Page 1

Allen-Bradley

SLC to SCANportt

Communications

User

Module

(Cat. No 1203–SM1)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations shown in this guide are intended solely for purposes

of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not

assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

death, property damage or economic loss.

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

SCANport is a registered trademark of Allen–Bradley Company, Inc.

SLC 500, SLC–5/02, and PLC–5/15 are registered trademarks of Allen–Bradley Company, Inc.

Page 3

Table of Contents

Preface

Who Should Use this Manual? P–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose of this Manual P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of this Manual P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Precautions P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC Product Compatibility P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terms and Abbreviations P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Techniques Used in this Manual P–4. . . . . . . . . . . . . . . . . . .

Allen–Bradley Support P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Product Support P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Product Assistance P–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Overview

Installing the SLC to

SCANport Module

Using Basic Mode

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is the SLC to SCANport Module? 1–1. . . . . . . . . . . . . . . . . . . . .

What Functions Does the SLC to SCANport Module Provide? 1–2. . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Install the Module 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determine the Length of the SCANport Cable(s) 2–2. . . . . . . . . . . . .

Determine the Placement of the SCANport Cables 2–2. . . . . . . . . . .

Locate the DIP Switch 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the SLC to SCANport Module 2–4. . . . . . . . . . . . . . . . . . . . .

Removing the SLC to SCANport Module 2–6. . . . . . . . . . . . . . . . . . . .

Where Do I Go From Here? 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Does Basic Mode Provide? 3–1. . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the SLC to SCANport Module for Basic Mode 3–1. . . . . . . .

Transferring Data 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel Status Input Image Definitions 3–5. . . . . . . . . . . . . . . . . . .

Channel Command Output Image Definitions 3–6. . . . . . . . . . . . . . .

Example of Basic Mode Data Transfer 3–6. . . . . . . . . . . . . . . . . . . . . .

Page 4

ii

Using Enhanced Mode

Troubleshooting

Specifications

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Does Enhanced Mode Provide? 4–1. . . . . . . . . . . . . . . . . . . . . .

What Are Datalinks? 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Is Safe State Configuration Data? 4–2. . . . . . . . . . . . . . . . . . .

What Is Messaging? 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the SLC to SCANport Module for Enhanced Mode 4–3. . . .

Using the I/O Image 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enhanced Mode Interface 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring G Files 4–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using M Files 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Examples of Enhanced Mode Data Transfer 4–16. . . . . . . . . . . . . . . . .

Datalinks 4–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED States 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

M0, M1, and G Files

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Specifications 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

European Union Directive Compliance 6–2. . . . . . . . . . . . . . . . . . . . . .

EMC Directive 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Voltage Directive 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Appendix Objectives A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M0–M1 Files A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring M0–M1 Files Using APS Software A–1. . . . . . . . . . . . . .

Addressing M0–M1 Files A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restrictions on Using M0–M1 Data File Addresses A–3. . . . . . . . . . .

Monitoring Bit Addresses A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M0/M1 Monitoring Option Disabled A–3. . . . . . . . . . . . . . . . . . . .

M0/M1 Monitoring Option Enabled A–4. . . . . . . . . . . . . . . . . . . . .

Transferring Data Between Processor Files and M0 and M1 Files A–4

Access Time A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC 5/02 Processor Example A–6. . . . . . . . . . . . . . . . . . . . . . . .

SLC 5/03 Processor Example A–7. . . . . . . . . . . . . . . . . . . . . . . .

Minimizing the Scan Time A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Capturing M0–M1 File Data A–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

G Files A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring G Files Using APS Software A–9. . . . . . . . . . . . . . . . . .

Editing G File Data A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1203–5.9 –– October 1996

Page 5

iii

SCANport Messaging

Appendix B

Appendix Objectives B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message and Reply Structures B–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Available SCANport Messages B–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

SLC SCANport Messaging Ladder Program B–4. . . . . . . . . . . . . . . . . .

Example Messages and Replies B–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Read Number of Parameters B–7. . . . . . . . . . . . . . . . . . . . . . . . . .

Read Parameter Value B–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Parameter Name Text B–9. . . . . . . . . . . . . . . . . . . . . . . . . . .

Write Value to Parameter B–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Full Parameter B–1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling Formulas B–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Default Parameter V alues B–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Restore Parameter Values from Non–volatile Storage B–16. . . . . . . . .

Save Parameter Values to Non–volatile Storage B–17. . . . . . . . . . . . .

Read Enum String for Value in Parameter B–18. . . . . . . . . . . . . . . . .

Read Product Number B–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Product Text B–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Product Series Number B–21. . . . . . . . . . . . . . . . . . . . . . . . . .

Read Product Software Version B–22. . . . . . . . . . . . . . . . . . . . . . . .

Scattered Read B–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scattered Write B–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read Parameter Link from Parameter Number B–27. . . . . . . . . . . . . .

Write Parameter Link from Parameter Number B–28. . . . . . . . . . . . . .

Error Codes B–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 1203–5.9 –– October 1996

Page 6

iv

Publication 1203–5.9 –– October 1996

Page 7

Preface

Preface

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics:

• who should use this manual

• the purpose of this manual

• safety precautions

• firmware support

• product compatibility

• terms and abbreviations

• conventions used in this manual

• Allen–Bradley support

Who Should Use this Manual?

Purpose of this Manual

Use this manual if you design, install, program, or troubleshoot

control systems that use the Allen–Bradley SLC to SCANport

communications module. You must have previous experience with

and a basic understanding of electrical terminology, configuration

procedures, equipment, and safety precautions for machinery and

control systems.

To efficiently use this communications module, you must be able to

program and operate an Allen-Bradley SLC controller.

This manual provides the information you need to install and use the

SLC to SCANport communications module. This manual describes

the procedures for installing, configuring, and troubleshooting the

SLC to SCANport communications module.

For information on specific product features, refer to the product

manual.

Important: Read this manual in its entirety before installing,

operating, servicing, or configuring the SLC to

SCANport communications module.

Publication 1203–5.9 –– October 1996

Page 8

P–2 Preface

Contents of this Manual

This manual contains the following information:

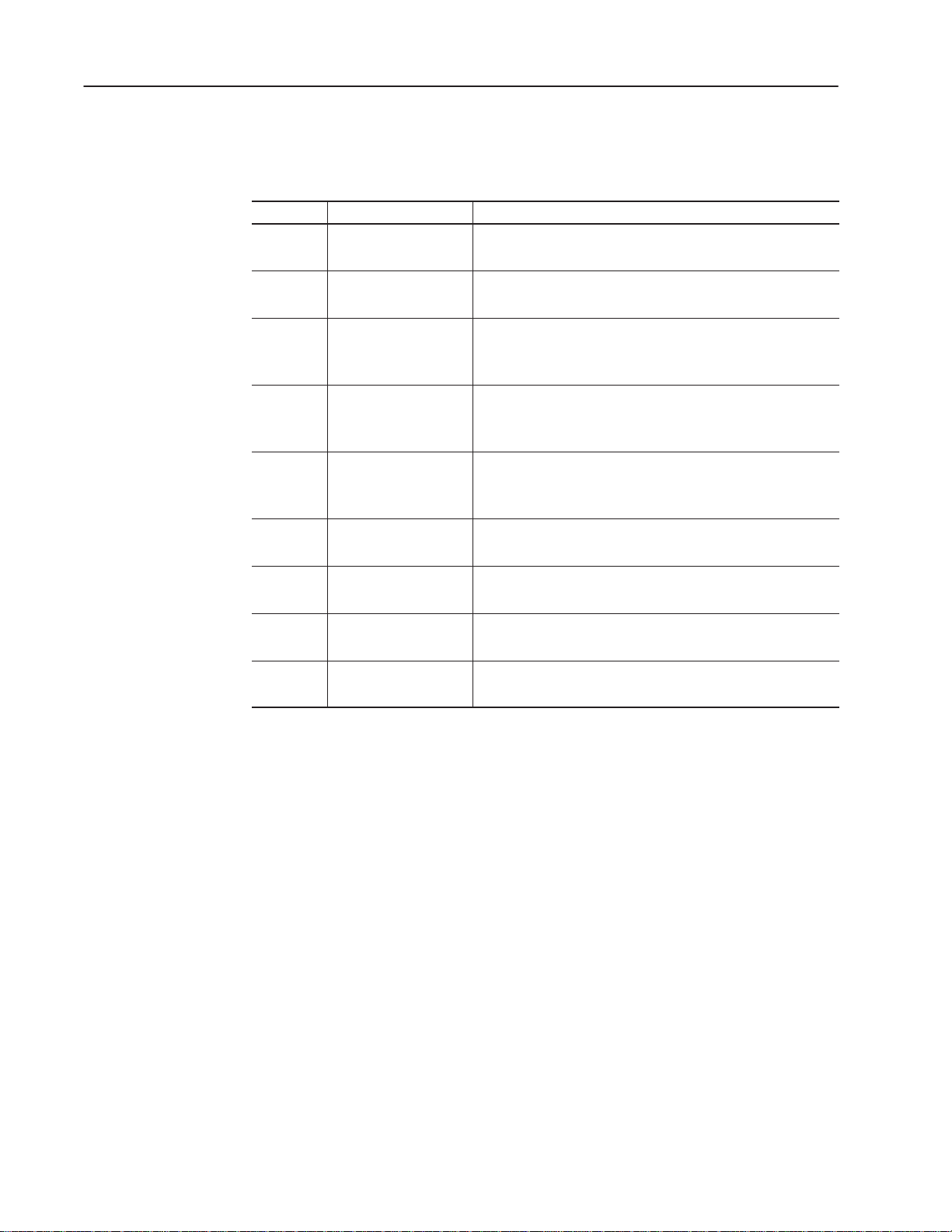

Chapter: Title: Contents:

Preface

Describes the purpose, background, and scope of this

manual.

1 Overview

Installing the SLC

2

3 Using Basic Mode

4

5 Troubleshooting

6 Specifications

A

B

to SCANport

Module

Using Enhanced

Mode

M0, M1, and G

Files

SCANport Message

Index

Provides an overview of the SLC to SCANport

communications module.

Provides the procedures you need to install your SLC to

SCANport communications module and attach it to the

SCANport network.

Provides information that you need to configure your

SLC to SCANport communications module for SLC

basic mode operation.

Provides information that you need to configure your

SLC to SCANport communications module for SLC

enhanced mode operation.

Provides information about the LED indications and

fault descriptions.

Provides the environmental, electrical, and

communications specifications.

Provides generic information about using the M0, M1,

and G files.

Provides a listing of some of the most commonly used

SCANport message structures.

Publication 1203–5.9 –– October 1996

Page 9

P–3 Preface

Safety Precautions

SLC Product Compatibility

Please read the following safety precautions carefully.

ATTENTION: Only personnel familiar with

SCANport devices and the associated machinery

!

!

The SLC to SCANport module is designed to be used with any SLC

processor or adapter capable of supporting SLC rack–based modules.

should plan or implement the installation, start-up,

configuration, and subsequent maintenance of this

communications module. Failure to comply may result

in personal injury and/or equipment damage.

ATTENTION: The SLC to SCANport module

contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required

when installing, testing, or servicing this assembly.

Component damage may result if you do not follow

ESD control procedures. If you are not familiar with

static control procedures, refer to Allen-Bradley

Publication 8000-4.5.2, Guarding against Electrostatic

Damage, or any other applicable ESD protection

handbook.

Terms and Abbreviations

The following terms and abbreviations are specific to this product.

For a complete listing of Allen–Bradley terminology, refer to the

Allen–Bradley Industrial Automation Glossary.

In this manual, we refer to the:

• 1203 SLC to SCANport communications peripheral as the SLC to

SCANport module.

• Any of the connected SCANport products as the drive or

SCANport device. The current list of SCANport devices include

the following: 1305 MICRO, 1336 FORCE, 1336 IMPACT,

1336 PLUS, 1394 digital motion control system, SMC Dialog

Plus, SMP–3 smart motor protector, and 1397 DC drive.

Publication 1203–5.9 –– October 1996

Page 10

P–4 Preface

Common Techniques Used in this Manual

"

Allen–Bradley Support

This manual follows these conventions:

• Bulleted lists provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Italic type is used for emphasis and chapter names.

We also use this convention to call attention to helpful information.

Allen–Bradley offers support services worldwide, with over 75

Sales/Support Offices, 512 authorized Distributors and 260

authorized Systems Integrators located throughout the United States

alone, plus Allen–Bradley representatives in every major country in

the world.

Local Product Support

Contact your local Allen–Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen–Bradley for technical assistance, please

review the information in the Troubleshooting chapter first. If you

are still having problems, then call your local Allen–Bradley

representative.

Publication 1203–5.9 –– October 1996

Page 11

Overview

Chapter

1

Chapter Objectives

What is the SLC to SCANport Module?

