reliability

AC 100V AC 120V AC 230V

Lifetime expectancy

*) 58 000h 68 000h 71 000h at 24V, 10A and 40°C

117 000h 122 000h 117 000h at 24V, 5A and 40°C

165 000h*) 192 000h*) 200 000h*) at 24V, 10A and 25°C

**) SN 29500, IEC 61709 478 000h 535 000h 581 000h at 24V, 10A and 40°C

MTBF

827 000h 926 000h 1 005 000h at 24V, 10A and 25°C

MTBF

**) MIL HDBK 217F 334 000h 341 000h 345 000h at 24V, 10A and 40°C; Ground

460 000h 469 000h 474 000h at 24V, 10A and 25°C; Ground

*) The Lifetime expectancy shown in the table indicates the minimum operating hours (service life) and is determined by the lifetime

expectancy of the built-in electrolytic capacitors. Lifetime expectancy is specied in operational hours and is calculated according to the

capacitor’s manufacturer specication. The manufacturer of the electrolytic capacitors only guarantees a maximum life of up to 15 years

(131 400h). Any number exceeding this value is a calculated theoretical lifetime which can be used to compare devices.

**) MTBF stands for Mean Time Between Failure, which is calculated according to statistical device failures, and indicates reliability of a

device. It is the statistical representation of the likelihood of a unit to fail and does not necessarily represent the life of a product.

The MTBF gure is a statistical representation of the likelihood of a device to fail. A MTBF gure of e.g. 1 000 000h means that

statistically one unit will fail every 100 hours if 10 000 units are installed in the eld. However, it’s impossible to determine if the failed

unit has been running for 50 000h or only for 100h.

Benign GB40

Benign GB25

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 11

Page 12

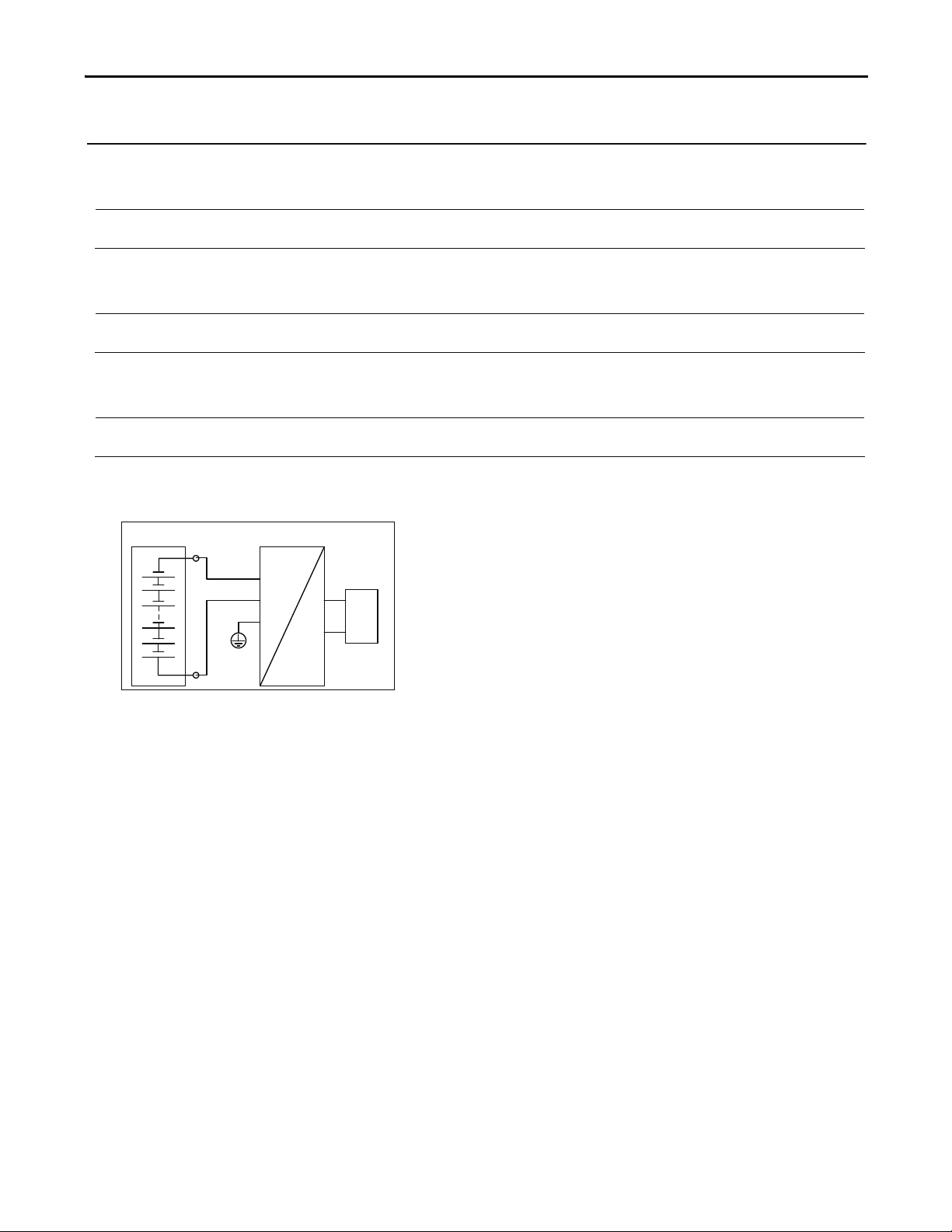

Bulletin 1606 Switched Mode Power Supplies

11. Functional Diagram

Fig. 11-1 Functional diagram

+

+

-

-

DC-ok

contact

Output

Over-

Voltage

Protection

PFC

Converter

Output

Voltage

Regulator

Power

Converter

Output

Filter

DC-ok

Relay

Output

Voltage

Monitor

Output

Power

Manager

Temper-

ature

Shutdown

Overload

LED

DC-ok

LED

Input Fuse

Input Filter

Input Rectier

Active Transient Filter &

Inrush Current Limiter

V

OUT

L

N

12. Terminals and Wiring

Bi-stable, quick-connect spring clamp terminals. IP20 Finger safe construction. Suitable for eld- and factory

installation. Shipped in open position.

