Page 1

OEM Starter Frame and Components

Bulletin 1503

2400 to 7200 volts

Installation Manual

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the Additional Resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Chapter 1 OEM Starter Frame Installation

Receiving ......................................................................................... 1-1

Installation ....................................................................................... 1-1

Standards and Codes ................................................................. 1-1

Imperial Tool Requirements ...................................................... 1-2

Metric Tool Requirements ......................................................... 1-2

Starter Frame Dimensions ......................................................... 1-3

Control Panel ............................................................................. 1-3

Torque Requirements ................................................................ 1-4

Fuses .......................................................................................... 1-4

Line and Load Connections ...................................................... 1-4

Commissioning ......................................................................... 1-4

Chapter 2

Component Installation

Component Layout .......................................................................... 2-1

Mounting Isolation Switch Handle Module .................................... 2-3

Mounting Isolation Switch and Trailer Fuse Block ......................... 2-5

Power Fuses ..................................................................................... 2-7

Contactor ........................................................................................ 2-10

Control Panel ................................................................................. 2-10

IntelliVAC .................................................................................... 2-10

Typical Electrical Diagrams for 400A FVNR Controller with

Electro-Mechanical Control and Electrically Held

Contactor, 120VAC ........................................................... 2-11

Electro-Mechanical Control and Mechanical Latch Contactor . 2-12

IntelliVAC Control and Electrically Held Contactor ............ 2-13

IntelliVAC Control and Mechanical Latch Contactor .......... 2-14

Door Interlock Assembly ............................................................... 2-15

Connecting Isolation Switch to Isolation Switch Handle .............. 2-17

Connecting Contactor to Isolation Switch Handle ........................ 2-18

Electrical Connection From Contactor to Trailer Fuse Block

(Clip-on Fuses) ......................................................................... 2-21

Electrical Connection From Contactor to Trailer Fuse Block

(Bolt-on Fuses) ......................................................................... 2-22

Incoming Line Connections ........................................................... 2-24

Load Connections .......................................................................... 2-24

Connecting Contactor to Control Power Transformer ................... 2-25

1503-IN050E-EN-P – June 2013

Page 4

ii Table of Contents – Bulletin 1503 OEM Starter Frame and Components • Installation Manual

Chapter 3

Power Lock-out Procedure .............................................................. 3-2

Contactor Interlock Rod Adjustment ............................................... 3-5

Isolation Switch Ground Adjustment ............................................... 3-7

Isolation Switch Auxiliary Contacts ................................................ 3-8

Adjusting the Normally Open (Isa) Contacts ............................ 3-9

Adjusting the Normally Closed (Isb) Contacts ....................... 3-10

Adjusting the ‘Change of State Point’ ......................................3-11

Adjustments for 400A Equipment

Door Interlock Circumvention ......................................................... 3-1

Chapter 4 Commissioning

Vacuum Bottle Integrity Test ........................................................... 4-1

Preliminary Checklist ...................................................................... 4-2

Contactor Operation .................................................................. 4-2

Electrical Connections .............................................................. 4-2

Final Checks .............................................................................. 4-2

Hi-pot and Megger Test ................................................................... 4-1

Chapter 5

Maintenance

Contactor .......................................................................................... 5-1

Isolation Switch Mechanism – Inspection and Lubrication ............ 5-1

Auxiliary Contacts Inspection and Replacement ............................. 5-3

Chapter 6

Spare Parts ....................................................................................... 6-1

Spare Parts

Appendix A OEM Kit Chart ................................................................................A-1

1503-IN050E-EN-P – June 2013

Page 5

OEM Starter Frame Installation

Chapter 1

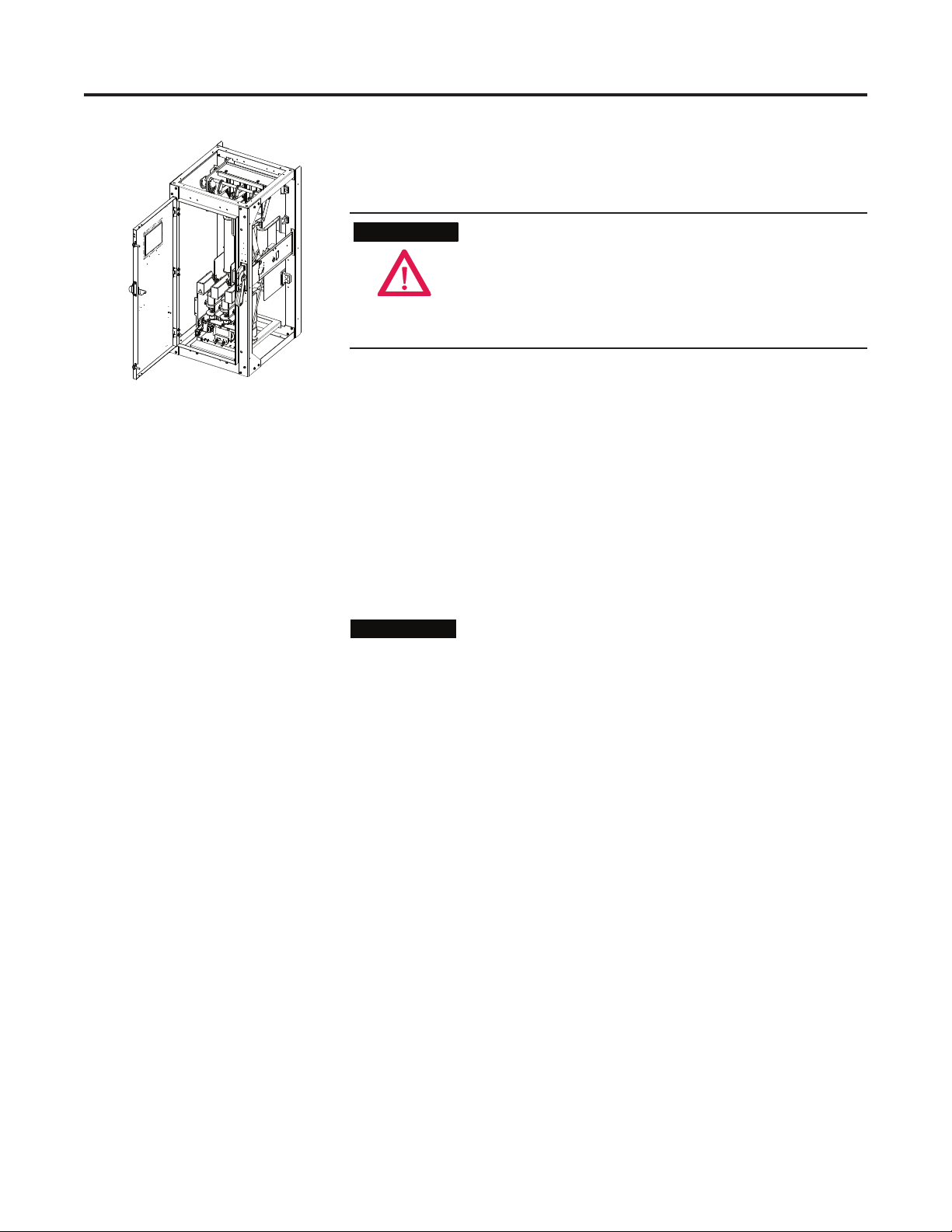

A T T E N T I O NA T T E N T I O N

Read this document before performing any installation

procedures or adjustments. Observe all applicable

safety procedures when working on the equipment.

Complete all installation procedures before connecting

the incoming line cable. Failure to do so may result in

damage to the equipment or injury to personnel.

Receiving Refer to General Handling Procedures for Medium Voltage Controllers

– Publication MV-QS050_-EN-P. This document is included with your

shipment and contains information regarding receiving, unpacking, initial

inspection, handling, storage, opening the medium voltage doors, and site

preparation.

Note: Refer to Appendix A for a listing of the items that are included in

your OEM Frame Kit.

Installation Standards and Codes

The OEM starter frame consists of a fusible non-load-break

I M P O R T A N TI M P O R T A N T

isolation switch, an isolation switch handle, a vacuum contactor, control

circuitry and a medium voltage door. These components are not a complete

motor controller. The user must add appropriate control circuitry for the

application, power fusing, current transformer, control power transformer,

overload protection and a suitable enclosure. It is recommended that the

user be familiar with the following safety and design standards and codes,

and any additional local codes that a medium voltage starter must comply with.

• CEC (Canadian Electrical Code)

• CSA 22.2 No. 14 (Canadian Standards Association) – Industrial Control

Equipment

• NEC (National Electrical Code)

• NEMA ICS Standards (National Electrical Manufacutrers’ Association)

• OSHA (Occupational Safety and Health Administration)

• UL 50 (Underwriters Laboratories) – Enclosures for Electrical Equipment

• UL 347 (Underwriters Laboratories) – High voltage Industrial Control

Equipment

• UL 508 (Underwriters Laboratories) – Industrial Control Equipment

• IEC 60204-1 – Safety of Machinery – Electrical Equipment of Machines,

Part 1: General Requirements

• IEC 62271-200 – AC Metal Enclosed Switchgear and Control Gear for

Rated Voltages Above 1kV and up to 52 kV

• IEC 60470 – High Voltage Alternating Current Contactors

• IEC 60529 – Degrees of Protection Provided by Enclosures (IP Code)

• IEC 62271-1 – Common Clauses for High voltage Switchgear and

Control Gear Standards

1503-IN050E-EN-P – June 2013

Page 6

1-2 OEM Starter Frame Installation

Installation (Cont.) Standards and Codes (Cont.)

The OEM starter frame assembly was fully tested and inspected at the

factory. Unless damage from shipping is suspected, the commissioning procedures in Chapter 4 of this manual should be the only additional checks

required for the unit.

Imperial Tool Requirements

I M P O R T A N TI M P O R T A N T

Some components of this product incorporate Imperial

hardware. Rockwell Automation recommends the use of the appropriate

tools to successfully complete the assembly and maintenance procedures

for these components. If you cannot obtain such tools, contact your area

Rockwell Automation sales offi ce for assistance.

The following Imperial size tools are recommended for installation and

maintenance of the OEM starter frame and components:

• Standard drive ratchet with extension

• Standard drive torque wrench

• Standard drive sockets: 9/32, 3/8, 7/16, 1/2, 9/16, 3/4 in.

• Open-end wrenches: 7/16, 1/2, 9/16, 11/16, 3/4, 7/8 in.

• Drill and drill bits: 0.172, 0.219, 0.281 in.

• Slot-head screwdrivers

• Feeler gauge set (0.125 in to 0.300 in.)

• Locking pliers

• High potential tester

Metric Tool Requirements

I M P O R T A N TI M P O R T A N T

Metric equivalent sizes are provided in parentheses

where applicable. It is important to note that all sizes given are not exact

substitutes for the corresponding Imperial sizes. To ensure proper installation, use the recommended metric hardware and dimensions for pilot holes

and clearance holes.

The following metric size tools are recommended for installing the OEM

frame and components with metric hardware.

• Standard drive ratchet with extension

• Standard drive torque wrench

• Standard drive sockets: 8, 10, 13, 15, 18 mm

• Open-end wrenches: 8, 10, 13, 15, 18 mm

• Drill and drill bits: 4.6, 5.5, 6.8 mm

• Slot-head screwdrivers

• Locking pliers

• Feeler gauge set (3mm to 8 mm)