Chapter 1 provides descriptions of the following:

• the SLC to SCANport module

• the available functions

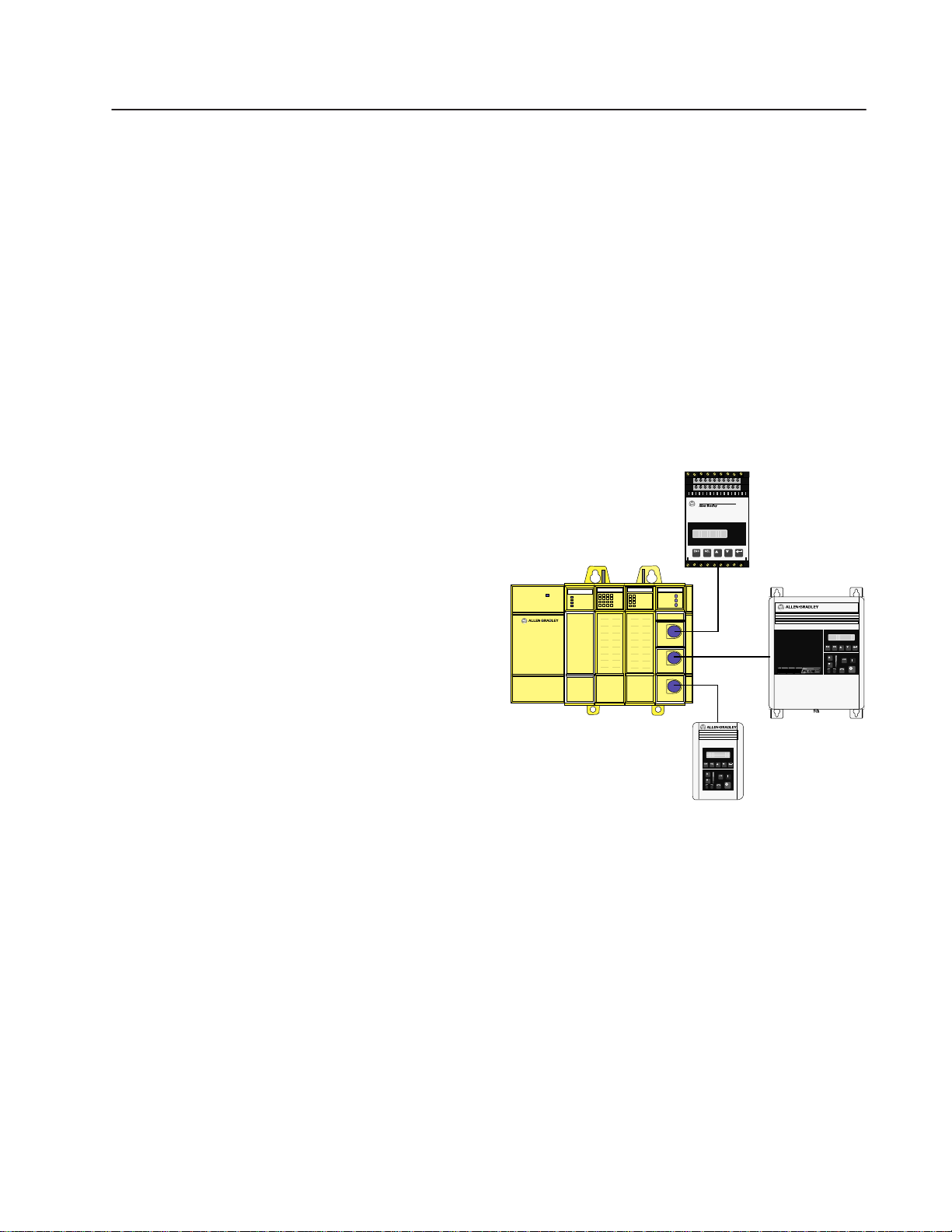

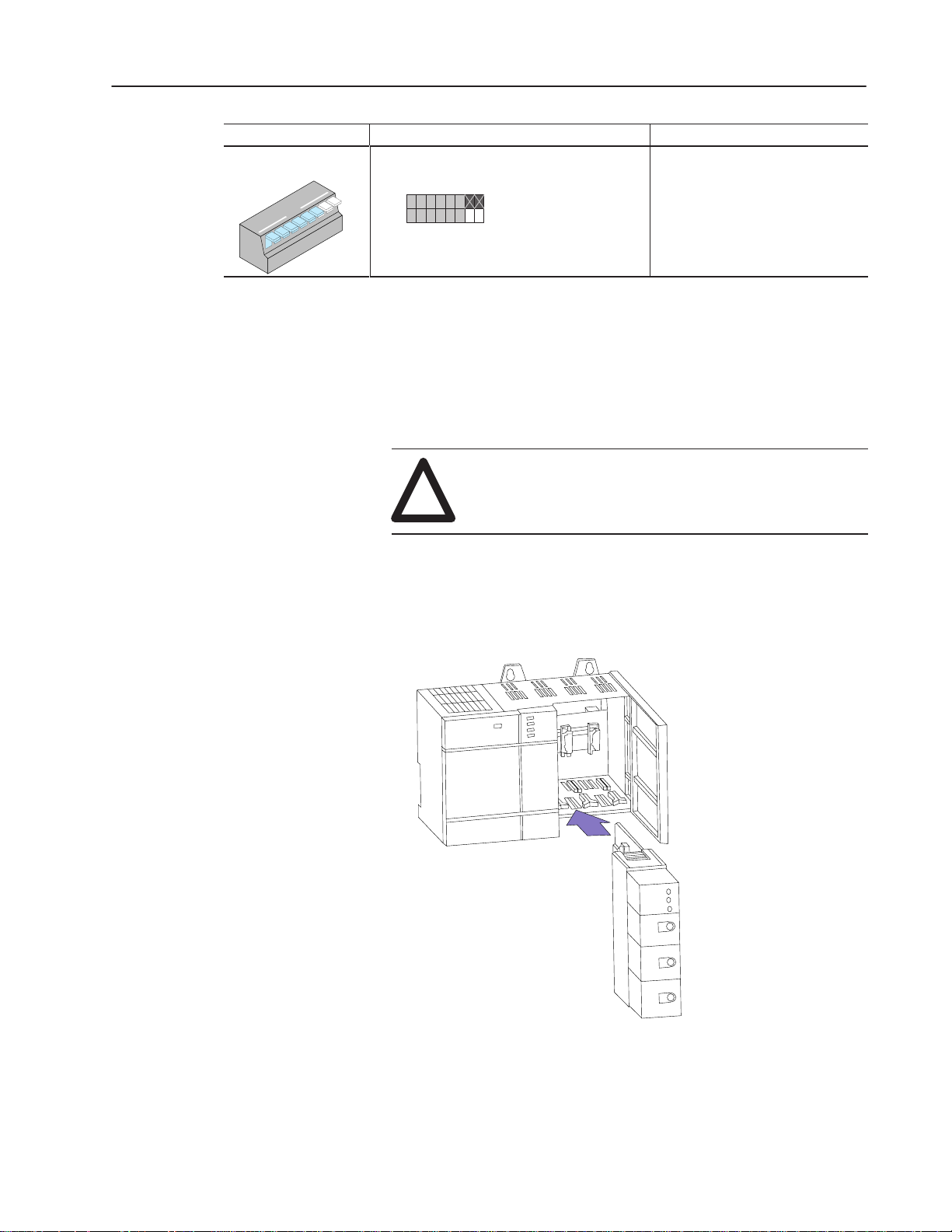

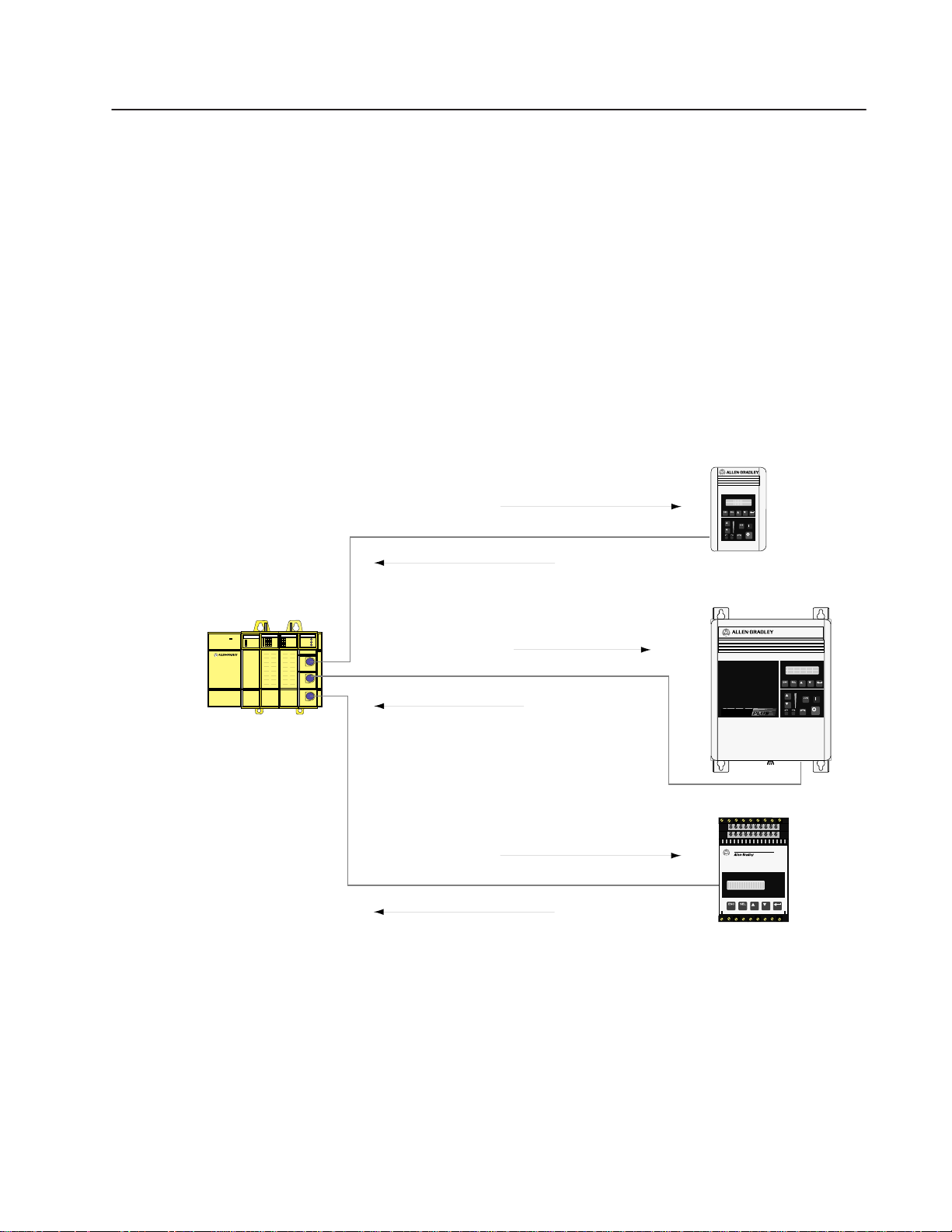

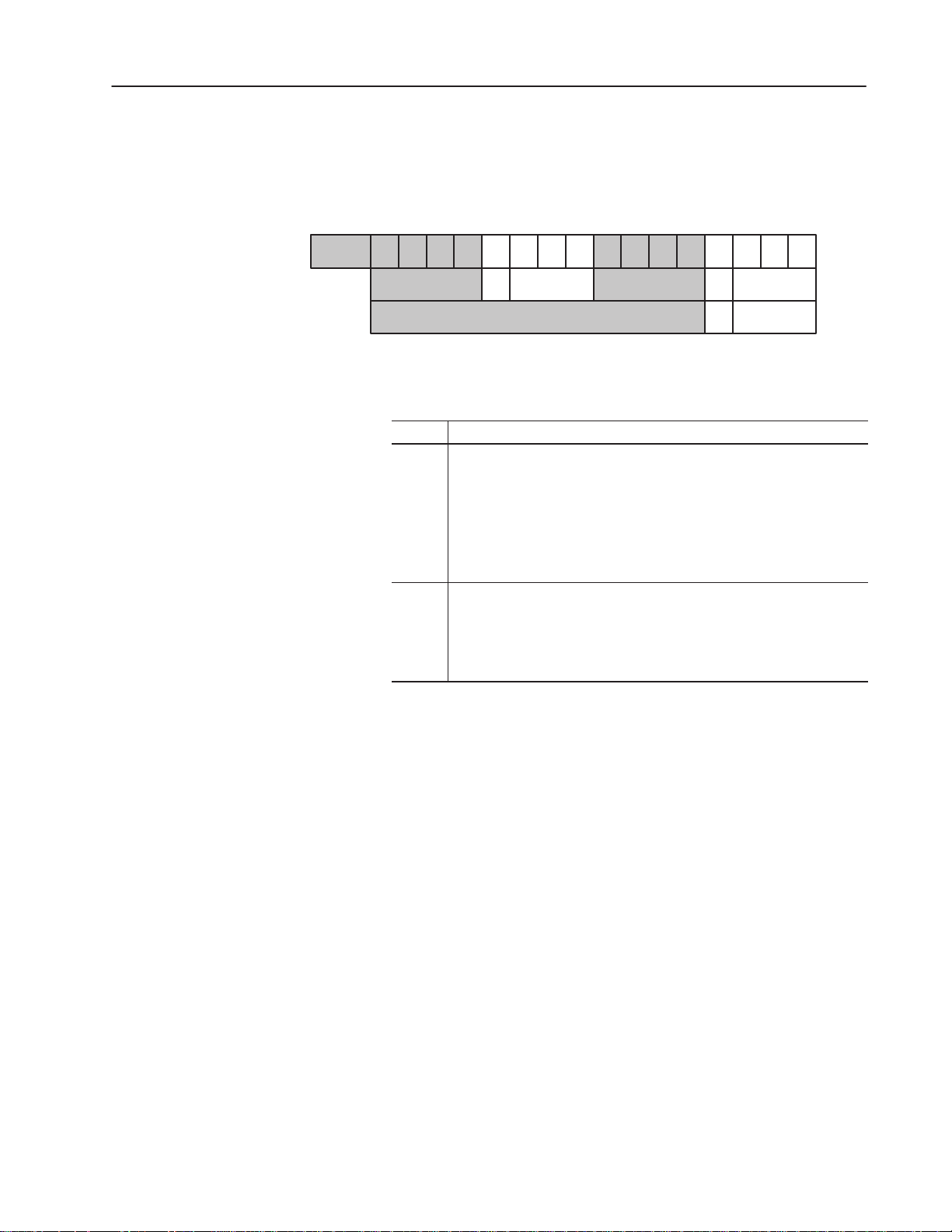

The SLC to SCANport module provides an interface between any

SLC processor or other product that can control modules within a

SLC rack and up to three SCANport devices as shown in Figure 1.1.