Input Output DC-OK-Signal

Type

spring-clamp terminals spring-clamp terminals spring-clamp terminals

Solid wire 0.5-6mm2 0.5-6mm2 0.5-6mm2

Stranded wire 0.5-4mm2 0.5-4mm2 0.5-4mm2

American Wire Gauge 20-10 AWG 20-10 AWG 20-10 AWG

Wire stripping length 10mm / 0.4inch 10mm / 0.4inch 10mm / 0.4inch

Screwdriver not applicable not applicable not applicable

Recommended tightening torque not applicable not applicable not applicable

Pull-out force 10AWG:80N, 12AWG:60N, 14AWG:50N, 16AWG:40N (according to UL486E)

Fig. 12-1 Connecting a wire

Instructions:

a) Use appropriate copper cables that are designed for minimum

operating temperatures of:

60°C for ambient up to 45°C and

75°C for ambient up to 60°C minimum

90°C for ambient up to 70°C minimum.

b) Follow national installation codes and installation regulations!

c) Ensure that all strands of a stranded wire enter the terminal

connection!

d) Up to two stranded wires with the same cross section are

permitted in one connection point (except PE wire).

e) Do not use the unit without PE connection.

f) Unused terminal compartments should be securely tightened.

g) Ferrules are allowed.

1.

Insert the wire

2.

Close the lever

To disconnect wire:

reverse the procedure.

12 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 13

13. Front Side and User Elements

Fig. 13-1 Front side

A

Input Terminals (Quick-connect spring-clamp terminals)

N, L Line input

PE (Protective Earth) input

B

Output Terminals (Quick-connect spring-clamp terminals, two pins per

pole)

+ Positive output

– Negative (return) output

C

DC-OK Relay Contact (Quick-connect spring-clamp terminals)

The DC-OK relay contact is synchronized with the DC-OK LED.

See section 8 for details.

D

Output voltage potentiometer

Open the ap to adjust the output voltage. Factory set: 24.1V

E

DC-OK LED (green)

On, when the output voltage is >90% of the adjusted output voltage

F

Overload LED (red)

On, when the voltage on the output terminals is <90% of the adjusted

output voltage, or in case of a short circuit in the output. Input voltage is

required

Flashing, when the unit has switched off due to over-temperature.

Indicators, LEDs

Overload LED DC-OK LED DC-OK Contact

Normal mode OFF ON Closed

During BonusPower OFF ON Closed

Overload (VOUT < 90%) ON OFF Open

Output short circuit ON OFF Open

Temperature Shut-down Intermitted OFF Open

No input power OFF OFF Open

A

B

C

D

E

F

Bulletin 1606 Switched Mode Power Supplies

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 13

Page 14

Bulletin 1606 Switched Mode Power Supplies

14. EMC

The power supply is suitable for applications in industrial environment as well as in residential, commercial and light

industry environment without any restrictions.

The CE Mark indicates conformance with the EMC directive 2004/108/EC, the low-voltage directive (LVD) 2006/95/EC

and the RoHS directive 2011/65/EC. A detailed EMC report is available upon request.

EMC Immunity

According generic standards: EN 61000-6-1 and EN 61000-6-2

Electrostatic discharge EN 61000-4-2 contact discharge

air discharge

8kV

15kV

Criterion A

Criterion A

Electromagnetic RF eld EN 61000-4-3 80MHz-2.7GHz 10V/m Criterion A

Fast transients (Burst) EN 61000-4-4 input lines

output lines

DC-OK signal (coupling clamp)

4kV

2kV

1kV

Criterion A

Criterion A

Criterion A

Surge voltage on input EN 61000-4-5

L

N

L

PE, N PE

2kV

4kV

Criterion A

Criterion A

Surge voltage on output EN 61000-4-5 + -

+ / - PE

1kV

1kV

Criterion A

Criterion A

Surge voltage on DC-OK EN 61000-4-5 DC-OK signal PE 1kV Criterion A

Conducted disturbance EN 61000-4-6 0.15-80MHz 10V Criterion A

Mains voltage dips EN 61000-4-11 0% of 100Vac

40% of 100Vac

70% of 100Vac

0% of 200Vac

40% of 200Vac

70% of 200Vac

0Vac, 20ms

40Vac, 200ms

70Vac, 500ms

0Vac, 20ms

80Vac, 200ms

140Vac, 500ms

Criterion A

Criterion C

Criterion A

Criterion A

Criterion A

Criterion A

Voltage interruptions EN 61000-4-11 0% of 200Vac (=0V) 5000ms Criterion C

Voltage sags SEMI F47 0706 dips on the input voltage according to SEMI F47 standard

80% of 120Vac (96Vac)

70% of 120Vac (84Vac)

50% of 120Vac (60Vac)

1000ms

500ms

200ms

Criterion A

Criterion A

Criterion A

Powerful transients VDE 0160 over entire load range 750V, 1.3ms Criterion A

Criteria:

A: Power supply shows normal operation behavior within the dened limits.

C: Temporary loss of function is possible. Power supply may shut-down and restarts by itself. The power supply will incur no damage or

hazard.

