Page 1

FLEX I/Ot SCANportt Module

(Cat. No. 1203FM1)

Installation Instructions

1

7

0

1

8

2

3

6

4

6

Channel 1 Channel 2

S

5

2

3

4

Module

Installation

Important: This module mounts on a special 1203 terminal base unit and should

not be used with any other flex base. You can remove and insert

modules under power. However, removal may cause the attached

SCANport device(s) to fault.

To mount this module, you need to:

FLEX I/O is a trademark of AllenBradley Co. Inc.

SCANport is a trademark of Allen-Bradley Co. Inc.

Page 2

1–2

FLEX I/O SCANportt Module Installation Instructions

1. Rotate keyswitch (2) on terminal base unit (3) clockwise to

position 1 as required for this type of module.

2. Make certain the flexbus connector (7) is pushed all the way to

the left to connect with the neighboring terminal base/adapter.

You cannot install the module unless the connector is fully

extended.

3. Make sure that the pins on the bottom of the module are straight

so they will align properly with the connector in the terminal

base unit.

4. Position the module (6) with its alignment bar (5) aligned with

the groove (4) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base

unit. The module is seated when the latching mechanism (1) is

locked into the module.

6. Repeat the above steps to install the next module in its terminal

base unit.

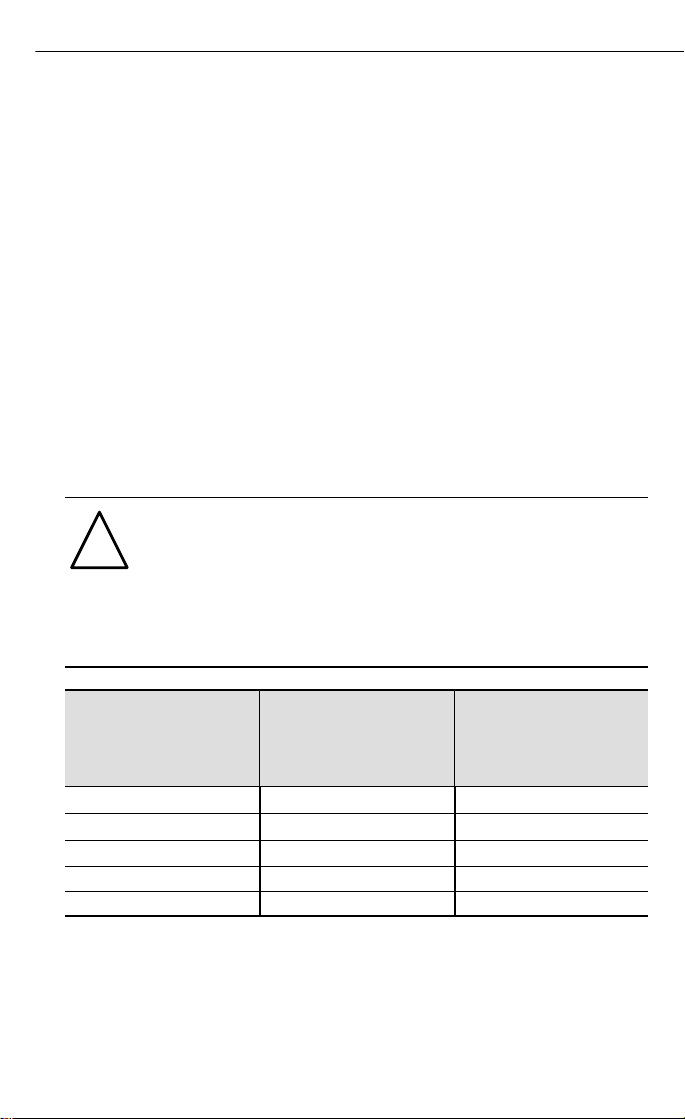

ATTENTION: The 1203–FM1 may require up to twice the adapter

power supply current of standard flex modules. When installing flex

!

modules, you can use a maximum of four 1203–FM1 modules with any

flex adapter. As a general rule, each 1203–FM1 requires the power

capacity of two of the standard flex modules, so you cannot install as many

standard modules as you normally would when using the 1203–FM1.

Refer to the following chart to determine the number of 1203 and standard

modules that may be installed together in your system.