Figure 1.1

Example SLC to SCANport Module Set Up

SLC Rack with

SLC to SCANport Module

SMC Dialog Plus

INPUT OUTPUT SCANport

SLC 5/01 CPU

POWER

PC RUN

CPU Fault

FORCED I/O

BATTERY LOW

08

19

210

311

412

513

614

715

08

19

210

311

412

513

614

715

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

Channel 2

Channel 3

1336 PLUS

1305

To connect more than three SCANport devices in a single rack, add

additional SLC to SCANport modules to your SLC rack system.

You can use your SLC to SCANport module in a 4, 7, 10, or 13 slot

SLC rack or a 2–slot expansion rack available for the fixed I/O

configurations of SLC–500 processors.

Important: An SLC rack using this module needs an enclosure of at

least 200 mm (8 in) in depth. You cannot place an SLC

rack using the SLC to SCANport module in a 150 mm

(6 in) deep enclosure.

Publication 1203–5.9 –– October 1996

Page 12

1–2 Overview

What Functions Does the SLC to SCANport Module Provide?

Your SLC processor or rack adapter determines what functions are

available for the SLC to SCANport module.

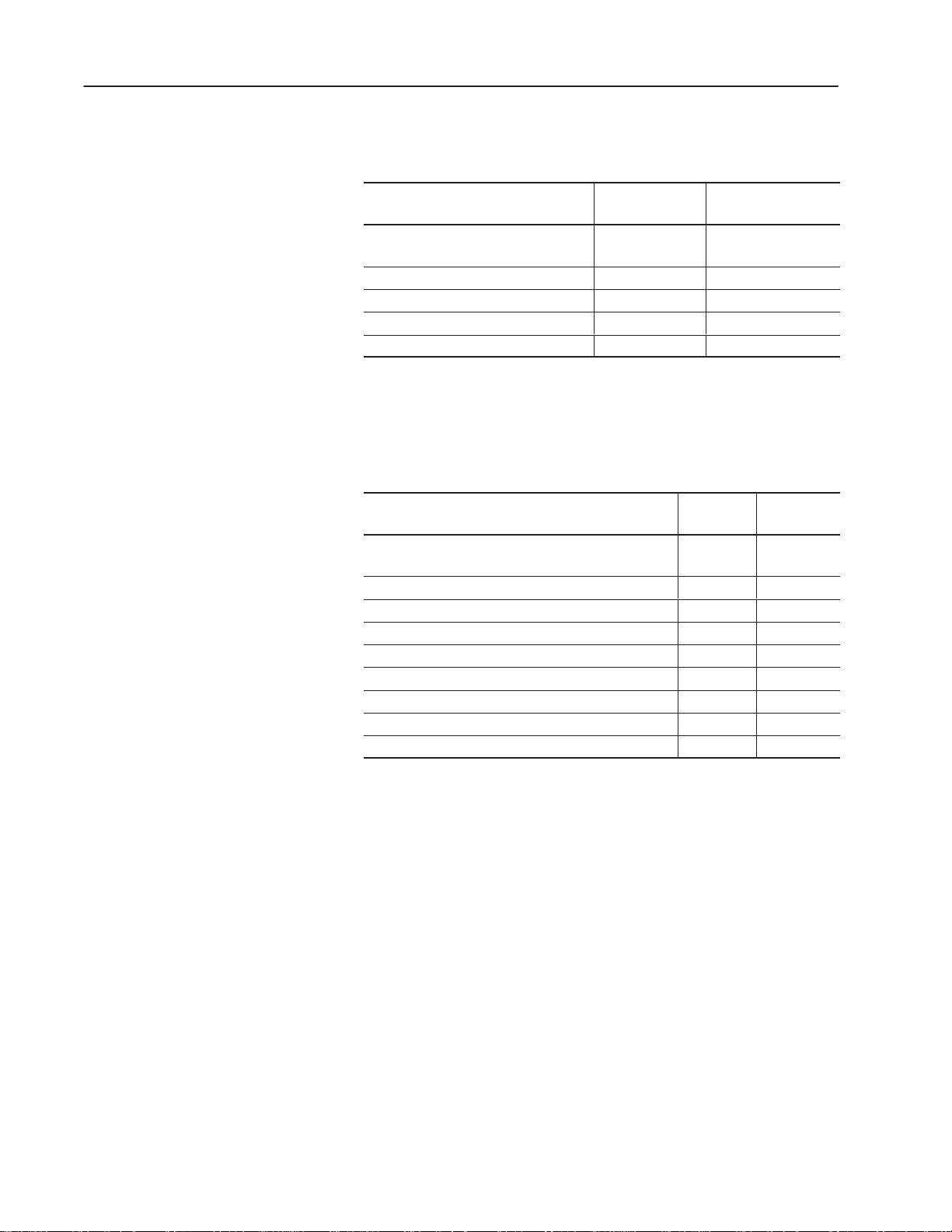

If the device in the left hand slot

of the SLC chassis is a:

Fixed style controller (using an

expansion rack)

SLC 5/01 controller Yes No

SLC 5/02, 5/03, or 5/04 controller Yes Yes

1747–OC open controller Yes Yes

Any SLC rack adapter Yes

➀

Future SLC product offerings may support enhanced mode

Is basic mode

supported?

Yes

Is enhanced mode

supported?

➀

No

➀

No

communication.

The following table provides information about basic mode and

enhanced mode.

Function

Maximum number of words of I/O per

SCANport device

T otal number of words of I/O for module 8 32

16–bit Logic Command (to SCANport device) Yes Yes

16–bit Logic Status (from SCANport device) Yes Yes

16–bit Reference (to SCANport device) Yes Yes

16–bit Feedback (from SCANport device) Yes Yes

Datalinks No Yes

Safe State Data No Yes

Messaging No Yes

Basic

Mode

2 10

Enhanced

Mode

Publication 1203–5.9 –– October 1996

Page 13

Chapter

Installing the SLC to SCANport Module

2

Chapter Objectives

Before You Install the Module

Chapter 2 covers the following information:

• what you need to do before you install the SLC to SCANport

module

• how to install the SLC to SCANport module

• how to remove the SLC to SCANport module

Important: You cannot place an SLC rack unit containing an SLC

to SCANport module in an enclosure that is less than

200 mm (8 in) deep.

Before you install your SLC to SCANport module, you need to:

• Determine the length of your SCANport cable(s).

• Determine the placement of your SCANport cables.

• Locate the DIP switch on your SLC to SCANport module.

Publication 1203–5.9 –– October 1996

Page 14

2–2 Installing the SLC to SCANport Module

Determine the Length of the SCANport Cable(s)

To connect your SLC to SCANport module to a SCANport device,

you need to use an Allen–Bradley SCANport cable. The maximum

cable length between any two peripheral devices connected to any

SCANport device cannot exceed 10 meters (33 feet). Therefore, in

Figure 2.1, A+B+C

you would not add the length of cable E to cables A, B, C, or D

because it connects to a separate SCANport device (or channel).

Figure 2.1

Example of SCANport Cable Lengths

≤10 meters and D+B+C≤10 meters. However,

E

SLC 5/01 CPU

POWER

PC RUN

CPU Fault

FORCED I/O

BATTERY LOW

SCANport

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

Channel 2

Channel 3

C

A

D

B

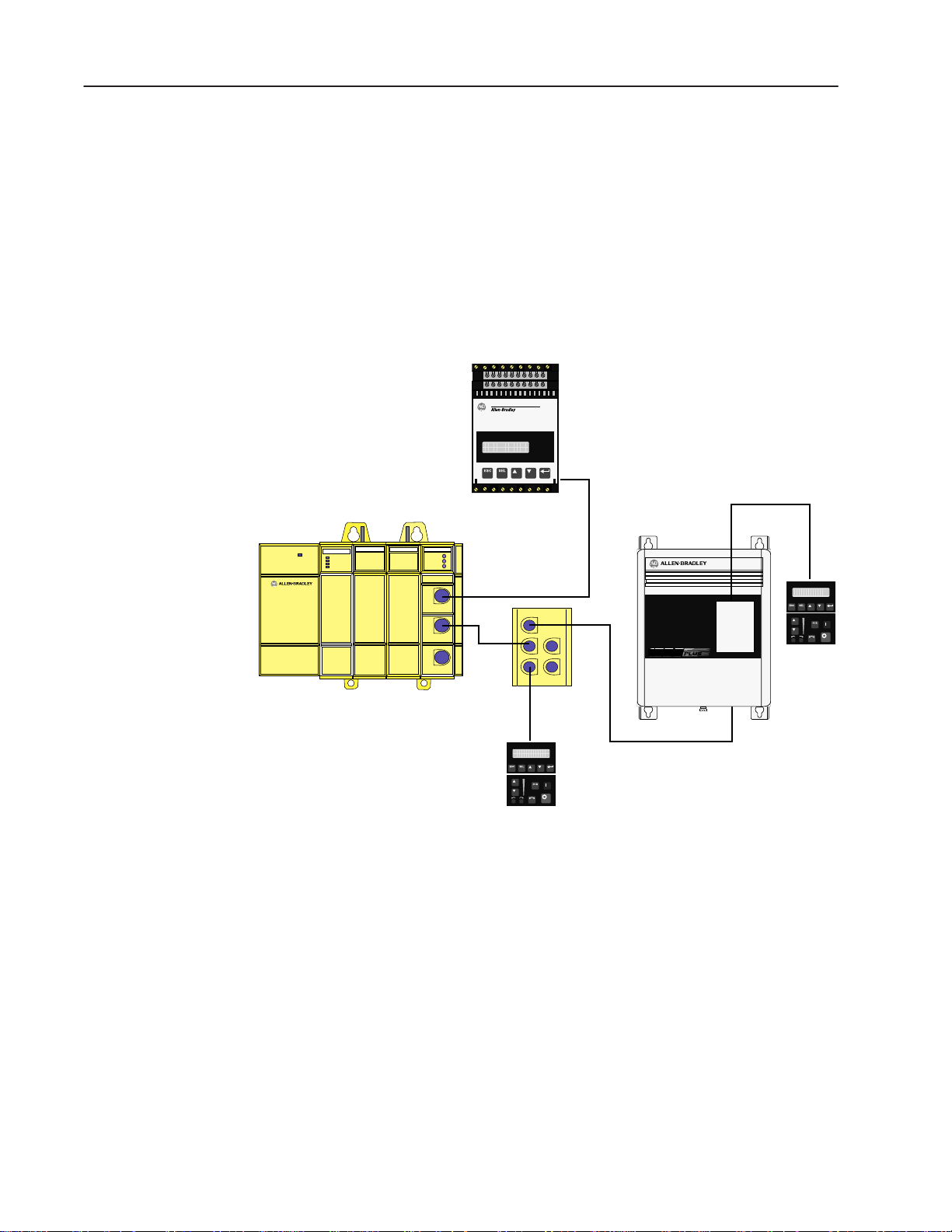

Determine the Placement of the SCANport Cables

You must keep the SCANport cables away from high power cables.

If your SCANport cables are placed too close to the power cables or

run in parallel with power cables, you may introduce noise into the

communications system, which can cause problems to your system.

Make sure you physically mount and connect SCANport products

following the installation guidelines available for each product.

Publication 1203–5.9 –– October 1996

Page 15

Figure 2.2

Examples of Cable Placements

2–3Installing the SLC to SCANport Module

SLC 5/01 CPU

POWER

PC RUN

CPU Fault

FORCED I/O

BATTERY LOW

B

SCANport

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

A

Channel 2

Channel 3

A

B

SLC 5/01 CPU

POWER

PC RUN

CPU Fault

FORCED I/O

BATTERY LOW

SCANport

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

Channel 2

Channel 3

A = Communications wire

B = Power wires

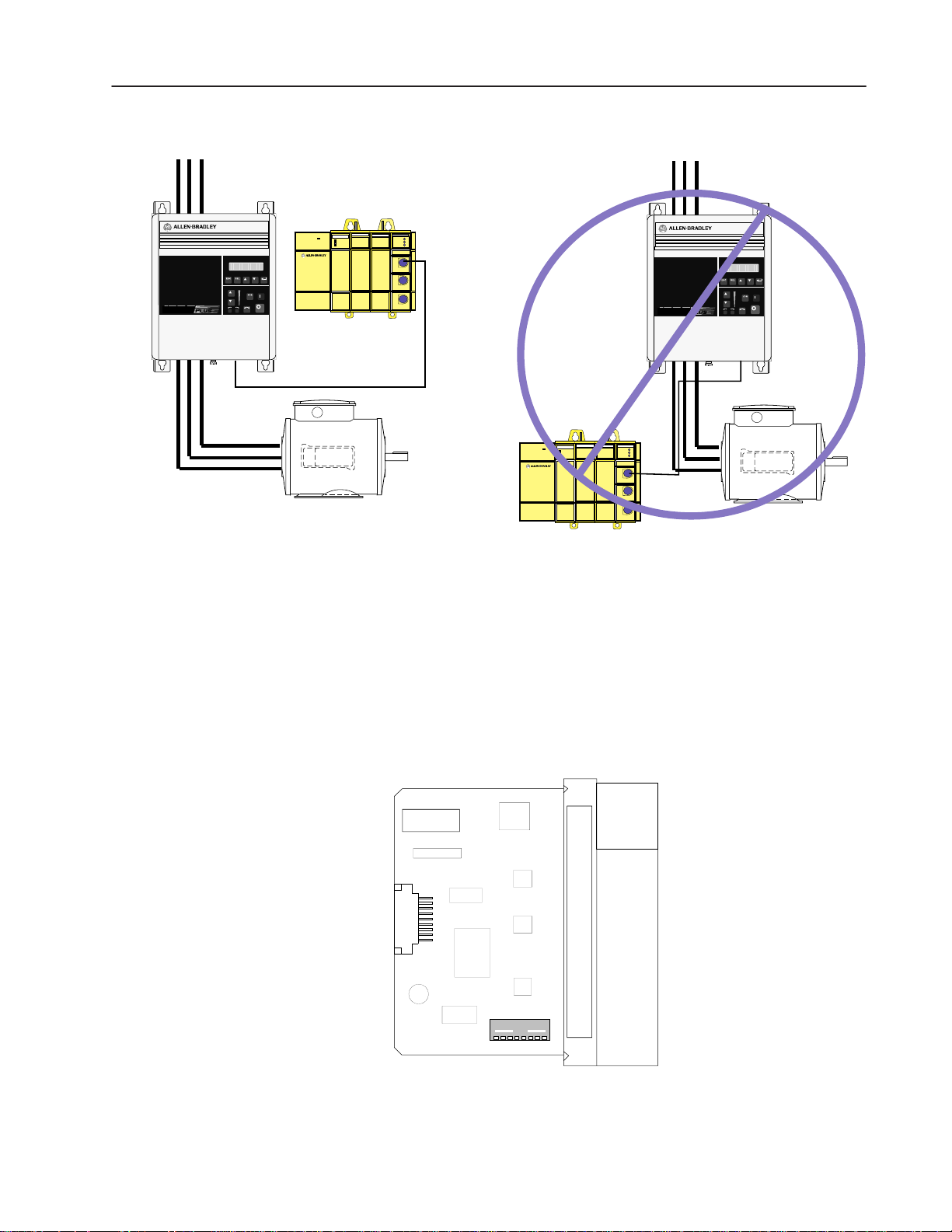

Locate the DIP Switch

You also need to locate a single configuration DIP switch on the

module as shown in Figure 2.3.