EMC Emission

According generic standards: EN 61000-6-3 and EN 61000-6-4

Conducted emission

input lines

EN 55011, EN 55022, FCC Part 15, CISPR 11, CISPR 22 Class B

Conducted emission

output lines **)

IEC/CISPR 16-1-2, IEC/CISPR 16-2-1 limits for DC power port

according EN 61000-6-3 fullled

Radiated emission EN 55011, EN 55022 Class B

Harmonic input current EN 61000-3-2 fullled for class A equipment

Voltage uctuations, icker EN 61000-3-3 fullled *)

This device complies with FCC Part 15 rules.

Operation is subjected to following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

*) tested with constant current loads, non pulsing.

**) for information only, not mandatory for EN 61000-6-3.

14 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 15

Switching Frequencies

The power supply has three converters with three different switching frequencies

included. Two are nearly constant. The other one is input voltage and load dependent.

Switching frequency 1 35kHz nearly constant

Switching frequency 2 105kHz nearly constant

Switching frequency 3 40kHz to 220kHz input voltage and load dependent

15. Environment

Operational temperature

*) -25°C to +70°C (-13°F to 158°F) reduce output power according Fig. 15-1

Storage temperature -40 to +85°C (-40°F to 185°F) for storage and transportation

Output de-rating 6W/°C 60-70°C (140°F to 158°F)

Humidity

**) 5 to 95% r.H. IEC 60068-2-30

Vibration sinusoidal 2-17.8Hz: ±1.6mm; 17.8-500Hz: 2g

2 hours / axis

IEC 60068-2-6

Shock 30g 6ms, 20g 11ms

3 bumps / direction, 18 bumps in total

IEC 60068-2-27

Altitude 0 to 2000m (0 to 6 560ft) without any restrictions

2000 to 6000m (6 560 to 20 000ft) reduce output power or ambient temperature,

see Fig. 15-2

IEC 62103, EN 50178, overvoltage category II

Altitude de-rating 15W/1000m or 5°C/1000m > 2000m (6500ft), see Fig. 15-2

Over-voltage category III IEC 62103, EN 50178, altitudes up to 2000m

II altitudes from 2000m to 6000m

Degree of pollution 2 IEC 62103, EN 50178, not conductive

*) Operational temperature is the same as the ambient temperature and is dened as the air temperature 2cm below the unit.

**) Do not energize in the presence of condensation.

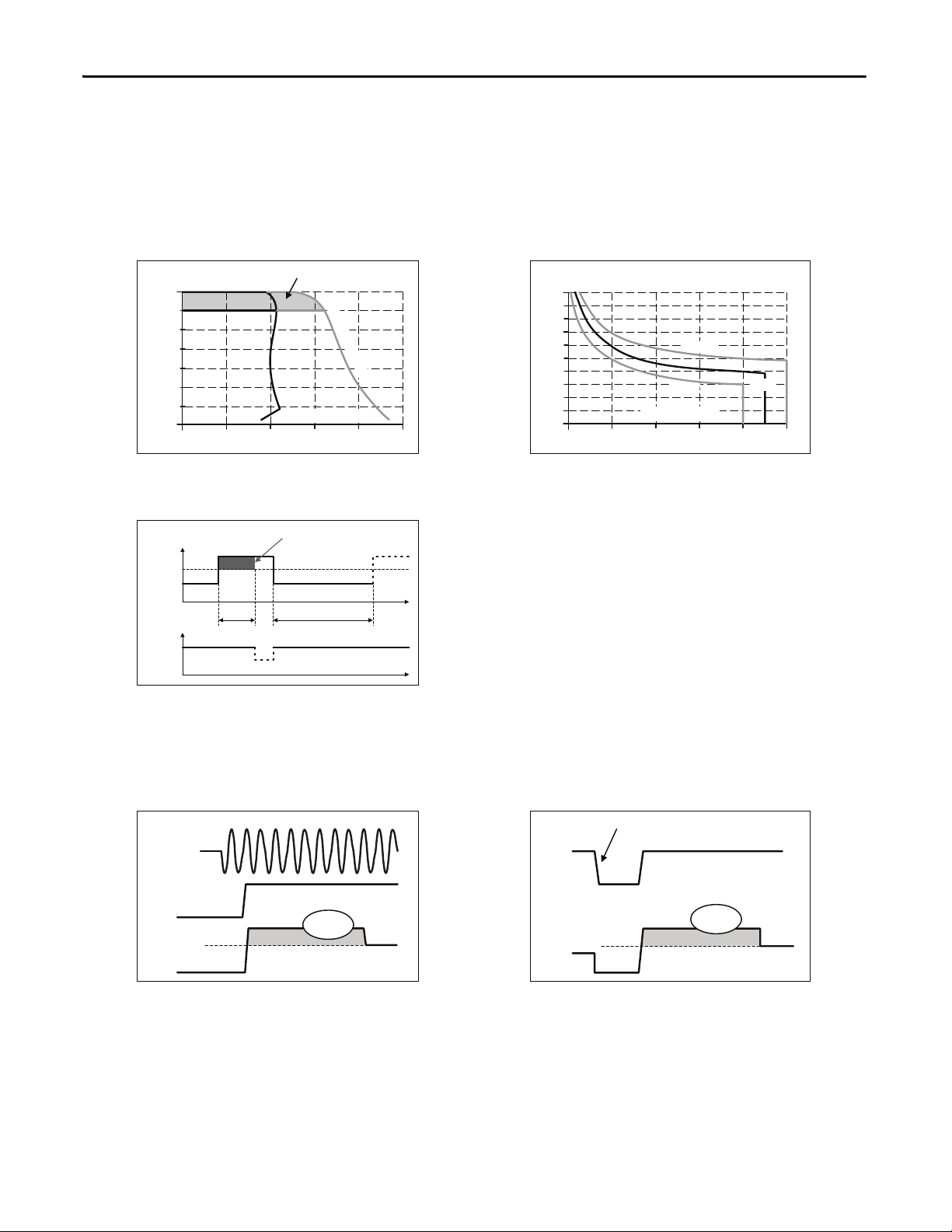

Fig. 15-1 Output current vs. ambient temp. Fig. 15-2 Output current vs. altitude

Allowed Output

Current at 24V

0

-25 0 20 40

2.5

5

7.5

10

12.5

15A

c

o

n

t

i

n

u

o

u

s

70°C60

Ambient Temperature

f

o

r

t

y

p

.