• High potential tester

1503-IN050E-EN-P – June 2013

Page 7

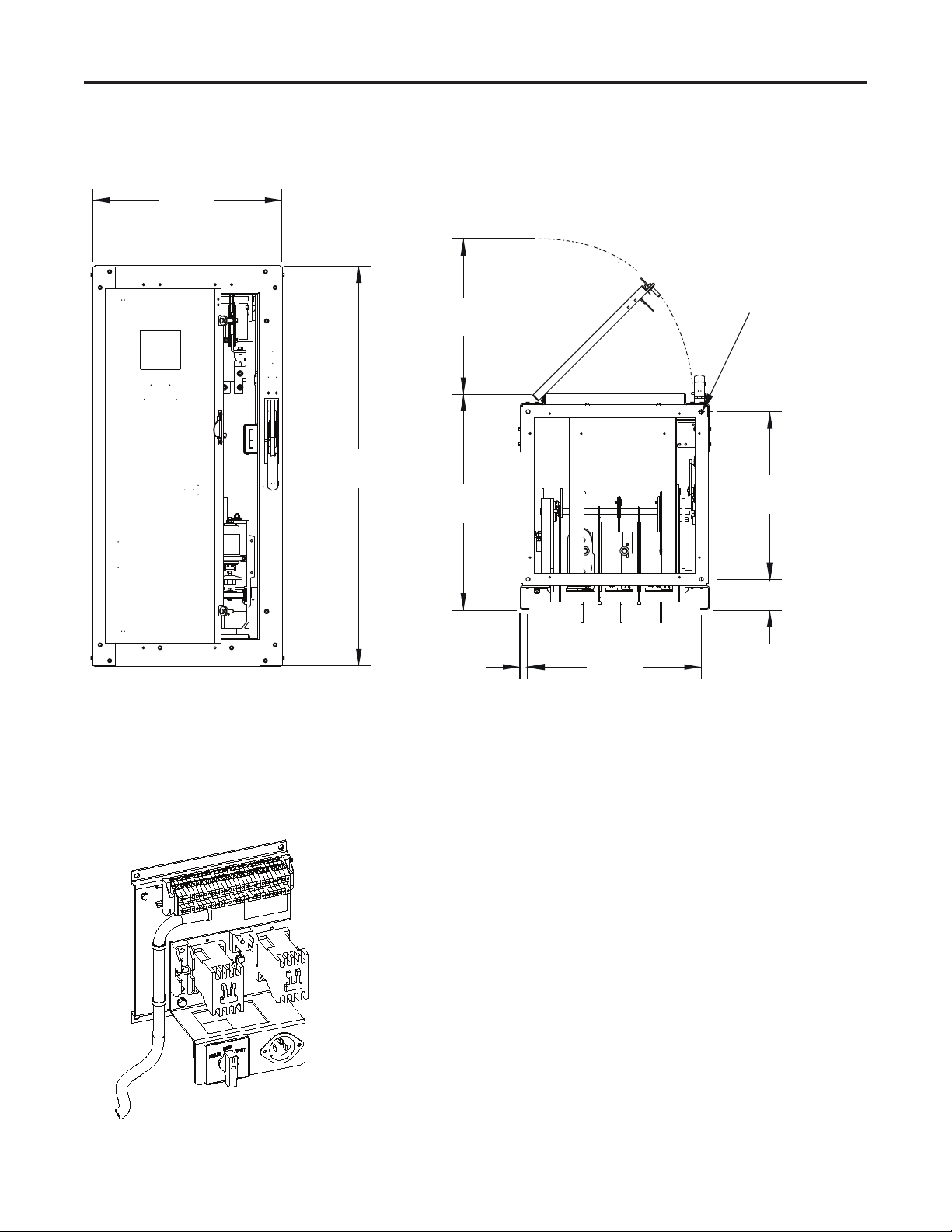

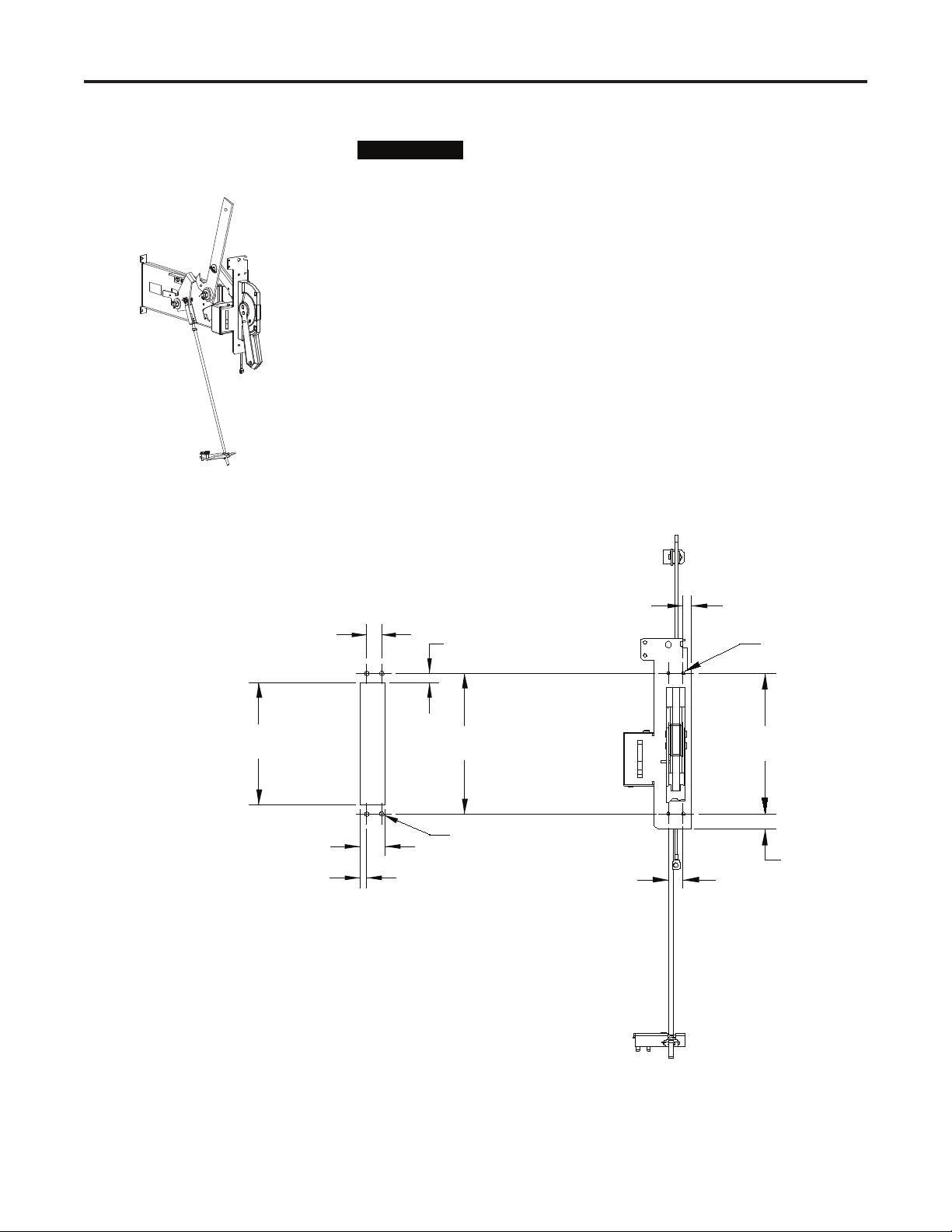

400 Amp Starter Frame Dimensions

23.85

[606]

21.50

[546]

50.36

[1279]

27.22

[691]

OEM Starter Frame Installation 1-3

All dimensions in inches [millimeters]

4 X ø.515 [13]

MOUNTING HOLES

21.17

[538]

FRONT VIEW

Figure 1.1 – Starter Frame Dimensions

Control Panel

1) Mount the control panel in a suitable location. Be aware that the control plug wiring harness is 10 ft. (3 meters) in length. Ensure that the

wiring harness route still allows for a proper connection to the contactor control plug.

2) Connect the control panel harness to the receptacle on the left side of

the contactor. Observe the matching number codes to ensure a proper

connection. See Control Panel, page 2-10, for more information and for

wiring diagrams.

0.97

[25]

21.89

[556]

BOTTOM VIEW

3.83

[97]

1503-IN050D-EN-P – June 2012

Page 8

1-4 OEM Starter Frame Installation

Installation (Cont.) IntelliVAC

Refer to Publication 1503-UM051_-EN-P or 1503-UM052_-EN-P for

IntelliVAC mounting instructions. Note that a suitable wire harness is

required (1503-WHxxx) to connect IntelliVAC to the vacuum contactor.

Refer to “IntelliVAC”, page 2-10 for more information and wiring diagrams.

Torque Requirements

Use the specifi ed torque values for all hardware whenever performing

maintenance or attaching components.

1/4 in. (M6) hardware

6 ft•lb (8 N•m)

5/16 in. (M8) hardware 12 ft•lb (15 N•m)

3/8 in. (M10) hardware 20 ft•lb (27 N•m)

1/2 in. (M12) hardware 48 ft•lb (65 N•m)

Fuses

Refer to the motor nameplate for the information necessary to determine

correct power fuse size. See page 2-7 for recommended power fuses.

A T T E N T I O NA T T E N T I O N

1) Install clip-on or bolt-on power fuses into the isolation switch fuse clips.

2) If control power is supplied by control power transformer within the

unit, fuses may be installed in the control circuit transformer primary

fuse clips at the top of the contactor (see page 2-24 for details).

Only qualifi ed personnel should select the fuse type and

rating. Failure to select the correct fuses may result in

injury to personnel and/or damage to equipment.

Line and Load Connections

See Incoming Line Connections (page 2-24) and Load Connections (page

2-24).

Commissioning

See Commissioning, Chapter 4.

1503-IN050E-EN-P – June 2013

Page 9

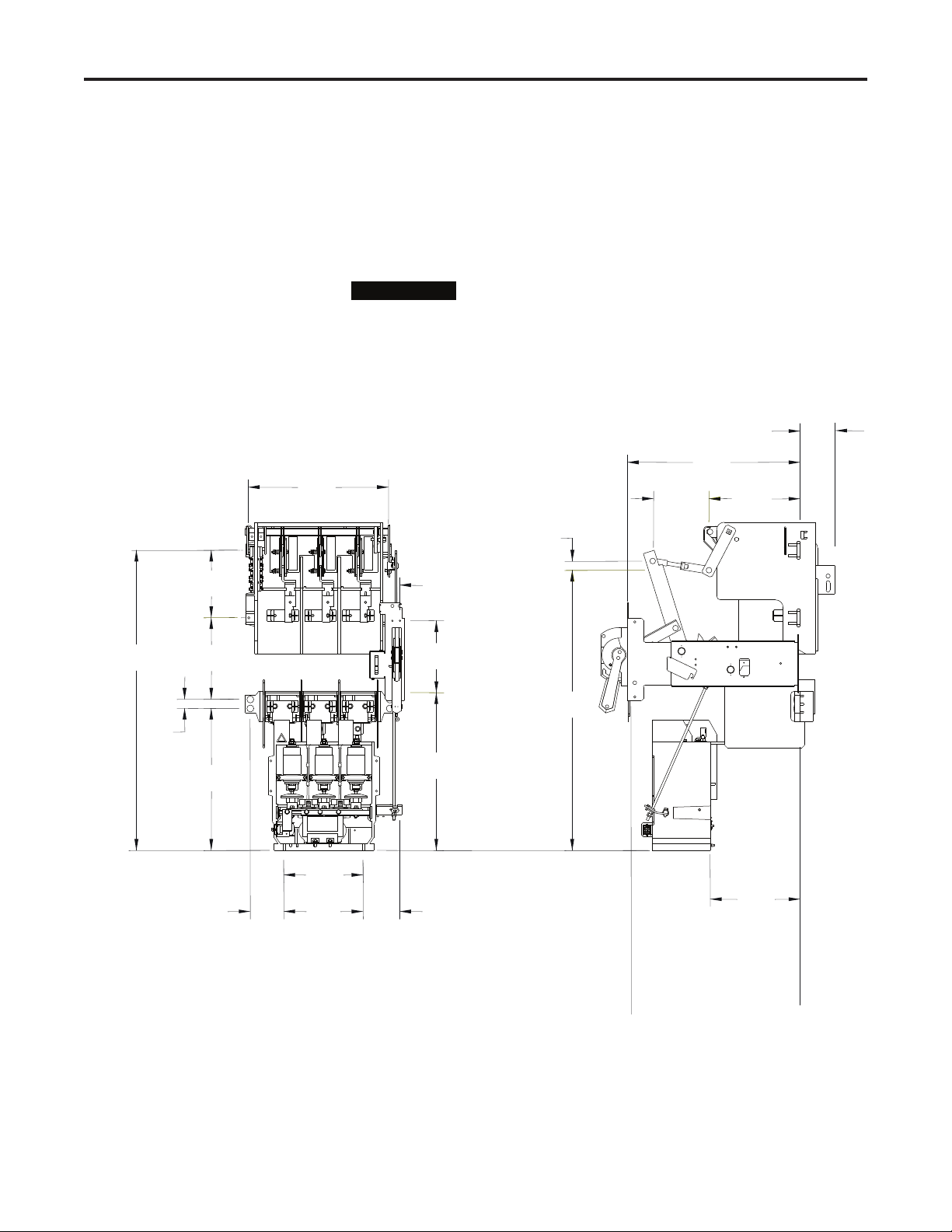

Chapter 2

Component Installation for 400A Equipment

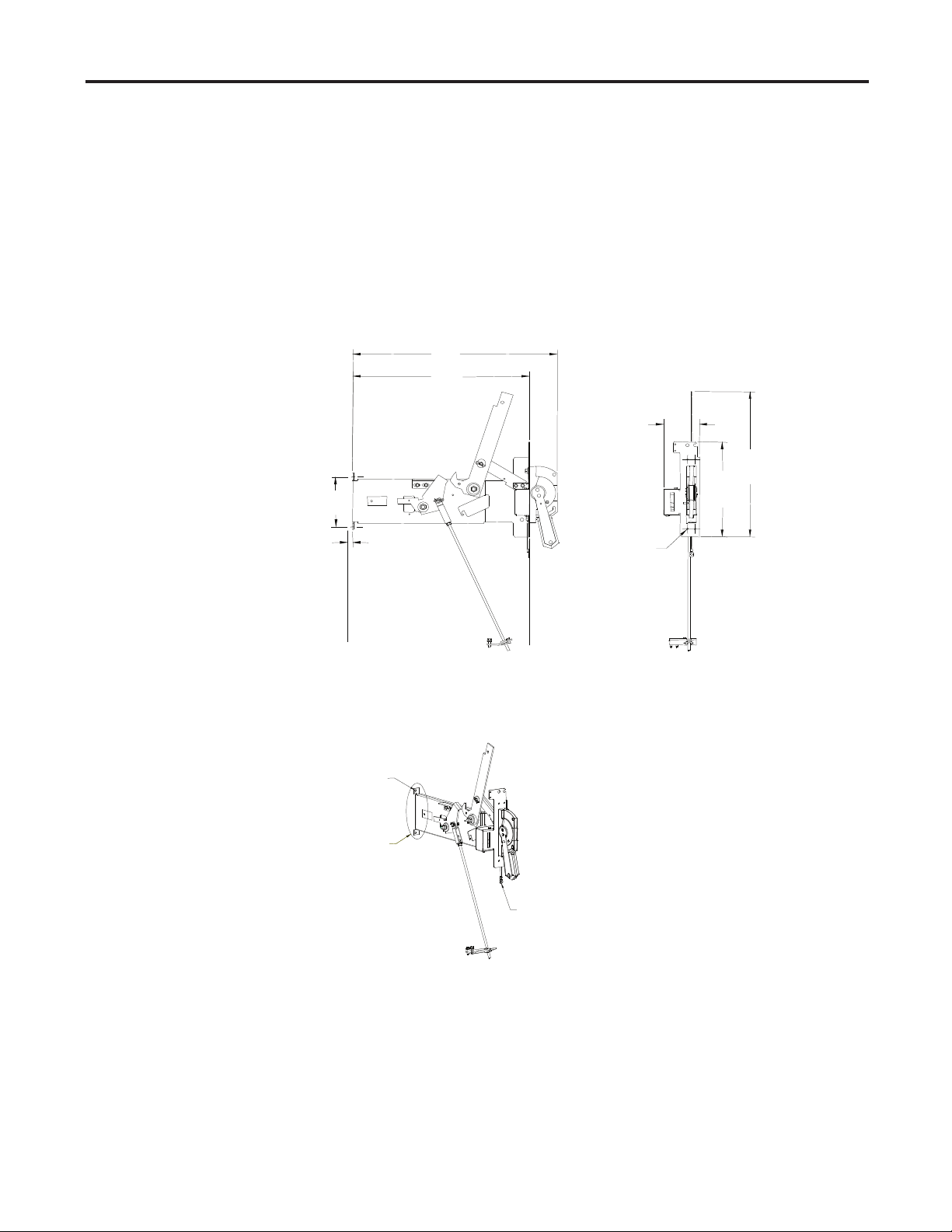

Component Layout Refer to the following diagram to determine the location of the OEM

components relative to each other.