Figure 2.3

Side View of the SLC to SCANport Module Showing DIP Switch Location

OPEN

1 7 865432

Publication 1203–5.9 –– October 1996

Page 16

2–4 Installing the SLC to SCANport Module

3

3

3

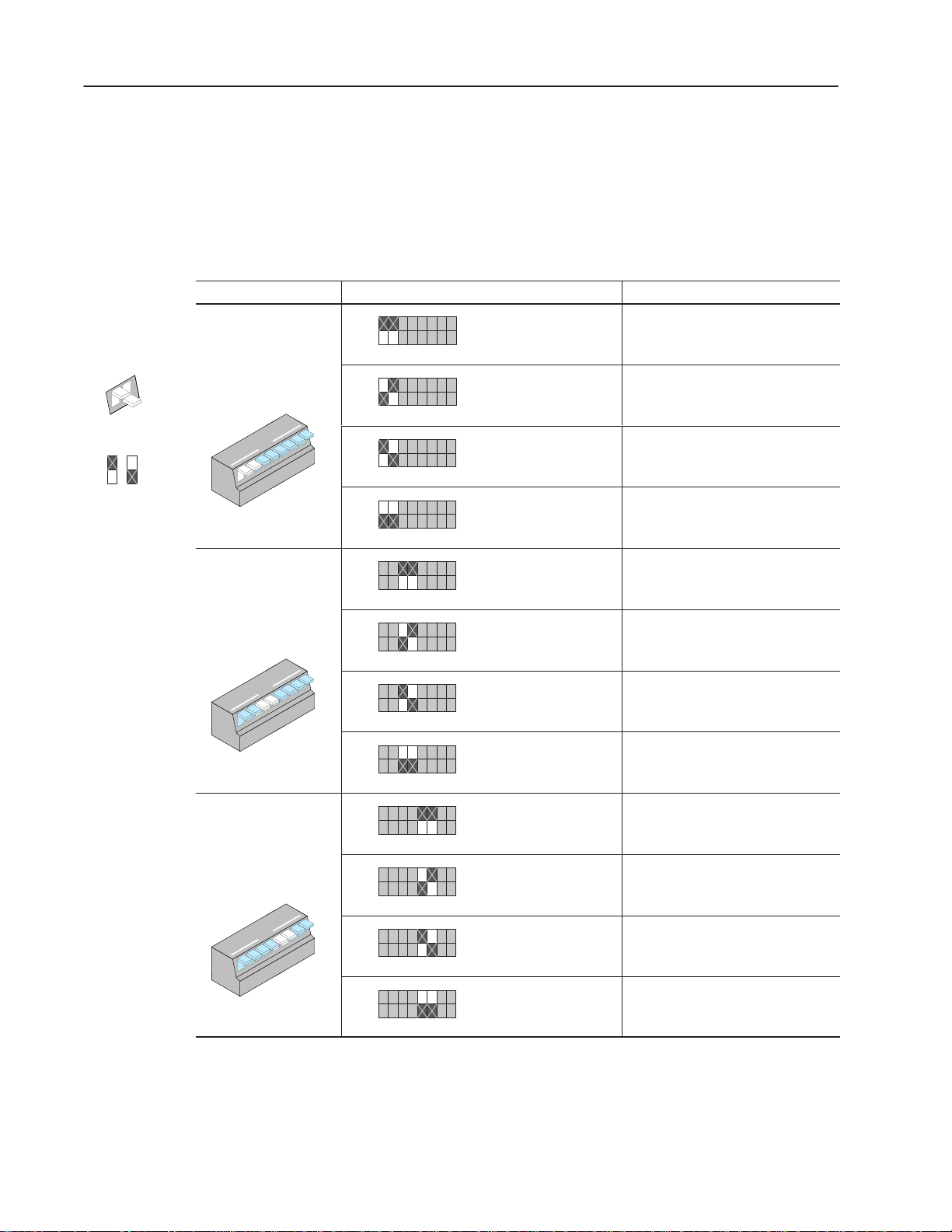

Installing the SLC to SCANport Module

Set this DIP switch: To these settings: To:

Channel 1 Fault/

Program State

(Switches 1 and 2)

12

Switch 1 = Open (Off)

Switch 2 = Closed (On)

O

O

N

F

F

Channel 2 Fault/

Program State

(Switches 3 and 4)

Channel 3 Fault/

Program State

(Switches 5 and 6)

OPEN

345678

12

OPEN

345678

12

OPEN

345678

12

To install the SLC to SCANport module into the chassis:

1. Set the DIP switches. For each SCANport device connected to

the SLC to SCANport module, you need to set two DIP switches

to select what happens when the SLC processor or rack adapter

faults or is placed in program for the appropriate channel.

O

–

12345678

O

–

12345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

O

–

12 345678

SW1 SW2

Open Open

(Off) (Off)

SW1 SW2

Closed Open

(On) (Off)

SW1 SW2

Open Closed

(Off) (On)

SW1 SW2

Closed Closed

(On) (On)

SW3 SW4

Open Open

(Off) (Off)

SW3 SW4

Closed Open

(On) (Off)

SW3 SW4

Open Closed

(Off) (On)

SW3 SW4

Closed Closed

(On) (On)

SW5 SW6

Open Open

(Off) (Off)

SW5 SW6

Closed Open

(On) (Off)

SW5 SW6

Open Closed

(Off) (On)

SW5 SW6

Closed Closed

(On) (On)

Fault SCANport device

(default)

Zero data

Hold last state

Safe state data (enhanced mode

only), Fault (basic mode only)

Fault SCANport device

(default)

Zero data

Hold last state

Safe state data (enhanced mode

only), Fault (basic mode only)

Fault SCANport device

(default)

Zero data

Hold last state

Safe state data (enhanced mode

only), Fault (basic mode only)

Publication 1203–5.9 –– October 1996

Page 17

Set this DIP switch: To:To these settings:

Switches 7 and 8

2–5Installing the SLC to SCANport Module

N

E

P

O

12345678

"

O

–

12 345678

SW7 SW8

Open Open

(Off) (Off)

Reserved

If you select a state other than Fault, the channel enable bits located

in the first two words of output data will retain their last state values.

This ensures that the enabled SCANport connections remain active

for those states. The I/O data transferred to the SCANport device

will change as configured by the DIP switch.

2. Turn off the chassis power supply.

ATTENTION: Do not install the SLC to SCANport

module with the chassis power supply on. Inserting or

!

removing the module with the chassis power supply on

may damage the module.

3. Select a slot for the module in the chassis. You may use any slot

except the leftmost slot, which is reserved for the SLC 5/xx

processor or rack adapter.

4. Insert the module into the slot you have selected.

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

Channel 2

Channel 3

Publication 1203–5.9 –– October 1996

Page 18

2–6 Installing the SLC to SCANport Module

5. Apply firm, even pressure to seat the module in the I/O chassis

backplane connectors. Make sure the plastic tabs snap into the

rack.

6. Connect the SCANport cable(s) from the SCANport device(s) to

the SCANport connections in the front of the module.

Important: You must keep in mind that the maximum cable

You can insert or remove SCANport cables while a rack is powered.

If a cable is removed while the channel is enabled, the connected

SCANport device will fault unless otherwise configured at the

SCANport device.

distance between any two devices connected to a

single channel cannot exceed 10 meters (33 feet)

of cable. Also, the SCANport cables must not

be in close contact with the power cables.

Removing the SLC to SCANport Module

Where Do I Go From Here?

To remove the SLC to SCANport module from the chassis, you need

to:

1. Remove the SCANport cables.

2. Make sure the rack power is removed.

3. Push in on the hooks on both ends of the module.

4. Gently pull the module from the chassis.

The SLC to SCANport module can operate in either basic mode or

enhanced mode. Refer to Chapter 1 for a description of basic mode

and enhanced mode.

If you plan to use: Go to:

Basic mode Chapter 3

Enhanced mode Chapter 4

Publication 1203–5.9 –– October 1996

Page 19

Using Basic Mode

16-bit analog feedback

Chapter

3

Chapter Objectives

What Does Basic Mode Provide?

INPUT OUTPUT SCANport

SLC 5/01 CPU

POWER

PC RUN

CPU Fault

FORCED I/O

BATTERY LOW

08

08

19

19

210

210

311

311

412

412

513

513

614

614

715

715

Chapter 3 covers the following information:

• a description of what basic mode provides

• how to configure the SLC to SCANport module for basic mode

• how to transfer data

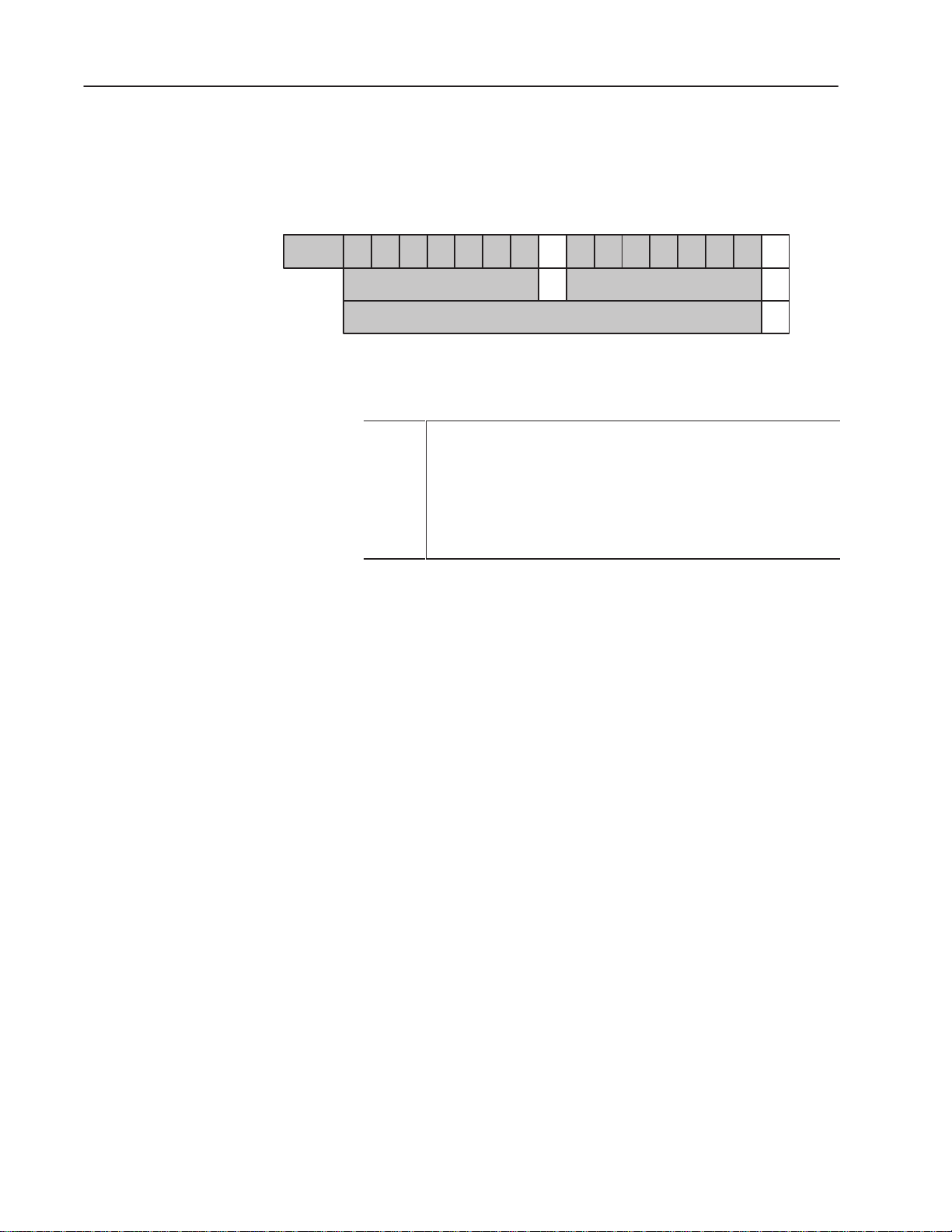

Basic mode sends a 16–bit logic command and a 16–bit analog

reference from the module to each SCANport device. It receives a

16–bit logic status and a 16–bit analog feedback signal from each

connected SCANport device.