4

s

Allowed Output

Current at 24V

0

0 2000 4000

6000m

2.5

5

7.5

10

12.5

15A

c

o

n

t

i

n

u

o

u

s

Altitude

f

o

r

t

y

p

.

4

s

A

.

.

.

T

a

m

b

<

6

0

°

C

B

.

.

.

T

a

m

b

<

5

0

°

C

C

.

.

.

T

a

m

b

<

4

0

°

C

A

B

C

Bulletin 1606 Switched Mode Power Supplies

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 15

Page 16

Bulletin 1606 Switched Mode Power Supplies

16. Protection Features

Output protection Electronically protected against overload, no-load and short-circuits

*)

Output over-voltage protection typ. 35Vdc

max. 39Vdc

In case of an internal power supply defect, a redundant

circuit limits the maximum output voltage. The output

shuts down and automatically attempts to restart.

Degree of protection IP 20 EN/IEC 60529

Penetration protection > 3.5mm e.g. screws, small parts

Over-temperature protection yes Output shut-down with automatic restart

Input transient protection MOV (Metal Oxide Varistor)

Internal input fuse T6.3A H.B.C. not user replaceable

*) In case of a protection event, audible noise may occur.

17. Safety Features

Input / output separation

*)

SELV IEC/EN 60950-1

PELV IEC/EN 60204-1, EN 50178, IEC 62103, IEC 60364-4-41

double or reinforced insulation

Class of protection I PE (Protective Earth) connection required

Isolation resistance > 5MOhm input to output, 500Vdc

PE resistance < 0.1Ohm

Touch current (leakage current) typ. 0.19mA / 0.44mA 100Vac, 50Hz, TN-,TT-mains / IT-mains

typ. 0.29mA / 0.65mA 120Vac, 60Hz, TN-,TT-mains / IT-mains

typ. 0.53mA / 1.04mA 230Vac, 50Hz, TN-,TT-mains / IT-mains

< 0.25mA / 0.54mA 110Vac, 50Hz, TN-,TT-mains / IT-mains

< 0.38mA / 0.79mA 132Vac, 60Hz, TN-,TT-mains / IT-mains

< 0.74mA /1.29mA 264Vac, 50Hz, TN-,TT-mains / IT-mains

*) double or reinforced insulation

18. Dielectric Strength

The output voltage is oating and has no ohmic connection to the ground. Type and factory tests are conducted by

the manufacturer. Field tests may be conducted in the eld using the appropriate test equipment which applies the

voltage with a slow ramp (2s up and 2s down). Connect all input-terminals together as well as all output poles before

conducting the test. When testing, set the cut-off current settings to the value in the table below.

Fig. 18-1 Dielectric strength

A B C D

Type test 60s 2500Vac 3000Vac 500Vac 500Vac

Factory test 5s 2500Vac 2500Vac 500Vac 500Vac

Field test 5s 2000Vac 2000Vac 500Vac 500Vac

Cut-off current setting > 10mA > 10mA > 20mA > 1mA

DA

C

B

B

N

L

Input DC-ok

Output

-

Earth, PE

+

To meet the PELV requirements according to EN60204-1 § 6.4.1, we

recommend that either the + pole, the – pole or any other part of

the output circuit be connected to the protective earth system.

This helps to avoid situations in which a load starts

unexpectedly or cannot be switched off when unnoticed earth

faults occur.

16 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 17

19. Certications

EC Declaration of Conformity

Complies with CE EMC and CE Low Voltage Directives

EC Declaration of Conformity

(additional for 1606-XLS240EA)

The CE mark indicates conformance with EMC directive

2004/108/EC and the ATEX directive 94/9/EC (Equipment and

protection systems intended for use in potentially explosive

atmospheres)

UL 508

IND. CONT. EQ.

LISTED E56639 for use in the U.S.A. (UL 60950-1)

and Canada (C22.2 No. 60950)

Industrial Control Equipment

UL 60950-1

RECOGNIZED UNDER FILE NUMBER E244404 for use in the U.S.A.

(UL 60950-1) and Canada (C22.2 No. 60950)

Information Technology Equipment, Level 3

ISA 12.12.01, CSA

C22.2 No. 213

CSA Certied inder File Number 2400020. CERIFIED for use in

the U.S.A. IISA 12.12.01) and Canada (C22.2 No. 213)

Hazardous Location Class I, Div. 2, Groups A, B, C, D

ATEX

(1606-XLS240EA only)

II 3G Ex nAC II T4

Marine GL

GL (Germanischer Lloyd) classied for marine and offshore

applications. Environmental category: C, EMC2. See below

for link to the Certicate.

SEMI F47

SEMI F47-0706 Voltage Sag Immunity Compliance.

See below for link to the Certicate.

GOST R

GOST R certication is applicable for products intended

for sale and use within Russia. See below for link to the

Certicate.

C-TICK

II 3G Ex nAC II T4

C-tick compliance is for products intended for sale and use within

the Australian market. See below for link to the C-tick Declarations

of Conformity.

Marine RINA

RINA (Registro Italiano Navale) certied. See below for link to

the Certicate.

Bulletin 1606 Switched Mode Power Supplies

Product certification information (including Certificates and Declarations of Conformity) can be found at www.ab.com/certification.