39.78

[1010]

1.20

[30]

8.96

[228]

10.80

[274]

18.82

[478]

18.55

[471]

I M P O R T A N TI M P O R T A N T

1.00

9.53

[242]

20.89

[531]

[25]

The mounting location of the trailer fuse block varies

depending on the type of power fuses used by the unit.

Figure 2.1 shows the component confi guration for units

using clip-on power fuses and Figure 2.2 shows the component confi guration for units using bolt-on power fuses.

4.60

[117]

22.85

[580]

7.33

[186]

1.19

[30]

37.11

[943]

12.05

[306]

4.44

[113]

10.50

[267]

(All dimensions in inches [millimeters])

Lower Mounting Surface

4.88

[124]

Figure 2.1 – OEM Component Layout (Clip-on Power Fuses)

(Frame and other parts not shown)

Front Mounting Surface

Rear Mounting Surface

11.87

[301]

1503-IN050E-EN-P – June 2013

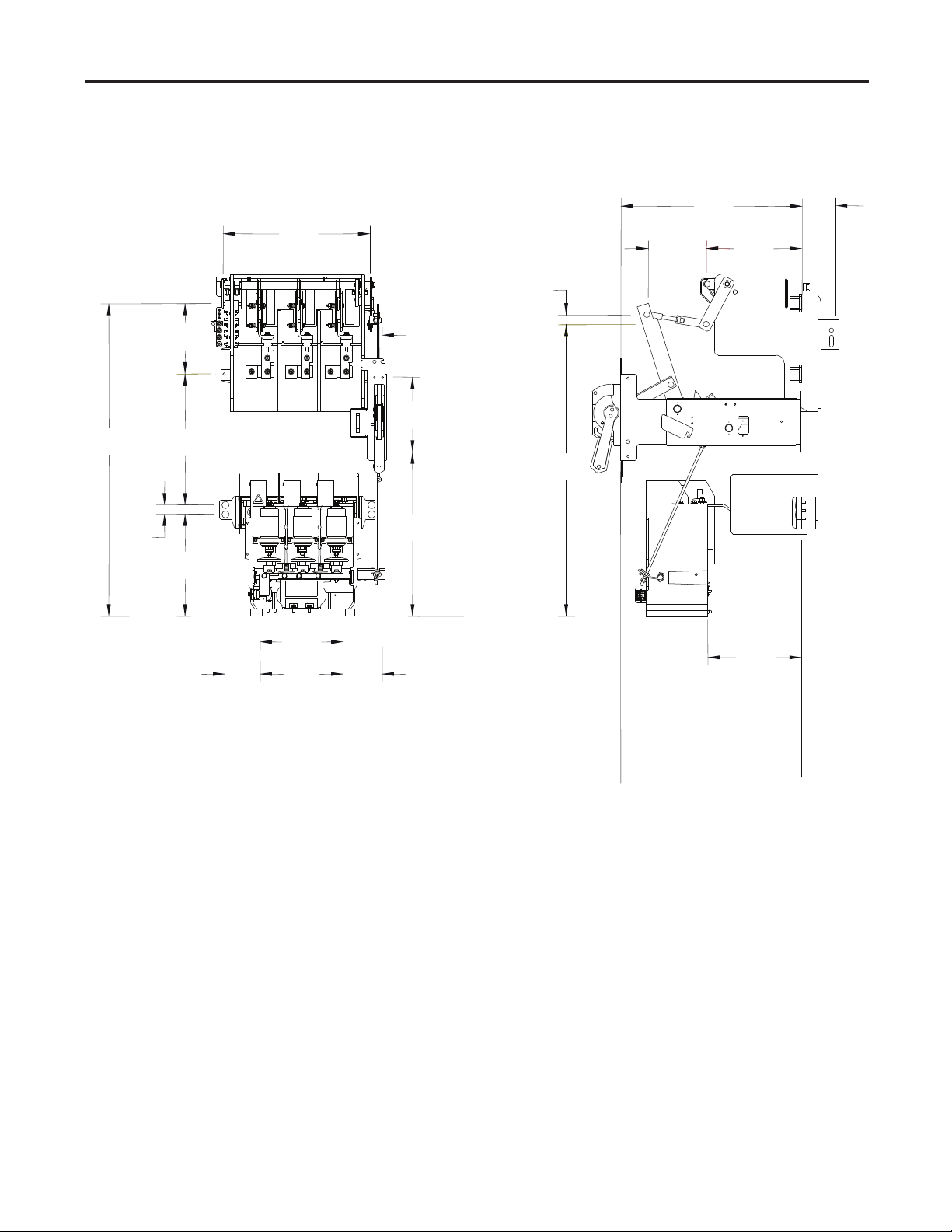

Page 10

2-2 Component Installation

Component Layout (cont.)

39.78

[1010]

1.20

[30]

8.96

[228]

16.67

[423]

12.95

[329]

4.44

[113]

18.55

[471]

10.50

[267]

1.00

[25]

9.53

[242]

20.89

[531]

Lower Mounting Surface

4.88

[124]

1.19

[30]

37.11

[943]

22.85

[580]

7.33

[186]

Front Mounting Surface

12.05

[306]

11.87

[301]

4.60

[117]

Rear Mounting Surface

1503-IN050E-EN-P – June 2013

(All dimensions in inches [millimeters])

Figure 2.2 – OEM Component Layout (Bolt-on Power Fuses)

(Frame and other parts not shown)

Page 11

Component Installation 2-3

The handle is shipped in the OFF, or open, position. All

Mounting Isolation Switch

Handle Module

I M P O R T A N TI M P O R T A N T

instructions assume the handle remains in the OFF

position during installation and adjustment procedures

unless otherwise stated.

Required Hardware:

• Six (6) ¼-20 x 0.5 in. (6.3 x 1.8 x 13mm Type B) self-tapping screws

• One (1) 5/16 in. (M8 x 1.25) grounding wire screw

Refer to the component layout shown in Figure 2.1 or 2.2 to determine the

mounting location and the location of the mounting holes for the isola-

tion switch handle module. Refer to Figure 2.3 for a detailed view of the

mounting holes.

1) Prepare a cut-out in the cabinet for the handle using the dimensions

shown in Figure 2.3.

Isolation Switch Handle

(OFF Position)

2) Drill four (4) 0.281-in. (6.8 mm) clearance holes in the locations indi-

cated for the retaining screws.

1.00

[25 ]

8.2 6

[21 0]

1.74

[4 4]

Front Mounting Surface

Cutout Dimensions

Front Mounting Surface

Cutout Dimensions

0.48

[12 ]

0.6 5

[17 ]

9.53

[242]

4 X Ø 0.281 [6.8]

CLEARANCE HOLES

1.0 0

[2 5]

0.53

[1 4]

4 X 0.21 9 (5.31)Ø

MOUNTING HOLES

9.53

[2 42]

1.06

[27]

Front View

(Handle cut away

to show lower

mounting holes)

Figure 2.3 – Handle Cut-out Dimensions

1503-IN050E-EN-P – June 2013

Page 12

2-4 Component Installation

Mounting Isolation Switch 3) From the inside of the cabinet, insert the handle through the cut-out and

Handle Module (cont.) line up the pilot holes with the pre-drilled holes in the handle assembly.

Use four (4) ¼-20 (6.3 x 1.8 Type B) self-tapping screws to attach the

front of the handle. Torque the screws according to the specifi cations

shown on page 1-4.

4) Mark the location of the rear mounting tabs of the handle module. Drill

two (2) 0.219-in. (5.5mm) pilot holes (see Figure 2.4).

26.23

[666]

22.67

[576]

4.61

[117]

19.93

[506]

7.02

[178]

13.00

[330]

0.125

[3]

Clearance

Clearance Holes

Rear Mounting Surface

2 X Ø 0.312

See Fig. 2.3

for Punching

Dimensions

Front Mounting Surface

LEFT SIDE VIEW

Grounding Wire

4 X Ø 0.219

Mounting Holes

(All dimensions in inches [millimeters])

Figure 2.4 – Mounting Rear of Isolation Switch Handle Module

FRON

T VIEW

(Cut away to show lower mounting holes)

1503-IN050E-EN-P – June 2013

Page 13

Component Installation 2-5

5) Install two (2) ¼-20 (6.3 x 1.8 Type B) self-tapping screws in the tabs

at the end of the handle module to attach it to the rear of the cabinet.

Torque the screws according to the specifi cations shown on page 1-4.

The rear mounting tabs may deform slightly when

I M P O R T A N TI M P O R T A N T

secured to the mounting surface. The deformation is

normal and helps to reduce any gap between the handle

module and the mounting surface.

6) Connect the green grounding wire to a suitable grounding surface.

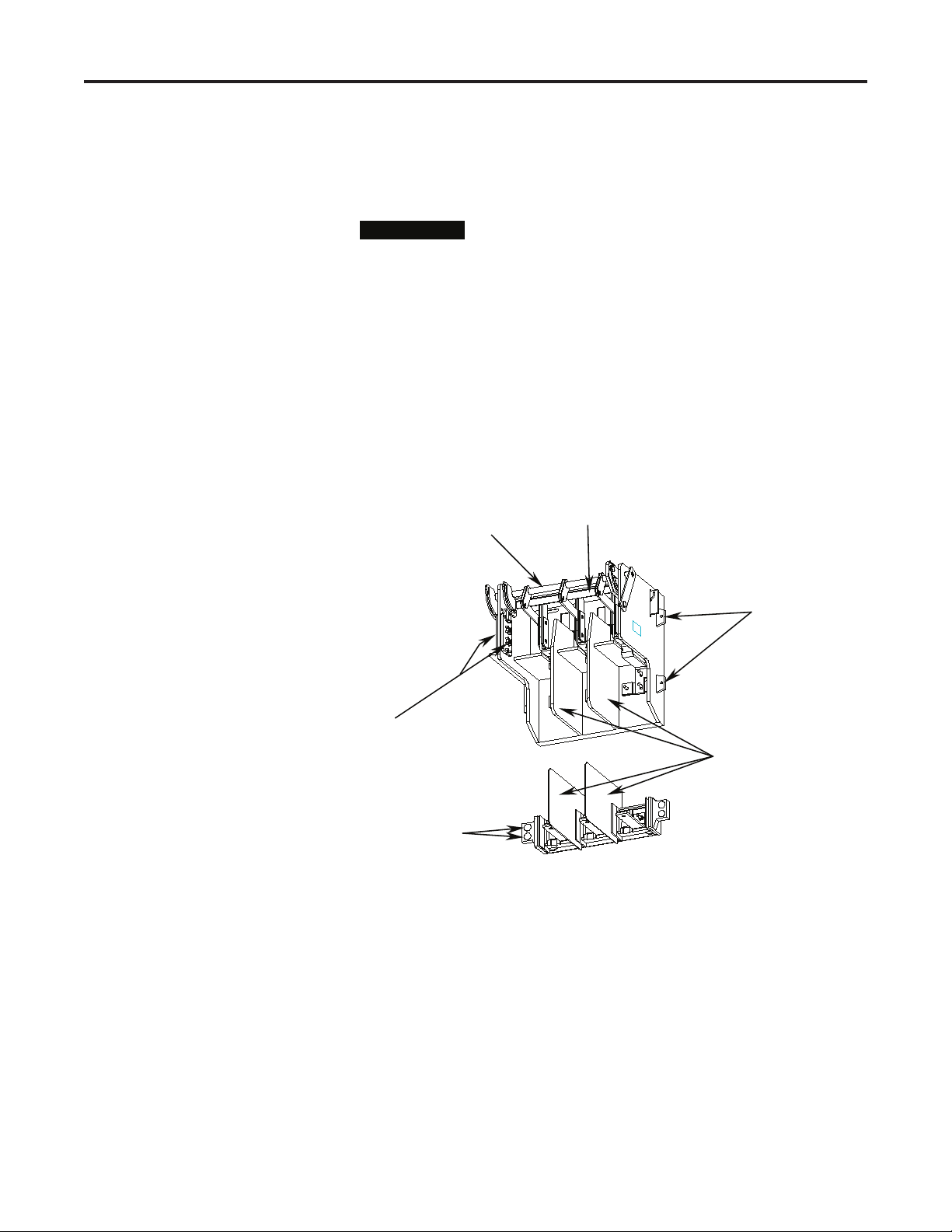

Mounting Isolation Switch Refer to the component layout shown in Figure 2.1 or 2.2 to determine the

and Trailer Fuse Block location of the isolation switch. Refer to Figure 2.6 to determine the

location of the mounting holes for the isolation switch.