If you are using this

number of standard

(1794) modules:

7 or 8

5 or 6

3 or 4 2 4

1 or 2 3 6

1203-5.7-- April 1996

Then, the maximum

number of 1203

modules that you can

use is:

0 0

1 2

0 4 8

The number of

SCANport connections

provided is:

Page 3

FLEX I/O SCANportt Module Installation Instructions

Wiring

To wire the 1203 base used by this module, connect a SCANport

cable from the SCANport device to the desired channel.

SCANport cables are available in either Male–to–Male or

Male–to–Female configurations. You can connect cables of up to

10 meters (33 feet) between a SCANport device and any

SCANport peripheral.

If you use a port expander, you must subtract the cable length between any device

"

and the expander from the maximum cable length used to connect a peripheral.

The following diagram shows a typical network configuration:

Flex Modules

SCANport devices

1–3

1203-5.7-- April 1996

Page 4

1–4

FLEX I/O SCANportt Module Installation Instructions

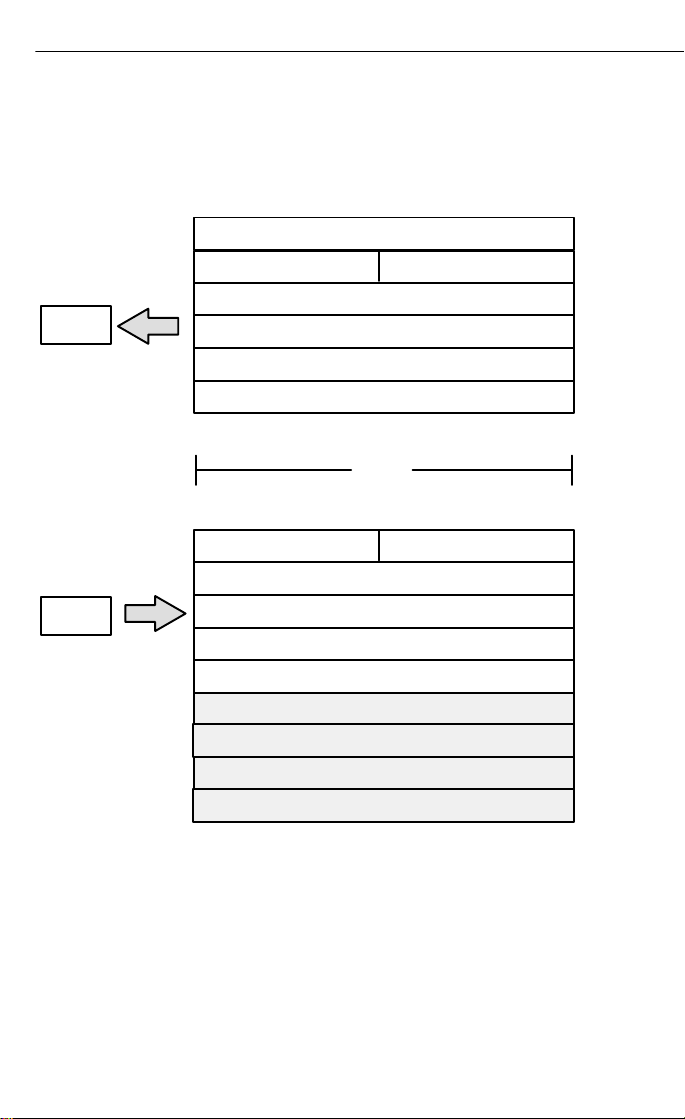

Image Table

The following Flex I/O image table represents the internal data

I/O mapping for the Flex I/O to SCANport module.

Read

6 Words

Write

5 W

ords

I/O Image

Connection Status Channel 2

Logic Status Channel 1

Analog Feedback Channel 1

Logic Status Channel 2

Analog Feedback Channel 2

Connection Enable Channel 2

Logic Command Channel 1

Analog Reference Channel 1

Logic Command Channel 2

Analog Reference Channel 2

Module Image

0

Connection

1 W

ord

Not Used

Not Used

Not Used

Not Used

Status Channel 1

Connection Enable Channel 1

1203-5.7-- April 1996

Page 5

FLEX I/O SCANportt Module Installation Instructions

1–5

Connection

Status W

ord Definition

Connection Status Channel 2 Connection Status Channel 1

Bit:

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Not Used V2 ID2 Not Used V1 ID1

Description

V1 SCANport channel 1 valid data bit. When high (1), the Logic Status

and Analog Feedback values are valid and can be used. When low

(0), the values should not be used.