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 17

Page 18

Bulletin 1606 Switched Mode Power Supplies

20. Environmental Compliance

The unit does not release any silicone and is suitable for use in paint shops.

The unit conforms to the RoHS directives 2002/95/EC and 2011/65/EC.

Electrolytic capacitors included in this unit do not use electrolytes such as Quaternary Ammonium Salt Systems.

Plastic housings and other molded plastic materials are free of halogens, wires and cables are not PVC insulated.

The production material within our production does not include following toxic chemicals:

Polychlorized Biphenyl (PCB), Polychlorized Terphenyl (PCT), Pentachlorophenol (PCP), Polychlorinated naphthalene

(PCN), Polybrom Biphenyll (PBB), Polybrom Bipheny-oxyd (PBO), Polybrominated Diphenylether (PBDE), Polychlorinated

Diphenylether (PCDE), Polydibromphenyl Oxyd (PBDO), Cadmium, Asbestos, Mercury, Silicia

21. Physical Dimensions and Weigth

Weight 900g / 1.98lb

DIN Rail Use 35mm DIN rails according to EN 60715 or EN 50022 with a height of 7.5 or 15mm.

The DIN rail height must be added to the unit depth (117mm) to calculate the total required

installation depth.

Installation Clearances See section 2.

Fig. 22-1 Front view Fig. 22-2 Side view

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

18 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

Page 19

Bulletin 1606 Switched Mode Power Supplies

22. Accessories

22.1. 1606-XLB Wall Mounting Bracket

This bracket is used to mount the power

supply onto a at surface without

a DIN rail.

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 19

Page 20

Bulletin 1606 Switched Mode Power Supplies

22.3. 1606-XLSBUFFER24 Buffer Module

er

t.

ures.

This buffer unit is a supplementary device for DC 24V power supplies. It delivers power to bridge typical mains failures

or extends the hold-up time after turn-off

of the AC power. In times when the pow

supply provides sufcient voltages, the

buffer unit stores energy in integrated

electrolytic capacitors. In case of mains

voltage fault, this energy is released again

in a regulated process. One buffer module can deliver 20A additional curren

DC

Buffer

Unit(s)

Power

Supply

Load

AC

+

-

The buffer unit does not require any control wiring. It can be added in parallel to

the load circuit at any given point. Buffer units can be added in parallel to increase

the output ampacity or the hold-up time.

22.4. 1606-XLSRED Redundancy Module

L N PE

+ +

- -

1606XLS240E

Power

Supply

Adj

Overload

DCok

24V,10A

Failure

Monitor

24V,10A

Load

optional

I I

L

N

PE

L N PE

+ +

- -

1606XLS240E

Power

Supply

Adj

Overload

DCok

24V,10A

XLSRED

Redundancy

Module

+

-

OUT

+

-

IN 1

+

-

IN 2

The 1606-XLSRED is a dual redundancy module, which includes two

diodes as decoupling devices. It

can be used for various purposes.

The most popular application is to

congure highly reliable and true

redundant power supply systems.

Another interesting application is

the separation of sensitive loads

from non-sensitive loads. This

avoids the distortion of the power

quality for the sensitive loads

which can cause controller fail

1606-

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

20 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

Page 21

Bulletin 1606 Switched Mode Power Supplies

23. Application Notes

23.1. Repetitive Pulse Loading

Typically, a load current is not constant and varies over time. This power supply is designed to support loads with a

higher short-term power demand (=BonusPower). The short-term duration is hardware-controlled by an output

power manager and is available on a repeated basis. If the BonusPower load lasts longer than the hardware

controller allows it, the output voltage will dip and the next BonusPower is available after the BonusPower recovery

time has elapsed (see section 6).

To avoid this, the following rules must be met:

a) The power demand of the pulse must be below 150% of the nominal output power.

b) The duration of the pulse power must be shorter than the allowed BonusPower time (see Output section).

c) The average (R.M.S.) output current must be below the specied continuous output current.

If the R.M.S. current is higher, the unit will respond with a thermal shut-down after a period of time. Use the

maximum duty cycle curve (Fig. 23-2) to check if the average output current is below the nominal current.