Grounding Bar

Shaft

Clearance Holes

Auxiliary Contacts

Inter-phase Barriers

Dome Plugs

Figure 2.5 – Typical Isolation Switch

Required Hardware:

– Eight (8) ¼-20 x 1.0 in. (6.3 x 1.8 x 25mm Type B) self-tapping screws

– Four (4) dome plugs (supplied)

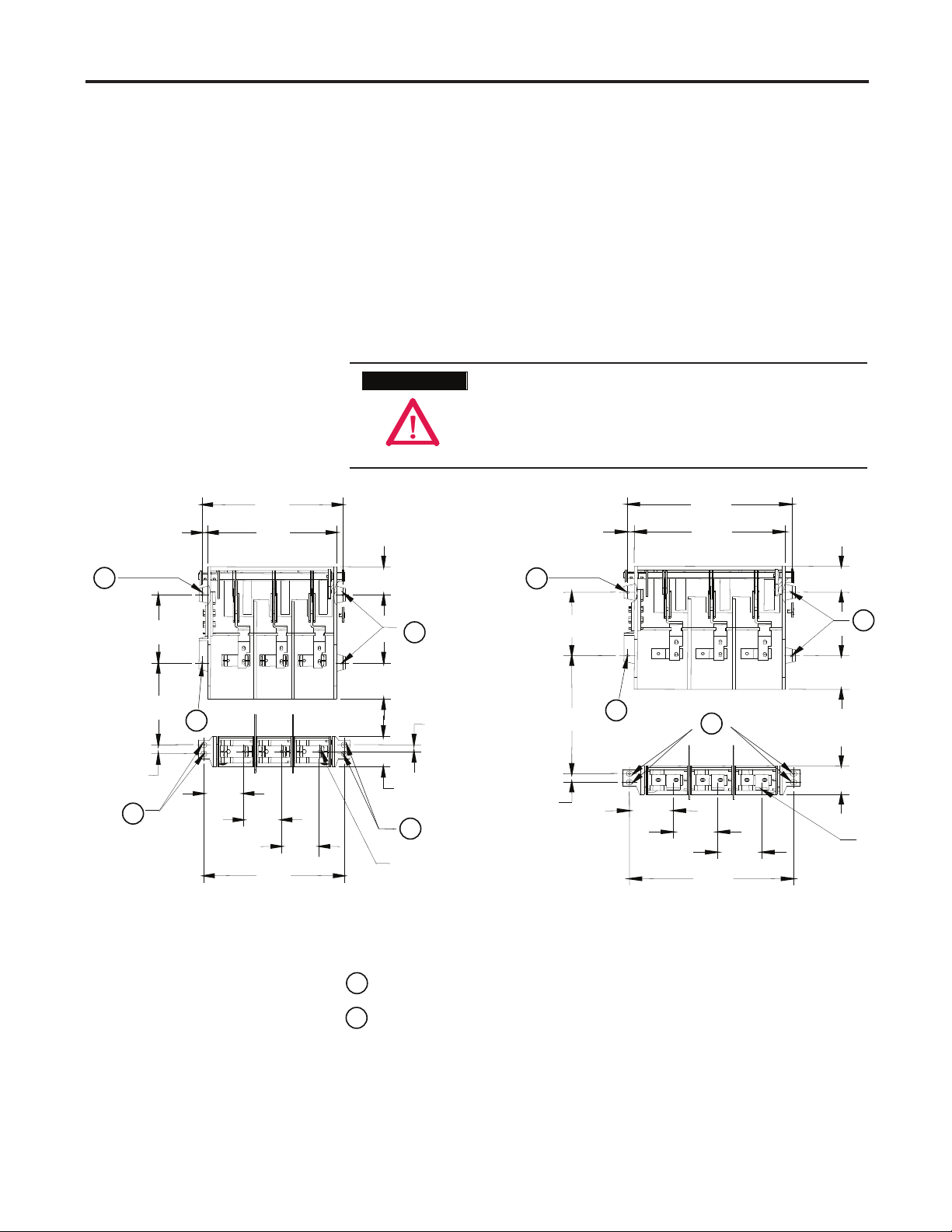

1) Drill four (4) 0.219 in. (5.5 mm) pilot holes in the mounting surface at

Location A as shown in Figure 2.6 for the isolation switch.

2) Attach the isolation switch using four (4) ¼-20 (6.3 x 1.8 Type B)

self-tapping screws. Torque the screws according to the specifi cations

1503-IN050E-EN-P – June 2013

Page 14

2-6 Component Installation

Mounting Isolation Switch Refer to the component layout shown in Figure 2.1 or 2.2 to determine the

and Trailer Fuse Block (cont.) location of the trailer fuse block. Refer to Figure 2.6 to determine the

location of the mounting holes for the trailer fuse block.

1) Drill four (4) 0.219 in. (5.5 mm) pilot holes at Location B as shown in

Figure 2.6 for the trailer fuse block.

2) Attach the trailer fuse block using four (4) ¼-20 (4.8 x 1.6 Type B)

self-tapping screws. Torque the screws according to the specifi cations

shown on page 1-4.

3) Install a dome plug over each screw.

A T T E N T I O NA T T E N T I O N

Reinstall any inter-phase barriers that were removed

while connecting the trailer fuse block. Failure to do so

may produce an electrical fault between the fuses and

damage the equipment.

18.55

[471]

0.76

[19]

A

8.96

[228]

10.80

[274]

1.20

[30]

B

A

5.25

[133]

17.02

5.00

[127]

18.50

[470]

[432]

5.00

[127]

3.69

[94]

4.78

[121]

A

0.90

[23]

4.00

[102]

B

Terminals

A

1.20

[30]

8.96

[228]

16.67

[423]

0.76

[19]

A

4.94

[125]

5.00

[127]

18.55

[471]

17.02

[432]

B

18.50

[470]

5.00

[127]

3.69

[94]

4.78

[121]

4.00

[102]

A

Terminals

FRONT VIEW (CLIP-ON FUSES)

(Cut away to show upper mounting tabs)

1503-IN050E-EN-P – June 2013

FRONT VIEW (BOLT-ON FUSES)

(Cut away to show upper mounting tabs)

A

Ø 0.310 Isolation switch clearance hole location

Ø 0.310 Trailer fuse block clearance hole location

B

(All dimensions in inches [millimeters])

Figure 2.6 – Orientation of Isolation Switch

Page 15

Component Installation 2-7

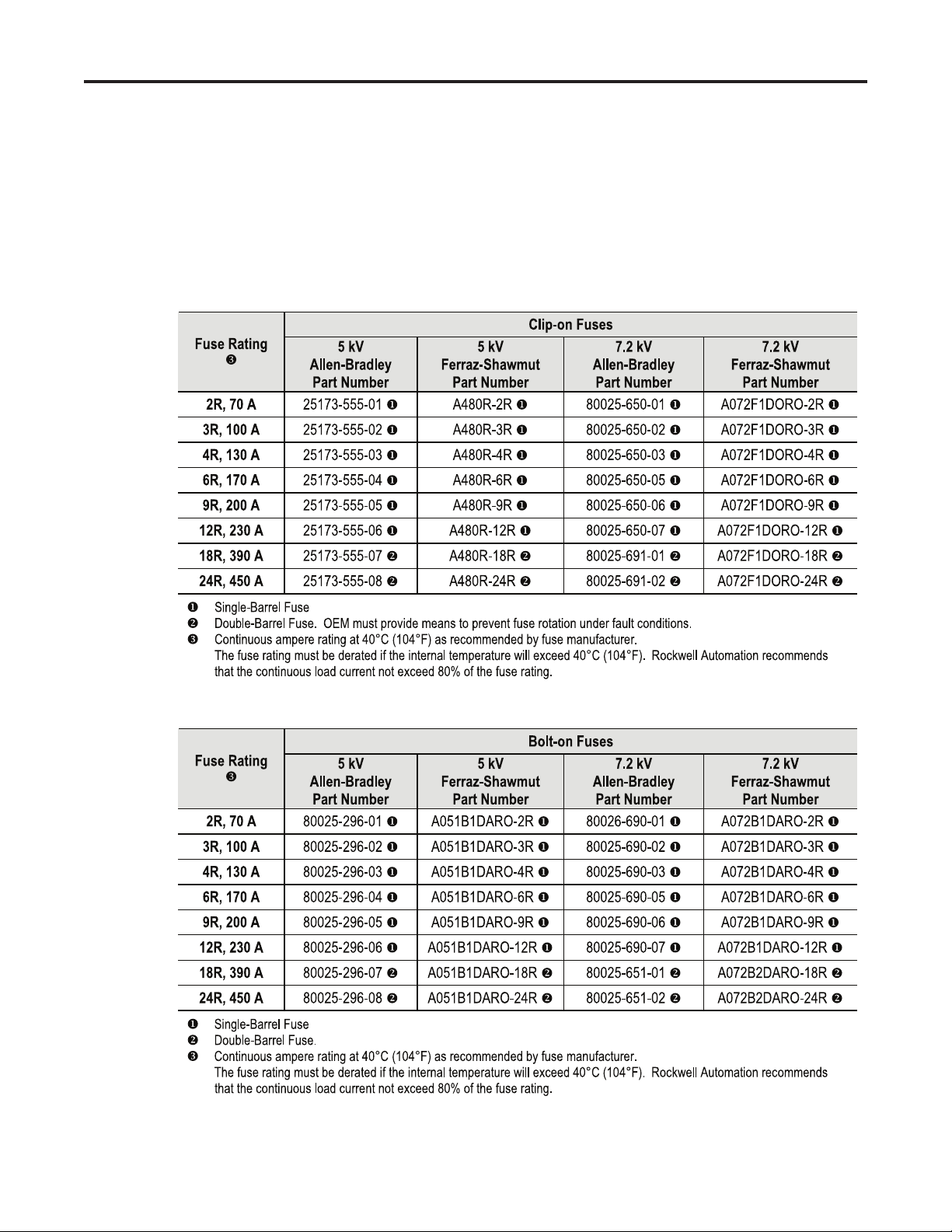

Power Fuses Ferraz-Shawmut medium voltage power fuses are recommeded for the

Bulletin 1503. These motor fuses have been tested and meet the

co-ordination requirements for the Bulletin 1502 vacuum contactor. The

fuses many be purchsed from Rockwell Automation, Ferraz-Shawmut, or

from a local distributor. The following part numbers are available.

(See Figures 2.7 and 2.8 for dimensions of fuses.)

Table 2.1 – Recommended Power Fuses

1503-IN050E-EN-P – June 2013

Page 16

2-8 Component Installation

Power Fuses (cont.)

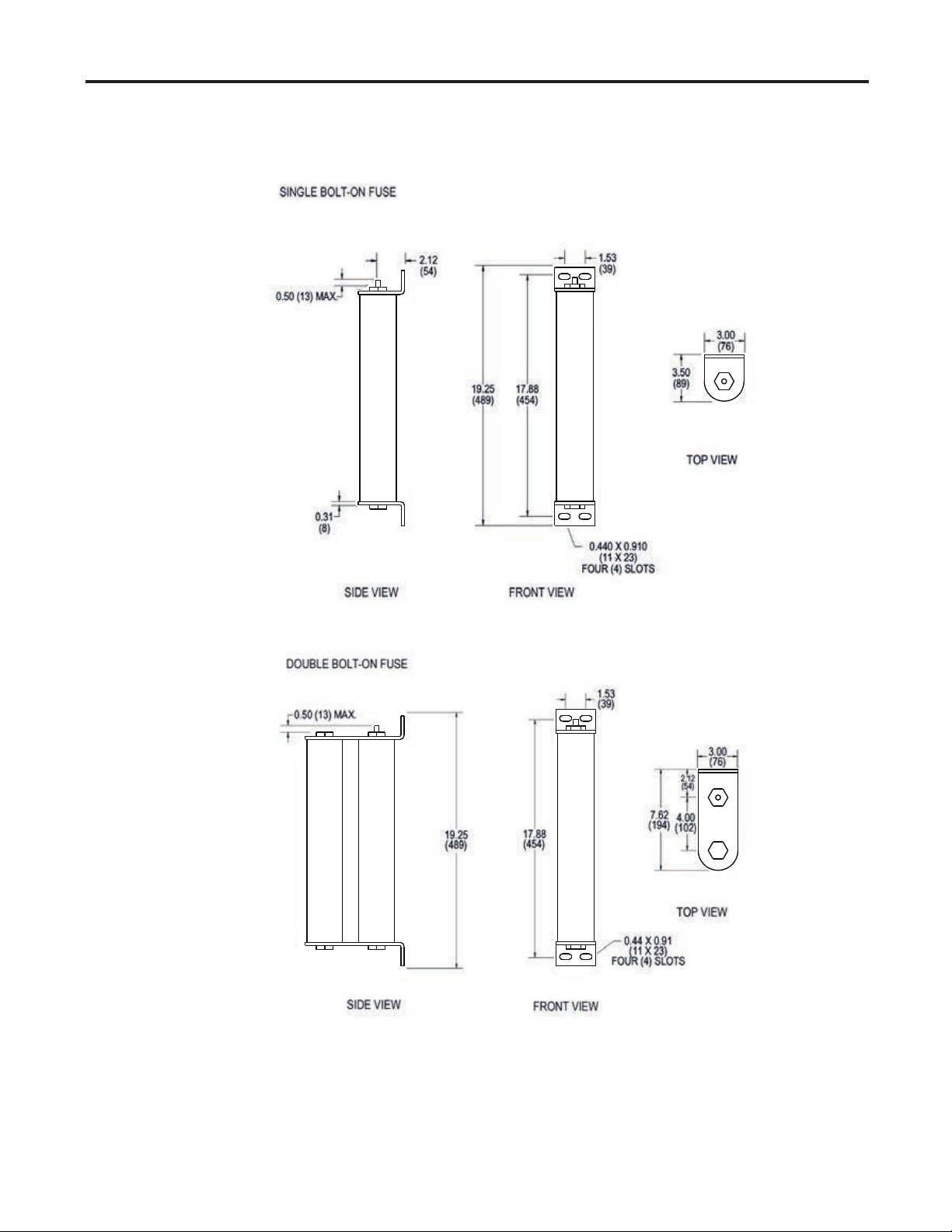

1503-IN050E-EN-P – June 2013

(All dimensions in inches [millimeters])