16-bit logic command

16-bit analog reference

16-bit logic status

16-bit analog feedback

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

Channel 2

Channel 3

16-bit logic command

16-bit analog reference

16-bit logic status

16-bit analog feedback

1305

1336

Configuring the SLC to SCANport Module for Basic Mode

16-bit logic command

16-bit analog reference (not used by SMC)

16-bit logic status

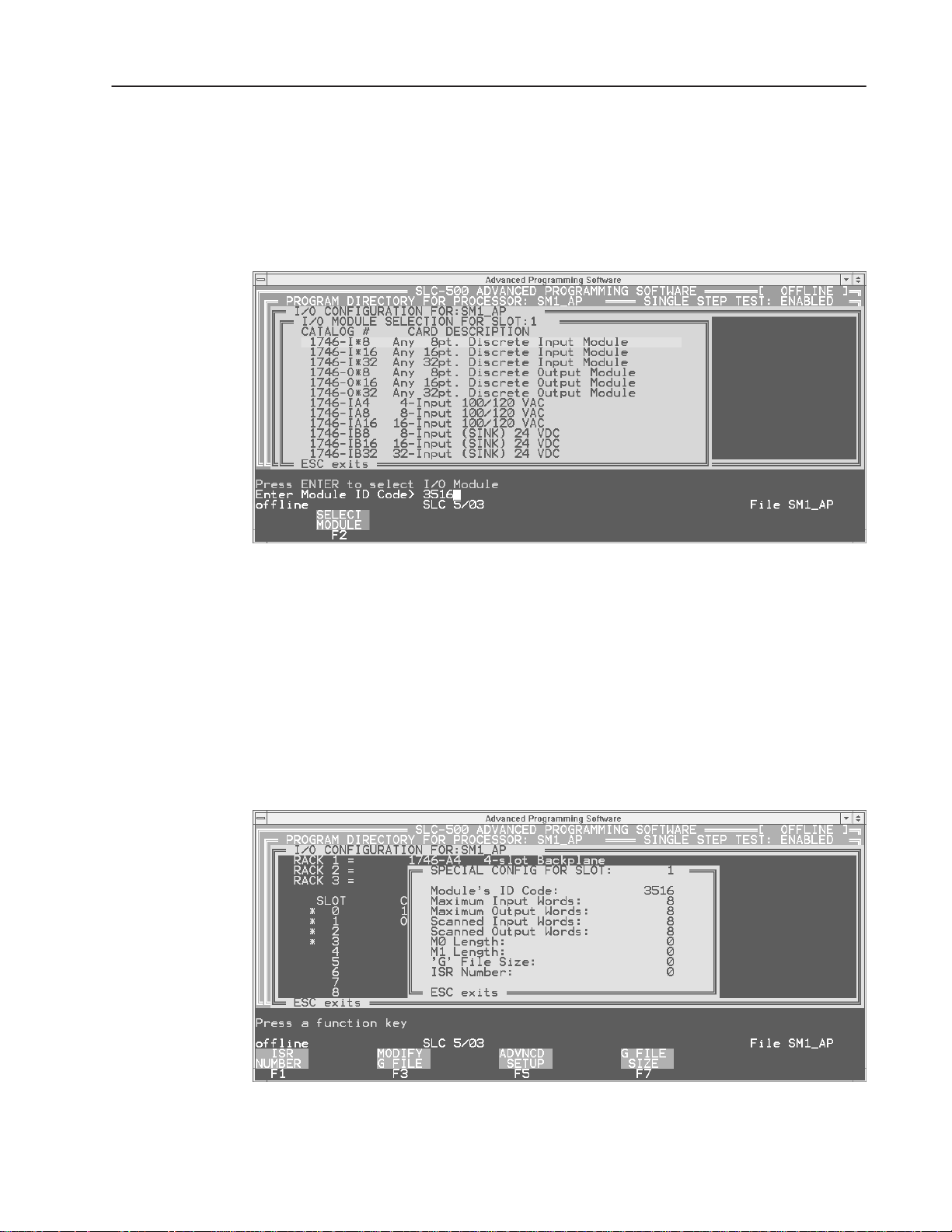

To configure the SLC to SCANport module for basic mode using the

Advanced Programming Software (APS), you need to:

1. Create a file.

2. Enter a file name. For example purposes, we are using SM1_AP

as the file name.

3. Highlight the processor as shown in Figure 3.1.

Publication 1203–5.9 –– October 1996

SMC

Page 20

3–2 Using Basic Mode

Highlight the processor

you want to use. For

example, 1747–L532.

Figure 3.1

Example APS Screen

4. Press the F2 key.

5. Depending on your processor and version of APS, you may be

asked to enter the operating system that your processor uses.

6. Press F5 to configure the I/O. The screen shown in Figure 3.2 is

displayed.

Figure 3.2

Example I/O Configuration Screen

Publication 1203–5.9 –– October 1996

Page 21

7. Move the cursor to the slot containing the SLC to SCANport

module.

8. Press F5 to modify the slot. The screen shown in Figure 3.3 is

displayed.

Figure 3.3

Prompt to Enter the Module ID Code

3–3Using Basic Mode

9. Enter the module ID code. For basic mode, the module ID code

is 3516.

10.Press the Enter key.

When you have entered the module ID code, you are returned to the

screen shown in Figure 3.2 with the selected module now shown. If

you press F9, the screen shown in Figure 3.4 shows the

configuration information for the SLC to SCANport module. You

should not need to change this information for basic mode.

Figure 3.4

Specialty Module Configuration Screen

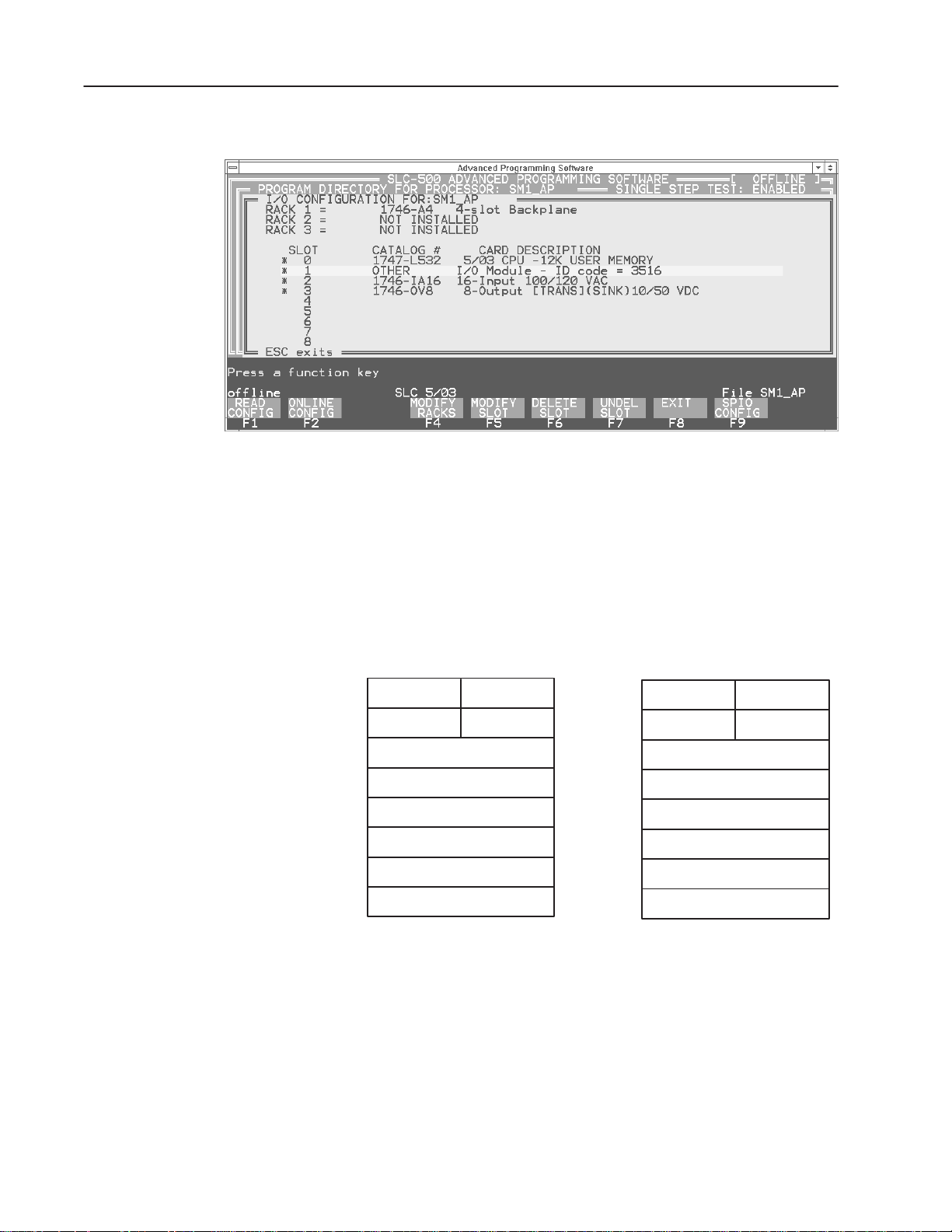

Figure 3.5 shows an example of a completed I/O configuration.

Publication 1203–5.9 –– October 1996

Page 22

3–4 Using Basic Mode

Figure 3.5

An Example of a Completed I/O Configuration

Transferring Data

To transfer data using the SLC to SCANport module, you need to be

familiar with how the SLC I/O image table represents the internal

data I/O mapping and how the input and output image channel status

bits are defined.

When the SLC to SCANport module is configured as a basic mode

module, the internal data I/O mapping is represented within the SLC

image table as the following:

Output Image Input Image

Channel 2 Cmd Channel 1 Cmd

Reserved Channel 3 Cmd

Logic Command Channel 1

Analog Reference Channel 1

Logic Command Channel 2

Analog Reference Channel 2

Logic Command Channel 3

Analog Reference Channel 3

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Channel 2 Stat Channel 1 Stat

Not Used Channel 3 Stat

Logic Status Channel 1

Analog Feedback Channel 1

Logic Status Channel 2

Analog Feedback Channel 2

Logic Status Channel 3

Analog Feedback Channel 3

Publication 1203–5.9 –– October 1996

Important: Different SCANport devices may define different

meanings for the bits in the Logic Command and Logic

Status fields. They may also use the Reference and

Feedback differently. Refer to the manual for the

specific SCANport device for more information.

Page 23

Channel Status Input Image Definitions

The Input Image Channel Status bits are defined as follows:

3–5Using Basic Mode

Channel 2 Status

Bit

15 14 13 12 1 1 10 9 8 765432 1 0

Not Used Not Used

V2 ID2 V1 ID1

Not Used

Channel 1 Status

V3 ID3

Channel 3 Status

Word 0

Word 1

These bits have the following definitions:

This: Represents:

SCANport Channel 1, 2, or 3 Connected Adapter Port ID

Number. This three bit field contains the adapter port number

ID1

ID2

ID3

V1

V2

V3

read from the connector that channel 1, 2, or 3 is connected to on

the SCANport device. ID1, ID2, and ID3 should be between 1

and 7. If ID1, ID 2, or ID3 is 7, the channel is not connected to

a SCANport device, or the SCANport device may not be

powered.

SCANport Channel 1, 2, or 3 Valid Data bit. When high (1), the

Logic Status and Analog Feedback values are valid and can be

used. The V1, V2, and V3 bit will only go high after the

program sets the corresponding data enable bit. When low (0),

the values are not valid.

Publication 1203–5.9 –– October 1996

Page 24

3–6 Using Basic Mode

Channel Command Output Image Definitions

The Output Image Channel Command bits are defined as follows:

Example of Basic Mode Data Transfer

Channel 2 Command

Bit

15 14 13 12 1 1 10 9 8 76543210

Not Used Not Used

DE

2

Not Used

Channel 1 Command

DE

1

DE

3

Channel 3 Command

Word 0

Word 1

These bits have the following definitions:

SCANport Channel 1, 2, or 3 Data Enable bit. While low (0),

the channel will not transfer I/O data between the module and

DE1

DE2

DE3

the connected SCANport device. When high (1), the channel

becomes active to the SCANport device and transfers the

appropriate I/O data. When reset to low (0), the channel

disconnects from the SCANport device. This usually causes

the connected SCANport device to fault.

This section contains an example program that uses basic mode data

transfer. The following portion of the program enables all three

SCANport channels on the SLC to SCANport module.

Figure 3.6

Example of Enabling the SCANport Channels

| Channel 1 |

| SCANport |

| Enable |

| O:1.0 |

|––––––––––––––––––––––––––––––––––––––––––––––––––––––( )––––––|

| | 0 | |

| |Channel 2 | |

| |SCANport | |

| |Enable | |

| | O:1.0 | |

| +–––( )––––| |

| | 8 | |

| |Channel 3 | |

| |SCANport | |

| |Enable | |

| | O:1.1 | |

| +–––( )––––+ |

| 0 |

Publication 1203–5.9 –– October 1996

Page 25

3–7Using Basic Mode

The portion of the program shown in Figure 3.7 provides start/stop

control and a frequency reference to the 1305 drive connected to

SCANport channel 1. The user start is a normally open push button,

while the user stop is a normally closed push button.