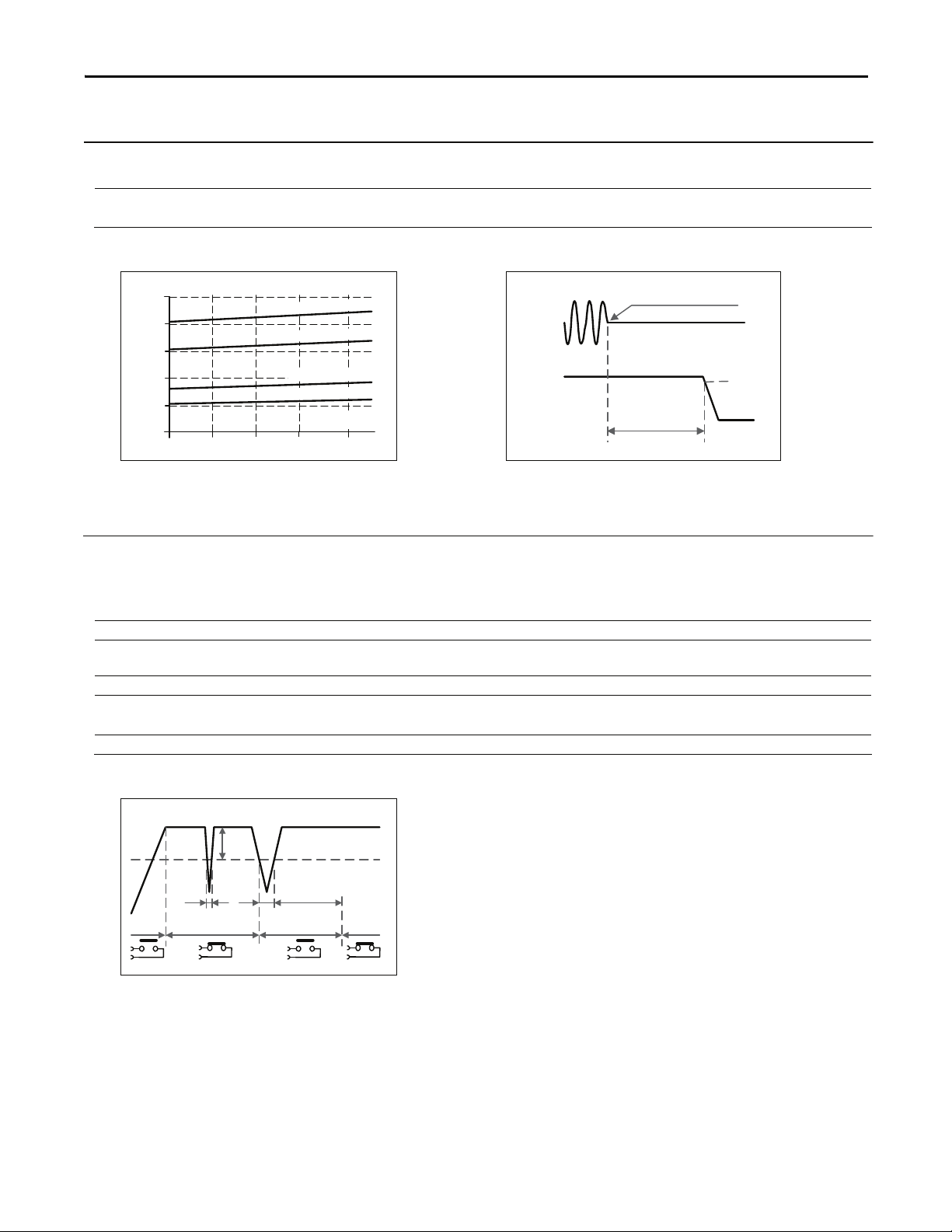

Fig. 23-1 Repetitive pulse loads, denitions Fig. 23-2 Max. duty cycle curve

150%100

100%

P

PEAKTPEAK

T

0

max.

P

0

150%

0

0.2

0.4

0.6

0.8

1.0

DutyCycle

110 120 130 140

P

0

=

1

0

%

P

0

=

5

0

%

P

0

=

7

5

%

P

0

=

1

0

0

%

P

PEAK

P

0

Base load (W)

P

PEAK

Pulse load (above 100%)

T

0

Duration between pulses (s)

T

PEAK

Pulse duration (s)

D

utyCycle

T0 =

T

peak -

(D

utyCycle

x T

peak

)

T

peak + T0

T

peak

D

utyCycle

=

Example: A load is powered continuously with 120W (= 50% of the rated output load). From time to time a peak

power of 360W (= 150% of the rated output load) is needed for 1 second.

The question is: How often can this pulse be supplied without overloading the power supply?

- Make a vertical line at P

PEAK

= 150% and a horizontal line where the vertical line crosses the P0 = 50%

curve. Read the max. duty cycle from the duty cycle-axis (= 0.37)

- Calculate the required pause (base load) length T

0

:

- Result: The required pause length = 1.7s

- Max. repetition rate = pulse +pause length = 2.7s

More examples for pulse load compatibility:

P

PEAK

P

0

T

PEAK

T0 P

PEAK

P

0

T

PEAK

T0

360W 240W 1s >25s 360W 120W 0.1s >0.16s

360W 0W 1s >1.3s 360W 120W 1s >1.6s

300W 120W 1s > 0.75s 360W 120W 3s >4.9s

D

utyCycle

T0=

T

peak -

(D

utyCycle

x T

peak

)

0.37

1s - (0.37 x 1s)

==1.7s

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 21

Page 22

Bulletin 1606 Switched Mode Power Supplies

23.2. Peak Current Capability

Solenoids, contactors and pneumatic modules often have a steady state coil and a pick-up coil. The inrush current

demand of the pick-up coil is several times higher than the steady-state current and usually exceeds the nominal

output current (including the PowerBoost). The same situation applies when starting a capacitive load.

Branch circuits are often protected with circuit breakers or fuses. In case of a short or an overload in the branch circuit,

the fuse needs a certain amount of over-current to trip or to blow. The peak current capability ensures the safe

operation of subsequent circuit breakers.

Assuming the input voltage is turned on before such an event, the built-in large sized output capacitors inside the

power supply can deliver extra current. Discharging this capacitor causes a voltage dip on the output. The following

two examples show typical voltage dips:

Fig. 23-3 Peak load with 2x the nominal

current for 50ms, typ.

Fig. 23-4 Peak load with 5x the nominal

current for 5ms, typ.

10ms/DIV

Output

Voltage

Output

Current

24V

0A

20A 20.5V

Output

Voltage

24V

Output

Current

0A

1ms/DIV

50A 14V

Peak load 20A (resistive) for 50ms

Output voltage dips from 24V to 20.5V.

Peak load 50A (resistive) for 5ms

Output voltage dips from 24V to 14V.

Please note: The DC-OK relay triggers when the voltage dips more than 10% for longer than 1ms.

23.3. Back-feeding Loads

Loads such as decelerating motors and inductors can feed voltage back to the power supply. This feature is also called

return voltage immunity or resistance against Back- E.M.F. (E

lectro Magnetic Force).

This power supply is resistant and does not show malfunctioning when a load feeds back voltage to the power supply.

It does not matter whether the power supply is on or off.

The maximum allowed feed-back-voltage is 35Vdc. The absorbing energy can be calculated according to the built-in

large sized output capacitor which is specied in section 6.