ID1 SCANport channel 1 connected peripheral port ID number. This three

bit field contains the port number that channel 1 is connected to on the

SCANport device. It should contain a value between 1 and 7. If this

field is 7, then the channel is not connected to the SCANport device, or

the SCANport device may not be powered.

V2 SCANport channel 2 valid data bit. When high (1), the Logic Status

and Analog Feedback values are valid and can be used. When low

(0), the values should not be used.

ID2 SCANport channel 2 connected peripheral port ID number. This three

bit field contains the port number that channel 2 is connected to on the

SCANport device. It should contain a value between 1 and 7. If this

field is 7, then the channel is not connected to the SCANport device, or

the SCANport device may not be powered.

Logic

Status/Analog Feedback Definition

The Logic Status and Analog Feedback values are defined within

the product manuals of the connected SCANport device(s).

1203-5.7-- April 1996

Page 6

1–6

FLEX I/O SCANportt Module Installation Instructions

Connection

Connection

Bit:

E1 SCANport channel 1 enable bit. When set to 1, the module will

E2 SCANport channel 2 enable bit. When set to 1, the module will

Logic

Enable W

ord Definition

Enable Channel 2Connection Enable Channel 1

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Not Used E2 Not Used E1

Description

attempt to connect to the SCANport device. When reset to 0, the

module stops communicating with the connected SCANport device.

This usually causes the device to fault.

attempt to connect to the SCANport device. When reset to 0, the

module stops communicating with the connected SCANport device.

This usually causes the device to fault.

Command/Analog Reference Definition

The Logic Command and Analog Reference values are defined

within the product manuals of the connected SCANport device(s).

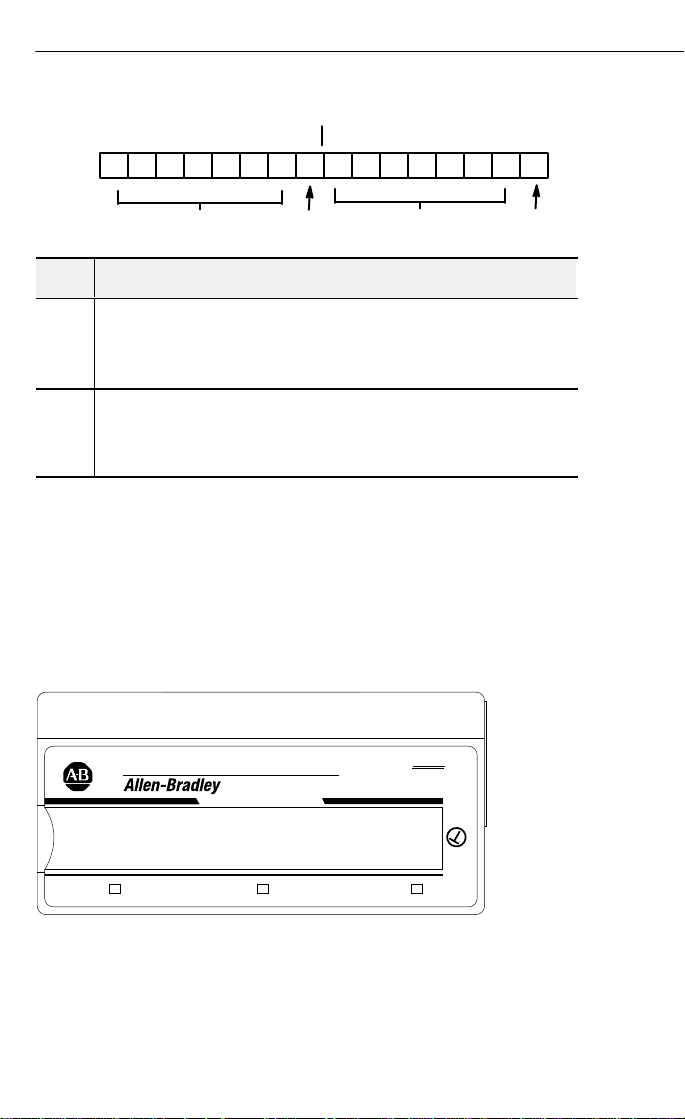

Indicators

LED

The status LEDs are located on the module’s top label.