Figure 3.7

Example of Drive 1 Control and Reference

| Drive 1 Drive 1 Drive 1 |

| User User START |

| Momentary Maintained Command |

| START NOT STOP Bit |

| Input Input |

| I:2.0 I:2.0 O:1.2 |

|–––––] [–––––––––––––––––––] [––––––––––––––––––––––––––––( )–––––|

| | 0 | 1 1 |

| |Drive 1 |Drive 1 | |

| |START |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.2 I:1.2 | |

| +–––] [––––––––]/[––––+ |

| 1 1 |

| Drive 1 Drive 1 |

| User STOP |

| Maintained Command |

| NOT STOP Bit |

| Input |

| I:2.0 O:1.2 |

|–––––]/[––––––––––––––––––––––––––––––––––––––––––––––––––( )–––––|

| | 1 | 0 |

| |Drive 1 |Drive 1 | |

| |STOP |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.2 I:1.2 | |

| +–––] [––––––––] [––––+ |

| 0 1 |

| Drive 1 |

| Frequency |

| Reference |

| +MOV–––––––––––––––+ |

|–––––––––––––––––––––––––––––––––––––––––––––|MOVE +–|

| |Source N20:0| |

| | 0| |

| |Dest O:1.3| |

| | 0| |

| +––––––––––––––––––+ |

Publication 1203–5.9 –– October 1996

Page 26

3–8 Using Basic Mode

| Drive 2 Drive 2 Drive 2 |

| User User START |

| Momentary Maintained Command |

| START NOT STOP Bit |

| Input Input |

| I:2.0 I:2.0 O:1.4 |

|–––––] [–––––––––––––––––––] [––––––––––––––––––––––––––––( )–––––|

| | 2 | 3 1 |

| |Drive 2 |Drive 2 | |

| |START |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.4 I:1.4 | |

| +–––] [––––––––]/[––––+ |

| 1 1 |

| Drive 2 Drive 2 |

| User STOP |

| Maintained Command |

| NOT STOP Bit |

| Input |

| I:2.0 O:1.4 |

|–––––]/[––––––––––––––––––––––––––––––––––––––––––––––––––( )–––––|

| | 3 | 0 |

| |Drive 2 |Drive 2 | |

| |STOP |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.4 I:1.4 | |

| +–––] [––––––––] [––––+ |

| 0 1 |

| Drive 2 |

| Frequency |

| Reference |

| +MOV–––––––––––––––+ |

|–––––––––––––––––––––––––––––––––––––––––––––|MOVE +–|

| |Source N20:1| |

| | 0| |

| |Dest O:1.5| |

| | 0| |

| +––––––––––––––––––+ |

The portion of the program shown in Figure 3.8 provides start/stop

control and a frequency reference to the 1305 drive connected to

SCANport channel 2. This section functions the same as that shown

in Figure 3.7 except for the changes in addresses.

Figure 3.8

Example of Drive 2 Control and Reference

Publication 1203–5.9 –– October 1996

Page 27

3–9Using Basic Mode

The portion of the program shown in Figure 3.9 provides start/stop

control and a frequency reference to the 1305 drive connected to

SCANport channel 3. This section functions the same as that shown

in Figure 3.7 and Figure 3.8 except for the changes in address.

Figure 3.9

Example of Drive 3 Control and Reference

| Drive 3 Drive 3 Drive 3 |

| User User START |

| Momentary Maintained Command |

| START NOT STOP Bit |

| Input Input |

| I:2.0 I:2.0 O:1.6 |

|–––––] [–––––––––––––––––––] [––––––––––––––––––––––––––––( )–––––|

| | 4 | 5 1 |

| |Drive 3 |Drive 3 | |

| |START |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.6 I:1.6 | |

| +–––] [––––––––]/[––––+ |

| 1 1 |

| Drive 3 Drive 3 |

| User STOP |

| Maintained Command |

| NOT STOP Bit |

| Input |

| I:2.0 O:1.6 |

|–––––]/[––––––––––––––––––––––––––––––––––––––––––––––––––( )–––––|

| | 5 | 0 |

| |Drive 3 |Drive 3 | |

| |STOP |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.6 I:1.6 | |

| +–––] [––––––––] [––––+ |

| 0 1 |

| Drive 3 |

| Frequency |

| Reference |

| +MOV–––––––––––––––+ |

|–––––––––––––––––––––––––––––––––––––––––––––|MOVE +–|

| |Source N20:2| |

| | 0| |

| |Dest O:1.7| |

| | 0| |

| +––––––––––––––––––+ |

Publication 1203–5.9 –– October 1996

Page 28

3–10 Using Basic Mode

address 15 data 0

I:1 0000 0000 0000 0000 Drives 1 & 2 SCANport Channel Status

I:1.1 0000 0000 0000 0000 Drive 3 SCANport Channel Status

I:1.2 0000 0000 0000 0000 Drive 1 Logic Status

I:1.3 0000 0000 0000 0000 Drive 1 Feedback

I:1.4 0000 0000 0000 0000 Drive 2 Logic Status

I:1.5 0000 0000 0000 0000 Drive 2 Feedback

I:1.6 0000 0000 0000 0000 Drive 3 Logic Status

I:1.7 0000 0000 0000 0000 Drive 3 Feedback

address 15 data 0

O:1 0000 0000 0000 0000 Drives 1 & 2 SCANport Channel Enables

O:1.1 0000 0000 0000 0000 Drive 3 SCANport Channel Enable

O:1.2 0000 0000 0000 0000 Drive 1 Logic Command

O:1.3 0000 0000 0000 0000 Drive 1 Reference

O:1.4 0000 0000 0000 0000 Drive 2 Logic Command

O:1.5 0000 0000 0000 0000 Drive 2 Reference

O:1.6 0000 0000 0000 0000 Drive 1 Logic Command

O:1.7 0000 0000 0000 0000 Drive 1 Reference

The following data table shows the input data read from the SLC to

SCANport module via the SLC backplane.

The following data table shows the data to be sent to the SLC to

SCANport module via the SLC backplane.

Publication 1203–5.9 –– October 1996

Page 29

Using Enhanced Mode

8 words in/8 words out

Chapter

4

Chapter Objectives

What Does Enhanced Mode Provide?

Chapter 4 covers the following information:

• a description of what enhanced mode provides

• how to configure the SLC to SCANport module for enhanced

mode

• how to use the I/O image

• how to configure G files

• how to use M files

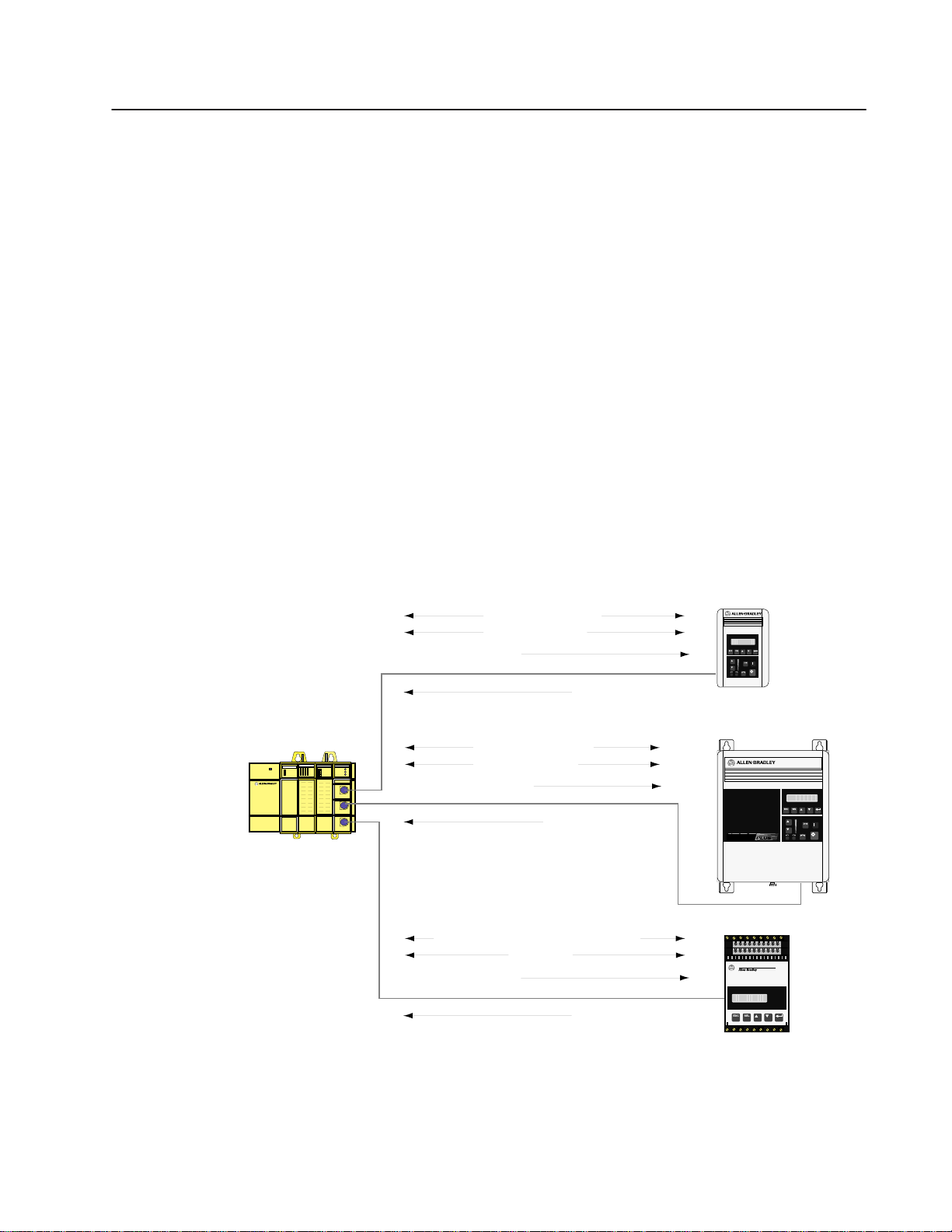

Enhanced mode supports the basic mode features which include a

16–bit logic command and a 16–bit analog reference from the

module to each SCANport device as well as a 16–bit logic status and

a 16–bit analog feedback signal back from each connected

SCANport device.

In addition, enhanced mode optionally provides datalinks, safe state

data, and messaging.

Messages

16-bit logic command

16-bit analog reference

16-bit logic status

16-bit analog feedback

1305

INPUT OUTPUT SCANport

SLC 5/01 CPU

POWER

PC RUN

CPU Fault

FORCED I/O

BATTERY LOW

08

08

19

19

210

210

311

311

412

412

513

513

614

614

715

715

8 words in/8 words out

CHANNEL 1

CHANNEL 2

CHANNEL 3

Channel 1

Channel 2

Channel 3

16-bit logic command

16-bit analog reference

Messages

16-bit logic status

16-bit analog feedback

1336

8 words in/8 words out (not used by SMC)

Messages

16-bit logic command

16-bit analog reference (not used by SMC)

SMC

16-bit logic status

16-bit analog feedback

Publication 1203–5.9 –– October 1996

Page 30

4–2 Using Enhanced Mode

What Are Datalinks?

Datalinks let you cyclically transfer parameter values to and from a

SCANport device (provided that the SCANport device supports

datalinks). By using datalinks, you can change the value of a

parameter without using the SLC to SCANport messaging function.

Each datalink consists of two 16–bit words of input and two 16–bit

words of output when enabled. Up to 8 words in and 8 words out of

data are available if supported in the connected SCANport device.

SCANport devices that support this function have a group of

parameters for datalink configuration. These parameters are

identified as Data In A1–D2 and Data Out A1–D2. To use datalinks,

you need to:

1. Set up a configuration file, called a G file, to enable the datalinks

from the SLC to SCANport module side.

2. Configure or link the Data In A1–D2 and Data Out A1–D2

parameters in the SCANport device.

Setting up the G file is covered in more detail later in this chapter.

What Is Safe State Configuration Data?

You can select constant values that your SLC to SCANport module

will maintain in the event of an SLC processor mode change or error.

These constant values are referred to as safe state data. When the

SLC is placed in program mode or an SLC fault occurs, the control

outputs can be set to automatically switch to the constant values set

in the safe state data words. This lets you define a safe operating

state for controlled devices that depend on a pre–programmed output

from the module.

ATTENTION: Use the G file to configure your safe

state values based on your knowledge of how the

!

Refer to Chapter 2 for the DIP switch configuration for

fault/program state.

SCANport devices connected on each channel operate.

Refer to the manual for your SCANport device for

additional information.

Publication 1203–5.9 –– October 1996

Page 31

4–3Using Enhanced Mode

What Is Messaging?

Messaging lets you get and modify SCANport device parameters as

well as providing access to other internal SCANport–related

information or services. To use messaging, you need to configure

the M file mechanism of the SLC processor. The M file mechanism

is covered later in this chapter. Appendix B, SCANport Messaging,

provides examples of SCANport messages.

Configuring the SLC to SCANport Module for Enhanced Mode

Highlight the processor

you want to use. For

example, 1747–L532.

To configure the SLC to SCANport module for enhanced mode

using the Advanced Programming Software (APS), you need to:

1. Create a file.

2. Enter a file name. For example purposes, we are using SM1_AP2

as the file name.

3. Highlight the processor as shown in Figure 4.1.

Figure 4.1

Example APS Screen

4. Press the F2 key.

5. Depending on your processor and version of APS, you may be

asked to enter the operating system that your processor uses.

Publication 1203–5.9 –– October 1996

Page 32

4–4 Using Enhanced Mode

6. Press F5 to configure the I/O using the screen shown in Figure

4.2.

Figure 4.2

An Example of the I/O Configuration Screen

7. Move the cursor to the slot containing the SLC to SCANport

module.

8. Press F5 to modify the slot using the screen shown in Figure 4.3.

Figure 4.3

Prompt to Enter the Module ID Code

9. Enter the module ID code. For enhanced mode, the module ID

code is 13616.