Figure 2.7 – Bolt-on Fuse Dimensions

Page 17

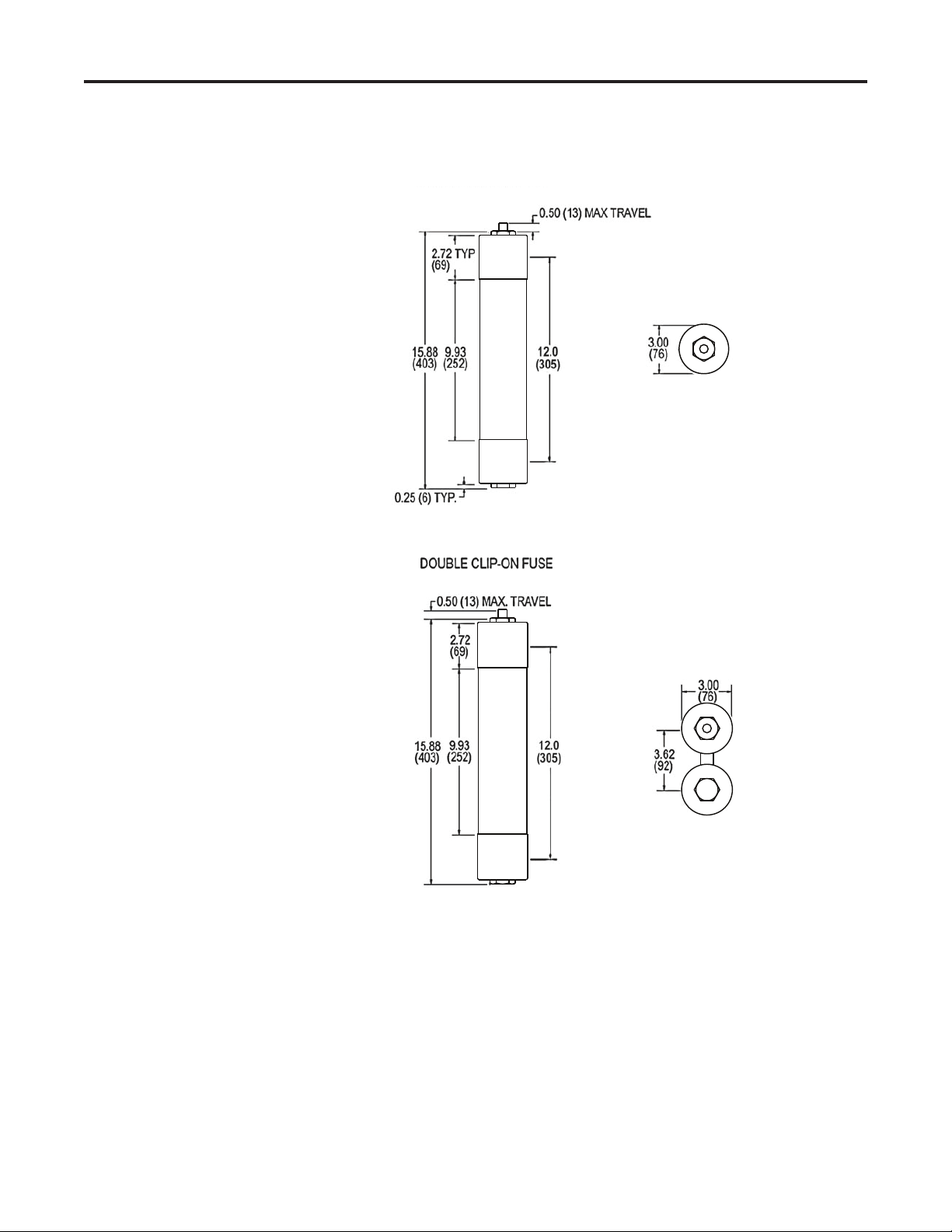

Component Installation 2-9

Figure 2.8 – Clip-on Fuse Dimensions

(All dimensions in inches [millimeters])

1503-IN050E-EN-P – June 2013

Page 18

2-10 Component Installation

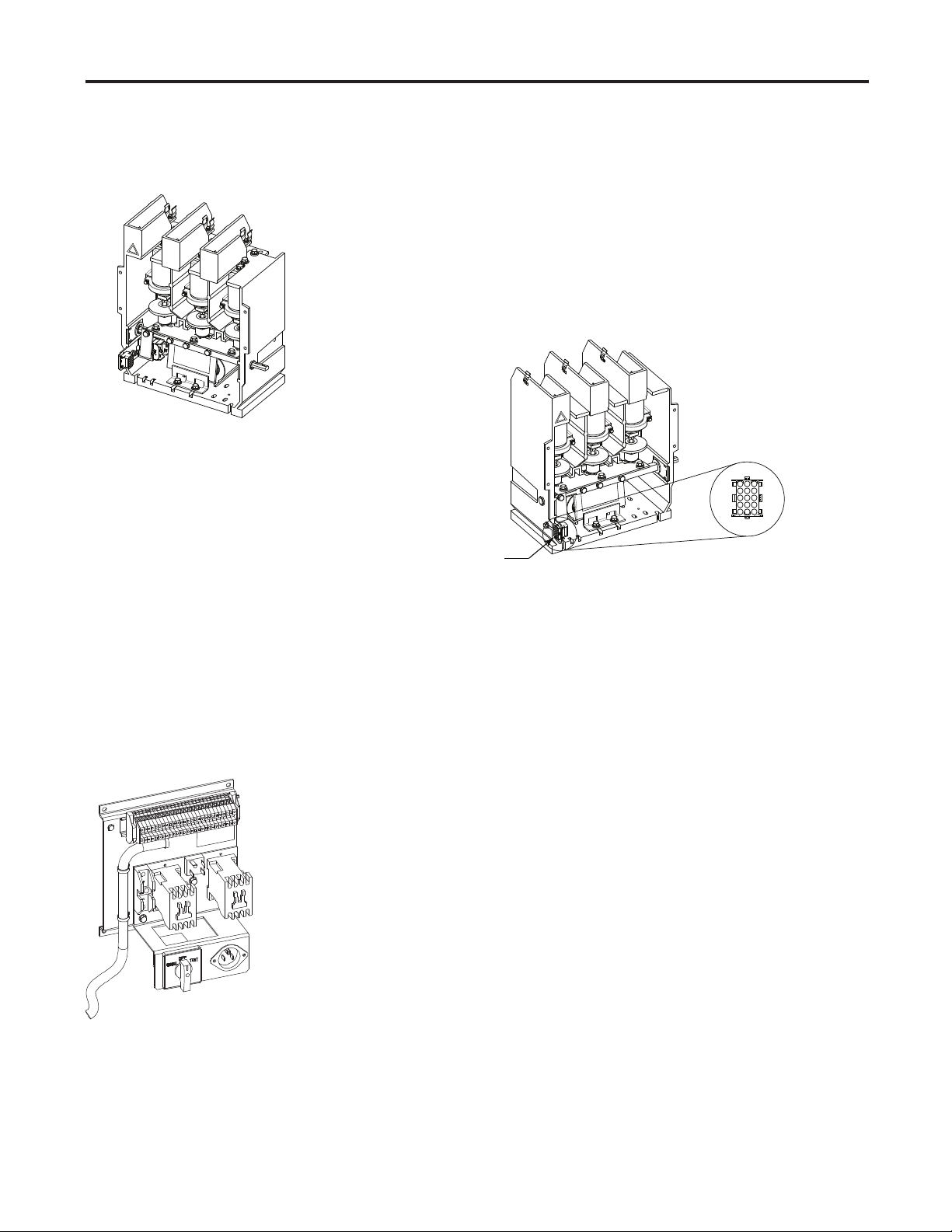

Contactor Refer to the following publications for the Bulletin 1502 Medium Voltage

Contactor:

• 400A – Publication 1502-UM050_EN-P ( Series D)

• 400A – Publication 1502-UM052_EN-P (Series E)

• 800A – Publication 1502-UM051_EN-P (Series E)

These user manuals contain detailed information on installation, adjustment

and maintenance for this product.

Contactor

Control Wire

Plug

Figure 2.9 – 120V and 230V Control Wire Plug Location and Confi gurations

Note: Refer to the appropriate vacuum contactor User Manual for detailed

wire plug pin confi gurations.

Control Panel Required Hardware:

– Four (4) 1/4-20 x 0.5 in. (6.3 x 1.8 x 13mm Type B) self-tapping screws

Mount the control panel in a suitable location. Be aware that the control plug

wiring harness is 10 ft. (3 meters) in length. Ensure that the wiring harness

route still allows for a proper connection to the contactor control plug.

Connect the control panel harness to the contactor control wire plug on the

lower left side of the contactor. The number codes on the plug must line up

with those on the contactor to ensure a proper connection. See Figure 2.9.

Use the terminal blocks on the control panel to connect the unit to a 120- or

230-volt grounded power source (whichever is applicable to the control panel)

and to other remote devices - see Figure 2.10 or 2.12 for electrical drawings.

IntelliVAC Refer to Publication 1503-UM051_EN-P or 1503-UM052_-EN-P for

information regarding the IntelliVAC control module. Refer to Figure 2.12

or 2.13 for typical electrical drawings.

1503-IN050E-EN-P – June 2013

Page 19

Component Installation 2-11

Figure 2.10 – Typical Schematic Diagram for 400 amp Full-Voltage Non-Reversing (FVNR) Controller

with Electro-Mechanical Control and Electrically Held Contactor, 120 V AC (Normal Drop-out Time)

1503-IN050E-EN-P – June 2013

Page 20

2-12 Component Installation

Figure 2.11 – Typical Schematic Diagram for 400A Full-Voltage Non-Reversing (FVNR) Controller

with Electro-Mechanical Control and Mechanical Latch Contactor

1503-IN050E-EN-P – June 2013

Page 21

Component Installation 2-13

CC

Figure 2.12 – Typical Schematic Diagram for 400A Full-Voltage Non-Reversing (FVNR) Controller

with IntelliVAC Control and Electrically Held Contactor

1503-IN050E-EN-P – June 2013

Page 22

2-14 Component Installation

Figure 2.13 – Typical Schematic Diagram for 400A Full-Voltage Non-Reversing (FVNR) Controller

with IntelliVAC Control and Mechanical Latch Contactor

1503-IN050E-EN-P – June 2013

Page 23

Component Installation 2-15

Door Interlock Assembly When properly installed the door interlock assembly (see Figure 2.13),

used in conjunction with the isolation switch, is designed to provide the

following interlocking features:

• When the isolation switch handle is in the ON position, a pin on the

handle overlaps the Z-clip to prevent the door from being opened.

• When the door is closed and the isolation switch handle is in the ON

position, a cover catch inside the door will be held in place by the

interlock defeater lever and provide another means for holding the door

closed while the unit is energized.

A T T E N T I O NA T T E N T I O N

The door interlock assembly must be installed for the

isolation switch handle to restrict access to the medium

voltage cell while the unit is energized. The isolation

switch handle alone will not provide safety interlocking.

If the door interlock assembly is not installed, the OEM

assumes the responsibility for providing a means to

isolate the medium voltage power cell while the unit is

energized. Failure to install a medium voltage power cell

isolation means can expose personnel to medium voltage

resulting in severe burns, injury or death.

Door Flange

Z-clip

Cover Catch

Figure 2.14 – Door Interlock Assembly

Rear Door Surface

Cover Catch

Mounting Bracket

1503-IN050E-EN-P – June 2013

Page 24

2-16 Component Installation

Door Interlock Assembly

I M P O R T A N TI M P O R T A N T

(cont.)

1) See Figure 2.15 for the mounting dimensions for the door interlock

assembly.

2) Drill two (2) 0.172 in. (4.6 mm) pilot holes on the right side of the door

for the Z-clip.

3) Drill two (2) 0.219 in. (5.5 mm) pilot holes on the front of the door for

the cover catch mounting bracket.

2.11

[54]

0.84

[21]

MAX.

Customer

supplied door

TOP VIEW

MIN.

All mounting hardware for the Door Interlock Assembly

is supplied. Metric equivalents are provided should the

user wish to substitute metric hardware.

Customer supplied

structure

1.55

[39]

Customer

supplied door

2 X Ø 0.219 [5.31]

Pilot Holes

(For rib-necked

carriage bolts)

0.88

[22]

0.65

[17]

2 X Ø 0.172 [4.09]

Pilot holes

Customer supplied

structure

1.95

[49]

0.35

[9]

FRONT VIEW

See Fig. 2.3

3.13

[80]

3.50

[89]

3.38

[86]

RIGHT SIDE VIEW

(All dimensions in inches [millimeters])

Figure 2.15 – Mounting Locations for Door Interlock Assembly

4) Attach the Z-clip using #10 (4.8 x 1.6 Type B) self-tapping screws, but

do not completely tighten them.

5) Attach the cover catch mounting bracket using #10-32 x 0.500

(M5 x 0.8) rib-necked carriage screws, lockwashers and hex nuts.

6) Attach the cover catch to the cover catch mounting bracket using the

supplied #10-32 x 0.219 pan-head machine screw.

1503-IN050E-EN-P – June 2013

I M P O R T A N TI M P O R T A N T

The pilot holes in the cover catch are threaded. To avoid

damaging the thread, use the hardware provided to attach

the cover catch to the mounting bracket.

Page 25

Component Installation 2-17

7) Move the handle to the OFF position. Swing the door closed and

inspect the position of the Z-clip with respect to the handle pin.