23.4. External Input Protection

The unit is tested and approved for branch circuits up to 20A. An external protection is only required if the supplying

branch has an ampacity greater than this. Check also local codes and local requirements. In some countries local

regulations might apply.

If an external fuse is necessary or utilized, minimum requirements need to be considered to avoid nuisance tripping of

the circuit breaker. A minimum value of 6A B- or 4A C-Characteristic breaker should be used.

22 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 23

Bulletin 1606 Switched Mode Power Supplies

23.5. Charging Batteries

The power supply can be used to charge lead-acid or maintenance free batteries. (Two 12V batteries in series)

Instructions for charging batteries:

a) Set output voltage (measured at no load and at the battery end of the cable) very precisely to the end-of-charge

voltage.

End-of-charge voltage 27.8V 27.5V 27.15V 26.8V

Battery temperature 10°C 20°C 30°C 40°C

b) Use a 15A or 16A circuit breaker (or blocking diode) between the power supply and the battery.

c) Ensure that the output current of the power supply is below the allowed charging current of the battery.

d) Use only matched batteries when putting 12V types in series.

e) The return current to the power supply (battery discharge current) is typ. 3mA when the power supply is switched

off (except if using a blocking diode).

23.6. Output Circuit Breakers

Standard miniature circuit breakers (MCBs or UL1077 circuit breakers) are commonly used for AC-supply systems and

may also be used on 24V branches.

MCBs are designed to protect wires and circuits. If the ampere value and the characteristics of the MCB are adapted to

the wire size that is used, the wiring is considered as thermally safe regardless of whether the MCB opens or not.

To avoid voltage dips and under-voltage situations in adjacent 24V branches which are supplied by the same source, a

fast (magnetic) tripping of the MCB is desired. A quick shutdown within 10ms is necessary corresponding roughly to

the ride-through time of PLCs. This requires power supplies with high current reserves and large output capacitors.

Furthermore, the impedance of the faulty branch must be sufciently small in order for the current to actually ow.

The best current reserve in the power supply does not help if Ohm’s law does not permit current ow. The following

table has typical test results showing which B- and C-Characteristic MCBs magnetically trip depending on the wire cross

section and wire length.

Fig. 23-5 Test circuit

Maximal wire length

0.75mm² 1.0mm² 1.5mm² 2.5mm²

C-2A

Power Supply

AC

+

-

DC

S1... Fault simulation switch

MCB

Wire length

Load

+

S1

-

C-3A

C-4A

C-6A

C-8A

C-10A

C-13A

B-6A

B-10A

B-13A

*) Don’t forget to consider twice the distance to the load (or cable length) when calculating the total wire length (+ and – wire).

*)

for a fast (magnetic) tripping:

23m 29m 48m 69m

20m 24m 38m 57m

12m 16m 22m 33m

5m 7m 9m 14m

3m 4m 5m 7m

2m 3m 4m 6m

1m 1m 2m 2m

11m 14m 24m 34m

5m 8m 11m 18m

4m 6m 8m 10m

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 23

Page 24

Bulletin 1606 Switched Mode Power Supplies

23.7. Parallel Use to Increase Output Power

Power supplies from the same family can be paralleled to increase

the output power. The output voltage shall be adjusted to the same value

(±100mV) with the same load conditions on all units, or the units can be left

with the factory settings.

If more than three units are connected in parallel, a fuse or circuit breaker

with a rating of 15A or 16A is required on each output. Alternatively, a diode

or redundancy module can also be utilized.

Keep an installation clearance of 15mm (left / right) between two power

Unit A

AC

Unit B

AC

DC

DC

+

+

Load

+

-

-

supplies and avoid installing the power supplies on top of each other. Do not

use power supplies in parallel in mounting orientations other than the standard mounting orientation (input terminals

on bottom and output terminals on the top of the unit) or in any other condition where a derating of the output

current is required (e.g. altitude, above 60°C, …).

Pay attention that leakage current, EMI, inrush current, harmonics will increase when using multiple power supplies.

23.8. Parallel Use for Redundancy

Power supplies can be paralleled for redundancy to gain higher system availability. Redundant systems require a

certain amount of extra power to support the load in case one power supply unit fails. The simplest way is to put two

power supplies in parallel. This is called a 1+1 redundancy. In case

one power supply unit fails, the other one is automatically able to

support the load current without any interruption. Redundant

systems for a higher power demand are usually built in a N+1

+

-

+

method. E.g. ve power supplies, each rated for 10A are paralleled

to build a 40A redundant system. For N+1 redundancy the same

restrictions apply as for increasing the output power, see also

section 23.7.

Please note: This simple way to build a redundant system does not

cover failures such as an internal short circuit in the secondary side

of the power supply. In such a case, the defective unit becomes a

load for the other power supplies and the output voltage can not

be maintained any more. This can be avoided by using decoupling

+ +

- -

24V,10A

Adj

DCok

Overload

1606XLS240E

Power

Supply

L N PE

I I

IN 1

IN 2

1606XLSRED

Redundancy

Module

OUT

+

-

-

optional

+ +

- -

24V,10A

Overload

1606XLS240E

Power

Supply

L N PE

Adj

DCok

diodes which are included in the 1606-XLSRED redundancy module.

L

Recommendations for building redundant power systems:

N

PE

a) Use separate input fuses for each power supply.

b) Monitor the individual power supply units. Therefore, use the DC-OK relay contact of the 16060-XLS power supply.

c) It is desirable to set the output voltages of all units to the same value (± 100mV) or leave it at the factory setting.