10.Press the Enter key.

Publication 1203–5.9 –– October 1996

Page 33

4–5Using Enhanced Mode

11. The slot is now configured for the SLC to SCANport module to

be used in enhanced mode. This is shown in Figure 4.4

Figure 4.4

Example I/O Configuration Screen

12.Press F9 to add the information to configure the specialty I/O

using the screen shown in Figure 4.5.

"

Figure 4.5

Specialty I/O Configuration Screen

If you are not familiar with G files and M0/M1 files, you should read

the sections that are provided later in this chapter that pertain to these

files before continuing.

13.Press F7 to set the G file size a value from 2 to 32 words using

the screen shown in Figure 4.5.

Publication 1203–5.9 –– October 1996

Page 34

4–6 Using Enhanced Mode

14.Press F3 to configure the G file data using the screen shown in

Figure 4.6. Figure 4.8 provides the definition of the G file data.

Figure 4.6

Screen Used to Configure G File Data

15.When you return to the screen shown in Figure 4.5, press F5 to

access the advanced set up menu to configure the size of the

messaging buffers.

16.Press F5 to enter the size of the M0 file. For this module, the

maximum file size is 800.

17.Press F6 to enter the size of the M1 file. For this module, the

maximum file size is 400.

Publication 1203–5.9 –– October 1996

Page 35

4–7Using Enhanced Mode

Using the I/O Image

The following SLC I/O image table represents the internal data I/O

mapping for the SLC to SCANport module when configured as an

enhanced mode module.

Figure 4.7

SLC I/O Image Table

Output Image

Channel 2 Cmd Channel 1 Cmd Word 0 Channel 2 Status Channel 1 Status

Reserved Channel 3 Cmd Word 1 Message Status Channel 3 Status

Logic Command Channel 1 Word 2 Logic Status Channel 1

Analog Reference Channel 1 Word 3 Analog Feedback Channel 1

Logic Command Channel 2 Word 4 Logic Status Channel 2

Analog Reference Channel 2 Word 5 Analog Feedback Channel 2

Logic Command Channel 3 Word 6 Logic Status Channel 3

Analog Reference Channel 3 Word 7 Analog Feedback Channel 3

Channel 1 Datalink A1 Input Word 8 Channel 1 Datalink A1 Output

Channel 1 Datalink A2 Input Word 9 Channel 1 Datalink A2 Output

Channel 1 Datalink B1 Input Word 10 Channel 1 Datalink B1 Output

Channel 1 Datalink B2 Input Word 11 Channel 1 Datalink B2 Output

Channel 1 Datalink C1 Input Word 12 Channel 1 Datalink C1 Output

Channel 1 Datalink C2 Input Word 13 Channel 1 Datalink C2 Output

Channel 1 Datalink D1 Input Word 14 Channel 1 Datalink D1 Output

Channel 1 Datalink D2 Input Word 15 Channel 1 Datalink D2 Output

Channel 2 Datalink A1 Input Word 16 Channel 2 Datalink A1 Output

Channel 2 Datalink A2 Input Word 17 Channel 2 Datalink A2 Output

Channel 2 Datalink B1 Input Word 18 Channel 2 Datalink B1 Output

Channel 2 Datalink B2 Input Word 19 Channel 2 Datalink B2 Output

Channel 2 Datalink C1 Input Word 20 Channel 2 Datalink C1 Output

Channel 2 Datalink C2 Input Word 21 Channel 2 Datalink C2 Output

Channel 2 Datalink D1 Input Word 22 Channel 2 Datalink D1 Output

Channel 2 Datalink D2 Input Word 23 Channel 2 Datalink D2 Output

Channel 3 Datalink A1 Input Word 24 Channel 3 Datalink A1 Output

Channel 3 Datalink A2 Input Word 25 Channel 3 Datalink A2 Output

Channel 3 Datalink B1 Input Word 26 Channel 3 Datalink B1 Output

Channel 3 Datalink B2 Input Word 27 Channel 3 Datalink B2 Output

Channel 3 Datalink C1 Input Word 28 Channel 3 Datalink C1 Output

Channel 3 Datalink C2 Input Word 29 Channel 3 Datalink C2 Output

Channel 3 Datalink D1 Input Word 30 Channel 3 Datalink D1 Output

Channel 3 Datalink D2 Input Word 31 Channel 3 Datalink D2 Output

Input Image

Enhanced Mode Interface

The Channel Status and Message Status bits provide additional status

information pertaining to the validity of certain pieces of data. This

information includes the port that the particular channel is connected

to on the SCANport device, the state of the I/O data, and the status of

each message buffer.

Publication 1203–5.9 –– October 1996

Page 36

4–8 Using Enhanced Mode

These status fields are defined as follows:

Channel 2 Status

Bit

15 14 13 12 1 1

D2

C2 B2 A2 D1 C1 B1 A1

M0

STA

MSTAT

CH3

X

Message Status Ch 1–3

10 9 8 765432 1 0

V2 ID2 V1 ID1

MSTAT

CH2

MSTAT

CH1

D3 C3 B3 A3

These bits have the following definitions:

This: Represents the:

SCANport Channel 1, 2, or 3 Connected Adapter Port ID Number. This three

ID1

ID2

ID3

V1

V2

V3

A–D1(–3)

M0 STA

MSTAT

CH1–3

bit field contains the adapter port number that channel 1, 2, or 3 is connected

to on the SCANport device. ID1, ID2, and ID3 should be between 1 and 7. If

ID1, ID2, or ID3 is 7, the channel is not connected to the SCANport device, or

the SCANport device may not be powered.

SCANport Channel 1, 2, or 3 Valid Data bit. When high (1), the Logic Status

and Analog Feedback values are valid and can be used. When low (0), the

values are not valid.

SCANport Channel 1, 2, or 3 Datalink A–D Valid Data bit. When high (1),

the data associated Datalink A–D of the corresponding channel is valid and

can be used. When low (0), the values are not valid.

M0 File Status bit. When high (1), the SLC program can enable any

previously written M0 file message to the module. When low (0), the SLC to

SCANport module is either actively reading the last sent M0 file data changes,

or the SLC program has not loaded any M0 file data into the module. If any

changes are made to the M0 file message buffers, the SLC program should

check this status bit before enabling that message to be sent out any SCANport

channel.

Message Status bits for the message buffer of the corresponding channel.

These two bit fields contain the status of each of the message buffers. There is

one message response buffer for each channel. The first bit (word 1, bits 9,

11, and 13) contains the READY bit. The READY bit is active (high=1) when

a message request can be enabled to the SCANport device. The second bit

(word 1, bits 8, 10, and 12) contains the DONE bit. The DONE bit is active

(high=1) when an M1 file message buffer contains response data to a message

request. When both the READY and the DONE bits are 0, the buffer is in a

BUSY state. This is the state during which the module is actually requesting

the data from the SCANport device. These status bits should never be high at

the same time.

Channel 1 Status

V3 ID3

Channel 3 Status

Word 0

Word 1

Publication 1203–5.9 –– October 1996

Important: Do not enable messages while writing to the message

buffer.

The Channel Command bytes contain I/O Data Enable and Message

Enable bits that are used to activate I/O Data and Messages to a

SCANport device. These functions are independent; you can use

either function by itself or use both functions together.

Page 37

4–9Using Enhanced Mode

The eight unique message buffers in the M0 file can contain a

message for any of the three SCANport channels. You can select

which message buffer is to be used for each channel with the

corresponding MSG ID bits. This lets a message be written into a

buffer only once and used as many times as needed.

To transmit a message, the MSG ID bits are set to select the desired

buffer and a channel’s Message Enable bit is set to 1. When the

message status bits indicate the message is done, the response can be

read from the M1 message buffer area for the corresponding

SCANport channel used. When the Message Enable bit is

subsequently cleared to 0, the DONE status bit will be reset and the

READY bit set to allow for another message sequence.

The definition for the channel command output image is as follows:

Channel 2 Command

Bit

15 14 13 12 1 1

Not Used MSG ID

10 9 8 765432 1 0

ME

DE

2

Not Used MSG ID

2

Not Used MSG IDReserved

Channel 1 Command

ME

DE

1

1

DE

ME

3

3

Channel 3 Command

Word 0

Word 1

These bits have the following definitions:

This: Represents the:

SCANport Channel 1, 2, or 3 Data Enable bit. While low (0),

the channel is not transferring I/O data (including datalink data)

DE1

DE2

DE3

ME1

ME2

ME3

MSG

ID

between the connected SCANport device. When high (1), the

channel becomes active to the SCANport device and transfers

the appropriate I/O data. When cleared to low (0), the channel

disconnects from the SCANport device, which usually causes

the connected SCANport device to fault.

SCANport Channel 1, 2, or 3 Message Enable bit. When set

high (1), the message selected by the Message ID field is

transmitted through the appropriate channel to the SCANport

device. This bit should be held high during the duration of the

request until the status DONE bit is asserted (1). The clearing

(0) of this bit clears the DONE status and returns the message

status to the READY state.

Message Identifier field. This field allows for the selection of

one of the eight message buffers in the M0 file area for each

channel. Multiple channels can use the same message ID buffer

simultaneously.

Publication 1203–5.9 –– October 1996

Page 38

4–10 Using Enhanced Mode

atalin

ation

ld

tat

onfiguration

ation

ata

Configuring G Files

You can use G files to enable additional I/O (datalinks) between the

SCANport device and the SLC to SCANport module. G files also

hold the safe state values for the output data to be transferred to the

SCANport devices when it is switch–configured to use it. The G file

data is specified as follows: G=g–file, s=slot

Figure 4.8

G File Image

G File Image

Reserved Gs:0

Datalink Enables Gs:1

Logic Command Channel 1 Gs:2

Analog Reference Channel 1 Gs:3

Logic Command Channel 2 Gs:4

Analog Reference Channel 2 Gs:5

Logic Command Channel 3 Gs:6

Analog Reference Channel 3 Gs:7

Channel 1 Datalink A1 Input Gs:8

Channel 1 Datalink A2 Input Gs:9

Channel 1 Datalink B1 Input Gs:10

Channel 1 Datalink B2 Input Gs:11

Channel 1 Datalink C1 Input Gs:12

Channel 1 Datalink C2 Input Gs:13

Channel 1 Datalink D1 Input Gs:14

Channel 1 Datalink D2 Input Gs:15

Channel 2 Datalink A1 Input Gs:16

Channel 2 Datalink A2 Input Gs:17

Channel 2 Datalink B1 Input Gs:18

Channel 2 Datalink B2 Input Gs:19

Channel 2 Datalink C1 Input Gs:20

Channel 2 Datalink C2 Input Gs:21

Channel 2 Datalink D1 Input Gs:22

Channel 2 Datalink D2 Input Gs:23

Channel 3 Datalink A1 Input Gs:24

Channel 3 Datalink A2 Input Gs:25

Channel 3 Datalink B1 Input Gs:26

Channel 3 Datalink B2 Input Gs:27

Channel 3 Datalink C1 Input Gs:28

Channel 3 Datalink C2 Input Gs:29

Channel 3 Datalink D1 Input Gs:30

Channel 3 Datalink D2 Input Gs:31

Datalink

Configur

Fie

Safe

S

e

Configur

C

Data

Publication 1203–5.9 –– October 1996

Page 39

The G file datalink configuration field is defined as follows:

4–11Using Enhanced Mode

Bit

15 14 13 12 11 10 9 8 765432 1 0

EC

Not Used

ED

EB

EA

3

3

3

ED

3

2

EB

EA

2EC2

2

ED

EC

EB

1

1

1

EA

Gs.1

1

These bits have the following definitions:

This: Represents:

EA1

EA2

EA3

EB1

EB2

EB3

EC1

EC2

EC3

ED1

ED2

ED3

SCANport Channel 1, 2, or 3 Datalink A Enable bit. When set

high (1), datalink A is enabled for the corresponding channel.

Note: The datalink is only active while the channel’s Data

Enable bit is also set.

SCANport Channel 1, 2, or 3 Datalink B Enable bit. When set

high (1), datalink B is enabled for the corresponding channel.

Note: The datalink is only active while the channel’s Data

Enable bit is also set.

SCANport Channel 1, 2, or 3 Datalink C Enable bit. When set

high (1), datalink C is enabled for the corresponding channel.

Note: The datalink is only active while the channel’s Data

Enable bit is also set.

SCANport Channel 1, 2, or 3 Datalink D Enable bit. When set

high (1), datalink D is enabled for the corresponding channel.

Note: The datalink is only active while the channel’s Data

Enable bit is also set.

Using M Files

You may enable datalinks with or without providing safe state data.

You can configure G files that are between 2 and 32 words in length.

ATTENTION: Configure your safe state values based

on your knowledge of how the SCANport devices

!

connected on each channel operate. Refer to the

manual for your SCANport device for additional

information.

To transfer messages between the SLC processor and any of the

SCANport devices connected through the SLC to SCANport

module, you need to use M files. The SLC to SCANport module

uses M0 and M1 files. The M0 file is a module output file

(write–only), while the M1 file is a module input file (read–only).

Messages to the SCANport module from the SLC processor are sent

using the M0 file, while the M1 file contains the responses.

Publication 1203–5.9 –– October 1996

Page 40

4–12 Using Enhanced Mode

e = slot location

Message Buffer 0

Request Length = n

Req Data 2

Req Data n

The M0 file image contains multiple transmit message buffers set up

as shown in Figure 4.9.

Figure 4.9

M0 File Structure

Service

Class

Instance

Attribute

Req Data 1

...

M0:e.000

M0:e.001

M0:e.002

M0:e.003

M0:e.004

M0:e.005

M0:e.0xx

Message Buffer 4

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Req Data 1

...