8) Set the Z-clip so that it is just above the handle pin. Do not set the Z-clip

more than 0.125 in. (3 mm) above the pin. Tighten the screws.

9) Close the door and move the isolation switch handle to the ON position. If the handle will not move to the ON position, the cover catch is

set too high and is not contacting the defeater lever. Open the door and

set the cover catch lower. Verify correct functioning.

10) Swing the door shut and move the isolation switch handle to the ON

position. Verify that the door interlock assembly is functioning properly.

The mechanical interlock is the primary safety mecha-

Connecting Isolation Switch

to Isolation Switch Handle

I M P O R T A N TI M P O R T A N T

nism preventing access to the medium voltage power

cell. The mechanism also prevents opening or closing

the isolation switch under load (ie. it is a non-load-break

switch). A secondary electrical interlock is intended to

disengage the contactor in the event of a mechanical in-

terlock failure. See page 3-8 for additional information.

When properly connected, the isolation switch operating mechanism is

designed to provide the following safety features:

• Prevent the opening of any medium voltage door interlocked with the

mechanism while the handle is in the ON position and the unit is energized.

• Prevent moving the handle to the ON position and energize the unit

while the medium voltage door is open.

• Disengage the contactor from the RUN mode when the handle is

moved from the ON to OFF position.

Connecting Rod

Connection Point

(Clevis and Cotter Pin)

Isolation Switch

Operating Lever

Disconnect Lever

Right Side View

Figure 2.16 – Handle Mechanism Connection

1503-IN050E-EN-P – June 2013

Page 26

2-18 Component Installation

Perform the handle mechanism connection with the handle in the OFF

Connecting Isolation Switch

position. The isolation switch should be in the open position with the isola-

to Isolation Switch Handle

(cont.)

tion switch blades resting against the ground bar. Refer to Figure 2.16.

1) Lengthen or shorten the threaded connecting rod until it lines up with

the top hole on the isolation switch operating lever.

2) Insert a clevis pin through the holes and secure it with a cotter pin.

Complete all installation procedures before beginning

I M P O R T A N TI M P O R T A N T

any adjustment procedures described in Chapter 3.

Connecting Contactor to When properly connected, the contactor interlock in conjunction with the

Isolation Switch Handle isolation switch handle mechanism, are designed to offer the following

safety features:

• prevent the isolation switch from being opened while the contactor is

closed and energized;

• prevent the contactor from closing if the isolation switch is in an

intermediate position (ie. at halfway point during adjustment);

• disengage the contactor if the isolation switch moved to the closed

position during a contactor test procedure.

Isolation Switch Operating Lever

Interlock Lever

Clevis

Contactor Interlock Rod

1503-IN050E-EN-P – June 2013

Contactor Operating Lever

Figure 2.17 – Contactor Interlock Rod Connection

Page 27

Component Installation 2-19

Required Hardware: (all hardware supplied)

Metric hardware is not supplied; however, metric

• Two (2) 1/4 in. (M6) lock washers

• Two (2) 1/4 in. (M6) fl at washers

• Two (2) 1/4-20 in. (M6 x 1.0) hex-head cap screws

• One (1) 5/16-18 in. (M8 x 1.25) nylock nut

• Two (2) 5/16 in. (M8) hex nuts

• One (1) 5/16 in. (M8) lock washer

• One (1) contactor operating lever

• One (1) 5/16-18 x 20.5 in. (M8 x 1.25 x 521 mm) contactor interlock rod

I M P O R T A N TI M P O R T A N T

equivalents are given should the user wish to substitute

metric hardware

1) Attach the contactor operating lever to the fl at section of the contactor

shaft using two 1/4-20 in. (M6 x 1.0) hex-head cap screws with two 1/4 in.

(M6) lock washers and two 1/4 in. (M6) fl at washers (see Figure 2.18).

The contactor operating lever is threaded for the supplied

I M P O R T A N TI M P O R T A N T

1/4-20 hex-head cap screws. In order to substitute metric

hardware, it is necessary to drill appropriate clearance

holes in the contactor operating lever and use M6 x 1.0

hex-head cap screws and nuts to secure the lever to the

contactor shaft.

2) From the top of the contactor interlock rod, turn a 5/16–18 in.

(M8 x 1.25) hex nut at least 2 in. (50 mm) down the rod. Place one

5/16 in. (M8) lock washer over the nut.

3) Insert a 5/16–18 (M8 x 1.25) hex nut into the clevis of the door

interlock lever (see Figure 2.17).

4) Turn the contactor interlock rod into the nut until approximately 1/2 in.

(13 mm) of the lever extends above the nut.

1503-IN050E-EN-P – June 2013

Page 28

2-20 Component Installation

Connecting Contactor to

Isolation Switch Handle

(cont.)

2-1/4-20 (M6 x 1.0) Hex. Head Cap

2-1/4-20 Hex Head Cap Screws

Contactor

Interlock Rod

Nylon Contactor

Bushing

Contactor

Operating Lever

2-1/4 in. (M6) Lock Washers

2-1/4 in. Lock Washers

2-1/4 in. (M6) Flat Washers

2-1/4 in. Flat Washers

Contactor

Shaft

Right Side View

Figure 2.18 – Connecting Contactor to Isolation Switch Handle

5) Tighten the bottom nut up to the clevis.

Screws

6) Insert the lower end of the rod into the nylon contactor bushing.

7) Turn a 5/16–18 in. (M8 x 1.25) nylock nut onto the lower end of the

rod and tighten it up to the fl at of the contactor operating lever.

Complete all installation procedures before beginning

I M P O R T A N TI M P O R T A N T

any adjustment procedures described in Chapter 3.

1503-IN050E-EN-P – June 2013

Page 29

Component Installation 2-21

Electrical Connection from

Contactor to Trailer Fuse Block

(Clip-on Fuses)

Required Hardware:

• three (3) horizontal bus links or suitable cable and lugs (bus links are

recommended to be 1/4 in. (6mm) thick and 1 in. (25mm) wide)

• three (3) 3/8-16 in. x 1 in. (M10 x 1.5 x 25mm) bolts

• three (3) 3/8-16 in. (M10 x 1.5) nuts

• three (3) 3/8 in. (M10) lock washers

• six (6) 3/8 in. (M10) fl at washers

Supplied Hardware:

• three (3) 5/16-18 x 1 in. bolts

• three (3) 5/16 in. lock washers

• three (3) 5/16 in. fl at washers

A T T E N T I O NA T T E N T I O N

Double-barrel, clip-on power fuses require an anti-turn

bracket to maintain suffi cient clearance between the

power phases. Do not use such fuses without this safety

feature. Failure to do so may result in injury to personnel

or damage to the equipment. The brackets are supplied

if specifi ed at the time of ordering, otherwise contact

Rockwell Automation to obtain the brackets. Order

Allen-Bradley part number 80253-262-51. Mounting

instructions are included with the kit.

Anti-turn Brackets

Figure 2.19 – Trailer Fuse Block with Anti-turn Brackets

1503-IN050E-EN-P – June 2013

Page 30

2-22 Component Installation

Electrical Connection From

Contactor to Trailer Fuse Block

(Clip-on Fuses)

1) Use the supplied 5/16 in. hardware to mount the bus link or suitable

cable to the trailer fuse block (see Figure 2.20). Torque the bolts to the

specifi cations shown on page 1-4.

(cont.)

The trailer fuse block is equipped with 5/16-18 nuts. The

I M P O R T A N TI M P O R T A N T

supplied hardware, or equivalent, must be used to avoid

damaging the thread in the nuts.

Trailer Fuse

Contactor

Attachment Point

(Line Side)

Trailer Fuse Block

Attachment Point

1503-IN050D-EN-P – June 2012

Figure 2.20 – Linking Trailer Fuse Block to Contactor (Clip-on Power Fuses)

2) Attach the bus links, or suitable cable, to the line side of the contactor

(upper terminals) using 3/8 in. (M10) hardware (see Figure 2.20).

Torque the bolts according to the requirments shown on page 1-4.

A T T E N T I O NA T T E N T I O N

Maintain at least 3 in. (76 mm) clearance between power

phase connections. Insuffi cient distance could cause

equipment damaging power faults in the unit.

Page 31

Component Installation 2-23

Electrical Connection from

Contactor to Trailer Fuse Block

(Bolt-on Fuses)

Required Hardware:

• three (3) horizontal bus links or suitable cable and lugs (bus links are

recommended to be 1/4 in. (6mm) thick and 1 in. (25mm) wide)

• six (6) 3/8-16 in. x 1 in. (M10 x 1.5 x 25mm) bolts

• six (6) 3/8-16 in. (M10 x 1.5) nuts

• six (6) 3/8 in. (M10) lock washers

• twelve (12) 3/8 in. (M10) fl at washers

1) Attach the bus links or cables to the line terminals on the trailer fuse

block (see Figure 2.21). Torque the bolts to the specifi cations shown on

page 1-4.

2) Attach the bus links, or suitable cable, to the line side of the contactor

(upper terminals) using 3/8 in. (M10) hardware. (See Fig. 2.21) Torque

the bolts according to the specifi cations shown on page 1-4.

A T T E N T I O NA T T E N T I O N

Maintain at least 3 in. (76 mm) clearance between power

phase connections. Insuffi cient distance could cause

equipment damaging power faults in the unit.

Trailer Block Fuse

Contactor

Attachment Point

(Line Side)

Trailer Fuse Block

Attachment Point

Figure 2.21 – Linking Trailer Fuse Block to Contactor (Bolt-on Power Fuses)

1503-IN050D-EN-P – June 2012

Page 32

2-24 Component Installation

Incoming Line Connections Mounting hardware is suitable for use with lugs incorporating two-hole

NEMA drilling. Secure incoming cables to line terminals of the isolation

switch with suitable lugs and ½ in. (M12) hardware. Torque the hardware

according to the specifi cations shown on page 1-4.

I M P O R T A N TI M P O R T A N T

Attach Incoming Line Cables Here

Figure 2.22 – Isolation Switch Incoming Line Connections (Rear View)

Cable size should not exceed 1-500 or 2-250 MCM per phase.

Load Connections Secure load cables to load terminals of contactor using suitable lugs and

3/8 in.(M10) hardware. Torque the hardware according to the specifi cations

shown on page 1-4.

I M P O R T A N TI M P O R T A N T

It is the user’s responsibility to determine a suitable means

of completing the power connection from the contactor

to the motor ie. current transformers, power fuses, etc.

Load Terminals

Figure 2.23 – Load Terminals - 400 A Contactor (Rear View)

1503-IN050E-EN-P – June 2013

Page 33

Component Installation 2-25

Connecting Contactor to

Control Power Transformer

I M P O R T A N TI M P O R T A N T

A control power transformer (CPT) is not supplied as

part of the OEM starter kit. This procedure only describes how to connect wires to the contactor that will

supply power to the control circuit. It is the user’s

responsibility to determine the correct CPT, primary fuse

sizes, power wire, lugs and current transformer for the

control circuit.

1) Remove the #10-32 hex head screw securing the fuse clips at the front

of the contactor (see Figure 2.24).

Remove Screws to mount lugs

(Front of Contactor)

Figure 2.24 – Attaching Control Power Wires to Contactor (Top View)

2) Attach lugs with a 90-degree bend (AB part # G6666 – suitable for

#12-10 AWG wire) and suitable power wire utilizing a #10 fl at washer

and lock washer .

3) Torque the screws to 32 in.·lbs.

4) Use wire clips provided on the contactor to fasten the control power

transformer cables in position. This is required to avoid cables coming

into contact with live parts and to meet dielectric test requirements.

1503-IN050E-EN-P – June 2013

Page 34

2-26 Component Installation

1503-IN050E-EN-P – June 2013

Page 35

Adjustments for 400 Amp Equipment

Chapter 3

Door Interlock Circumvention To ensure proper functioning of the isolation switch as-

Some of the following sections may require moving the isolation switch

I M P O R T A N TI M P O R T A N T

sembly, perform the following adjustments in the order

they are presented.

A T T E N T I O NA T T E N T I O N

handle to the ON position while the medium voltage door is open. The

interlocking safeguards in the mechanism are designed to prevent the

handle from moving to the ON position while the cabinet door is open.

The door interlock mechanism is designed to prevent

access to the medium voltage cell while the unit

is energized. When the unit is in operation, do not

circumvent this interlocking safety feature. Always

disconnect and lock out incoming power (see Power

Lock-out Procedure, pg 3-2) before proceeding with any

adjustments requiring the handle to be moved to the ON

(closed) position. Failure to do so may result in electric

shock causing severe burns, injury or death.

• To circumvent this safety feature, use a screwdriver, or other tool, to

depress the door interlock defeater lever in the switch.

• Hold the lever down while moving the handle to the ON (closed) posi-

tion.

Interlock Defeater

Lever

Figure 3.1 – Door Interlock Defeater Lever

1503-IN050D-EN-P – June 2012

Page 36

3-2 Adjustments

Power Lock-out Procedure

A T T E N T I O NA T T E N T I O N

Always perform the power lock-out procedure before

proceeding with servicing the equipment Use suitable

personal protective equipment (PPE) per local codes or

regulations. Failure to do so may result in severe burns,

injury or death.

A T T E N T I O NA T T E N T I O N

The following procedure requires moving the isolation

switch handle to the ON position. To avoid shock

hazards, disconnect and lock out incoming power before

proceeding with servicing the equipment. Failure to

lock out incoming power will result in a live power cell

once the isolation switch handle is in the ON position

and may cause severe burns, injury or death. Rockwell

Automation does not assume any responsibility for

injuries to personnel who have not completed the following

safety procedure prior to servicing the equipment.

1) Disconnect and lock out all feeder power supplies to the starter.

2) Move the isolation switch handle to the OFF position.