CH1 CH2

1203-5.7-- April 1996

SCANPORT

MODULE

Flex I/O

1203-FM1

1

Page 7

FLEX I/O SCANportt Module Installation Instructions

The status LEDs provide the following information:

LED State Description

Module Status

Off Not powered The module is not receiving power.

Green

On-line,

operational

Communications

Red

to the flex adapter

is not operational

Channel 1 or Channel 2 Status

Off

Flashing

green

Solid

green

Flashing

red

No module power The module is not receiving power.

Channel not

enabled

Channel

operational

Channel

communication

problem

Channel

connection or

Solid red

power problem.

Module hardware

problem.

I/O signals are operational between the module

and the flex adapter.

I/O signals are not operational between the

module and the flex adapter.

The enable bit for the channel has not been set.

I/O signals are operational between the module

and the SCANport device.

The module cannot maintain or establish

communications with the SCANport device. You

need to:

•Check the configuration.

•Remove the SCANport cable.

•Re-insert the SCANport cable into the channel

to reset the condition.

The SCANport connection is not operational or the

SCANport device is not powered.

1–7

1203-5.7-- April 1996

Page 8

1–8

Environmental conditions

Temperature

(

)

Operating

0 to

+55°C

(32 to

131°F)

)

Non-operating

40 to

+85°C

185°F)

Humidity

g

Operating

5 to 80% non-condensing

g

Non-operating

5 to 95% non-condensing

Shock

(±1)

Operating

30g peak acceleration

11(±1)ms

pulse width

(±1)

Non-operating

50g peak acceleration

11(±1)ms

pulse width

FLEX I/O SCANportt Module Installation Instructions

Specifications

Category Description

Input voltage rating 5V supplied from Flexbus

Indicators 3 bi-color LEDs

Flexbus current 160mA maximum (refer to Attention on page 2)

Power consumption 0.8W

Keyswitch position 1

Dimensions

Environmental conditions

Temperature

Operating

Non-operating

Humidity

Operating

Non-operating

Shock

Operating

Non-operating

Vibration

Regulatory agencies As specified by product label

45.7H x 94.0W x 53.3D in millimeters

(1.8H x 3.7W x 2.1D in inches)

32 to 131°F

(-40 to

,

,

ms pulse width

ms pulse width

0 to +55°C

-40 to +85°C (-40 to 185°F

-

5 to 80% non-condensin

5 to 95% non-condensin

30g peak acceleration, 11

50g peak acceleration, 11

5g @ 10-500Hz per IEC 68-2-6

1203-5.7-- April 1996

Page 9

FLEX I/O SCANportt Module Installation Instructions

1–9

European

Union Directive Compliance

If this product has the CE mark it is approved for installation

within the European Union and EEA regions. It has been

designed and tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

• EN 50081-2EMC – Generic Emission Standard, Part 2 – Industrial Environment

• EN 50082-2EMC – Generic Immunity Standard, Part 2 – Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For Noise Immunity, publication

1770-4.1

• Guidelines for Handling Lithium Batteries, publication AG-5.4

• Automation Systems Catalog, publication B111

1203-5.7-- April 1996

Page 10

1–10

FLEX I/O SCANportt Module Installation Instructions

With major offices worldwide.

World

Headquarters,

AllenBradley,

1201 South Second Street,

Milwaukee, WI 53204 USA,

T

el: (1) 414 3822000 Fax: (1) 414 3824444

Publication 12035.8 - April 1996

1203-5.7-- April 1996

Copyright

1996 AllenBradley Company

PN95654201

, Inc. Printed in USA

Page 11

FLEX I/O SCANportt Module Installation Instructions1–46

With majo

World Headquarters,

AllenBradley,

1201 South Second Street,

Milwaukee, WI 53204 USA,

Tel: (1) 414 3822000 Fax: (1) 414 3824444

Publication 12035.8ML - April 1996 PN95654201

r o

ffices worldwide.

Copyright 1996 AllenBradley Company, Inc. Printed in USA

Loading...

Loading...