M0:e.400

M0:e.401

M0:e.402

M0:e.403

M0:e.404

M0:e.405

M0:e.4xx

Message Buffer 1

Message Buffer 2

Message Buffer 3

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Req Data 1

...

Req Data 1

...

Req Data 1

...

M0:e.100

M0:e.101

M0:e.102

M0:e.103

M0:e.104

M0:e.105

M0:e.1xx

M0:e.200

M0:e.201

M0:e.202

M0:e.203

M0:e.204

M0:e.205

M0:e.2xx

M0:e.300

M0:e.301

M0:e.302

M0:e.303

M0:e.304

M0:e.305

M0:e.3xx

Message Buffer 5

Message Buffer 6

Message Buffer 7

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Req Data 1

...

Req Data 1

...

Req Data 1

...

M0:e.500

M0:e.501

M0:e.502

M0:e.503

M0:e.504

M0:e.505

M0:e.5xx

M0:e.600

M0:e.601

M0:e.602

M0:e.603

M0:e.604

M0:e.605

M0:e.6xx

M0:e.700

M0:e.701

M0:e.702

M0:e.703

M0:e.704

M0:e.705

M0:e.7xx

Publication 1203–5.9 –– October 1996

The M0 file contains eight separate buffer areas. Each area can be

used to send messages to any of the three channels. You need to

access a unique area of the M0 files for each message buffer used.

Individual message request status bits (located in Word 1 of the I/O

input image) are used to monitor the progress of each message

request enabled. The Message ID selection field and Message

Enable bits (located in Words 0 and 1 of the I/O output image)

initiate each message transaction and subsequently free the receive

buffer for the next message.

Page 41

Echo of G File Contents

and DIP Switch Read Out

e = slot location

The M1 file image contains the contents of the multi–position DIP

switch, an echo of the contents of the G file data, and three receive

message buffers as shown in Figure 4.10.

Figure 4.10

M1 File Structure

Reserved

Datalink Enables

Logic Command Channel 1

Analog Reference Channel 1

Logic Command Channel 2

Analog Reference Channel 2

Logic Command Channel 3

Analog Reference Channel 3

Channel 1 Datalink A1 In

Channel 1 Datalink A2 In

Channel 1 Datalink B1 In

Channel 1 Datalink B2 In

Channel 1 Datalink C1 In

Channel 1 Datalink C2 In

Channel 1 Datalink D1 In

Channel 1 Datalink D2 In

Channel 2 Datalink A1 In

Channel 2 Datalink A2 In

Channel 2 Datalink B1 In

Channel 2 Datalink B2 In

Channel 2 Datalink C1 In

Channel 2 Datalink C2 In

Channel 2 Datalink D1 In

Channel 2 Datalink D2 In

Channel 3 Datalink A1 In

Channel 3 Datalink A2 In

Channel 3 Datalink B1 In

Channel 3 Datalink B2 In

Channel 3 Datalink C1 In

Channel 3 Datalink C2 In

Channel 3 Datalink D1 In

Channel 3 Datalink D2 In

DIP SW

M1:e.000

M1:e.001

M1:e.002

M1:e.003

M1:e.004

M1:e.005

M1:e.006

M1:e.007

M1:e.008

M1:e.009

M1:e.010

M1:e.011

M1:e.012

M1:e.013

M1:e.014

M1:e.015

M1:e.016

M1:e.017

M1:e.018

M1:e.019

M1:e.020

M1:e.021

M1:e.022

M1:e.023

M1:e.024

M1:e.025

M1:e.026

M1:e.027

M1:e.028

M1:e.029

M1:e.030

M1:e.031

Channel 1

Receive Buffer

Channel 2

Receive Buffer

Channel 3

Receive Buffer

Service (echo or error)

Class (echo)

Instance (echo)

Attribute (echo)

Response Length = n

Resp Data 2

Resp Data n

Service (echo or error)

Response Length = n

Resp Data 2

Resp Data n

Service (echo or error)

Response Length = n

Resp Data 2

Resp Data n

Resp Data 1

Class (echo)

Instance (echo)

Attribute (echo)

Resp Data 1

Class (echo)

Instance (echo)

Attribute (echo)

Resp Data 1

4–13Using Enhanced Mode

M1:e.100

M1:e.101

M1:e.102

M1:e.103

M1:e.104

M1:e.105

...

...

...

M1:e.1xx

M1:e.200

M1:e.201

M1:e.202

M1:e.203

M1:e.204

M1:e.205

M1:e.2xx

M1:e.300

M1:e.301

M1:e.302

M1:e.303

M1:e.304

M1:e.305

M1:e.3xx

SCANport messages access data structures within the SCANport

device. These data structures are called objects. An object contains

information for a particular purpose. For example, a parameter

object can contain information such as parameter values, parameter

names, scaling information, and units.

Publication 1203–5.9 –– October 1996

Page 42

4–14 Using Enhanced Mode

This field: Specifies:

Service

Class

Instance

Attribute

Request

length

Figure 4.11 shows the first M0 message buffer structure.

Figure 4.11

SLC to SCANport Module M0 Buffer 0 Message Structure

M0:e.b00

M0:e.b01

M0:e.b02

M0:e.b03

M0:e.b04

M0:e.b05

M0:e.bxx

e = slot location

b = buffer 0–7

Header

Information

Service

Class

Instance

Attribute

Request Length = n

Req Data 2

Req Data n

Req Data 1

...

Where:

The action or service requested. The following service values are

available:

Enter this value: T o request this service:

0001H (1 decimal) Read Parameter Full/All Info

0005H (5 decimal) Reset to Default

000eH (14 decimal) Get Attribute Single

0010H (16 decimal) Set Attribute Single

0015H (21 decimal) Restore from Storage

0016H (22 decimal) Save to Storage

0032H (50 decimal) Get Attribute Scattered

0034H (52 decimal) Set Attribute Scattered

004bH (75 decimal) Read Enum String

➀

Not all SCANport devices support these services.

For example, if you enter a service value of 0001H (1 decimal), you

are requesting that the SCANport device provide all available

information about a particular object. A service value of 000eH is a

request for only one piece of information about a particular object.

The type of object to access within the SCANport device. The class

is the first index into the SCANport device’s database. It directs the

message to the desired functional database. For example, a class

value of 000fH (15 decimal) indicates that the message is intended to

access the parameter database.

A particular occurrence of an object in the SCANport device. The

instance provides an index into the referenced functional database.

For example, when accessing the parameter database, the instance

value is the parameter number. If you want to access information

about all instances of the object, specify an instance of 0.

A specific piece of information about an object. Values are always

less than 256. For example, in a parameter object, an attribute value

of 0001H (1 decimal) indicates that the message is accessing the

parameter value. An attribute value of 0007H (7 decimal) indicates

that the message is accessing the parameter name text string.

The length, in bytes, in this request. This value is normally less than

or equal to 96 bytes. However, Get/Set Attribute Scattered messages

can be longer.

➀

➀

➀

➀

Publication 1203–5.9 –– October 1996

Page 43

This field: Specifies:

The actual data portion of the request message. Up to a maximum of

Req Data

96 bytes of message data is available. This field is optional

depending on the type of message sent.

The response from the SCANport device appears in the message

buffer of the channel used (Channel 1 = M1:e.100–199, Channel 2 =

M1:e.200–299, Channel 3 = M1:e.300–399).

Figure 4.12 shows the structure of the message response buffers

inside the SLC M1 file.

Figure 4.12

M1 File Message Response Buffer Structures

M0:e.b00

M0:e.b01

M0:e.b02

M0:e.b03

M0:e.b04

M0:e.b05

M0:e.bxx

Header

Information

Service (error or echo)

Class (echo)

Instance (echo)

Attribute (echo)

Response Length = n

Resp Data 2

Resp Data n

Resp Data 1

...

4–15Using Enhanced Mode

e = slot location

b = buffer 0–7

Where:

This field: Contains:

The same value as the service field of the request message if the

message transaction was successful. If an error occurred, the service

Service

will be 0014H (20 decimal) and additional error information will be

placed in the response data field.

The error codes are provided at the end of this appendix.

Class

Instance

Attribute

Response

Length

Resp

➀

Data

The same value that was used for the class field in the request

message.

The same value that was used for the instance field in the request

massage.

The same value that was used for the attribute field in the request

message.

The amount of data, in bytes, in this response. Most messages

contain 96 or fewer bytes of data. However, Get/Set Attribute

➀

Scattered messages can be longer.

The actual data portion of this response. This field varies in length

depending on the message. If an error occurred, this field contains

the SCANport error code.

➀

The size of the returned packets determines the response length.

Some SCANport devices may return lengths greater than the actual

amount of data in the response. These products always return a

length which is a multiple of six. For example, a 1336 PLUS drive

may reply to a Read Number of Parameters message with a length of

six in the response. The first two bytes contain the complete

response data. The extra data bytes should be ignored.

Publication 1203–5.9 –– October 1996

Page 44

4–16 Using Enhanced Mode

Examples of Enhanced Mode Data Transfer

The following examples are portions of the same program that is

used to transfer data using the enhanced mode mechanism.

Figure 4.13 shows an example configuration of the G file for the

SLC to SCANport module. The Advanced Programming Software

(APS) sets the first word; do not modify this word. Each bit in the

second word enables a datalink. Refer to the manual for your

SCANport device for more information about datalinks.

Each additional word in the G file contains safe state data. This is

the data that is sent to the attached SCANport device(s) if the SLC to

SCANport module DIP switch is configured to use safe state data

and the SLC becomes faulted or is changed to program mode.

Publication 1203–5.9 –– October 1996

Page 45

Figure 4.13

Example G File Configuration

address 15 data 0

G1:0 0000 0000 0000 0000 Reserved (Used by SLC)

G1:1 0000 0000 0000 0000 Datalink Enables

|||| |||| |||| ||||

++++ |||| |||| |||+––– Channel 1 Datalink A Enable

| |||| |||| ||+–––– Channel 1 Datalink B Enable

| |||| |||| |+––––– Channel 1 Datalink C Enable

| |||| |||| +–––––– Channel 1 Datalink D Enable

| |||| ||||

| |||| |||+–––––––– Channel 2 Datalink A Enable

| |||| ||+––––––––– Channel 2 Datalink B Enable

| |||| |+–––––––––– Channel 2 Datalink C Enable

| |||| +––––––––––– Channel 2 Datalink D Enable

| ||||

| |||+––––––––––––– Channel 3 Datalink A Enable

| ||+–––––––––––––– Channel 3 Datalink B Enable

| |+––––––––––––––– Channel 3 Datalink C Enable

| +–––––––––––––––– Channel 3 Datalink D Enable

|

+––––––––––––––––––– Not Used

4–17Using Enhanced Mode

G1:2 0000 0000 0000 0000 Safe State Data – Channel 1 Logic Command

G1:3 0000 0000 0000 0000 Safe State Data – Channel 1 Reference

G1:4 0000 0000 0000 0000 Safe State Data – Channel 2 Logic Command

G1:5 0000 0000 0000 0000 Safe State Data – Channel 2 Reference

G1:6 0000 0000 0000 0000 Safe State Data – Channel 3 Logic Command

G1:7 0000 0000 0000 0000 Safe State Data – Channel 3 Reference

G1:8 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink A1

G1:9 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink A2

G1:10 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink B1

G1:11 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink B2

G1:12 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink C1

G1:13 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink C2

G1:14 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink D1

G1:15 0000 0000 0000 0000 Safe State Data – Channel 1 Datalink D2

G1:16 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink A1

G1:17 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink A2

G1:18 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink B1

G1:19 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink B2

G1:20 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink C1

G1:21 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink C2

G1:22 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink D1

G1:23 0000 0000 0000 0000 Safe State Data – Channel 2 Datalink D2

G1:24 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink A1

G1:25 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink A2

G1:26 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink B1

G1:27 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink B2

G1:28 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink C1

G1:29 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink C2

G1:30 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink D1

G1:31 0000 0000 0000 0000 Safe State Data – Channel 3 Datalink D2

Publication 1203–5.9 –– October 1996

Page 46

4–18 Using Enhanced Mode

| Channel 1 |

| SCANport |

| Enable |

| O:1.0 |

|–––––––––––––––––––––––––––––––––––––––––––––––––––––––––( )––––––|

| | 0 | |

| |Channel 2 | |

| |SCANport | |

| |Enable | |

| | O:1.0 | |

| +–––( )––––| |

| | 8 | |

| |Channel 3 | |

| |SCANport | |

| |Enable | |

| | O:1.1 | |

| +–––( )––––+ |

| 0 |

Figure 4.14 shows a portion of the program that enables all three

SCANport channels on the SLC to SCANport module.

Figure 4.14

Example of Enabling the SCANport channels

Publication 1203–5.9 –– October 1996

Page 47

4–19Using Enhanced Mode

The portion of the program shown in Figure 4.15 provides start/stop

control and a frequency reference to the 1305 drive connected to

SCANport channel 1. The user start is a normally open push button,

while the user stop is a normally closed push button.

Figure 4.15

Example of Drive 1 Control and Reference

| Drive 1 Drive 1 Drive 1 |

| User User START |

| Momentary Maintained Command |

| START NOT STOP Bit |

| Input Input |

| I:2.0 I:2.0 O:1.2 |

|–––––] [–––––––––––––––––––] [––––––––––––––––––––––––––––( )–––––|

| | 0 | 1 1 |

| |Drive 1 |Drive 1 | |

| |START |RUNNING | |

| |Command |Status | |

| |Bit |Bit | |

| | O:1.2 I:1.2 | |

| +–––] [––––––––]/[––––+ |

| 1 1 |

| Drive 1 Drive 1 |

| User STOP |

| Maintained Command |

| NOT STOP Bit |

| Input |