3) If the unit is equipped with power factor correction capacitors, stored

energy must be dissipated before entering the power cell. Wait at least

fi ve minutes before entering the power cell or dissipate the power using

the following procedure:

a) Verify that the isolation switch handle is in the OFF position.

b) Open the low voltage door.

c) Plug the appropriate power supply (120 or 230V) into the auxiliary

power receptacle on the control panel (see Figure 3.2).

d) Move the control switch to the TEST position.

Auxiliary Power Receptacle

Test Switch

Figure 3.2 – Control Panel (120V shown)

1503-IN050E-EN-P – June 2013

Page 37

Adjustments 3-3

e) Electrically operate the contactor by pushing the START button

on the unit or at a remote location.

f) Disengage the contactor and move the control switch to the NOR-

MAL position. Disconnect the external power supply.

g) Complete the Power Lock-out procedure

4) Open the medium voltage door.

5) Visually inspect that the isolation switch blades fully engage the

grounding pins on the grounding bar. The isolation switch shutters

should be closed (see Figure 3.3).

Grounding Bar

Isolation Switch Blades must

fully engage Grounding Pins

of Grounding Bar

(Verify for each phase)

Isolation Switch Shutters

must be closed.

(Verify for each phase)

Figure 3.3 – Inspecting Isolation Switch in Open Position

6) Check the line and load sides of the contactor with a hot stick or appro priate voltage measuring device to verify that they are voltage free (see

Figure 3.4).

a) Check for line-side voltage at the top vacuum bottle terminals.

b) Check for load-side voltage at the bottom vacuum bottle terminals.

1503-IN050E-EN-P – June 2013

Page 38

3-4 Adjustments

Power Lock-out Procedure

Check line-side power here

(cont.)

Check load-side power here

Figure 3.4 – Contactor Voltage Checkpoints

7) Use the Door Interlock Circumvention procedure described on page 3-1.

to move the isolation switch handle to the ON position.

8) Check the isolation switch blades with a hot stick or appropriate voltage measuring device to verify that they are voltage free (see Figure

3.5).

Figure 3.5 – Isolation Switch Voltage Check Points

9) Once all power circuits are verifi ed to be voltage free, move the isola-

tion switch handle back to the OFF position. The unit is now safe to

service.

1503-IN050E-EN-P – June 2013

Page 39

Adjustments 3-5

To avoid shock hazards, lock out incoming power (see

Contactor Interlock Rod

Adjustment

A T T E N T I O NA T T E N T I O N

page 3-2) before working on the equipment. Verify with

a hot stick or appropriate voltage measuring device that

all circuits are voltage free. Failure to do so may result in

severe burns, injury or death.

1) Complete the Power Lock-out Procedure (see Page 3-2).

2) Open the medium voltage door. Use the Door Interlock Circumvention

procedure described on page 3-1 to move the isolation switch handle

halfway between the OFF and ON position (see Figure 3.6). Keep the

handle in this position until the adjustment procedure is completed.

3) With the contactor in the OFF position, insert a 0.050 in. (1.3 mm)

feeler gauge in the gap between the interlock lever and the isolation

switch operating lever. The gap must be between 0.045 in. to 0.060 in.

(1.1 mm to 1.5 mm).

4) To reduce the gap distance, follow steps 5-7.

To increase the gap distance follow steps 8-10.

Gap

(0.03 in. to 0.78 in.)

(1.00 mm to 2.0 mm)

Interlock Lever

Stop Bracket

Contactor Operating Lever

Isolation Switch Operating Lever

Isolation Switch Handle

at Halfway Position

Contactor Interlock Rod

Nylock Nut

Figure 3.6 – Isolation Switch Handle Adjustments

1503-IN050E-EN-P – June 2013

Page 40

3-6 Adjustments

Contactor Interlock Rod

To Reduce the Gap Distance

Adjustment (cont.)

5) Loosen the two screws in the stop bracket and move the stop bracket

up against the interlock lever.

6) With the feeler gauge positioned in the gap, move the interlock lever

and the stop bracket closer to the isolation switch operating lever to

reduce the gap space. Tighten the stop bracket screws.

7) Tighten the nylock nut until it is snug against the contactor operating

lever. Do not overtighten the nylock nut as it will move the interlock

lever and reduce the gap. Proceed to Step 11.

To Increase the Gap Distance

8) Loosen the two screws in the stop bracket and move the stop bracket

away from the interlock lever.

9) Loosen the nylock nut until the gap reaches the desired size.

10) Move the stop bracket until it just touches the interlock lever and

tighten the screws.

11) Apply Loctite 290 (or equivalent adhesive) to the stop bracket screws

and torque the screws to 6 ft.-lb. (8 N•m).

12) Move the isolation switch handle to the ON position.

13) Manually close the contactor by attaching locking pliers to the contac-

tor operating lever and pushing down until the armature plate contacts

the magnetic cores (see Figure 3.7). Verify that the interlock lever

overlaps the isolation switch operating lever by at least 0.125 in. (3 mm)

(see Figure 3.8).

Armature Plate

Magnetic Core

1503-IN050E-EN-P – June 2013

Figure 3.7 – Closing Contactor Manually (Some parts not shown)

Page 41

Isolation Switch

Overlap 0.125 in. min.

(3 mm)

Interlock Lever

Figure 3.8 – Isolation Switch Operating Lever Overlap

Operating Lever

Adjustments 3-7

Isolation Switch Ground

Adjustment

14) Open the contactor. Verify that the interlock lever and the rod move

freely and that the return springs move the assembly back to the starting

position.

A T T E N T I O NA T T E N T I O N

To avoid shock hazards, lock out incoming power before

working on the equipment. Verify with a hot stick or appropriate voltage measuring device that all circuits

are voltage free. Failure to do so may result in severe

burns, injury or death.

1) Move the isolation switch handle to the OFF position.

2) Inspect the grounding of the isolation switch blades. When the isolation

switch handle is in the OFF (open) position, the isolation switch blades

must fully engage the ground pins of the ground bar. The isolation

switch blades must also be within 0.060 in. (1.5 mm) of the ground bar

when the handle is in the OFF (open) position (see Figure 3.9). When

the isolation switch handle is in the ON or closed position, the blades

must fully engage the line stabs (see Figure 3.5).

3) To adjust the distance from the blades to the bar, disconnect the

threaded connecting rod at the isolation switch operating lever (see

Figure 2.16).

4) Turn the threaded connecting rod to lengthen or shorten it. This will

adjust the position of the isolation switch blades in the ON and OFF

position.

1503-IN050E-EN-P – June 2013

Page 42

3-8 Adjustments

Isolation Switch Ground

Adjustment (cont.)

Ground Bar

Auxiliary Contact

Figure 3.9 – Isolation Switch Ground Adjustment

Maximum Gap 0.06 in. (1.5 mm) between Ground Bar

and Isolation Switch Blade in open position

Isolation Switch Blade

Incoming Line Stab

Isolation Switch (Cut-away view from right side)

Isolation Switch Auxiliary The auxiliary contacts are mounted on the left side of the isolation switch,

Contacts slightly below the cams on the isolation switch shaft.

Normally open contacts (Isolation Switch a Contacts - ISa) are on the

outside of the isolation switch housing, and normally closed contacts

(Isolation Switch b Contacts - ISb) are on the inside of the housing.

Isa Auxiliary Contacts (N.O.)

Isb Auxiliary Contacts (N.C.)

1503-IN050E-EN-P – June 2013

Figure 3.10 – Location of Isa and Isb Auxiliary Contacts

Page 43

Adjustments 3-9

ISa and ISb contacts are exactly the same (700 CPM). The cam controls the

normally open or normally closed status of the contacts.

Refer to Figures 2.10 to 2.13 for wiring diagrams.

Important: The Isolation Switch Ground Adjustment procedure (page 3-7)

must be completed before adjusting the auxiliary contacts to ensure proper

synchronization of the assembly.

Adjusting the Normally Open (ISa) Contacts

A T T E N T I O NA T T E N T I O N

To avoid shock hazards, lock out incoming power

before working on the equipment. Verify with a hot stick

appropriate voltage measuring device that all circuits are

voltage free. Failure to do so may result in severe burns,

injury or death.

1) Move the isolation switch handle to the ON (closed) position.

2) Loosen the bolt holding the outside cam to the shaft. Do not loosen the

bolt entirely. The cam should not be able to rotate freely on the shaft.

3) Insert a 0.25 in. (6.35 mm) diameter pin into the cam groove between

the cam follower and the end of the cam groove.

Cam

Gap

0.25 in.

Cam Follower

(6.35 mm)

AMP

20

SER. A

700-CPM

Auxiliary Contact

CATALOG NO.

Left Side View

Figure 3.11 – Adjusting Auxiliary Contacts (Isa Auxiliary Contact Shown)

1503-IN050D-EN-P – June 2012

Page 44

3-10 Adjustments

4) Adjust the cam on the shaft so that the gap from the cam follower to

Isolation Switch Auxiliary

Contacts (cont.)

5) Move the isolation switch handle to the OFF (open) position and check

6) Tighten the bolt holding the cam to the shaft. Move the isolation switch

7) Verity that auxiliary contact ISa is open when the isolation switch is

the end of the cam groove is the width of the pin — 0.25 in. (6.35 mm).

that nothing prevents the cam from rotating with the shaft.

handle to the ON position and recheck the gap using the pin.

open. Verify that ISa contact is closed when isolation switch is closed.

Adjusting the Normally Closed (ISb) Contacts

1) Move the isolation switch handle to the OFF (open) position.

2) Loosen the bolt holding the inside cam to the shaft. Do not loosen the

bolt entirely. The cam should not be able to rotate freely on the shaft.

3) Insert a 0.25 in. (6.35 mm) diameter pin into the cam groove between

the cam follower and the end of the cam groove.

4) Adjust the cam on the shaft so that the gap from the cam follower to

the end of the cam groove is the width of the pin — 0.25 in. (6.35 mm).

5) Move the isolation switch handle to the ON (closed) position and

check that nothing prevents the cam from rotating with the shaft.

6) Tighten the bolt that holds the cam to the shaft. Move the isolation

switch handle to the OFF position and recheck the gap using the pin.

7) Operate the handle several times, then recheck the 0.25 in. (6.35 mm)

clearance between the end of the cam groove and the follower pin for

both cams.

8) Verify that auxiliary contact ISb is closed when isolation switch is

open. Verify that ISb contact is open when isolation switch is closed.

1503-IN050E-EN-P – June 2013

Page 45

Adjusting the ‘Change of State Point’

Adjustments 3-11

This procedure sets the secondary electrical interlock.

I M P O R T A N TI M P O R T A N T

When properly adjusted, the electrical interlock is

designed to open the control circuit power connections

before the isolation switch opens when the handle is

moved to the OFF position.

1) Once the auxiliaries have been adjusted, move the isolation switch

handle to the ON position.

2) Connect a conductivity measuring device across the closed auxiliary

contacts.

3) Slowly move the isolation switch handle towards the OFF position and

observe the point at which the movable isolation switch blades separate

from the incoming line stabs. The auxiliary contacts must change state

from the closed to open position before the isolation switch blades lose

contact with the incoming line stabs. This prevents the isolation switch

from being opened while the unit is energized and under load conditions.

A T T E N T I O NA T T E N T I O N

The auxiliary contacts must be properly adjusted to

avoid opening the isolation switch under load conditions.

Improper adjustment may result in damage to the

equipment and/or severe burns, injury or death to

personnel.

4) If the auxiliaries do not change state before the isolation switch opens,

adjust the threaded connecting rod as described in the Isolation Switch

Adjustment procedure (see page 3-7).

1503-IN050e-EN-P – June 2013

Page 46

3-12 Adjustments

1503-IN050E-EN-P – June 2013

Page 47

Chapter 4

Commissioning

Hi-Pot and Megger Test Insulation integrity should be checked before energizing electrical

equipment. Use a high voltage AC insulation tester or a Megger for this

test. If a Megger is used, a 5000 volt type is recommended.

A T T E N T I O NA T T E N T I O N

Exercise caution when performing high voltage tests on

the equipment. Failure to do so may result in electric

shock causing severe burns, injury or death.

A T T E N T I O NA T T E N T I O N

To avoid shock hazards, lock out incoming power before

working on the equipment. Verify with a hot stick or

appropriate voltage measuring device that all circuits are

voltage free. Failure to do so may result in severe burns,

injury or death.

Insulation can be tested from phase to phase and from phase to ground.

The recommended level for AC Hi-Pot testing is (2 X V

) volts, where V

LL

is the rated line-to-line voltage of the power system. The leakage current

must be less than 20 mA. Record the result for future comparison testing.

If a Megger is used, it should indicate 50 megohms or greater if the unit is

isolated from the line and the motor. If the unit is connected to a motor, the

Megger should indicate 5 megohms or greater.

LL

Vacuum Bottle Integrity Test Refer to the following publications for the procedure to test vacuum bottle

integrity of the Bulletin 1502 contactor:

• 400A – Publication 1502-UM050_EN-P ( Series D)

• 400A – Publication 1502-UM052_EN-P (Series E)

• 800A – Publication 1502-UM051_EN-P (Series E)

These user manuals contain detailed information on installation, adjustment

and maintenance for this product.

1503-IN050E-EN-P – June 2013

Page 48

4-2 Commissioning

Preliminary Checklist Contactor Operation

A T T E N T I O NA T T E N T I O N

To avoid shock hazards, lock out incoming power before

working on the equipment. Verify with a hot stick or

appropriate voltage measuring device that all circuits are

voltage free. Failure to do so may result in severe burns,

injury or death.

1) Connect the appropriate external power supply (120 or 230 VAC) to

the test receptacle in the control panel. Turn the selector switch to the

TEST position (see Figure 3.2).

2) Electrically operate the contactor several times. Inspect the armature

plate to verify that it fully contacts the cores (400A) or yolk plate (800A).