Failure

Monitor

24V,10A

Load

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

24 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

Page 25

Bulletin 1606 Switched Mode Power Supplies

23.9. Daisy Chaining of Outputs

Daisy chaining (jumping from one power supply output to the next) is allowed as long as the average output current

through one terminal pin does not exceed 25A. If the current is higher, use a separate distribution terminal block as

shown in Fig. 23-7.

Fig. 23-6 Daisy chaining of outputs Fig. 23-7 Using distribution terminals

Power

+ +

- -

Supply

Input

Output

Load

+

-

max 25A!

Power

+ +

- -

Supply

Input

Output

Load

+

-

Distribution

Terminals

Power

+ +

- -

Supply

Input

Output

Power

+ +

- -

Supply

Input

Output

23.10. Series Operation

Unit A

AC

DC

Unit B

AC

DC

-

+

-

+

Load

+

-

Earth

(see notes)

Power supplies of the same type can be connected in series for higher

output voltages. It is possible to connect as many units in series as needed,

providing the sum of the output voltage does not exceed 150Vdc. Voltages

with a potential above 60Vdc are no longer SELV and can be dangerous.

Such voltages must be installed with a protection against touching.

Earthing of the output is required when the sum of the output voltage is

above 60Vdc.

Avoid return voltage (e.g. from a decelerating motor or battery) which is

applied to the output terminals.

Keep an installation clearance of 15mm (left / right) between two power supplies and avoid installing the power

supplies on top of each other. Do not use power supplies in series in mounting orientations other than the standard

mounting orientation (input terminals on bottom and output terminals on the top of the unit).

Pay attention that leakage current, EMI, inrush current, harmonics will increase when using multiple power supplies.

23.11. Inductive and Capacitive Loads

The unit is designed to supply any kind of load, including unlimited inductive of capacitive loads.

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 25

Page 26

Bulletin 1606 Switched Mode Power Supplies

23.12. Operation on Two Phases

240V

+15%

max.

Fuse

L2

L1

L3

L

N

PE

Power Supply

AC

DC

internal

fuse

The power supply can also be used on two phases of a three-phase-system.

Such a phase-to-phase connection is allowed as long as the supplying

voltage is below 240V+15%. Use a fuse or a circuit breaker to protect the N

input. The N input is internally not protected and is in this case connected to

a hot wire. Appropriate fuses or circuit breakers are specied in section 23.4,

“External Input Protection”.

23.13. Use in a Tightly Sealed Enclosure

When the power supply is installed in a tightly sealed enclosure, the temperature inside the enclosure will be higher

than outside. In such situations, the inside temperature denes the ambient temperature for the power supply.

The following measurement results can be used as a reference to estimate the temperature rise inside the enclosure.

The power supply is placed in the middle of the box, no other heat producing items are inside the box

Enclosure: Rittal Typ IP66 Box PK 9519 100, plastic, 180x180x165mm

Load: 24V, 8A; (=80%) load is placed outside the box

Input: 230Vac

Temperature inside enclosure: 47°C (in the middle of the right side of the power supply with a distance of 2cm)

Temperature outside enclosure: 27°C

Temperature rise: 20K

26 Rockwell Automation Publication 1606-RM044A-EN-P — March 2014

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Page 27

Bulletin 1606 Switched Mode Power Supplies

23.14. Mounting Orientations

Mounting orientations other than input terminals on the bottom and output on the top require a reduction in

continuous output power or a limitation in the maximum allowed ambient temperature. The amount of reduction

inuences the lifetime expectancy of the power supply. Therefore, two different derating curves for continuous

operation can be found below:

Curve A1 Recommended output current.

Curve A2 Max allowed output current (results in approximately half the lifetime expectancy of A1).

Fig. 23-8

Mounting

Orientation A

(Standard

orientation)

Power

Supply

OUTPUT

Output Current

0

10 20 30 40

60°C

2.5

5

7.5

10A

INPUT

50

A

1

Ambient Temperature

Fig. 23-9

Mounting

Orientation B

(Upside down)

Power

Supply

OUTPUT

INPUT

Output Current

0

10 20 30 40

60°C

2.5

5

7.5

10A

50

A

2

Ambient Temperature

A

1

Fig. 23-10

Mounting

Orientation C

(Table-top

mounting)

Output Current

0

10 20 30 40

60°C

2.5

5

7.5

10A

50

Ambient Temperature

A

1

A

2

Fig. 23-11

Mounting

Orientation D

(Horizontal cw)

Power

Supply

OUTPUT

INPUT

Output Current

0

10 20 30 40

60°C

2.5

5

7.5

10A

50

Ambient Temperature

A

1

A

2

Fig. 23-12

Mounting

Orientation E

(Horizontal ccw)

Power

Supply

OUTPUT

INPUT

Output Current

0

10 20 30 40

60°C

2.5

5

7.5

10A

50

Ambient Temperature

A

1

A

2

All parameters are specified at 24V, 10A, 230Vac, 25°C ambient and after a 5 minutes run-in time, unless noted otherwise.

Rockwell Automation Publication 1606-RM044A-EN-P — March 2014 27

Page 28

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

notes, sample code and links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools. You can also visit our Knowledgebase at http://

www.rockwellautomation.com/knowledgebase for FAQs, technical information, support chat and forums,

software updates, and to sign up for product notification updates.

, you can find technical manuals, technical and application

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer

Tech Co nn ec t

representative, or visit http://www.rockwellautomation.com/support/

SM

support programs. For more information, contact your local distributor or Rockwell Automation

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in

this manual. You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Wor ldwide Loca tor at http://ww w.rockwellautomation.com/rockwellautomation/support/overview.page, or contact your local

Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be returned, follow these

procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to your

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to

improve this document, complete this form, publication RA-DU002

literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf.

Publication 1606-RM044A-EN-P — March 2014

DIR# 10000051149 Ver 00 Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://

Loading...

Loading...