3) Turn the selector switch back to the OFF position and disconnect the

test power supply.

Electrical Connections

1) Verify correct power cable phase sequencing and that the connections

are tight. See Torque Requirements, page 1-4.

2) Verify power fuse ratings and condition.

3) Verify control fuse ratings and condition.

4) Check that components were not damaged during power cable

installation, and that electrical spacings are suffi cient.

Final Checks

1) Remove all tools from the cabinet. All tools and hardware used

during installation and commissioning must be accounted for prior to

energizing the unit.

2) Remove all temporary jumpers and grounding devices used during the

installation procedures.

3) Ensure that all barriers or covers removed during installation have been

securely reattached.

4) Close and secure all doors. Verify that all interlocks preventing access

to medium voltage power cells are functioning correctly.

A T T E N T I O NA T T E N T I O N

5) Restore incoming power from main power supply.

6) Move the isolation switch handle to the ON position.

7) The controller is now ready to supply power to the load.

Use suitable personal protective equipment (PPE) per

local codes or regulations. Failure to do so may result in

severe burns, injury or death.

1503-IN050E-EN-P – June 2013

Page 49

Maintenance

Chapter 5

Establish a maintenance and inspection schedule for the

I M P O R T A N TI M P O R T A N T

equipment. Annual servicing (or every 20,000 operations

– whichever comes fi rst) is the minimum recommended;

however, extreme operating conditions may warrant additional attention.

Contactor Refer to the following publications for detailed maintenance information

on the Bulletin 1502 contactor:

• 400A – Publication 1502-UM050_EN-P ( Series D)

• 400A – Publication 1502-UM052_EN-P (Series E)

• 800A – Publication 1502-UM051_EN-P (Series E)

These user manuals contain detailed information on installation, adjustment

and maintenance for this product.

Isolation Switch Mechanism

Inspection and Lubrication

A T T E N T I O NA T T E N T I O N

To avoid shock hazards, lock out incoming power (see

page 3-2) before working on the equipment. Verify with

a hot stick or appropriate voltage measuring device that

all circuits are voltage free. Failure to do so may result in

severe burns, injury or death.

1) Complete the Power Lock-out Procedure (see Page 3-2).

2) Open the medium voltage door.

3) Inspect the condition of the clevis pin and cotter pins shown in Figure

5.1. Replace any worn parts.

1503-IN05E-EN-P – June 2013

Page 50

5-2 Maintenance

Isolation Switch Mechanism

Inspection and Lubrication

(cont.)

Interlock Lever

Lubrication Points

(Only at replacement)

Threaded

Connecting Rod

Clevis Pins and

Cotter Pins

Contactor

Interlock Rod

Isolation Switch

Operating Lever

Figure 5.1 – Isolation Switch Handle Mechanism Lubrication Points

4) If it is necessary to replace the isolation switch operating lever or the

interlock lever, apply Dow Corning 55 O-ring lubricant (or equivalent)

to the pivot points before installing the new components (see Figure

5.1).

5) Inspect the mounting hardware on the isolation switch operating lever

and contactor interlock rod (see Figure 5.1). Tighten any loose hardware.

6) Inspect the isolation switch blades and the incoming line stabs (see

Figure 3.9). The mating surfaces must be clean and well lubricated.

7) Remove any dirt and dried grease.

Do not scrape or fi le the parts. This may remove the plat-

I M P O R T A N TI M P O R T A N T

ing and expose the underlying copper to corrosion.

8) Lubricate the isolation switch blades and the isolation switch blade pivot

points with Nyogel 759G - part number T9327-105 (see Figure 5.2).

Lubricate the isolation switch blades a minimum of once

I M P O R T A N TI M P O R T A N T

per year to avoid excessive wear to the components and

to prevent the isolation switch blades from overheating.

1503-IN050E-EN-P – June 2013

Page 51

Lubricate Isolation Switch Blades

Lubricate Pivot Points

Maintenance 5-3

Figure 5.2 – Isolation Switch Lubrication Points

To avoid shock hazard, lock out incoming power before

Auxiliary Contacts

Inspection and Replacement

A T T E N T I O NA T T E N T I O N

working on the equipment. Verify with a hot stick or

appropriate voltage measuring device that all circuits are

voltage free. Failure to do so may result in severe burns,

injury or death.

1) Move the isolation switch handle to the OFF position and open the

controller door.

2) Inspect the auxiliary contacts for wear, scorching or heat damage.

Replace any damaged contacts. The contacts have a mean time between

failure (MTBF) rating of 20 million operations if used within the oper-

ating specifi cations.

3) To remove the contact, turn both of the D-head fasteners until the fl at

sections are aligned with the edge of the contact (See Figure 5.3).

4) Remove the contact from the housing.

5) Disconnect the wires from the auxiliary contact.

6) Reverse the procedure to replace the auxiliary contact.

7) Ensure the contact is correctly positioned into the contact carrier (See

Figure 5.3).

1503-IN050E-EN-P – June 2013

Page 52

5-4 Maintenance

Auxiliary Contacts

Inspection and Replacement

(cont.)

AMP

20

SER. A

700-CPM

Correct Positioning

CATALOG NO.

D-head

Fastener

CATALOG NO.

700-CPM

SER. A

20

AMP

Incorrect Positioning

Install as Shown Above

Figure 5.3 – Auxiliary Contact Orientation

1503-IN050E-EN-P – June 2013

Page 53

Spare Parts

Chapter

6

Refer to the following publications for information on spare parts for the Bulletin 1502 medium

voltage 400A contactor (120V and 230V):

• 400A – Publication 1502-UM050_EN-P ( Series D)

• 400A – Publication 1502-UM052_EN-P (Series E)

• 800A – Publication 1502-UM051_EN-P (Series E)

These user manuals contain detailed information on installation, adjustment and maintenance for this

product.

1503-IN050E-EN-P – June 2013

Page 54

6-2 Spare Parts

1503-IN050E-EN-P – June 2013

Page 55

Appendix A

Table A.1 – Items That Should be Included with the Power Cell and Frame

Final Part

Number

Qty

Description

Saleable Part

Number

RA Internal

Part Number

1503F-E4GCD

1

400 Amp, 2.3 – 5.0 kV, Electrically held, Clip On Fuse, Electro-Mechanical,

110-120 VAC Control Frame

1503F-E4GCD

80158-951-61

1

Electrically Held 120V Control panel

1503C-E4D

80158-143-51

1503F-E4GCE

1

400 Amp, 2.3 – 5.0 kV, Electrically Held, Clip On Fuse, ElectroMechanical, 220-230VAC Control Frame

1503F-E4GCE

80158-951-65

1

Electrically Held 230V Control Panel

1503C-E4E

80158-143-53

1503F-E4GCU

1

400 Amp, 2.3 – 5.0 kV, Electrically Held, Clip On Fuse, IntelliVAC, 110120VAC Control Frame

1503F-E4GCU

80178-373-58

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHE4V

80178-142-57

1503F-E4GBD

1

400 Amp, 2.3 – 5.0 kV, Electrically Held, Bolt On Fuse, ElectroMechanical, 110-120VAC Control Frame

1503F-E4GBD

80158-951-59

1

Electrically Held 120V Control Panel

1503C-E4D

80158-143-51

1503F-E4GBE

1

400 Amp, 2.3 – 5.0 kV, Electrically Held, Bolt On Fuse, ElectroMechanical, 220-230VAC Control Frame

1503F-E4GBE

80158-951-63

1

Electrically Held 230V Control Panel

1503C-E4E

80158-143-53

1503F-E4GBU

1

400 Amp, 2.3 – 5.0 kV, Electrically Held, Blot On Fuse, IntelliVAC, 110-120

VAC Control Frame

1503F-E4GBU

80178-373-55

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHE4V

80158-142-57

1503F-M4GCD

1

400 Amp, 2.3 - 5.0 kV, Mechanical Latch, Clip On Fuse, ElectroMechanical, 110-120VAC Control Frame

1503F-M4GCD

80158-951-69

1

Mechanical Latch 120V Control Panel

1503C-M4D

80158-143-52

1503F-M4GCU

1

400 Amp, 2.3 – 5.0 kV, Mechanical Latch, Clip On Fuse, IntelliVAC< 110120 VAC Control Frame

1503F-M4GCU

80178-373-63

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness – IntelliVAC

1503-WHM4V

80158-142-52

1503F-M4GBD

1

400 Amp, 2.3 – 5.0 kV, Mechanical Latch, Blot On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-M4GBD

80158-951-67

1

Mechanical Latch 120V Control Panel

1503C-M4D

80158-143-52

1503F-M4GBU

1

400 Amp, 2.3 – 5.0 kV, Mechanical Latch, Blot On Fuse, IntelliVAC< 110120VAC Control Frame

1503F-M4GBU

80178-373-61

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness – IntelliVAC

1503-WHM4V

80158-142-52

1503F-E4KCD

1

400 Amp, 5.1 – 6.9 kV, Electrically Held, Clip On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-E4KCD

80158-951-62

1

Electrically Held 120V Control Panel

1503C-E4D

80158-143-51

1503F-E4KCE

1

400 Amp, 5.1 – 6.9 kV, Electrically Held, Clip On Fuse, ElectroMechanical, 220-230 VAC Control Frame

1503F-E4KCE

80158-951-66

1

Electrically Held 230V Control Panel

1503C-E4E

80158-143-53

1503F-E4KCU

1

400 Amp, 5.1 – 6.9 kV, Electrically Held, Clip On Fuse, IntelliVAC, 110-120

VAC Control Frame

1503F-E4KCU

80178-373-68

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

Wire Harness-IntelliVAC

1503-WHE4V

80158-142-57

1503F-E4KBD

1

400 Amp, 5.1 – 6.9 Electrically Held, Blot On Fuse, Electro-Mechanical,

110-120 VAC Control Frame

1503F-E4KBD

80158-951-60

1

Electrically Held 120V Control Panel

1503C-E4D

80158-951-51

1503F-E4KBE

1

400 Amp, 5.1 – 6.9 kV, Electrically Held, Bolt On Fuse, ElectroMechanical, 220-230 VAC Control Frame

1503F-E4KBE

80158-951-64

1

Electrically Held 230V Control Panel

1503C-E4E

80158-143-53

OEM Kit Chart

1503-IN050E-EN-P – June 2013

Page 56

A-2 OEM Kit Chart

Table A.1 – Items That Should be Included with the Power Cell and Frame (cont.)

Final Part

Number

Qty

Description

Saleable Part

Number

RA Internal

Part Number

1503F-E4KBU

1

400 Amp, 5.1 – 6.9 kV, Electrically Held, Blot On Fuse, IntelliVAC, 110-120

VAC Control Frame

1503F-E4KBU

80178-373-65

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHE4V

80158-142-57

1503F-M4KCD

1

400 Amp, 5.1 – 6.9 kV, Mechanical Latch, Clip ON Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-M4KCD

80158-951-70

1

IntelliVAC Base

1503C-M4D

80158-143-52

1

Wire Harness-IntelliVAC

1503F-M4KCU

80178-373-73

1503-M4KBD

1

400 Amp, 5.1 – 6.9 kV, Mechanical Latch, Bolt On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503VC-BMC5

80178-370-52

1

Mechanical Latch 120V Control Panel

1503-WHM4V

80158-142-59

1503F-M4KBU

1

400 Amp, 5.1- 6.9 kV, Mechanical Latch, Blot On Fuse, IntelliVAC, 110120 VAC Control Frame

1503F-M4KBD

80158-951-68

1

IntelliVAC Base

1503C-M4D

80158-143-52

1

Wire Harness-IntelliVAC

1503-WHM4V

80158-142-59

1503F-E6GBD

1

600 Amp, 2.3 – 5.0 kV, Electrically Held, Blot On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-E6GBD

80158-333-57

1

Electrically Held 120V Control Panel

1503FC-E8D

80158-143-54

1503F-E6GBU

1

600 Amp, 2.3 – 5.0 kV, Electrically Held, Blot On Fuse, IntelliVAC, 110-120

VAC Control Frame

1503F-E6GBU

80178-374-52

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHE8V

80178-142-58

1503F-M6GBD

1

600 Amp, 2.3 – 5.0 kV, Mechanical Latch, Blot On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-M6GBD

80158-333-60

1

Mechanical Latch 120V Control Panel

1503C-M8D

80158-143-60

1503F-M6GBU

1

600 Amp, 2.3 – 5.0 kV, Mechanical Latch, Blot On Fuse, IntelliVAC 110–

120 VAC Control Frame

1503F-M6GBU

80178-374-55

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHM8D

80158-142-55

1503F-E6KBD

1

600 Amp, 5.1 – 6.9 kV, Electrically Held, Bolt On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-E6KBD

80158-333-58

1

Electrically Held 120V Control Panel

1503C-E8D

80158-143-54

1503F-E6KBU

1

600 Amp, 5.1 – 6.9 kV, Electrically Held, Bolt On Fuse, IntelliVAC, 110-120

VAC Control Frame

1503F-E6KBU

80178-374-57

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHE8V

80158-142-58

1503F-M6KBD

1

600 Amp, 5.1 – 6.9 kV, Mechanical Latch, Bolt On Fuse, ElectroMechanical, 110-120 VAC Control Frame

1503F-M6KBD

80158-333-61

1

Mechanical Latch 120V Control Panel

1503C-M8D

80158-143-55

1503F-M6KBU

1

600 Amp, 5.1 – 6.9 kV, Mechanical Latch, Bolt On Fuse, IntelliVAC 110120 VAC Control Frame

1503F-M6KBU

80178-374-60

1

IntelliVAC Base

1503VC-BMC5

80178-370-52

1

Wire Harness-IntelliVAC

1503-WHM8D

80158-142-55

1503-IN050E-EN-P – June 2013

Page 57

Page 58

Loading...

Loading...